Patents

Literature

81results about How to "Avoid color mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

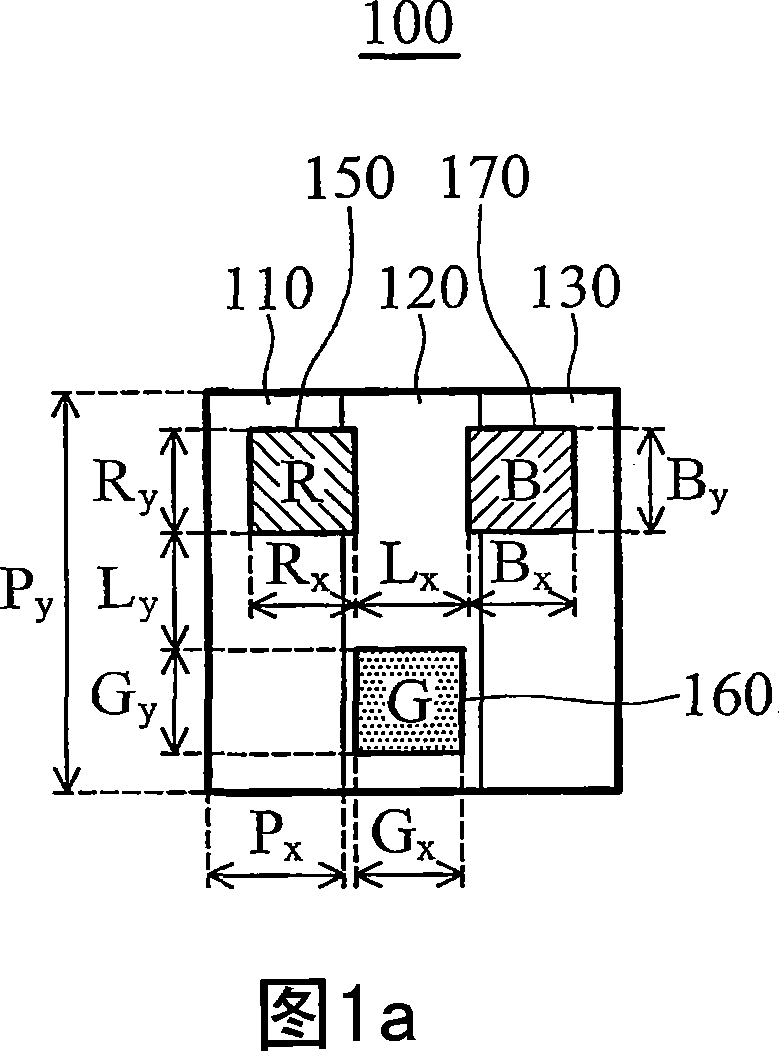

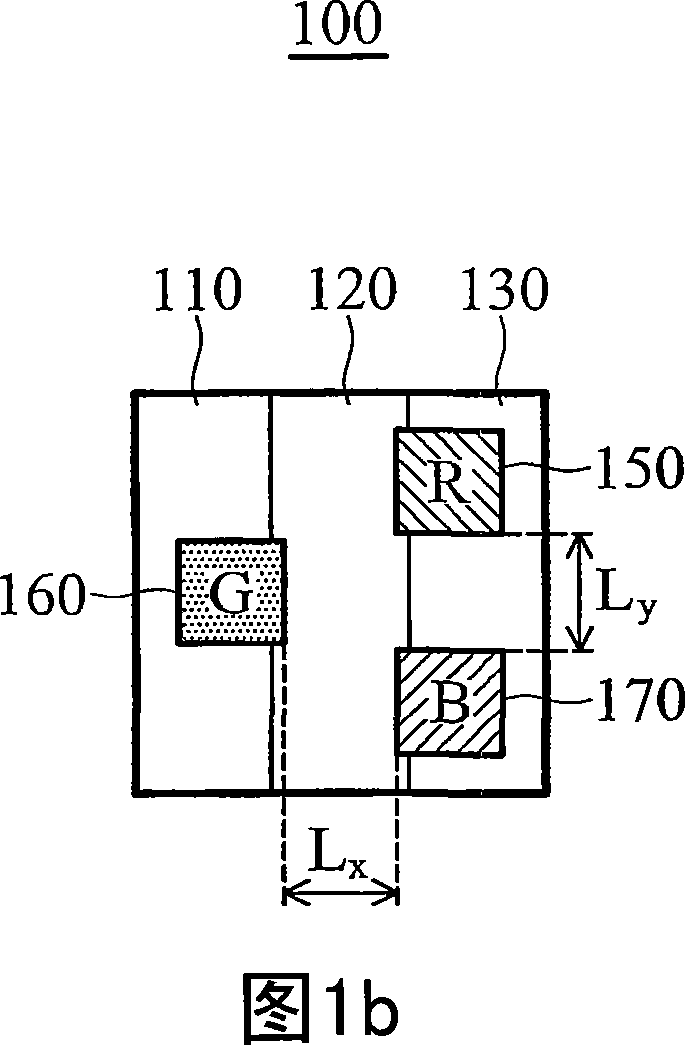

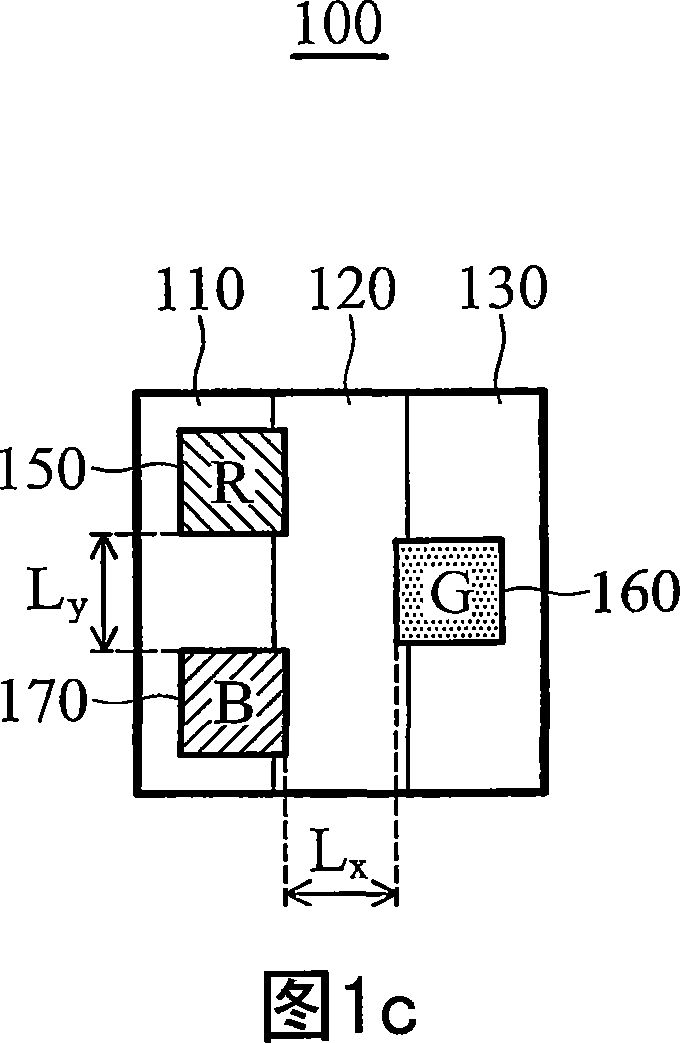

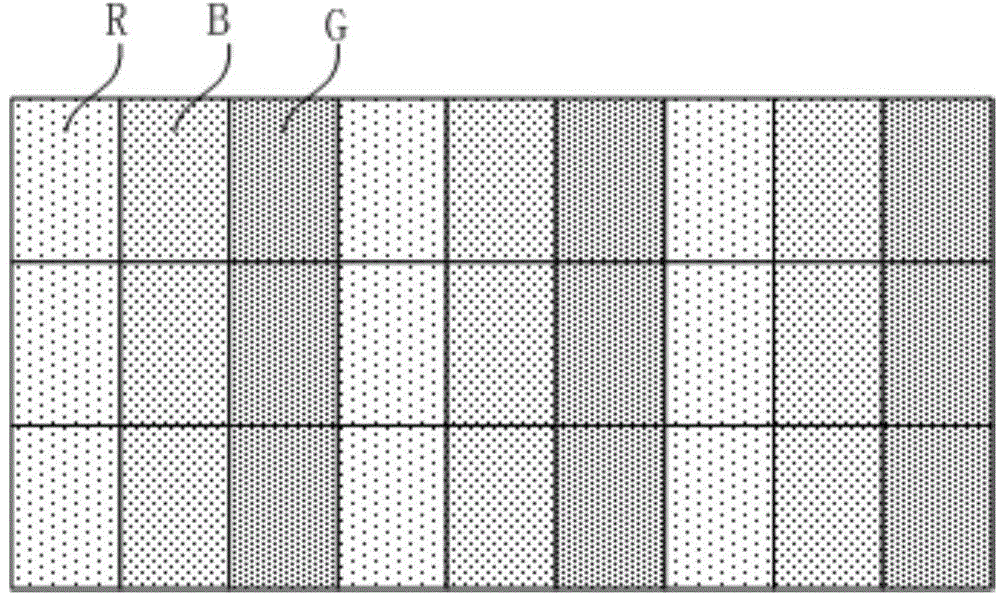

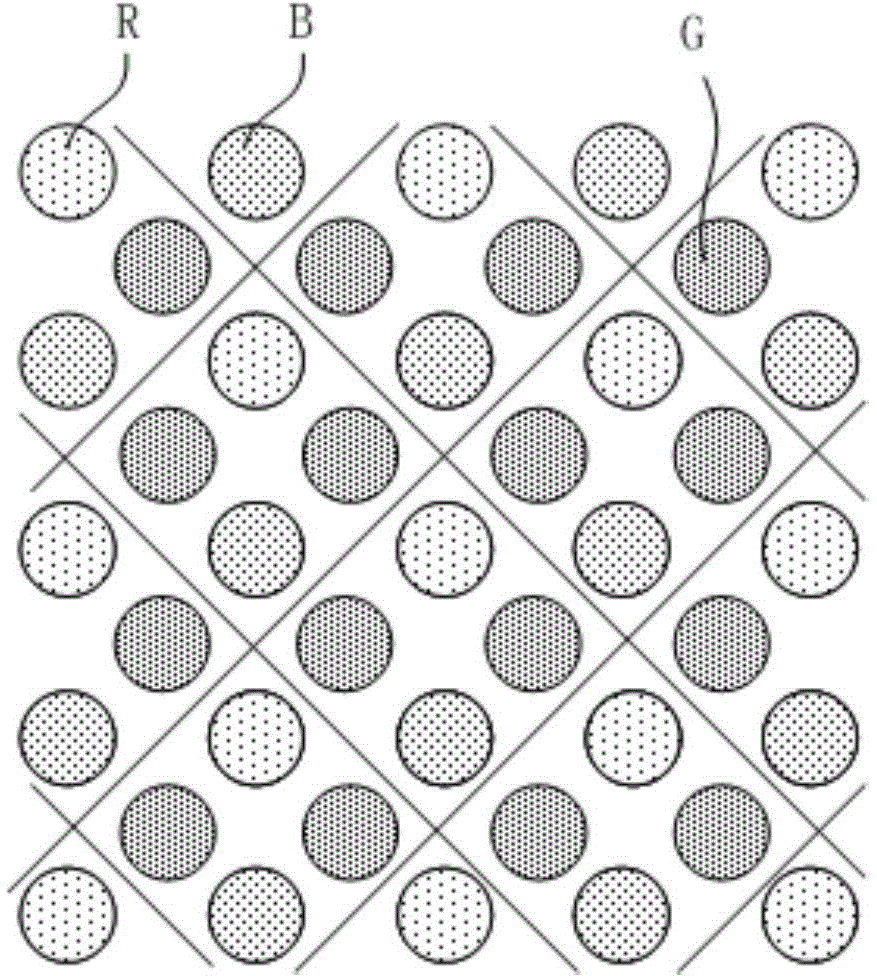

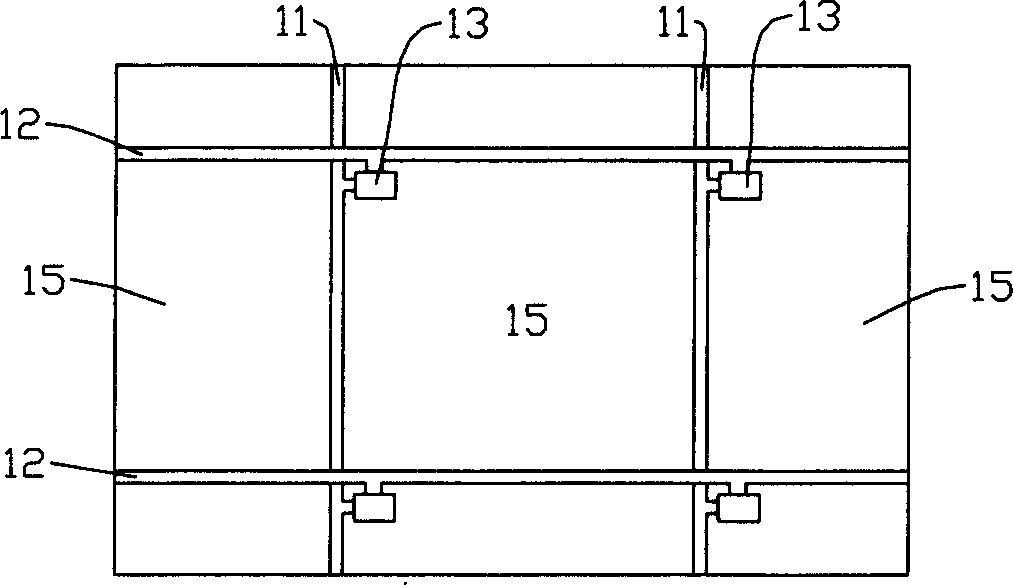

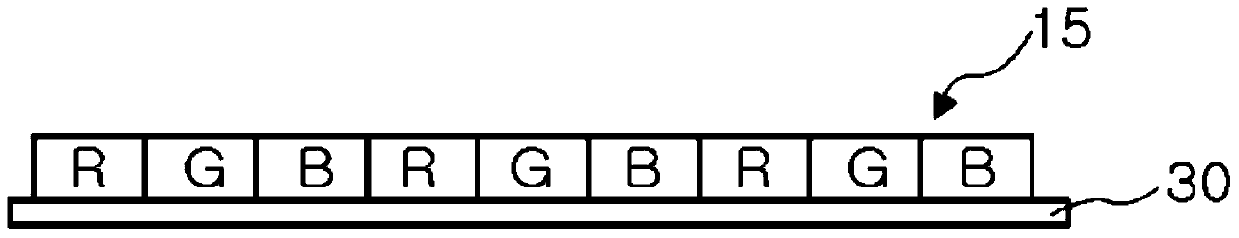

Organic lighting element color pixel array mode and its forming method

InactiveCN101051648AIncrease opening ratioReduced Alignment DifficultySolid-state devicesSemiconductor/solid-state device manufacturingEffect lightLuminescence

A color display panel has an array with a plurality of pixels, each pixel comprises a first sub pixel, a second sub pixel and a third sub pixel, and a red luminescence zone, green luminescence zone and blue luminescence zone. The display panel comprises pixel arrangement of the red luminescence zone, green luminescence zone and blue luminescence zone, which forms a triangle, geometry center of each luminescence zone is positioned at different vertexes of the triangle, such that a side of the triangle substantially is in parallel with on of row direction and column direction, arbitrary luminescence zones bothering with different colors of the row direction are defined to have a distance gap, and arbitrary luminescence zones bothering with different colors of the column direction are defined to have a distance gap, the two gaps distance is substantially or almost equal. The invention can reduce the contraposition difficulty of mask manufacturing technique, besides can increase the opening ratio of the luminescence area of sub pixel, to avoid the color blending circumstance of full color OLED display panel.

