Patents

Literature

305results about How to "Avoid mixing colors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

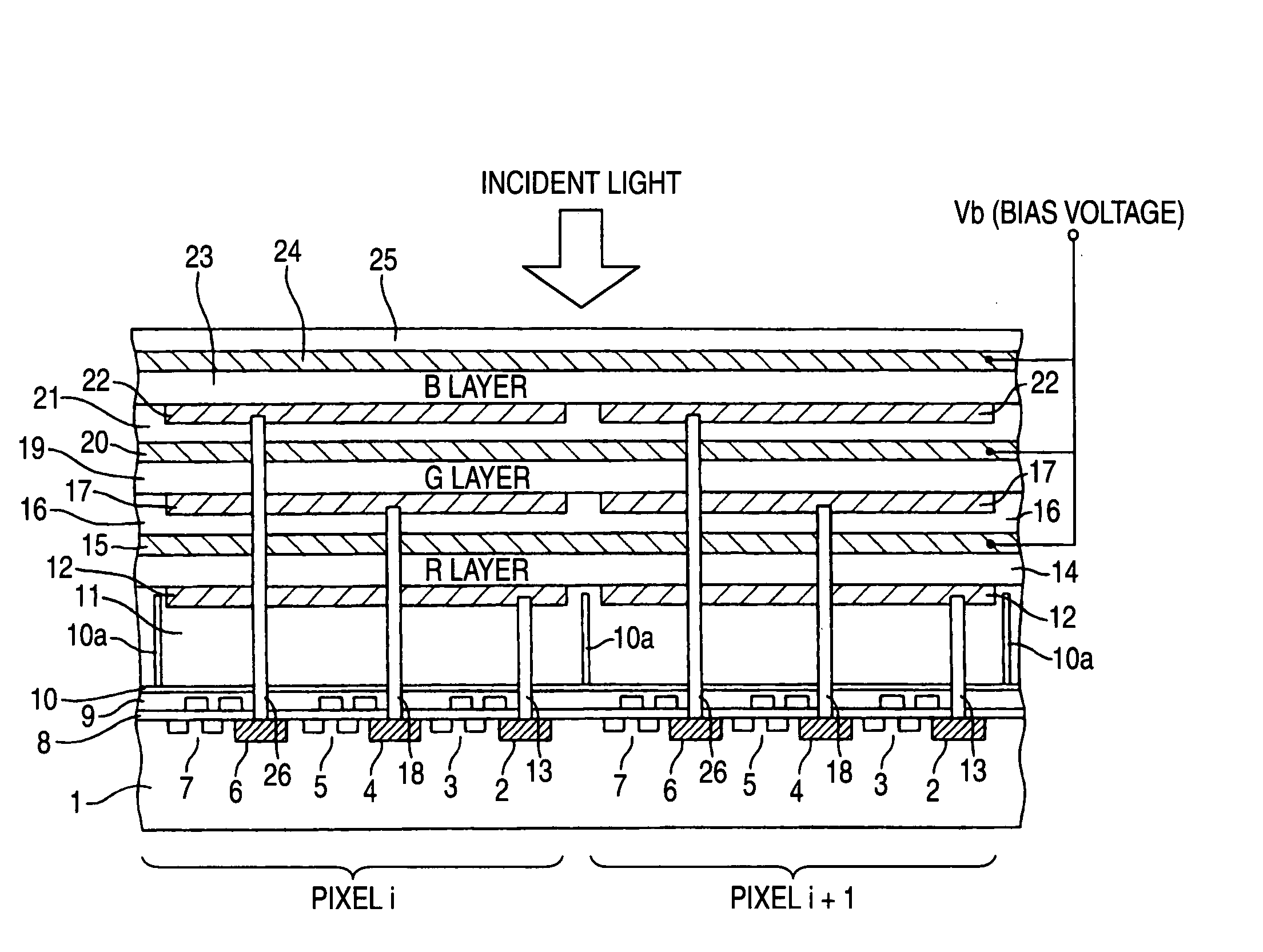

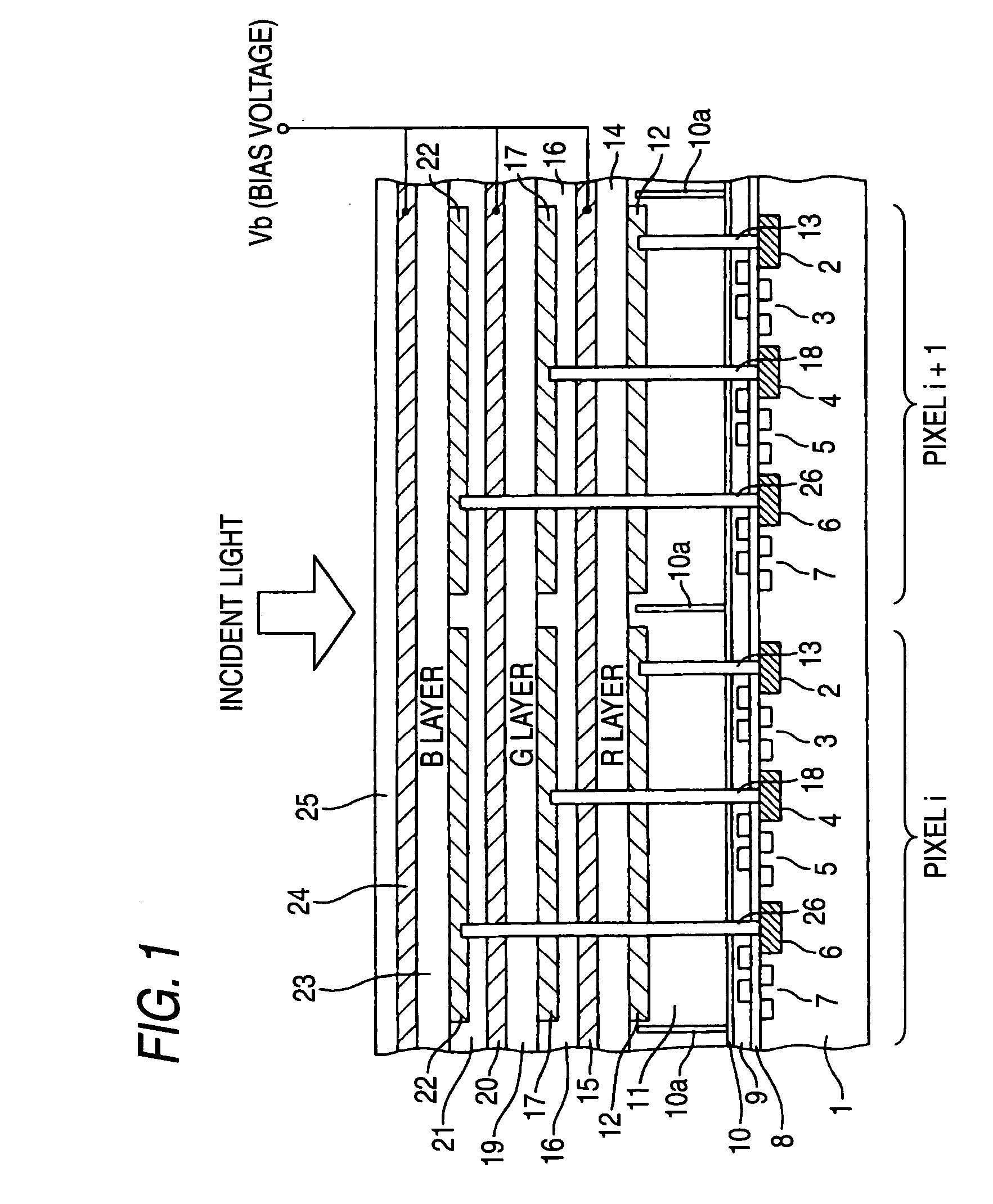

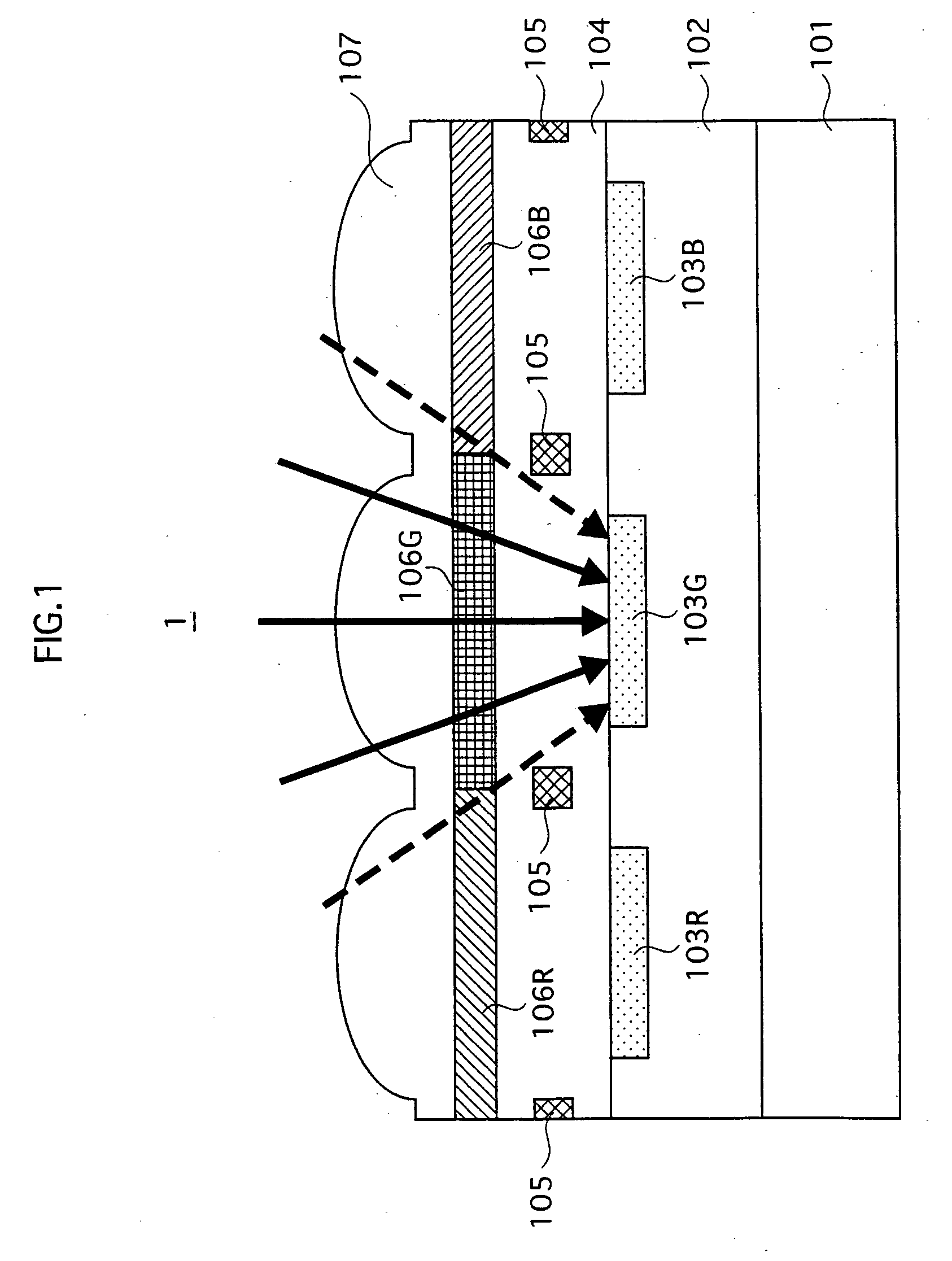

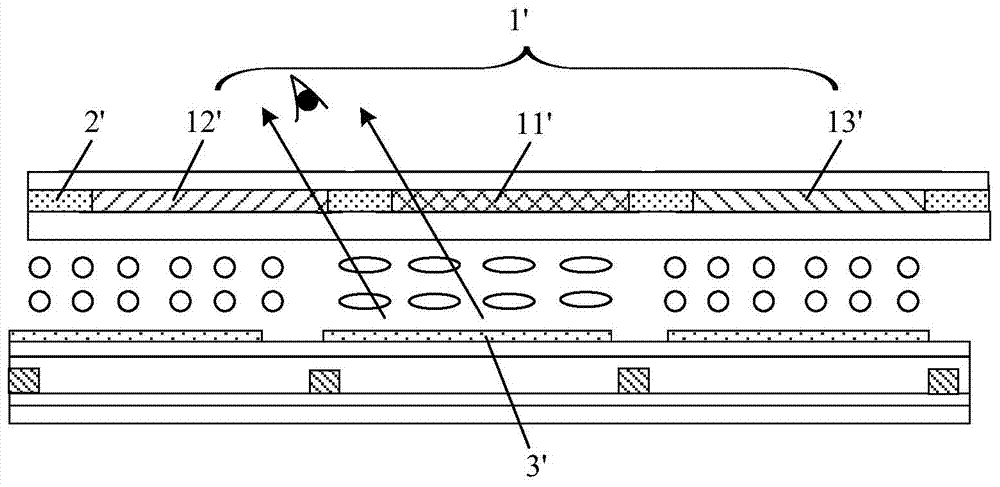

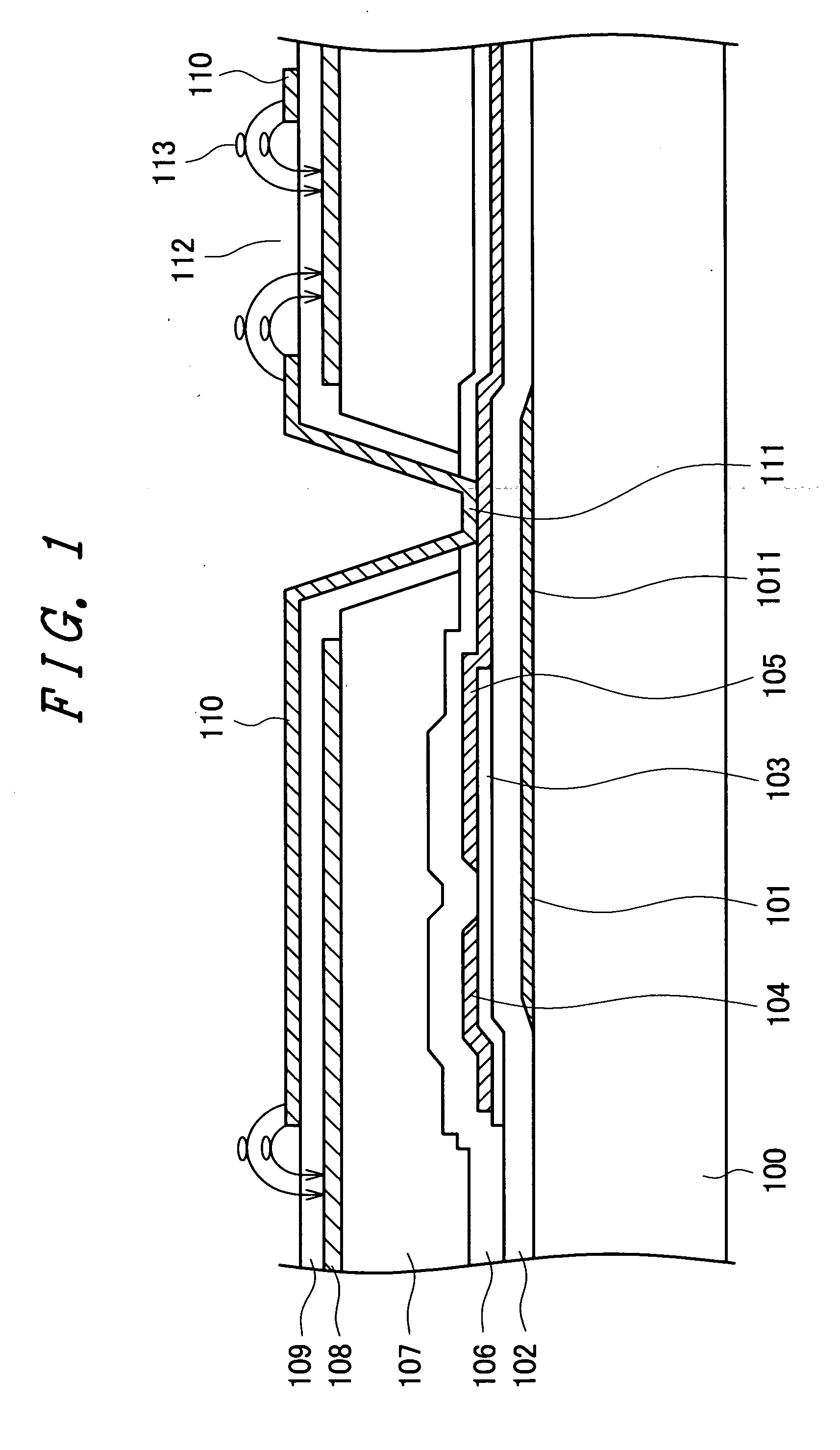

Photoelectric conversion layer-stacked solid-state imaging element

InactiveUS20060181629A1High-quality color imageEnsure sufficient separationTelevision system detailsTelevision system scanning detailsPhotoelectric conversionSemiconductor

A photoelectric conversion layer-stacked solid-state imaging element comprises: a semiconductor substrate having a signal reading circuit formed thereon; at least one layer of photoelectric conversion layer each of which is provided interposed between a common electrode layer and a plurality of pixel electrode layers corresponding to pixels, said at least one layer of photoelectric conversion layer being stacked above the semiconductor substrate via a light shielding layer; and inhibiting structures each of which inhibits a reflected light produced by reflection of incident light on the light shielding layer, the incident light having passed through said at least one layer of photoelectric conversion layer and entered into a pixel, from entering in direction toward adjacent pixels.

Owner:FUJIFILM CORP

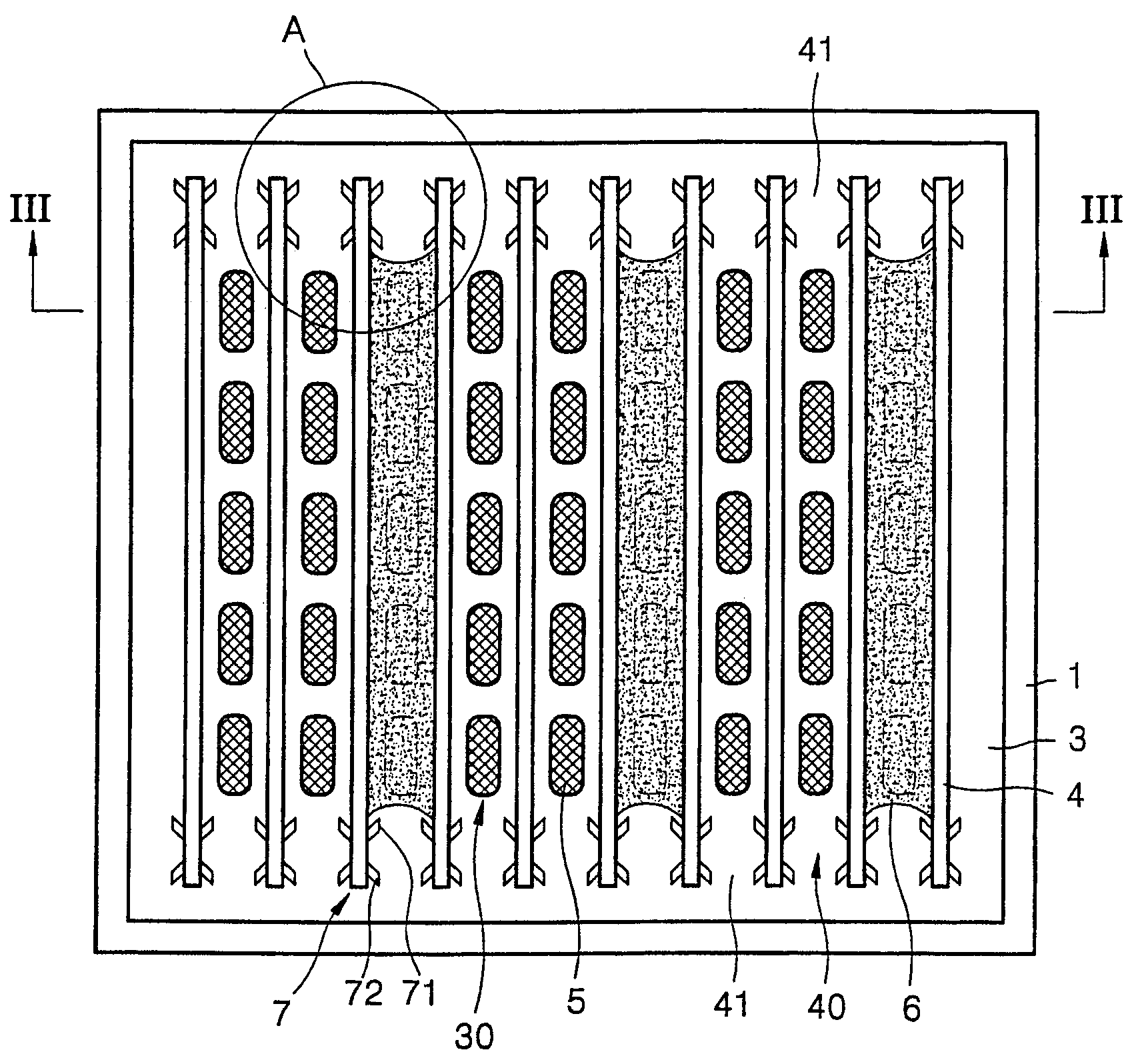

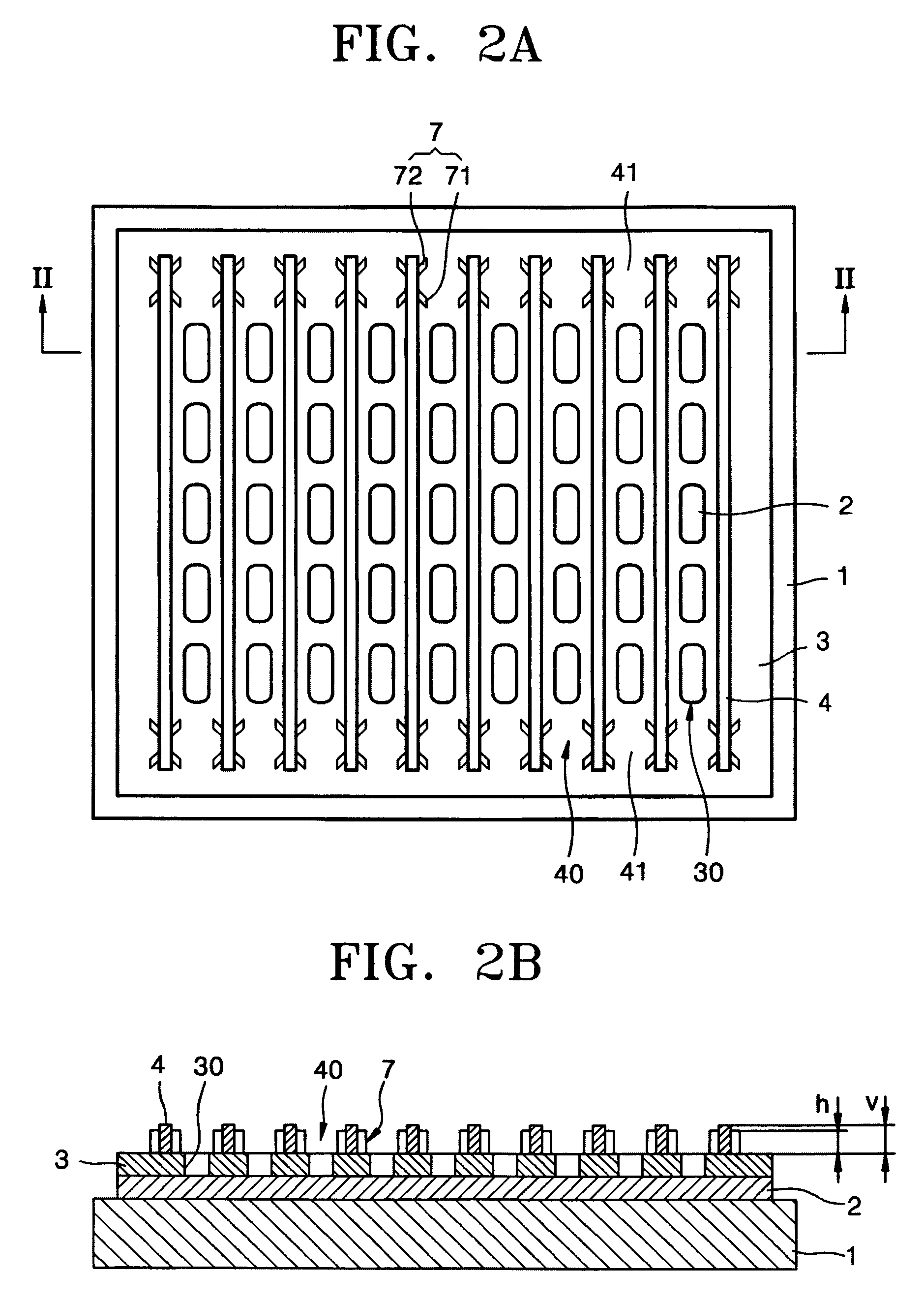

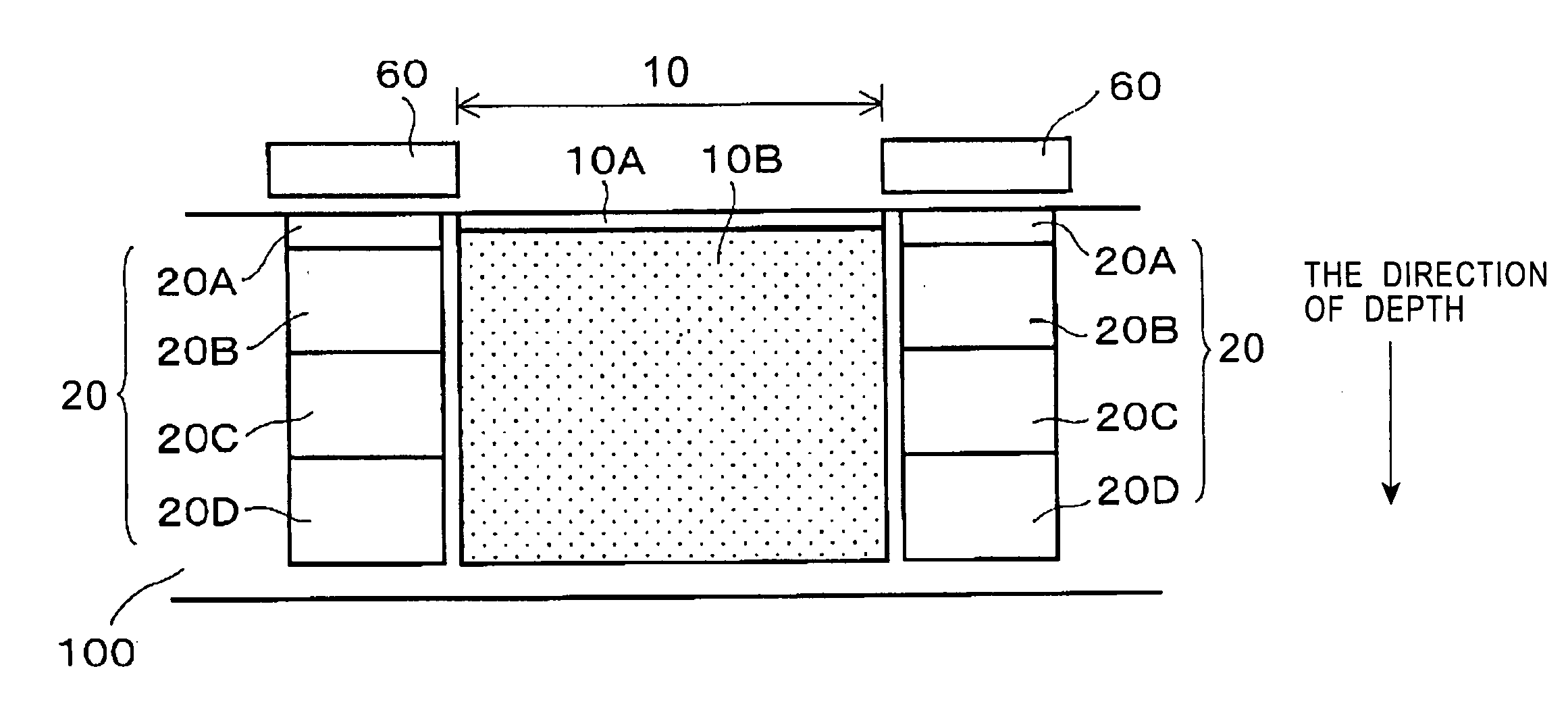

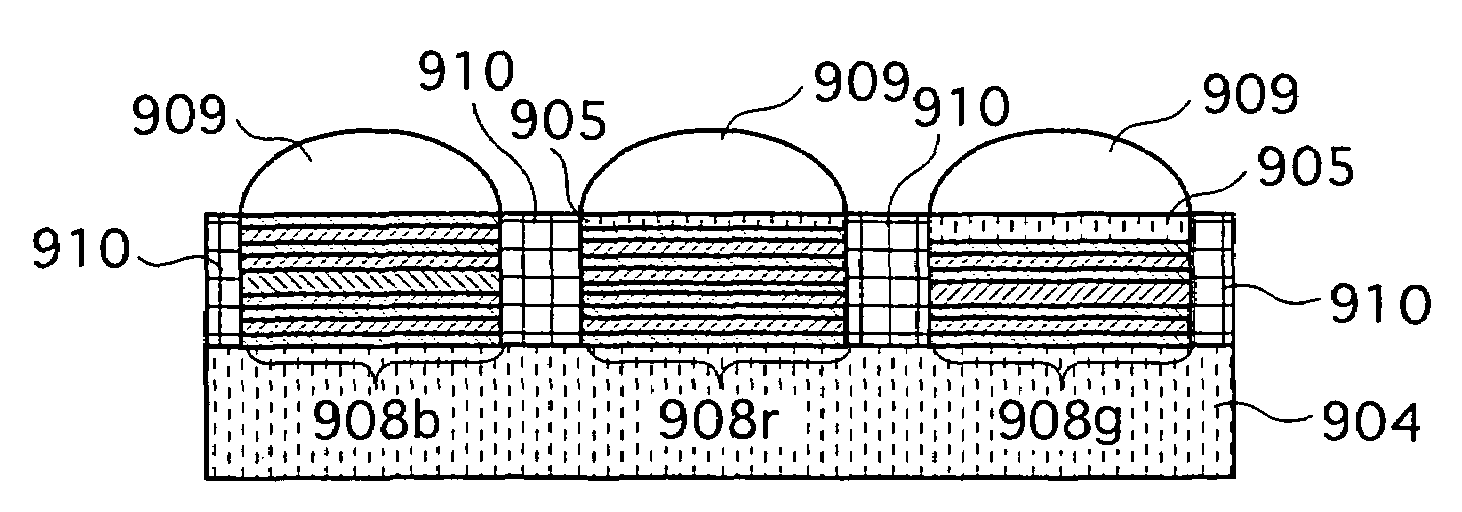

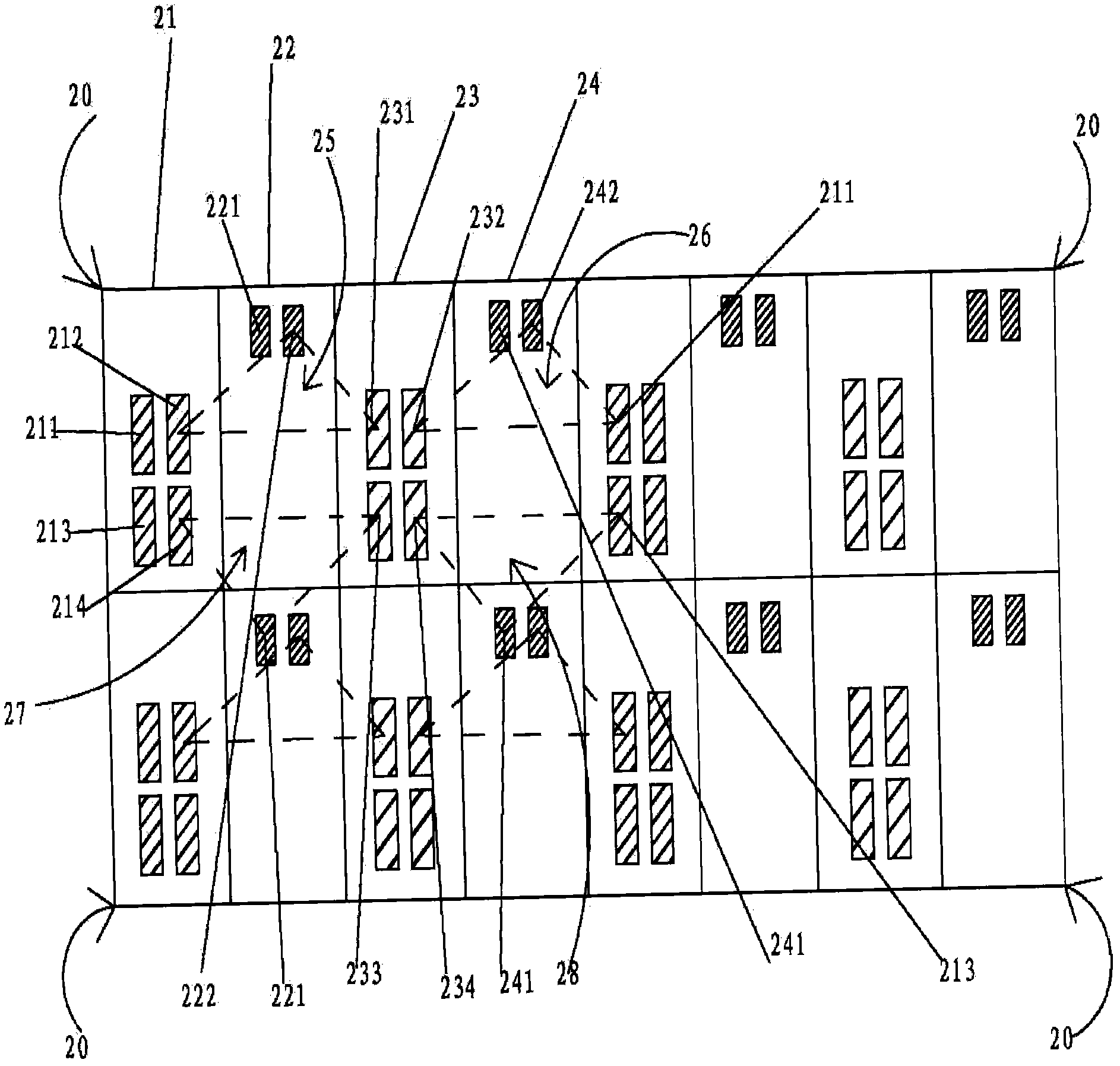

Polymer organic light emitting diode

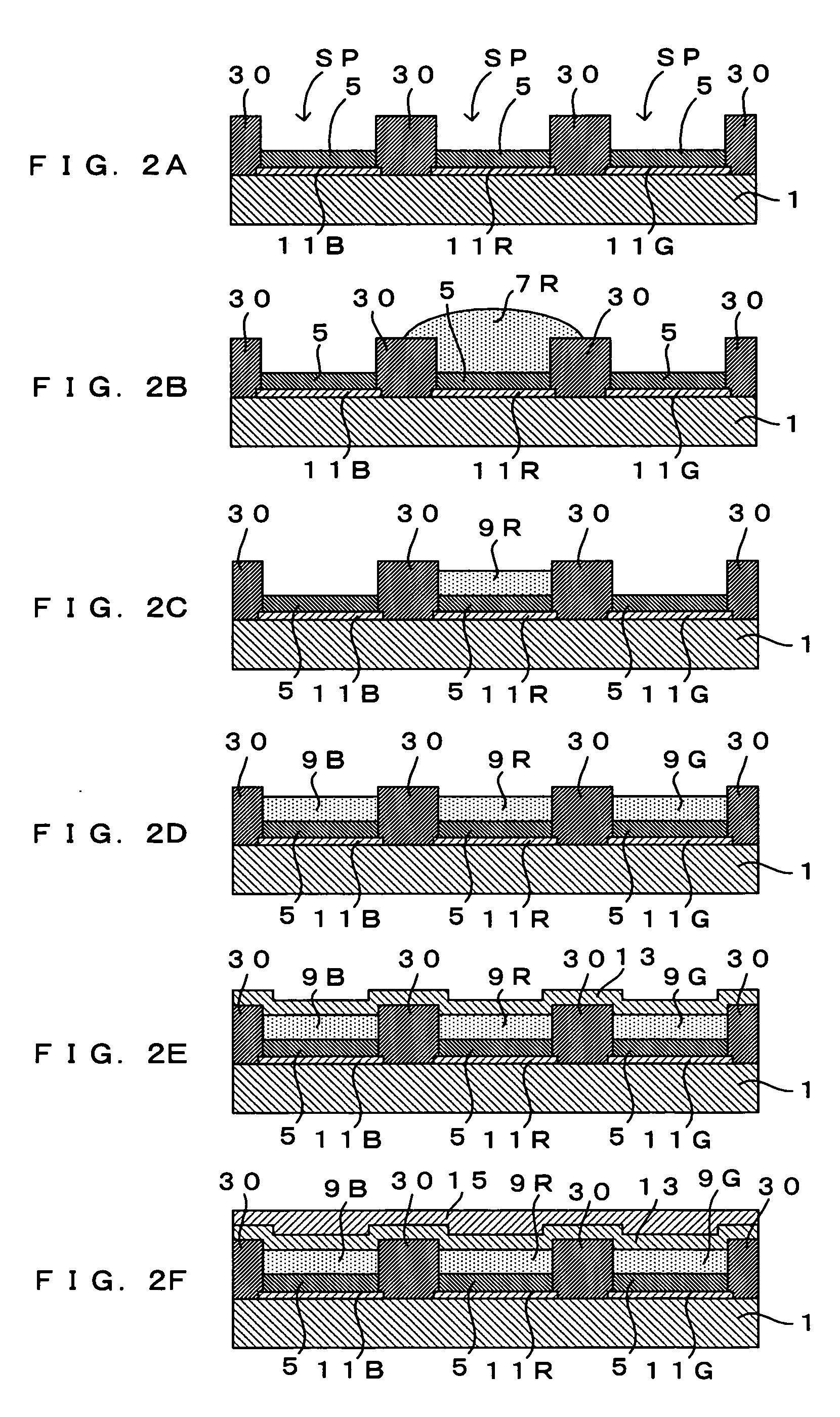

ActiveUS7091660B2Uniform layer thicknessAvoid mixing colorsDischarge tube luminescnet screensElectroluminescent light sourcesPhysicsColor mixing

An organic light emitting diode (OLED) is used to realize a full-color display device. More particularly, a polymer OLED is used to increase uniformity in thickness of a layer formed of polymer ink, and to prevent mixing of colors. The OLED includes a substrate having a first electrode layer formed thereon in a predetermined pattern, an insulator layer formed on the substrate forming a channel in a predetermined pattern, an organic polymer layer formed based on the channel and having at least an emission layer, a barrier formed at either side of the insulator layer of at least one end of the channel for preventing ink for the organic polymer layer from running out of both ends of the channel, and a second electrode layer formed on the polymer organic layer.

