Inversion driving circuit for IGBT (insulated gate bipolar transistor) induction heating power source

An induction heating power supply and inverter drive technology, applied in the electrical field, can solve problems such as poor anti-overload capability, and achieve the effect of ensuring quality, strong stability and anti-interference performance, and ensuring work reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in conjunction with accompanying drawing and specific embodiment:

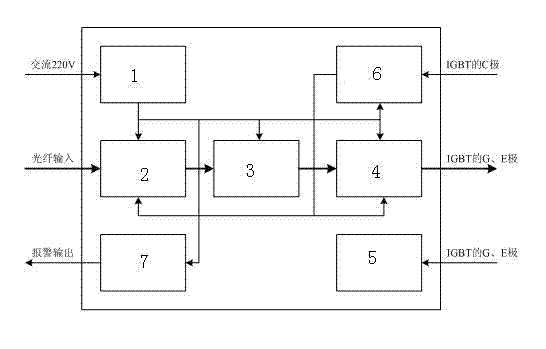

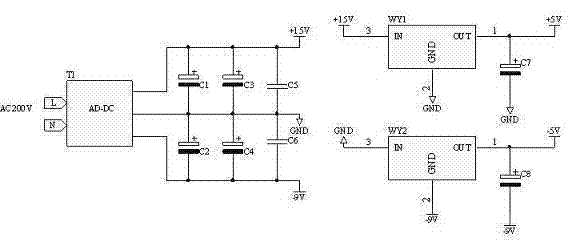

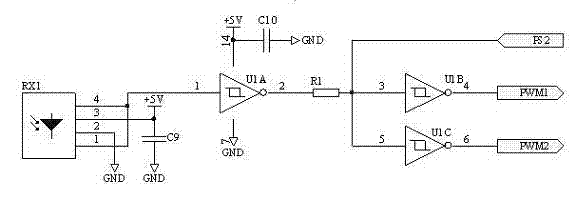

[0024] like figure 1As shown, an inverter drive circuit of an IGBT induction heating power supply, the inverter drive circuit includes a pulse signal receiving and sorting circuit 2, an isolation circuit 3 and a current amplification circuit 4; the pulse signal receiving and sorting circuit 2 communicate with the main control board of the power supply through an optical fiber to receive the optical pulse signal transmitted by the main control board of the power supply through the optical fiber, and convert the optical pulse signal into an electrical pulse signal; the isolation circuit 3 is connected with the pulse signal receiving and The sorting circuit 2 is connected, and the electric pulse signal is electro-optical and photoelectrically converted to obtain the electric pulse signal for one-way transmission; the current amplification circuit 4 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com