Owner:AU OPTRONICS CORP

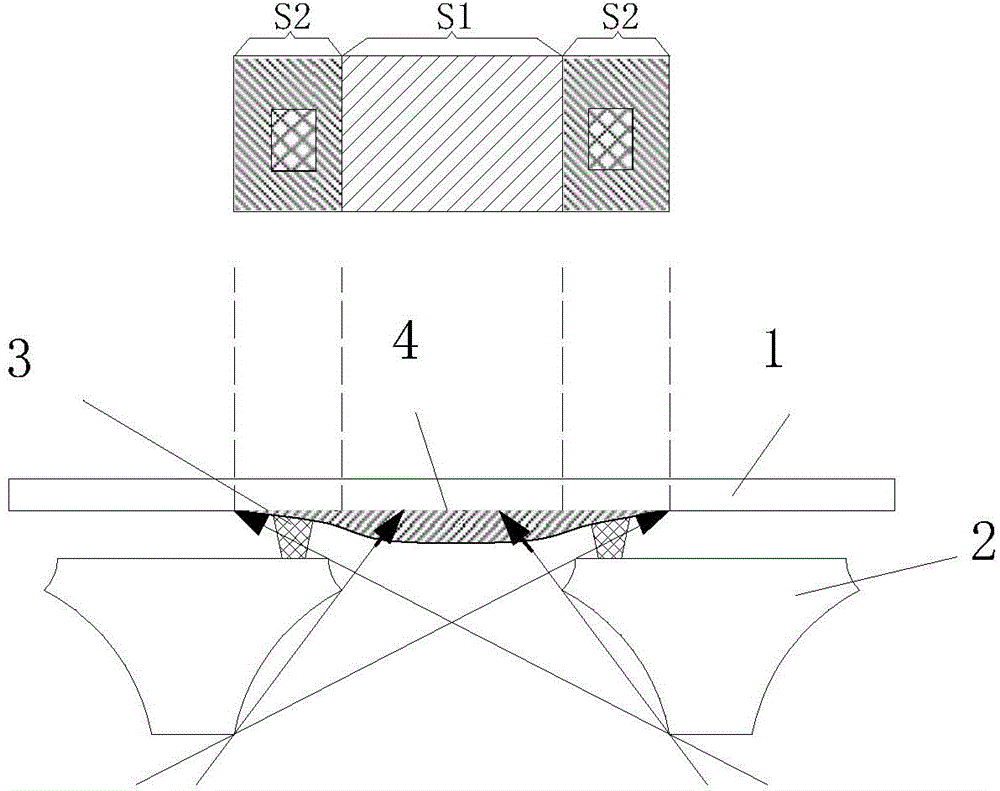

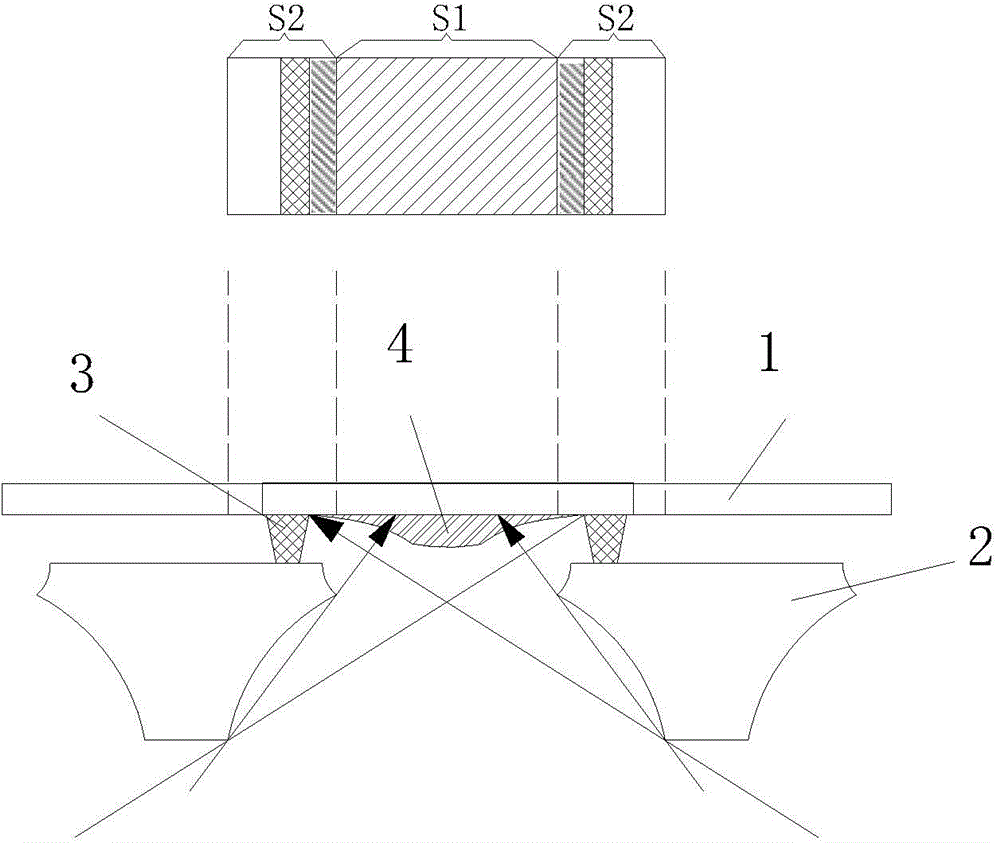

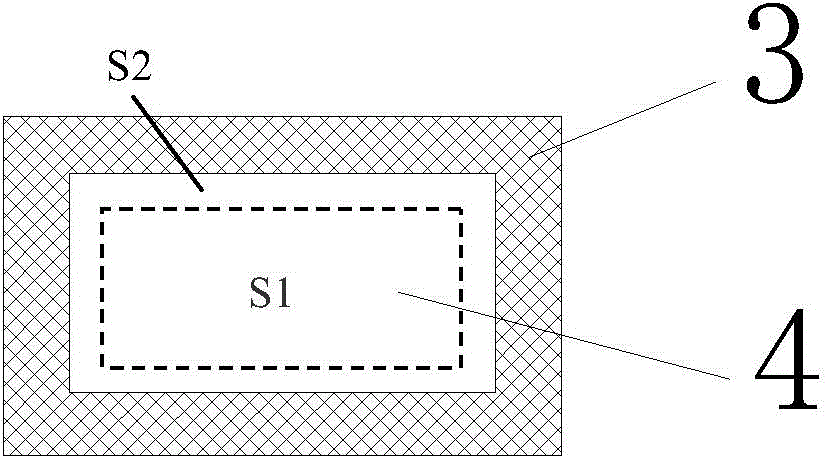

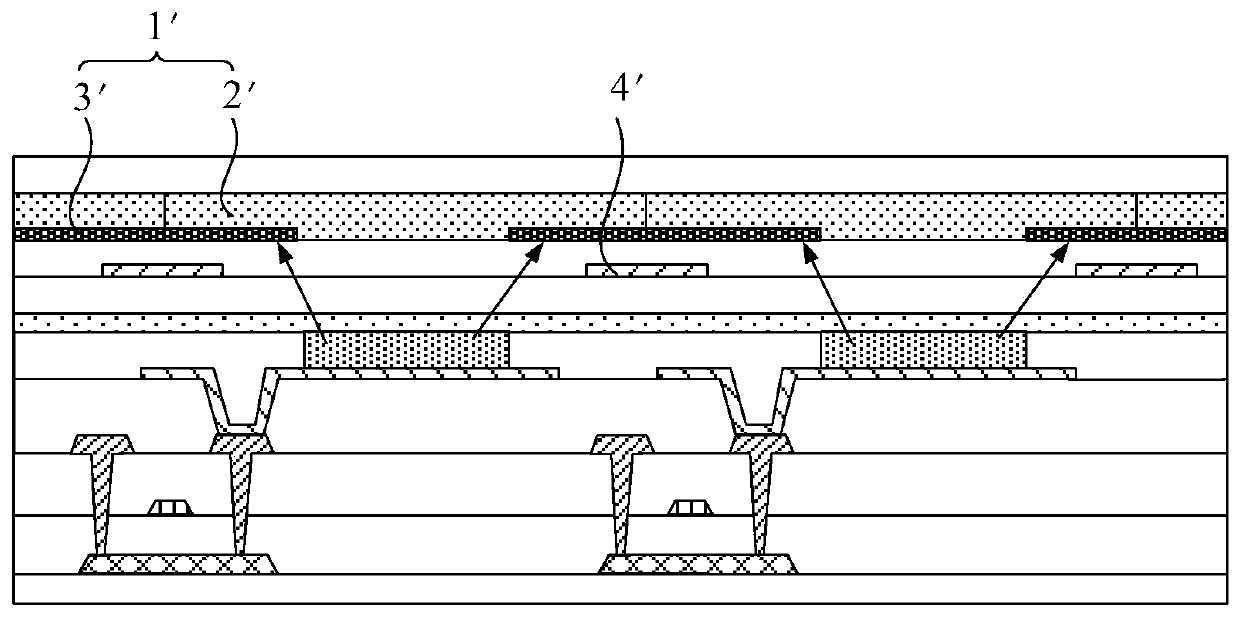

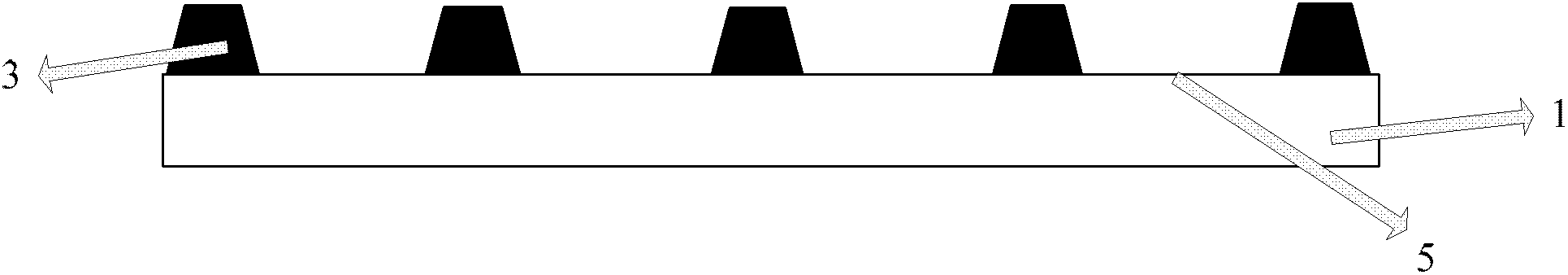

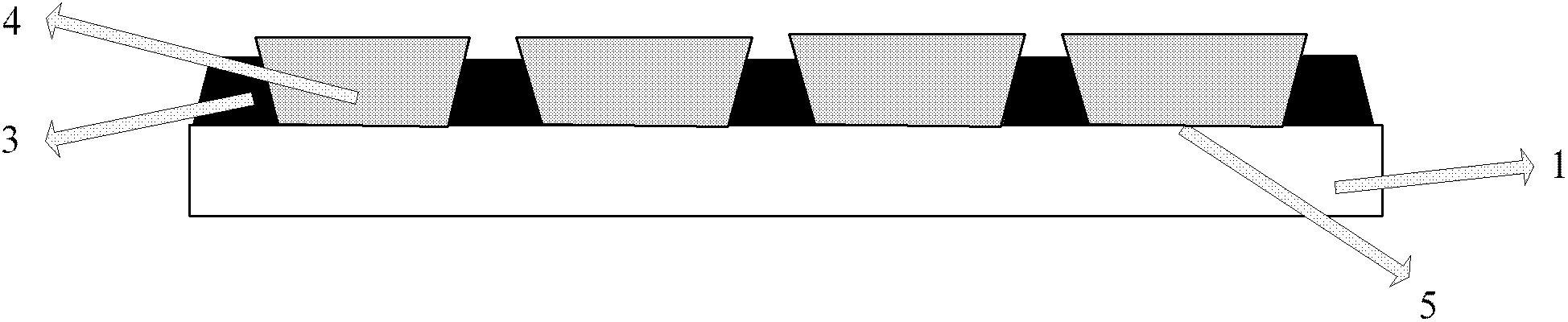

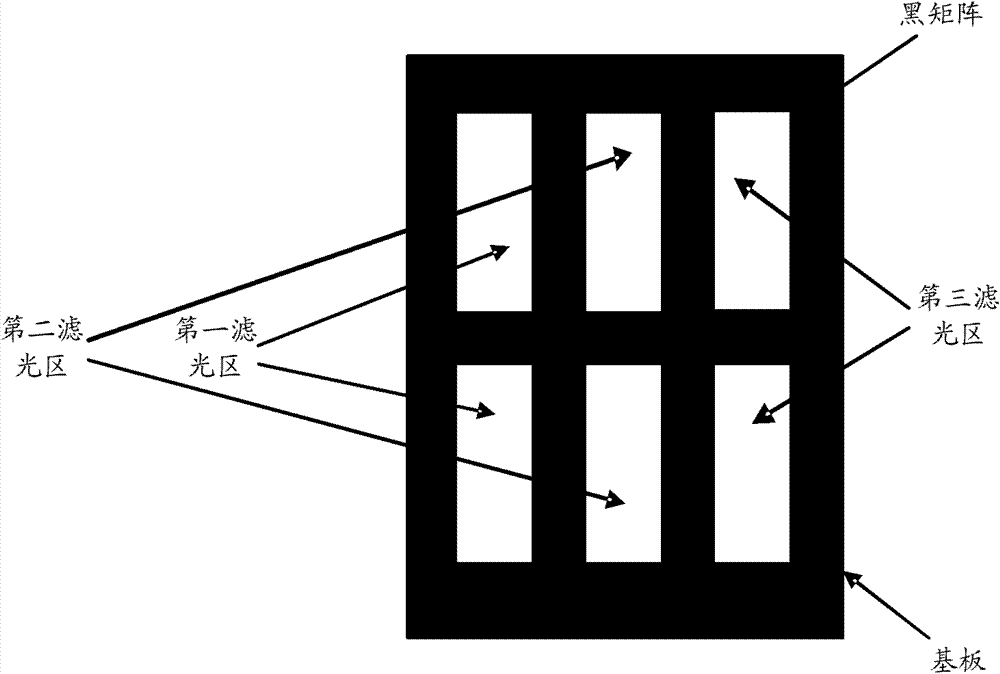

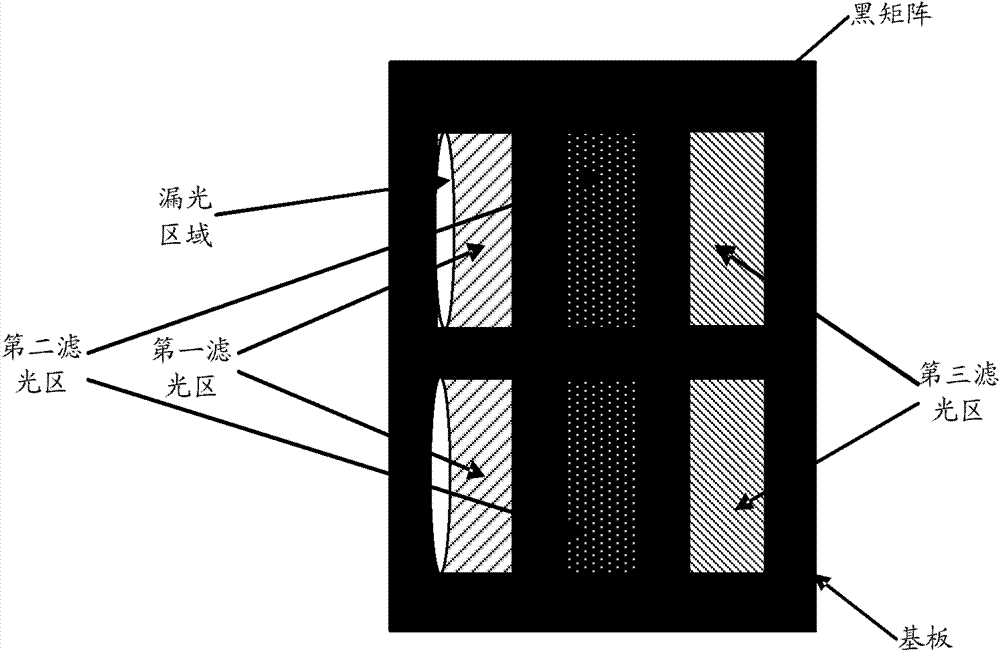

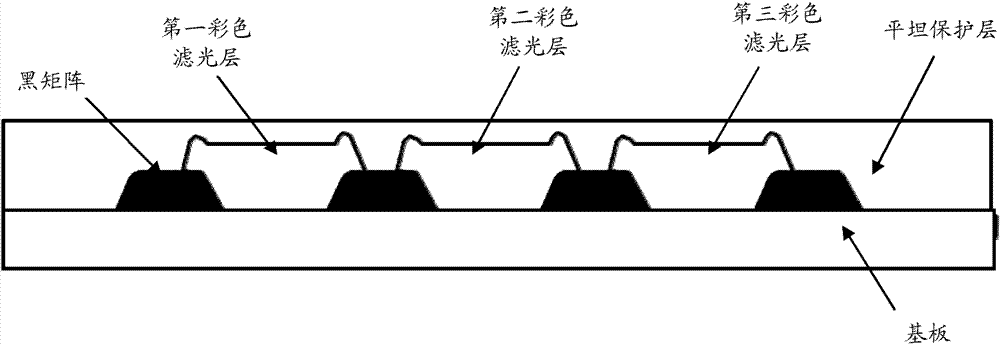

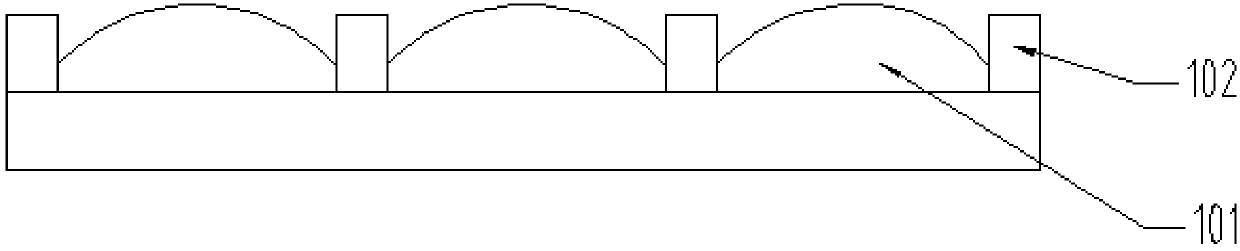

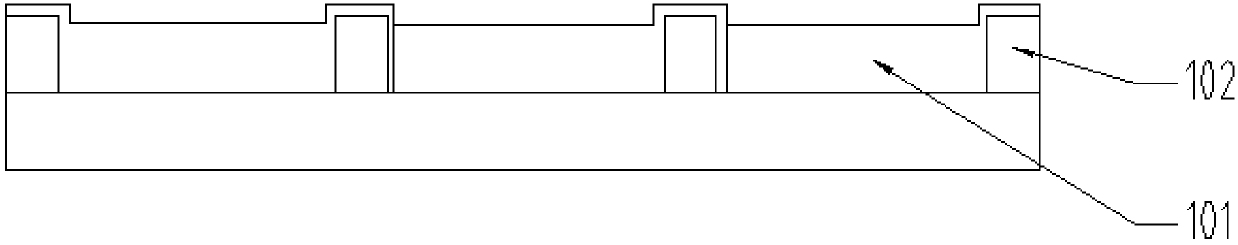

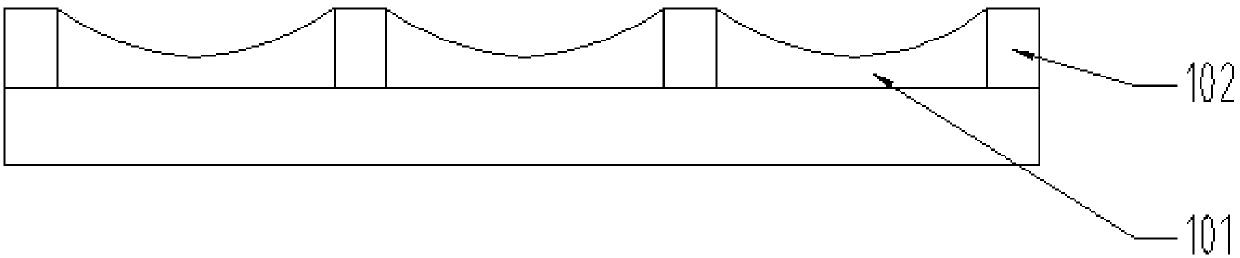

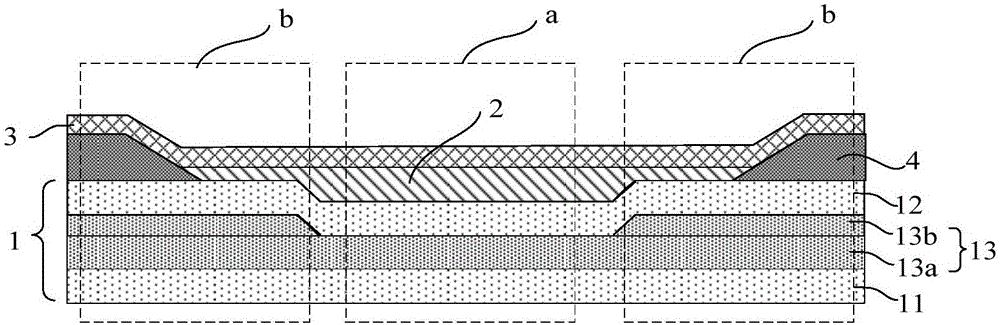

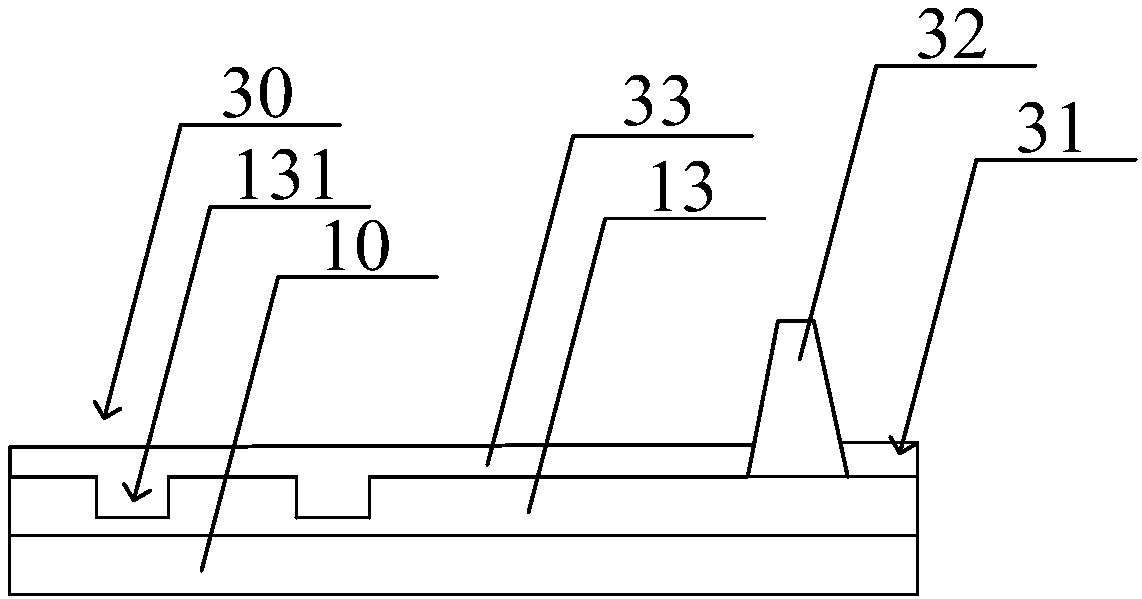

Color film substrate, manufacturing method thereof and display device

InactiveCN103941466AAvoid mixing colorsAvoid color mixingNon-linear opticsOptical elementsImage resolutionColor film

The embodiment of the invention discloses a color film substrate, a manufacturing method of the color film substrate and a display device, and relates to the technical field of display. Under the condition of ensuring that the display device has the high aperture opening ratio and resolution ratio, the color mixing phenomenon of the display device is prevented. The color film substrate comprises a color filter layer, the color filer layer comprises color filer units of at least two colors, the color filer units are distributed in a matrix mode, a black matrix is arranged between every two adjacent color filter units, and the color film substrate further comprises light blocking protrusions which are arranged in an area where the blade matrixes are located, so that color mixing between the color filter units of different colors is prevented.

Owner:BOE TECH GRP CO LTD +1

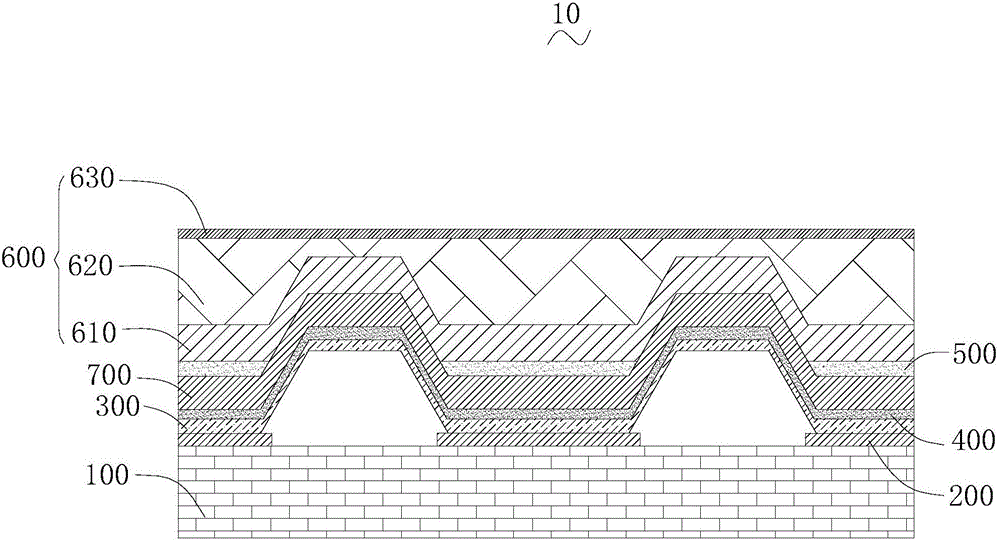

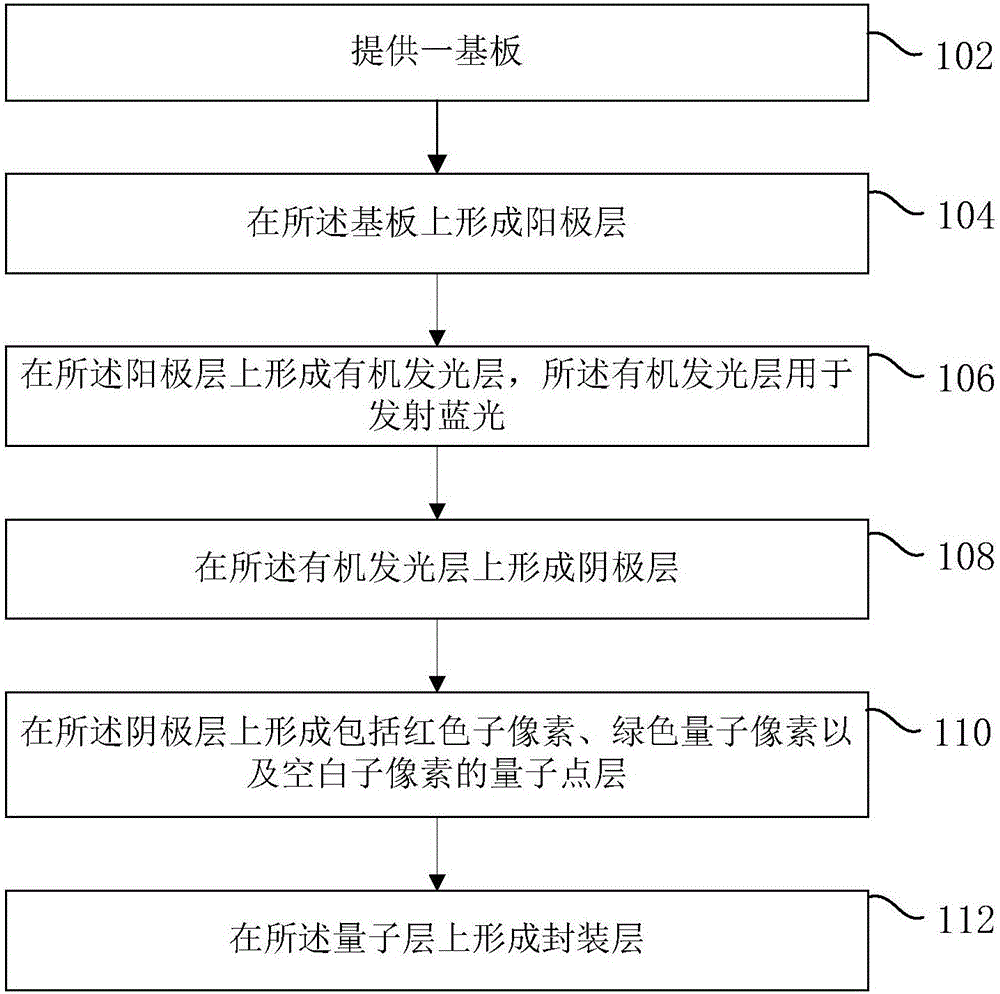

Organic light emitting display device and manufacture method thereof

InactiveCN106684112AImprove color saturationBoost, color gamutSolid-state devicesSemiconductor/solid-state device manufacturingGamutDisplay device

The invention relates to an organic light emitting display device and a manufacture method thereof. The method includes providing an LTPS substrate; forming an anode layer on the substrate; forming an organic light emitting layer on the anode layer and forming a cathode layer on the organic light emitting layer, wherein the organic light emitting layer is used for emitting blue light; forming a quantum dot layer including red sub pixels, green sub pixels and blank sub pixels on the cathode layer; and forming a packaging layer on the quantum dot layer. Through forming the quantum dot layer on the cathode layer directly, through exciting the red sub pixels and the green sub pixels of the quantum dot layer with the blue light emitted by the organic light emitting layer and through penetration of the blue light by the blank sub pixels, light of different colors is emitted. Color saturation and color gamut are improved effectively. Besides, cost is reduced effectively and production efficiency is improved.