Owner:SAMSUNG DISPLAY CO LTD

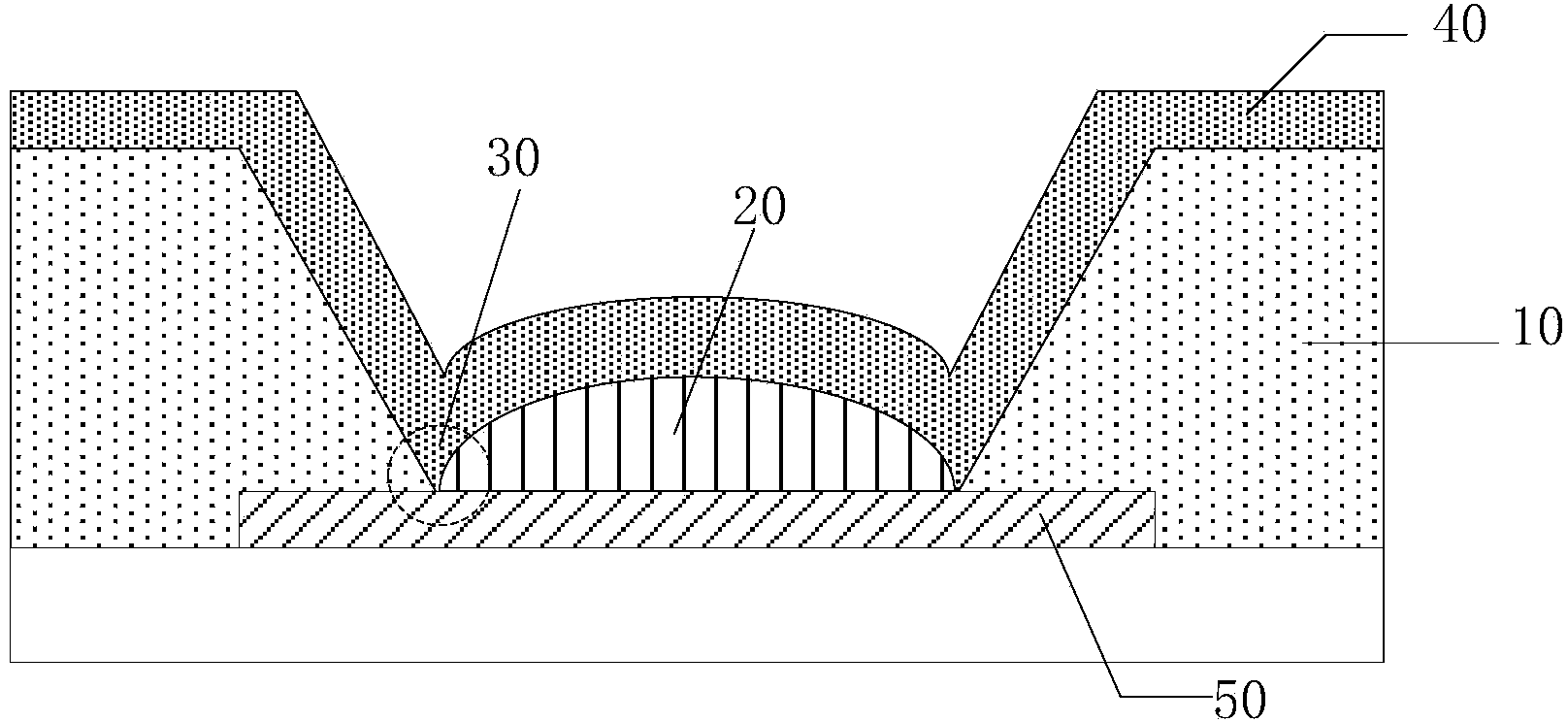

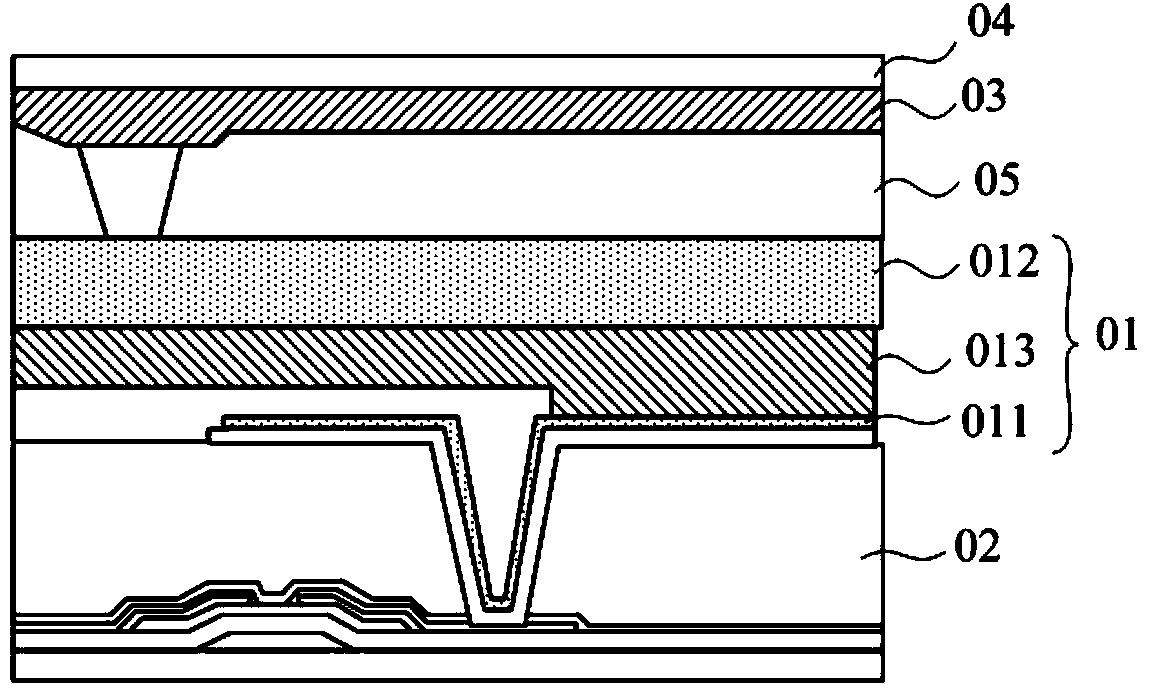

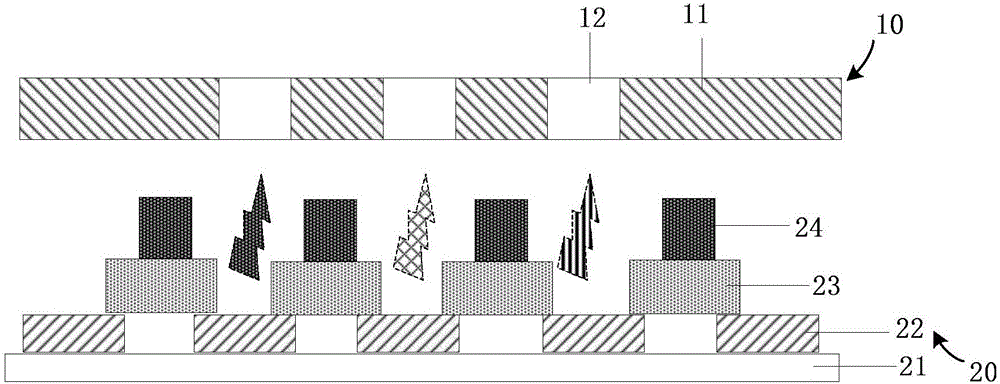

Organic electroluminescent display (OLED), manufacturing method thereof and display device

ActiveCN104167430AImprove luminous performanceAvoid disconnectionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceLuminescent material

The invention discloses an organic electroluminescent display (OLED), a manufacturing method of the organic electroluminescent display (OLED) and a display device. A pixel defining layer arranged in the organic electroluminescent display (OLED) is provided with opening areas corresponding to pixel areas of the OLED, an opening of each opening area is larger than the bottom face of the opening area, and thus the problem that a cathode may break later can be avoided; because the upper surface of the pixel defining layer is made from lyophobic material, and luminescent material with which the pixel defining layer is coated later cannot remain on the upper surface of the pixel defining layer easily, the problem that colors of the adjacent pixel areas are mixed can be avoided; meanwhile, the inclined faces of the corresponding opening areas of the pixel defining layer are made from lyophilic material so that it can be guaranteed that the opening areas are evenly filled with the luminescent material with which the pixel defining layer is coated later. Therefore, according to the OLED, the uniformity of a film layer formed later on the pixel defining layer can be guaranteed, and the luminescence property of the OLED is improved.

Owner:BOE TECH GRP CO LTD

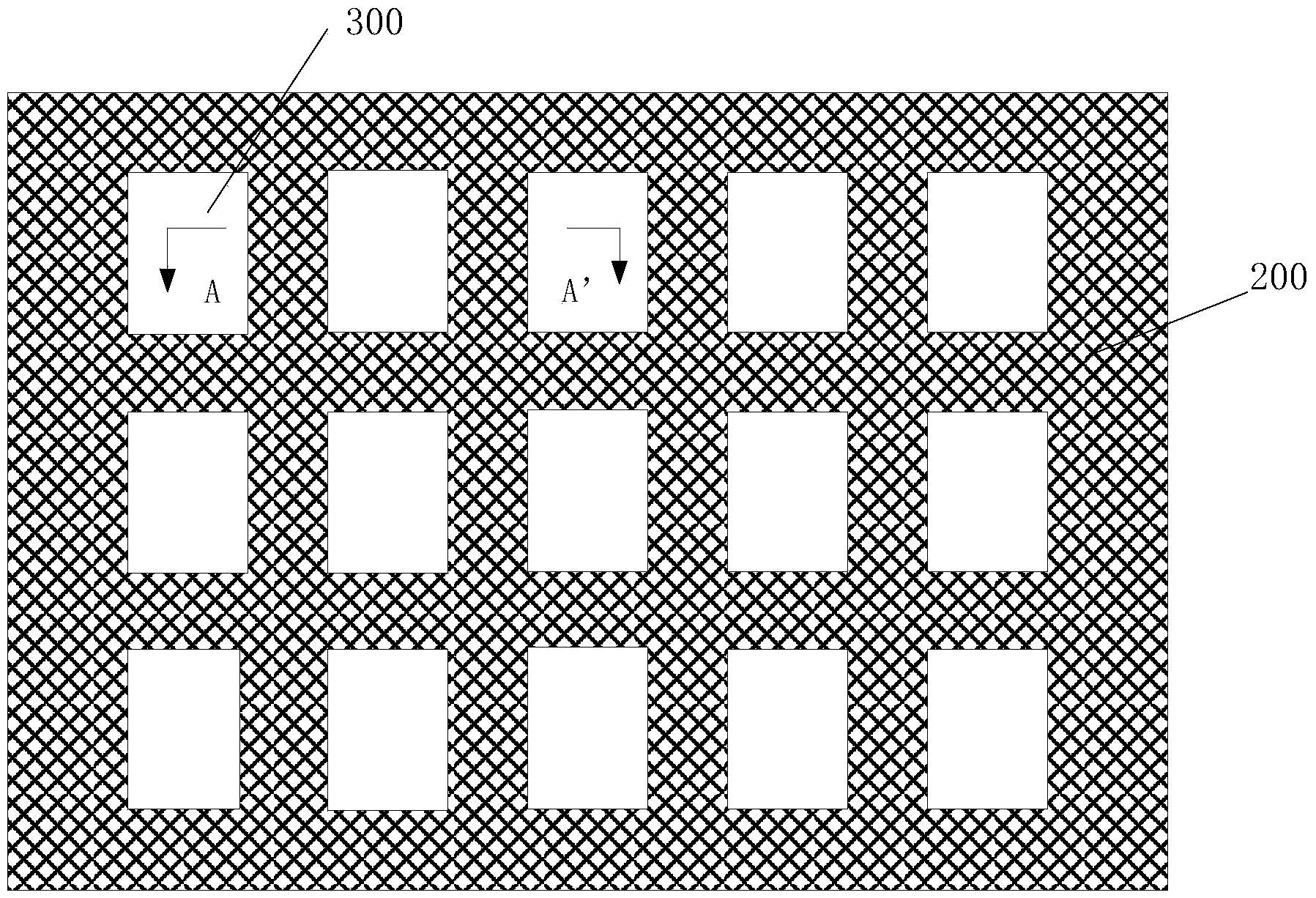

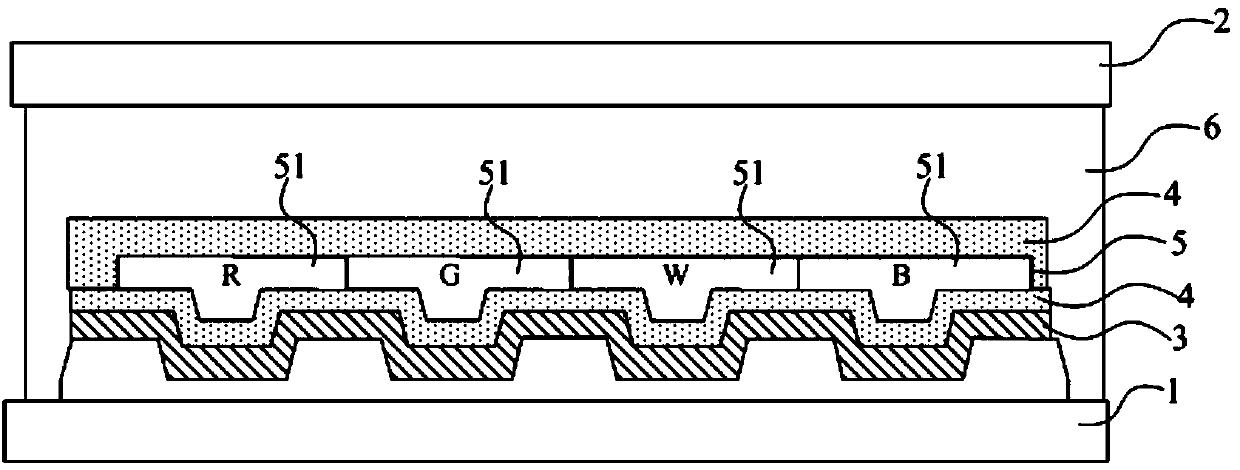

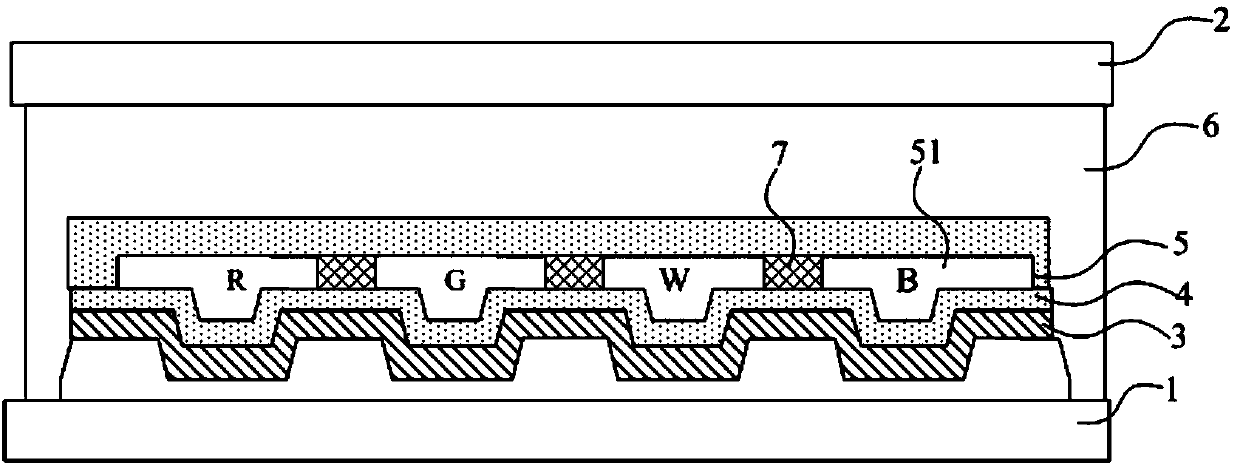

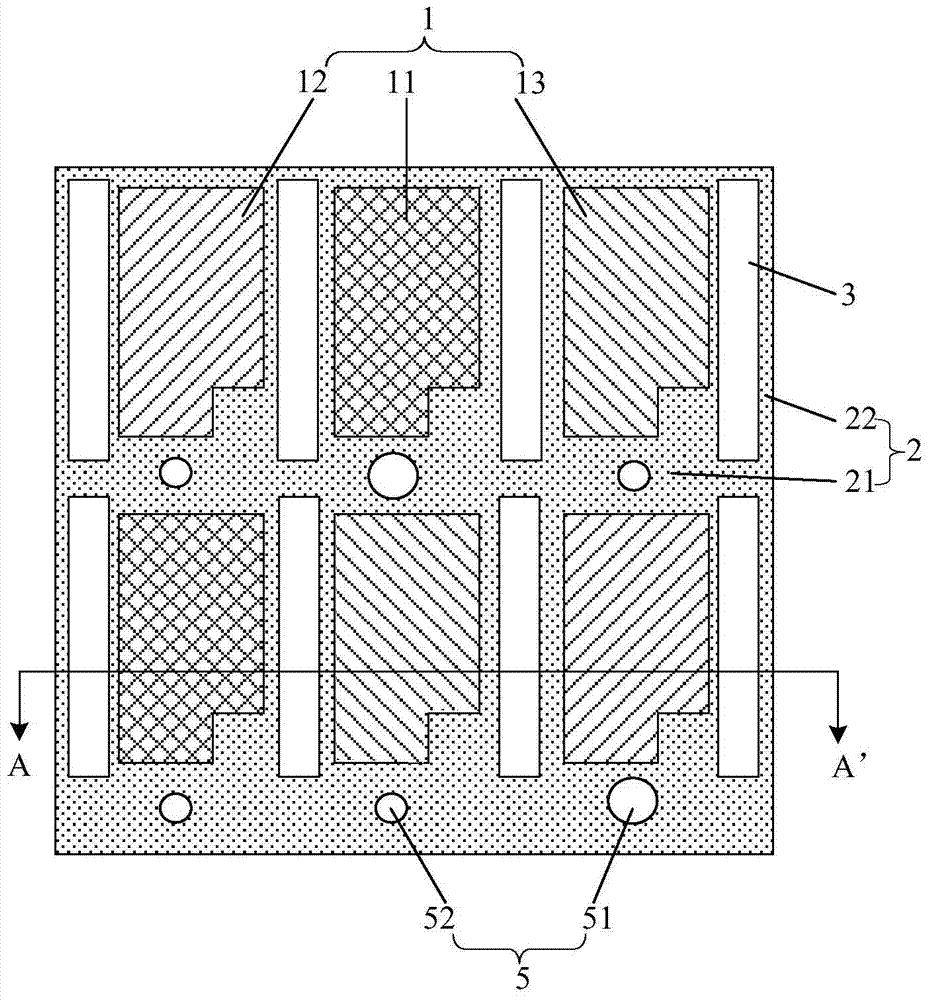

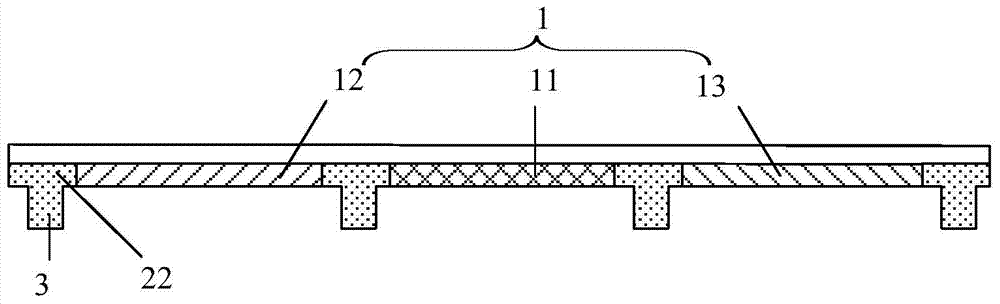

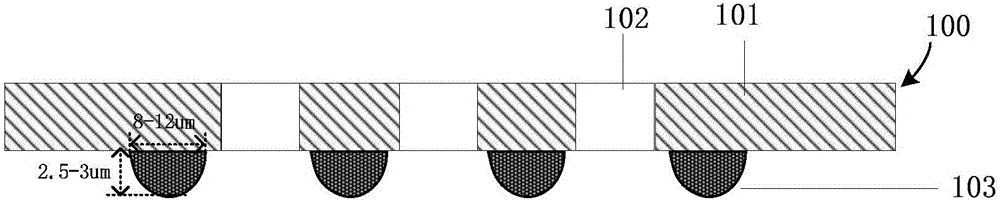

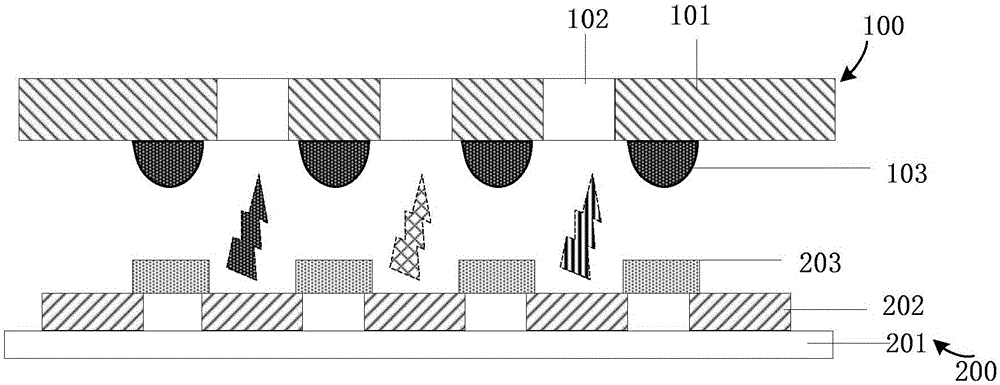

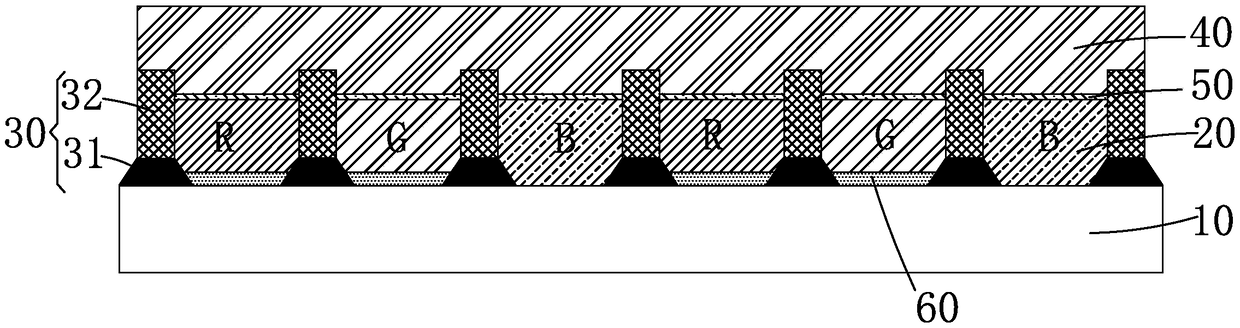

Color film substrate, manufacturing method thereof, OLED display panel and display apparatus

ActiveCN105118928AImprove removal efficiencyImprove the display effectSolid-state devicesSemiconductor/solid-state device manufacturingDisplay contrastColor film

The invention discloses a color film substrate and manufacturing method thereof, and an OLED display panel and a display apparatus. The color film substrate comprises a substrate, and a black matrix layer and a blocking mat layer sequentially arranged on the substrate in a stacked way. The blocking mat layer comprises a plurality of blocking mats arranged in the same layer. The orthographic projection of the graph of each blocking mat on the substrate is located inside the area where the graph of the black matrix layer is located. In this way, the aperture ratio of the color film substrate will not be occupied. The surface of each blocking mat is provided with an auxiliary function layer which is used for absorbing or reflecting light irradiated to surfaces of the blocking mats. Optical crosstalk among adjacent sub-pixel units on the color film substrate can be prevented. Color mixing is further prevented. The light extraction efficiency and the display contrast can be further enhanced. The display effects are also improved.

Owner:BOE TECH GRP CO LTD

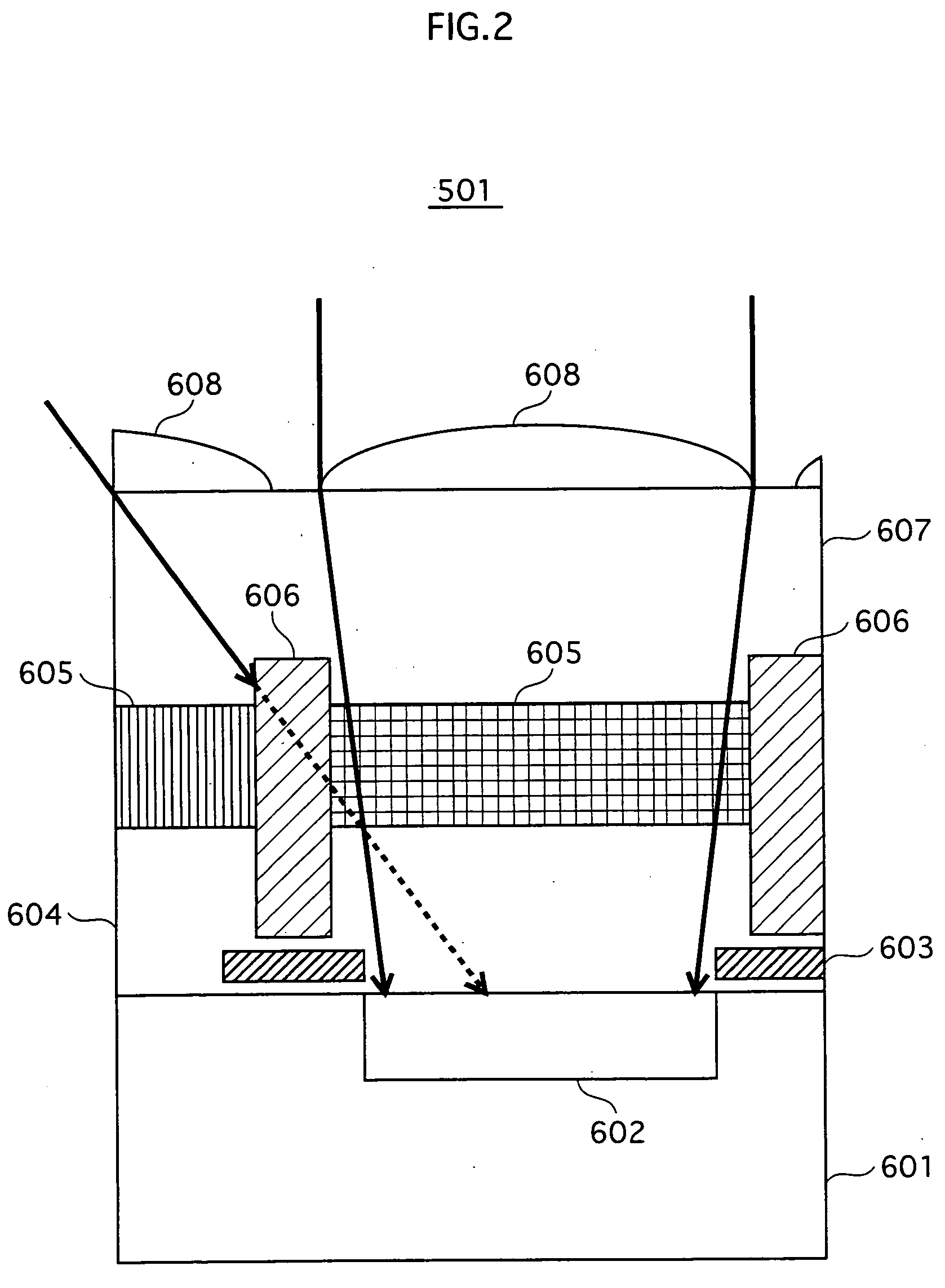

Solid-state imaging device and camera

InactiveUS20070188635A1Improve image qualityAvoid mixing colorsTelevision system detailsTelevision system scanning detailsPhotodiodeSemiconductor

A solid-state imaging device 101 is composed of a transparent film 204, a color filter 205, a planarizing film 207, and a plurality of microlenses 208 that are sequentially formed on a semiconductor substrate 201. A photodiode 202 is formed in a surface of the semiconductor substrate 201 that is closer to the transparent film 204. A light shielding film 203 is formed in a surface of the transparent film 204 that is closer to the semiconductor substrate 201. Color filters 205 respectively corresponding to two adjacent pixels are partitioned by a light shielding wall 206. The light shielding wall 206 is a λ / 4 multilayer film that reflects visible light.

Owner:PANASONIC CORP

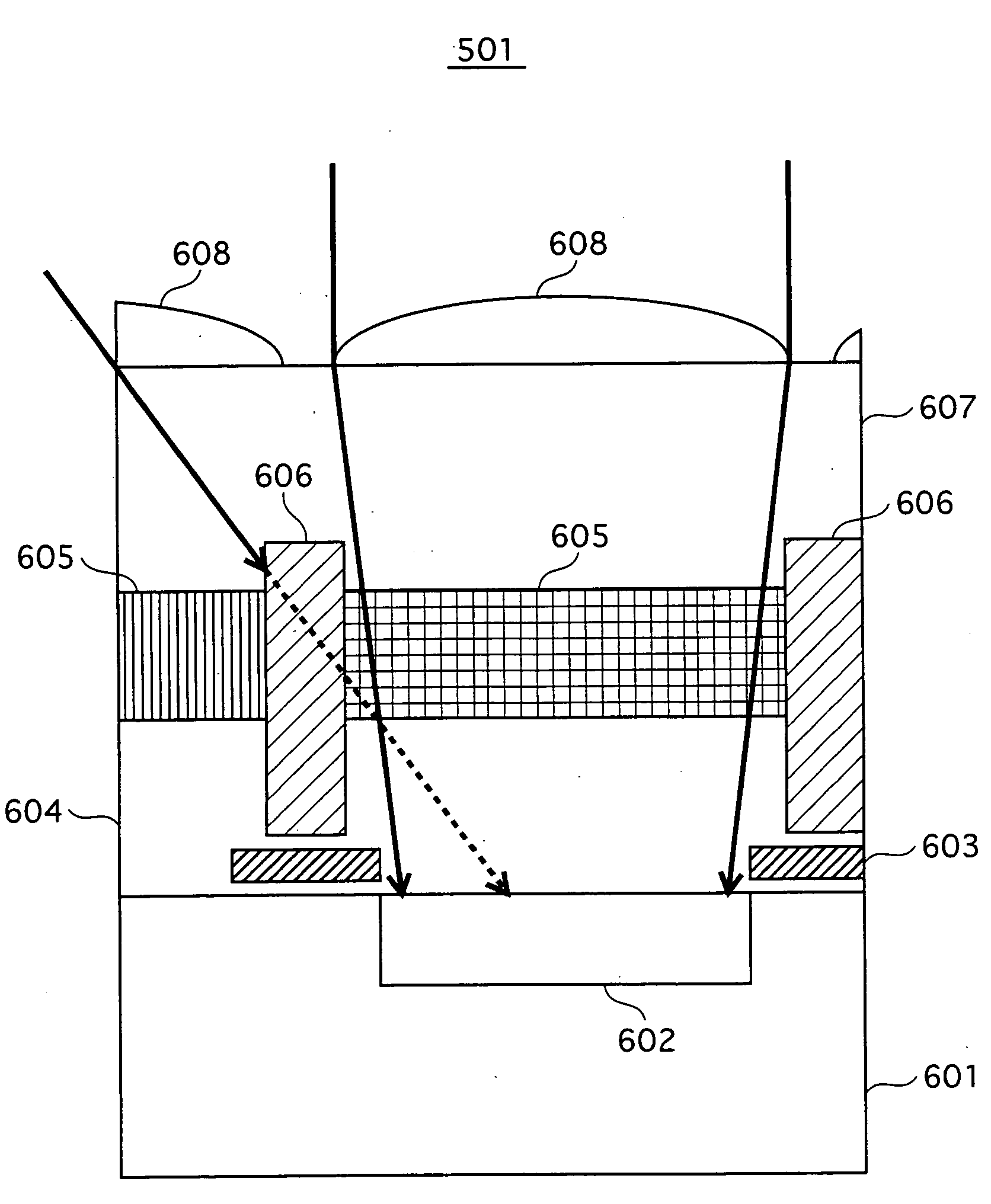

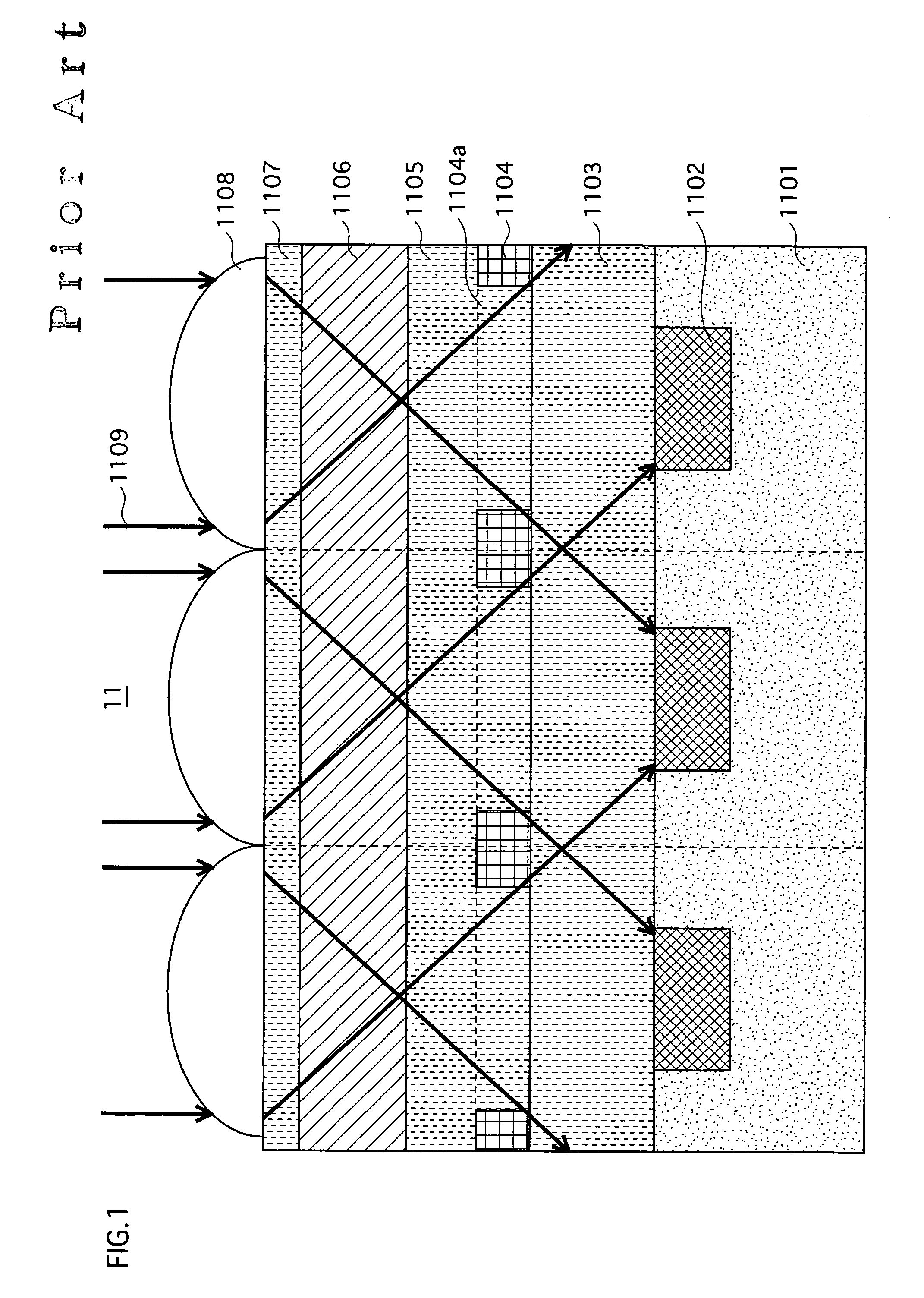

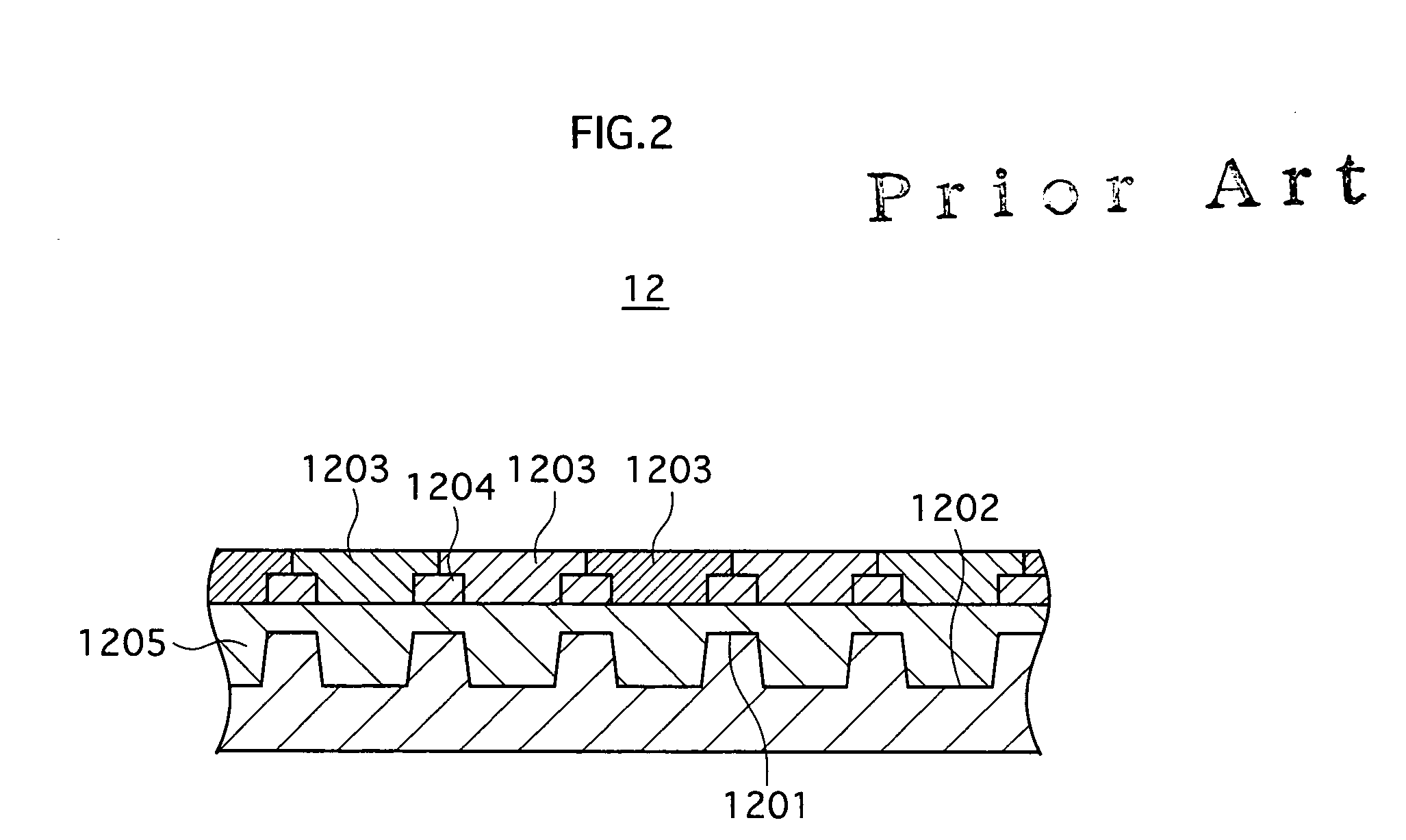

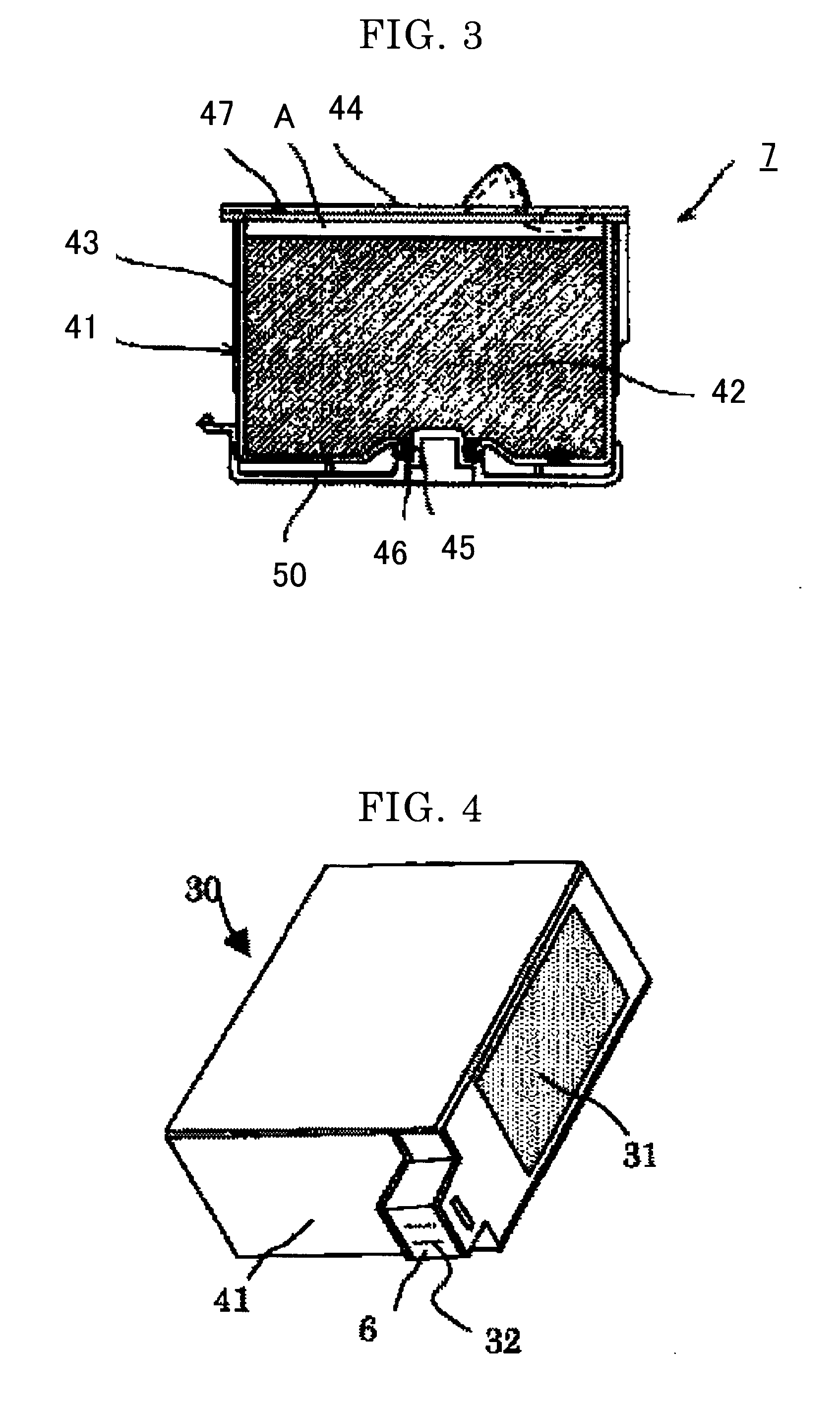

Solid-state imaging device, manufacturing method for solid-state imaging device, and camera using the same

