Patents

Literature

35results about How to "Increase output signal strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

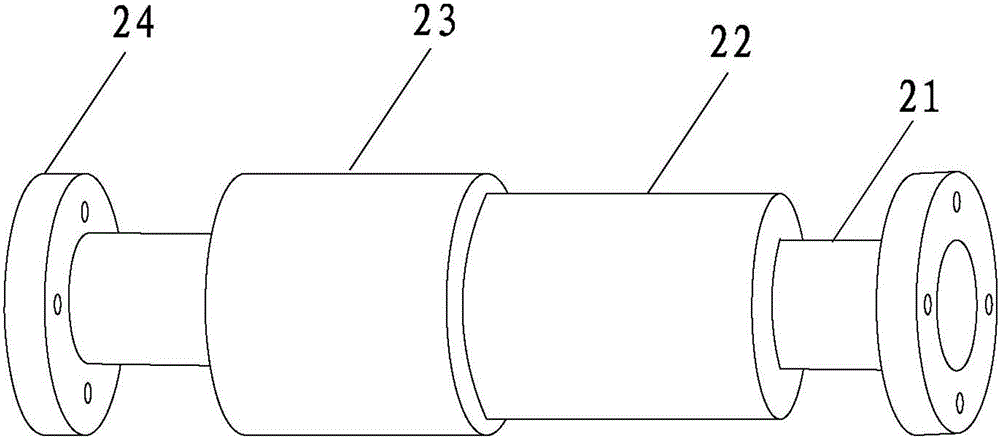

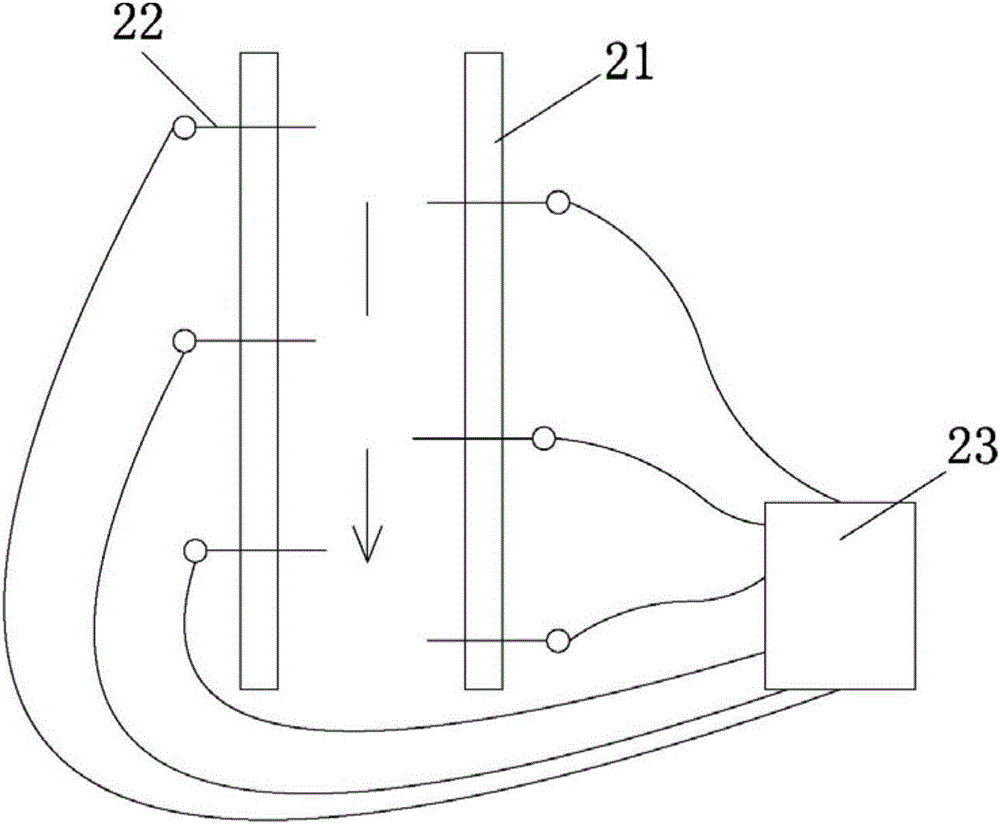

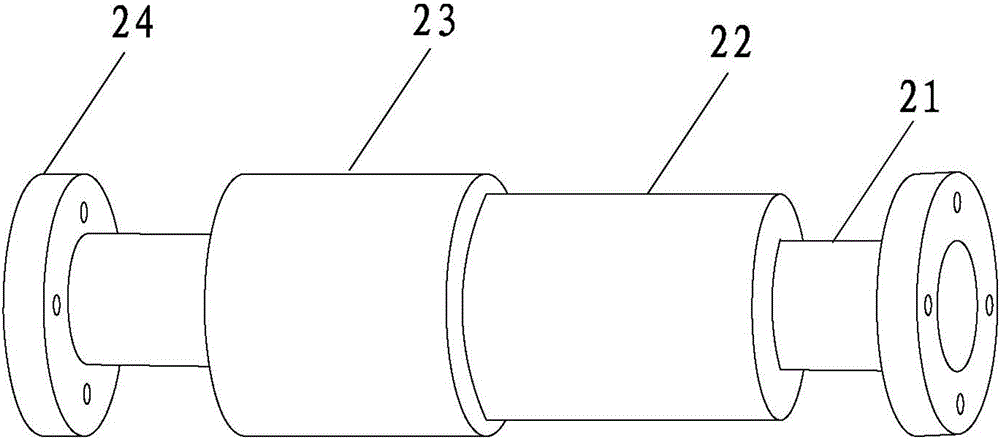

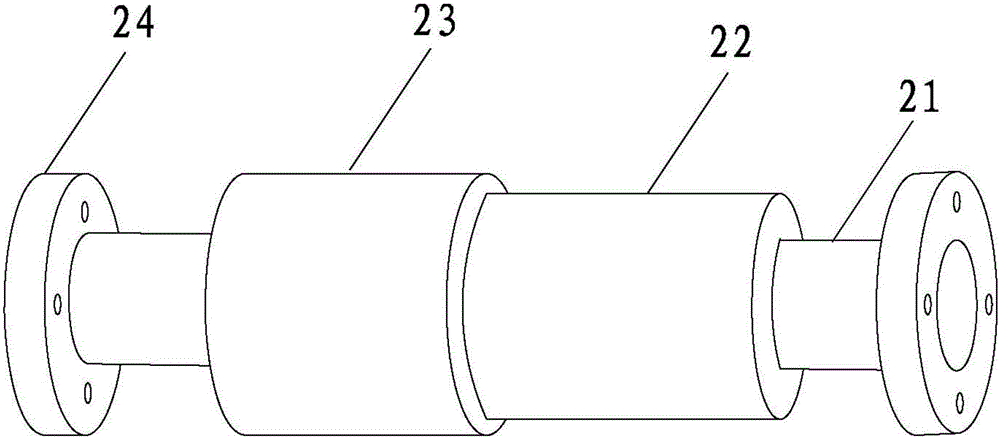

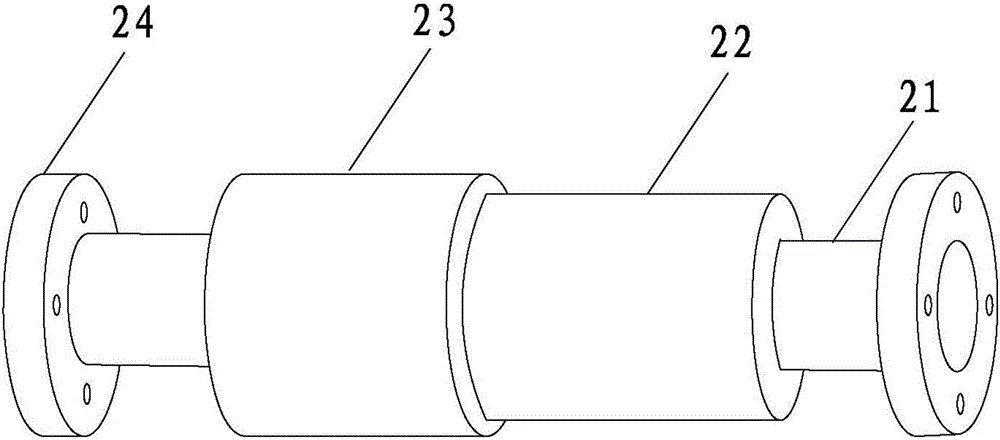

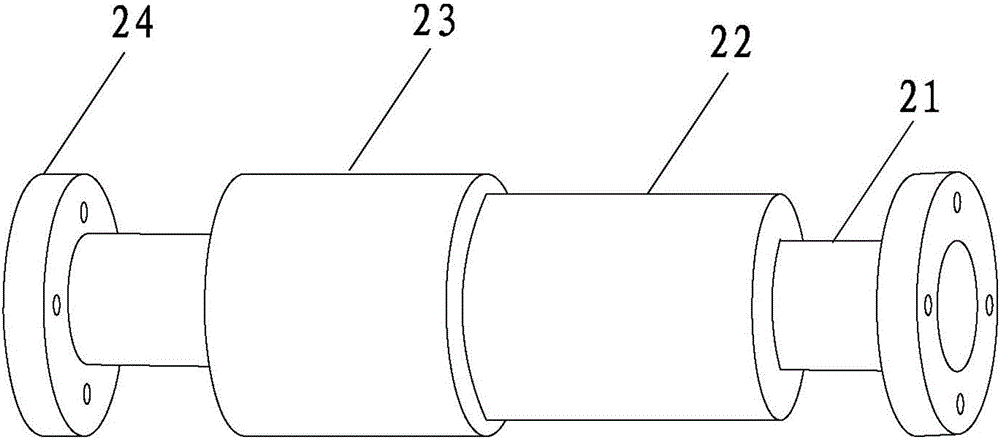

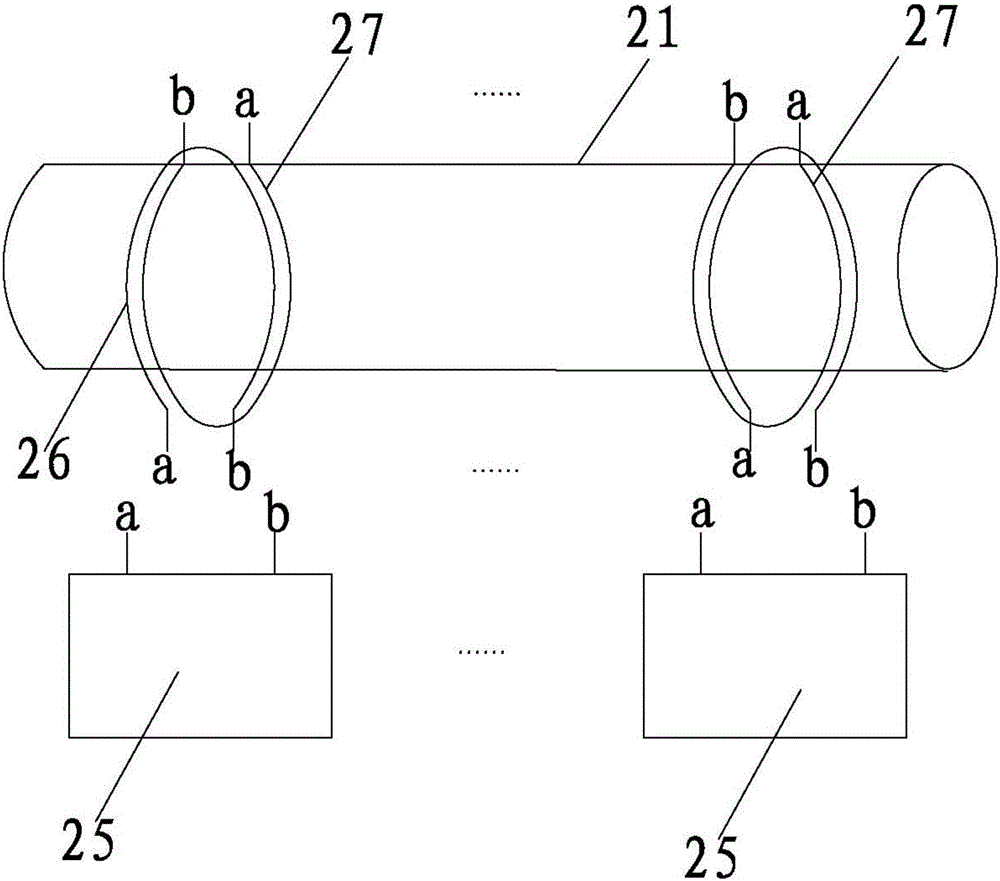

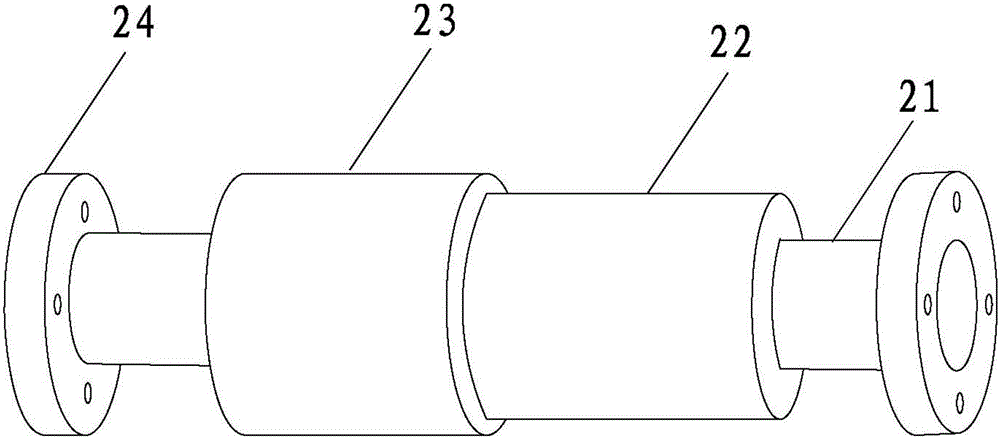

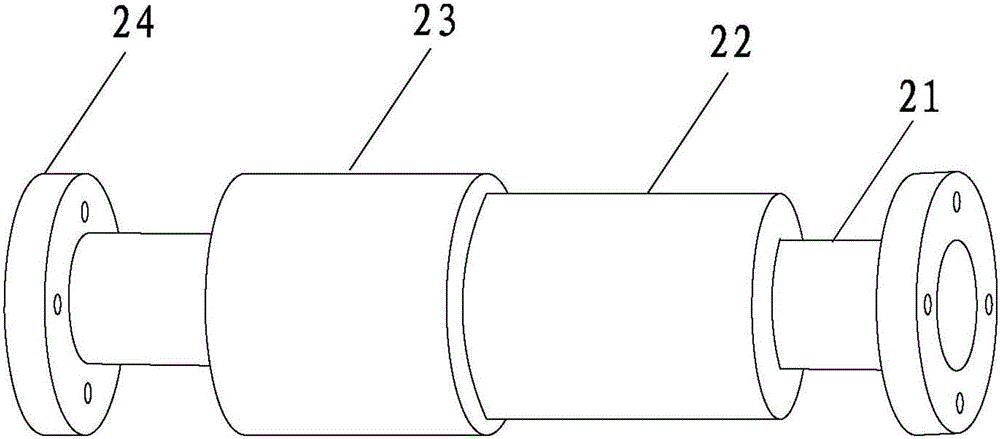

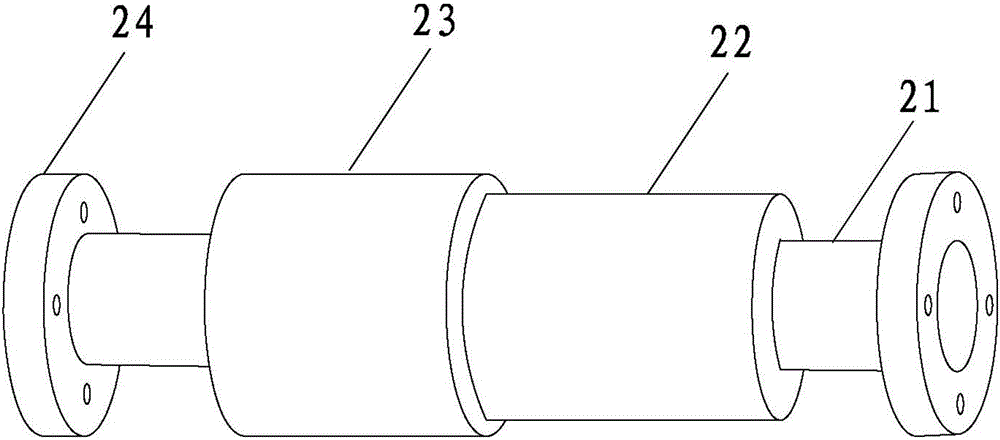

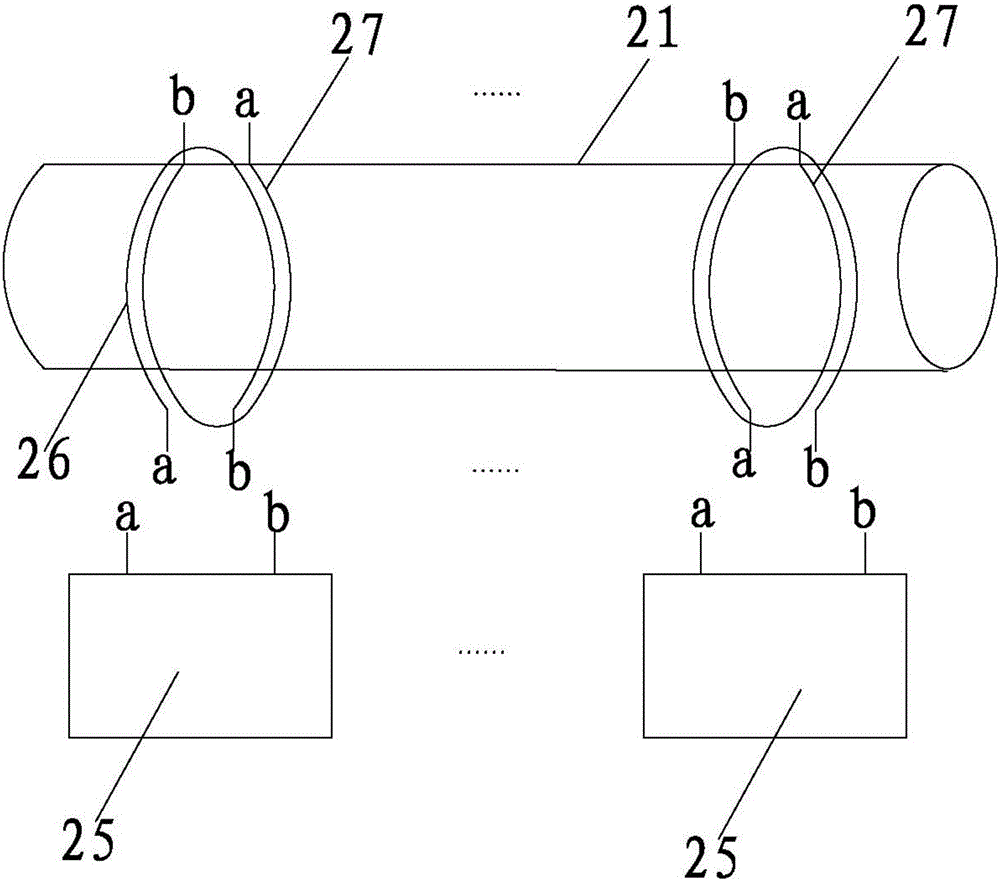

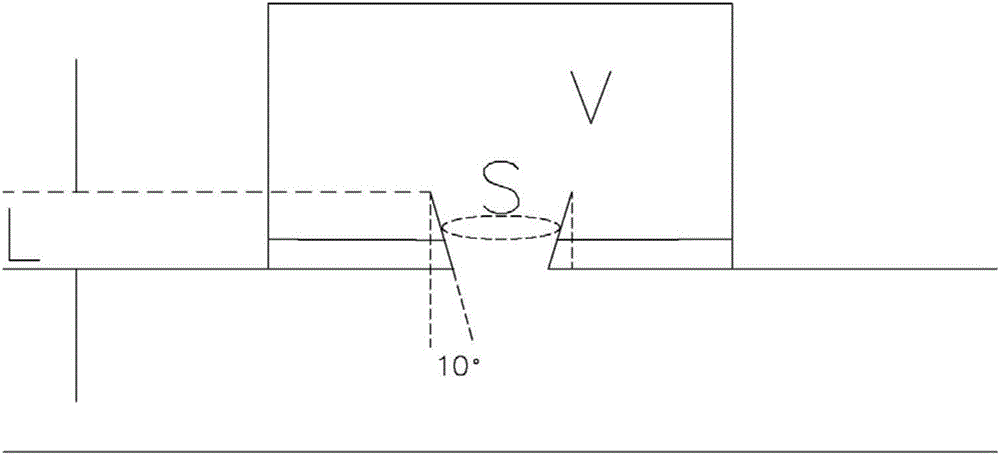

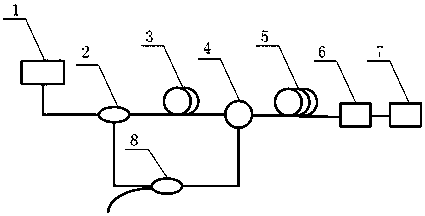

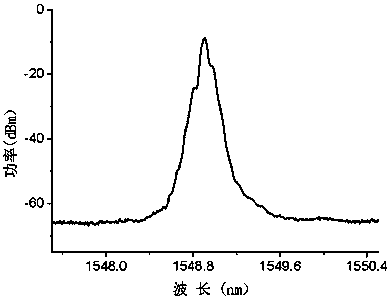

Micro-tapered fiber for producing ultra-narrow linewidth fiber laser, and laser

ActiveCN103149628AGuaranteed single frequency operationIncrease output signal strengthCladded optical fibreCoupling light guidesResonant cavityHigh signal intensity

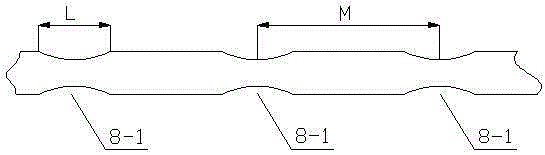

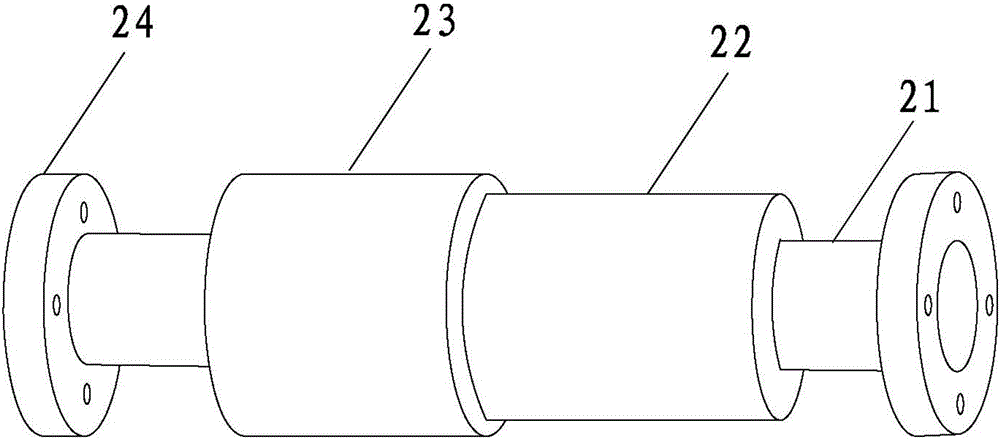

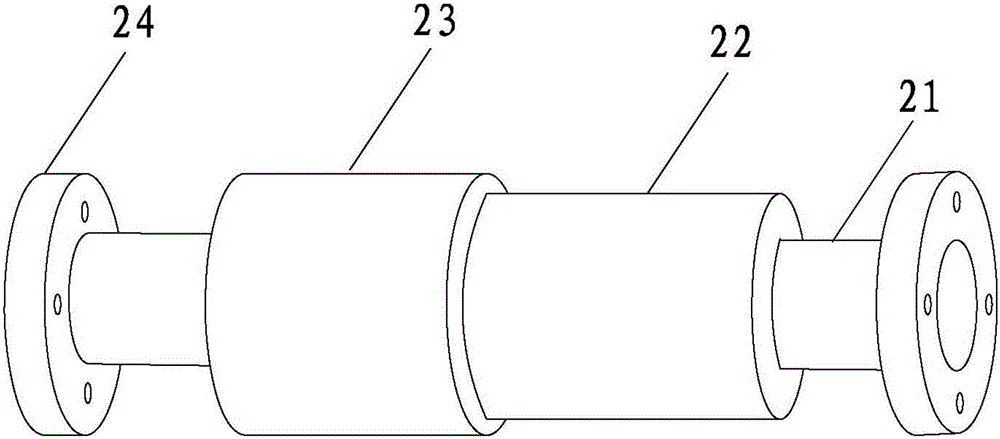

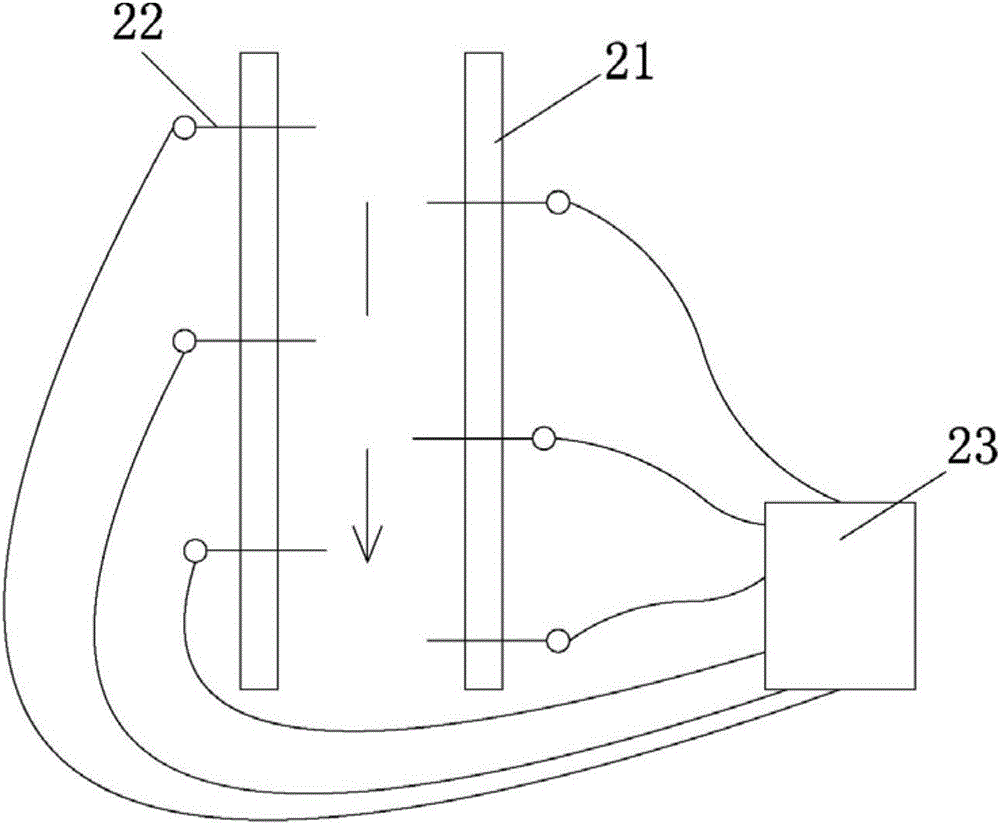

The invention relates to a micro-tapered fiber for producing an ultra-narrow linewidth fiber laser. The micro-tapered fiber is produced by ordinary single-mode fibers through a tapering process. A plurality of tapering regions are formed on the ordinary single-mode fibers through multiple tapering operations, and the whole micro-tapered fiber is connected into the laser, so that the length of a resonant cavity of the laser is more than or equal to 80m; the tapering regions on the ordinary single-mode fibers can effectively suppress the Brillouin gain and ensure the stability of single-frequency operation of the laser, and meanwhile, the large-length resonant cavity can meet the requirement of vast accumulation of Rayleigh gain and improve the signal strength. The micro-tapered fiber provided by the invention has the beneficial technical effects that the single-frequency operation of the laser is ensured, and meanwhile, the accumulation of Rayleigh gain can be effectively realized, and the output signal strength is improved; the tuning range is unrelated to the matching of the pumping wavelength and the length of the laser cavity, and additional linewidth compression is not needed; and the structure is simple, the implementation is easy, and the fiber is a novel narrow-linewidth light source.

