Patents

Literature

178 results about "Piezoresistive effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

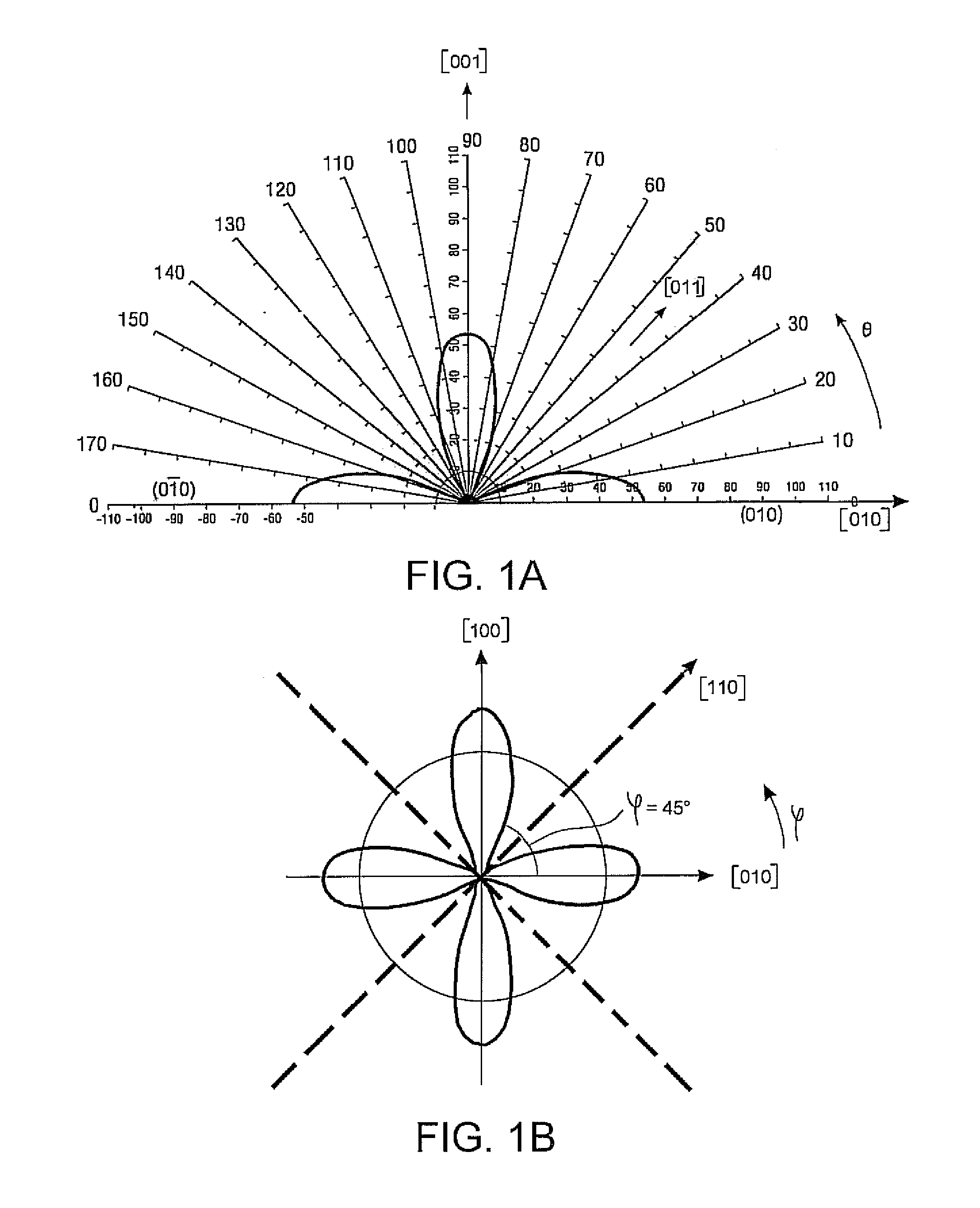

The piezoresistive effect is a change in the electrical resistivity of a semiconductor or metal when mechanical strain is applied. In contrast to the piezoelectric effect, the piezoresistive effect causes a change only in electrical resistance, not in electric potential.

Pressure sensing or force generating device

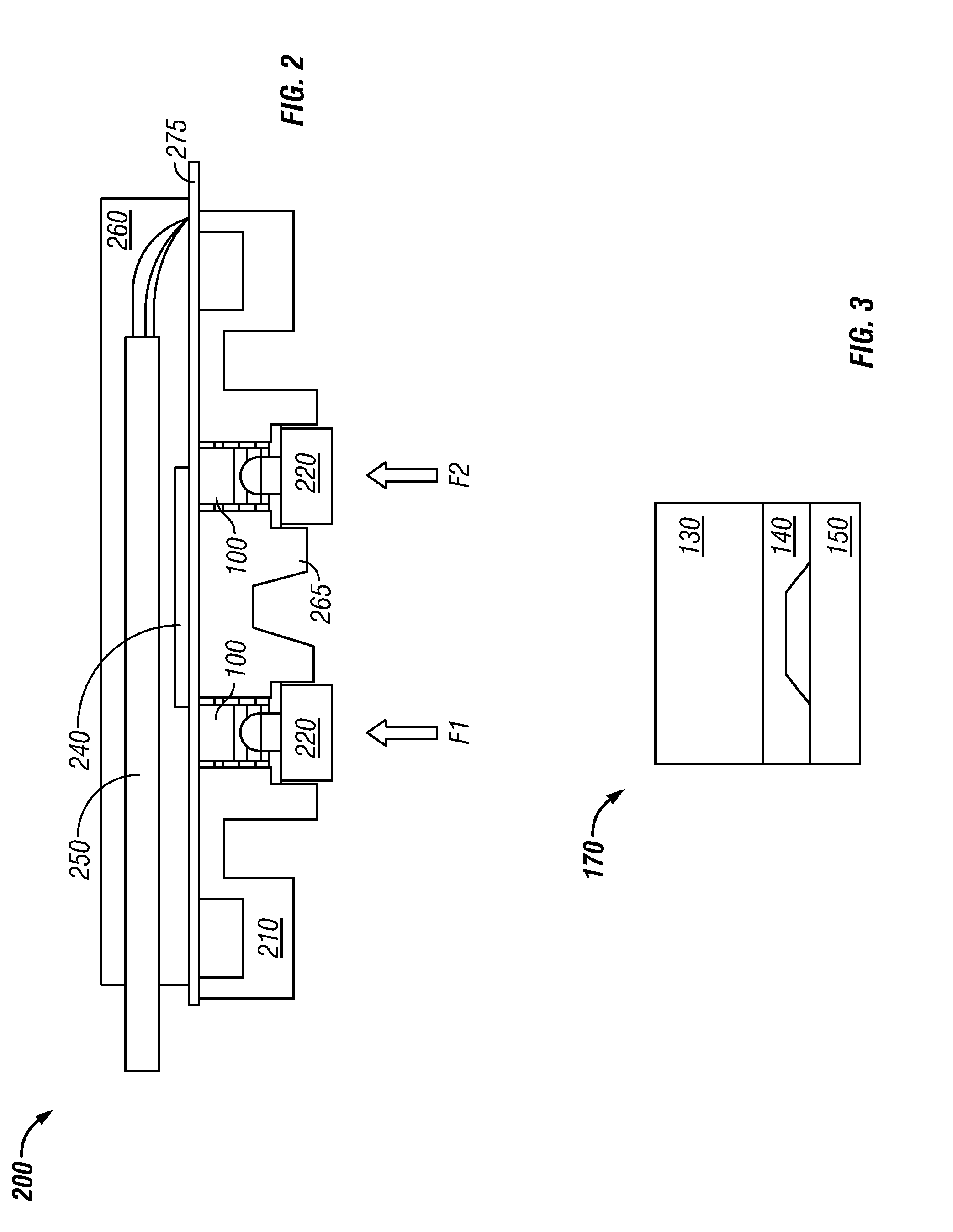

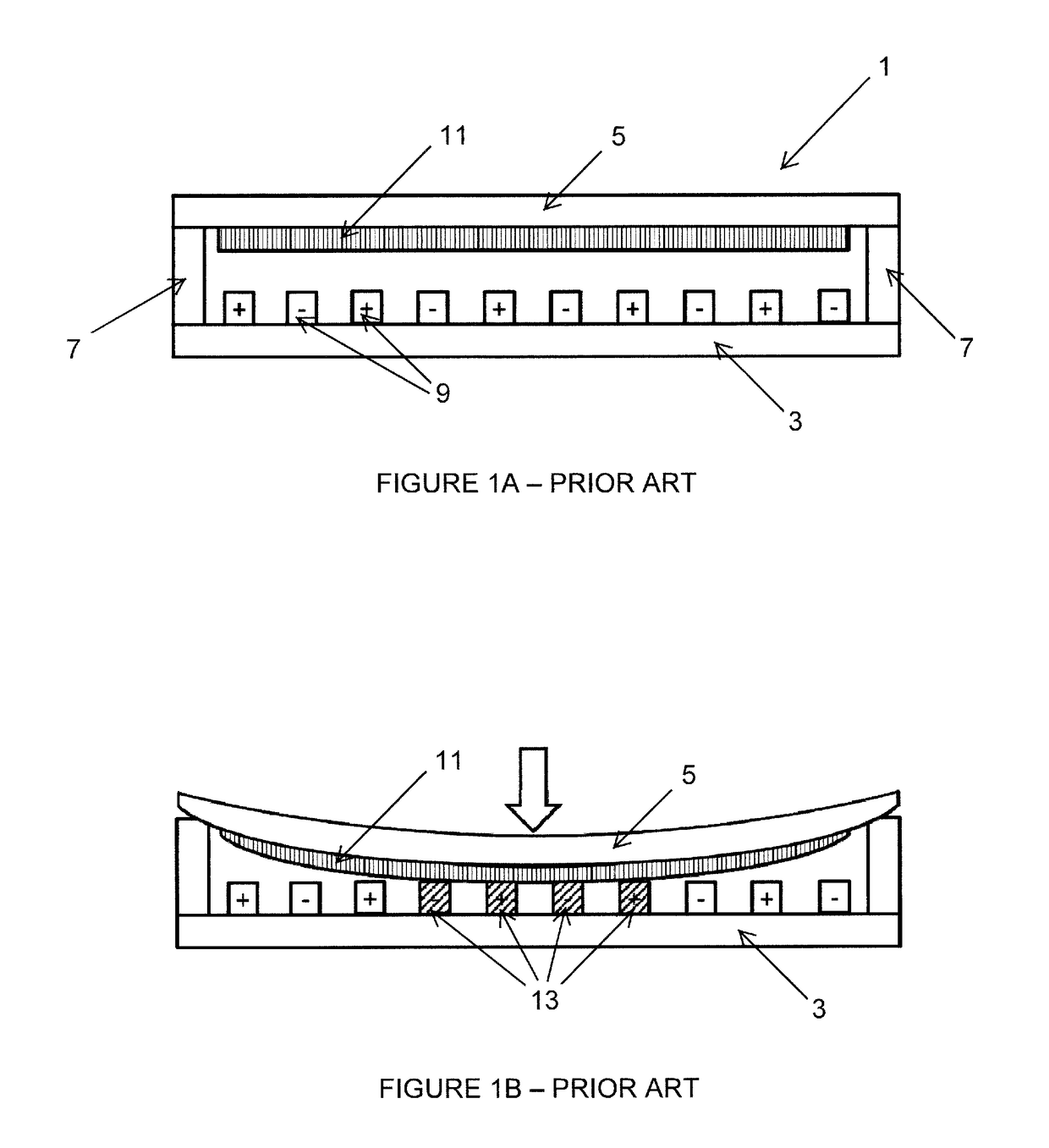

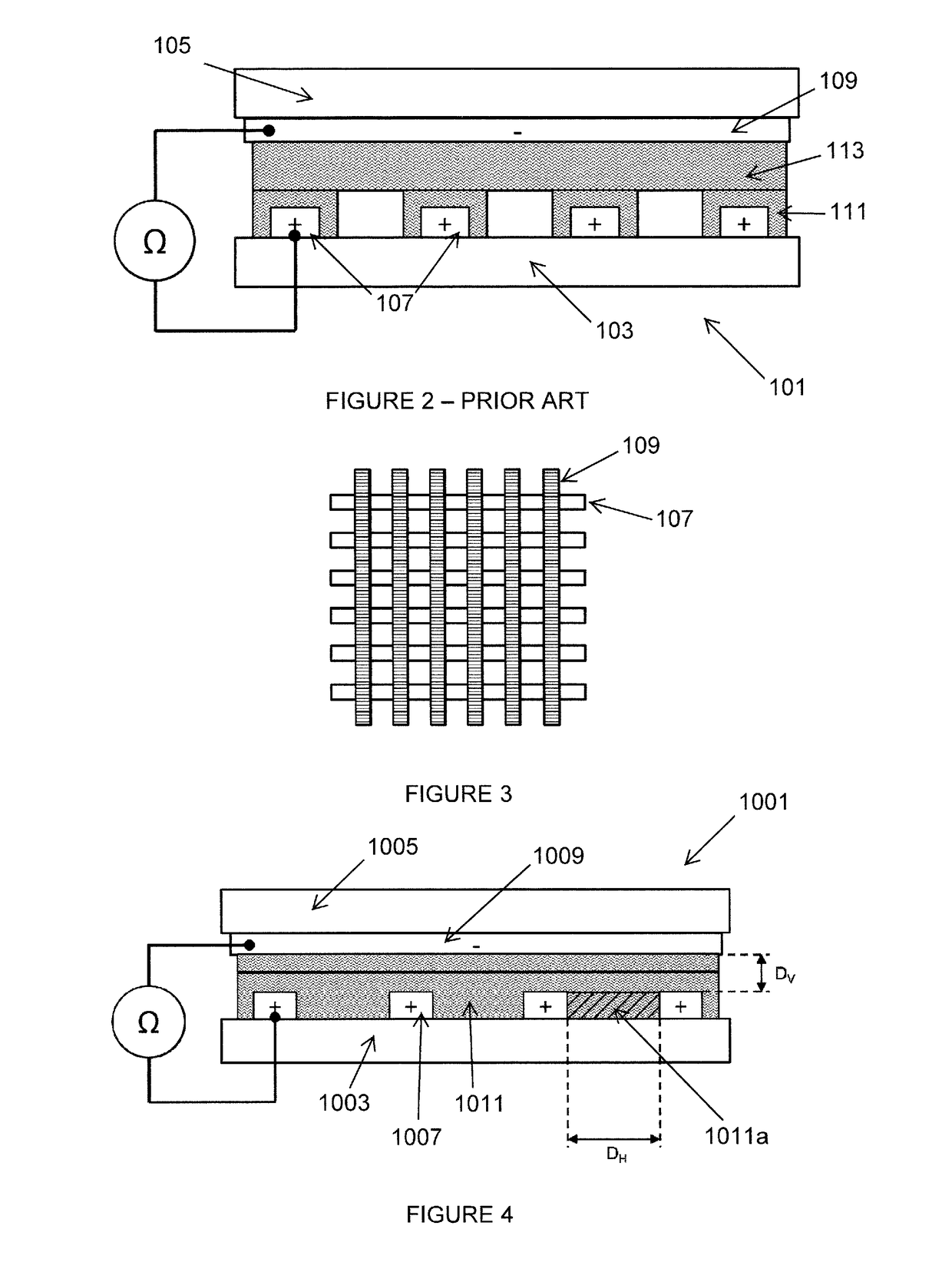

ActiveUS20120055257A1Few contactsShorten the counting processPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCapacitanceCapacitive effect

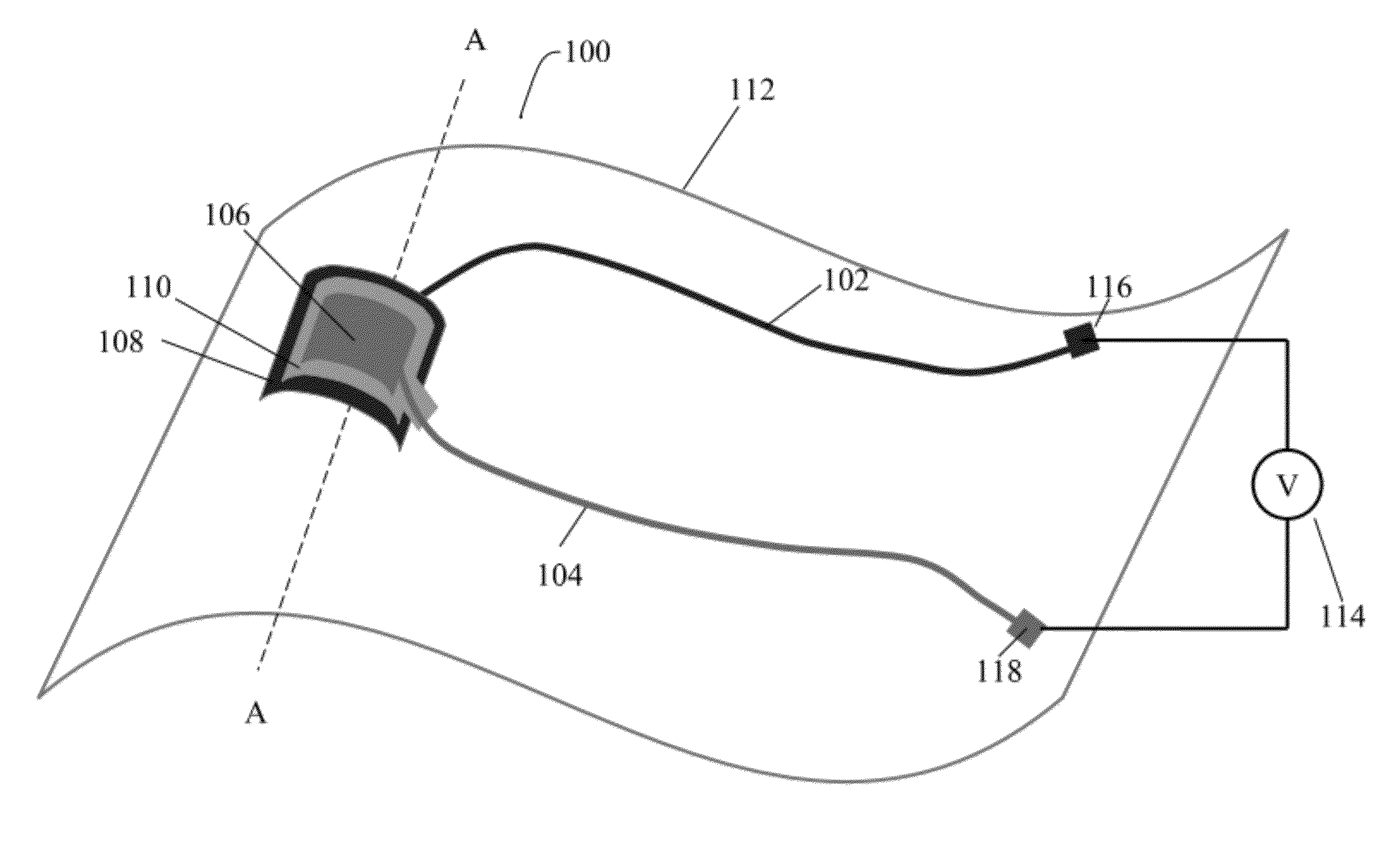

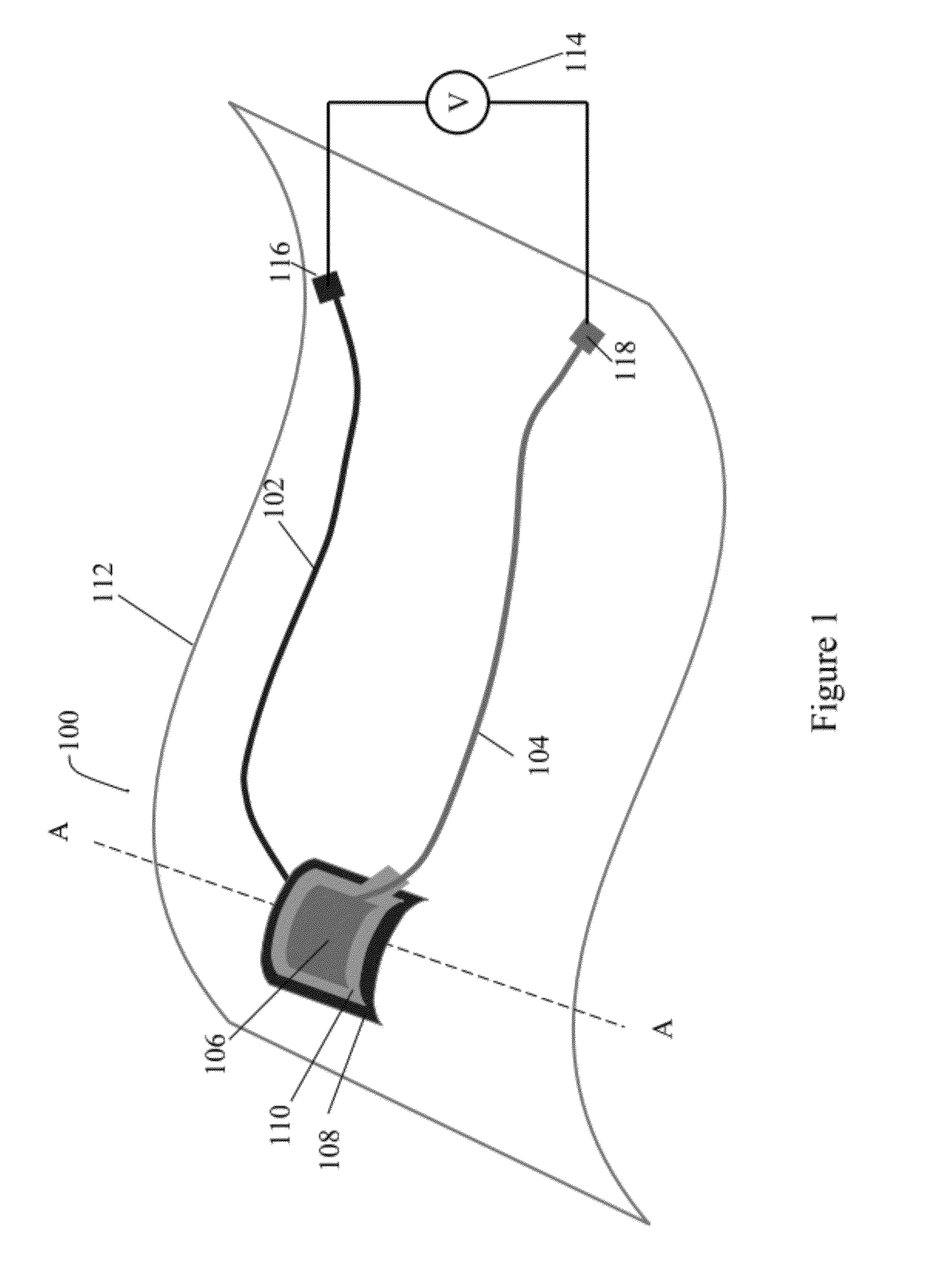

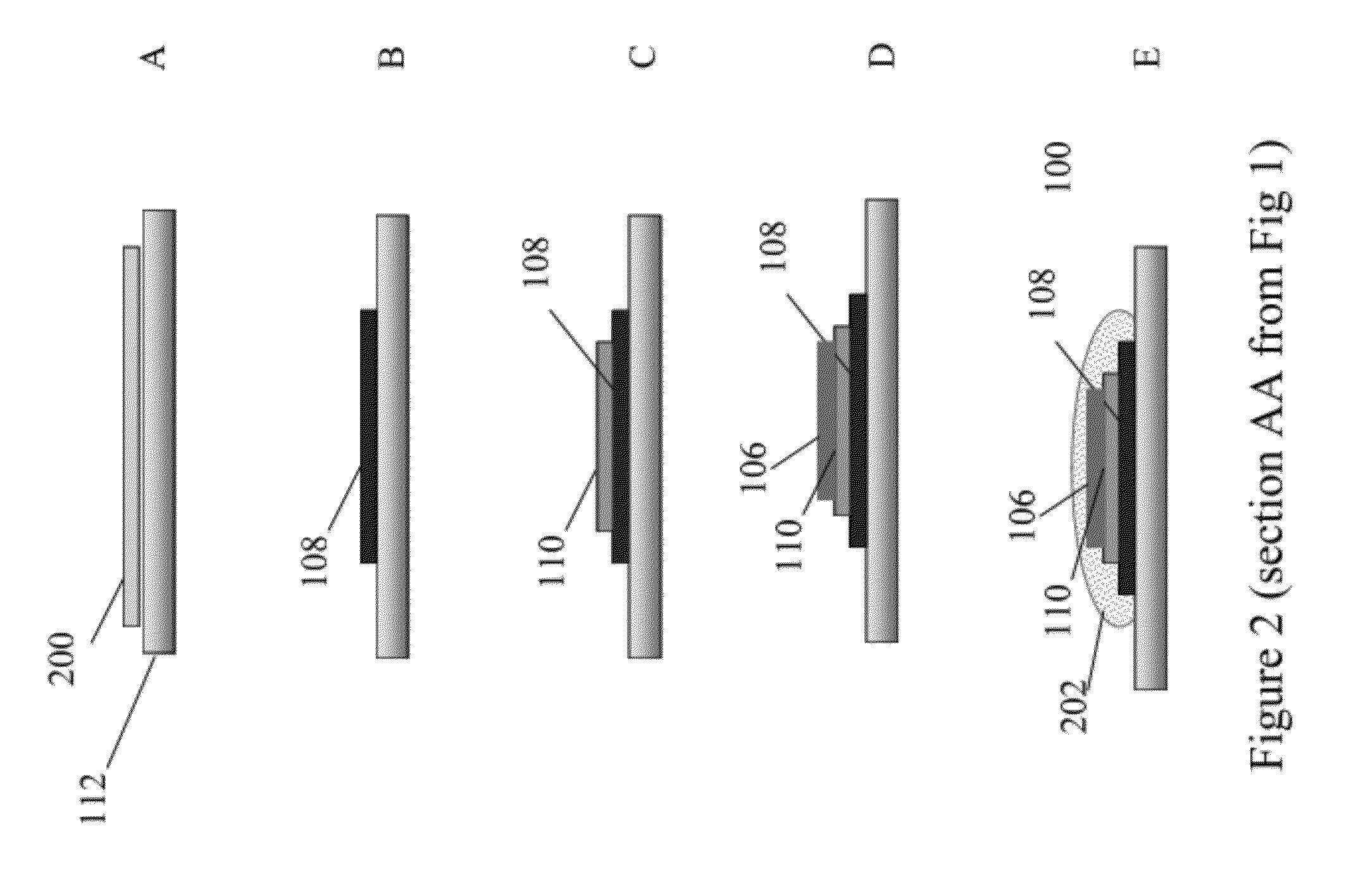

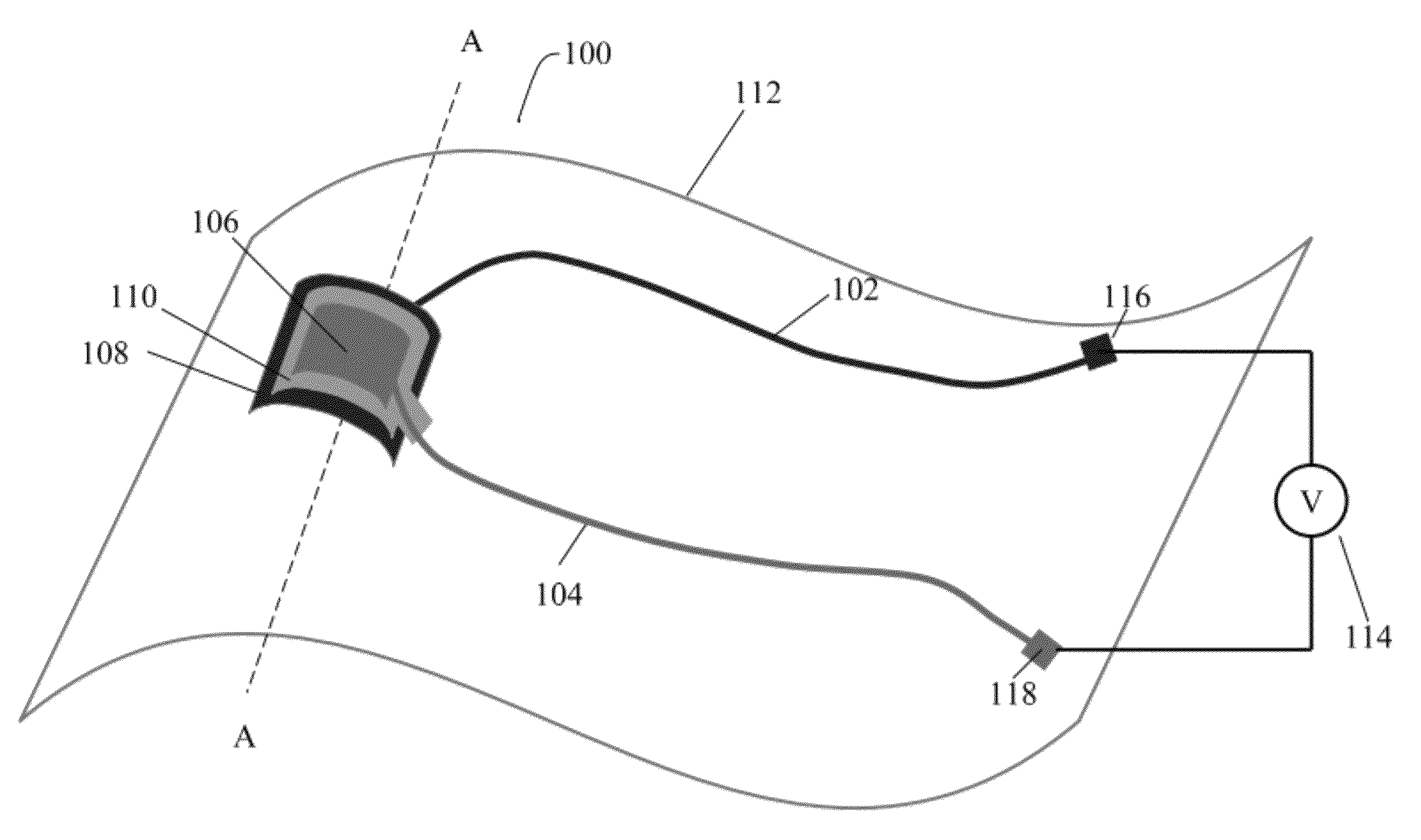

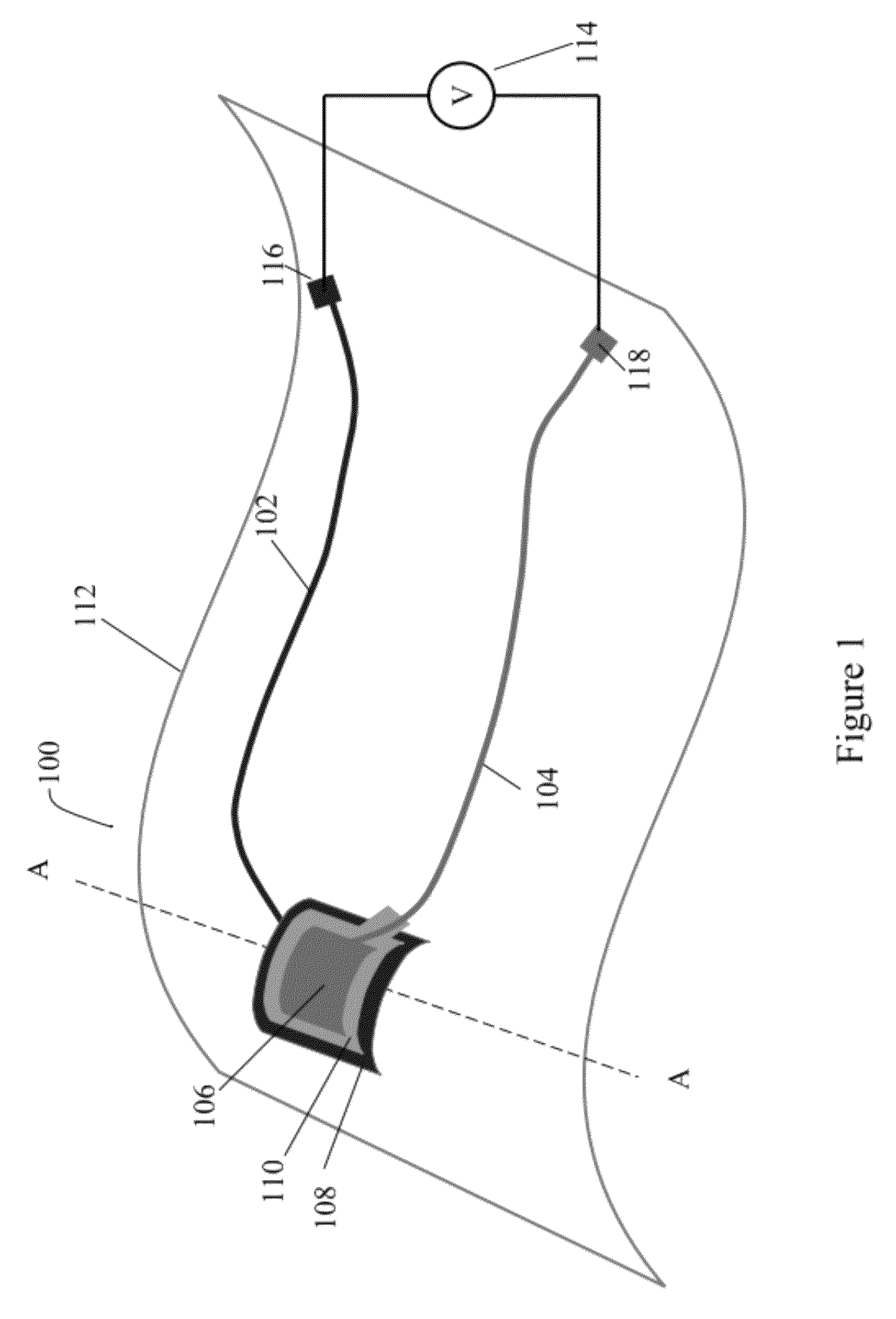

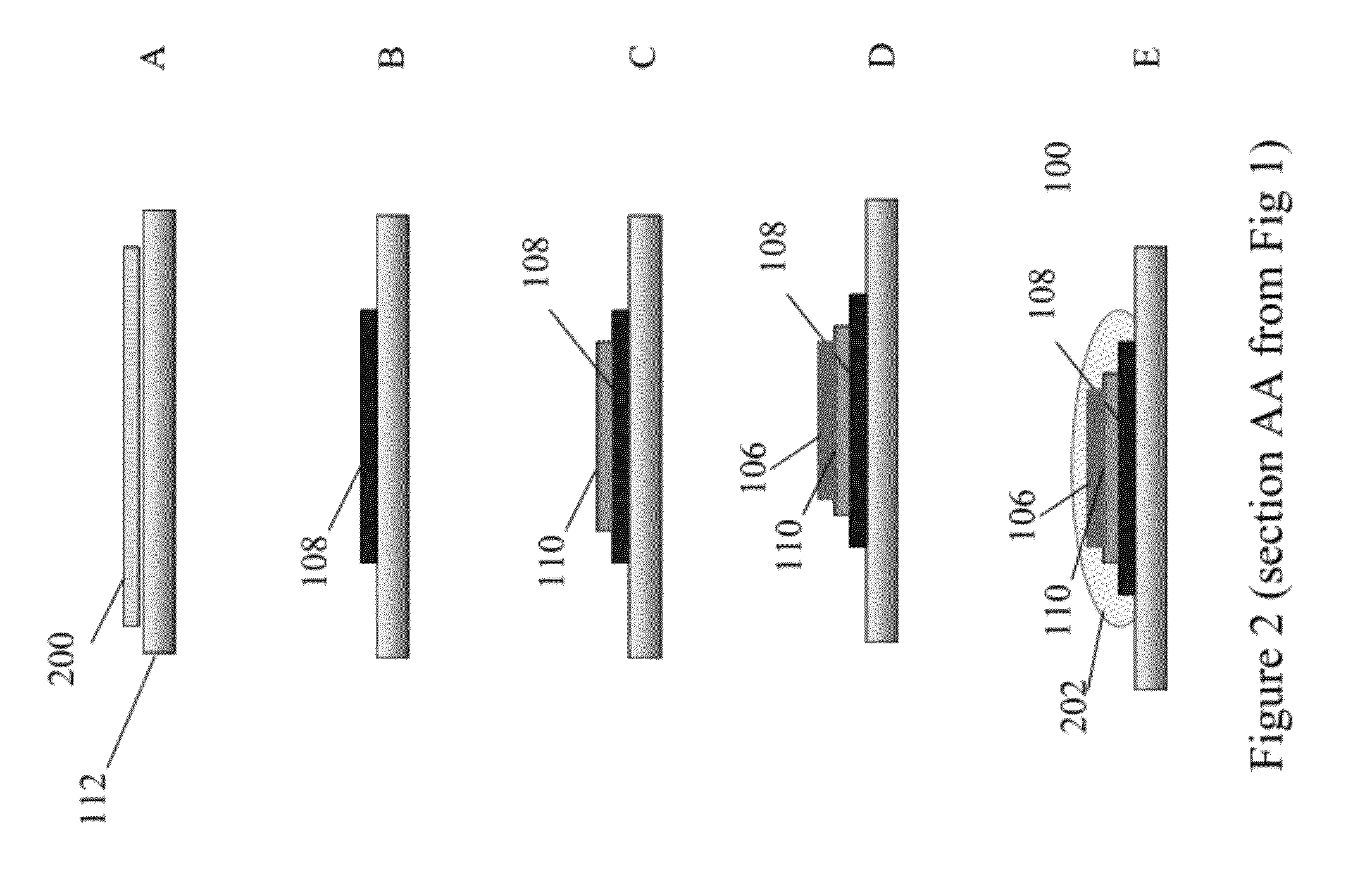

In one aspect, the present invention relates to a pressure sensing / force generating device comprising a non-planar substrate, a printed pressure sensitive element comprising (a) a piezoelectric material containing ink composition capable of producing a piezoelectric effect / piezoresistive effect and / or (b) a dielectric material containing ink composition capable of producing a capacitive effect. It also includes a first printed electrode comprising a conductive ink composition, and a second printed electrode comprising a conductive ink composition. The first and second electrodes are in electrical contact with the printed pressure sensitive element. The first and second printed electrodes and the printed pressure sensitive element collectively form a pressure sensitive junction, which is coupled to the non-planar substrate. The present invention further relates to medical devices comprising the pressure sensing / force generating device and methods of making such devices.

