Patents

Literature

101results about How to "Less generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

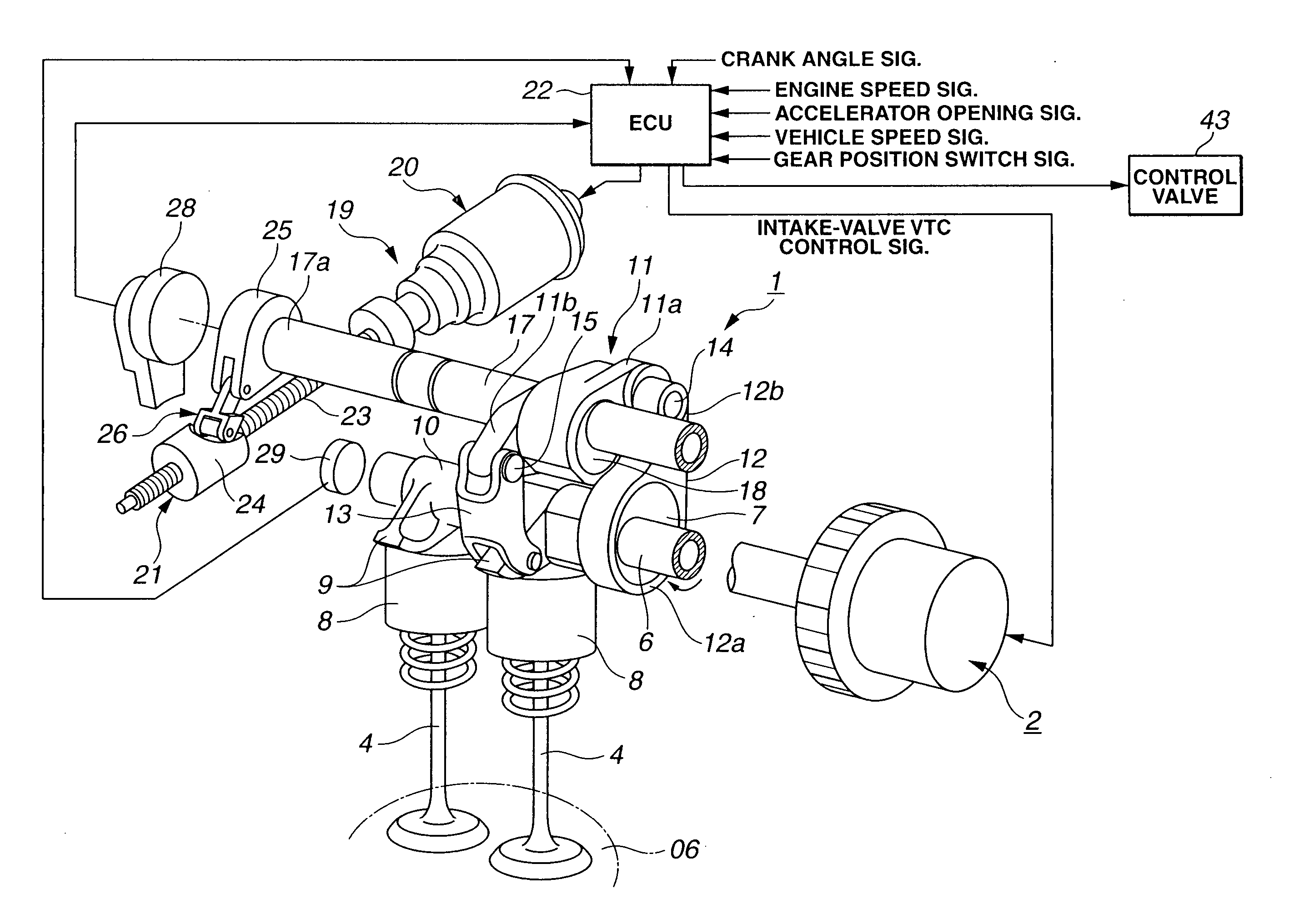

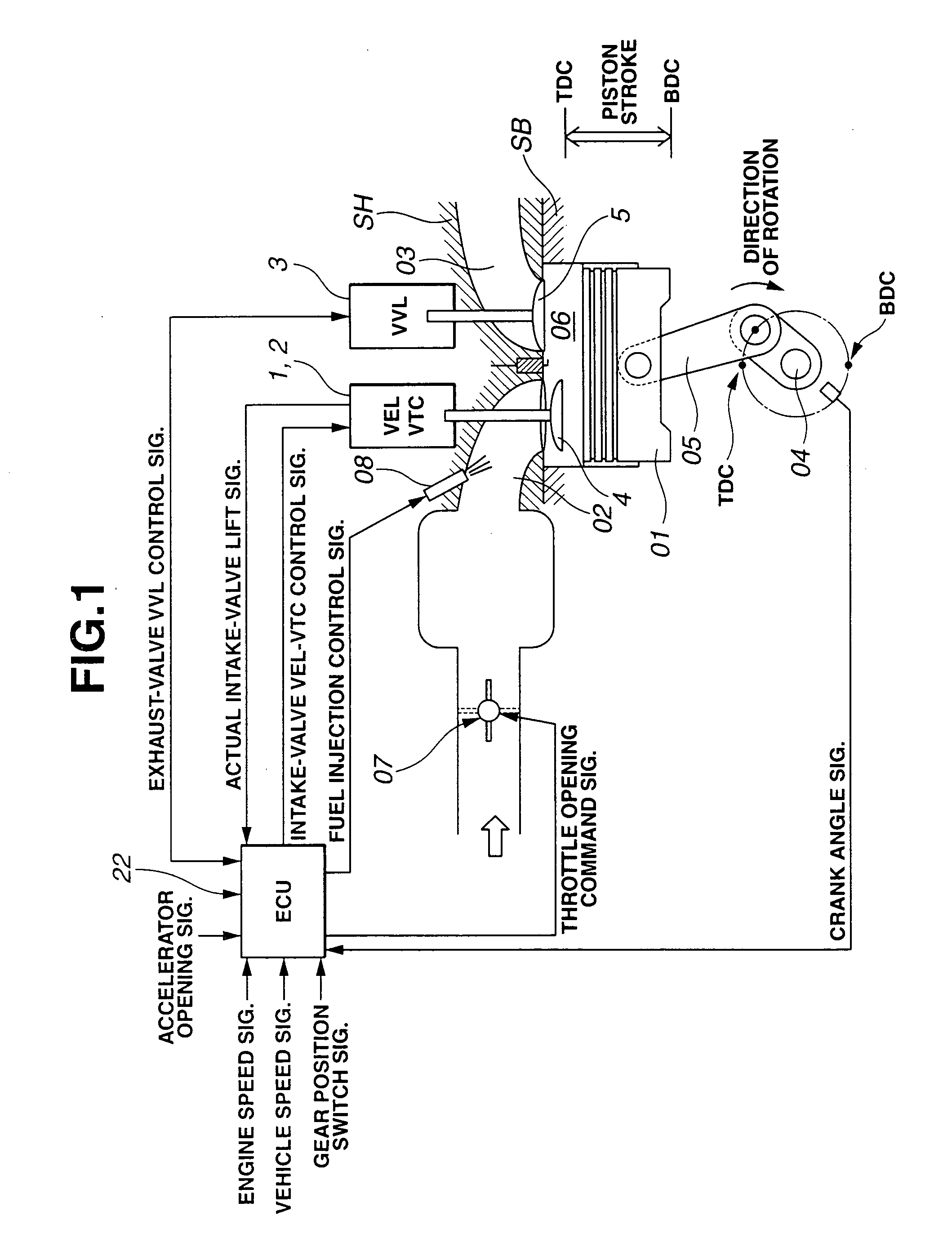

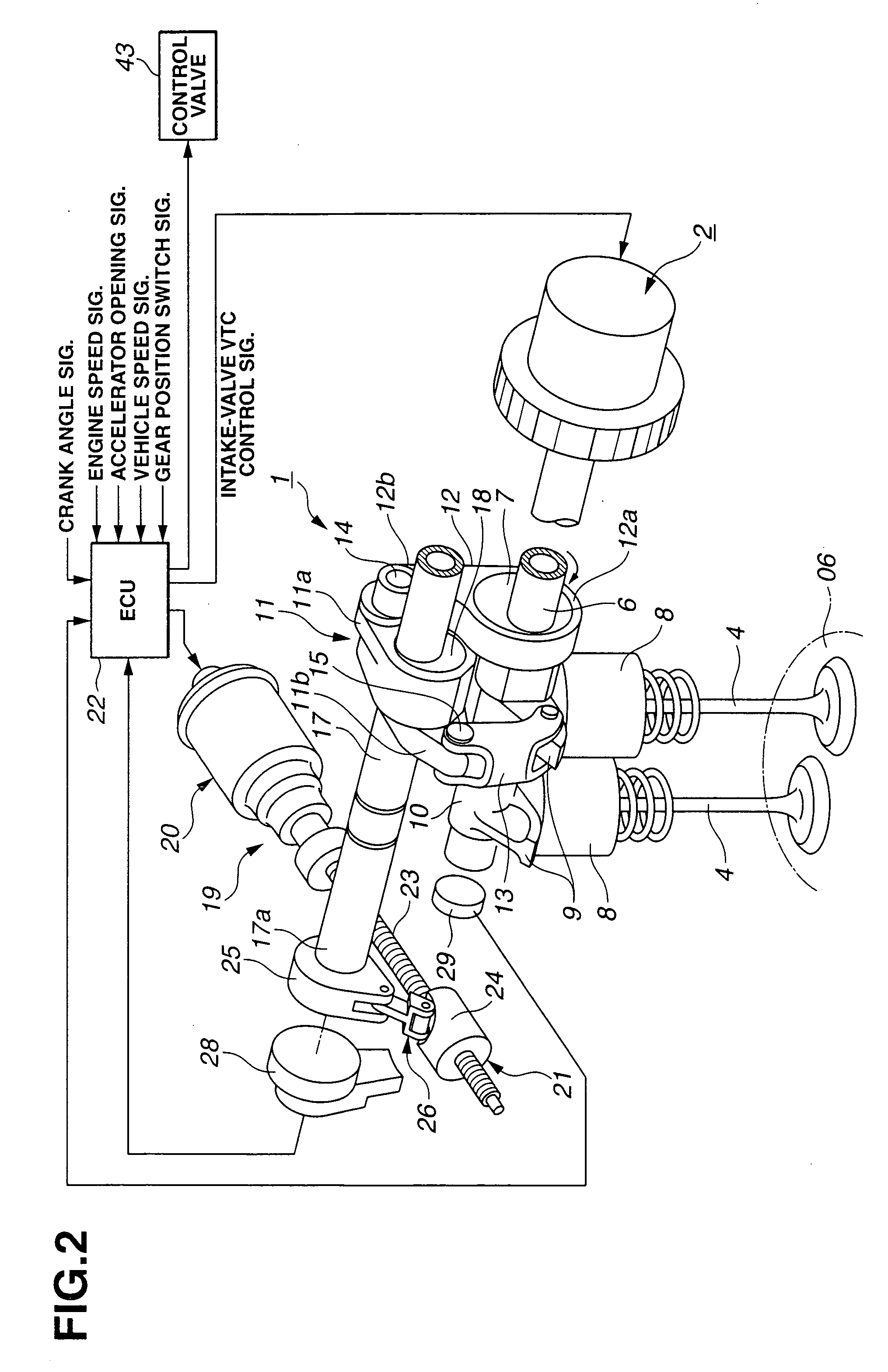

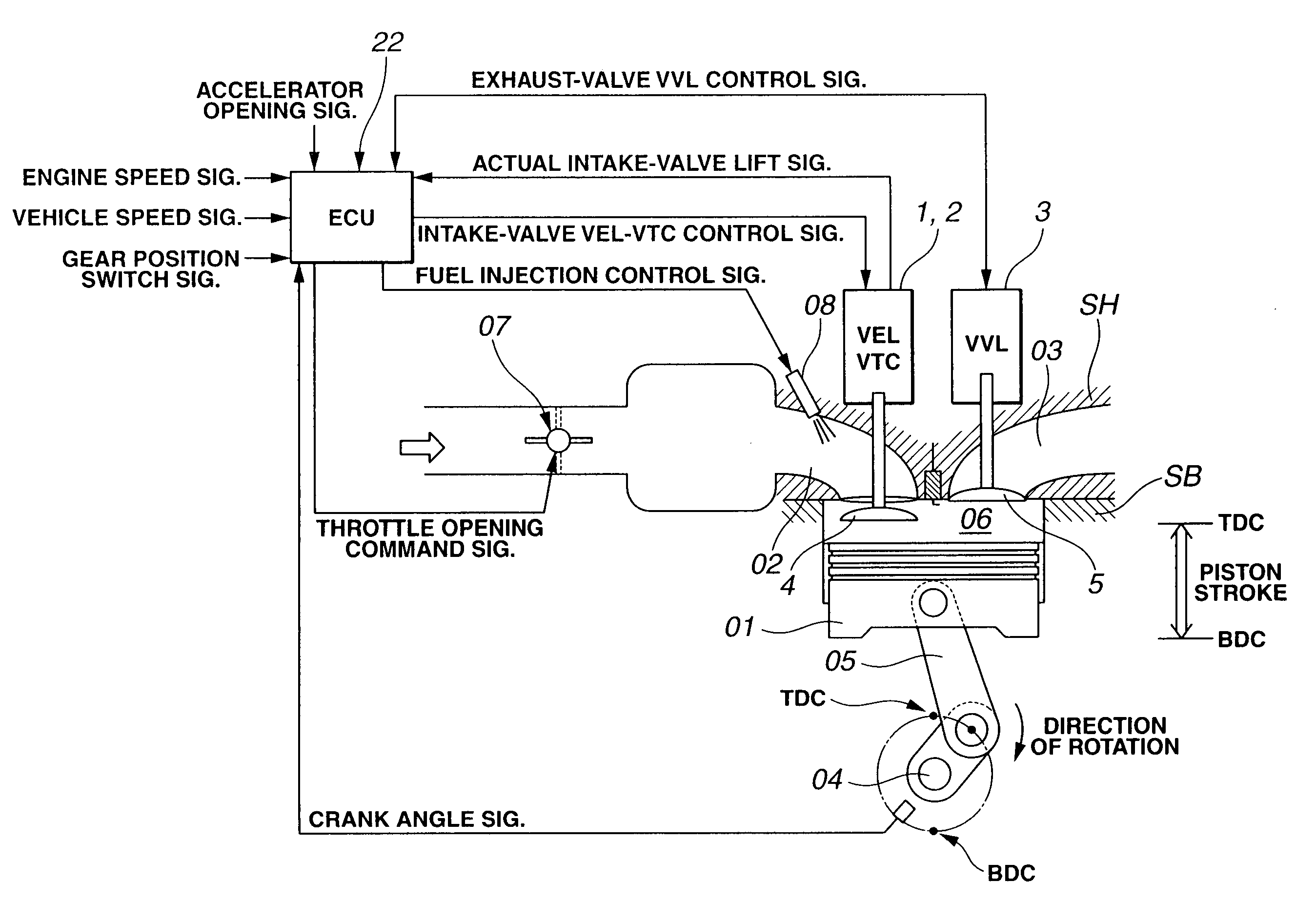

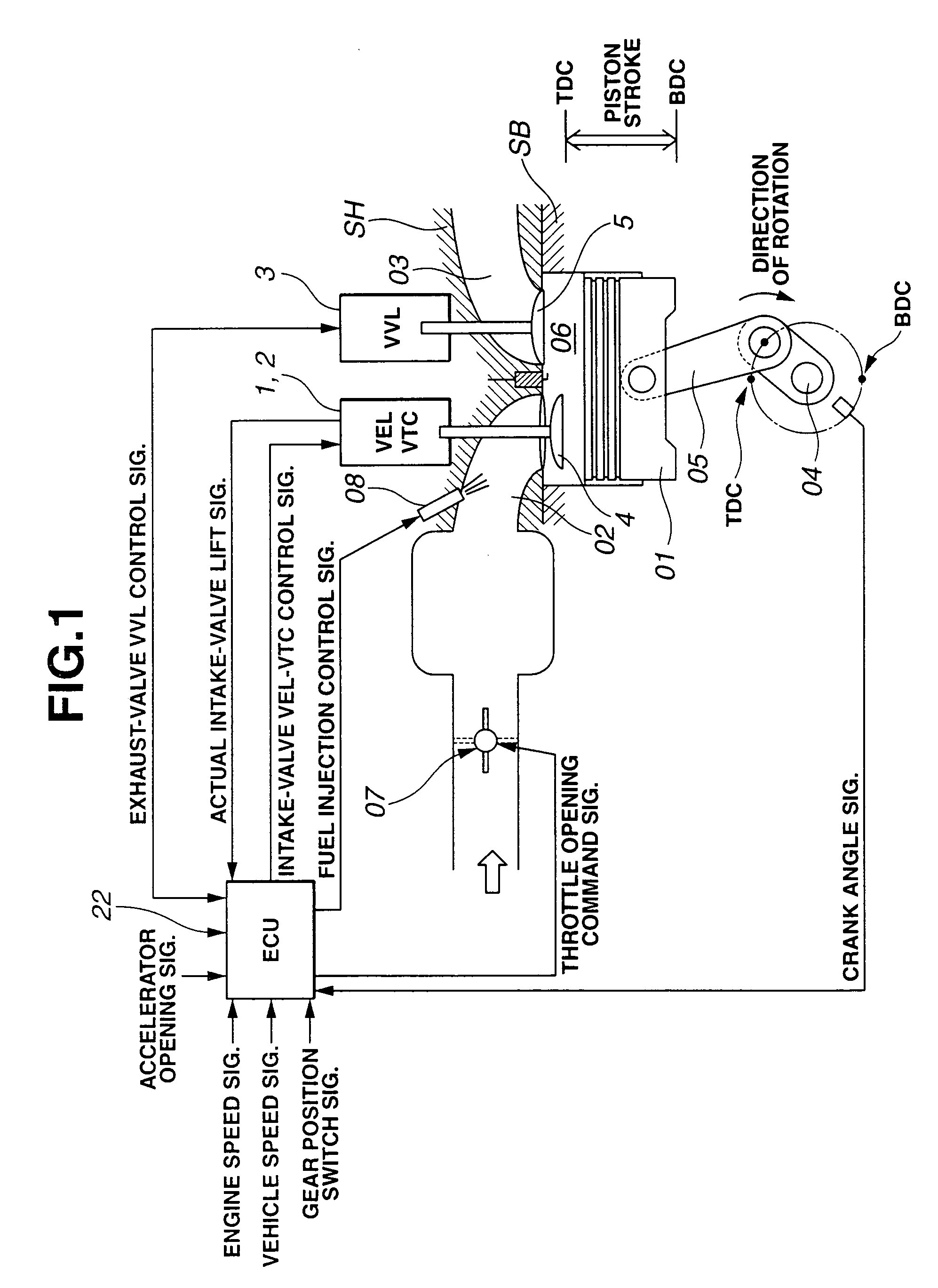

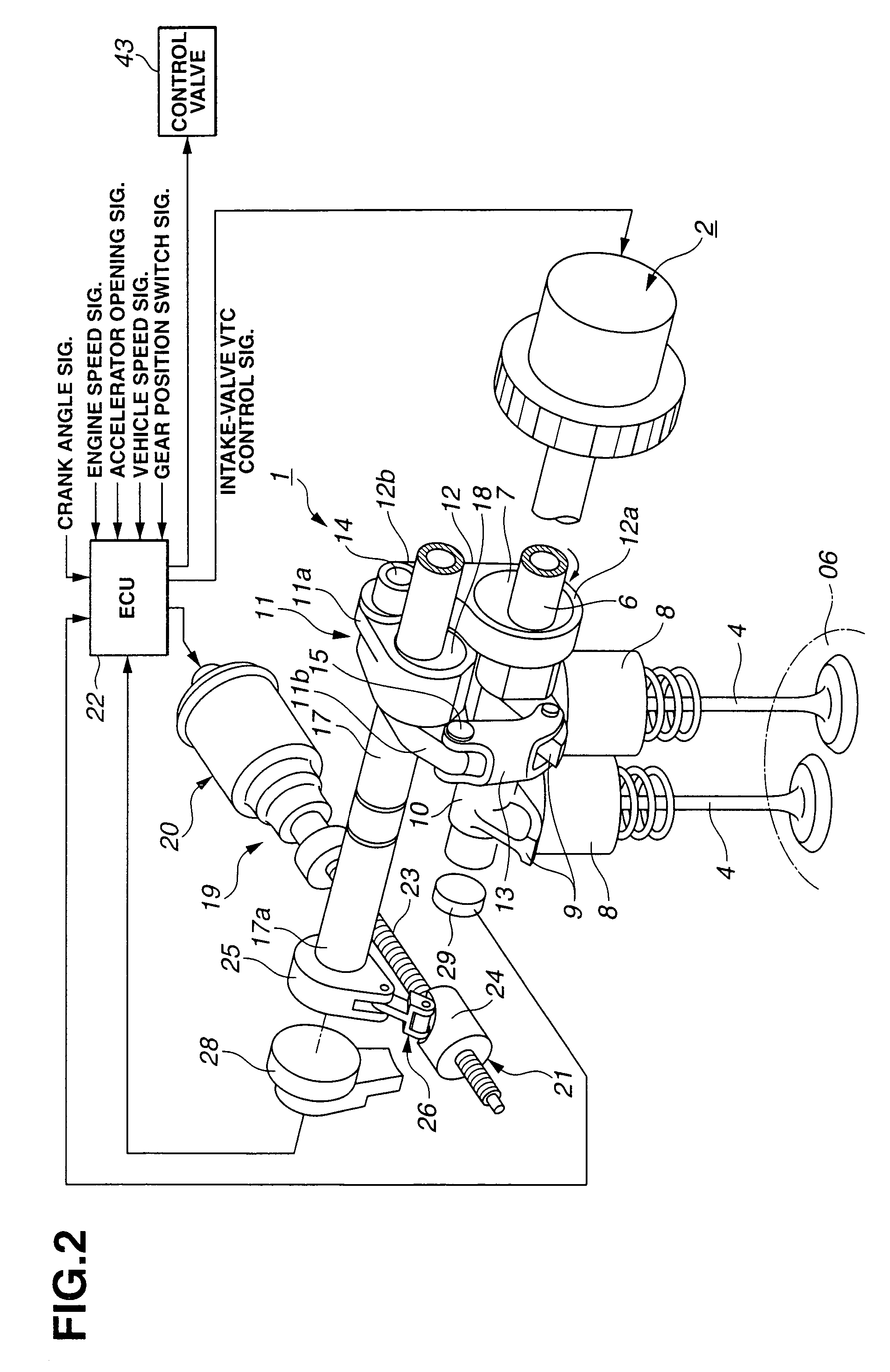

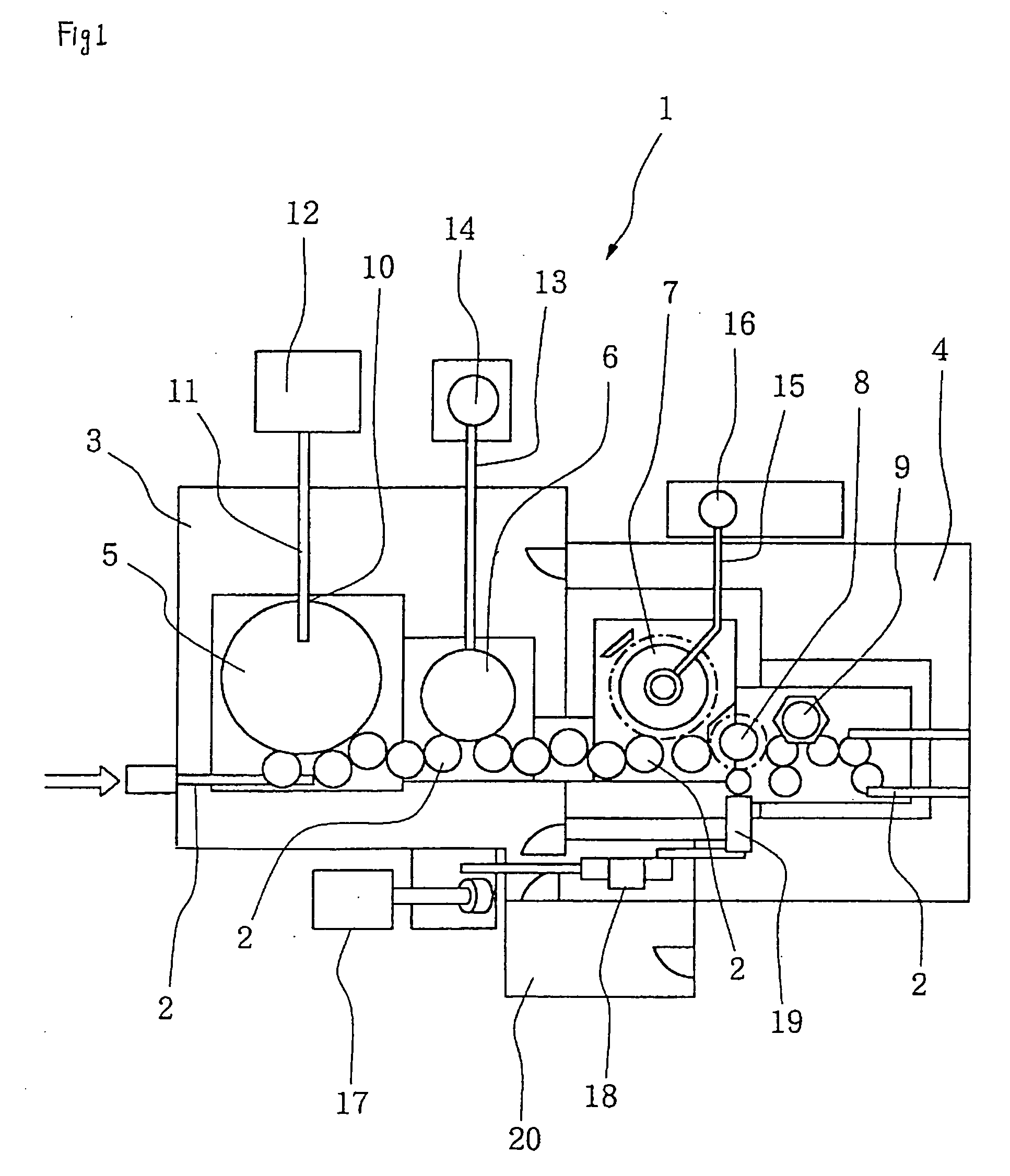

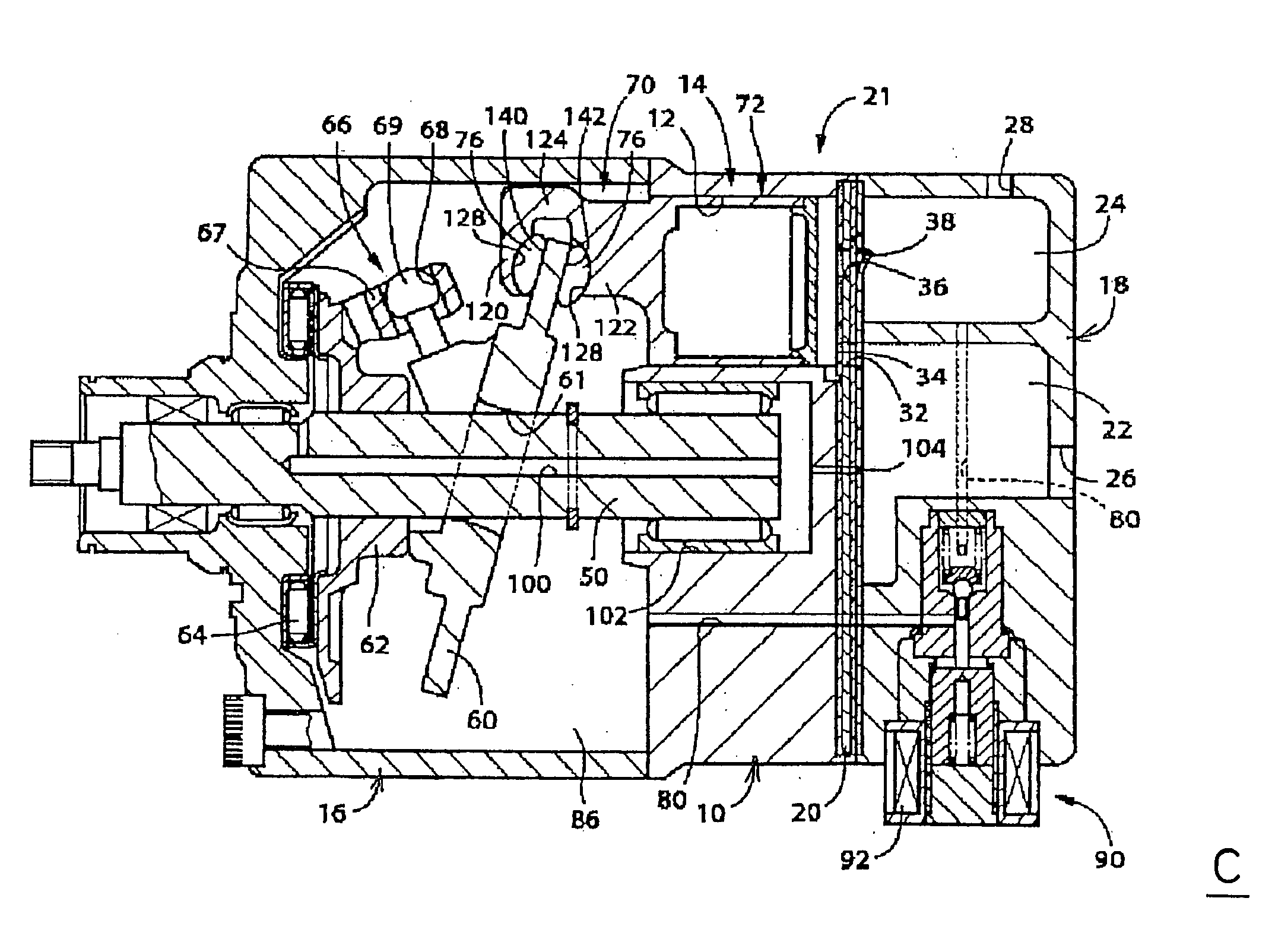

Cylinder cutoff control apparatus of internal combustion engine

InactiveUS20060037578A1Reduced engine braking effectTendency increaseValve arrangementsElectrical controlExhaust valveTop dead center

A cylinder cutoff control apparatus of an engine initiates a cylinder cutoff mode only when two conditions, namely a low load condition such as a vehicle cruising condition and an intake valve closure timing controlled to a given timing value before a bottom dead center, are both satisfied. A fuel cutoff mode is executed prior to the cylinder cutoff mode. During a transition to the cylinder cutoff mode, the control apparatus holds an intake valve open timing at a given timing value substantially corresponding to a top dead center, simultaneously with reducing an intake valve lift amount of each intake valve, subjected to cylinder cutoff control, to a zero lift. Immediately when the intake valve lift amount is reduced to below a lift threshold value, an exhaust valve lift amount of each exhaust valve, subjected to the cylinder cutoff control, is controlled to a zero lift.