InactiveUS20070058055A1Easy to manufactureDistanceTelevision system detailsTelevision system scanning detailsLength waveColor mixing

A solid-state imaging device includes a plurality of light-receiving units two-dimensionally arrayed in a semiconductor substrate, a filter unit operable to transmit incident lights of selected wavelengths to the plurality of light receiving units and a light shielding unit operable to shield incident light, the light shielding unit having a plurality of apertures, each aperture opposing a corresponding light receiving unit. Here, on a path of incident light from the light shielding unit to the plurality of light shielding units, the filter unit is disposed between the light shielding unit and the plurality of light-receiving units. The solid-state imaging device prevents color mixing caused by oblique light.

Owner:PANASONIC CORP

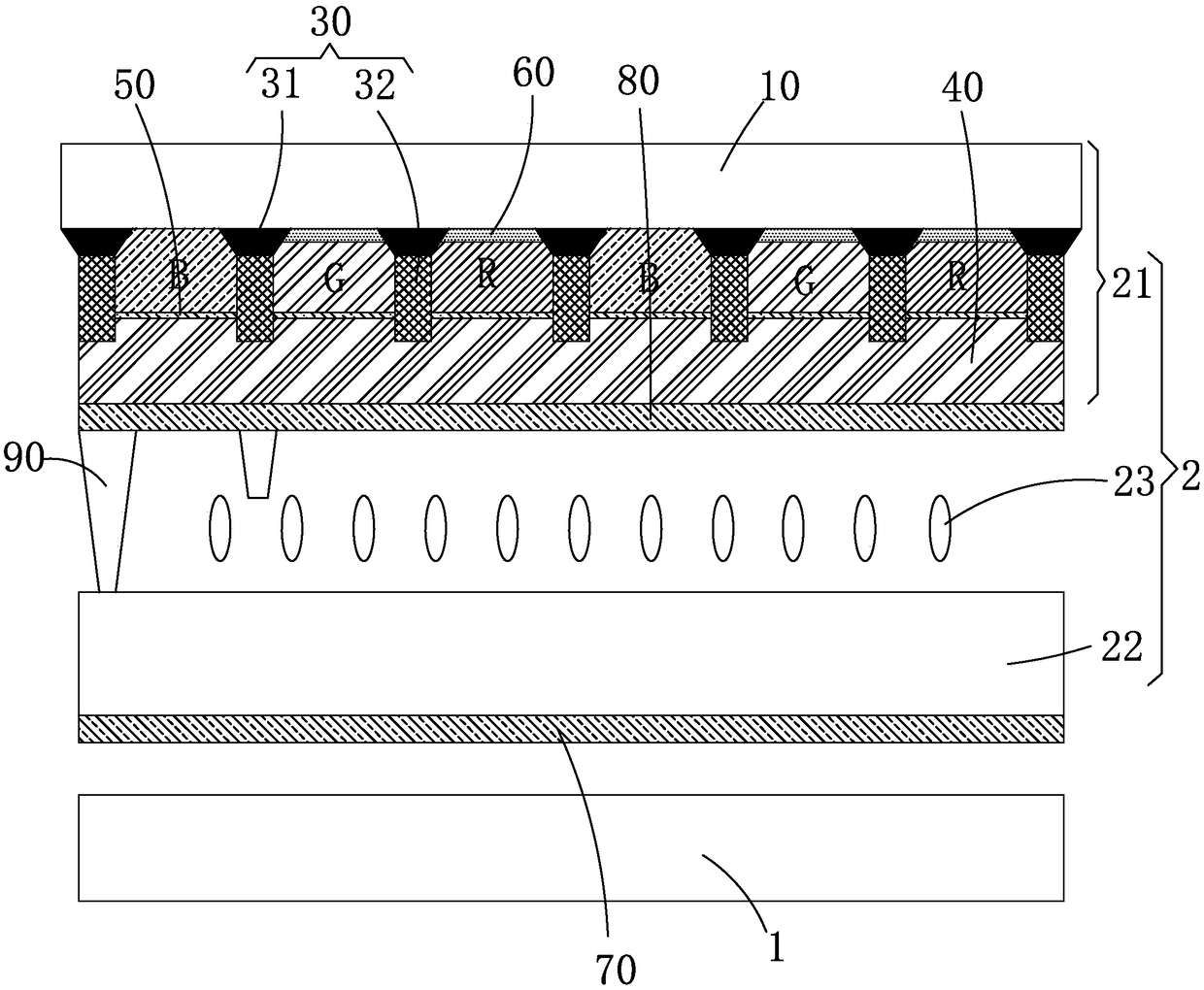

OLED display panel, manufacturing method of OLED display panel and display device

InactiveCN103996696AAlleviate the problem of big view role biasLarge viewing angleSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses an OLED display panel, a manufacturing method of the OLED display panel and a display device. The OLED display panel comprises an array substrate and a packaging cover plate oppositely arranged and further comprises an OLED layer formed on the face, facing the packaging cover plate, of the array substrate, and the OLED layer comprises a plurality of OLEDs. The OLED display panel further comprises at least one thin film packaging layer, a color filtering layer and pasting glue, wherein the thin film packaging layer covers the OLED layer and is bonded with the array substrate, the color filtering layer is formed on the face, facing the packaging cover plate, of the thin film packaging layer, the portion between the array substrate and the packaging cover plate is filled with the pasting glue so that the array substrate and the packaging cover plate can be pasted, and the pasting glue covers the color filtering layer and the thin film packaging layer. According to the OLED display panel, the distance between the OLED layer and the color filtering layer is small, and the large view angle color cast problem of the OLED display panel can be relieved.

Owner:BOE TECH GRP CO LTD

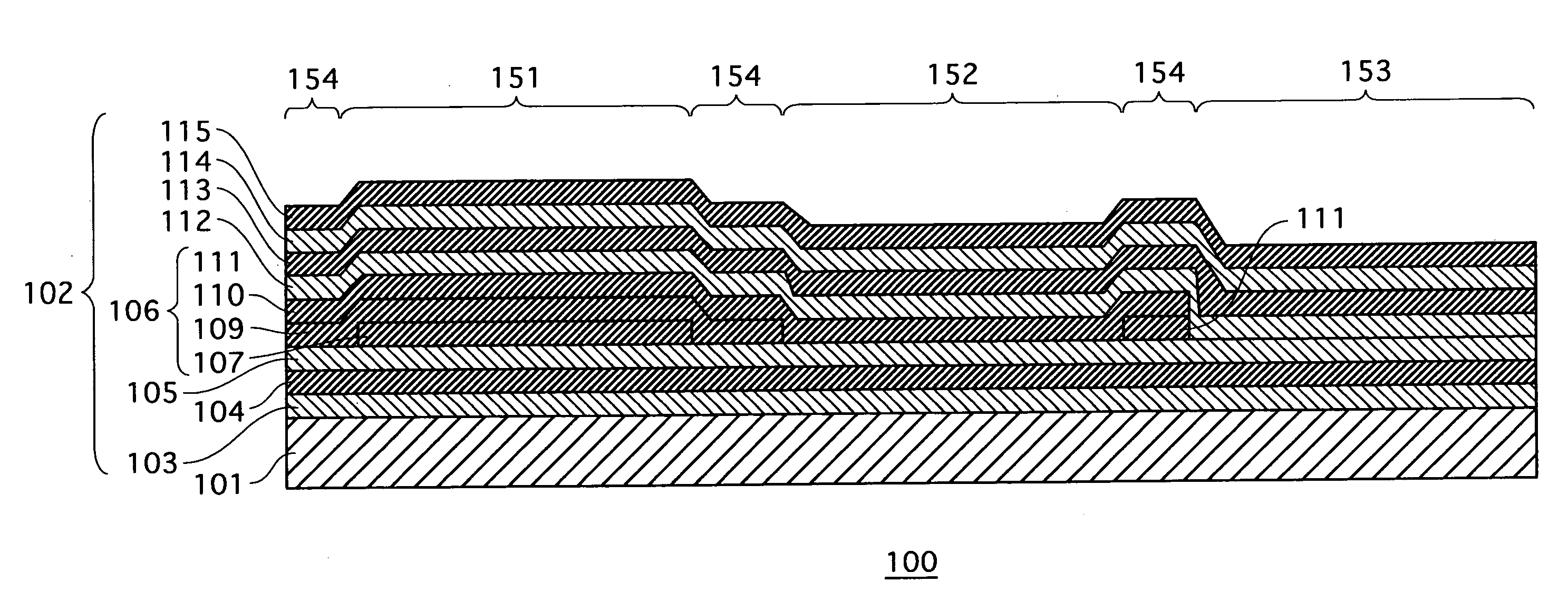

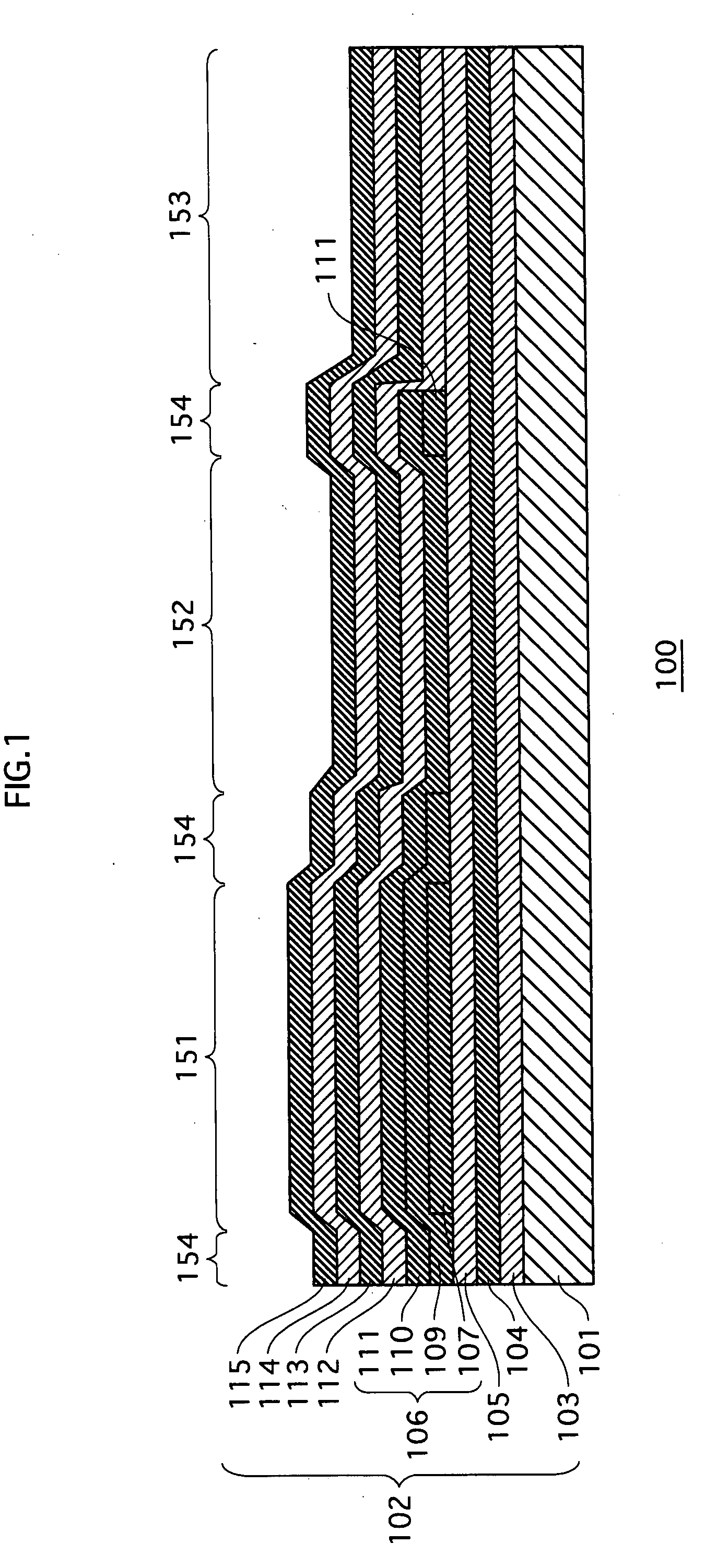

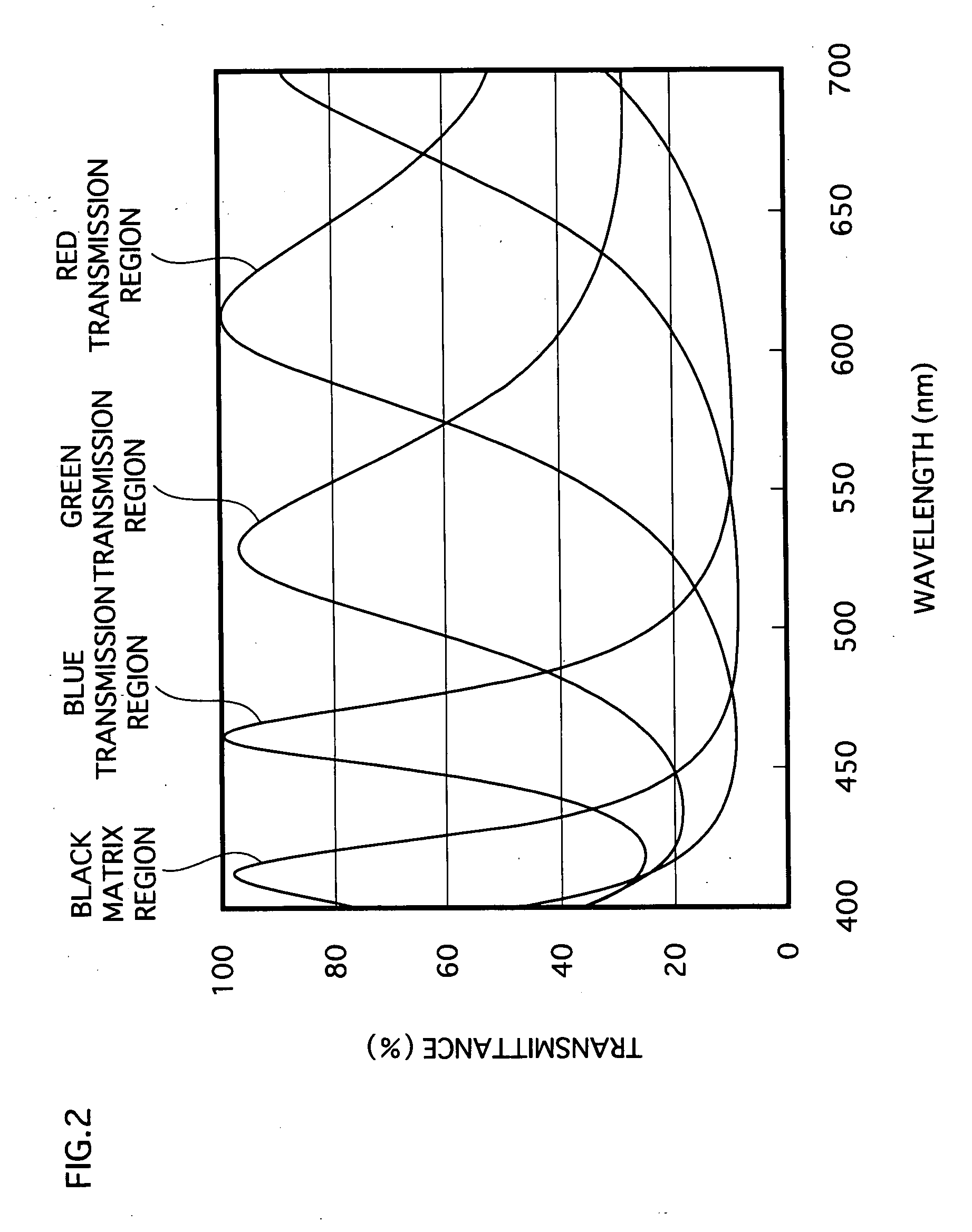

Optical interference filter that performs excellent color separation, and liquid crystal display, electroluminescence display and projection display apparatus having the optical interference filter

InactiveUS20080062359A1Avoid mixingAvoid mixing colorsDischarge tube luminescnet screensElectroluminescent light sourcesLiquid-crystal displayDisplay device

An optical interference filter whose major component is a film member. The film member includes a plurality of window regions arranged discretely in a surface direction selectively transmit, using an effect of optical interference, light having a waveband that substantially belongs to a visible spectrum, the plurality of window regions being arranged discretely in the surface direction, and one or more boundary regions selectively transmit, using the effect of the optical interference, light having a waveband that substantially belongs to an invisible spectrum excluding the visible spectrum, the one or more the boundary regions being located between adjacent window regions.

