Biomass cyclone pyrolysis-suspension combustion composite gasification device and gasification method thereof

A technology of suspension combustion and gasification device, which can be used in granular/powder fuel gasification, manufacture of combustible gas, petroleum industry, etc., and can solve the problem of low carbon conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

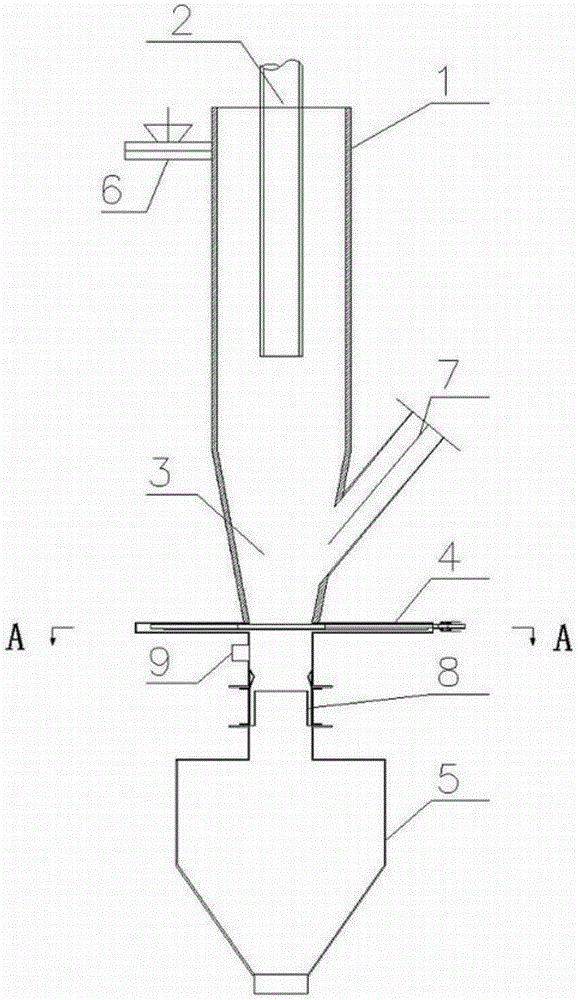

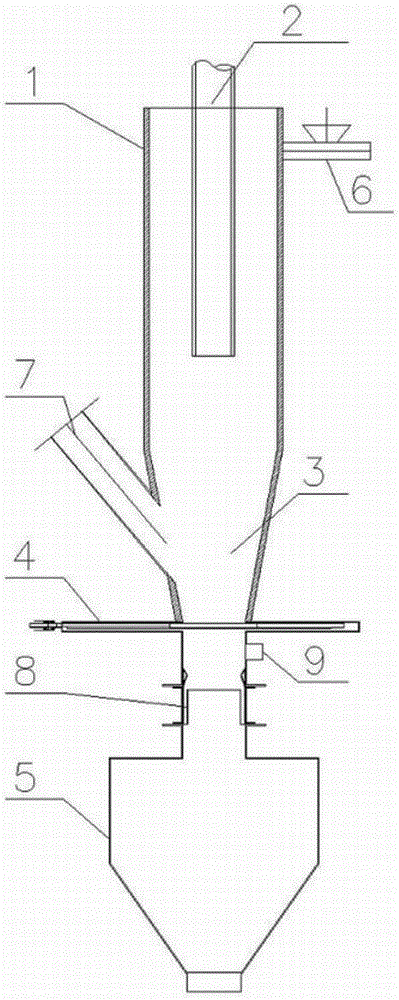

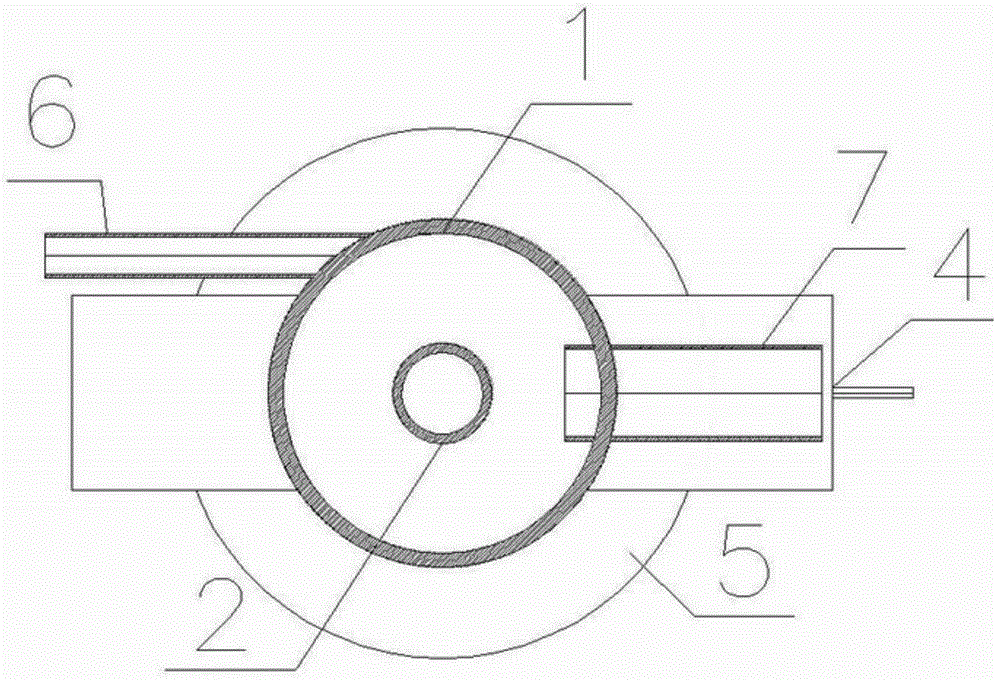

[0021] The composition of the biomass cyclone pyrolysis-suspension combustion composite gasification device in this embodiment includes: a cyclone pyrolysis chamber 1, a central exhaust pipe 2 coaxially suspended in the cyclone pyrolysis chamber 1, and an inner wall of the cyclone pyrolysis chamber 1 The lower port is coaxially connected with the upper port of the suspension combustion chamber 3, the lower end of the suspension combustion chamber 3 is fixedly connected to the switching grate 4, the lower part of the switching grate 4 is connected to the air ring 8, the lower part of the air ring 8 is fixedly connected to the ash hopper 5, and the switching grate 4 An ignition hole 9 is set between the wind ring 8; the upper part of the cyclone pyrolysis chamber 1 is plugged with one or more biomass fuel feeding pipes 6 along the tangential direction of its outer surface; the lower part of the suspension combustion chamber 3 is plugged with ignition fuel feeding Tube 7. The air...

specific Embodiment approach 2

[0023] The difference between this embodiment and specific embodiment one is:

[0024] In the biomass cyclone pyrolysis-suspension combustion composite gasification device, the switching grate 4 has a blanking gear and a gap grate, and the blanking gear and the gap grate work together with the suspension combustion chamber 3 Concentric axis setting.

specific Embodiment approach 3

[0025] The difference between this embodiment and specific embodiment 1 or 2 is: the biomass cyclone pyrolysis-suspension combustion composite gasification device, the biomass fuel feeding pipe 6 is cylindrical, and the biomass fuel feeding pipe 6 is horizontal The directions are evenly arranged on the outer wall of the cyclone pyrolysis chamber 1, and are arranged in the needle direction at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com