Measurement method for differential vertical micro force measurement device

A technology of measuring device and measuring method, which is applied in the field of measurement, can solve problems such as the failure to establish a small force value, the influence of micro force calibration or measurement, and inconvenient operation, and achieve the effect of simple structure, accurate results, and favorable measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

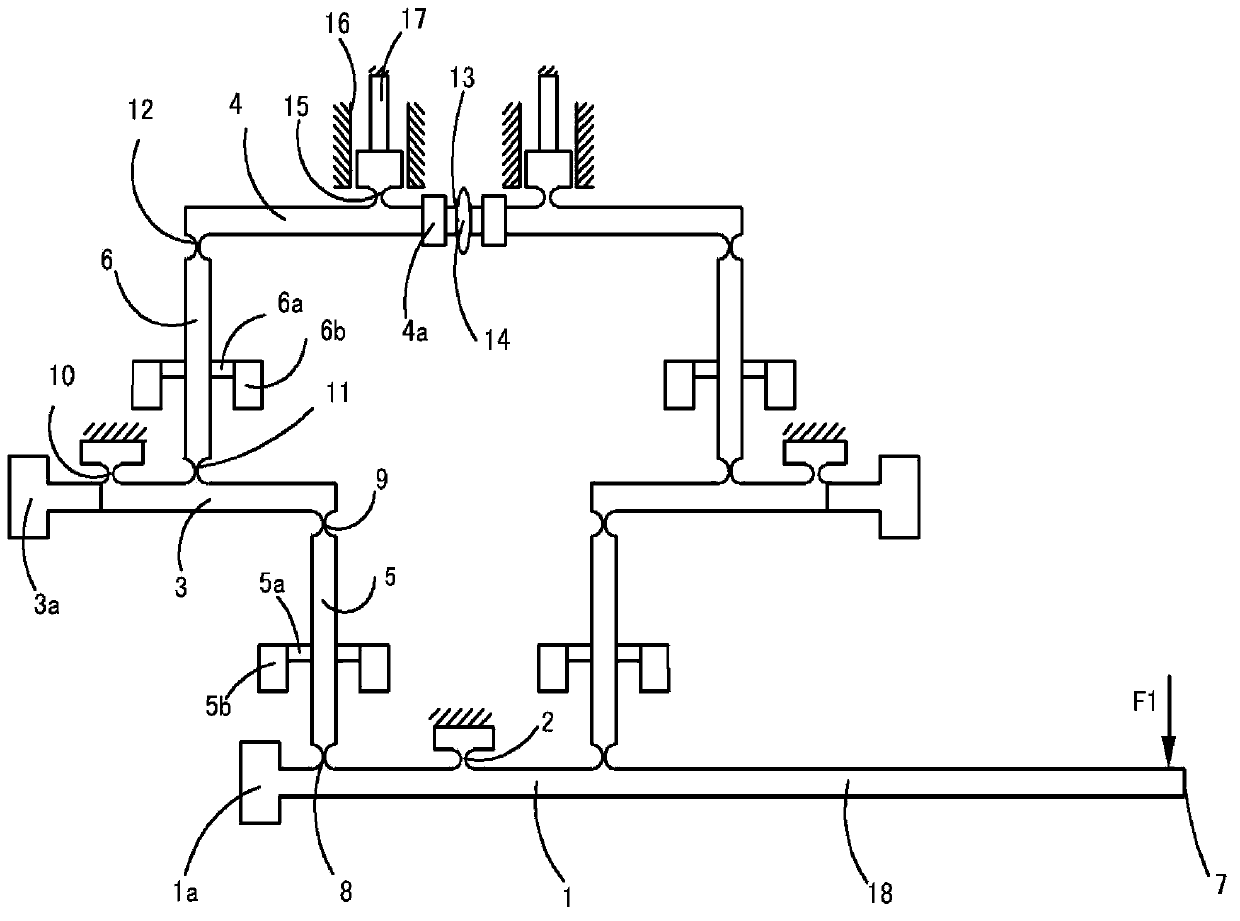

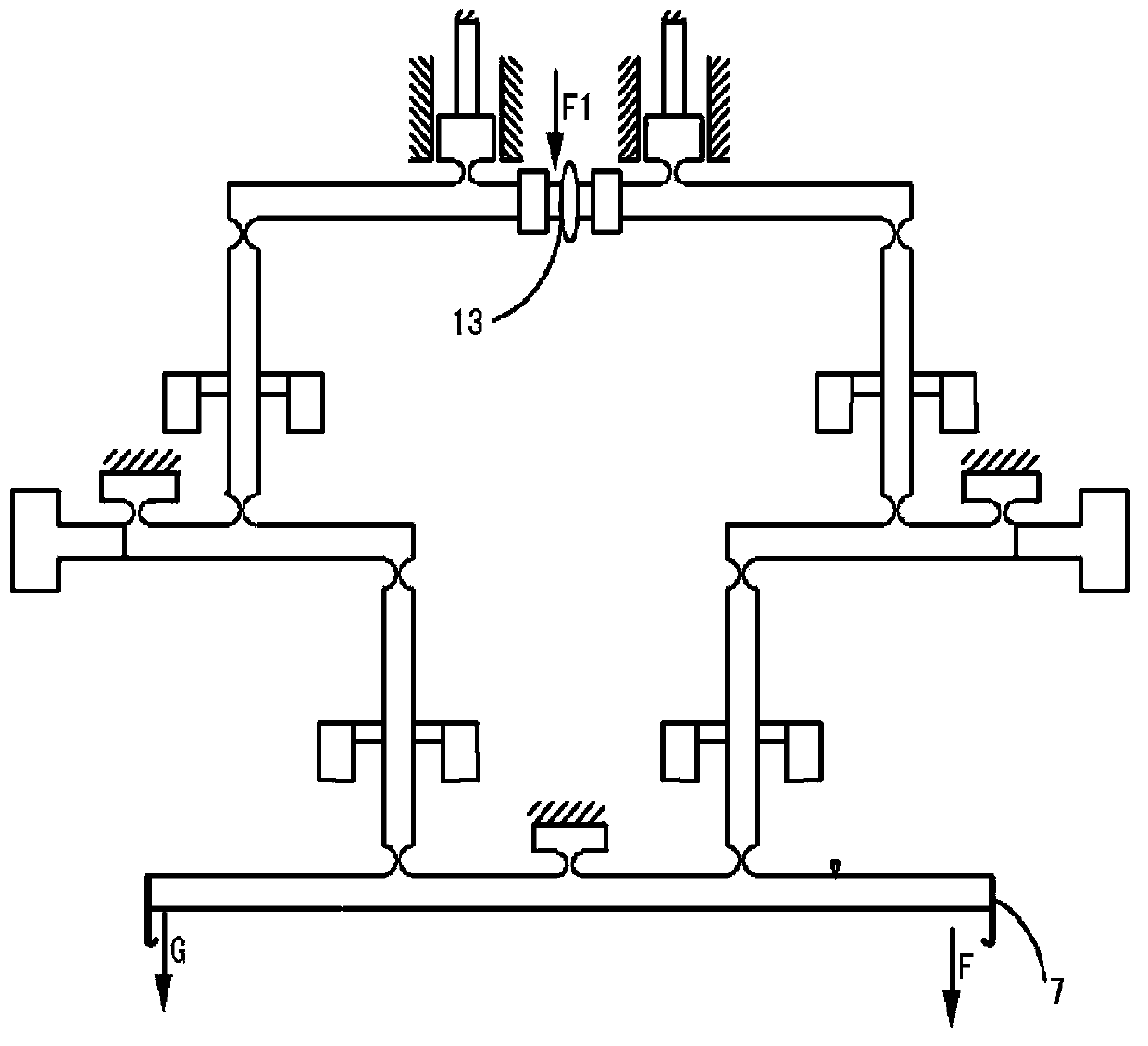

[0027] see figure 1 , in this embodiment, a first-level fulcrum 2 is set in the middle of a horizontally placed first-level lever 1, with the first-level fulcrum 2 as the center, and in the same vertical plane, a pair of second-level levers 3 are symmetrically located at the first-level fulcrum 2 The two sides of each side are connected with the first-level lever 1 through the first-level transition rod 5 on each side, and a pair of second-level levers 3 are also connected with the third-level lever 4 on each side through the second-level transition rod 6, wherein:

[0028] figure 1 As shown, one end of the first-level lever 1 forms a free end 7 through the extension section 18 along the horizontal direction, and the free end 7 is used as the input end of the measured micro force F1, and the non-free end of the first-level lever 1 passes through the first-level flexible end on the side of the rod. The hinge 8 is connected to the bottom end of the primary transition rod 5; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com