Patents

Literature

85results about How to "Increase particle concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

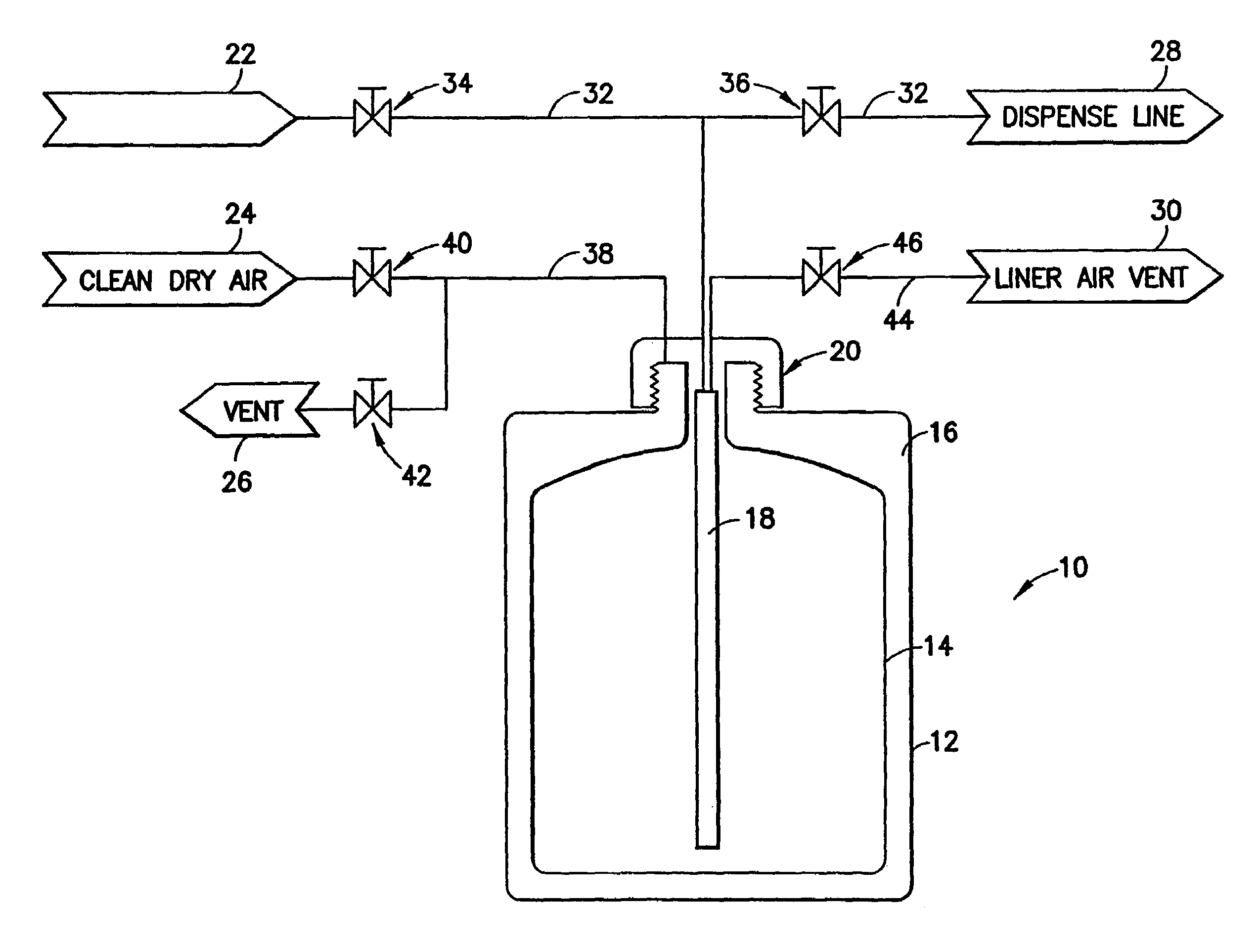

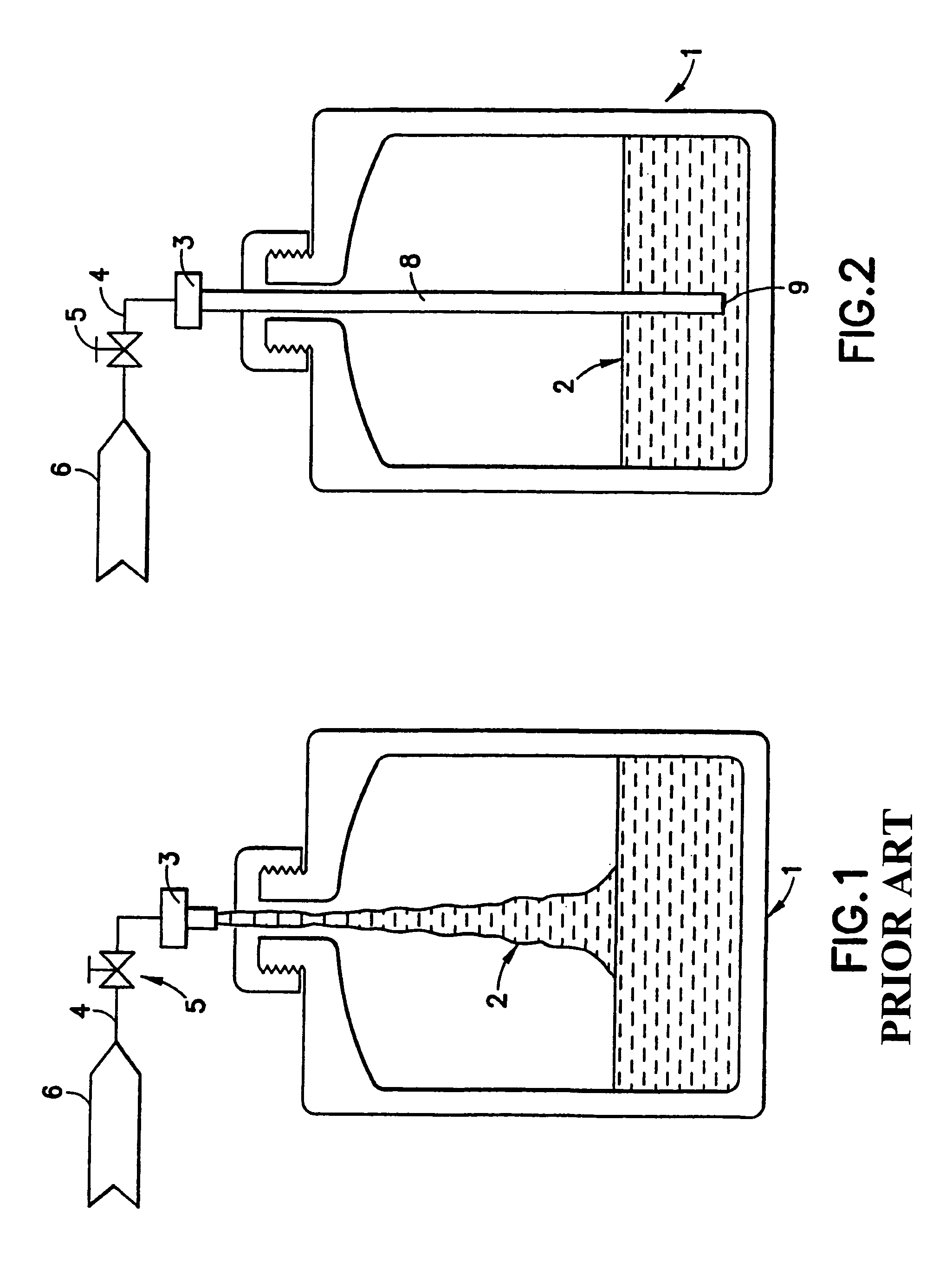

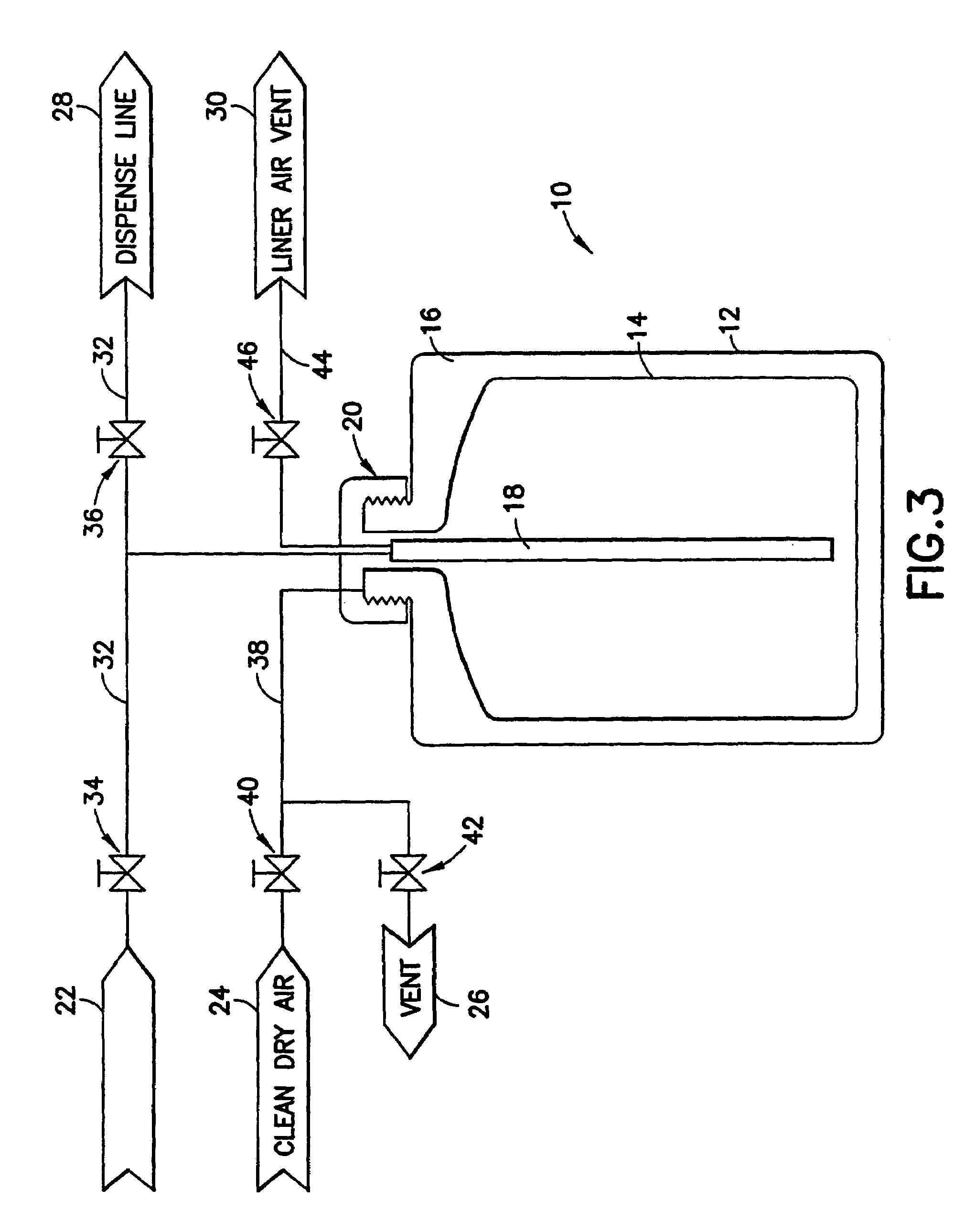

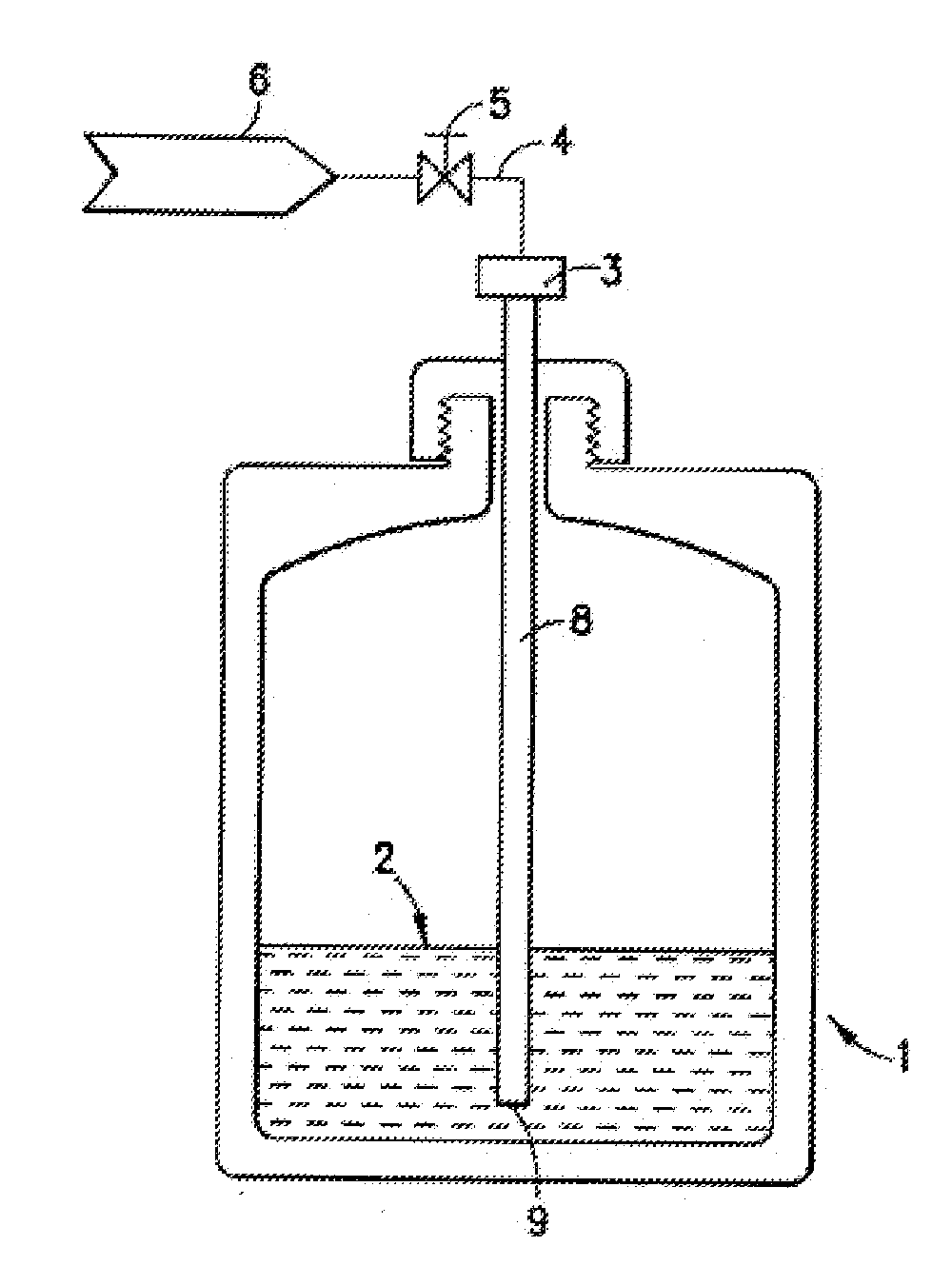

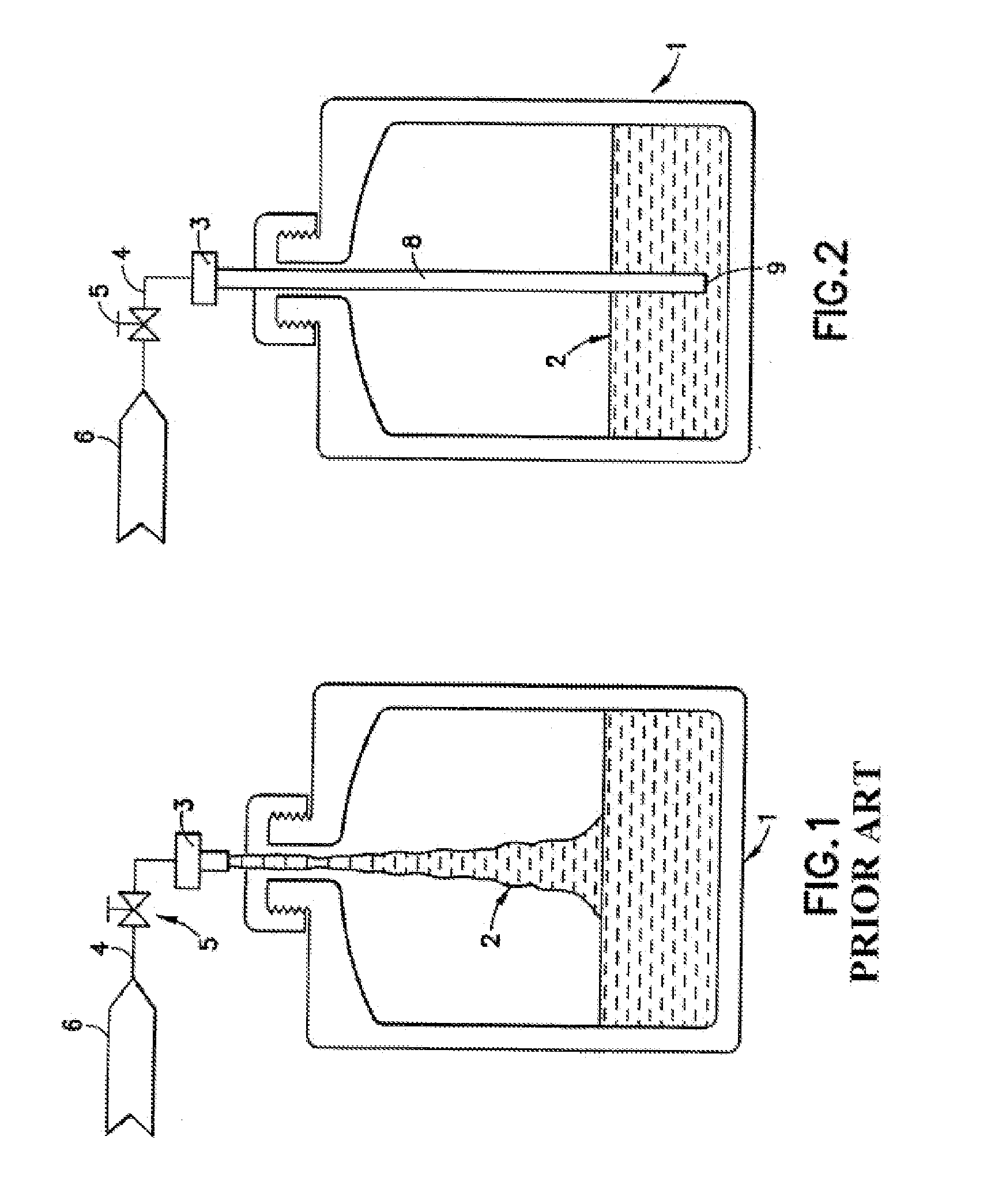

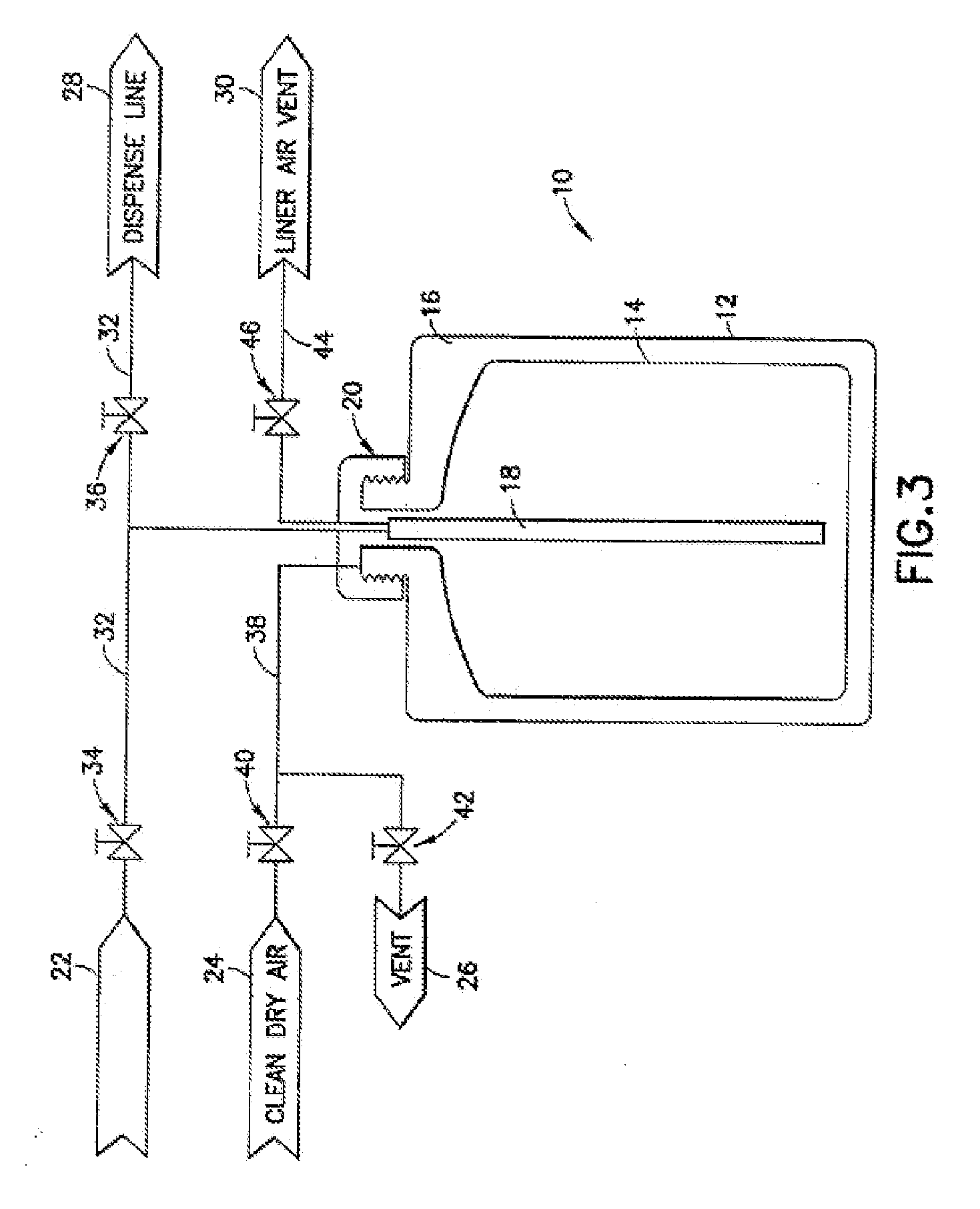

Apparatus and method for minimizing the generation of particles in ultrapure liquids

ActiveUS7188644B2Reduce Particle GenerationLess particle generationSpraying apparatusLiquid transferring devicesAir liquid interfaceEngineering

A system and method of reducing particle generation in packaging containers used to transport ultra pure liquids. Particle generation in the containers is reduced by reducing the air-liquid interface present during filling, transport, and dispensing of the liquid.

Owner:ADVANCED TECH MATERIALS INC

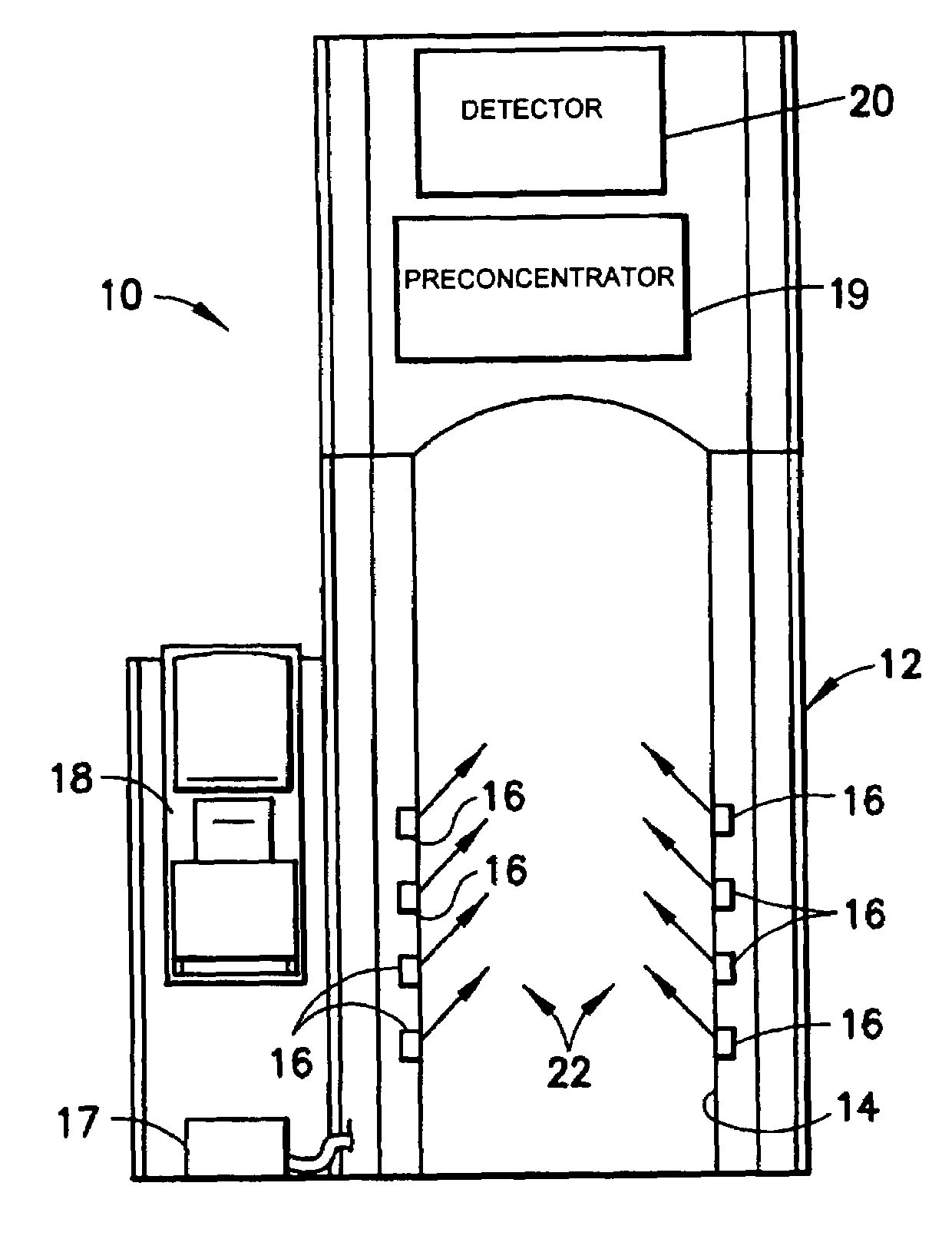

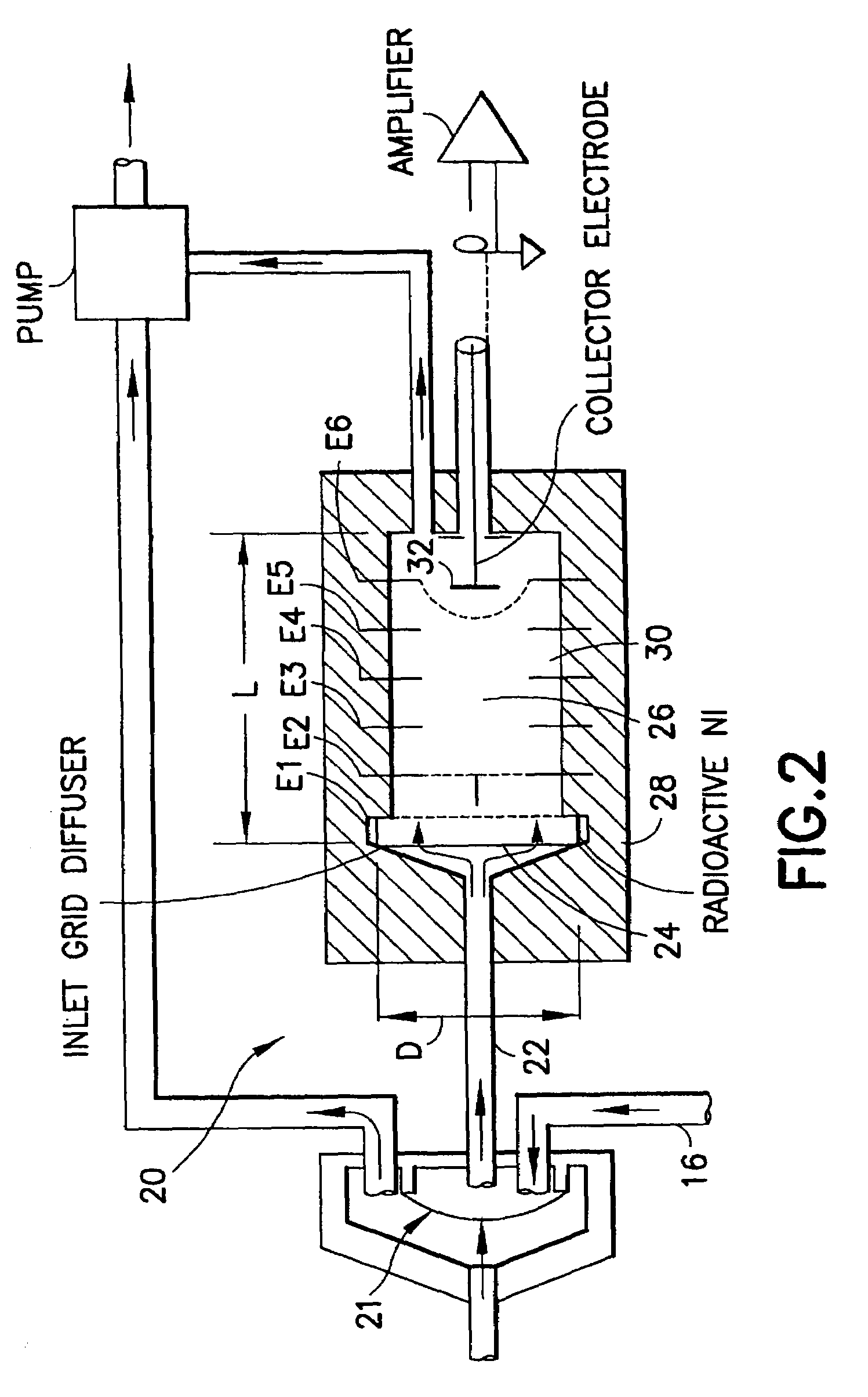

Particle sampling preconcentrator

ActiveUS7141786B2Improve collection efficiencyIncrease particle concentrationParticle separator tubesComponent separationEngineeringTrace Amounts

An apparatus is provided for identifying trace amounts of substances of interest in an air flow. The apparatus includes an inlet for receiving the air flow and an outlet for exhausting major portions of the air flow. The outlet is offset from the inlet. A porous impactor is disposed in alignment with the inlet and is impacted by particles entrained in the air flow. The porous impactor is heated sufficiently to vaporize particles impinging thereon. A detector communicates with the porous impactor and is operative for identifying substances of interest in the vaporized particles.

