Patents

Literature

1303results about How to "Reduced processing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

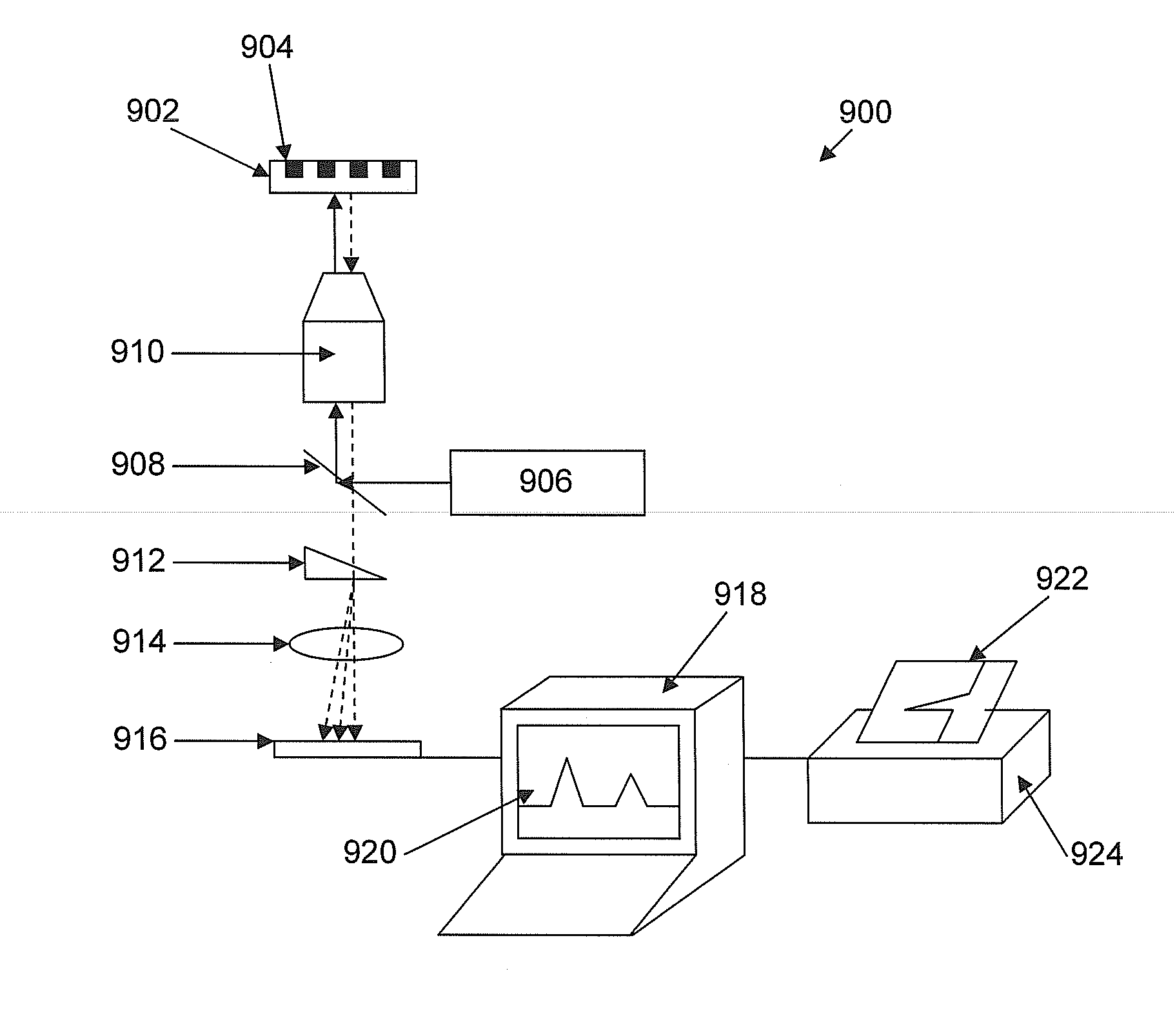

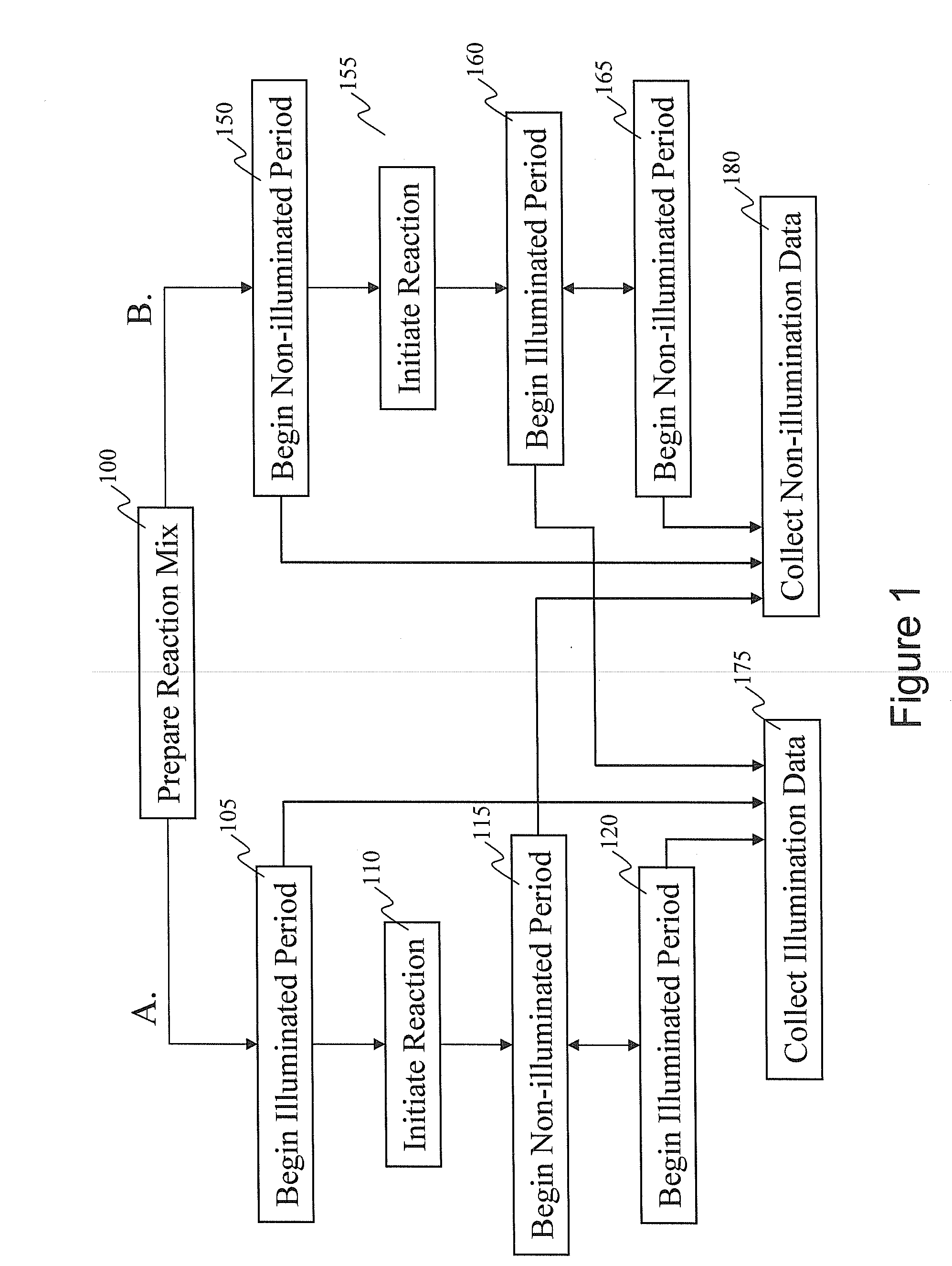

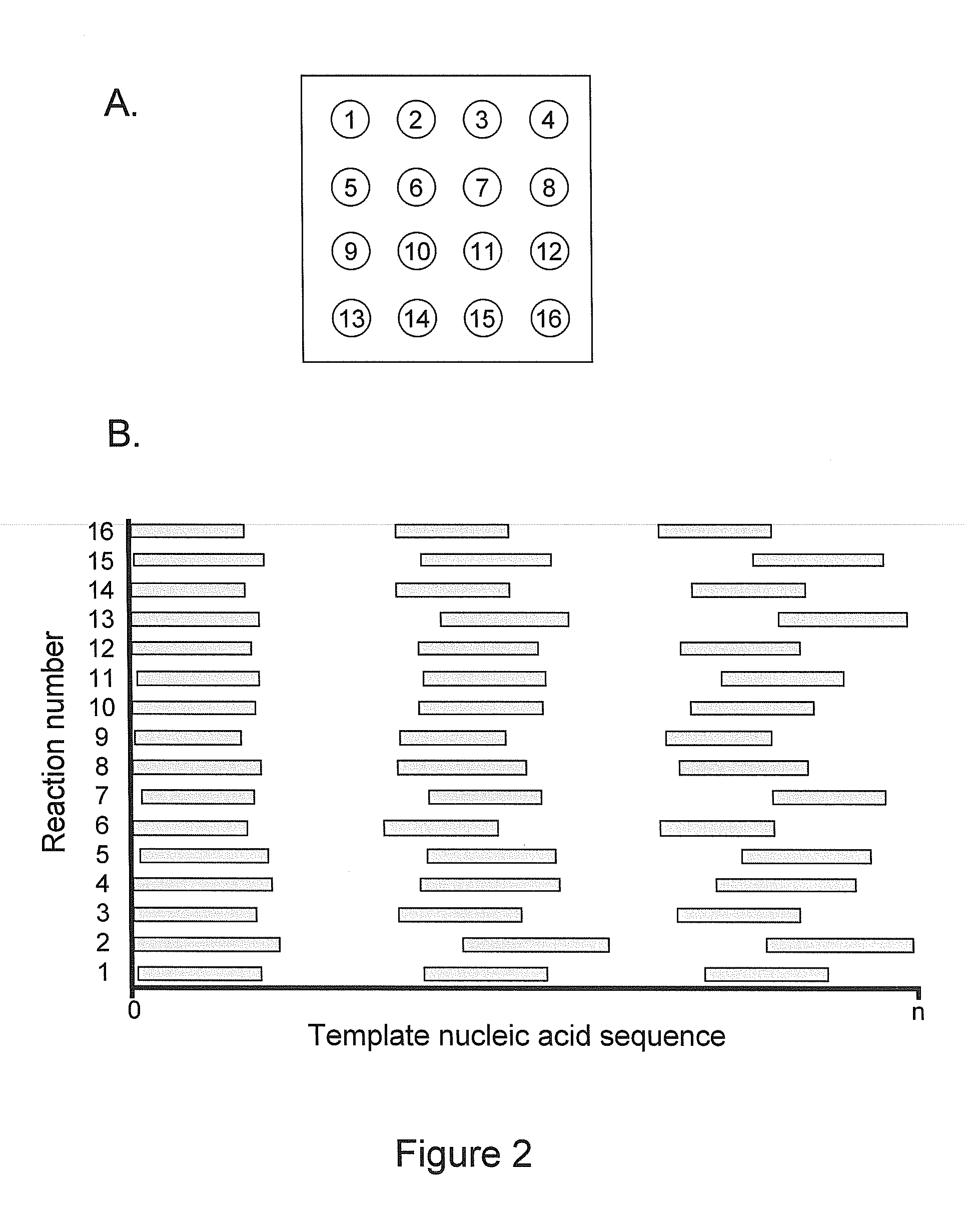

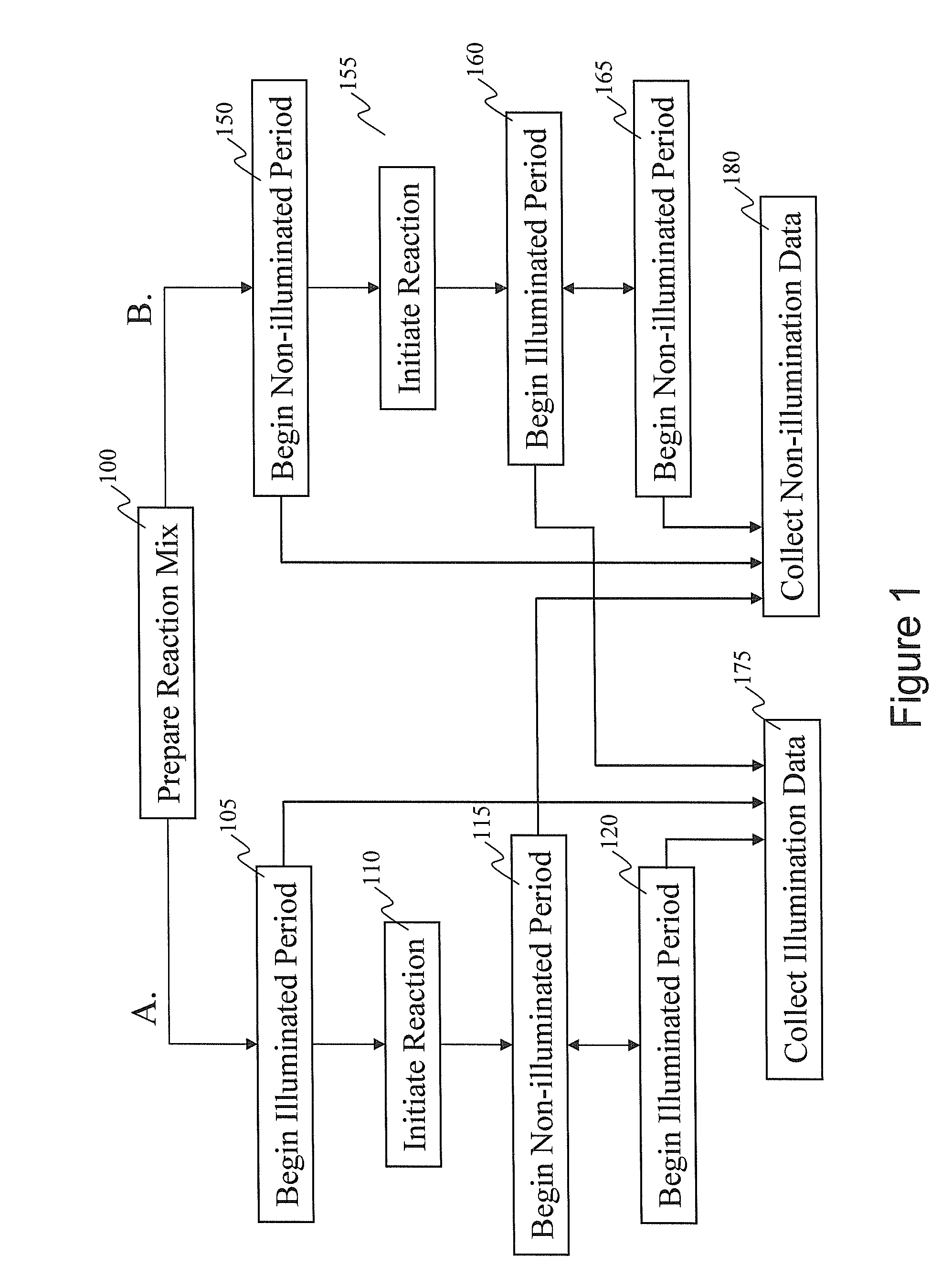

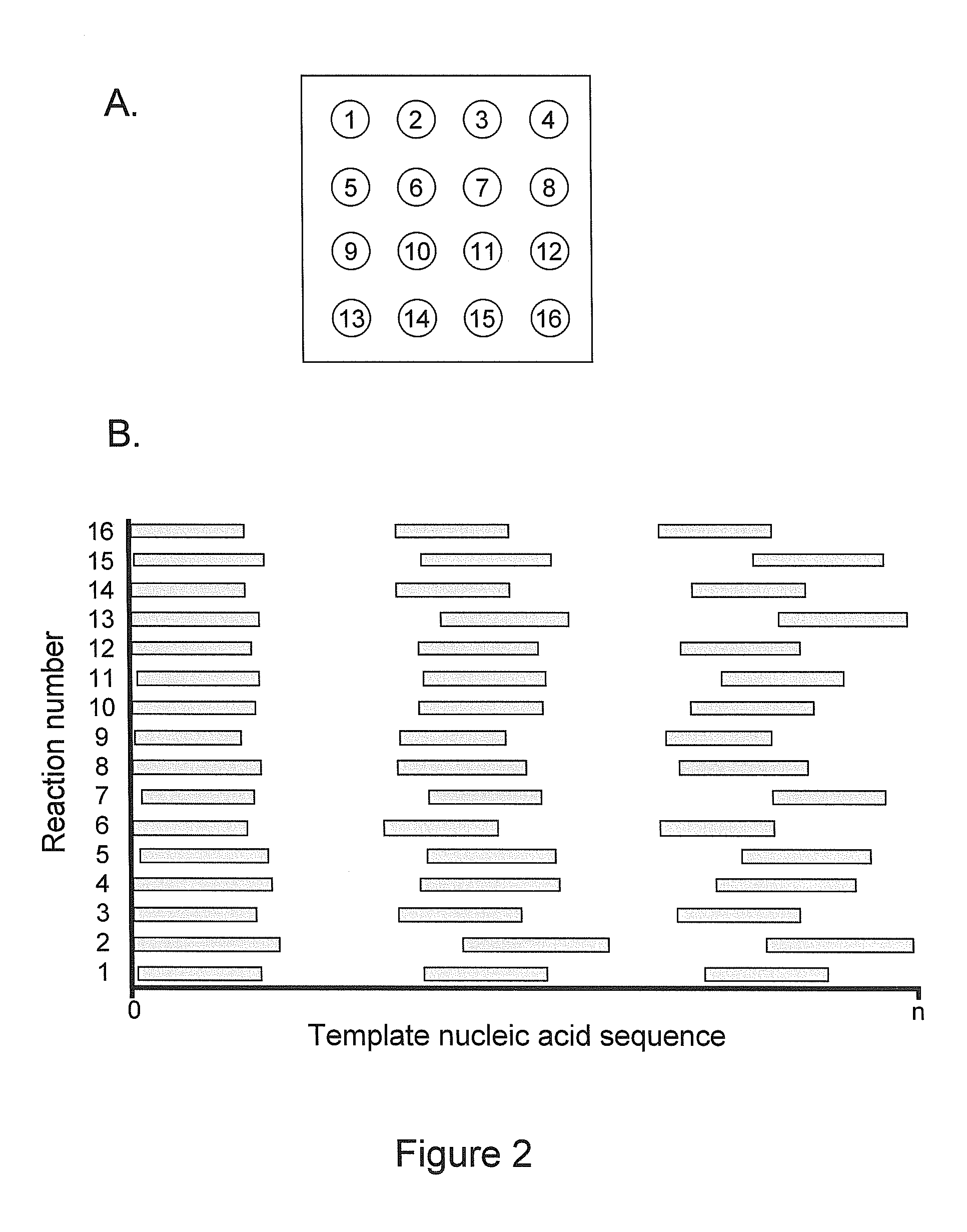

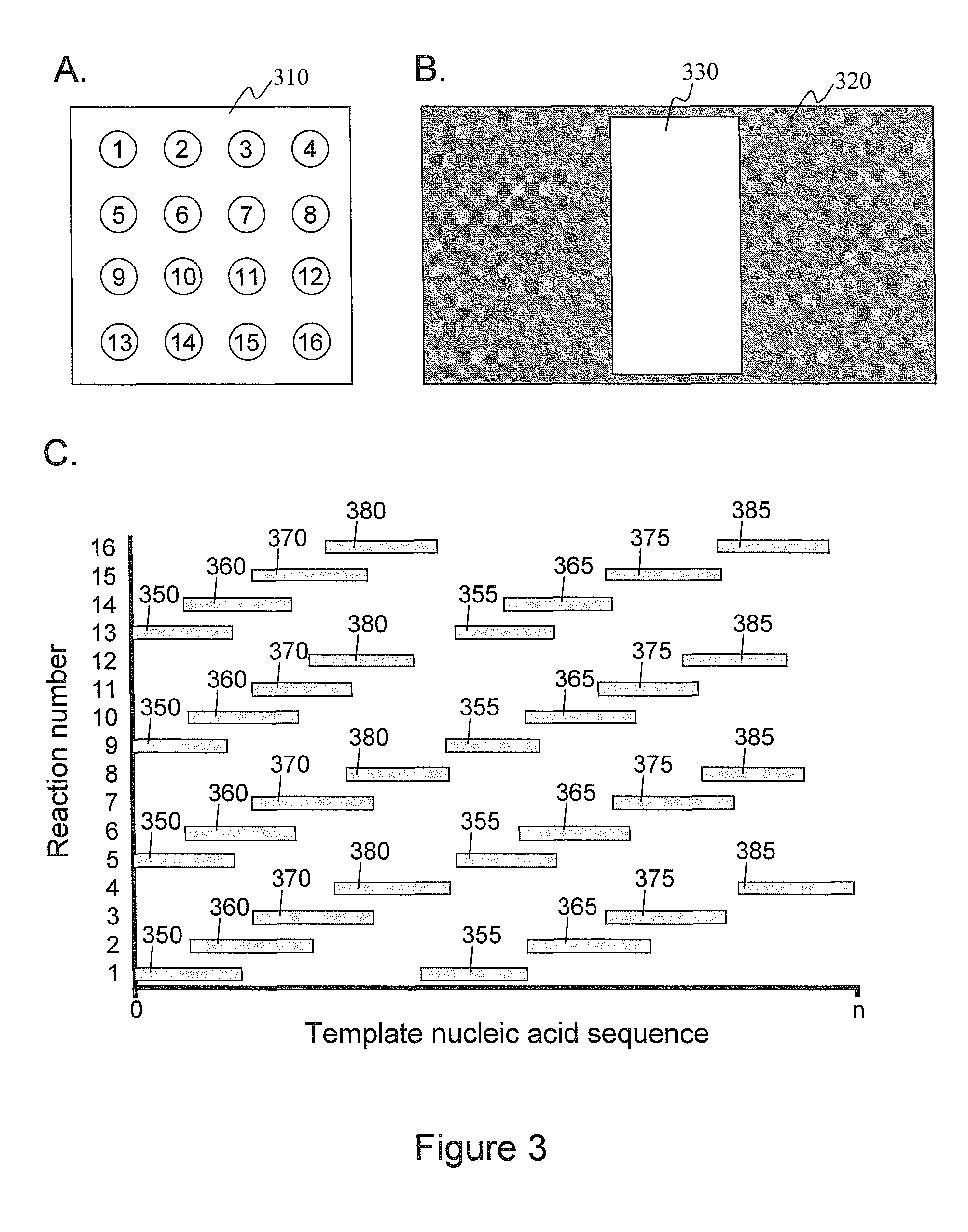

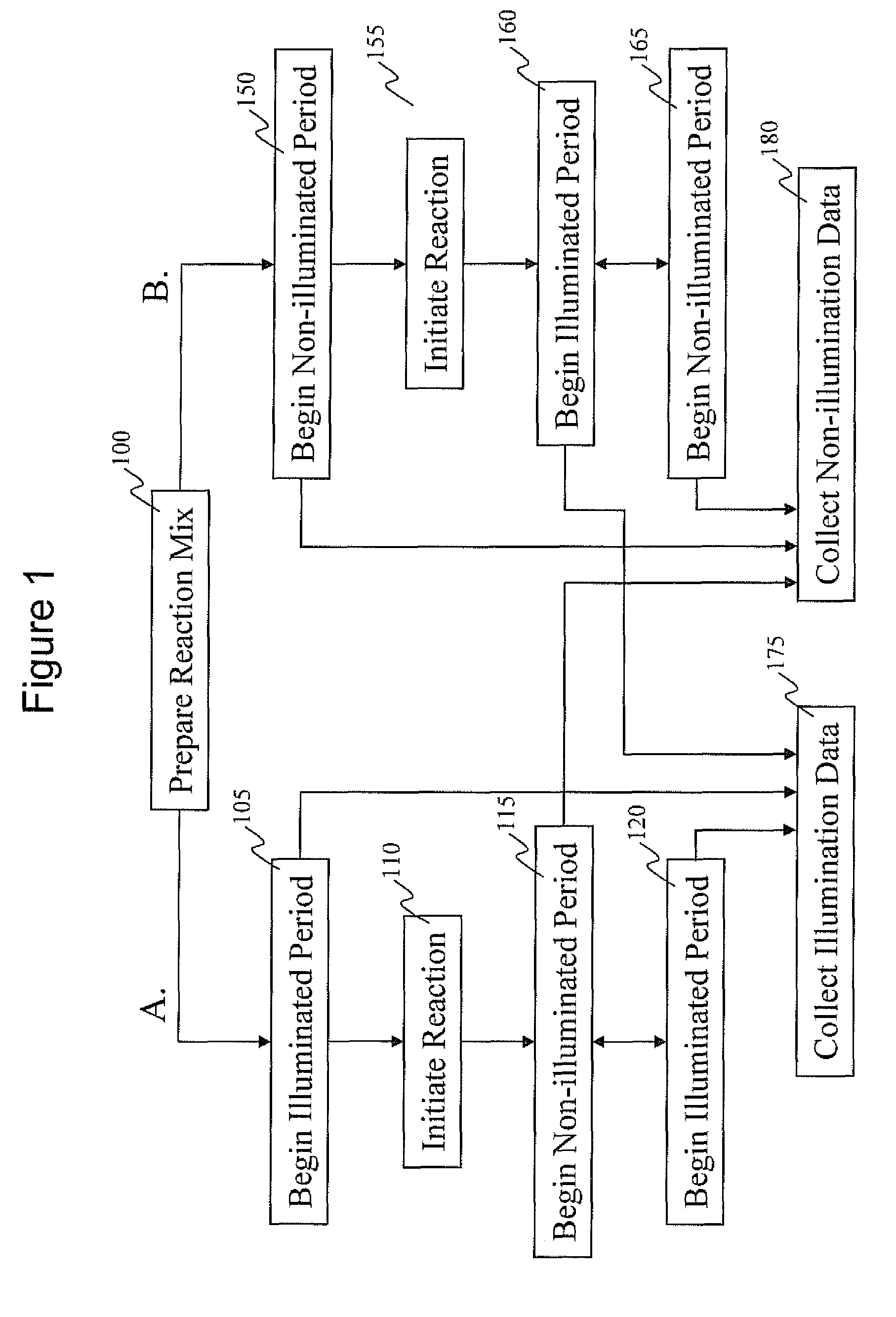

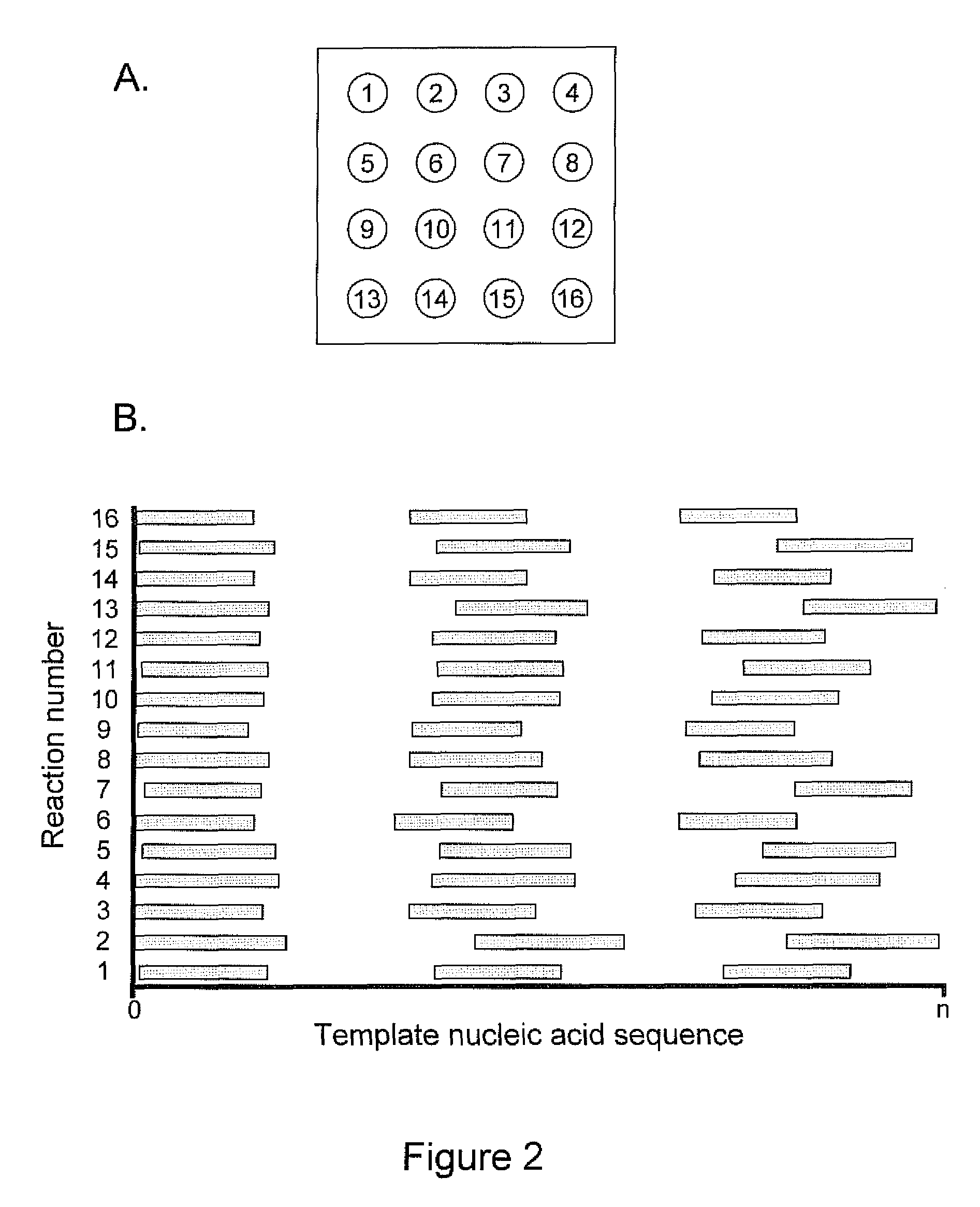

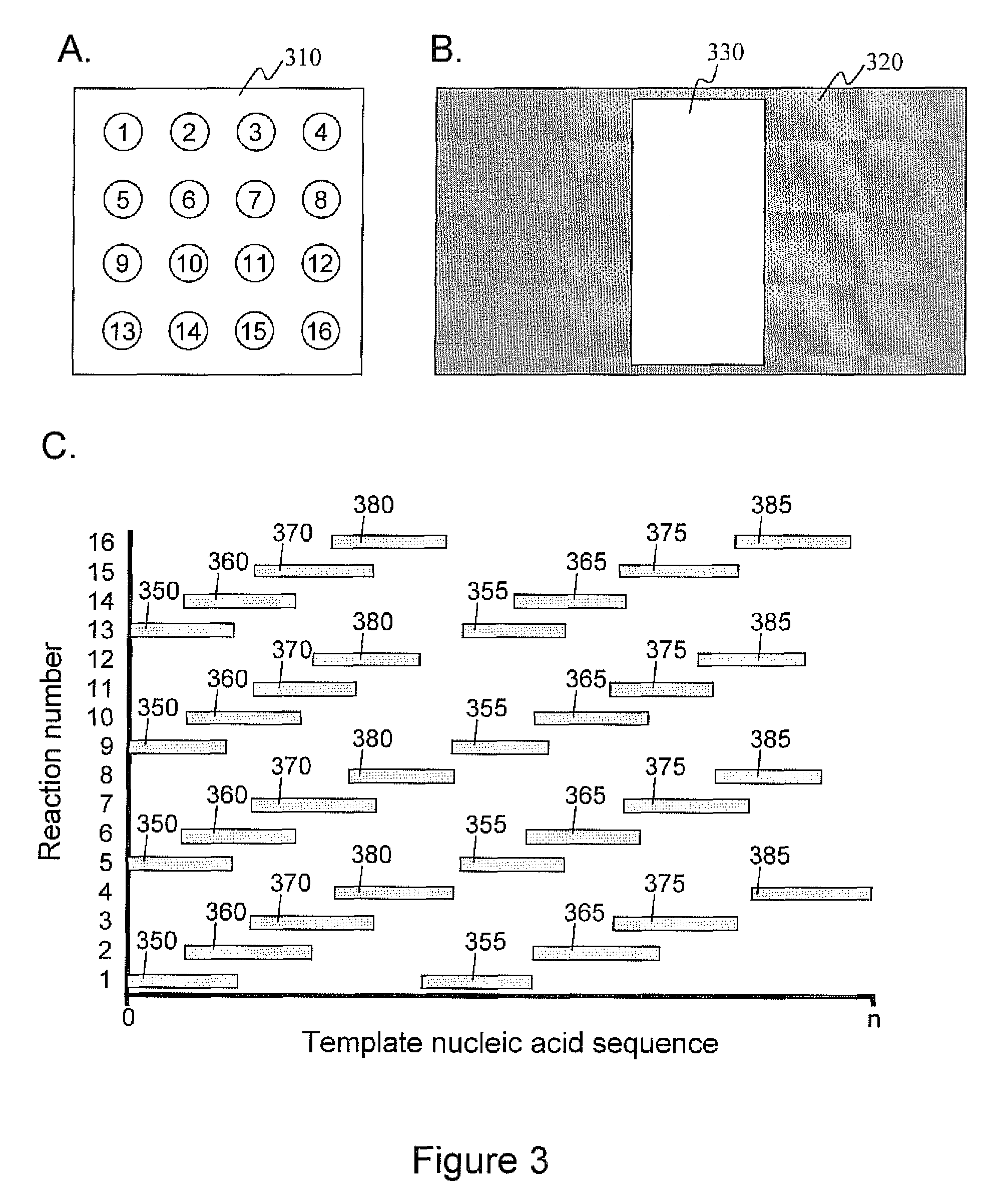

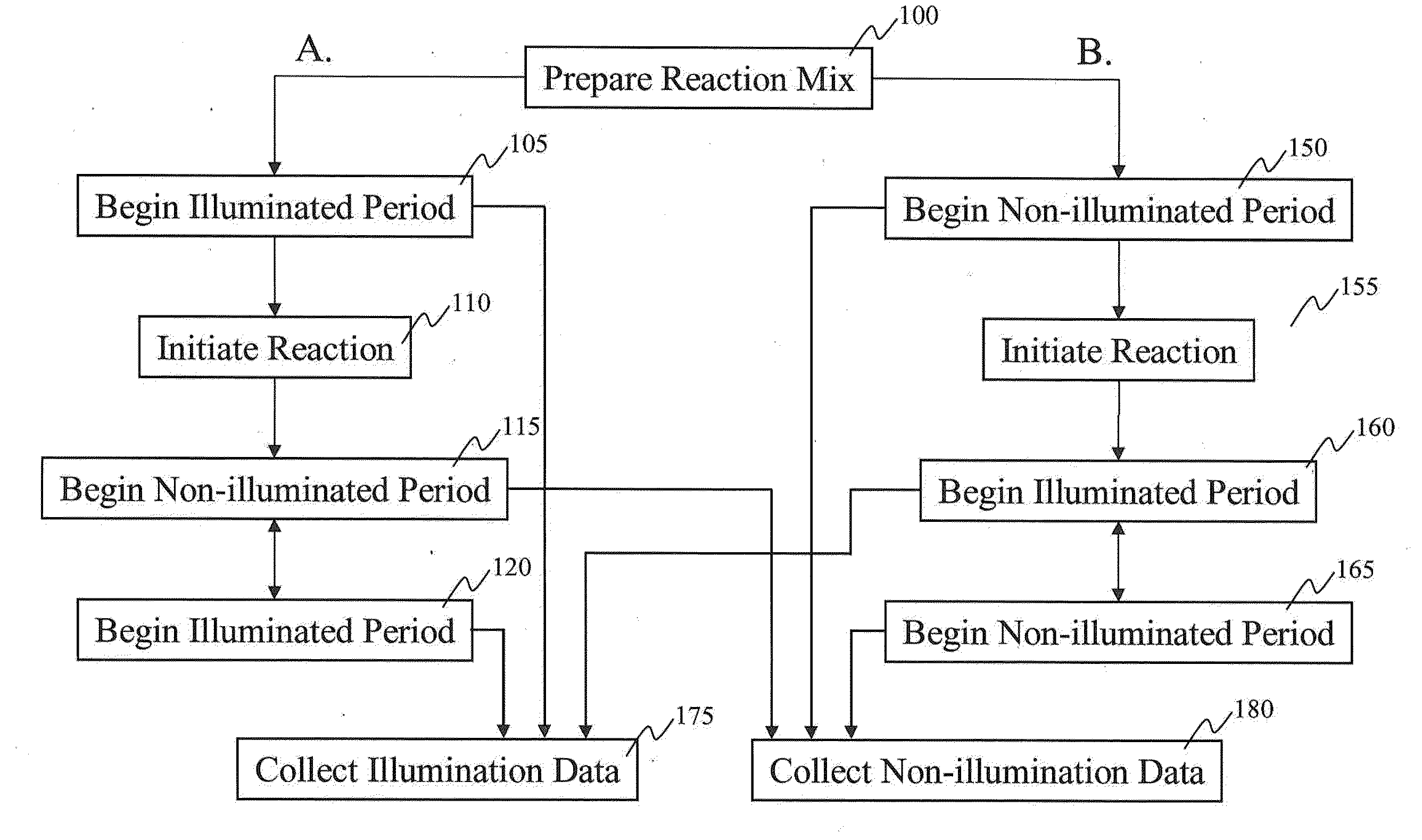

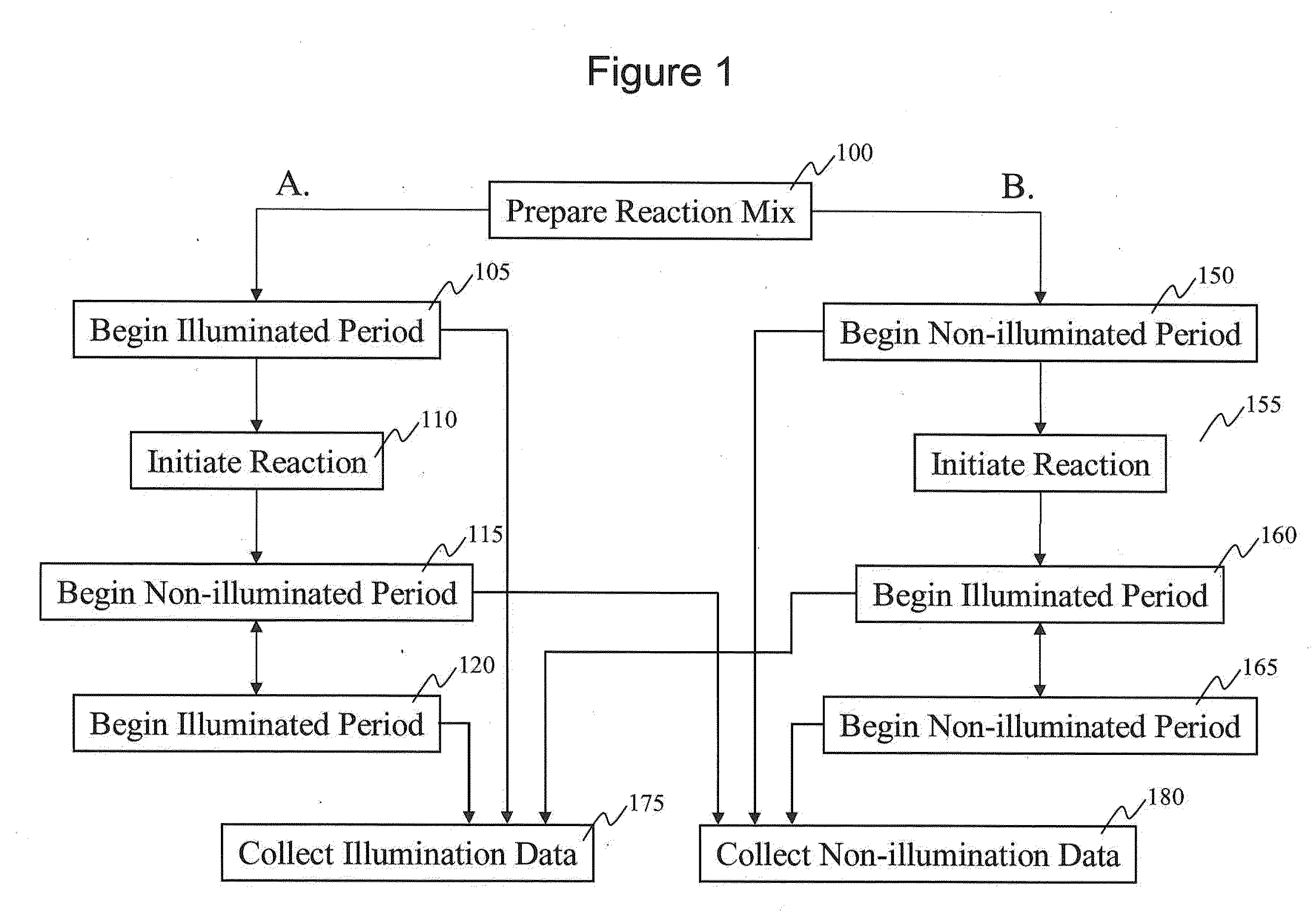

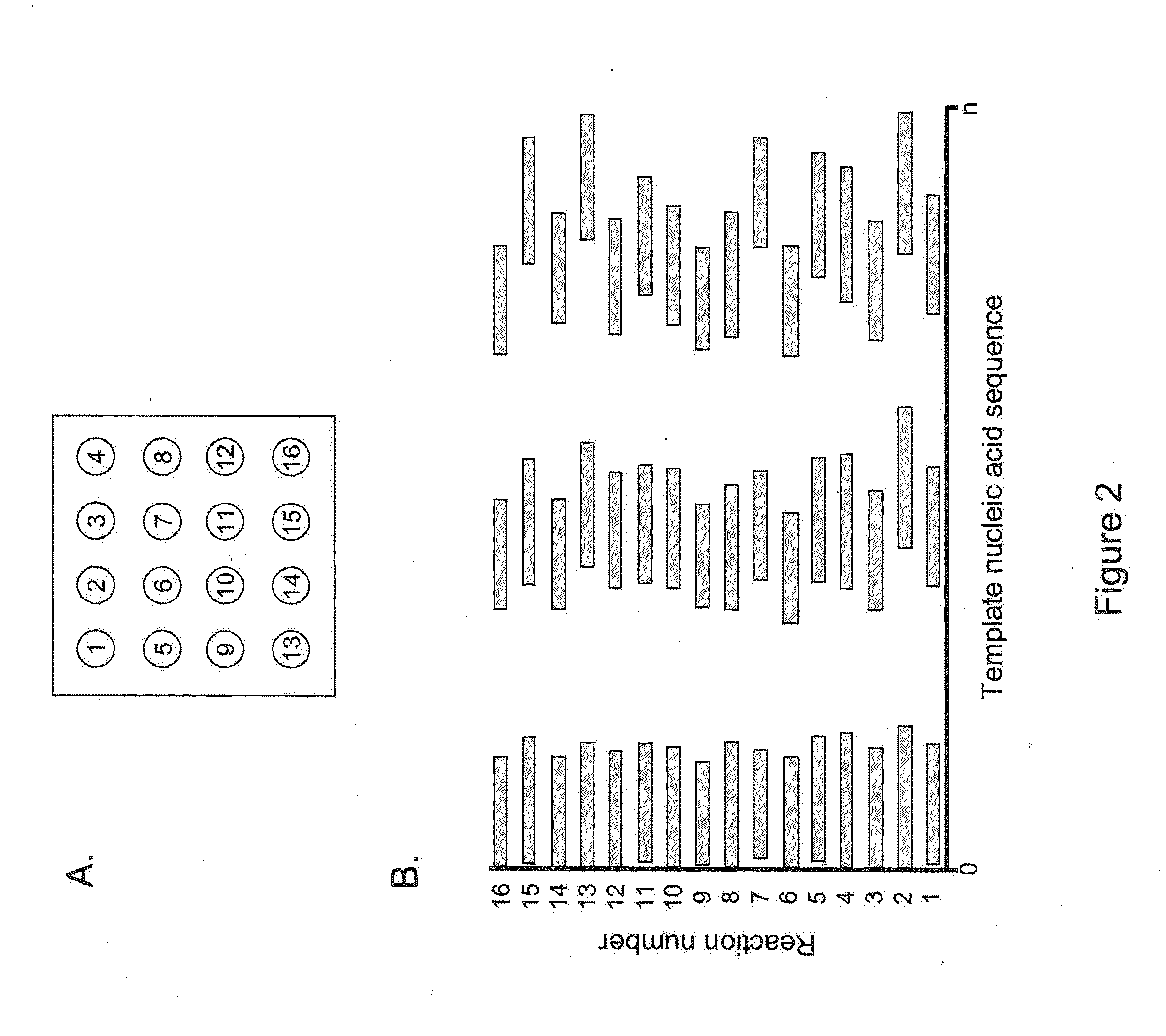

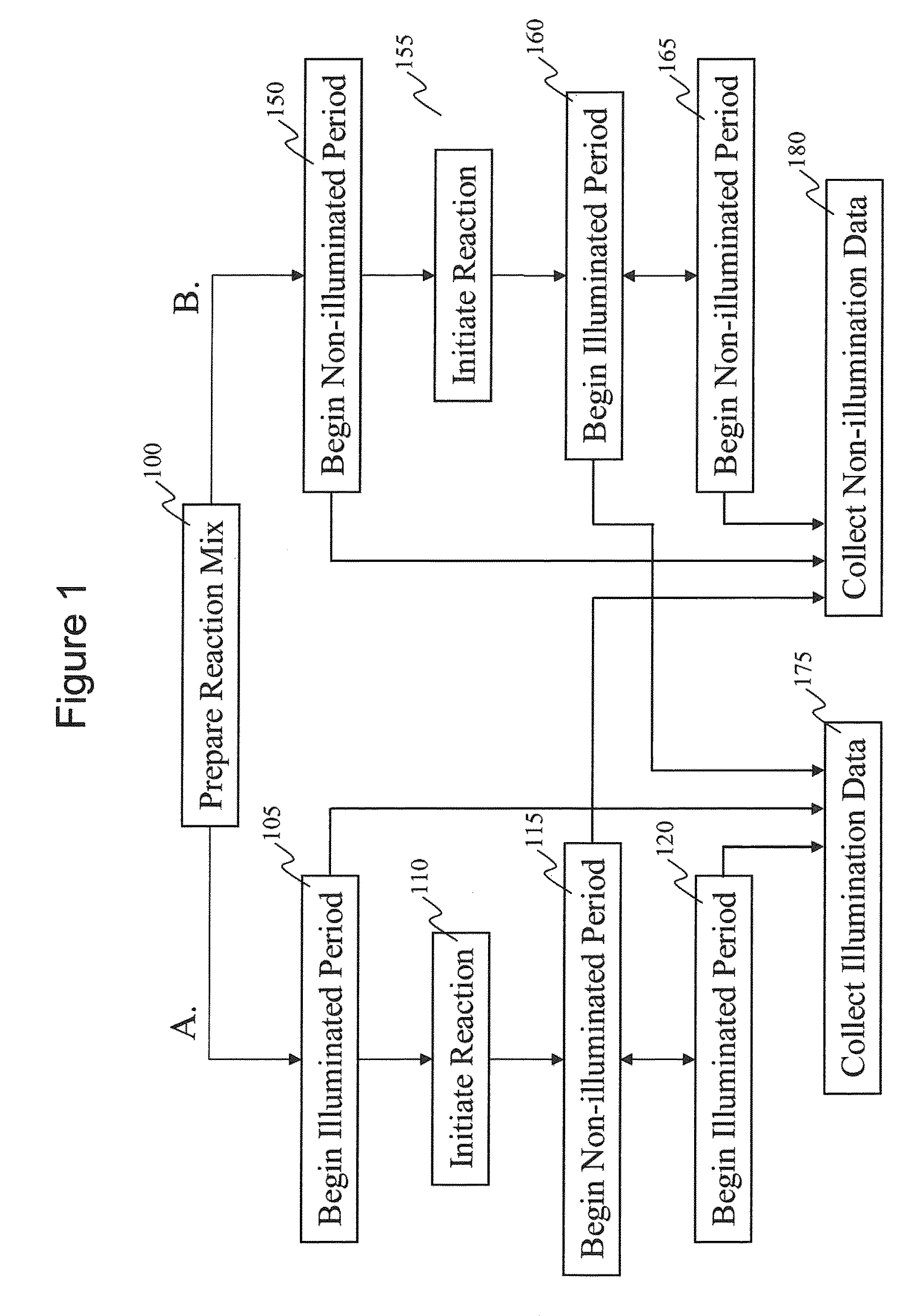

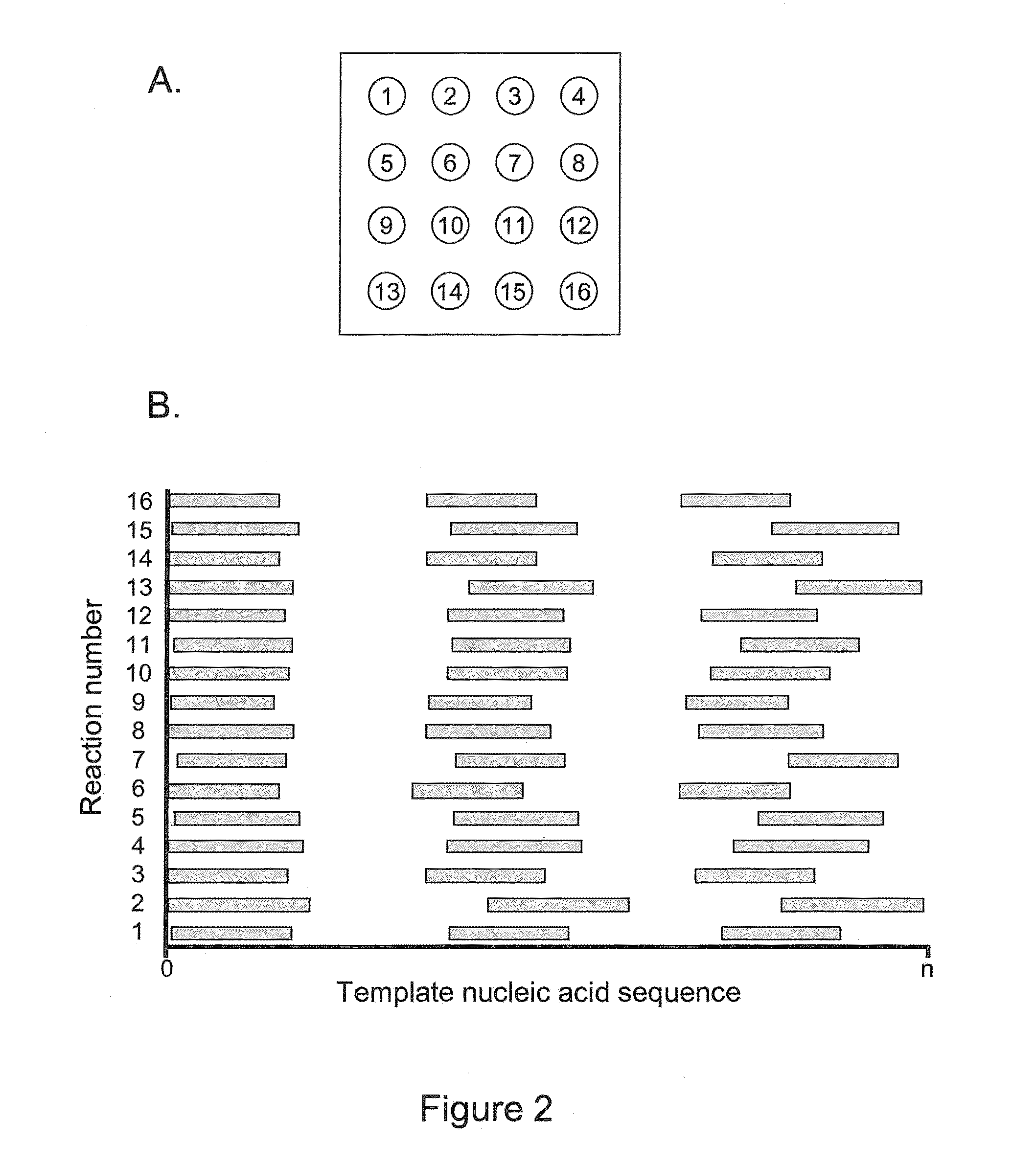

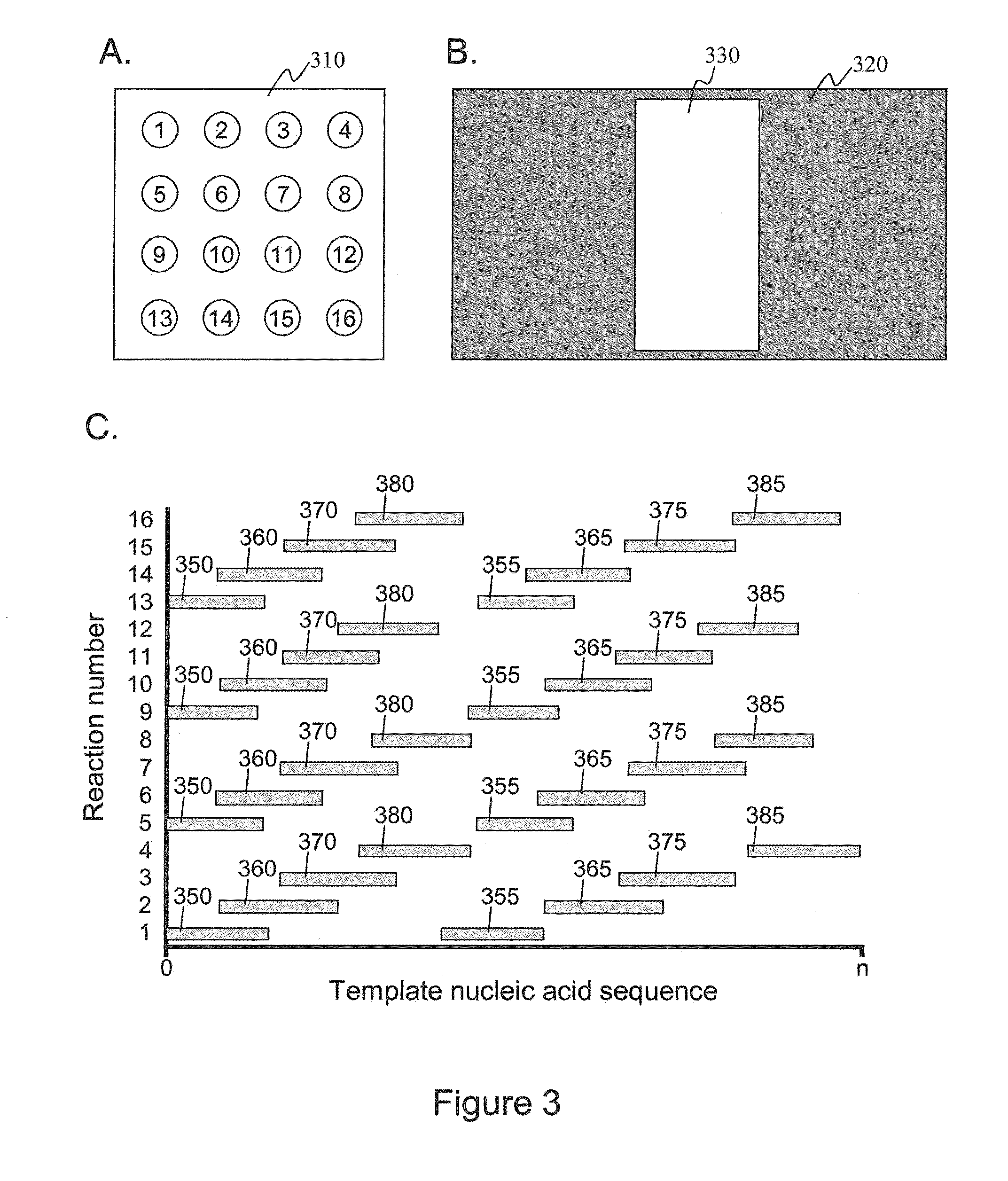

Intermittent detection during analytical reactions

ActiveUS20100075309A1Increase flexibilityAvoid damageAnalysis using chemical indicatorsMicrobiological testing/measurementReagentAnalytical chemistry

