Patents

Literature

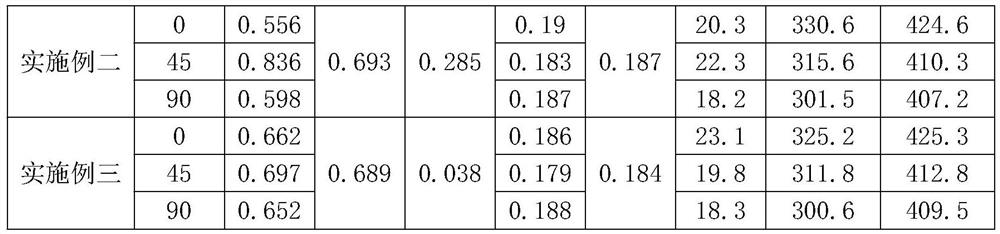

48results about How to "Eliminate deformation stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

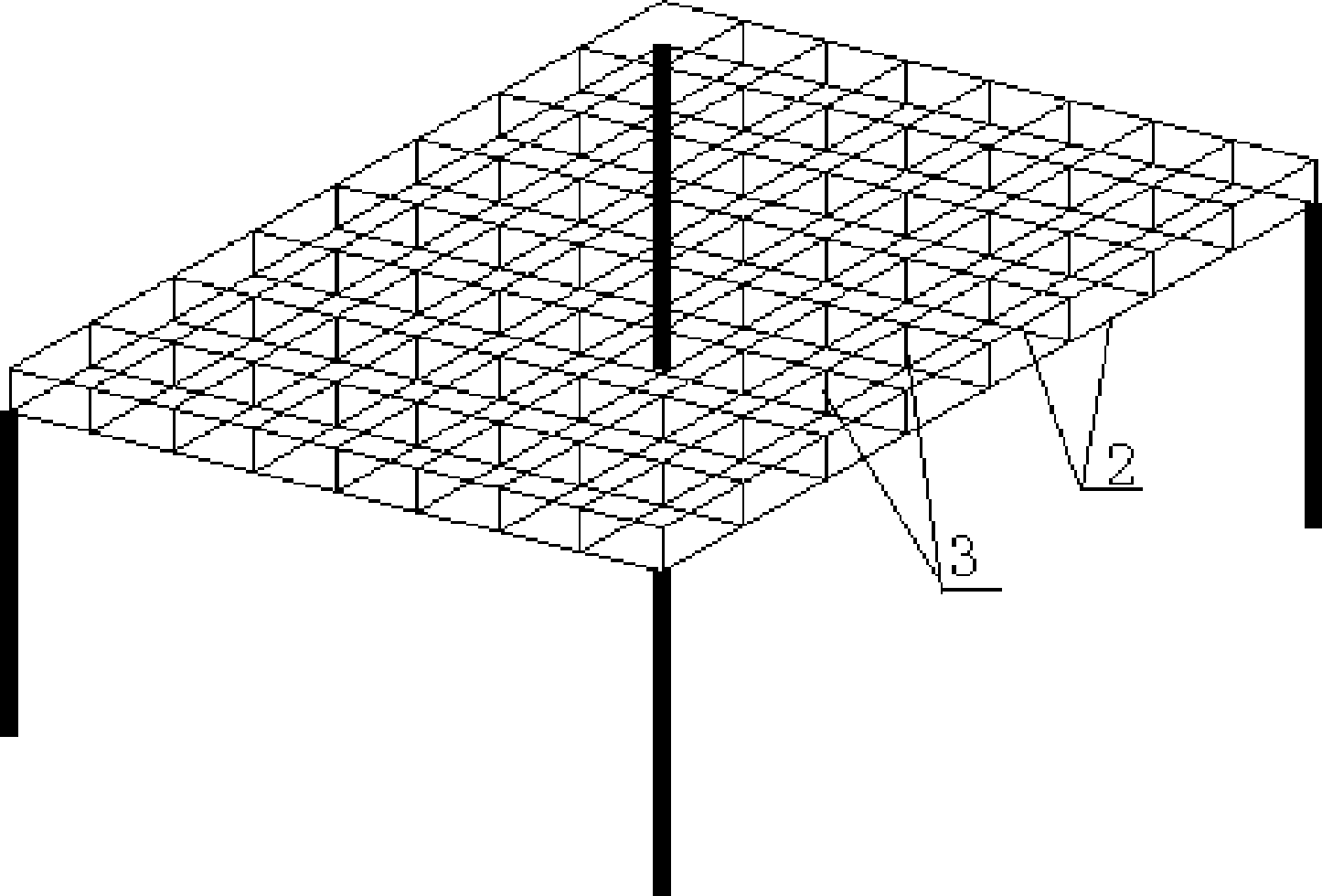

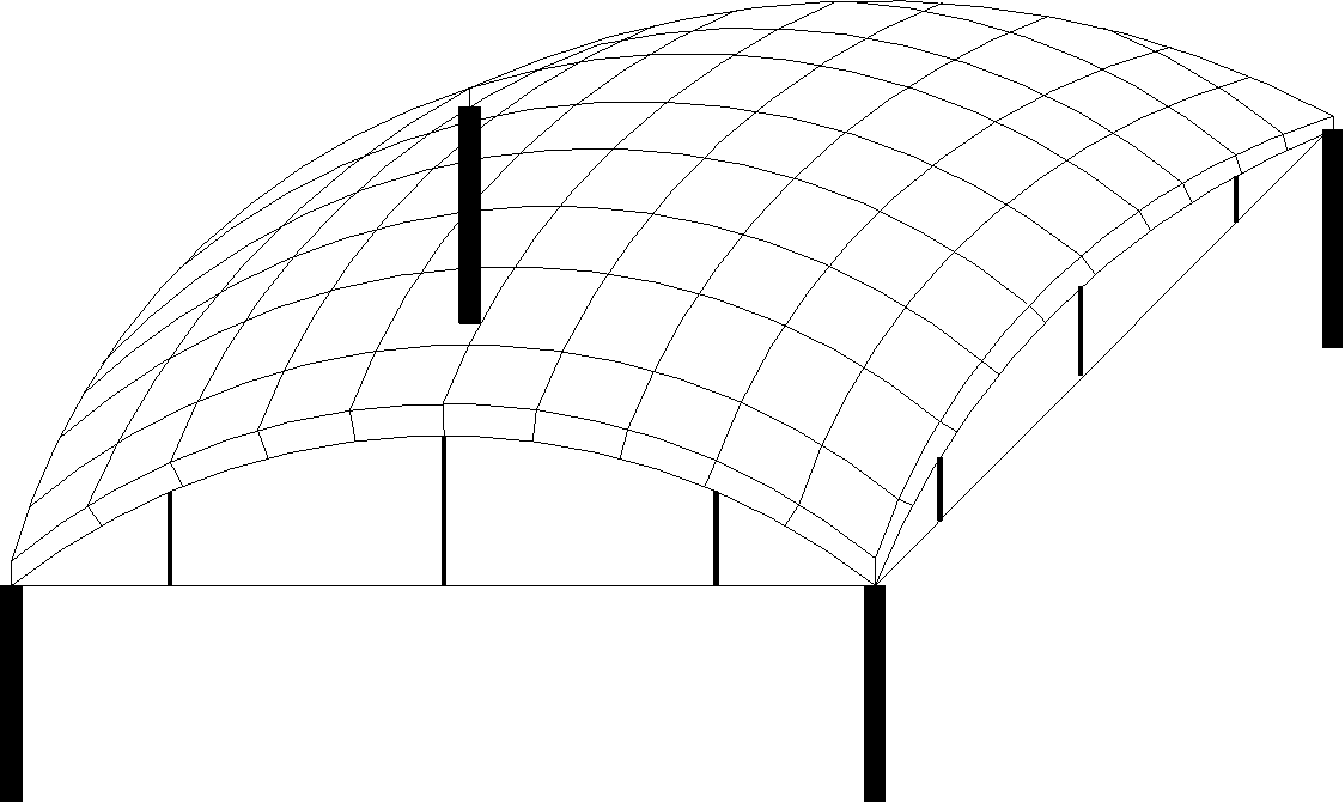

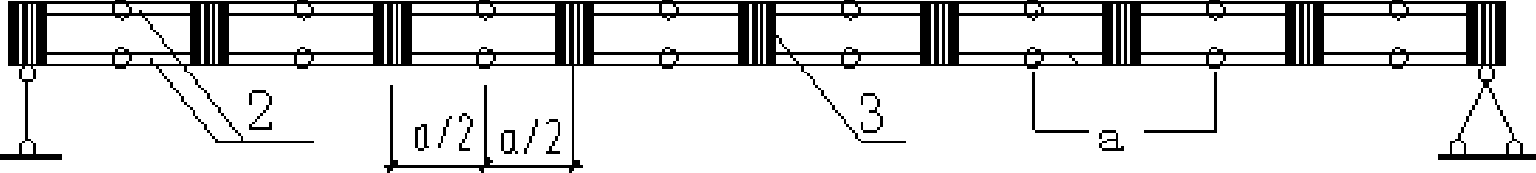

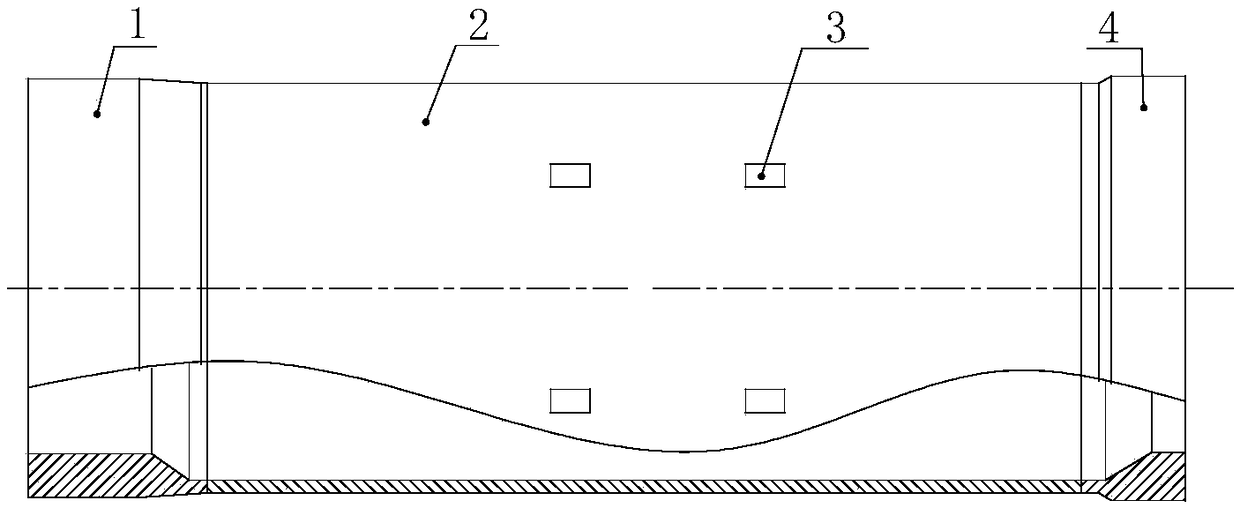

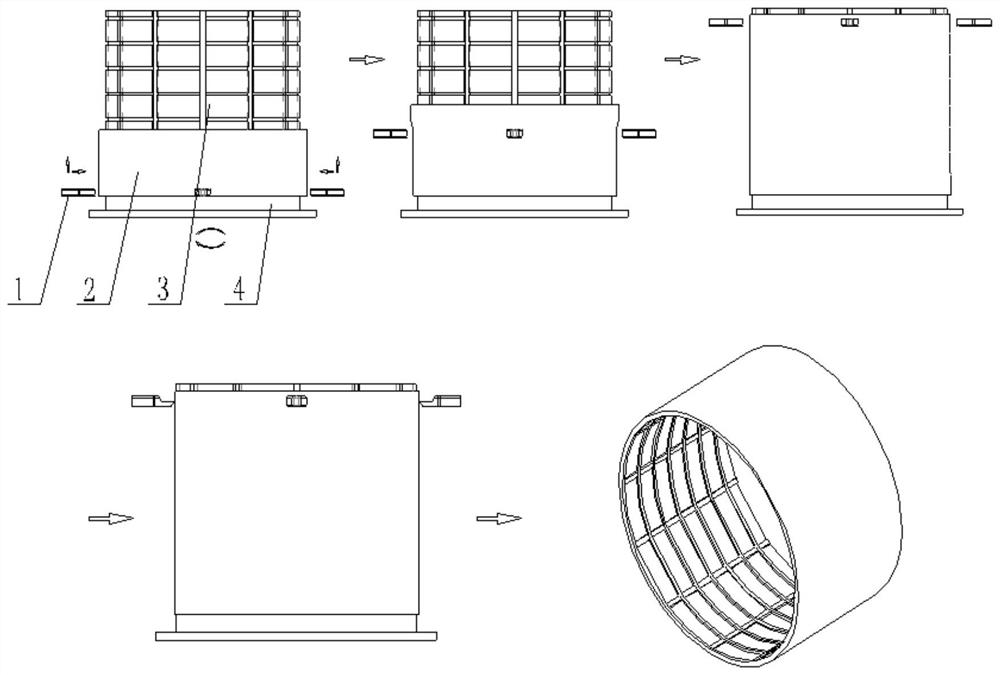

Assembly of integral flat-plate type or hood face section steel hollow lattice construction and production method

InactiveCN101397822AIncrease stiffnessReduce the height of the structureBuilding roofsFloorsRegular gridEngineering

The invention relates to a wholly assembled flat or curved steel vierendeel grid structure and a producing method thereof. The producing method comprises the steps: firstly, the two ends of a cylinder steel pipe are welded with a supporting plate respectively; the surface of the supporting plate and the pipe wall of the cylinder steel pipe are taken as welding points, 8 chords with T-shaped sections are respectively welded at the two ends of the cylinder steel pipe to form a double-layer assembling crisscross unit; chords of two or more double-layer assembling crisscross units are connected by a double spicing plate on the construction site so as to assemble the flat or curved grid structure. The flat or curved grid structure produced by the method has dexterous and firm structure; the welding technique is finished in factories, thus being capable of improving the precision and quality of production; the grid is formed by a vierendeel beam rather than a vierendeel truss rod so that water pipelines and electrical wires can go through the grids conveniently, takes regular grid shapes and plays a role of hanging floors and roofs.

