Patents

Literature

1693 results about "Top dead center" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

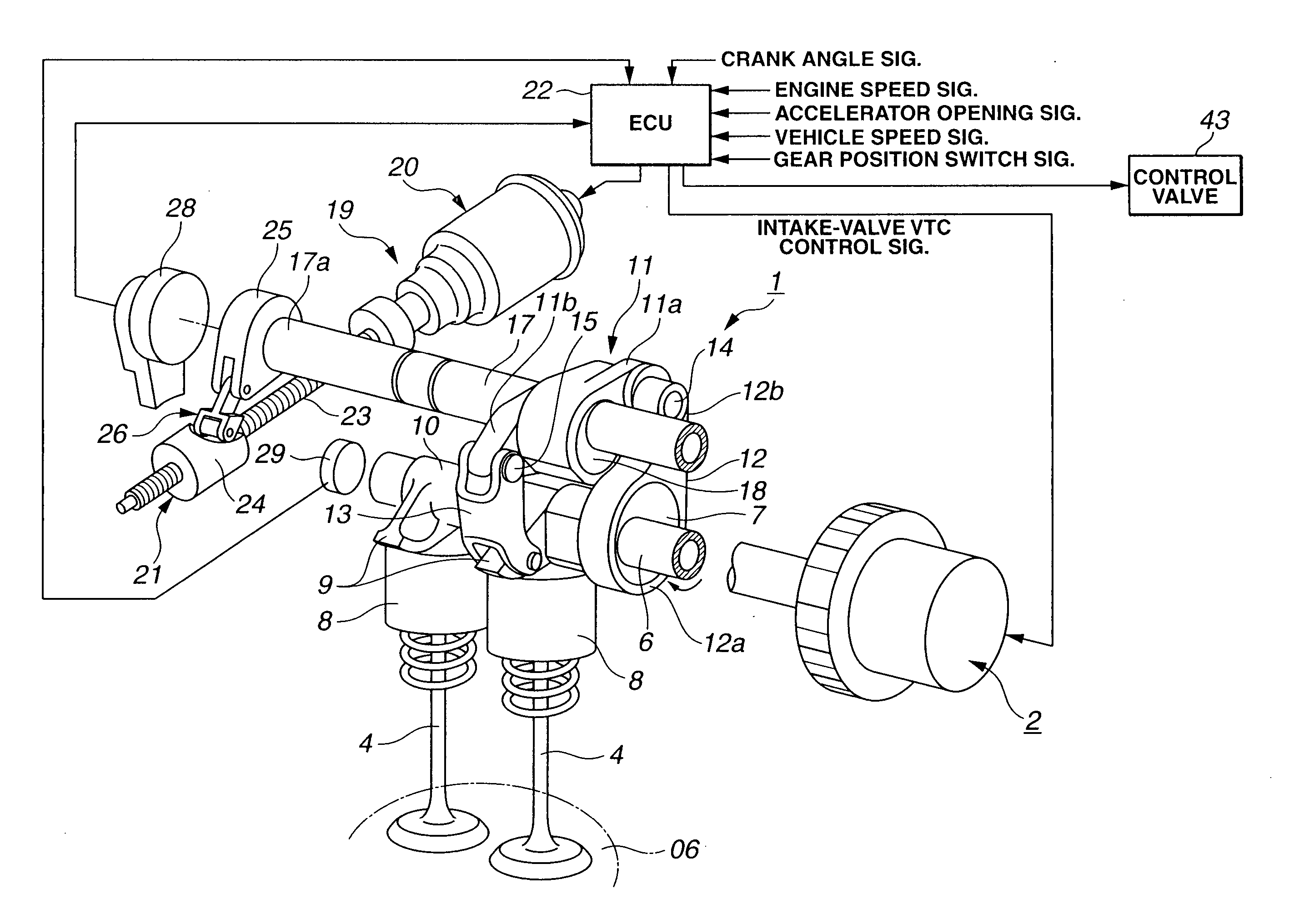

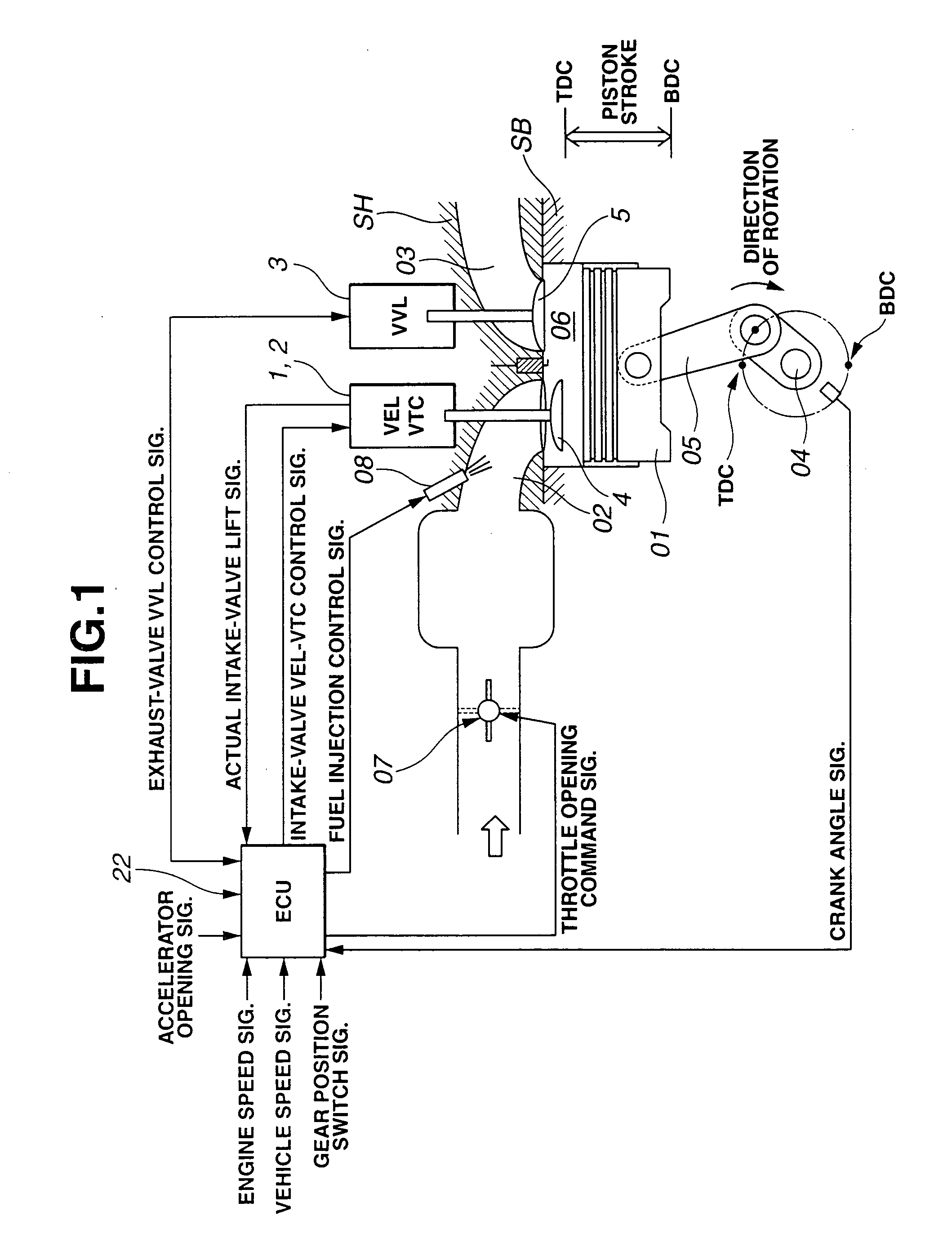

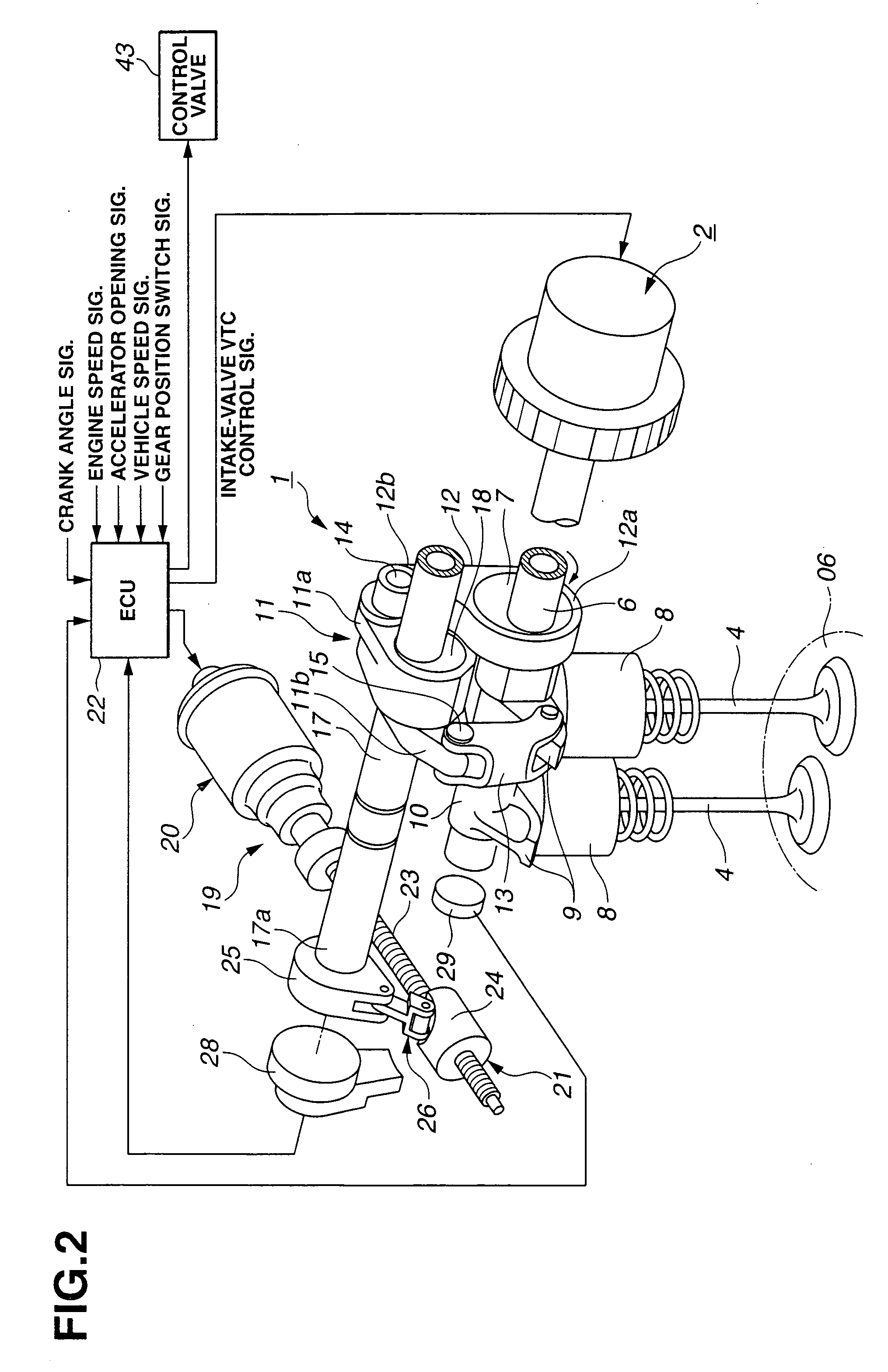

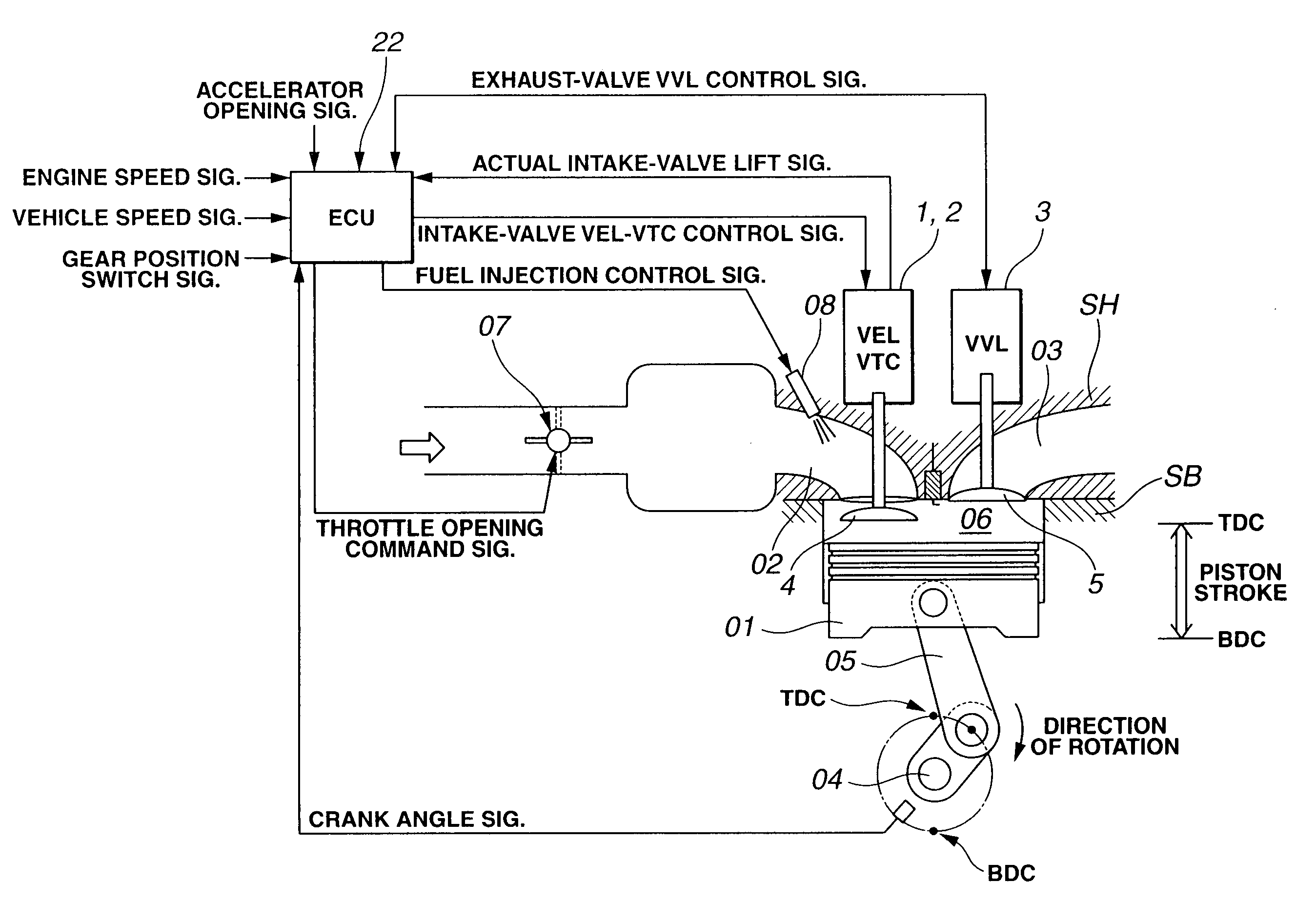

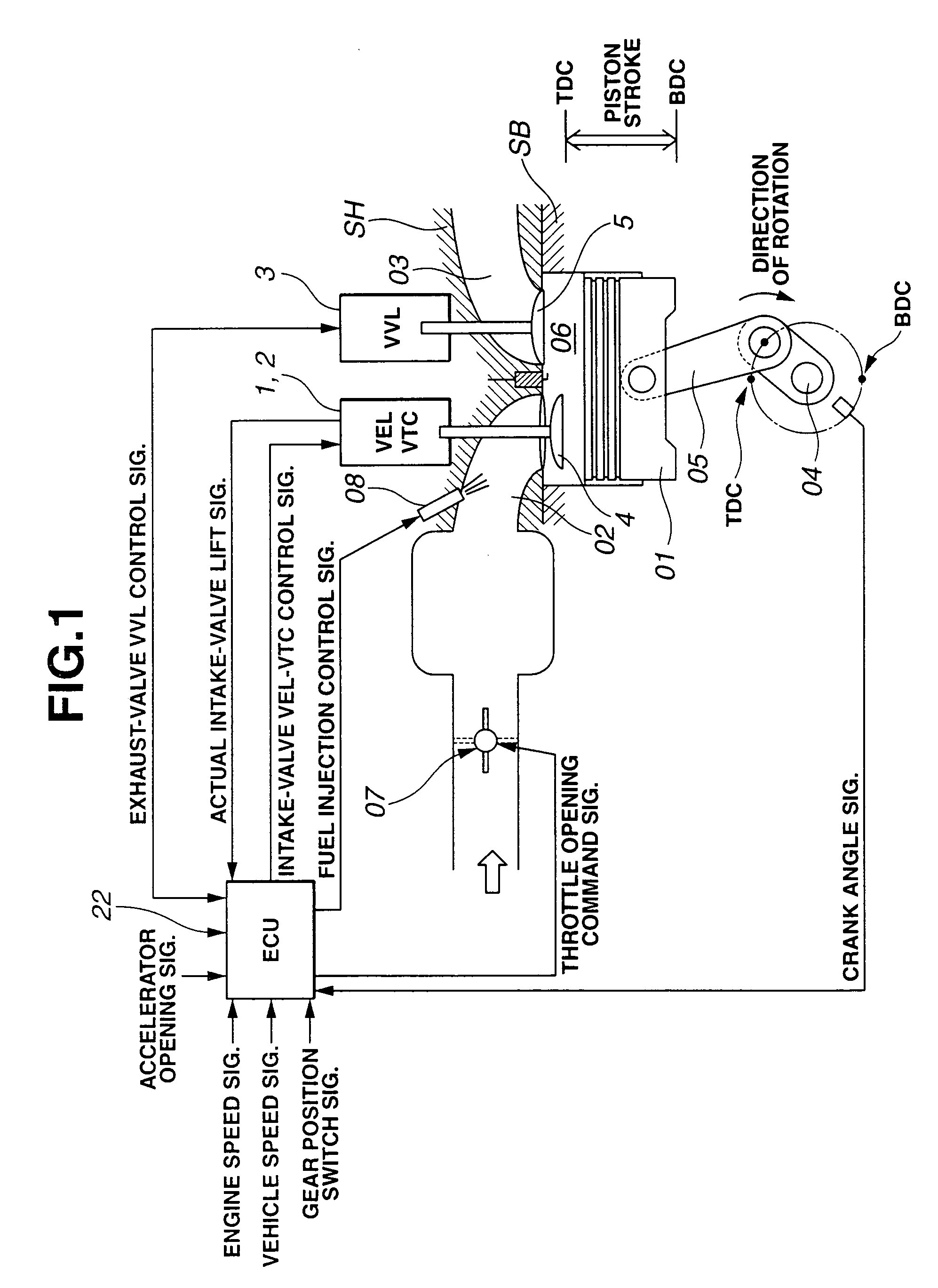

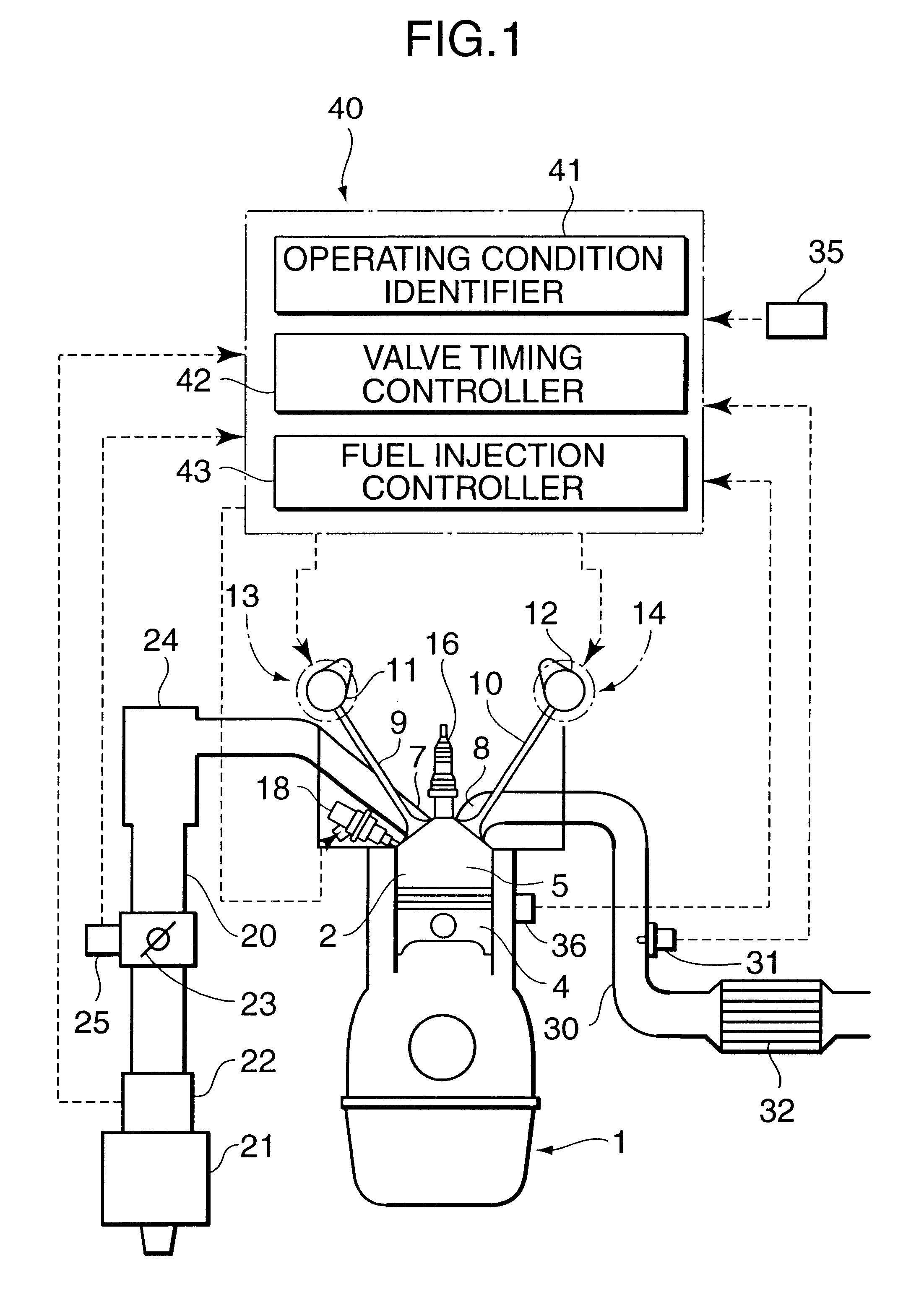

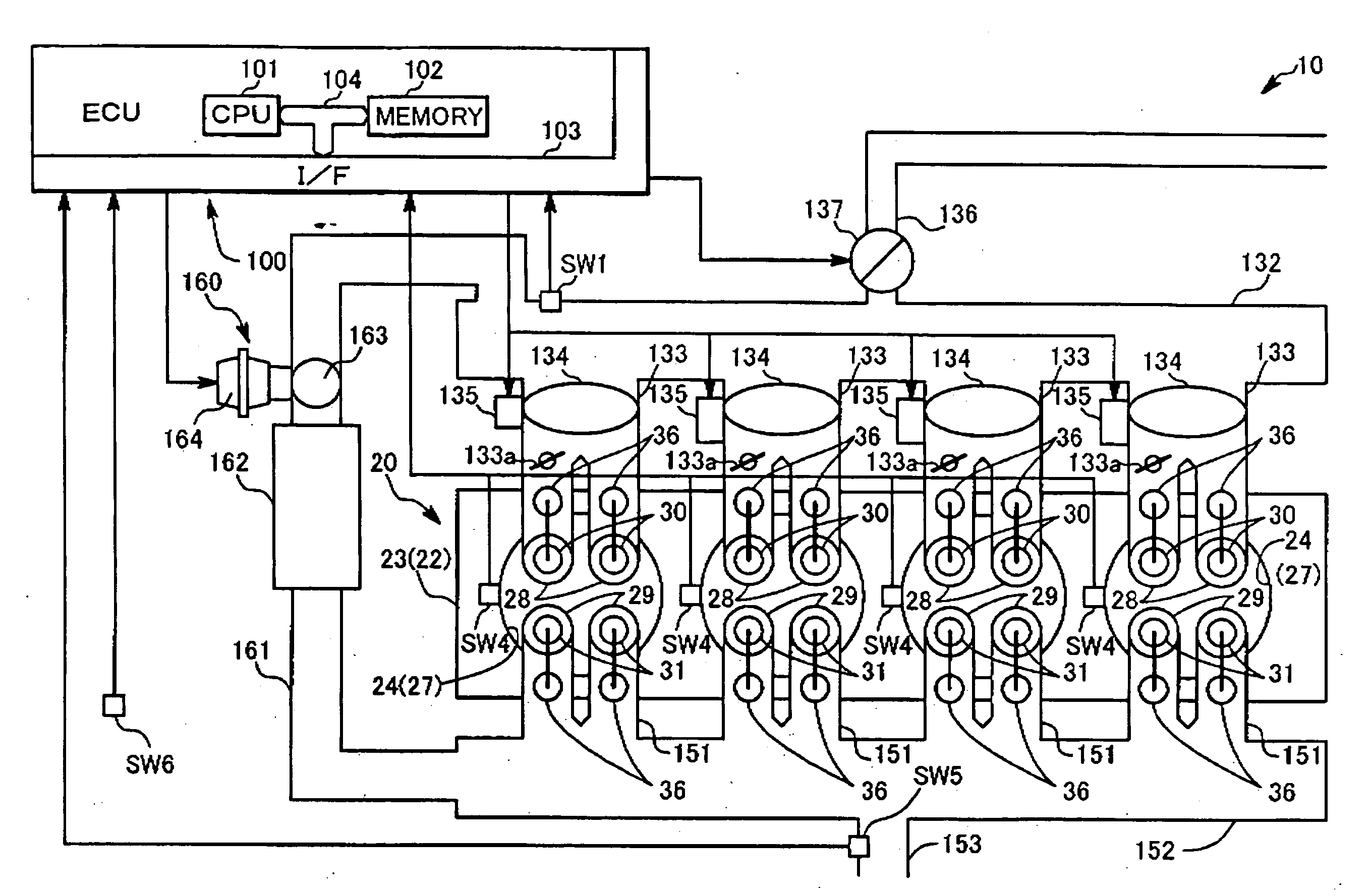

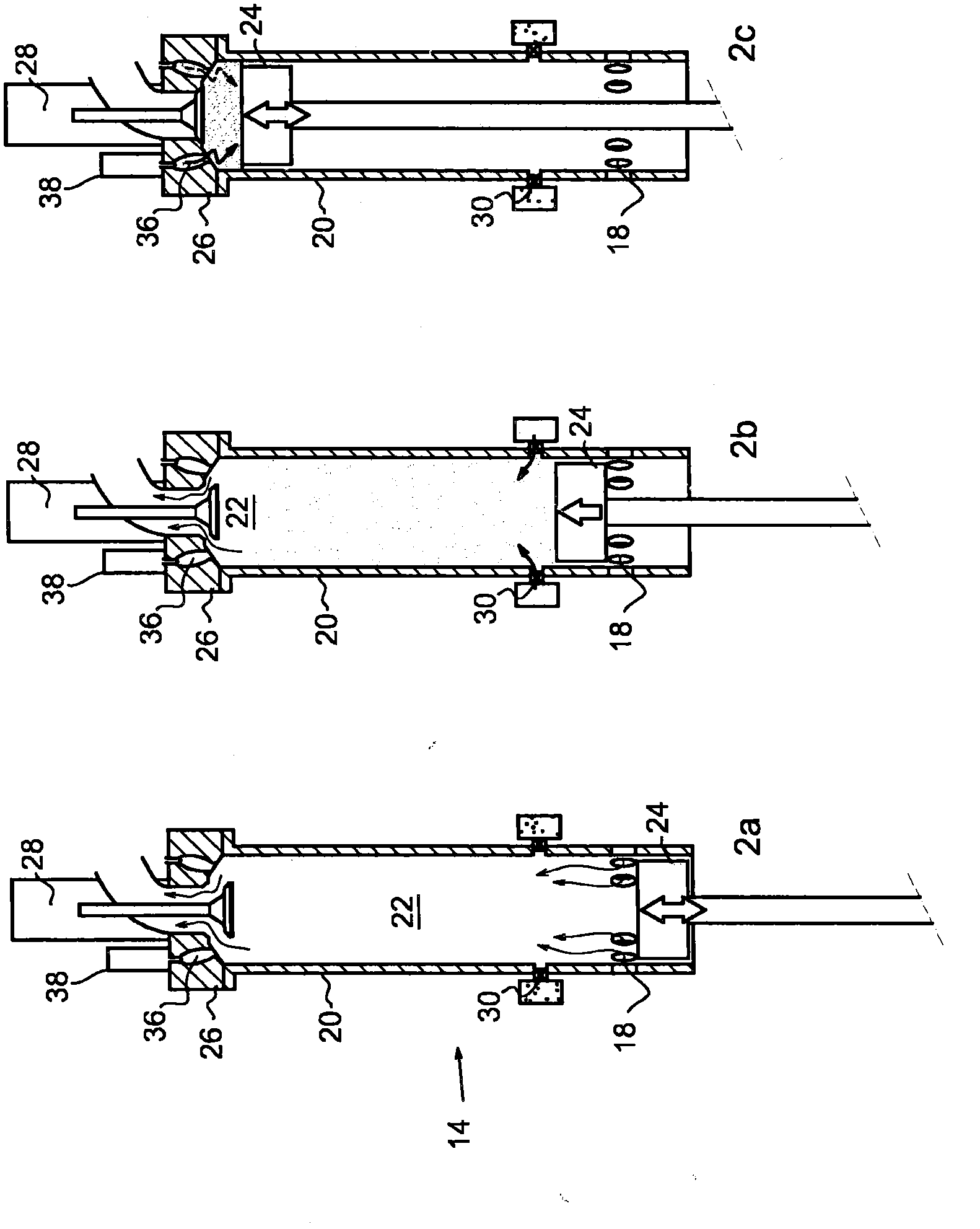

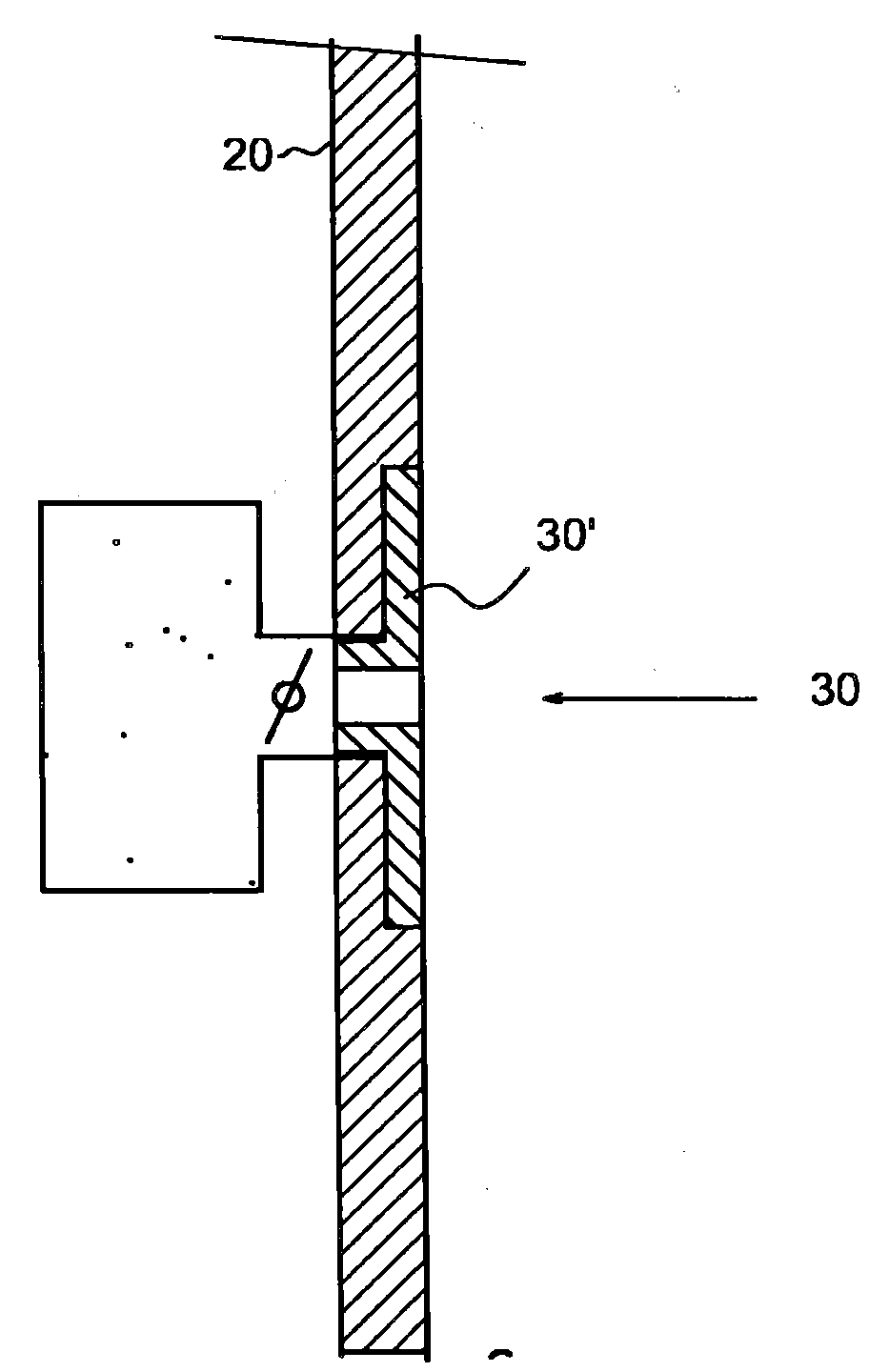

Cylinder cutoff control apparatus of internal combustion engine

InactiveUS20060037578A1Reduced engine braking effectTendency increaseValve arrangementsElectrical controlExhaust valveTop dead center

A cylinder cutoff control apparatus of an engine initiates a cylinder cutoff mode only when two conditions, namely a low load condition such as a vehicle cruising condition and an intake valve closure timing controlled to a given timing value before a bottom dead center, are both satisfied. A fuel cutoff mode is executed prior to the cylinder cutoff mode. During a transition to the cylinder cutoff mode, the control apparatus holds an intake valve open timing at a given timing value substantially corresponding to a top dead center, simultaneously with reducing an intake valve lift amount of each intake valve, subjected to cylinder cutoff control, to a zero lift. Immediately when the intake valve lift amount is reduced to below a lift threshold value, an exhaust valve lift amount of each exhaust valve, subjected to the cylinder cutoff control, is controlled to a zero lift.

