High-density pressurized fluidized bed coal gasification apparatus and method

A high-density, coal gasification technology, applied in the field of coal gasification, can solve the problems of difficult treatment of by-product tar and phenol, low investment in carbon conversion rate, and low oxygen consumption in the gasification process, so as to improve gasification intensity and overcome carbon conversion The effect of low carbon conversion rate and high carbon conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

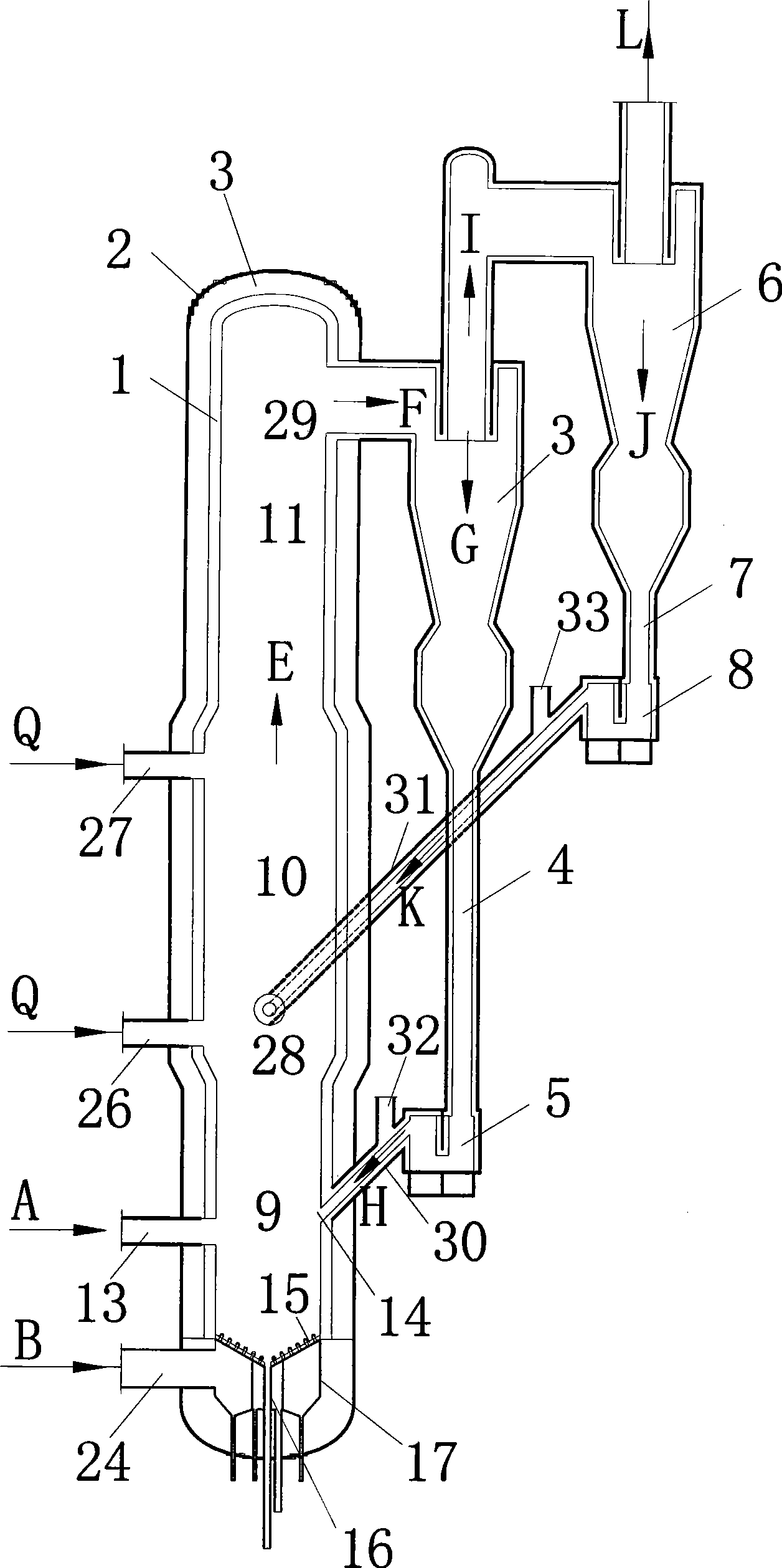

