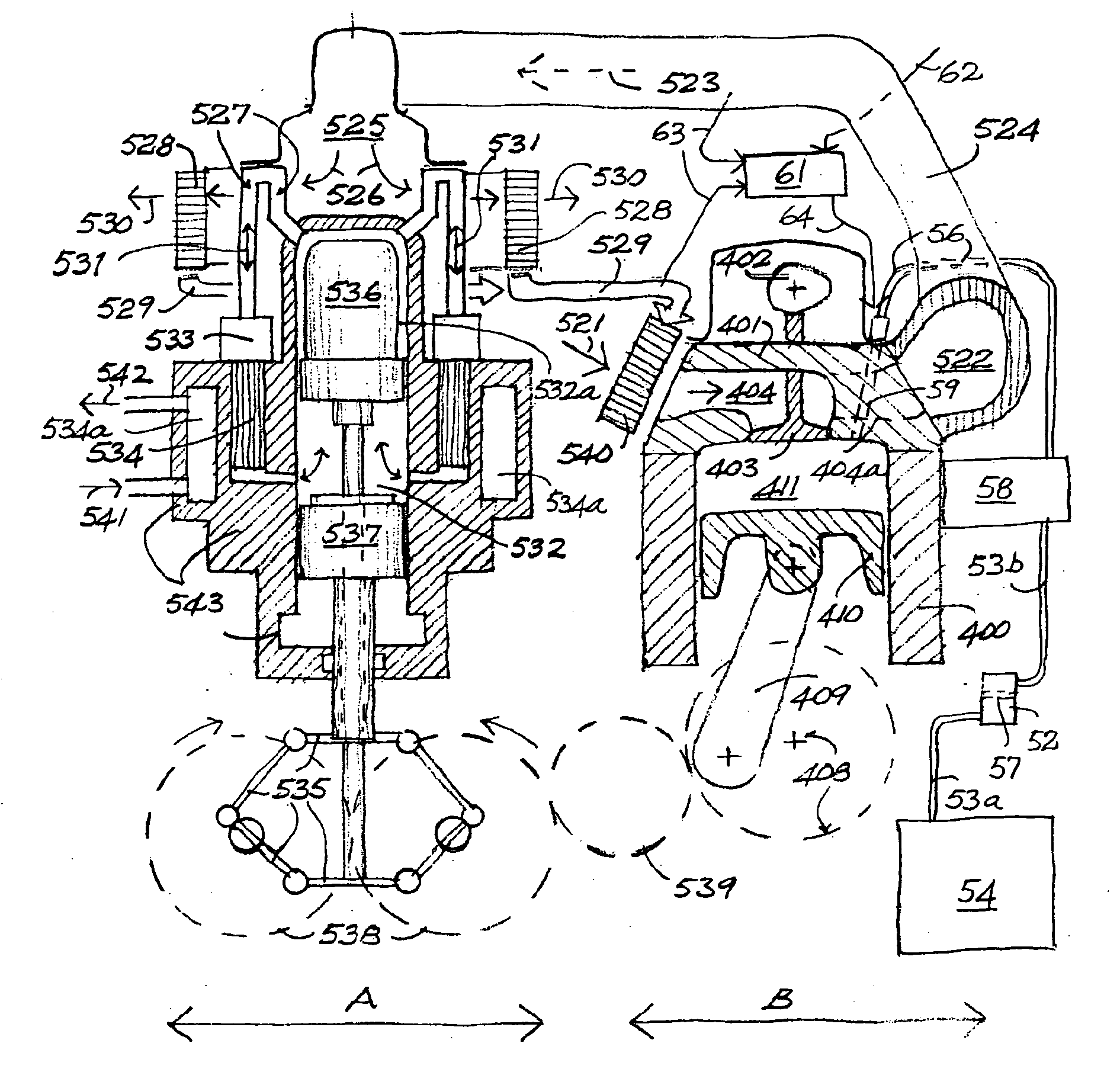

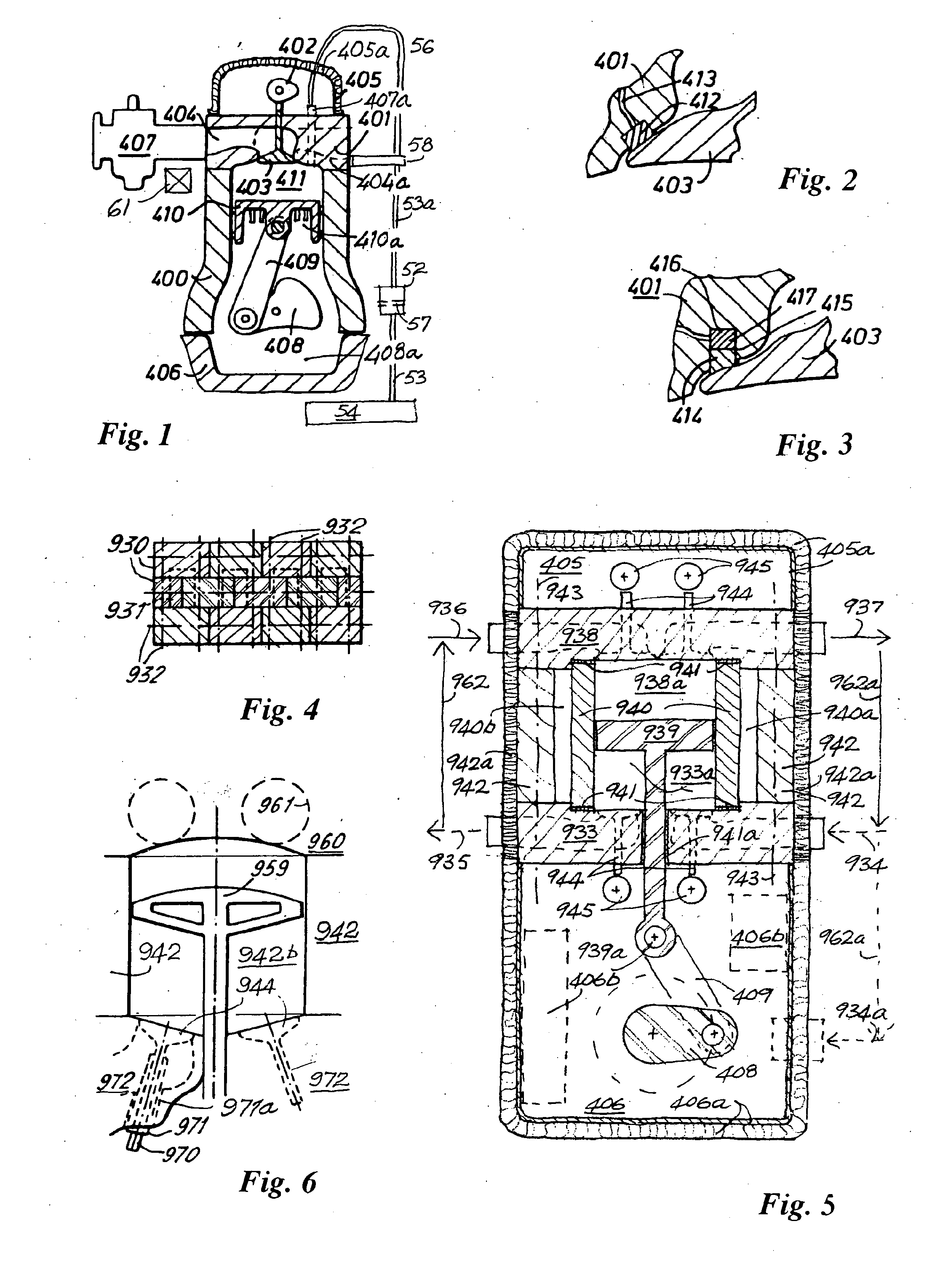

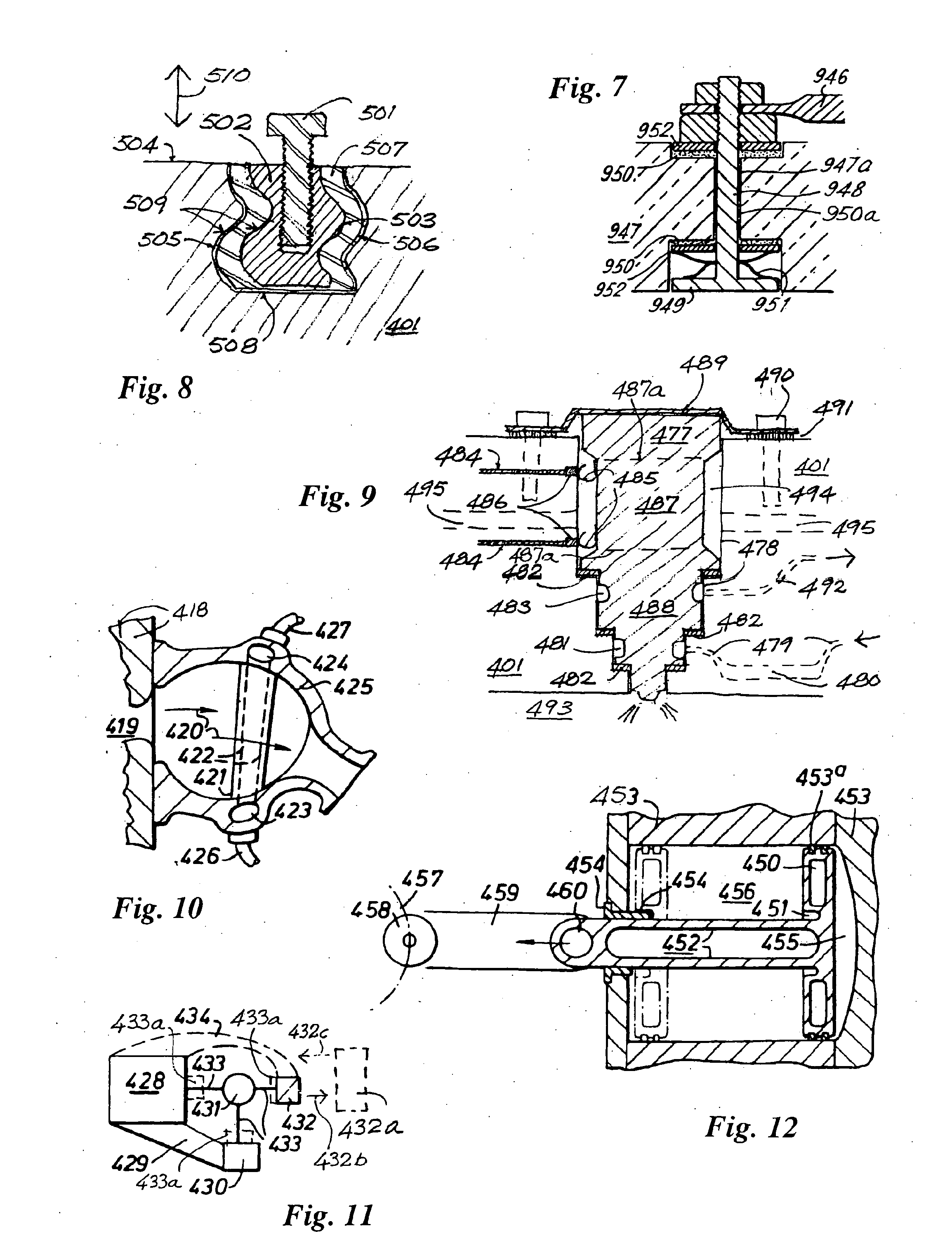

Reciprocating machine & other devices

a technology of reciprocating machines and other devices, applied in the direction of machines/engines, mechanical devices, positive displacement engines, etc., can solve the problems of reduced efficiency, reduced efficiency, and reduced efficiency of engines, so as to reduce co2 emissions, improve efficiency, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0184]Herein, un-cooled engines are described first, followed by disclosure relating to control of regulated emissions, aircraft, marine craft, continuously variable transmissions, means for removing CO2 emissions from exhaust gases and, lastly, cooled engines at all times operating at or close to maximum design temperature.

[0185]An important objective of the invention is to provide engines having greater power-to-weight ratios, power-to-bulk ratios, and substantially greater efficiencies, with lower CO2 and other emissions than equivalent contemporary units. This is achieved by four principal means: (1) the rearrangement of the components associated with a single piston / cylinder into a more compact and simple configuration, (2) the reduction in most applications of the number of piston / cylinder assemblies required, (3) the substantial reduction of reciprocating masses, and therefore the reduction of size and mass of key structural components, (4) the virtual elimination of heat los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com