Owner:HITACHI LTD

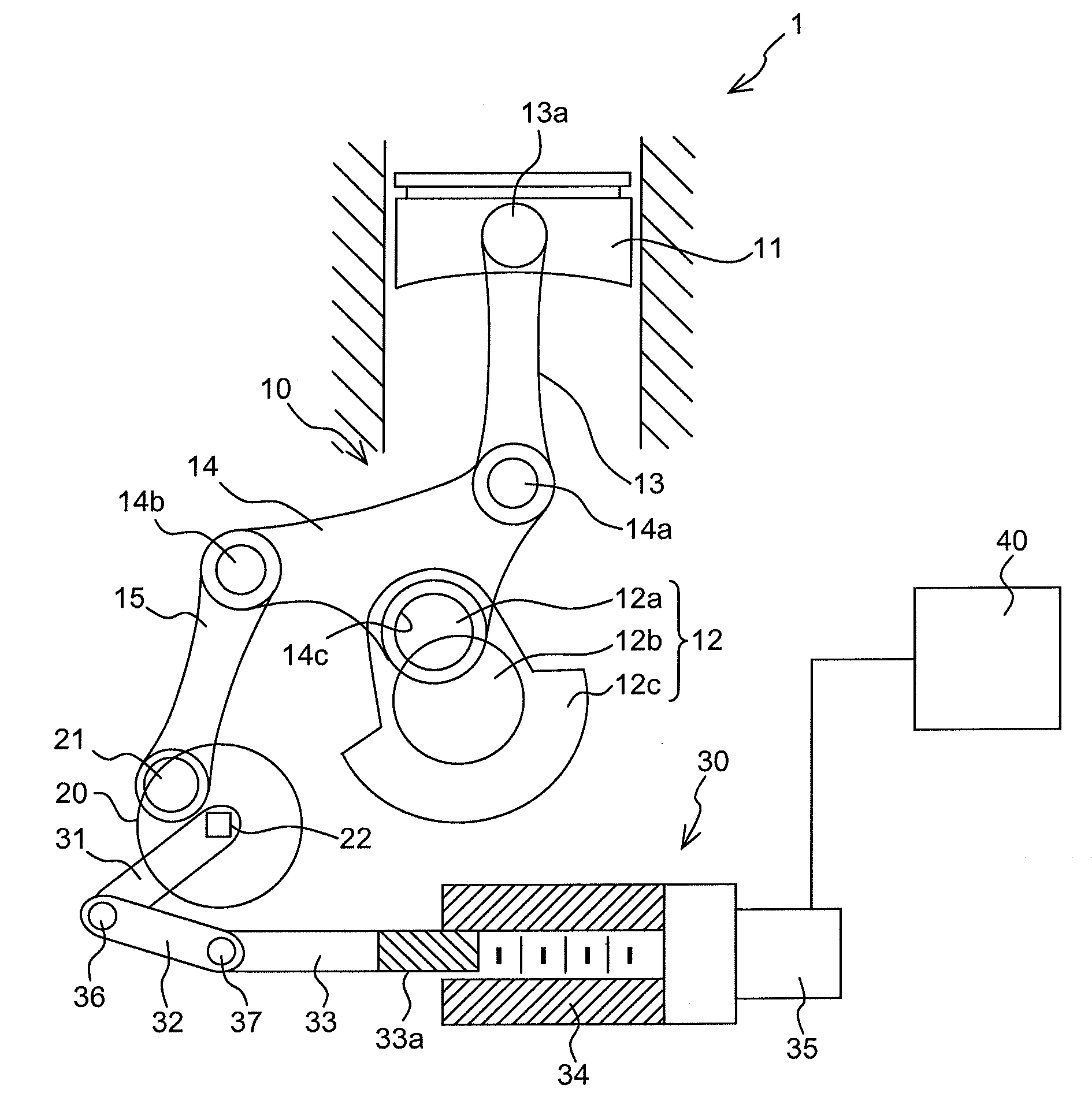

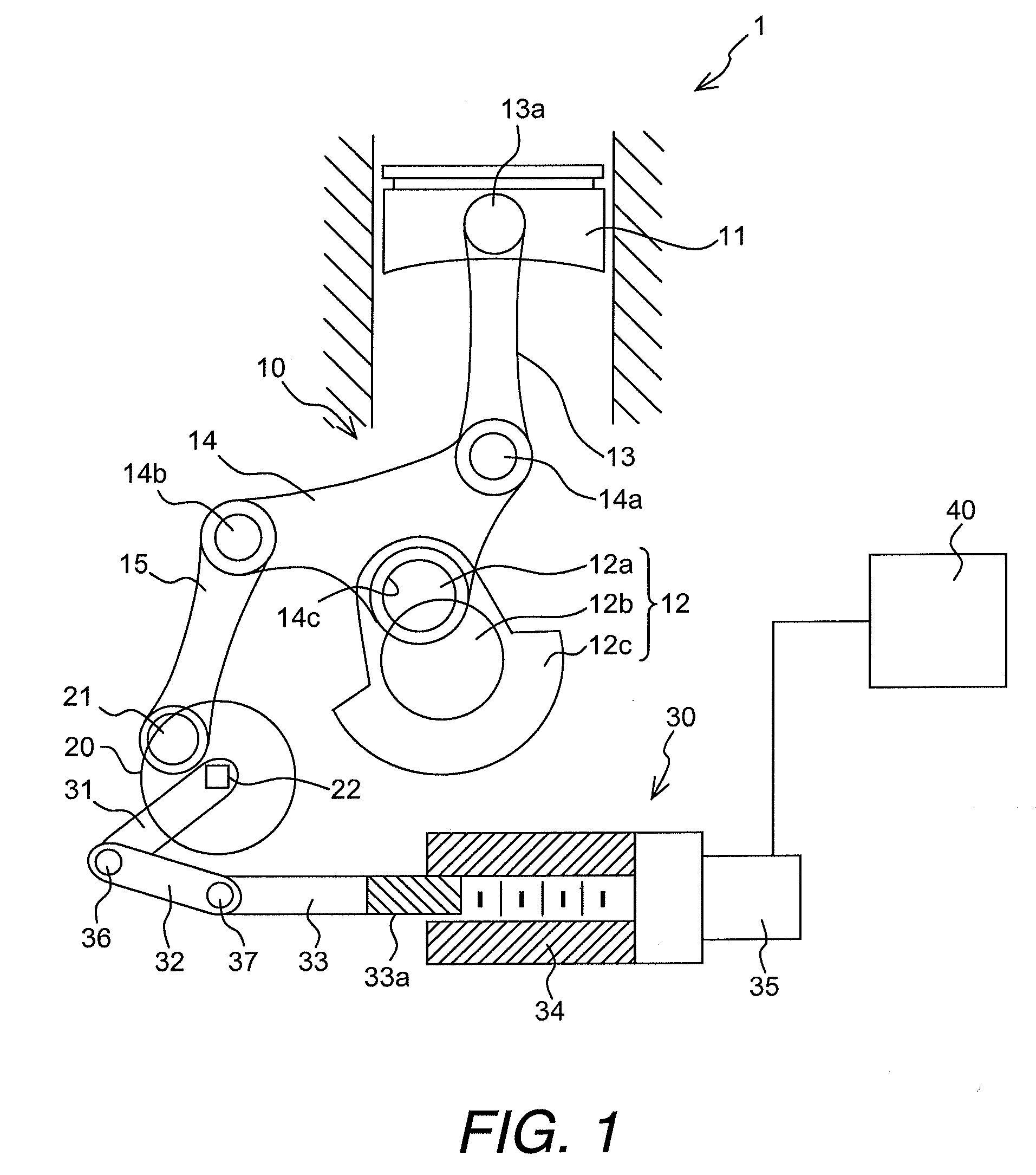

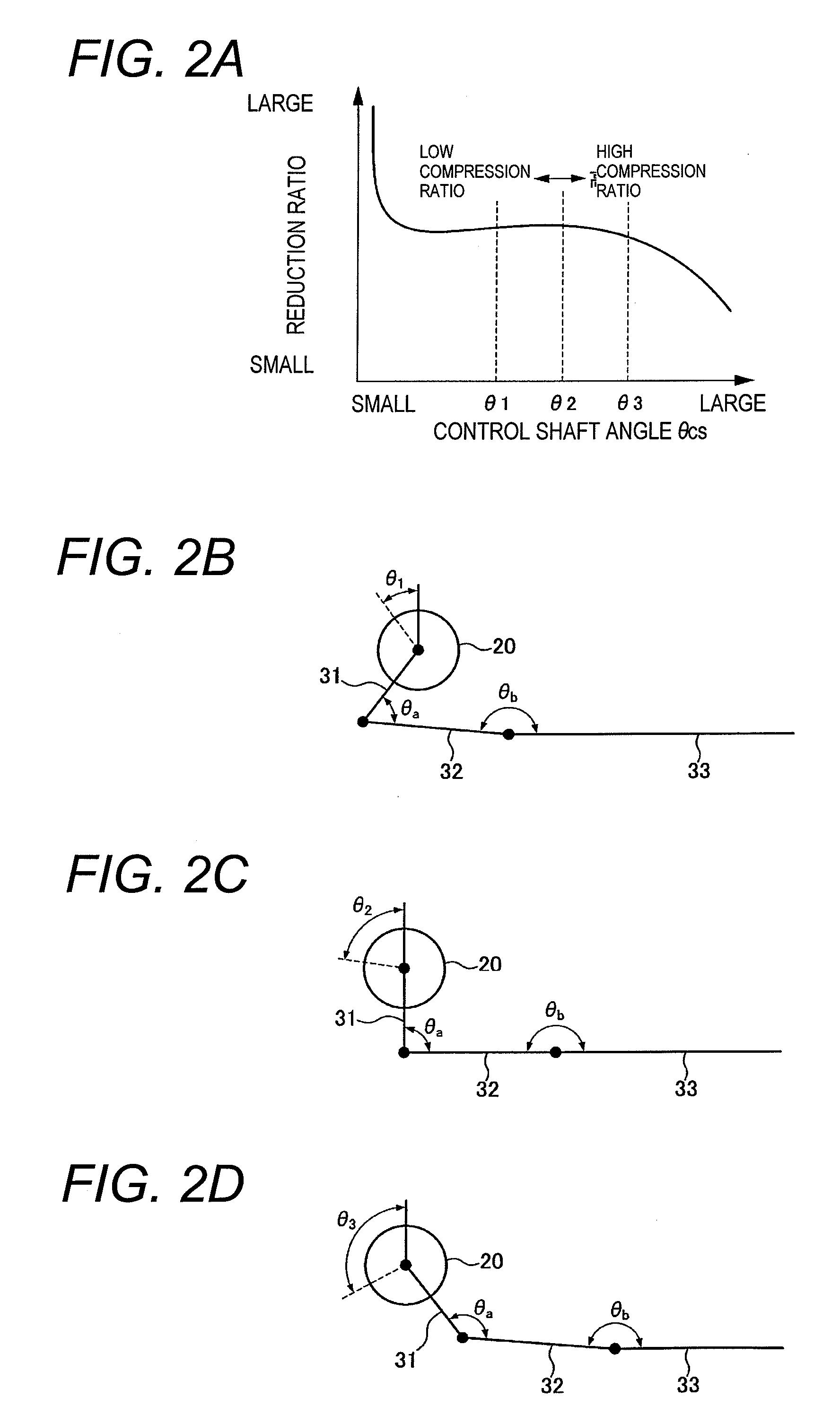

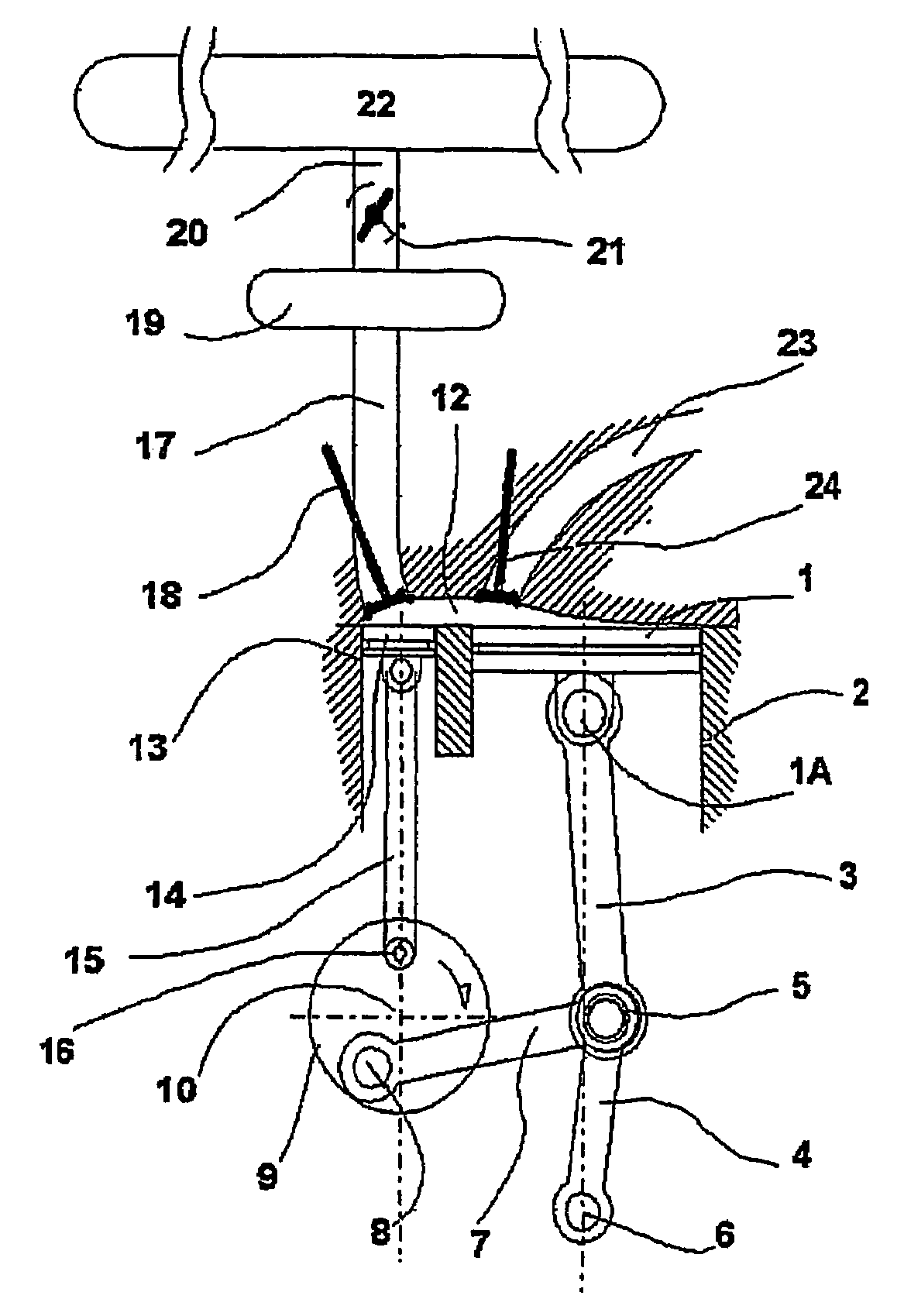

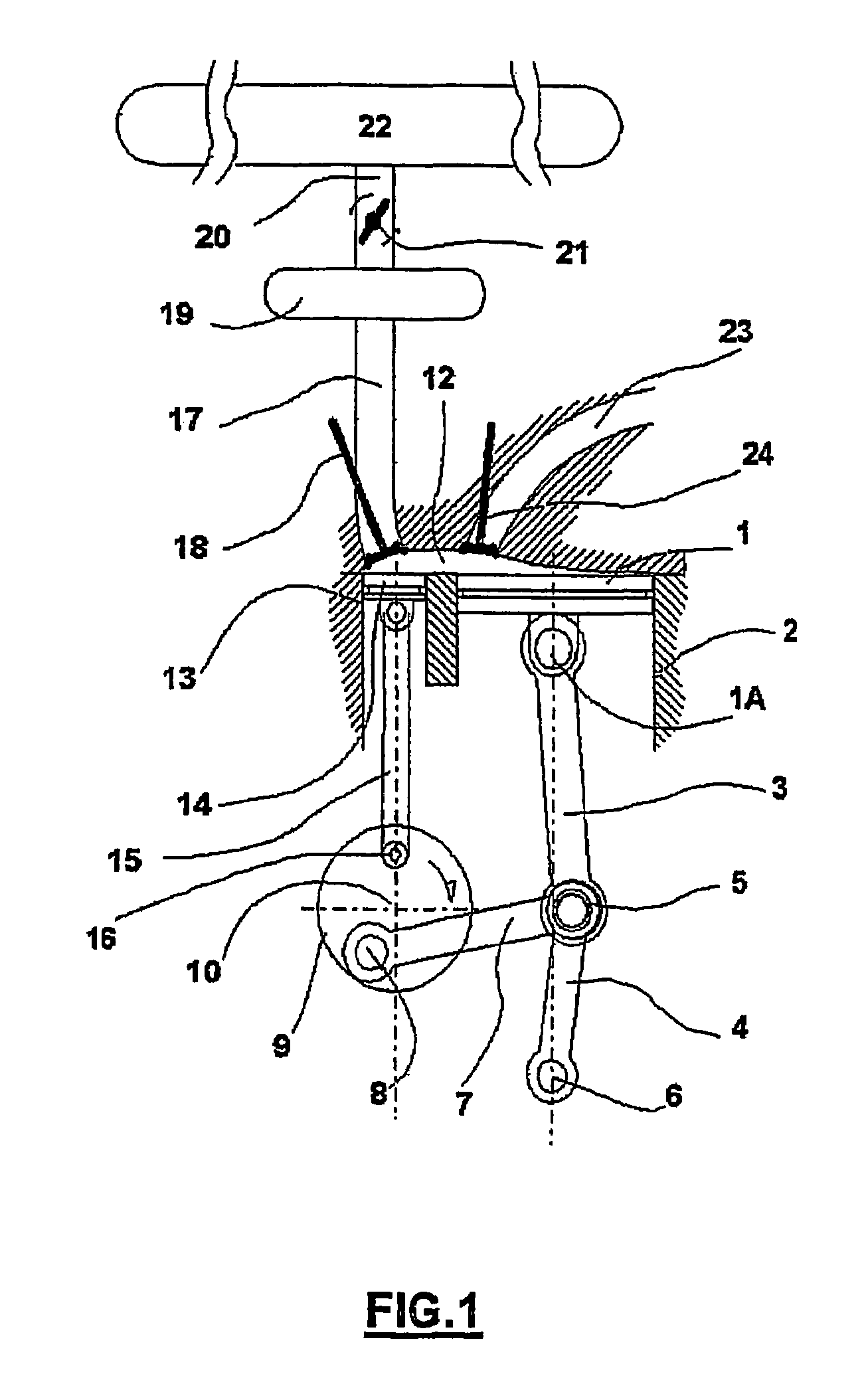

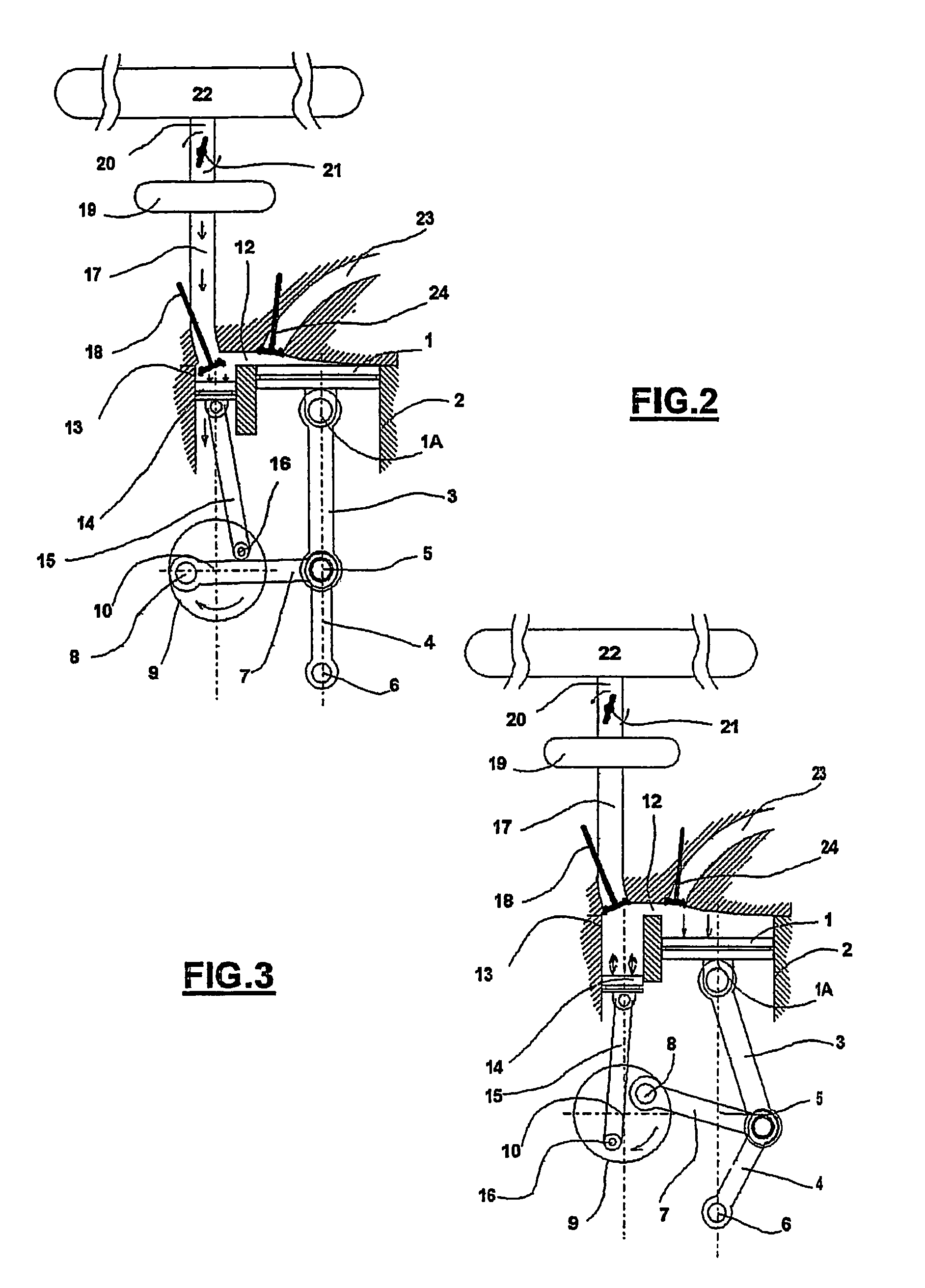

Multi-link variable compression ratio engine

ActiveUS20090107454A1Frequently knockedInhibitionConnecting rodsMachines/enginesTop dead centerReduction ratio

A multi-link variable compression ratio engine is provided with a crankshaft, a piston, a control shaft, a linkage, a motor and a reduction mechanism. The crankshaft moves the piston within an engine cylinder. The control shaft has an eccentric axle eccentric relative to its center-axis. The linkage operatively connects the piston to the crankshaft and the crankshaft to the eccentric axle of the control shaft. The motor rotates the control shaft so a top-dead-center position of the piston changes to vary compression ratios by changing the positions of the eccentric axle and the linkage. The reduction mechanism couples the motor to the control shaft to transmit a reduced rotation of the motor to the control shaft so a reduction ratio of a rotation angle of the motor to a rotation angle of the control shaft is less at high-compression ratios than at intermediate compression ratios.

Owner:NISSAN MOTOR CO LTD

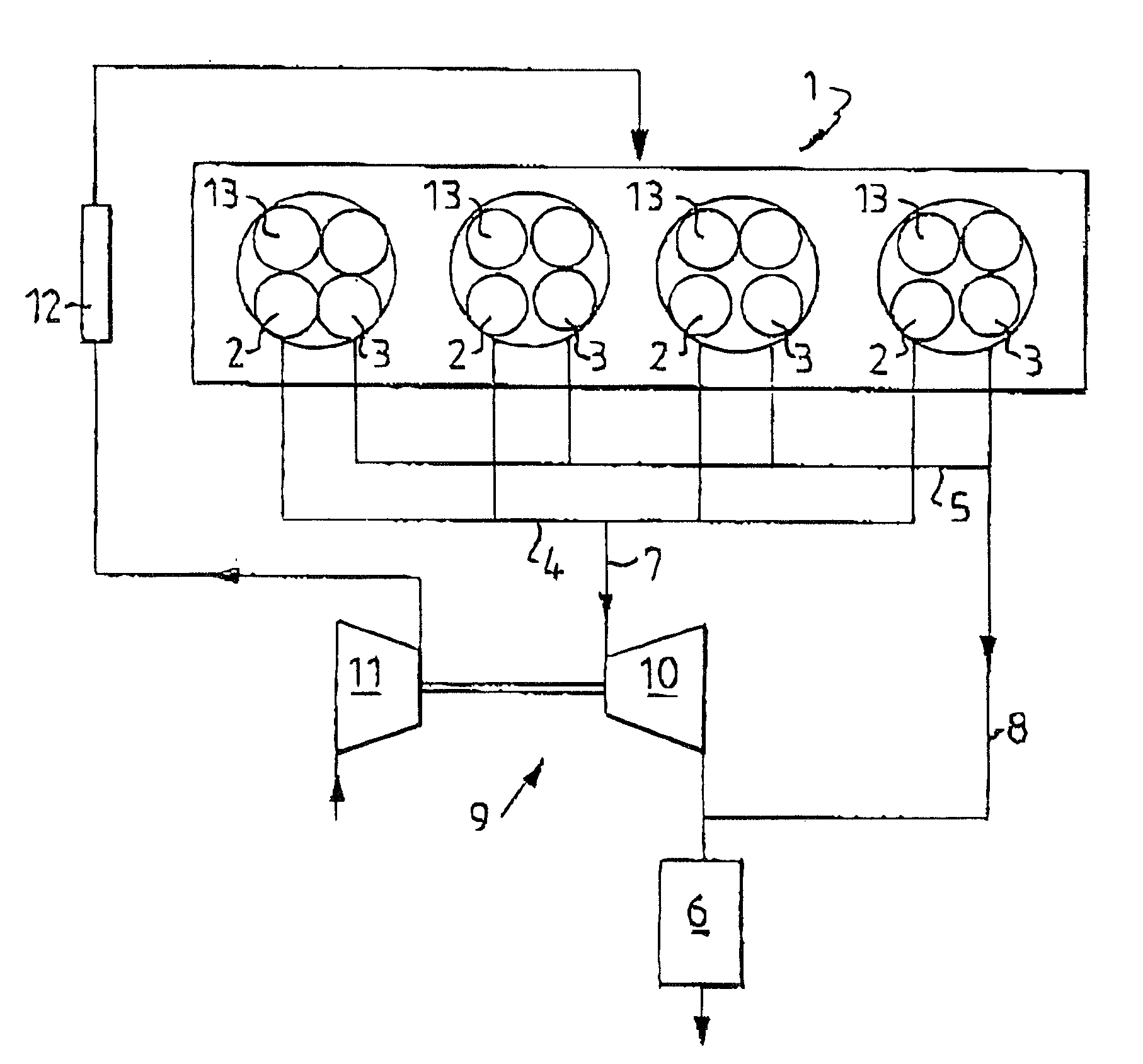

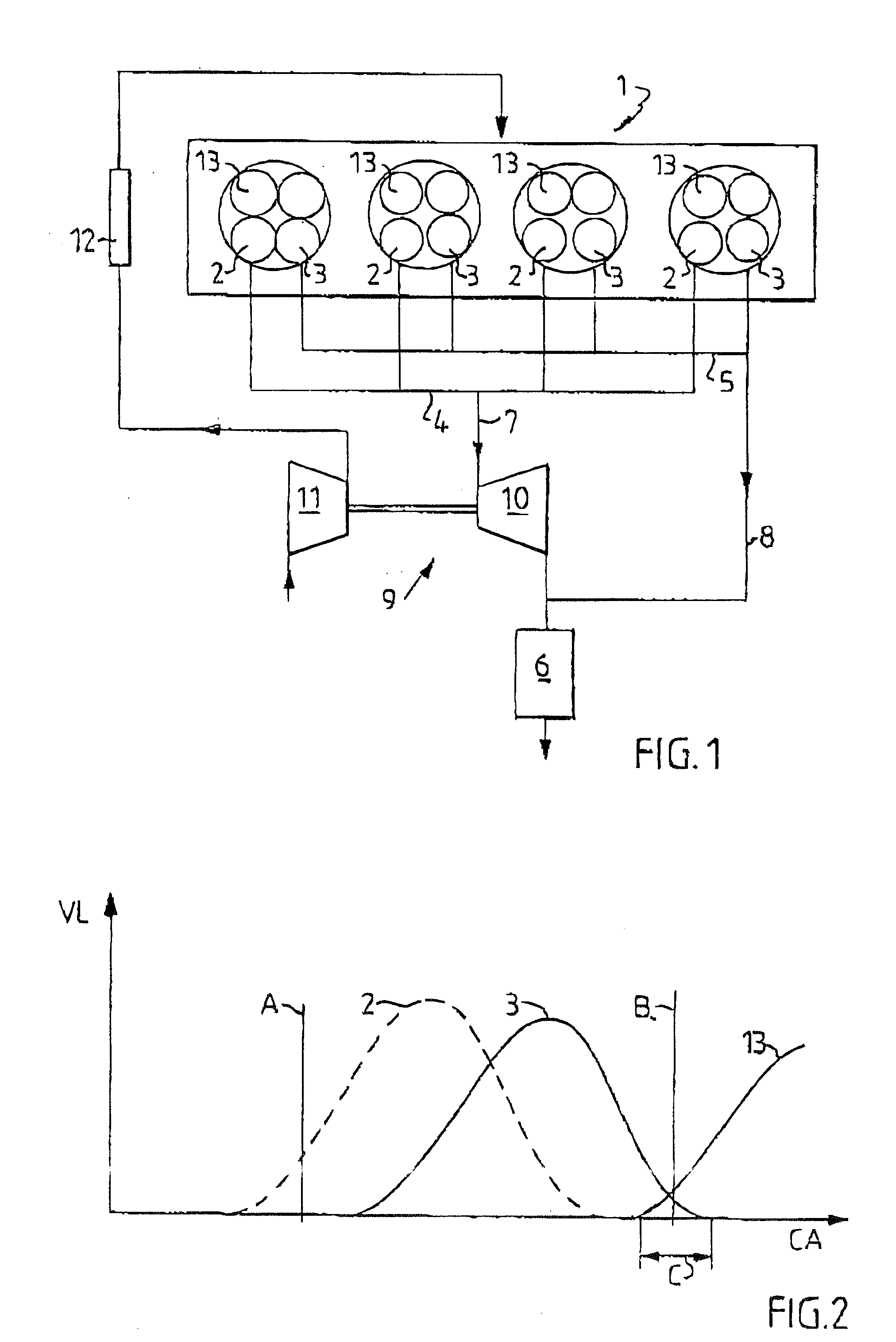

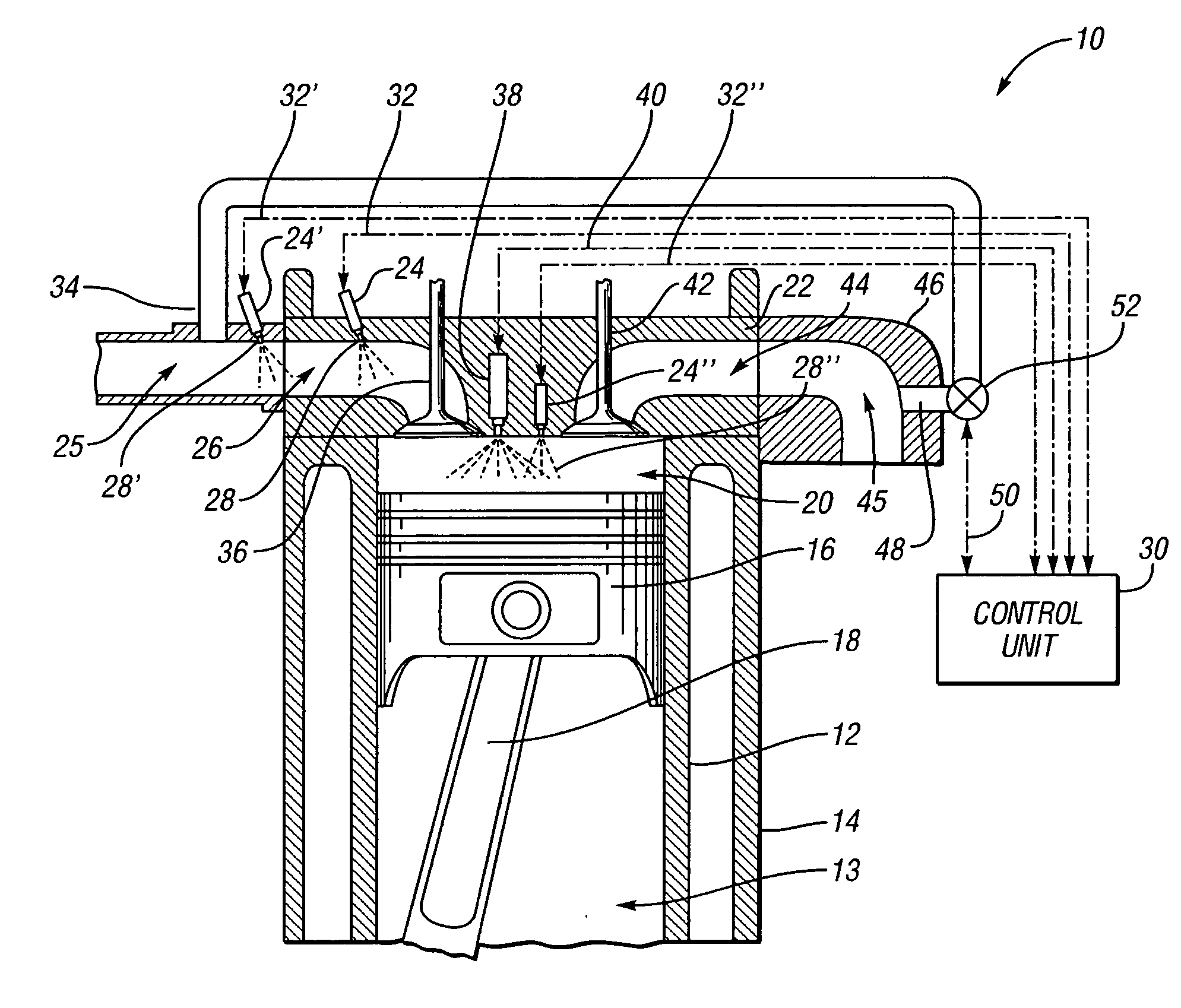

Internal combustion engine

InactiveUS6595183B1Increase mass flowIncrease torqueValve arrangementsElectrical controlExhaust valveTop dead center

A multicylinder internal combustion engine with an exhaust-driven turbocompressor and with a divided exhaust flow has at least two exhaust valves and one intake valve per cylinder. A first exhaust valve is connected to a first exhaust manifold which leads to the turbine of the compressor, while a second exhaust valve is connected to a second exhaust manifold which opens downstream of the turbine. In the top dead center position of the piston, the second exhaust valve and the intake valve are open at the same time for a period. The synchronization between these valves is such that the length of the period during which they are open together increases with the engine speed when the engine is driven at high load. In this way, the possibilities are improved of the engine providing good torque over a wide engine speed range.

Owner:SAAB AUTOMOBILE AB

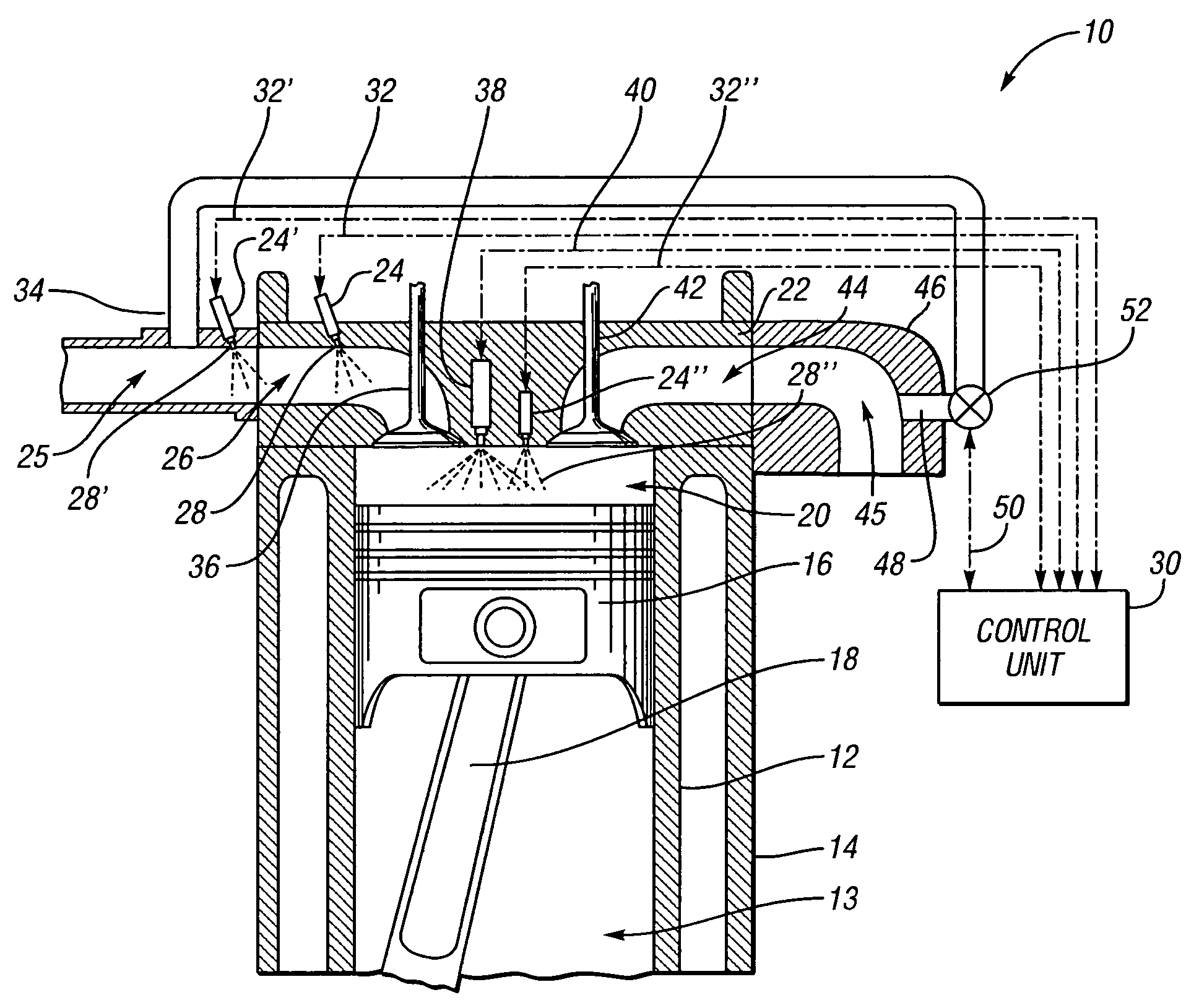

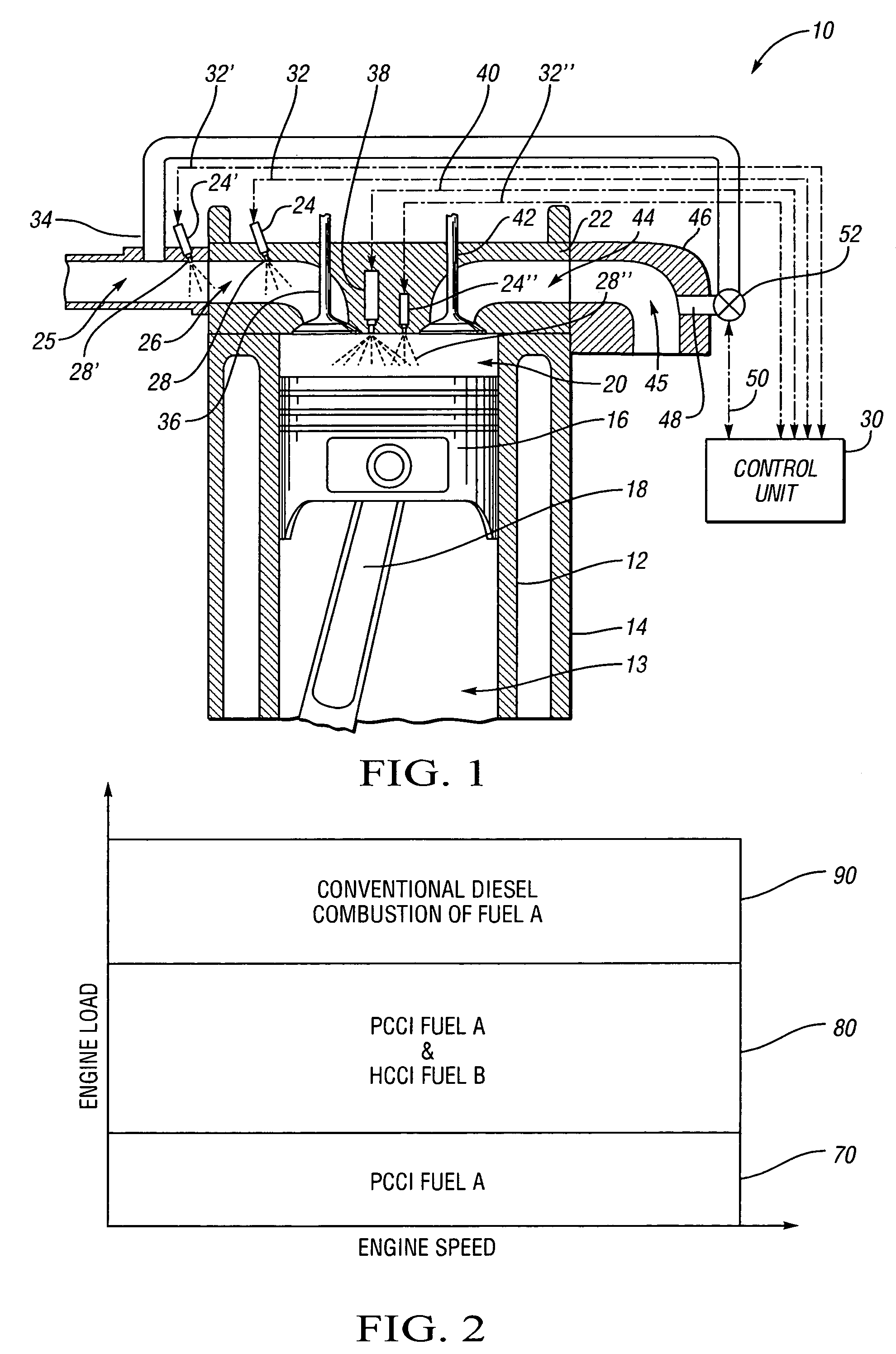

Dual Fuel Injection Compression Ignition Engine And Method Of Operating Same

A method of operating an electronically controlled dual fuel compression ignition engine includes injecting a pilot ignition quantity of liquid fuel into an engine cylinder from a dual fuel injector in an engine cycle during an auto ignition condition. An amount of gaseous fuel is also injected into the engine cylinder from the dual fuel injector in the same engine cycle. The amount of gaseous fuel is divided between a pre-mix quantity of gaseous fuel, which may be injected about 90° before top dead center, and a post ignition quantity of gaseous fuel that may be injected after top dead center, with both quantities being greater than zero. An engine controller may change a ratio of the pre-mix quantity of gaseous fuel to the post ignition quantity of gaseous fuel responsive to changing from a first engine speed and load to a second engine speed and load. The pilot ignition quantity of liquid fuel is compression ignited, which in turn causes the gaseous fuel to be ignited. A pre-mix quantity of liquid fuel may also be included in order to speed the combustion process at higher engine speeds.

Owner:CATERPILLAR INC

Cylinder cutoff control apparatus of internal combustion engine

A cylinder cutoff control apparatus of an engine initiates a cylinder cutoff mode only when two conditions, namely a low load condition such as a vehicle cruising condition and an intake valve closure timing controlled to a given timing value before a bottom dead center, are both satisfied. A fuel cutoff mode is executed prior to the cylinder cutoff mode. During a transition to the cylinder cutoff mode, the control apparatus holds an intake valve open timing at a given timing value substantially corresponding to a top dead center, simultaneously with reducing an intake valve lift amount of each intake valve, subjected to cylinder cutoff control, to a zero lift. Immediately when the intake valve lift amount is reduced to below a lift threshold value, an exhaust valve lift amount of each exhaust valve, subjected to the cylinder cutoff control, is controlled to a zero lift.

Owner:HITACHI LTD

Compression-ignited IC engine and method of operation

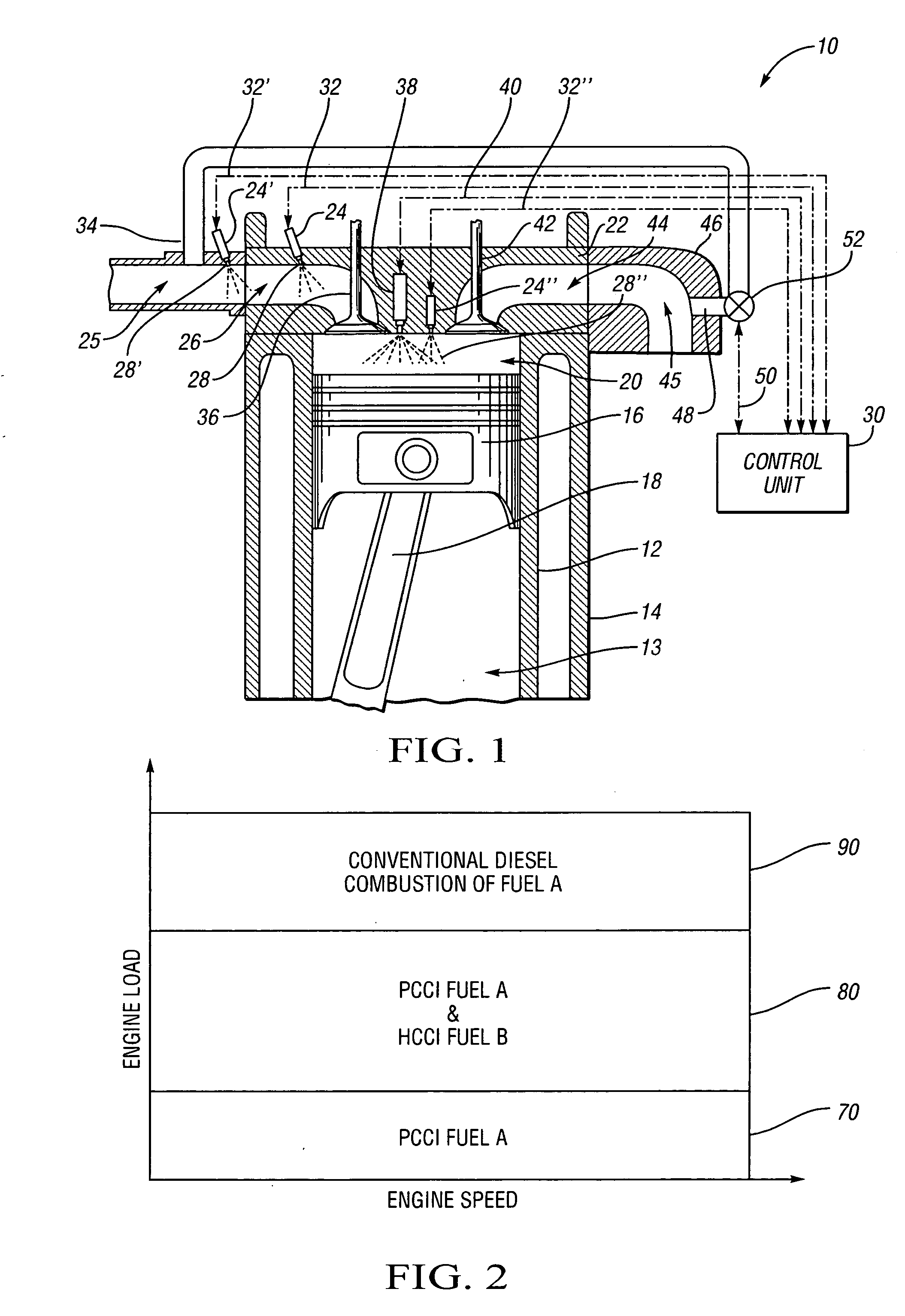

InactiveUS20060180121A1Emission reductionImprove efficiencyElectrical controlInternal combustion piston enginesCombustionTop dead center

The present invention is a compression ignition internal combustion engine and method of operation which expands the load limit of quietly operating a premixed charge compression ignition (PCCI) engine by injecting a secondary fuel B, in ratios lean of stoichiometric, either into the intake air stream or directly into the cylinder to form a homogeneous fuel B and air mixture. Near top dead center of the compression stroke, a PCCI-type direct injection of fuel A event is used to initiate combustion of both fuel A and B at the proper time. At low loads the combustion mode is characterized a PCCI-type with high EGR rates. At medium loads the combustion mode is that of homogeneous combustion of fuel B coupled with PCCI combustion of fuel A. At the highest loads the engine will revert to a conventional diesel combustion mode of fuel A to maintain power density.