Owner:TRULY HUIZHOU SMART DISPLAY

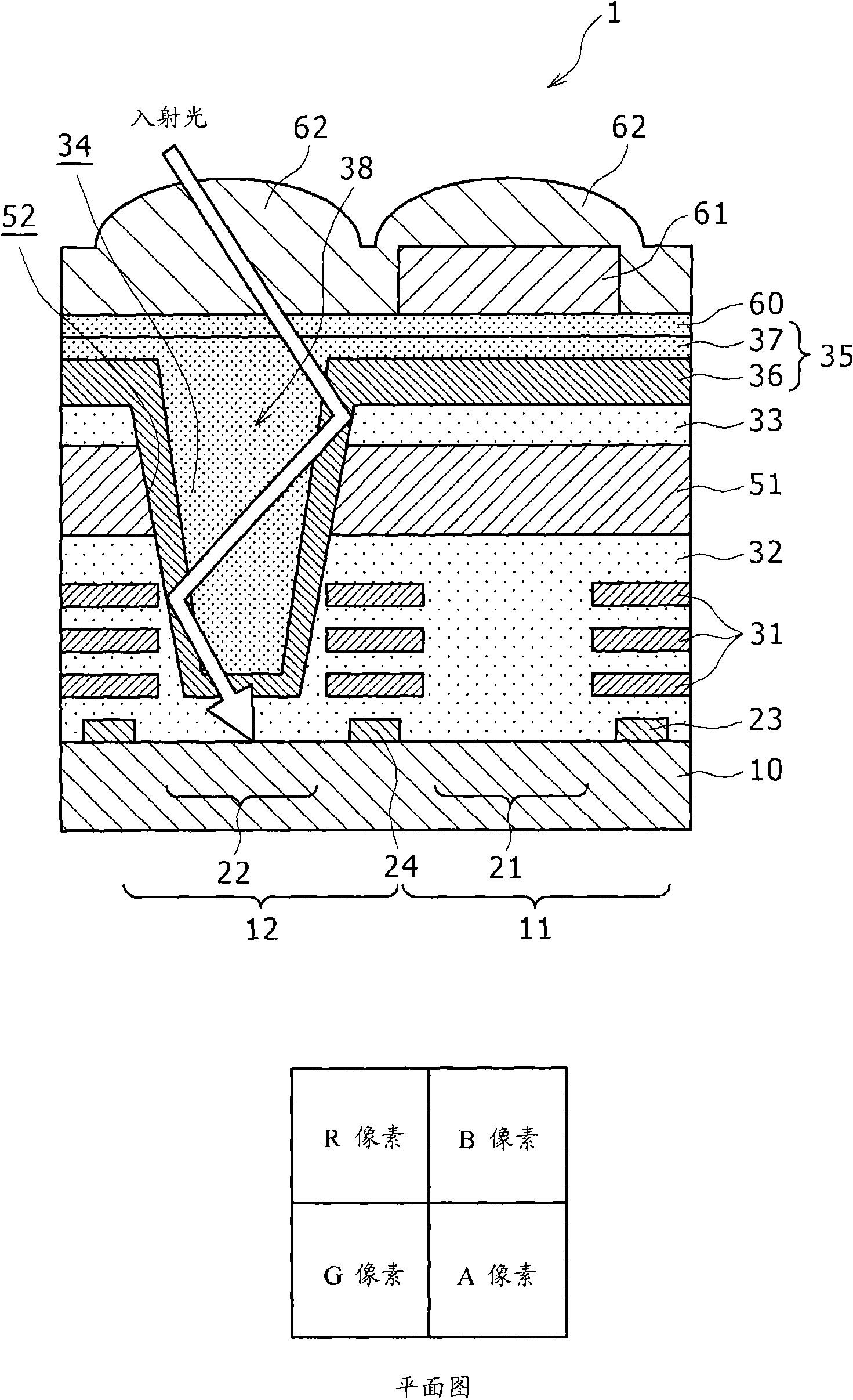

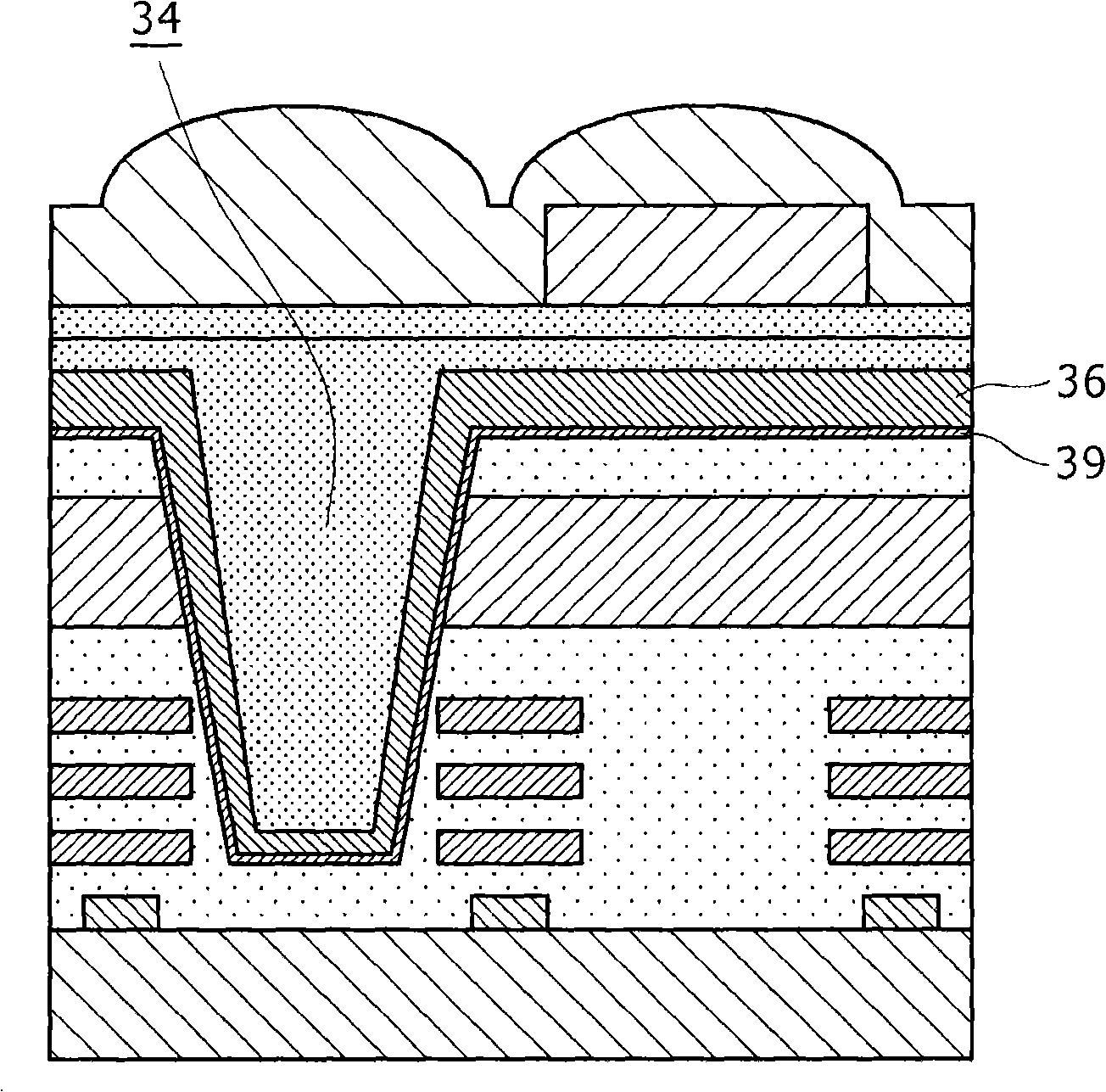

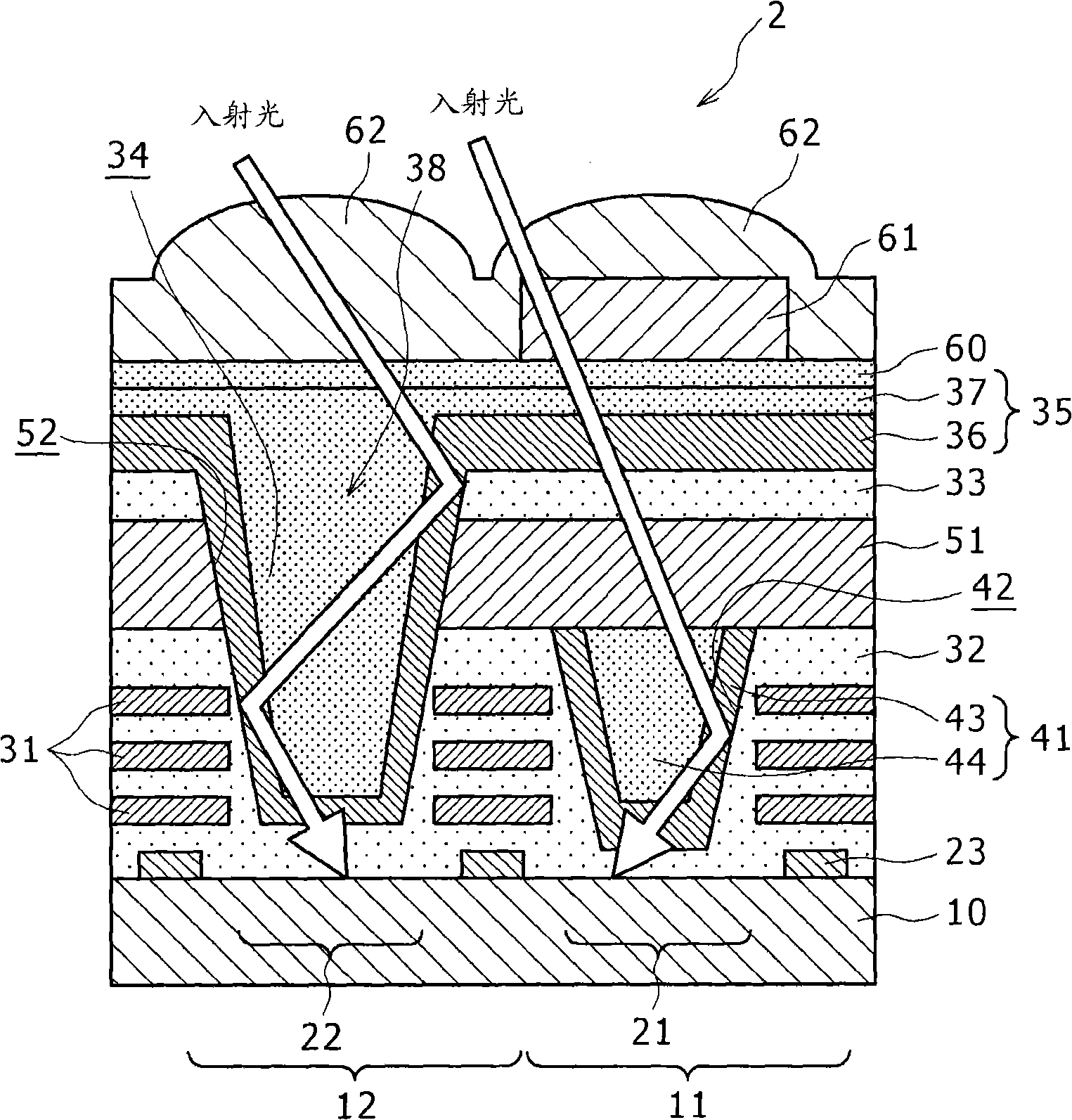

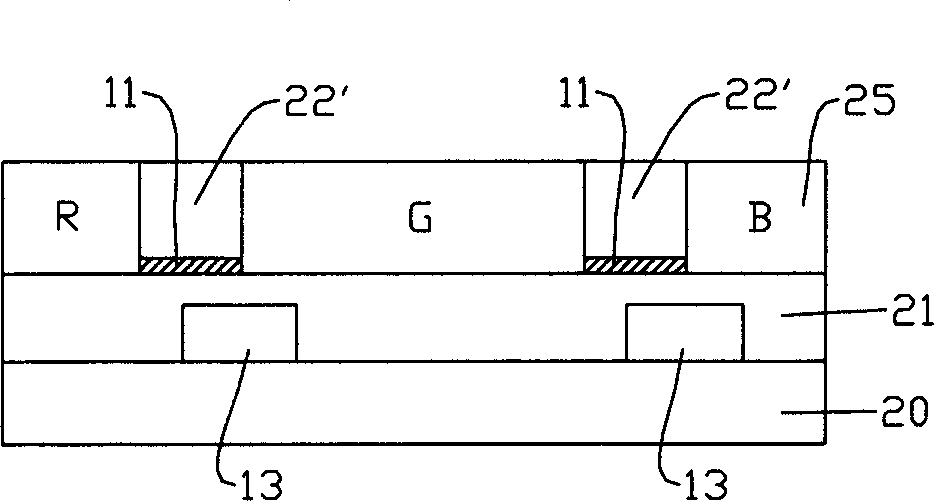

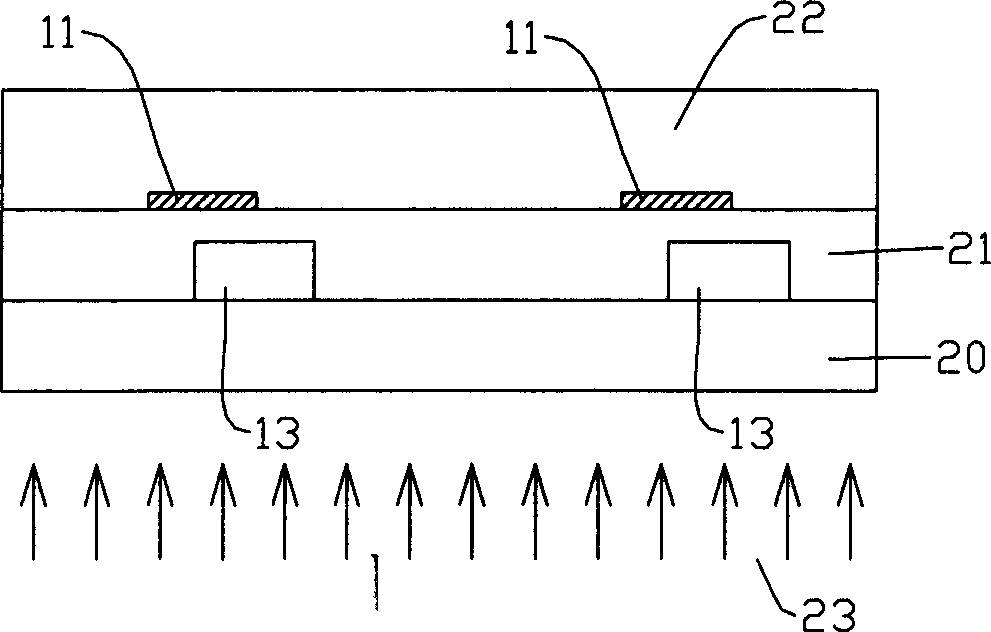

Solid-state image pickup device and a method of manufacturing the same, and image pickup apparatus

InactiveCN101308860AHigh sensitivityAvoid color mixingTelevision system detailsSolid-state devicesPhotoelectric conversionLight filter

Disclosed herein is a solid-state image pickup device, including: a first pixel for receiving a visible light of an incident light to subject the visible light to photoelectric conversion; a second pixel for receiving the visible light and a near-infrared light of the incident light to subject each of the visible light and the near-infrared light to the photoelectric conversion; a color filter layer; and an infrared light filter layer for absorbing or reflecting an infrared light, and transmitting the visible light.

