Patents

Literature

3544results about "Pistons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reciprocating machine & other devices

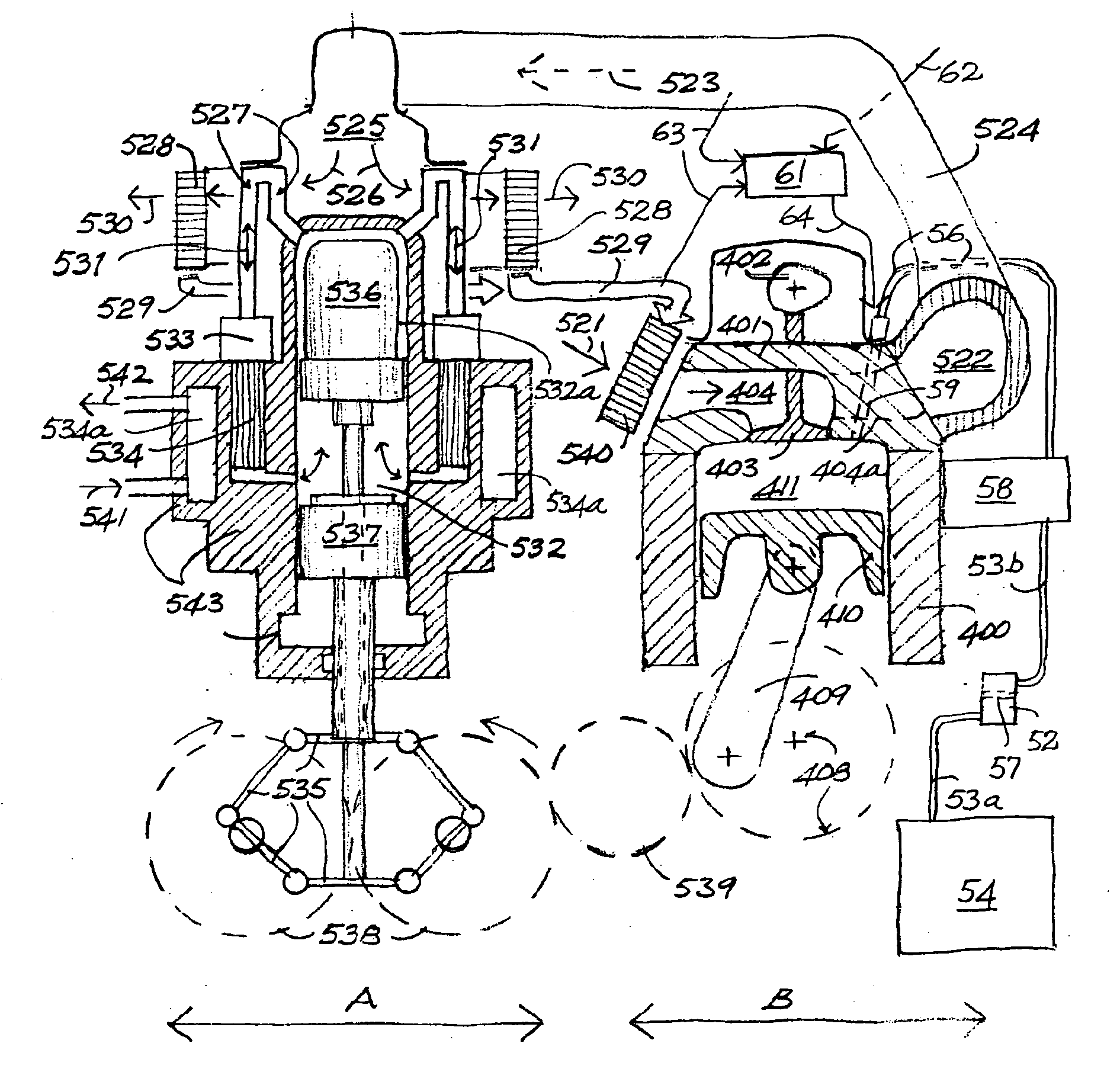

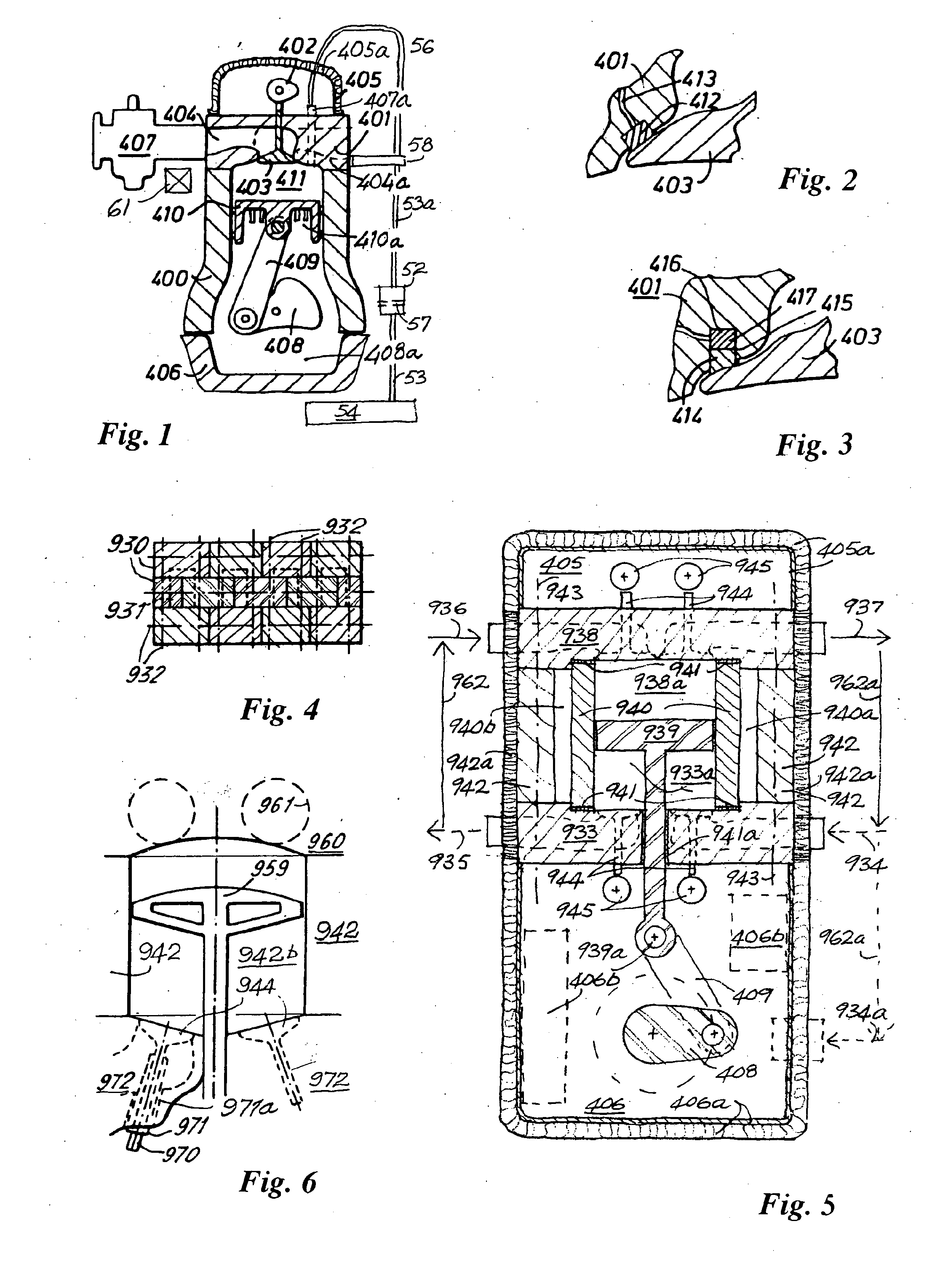

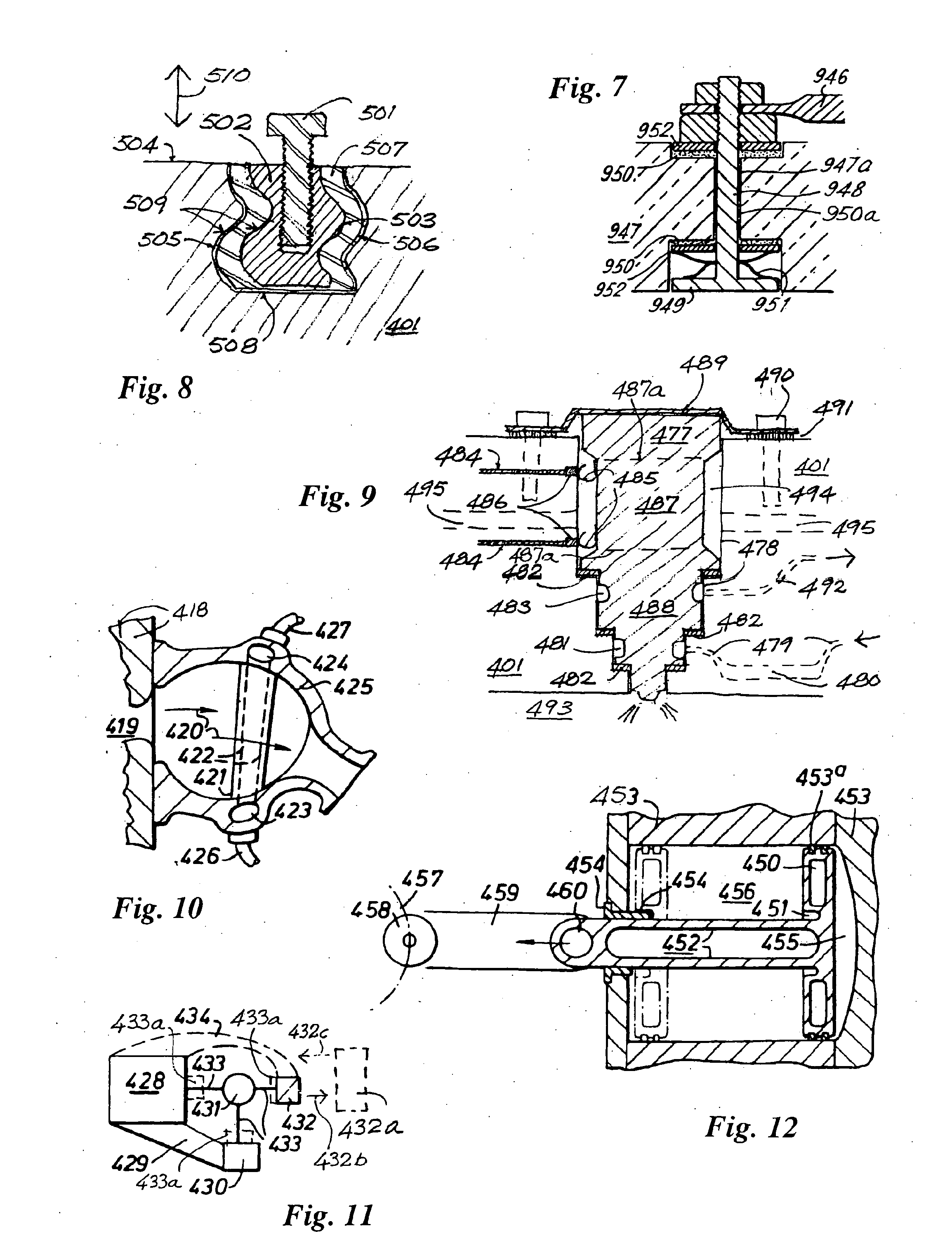

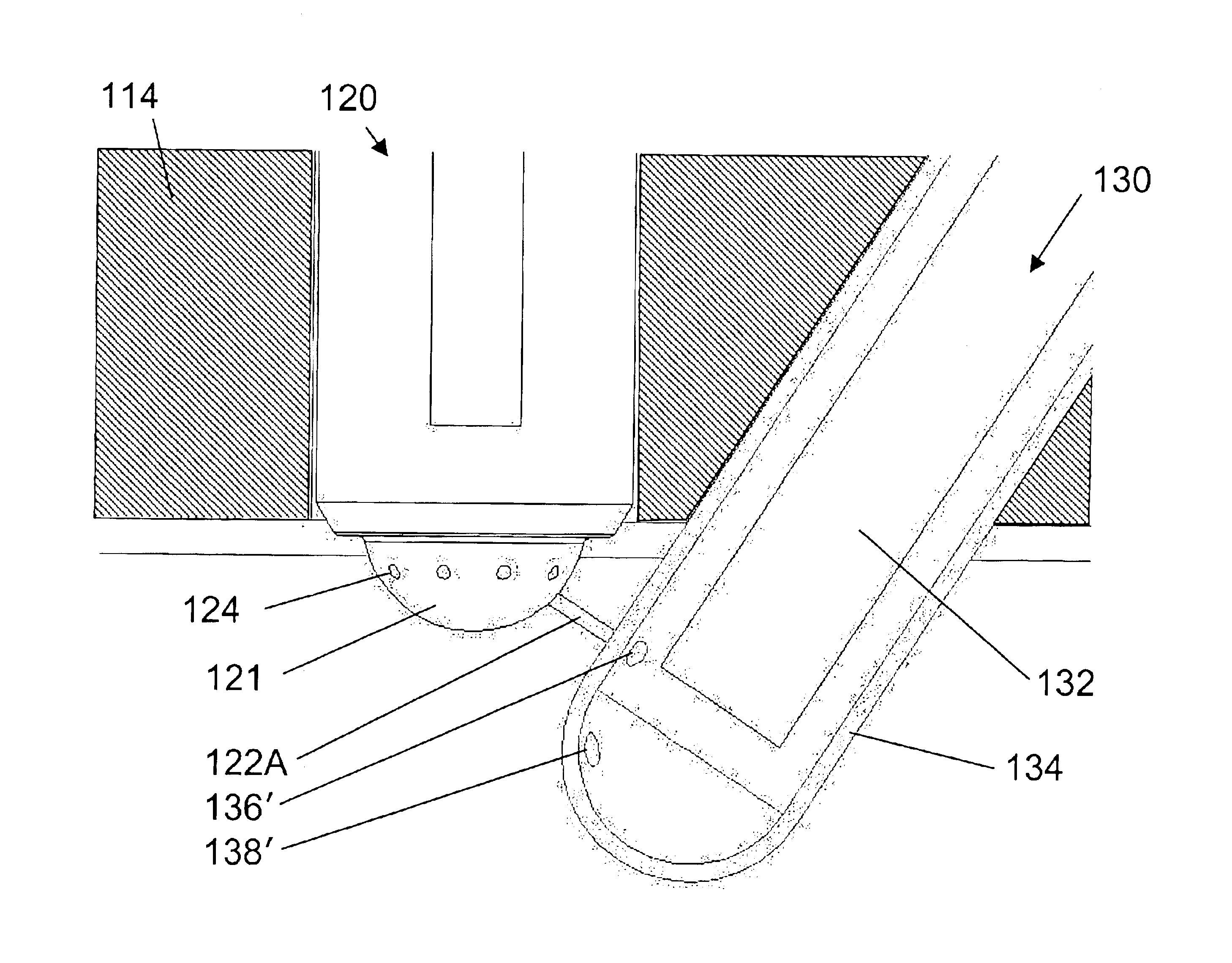

InactiveUS20120227389A1Improve power densityImprove efficiencyLiquid coolingCasingsCombustionReciprocating motion

The disclosure relates to reciprocating fluid working devices including internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, a single piston reciprocating between a pair of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components which reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Also disclosed are improved vehicles, aircraft, marine craft, transmissions and exhaust emission systems suited to the engines of the invention.

Owner:HINDERKS MITJA VICTOR

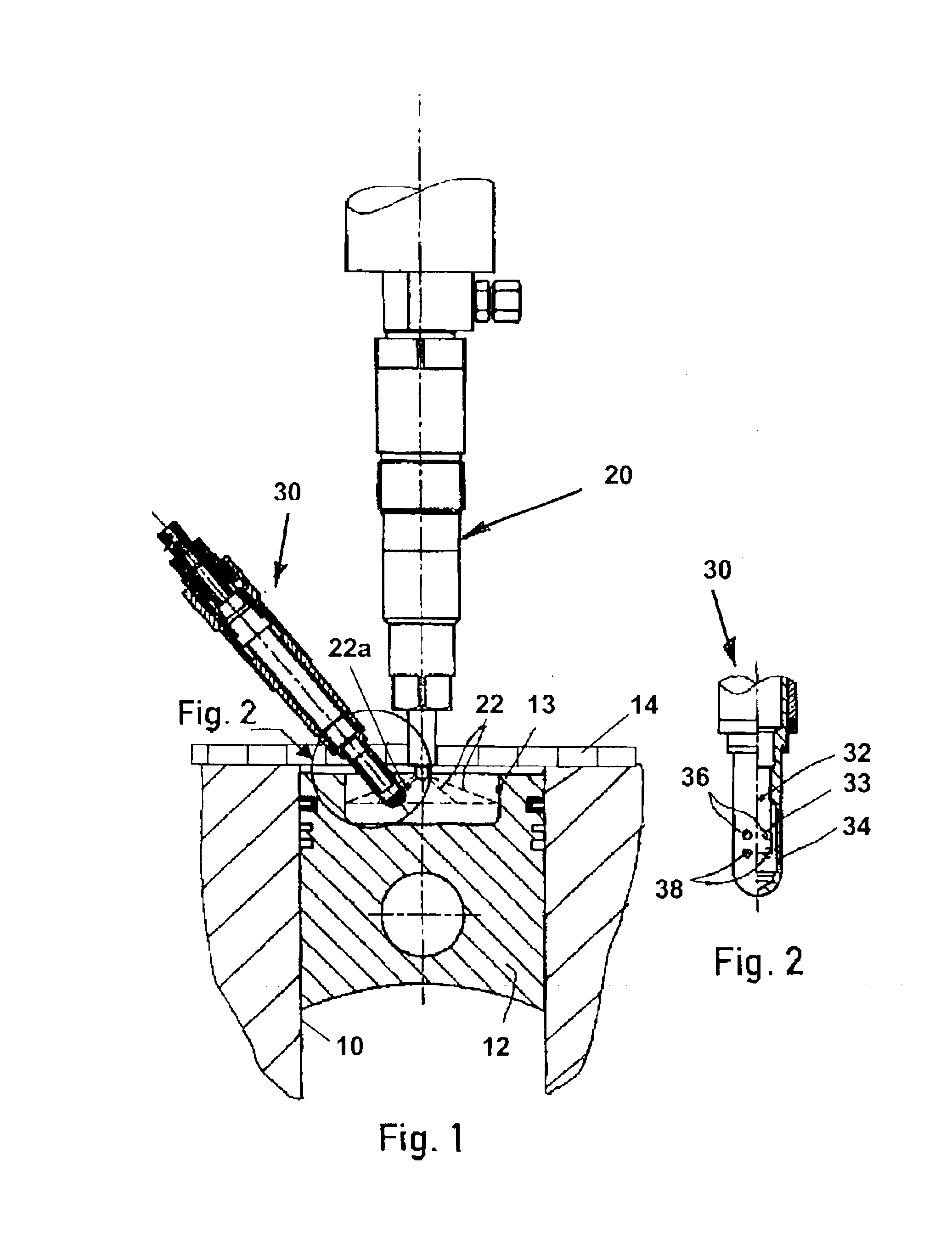

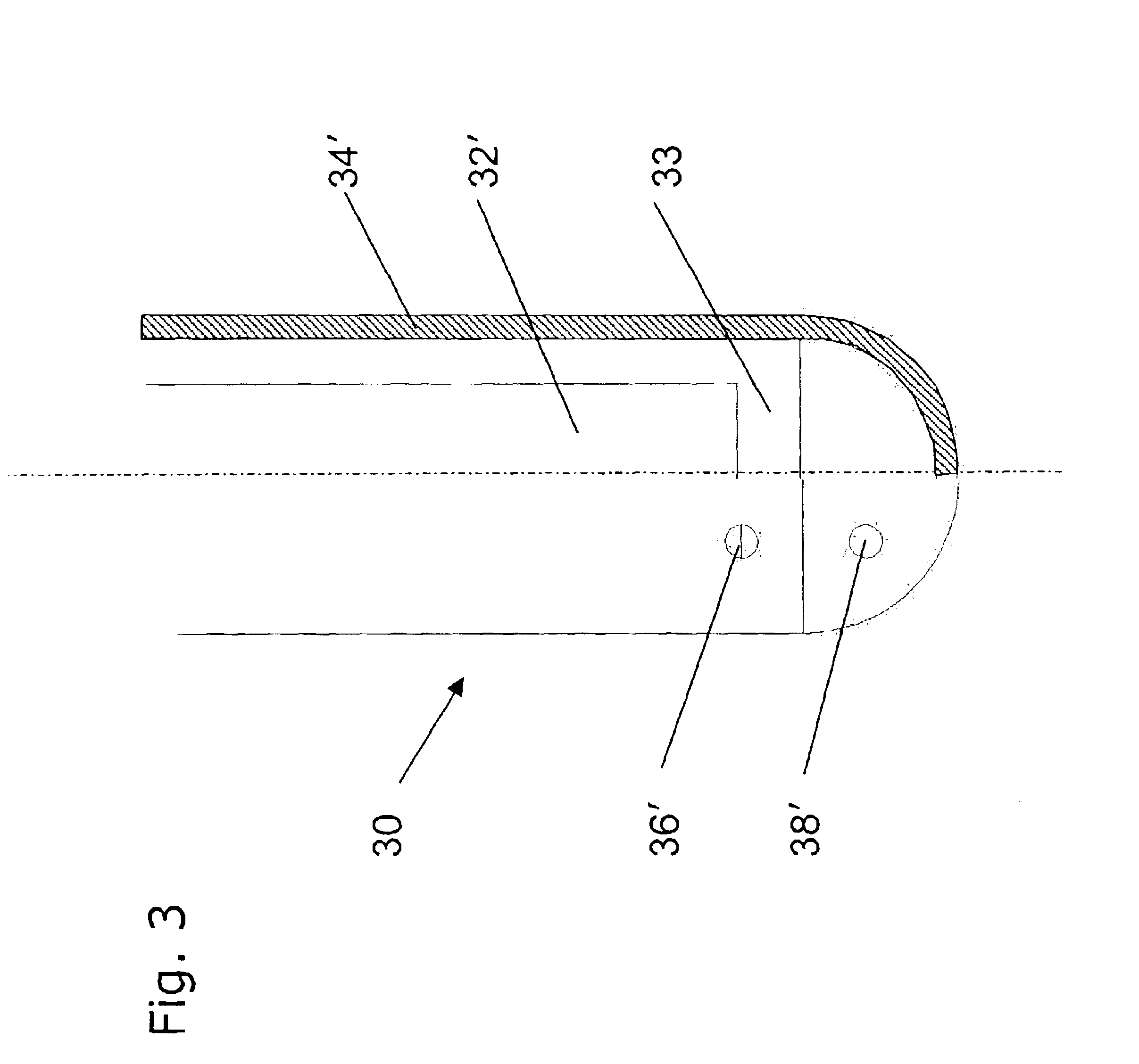

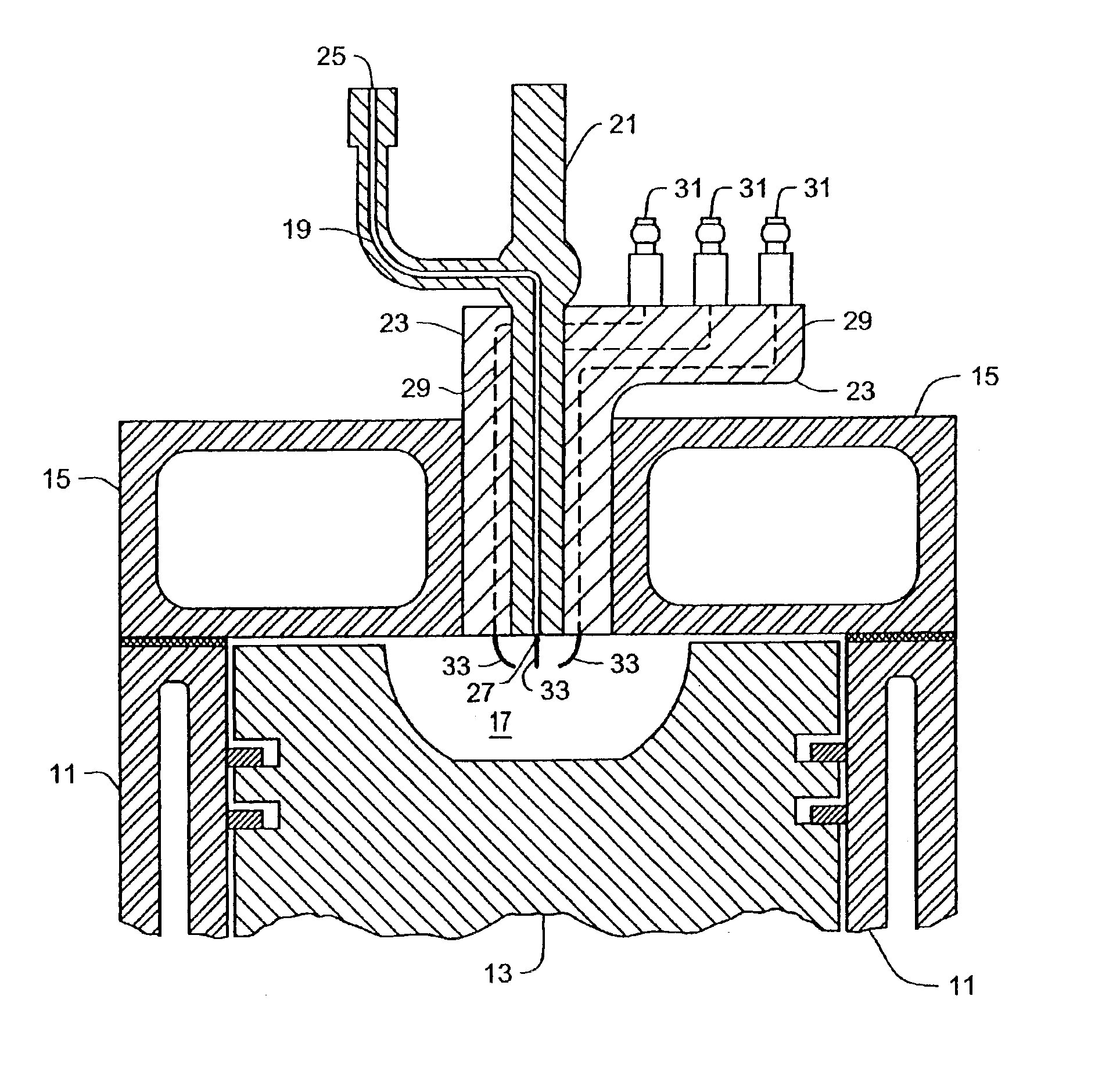

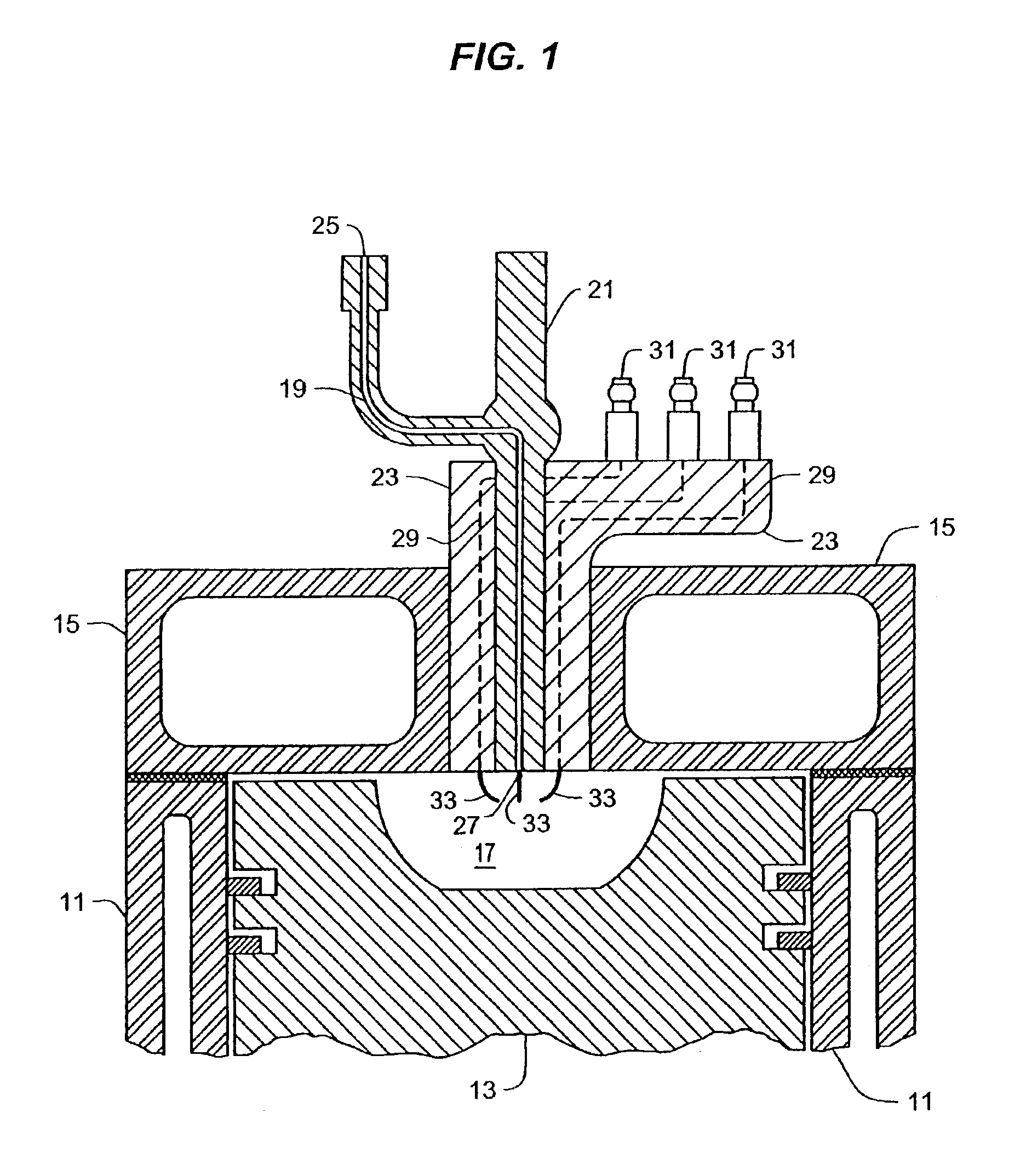

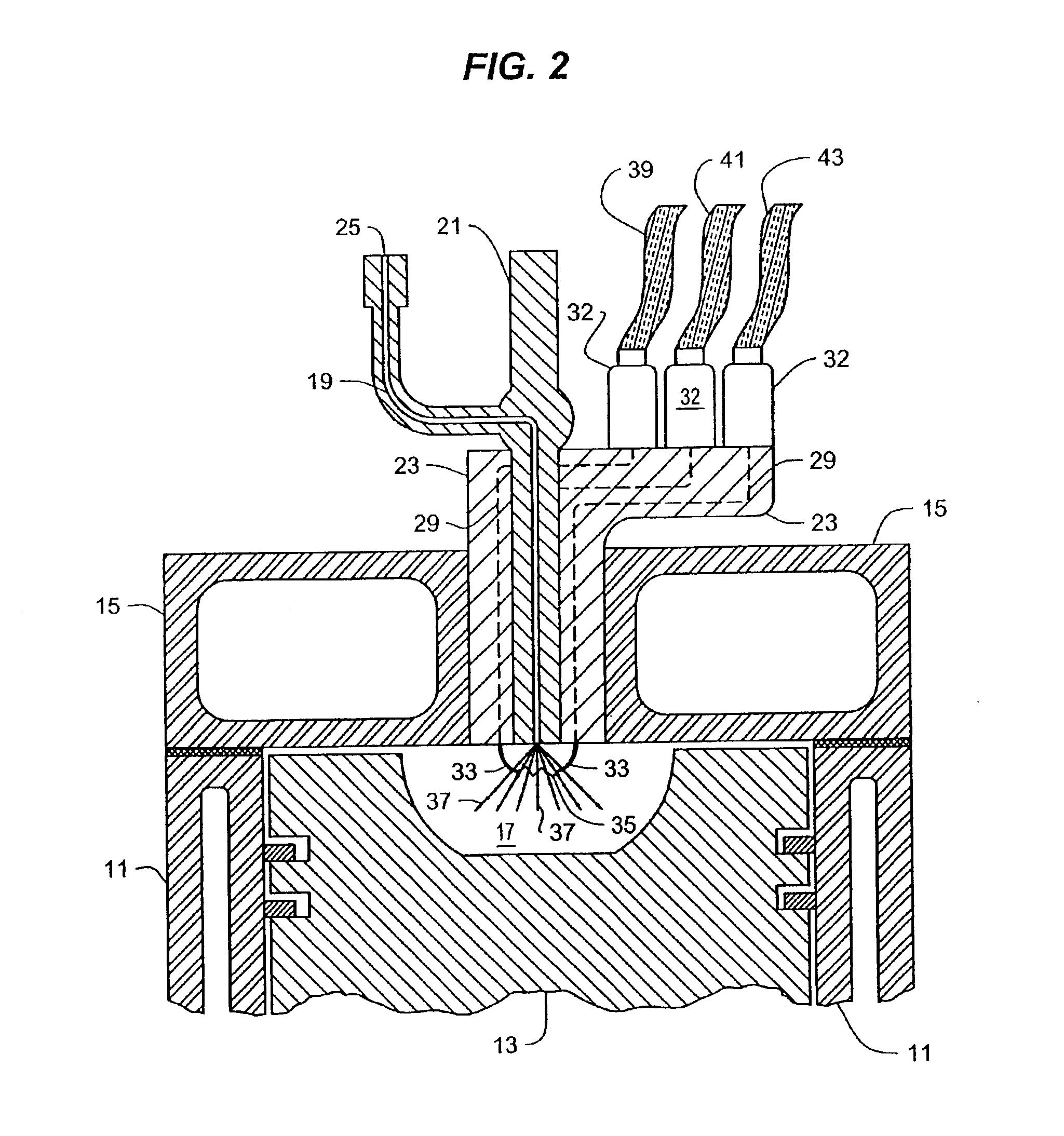

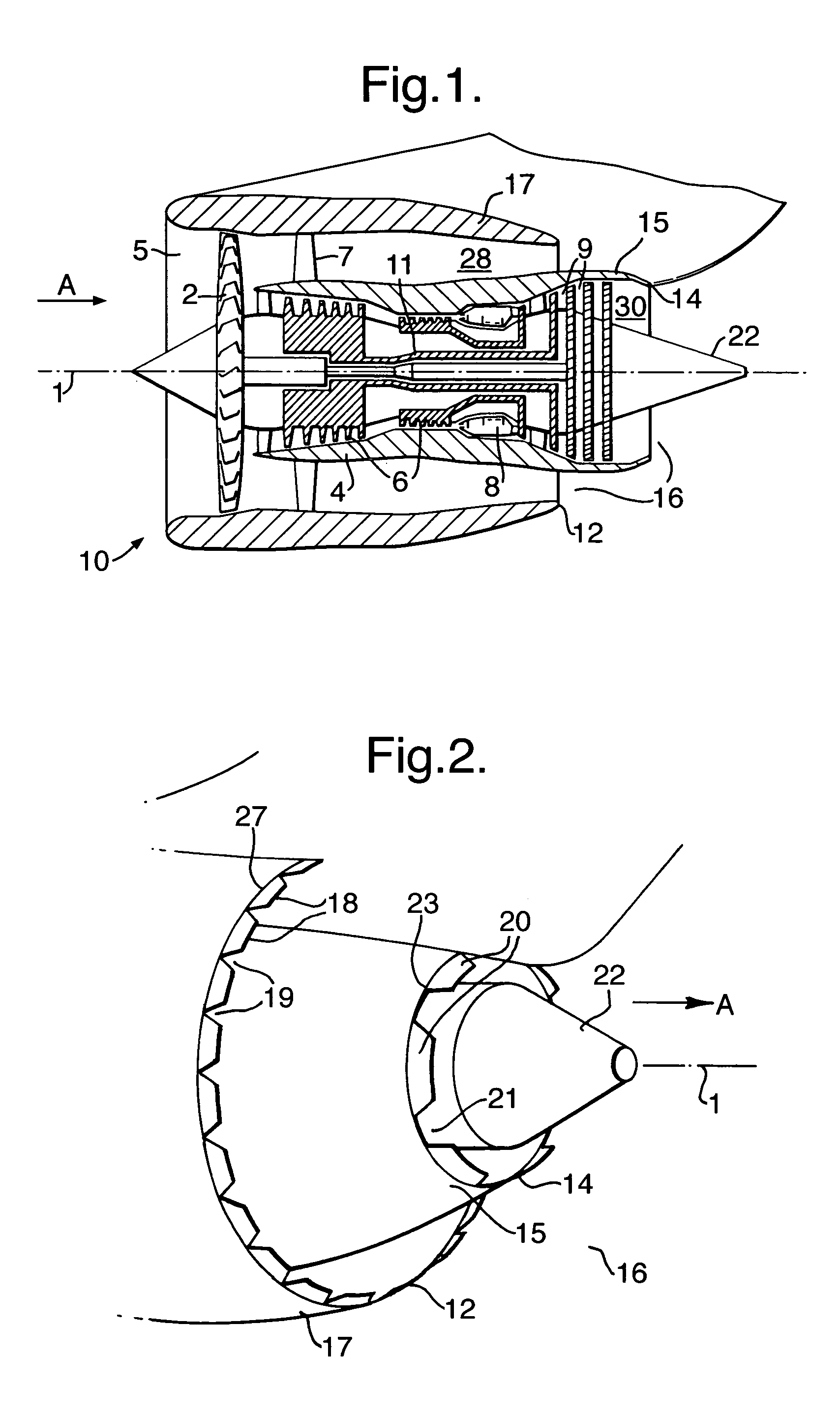

Internal combustion engine with injection of gaseous fuel

InactiveUS6854438B2Reduce modificationReduce manufacturing costIncandescent ignitionInternal combustion piston enginesInternal combustion engineFuel injection

An internal combustion engine comprises a fuel injection nozzle for injecting a gaseous fuel directly into the combustion chamber. shield, is installed in close proximity to the fuel injection nozzle, provides a shielded space around a hot surface igniter and restricts flow between the shielded space and the combustion chamber. The nozzle comprises a fuel injection port oriented to direct a fuel spray against a surface of the sleeve An inlet in the sleeve allows air and fuel to enter the shielded space to form a combustible mixture therein. The sleeve contains a substantial amount of the combustible mixture within the shielded space until it ignites and pressure builds within the shielded space to propel a combustion flame through at least one discharge opening and into contact with the fuel sprays emerging from the fuel injection nozzle.