Owner:GM GLOBAL TECH OPERATIONS LLC

Fuel injection system having pre-injection and main injection

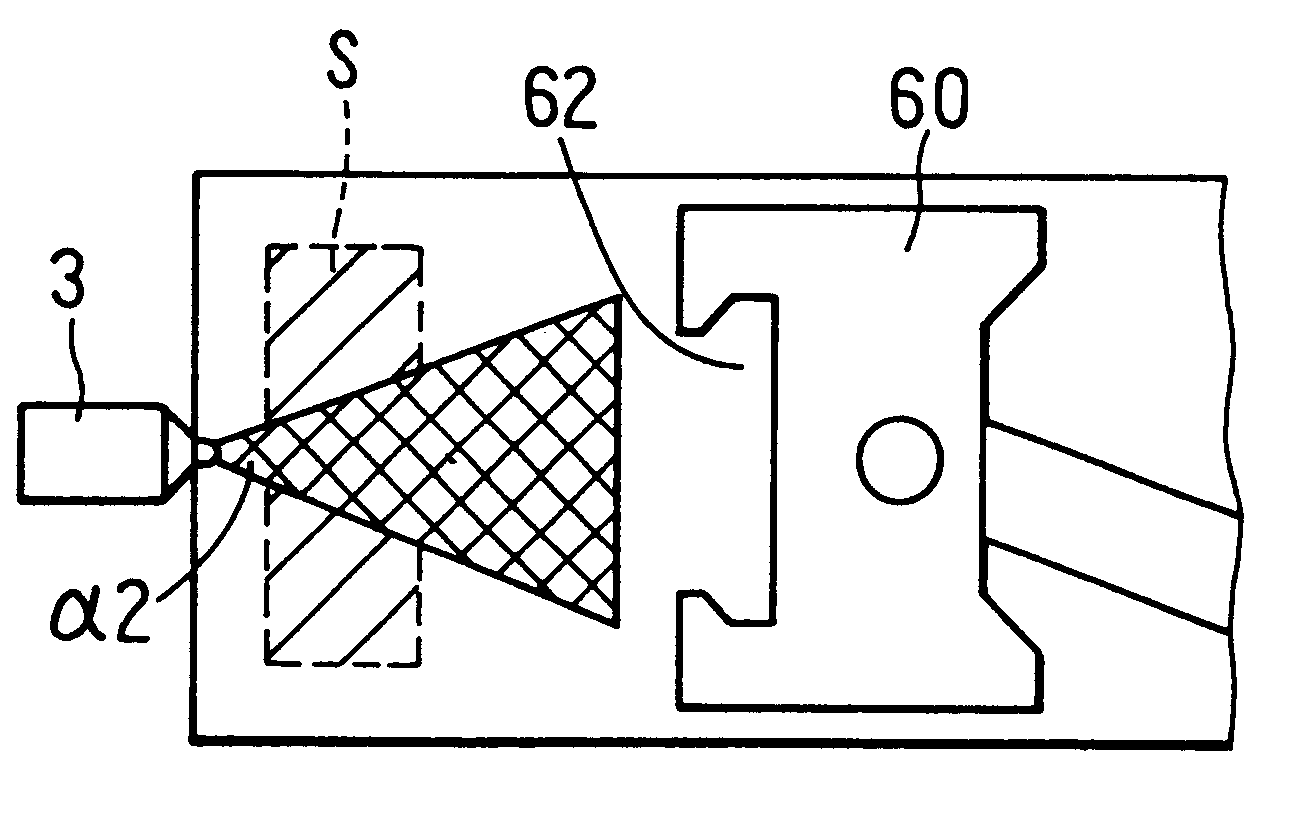

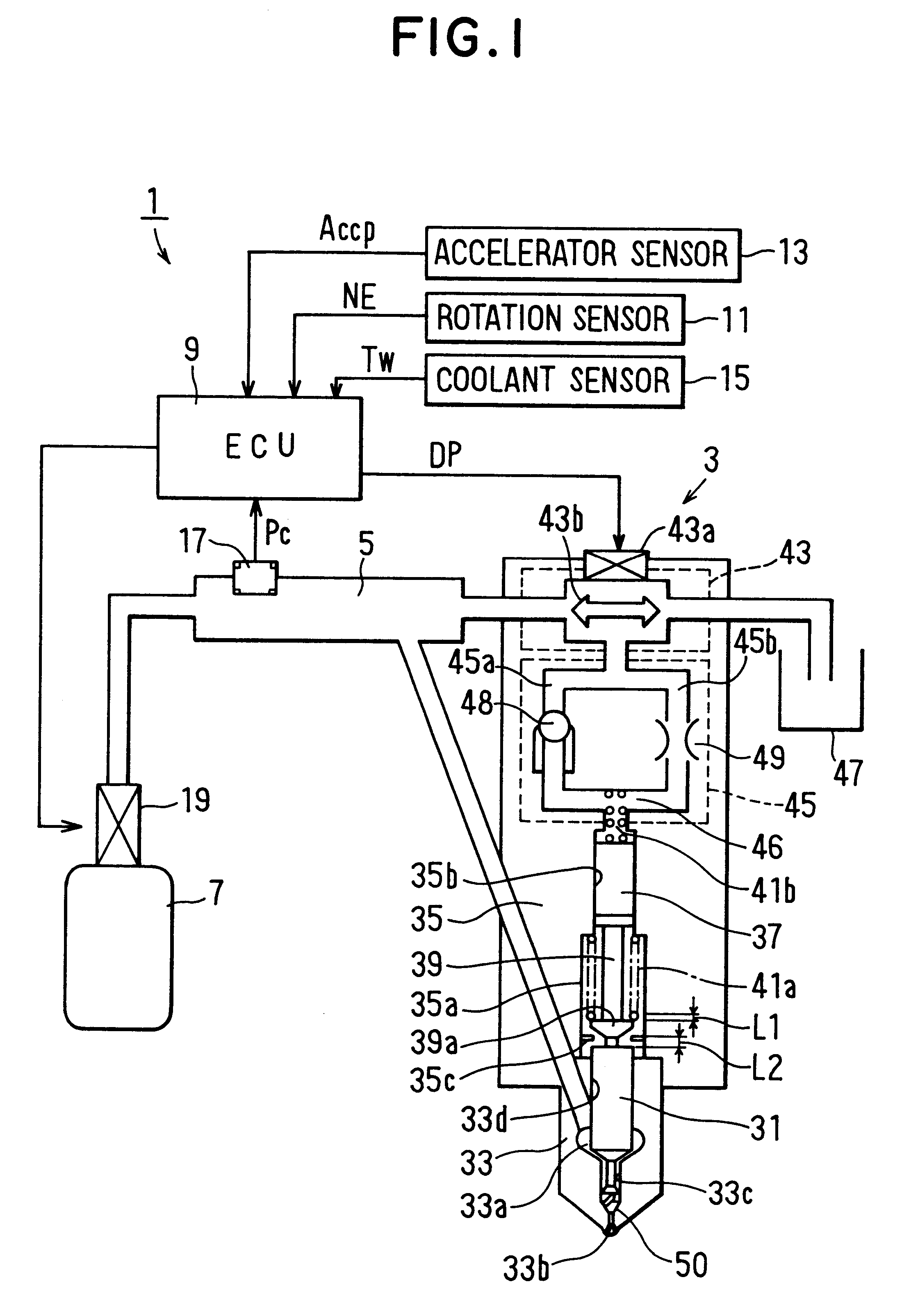

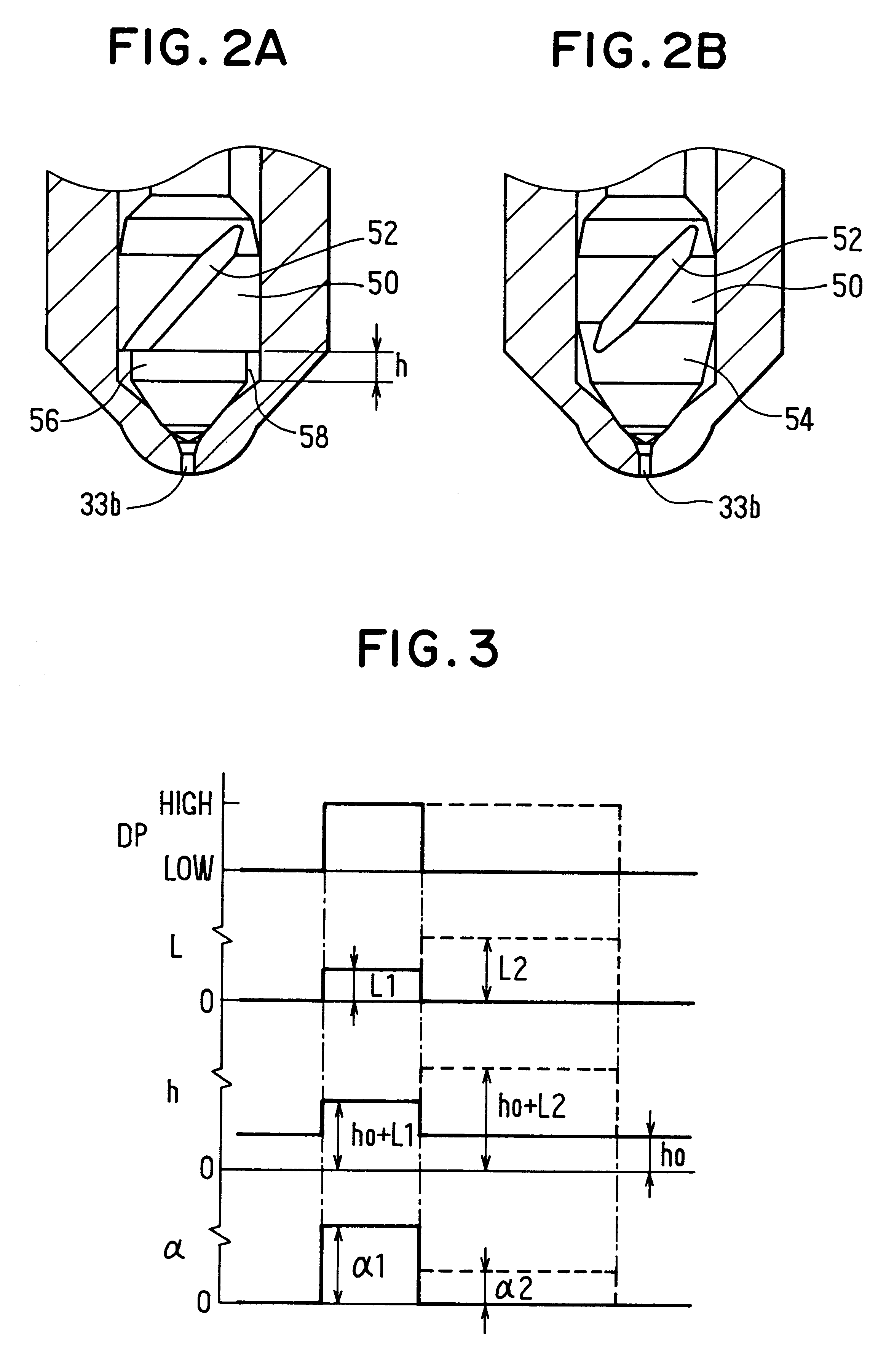

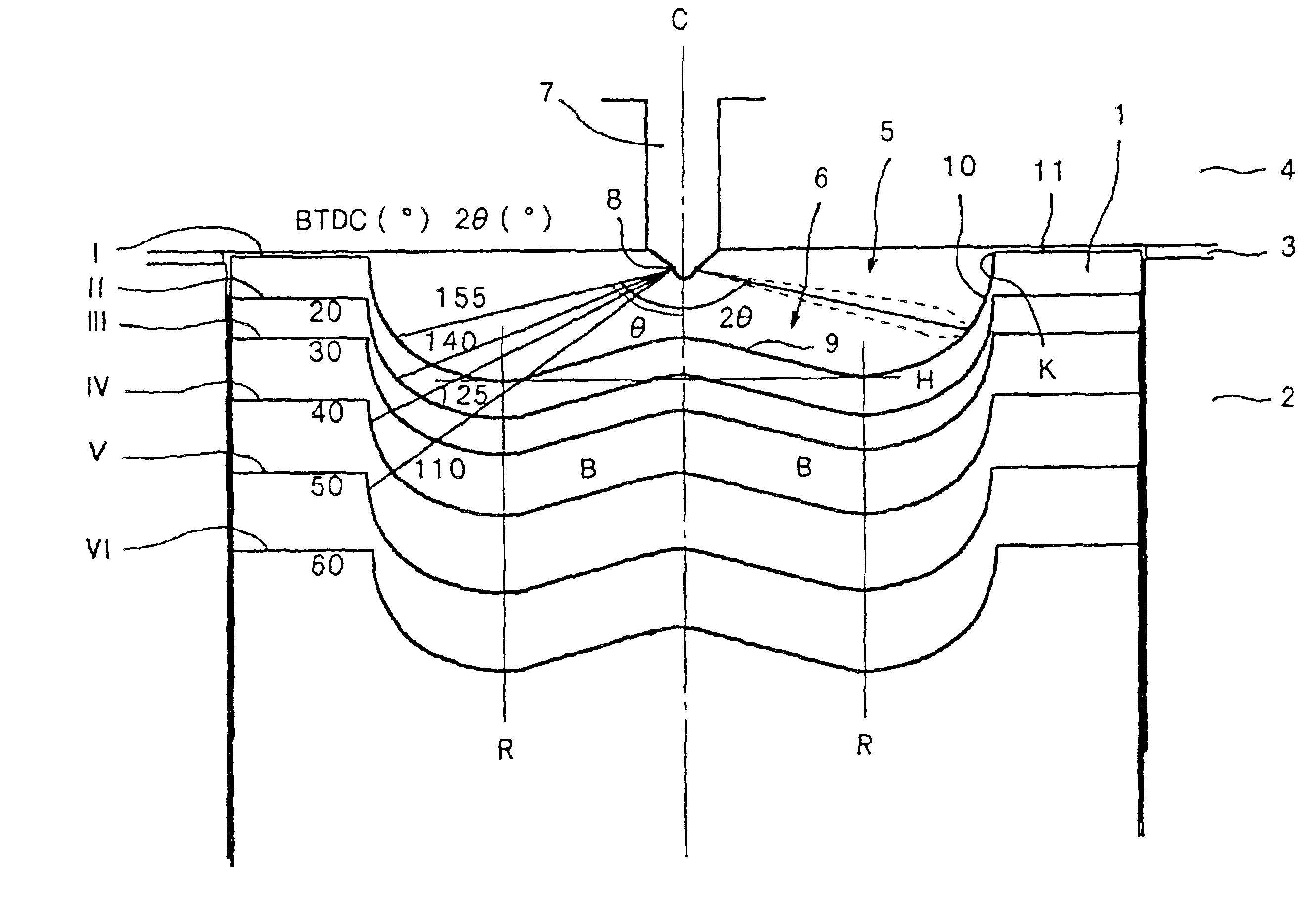

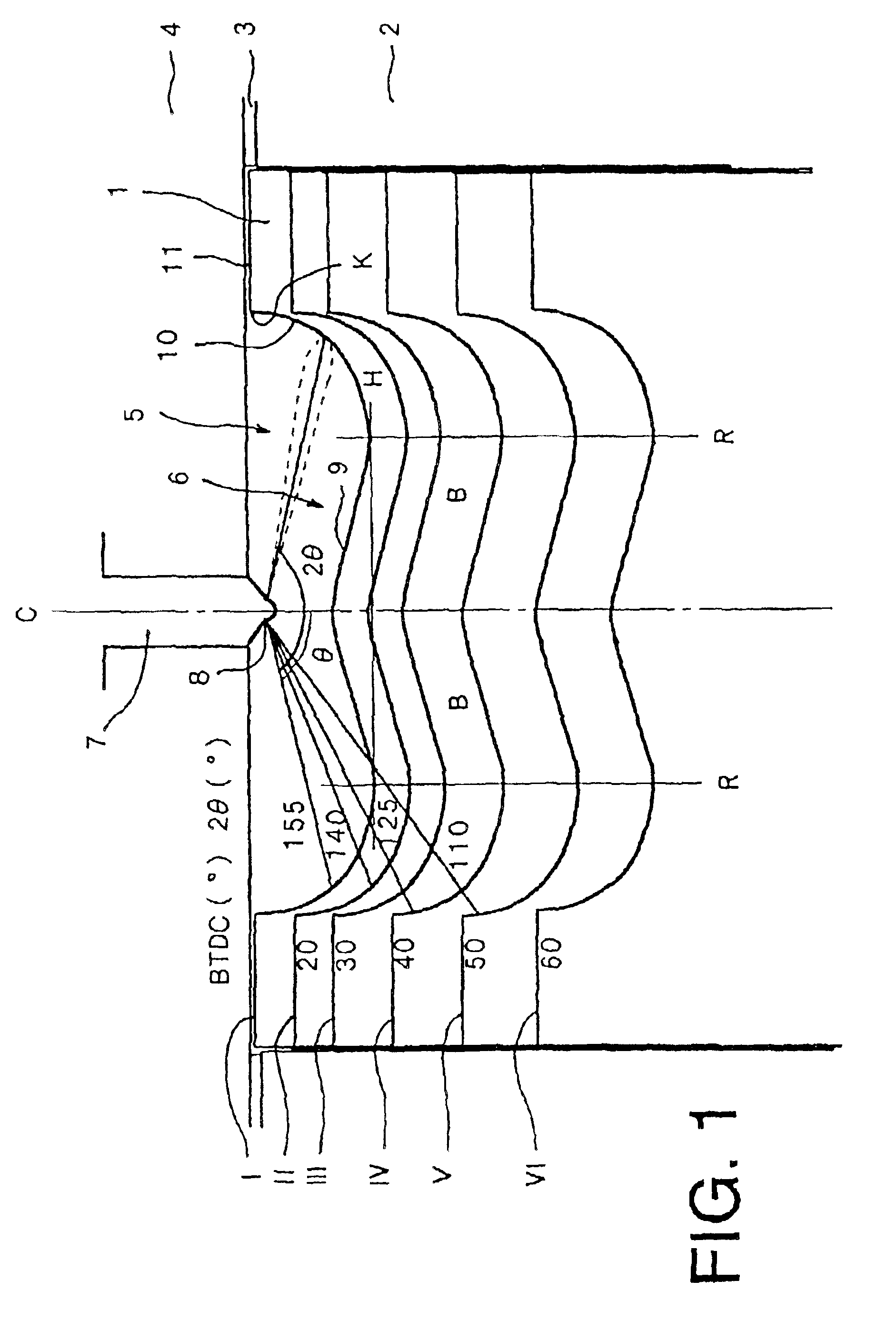

InactiveUS6302080B1Improve permeabilityIncrease the angleElectrical controlInternal combustion piston enginesTop dead centerEngineering

The angle of fuel spray at the time of pre-injection is set to a wider angle of spray and the angle of fuel spray at the time of main injection is set to a narrower angle of spray. The pre-injection timing is set so that when fuel spray after the pre-injection is diffused in a cylinder and stratified, the stratified fuel spray is ignited by a rise in the pressure in the cylinder in association with movement of a piston from the bottom dead center to the top dead center. The main injection timing is set so that when the spray stratified by the pre-injection is burned, the fuel spray injected by the main injection passes through the combustion zone while being ignited in the combustion zone, reaches a combustion chamber of the piston, and is burned in the combustion chamber.

Owner:DENSO CORP

Automotive four-cycle engine

InactiveUS6626164B2Sufficient effectAvoid increase in combustion temperature and exhaust gas temperatureValve arrangementsElectrical controlExhaust valveTop dead center

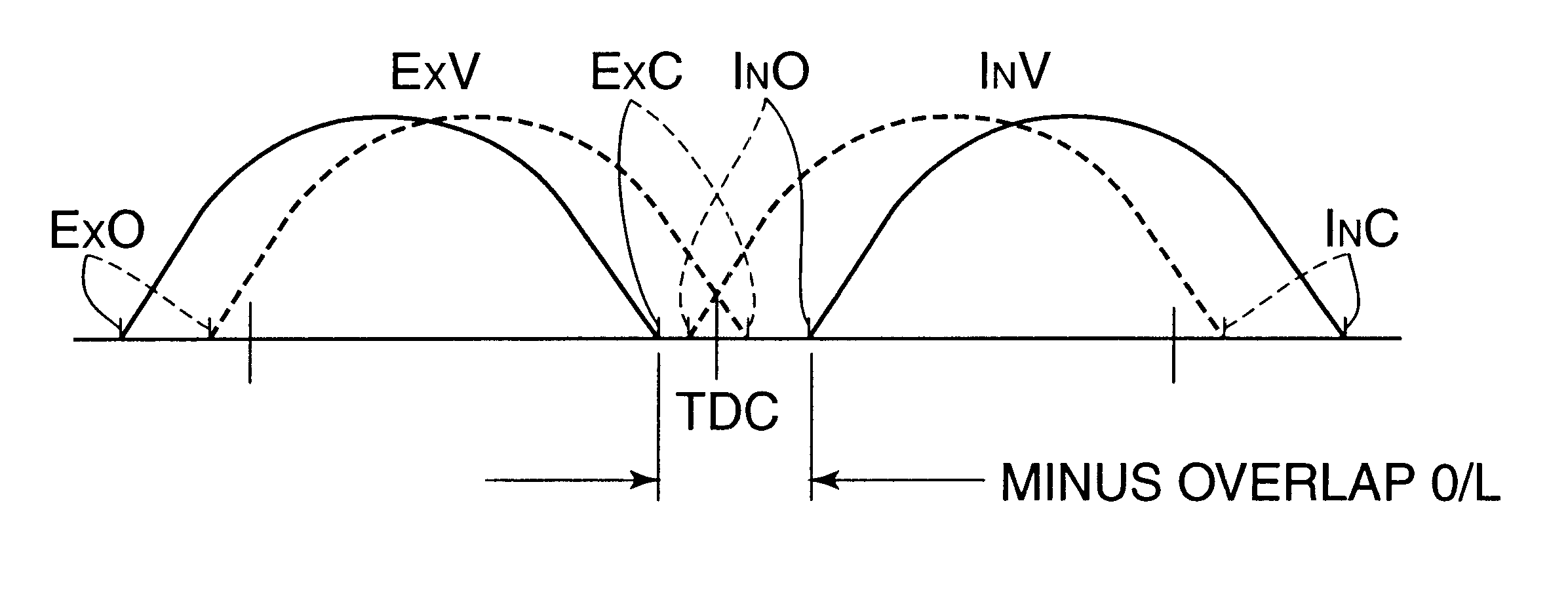

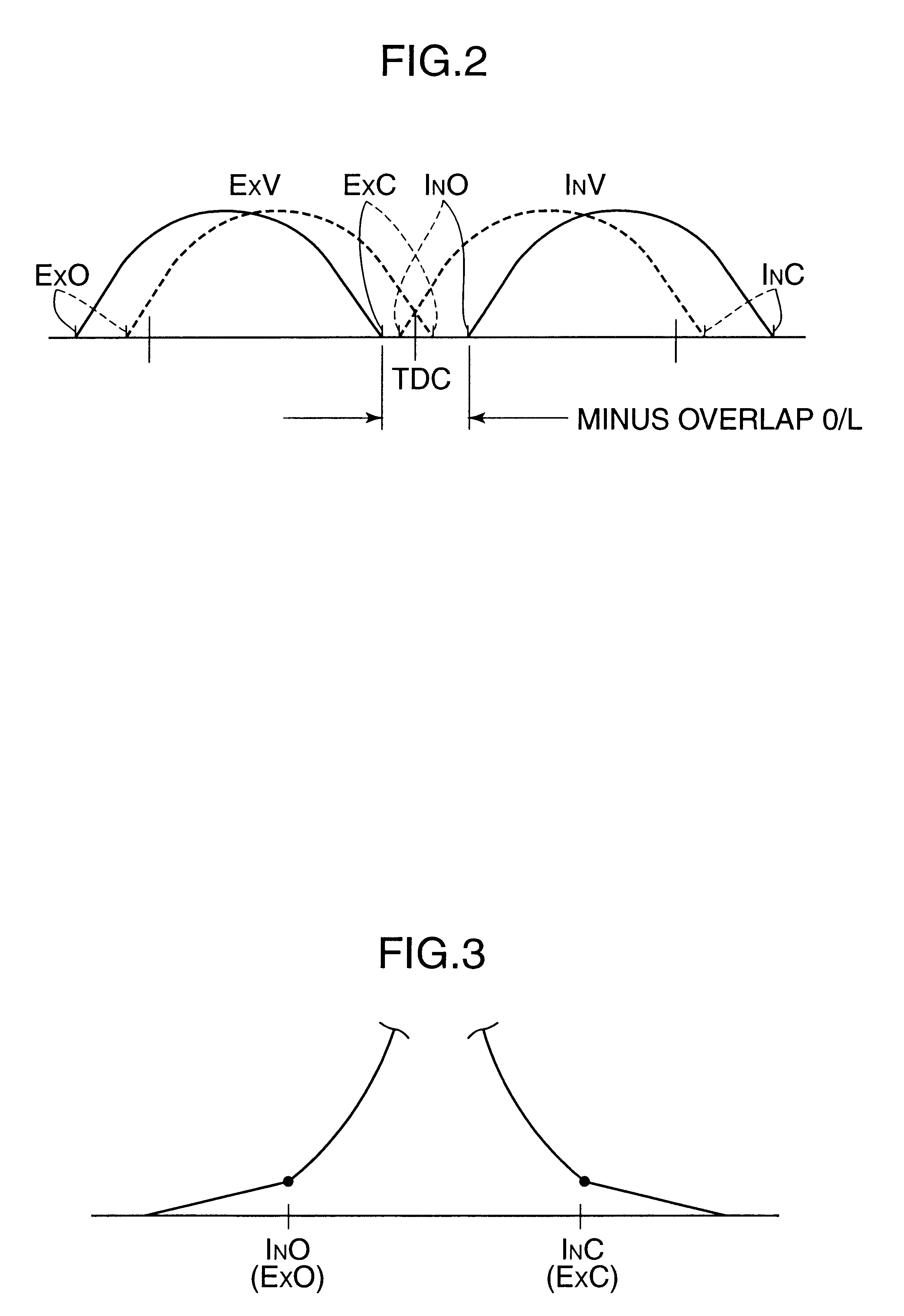

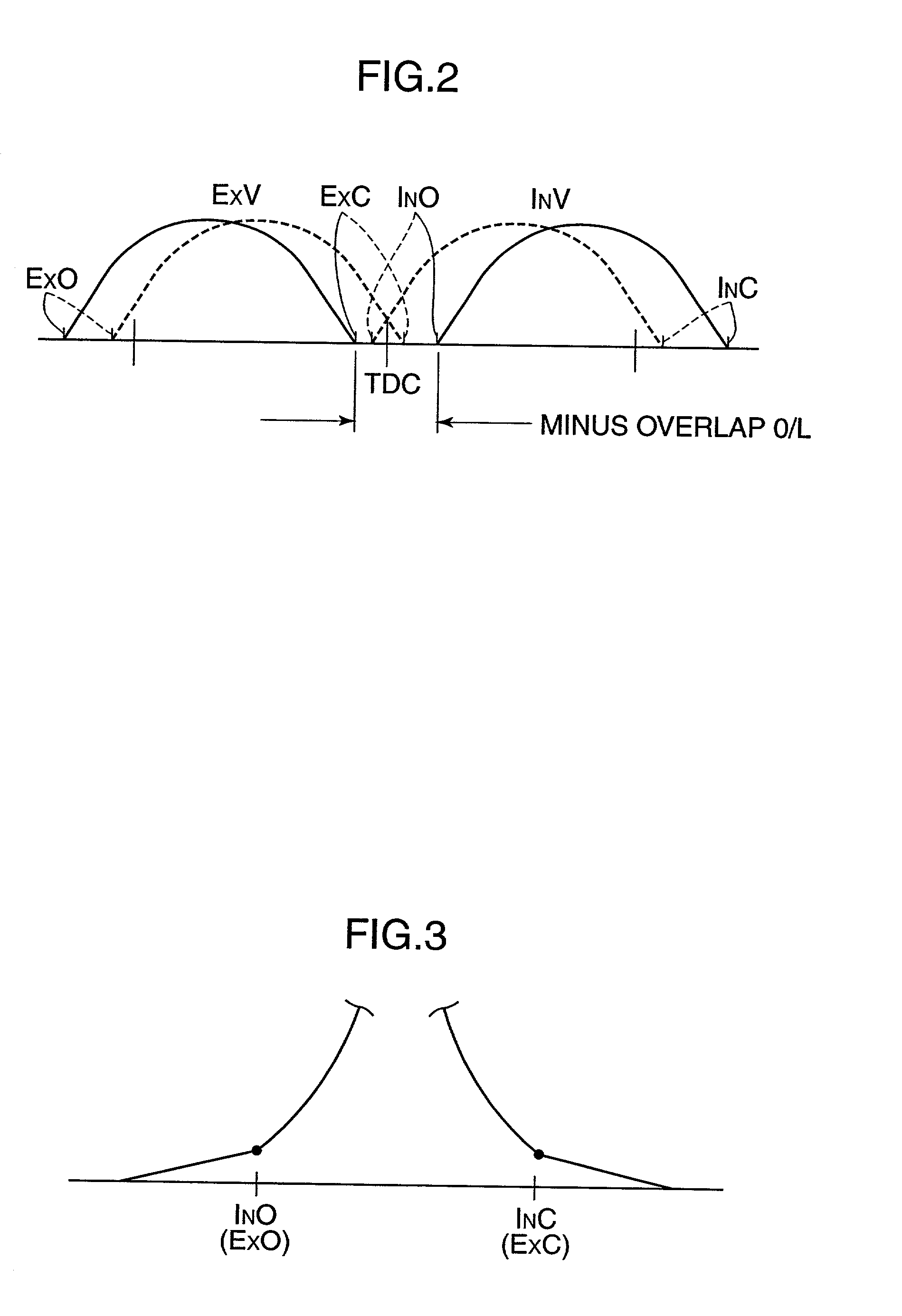

A four-cycle engine is provided with valve timing adjusters for adjusting opening and closing timing an and an exhaust valve. In medium- to high-speed ranges in medium- to high-load regions of the engine, a closing point (ExC) of the exhaust valve defined as a point of transfer from an acceleration portion to a constant speed portion on its valve lift characteristics curve is set to a point a specific period before an intake top dead center, and an opening point (InO) of the intake valve defined as a point of transfer from a constant speed portion to an acceleration portion on its valve lift characteristics curve is set to a point after the intake top dead center. In addition, the period from the closing point (ExC) of the exhaust valve to the opening point (InO) of the intake valve is made longer in the medium-speed range than in the high-speed range in the medium- to high-load regions of the engine.

Owner:MAZDA MOTOR CORP

Compression-ignited IC engine and method of operation

InactiveUS7121254B2Improve efficiencyEmission reductionElectrical controlNon-fuel substance addition to fuelCombustionTop dead center

The present invention is a compression ignition internal combustion engine and method of operation which expands the load limit of quietly operating a premixed charge compression ignition (PCCI) engine by injecting a secondary fuel B, in ratios lean of stoichiometric, either into the intake air stream or directly into the cylinder to form a homogeneous fuel B and air mixture. Near top dead center of the compression stroke, a PCCI-type direct injection of fuel A event is used to initiate combustion of both fuel A and B at the proper time. At low loads the combustion mode is characterized a PCCI-type with high EGR rates. At medium loads the combustion mode is that of homogeneous combustion of fuel B coupled with PCCI combustion of fuel A. At the highest loads the engine will revert to a conventional diesel combustion mode of fuel A to maintain power density.

Owner:GM GLOBAL TECH OPERATIONS LLC

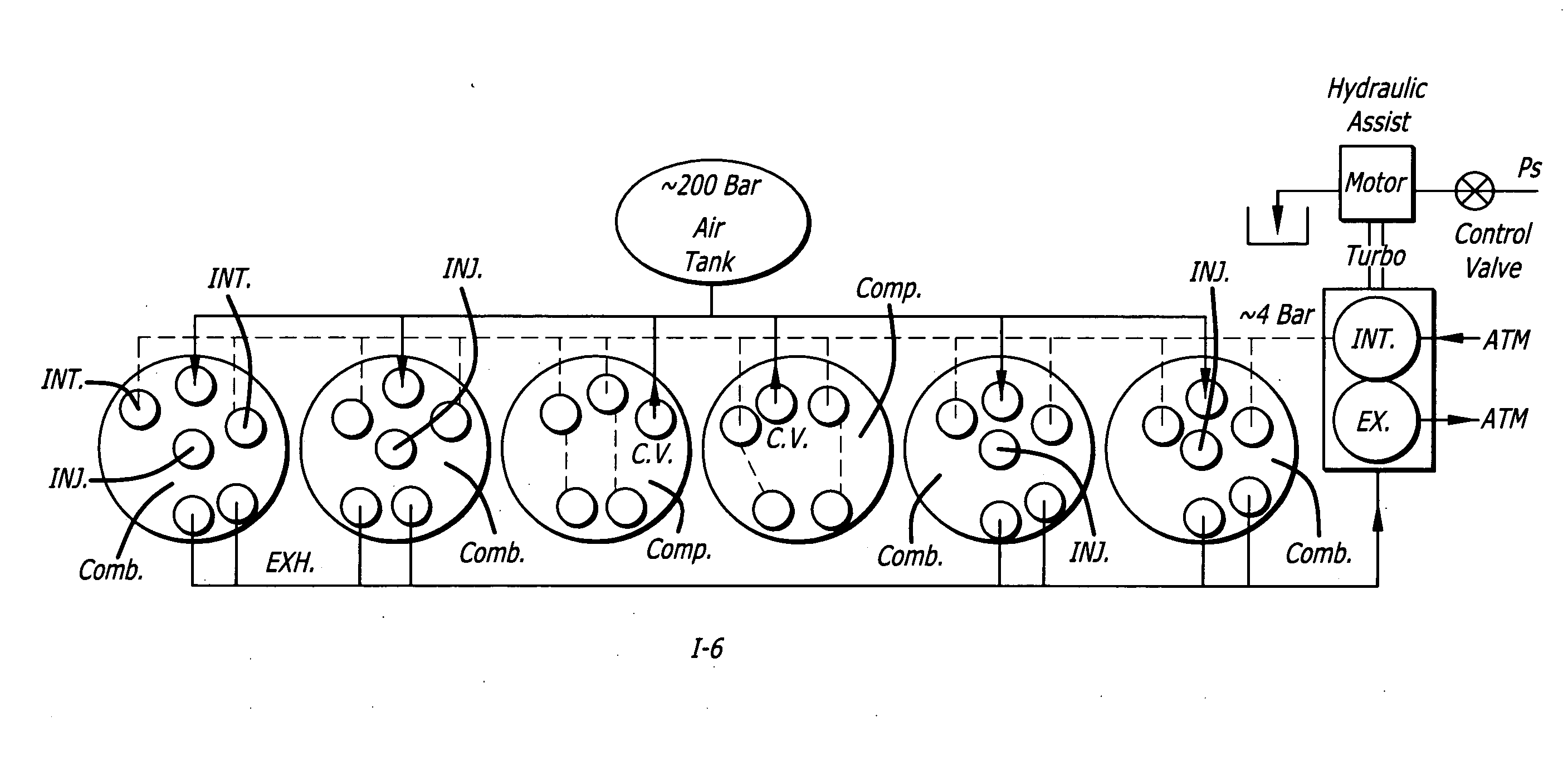

Engine with an active mono-energy and/or bi-energy chamber with compressed air and/or additional energy and thermodynamic cycle thereof

ActiveUS7469527B2Usable and available energyQuantity of usable and availableFlexible wall reciprocating enginesCombustion enginesTop dead centerEngineering

An engine uses a top dead center piston stop device. It is fed by compressed air, via a working capacity, which, in the bi-energy version, includes a device for heating the air supplied by additional energy. The active expansion chamber consists of a variable volume or charge piston sliding in a cylinder, coupled to a space above the engine piston via a passage. When stoped at upper dead center, the pressurized air is admitted into the expansion chamber with the smallest volume thereof and, under the effect of thrust, increases the volume thereof by producing work; the expansion chamber is then kept at a maximum volume during expansion of the engine cylinder driving back the engine piston in its downward stroke, providing work of its own. During exhaust, the two pistons travel in an upward stroke and simultaneously reach top dead center in order to resume a new cycle.

Owner:MDI MOTOR DEV INT SA

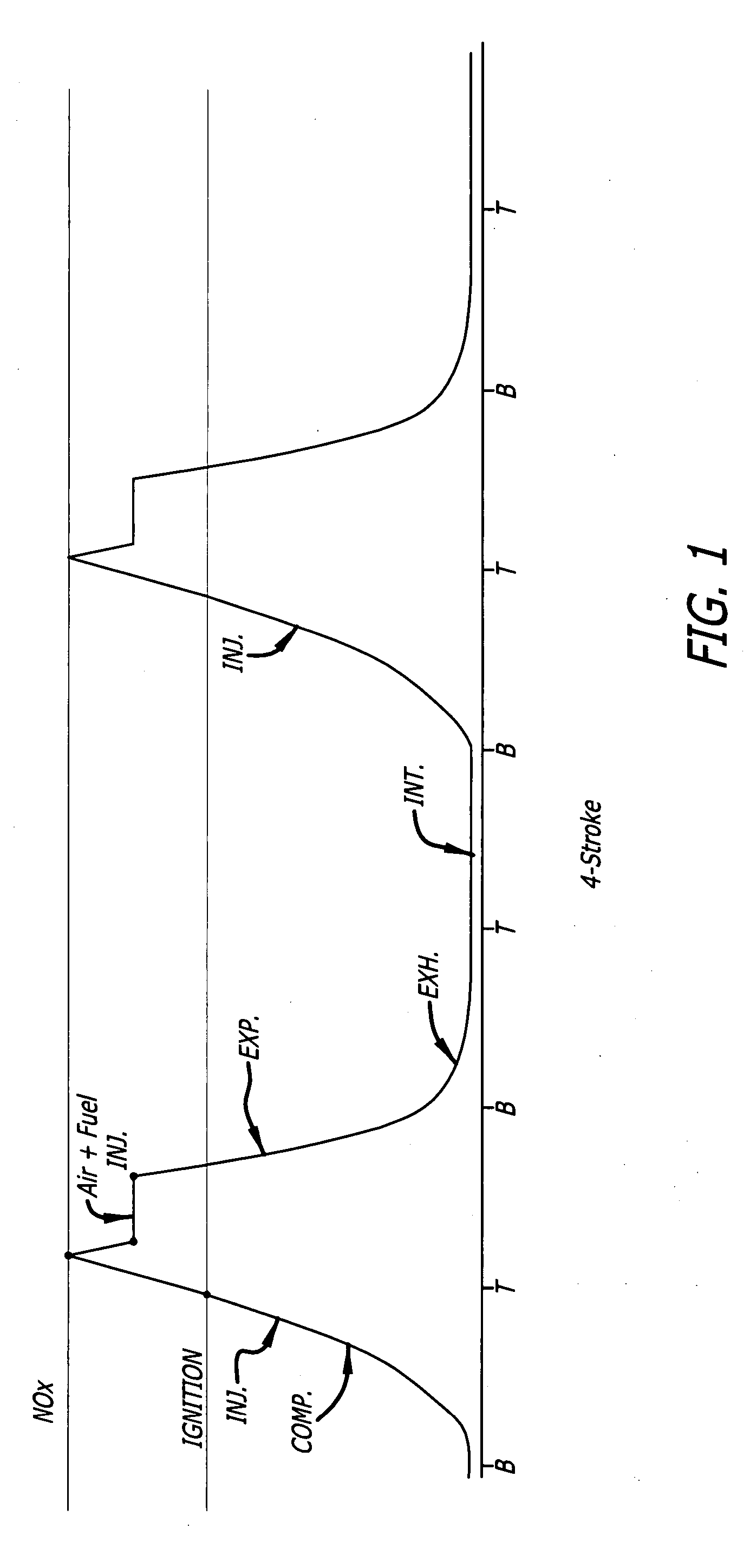

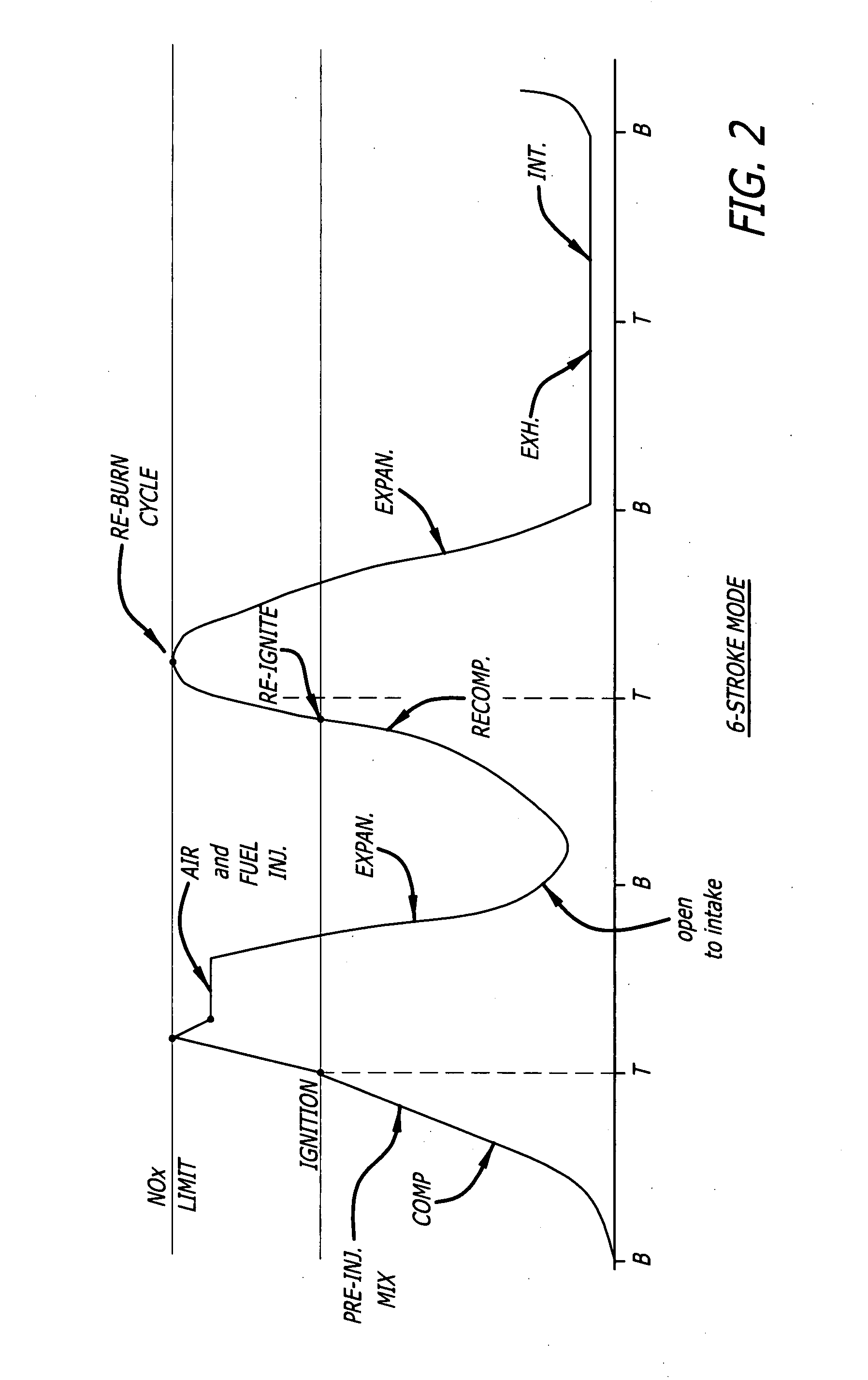

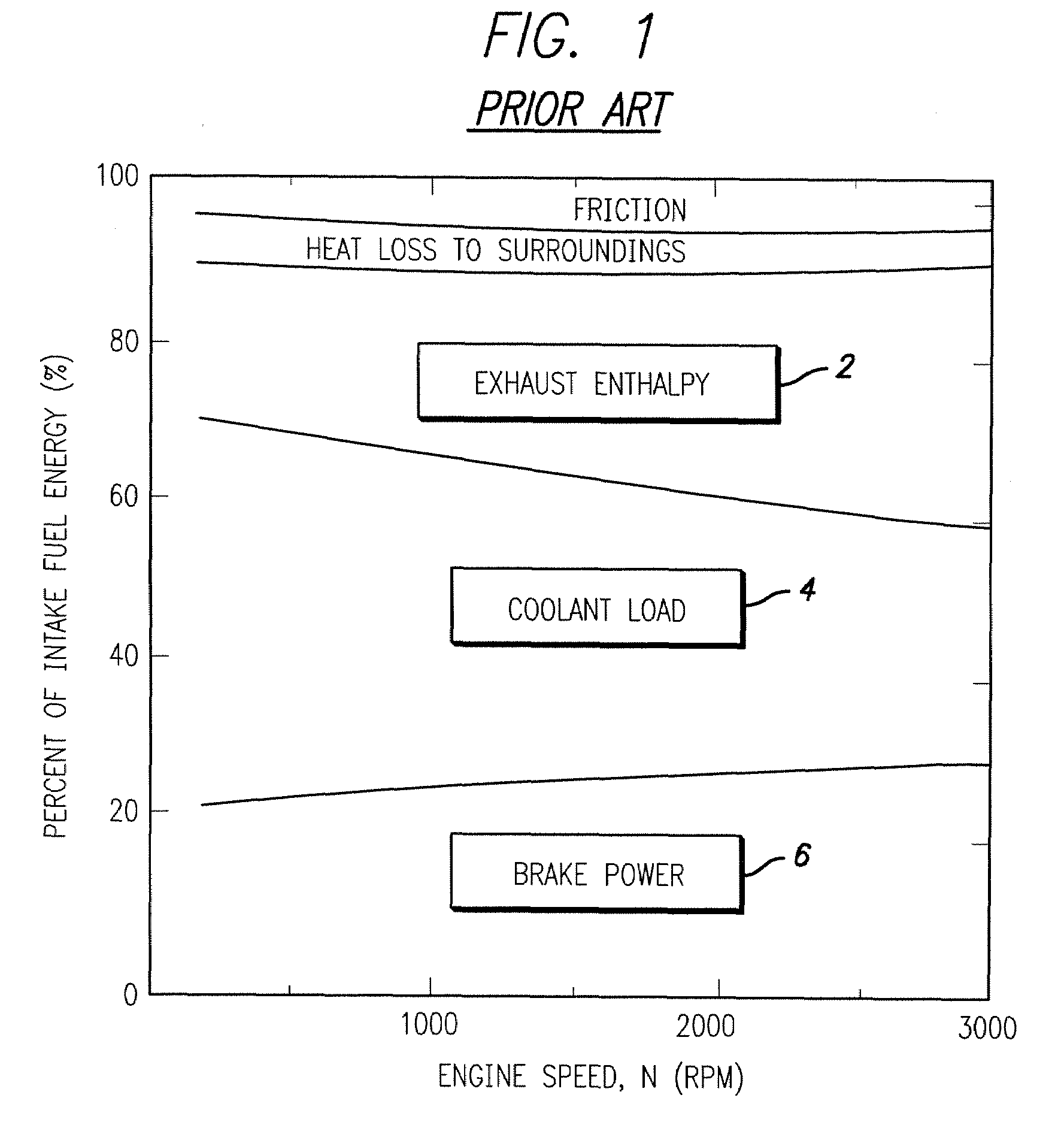

Low emission high performance engines, multiple cylinder engines and operating methods

InactiveUS20070245982A1Electrical controlNon-fuel substance addition to fuelCombustion chamberTop dead center

Low emission high performance engines, multiple cylinder engines and operating methods based on compression ignition of a combustion chamber charge already containing at least some fuel and air. Air is injected into the combustion chamber after top dead center is reached to maintain combustion until all fuel is consumed. Various modes of operation are disclosed.