Owner:RAPISCAN SYST INC (US)

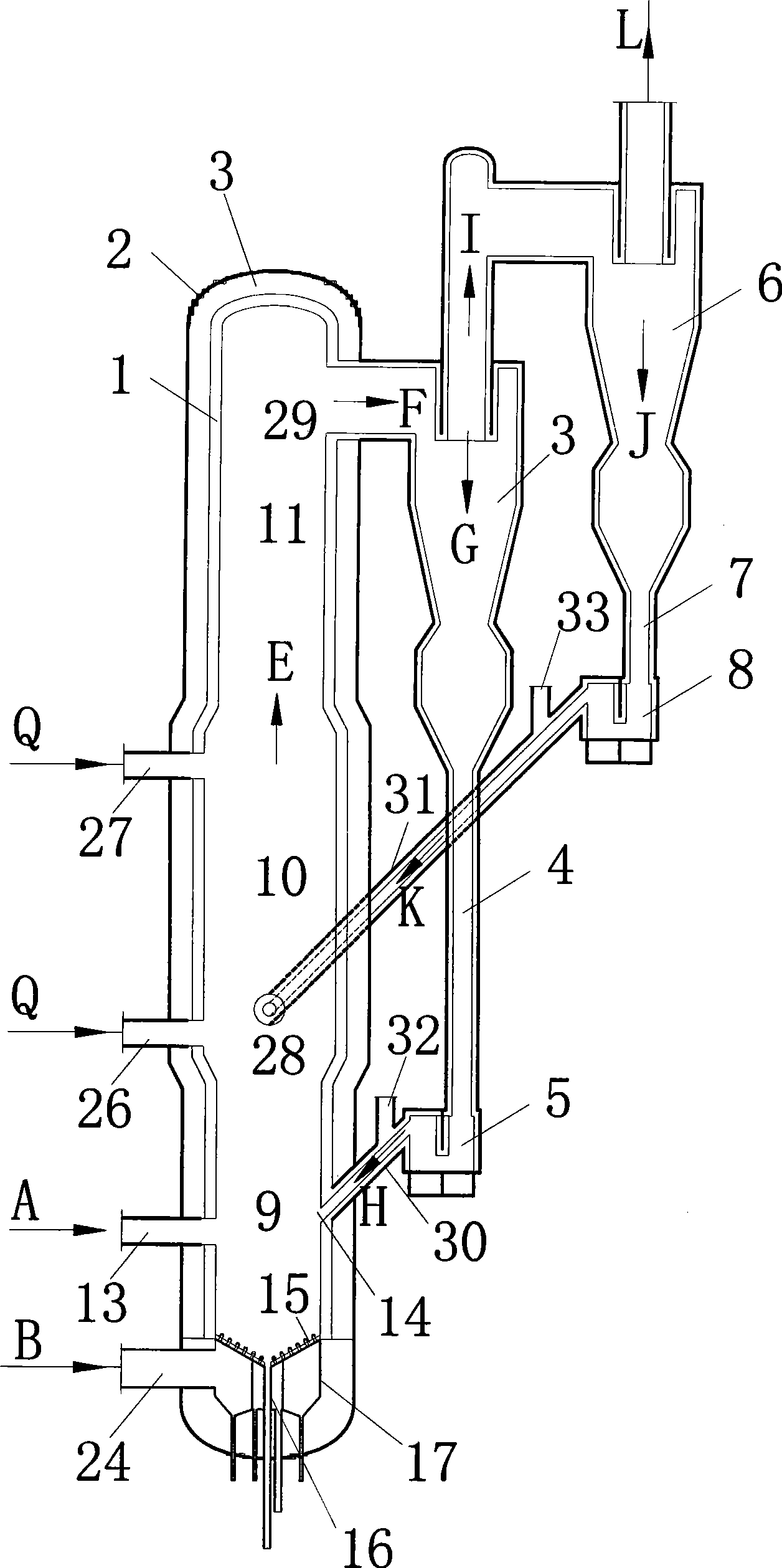

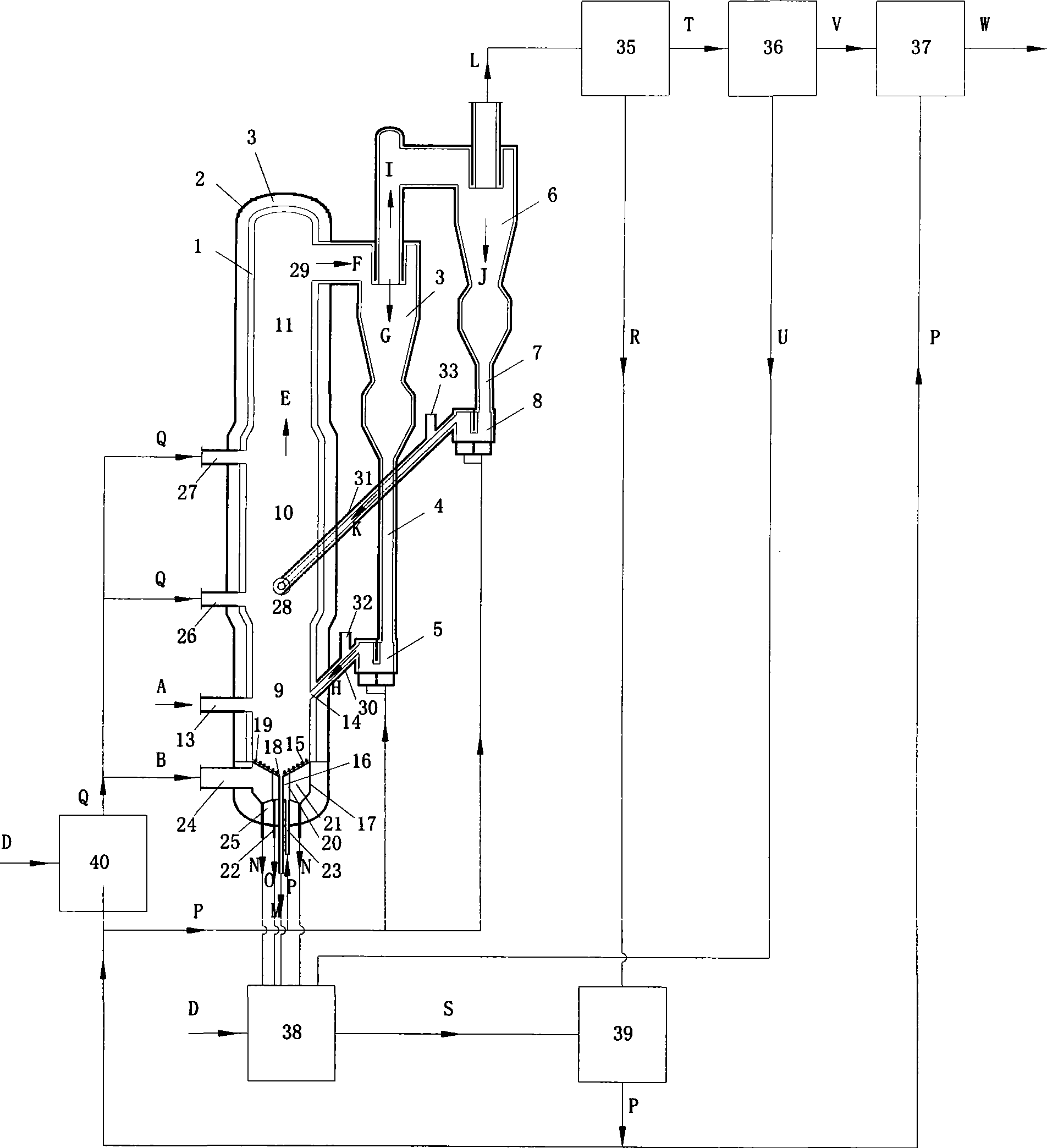

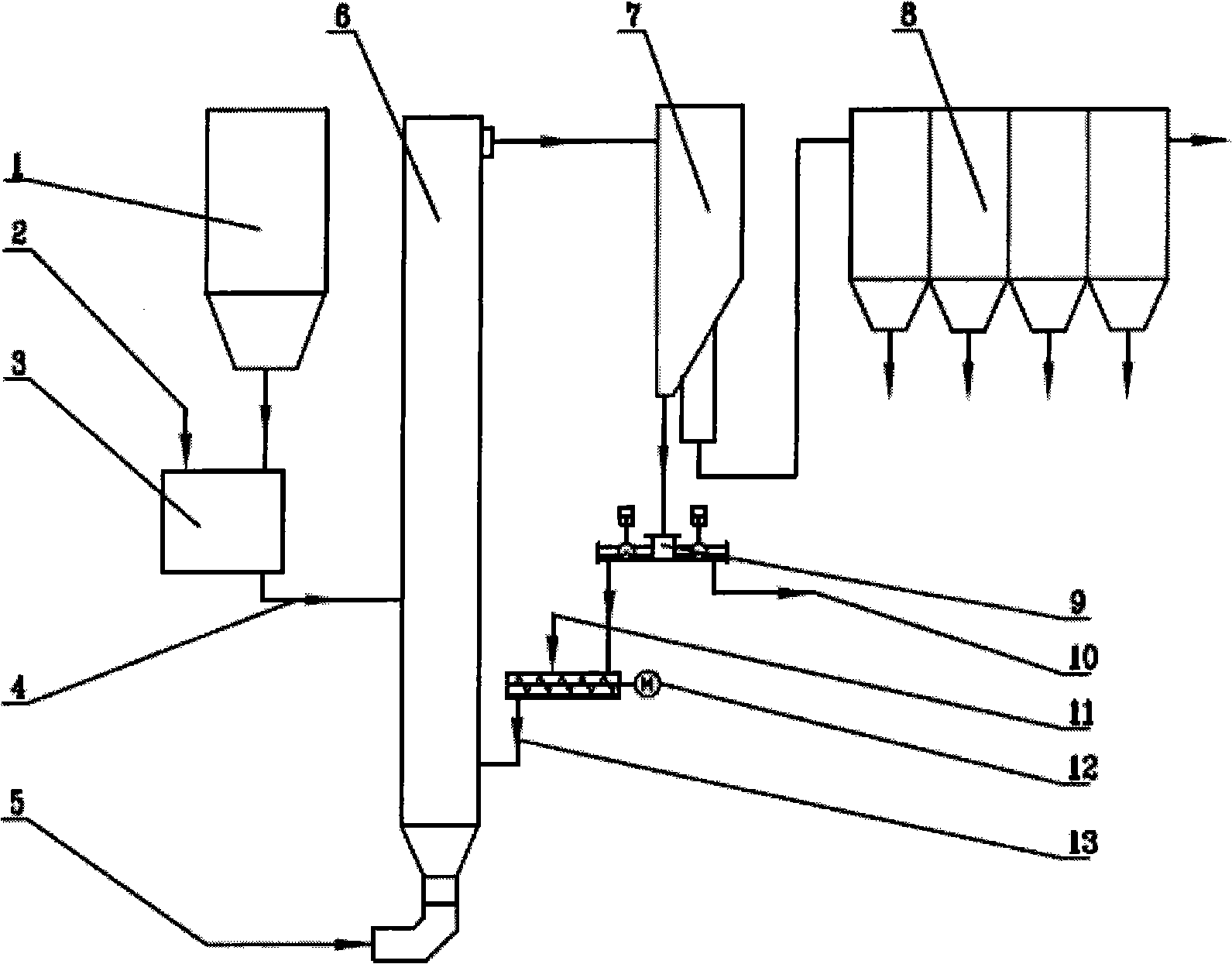

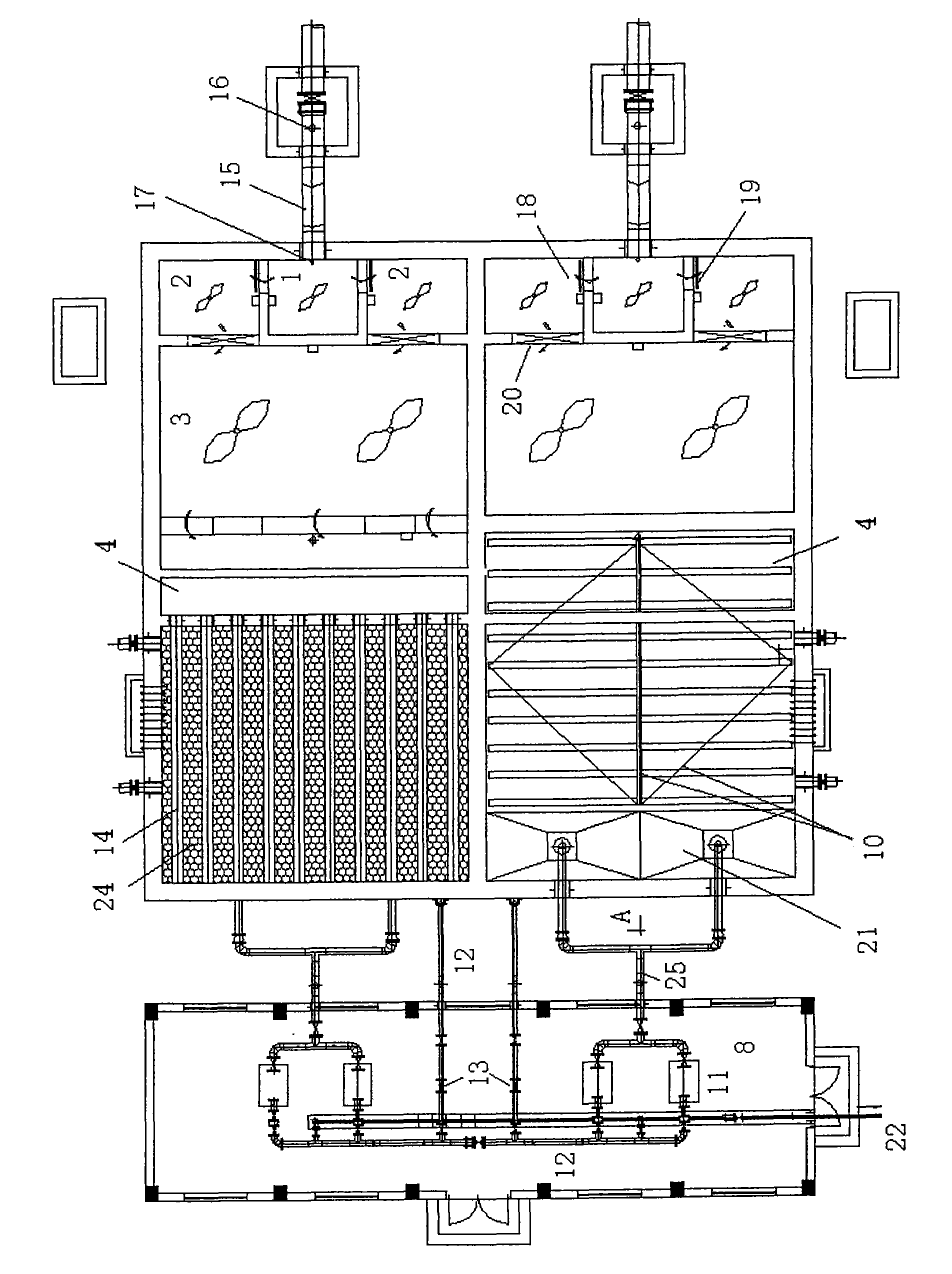

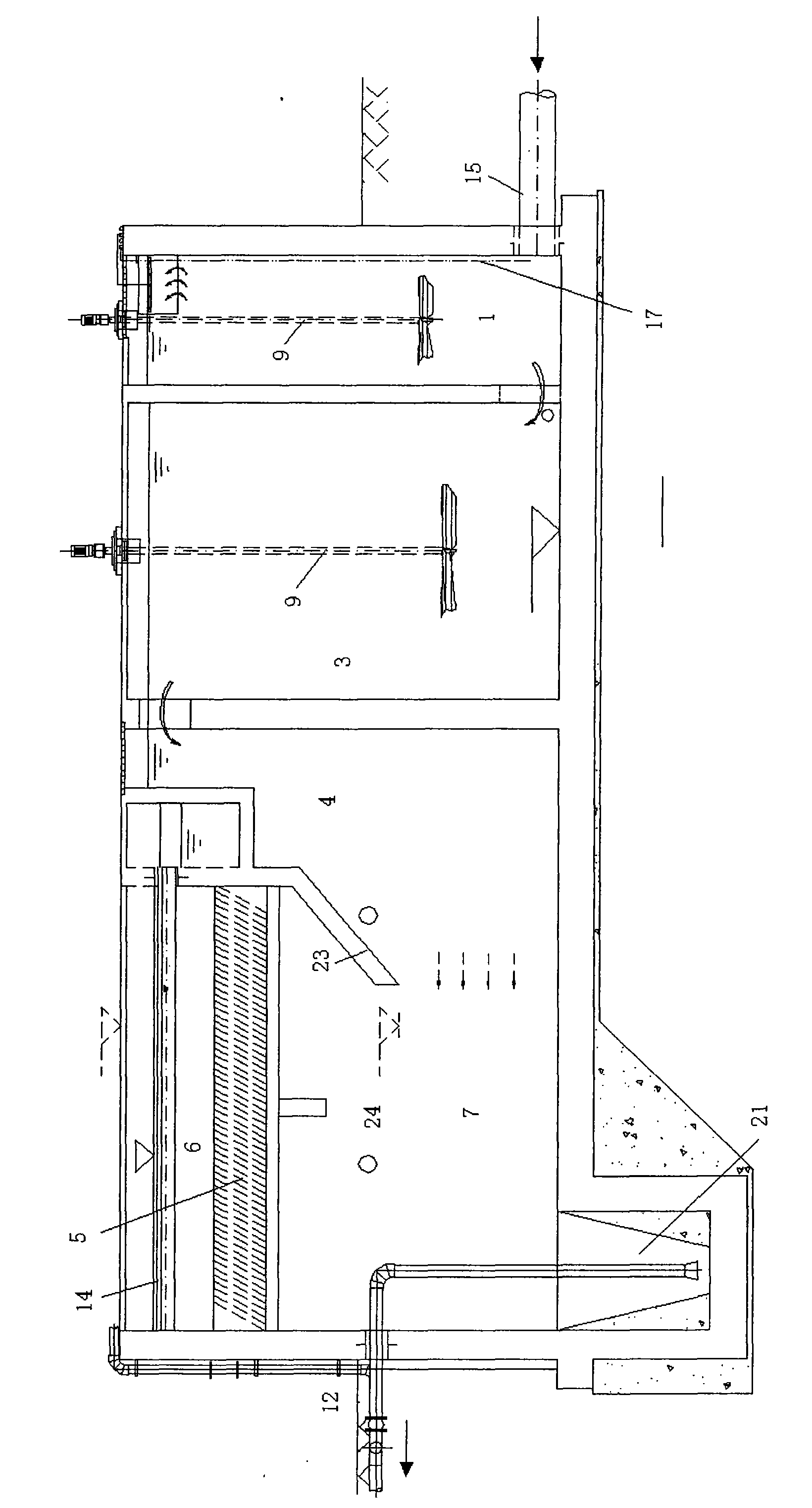

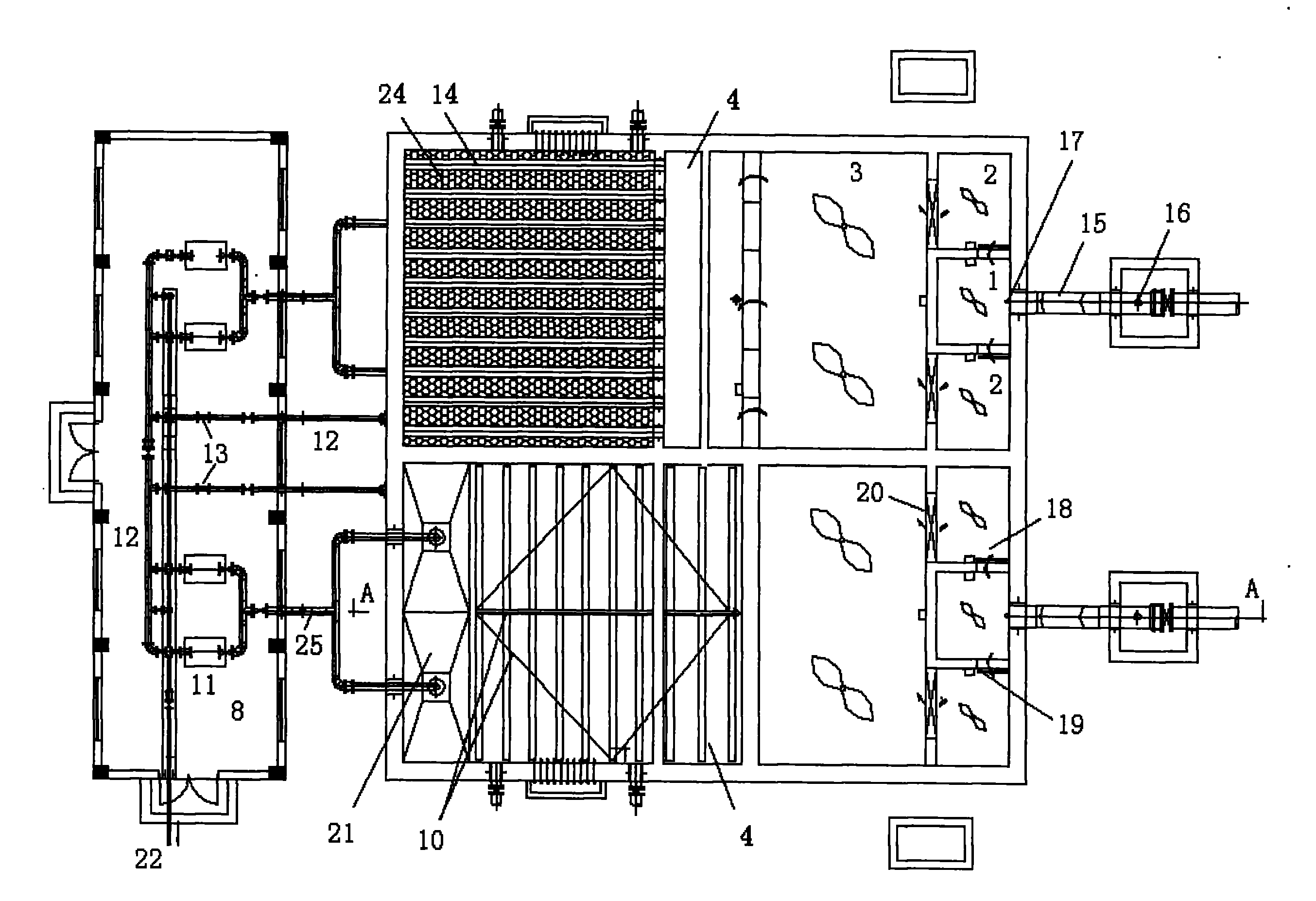

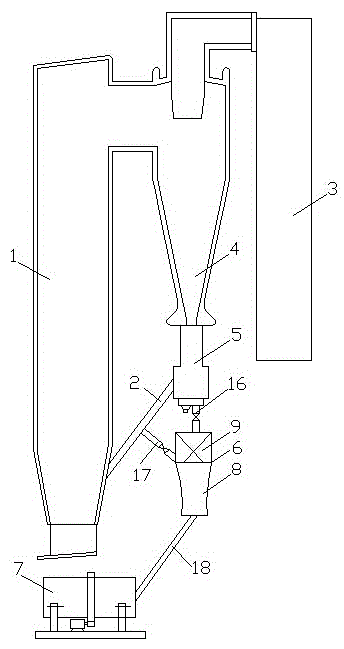

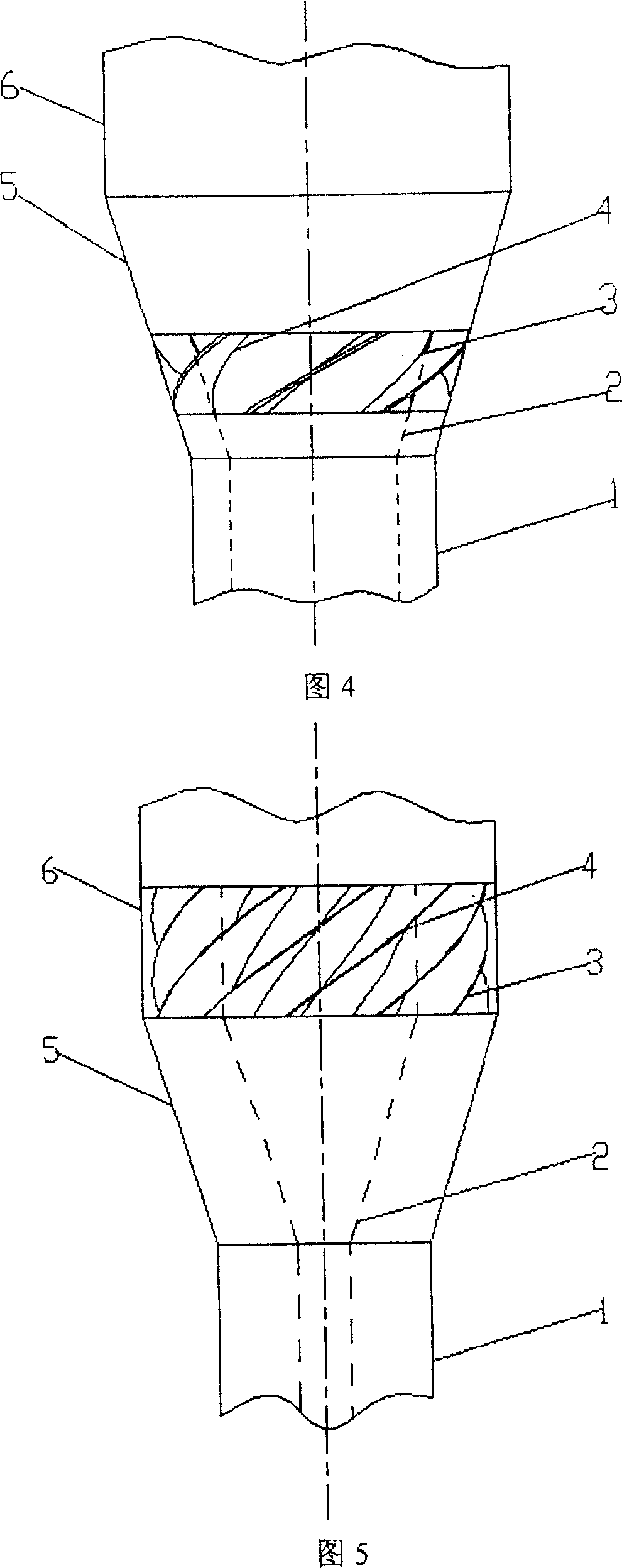

High-density pressurized fluidized bed coal gasification apparatus and method

ActiveCN101372635AGood amplification performance of flow dynamic characteristicsImprove carbon conversionCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringTransformation ratio

A high-density pressurized fluid bed coal gasification device and a method relate to a gasification device and a method which are especially suitable for the efficient treatment of the high-sulfur, high-ash and high ash fusion point coal with high reserve volume in China and have the advantages of broad coal type adaptability, high carbon transformation ratio in the gasification process, high heat value of coal gas, low investment and excellent environment-friendly performance. A gasification reactor (1) is arranged in a pressure shell (2) and is divided into a dense-phase turbulent flow fluidizing section (9), a high-density core-annulus flow section (10) and a density rapid flow section (11) from bottom to top, and according to the gasification character of the goal with high sulfur, high ash and high ash fusion point, flow states with different features are adopted for pressurizing and sectionalized gasification from bottom to top and the pressure for gasification is 1.0-2.5MPa.