Owner:SONY CORP

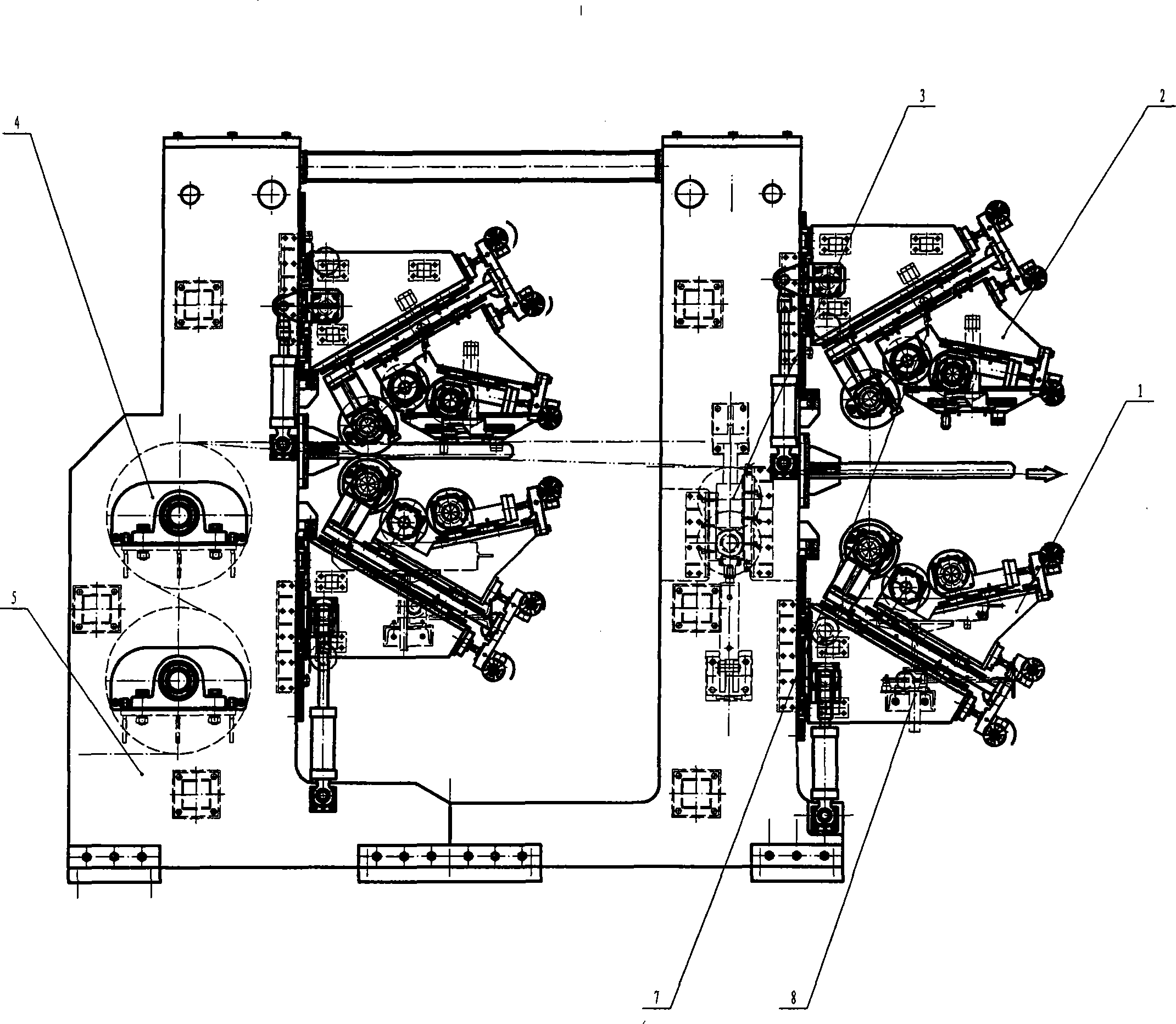

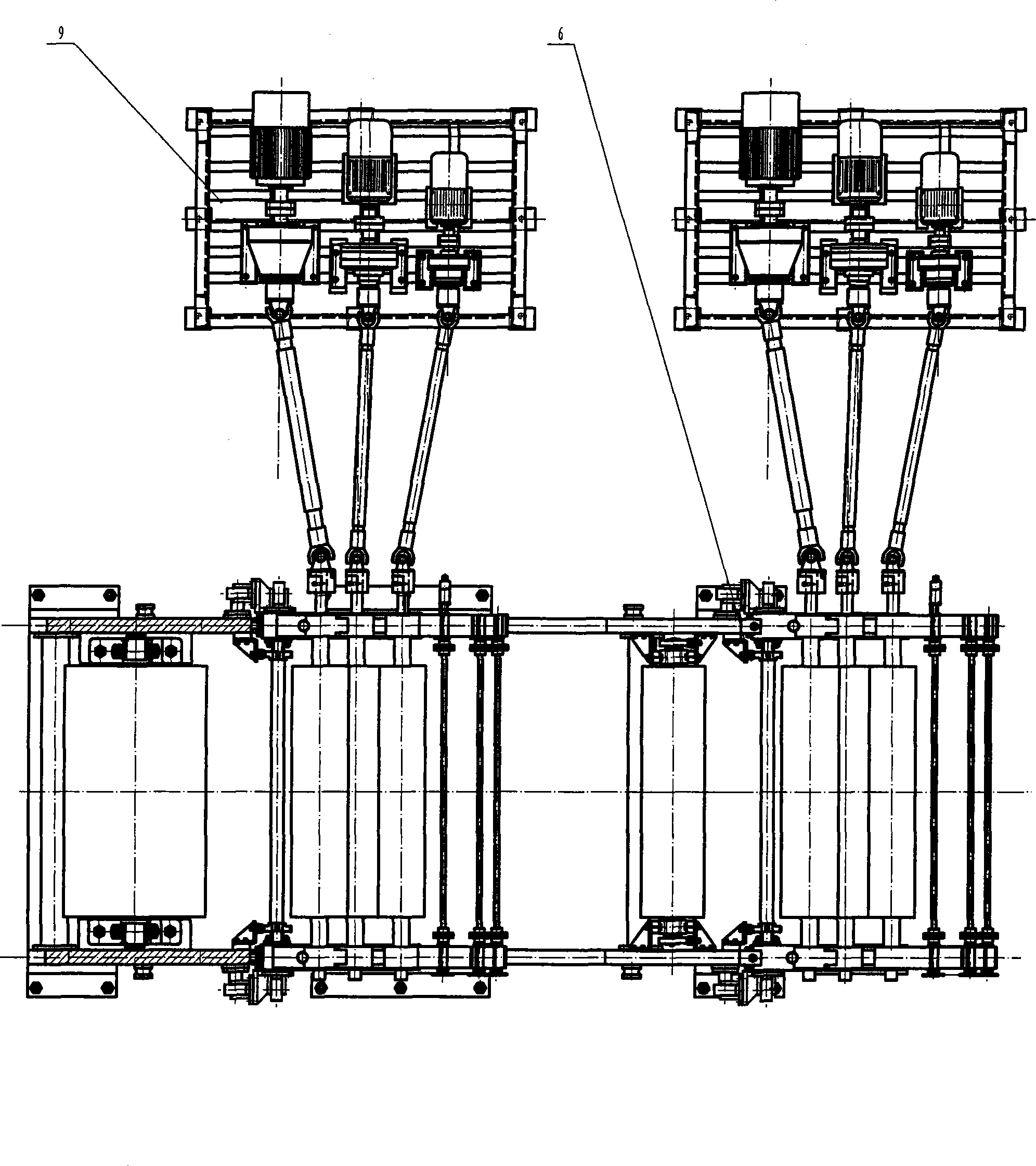

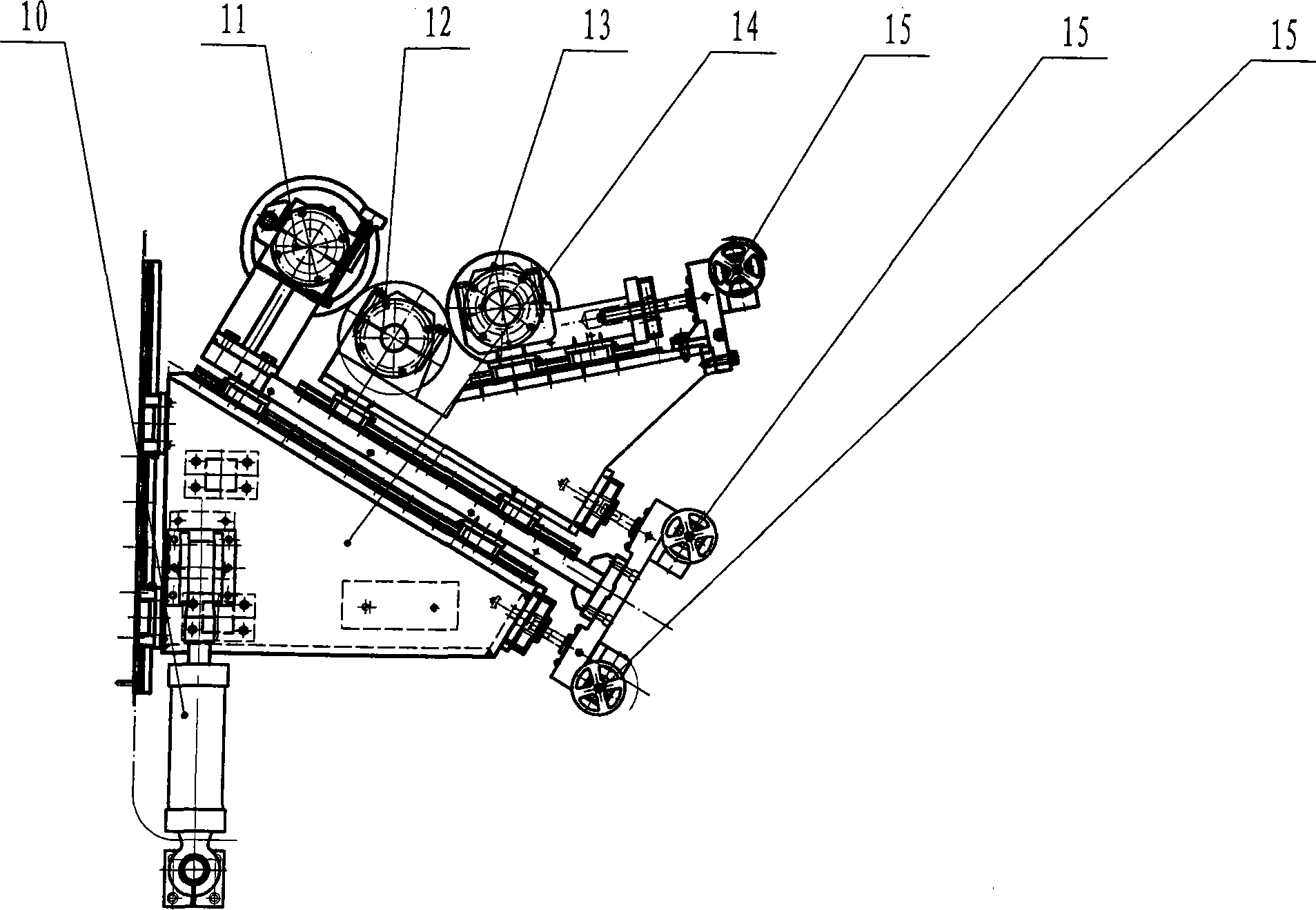

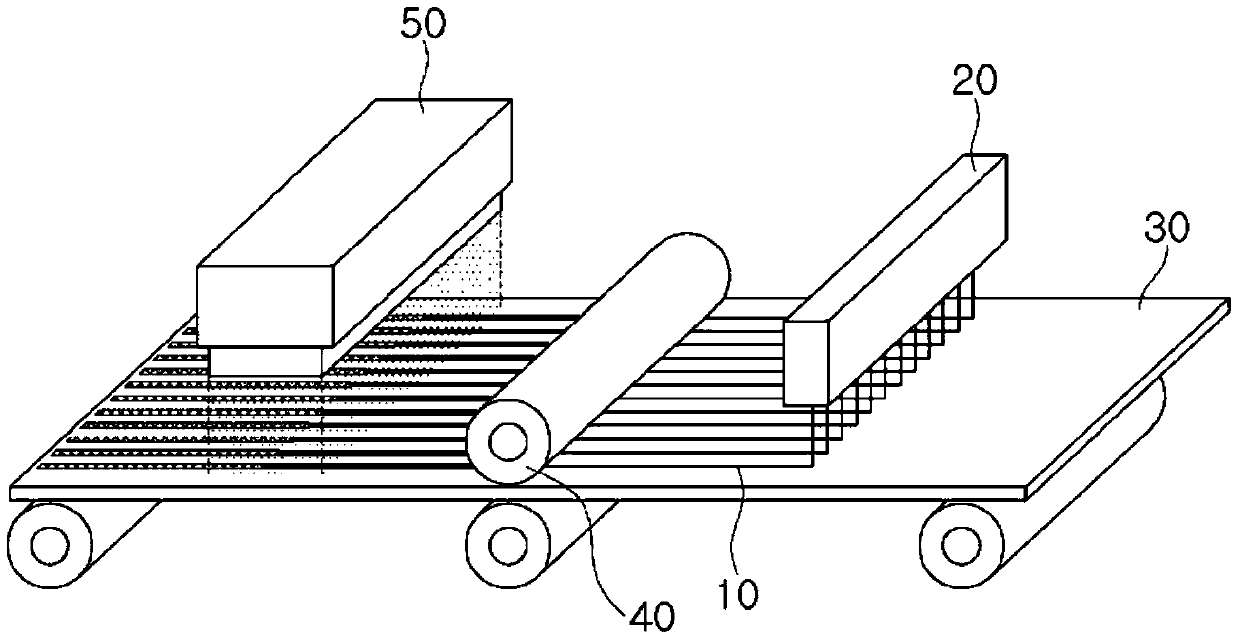

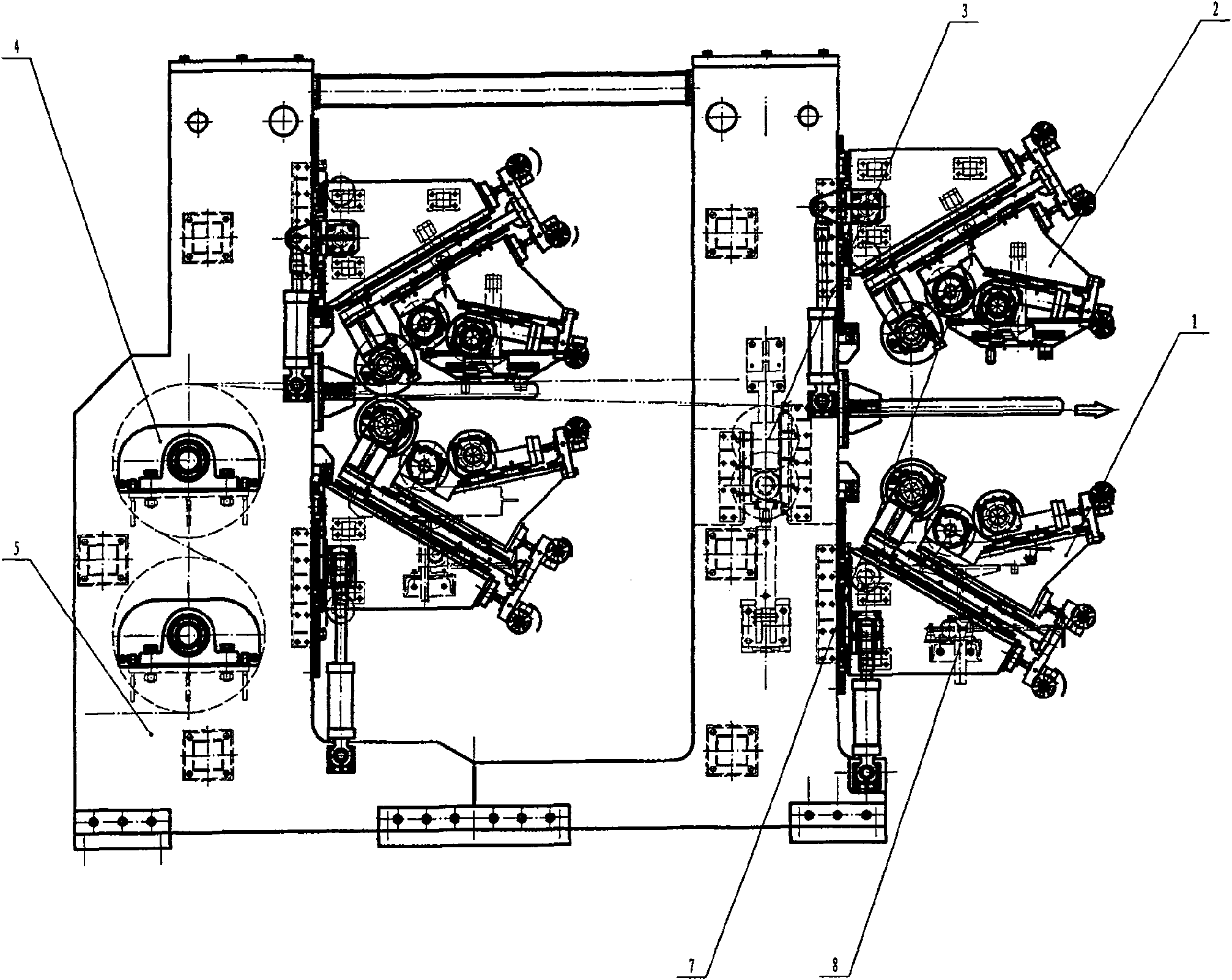

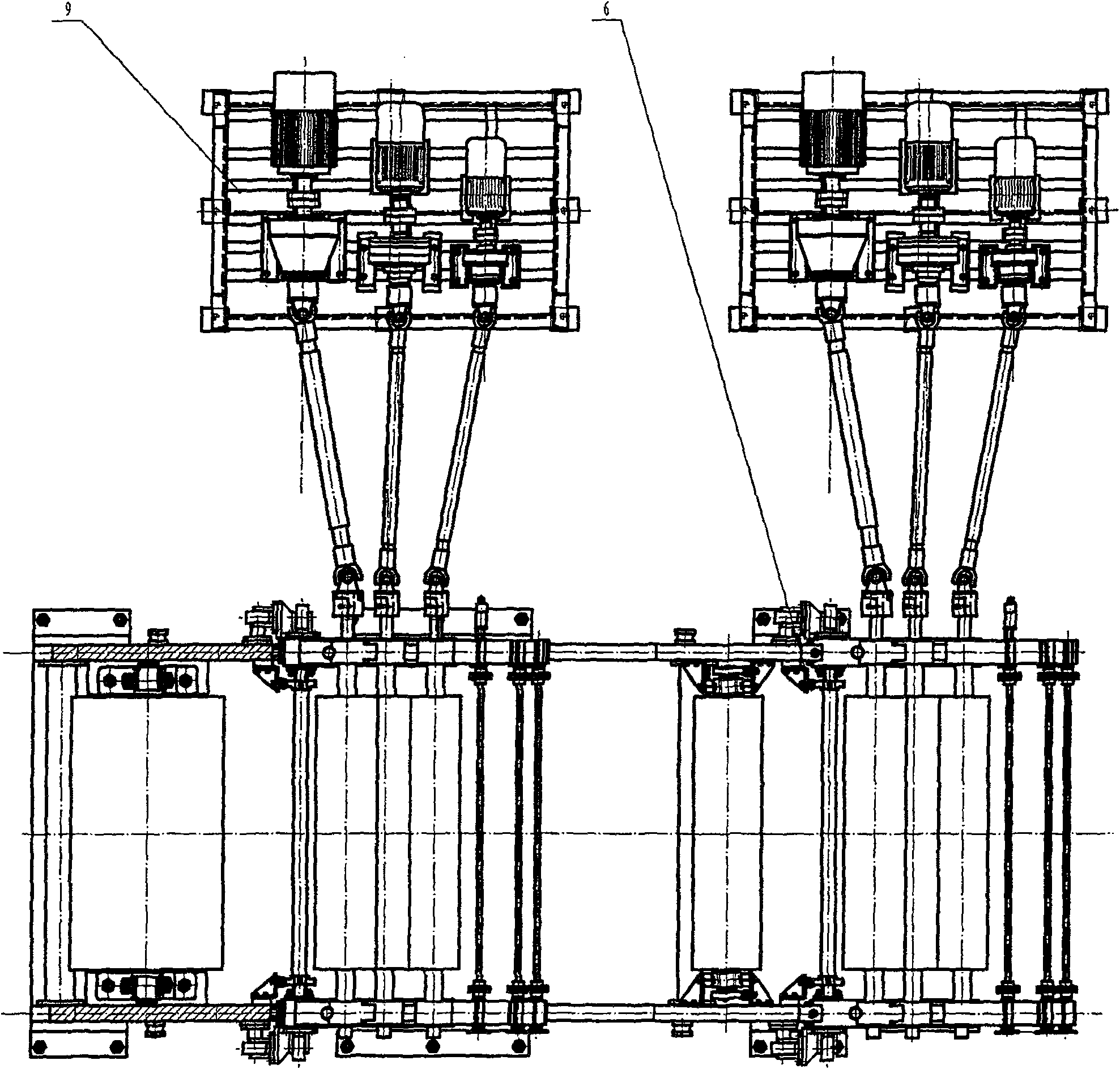

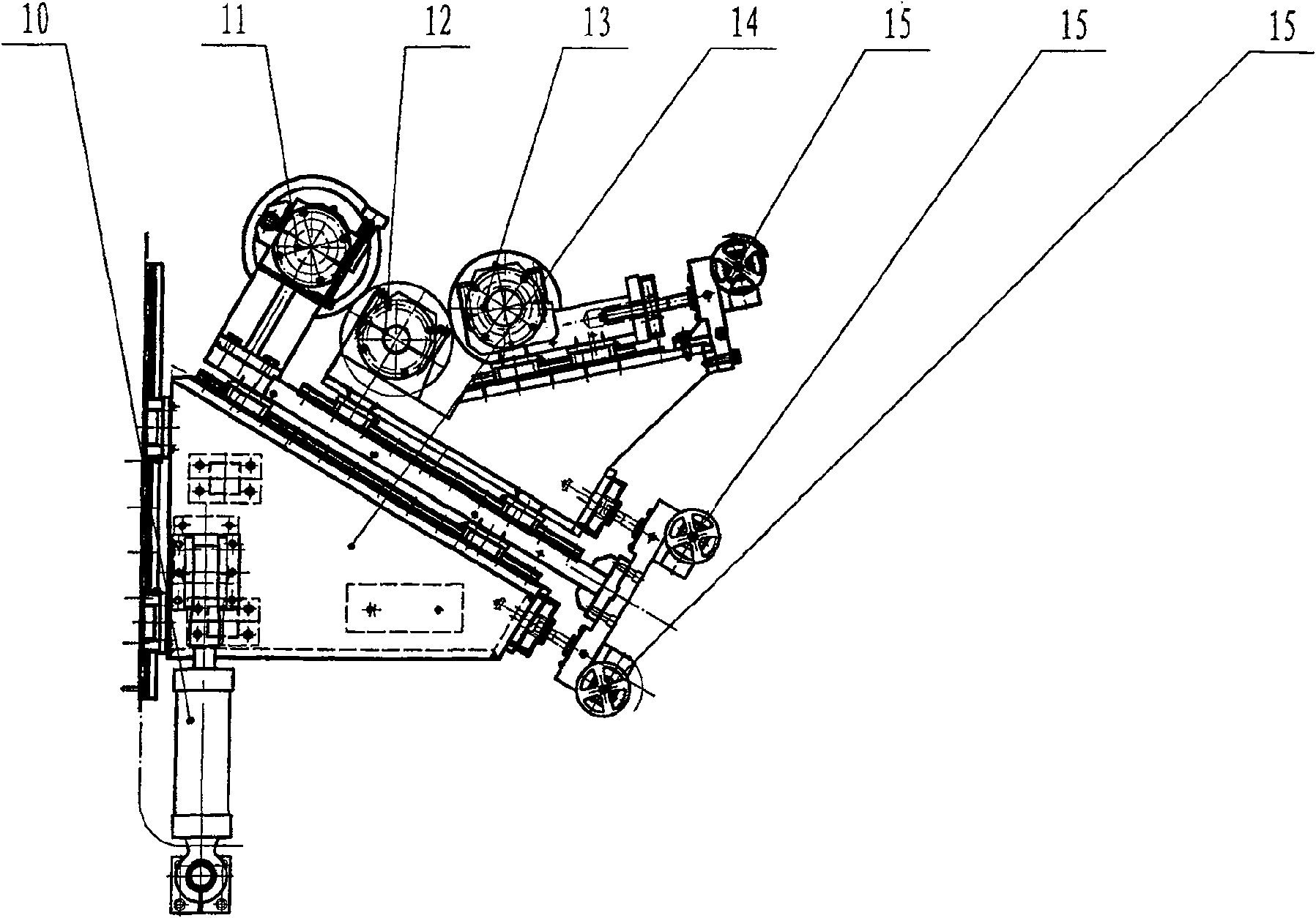

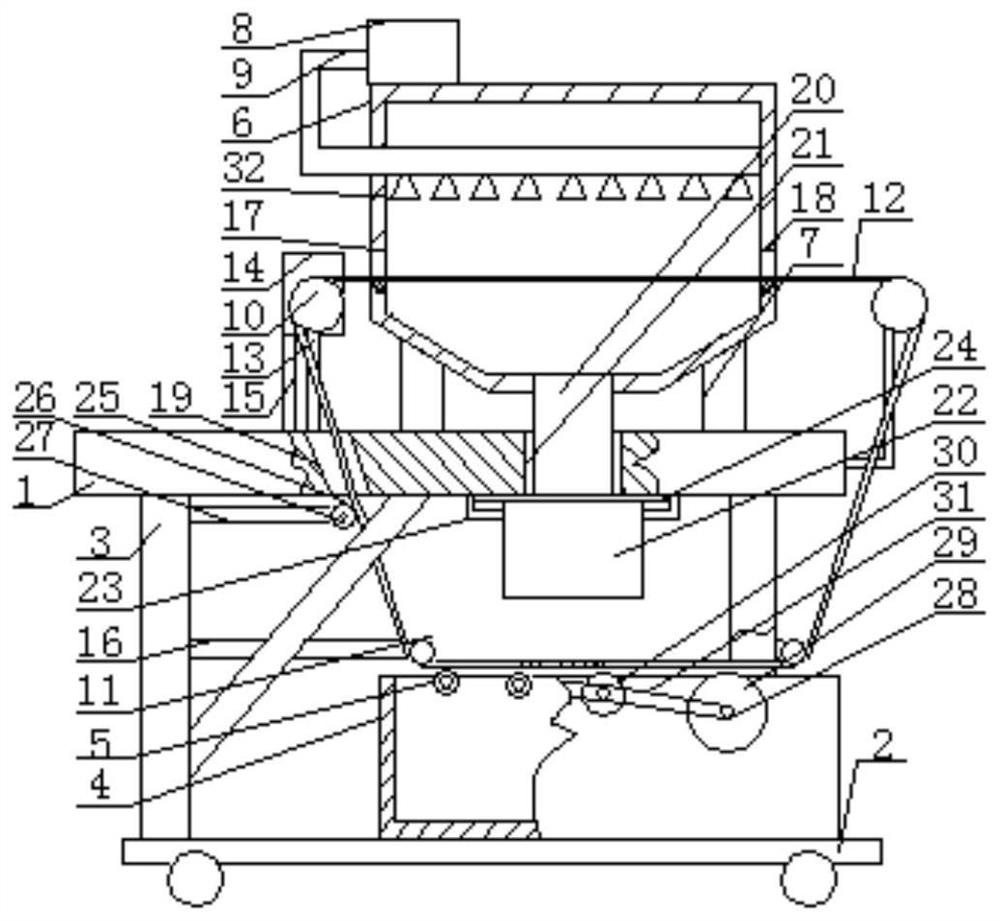

Roller coater

ActiveCN101244413ASolve the problem of coating qualityRealize online maintenance and color changeLiquid surface applicatorsCoatingsLacquerEngineering

The invention provides a roller machine suitable for coating chemical coating, which is characterized in that the roller machine comprises two sets of coating mechanism arranged top to top, a support roller mechanism, a turning roller component, a frame, a synchronous mechanism, a shower, a back-coated lifting device and a transmission mechanism. Back coating frames of a coating roller device, a reclaiming roller device and a regulating roller device fitted with specially made polyurethane material are driven by an oil cylinder and synchronous lifting at both sides is assured by the synchronous mechanism in the coating mechanism; clearance among the coating roller device, the reclaiming roller device and the regulating roller device is regulated by the regulating mechanism to regulate coating thickness. The shower line is in a lacquer tray of a front coating mechanism and a flat mouth shower with a valve is arranged on the shower line; flow rate of the paint is controlled and coating thickness is adjusted by regulating the valve. Jet tube mode is adopted in the lacquer tray of a bottom roller in the back coating mechanism; paint is agitated to prevent from deposition. The roller machine has the advantages that double-roller coating structure is adopted and one is used and the other is standby, maintenance and exchanging color are carried out online, time is saved and productivity is improved.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH +1

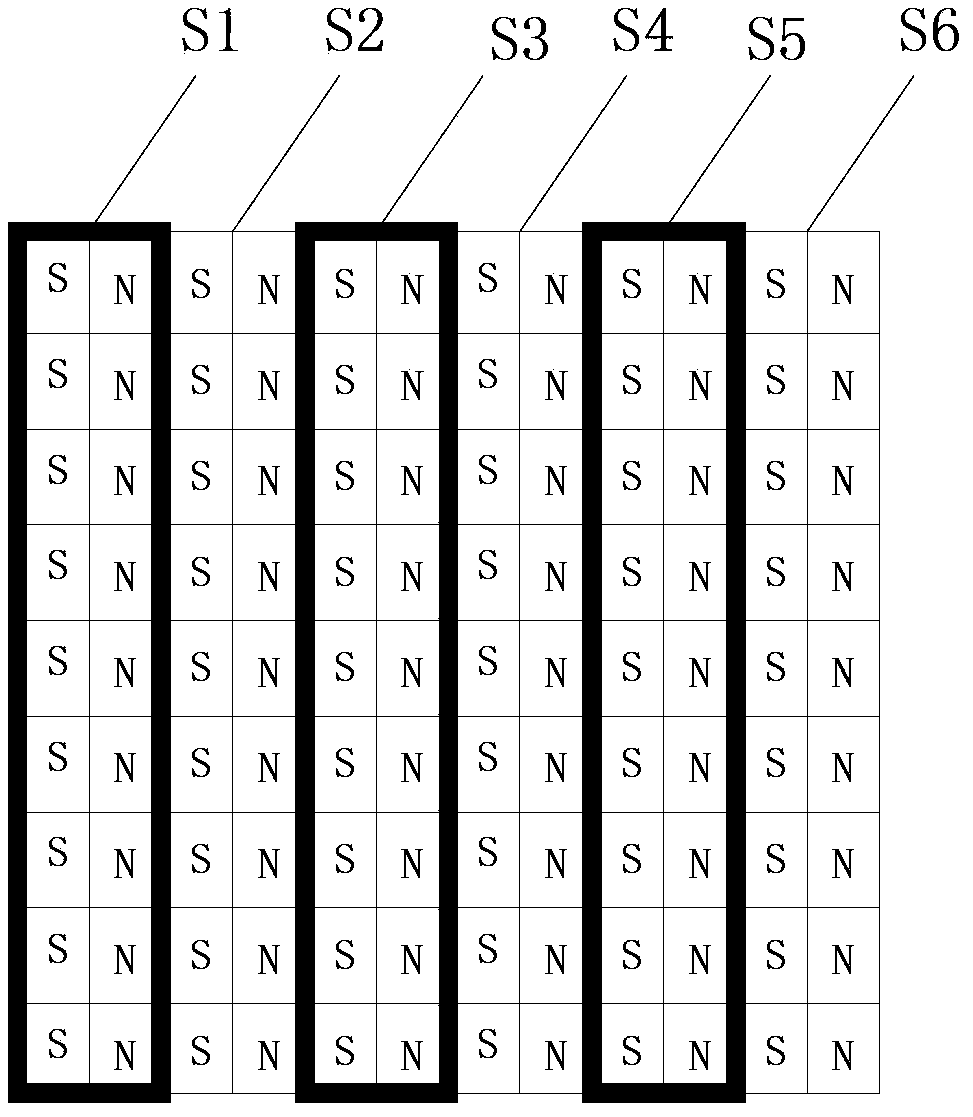

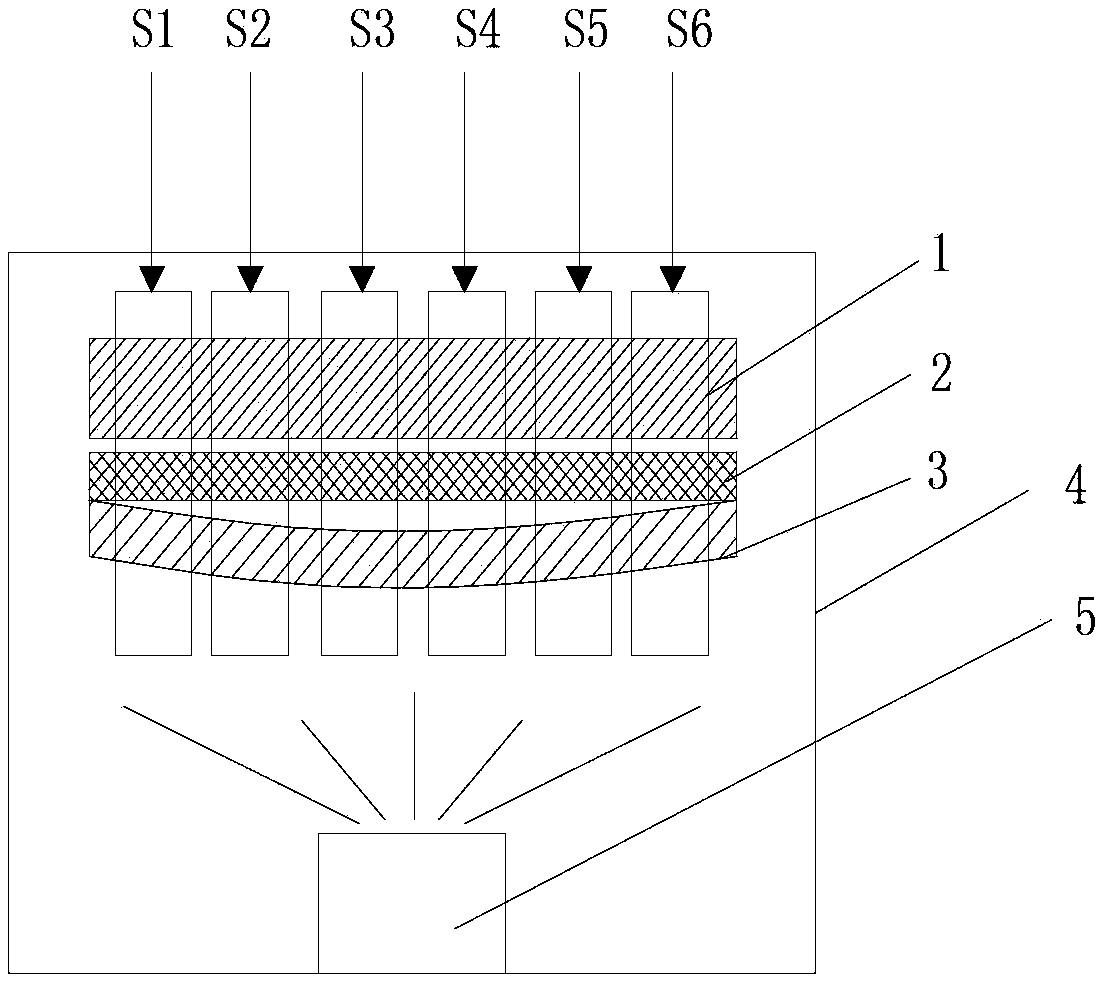

Electromagnetic vapor-plating device

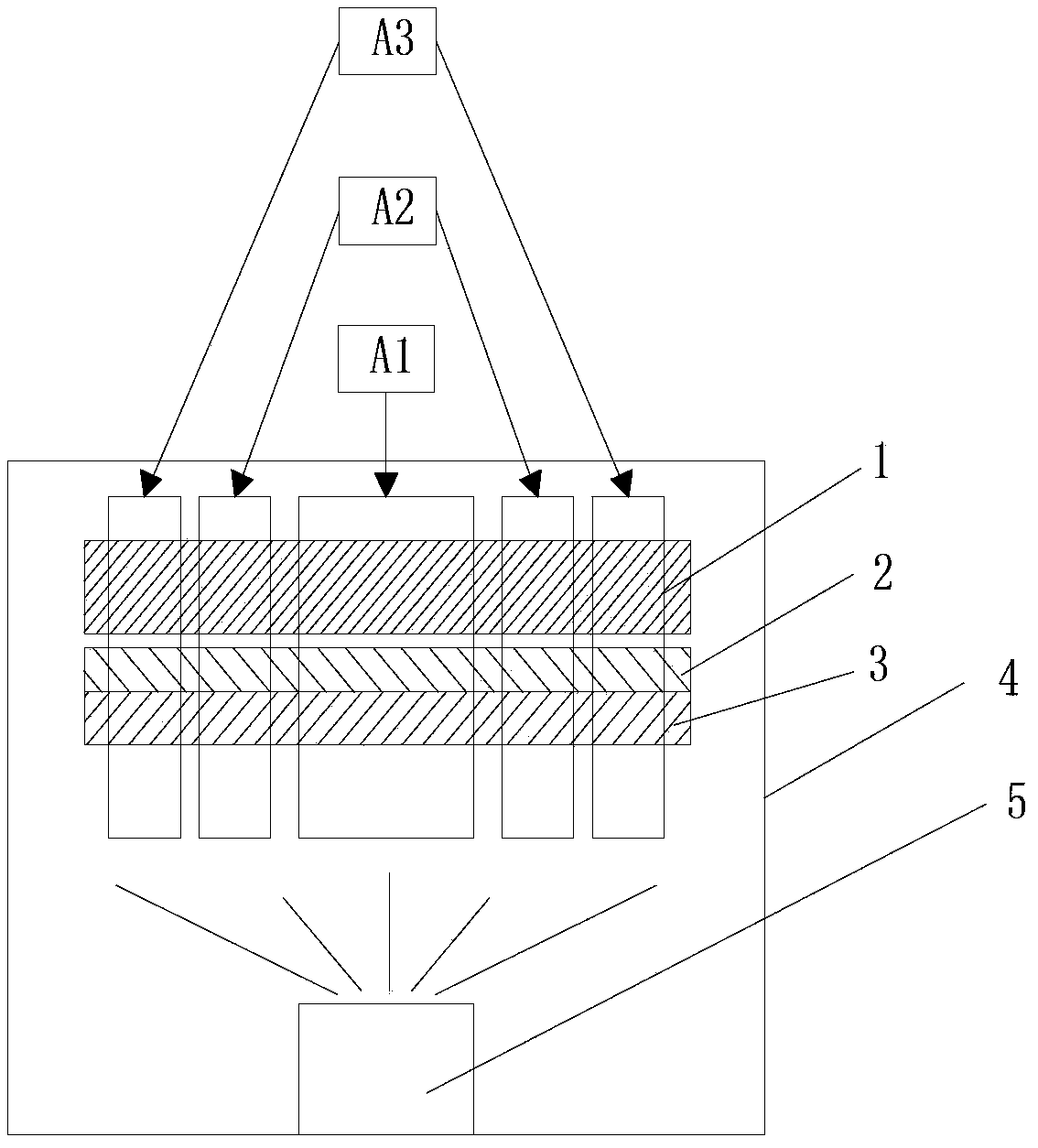

InactiveCN104131251AImprove fitReal-time adjustment of magnetic strengthSolid-state devicesVacuum evaporation coatingMagnetic tension forcePower flow

The present disclosure discloses an electromagnetic vapor deposition apparatus comprising a plurality of electromagnets which form a plurality of electromagnetic regions when electronic current passes through. A programmable control equipment is electronically connected to each magnet unit to control magnetic polarity and magnetic intensity of each magnet unit. The programmable control equipment can adjust the magnetic intensity of each of the plurality of electromagnetic regions to adsorb the metal mask tightly. Meanwhile, the problem of colors mixing is overcome.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

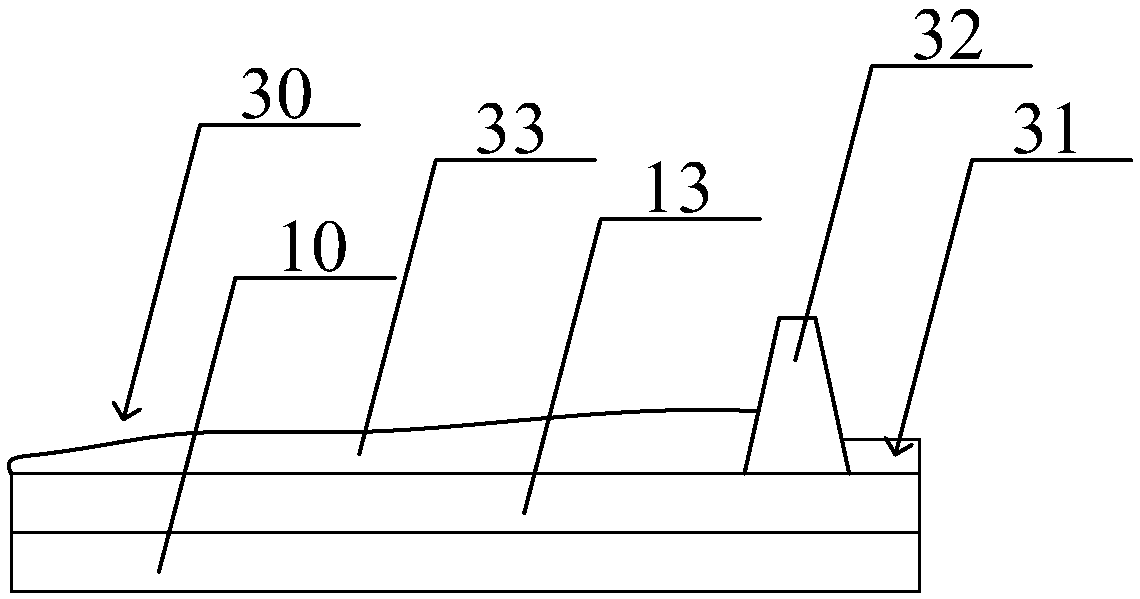

Method for reducing OLED color mixture defect and OLED display panel

InactiveCN105633301AReduce color mixing defectsAvoid enteringSolid-state devicesSemiconductor/solid-state device manufacturingEvaporationChemistry

The present invention provides a method for reducing OLED color mixture defect and an OLED display panel. According to the method, a spacer layer is manufactured on a substrate for surrounding each evaporation area, during the process of OLED evaporation, evaporation gas only forms one layer of thin film on a preset evaporation area (i.e., a pixel unit area), and for a non-preset evaporation area (i.e., a non-pixel unit area), due to blocking of the circular spacer layer, the evaporation gas cannot enter the non-pixel unit area to cause shadow and color mixture situations, thereby improving device yield.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

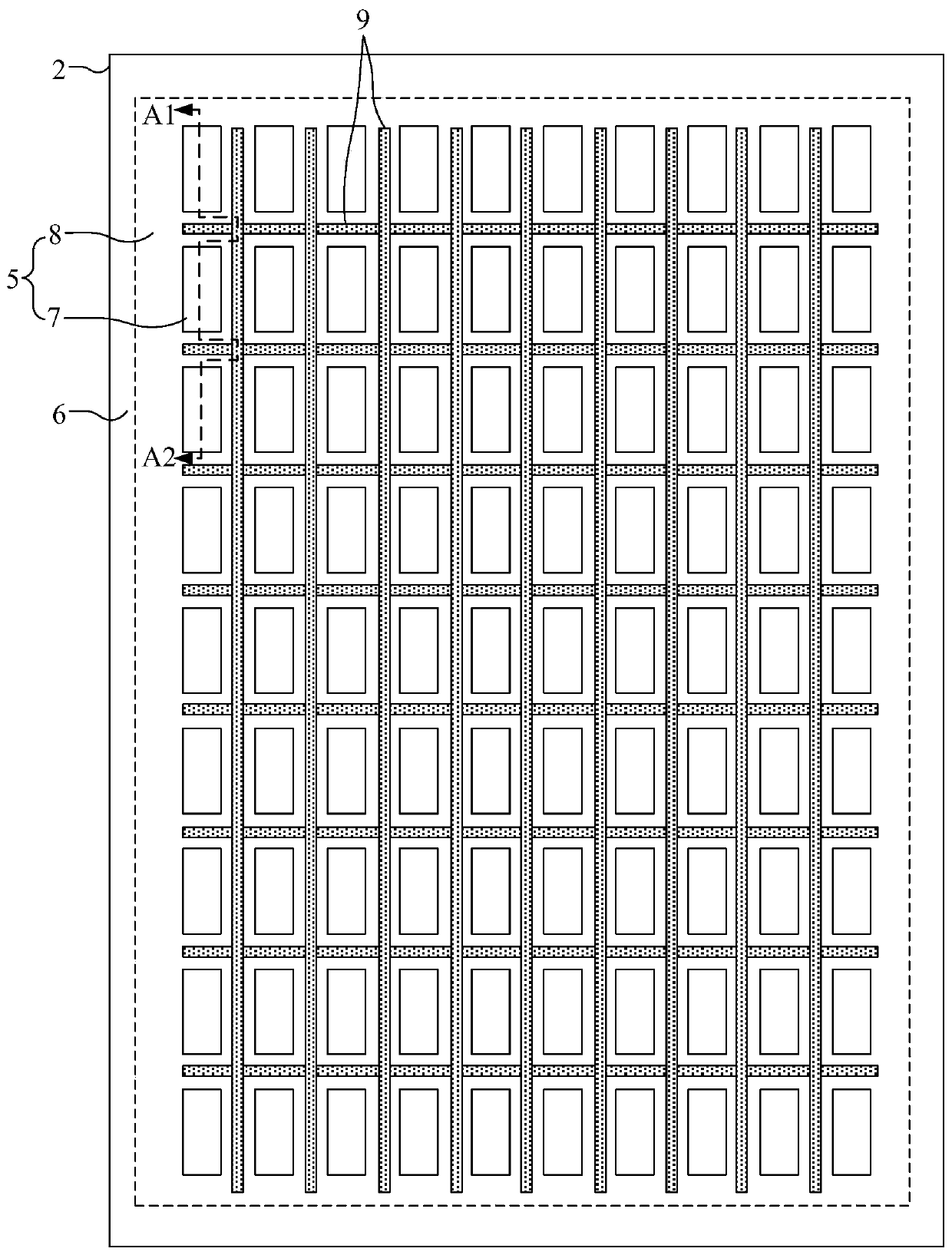

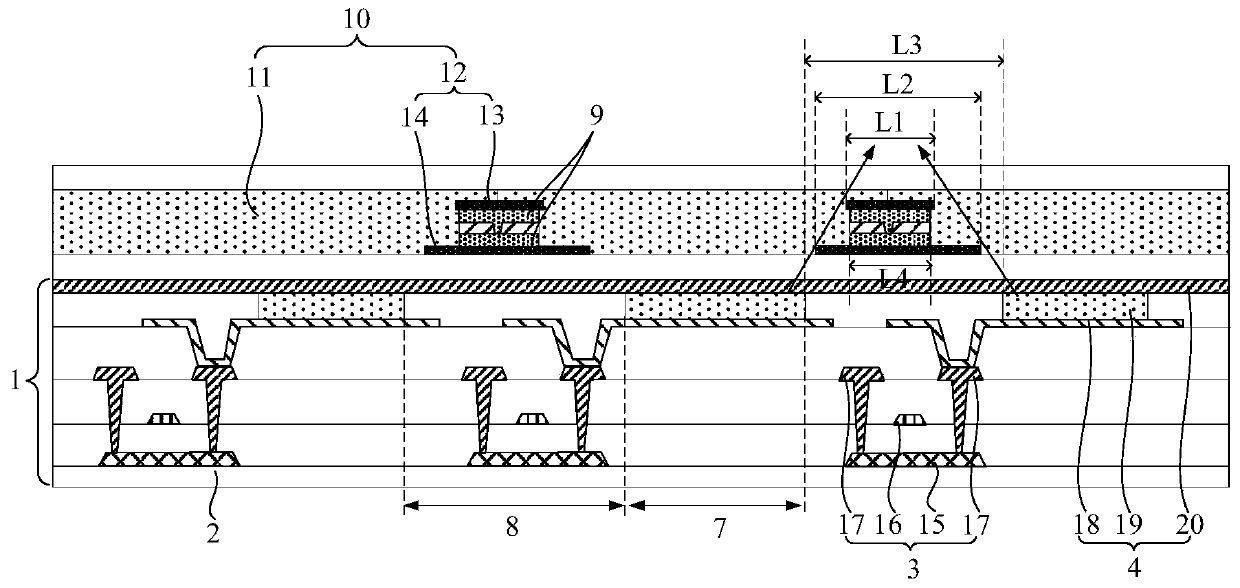

Display panel and display device

ActiveCN110910770AAvoid reflectionsReduce reflectivitySolid-state devicesInput/output processes for data processingDisplay deviceEngineering

The embodiment of the invention provides a display panel and a display device, relates to the technical field of display, and aims to reduce the influence of a shading layer on large-viewing-angle light emission. The display panel comprises an array substrate, wherein the array substrate comprises a first substrate, a pixel circuit layer and a light-emitting device layer; a display area and a non-display area surrounding the display area, wherein the display area comprises a light emitting part and a non-light emitting part; the touch control metal wire is located at the non-light-emitting part; a light filtering layer is located on the side, back to the first substrate, of the light emitting device layer, and the light filtering layer comprises a plurality of color resistors and a plurality of light shielding layers; a shading layer is positioned on the non-light-emitting part, wherein the shading layer comprises a first shading layer and a second shading layer; wherein the first shading layer is located on the side, opposite to the first substrate, of the second shading layer, and the touch metal wire is located between the first shading layer and the second shading layer, and the width of the first shading layer in the direction perpendicular to the extending direction of the first shading layer is L1, and the width of the second shading layer in the direction perpendicularto the extending direction of the second shading layer is L2, and L1 is smaller than L2.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Method for mfg. optical elements

An optical element comprising at least a plurality of pixels formed on a substrate and partition walls arranged respectively between adjacent pixels is manufactured by a method comprising steps of forming partition walls of a resin composition on a substrate, performing a dry etching process of irradiating the substrate carrying the partition walls formed thereon with plasma in an atmosphere containing gas selected at least from oxygen, argon and helium, performing a plasma treatment process of irradiating the substrate subjected to the dry etching process with plasma in an atmosphere containing at least fluorine atoms, and forming pixels by applying ink to the areas surrounding by the partition walls by means of an ink-jet system.