Owner:STURMAN DIGITAL SYST

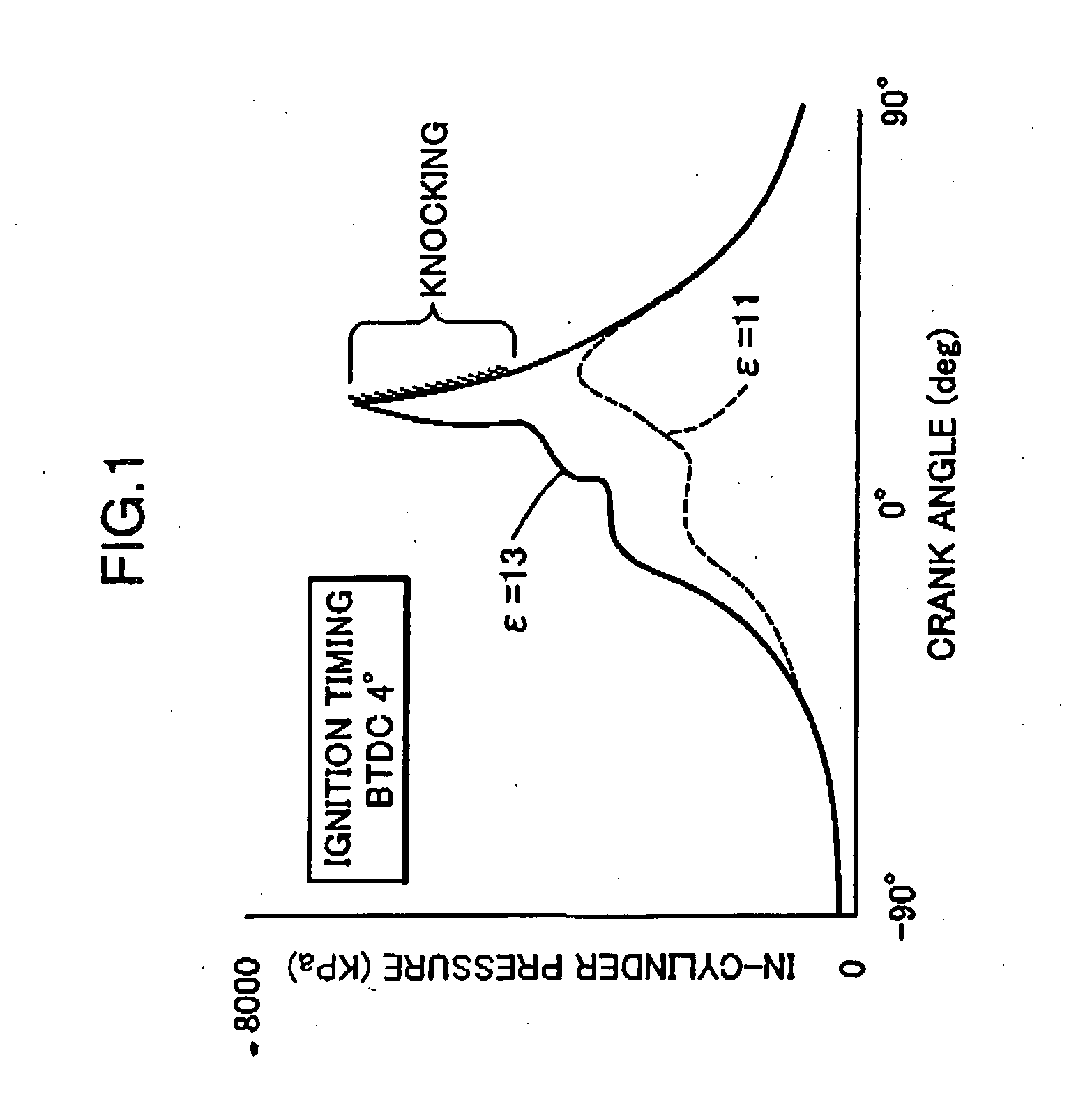

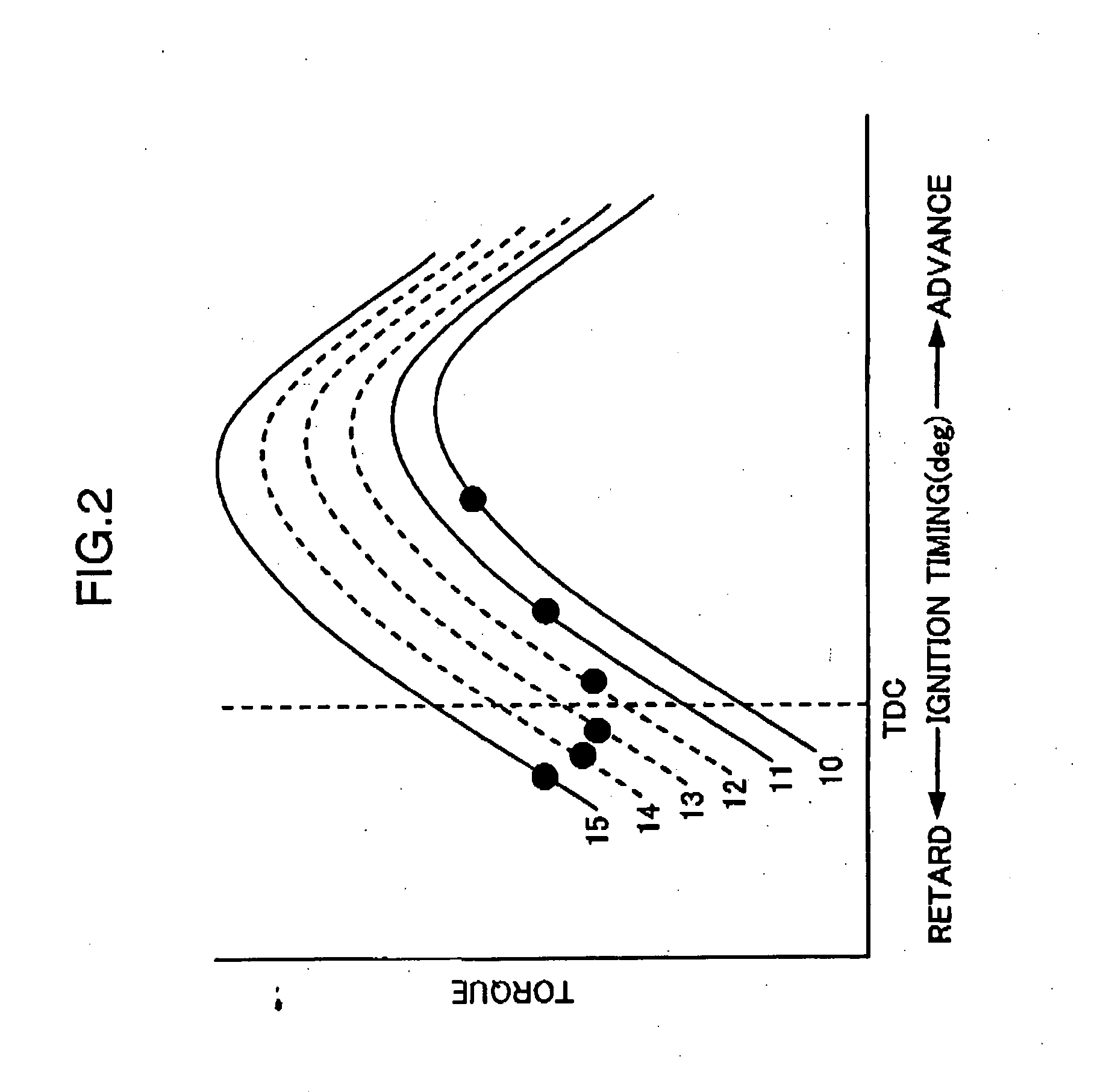

Spark-ignition gasoline engine

ActiveUS20070227503A1Improve fuel economyShorten burn timeElectrical controlInternal combustion piston enginesLow speedTop dead center

Disclosed is a spark-ignition gasoline engine, which comprises control means operable, when an engine operation zone is a high-load operation zone including a WOT region within at least a low speed range, to adjust a closing timing of an intake valve in such a manner as to maintain an effective compression ratio at 13 or more, and retard an ignition timing to a point within a predetermined stroke range just after a top dead center of a compression stroke, wherein the effective compression ratio is calculated based on an intake-valve closing timing defined by a valve lift amount of 1 mm. The present invention can provide a spark-ignition gasoline engine having both a low-cost performance and a high engine-power performance even in a high-load operation zone (particularly WOT region) in a low speed range.

Owner:MAZDA MOTOR CORP

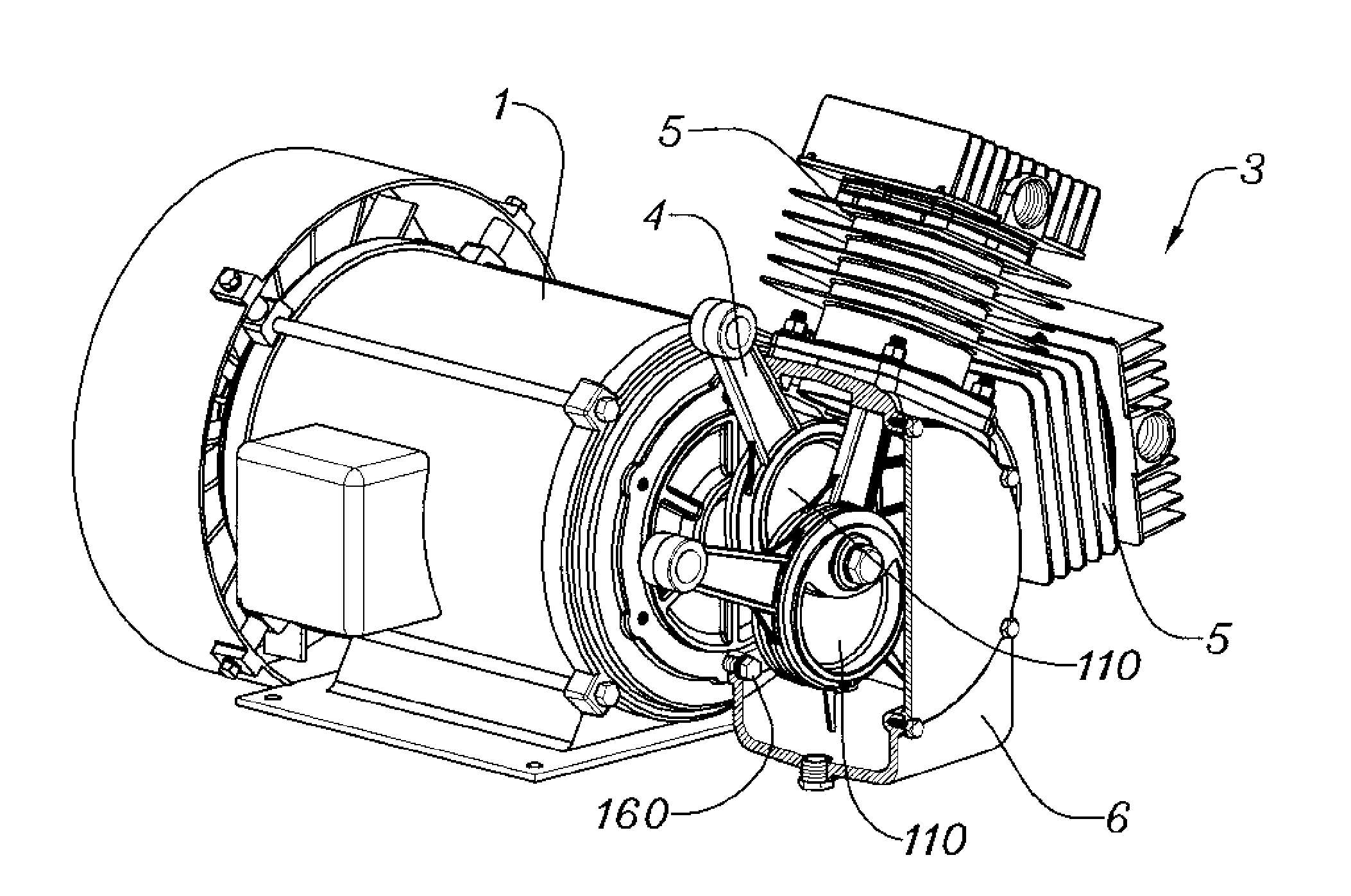

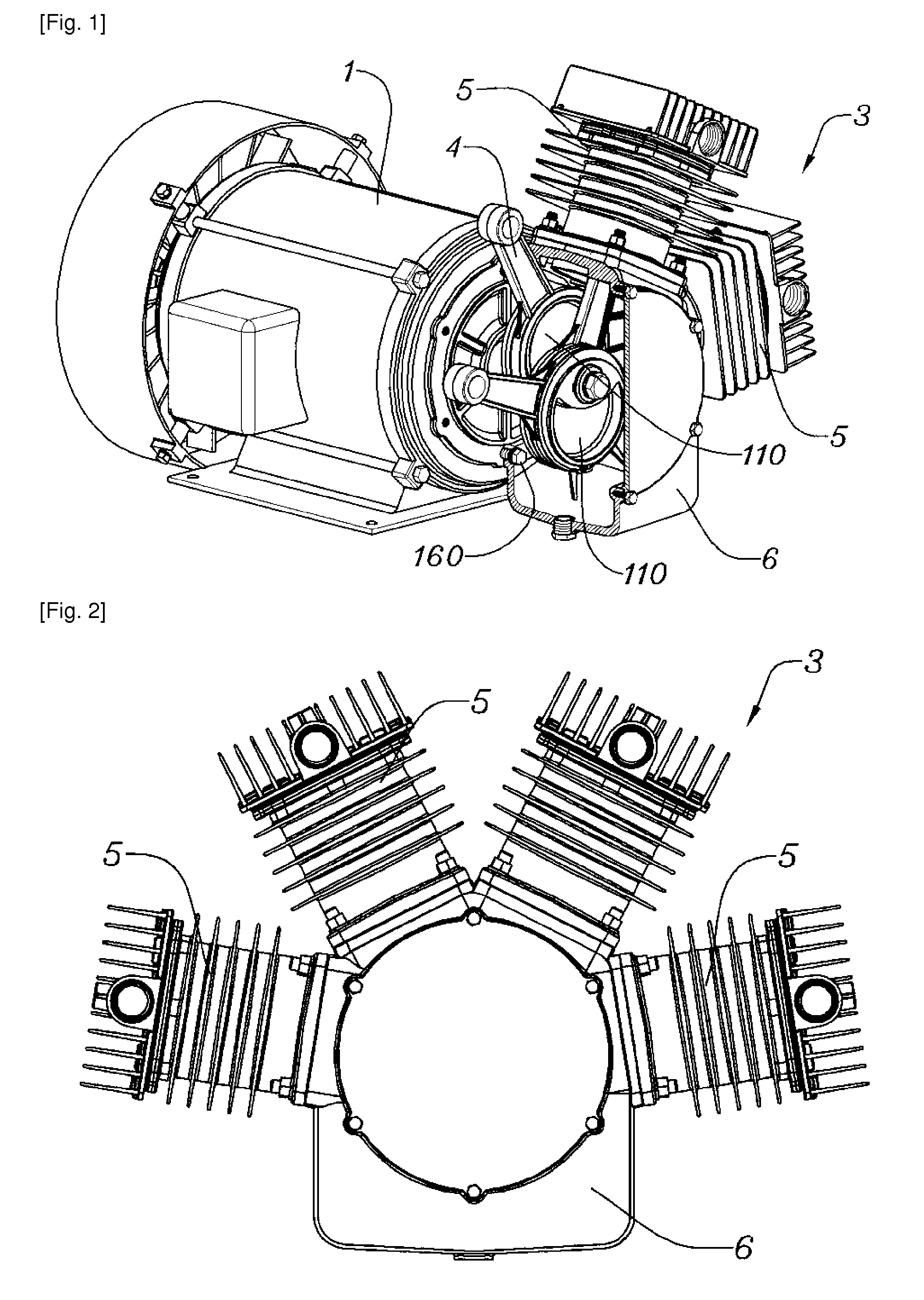

Direct crankshaft of air compressor

InactiveUS8388317B2Configured more compactlyCompact configurationPositive displacement pump componentsPortable liftingCompression PumpEngineering

There is provided a direct crankshaft of an air compressor for producing compressed air in which a crankshaft is implemented by two crank plates integrally overlapped with each other so that compression cylinders can be arranged in the radial direction to exhibit an excellent air cooling performance, top dead centers and bottom dead centers of the compression cylinders are symmetrically arranged so that the cancellation between pressurizing and vacuuming phenomena and the running of a motor can be smoothly performed, and the motor is integrated with a compression pump so that various driving components such as belts, pulleys, covers, and the like are eliminated and manufacturing costs are remarkably reduced. The direct crankshaft includes crank plates integrated with each other to form an overlapping unit. The overlapping unit has a shaft coupling hole through which a motor shaft penetrates such that the direct crankshaft is directly coupled with a motor.

Owner:KOHANDS CO LTD

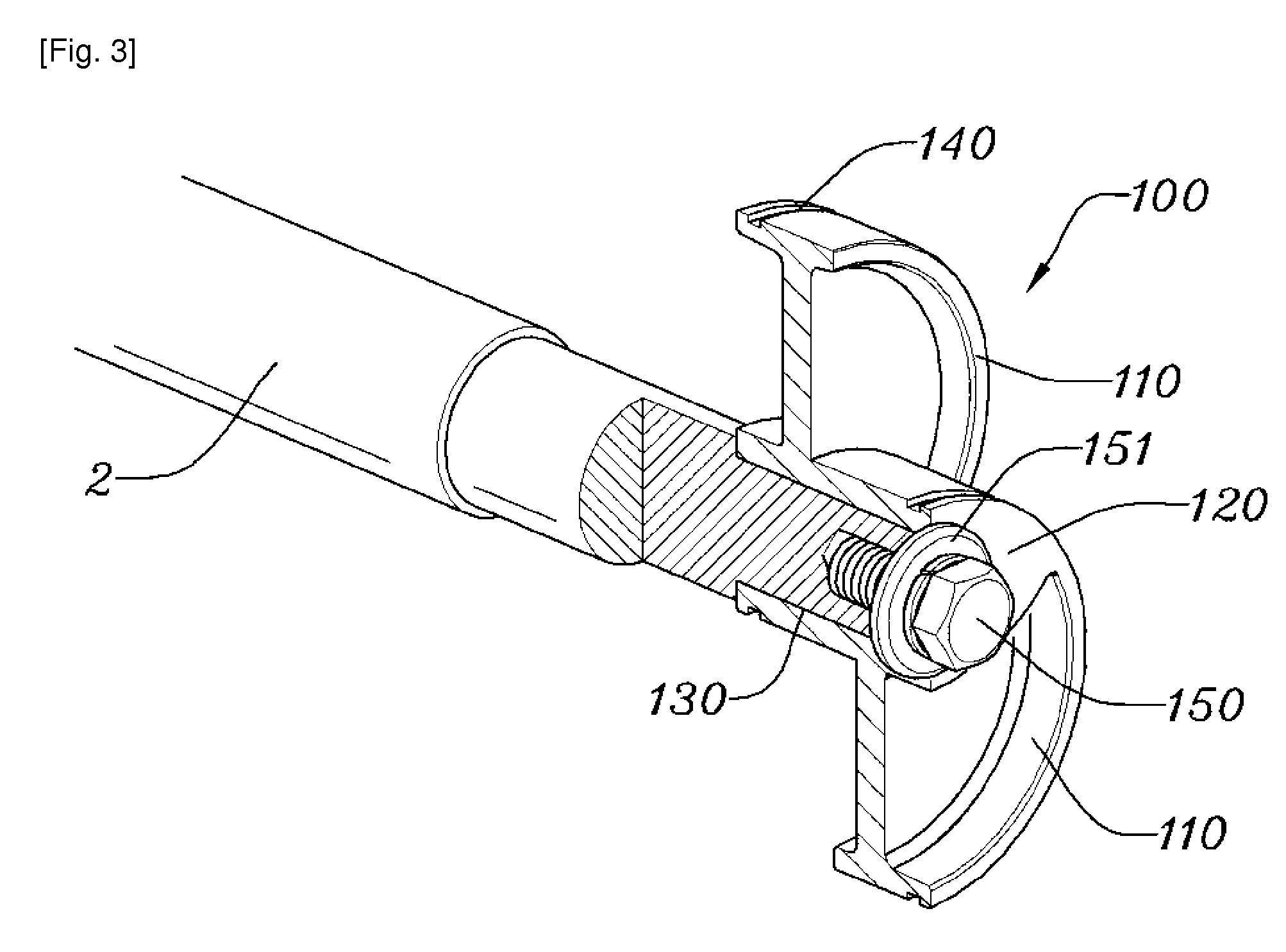

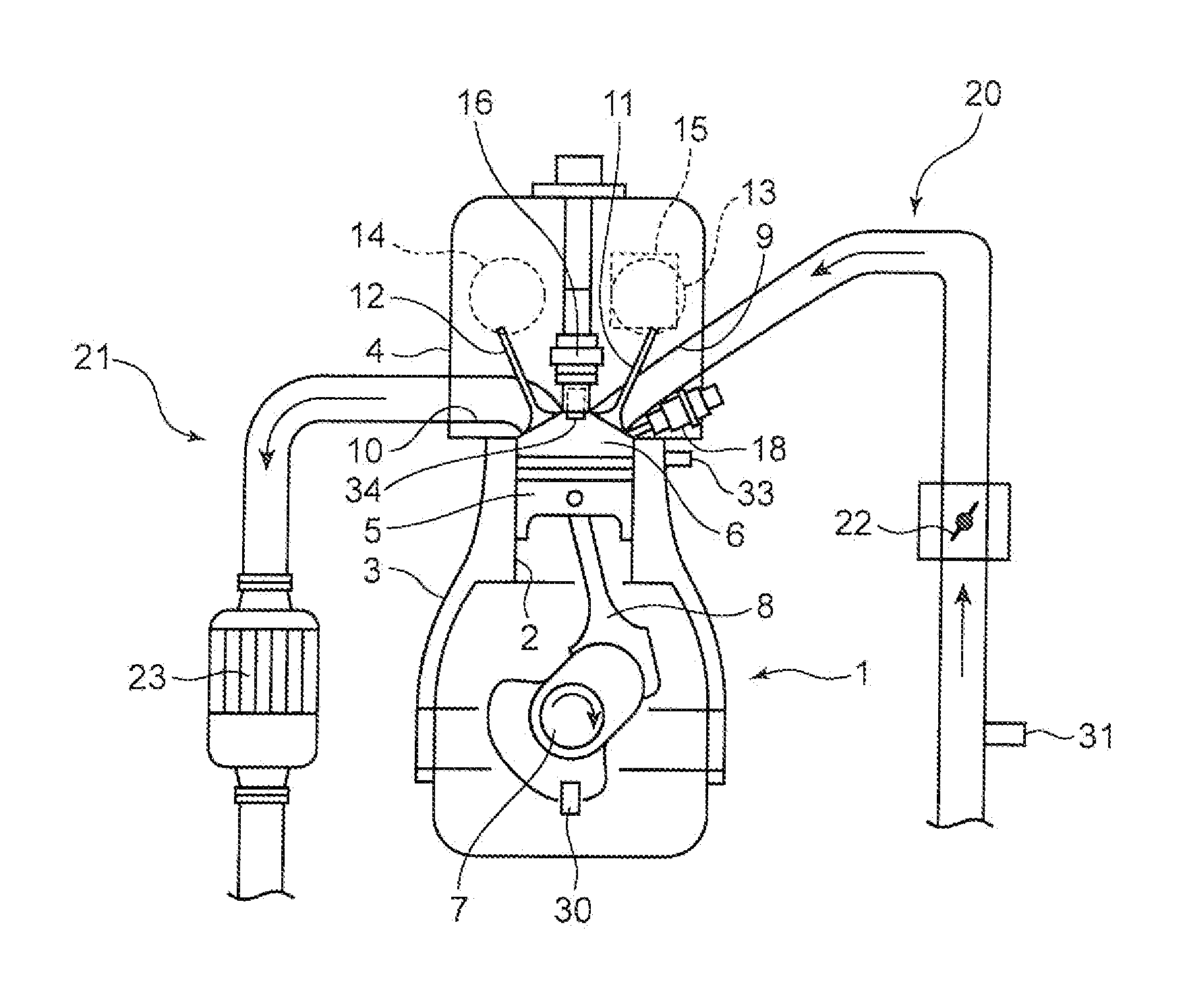

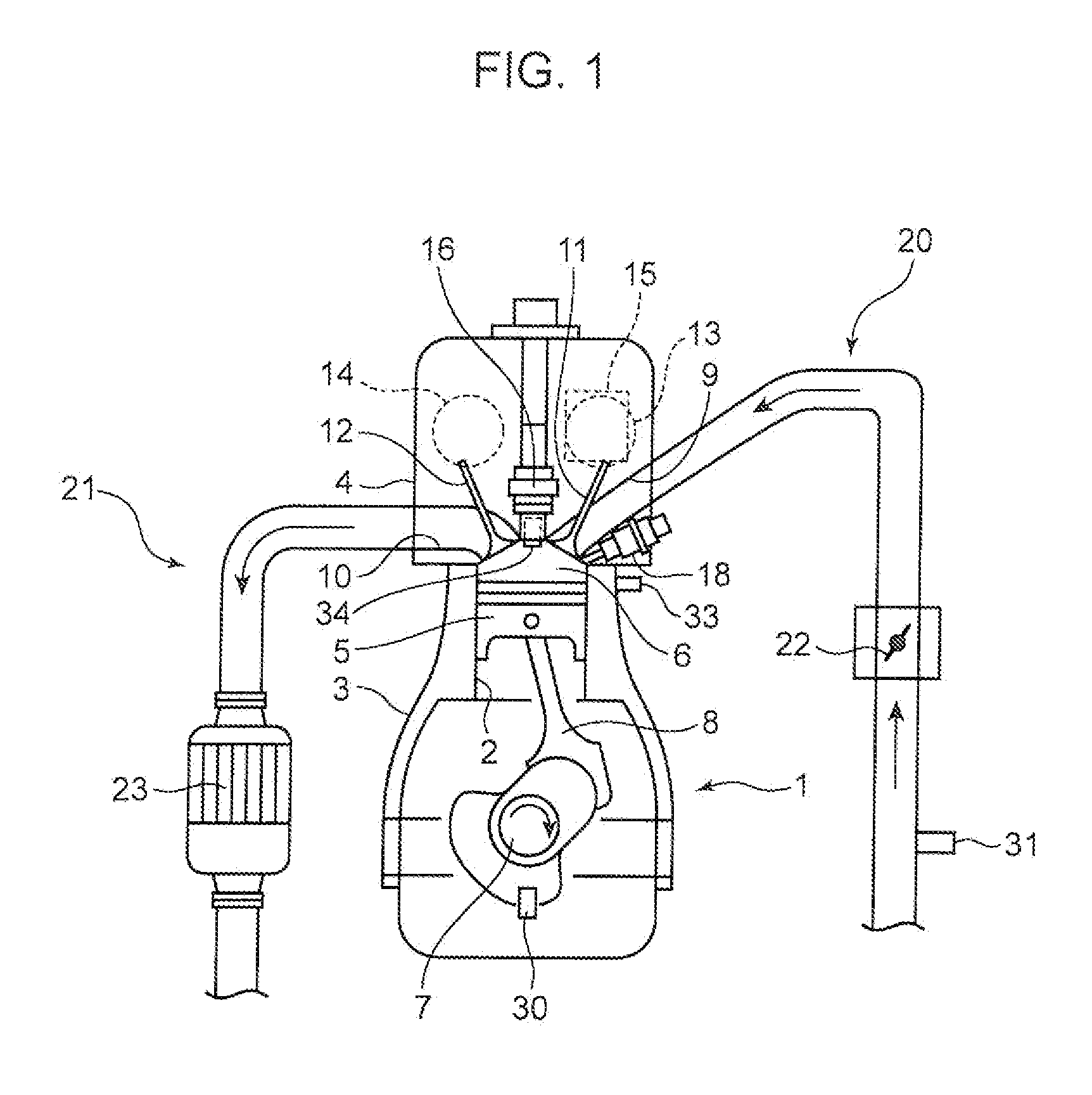

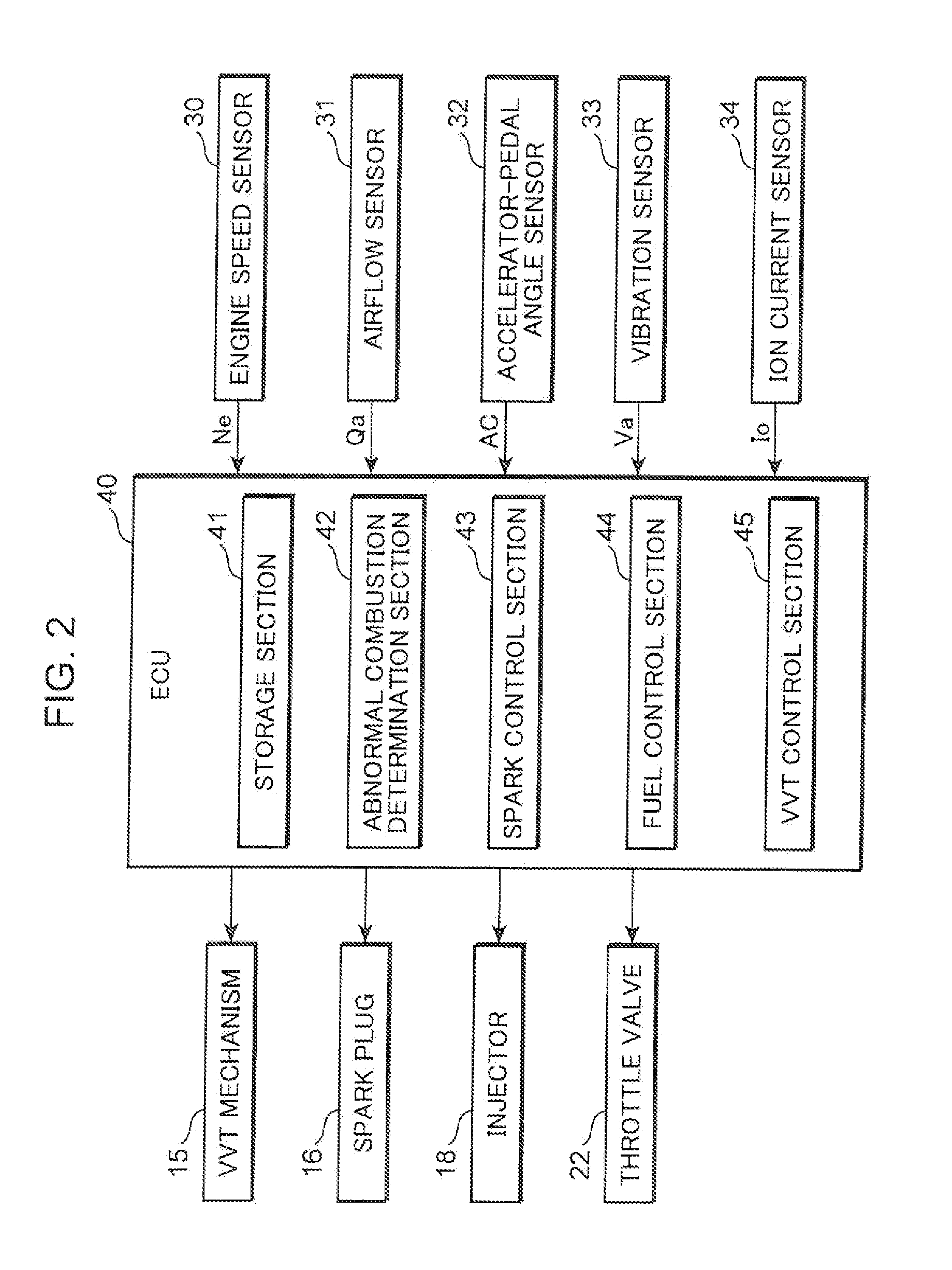

Abnormal combustion detection method for spark-ignition engine, and spark-ignition engine

ActiveUS20110246049A1Enough can be detectedInternal-combustion engine testingAnalogue computers for vehiclesTop dead centerEngineering

When a maximum value of vibration intensity (maximum vibration intensity) (Vmax) acquired from a vibration sensor (33) in a low engine speed / high engine load (operating region (R)) is equal to or greater than a given threshold value (X), a spark timing of a spark plug (16) is shifted from a point set in a normal state on a retard side with respect to a compression top dead center, farther toward the retard side. Then, when a maximum vibration intensity (Vmax2) acquired after the spark timing retard is greater than a maximum vibration intensity (Vmax1) acquired before the spark timing retard, it is determined that preignition occurs. This technique makes it possible to reliably detect preignition using the vibration sensor, while distinguishing the preignition from knocking. An in-cylinder pressure sensor for detecting an in-cylinder pressure of an engine may be used to determine the presence or absence of the preignition, in the same manner.

Owner:MAZDA MOTOR CORP

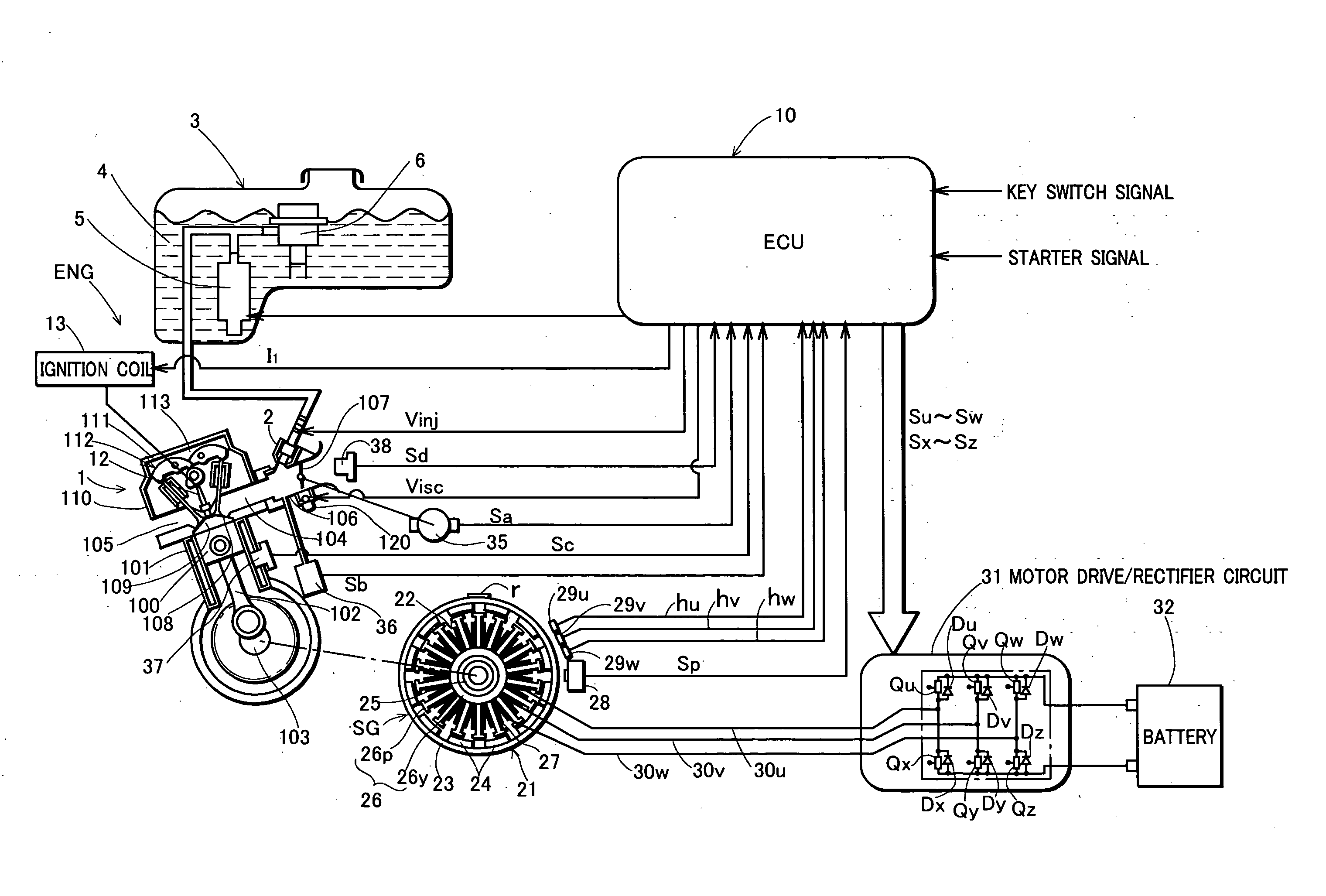

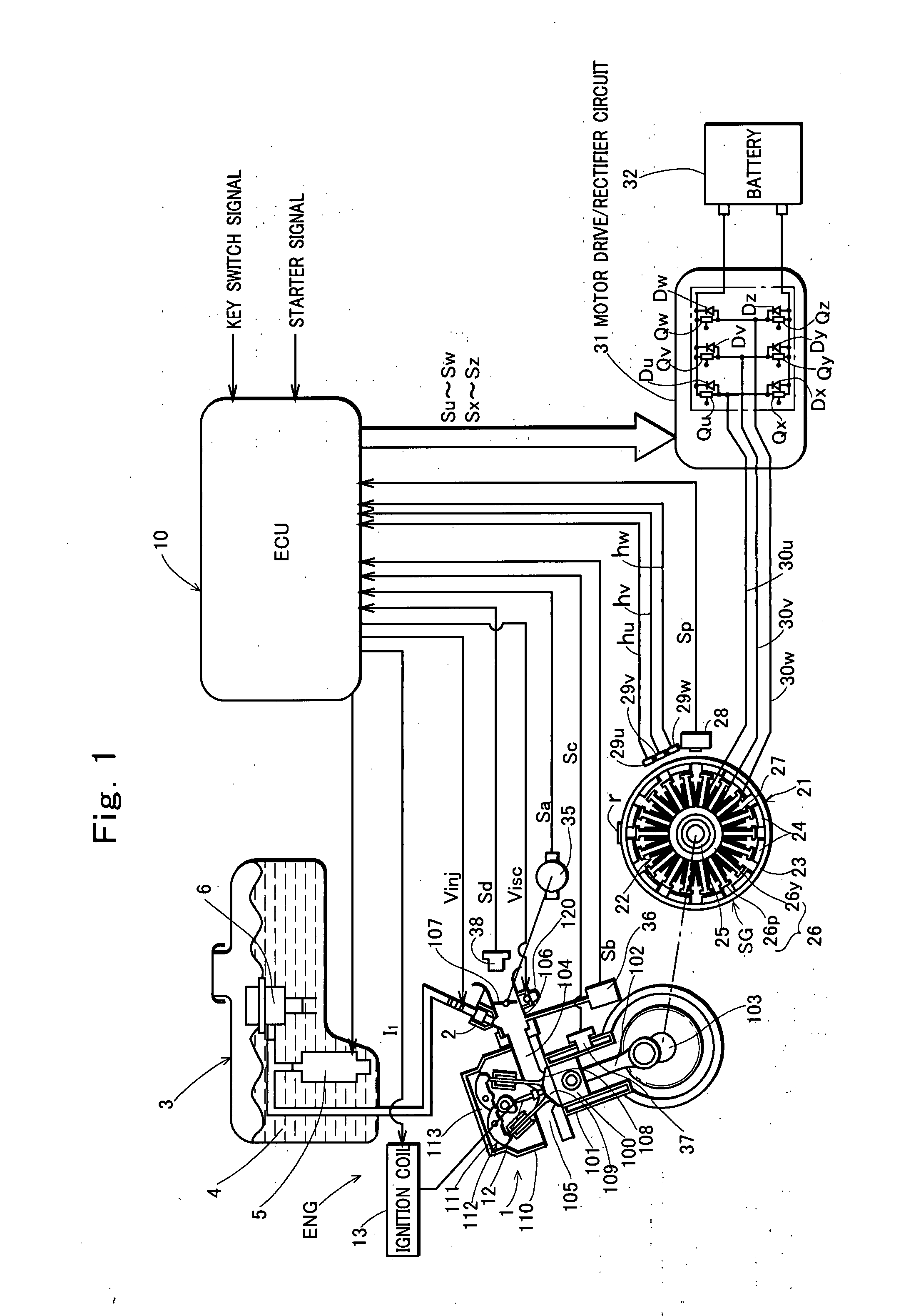

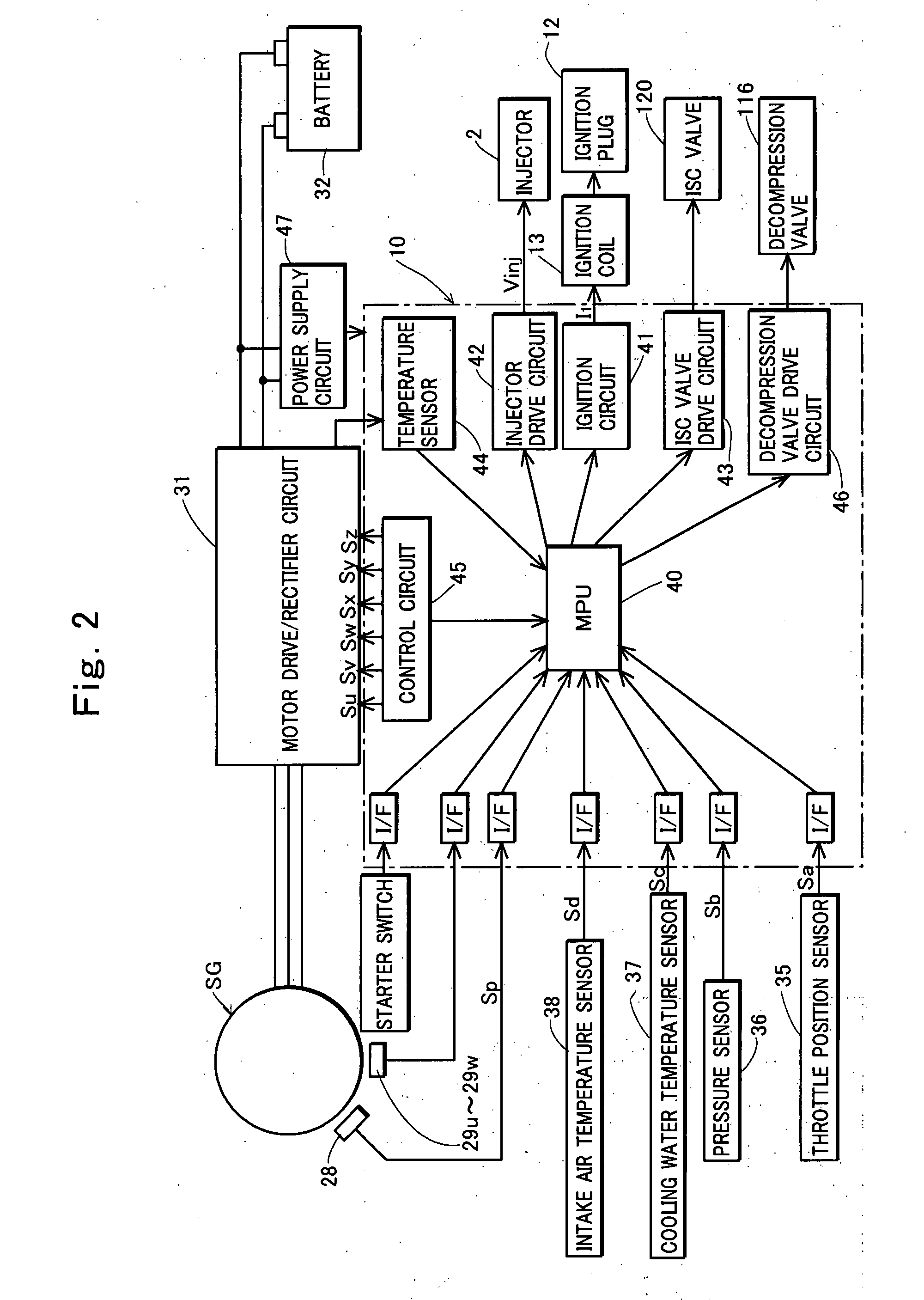

Engine starting device

InactiveUS20070204827A1Startability is improvedImprove performanceElectrical controlElectric ignition installationTop dead centerCrankshaft

An engine starting device which makes fuel injected in preparation for ignition performed in a cylinder of an engine after starting drive of a starter motor in a forward rotational direction so as to start the engine, and makes ignition performed in a suitable ignition position at the time of engine start while the starter motor is driven in a forward rotational direction, the engine starting device being comprised so as to continue driving the starter motor in a direction for starting the engine, even when a crankshaft stops before a piston in a cylinder of the engine reaches a top dead center of a compression stroke.