Owner:PACIFIC BIOSCIENCES

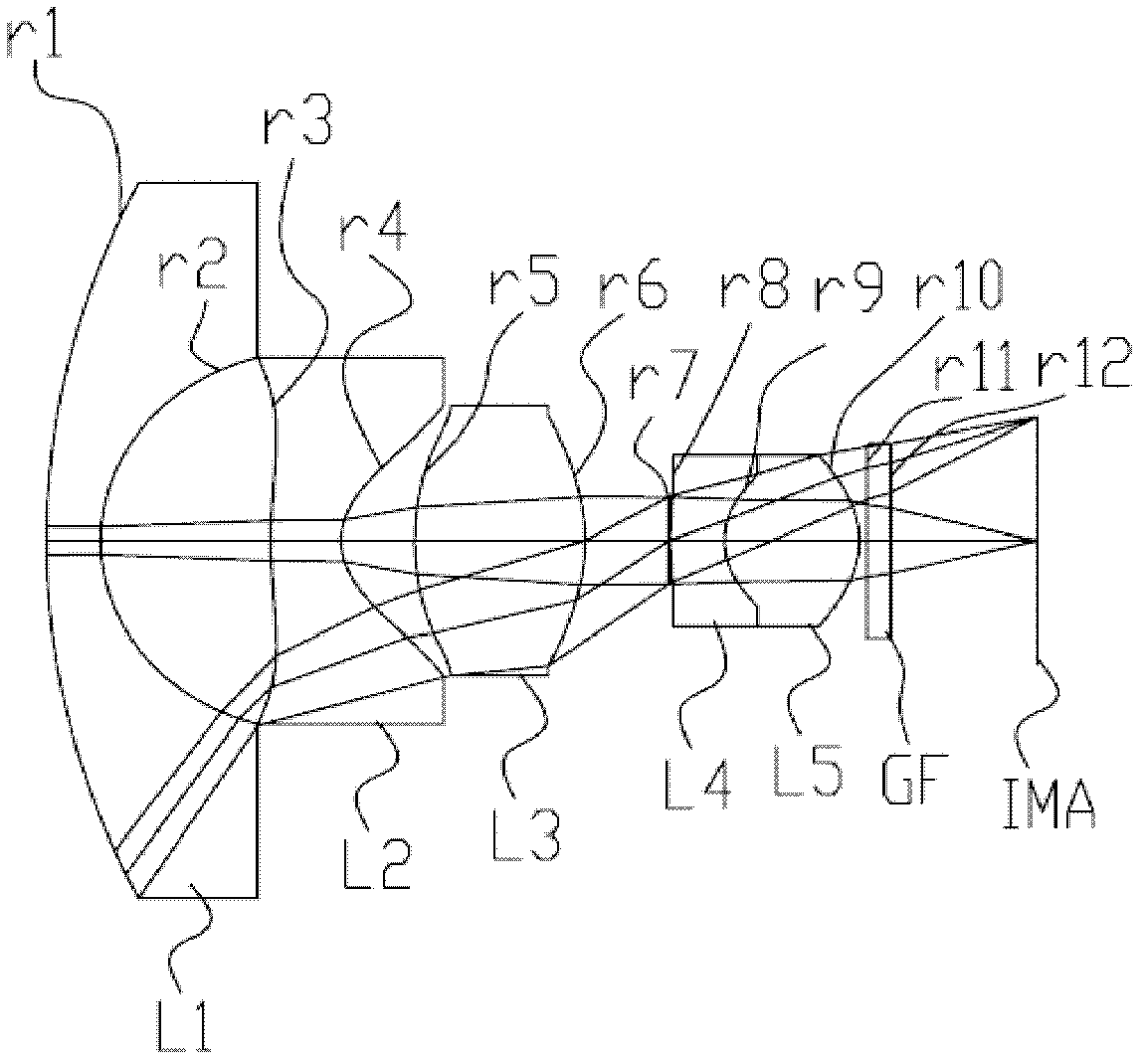

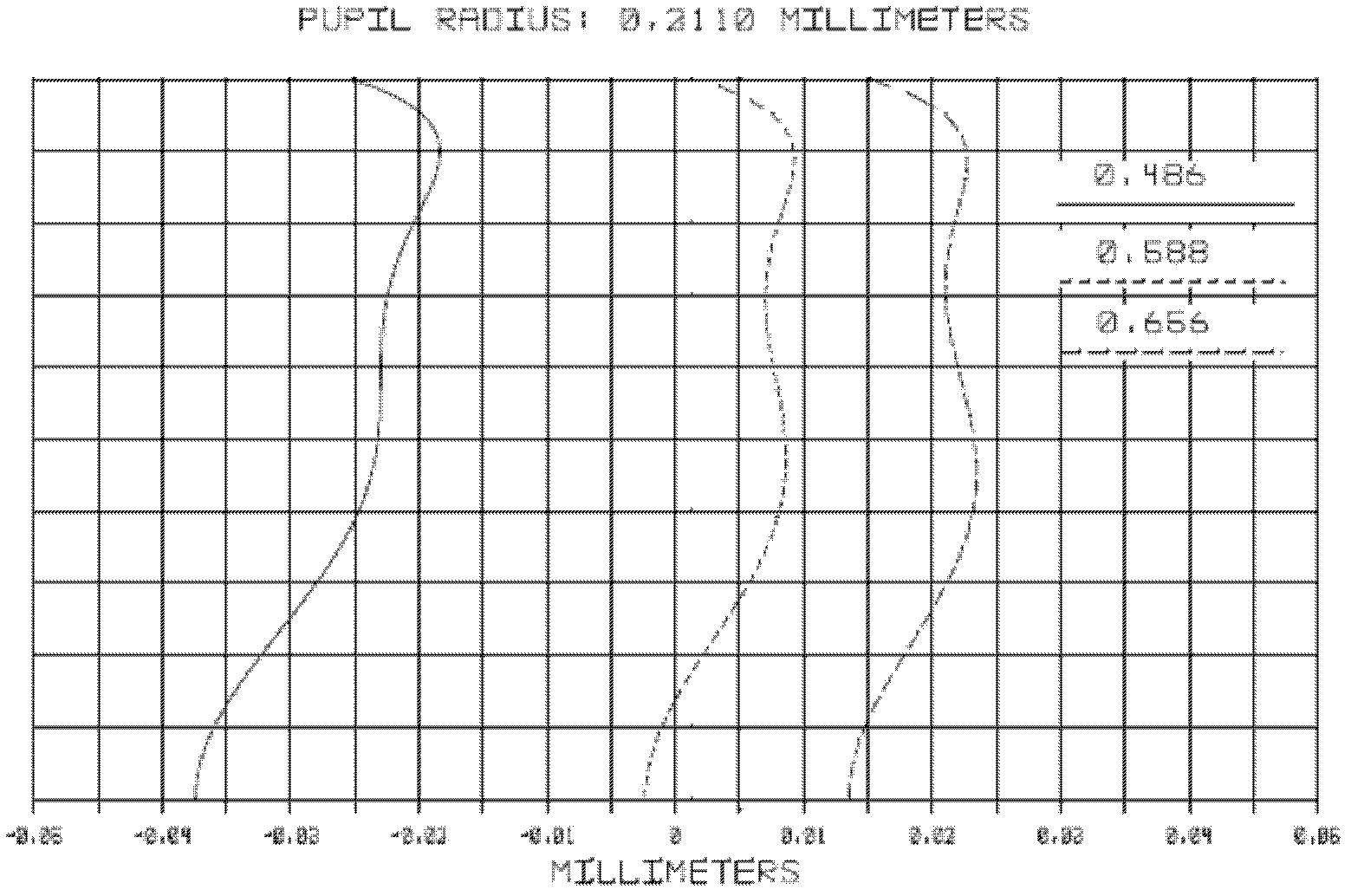

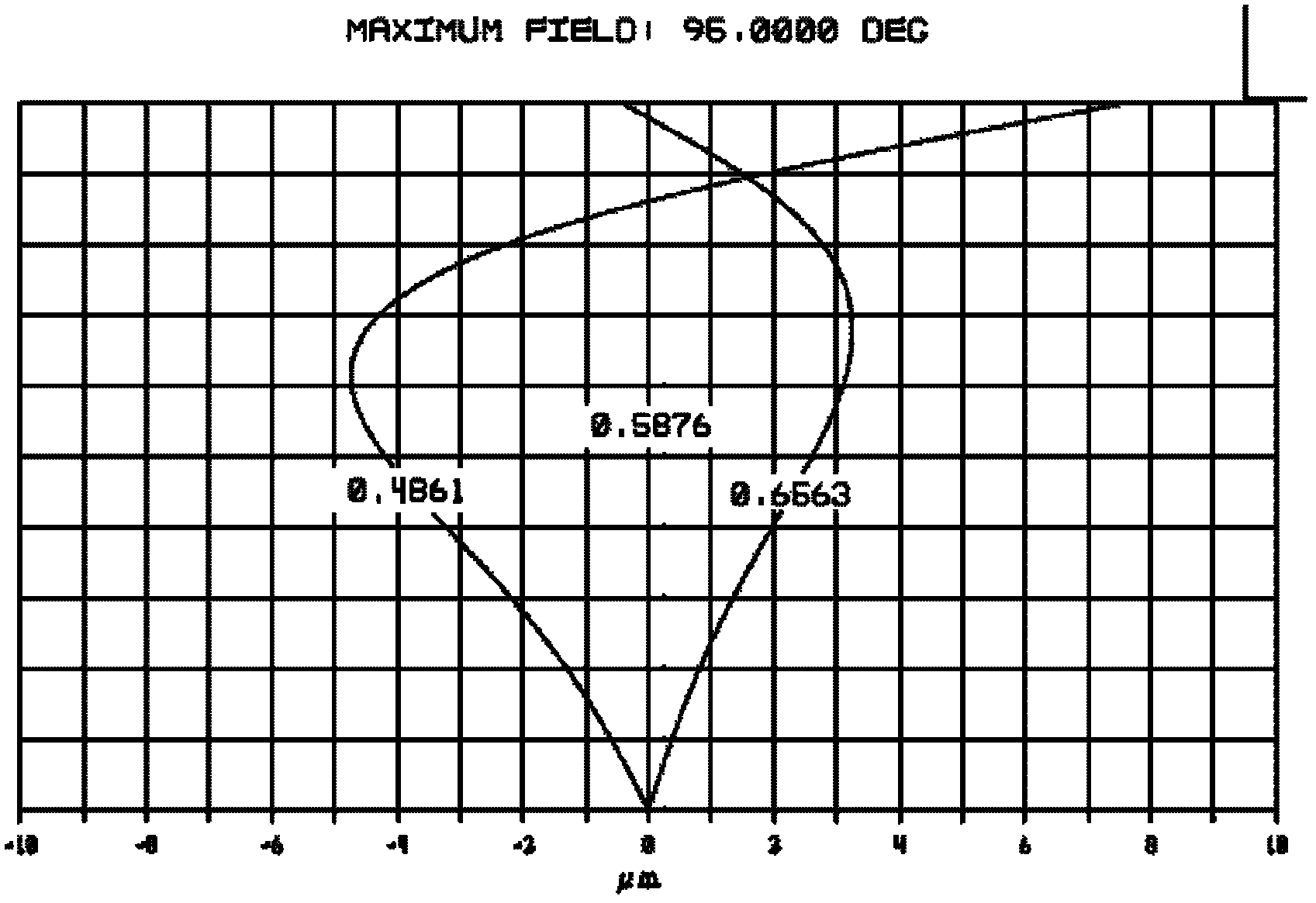

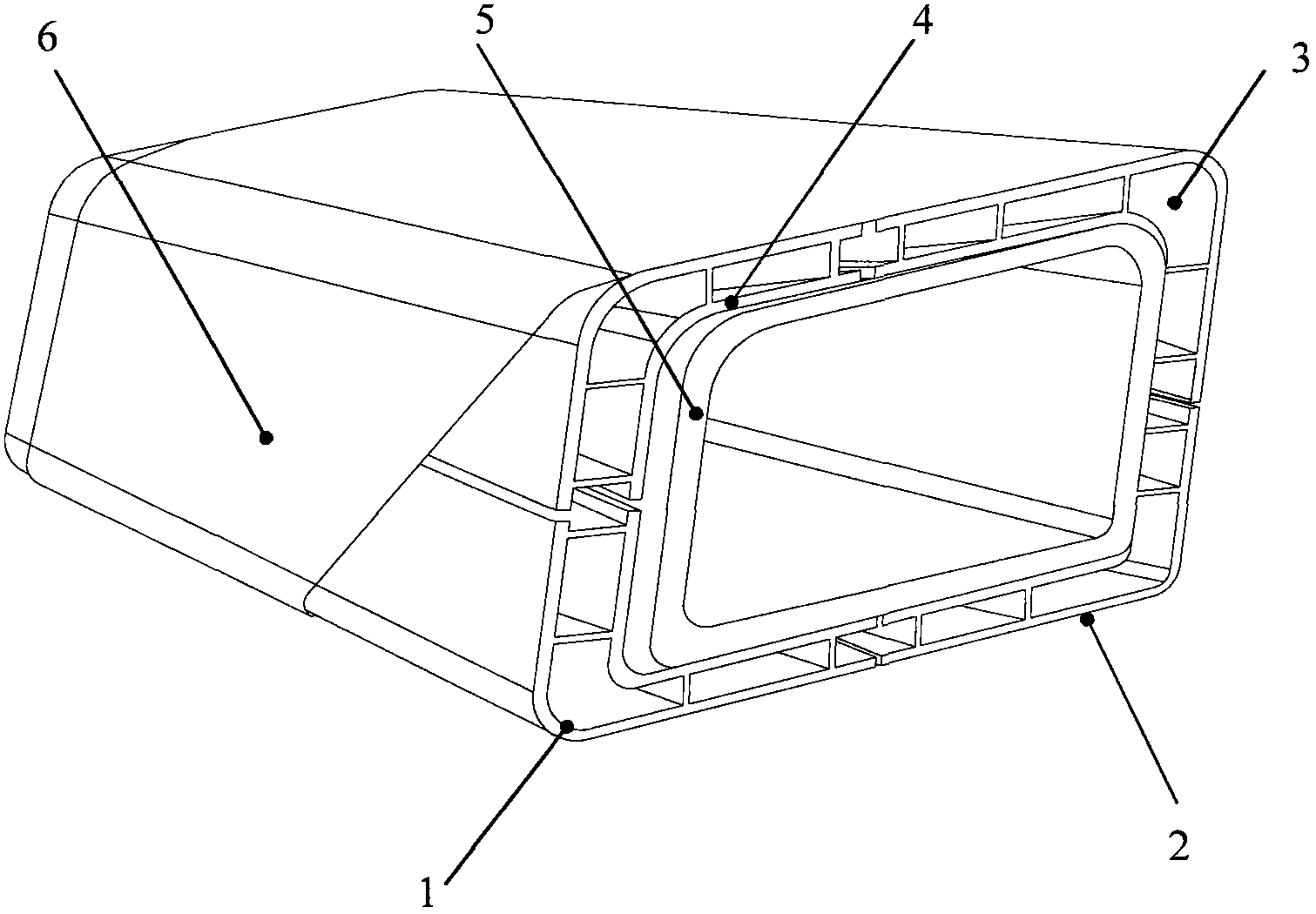

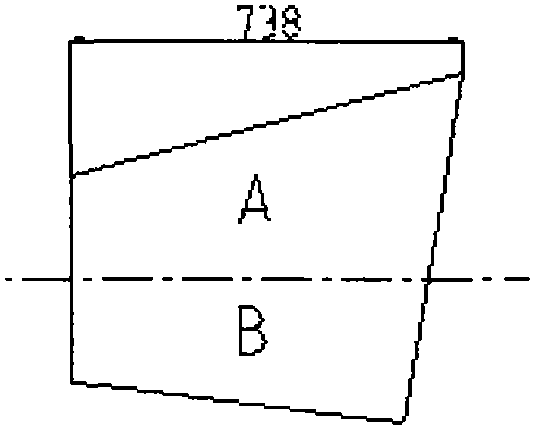

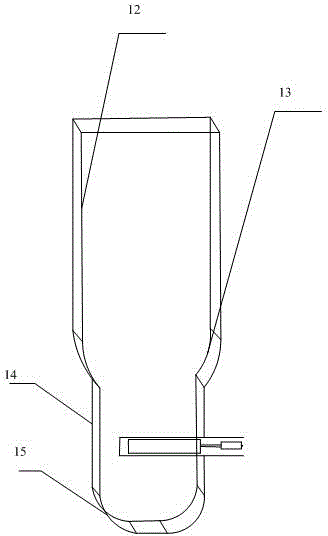

A super wide-angle lens

ActiveCN102289052AProtection against scratchesIncrease chromatic aberrationOptical elementsCamera lensLarge size

The invention discloses an ultra wide angle camera lens. The ultra wide angle lens comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens in sequence from an object space to an image space, wherein the first lens, the second lens and the fourth lens have negative focal power, the third lens and the fifth lens have positive focal power, the fourth lens and the fifth lens are adhered together to form a cemented lens with the positive focal power, the condition that BFL (Back Focal Length) / EFL (Effective Focal Length) is not smaller than 2.4 is also satisfied, BFL is a distance from an outermost point at the image space of a fifth lens element of the ultra wide angle camera lens to an imaging plane, and EFL is a focal length value of the ultra wide angle camera lens. In the invention, the ultra wide angle camera lens remains a longer BFL under the condition that a TTL (Total Length of Lens) is kept so as to meet requirements for larger sizes of electronic elements and devices at the periphery of an image sensor during the design of a camera; and the lens elements and optical filters are further from the image sensor due to longer BFL, so that the requirement for the surface cleanliness of the respective lens elements and optical filters can be effectively reduced, and the camera is easier to assemble and produce.