Owner:CANON KK

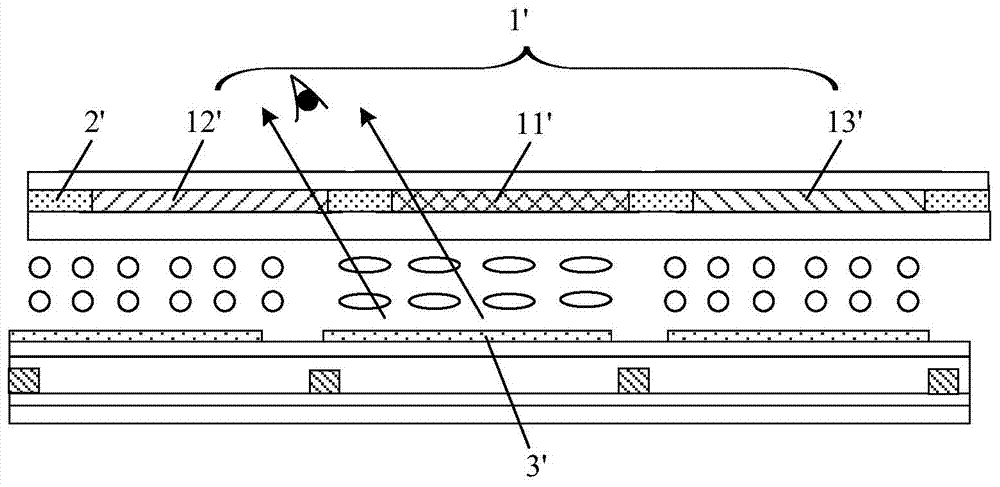

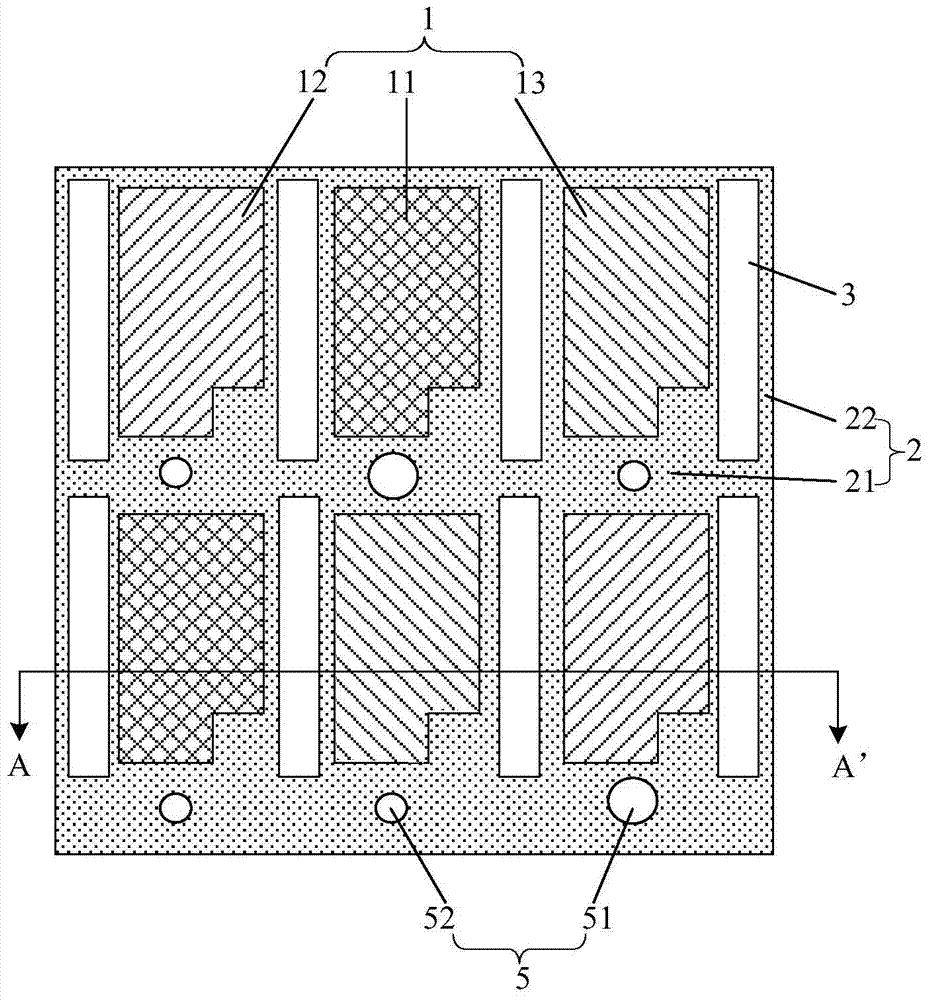

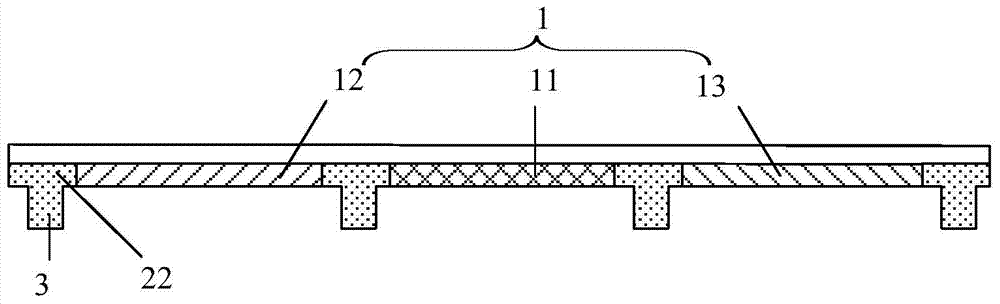

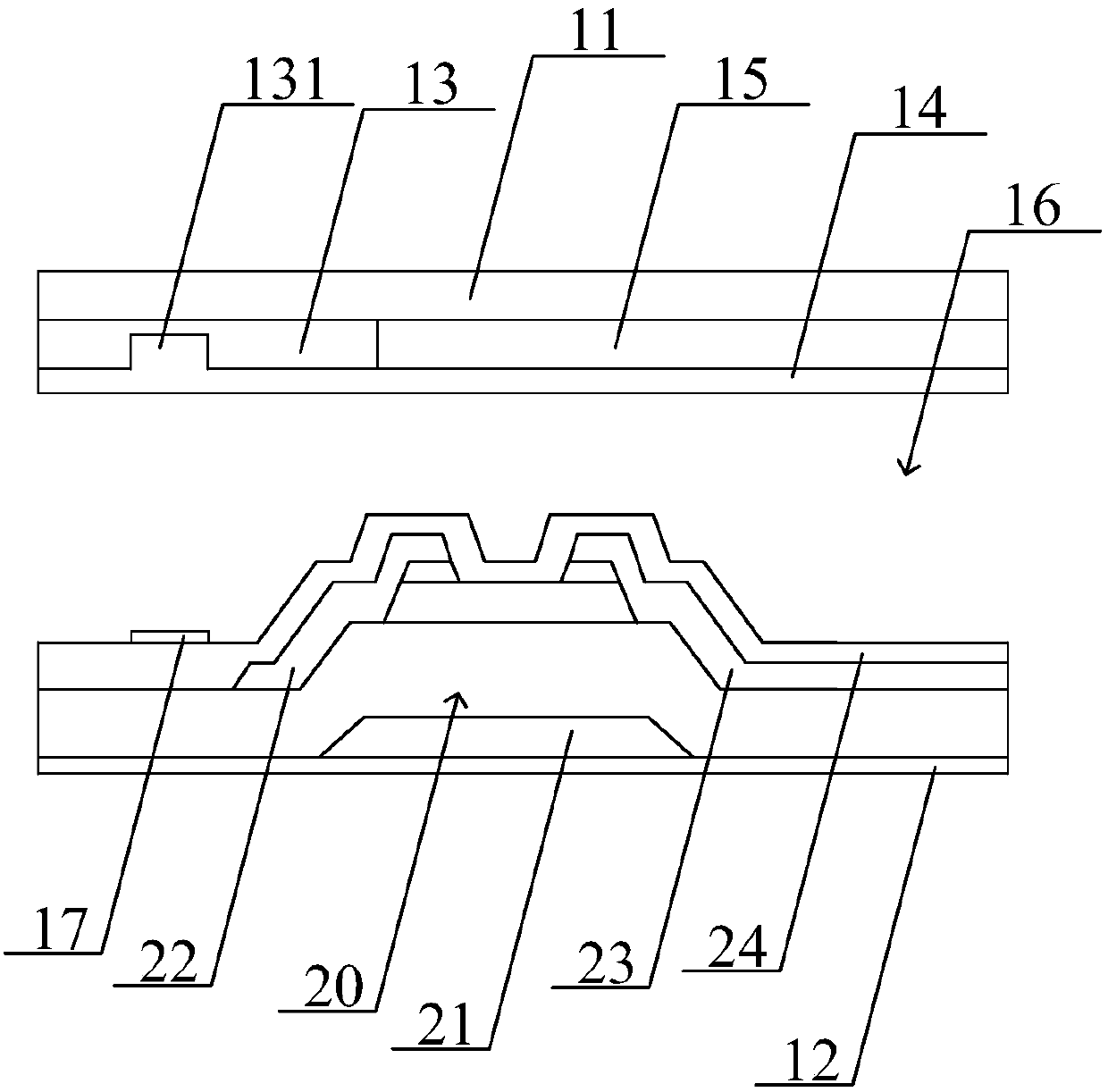

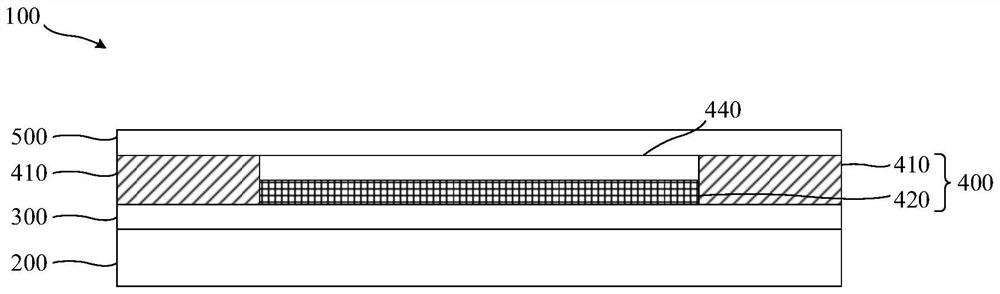

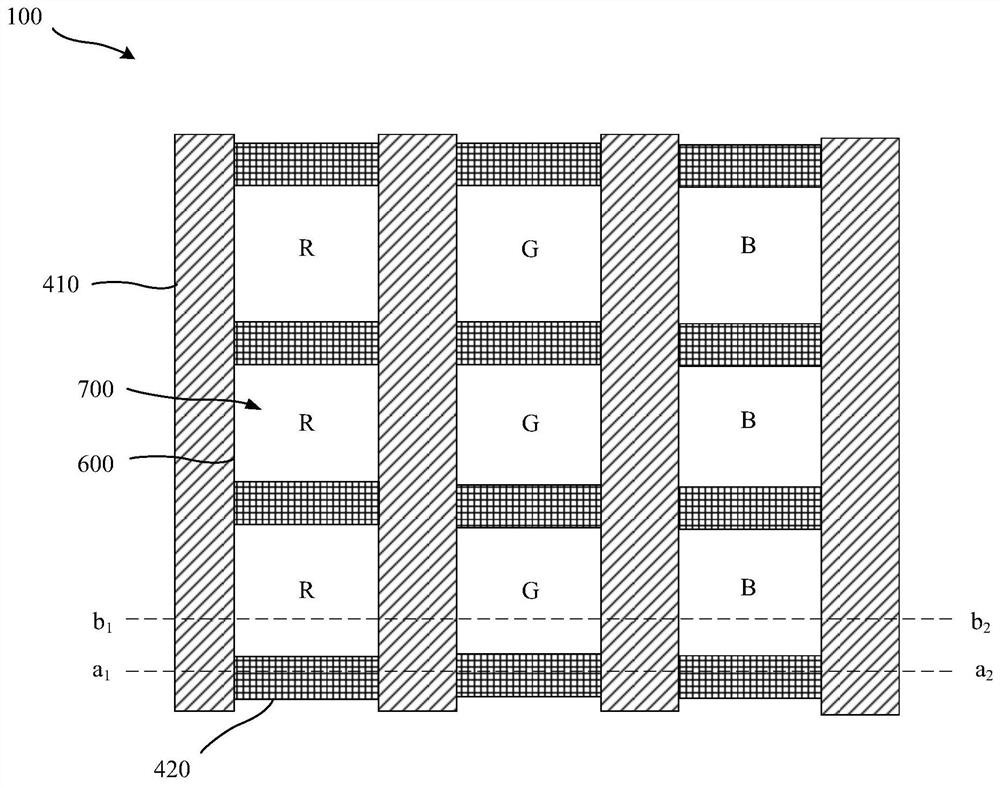

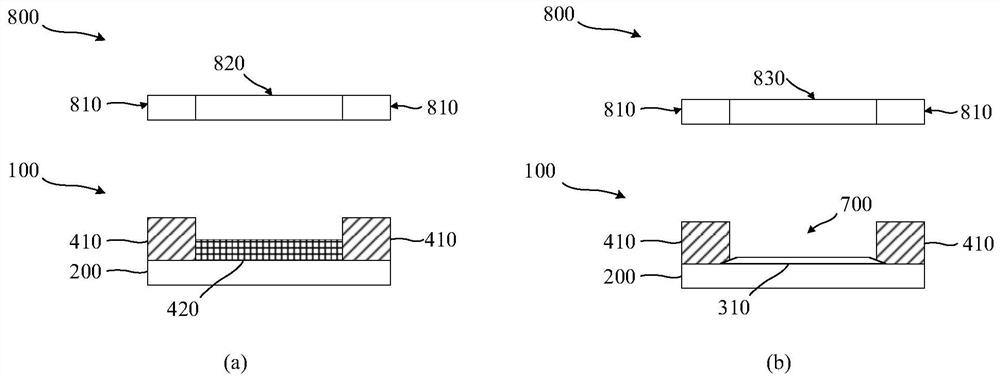

Organic light-emitting display device and manufacturing method thereof

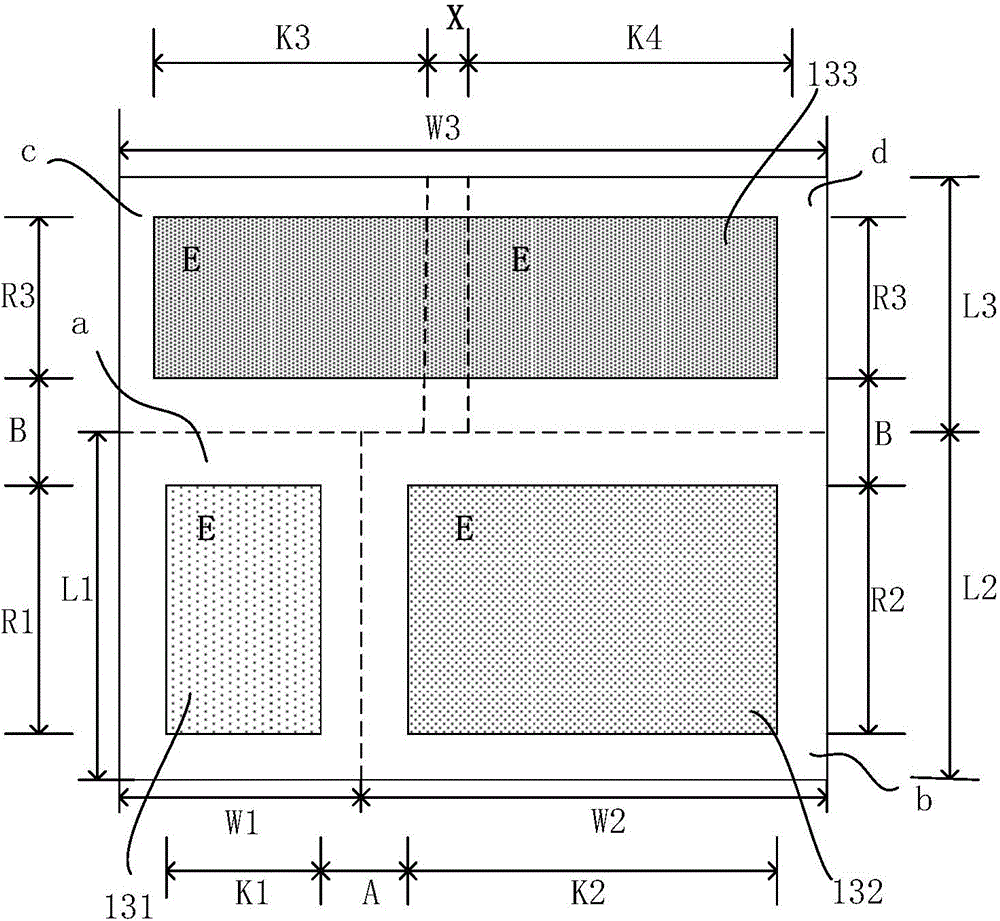

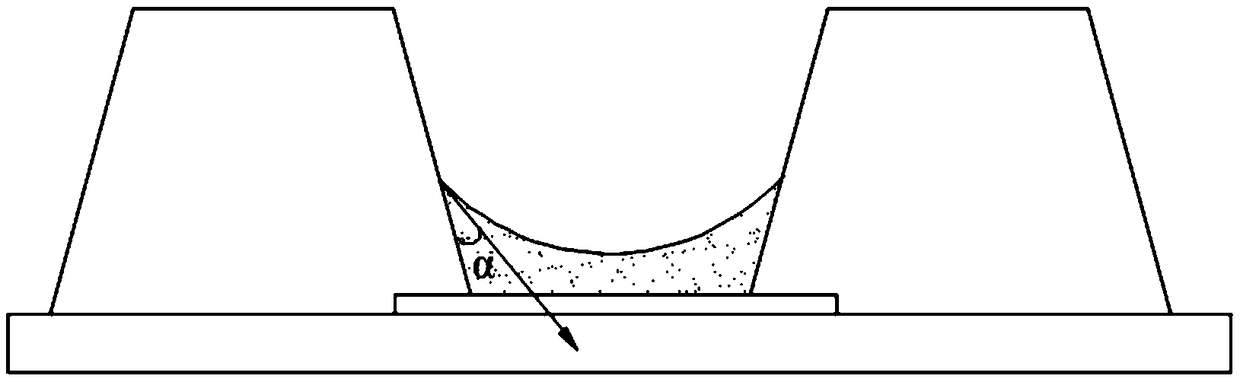

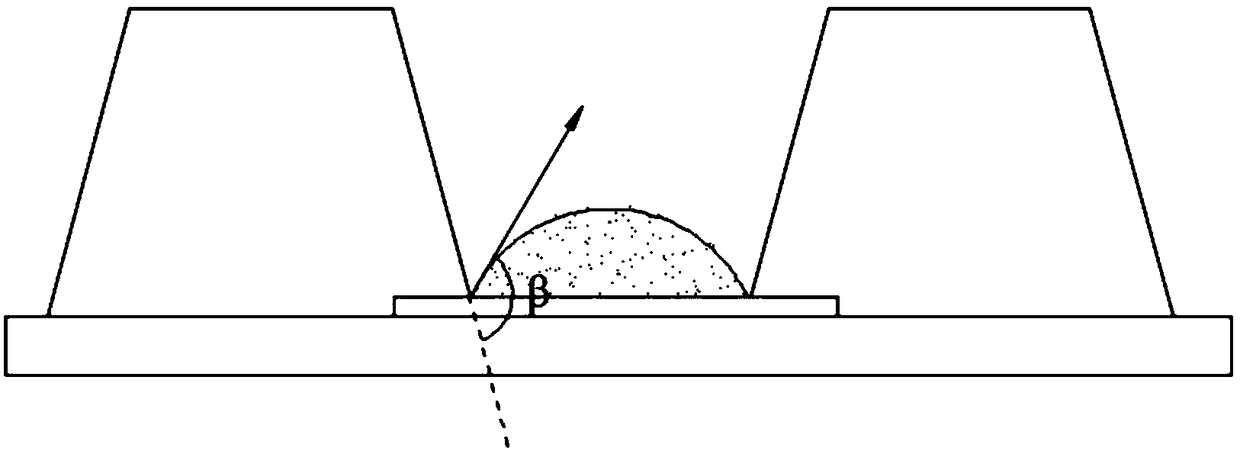

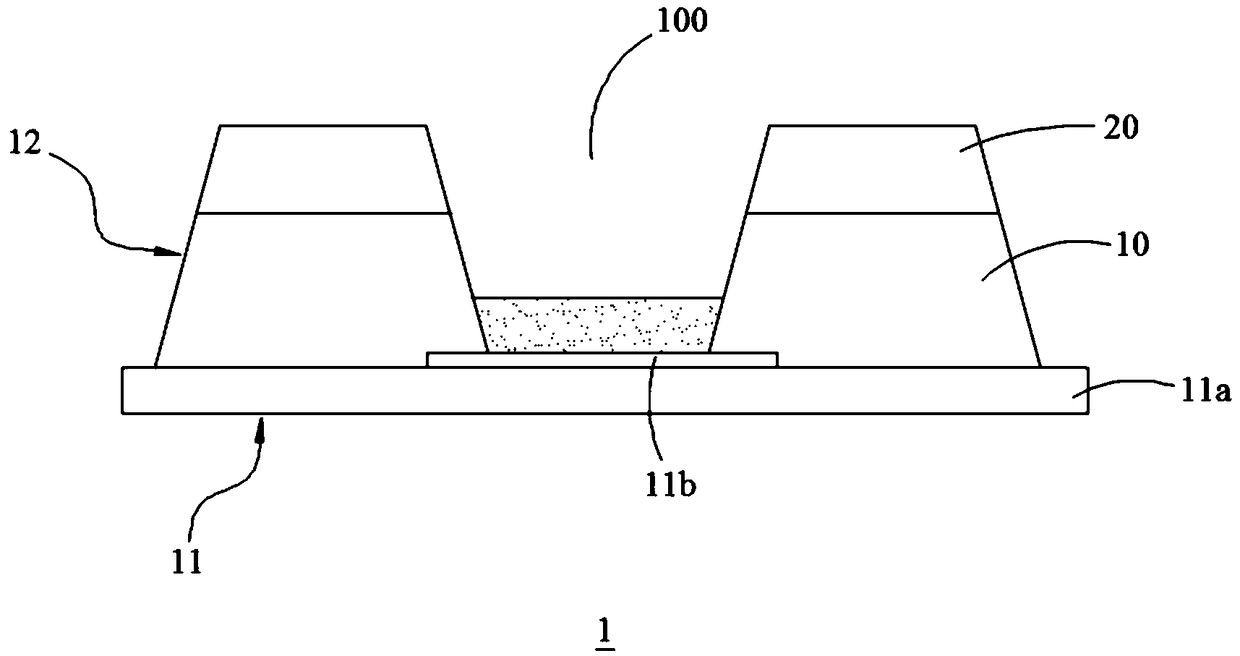

ActiveCN104659069AThe image shows a balanced center of gravityImprove yieldElectroluminescent light sourcesSolid-state devicesDisplay deviceOptoelectronics

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

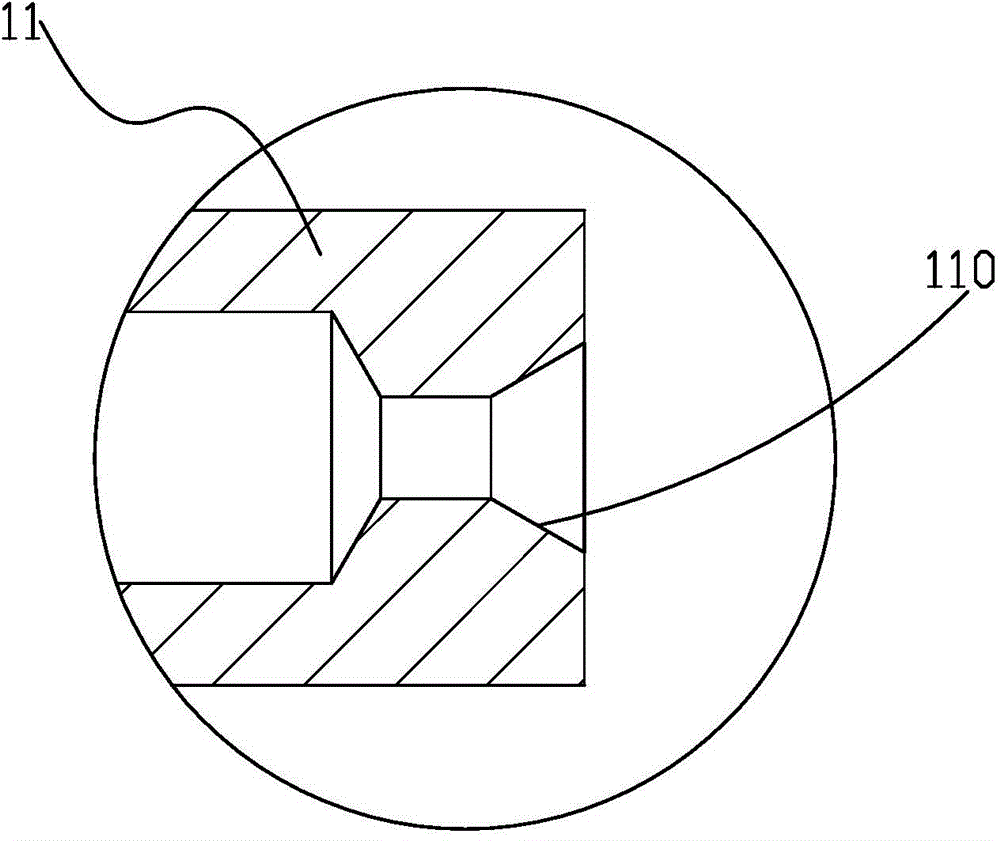

Pixel-defining structure and preparation method thereof, and OLED device

InactiveCN109148516AHydrophilicHydrophobicSolid-state devicesSemiconductor/solid-state device manufacturingCoffee ring effectComposition process