Owner:WESTPORT POWER

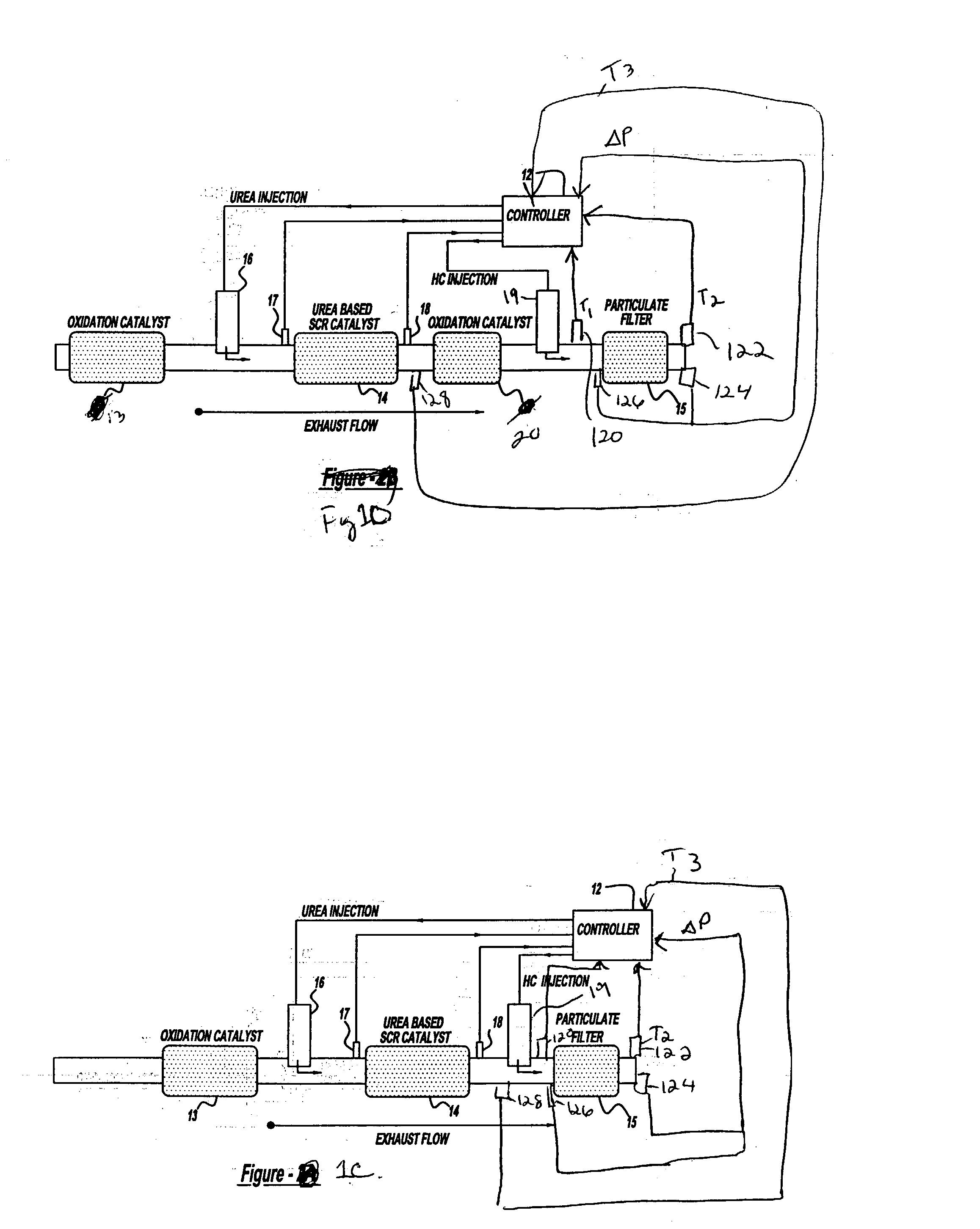

Pressure sensor diagnosis via a computer

InactiveUS6947831B2Reduce stepsLower regenerationAnalogue computers for vehiclesElectrical controlParticulatesDifferential pressure

A method is described for controlling regeneration of a particulate filter based on at least a sensor, such as a differential pressure sensor. Degradation of the sensor is then detected in a variety of ways. One approach takes advantage of the slowly varying flow resistance of the filter compared with the more rapid variations in flow caused by changing engine conditions. Default operation is then taken when a degraded sensor is detected.

Owner:FORD GLOBAL TECH LLC

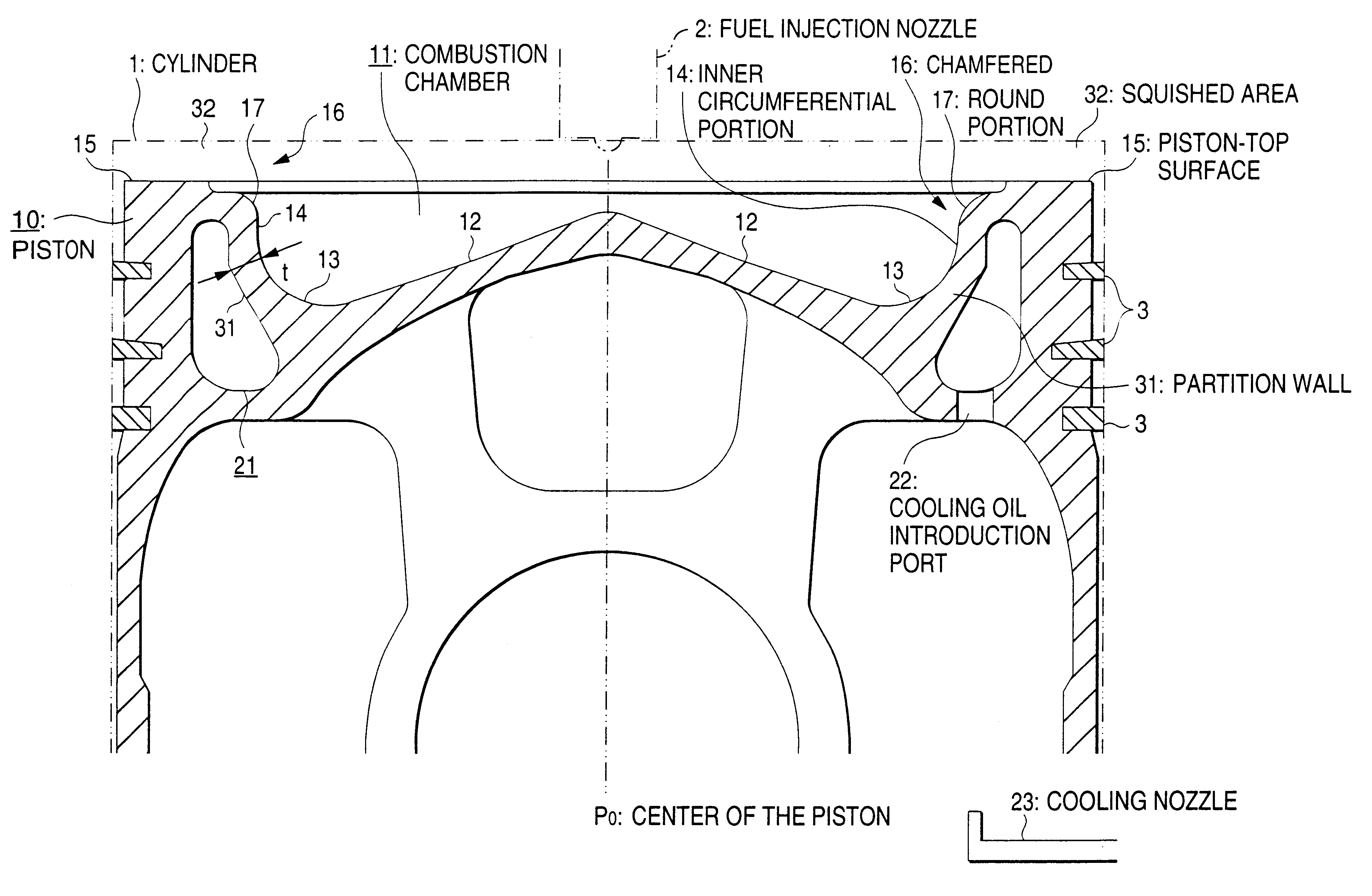

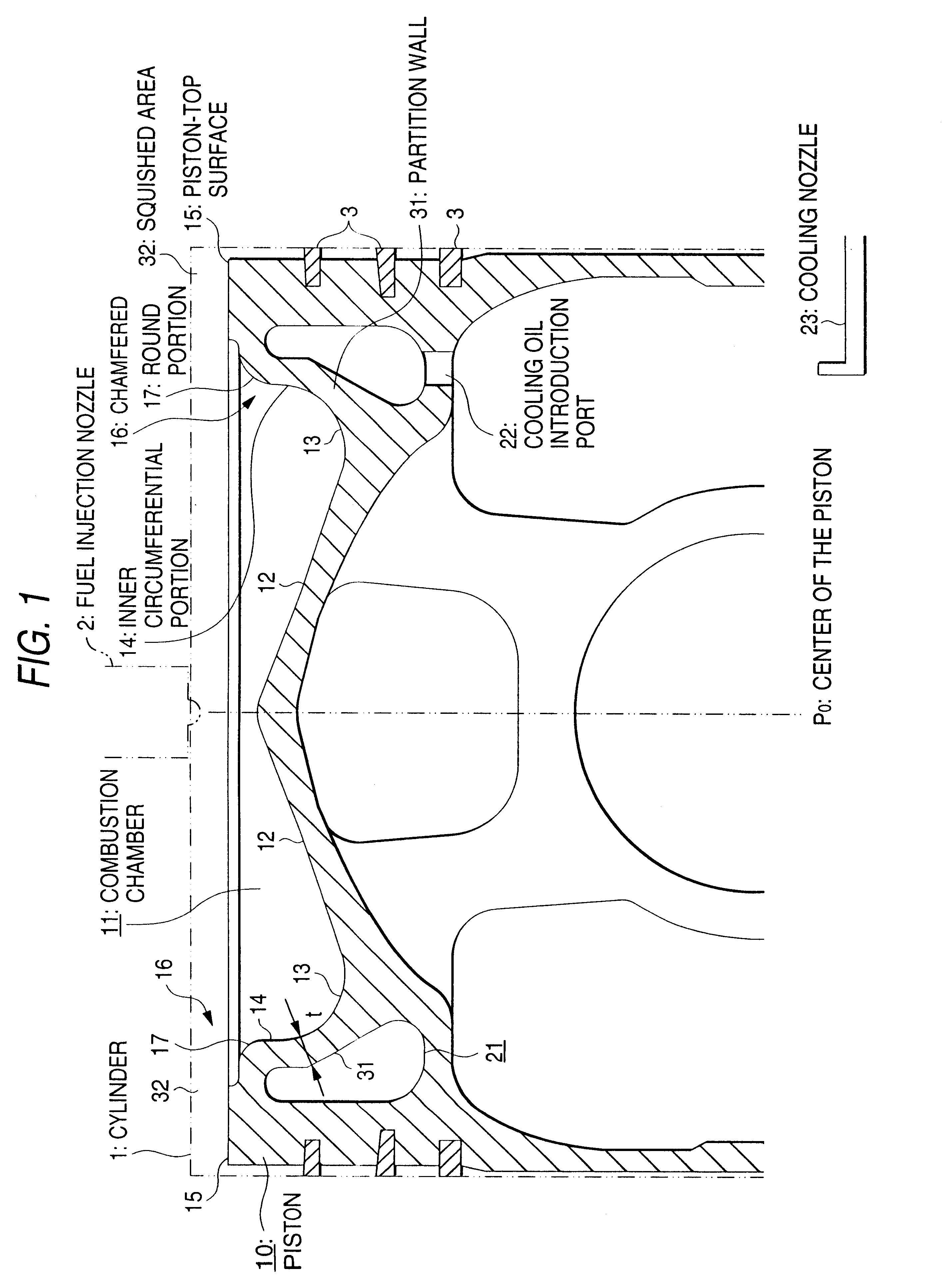

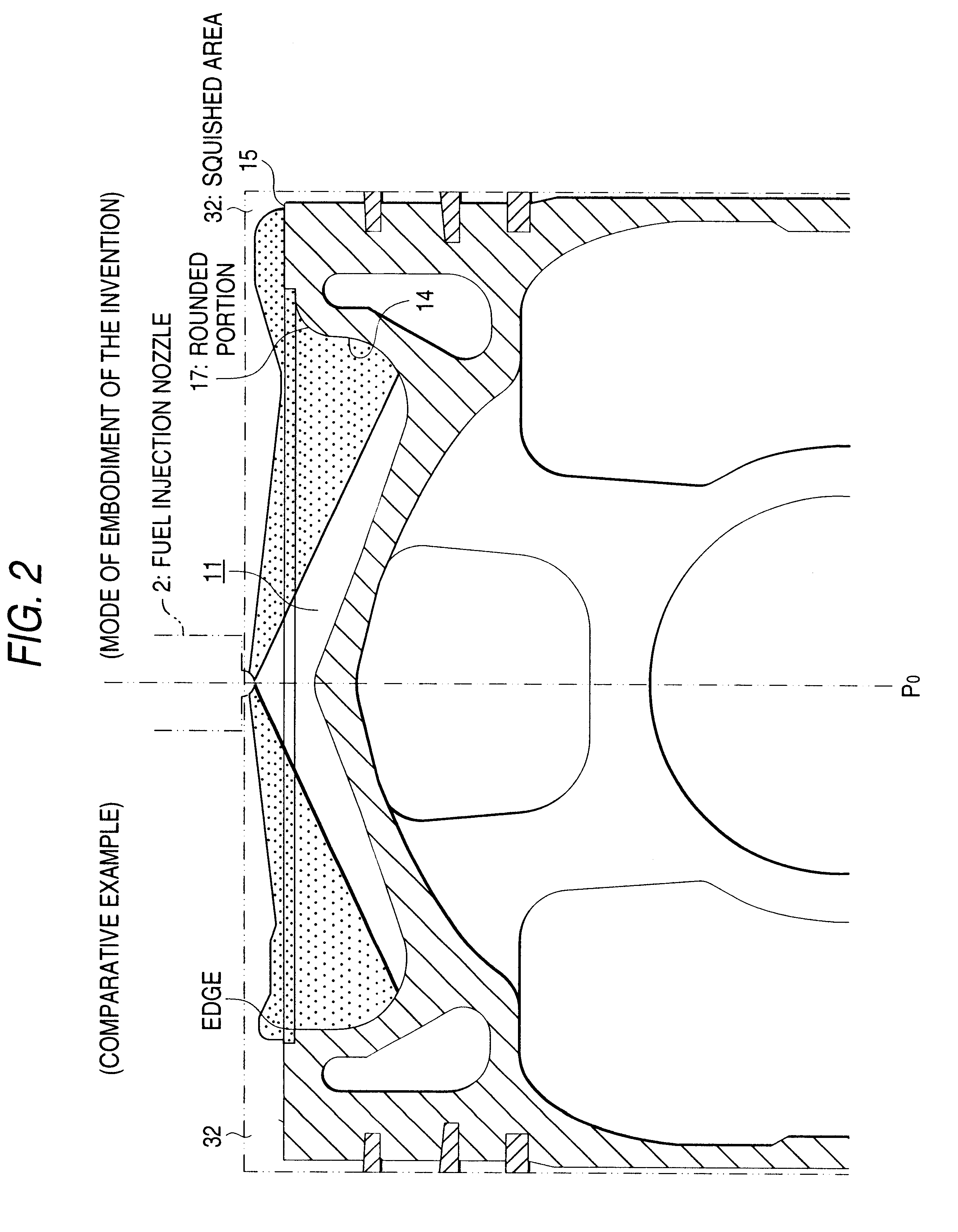

Piston for internal combustion engines

InactiveUS6314933B1Low temperature resistanceIncreased durabilityInternal combustion piston enginesAir coolingCombustion chamberReciprocating motion

A piston for internal combustion engines, capable of being manufactured easily and improving the durability of a combustion chamber, moved reciprocatingly in a cylinder of an internal combustion engine, and provided in a top surface thereof with a combustion chamber formed by recessing the same top surface, and in an outer circumferential wall of the combustion chamber with a cooling cavity the inner diameter of a lower portion of an inner circumferential surface of which is set smaller than that of an upper portion thereof, wherein a cross-sectionally angular portion defined by an upper edge portion, at which the combustion chamber is opened in the interior of a cylinder, of an inner circumferential surface of the combustion chamber and a piston-top surface is chamfered greatly in conformity with the cross-sectional shape of the upper portion of the inner circumferential surface of the cooling cavity to such an extent that the thickness of an upper portion of an inner circumferential wall of the cooling cavity does not greatly vary.

Owner:KOMATSU LTD

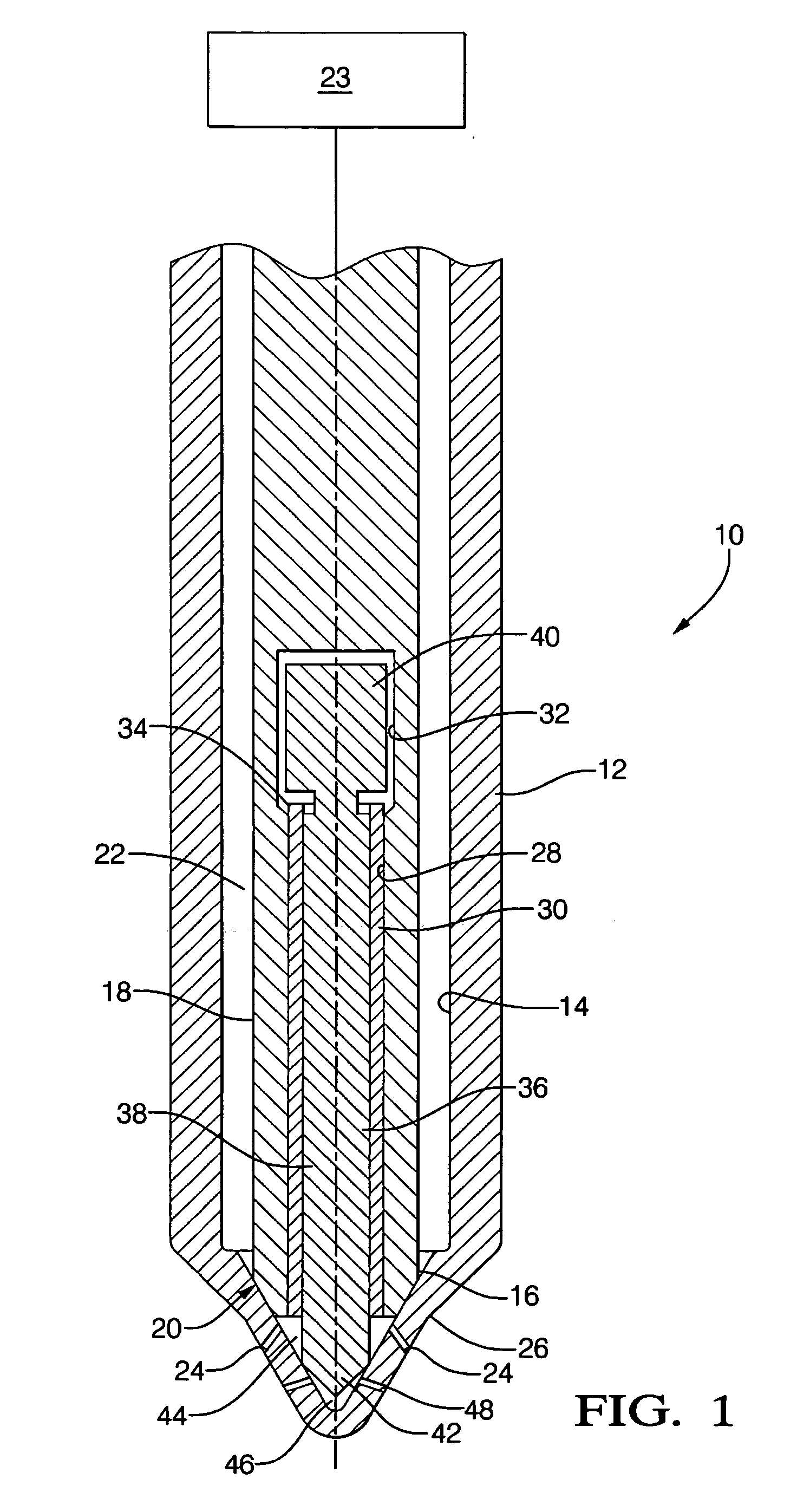

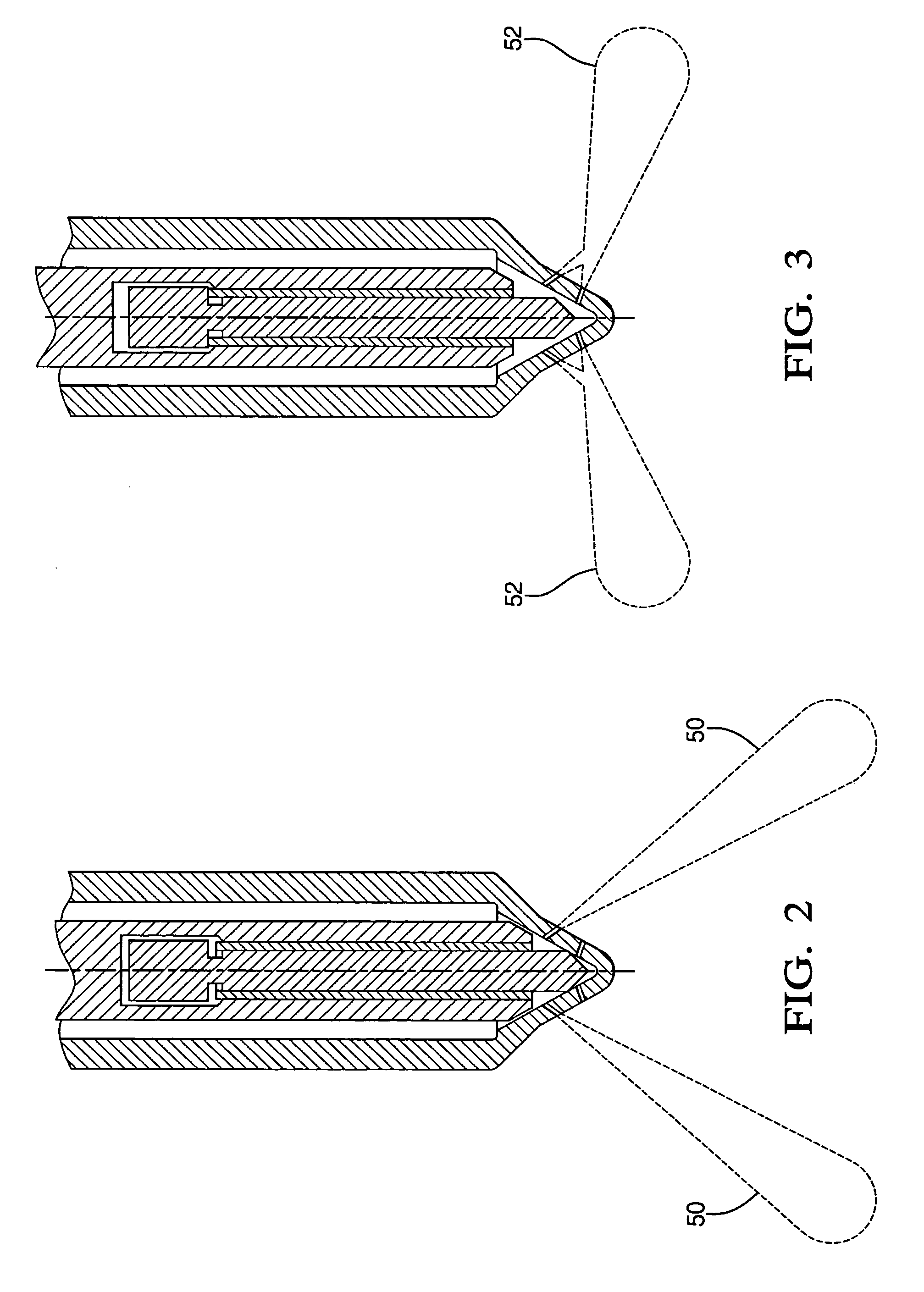

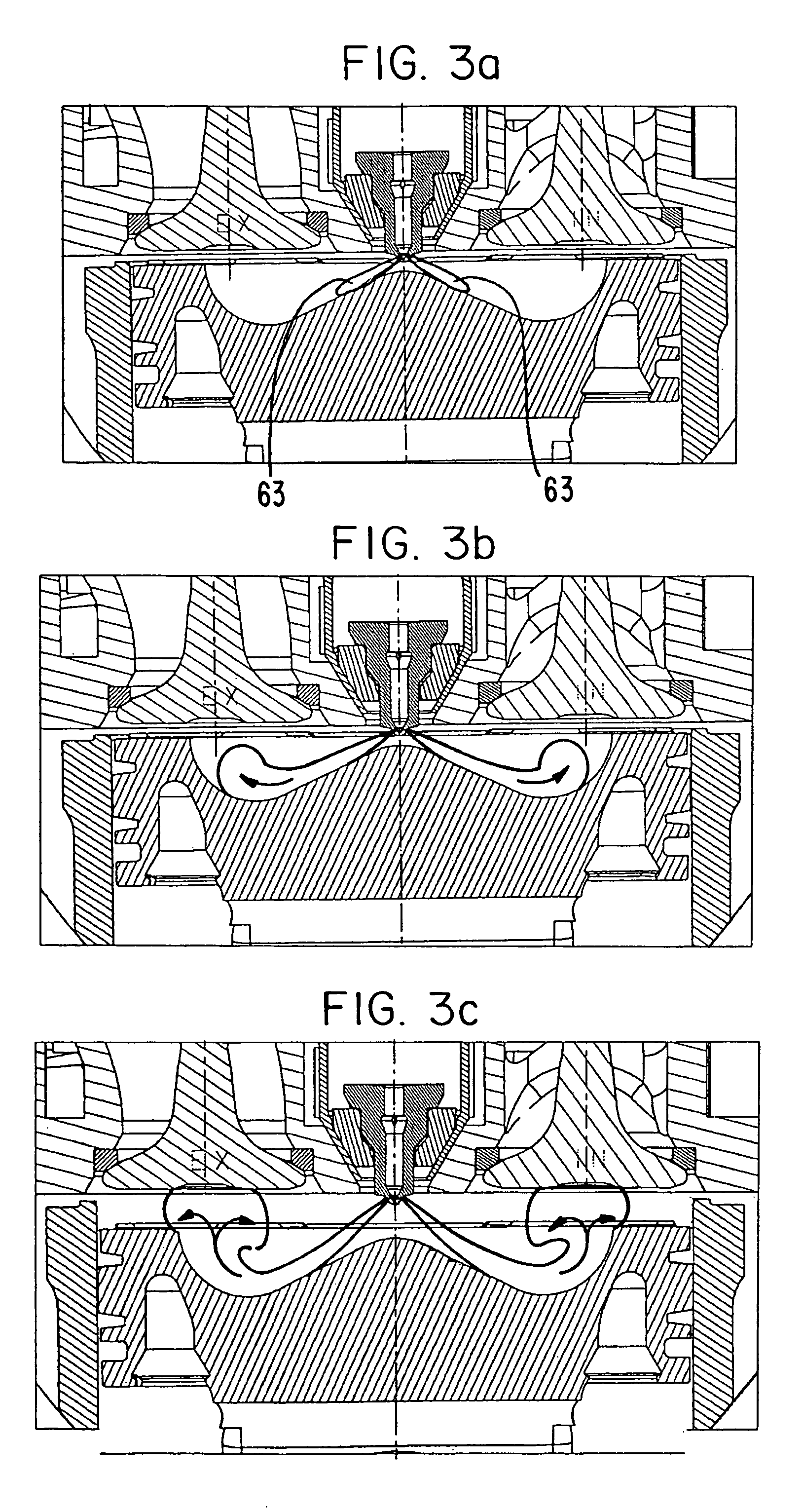

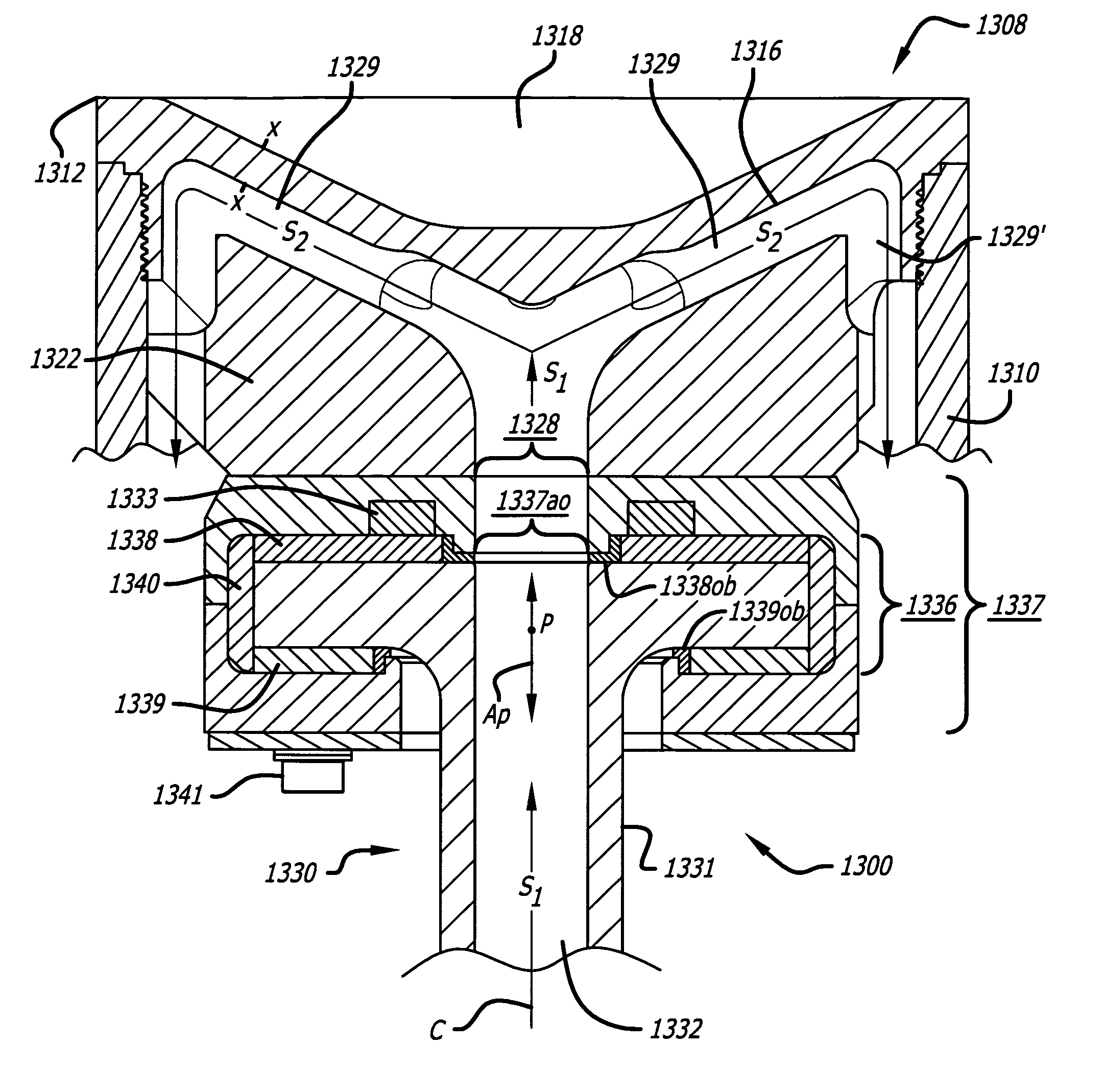

Apparatus and method for mode-switching fuel injector nozzle

InactiveUS20050224606A1Prevent penetrationElectrical controlInternal combustion piston enginesCombustionInjector nozzle

A fuel injector nozzle and method for dispersing fuel during a normal combustion operation and a supplemental combustion operation, the fuel injector nozzle comprising: a plurality of first outlet openings configured to disperse fuel in a first arrangement; and a plurality of second outlet openings configured to collide with the fuel passing through the plurality of first openings to disperse fuel in a second arrangement, wherein either the first or second arrangement is selected by the position of the piston.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

