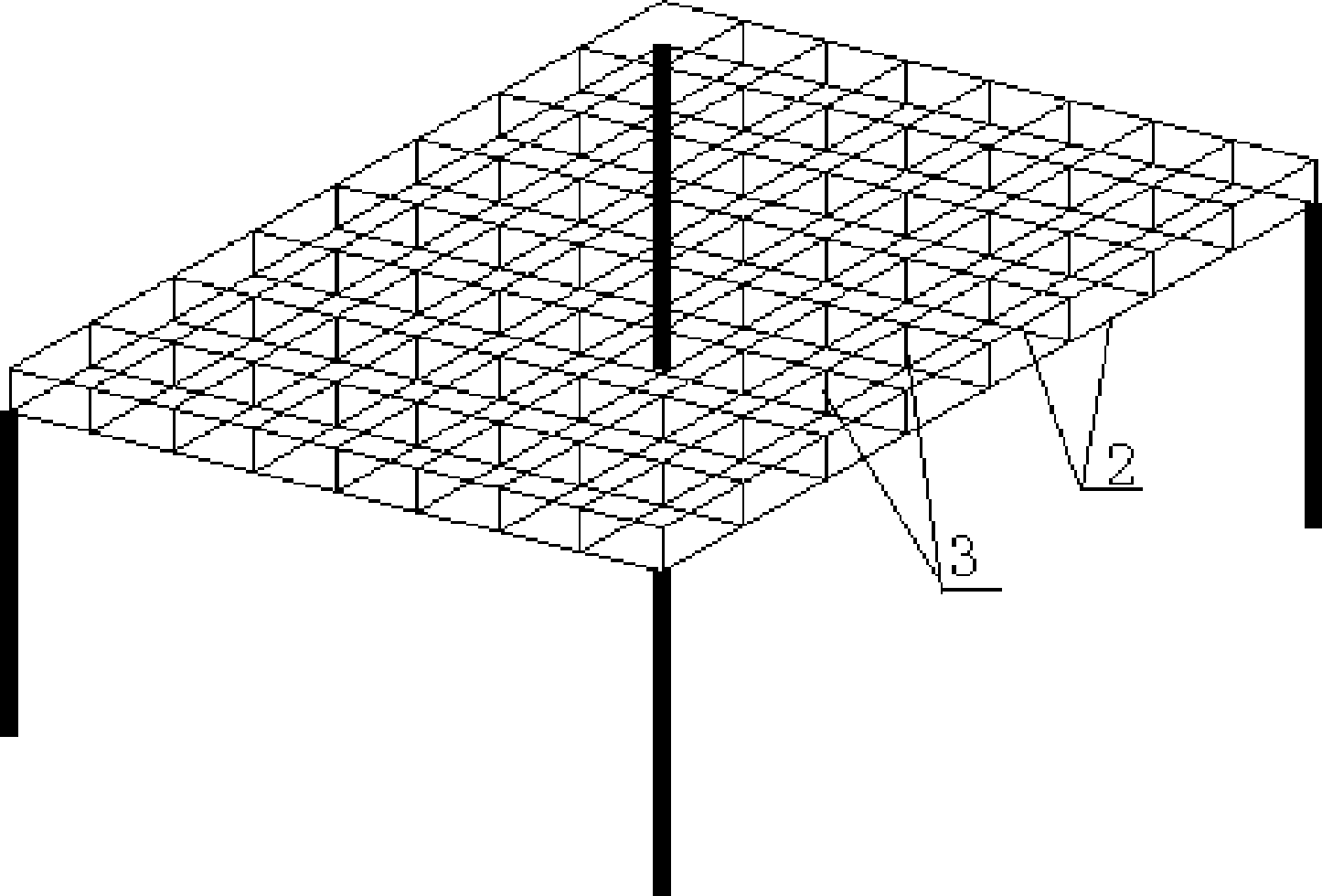

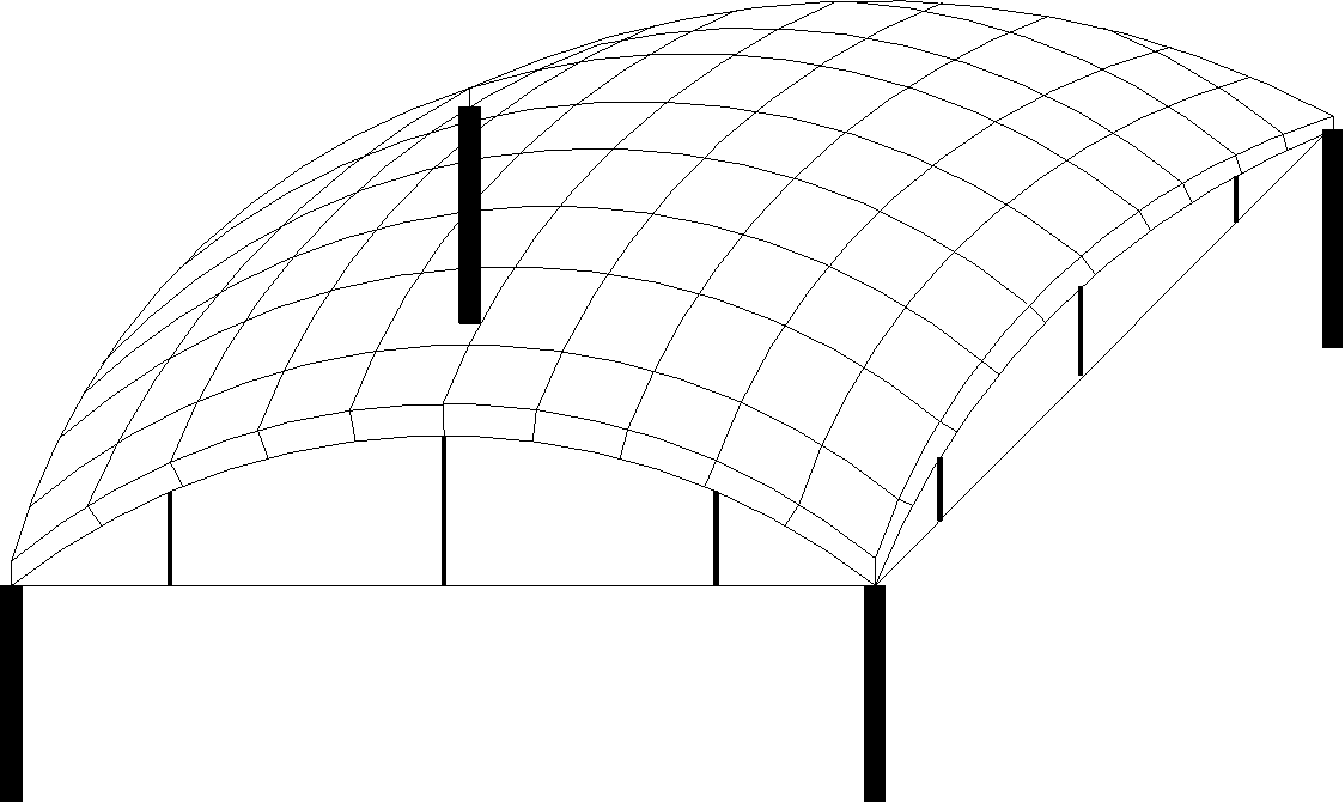

Assembly of integral flat-plate type or hood face section steel hollow lattice construction and production method

A technology of grid structure and manufacturing method, which is applied to floors, building components, building structures, etc., can solve the problems of increased steel consumption, more grids, and large welding workload, and achieves elimination of welding deformation and welding stress. The effect of good structural integrity and structural quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

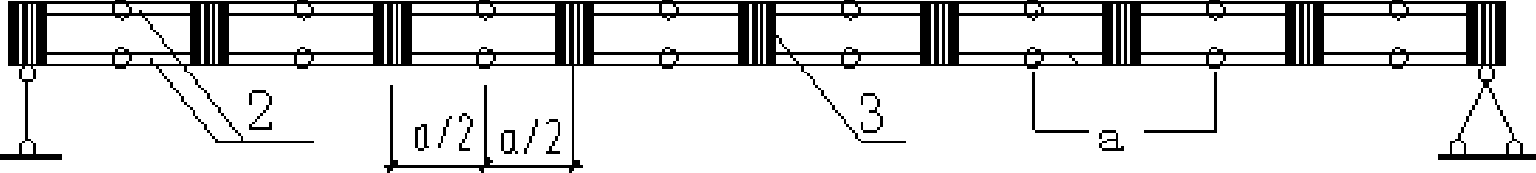

[0022] Embodiments of the present invention: the double-layer cross-shaped unit 1 of the present invention is as Figure 8 As shown, the double-layer cross-shaped unit 1 is a rigid weldment, which is to weld a supporting plate 4 at both ends of a square or circular columnar steel pipe 1, and then weld four supporting plates on each supporting plate 4. For the chords 2 with a T-shaped cross-section, the flange ends of the four chords 2 are processed into triangles, and then welded on the supporting plate 4 after being joined together. The four chords welded on the supporting plate 4 are arranged in a cross shape. cloth (such as Figure 10 shown), and the welds at the butt joints are milled flat, and then a cover plate 5 is welded on the upper ends of the four chord joints; the web of the chord 2 is welded on the cylindrical steel pipe 3 (such as Figure 9 shown); and from Figure 9 It can be clearly seen that there is a certain spacing (empty stomach) between the chords 2 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com