Owner:HITACHI LTD

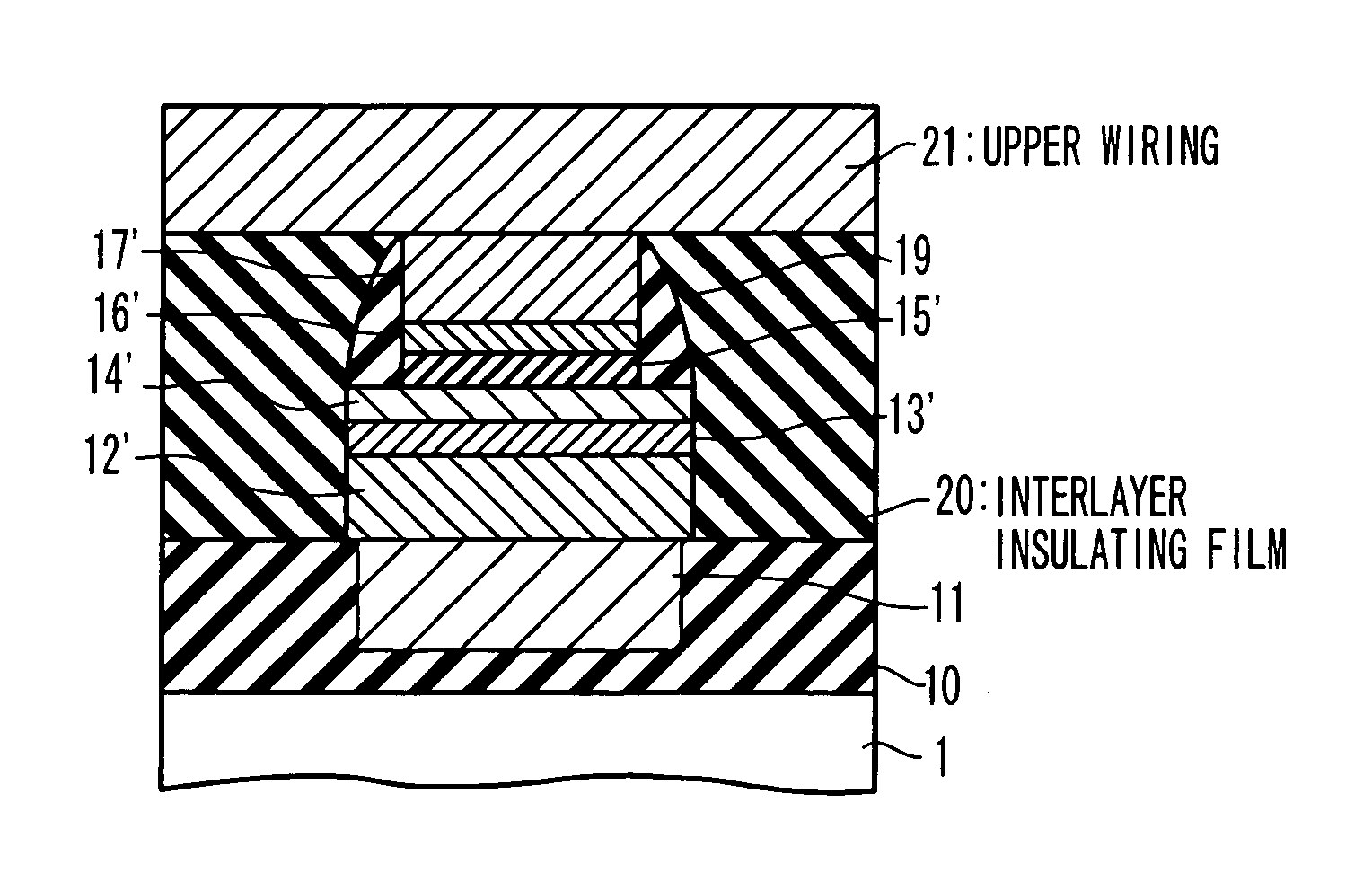

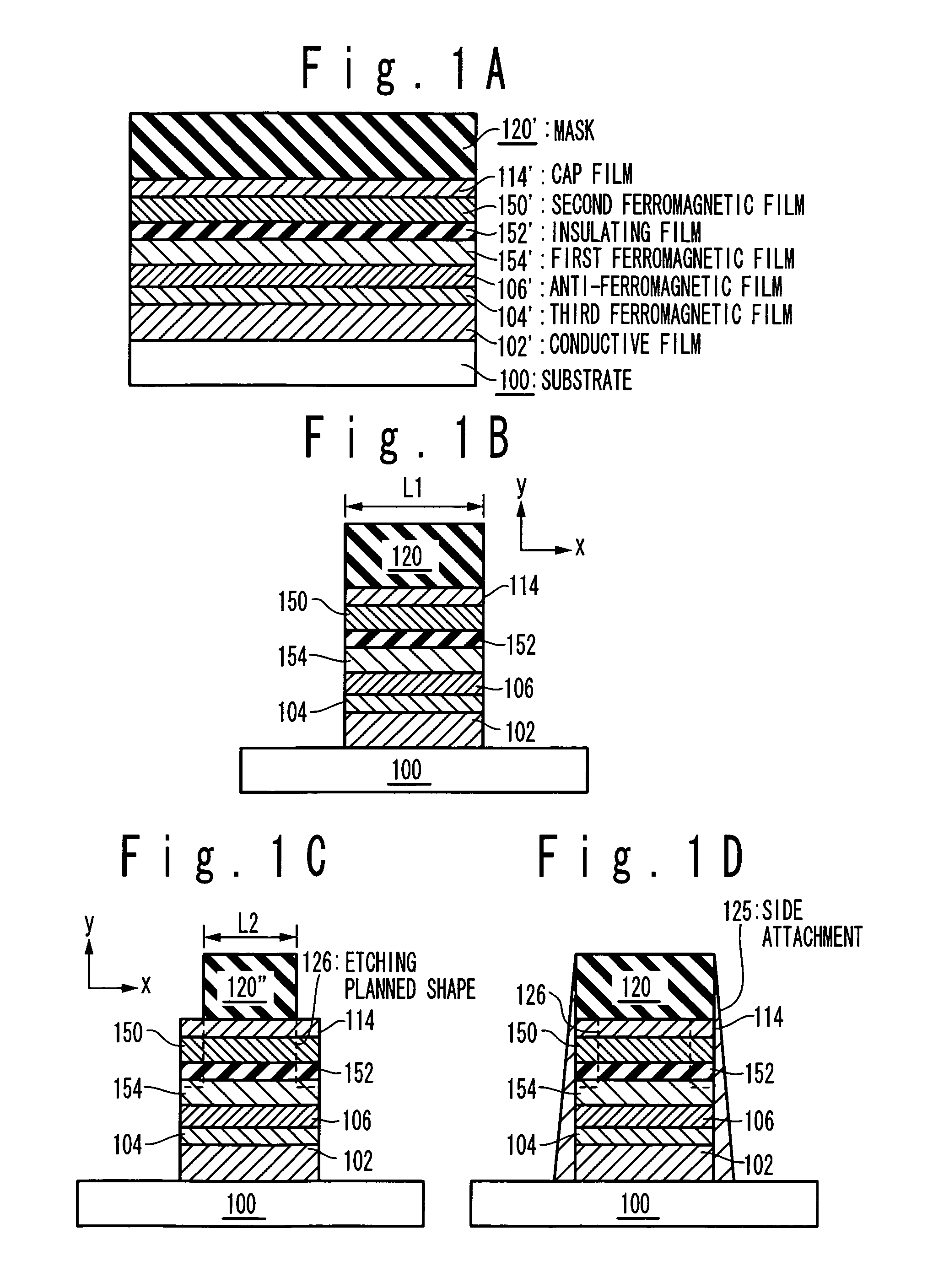

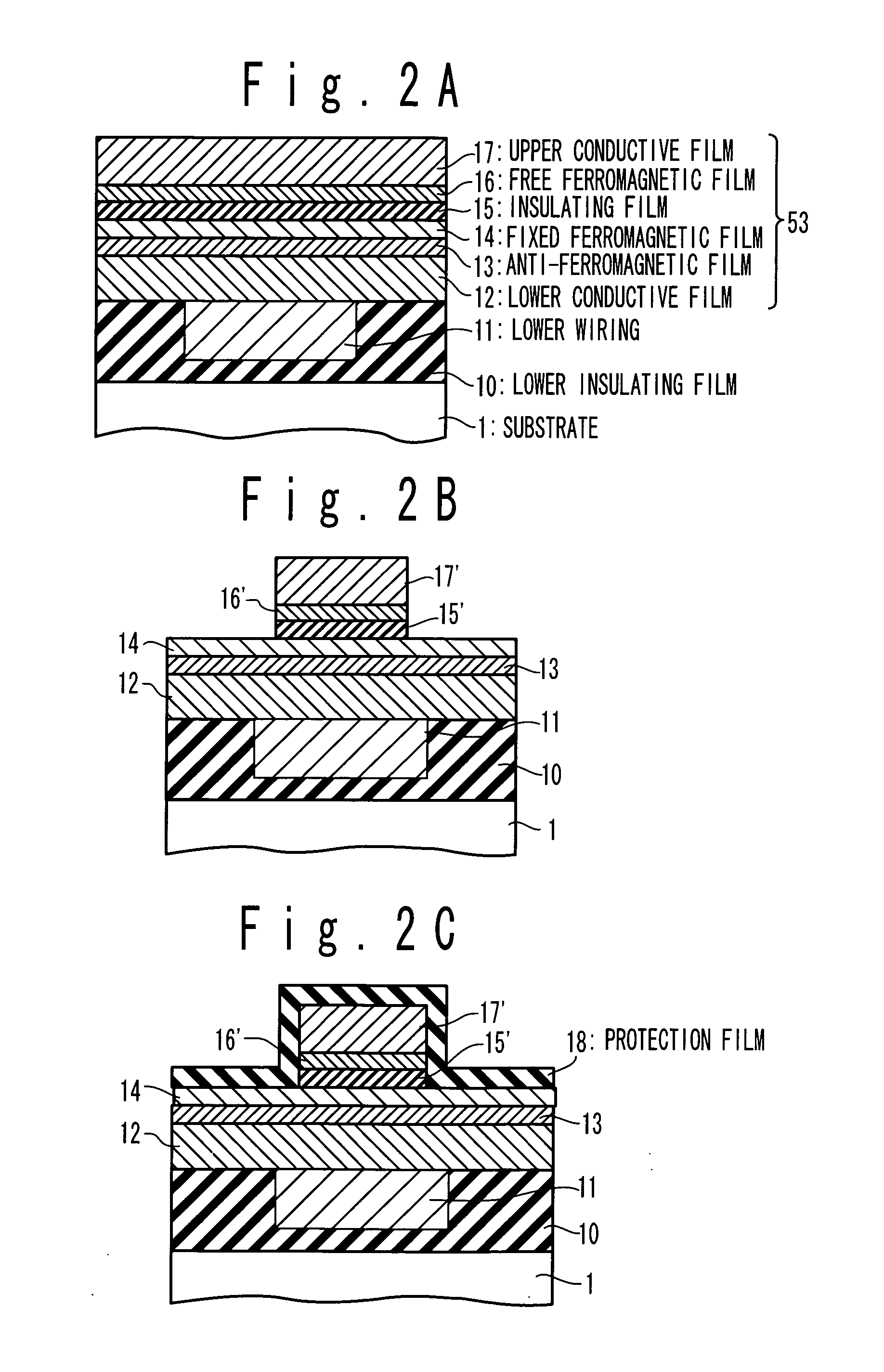

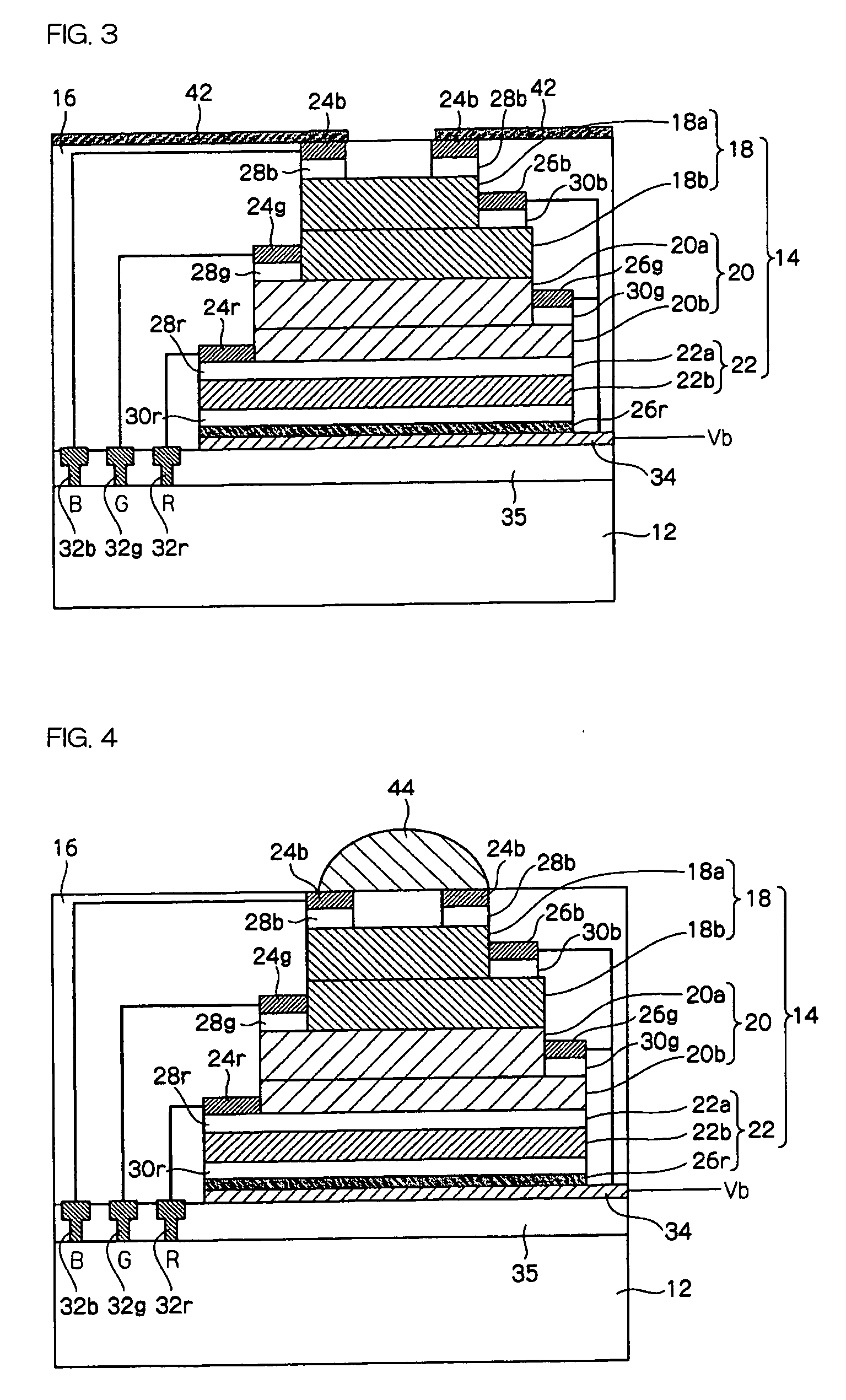

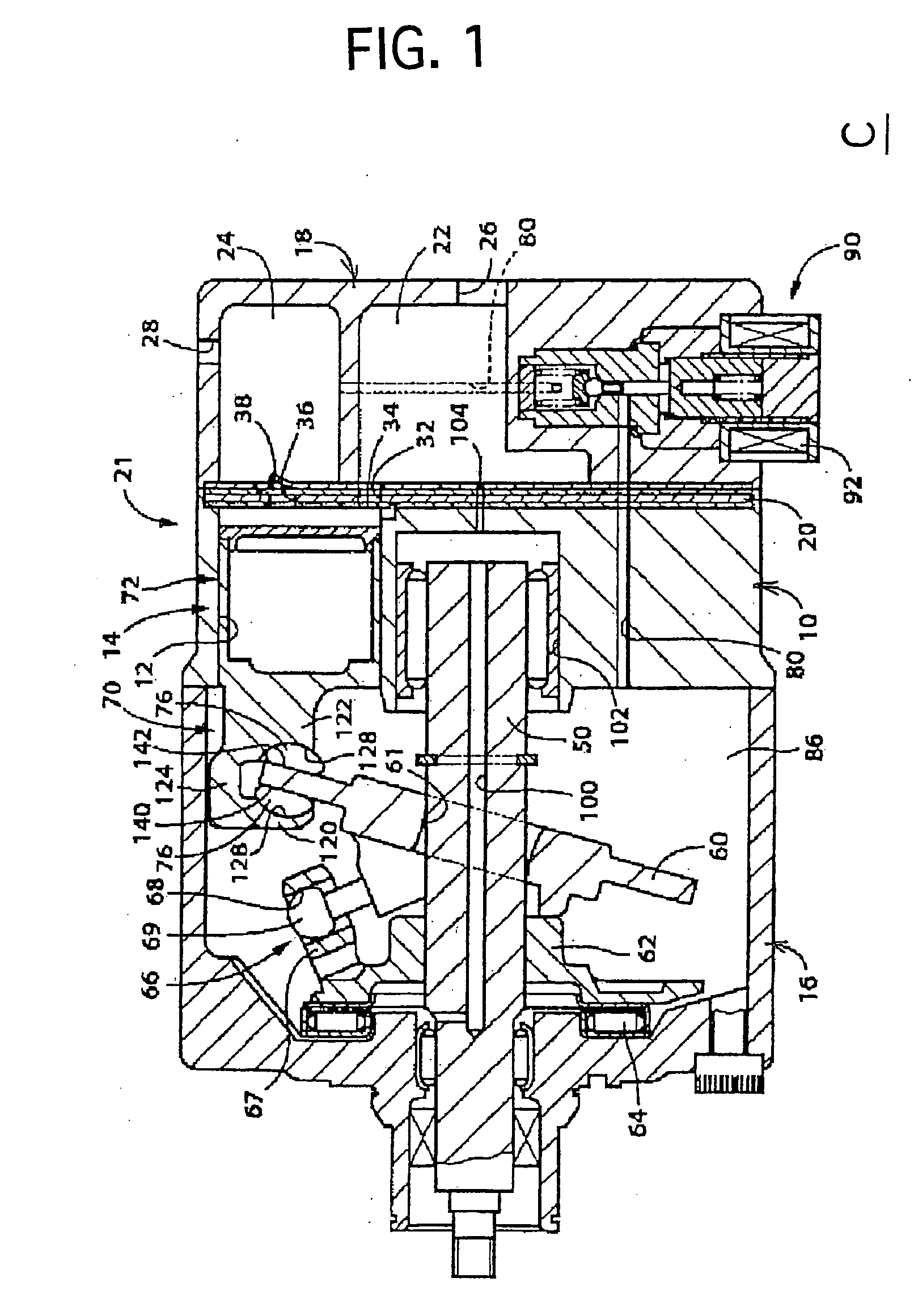

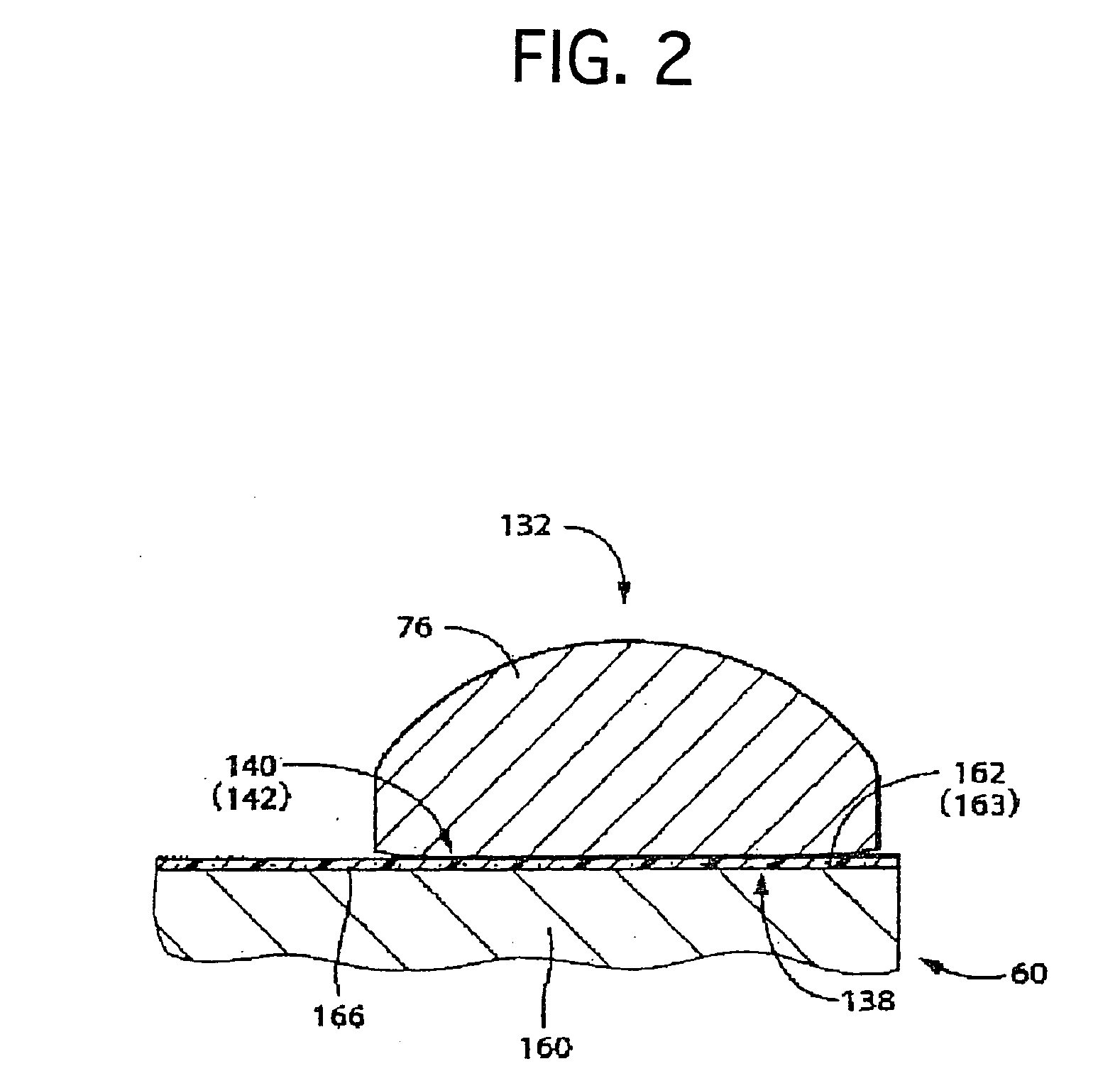

Magnetic memory and method of manufacturing the memory

InactiveUS20060261425A1High yieldAvoid it happening againMagnetic-field-controlled resistorsSolid-state devicesMagnetic memoryEngineering

A magnetic memory includes a substrate, a lower portion structure of a magnetic element, an upper portion structure of the magnetic element, and a sidewall insulating film. The lower portion structure of the magnetic element is a portion of the magnetic element provided on the upside of the substrate. The upper portion structure of the magnetic element is a remaining portion of the magnetic element provided on the upside of the lower portion structure of the magnetic element. The sidewall insulating film is provided to surround the upper portion structure of the magnetic element and is formed of an insulating material. That is, the lower portion structure of the magnetic element is formed from one layer or a plurality of layers on a side close to the substrate, among a plurality of laminated films of the magnetic element provided on the upside of the substrate. The upper portion structure of the magnetic element is formed from layers other than the lower portion structure of the magnetic element among the plurality of laminated films of the magnetic element. Also, the side of the upper portion structure of the magnetic element is electrically insulated from other portions by the sidewall insulating film. That is, it is possible to avoid a short-circuit.