Owner:SOUTHEAST UNIV

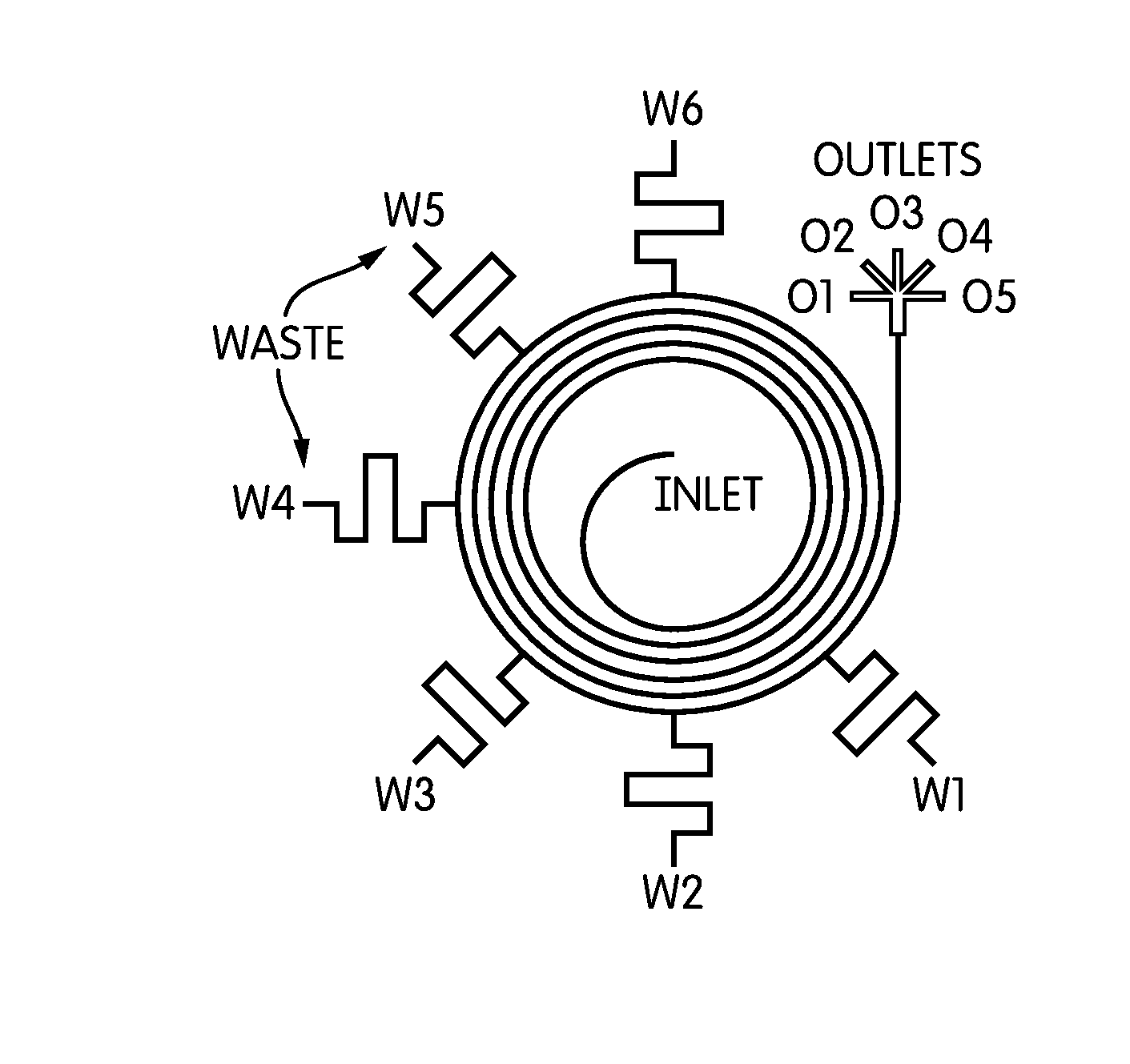

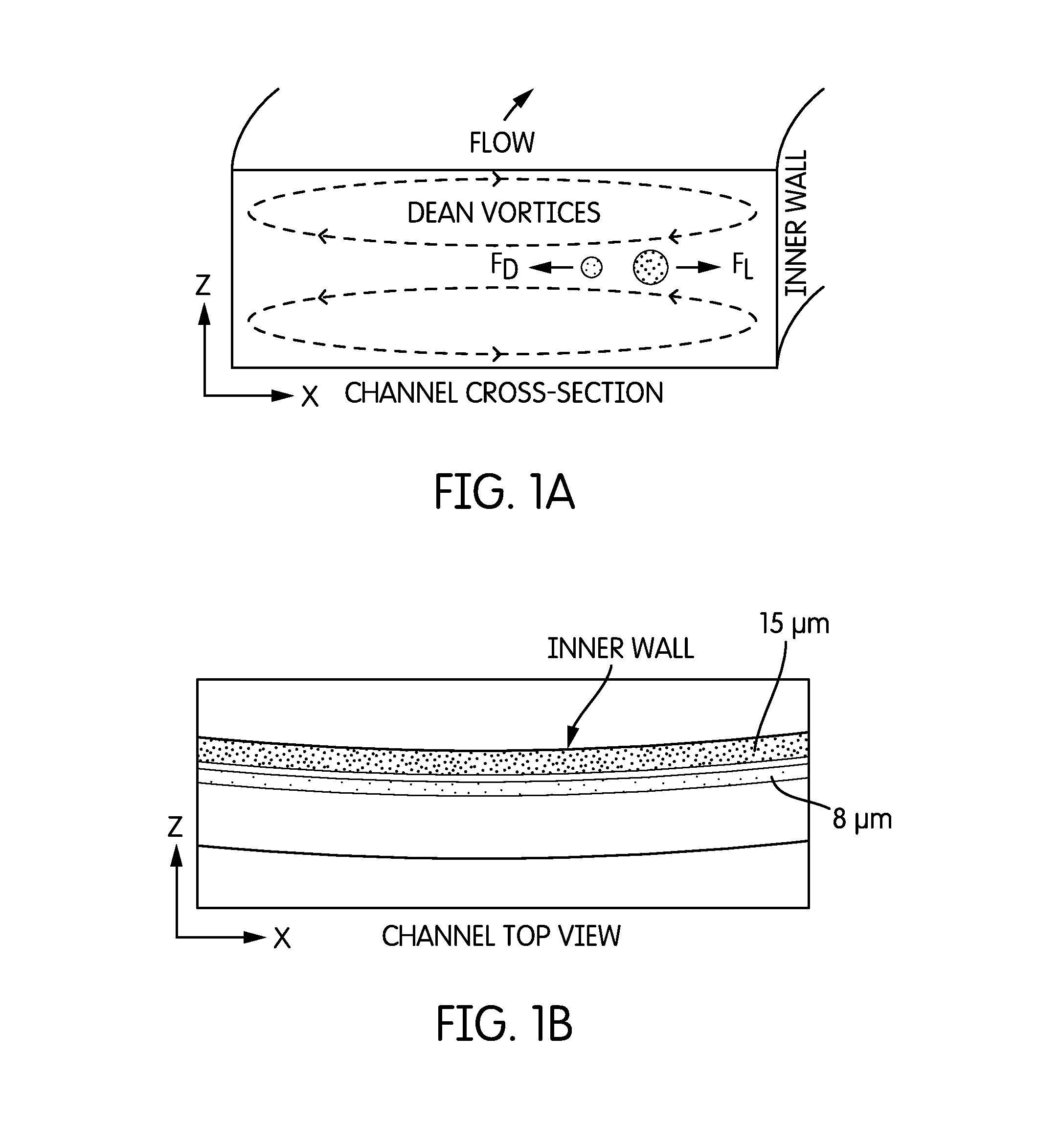

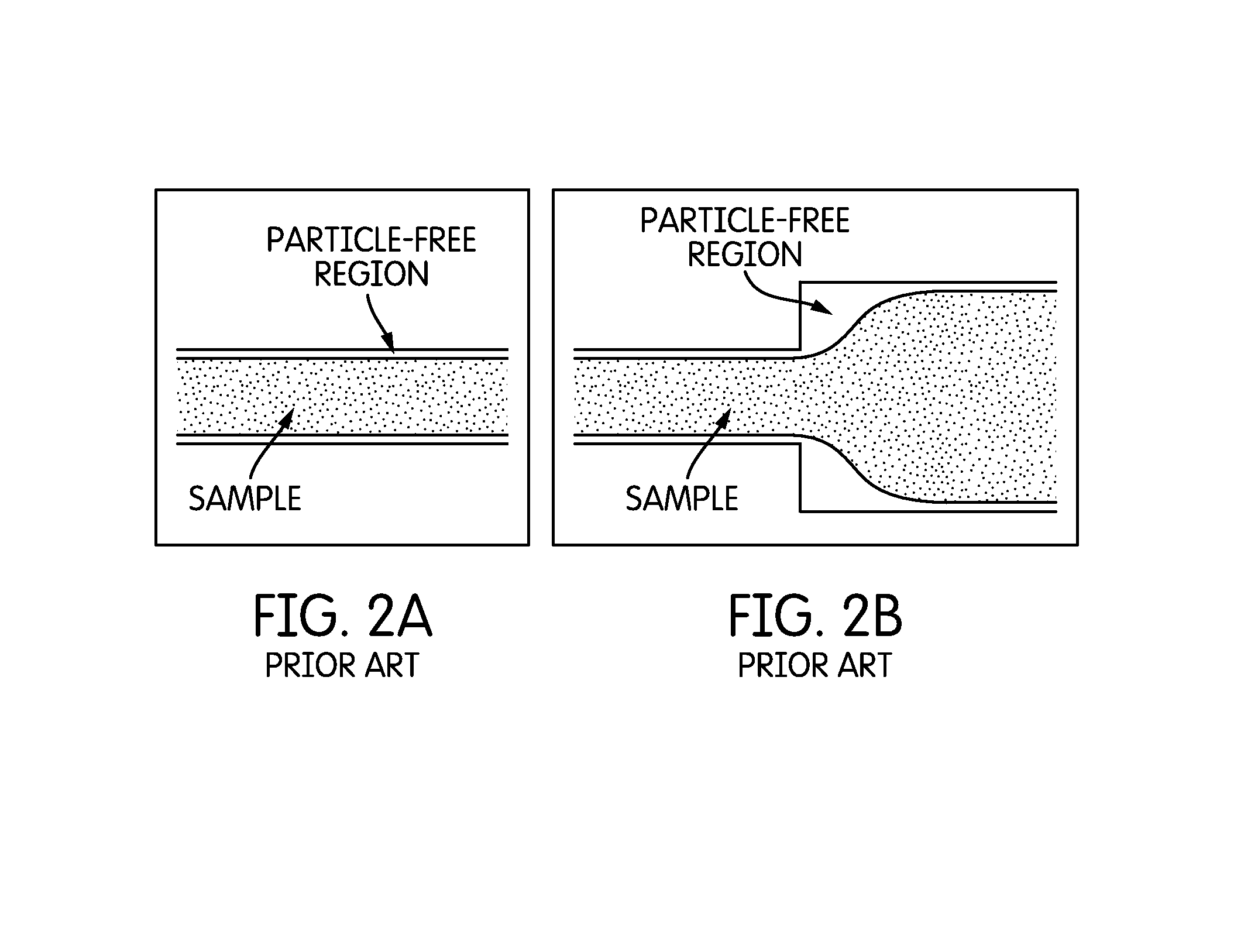

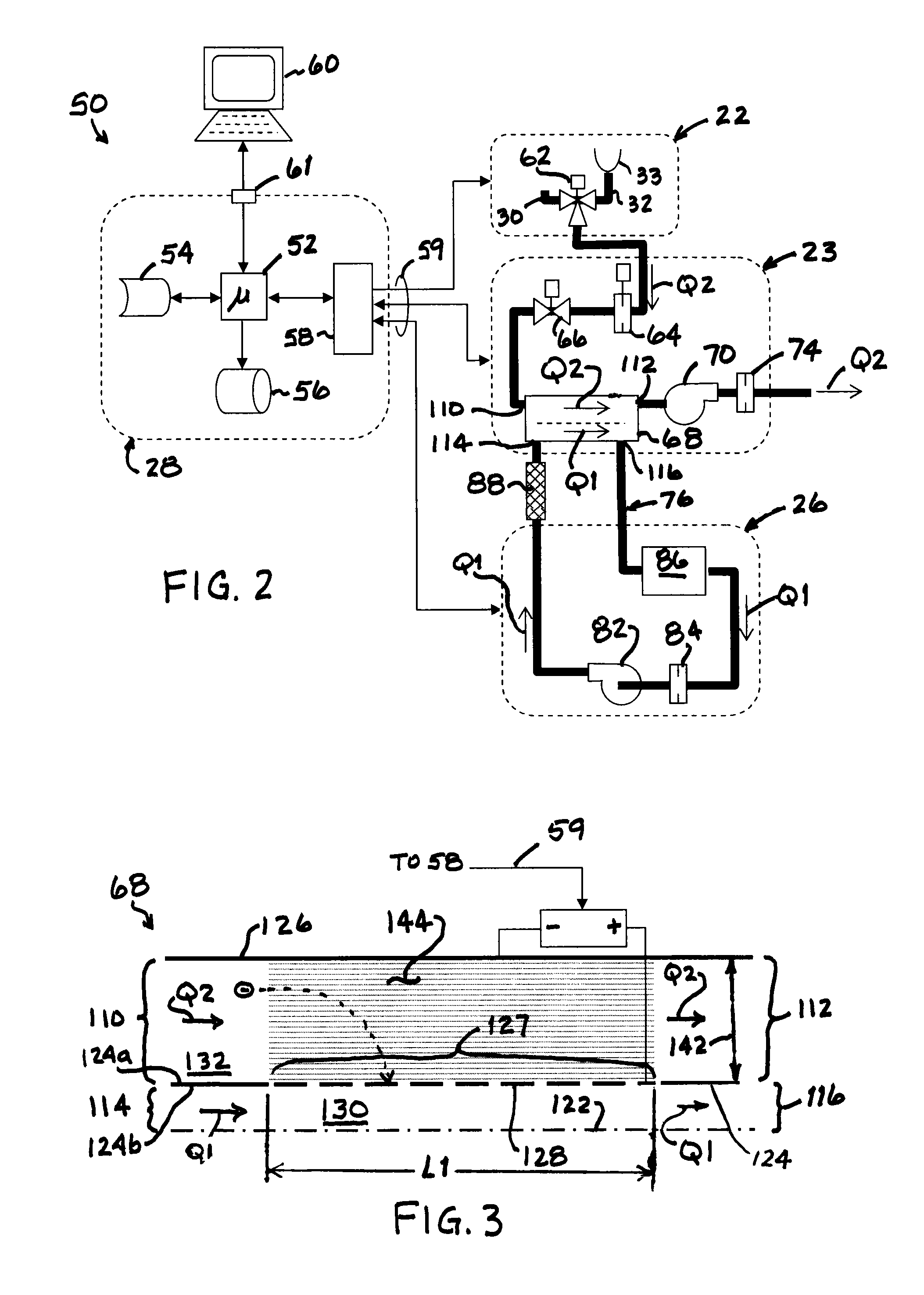

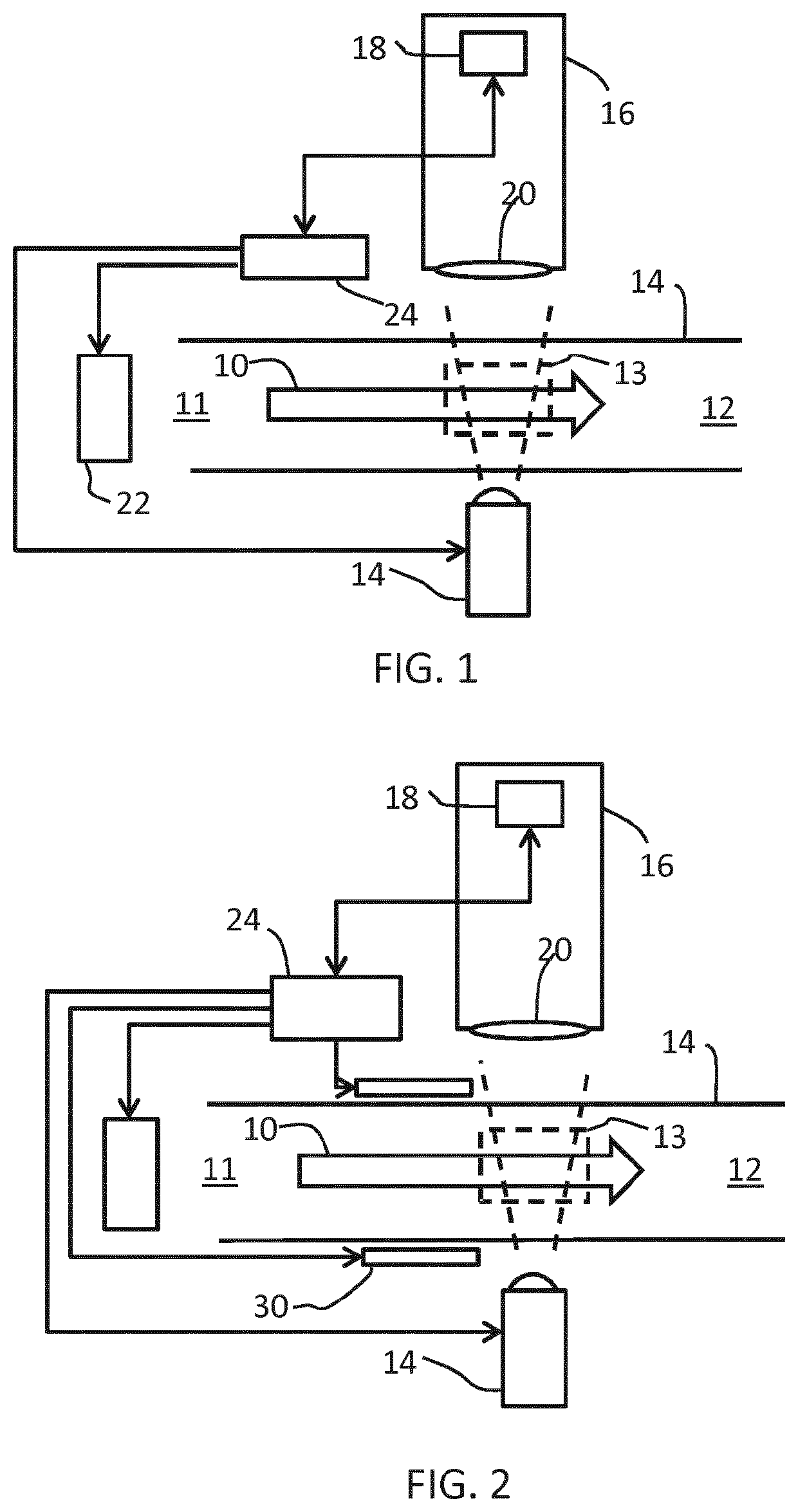

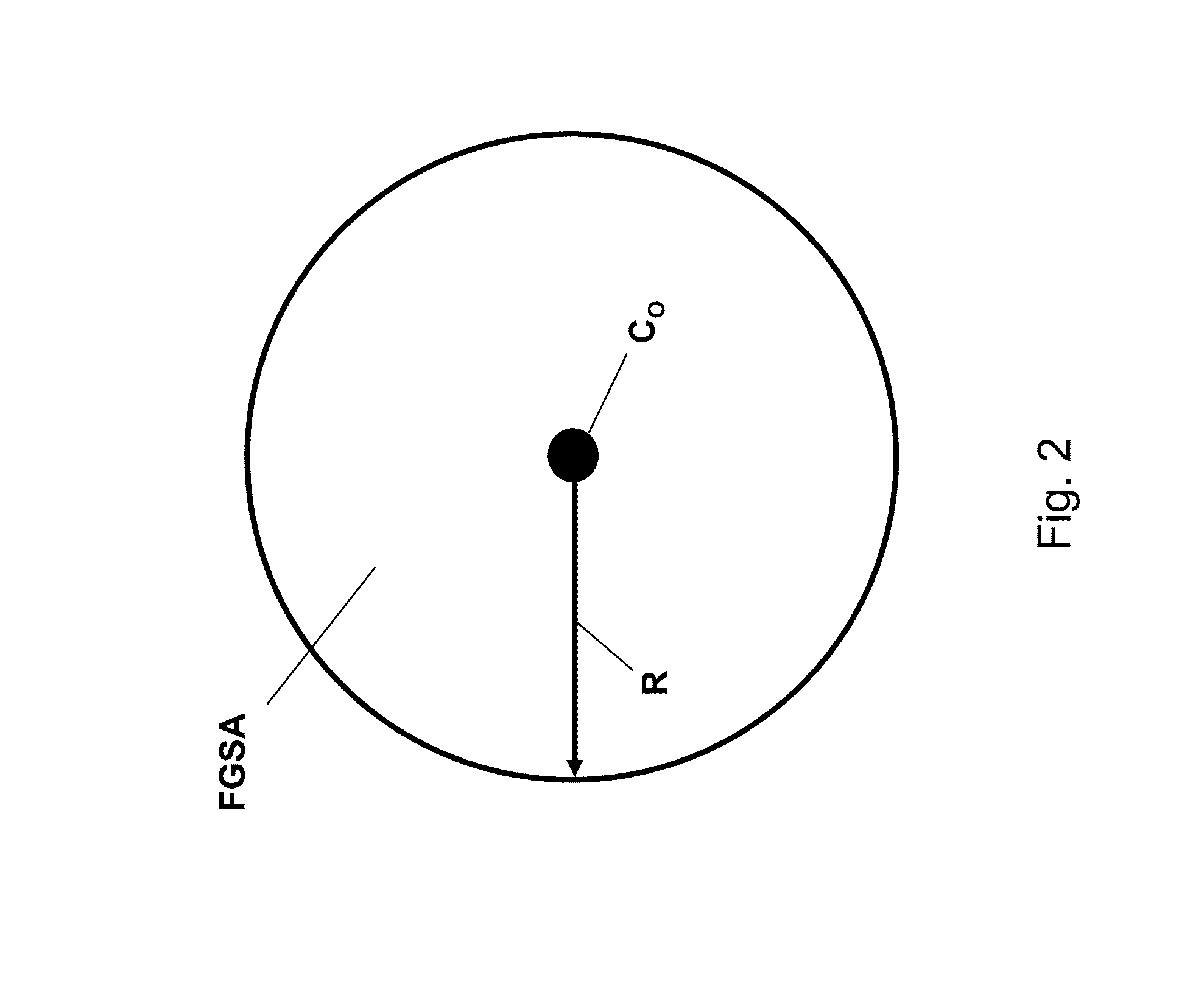

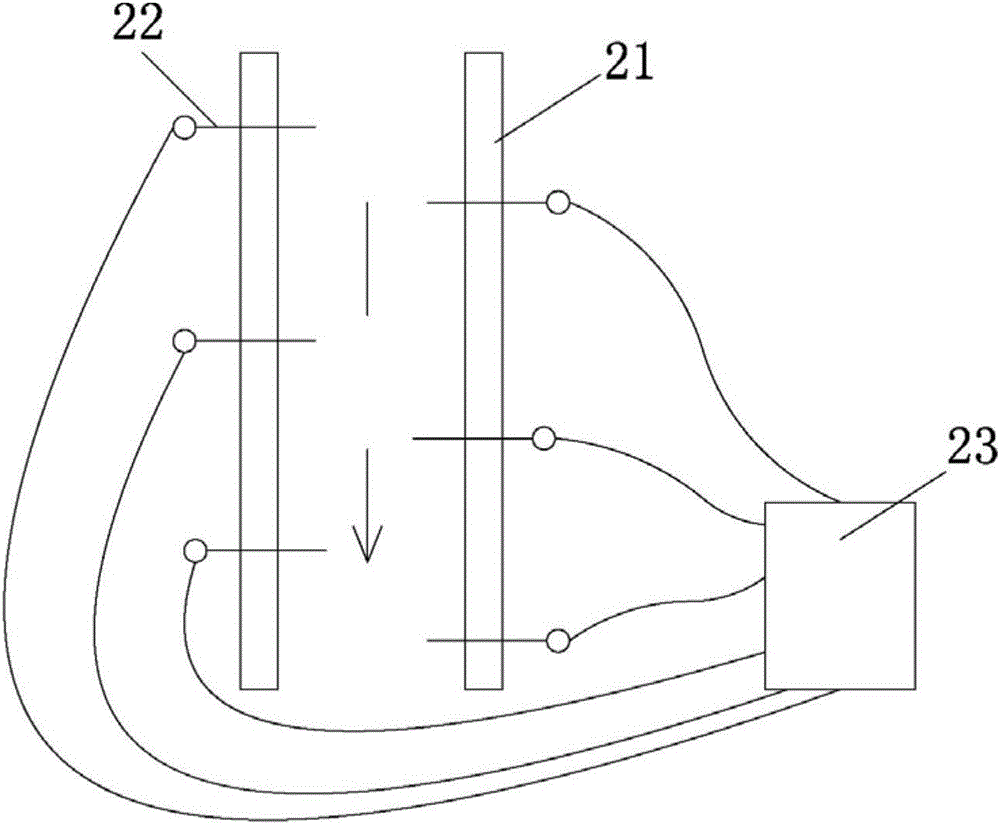

Particle separation and concentration using spiral inertial filtration

ActiveUS20140093867A1Increase particle concentrationLower the volumeMicrobiological testing/measurementPreparing sample for investigationChannel geometryFiltration

A spiral inertial filtration device is capable of high-throughput (1 mL / min), high-purity particle separation while concentrating recovered target particles by more than an order of magnitude. Large fractions of sample fluid are removed from a microchannel without disruption of concentrated particle streams by taking advantage of particle focusing in inertial spiral microfluidics, which is achieved by balancing inertial lift forces and Dean drag forces. To enable the calculation of channel geometries in the device for specific concentration factors, an equivalent circuit model was developed and experimentally validated. Large particle concentration factors were achieved by maintaining either average fluid velocity or Dean number throughout the entire length of the channel during the incremental removal of sample fluid. Also provided is the ability to simultaneously separate more than one particle from the same sample.

Owner:UNIV OF MARYLAND

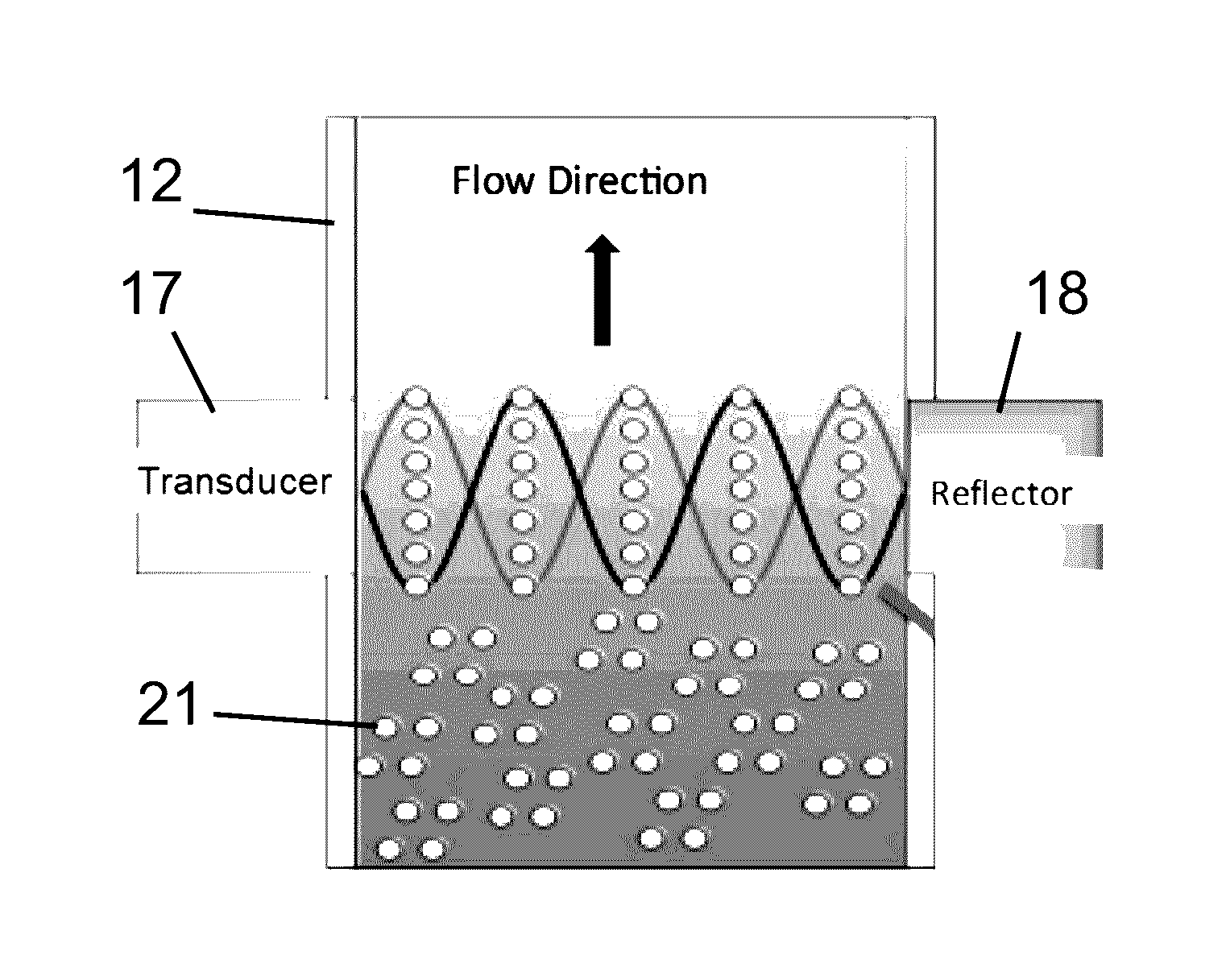

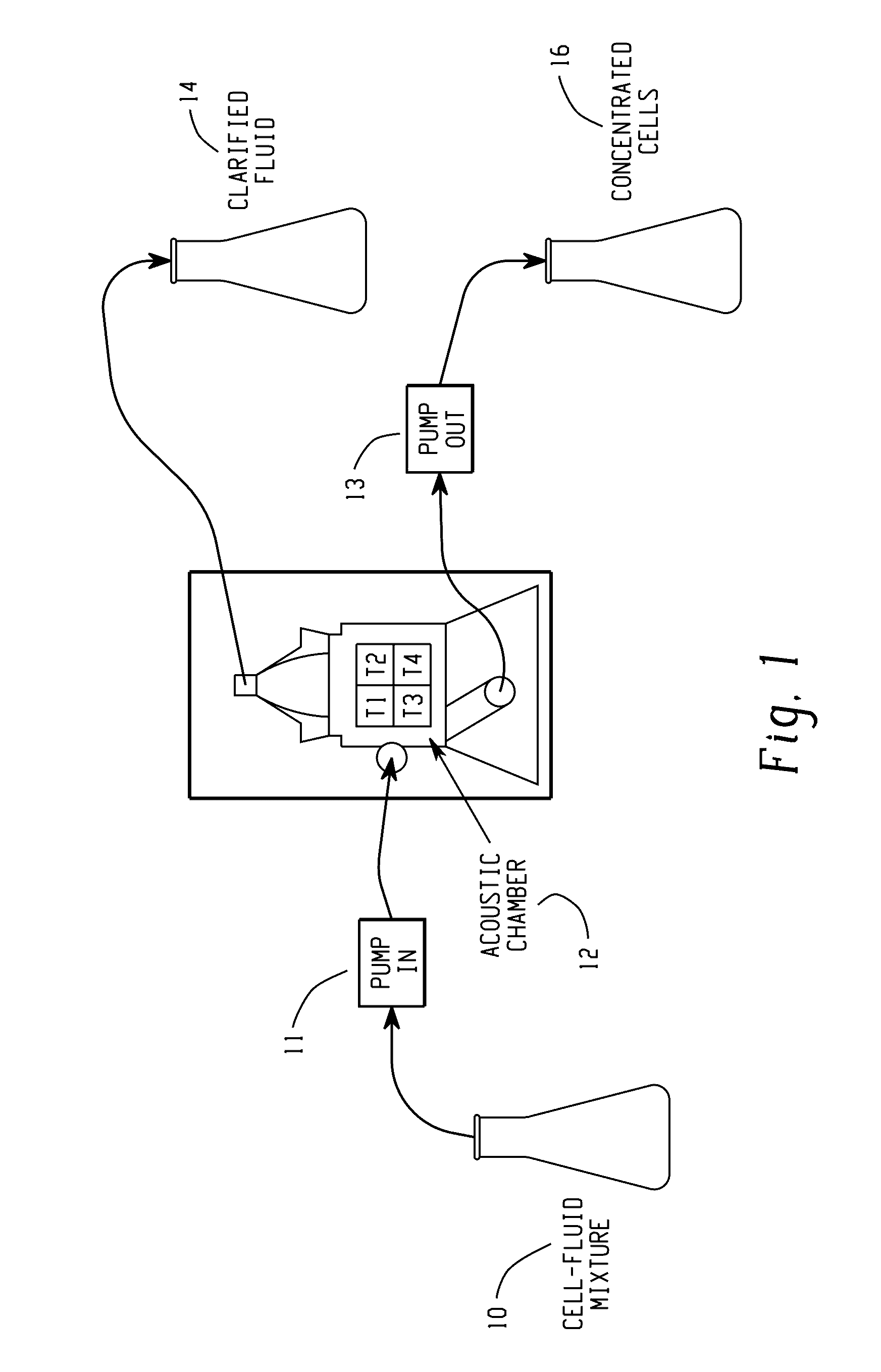

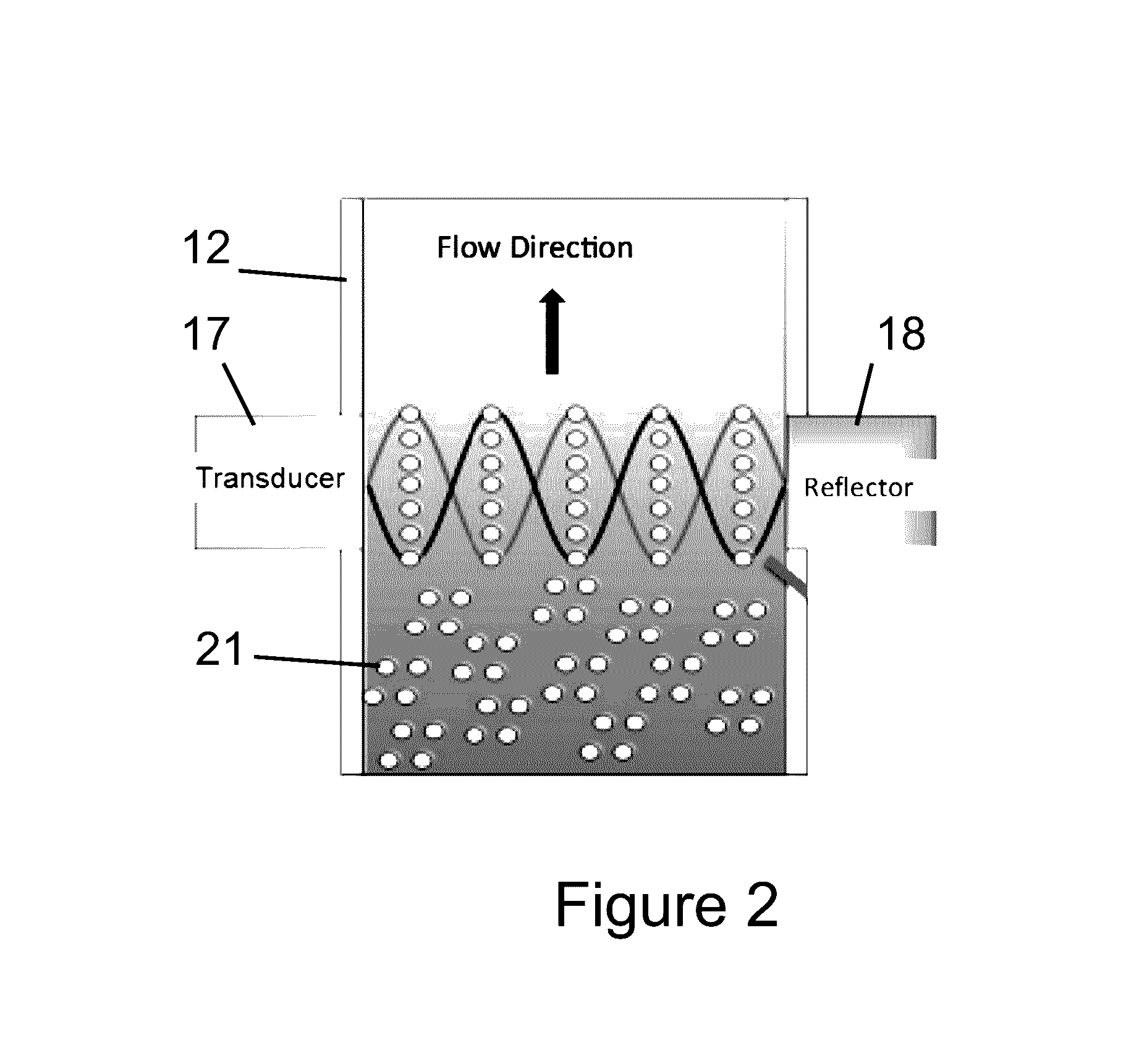

Methods and apparatus for particle aggregation using acoustic standing waves

ActiveUS9533241B2Easy to separateIncrease particle concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsUltrasonic sensorTrapping

Devices for separating materials from a host fluid are disclosed. The devices include an acoustic chamber having an inlet and an outlet. An ultrasonic transducer and reflector create a multi-dimensional acoustic standing wave in the acoustic chamber that traps the materials and permits a continuous separation of the materials from the host fluid. The materials and the host fluid can thus be separately collected. Multiple sets of trapping lines are generated by the acoustic standing wave, and the transducer is oriented to minimize cross-sectional area for straight vertical channels between the trapping lines.

Owner:FLODESIGN SONICS

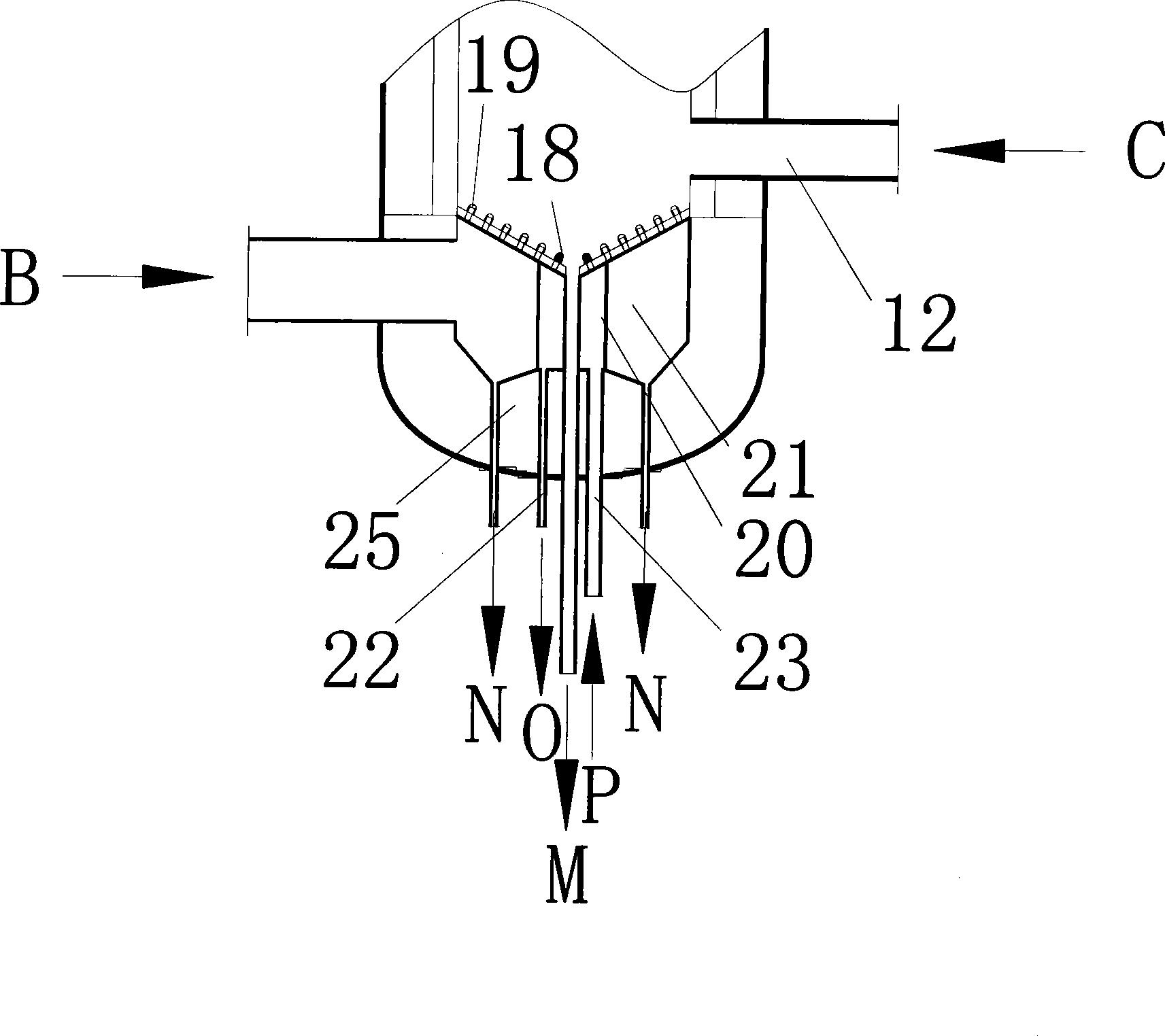

Circulating fluid bed flue gas desulfurization technique and device

InactiveCN101357298AIncrease profitSimple structureDispersed particle separationFlue gasProcess engineering

The invention discloses a circulating fluidized bed flue gas desulfurization process which takes a calcium-based desulfurizing agent as a bed material and a device thereof. The process and the device are characterized in that a lime preparation and supply system comprises a main powder silo and a digester; a flue gas inlet structure, a circulating fluidized bed desulfurization reaction tower, a primary dust collector, a secondary dust collector are connected from beginning to end; the lime preparation and supply system is connected with a venturi fluidization throat pipe arranged at the lower part of the circulating fluidized bed desulfurization reaction tower; the upstream of a feed back distributing tank is connected with an ash hopper of the primary dust collector, and the downstream thereof is connected with a discharge pipe and a circulating ash humidification activator, and the humidified and activated circulating ash enters a venturi pipe outlet arranged at the lower part of the circulating fluidized bed desulfurization reaction tower. The flue gas enters from the bottom of the desulfurization reaction tower, contacts and reacts with a desulfurizing agent and the circulating ash in the tower, desulfurization by-products enter the dust collector together with the flue gas, most of the circulating ash separated by the dust collector is delivered to the tower by the humidification activator. The circulating fluidized bed flue gas desulfurization process and the device thereof have the advantages that when the amount of the water in the tower is the same, desulfurization efficiency can be greatly improved; when the desulfurization reaction tower is not injected with water or injected with little water, the problems of sticking wall and scale formation can be effectively avoided.