Owner:贵州喀斯特钢结构有限公司 +2

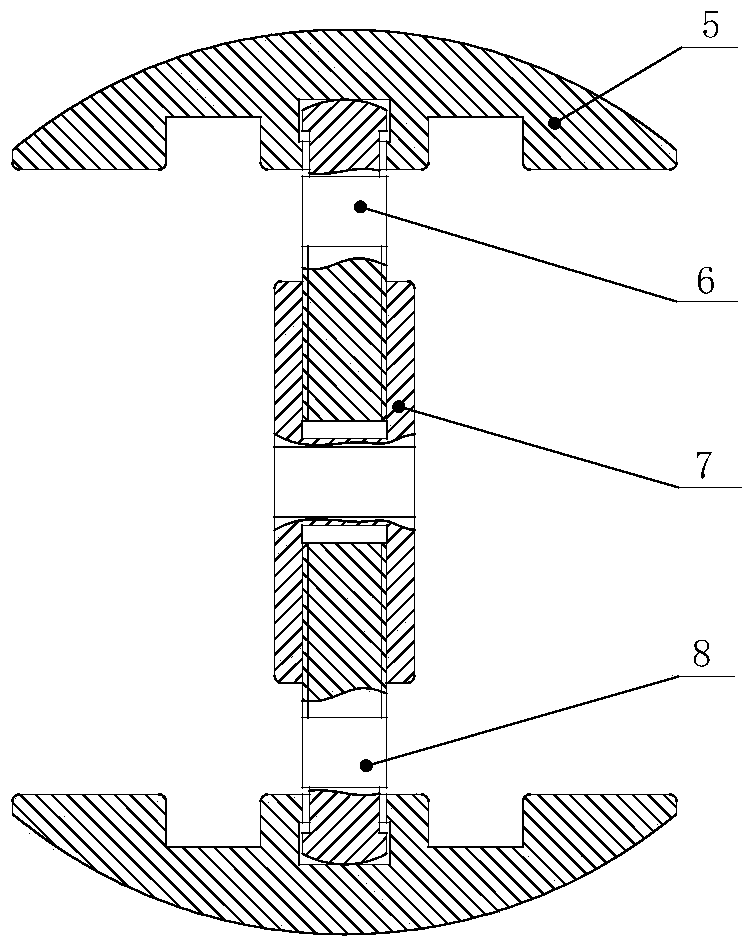

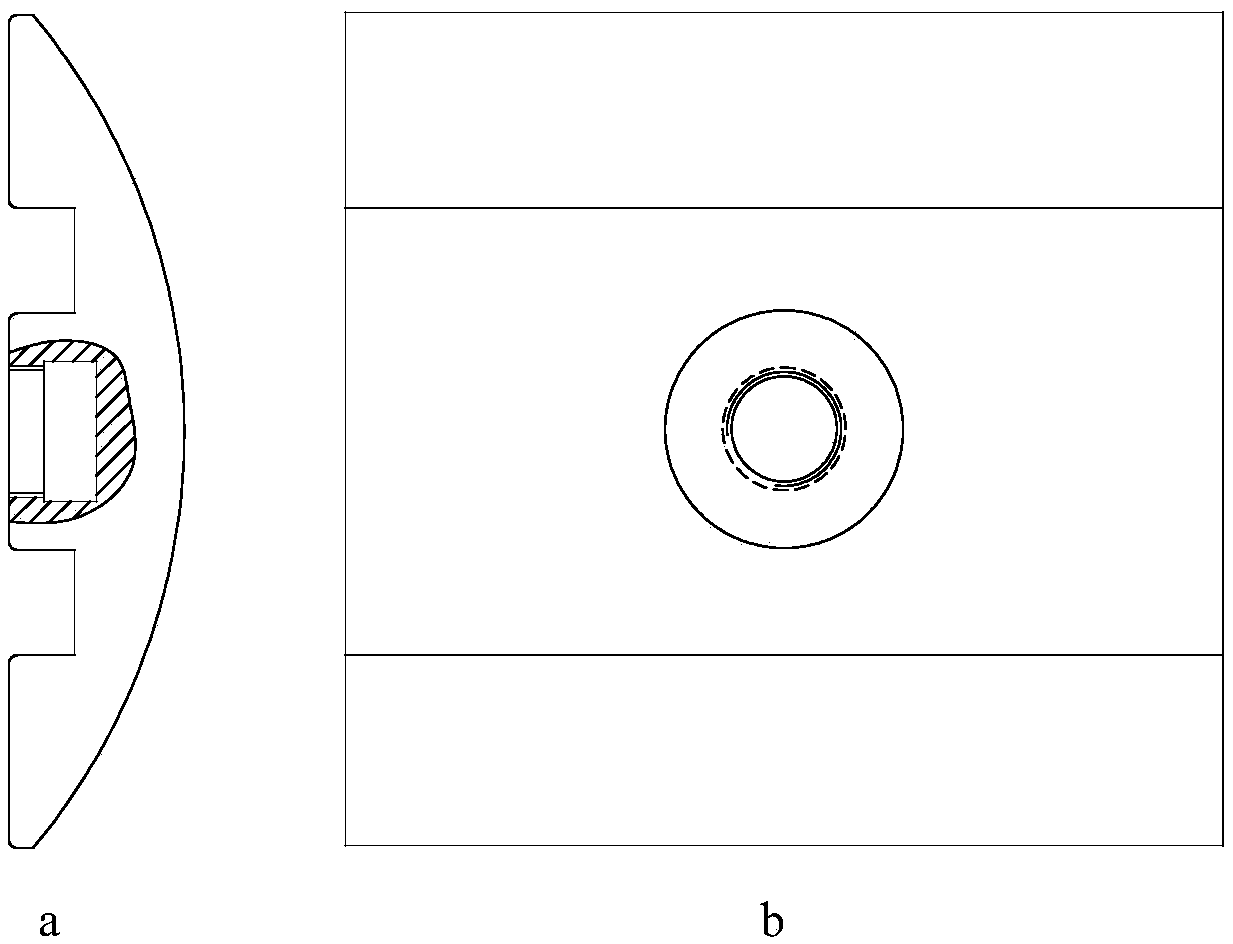

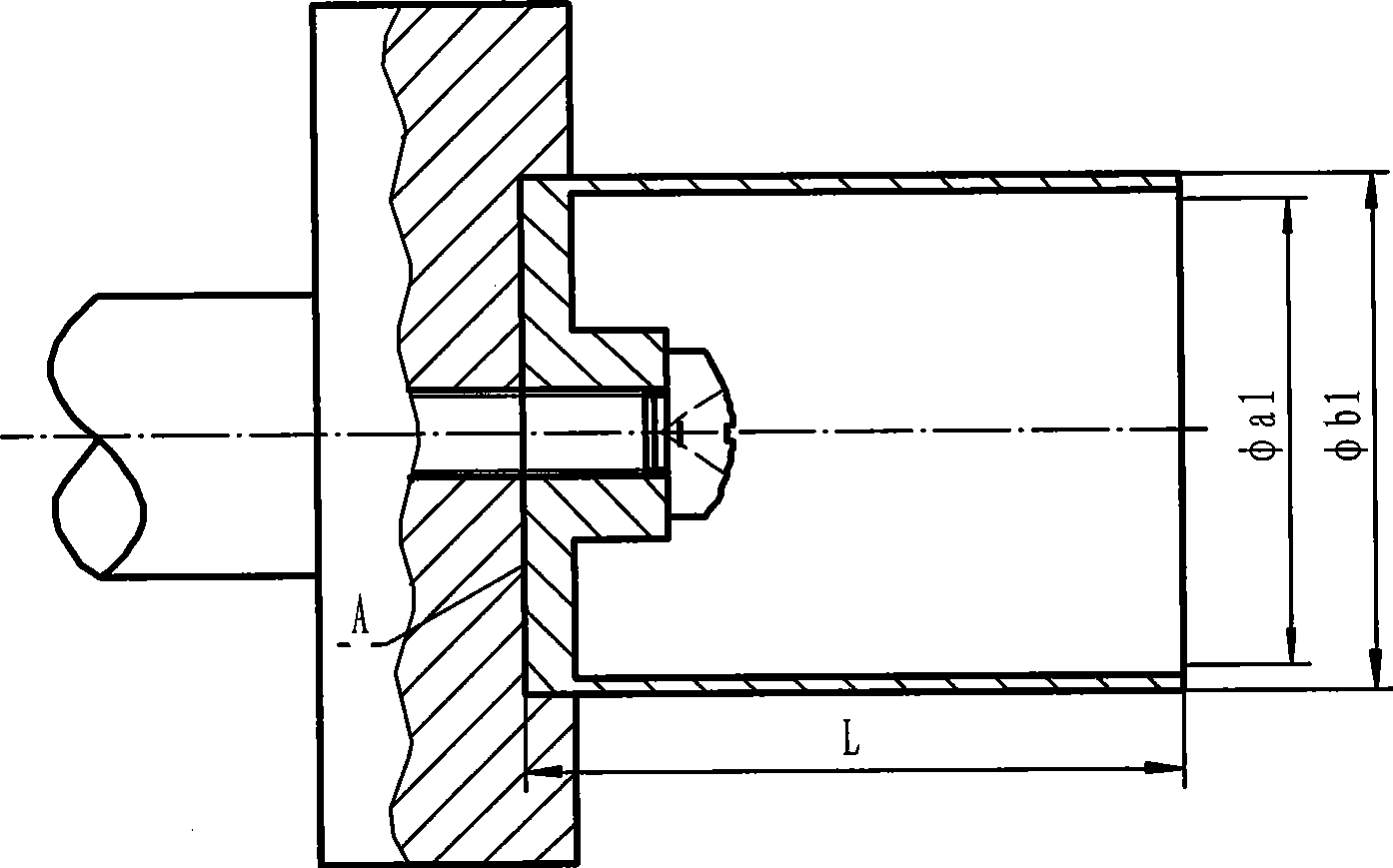

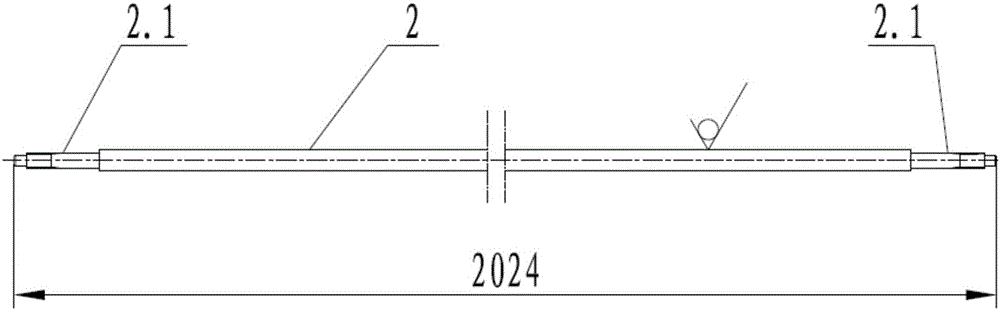

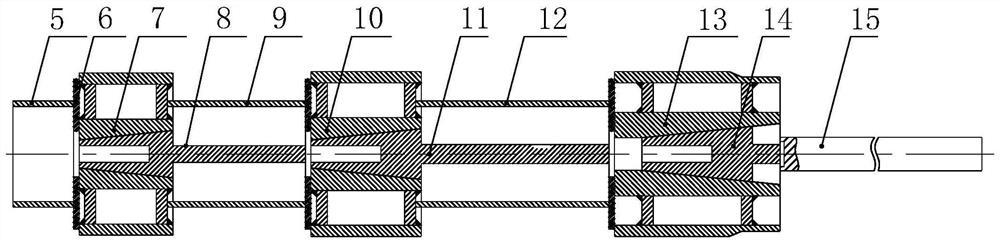

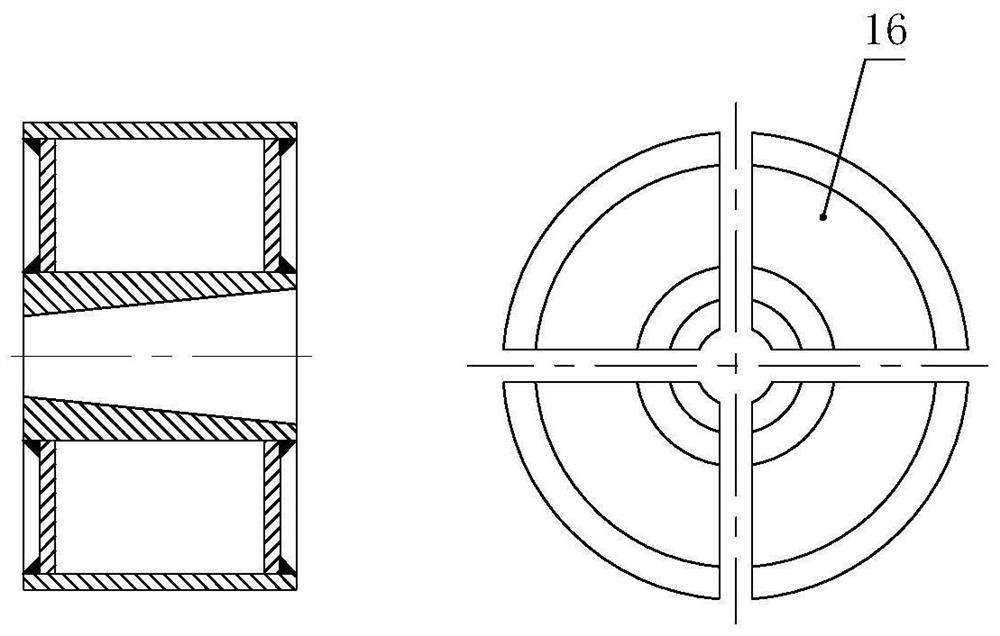

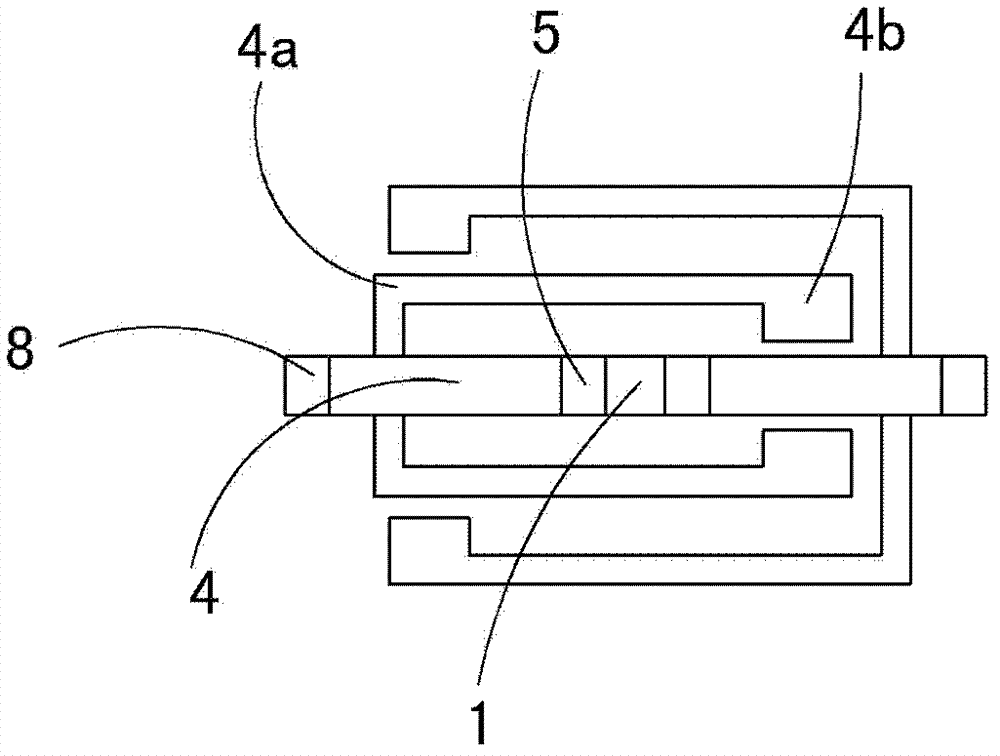

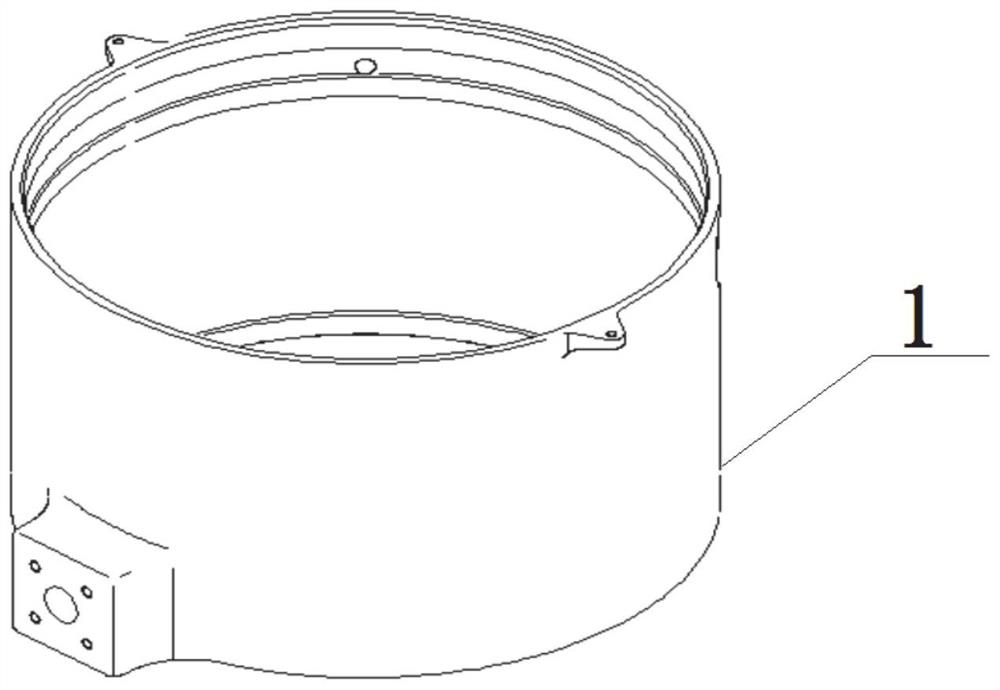

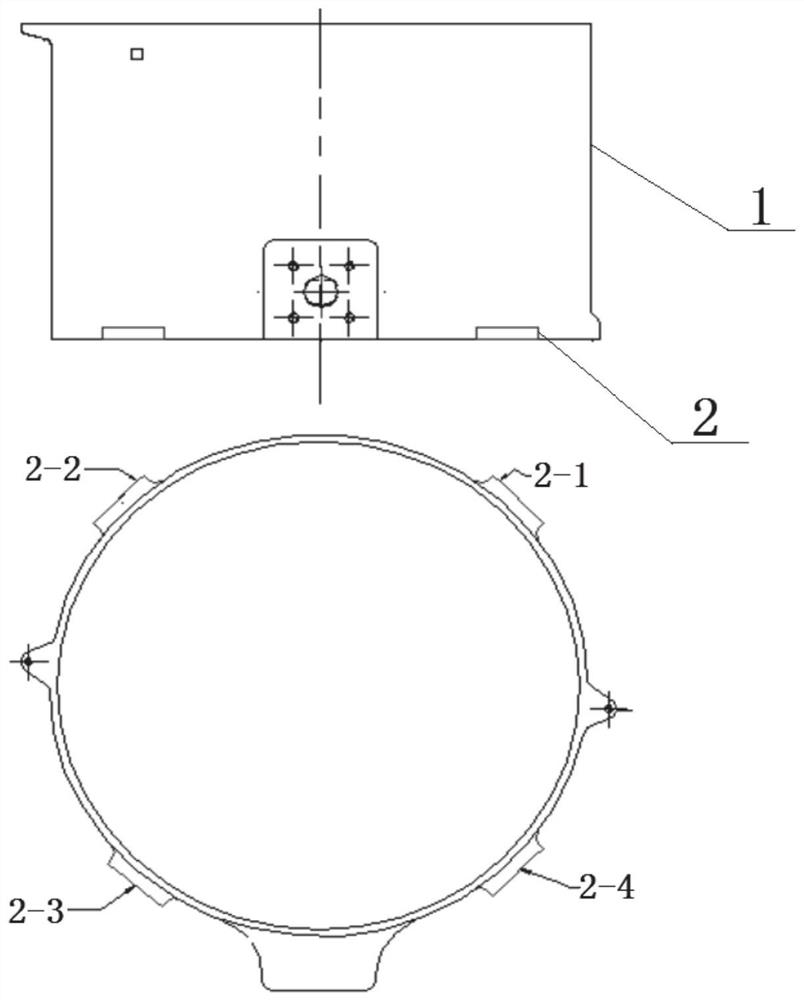

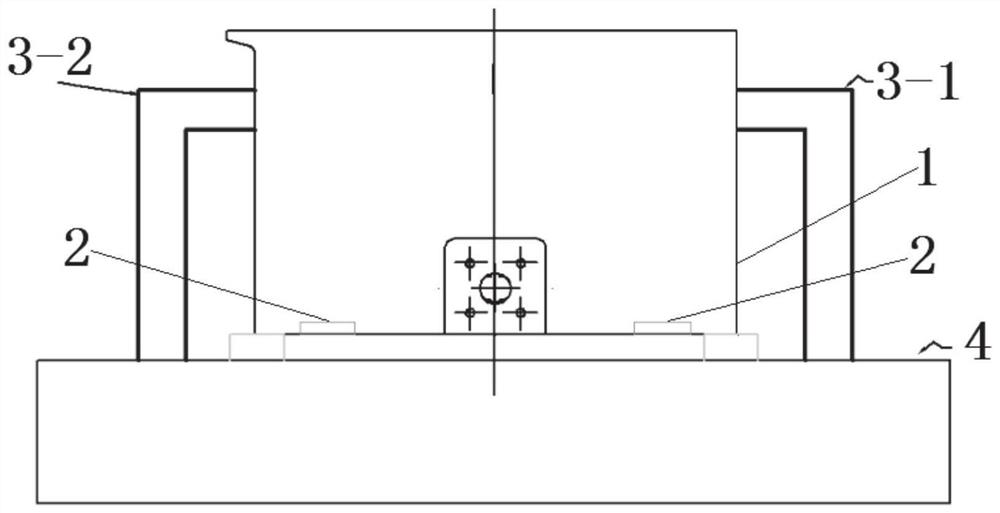

Extensible and retractable inner supporting tool

ActiveCN109366052ALarge stretchEasy accessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStress relief

The invention discloses an extensible and retractable inner supporting tool. One end of a left-handed screw is installed in a screw installation hole in the plane geometric center of a supporting plate, and the left-handed screw is in rotating fit with the screw installation hole. A left-hand thread at the other end of the left-handed screw is installed in a threaded hole in the center at one endof a sleeve. One end of a right-handed screw is installed in a screw installation hole in the plane geometric center of the other supporting plate, and the right-handed screw is in rotating fit with the screw installation hole. A right-hand thread at the other end of the right-handed screw is loaded in a threaded hole in the center at the other end of the sleeve. The extensible and retractable inner supporting tool has extending and retracting functions; in a shortened state, the extensible and retractable inner supporting tool can be put into a shell and then extends to support a cylinder, rigid restraining to the cylinder is achieved, and the welding deformation is reduced; and by means of stress relief annealing heat treatment through the belt tool, deformation stress is eliminated, andtherefore the cylinder circular degree after welding is guaranteed, and the circular degree of the shell is reduced to 2.5 mm from 10 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Method for manufacturing frame of combined bicycle

The invention provides a method for manufacturing a frame of a bicycle. The method comprises the following steps of: (1) manufacturing frame fittings, wherein the frame fittings comprise frame pipes and joints, the frame pipes comprise an upper pipe, a back upper fork, a back lower fork, a lower pipe and a middle pipe which are all made of aluminum alloy, and the joints comprise a head pipe joint, a middle pipe joint and a five-way joint which are all made of magnesium alloy; (2) processing surfaces of the frame fittings; (3) molding the frame pipes and the joints by gluing; (4) grinding and polishing the frame; and (5) performing baking finish on the surface of the frame. The whole frame utilizes the gluing molding technology so that the frame has beautiful appearance, better streamline form, and higher size precision; furthermore, the deformation and stress concentration caused by welding in the traditional manufacturing method are eliminated.

Owner:GUANGZHOU LEONIS MACHINERY

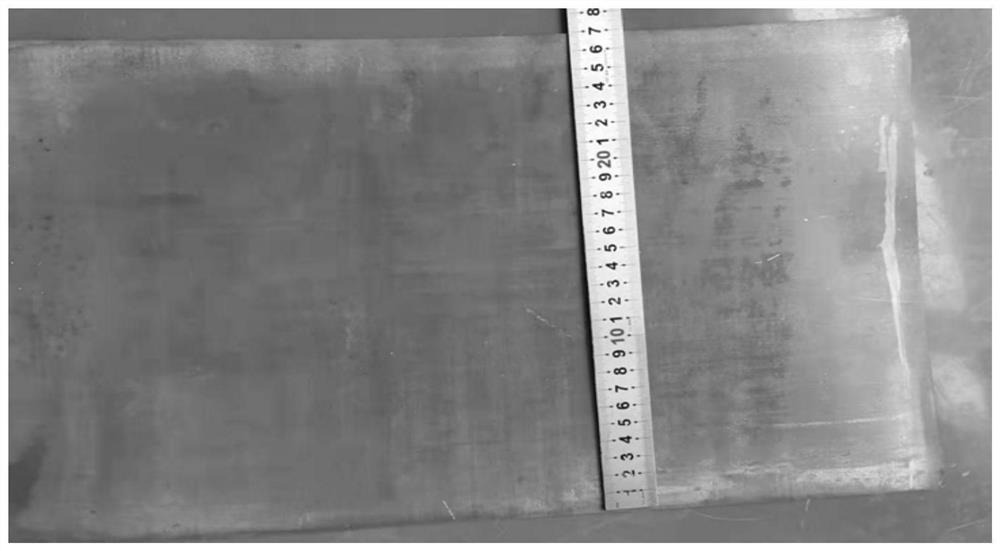

Manufacturing process for thin-wall metal hollow rotor cup

InactiveCN101478200AImprove uniformityEliminate deformation stressManufacturing stator/rotor bodiesAdhesiveEngineering

The invention relates to a manufacturing process for a thin-wall metal hollow rotor cup. The low temperature annealing working procedure is added before and after rough turning to eliminate the deformation stress; the positioning and clamping, the selection of a cutting tool as well as the detection of a dimensional tolerance are fully considered during the finish turning to prevent the workpieces from being distorted and enhance the uniformity of the cup wall; and the manufacturing process adopts the scheme that a rotating axle is pressed in when the mandrel is not taken out of the rotor cup, and the contact surface is coated with adhesive. Therefore, the process is simplified, and the concentricity between the rotor cup and the axle core is ensured.

Owner:XIAN MICROMOTOR RES INST

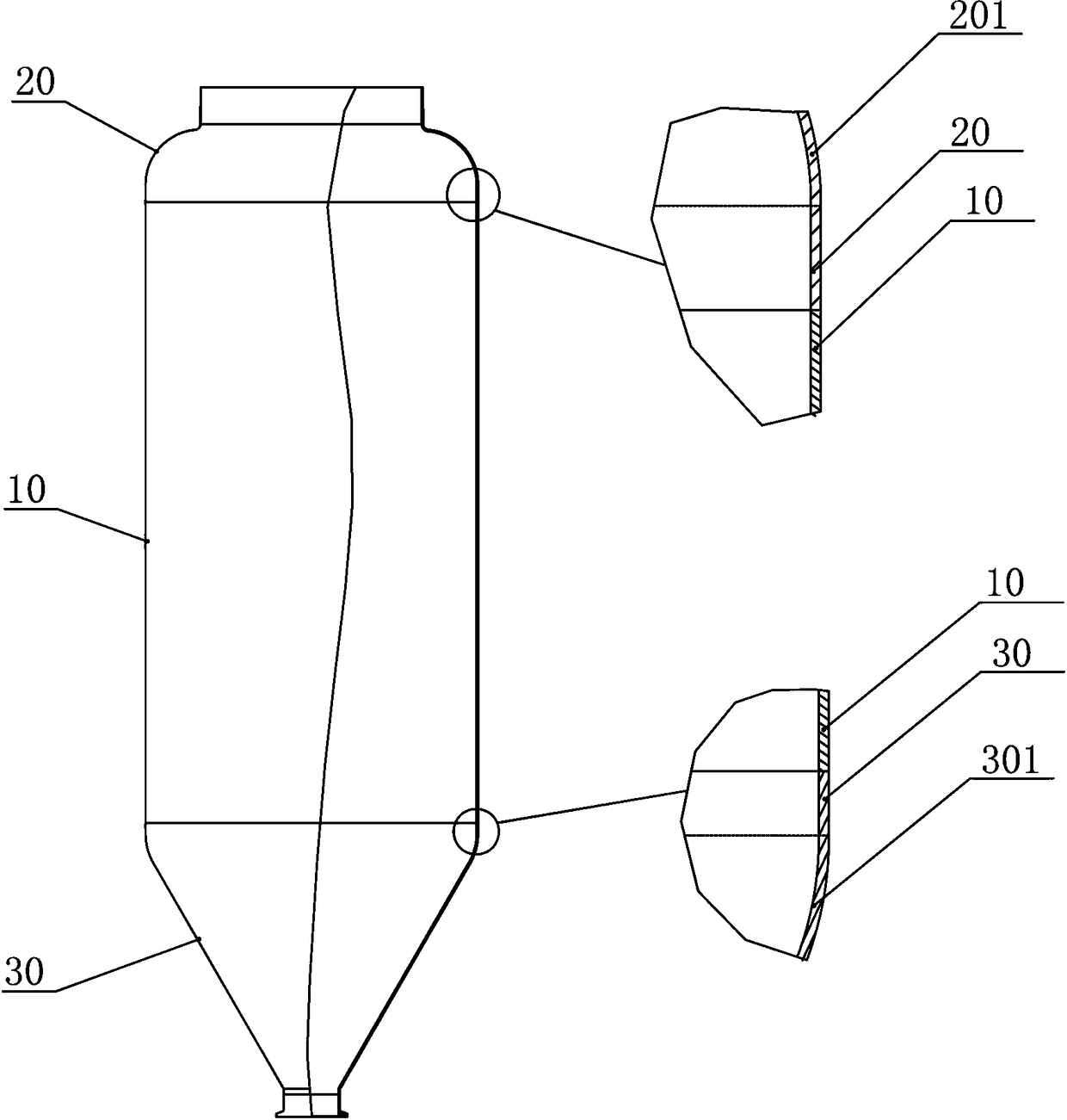

Storage tank barrel section integrated forming method and integrated storage tank barrel section

InactiveCN111687592AImprove reliabilityIncrease profitCosmonautic vehiclesCosmonautic propulsion system apparatusNumerical controlSpinning

The invention provides a storage tank barrel section integrated forming method and an integrated storage tank barrel section. An original barrel blank is obtained through a blank making process; a spinning die is arranged, the original barrel blank is arranged outside a tool, a barrel blank material is extruded into the spinning die through a flowing spinning technology until the barrel blank material is attached to the spinning die, and a spinning rear barrel section is formed; overall solid solution aging is adopted, the performance of the barrel blank material is improved to a T6 state, meanwhile, the internal structure performance of the barrel blank material is uniform, and a part is formed; carrying out turning and flattening on a local recess, caused by extrusion, on the outer sideof the part; and the spinning die is unloaded, the formed part is taken out after a spinning wheel returns, and nondestructive inspection is carried out on the formed part. According to the storage tank barrel section integrated forming method and the integrated storage tank barrel section, the barrel blank is formed through integral ring rolling or roll welding, integral forming of the storage tank barrel section with a rib structure is achieved through combined machining modes of flow spinning forming, integral heat treatment, numerical control precision machining and the like, the materialutilization rate, the product reliability and the size precision are improved, and integral near-net forming of the storage tank barrel section of a carrier rocket is achieved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

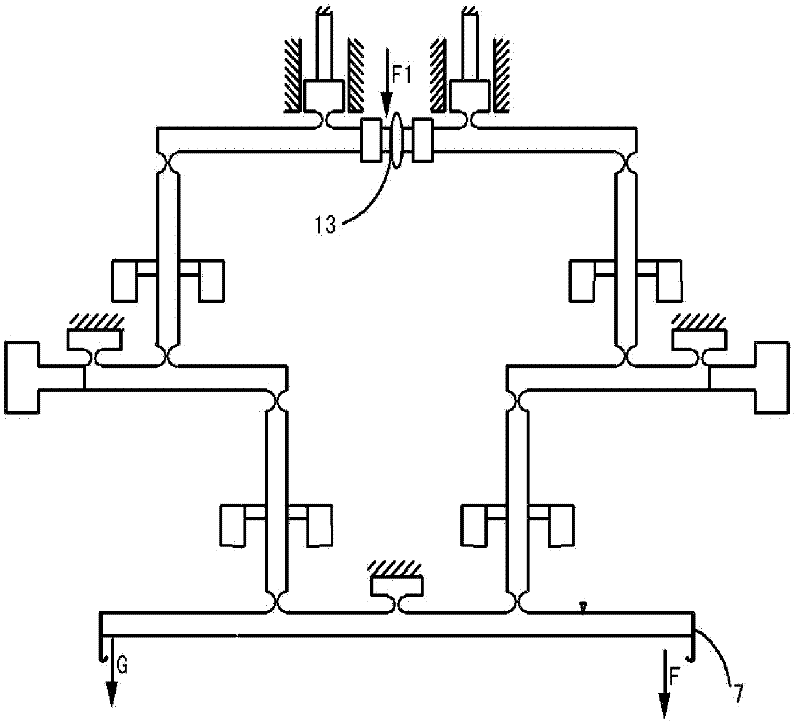

Differential type vertical micro-force loading device and method

InactiveCN102305687AEasy to operateReduce frictionForce measurementForce/torque/work measurement apparatus calibration/testingVertical planeMicroelectromechanical systems

The invention discloses a differential type vertical micro-force loading device and method, which is characterized in that a secondary pivot horizontally placed at the middle of a secondary lever, a pair of primary levers is symmetrically distributed at two sides of the secondary pivot in one vertical plane with the secondary pivot as a center, and the primary levers are respectively linked with the secondary lever by a transition lever at own side. The differential type vertical micro-force loading device and method can be used for calibrating micro-force sensors, microelectromechanical systems, and various micro-force detectors, and provides support for the force measuring system of the micro-force.

