Preparation method of flexible-package high-power lithium ion power battery

A power battery, high-power technology, applied in the manufacture of electrolyte batteries, battery components, non-aqueous electrolyte batteries, etc., can solve the problem of shortening the battery cycle performance conductive carbon black content, reducing battery energy density, increasing battery heat, etc. problem, to achieve the effect of shortening the current passing path, reducing heat generation, and reducing contact internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

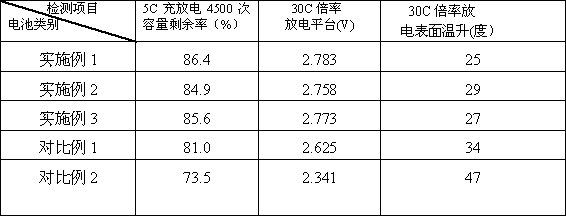

Examples

Embodiment 1

[0030] Preparation of positive pole piece: mix 90 parts by weight of lithium iron phosphate, 2 parts by weight of conductive carbon black Super Li, 3 parts by weight of carbon nanotubes, and 5 parts by weight of polyvinylidene fluoride, and add 150 parts by weight of N- Methyl pyrrolidone is stirred to form a slurry, which is evenly coated on the positive electrode base fluid carbon-coated aluminum foil, the coating density is 120g / ㎡, the carbon-coated aluminum foil thickness is 25 microns, the coating active material is conductive carbon black, and the coating thickness is unidirectional After drying at 3 micrometers at 110°C for 10 hours, it was rolled with a roller to make a positive pole piece.

[0031] Preparation of negative pole piece: Mix 92 parts by weight of lithium iron phosphate, 2 parts by weight of carbon nanotubes, and 8 parts by weight of polyvinylidene fluoride, and add 150 parts by weight of N-methylpyrrolidone and stir to form a slurry, Evenly coat the negative...

Embodiment 2

[0038] Preparation of positive pole piece: Mix 92 parts by weight of lithium iron phosphate, 3 parts by weight of conductive carbon black Super Li, 2 parts by weight of carbon nanotubes, and 3 parts by weight of polyvinylidene fluoride, and add 155 parts by weight of N- Methyl pyrrolidone is stirred to form a slurry, and it is evenly coated on the positive electrode base fluid carbon-coated aluminum foil, the coating density is 200g / ㎡, the carbon-coated aluminum foil thickness is 15 microns, the coating active material is conductive carbon black, and the coating thickness is unidirectional 0.5 micron, dried at 120°C for 11 hours and then rolled with a roller to make a positive pole piece.

[0039] Preparation of negative pole piece: Mix 90 parts by weight of lithium iron phosphate, 5 parts by weight of carbon nanotubes, and 8 parts by weight of polyvinylidene fluoride, and add 145 parts by weight of N-methylpyrrolidone and stir to form a slurry, Coat evenly on the negative base f...

Embodiment 3

[0046] Preparation of positive pole piece: mix 95 parts by weight of lithium iron phosphate, 5 parts by weight of conductive carbon black Super Li, 5 parts by weight of carbon nanotubes, and 6 parts by weight of polyvinylidene fluoride, and add 150 parts by weight of N- Methyl pyrrolidone is stirred to form a slurry, which is uniformly coated on the positive electrode base fluid carbon-coated aluminum foil, the coating density is 180g / ㎡, the carbon-coated aluminum foil thickness is 20 microns, the coating active material is conductive carbon black, and the coating thickness is unidirectional After drying at 120°C for 12 hours at 2 microns, it is rolled with a roller compactor to make a positive pole piece.

[0047] Preparation of negative pole piece: Mix 92 parts by weight of lithium iron phosphate, 3 parts by weight of carbon nanotubes, and 8 parts by weight of polyvinylidene fluoride, and add 155 parts by weight of N-methylpyrrolidone and stir to form a slurry, It is evenly coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com