Owner:黄盛珠

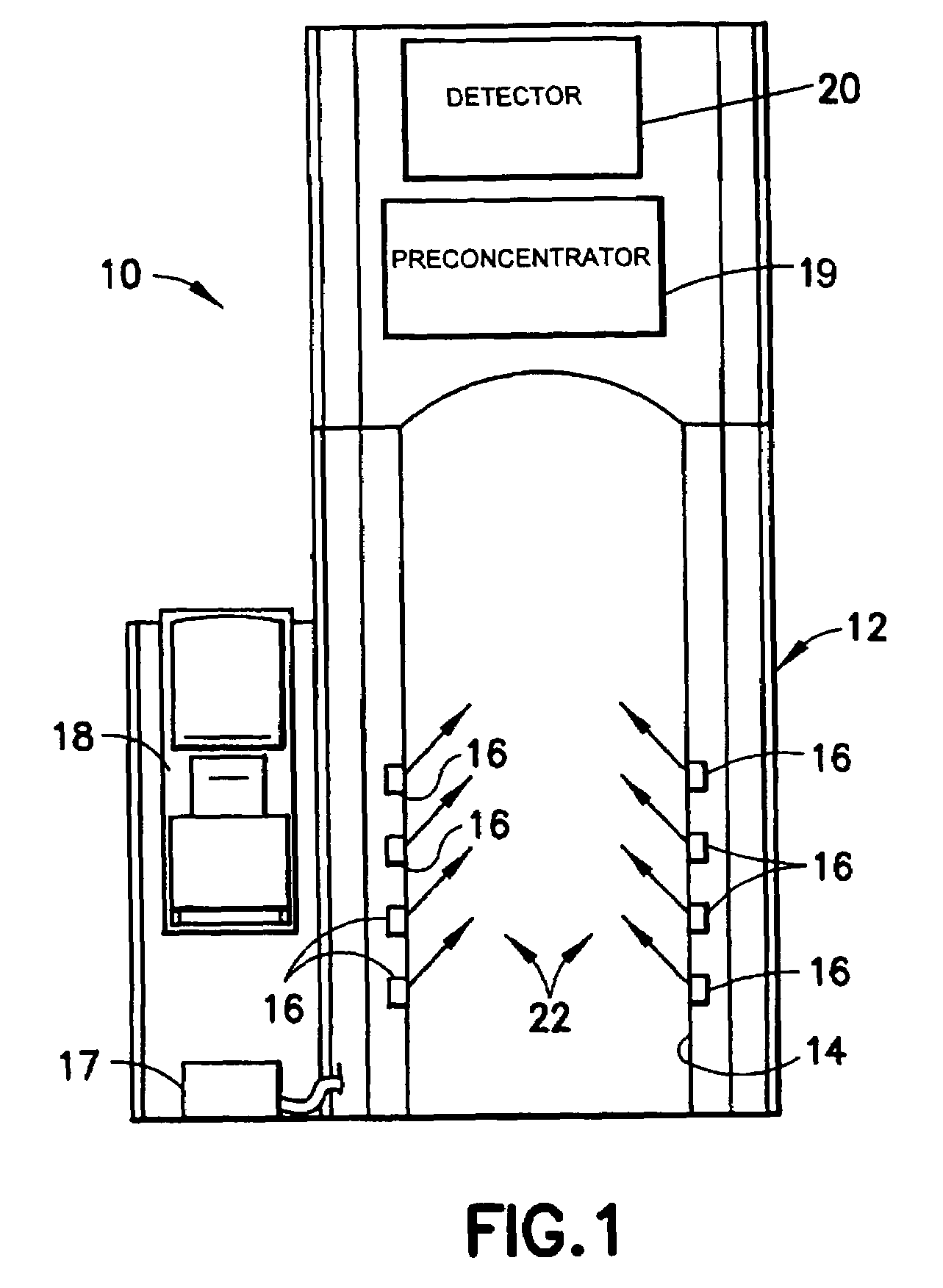

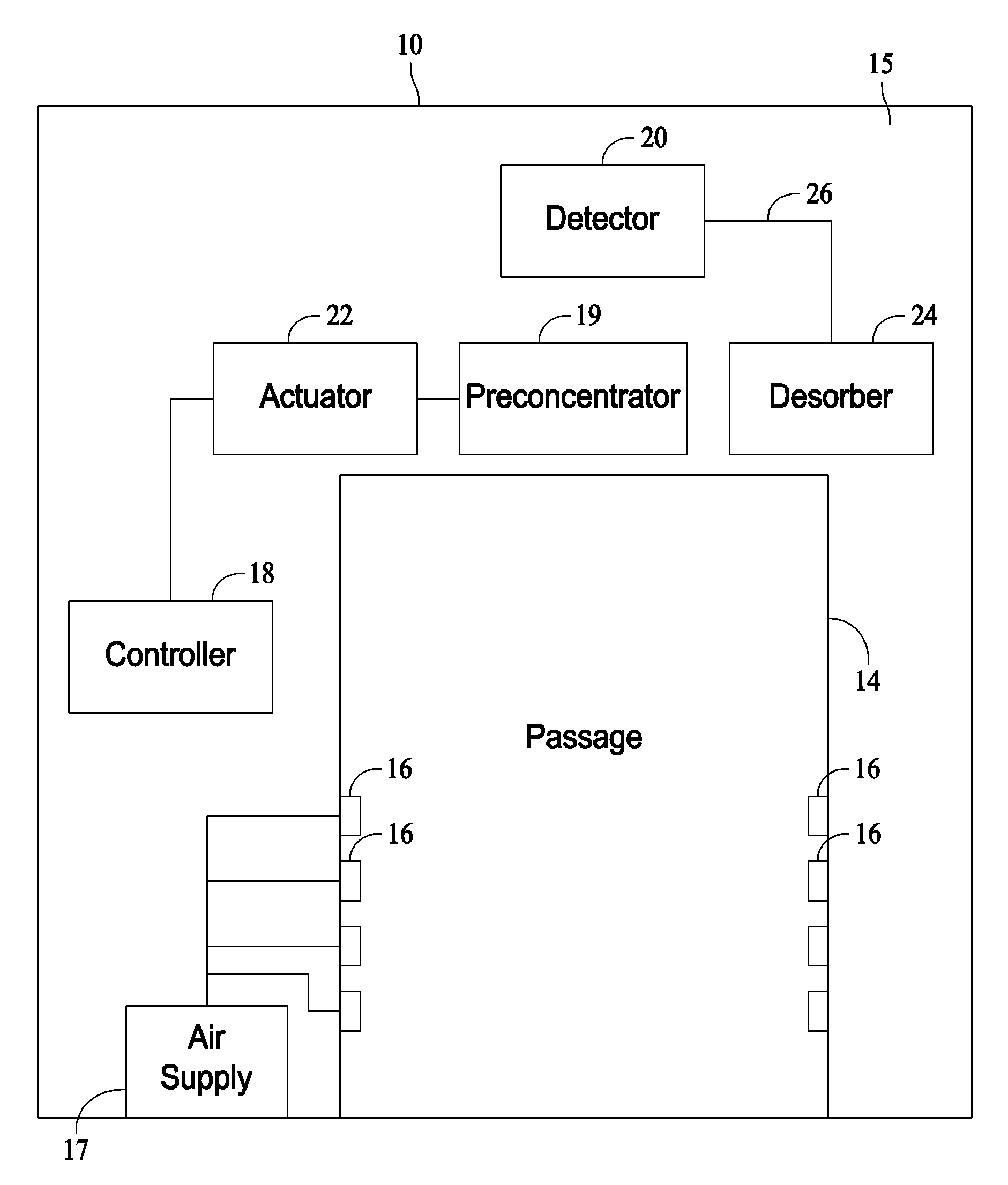

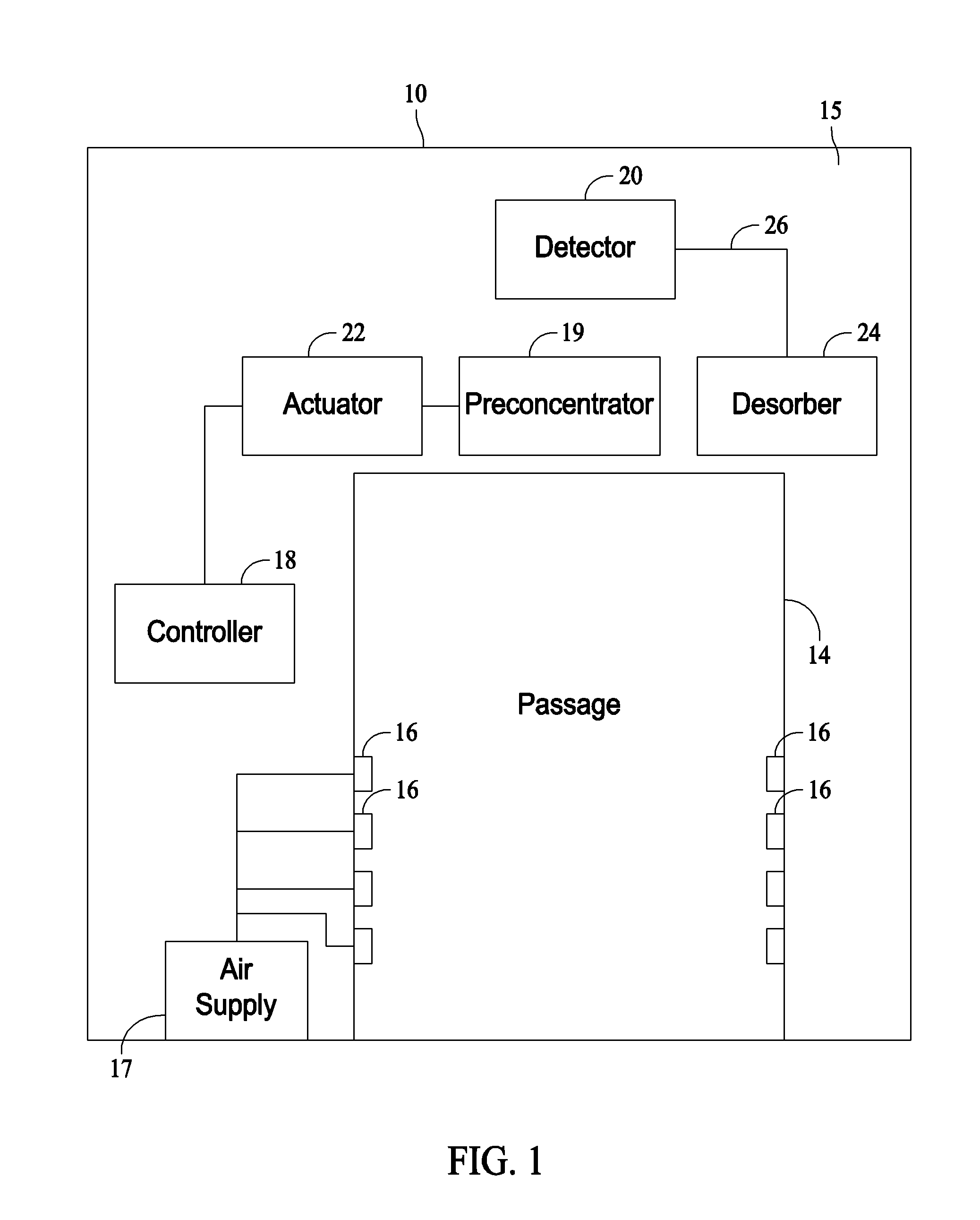

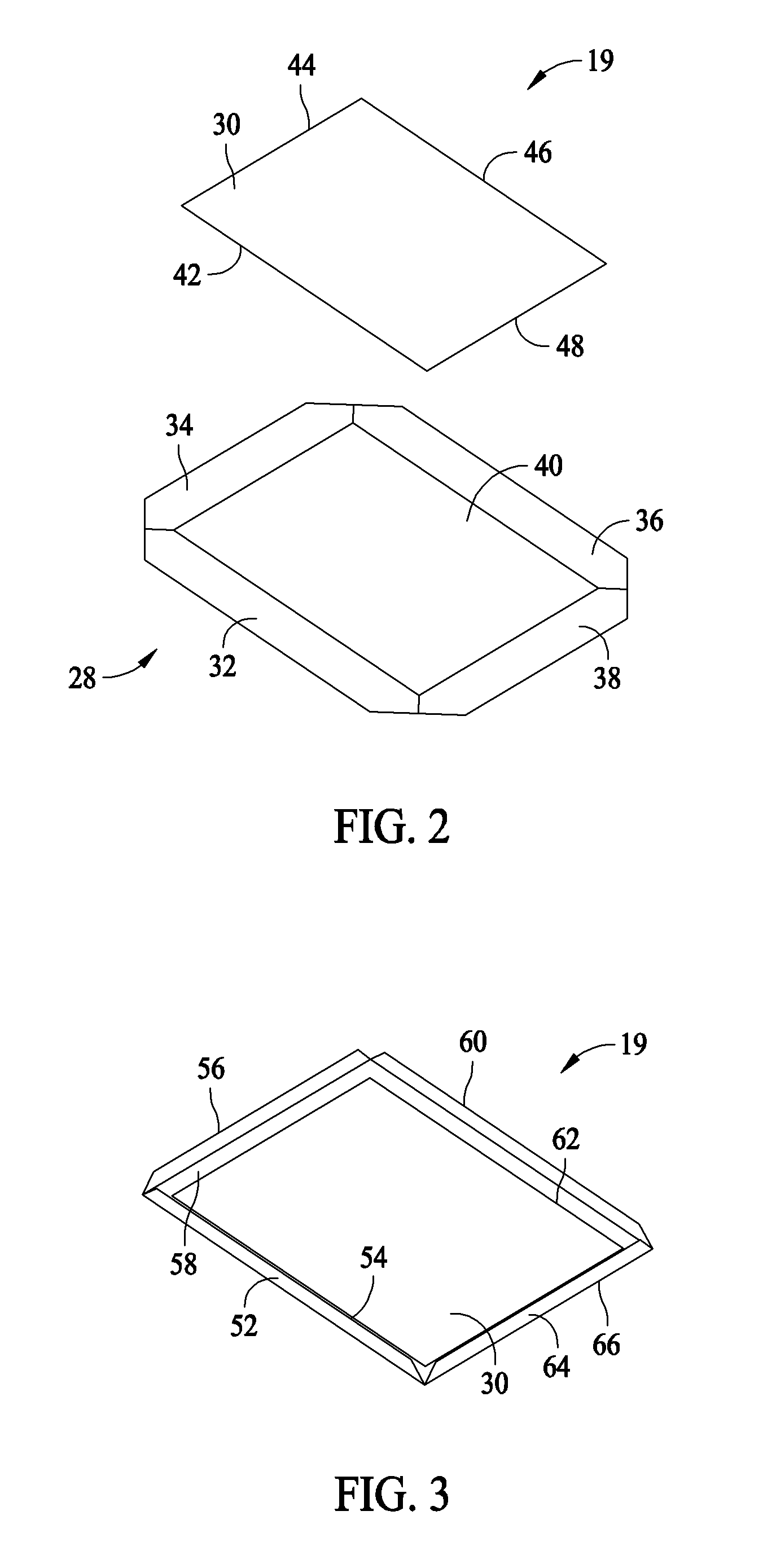

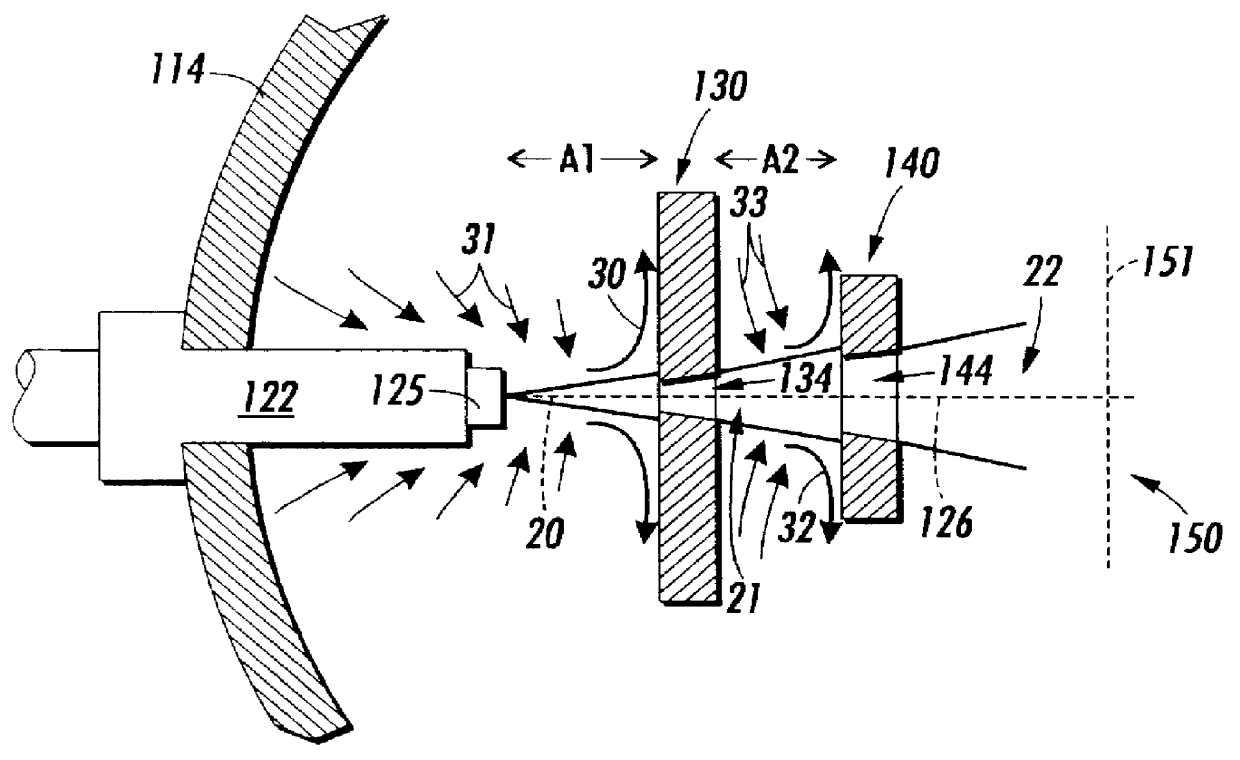

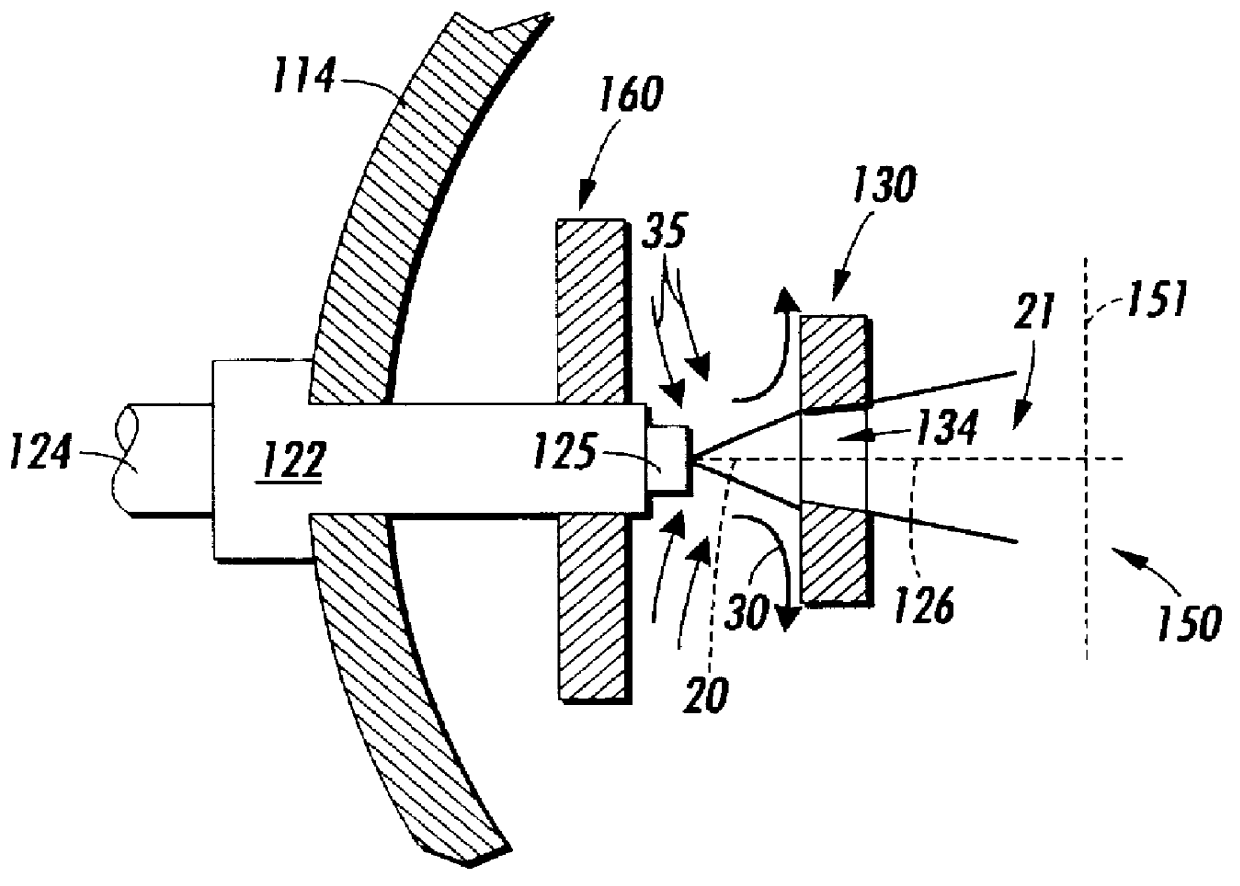

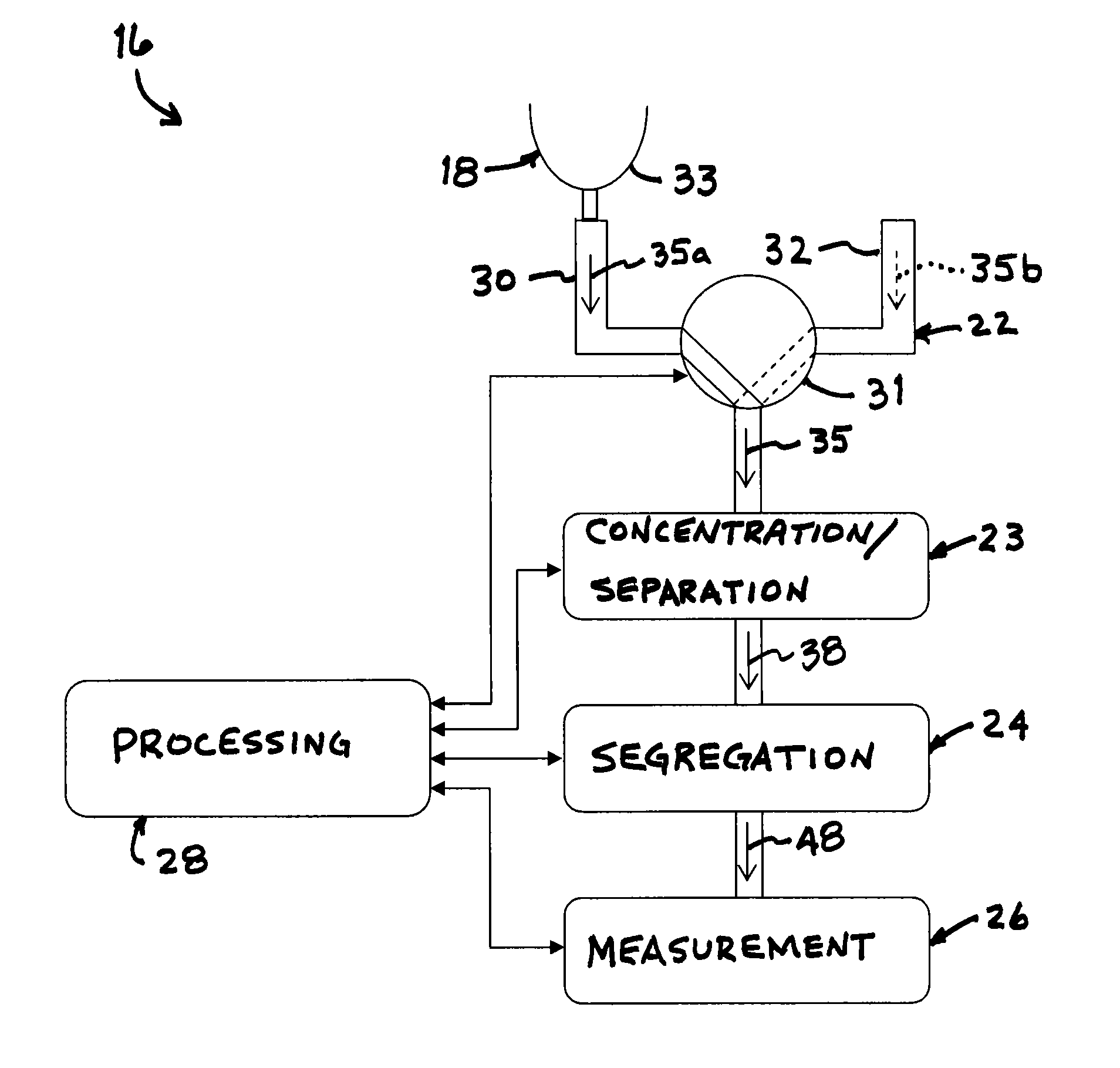

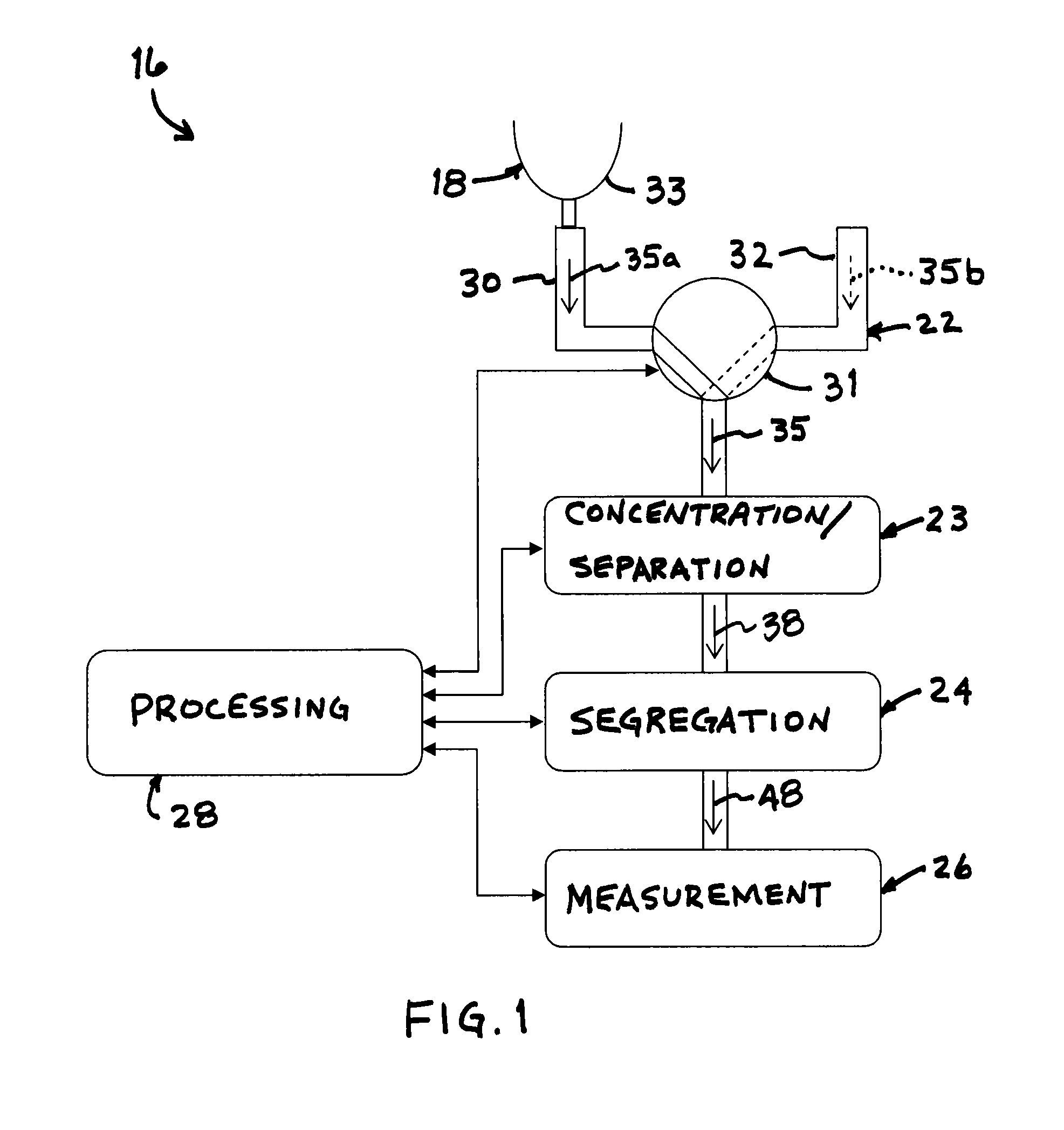

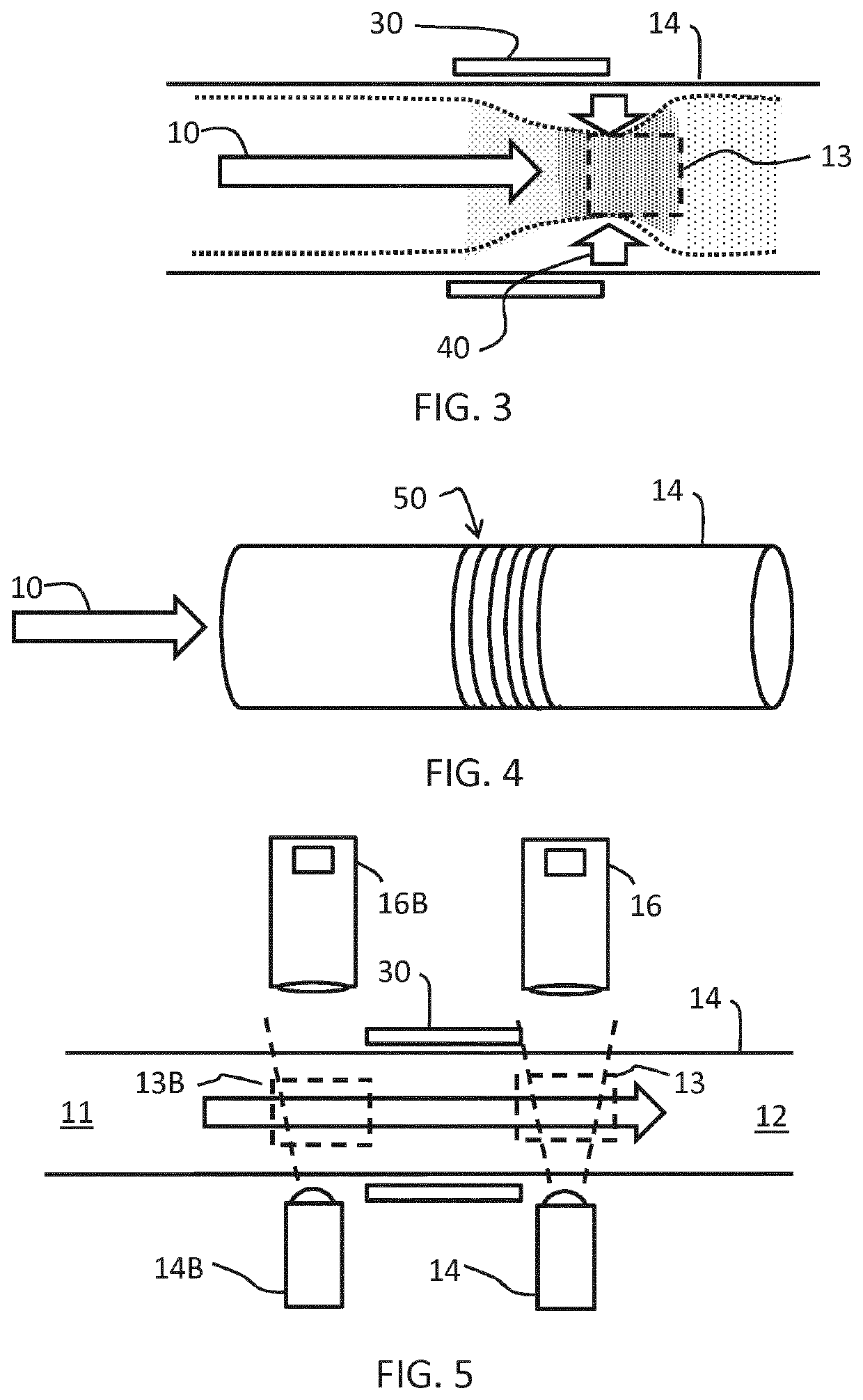

Systems and methods for detecting particles

ActiveUS7721588B2Increase particle concentrationQuickly accurately efficiently identifyDispersed particle filtrationWithdrawing sample devicesEngineeringExplosive material

A method of detecting particles during inspection is provided. The method includes establishing a security checkpoint including a detection system, wherein the detection system includes a chamber defining a passage and includes a plurality of jets. The method also includes passing an individual through the passage, enhancing a convection plume including particles from the individual by blowing air through at least one of the plurality of jets, and absorbing the particles in a preconcentrator including a filter encased in a frame having a high thermal conductivity. Moreover, the method includes evaporating the particles absorbed in the preconcentrator and using a detector to determine whether the particles are from at least one of an explosive material and a narcotic substance.

Owner:RAPISCAN SYST INC (US)

Apparatus and method for grinding particulate material

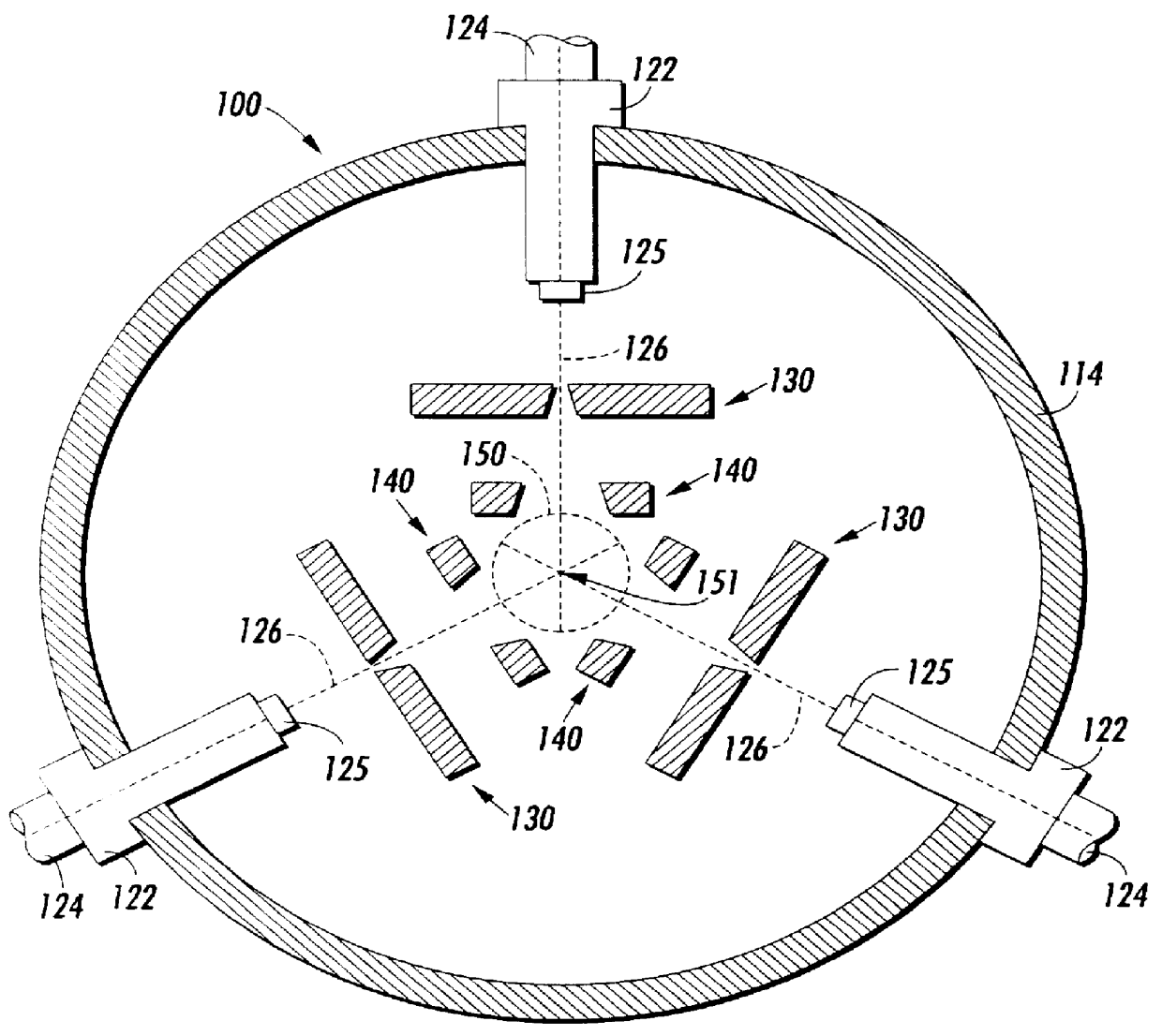

InactiveUS6138931AMinimize loss of efficiencyIncrease particle concentrationGas current separationGrain millingEngineeringParticulate material

An apparatus for grinding particulate material includes a grinding chamber. Fluid sources mounted on the peripheral wall of the grinding chamber generate a stream of fluid directed along the source axis of the fluid source towards the inside of the grinding chamber. Fluid flow guides associated with fluid sources have a first aperture. Guide members associated with fluid sources have a second aperture. Each guide member co-operates with the fluid stream of the associated fluid source and the associated fluid flow guide to draw fluid towards an upstream portion of the fluid stream and to direct fluid away from a downstream portion of the fluid stream. The fluid streams from the fluid sources overlap in an empty zone of the grinding chamber. The particulate material is introduced into the fluid streams, accelerated by the fluid streams and directed towards the empty zone. Thus particles from different streams collide in the empty zone.

