Metal-air battery based on silver-copper catalysis and preparation method thereof

A metal-air battery and air electrode technology, which is applied to battery electrodes, fuel cell half-cells, primary battery-type half-cells, circuits, etc., can solve problems such as seawater corrosion, poor adaptability of battery types, carbon dioxide poisoning, etc., to achieve Corrosion resistance, good resistance to carbon dioxide and seawater corrosion, effect of promoting reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

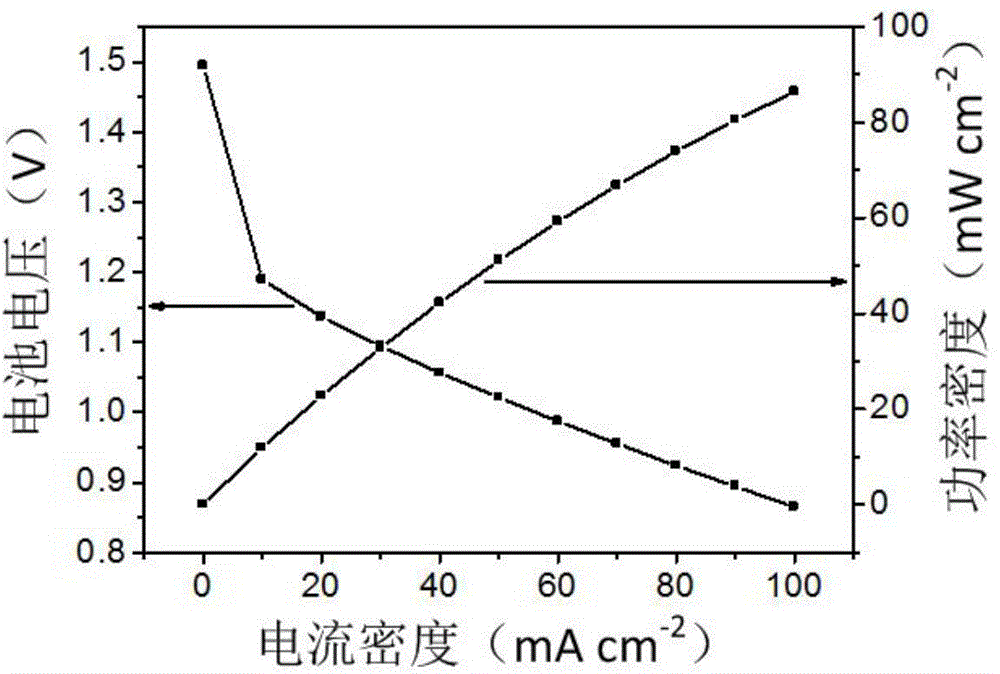

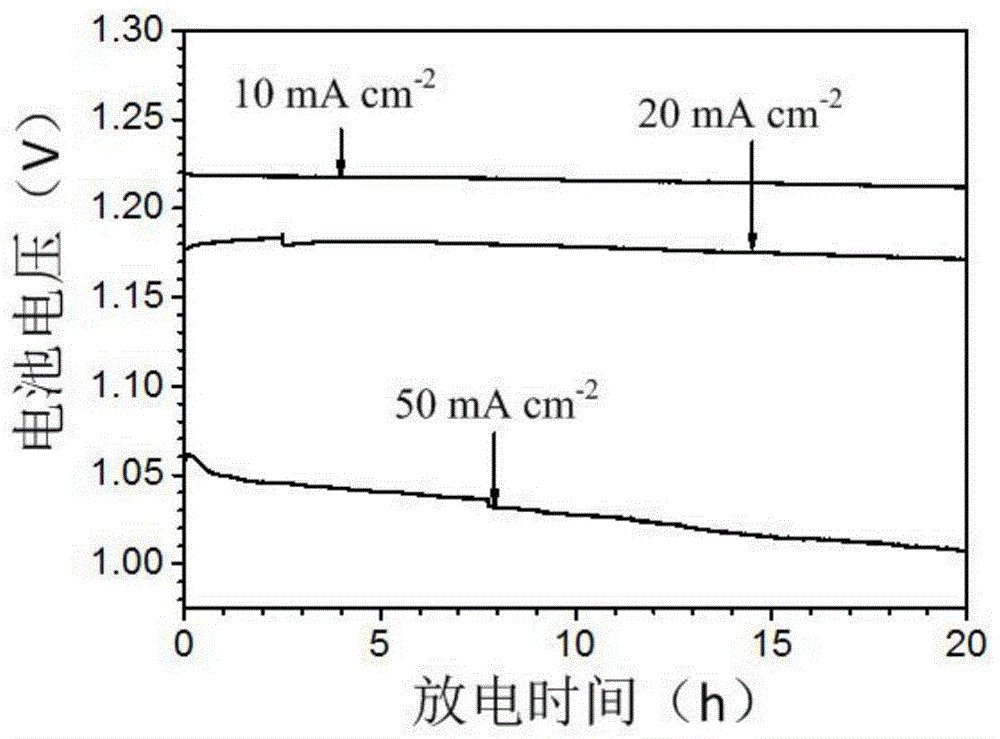

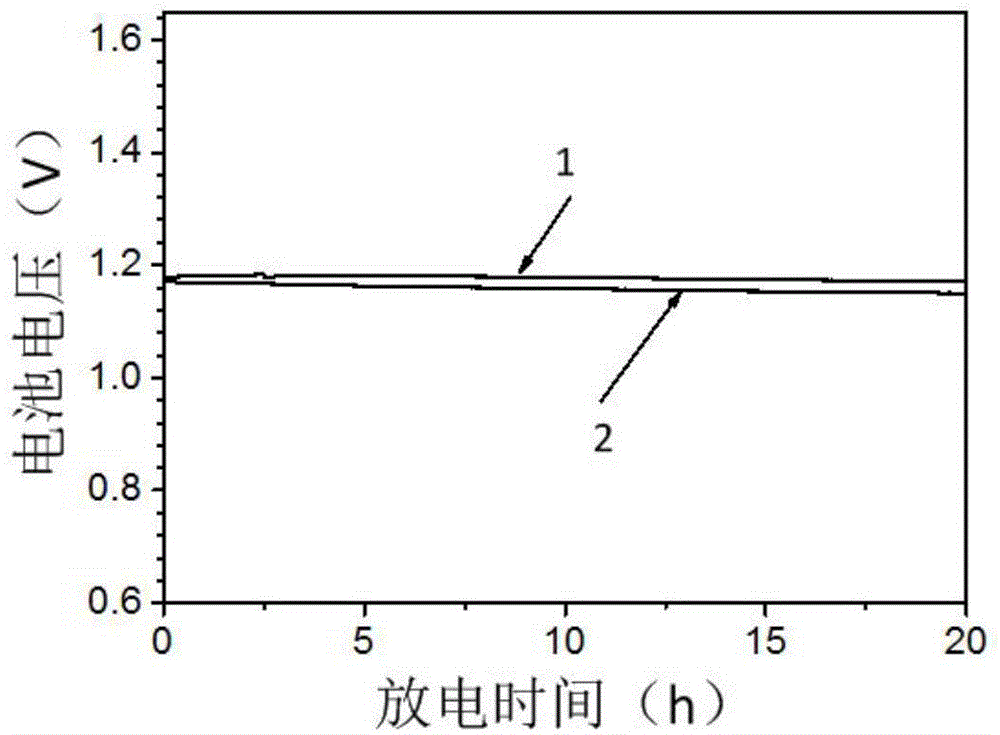

Embodiment 1

[0056] This embodiment is a zinc-air primary battery based on silver copper catalysis and a preparation method thereof. The metal-air battery includes a metal anode, an air electrode, an electrolyte, a glass fiber separator and a battery case, and is assembled according to a conventional method. The feature of this embodiment is that the catalyst layer of the metal-air battery is composed of carbon-free and adhesive-free Ag-Cu nano-alloy, and the catalyst layer is directly electrodeposited with a layer of Ag-Cu alloy on the foamed nickel. The microscopic morphology of the Ag-Cu alloy is spherical nanoparticles. The diameter of the spherical nanoparticles is 200-600 nanometers, and the small particles are evenly distributed on the spherical surface. The atomic ratio of the Ag-Cu alloy is Ag:Cu=75:25. The constituent elements of the Ag-Cu alloy are zero-valent Ag and Cu. The Ag-Cu alloy is a solid solution phase.

[0057] The manufacturing process of the metal-air battery is:

[...

Embodiment 2