Owner:HEFEI UNIV OF TECH

Novel hot rolling and precision forging technique for waste oil pipes

ActiveCN106734330AReduce frictional resistanceUniform deformationMetal rolling arrangementsCurrent technologySizing

The invention provides a novel hot rolling and precision forging technique for waste oil pipes and belongs to the waste oil pipe restoration technology. The defects of other current technologies are overcome. The production technique comprises the following steps of primary selection, descaling, flaw detection, rough rolling, precision forging and sizing, straightening, penetrating, length fixing, top cropping, detection and storage, specifically, the oil pipes are put into storage after passing the detection. The novel hot rolling and precision forging technique has the significance that firstly, the production cost is low; secondly, the product models are complete; thirdly, the product quality is high; fourthly, pollution is avoided during production; and fifthly, the production efficiency is improved.

Owner:PUYANG SHUNKANG PETROLEUM ENG TECH

Preparation method of seamless steel tubes

The invention relates to a preparation method of seamless steel tubes. The method comprises steps as follows: 1) tube blanks are heated, are perforated on a perforating machine after being heated and are punched on a punching machine; 2) the tube blanks are subjected to pickling, phosphating and saponification treatment and are cold-drawn on a cold-drawing machine after treatment is completed; 3) the tube blanks are subjected to heat treatment in an annealing furnace; 4) the tube blanks are subjected to pickling, phosphating and saponification treatment and are cold-drawn on a cold-drawing machine after treatment is completed; 5) the tube blanks are subjected to phosphating and saponification treatment and are subjected to degreasing treatment after treatment is completed; 6) the tube blanks are subjected to tying treatment on a tying machine; 7) the tube blanks are subjected to pickling, phosphating and saponification treatment for the fourth time and are cold-drawn on the cold-drawing machine after treatment is completed; 8) the tube blanks are subjected to tying treatment on the tying machine; 9) the tube blanks are subjected to heat treatment in an anaerobic annealing furnace; 10) the tube blanks are subjected to straightening treatment on a straightening machine; 11) the tube blanks are subjected to tube cutting treatment on a tube cutting machine. With the method, automatic feeding is adopted, the labor is saved, two steel tubes can be cold-drawn simultaneously, and the cold-drawing efficiency of the steel tubes can be improved.

Owner:江苏宏亿精工股份有限公司

Die-casting double-bottom cooking utensil and manufacturing method thereof

ActiveCN103549873AManufacturing process advantagesPrecise positioningCooking-vessel materialsPunchingDie casting

The invention provides a die-casting double-bottom cooking utensil and a manufacturing method of the die-casting double-bottom cooking utensil, which belong to the technical field of machinery and solve the problem that a double-bottom sheet in an existing double-bottom pan body is easily deformed or easily falls off through heating. The manufacturing method comprises the following steps of A. manufacturing a metal sheet; B. punching; C. turning over edges; D. closing molds; E. casting molten aluminum; F. demolding. The die-casting cooking utensil comprises an open body which is made of an aluminum material, wherein the body is provided with a chassis for heating, the chassis is provided with the metal sheet which is made of a magnetic-conducting material, the metal sheet is provided with a plurality of through connecting holes, the chassis is provided with a plurality of connecting parts which are embedded into the connecting holes, the connecting parts and the connecting holes are in one-to-one correspondence, and a clamping structure which can be used for fixedly connecting each connecting part and the corresponding connecting hole is arranged between the connecting part and the connecting hole. The die-casting double-bottom cooking utensil has the advantages that the metal sheet is more firmly connected and does not easily fall off, and the like.

Owner:ZHEJIANG SUPOR CO LTD

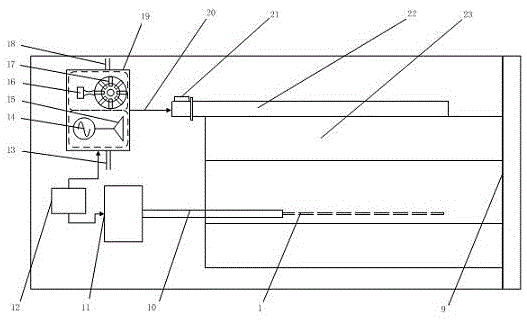

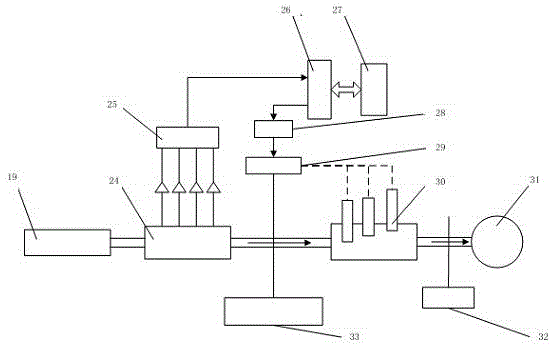

Rotating pulse cold forging unit for steel tube

InactiveCN106040934AHigh dimensional accuracyEliminate deformation stressForging hammersUpsetting pressesReciprocating motionEngineering

The invention discloses a rotating pulse cold forging unit for a steel tube. The rotating pulse cold forging unit comprises an axial conveyer used for conveying a mother tube forwards, a radial cold forging machine used for performing cold forging processing on the mother tube, and an axial traction machine used for pulling a finished tube forwards after the tail end of the mother tube leaves the axial conveyer which are sequentially arranged in the forward direction of the steel tube. According to the rotating pulse cold forging unit, through high frequency pulse continuous reciprocating motion, the forging processing of diameter decreasing and wall thickness decreasing of the mother tube is achieved, the cold forging production speed is greatly increased and can reach 1 to 4 m / min, the dimensional accuracy of the steel tube subjected to cold forging is relatively high, and the purpose of non-cutting processing can be achieved; the mechanical property of a product is good, the surface rigidity is improved, and the tensile strength, yield strength and fatigue strength are improved; the deformation stress of ingredients is eliminated, and the failure treatment is not needed; and the procedures like head driving, pickling, saponification and phosphorization are not needed, so that the rotating pulse cold forging unit does not cause any pollution to the environment.

Owner:王剑波

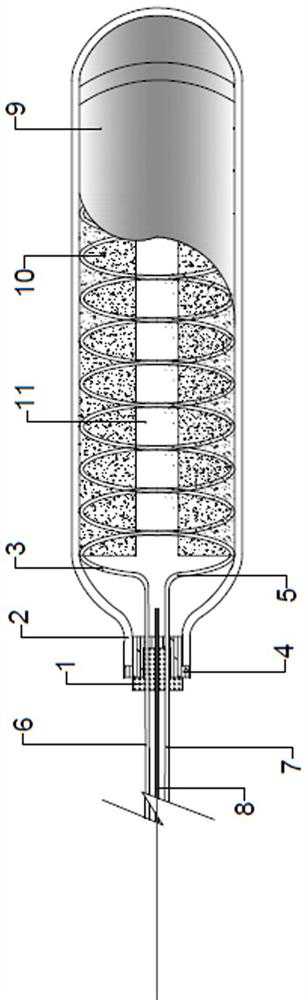

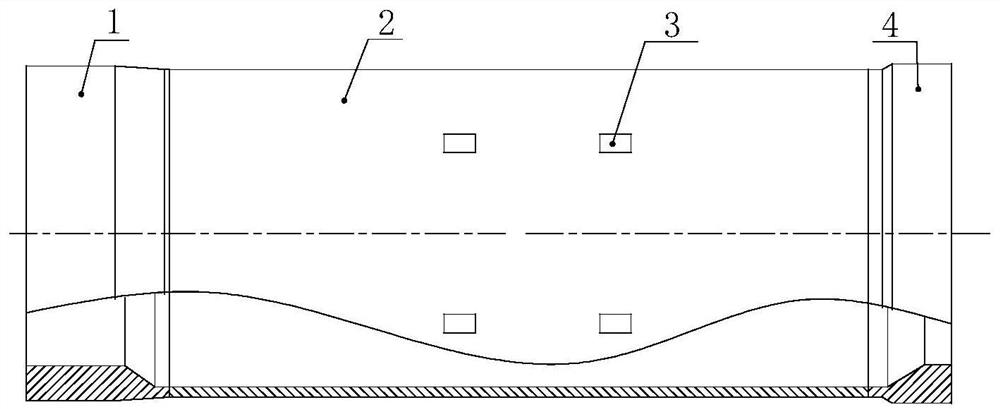

Solid hydrogen source device for hydrogen fuel

ActiveCN112066242ASimple structureEasy to processVessel mounting detailsReactant parameters controlHeat mass transferEngineering

The invention relates to a solid hydrogen source device for hydrogen fuel, and belongs to the technical field of hydrogen storage devices. Safety, portability and environmental adaptability of a solidhydrogen source to hydrogen utilization are achieved. According to the solution, a tank opening is formed in a hydrogen storage tank, a valve is mounted at the tank opening, a sealing ring is mountedbetween the valve and the tank opening, a heat exchange pipeline is of a double-spiral structure and is fixedly arranged on the inner wall of the hydrogen storage tank in a coiling manner, and a heatmass transfer inlet and a heat mass transfer outlet of the heat exchange pipeline respectively penetrate through the valve and extend to the outside of the hydrogen storage tank; a cavity is formed in the axis position in a tank body of the hydrogen storage tank, a hydrogen charging / discharging pipeline penetrates through the valve and communicates with the cavity, a plurality of material bins are arranged on the periphery of the cavity, the size of each material bin is not smaller than 4 / 5 of that of an inner cavity of the tank body of the hydrogen storage tank, a diaphragm is arranged on aside wall of each material bin, and the material bins are filled with solid hydrogen storage alloy powder. The device is simple in structure, safe, efficient, portable and suitable for various environments and has good reproducibility and stability.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

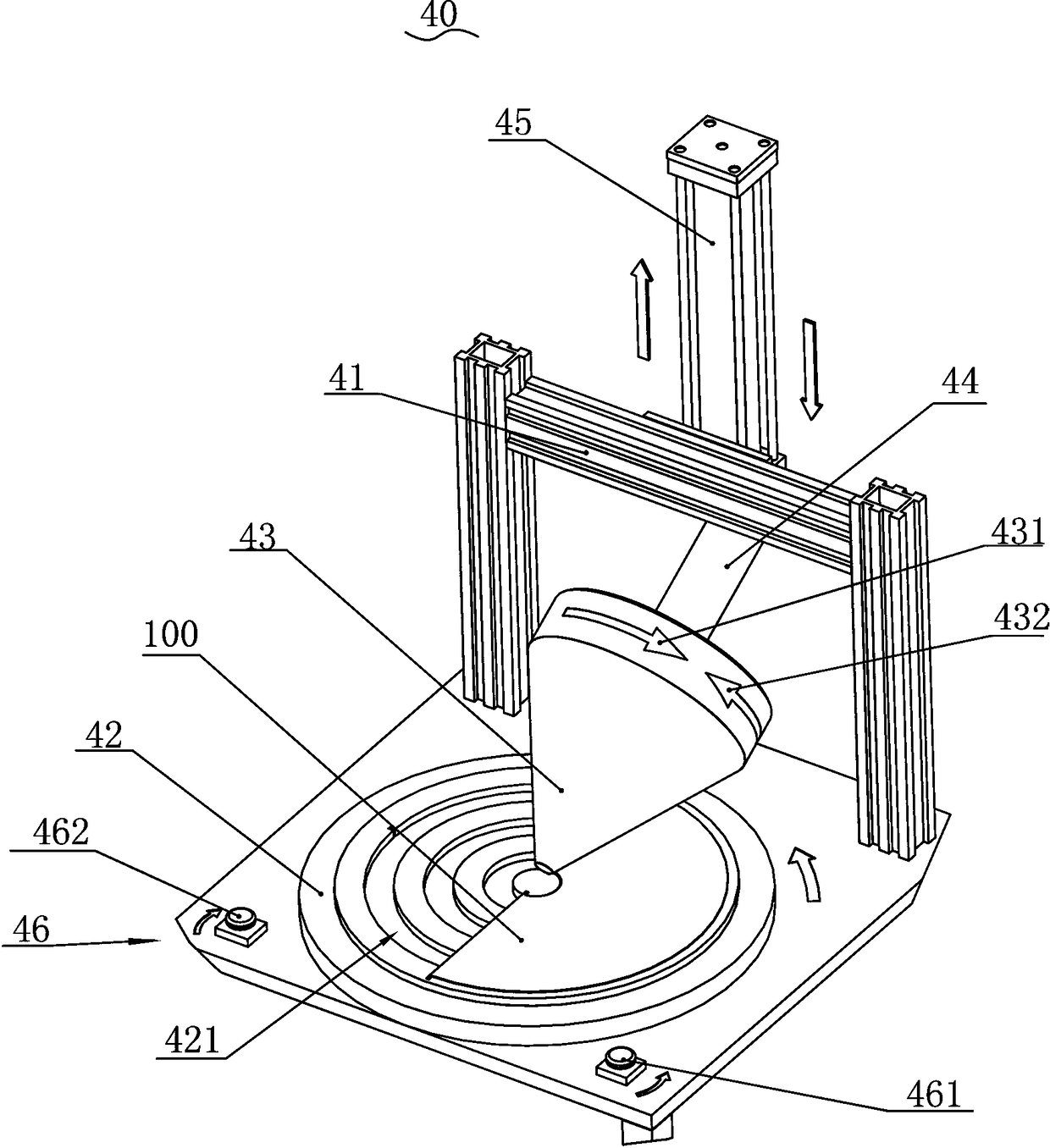

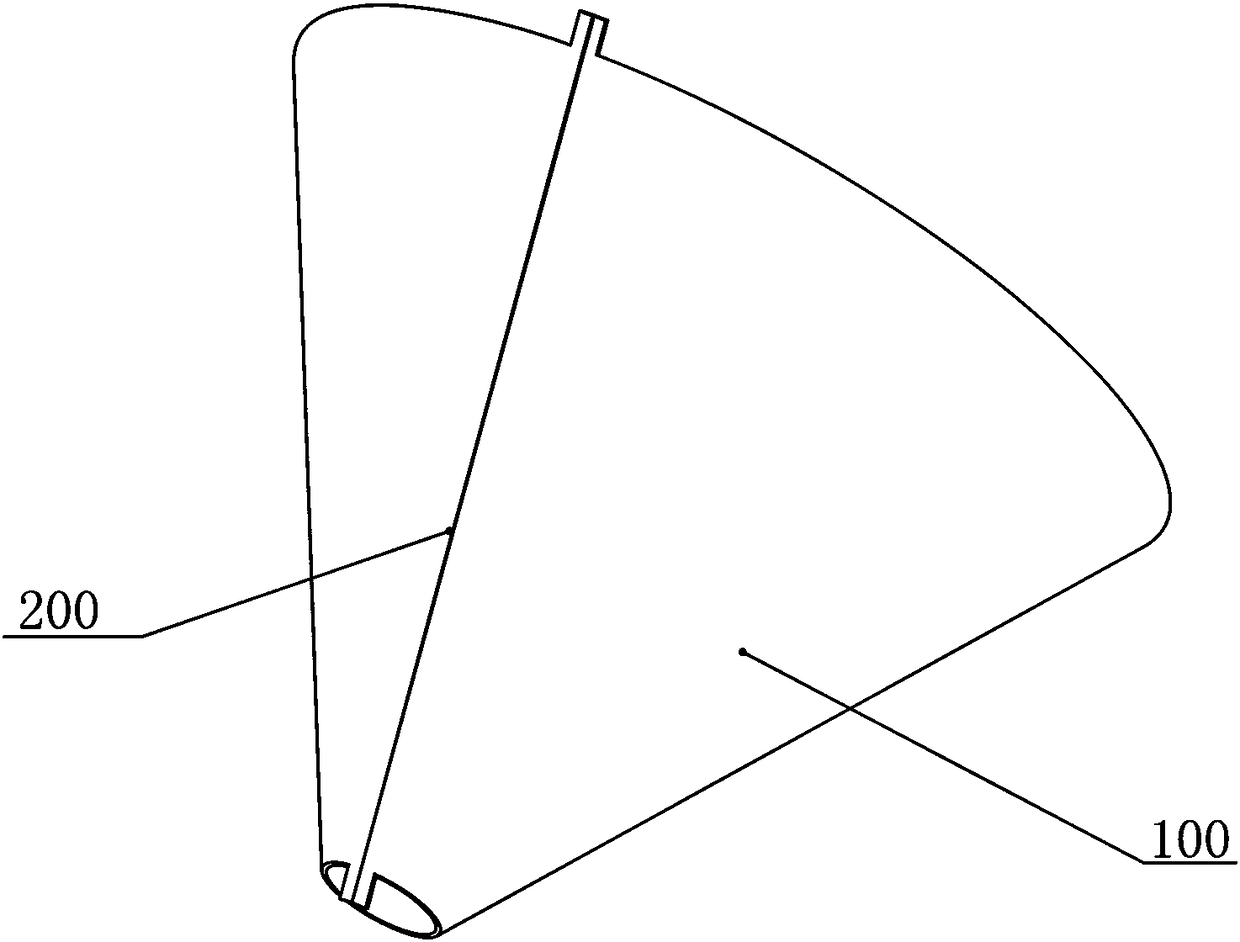

Manufacturing method of stainless steel tapered tank body

The invention provides a manufacturing method of a stainless steel tapered tank body. The manufacturing method comprises the following steps: 1) one rectangular stainless steel plate is directly coiled and welded to form a cylindrical cylinder; 2) the other rectangular stainless steel plate is pressed and welded to form a top round tank; 3) an arc-shaped stainless steel plate is rolled and weldedthrough a tapered rolling device to form a tapered bottom round tank; 4) the tapered bottom round tank and the matched end face of the bottom of the cylindrical cylinder are in seamless butt joint through laser argon arc welding, and seamless butt joint is carried out on the matched end face of the top round tank and the cylindrical cylinder by adopting laser argon arc welding; and 5) mirror surface profiling polishing is carried out on the inner wall of the whole inner tank after laser argon arc welding is completed. Compared with the prior art, the manufacturing method greatly eliminates deformation stress through segmented welding, the inner wall of the tank body with a smooth mirror face, no gap, no pit and no section difference can be realized through polishing on the inner wall, andno residual dirt remains on the inner wall of the tank body, so that the rapid propagation of bacteria on the inner wall of the tank body can be effectively inhibited, and the effect of improving thefermentation or fresh-keeping and antibacterial effects can be achieved.