Owner:CHONGQING UNIV

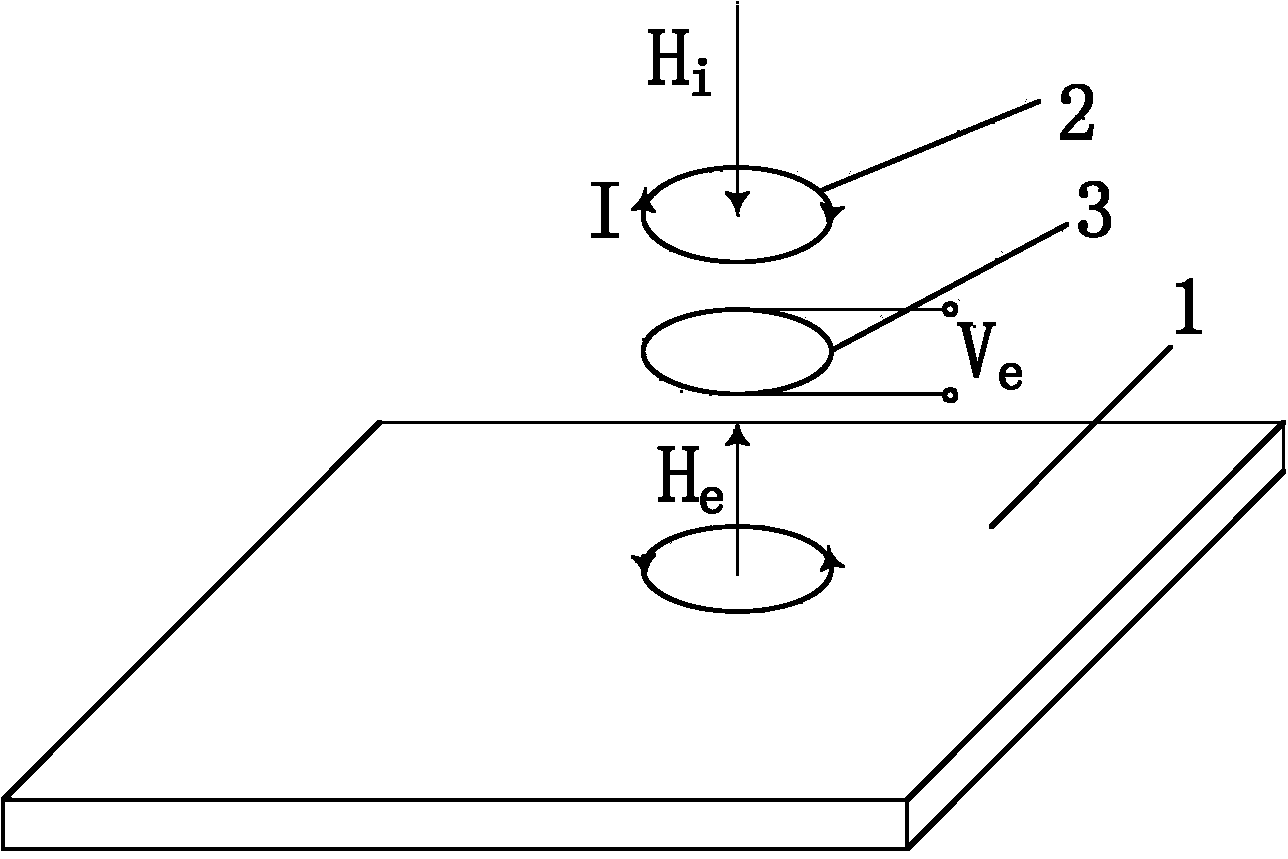

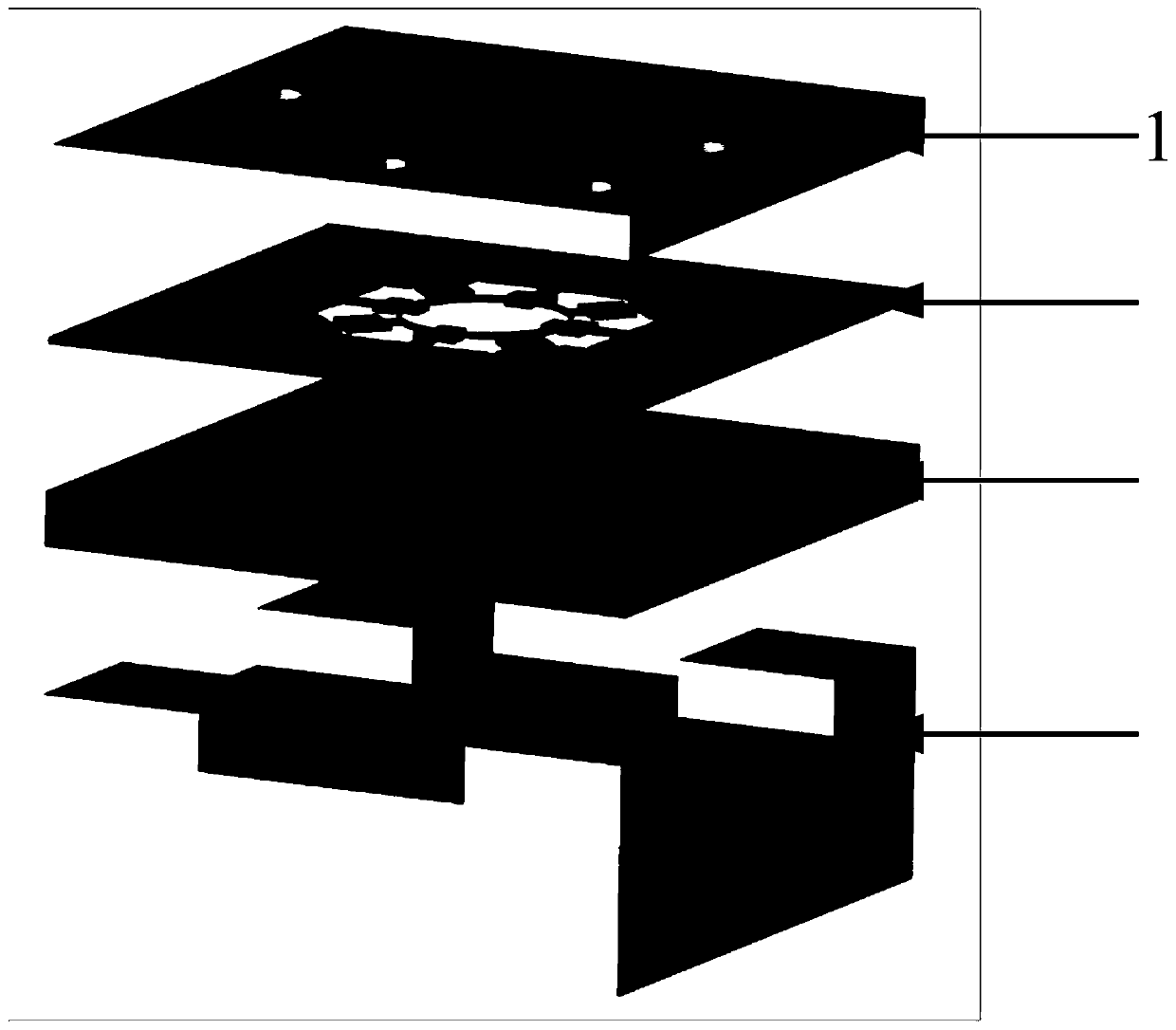

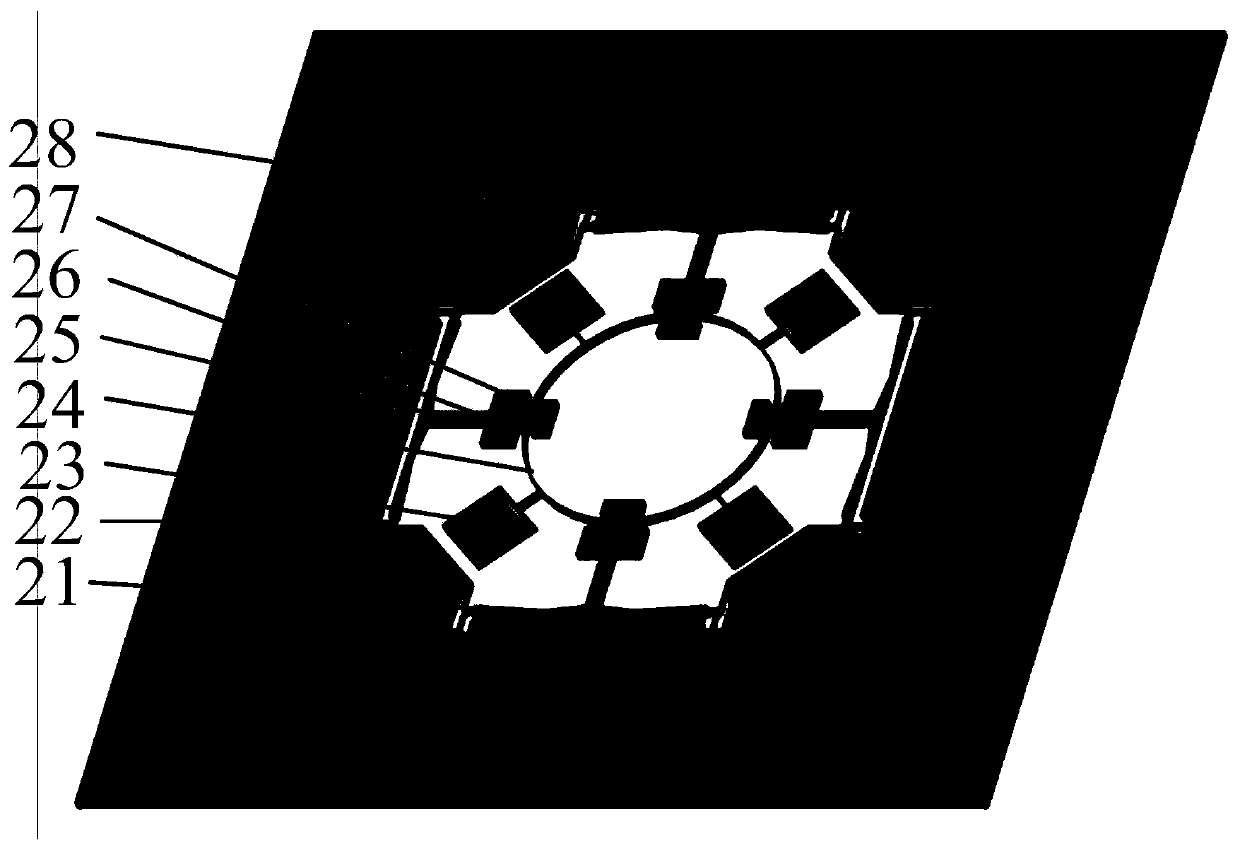

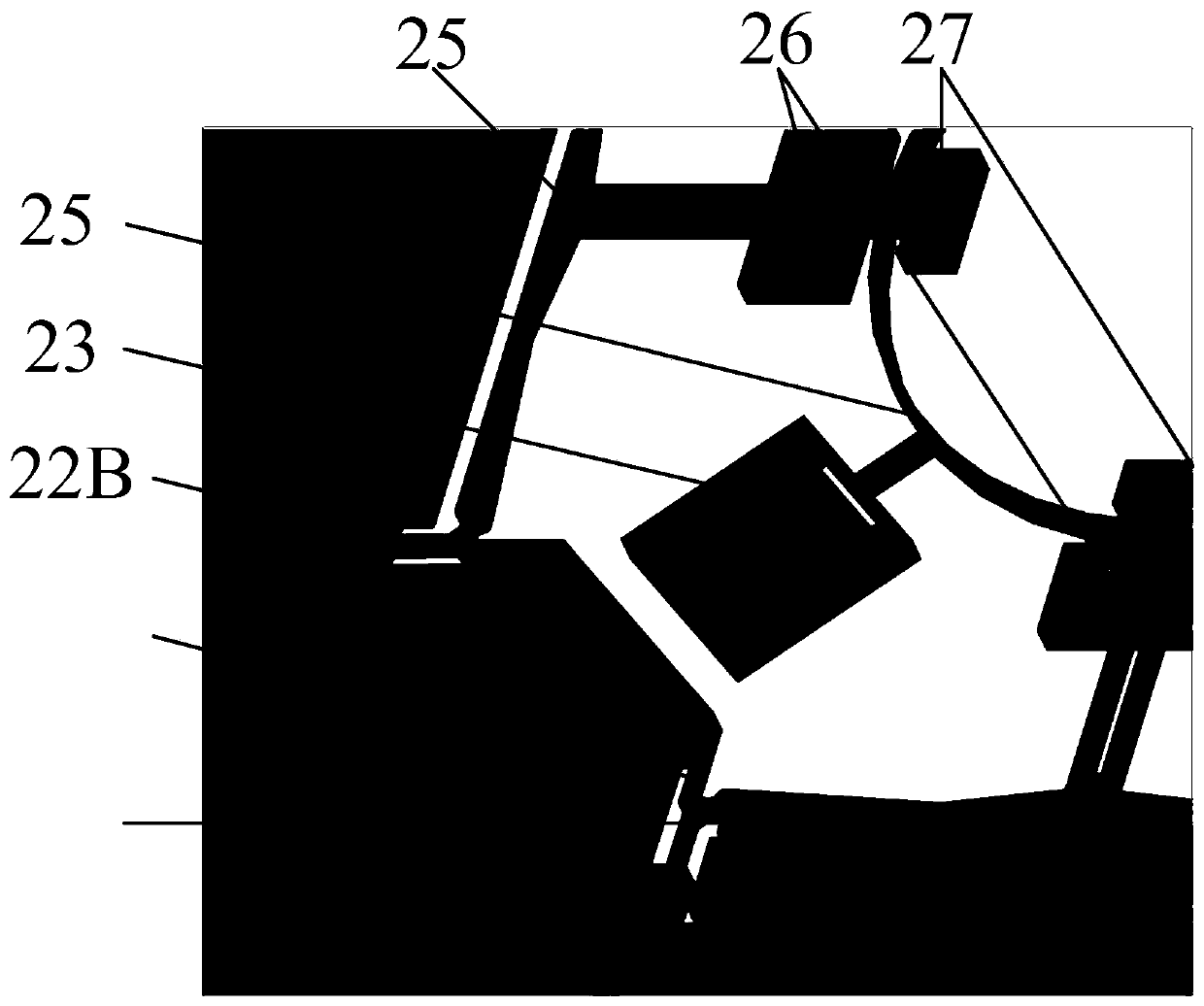

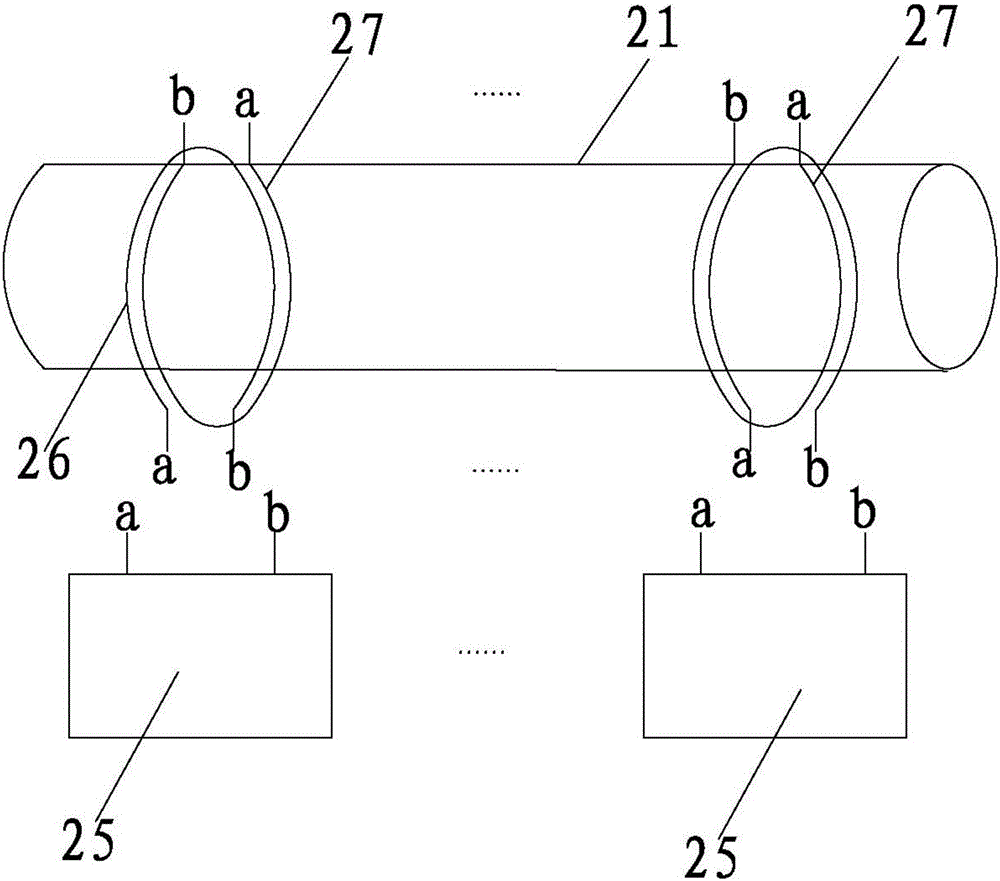

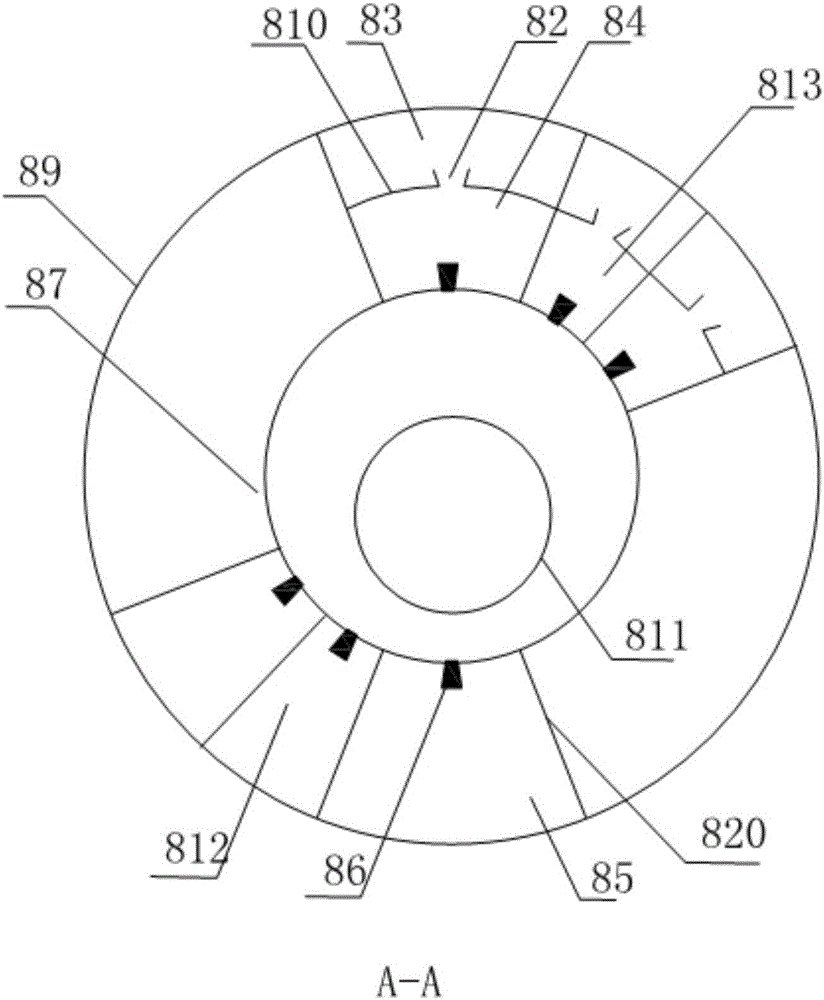

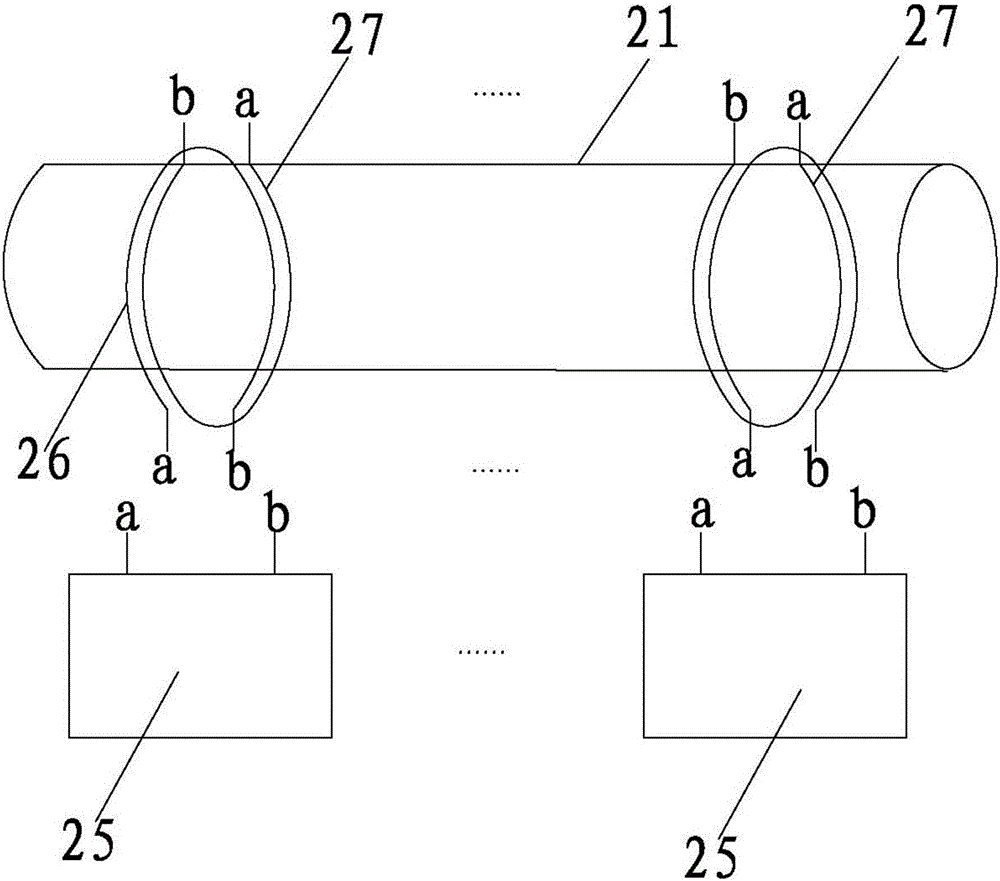

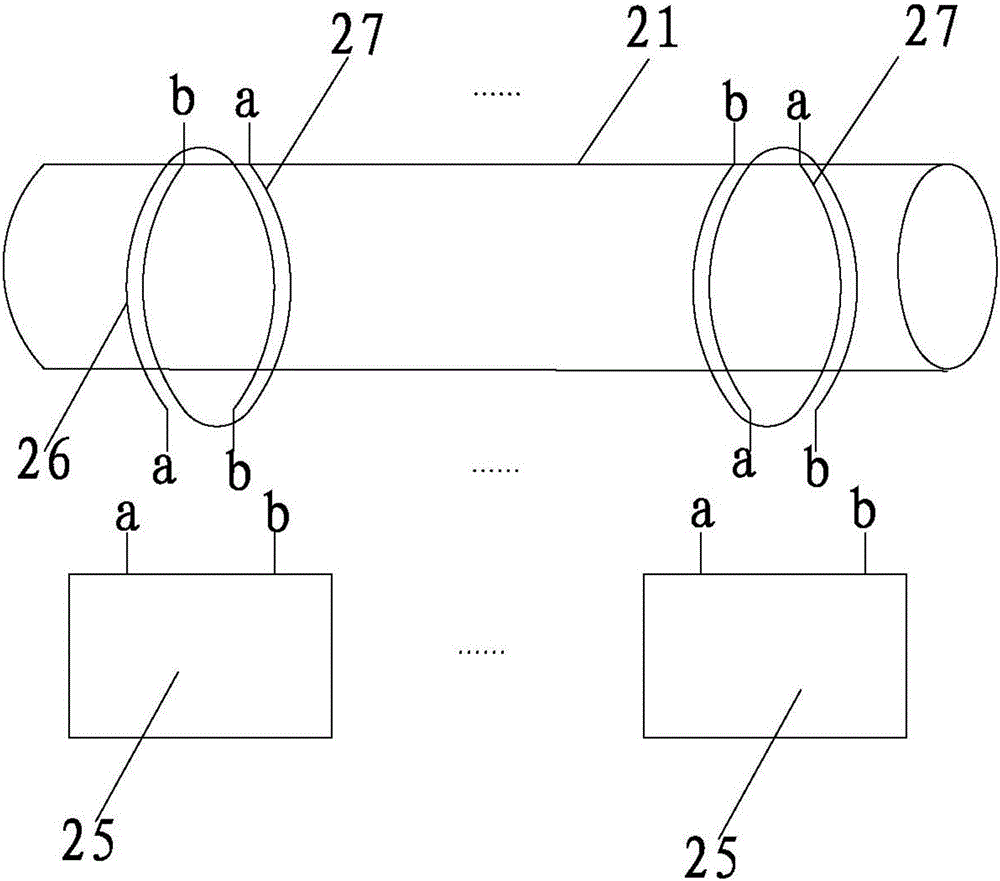

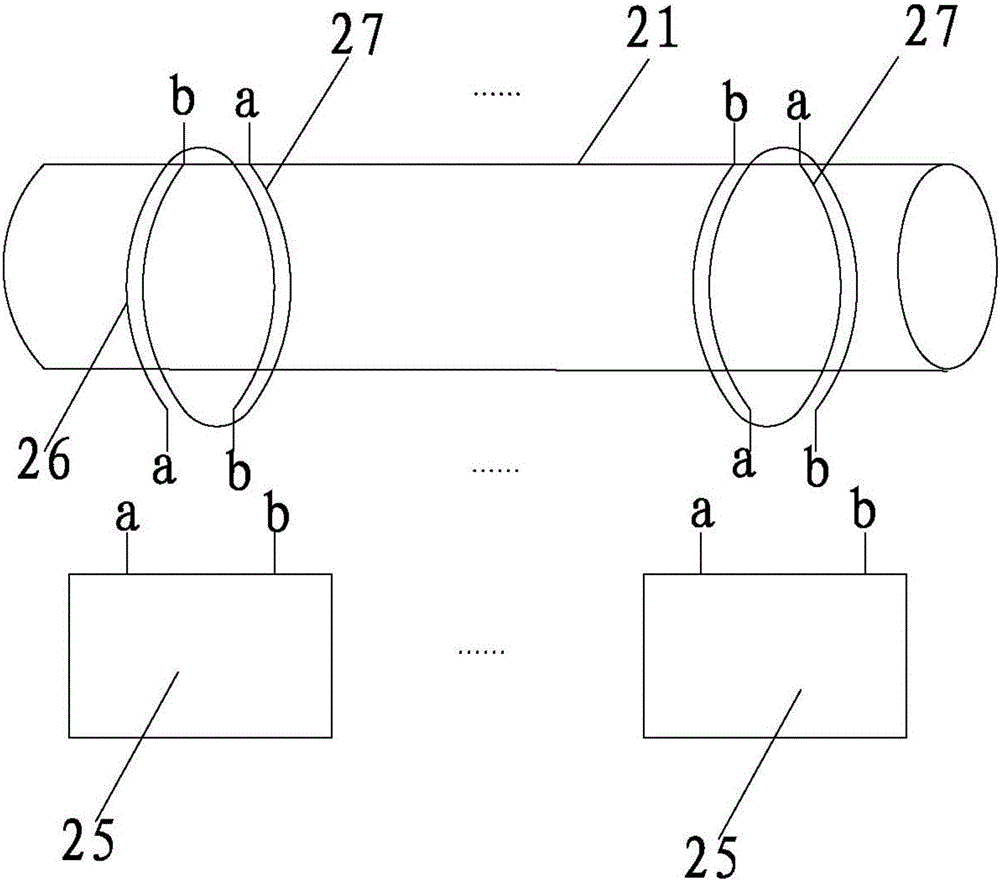

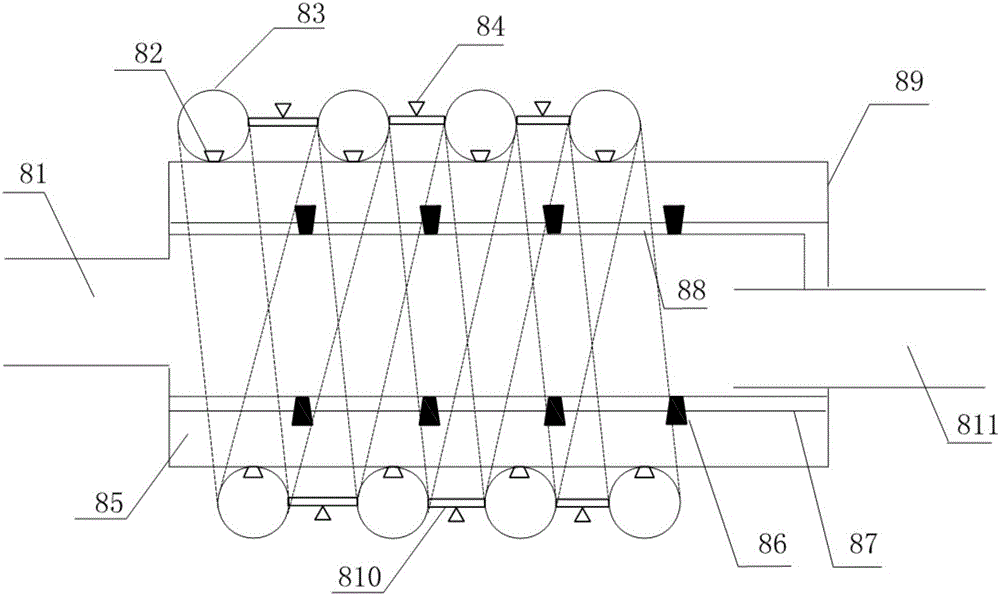

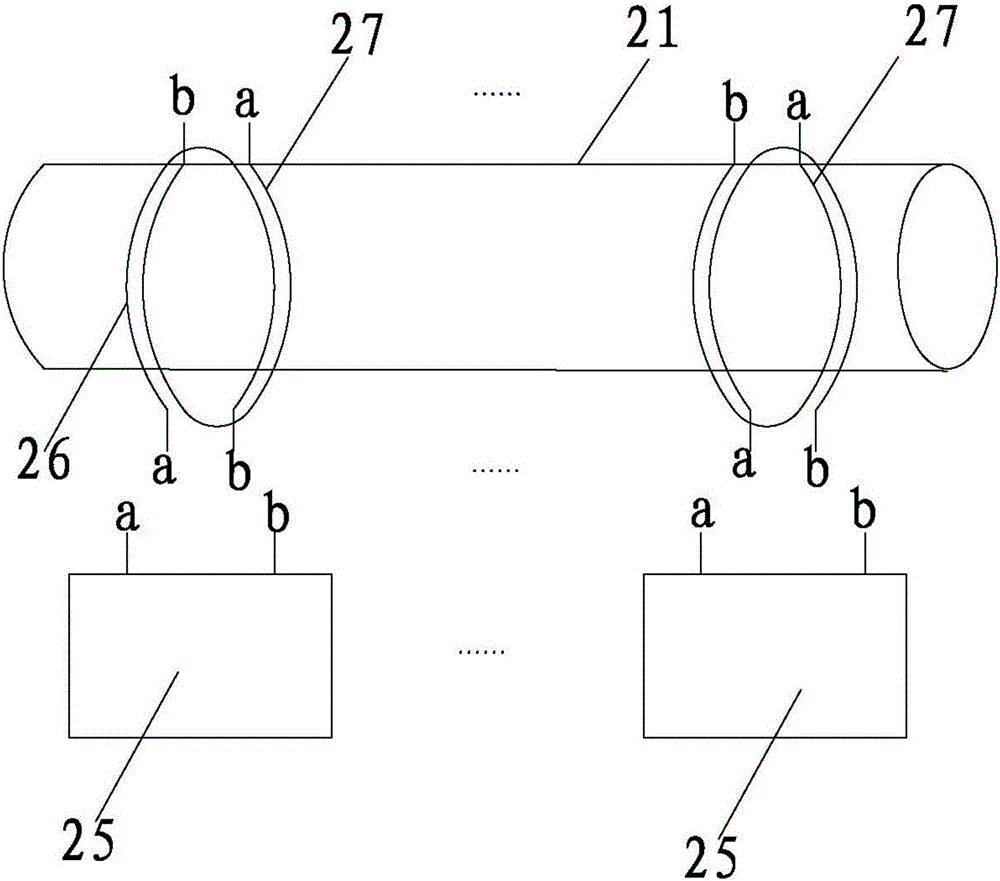

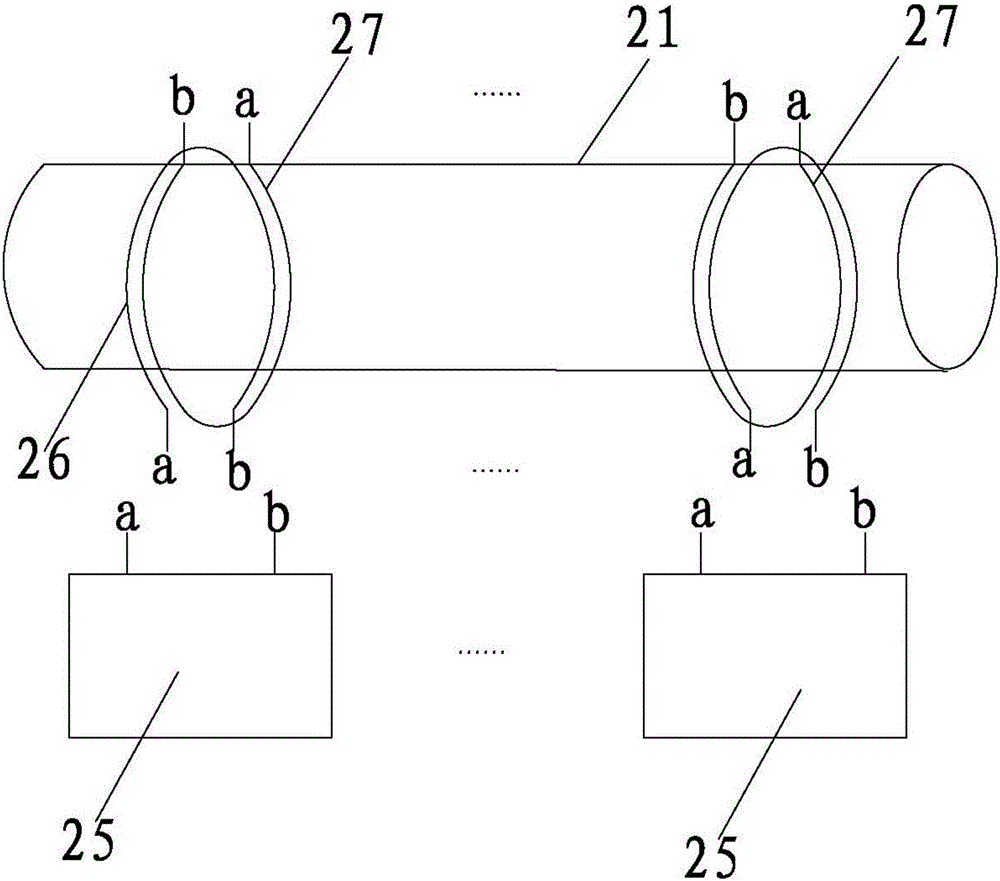

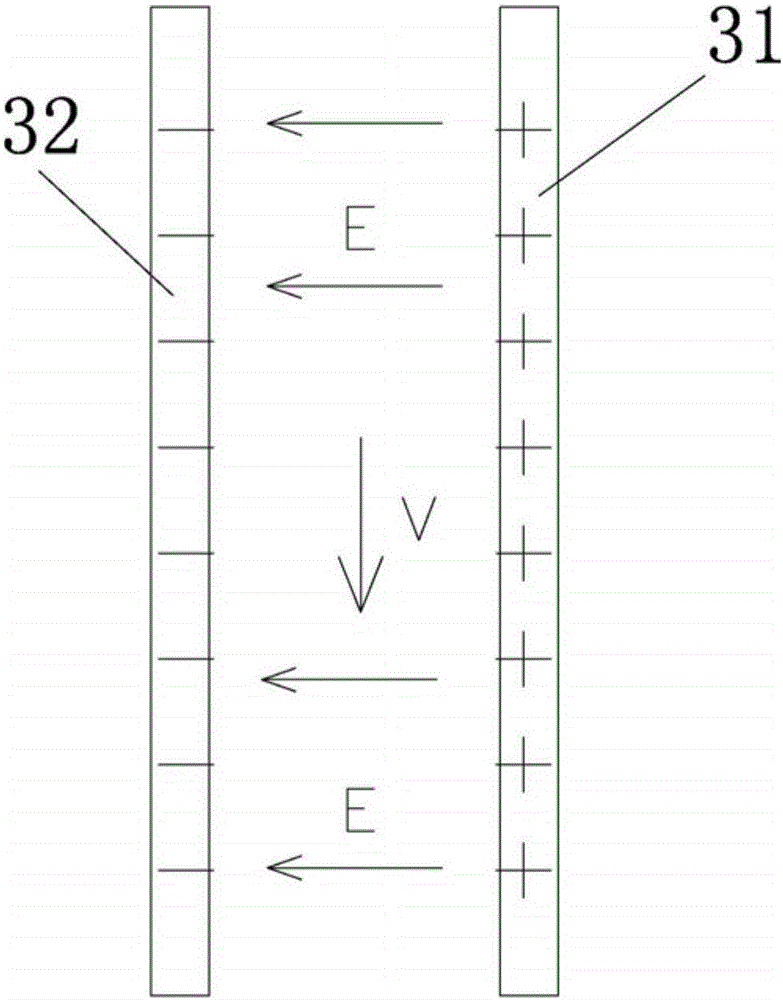

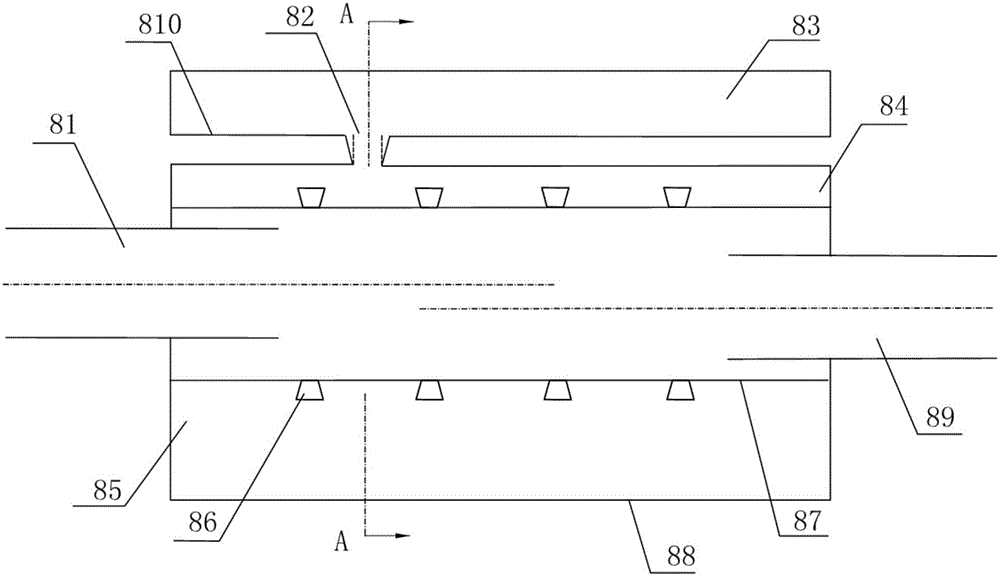

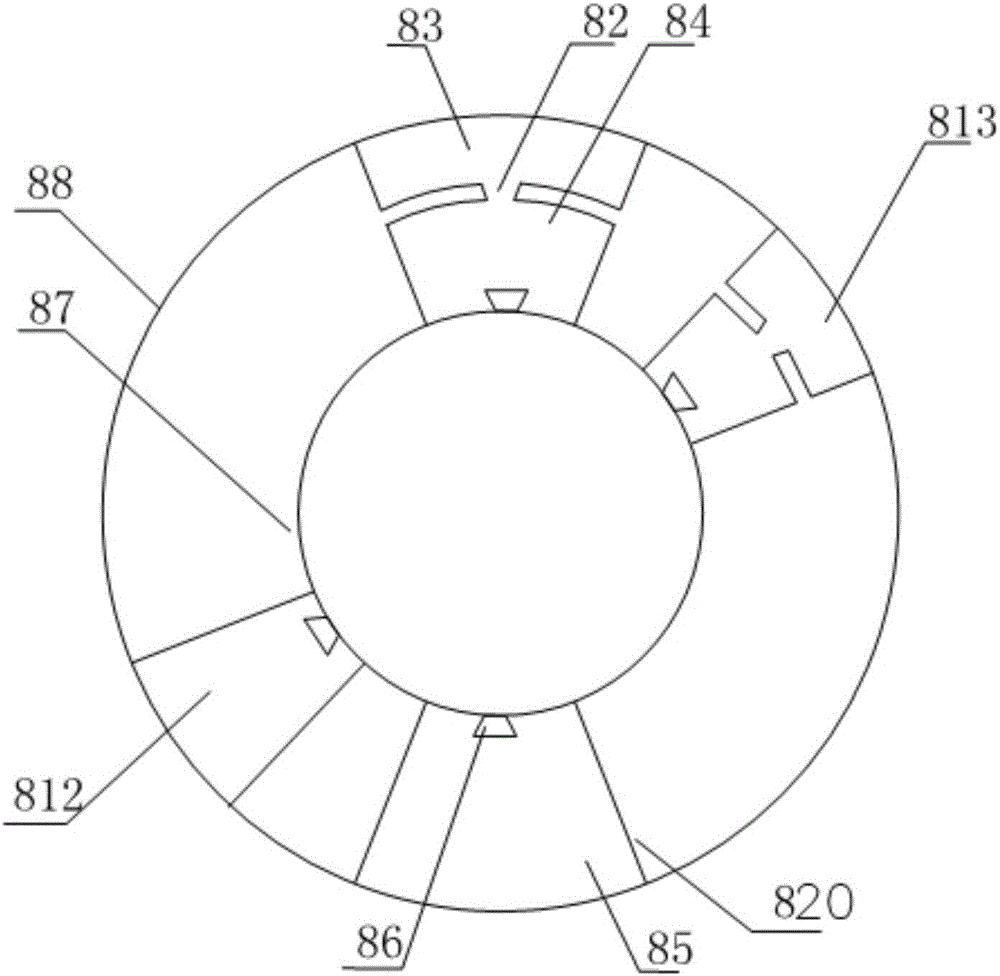

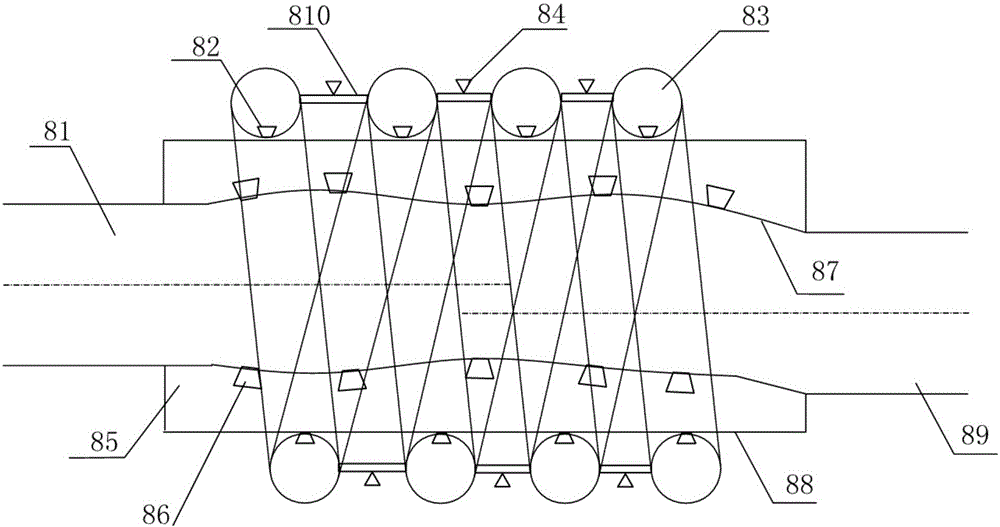

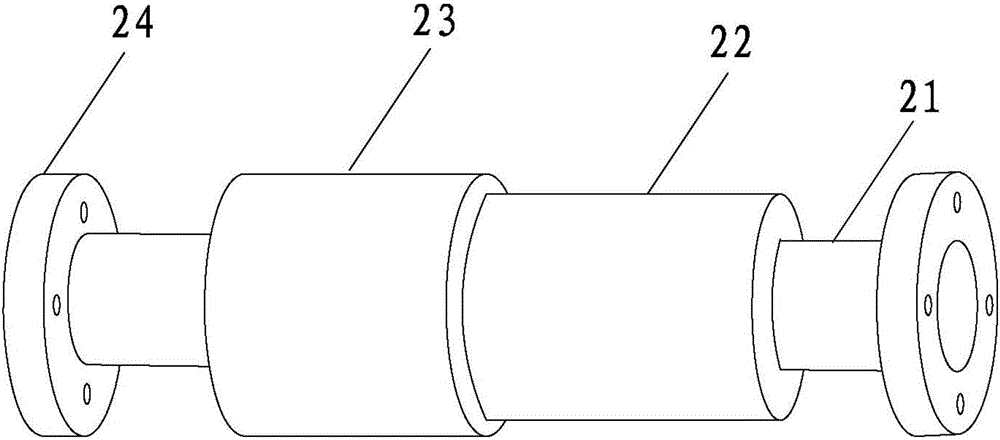

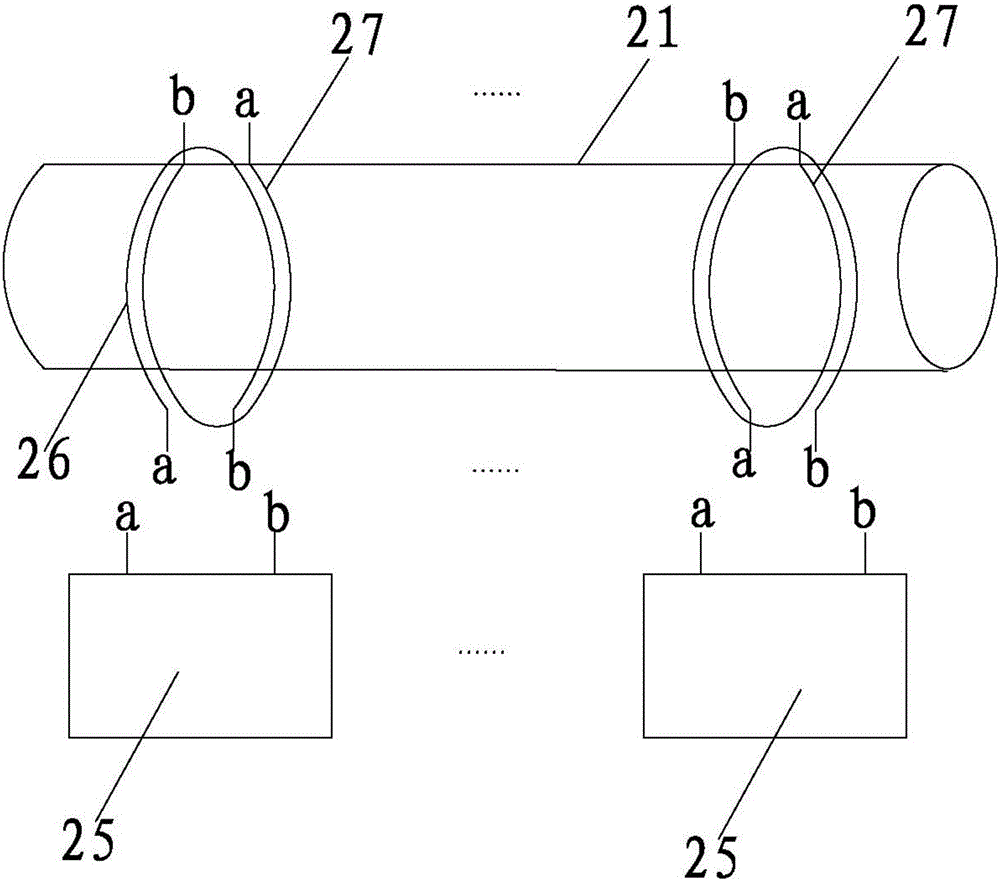