Owner:PANASONIC CORP

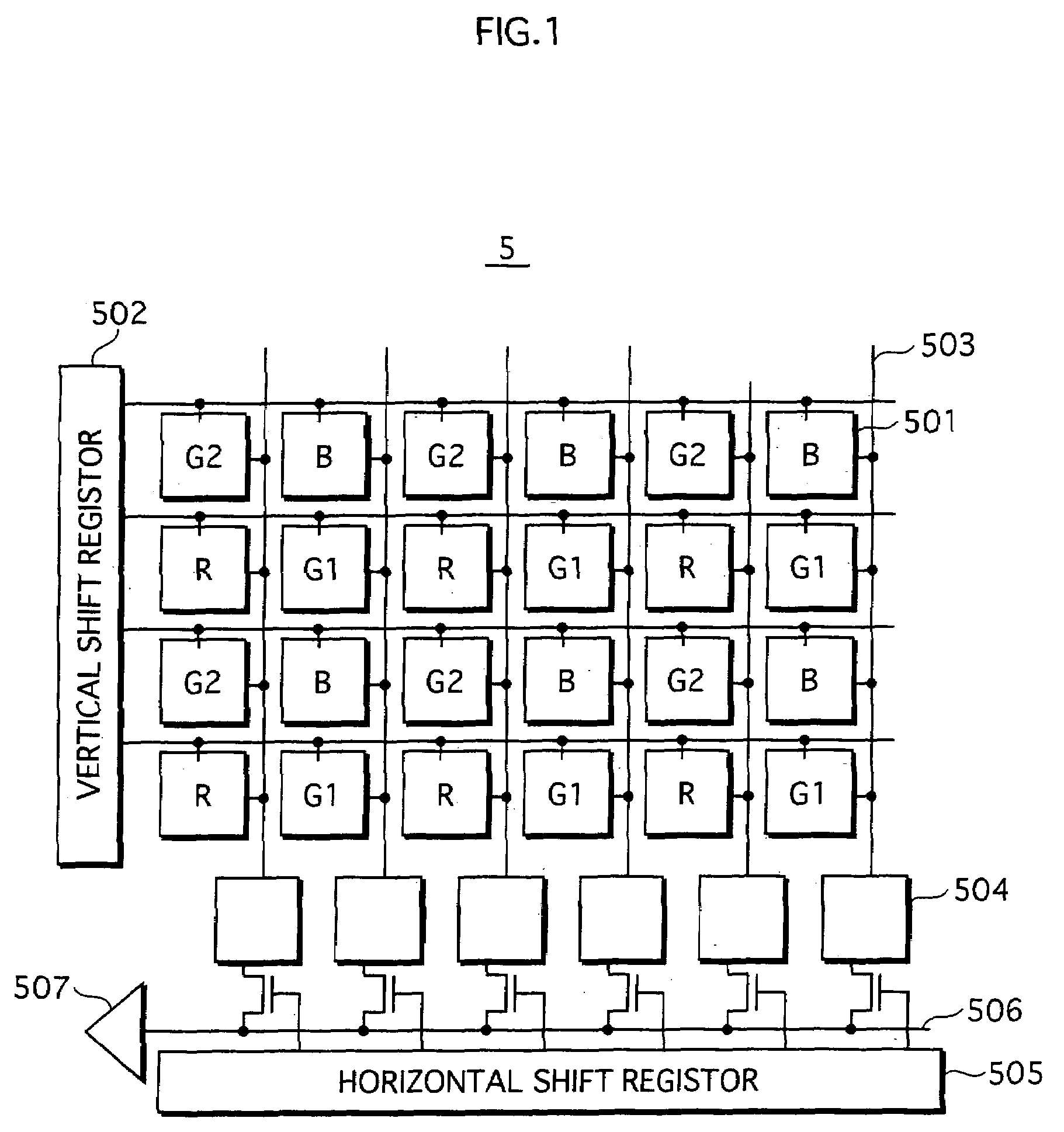

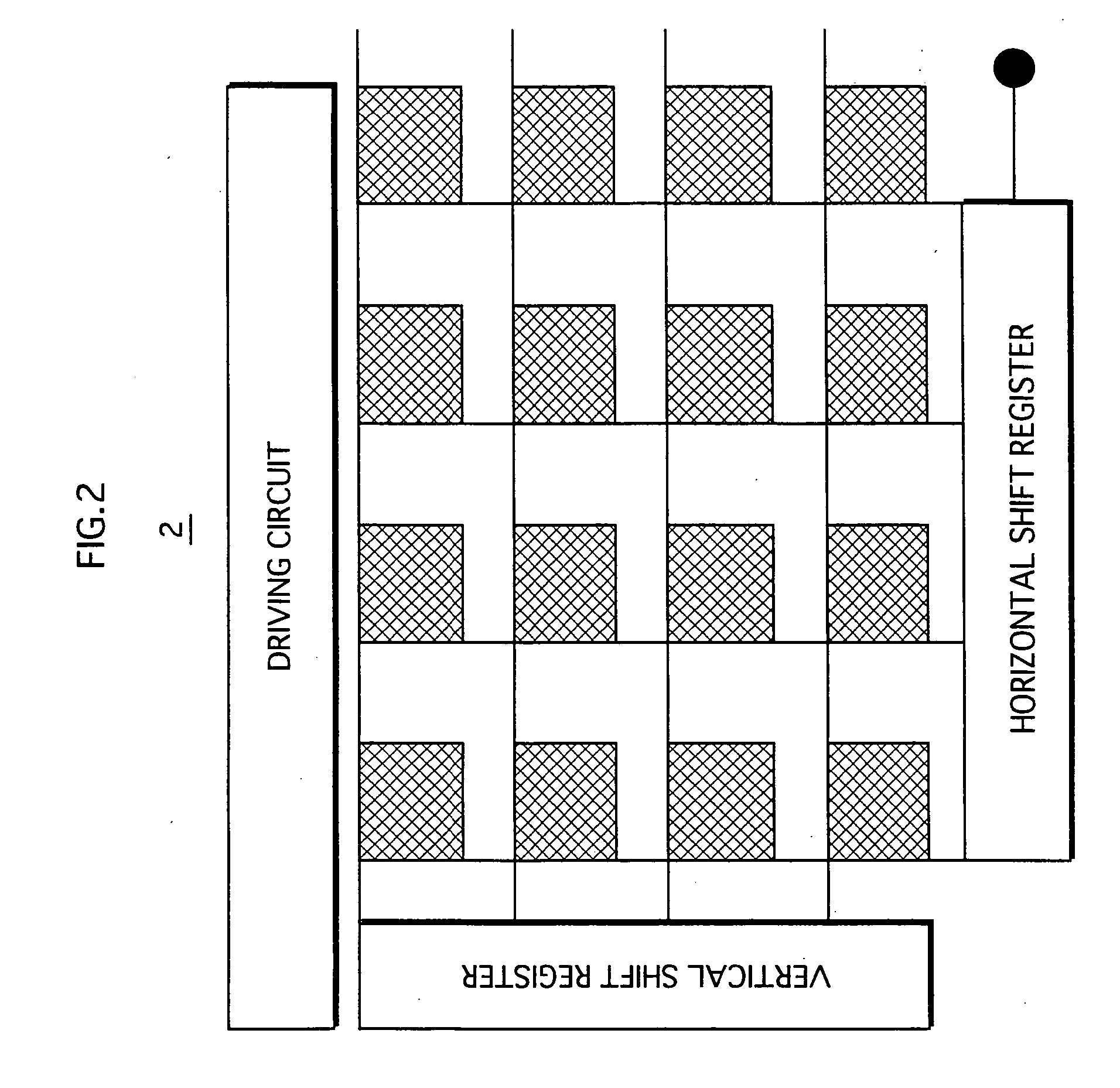

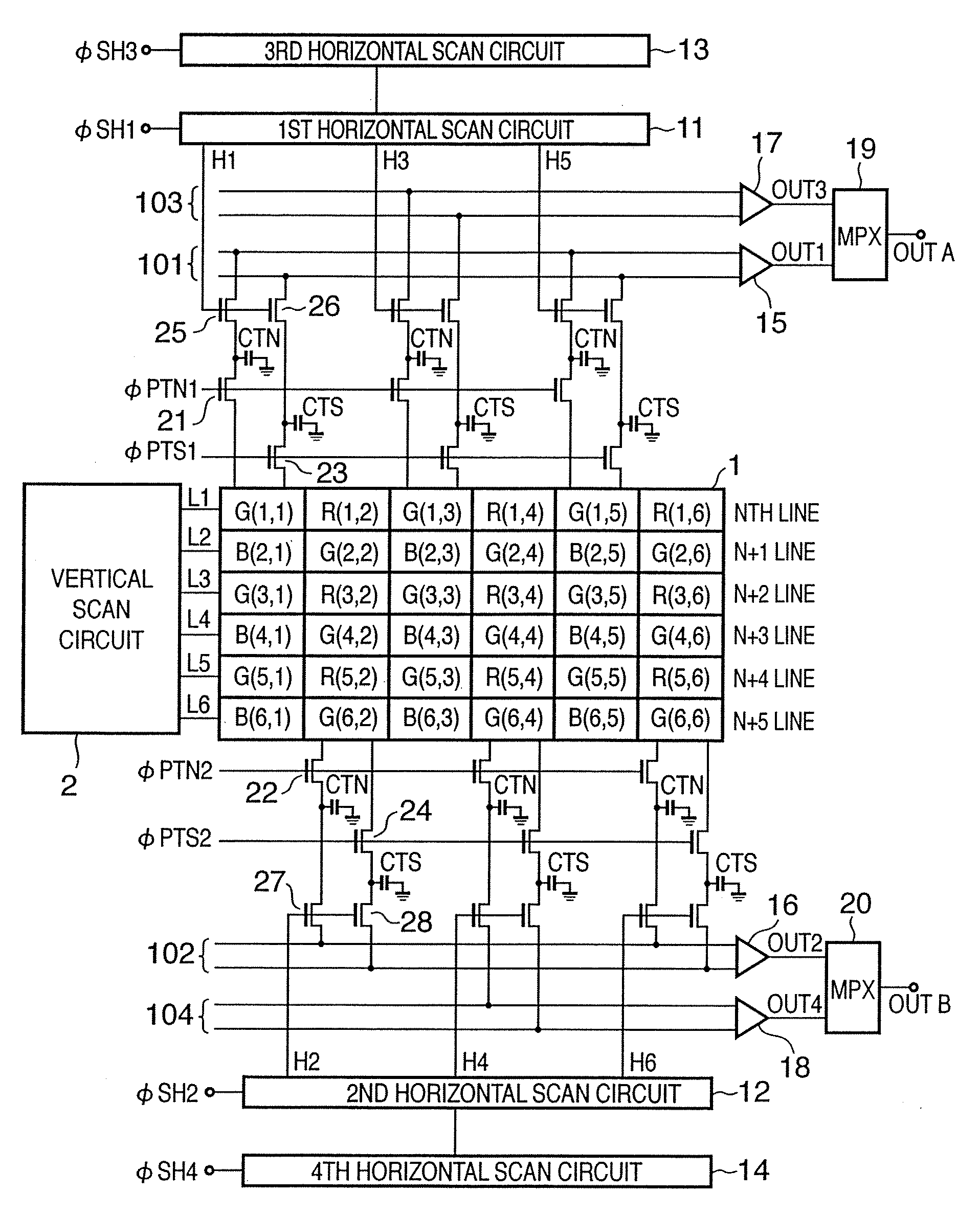

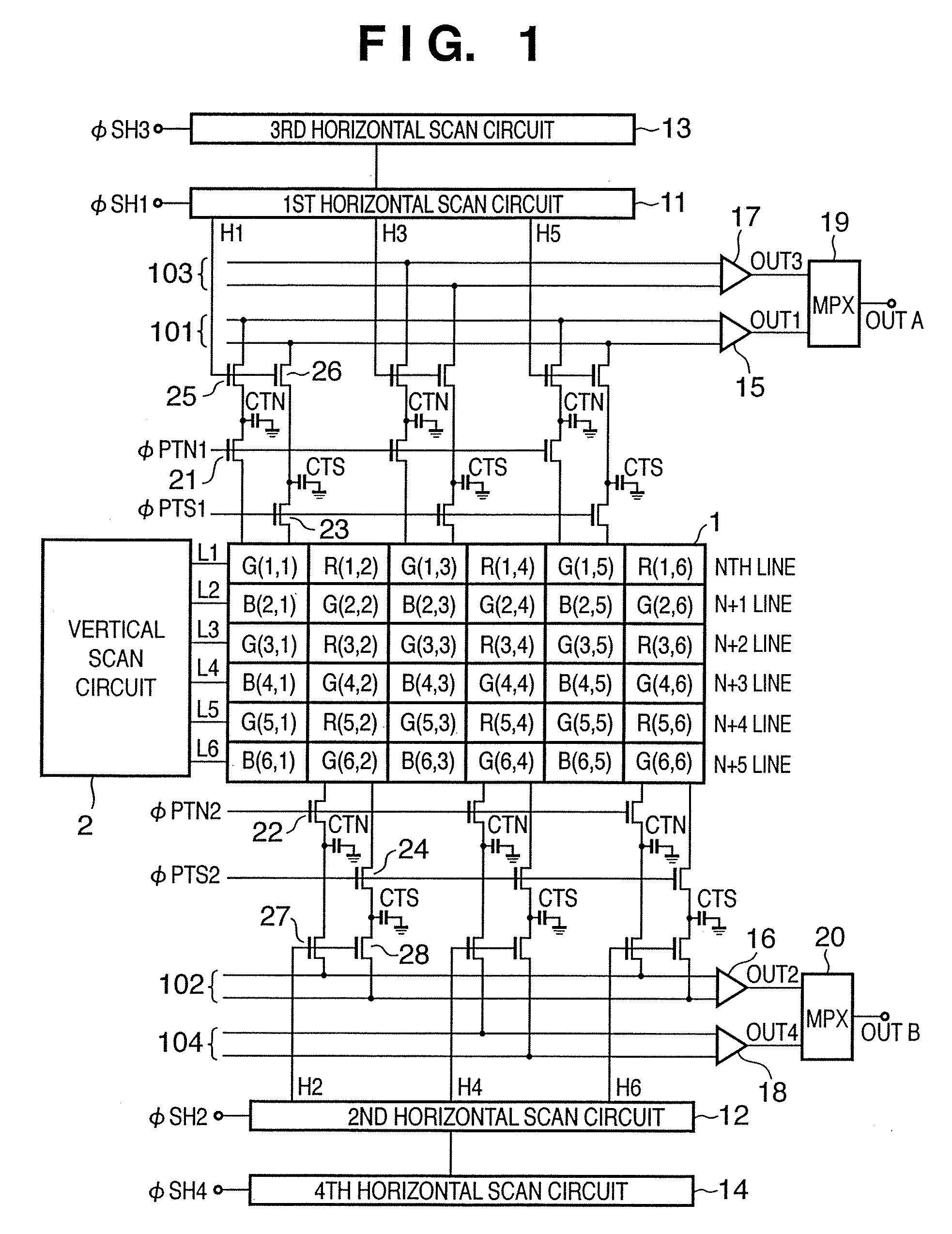

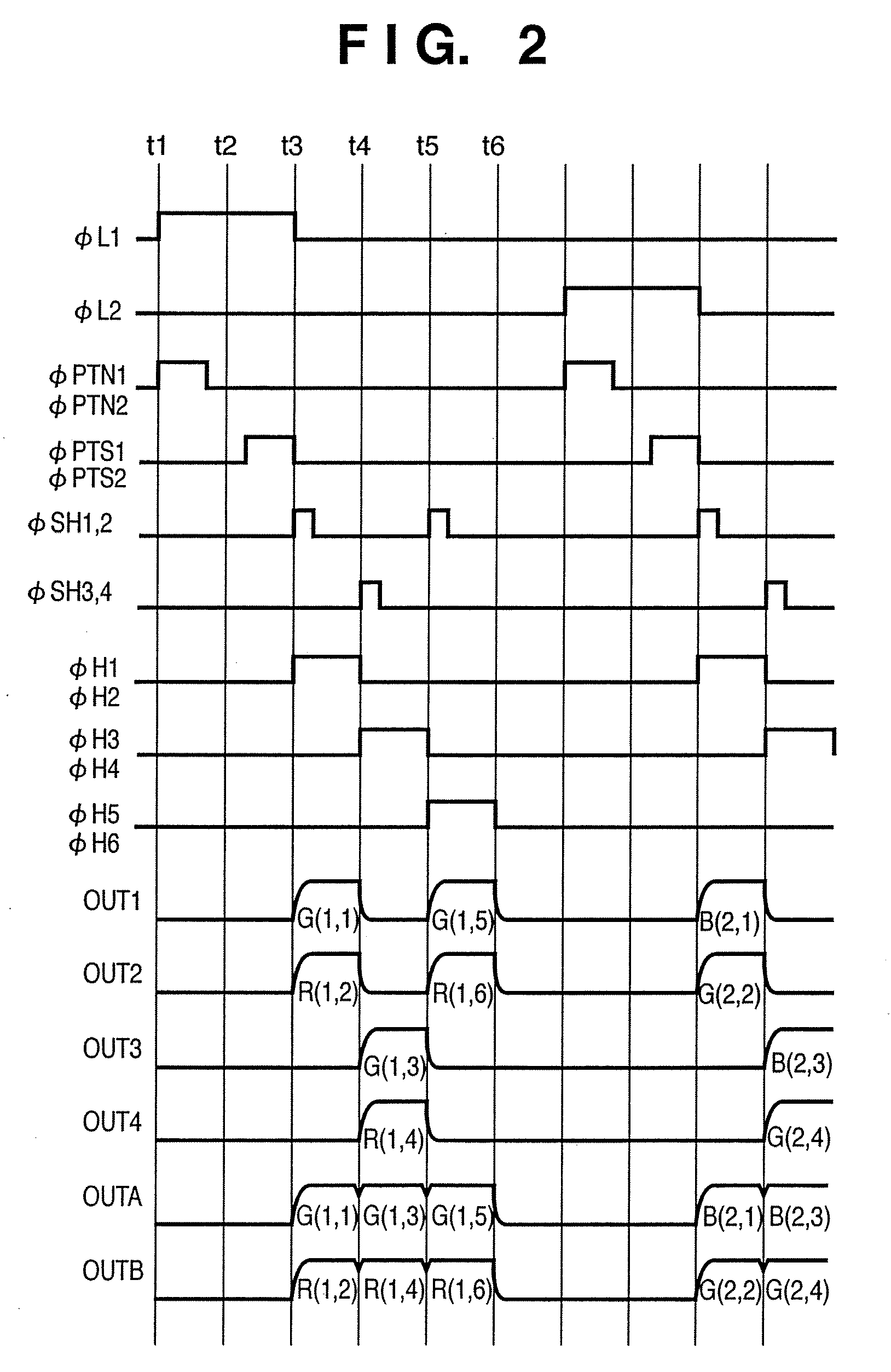

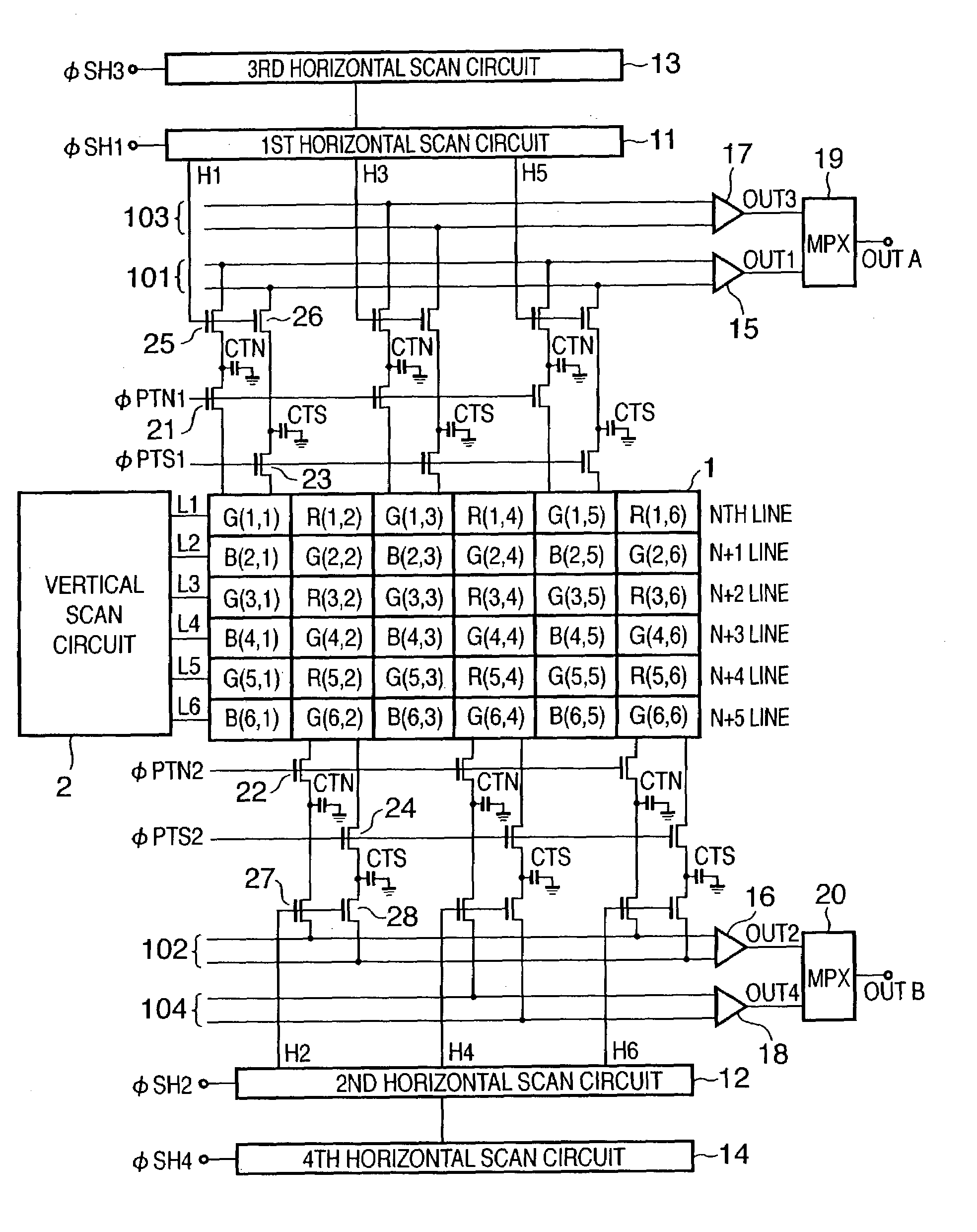

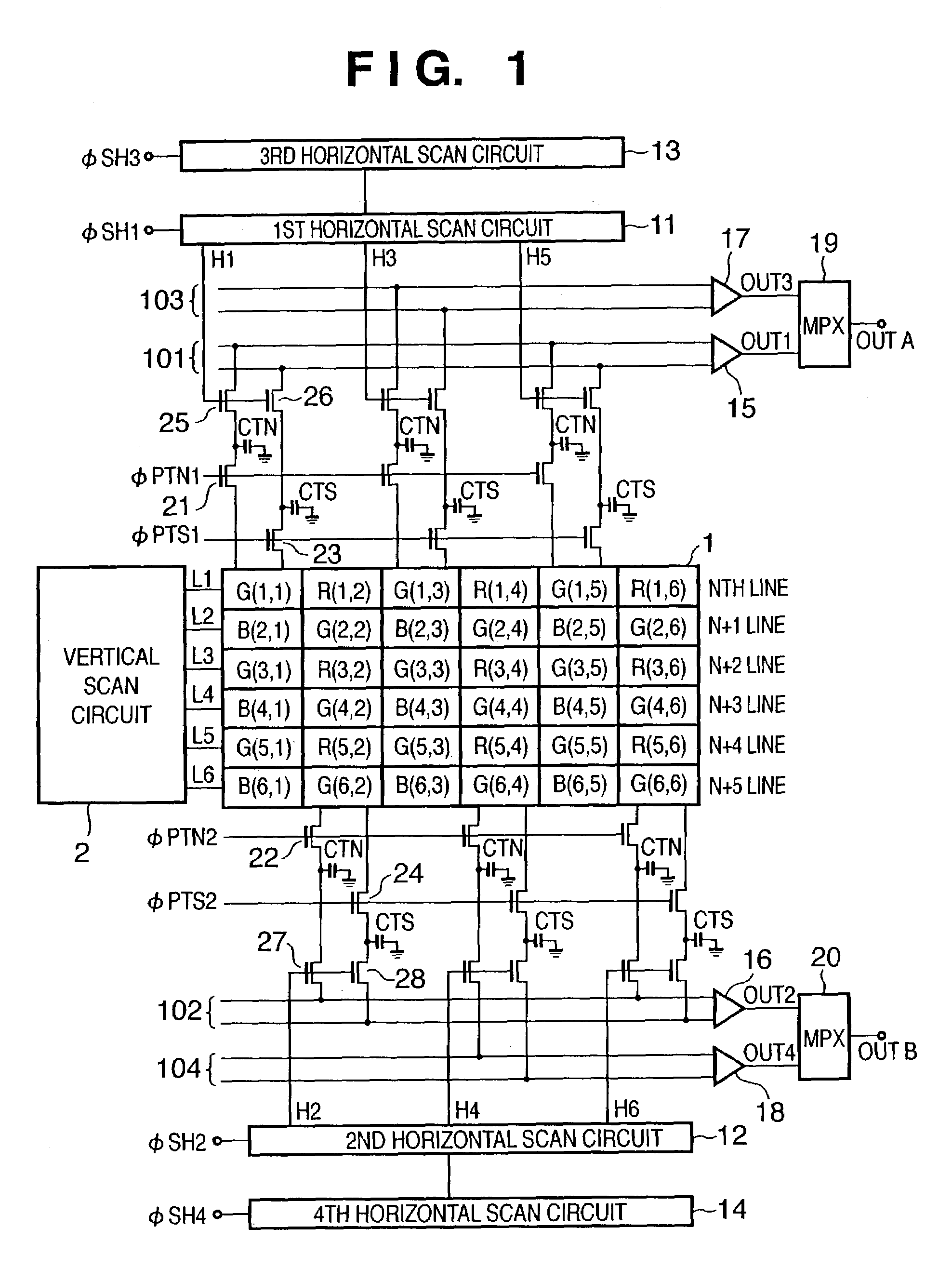

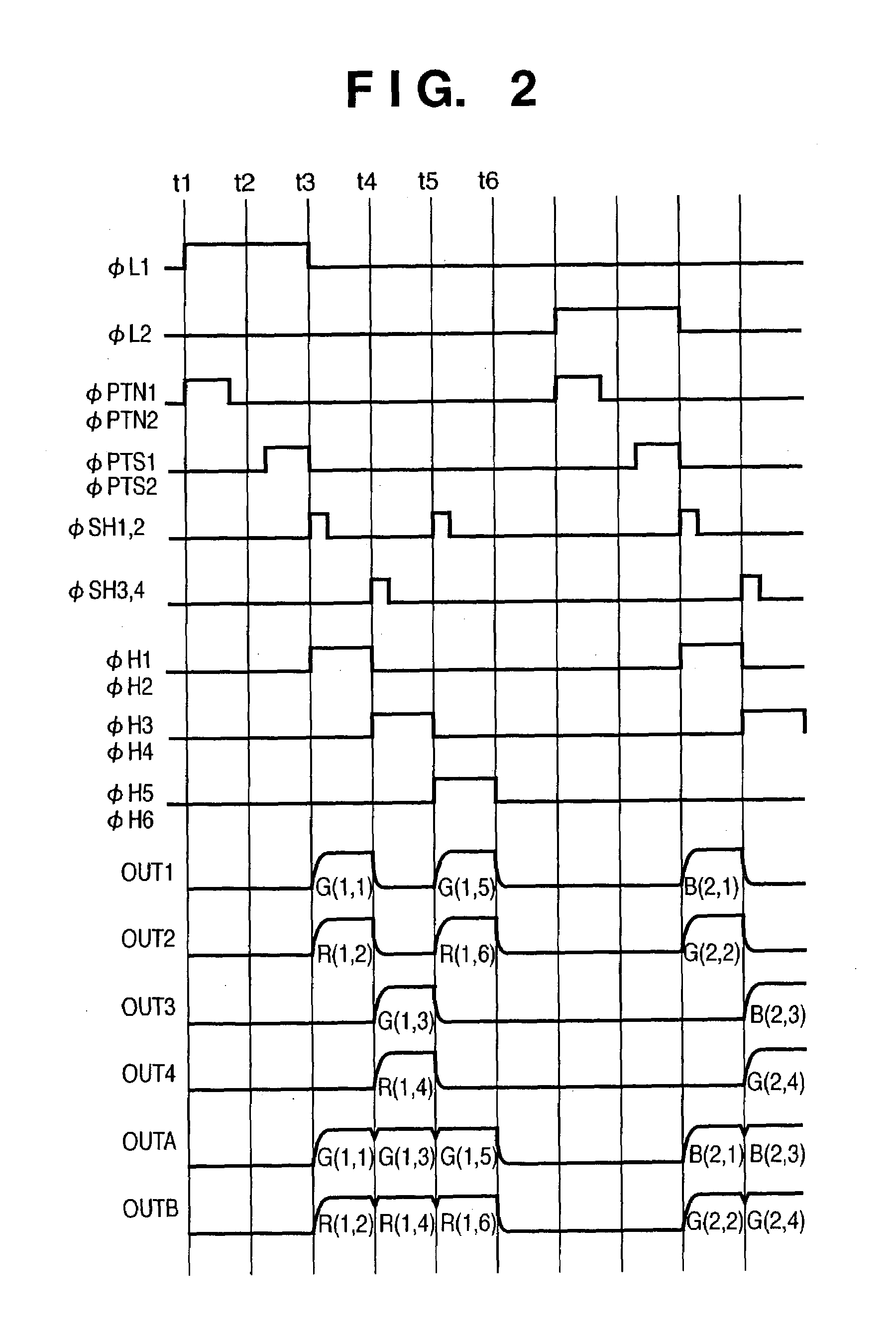

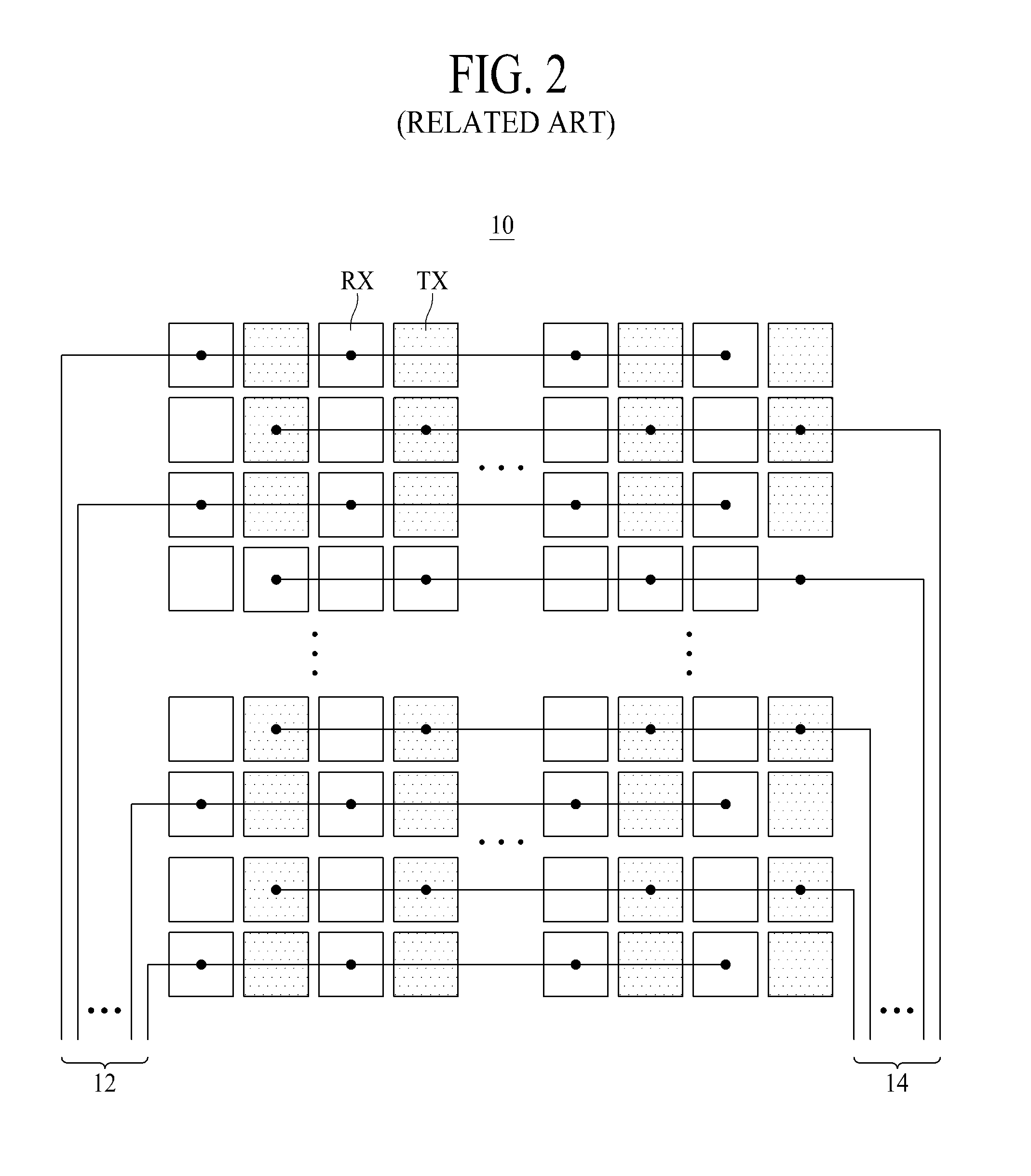

Signal readout structure for an image sensing apparatus

InactiveUS20070052831A1Improve picture qualityAvoid mixing colorsTelevision system detailsTelevision system scanning detailsTime-division multiplexingComputer science

An image sensing apparatus includes a photoelectric converter having a plurality of pixels covered by a color filter composed of a plurality of colors, a plurality of common readout units adapted to sequentially output signals from the plurality of pixels, a time division multiplex (TDM) unit for time division multiplexing signals from the plurality of common readout units, and a readout control unit for reading the signals from the plurality of pixels to the common readout units in such a way that signals from pixels covered by color filters of the same color are continuously multiplexed.

Owner:CANON KK

Color film substrate, manufacturing method thereof and display device

InactiveCN103941466AAvoid mixing colorsAvoid color mixingNon-linear opticsOptical elementsImage resolutionColor film

The embodiment of the invention discloses a color film substrate, a manufacturing method of the color film substrate and a display device, and relates to the technical field of display. Under the condition of ensuring that the display device has the high aperture opening ratio and resolution ratio, the color mixing phenomenon of the display device is prevented. The color film substrate comprises a color filter layer, the color filer layer comprises color filer units of at least two colors, the color filer units are distributed in a matrix mode, a black matrix is arranged between every two adjacent color filter units, and the color film substrate further comprises light blocking protrusions which are arranged in an area where the blade matrixes are located, so that color mixing between the color filter units of different colors is prevented.

Owner:BOE TECH GRP CO LTD +1

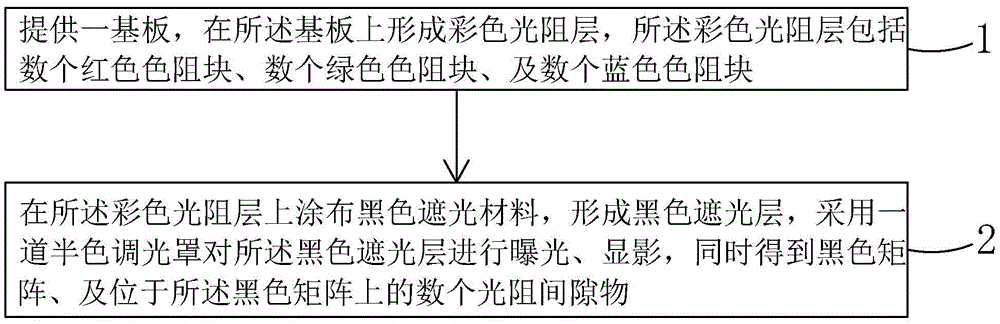

Manufacturing method of color membrane substrate

InactiveCN105467660AAvoid mixing colorsImprove viewing angleNon-linear opticsColor mixingAngle of view

The invention provides a manufacturing method of a color membrane substrate. A halftone photomask is adopted for exposing and developing a black shading layer, and a black matrix and black photoresistance gap substances on the black matrix are manufactured at the same time, so that the problems such as color mixing and color differences generated when adjacent color blocking blocks on a color photoresistance layer are stacked or are not equal in height are effectively solved, and the angle of view of a product and the display quality of the product can be effectively improved; meanwhile, the manufacturing process can be shortened, materials can be saved, and the yield can be increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