Owner:UNIND SHENZHEN CO LTD

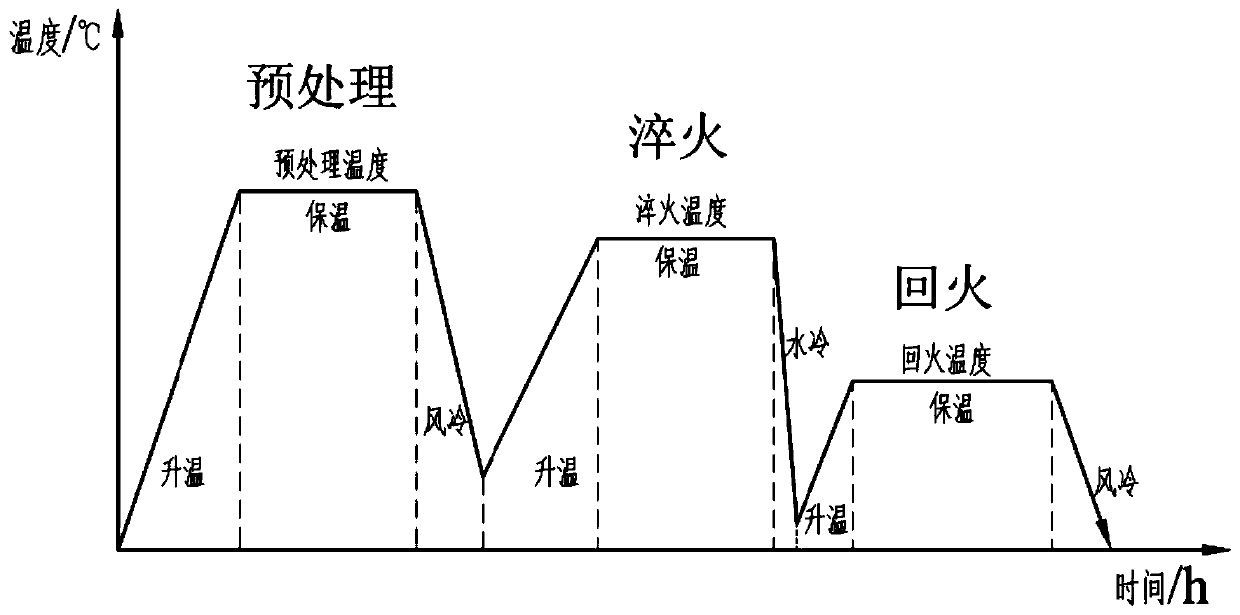

A3 axle steel, and A3 axle and heat treatment process method thereof

ActiveCN110964988AImprove hardenabilityImprove toughnessFurnace typesHeat treatment furnacesTemperingCrazing

The invention discloses A3 axle steel, and A3 axle and a heat treatment process method thereof, and belongs to the technical field of heat treatment processes of axle steel. In the prior art, an A3 material axle is poor in hardenability, low in strength and toughness and poor in overall performance. The A3 axle steel comprises the following components in percentage by mass: 0.34%-0.37% of carbon,0.25%-0.40% of silicon, 1.40%-1.50% of manganese, less than or equal to 0.020% of phosphorus, less than or equal to 0.015% of sulfur, 0.20%-0.30% of chromium, 0.13%-0.20% of nickel, less than or equalto 0.30% of copper, less than or equal to 0.40% of molybdenum, 0.035%-0.045% of vanadium and 0.015%-0.040% of aluminum. Heat treatment is conducted through the modes of forging heating, pretreatment,quenching and tempering. According to the invention, the contents of carbon and manganese are properly increased in the aspect of axle components so as to reinforce and increase the hardenability ofthe axle, and a proper amount of chromium and nickel are added to improve the strength and toughness of the axle; and the heating temperature and the heat preservation time are strictly controlled inseveral heat treatment steps, so that the final axle has high strength and toughness resistance, quenching cracks are avoided, the overall structure is uniform, toughness matching is good, and operability is high.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

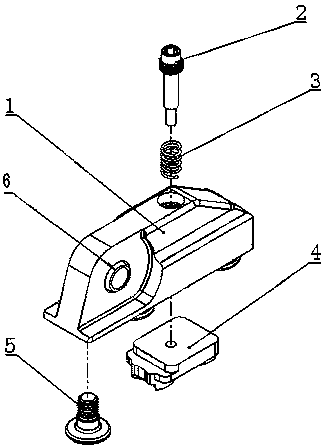

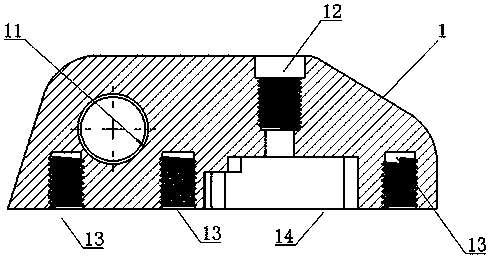

Supporting leg locking device for aviation seat

The invention discloses a supporting leg locking device for an aviation seat. The supporting leg locking device for the aviation seat comprises a supporting leg locking seat. A plurality of fixed screw thread holes are formed in the bottom of the supporting leg locking seat. The fixed screw thread holes and fixed screws are installed in a matched mode. The fixed screws enable the supporting leg locking seat to be fixed on a sliding rail on an aircraft floor, and seat connecting holes for fixing the seat are horizontally formed in the supporting leg locking seat. The aviation seat can be fixedto the sliding rail firmly, the supporting leg locking device for the aviation seat has the characteristics of rapid installation and disassembly, and it is guaranteed that the seat is not prone to being loosened by passenger misoperation under the locked state; and at the same time, when the aircraft floor is deformed, a swing axle sleeve can swing at a certain angle in the supporting leg lockingseat to eliminate the stress of floor deformation and play an adaptive role to avoid potential safety hazards.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