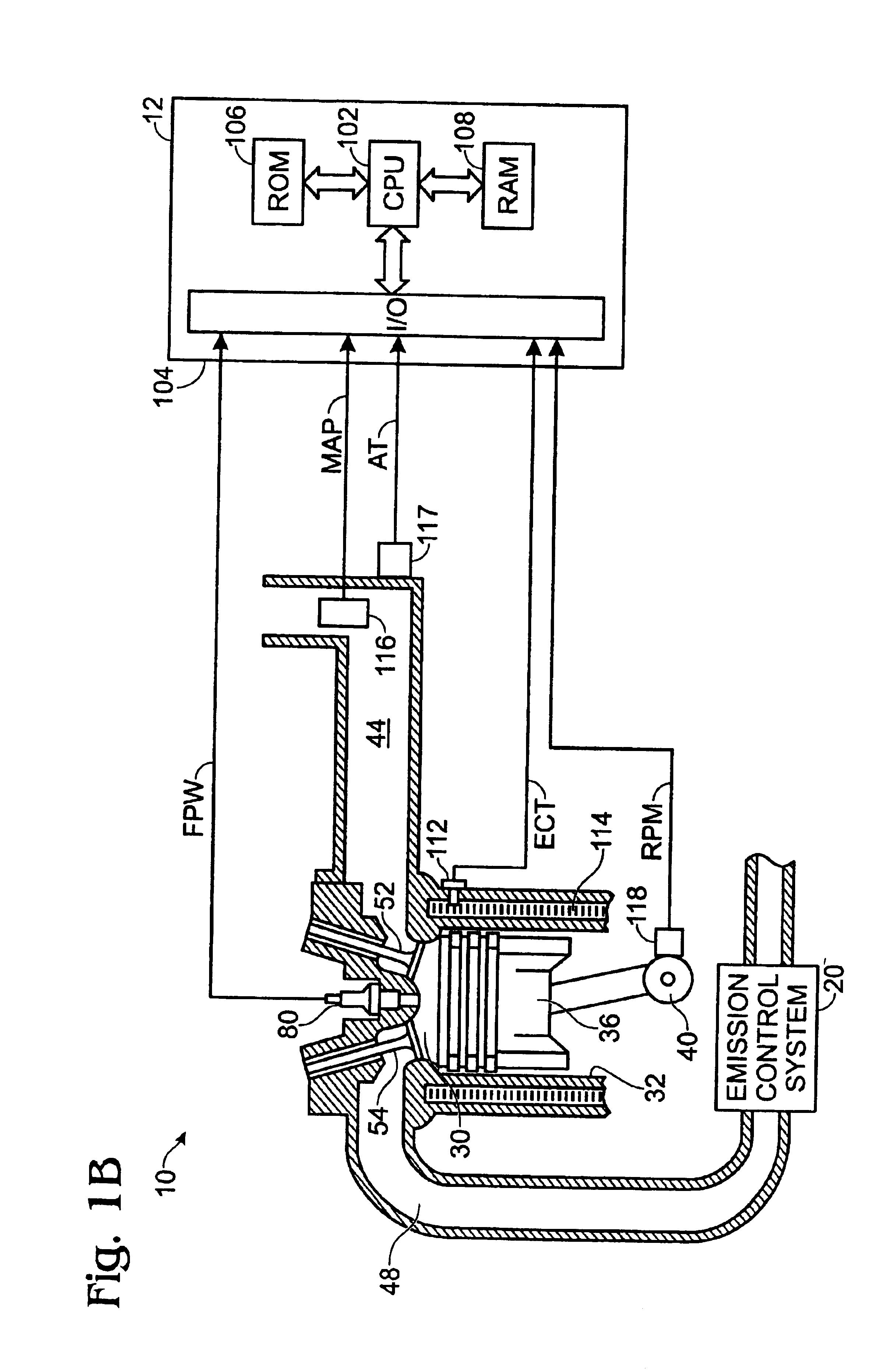

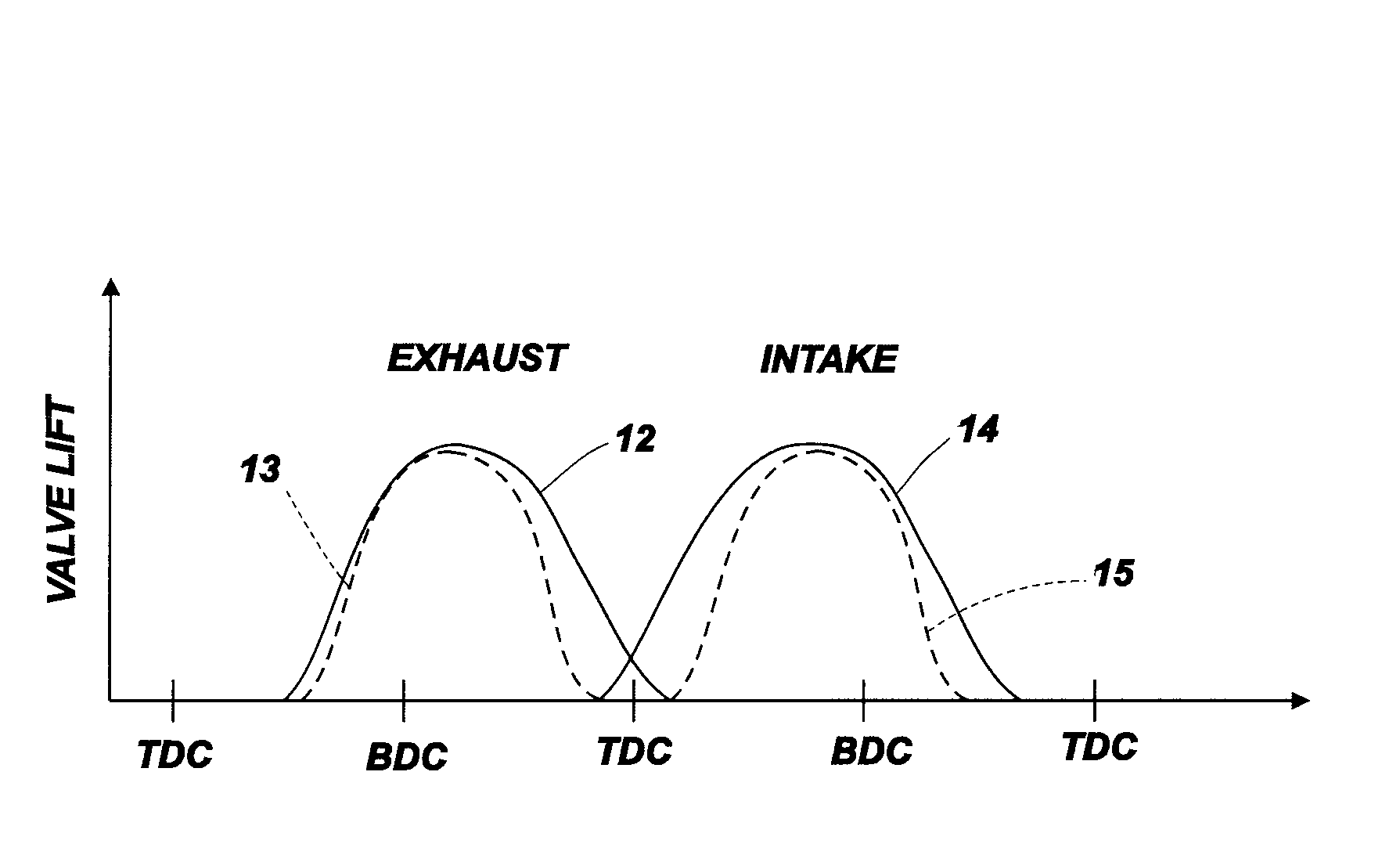

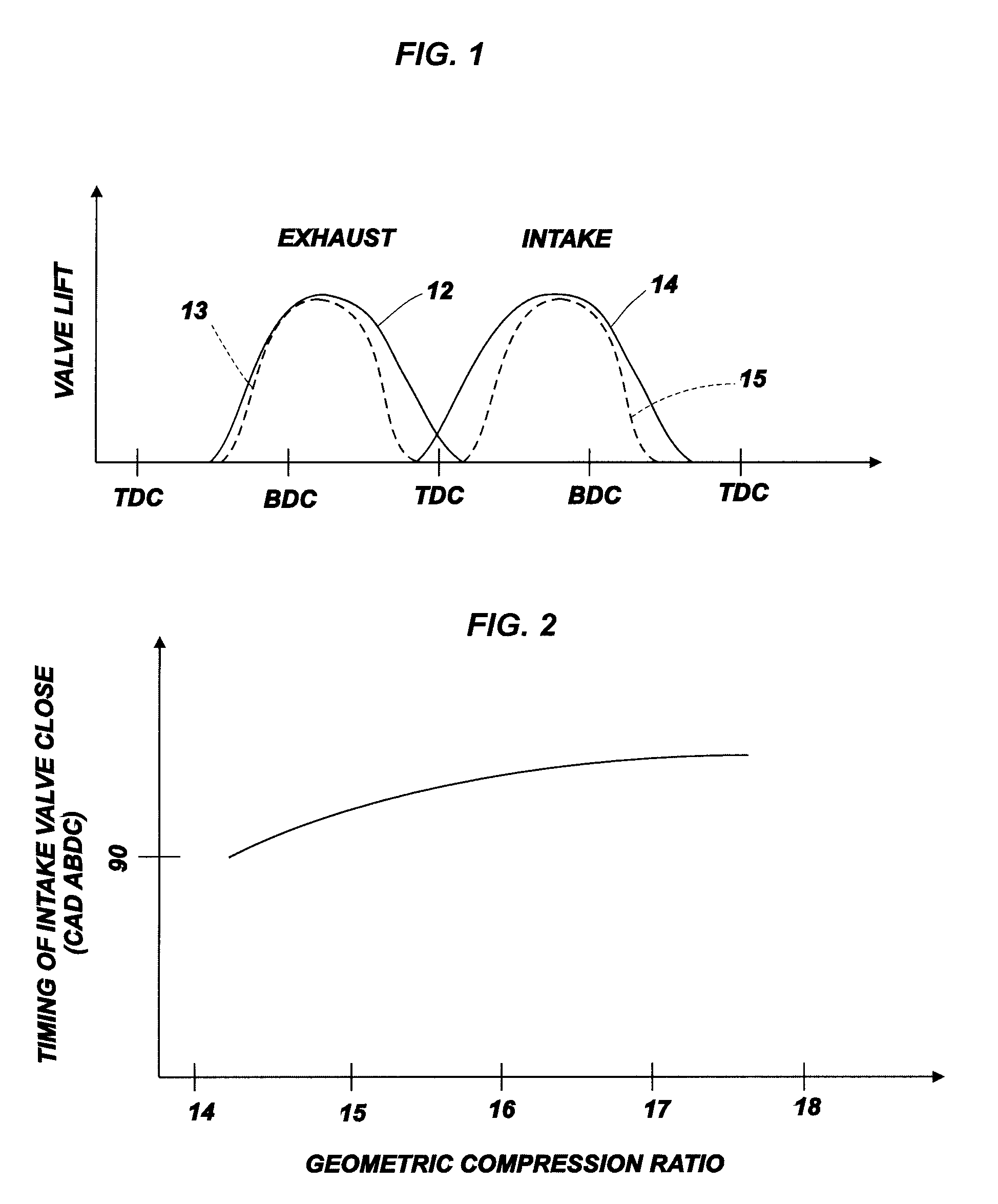

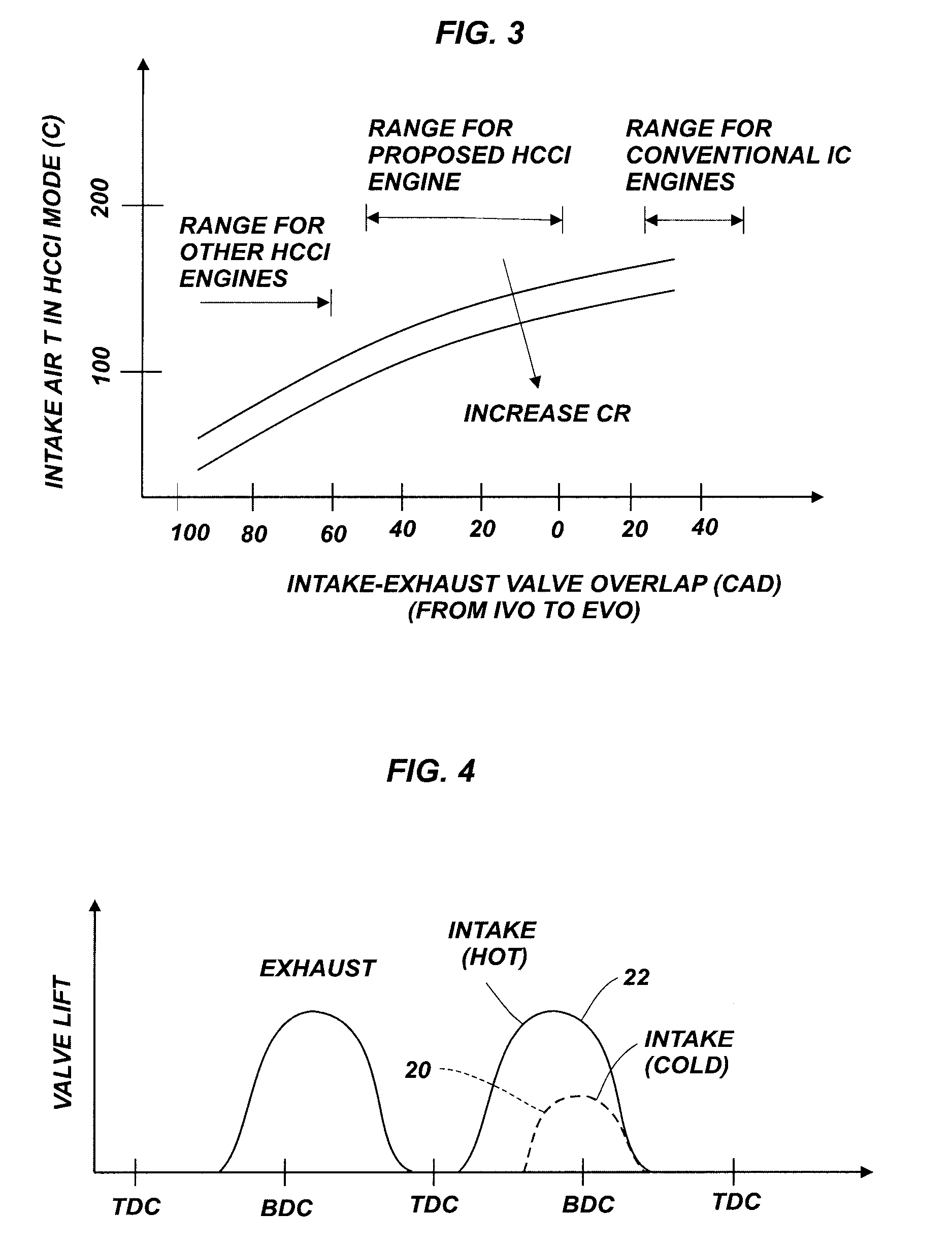

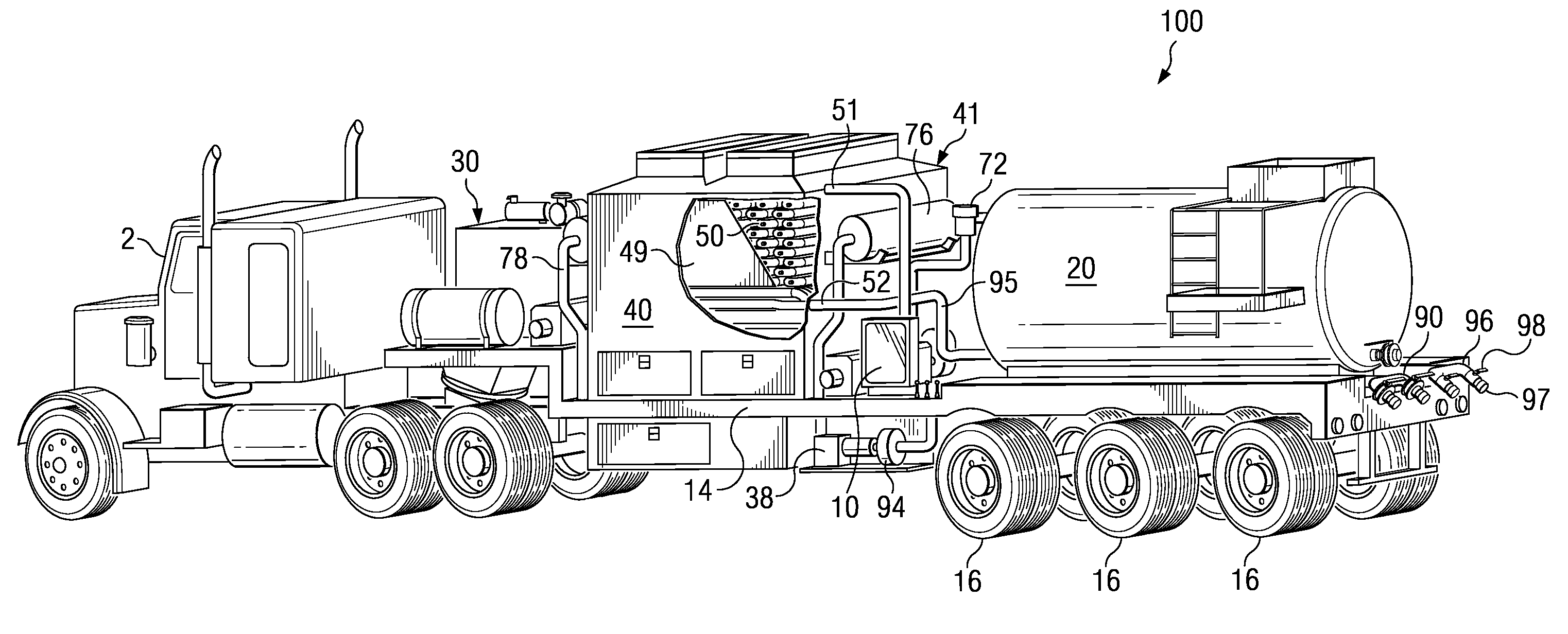

Method and apparatus for controlling operation of dual mode hcci engines

InactiveUS20050183693A1Overcome deficienciesOvercomes drawbackValve arrangementsElectrical controlTemperature controlExhaust valve

An intake and exhaust system for a dual mode HCCI engine, which provides superior intake temperature control and homogeneity for engine operation in SI and HCCI modes, as well as during transition between SI and HCCI modes and vice-versa. The system includes adjusted intake cam movement event lengths for intake valve operation at specified modes of operation. The system further includes at least one cam profile switching device operatively connected to intake and exhaust valves in an engine for controlling event length, maximum lift, and valve opening / closing timings for the intake and exhaust valves. The system yet further includes a bifurcated intake system and camless valve actuators for controlling intake valves for facilitating operation in SI or HCCI modes, as well as transition between SI and HCCI modes and vice-versa.

Owner:FORD GLOBAL TECH LLC

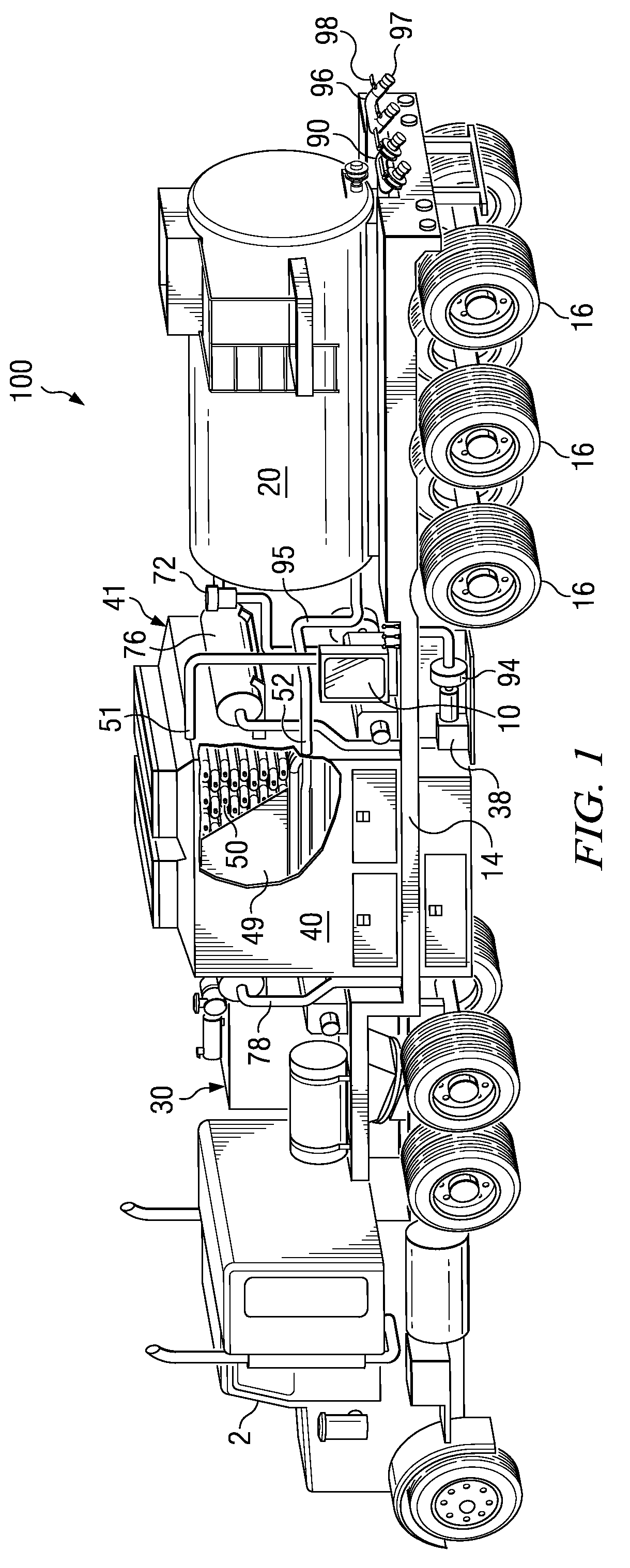

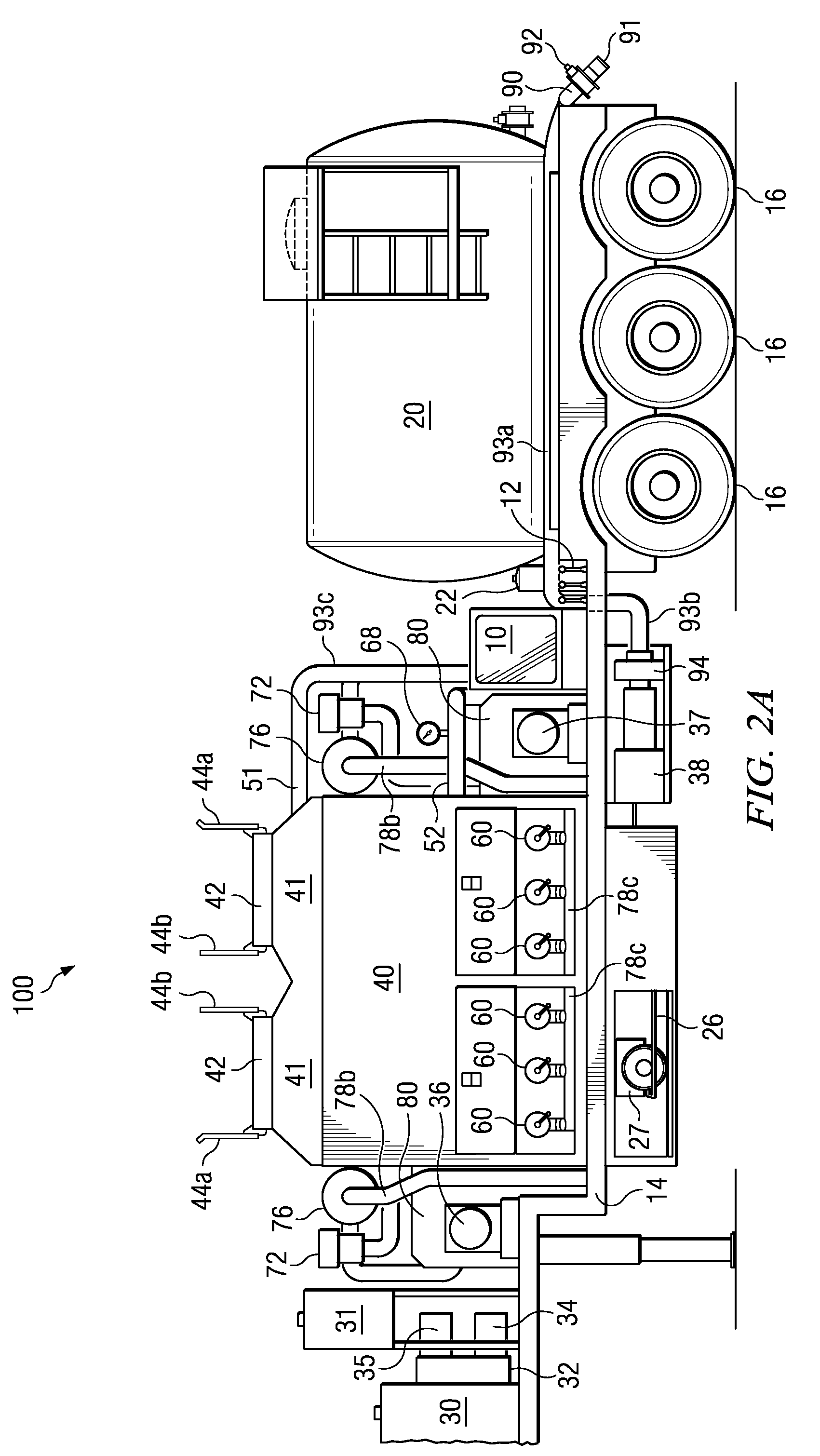

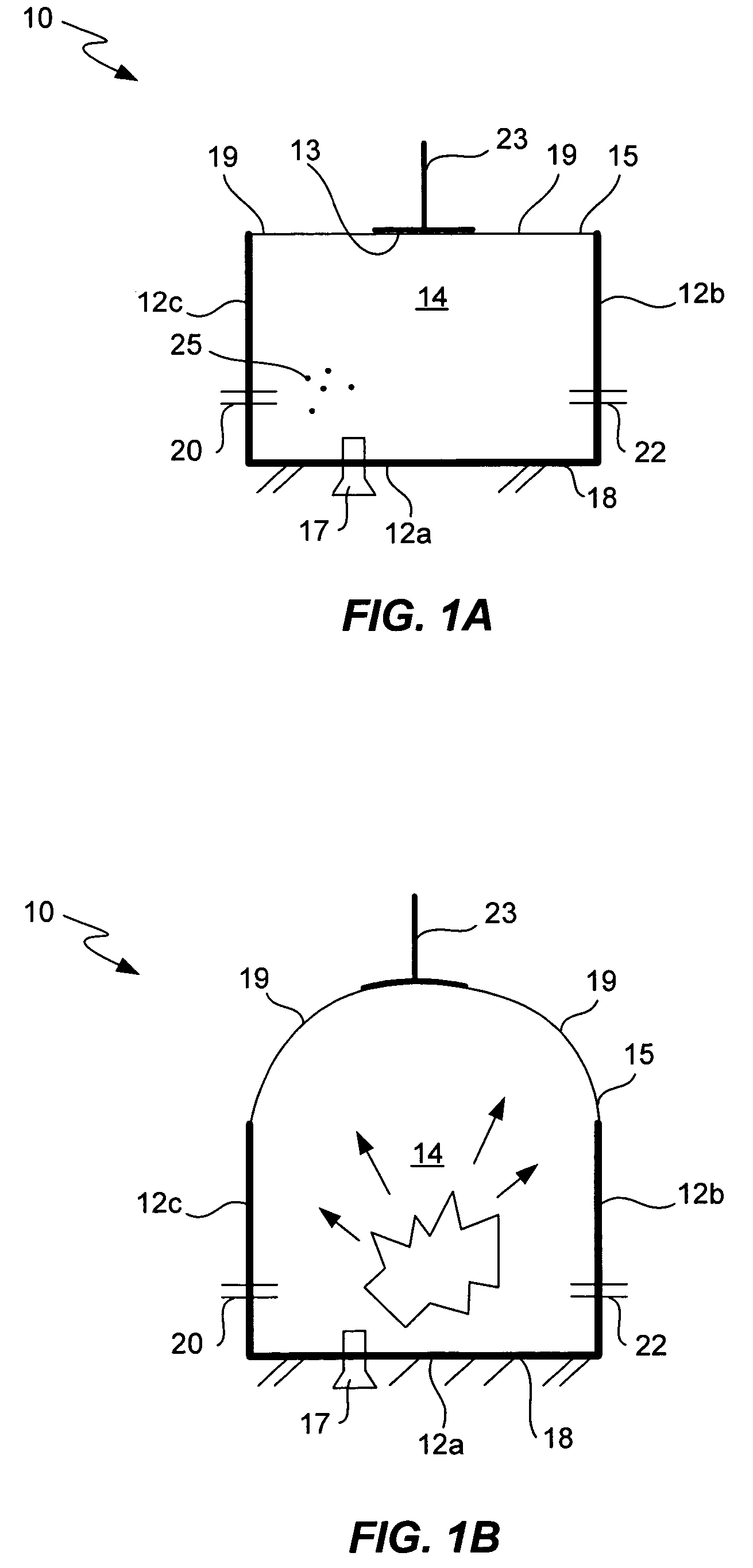

Oil-fired frac water heater

ActiveUS8534235B2Maximize atomization and combustionMaximize combustionAir-treatment apparatus arrangementsAir heatersFuel tankHydraulic fracturing

Owner:CHANDLER RONALD L

Method for manufacturing clad components

A method for manufacturing a clad component in which a cladding workpiece having a section comprising a first metal onto which a number of metal beads are rigidly bonded is inserted into a mold. A molten second metal is poured into the mold, where it flows about and covers the beads and is then permitted to cool. This process forms an article made of the second metal, which is mechanically interlocked to the beads, clad by the first metal. Typically the first metal is a high-melting point strong metal, such as steel, and the second metal is a lower-melting point, weaker, but lighter metal, such as aluminum.

Owner:NANOMETAL

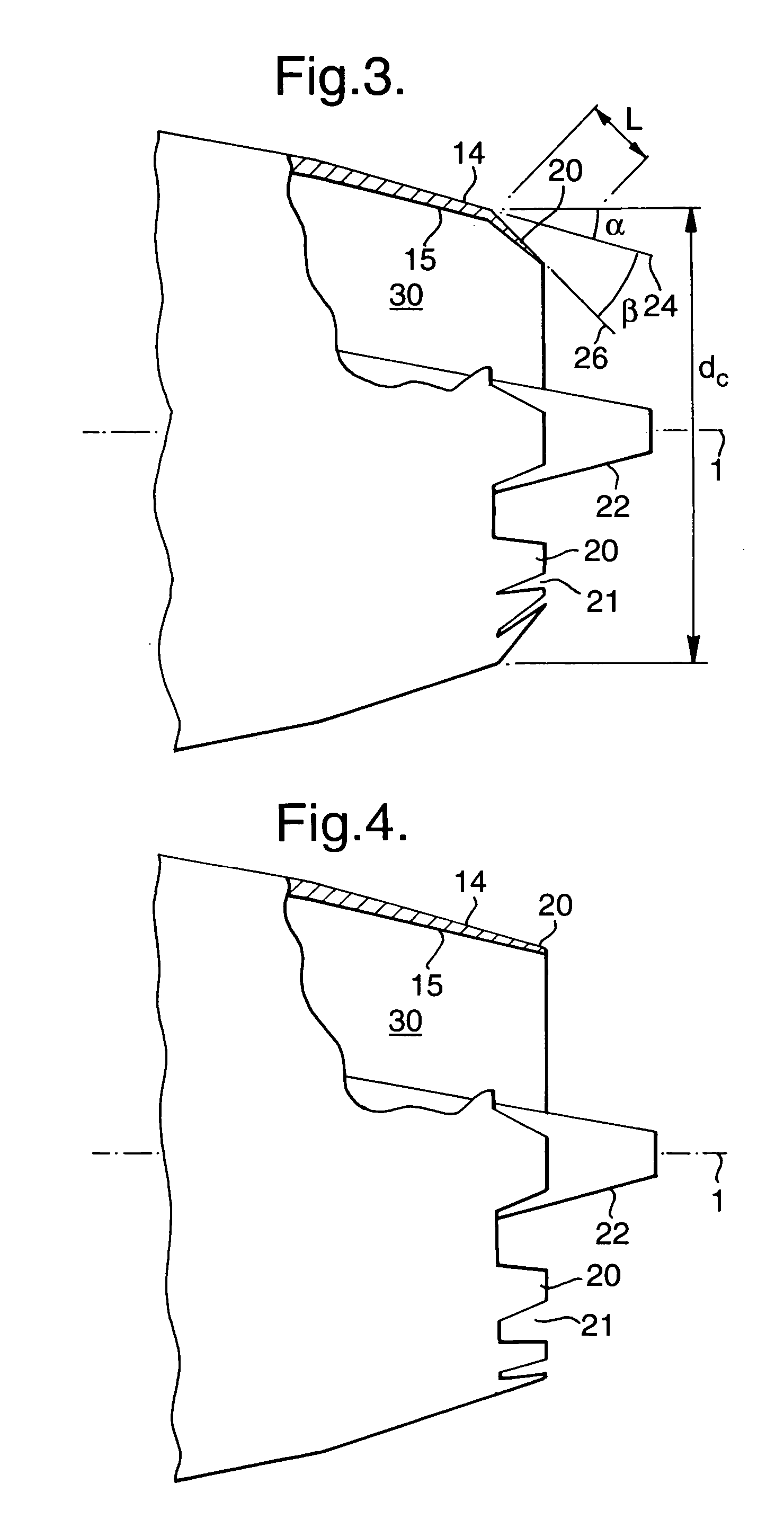

Internal combustion engine producing low emissions

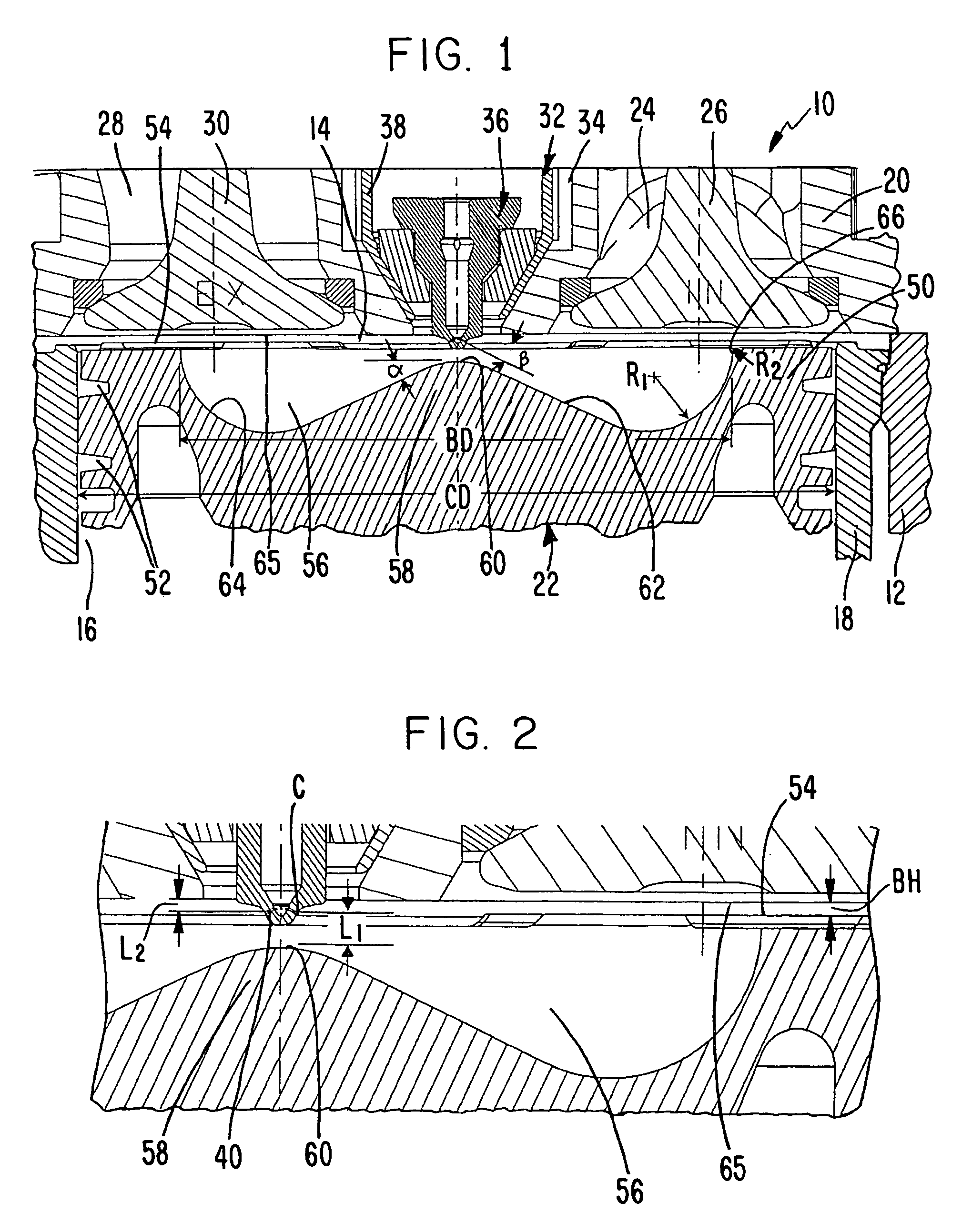

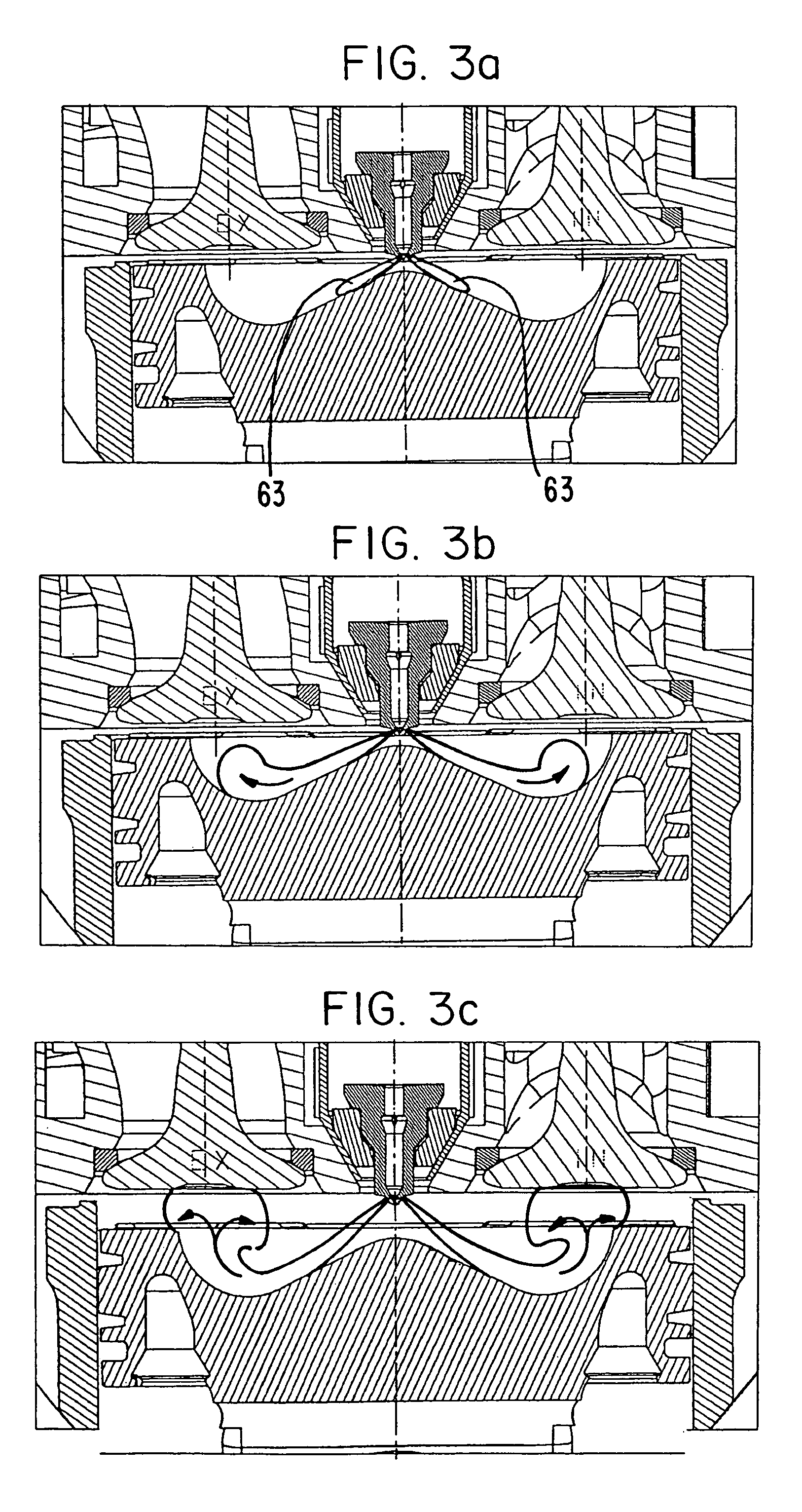

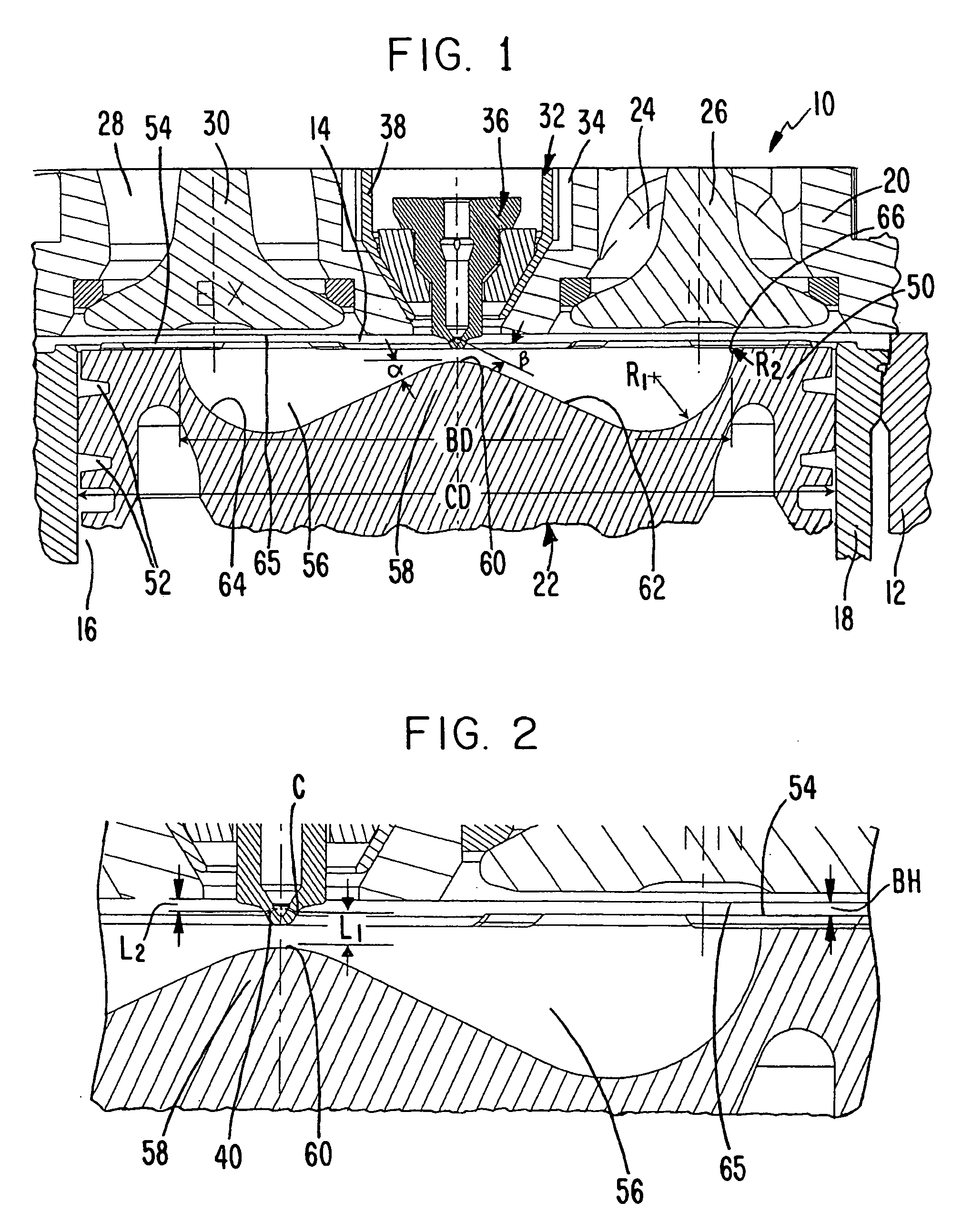

InactiveUS7210448B2Emission reductionMinimizing sootInternal combustion piston enginesFuel injection apparatusParticulatesCombustion chamber

An engine is provided which includes various precise configuration parameters, including dimensions, shape and / or relative positioning of the combustion chamber features, resulting in a combustion process minimizing NOx emissions and particulates. The combustion chamber includes one or more of the following: a spray angle relative to an inner bowl floor angle; a vertical distance from the tip of the piston bowl to the injection orifices; a number of injection orifices; a swirl ratio; a vertical distance from the injection orifices to an inner face of the cylinder head; a radius of curvature of an outer bowl section; chamfer with dimensional parameters; and a transition radius.

Owner:CUMMINS INC

Internal combustion engine producing low emissions

InactiveUS20060070603A1Emission reductionMinimizing sootInternal combustion piston enginesFuel injection apparatusParticulatesCombustion chamber

An engine is provided which includes various precise configuration parameters, including dimensions, shape and / or relative positioning of the combustion chamber features, resulting in a combustion process minimizing NOx emissions and particulates. The combustion chamber includes one or more of the following: a spray angle relative to an inner bowl floor angle; a vertical distance from the tip of the piston bowl to the injection orifices; a number of injection orifices; a swirl ratio; a vertical distance from the injection orifices to an inner face of the cylinder head; a radius of curvature of an outer bowl section; chamfer with dimensional parameters; and a transition radius.

Owner:CUMMINS INC

Pressure sensor diagnosis via a computer

InactiveUS20040200271A1Accelerate emissionsReduce stepsAnalogue computers for vehiclesElectrical controlParticulatesDifferential pressure

A method is described for controlling regeneration of a particulate filter based on at least a sensor, such as a differential pressure sensor. Degradation of the sensor is then detected in a variety of ways. One approach takes advantage of the slowly varying flow resistance of the filter compared with the more rapid variations in flow caused by changing engine conditions. Default operation is then taken when a degraded sensor is detected.