Owner:NEC CORP

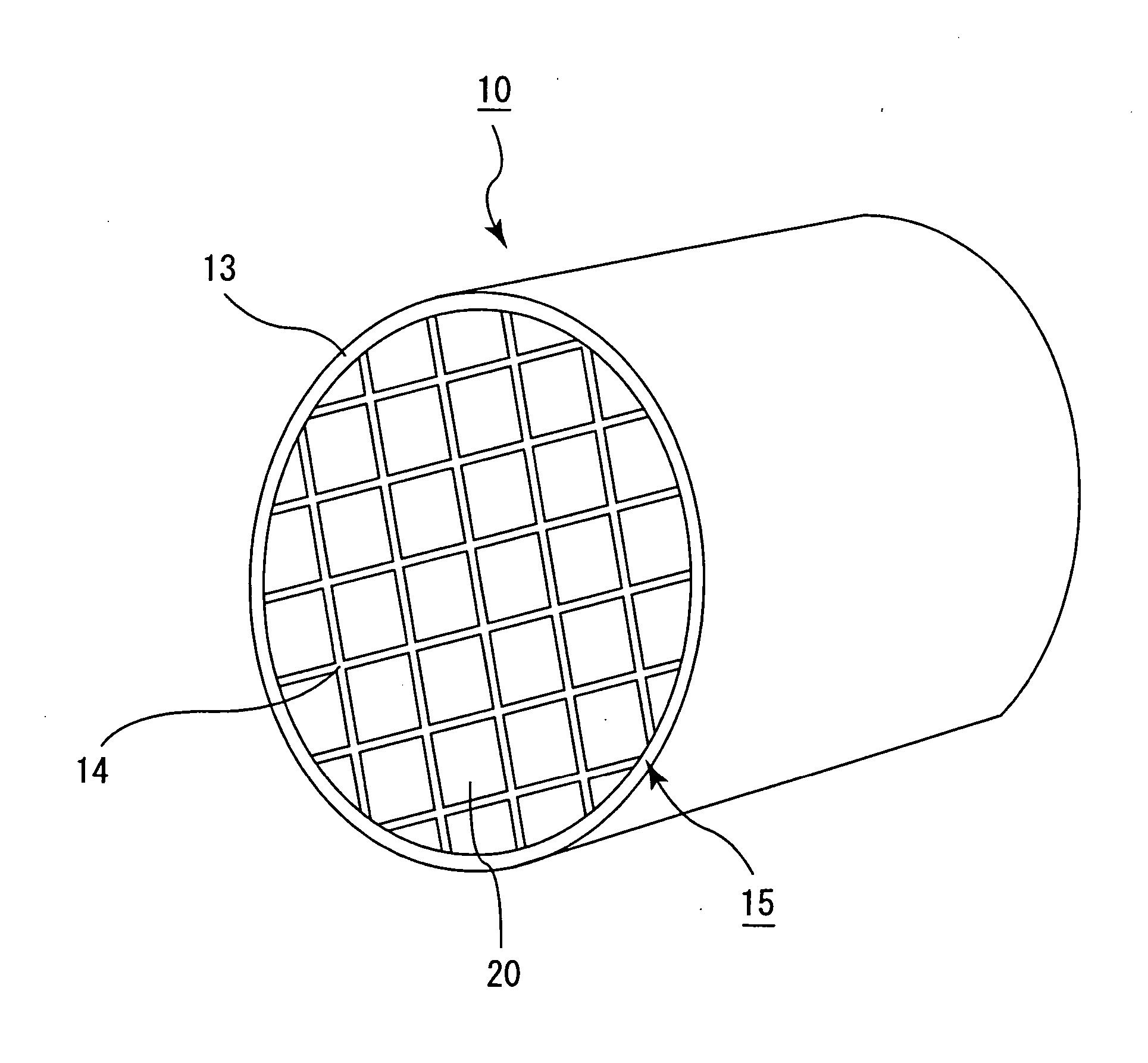

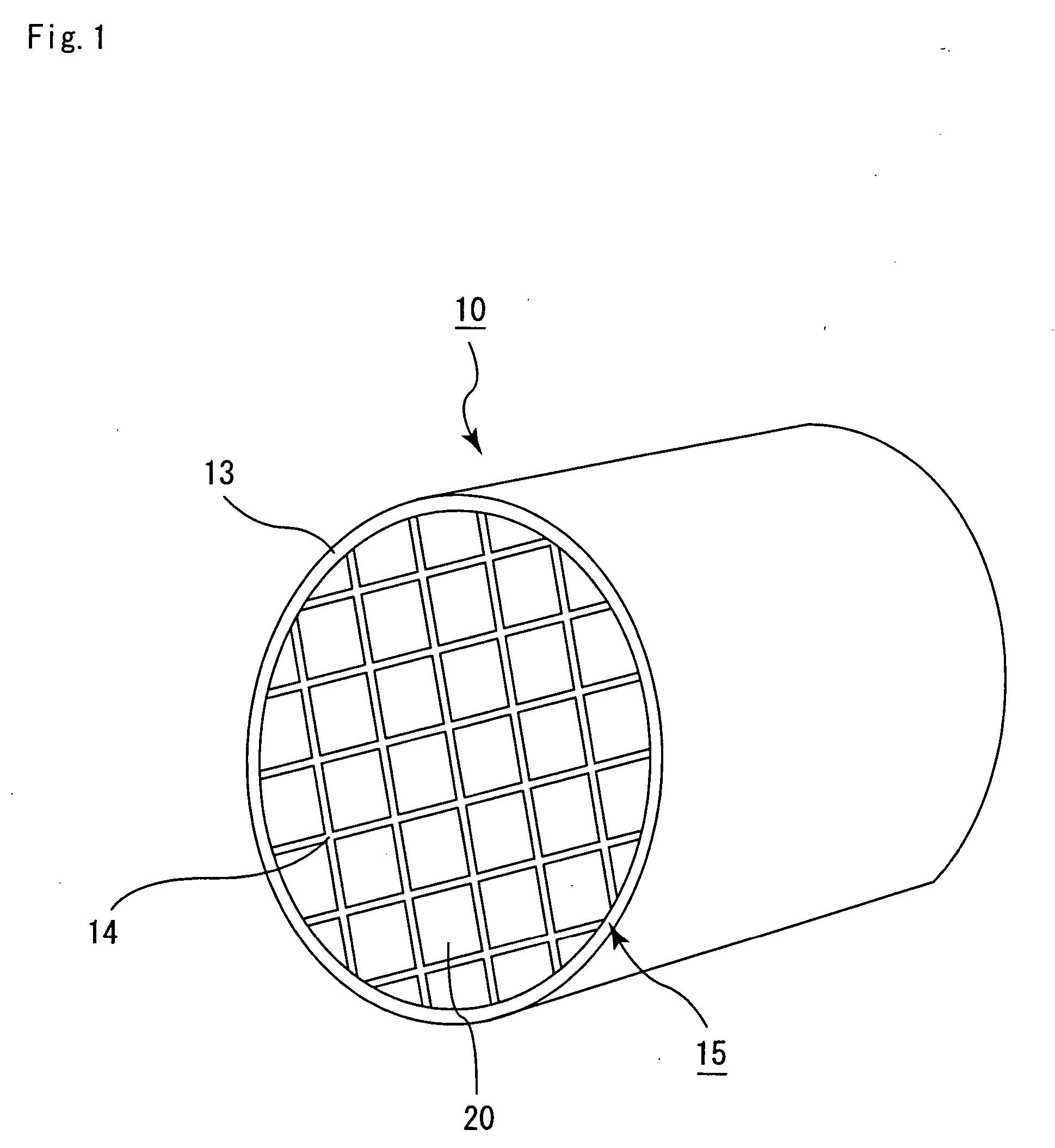

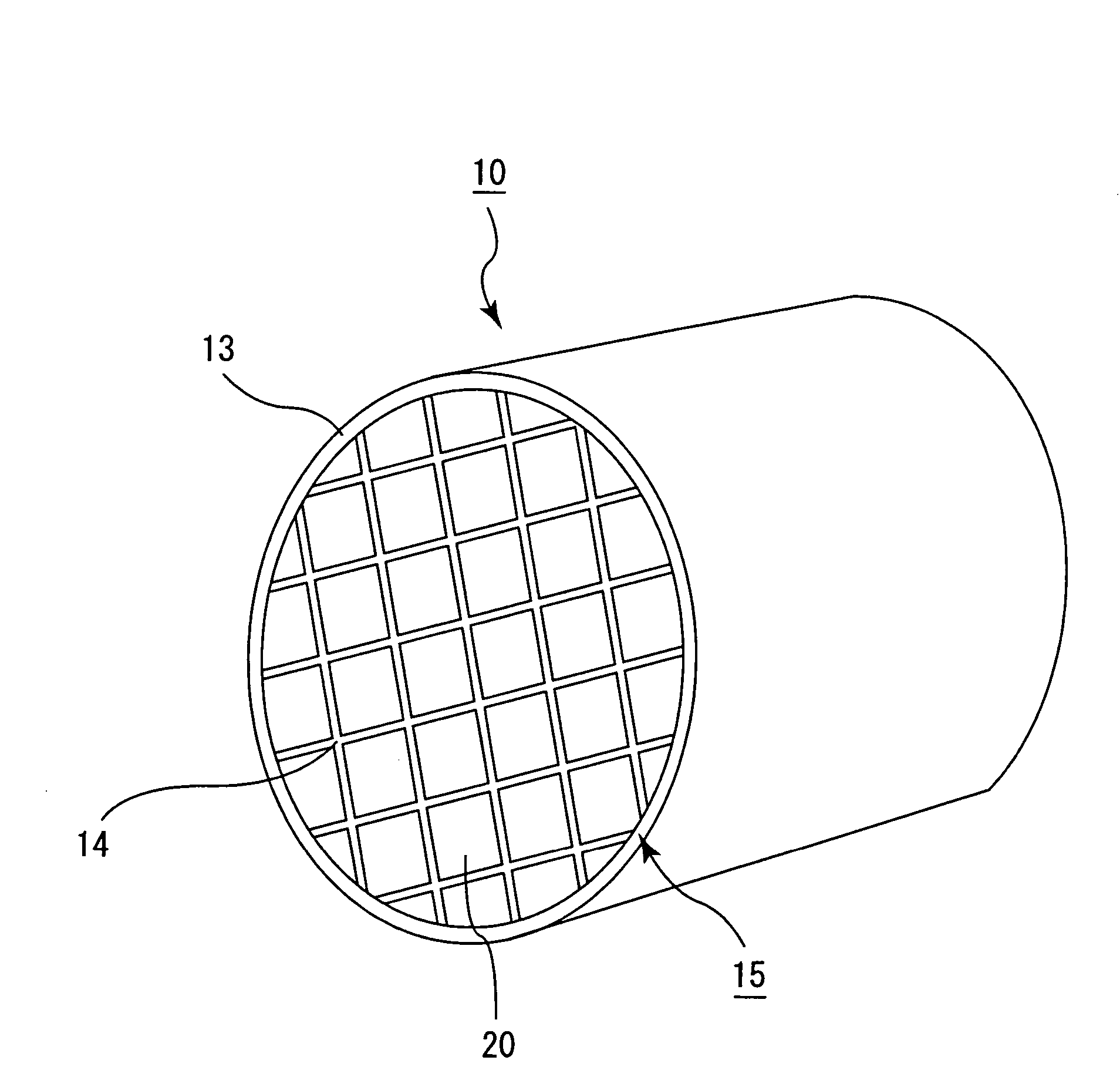

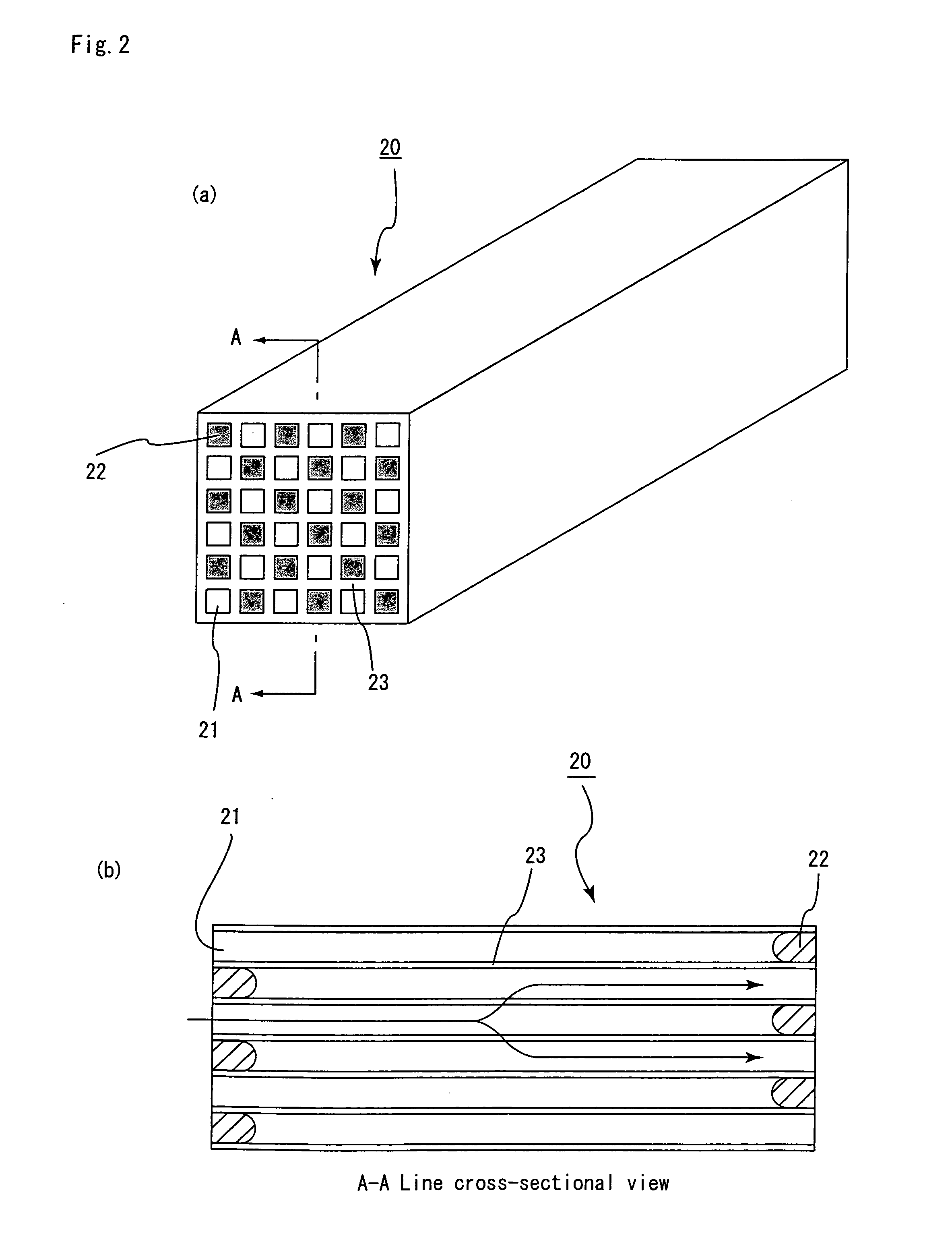

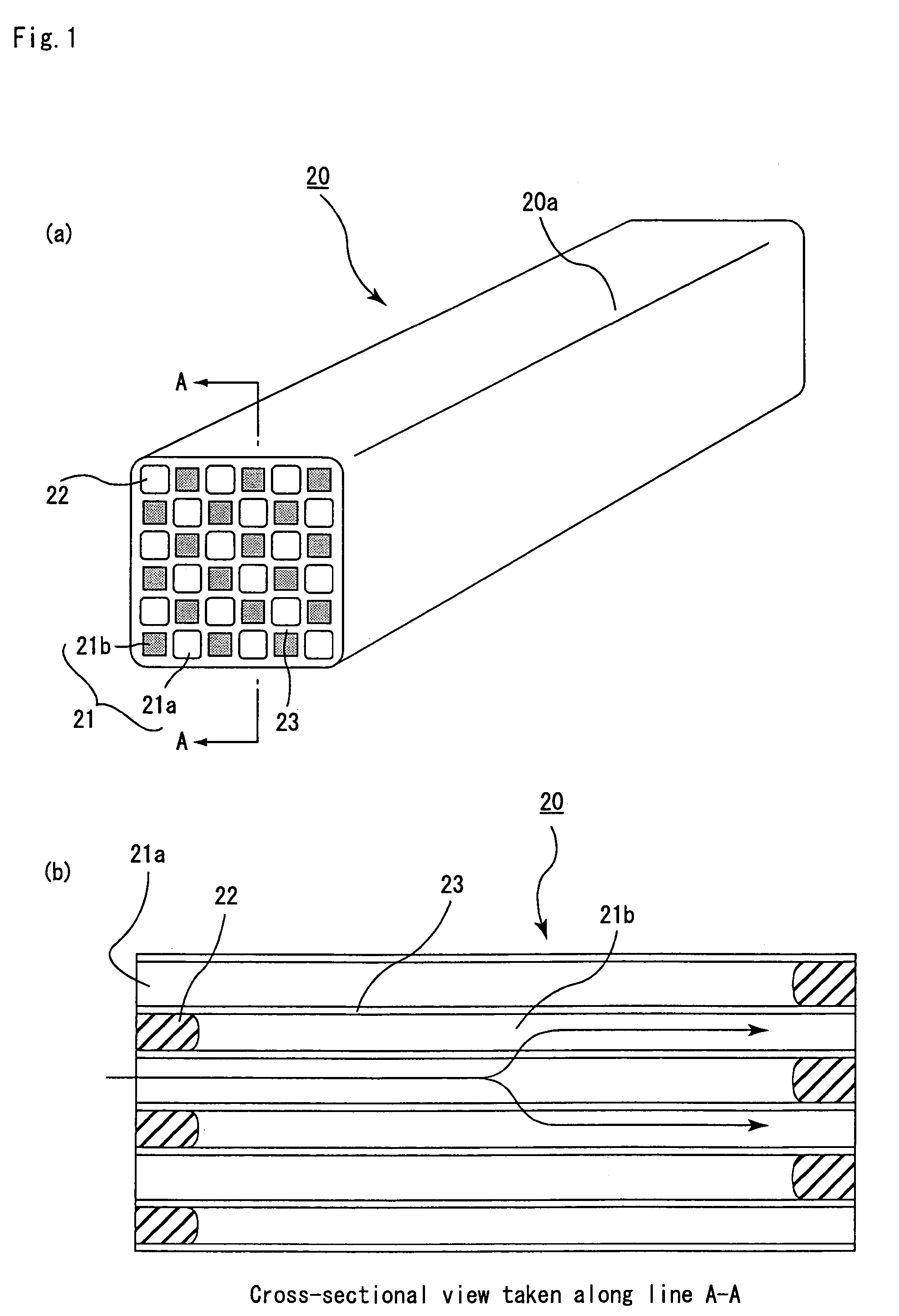

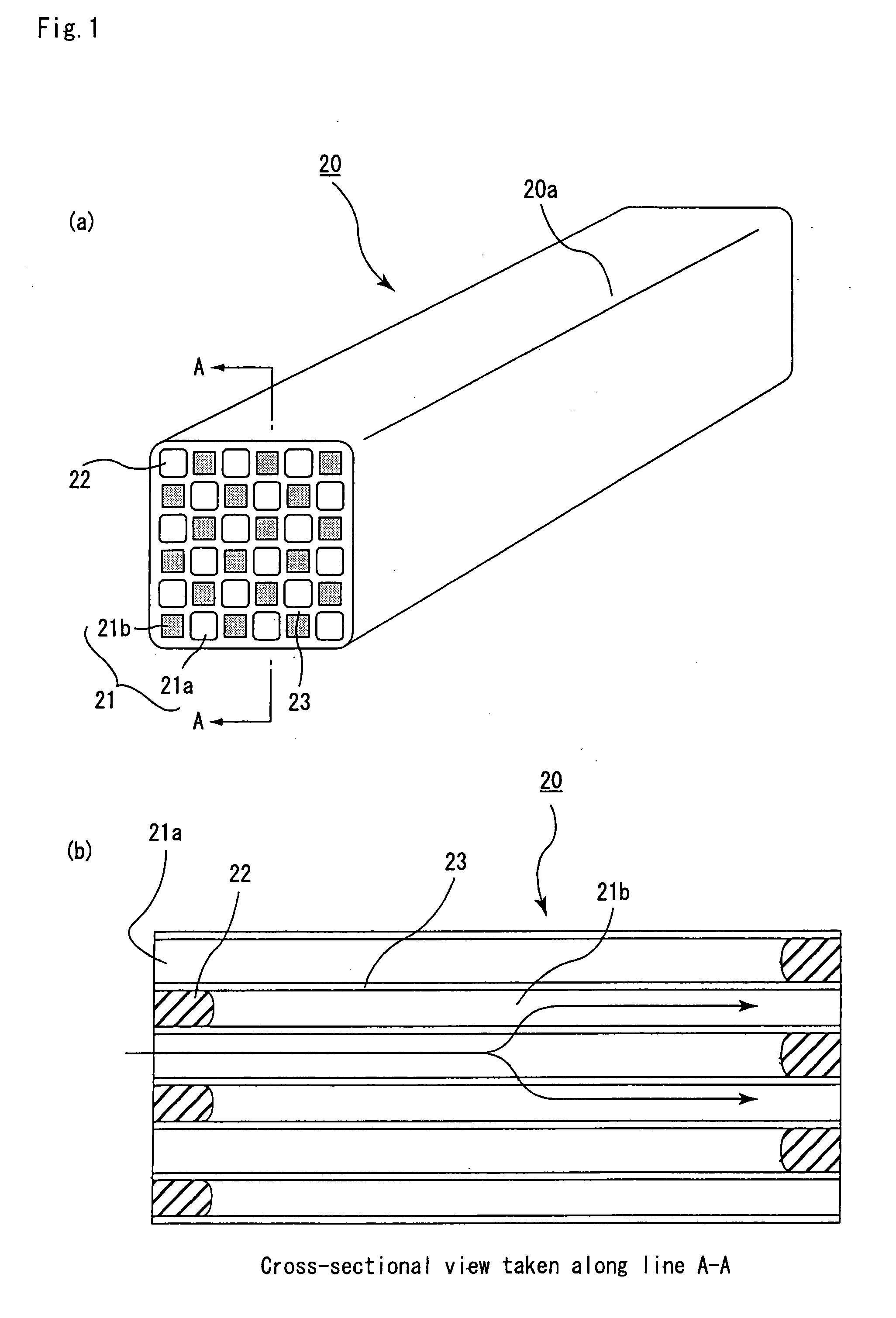

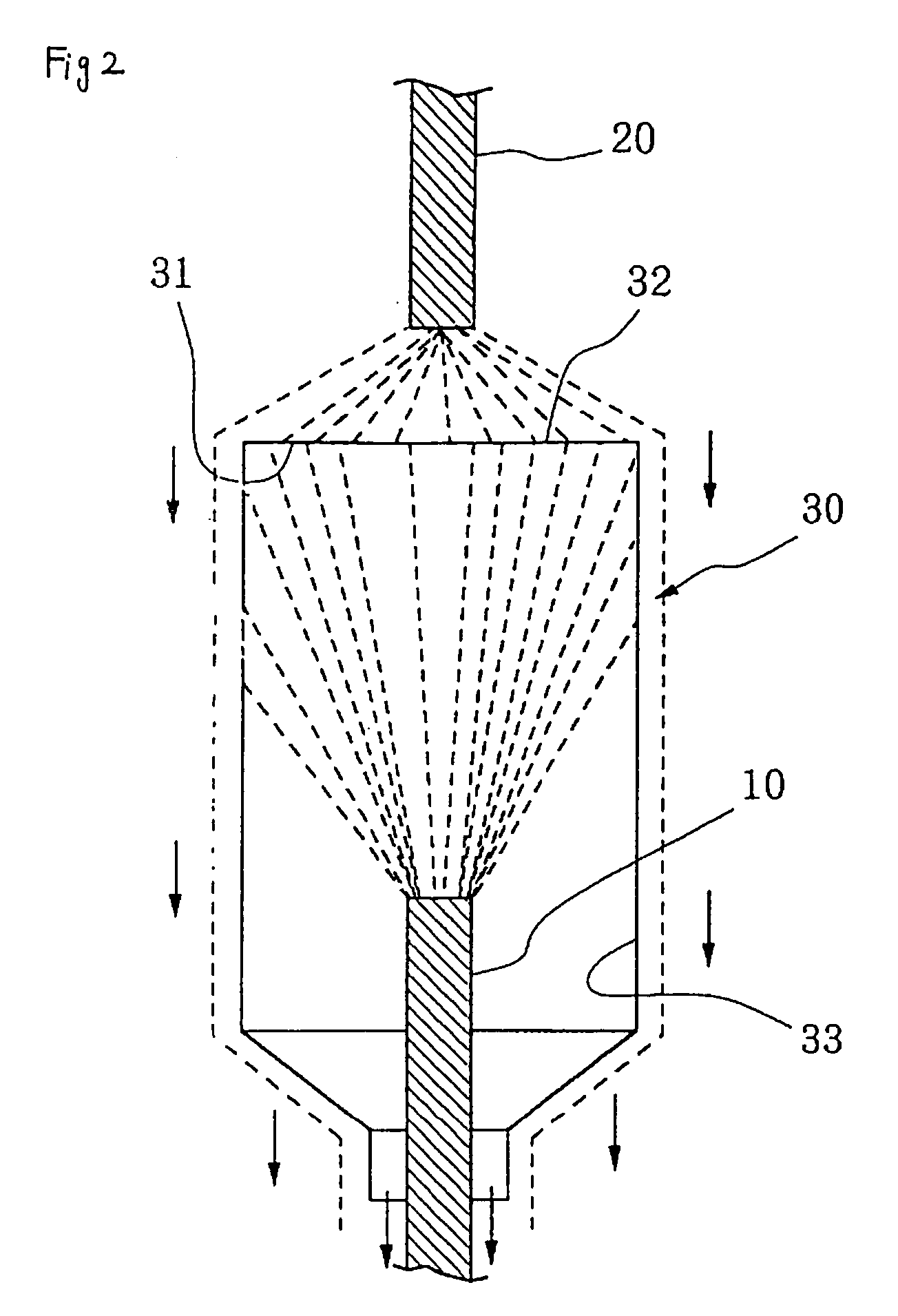

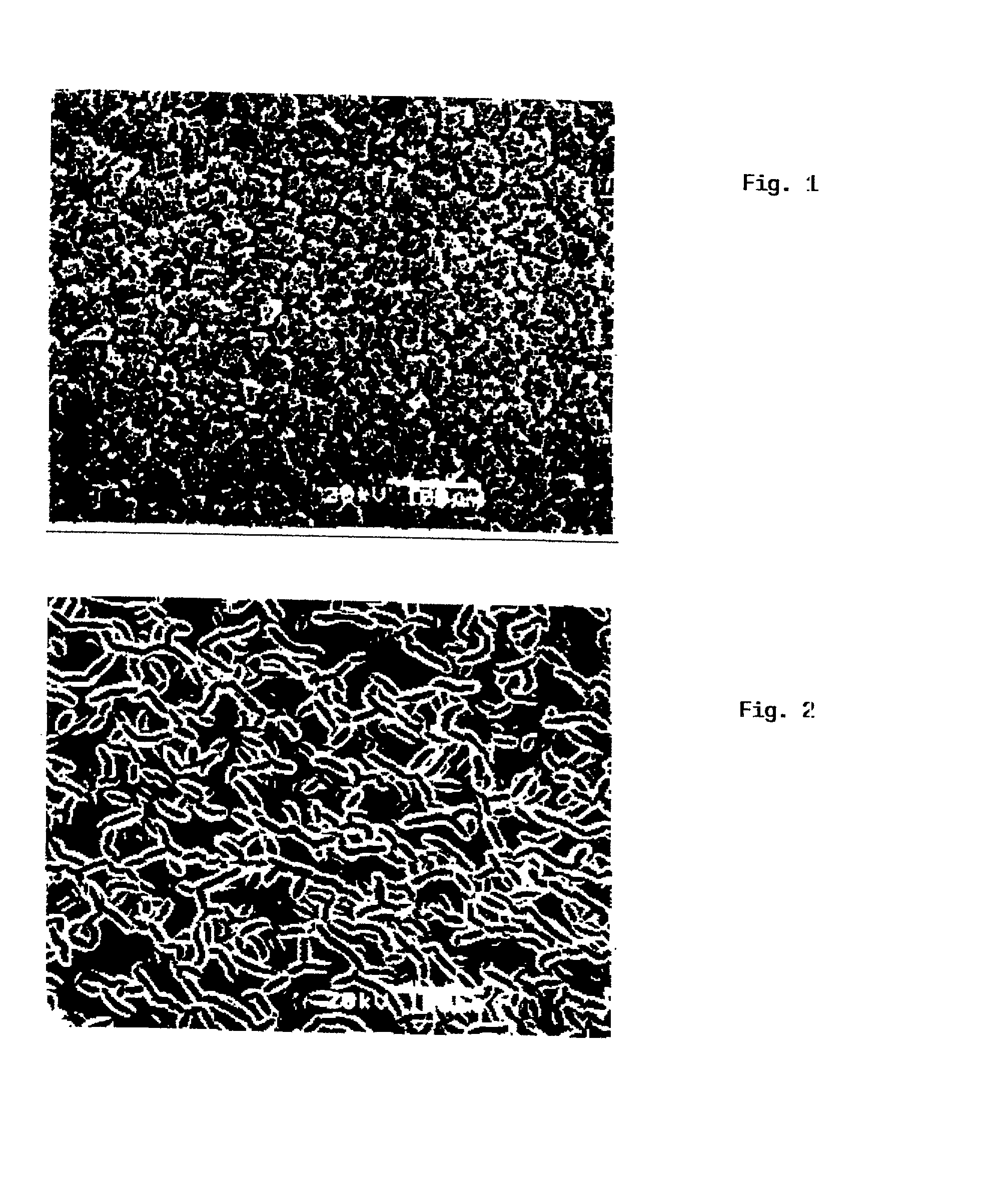

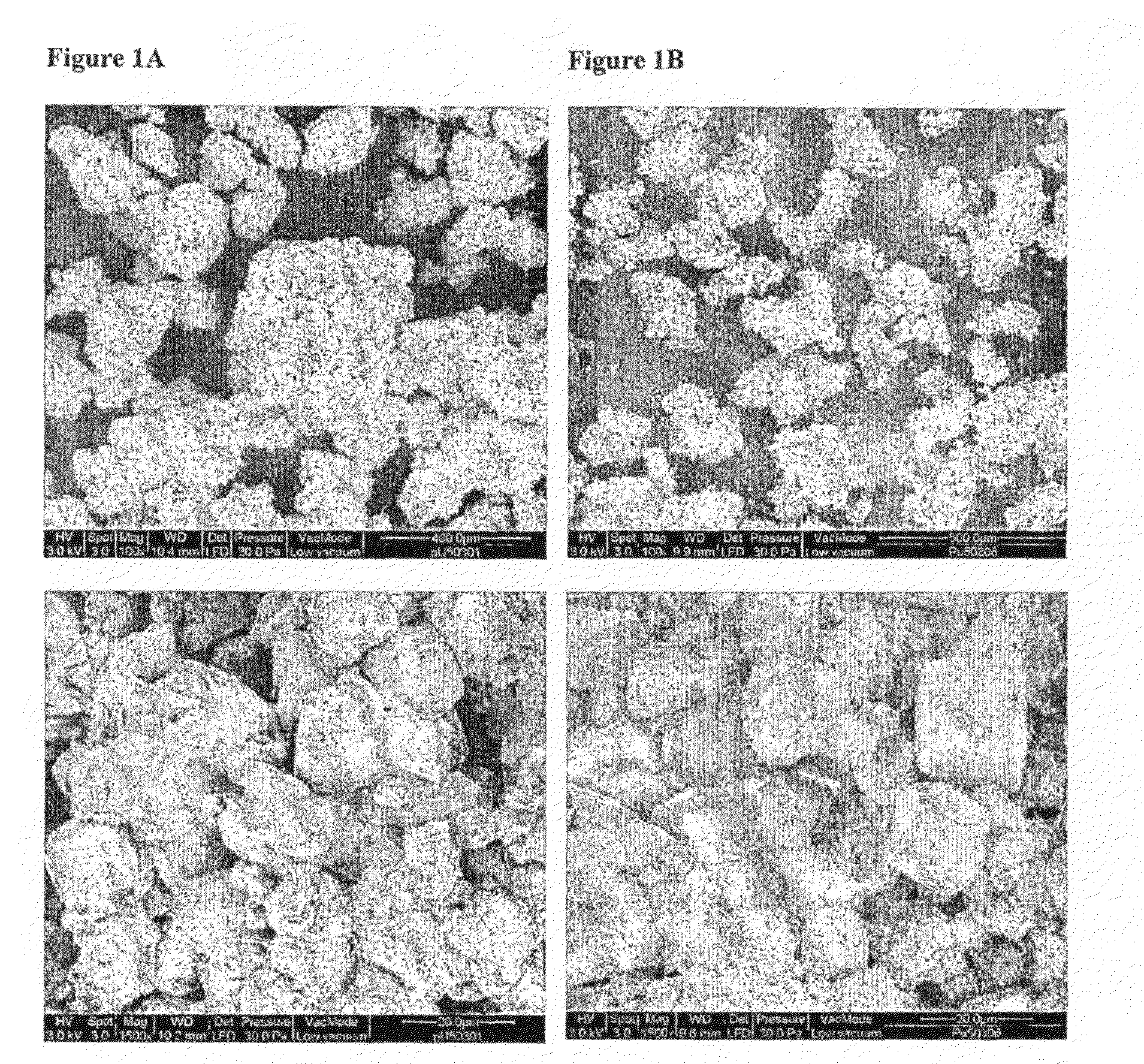

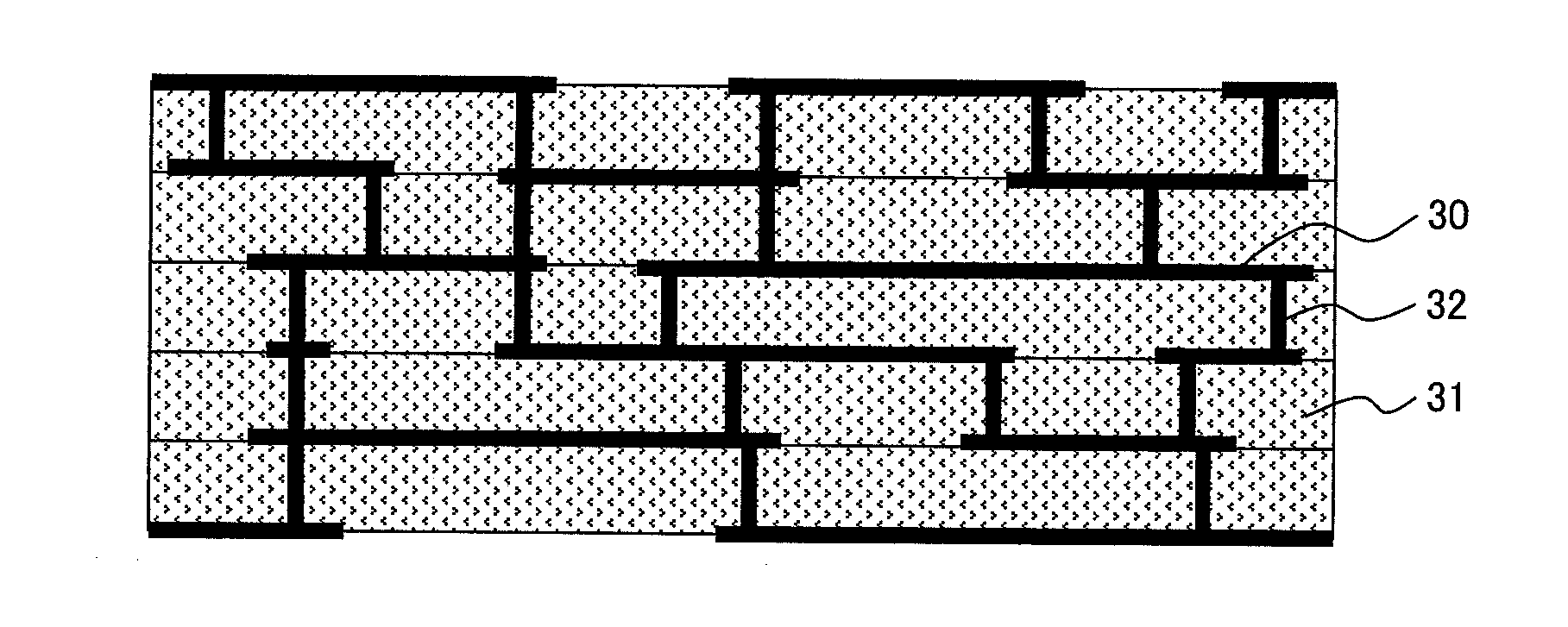

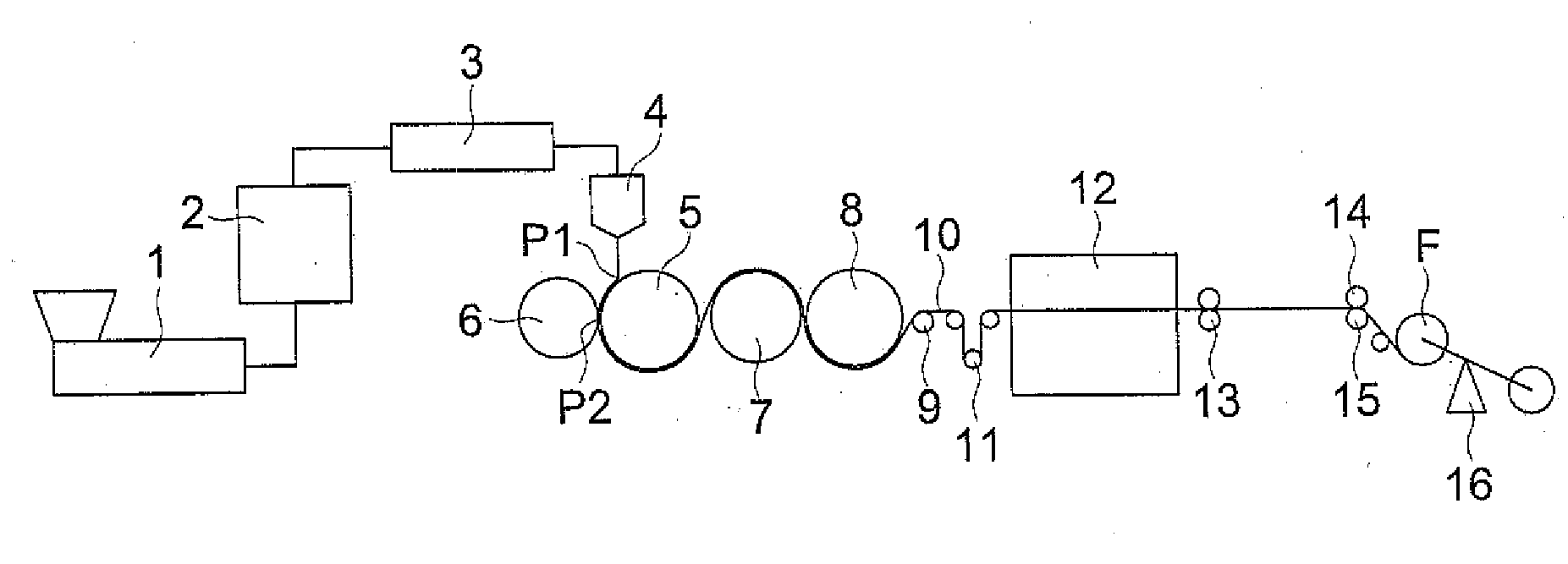

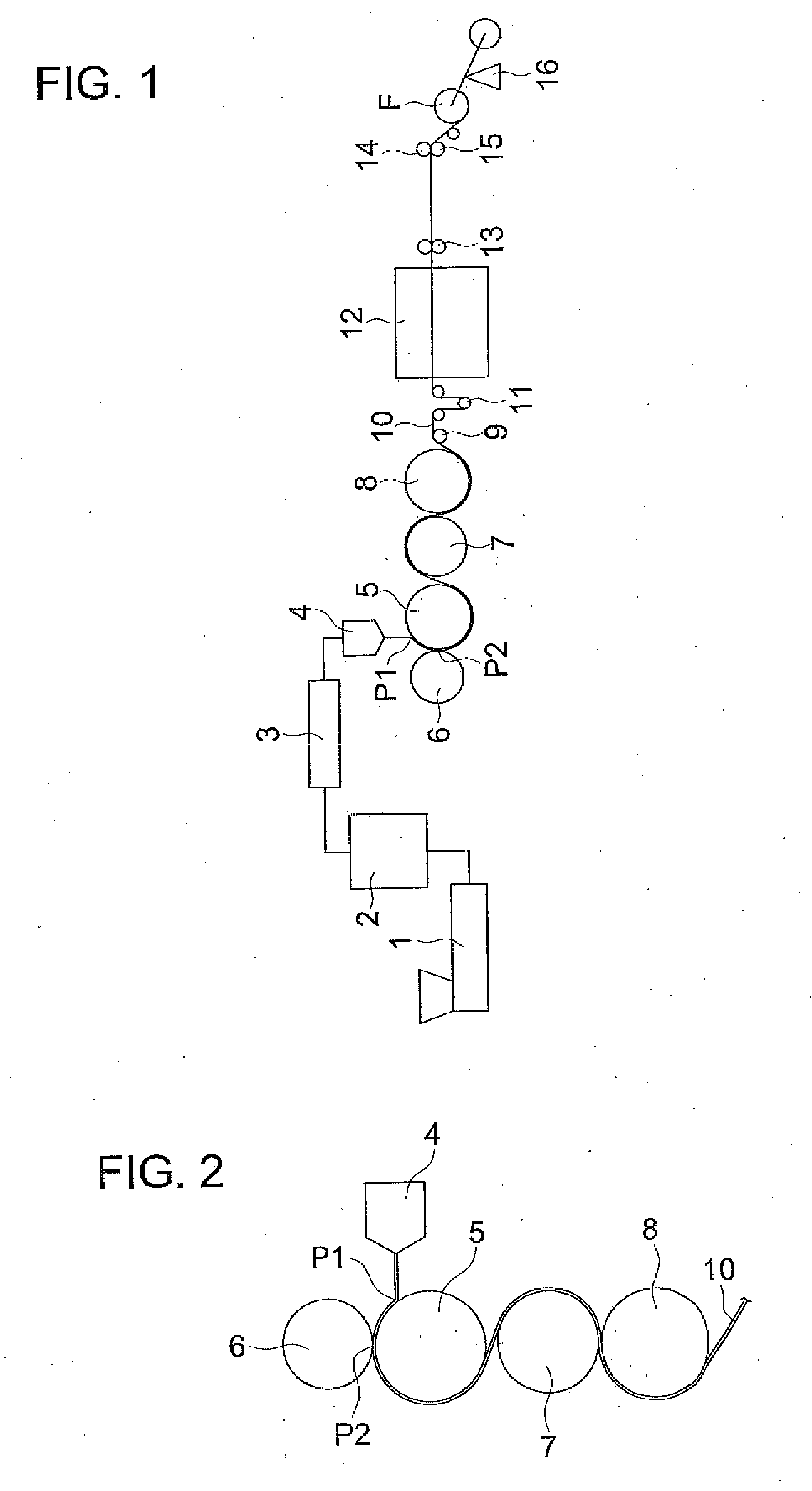

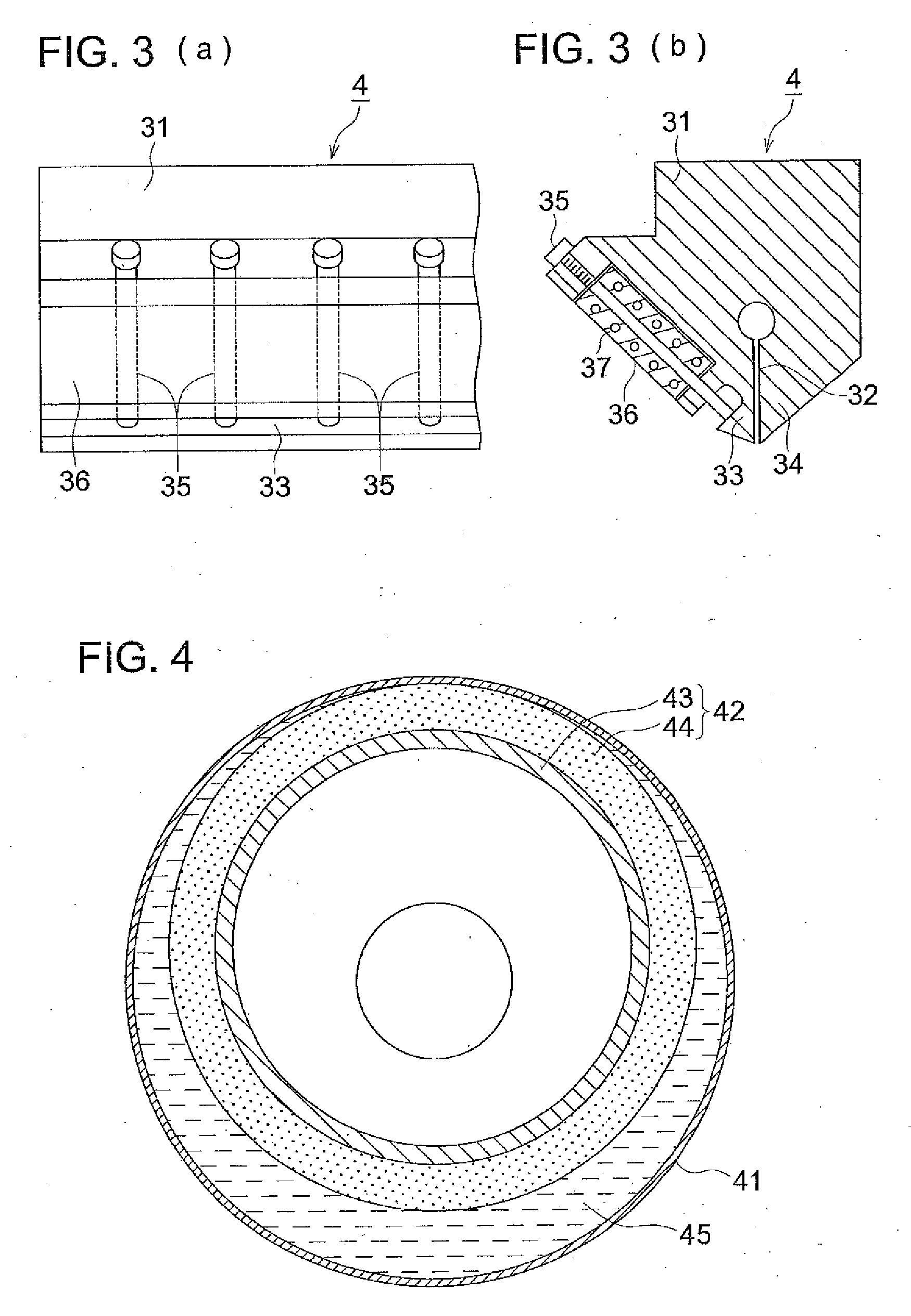

Honeycomb filter for exhaust gas decontamination

ActiveUS20050076626A1Reduce thermal stressHigh strengthCombination devicesAuxillary pretreatmentParticulatesHoneycomb

A honeycomb filter for purifying exhaust gases, which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change, is less likely to generate cracks, and is excellent in strength and durability. The honeycomb filter has a structure in which a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with a partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separates the through holes are allowed to function as a filter for collecting particulates. A thermal expansion coefficient αL of the adhesive layer and a thermal expansion coefficient αF of the porous ceramic member is as follows: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

Honeycomb filter for exhaust gas decontamination

ActiveUS7309370B2High strengthIncreased durabilityCombination devicesAuxillary pretreatmentParticulatesHoneycomb

A honeycomb filter for purifying exhaust gases, which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change, is less likely to generate cracks, and is excellent in strength and durability. The honeycomb filter has a structure in which a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with a partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separates the through holes are allowed to function as a filter for collecting particulates. A thermal expansion coefficient αL of the adhesive layer and a thermal expansion coefficient αF of the porous ceramic member is as follows:0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

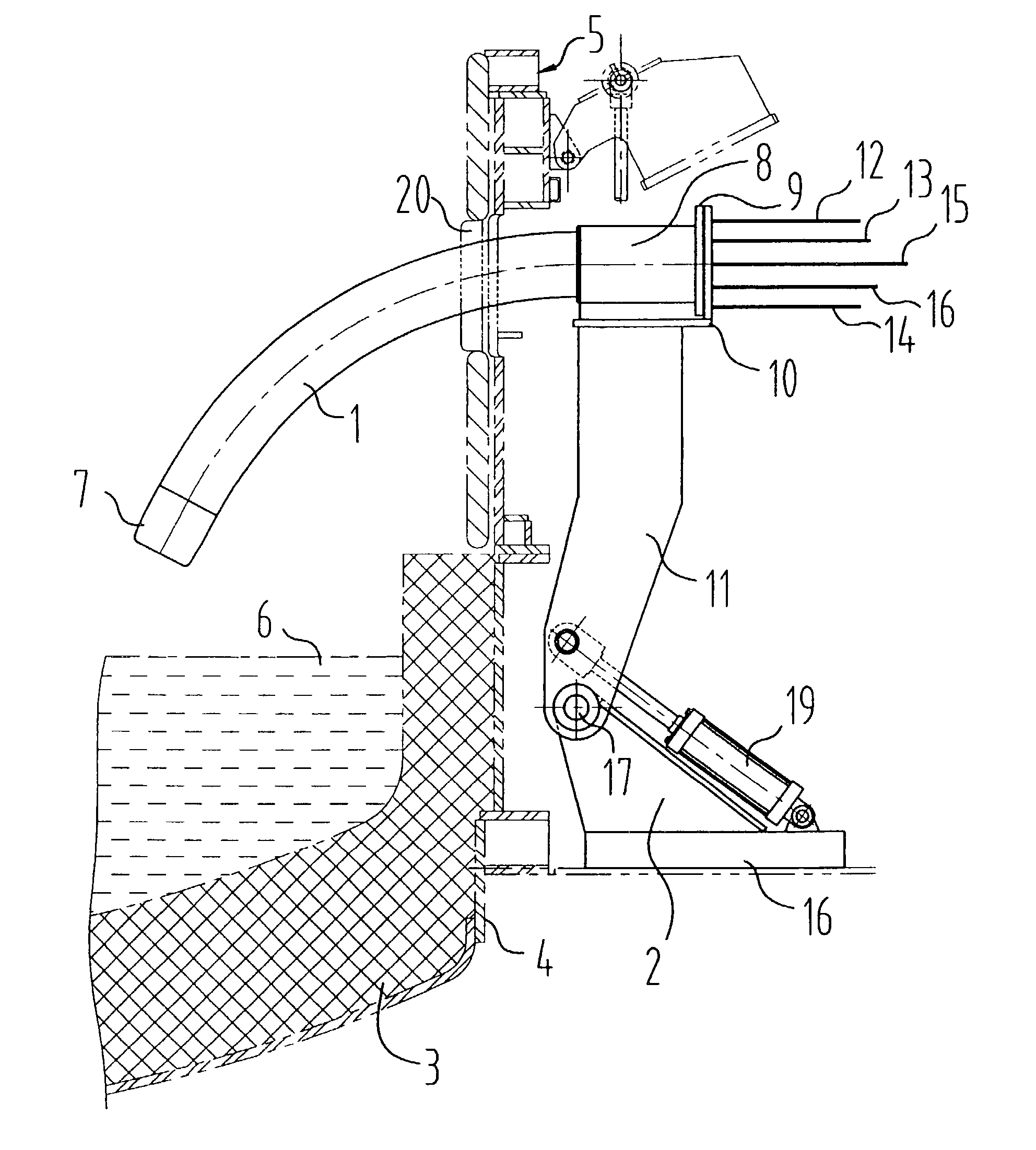

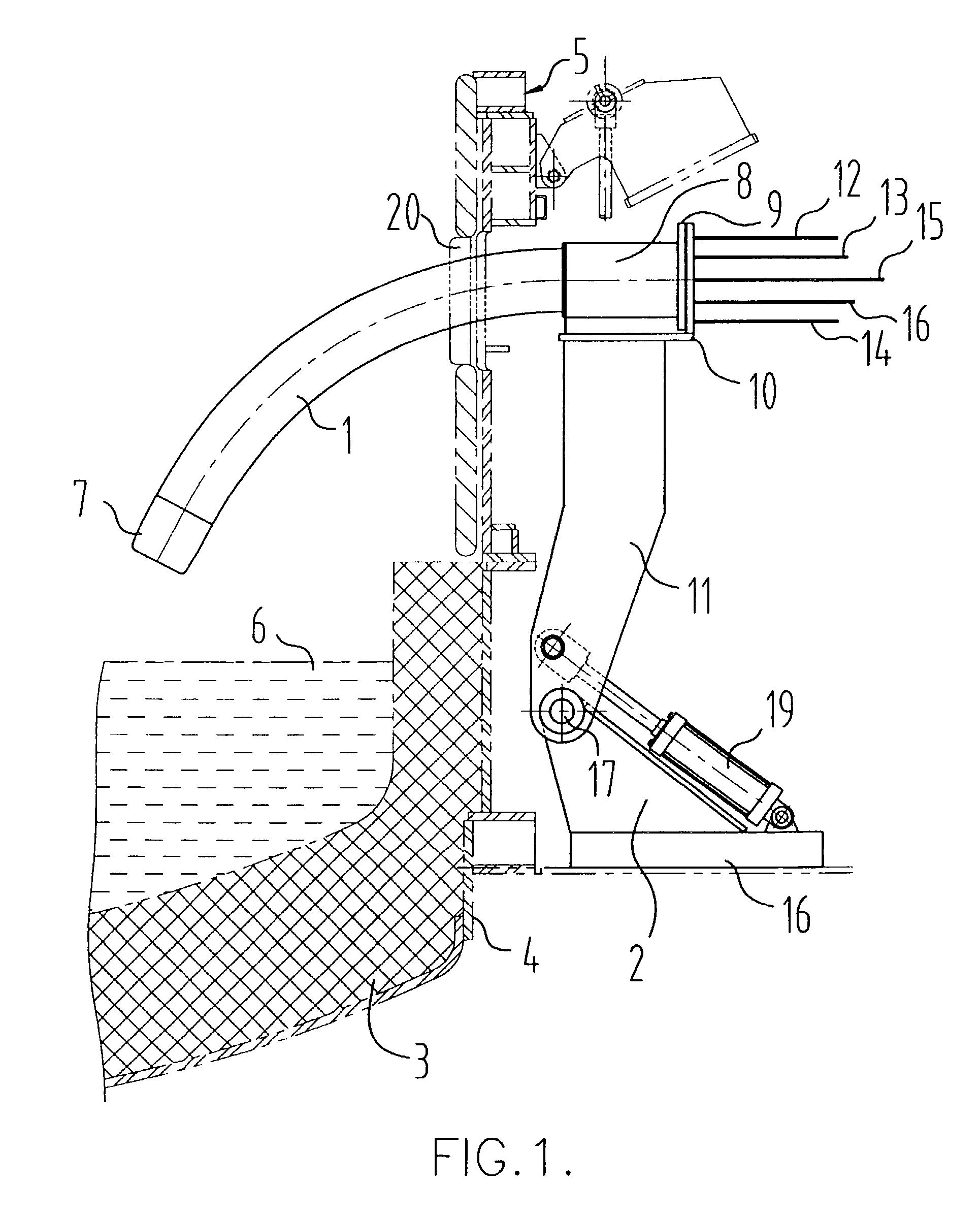

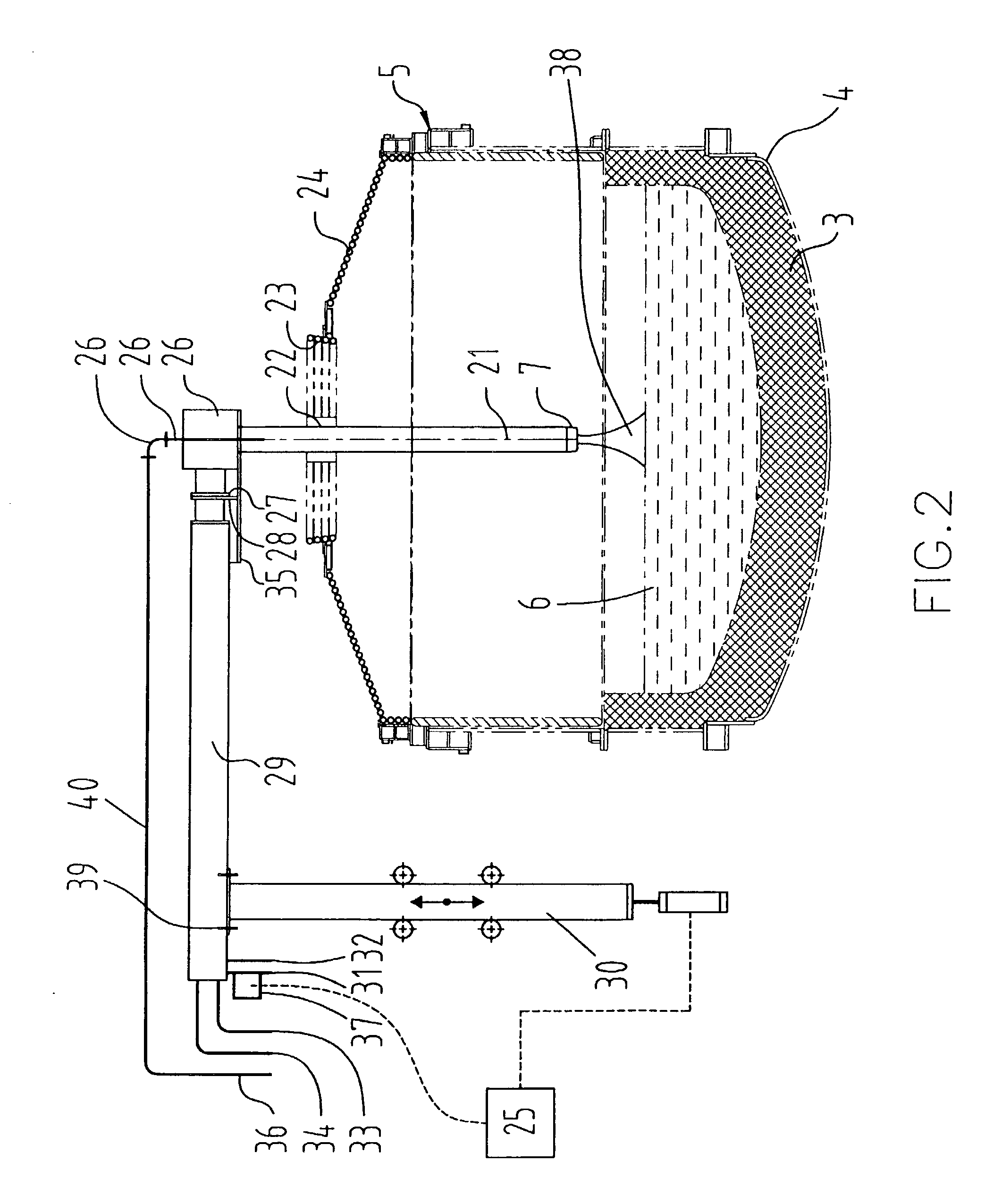

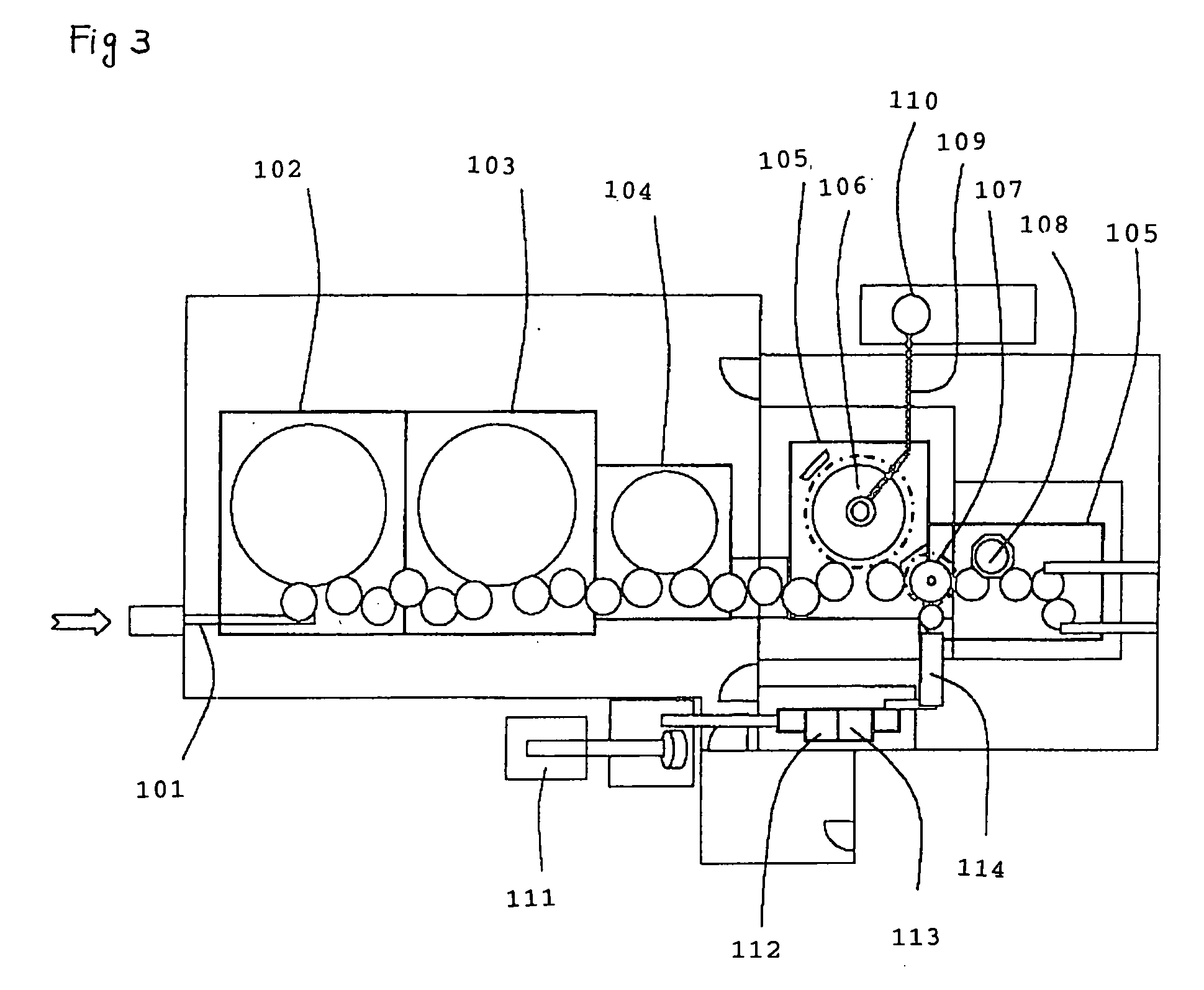

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

Cylinder cutoff control apparatus of internal combustion engine

A cylinder cutoff control apparatus of an engine initiates a cylinder cutoff mode only when two conditions, namely a low load condition such as a vehicle cruising condition and an intake valve closure timing controlled to a given timing value before a bottom dead center, are both satisfied. A fuel cutoff mode is executed prior to the cylinder cutoff mode. During a transition to the cylinder cutoff mode, the control apparatus holds an intake valve open timing at a given timing value substantially corresponding to a top dead center, simultaneously with reducing an intake valve lift amount of each intake valve, subjected to cylinder cutoff control, to a zero lift. Immediately when the intake valve lift amount is reduced to below a lift threshold value, an exhaust valve lift amount of each exhaust valve, subjected to the cylinder cutoff control, is controlled to a zero lift.

