System for sealing off gap

A technology of gaps and sealing strips, applied in the structural field of steam turbines, to achieve the effect of improving thermal shock resistance and sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

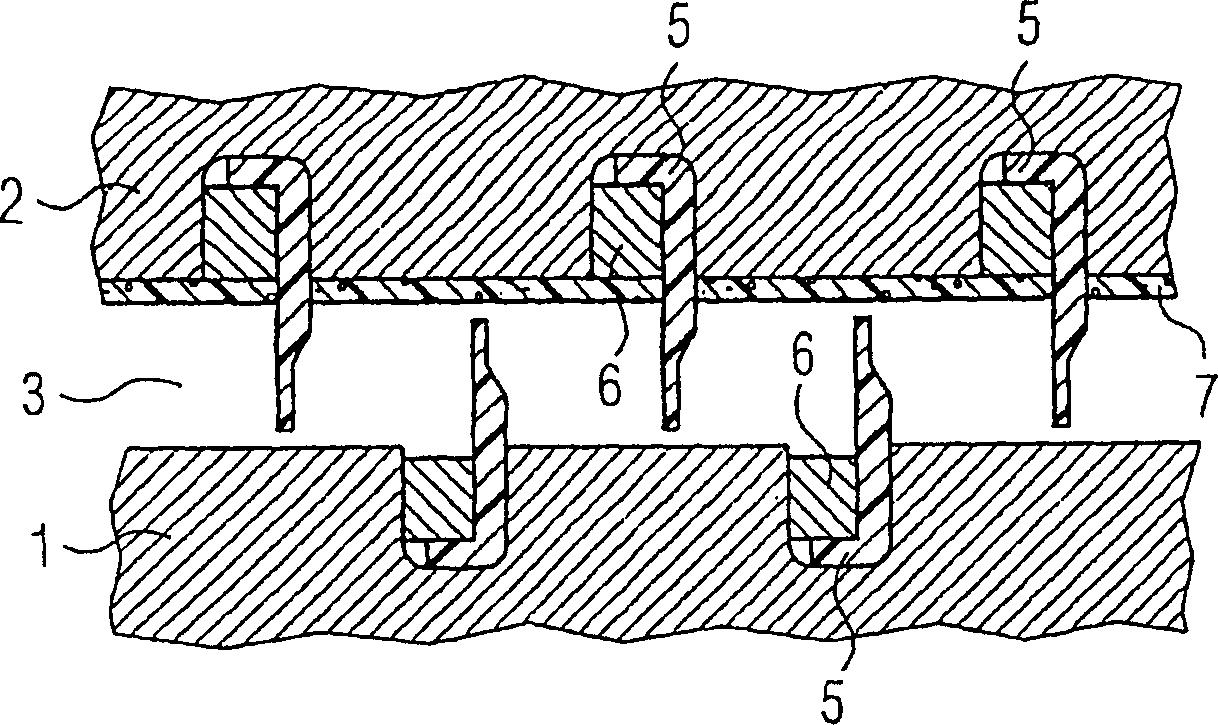

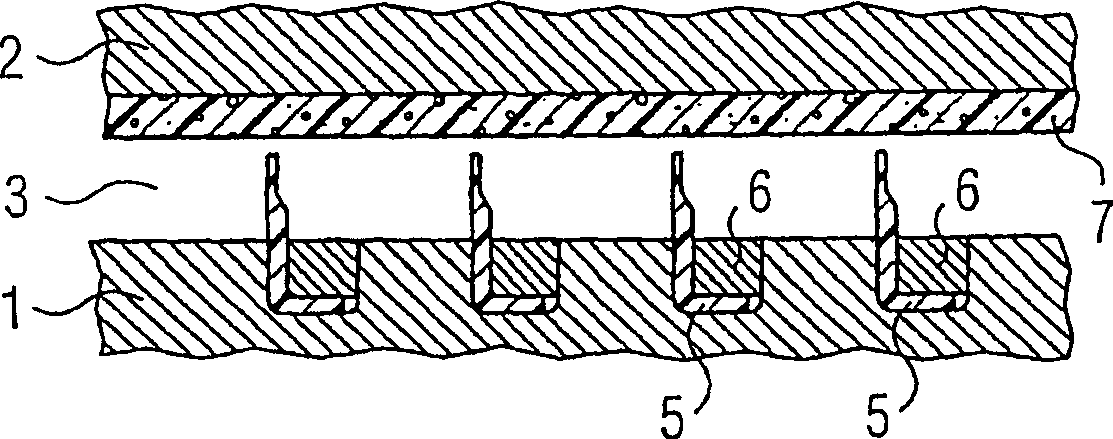

[0021] In all figures, parts that are identical to each other are provided with the same reference numerals.