Owner:MICROPEN TECH CORP

Pressure sensing or force generating device

ActiveUS8479585B2Few contactsDensely packedForce measurement using piezo-electric devicesUsing electrical meansCapacitive effectPressure sense

In one aspect, the present invention relates to a pressure sensing / force generating device comprising a non-planar substrate, a printed pressure sensitive element comprising (a) a piezoelectric material containing ink composition capable of producing a piezoelectric effect / piezoresistive effect and / or (b) a dielectric material containing ink composition capable of producing a capacitive effect. It also includes a first printed electrode comprising a conductive ink composition, and a second printed electrode comprising a conductive ink composition. The first and second electrodes are in electrical contact with the printed pressure sensitive element. The first and second printed electrodes and the printed pressure sensitive element collectively form a pressure sensitive junction, which is coupled to the non-planar substrate. The present invention further relates to medical devices comprising the pressure sensing / force generating device and methods of making such devices.

Owner:MICROPEN TECH CORP

Fluid flow monitor

ActiveUS7775126B2Fluid pressure measurement by electric/magnetic elementsMedical devicesMicrocontrollerEngineering

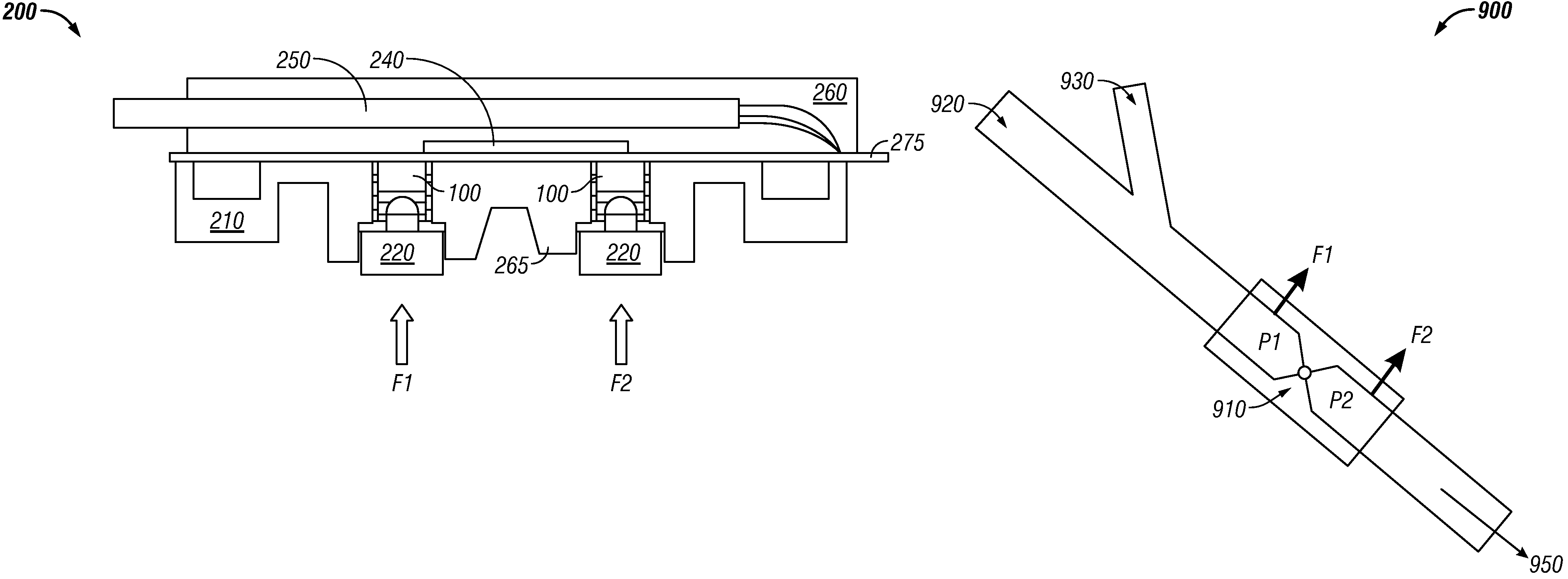

A differential force sensor method and apparatus for automatically monitoring manual injections through an intravenous line. The differential force sensor includes two piezoresistive sense die that are packaged in close proximity utilizing a number of packaging processes. The two piezoresistive sense die can be utilized to measure forces exerted on a diaphragm on either side of an orifice. The piezoresistive sense die can be packaged in close proximity to make intimate contact with the diaphragms on either side of the orifice. The differential force sensor further includes two plungers that make intimate contact with the diaphragm and transfer the force into the piezo-resistive sense dies. Additionally, one or more ASICs and microcontrollers can be utilized to provide thermal calibration and differential calculation.

Owner:HONEYWELL INT INC

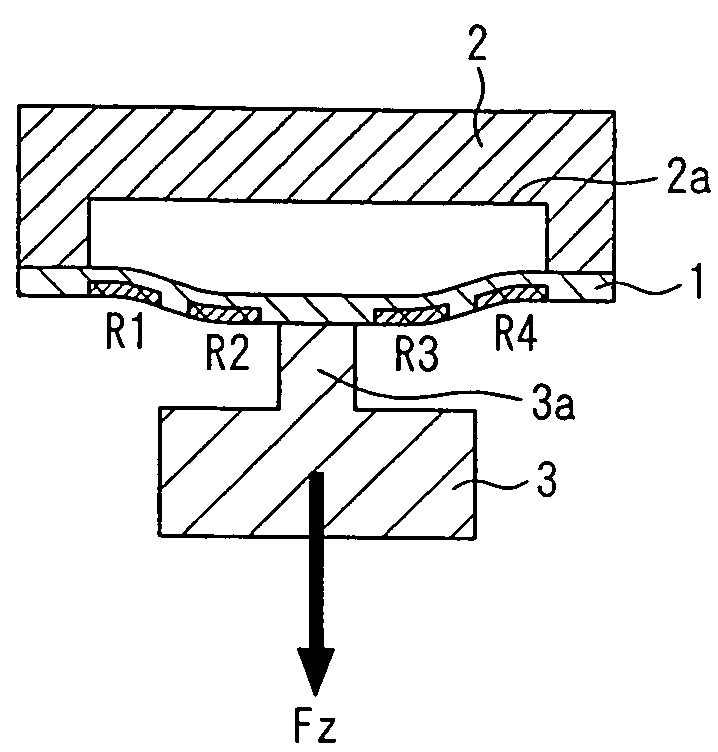

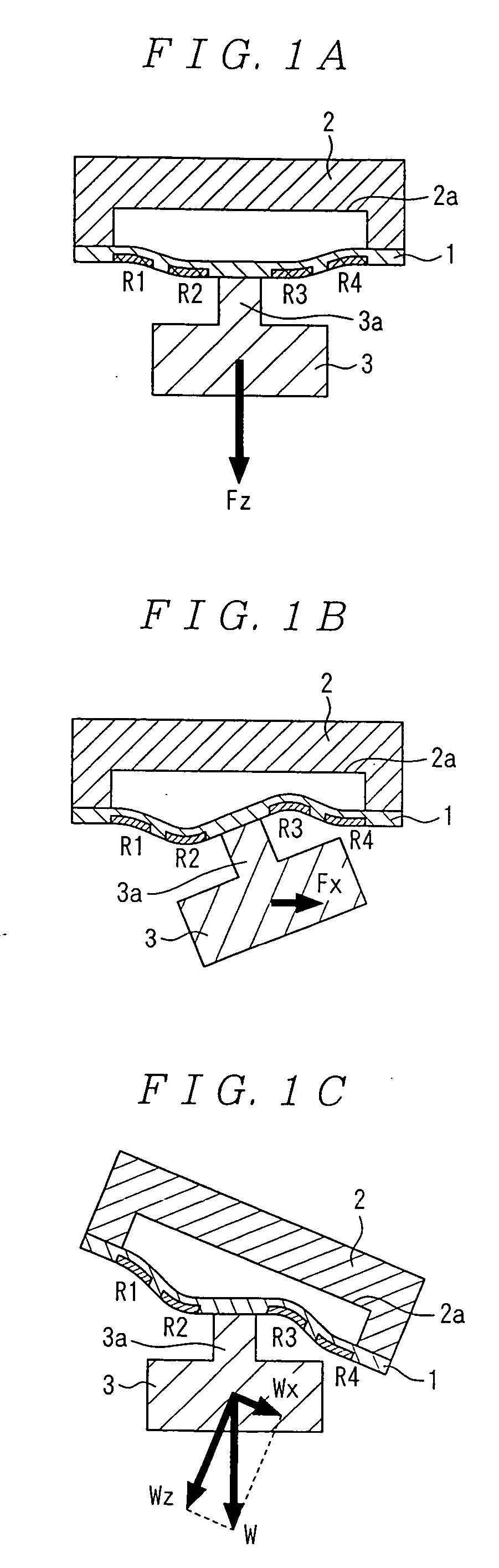

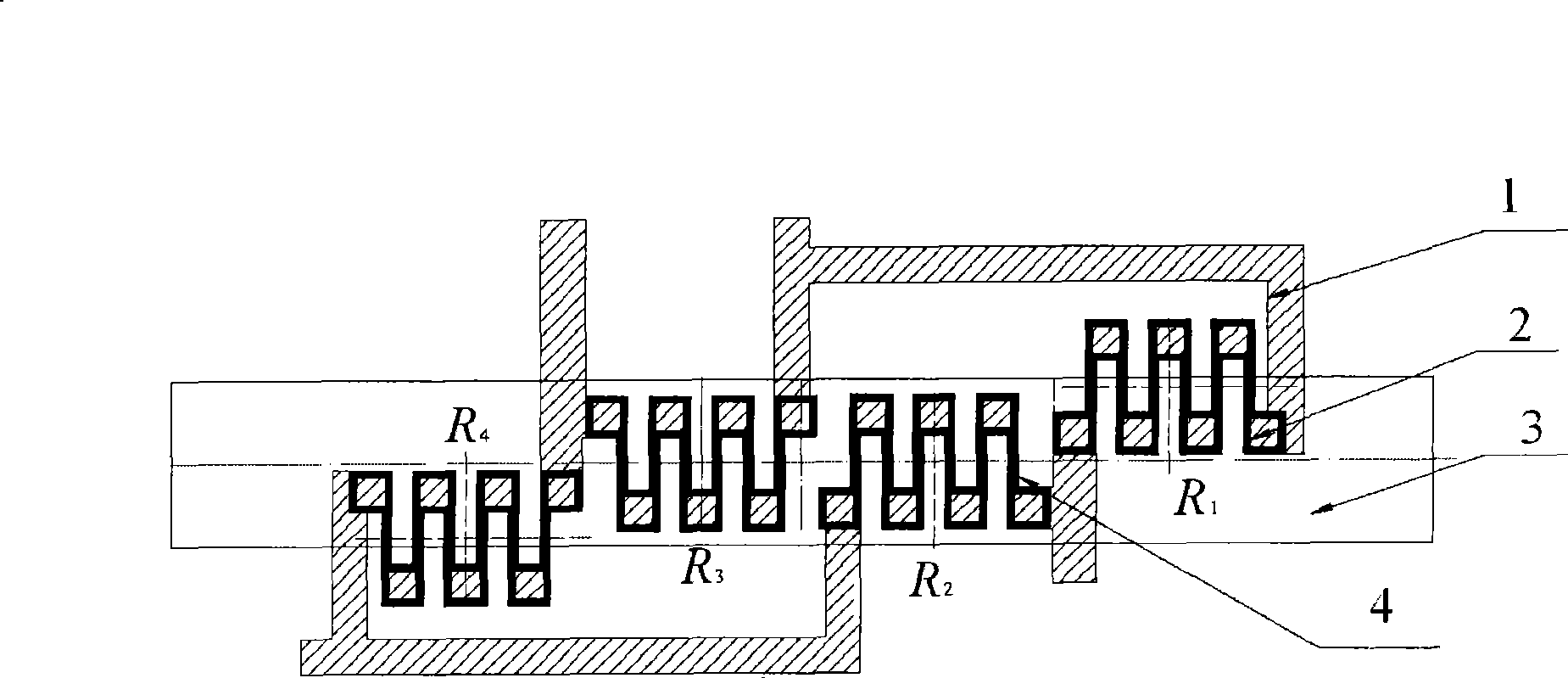

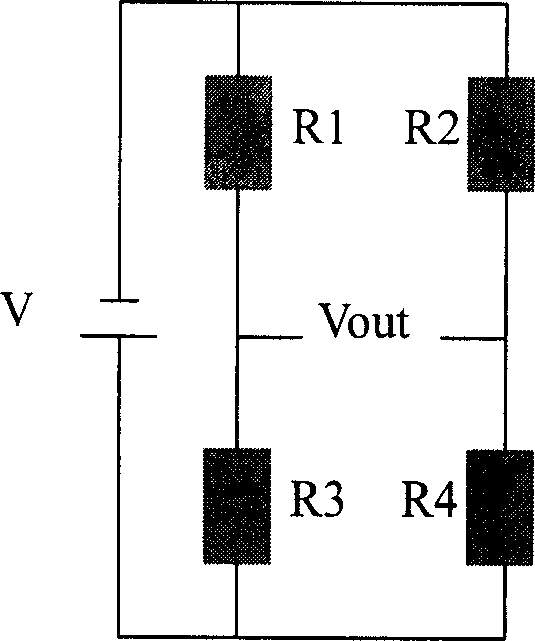

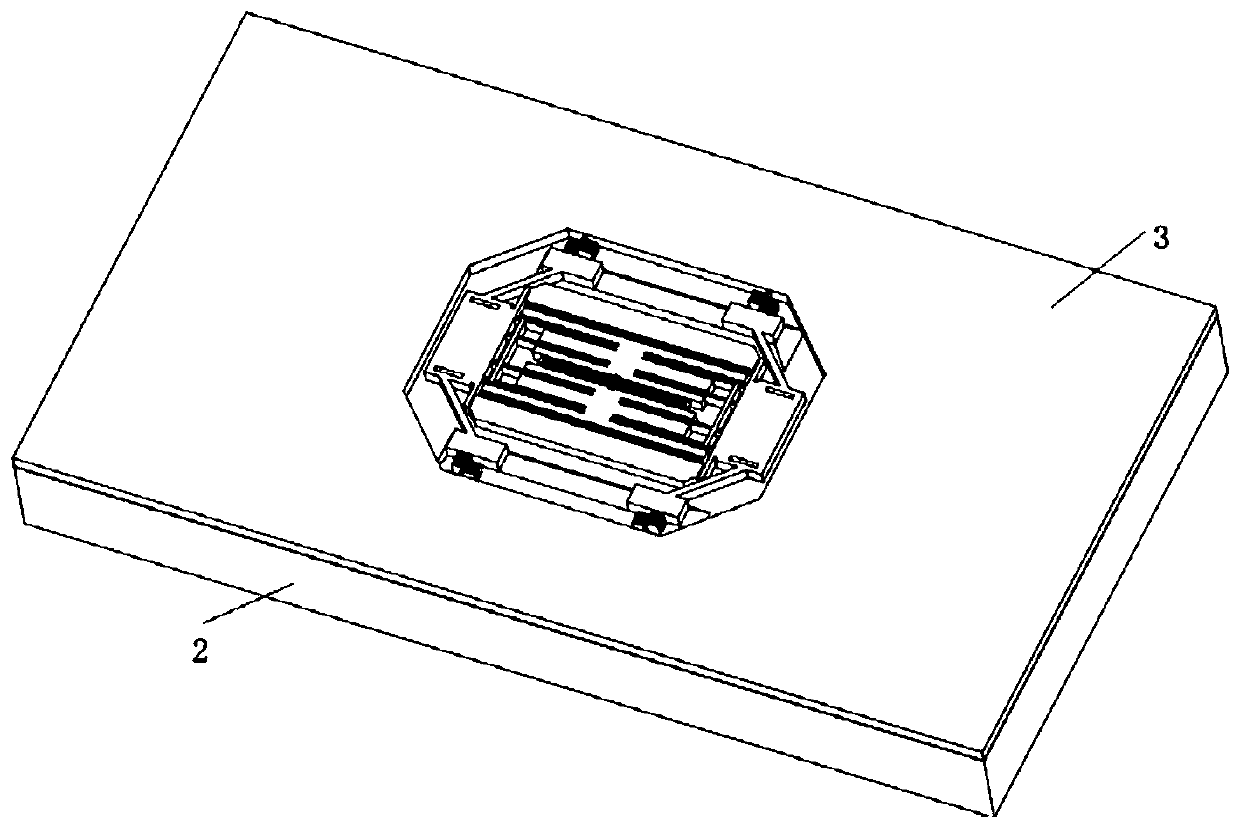

Inclination sensor, method of manufacturing inclination sensor, and method of measuring inclination

InactiveUS20050151448A1Increase in sizeAccurate measurementAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesSiliconPiezoresistive effect

A tilt sensor capable of measuring a tilt angle by utilizing piezoresistive effect without selectively etching a substrate having piezoresistors formed therein, wherein the backside of the silicon substrate 1 having piezoresistors R1 to R4 formed therein is uniformly ground to a deflectable thickness, both ends of the silicon substrate 1 are supported by a support member 2, and a weight member 3 is provided at the center of the silicon substrate 1 through a convex portion 3a.

Owner:ASAHI KASEI ELECTRONICS CO LTD

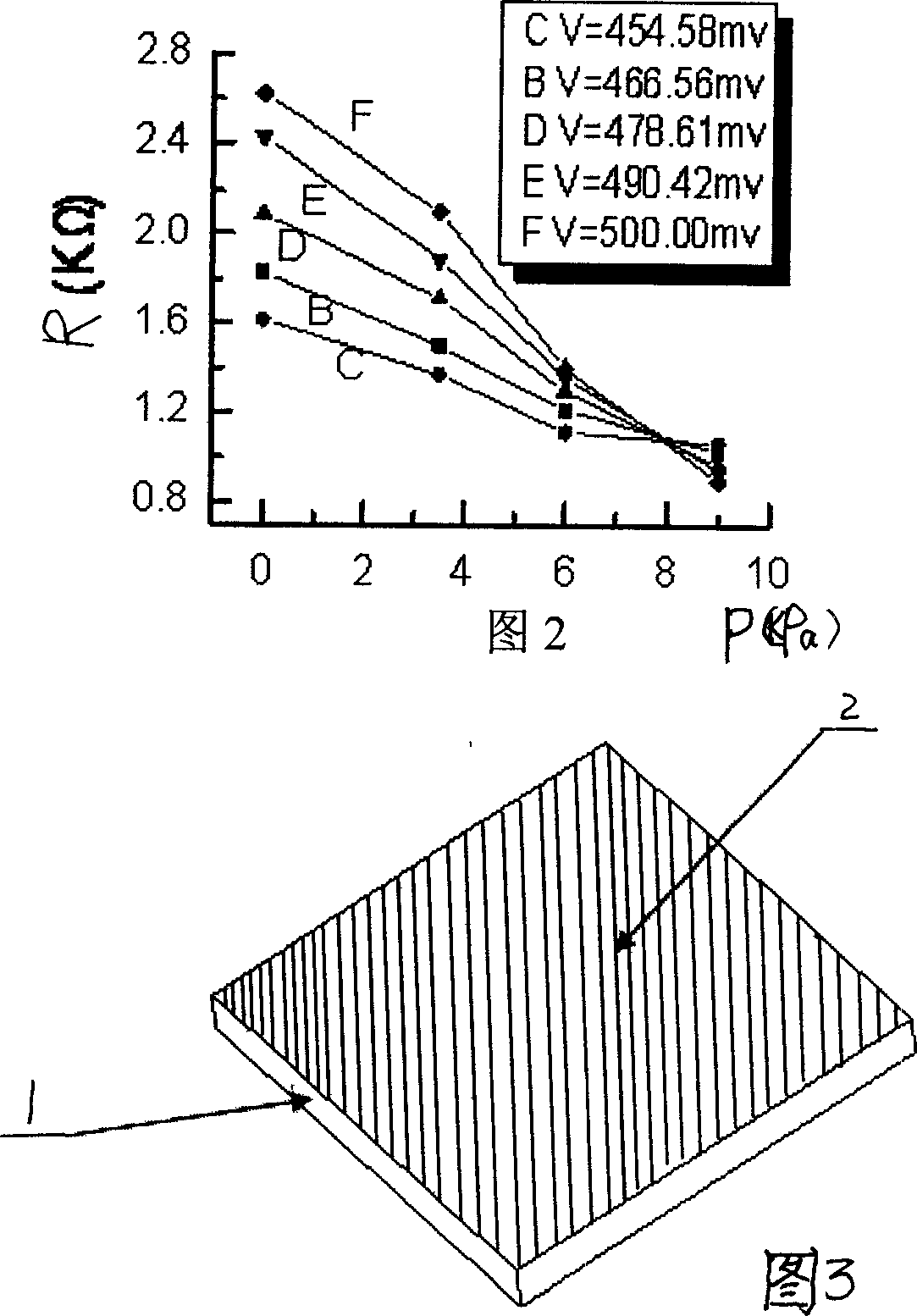

Pressure sensor and production method thereof

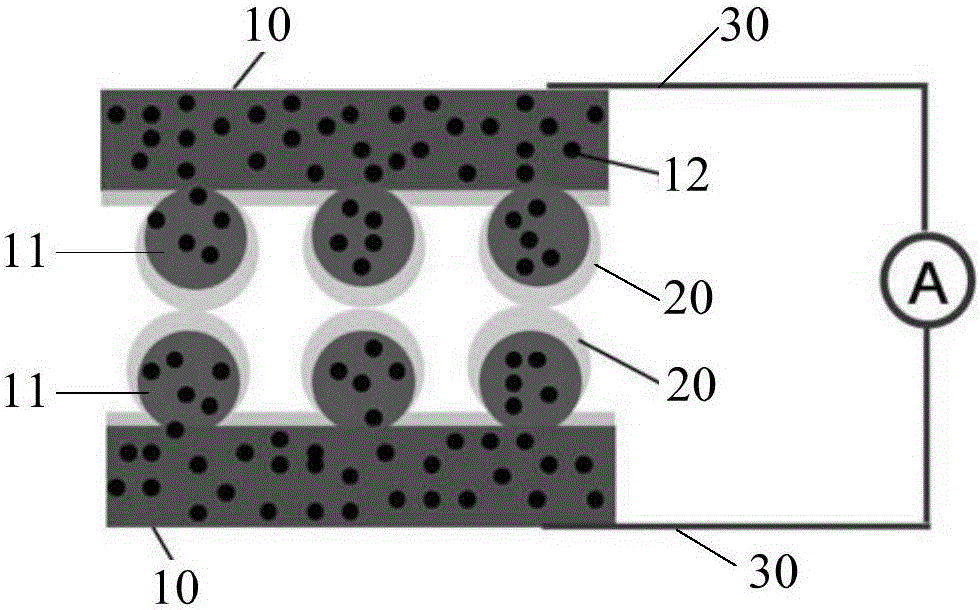

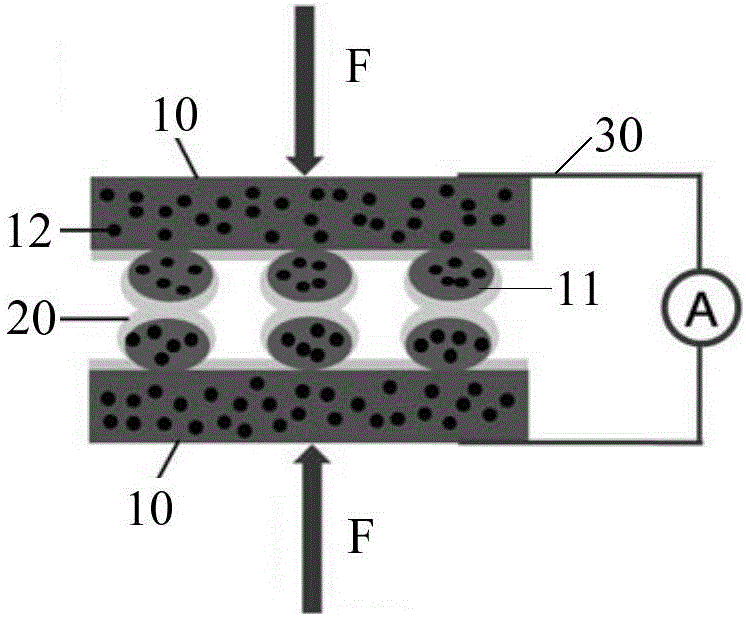

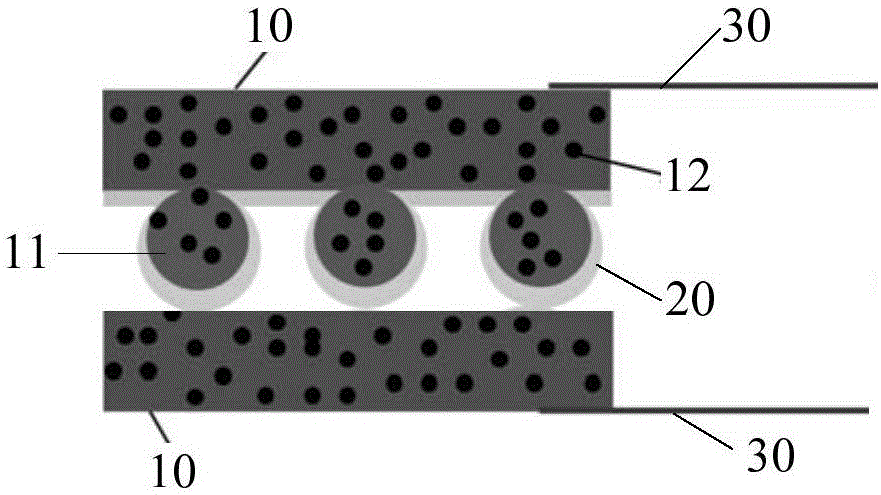

ActiveCN106768520ASimple structureWide range of pressure detectionForce measurementElectrical resistance and conductanceConvex structure

The invention discloses a pressure sensor and a production method thereof. The pressure sensor comprises two external electrodes, and two substrates which are oppositely arranged and are elastic, wherein a convex structure is arranged on the contact surface of at least one substrate; the contact surfaces are opposite surfaces of the two substrates; the substrates are conductors; each substrate is connected with one external electrode; the surface of the convex structure is covered by a conductive layer. According to the pressure sensor provided by the invention, a piezoresistive effect that under the action of a pressure, the elastic and conductive substrates deform to cause resistance change is utilized, an effect that under the action of a pressure, the contact surface area of the conductive layer on the surface of the convex structure of the substrate changes to cause contact resistance change is utilized, and through a synergistic effect of the two effects, the pressure detection range is greatly widened; compared with the conventional way that a circuit layer is arranged between the two substrates, the contact surface area of the conductive layer in the pressure sensor during deformation of the convex structure changes more, so that the sensitivity and the reliability of the pressure sensor are further improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