Owner:HITACHI LTD

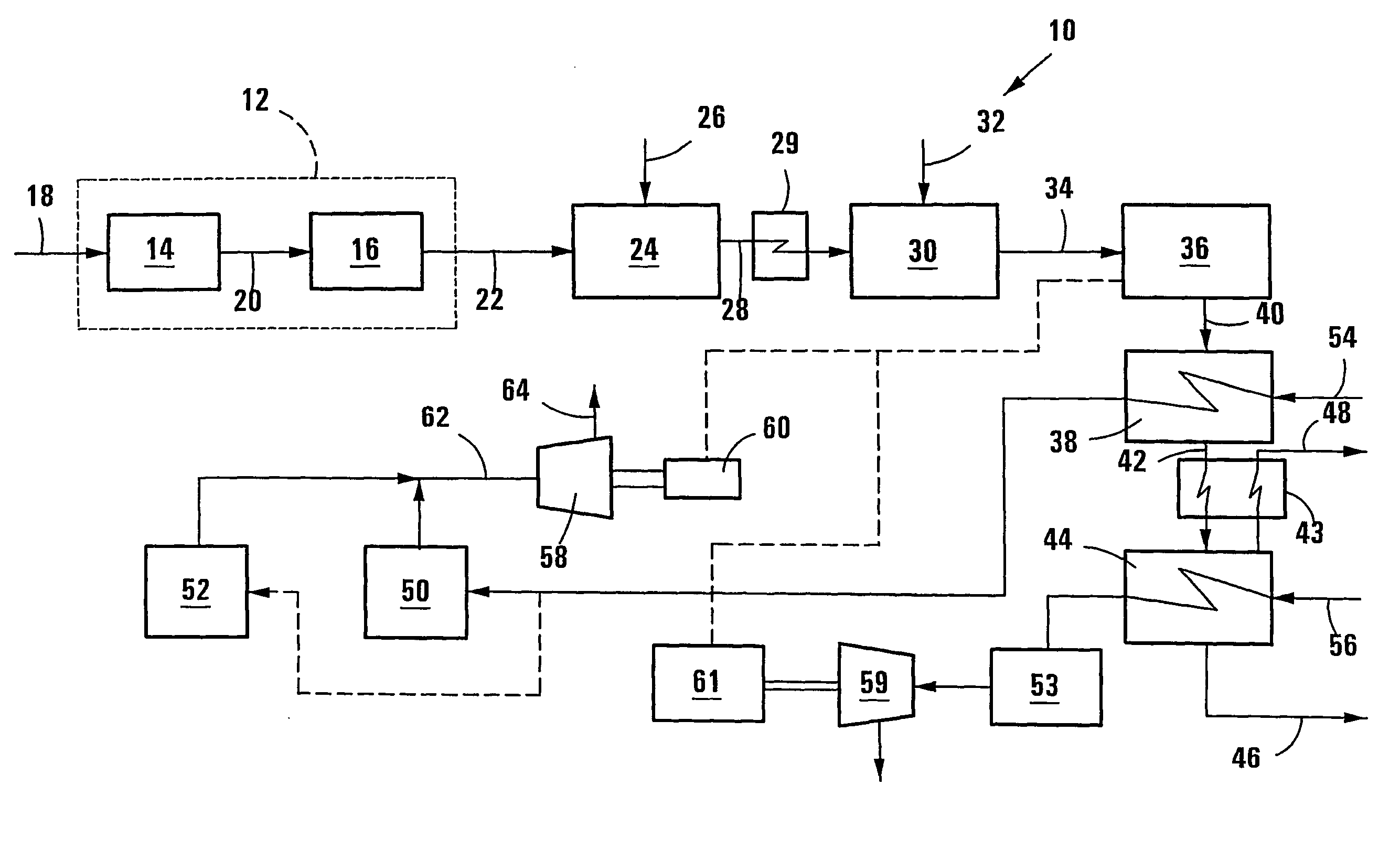

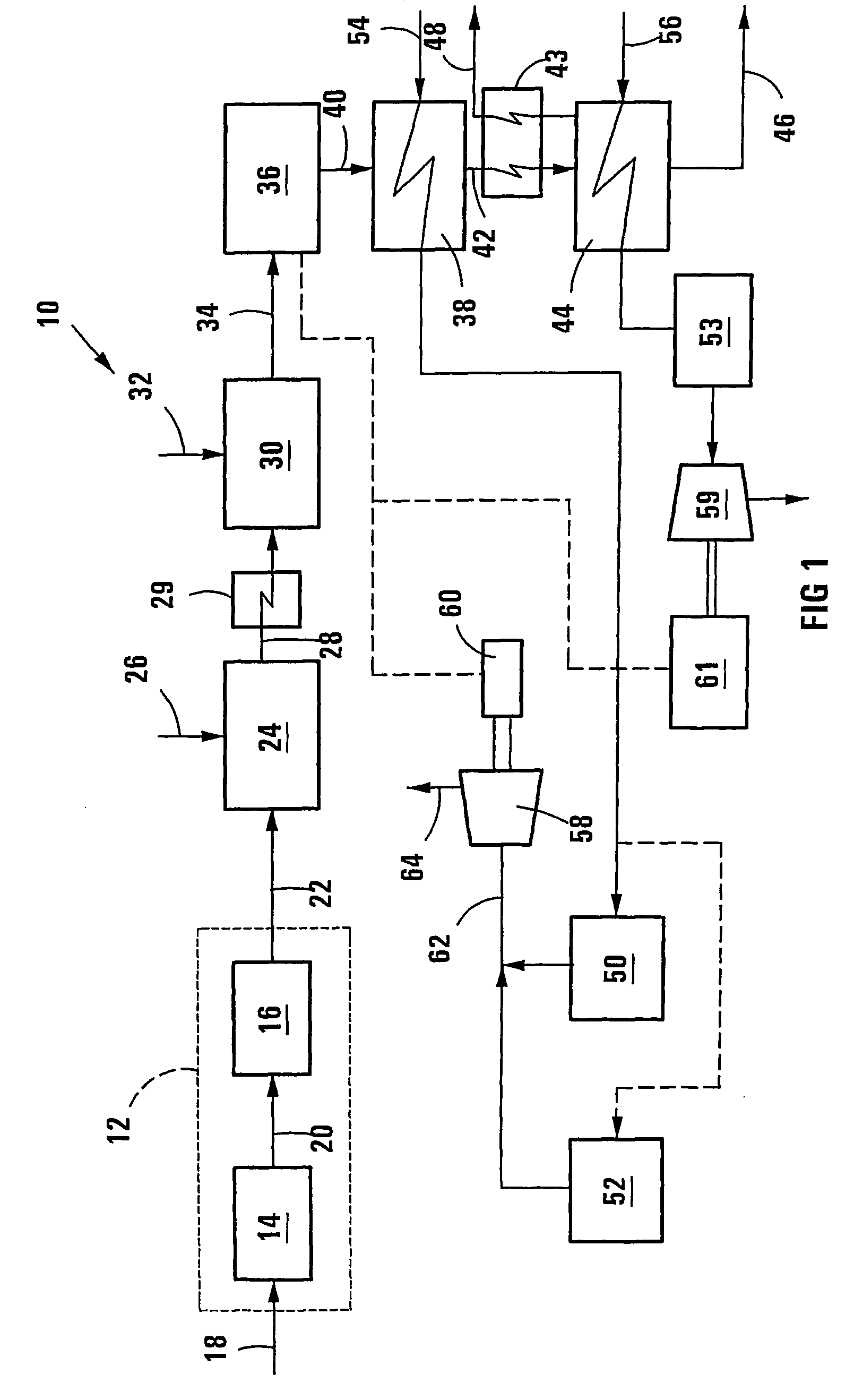

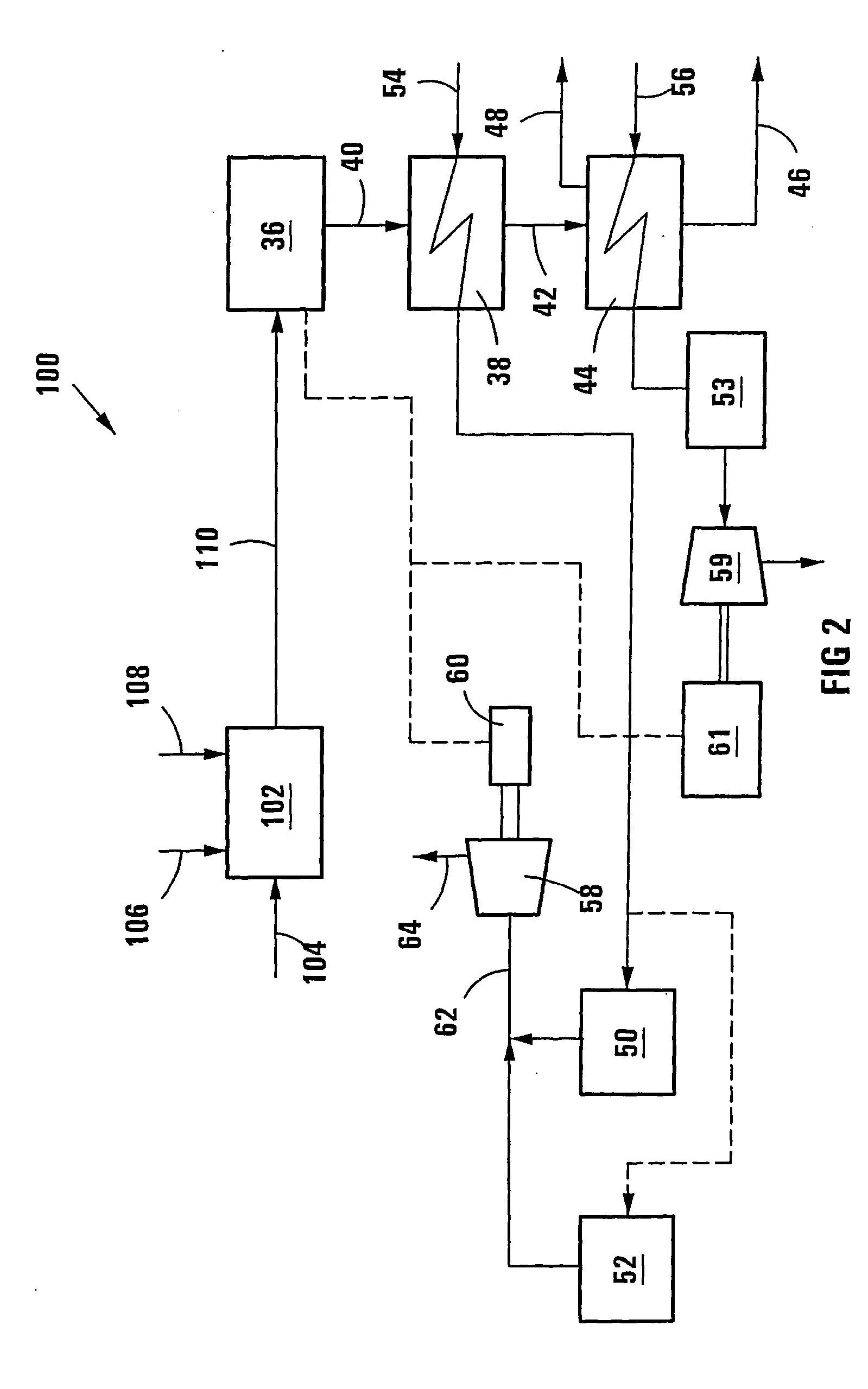

Production of synthesis gas and synthesis gas derived products

A process for upgrading raw synthesis gas comprising at least CH4, CO2, CO and H2, includes heating the raw synthesis gas by addition of energy derived from electricity to provide an upgraded synthesis gas comprising less CH4 and CO2 and more CO and H2 than the raw synthesis gas. The invention extends to a process for producing synthesis gas, which process includes reforming a hydrocarbonaceous gas feedstock which includes CH4 to raw synthesis gas comprising at least CH4, CO2, CO and H2, and upgrading the raw synthesis gas in a process which includes heating the raw synthesis gas by addition of energy derived from electricity to provide an upgraded synthesis gas comprising less CH4 and CO2 and more CO and H2 than the raw synthesis gas.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Pressure-sensitive adhesive tape and pressure-sensitive adhesive composition for medical adhesive tape

InactiveUS20060216523A1Good moisture permeabilityLess generationSurgical adhesivesPolyureas/polyurethane adhesivesVitrificationOligomer

An adhesive composition for medical adhesive tapes, comprising a base polymer containing a pressure-sensitive adhesive polymer obtained by crosslinking or curing a precursor containing a urethane acrylate oligomer and an ultraviolet (UV) initiator, the base polymer having a glass transition temperature (Tg) of 0° C. or less.

Owner:3M INNOVATIVE PROPERTIES CO

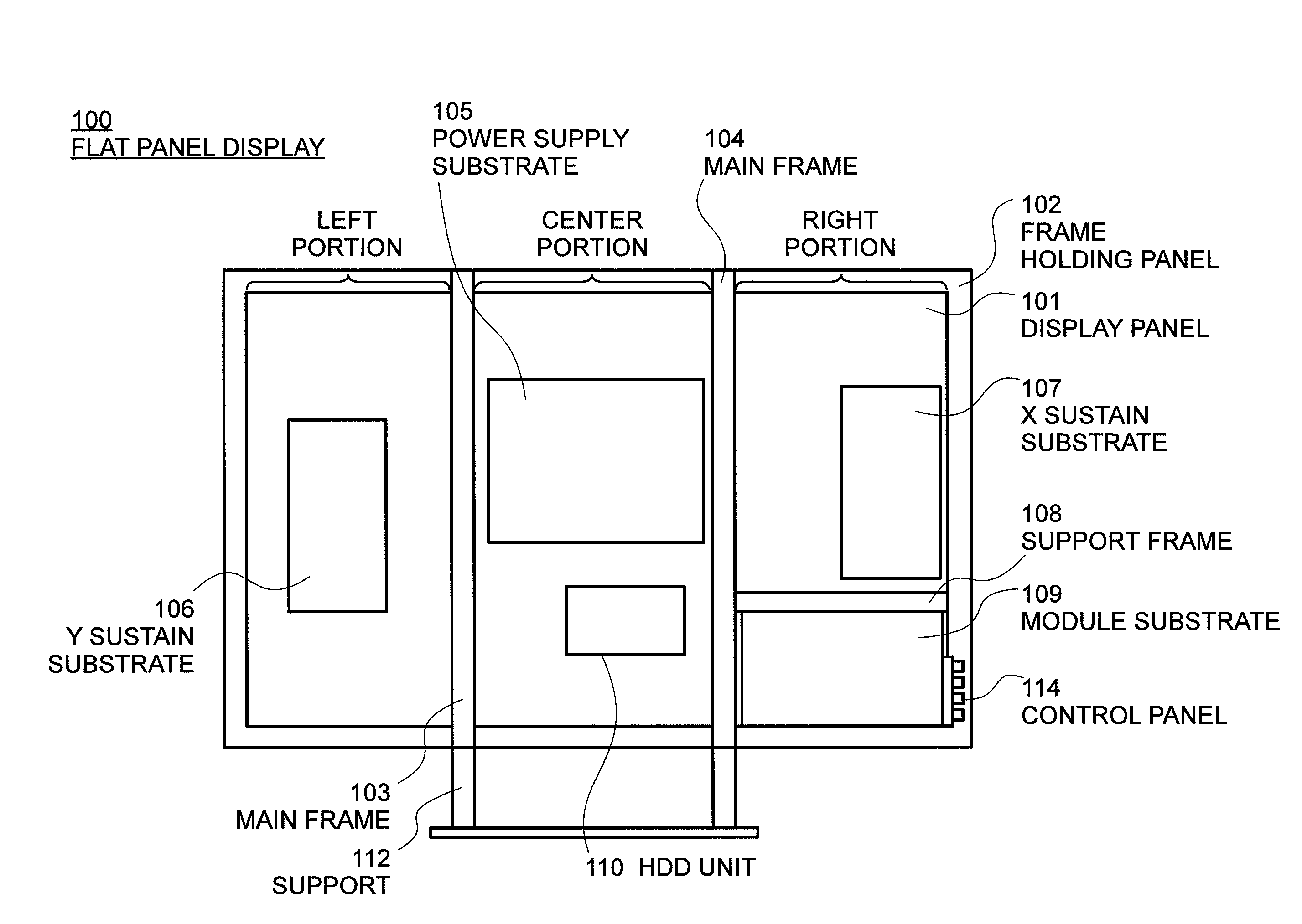

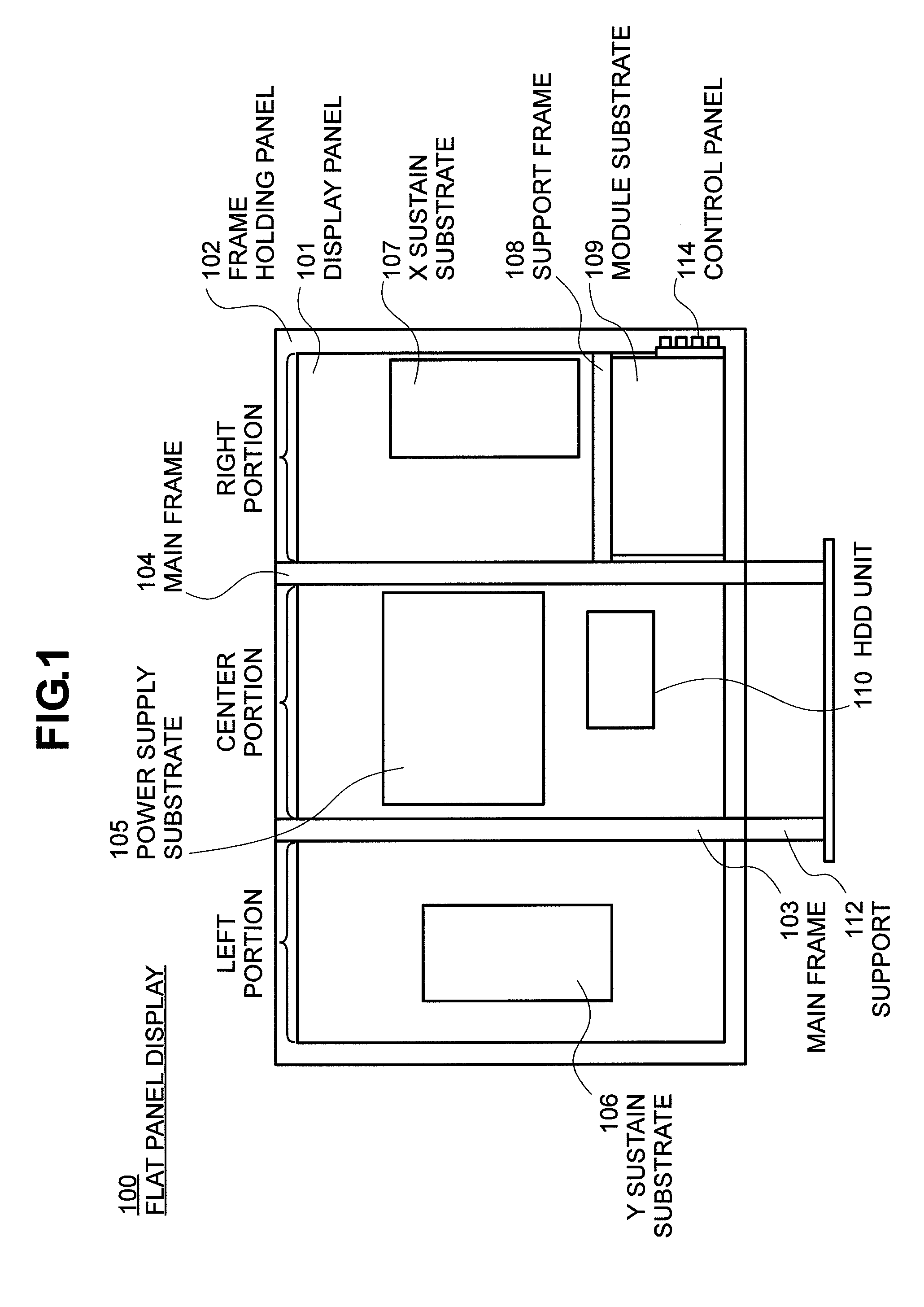

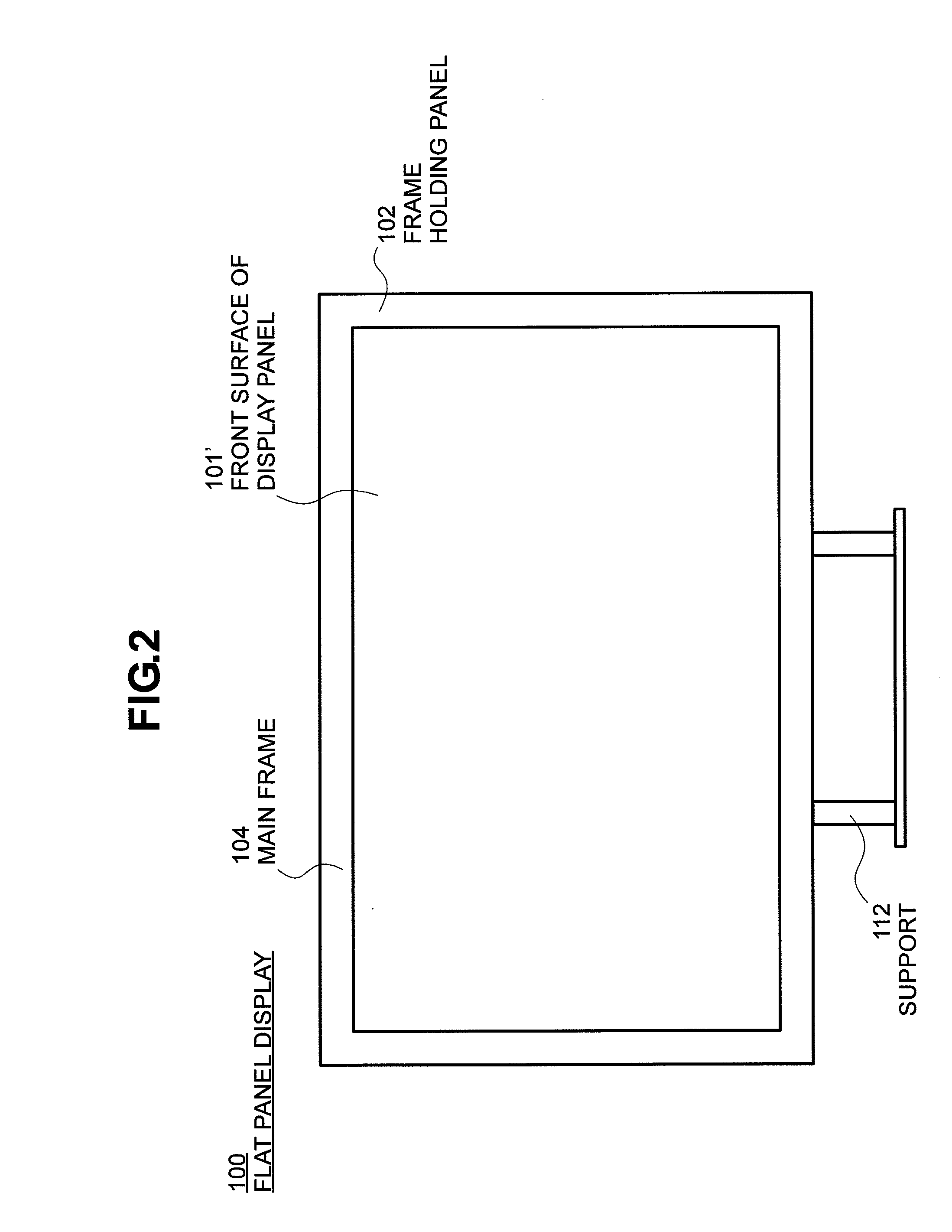

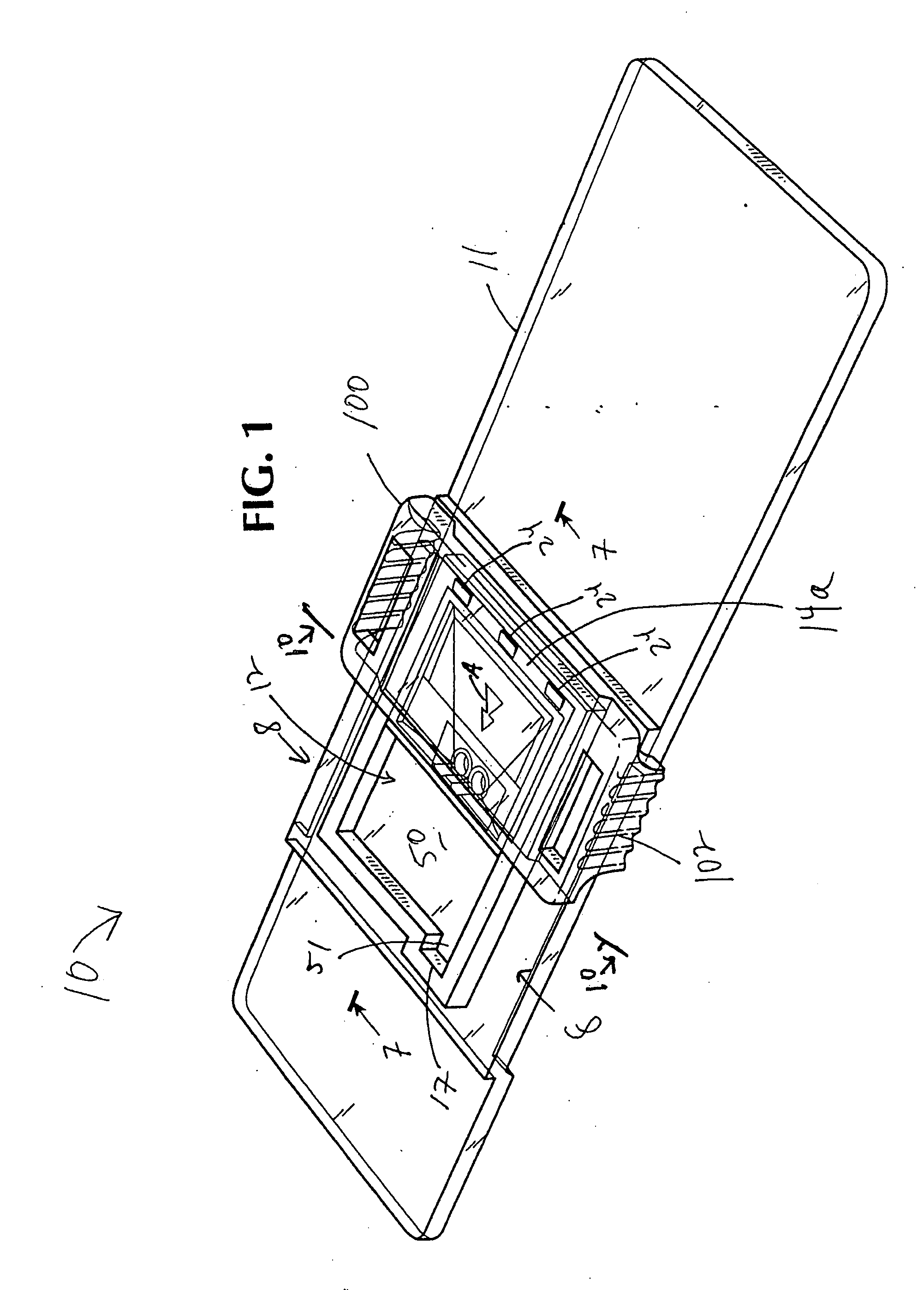

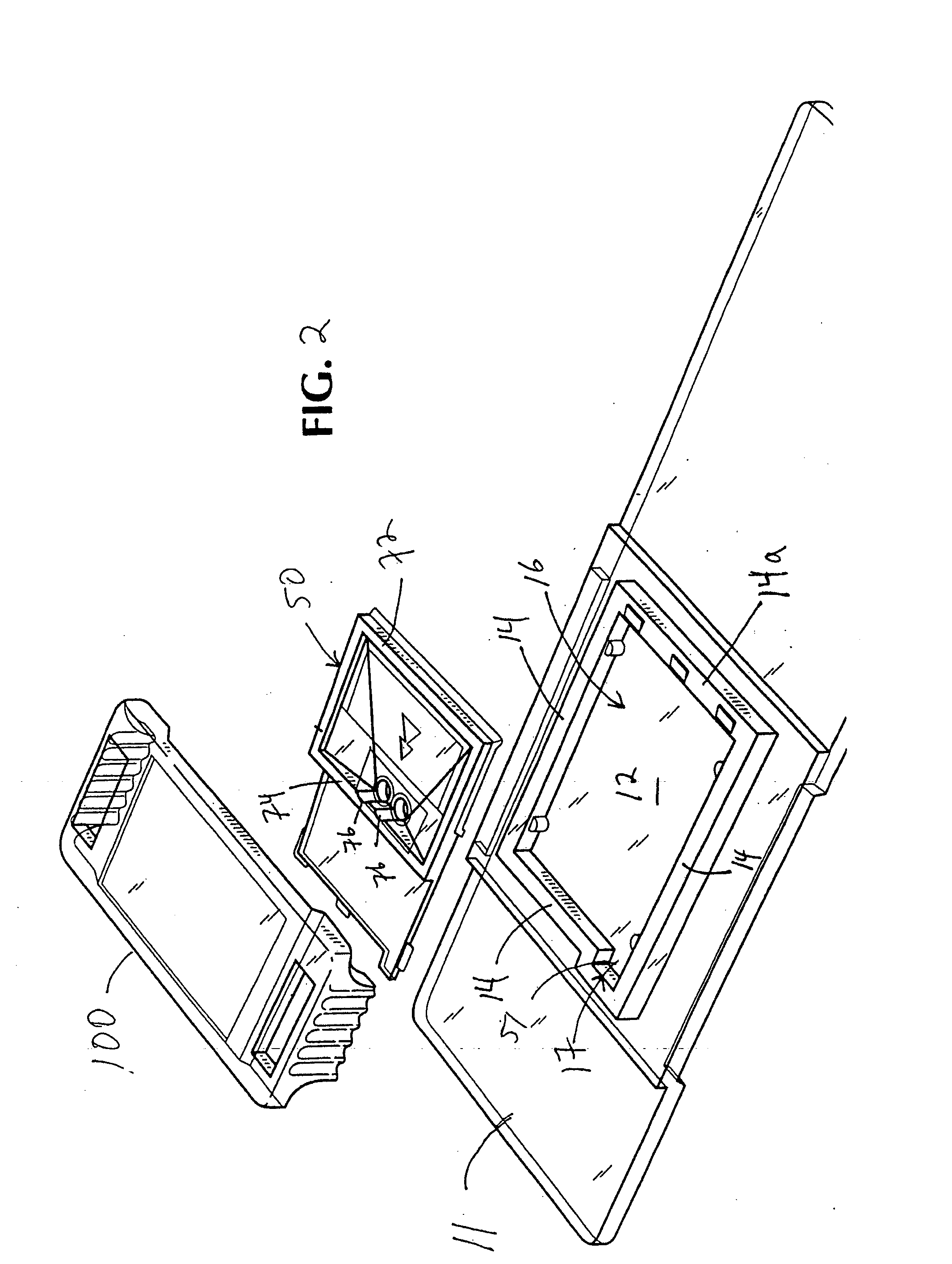

Flat Panel Display

InactiveUS20090115919A1Reduce the numberShorten the lengthTelevision system detailsColor television detailsDisplay deviceThermal radiation

Space is decreased in the direction of thickness on a side of a substrates mounted on a back of a flat panel display to adapt requirement for increasing and thinning its size, and most flat panel displays forcibly radiate heat with a fan provided thereon. The present invention provides a flat panel display having fewer heat radiating fans to secure a channel for causing a heat radiating air to flow. Portions where electronic circuit device on a back of a display panel are mounted are divided into three: left; center; and right portions; with a main frame as a border, the electronic circuit device are constructed of four module substrates, the substrate which is the greatest in heating value in the four module substrates (hereinafter referred to as a substrate) is arranged in the center portion and the substrates which are the smallest and the second smallest in heating value therein are arranged in the same portion.