The invention provides a pixel-defining structure and a preparation method thereof, and an OLED device. The preparation method comprises the following steps: providing a substrate; forming a pixel defining film on the substrate by a composition process; performing surface treatment on the top of the pixel defining film to form a first pixel defining layer having hydrophilicity and a second pixel defining layer having hydrophobicity. In the pixel defining structure prepared by the preparation method provided by the inveniton, the first pixel defining layer of the pixel defining film has hydrophilicity, the second pixel defining layer is hydrophobic, such that the contact angle between the first pixel defining layer and the ink of the organic luminescent material is small, the contact anglebetween the second pixel defining layer and the ink of the organic luminescent material is large, so that the coffee ring effect can be reduced, an organic electroluminescent film with uniform film thickness can be formed, and since the second pixel defining layer has hydrophobicity, the ink of different organic luminescent materials can be prevented from flowing into adjacent pixel regions to cause color mixing, and the performance of the OLED device can be improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

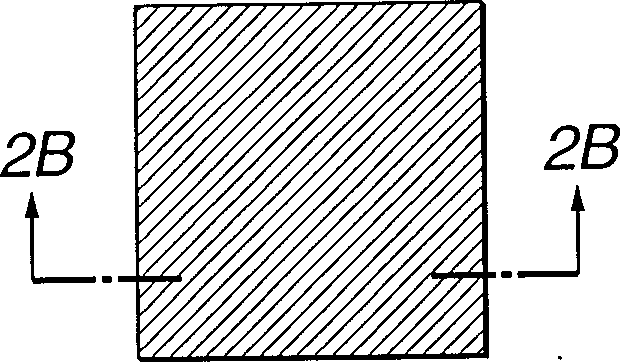

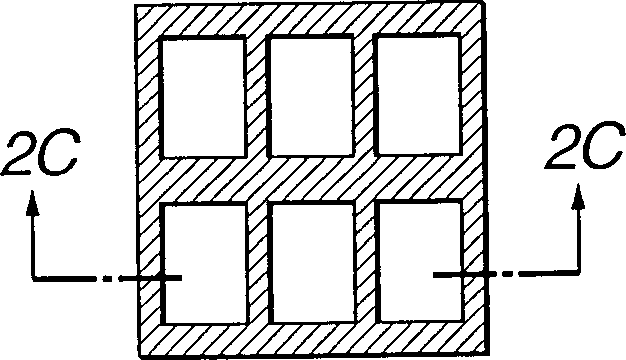

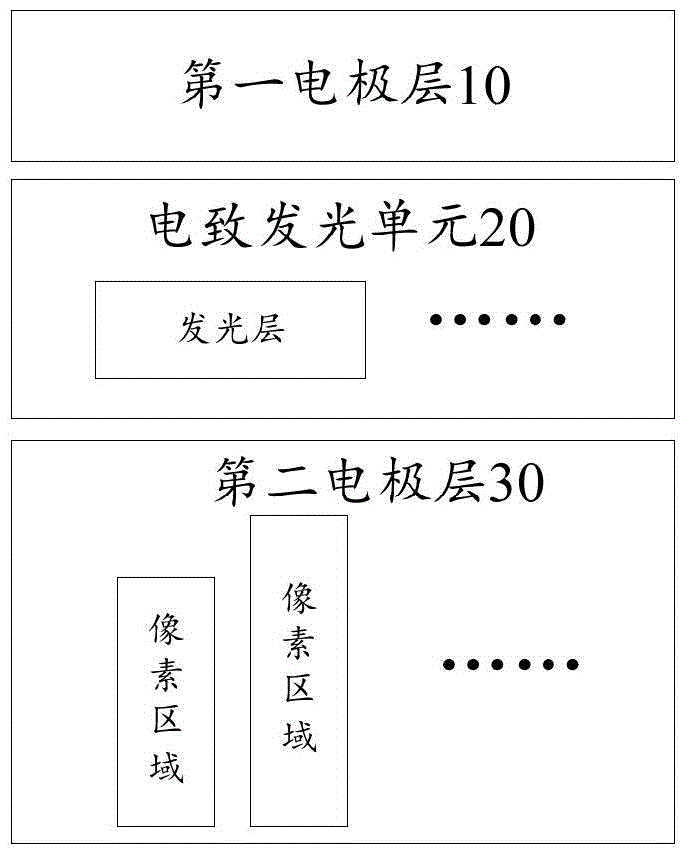

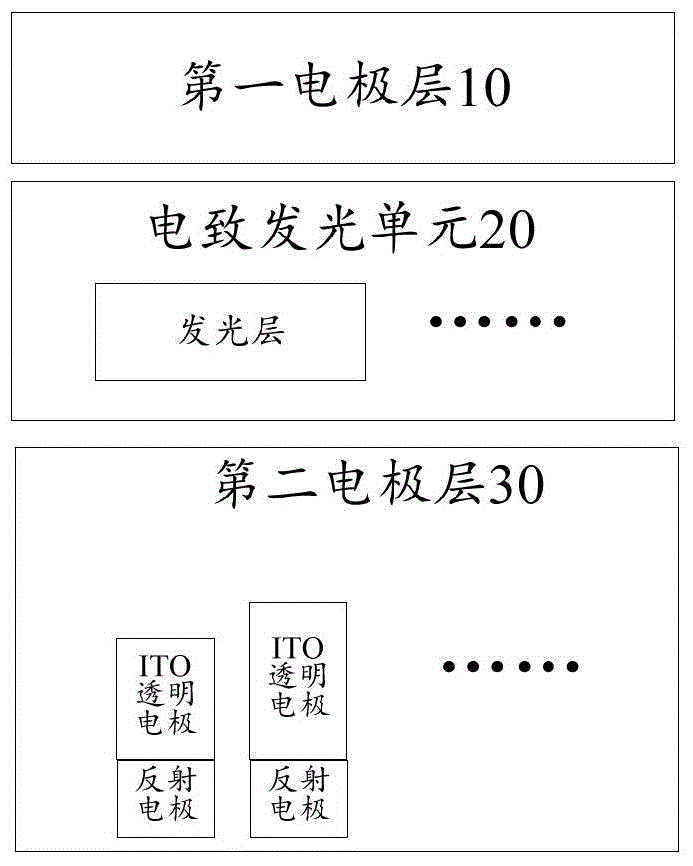

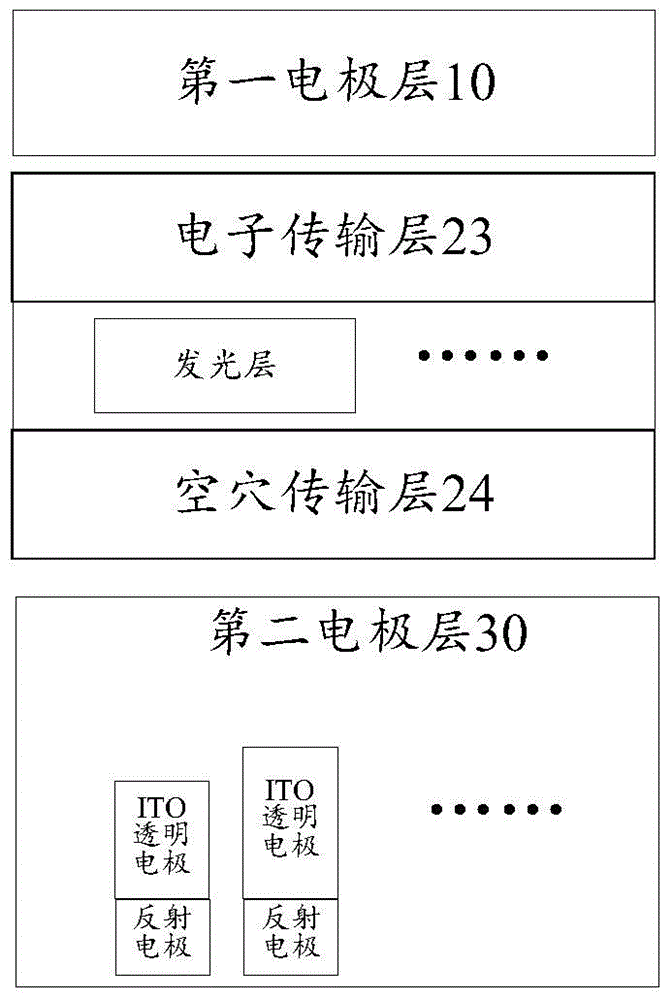

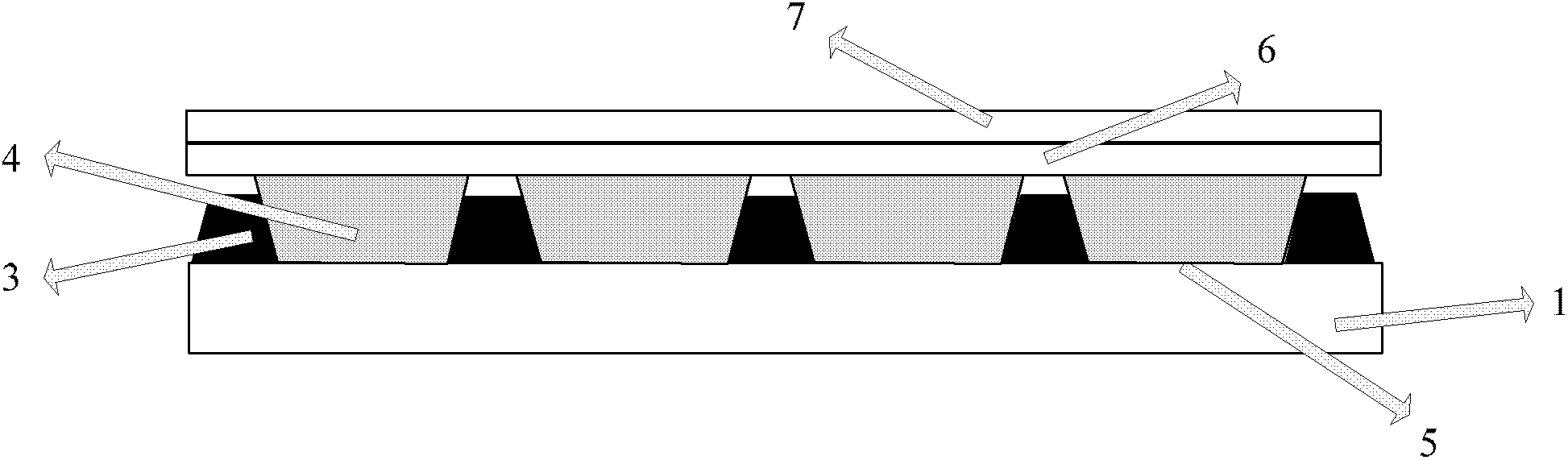

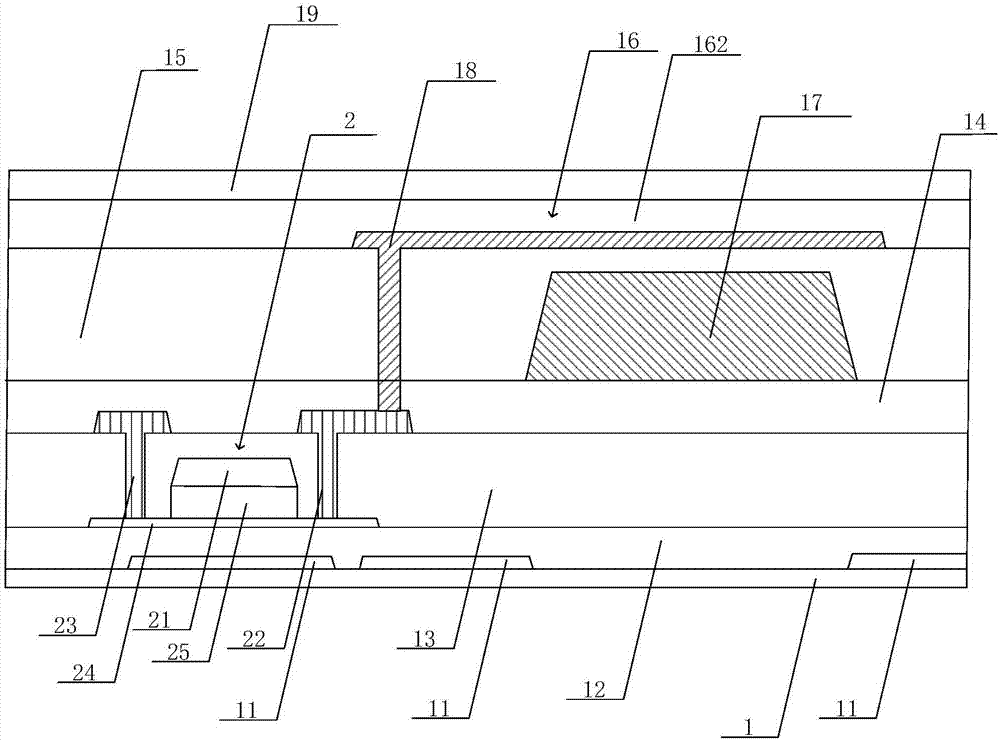

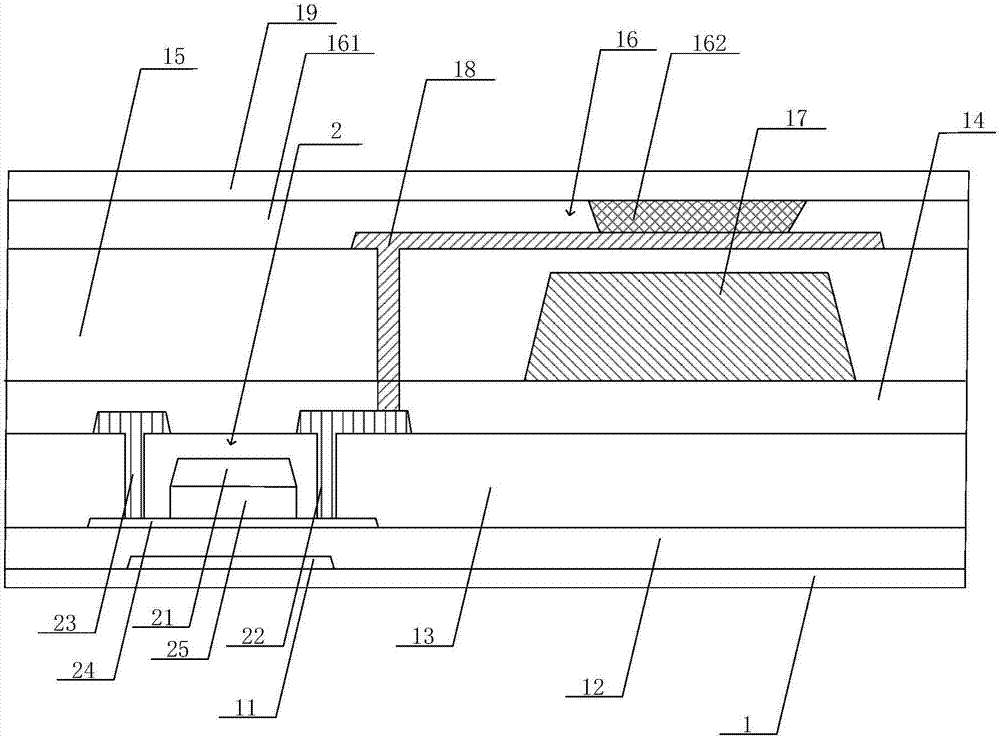

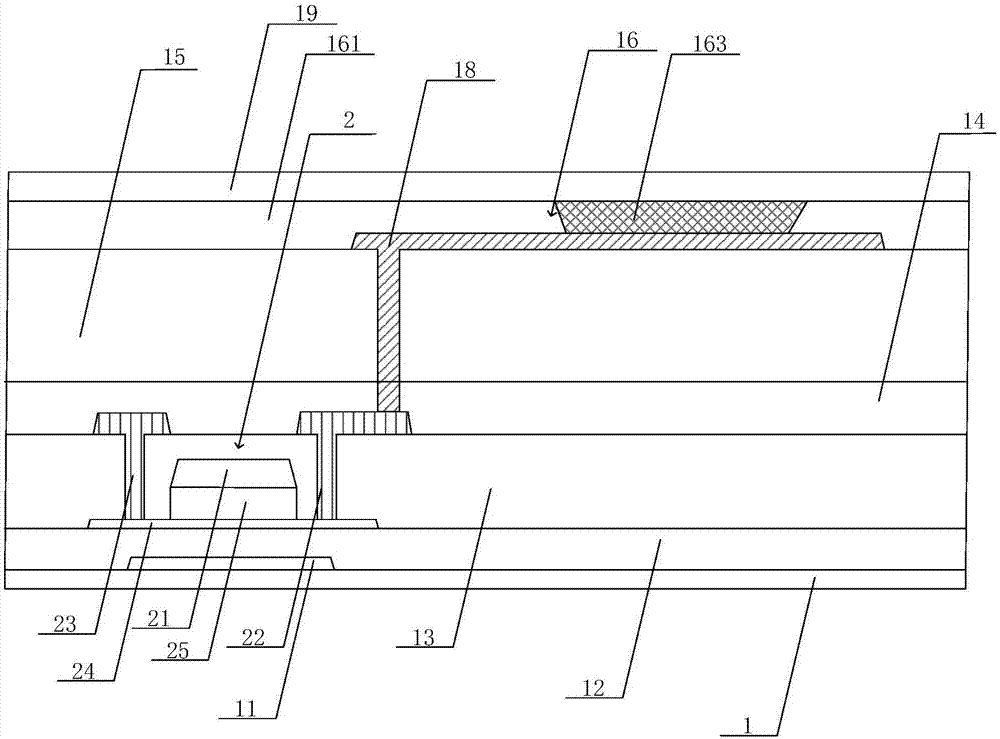

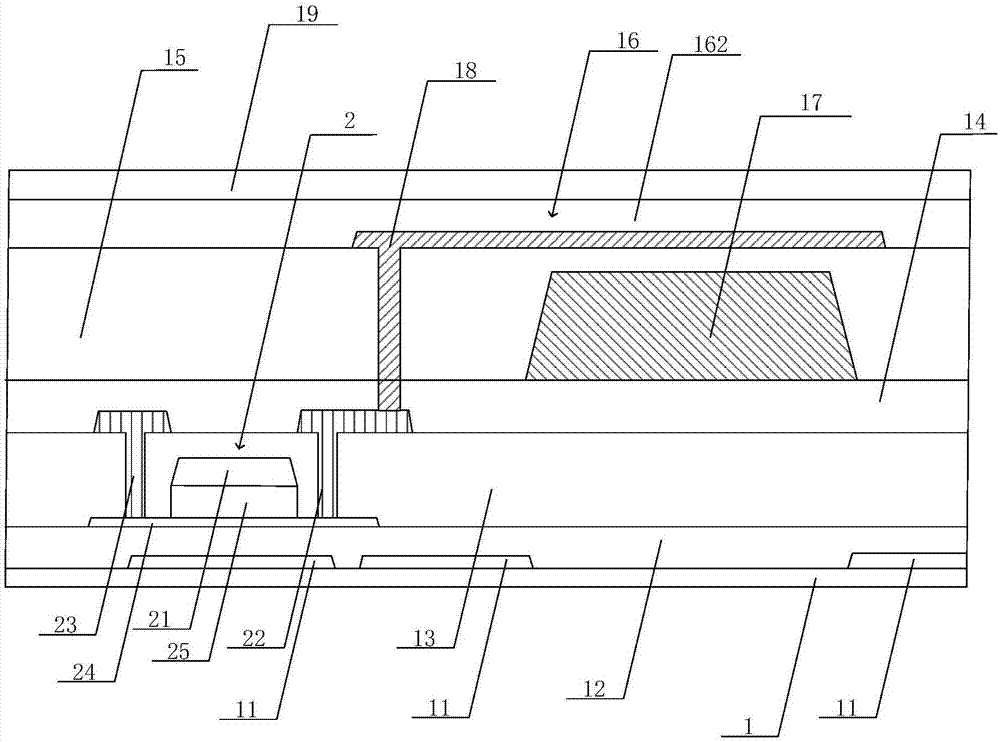

OLED (Organic Light Emitting Diode) unit, manufacturing method of OLED unit and display panel

InactiveCN104681736AAvoid color mixingReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingElectricityLight-emitting diode

The invention discloses an OLED (Organic Light Emitting Diode) unit, a manufacturing method of the OLED unit and a display panel and belongs to the technical field of display. The OLED unit comprises a first electrode layer, an electroluminescent unit and a second electrode layer, wherein the electroluminescent unit is located between the first electrode layer and the second electrode layer and comprises at least one luminous layer; each luminous layer corresponds to two pixel areas; the second electrode layer comprises the pixel areas; and each luminous layer is overlapped with the two pixel areas corresponding to a projection area in the second electrode layer. According to the unit, each luminous layer can correspond to the two pixel areas, the quantity of the luminous layers in the OLED unit is reduced, and the area of the luminous layers is increased, so that the alignment difficulty between the luminous layers and the pixel areas is reduced, and a color mixture phenomenon of the display panel is avoided.

Owner:BOE TECH GRP CO LTD

Color filter and manufacturing method thereof

InactiveCN102645691AAvoid color mixingIncrease brightnessOptical filtersNon-linear opticsColor filmTransmittance

The invention discloses a color filter and a manufacturing method thereof. The color filter is characterized in that white matrices are arranged on a substrate of the color filter; and color film layers are arranged in lattices partitioned by the white matrices. The color filter has the effect of improving the light transmittance, the brightness of the liquid crystal display and the backlight utilization efficiency.

Owner:BOE TECH GRP CO LTD

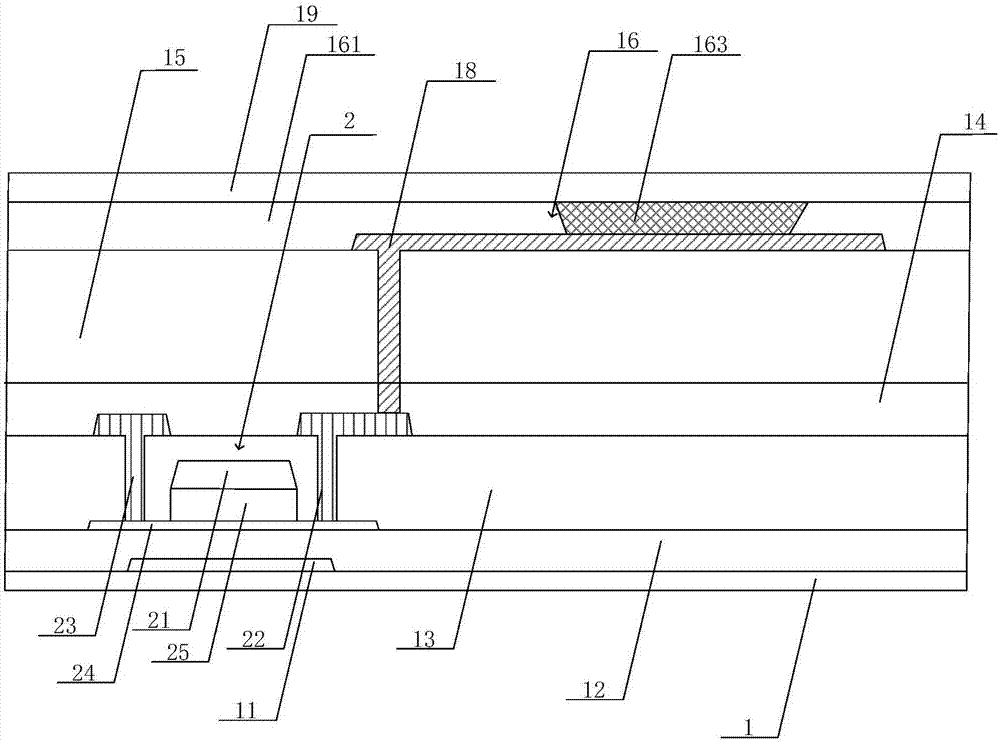

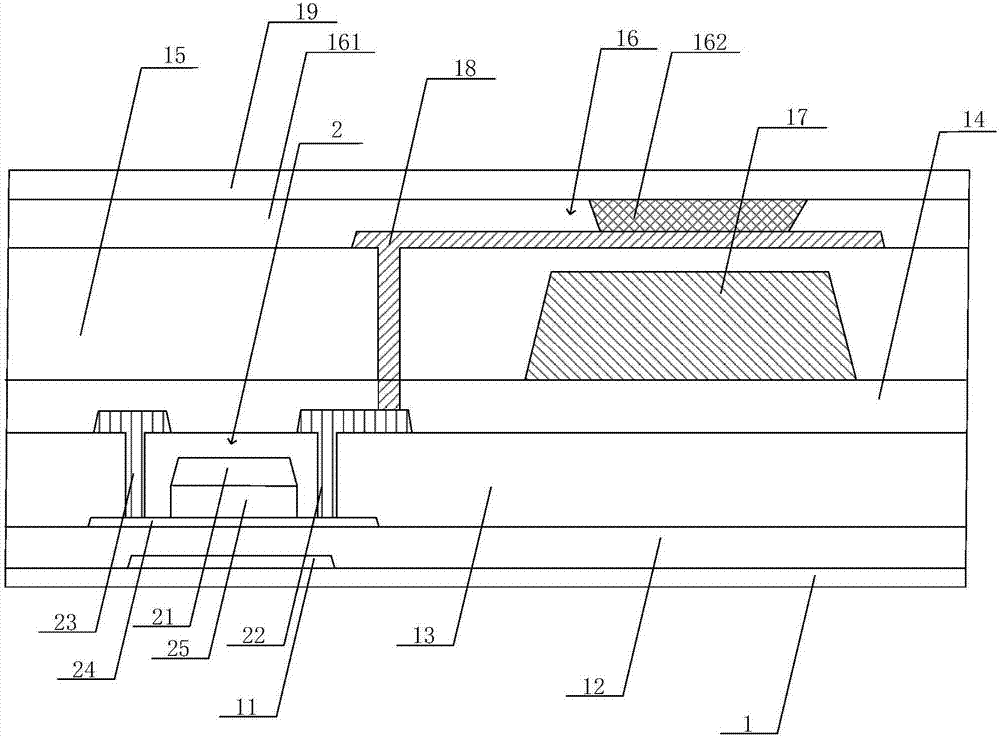

Display panel and method of manufacturing the same

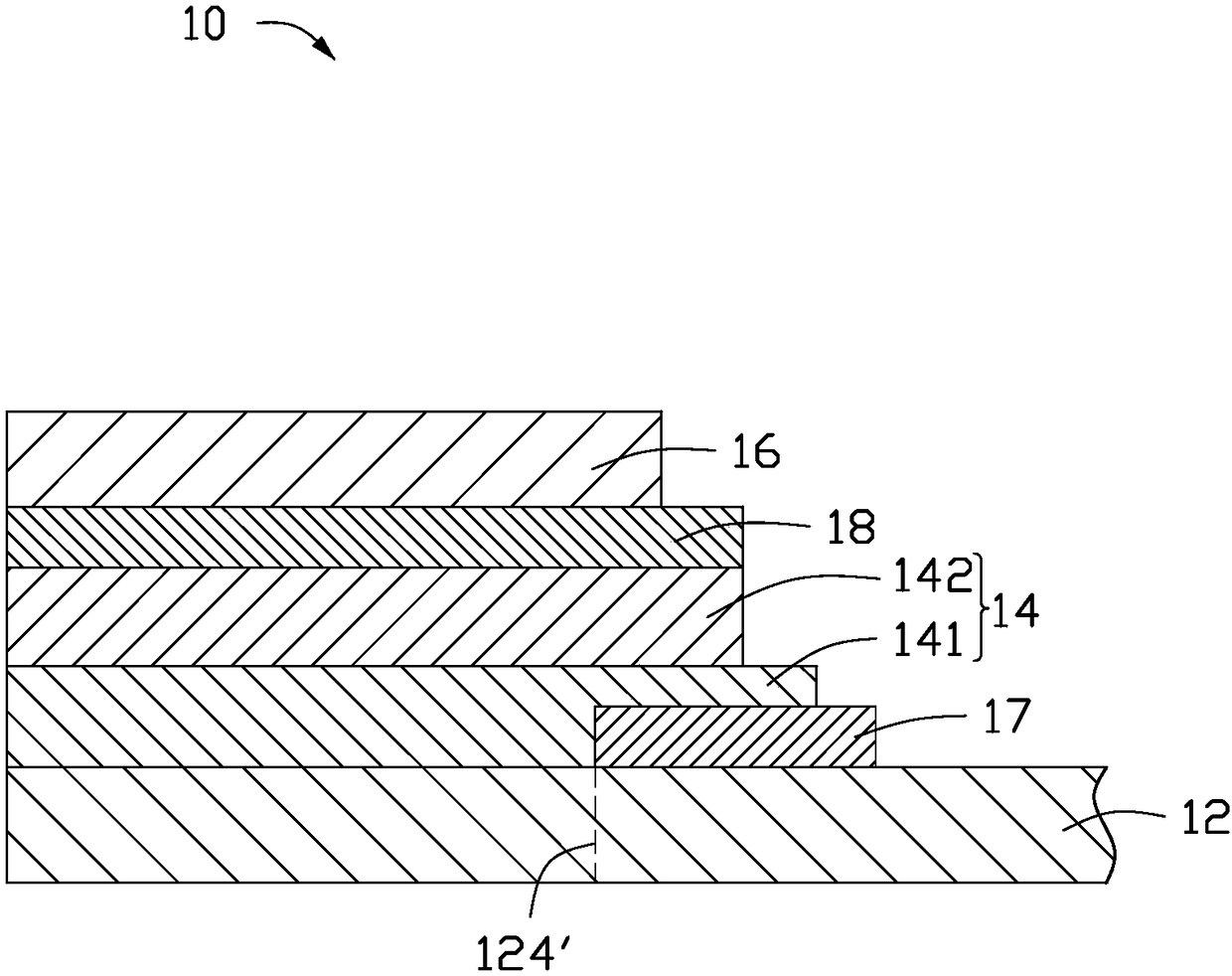

InactiveCN107154419AImprove protectionImprove the display effectSolid-state devicesSemiconductor/solid-state device manufacturingActive switchEngineering

The invention discloses a display panel and a method of manufacturing the same. The manufacturing method comprises: providing a substrate; forming an active switch on the substrate; forming a light emitting layer electrically connecting to the active switch on the active switch; and forming a passivation layer having a recessed part between the active switch and the light emitting layer; and filling a color photoresist layer aligned to the light emitting layer in the recessed part of the passivation layer. With the recessed part of the passivation layer, the color photoresist layer can be formed in the recessed part directly in a filing manner.