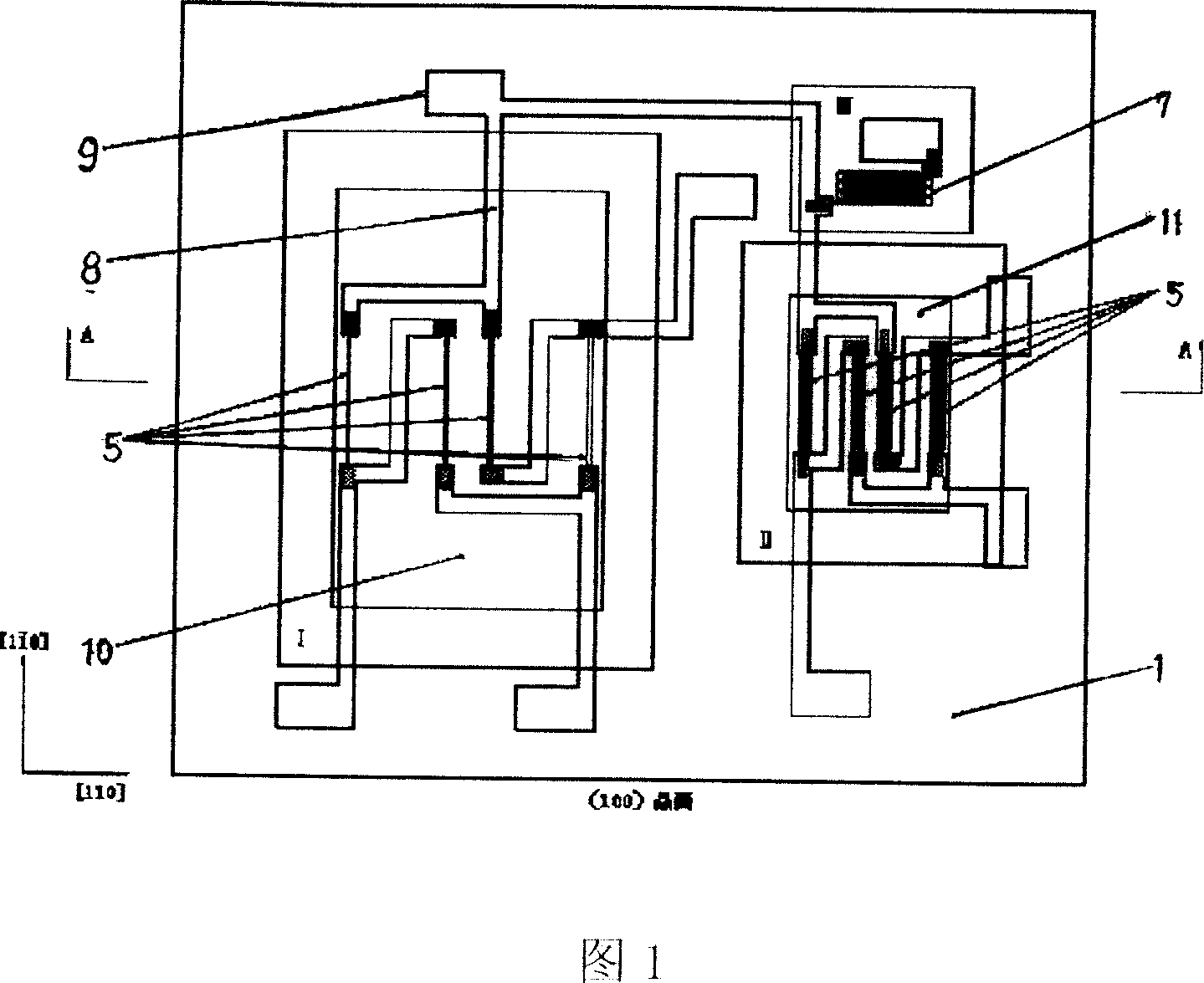

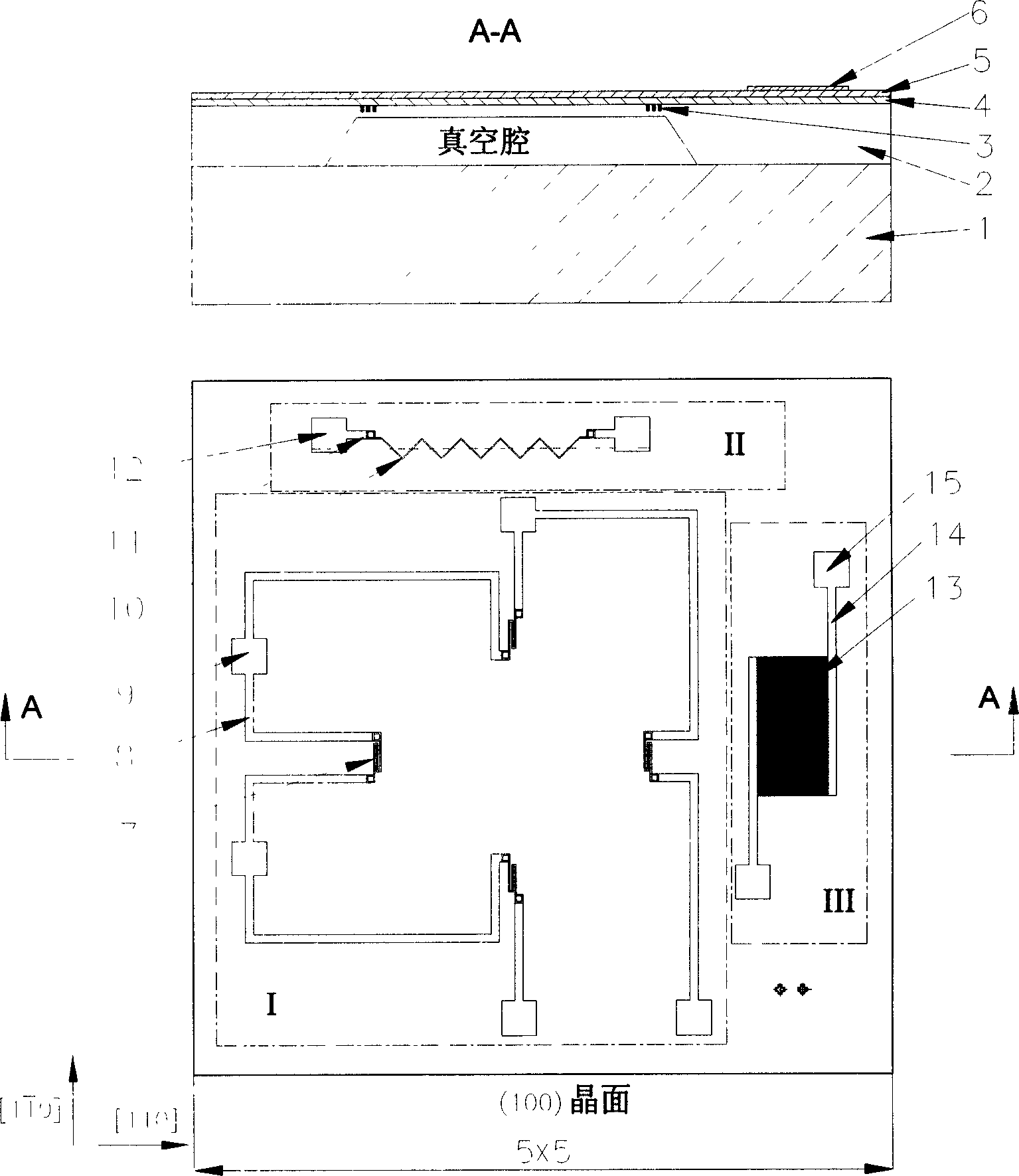

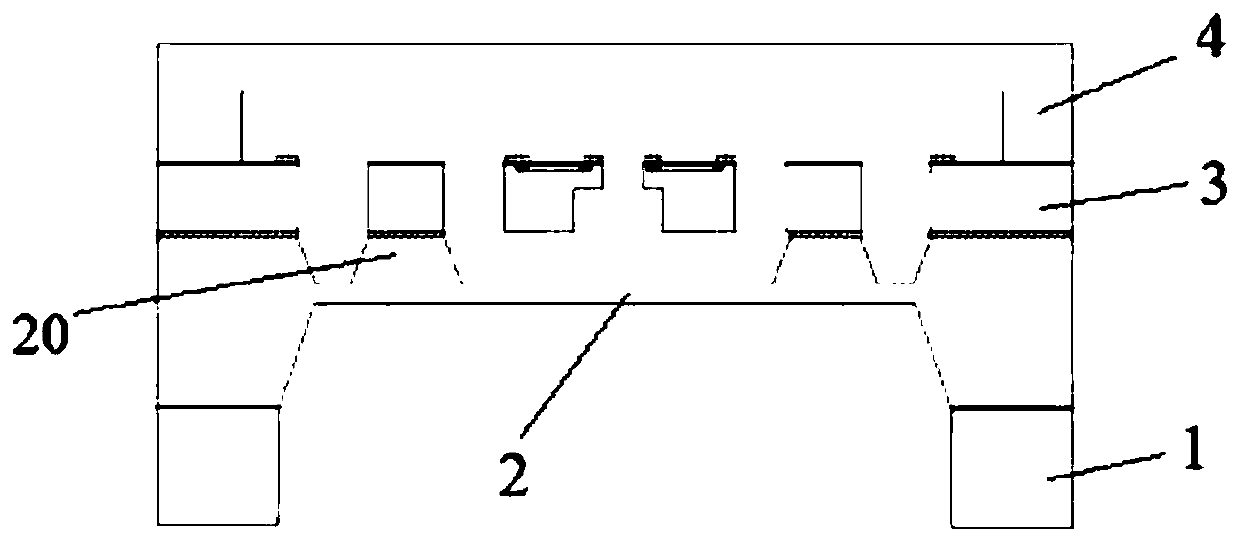

Monolithic integrated sensor chip for measing three parameters of pressure difference, absolute pressure and temperature and its making process

ActiveCN1974372AHigh precisionFunction increaseTelevision system detailsSemiconductor/solid-state device detailsElectrical resistance and conductanceSilicon membrane

The invention relates to a differential pressure / absolute pressure / temperature three parameter monolithic integrated sensor chip, wherein the chip structure includes a sensing resistor, silicon membrane and glass substrate, a relatively independent pressure difference sensing unit I and an absolute pressure sensing unit II are formed in the chip, and a temperature sensing unit III is arranged on a peripheral silicon substrate. The invention is characterized in that in the same chip three sensing units of differential pressure, absolute pressure and temperature are integrated, four raised independent P type silicon resistor strips are respectively distributed on fronts of the differential pressure sensing unit I and the absolute pressure sensing unit II, namely a differential pressure resistor (5) and an absolute pressure resistor (6), and one raised silicon resistor strip, namely a temperature sensing resistor (7), is respectively distributed on the temperature sensing unit III. The inventive method makes the performance of the differential pressure / absolute pressure / temperature three parameter sensor to be reliable, the cost to be lowered, so that the batch production is realized. The measurement of pressure, differential pressure and temperature under a high wide temperature environment is solved.

Owner:SHENYANG ACAD OF INSTR SCI

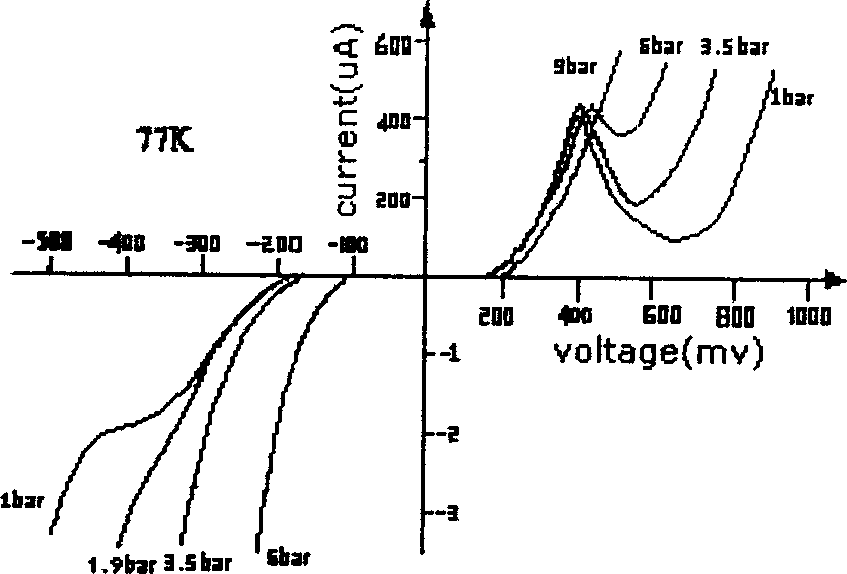

Resonance tunnel through pressure resistance type micro acceleration meter

InactiveCN1752757AHave quantum effectsSize andAcceleration measurement using interia forcesQuantum wellResonance

The present invention relates to a resonant tunneling piezoresistance microaccelerometer. Said invention utilizes the characteristics of that superlattice quantum well film has the piezoresistance effect, and on the super lattice film the resonant tunneling voltage-sensitive resistors are made, the substrate of said superlattice film can be made into peripheral base, cross-shaped cantilever connected with base and force-transferring mechanism of mass block whose periphery is connected with cantilever, and four resonant tunneling voltage-sensitive resistors are positioned in the connected place of cantilever and base. The resonant tunneling piezoresistance microaccelerometer is quantum device made up by adopting MEMS process.

Owner:ZHONGBEI UNIV

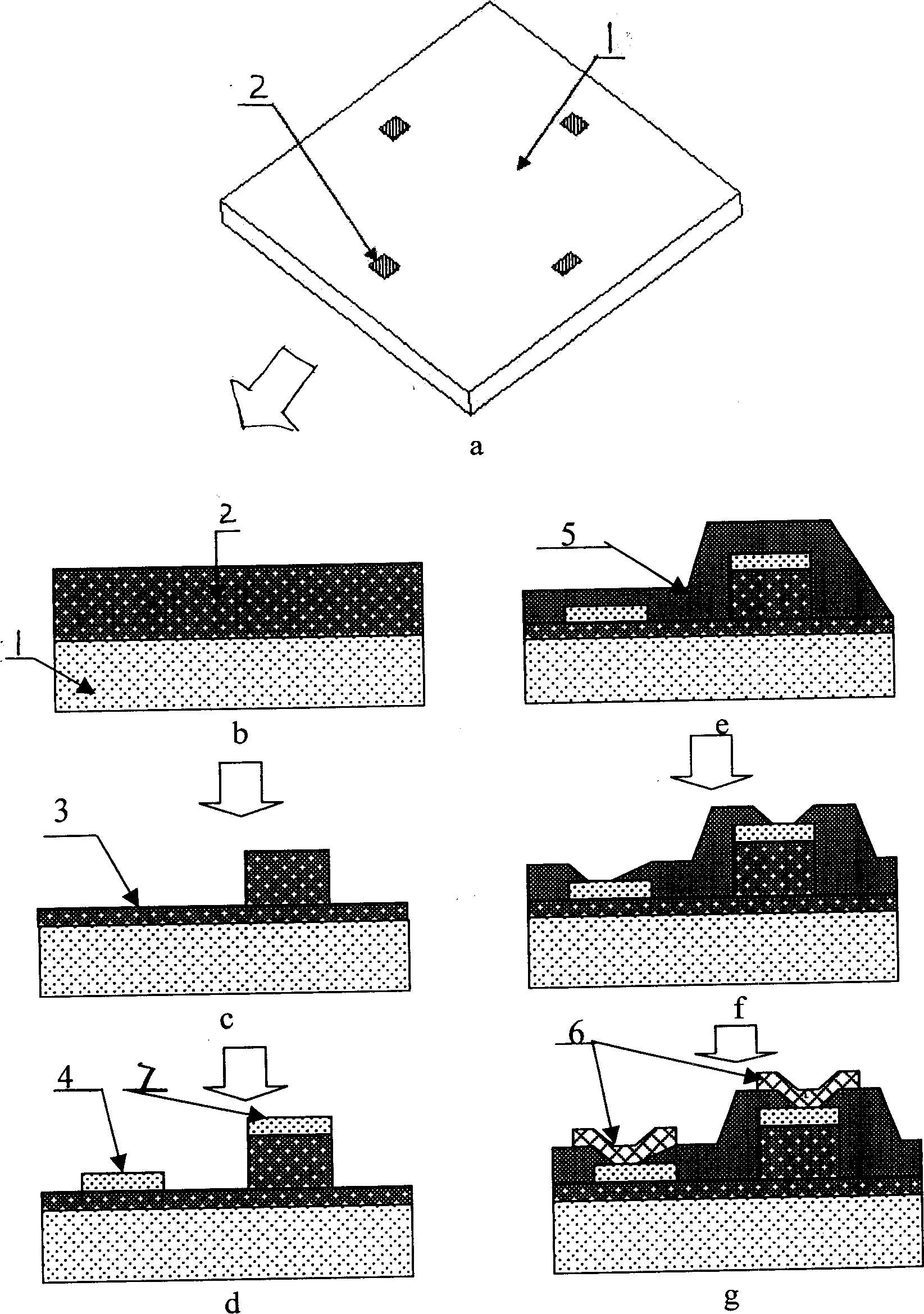

Manufacturing method of multifunction integrated sensor chip

InactiveCN1725439AReduce volumeReduce energy consumptionDecorative surface effectsSemiconductor/solid-state device manufacturingCapacitanceTemperature Unit

This invention discloses a preparing method for a multifunction integrated sensor chip, which applies micro-mechanical electronic technology and IC micro-processing technology to process three sensing units sensing pressure, temperature and humidity on an area of 5mmx5mm tube core, the pressure unit based on the piezo-resistance effect is used to test the pressure variance of environment, the temperature unit is used to test the change of environment temperature based on the thermal resistance effect and the humidity unit based on the capacitance theory used to test the variance of the environment humidity.

Owner:XI AN JIAOTONG UNIV

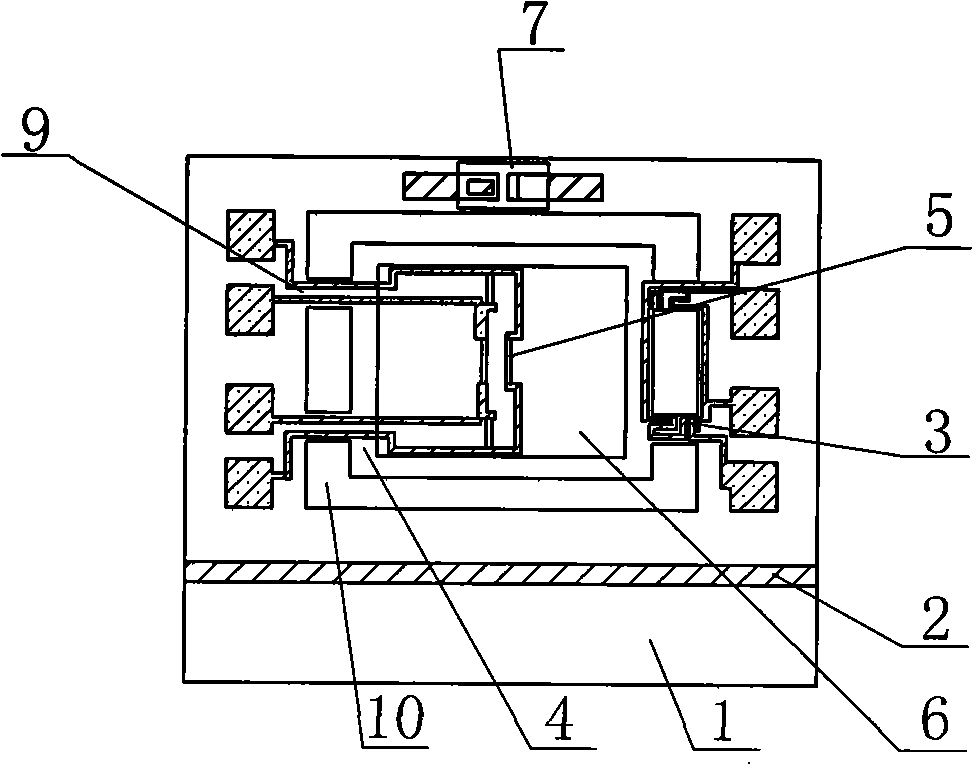

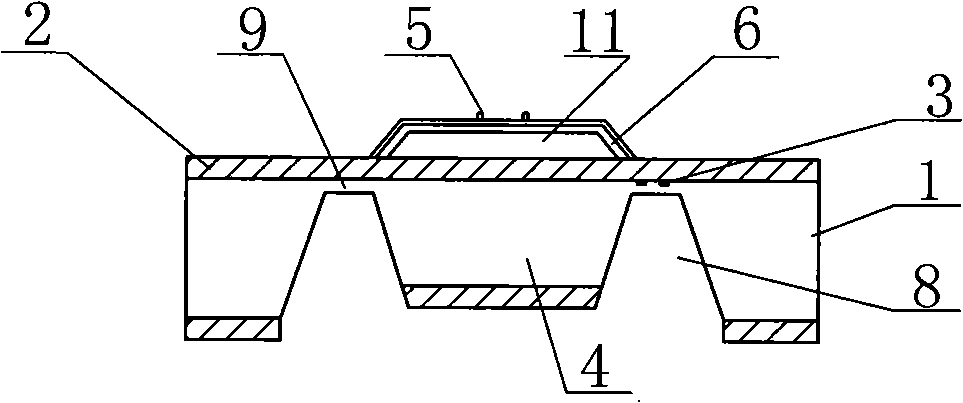

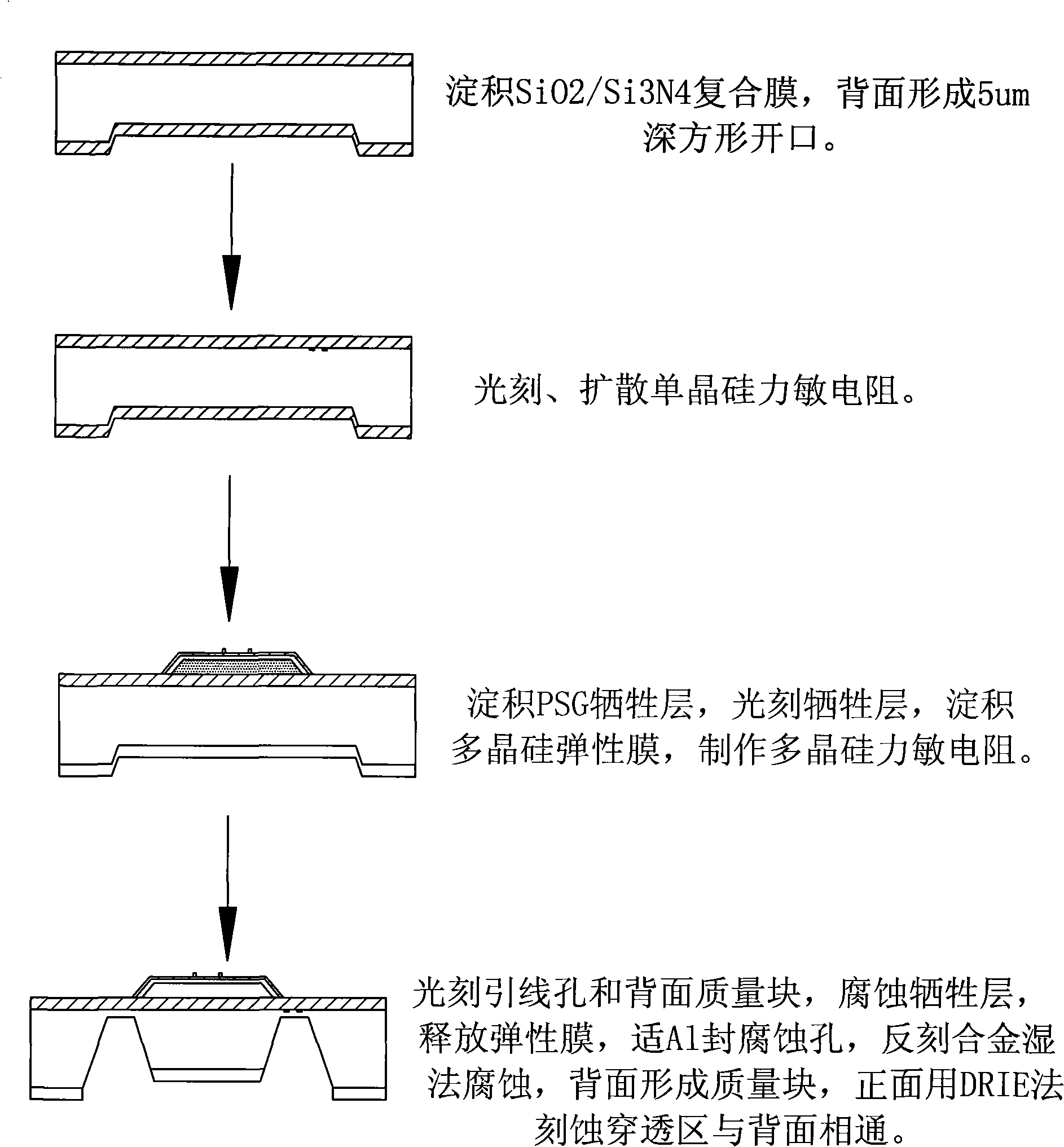

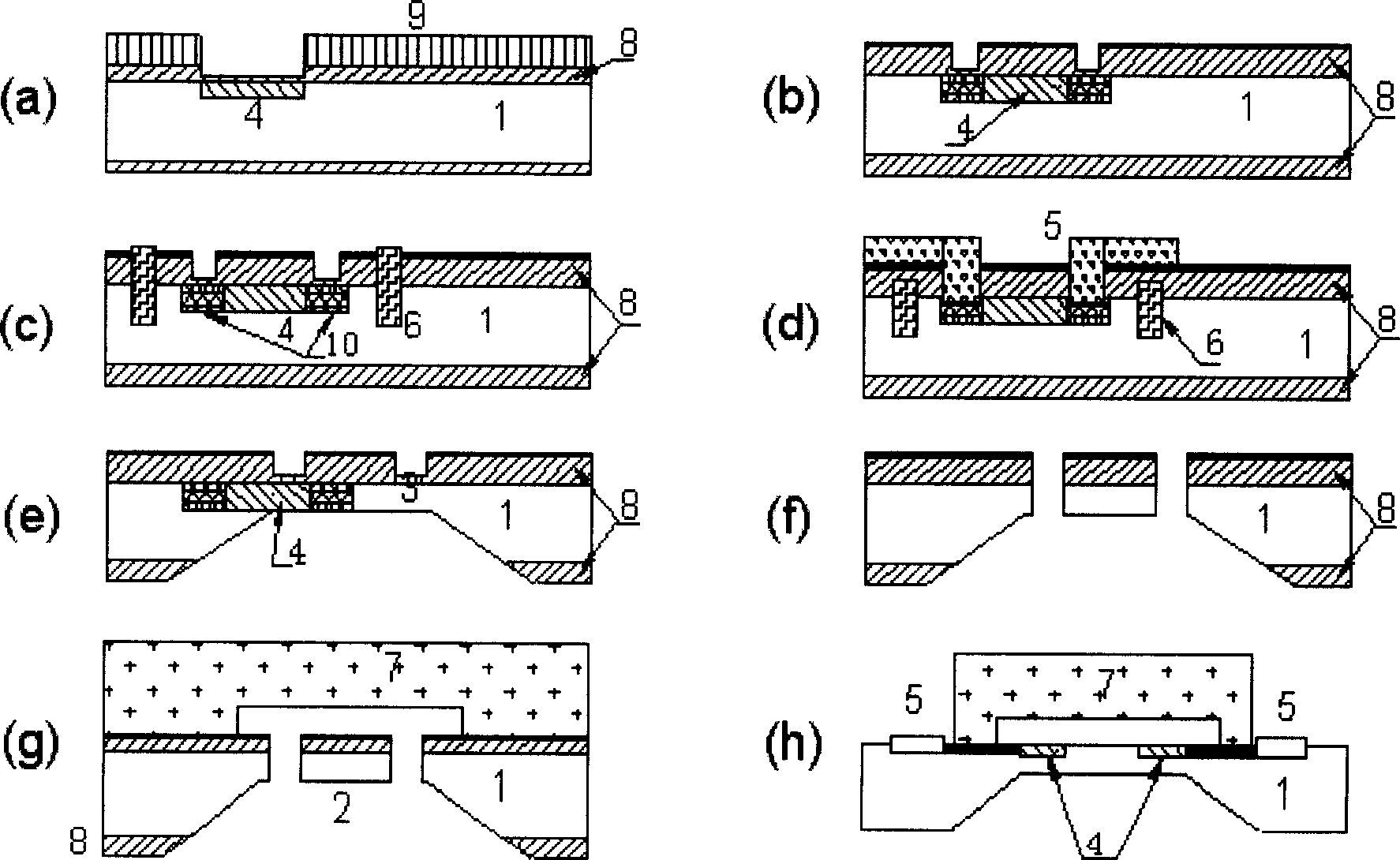

Minitype silicon accelerometer having functions of measuring pressure intensity and temperature variation and its machining method

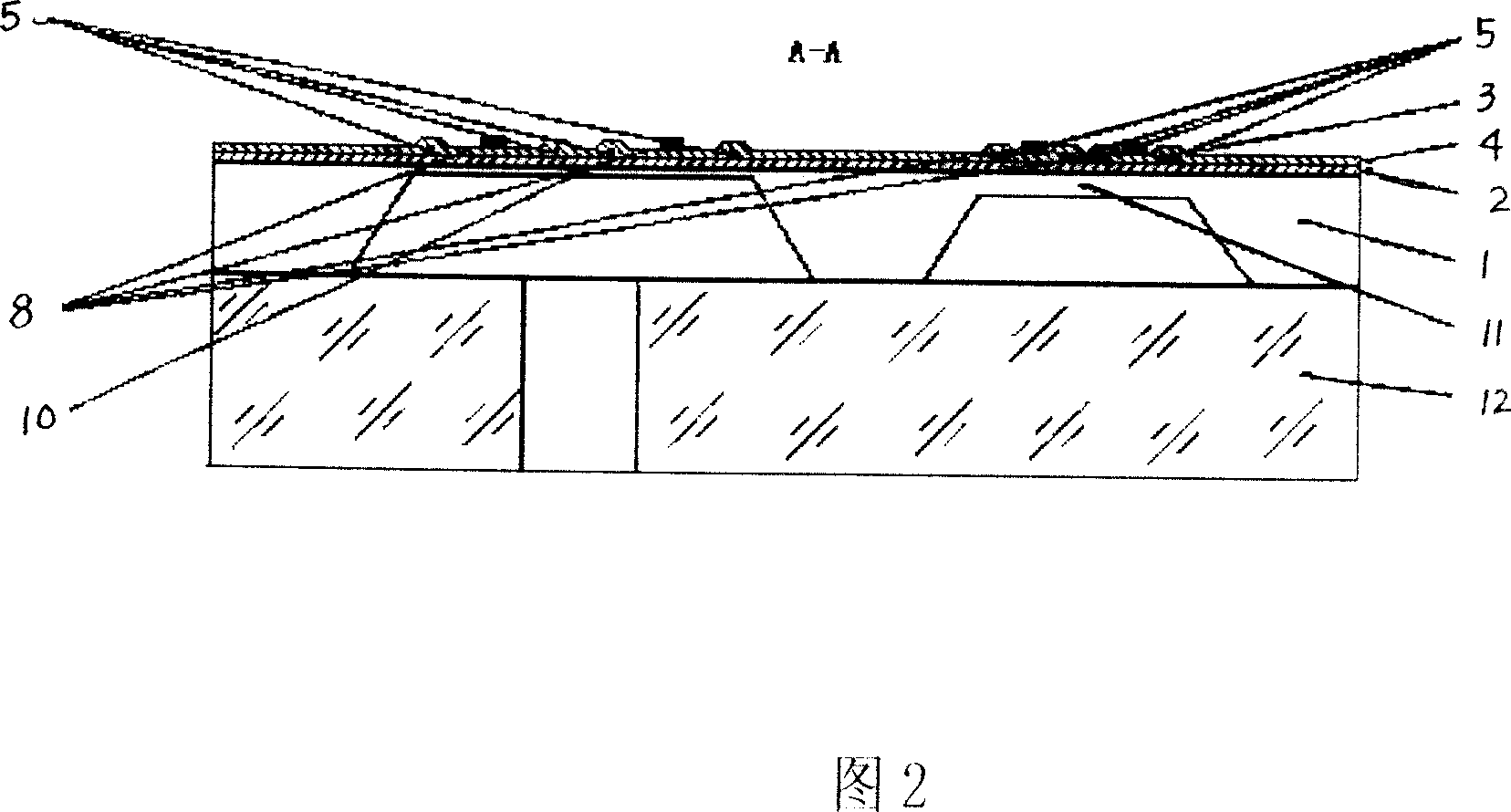

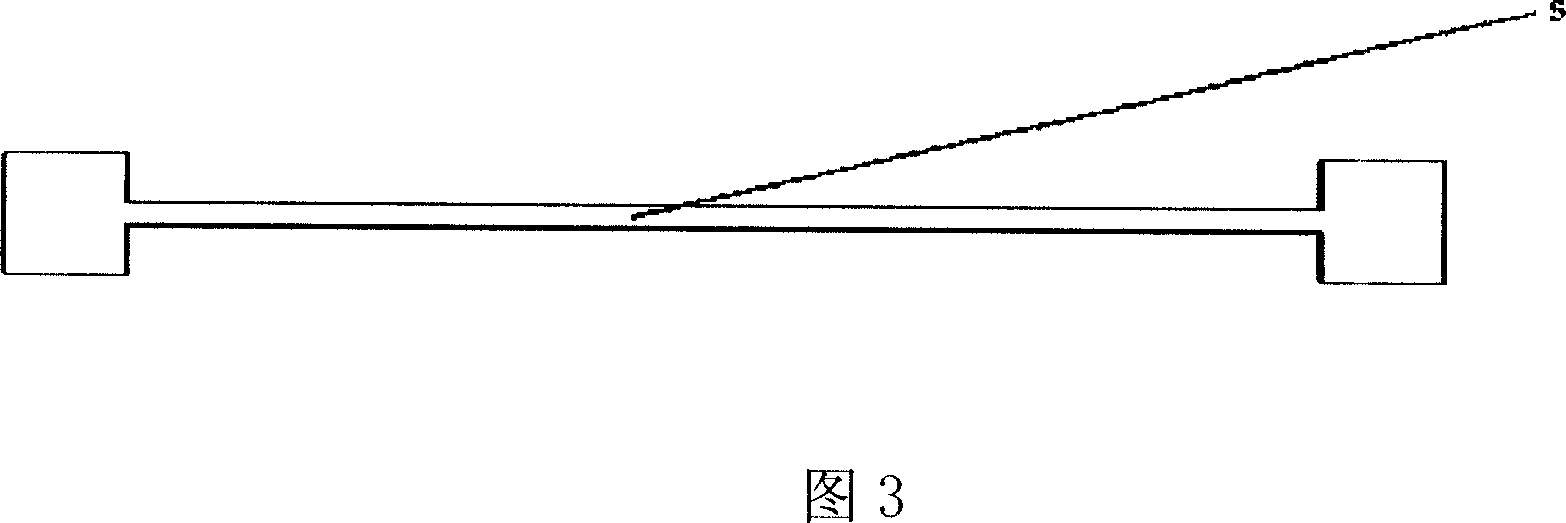

InactiveCN101329361ATelevision system detailsAcceleration measurement using interia forcesComposite filmInsulation layer

The invention provides a micro-silicon accelerometer which has the functions of measuring pressure and temperature. The micro-silicon accelerometer not only can measure the change of the pressure and the environment temperature of a system, but also can measure the acceleration; the invention also provides a processing method. The micro-silicon accelerometer comprises a silicon single-crystal underlay (1) of single crystallographic orientation; the two surfaces of the silicon underlay (1) are covered by a composite film insulation layer (2); the two cantilever beam areas of the frontal surface of the silicon single-crystal underlay (1) are provided with four heat diffusion resistances (3) so as to assemble a wheatstone bridge. The micro-silicon accelerometer is characterized in that a mass area which is connected with the two cantilever beams is a silicon mass block (4); furthermore, the frontal surface of the mass block (4) is provided with a multi-layer structure of silicon dioxide / PSG / polycrystalline silicon / silicon dioxide / polycrystalline silicon; wherein, the polycrystalline silicon on the top is prepared to be four force-sensitive resistances (5) with longitudinal piezoresistive effect; a middle polycrystalline film is an elastic film (6) of a pressure sensor; furthermore, the PSG and a phosphorosilicate glass layer which is arranged below the polycrystalline elastic film form a hollow chamber (11); an internal aluminium wire is connected with four force-sensitive resistances (5) with the longitudinal piezoresistive effect so as to assemble the wheatstone bridge used for measuring the pressure change; furthermore, a boron-phosphorus area is arranged on the frame of the accelerometer so as to assemble the EB-junction (7) of an n-p-n triode.