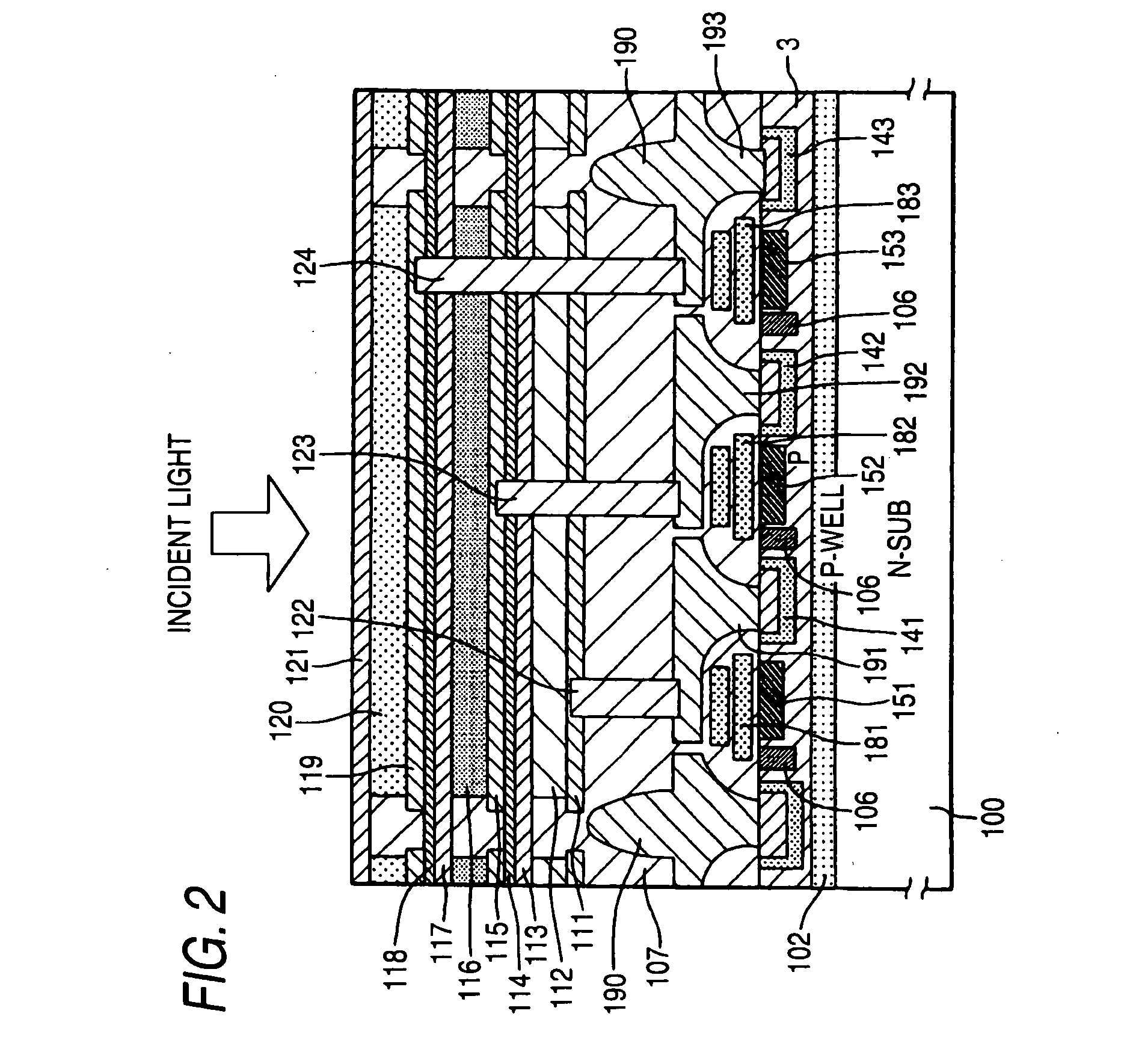

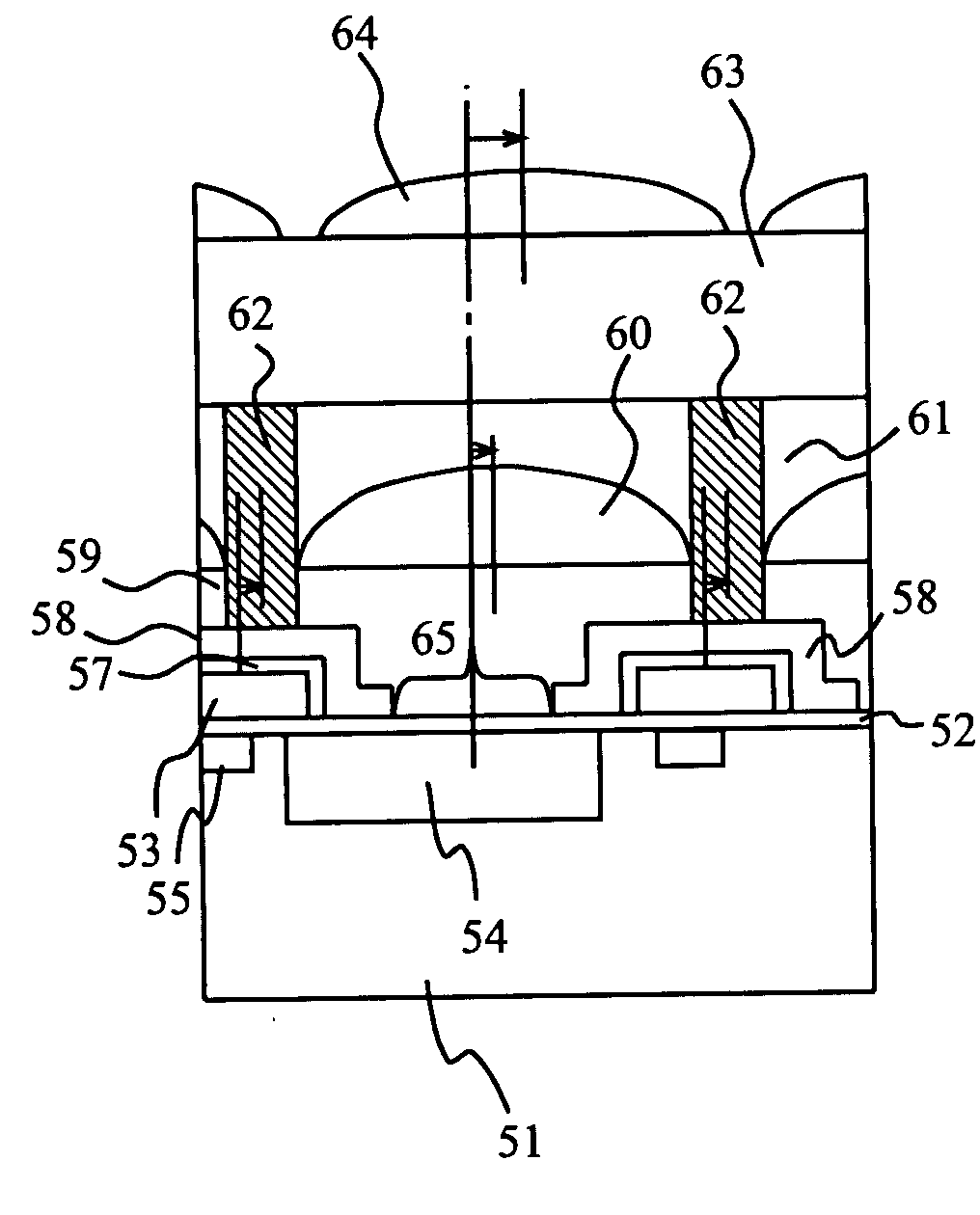

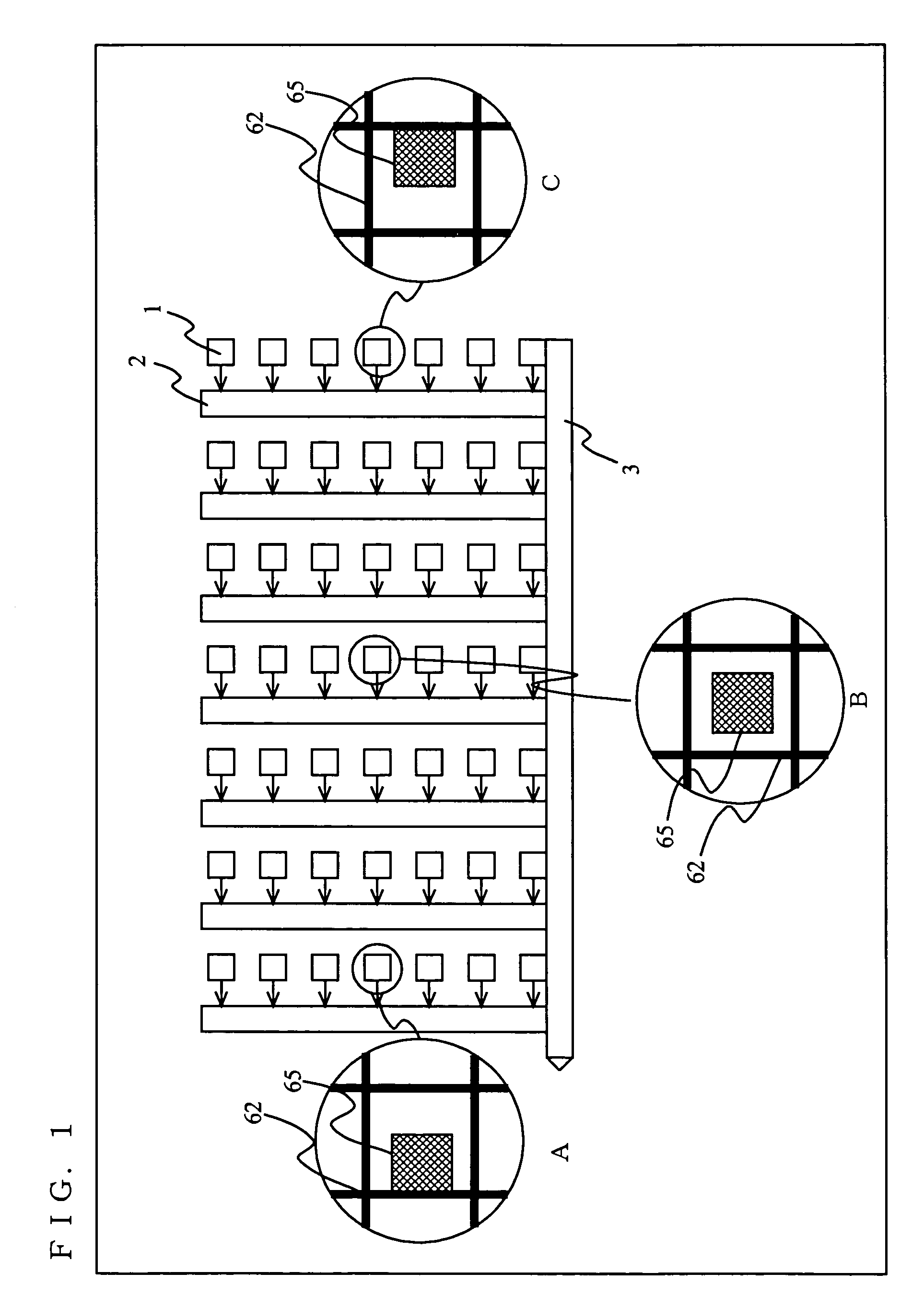

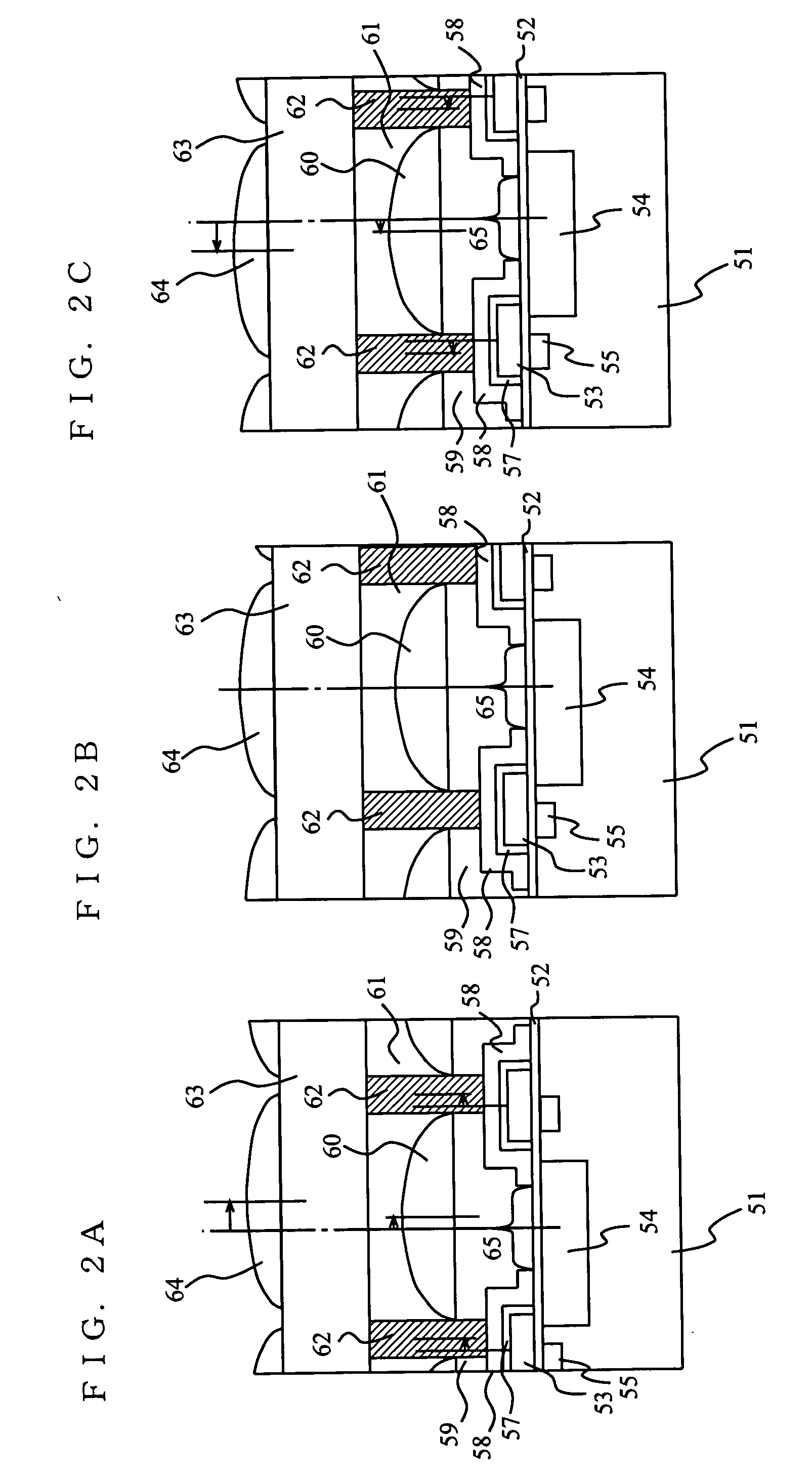

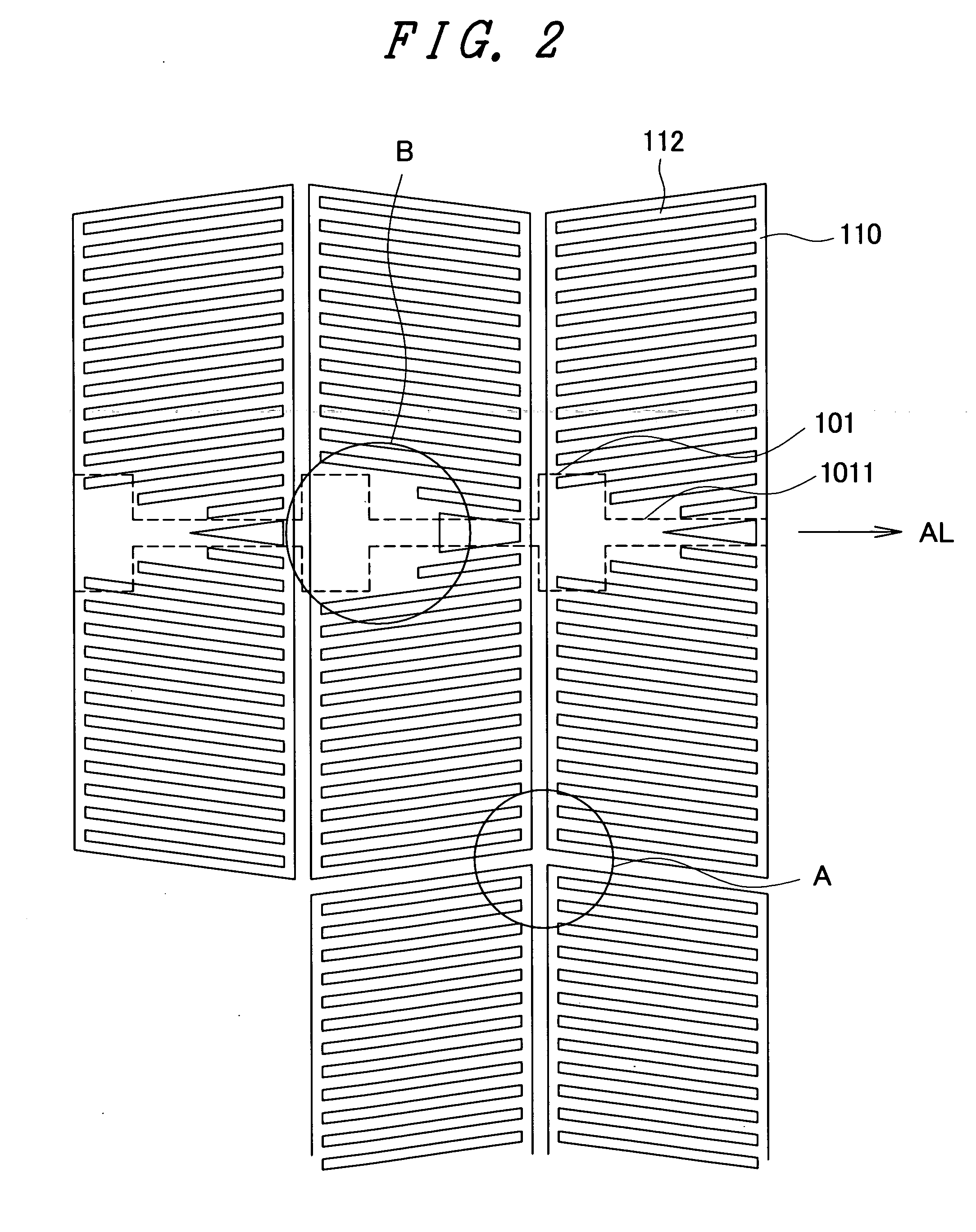

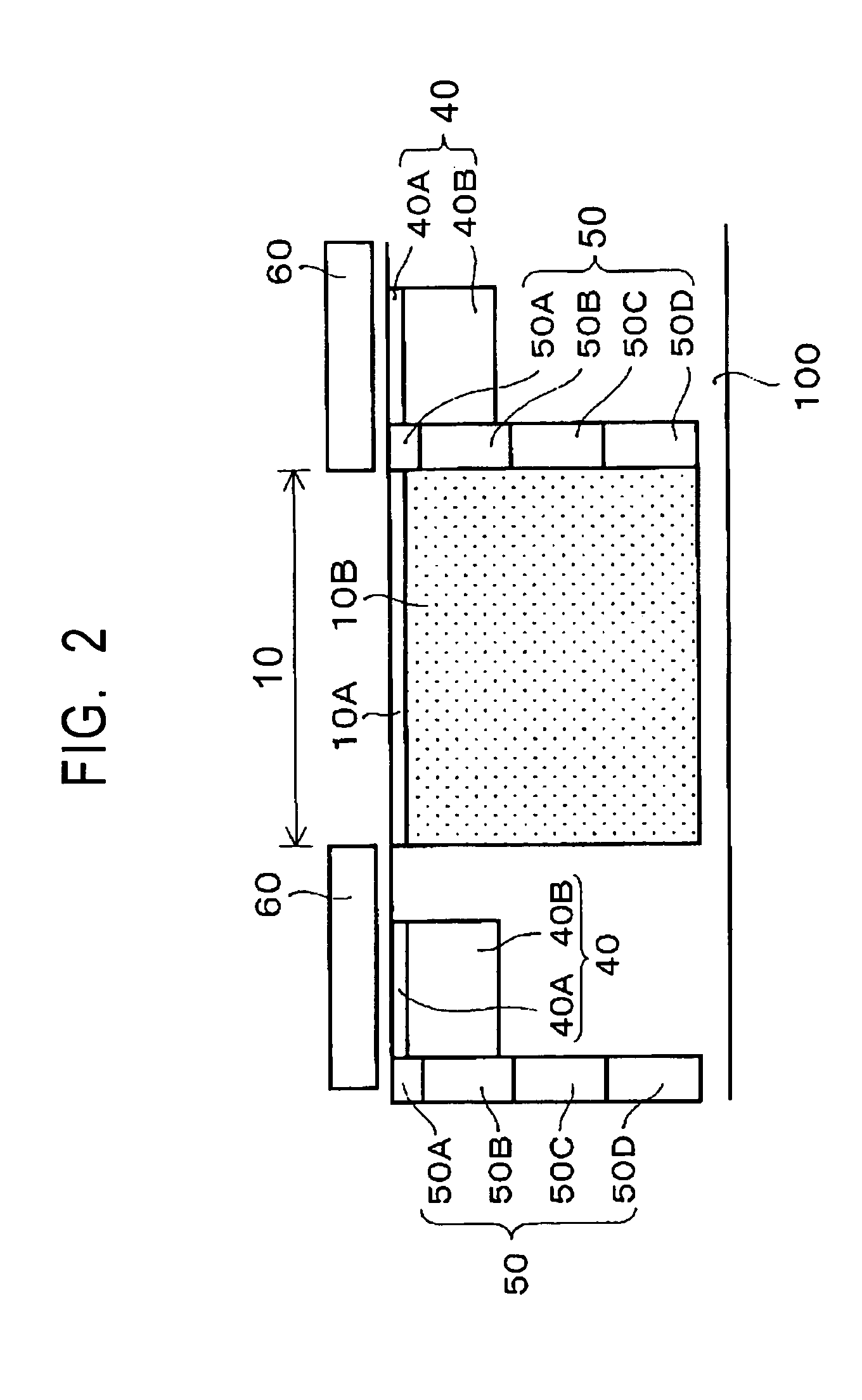

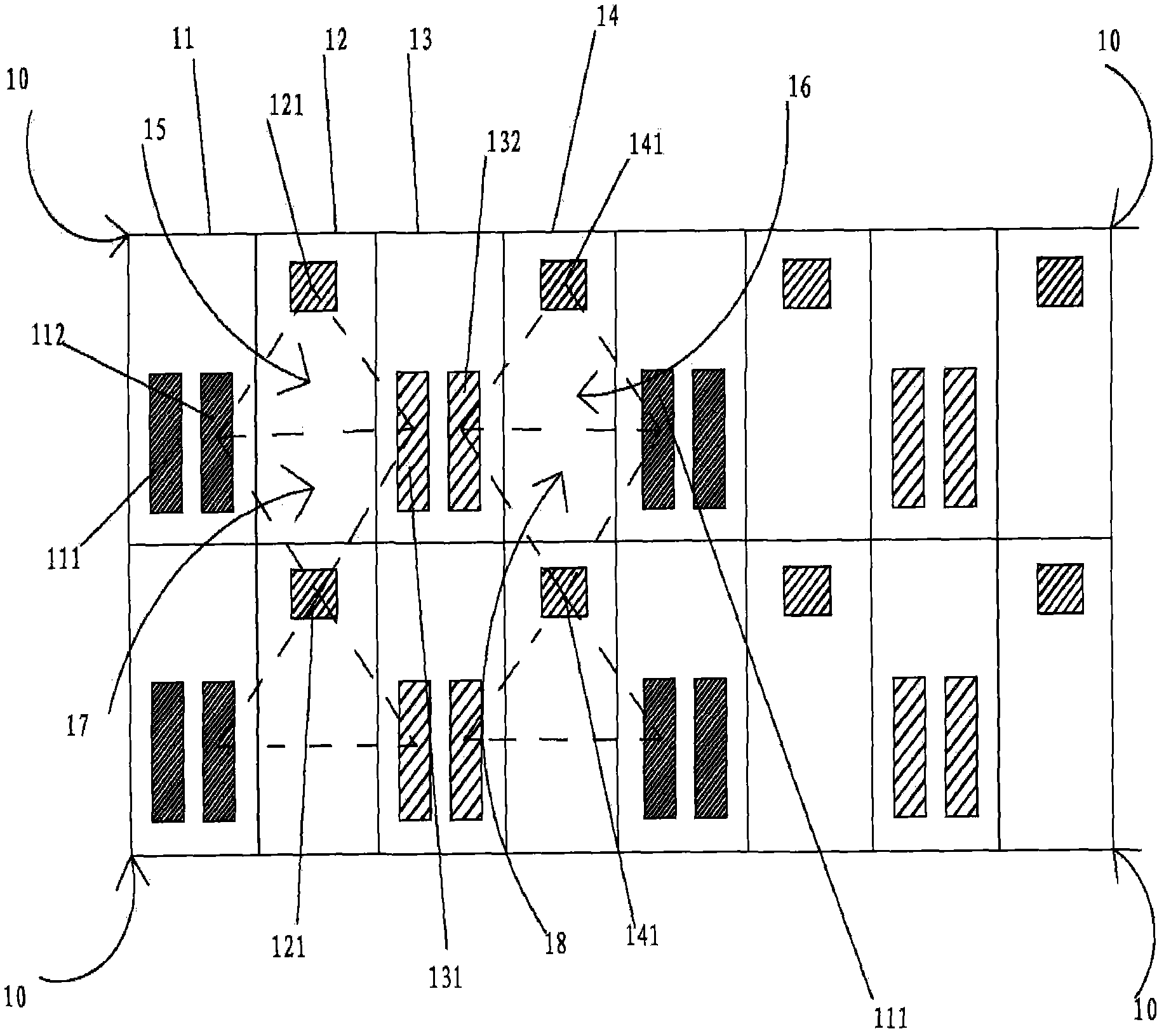

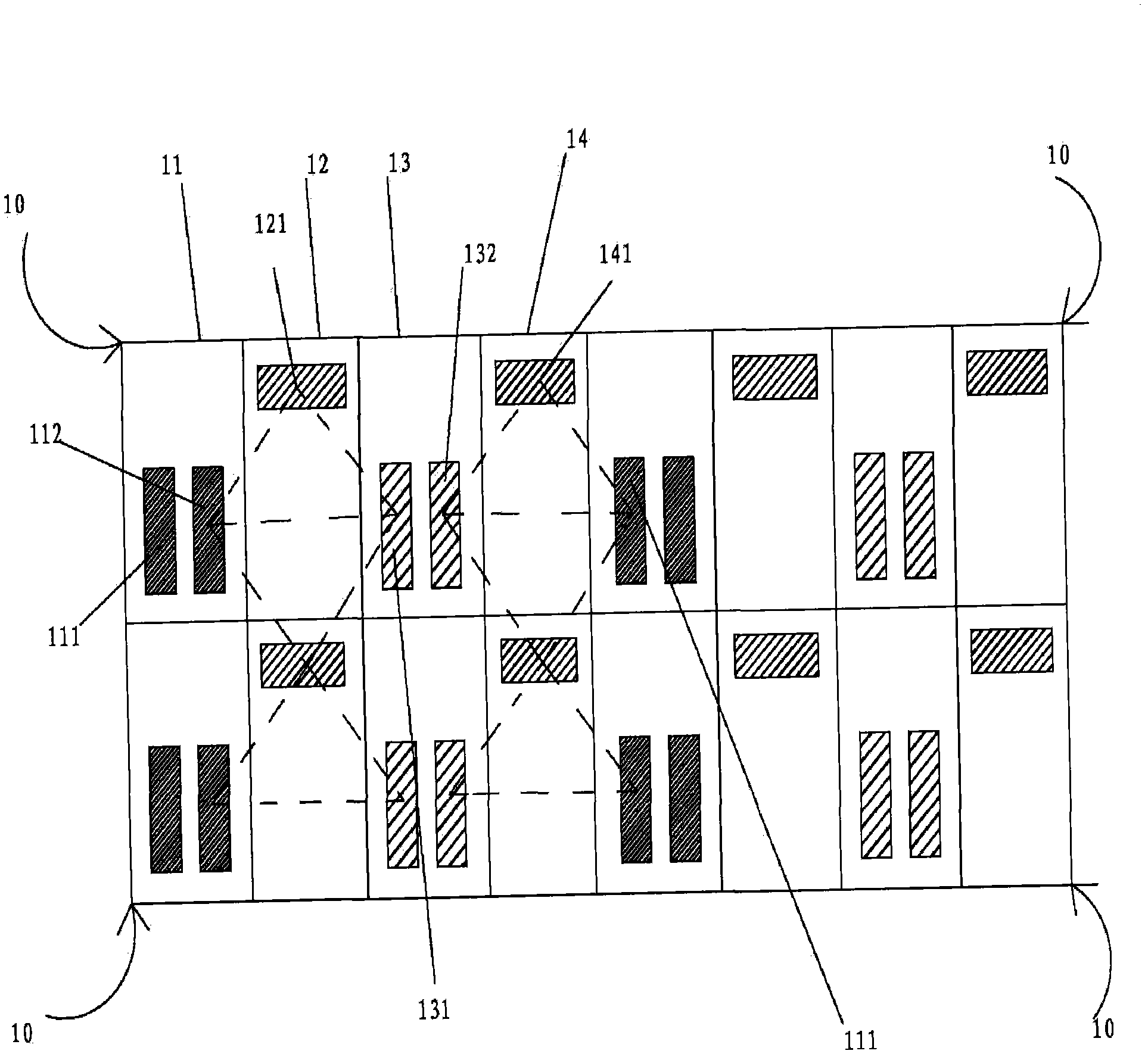

Solid-state imaging device and manufacturing method thereof

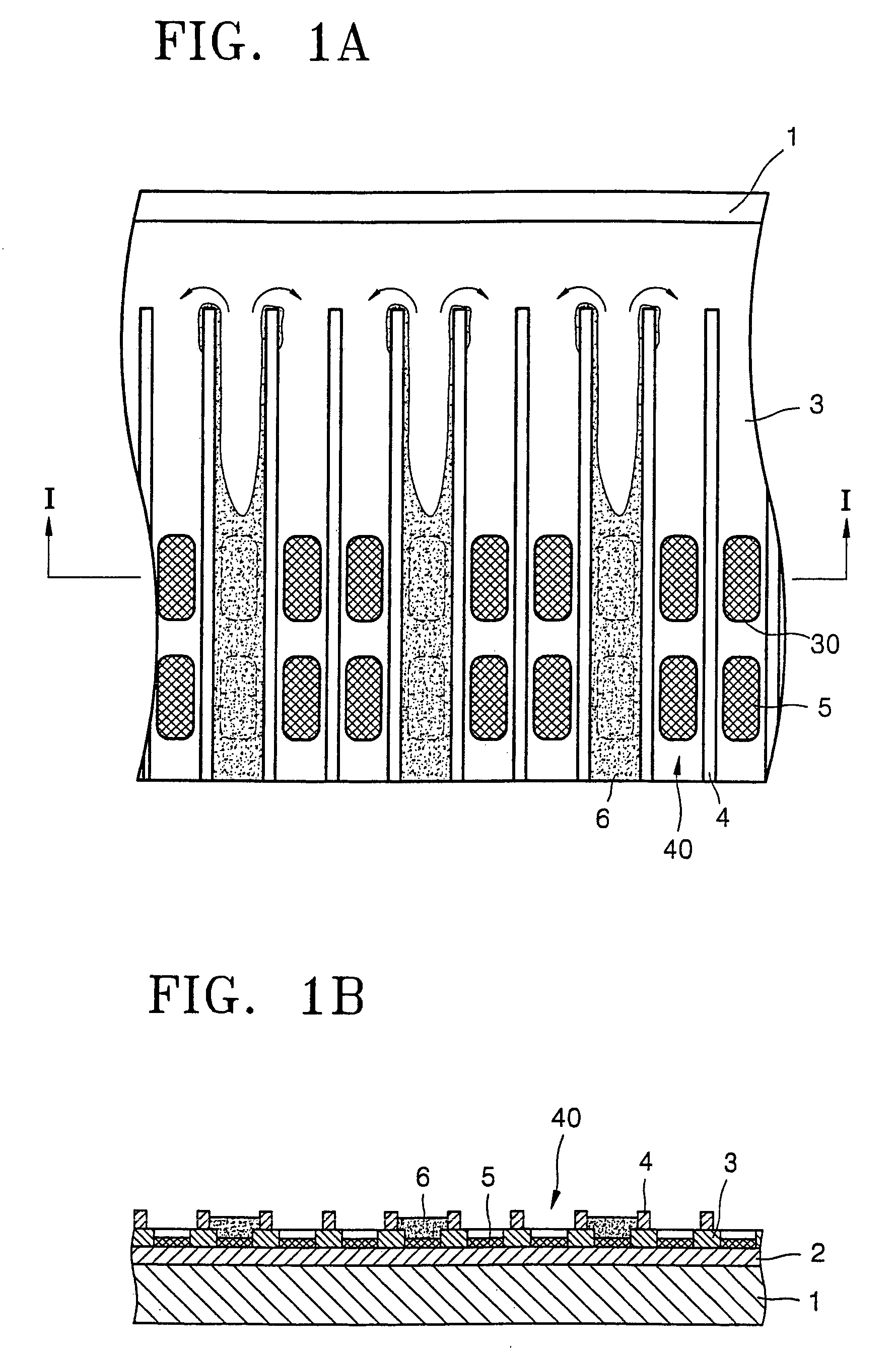

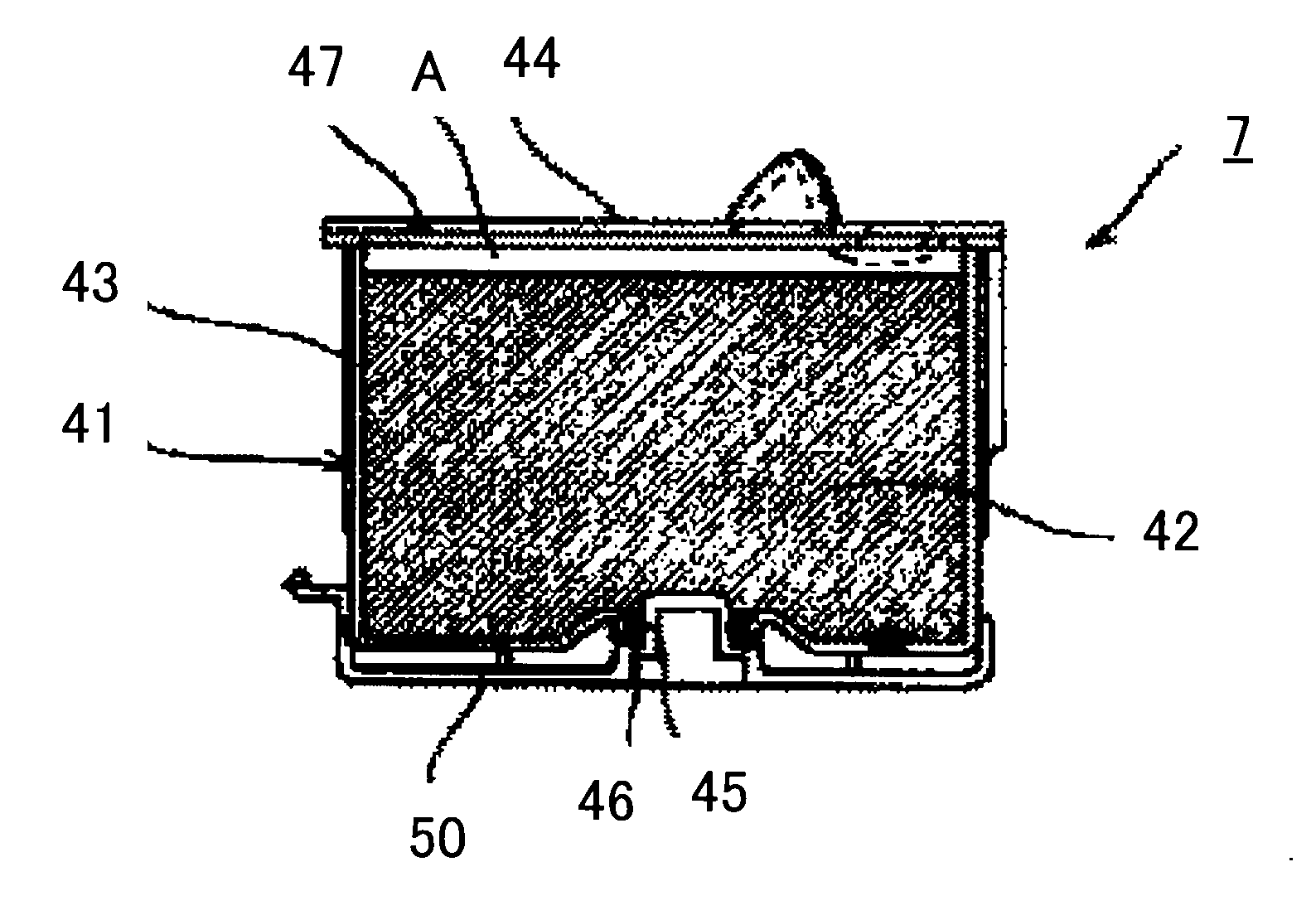

ActiveUS20050045928A1Avoid mixing colorsReduce variationTelevision system detailsSolid-state devicesGrid patternEngineering

The solid-state imaging device according to the present invention comprises: a plurality of light-sensitive elements 1 arranged in a matrix form at regular spacings in a photoreceiving region provided on a semiconductor substrate; a plurality of detecting electrodes provided on the semiconductor substrate corresponding to the plurality of the light-sensitive elements for detecting an electrical charge generated by each light-sensitive element; a light-shielding film 58 coating the plurality of detecting electrodes and having an aperture 65 over each light-sensitive element; and a plurality of reflecting walls 62, which are formed in a grid pattern over the light-shielding film so as to partition the apertures individually over the respective light-sensitive elements, for reflecting a portion of light entering the semiconductor substrate from above onto the aperture on each light-sensitive element. The plurality of reflecting walls are formed so that a middle point of the reflecting walls opposing each other across the aperture is displaced from a center of the aperture toward a center of the photoreceiving region.

Owner:COLLABO INNOVATIONS INC

Evaporation mask plate, manufacturing method thereof, OLED display substrate and evaporation method

InactiveCN106816554AAvoid mixing colorsReduce usageVacuum evaporation coatingSolid-state devicesImage resolutionEvaporation

The present invention provides an evaporation mask plate, a manufacturing method thereof, an OLED display substrate and an evaporation method. The evaporation mask plate comprises a body, evaporation opening areas formed in the body and a spacer arranged on the body. The spacer is at least arranged between adjacent evaporation opening areas and is used for evaporating organic light-emitting layers of different colors. According to the technical scheme of the invention, during the evaporating process of organic light-emitting layers on the OLED display substrate, the evaporating materials of adjacent organic light-emitting layers of different colors are blocked out by the spacer arranged on the evaporation mask plate. Therefore, the color mixing phenomenon of the organic light-emitting layers is avoided. As a result, no spacer is arranged on the OLED display substrate, so that the process flow is reduced. The process time is shortened. Moreover, the dimension of a pixel definition layer on the OLED display substrate is reduced, and the application amount of organic materials is reduced. At the same time, the resolution and the aperture ratio of the OLED display substrate are improved.

Owner:BOE TECH GRP CO LTD +1

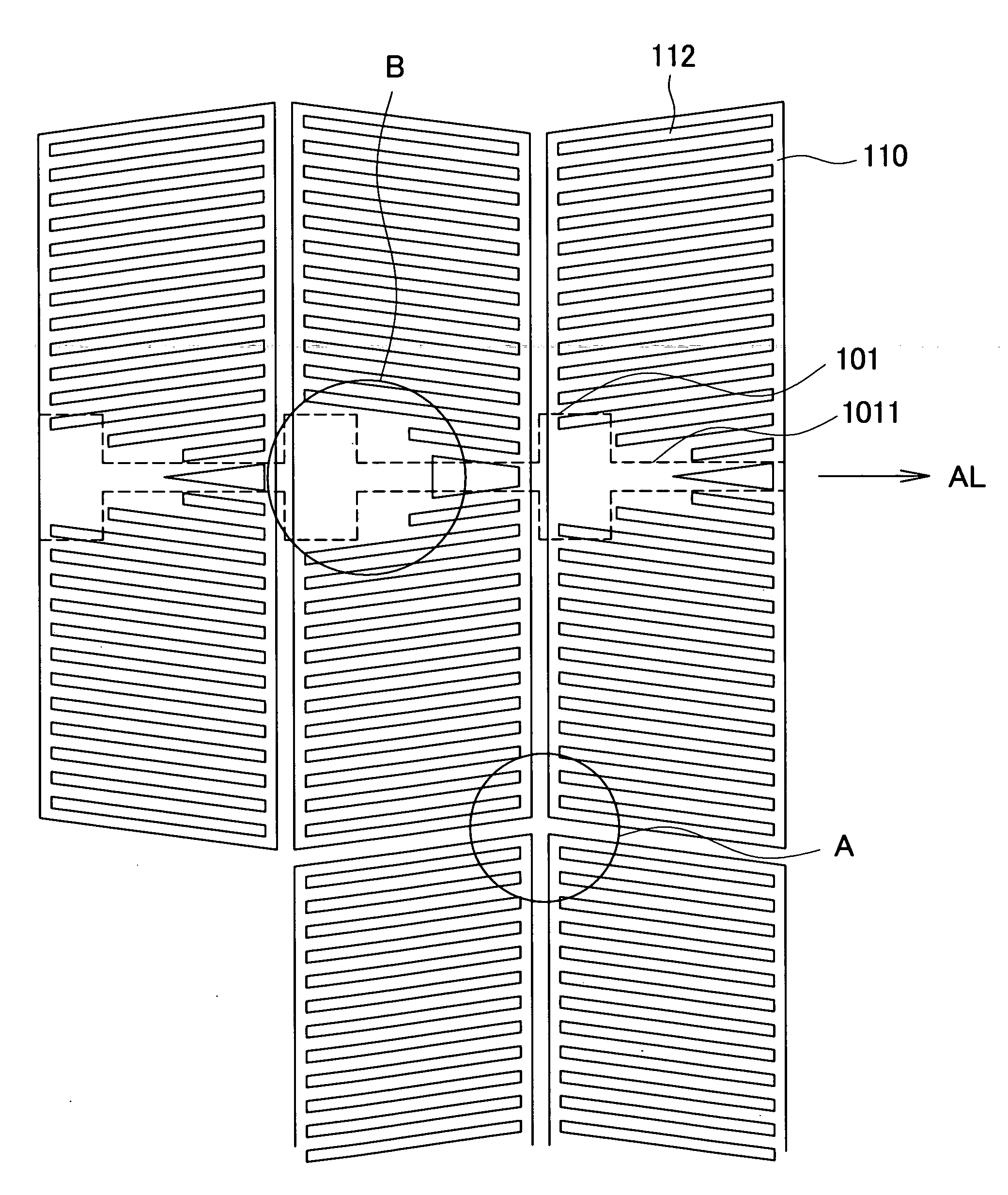

Liquid crystal display device

ActiveUS20090103025A1Reduce directivityImprove transmittanceNon-linear opticsBrightness perceptionElectric field

The present invention realizes an IPS liquid crystal display device which exhibits small directivity of viewing angle and high brightness. Below a pixel electrode having a comb-teeth-shaped electrode and having a laterally-extending trapezoidal profile, a planar common electrode not shown in the drawing is formed by way of an insulation film. When a video signal is applied to the pixel electrode, an electric field is generated between the pixel electrode and the common electrode via slit portions formed in the pixel electrode thus controlling liquid crystal molecules. The pixel electrodes are arranged in a packed state by alternately reversing the direction of the trapezoidal shape in the longitudinal direction. Since a light blocking film is not present between two pixel electrodes arranged adjacent to each other in the longitudinal direction, the liquid crystal display device can acquire high transmissivity. As a result, a liquid crystal display device having high brightness can be realized.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

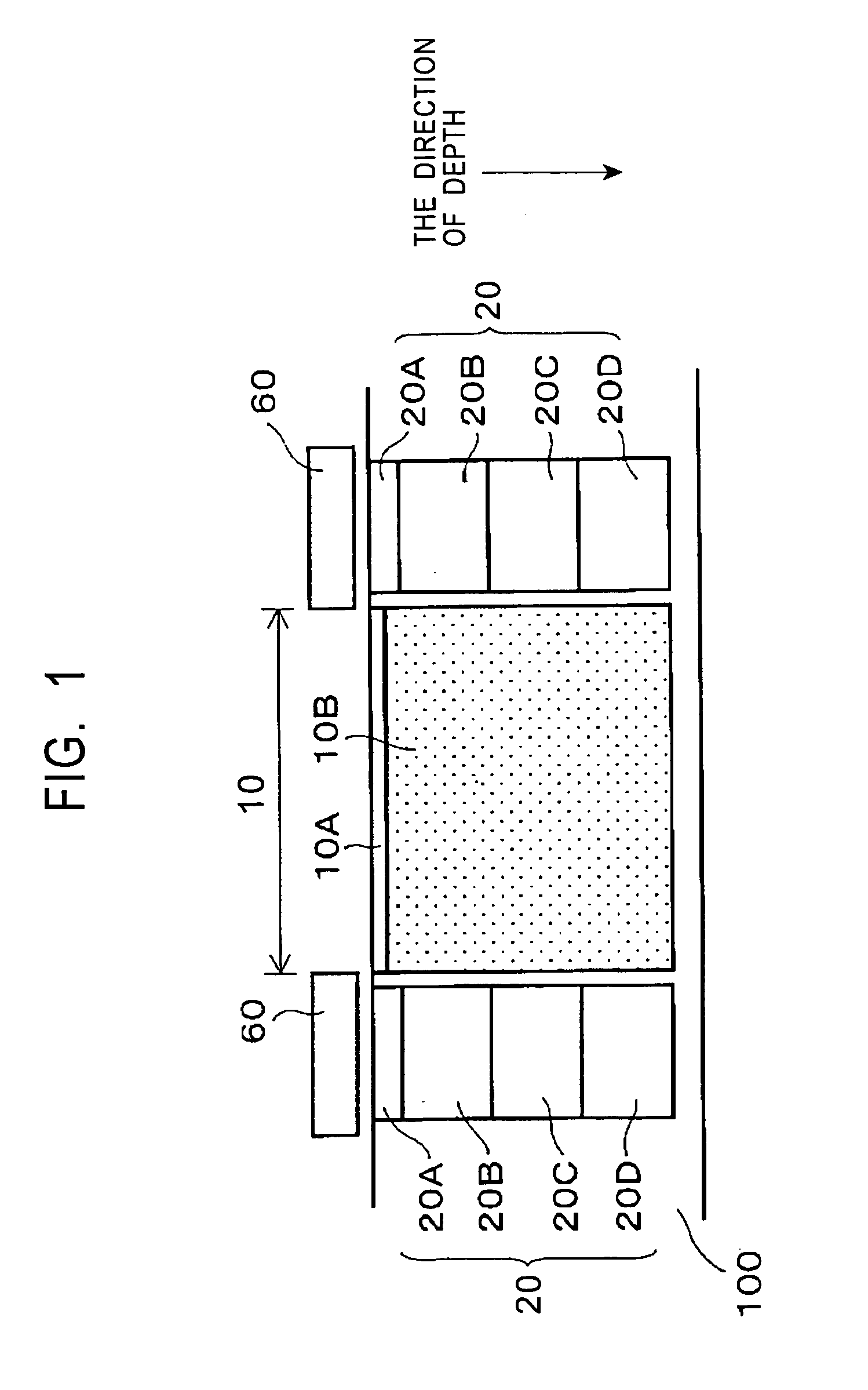

Solid-state imaging device and method for manufacturing the same

ActiveUS20050035375A1Signal leakageAvoid mixing colorsTransistorSolid-state devicesEngineeringImpurity ions

Channel stop sections are formed by multiple times of impurity ion implanting processes. Four-layer impurity regions are formed across the depth of a semiconductor substrate (across the depth of the bulk), so that a P-type impurity region is formed deep in the semiconductor substrate; thus, incorrect movement of electric charges is prevented. Other four-layer impurity regions of another channel stop section are decreased in width step by step across the depth of the substrate, so that the reduction of a charge storage region of a light receiving section due to the dispersion of P-type impurity in the channel stop section is prevented in the depth of the substrate.

Owner:SONY CORP

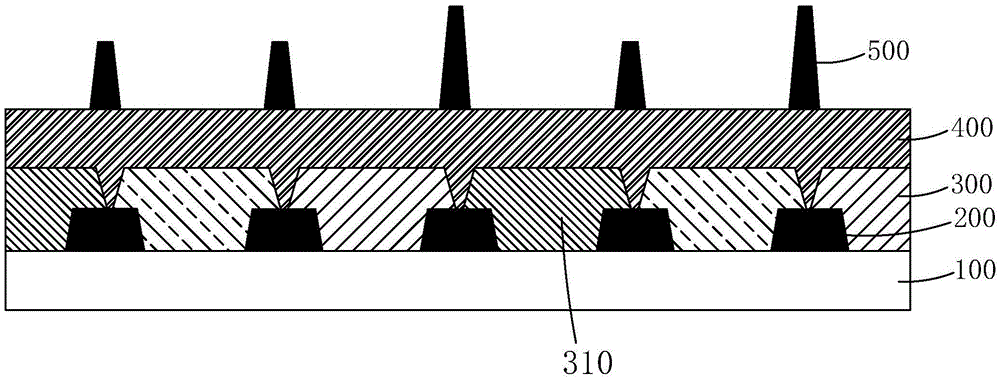

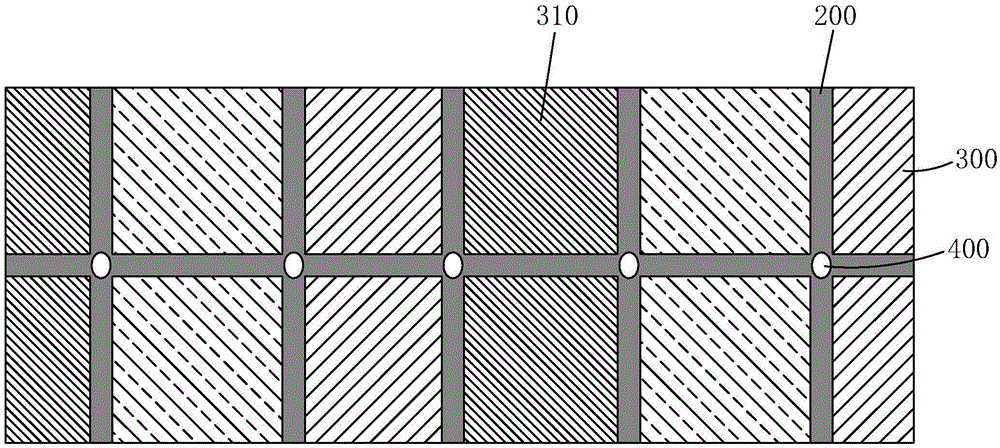

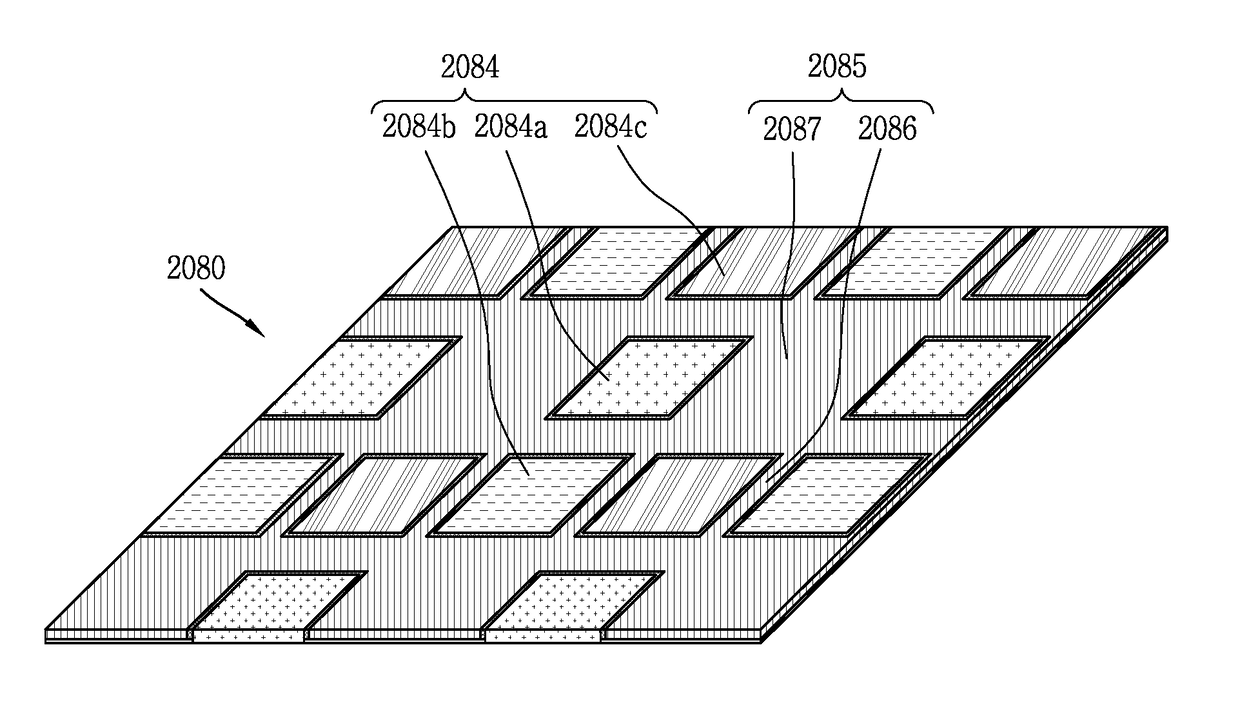

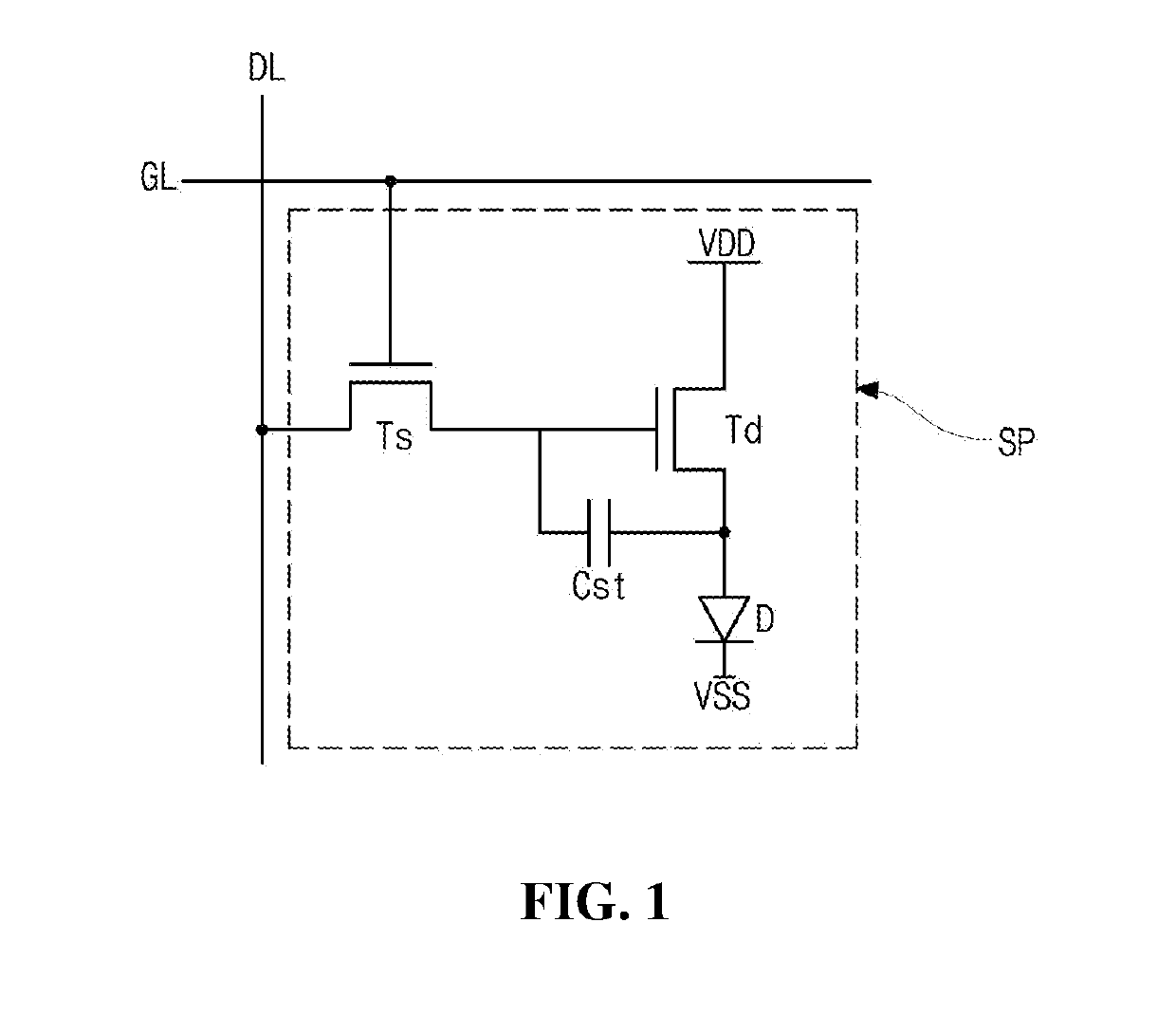

Display device using semiconductor light emitting device and method for manufacturing

ActiveUS20170200765A1Increase paddingAvoid mixing colorsSolid-state devicesSemiconductor devicesPhosphorFluorescence

A display device include a substrate including a wiring electrode; an adhesive layer disposed on the substrate; a plurality of semiconductor light emitting devices adhered to the adhesive layer, and electrically connected to the wiring electrode; and a phosphor layer disposed to cover the plurality of semiconductor light emitting devices. Further, the phosphor layer includes a plurality of phosphor portions for converting a wavelength of light, and a plurality of partition wall portions formed between the plurality of phosphor portions, and the plurality of partition wall portions are sequentially disposed between the phosphor portions along a first direction and a second direction crossing each other, respectively, and at least one of the sequentially disposed partition wall portions overlaps with at least one of the plurality of semiconductor light emitting devices.