[0065] This embodiment is a zinc-air primary battery based on silver copper catalysis and a preparation method thereof. The metal-air battery includes a metal anode, an air electrode, an electrolyte, a glass fiber separator and a battery case, and is assembled according to a conventional method. The feature of this embodiment is that the catalyst layer of the metal-air battery is composed of a carbon-free and adhesive-free Ag-Cu nano-alloy, and the catalyst layer is characterized in that a layer of Ag-Cu is directly electrodeposited on the foamed nickel. Alloy, the microscopic morphology of Ag-Cu alloy is spherical nano-particles, the diameter of spherical nano-particles is 200-600 nanometers, and small particles are evenly distributed on the spherical surface. The atomic ratio of the Ag-Cu alloy is Ag:Cu=50:50. The constituent elements of the Ag-Cu alloy are zero-valent Ag and Cu. The Ag-Cu alloy is a solid solution phase.

[0066] The preparation process of the metal-air bat...

Embodiment 3

[0074] This embodiment is a zinc-air primary battery based on silver copper catalysis and a preparation method thereof. The metal-air battery includes a metal anode, an air electrode, an electrolyte, a glass fiber separator and a battery case, and is assembled according to a conventional method. The feature of this embodiment is that the catalyst layer of the metal-air battery is composed of a carbon-free and adhesive-free Ag-Cu nano-alloy, and the catalyst layer is characterized in that a layer of Ag-Cu is directly electrodeposited on the foamed nickel. Alloy, the microscopic morphology of Ag-Cu alloy is spherical nano-particles, the diameter of the spherical nano-particles is 200-600 nanometers, and the small particles are evenly distributed on the spherical surface. The atomic ratio of the Ag-Cu alloy is Ag:Cu=25:75. The constituent elements of the Ag-Cu alloy are zero-valent Ag and Cu. The Ag-Cu alloy is a solid solution phase. The anode of the metal-air battery is Mg-9L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com