Owner:MAXELL HLDG LTD

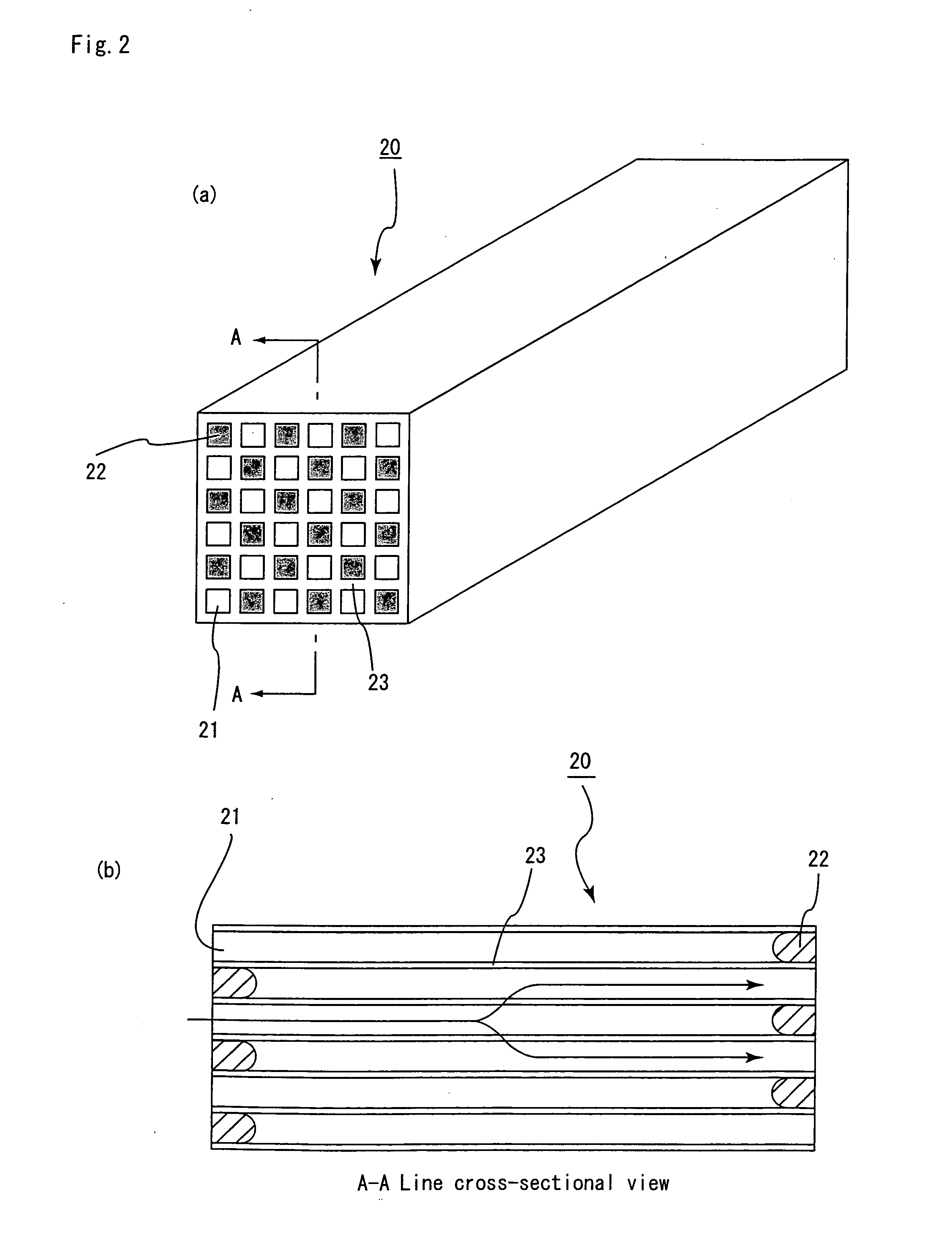

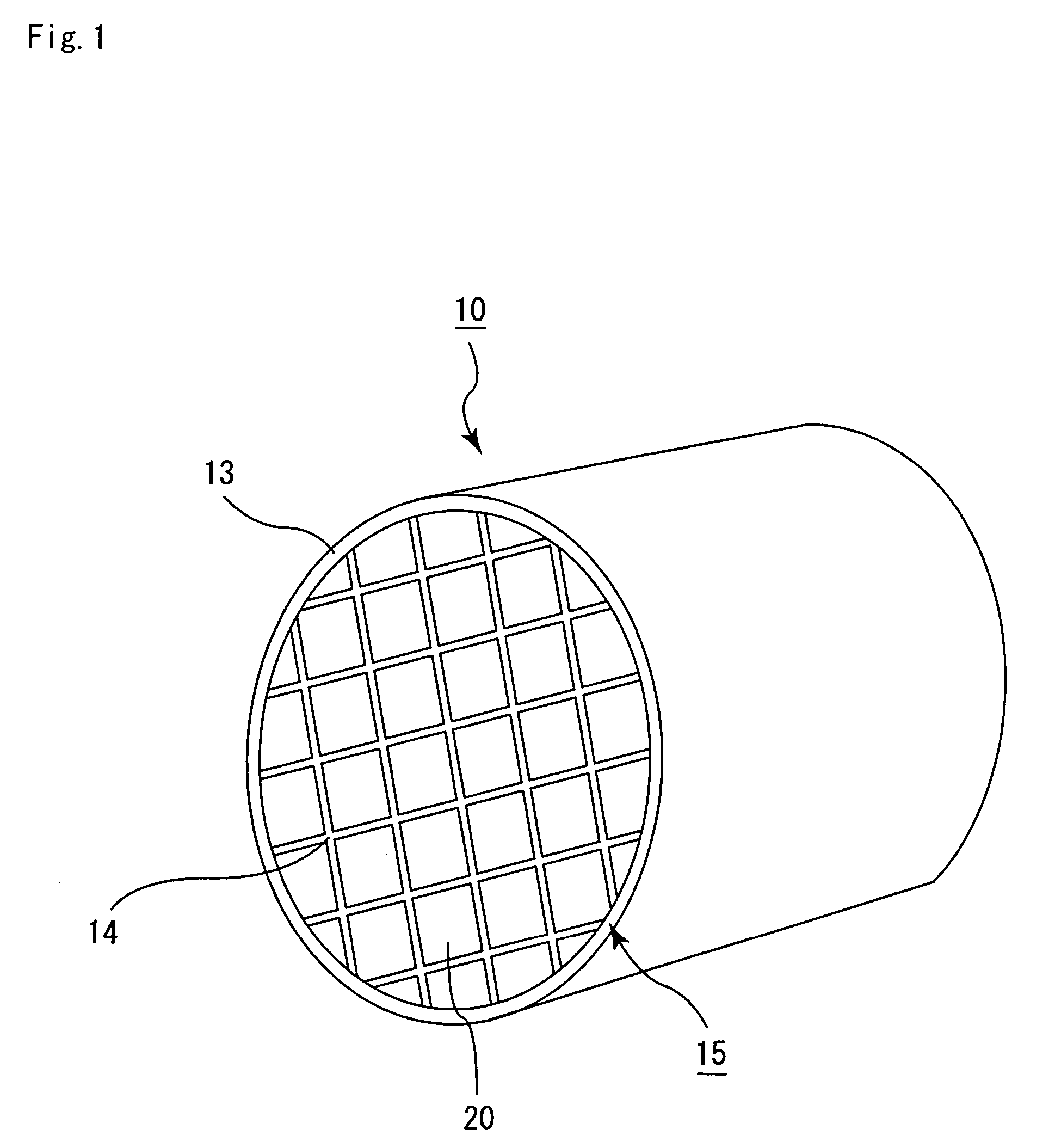

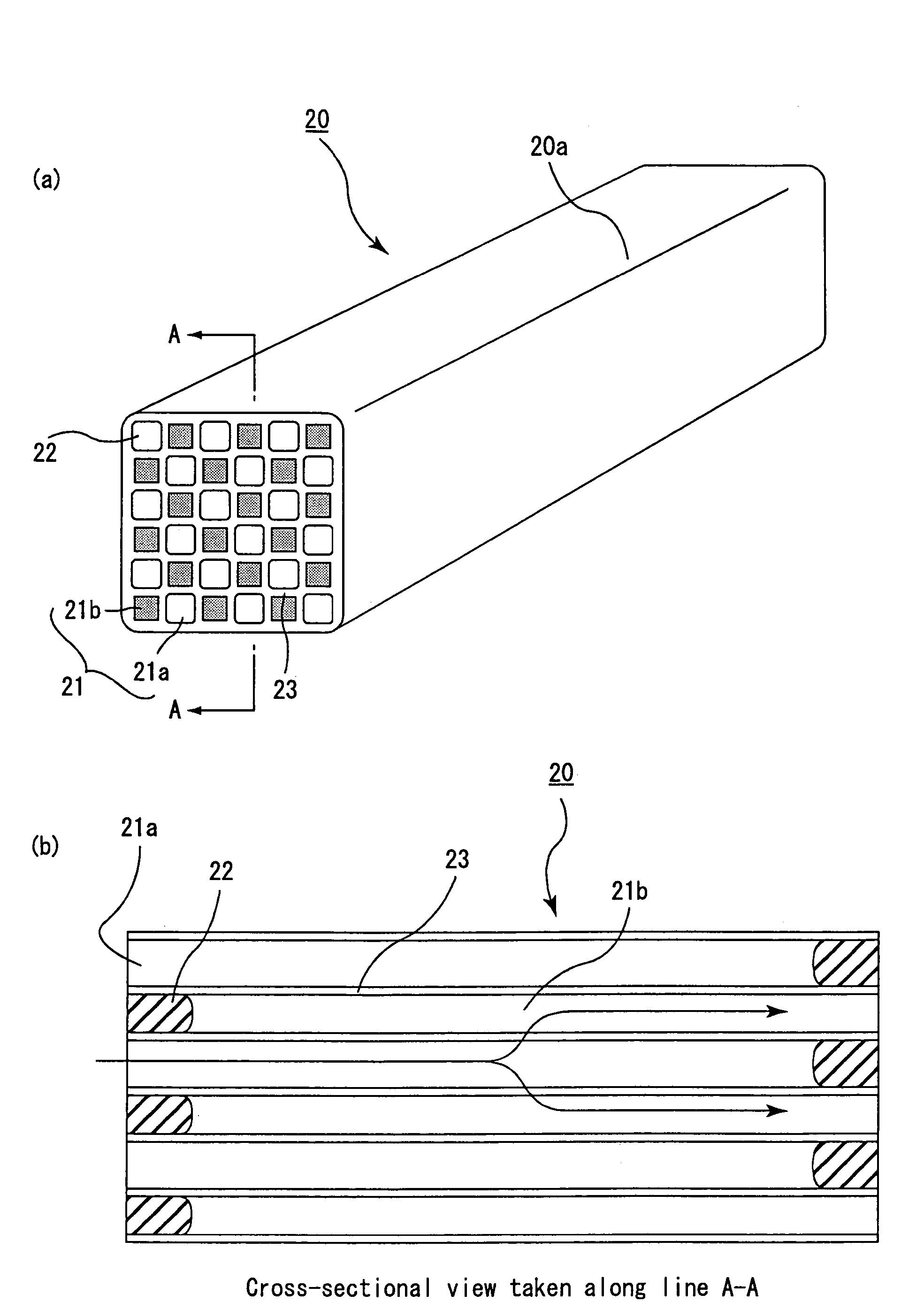

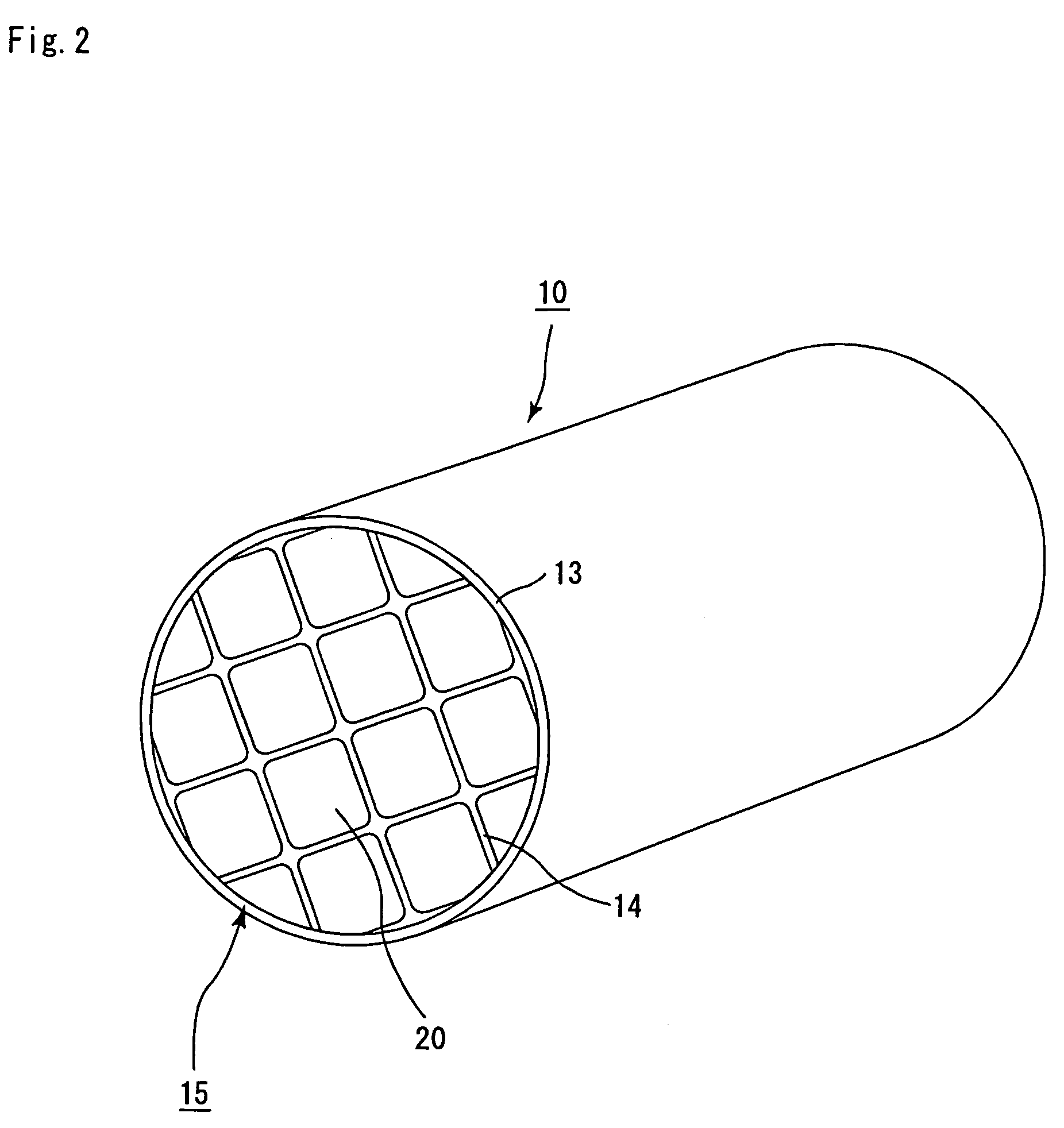

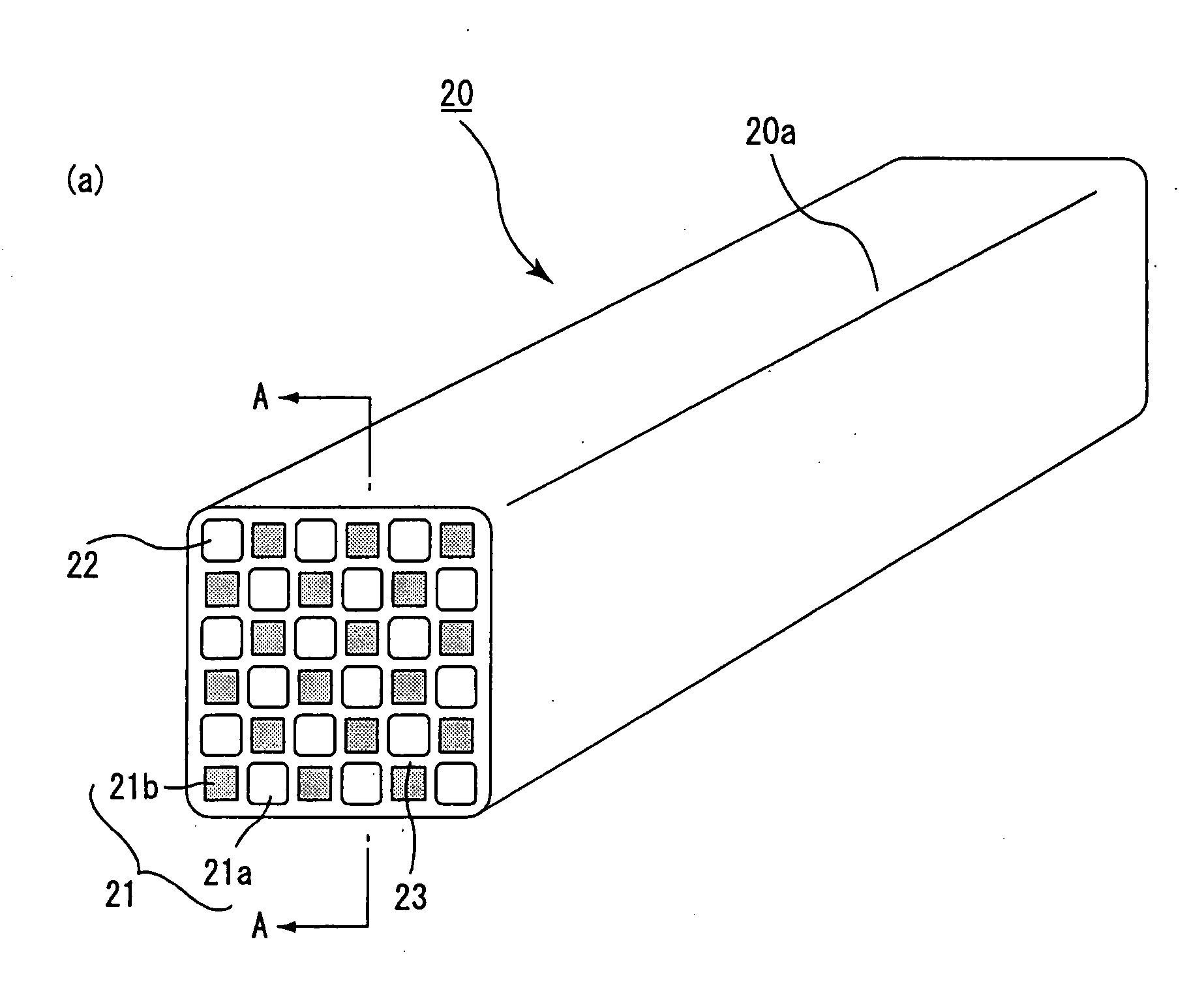

Honeycomb structure

ActiveUS7316722B2Low pressure lossGood partitionCombination devicesAuxillary pretreatmentParticulatesEngineering

An object of the present invention is to provide a honeycomb structural body (filter) which has a low pressure loss upon collecting particulates, makes it possible to deposit a great amount of particulates and ashes, and is less likely to produce cracks. The columnar honeycomb structural body of the present invention includes a plurality of through holes placed in parallel with one another in the length direction, and wall portion that separates the plurality of through holes from one another and constitutes a circumferential face, wherein the plurality of through holes are composed of a group of large-capacity through holes, with one end thereof being sealed so as to cause the total of areas of cross-section perpendicular to the length direction to become relatively greater, and a group of small-capacity through holes, with the other end thereof being sealed so as to cause the total of areas of the above-mentioned cross-section to become relatively smaller, and the above-mentioned circumferential face of the columnar honeycomb structural body has a chamfered corner portion.

Owner:IBIDEN CO LTD

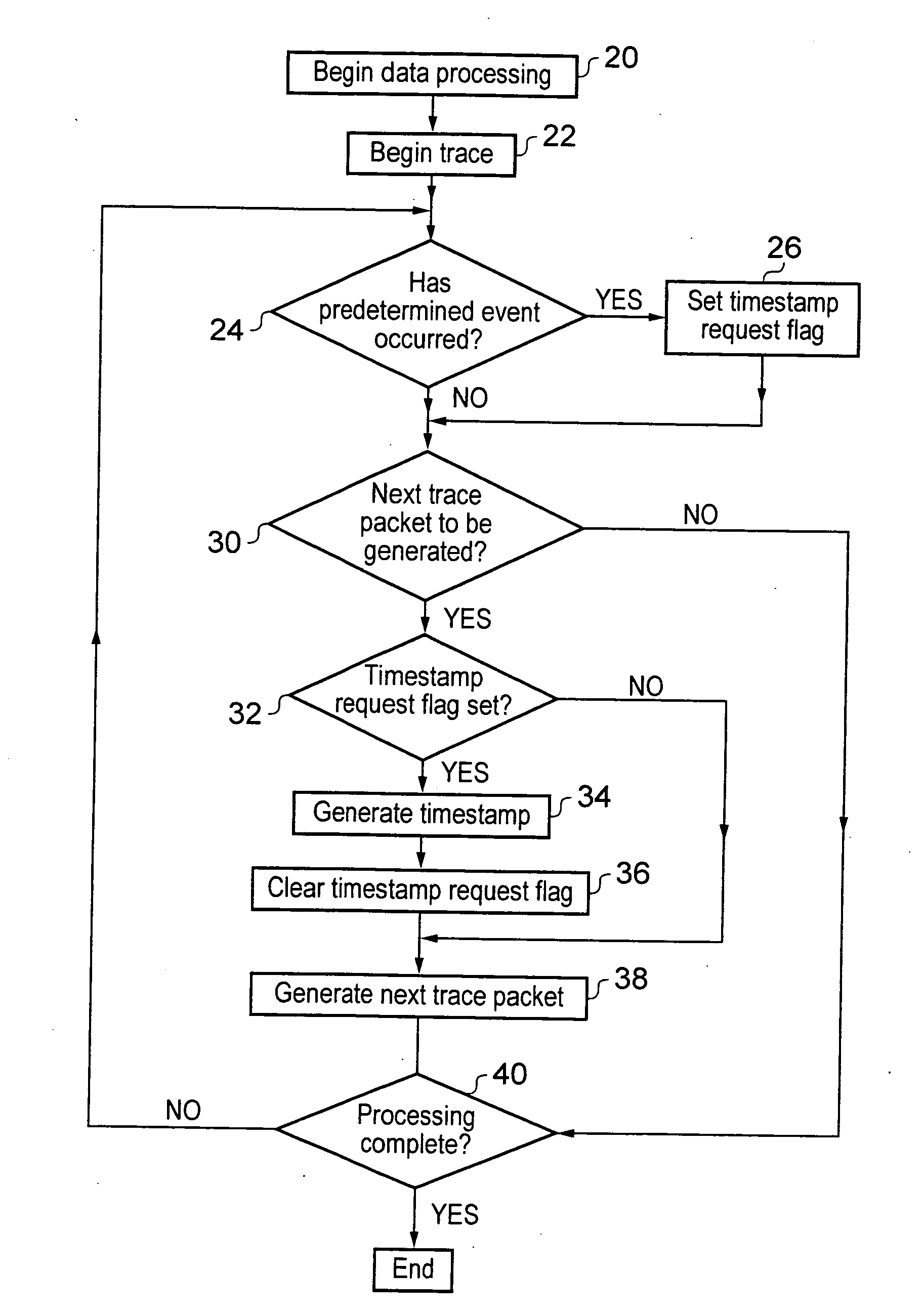

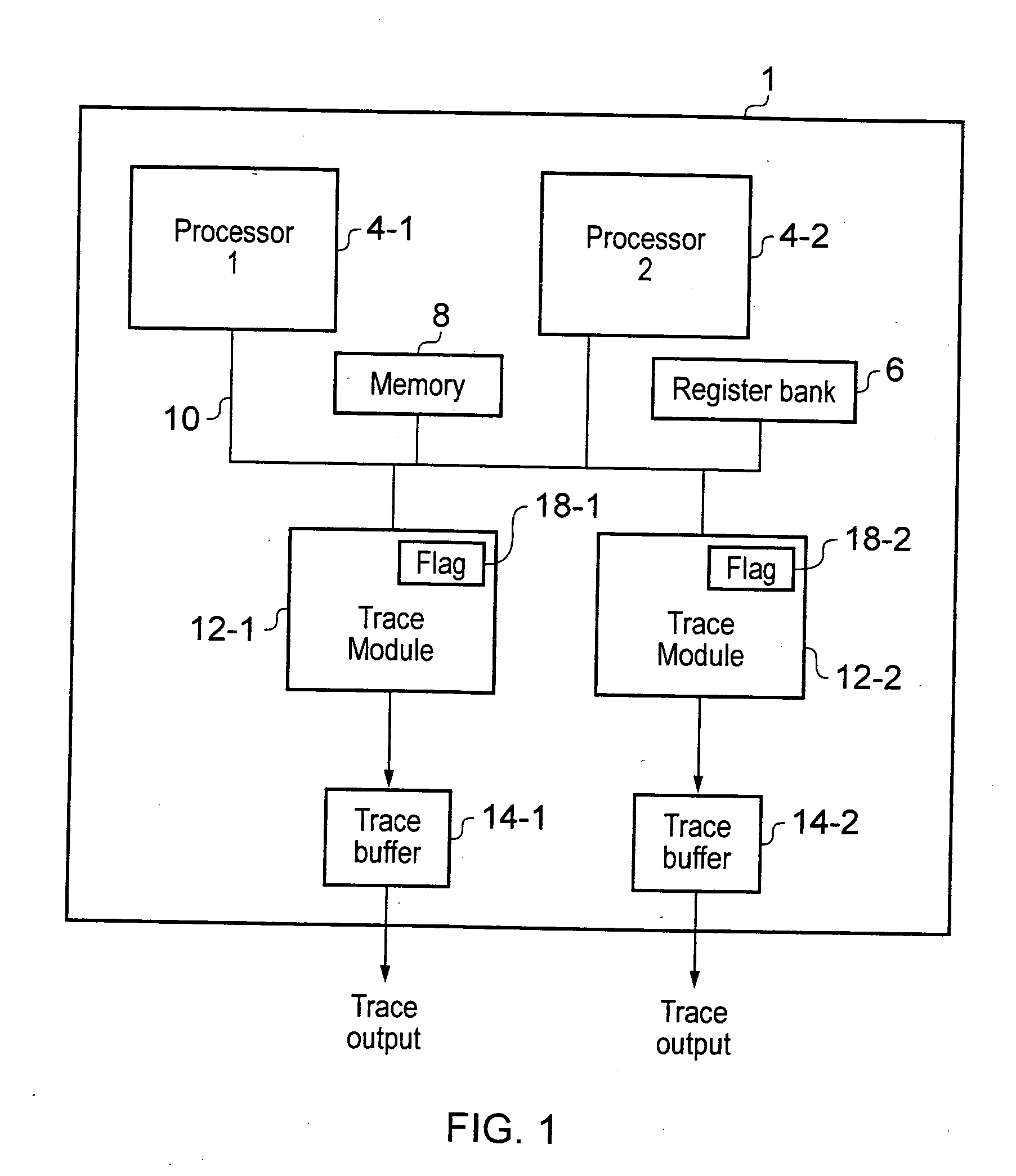

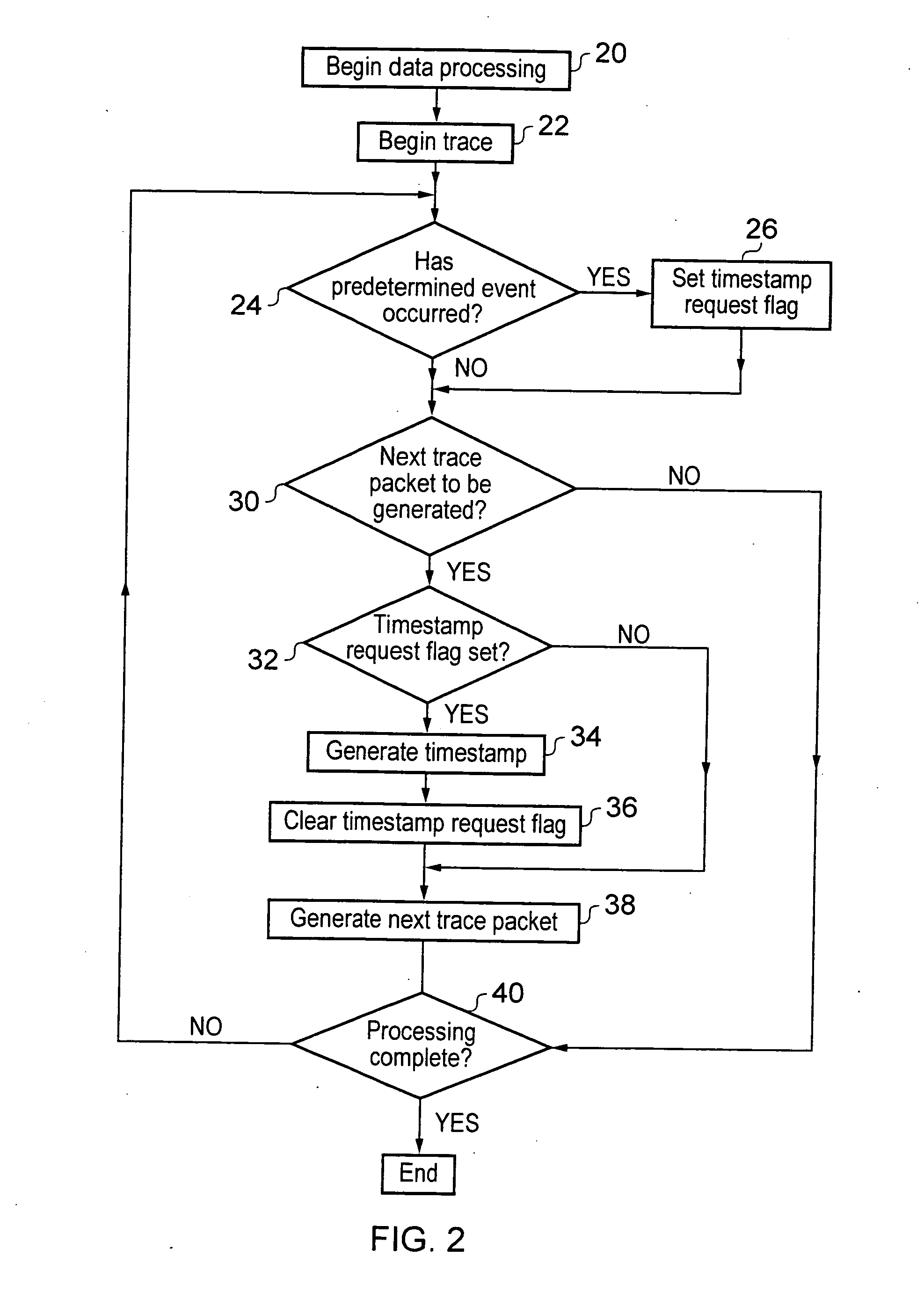

Method, apparatus and trace module for generating timestamps

ActiveUS20110219376A1Trace bandwidthSave resourcesError detection/correctionMultiprogramming arrangementsTimestampComputer science

The present invention relates to the field of data processing, in particular, a method, apparatus 1 and trace module 12 for generating timestamps while tracing characteristics of a data processing apparatus or processing being performed by the data processing apparatus. When a predetermined event occurs, a timestamp request flag 18 is set to indicate that a timestamp request is pending. Upon generation of a following trace packet, it is determined whether the timestamp request flag indicates that a timestamp request is pending, and if a request is pending then a timestamp is generated corresponding to the following trace packet, and the timestamp request flag is set to indicate that there is no pending timestamp request.

Owner:ARM LTD

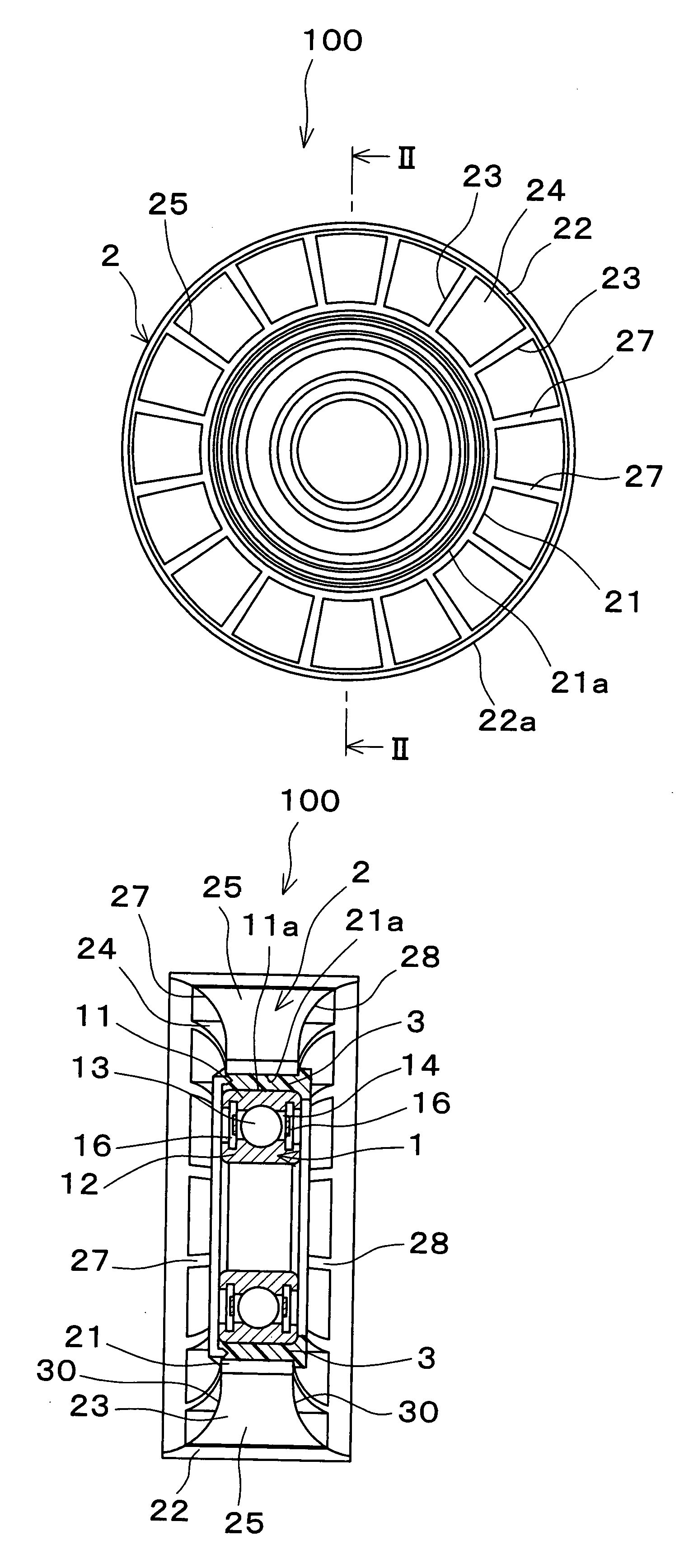

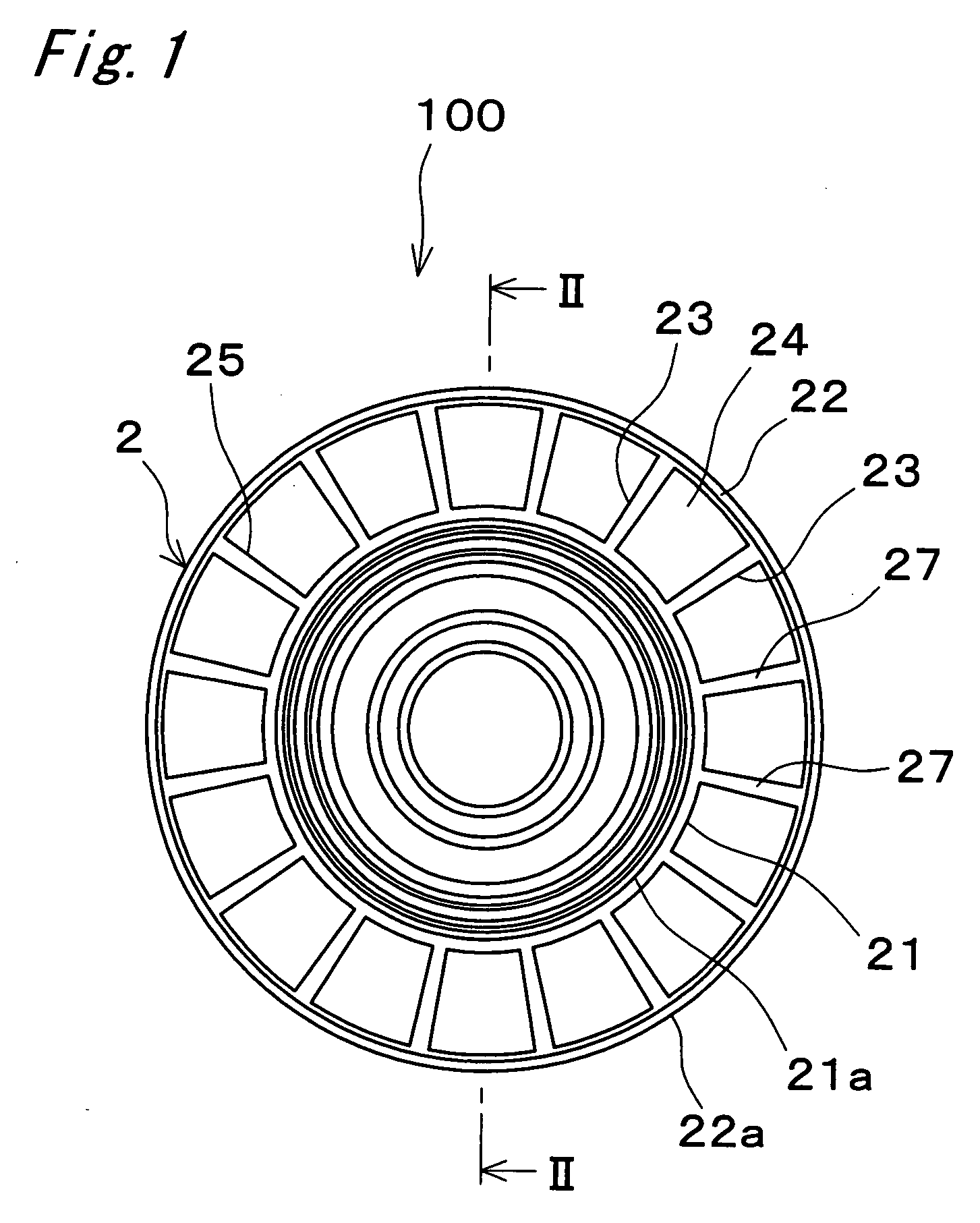

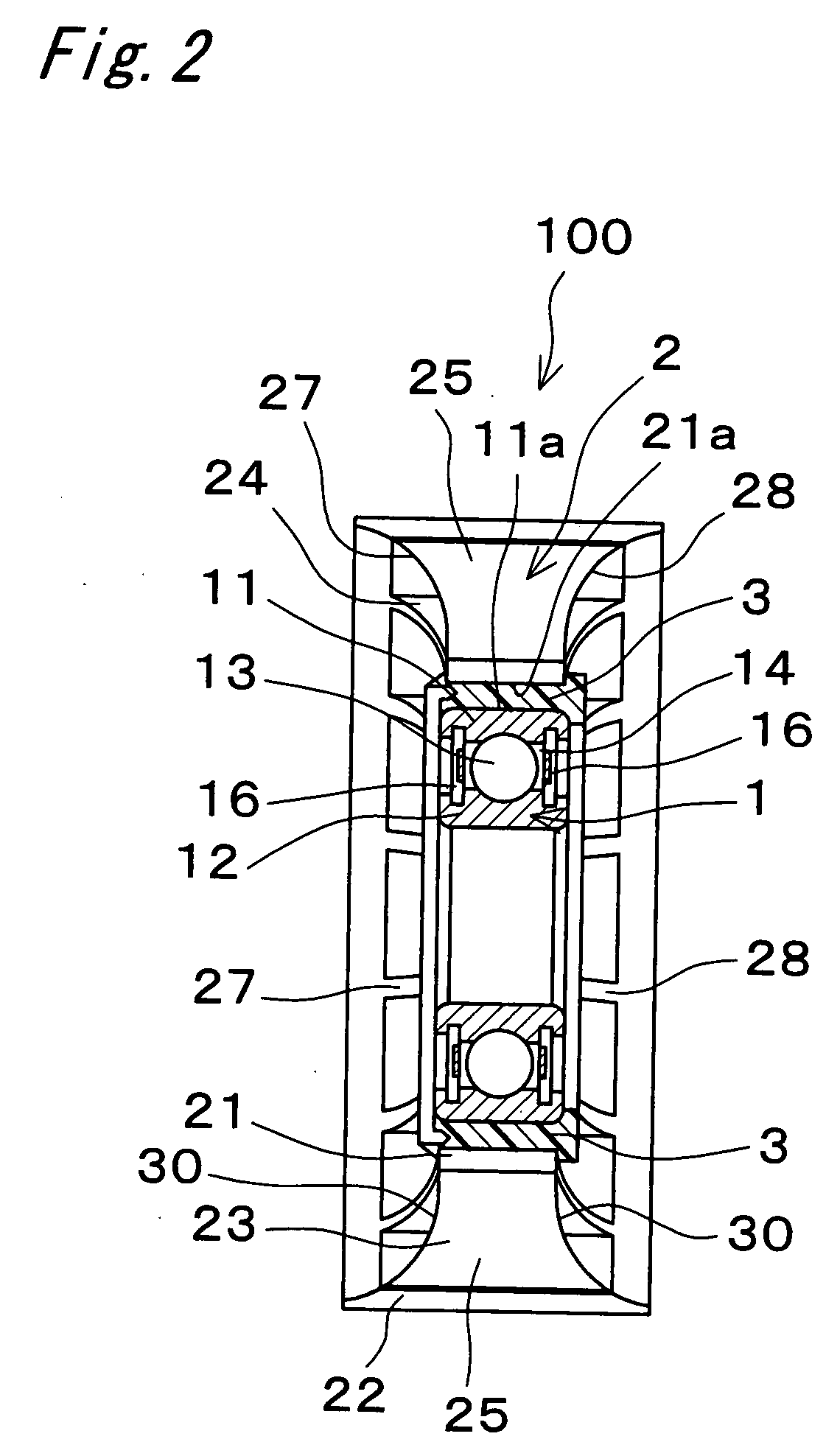

Pulley assembly and pulley usable therefor

InactiveUS20070232427A1Wind noise is generatedReduce generationGearingPortable liftingThermal expansionSpoke

In a pulley assembly, an annular joint member made of a high polymer material is disposed between an outer ring of a bearing and a light metal pulley. The joint member has a coefficient of thermal expansion larger than that of the pulley. The outer ring has a coefficient of thermal expansion smaller than that of the pulley. The pulley has an annular boss, an annular rim, and a plurality of spokes which have side faces each consisting of a surface parallel to an axial direction of the pulley. Front faces of the spokes are positioned on one identical imaginary surface of revolution, and rear faces of the spokes are also positioned on one identical imaginary surface of revolution.

Owner:JTEKT CORP

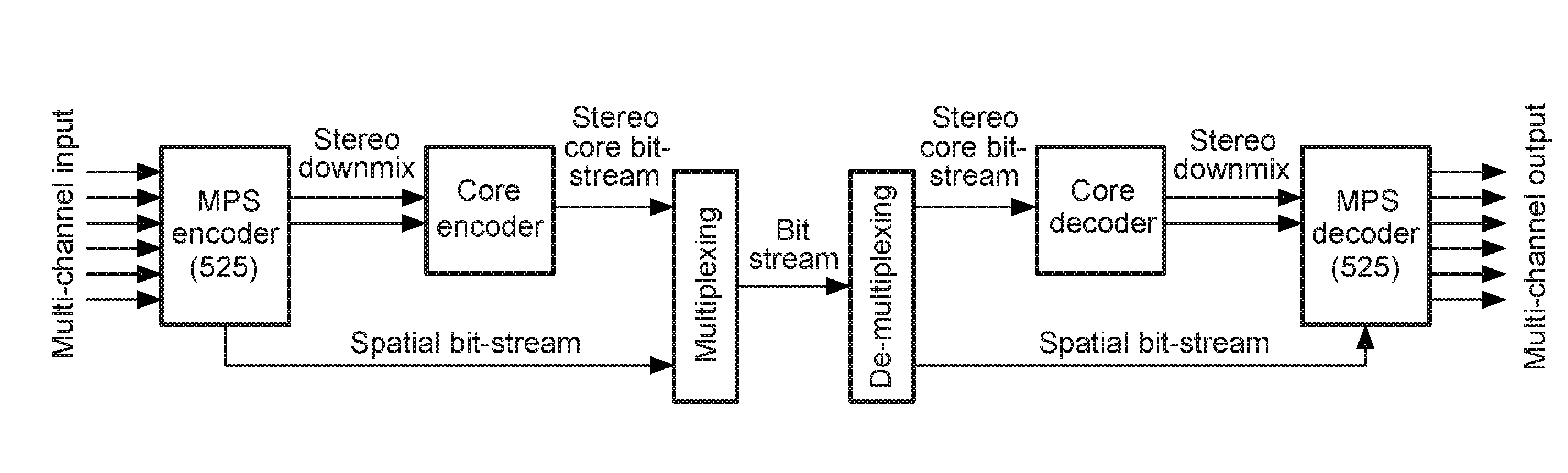

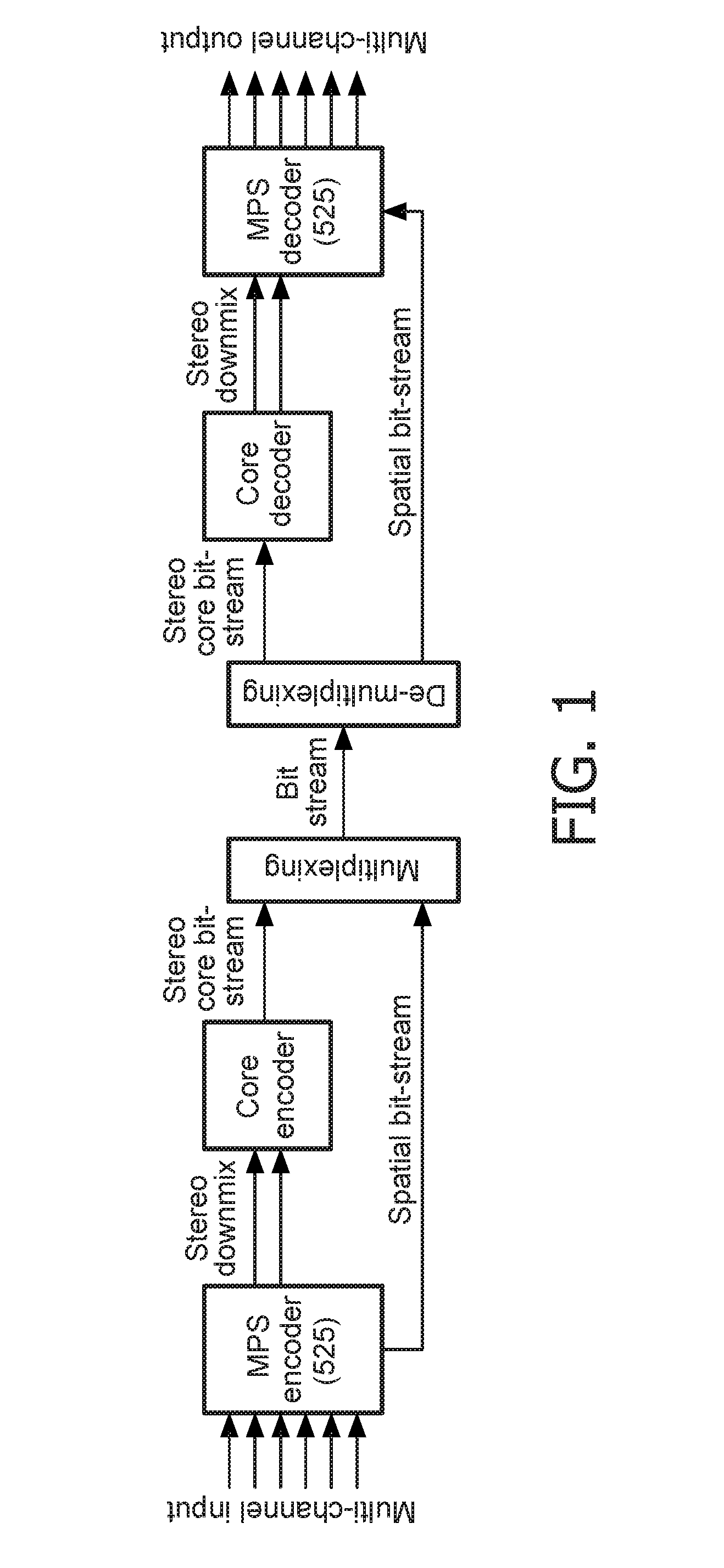

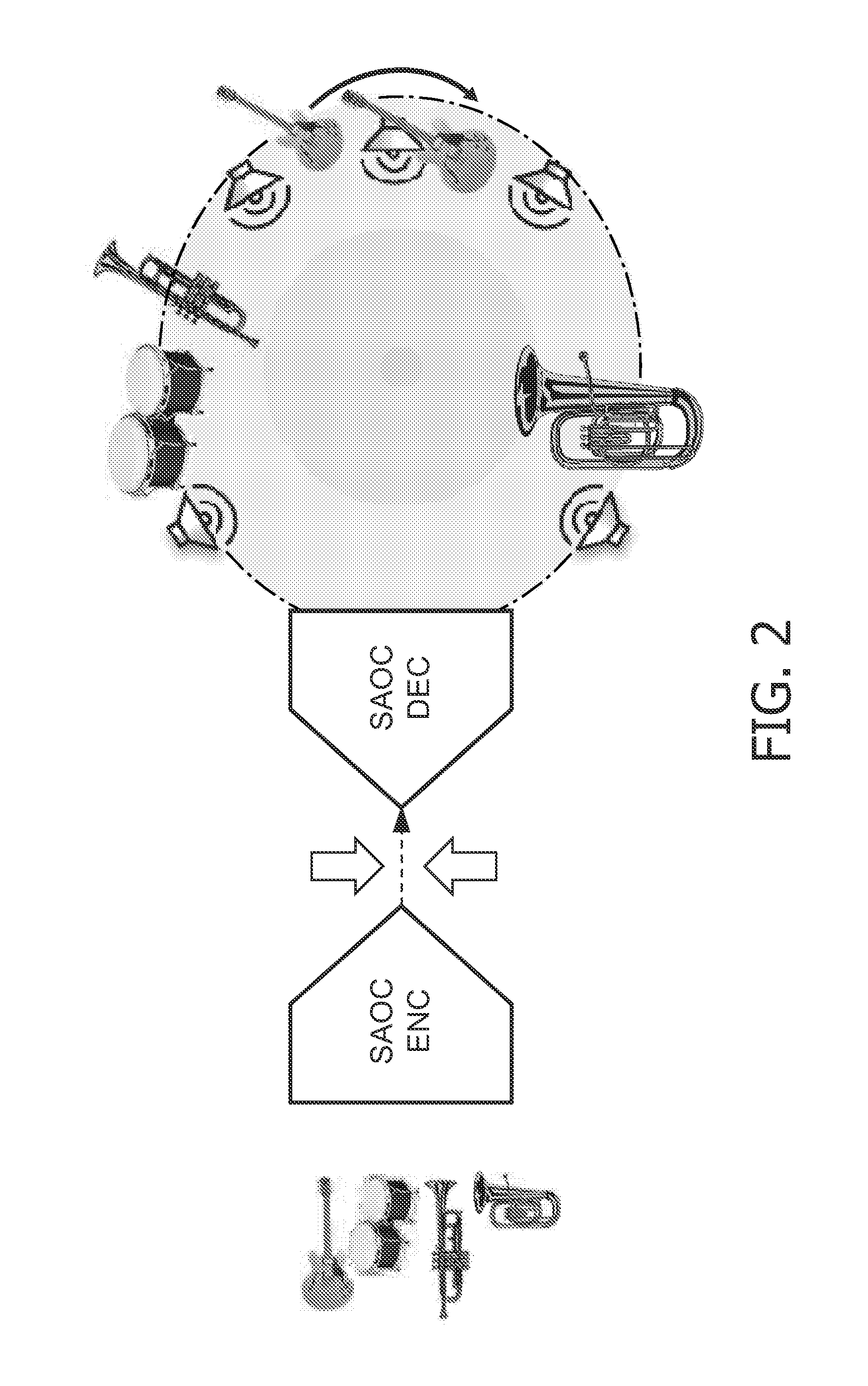

Binaural audio processing

ActiveUS20150358754A1Easy to operateEfficient representationSpeech analysisTwo-channel systemsData setVirtual position

A transmitting device comprises a binaural circuit (601) which provides a plurality of binaural rendering data sets, each binaural rendering data set comprising data representing parameters for a virtual position binaural rendering. Specifically, head related binaural transfer function data may be included in the data sets. A representation circuit (603) provides a representation indication for each of the data sets. The representation indication for a data set is indicative of the representation used by the data set. An output circuit (605) generates a bitstream comprising the data sets and the representation indications. The bitstream is received by a receiver (701) in a receiving device. A selector (703) selects a selected binaural rendering data set based on the representation indications and a capability of the apparatus, and an audio processor (707) processes the audio signal in response to data of the selected binaural rendering data set.