Owner:XEROX CORP

Device and method for separating and increasing the concentration of charged particles in a sampled aerosol

ActiveUS8192523B1Improve concentrationMinimal flowCombination devicesRespiratory device testingRespiratorFilter media

A respirator leak detection system and method for increasing the sensitivity and accuracy of leak detection through the fit seal of a respirator. A charged particle separator is used to separate charged particles that pass therethrough and to draw charged particles away from an aerosol flow into a clean gas flow. The separator may also be configured as an aerosol concentrator that takes in a major aerosol flow and outputs a minor flow of higher particle concentration. Neutral particles having no charge, which may have passed through the filtering medium respirator and which are not indicative of fit seal leaks are not entrained in the output flow for subsequent detection, thus increasing the accuracy of the filter leak detection system.

Owner:TSI INC

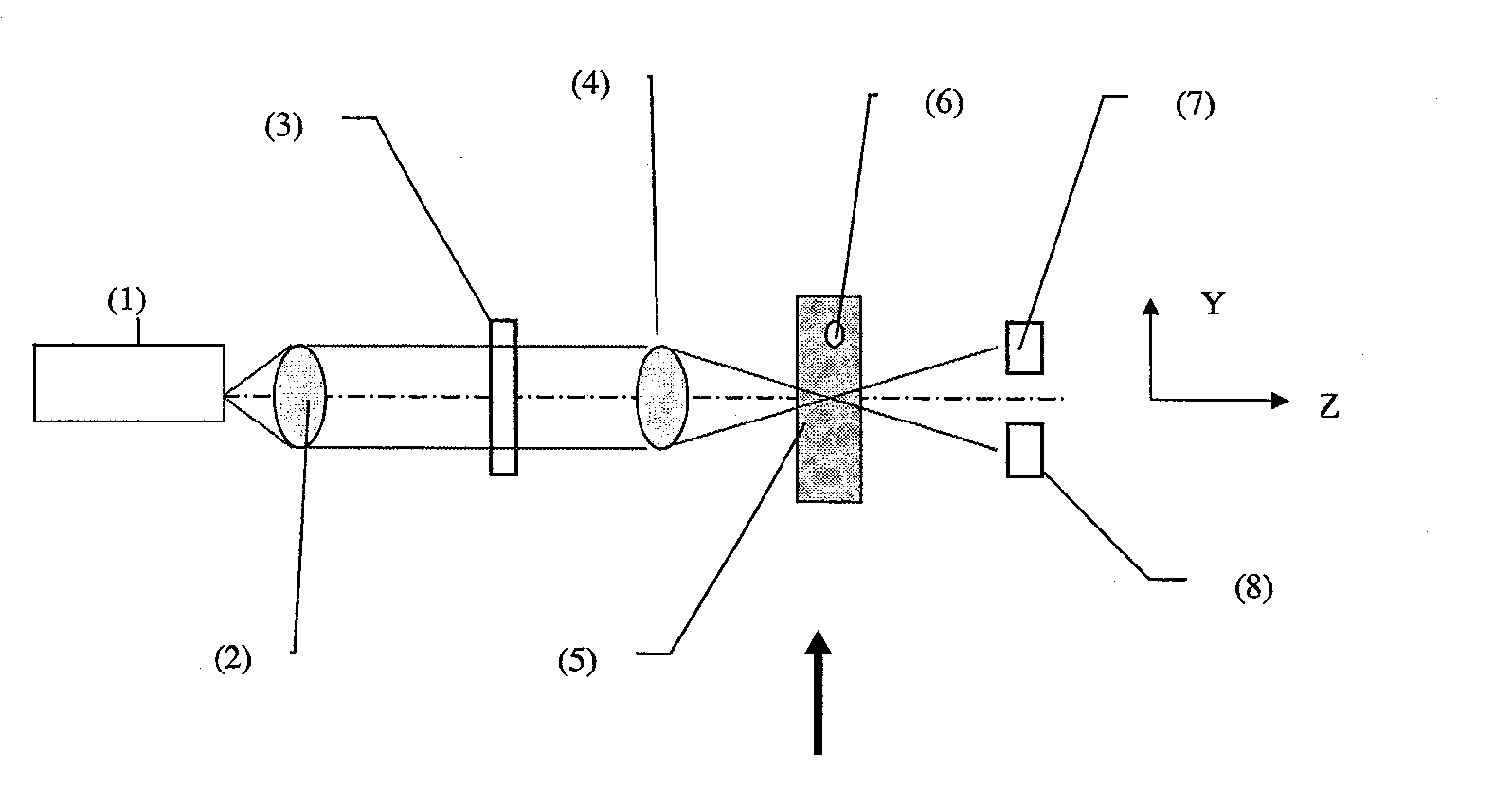

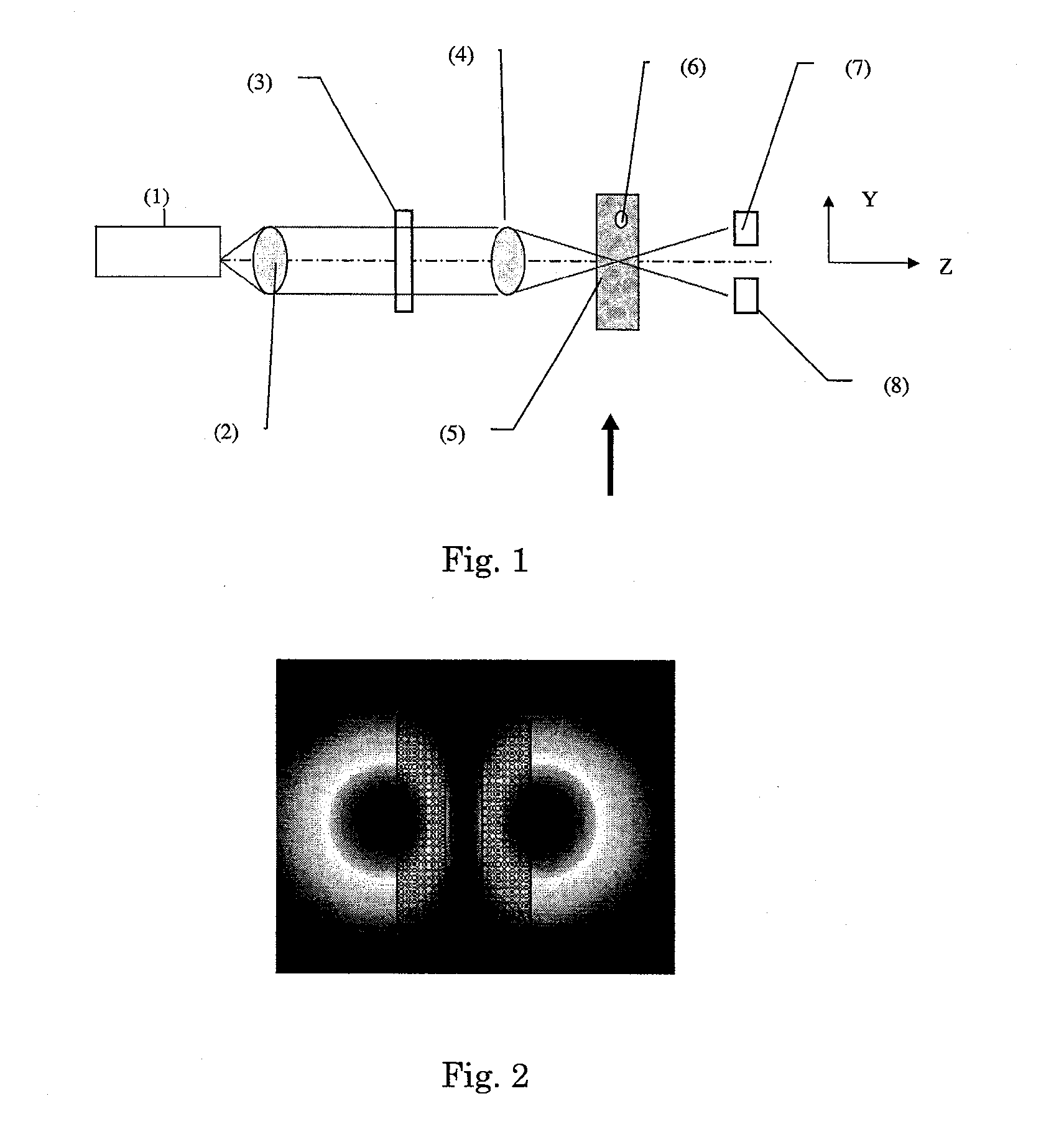

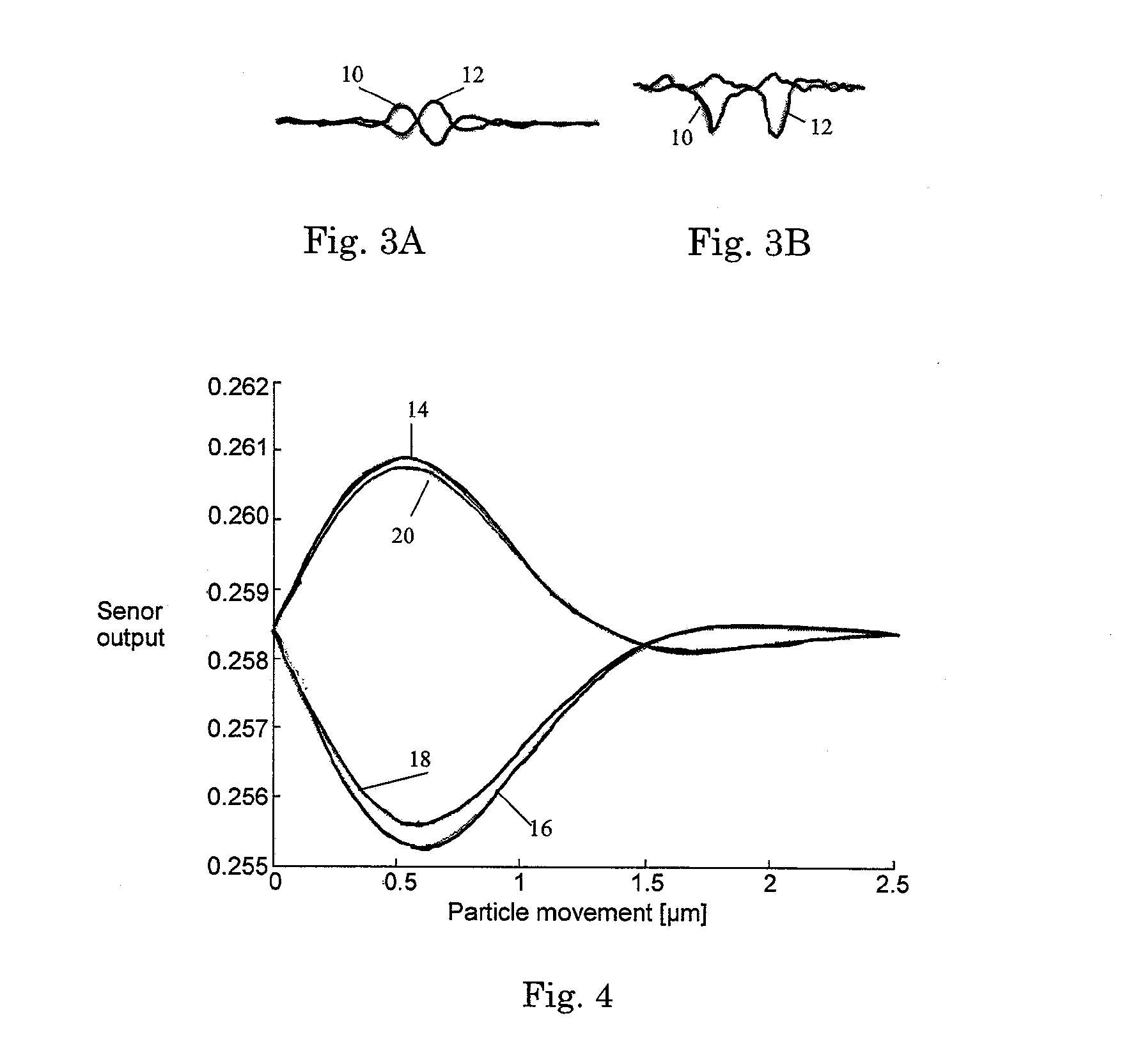

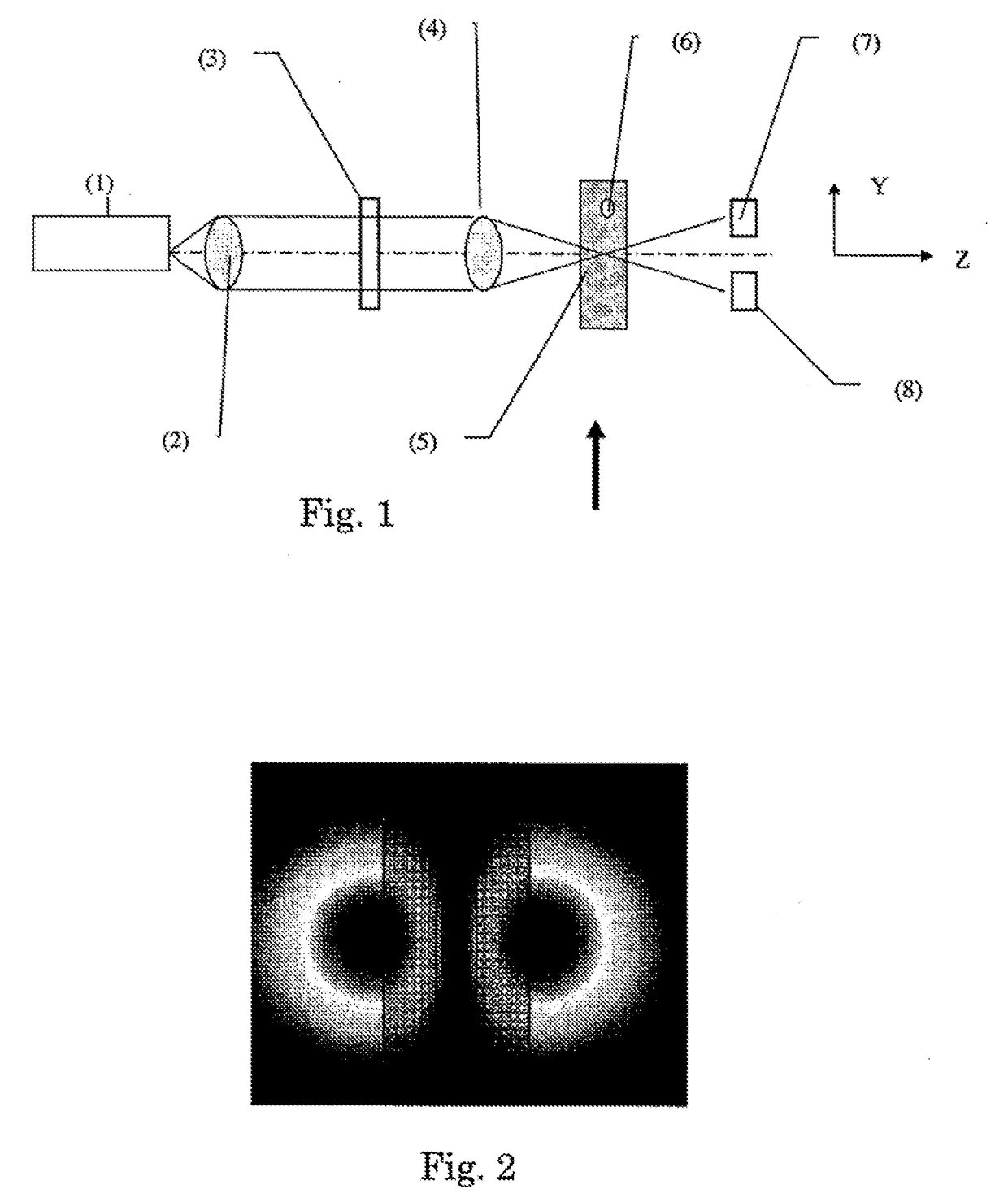

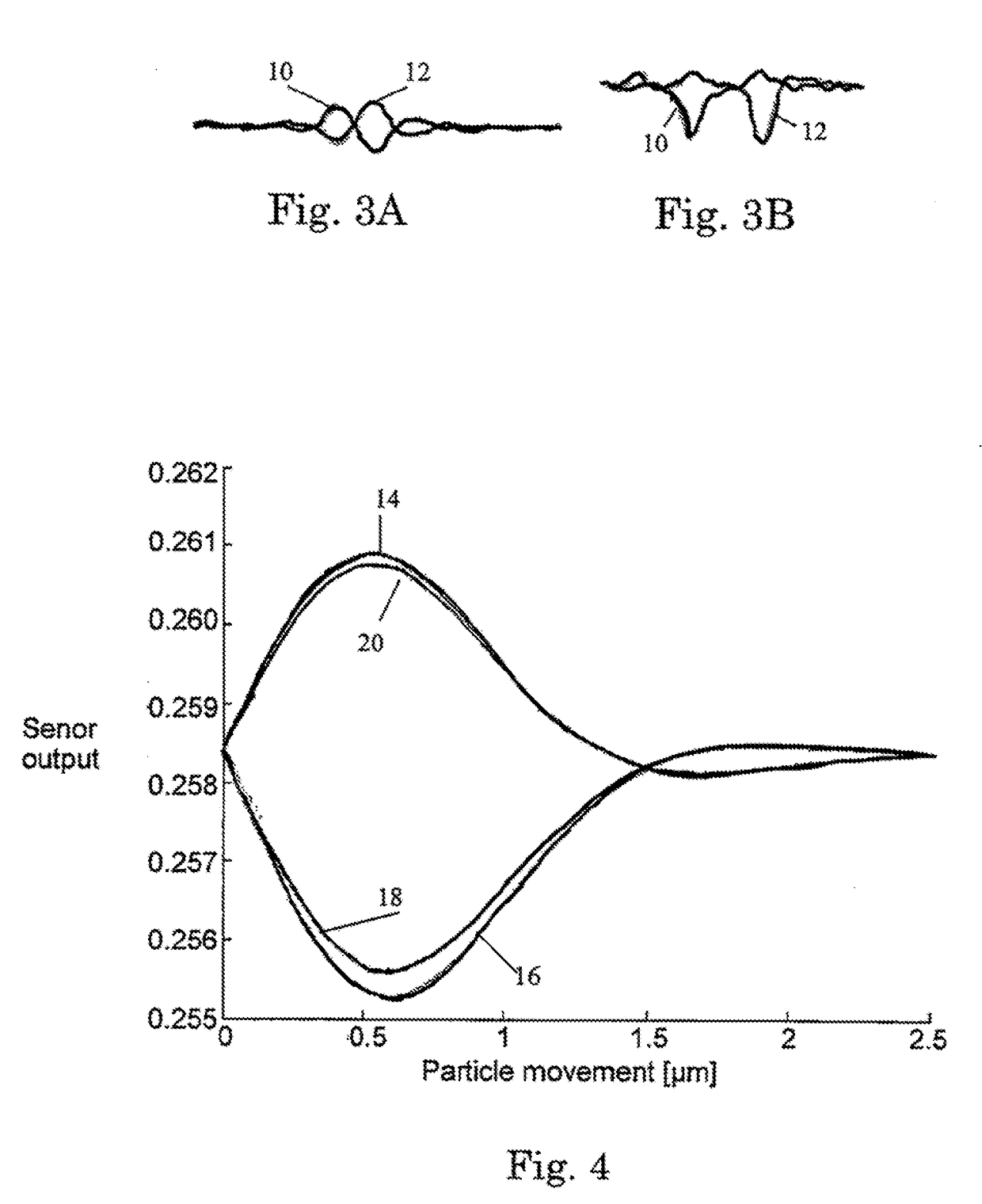

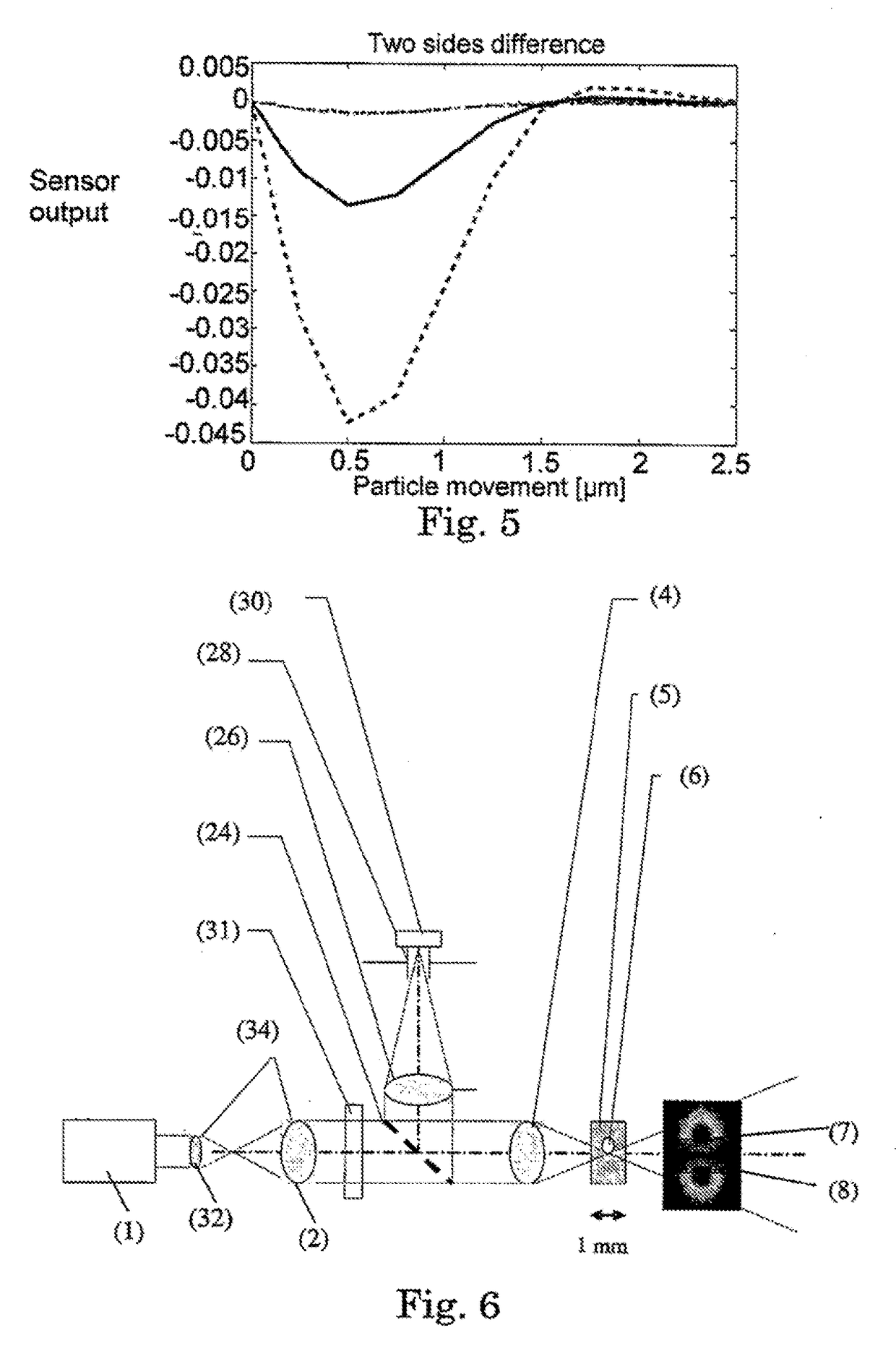

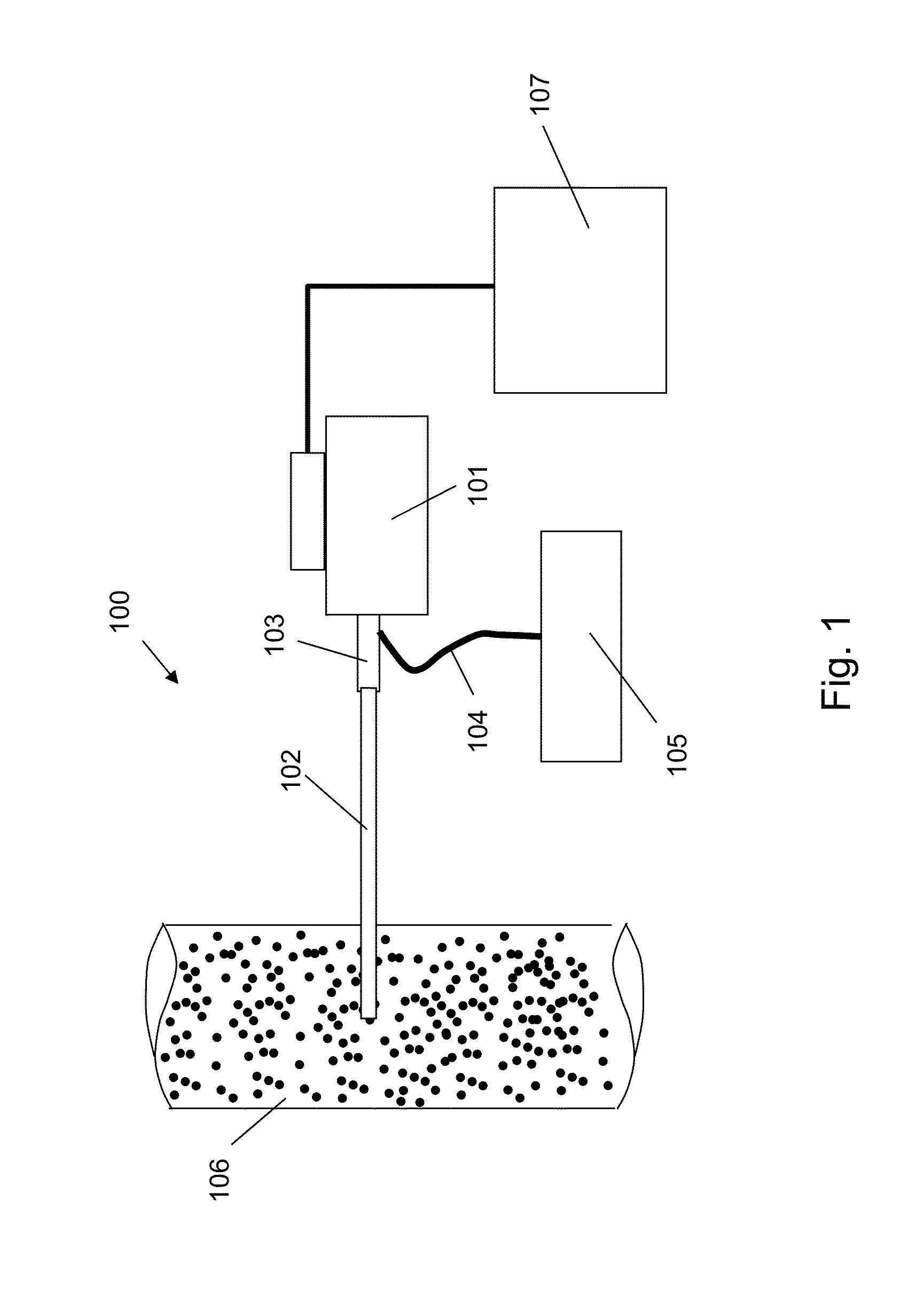

Detection scheme for particle size and concentration measurement

InactiveUS20150260628A1High sensitivityHigh particle concentrationMaterial analysis by optical meansParticle size analysisLaser beamsParticle physics

The present invention provides a system and method of particle size and concentration measurement that comprises the steps of: providing a focused, synthesized, structured laser beam, causing the beam to interact with the particles, measuring the interaction signal and the number of interactions per unit time of the beam with the particles, and using algorithms to map the interaction signals to the particle size and the number of interactions per unit time to the concentration.

Owner:PARTICLE MEASURING SYST

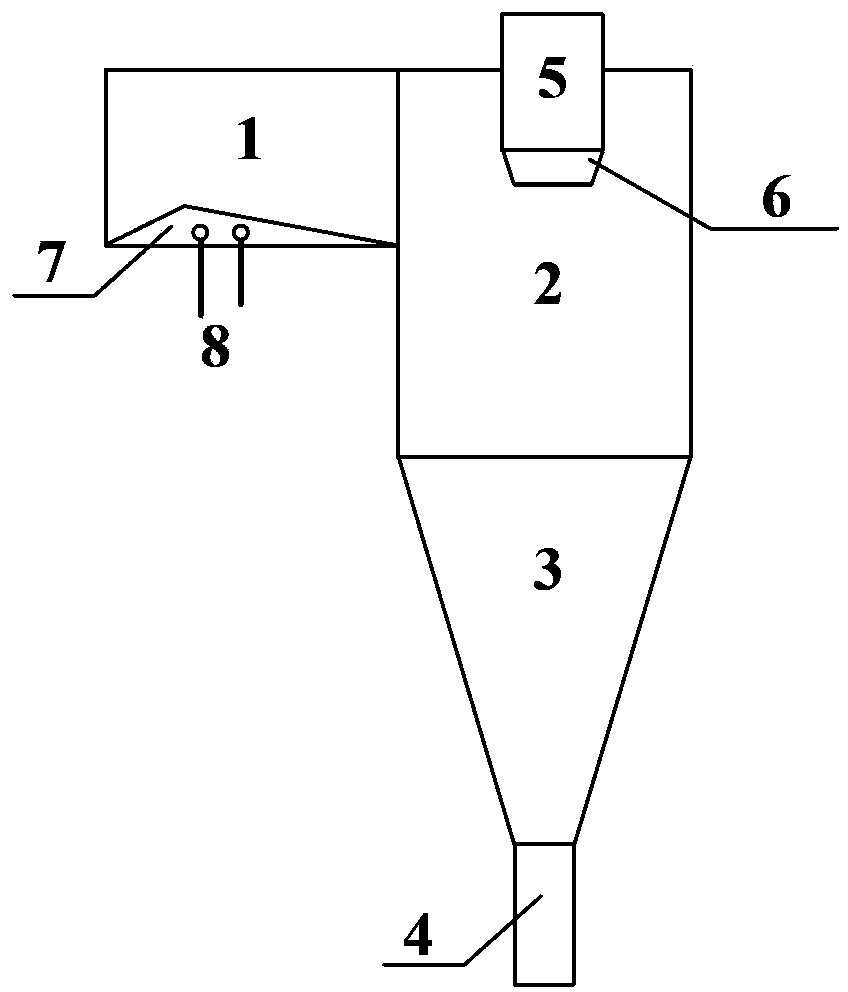

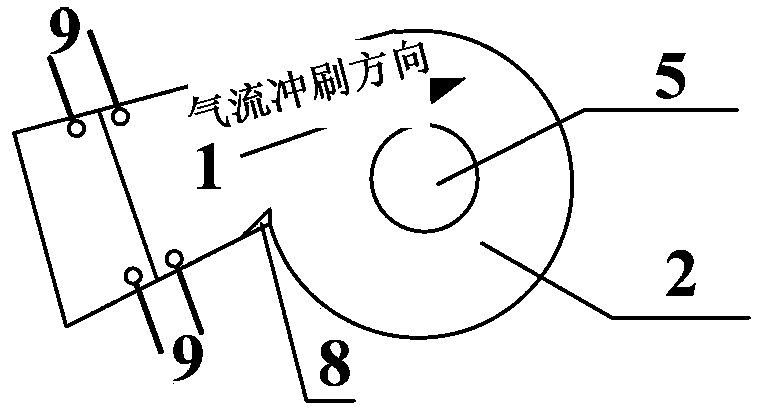

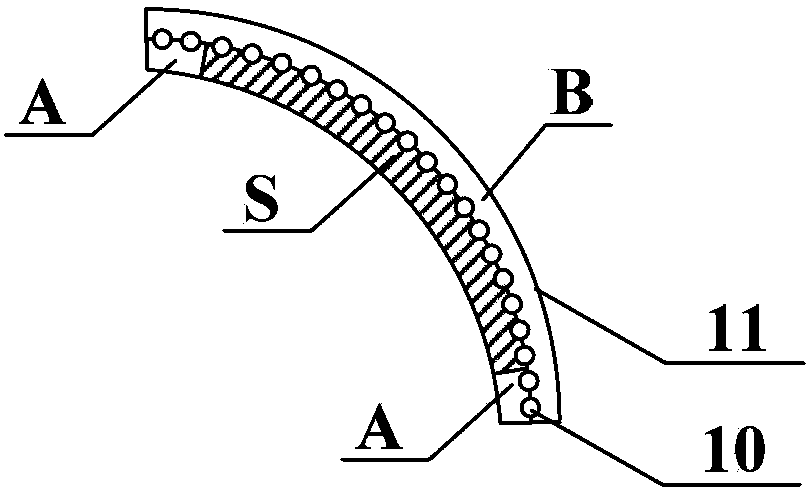

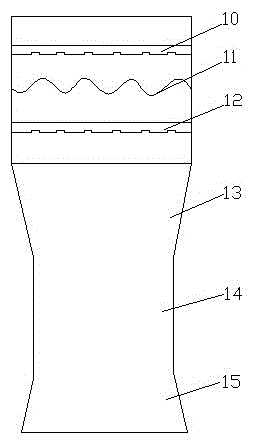

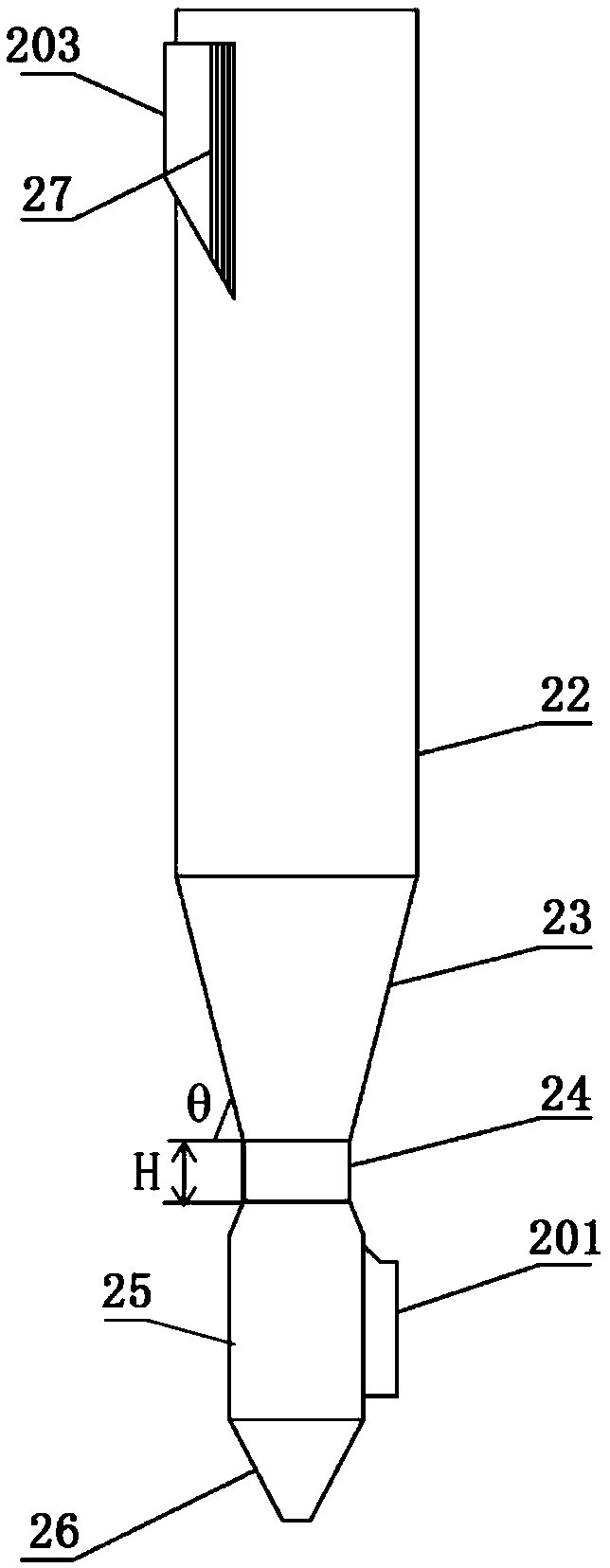

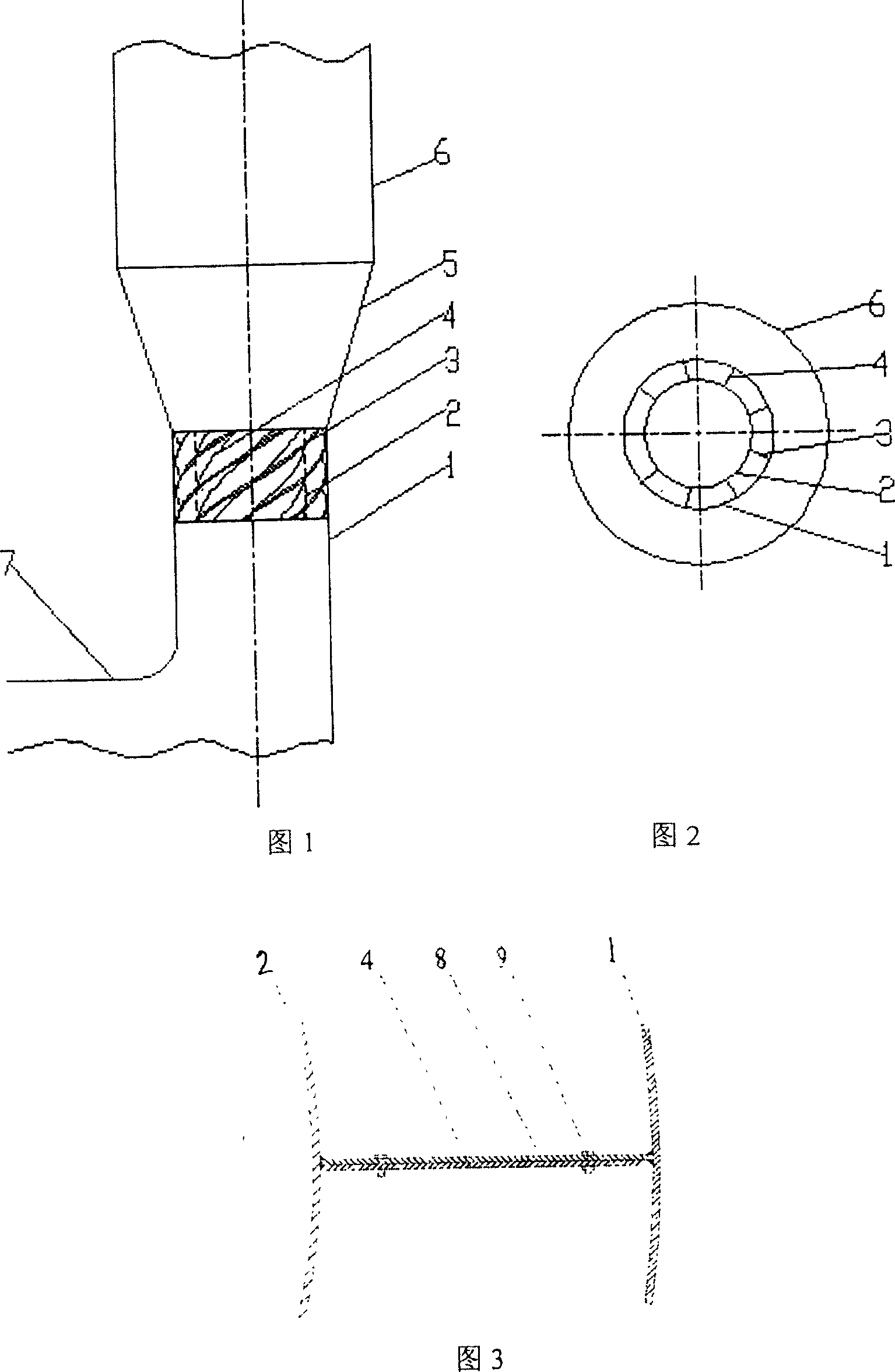

Cyclone separator with wear-resistant target section and guiding device for circulating fluidized bed boiler