Flexible array type eddy current sensor with circular periodic structure

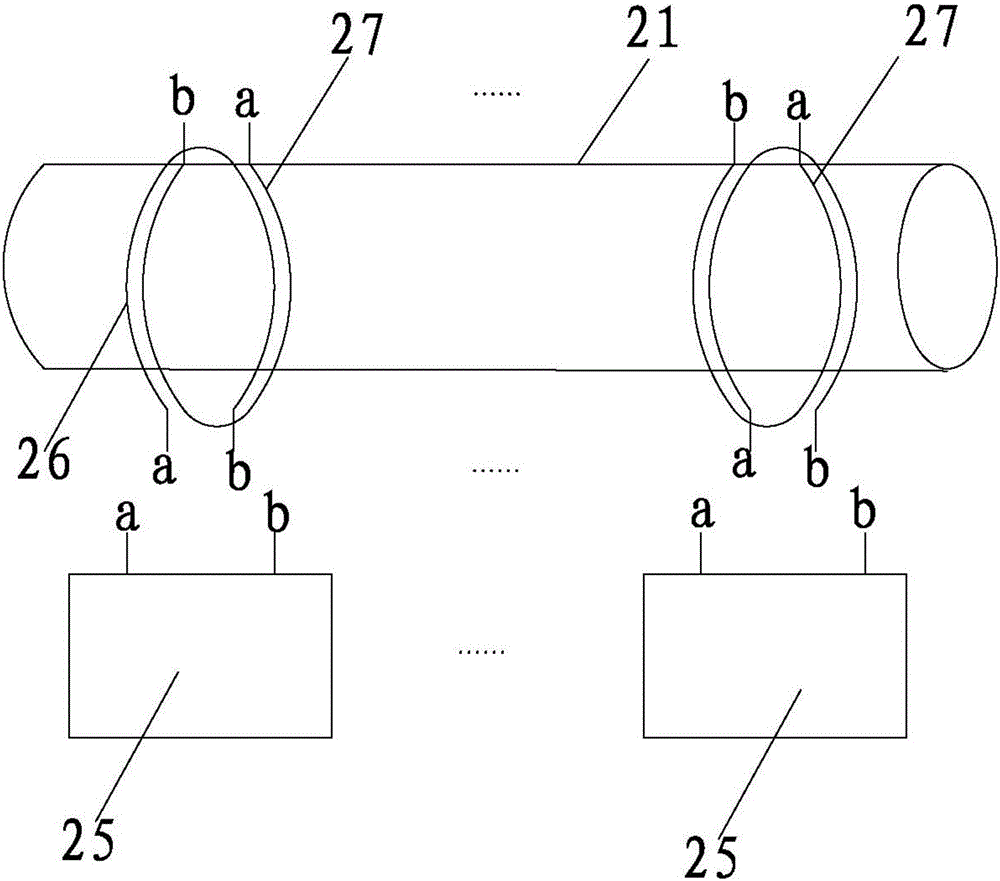

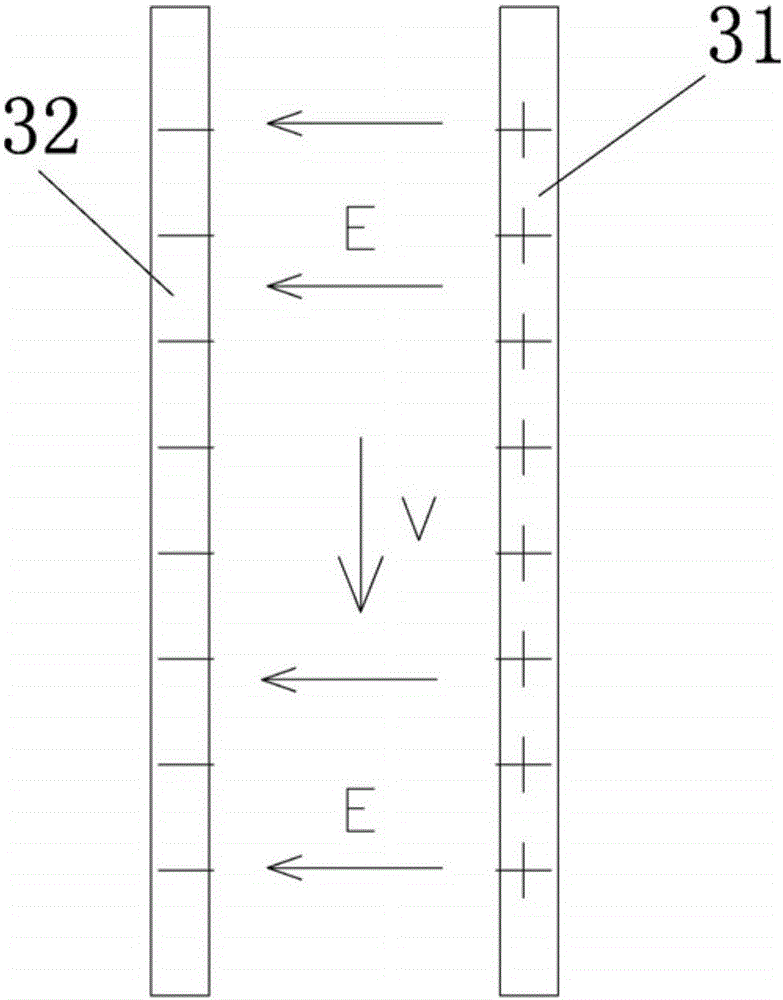

InactiveCN103760232AImprove adaptabilityImprove detection efficiencyMaterial magnetic variablesCoil arrayImage resolution

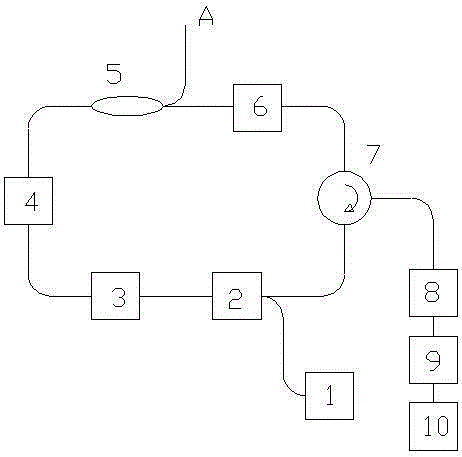

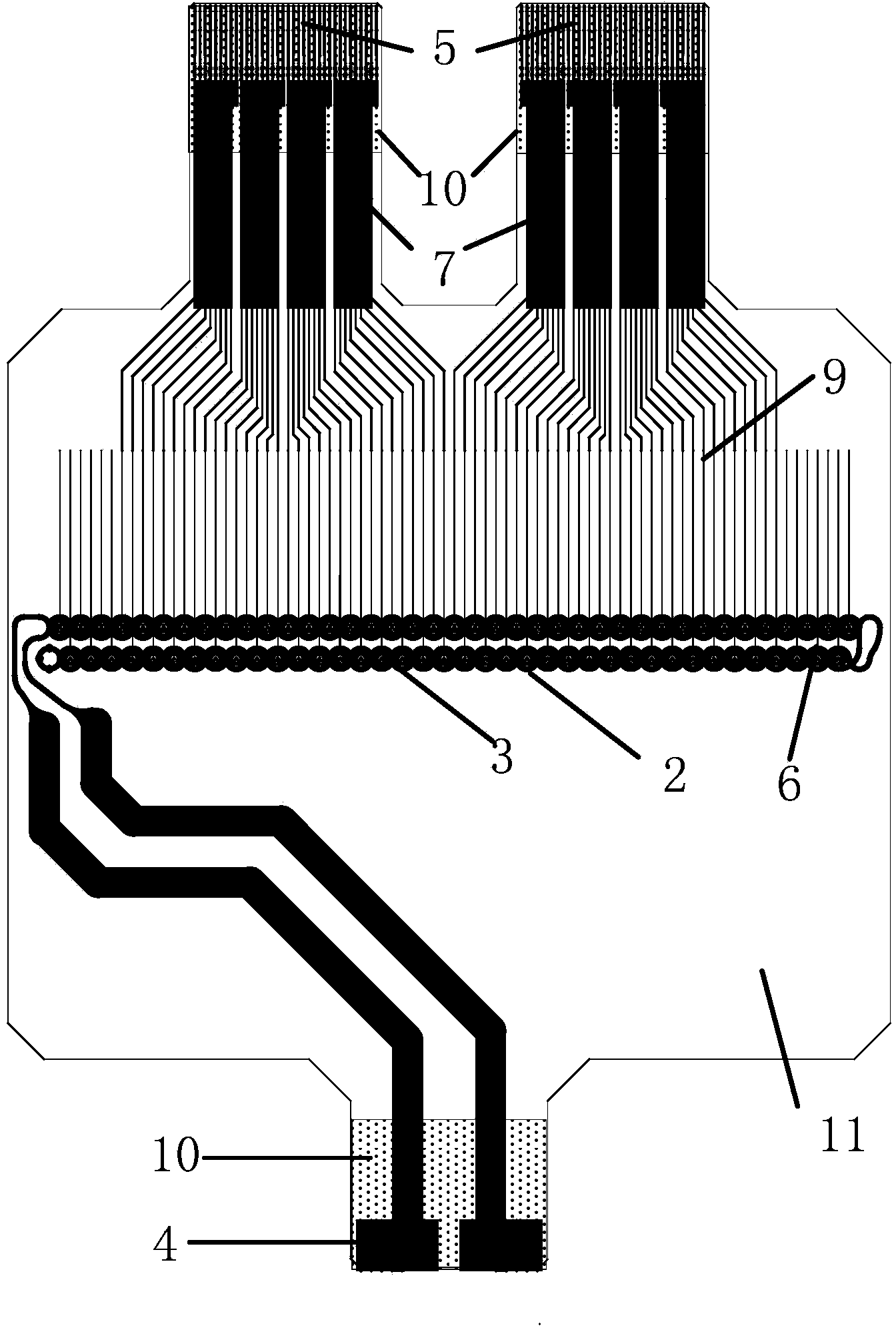

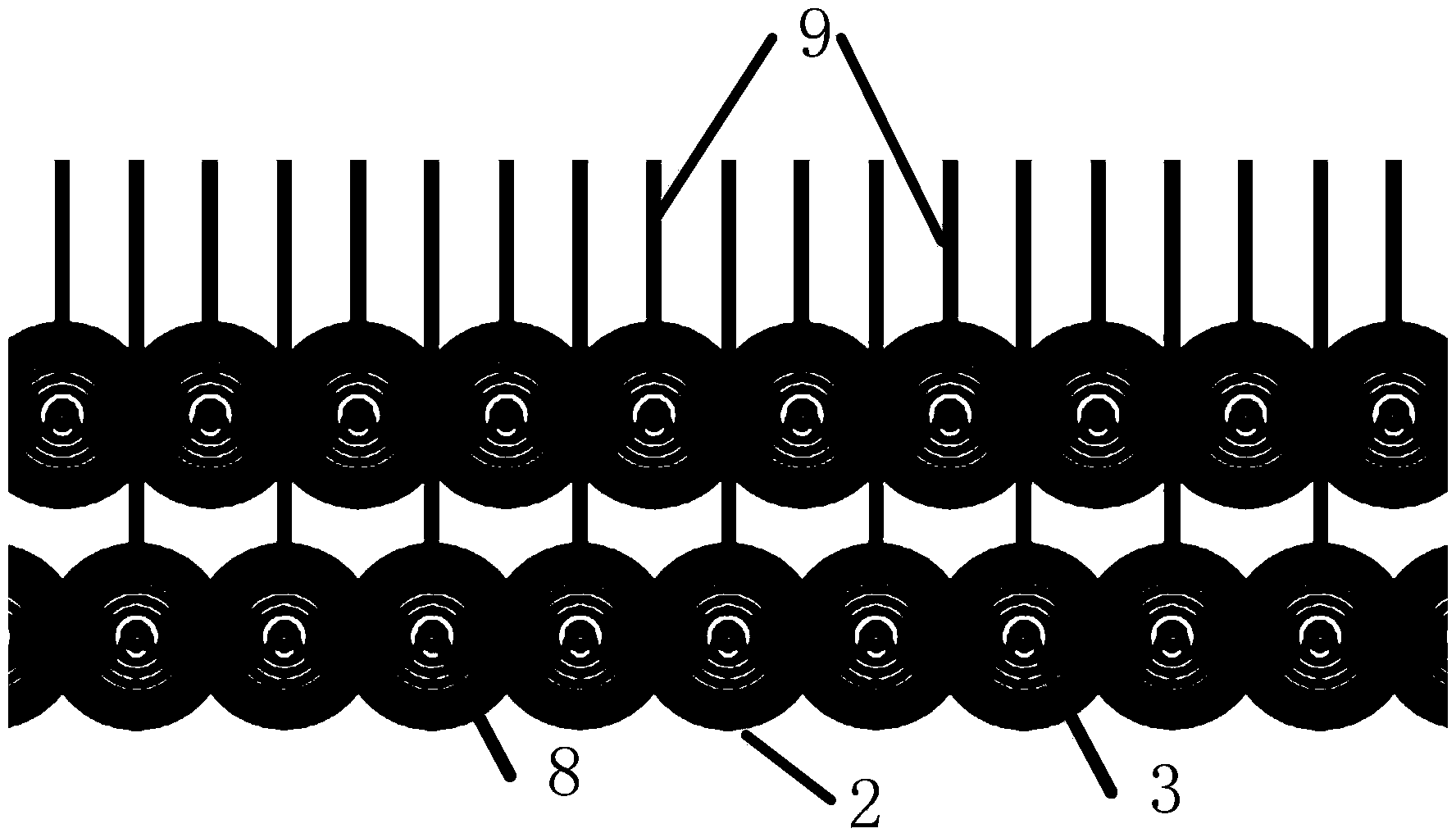

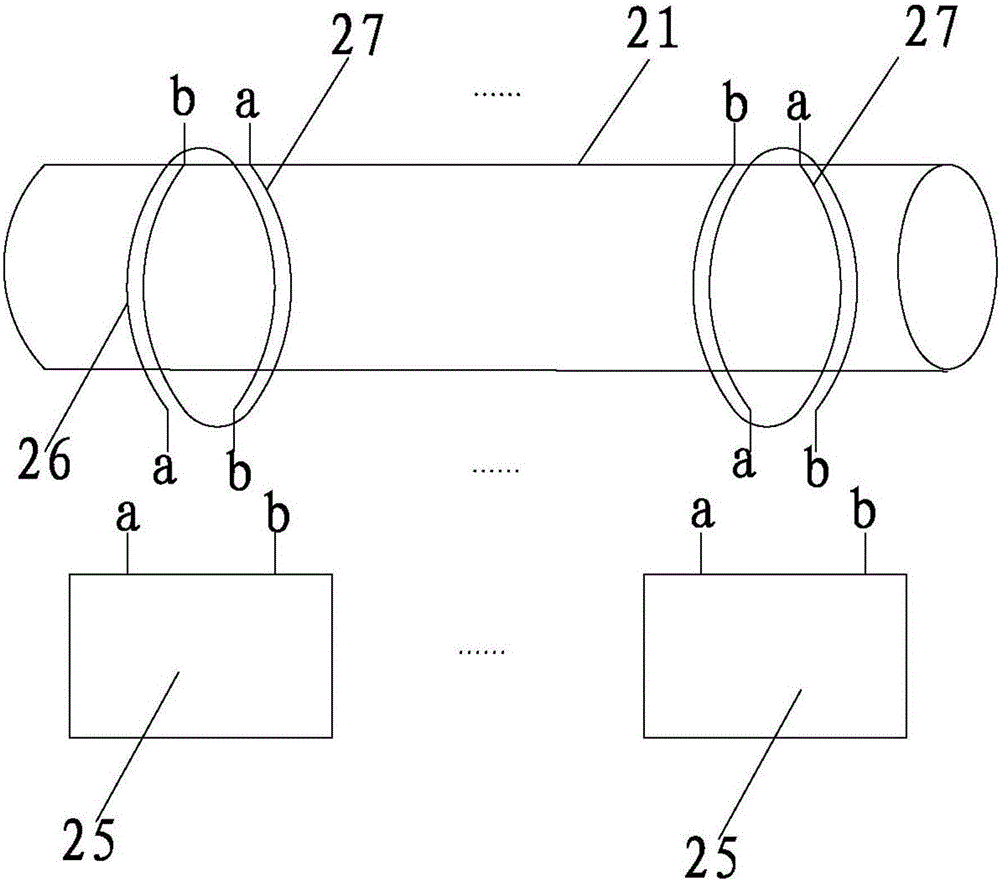

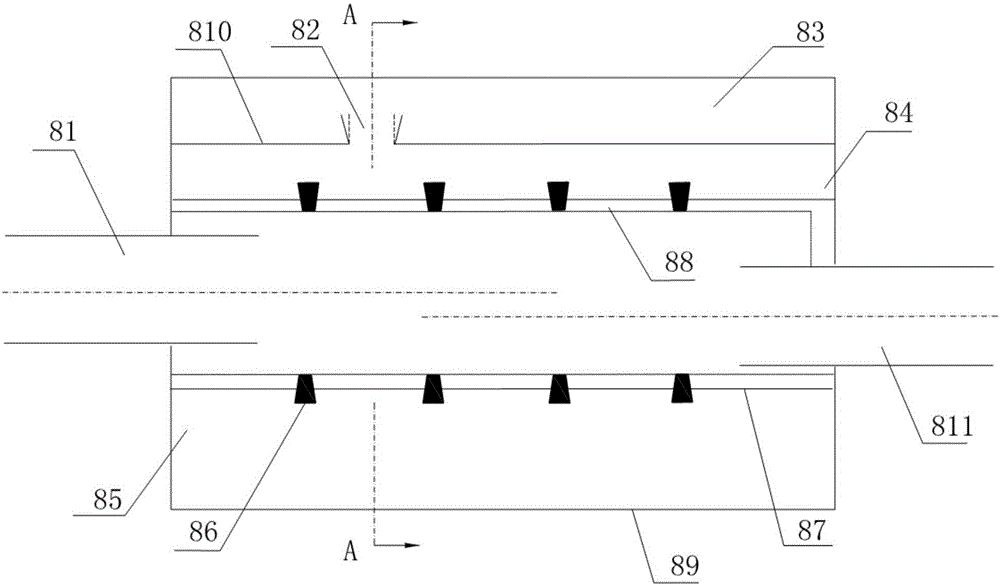

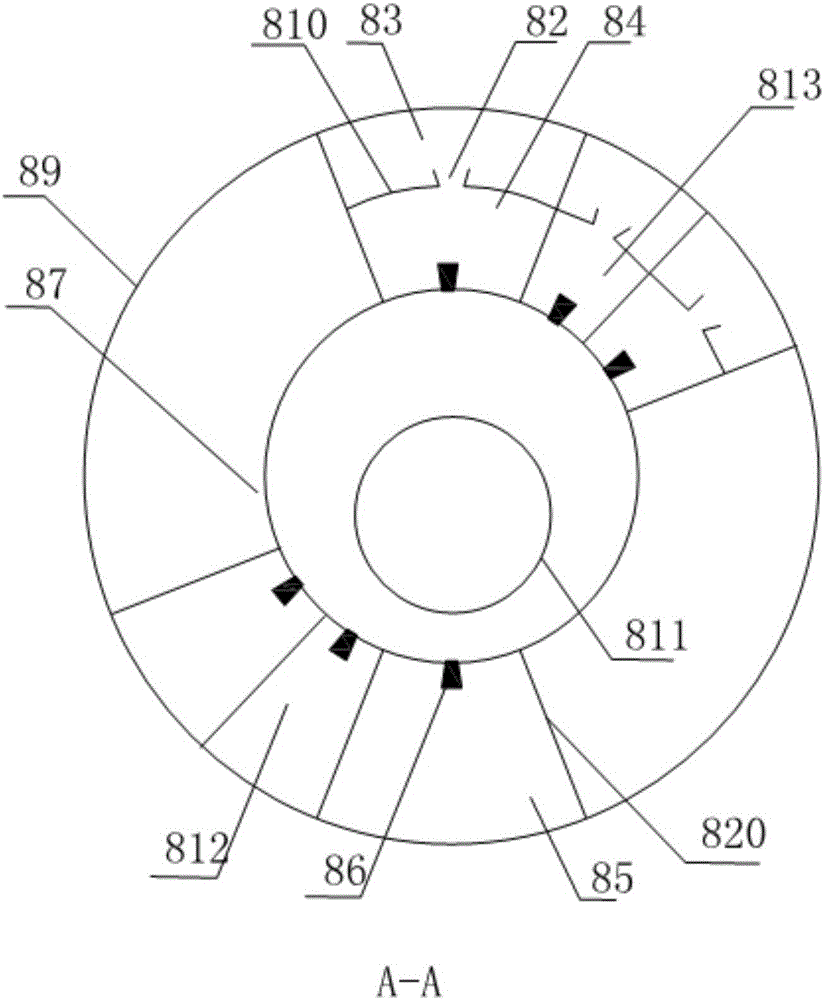

The invention discloses a flexible array type eddy current sensor with a circular periodic structure. The flexible array type eddy current sensor comprises four layers of structures, wherein the top layer and the bottom layer are excitation coils, and the two middle layers are detection coil arrays; the excitation coils are periodically circular closed-loop coils formed by routing upper and lower staggered semicircular periodic coils; the detection coil arrays comprise a plurality of detection coils; the detection coils adopt double-layer spiral structures; the upper layer of the detection coils and the lower layer of the detection coils are conducted through penetrating holes; the spiral winding directions of the upper layer of the detection coils and the lower layer of the detection coils are opposite. The flexible array type eddy current sensor with the circular periodic structure has the advantages of simple structure, convenience in manufacturing, high space resolution, full coverage (no scanning dead corner), high output signal, high tiny defect detection capacity, high detection efficiency and the like.