Owner:淮安纳微传感器有限公司

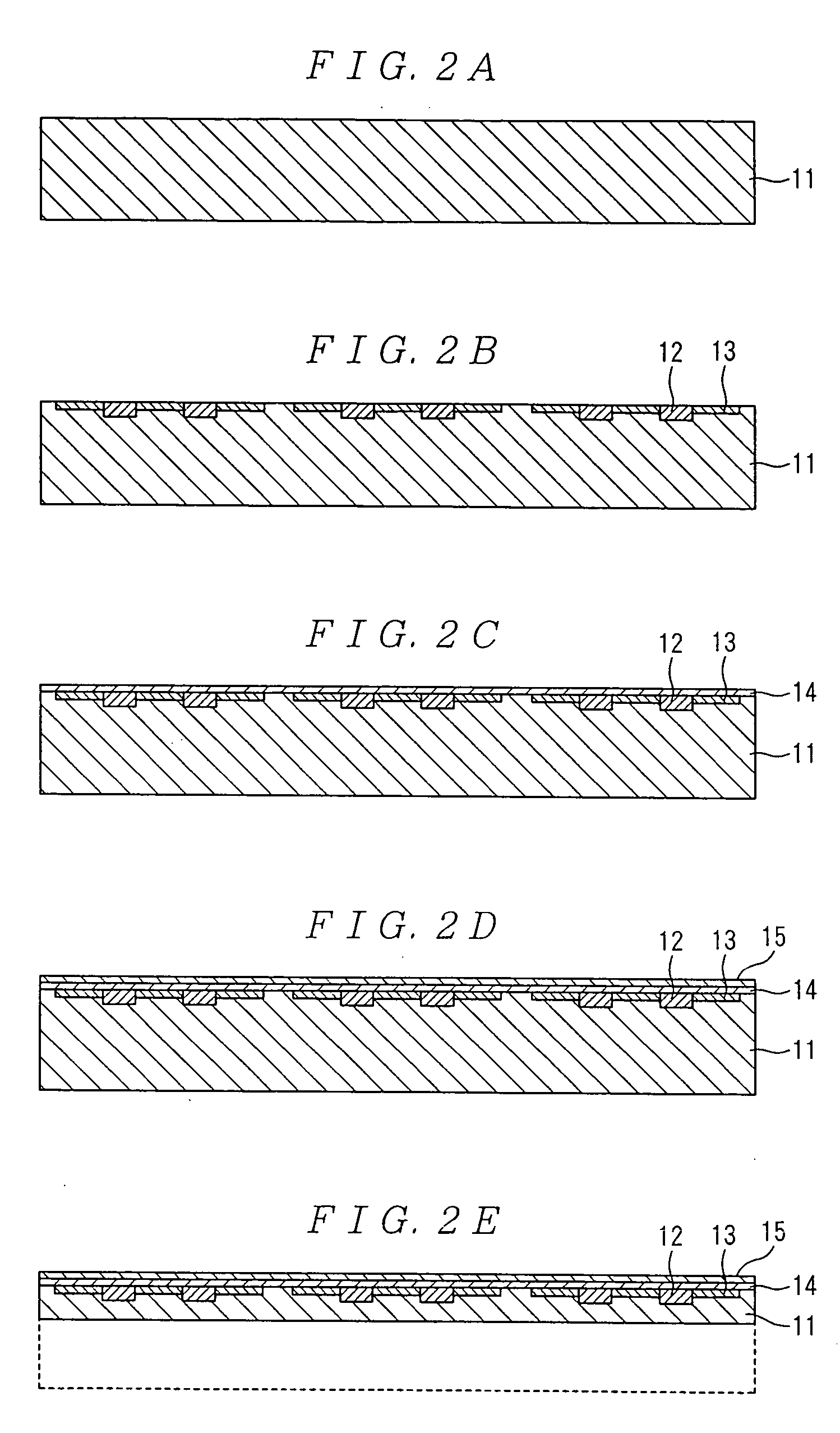

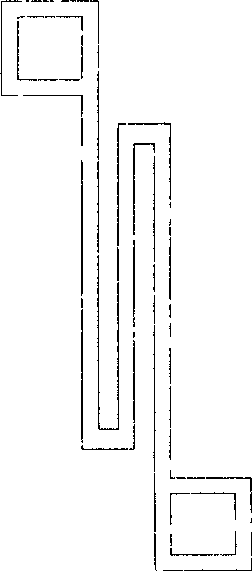

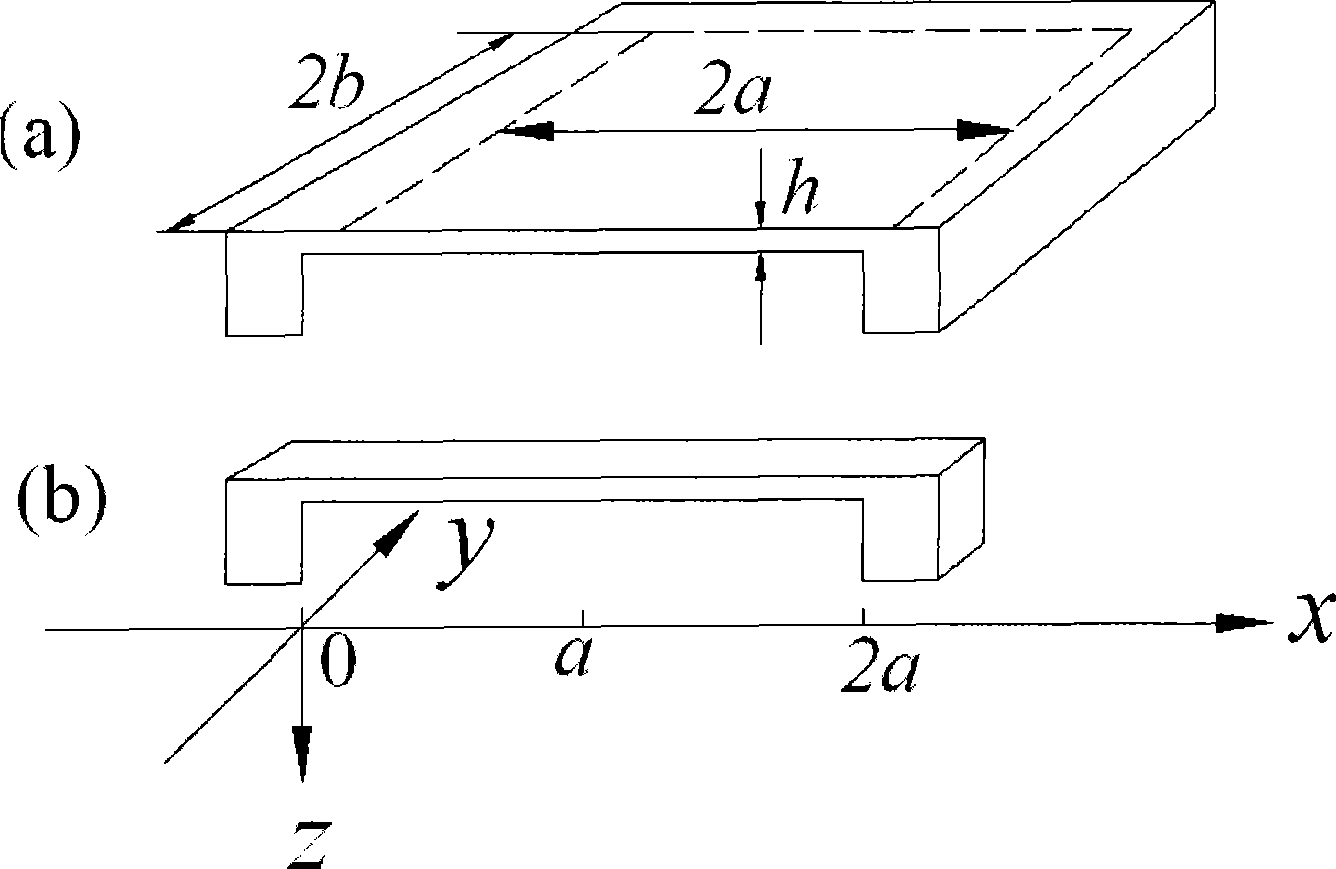

Absolute pressure transducer chip based on surface micro-machining and its production method

ActiveCN101487747AHigh sensitivityImprove stabilityTelevision system detailsSemi-permeable membranesPolycrystalline siliconResistor

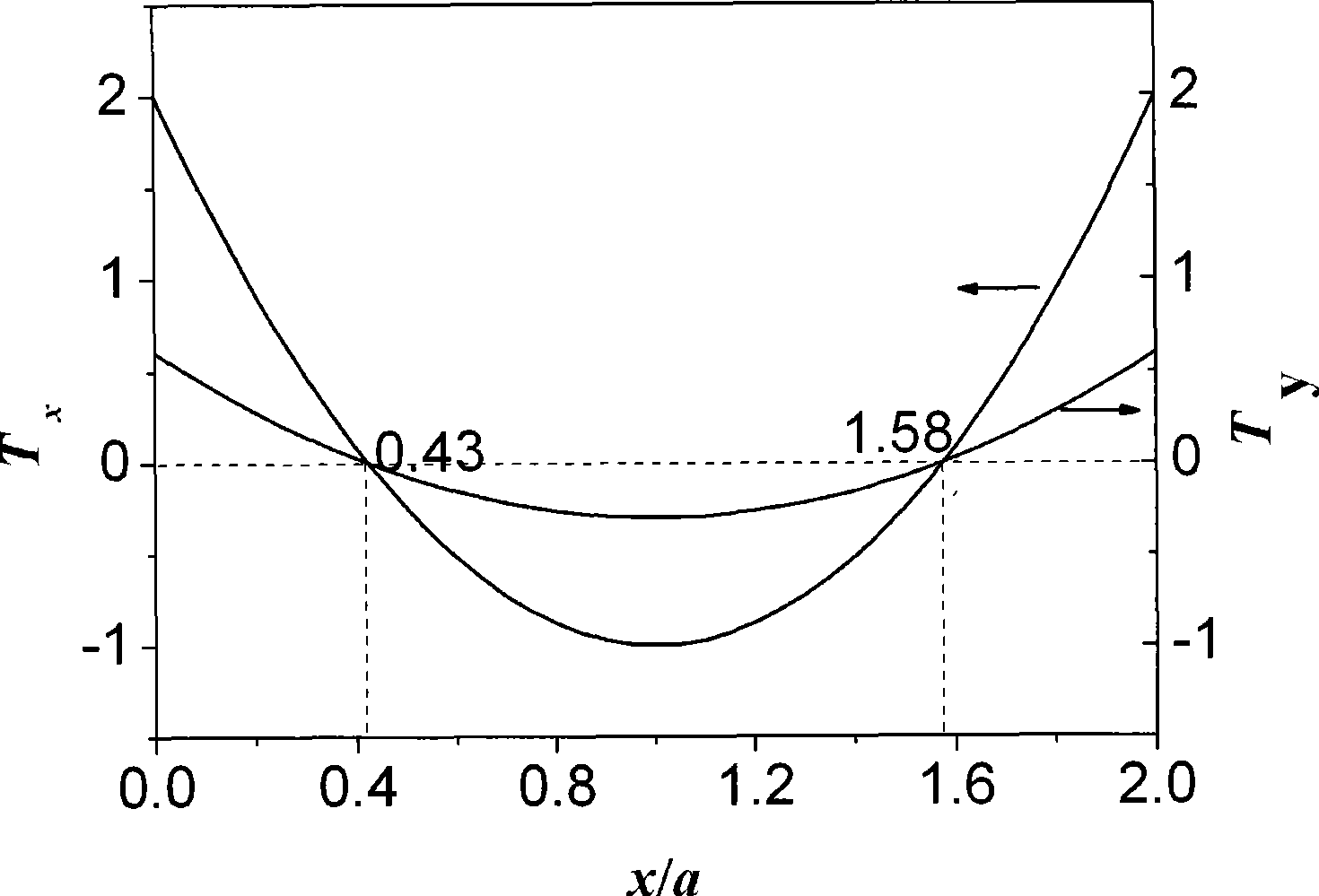

The invention relates to an absolute pressure sensor chip based on surface micromachining and a manufacturing method. The manufacturing method is characterized by comprising the following steps: adopting a low-stress silicon nitride film as a core structural layer of the pressure sensor chip and using a polycrystalline silicon film to form a force-sensitive resistor track; designing a film area of the low-stress silicon nitride film into a long rectangle, fully utilizing longitudinal piezoresistive effect of the polycrystalline silicon resistor track according to the stress distribution of the film area, and making the most of a tensile stress area on the film to put part of a pair of resistor tracks on the external surface of the film and arrange another two resistor tracks on the central position of the film; and separately contacting a folded bent angle part of each resistor track with a hole depositing metal to conduct the bent angle part. By adopting surface micromachining technology compatible with IC technology, the method can manufacture the absolute pressure sensor chip with a measuring range of 1KPa-1MPa and with high sensitivity, good stability and high precision.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

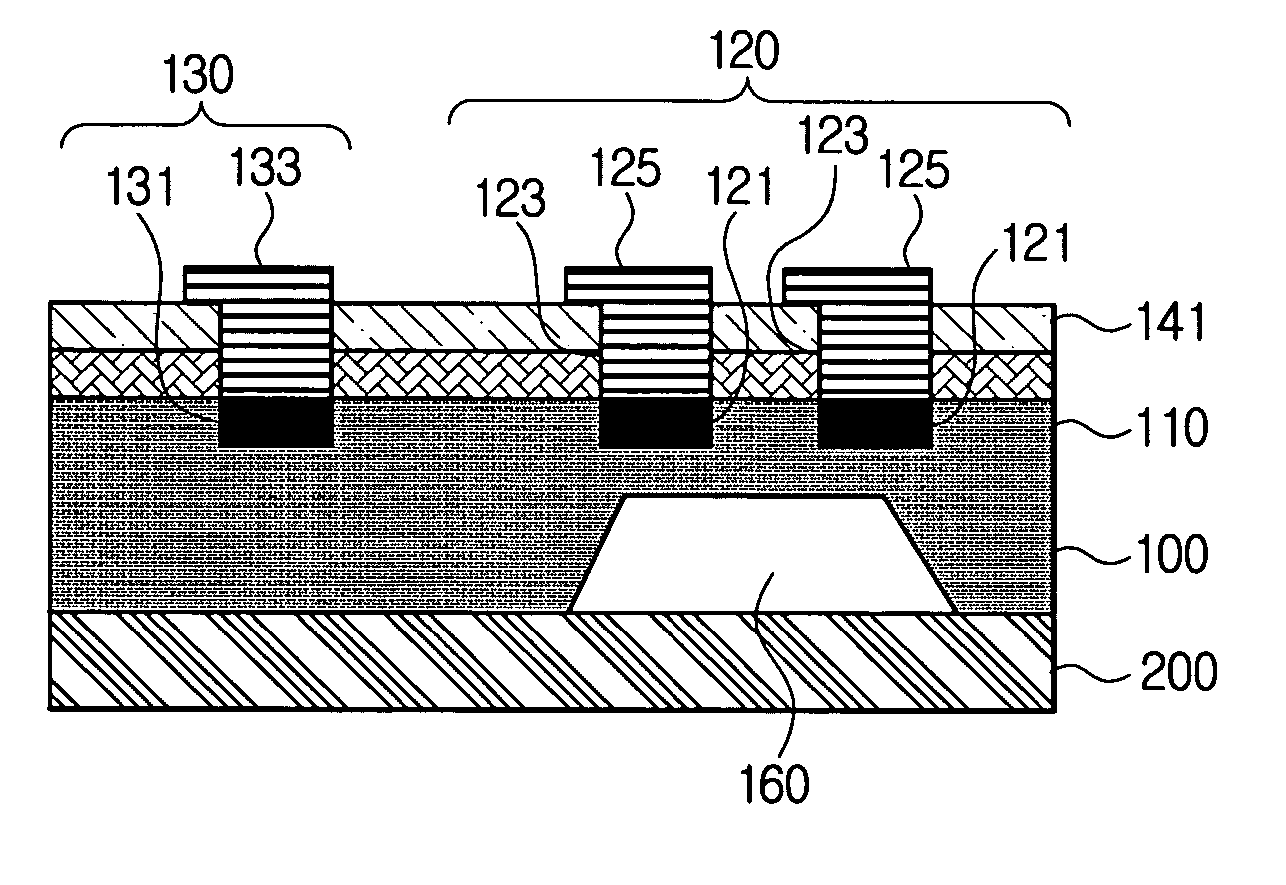

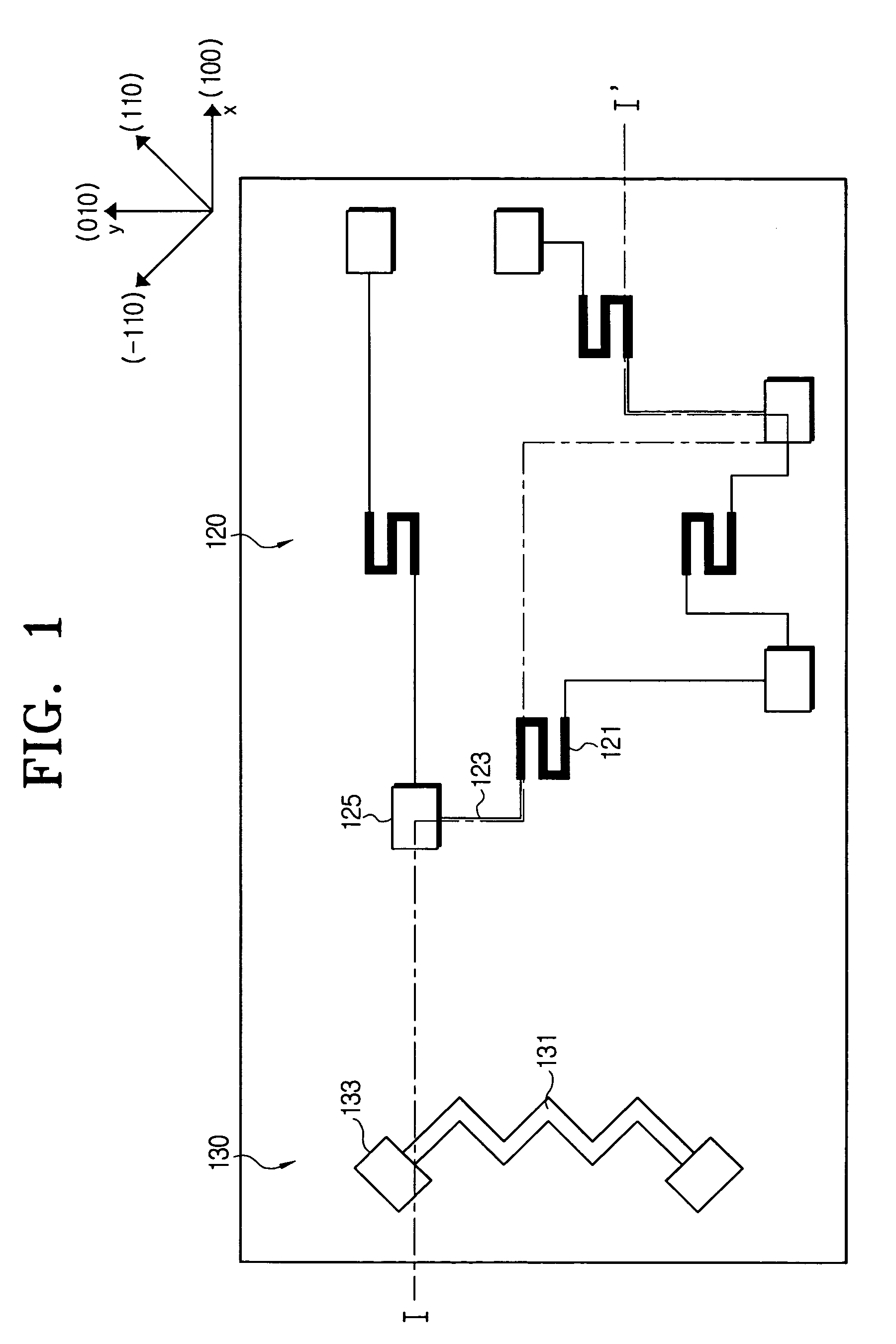

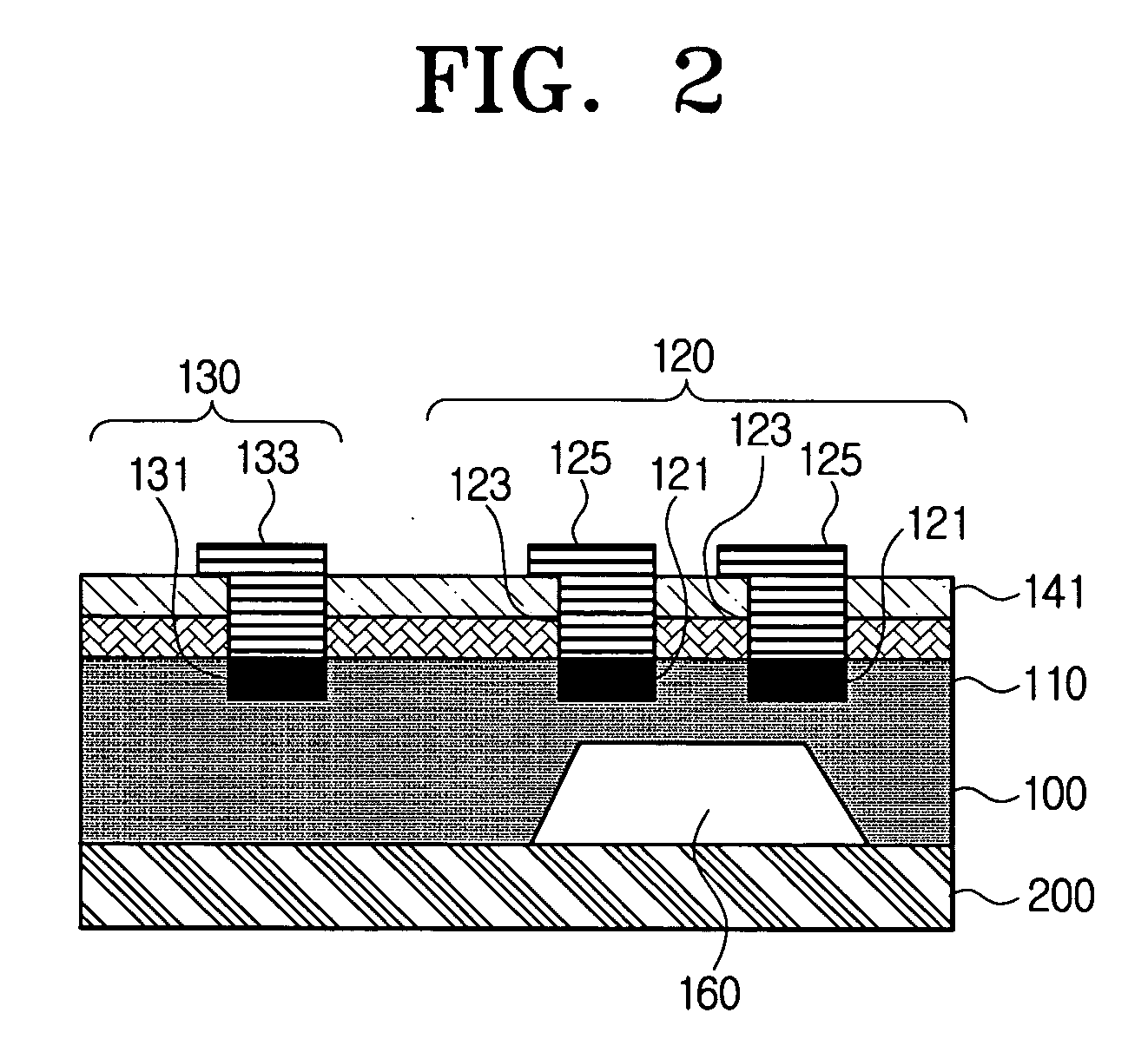

Monolithic multi-functional integrated sensor and method for fabricating the same

ActiveUS20050274193A1Accurately measure both pressureAccurate temperatureFluid pressure measurement using ohmic-resistance variationThermometers using electric/magnetic elementsElectrical resistance and conductanceEngineering

A monolithic multi-functional integrated sensor and method for making the monolithic multi-functional integrated sensor. The monolithic multi-functional integrated sensor includes: a pressure sensor including a plurality of piezoresistors having resistance values which vary with a change in external pressure, the piezoresistors being disposed in a direction so as to be subject to a piezoresistive effect produced by the external pressure at or beyond a predetermined first level; and a temperature sensor including a resistor having a resistance value which varies with a change in temperature, the resistor being disposed in a direction so as to be subject to a piezoresistive effect produced by the external pressure below a predetermined second level.

Owner:SAMSUNG ELECTRONICS CO LTD

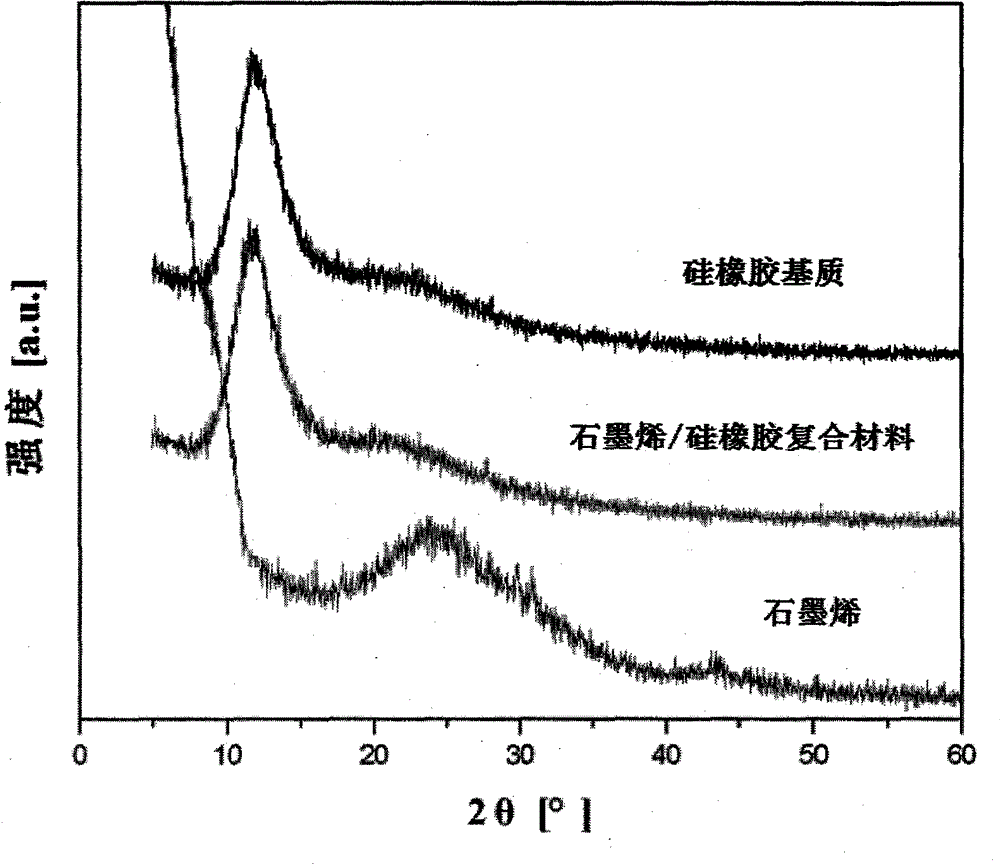

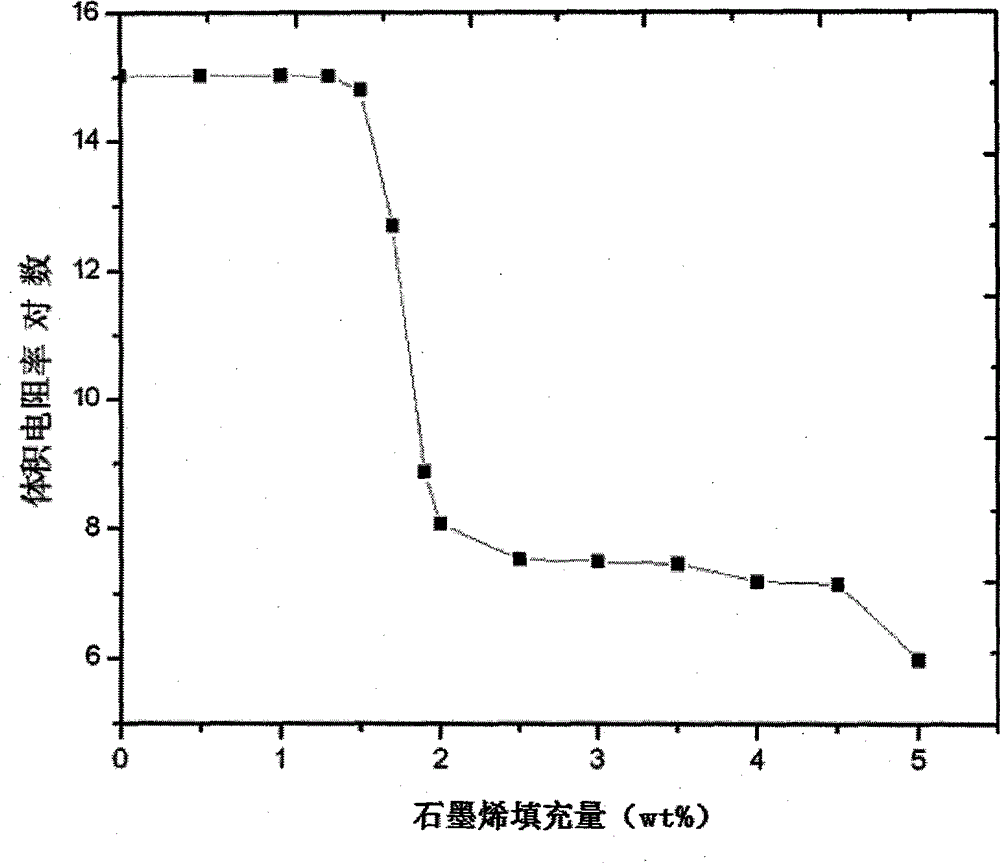

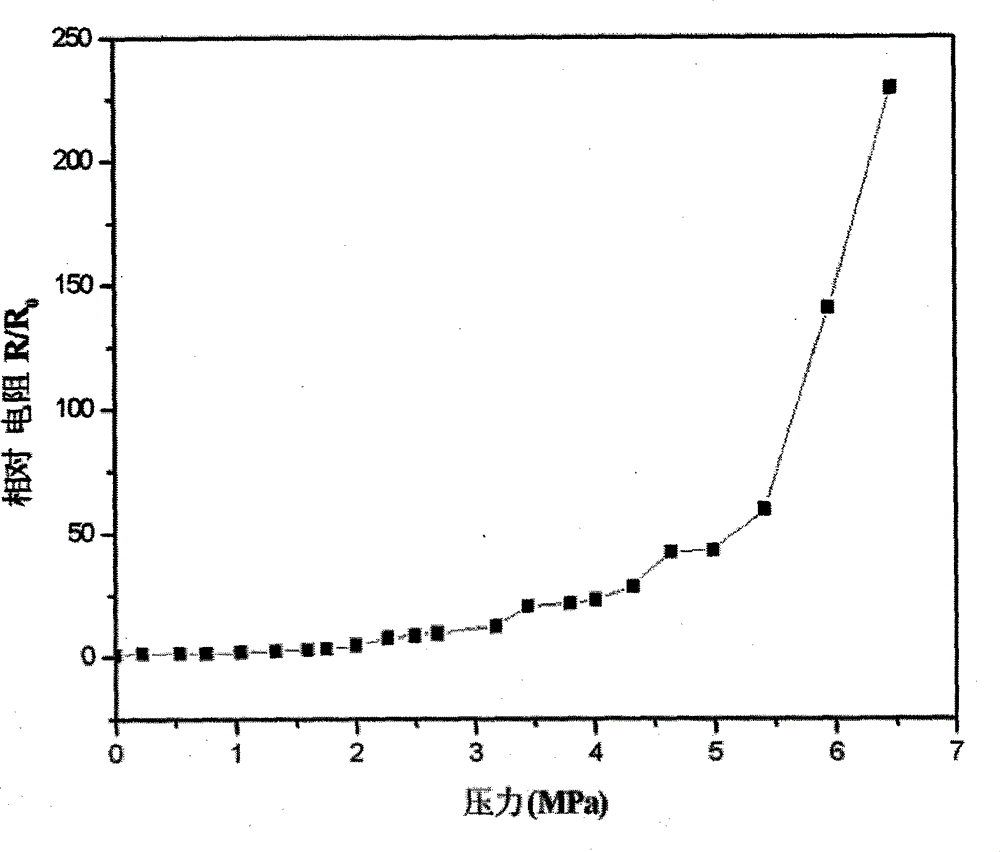

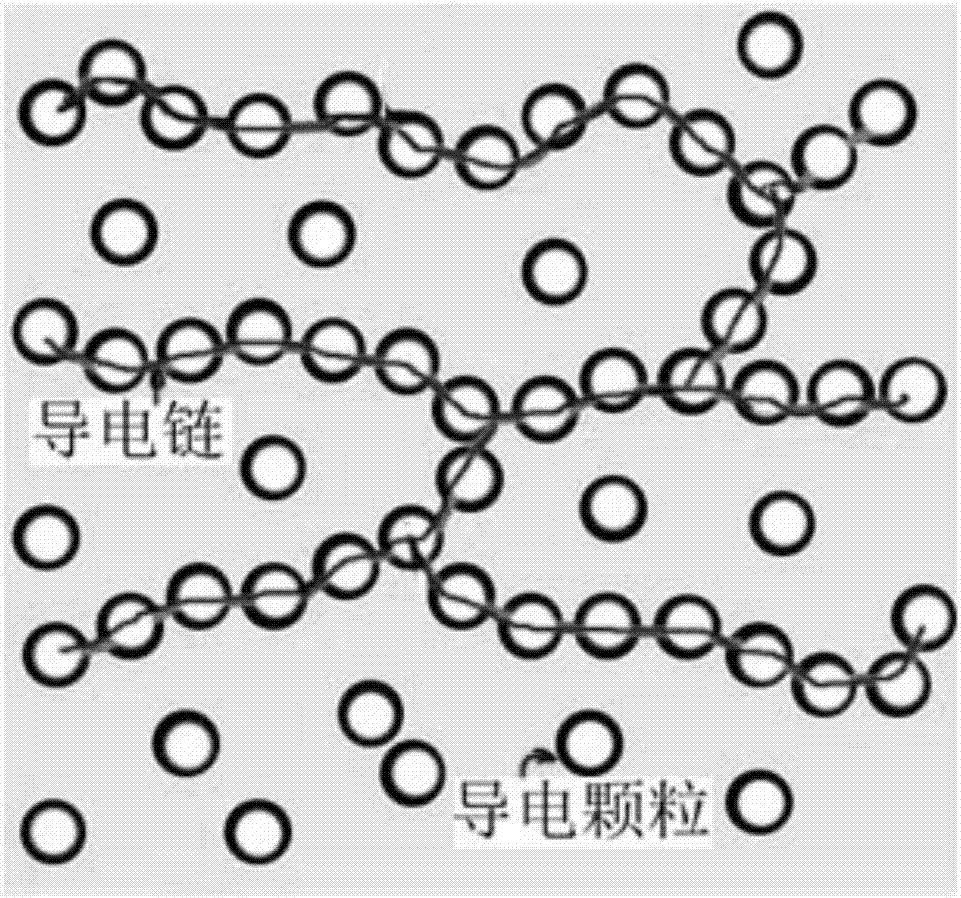

Preparation method of graphene/silicon rubber pressure-sensitive conductive composite

The invention relates to a preparation method of a graphene / silicon rubber pressure-sensitive conductive composite and belongs to the technical field of composite preparation. The preparation method comprises the following steps: dispersing the graphene used as a packing into a silicon rubber matrix by using an ultrasonic-assisted solution mixing method, and furthermore, preparing the graphene / silicon rubber pressure-sensitive conductive composite by using a high-temperature sulphidization method. The graphene has a high diameter-thickness ratio, and a conductive network can be formed in silicon rubber by using a relatively small quantity of graphene through the ultrasonic-assisted solution mixing and high-temperature sulphidization methods, so that the percolation threshold of the graphene / silicon rubber composite is relatively low; in addition, the system is sensitive to pressure so as to achieve a remarkable positive piezoresistive effect. The composite provided by the invention is widely applied to the fields of antistatic rubber, electromagnetic shielding products and pressure sensors.