Owner:KONINKLJIJKE PHILIPS NV

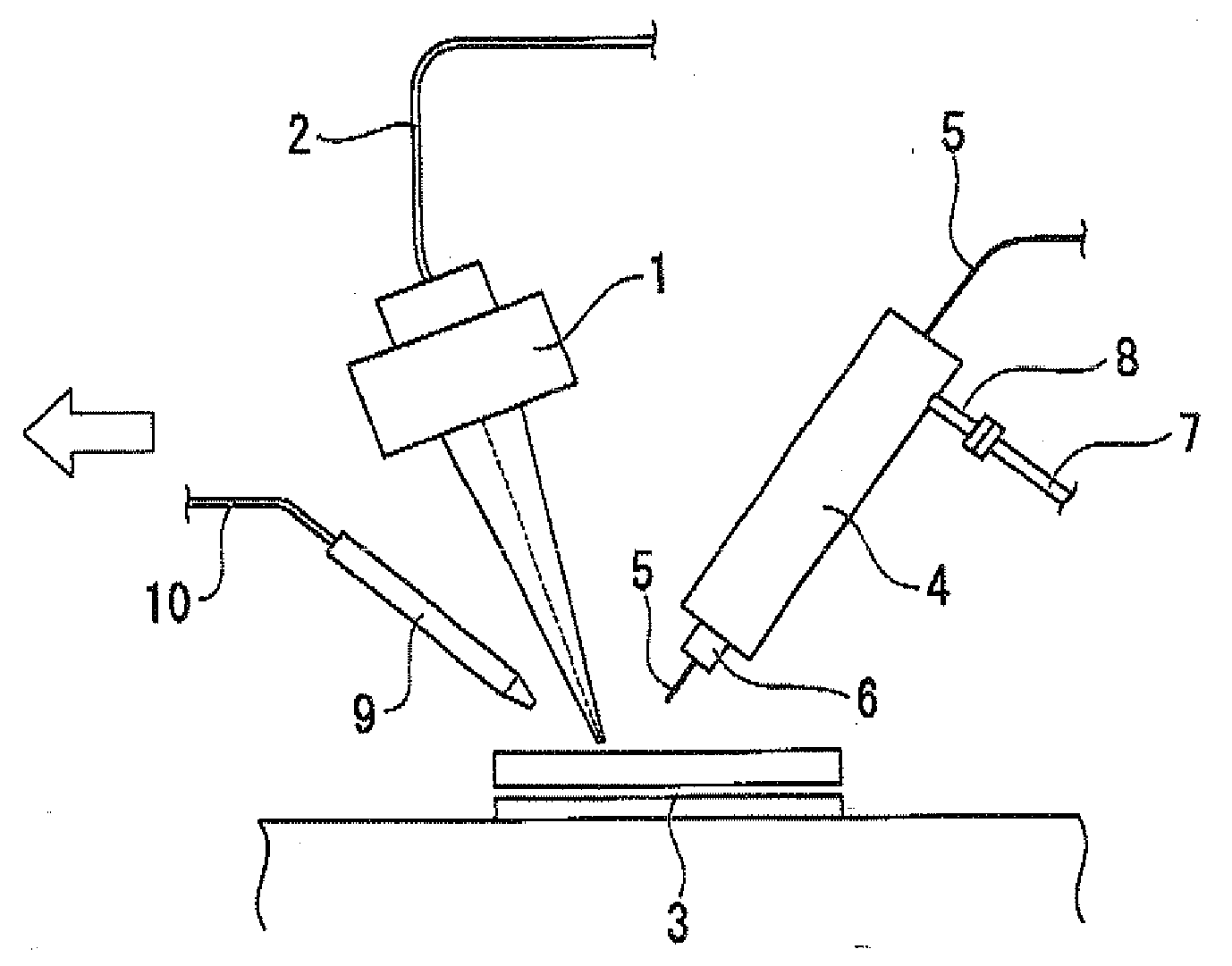

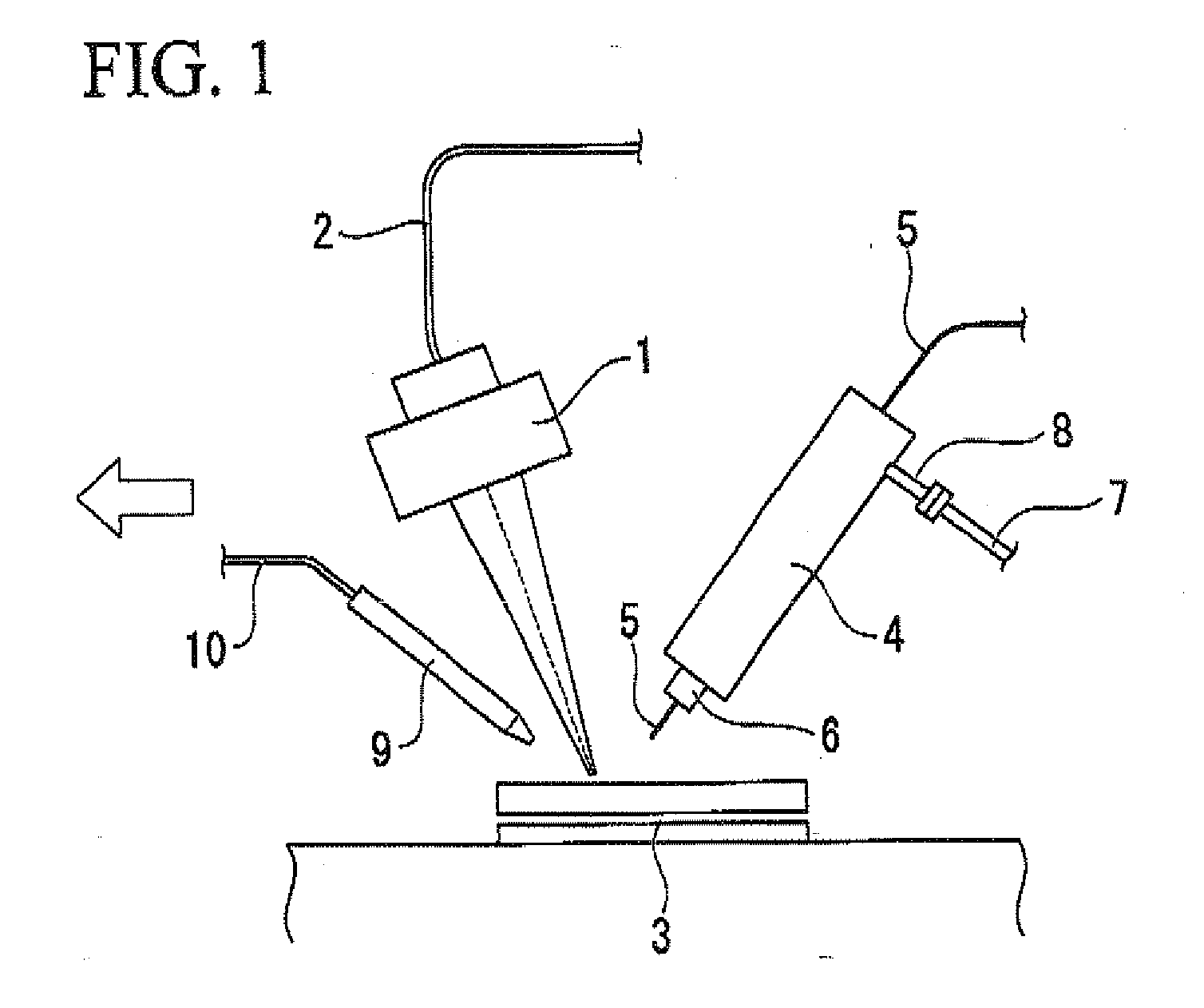

Shielding gas for hybrid welding and hybrid welding method using the same

InactiveUS20090095720A1Shielding property is decreasedGeneration of pit can be preventedWelding/cutting media/materialsWelding/soldering/cutting articlesSheet steelShielding gas

A shield gas for use in welding of galvanized steel sheet with the simultaneous use of laser welding and arc welding, wherein, providing that A refers to the vol. % of carbon dioxide gas and B to the vol. % of oxygen gas in the shield gas, in the event of overlapped welding of steel sheets, at least one of which is a galvanized steel sheet, when the gap between the steel sheets is 0, 15≦A≦50, 5≦B≦9 and B≧21−0.8A, when the ratio of G / T, in which G is the gap between the steel sheets and T the thickness of the steel sheet positioned on the side of welding torch, is 1 or below and when the thicknesses of the steel sheets are identical with each other, 15≦A≦50, 3≦B≦9 and B≧0.1A, and when the ratio of G / T is 1 or below and when the thicknesses of the steel sheets are different from each other, 10≦A≦50, 3≦B≦9 and B≧0.1A and B≧15−0.6A, and in the event of overlapped fillet welding, when both the steel sheets to be welded are galvanized steel sheets, 3≦A≦25, 5≦B≦13 and B≧10−0.33×A, and when one of the steel sheets to be welded is a galvanized steel sheet, 3≦A≦25, 5≦B≦13 and B≧10.5−0.5×A, the balance being argon gas.

Owner:NIPPON SANSO CORP

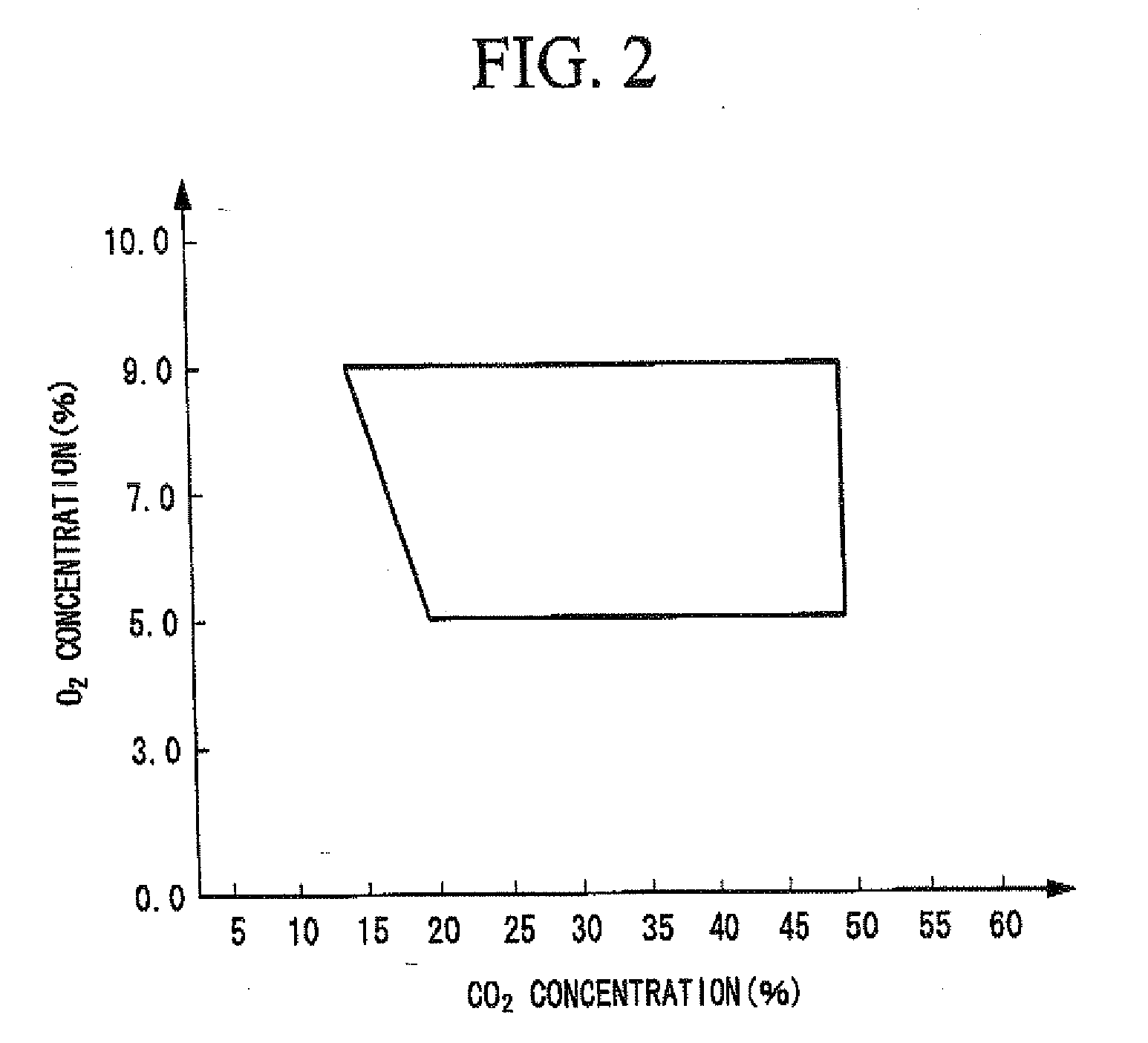

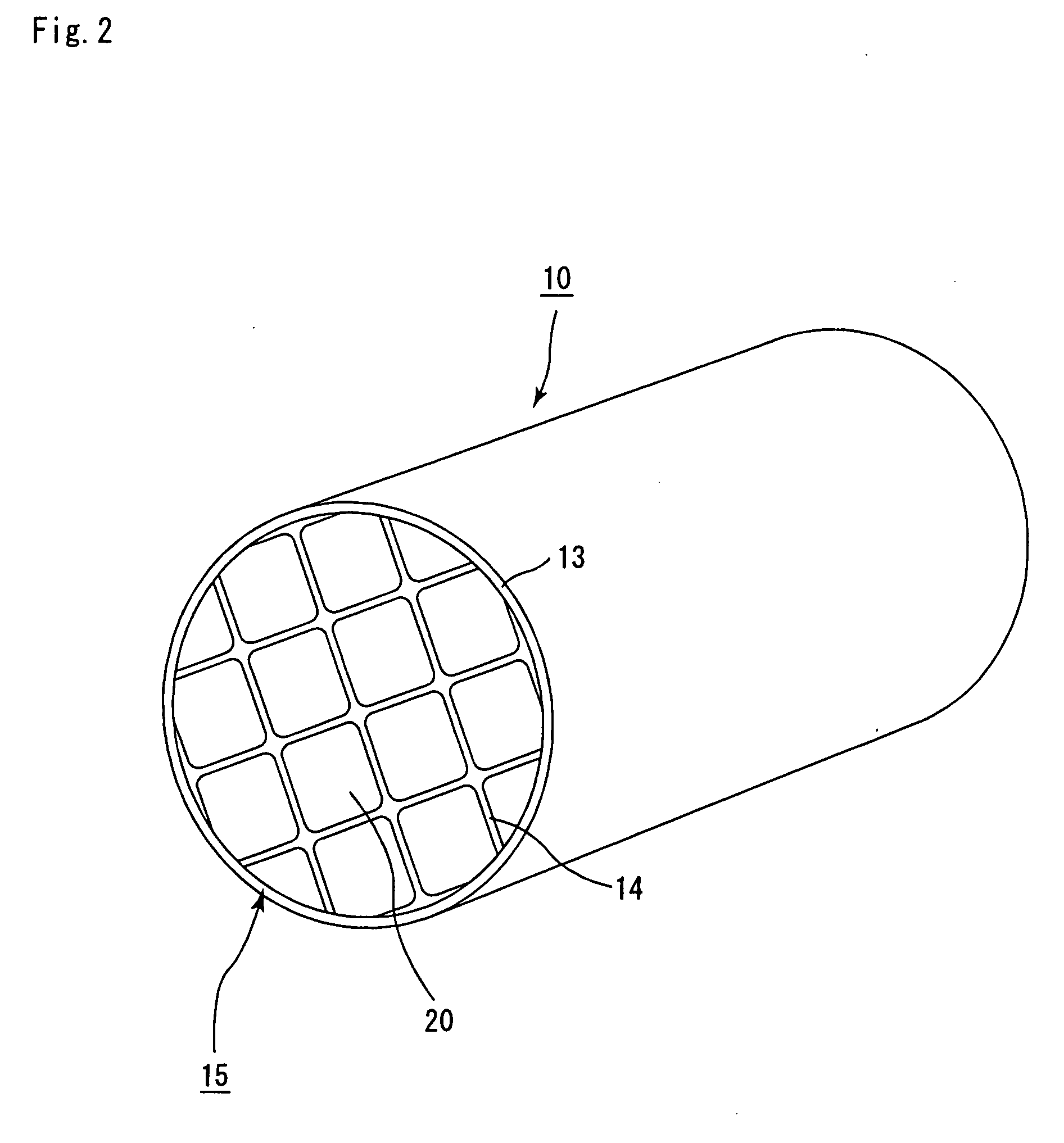

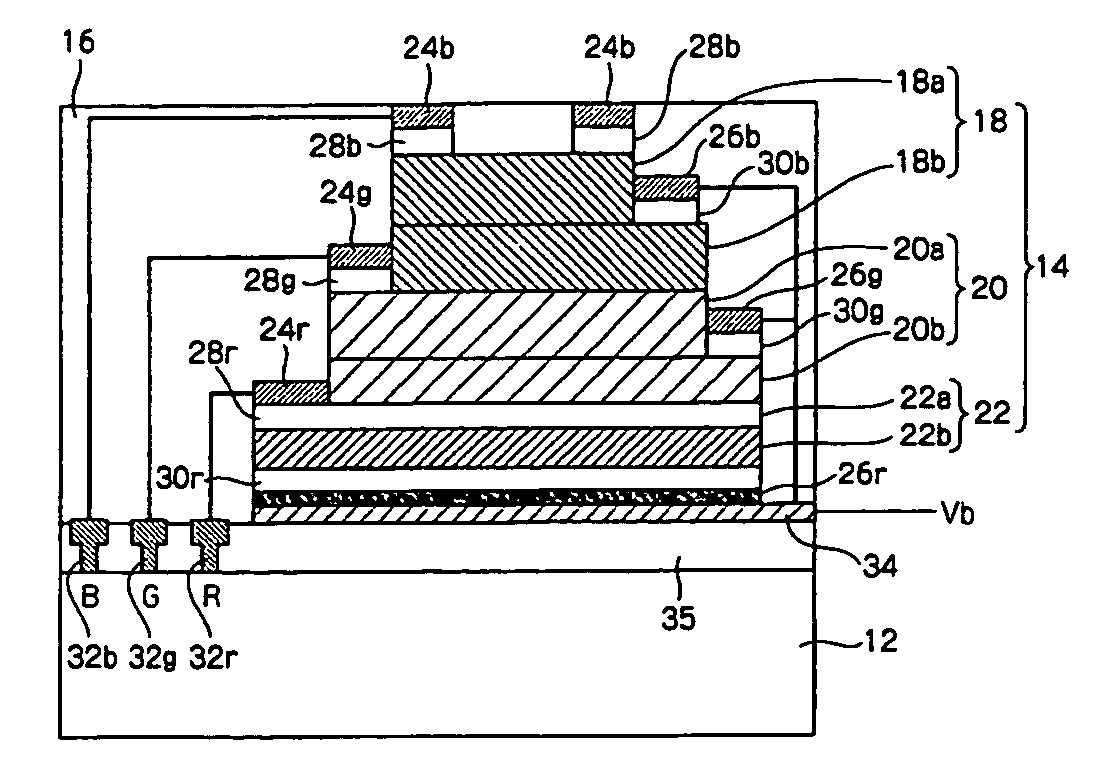

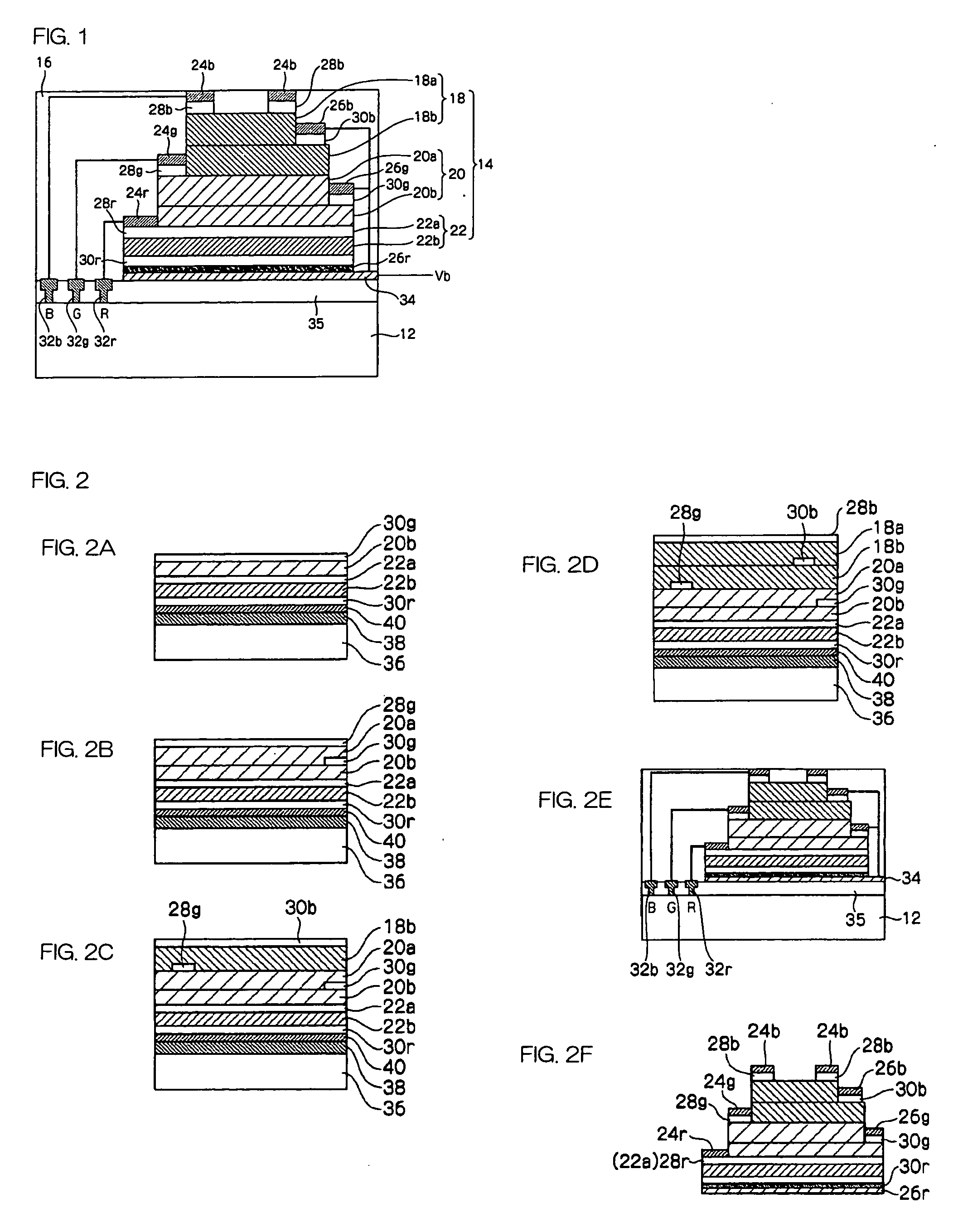

Light emitting device

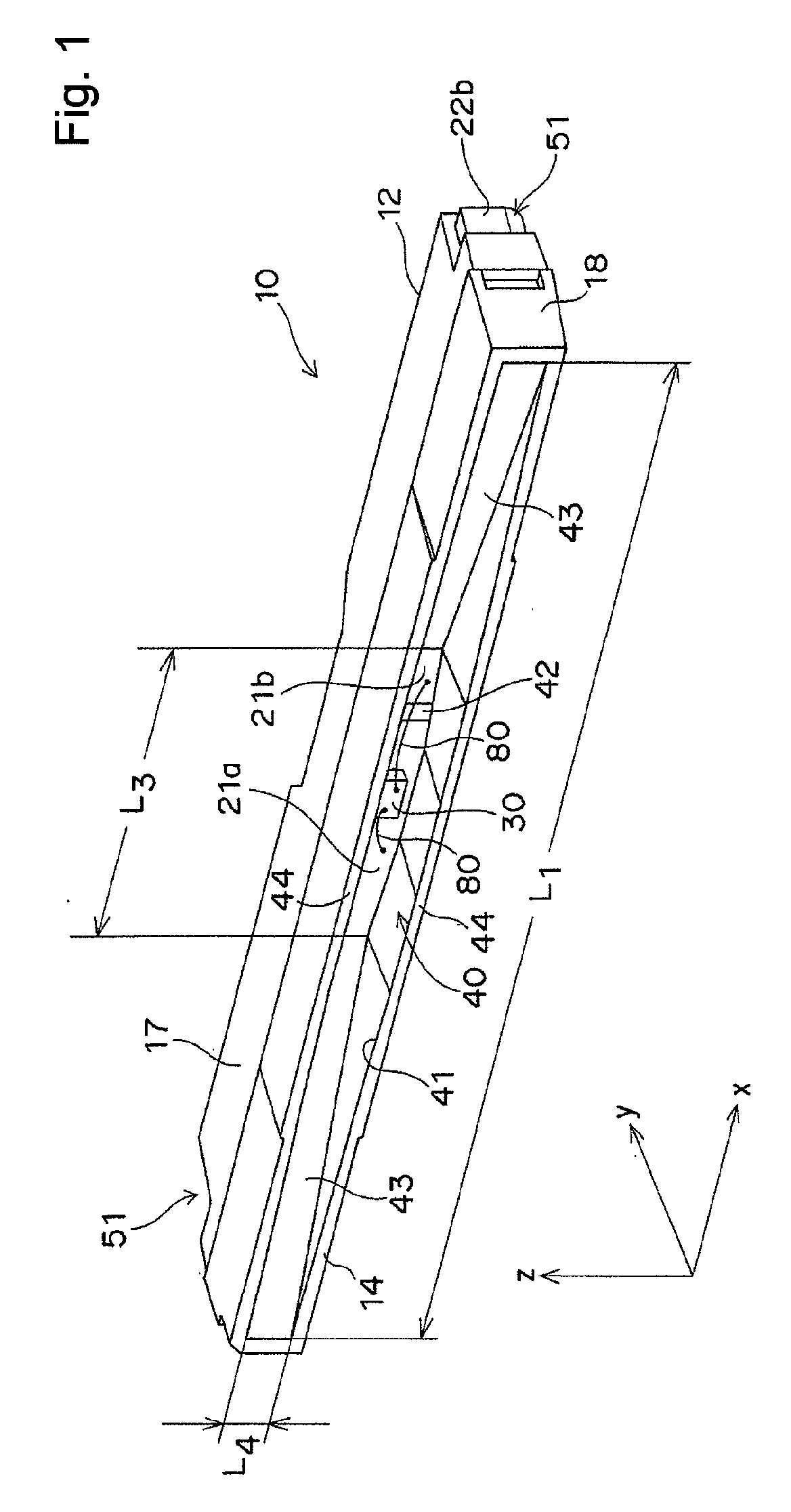

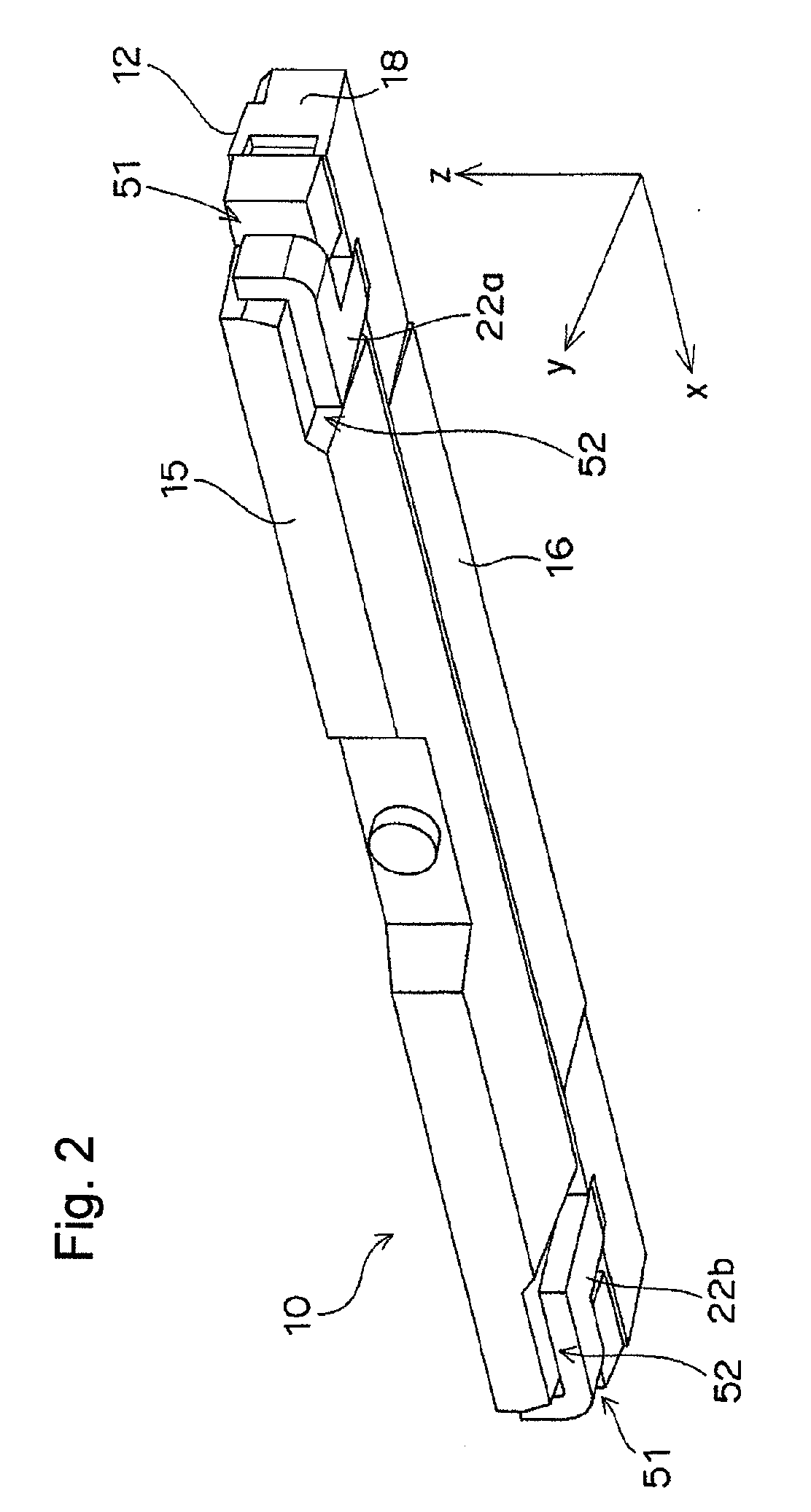

ActiveUS20090114936A1Reduce brightness unevennessSuppress luminescenceSolid-state devicesPlanar/plate-like light guidesShaped beamBand shape

To provide a light emitting device that makes it possible to form a surface light emitting apparatus of less unevenness in luminance.The light emitting device 10 of the present invention comprises a light emitting element 30, connecting terminals 21a, 21b connected with the light emitting element30, a package 12 which has a recess 40 wherein the light emitting element 30 is mounted and from which a part of each connecting terminal 21a, 21b is projected outward, an opening 41 of the recess 40 being elongated in one direction, wherein both side walls of the recess 40 positioned in the longitudinal direction of the recess 40 are inclined surface 43, an angle θ between both the inclined surfaces 43 being 90 degrees or more. In the light emitting device 10 of the present invention, light emitted by the light emitting element 30 is spread sufficiently in the longitudinal direction of the opening 41 so as to produce a band-shaped beam. As a result, when a plurality of light emitting devices 10 are disposed along the longitudinal direction of the light receiving surface 72 of the light guide plate 71 for constituting the surface light emitting apparatus 70, unevenness in luminance can be suppressed from occurring as dark portions are less likely to be generated between adjacent light emitting devices 10.