Owner:NAT UNIV OF DEFENSE TECH

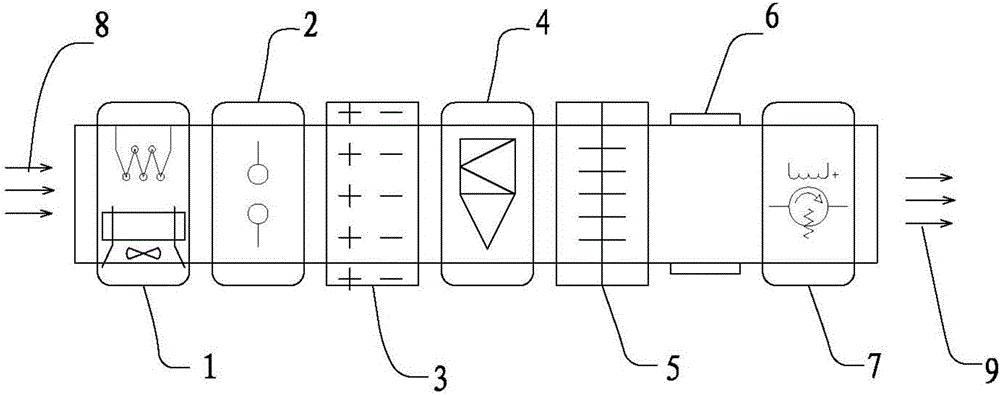

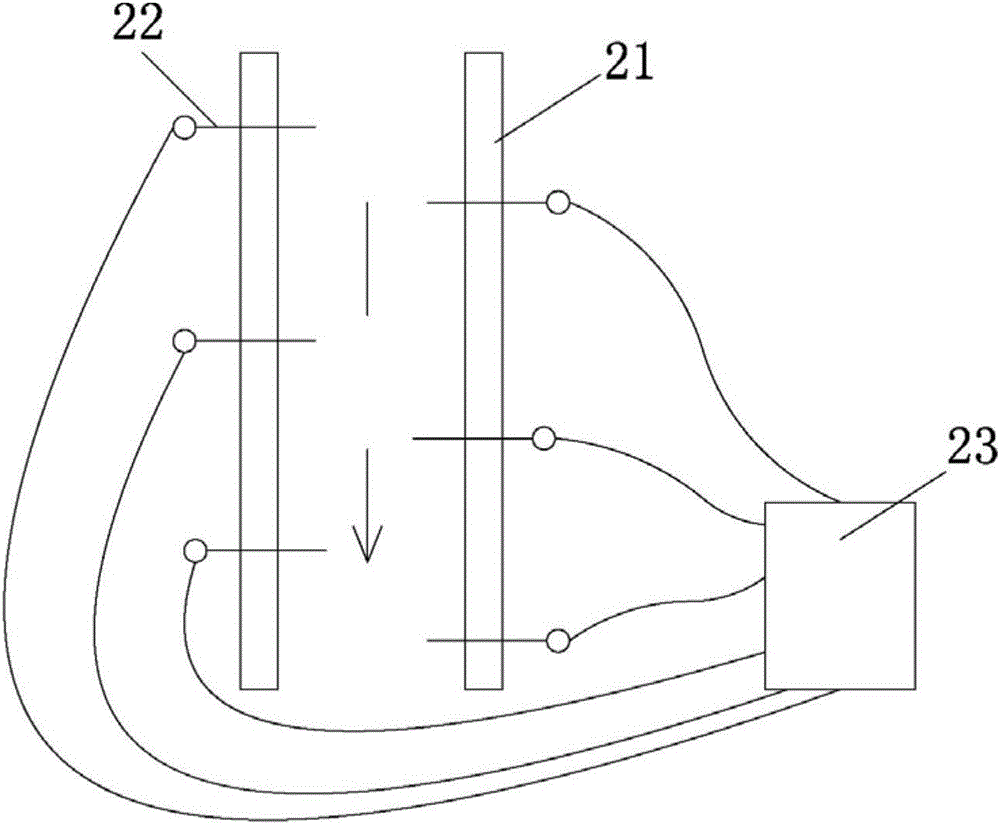

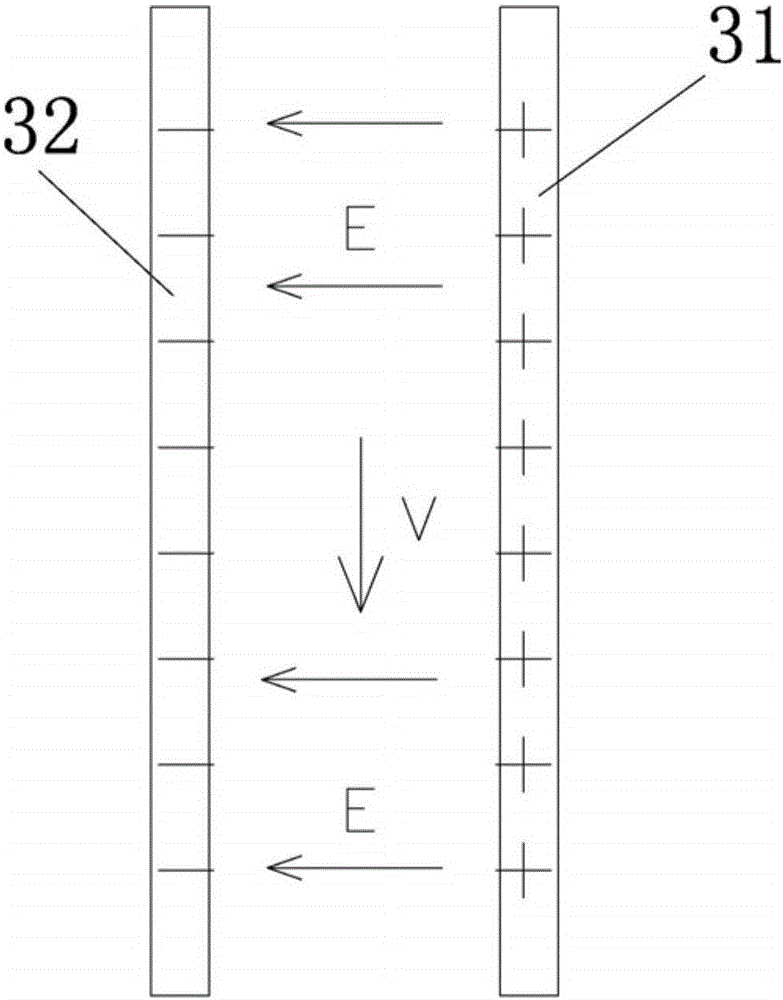

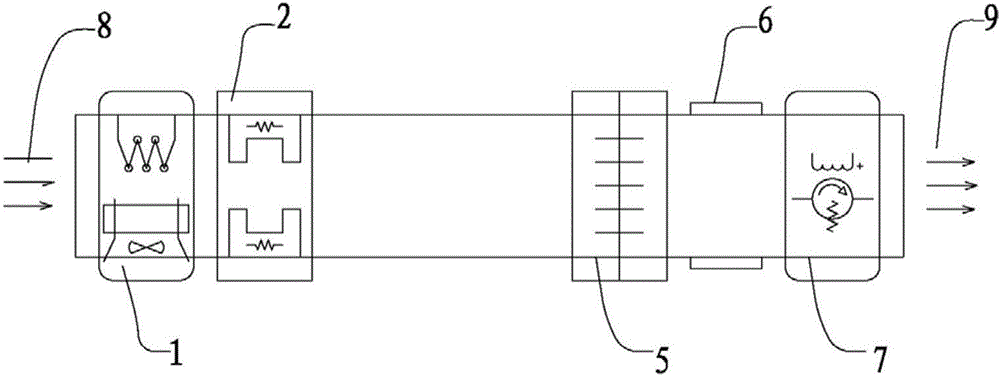

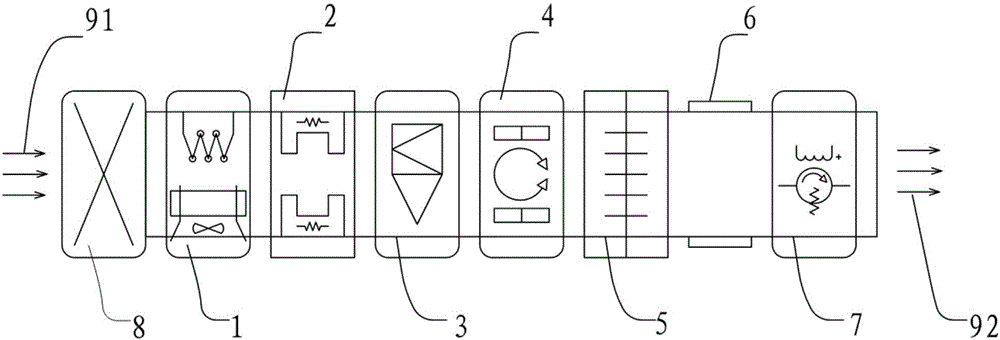

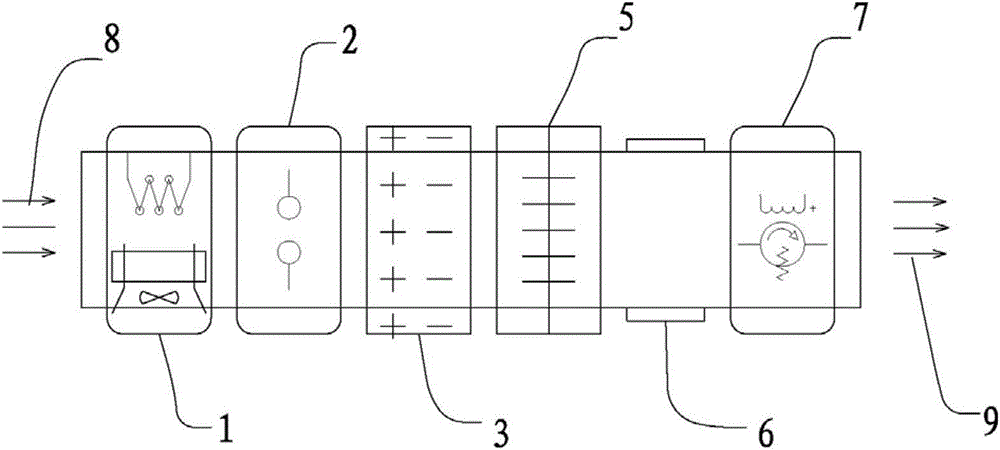

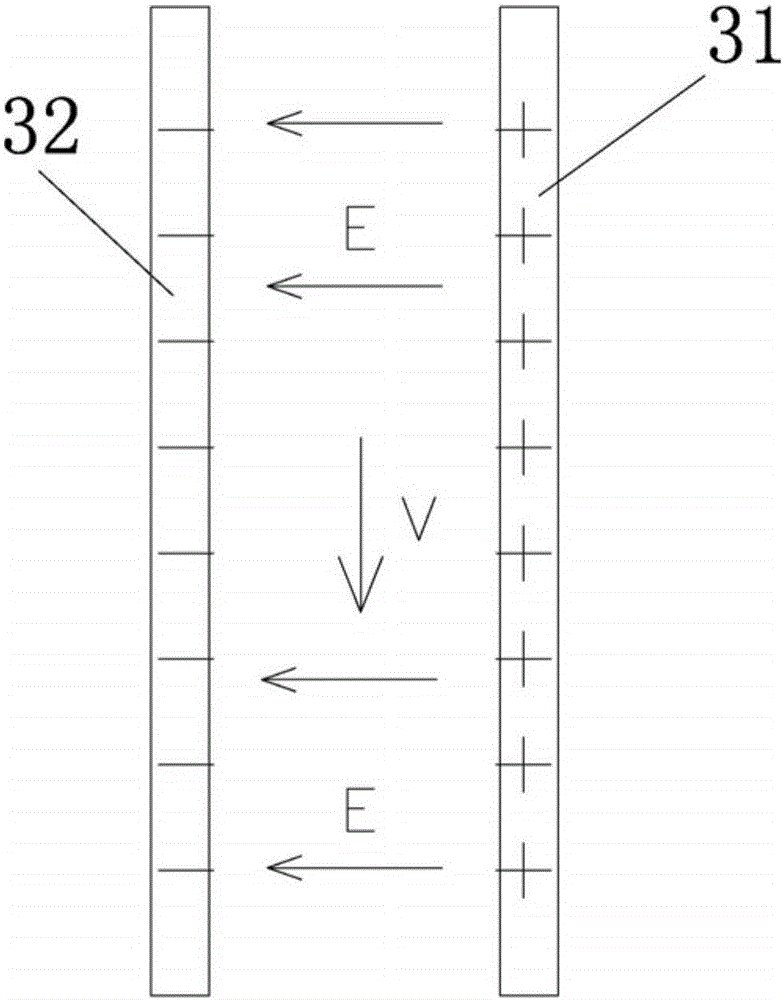

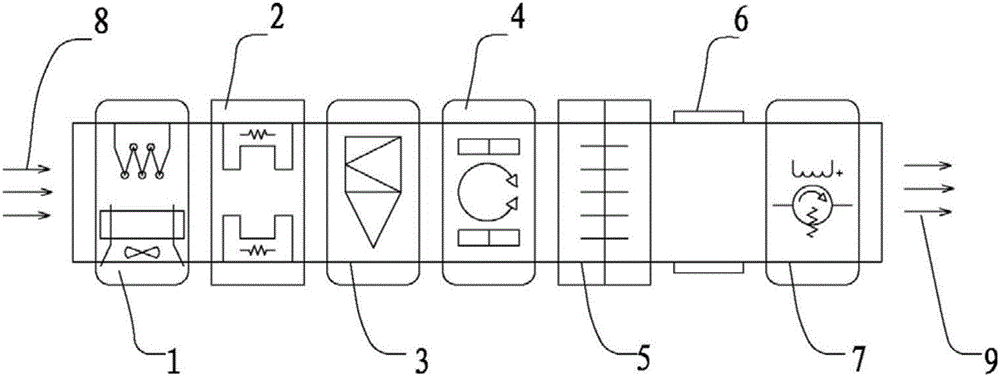

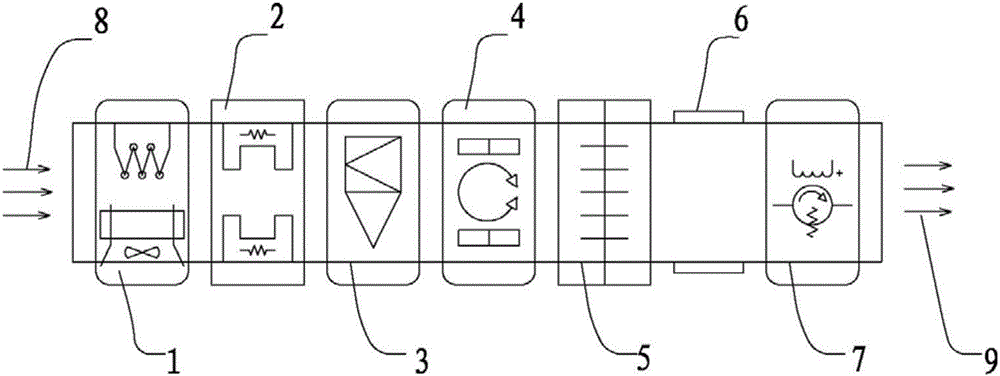

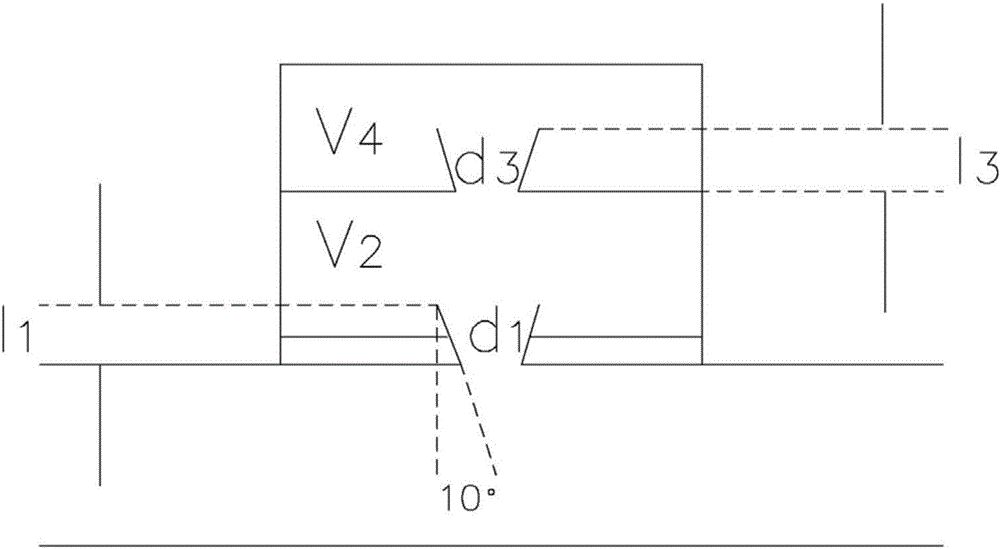

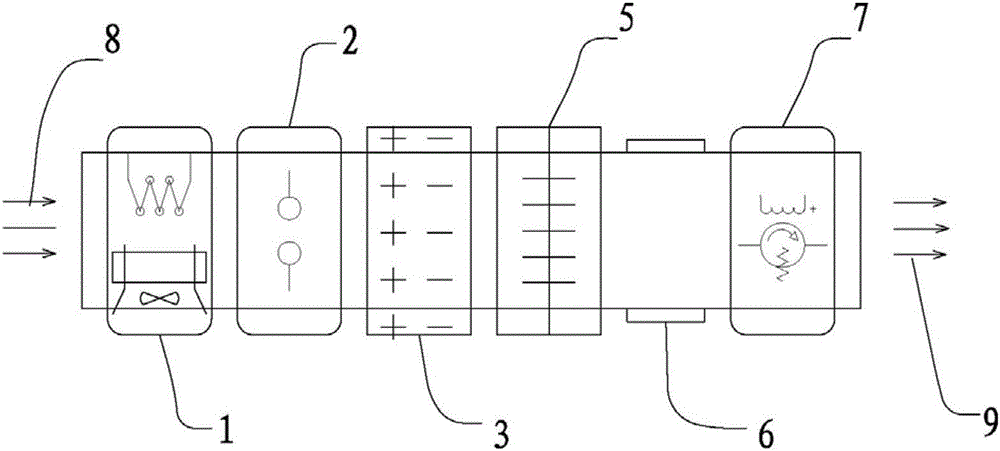

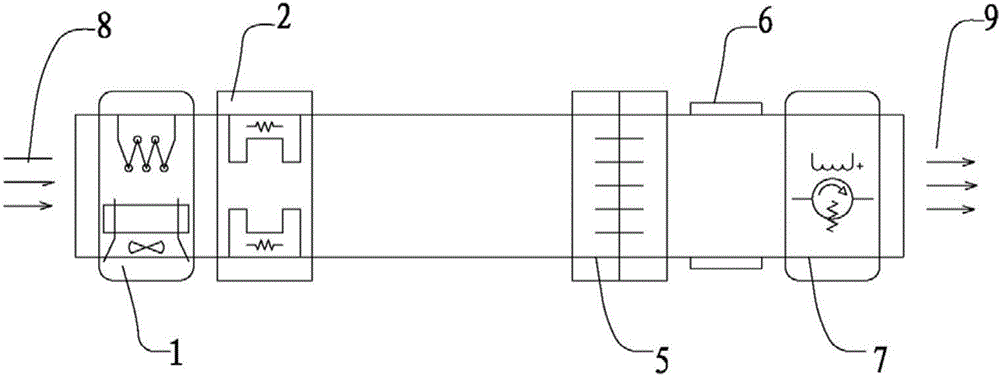

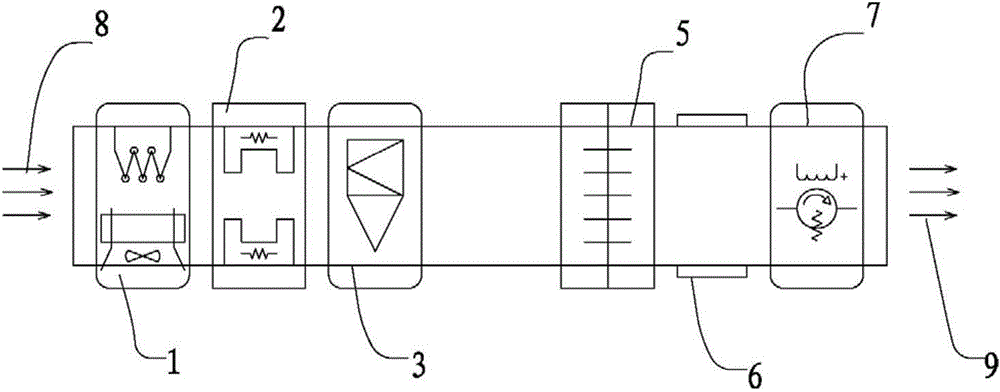

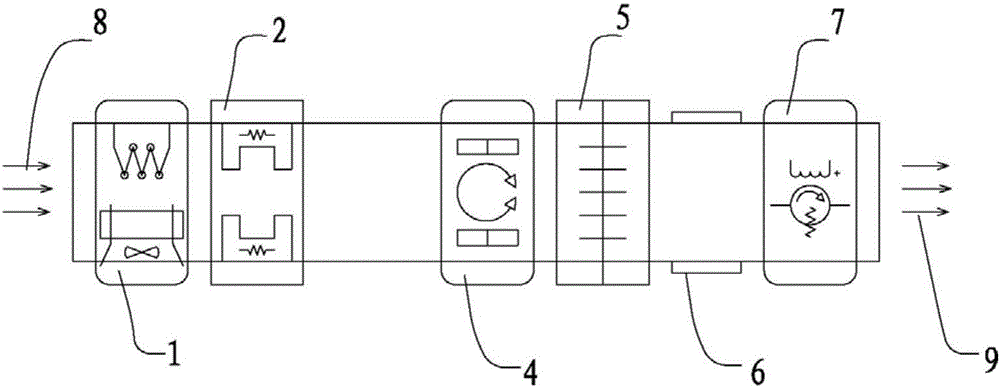

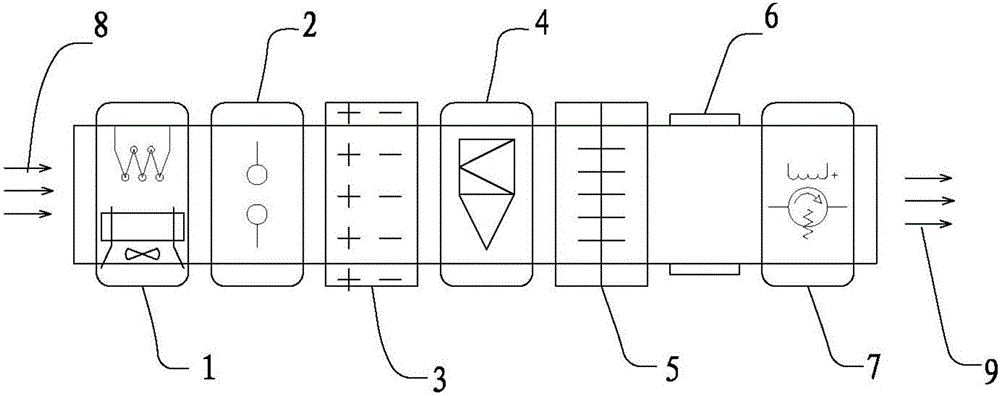

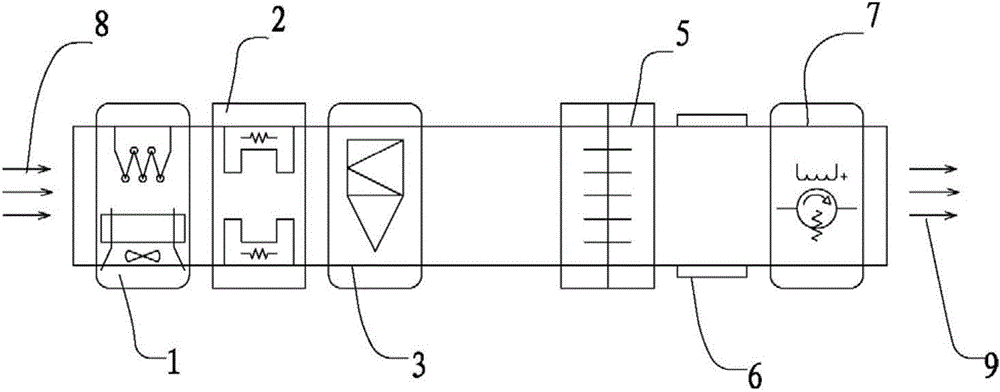

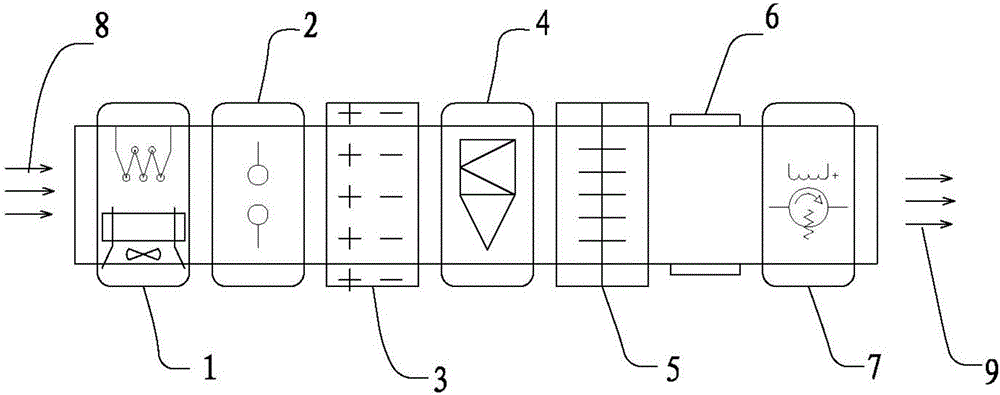

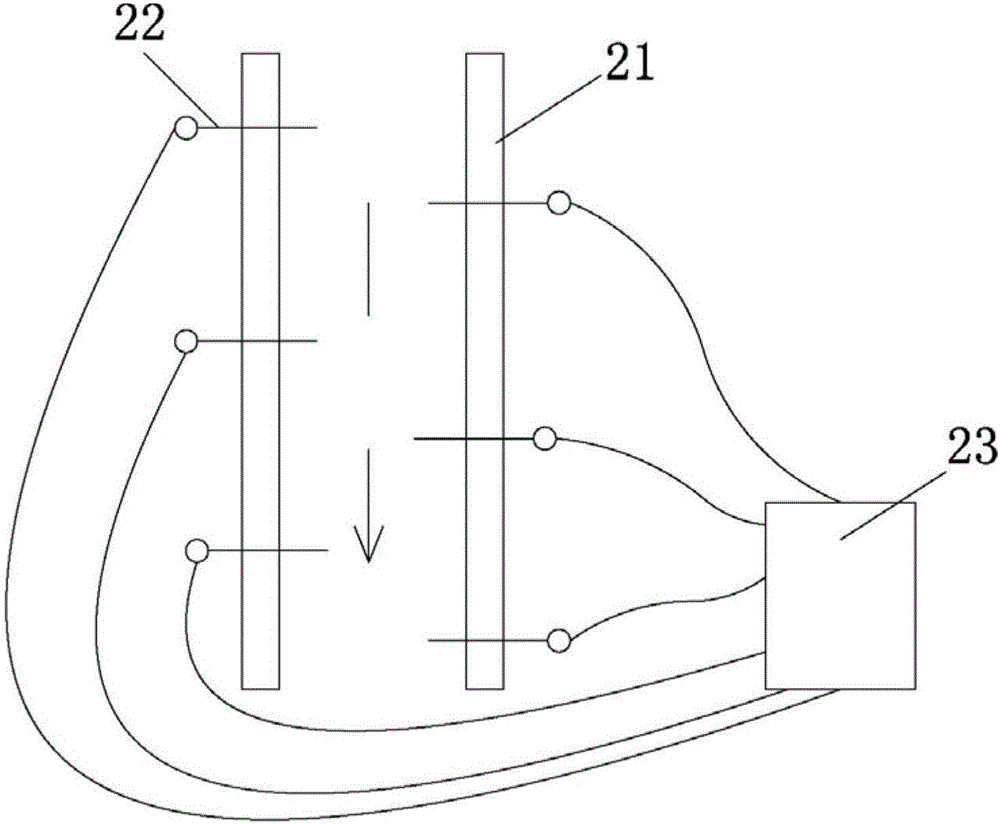

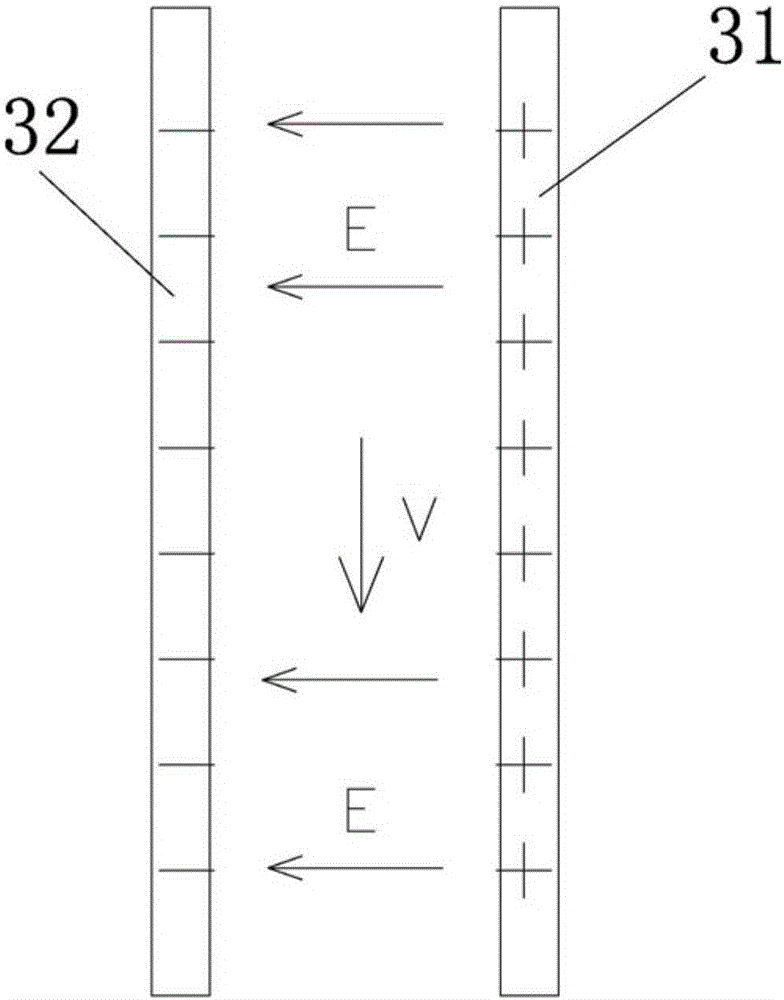

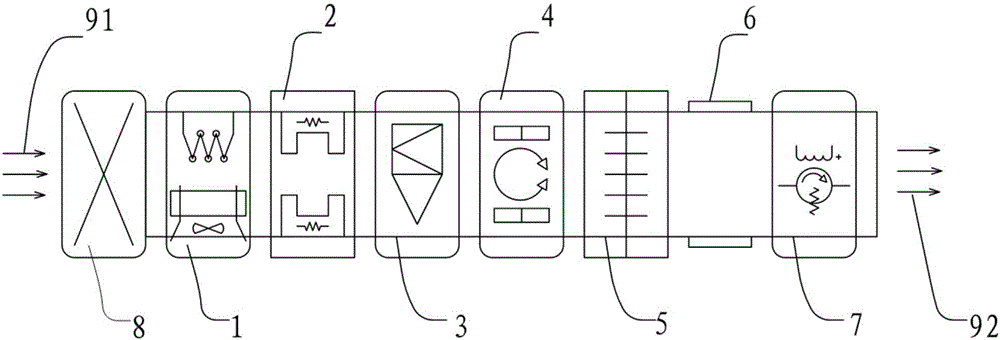

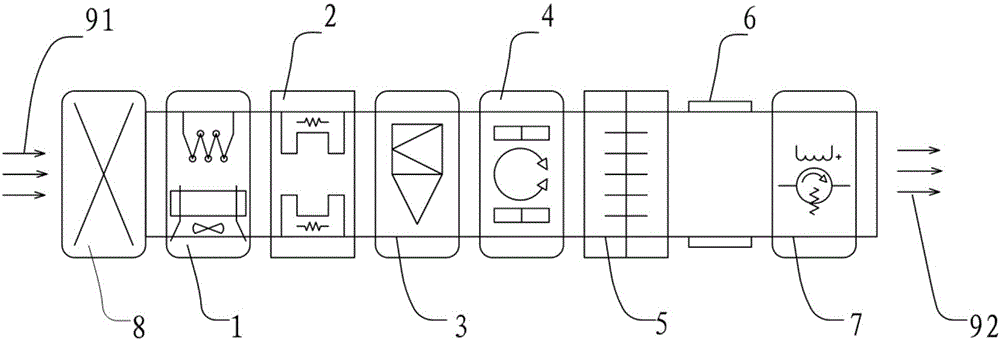

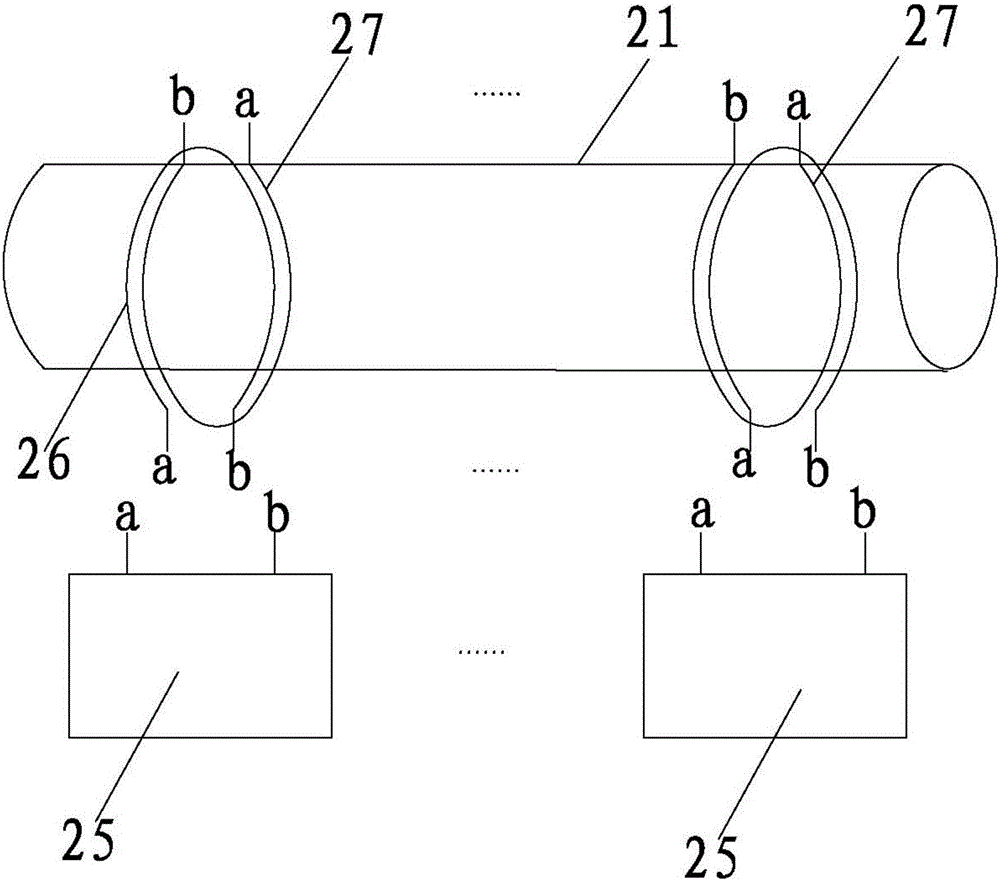

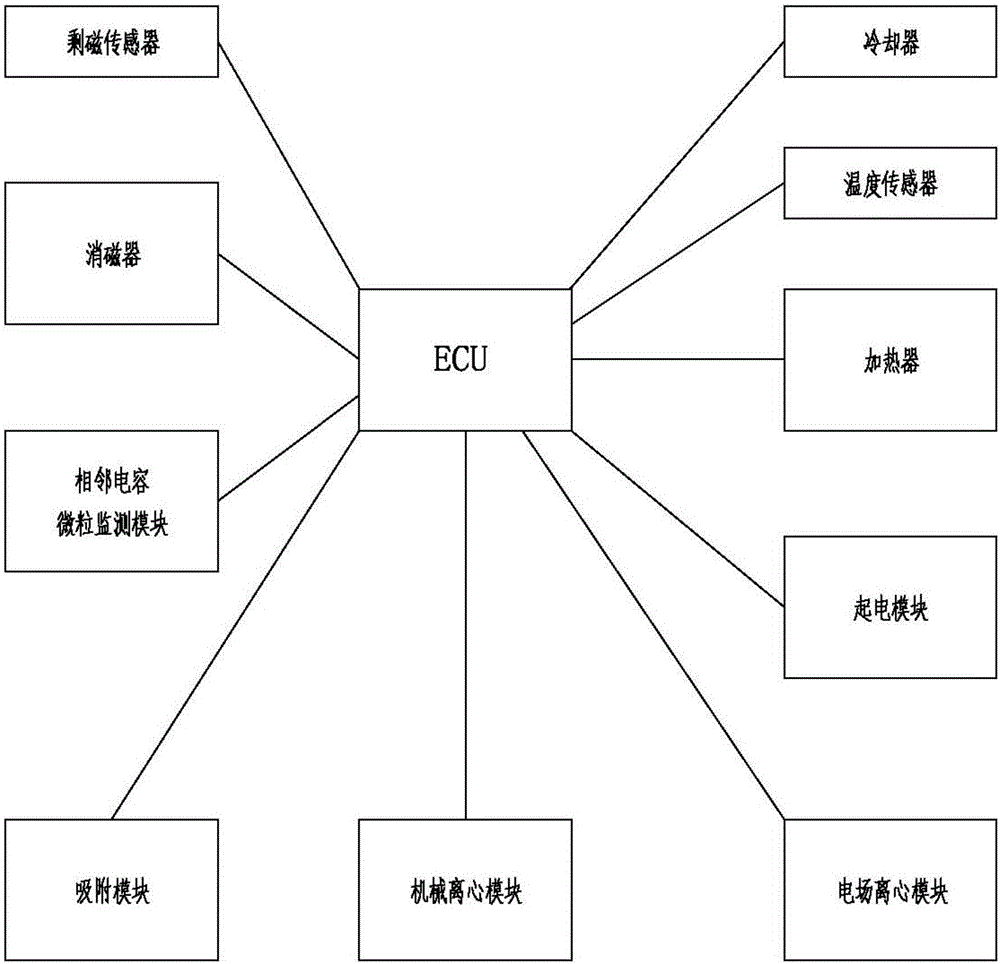

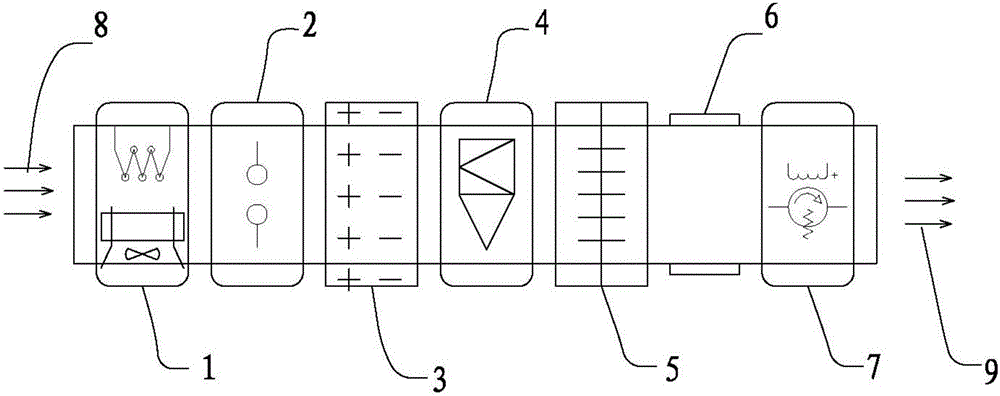

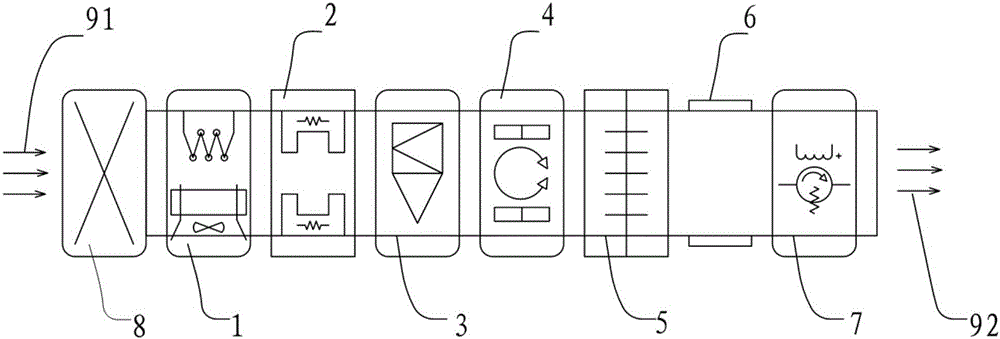

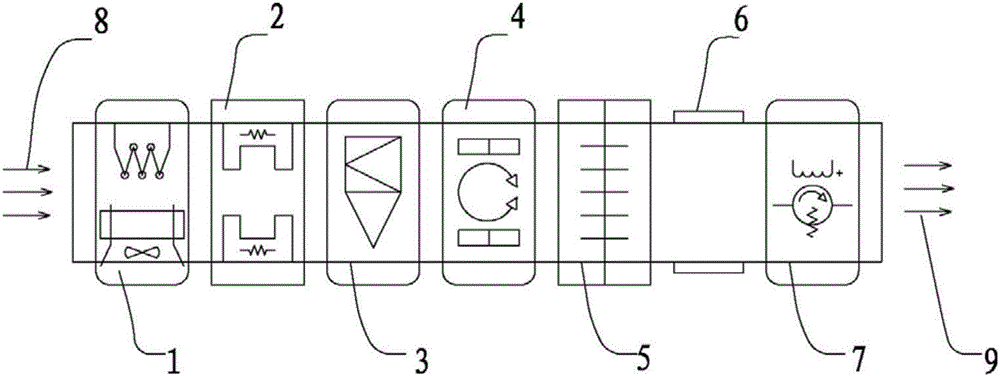

Method for online wear particle monitoring by adoption of electrification, electric control loop adsorption and adjacent capacitance

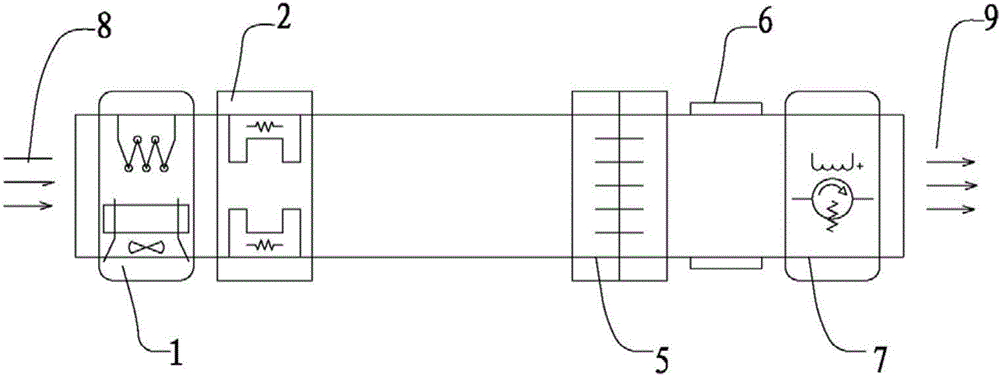

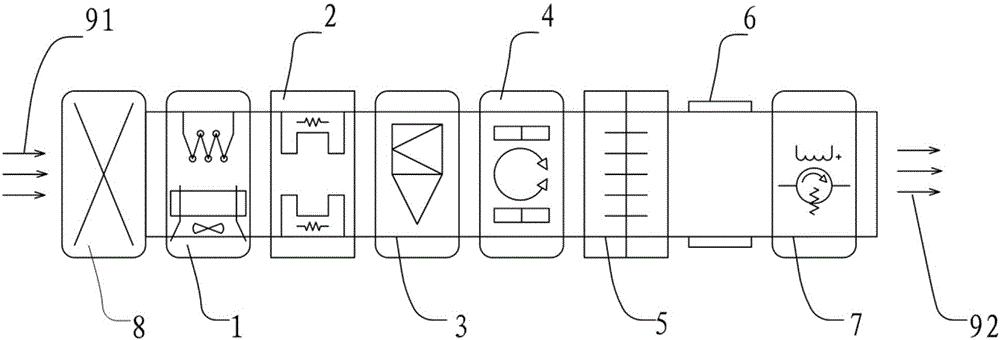

InactiveCN105864152AIncrease output signal strengthHigh dielectric constantFluid-pressure actuator testingEdge effectsEngineering

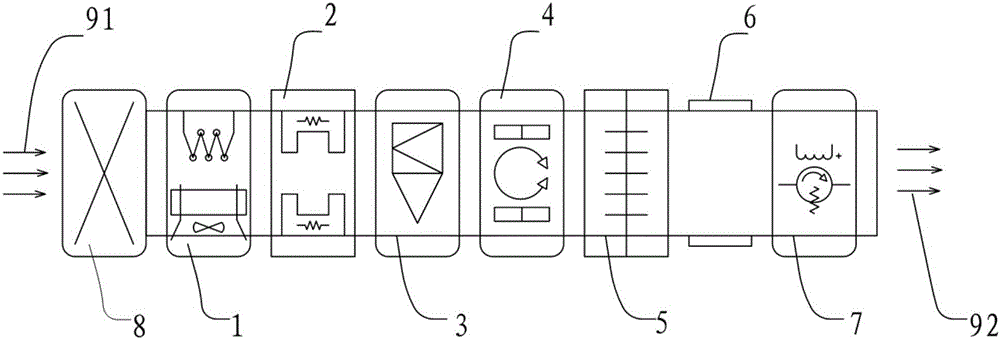

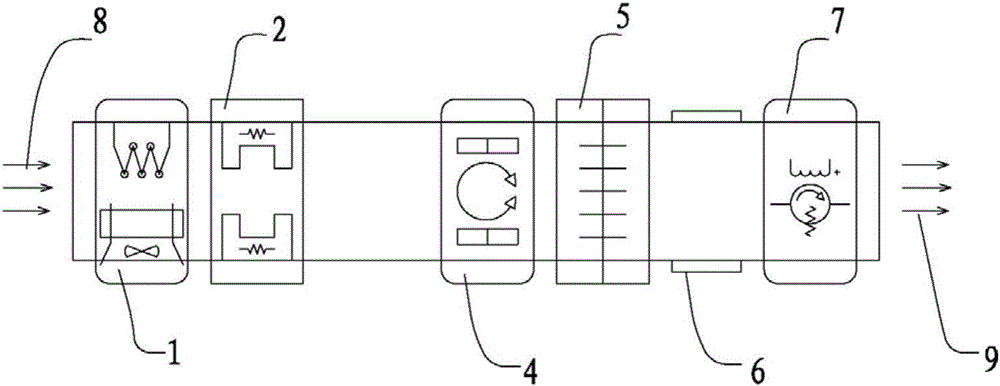

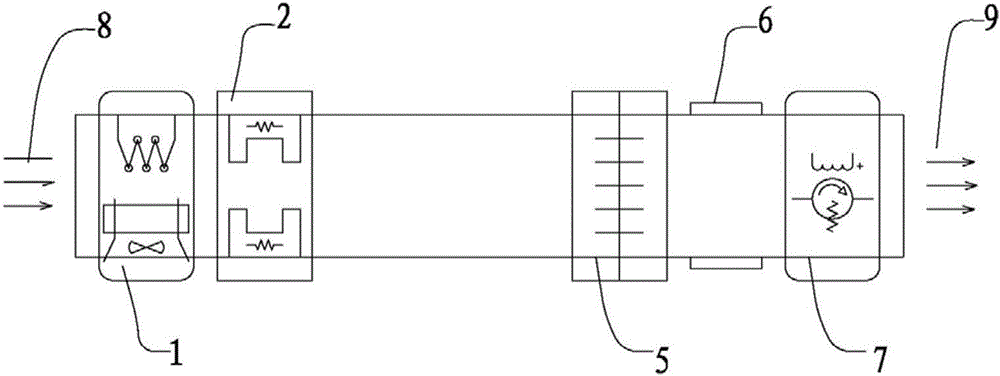

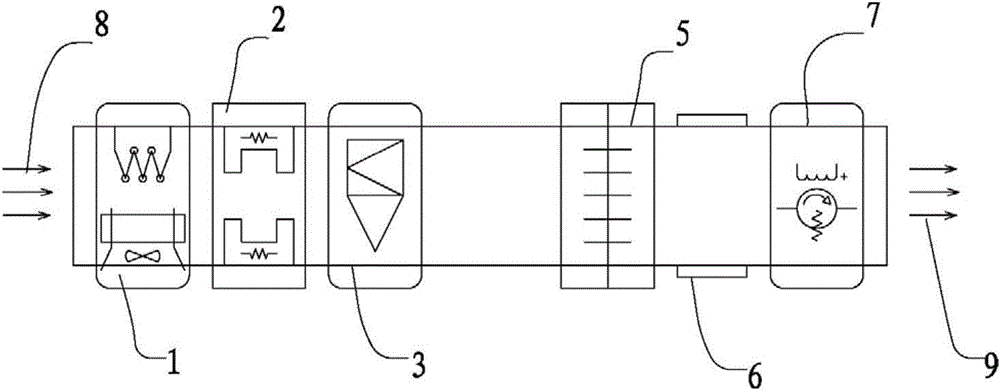

The invention relates to an on-line monitoring method of wear particles using electrification, electric control ring adsorption and adjacent capacitors, which sequentially passes through a temperature control module, an electrification module, an electric field centrifugal module, a mechanical centrifugal module, an adsorption module, and adjacent capacitor particles The monitoring module and the degaussing module perform on-line monitoring of wear particles; one end of the temperature control module is provided with an oil inlet; the adsorption module is specifically a homopolar adjacent type