Owner:LG ELECTRONICS INC

Signal readout structure for an image sensing apparatus

InactiveUS7148927B2Improve picture qualityAvoid mixing colorsTelevision system detailsTelevision system scanning detailsTime-division multiplexingComputer science

An image sensing apparatus includes a photoelectric converter having a plurality of pixels covered by a color filter composed of a plurality of colors, a plurality of common readout units adapted to sequentially output signals from the plurality of pixels, a time division multiplex (TDM) unit for time division multiplexing signals from the plurality of common readout units, and a readout control unit for reading the signals from the plurality of pixels to the common readout units in such a way that signals from pixels covered by color filters of the same color are continuously multiplexed.

Owner:CANON KK

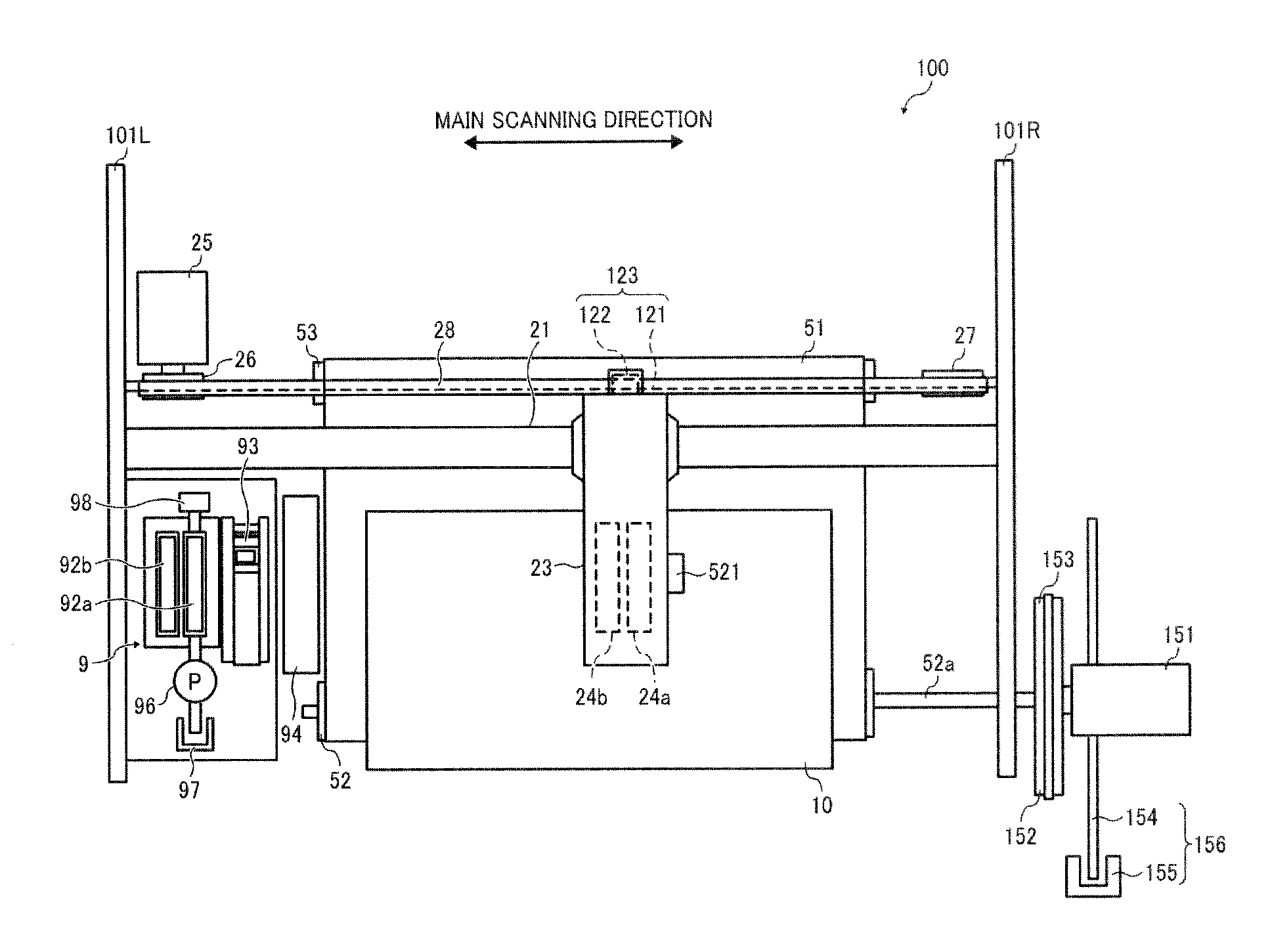

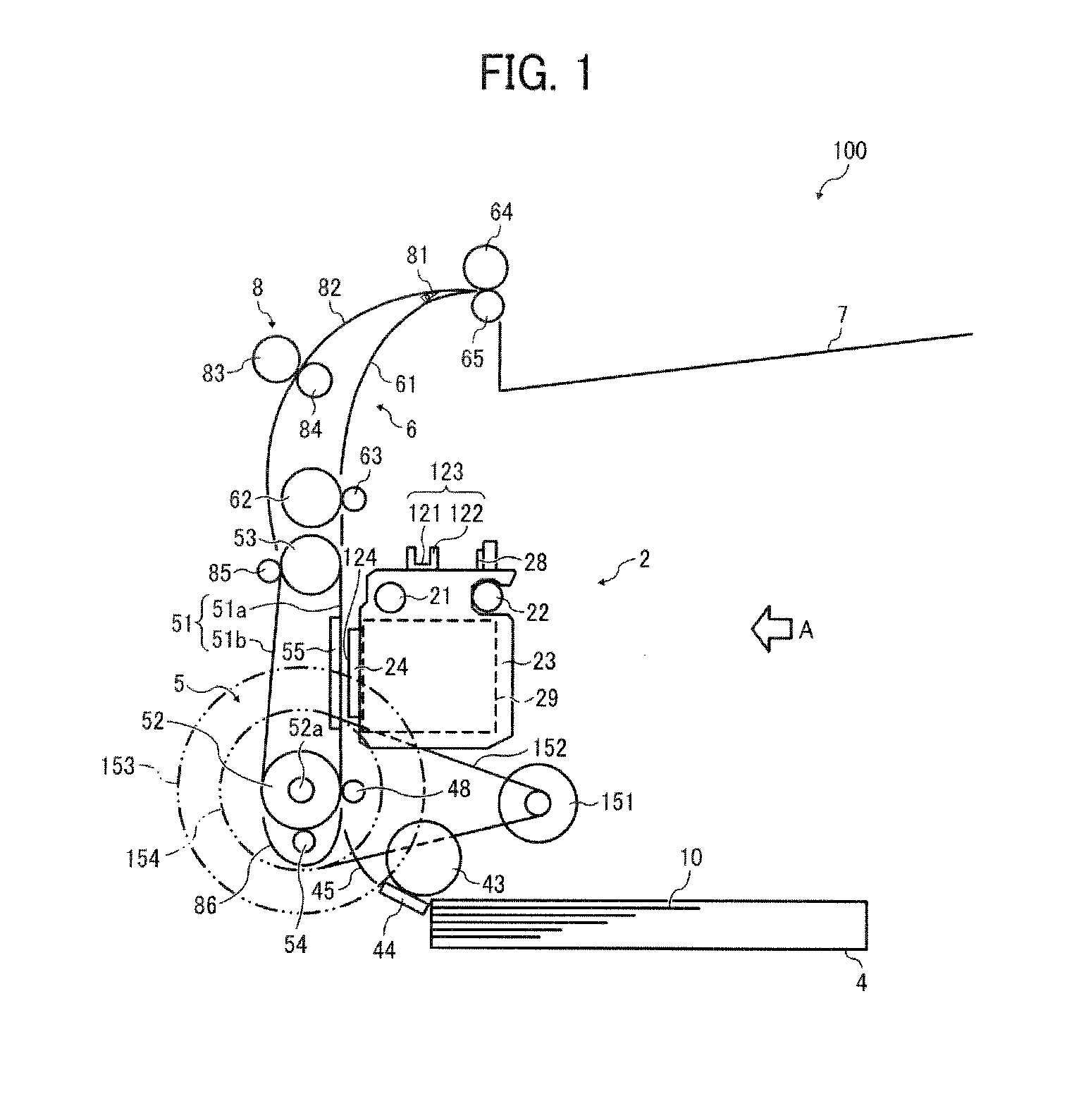

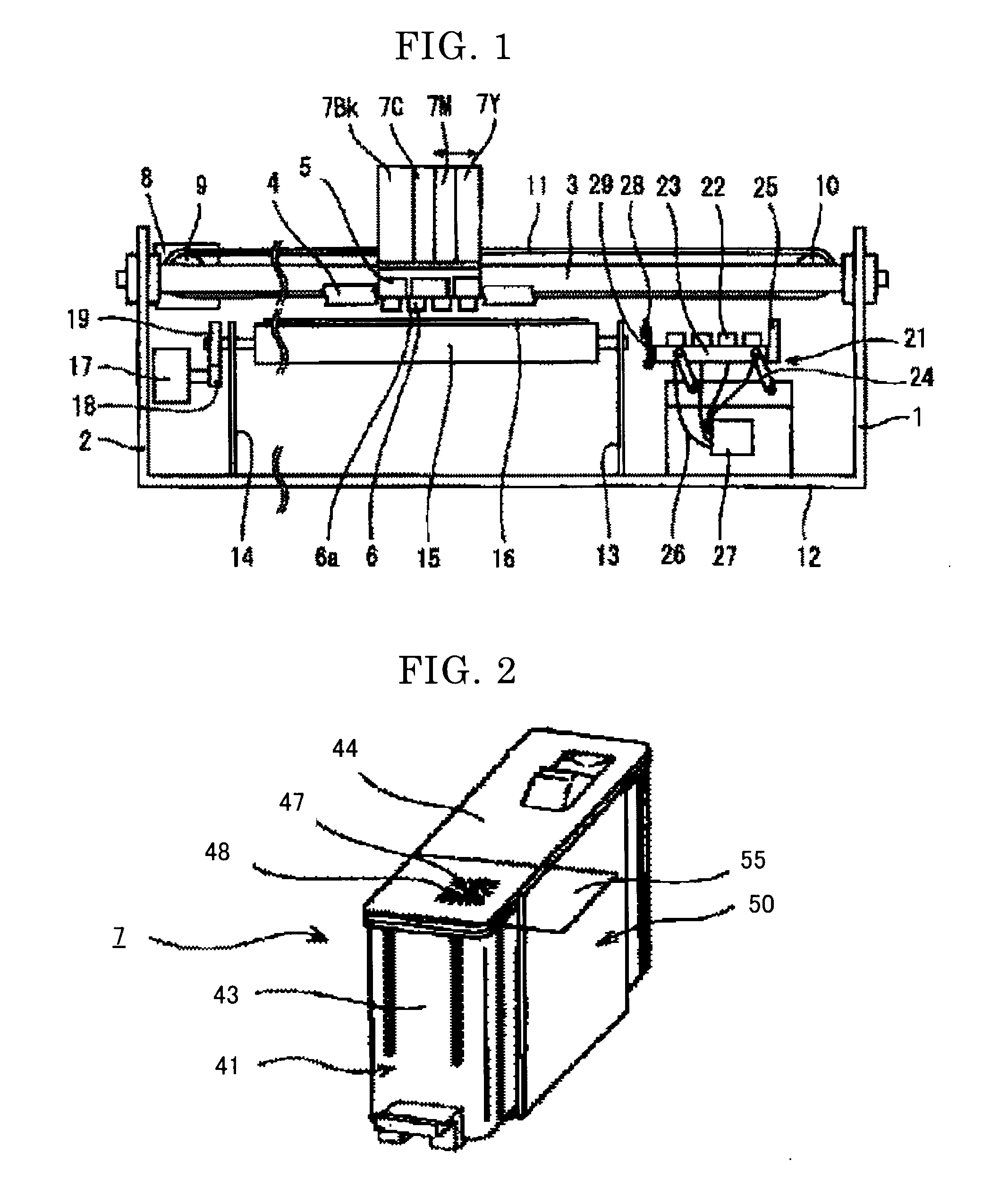

Image forming apparatus

ActiveUS20120056933A1Prevent color mixingAvoid mixing colorsOther printing apparatusSpray nozzleRecording head

An image forming apparatus including: a recording head having a nozzle surface in which nozzles to eject liquid droplets in a horizontal direction or a direction slanted from the horizontal direction are formed, the nozzle surface being disposed in a vertical direction or a direction slanted from the vertical direction; a head tank to supply liquid to the recording head; a suction cap to cap the nozzle surface of the recording head; a suction member connected to the suction cap to suck out liquid from the nozzles by the suction cap; a valve member to open or close a sealed space formed by capping the nozzle surface with the suction cap to atmosphere; a liquid supplier to supply the liquid to the head tank and return the liquid from the head tank; and a control unit to control servicing of the recording head.

Owner:RICOH KK

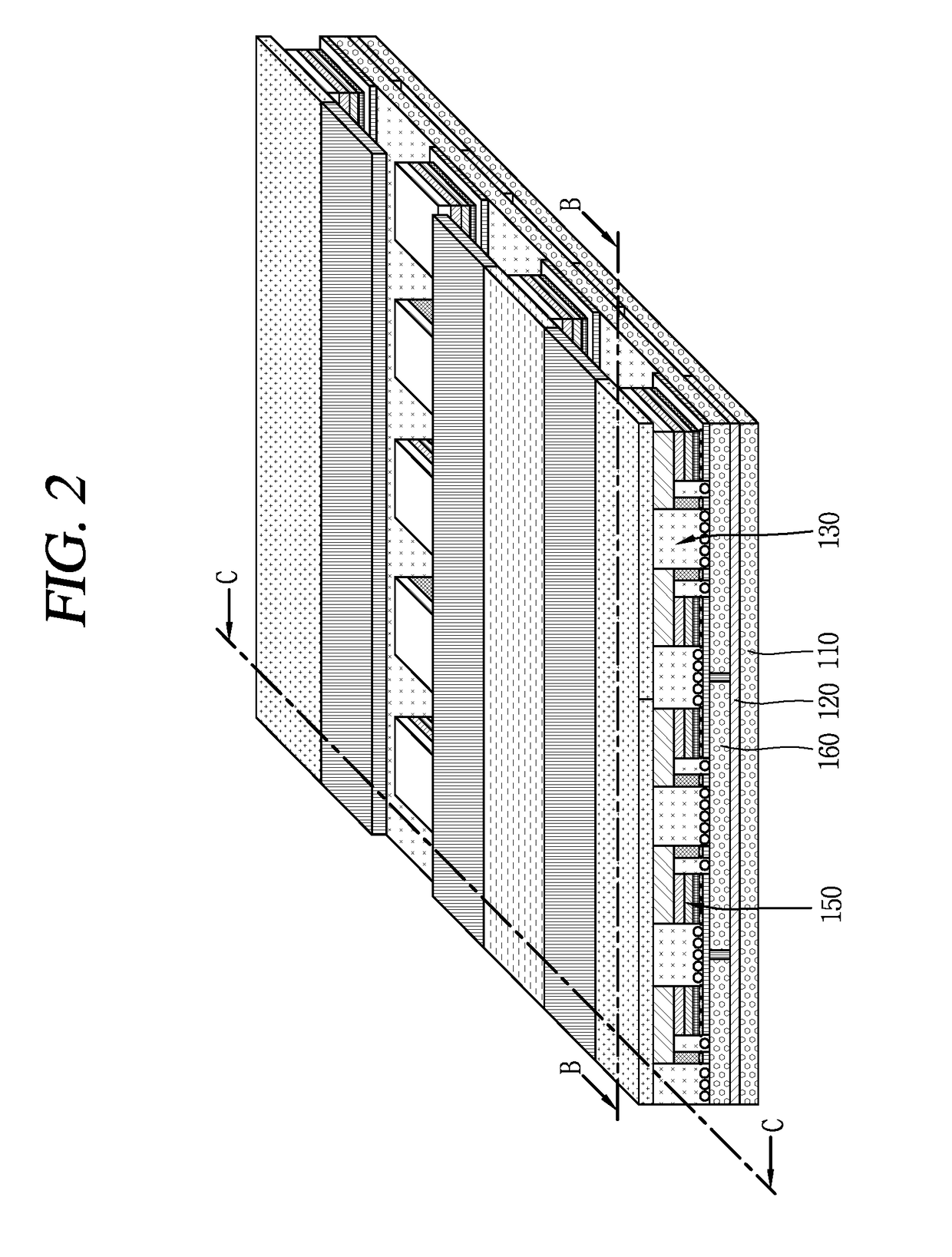

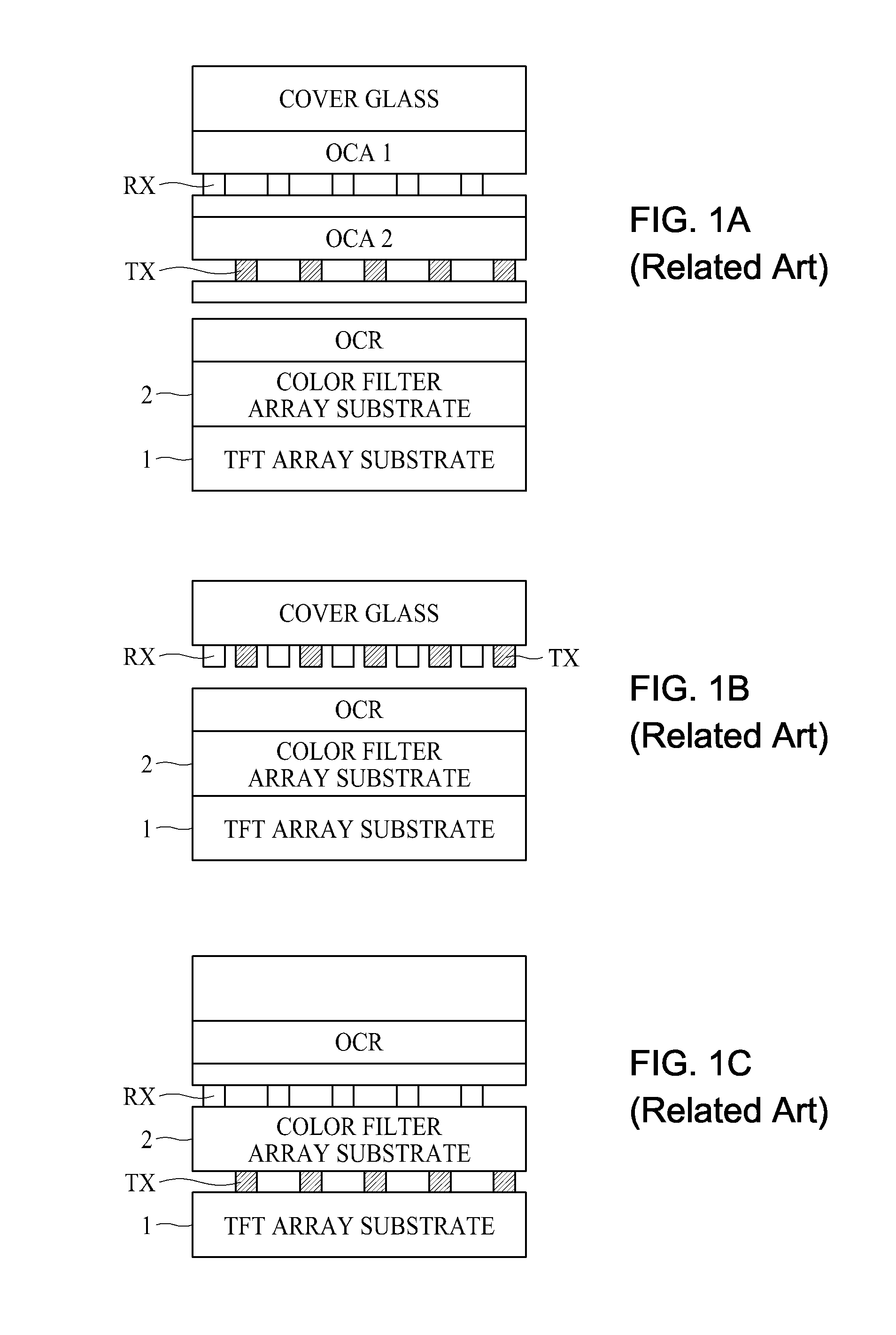

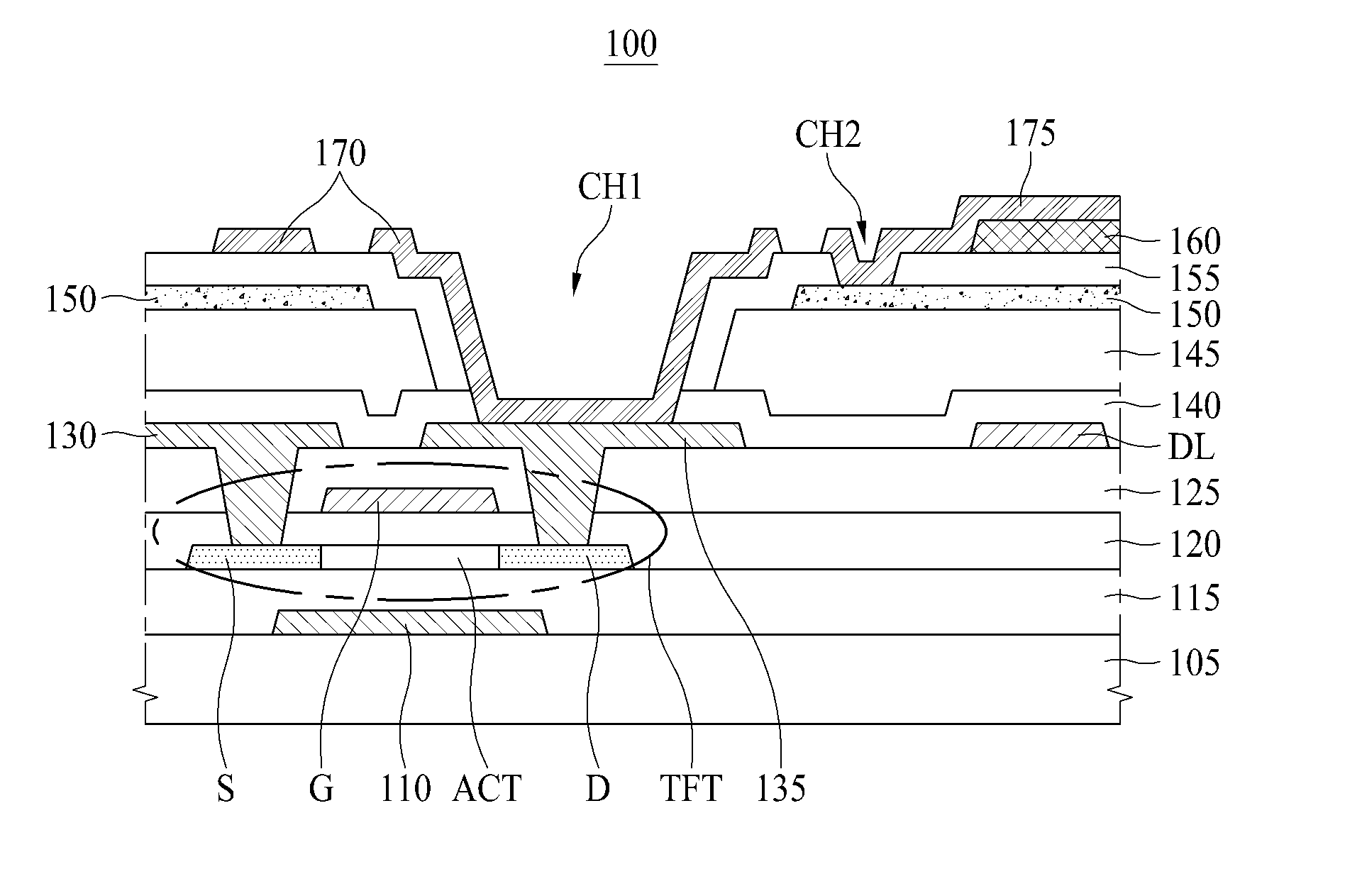

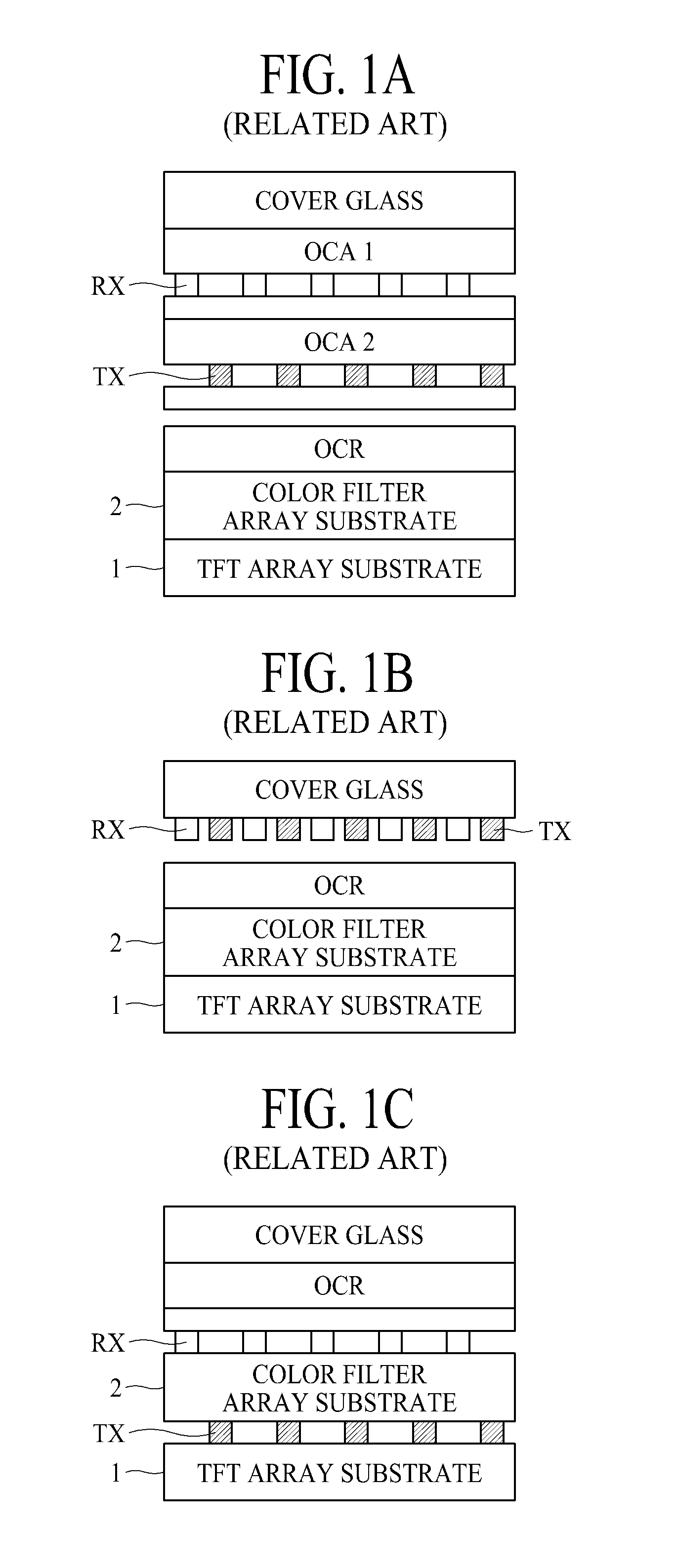

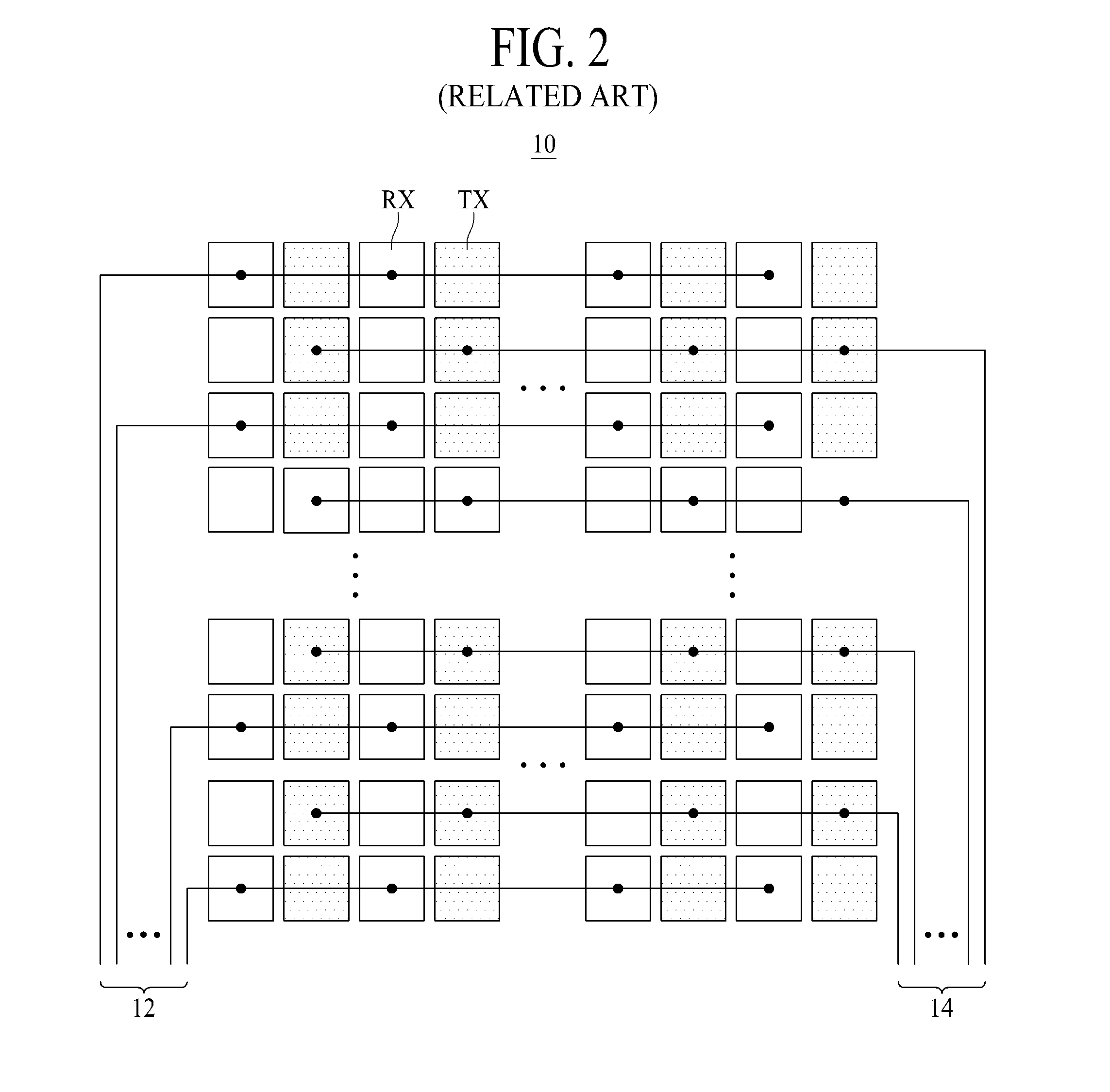

In-cell touch liquid crystal display apparatus and method of manufacturing the same

ActiveUS20160187693A1Avoid mixing colorsReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

Disclosed are an in-cell touch liquid crystal display (LCD) apparatus having a pixel electrode top structure and a method of manufacturing the same. The in-cell touch LCD apparatus is implemented in the pixel electrode top structure, thereby preventing color mixing between red, green, and blue pixels. The method of manufacturing the in-cell touch LCD apparatus decreases the number of masks necessary to manufacture a TFT array substrate, thereby reducing a manufacturing time and the manufacturing cost.