Owner:FORD GLOBAL TECH LLC

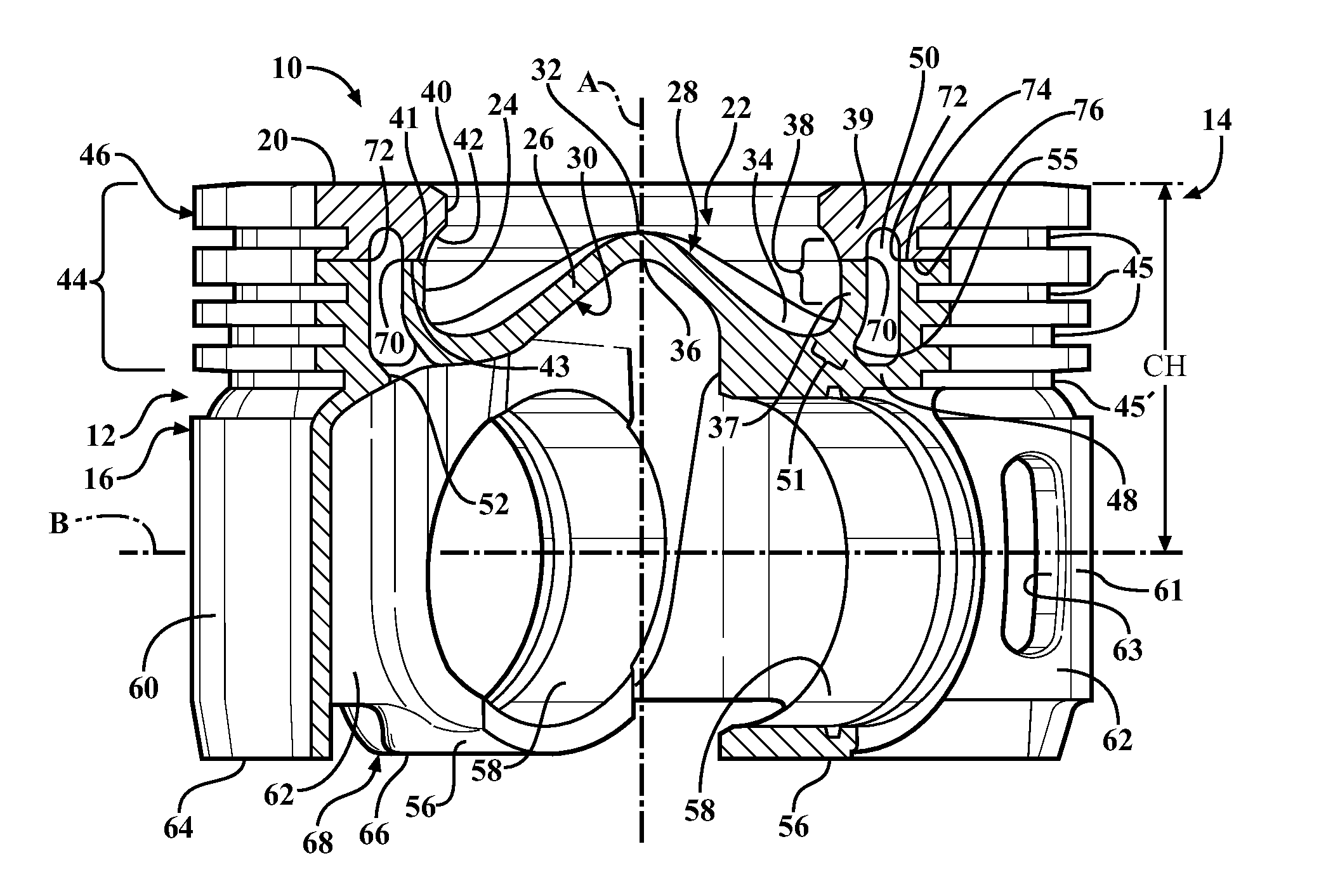

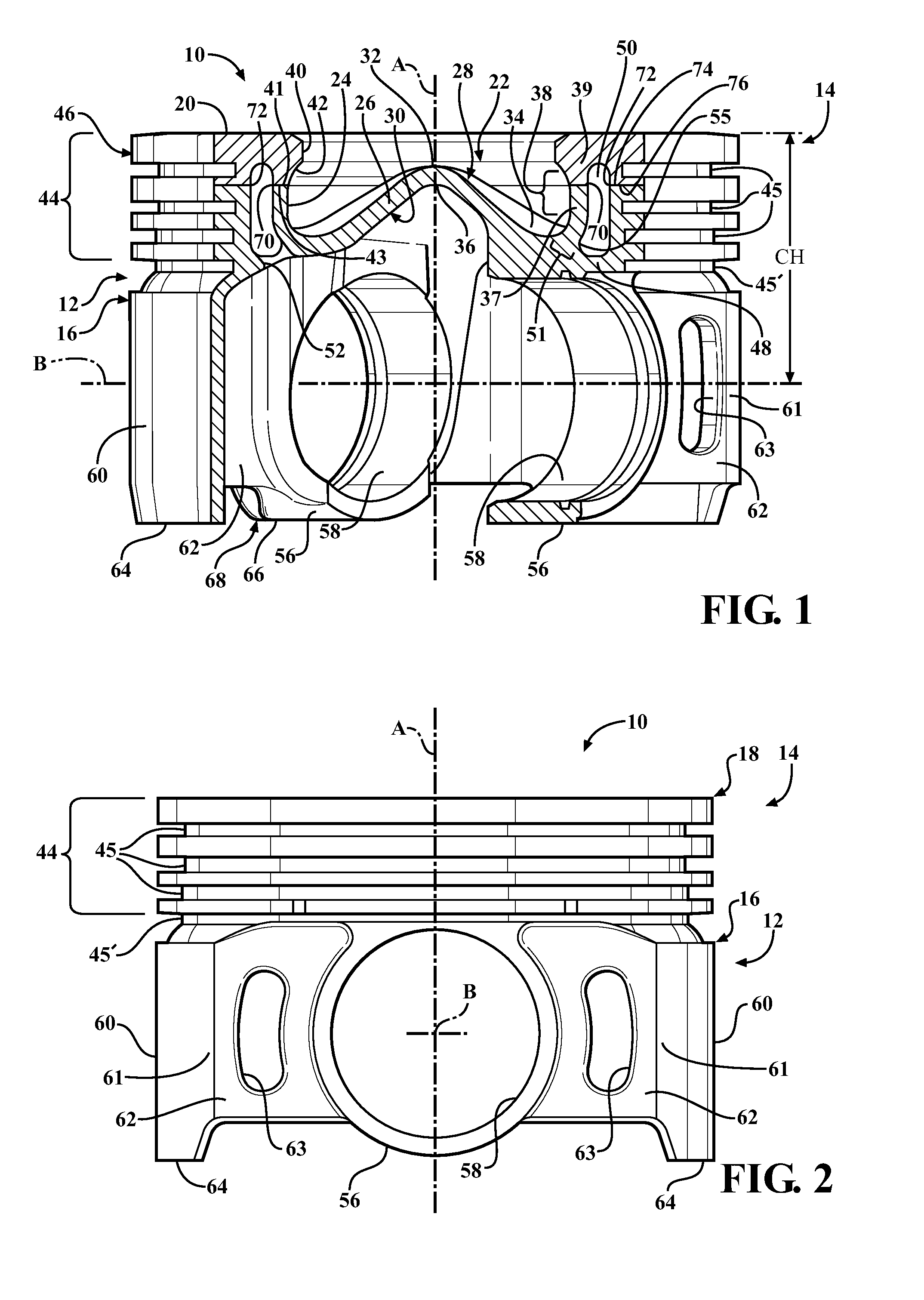

Steel piston with cooling gallery and method of construction thereof

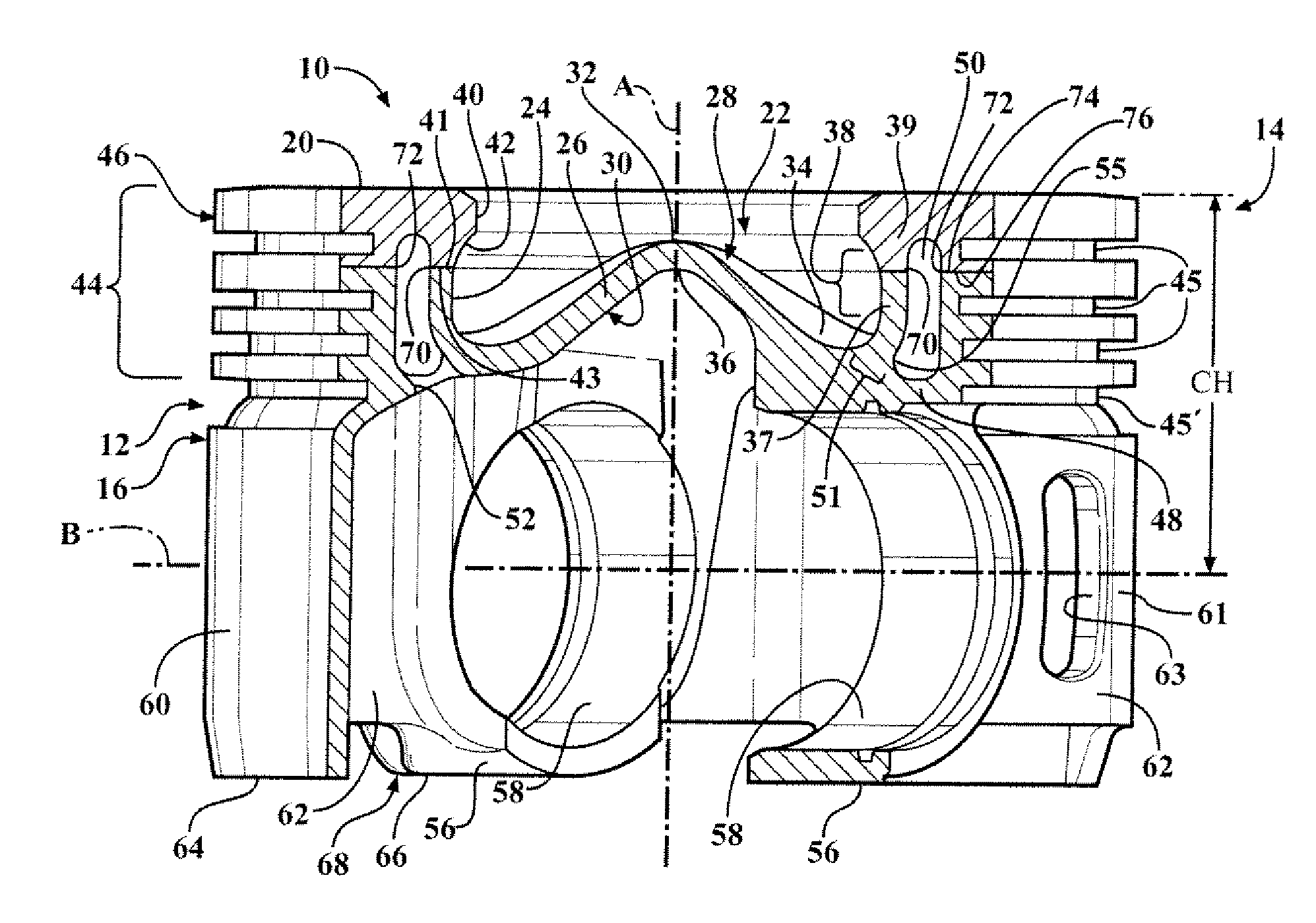

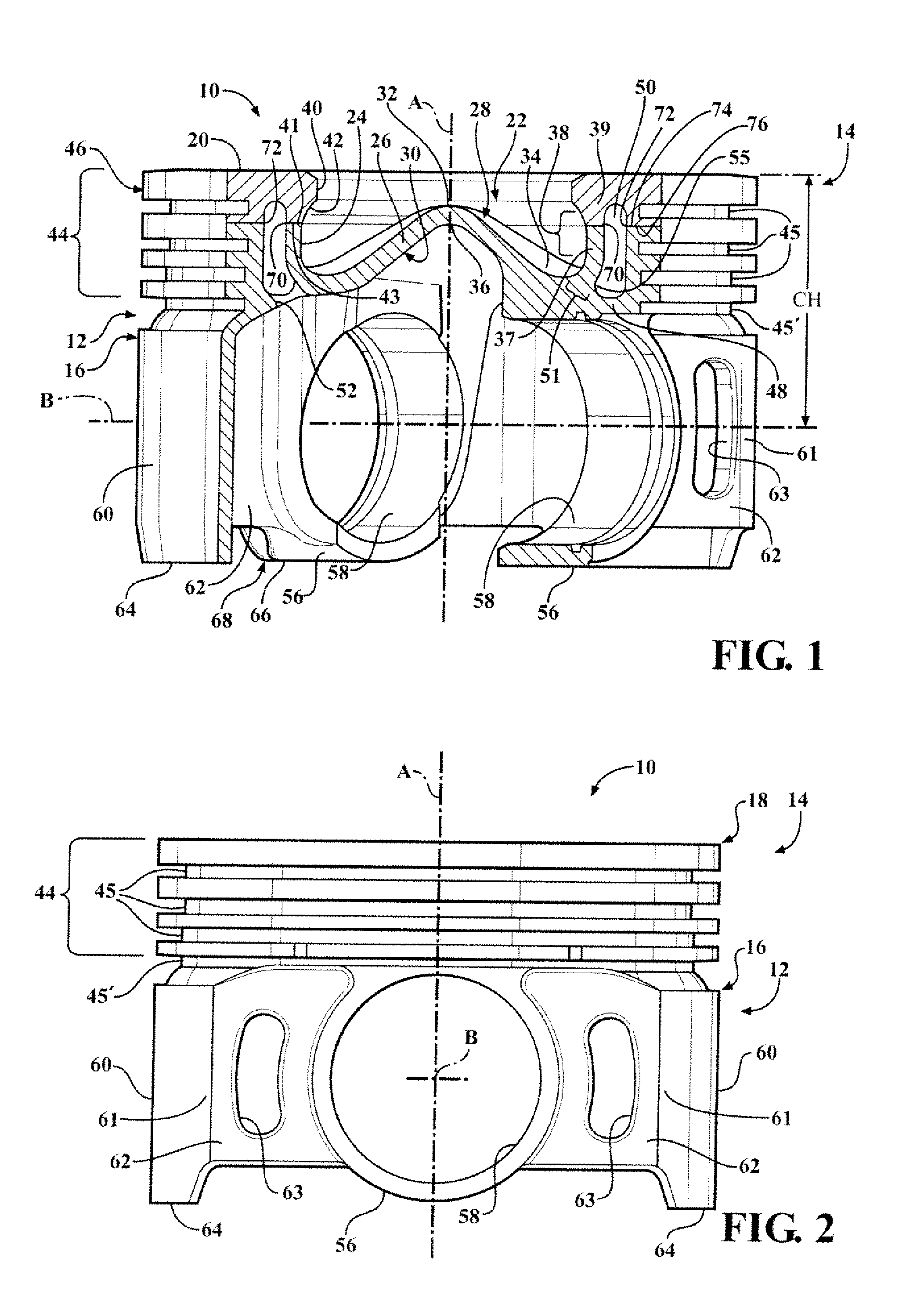

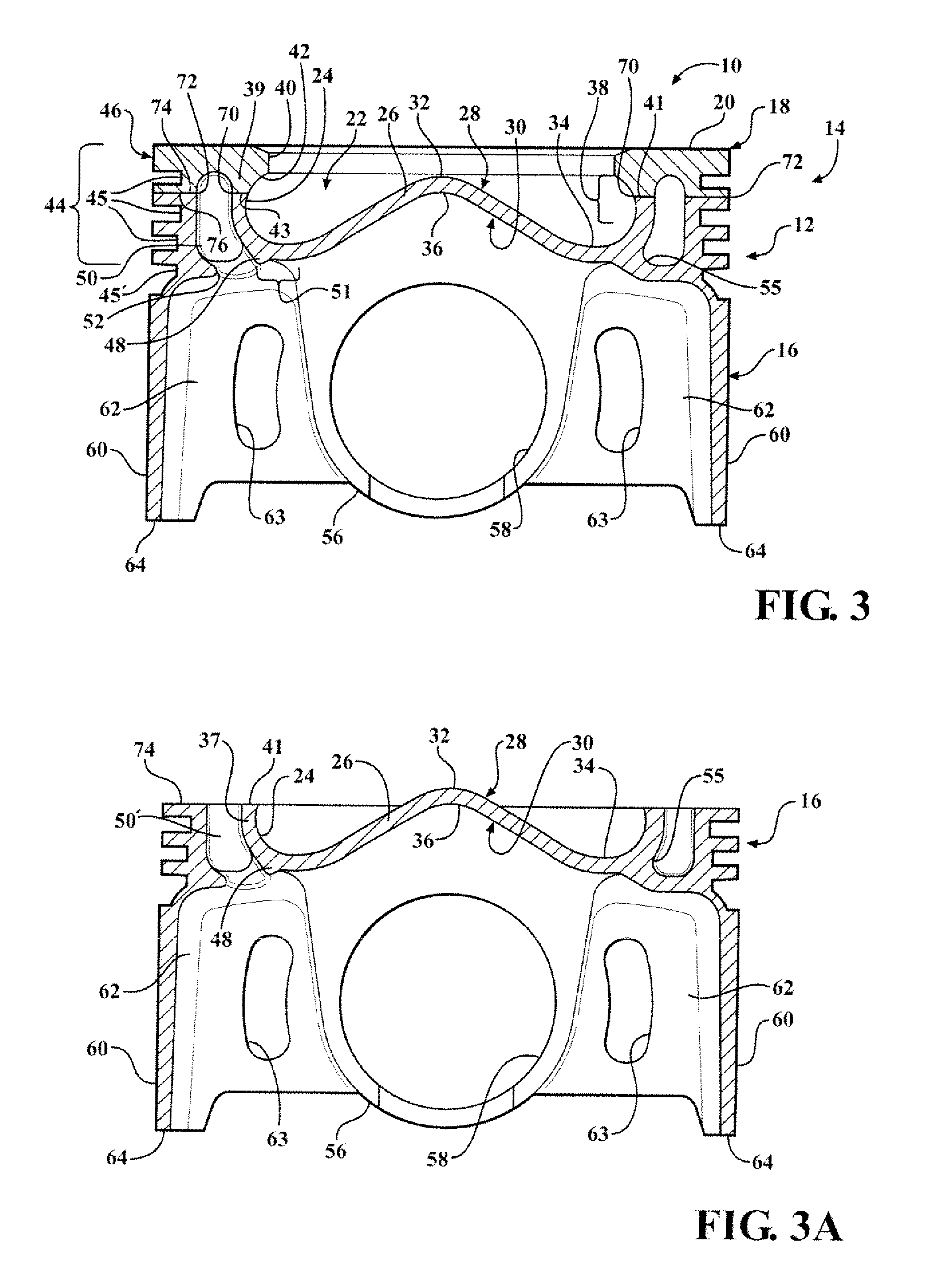

ActiveUS20120037112A1High strengthIncreased durabilityInternal combustion piston enginesPistonsCombustionEngineering

A piston and method of construction is provided. The piston includes a top part fixed to a bottom part. The top part has an uppermost surface with annular inner and outer upper joining surfaces depending therefrom. The bottom part has a pair of pin bosses with pin bores aligned with one another along a pin bore axis; a pair of upwardly extending annular inner and outer lower joining surfaces and a combustion bowl wall. Inner and outer weld joints fix the inner and outer upper and lower joining surfaces to one another. An annular cooling gallery is formed laterally between the upper and lower joining surfaces. The inner weld joint joining the top part to the bottom part is located within the combustion bowl wall and configured to minimized the compression height of the piston.

Owner:TENNECO INC

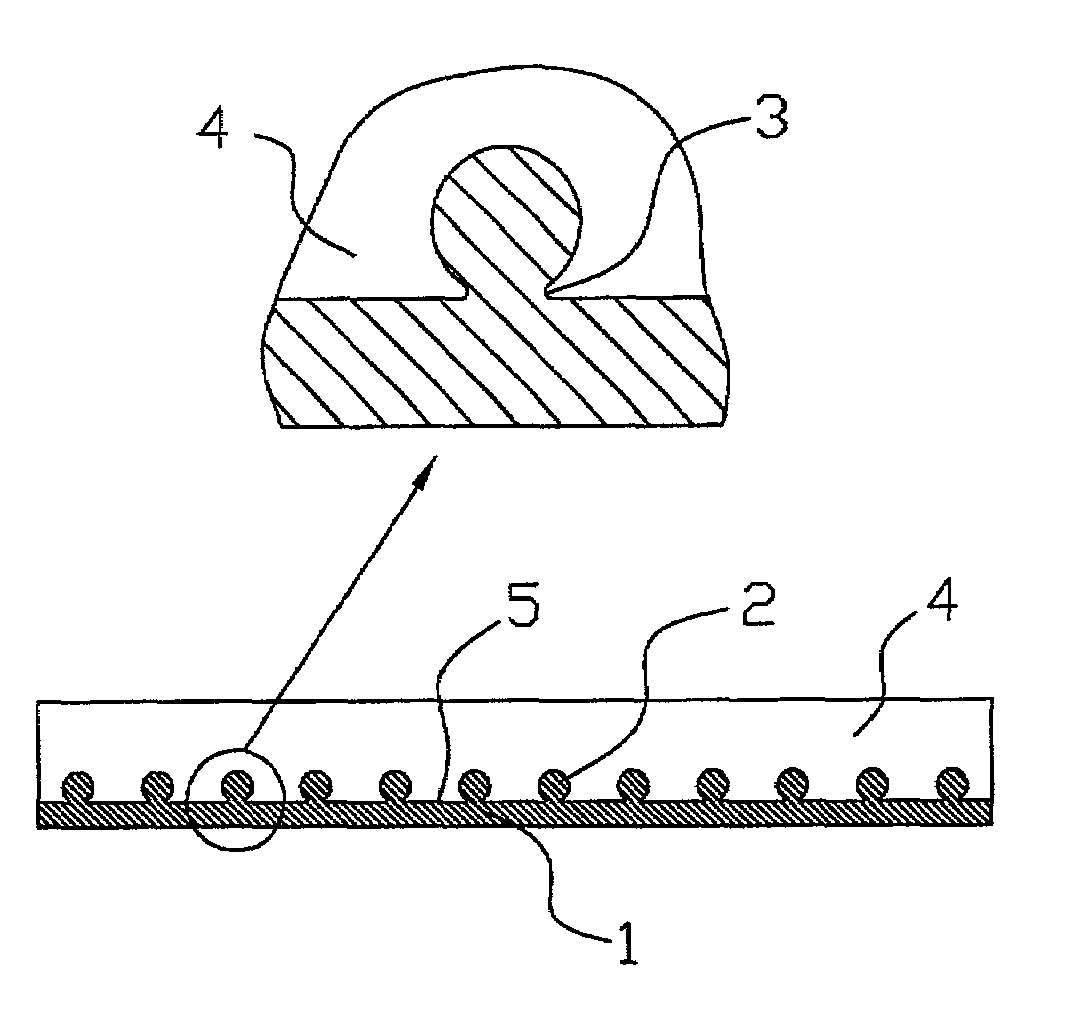

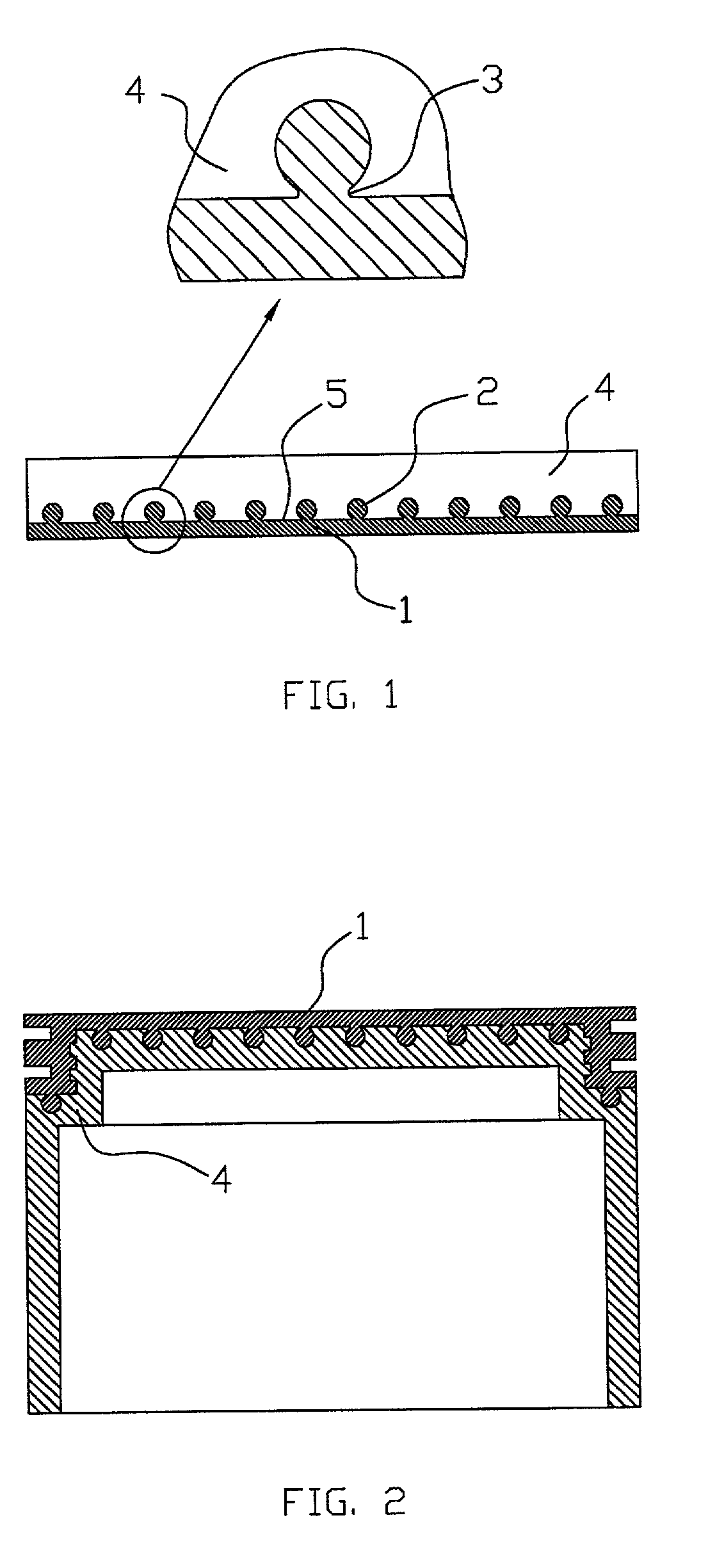

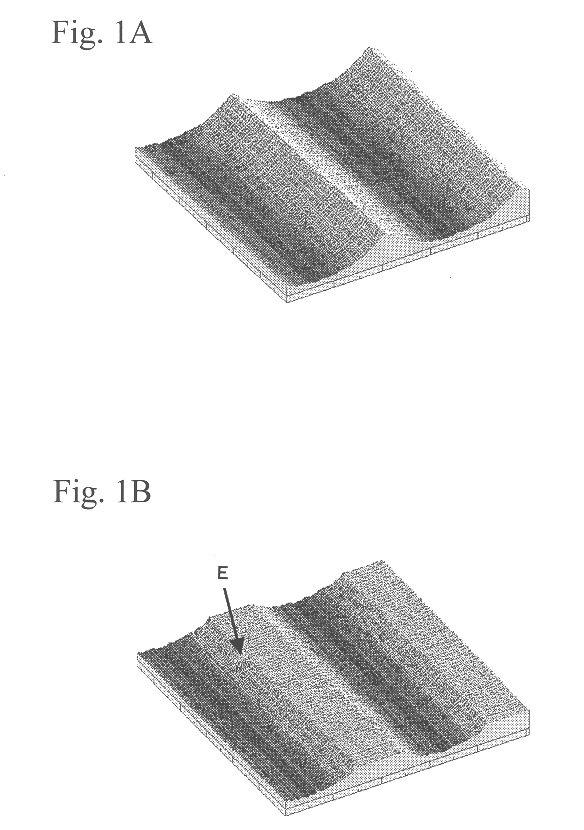

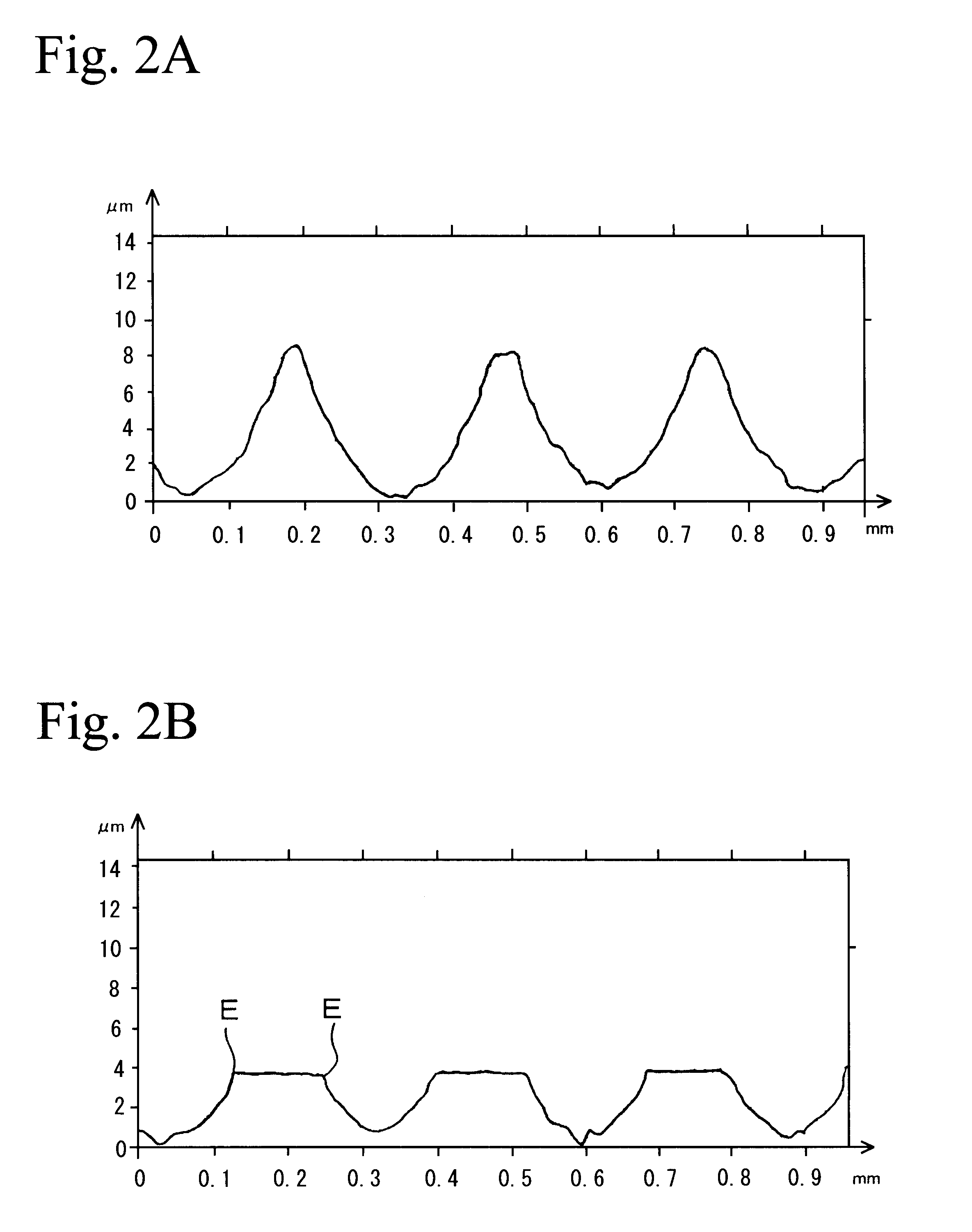

Sliding members and piston for internal combustion engine

InactiveUS6523456B1Avoid unusual noiseClearanceCylindersMachines/enginesInternal combustion enginePiston

A sliding surface of at least one of sliding members sliding with respect to each other in a sliding direction comprises a protrusion extending along a direction intersecting the sliding direction and fine dimples provided on a surface of the protrusion. In the sliding members, lubricating oil is accumulated in the dimples, and is easily extracted through a drain portion formed by dimple in a running-in operation.

Owner:HONDA MOTOR CO LTD

Compliant walled combustion devices

InactiveUS7237524B2Reduce thicknessImprove efficiencyCasingsCylinder headsCombustion chamberCoupling

Owner:SRI INTERNATIONAL

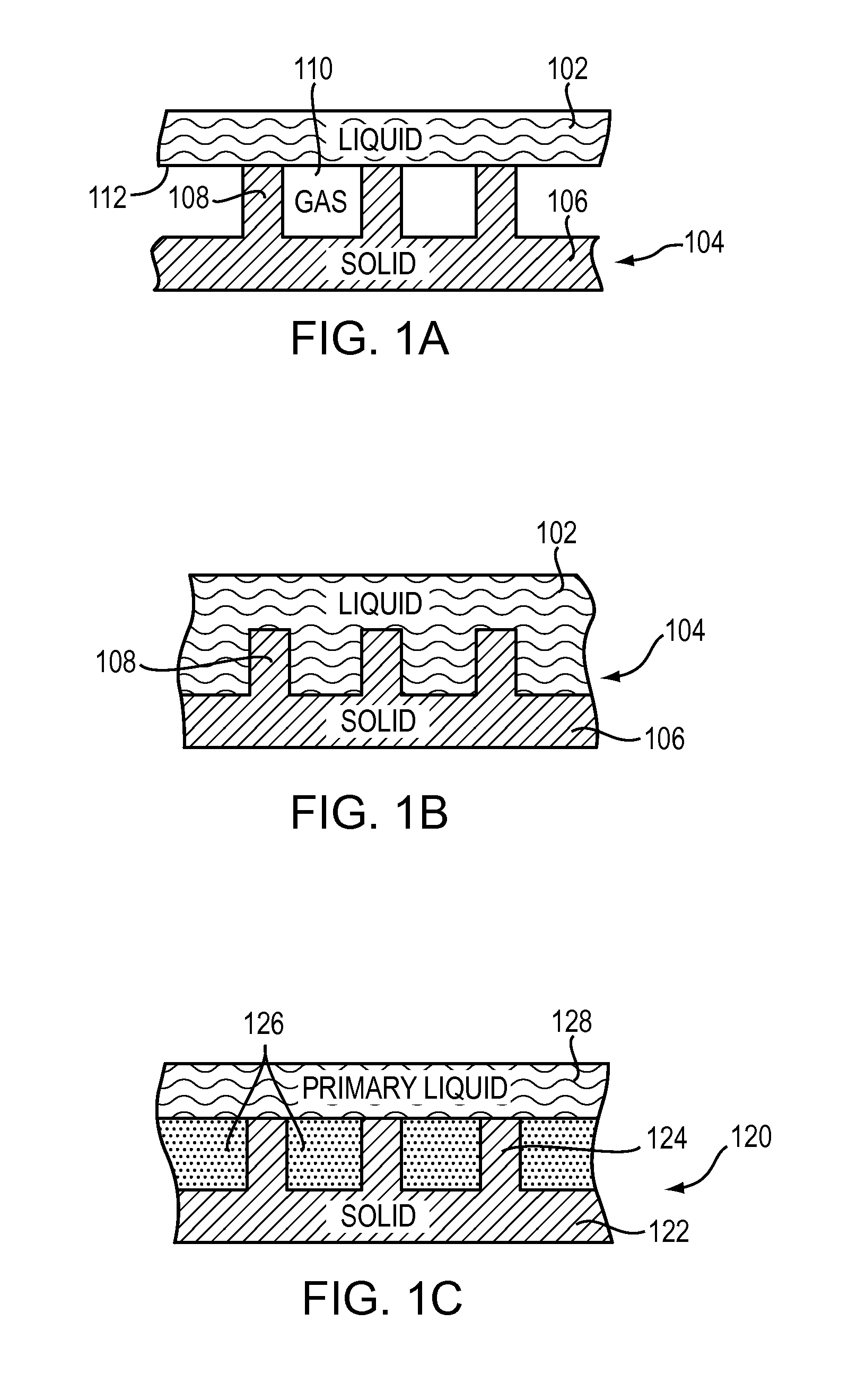

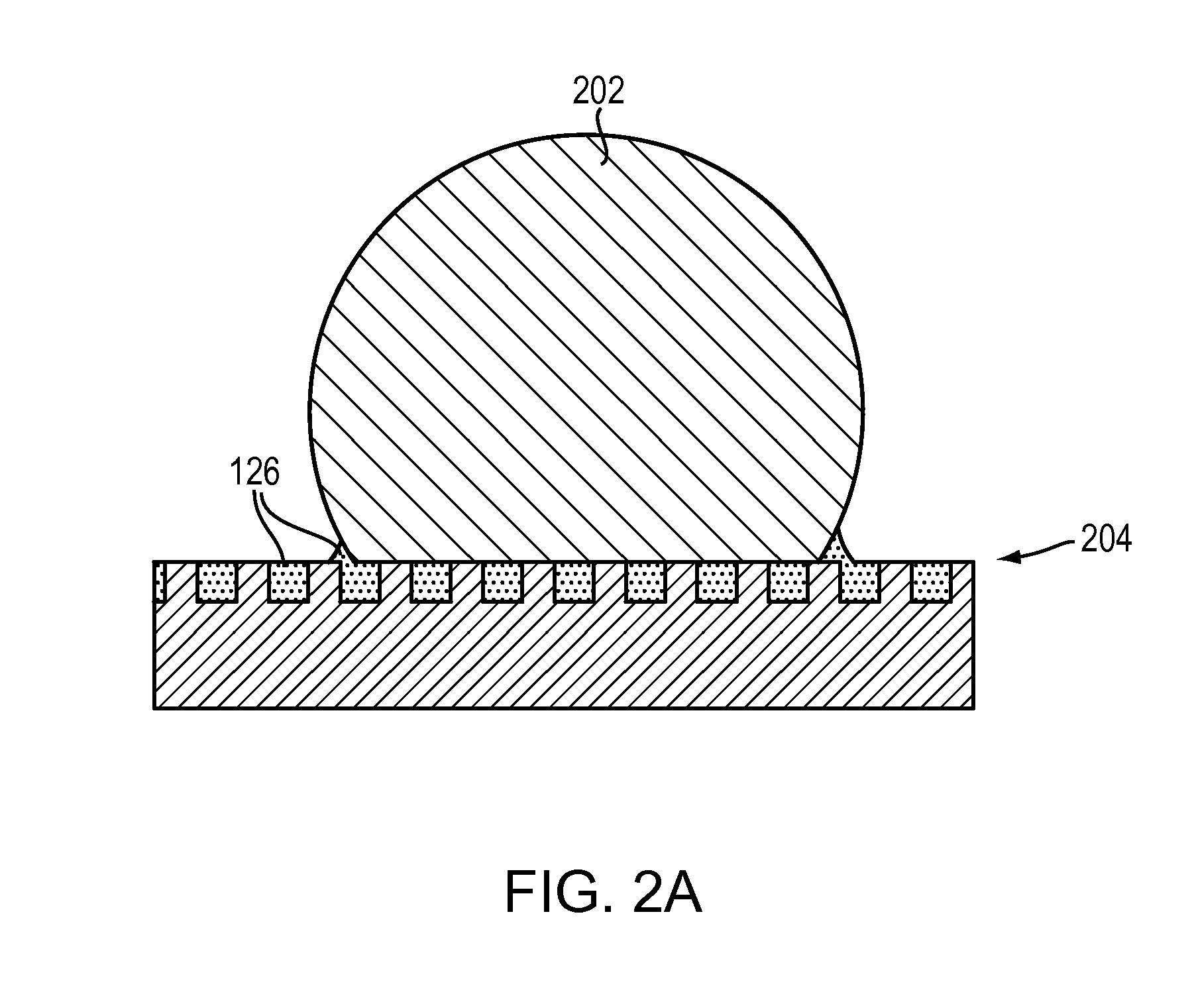

Liquid-impregnated surfaces, methods of making, and devices incorporating the same

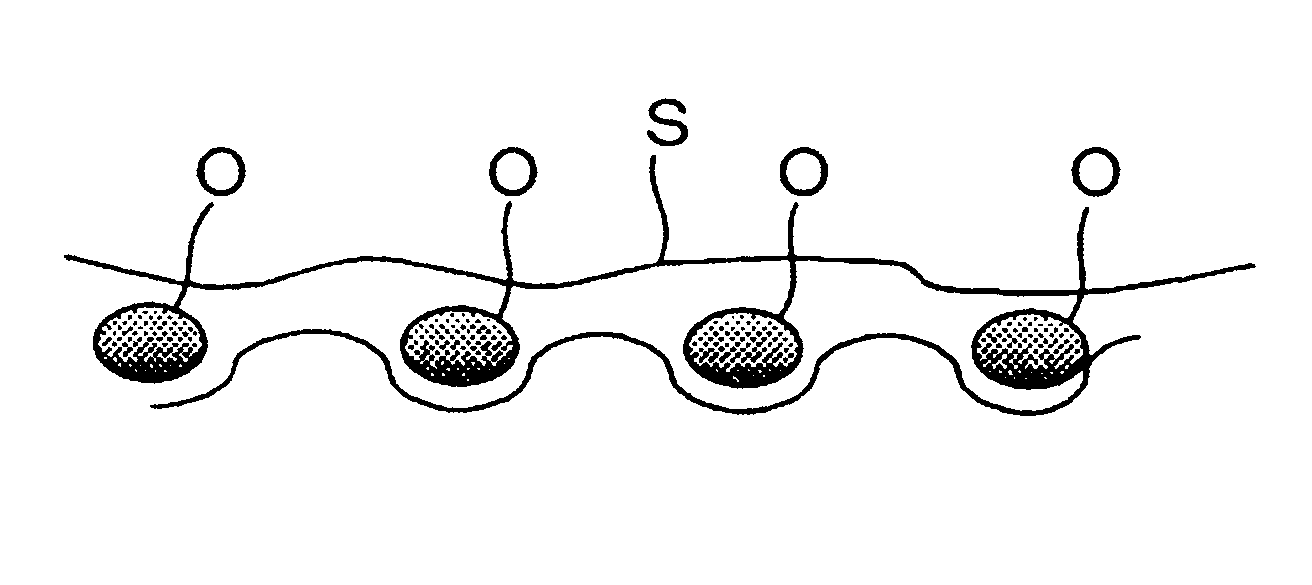

ActiveUS20130034695A1Improve skidReduce resistanceDe-icing equipmentsRecord information storageNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

Plasma ignition for direct injected internal combustion engines

InactiveUS6883490B2Extend engine lifeGreater engine durabilitySparking plugsPower operated startersCombustion chamberPollutant emissions