Owner:TAISHAN MEDICAL UNIV

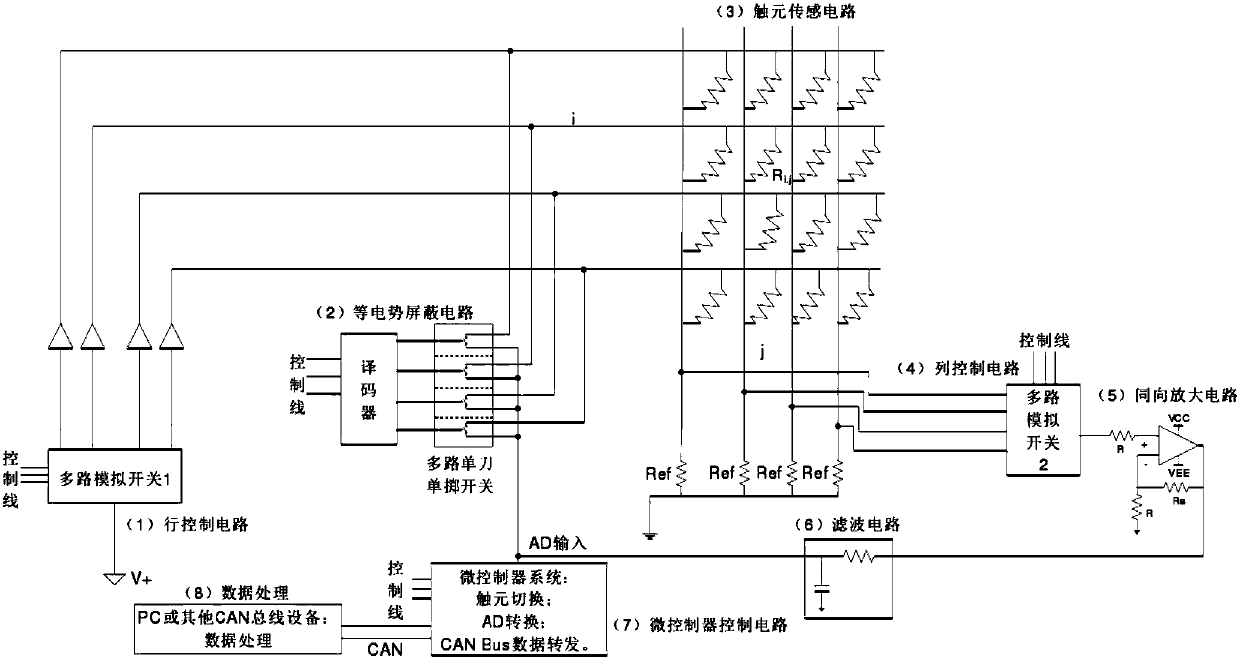

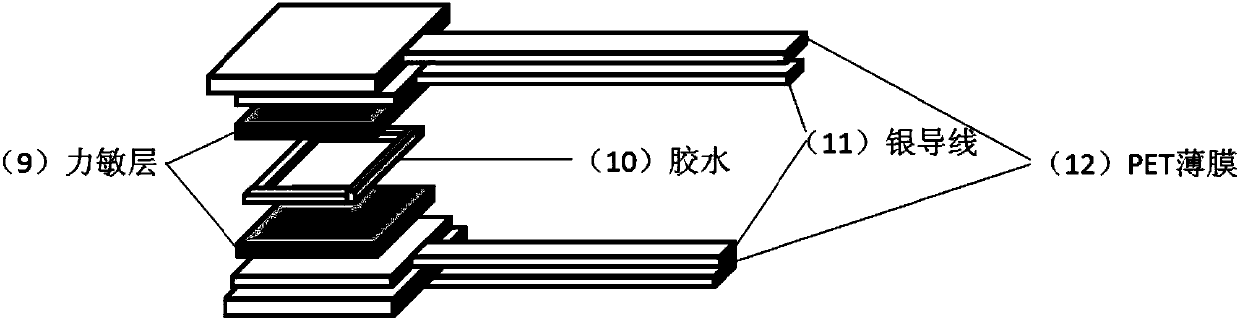

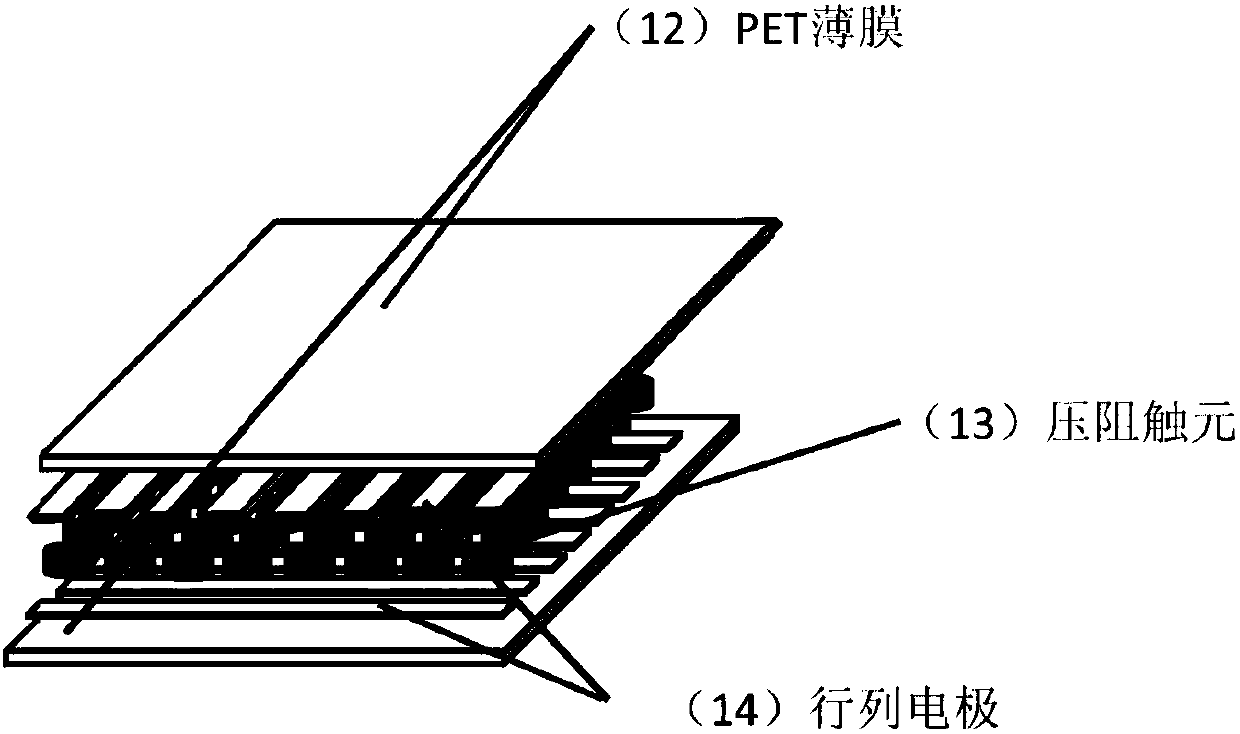

Flexible array pressure measurement sensor based on piezoresistive effect and measurement element thereof

PendingCN107631818ASolve densitySolve the speed problemForce measurement using piezo-resistive materialsMeasurement pointEquipotential

The invention relates to a flexible array pressure measurement sensor based on piezoresistive effect. The sensor herein includes a row control circuit, a touch element sensing unit, a column control circuit, a same direction amplifier circuit, a filter circuit, a micro-control circuit and a control communication port which are successively connected, and also includes an equipotential shielding circuit. The row control circuit, the equipotential shielding circuit, and the column control circuit are connected to the micro-control circuit. The invention also discloses a measurement method. The method herein includes the following steps: representing the forces at different positions in the touch element sensing unit with variations of different resistances, a measurement point switching circuit selecting to connect different sensitive units to a signal modulation circuit through a row and column simulation circuit, converting the variation of the resistances of the sensitive units to voltages, and obtaining a pressure by calibrating the corresponding relationship between the voltages and voltages. According to the invention, the sensor and the measurement method herein, based on theplan for distributing the sensitive units in rows and columns, can measure the distributed force on the surface with a density of 22 point / cm<2>, and overcome the low density of pressure measurement sensors at home and abroad and too slow detection velocity.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Piezoresistive strain gauge with ceramic substrate

ActiveCN103047927ASimple processLow costForce measurementElectrical/magnetic solid deformation measurementElectrical conductorStrain gauge

The invention provides a piezoresistive strain gauge with a ceramic substrate. The piezoresistive strain gauge comprises a ceramic substrate, a conductor layer, a resistive layer with a piezoresitive effect, an insulation protective layer and a seal glass layer, wherein the conductor layer and the resistive layer are manufactured on the upper surface of the ceramic substrate, the insulation protective layer covers on the upper parts of the conductor layer and the resistive layer, and the seal glass layer is manufactured on the lower surface of the ceramic substrate. The piezoresistive strain gauge disclosed by the invention can be used to manufacture high-temperature-resistant and corrosion-resistant force sensors for weighing, pressure and the like, and is high in precision, good in stability and long in service life.

Owner:ADVANCED PLATINUM TECH

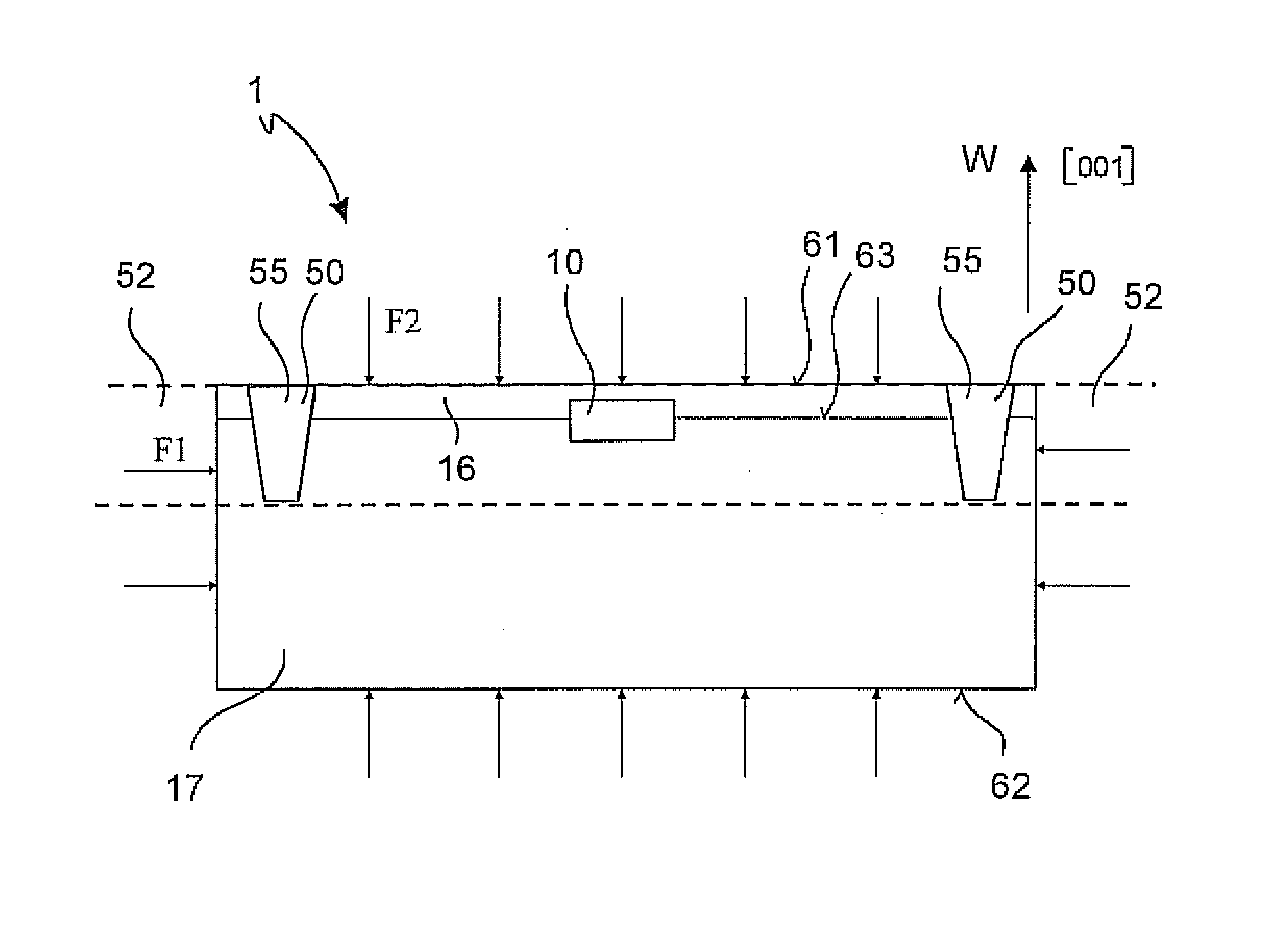

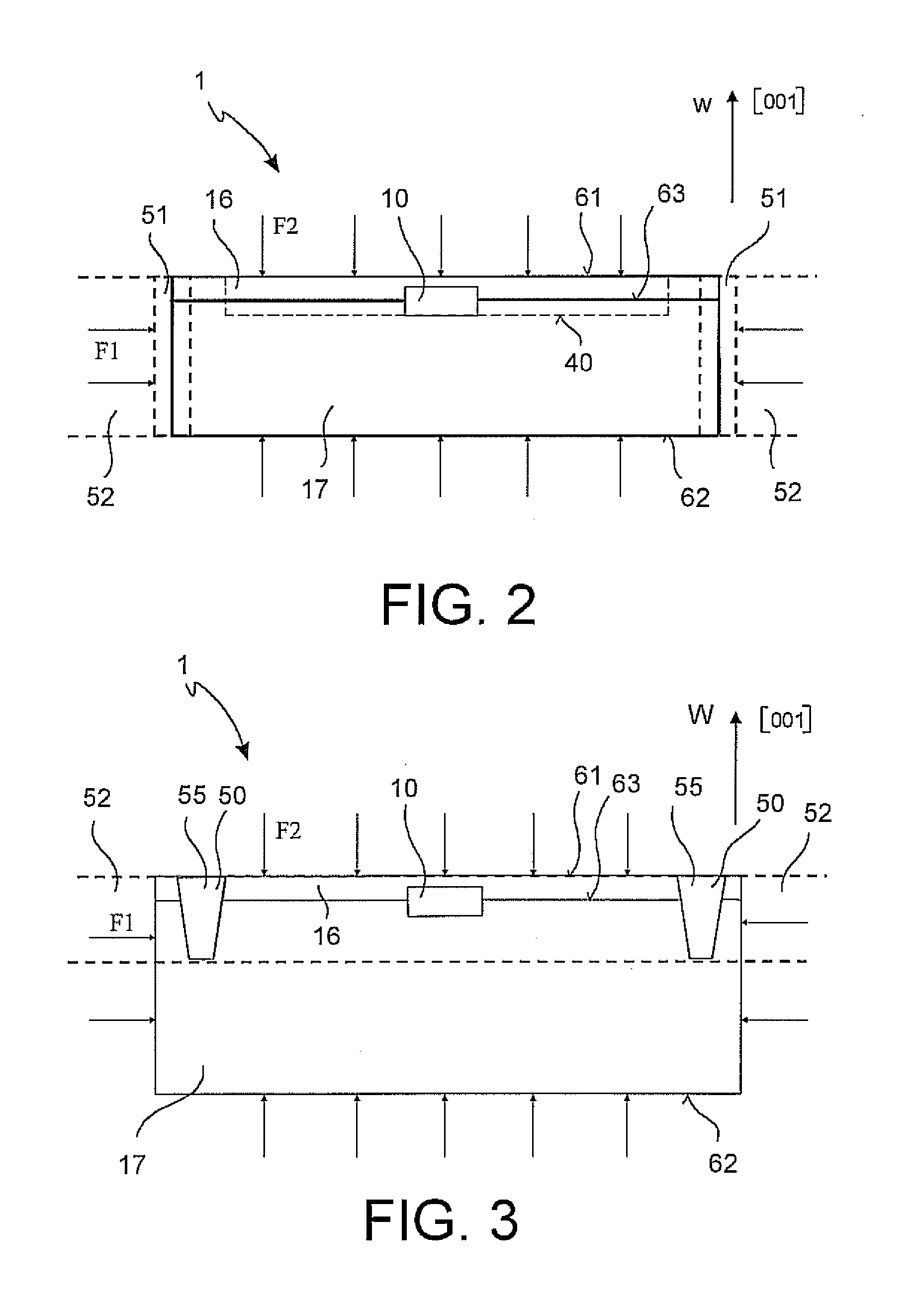

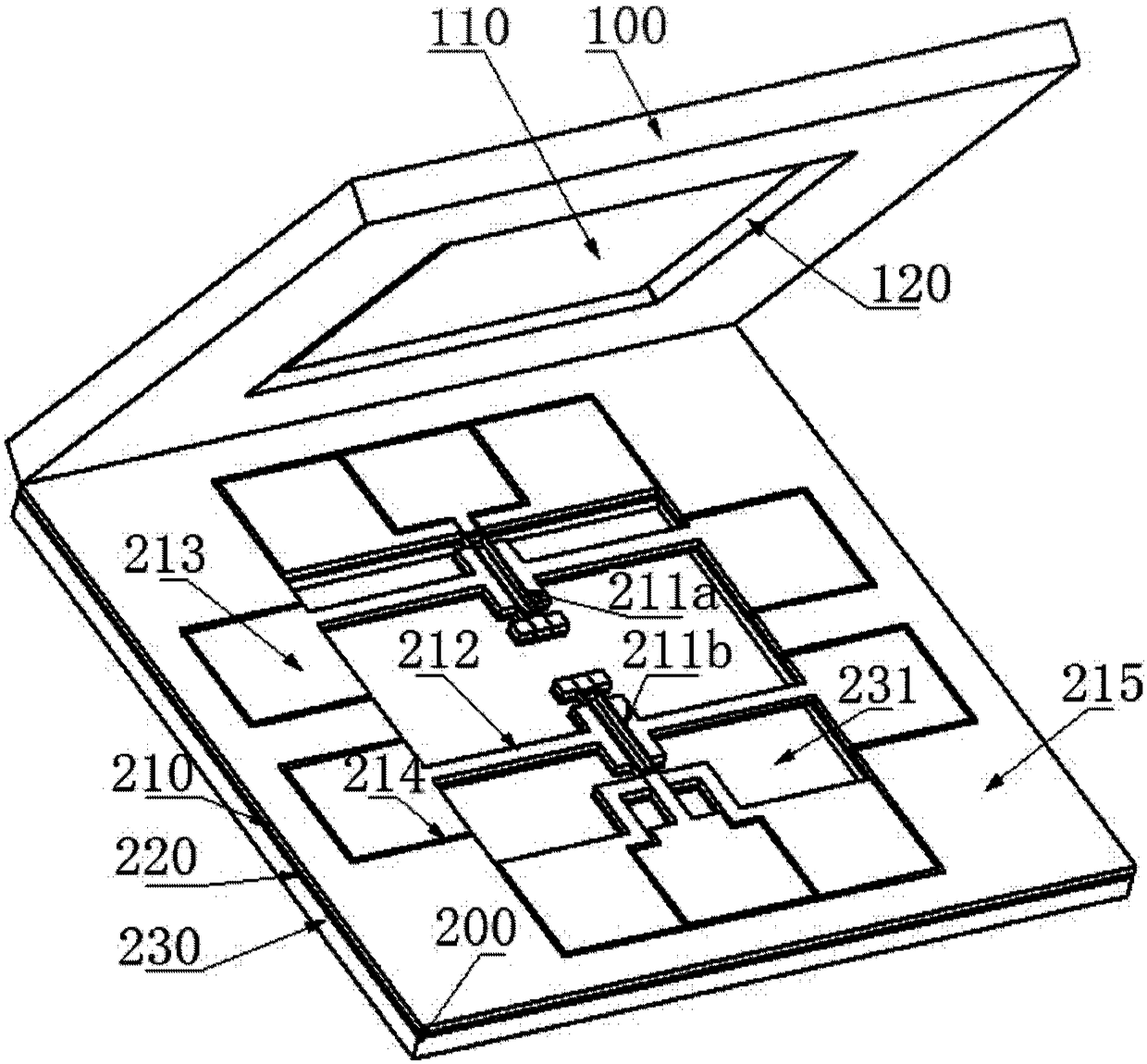

Integrated electronic device for monitoring mechanical stress within a solid structure

ActiveUS20140182390A1Acceleration measurement using interia forcesSolid-state devicesSolid structureEngineering

The integrated electronic device is for detecting a local parameter related to a force observed in a given direction, within a solid structure. The device includes at least one sensor configured to detect the above-mentioned local parameter at least in the given direction through piezo-resistive effect. At least one damping element, integrated in the device, is arranged within a frame-shaped region that is disposed around the at least one sensor and belongs to a substantially planar region comprising a plane passing through the sensor and perpendicular to the given direction. Such at least one damping element is configured to damp forces acting in the planar region and substantially perpendicular to the given direction.

Owner:STMICROELECTRONICS INT NV

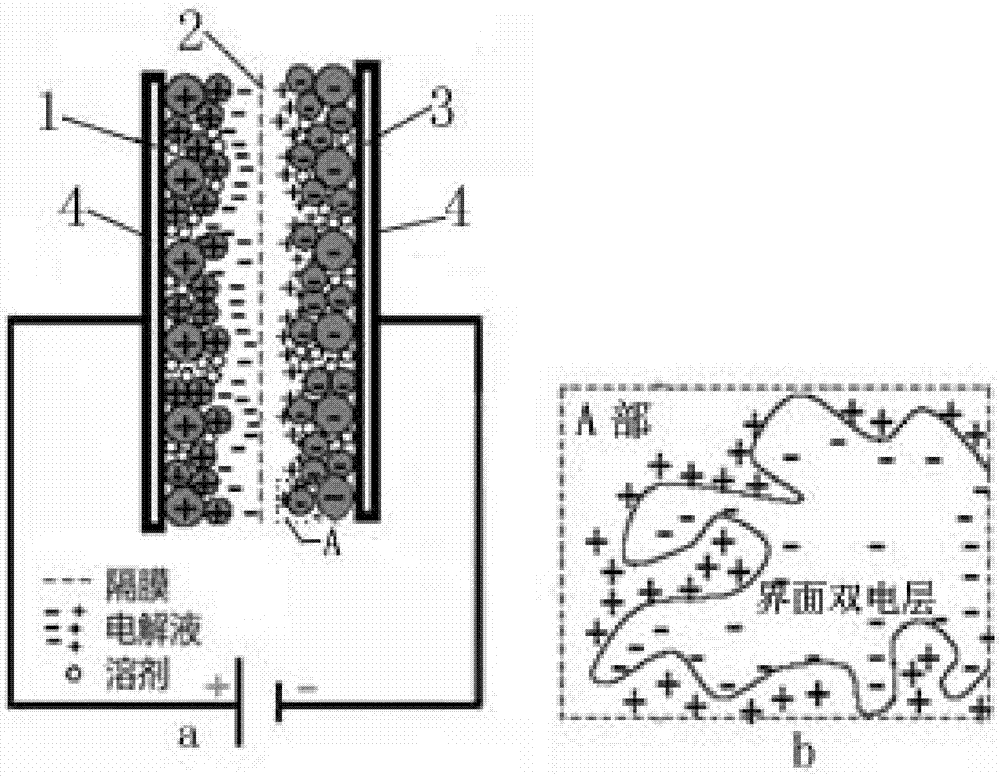

Self-powered acceleration sensor based on piezoresistive effect and manufacturing method thereof

ActiveCN106872727AEnsuring hermetic packagingSensitive to overload shockAcceleration measurement using interia forcesInter layerClassical mechanics

The invention discloses a self-powered acceleration sensor based on a piezoresistive effect and a manufacturing method thereof, which belongs to the field of acceleration sensors. The self-powered acceleration sensor uses a laminated structure. A current collector, a positive electrode, a diaphragm, a negative electrode and a current collector are successively stacked. The self-powered acceleration sensor senses an acceleration impact signal through the piezoresistive effect of a composite material electrode film. According to the invention, a current collector is made of titanium and other metal materials; a polar needle and a current collector are reliably connected through laser welding; the preparation of a porous electrode uses a dry process; an electrode material with piezoresistive properties is prepared through the combination of polytetrafluoroethylene and a carbon material; the self-powered acceleration sensor is packaged in a metal or plastic housing with a flexible package structure and process through inter-layer airtight package and flexible resin glue encapsulation; self-powered sensing of a high g acceleration signal is realized; and the self-powered acceleration sensor has wide application potentials in the fields of automobile industry, aerospace and weaponry equipment.