adsorption ring. The invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through electrification, electric field centrifugation and mechanical centrifugation modules, the wear particles in the oil are aggregated into large particles and move to the pipe wall Adjacent and adsorbed by the adsorption module to increase the output monitoring signal strength of the adjacent capacitive sensor; through the temperature control module and the rational design of the adjacent capacitive sensor plate layer structure, suppress noise and optimize the overall performance of the adjacent capacitive sensor monitoring device.

Owner:张国云

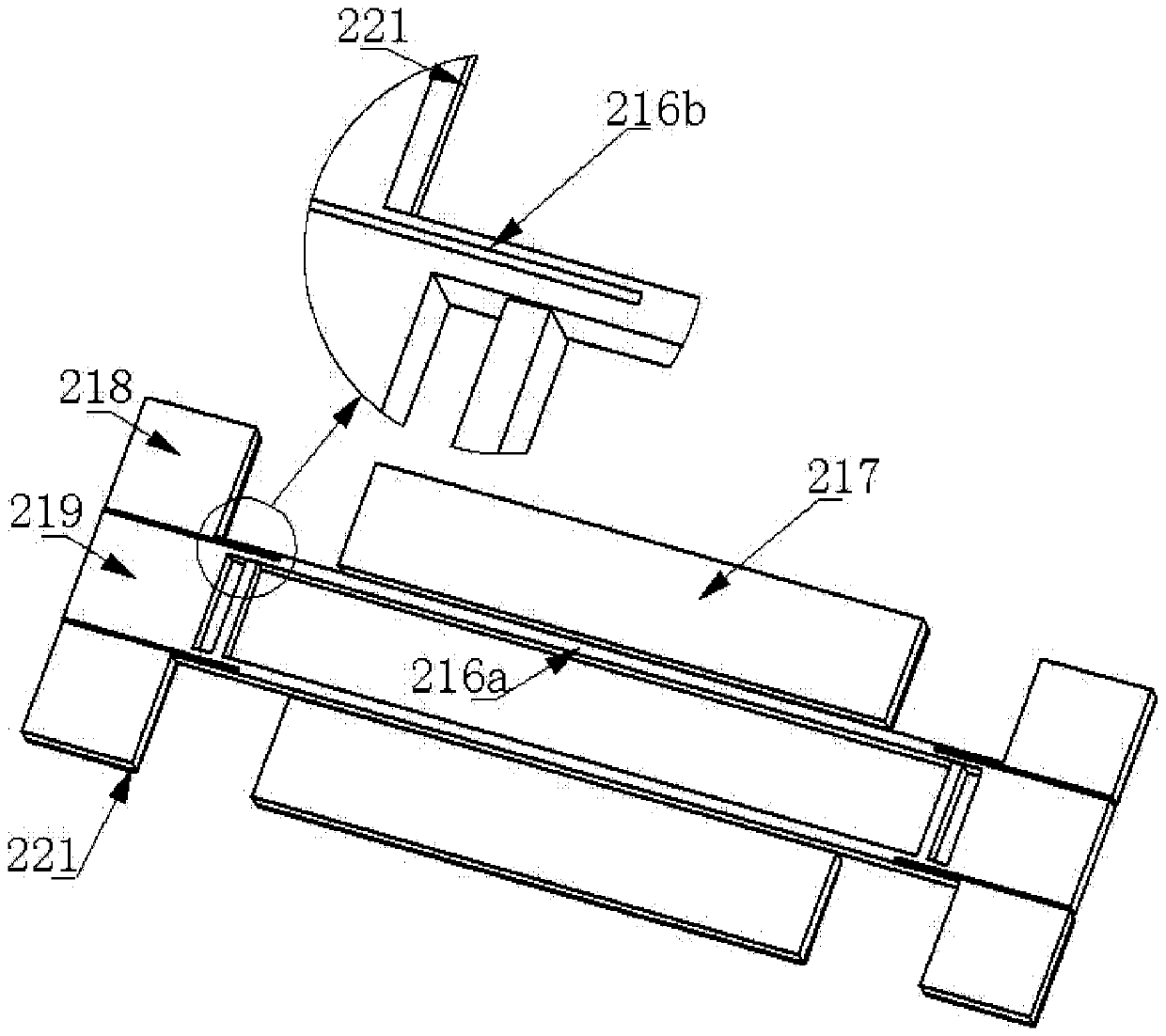

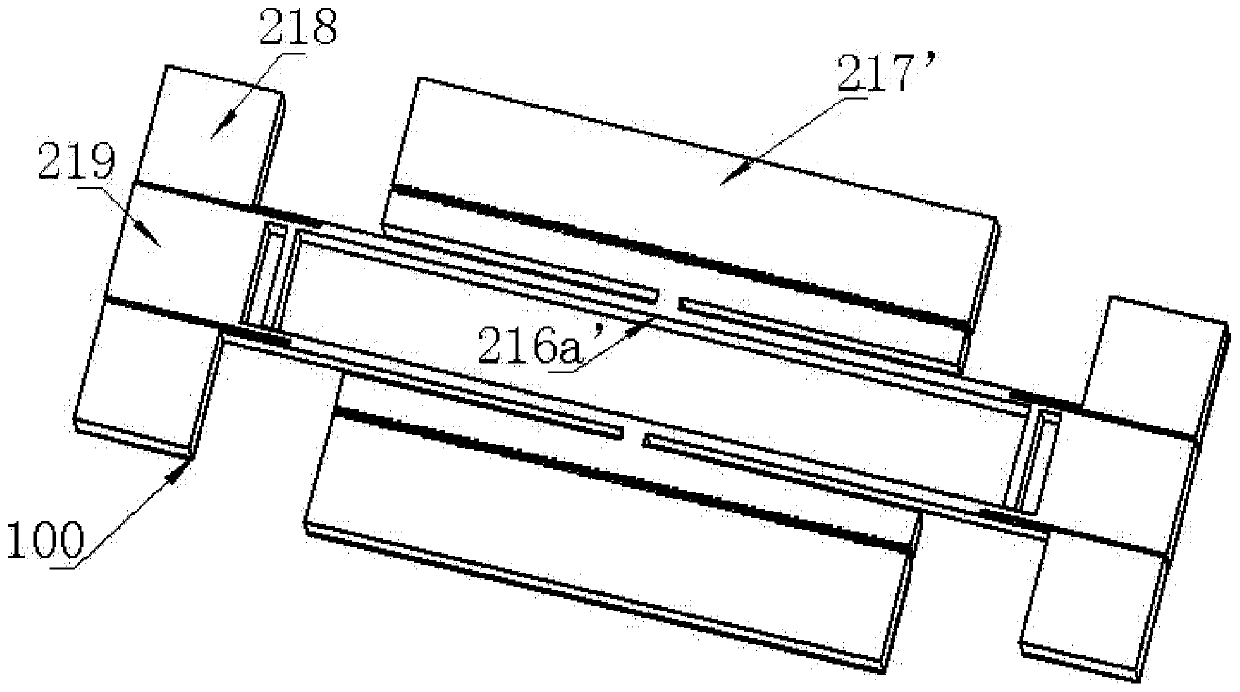

Resonator based on electrostatic driving and differential piezoresistance detection and pressure sensor thereof

InactiveCN110672236AHigh Q valueIncrease output signal strengthForce measurement by measuring frquency variationsForce measurement using piezo-electric devicesEngineeringMechanical engineering

The invention belongs to the technical field of sensors, in particular to a resonator based on electrostatic driving and differential piezoresistance detection and a pressure sensor thereof. The pressure sensor comprises a cover cap, a resonator, a pressure sensing structure and a base, the cover cap, the resonator and the pressure sensing structure are rigidly connected through bonding to form avacuum cavity, and an electrostatic driving electrode, a first mass block, a second mass block, a resonance beam, a piezoresistive strip and a first connecting block are located in the vacuum cavity;and the base is in rigid connection with the pressure sensing structure through bonding and is not in contact with the pressure sensing film. An in-plane dynamic balance resonance mode of the annularresonance beam is adopted, the Q value of the sensor is increased, and the thermal elastic loss is reduced; and the working mode of electrostatic driving / differential piezoresistance detection is adopted, the output signal strength of the sensor is improved, the temperature of the resonator can be represented in situ, and the pressure measurement precision is improved through temperature compensation of the sensor.