Owner:JAYNE MICHAEL E

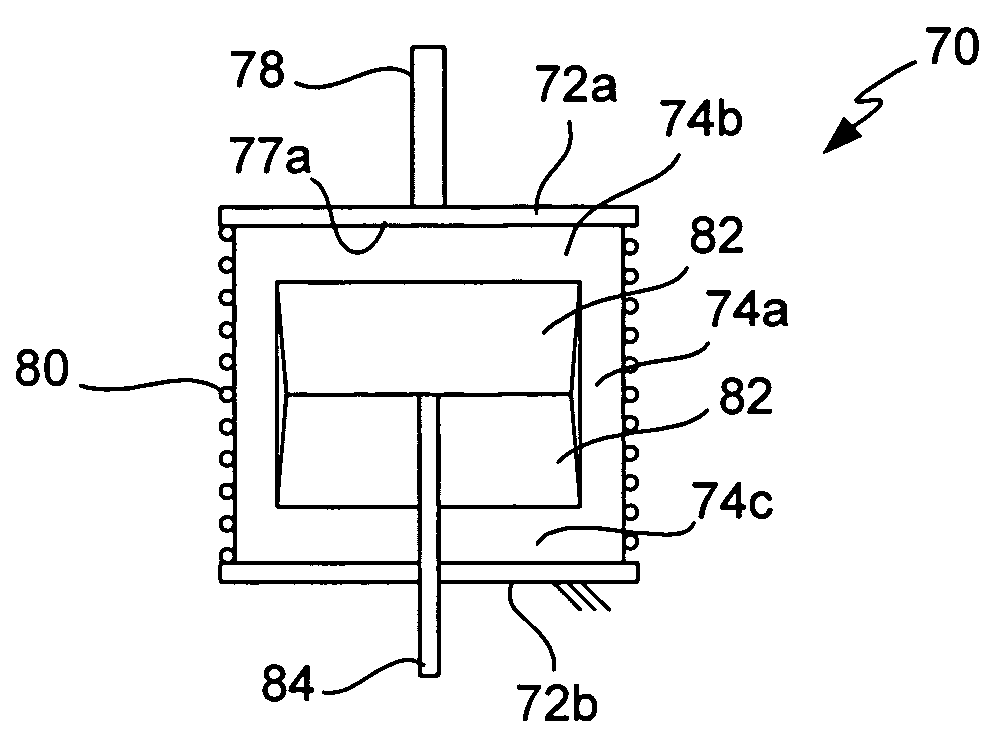

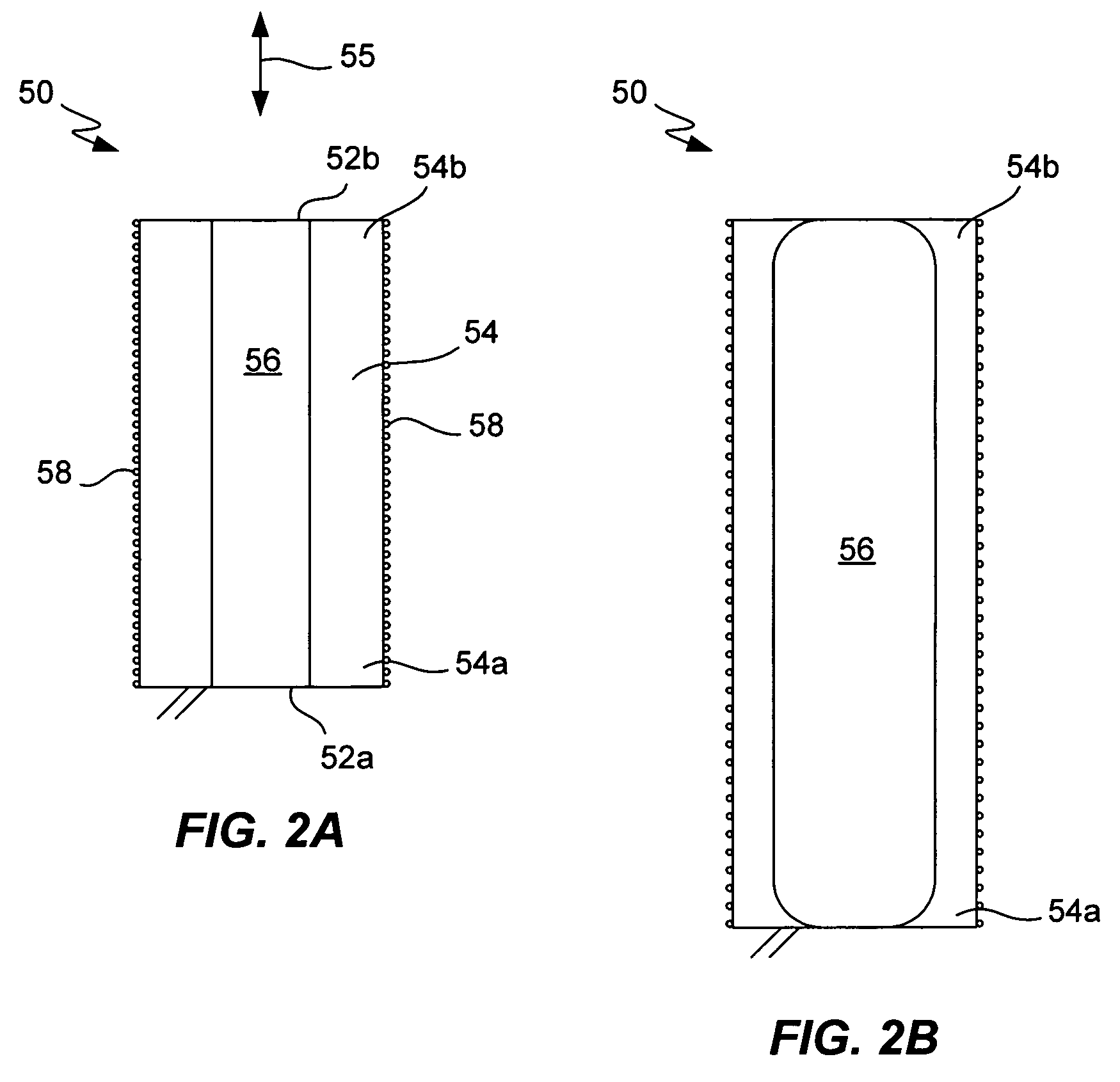

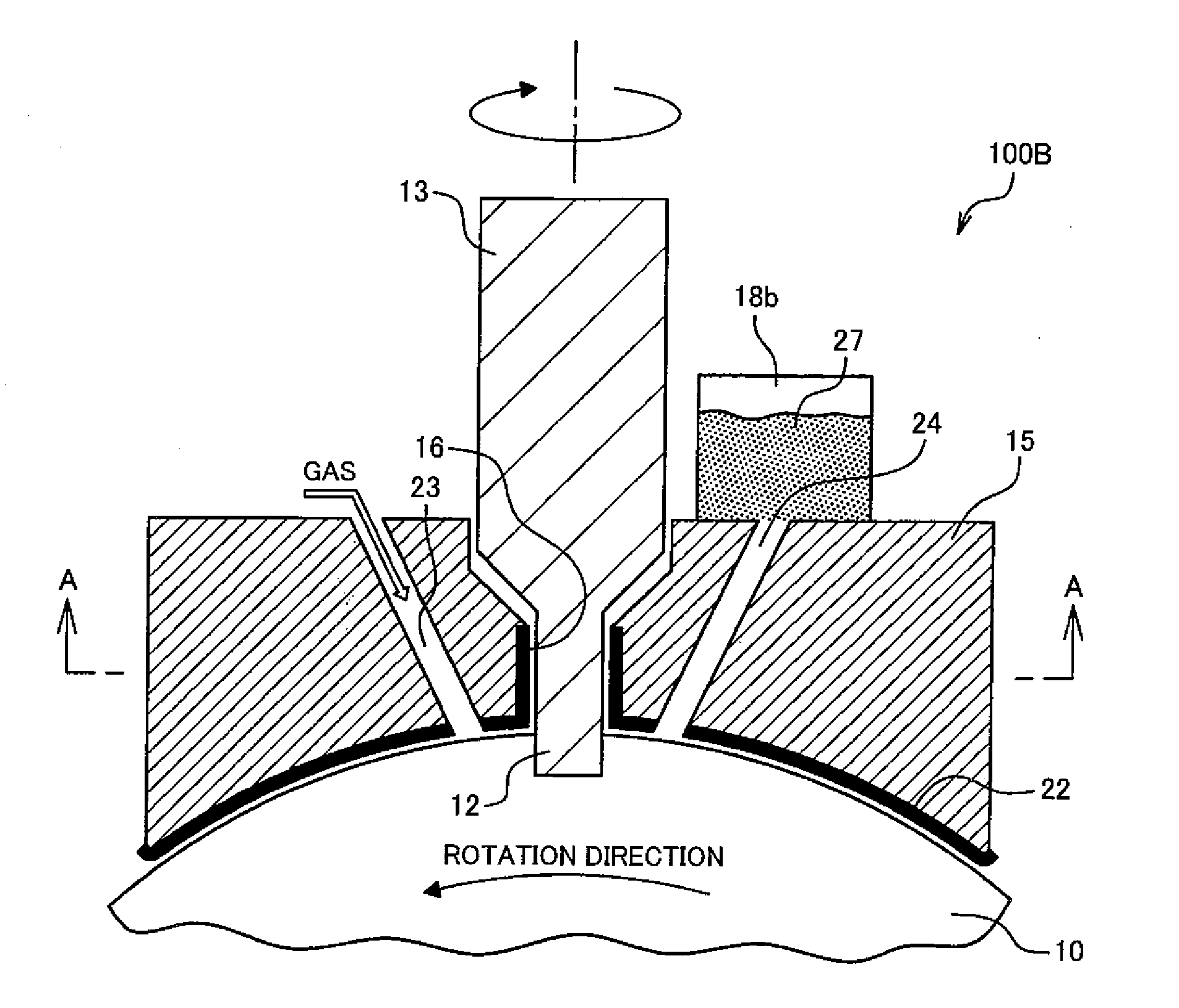

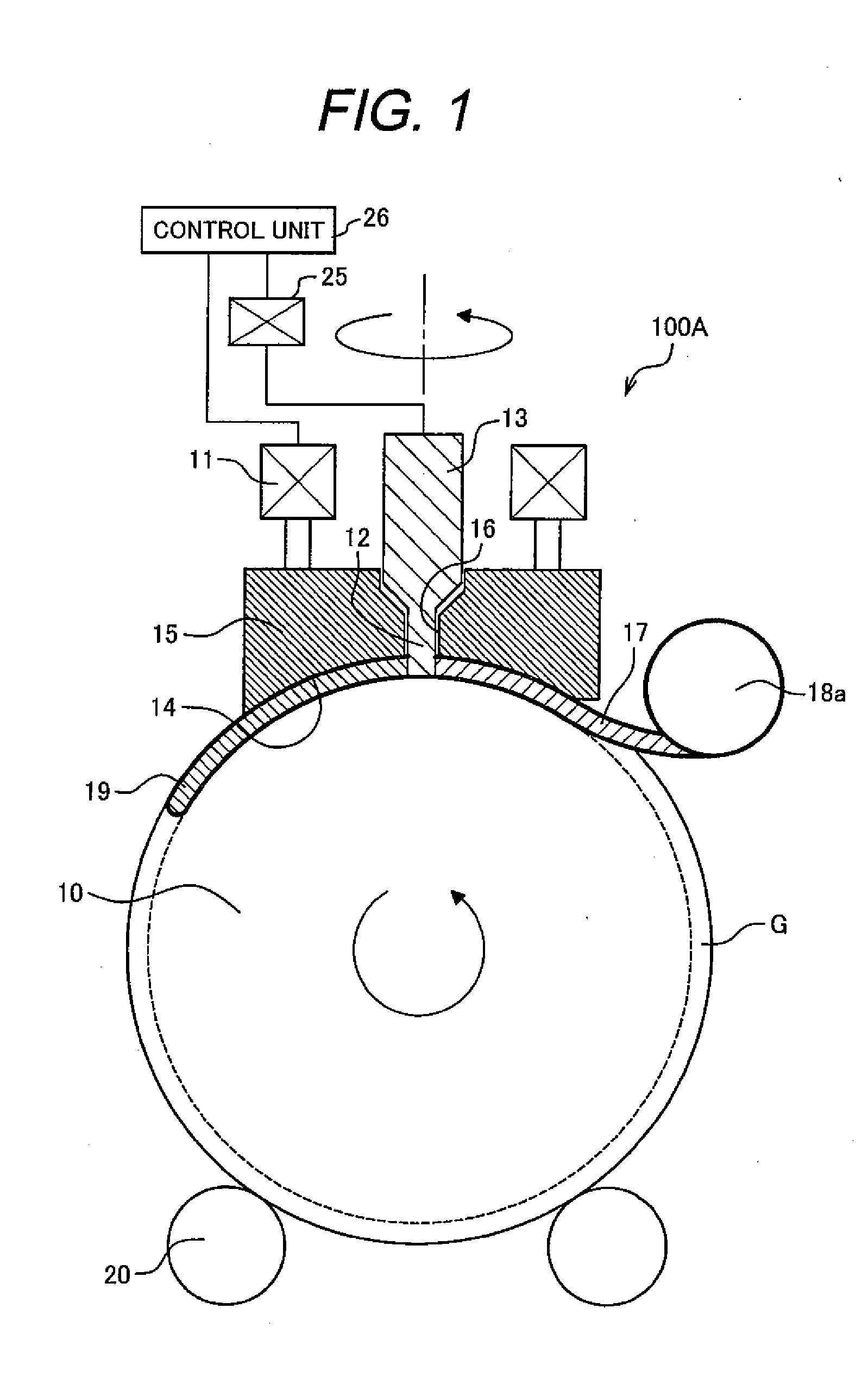

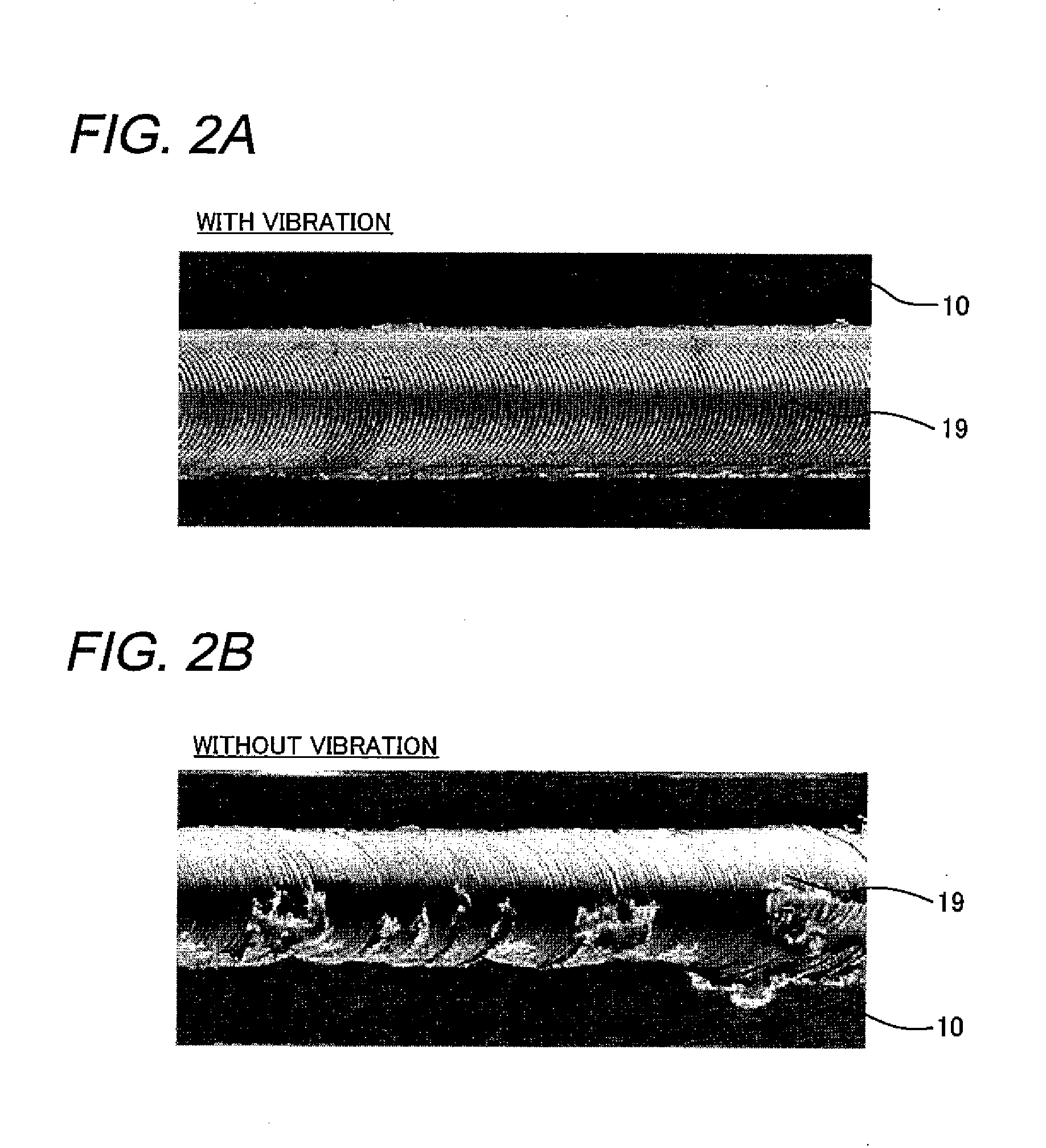

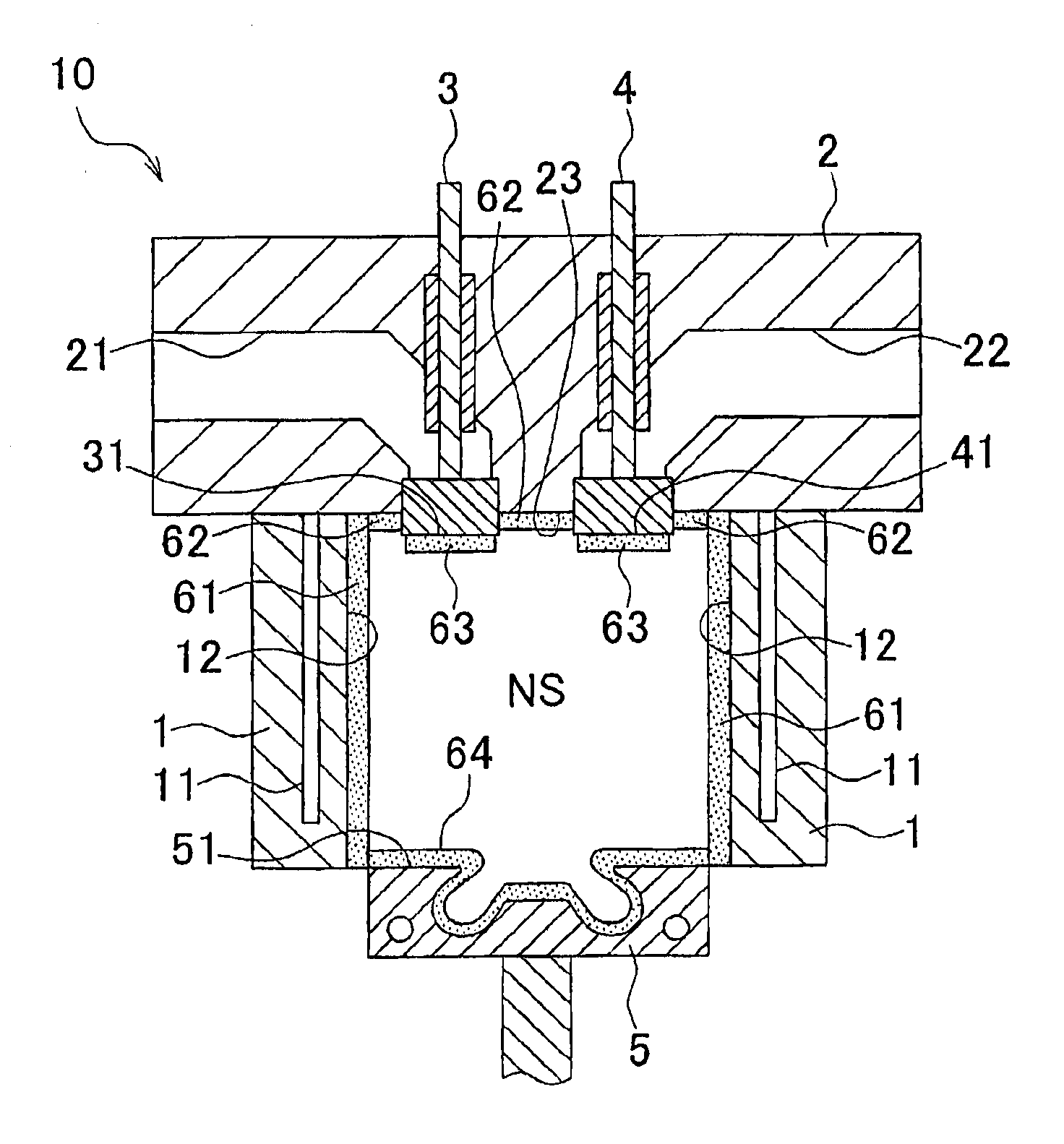

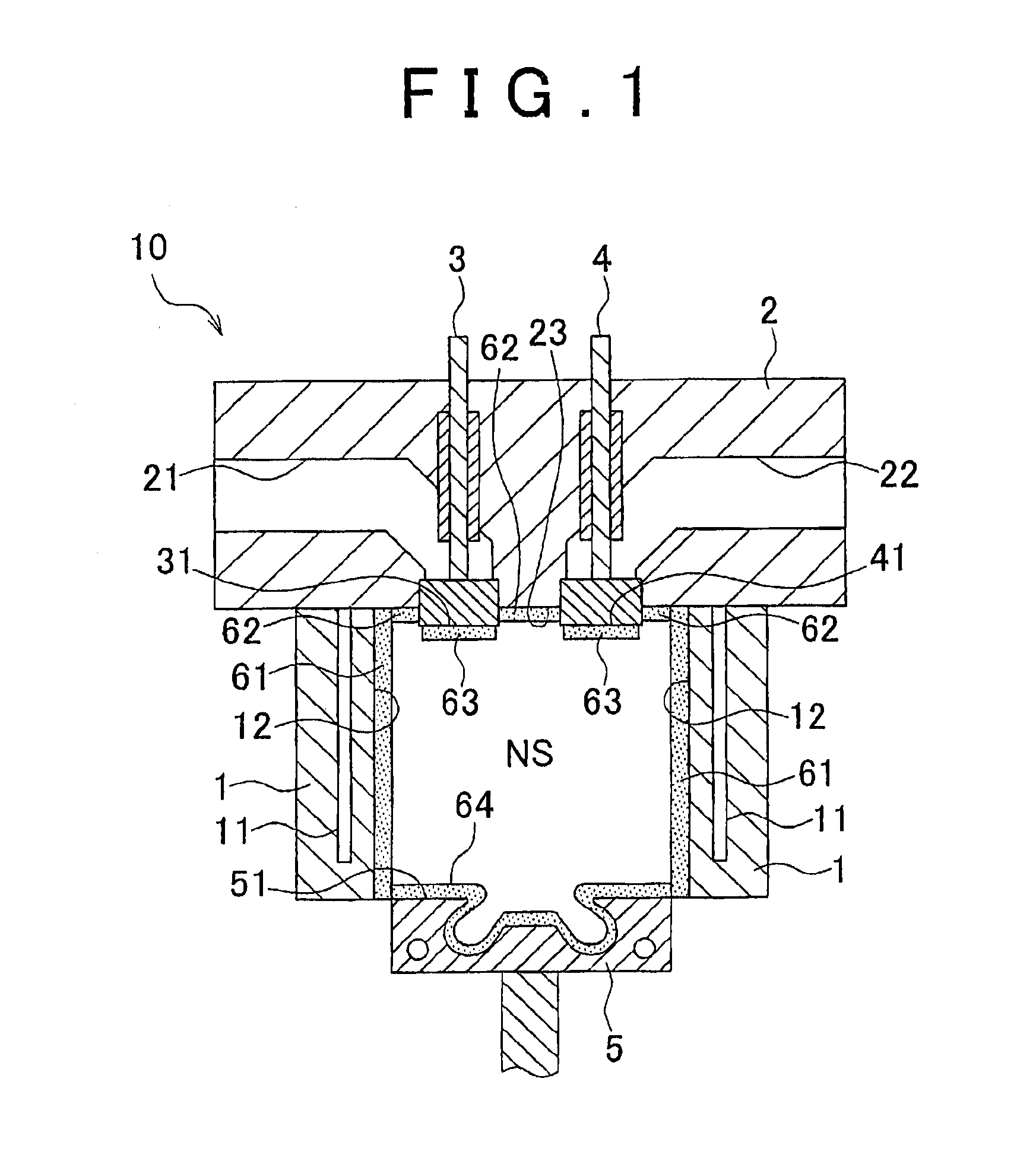

Apparatus for friction stir and friction stir processing

InactiveUS20090152328A1InhibitionWelding/cutting auxillary devicesPistonsEngineeringFriction stir processing

An apparatus for a friction stir and a friction stir processing of the present invention suppress an occurrence of a surface defect in an area processed by the friction stir. The apparatus for the friction stir includes a tool having a columnar tip-side part, a rotating unit for rotating the tool on a central axis, a first pressing unit for pressing a tip of the tool rotated by the rotating unit against a work, a jig having a tool insertion hole into which the tip-side part of the tool is inserted so that the tip-side part of the tool is encircled around the jig, a second pressing unit for slidably pressing the jig against the work, and a press control unit for controlling the first pressing unit so that the tip-side part of the tool is gradually pulled out of the work by the first pressing unit while moving the tool and the jig relative to the work, in a state that the tool is rotated by the rotating unit and the tip of the tool has been sunk into the work to a predetermined depth by the first pressing unit.

Owner:HITACHI LTD

Exhaust emission control apparatus and method for internal combustion engine

InactiveUS7073480B2Increase in smoke generationShorten the overall cycleElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

Owner:NISSAN MOTOR CO LTD

Internal combustion engine and method of producing same

ActiveUS20130146041A1Improve abilitiesIncreased durabilityAnodisationCylinder headsPorosityCombustion chamber

An internal combustion engine in which an anodic oxidation coating film is formed on all or a portion of a wall that faces a combustion chamber, wherein the anodic oxidation coating film has a structure that is provided with a bonding region in which each of hollow cells forming the coating film is bonded to the adjacent hollow cells, and a nonbonding region in which three or more adjacent hollow cells are not bonded to each other, and wherein a porosity of the anodic oxidation coating film is determined by a first void present in the hollow cell and a second void that forms the nonbonding region.

Owner:TOYOTA JIDOSHA KK

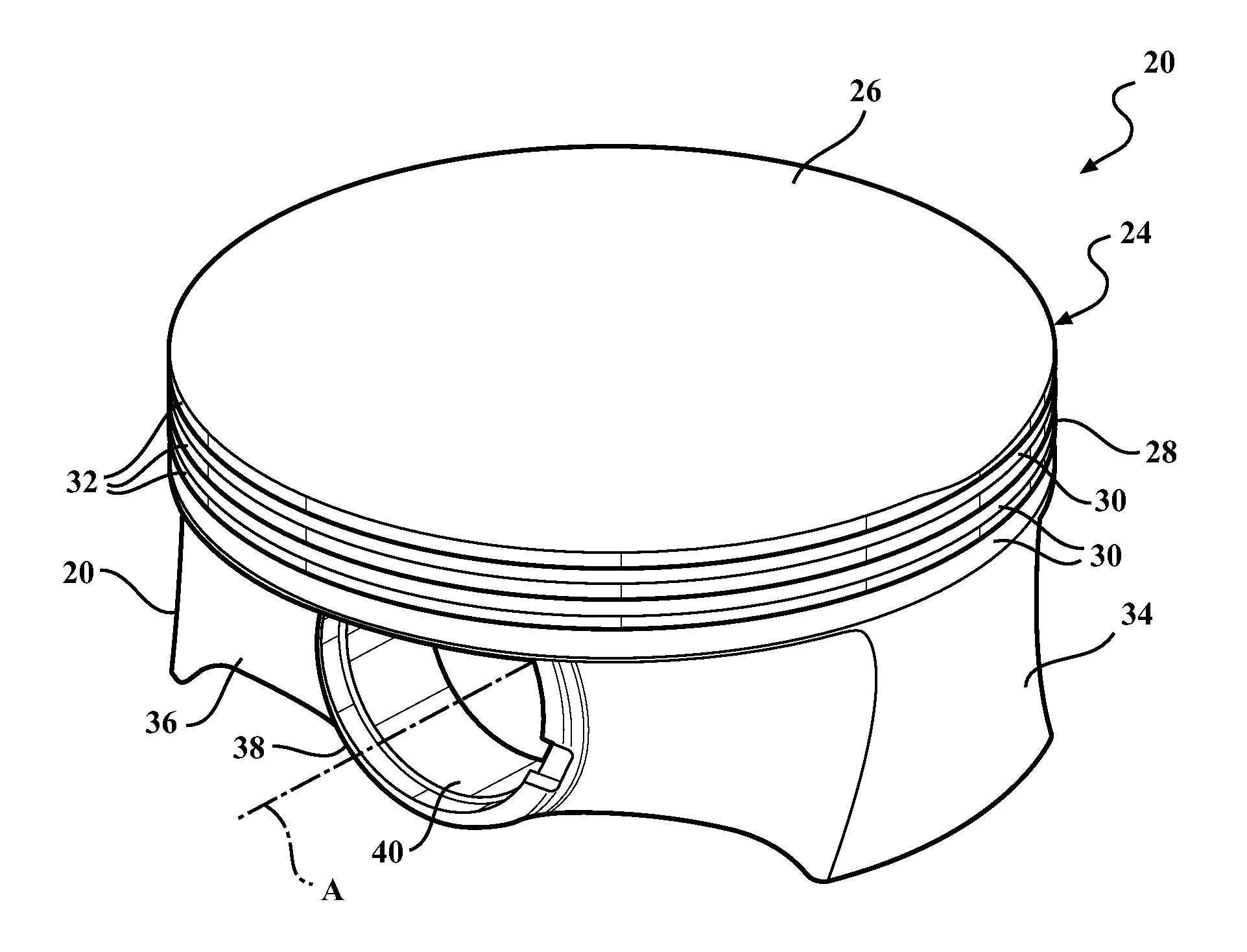

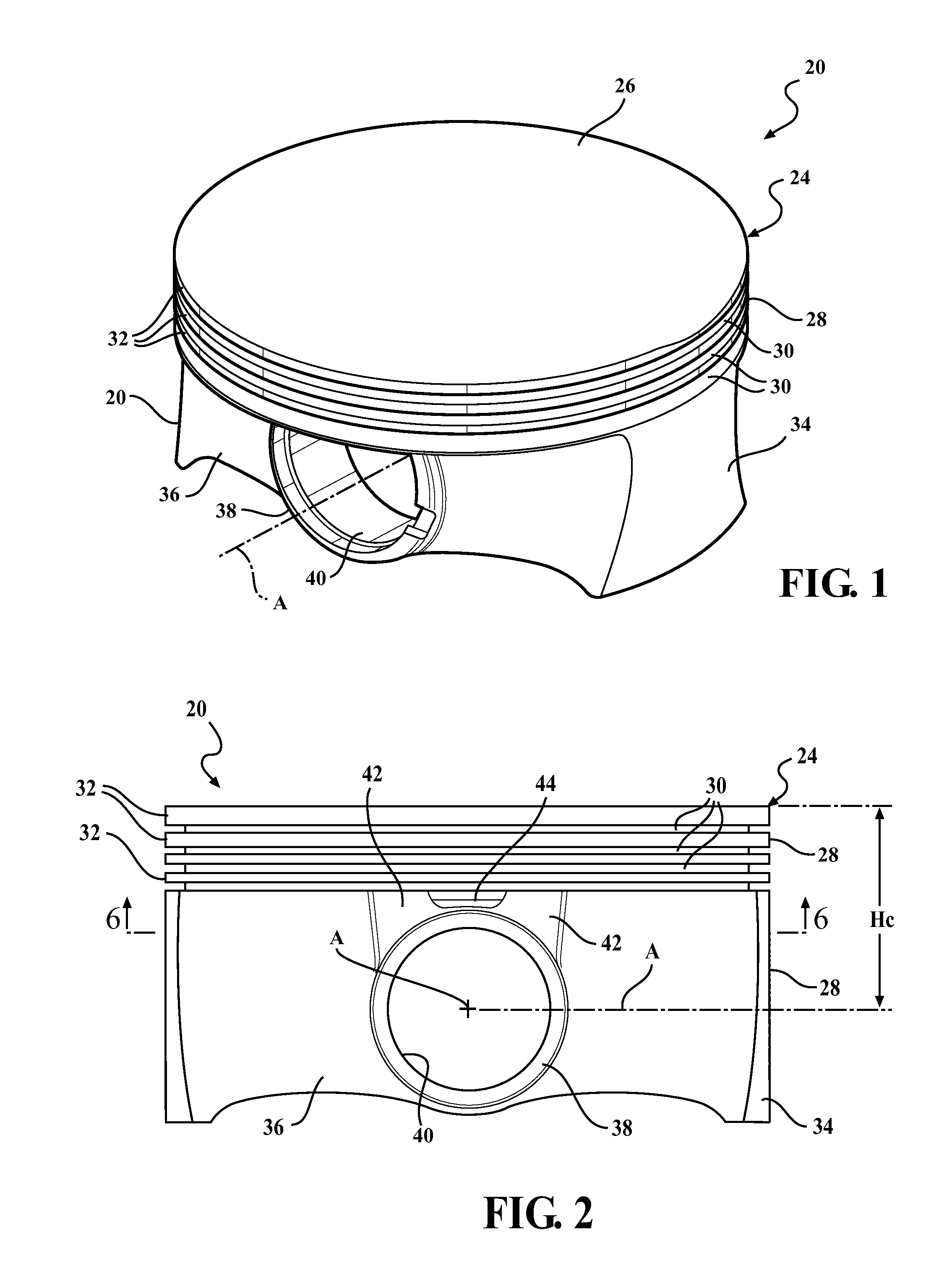

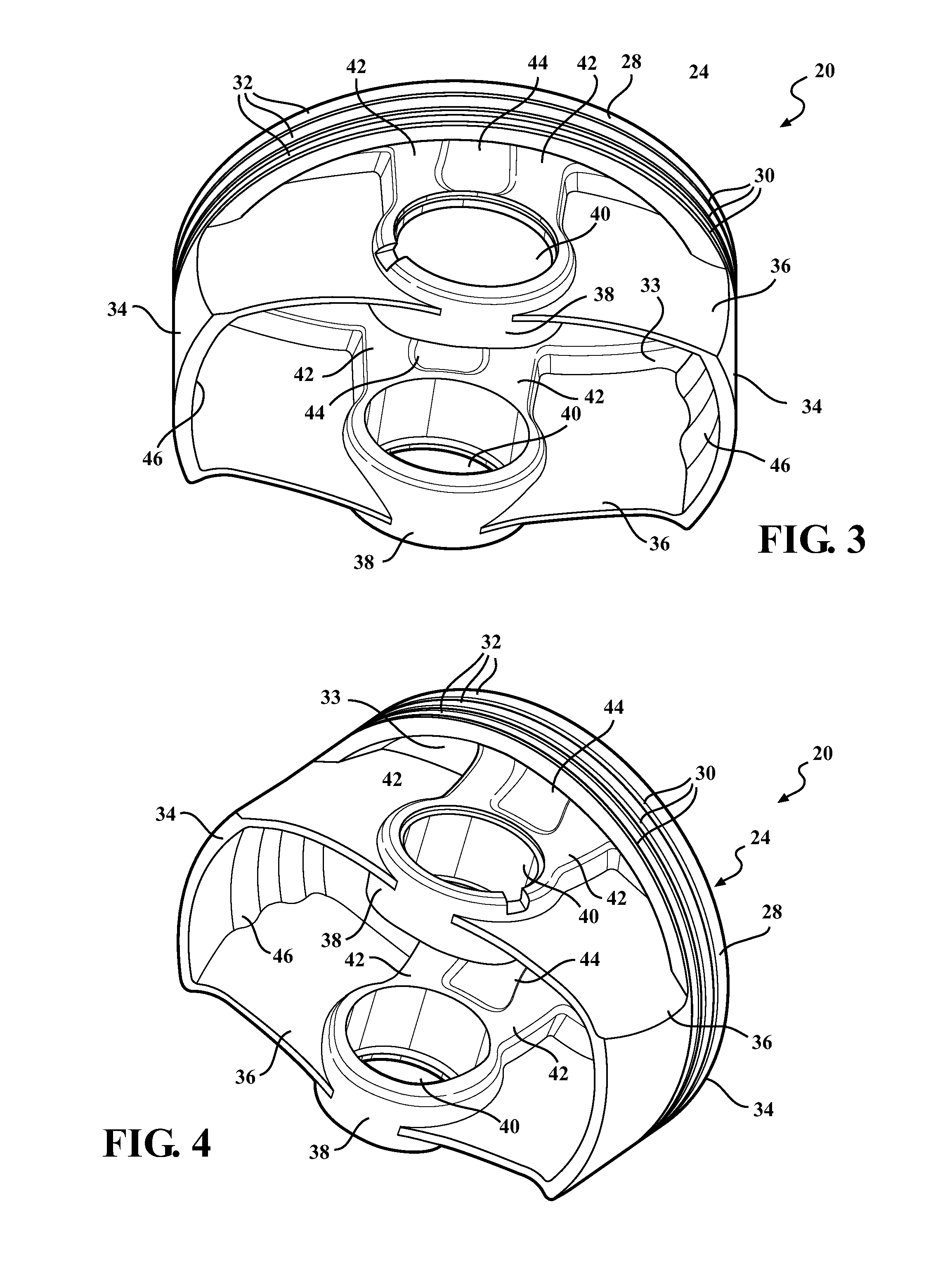

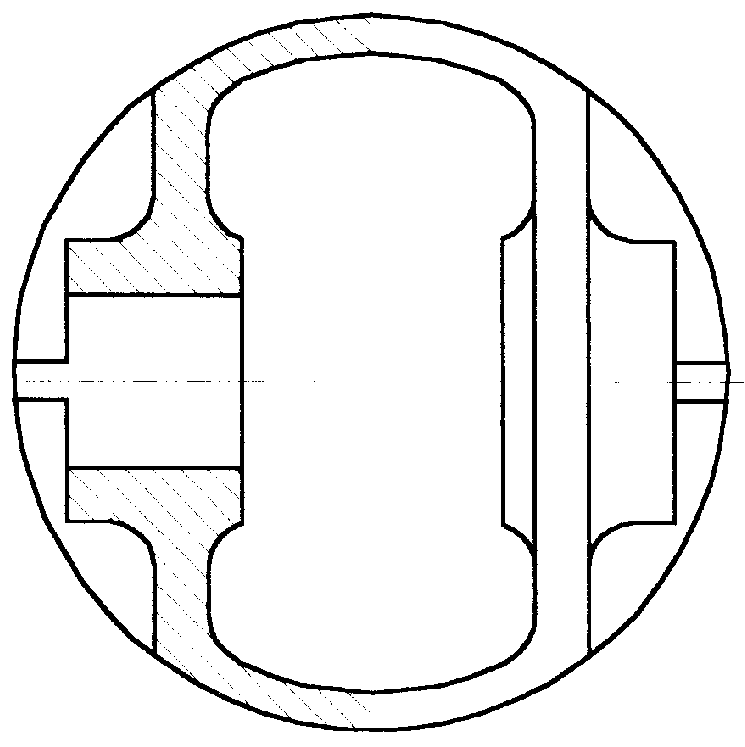

Engine piston

ActiveUS20130233270A1Increase undercrown surface areaImprove cooling effectMachines/enginesPistonsPistonWrist

A piston for an internal combustion engine is provided. The piston includes a piston body of steel and including a crown portion, a pair of skirt portions and a pair of pin boss panels. The crown portion has an upper combustion surface, a lower surface having an undercrown surface area and an outer annular ring belt with at least one ring groove. The pin boss panels depend from the crown portion and extend in spaced relationship with one another between the skirt portions. Each pin boss panel includes a pin boss having a pin bore, and the pin bores are aligned with one another for receiving a wrist pin. Each pin boss panel also has at least one recess located vertically between the associated one of the pin bores and the crown portion to increase the undercrown surface area for improved cooling of the crown portion.