Owner:KOKUSAN DENKI CO LTD

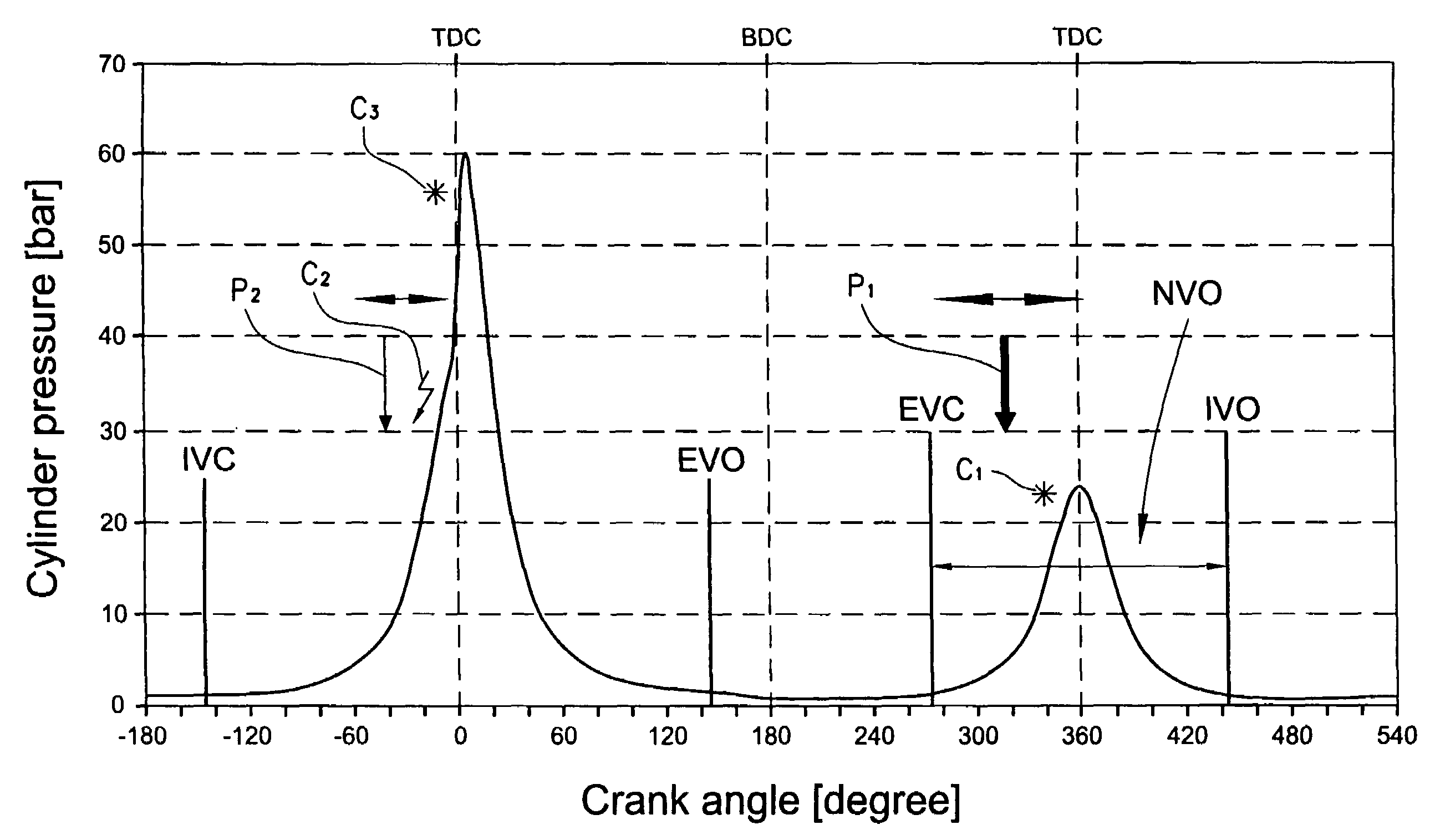

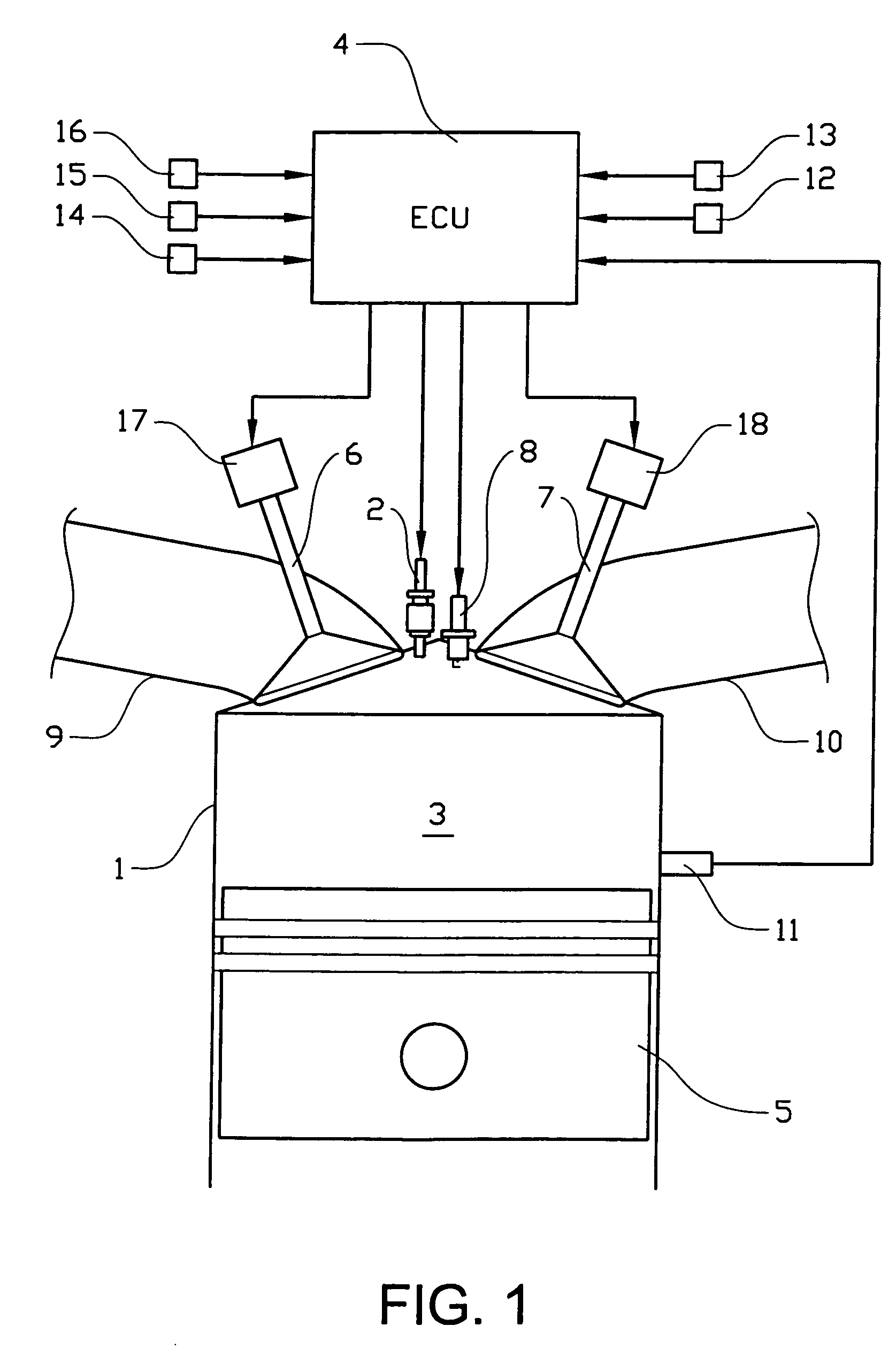

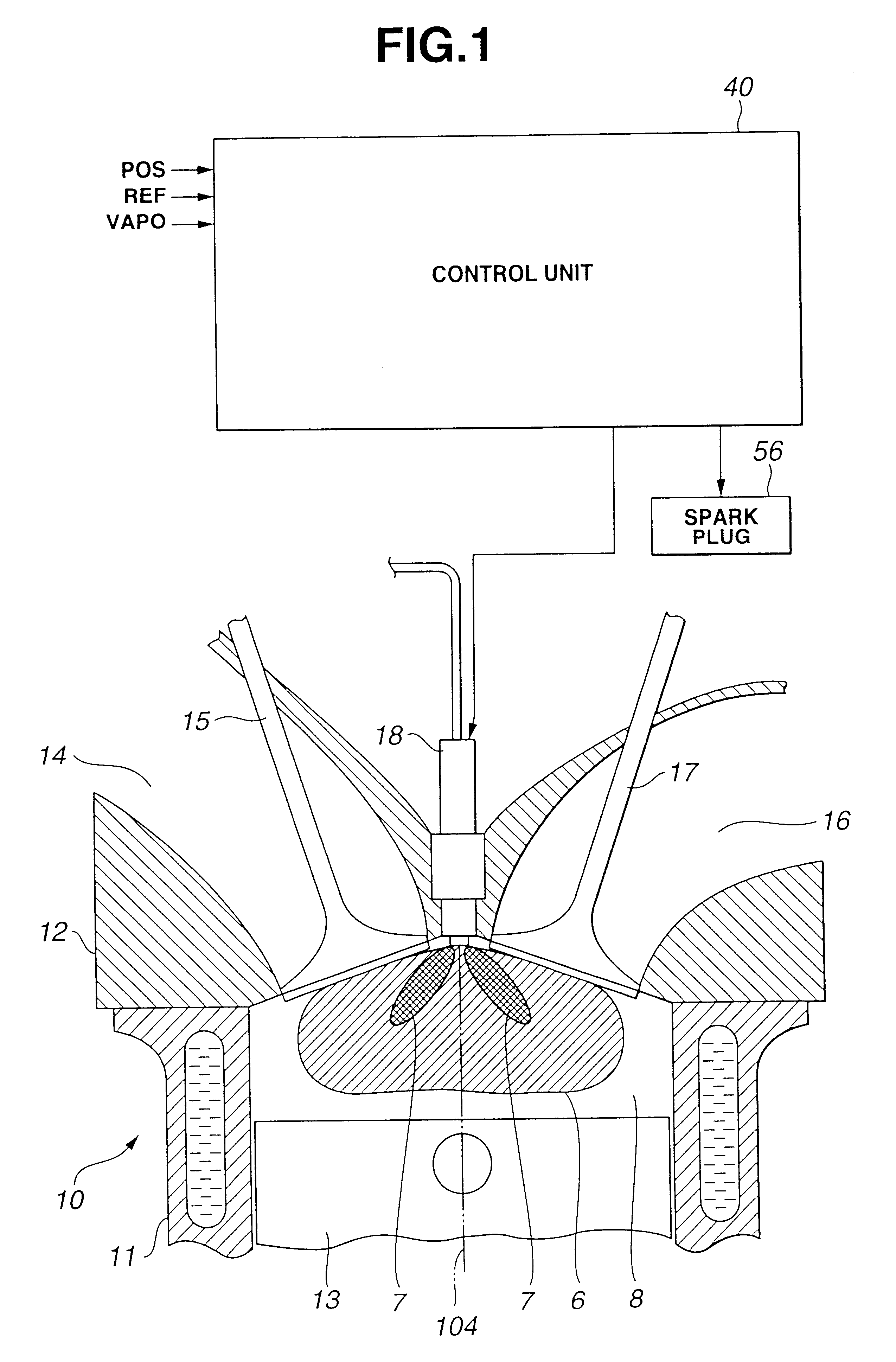

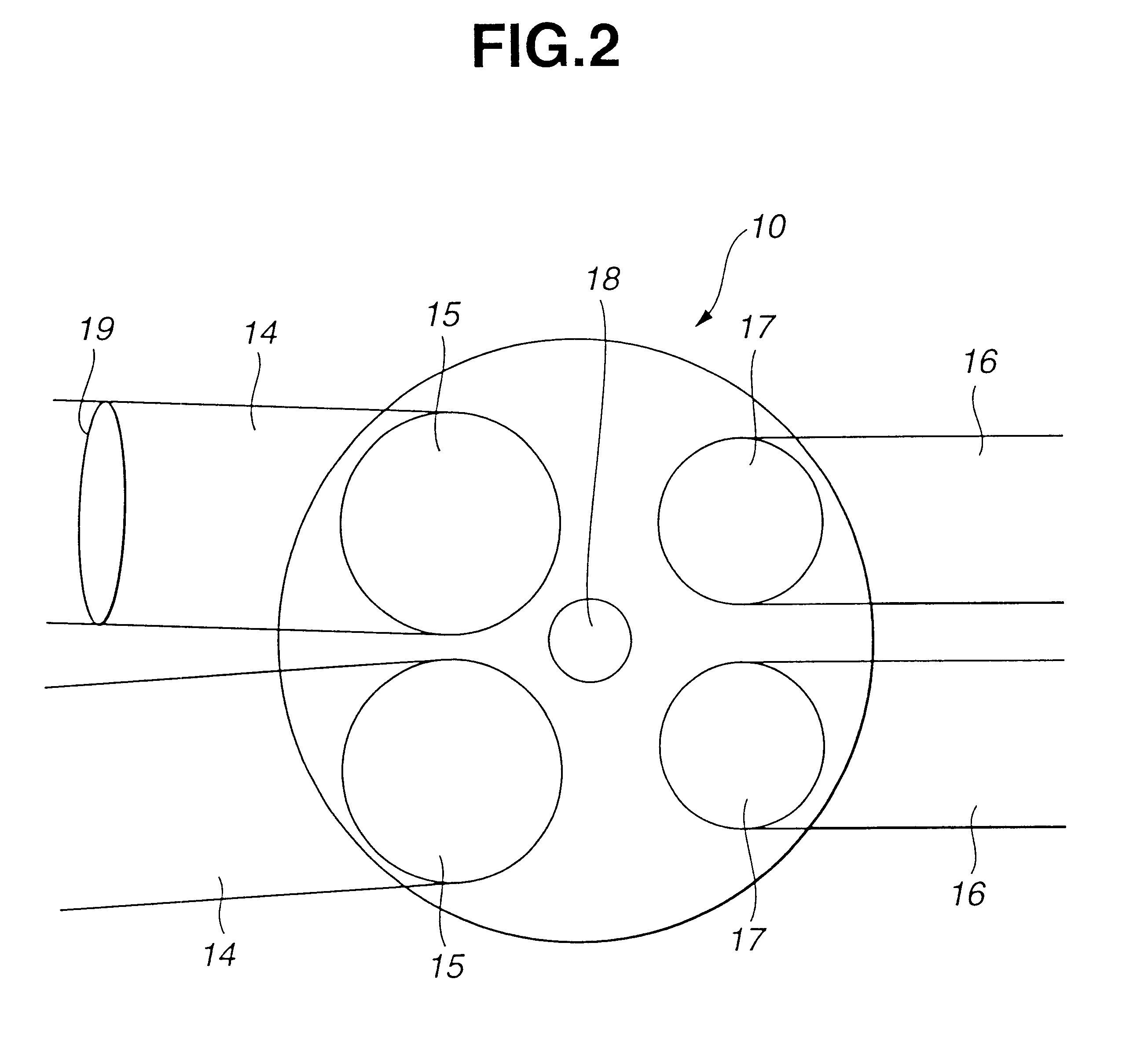

Internal combustion engine and method for auto-ignition operation of said engine

ActiveUS7194996B2Improve thermal efficiencyImprove flammabilityElectrical controlInternal combustion piston enginesCompression actionTop dead center

The invention relates to an internal combustion engine that can be operated in compression ignition mode, the engine comprising a fuel injector for each cylinder; a fuel injection controller for controlling fuel injection quantity and a piston in each cylinder whose compression action causes a mixture of air and fuel to be ignited. The engine is further provided with inlet and outlet valves and sensors for measuring various engine operating parameters. During compression ignition mode, the control unit controls the fuel injector to perform a first fuel injection before top dead center of the exhaust stroke during a period of negative valve overlap, and a second fuel injection during the piston compression stroke. The control unit may perform a switch between a first fuel injection strategy and at least one further fuel injection strategy in response to a change in load demand on the engine.

Owner:FORD GLOBAL TECH LLC

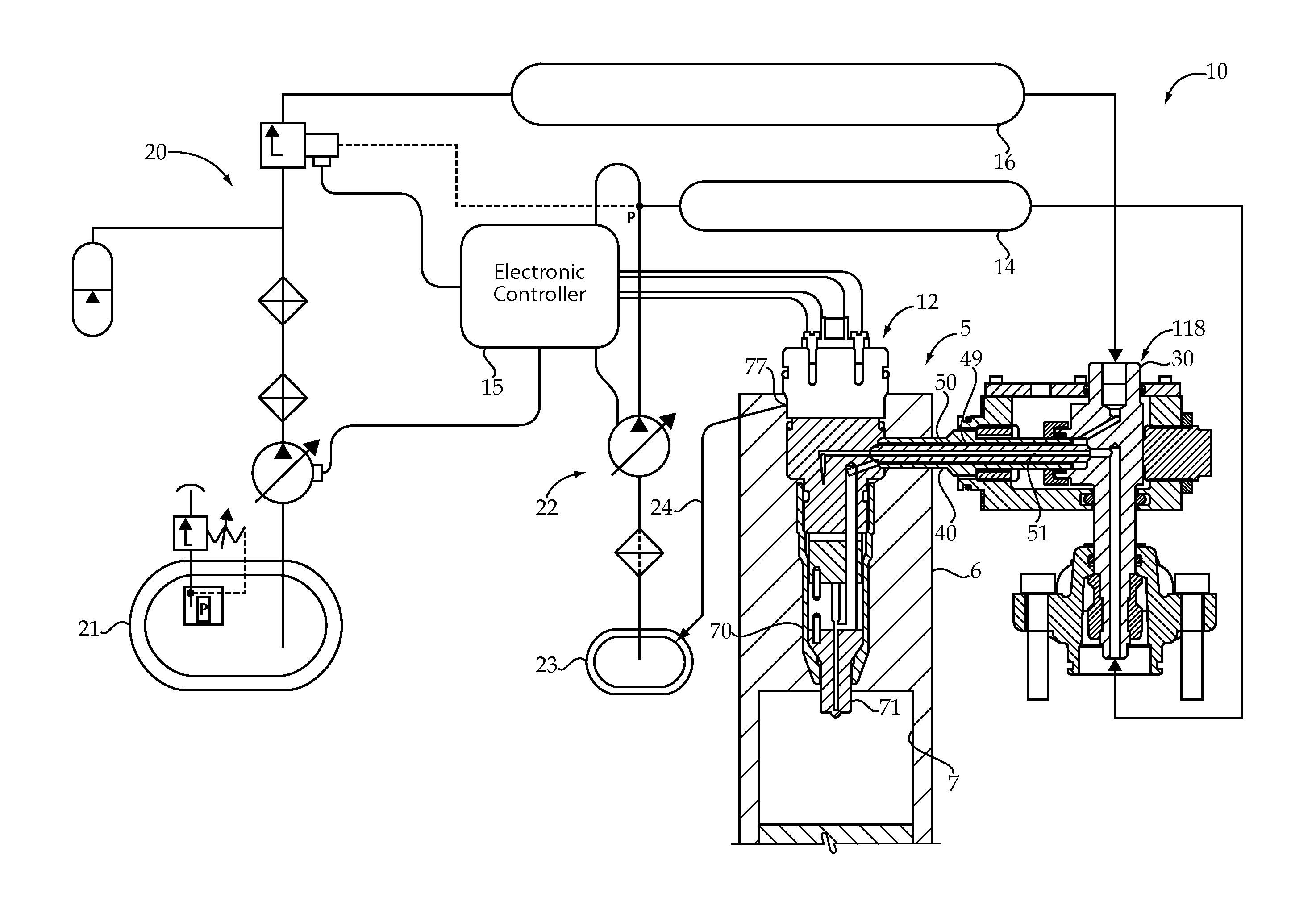

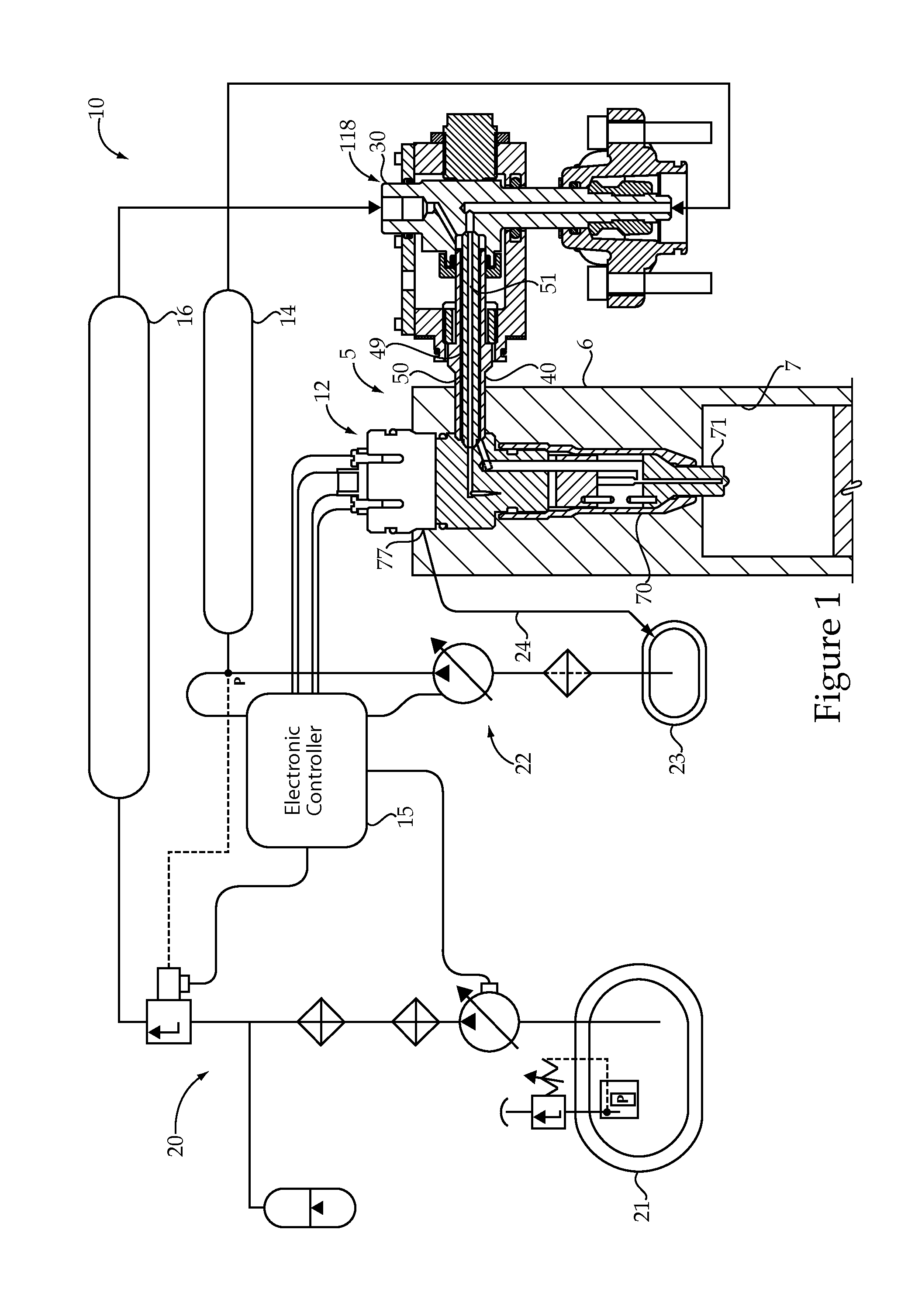

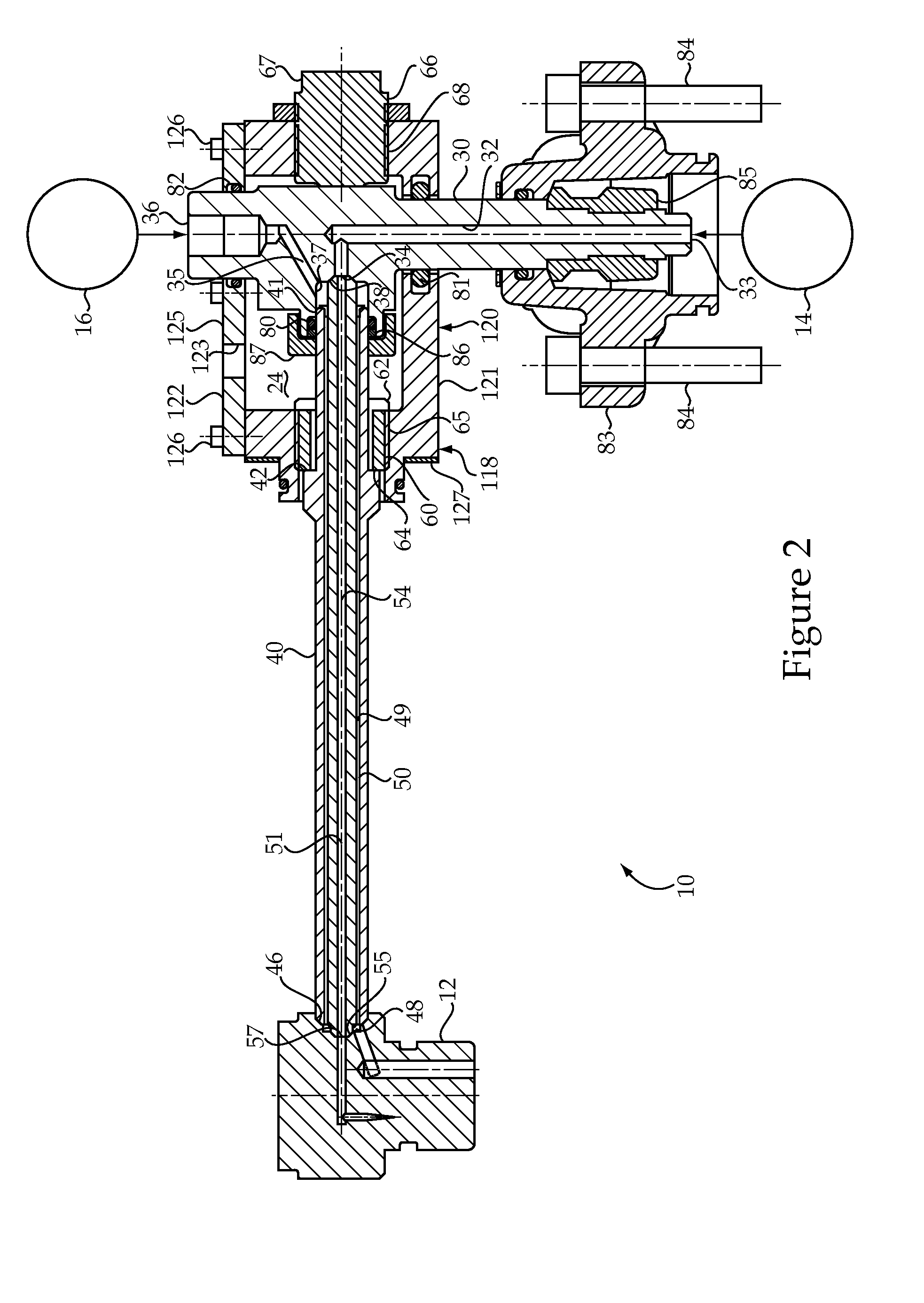

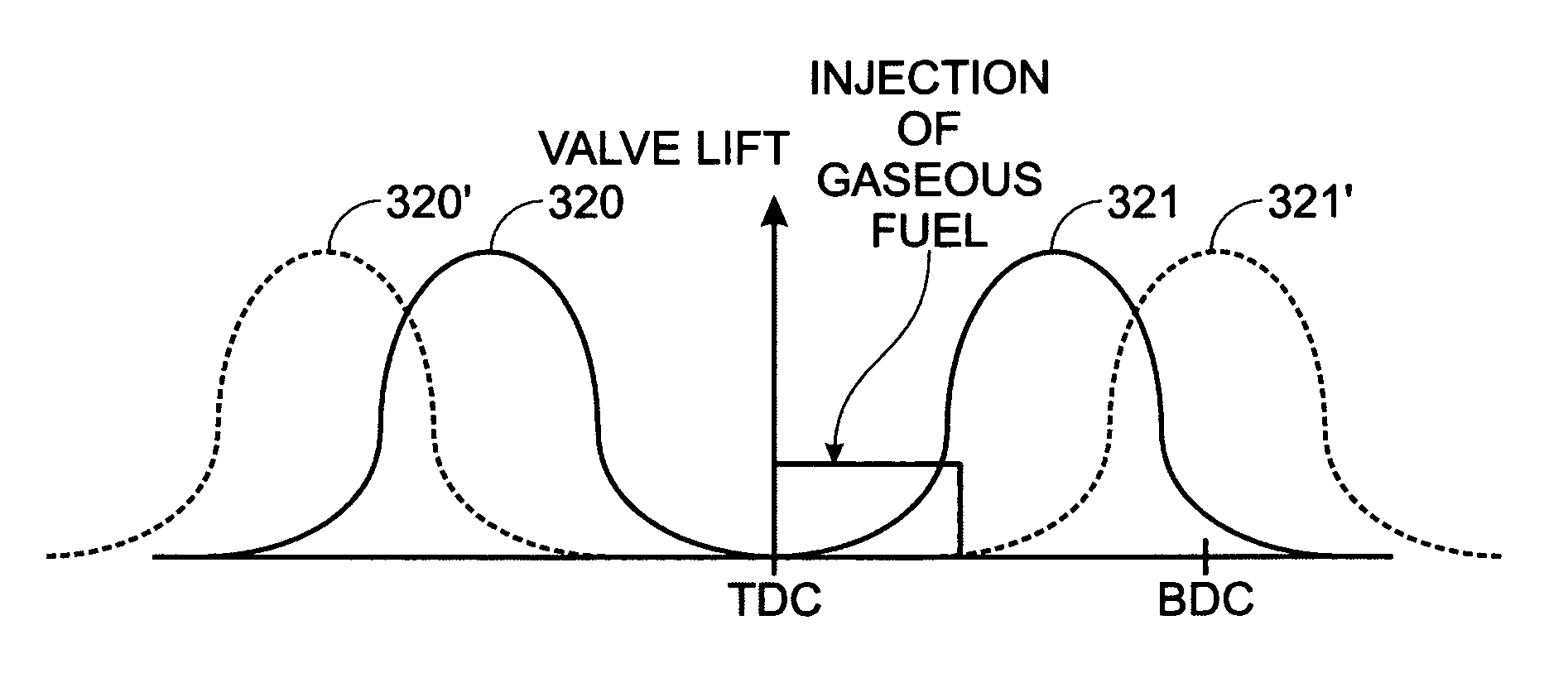

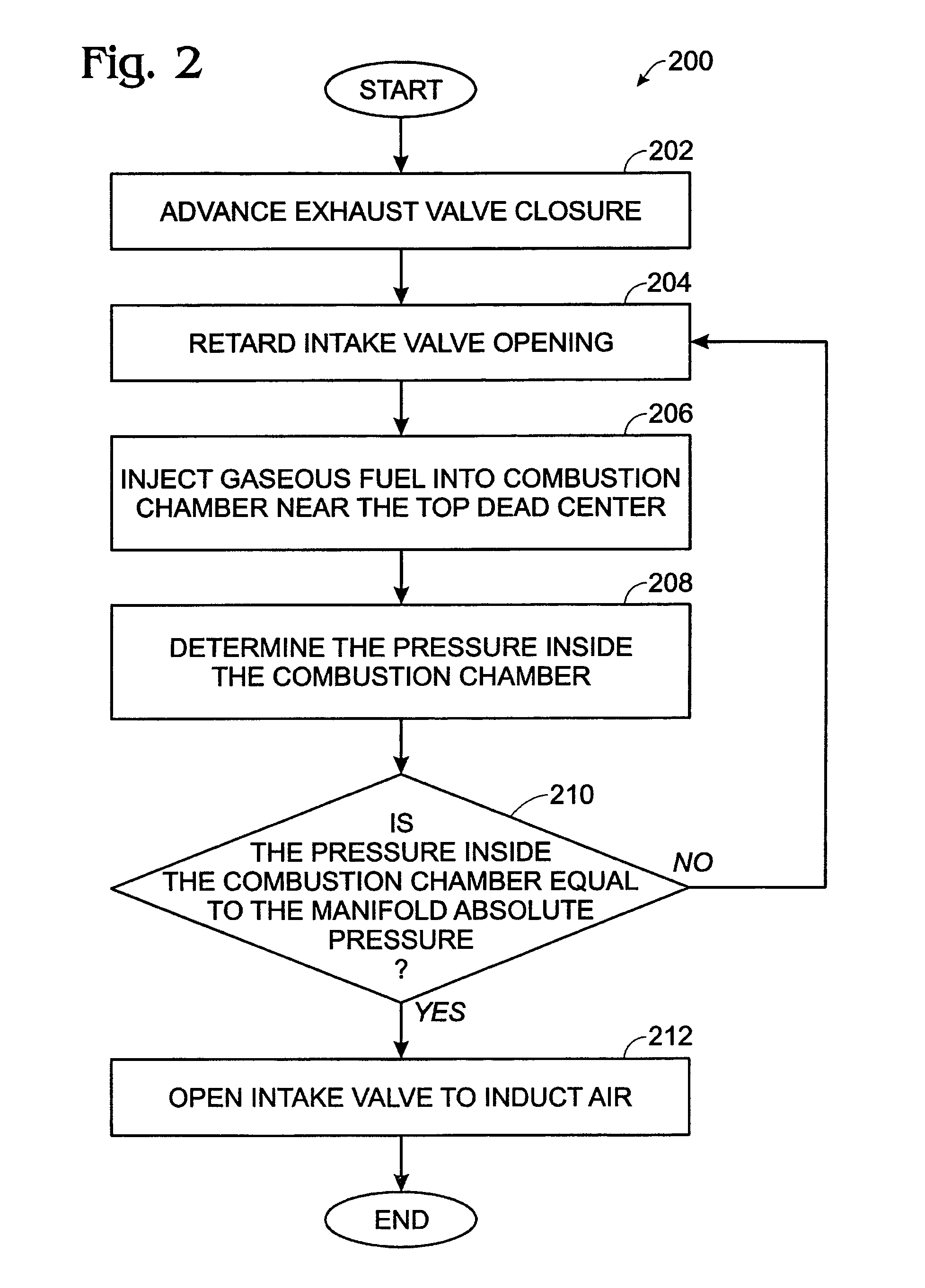

System and method for direct injection of gaseous fuel into internal combustion engine

InactiveUS7117830B1Reduce exhaustReduce volumeValve arrangementsElectrical controlExhaust valveTop dead center

A method for an engine capable of burning gaseous fuel, the engine also including a combustion chamber, at least one intake valve, and at least one exhaust valve, an injector to directly inject pressurized gaseous fuel into the combustion chamber, and a variable valve timing system coupled to the intake valves and exhaust valves, the method comprising closing the exhaust valve before top dead center of piston position to increase combustion chamber pressure achieved at top dead center and to trap exhaust gas in the cylinder; and starting injection of a gaseous fuel directly into the combustion chamber after the exhaust valve is closed and before the intake valve is opened.

Owner:FORD GLOBAL TECH LLC

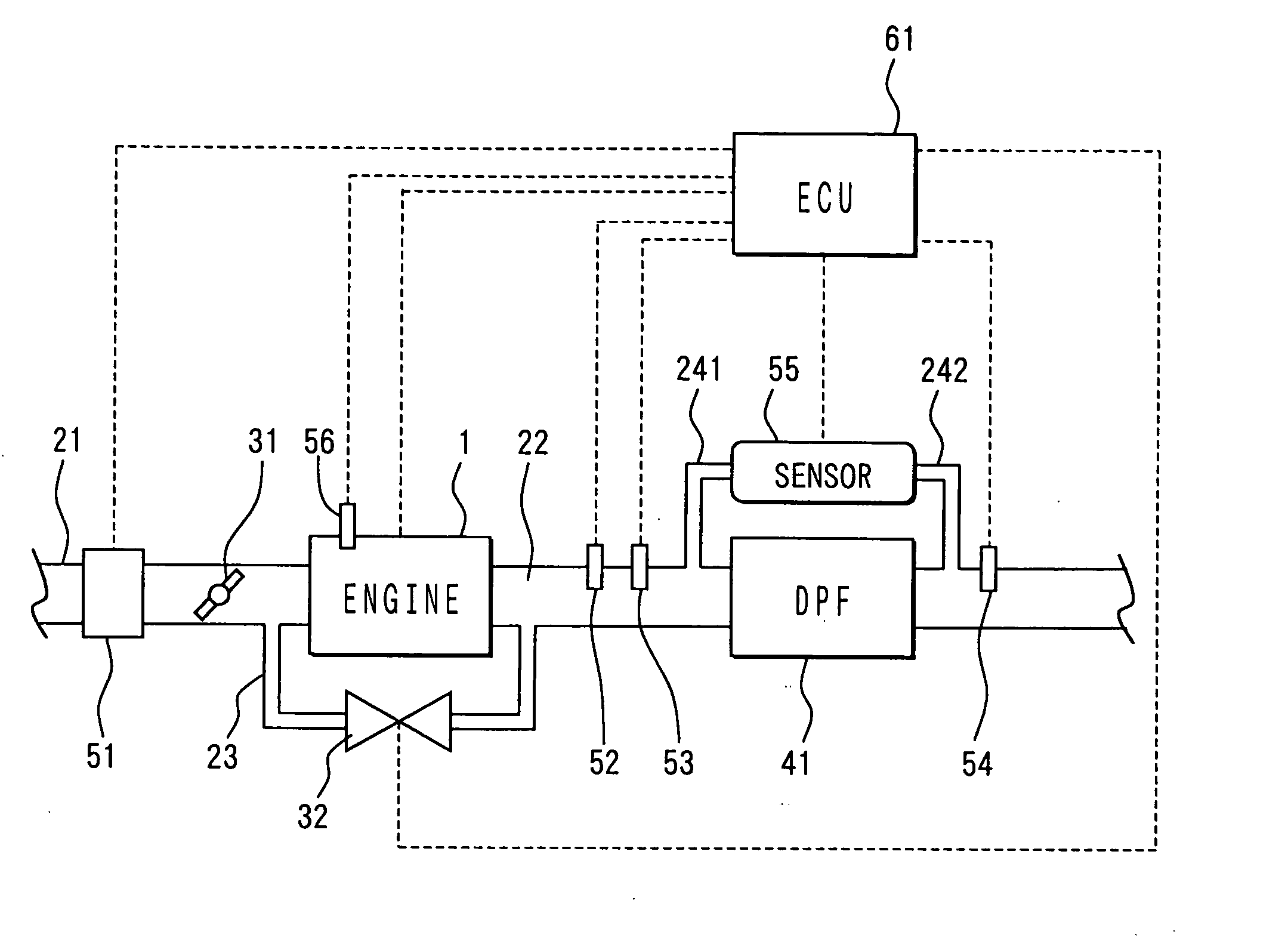

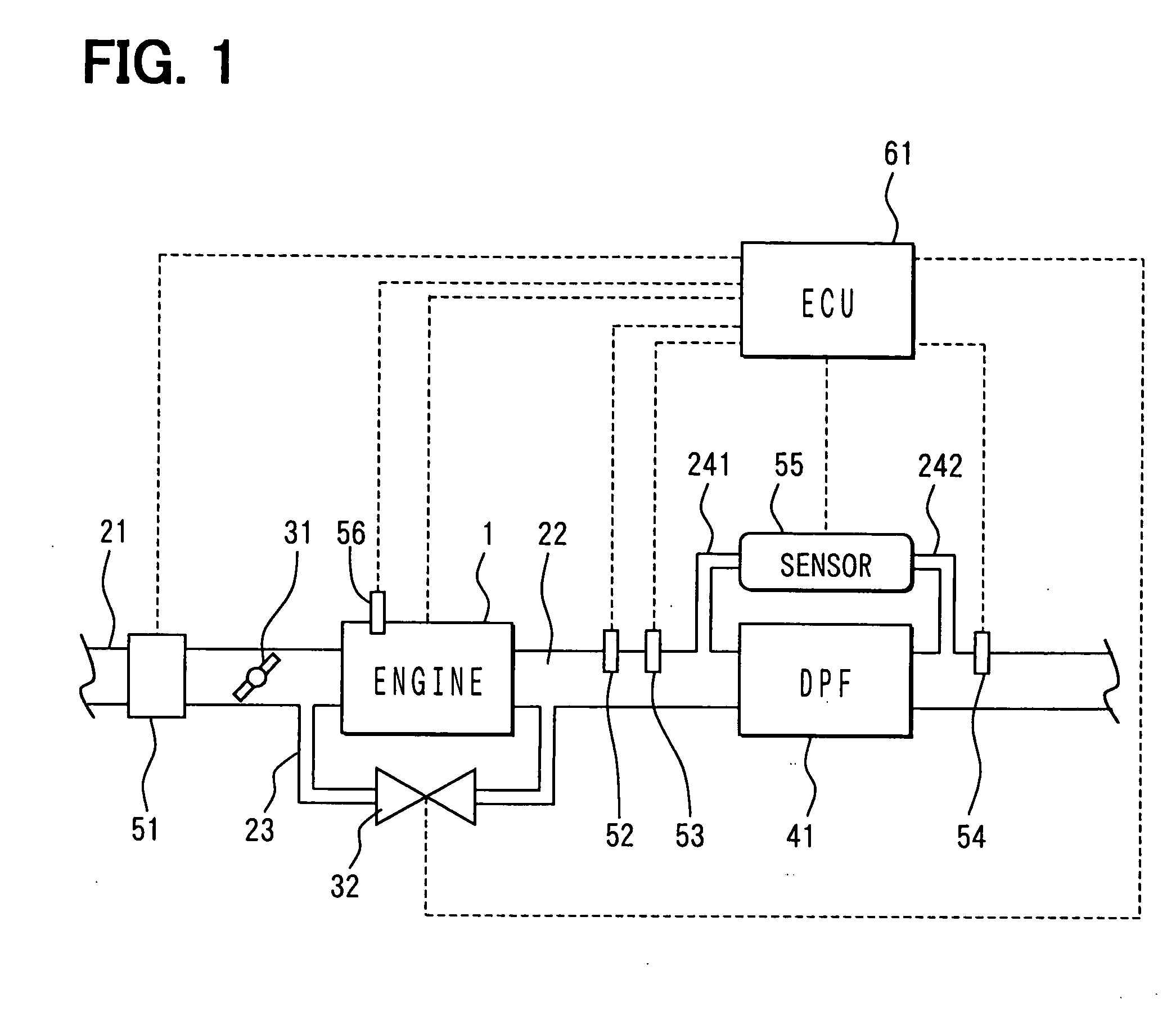

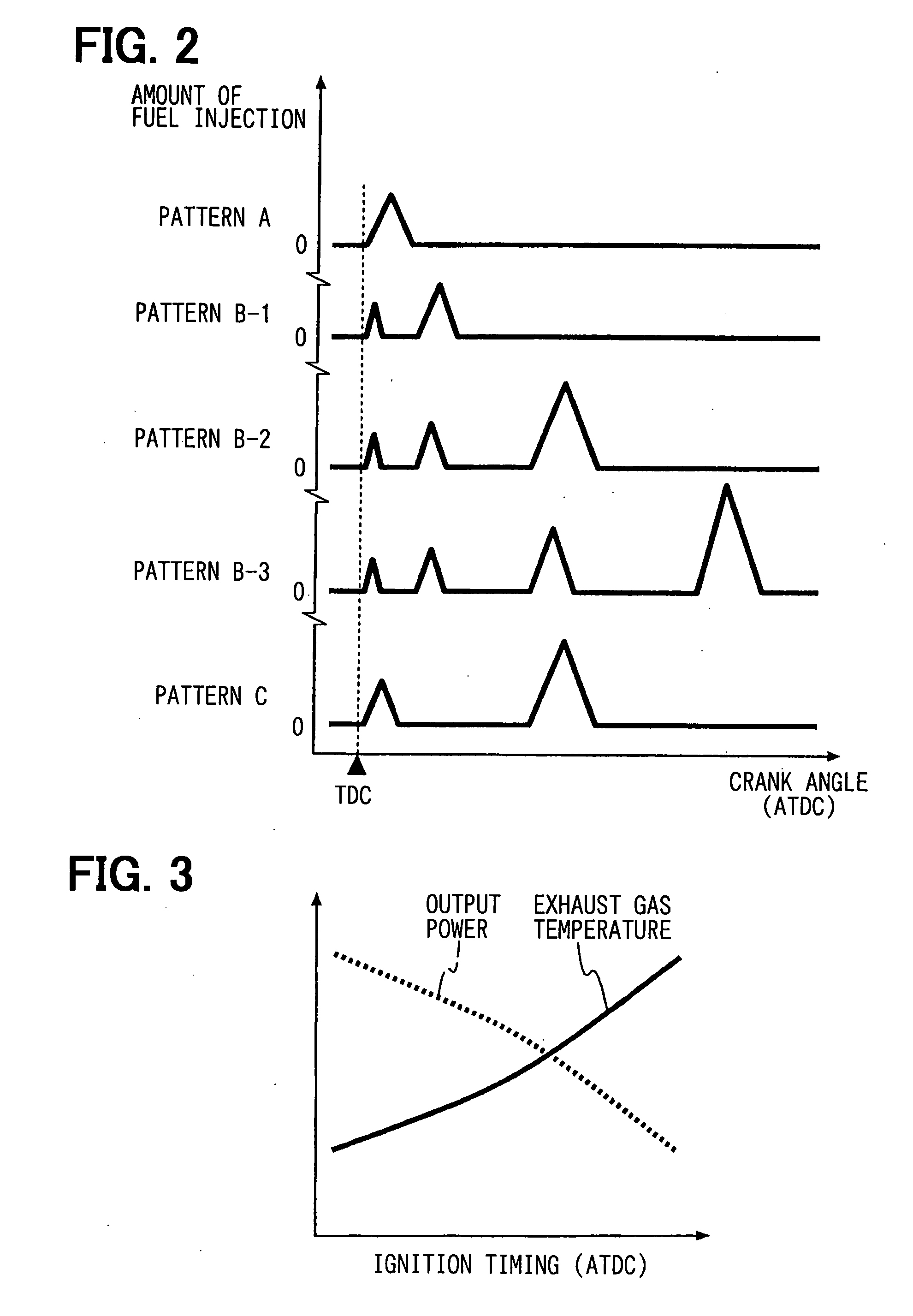

Exhaust gas cleaning device for internal combustion engine

ActiveUS20050252198A1Efficient regenerationReduce fuel consumptionElectrical controlInternal combustion piston enginesParticulatesTop dead center

In an engine, when it is determined that catalyst, which is held on a filter substrate of a particulate filter, is not in an active state, an ECU executes a fuel injection for mainly obtaining an engine power near a top dead center of a crank. Then, the ECU executes a subsequent fuel injection after lapse of a sufficient injection interval, which does not cause misfiring, to increase the temperature of exhaust gas outputted from the engine. In this way, the temperature of the filter is rapidly increased.