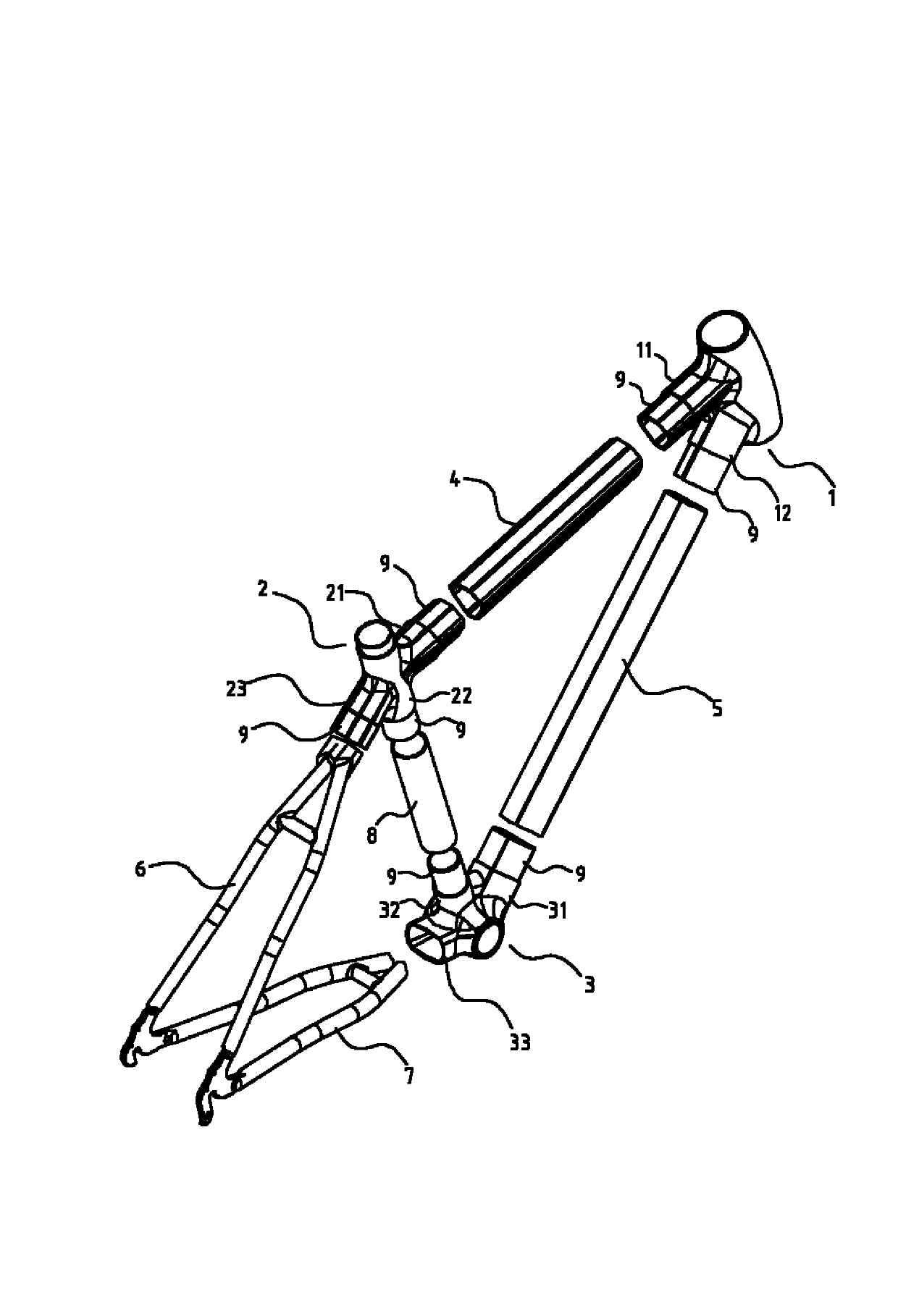

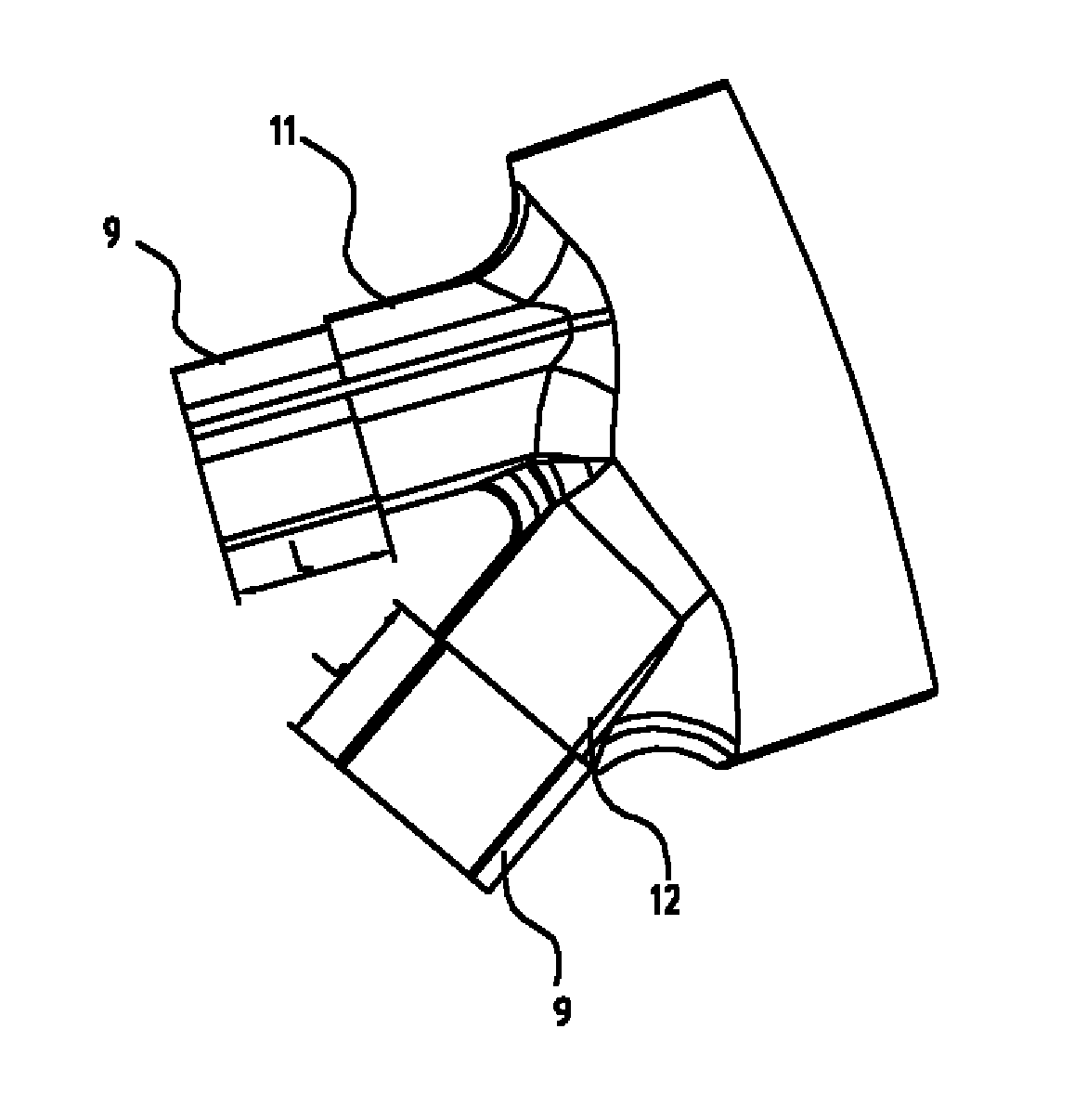

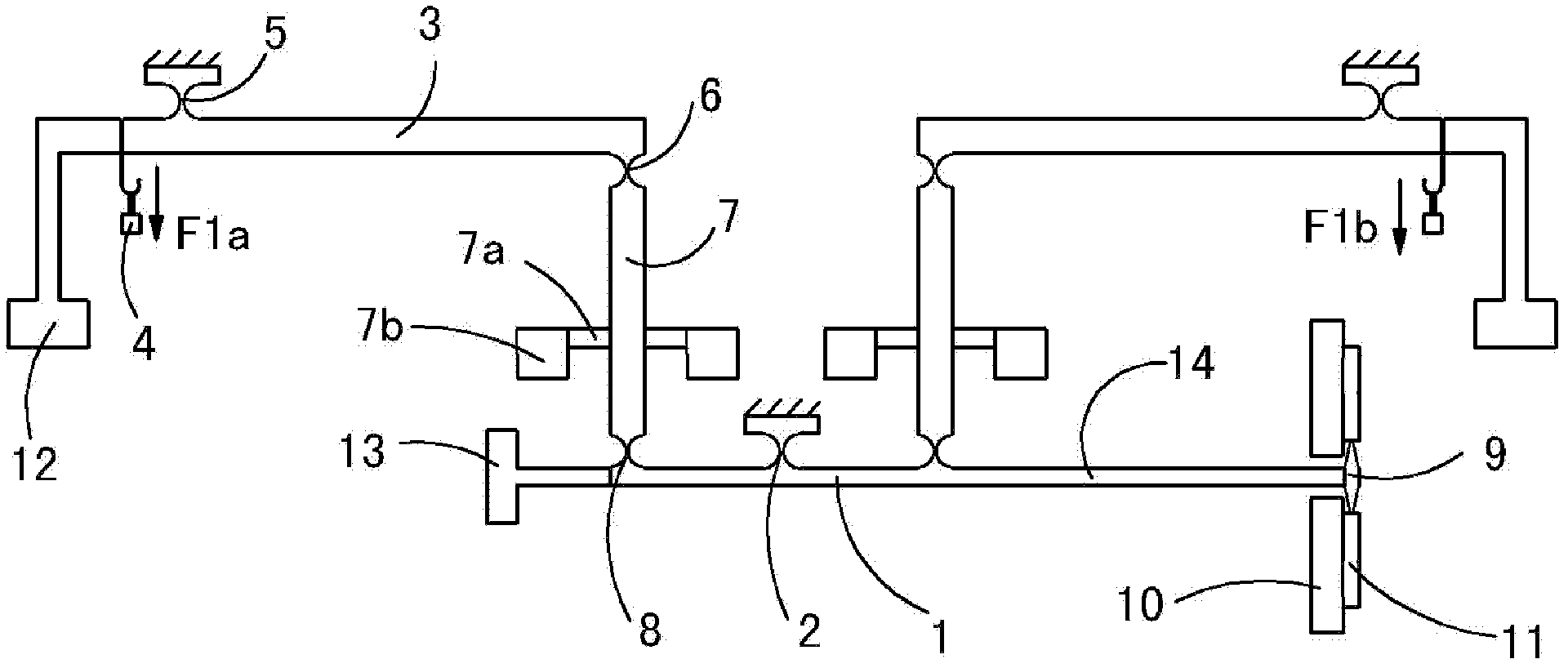

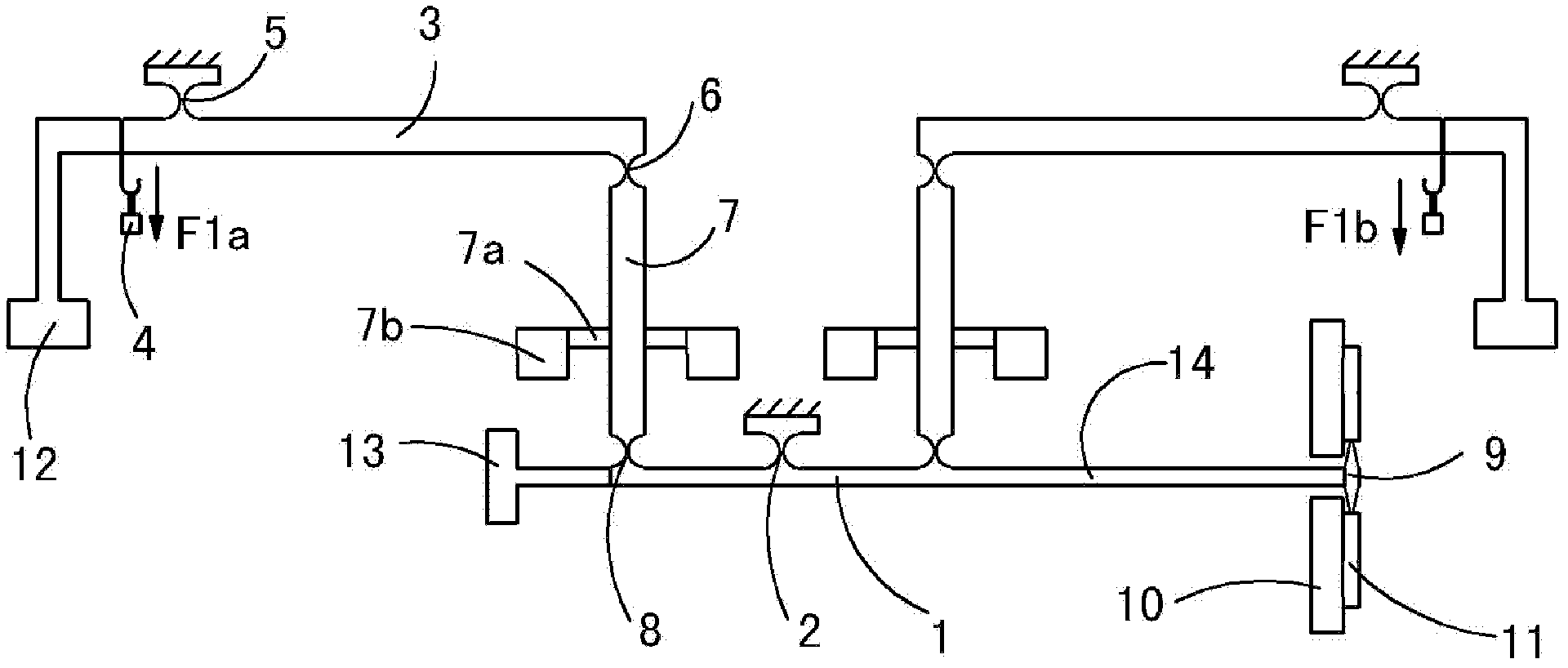

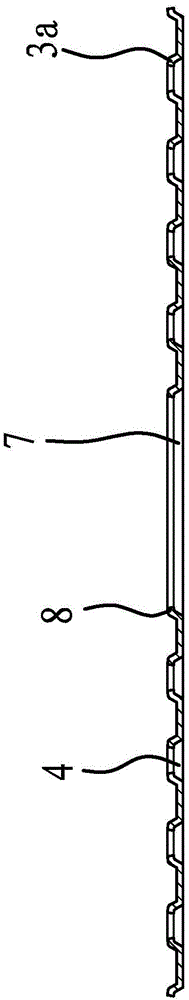

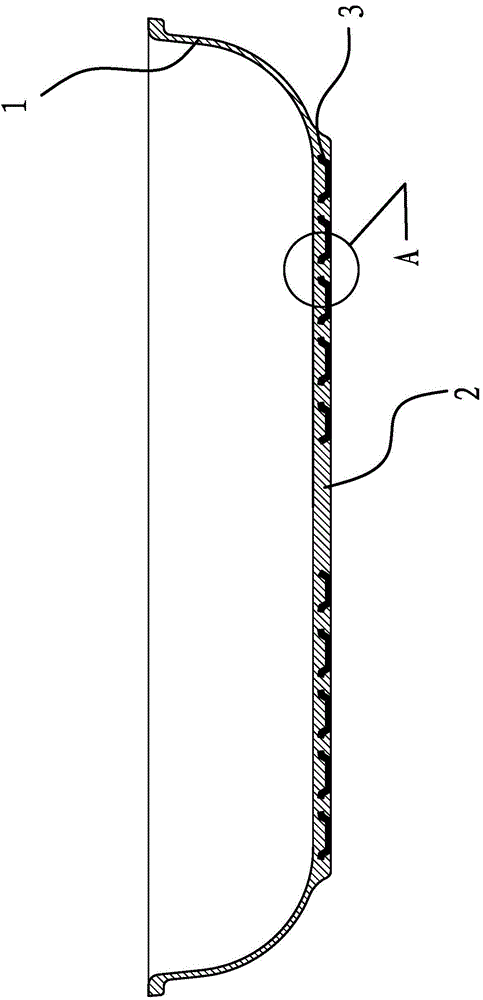

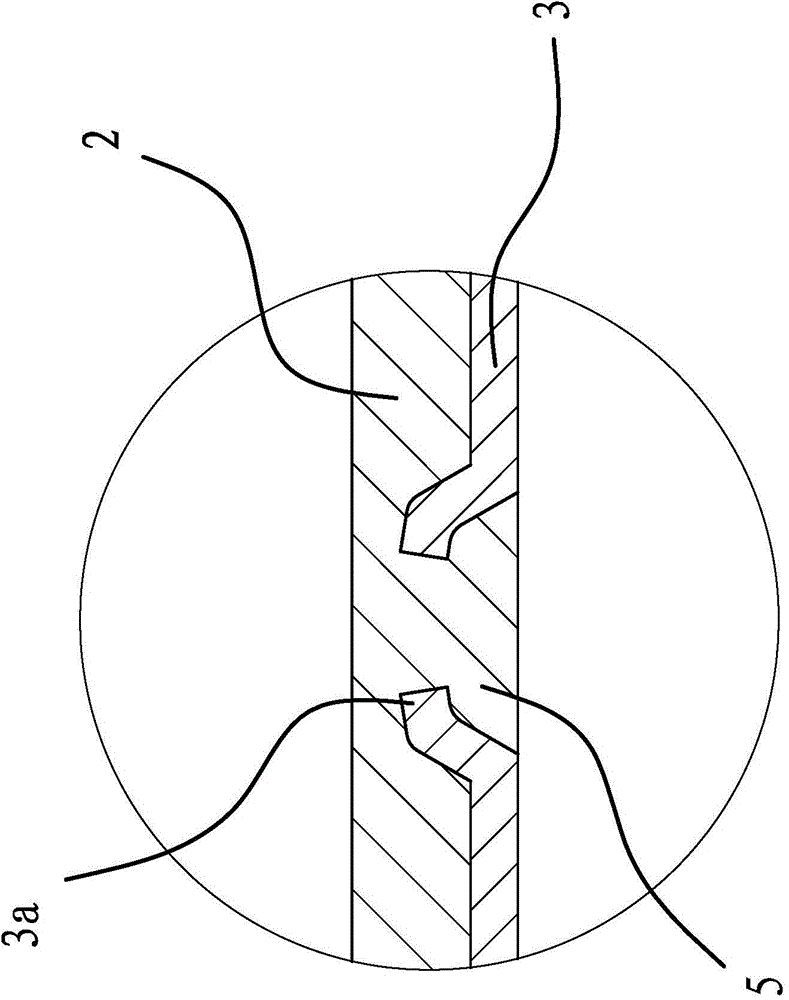

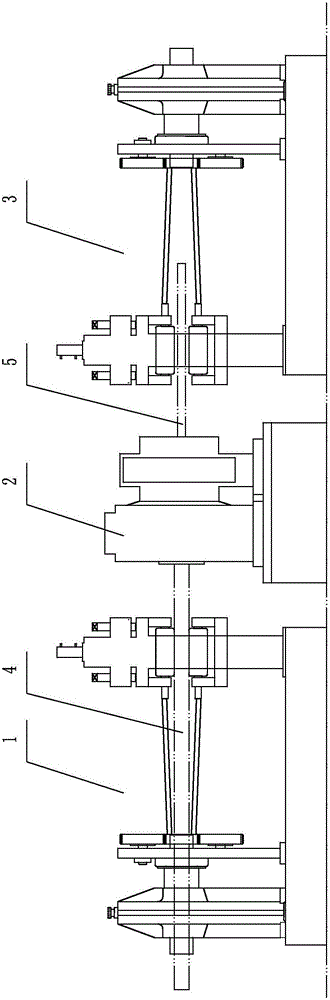

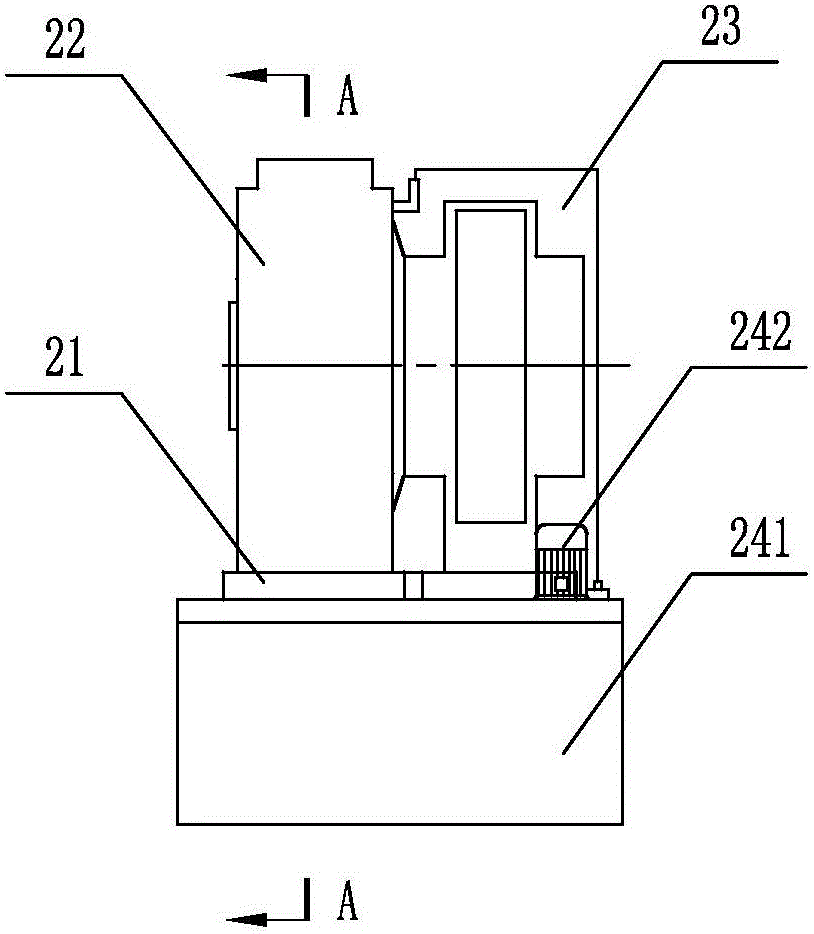

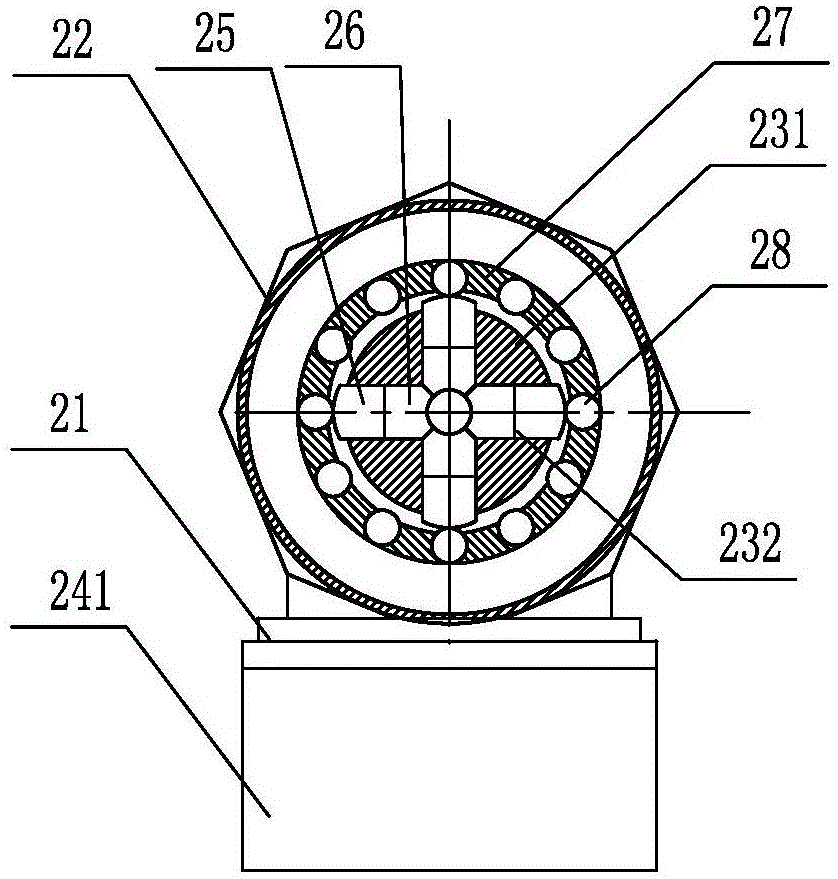

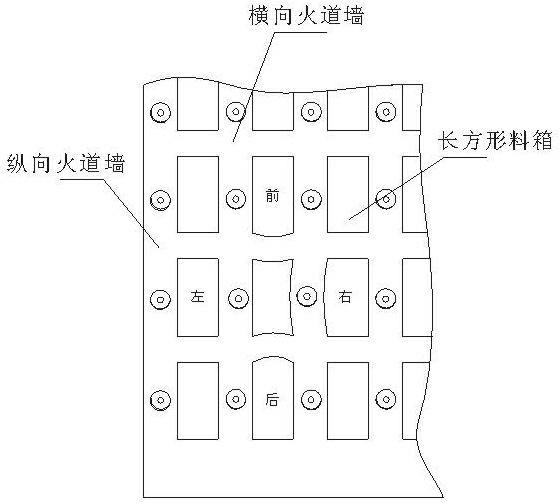

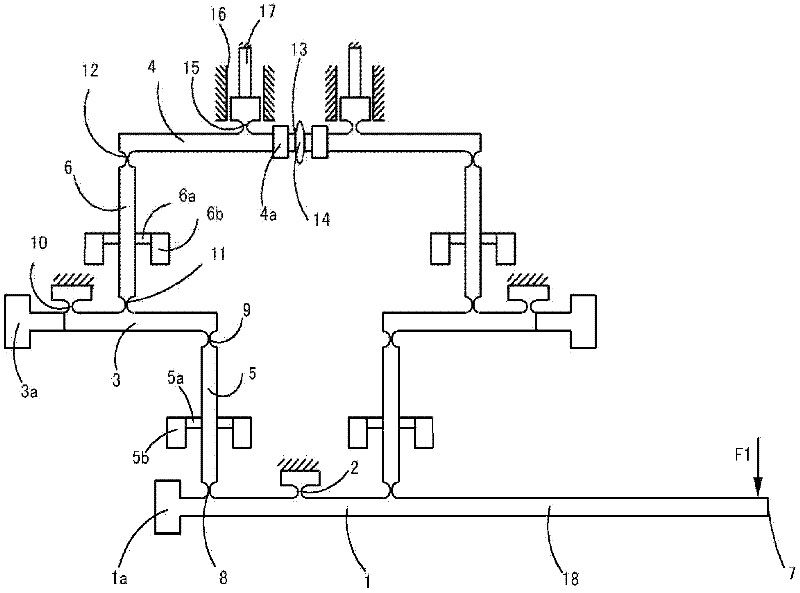

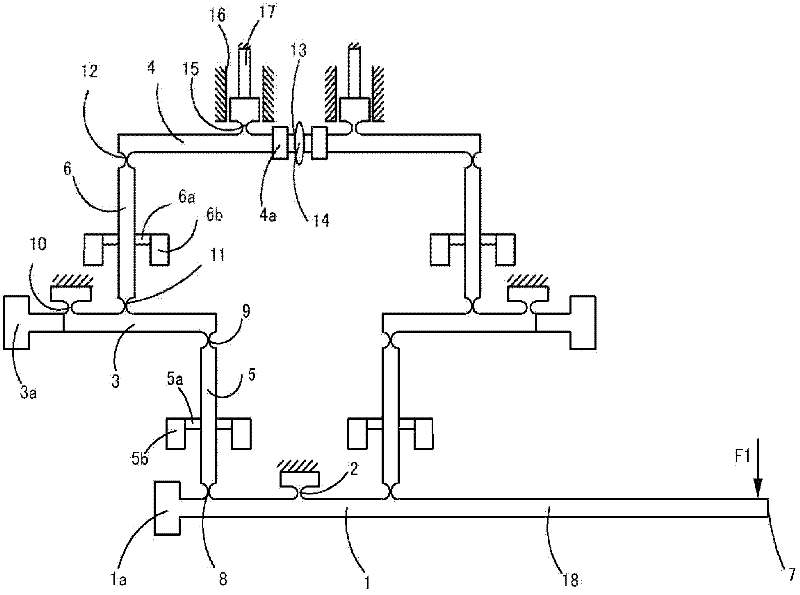

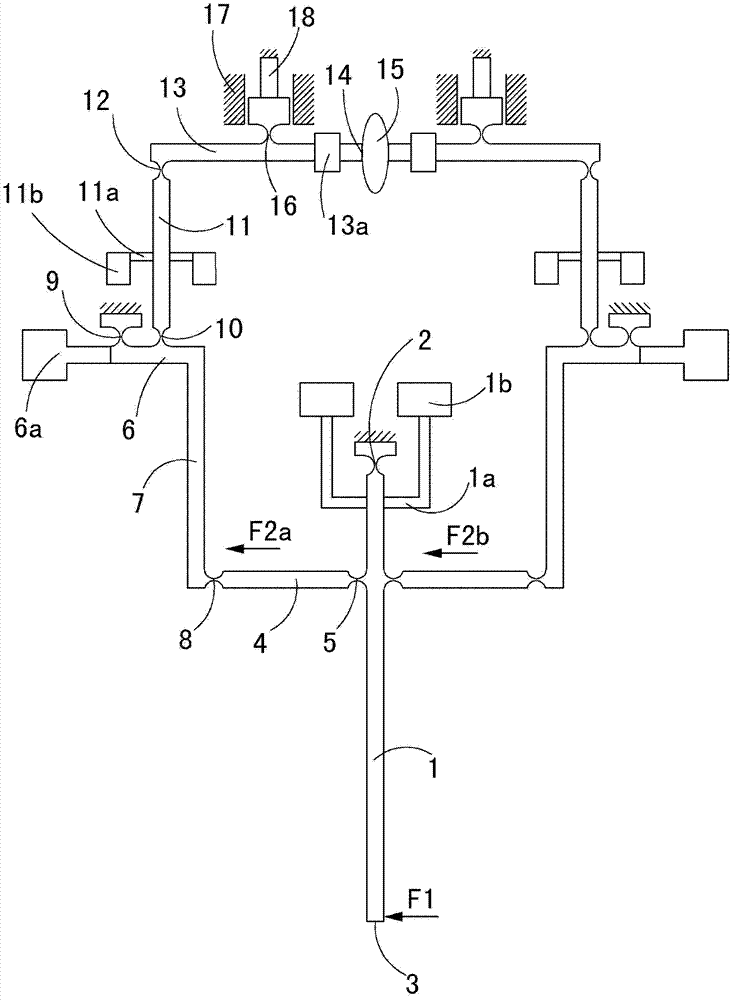

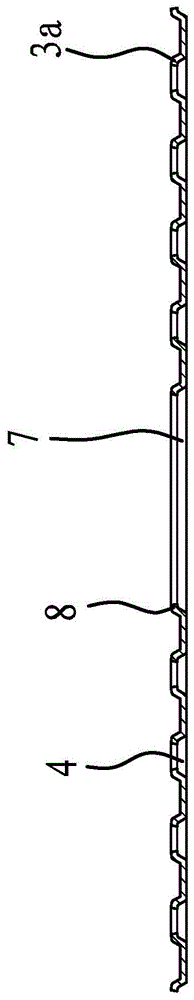

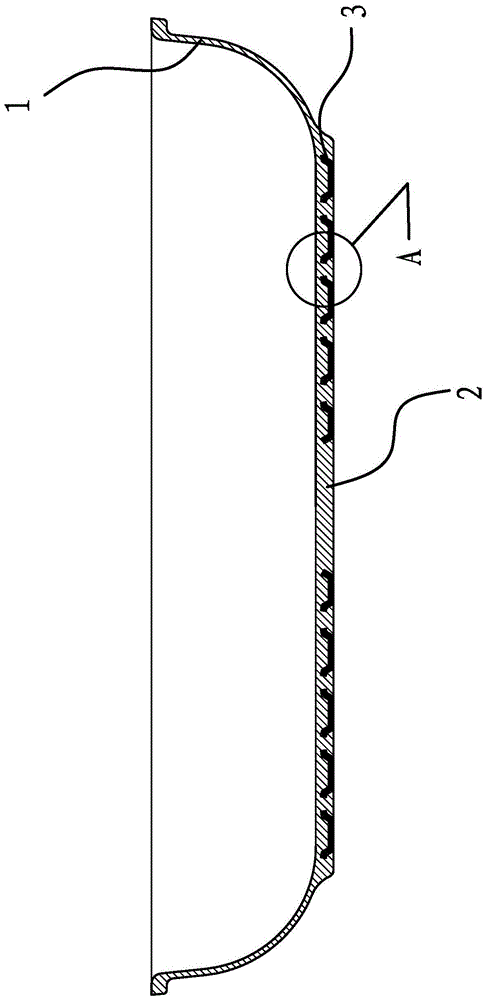

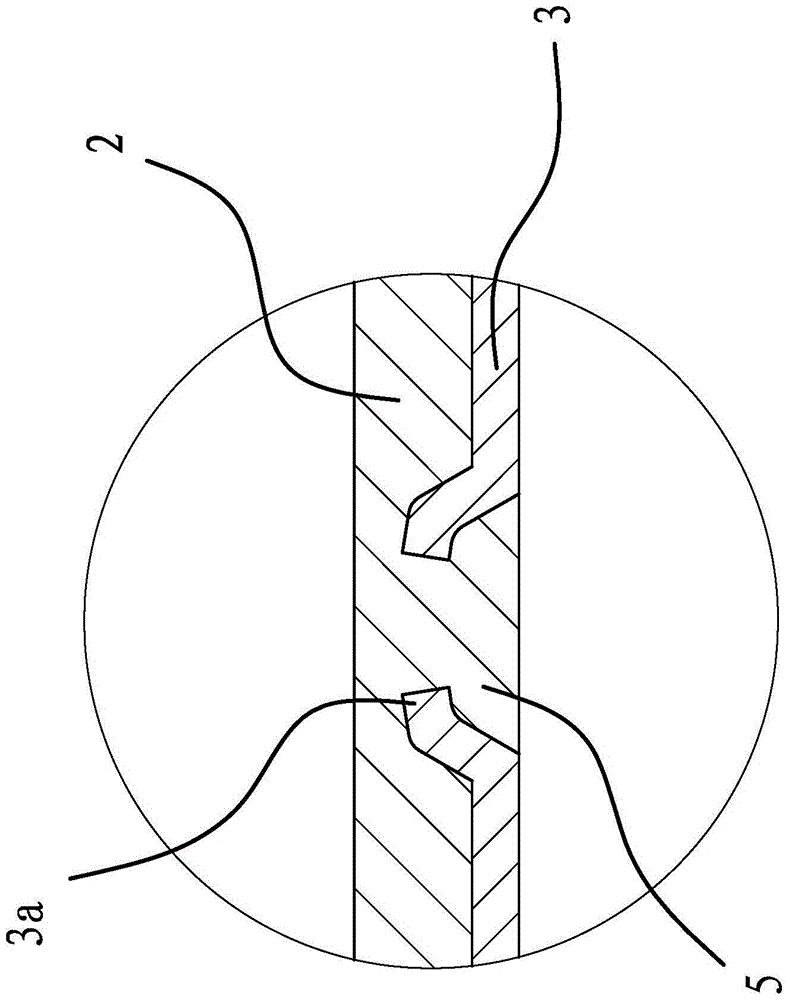

Method for correcting deformed fire path wall of roasting furnace

InactiveCN102435071APrevent springbackEliminate deformation stressFurnace componentsCorrection methodEngineering

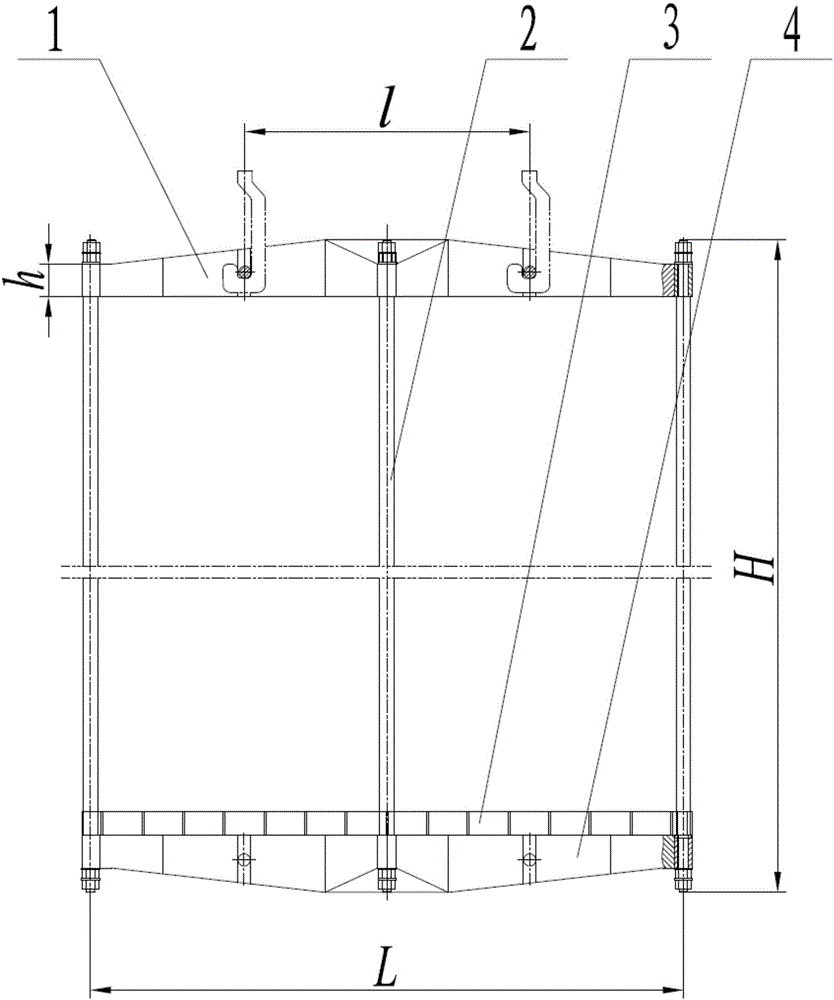

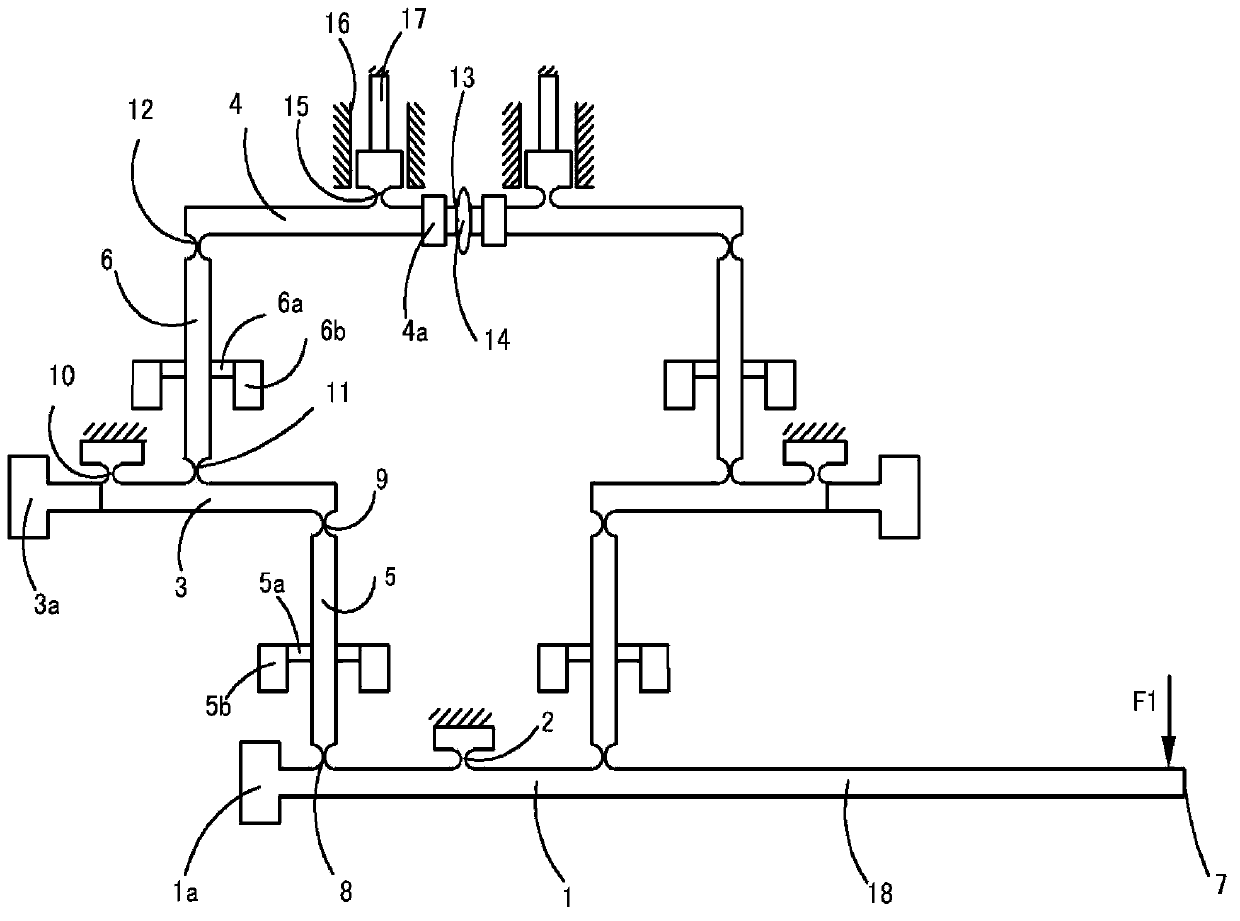

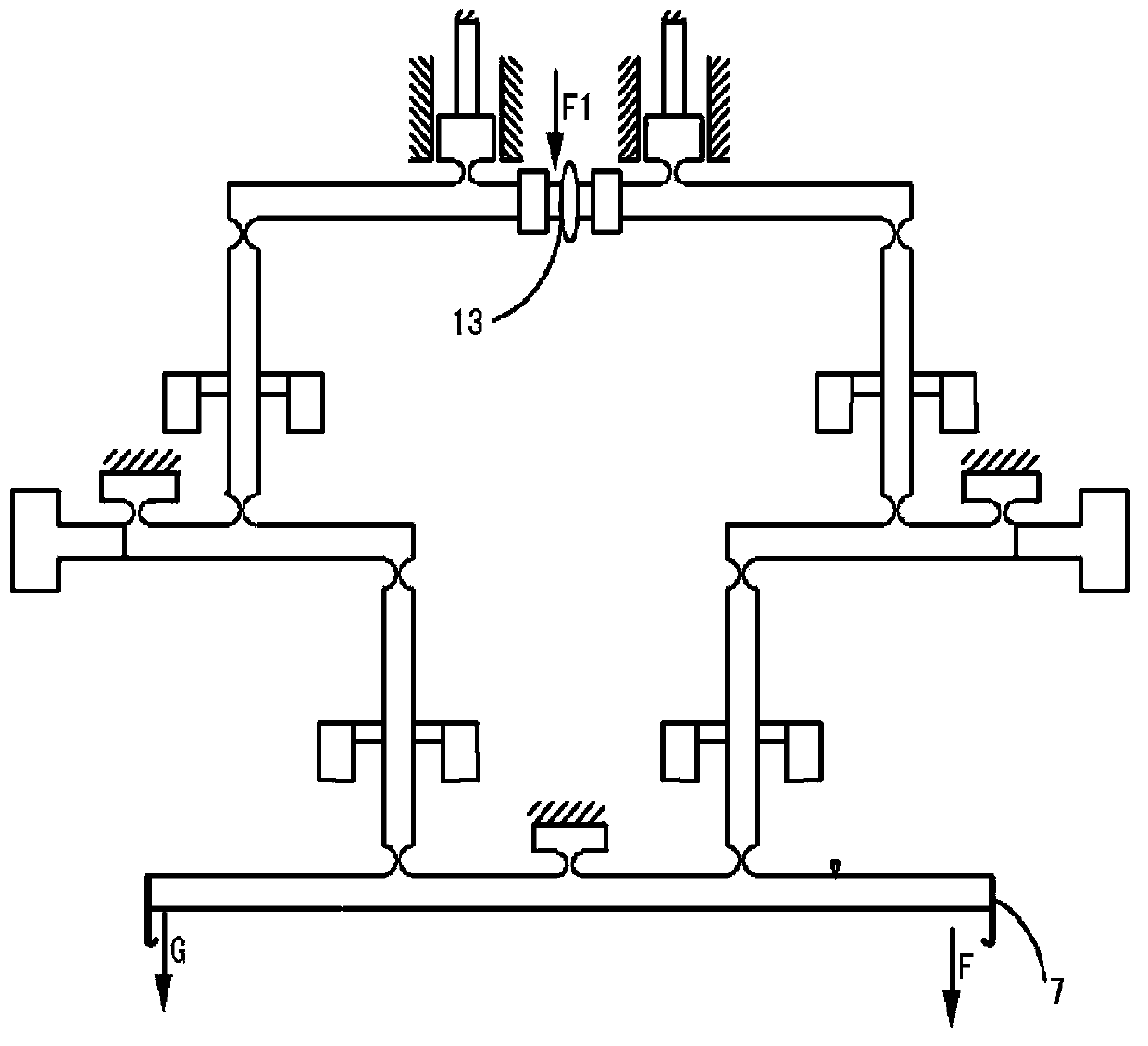

The invention discloses a method for correcting a deformed fire path wall of a roasting furnace. The correcting method performs completely correction for the deformed area of the fire path wall on the basis of a designed wall-correcting machine. The wall-correcting machine consists of a cross wall pushing plate (1), a horizontal hydraulic cylinder (2), a hinge support seat (3), a machine frame (4), a longitudinal wall pushing plate (5), a lower longitudinal hydraulic cylinder (6), an upper longitudinal hydraulic cylinder (7), a wall protection plate (8) and a balancing weight (9), wherein the longitudinal wall pushing plate and the cross wall pushing plate of the wall-correcting machine are aligned to a convex surface of the deformed fire path wall and not aligned to a concave surface of the deformed fire path wall, therefore, a rectangular material box located by the convex surface of the deformed fire path all is the place where the wall-correcting machine is mounted; the interior of the rectangular material box is provided with two layers of carbon anode blocks and is uniformly paved with auxiliary materials in a layered manner; and the concave surface of the deformed fire path wall must be an empty box so as to contribute to correcting the deformed fire path wall. The method is simple and practical, has good effect, does not influence normal work, does not damage the deformed fire path wall and can obtain greater economic benefits to a user.