Owner:LG DISPLAY CO LTD

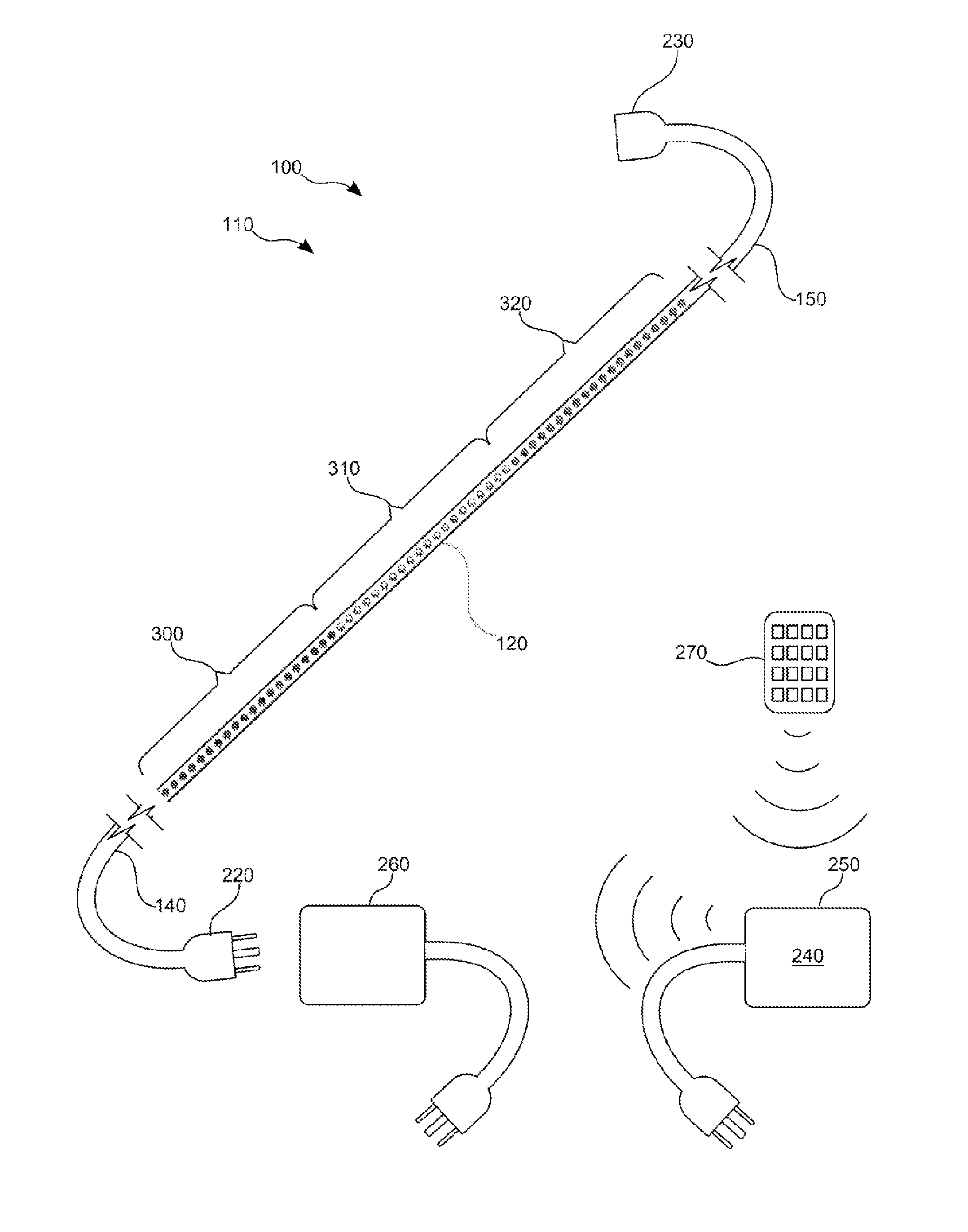

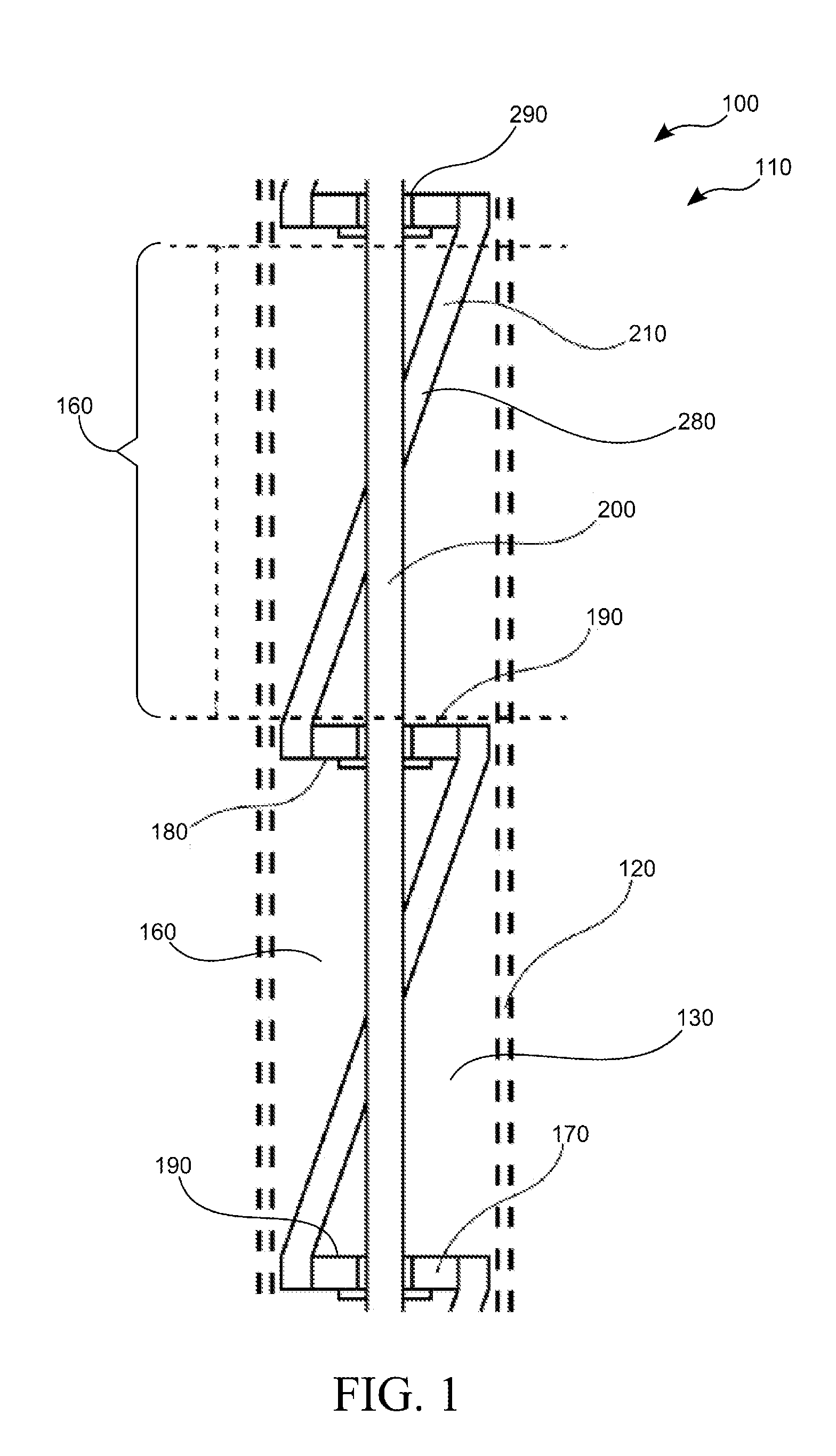

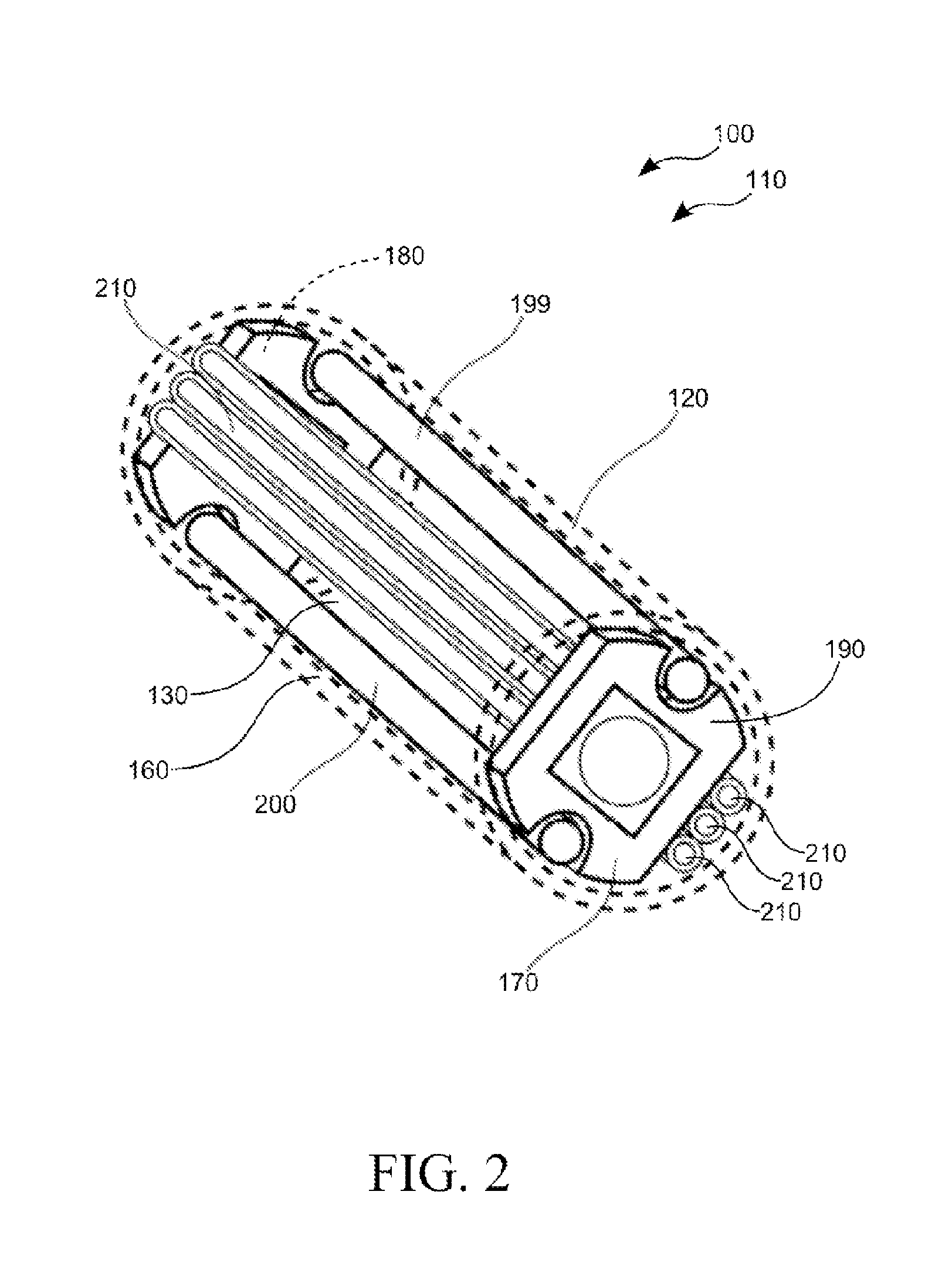

Holiday magic systems

ActiveUS9291318B1Facilitates evenly viewingAvoid mixing colorsPoint-like light sourceElectrical apparatusRope lightProgrammable logic controller

A programmable light rope system is a wirelessly operated rope light assembly having an LED rope light with a programmable light controller, a transmitter, a receiver, and a remote controller. The light rope is constructed with color chambers that are formed by the space between LEDs. The LEDs are positioned perpendicularly to the linear axis of and within the inner volume of the transparent tube and the color control wires diagonally connect the LEDs forming a 7-shaped profile within each color chamber. The programmable light controller allows over 44 million possibilities of color and flashing combinations with 11 colors and multiple shades of each color.

Owner:BENSON JEFFREY

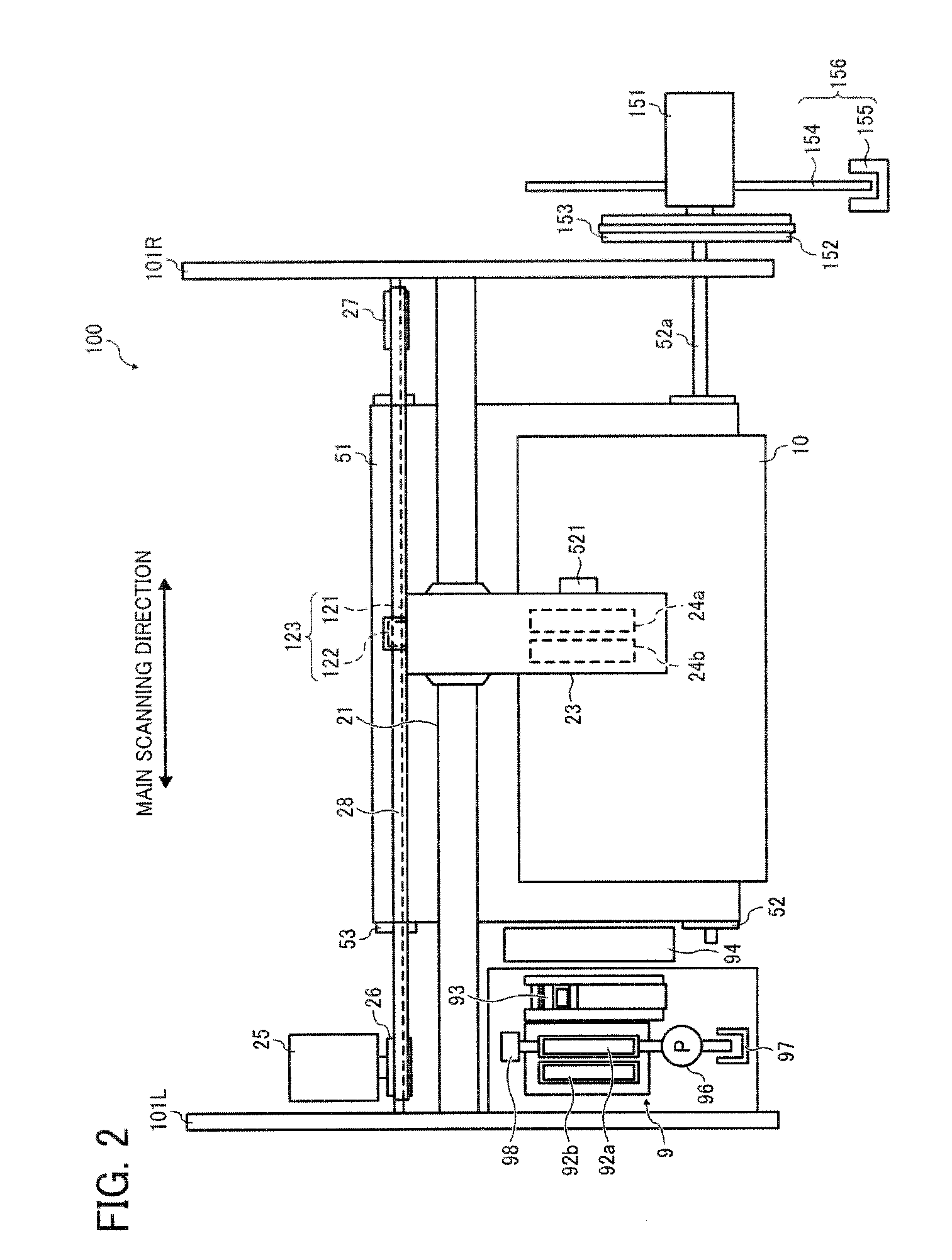

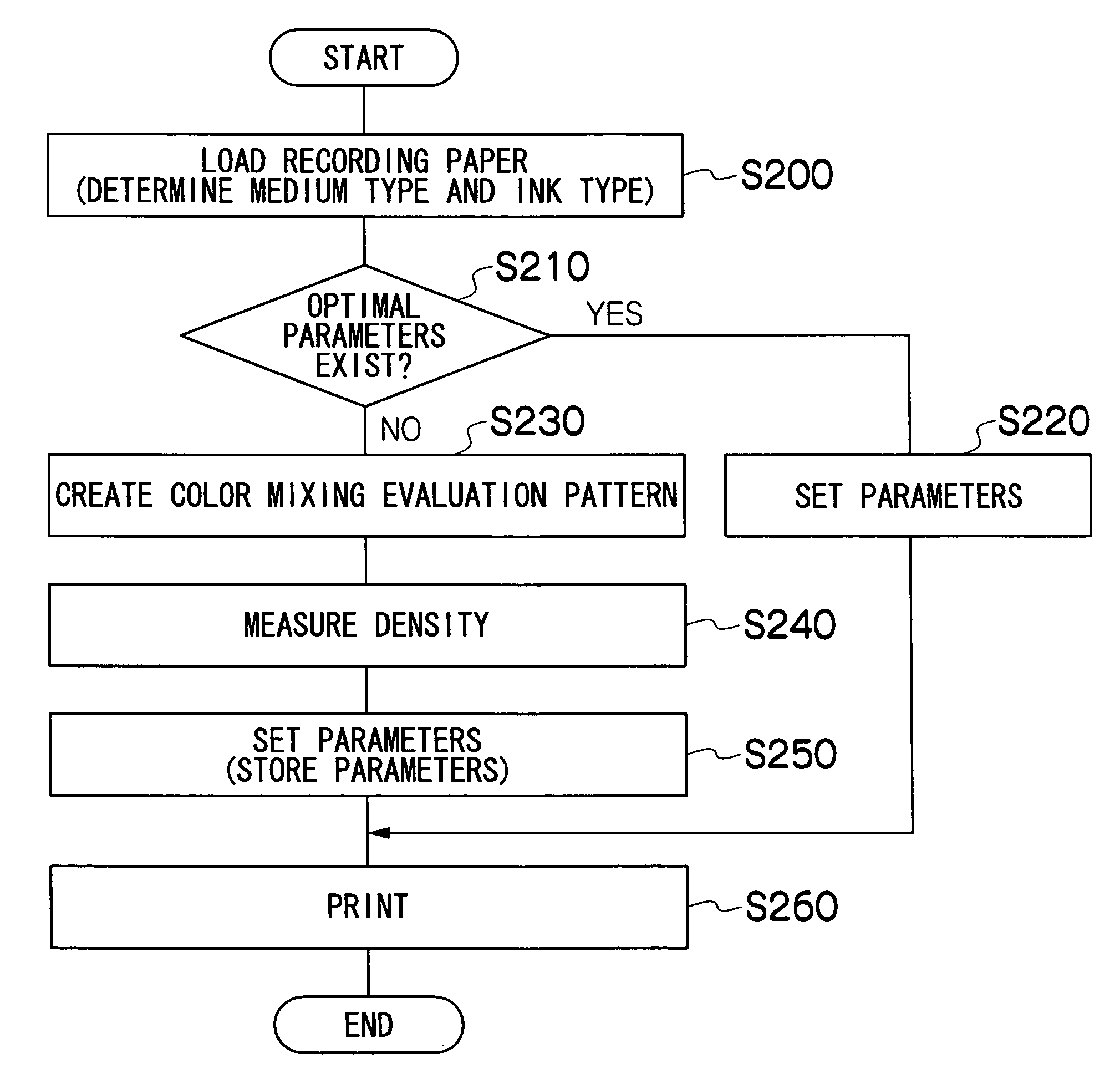

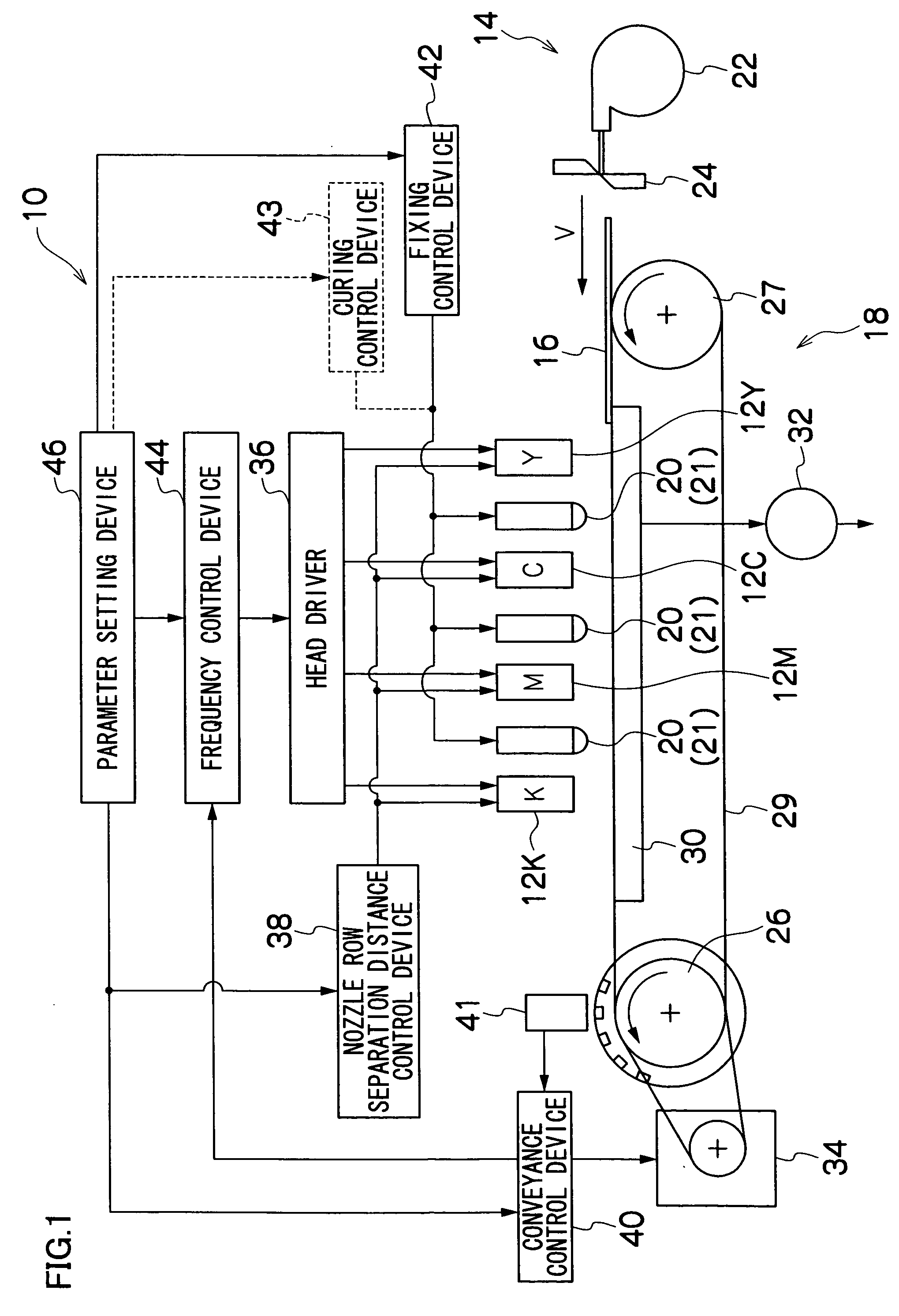

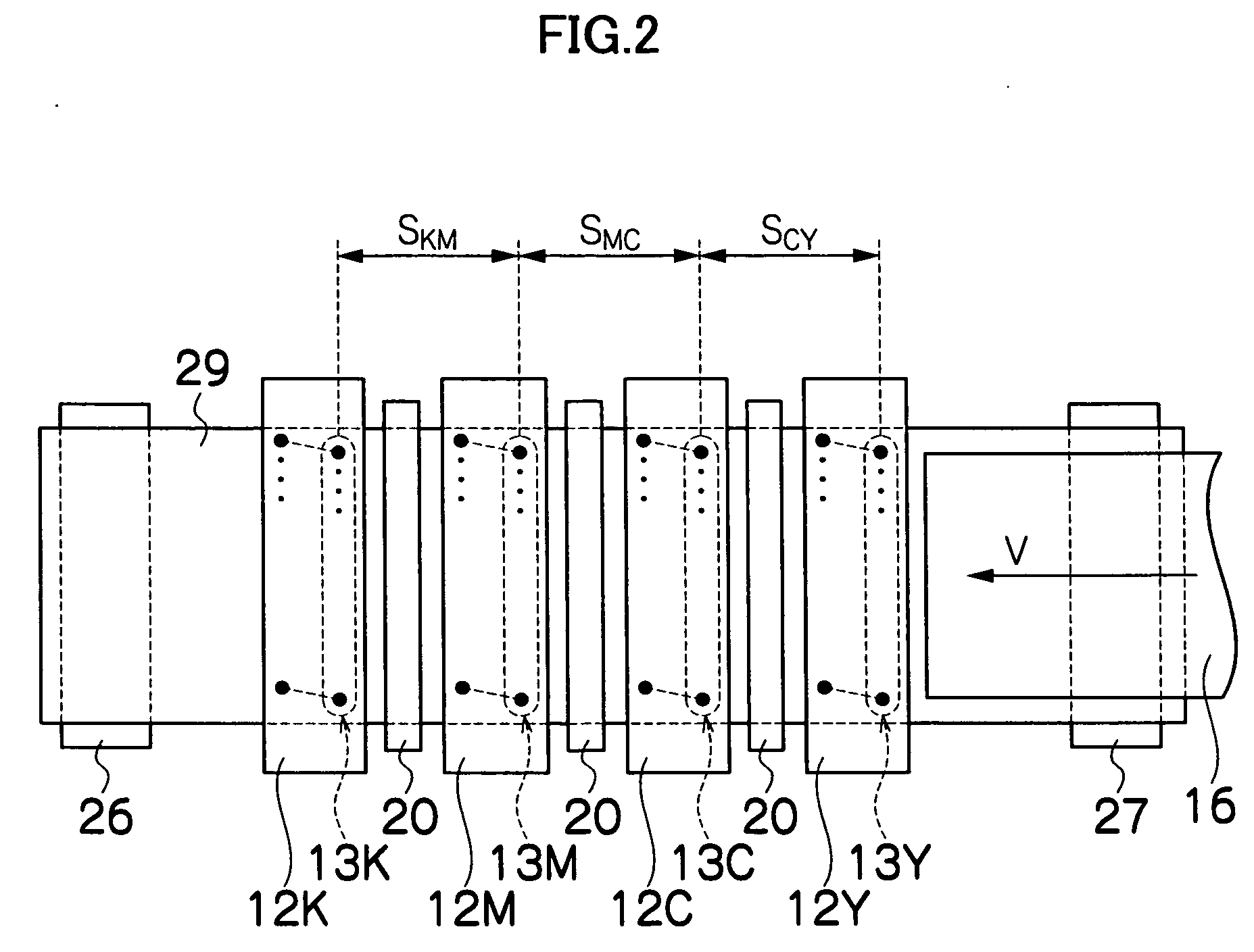

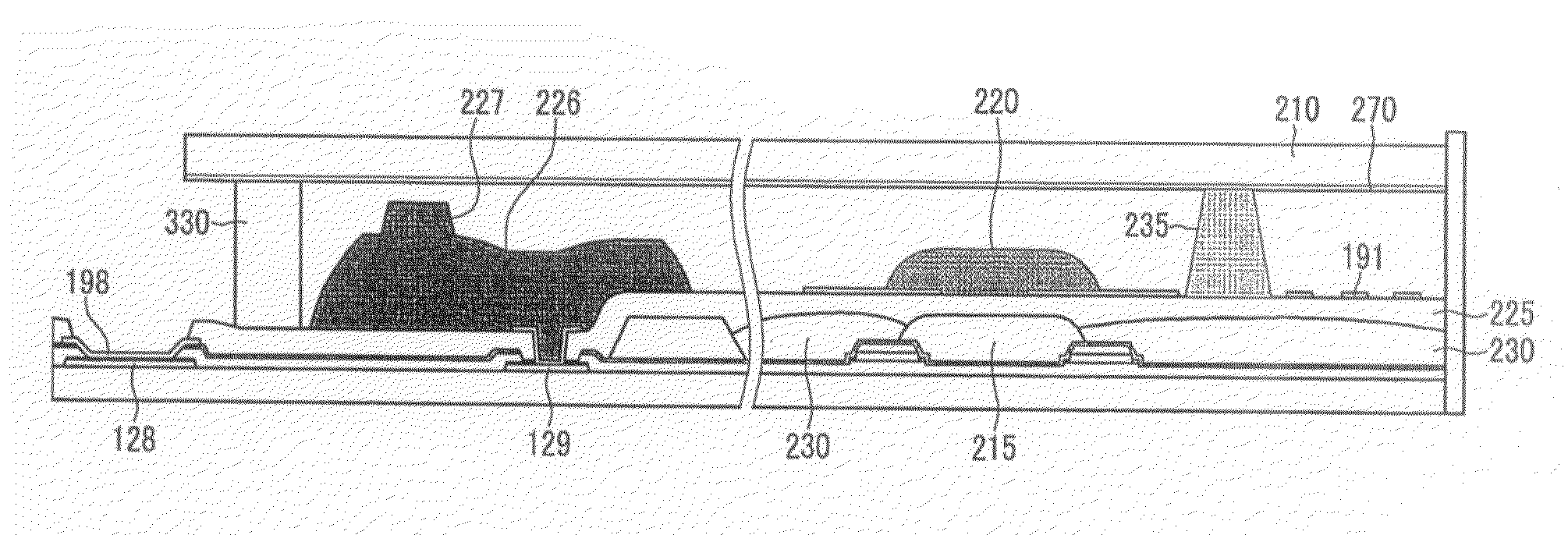

Image recording apparatus

InactiveUS20050219293A1Avoid mixing colorsHigh speed recordingOther printing apparatusImage recordingFixed energy

The image recording apparatus comprises: a plurality of nozzle rows of respective colors in each of which a plurality of nozzles are arranged independently for each of inks of the respective colors, the plurality of nozzles discharging the inks onto a recording medium; a conveyance device which performs relative conveyance of the recording medium in a relative conveyance direction relatively with respect to the plurality of nozzle rows; and a fixing device which fixes the inks deposited on the recording medium from the plurality of nozzles, wherein the image recording apparatus records an image by discharging the inks of the respective colors onto the recording medium from the plurality of nozzles while the relative conveyance by the conveyance device, and the image recording apparatus further comprises at least one of: a nozzle row separation distance control device which controls a nozzle row separation distance S between a first nozzle row and a second nozzle row which are positioned adjacently in the plurality of nozzle rows of the respective colors and which discharge the inks in a consecutive fashion; a relative conveyance velocity control device which controls a relative conveyance velocity V of the recording medium in the relative conveyance with respect to the plurality of nozzle rows; and a fixing control device which controls a fixing energy of the fixing device in such a manner that a fixing time t1 required for the ink discharged from the first nozzle row to become fixed in the recording medium is a prescribed time period, wherein at least one of the nozzle row separation distance S, the relative conveyance velocity V and the fixing time t1 is controlled so as to satisfy a relationship S / V>t1.

Owner:FUJIFILM CORP

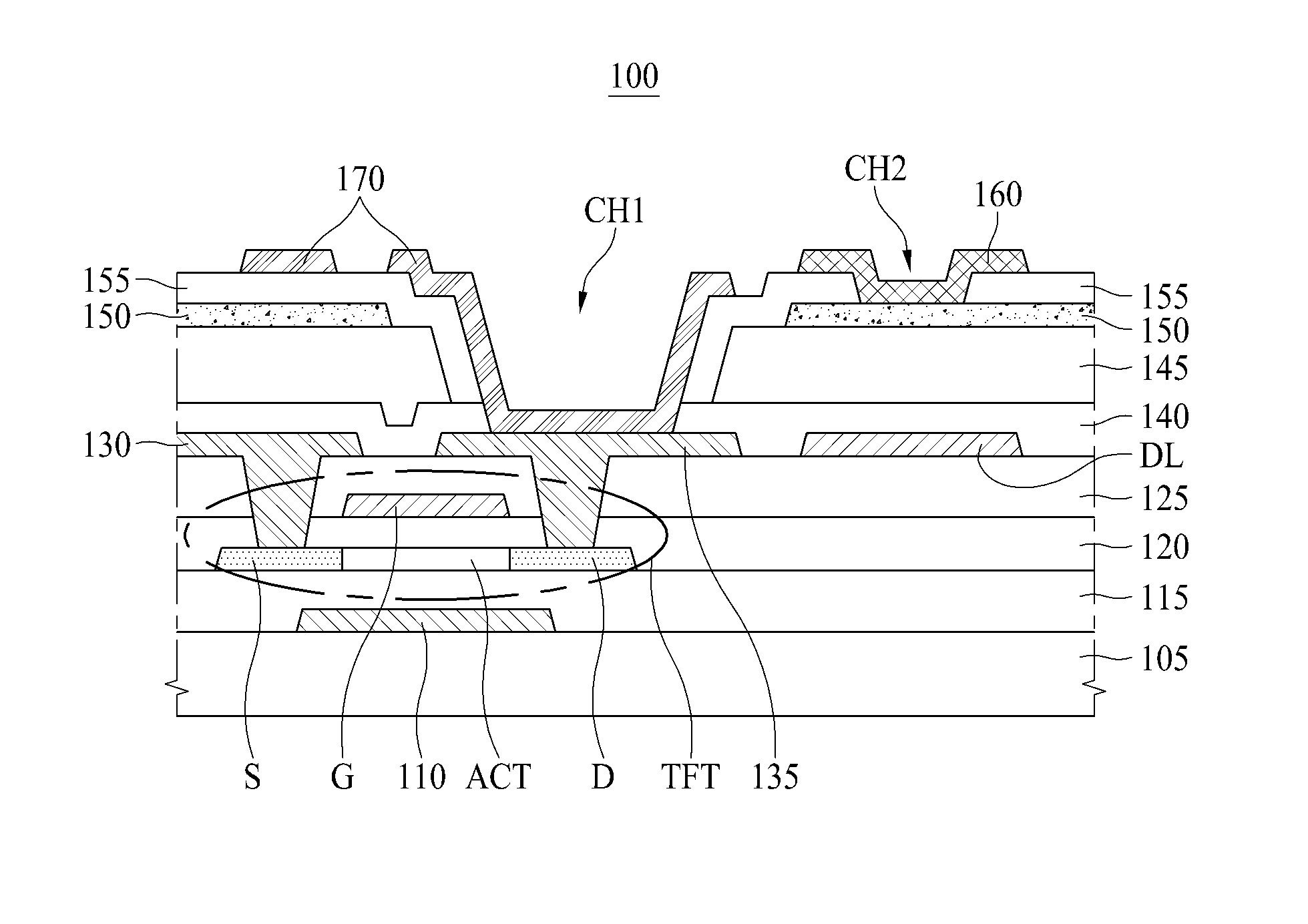

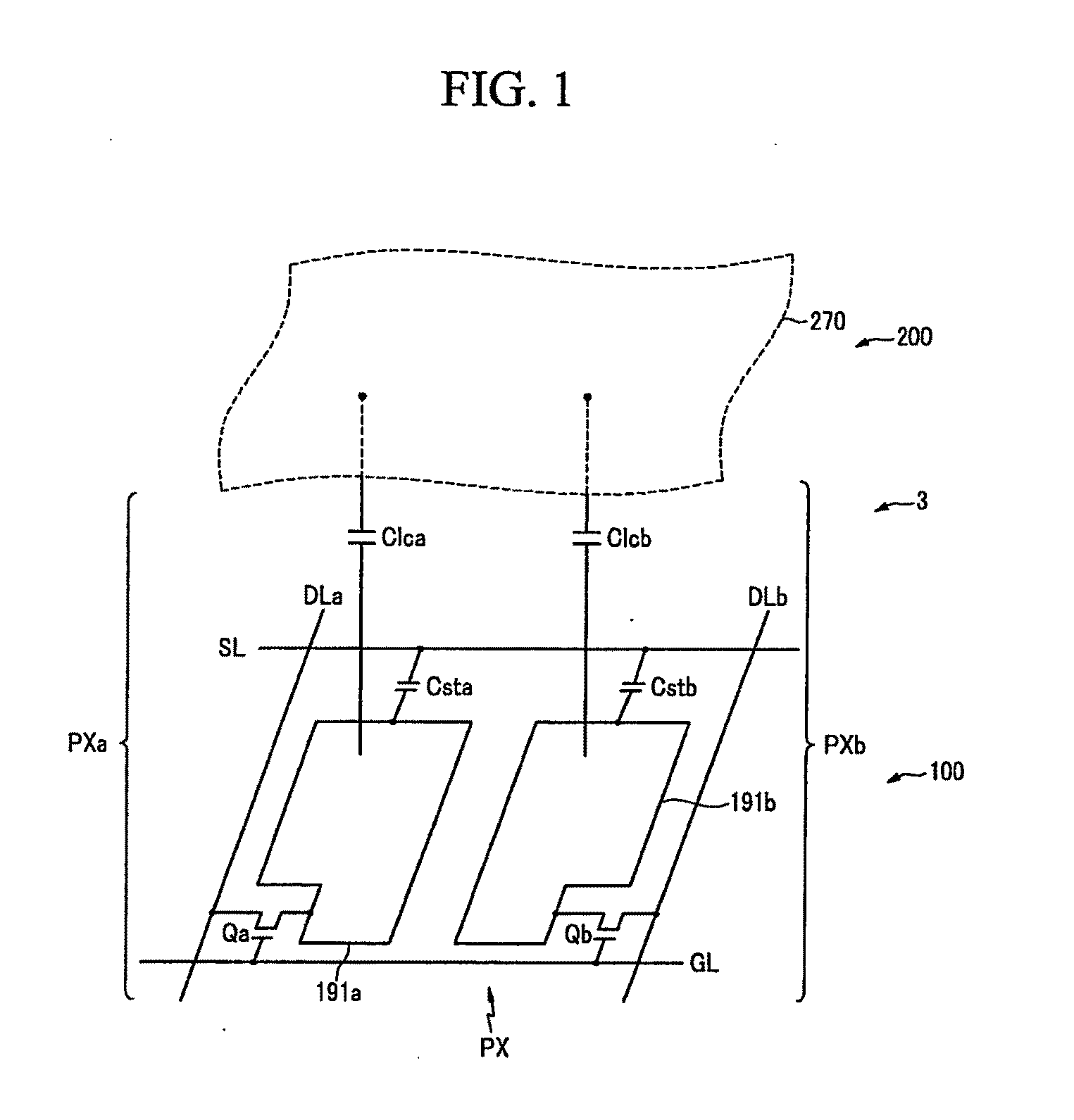

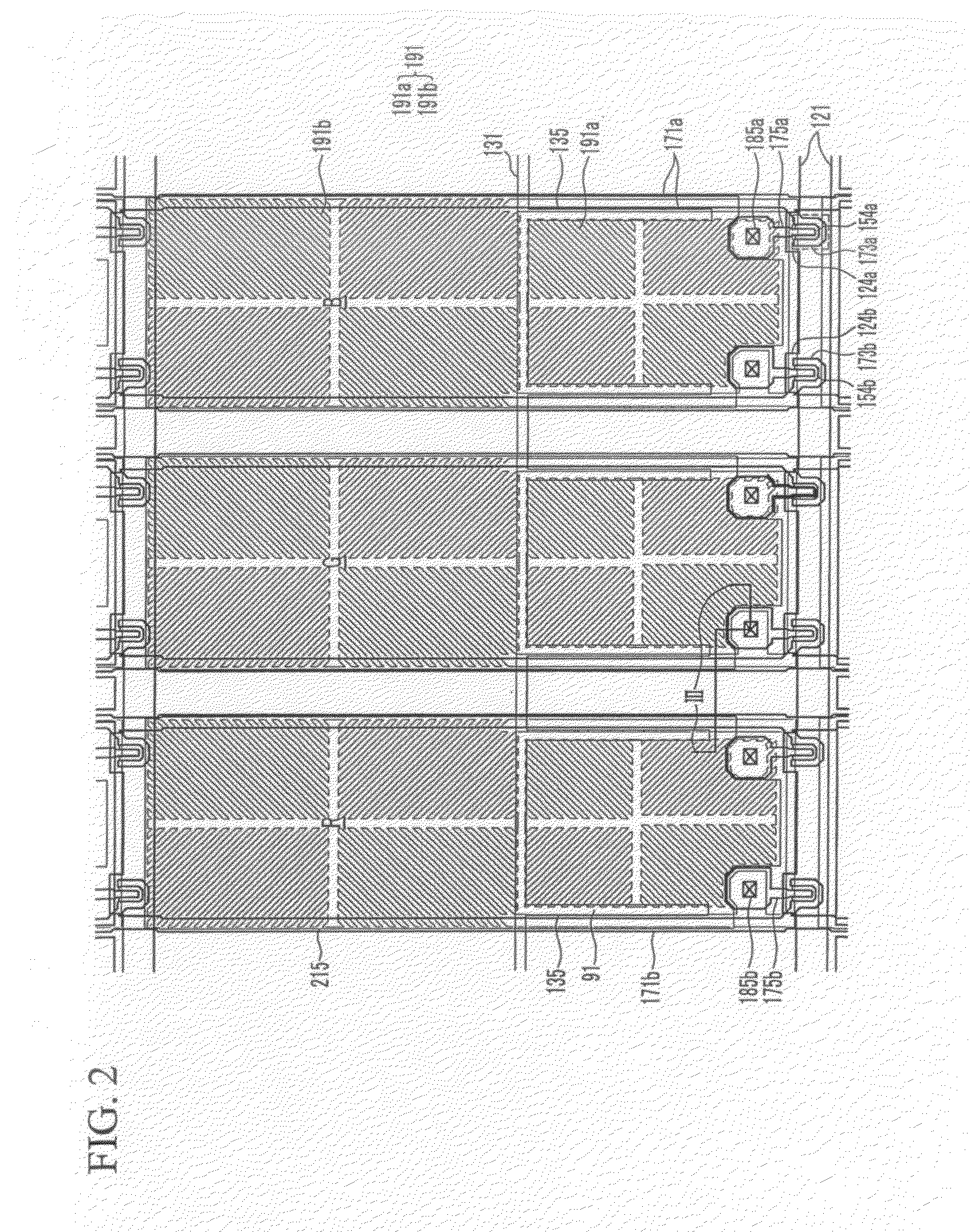

Thin film transistor array panel and manufacturing method of the same

ActiveUS20100051951A1Well formedIncrease impressionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPellicle membrane

A thin film transistor (“TFT”) array panel includes; an insulation substrate, a TFT disposed on the insulation substrate and including a drain electrode, a passivation layer covering the TFT and including a contact portion disposed therein corresponding to the drain electrode, a partition comprising an organic material disposed on the passivation layer, and including a transverse portion, a longitudinal portion, and a contact portion disposed on the drain electrode, a color filter disposed on the passivation layer and disposed in a region defined by the partition, an organic capping layer disposed on the partition and the color filter, and a pixel electrode disposed on the organic capping layer, and connected to the drain electrode through the contact portion of the passivation layer and the contact portion of the partition, wherein a contact hole is formed in the organic capping layer corresponding to the contact portion of the passivation layer.