ActiveCN103398375AIncreased flow velocityIncrease flow rateFluidized bed combustionApparatus for fluidised bed combustionRefractory wearCyclone

A cyclone separator with a wear-resisting target section and a guiding device for a circulating fluidized bed boiler. The cyclone separator comprises a separator inlet flue, a separator barrel body connected with an outlet of the separator inlet flue, a separator cone and a separator standpipe, which are successively connected below the separator cylinder body, and a separator central cylinder inserted into the upper part of the separator barrel body. The lower part of the separator central cylinder is provided with a central cylinder necking; the separator inlet flue is a tapered inlet flue, which is provided inside with a smoke guiding boss, and a smoke diversion part at the outlet; the smoke guiding boss and the smoke diversion part are covered with a high-strength refractory wear-resistant material layer; and one or a plurality of soot blowing mouths are arranged surrounding the smoke guiding boss. Optimization on the flow field in the cyclone separator reduces the direct impact of airflow and wear on the refractory wear-resistant material in the target section, and can improve the continuous operation cycle of the circulating fluidized bed boiler.

Owner:HUANENG CLEAN ENERGY RES INST

Water coagulation processing method

InactiveCN101475248AIncrease particle concentrationDamage protectionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationSuspended particlesColloid

The invention discloses a water coagulation treatment method. The method comprises that: a coagulating agent is adopted to carry out coagulation treatment on water; and in the process of water coagulation treatment, a catalyst and an oxidant are thrown into the water. Through the addition of the catalyst and the oxidant in the process of the water coagulation treatment, the catalyst forms a solid-liquid reaction interface in the water; and the oxidant undergoes rapid oxidation reaction on the interface and oxides organisms to destroy the protective function of the organisms on suspended particles. The adsorptive action of the catalyst can combine with colloid particles in the water to form a microfloc nucleus so as to increase the concentration of particles in the water and be favorable for the formation and growth of floc in the coagulation reaction.

Owner:SUN YAT SEN UNIV

Detection scheme for particle size and concentration measurement

ActiveUS20170176312A1Particle diameter dependencyHigh sensitivityParticle size analysisIndividual particle analysisParticle interactionParticle physics

Owner:PARTICLE MEASURING SYST

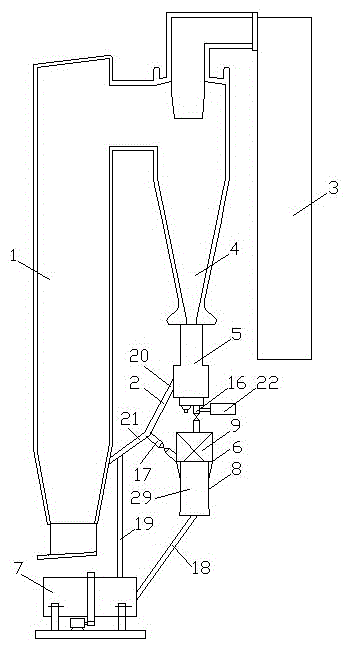

Circulation fluidized bed swirl-direct flow composite fluidizing device

InactiveCN1820836AReduce stickinessSmall sizeDispersed particle separationChemical/physical processesIndustrial wasteAirflow

The present invention belongs to the field of industrial waste gas purifying technology, and is one circular composite swirl-uniflow fluidizing device for fume desulfurizing fluidized bed. The fluidizing device includes an inlet fume channel, a Venturi tube, a reducing section and a desulfurizing barrel connected successively from bottom to top, and features that it includes also an inner sleeve installed inside the Venturi tube and a swirl fluidizing unit installed between the inner sleeve and the Venturi tube. Partial fume flows inside the inner sleeve and the rest flows in the swirl fluidizing unit, so as to form the composite fume fluidizing comprising the uniflow fluidizing inside the inner sleeve and swirl fluidizing outside the inner sleeve. The composite fluidizing device has simple structure, less gas flow deflection, high fluidizing effect, long grain retaining period, great inner circulation multiple and high desulfurizing efficiency.

Owner:SHANDONG UNIV

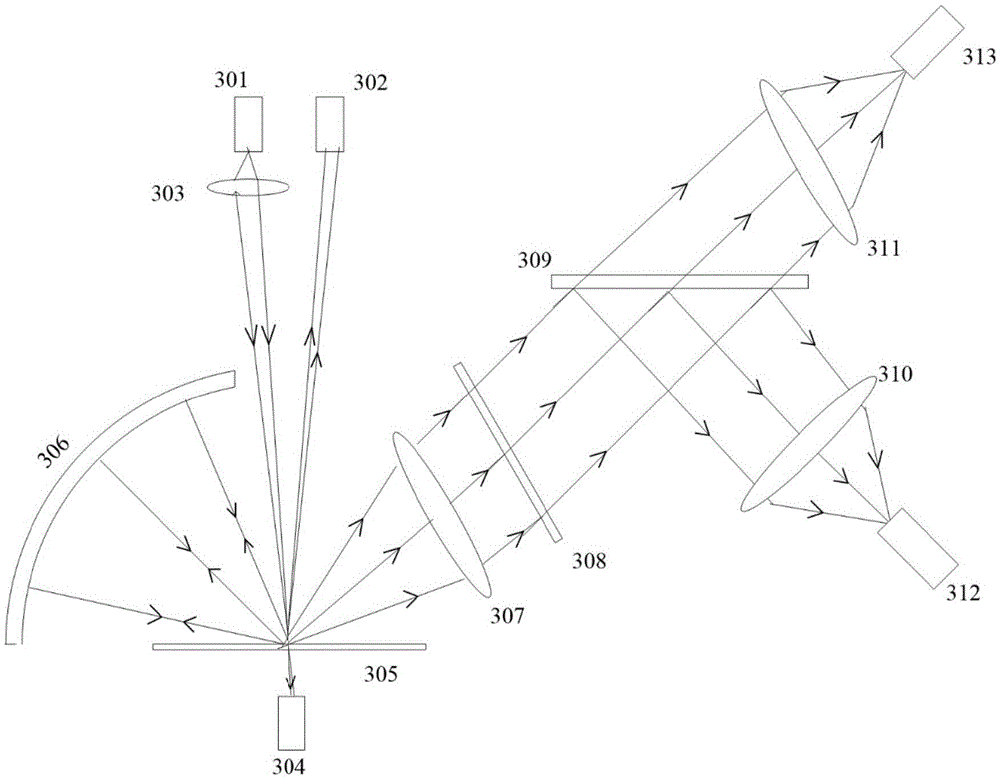

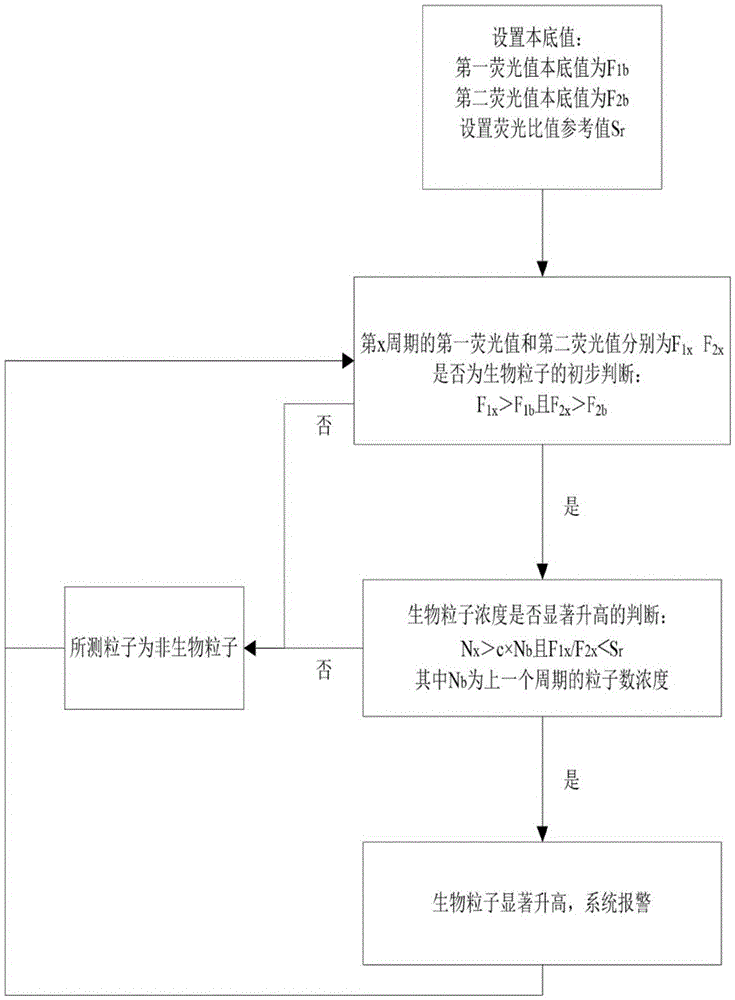

Optical detection system for bioaerosol and detection method

InactiveCN105628658AIncrease powerReduce volumeFluorescence/phosphorescenceSignal-to-noise ratio (imaging)Fluorescence

The invention provides an optical detection system for bioaerosol and a detection method. The detection system comprises a particle counting unit, a gathering unit, a fluorescence detecting unit and a result determining unit. The detection method comprises the following steps: firstly, particle counting is performed on an aerosol sample in the particle counting unit, then particles of the aerosol sample are gathered by the gathering unit, and the gathered aerosol sample is subjected to fluorescence detection by the fluorescence detection unit; the result determining unit receives detection signals of the particle counting unit and the fluorescence detecting unit, and determines whether the detected aerosol sample is bioaerosol. The fluorescence detecting unit adopts a split light path system, and an ultraviolet semiconductor laser is adopted as an ultraviolet light source. The detection system provided by the invention has the advantages of high sensitivity and signal-to-noise ratio, structure flexibility and wide adaptability; the detection method based on the detection system increases the determination basis, has better reliability and reduces the probability of false alarm.

Owner:SHANGHAI DAHENG OPTICS & FINE MECHANICS

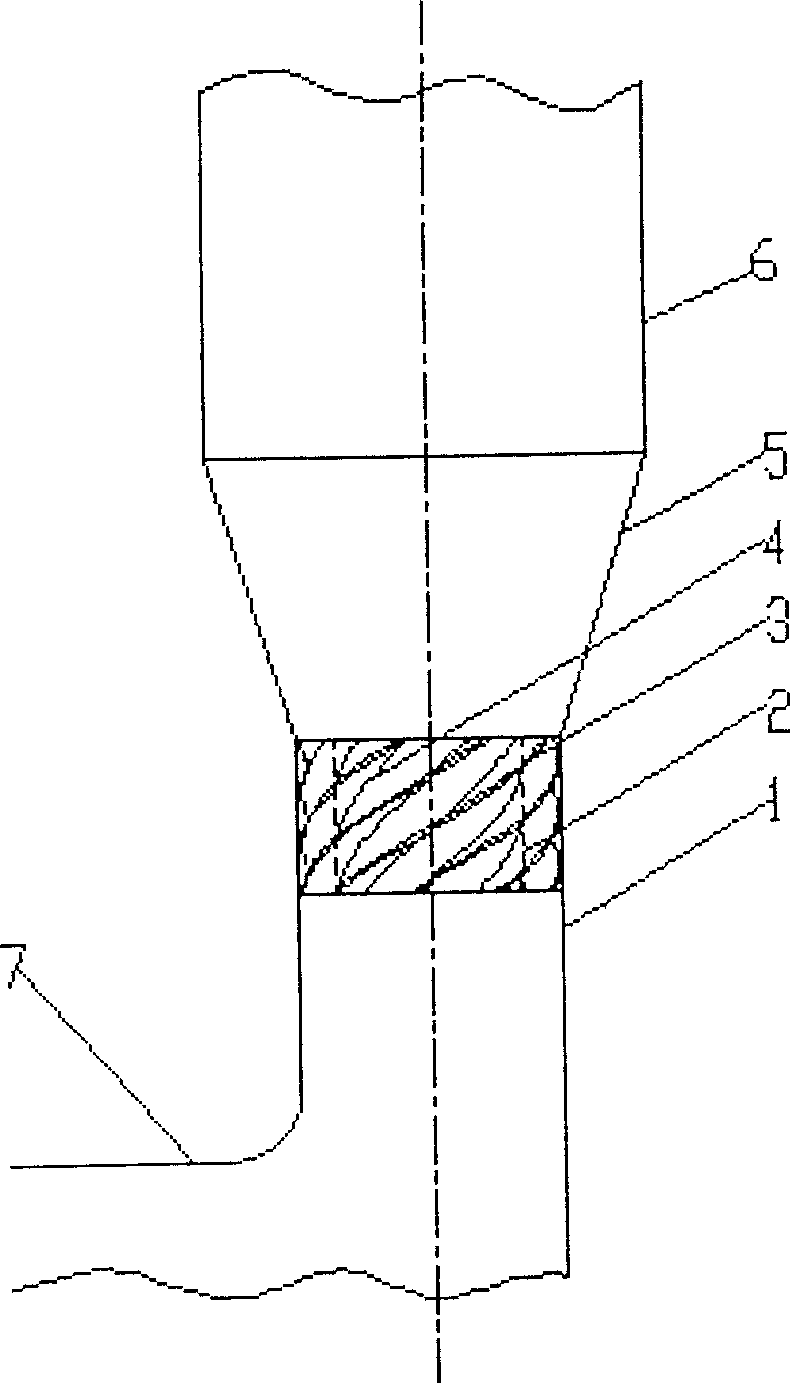

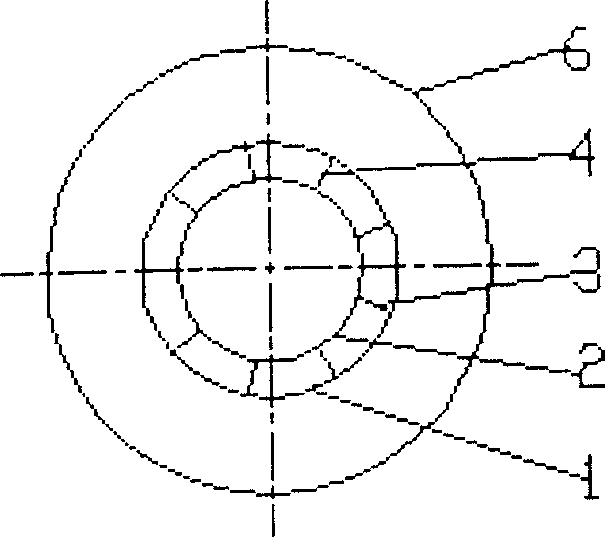

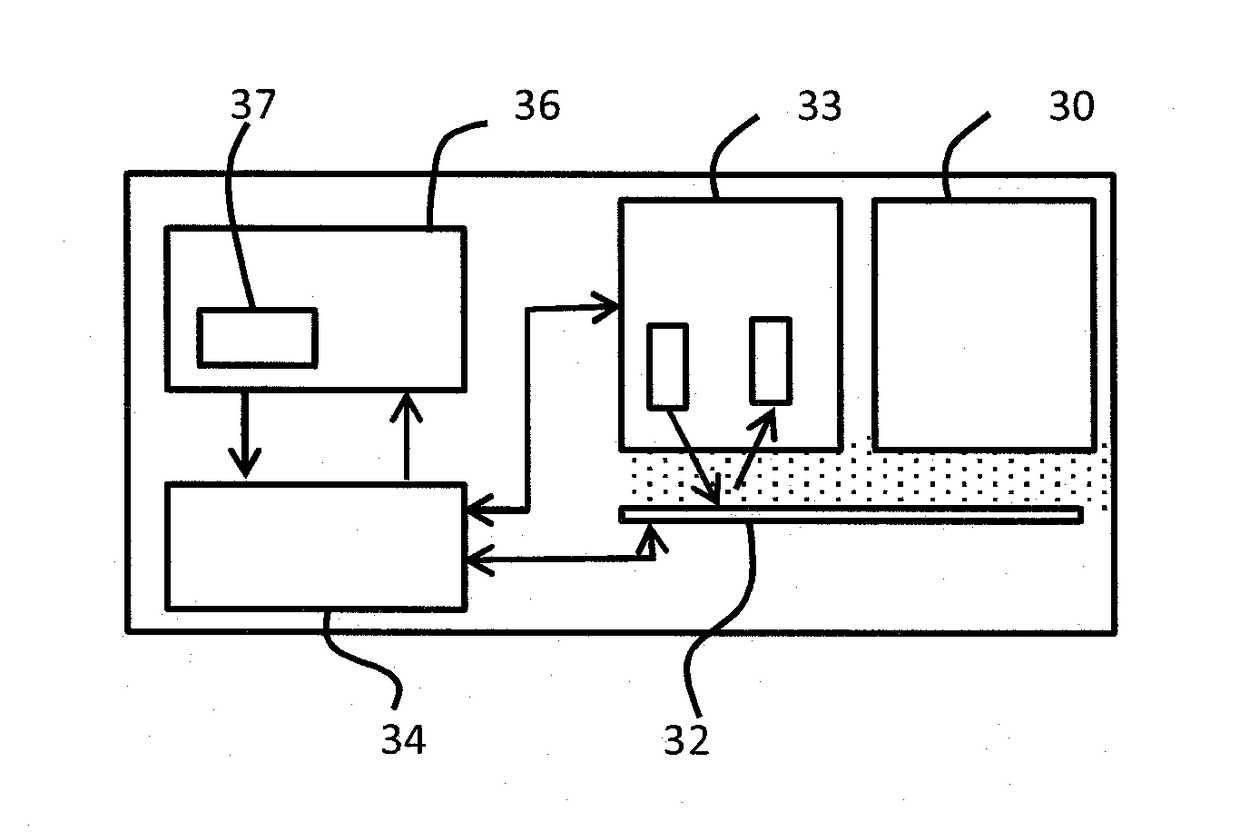

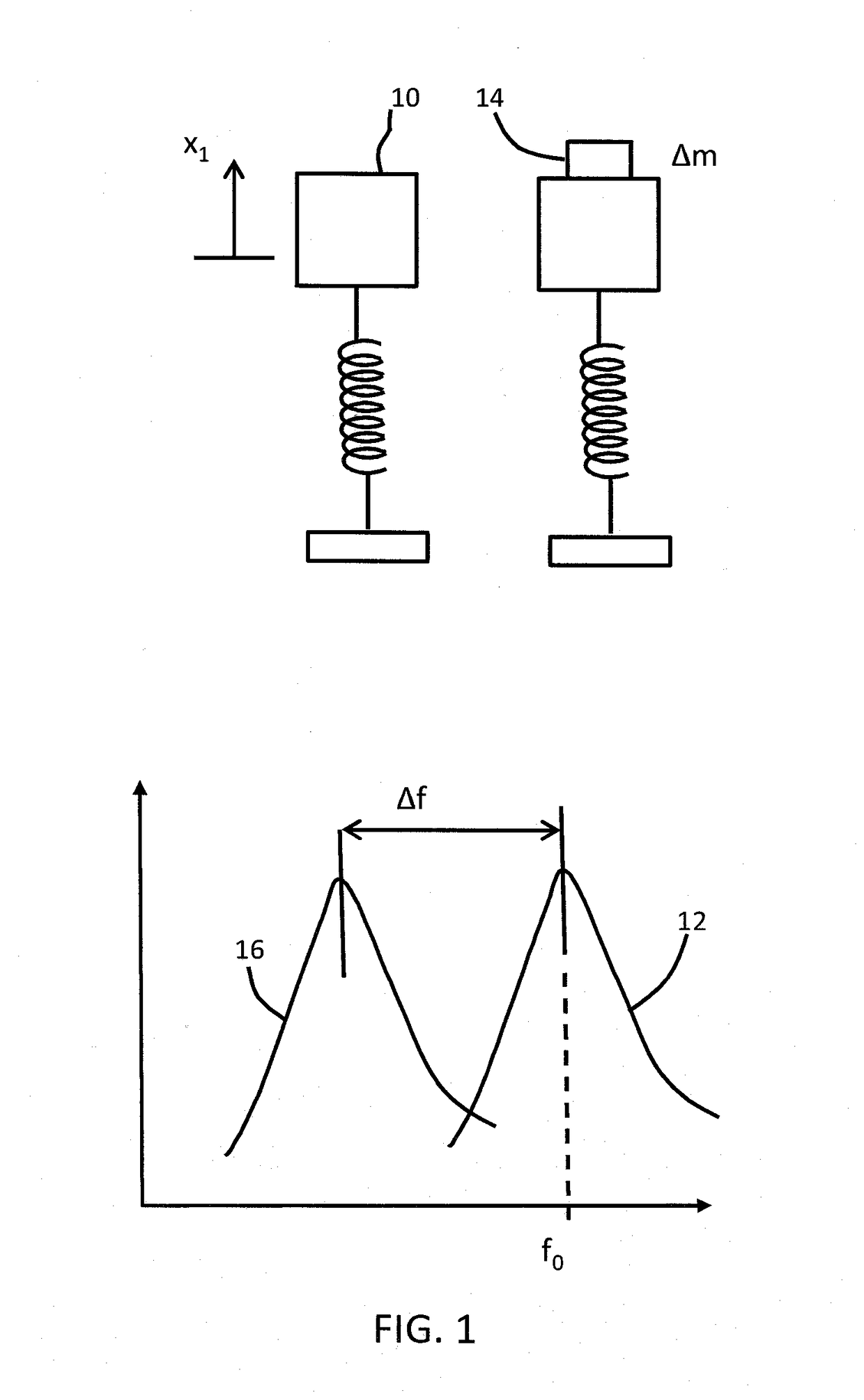

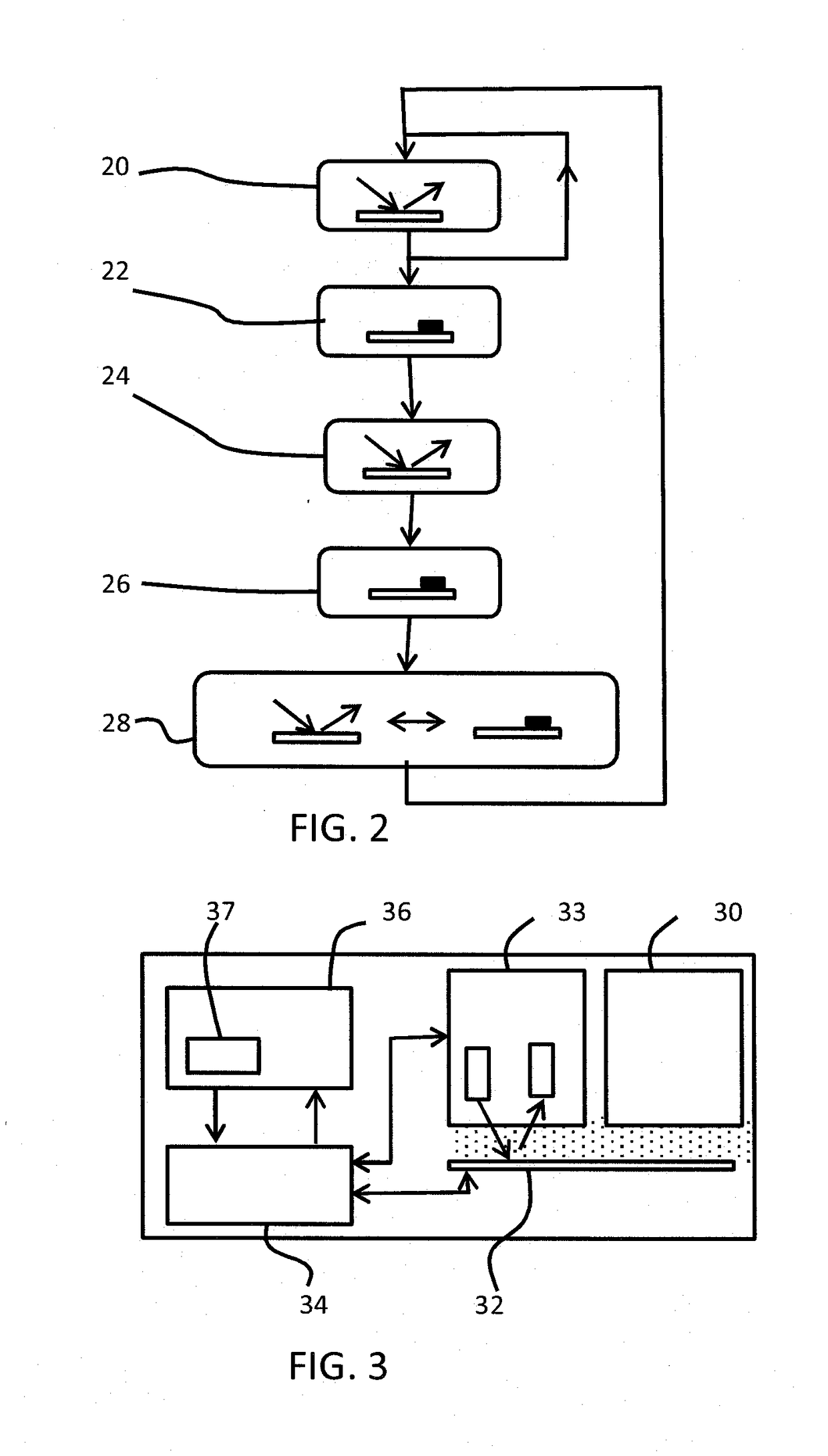

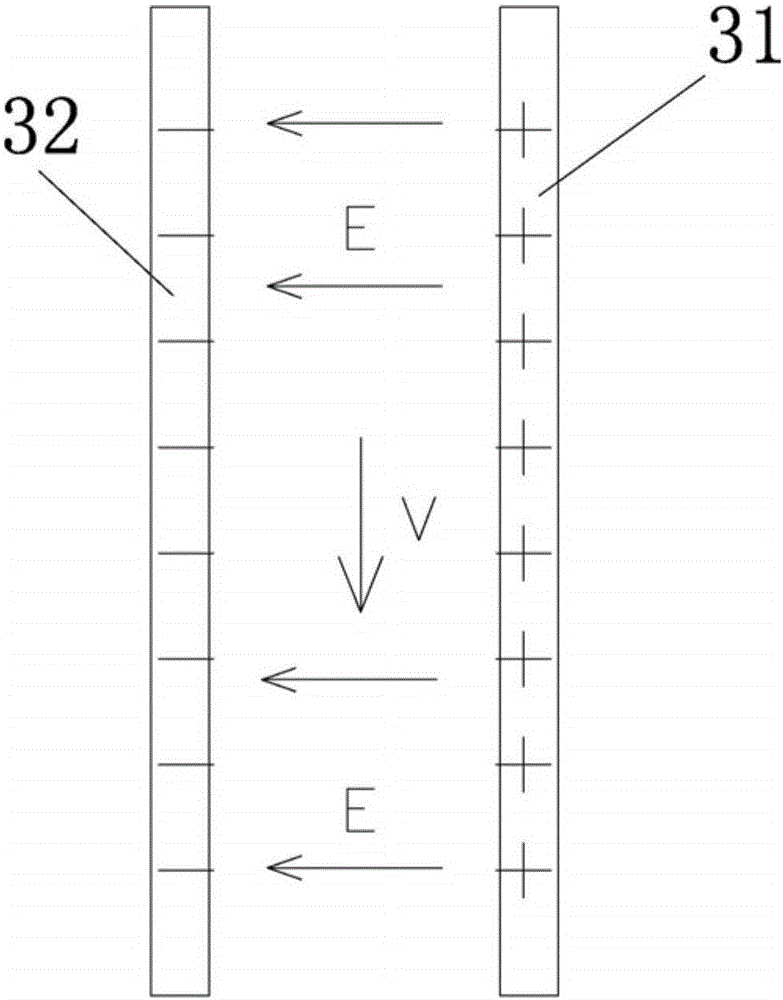

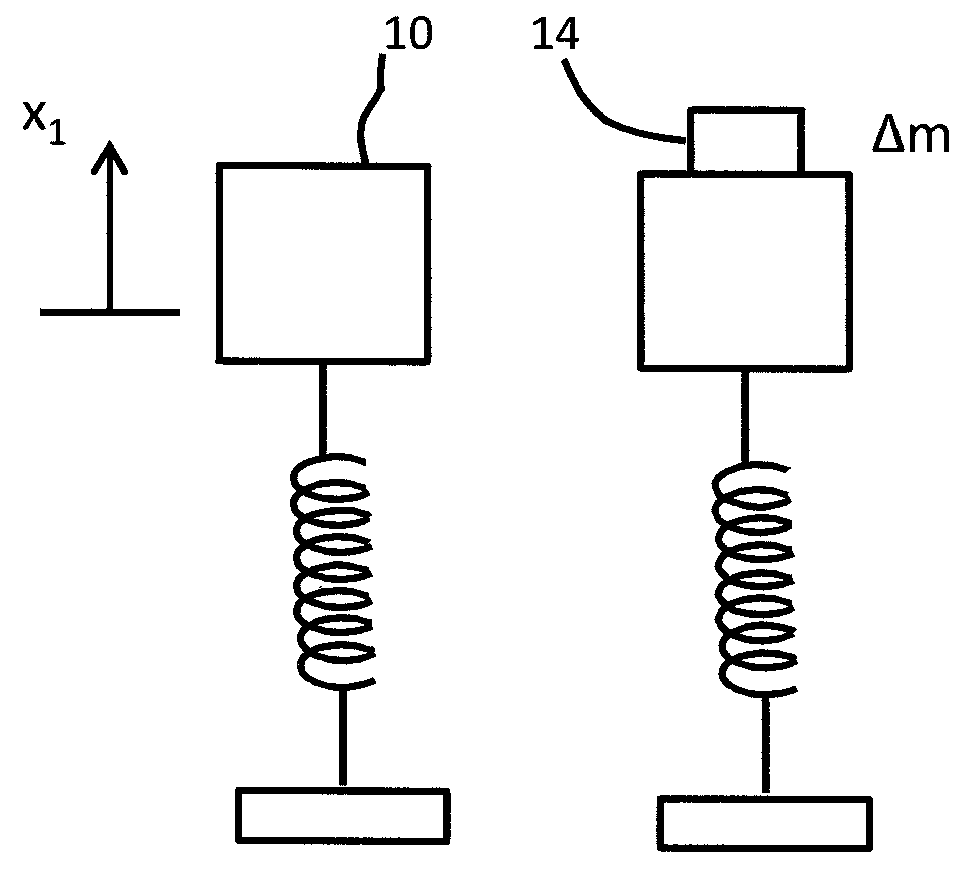

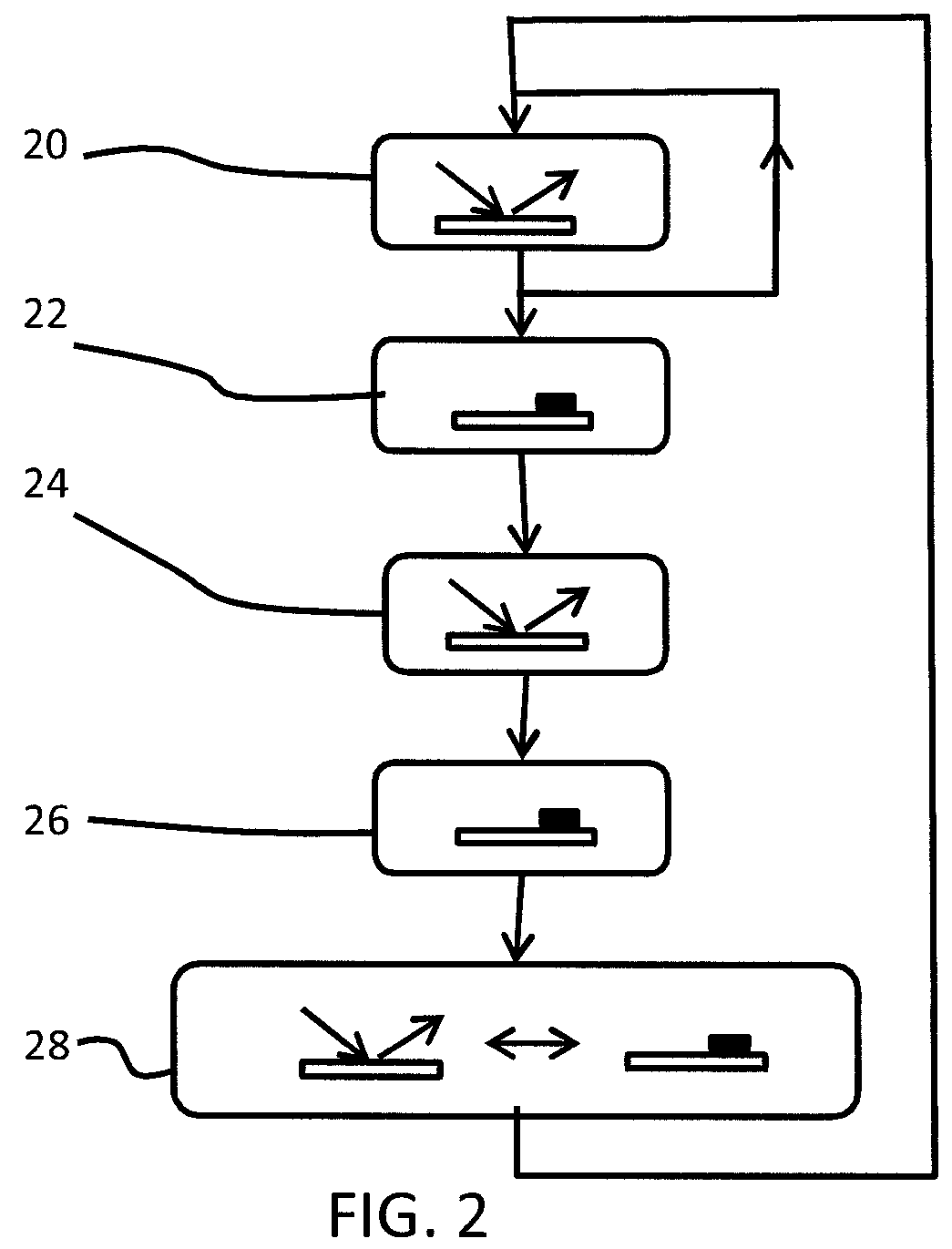

Aerosol sensor and sensing method

ActiveUS20170097294A1Accurate informationEfficient use ofAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansSensor systemPhysics

A sensor system is provided for measuring particle concentration and mass concentration in an aerosol. An optical sensor (33) is used for measuring a particle concentration and a mechanical sensor (32) is used for measuring a mass of collected particles. A particle concentration in the aerosol is monitored using the optical sensor (33), until detection of a particle generating event. Upon detection of a particle generating event, a mass measurement using the mechanical sensor (32) is performed and the mass measurement is used to calibrate the optical sensor (33). This approach enables the lifetime of the mechanical sensor to be extended, because it is only used when events are detected. The optical sensor, which typically is less accurate for mass sensing, is calibrated by the mechanical sensor.