Owner:NICHIA CORP

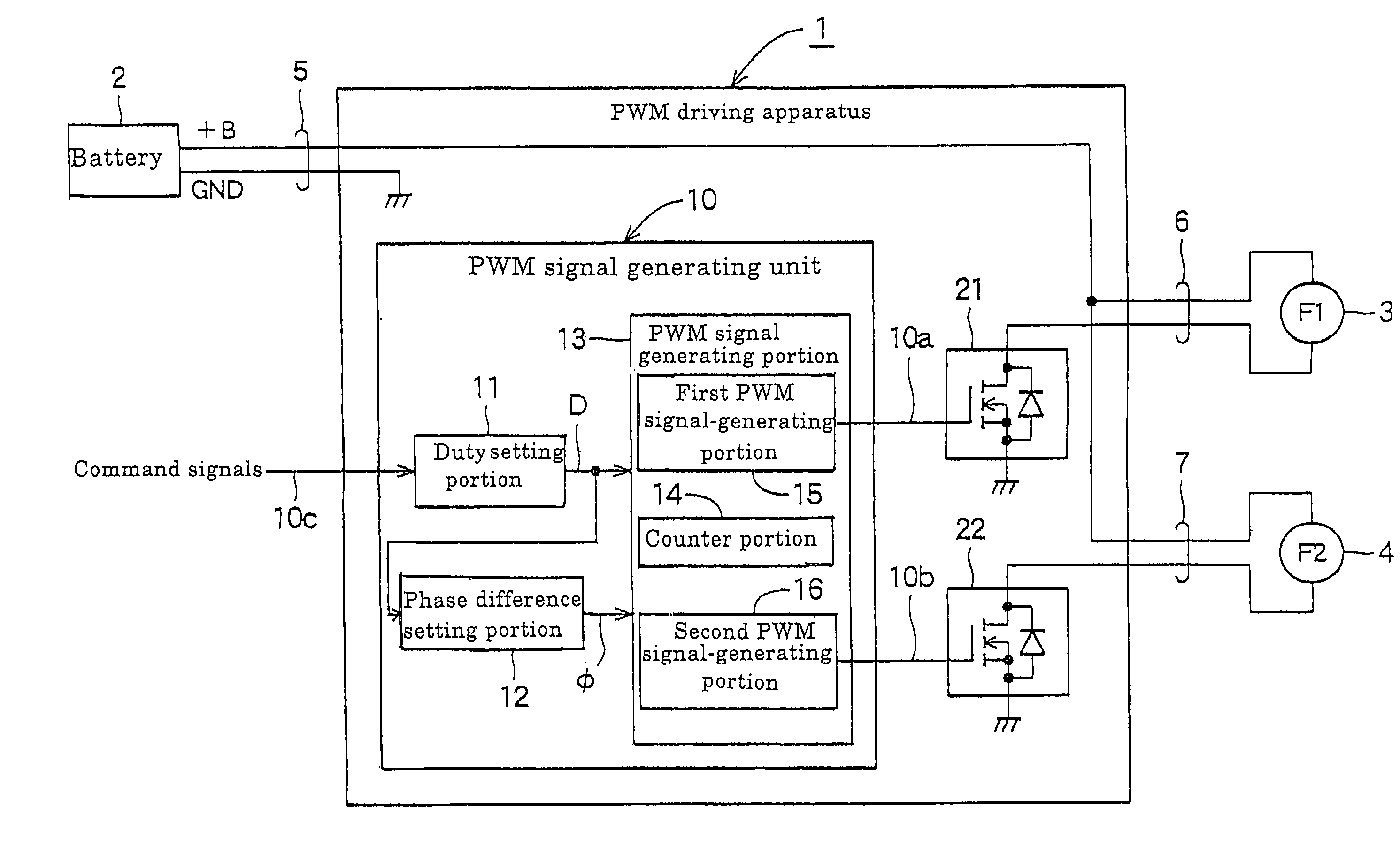

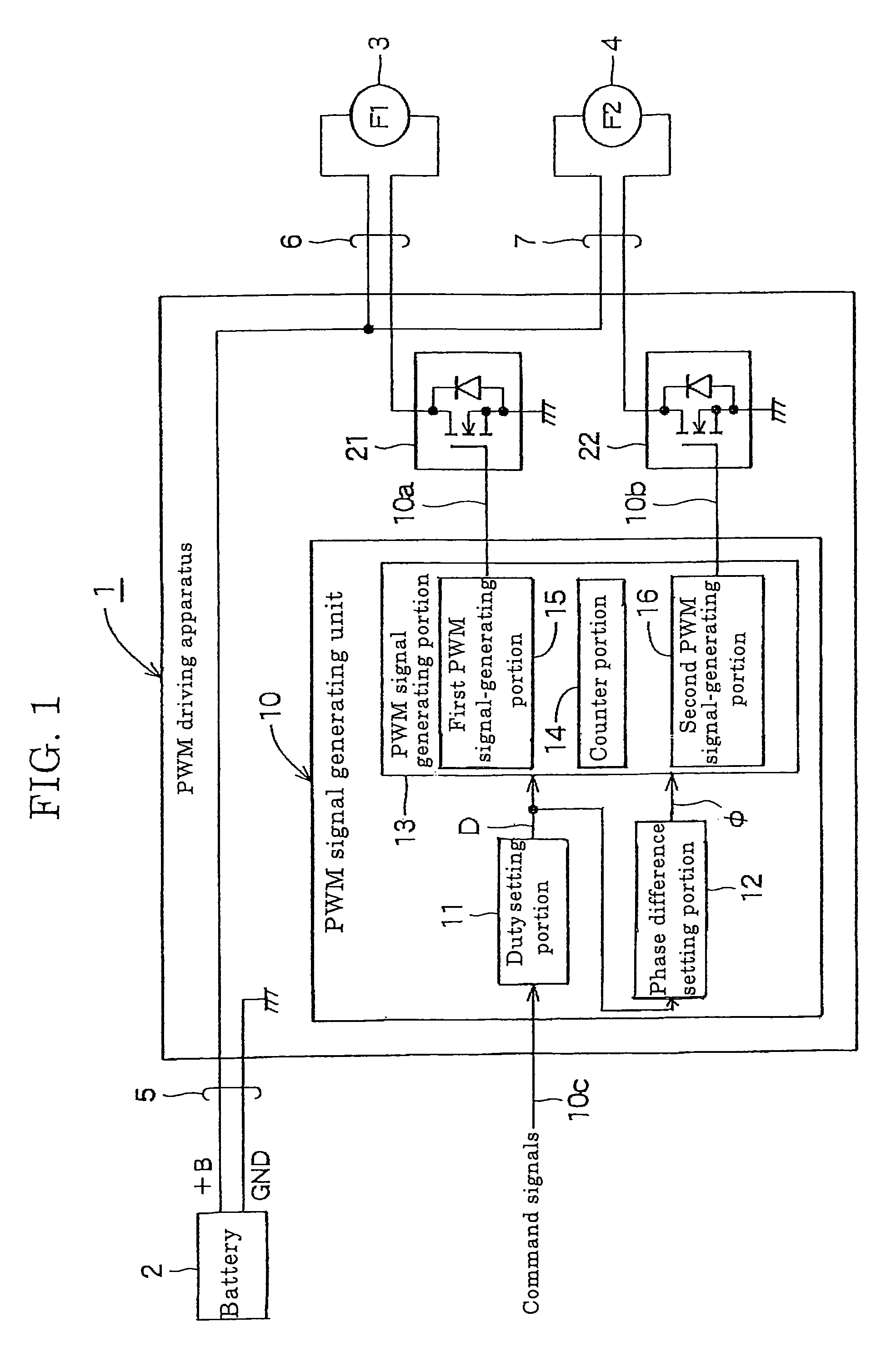

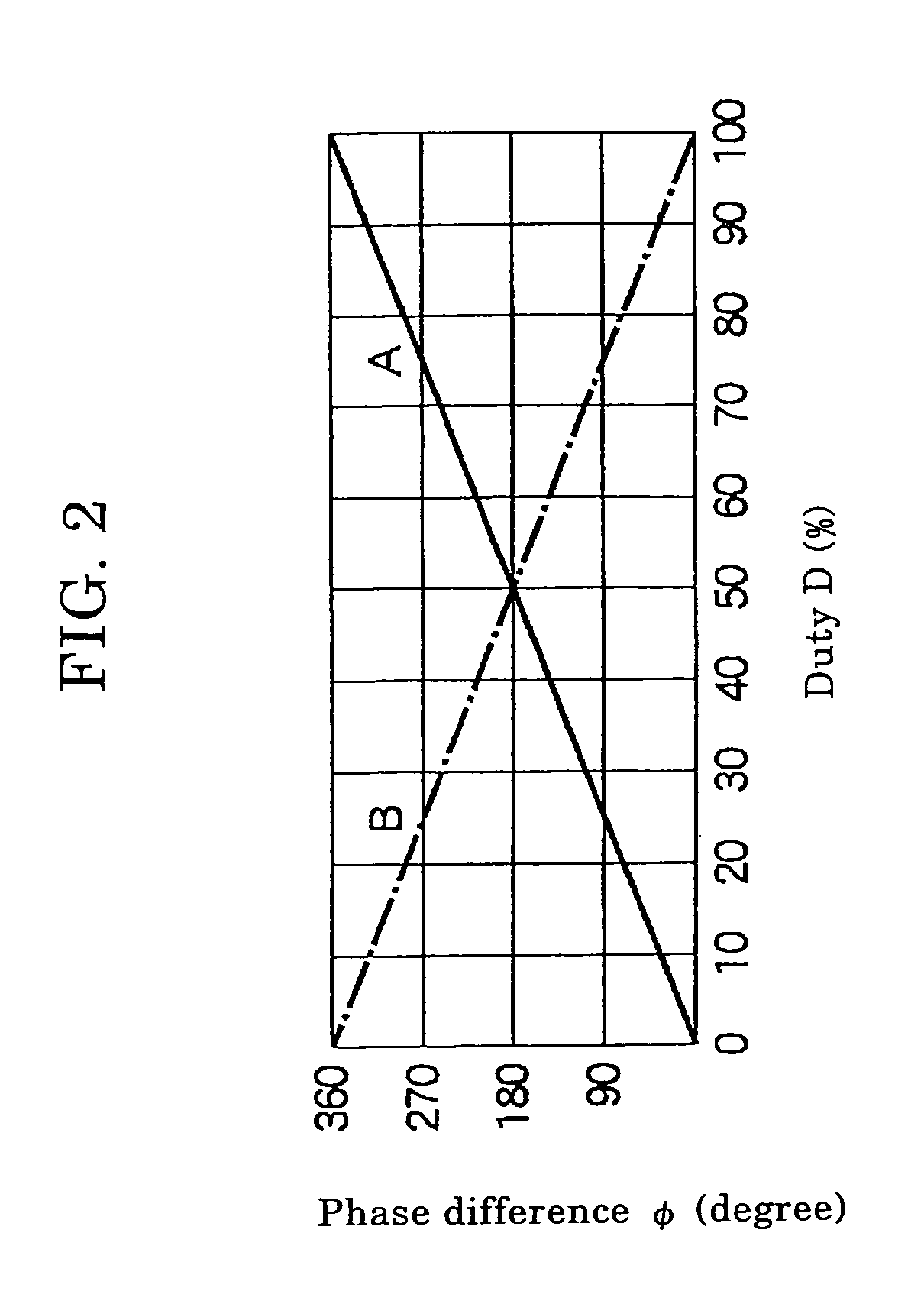

PWM driving apparatus

InactiveUS7079758B2Promote generationLess generationCoolant flow controlPump componentsPhase differencePwm signals

When a PWM signal generating unit (10) sets a duty D of a PWM signal based on command signals (10c), the PWM signal generating unit (10) sets a phase difference φ between each of the PWM signals based on a relation formula of φ (degree)=360 (degree)×D (%) / 100 (%), and generates and outputs first PWM signals (10a) and second PWM signals (10b) in which the duty is D (%) and the phase difference is φ (degree). The first PWM signals (10a) and the second PWM signals (10b) are respectively supplied to a first load driving circuit (21) and a second load driving circuit (22) to operate a first motor fan (3) and a second motor fan (4) by a PWM control, respectively.

Owner:CALSONIC KANSEI CORP

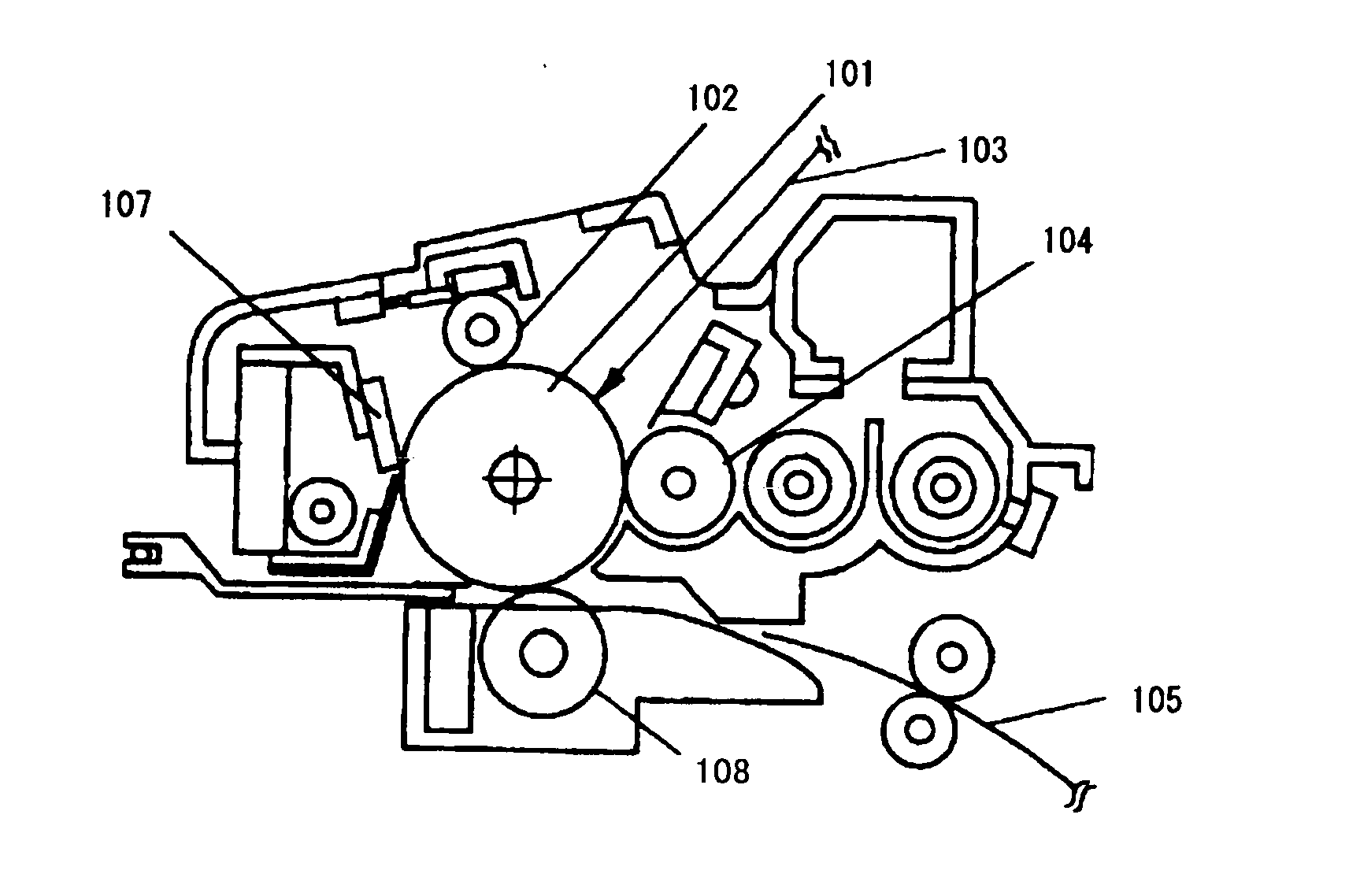

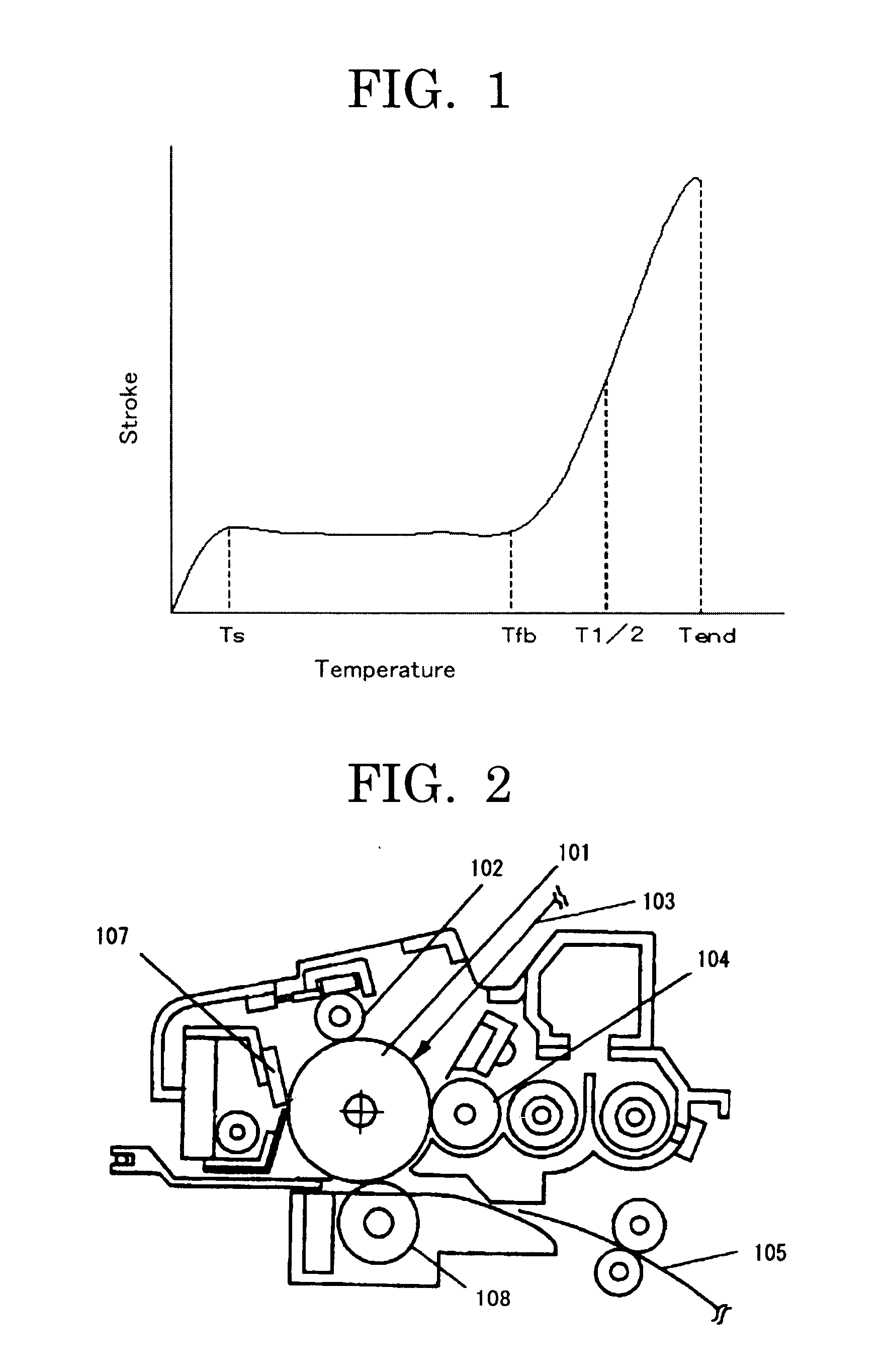

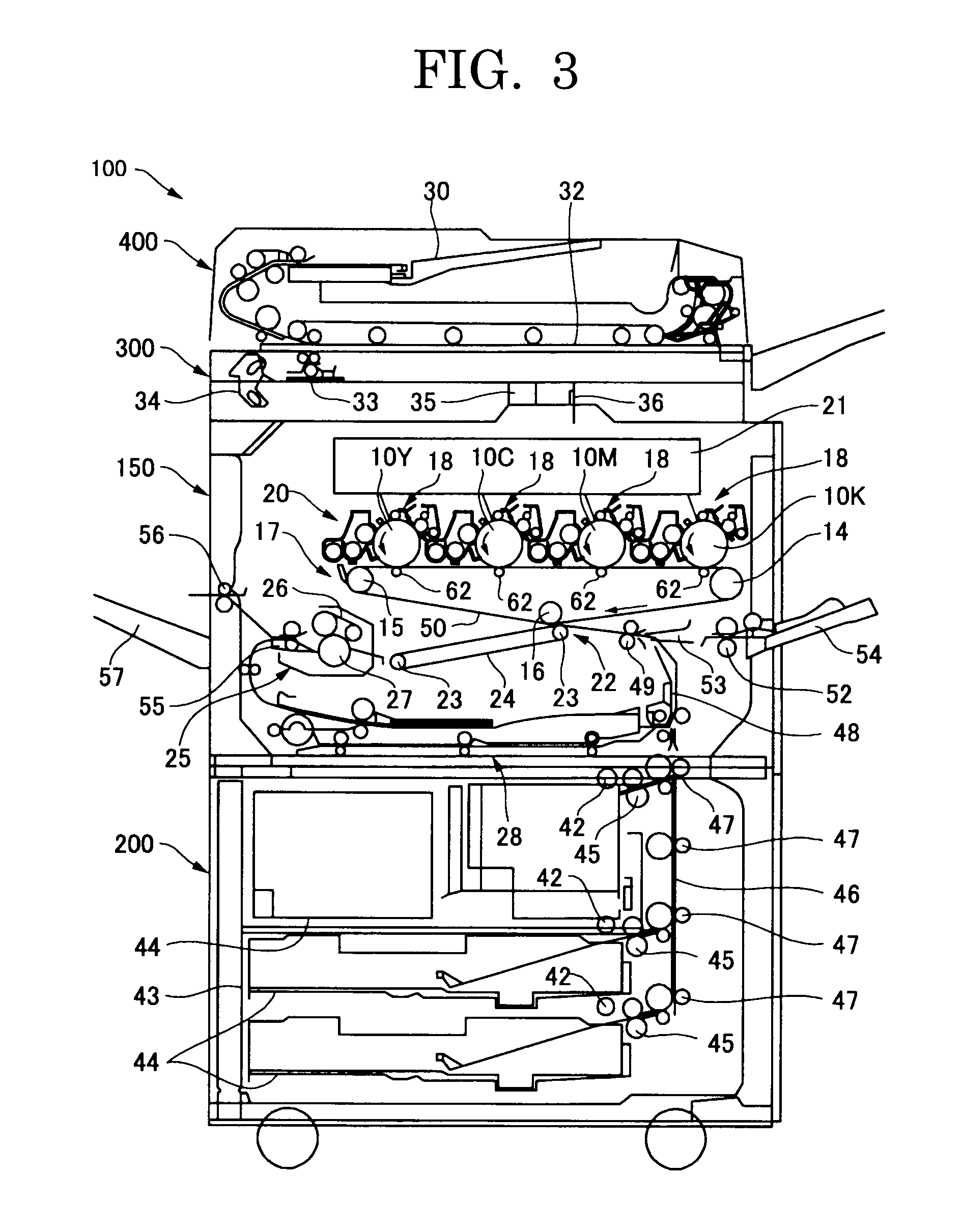

Toner

InactiveUS20110294058A1Excellent fluidityExcellent abilityElectrographic process apparatusDevelopersWaxEngineering

A toner containing a wax, wherein the wax has a mass decrease at 165° C. of 10% by mass or less, a molecular chain consisting of C—H bonds and C—C bonds, and a penetration of 5 mm to 25 mm, wherein a product of a ½ method softening point (° C.) of the toner and an amount of the wax on a surface of the toner is 8 to 20, and wherein the toner is obtained by a method including emulsifying or dispersing in an aqueous medium a toner material liquid, which is a liquid containing a toner material, which contains the wax.

Owner:RICOH KK

Honeycomb structural body

InactiveUS20080086993A1Low pressure lossGood partitionCombination devicesAuxillary pretreatmentParticulatesEngineering

An object of the present invention is to provide a honeycomb structural body (filter) which has a low pressure loss upon collecting particulates, makes it possible to deposit a great amount of particulates and ashes, and is less likely to produce cracks. The columnar honeycomb structural body of the present invention includes a plurality of through holes placed in parallel with one another in the length direction, and wall portion that separates the plurality of through holes from one another and constitutes a circumferential face, wherein the plurality of through holes are composed of a group of large-capacity through holes, with one end thereof being sealed so as to cause the total of areas of cross-section perpendicular to the length direction to become relatively greater, and a group of small-capacity through holes, with the other end thereof being sealed so as to cause the total of areas of the above-mentioned cross-section to become relatively smaller, and the above-mentioned circumferential face of the columnar honeycomb structural body has a chamfered corner portion.

Owner:IBIDEN CO LTD

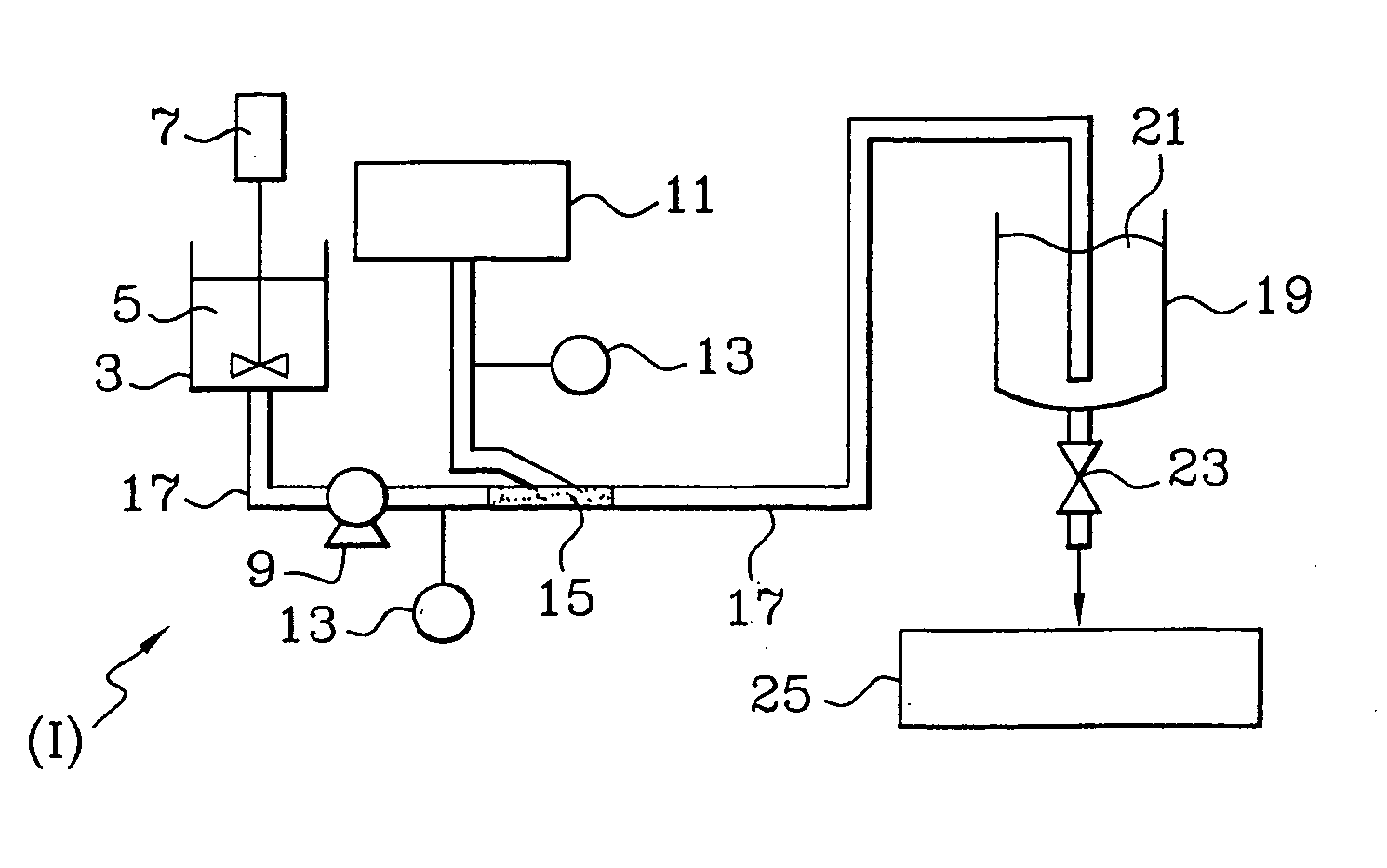

Method and system for sterilizing food packaging container or food filling system

InactiveUS20040146620A1Maximum sterilizing effectLess generationPackage sterilisationFood preservationFood packagingBiomedical engineering

The present invention provides a method of sterilizing a food packaging container or a food charging system, which comprises a chemical sterilizing treatment which involves contacting an aqueous sterilizing solution containing a hypochlorous acid-containing, chlorine-based sterilizing agent and a pH adjusting agent with the surface of a food packaging container or the surface of a line pipe, an instrument and a chamber in a food packaging system and a heat sterilizing treatment which involves increasing the temperature of the surface to be sterilized, the two sterilizing treatments being carried out simultaneously or in separate steps. The invention also provides a sterilizing device which has a predetermined sterilizing effect on a wide variety of microbial species, can be easily handled, does not corrode a treated surface over a prolonged period of time, is free of a pungent smell and does not require any special treatment for disposal of waste liquor.

Owner:TOYO SEIKAN KAISHA LTD +1

Solid-state image pickup device

InactiveUS20060042677A1Avoid mixing colorsFavorable photoelectric conversion layerTelevision system detailsPV power plantsCompound (substance)Engineering

The present invention provides a solid state image pickup device, including a silicon substrate and a photoelectric conversion unit which receives external incident light and generates signals in accordance therewith, and which is formed on or above the surface of the silicon substrate, wherein a signal transmission circuit for reading out the signals generated in the photoelectric conversion unit is formed on the silicon substrate; the photoelectric conversion unit includes a photoelectric conversion layer which has a laminated structure of plural compound semiconductor layers, which are different from each other in light wavelength to absorb and are provided with the laminated structure so that the shorter a light absorption wavelength of a compound semiconductor layer is, the closer to a light incident side the compound semiconductor layer resides; and the plural compound semiconductor layers are respectively connected to pixel electrodes formed on the signal transmission circuit.

Owner:FUJIFILM HLDG CORP +1

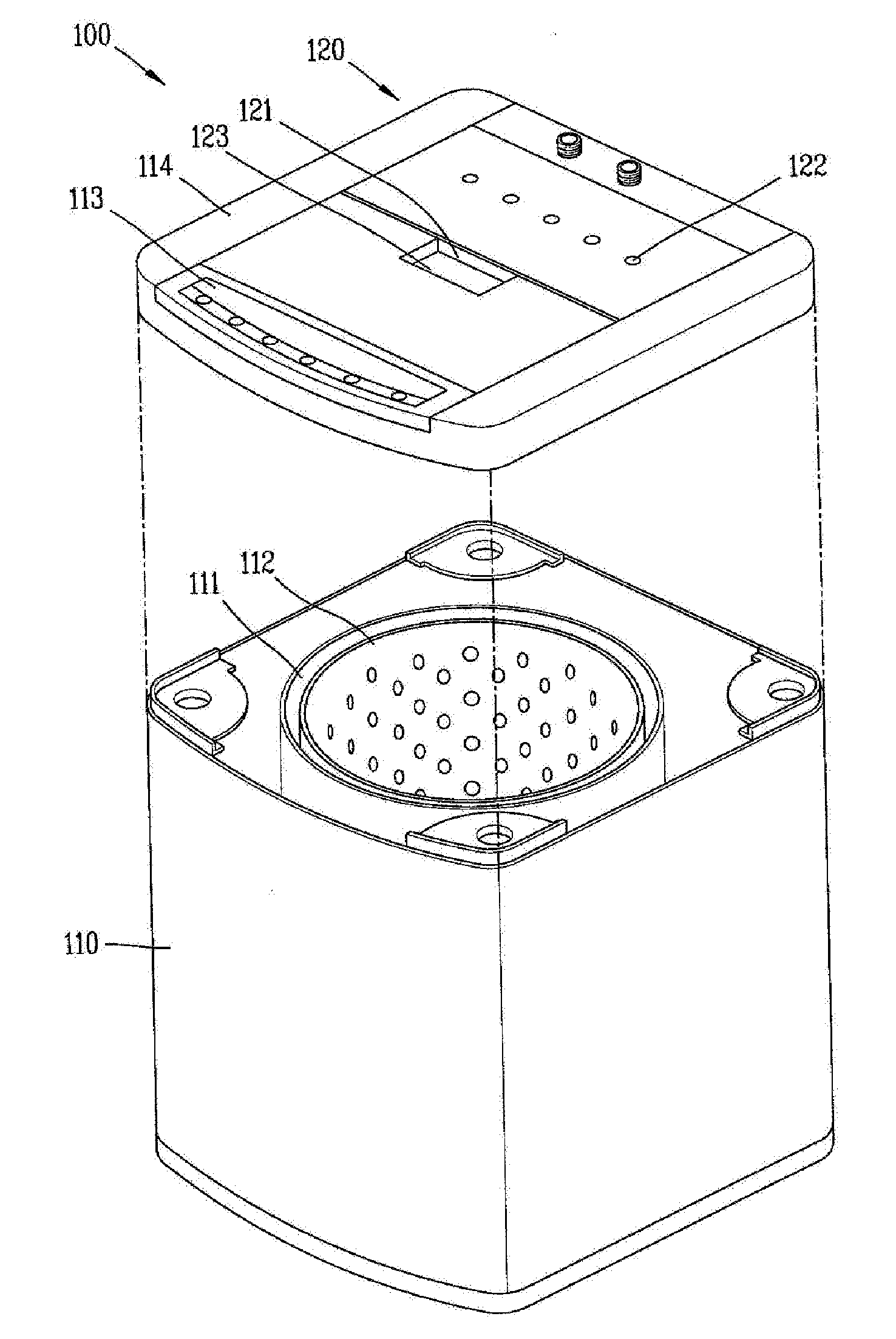

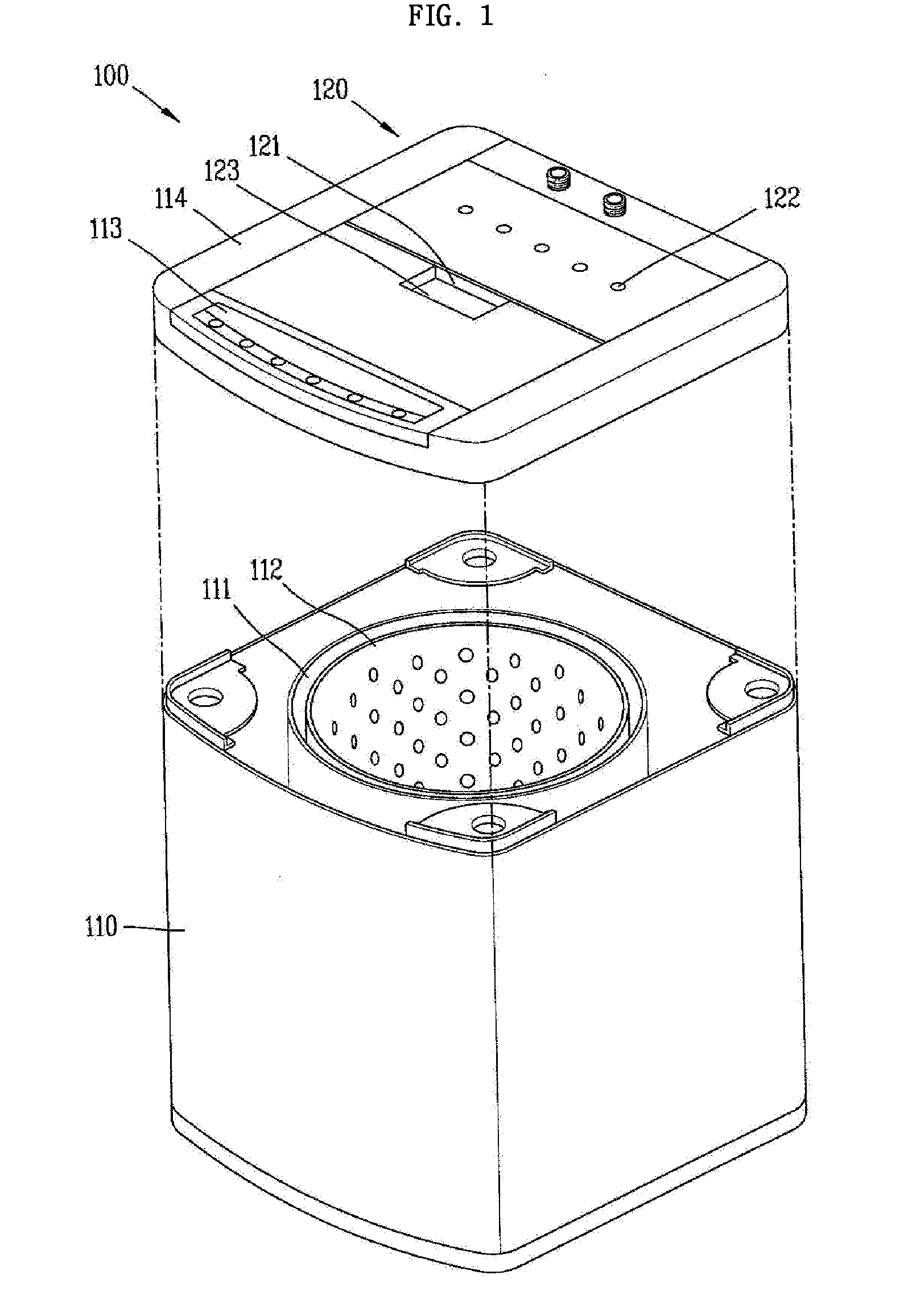

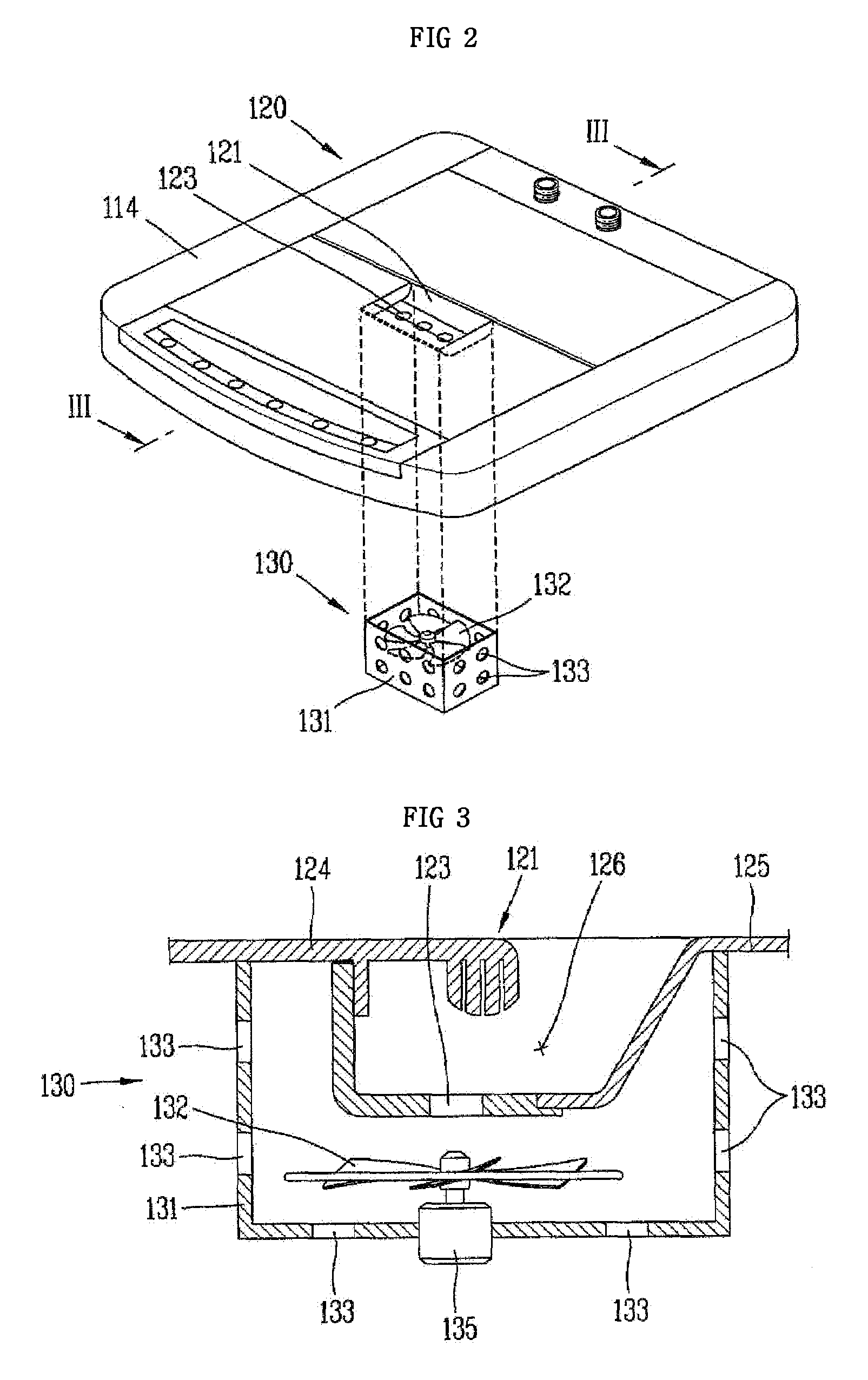

Washing machine having dehumidifying apparatus and dehumidifying method thereof

InactiveUS20080295696A1Effective exhaustActive connectionCombination devicesAuxillary pretreatmentForeign matterEngineering

Disclosed is a washing machine having a dehumidifying apparatus and a dehumidifying method thereof, the washing machine comprising: a casing forming an appearance, a door installed at one side of the casing so as to receive laundry therein, a top cover opened / closed by the door, an outer tub installed in the casing, an inner tub rotatably installed in the outer tub, and a dehumidifying apparatus for removing moisture generated from the laundry, accordingly it is capable of less generating a foreign substance or odor caused by moisture left in the washing machine after the washing completion and of increasing a dehumidifying efficiency by periodically or repeatedly dehumidifying the washing machine using the dehumidifying apparatus.

Owner:LG ELECTRONICS INC

Sliding film, sliding member, composition for sliding film, sliding device, swash-plate type compressor, process for forming sliding film, and process for producing sliding member

InactiveUS20050257684A1Avoid temperatureLonger heldMetallic material coating processesAdditivesVitrificationLatent heat

A sliding film includes a solid lubricant, a binder resin, and a low-melting-point material. The binder resin is for holding the solid lubricant on a surface of a substrate, and exhibits a glass transition temperature. The low-melting-point material exhibits a melting point lower than the glass transition temperature of the binder resin. The low-melting-point material demonstrates a latent heat which can absorb frictional heat generated between sliding members, and accordingly retards the degradation of the binder resin. As a result, the sliding film produces high seizure resistance.