Owner:NINGBO SUNNY AUTOMOTIVE OPTECH

Intermittent detection during analytical reactions

ActiveUS8143030B2Increase flexibilityAvoid damageMicrobiological testing/measurementMaterial analysis by optical meansReagentAnalytical chemistry

Owner:PACIFIC BIOSCIENCES

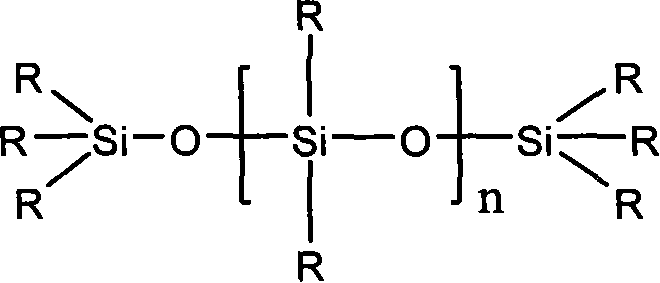

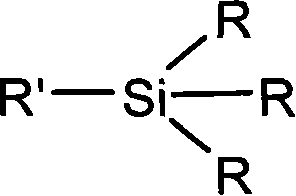

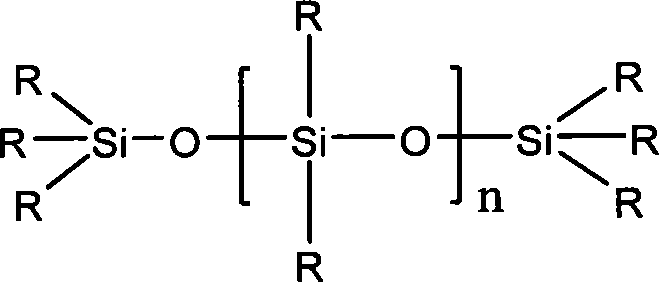

High heat conduction organosilicon filling and sealing gum

InactiveCN101054507AImprove mechanical propertiesGood electrical propertiesOther chemical processesAdhesivesHeat conductingCohesive strength

The invention discloses an organic silicon potting adhesive with a high heat conduction capacity. The curing time of the additive type organic silicon potting adhesive with a high heat conduction capacity can be controlled by the temperature and the amount of the catalyst. The condensate has good mechanical and electrical properties, especially outstanding cohesive strength, high and low temperature resistance and radiation resistance. The inventive heat-conducting organic silicon potting adhesive includes component A and B: said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, 3-20 shares of reinforced-filling, 1-10 shares of catalyst; said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, and 1-10 shares curing agent.

Owner:NANJING UNIV OF TECH

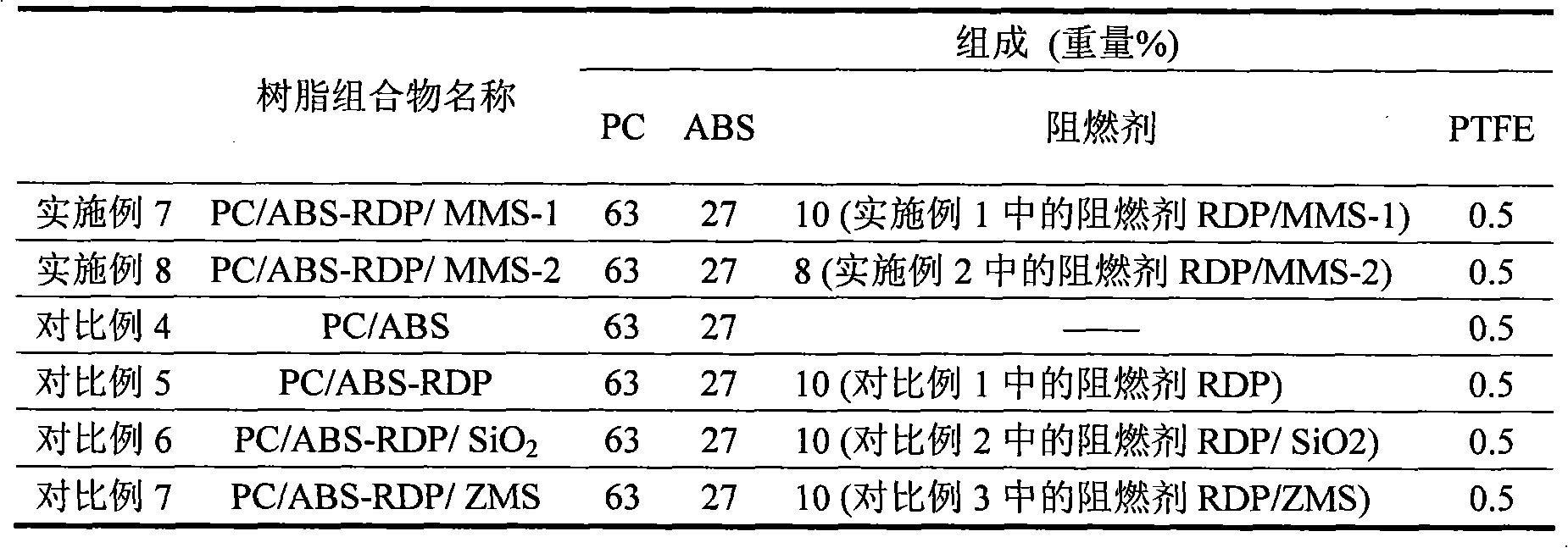

Halogen-free flame-proof static resistant polycarbonate composition and method for producing the same

The invention discloses a halogen-free flame retardant antistatic polycarbonate composition and a preparation method thereof. The composition comprises the components based on parts by weight: 50-70 parts of polycarbonate, 5-20 parts of polymer which can form a third phase, 8-15 parts of impact modifier, 3-15 parts of phosphonium flame retardant, 0.2 part of fluoro-polyolefine additive, 1-10 parts of conducting material and 0.1-1 part of other accessory ingredient. When in operation, the polymer which can form the third phase, the phosphonium flame retardant, the conducting material and other accessory ingredient are firstly melted and extruded by a double screw extruder to prepare intermediate composition; after being melted and extruded by the double screw extruder, the intermediate composition, the polycarbonate, the impact modifier and the fluoro-polyolefine additive are pelleted and then dried. The composition prepared by the invention does not contain chlorine and bromine, has excellent antistatic property, flame retardance, impact resistance and formability and needs a little conductive filler.

Owner:SOUTH CHINA UNIV OF TECH

Intermittent detection during analytical reactions

ActiveUS8383369B2Increase flexibilityAvoid damageMicrobiological testing/measurementMaterial analysis by optical meansReagentAnalytical chemistry

Owner:PACIFIC BIOSCIENCES

Intermittent detection during analytical reactions

ActiveUS20110195406A1Increase flexibilityAvoid damageMicrobiological testing/measurementTransferasesReagentAnalytical chemistry

Owner:PACIFIC BIOSCIENCES

Biologic degradable copolyester and preparation process thereof

A biodegradable copolyester (butanediester polysuccinate for example) is prepared from butanedioic acid, butanediol, copolydiol and copolydiacid through copolymerizing to obtain atactic linear copolyester, and condensation.

Owner:TSINGHUA UNIV

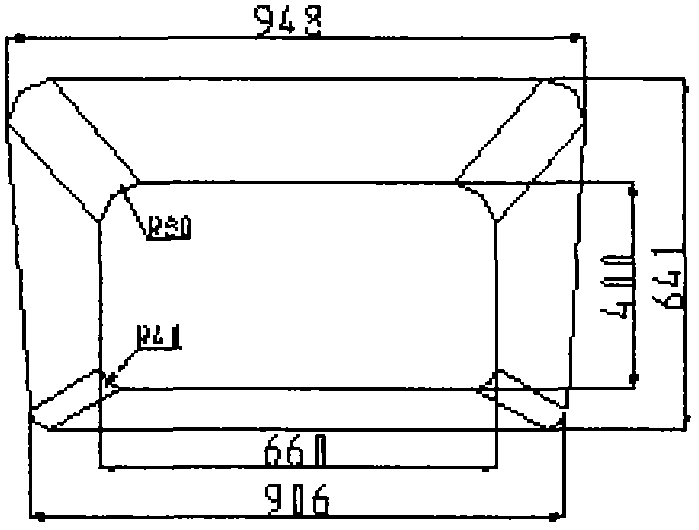

Integral forming method for thin-walled titanium alloy part with irregularly-shaped curved surface and die

InactiveCN102672435AOvercoming shape constraintsOvercome the processShaping toolsLaser beam welding apparatusTitanium alloyMetal

The invention belongs to the field of sheet metal and welding processing, and relates to an integral forming method for a thin-walled titanium alloy part with an irregularly-shaped curved surface. The integral forming method aims at overcoming the defects that the shape of parts processed through the prior art is limited or the procedure and the cost are higher, and effectively ensuring the precision forming of a thin-walled component with an irregular shape. The integral forming method comprises the steps as follows: a parting surface is determined; blanking is carried out; in the preforming step, a plate is bent from a flat into a circular arc through a bending die or a bending machine; welding is carried out; in the hot shaping step, a hot shaping die is put in the inner part of a part that is processed through the assembly welding under the ordinary temperature, and the part is supported tightly due to the dead weight of the die and is heated in a hot shaping machine; and in addition, a pressing machine applies pressure to the hot shaping die when the part is heated until material is softened, so as to enable the part to reach the needed size. The integral forming method comprehensively utilizes the advantages of various processes, can obtain the large-sized thin-walled titanium alloy part with the irregularly-shaped curved surface through only two weld joints, and achieves higher surface quality of the part.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Copper alloy for connector use and producing method thereof

InactiveCN1403609AAvoid it happening againReduce contact resistanceMetal/alloy conductorsPunchingStress relaxation

The present invention provides one kind of copper alloy for connector and with low cost, high strength and excellent conducting performance and punching performance and its making process. The alloy contains Zn in 23-28 wt% and Sn 0.3-1.8 wt% and the sum of 0.25 Zn wt%+Sn wt% is 6.0-8.5. Through casting, cooling, hot rolling at temperature below 900 deg.c, repeated cold rolling and annealing, copper alloy belt is produced with 0.2 % yield strength over 600 N / sq mm, tensile strength over 650 N / sq mm, conductivity over 20 % IACS, youngs modules below 120 Kn / sq mm and stress relaxation rate below 20%.

Owner:DOWA METALTECH CO LTD

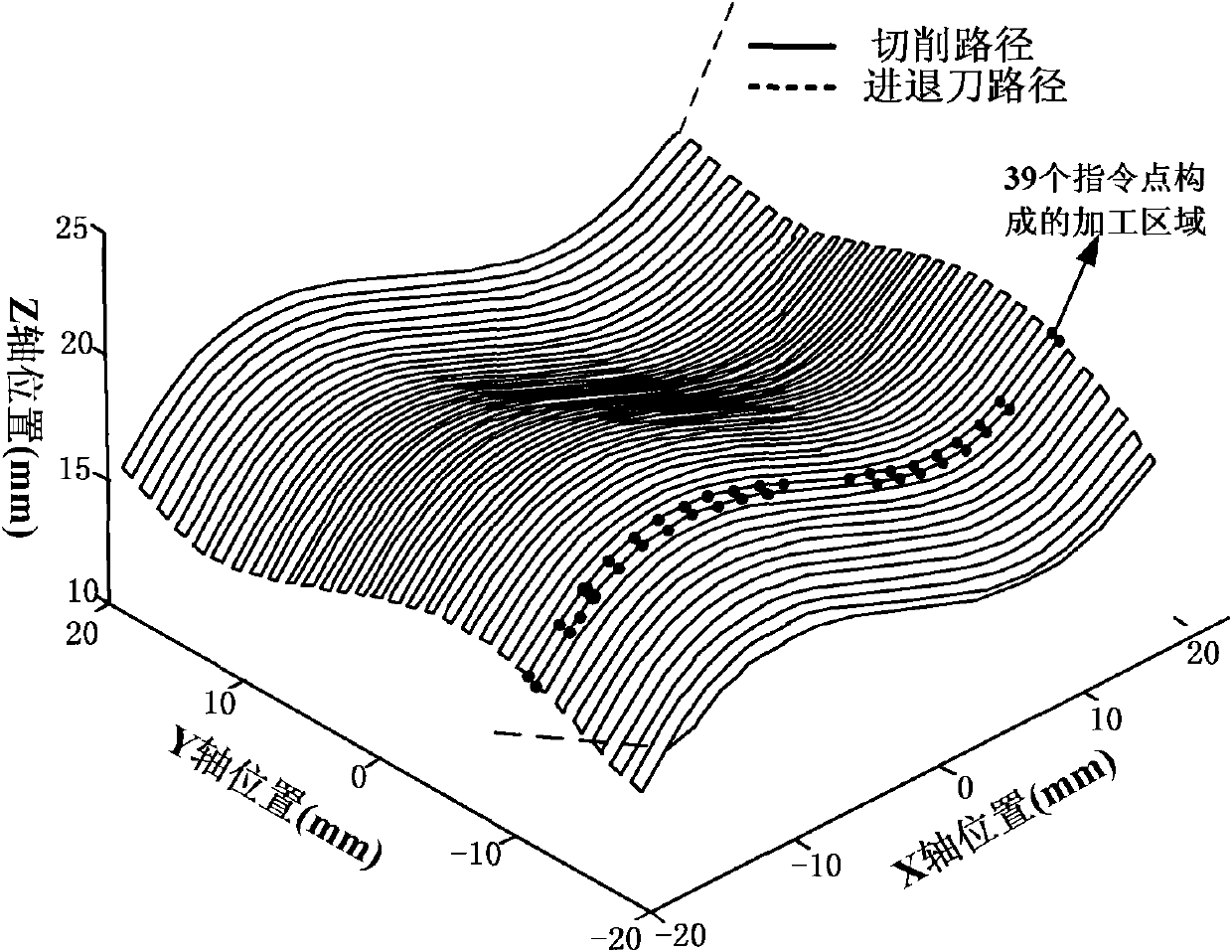

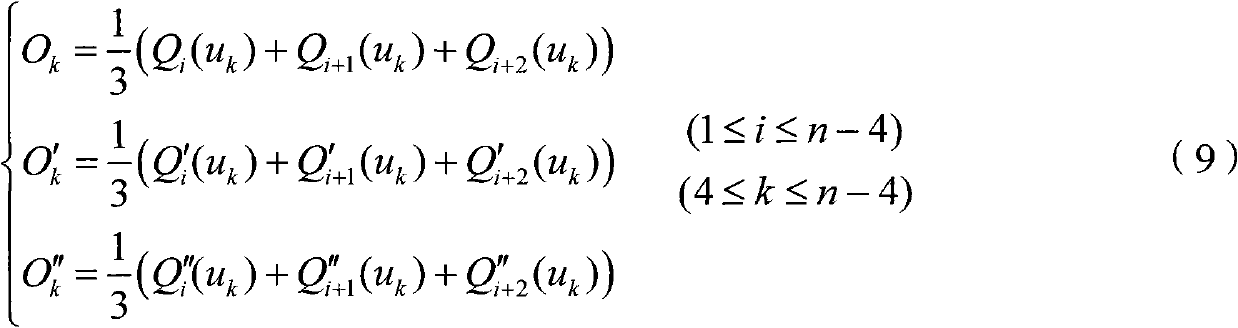

Command point shaping, compressing and interpolating method suitable for numerical control device

ActiveCN101907876AIncreased transfer speedImprove processing efficiencyNumerical controlProcessing accuracyLine segment

The invention relates to a command point shaping, compressing and interpolating method suitable for a numerical control device. The method comprises the following steps of: inserting an arc which has a distance with the middle point of a tolerance set by the numerical control device and is tangential with segments of adjacent command points to the middle point of every three adjacent command points when a numerical control processing procedure judges that any three adjacent command points on a processed curve surface meet a continuous processing condition, wherein the tangential points are used as interpolation points; trimming the interpolation points to reduce calculation errors and rounding errors in the process of reckoning the interpolation points; selecting a characteristic interpolation point through judging the bending directions of processing paths of all the interpolation points; fitting by using a continuous polynomial spline curve with a second derivative to generate a smooth curve; approximately calculating the interpolation points of a current interpolation period and sending the positions of the interpolation points to a servo system of the numerical control device; and driving a servo motor to move. The invention furthest improves the processing efficiency and reduces the influences of the calculation errors and the rounding errors on the processing precision and the processed surface smoothness.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

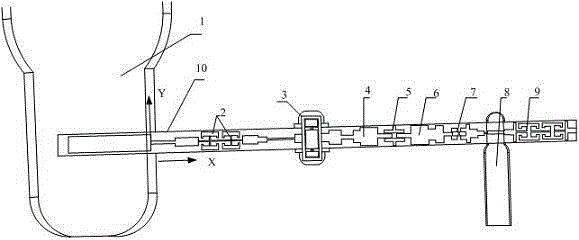

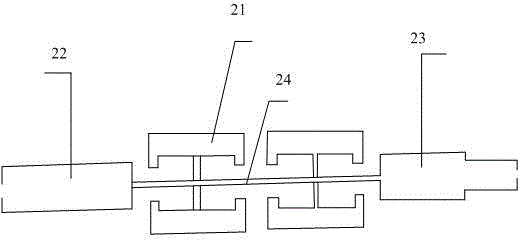

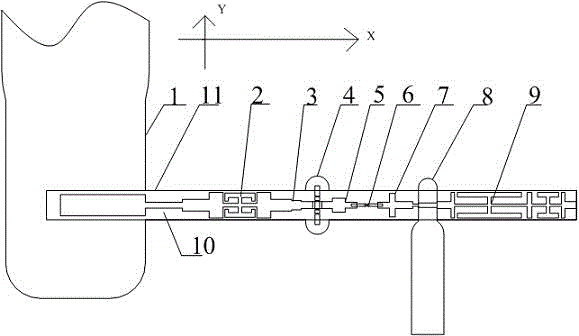

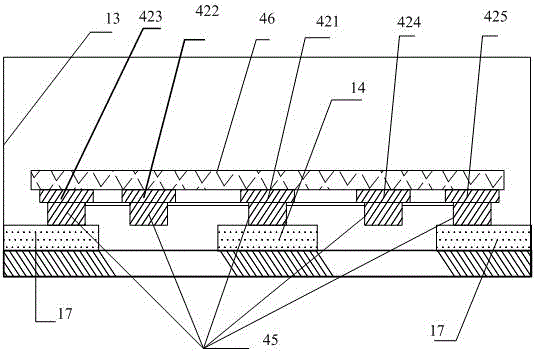

Single-substrate integrated terahertz front end

ActiveCN104362421AReduce the numberReduce processingCoupling devicesIntermediate frequencyBand-pass filter

The invention discloses a single-substrate integrated terahertz front end. The single-substrate integrated terahertz front end comprises a dielectric substrate, an inputting waveguide micro-strip transition and a micro-strip air cavity; the micro-strip air cavity is the air cavity; the inputting wave micro-strip transition (a standard waveguide opening WR-15), a CMRC (compact microstrip resonant cell) structure micro-strip low-pass filter, a parallel double-frequency-doubling diode, a frequency-doubling matching branch knot, a local oscillator band-pass filtering device, a frequency-mixing matching branch knot, a frequency-mixing diode, a radiofrequency waveguide micro-strip transition (a standard waveguide WR-2.2) and an intermediate-frequency low-pass filtering device are sequentially arranged on the single-substrate integrated terahertz front end from left to right. The number of dielectric substrates is reduced; circuits are integrated on the substrate; the number of machined cavities is also reduced; the single-substrate integrated terahertz front end is easy to machine and assemble; designing and machining on the waveguide transition are reduced; and the size of the cavity is also reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