Owner:TSINGHUA UNIV

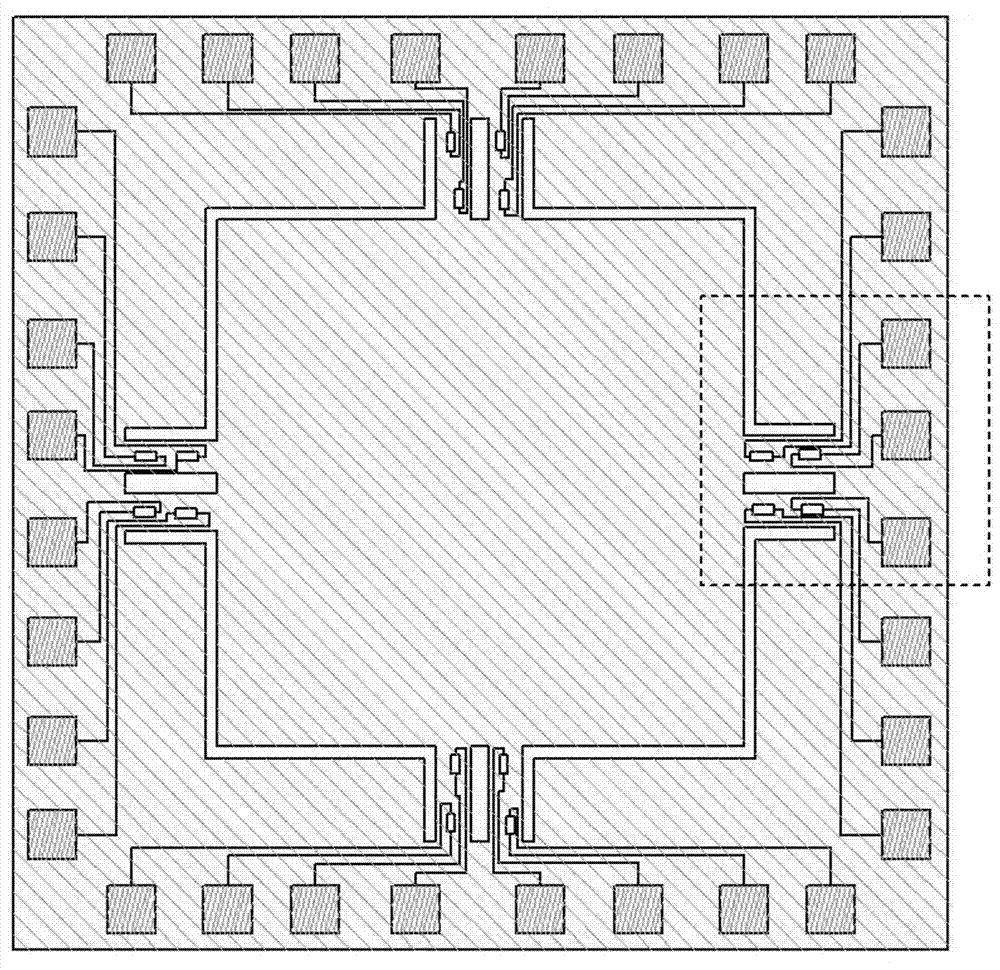

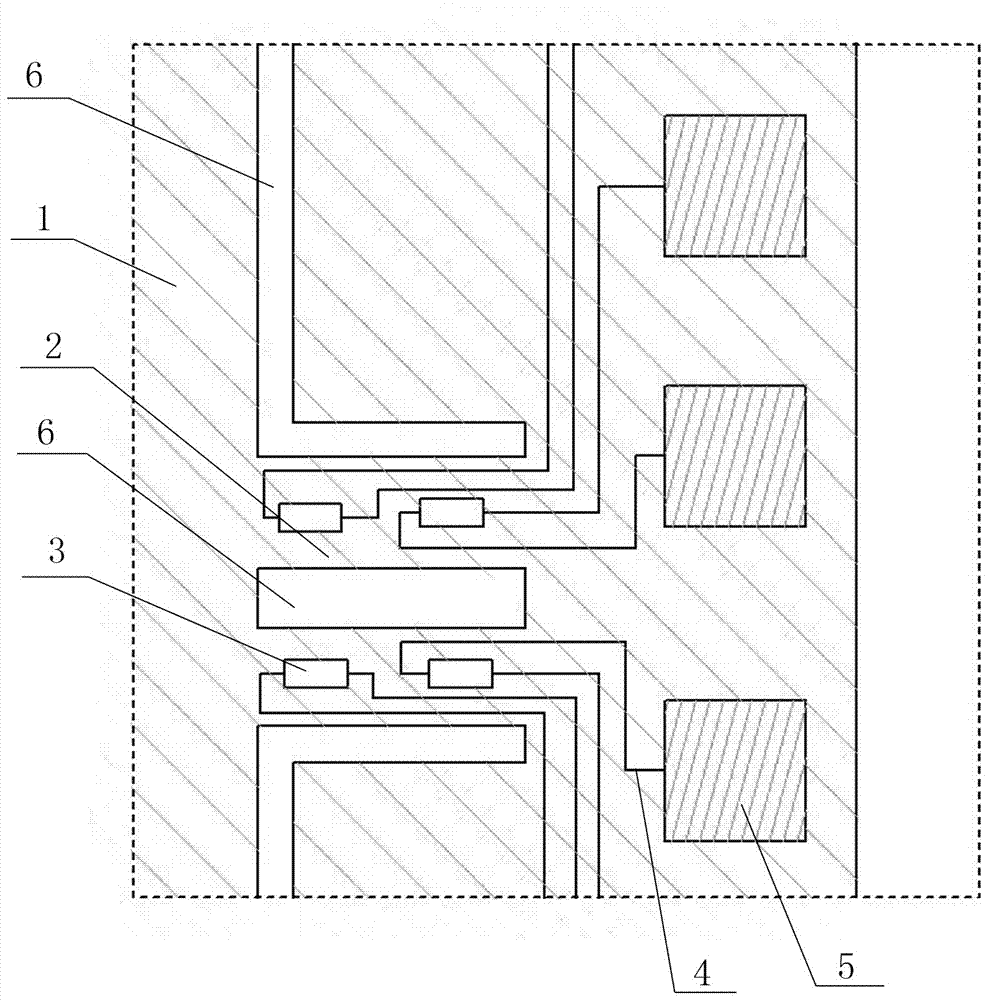

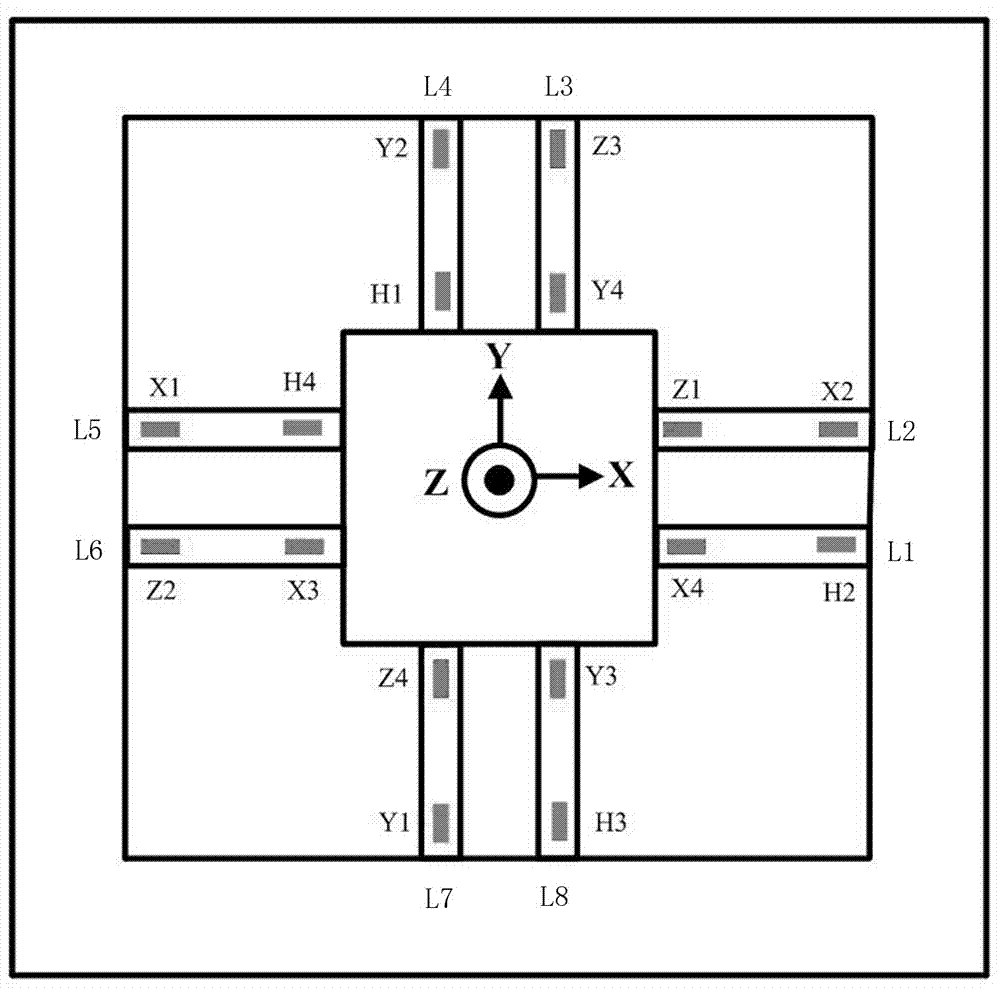

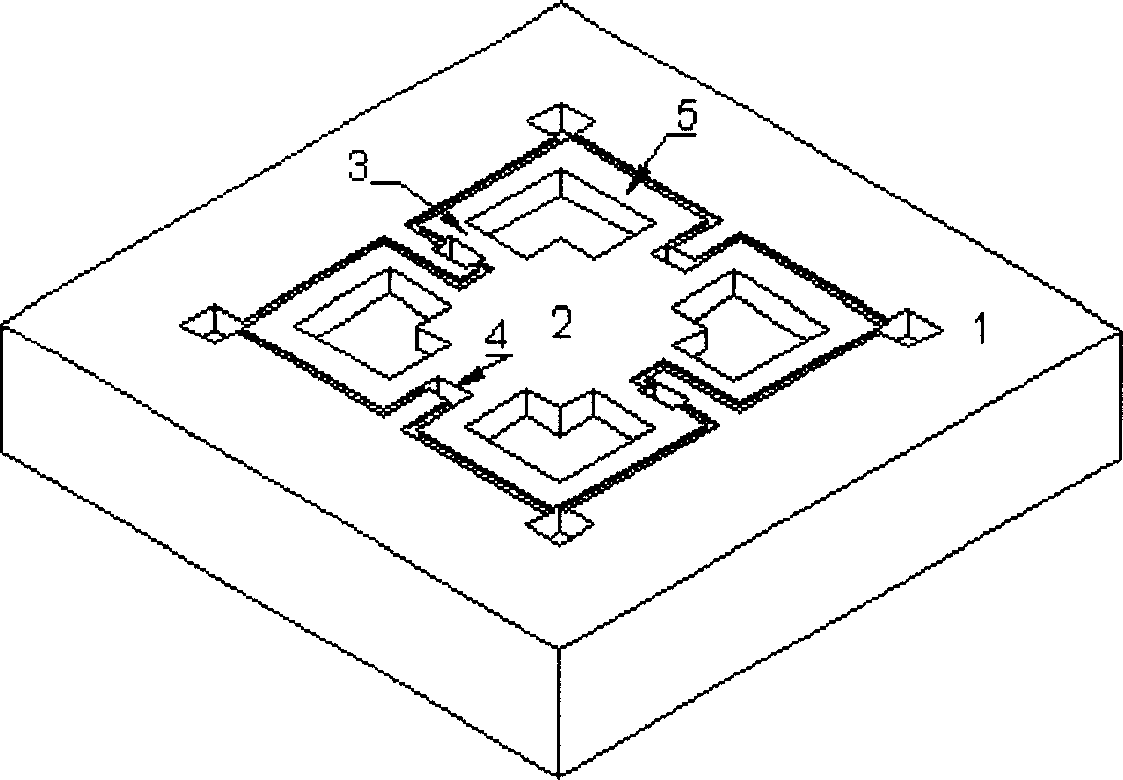

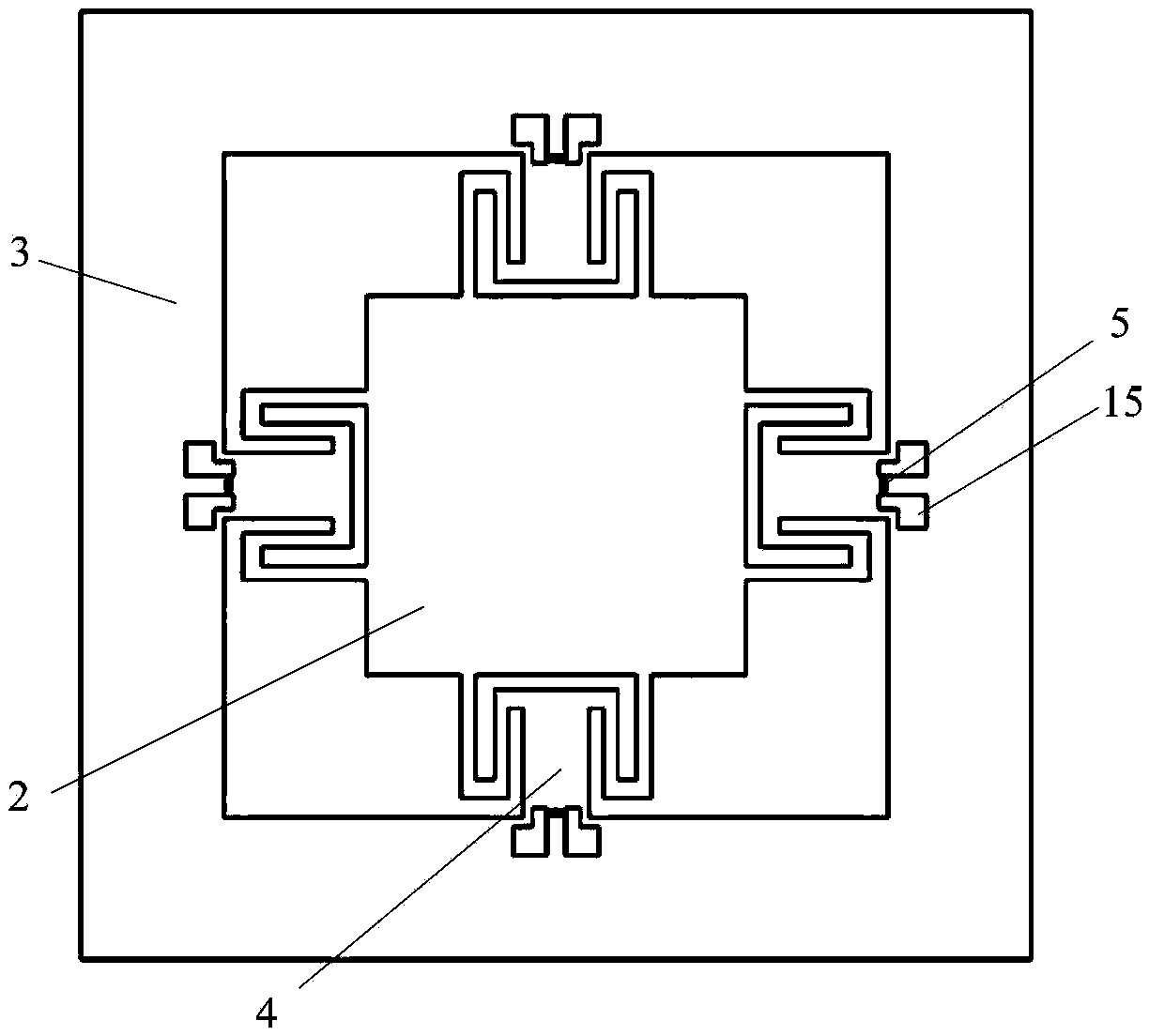

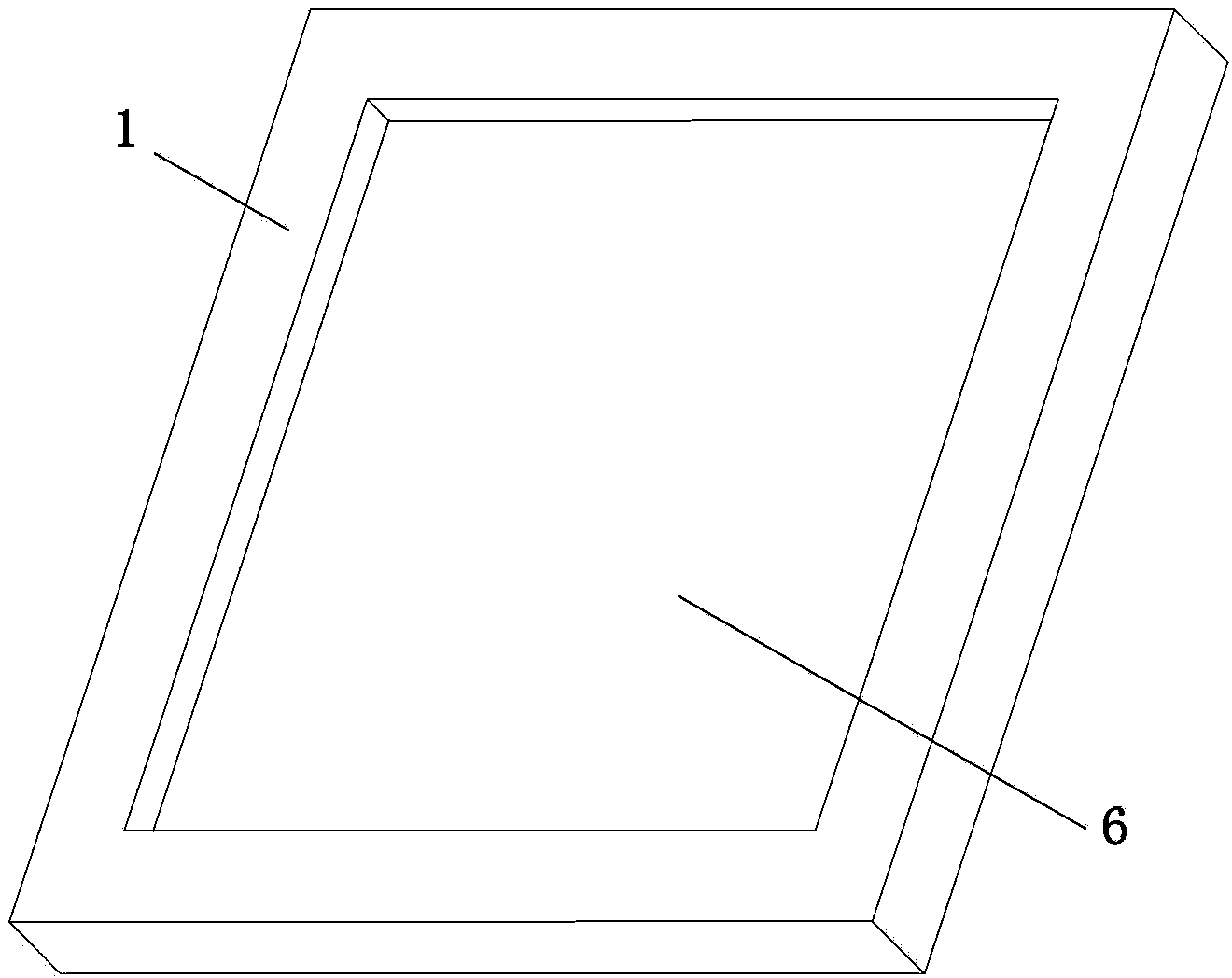

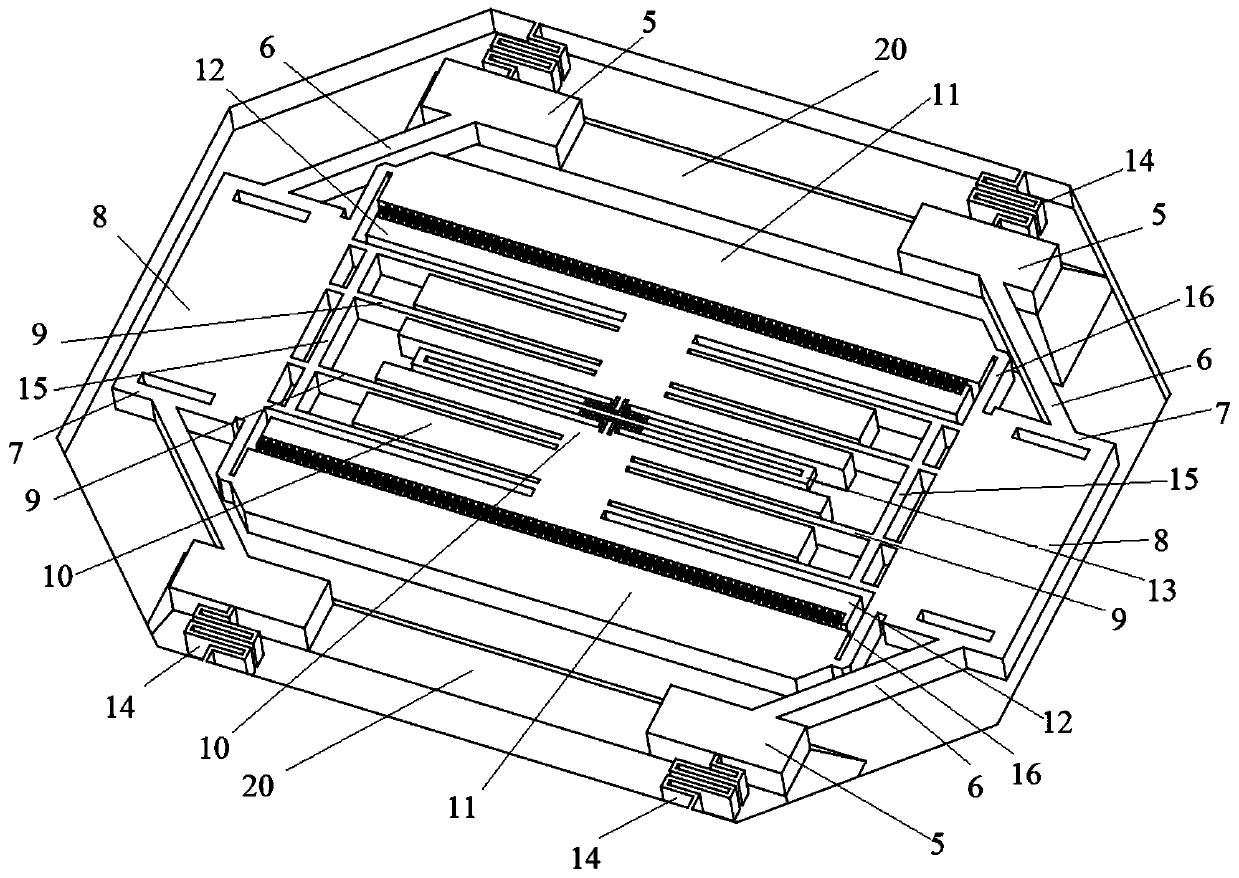

Piezoresistive tri-axial acceleration sensor with anti-overload capability and preparation method thereof

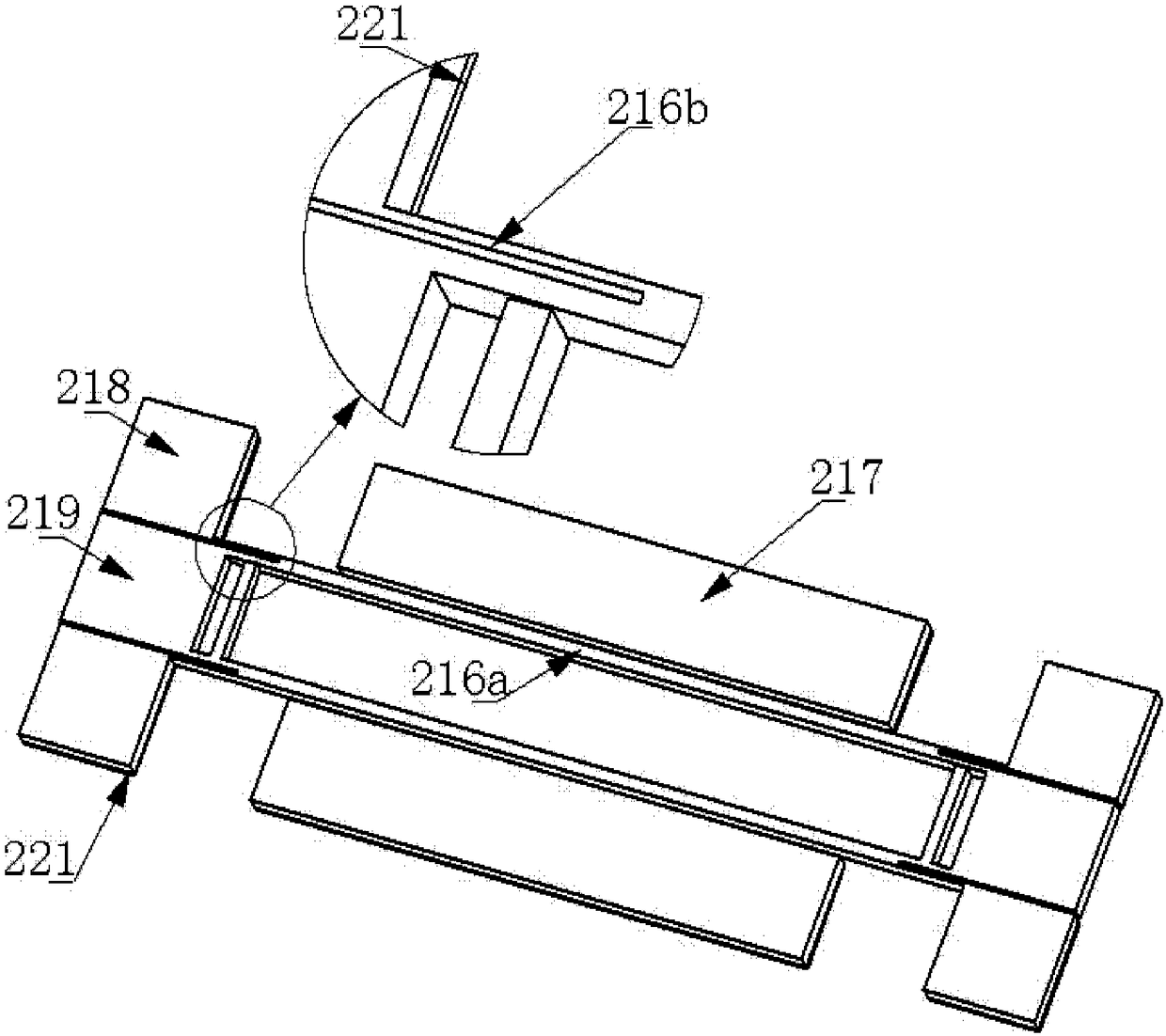

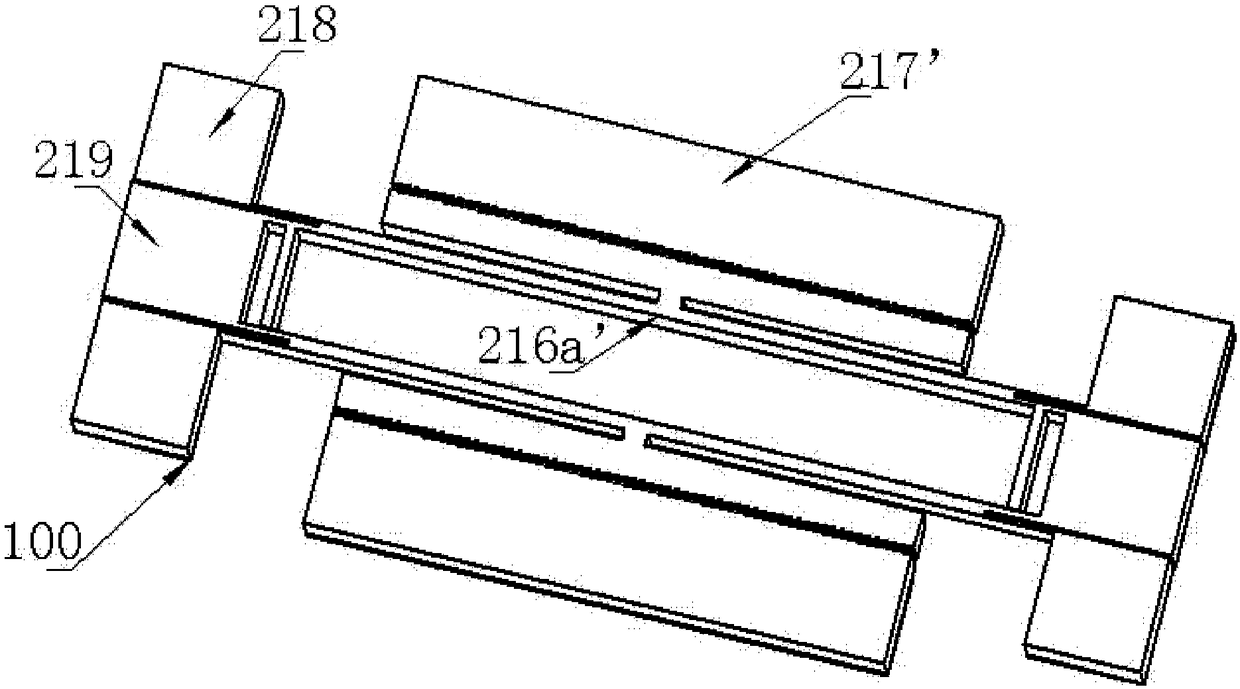

InactiveCN107290567AAnti-overload capacity reachesSimple structureTelevision system detailsAcceleration measurement using interia forcesClassical mechanicsAcceleration Unit

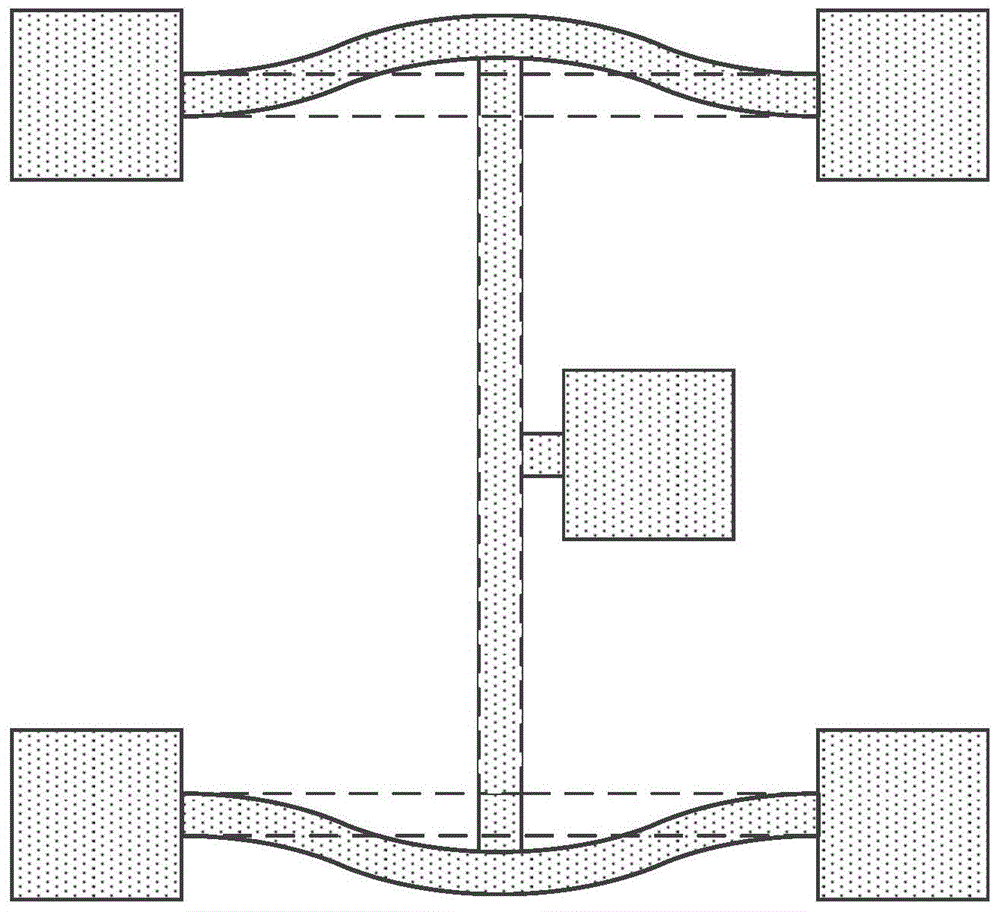

The invention discloses a piezoresistive tri-axial acceleration sensor with an anti-overload capability. The sensor comprises a substrate; a mass block (1) and eight rectangular beams (2) are formed at the center of the substrate through etching; four edges of the upper part of the mass block (1) are integrally connected with the substrate through the rectangular beams (2), namely, the right edge of the mass block (1) is connected with the frame of the substrate through the beam L1 and the beam L2, and the upper edge of the mass block (1) is connected with the frame of the substrate through the beam L3 and the beam L4, the left edge of the mass block (1) is connected with the frame of the substrate through the beam L5 and the beam L6, and the lower edge of the mass block (1) is connected with the frame of the substrate through the beam L7 and the beam L8; and anti-overload gaps (6) are left between the beams, between the edges of the mass block and the substrate, and between the beams and the substrate. According to the piezoresistive tri-axial acceleration sensor with the anti-overload capability of the invention, the anti-overload capability of the tri-axial acceleration sensor in the X direction, Y direction and Z direction of the Cartesian coordinate system is realized by means of limiting the displacement of the mass block.

Owner:ZHONGBEI UNIV

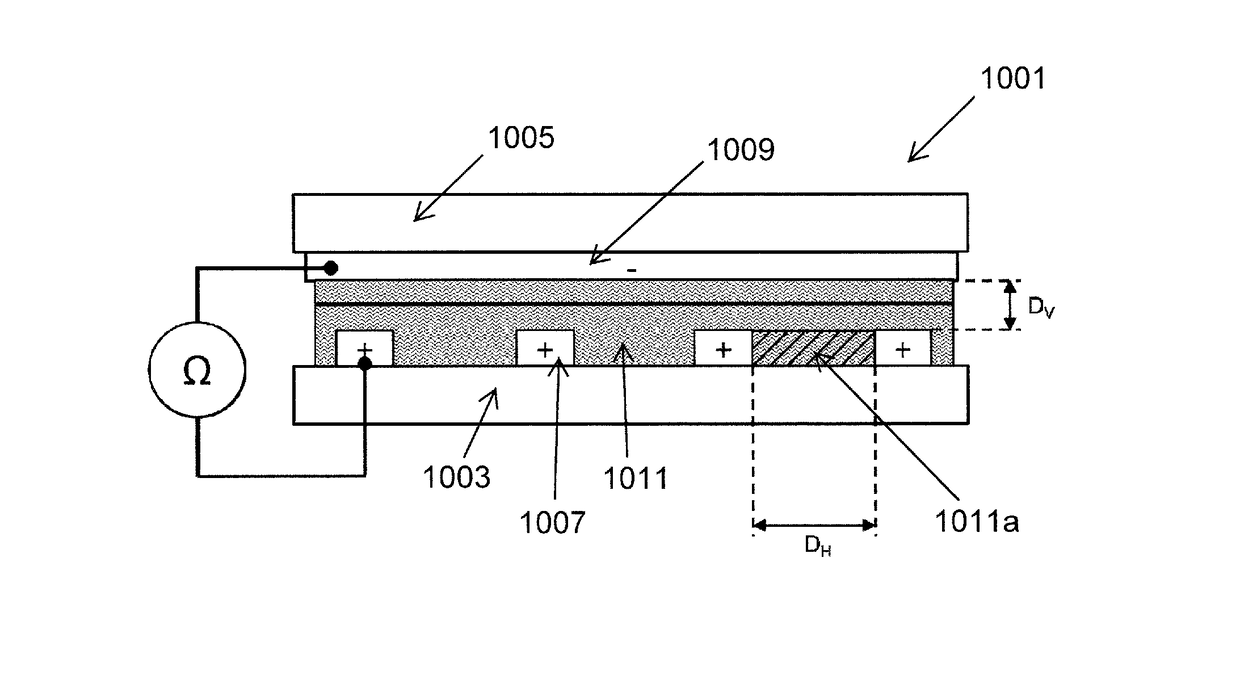

Piezoresistive Device

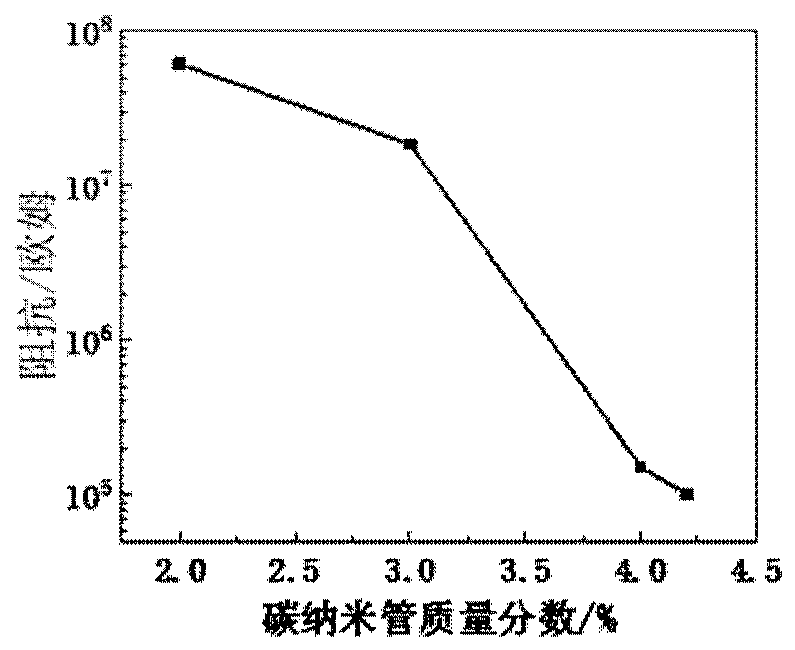

InactiveUS20170350772A1Speed up dryingEqually distributedForce measurement using piezo-resistive materialsNon-conductive material with dispersed conductive materialConductive polymerCarbon nanotube

The present invention relates to piezoresistive devices and pressure sensors incorporating such devices. At its most general, the invention provides a piezoresistive device, comprising a piezoresistive material positioned between an upper conductive layer and a lower conductive layer, wherein the piezoresistive material comprises carbon nanoparticles (most preferably graphene nanoplatelets, graphene or carbon nanotubes) dispersed in a polymer matrix material. The invention also relates to methods of manufacturing and using such devices.

Owner:HAYDALE GRAPHENE IND

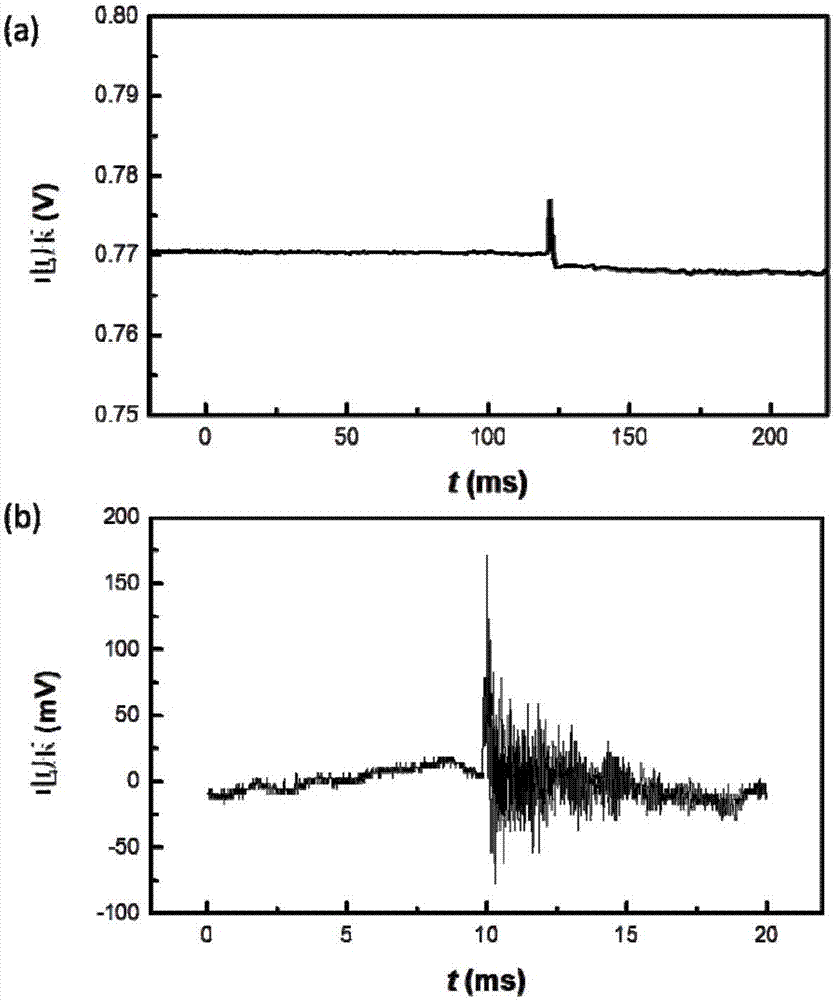

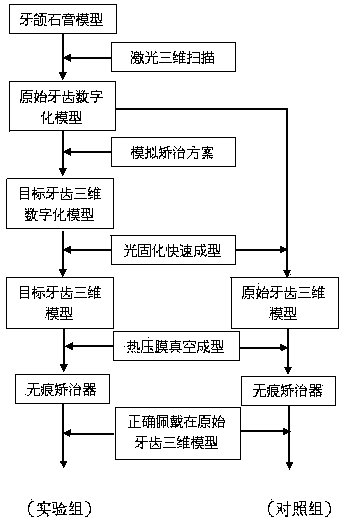

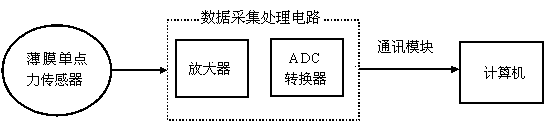

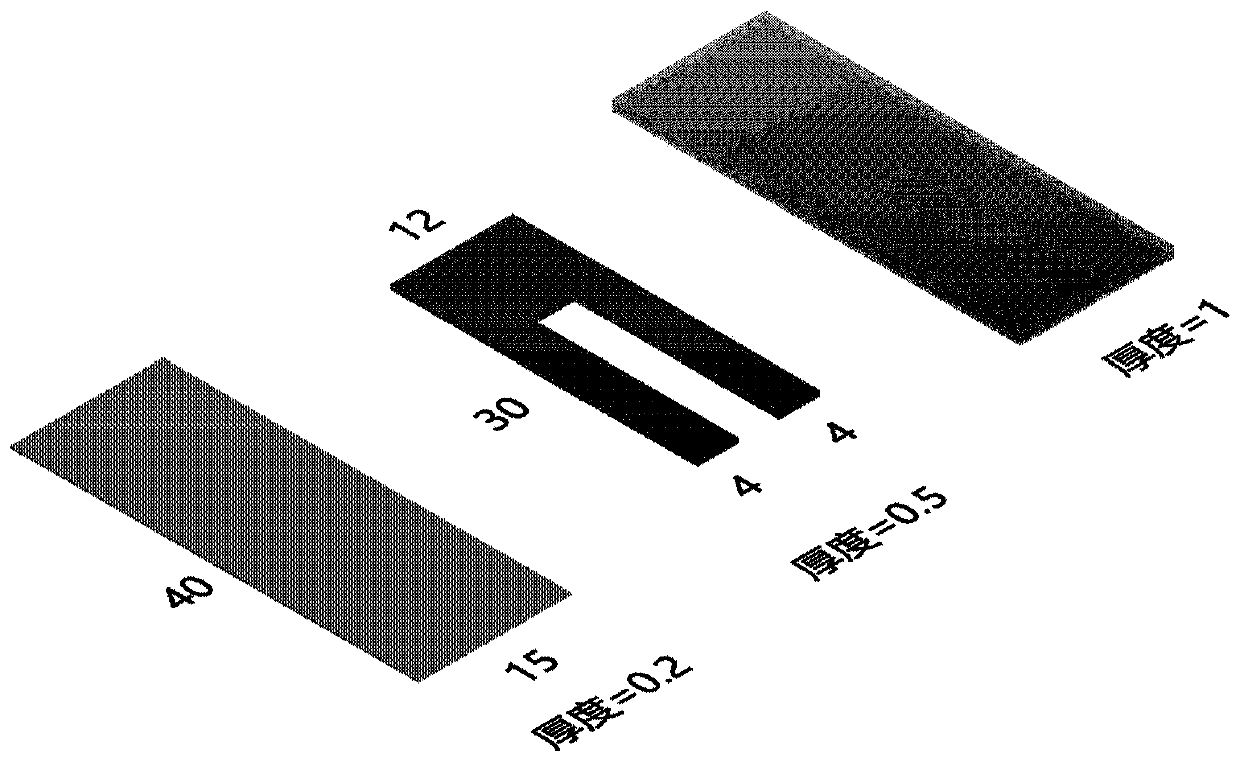

Real-time detection method of orthodontic force of bracket-free seamless appliance

The invention provides a real-time detection method of orthodontic force of a bracket-free seamless appliance specific to real-time detection problem of orthodontic force of the bracket-free seamless appliance for stomatology. Aiming at the phenomenon that the orthodontic force of the seamless appliance for stomatology is small and the contact area and contact gap are small when the seamless appliance is worn on teeth surfaces, the real-time detection of the orthodontic force of the bracket-free seamless appliance can be realized by using the piezoresistive effect of a thin-film single-point sensor and the excellent physical properties such as small size, soft material and thinness of a sensor, and the stress variation trend of one tooth or an arbitrary part on multiple teeth can be detected according to research needs; and through research of acting force system and acting effect of the seamless appliance, an orthodontist formulates a relatively reasonable and effective therapeutic scheme, and a designer designs a relatively perfect individual seamless appliance; and the real-time detection method is high in detection accuracy, good in timeliness, simple and practicable in a detection process and low in cost.