Owner:DENSO CORP

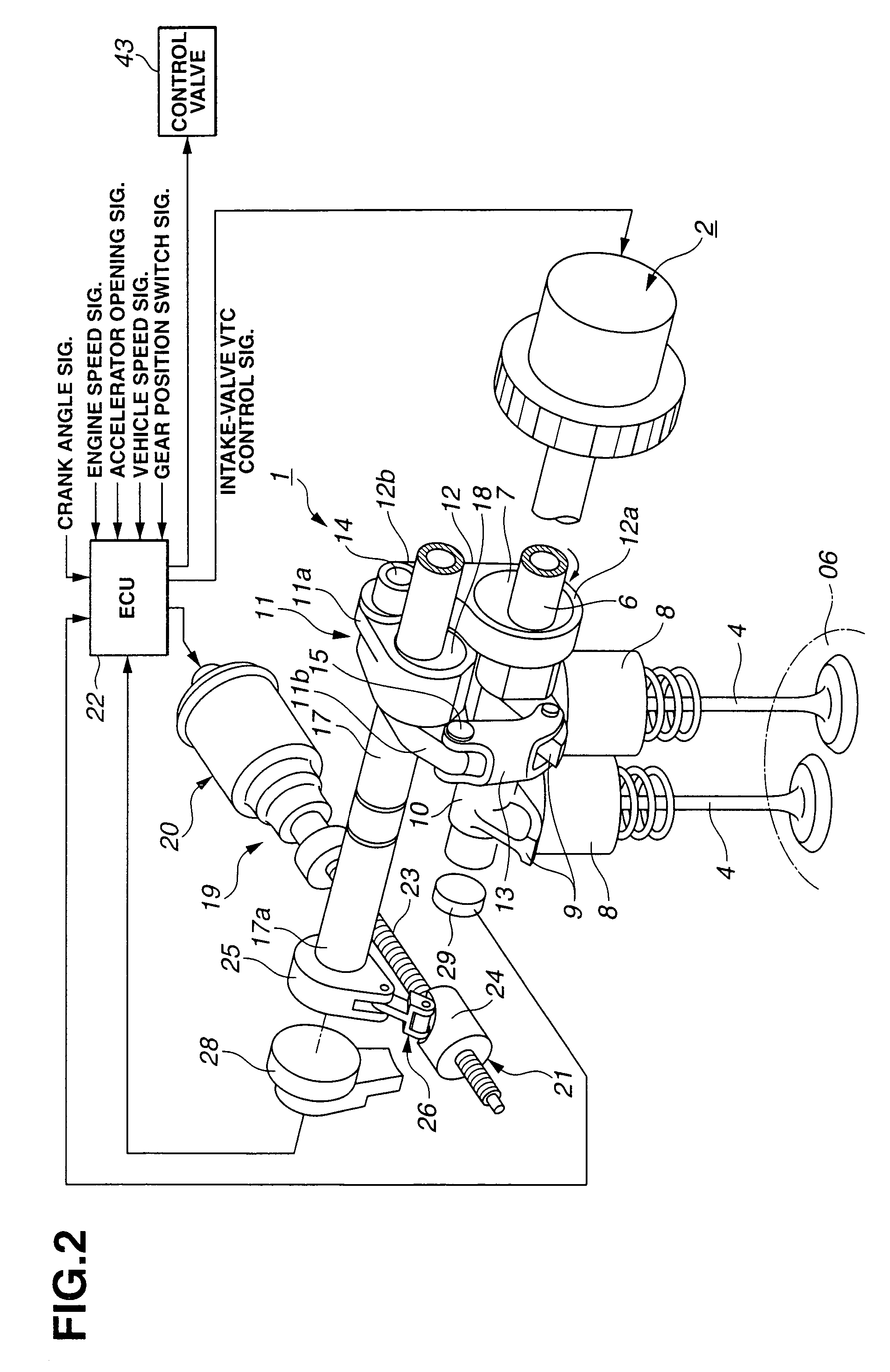

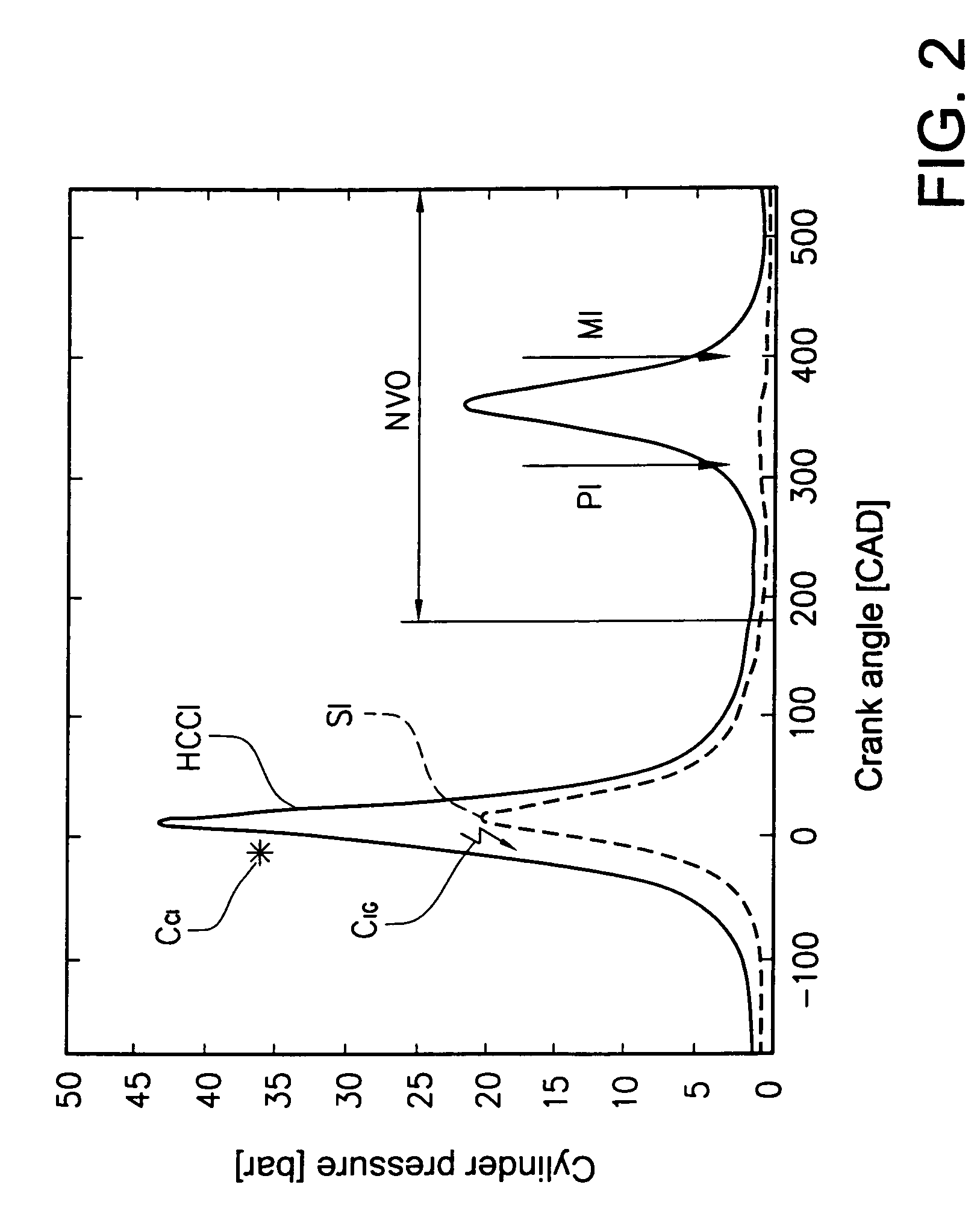

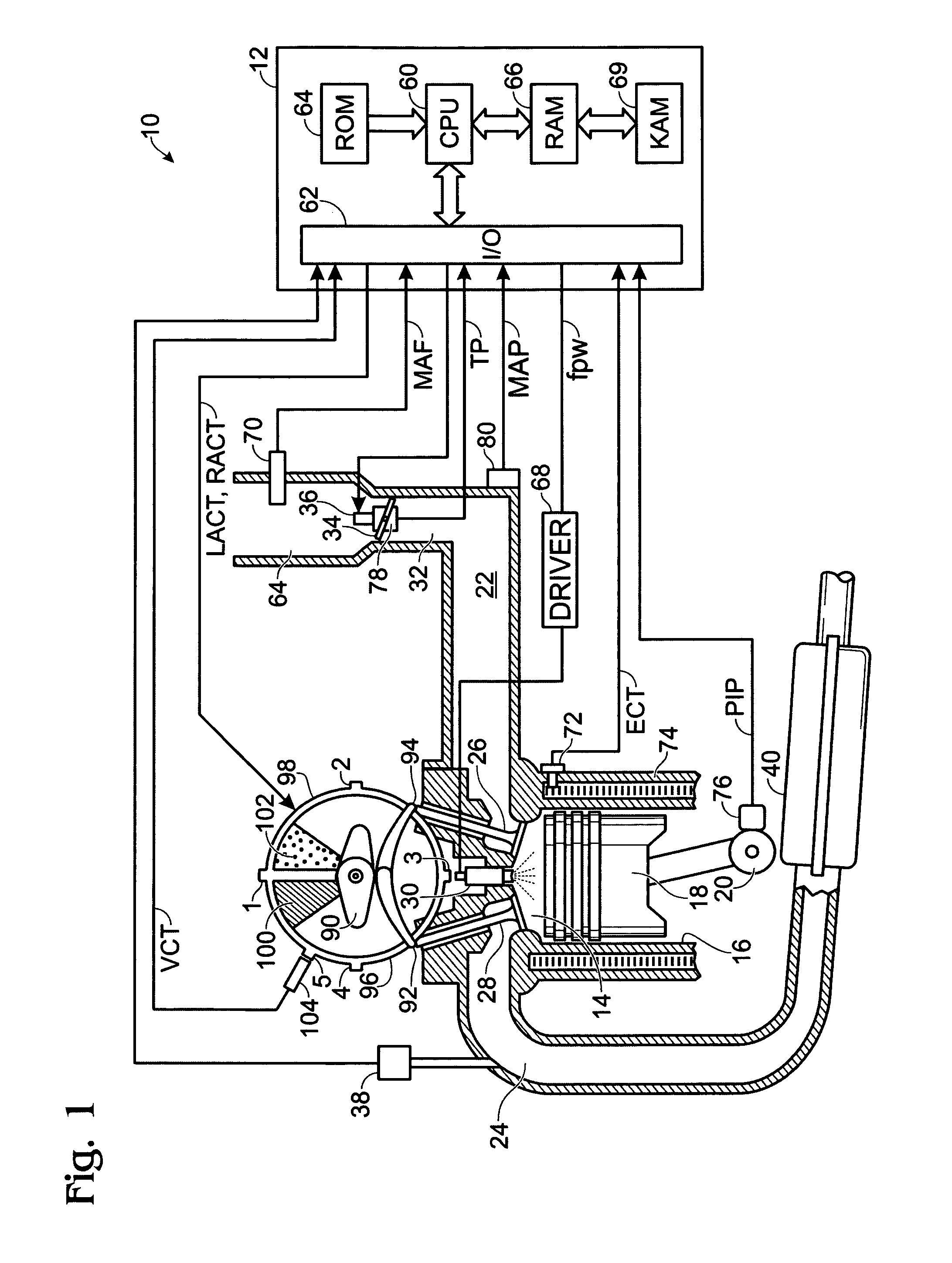

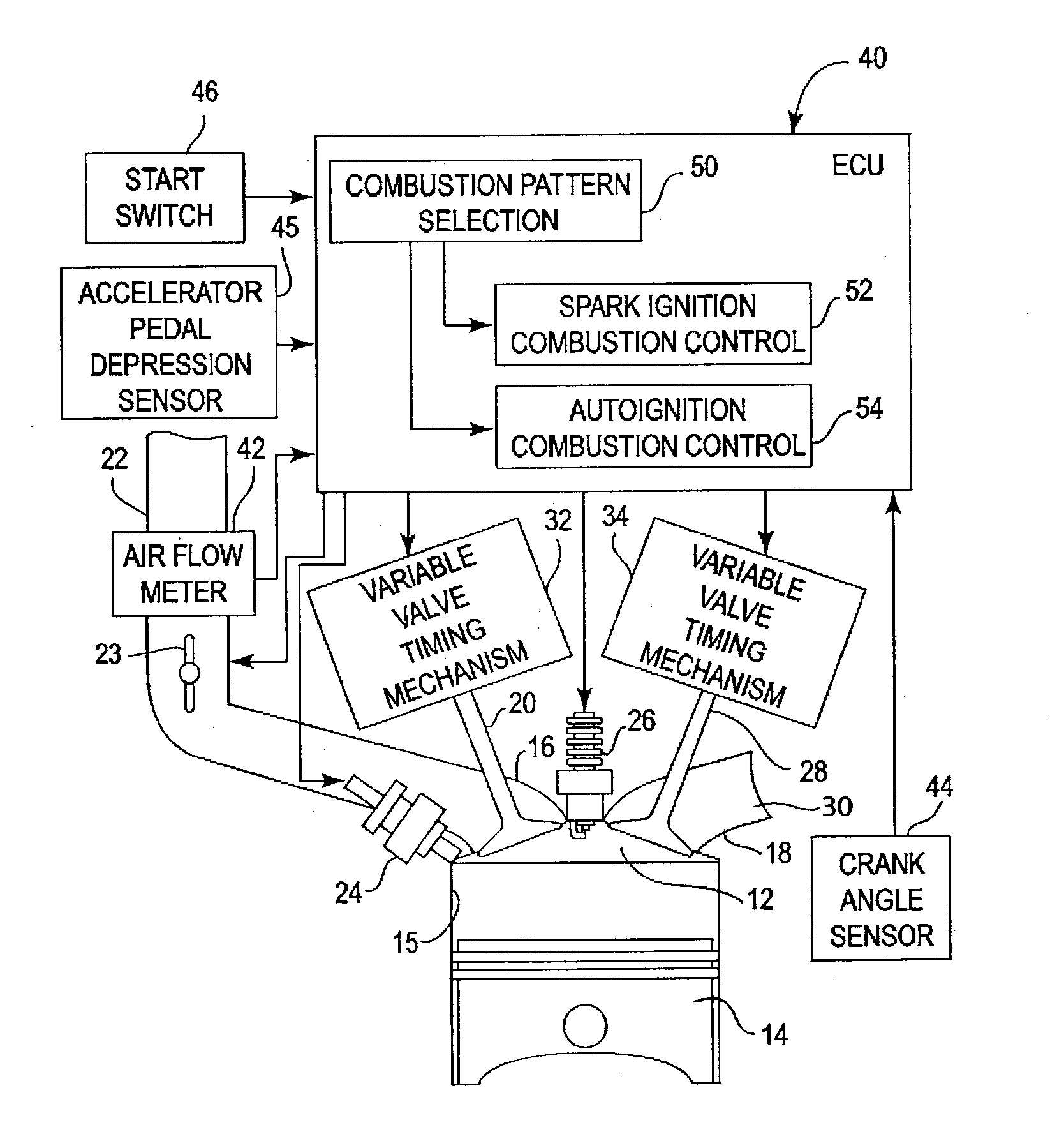

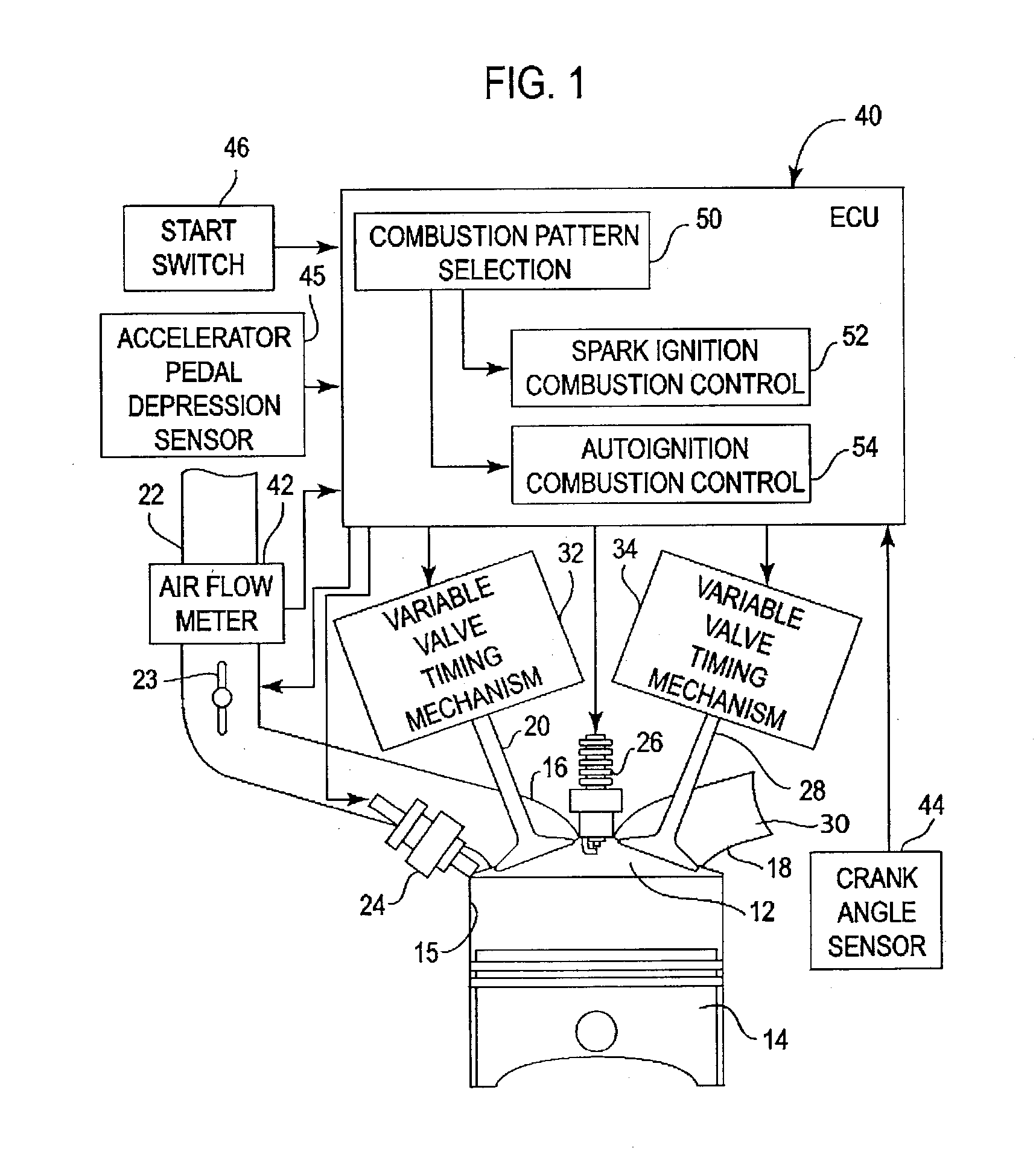

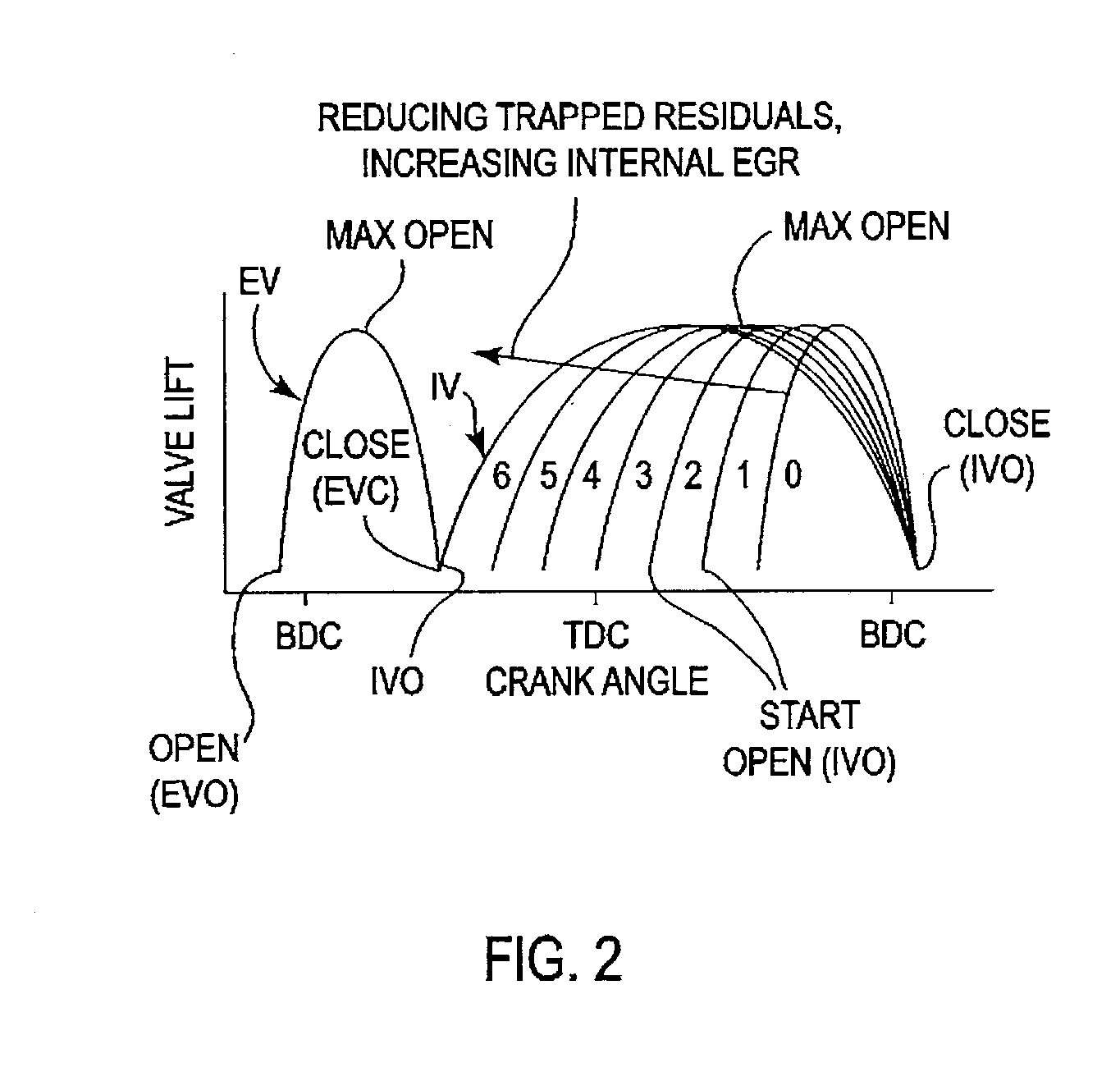

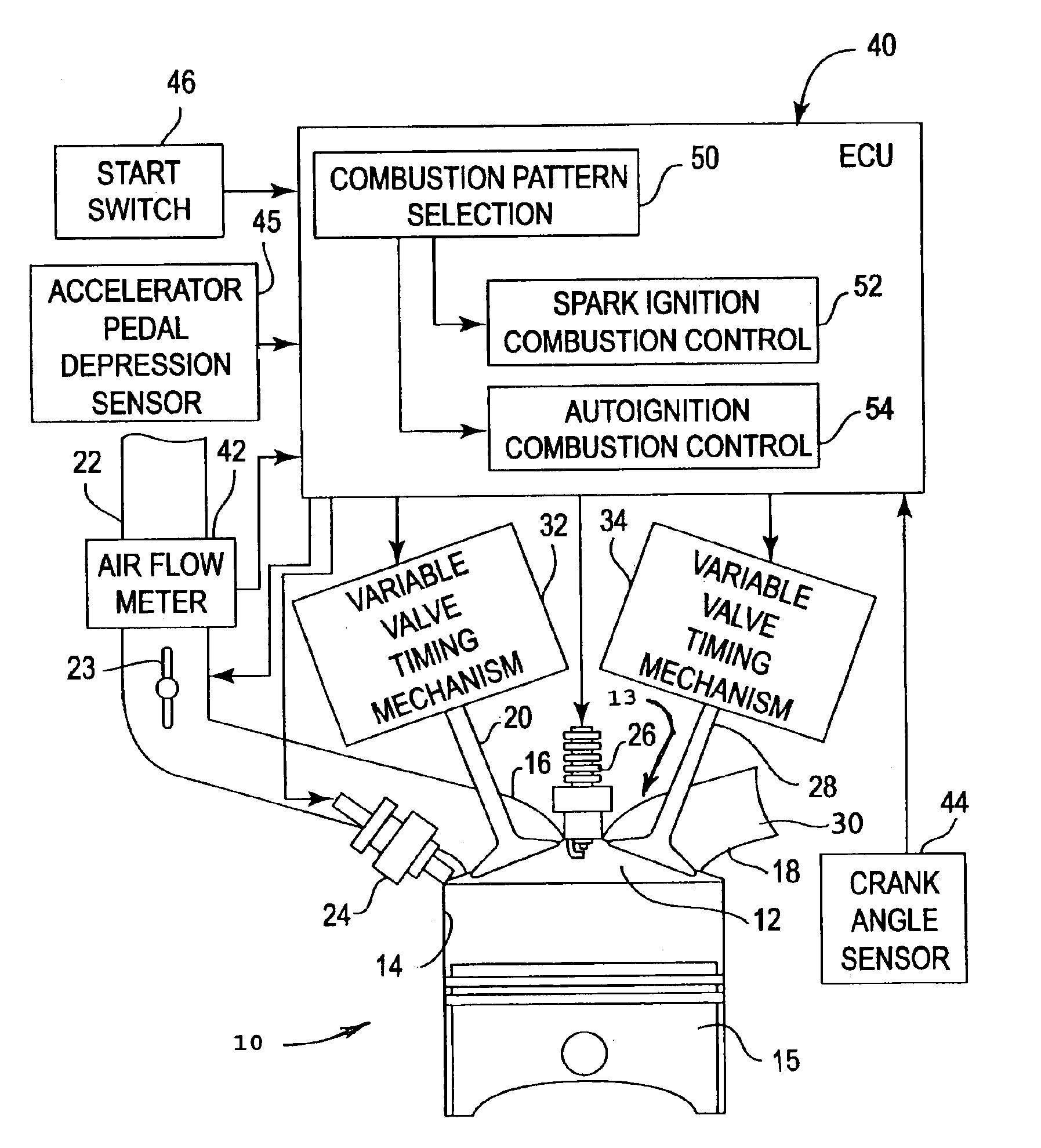

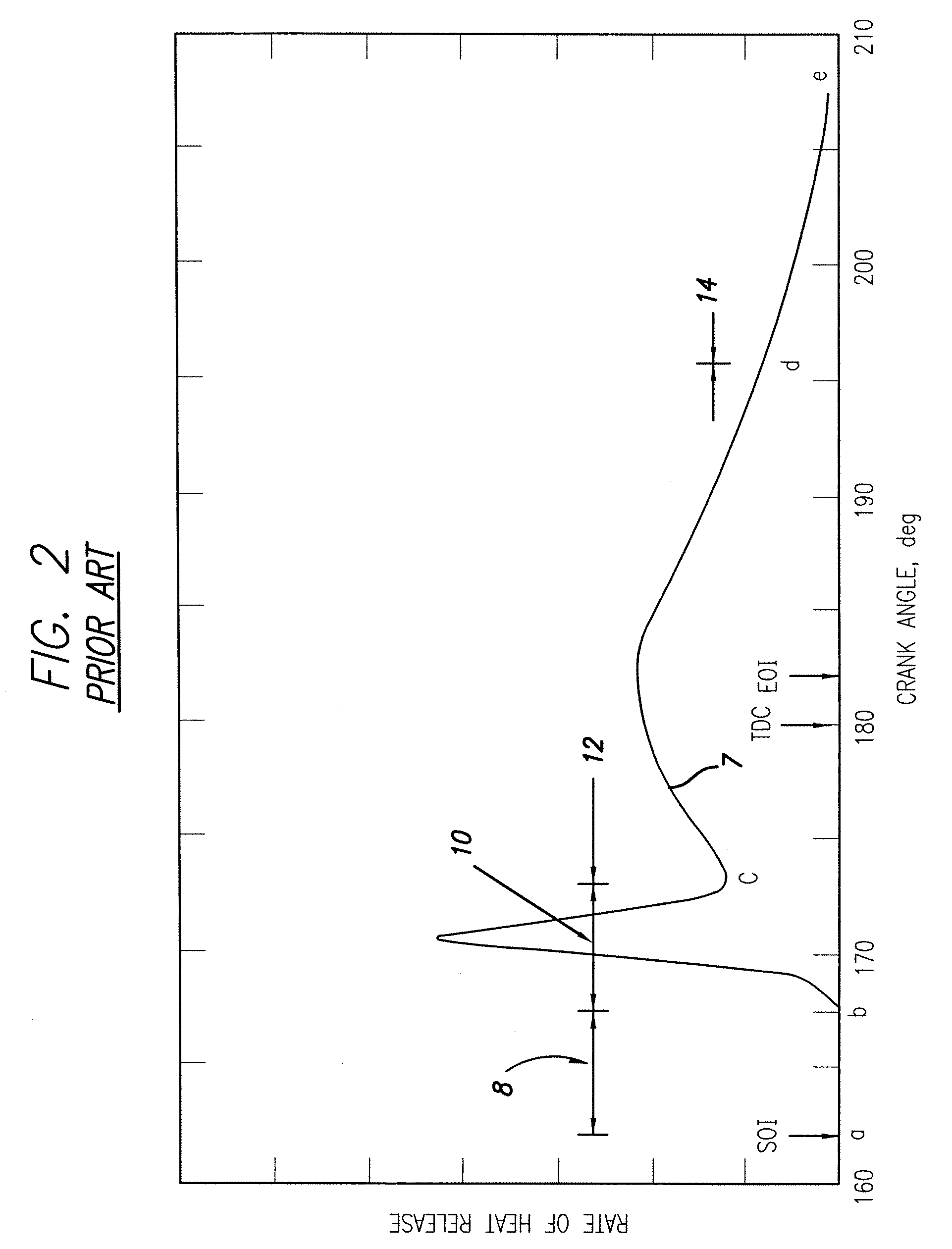

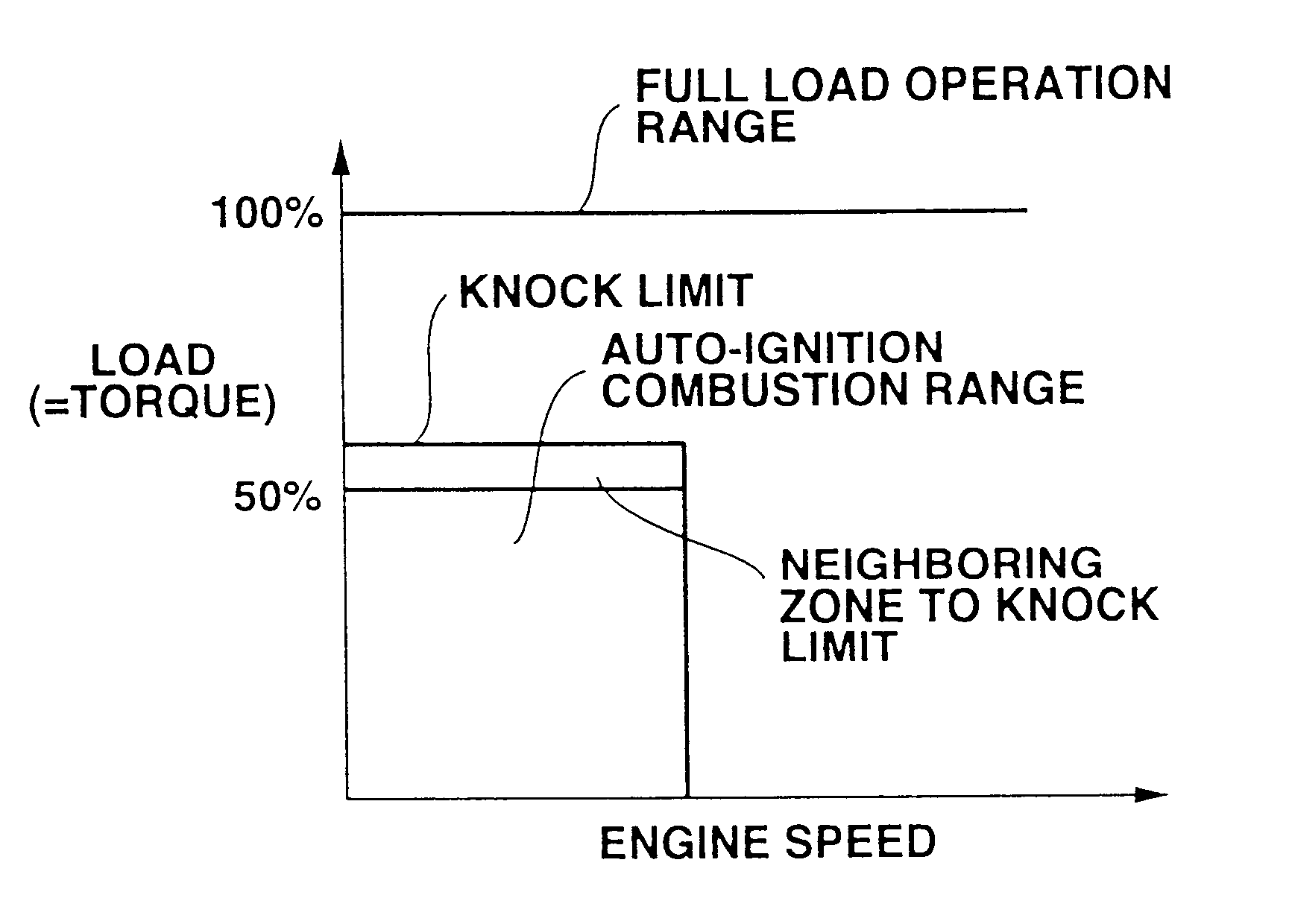

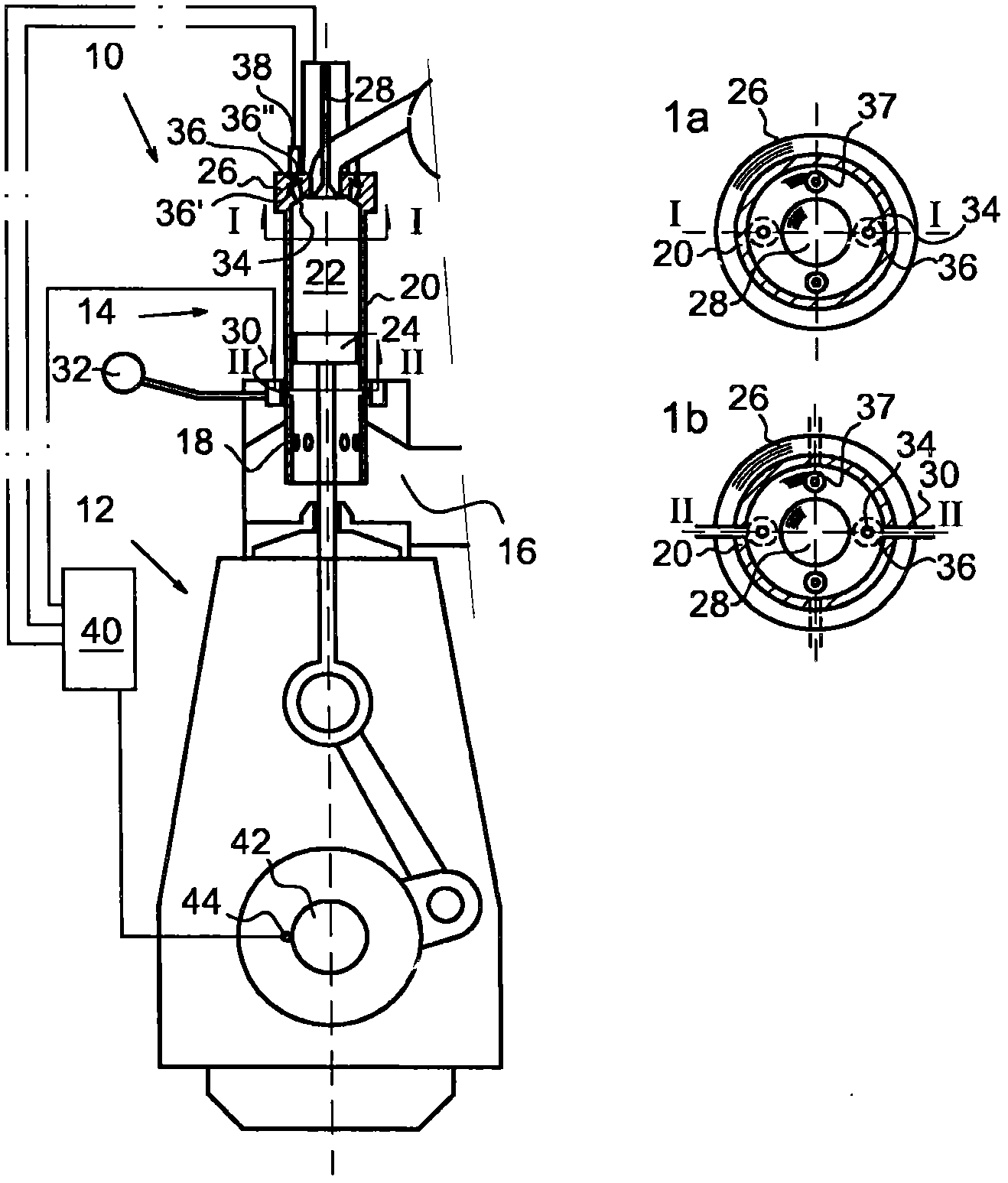

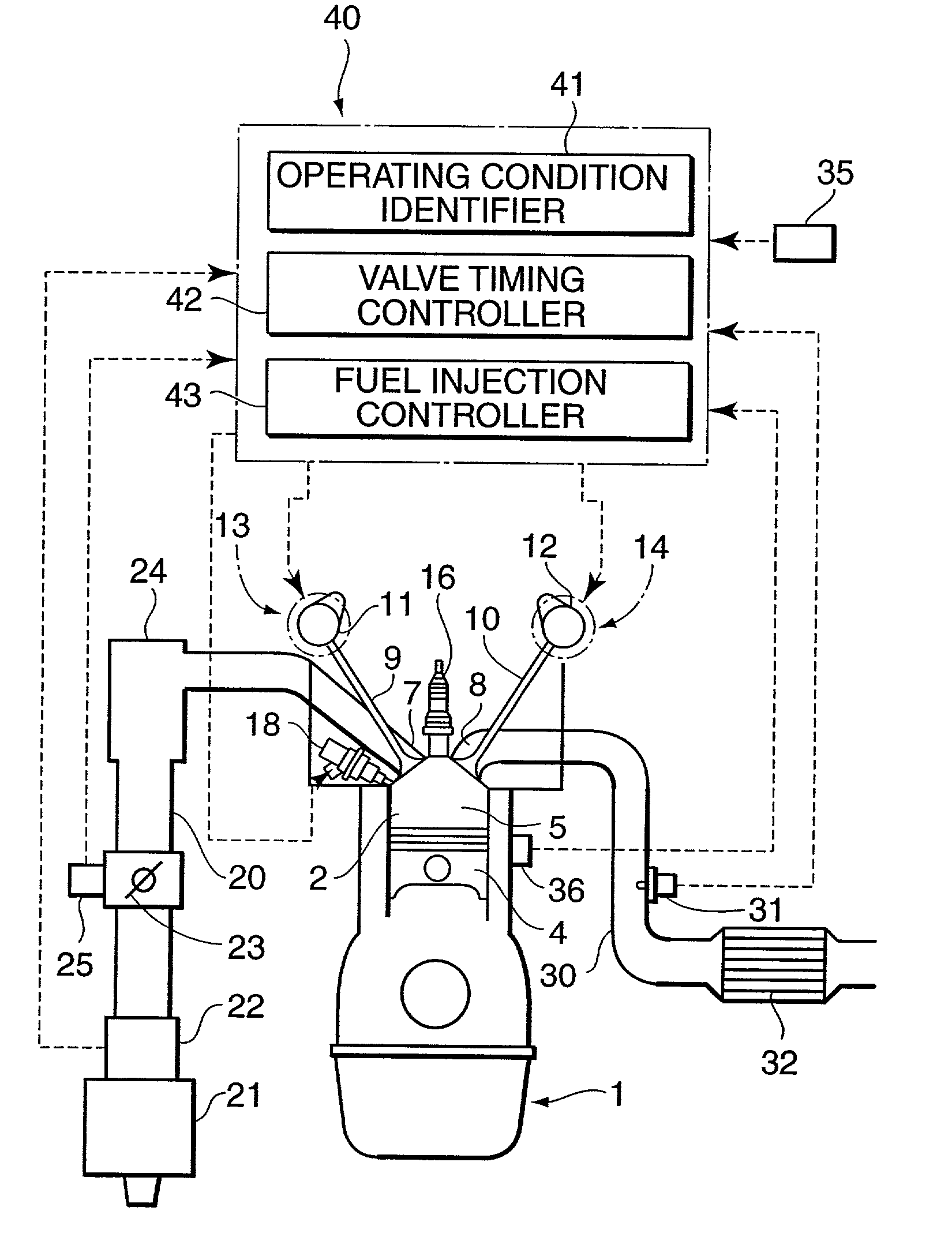

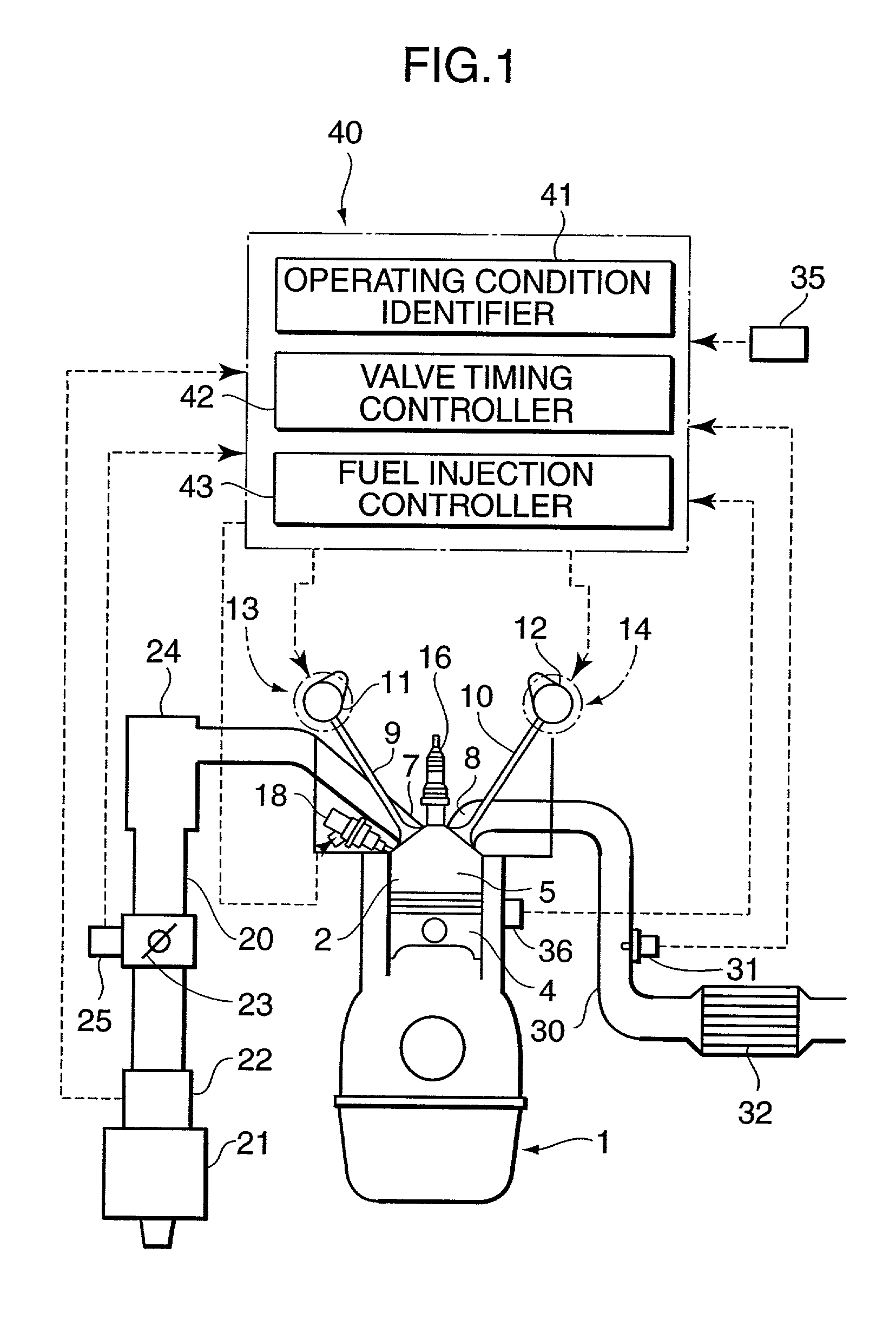

Control of autoignition timing in a hcci engine

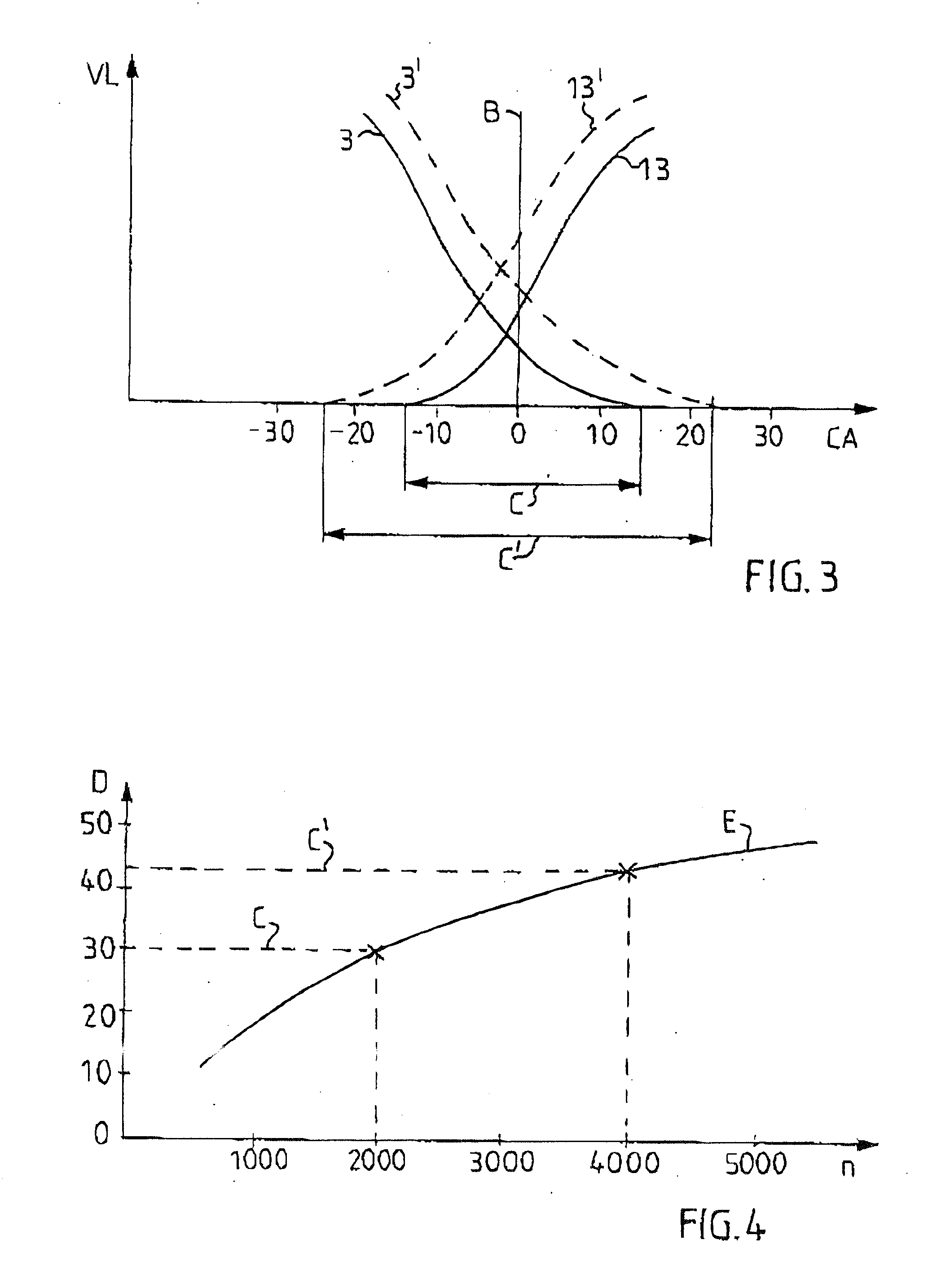

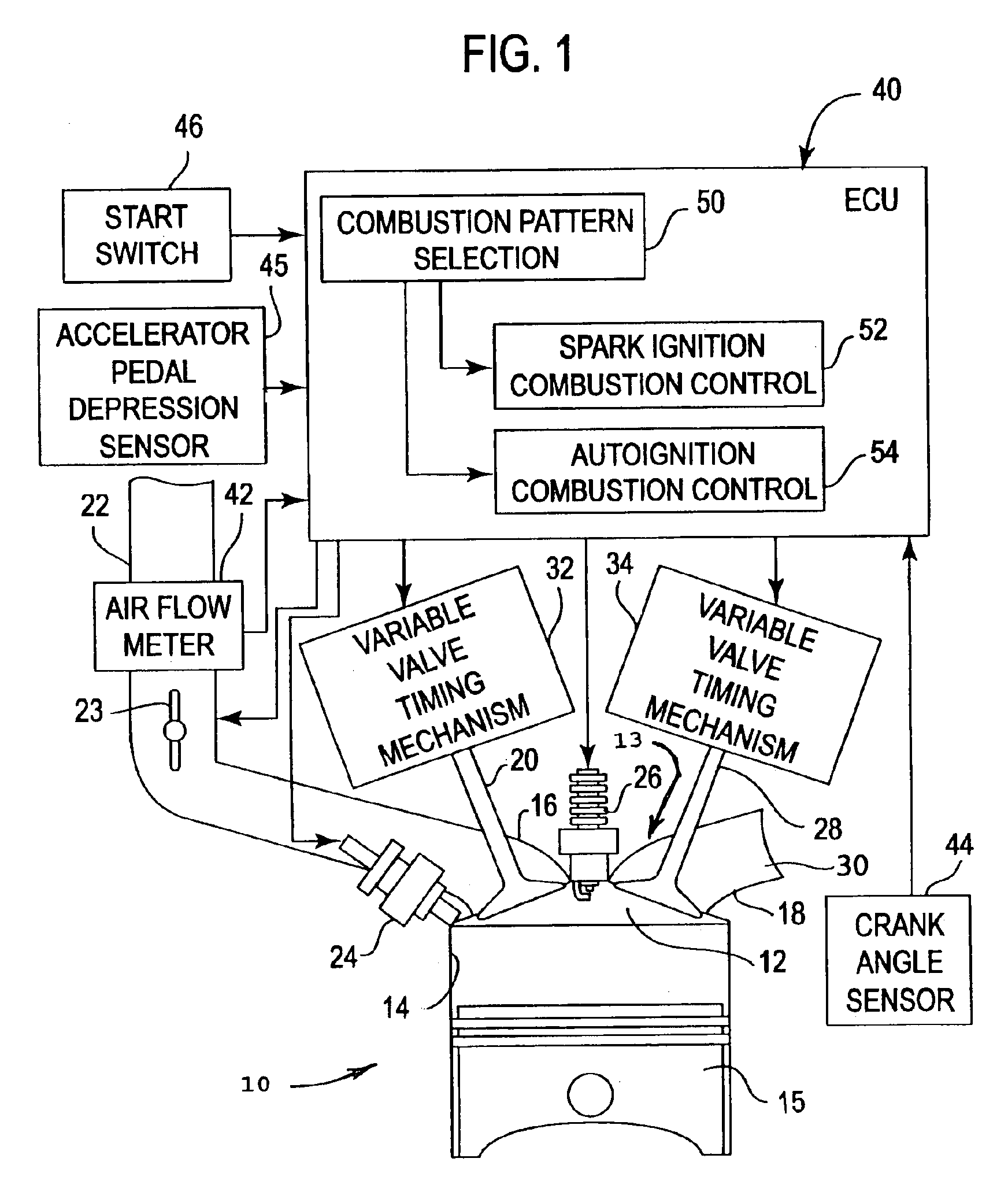

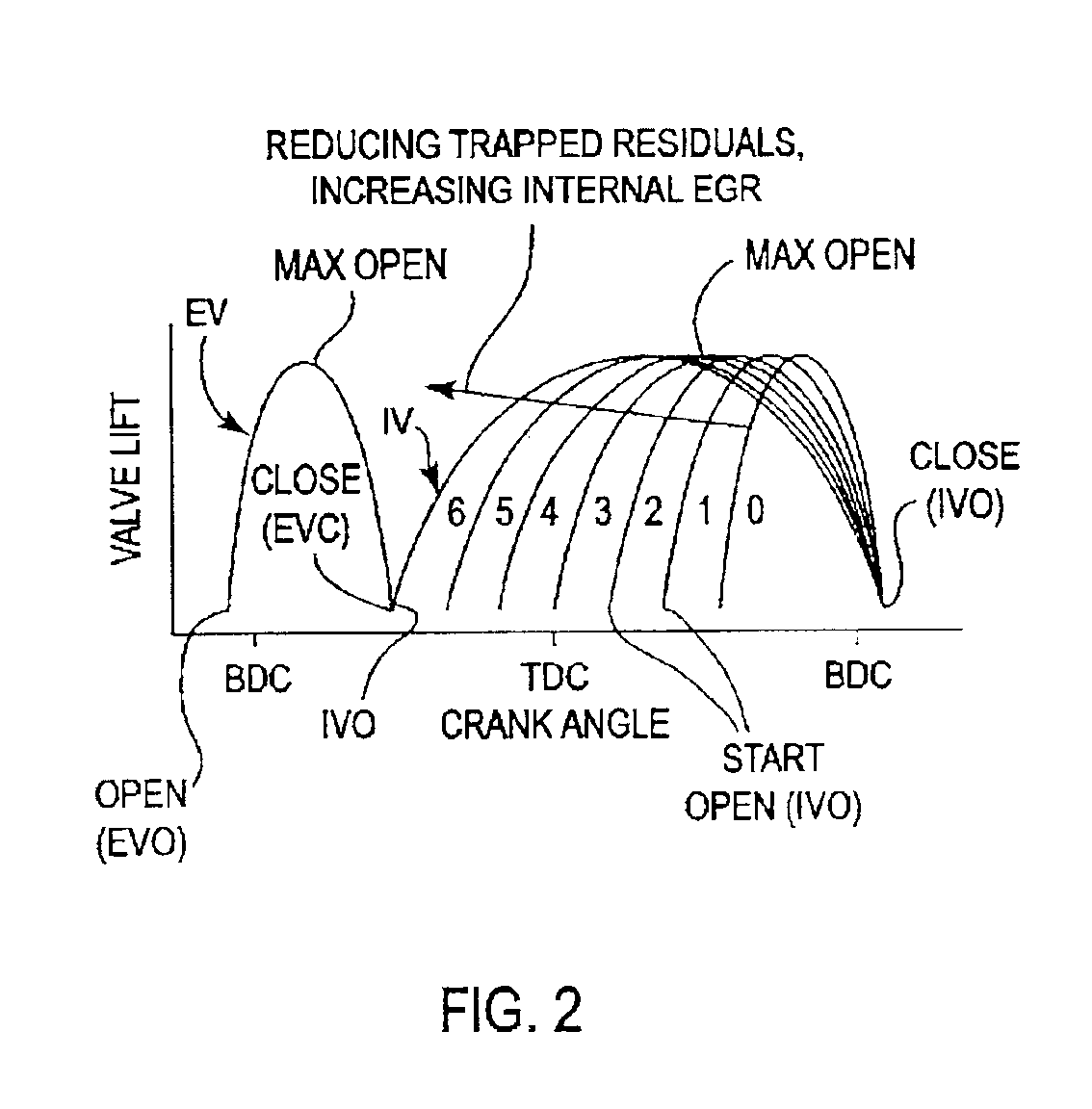

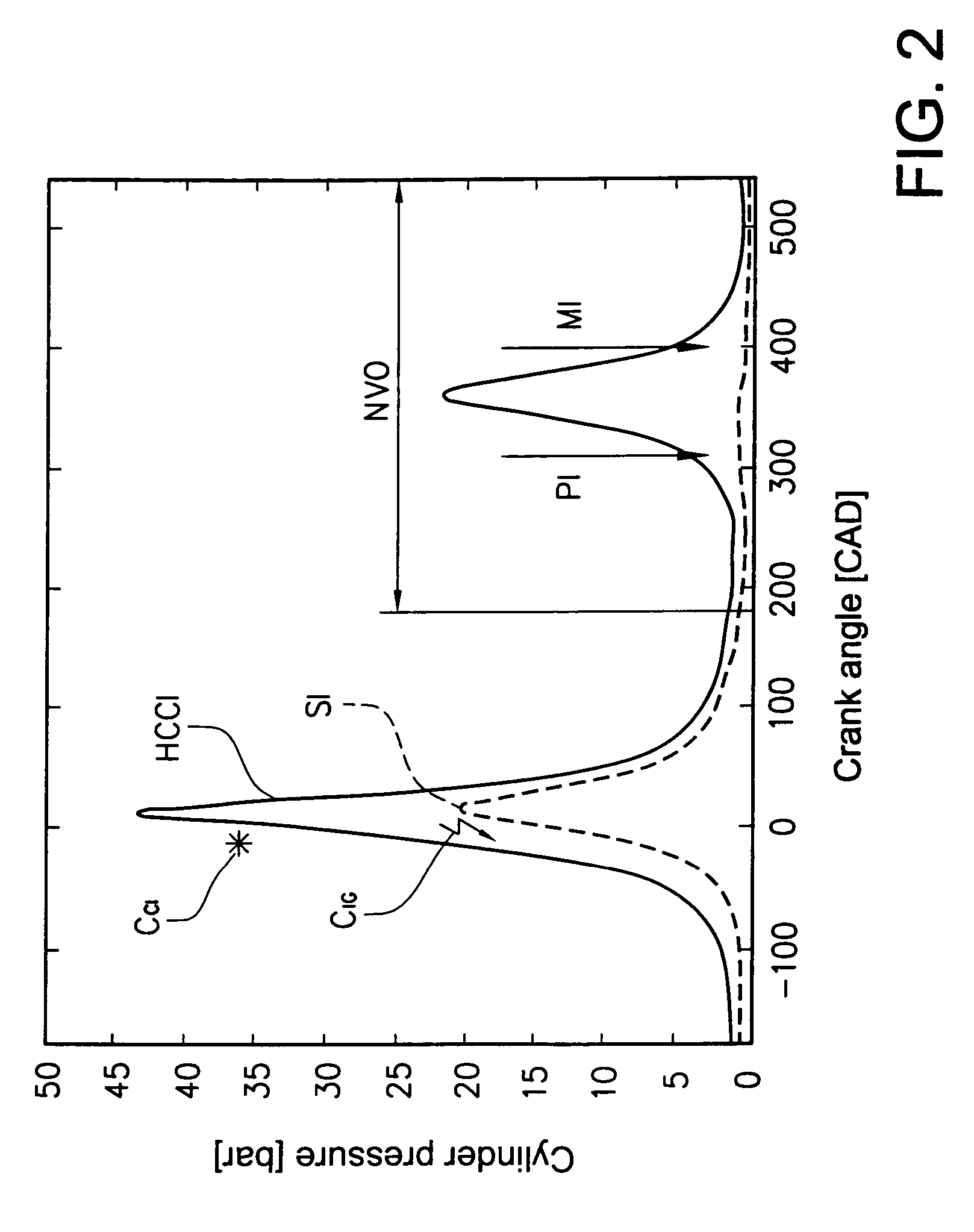

ActiveUS20040134449A1Reduces and minimizesCompensation effectElectrical controlInternal combustion piston enginesCombustion chamberExhaust valve

Method and system embody a valve timing strategy to control the autoignition timing of a four stroke internal combustion engine (10) operated in an HCCI mode at different engine operating conditions such as different engine speed and torque. A particular valve timing strategy varies lift timing of the intake valve (20) relative to the exhaust valve (28), or vice versa, and relative to top dead center in response to a change in engine torque, for example, to vary amount of trapped residual burned gas in the combustion chamber (12) flowing to an intake or exhaust port (16,18) and back to the combustion chamber during which the residual gas is cooled. Control of the flow of residual gas between the combustion chamber and intake or exhaust port and thus its temperature by the valve timing strategy, in turn, is used to control the temperature of the fresh air / residual gas / fuel mixture in the combustion chamber (12) and thus autoignition timing in response to a change in engine torque.

Owner:FORD GLOBAL TECH LLC

Control of autoignition timing in a HCCI engine

InactiveUS7093568B2Reduces and minimizesCompensation effectElectrical controlInternal combustion piston enginesCombustion chamberExhaust valve

Method and system embody a valve timing strategy to control the autoignition timing of a four stroke internal combustion engine (10) operated in an HCCI mode at different engine operating conditions such as different engine speed and torque. A particular valve timing strategy varies lift timing of the intake valve (20) relative to the exhaust valve (28), or vice versa, and relative to top dead center in response to a change in engine torque, for example, to vary amount of trapped residual burned gas in the combustion chamber (12) flowing to an intake or exhaust port (16,18) and back to the combustion chamber during which the residual gas is cooled. Control of the flow of residual gas between the combustion chamber and intake or exhaust port and thus its temperature by the valve timing strategy, in turn, is used to control the temperature of the fresh air / residual gas / fuel mixture in the combustion chamber (12) and thus autoignition timing in response to a change in engine torque.

Owner:FORD GLOBAL TECH LLC

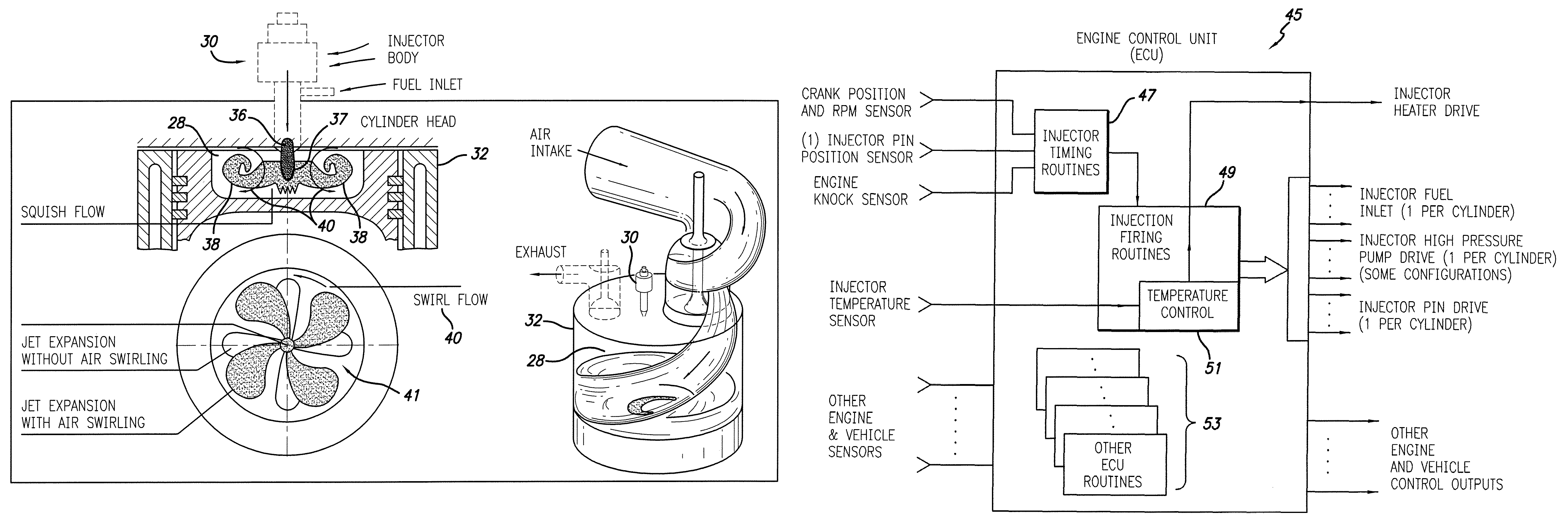

Fuel injector having algorithm controlled look-ahead timing for injector-ignition operation

InactiveUS7444230B2Increase temperatureIncrease chanceElectrical controlInternal combustion piston enginesTop dead centerHeuristic

The present invention provides an injector-ignition fuel injection system for an internal combustion engine, comprising an ECU controlling a heated catalyzed fuel injector for heating and catalyzing a next fuel charge, wherein the ECU uses a one firing cycle look-ahead algorithm for controlling fuel injection. The ECU may further incorporate a look-up table, auto-tuning functions and heuristics to compensate for the rapid rotational de-acceleration that occurs near top dead center in lightweight small ultra-high compression engines as may be used with this invention. The ECU may further ramp heat input to the injector in response to engine acceleration requests and, under such circumstances, may extend its look-ahead for up to four firing cycles.