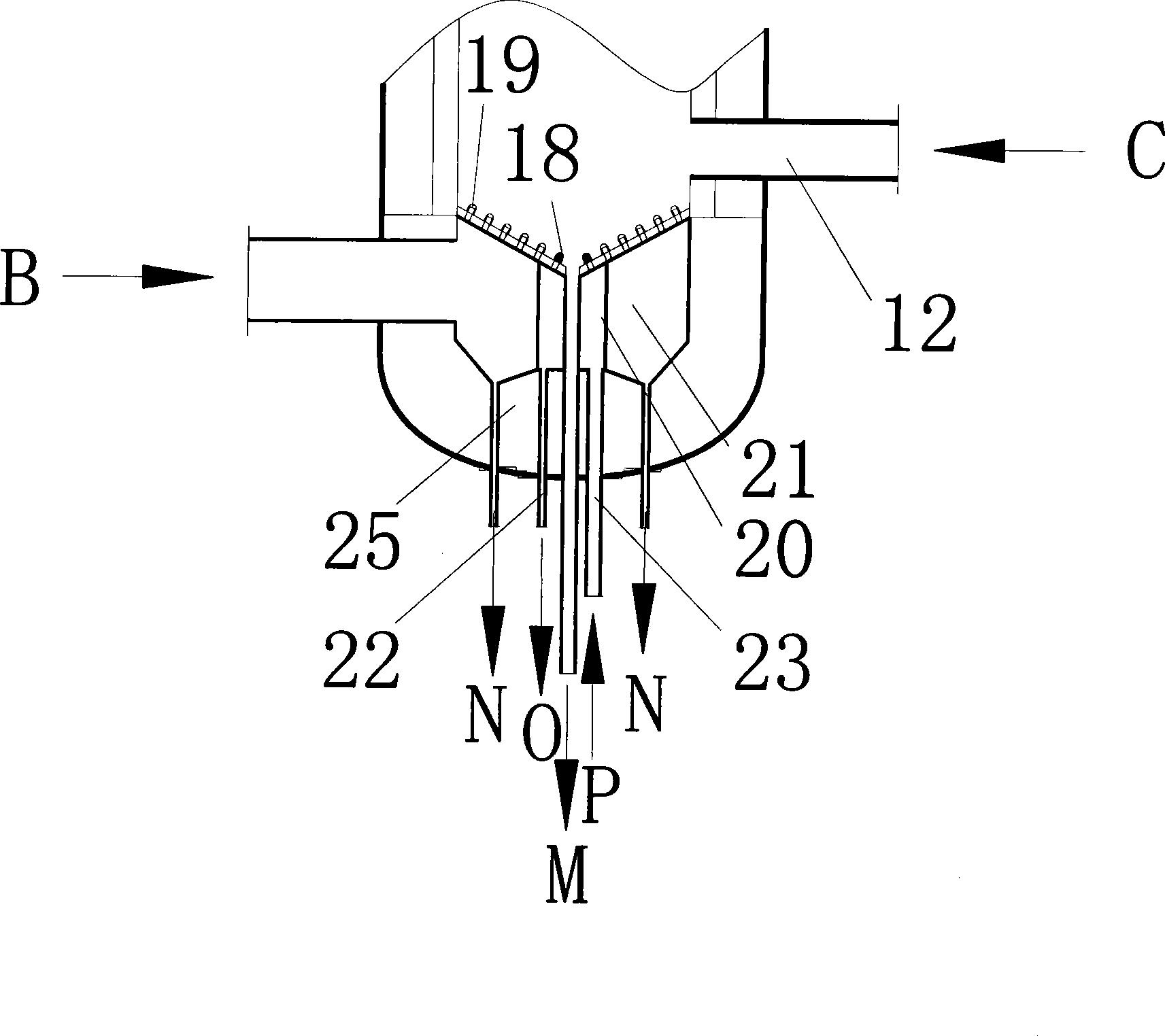

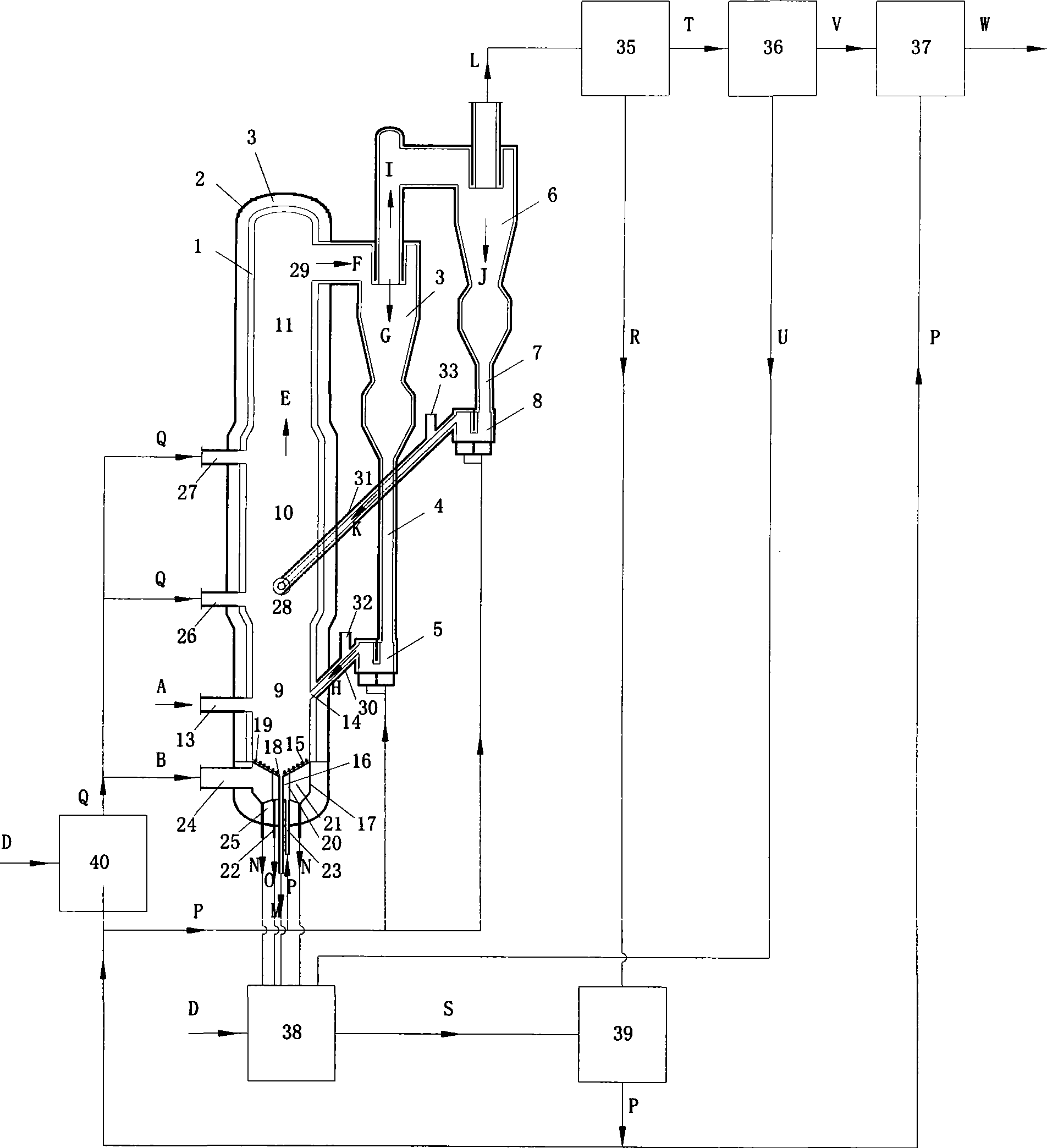

[0022] See attached figure 1 and figure 2 The gasification reactor 1 is divided into a dense-phase turbulent fluidization section 9, a high-density annular core flow section 10, and a high-density fast flow section 11, which are pressurized and segmented according to the gasification characteristics of coal with high sulfur, high ash, and high ash melting point Gasification, the gasification pressure is 1.0-2.5MPa. The dense-phase turbulent fluidization section 9 is a dense-phase area with a particle volume concentration of 0.3-0.45 and a material layer height of 2-5 m. It adopts a turbulent fluidization operation mode with a temperature of 850-1050 degrees and a gas velocity of 1-1.5 m / s. The function is to achieve good mixing and heat and mass transfer of bed material, coal and limestone A, gasification agent Q and primary return material H, as well as to carry out coal devolatilization, combustion and partial gasification reaction; the particle size of bed material is 0-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com