Owner:TENNECO

Steel piston with cooling gallery and method of construction thereof

ActiveUS20110107997A1High strengthIncreased durabilityValve arrangementsMachines/enginesCombustionEngineering

A piston and method of construction is provided. The piston includes a top part fixed to a bottom part. The top part has an uppermost surface with annular inner and outer upper joining surfaces depending therefrom. The bottom part has a pair of pin bosses with pin bores aligned with one another along a pin bore axis; a pair of upwardly extending annular inner and outer lower joining surfaces and a combustion bowl wall. Inner and outer weld joints fix the inner and outer upper and lower joining surfaces to one another. An annular cooling gallery is formed laterally between the upper and lower joining surfaces. The inner weld joint joining the top part to the bottom part is located within the combustion bowl wall and configured to minimized the compression height of the piston.

Owner:TENNECO

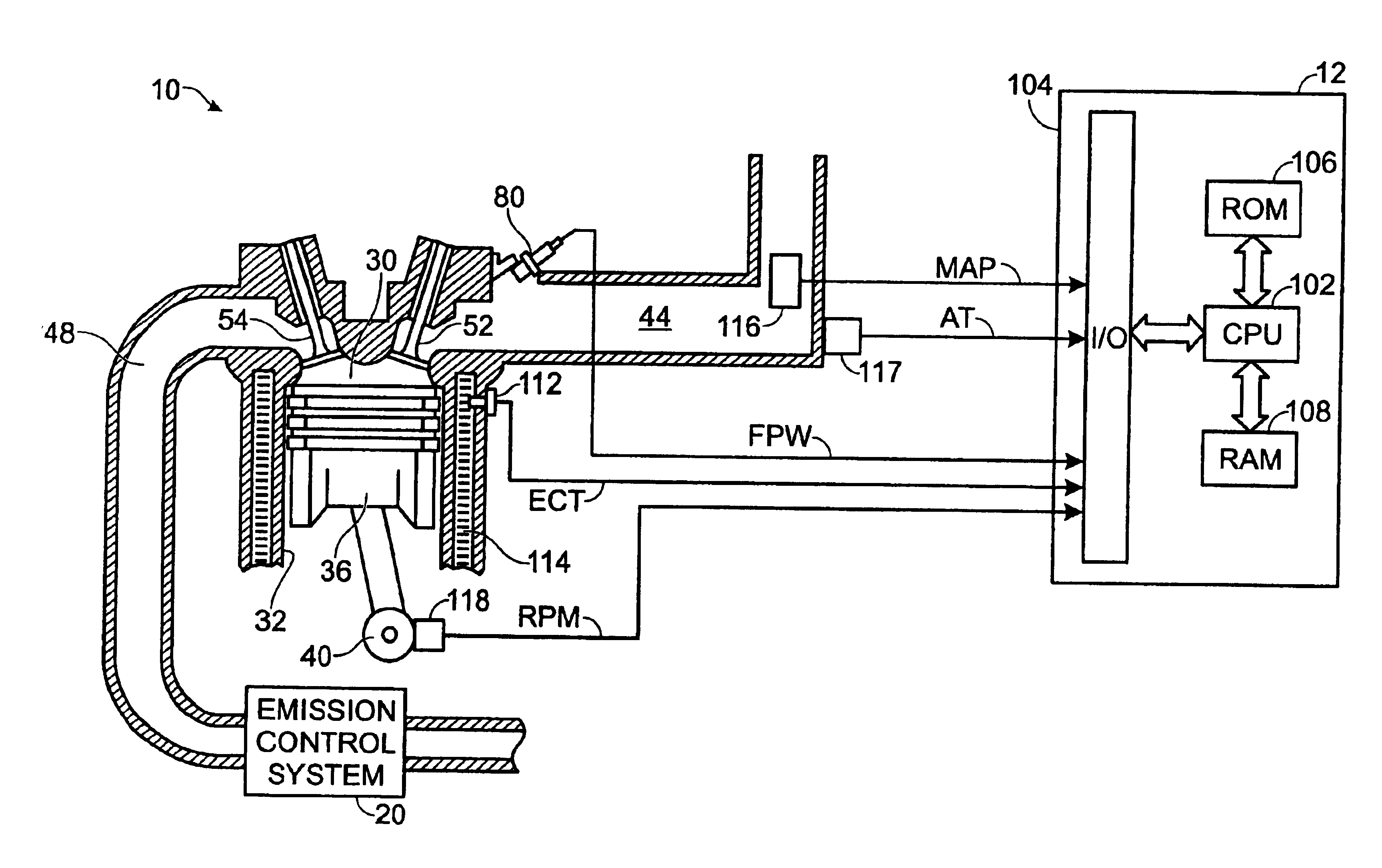

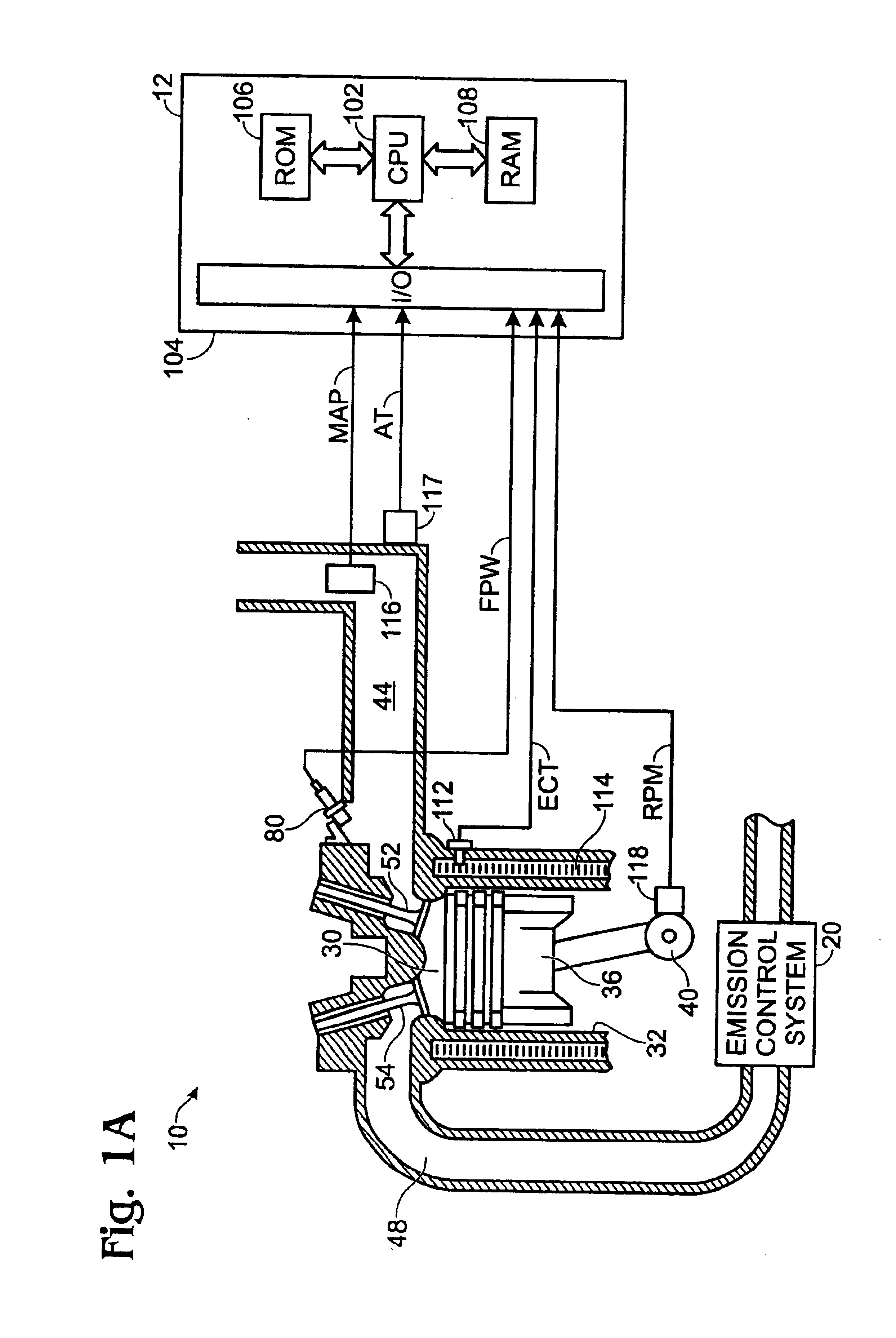

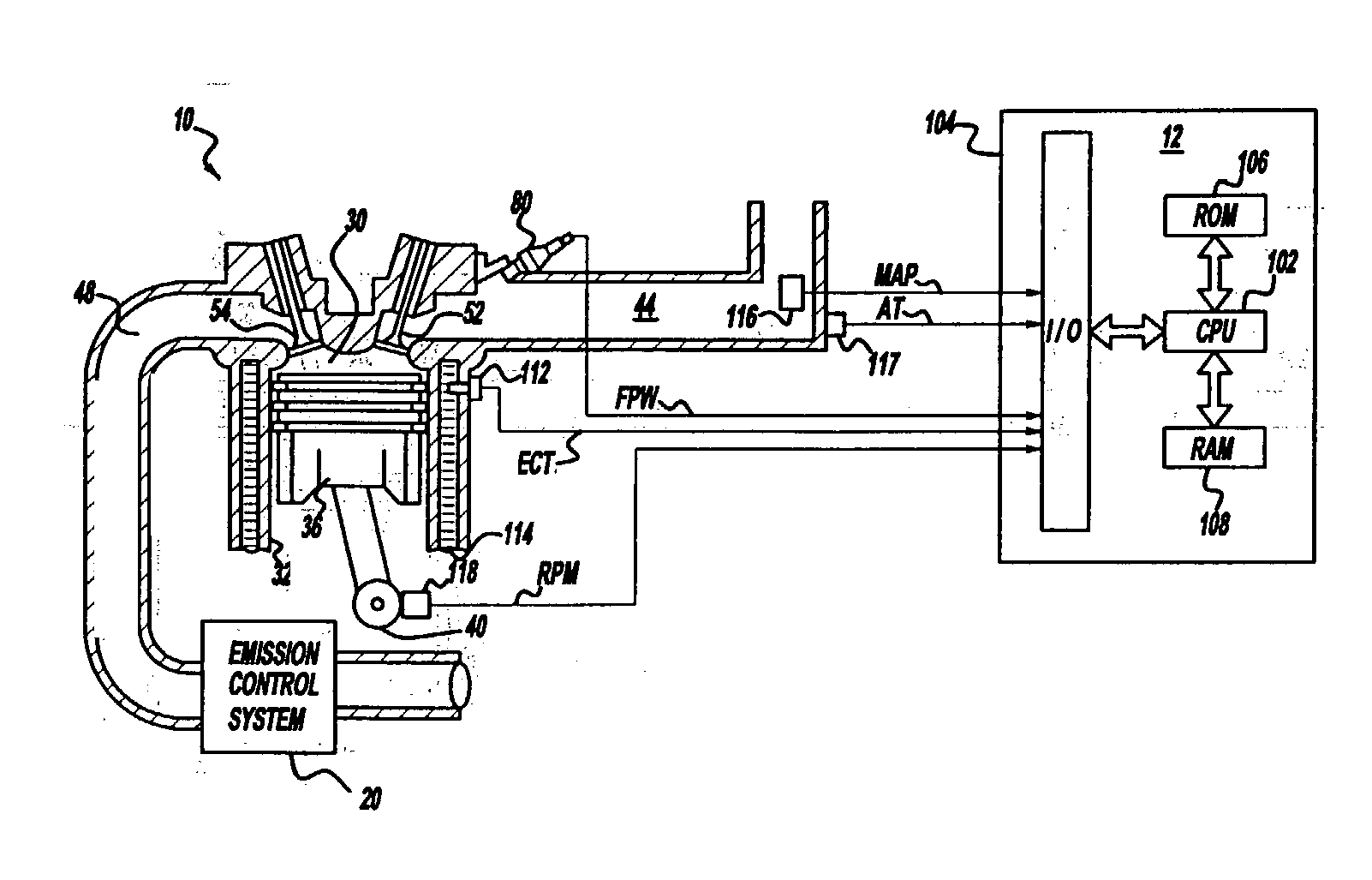

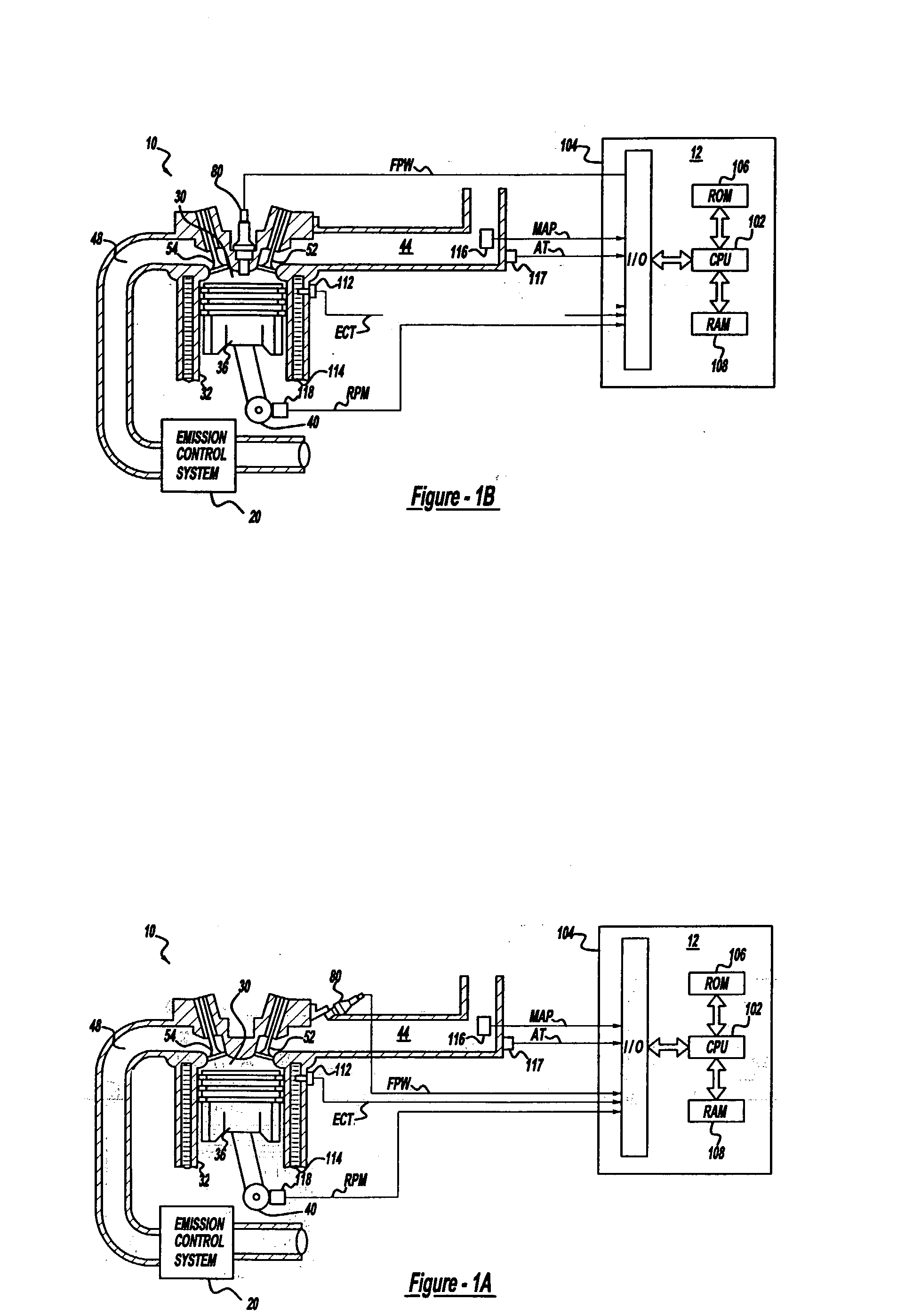

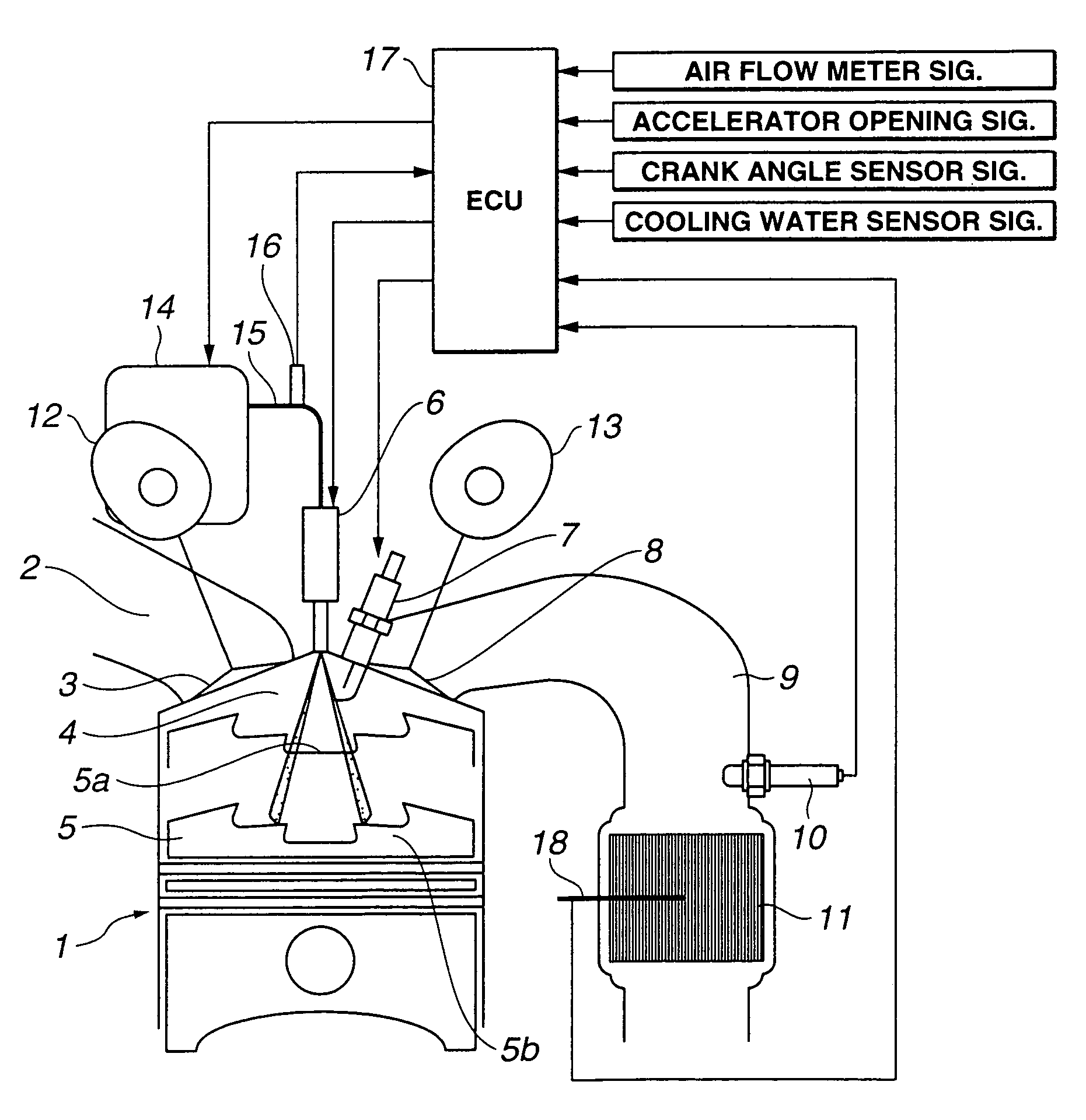

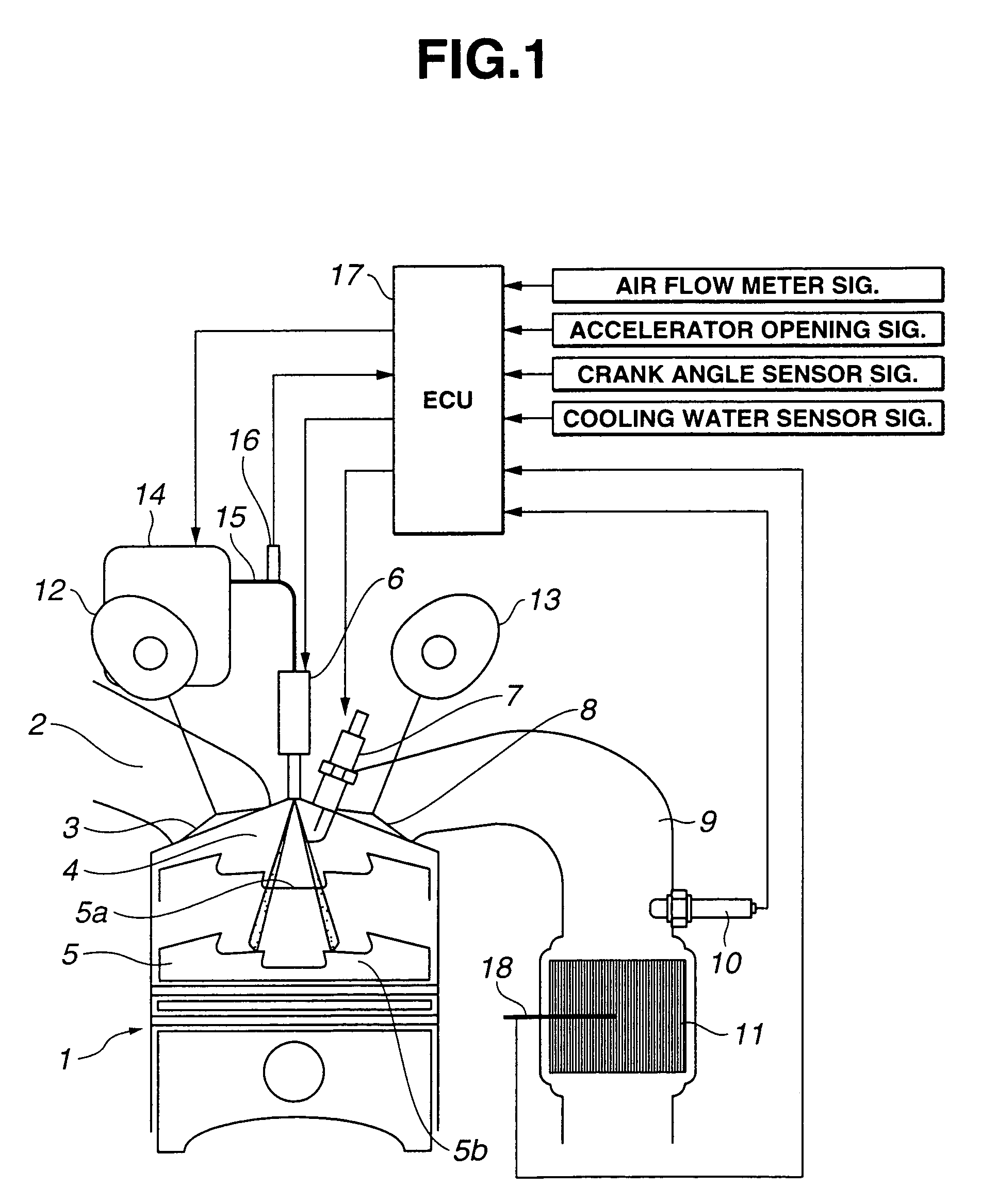

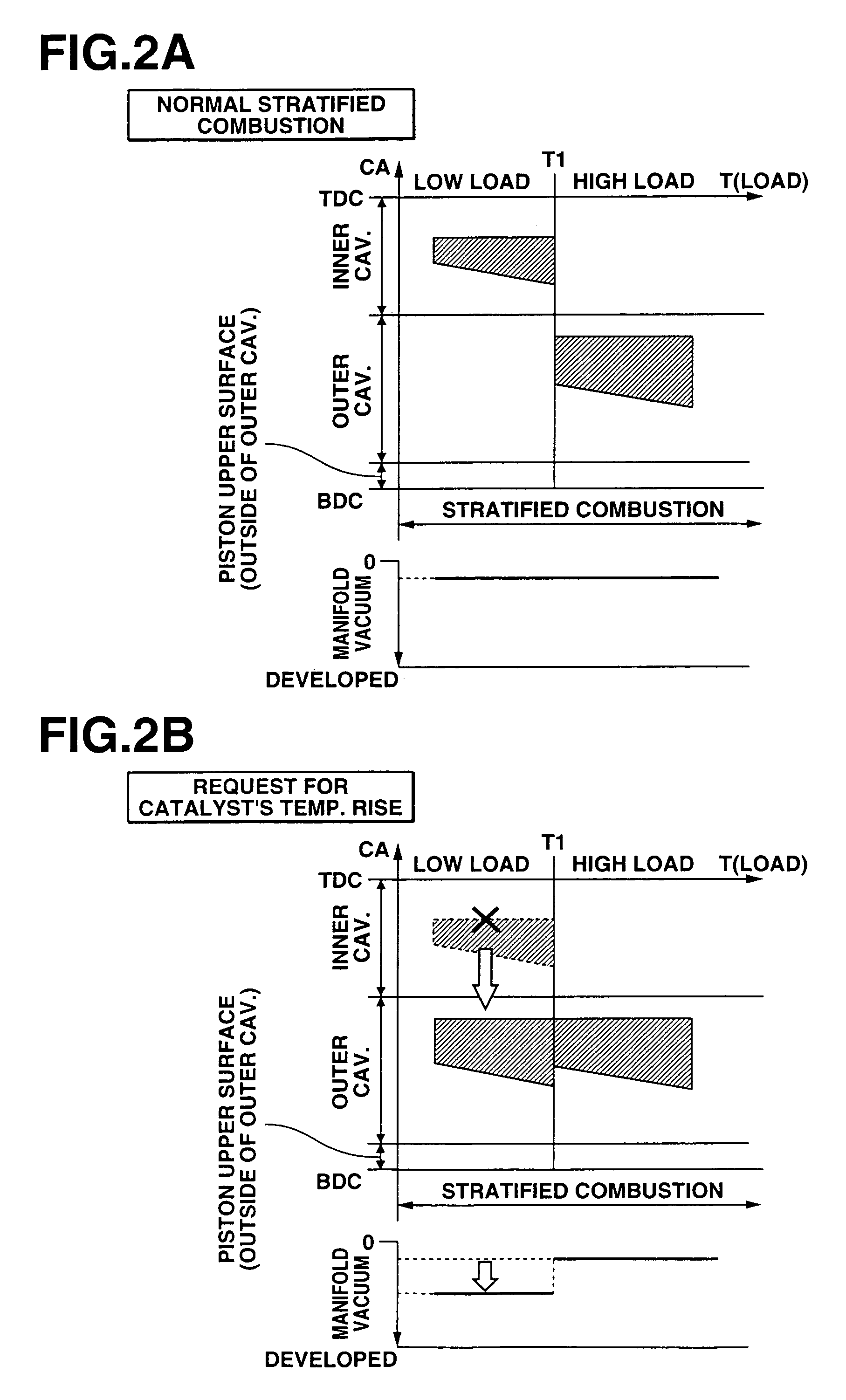

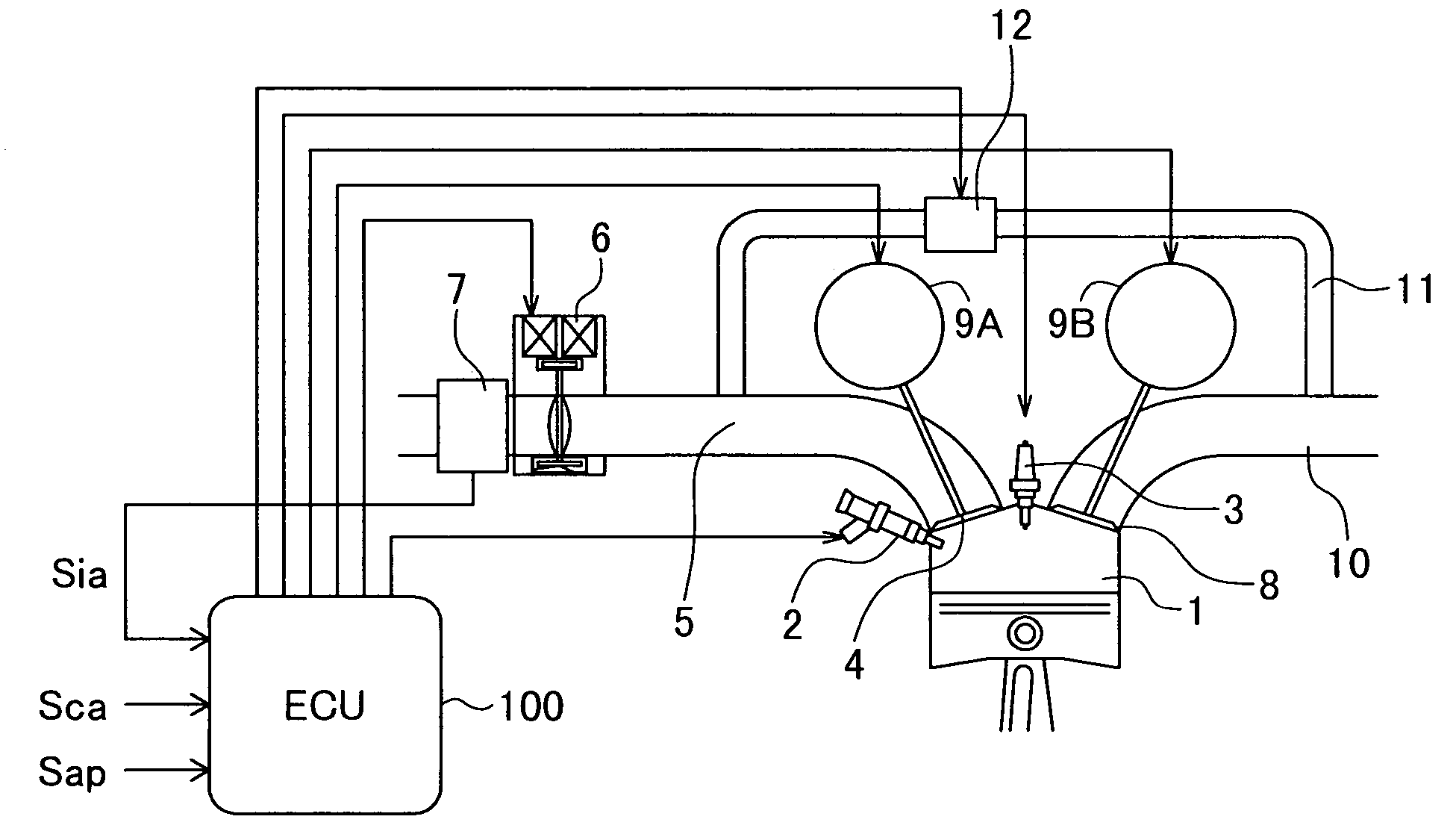

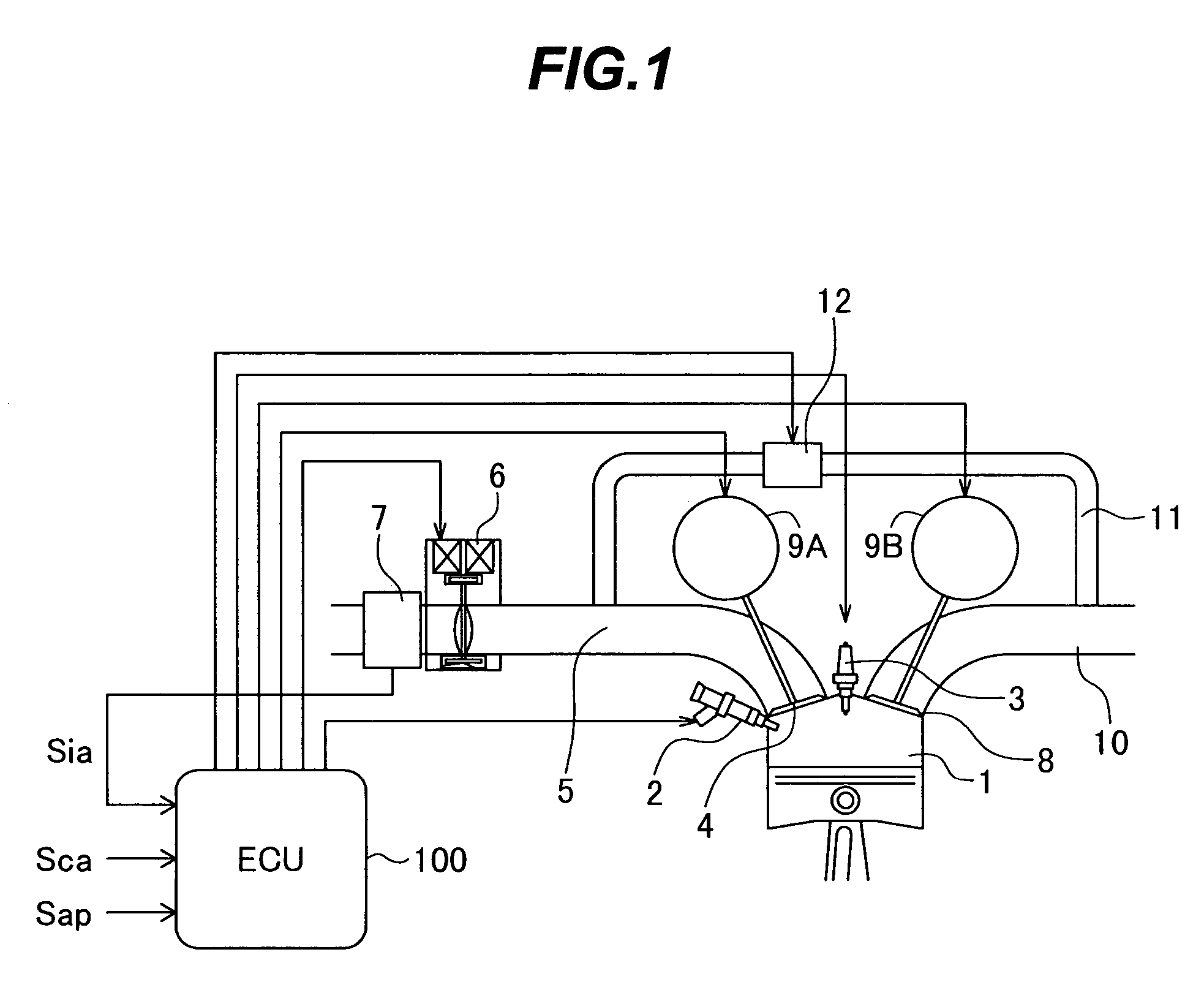

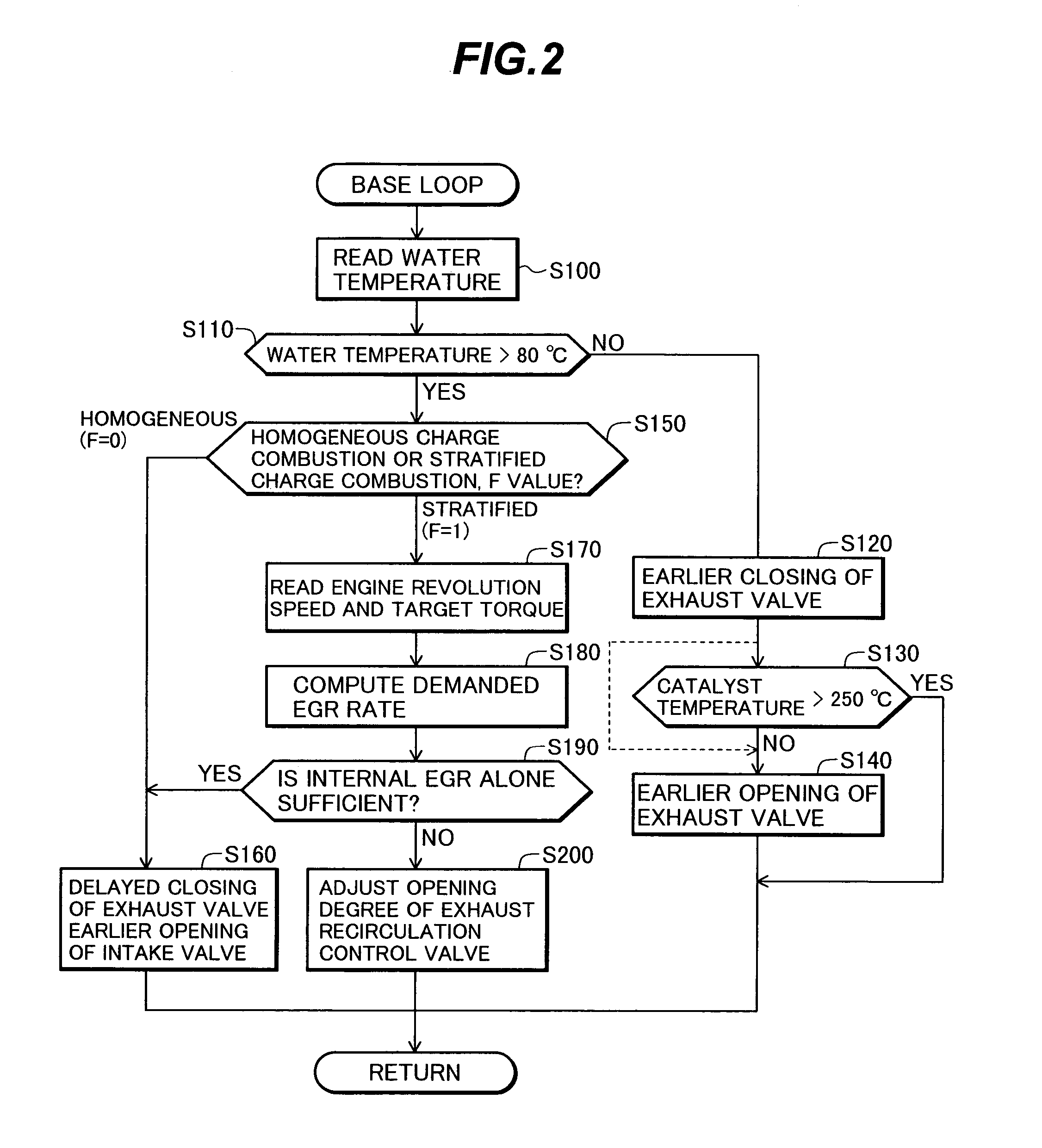

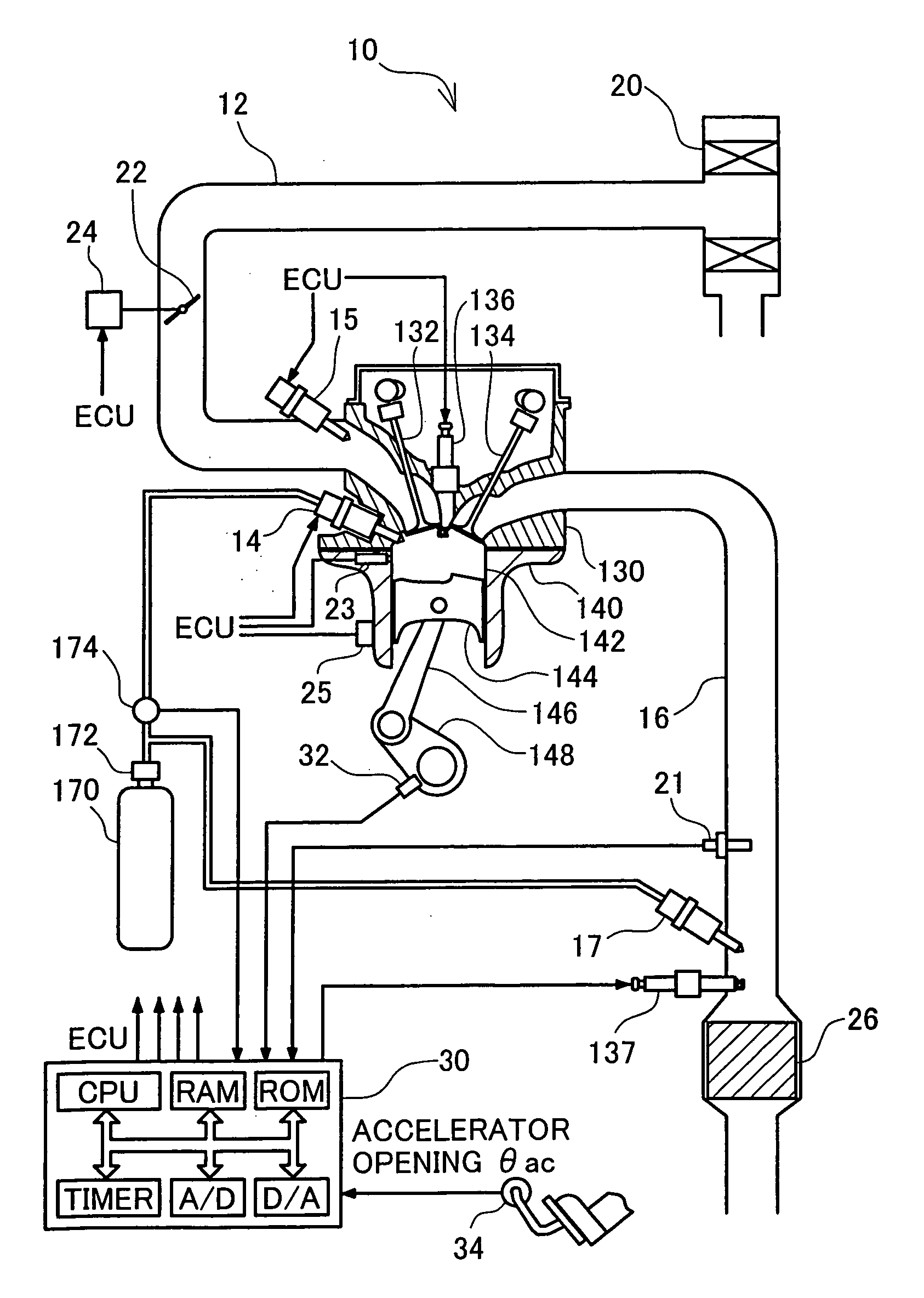

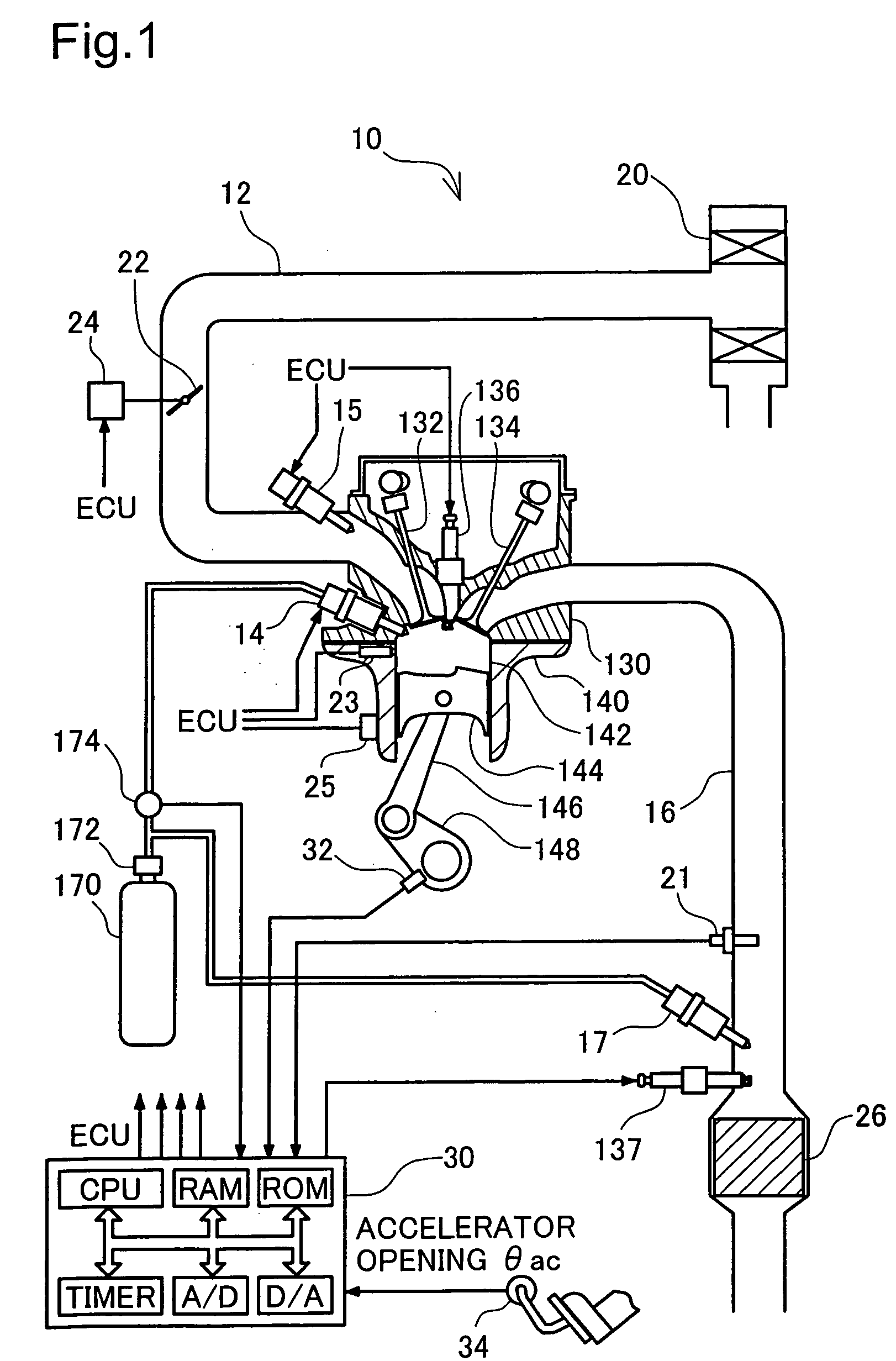

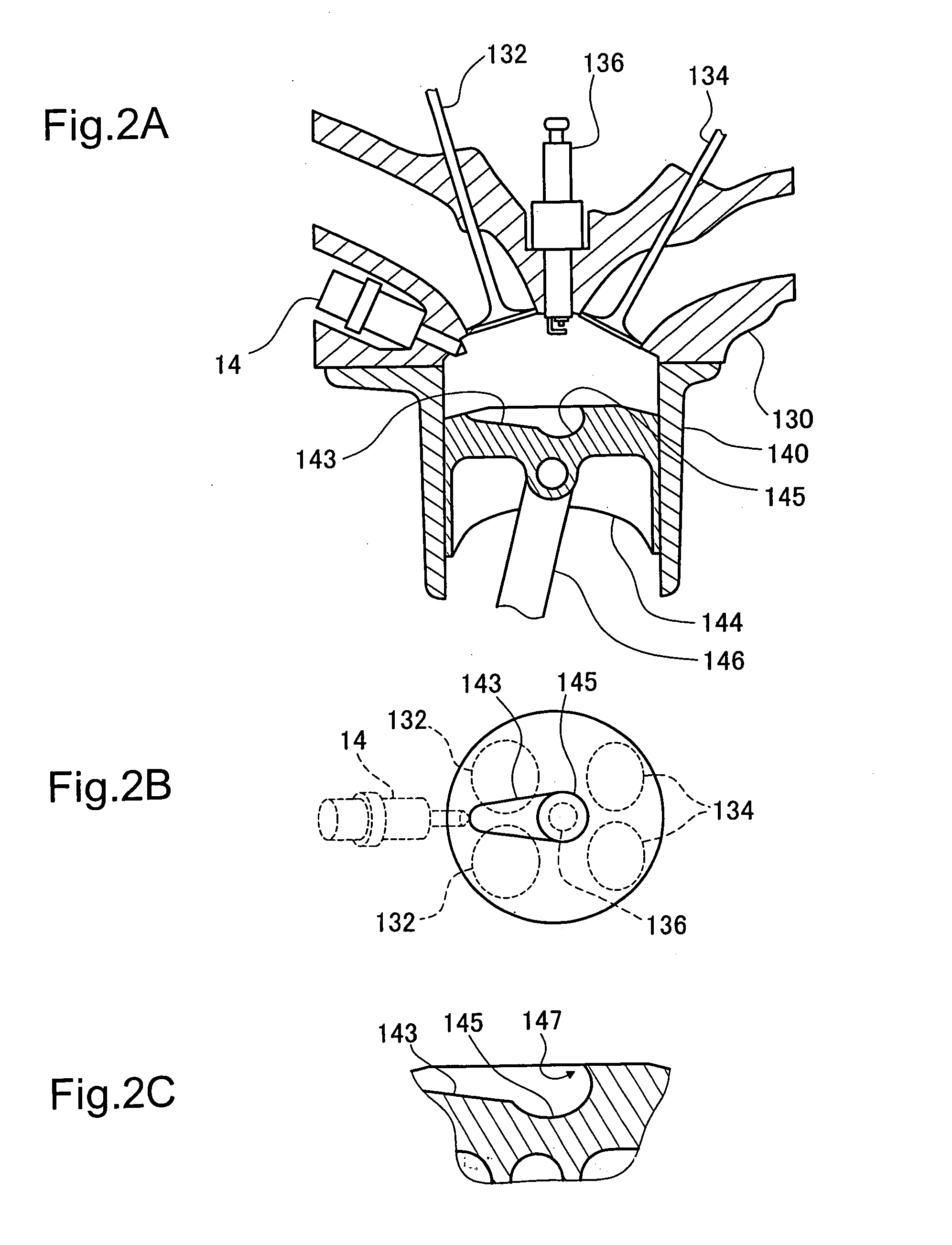

Controller of cylinder injection type internal combustion engine

InactiveUS7000380B2Reduce the amount requiredValve arrangementsElectrical controlExhaust valveCombustion chamber

The present invention is intended to provide a control system for an direct injection internal combustion engine capable of effectively reducing the amounts of both HC and NOx exhausted from a combustion chamber during a period from the start of the engine operation to the stop of the engine operation. It comprises an external EGR passage (11) for returning a part of exhaust gas from an exhaust pipe (10) to an intake pipe (5), an external EGR control valve (12) for controlling an amount of exhaust gas returned to the external EGR passage (11), and a valve timing varying mechanism (9A, 9B) for varying timing of opening and closing at least one of an intake valve and an exhaust valve. An ECU 100 controls the valve timing varying mechanism (9A, 9B) to always return internal EGR gas in an operation region where exhaust gas recirculation is required, and controls the external EGR control valve (12) to return exhaust gas in a combination of internal EGR and external EGR when an internal EGR rate provided by the valve timing varying mechanism (9A, 9B) is not sufficient to satisfy an EGR rate demanded depending on an operation state.