Owner:ECOMOTORS

Auto-ignition combustion management in internal combustion engine

InactiveUS6401688B2High densityElectrical controlCombustion enginesCombustion chamberTop dead center

Owner:NISSAN MOTOR CO LTD

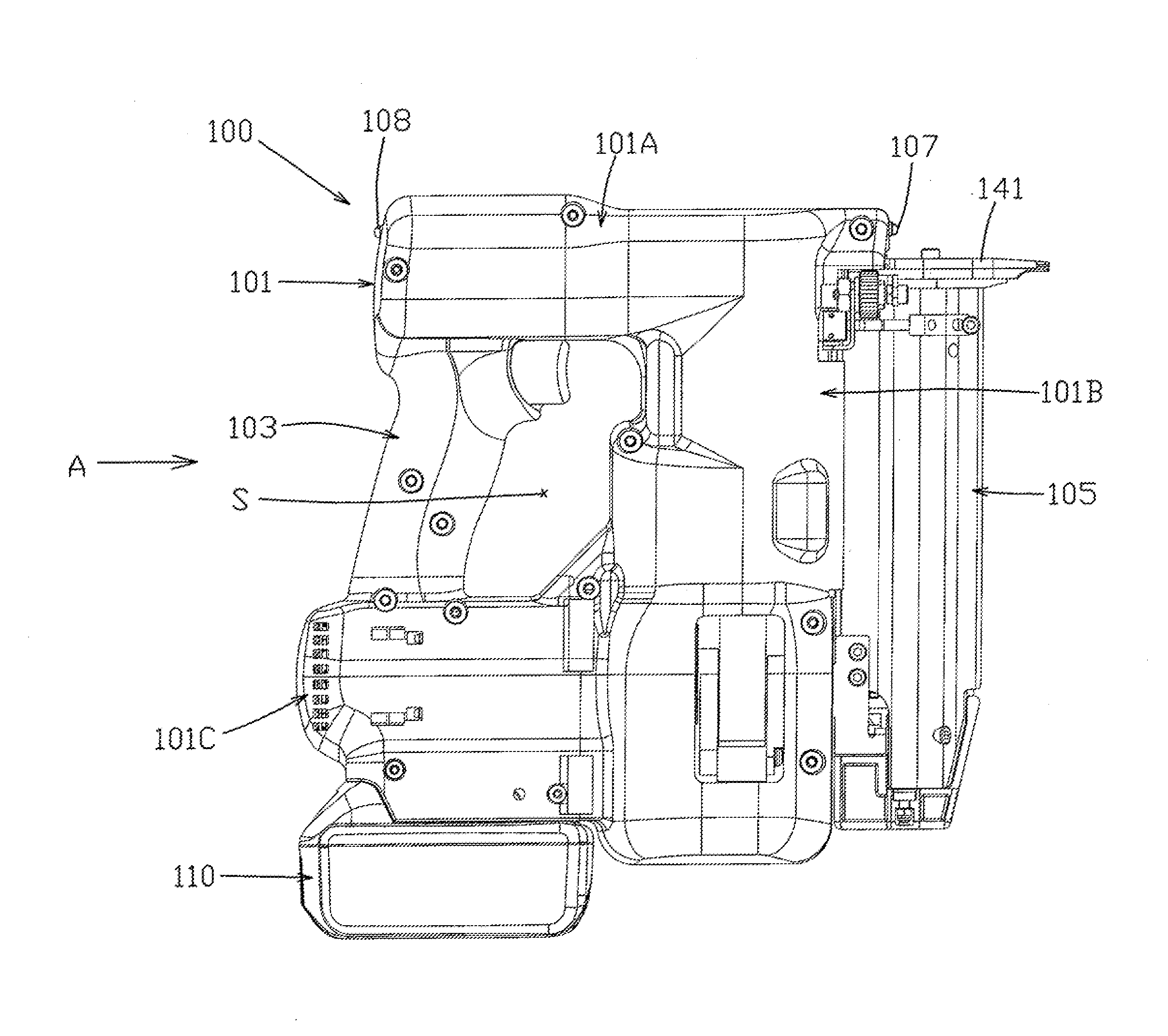

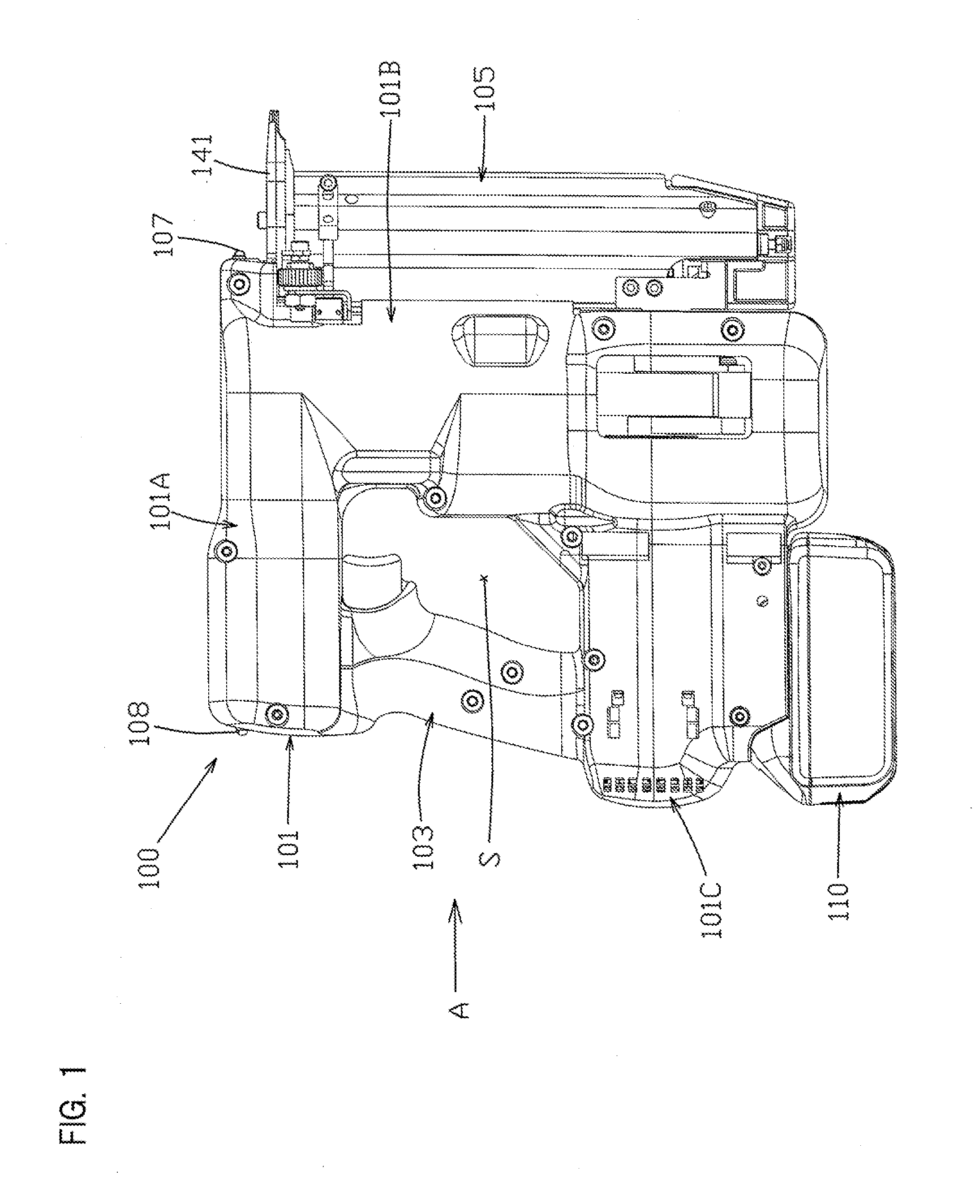

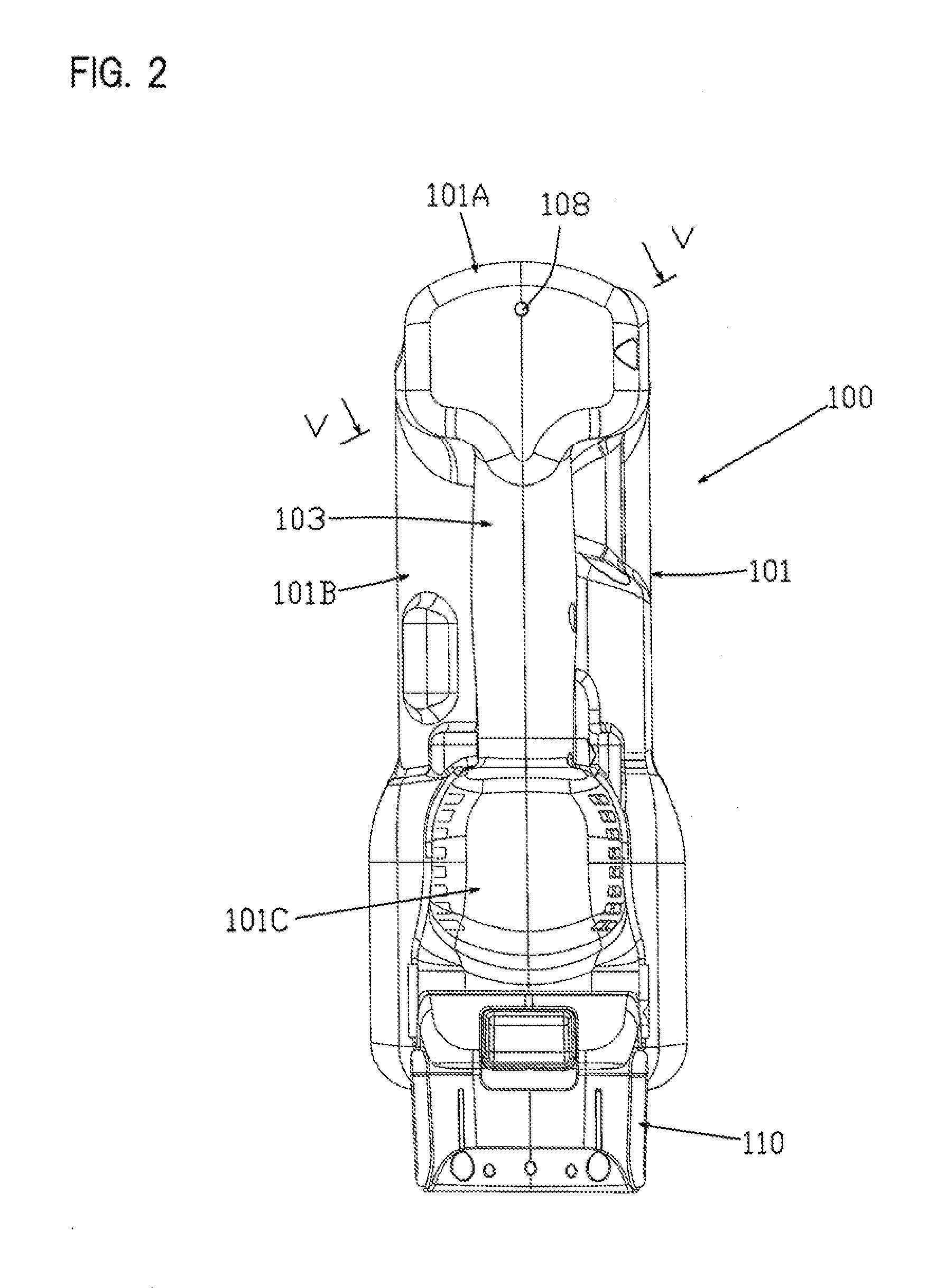

Driving tool

ActiveUS20150158160A1Smoothly and reliably performedAccurate and reliable processServomotor componentsServomotorsTop dead centerPneumatic tool

An electro-pneumatic tool drives a fastener into a workpiece by energizing an electric motor to drive a first piston and generate compressed air in a first cylinder. The compressed air is then supplied to a second cylinder and causes a second piston to move and drive the fastener into the workpiece. After the first piston has passed through its top dead center, braking is applied to the first piston according to one or more braking parameters. Then, if a control unit determines that the first piston has come to a stop at a position that is outside a predetermined range about the bottom dead center of the first piston, one or more of the braking parameters is changed in a subsequent fastener driving cycle to cause the first piston to stop closer to its bottom dead center after conclusion of the subsequent fastener driving cycle.

Owner:MAKITA CORP

Two-stroke internal combustion engine, method of operating two-stroke internal combustion engine and method of converting two-stroke engine

ActiveCN103748334AEmission reductionSimple structureInternal combustion piston enginesGaseous engine fuelsExhaust valveTop dead center

The invention relates a two-stroke internal combustion engine (10) comprising at least one cylinder (20) with a piston (24) arranged reciprocateably between its top dead center and bottom dead center, and a cylinder cover (26) defining a combustion chamber (22), oxygen containing gas inlet (18) in the lower part of the cylinder (20) to be open into the combustion chamber (22) at least while the piston is at its bottom dead center position, a gaseous fuel inlet (30) arranged in the cylinder between the oxygen containing gas inlet (18) and the cylinder cover(26), and an exhaust valve (28) arranged to the cylinder cover at a center axis of the cylinder. The cylinder cover(26) is provided with pilot ignition pre-chambers (36) opening into the combustion chamber (22) through pre-chamber ports (34).The preset invention relates also to method of operating the two-stroke engine (10).

Owner:WAERTSILAE SCHWEIZ AG

Automotive four-cycle engine

InactiveUS20020166536A1Improve engine performanceRaise the combustion temperatureValve arrangementsElectrical controlExhaust valveTop dead center

A four-cycle engine is provided with valve timing adjusters for adjusting opening and closing timing an and an exhaust valve. In medium- to high-speed ranges in medium- to high-load regions of the engine, a closing point (ExC) of the exhaust valve defined as a point of transfer from an acceleration portion to a constant speed portion on its valve lift characteristics curve is set to a point a specific period before an intake top dead center, and an opening point (InO) of the intake valve defined as a point of transfer from a constant speed portion to an acceleration portion on its valve lift characteristics curve is set to a point after the intake top dead center. In addition, the period from the closing point (ExC) of the exhaust valve to the opening point (InO) of the intake valve is made longer in the medium-speed range than in the high-speed range in the medium- to high-load regions of the engine.