Owner:王国强 +1

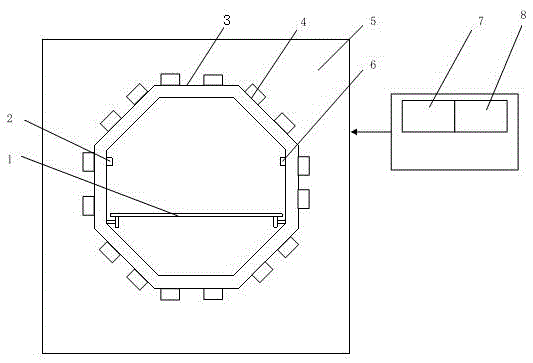

Method and device for microwave curing of fiber-reinforced resin-based composite components

The invention relates to a method and a device for curing a fiber-reinforced resin-based composite material component by utilizing microwaves. The microwaves which are generated by a microwave source with linearly-adjustable power are guided into a resonant cavity, and the microwaves penetrate through and heat the composite material, so that the composite material can be quickly cured and formed. By adopting the advanced octagonal microwave-mode resonant cavity, the uniformity of an electromagnetic field inside the device can be realized; the interference of the reflection wave on the microwave source can be reduced by adopting an automatic impedance matching system, so that the optimal transmission of the microwave power can be realized. A vacuum pipe connector and a temperature sensor are arranged on the inner side wall of the octagonal multi-mode resonant cavity, a glass worktable is arranged inside the resonant cavity, and the rotation of a ball screw is controlled through a stepper motor to control the back-forth movement of the worktable. A choking groove is adopted to prevent the leakage of the microwave. By adopting the method and the device, the problems of the traditional autoclave forming method that the time for manufacturing the fiber-reinforced composite material is long, the energy consumption is high and the heat is non-uniform can be solved, the curing time can be saved, and the quality and performance of the composite material component can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

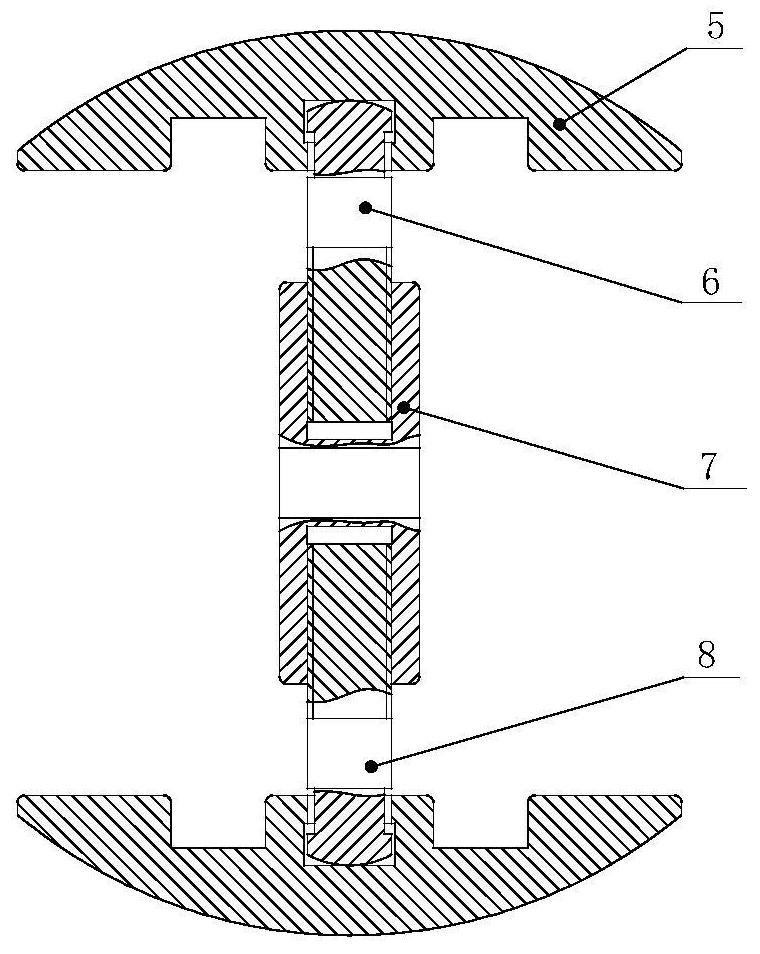

Solid solution aging heat treatment device

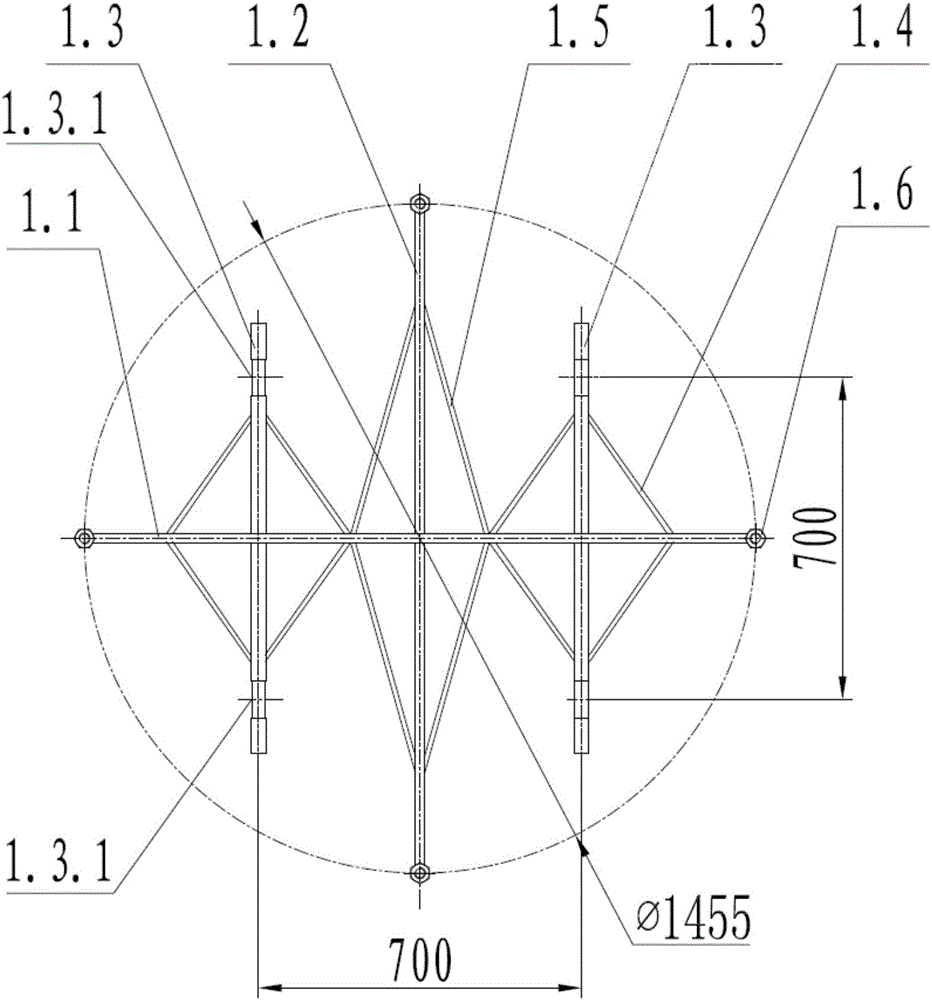

ActiveCN106011439AReduce replacement costsReduce maintenance costsFurnace typesHeat treatment furnacesCross connectionEngineering

Disclosed is a solid solution aging heat treatment device. The solid solution aging heat treatment device comprises an upper bearing support, four bearing rods and a lower bearing support. The upper bearing support and the lower bearing support are the same in structure and size and are symmetrically arranged. The four bearing rods are symmetrically distributed and connected with the upper bearing support and the lower bearing support. The upper bearing support comprises a transverse beam, a longitudinal beam, two lifting rods, eight first reinforcing plates and four second reinforcing plates. The transverse beam and the longitudinal beam are connected to form a crossed framework in a vertically and horizontally crossed mode. The lifting rods are perpendicular to the transverse beam and are in central symmetry about the transverse beam. The first reinforcing plates are symmetrically arranged between the lifting rods and the transverse beam and divided into two sets, and the four first reinforcing plates of each set surround the intersection point of the corresponding lifting rod and the transverse beam to form a rhombic structure. The second reinforcing plates are arranged between the transverse beam and the longitudinal beam and surround the intersection point of the transverse beam and the longitudinal beam to form a rhombic structure. When the solid solution aging heat treatment device are used in the obverse and reverse processes, the deformation stress left by the use state before the current use state can be eliminated, and therefore the service life is greatly prolonged.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

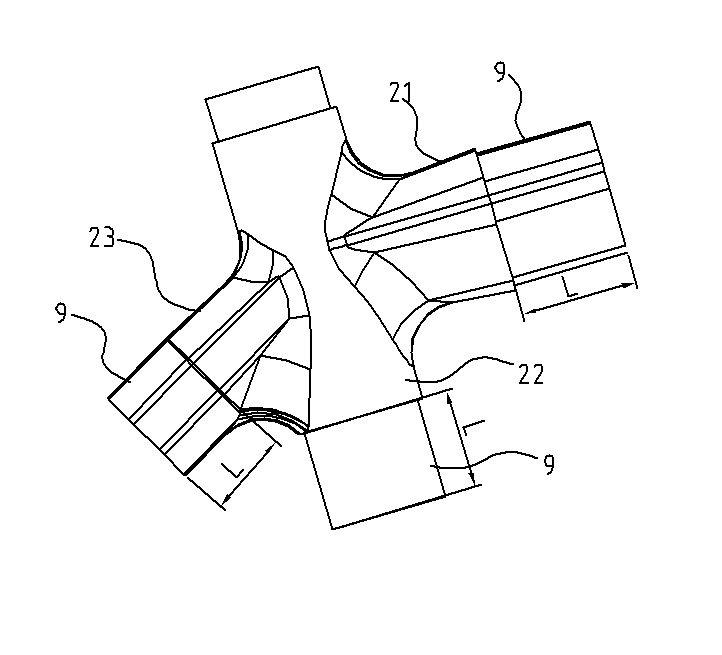

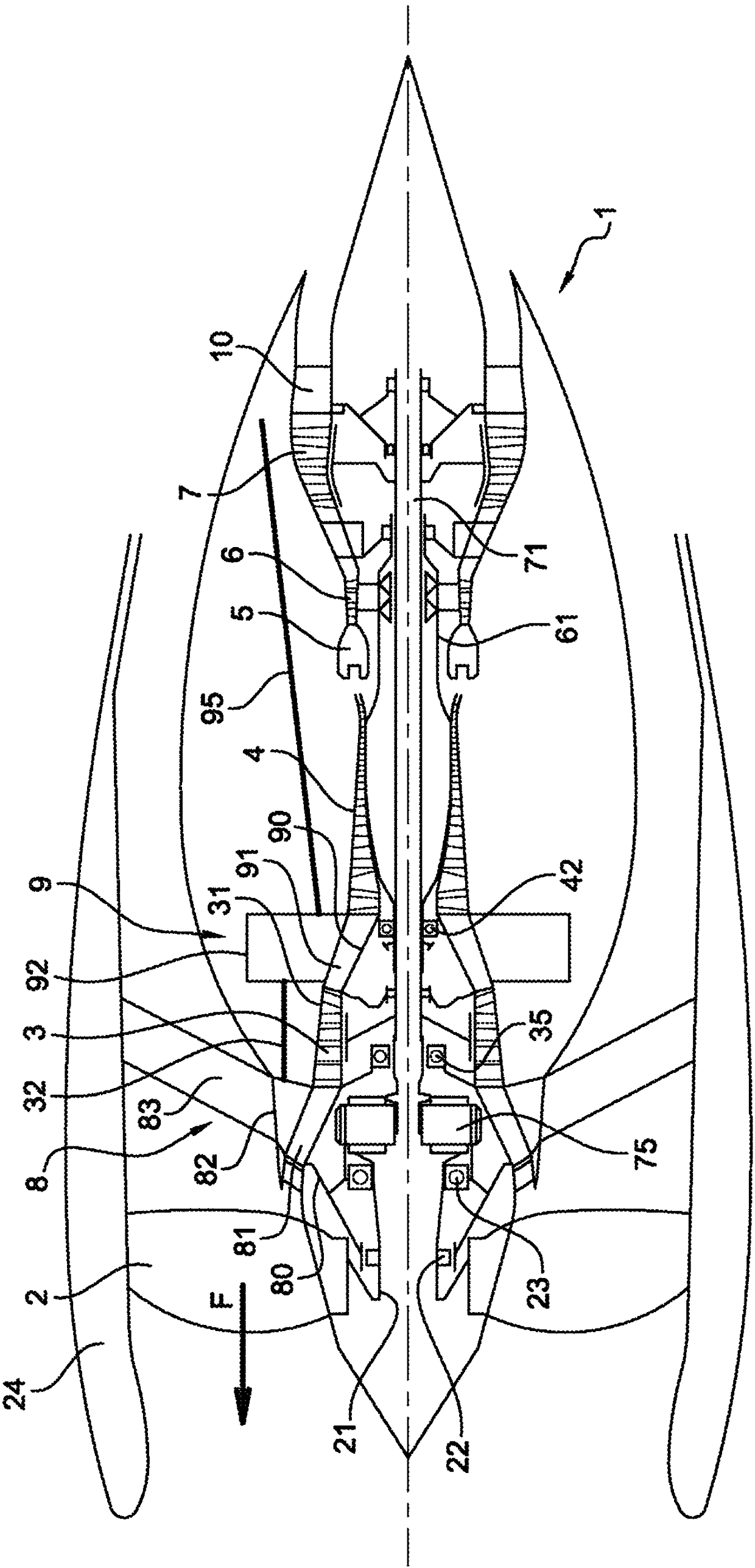

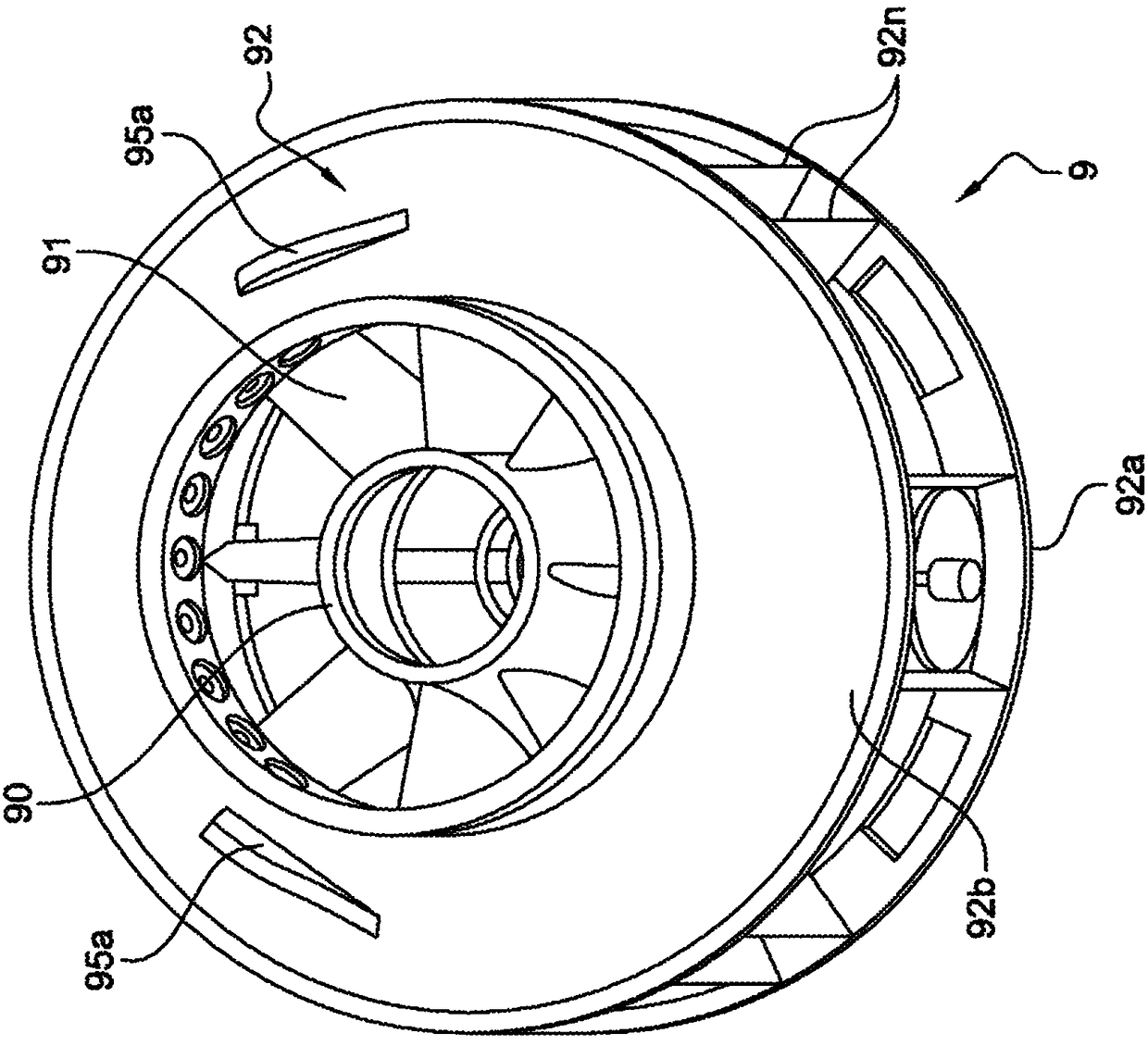

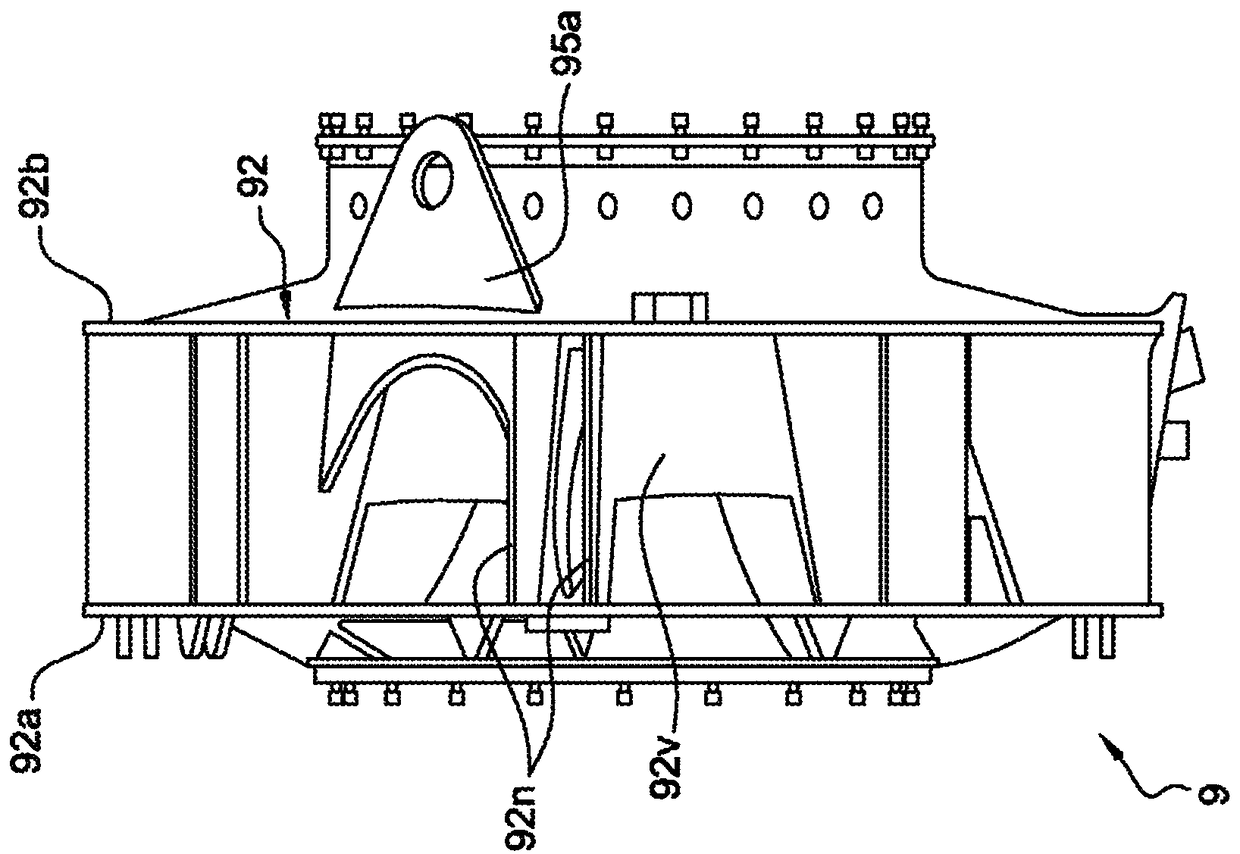

Turbojet engine with thrust take-up means on the inter-compressor case

ActiveCN108474265AReduce necessityEliminate deformation stressEngine manufactureEfficient propulsion technologiesTurbojet engineGas generator

The present invention relates to a multiflow turbojet engine comprising: a. an upstream fan (2) driven by a gas generator; b. the gas generator comprising first (3) and second (4) coaxial compressors;c. an intake case (8) forming a mounting for the rotors of the fan (2) and the first compressor (3); d. an inter-compressor case (9) downstream from the intake case (8) and forming a mounting for therotor of the second compressor (4); and e. attachment means for thrust take-up control rods (95) arranged in the inter-compressor case. The turbojet engine is characterised in that it comprises a structural force shroud (32) connecting the intake case (8) to the inter-compressor case (9), the case (31) of the first compressor being floating.