Owner:KONINKLJIJKE PHILIPS NV

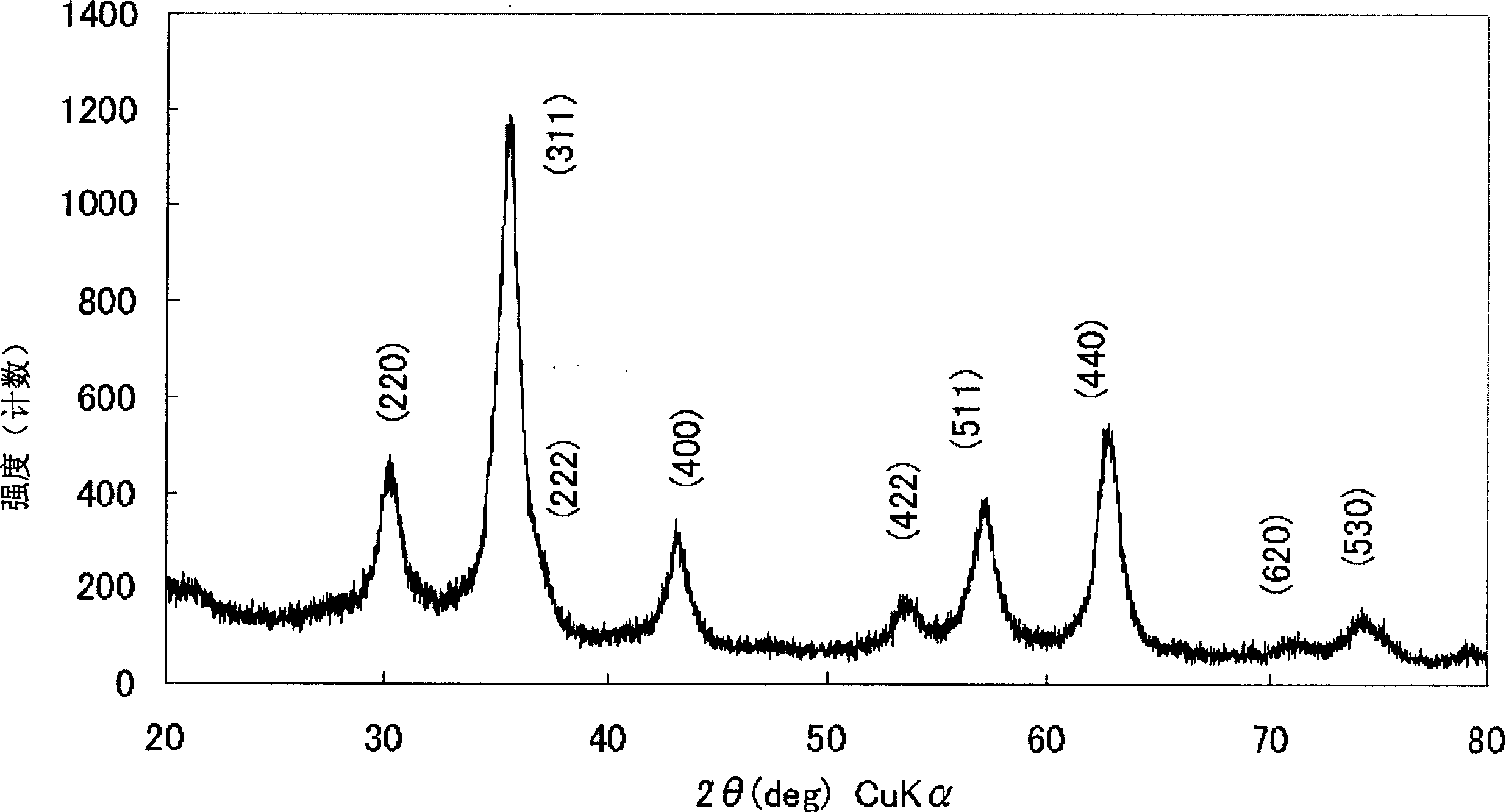

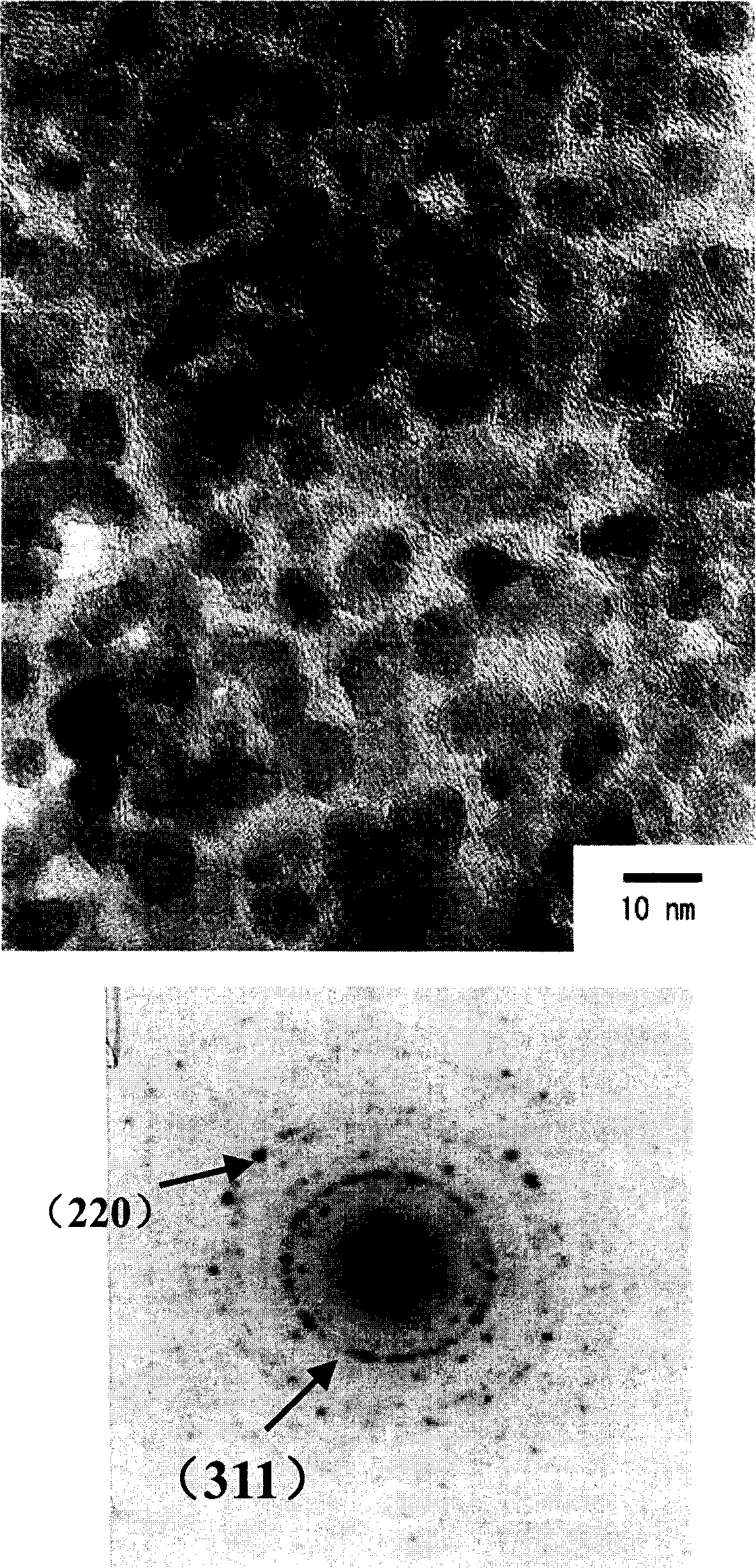

Ferrimagnetism fluid

InactiveCN1797624AImprove flow characteristicsExcellent magnetic propertiesMagnetic liquidsInductances/transformers/magnets manufactureIron saltsManganese

The method includes following steps: using chemical coprecipitation method to prepare mixed liquor of ammonia (or sodium hydroxide), bivalent iron salt (manganese, nickel, cobalt etc.) and tervalent iron salt; dropping the mixed liquor to ion exchange water, and keeping pH of solution at 7; mixing round the solution to generate suspending liquid of ferrite; using ultrasonic to coat a layer of surface active agent on surfaces of fine grains evenly; finally, using ultrasonic to disperse fine grains on solvent evenly.

Owner:巨东英 +1

High-intensity active carbon sedimentation basin and sedimentation process

ActiveCN102078709AGood removal effectImprove the disadvantages of low utilizationSedimentation settling tanksWater/sewage treatment by sorptionSludgeWater quality

The invention discloses a high-intensity active carbon sedimentation basin. The sedimentation process thereof is characterized by comprising the following steps: reflowing the enriched sludge and the active carbon to a mixing basin by using the concentrating and separating effects of the sedimentation process and the active carbon on the turbidity materials, and obtaining the mixed liquid of which the concentrations of the sludge and the active carbon particles are high; and strengthening the removal of the turbidity materials and the organics in water by the capturing and adsorbing effects of the two carriers. According to the invention, the defect of the original conventional treating process that the utilization ratio of the added active carbon is low is overcome, and relatively stronger removal ability for stink smell, chroma and organics is provided for the conventional sedimentation process. The high-intensity active carbon sedimentation basin has the characteristics of good water quality, small drug consumption, high solid content of sludge, small occupation area, flexible operation control and strong adaptation ability on raw water quality. The sedimentation basin is developed based on the III-type raw water or raw water higher than III type, and has double functions of conventional treatment and deep treatment; and a completely new path to treat the serious raw water is provided. The sedimentation basin can be applied to the conventional treatment process or combined with the deep processing process when the quality of the raw water is poor.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

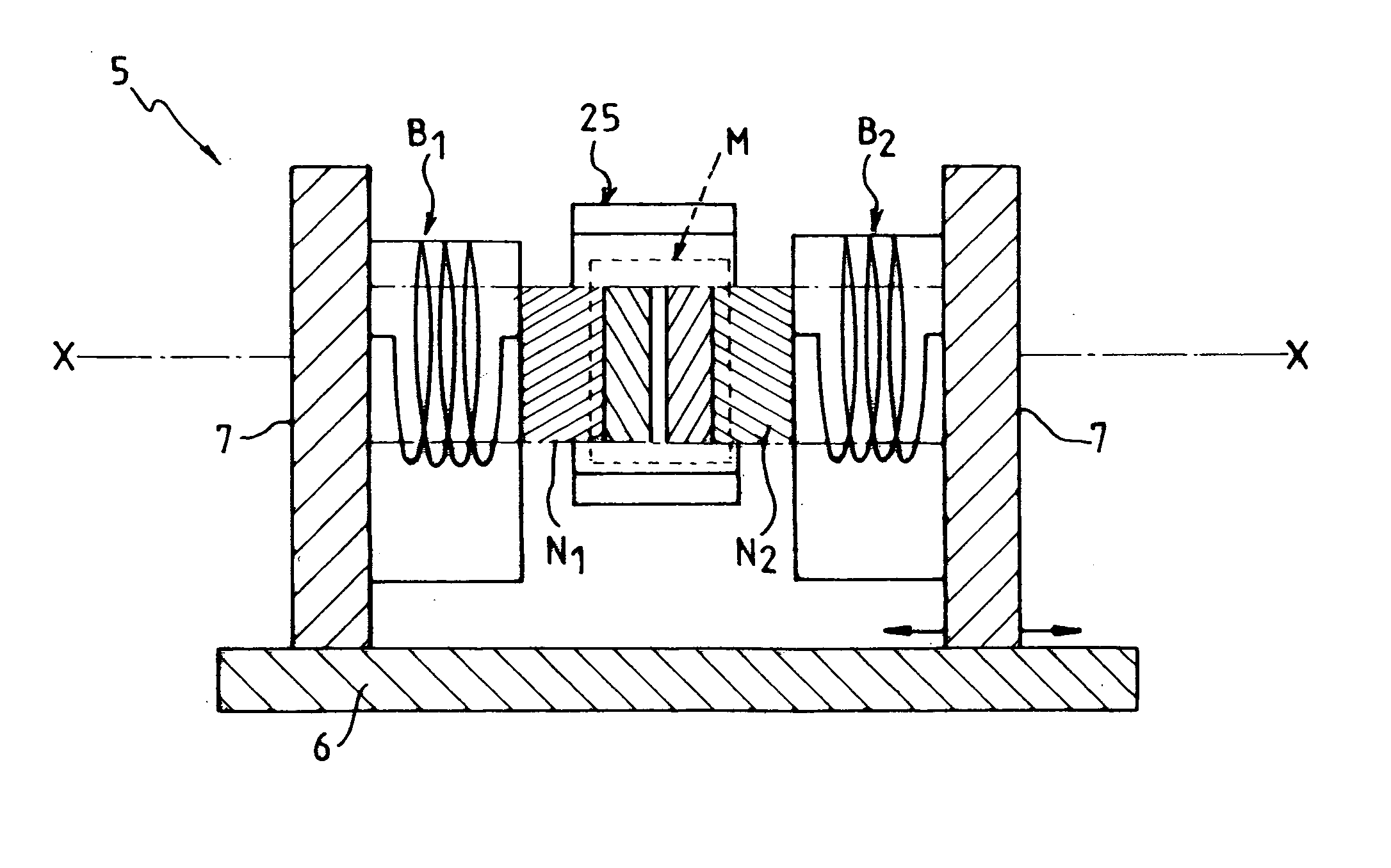

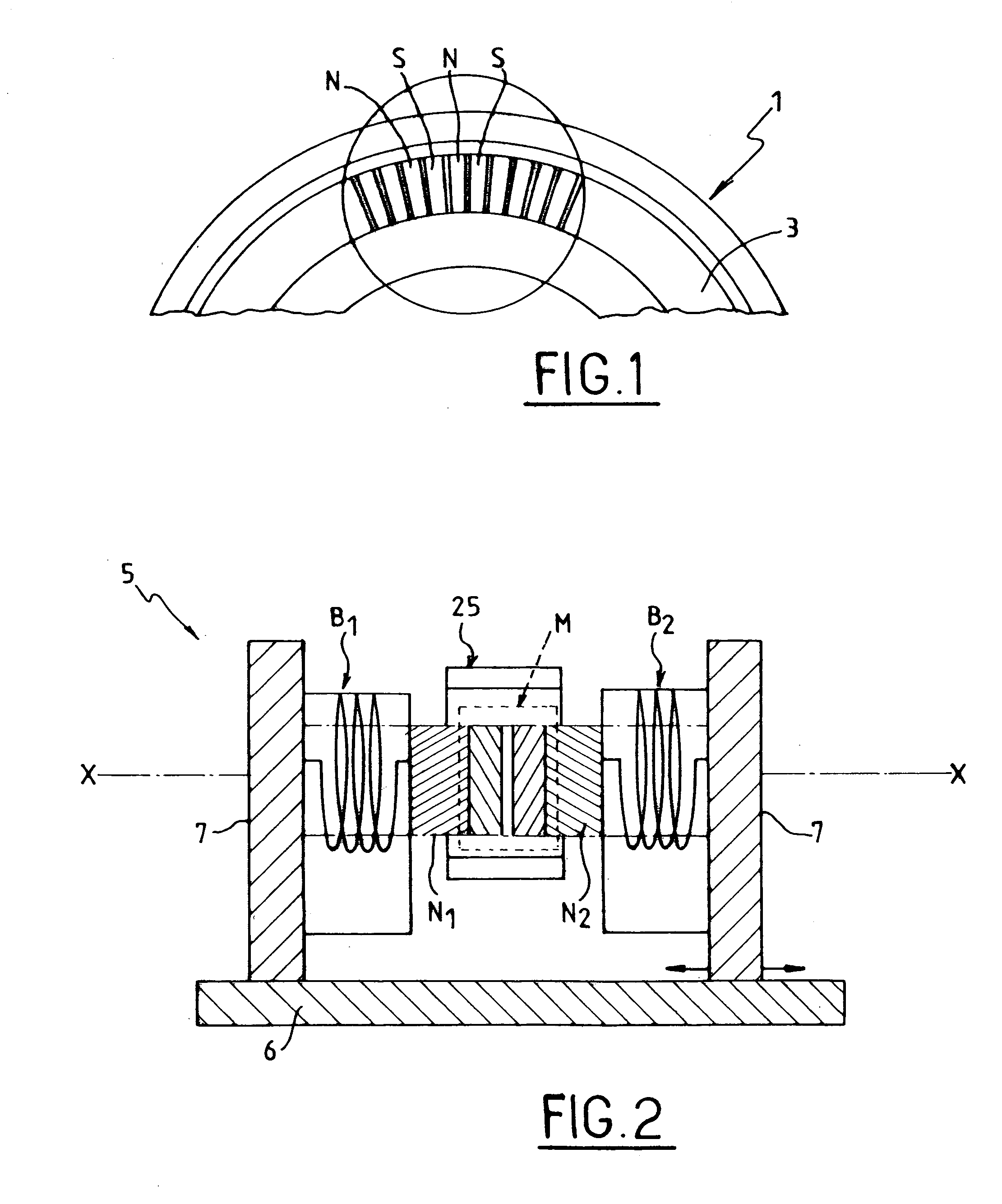

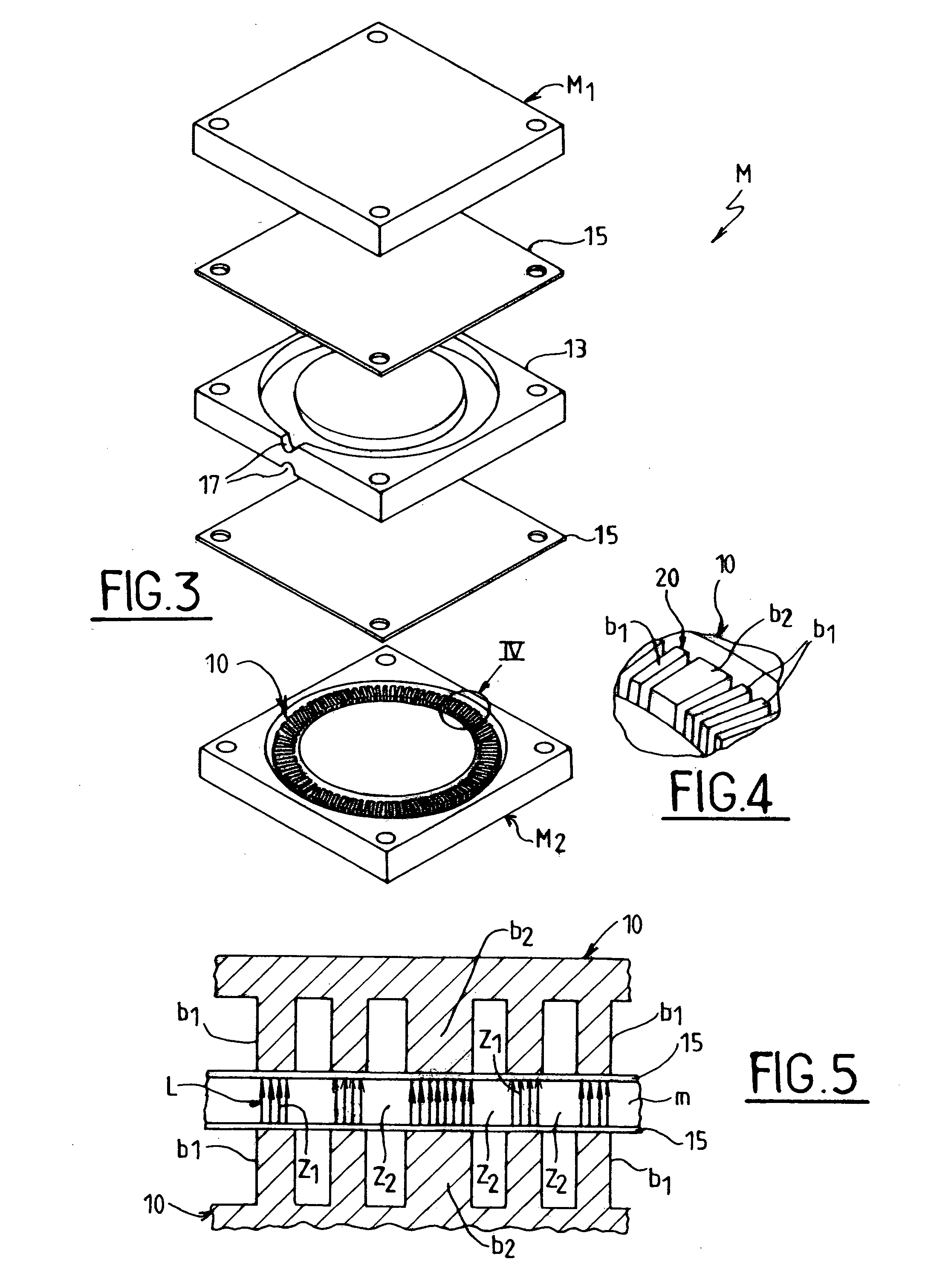

Method of fabricating a magnetic coder device, and the device obtained thereby

InactiveUS20040251652A1Easy to operateHigh densityMagnetic bodiesLinear/angular speed measurementMagnetizationMagnetic poles

A method of fabricating a magnetic coder device, the method being of the type consisting in making a mixture of ferromagnetic particles or ferrites in a matrix, in molding the matrix, and in subjecting the molded matrix to a magnetic field so as to obtain a continuous alternation of north and south magnetic poles, which method consists in using a matrix having viscosity that is sufficiently low to enable the ferrites to migrate, in applying a magnetic field during the molding operation while maintaining the matrix at a given temperature in order to reduce its viscosity and thereby making it easier to cause the ferromagnetic particles to migrate and become oriented in their direction of easy magnetization, and to obtain discontinuous shapes having high particle concentration, and in suddenly cooling the matrix while the magnetic field is maintained so as to freeze the particles in the matrix.

Owner:HUTCHINSON SA

Circulating fluidized bed boiler capable of adjusting circulating ash flow

ActiveCN104990071AIncrease temperatureReduce loadFluidized bed combustionApparatus for fluidised bed combustionCombustionSlag

The invention discloses a circulating fluidized bed boiler capable of adjusting a circulating ash flow. The circulating fluidized bed boiler comprises a hearth, an ash return pipe, a tail flue, a cyclone separator and an ash returner, and is characterized by further comprising an ash conditioner and a slag cooler, wherein the ash conditioner consists of a venturi fluidized air chamber and a cylindrical ash cooling chamber; the venturi fluidized air chamber is communicated with the ash cooling chamber; a first flow equalizing annular plate, a snakelike cooling coil and a second flow equalizing annular plate are connected into the ash cooling chamber; the first flow equalizing annular plate and the second flow equalizing annular plate are both porous structures; the venturi fluidized air chamber is formed by an expansion section, a cylinder section and a shrinkage section, which are communicated with each other; the ash cooling chamber is connected with an ash return valve of the ash returner through an ash discharge pipe; an ash return pipe is connected between the ash return pipe and the ash cooling chamber; an isolating valve is mounted on the ash return pipe; and the venturi fluidized air chamber is connected with the slag cooler through the ash discharge pipe. The circulating fluidized bed boiler is advantageous in that, circulating ash can be introduced to the boiler to adjust the load inside in a large range, so that the combustion efficiency of a fuel in the boiler is greatly improved, and the inner wall wear of the boiler is reduced.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

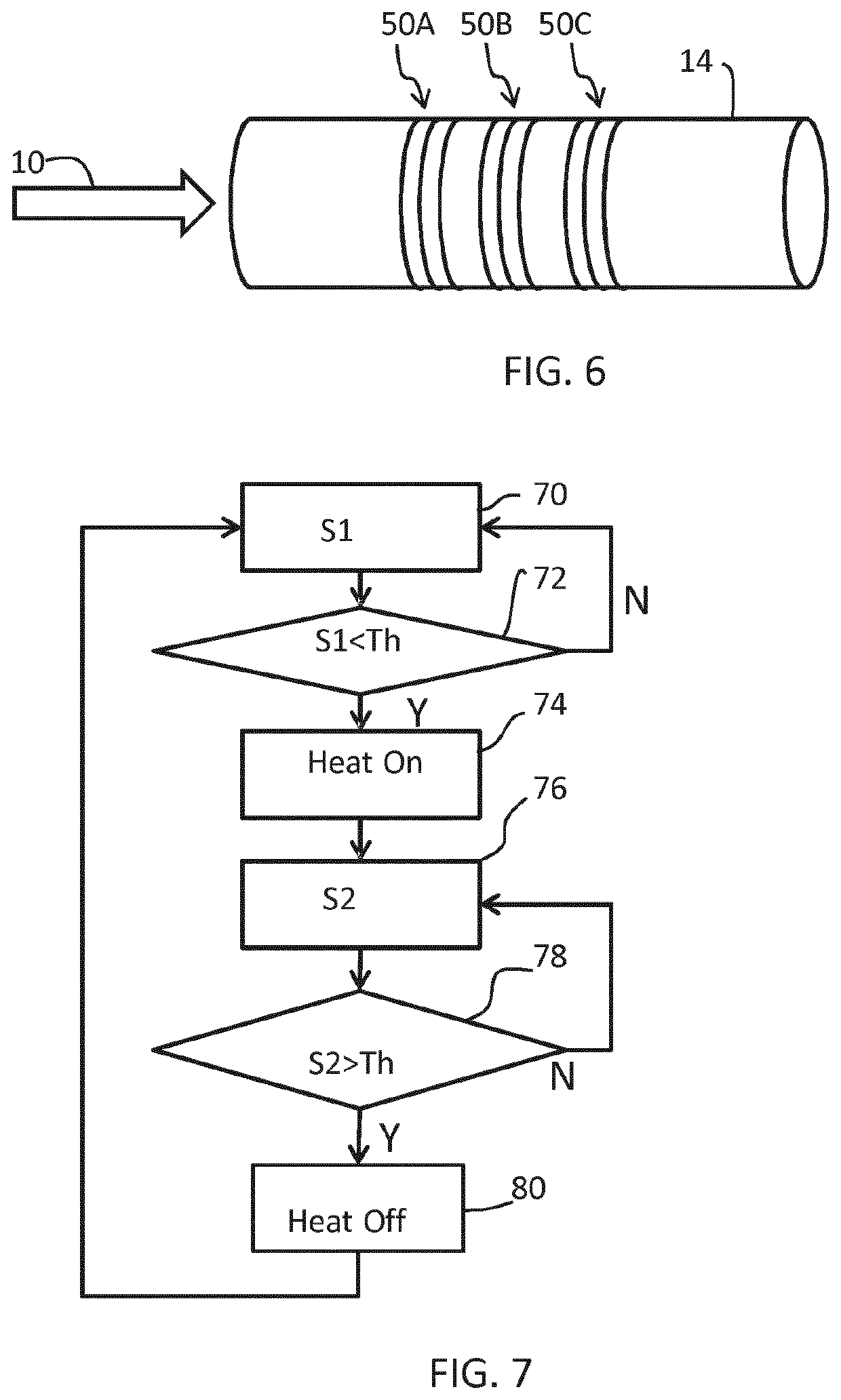

Particle sensor and particle sensing method

ActiveUS20200116604A1Without adversely affectingProvide quicklyHeating or cooling apparatusPreparing sample for investigationEngineeringMechanical engineering

A particle sensing system is for sensing particles entrained in a fluid. The system comprises a flow channel having a longitudinal direction along which the fluid is to be passed, a heating arrangement for heating the fluid and thereby applying a positive thermophoretic force on the fluid in a direction perpendicular to the longitudinal direction of the flow channel and a first sensor for sensing the particles in the fluid after heating by the heating arrangement. The thermophoretic force increases the concentration of the particles at the first sensor.