Owner:MAZDA MOTOR CORP

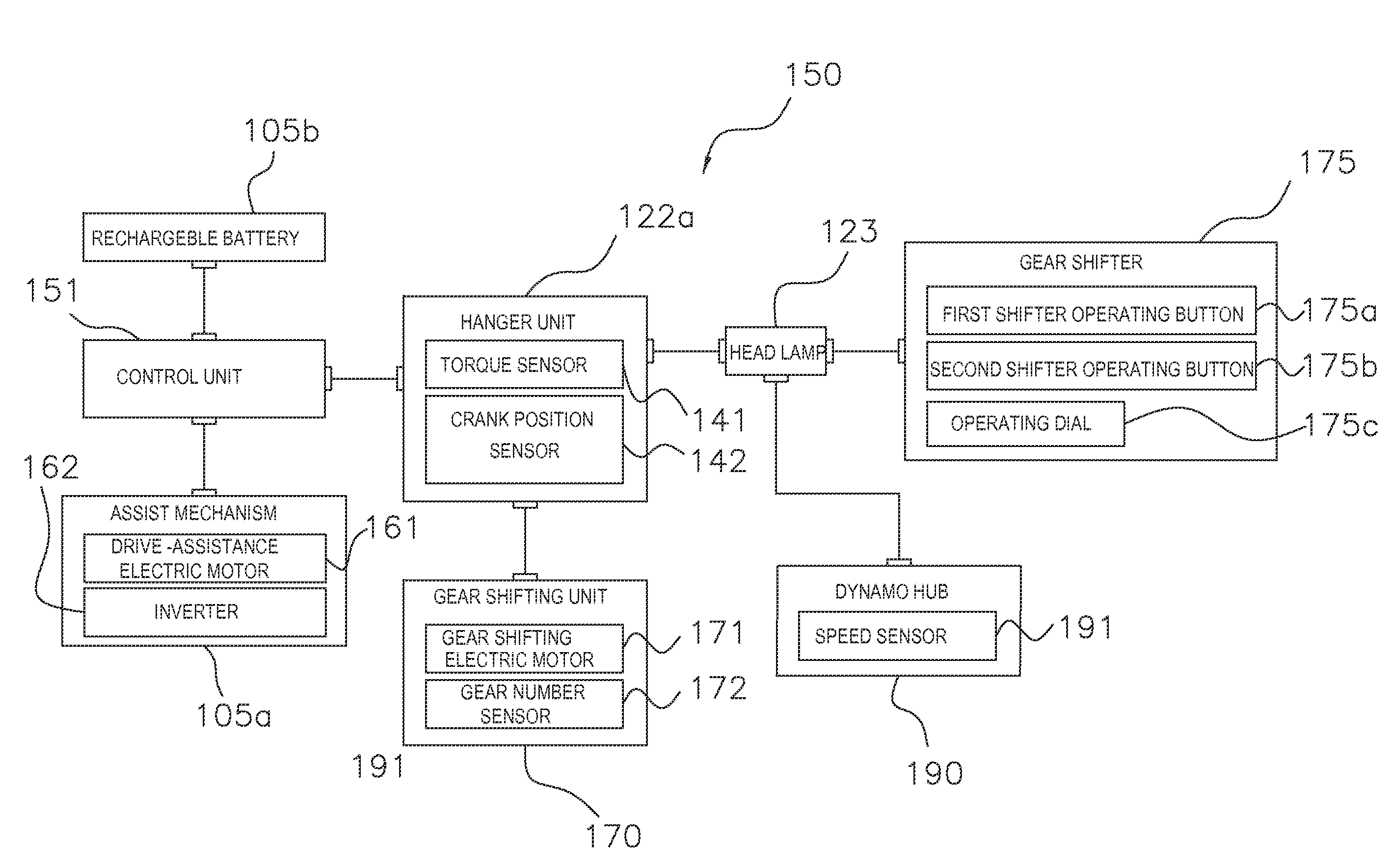

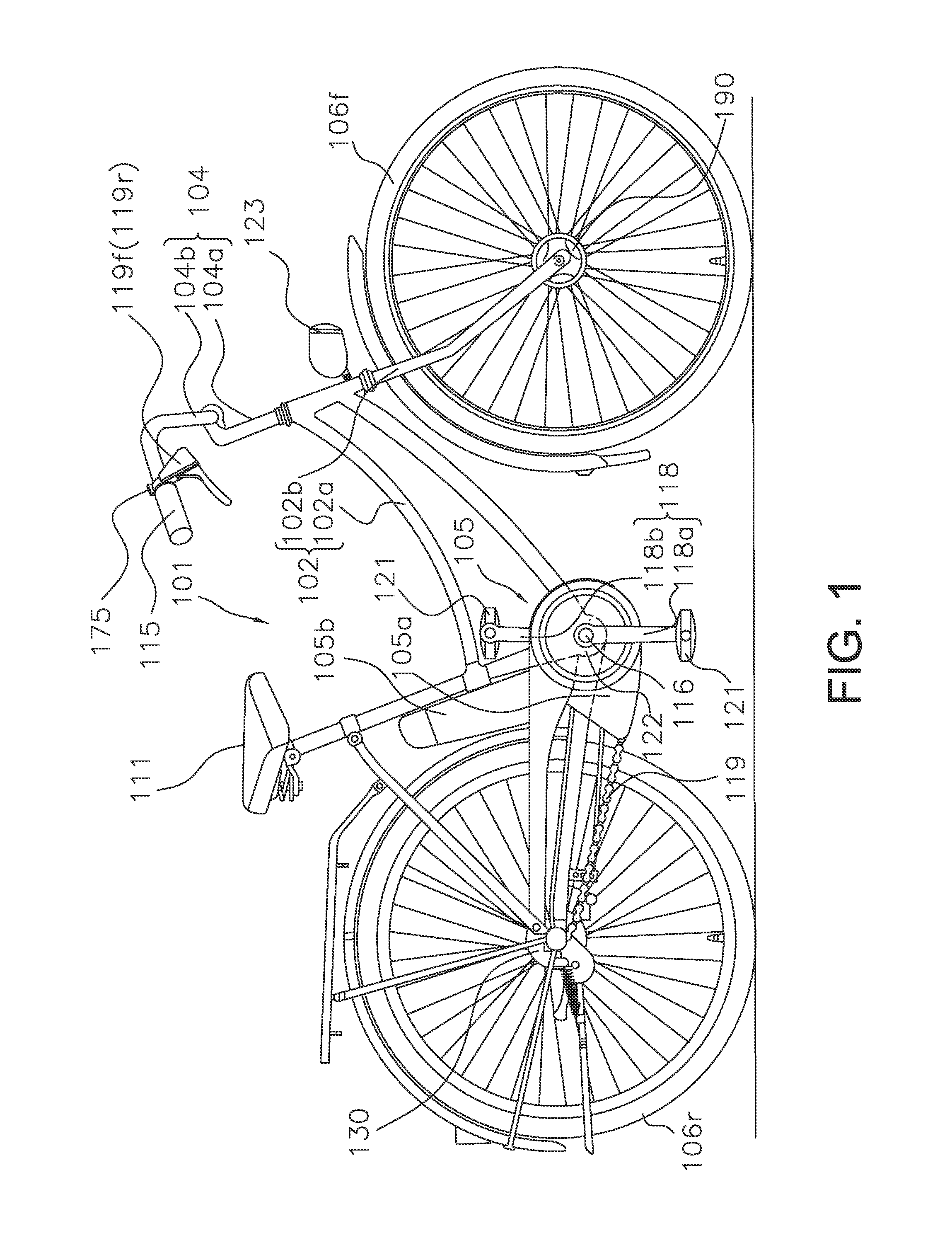

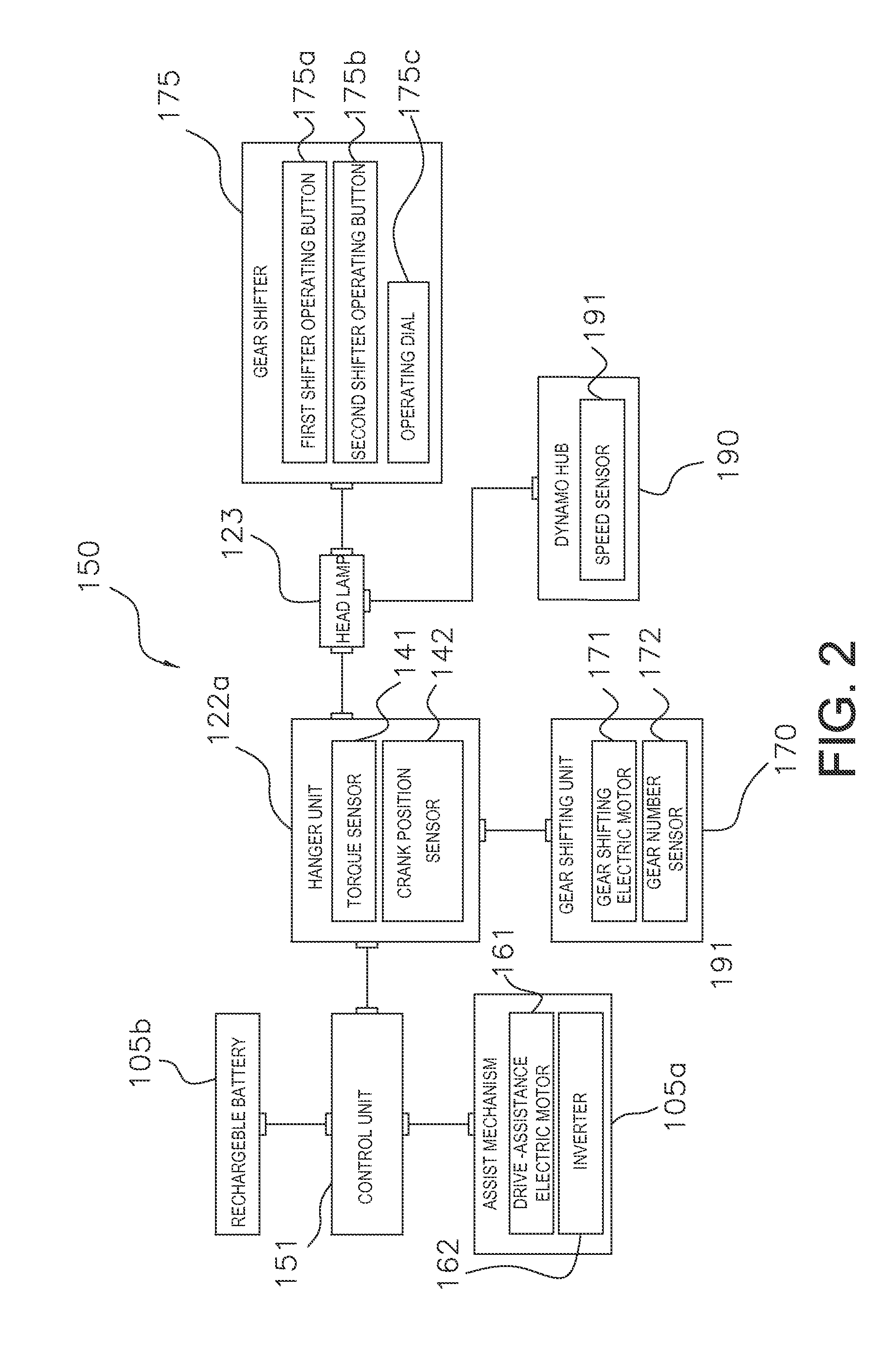

Bicycle drive apparatus

ActiveUS20130054065A1Guaranteed uptimeTension of chain is smallDigital data processing detailsCycle control systemsMicrocomputerTop dead center

A bicycle drive apparatus includes a bicycle crankset, a bicycle transmission, a drive assistance electric motor and a microcomputer. The microcomputer includes an output control section. The output control section has a first control and a second control that makes an output of the drive assistance electric motor smaller than an output of the drive assistance electric motor occurring during the first control only upon determining a crank arm of the bicycle crankset is positioned within a prescribed range of at least one of a top dead center position and a bottom dead center position of the bicycle crankset. The output control section is configured to vary the output of the drive assistance electric motor according to a pedaling force. The output control section switches from the first control to the second control upon receiving a shift command to shift the transmission.

Owner:SHIMANO INC

Direct injection diesel engine

InactiveUS6840209B2Avoid dischargeAmelioration of [the amount of] exhaust gasElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionCombustion

Cleaning of exhaust gas and reduction of fuel costs are aimed at while realizing homogenious charge (or pre-mixing) compression ignition combustion and performing fuel injection in a suitable manner in all regions of engine operation. In a direct injection diesel engine there are provided an conventional injection mode in which fuel is injected with a timing (I) in the vicinity of the compression top dead center of piston (1) and a homogenious charge compression injection mode in which fuel is injected with a timing (II to V) which is earlier than that in the conventional injection mode, and such that fuel ignition does not occur at least until injection has been completed, fuel injection being performed by the conventional injection mode during full load operation of the engine and fuel injection being performed by the homogenious charge compression injection mode during part (low / medium) load operation of the engine. Ordinary diffusion combustion is realized when operating the engine under full load yet while receiving the benefit of amelioration of exhaust gas etc due to homogenious charge compression ignition combustion; thus, suitable fuel injection can be implemented over the entire operating range.

Owner:ISUZU MOTORS LTD

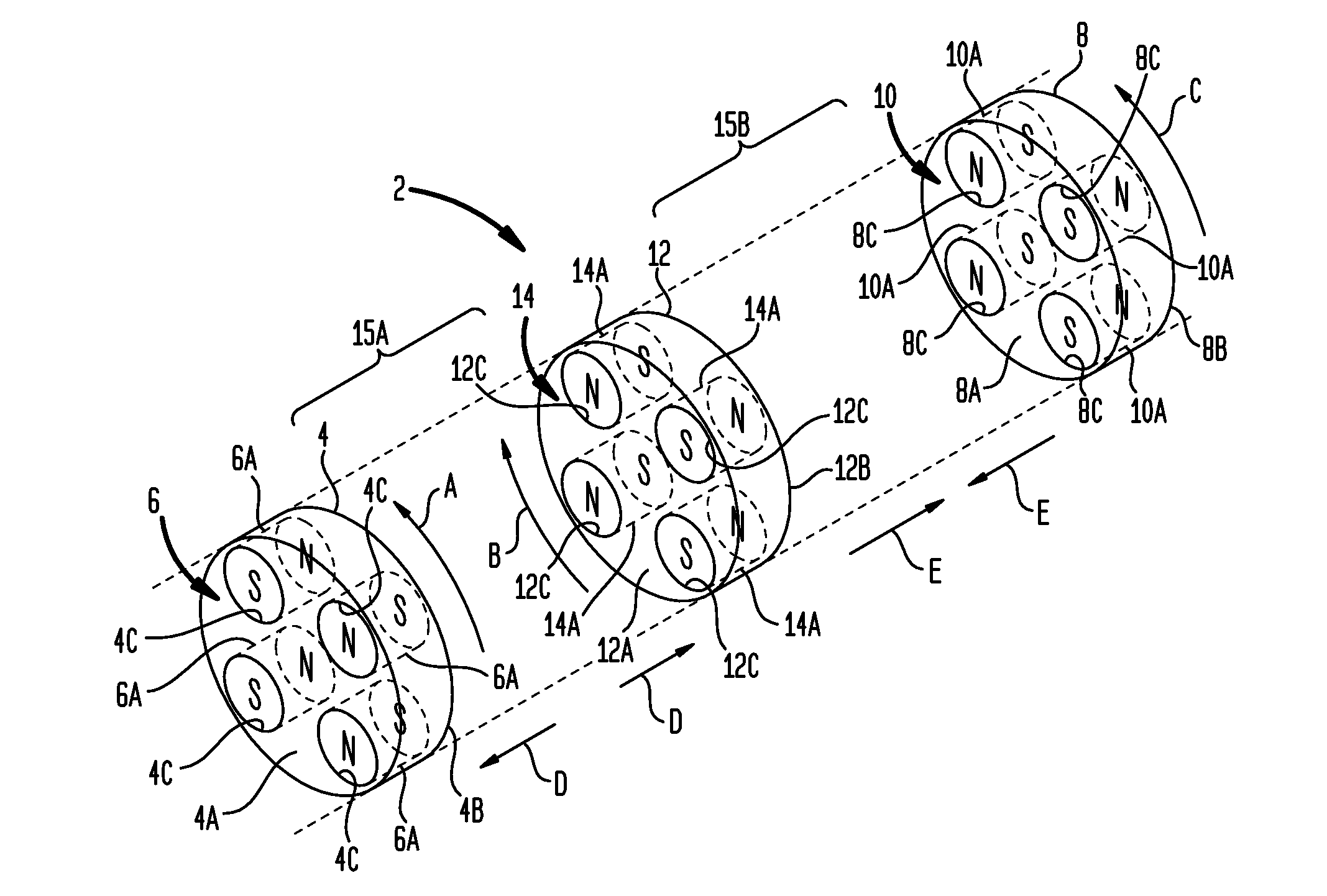

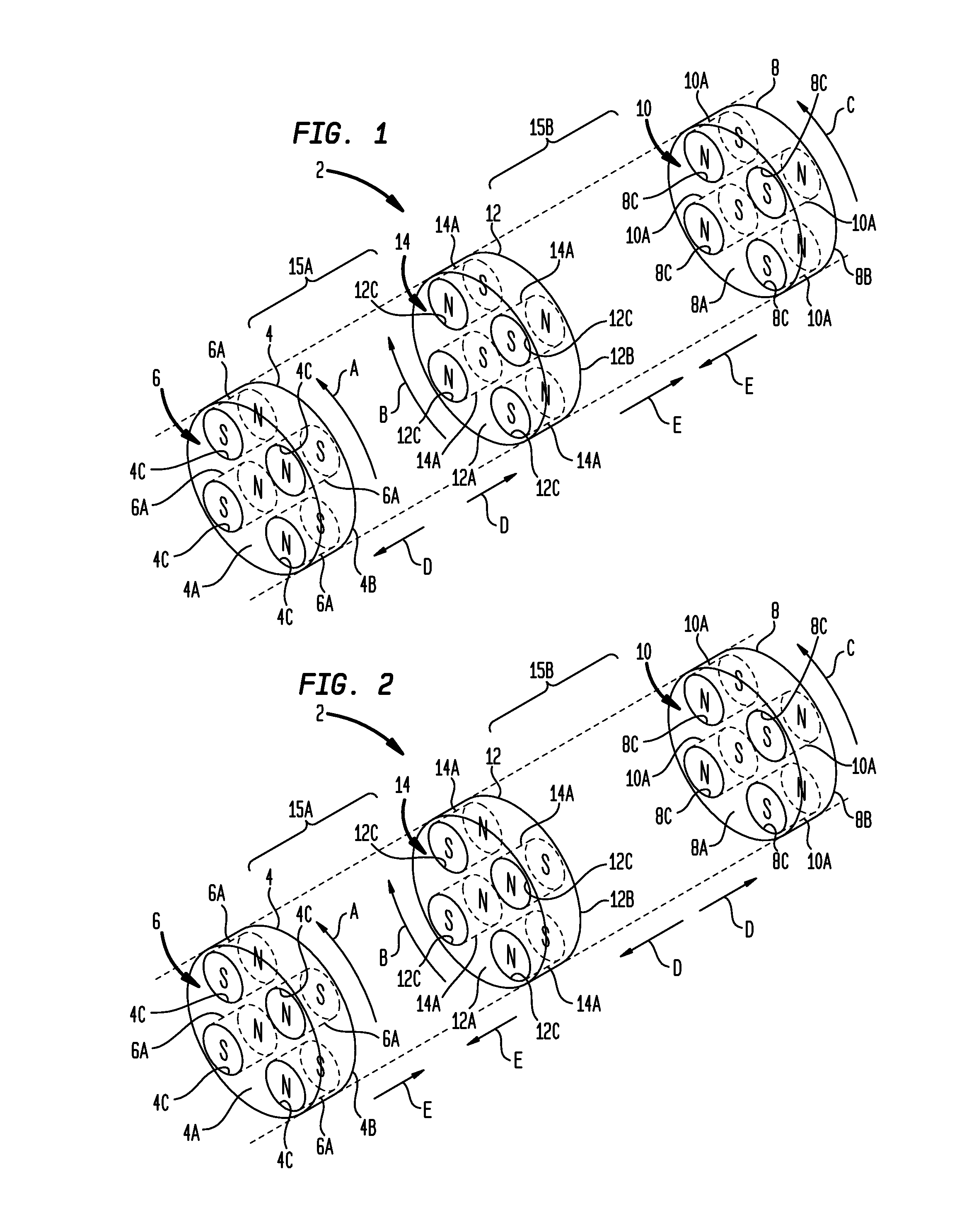

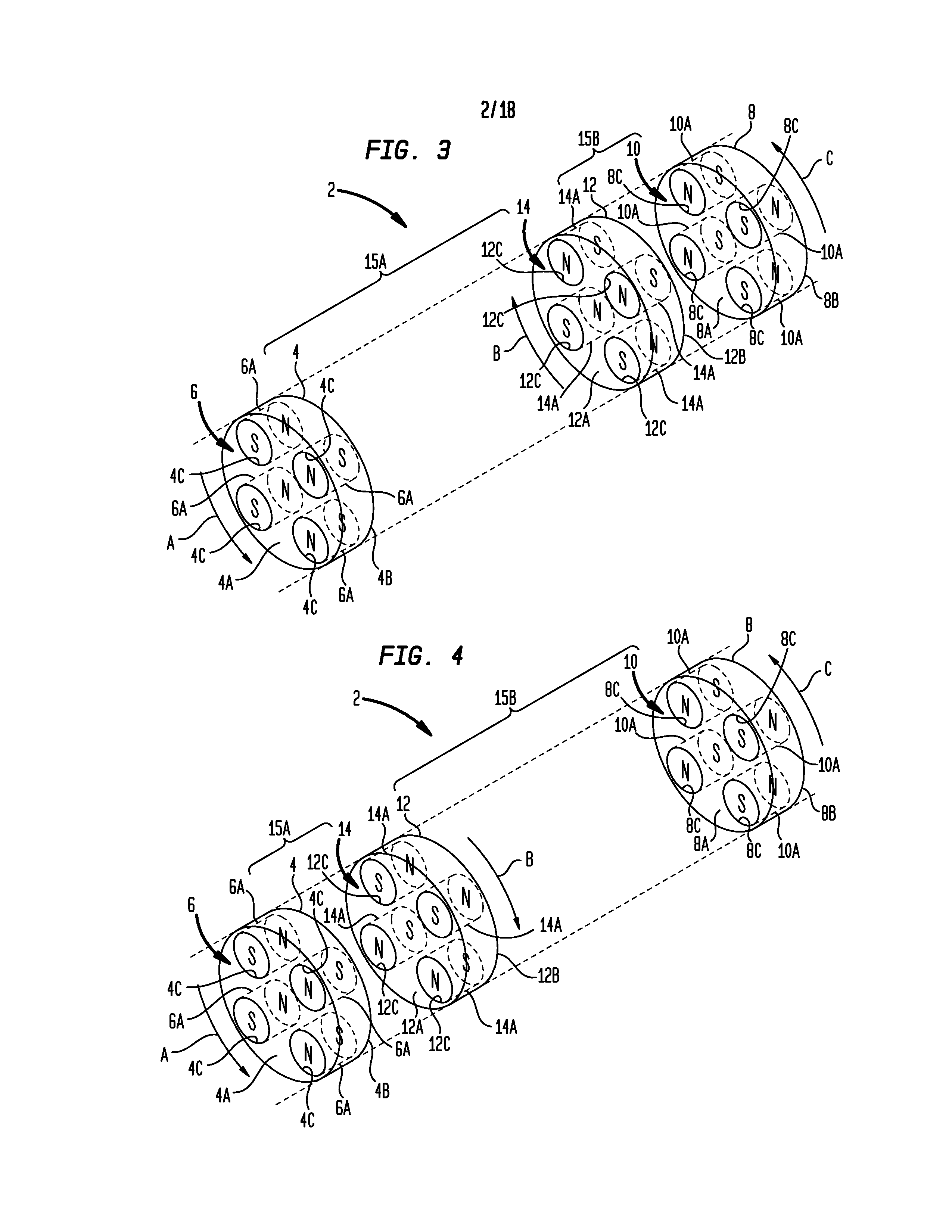

Permanent magnet drive apparatus and operational method

InactiveUS8487484B1Magnetic circuitPermanent-magnet clutches/brakesMagnetic tension forcePush and pull

A magnetic drive apparatus includes first and second magnet carriers carrying first and second permanent magnet arrangements. An intermediate magnet carrier disposed between the first and second magnet carriers carries a third permanent magnet arrangement. The magnet carriers are arranged for rotation relative to each other such that the magnet arrangements produce magnetic interactions that result in power stroke forces causing the magnet carriers to undergo relative reciprocation in first and second stroke directions during power zone portions of the relative rotation. The magnetic interactions impart substantially no power stroke forces during dead zone portions of the relative rotation. The dead zones include magnet carrier relative rotation positions wherein opposing magnetic poles are mutually coaxially aligned but produce a substantially equal balance of push and pull magnetic forces. The apparatus may be synchronized so that the dead zones coincide with top dead center and bottom dead center relative reciprocation positions.

Owner:COLSON ANDREW E JR MR

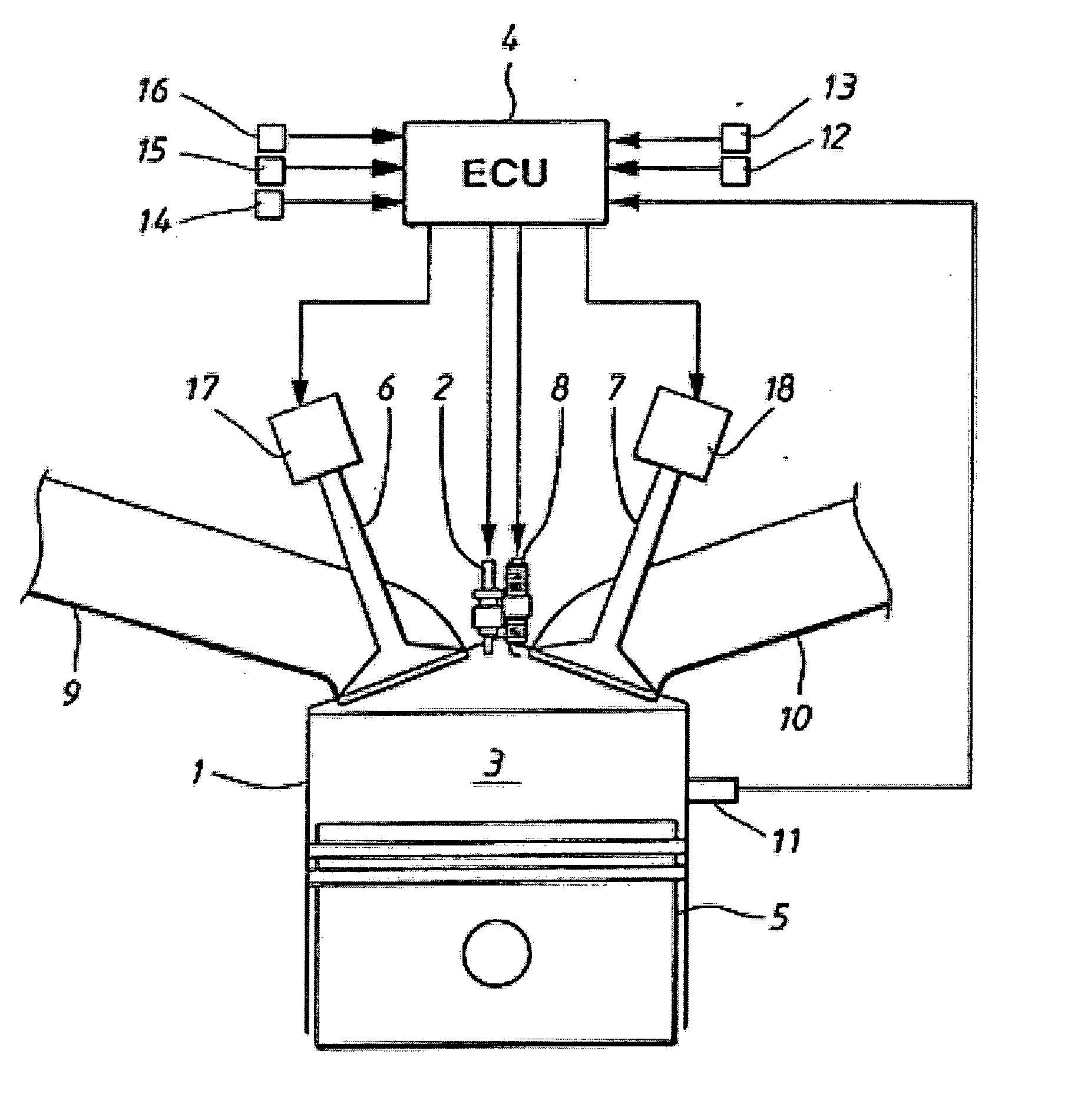

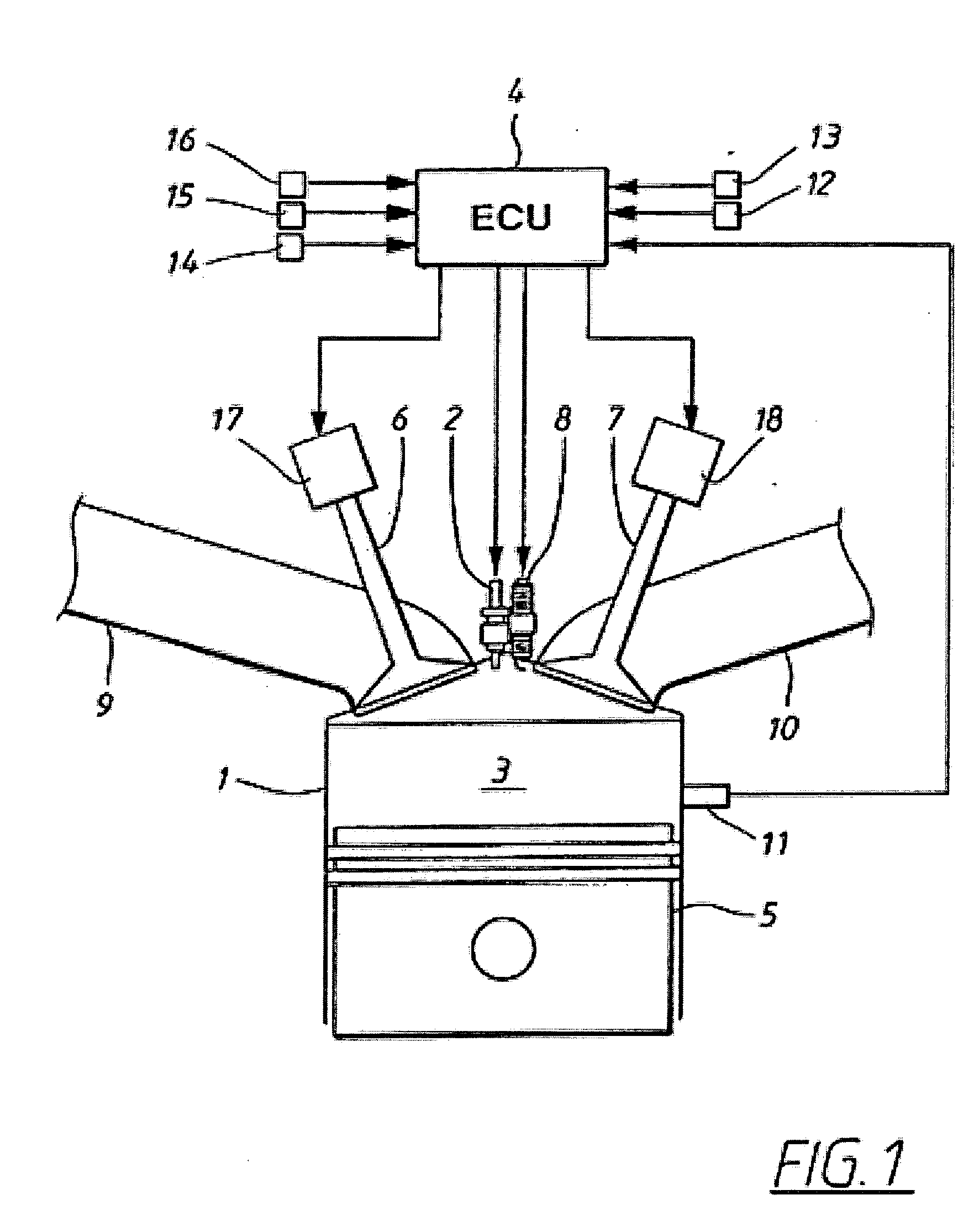

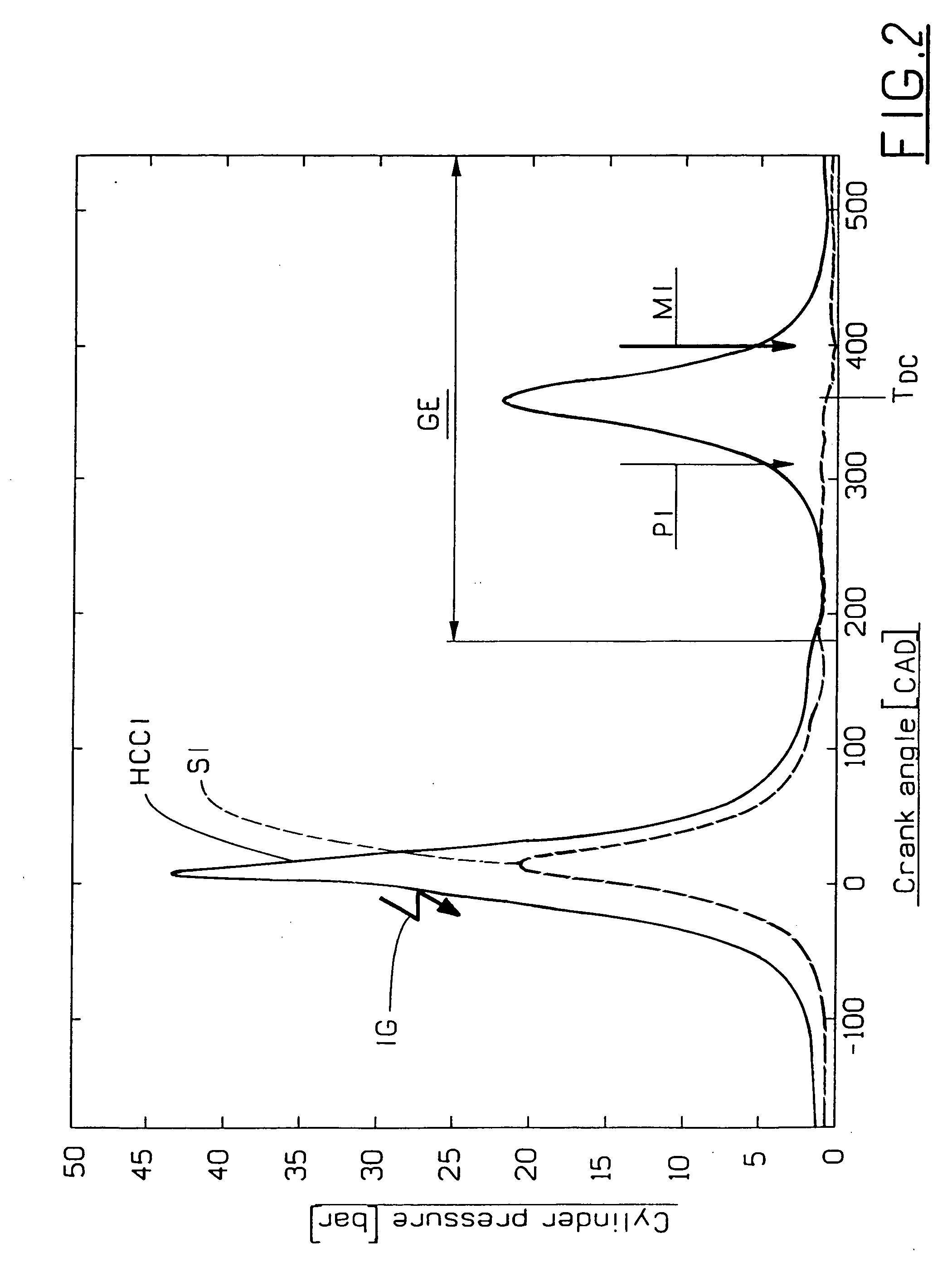

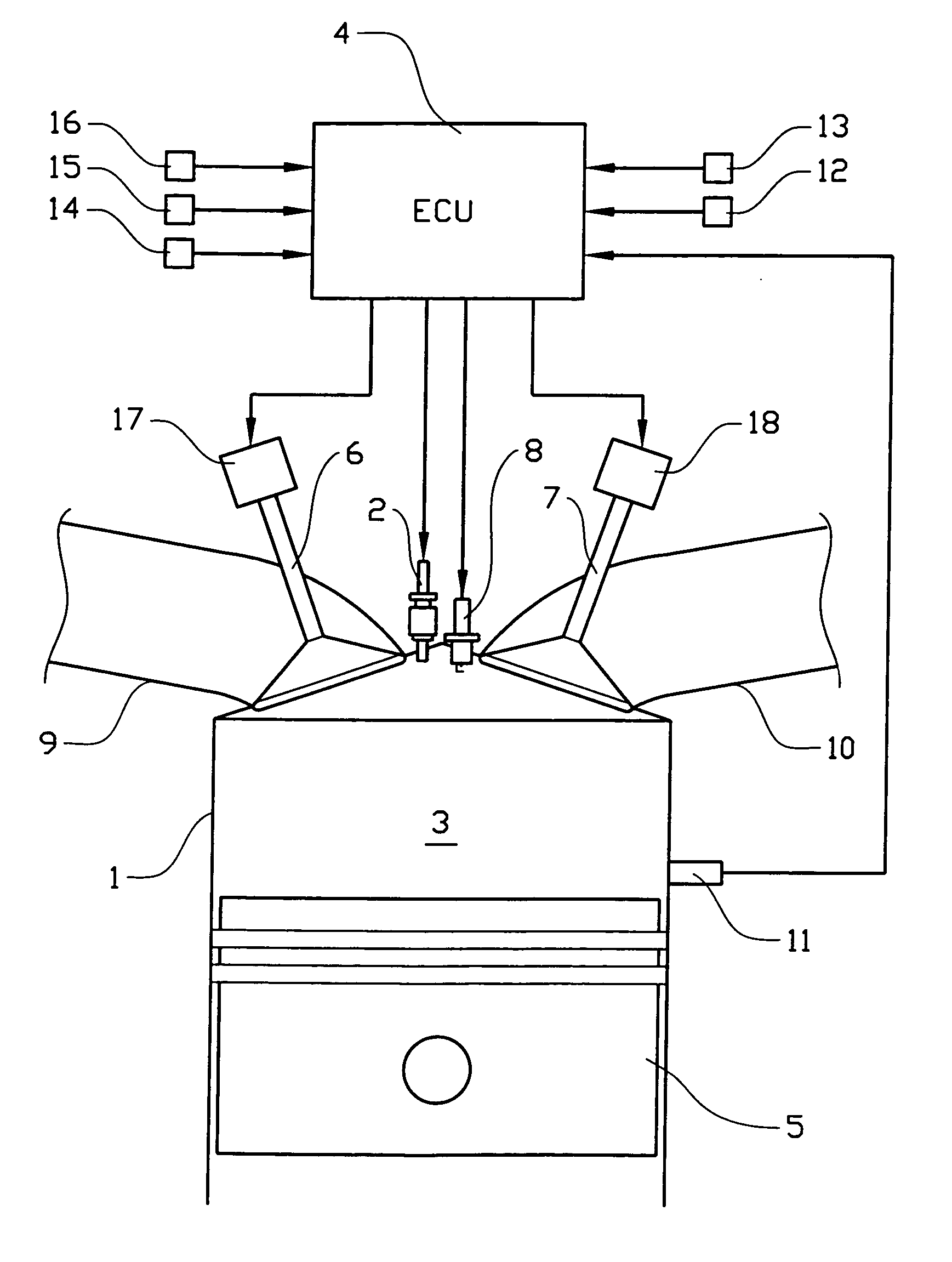

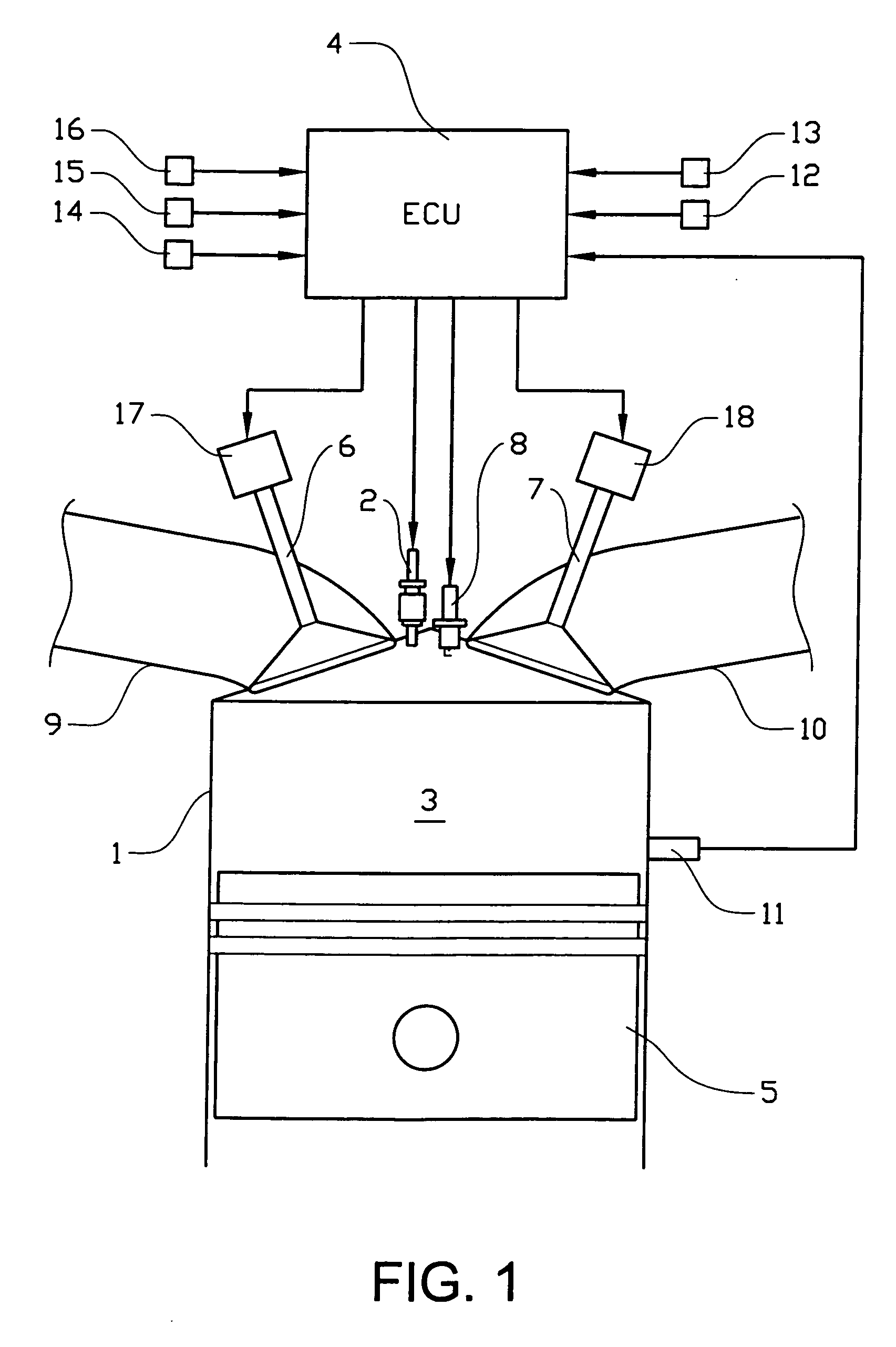

Method for auto-ignition operation and computer readable storage device for use with an internal combustion engine

ActiveUS20050211219A1Improve thermal efficiencyImprove flammabilityValve arrangementsElectrical controlCompression actionTop dead center

An internal combustion engine that can be operated in compression ignition mode, comprising a fuel injector (2) for each cylinder; a fuel injection control unit (4) for controlling fuel injection quantity and a piston (5) in each cylinder whose compression action causes a mixture of air and fuel to be ignited. The engine is further provided with inlet and outlet valves (6, 7) and sensors (12-16) for measuring various engine operating parameters, is disclosed. During compression ignition mode, the control unit controls the fuel injector to perform a first fuel injection before, and a second fuel injection after top dead center of the piston stroke during or after a negative valve overlap period. A method for operating the engine and a computer readable storage device (4) having stored therein data representing instructions executable by a computer to implement a compression ignition for an internal combustion engine is also described.

Owner:FORD GLOBAL TECH LLC

Internal combustion engine and method for auto-ignition operation of said engine

ActiveUS20060174853A1Improve thermal efficiencyReduce nitrogen oxide emissionsElectrical controlInternal combustion piston enginesCompression actionTop dead center

The invention relates to an internal combustion engine that can be operated in compression ignition mode, the engine comprising a fuel injector for each cylinder; a fuel injection controller for controlling fuel injection quantity and a piston in each cylinder whose compression action causes a mixture of air and fuel to be ignited. The engine is further provided with inlet and outlet valves and sensors for measuring various engine operating parameters. During compression ignition mode, the control unit controls the fuel injector to perform a first fuel injection before top dead center of the exhaust stroke during a period of negative valve overlap, and a second fuel injection during the piston compression stroke. The control unit may perform a switch between a first fuel injection strategy and at least one further fuel injection strategy in response to a change in load demand on the engine.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com