Owner:SAFRAN AIRCRAFT ENGINES SAS

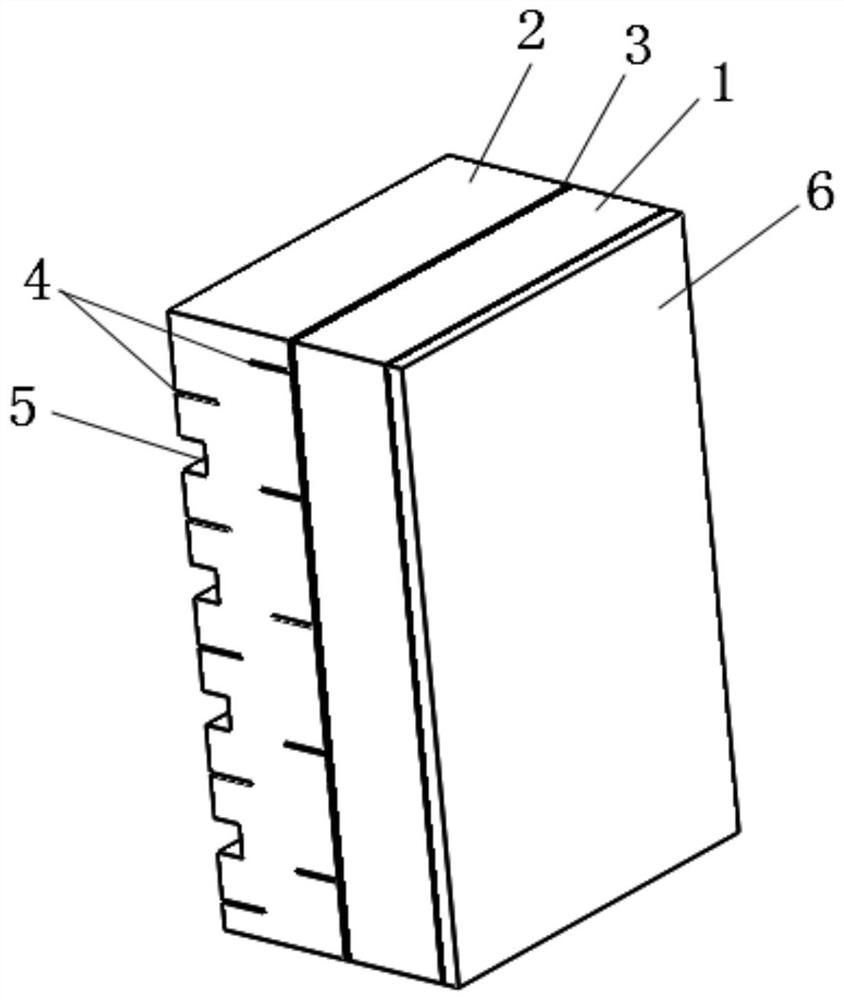

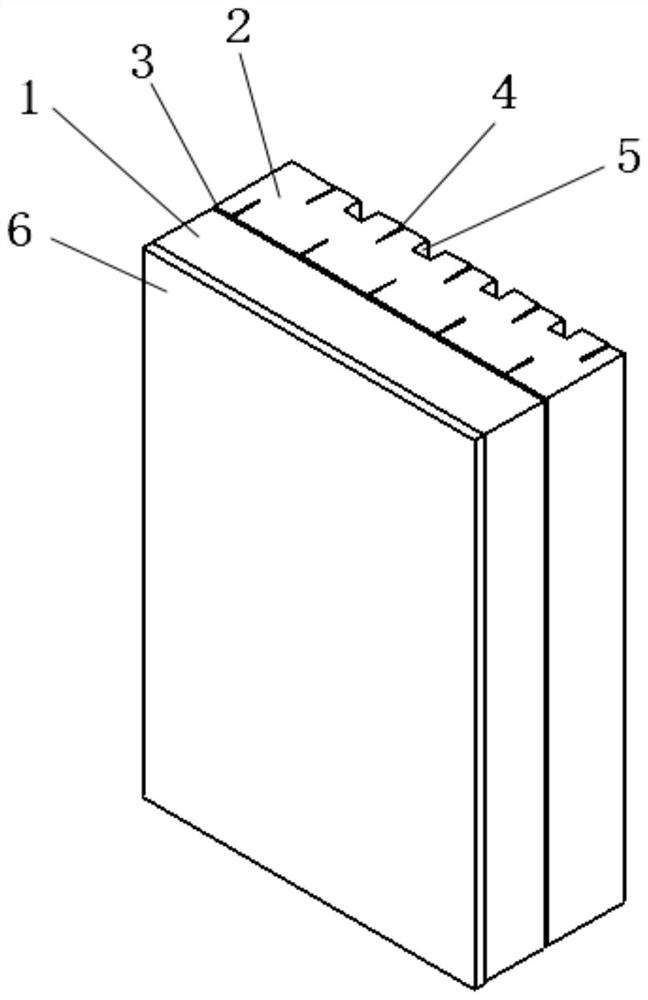

External wall heat preservation formwork and production method thereof

PendingCN112900844AGood adhesionImprove mechanical propertiesLayered productsForming/stuttering elementsPhysical chemistryProcess engineering

The invention provides an external wall heat preservation formwork and a production method thereof. According to the adopted scheme, the external wall heat preservation formwork comprises an inorganic wrapping organic particle layer and an organic heat preservation layer, wherein the organic heat preservation layer is located on one side of the inorganic wrapping organic particle layer, gridding cloth is arranged between the inorganic wrapping organic particle layer and the organic heat preservation layer, and the inorganic wrapping organic particle layer, the gridding cloth and the organic heat preservation layer are integrated. The gridding cloth is arranged between the inorganic wrapping organic particle layer and the organic heat preservation layer, a good enhancement effect is achieved, stress concentration is avoided, and the stability of the performance of a whole formwork body is guaranteed; and meanwhile, the weight and thickness are reduced, the high volume weight performance is achieved, construction is easy, the construction efficiency is improved, and cost is saved.

Owner:山东国创节能科技股份有限公司

Differential vertical micro-force measuring device and measuring method

InactiveCN102288332ASimple structureEasy to processForce measurementMeasurement deviceVertical plane

The invention discloses a differential vertical micro force measuring device and a measuring method thereof. The device is characterized in that: a first-stage supporting point is arranged on the middle part of a horizontally-arranged first-stage lever, a pair of second-stage levers is symmetrically positioned on the two sides of the first-stage supporting point in the same vertical plane by taking the first-stage supporting point as a center, and each second-stage lever is connected with the first-stage lever through a first-stage transition rod on the side of the second-stage lever, and is connected with a third-stage lever through a second-stage transition rod on the side of the second-stage lever. By the device and the method, support can be provided for a force measuring system for amicro force value.

Owner:HEFEI UNIV OF TECH

Manufacturing process for thin-wall metal hollow rotor cup

InactiveCN101478200BImprove uniformityEliminate deformation stressManufacturing stator/rotor bodiesAdhesiveEngineering

The invention relates to a manufacturing process for a thin-wall metal hollow rotor cup. The low temperature annealing working procedure is added before and after rough turning to eliminate the deformation stress; the positioning and clamping, the selection of a cutting tool as well as the detection of a dimensional tolerance are fully considered during the finish turning to prevent the workpieces from being distorted and enhance the uniformity of the cup wall; and the manufacturing process adopts the scheme that a rotating axle is pressed in when the mandrel is not taken out of the rotor cup, and the contact surface is coated with adhesive. Therefore, the process is simplified, and the concentricity between the rotor cup and the axle core is ensured.

Owner:XIAN MICROMOTOR RES INST

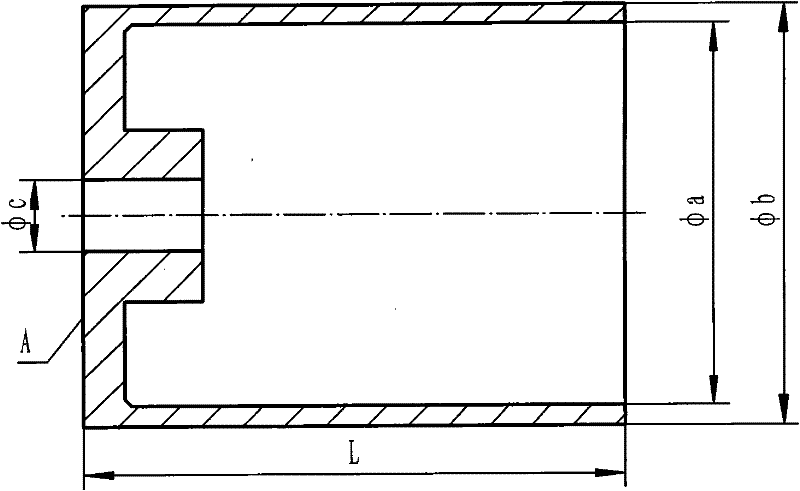

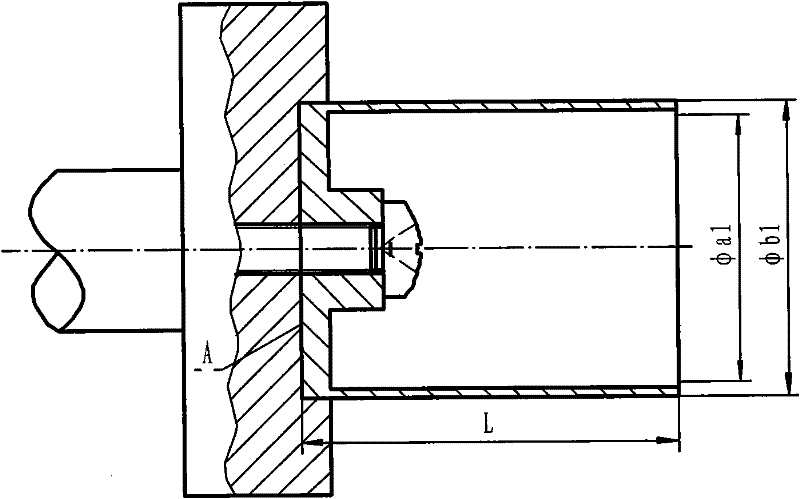

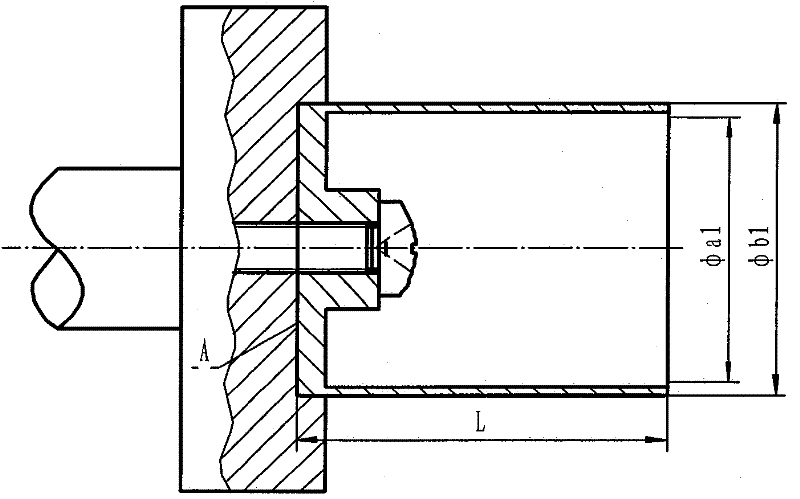

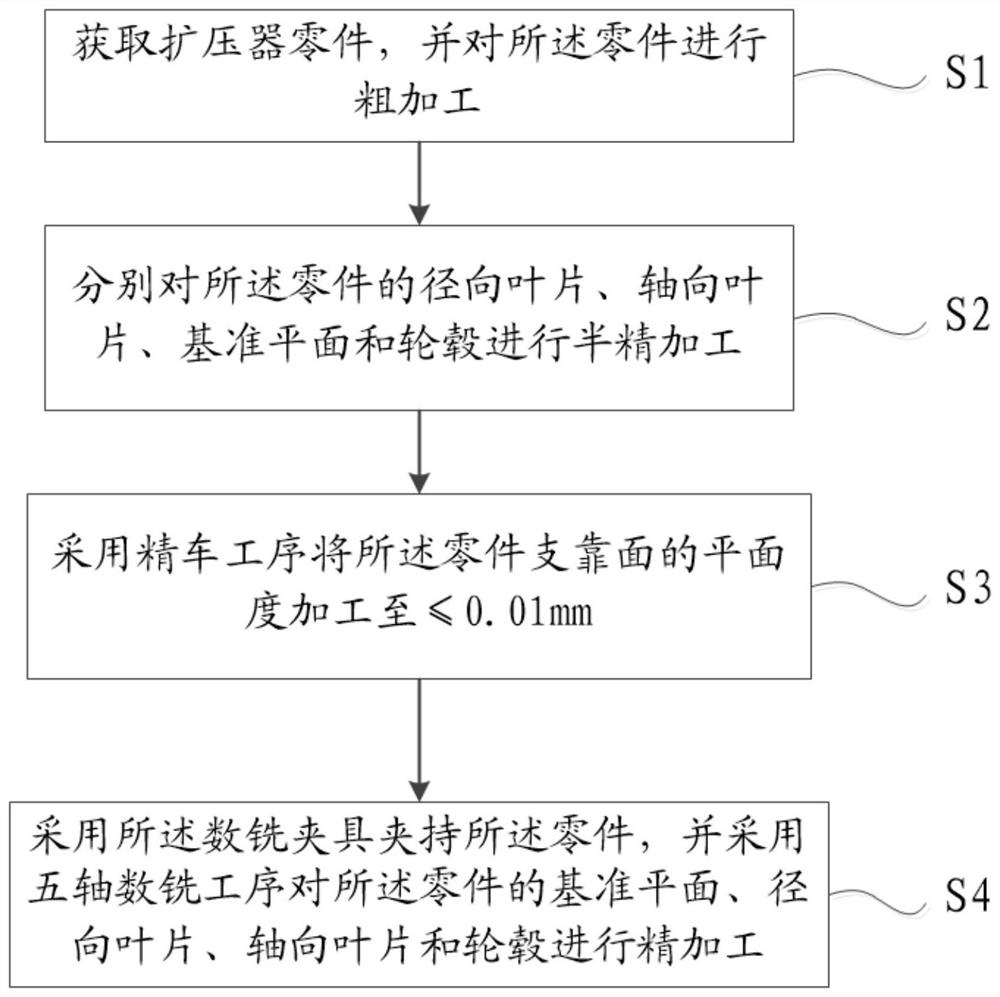

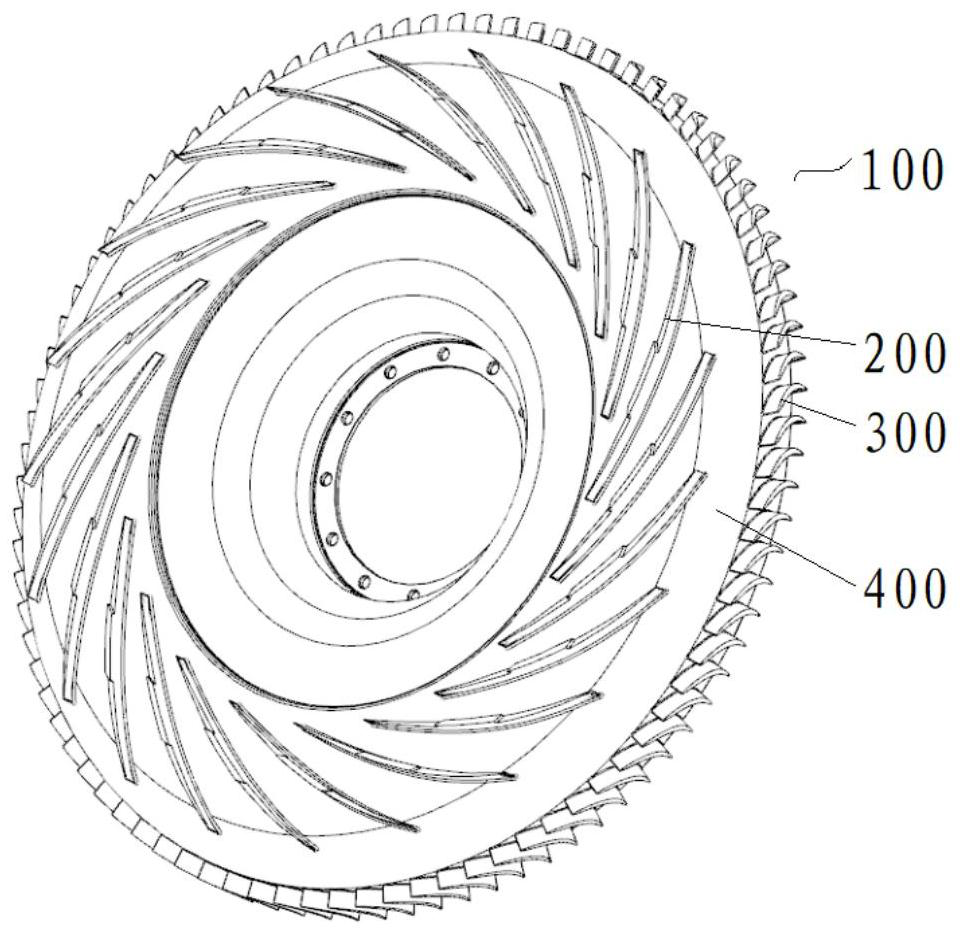

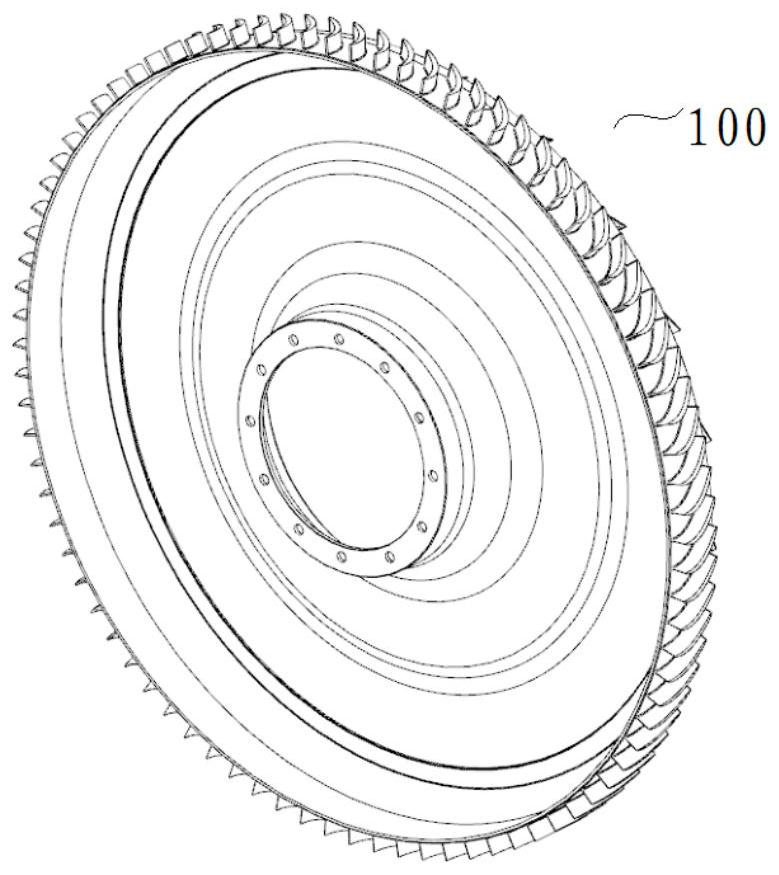

Machining process for air flow channel of diffuser and numerical control milling clamp

ActiveCN114029708AEasy to operateEliminate deformation stressMilling equipment detailsPositioning apparatusNumerical controlEngineering

The invention discloses a machining process for an air flow channel of a diffuser and a numerical control milling clamp. The machining process comprises the steps that a diffuser part is obtained, and rough machining is conducted; semi-finishing are carried out on radial blades, axial blades, a reference plane and a hub of the part respectively; the planeness of the supporting face on the inner side of the end face of the part is machined to be smaller than or equal to 0.015 mm through the finish turning procedure; a numerical milling clamp is adopted to clamp the part, and a five-axis numerical milling procedure is adopted to carry out finish machining on the reference plane, the radial blades, the axial blades and the hub of the part. According to the machining process, the allowance is removed in the rough machining stage and the semi-finish machining stage, and stress deformation generated in the rough machining stage is eliminated; in the finish machining stage, a numerical turning procedure is adopted for preparing for clamping of a subsequent five-axis numerical milling procedure, pressing deformation is avoided, then the radial blades, the axial blades and a switching arc are combined in one five-axis numerical milling procedure, one-time tool clamping is carried out, size machining is completed, and it is guaranteed that the blade profile size and the surface roughness of the air flow channel meet the requirements.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

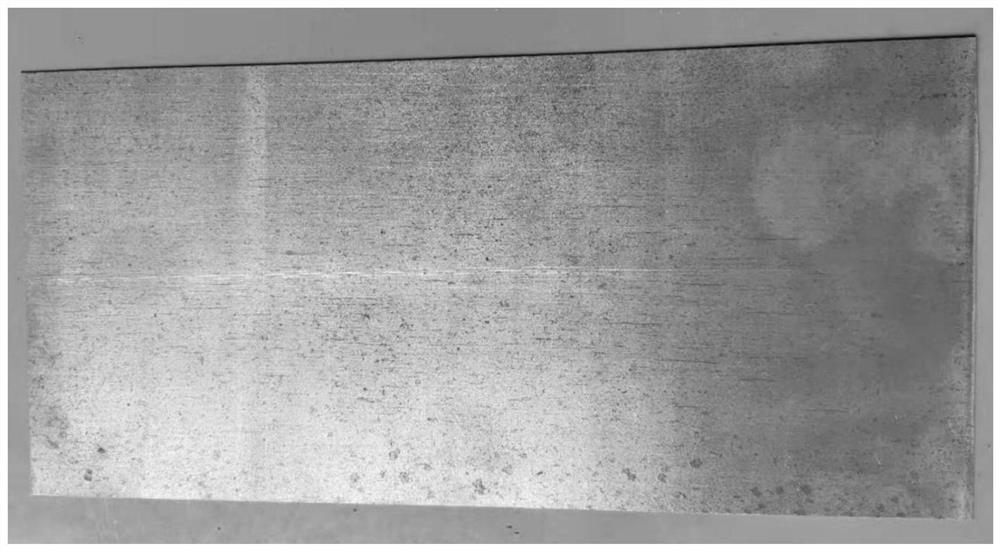

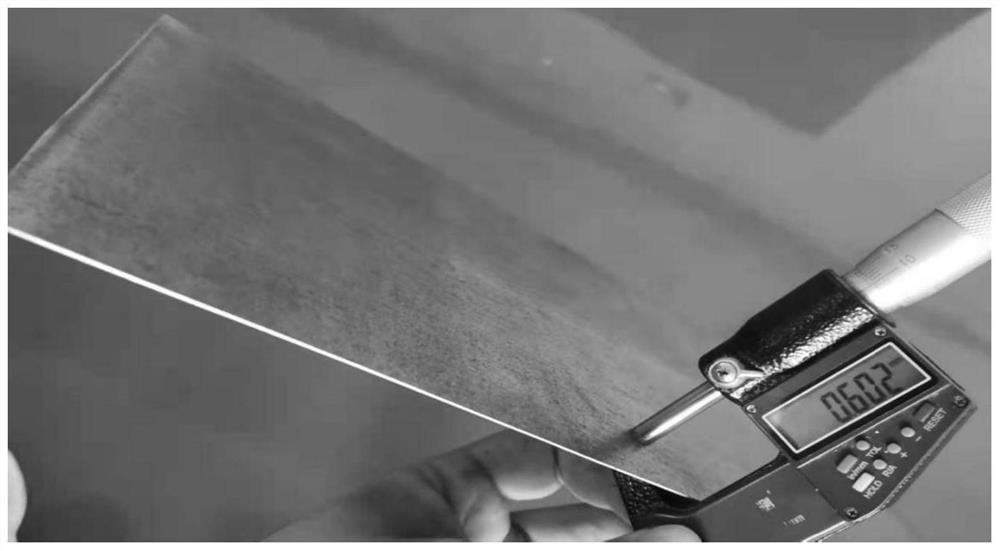

High-strength heat-resistant magnesium alloy sheet and manufacturing method thereof