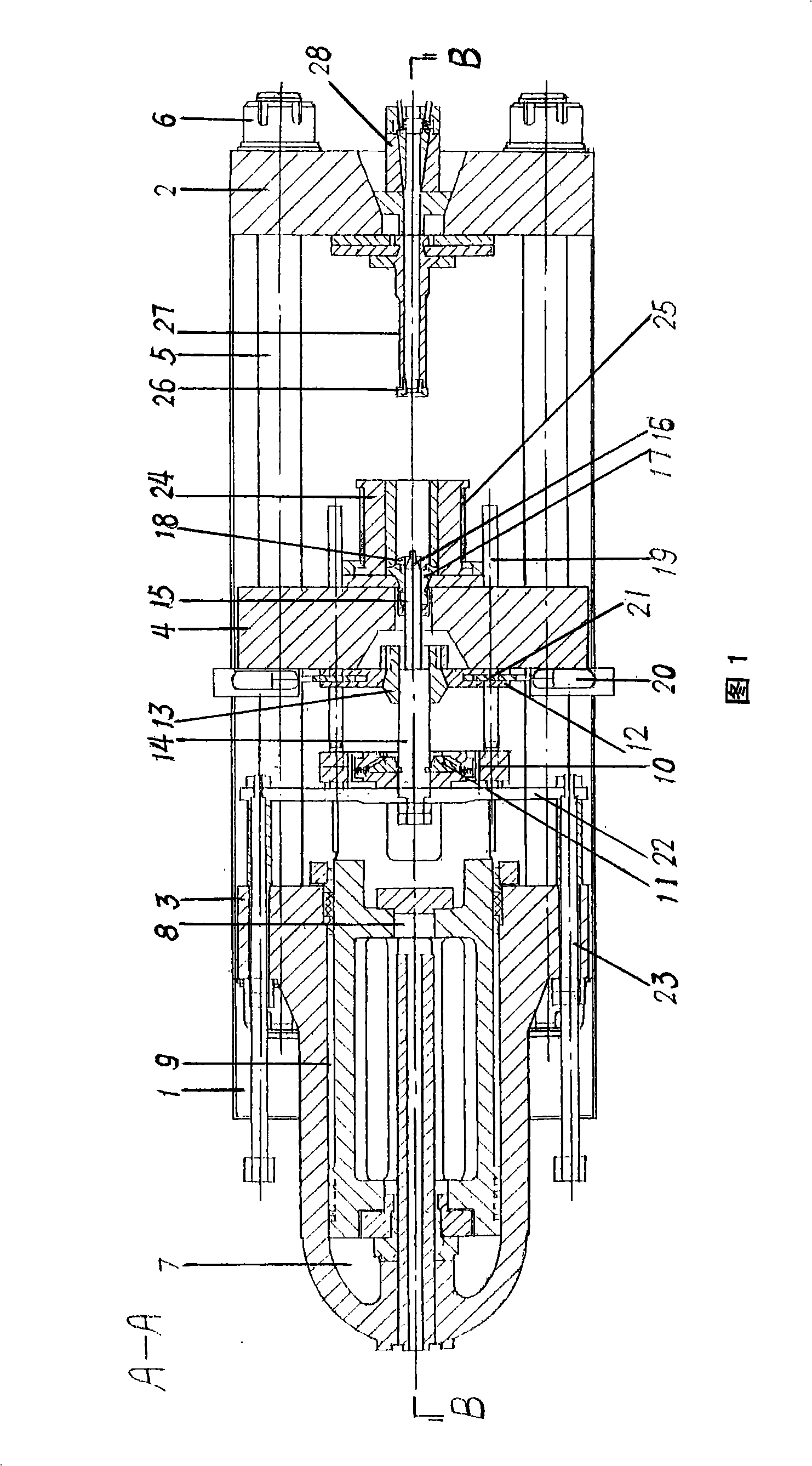

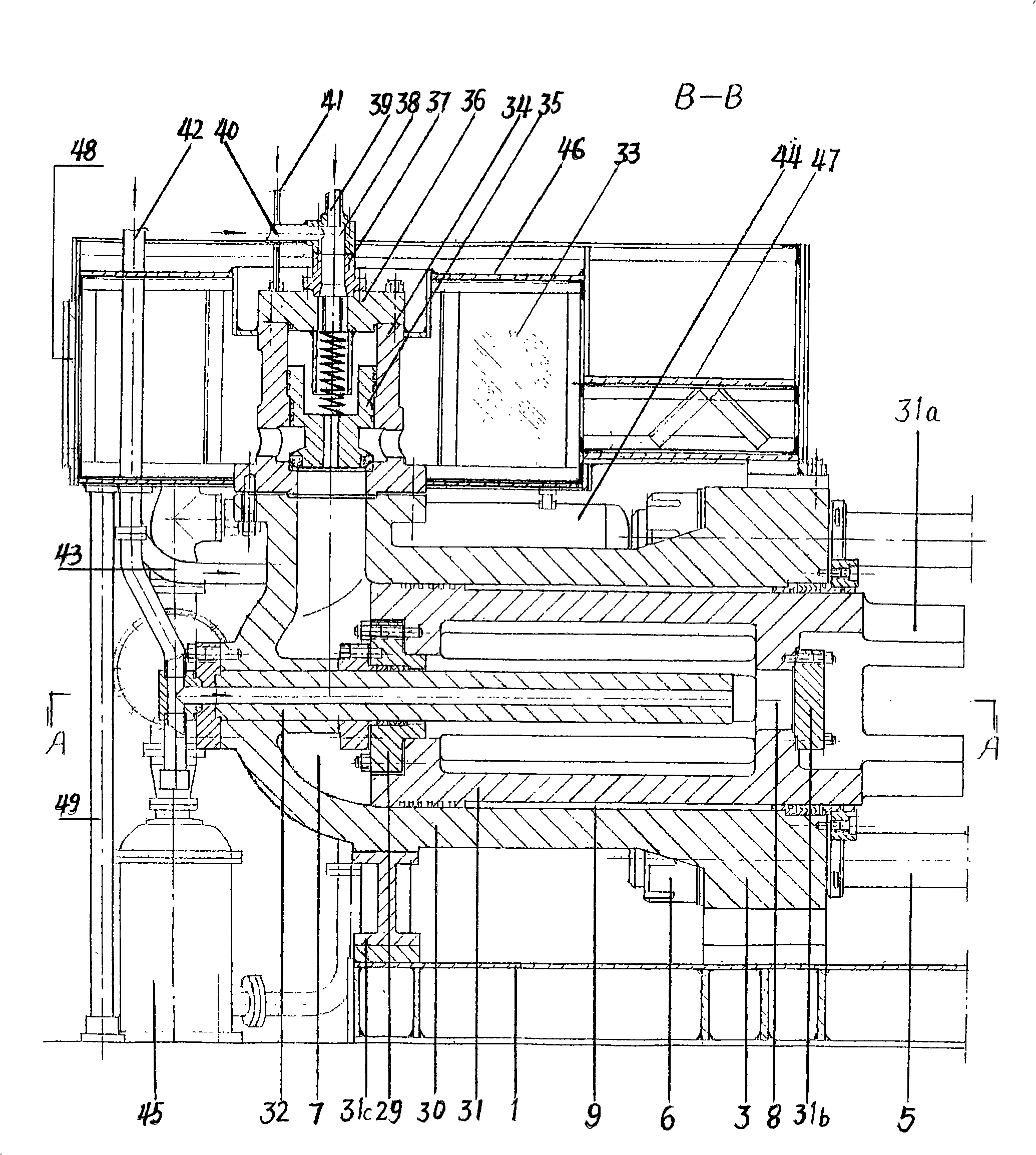

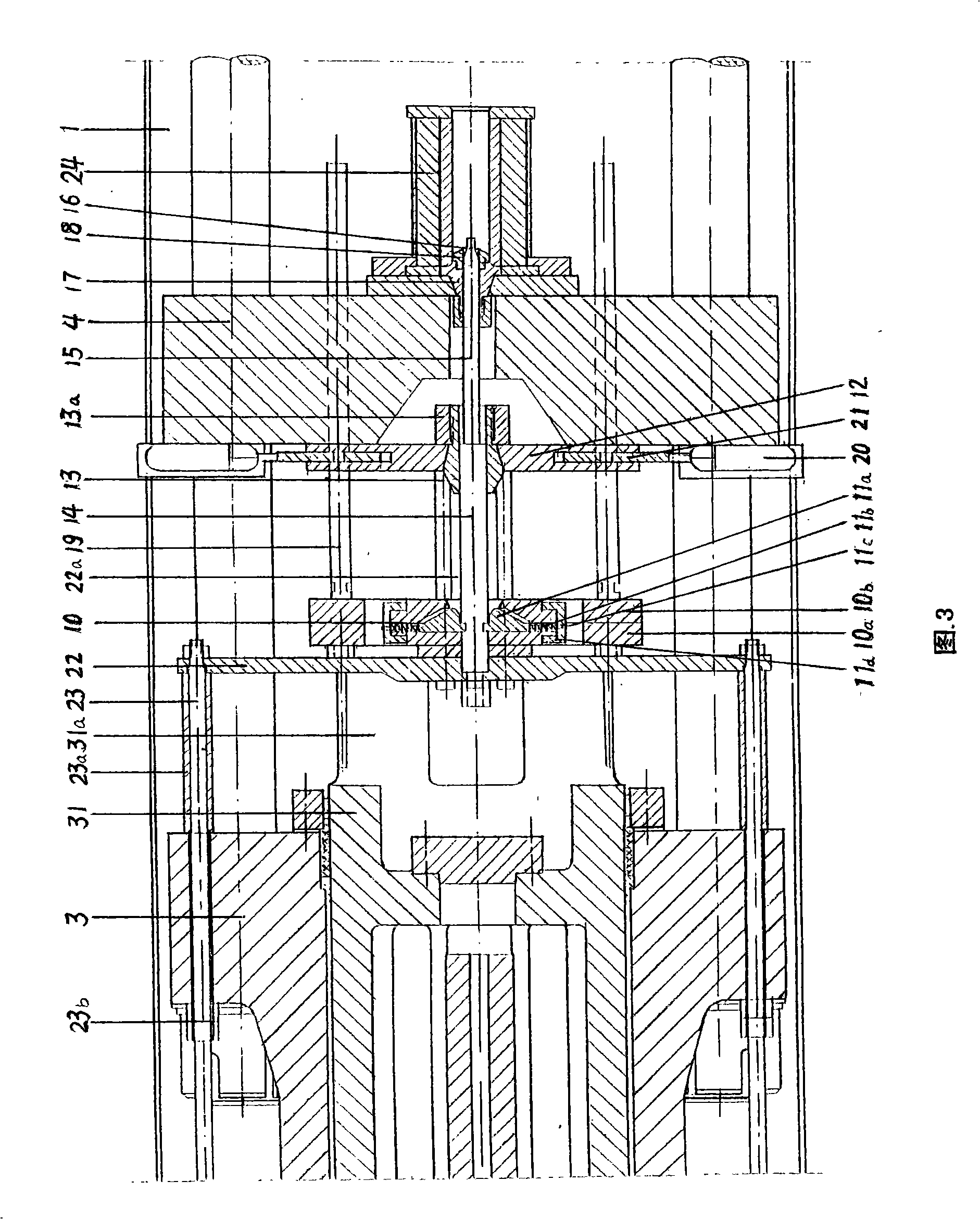

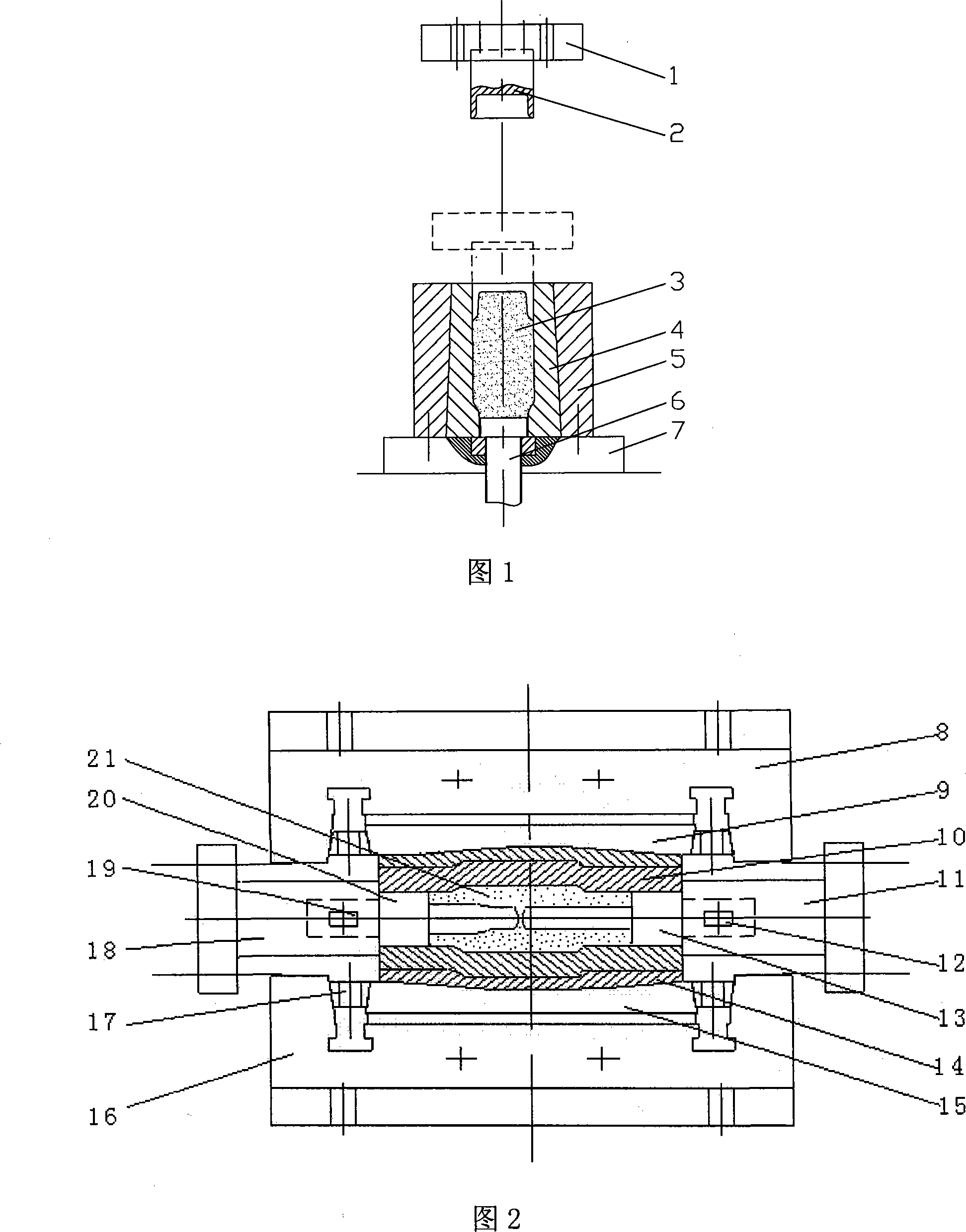

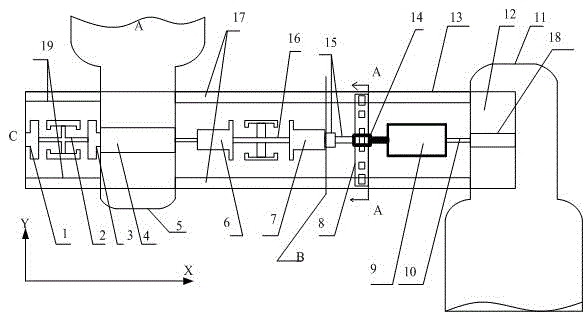

Alloyed steel horizontal type indirect extrusion machine

The invention discloses a horizontal reverse alloy steel extrusion machine, which belongs to the novel technical field of seamless steel pipe and relates to a seamless steel pipe manufacturing facility. The purpose is to settle the problems of complex process, inefficiency, high energy consumption and pollution of the environment with the prior domestic cold drawing techniques of small-bore seamless alloy steel tube. The machine consists of a rigid framework, a liquid-filled combined hydraulic cylinder and a die assembly, wherein, the rigid framework consists of an anterior fixed beam, a posterior fixed beam and an intermediate moving beam on the frame, which are connected in series by a four tensile columns; the liquid-filled combined hydraulic cylinder has a compact structure and is capable of executing the operations of die displacement, material feeding, perforation, extrusion and die removal; the die assembly consists of a perforation and extrusion and automatic switching system, a hot extrusion / molding system and a die removal and disengaging and residual extrusion and cutting system. The machine is capable of achieving once-and-for-all heating and once-and-for-all molding to directly produce finished products of small-bore seamless alloy steel pipes. Compared with forward extrusion, the deviations of the displacement of the piercing mandril and the dies are small, and no friction occurs between the billets and the internal wall of the container, thereby the machine can directly adopt continuous casting billets to extrude small-bore pipes, and has the advantages of simple process, high quality, high efficiency, low energy consumption, etc.

Owner:周家镳

Intermittent detection during analytical reactions

ActiveUS8628940B2Increase flexibilityAvoid damageMicrobiological testing/measurementMaterial analysis by optical meansReagentAnalytical chemistry

Owner:PACIFIC BIOSCIENCES

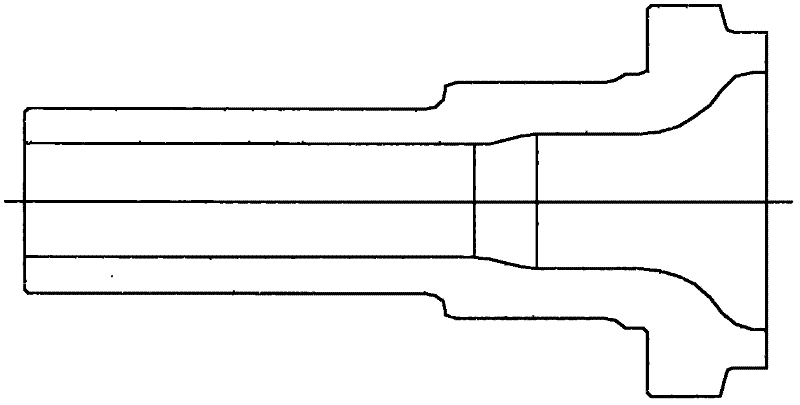

Drill pipe joint precision die forging process

InactiveCN101181730AEasy to moldSmall machining allowanceForging/hammering/pressing machinesMedium frequencyMaterial consumption

The invention discloses a precise die forging technique of a petroleum drill rod connector and is characterized in that: 1) flan material is prepared with a band saw; 2) the flan material is heated quickly at a temperature that is suitable for forging by a medium frequency electric induction furnace; 3) then the flan material is extruded in a close type into a prefabricated flan and a flan makes concave die on a quick flan-making oil hydraulic machine; 4) a molding concave by die level method extrudes and presses the prefabricate flan into a connector die forging piece on the quick flan-making oil hydraulic machine which can implement combination of the upper molding concave die and the lower molding concave die and relative extrusion and pressing from right and left and inner holes of the connector die forging piece is provided with wad; 5) finally a hole punching die punches away the recess inside the inner hole of the forging piece on a special hole punching oil hydraulic machine to obtain the connector forging piece with accurate specifications, excellent structure performance and central through holes. The invention has the advantages of good streamline distribution, material conservation, environmental protection and high production efficiency.

Owner:JIANGYIN LONGCHENG DRILLING & PRODN MACHINERY MFG

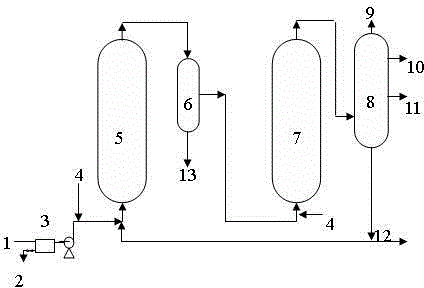

Ferrite stainless steel cold-rolled steel band and manufacturing method thereof

ActiveCN101649418AEasy to processReduced processing performanceTemperature control deviceManufacturing convertersSS - Stainless steelMolten steel

The invention relates to a ferrite stainless steel cold-rolled steel band and a manufacturing method thereof. The ferrite stainless steel cold-rolled steel band comprises the following chemical ingredients in percentage by weight: 0.02%-0.04% of C, 0.10%-0.50% of Si, 0.10%-1.00% of Mn, 14.0%-19.0% of Cr, less than or equal to 0.030% of P, less than or equal to 0.010% of S, more than 0% while lessthan or equal to 0.030% of N, more than 0% while less than or equal to 0.60% of Ni, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps: (1) smelting, i.e. smelting liquid steel according to the requirement of the steel band; (2) continuous casting, i.e. casting into a continuous casting billet; (3) casting billet hot rolling, i.e. rolling the casting billet into a hot rolled coil; (4) hot coiling annealing, i.e. preserving the temperature at 800 DEG C-880 DEG C for the temperature preserving time of 10-13 hours, freely reducing the temperature to 600 DEG C after the temperature preservation is completed; (5) cold rolling, i.e. adopting once cold rolling or twice cold rolling among cold rolled finished products; and (6) cold coiling annealing, i.e. controlling annealing temperature at 860+ / -20 DEG C, and controlling annealing time according to 2-5 minutes / mm. The ferrite stainless steel cold-rolled steel band has good cold processingforming property and excellent crinkling and breaking resistance.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

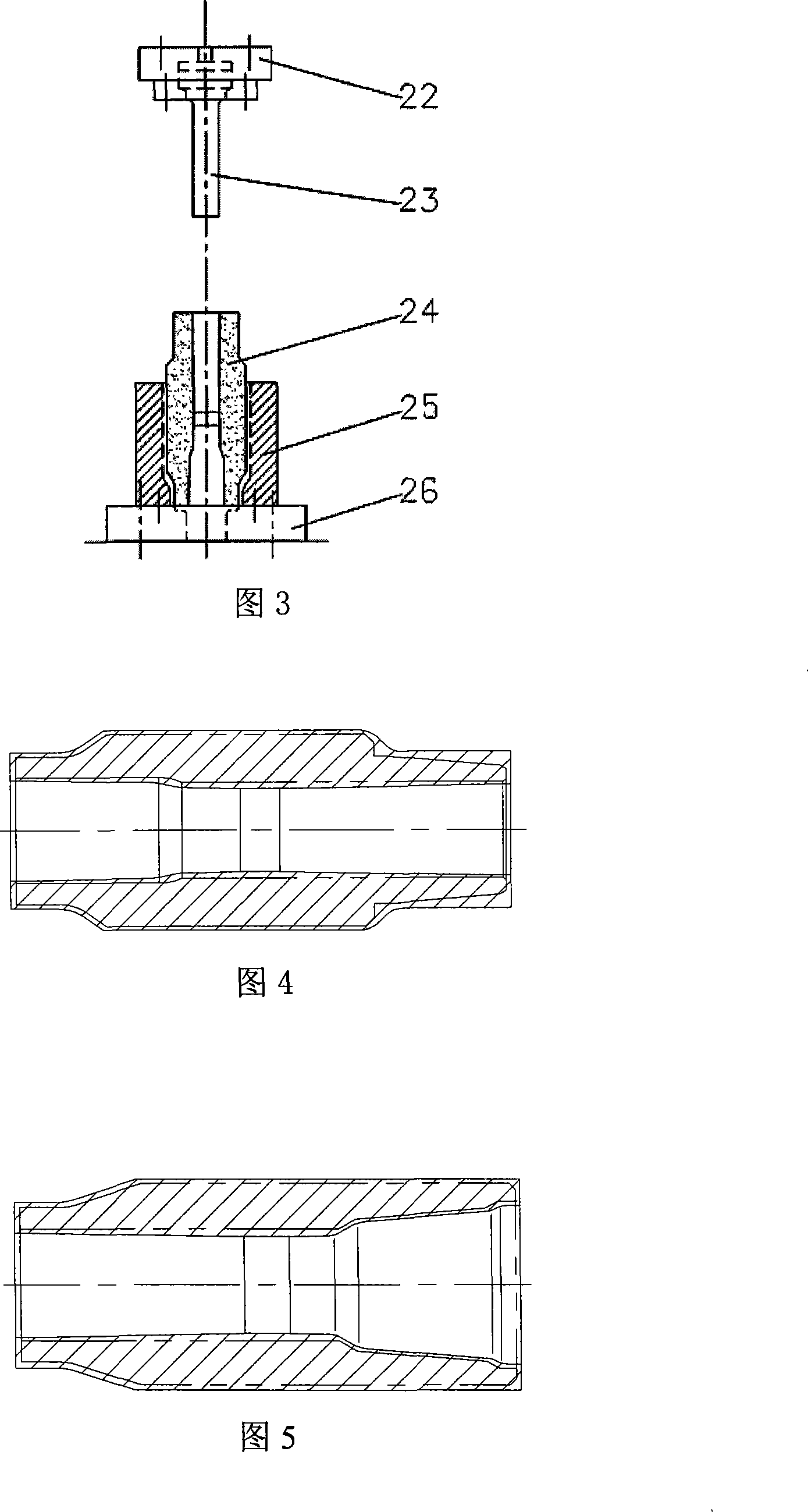

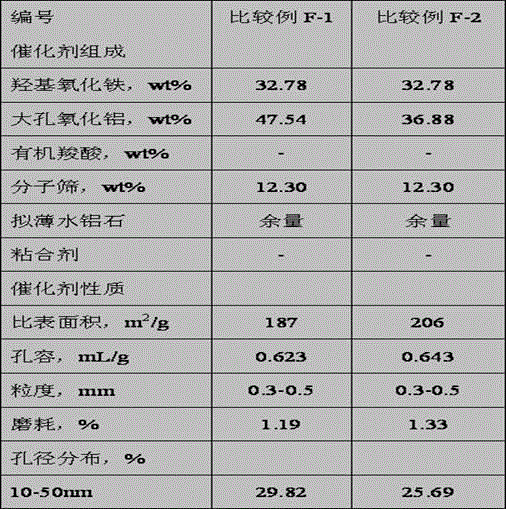

Method for hydrogenation of coal tar via fluidized bed

ActiveCN104593060AConsistent activityEasy to removeTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a method for hydrogenation of coal tar via a fluidized bed. The method comprises the following steps: subjecting a coal tar raw material to hydro-upgrading; carrying out separation to remove water; and then carrying out hydrorefining and fractionation so as to obtain a gasoline fraction, a diesel fraction and hydrogenation tail oil. A hydro-upgrading catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, a molecular sieve and pseudo-boehmite; and a hydrofining catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina and a binder. The method provided by the invention adopts cheap iron oxyhydroxide as an active metal component, the hydro-upgrading catalyst and the hydro-refining catalyst are graded, so cost is low. According to the invention, moderate cracking of coal tar is carried out before refining of coal tar, so impurities in coal tar are effectively removed, product distribution and product quality are adjusted, and the running period of a device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

