Color film substrate, manufacturing method thereof and display device

The technology of a color filter substrate and a manufacturing method is applied in the display field and can solve the problems of reducing the aperture ratio of the display device and reducing the resolution of the display device by distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

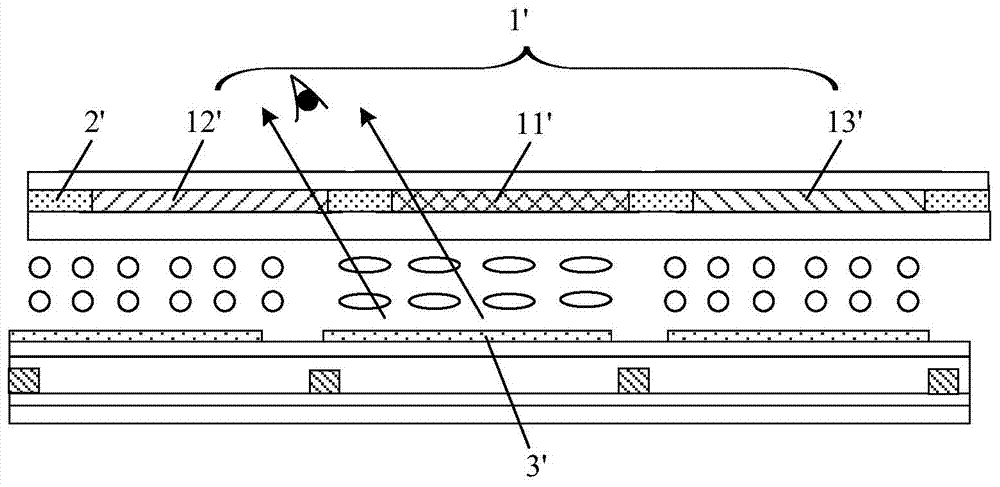

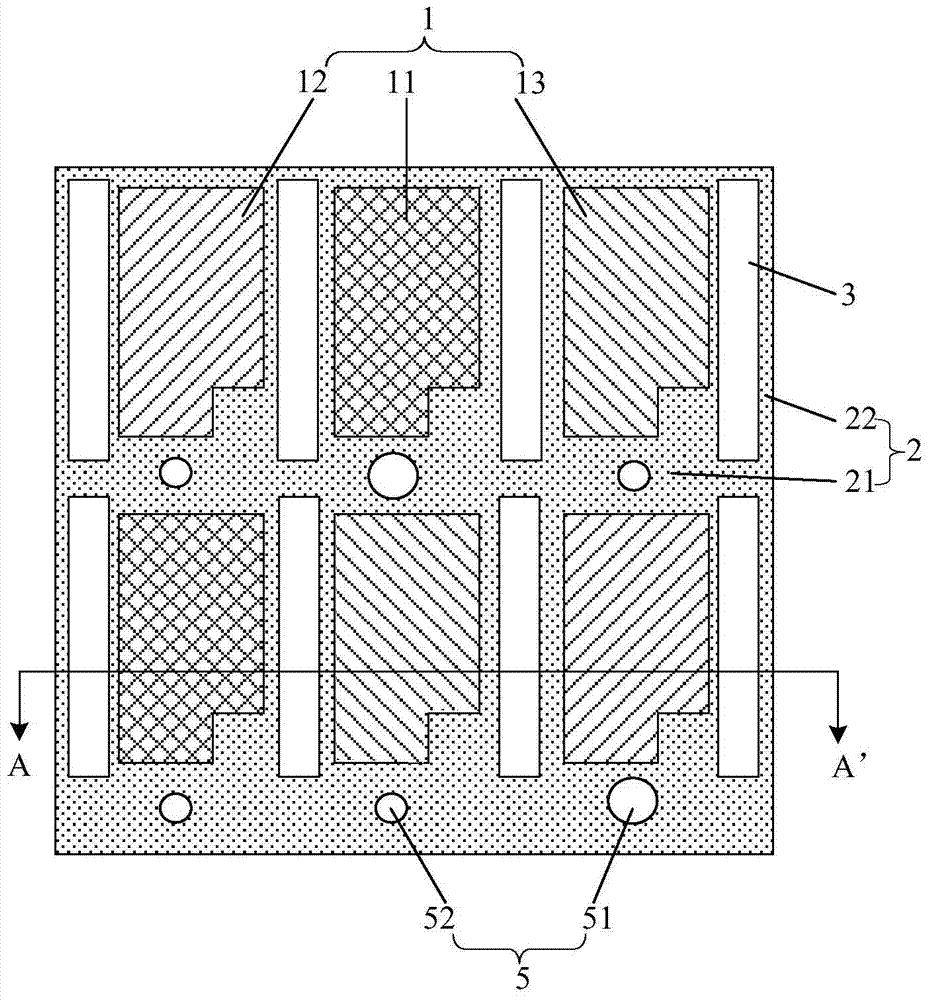

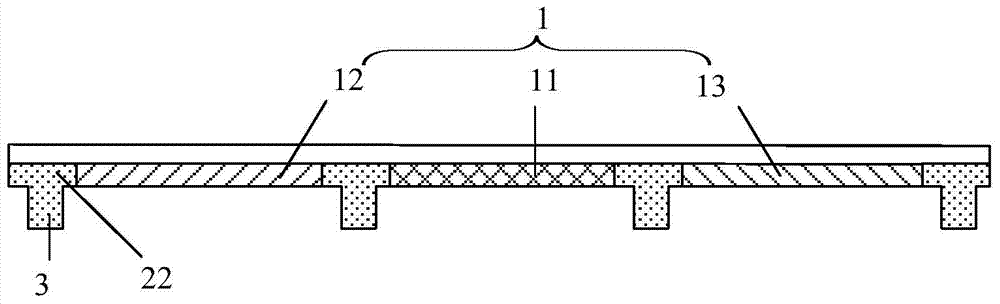

[0053] Embodiments of the present invention provide a figure 2 and image 3 The color filter substrate shown.

[0054] The color filter substrate includes a color filter layer 1, and the color filter layer 1 includes color filter units of at least two colors distributed in a matrix, and a black matrix 2 is arranged between adjacent color filter units. Specifically, the color filter layer 1 includes a red filter unit 11 , a green filter unit 12 and a blue filter unit 13 . The color filter units of different colors in the color filter layer 1 are generally made of color photosensitive resins of corresponding colors.

[0055] Further, the color filter substrate further includes a light-shielding protrusion 3 located in the area where the black matrix 2 is located, so as to prevent color mixing between color filter units of different colors.

[0056] It should be noted that the light-blocking protrusion 3 must be made of opaque material, and the specific material can be select...

Embodiment 2

[0068] The embodiment of the present invention provides a method for manufacturing a color filter substrate, such as Image 6 As shown, the production method includes:

[0069] Step S601 , forming a pattern including a color filter layer, a black matrix, and light-shielding protrusions on a base substrate.

[0070] Wherein, the color filter layer 1 includes color filter units of at least two colors distributed in a matrix.

[0071] The black matrix 2 is located between adjacent color filter units.

[0072] The light blocking protrusion 3 is located in the area where the black matrix 2 is located to prevent color mixing between color filter units of different colors.

[0073] Optionally, the lateral width of the light blocking protrusion 3 is less than or equal to the lateral width of the black matrix 2 .

[0074] Optionally, the longitudinal length of the light blocking protrusion 3 is greater than or equal to the longitudinal maximum length of the color filter layer 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com