Owner:TOYOTA IND CORP +1

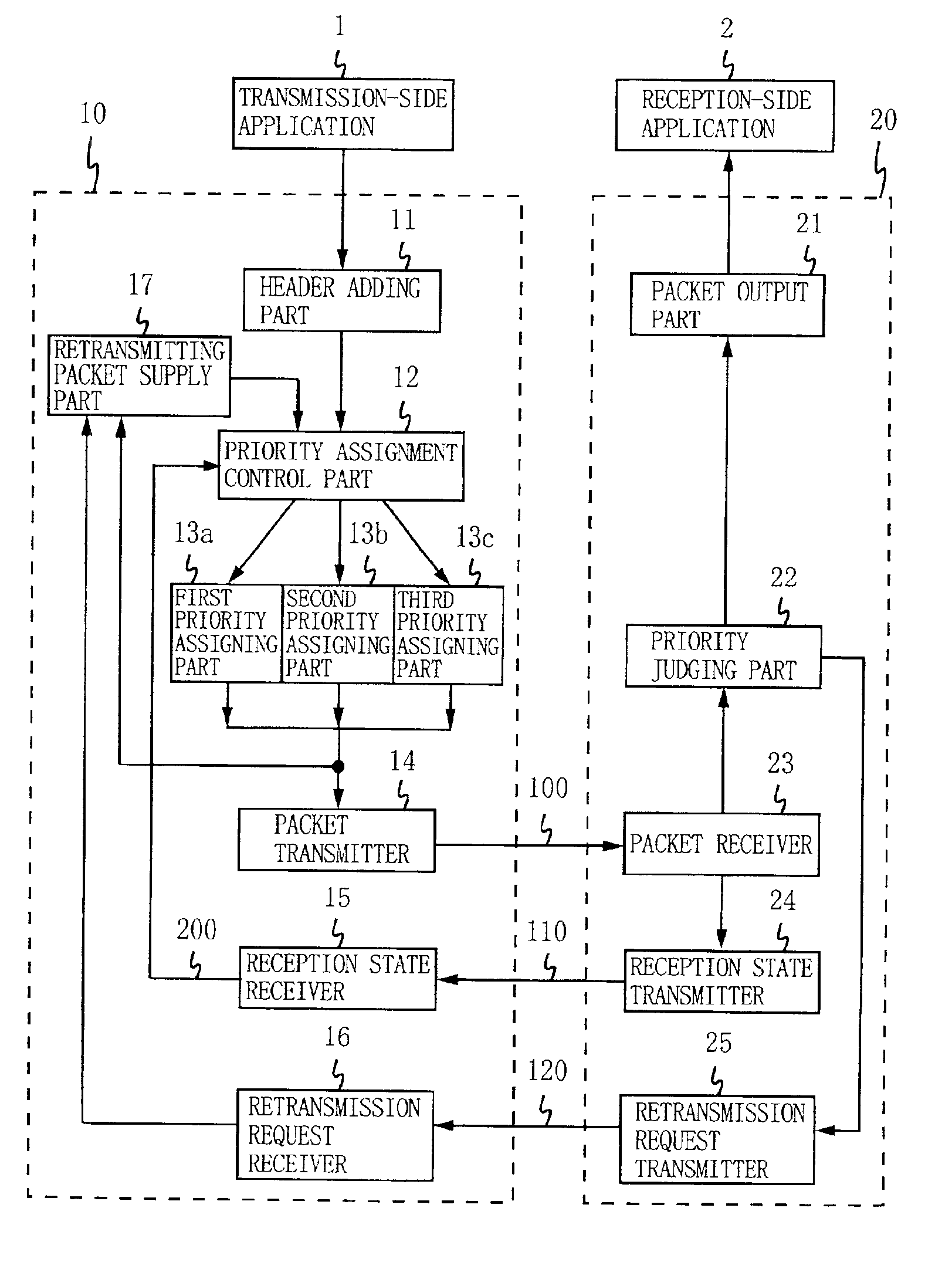

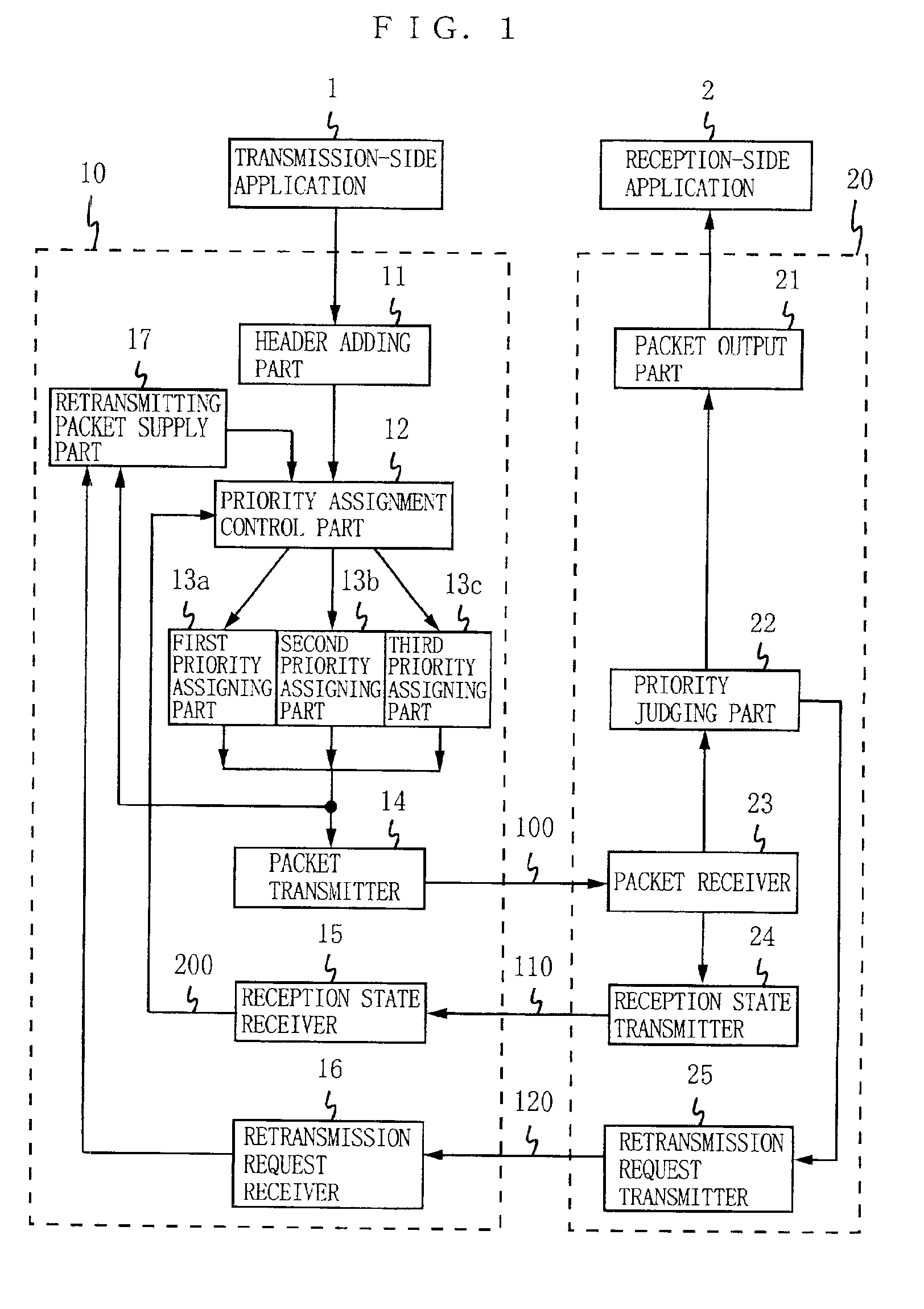

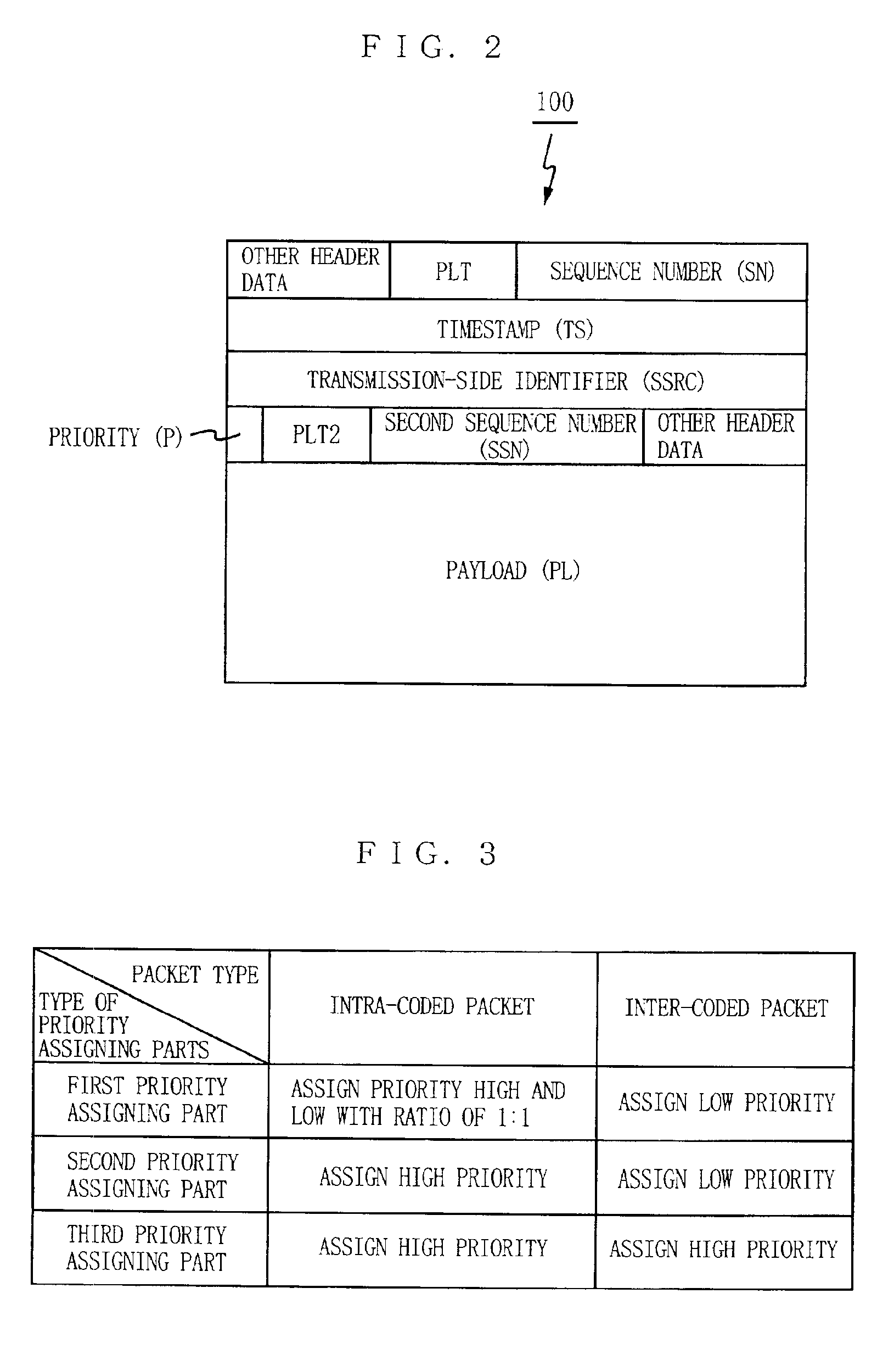

Transmission apparatus and method for changing data packets priority assignment depending on the reception feedback

ActiveUS6987730B2Efficient executionLess generationError prevention/detection by using return channelTransmission systemsPacket lossComputer science

A data transmitter 10 transmits packets each with a sequence number and a priority added. A data receiver 20 detects any packet loss by referring to the sequence numbers added to the packets, and if detecting any packet of high priority as having been lost, requests for packet retransmission. Based on information about thus detected packet loss, the data receiver 20 generates and transmits an RR packet 110 indicating the packet reception state. The data transmitter 10 extracts from the RR packet 110 a packet loss ratio 200, and therewith, changes manners of priority assignment. The manners are so changed that the packet of high priority is found with a lower ratio when the packet loss ratio 200 is high, and when the packet loss ratio 200 is low, found with a higher ratio.

Owner:PANASONIC CORP

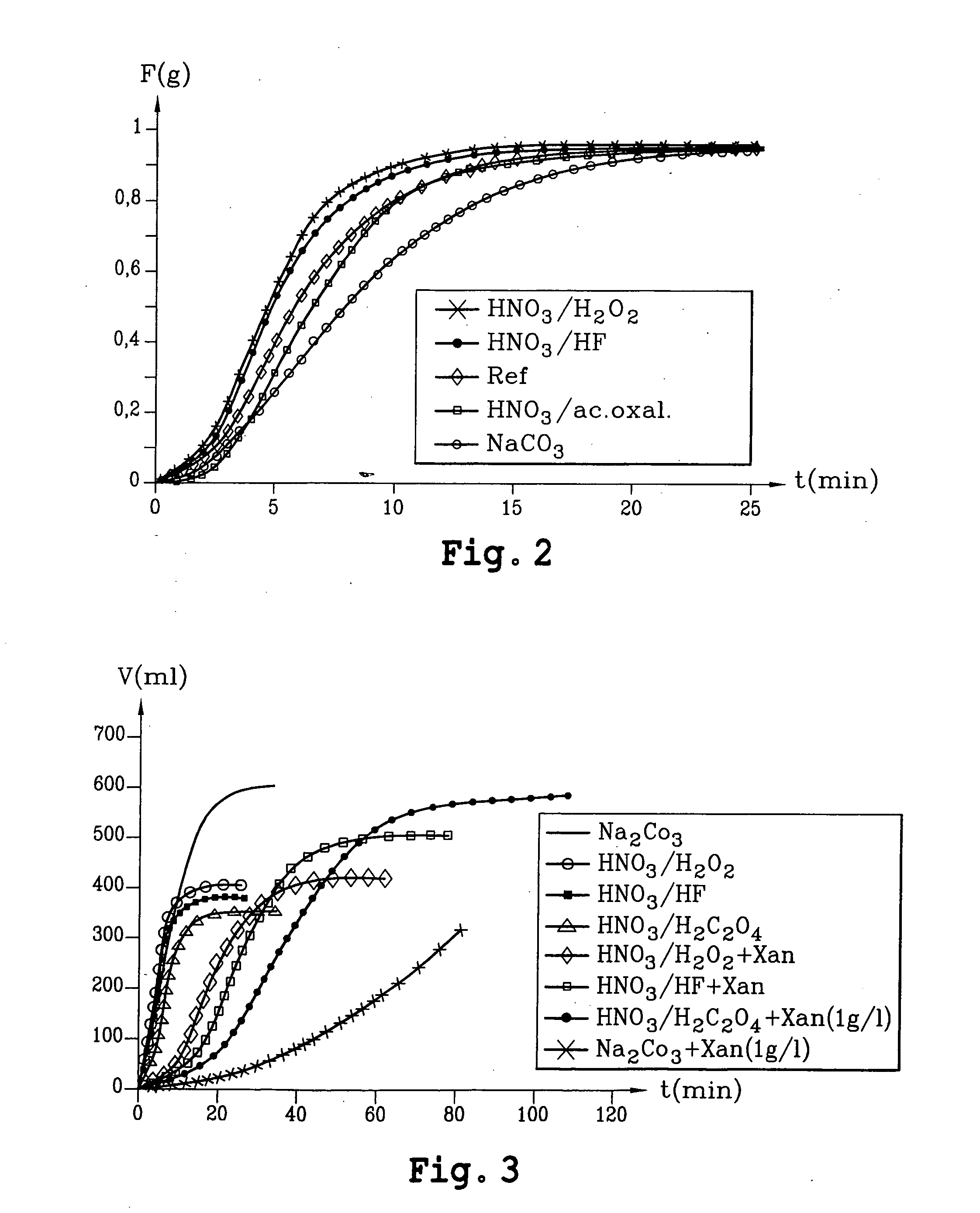

Composition, foam and process for the decontamination of surfaces

InactiveUS20060211592A1Simple procedureReduce pollutionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSURFACTANT BLENDChemistry

The invention relates to a composition which makes it possible to obtain a gelled aqueous foam capable of decontaminating, stripping or degreasing a surface. The composition of the present invention comprises one or more surfactants, one or more acidic or basic reactants and a gelling agent. The decontamination foam obtained from this composition exhibits long lifetimes, generally of between 1 and 10 hours, guaranteeing a prolonged time of action on the surface and a high decontamination effectiveness. These foams can be used to remove the radioactivity from an inaccessible plant, which is large in size and complex in design, by simple filling or by simple spraying over an accessible surface.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Plasma resistant quartz glass jig

InactiveUS20020046992A1Less generationAdvantageously producedElectric discharge tubesSemiconductor/solid-state device manufacturingSurface roughnessHydrogen molecule

It is an object of the present invention to provide a quartz glass jig excellent in the plasma etching resistant characteristics, which does not generate an abnormal etching and particles when used for a plasma generating apparatus. The above Object is obtained by a plasma resistant quartz glass jig that is used for an apparatus of generating plasma, wherein the surface roughness Ra of the quartz glass surface is in a range of from 5 mum to 0.05 mum, the number of microcracks of the surface is not more than 500 microcracks / cm2, and the hydrogen molecule concentration in the quartz glass is at least 5x1016 molecules / cm3.

Owner:HERAEUS QUARZGLAS +1

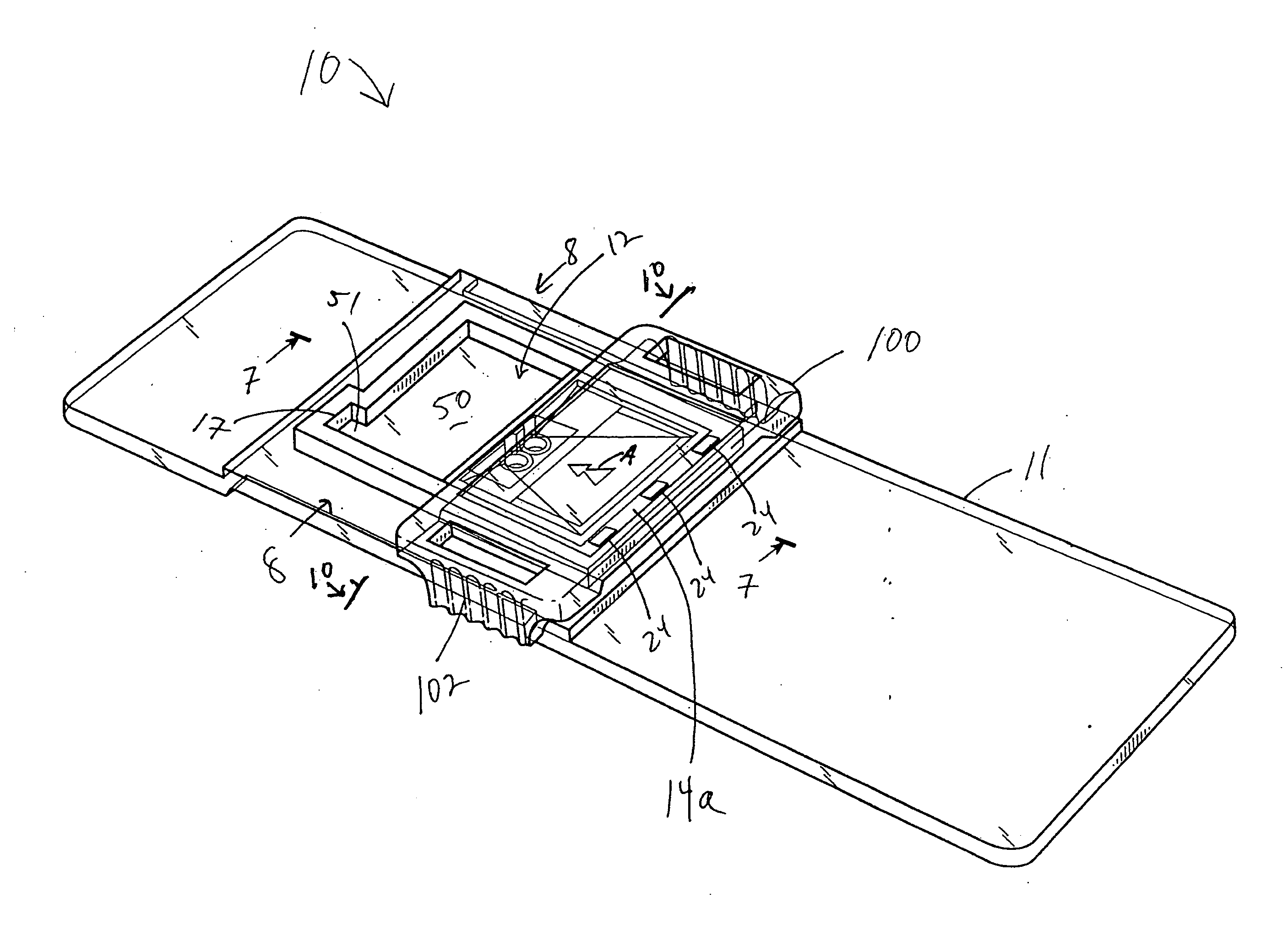

Assay devices

InactiveUS20060105469A1Relieve pressureLess generationPreparing sample for investigationMaterial analysis by optical meansAnalyteEngineering

Assay devices are disclosed comprising a base defining a cavity and an insert received in the cavity. The cavity has major surface and at least one sidewall, preferably surrounding the major surface. The insert comprises a first surface with a portion opposing the major surface of the cavity. A space is provided between the portion of the first surface and the major surface for the receipt of a fluid sample. The space has an entrance defined by the first surface of the insert and the major surface. The insert also comprises a second surface opposing the first surface and having an input portion for the application of a fluid sample. The input portion is in fluid communication with the entrance to the space, such that a fluid sample applied to the input portion passes to the entrance to the space and into the space. At least one or more passages is preferably defined through the insert, for passage of the fluid sample through the insert, to the entrance to the space. The second surface of the insert also comprises a reading portion for analyzing the fluid sample in the space. Reagents may be provided in the space for identifying and quantifying the presence of one or more analytes in the fluid sample. Preferably, the assay device is transparent. The portion of the first surface and the first surface of the insert and the major surface of the cavity may be separated by a distance effective to cause capillary flow of the fluid sample into the space from the entrance to the space.

Owner:UMEDIK

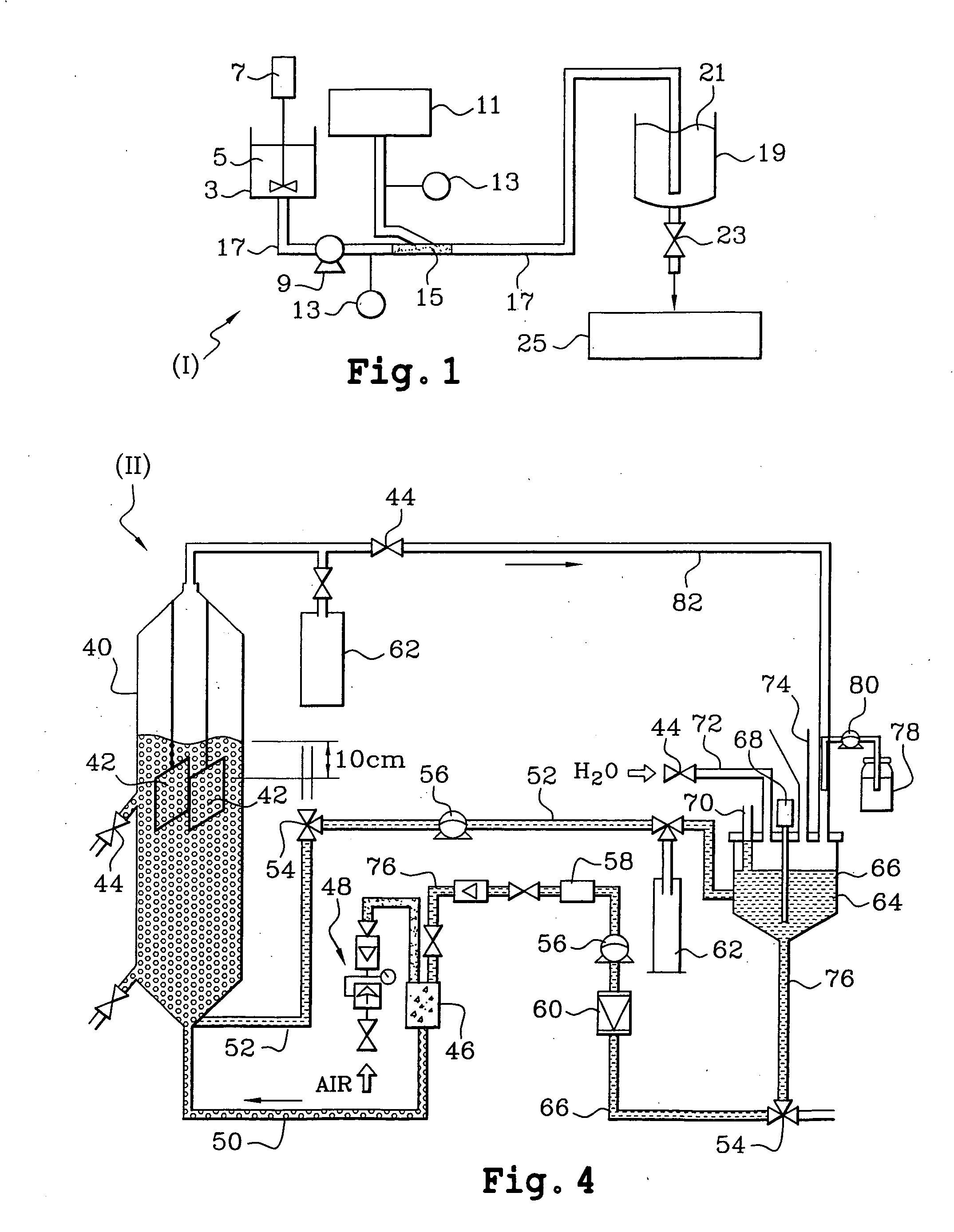

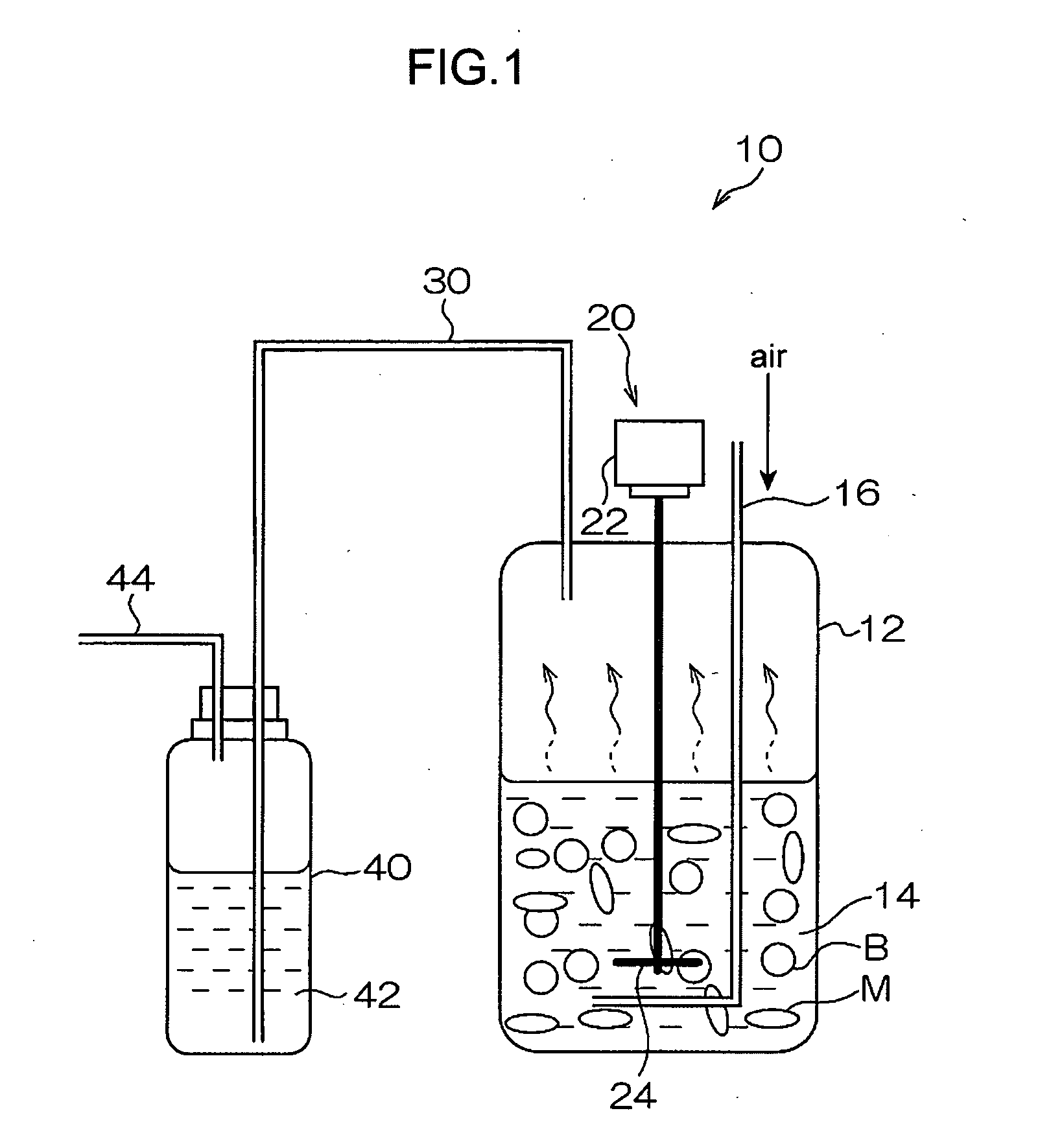

Isopropyl alcohol- producing bacterium and method of producing isopropyl alcohol using the same

ActiveUS20100311135A1Decrease productivityProduce significantBioreactor/fermenter combinationsBiological substance pretreatmentsAcetoacetate decarboxylase activityBiochemistry

The invention provides: an isopropyl alcohol-producing bacterium which has an acetoacetate decarboxylase activity, an isopropyl alcohol dehydrogenase activity, a CoA transferase activity and a thiolase activity having been imparted thereto and is capable of producing isopropyl alcohol from a plant-derived material; a method of producing isopropyl alcohol whereby isopropyl alcohol is produced from a plant-derived material by using this isopropyl alcohol-producing bacterium; and an apparatus therefor.

Owner:MITSUI CHEM INC

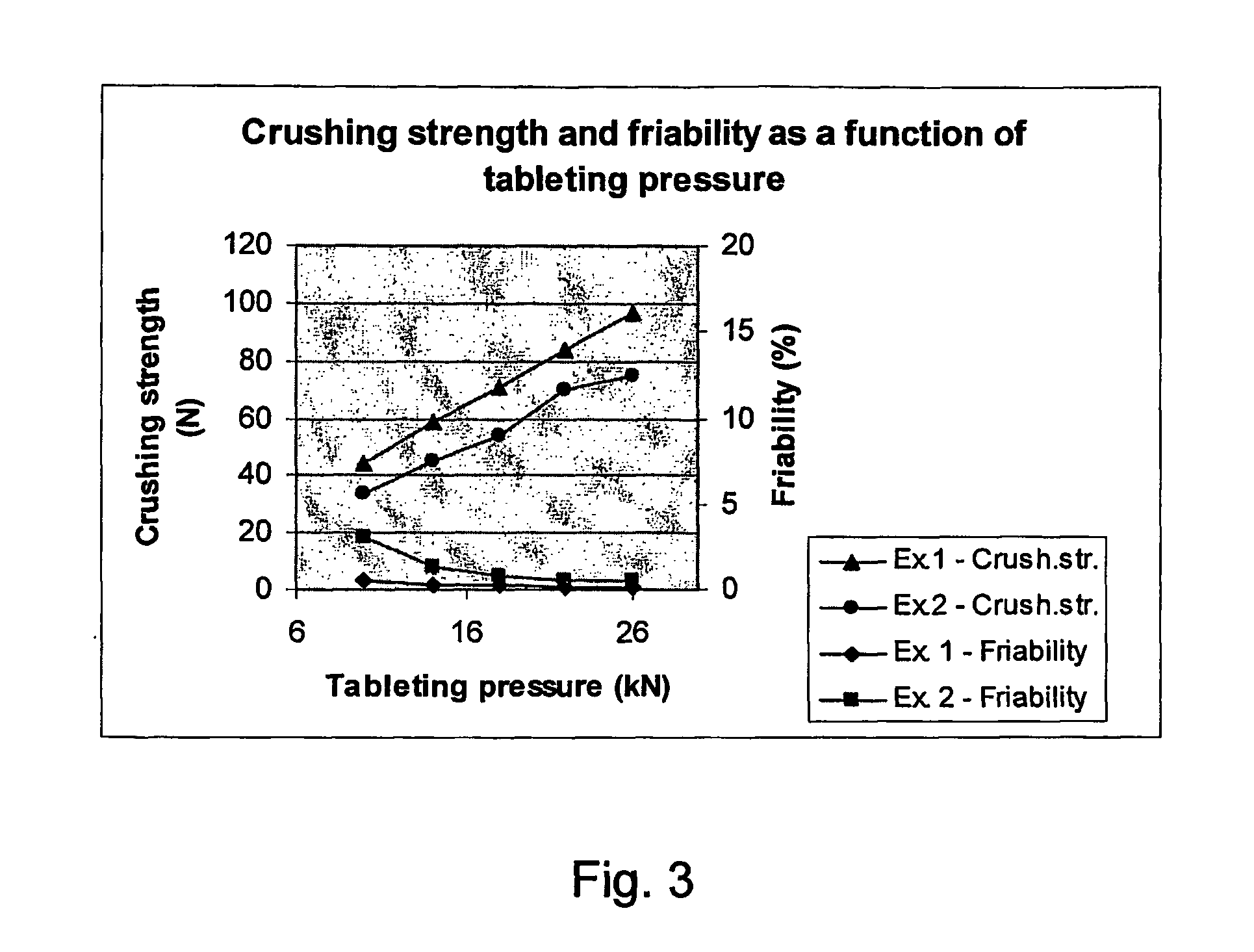

Film-Coated and/or Granulated Calcium-Containing Compounds and Use Thereof in Pharmaceutical Compositions

ActiveUS20090252805A1Small sizeShort processing timePowder deliverySugar food ingredientsDrugWater soluble polymers

Calcium-containing compounds have been at least partly film-coated and / or granulated with a water-soluble substance and a water-soluble polymeric substance and use of such coated compounds in pharmaceutical compositions. The at least partly film-coated and / or granulated calcium-containing compounds have proved suitable for the preparation of tablets having a very high load of elemental calcium and a conveniently small size. A drug load of about 96% or more is obtained in tablets of the invention that have sufficient mechanical and organoleptic properties.

Owner:TAKEDA AS

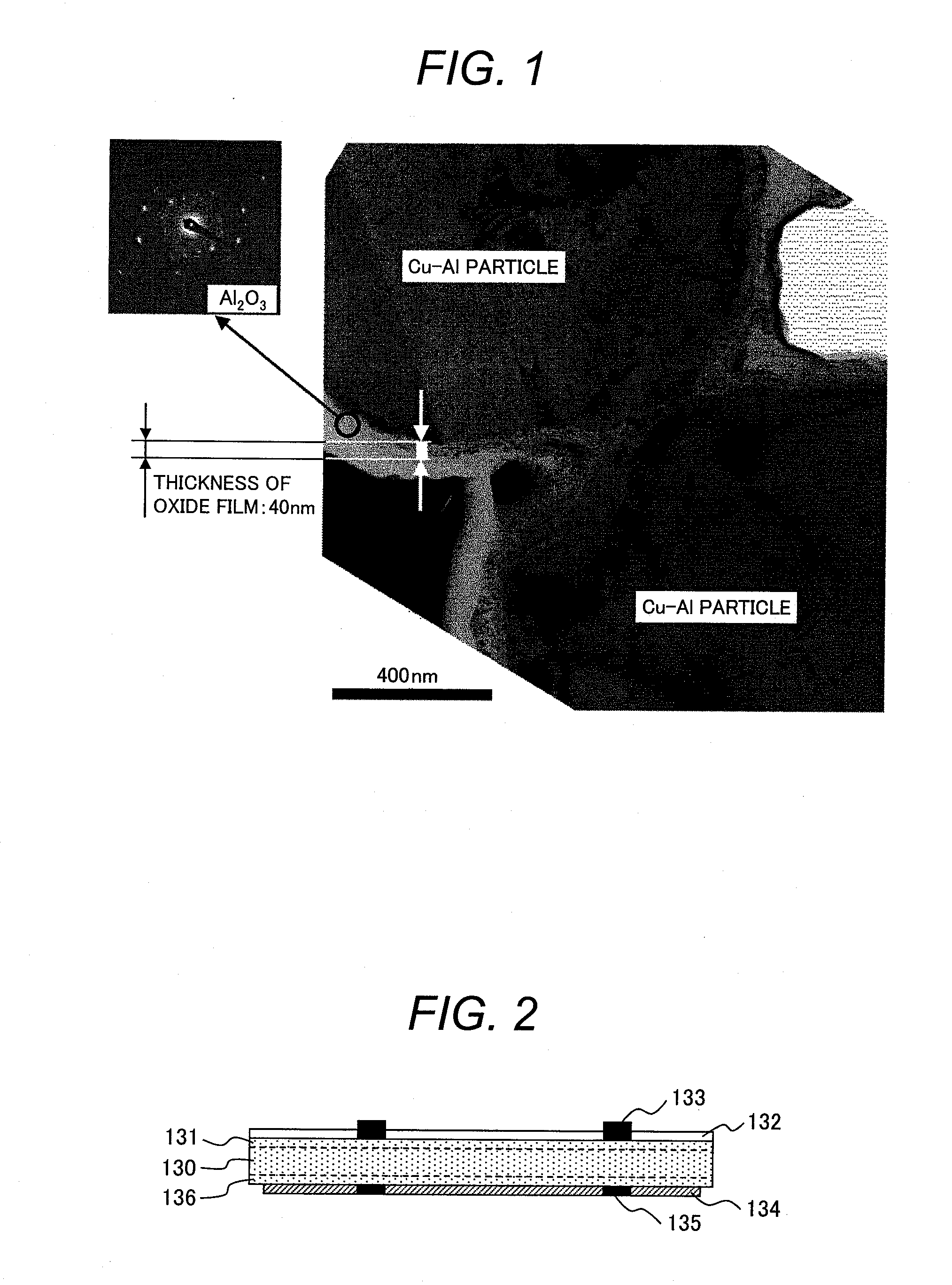

Cu-Al ALLOY POWDER, ALLOY PASTE UTILIZING SAME, AND ELECTRONIC COMPONENT

InactiveUS20120125670A1Satisfactory migration resistanceResistant to oxidationNon-insulated conductorsAddress electrodesAluminium oxideAlloy

In an electronic component having a wiring and / or an electrode prepared through firing of a paste or in an electronic component having a wiring in contact with a glass or glass ceramic member, provided is an electronic component using a Cu-based wiring material which less suffers from increase in electric resistance due to oxidation, which less causes bubbles in the glass or glass ceramic, and has satisfactory migration resistance. The Cu—Al alloy powder includes a Cu—Al alloy powder including Cu and, preferably, 50 percent by weight or less of Al; and an aluminum oxide film having a thickness of 80 nm or less and being present on the surface of the Cu—Al alloy powder. The powder, when compounded with a glass or glass ceramic material to give a paste, can be used to form wiring (interconnections), electrodes, and / or contact members.

Owner:HITACHI CHEM CO LTD

Optical film, method of manufacturing the same, polarizing plate, and liquid crystal display device

InactiveUS20090246416A1Reduce wrinklesIncrease contrastLiquid crystal compositionsOptical articlesCelluloseHydrogen atom

In the present invention, provided is an optical film exhibiting less generation of horseback failure, winding core transfer and wrinkles on a film when starting winding, and also provided is a manufacturing method thereof, further together with a polarizing plate and a liquid crystal display device exhibiting high contrast. Also disclosed is an optical film possessing a cellulose ester and a UV absorbent represented by the following Formula (1):wherein R1 representsR2 represents a methyl group, a t-butyl group, a t-amyl group or a t-octyl group; R3 represents a substituent; each of R4 and R5 represents a hydrogen atom or a substituent; m is an integer of 0-3; and n is an integer of 0-4.

Owner:KONICA MINOLTA OPTO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com