Owner:SAMSUNG DISPLAY CO LTD

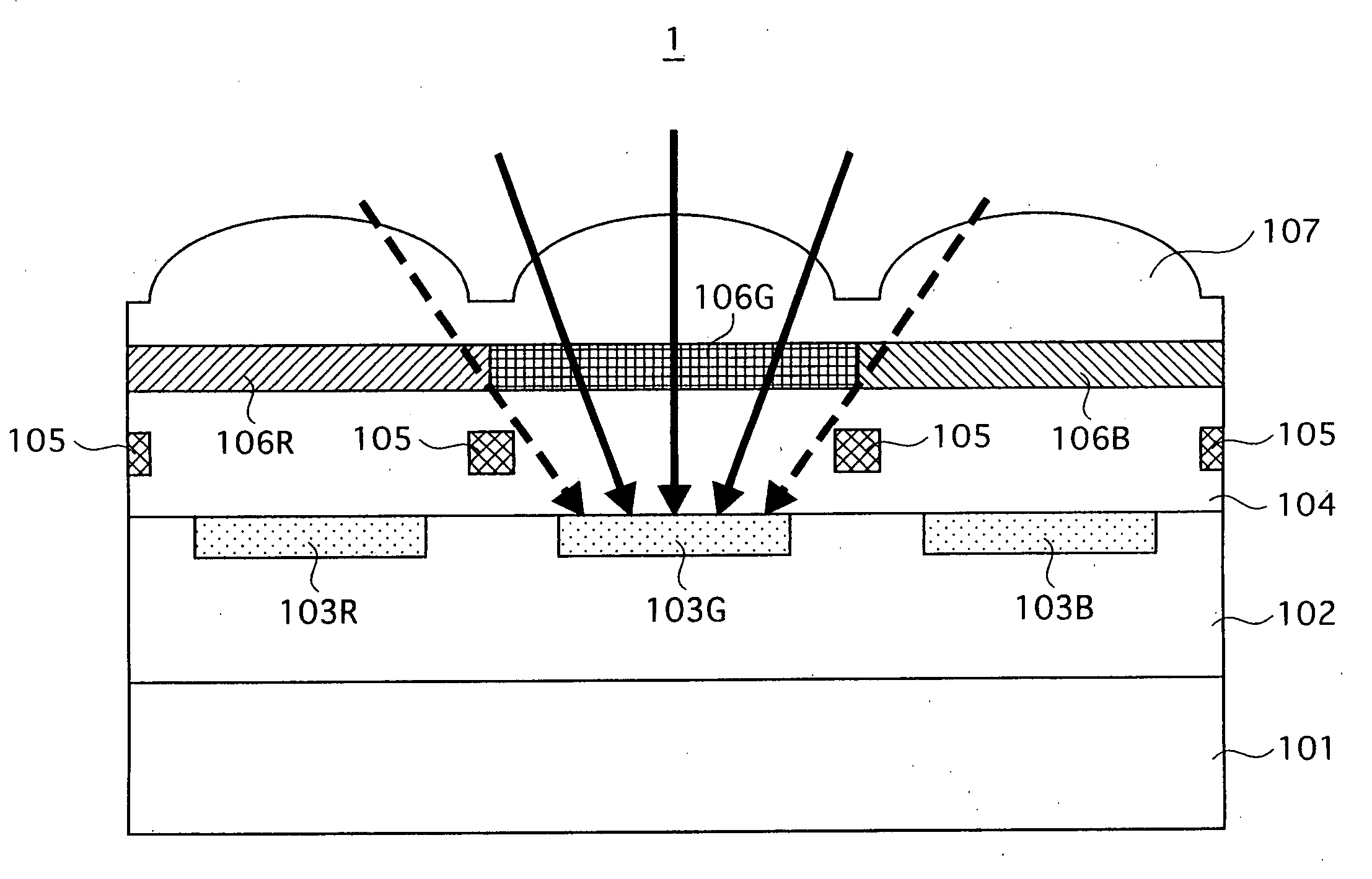

Solid-state imaging device and manufacturing method for the same

ActiveUS7416915B2Reduce thicknessEliminate color-mixingTelevision system detailsRadiation pyrometryEngineeringPhotoelectric conversion

Photoelectric converters are arranged two-dimensionally in a semiconductor substrate. A planarizing layer, a light shielding film, a further planarizing layer and condenser lenses are formed sequentially on the semiconductor substrate and the photoelectric converters. The light shielding film has apertures at positions corresponding to the photoelectric conversion devices. Multilayer interference filters that transmit either a red, green or blue wavelength component of light are disposed in the apertures.

Owner:PANASONIC CORP

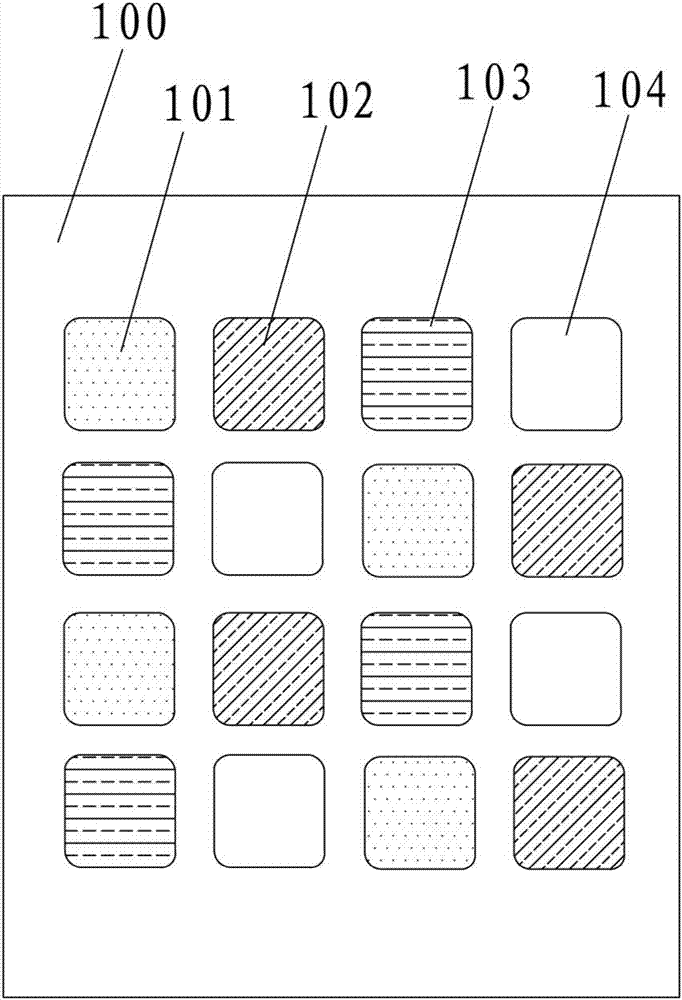

Pixel structure of organic light emitting diode (OLED)

InactiveCN102354702AHigh-resolutionIncrease opening ratioSolid-state devicesSemiconductor devicesImage resolutionLight-emitting diode

The invention provides a pixel structure of an organic light emitting diode (OLED). The pixel structure is arranged on a substrate and comprises a plurality of pixels, wherein the pixels are arranged in a matrix in the X-axis and Y-axis directions; each pixel comprises a first subpixel, two second subpixels and a third subpixel; the first subpixel, one second subpixel, the third subpixel and the other second subpixel are arranged in sequence in the X-axis direction; the first subpixel comprises two first light emitting zones; each second subpixel comprises a second light emitting zone; the third subpixel comprises two third light emitting zones; and the adjacent first light emitting zone, second light emitting zone and third light emitting zone are arranged in a triangle, the geometric centers of the three light emitting zones are arranged on different peaks of the triangle, and one side of the triangle formed by connecting the geometric centers of the first light emitting zone and the third light emitting zone, is parallel to the X-axis. The pixel structure has the following advantages: by adopting the pixel structure, color mixture can be avoided, the resolution can be increased and the aperture ratio can be increased and the service life can be prolonged.

Owner:AU OPTRONICS CORP

Inkjet recording ink, ink cartridge, inkjet recording device, inkjet recording method, and ink recorded matter

ActiveUS20120188312A1Excellent ejection stabilityGood storage stabilityOrganic chemistryDuplicating/marking methodsPhosphoniumHydrogen atom

To provide an inkjet recording ink, which contains water, a water-soluble organic solvent, a colorant, and a surfactant, wherein the colorant contains a surfactant-dispersible pigment (A) dispersed by the surfactant, and a resin-coated pigment (B), and wherein the surfactant is a surfactant selected from the group consisting of anionic surfactants represented by the following formula (1), and having HLB value of 12 or higher:R1—O—(CH2CH2O)m-A (1)where R1 is a C2-C24 alkyl group, alkenyl group, alkylphenyl group, or alkylallyl group; A is —COOM1, —SO3M2, or —PO(OM3)OM4, where M1, M2 and M4 are each independently alkali metal, quaternary ammonium, quaternary phosphonium, or alkanolamine, and M3 is a hydrogen atom or R2(CH2CH2O)n with proviso that R2 is a C1-C4 alkyl group, alkenyl group, alkylphenyl group, or alkylallyl group, and n is an integer of 4 to 20; and m is and integer of 15 to 40.

Owner:RICOH KK

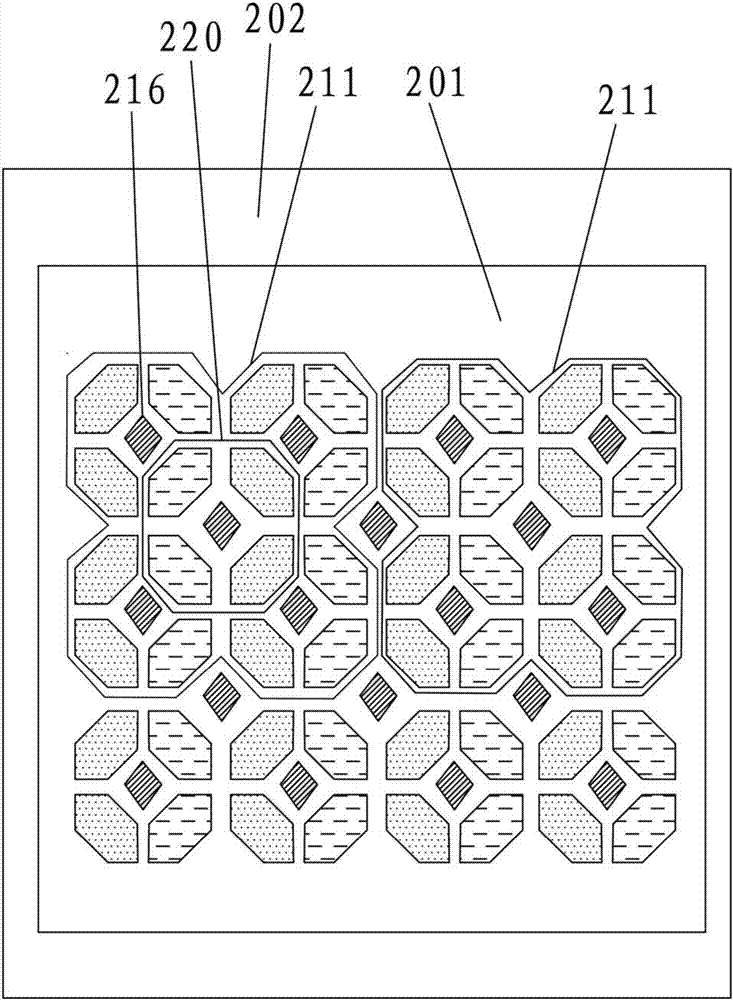

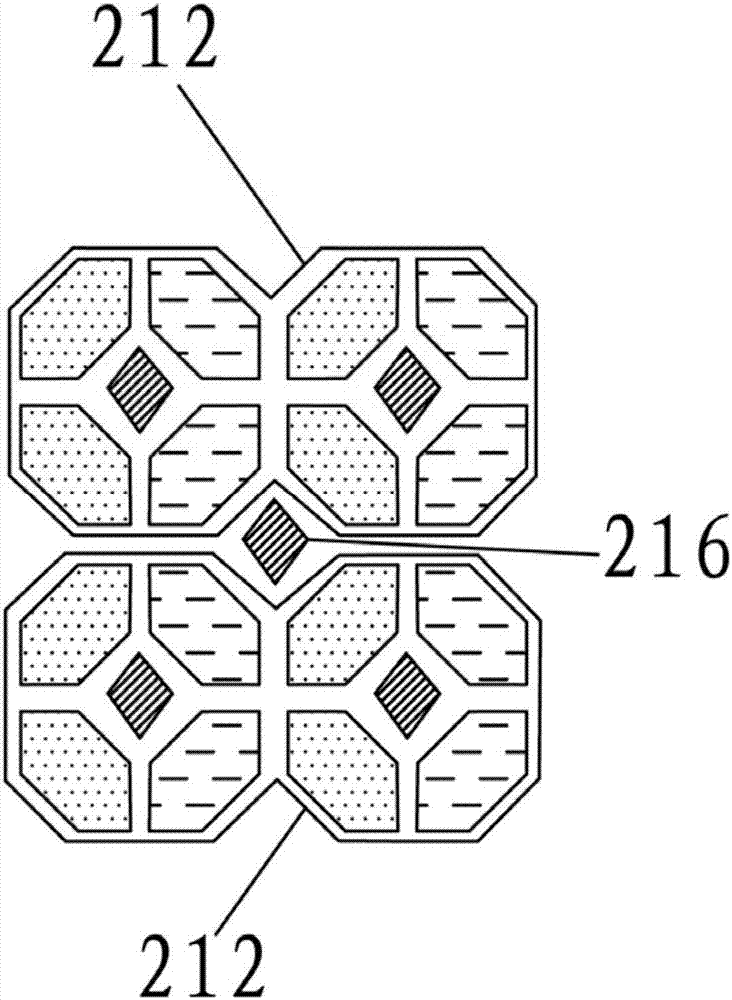

Display pixel configuration structure, display panel and preparation method of display panel

ActiveCN106981501AReduce manufacturing difficultyAvoid mixing colorsSolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionCrowds

The invention discloses a display pixel configuration structure. The display pixel configuration structure comprises a pixel crowd arranged in an array, wherein the pixel crowd comprises two pixel group pairs arranged oppositely, and each pixel crowd pair comprises two adjacent pixel groups; each pixel group comprises a first sub-pixel pair and a second sub-pixel arranged oppositely and a third sub-pixel positioned at the central position between the first sub-pixel pair and the second sub-pixel pair, wherein in the pixel group, the first sub-pixel pair and the second sub-pixel pair are arranged along a row direction respectively, or the first sub-pixel pair and the second sub-pixel pair are arranged along a line direction respectively; the third sub-pixel is arranged at the central position between the adjacent pixel groups; the third sub-pixel is arranged at the central position among four pixel groups, and each third sub-pixel is adjacent to two first sub-pixels and two second sub-pixels respectively. According to the display pixel configuration structure, the manufacturing difficulty of a mask plate is reduced, and the pixel resolution ratio is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

In-cell touch liquid crystal display apparatus and method of manufacturing the same

ActiveUS20160187690A1Avoid mixing colorsReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

Disclosed are an in-cell touch liquid crystal display (LCD) apparatus having a pixel electrode top structure and a method of manufacturing the same. The in-cell touch LCD apparatus is implemented in the pixel electrode top structure, thereby preventing color mixing between red, green, and blue pixels. The method of manufacturing the in-cell touch LCD apparatus decreases the number of masks necessary to manufacture a TFT array substrate, thereby reducing a manufacturing time and the manufacturing cost.

Owner:LG DISPLAY CO LTD

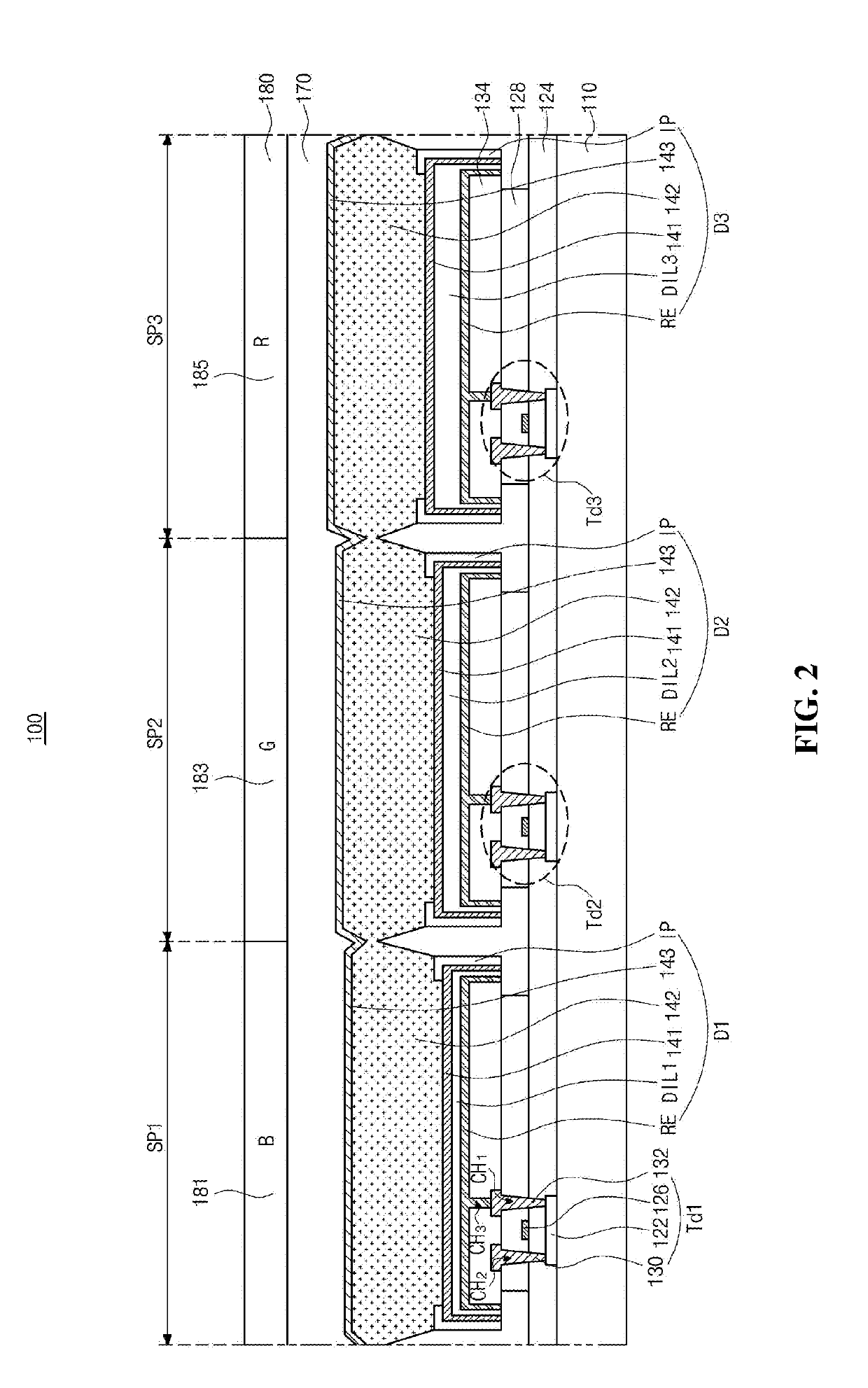

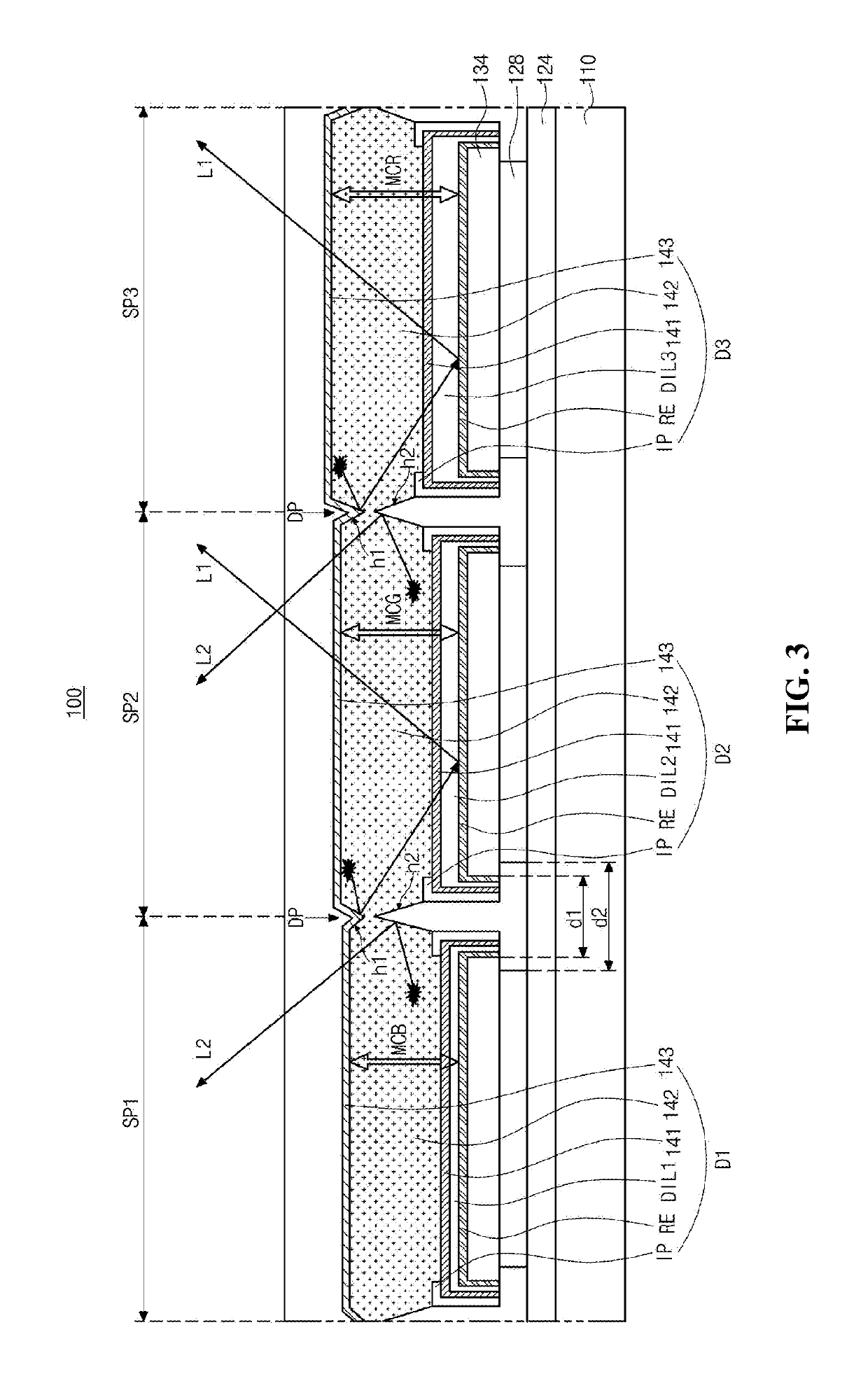

Electroluminescent display device

ActiveUS20190189701A1Improve optical efficiencyAvoid mixing colorsSolid-state devicesSemiconductor/solid-state device manufacturingDielectric layerElectroluminescent display

An electroluminescent display device includes a substrate including first, second, and third sub-pixel regions; an interlayer insulating layer and a passivation layer each separately disposed at the first, second, and third sub-pixel regions on the substrate; a reflective electrode disposed on the passivation layer of each of the first, second, and third sub-pixel regions; first, second, and third dielectric layers disposed corresponding to the first, second, and third sub-pixel regions, respectively, on the reflective electrode; a first electrode disposed on each of the first, second, and third dielectric layers; an insulating pattern covering an edge of the first electrode; a light-emitting layer disposed on the first electrode and the insulating pattern and substantially all over the substrate including the first, second, and third sub-pixel regions; and a second electrode disposed on the light-emitting layer, wherein the first, second, and third dielectric layers have different thicknesses.

Owner:LG DISPLAY CO LTD

Color filter substrate and liquid-crystal display device

InactiveCN109375410AIncrease profitAvoid mixing colorsNon-linear opticsLiquid-crystal displayQuantum dot

The invention provides a color filter substrate and a liquid-crystal display device. The color filter substrate comprises a substrate base plate, multiple quantum dot filtering units arranged on the substrate base plate in an arrayed way and retaining walls arranged on the substrate base plate and located among the quantum dot filtering units. Each retaining wall comprises a black matrix layer arranged on the substrate base plate and a reflection layer arranged on the black matrix layer, wherein the thickness of each retaining wall is greater than that of each quantum dot filtering unit, and the reflection layer can reflect light irradiated to the surface of the reflection layer into the quantum dot filtering units for secondary utilization. The phenomenon is avoided that light penetratesinto other quantum dot filtering units to cause color mixture while the light utilization rate is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

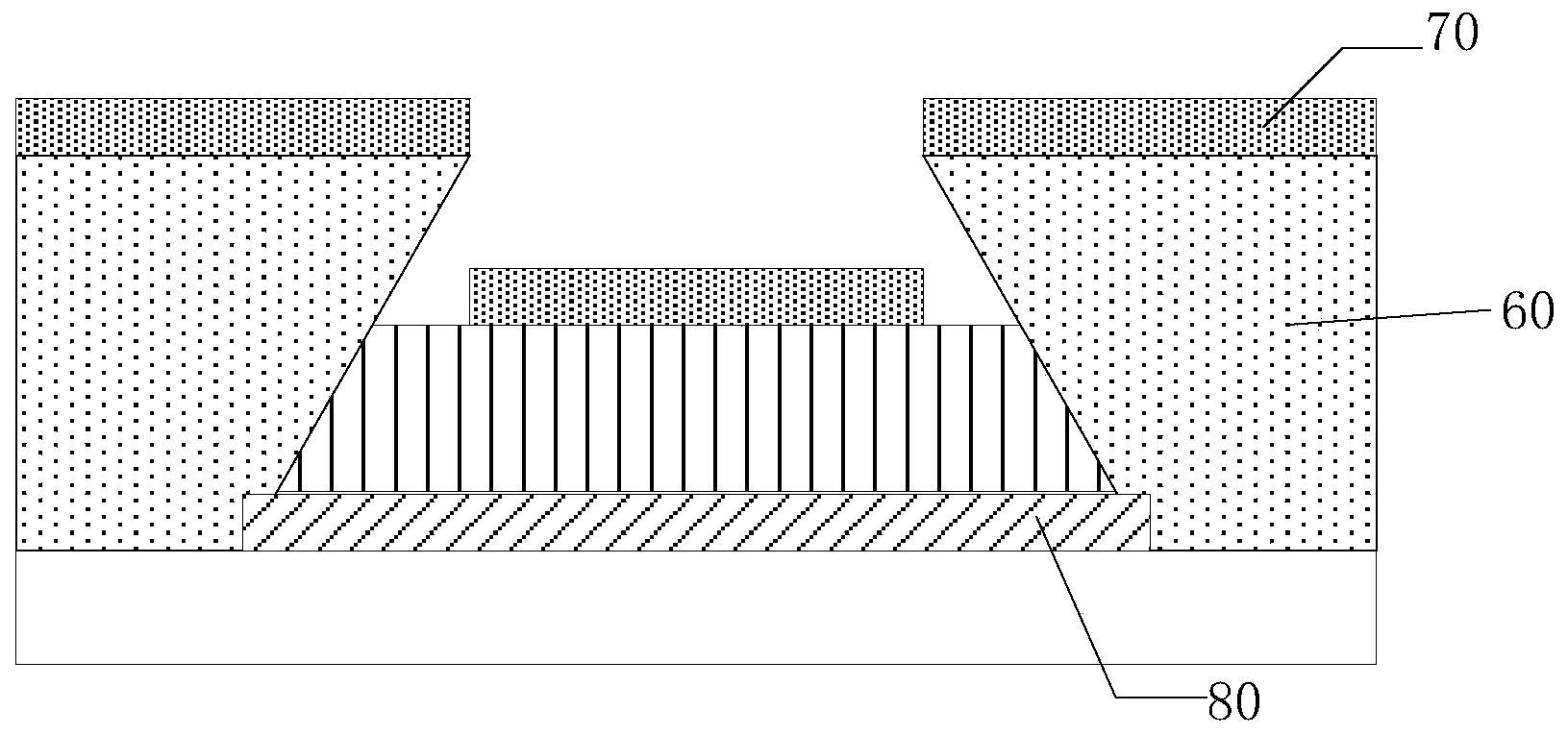

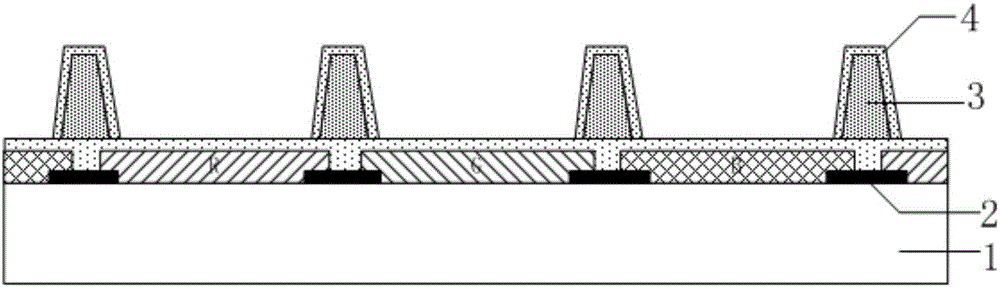

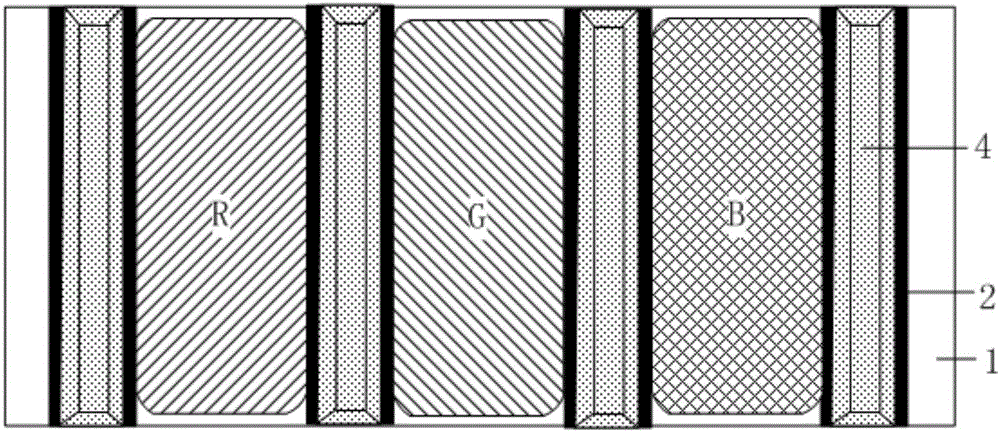

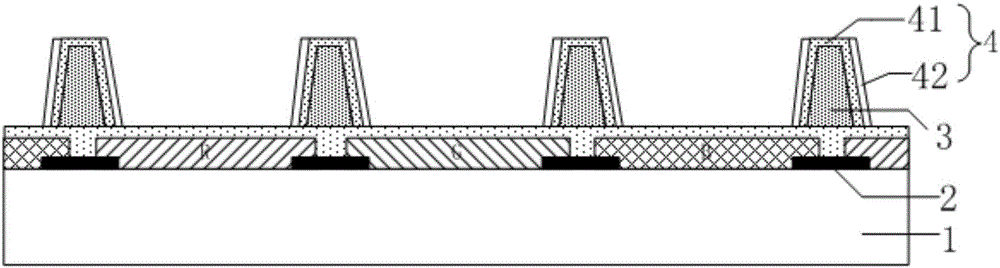

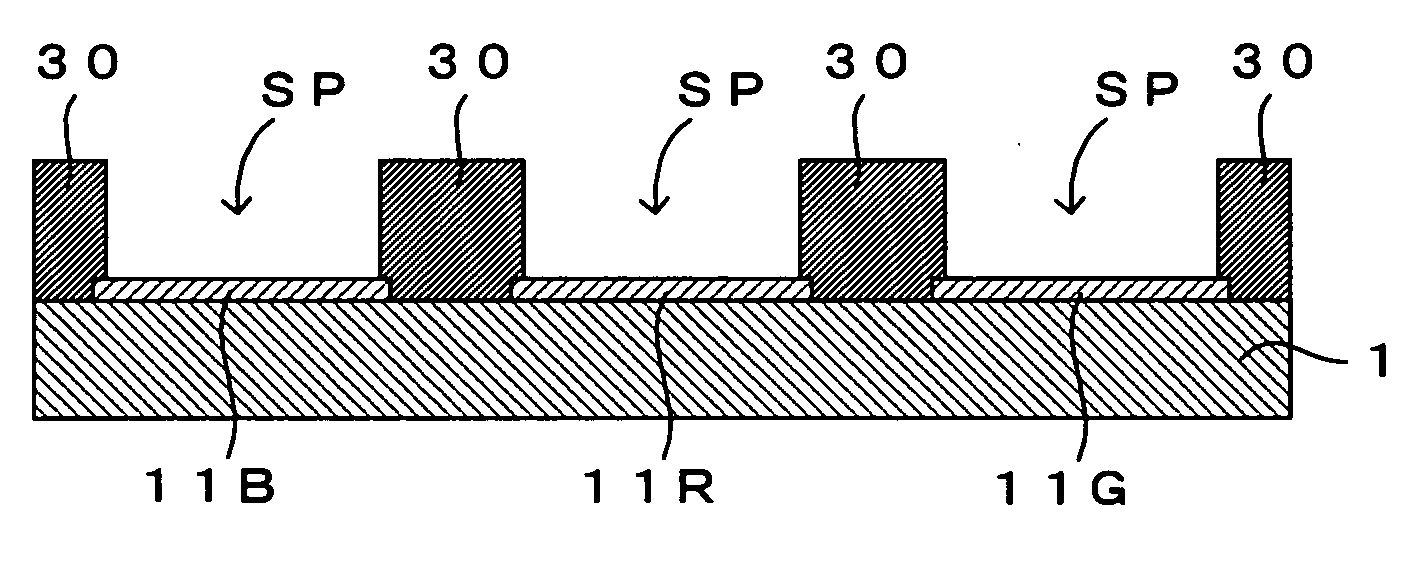

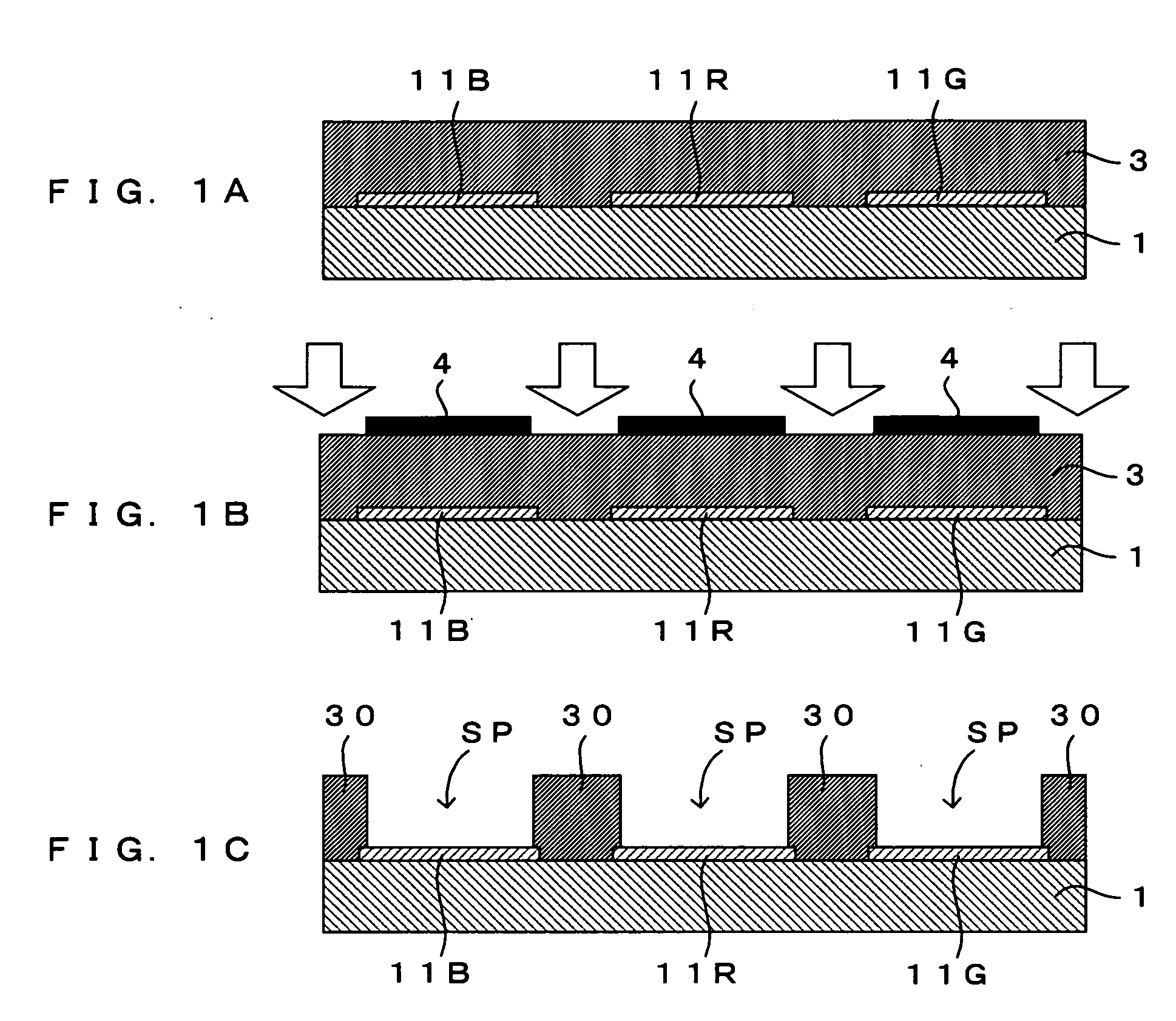

Substrate for organic EL and method for manufacturing the same

InactiveUS20060170338A1Avoid mixing colorsElectrode assembly support/mounting/spacing/insulationIncadescent body mountings/supportOrganic layerEngineering

A non-oil repellent photosensitive material layer 2 and an oil repellent photosensitive material layer 3 formed by coating on a substrate 1 are exposed at the same time with light having a single wavelength (I-line) in accordance with bank regions and thereafter developed. In consequence, banks 300 are formed having a double-layer structure which is comprised of bottom layer portions 31 of a non-oil repellent material and top layer portions 32 of an oil repellent material. This blocks organic EL materials supplied between the banks 300 from moving beyond tops of the banks 300 and prevents color mixing of the organic EL materials. Further, since the bottom layer portions 31 between which organic layers are formed are made of the non-oil repellent material, the profiles of the organic layers will not change due to surface tension.

Owner:DAINIPPON SCREEN MTG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com