Owner:HKC CORP LTD +1

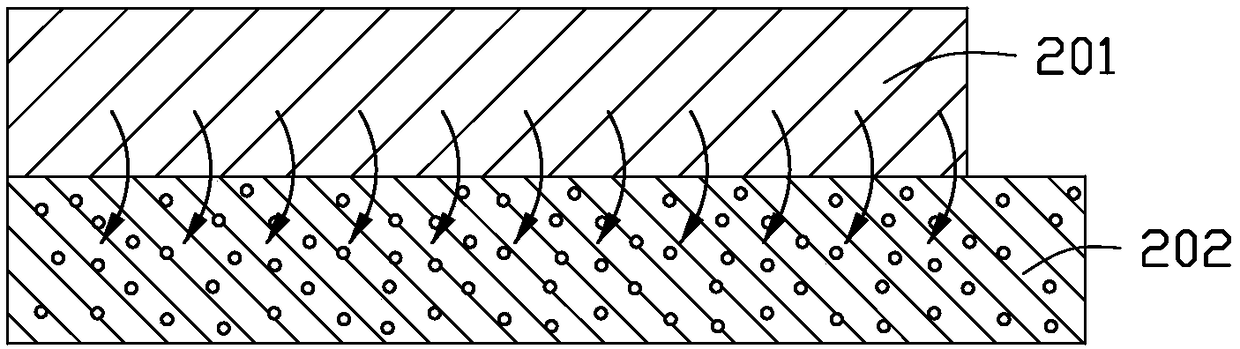

Display device using semiconductor light-emitting diode

ActiveCN110050511AIncrease brightnessIncreased durabilityElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

The present invention relates to a display device, and more particularly, to a display device using a semiconductor light-emitting diode. The display device according to the present invention comprises: a substrate having a wiring electrode formed thereon; a plurality of semiconductor light-emitting diodes electrically connected to the wiring electrode; an insulating layer provided to fill space between the semiconductor light-emitting diodes; a polarizing filter layer which is overlapped on the insulating layer and filters light incident into a specific direction; and a wavelength conversionlayer which is overlapped on the polarizing filter layer and provided to convert the wavelength of light.

Owner:LG ELECTRONICS INC

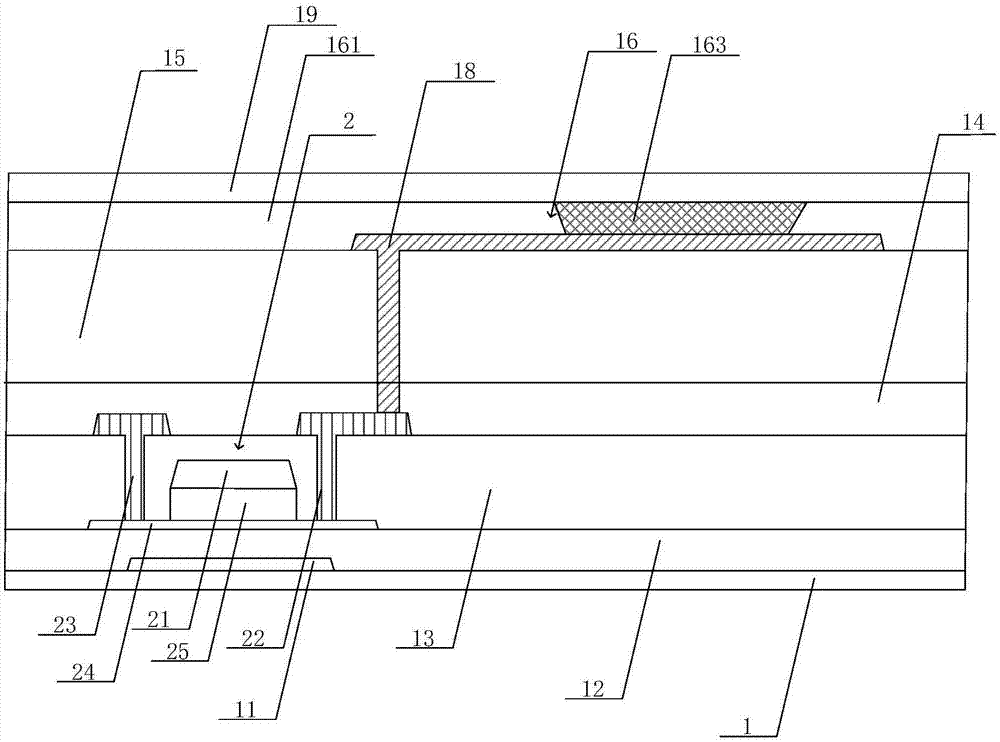

Display panel and manufacturing method thereof

InactiveCN107068717AImprove protectionImprove the display effectSolid-state devicesSemiconductor/solid-state device manufacturingActive switchEngineering

The invention discloses a display panel and a manufacturing method thereof. The manufacturing method comprises the steps of providing a substrate; forming an active switch on the substrate; forming a flat layer on the active switch, wherein the flat layer is provided with a pixel defining recess; and forming a light emitting layer in the pixel definition recess, wherein the light emitting layer is electrically connected to the active switch, so that display effects of a self-luminous display effect are well ensured.

Owner:HKC CORP LTD +1

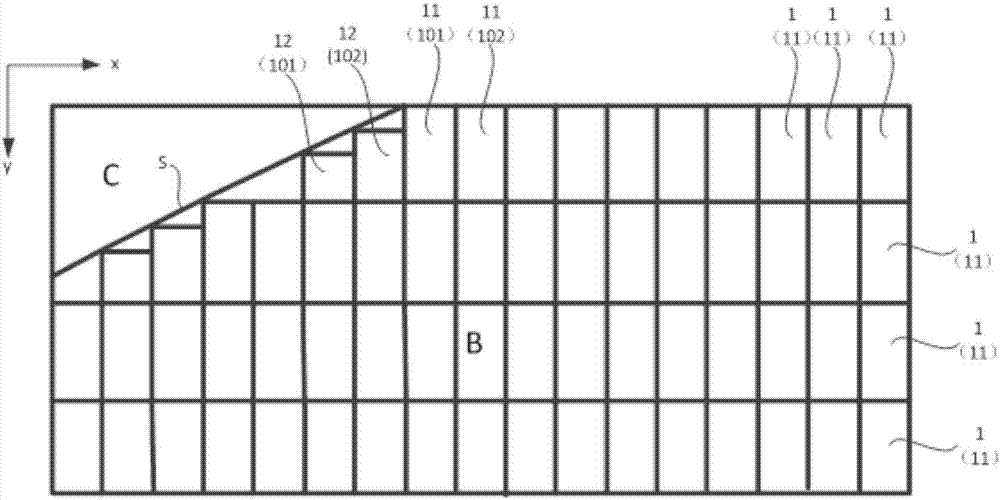

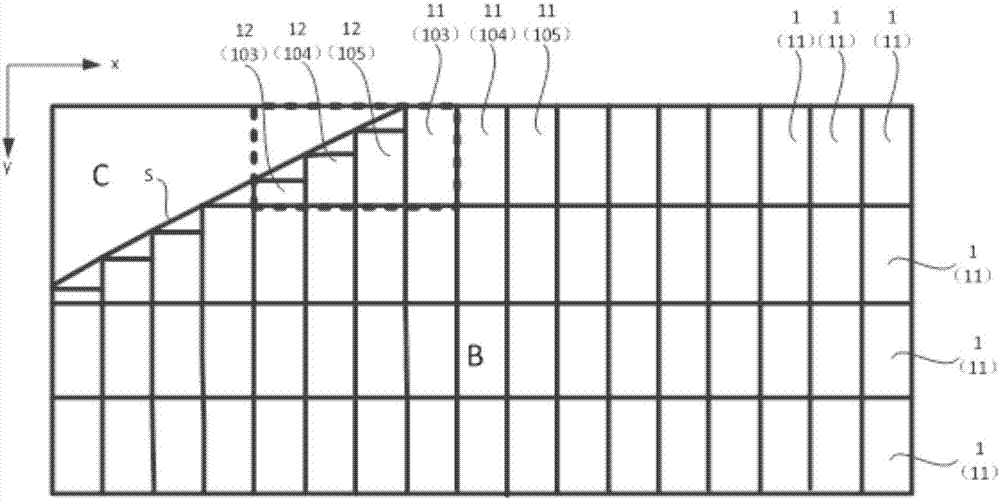

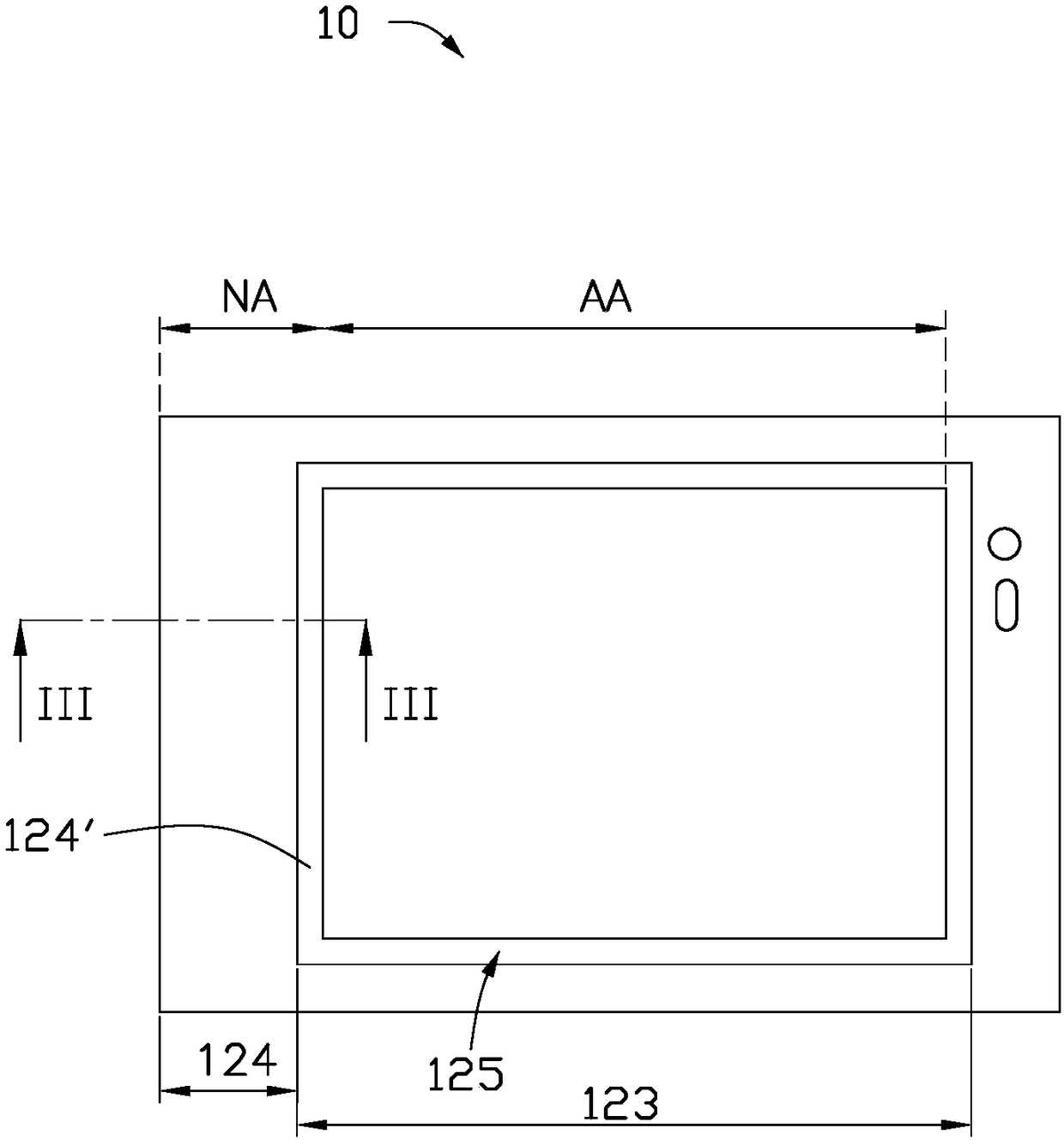

Display panel and display device

ActiveCN107505759AIncrease opening ratioDisplay edge boundaries are smoothNon-linear opticsInput/output processes for data processingDisplay deviceComputer science

The invention relates to the technical field of displaying, and discloses a display panel and a display device. The display panel is provided with a non-rectangular display area and a non-display area which surrounds the display area; the display panel comprises subsidiary pixels which are distributed in an array mode, and adjacent subsidiary pixels form pixel units in the line direction of the array; the subsidiary pixels comprise internal subsidiary pixels which are totally located in the display area and edge subsidiary pixels which are arranged along the edges of the display area and of which the aperture is smaller than that of the internal subsidiary pixels; light-shading strips are arranged between each edge subsidiary pixel and the corresponding subsidiary pixel adjacent to the edge subsidiary pixel in the line direction, and extend in the line direction of the array. The display panel can improve the continuity of the non-rectangular display panel of displaying information and the gentleness of the display edge limit, and the occurrence of edge color mixing and color deviation can be avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

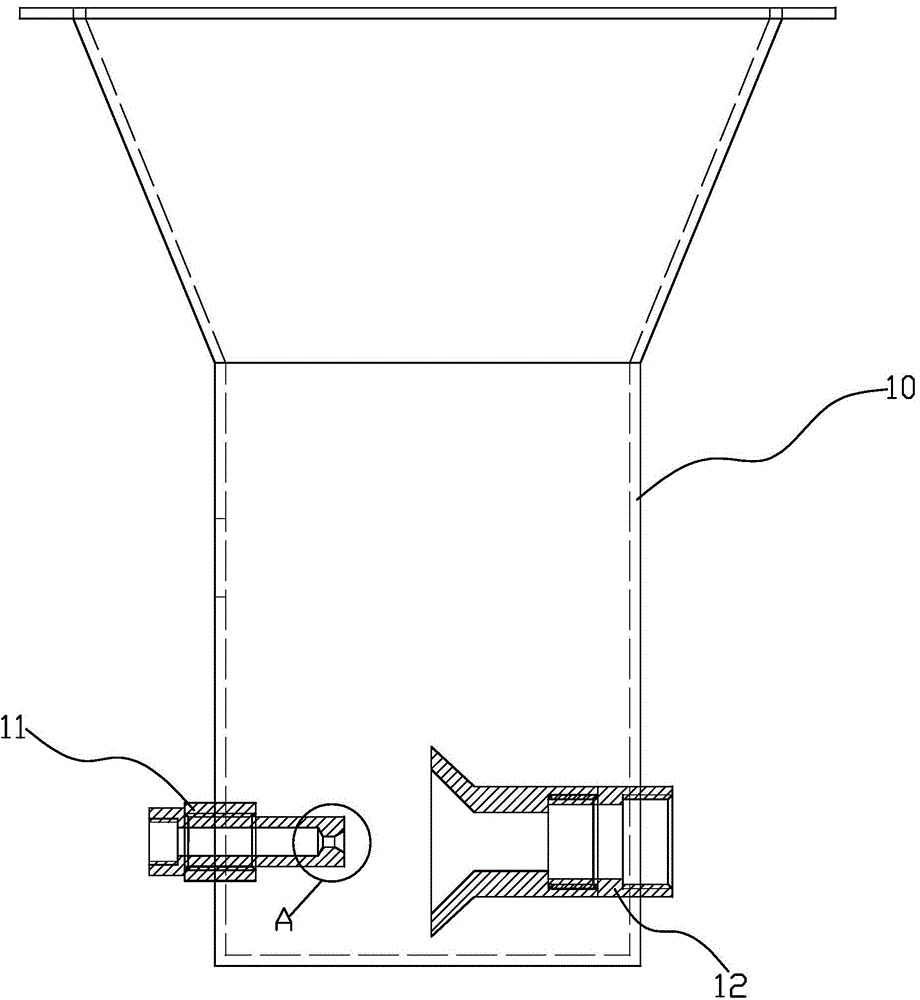

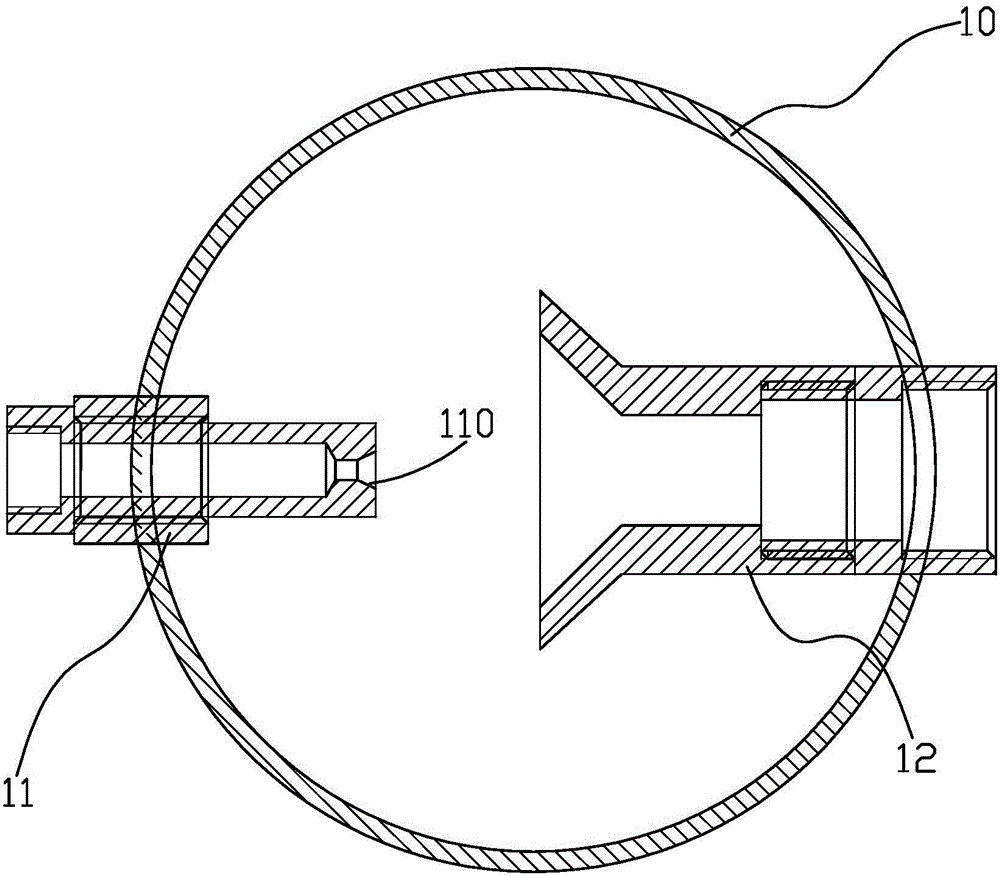

Powder pump structure used for powder spraying production line

InactiveCN104874501AQuick changeThe process of cleaning powder is simple and convenientLiquid spraying apparatusEngineeringColor mixing

The invention discloses a powder pump structure used for a powder spraying production line. The powder pump structure comprises a hopper used for storing sprayed powder, one side wall of the bottom of the hopper is provided with an air nozzle connected with an external air inlet pipe, and the other side wall of the bottom of the hopper opposite to the air nozzle is provided with a powder outlet pipe used with the air nozzle. When different colors of powder are replaced, air can enter from the upper portion of the hopper to blow off powder accumulated in the hopper, and air can blow from the air nozzle to the powder outlet pipe so as to clean powder of the air nozzle and the powder outlet pipe. The integral powder cleaning process is simple, quick and convenient and is good in cleaning effect, and different colors of powder can be quickly realized. Meanwhile, color mixing can be avoided to the greatest extent, and social competitive powder of enterprises is greatly enhanced.

Owner:ZHONGSHAN JUNHE ELECTRO MECHANICAL APP

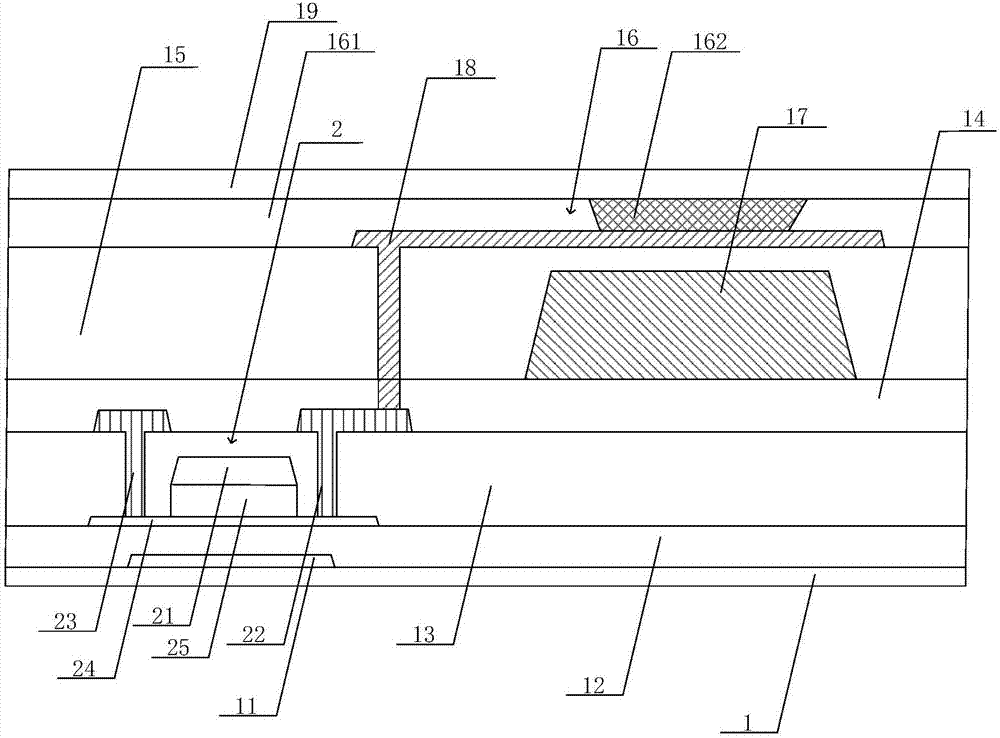

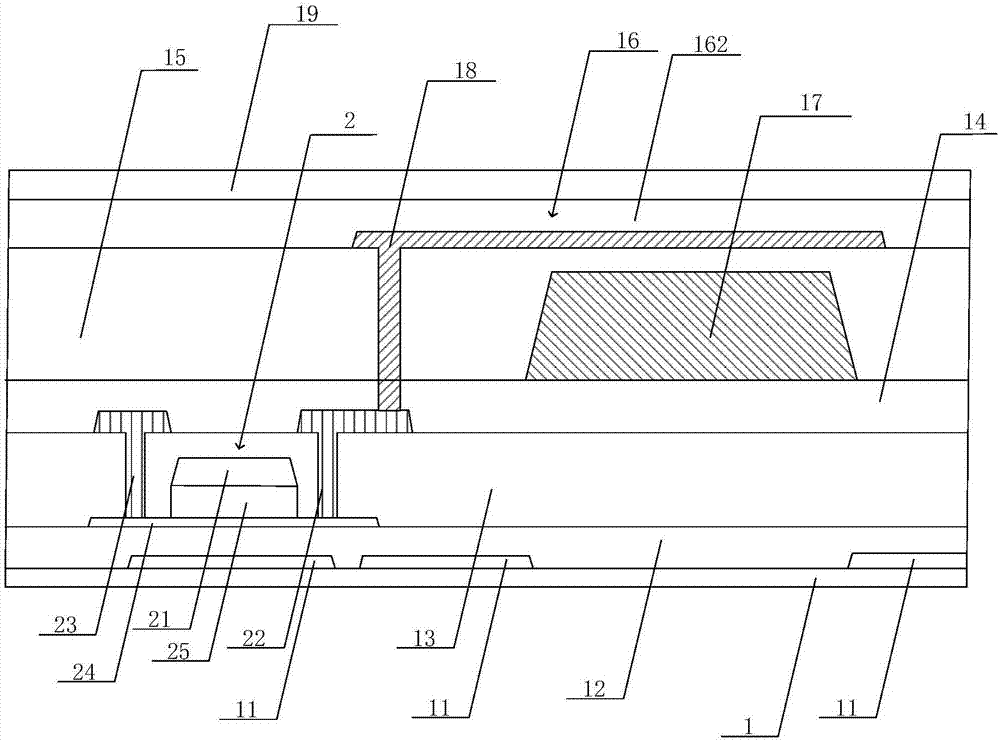

Display panel and manufacturing method thereof

InactiveCN107170899AImprove protectionImprove the display effectSolid-state devicesSemiconductor/solid-state device manufacturingActive switchEngineering

The invention discloses a display panel and a manufacturing method thereof. The manufacturing method comprises the steps of: providing a substrate; forming an active switch on the substrate; forming a light emitting layer on the active switch, and electrically connecting the light emitting layer to the active switch; forming a flat layer between the active switch and the light emitting layer, wherein the flat layer is provided with a through hole; and, filling a colourful photoresist layer in the through hole of the flat layer, wherein the colourful photoresist layer is aligned to the light emitting layer. Thereby, the display effect of a self-light-emitting display panel can be well ensured.