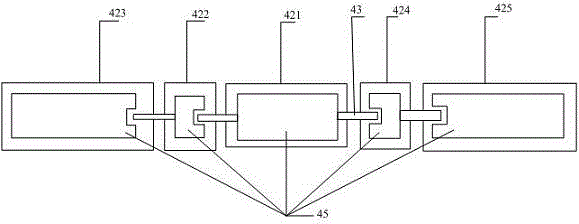

Terahertz subharmonic frequency doubling and mixing device based on monolithic integrated circuit

ActiveCN104467681AReduce the numberSmall sizeModulation transference by semiconductor devices with minimum 2 electrodesHarmonicLow-pass filter

The invention discloses a terahertz subharmonic frequency doubling and mixing device based on a monolithic integrated circuit. The device comprises a fundamental wave input waveguide micro-strip transition, a CMRC structure local oscillator low-pass filter, a frequency doubling matching circuit, a four-die frequency doubling diode, a local oscillator matching circuit, a frequency mixing diode, a radio frequency matching circuit, a radio frequency input waveguide micro-strip transition, and a CMRC structure intermediate frequency low-pass filter. According to the terahertz subharmonic frequency doubling and mixing device based on the monolithic integrated circuit, on the one hand, the number of dielectric substrates is decreased, and circuits are integrated on one substrate, so that the number of cavities to be processed is decreased, and processing and assembling are easy; on the other hand, waveguide transitions to be designed and processed are reduced, and the cavity size is reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

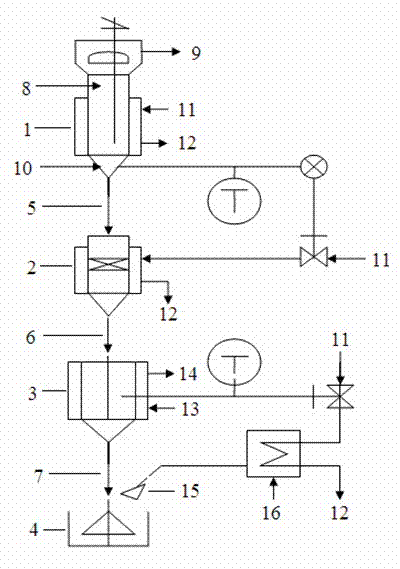

Method for extracting salt from coking desulphurization waste solution and special device thereof

InactiveCN102161541AEffective interceptionAvoid diversionThiocyanic acidWater/sewage treatment bu osmosis/dialysisFiltrationDecomposition

The invention discloses a method for extracting salt from coking desulphurization waste solution and a special device thereof. The method comprises the following steps of: heating raw material waste solution for decomposition, adsorbing and decolorizing, then heating, evaporating and concentrating to obtain concentrated solution, performing heat filtration at constant temperature to remove fine sulfur particles, cooling and crystallizing in a crystallizer, filtering at constant temperature, separating filtrate to obtain crystals, washing the crystals to obtain high-purity ammonium thiocyanate, dissolving mixed salt crystals in ammonium sulfate mother liquor, regulating the acidity to be below 20 percent, preheating to ensure that the temperature is between 90 and 110 DEG C, blowing air oroxygen, performing oxidative transformation for 1min to obtain ammonium sulfate transformation liquid, and adding ammonium sulfate production mother liquor to obtain an ammonium sulfate product. By the method, a high-purity product can be extracted from the waste solution through one-time operation, so that processing and treatment times are reduced; solid-phase impurities are effectively intercepted and prevented from transferring to the crystals at constant temperature; and the mixed salt is subjected to oxidative transformation treatment, all ammonium thiosulfate is transformed into the ammonium sulfate product with high nitrogen content, the process is simple, operation cost is low, and product marketing is broad.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

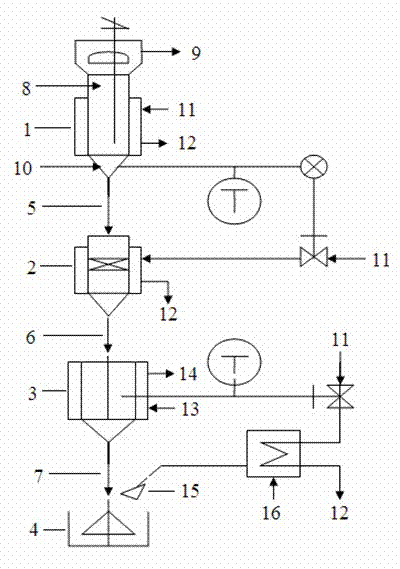

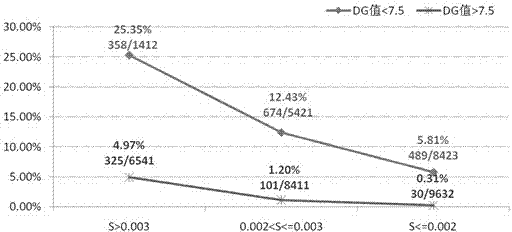

Austenite stainless steel and production method thereof

ActiveCN103924163AAvoid microcracksImprove yieldProcess efficiency improvementSS - Stainless steelThermal treatment

The invention relates to austenite stainless steel and a production method thereof, and belongs to the technical field of stainless steel processing. The stainless steel product mainly comprises the following chemical components in percentage by weight: less than or equal to 0.03 percent of C, 0.4-0.6 percent of Si, 1.0-1.5 percent of Mn, 16.5-18.0 percent of Cr, 10.0-11.0 percent of Ni, 0.010-0.050 percent of N, 2.00-2.50 percent of Mo, less than or equal to 0.040 percent of P, less than or equal to 0.003 percent of S, 20-40ppm of B and the balance of Fe and inevitable impure elements, wherein the DG value is between 6 and 9, the value of Md30 is 30DEG C below zero- 60 DEG C below zero. The production process comprises the following steps: intensively deoxidizing and desulfurizing, adding Fe-B to refine the grain size of an as-cast billet, adding Ca-Si wires into a ladle furnace (LF) and prolonging the time of soft blowing and standing, controlling the superheat degree to be 20-40 DEG C and constant pulling speed of 1.1-1.15m / min; and weakening secondary cooling water, performing hot rolling, cold rolling and thermal treatment, and pickling. By adopting the method, the problem of surface defects occurring in the stainless steel processing process can be alleviated, and the cold rolling yield can be increased.

Owner:GUANGDONG GUANGQING METAL TECH

Single-cylinder plug pin type telescopic arm, crane and telescoping method of single-cylinder plug pin type telescopic arm

The invention relates to a single-cylinder plug pin type telescopic arm, a crane and a telescoping method of the single-cylinder plug pin type telescopic arm. The single-cylinder plug pin type telescopic arm comprises a basic arm and at least one section of telescopic arm which is sleeved in the basic arm, wherein coaxial central holes are formed in the tails of the telescopic arms; a telescopic oil cylinder is arranged in the central holes and comprises a cylinder rod and a cylinder barrel; at least two cylinder heads are fixedly sleeved outside the cylinder barrel in the longitudinal direction; at least three arm pin holes are respectively formed in the basic arm and the telescopic arm in the longitudinal direction. The single-cylinder plug pin type telescopic arm provided by the invention adopts the telescopic oil cylinder and the at least two cylinder heads; each cylinder head can be used for locking and unlocking the telescopic oil cylinder and any one telescopic arm; in a relay manner, the telescopic arms stretch or shrink; telescoping of the single-cylinder plug pin type telescopic arm is realized; the length of the oil cylinder is reduced; the cylinder diameter and the rod diameter of the oil cylinder are reduced; the cost of the oil cylinder is lowered; the loading weight is reduced; the hoisting capability is improved; the design capability of the crane is improved.

Owner:XUZHOU HEAVY MASCH CO LTD

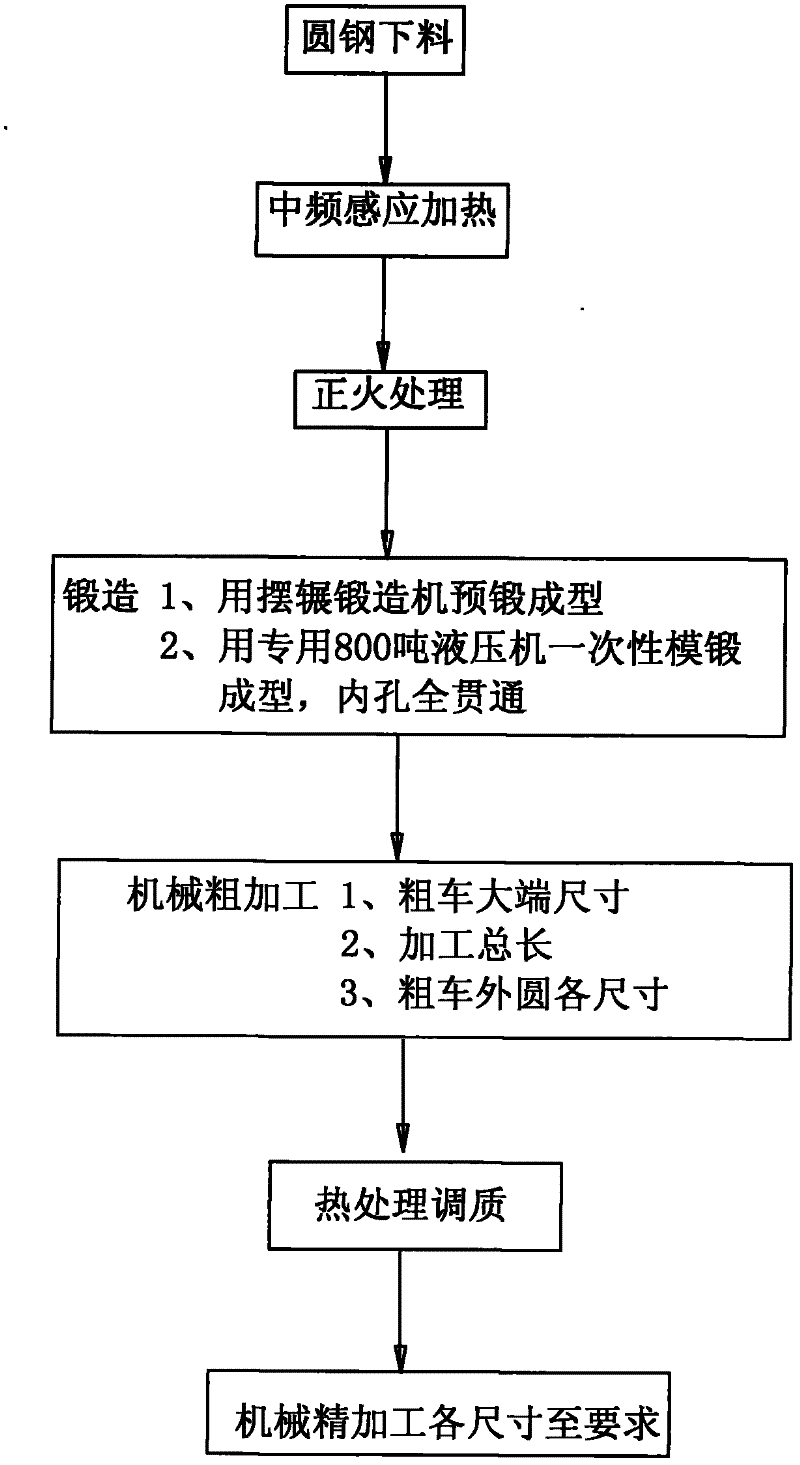

Manufacturing technology for half-axis sleeve tube

InactiveCN102476259ALow costSmall machining allowanceMetal-working apparatusManufacturing technologyMid-frequency

The invention relates to a manufacturing technology for a half-axis sleeve tube, and the manufacturing technology comprises the following steps: blanking; forging; performing normalizing treatment; performing mechanical fine machining; performing quenching and tempering treatment; and performing the mechanical fine machining. In the manufacturing technology, a heating and forging method comprises the following steps: 1) mid-frequency inductively heating a round steel material to be at a preset temperature of 1100 DEG C to 1200 DEG C; 2) using a rolling forging machine to pre-forge and form; and 3) using a special 800-ton frame type hydraulic press to perform once die-forging forming treatment and completely running through an inner hole. According to the manufacturing technology, a processing process and labor hours are reduced, a tool cost is saved, a forged piece is free from any burr, the use ratio of materials can reach 99%, and the production efficiency and product quality of the half-axis sleeve tube are increased.

Owner:GUIZHOU SHUNFENG AUTOMOBILE PARTS MFG

Method for manufacturing ceramic of multi-layer structure

ActiveCN106116688ATight outer surfaceHigh light chromaCeramic materials productionCeramicwareWork in processCeramic tiles

The invention provides a method for manufacturing ceramic of a multi-layer structure. The method includes the following steps that a common ceramic brick material is used for manufacturing surface blank, a foamed ceramic bottom blank material is used for preparing foamed ceramic bottom blank, the surface blank and the foamed ceramic bottom blank are pressed into multiple layers in a spaced mode, the uppermost layer of a tile serves as the surface blank, and after the surface blank is dried, a semi-finished product is obtained; the semi-finished product is colored and subjected to one-time cofiring to form a ceramic tile of the multi-layer structure where the foamed ceramic bottom blank layer and the non-porous surface blank layer coexist. The ceramic tile of the multi-layer structure has the advantages that the ceramic tile is light and convenient to attach, the surface blank is compact, and photochromism is high.

Owner:XINLAILI CERAMIC DEV CO LTD

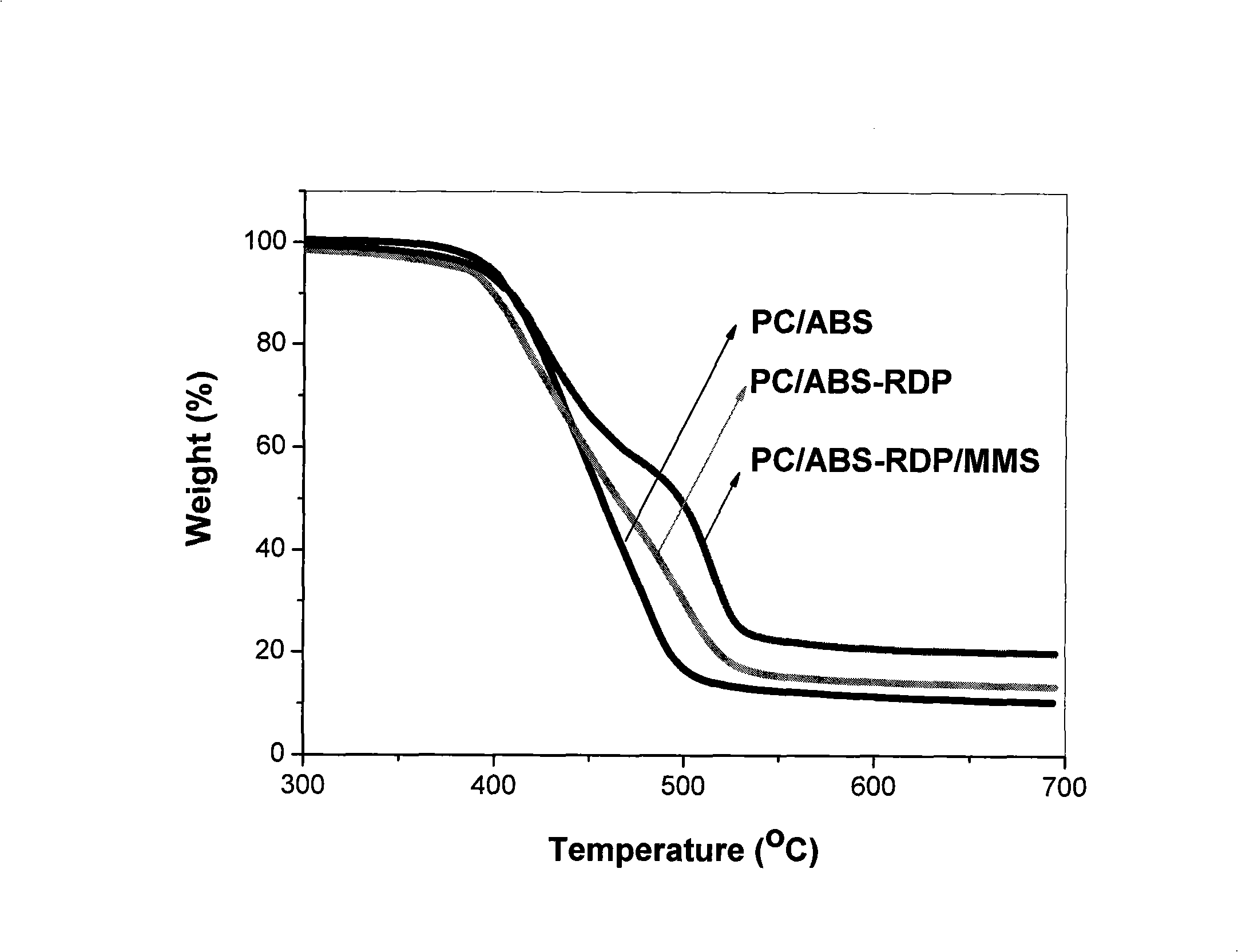

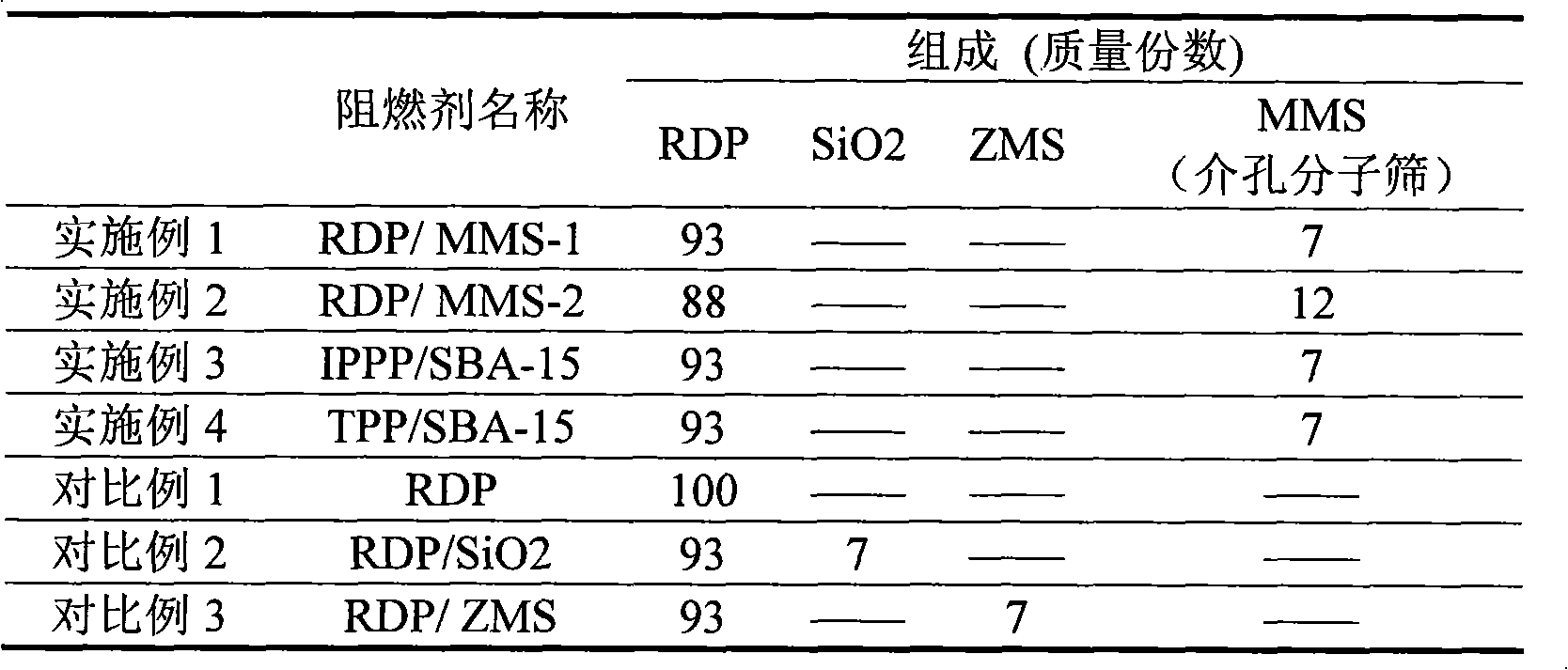

Organic-inorganic composite flame retardants with mesoporous molecular sieve and method for preparing same

InactiveCN101338201ALarge specific surface areaAperture continuously adjustableFireproof paintsMolecular sieveMacromolecule

The invention discloses an organic-inorganic composite flame retardant agent containing a mesopore molecular sieve. The flame retardant agent comprises 0.1-50 weight percent of mesopore molecular sieve and 50-99.9 weight percent of organic flame retardant agent. The preparation method of the flame retardant agent and flame retardant resin containing the flame retardant agent are also disclosed. The composite flame retardant agent obtained through the invention plays roles of both the self-flame retardant function of organic flame retardant molecules and the mesopore molecular sieve and the synergistic effect between the organic flame retardant molecules and the mesopore molecular sieve. The flame retardant efficacy is improved greatly. In addition, the mesopore molecular sieve can also play a releasing role of a microcapsule. As a novel highly efficient halogen-free composite flame retardant agent, the organic-inorganic composite flame retardant agent can be widely applied to the polymer material flame retarding field.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