Owner:FUZHOU UNIV

Pressure resistance large overloading accelerometer and preducing method thereof

InactiveCN1740796AHigh sensitivitySimple designAcceleration measurement using interia forcesAccelerometerSignal processing circuits

The present invention provides a piezoresistive large-overload accelerometer. It is made up by adopting Si base MEMS technique. Said invention also provides the concrete steps of its preparation method. It can convert mechanical impact signal into electric signal, after the output signal is undergone the processes of amplification and temperature compensation, it can be used for calibrating acceleration extent.

Owner:北京青鸟元芯微系统科技有限责任公司

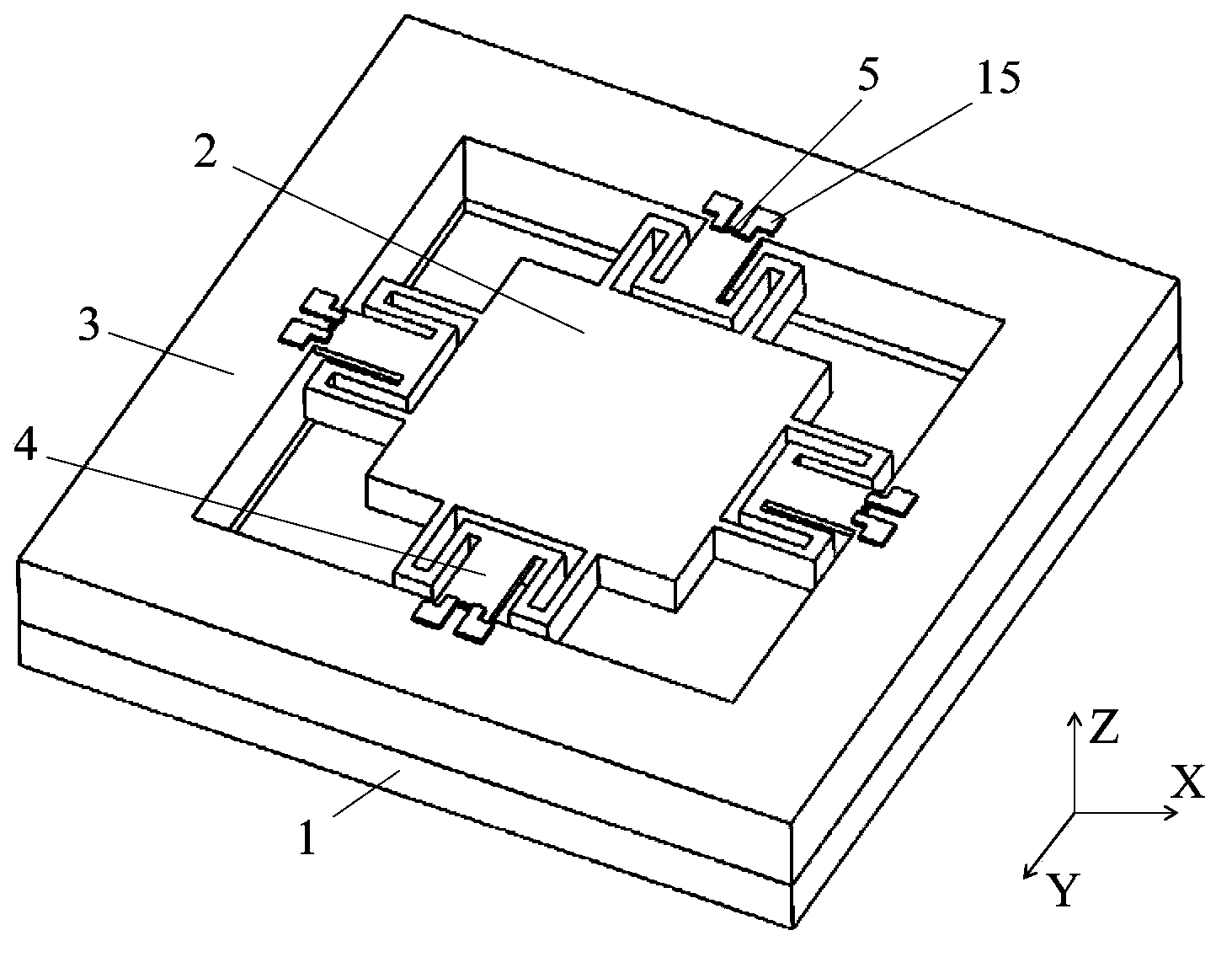

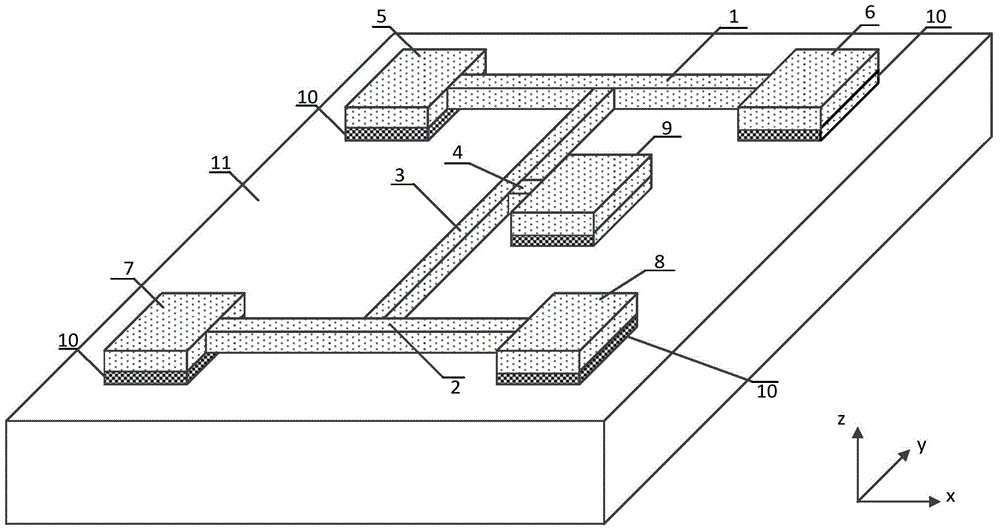

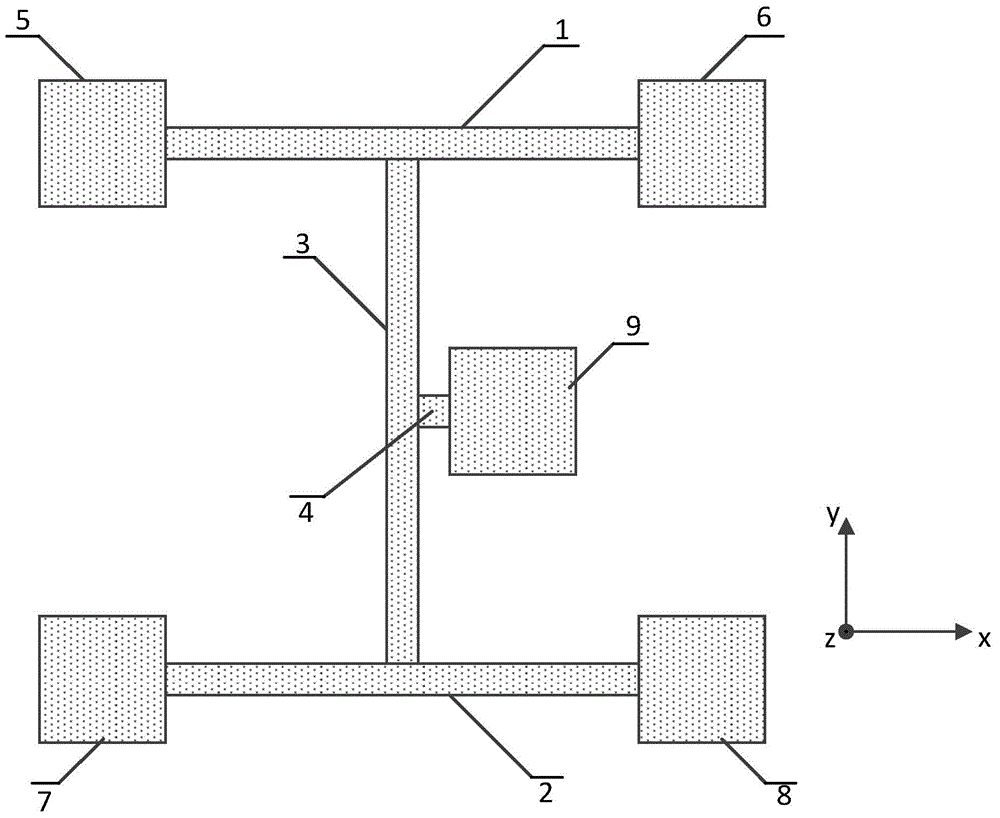

Novel micro-accelerometer based on mesoscopic piezoresistive effect

InactiveCN103364585AReasonable structural designHigh detection sensitivityAcceleration measurement using interia forcesAccelerometerThin membrane

A novel micro-accelerometer based on the mesoscopic piezoresistive effect is mainly and structurally composed of a bonding substrate, a sensitive mass block, a supporting frame body, resonant tunneling devices and combined beams. Each resonant tunneling deice is composed of a resonant tunneling material thin film layer, a resonant tunneling device positive pole and a resonant tunneling device negative pole. Each combined beam is composed of a detection beam, a connection block and a transverse buffering beam. The bonding substrate serves as a carrier, the supporting frame body is bonded on the bonding substrate, the center position of each of the four edges of the supporting frame body is connected with one combined beam, one combined beam is connected to the center position of each of the four edges of the sensitive mass block, the other sides of the combined beams are connected with the supporting frame body, and each combined beam is composed of the detection beam, the connection block and the transverse buffering beam. Each resonant tunneling material thin film layer is of a multi-potential-barrier voltage-sensitive structure and can enable the sensitivity of a silicon piezoresistive device to be improved by 1-2 orders of magnitude. The novel micro-accelerometer based on the mesoscopic piezoresistive effect is reasonable and compact in structure, convenient to detect, high in precision, good in reliability and suitable for miniaturization, and has strong lateral resistance.

Owner:ZHONGBEI UNIV

Coupling resonance type resonant strain sensor

ActiveCN106323155AHigh Q valueHigh resolutionElectrical/magnetic solid deformation measurementImage resolutionResonance

The invention provides a coupling resonance type resonant strain sensor, which comprises two sensitive girders, and a detection girder connected between the two sensitive girders. The two ends of each sensitive girder are fixed and supported. The sensitive girders are working in a force-sensitive transverse vibration mode correspondingly. The detection girder is working in a longitudinal vibration mode significant in integrated piezoresistive effect. The sensitive girders and the detection girder are together in coupling resonance. An external driving force drives the entire structure to vibrate at a coupling resonant frequency. The stress applied onto the sensitive girders changes the resonant frequency of the sensitive girders, so that the coupling resonant frequency of the entire structure is changed along with the changing resonant frequency of the sensitive girders. Based on the piezoresistive effect of the detection girder, the resonant frequency is measured, so that the stress value can be further measured. According to the technical scheme of the invention, the coupling resonance type resonant strain sensor is packaged in the vacuum state through the high-temperature process, and is high in Q value, high in resolution, high in sensitivity, and good in long-term stability. The coupling resonance type resonant strain sensor has a wide application prospect in the field of stress detection.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Farraginous carbon fiber composite material, preparation method and application thereof

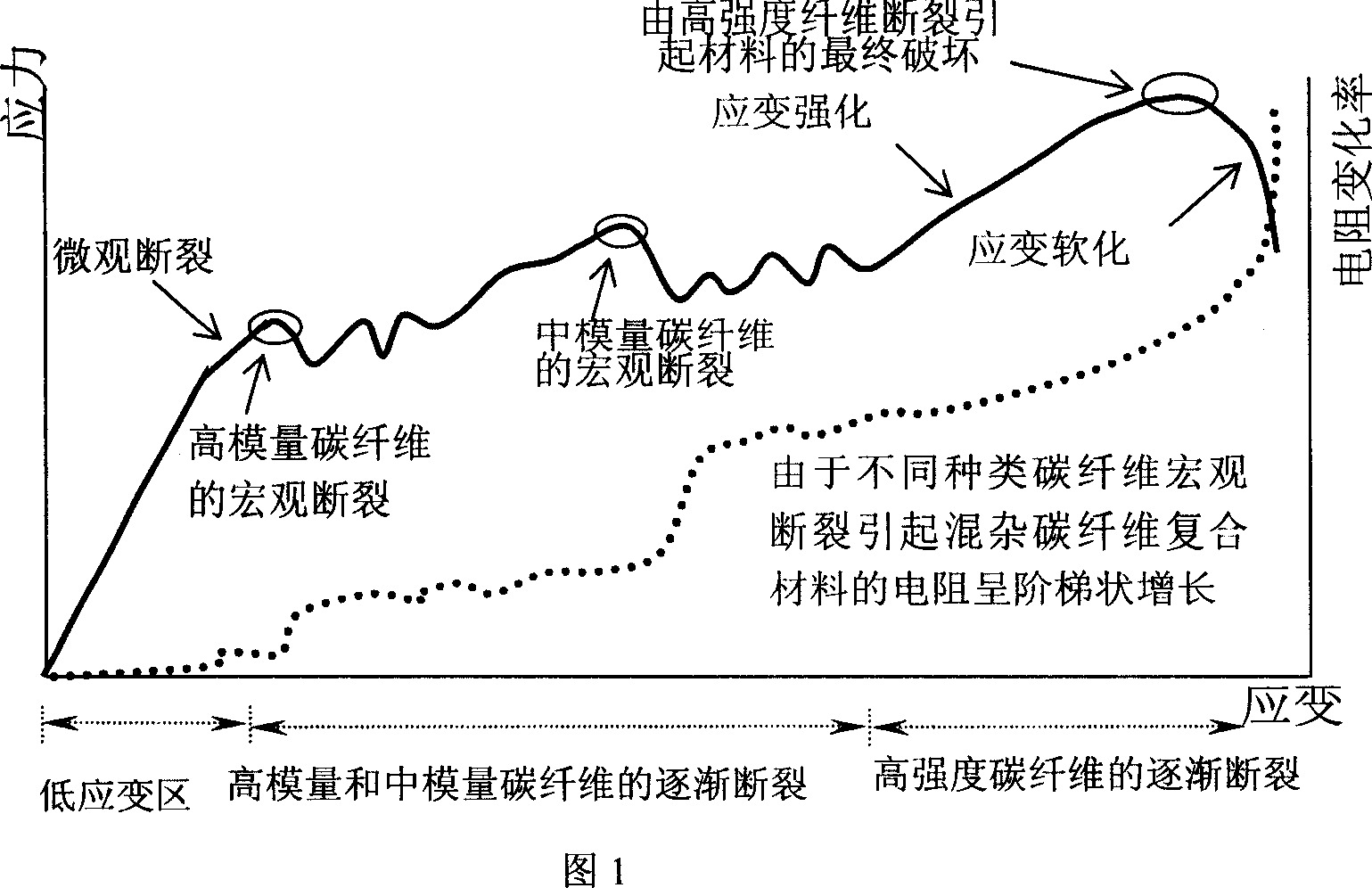

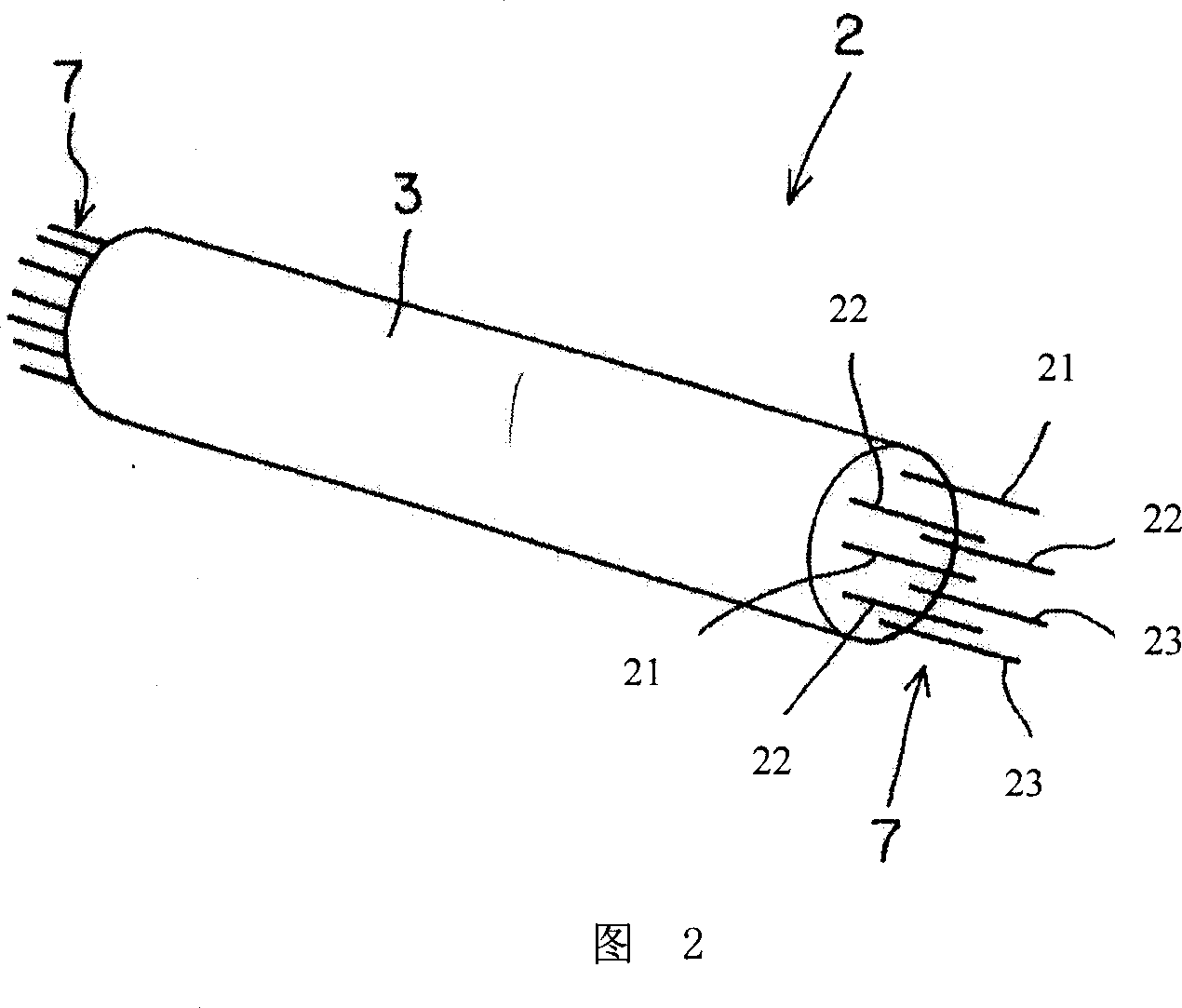

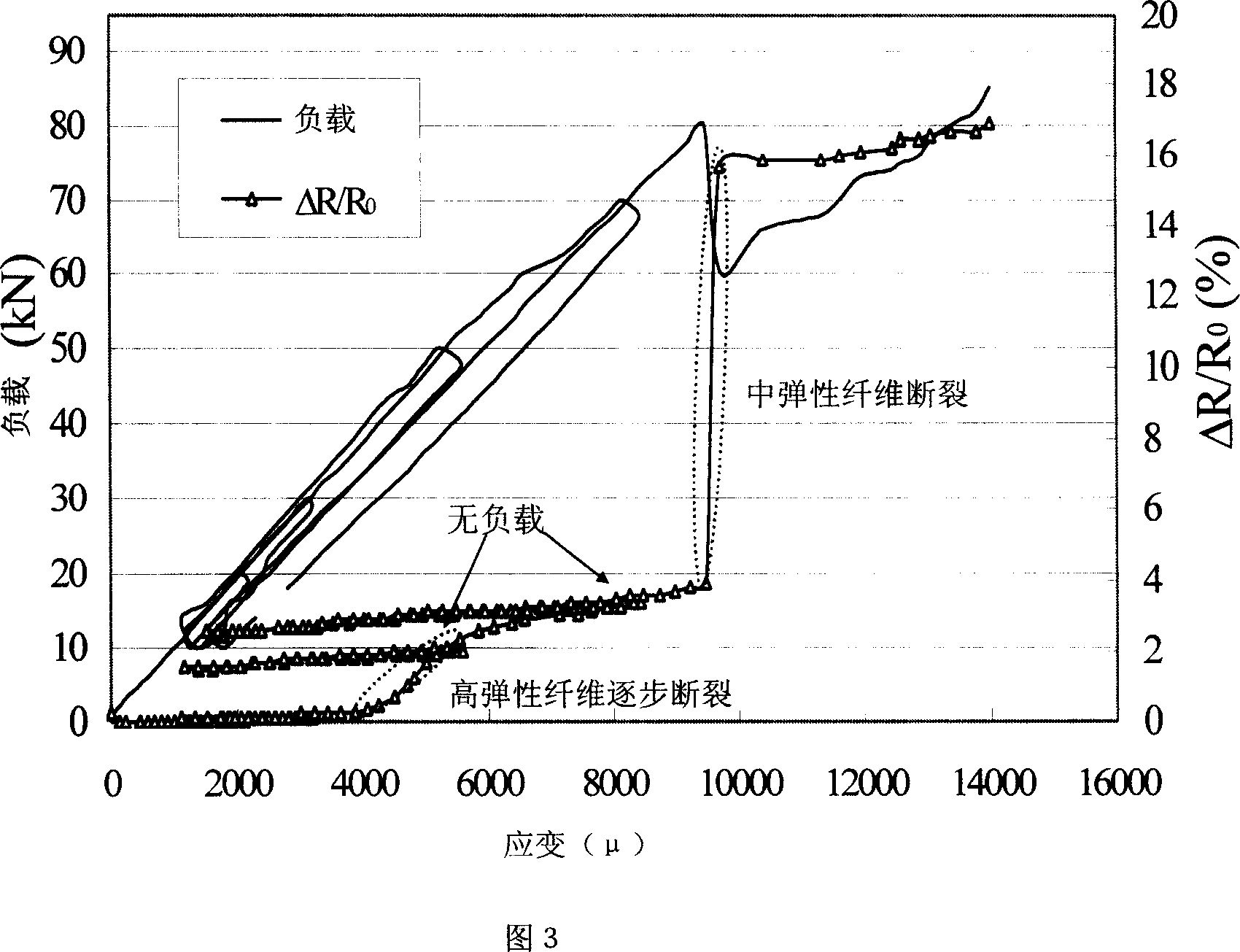

InactiveCN1924124AImprove resistance change rateAvoid the defect of losing the sensing functionFibre treatmentForce measurementFiberHigh intensity

This invention discloses one mixture carbon fiber compound materials and its application, which comprises the following parts: spring mode volume as 500-650GPa carbon fiber A; spring mode as 360- 450GPa carbon fiber B and string intensity as 3200-5000MPa carbon fiber C. Due to used carbon fiber of high intensity and rigidity, it comprises good conductivity and piezoelectricity effect.

Owner:吴智深 +1

Piezoresistive MEMS sensor

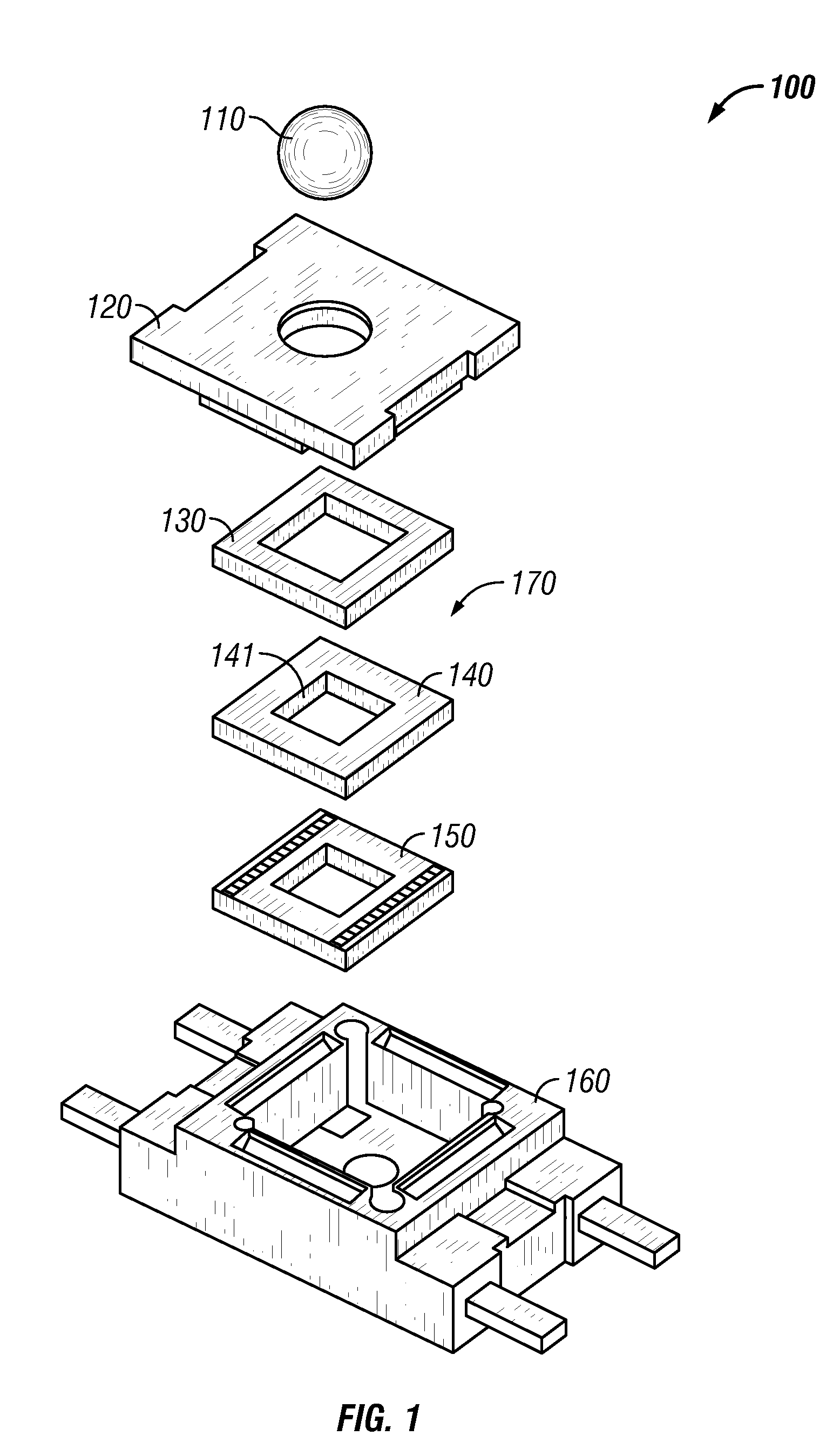

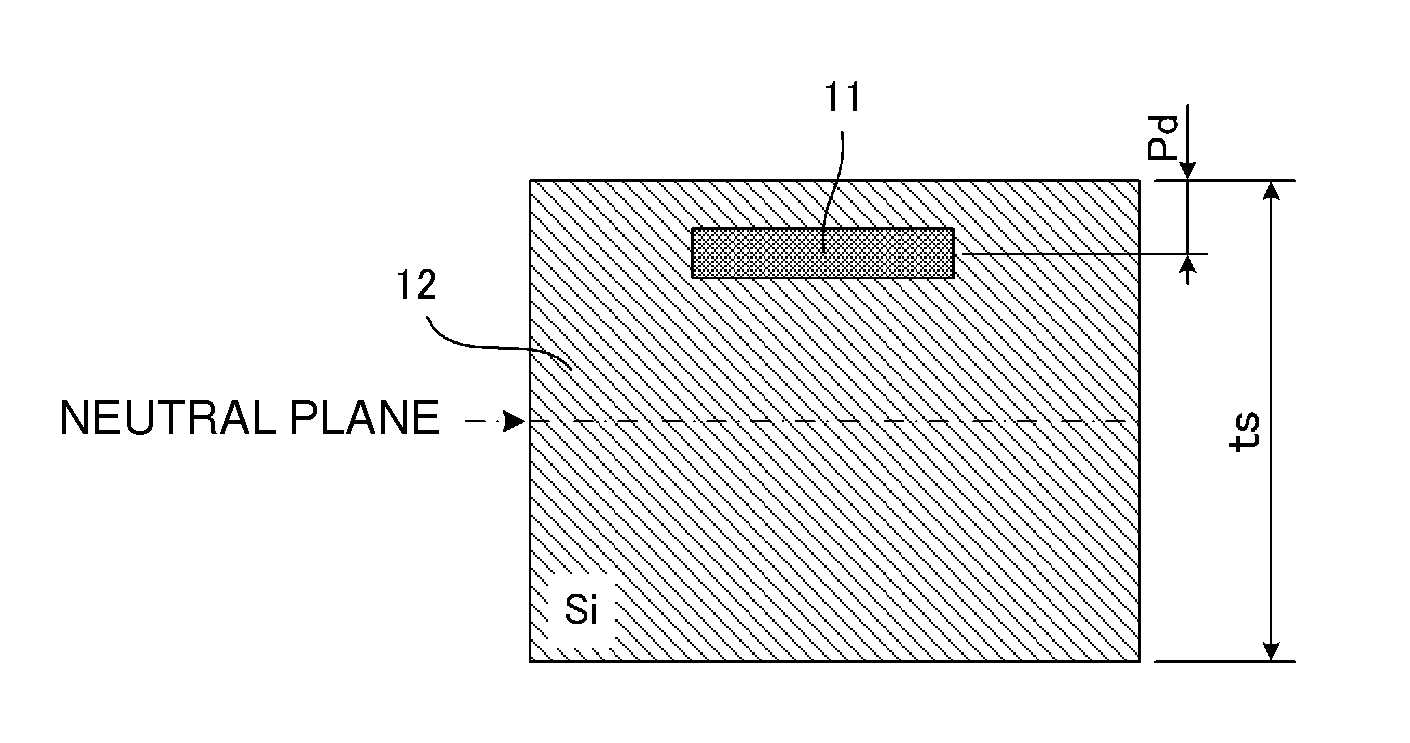

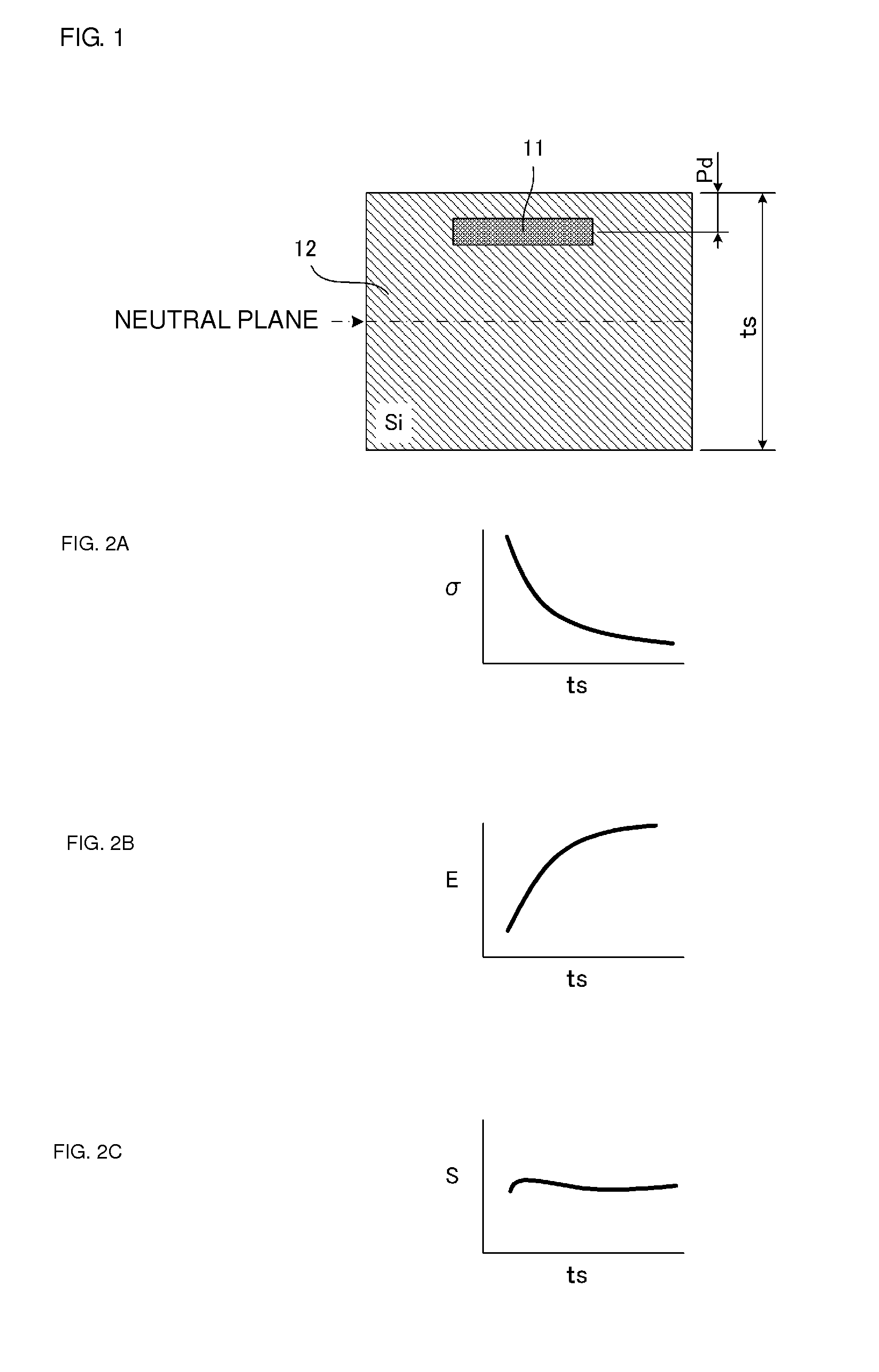

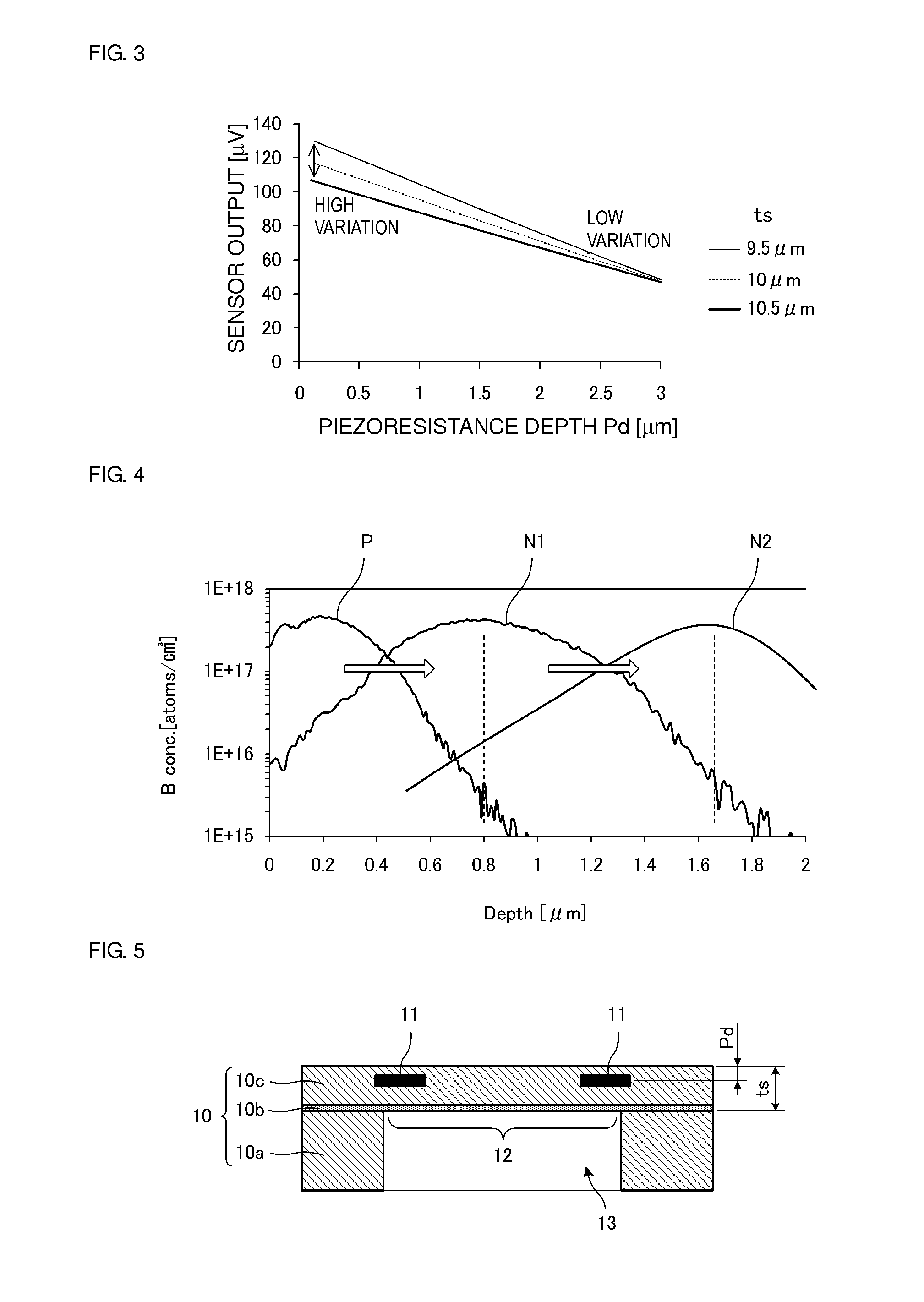

InactiveUS20150241465A1Reduce impactSensitivity of sensorAcceleration measurement using interia forcesFluid pressure measurement using ohmic-resistance variationMems sensorsSoi substrate

A pressure sensor includes a SOI substrate that includes a Si substrate, a SiO2 layer, and a surface Si film. An opening portion is formed in the Si substrate through etching, and a displacement portion having a membrane structure is defined by the surface Si film and the SiO2 layer in this area. A piezoresistive element is provided in the displacement portion. The displacement portion bends in response to a pressure to be detected and a resistance value of the piezoresistive element changes in response thereto. A thickness of the membrane-structure displacement portion is not less than about 1 μm and not greater than about 10 μm, and a depth of a peak of an impurity concentration of the piezoresistive element is greater than about 0.5 μm and at a position less than about ½ of the depth of the thickness of the displacement portion.

