High-speed turn-milling combined machining power electric main shaft device and manufacturing method thereof

A compound processing and spindle device technology, which is applied to other manufacturing equipment/tools, positioning devices, manufacturing tools, etc., can solve the problems of increasing equipment introduction costs, equipment maintenance costs, and restricting rapid development, achieving high dynamic characteristics and reducing additional Load, the effect of ensuring the reliability of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

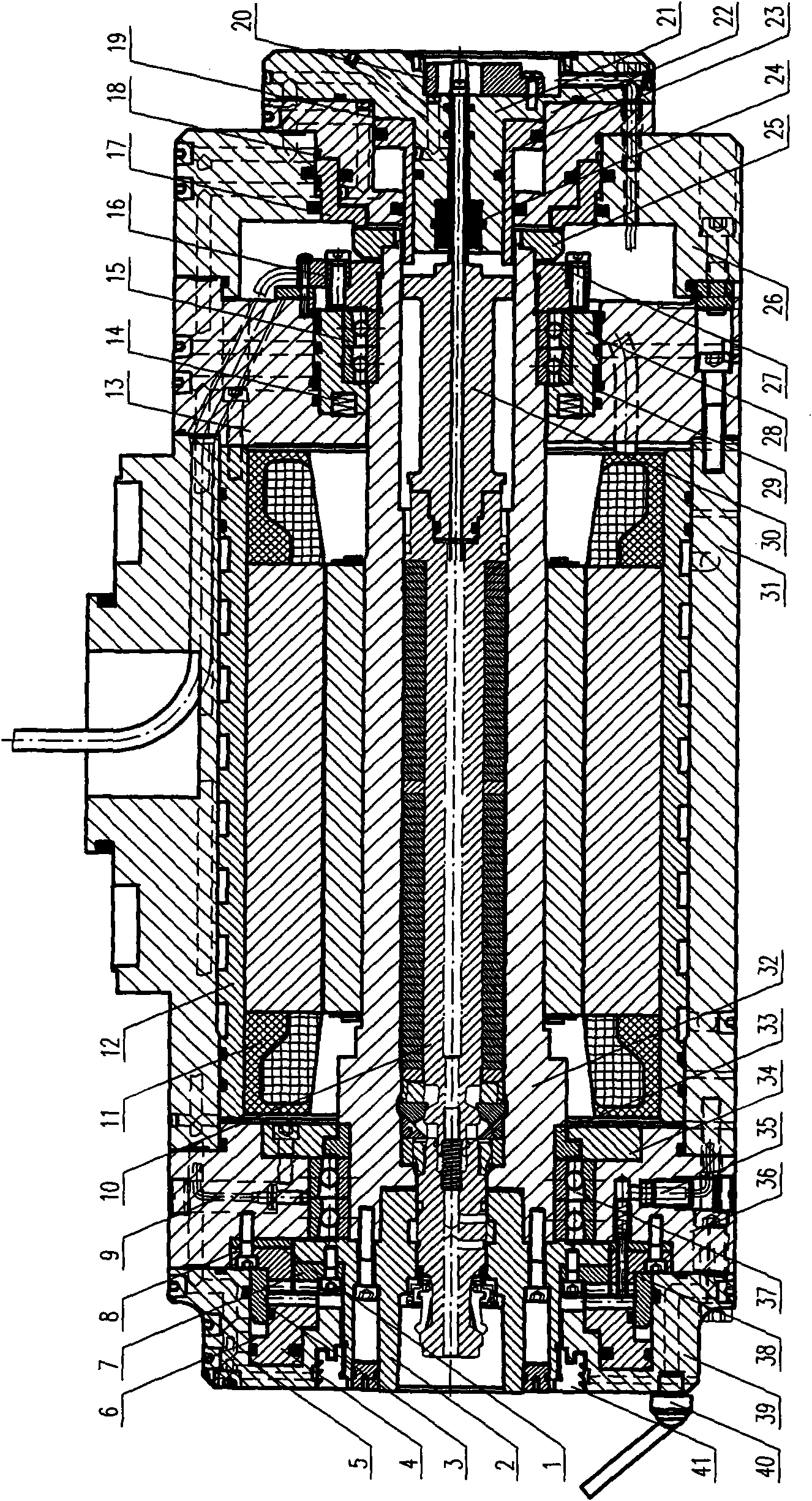

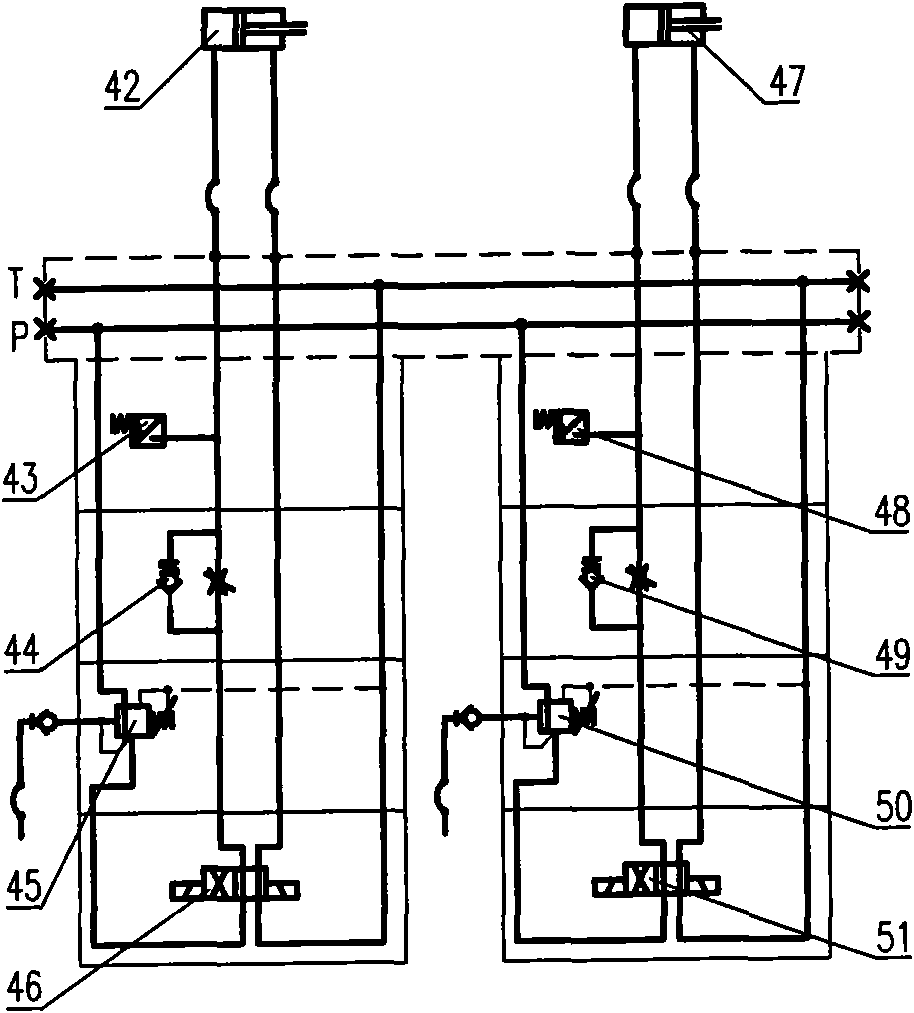

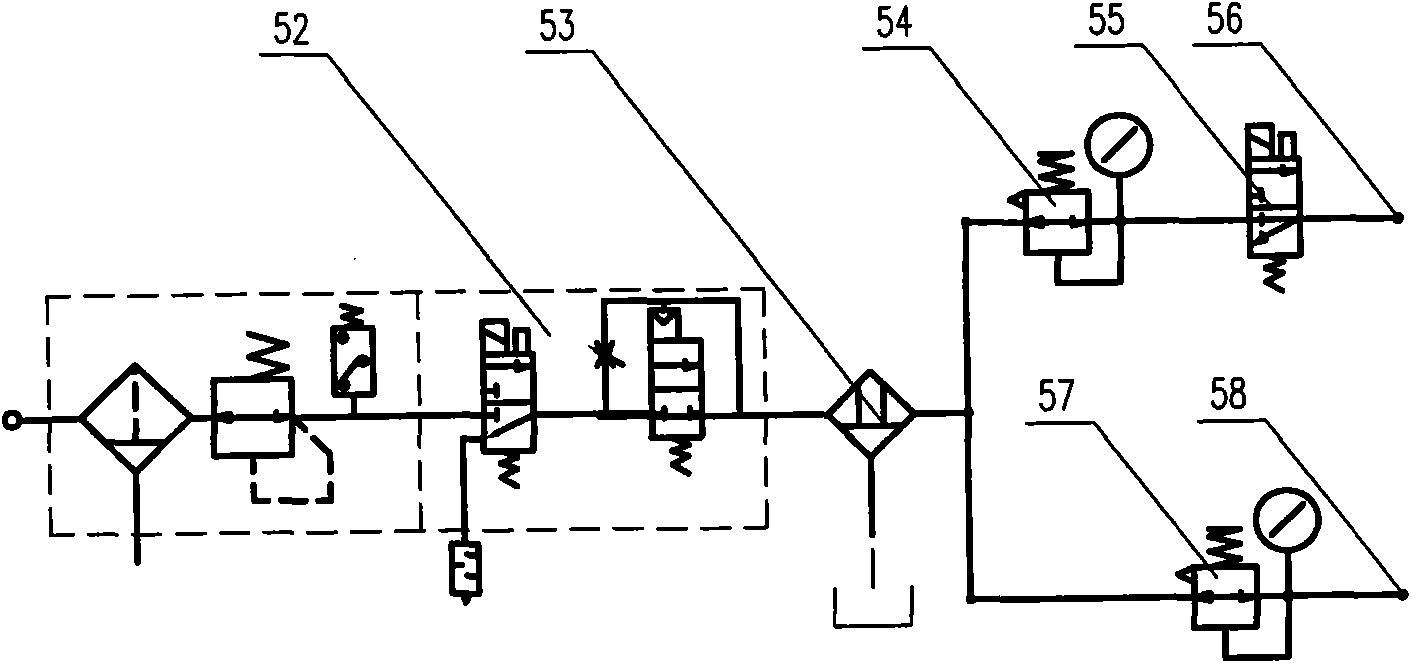

[0012] The power electric spindle device for high-speed turning-milling compound machining is installed on the high-speed five-axis turning-milling compound machining machine tool, and has supporting electrical, hydraulic and control parts correspondingly combined with the system on the machine tool, see figure 1 , which is characterized in that a water jacket 12, a built-in motor 11 and a main shaft 32 are installed concentrically in the spindle box 31 from outside to inside, a broach mechanism 10 is installed in the inner hole of the main shaft 32, and a broach sleeve 2 is installed on the front end of the broach mechanism 10, and the broach The rear end of the mechanism 10 is connected with the connecting sleeve 30 and the knife unloading mechanism; the front bearing 37 and the rear bearing 15 installed on the outer walls of the two ends of the main shaft 32 form the bearing variable preload structure respectively; a circular grating 16 is installed on the locking nut 27 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com