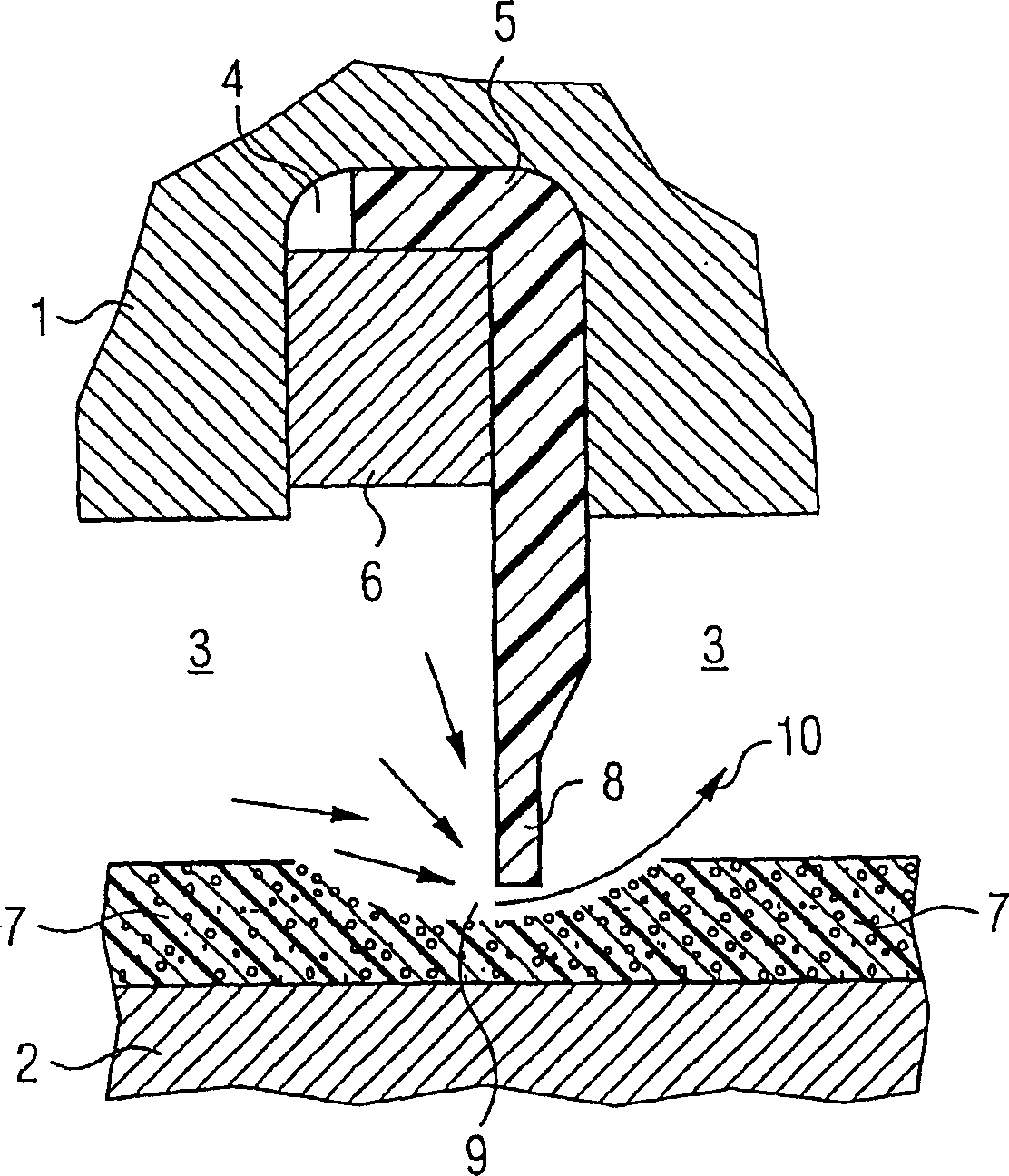

[0022] exist figure 1 In this case, elements 1 and 2 of a steam turbine (not shown in detail) form a gap a few millimeters wide which is sealed against the steam flow. The element 1 is preferably a rotor part that rotates in the operating state and has a groove 4 for receiving a sealing strip 4 as a sealing lip, the cross-sectional shape of the sealing strip 5 is "L"-shaped and its section is shorter The legs rest on the bottom of the groove 4 . The sealing strip 5 consists of one or more parts complementary to each other in the circumferential direction to form a ring and is fixed in the groove 4 by a calking wire 6 .

[0023] The element 2 on the other side of the gap 3 relative to the element 1 is preferably stationary during operation and has a coating designed as a contact layer 7 . The coating has a thickness of 0.5 to 0.1 times the width of the gap 3, is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com