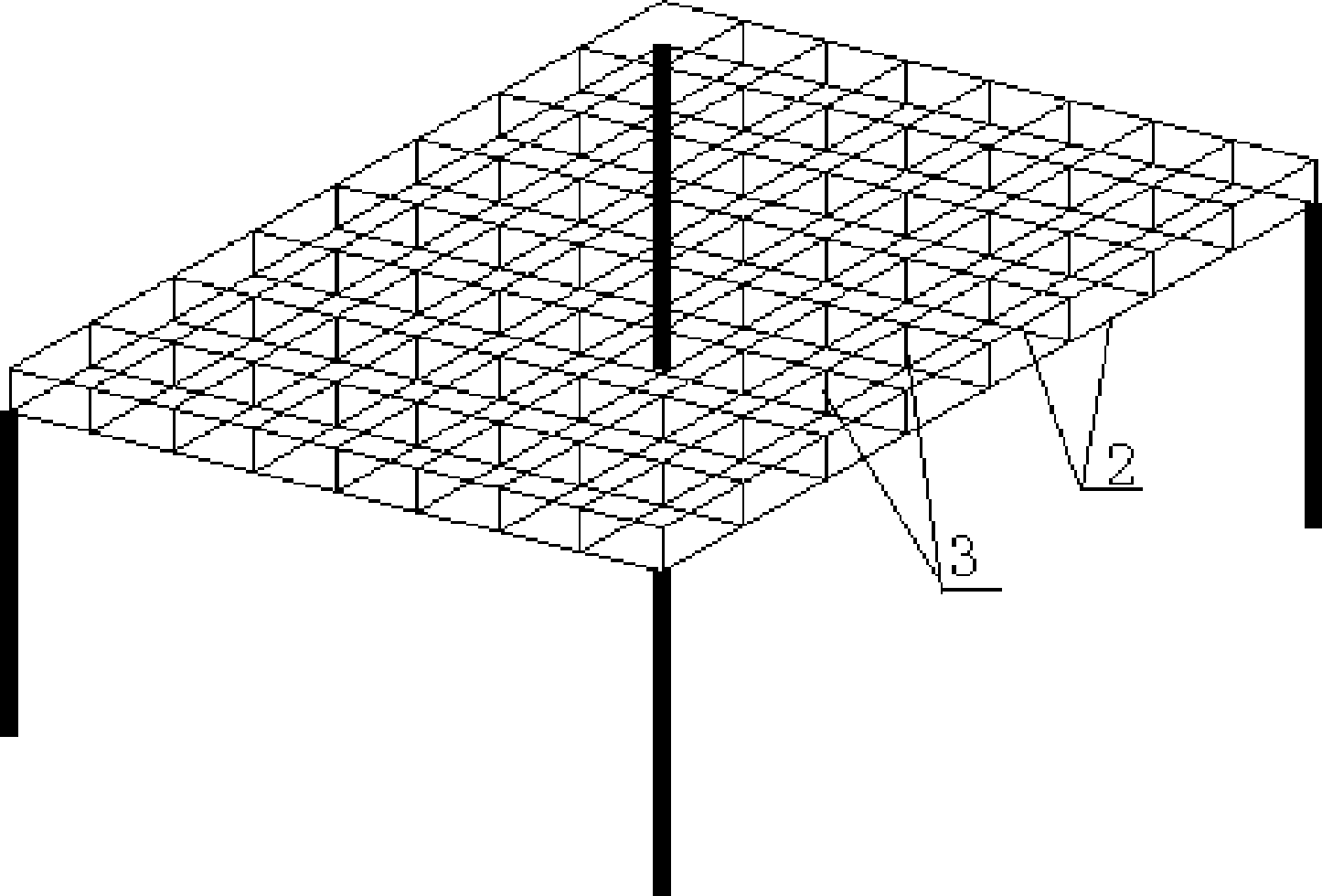

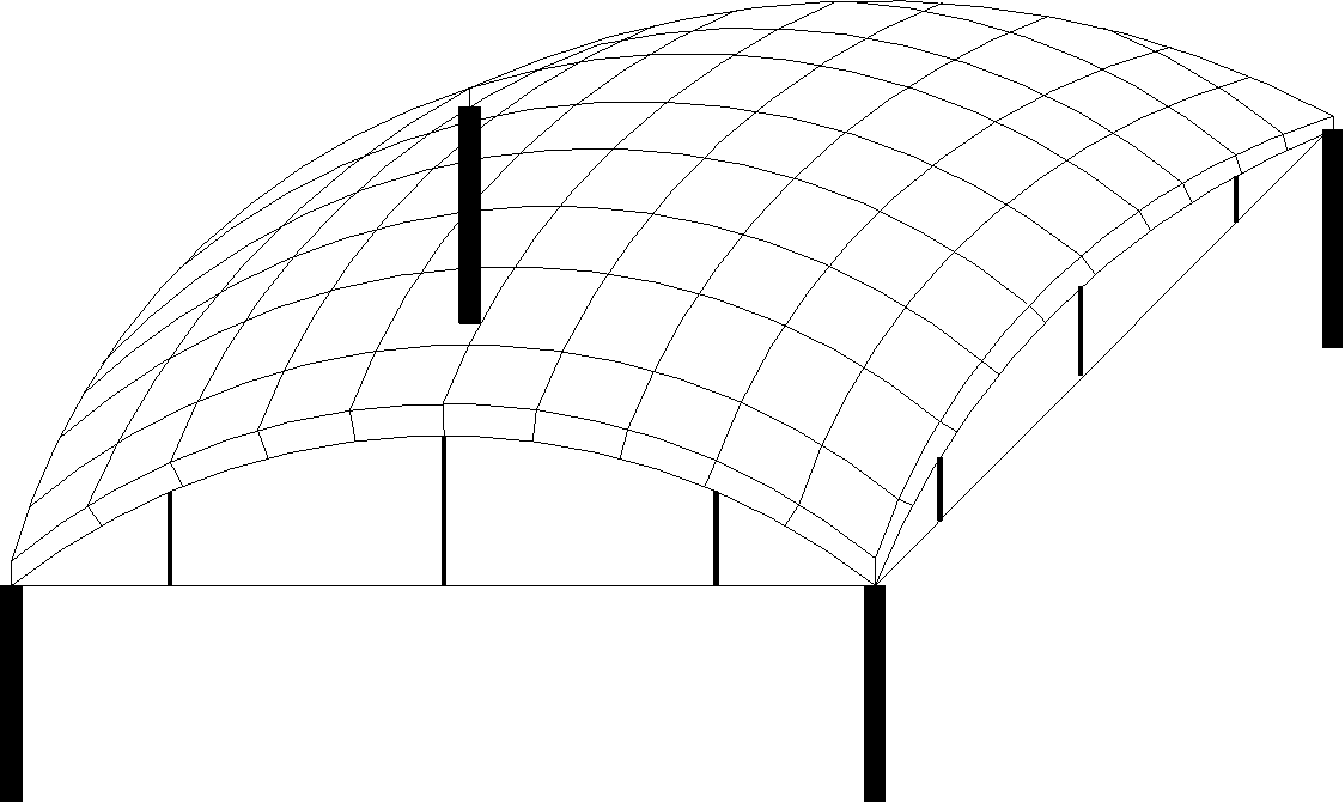

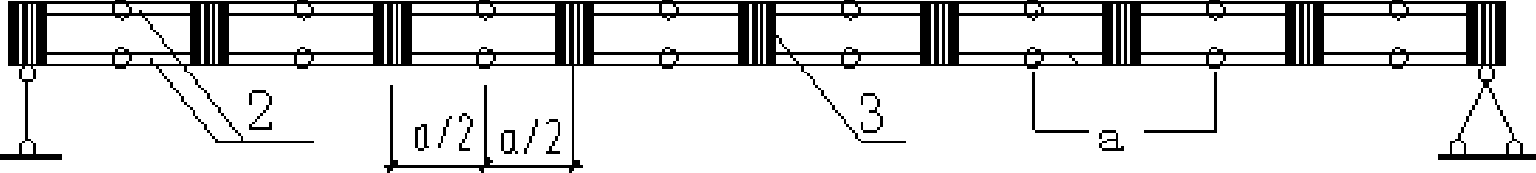

Assembly of integral flat-plate type or hood face section steel hollow lattice construction and production method

InactiveCN101397822AIncrease stiffnessReduce the height of the structureBuilding roofsFloorsRegular gridEngineering

The invention relates to a wholly assembled flat or curved steel vierendeel grid structure and a producing method thereof. The producing method comprises the steps: firstly, the two ends of a cylinder steel pipe are welded with a supporting plate respectively; the surface of the supporting plate and the pipe wall of the cylinder steel pipe are taken as welding points, 8 chords with T-shaped sections are respectively welded at the two ends of the cylinder steel pipe to form a double-layer assembling crisscross unit; chords of two or more double-layer assembling crisscross units are connected by a double spicing plate on the construction site so as to assemble the flat or curved grid structure. The flat or curved grid structure produced by the method has dexterous and firm structure; the welding technique is finished in factories, thus being capable of improving the precision and quality of production; the grid is formed by a vierendeel beam rather than a vierendeel truss rod so that water pipelines and electrical wires can go through the grids conveniently, takes regular grid shapes and plays a role of hanging floors and roofs.

Owner:贵州喀斯特钢结构有限公司 +2

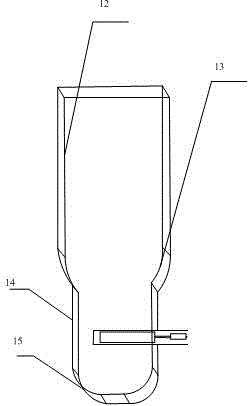

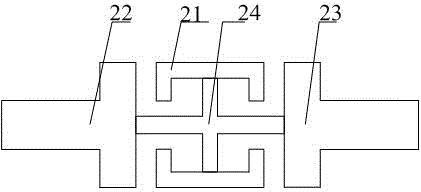

Terahertz frequency tripler based on coplanar waveguide transmission wires

ActiveCN104600403AReduced assembly stepsReduced processing performanceWaveguide type devicesLow-pass filterCoplanar waveguide

The invention discloses a terahertz frequency tripler based on coplanar waveguide transmission wires. The terahertz frequency tripler based on the coplanar waveguide transmission wires comprises three waveguides, including a fundamental wave input wave guide, an output waveguide and a main body waveguide, a dielectric substrate inside the main body waveguide, and electrical structures arranged on the dielectric substrate through the coplanar waveguide transmission wires in an integrated mode, wherein the electrical structures are composed of a DC (direct current) bias low-pass filter, an input matching transmission wire, a fundamental wave low-pass filter, a fundamental wave matching transmission wire, a triple-harmonic matching transmission wire, a three-stage matching transmission wire, a four-stage matching transmission wire and an output matching transmission wire from left to right and takes the coplanar waveguide transmission wires as a ground wire. The coplanar waveguide transmission wires substitute traditional microstrip wires and traditional suspended microstrip wires for designing the peripheral passive circuit of the frequency tripler; the inside of the circuit is directly connected with a cavity wall to achieve a radio frequency grounding and DC circuit; by means of a fundamental wave input duplexer, DC bias and other circuits can be designed simultaneously, subsequent assembling steps can be reduced, and the circuit structure is easy to process and assemble.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