Owner:HKC CORP LTD +1

A process for making color filter

InactiveCN1523381AHigh color reproductionAvoid interminglingPhotomechanical apparatusNon-linear opticsResistColor gel

The invention discloses a color optical filter making method, depending on the method to form photoresist or insulating space substance in non-pixel region, and avoiding the color relative permeation and mix phenomenon of other adjacent colorizing materials, so as to make the color optical filter with good color reappearance and color resolution. It includes: forming an interbedded insulating layer on a basal plate; forming many scanning lines and many signal lines on the interbedded insulating layer to define many pixel regions and a non-pixel region; forming a photoresist or insulating layer on the interbedded insulating layer; composing a picture of the photoresist or insulating layer to form photoresist or insulating space substance in the non-pixel region; and using spray-ink method to project a colorizing material in many pixel regions.

Owner:TPO DISPLAY

Flexible color filter substrate using phase-change ink, and method for manufacturing same

ActiveCN103797562AAvoid color mixingReduce light leakageSemiconductor/solid-state device manufacturingNon-linear opticsColor gelEngineering

Owner:LG CHEM LTD

Protective cover plate and electronic device applying same

ActiveCN108323056AAvoid color mixingColor mixing will not causeCasings/cabinets/drawers detailsTelephone set constructionsEngineeringSemi transparent

Owner:INTERFACE TECH CHENGDU CO LTD +2

Color filter and manufacturing method thereof

InactiveCN102778714AAvoid large gapsAvoid light leakageOptical filtersPhotomechanical apparatusEngineeringColor filter array

The invention discloses a color filter and a manufacturing method thereof, wherein color filter areas are arranged on a substrate at intervals in order, the area of the bottom surface of each color filter area which contacts with the substrate is caused to be less than that of the contacted top surface which does not contact with the substrate, and grid-shaped openings are formed between the adjacent color filter areas respectively; and black matrixes which are closely connected with the adjacent color filter areas are formed in the openings respectively by a back-face exposure method. The surface evenness of the color filter is effectively improved; and moreover, the finally-formed black matrixes are closely connected with the adjacent color filter areas, so that the phenomena of light leak and color mixing caused by the imprecise alignment of photo masks during exposure are prevented.

Owner:BOE TECH GRP CO LTD

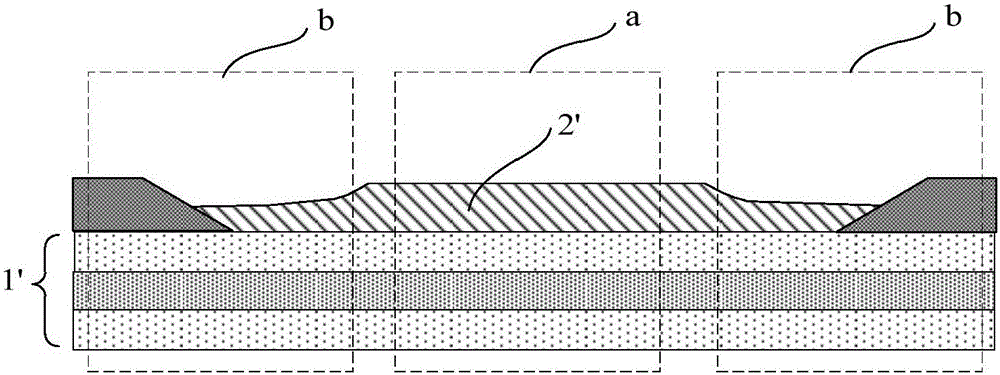

Color film base plate and preparation method thereof

ActiveCN107861285APrevent color mixing functionPrevent protrudingNon-linear opticsColor filmEngineering

The invention provides a color film base plate and a preparation method thereof. The color film base plate comprises a base plate, colorful color resistances prepared on the surface of the base plate,and baffle walls prepared on the surface of the base plate and defines corresponding area of the colorful color resistances. Each of the baffle walls of different colors among the colorful color resistances at least comprises a first sub-baffle wall and a second sub-baffle wall which are parallel to each other and oppositely installed, the first sub-baffle wall has first predetermined close and distant liquidity, and the second sub-baffle wall has second predetermined close and distant liquidity; so as to solve the problem of color mixture and color deviation of a display panel when the colorful color resistances are printed.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

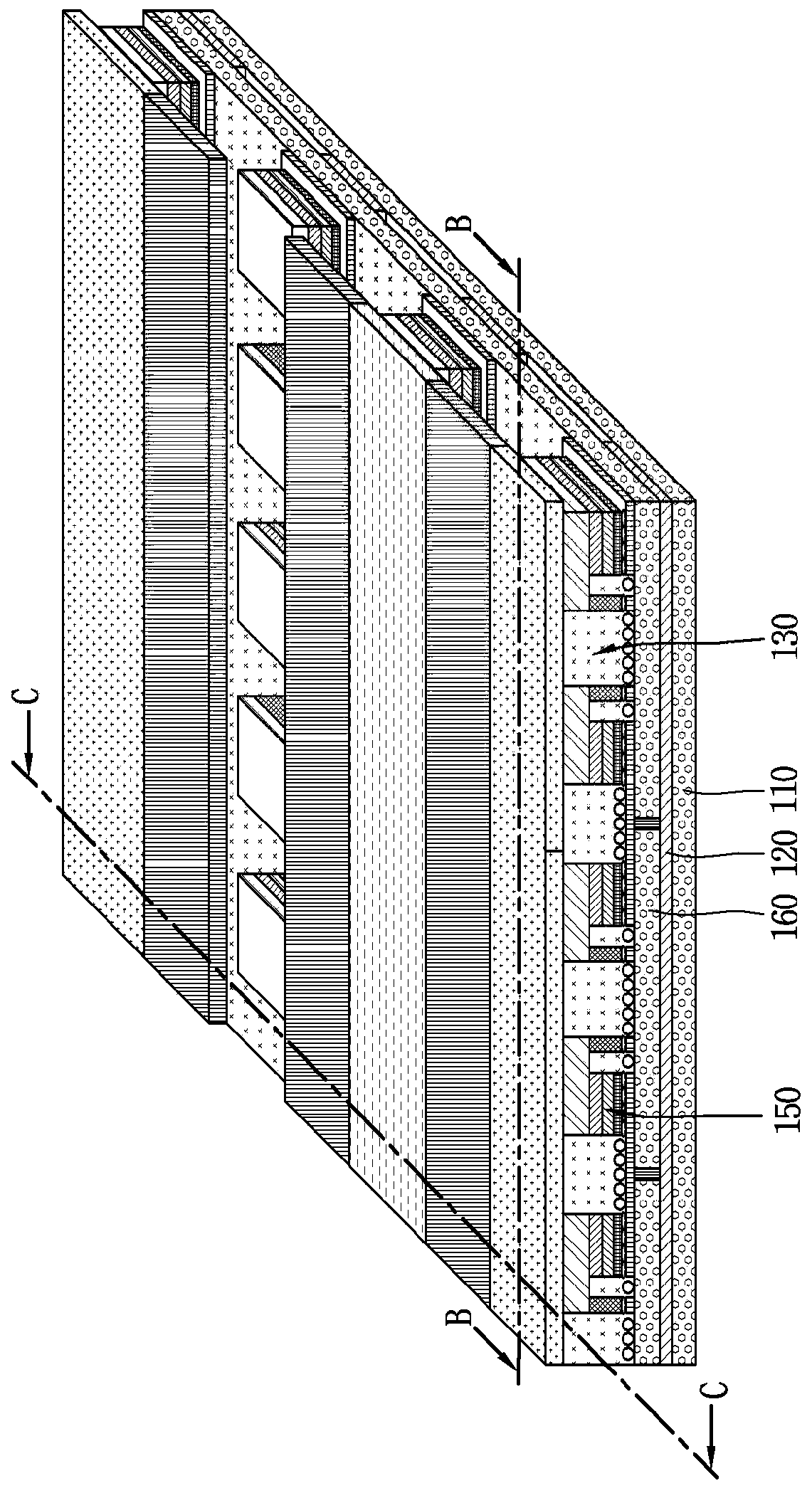

OLED backboard and manufacturing method thereof, and display device

ActiveCN105977396AAvoid color mixingUniform luminanceFinal product manufactureSolid-state devicesDisplay deviceEngineering

The invention provides an OLED backboard and manufacturing method thereof, and a display device. The OLED backboard includes a substrate and a plurality of organic light-emitting diodes formed on the substrate, each organic light-emitting diode includes a bottom electrode, a top electrode, and organic luminescent materials between the bottom electrode and the top electrode, the thickness of the bottom electrode at the first edge area of the corresponding organic light-emitting diode is greater than that of the central area of the organic light-emitting diode, so that the conductive capability of the first edge area of the bottom electrode is enhanced, and the brightness of the organic luminescent materials at the first edge area is improved, the brightness of the organic light-emitting diodes at the first edge area and the central area is uniform, the OLED color mixing can be prevented, and the display quality of the OLED display device at a large visual angle can be effectively improved.

Owner:BOE TECH GRP CO LTD +1

Display panel and manufacturing method thereof

PendingCN108037609AAvoid accumulationAvoid the mura phenomenonNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a display panel and a manufacturing method thereof. The display panel comprises substrates comprising the first substrate and the second substrate which are disposed oppositely, a black matrix layer formed on the first substrate, alignment layers formed on the black matrix layer and the second substrate, a color filter layer formed on the first substrate or the second substrate, a liquid crystal layer formed between the first substrate and the second substrate, and an active switch formed on the second substrate; at least one groove is formed in the black matrix layer;a light shielding layer is arranged at the position, corresponding to the first substrate, on the grooves, and an orthographic projection area of the light shielding layer on the first substrate completely covers orthogonal projection areas of the grooves in the first substrate. Through arrangement of the grooves in the black matrix layer, the influence of the alignment layers on the liquid crystal layer is effectively reduced, the phenomenon that uneven brightness of the display panel causes various traces when the display panel is lighted is effectively prevented, and the light shielding layer can effectively prevent light leakage at the grooves of the black matrix layer.

Owner:HKC CORP LTD

Roller coater

ActiveCN100591426CSolve the problem of coating qualityRealize online maintenance and color changeLiquid surface applicatorsCoatingsLacquerMechanical engineering

The invention provides a roller machine suitable for coating chemical coating, which is characterized in that the roller machine comprises two sets of coating mechanism arranged top to top, a supportroller mechanism, a turning roller component, a frame, a synchronous mechanism, a shower, a back-coated lifting device and a transmission mechanism. Back coating frames of a coating roller device, a reclaiming roller device and a regulating roller device fitted with specially made polyurethane material are driven by an oil cylinder and synchronous lifting at both sides is assured by the synchronous mechanism in the coating mechanism; clearance among the coating roller device, the reclaiming roller device and the regulating roller device is regulated by the regulating mechanism to regulate coating thickness. The shower line is in a lacquer tray of a front coating mechanism and a flat mouth shower with a valve is arranged on the shower line; flow rate of the paint is controlled and coating thickness is adjusted by regulating the valve. Jet tube mode is adopted in the lacquer tray of a bottom roller in the back coating mechanism; paint is agitated to prevent from deposition. The roller machine has the advantages that double-roller coating structure is adopted and one is used and the other is standby, maintenance and exchanging color are carried out online, time is saved and productivity is improved.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH +1

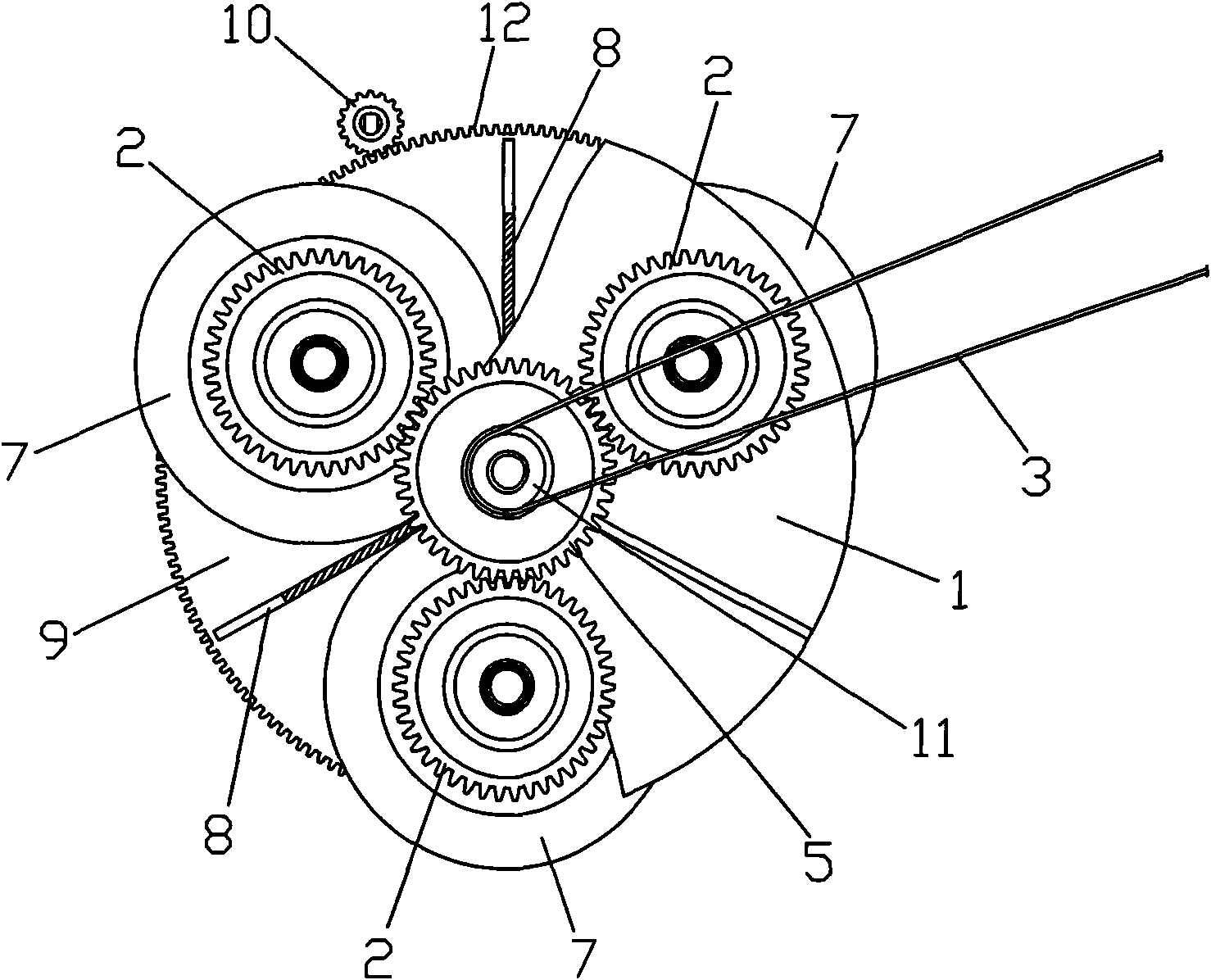

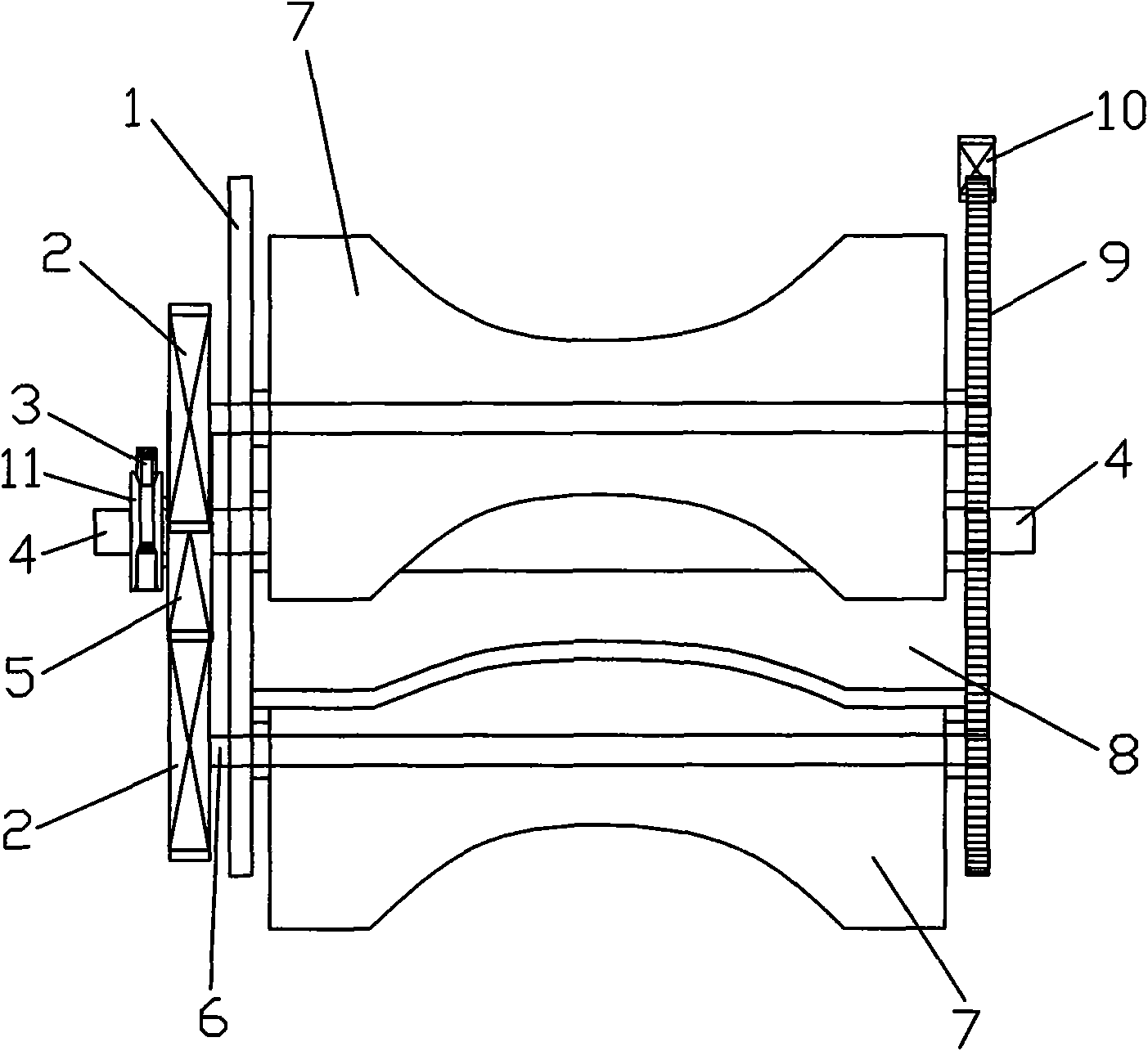

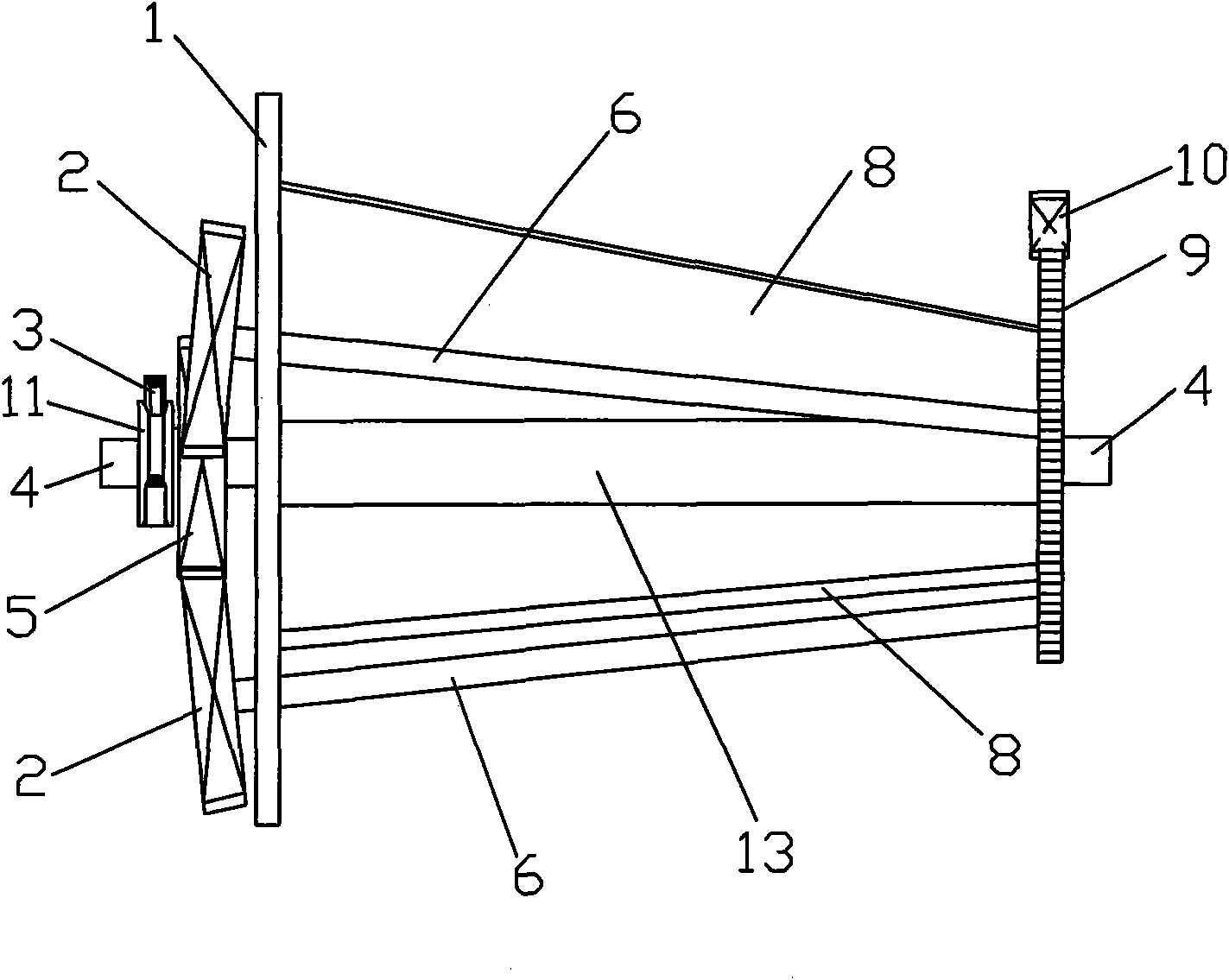

U-shaped roller device with tri-color shoe polish brushes and for automatic shoe polisher

The invention discloses a U-shaped roller device with tri-color shoe polish brushes and for an automatic shoe polisher. The device is applied to the automatic shoe polisher and comprises a roller formed by round left and right side plates arranged parallel. A principal axis simultaneously penetrates the circle centers of the left side plate and the right side plate. Three division plates are arranged between the left side plate and the right side plate at an interval angle of 120 degrees. The division plates divide the roller into three equal cavities, one of which is provided with a brush inside. The middle of the brush is provided with a joint axis. The left and right ends of the joint axis are respectively matched with the left side plate and the right side plate. The roller device effectively gathers the shoe polish brushes in three colors. The division plates are arranged between the brushes, thus playing roles of separation and preventing brush color contamination. When the colors are required to be changed, the roller is only rotated to enable the brushes in the corresponding colors to face the working face. The structure diminishes the volume and simultaneously reduces theflying dust effectively. The product structure is simplified.

Owner:SHENZHEN XUNFENG TECH

A textile production line

ActiveCN111235797BReduce manufacturing costImprove production yieldTextile treatment machine arrangementsTextile treatment cleaning apparatusProcess engineeringTextile production

The invention discloses a textile production line. The textile production line comprises a workbench, wherein a bottom plate is arranged below the workbench; the top surface of the bottom plate is fixedly connected with the workbench through a plurality of vertical rods; a cleaning box is fixedly installed on the top surface of the bottom plate; a plurality of cleaning brush rollers are installedon the cleaning box; and a power device is connected to rotating shafts of the cleaning brush rollers. The textile production line is reasonable in structural design and convenient to use, dye can becollected, the production cost of a manufacturer is saved, the production benefit of the manufacturer is improved, the textile fabric can be dried, the dye tainted on a belt can be cleaned, attachingof the dye to subsequent textile fabric is avoided, color mixing can be prevented, and the textile fabric looks more attractive; and in addition, the machine can run slowly without stopping in the drying process of the textile fabric, and the textile fabric is not lost.

Owner:东营市中信同创石油科技有限公司

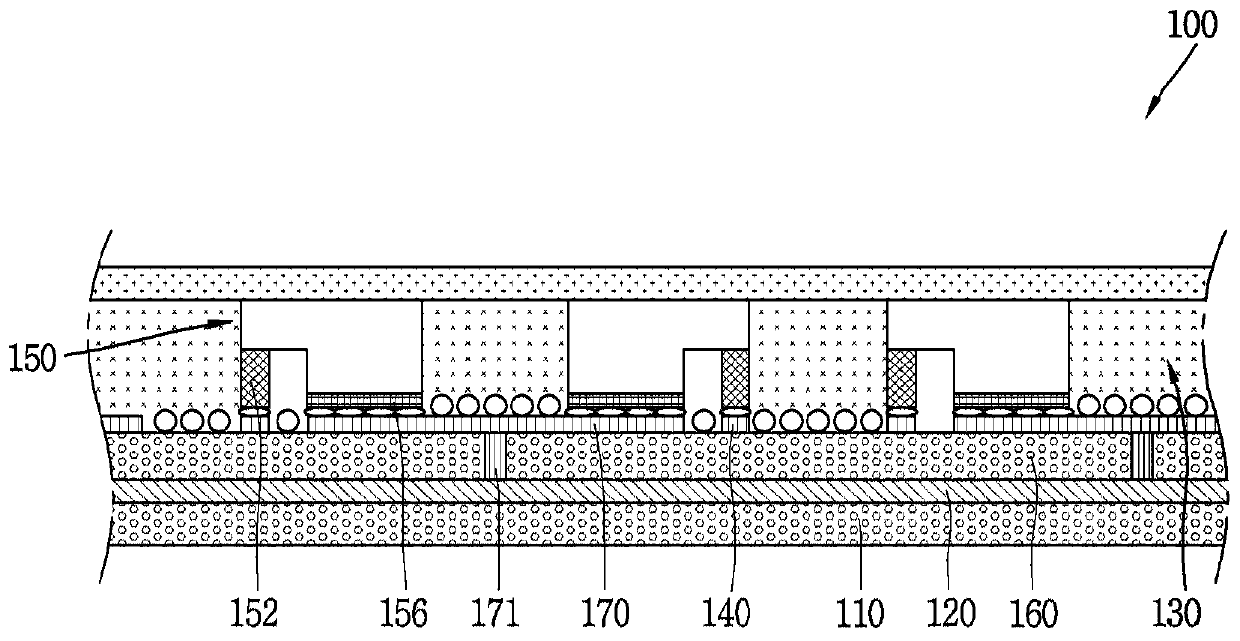

Display panel and manufacturing method thereof

InactiveCN111668283AAvoid color mixingImprove the display effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringColor mixing

The invention discloses a display panel and a manufacturing method thereof. The display panel comprises an array substrate, an anode layer located on the array substrate, a shading layer located on the anode layer and a cathode layer located on the shading layer, wherein the shading layer comprises a plurality of first shading units and a plurality of second shading units, the first shading unitsare perpendicular to the second shading units, and the second shading units are located between every two adjacent first shading units; the two adjacent second shading units and the two adjacent firstshading units form an opening, the anode layer is exposed through the opening, and the opening is filled with a light emitting unit, wherein the thickness of the second shading unit is smaller than that of the first shading unit, and the thickness of the second shading unit is larger than or equal to that of the light-emitting unit. According to the invention, the shading layer is formed by usingthe shading material to form a pixel definition layer, so that the color mixing phenomenon among the light-emitting units with different colors is avoided, and the display effect is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com