Owner:CETC CHIPS TECH GRP CO LTD

Wear particle online monitoring device adopting adsorption and adjacent capacitance

InactiveCN105864151AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator testingMaterial capacitanceTemperature controlWear particle

The invention relates to an on-line monitoring device for wear particles using adsorption and adjacent capacitors, in which a temperature control module, a magnetization module, an adsorption module, an adjacent capacitor particle monitoring module and a degaussing module are connected in sequence; one end of the temperature control module is provided with Oil inlet; One end of the degaussing module is provided with an oil outlet, which is composed of a residual magnetic sensor and a degausser. The present invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through the magnetization module, the wear particles in the oil are magnetized and adsorbed by the adsorption module to improve the output of adjacent capacitive sensors Monitor signal strength; suppress noise and optimize the overall performance of the adjacent capacitive sensor monitoring device through the temperature control module and reasonable design of the plate layer structure of the adjacent capacitive sensor.

Owner:SHAOXING UNIVERSITY

Method for monitoring wear particles on line by virtue of filtration, electromagnetic centrifugation and adjacent capacitance

InactiveCN105973777AGrowth inhibitionIncrease output signal strengthParticle suspension analysisEdge effectsFiltration

The invention relates to a method for monitoring wear particles on line by virtue of filtration, electromagnetic centrifugation and adjacent capacitance. The wear particles are monitored on line sequentially through a filter, a temperature control module, a magnetization module, a cyclone centrifugation module, a rotating magnetic field centrifugation module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetization module, wherein an oil inlet is formed in one end of the filter; an oil outlet is formed in one end of the demagnetization module. According to the method, a capacitance edge effect-based adjacent capacitance sensor technology is introduced to implement nonintrusive and unconstrained monitoring of the wear particles; the wear particles in oil are magnetized and aggregated into large particles through the magnetization, cyclone centrifugation and rotating magnetic field centrifugation modules, move to the vicinity of tube walls and are adsorbed by the adsorption module, so that the output monitoring signal strength of an adjacent capacitance sensor is improved; by the temperature control module and a reasonably designed adjacent capacitance sensor plate layer structure, noise is suppressed, and the overall performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:李伟波

Wear particle detecting method adopting electrification, electric control loop adsorption and adjacent capacitance

InactiveCN105889192AIncrease output signal strengthHigh dielectric constantFluid-pressure actuator componentsEngineeringElectric control

The invention relates to a wear particle detecting method adopting electrification, electric control loop adsorption and adjacent capacitance. Wear particle online monitoring is carried out by virtue of a temperature control module, an electrification module, an electric field centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module; one end of the temperature control module is provided with an oil inlet; and the adsorption module is specifically a homopolar adjacent type adsorption ring. According to the wear particle detecting method, an adjacent capacitance sensor technology based on a capacitance edge effect is introduced, so that non-intrusive and non-restriction monitoring of the wear particles is realized; wear particles in an oil liquid are polymerized into large particles by electrification and electrical field centrifugation and are moved to positions near a tube wall for being adsorbed by the adsorption module, so that output monitoring signal strength of the adjacent capacitance sensor is improved; and by virtue of the temperature control module and a reasonably designed polar plate structure of the adjacent capacitance sensor, noises are restrained, and the overall performance of the adjacent capacitor sensor monitoring device is optimized.

Owner:张国云

Wear particle monitoring equipment using hydraulic filtration, centrifugation and adjacent capacitance

InactiveCN106015173AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator testingFluid-pressure actuator componentsAdaptive filterFiltration

The invention relates to a wear particle monitoring device using hydraulic filtering, centrifugal separation and adjacent capacitors, including a filter, a temperature control module, a magnetization module, a mechanical centrifugal module, a rotating magnetic field centrifugal module, an adsorption module, and an adjacent capacitor particle monitoring module It is connected with the degaussing module in turn; the filter adopts a variable structure working condition adaptive filter, and one end of it is provided with an oil inlet; one end of the degaussing module is provided with an oil outlet. The invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through magnetization, mechanical centrifugation and rotating magnetic field centrifugal module, the wear particles in the oil are magnetized, aggregated into large particles and moved to Near the pipe wall and adsorbed by the adsorption module to improve the output monitoring signal strength of the adjacent capacitive sensor; through the temperature control module and the reasonable design of the plate layer structure of the adjacent capacitive sensor, the noise is suppressed and the overall monitoring device of the adjacent capacitive sensor is optimized performance.

Owner:SHAOXING UNIVERSITY

Monitoring method adopting rotating magnetic-filed centrifuging, adsorbing and proximity capacitance for wear particles

InactiveCN105889181AInhibits bubble growthIncrease particle concentrationFluid-pressure actuator testingWear particleTemperature control

The invention relates to a monitoring method adopting rotating magnetic-filed centrifuging, adsorbing and proximity capacitance for wear particles. The monitoring method is characterized in that online monitoring of the wear particles is realized by a temperature control module, a magnetization module, a rotating magnetic field centrifugal module, an adsorption module, a proximity capacitance particle monitoring module and a demagnetization module in sequence; an oil inlet is formed in one end of the temperature control module; an oil outlet is formed in one end of the demagnetization module; and the demagnetization module consists of a residual magnetism sensor and a demagnetizer. According to the monitoring method disclosed by the invention, a proximity capacitance sensor technology based on a capacitance edge effect is introduced, and non-intrusive and unconstrained monitoring of the wear particles is realized; the wear particles in the oil are magnetized and polymerized into large particles by magnetizing and mechanical centrifuging, and move near a pipe wall and are adsorbed by the adsorption module, so that the intensity of an output monitoring signal of a proximity capacitance sensor is improved; and by using the temperature control module and reasonably designing the structure of a polar plate layer of the proximity capacitance sensor, noises are inhibited and overall performance of a monitoring device of the proximity capacitance sensor is optimized.

Owner:SHAOXING UNIVERSITY

Wear particle online monitoring method using centrifugation, adsorption and adjacent capacitance

InactiveCN106018214AGrowth inhibitionIncrease output signal strengthParticle suspension analysisEdge effectsEngineering

The invention relates to a wear particle online monitoring method using centrifugation, adsorption and adjacent capacitance. Wear particle online monitoring is conduced sequentially by means of a temperature control module, a magnetization module, a mechanical centrifugation module, a rotary magnetic field centrifugation module, an adsorption module, an adjacent capacitance wear particle monitoring module and a demagnetization module. An oil inlet is formed in one end of the temperature control module, an oil outlet is formed in one end of the demagnetization module, and the demagnetization module is composed of a remanence sensor and a demagnetizer. The adjacent capacitance sensor technology based on the capacitance edge effect is introduced, and non-intrusive and unrestricted monitoring of wear particles is achieved. By means of the magnetization, mechanical centrifugation and rotary magnetic field centrifugation modules, wear particles in oil are magnetized and polymerized into large particles and move to the position near a pipe wall to be adsorbed by the adsorption module so that the intensity of output monitoring signals of an adjacent capacitance sensor can be increased. By means of the temperature control module and a reasonably designed polar plate structure of the adjacent capacitance sensor, noise is suppressed, and the overall performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Online abrasion particle monitoring system adopting centrifugation, electric shock hammer adsorption and adjacent capacitance

InactiveCN105954157AGrowth inhibitionIncrease output signal strengthParticle and sedimentation analysisTemperature controlCentrifugation

The invention relates to an online abrasion particle monitoring system adopting centrifugation, electric shock hammer adsorption and adjacent capacitance. A temperature control module, a magnetizing module, a mechanical centrifugal module, a rotary magnetic field centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module of the system are sequentially connected, wherein an oil inlet is formed in one end of the temperature control module; the adsorption module is a like-pole adjacent type adsorption ring with an electric shock hammer specifically. According to the system, the adjacent capacitance transducer technology based on the capacitance fringe effect is introduced, and non-invasion and unrestraint monitoring of abrasion particles is realized; the abrasion particles in oil are magnetized and aggregated to form large particles through the magnetizing module, the mechanical centrifugal module and the rotary magnetic field centrifugal module, and the large particles move to the vicinity of a tube wall and are adsorbed by the adsorption module, so that the strength of output monitoring signals of adjacent capacitance transducers is improved; by means of a temperature control module and reasonable design of polar plate layer structures of the adjacent capacitance transducers, noise is inhibited, and the overall performance of an adjacent capacitance transducer monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Online wear particle monitoring system adopting electric shock hammer adsorption and adjacent capacitance

InactiveCN105891060AInhibits bubble growthHigh dielectric constantParticle and sedimentation analysisEngineeringWear particle

The invention relates to an online wear particle monitoring system adopting electric shock hammer adsorption and adjacent capacitance. The system comprises a temperature control module, a magnetization module, an absorption module, an adjacent capacitance particle monitoring module and a demagnetization module which are sequentially connected, wherein a liquid oil inlet is formed in one end of the temperature control module; the absorption module is specifically a homopolar adjacency type absorption ring provided with an electric shock hammer. The online wear particle monitoring system introduces an adjacent capacitance transducer technology based on a capacitance edge effect, thus realizing non-intrusive and unconstrained monitoring for wear particles; the wear particles in liquid oil are magnetized by the magnetization module and are absorbed by the absorption module, so that the intensities of monitoring signals output by an adjacent capacitance transducer are improved; by arranging the temperature control module and reasonably designing an adjacent capacitance transducer polar plate layer structure, noise suppression is realized and the whole performance of an adjacent capacitance transducer monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Abrasion particle monitoring equipment using filter waves, electromagnetic centrifugation and adjacent capacitances

InactiveCN105909594AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator testingTemperature controlEdge effects

The invention relates to abrasion particle monitoring equipment using filter waves, electromagnetic centrifugation and adjacent capacitances. A filter, a temperature control module, a magnetization module, a mechanical centrifugal module, a rotating magnetic field centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetization module of the abrasion particle monitoring equipment are sequentially connected. An oil liquid inlet is formed in one end of the filter. An oil liquid outlet is formed in one end of the demagnetization module. According to the abrasion particle monitoring equipment using the filter waves, electromagnetic centrifugation and the adjacent capacitances, the adjacent capacitance sensor technology based on the capacitance edge effect is introduced, and abrasion particle non-intrusive and unconstrained monitoring is achieved; abrasion particles in oil liquid are magnetized and aggregated into large particles through the magnetization module, the mechanical centrifugal module and the rotating magnetic field centrifugal module and move to the position near a pipe wall to be adsorbed by the adsorption module so that the output monitoring signal strength of an adjacent capacitance sensor can be improved; and through the temperature control module and reasonable design of the polar plate layer structure of the adjacent capacitance sensor, noise is suppressed, and the overall performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Online abrasion particle monitoring system adopting electrification, electric control ring adsorption and adjacent capacitance

InactiveCN105954155AIncrease output signal strengthHigh dielectric constantMaterial analysisMicro particlesSignal intensity

The invention relates to an online abrasion particle monitoring system adopting electrification, electric control ring adsorption and adjacent capacitance. A temperature control module, an electrification module, a mechanical centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module of the system are sequentially connected, wherein an oil inlet is formed in one end of the temperature control module; the adsorption module is a like-pole adjacent type adsorption ring specifically. According to the system, the adjacent capacitance transducer technology based on the capacitance fringe effect is introduced, and non-invasion and unrestraint monitoring of abrasion particles is realized; the abrasion particles in oil are aggregated to form large particles through electrification and electric field centrifugation, and the large particles move to the vicinity of a tube wall and are adsorbed by the adsorption module, so that the strength of output monitoring signals of adjacent capacitance transducers is improved; by means of a temperature control module and reasonable design of polar plate layer structures of the adjacent capacitance transducers, noise is inhibited, and the overall performance of an adjacent capacitance transducer monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Online abraded particle monitoring method adopting electric shock hammer adsorption and adjacent capacitance

InactiveCN105864150AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator testingTemperature controlMagnetization

The invention relates to an on-line monitoring method of wear particles using electric hammer adsorption and adjacent capacitors, which sequentially conducts online monitoring of wear particles through a temperature control module, a magnetization module, an adsorption module, an adjacent capacitor particle monitoring module, and a degaussing module; One end of the temperature control module is provided with an oil inlet; the adsorption module is specifically a homopolar adjacent adsorption ring with an electric hammer. The present invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through the magnetization module, the wear particles in the oil are magnetized and adsorbed by the adsorption module to improve the output of adjacent capacitive sensors Monitor signal strength; suppress noise and optimize the overall performance of the adjacent capacitive sensor monitoring device through the temperature control module and reasonable design of the plate layer structure of the adjacent capacitive sensor.

Owner:张国云

Abrasion particle monitoring device using temperature control, electronic control ring adsorption and adjacent capacitance

InactiveCN105937516AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator componentsTemperature controlComputer module

The invention relates to an abrasion particle monitoring device using temperature control, electronic control ring adsorption and adjacent capacitance. A temperature control module, a magnetization module, a mechanical centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetization module of the abrasion particle monitoring device are sequentially connected. An oil inlet is formed in one end of the temperature control module. The adsorption module is particularly a homopolar adjacent type adsorption ring. According to the abrasion particle monitoring device, the adjacent capacitance sensor technology based on the capacitance fringe effect is introduced, and non-invasion and unrestraint monitoring of abrasion particles is achieved; the abrasion particles in oil are magnetized and gathered into large particles through magnetizing and mechanical centrifuging and move to the portion nearby a pipe wall to be adsorbed by the adsorption module, and therefore the output monitoring signal intensity of an adjacent capacitance sensor can be improved; and by arranging the temperature control module and reasonably designing the pole plate layer structure of the adjacent capacitance sensor, noise is restrained and the overall performance of the adjacent capacitance sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Abrasion particle monitoring method based on magnetic field centrifugation, electric shock hammer adsorption and adjacent capacitance

InactiveCN105909593AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator testingFluid-pressure actuator componentsTemperature controlCentrifugation

The invention relates to an abrasion particle monitoring method based on magnetic field centrifugation, electric shock hammer adsorption and adjacent capacitance. According to the abrasion particle monitoring method, online monitoring of abrasion particles is conducted sequentially through a temperature control module, a magnetization module, a rotating magnetic field centrifugation module, an adsorption module, an adjacent capacitive particle monitoring module and a demagnetization module. An oil inlet is formed in one end of the temperature control module. The adsorption module is specifically a homopolar adjacent type adsorption ring provided with an electric shock hammer. According to the abrasion particle monitoring method, an adjacent capacitance sensor technique based on the capacitance fringe effect is introduced, so that non-invasion unconstrained monitoring of the abrasion particles is achieved; the abrasion particles in the oil are magnetized and aggregated into big particles through the magnetization module and the rotating magnetic field centrifugation module, move to the position near the pipe wall, and are adsorbed by the adsorption module, and thus the intensity of a monitoring signal output by an adjacent capacitance sensor is increased; and through the temperature control module and the reasonable design of the structure of an adjacent capacitance sensor polar plate layer, noise is restrained, and the overall performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Wear particle monitoring system adopting electrification, rotational flow centrifugation, adsorption and adjacent capacitance

InactiveCN105928842AIncrease output signal strengthHigh dielectric constantParticle and sedimentation analysisEngineeringRotational flow

The invention relates to a wear particle monitoring system adopting electrification, rotational flow centrifugation, adsorption and adjacent capacitance. A temperature control module, an electrification module, an electric field centrifugation module, a mechanical centrifugation module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module of the system are sequentially connected. An oil liquid inlet is formed in one end of the temperature control module. The mechanical centrifugation module is a rotational flow centrifugation module. The adjacent capacitance sensor technology based on the capacitance edge effect is introduced, and wear particles are monitored without invasion or restriction. By means of the electrification module, the electric field centrifugation module and the mechanical centrifugation module, the wear particles in oil liquid are aggregated into large particles, move to the position close to the pipe wall and are adsorbed by the adsorption module, so that the intensity of monitoring signals output by an adjacent capacity sensor is improved. By means of the temperature control module and the adjacent capacitance sensor pole plate layer structure designed reasonably, noise is restrained, and the overall performance of a monitoring device of the adjacent capacitance sensor is optimized.

Owner:SHAOXING UNIVERSITY

Worn particle monitoring system using temperature control, electric shock hammer adsorption and adjacent capacitance

InactiveCN105973766AGrowth inhibitionIncrease output signal strengthParticle and sedimentation analysisTemperature controlEdge effects

The invention relates to a worn particle monitoring system using temperature control, electric shock hammer adsorption and adjacent capacitance. A temperature control module, a magnetizing module, a mechanical centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module of the worn particle monitoring system using the temperature control, electric shock hammer adsorption and adjacent capacitance are connected in sequence; an oil inlet is formed in one end of the temperature control module; the adsorption module is a homopolar adjacent type adsorption ring with an electric shock hammer specifically. According to the worn particle monitoring system using temperature control, electric shock hammer adsorption and adjacent capacitance, a capacitance edge effect-based adjacent capacitance sensor technology is introduced, and non-intrusive and unrestraint monitoring of worn particles is realized; the worn particles in oil is magnetized and aggregated into large particles through magnetizing and mechanical centrifuging, and the large particles move near a pipe wall and are adsorbed by the adsorption module, so that the output monitoring signal intensity of an adjacent capacitance sensor is improved; noises are restrained and the overall performance of the adjacent capacitance sensor monitoring device is optimized through the temperature control module and by reasonably designing an adjacent capacitance sensor polar plate layer structure.

Owner:SHAOXING UNIVERSITY

Method for monitoring wear particles on line by virtue of electrification, electric hammer adsorption and adjacent capacitance

InactiveCN105973948AIncrease output signal strengthHigh dielectric constantMaterial capacitanceTemperature controlElectricity

The invention relates to an on-line monitoring method of wear particles using electrification, electric hammer adsorption and adjacent capacitors, which sequentially monitors the particles through a temperature control module, an electrification module, an electric field centrifugal module, a mechanical centrifugal module, an adsorption module, and adjacent capacitor particles The module and the degaussing module carry out online monitoring of wear particles; one end of the temperature control module is provided with an oil inlet; the adsorption module is specifically a homopolar adjacent adsorption ring with an electric hammer. The invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through electrification, electric field centrifugation and mechanical centrifugation modules, the wear particles in the oil are aggregated into large particles and move to the pipe wall Adjacent and adsorbed by the adsorption module to increase the output monitoring signal strength of the adjacent capacitive sensor; through the temperature control module and the rational design of the adjacent capacitive sensor plate layer structure, suppress noise and optimize the overall performance of the adjacent capacitive sensor monitoring device.

Owner:张国云

Wear particle monitoring method using filtering, electromagnetic centrifugal separation and adjacent capacitance

InactiveCN106018213AGrowth inhibitionIncrease output signal strengthParticle suspension analysisCycloneAdaptive filter

The invention relates to a wear particle monitoring method using filtering, electromagnetic centrifugal separation and adjacent capacitance. Wear particles are monitored by a filter, a temperature control module, a magnetization module, a cyclone centrifugal module, a rotating magnetic field centrifugal module, an adsorption module, an adjacent capacitive particle monitoring module and a degaussing module sequentially; a working condition adaptive filter is used as the filter, and an oil inlet is formed in one end of the filter; an oil outlet is formed in one end of the degaussing module. According to the wear particle monitoring method, an adjacent capacitive sensor technology based on the capacitance edge effect is introduced, and wear particle non-intrusive and unconstrained monitoring is realized; wear particles in oil are magnetized and polymerized into large particles by the magnetization module, the cyclone centrifugal module and the rotating magnetic field centrifugal module, move to the vicinity of a pipe wall and are absorbed by the adsorption module, so that the strength of monitoring signals output by an adjacent capacitive sensor is improved; noise is restrained and the whole performance of the adjacent capacitive sensor monitoring device is optimized by the temperature control module and a reasonably designed adjacent capacitive sensor polar plate layer structure.

Owner:李伟波

Method for monitoring wear particles with hydraulic filtering, centrifugal separation and adjacent capacitors

InactiveCN105842305AGrowth inhibitionIncrease output signal strengthPreparing sample for investigationCentrifugal force sediment separationAdaptive filterMagnetization

The invention relates to a method for monitoring wear particles with hydraulic filtering, centrifugal separation and adjacent capacitors. Monitoring of wear particles is conducted through a filter, a temperature control module, a magnetization module, a mechanical centrifugal module, a rotating magnetic field centrifugal module, an absorption module, an adjacent capacitor particle monitoring module and a degaussing module in sequence; a variable structure work condition self-adapting filter is adopted for the filter, and one end of the filter is provided with an oil liquid inlet; one end of the degaussing module is provided with an oil liquid outlet. An adjacent capacitor sensor technology based on the capacitor edge effect is introduced, and non-intrusive and no-constraint monitoring of the wear particles is achieved; the wear particles in oil liquid are magnetized and aggregated into large particles through the magnetization module, the mechanical centrifugal module and the rotating magnetic field centrifugal module, move to the position near the pipe wall and are absorbed by the absorption module, so that strength of output monitoring signals of adjacent capacitor sensors is improved; the temperature control module is utilized, polar plate layer structures of the adjacent capacitor sensors are designed reasonably, noise is inhibited, and the overall performance of an adjacent capacitor sensor monitoring device is optimized.