Owner:HITACHI LTD

Internal combustion engine of compressing and auto-igniting air-fuel mixture and method of controlling such internal combustion engine

ActiveUS20050155344A1Effective controlEffective timeElectrical controlNon-fuel substance addition to fuelCombustion systemCombustion chamber

The technique of the present invention produces a first fuel-air mixture containing a first fuel and the air at a specific ratio, which does not allow for auto ignition of the first fuel-air mixture by simple compression, in a combustion chamber. The technique then injects a second fuel, which has a higher octane value than that of the first fuel, into a partial area of the combustion chamber, so as to produce a second fuel-air mixture. The technique ignites the second fuel-air mixture for combustion, so as to compress and auto-ignite the first fuel-air mixture. The second fuel has the higher octane value, so that a combustion start timing of the second fuel-air mixture is reliably regulated by ignition. Namely the technique positively controls the timing of auto ignition of the first fuel-air mixture. Setting an adequate value to the ignition timing thus effectively prevents the occurrence of knocking in an internal combustion engine that adopts a premix compression ignition combustion system.

Owner:TOYOTA JIDOSHA KK

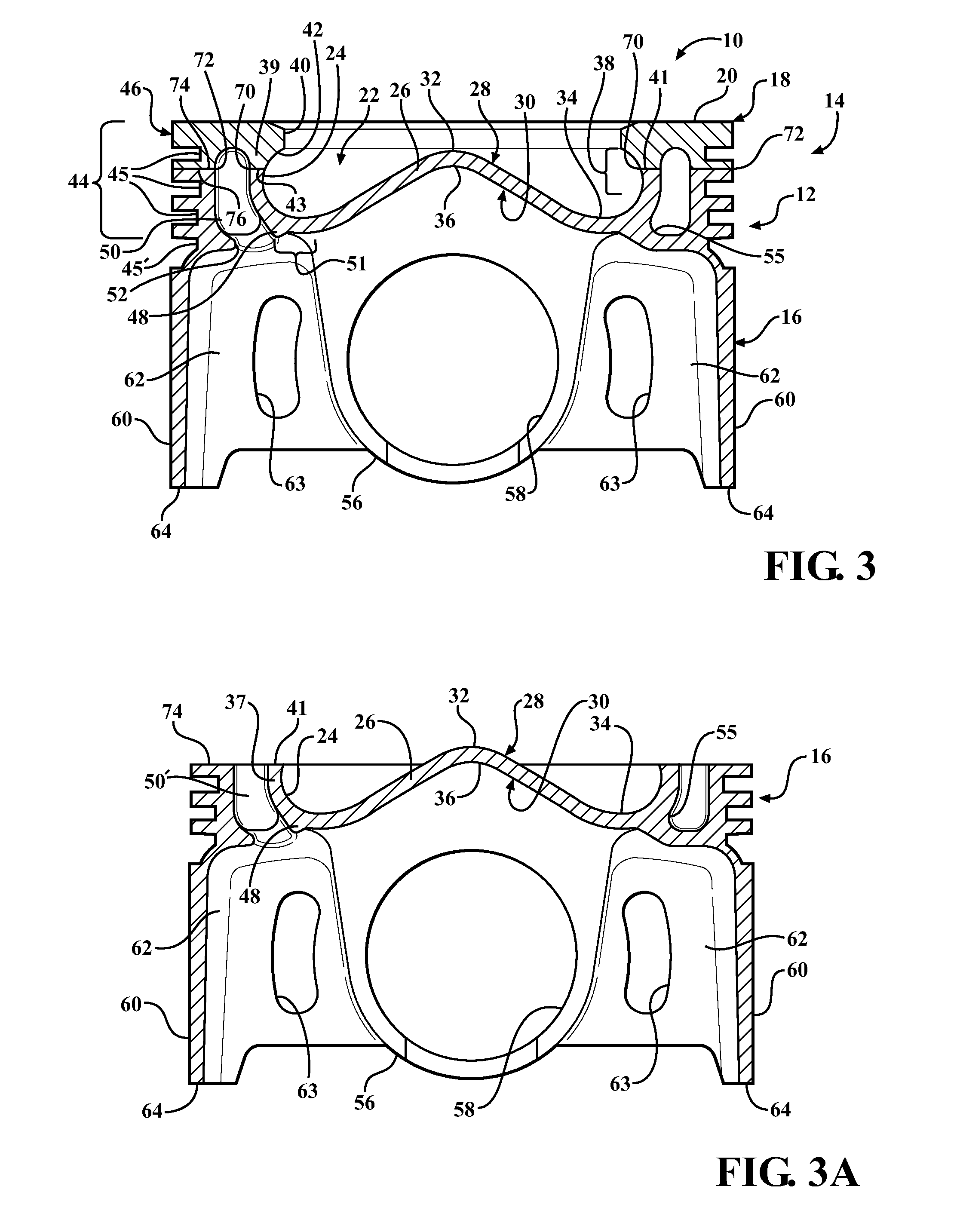

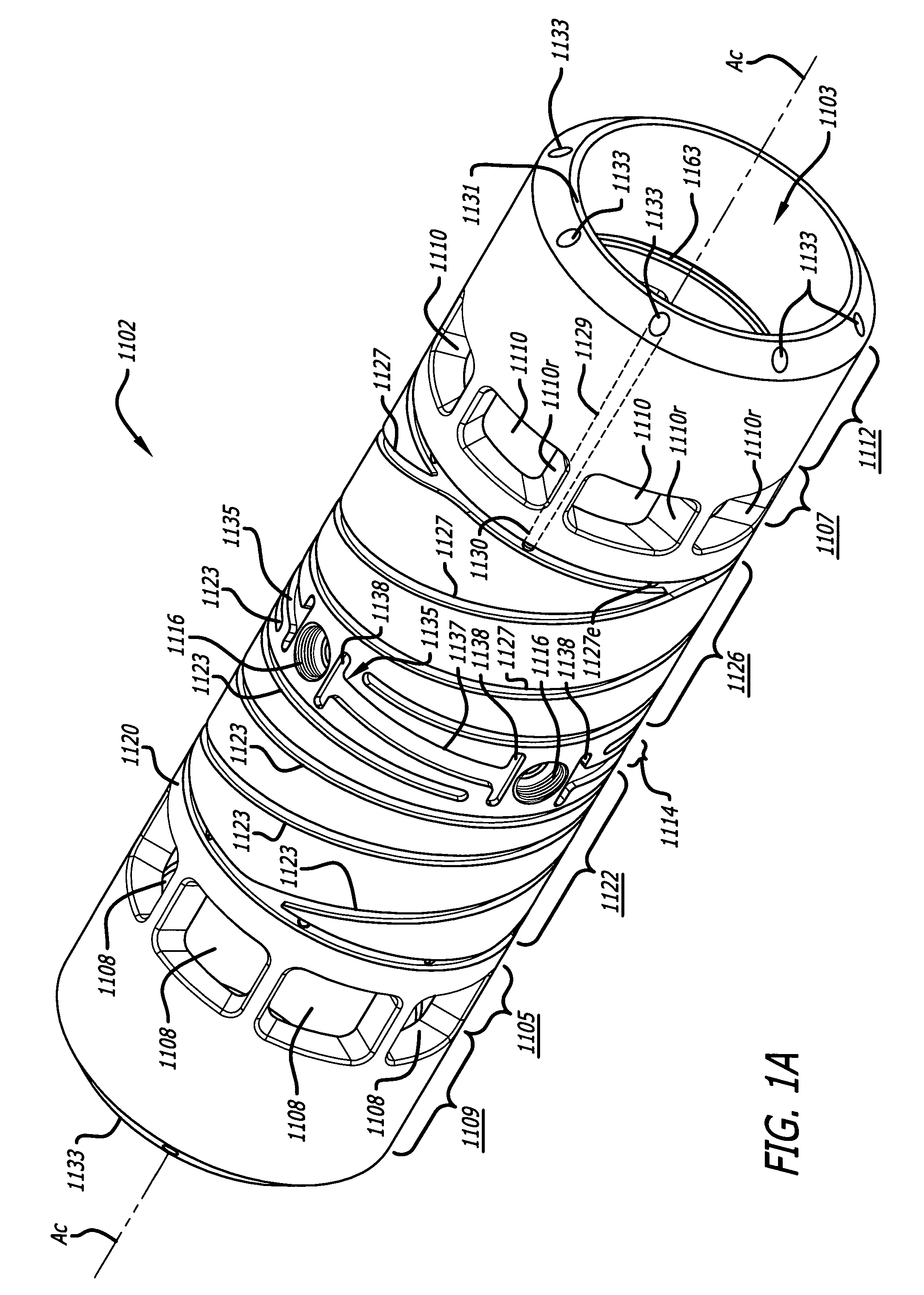

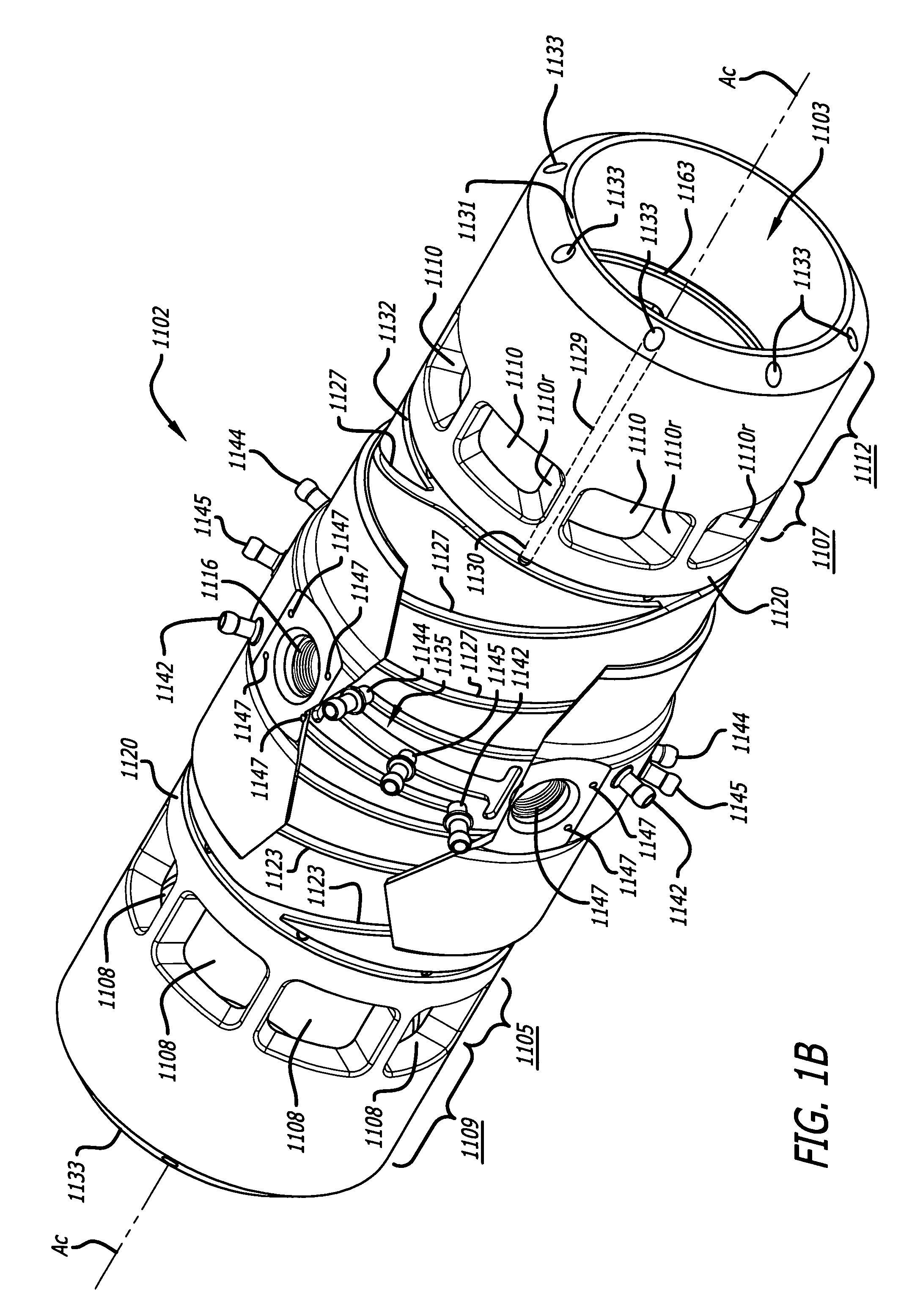

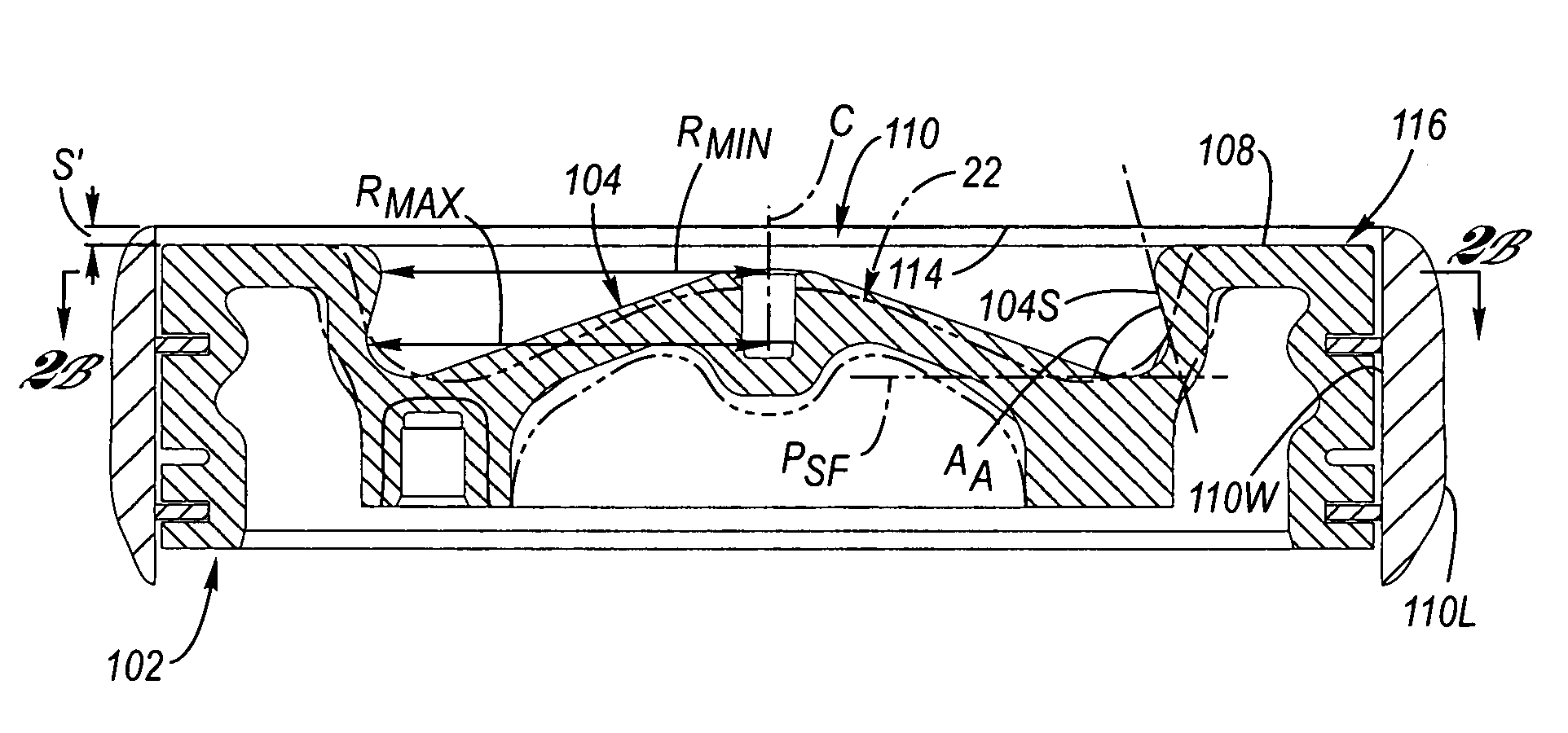

Cylinder and piston assemblies for opposed piston engines

In an opposed piston engine, a pair of pistons are disposed in opposition in the bore of a cylinder. The cylinder includes first liquid coolant grooves having a first cooling capacity to cool a portion of the cylinder extending from a central portion toward an exhaust port, and second liquid coolant grooves having a second cooling capacity, less than the first cooling capacity, to cool a portion of the cylinder extending from the central portion toward an inlet port. Each piston includes a cylindrical skirt with a crown and an open end opposite the crown, a piston rod with a bore, a first end attached to a back surface of the crown, and a second end extending through the open end of the skirt, a radial array of liquid coolant flow passages in communication with the bore and disposed between the first end and the back surface of the crown, and a single wristpin retained on the second end section of the piston rod and positioned externally to the piston.