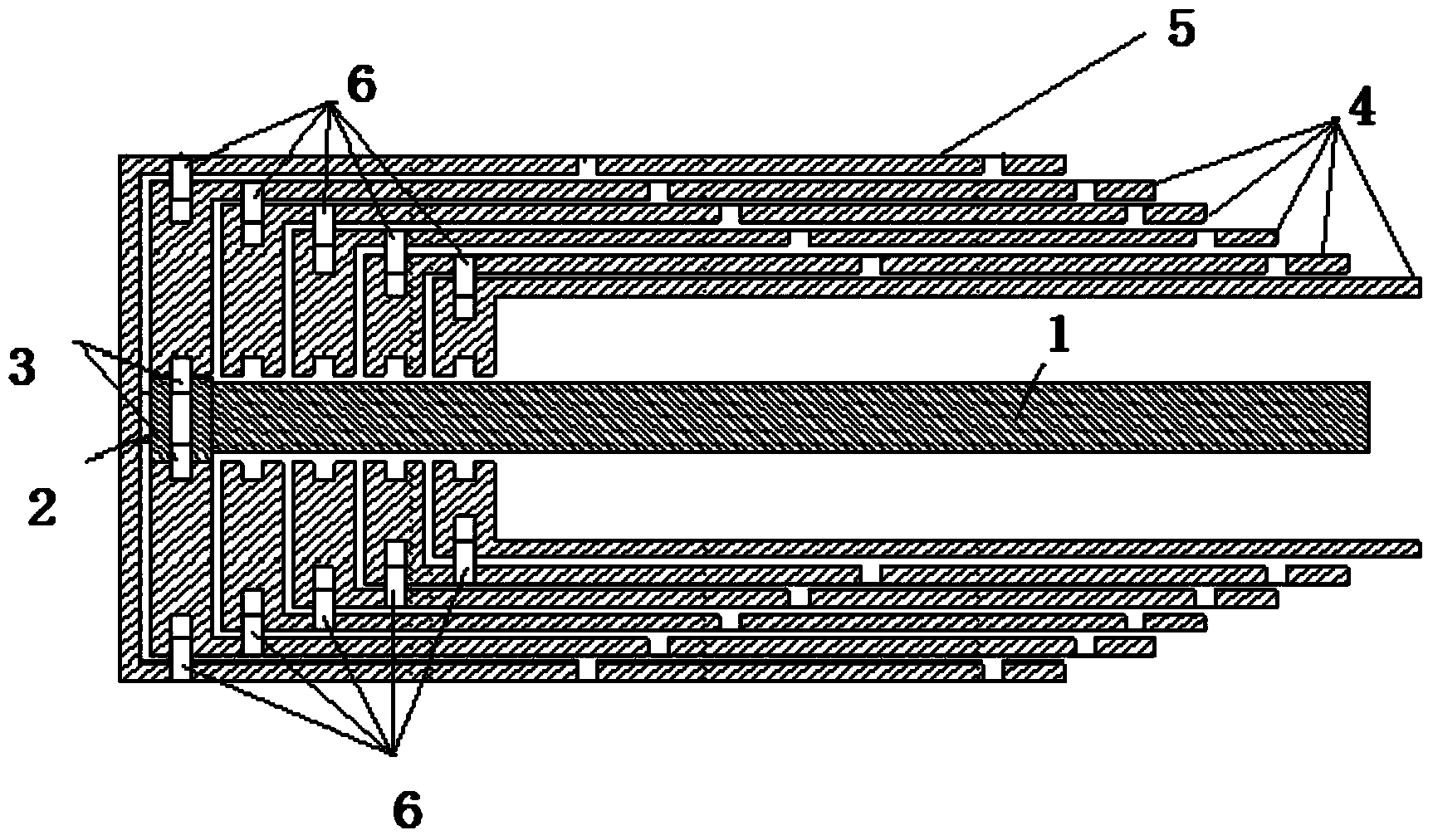

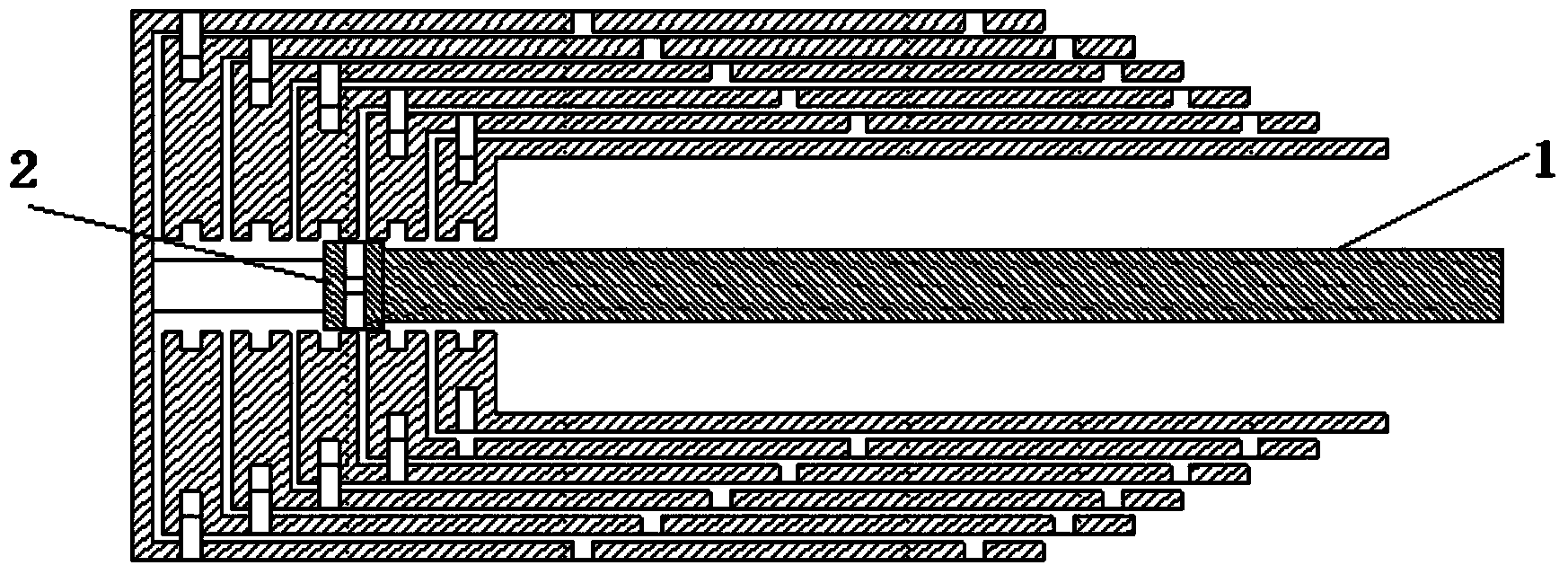

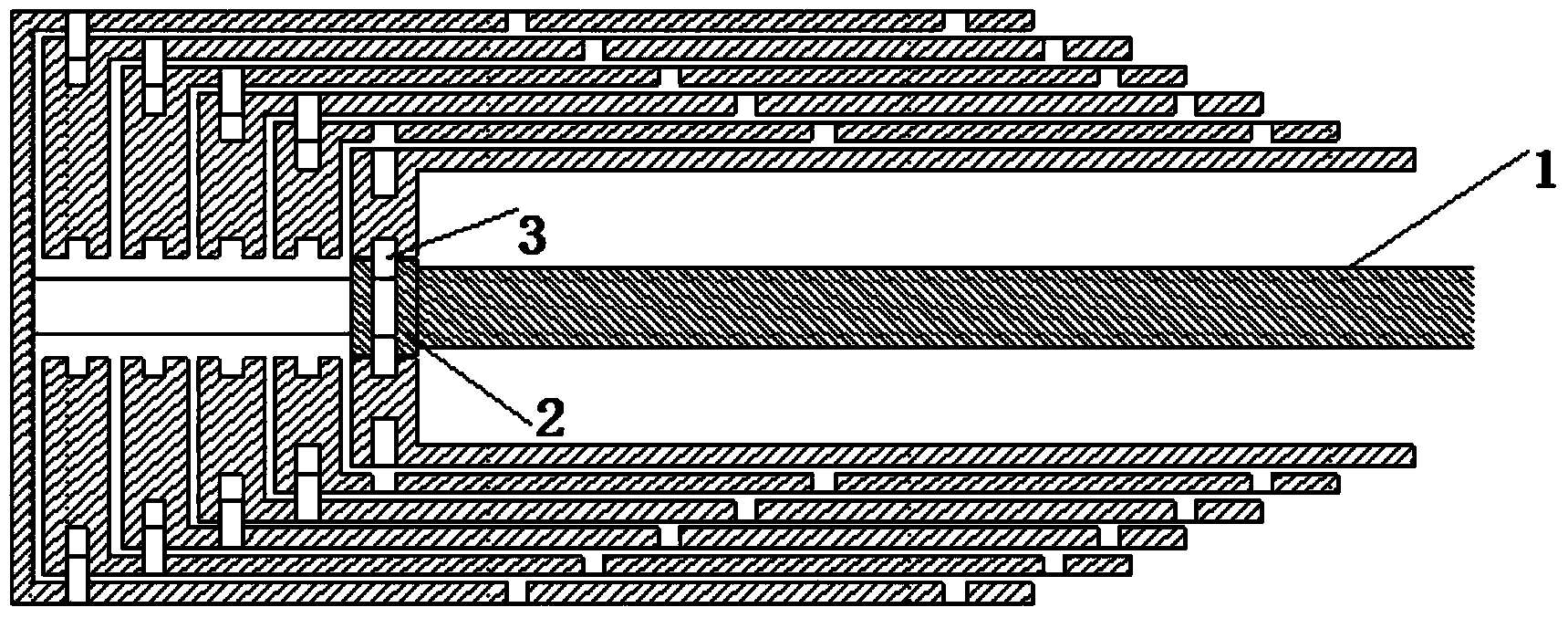

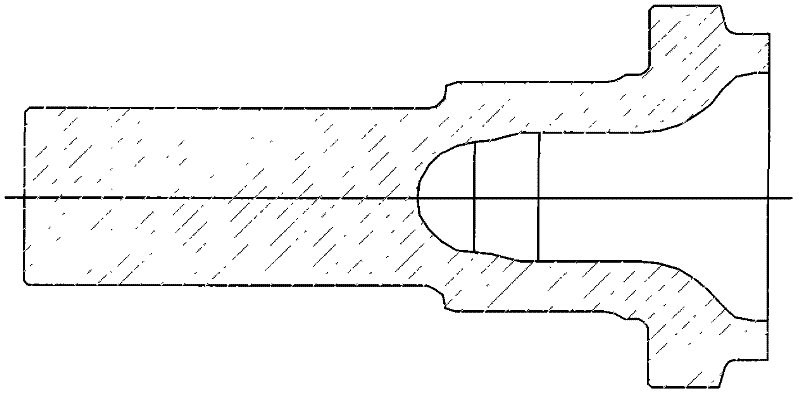

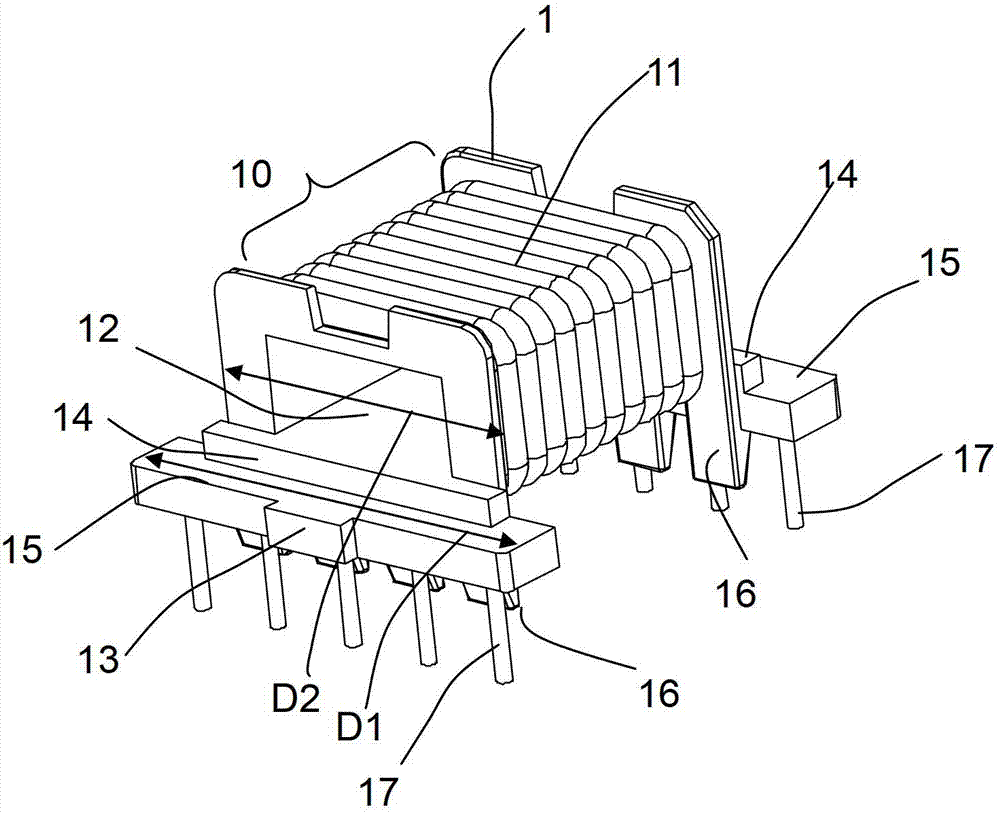

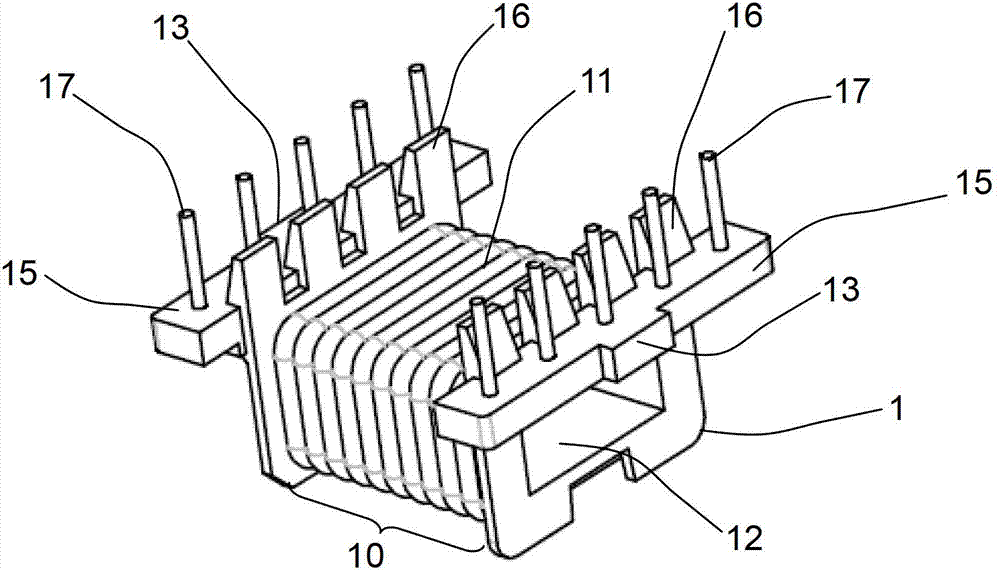

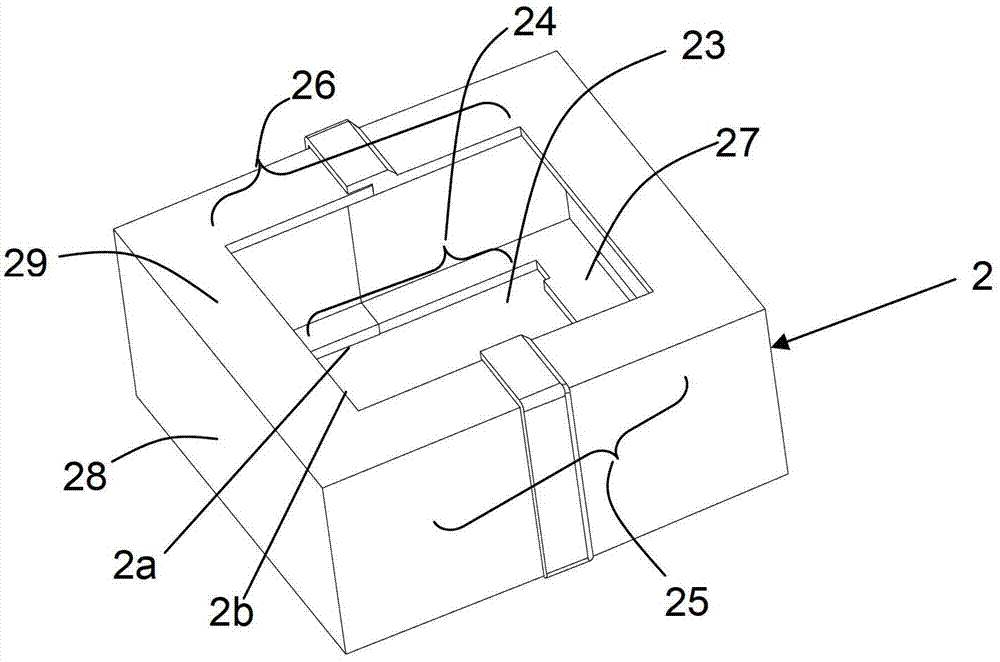

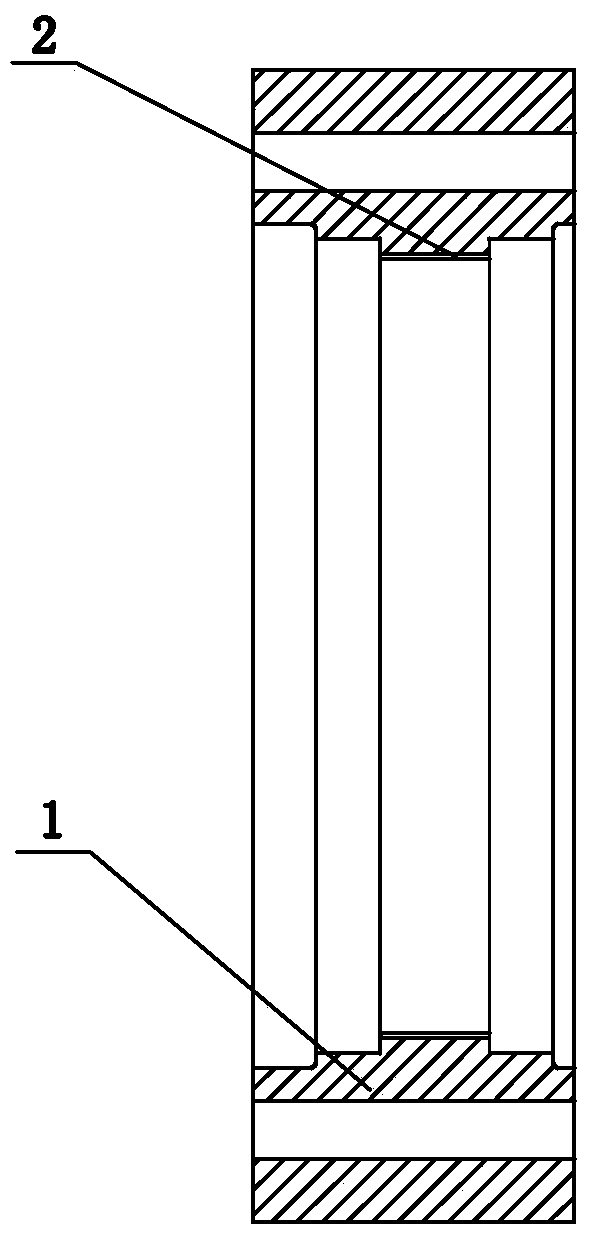

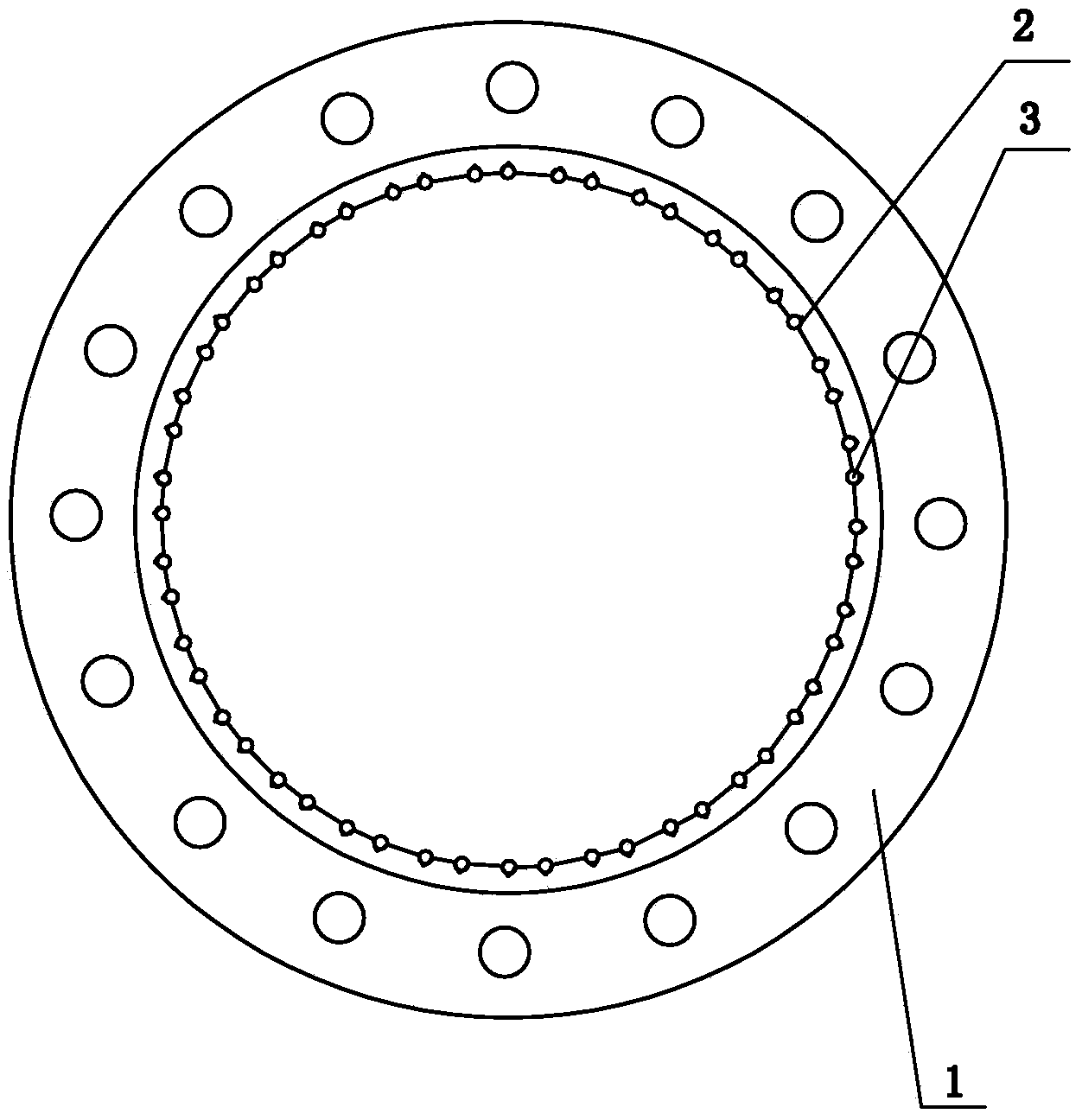

Electronic transformer

ActiveCN103035364AIncrease the safety distanceSimple structureTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerPrinted circuit board

The invention discloses an electronic transformer, which comprises a winding framework (1) and a magnetic core (3), wherein the winding framework (1) is provided with a winding terminal (17); the magnetic core (3) is arranged on the winding framework (1); the electronic transformer is characterized by also comprising an insulating isolating cover (2) with an opening (2a), wherein a cover body of the insulating isolating cover (2) covers an exposed surface of the magnetic core (3); the winding framework (1) is locally exposed from the opening (2a) of the isolating cover (2); and the winding terminal (17) is arranged on an exposed part of the winding framework (1). The electronic transformer has the advantages of small and skillful size, simple manufacturing process and capability of guaranteeing sufficient electric safety distances between the magnetic core and the winding terminal and between the transformer and other electronic devices on a PCB (Printed Circuit Board) substrate.

Owner:MORNSUN GUANGZHOU SCI & TECH

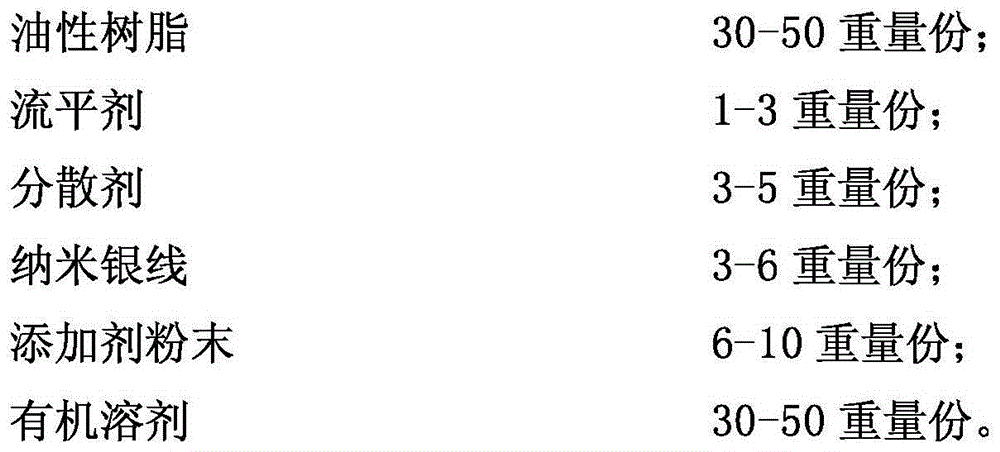

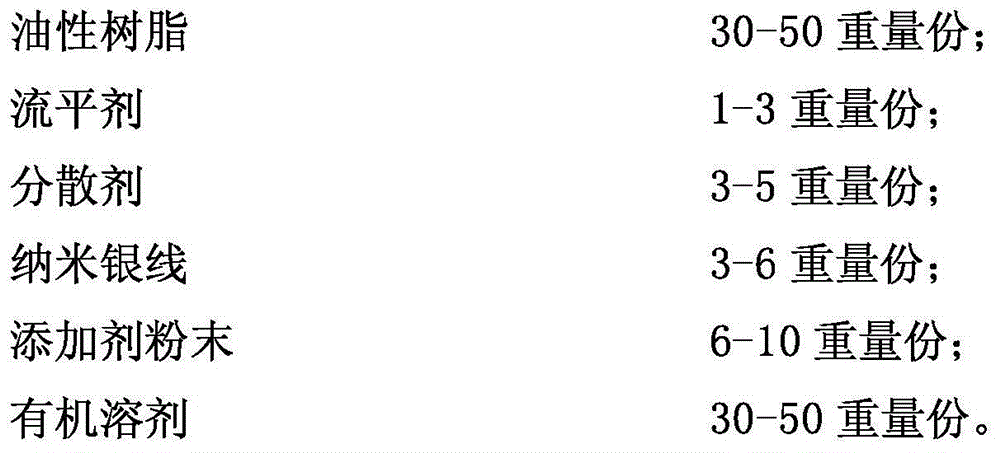

Heat-resistant flexible transparent conductive film and preparation method thereof

InactiveCN104464880AImprove conductivityImprove heat resistanceConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialFiberCarbon fibers

The invention discloses a heat-resistant flexible transparent conductive film and a preparation method of the film. According to the film, the surface of PET is coated with coating, and then the film is prepared after being dried . According to the formula of the coating, the coating is composed of nanometer silver wires, oleoresin, additive powder, flatting agents and a proper quantity of organic solvents. The nanometer silver wires excellent in electrical conductivity and mixed additives composed of carbon fibers, nanometer limestone powder, nanometer palygorskite powder, nanometer aluminum oxide powder and propyl gallate are adopted for improving the electrical conductivity and the heat resistance of the film. The heat-resistant flexible transparent conductive film is low in cost and raw materials are easy to obtain.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

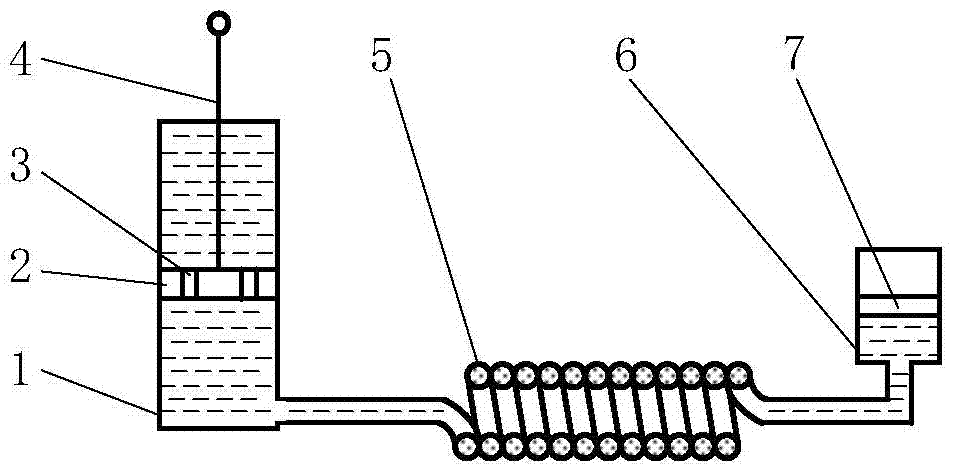

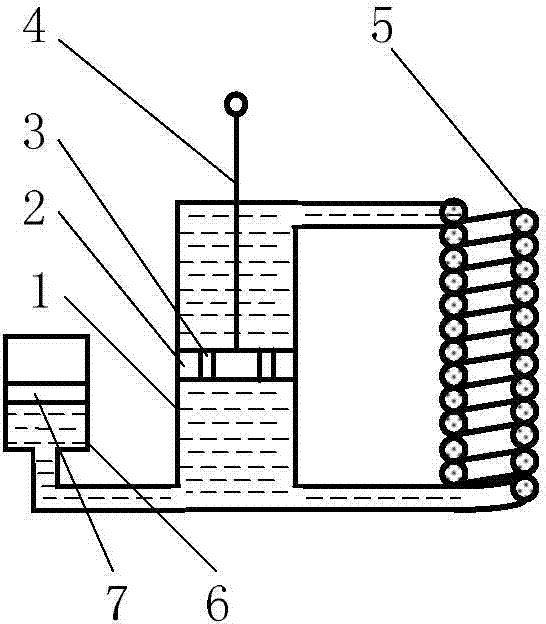

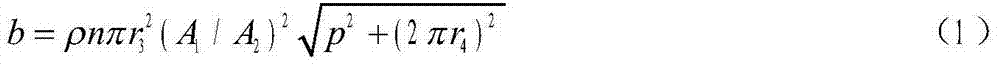

Inert and damping integrated gas-filled damper

InactiveCN104763768ALow costExtend your lifeSpringsSprings/dampers design characteristicsNuclear engineeringNitrogen gas

The invention provides an inert and damping integrated gas-filled damper. The inert and damping integrated gas-filled damper comprises a cylinder barrel, a piston, a damping valve, a piston rod, a metal spiral tube, an external nitrogen gas tank and a floating piston, wherein the piston and the piston rod are connected and are arranged in the cylinder barrel for dividing the cylinder barrel into a rod cavity and a rodless cavity, and a damping valve is arranged on the piston; at least one of the rod cavity and the rodless cavity is communicated with the metal spiral tube; the floating piston is arranged in the external nitrogen gas tank, and used for dividing the external nitrogen gas tank into upper and lower cavities; the external nitrogen gas tank and the metal spiral tube are connected in parallel or in series; one of upper and lower cavities of the external nitrogen gas tank is communicated with the metal spiral tube; the rod cavity and the rodless cavity of the cylinder barrel, the metal spiral tube, and one cavity, communicated with the metal spiral tube, of the external nitrogen gas tank is filled up with oil, and the other cavity of the external nitrogen gas tank is filled up with nitrogen gas. The inert and damping integrated gas-filled damper disclosed by the invention is simple in structure, relatively few in components, easy to process and assemble, relatively low in cost, high in production efficiency, and the service life of the searching damper is greatly prolonged.

Owner:JIANGSU UNIV

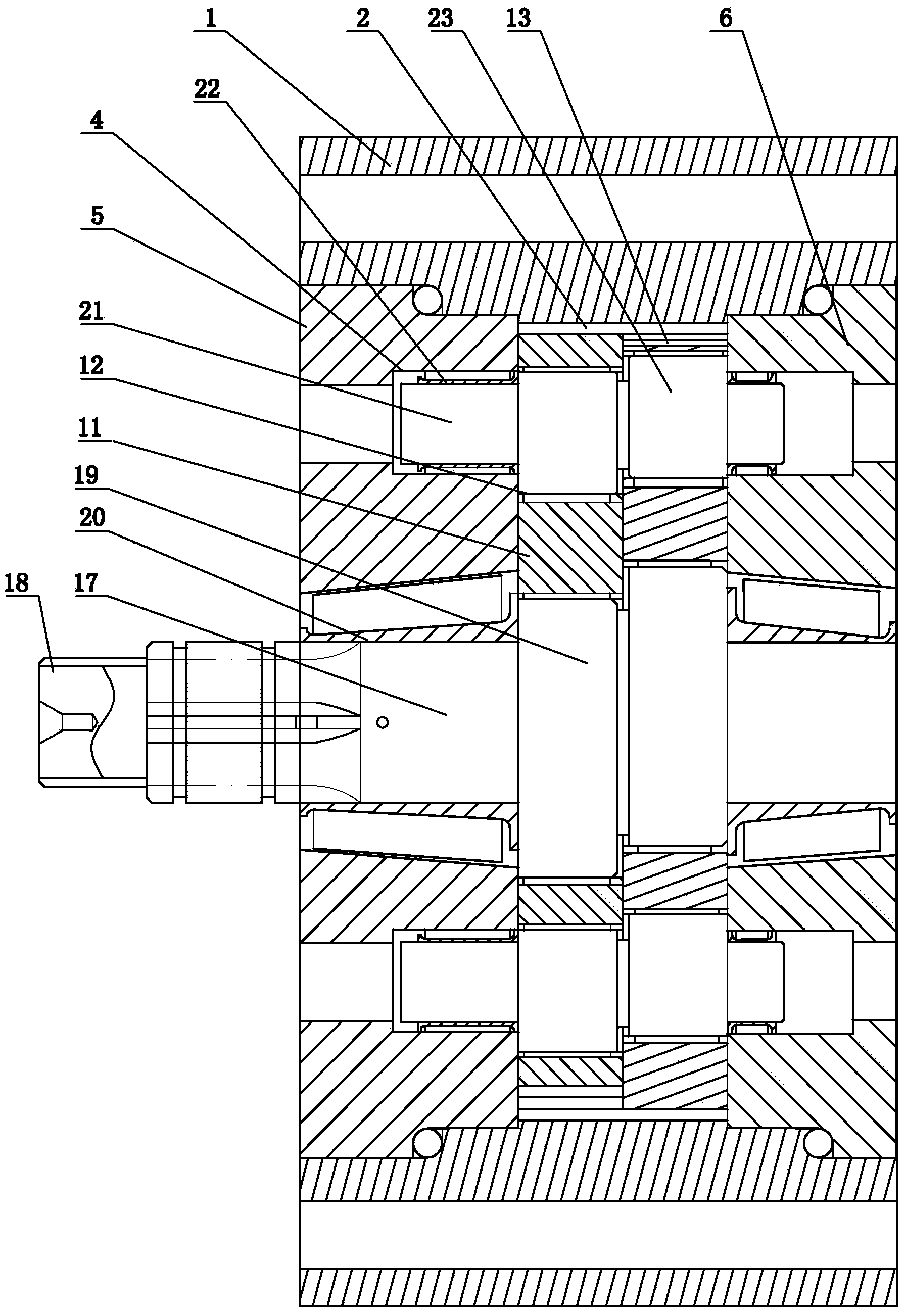

Bearing type RV speed reducer

InactiveCN103527719AReduce processing difficultyHigh transmission reliabilityToothed gearingsGearing detailsDrive wheelReduction drive

The invention discloses a bearing type RV speed reducer, and belongs to the technical field of speed reducers. The speed reducer comprises a pin wheel housing, an installation frame is arranged in the pin wheel housing in a rotary mode, the installation frame is provided with two cycloid gears in transmission connection with the pin wheel housing through needle rollers, the installation frame is rotatably provided with a power input shaft, the power input end of the power input shaft extends out of the installation frame, the power input shaft is provided with two eccentric drive wheels which penetrate through the centers of the two cycloid gears respectively and are matched with the corresponding cycloid gears, the installation frame is rotatably provided with at least two positioning shafts which are symmetric to the rotation center of the power input shaft, and each positioning shaft is provided with two eccentric transmission wheels which penetrate through the two cycloid gears respectively and are matched with the cycloid gears. Power center input and first speed reduction are achieved. Compared with the prior art, the bearing type RV speed reducer reduces the number of power input shafts and use of sun gears and planetary gears, manufacturing cost is low, transmission is reliable, machining and installation are convenient to achieve, and service life is prolonged.

Owner:SHANDONG SHKE MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com