Owner:KONINKLJIJKE PHILIPS NV

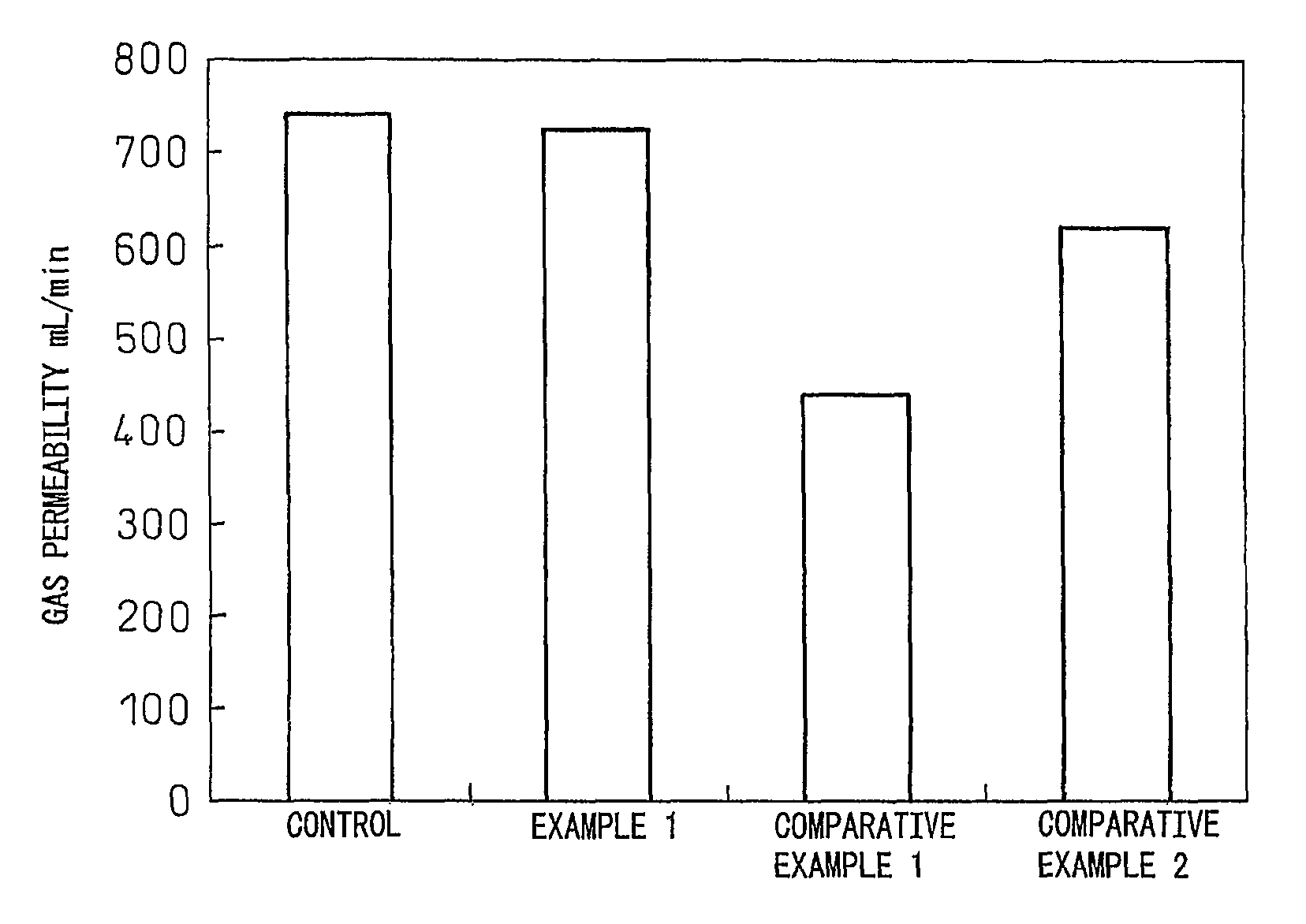

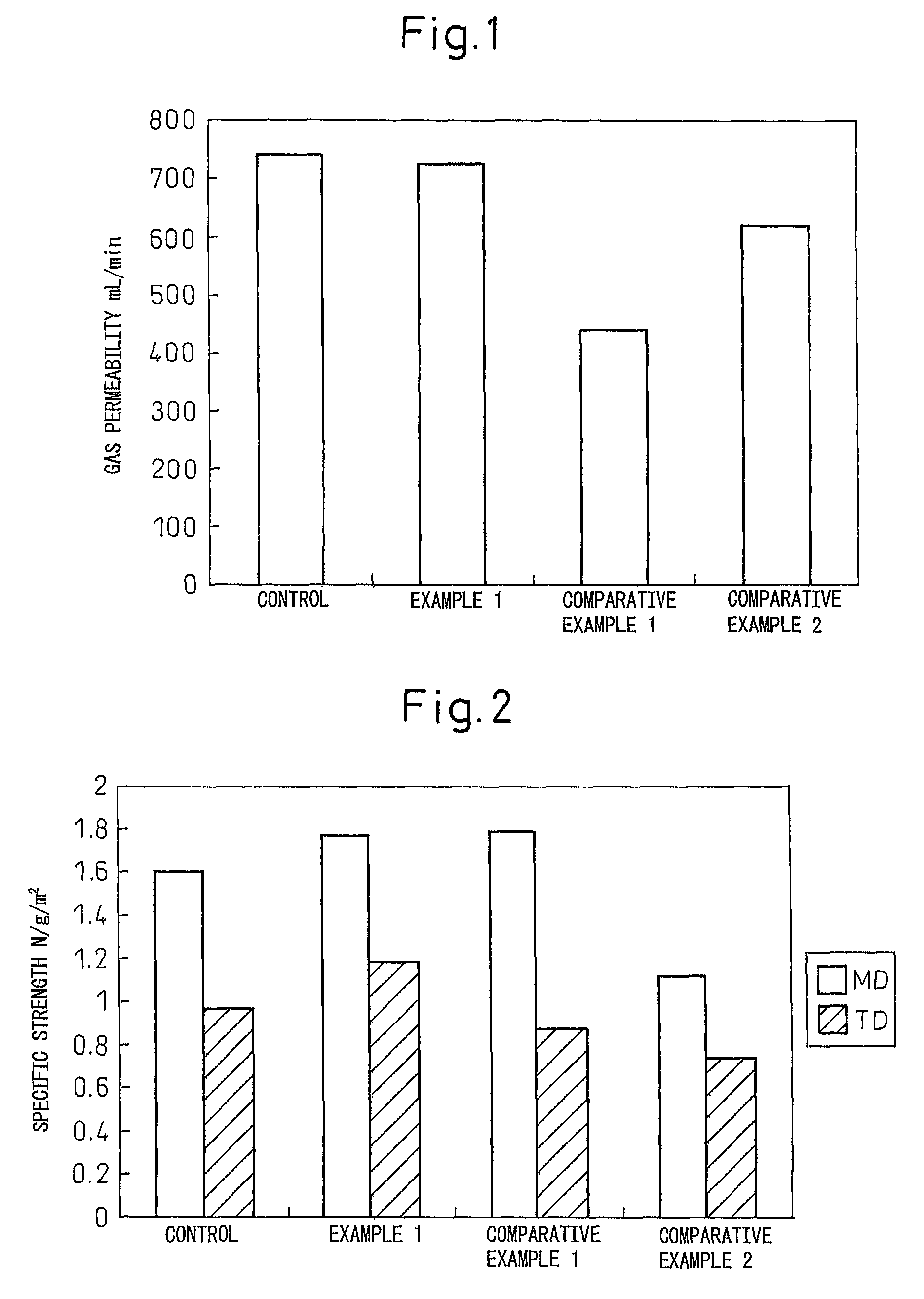

Method for producing porous film or tape of expanded polytetrafluoroethylene supporting catalyst particles, and ozone-removing filter

ActiveUS8974739B2Molding workability is satisfactoryHigh strengthCombination devicesExhaust apparatusDispersed mediaImproved method

An improved method for producing an expanded polytetrafluoroethylene (PTFE) porous film or tape supporting catalyst particles.The method for producing an expanded PTFE porous film or tape supporting catalyst particles according to the invention comprises a step of preparing tape-like porous PTFE, a step of impregnating the tape-like porous PTFE with a solution or dispersion of catalyst particles, a step of substantially removing the solvent or dispersing medium, and a step of further stretching the tape-like porous PTFE containing the catalyst particles in the machine direction (MD) and / or the transverse direction (TD).

Owner:W L GORE & ASSOC GK

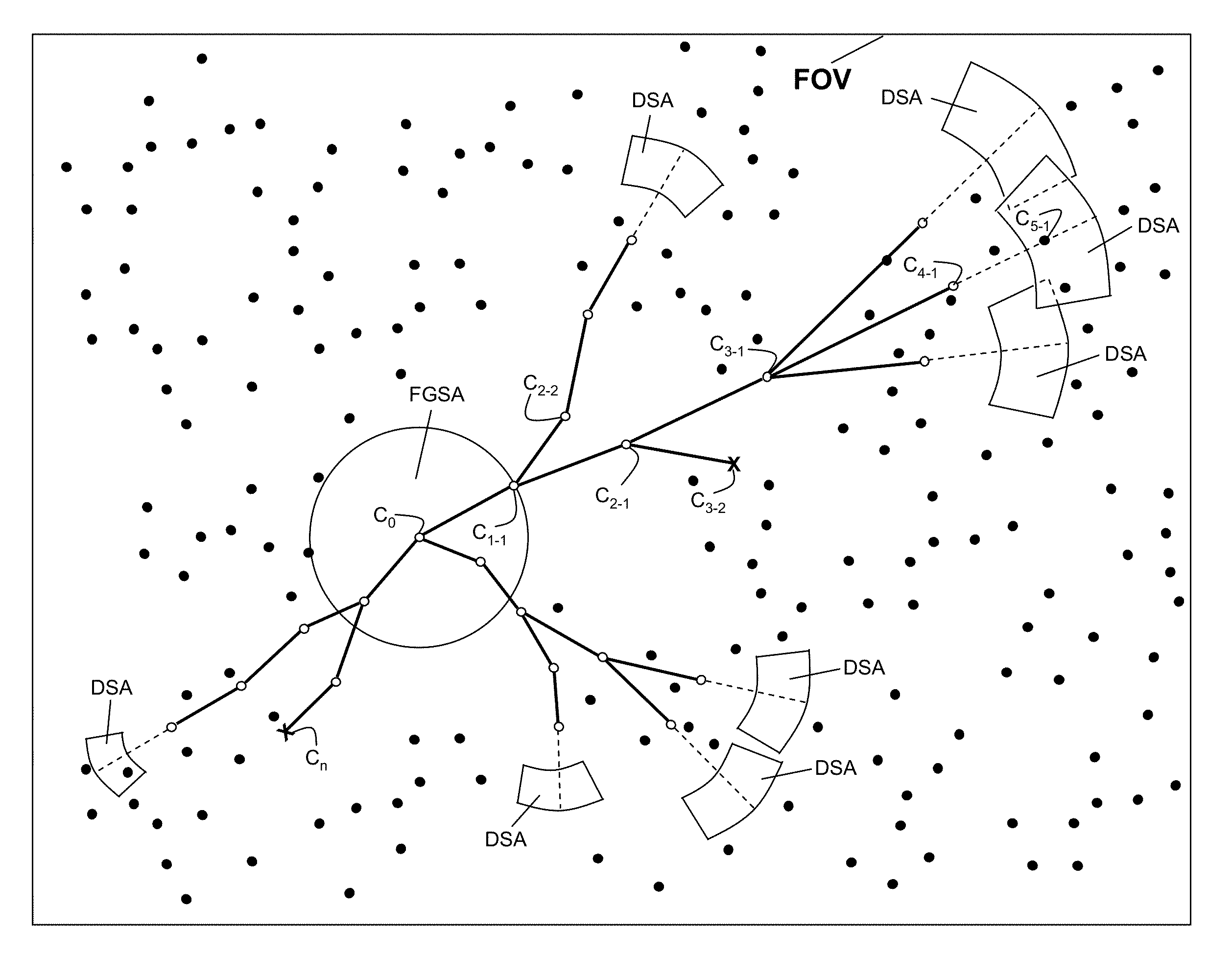

Method of particle trajectory recognition in particle flows of high particle concentration using a candidate trajectory tree process with variable search areas

InactiveUS8391552B1High accuracyShort computation timeCharacter and pattern recognitionFull-field flow measurementPopulationParticle flow

The application relates to particle trajectory recognition from a Centroid Population comprised of Centroids having an (x, y, t) or (x, y, f) coordinate. The method is applicable to visualization and measurement of particle flow fields of high particle. In one embodiment, the centroids are generated from particle images recorded on camera frames. The application encompasses digital computer systems and distribution mediums implementing the method disclosed and is particularly applicable to recognizing trajectories of particles in particle flows of high particle concentration. The method accomplishes trajectory recognition by forming Candidate Trajectory Trees and repeated searches at varying Search Velocities, such that initial search areas are set to a minimum size in order to recognize only the slowest, least accelerating particles which produce higher local concentrations. When a trajectory is recognized, the centroids in that trajectory are removed from consideration in future searches.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

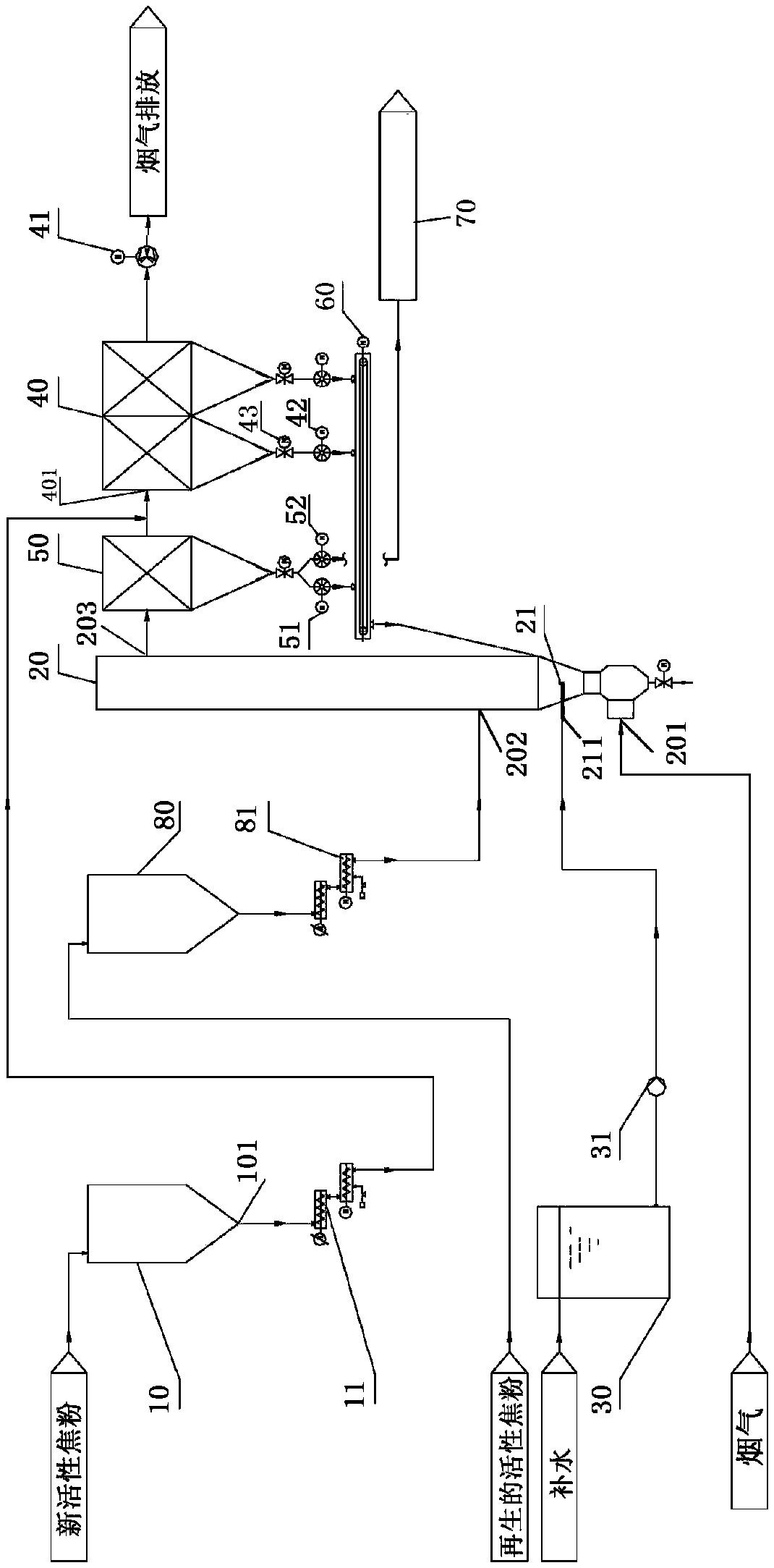

Powder activated coke adsorption desulfurization device and method for adsorbing and desulfurizing flue gas by utilizing powder activated coke adsorption desulfurization device

PendingCN108722114AProlong the action timeImprove utilization efficiencyGas treatmentDispersed particle separationFluidized bedFlue gas

The invention provides a powder activated coke adsorption desulfurization device and a method for adsorbing and desulfurizing flue gas by utilizing powder activated coke adsorption desulfurization device. The powder activated coke adsorption desulfurization device comprises a fluidized bed desulfurization device, the fluidized bed desulfurization device is provided with a flue gas inlet, a powderactivated coke inlet and a desulfurized gas outlet, and the powder activated coke inlet is used for adding powder activated coke. Compared with the existing adsorption treatment of flue gas by using granular activated coke, the powder activated coke adsorption desulfurization device provided by the application uses a finer powder activated coke as an adsorbent and a fluidized bed desulfurization device as a desulfurization device, which is beneficial to greatly improve the utilization efficiency of the adsorbent and the removal efficiency of the SO2, and reduces the number of devices, the floor space, and the investment and operating costs.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Apparatus and method for minimizing the generation of particles in ultrapure liquids

InactiveUS20070113923A1Quantity minimizationIncrease particle concentrationSpraying apparatusLiquid transferring devicesAir liquid interfaceEngineering

A system and method of reducing particle generation in packaging containers used to transport ultra pure liquids. Particle generation in the containers is reduced by reducing the air-liquid interface present during filling, transport, and dispensing of the liquid.

Owner:KELLY WAYNE +1

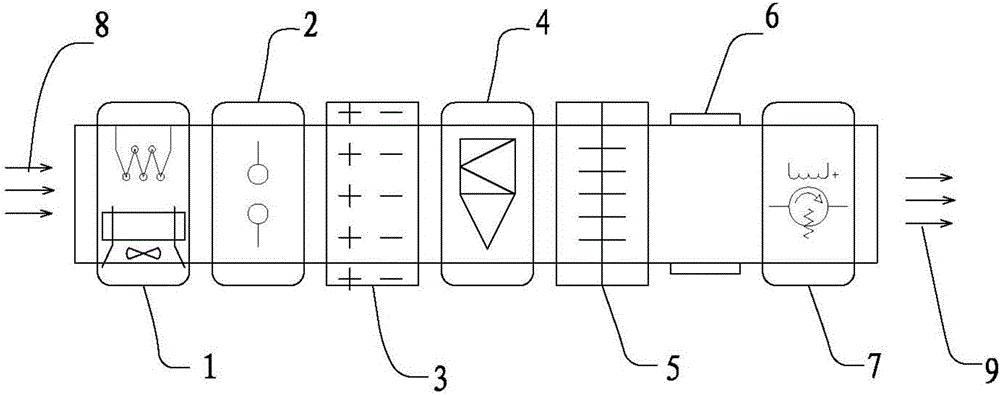

Method for online wear particle monitoring by adoption of electrification, electric control loop adsorption and adjacent capacitance

InactiveCN105864152AIncrease output signal strengthHigh dielectric constantFluid-pressure actuator testingEdge effectsEngineering

The invention relates to an on-line monitoring method of wear particles using electrification, electric control ring adsorption and adjacent capacitors, which sequentially passes through a temperature control module, an electrification module, an electric field centrifugal module, a mechanical centrifugal module, an adsorption module, and adjacent capacitor particles The monitoring module and the degaussing module perform on-line monitoring of wear particles; one end of the temperature control module is provided with an oil inlet; the adsorption module is specifically a homopolar adjacent type adsorption ring. The invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through electrification, electric field centrifugation and mechanical centrifugation modules, the wear particles in the oil are aggregated into large particles and move to the pipe wall Adjacent and adsorbed by the adsorption module to increase the output monitoring signal strength of the adjacent capacitive sensor; through the temperature control module and the rational design of the adjacent capacitive sensor plate layer structure, suppress noise and optimize the overall performance of the adjacent capacitive sensor monitoring device.

Owner:张国云

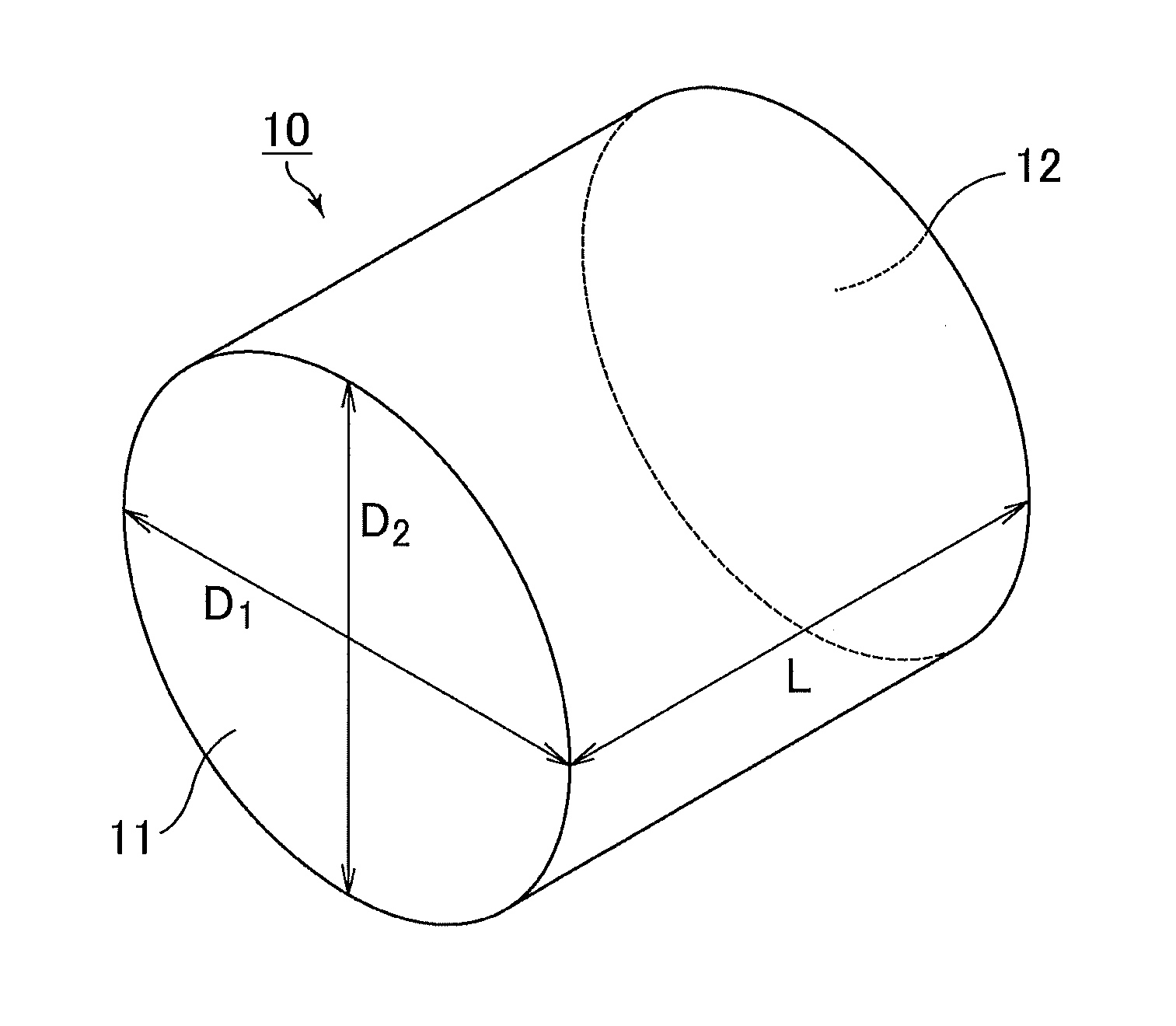

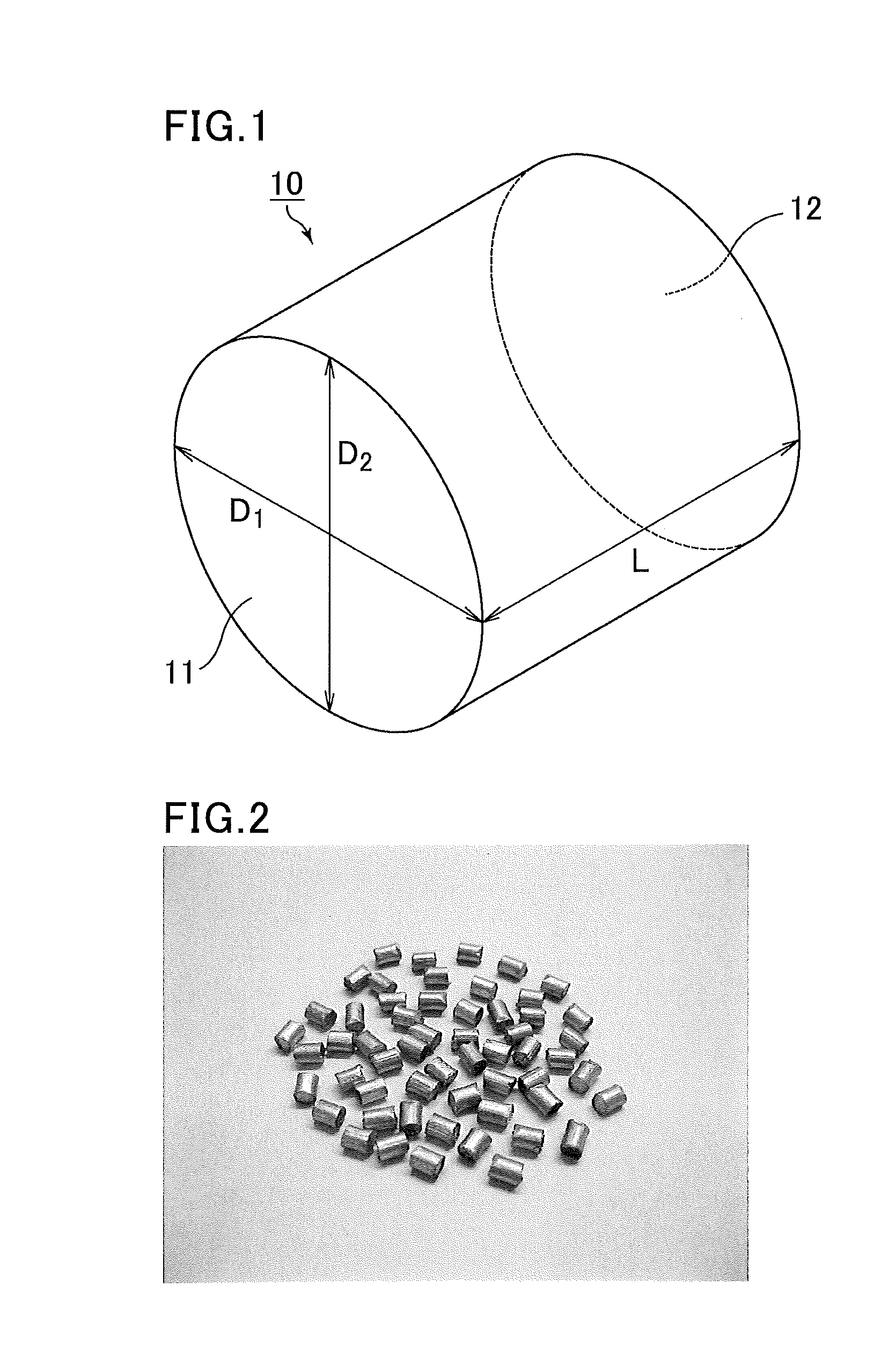

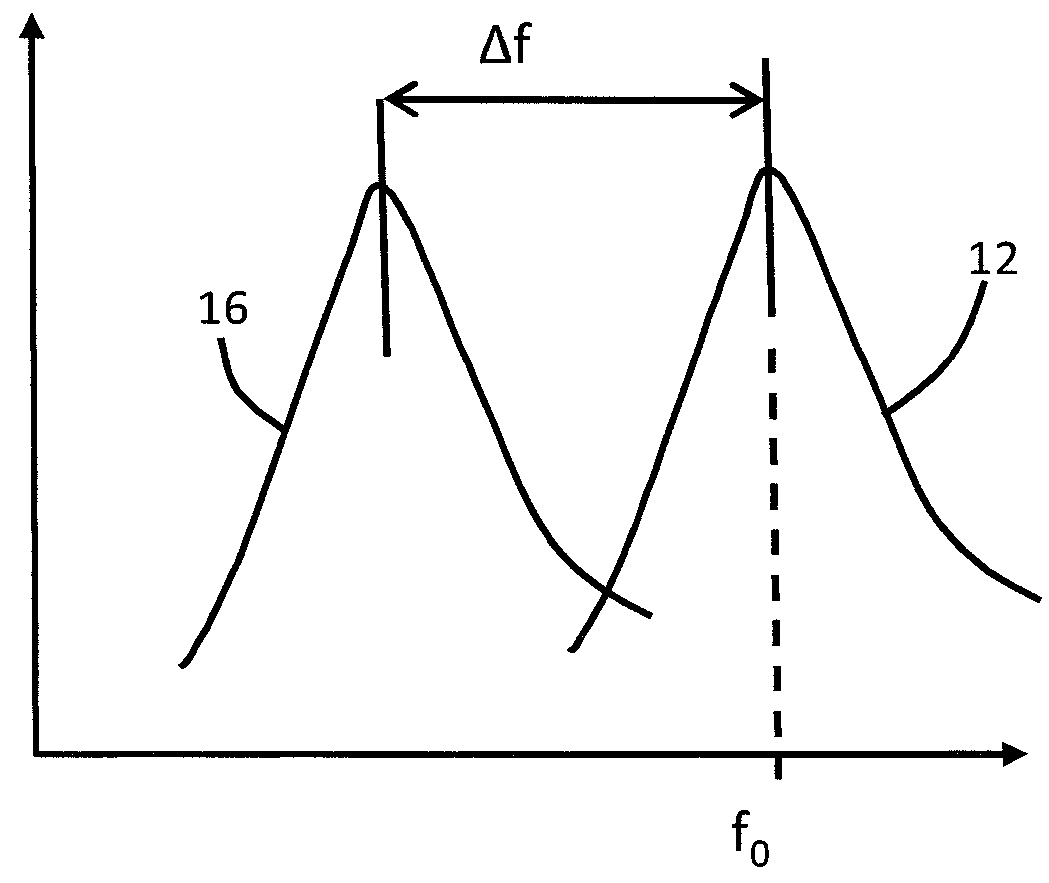

Masterbatch, masterbatch group, production method for masterbatch, and synthetic resin molded article

The present invention aims to provide a masterbatch containing a large amount of an aluminum component and having high pellet strength, wherein aluminum particles retain their inherent brightness and the amount of a component which may impair the strength or appearance of a synthetic resin molded article is small. The masterbatch of the present invention contains aluminum particles, a heat-resistant wetting agent, and a resin, wherein the proportion of the aluminum particles in the masterbatch is 50 to 80% by weight, the resin has a melt flow rate of 0.2 to 60 g / 10 min, and the proportion of wax having a melt flow rate of more than 60 g / 10 min and a melt viscosity at 140° C. of 15 to 8000 mPa·s in the masterbatch is 10% by weight or less.

Aerosol sensor and sensing method

ActiveUS10006846B2Accurate measurementExtended service lifeAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansEngineeringOptical transducers

A sensor system is provided for measuring particle concentration and mass concentration in an aerosol. An optical sensor (33) is used for measuring a particle concentration and a mechanical sensor (32) is used for measuring a mass of collected particles. A particle concentration in the aerosol is monitored using the optical sensor (33), until detection of a particle generating event. Upon detection of a particle generating event, a mass measurement using the mechanical sensor (32) is performed and the mass measurement is used to calibrate the optical sensor (33). This approach enables the lifetime of the mechanical sensor to be extended, because it is only used when events are detected. The optical sensor, which typically is less accurate for mass sensing, is calibrated by the mechanical sensor.

Owner:KONINKLJIJKE PHILIPS NV

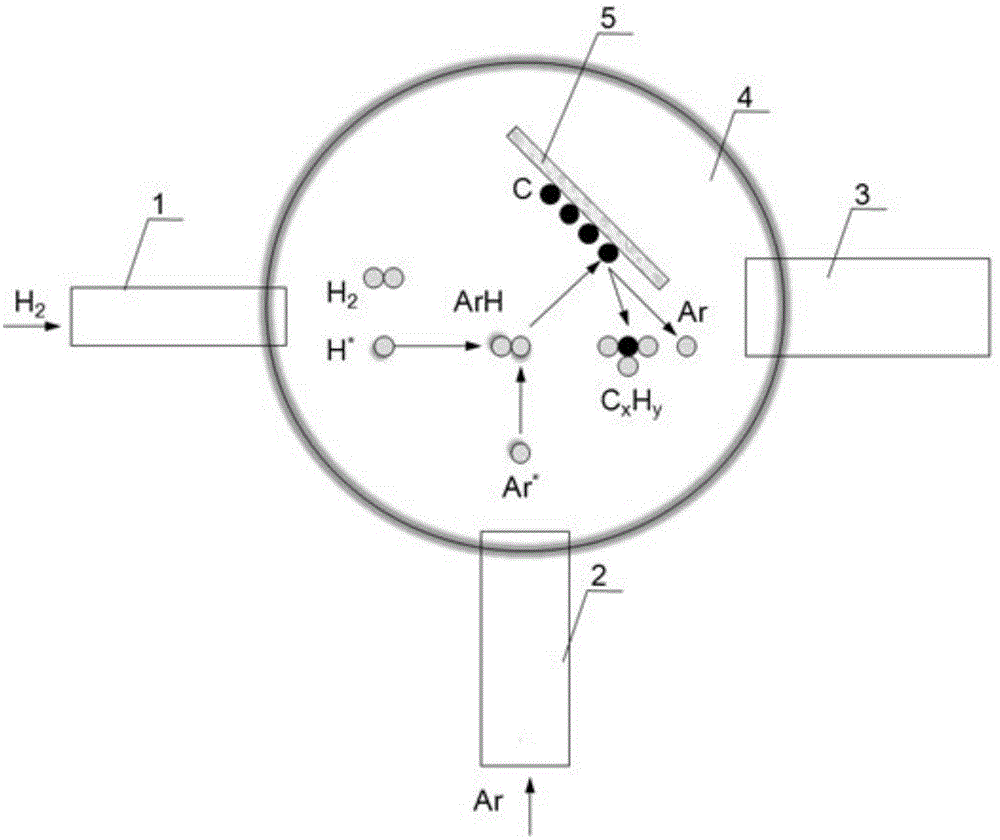

ArH cleaning method for carbon pollution on surface of optical element

InactiveCN104865700AReduce adverse effectsReduce the temperatureOptical elementsChemical reactionOptical processing

An ArH cleaning method for carbon pollution on surface of an optical element belongs to the technical field of optical processing. The ArH cleaning method comprises the steps of placing an optical element sample in a cleaning chamber, satisfying a requirement that the vacuum degree of the cleaning chamber is above 10-5mbar by means of a vacuum pump; starting an RF plasma transmitter with an RF frequency of 13.56MHz, introducing argon with a supplying flow of 2sccm, so that the whole cleaning chamber is filled with excited-state argon particles, thereby preventing direct emission to the surface of the optical element sample when the argon is introduced, and preventing optical element surface damage caused by plasma bombardment on the sample surface; starting a hydrogen atom emitter, setting the heating temperature to 2300K, introducing the hydrogen for a supplying flow of 1sccm, making the generated hydrogen atoms combine with argon particles for obtaining an excited-state complex ArH; leading chemical reaction between the carbon on the optical element sample and the ArH, thereby generating a volatile hydrocarbon; and pumping the hydrocarbon and the argon which returns to a ground state, thereby finishing cleaning.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Circulation fluidized bed swirl-direct flow composite fluidizing device

InactiveCN100368070CReduce stickinessSmall sizeDispersed particle separationChemical/physical processesTime extensionFluidized bed

The present invention belongs to the field of industrial waste gas purifying technology, and is one circular composite swirl-uniflow fluidizing device for fume desulfurizing fluidized bed. The fluidizing device includes an inlet fume channel, a Venturi tube, a reducing section and a desulfurizing barrel connected successively from bottom to top, and features that it includes also an inner sleeve installed inside the Venturi tube and a swirl fluidizing unit installed between the inner sleeve and the Venturi tube. Partial fume flows inside the inner sleeve and the rest flows in the swirl fluidizing unit, so as to form the composite fume fluidizing comprising the uniflow fluidizing inside the inner sleeve and swirl fluidizing outside the inner sleeve. The composite fluidizing device has simple structure, less gas flow deflection, high fluidizing effect, long grain retaining period, great inner circulation multiple and high desulfurizing efficiency.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com