ActiveCN113862538AAvoid demandIncrease productivityTemperature control deviceFurnace typesSolution treatmentLarge deformation

The invention provides a manufacturing method for a high-strength heat-resistant magnesium alloy sheet. The manufacturing method comprises the following steps of: S1) hot rolling, specifically, conducting hot rolling treatment on a blank to obtain a sheet material with a thickness of b1; S2) conducting solution treatment on the sheet material obtained in the step S1); S3) conducting cold rolling treatment on the sheet material subjected to solution treatment to form a sheet material with a target thickness b0; and S4) conducting aging treatment on the cold-rolled sheet material, wherein a blank is an Mg-Gd-Y series alloy, and b1=b0 / [1-(2%-8%)]. By using the manufacturing method disclosed by the invention, hot rolling is firstly conducted, and then large-deformation machining is conducted, so that the production efficiency of the sheet material is improved; alloy elements are fully dissolved into a matrix through solution treatment, so that the plasticity of the material is improved, and the subsequent cold rolling performance and the final mechanical properties of the material are improved; warping of the sheet material after solid solution can be improved through cold rolling, and grains can be refined with cold deformation so as to improve the mechanical properties of the sheet material; and the cold-rolled sheet material can be annealed with aging treatment, so that the microstructure of the sheet material is improved, the deformation stress is eliminated, and the comprehensive performance is improved.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

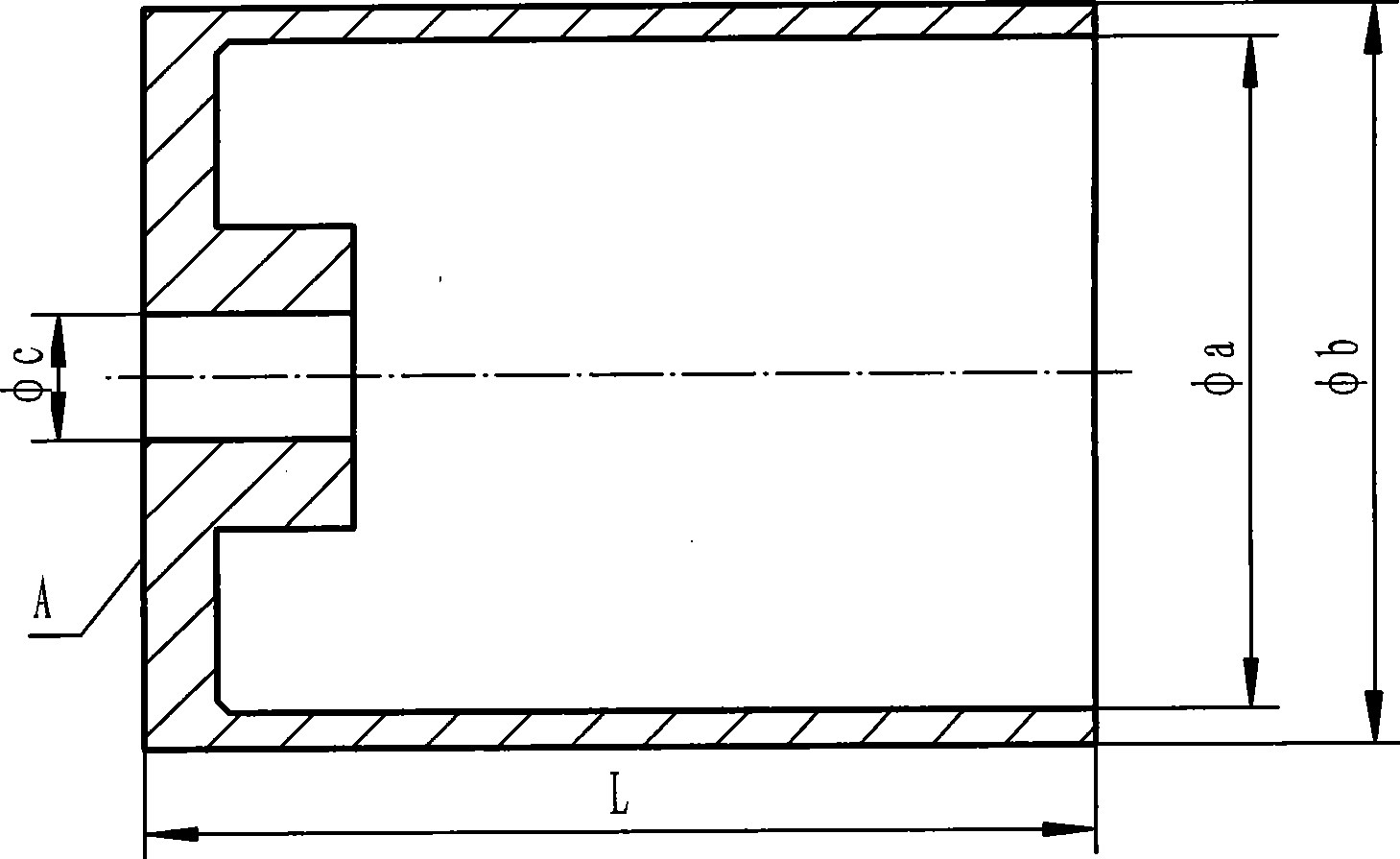

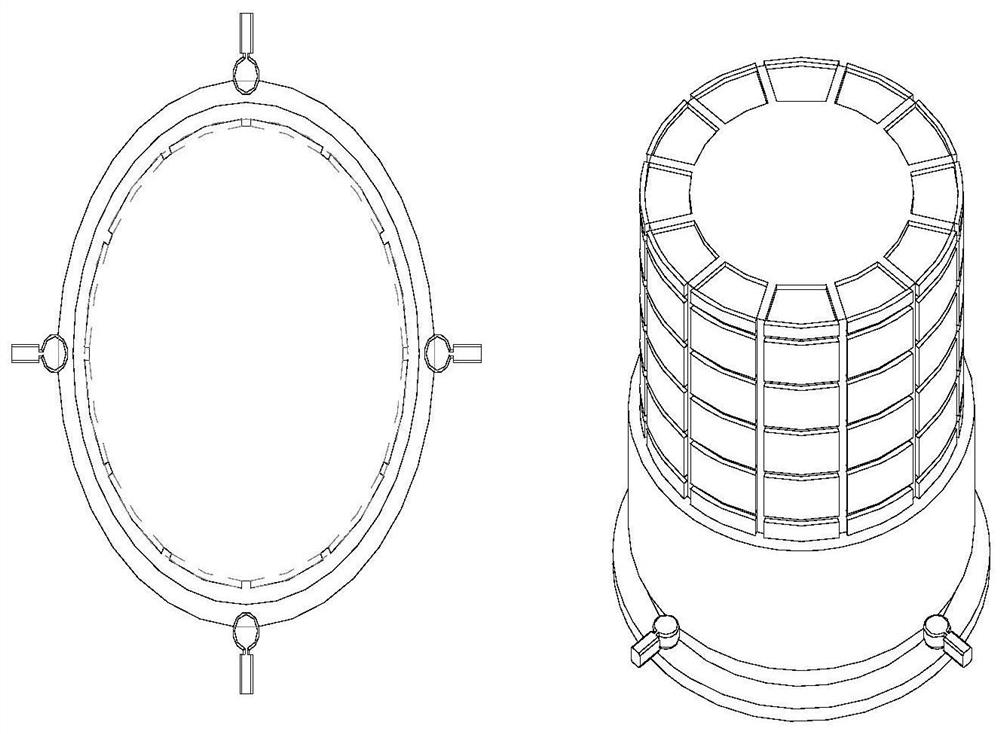

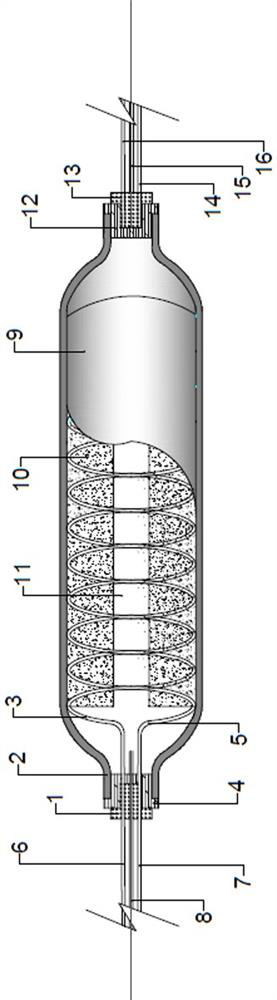

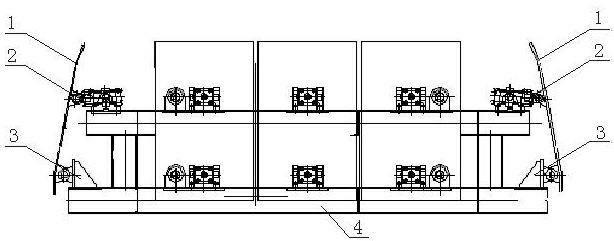

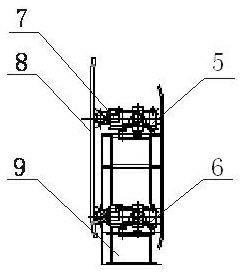

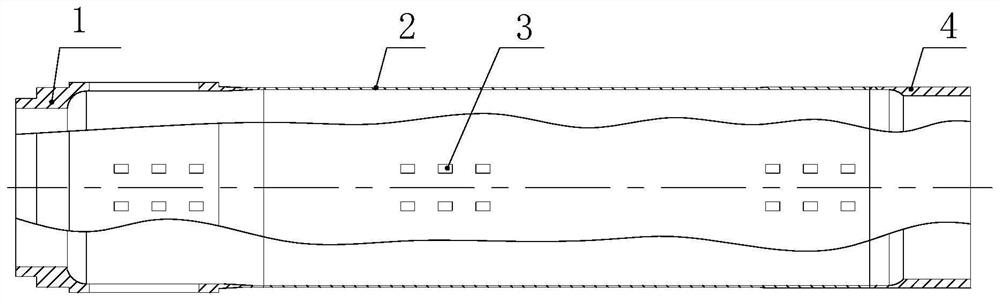

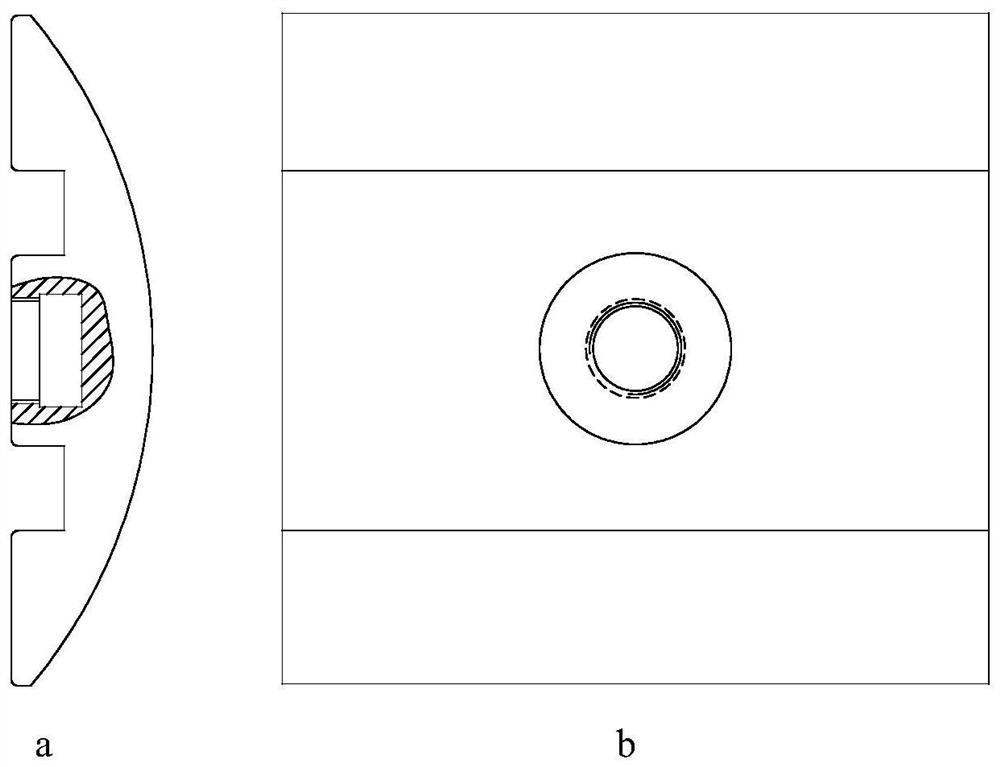

Segmented series-connection type telescopic inner supporting tool and method

PendingCN112570975AAchieving processing powerRealize the scaling functionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention discloses a segmented series-connection type telescopic inner supporting tool and method, and belongs to the field of local shape correction of a solid engine shell and control over welding deformation of external parts. The inner supporting tool comprises inner supporting assemblies, mandrels and an ejector rod; each inner supporting assembly comprises an inner supporting cylinder,an inner end plate and an inner supporting jacking tool; the multiple inner supporting assemblies are connected end to end and are coaxially arranged, and one mandrel is coaxially arranged between every two adjacent inner supporting assemblies; each mandrel is of a cylindrical structure, one end of each mandrel is coaxially provided with a conical circular truncated cone structure, and a blind hole is formed in the center axis of the top of each conical circular truncated cone; the ejector rod is a cylinder with a circular groove formed in one end along the central axis; and the inner diameterof the circular groove is larger than the outer diameter of cylinders of the mandrels. According to the segmented series-connection type telescopic inner supporting tool and method, shell welding deformation control and shape correction treatment in the welding process of the external parts of the solid engine shell can be achieved. Tests prove that after the sectional series-connection type telescopic inner supporting tool is used for welding the external parts of the shell, welding deformation is effectively controlled, the shape correction effect on the shell is achieved, and the roundnessof the shell is reduced to 1.0 mm from 10 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Differential type horizontal micro-force measuring device and measuring method thereof

InactiveCN102359843BSimple structureEasy to processForce measurementForce/torque/work measurement apparatus calibration/testingVertical planeMeasurement device

Owner:HEFEI UNIV OF TECH

A retractable inner support tooling

ActiveCN109366052BGuaranteed roundnessImplement rigid constraintsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStress relief

The invention discloses an extensible and retractable inner supporting tool. One end of a left-handed screw is installed in a screw installation hole in the plane geometric center of a supporting plate, and the left-handed screw is in rotating fit with the screw installation hole. A left-hand thread at the other end of the left-handed screw is installed in a threaded hole in the center at one endof a sleeve. One end of a right-handed screw is installed in a screw installation hole in the plane geometric center of the other supporting plate, and the right-handed screw is in rotating fit with the screw installation hole. A right-hand thread at the other end of the right-handed screw is loaded in a threaded hole in the center at the other end of the sleeve. The extensible and retractable inner supporting tool has extending and retracting functions; in a shortened state, the extensible and retractable inner supporting tool can be put into a shell and then extends to support a cylinder, rigid restraining to the cylinder is achieved, and the welding deformation is reduced; and by means of stress relief annealing heat treatment through the belt tool, deformation stress is eliminated, andtherefore the cylinder circular degree after welding is guaranteed, and the circular degree of the shell is reduced to 2.5 mm from 10 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Technology and tool for reducing deformation of annular casting thin-walled part after machining and casting

PendingCN112059112AReduced problems with deformed ellipsesImprove sealingFoundry mouldsFurnace typesSand blastingMachining

The invention relates to a technology and tool for reducing deformation of an annular casting thin-walled part after machining and a casting, and belongs to the field of thin-walled annular part machining. The technology comprises the steps as follows: a pressing block structure is additionally arranged in a lower area of the annular casting thin-walled part; shakeout cleaning treatment is conducted on the surface of the annular casting thin-walled part; then surface sand blasting treatment is conducted, and standing is conducted after sand blasting; lateral supports are symmetrically added tothe side walls of the annular casting thin-walled part, and then inner diameter machining is conducted; the inner diameter machining comprises two steps of rough machining and finish machining, and after the rough machining, all pressing plates and the lateral supports are loosened for standing; and after standing, alignment machining is conducted again. According to the scheme, the influence ofcasting and machining stress is reduced mainly by eliminating reasons causing ellipse; and the deformation problem is solved from the aspects of a clamping method, machining allowance and sequence adjustment.

Owner:中船发动机有限公司

Measurement method for differential vertical micro force measurement device

The invention discloses a measurement method for a differential vertical micro force measurement device. The differential vertical micro force measurement device is characterized in that a primary fulcrum is set in the middle of a primary lever arranged horizontally; a pair of secondary levers are symmetrically arranged at two sides of the primary lever in the same vertical plane with the primary lever as a center; the respective side is connected with the primary lever through a primary transition rod; and the pair of secondary levers are respectively connected with a tertiary lever at the respective side through a secondary transition rod. The measurement method for the differential vertical micro force measurement device can provide support for a force measuring system for micro force values.

Owner:HEFEI UNIV OF TECH

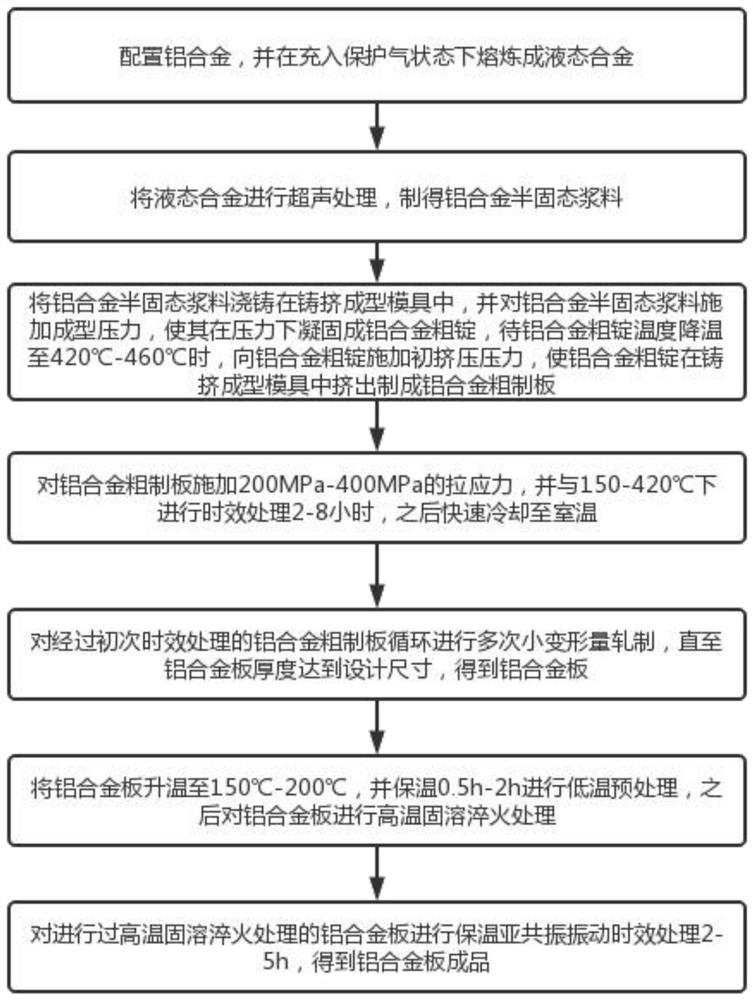

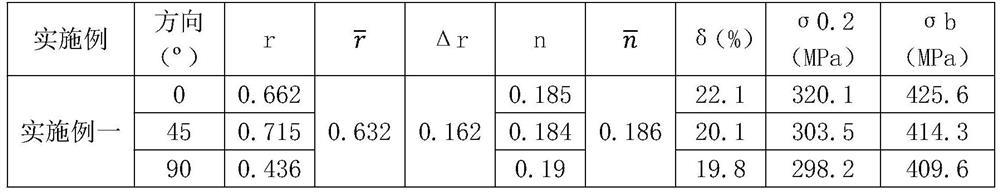

Preparation process of high-strength aluminum alloy plate and aluminum alloy plate

InactiveCN114196843AImprove performanceImprove liquidityFurnace typesHeat treatment furnacesMetal formingSemi solid

The invention discloses a high-strength aluminum alloy plate preparation process and an aluminum alloy plate, and relates to the field of aluminum alloy plates, the preparation process comprises alloy preparation, ultrasonic treatment, casting extrusion molding, primary aging treatment, rolling into a plate, solid solution quenching and secondary aging treatment; the aluminum alloy plate is made of an Al-Zn-Mg-Cu series alloy, and is specifically made of the following metals in percentage by mass: 4.5 to 5.2 percent of Zn, 1.2 to 2.0 percent of Mg, 1.0 to 1.8 percent of Cu, 0.02 to 0.06 percent of Ni, 0.05 to 0.15 percent of Ti, 0.01 to 0.02 percent of Y, 0.02 to 0.05 percent of Zr and the balance of Al. The method has the beneficial effects that the semi-solid forming and casting-extruding integrated forming technology is adopted, the grain size in the aluminum alloy is effectively reduced in the metal forming step, meanwhile, multi-time multi-stage aging treatment is adopted, deformation stress generated in the rolling process of the alloy is fully eliminated, recrystallization in the alloy is promoted, and therefore the service life of the aluminum alloy is prolonged. And the grain size in the aluminum alloy is improved, the plasticity of the aluminum alloy is effectively improved, and the punch forming performance of the alloy is improved.

Owner:昆山风雷益铝业有限公司

Die-cast double-bottom cooker and manufacturing method thereof

The invention provides a die-cast double-bottom cooker and a manufacturing method thereof, belonging to the technical field of machinery. The utility model solves the problem that the double bottom sheet in the existing double bottom pot body is easily deformed or falls off when heated. The die-cast double-bottom cooker and its manufacturing method, wherein the manufacturing method includes the following steps: A, making metal sheets; B, punching; C, flanging; D, clamping molds; E, casting aluminum water; F, demoulding. The die-cast double-bottom cooker includes an open body made of aluminum material, on which there is a bottom plate for heating, on the bottom plate there is a metal sheet of magnetically permeable material, and on the metal sheet there are several through connection holes The above-mentioned chassis has a plurality of connecting parts embedded in the above-mentioned connecting holes, and the connecting parts correspond to the connecting holes one by one, and there is a snap-fit structure between the connecting holes and the connecting parts, which can make the two fixedly connected. The die-cast double-bottom cooker has the advantages of more firm connection of the metal sheets, not easy to fall off, and the like.

Owner:ZHEJIANG SUPOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com