Owner:ACHATES POWERS INC

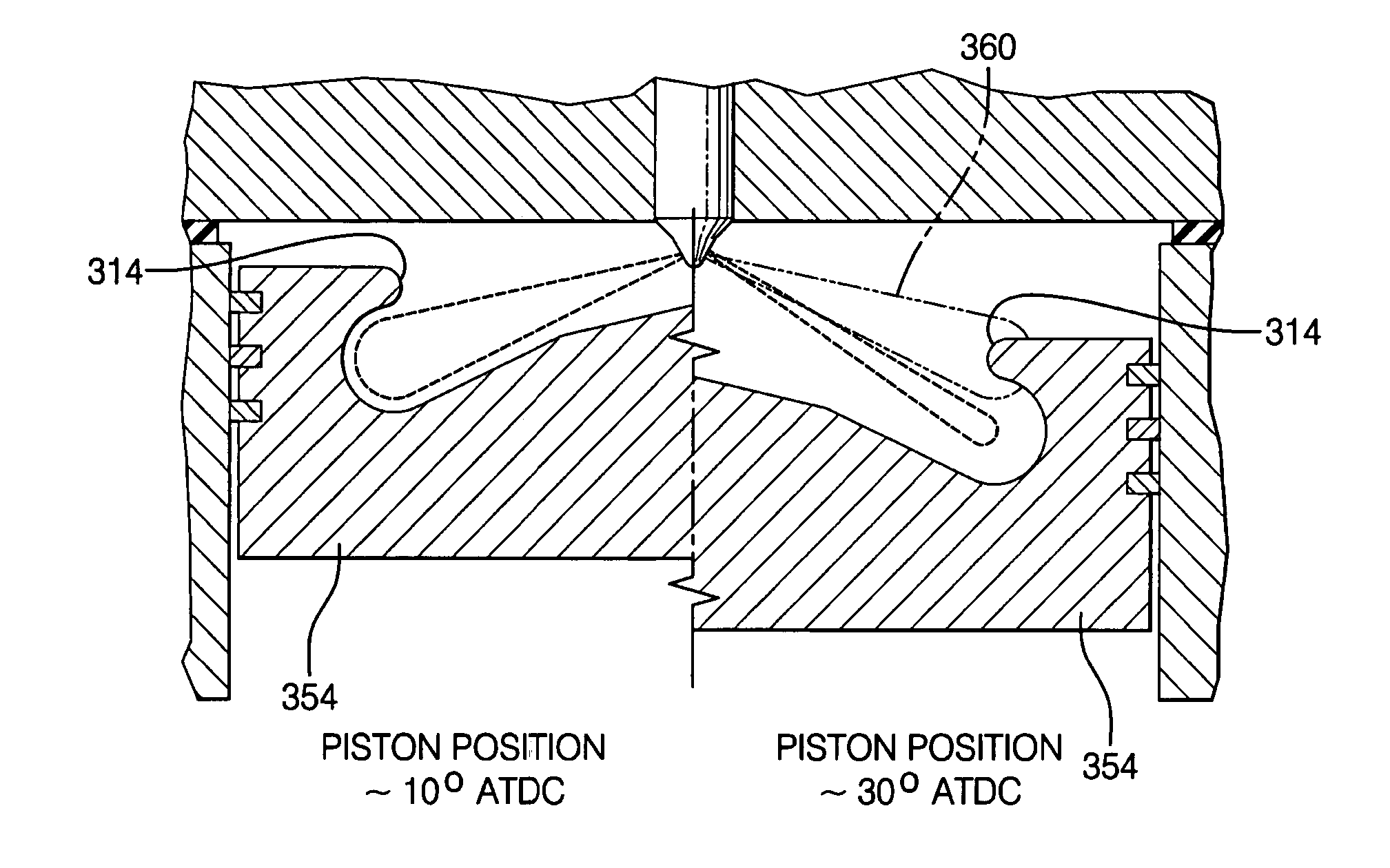

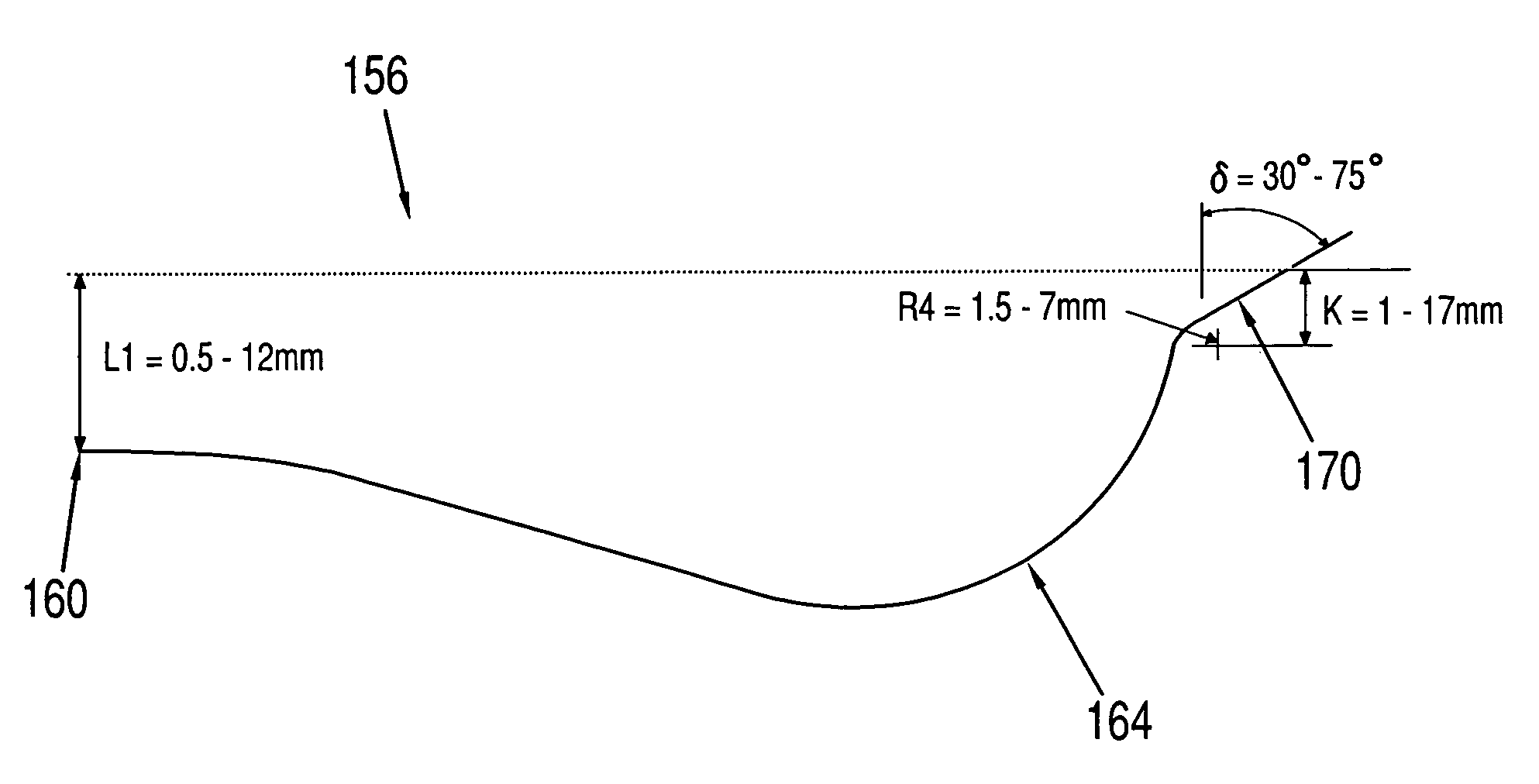

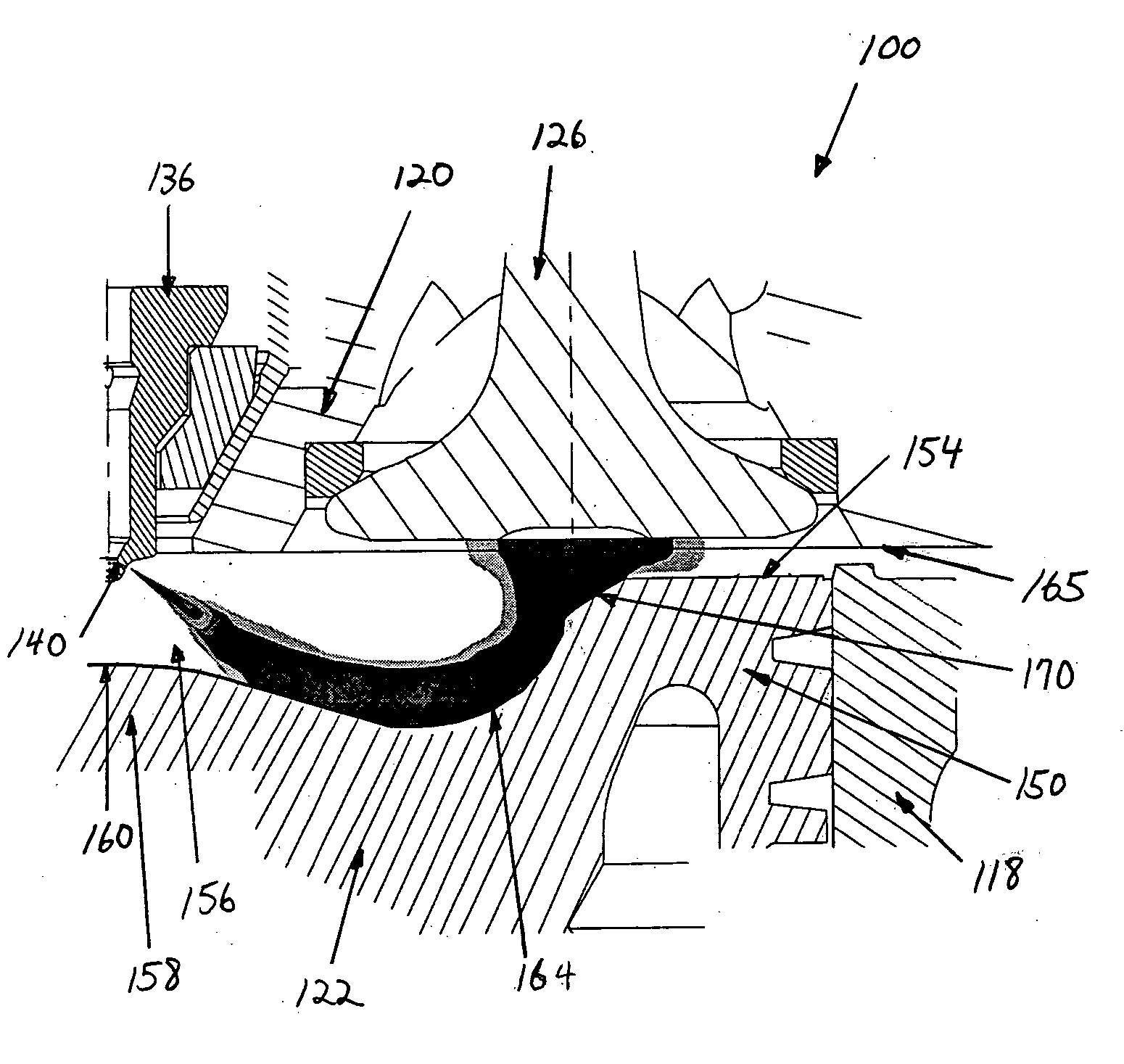

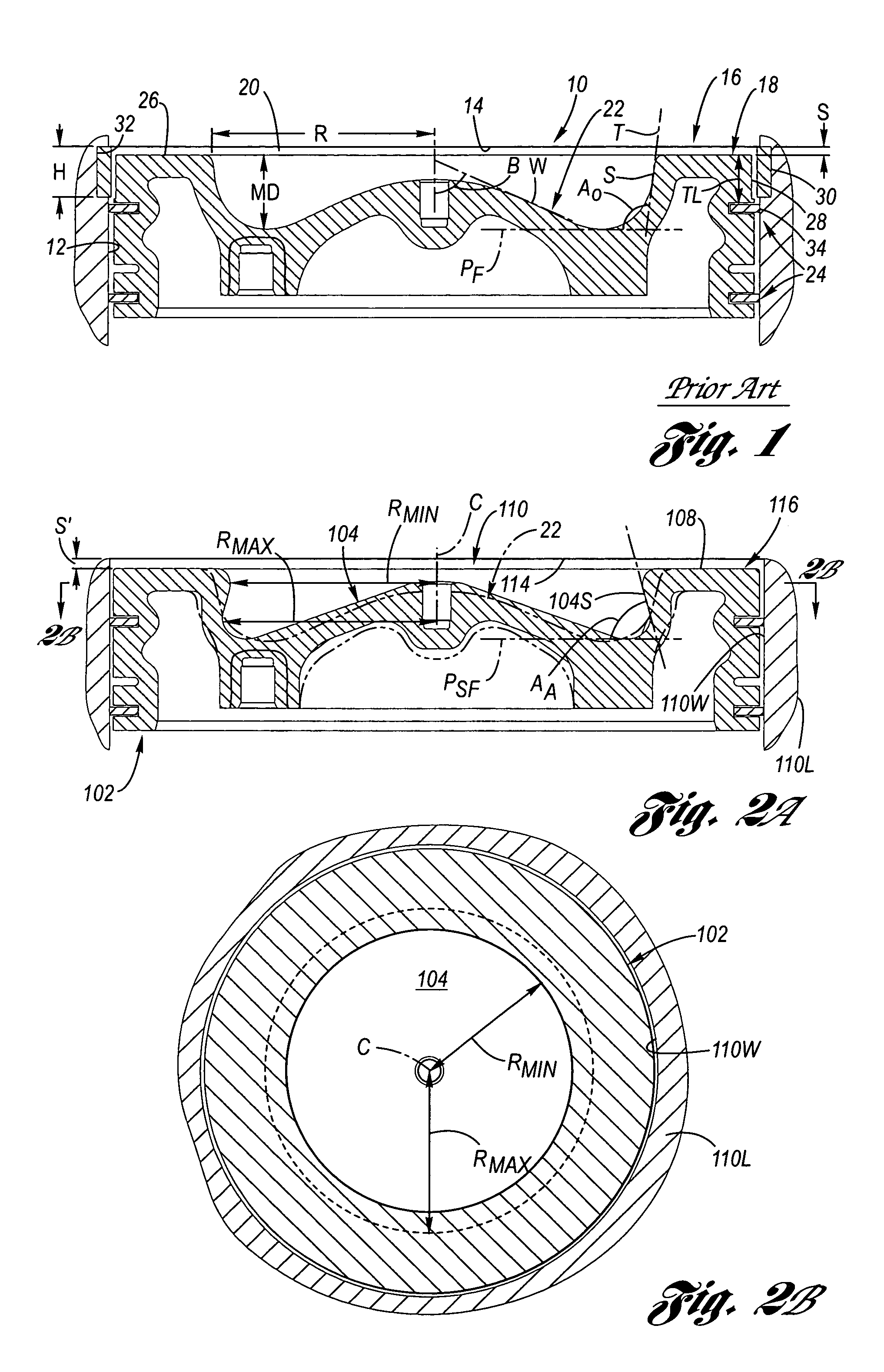

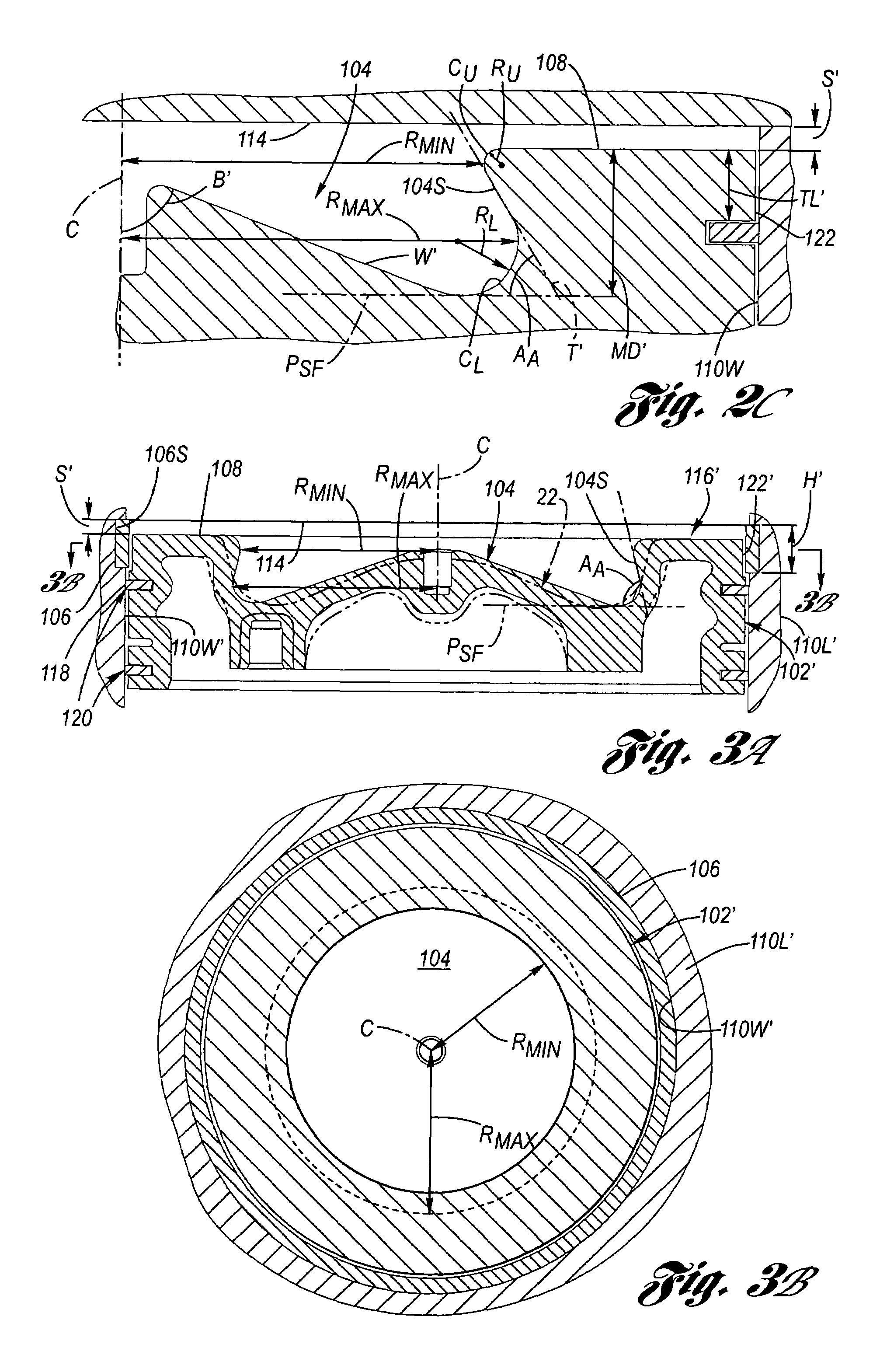

Large-bore, medium-speed diesel engine having piston crown bowl with acute re-entrant angle

ActiveUS7438039B2Excellent characteristicsImprove performanceInternal combustion piston enginesPistonsInternal combustion engineDiesel engine

A large-bore (at least 180 mm diameter) diesel engine cylinder configuration featuring a piston crown bowl having an acute re-entrant angle and, optionally, an anti-polish ring. The acute re-entrant angle crown bowl involves a maximum radius of the crown bowl exceeding a minimum crown bowl radius, wherein the maximum crown bowl radius is located farther from the squish face than is the minimum crown bowl radius. The acute re-entrant angle crown bowl applied to large-bore, medium-speed diesel engines yields an improvement in performance and emissions characteristics. The anti-polish ring may be integrally formed with the cylinder liner and used in any internal combustion engine.

Owner:ELECTRO-MOTIVE DIESEL

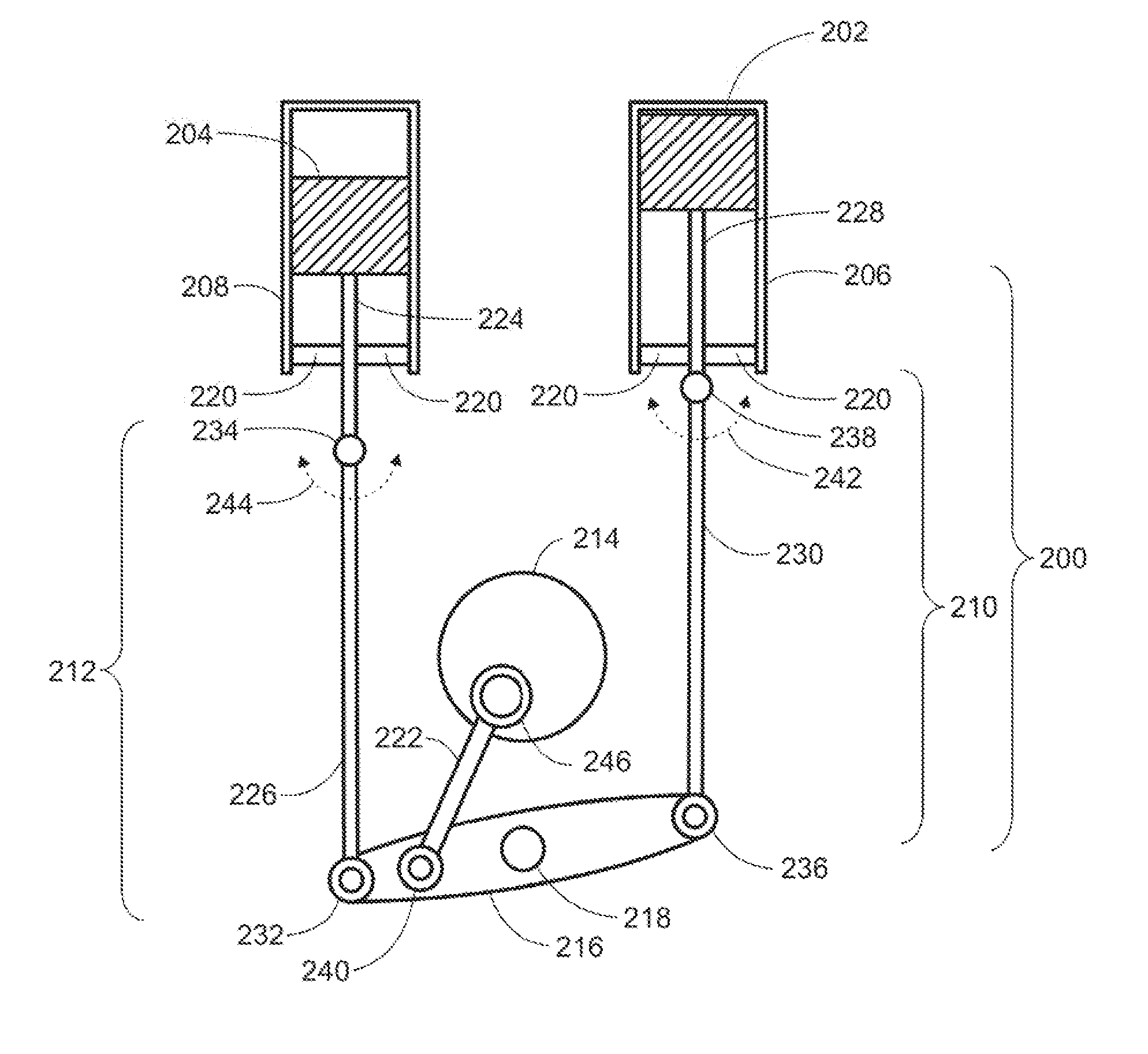

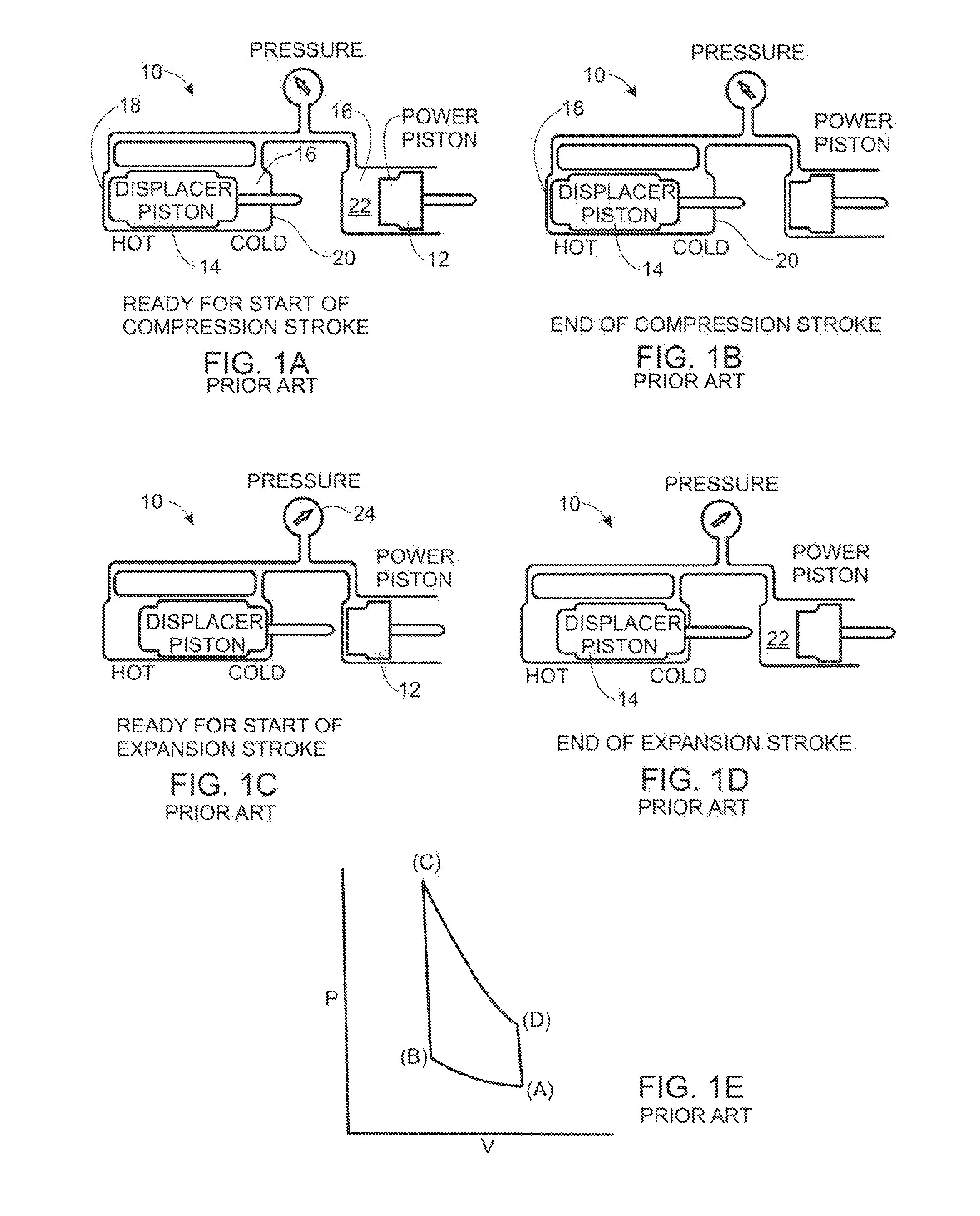

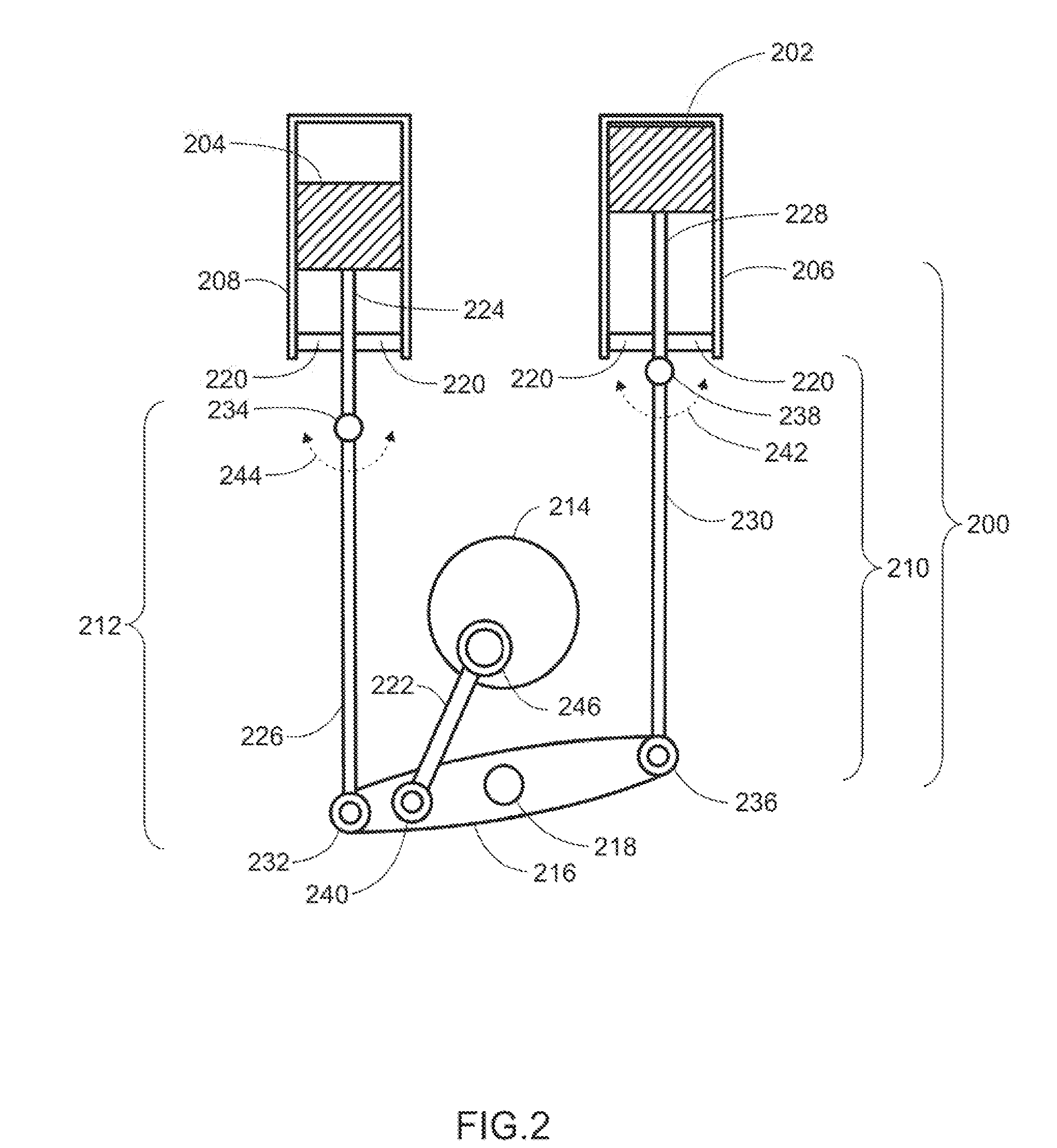

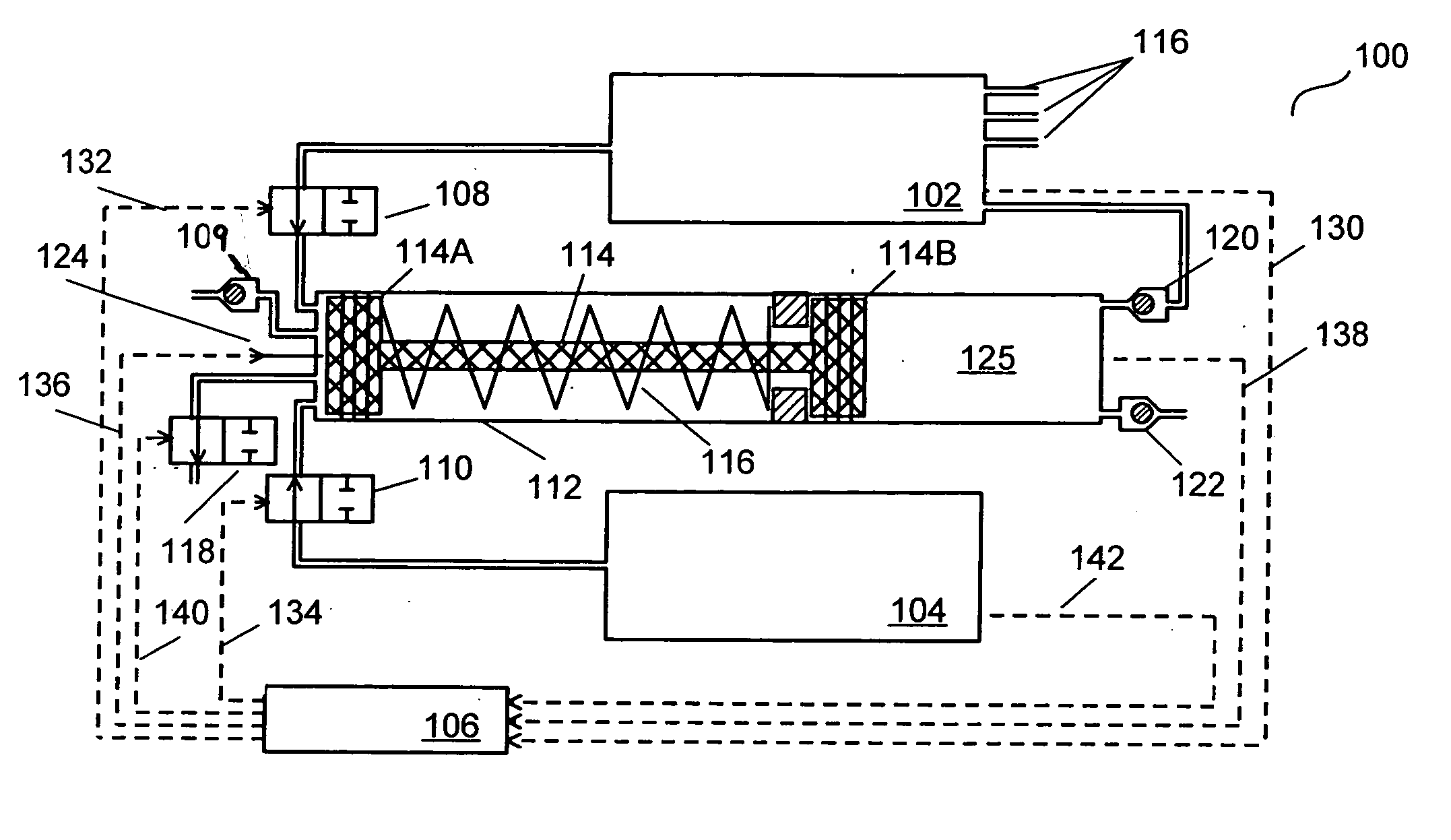

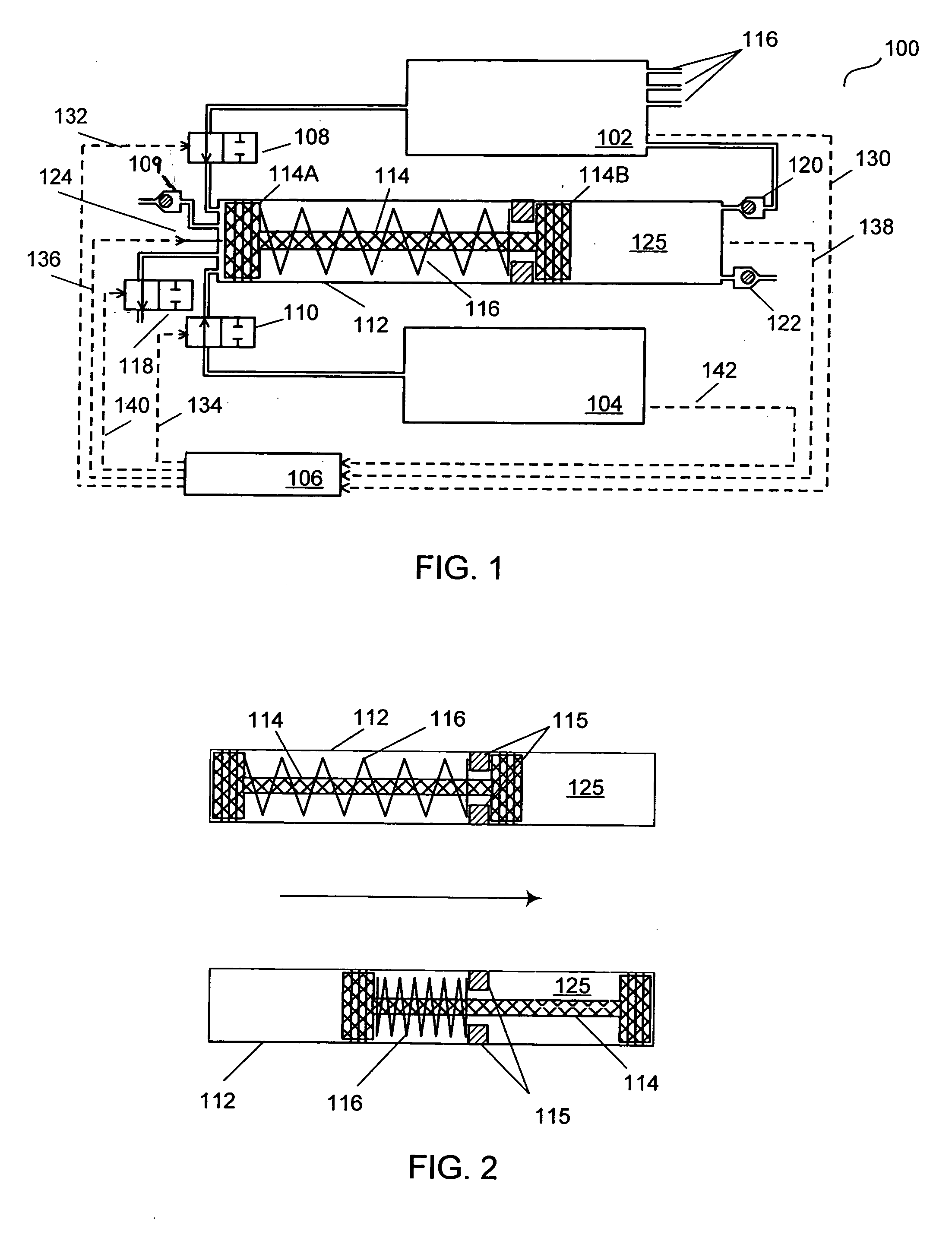

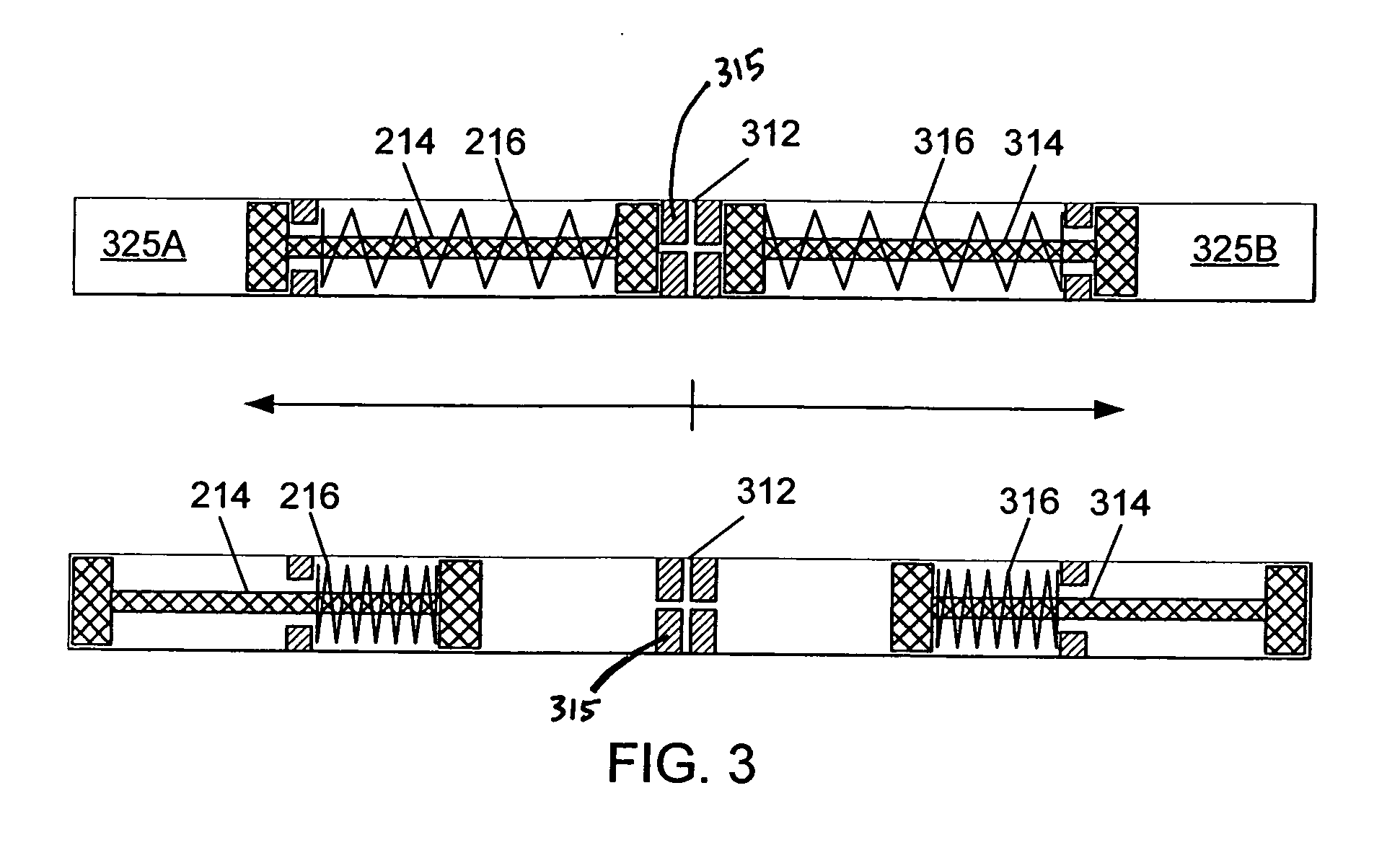

Stirling cycle machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. An airlock is included between the workspace and the crankcase and a seal is included for sealing the workspace from the airlock and crankcase. A burner and burner control system is also included for heating the machine and controlling ignition and combustion in the burner.

Owner:NEW POWER CONCEPTS

Free piston compressor

InactiveUS20050284427A1Increase energy densityImprove efficiencyPistonsFree piston enginesEngineeringHigh pressure

Methods and systems associated with free piston compressors. Fuel is ignited within a combustion chamber to increase pressure. A free piston is displaced within the combustion chamber. The free piston acts as an inertial load to high-pressure gas generated by combustion of the fuel. High pressure gas is pumped from the combustion chamber into a reservoir using the free piston. A spring, magnet, or other mechanism engaging the free piston may be used to assist the process. In the case of a spring, the spring assists returning the free piston to its approximate initial position as the spring expands. In the case of a magnet, the magnet may engage opposite ends of the free piston during the process. Two or more free pistons may be used. The system may be used as a power source for equipment such as a robot.

Owner:VANDERBILT UNIV

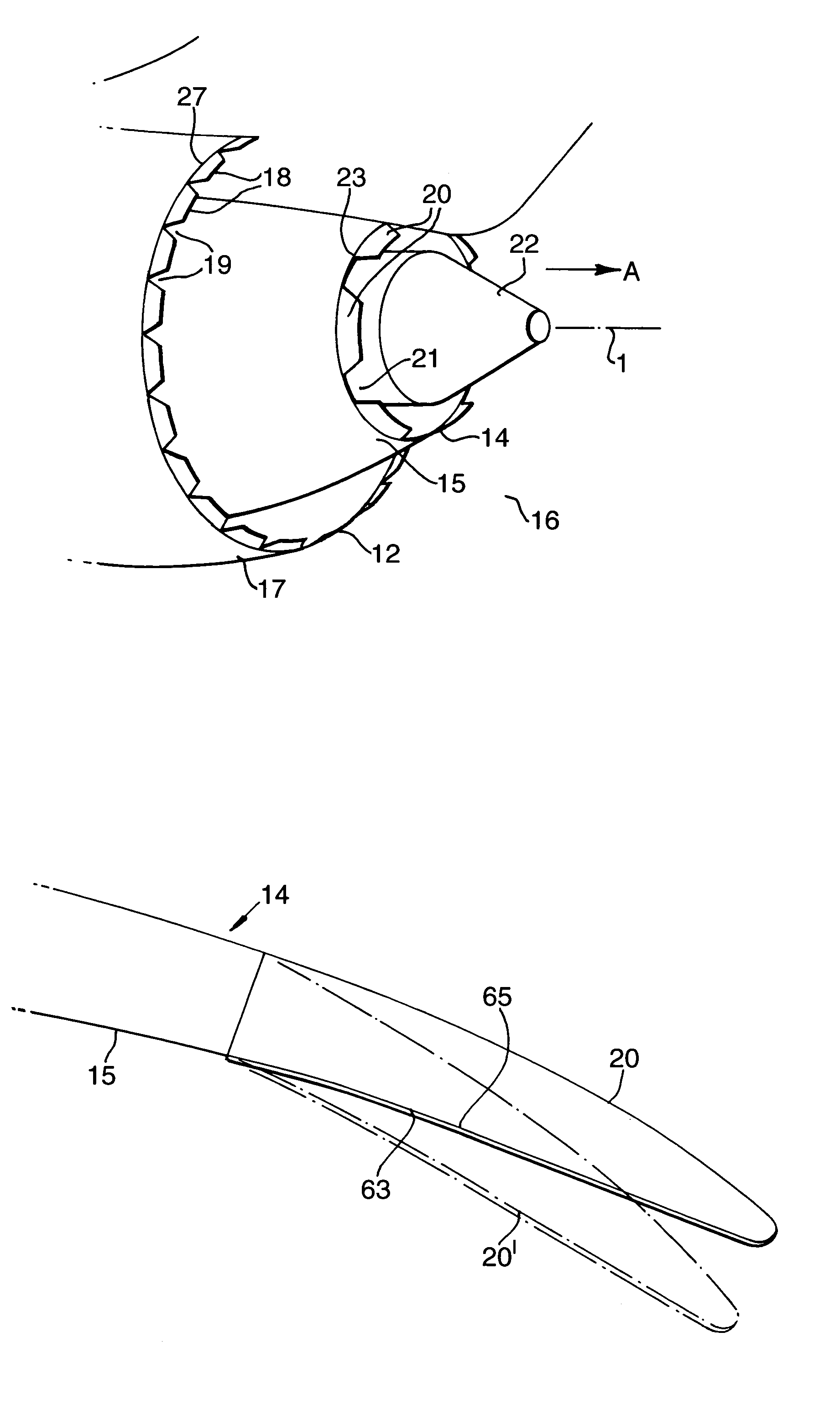

Gas turbine engine exhaust nozzle having a noise attenuation device driven by shape memory material actuators

A gas turbine engine exhaust nozzle arrangement for the flow of exhaust gases therethrough between an upstream end and a downstream end thereof comprising a nozzle and a plurality of tabs which extend in a generally axial direction from a downstream portion of the nozzle wherein the nozzle further comprises an actuation mechanism capable of moving the tabs between a first deployed position, where the tabs interact with a gas stream to reduce exhaust noise thereof, and a second non-deployed position, where the tabs are substantially aerodynamically unobtrusive.

Owner:ROLLS ROYCE PLC

Sliding element, in particular piston ring, having a coating and process for producing a sliding element

ActiveUS20130140776A1Increase valueProducibilityPiston ringsBraking action transmissionPiston ringMetal

A sliding element, in particular piston ring, has on at least one running surface, from the inside outwards, a coating having a metal-containing adhesive layer and a ta-C type DLC layer with a thickness of at least 10 μm.In a process for the production of a sliding element, in particular a piston ring, coating with a metal-containing adhesive layer and a ta-C type DLC layer in a thickness of at least 10 μm is carried out.

Owner:FEDERAL MOGUL BURSCHEID

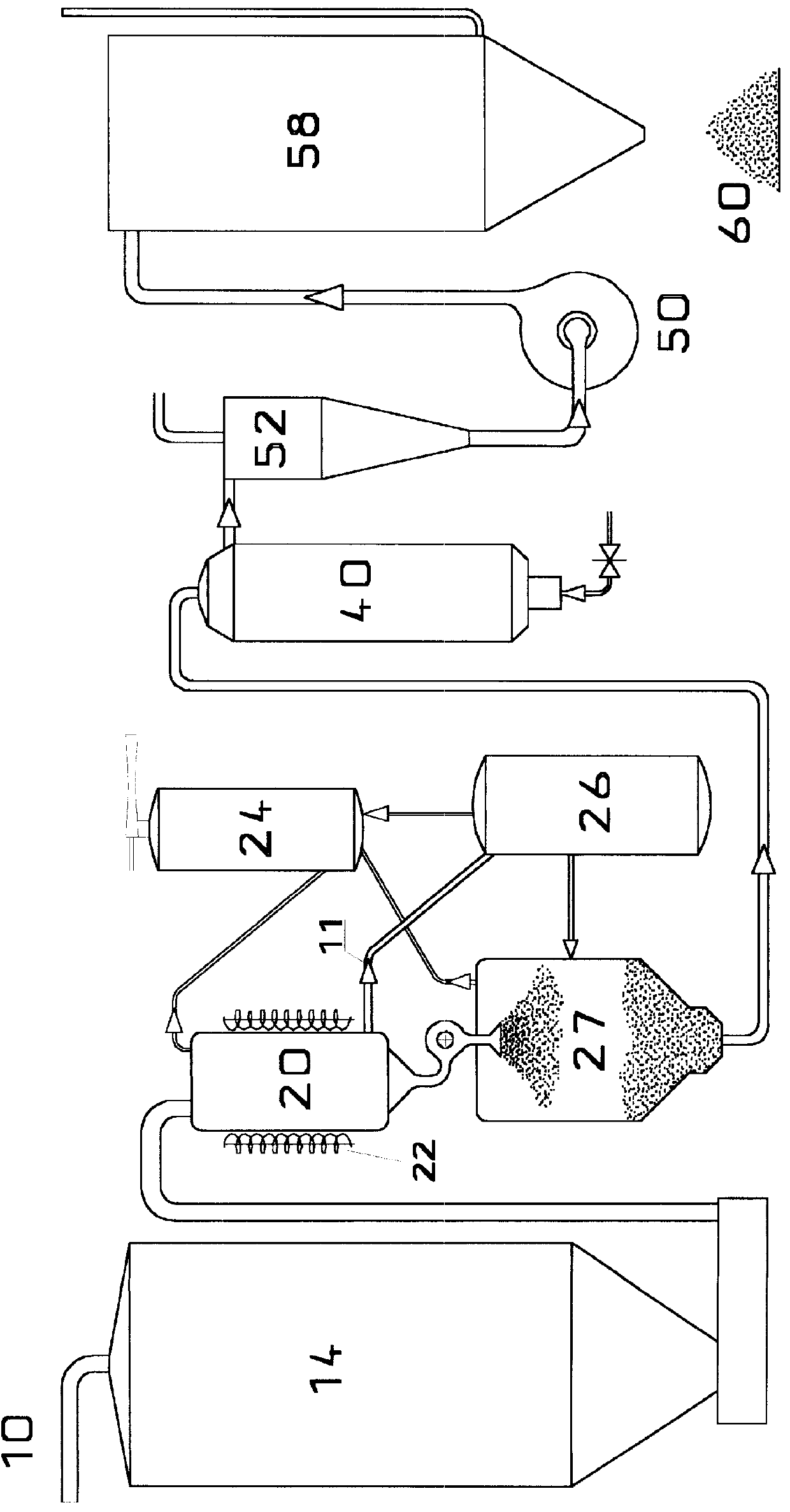

Carbon artifacts and compositions and processes for their manufacture

InactiveUS6013371ASaving evaporation requirementSimple processCasingsLayered productsFiberCarbon composites

Producing of near net shape carbon (optionally carbon-carbon composite) pistons and other artifacts by sintering (with or without carbon fibers, preferably pitch-based carbon fibers and most preferably blends of vapor grown carbon fibers(VGCF)) homogeneous powders derived from petroleum pitch. The powders preferably exhibit properties equal to or exceeding those of POCO AXF-5Q. Preferred specific technical steps are substantially as follows: 1. Individually prepare, by evaporation, heat treating and / or oxidizing of carbon-containing pitches, followed by oxidizing, comminuting and / or spray drying, to produce sinterable pitch powders (and optionally create uniform dryblends of pitch powder with various fractions of vapor-grown or other carbon fiber.) 2. Produce near net shape carbon-carbon artifacts, such as cup shapes which are convertible to internal-combustion (i-c) pistons with minimal machining, by pressing or injecting into molds, then sintering and carbonizing. Both uniaxially (e.g. injection molded) and isostatically compacted powder blends, can be employed. Related apparatus, compositions and artifacts are also taught.

Owner:MOTORCARBON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com