Owner:MURATA MFG CO LTD

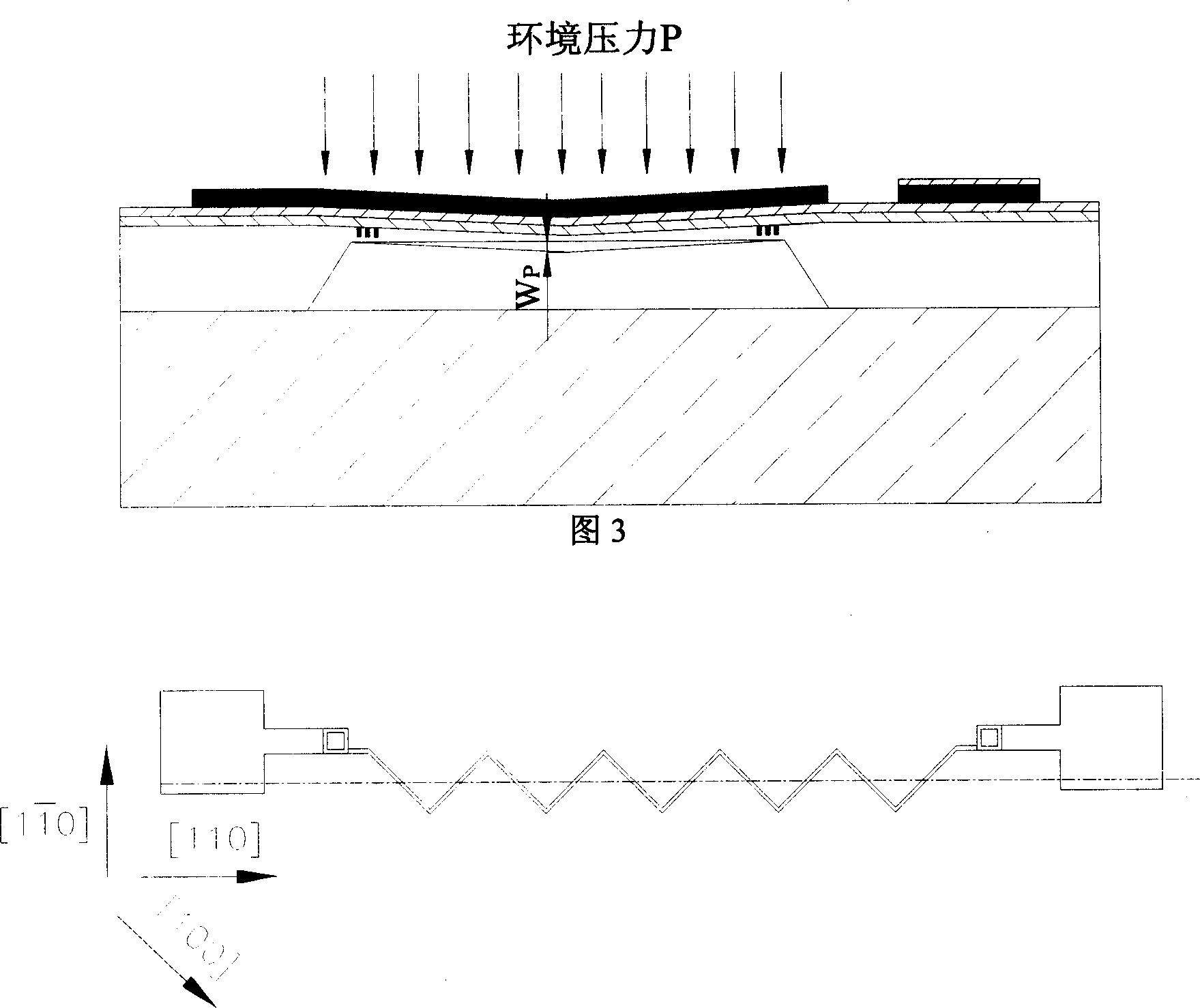

Resonant pressure sensor based on piezoresistive detection and preparation method thereof

ActiveCN108516518AIncrease output signal strengthImprove anti-interference abilityFluid pressure measurement using ohmic-resistance variationDecorative surface effectsAnchor pointSingle beam

The invention relates to a resonant pressure sensor based on piezoresistive detection and a preparation method thereof. The resonant pressure sensor comprises a pressure sensitive film, a resonator located on the pressure sensitive film and six anchor points, wherein the resonator comprises a double-end fixed support beam and two driving electrodes arranged on the two sides of the double-end fixedsupport beam, wherein the double-end fixed support beam comprises two end parts and two single beams connected to the two end parts; etching is carried out on root regions of the two single beams symmetrically; body pressure resistance is formed at the root parts of the two single beams; the same three-electrode structures are arranged at the two end parts, one three-electrode structure is suspended, and the other three-electrode structure takes an electrode in the middle position as a grounding end and the electrodes at the two sides as detection electrodes; the six anchor points are arranged under the two three-electrode structures respectively; and the double-end fixed support beam is fixedly supported on the pressure sensitive film. According to the resonant pressure sensor and the preparation method, a piezoresistive detection and resonator tuning fork vibration mode is adopted, so that the output signal strength is improved, and the anti-interference capability and the stabilityare enhanced.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Wide-range air velocity transducer and manufacturing method thereof

ActiveCN109001486AAccurate measurementLow costIndication/recording movementFluid speed measurement using thermal variablesAir velocityTransducer

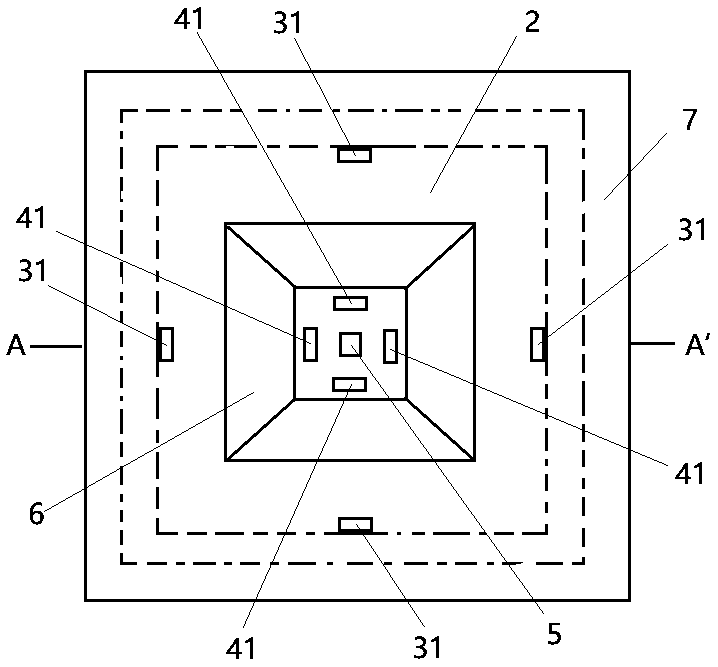

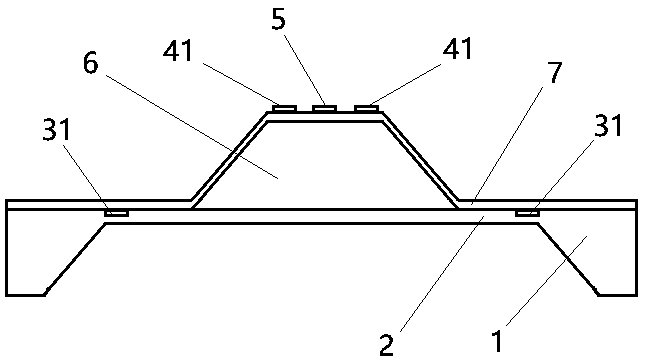

The invention relates to a wide-range air velocity transducer and a manufacturing method thereof. The wide-range air velocity transducer comprises a substrate (1), an elastic thin film (2), a heatingelement (5), a protruded table top (6), a thermal insulating layer (7), four pressure transducers (31) and four temperature transducers (41). On the basis of the design scheme, hardware is combined toconstitute the wide-range air velocity transducer, and correspondingly, the invention further relates to the manufacturing method of the wide-range air velocity transducer; thus according to the whole technical scheme, the thermal transducer principle is adopted, and air velocity and direction data can be accurately measured under the low air velocity; the piezoresistive effect is adopted, and air velocity and direction data can be accurately measured under the high air velocity; a bulk-silicon micromachining technology is adopted, the process is reliable, batch manufacturing is easy, and thecost is low; and not only that, a two-dimensional symmetrical structure is further adopted, and temperature drift is small.

Owner:SOUTHEAST UNIV

Double H-shaped compression beam silicon micro-resonant pressure sensor chip and preparation method thereof

ActiveCN109879239AReduce twistHigh sensitivityForce measurement by measuring frquency variationsPrecision positioning equipmentElectrical resistance and conductanceClassical mechanics

The invention discloses a double H-shaped compression beam silicon micro-resonant pressure sensor chip and a preparation method thereof. The sensor chip comprises a resonant layer and a pressure-bearing membrane. The resonant layer comprises a resonant beam and a balance beam. The four resonant beams form a group of H-shaped beams. The two groups of H-shaped beams are symmetrically arranged. The end parts of the resonant beams are fixed on the balance beams, the two balance beams are connected with the rigid mass block through extension parts of the resonant beams, the mass block is arranged between the adjacent resonant beams, the coupling beam is arranged in the middle of the mass block, the vibration pick-up resistor is arranged in the middle of the coupling beam, and the two mass blocks positioned on the outer side are respectively and fixedly connected with the two movable electrodes. When pressure is applied to the pressure-bearing diaphragm for loading; The resonant beam is pressed to deform, the inherent frequency of the resonant beam is changed, meanwhile, when the resonant beam is excited to vibrate and in a resonant state through the fixed electrode, the vibration pick-up resistors on the coupling beam are in the pressed / pulled state in a circulating mode, the vibration pick-up resistance value is changed based on the piezoresistive effect, and therefore the inherentfrequency of the resonant beam is picked up.

Owner:XI AN JIAOTONG UNIV

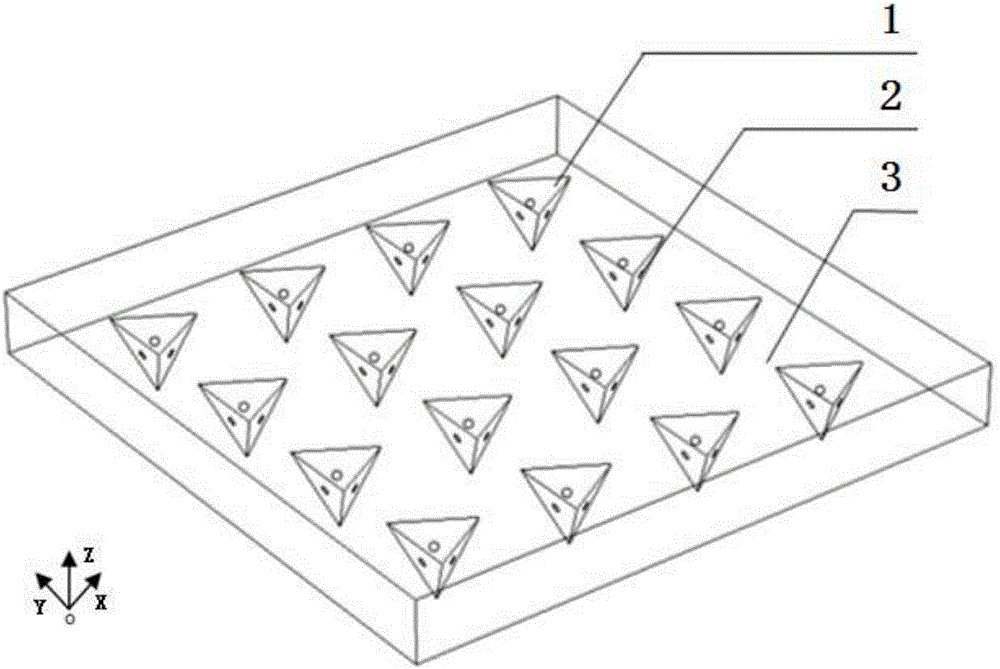

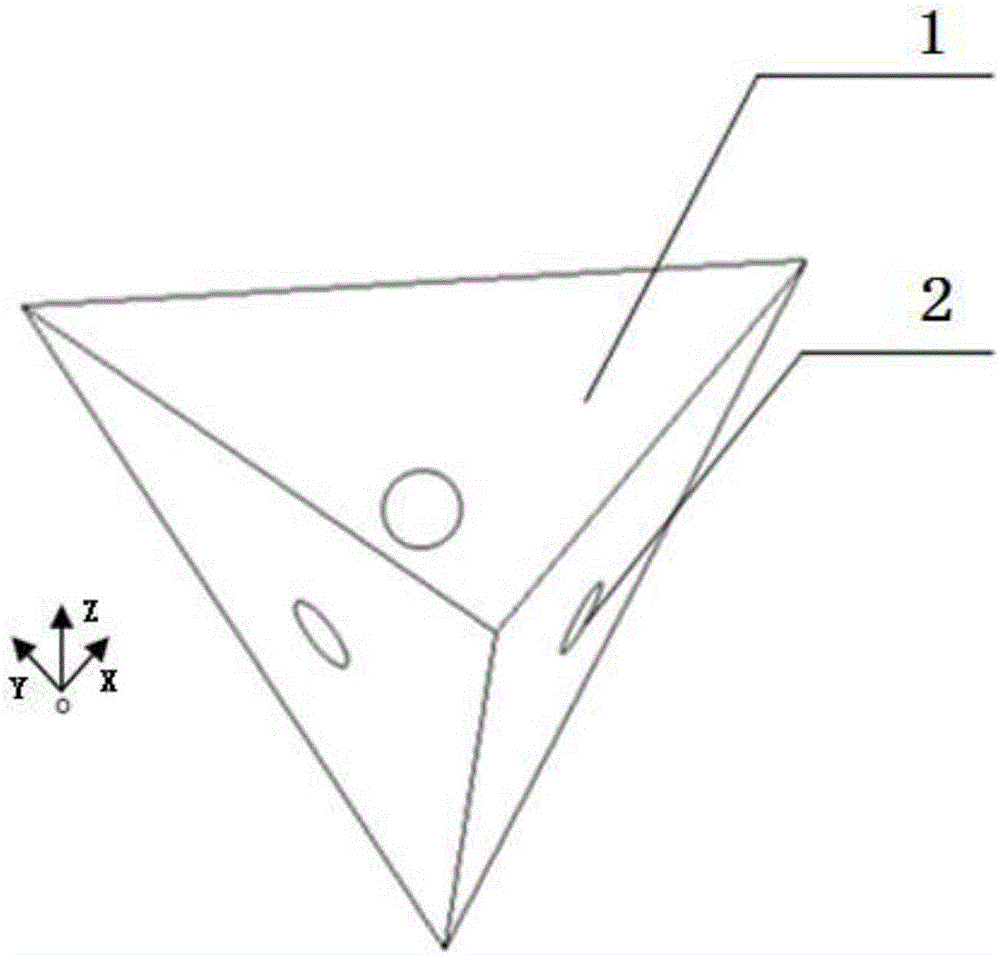

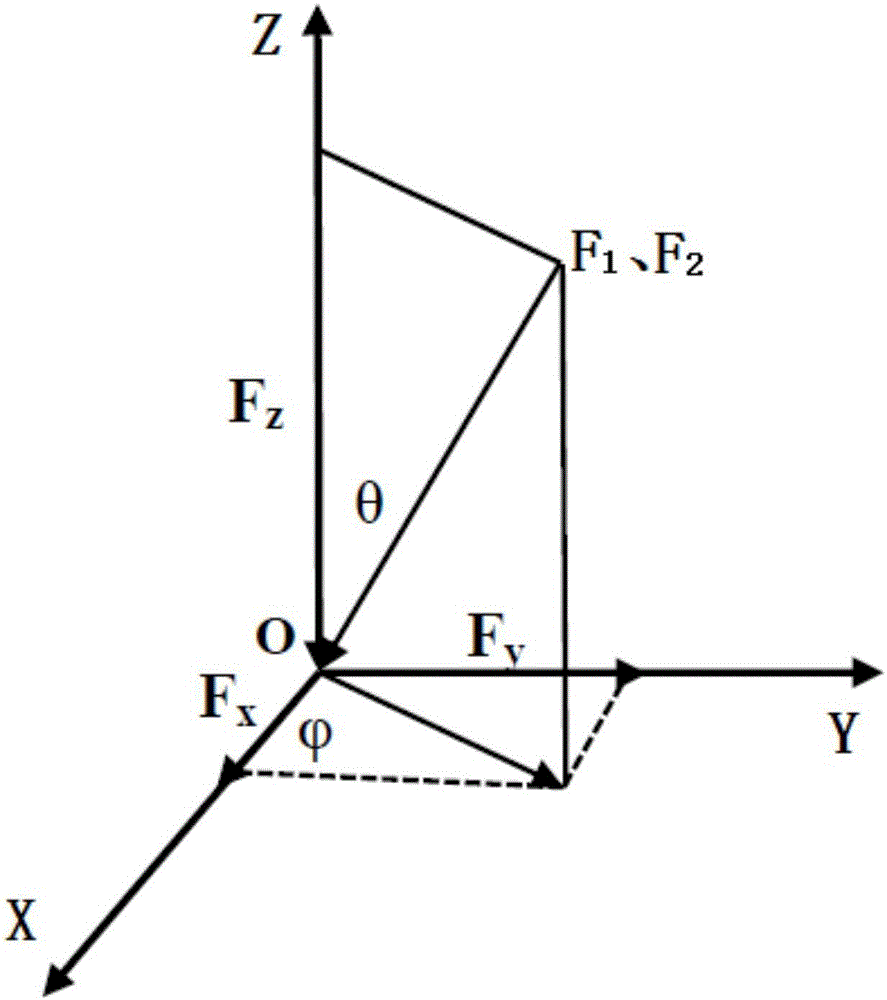

Regular tetrahedral three-dimensional force flexible tactile sensor array

ActiveCN106482874AReduce couplingImprove efficiencyForce measurement using piezo-resistive materialsElectrical resistance and conductanceCoupling

The invention provides a regular tetrahedral three-dimensional force flexible tactile sensor array, the array comprises a plurality of arrayed three-dimensional force flexible tactile sensing units with the same structures in a flexible substrate, and the three-dimensional force flexible tactile sensing units have regular tetrahedral structures prepared by flexible electroconductive rubber having piezoresistive effect; upper end surfaces of all regular tetrahedral structures are arranged on a same plane, when an intersection point of three lower side surfaces of one regular tetrahedral structure is considered as an original point, a three-dimensional rectangular coordinate system of the regular tetrahedral structure is established around the point, one edge of the upper end surface of the regular tetrahedral structure is parallel to an Y axis, and the projection of an intersection point of the other two edges is on the positive direction of a X axis; the upper end surface of the regular tetrahedral structure and the three lower side surfaces equally form three resistors, and an electric contact for outputting corresponding resistance signal is arranged on the center of each lower side surface. According to the invention, the coupling degree of sensor resistance data can be reduced, and the decoupling precision and the response speed are substantially improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

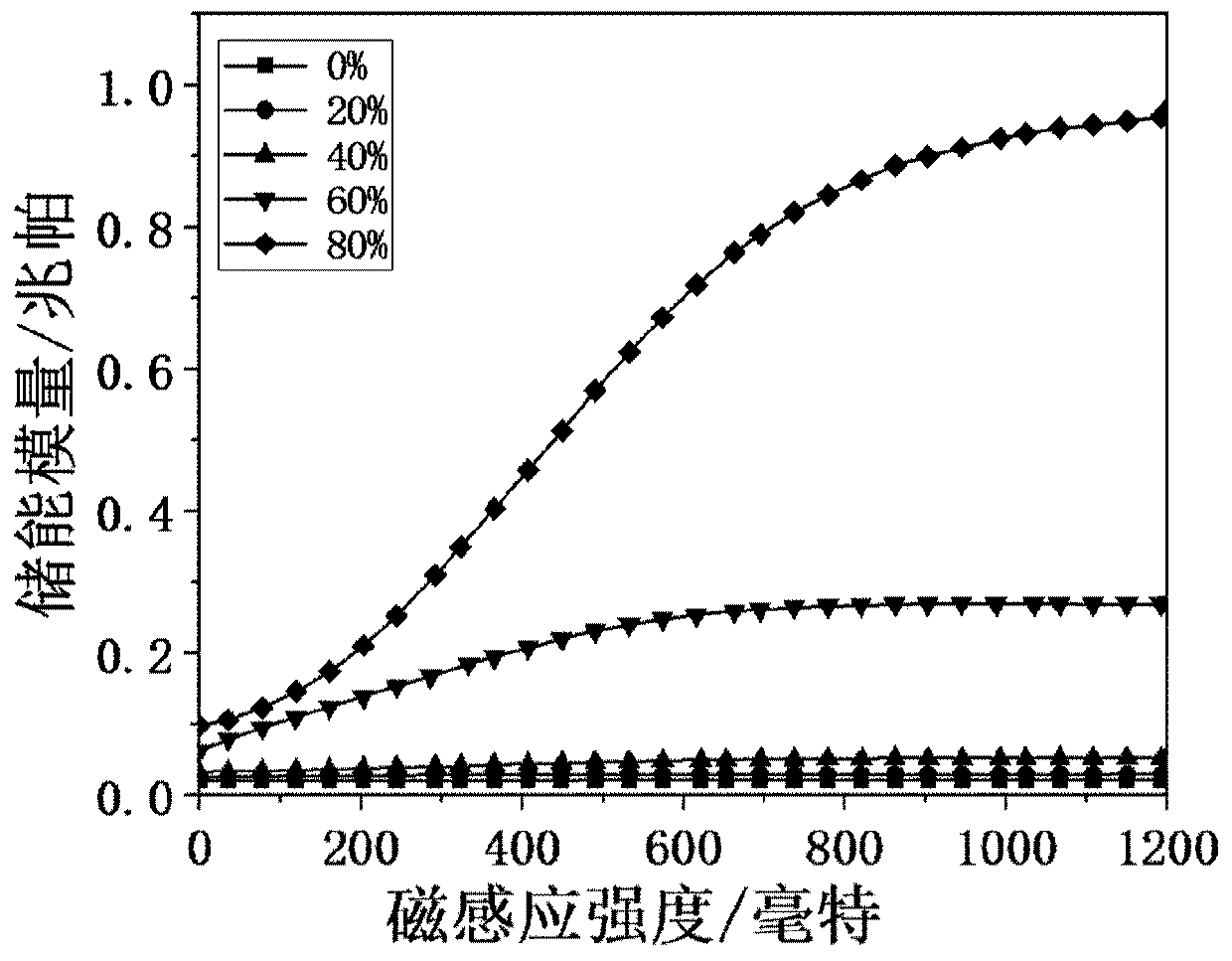

Multifunctional flexible sensing material and preparation method and application thereof

PendingCN110426060AExtended Response Signal CategoryGood sensory feedback abilityLamination ancillary operationsLayered product treatmentElectrical resistance and conductanceEngineering

The invention relates to a multifunctional flexible sensing material and a preparation method and application thereof. The multifunctional flexible sensing material comprises a magneto-rheological layer and an electric conduction layer. The magneto-rheological layer has a magneto-rheological effect and can be subjected to stress strain under the effect of a magnetic field; the electric conductionlayer is formed on the magneto-rheological layer, has a piezoresistive effect and can generate resistance change under the stress strain, and a temperature sensing layer is further formed on the electric conduction layer. According to the multifunctional flexible sensing material, the corresponding signal type of the flexible sensing material is extended, so that the flexible sensing material hasgood sensing feedback capacity for magnetism, force and temperature signals, the preparation technology is simple, the circulation stability is good, and the material has high application potential inthe aspect of multi-signal sensing and large-scale production in the field of flexible sensing.

Owner:UNIV OF SCI & TECH OF CHINA

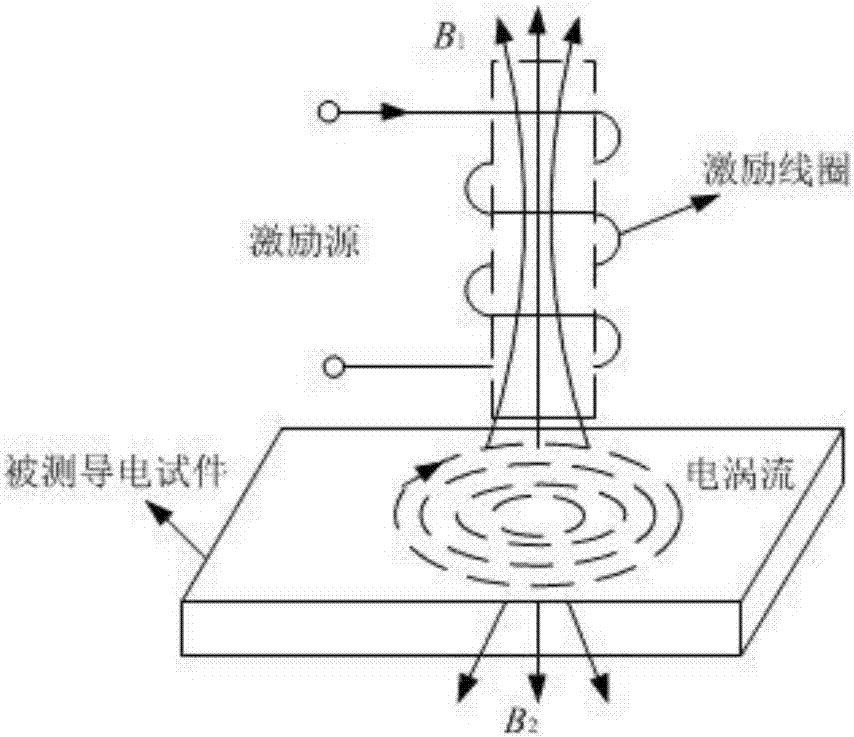

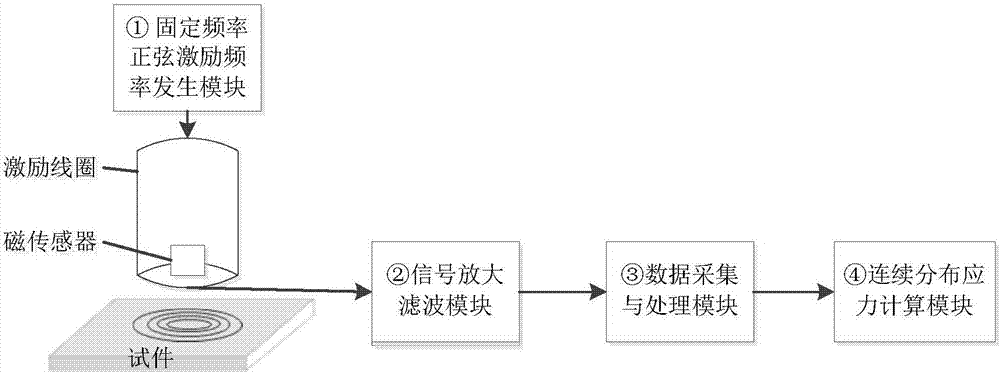

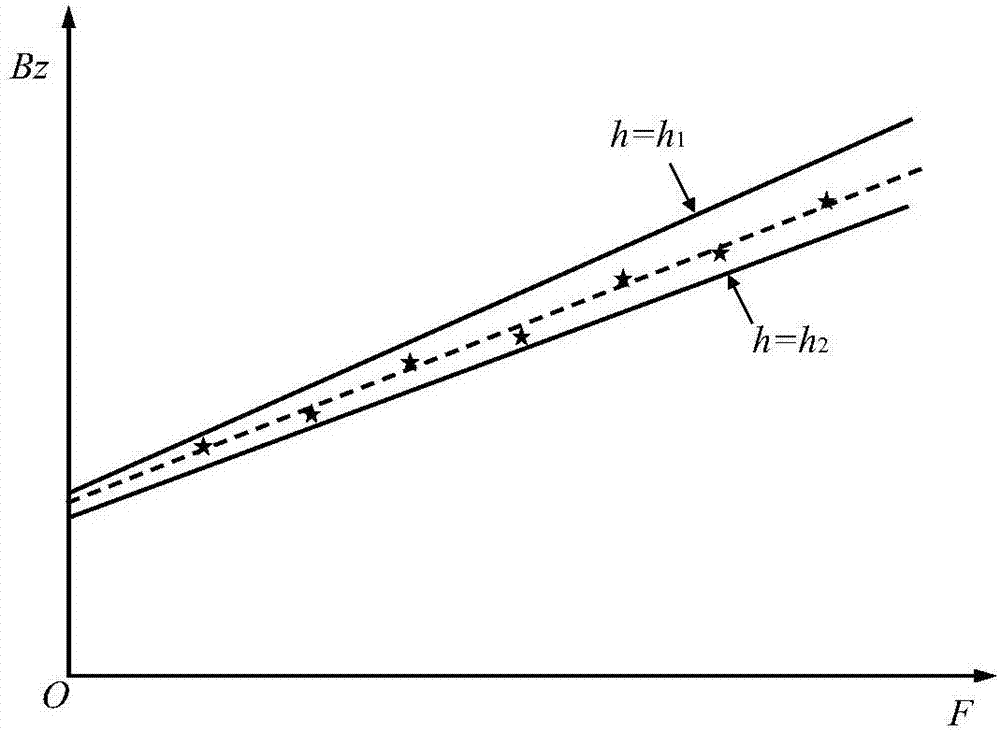

Conductive solid nondestructive detection circuit and continuous stress quantitative evaluation method based on conductive solid nondestructive detection circuit

InactiveCN107144627AEnsure safetyForce measurement using piezo-resistive materialsMaterial magnetic variablesStress distributionElectrical conductor

The invention discloses a conductive solid nondestructive detection circuit and a continuous stress quantitative evaluation method based on the conductive solid nondestructive detection circuit. The method comprises the following steps: acquiring nondestructive detection signals through a conductor nondestructive detection circuit; conducting quantitative evaluation on the continuous stress distribution of the conductive solid by an experiment and numerical simulation combined mode; specifically, determining the relation between the nondestructive detection signals and external loads through experiments; acquiring the distribution law of conductivity through the piezoresistive effect, and acquiring the relation between continuous stress distribution and the external loads through a numerical calculation model; and acquiring the stress of any one point of the conductor according to the estimated magnitude of the external force, thereby realizing quantitative evaluation of the continuous stress distribution of the conductive solid. The method disclosed by the invention lays the foundation for early damage prediction of the conductive solid, can be used for realizing fitness prediction of conductor and semiconductor key members, and is of great importance in guaranteeing the safety of key structures.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com