Owner:李伟波

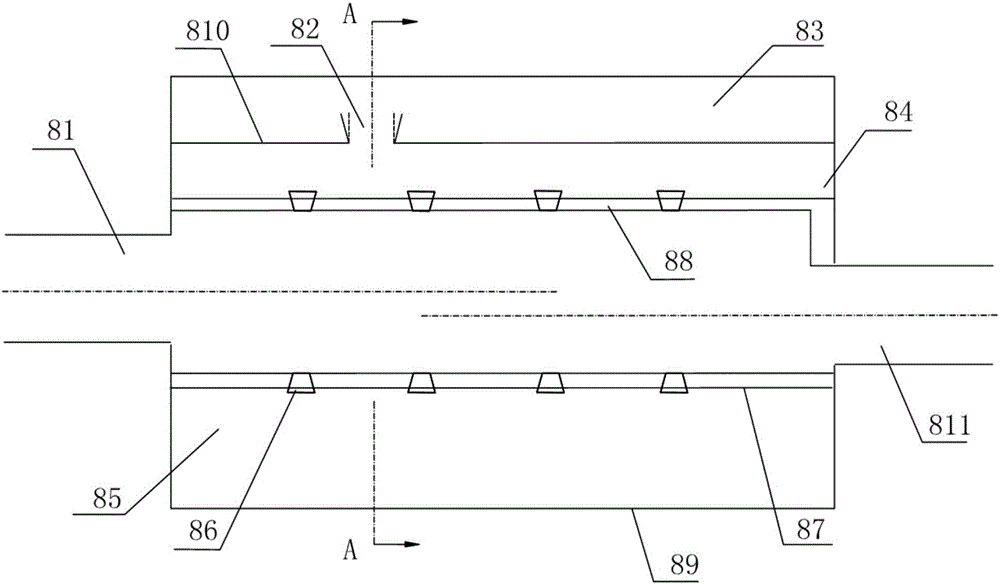

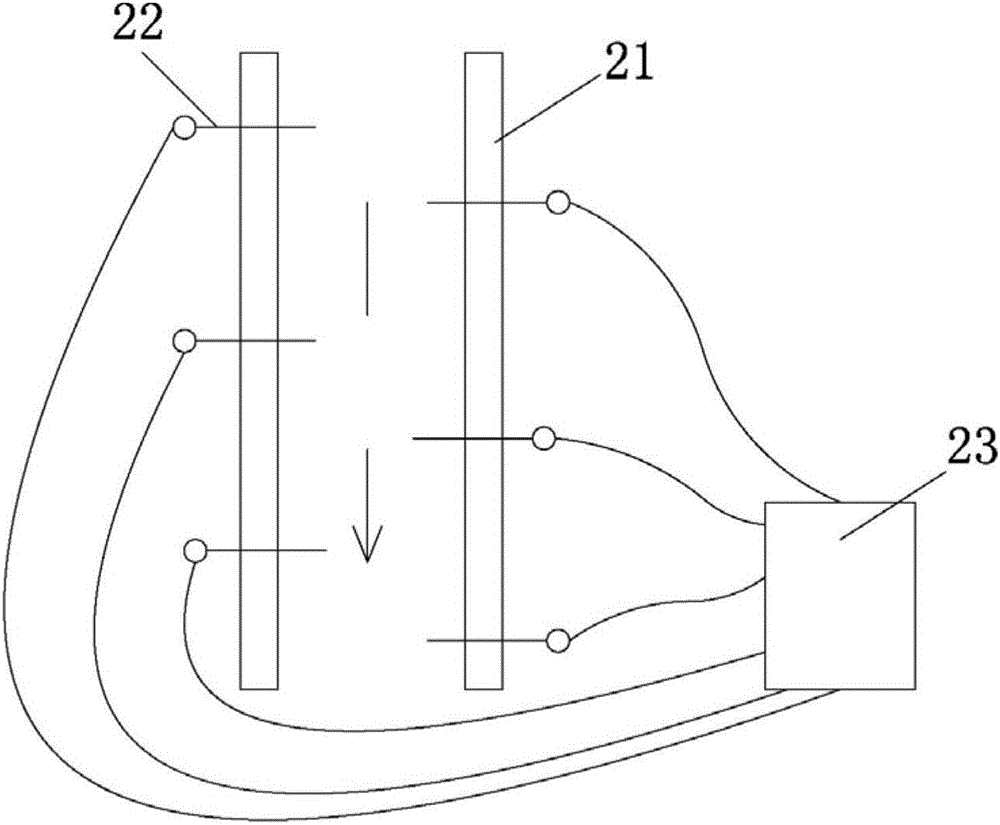

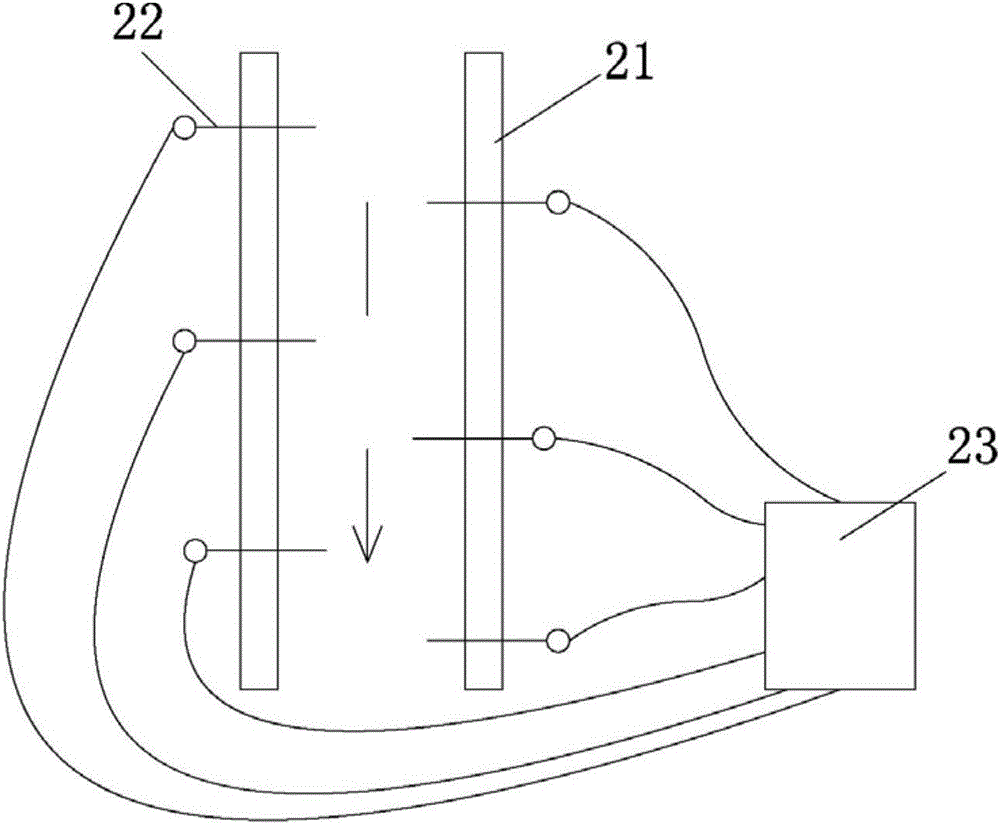

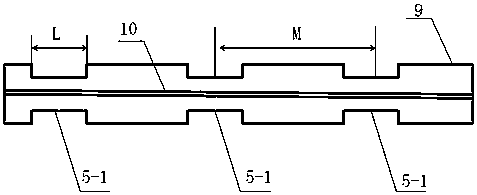

Narrow linewidth laser output method based on micro-groove fiber

ActiveCN105762644BGuaranteed single frequency operationIncrease output signal strengthLaser using scattering effectsActive medium shape and constructionFiberGrating

The invention discloses a micro groove fiber-based narrow linewidth laser output method. A fiber grating serves as a wavelength selection device, an erbium-doped fiber serves as a gain medium, the micro groove fiber is adopted for realizing laser linewidth compression, and narrow linewidth laser output is realized. The method of the invention can be applied to fields such as distributed fiber vibration sensing, gas detection, environment monitoring and scientific research, and the structure is simple and the cost is low.

Owner:ZHEJIANG NORMAL UNIVERSITY

Abrasion particle online monitoring method through adsorption and adjacent capacitance

InactiveCN105909614AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator componentsTemperature controlMagnetization

The invention relates to an abrasion particle online monitoring method through adsorption and adjacent capacitance. Abrasion particle online monitoring is sequentially conducted through a temperature control module, a magnetization module, an adsorption module, an adjacent capacitance abrasion particle monitoring module and a demagnetization module. One end of the temperature control module is provided with an oil inlet. One end of the demagnetization module is provided with an oil outlet, and the demagnetization module is composed of a residual magnetism sensor and a magnetic eraser. The adjacent capacitance sensor technology based on the capacitance edge effect is introduced, and non-intrusive and unconstrained monitoring of abrasion particles is achieved; the abrasion particles in oil are magnetized through the magnetization module and are adsorbed through the adsorption module, so that the intensity of output monitoring signals of adjacent capacitance sensors is improved; and through the temperature control module and the reasonable design of polar plate layer structures of the adjacent capacitance sensors, noise is suppressed, and the whole performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:张国云

Abraded micro-particle online monitoring method adopting temperature control, adsorption and adjacent capacitor

InactiveCN105973780AGrowth inhibitionIncrease output signal strengthParticle suspension analysisDemagnetizing deviceTemperature control

The invention relates to an abraded micro-particle online monitoring method adopting temperature control, adsorption and an adjacent capacitor. Abraded micro-particle online monitoring is carried out by adopting a temperature control module, a magnetizing module, a mechanical centrifuging module, an adsorption module, an adjacent capacitor micro-particle monitoring module and a demagnetizing module in sequence; an oil liquid inlet is arranged at one end of the temperature control module; an oil liquid outlet is arranged at one end of the demagnetizing module; the demagnetizing module is composed of a residual magnetism sensor and a demagnetizing device. By introducing an adjacent capacitor sensor technology based on a capacitor edge effect, non-invasion and restriction-free monitoring of abraded micro-particles is realized; the abraded micro-particles in oil liquid are magnetized through magnetizing and mechanical centrifuging and are polymerized into large particles, and the large particles move to the nearby place of a pipe wall and are adsorbed by the adsorption module, so that the intensity of a monitoring signal output by an adjacent capacitor sensor is improved; the temperature control module is adopted and a polar plate layer structure of the adjacent capacitor sensor is reasonably designed, so that noises are inhibited and the whole performance of an adjacent capacitor sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

On-line wear particle monitoring equipment adopting electrification, electric shock hammer adsorption and adjacent capacitance

InactiveCN106018186AIncrease output signal strengthHigh dielectric constantParticle suspension analysisParticle and sedimentation analysisEngineeringElectric shock

The invention relates to on-line wear particle monitoring equipment adopting electrification, electric shock hammer adsorption and adjacent capacitance. A temperature control module, an electrification module, an electric field centrifugation module, a mechanical centrifugation module, an adsorption module, an adjacent capacitance particle monitor module and a demagnetization module of the equipment are sequentially connected; one end of the temperature control module is provided with an oil liquid inlet; the adsorption module particularly is homopolar adjacent type adsorption rings with electric shock hammers. According to the equipment, non-intrusive and unconstrained wear particle monitoring is achieved by introducing an adjacent capacitance sensor technique based on a capacitance edge effect; through the electrification module, the electric field centrifugation module and the mechanical centrifugation module, wear particles in oil liquid are aggregated into large particles and move to the positions near the tube wall to be adsorbed by the adsorption module, so that the output monitoring signal intensity of an adjacent capacitance sensor is improved; by arranging the temperature control module and reasonably designing the structure of a polar plate layer of the adjacent capacitance sensor, noise is inhibited, and the whole performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Wear particle online monitoring device using filtering, centrifuge and adjacent capacitance

InactiveCN105866198AGrowth inhibitionIncrease output signal strengthMaterial capacitanceTemperature controlEdge effects

The invention relates to a wear particle online monitoring device using filtering, centrifuge and adjacent capacitance. The wear particle online monitoring device using filtering, centrifuge and adjacent capacitance comprises a filter, a temperature control module, a magnetizing module, a mechanical centrifugal module, a rotary magnetic-field centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module, which are sequentially connected. The filter is a pressure pulse filter with the full-band hydraulic system. One end of the filter is provided with an oil inlet, and one end of the demagnetizing module is provided with an oil outlet. The wear particle online monitoring device can realize non-intruding and restraint-free monitoring by introducing the adjacent capacitance sensor technology based on capacitance edge effect. Through magnetization, mechanical centrifuge and the rotary magnetic-field centrifugal module, wear particles in oil can be magnetized and gathered to be large particles moving to the pipe wall and to be adsorbed by the adsorption module, so that intensity of output monitoring signals of the adjacent capacitance sensor is improved. Through the temperature control module and the adjacent capacitance sensor plate structure reasonably designed, noise can be suppressed, and the overall performance of the adjacent capacitance sensor-monitoring device can be optimized.

Owner:SHAOXING UNIVERSITY

Resonant pressure sensor based on piezoresistive detection and its preparation method

ActiveCN108516518BIncrease output signal strengthImprove anti-interference abilityFluid pressure measurement using ohmic-resistance variationDecorative surface effectsTuning forkInterference resistance

The invention relates to a resonant pressure sensor based on piezoresistive detection and a preparation method thereof. The resonant pressure sensor comprises a pressure sensitive film, a resonator located on the pressure sensitive film and six anchor points, wherein the resonator comprises a double-end fixed support beam and two driving electrodes arranged on the two sides of the double-end fixedsupport beam, wherein the double-end fixed support beam comprises two end parts and two single beams connected to the two end parts; etching is carried out on root regions of the two single beams symmetrically; body pressure resistance is formed at the root parts of the two single beams; the same three-electrode structures are arranged at the two end parts, one three-electrode structure is suspended, and the other three-electrode structure takes an electrode in the middle position as a grounding end and the electrodes at the two sides as detection electrodes; the six anchor points are arranged under the two three-electrode structures respectively; and the double-end fixed support beam is fixedly supported on the pressure sensitive film. According to the resonant pressure sensor and the preparation method, a piezoresistive detection and resonator tuning fork vibration mode is adopted, so that the output signal strength is improved, and the anti-interference capability and the stabilityare enhanced.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

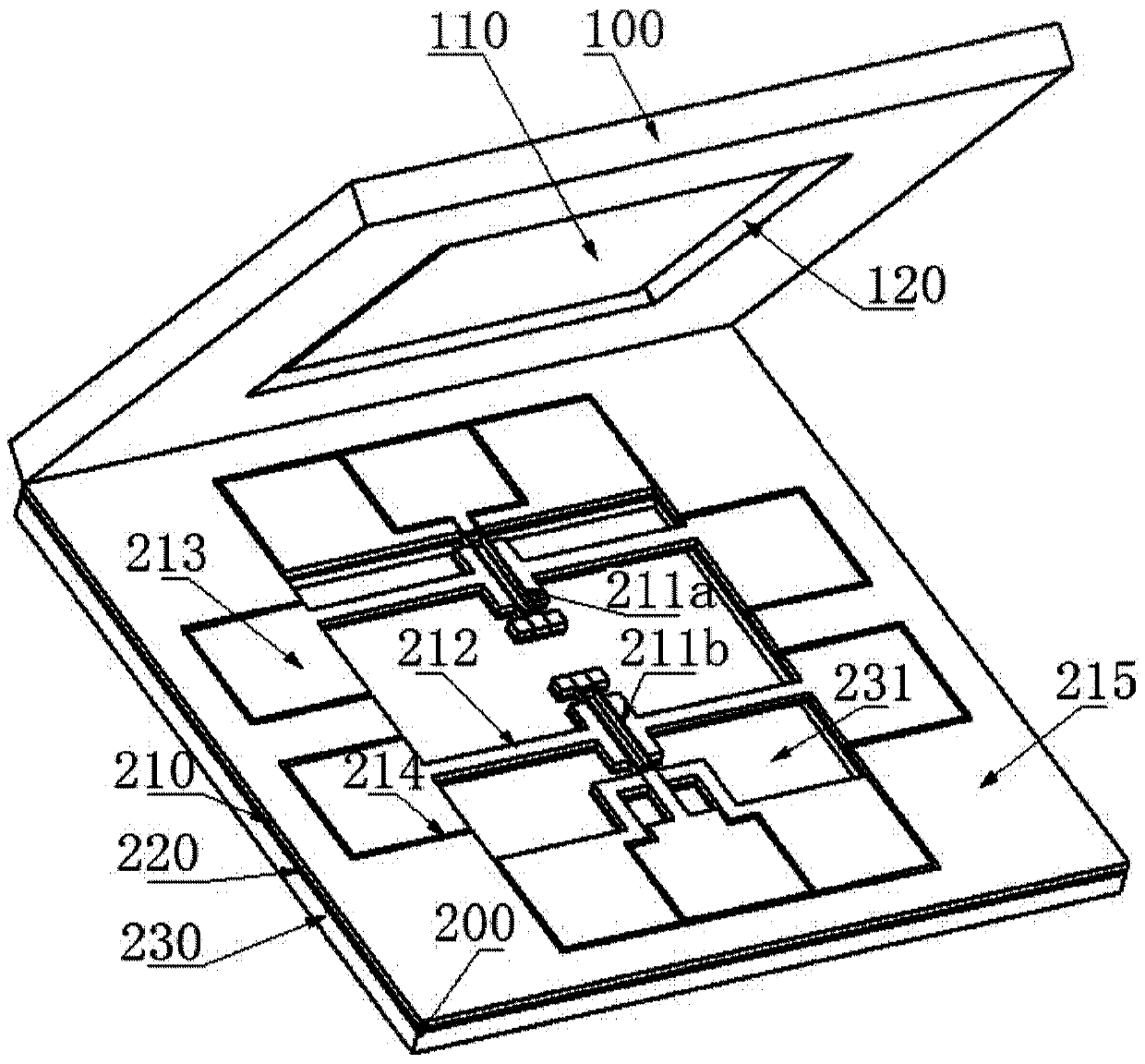

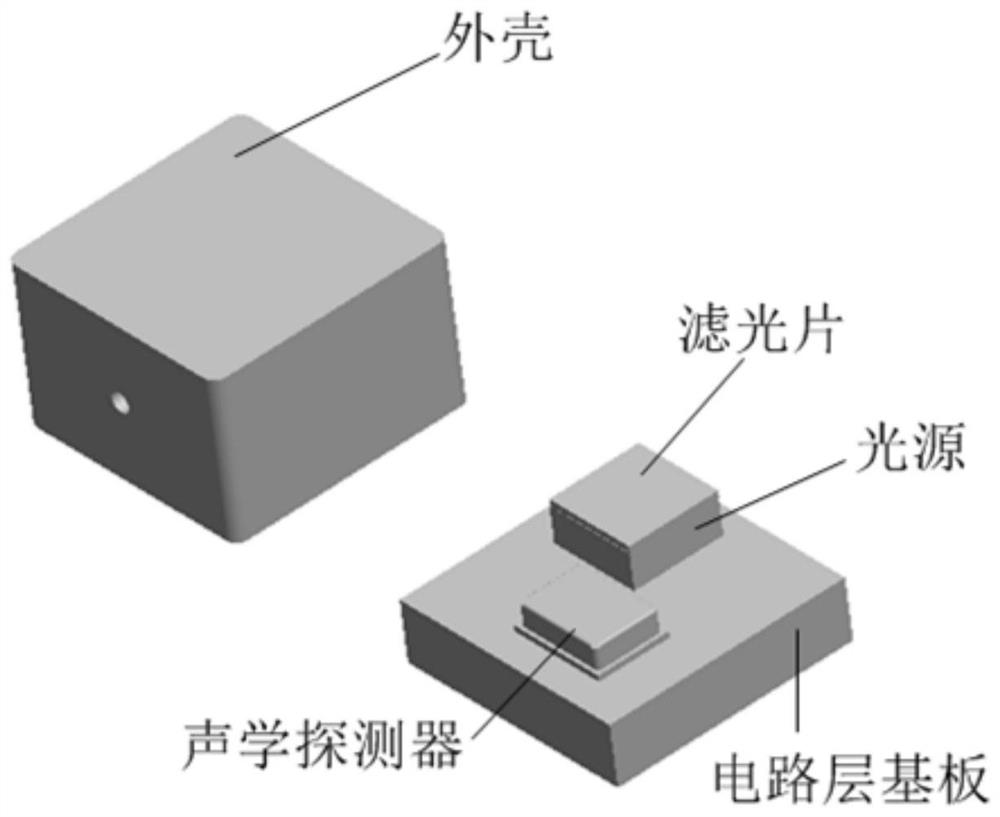

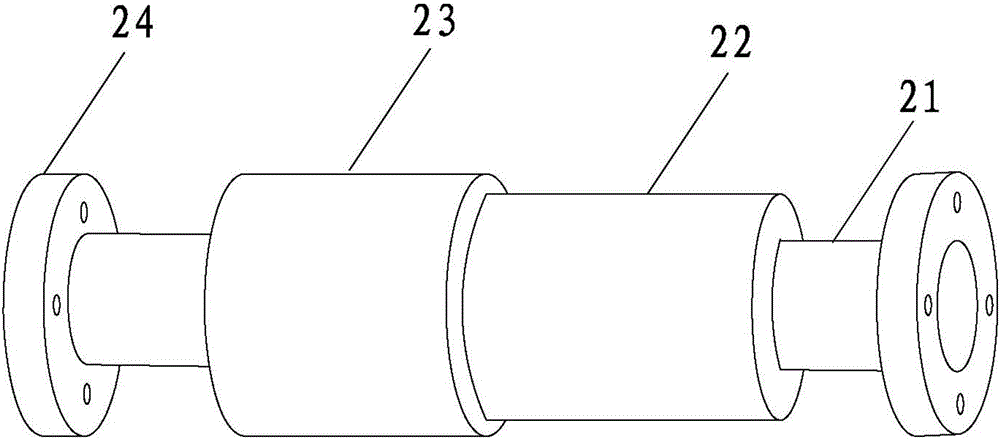

Resonance type gas sensor

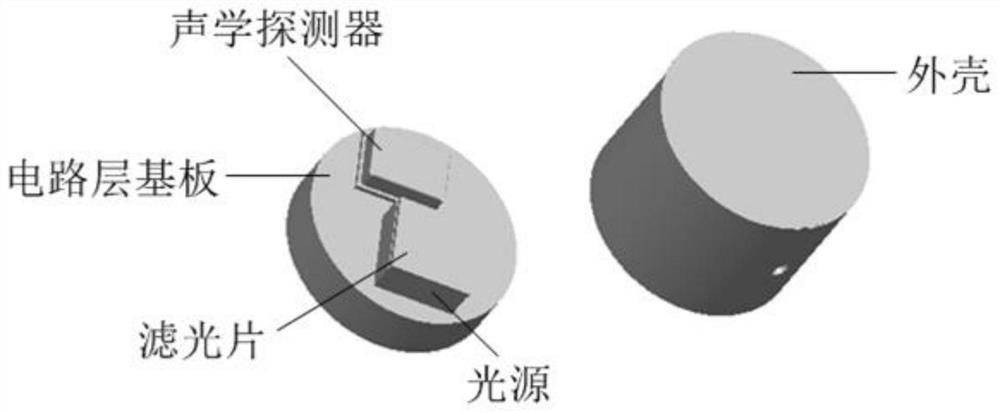

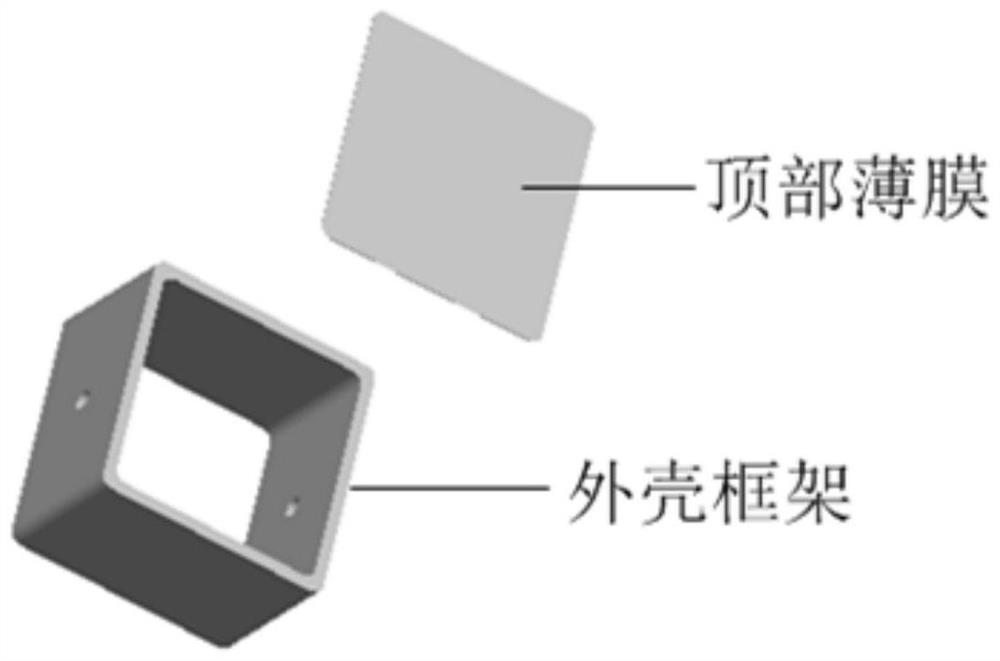

PendingCN112816419AReduce volumeHigh measurement accuracyMaterial analysis by optical meansHemt circuitsAcoustics

The invention relates to the technical field of gas sensors, in particular to a resonance type gas sensor which comprises an integrated light source, a photoacoustic cell, an acoustic detector and a circuit layer substrate. The integrated light source and the acoustic detector are arranged on the circuit layer substrate, an optical filter is arranged on the integrated light source, and the photoacoustic cell is a semi-closed cavity. The photoacoustic cell and the circuit layer substrate are matched in shape and structure and jointly form a closed cavity with a hole. The integrated light source, the photoacoustic cell and the acoustic detector which are arranged on the circuit layer substrate are wrapped in a cavity of the photoacoustic cell. The photoacoustic cell comprises a supporting framework and a plurality of resonance surfaces, the supporting framework and the resonance surfaces are adhered and combined to form a semi-closed cavity, at least one of the resonance surfaces is thin, one or more small air holes are formed in any one or more of the resonance surfaces, and a waterproof breathable film or a waterproof sound transmission film is arranged on the outer side of each air hole. The resonance type gas sensor provided by the invention is higher in sensitivity, higher in measurement precision and higher in resolution.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST +1

Wear particle online monitoring device adopting rotational flow centrifugation, adsorption and adjacent capacitance

InactiveCN105928843AGrowth inhibitionIncrease output signal strengthParticle and sedimentation analysisTemperature controlWear particle

The invention relates to a wear particle online monitoring device adopting rotational flow centrifugation, adsorption and adjacent capacitance. A temperature control module, a magnetizing module, a mechanical centrifugation module, a rotary magnetic field centrifugation module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module of the monitoring device are sequentially connected. An oil liquid inlet is formed in one end of the temperature control module. The mechanical centrifugation module is a rotational flow centrifugation module. The adjacent capacitance sensor technology based on the capacitance edge effect is introduced, and wear particles are monitored without invasion or restriction. By means of the electrification module, the mechanical centrifugation module and the rotary magnetic field centrifugation module, the wear particles in oil liquid are magnetized and aggregated into large particles, move to the position close to the pipe wall and are adsorbed by the adsorption module, so that the intensity of monitoring signals output by an adjacent capacity sensor is improved. By means of the temperature control module and the adjacent capacitance sensor pole plate layer structure designed reasonably, noise is restrained, and the overall performance of the monitoring device of the adjacent capacitance sensor is optimized.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com