U-shaped roller device with tri-color shoe polish brushes and for automatic shoe polisher

An automatic wiping and brushing technology, which is applied to household cleaning devices, cleaning of boots and shoes, cleaning equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

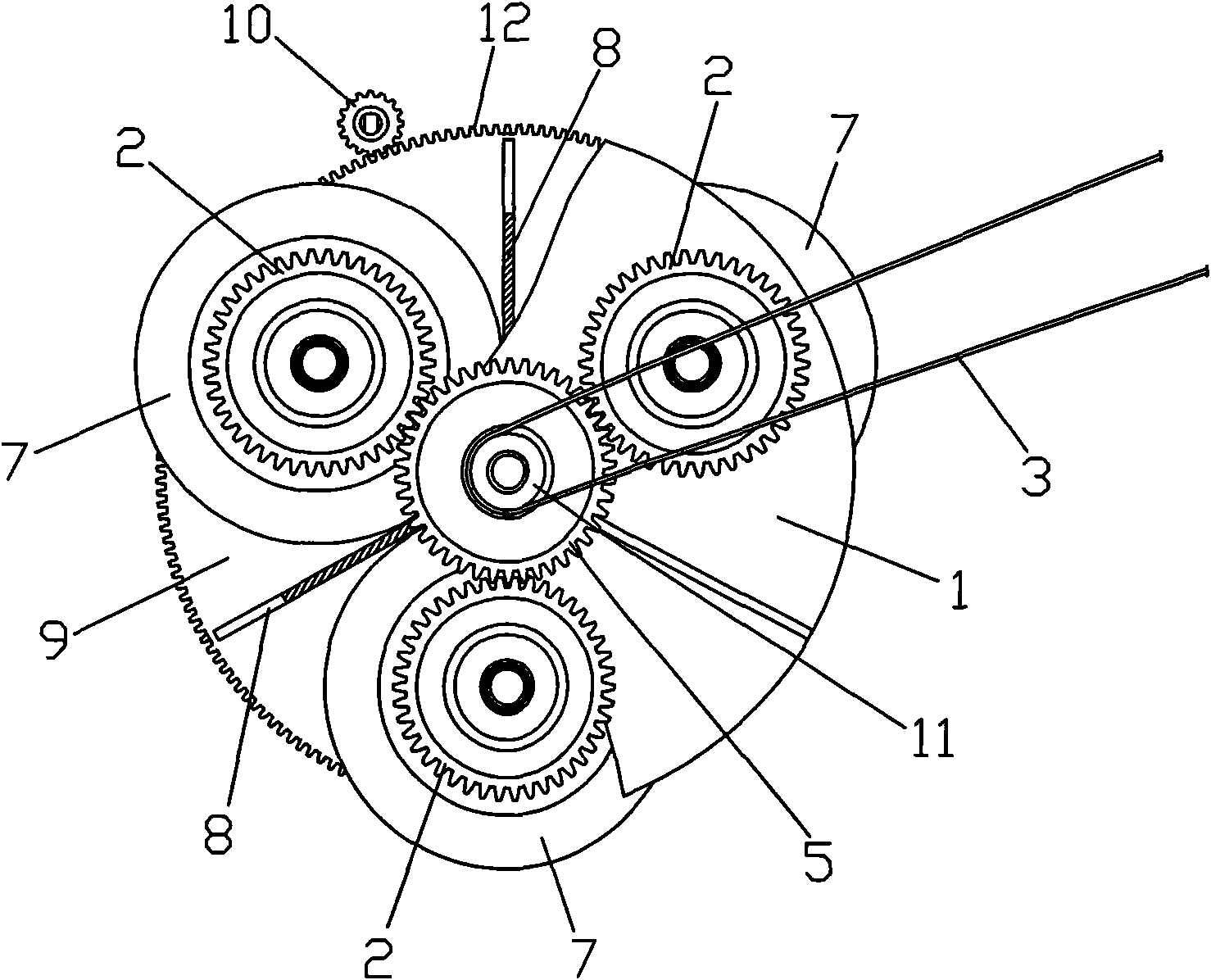

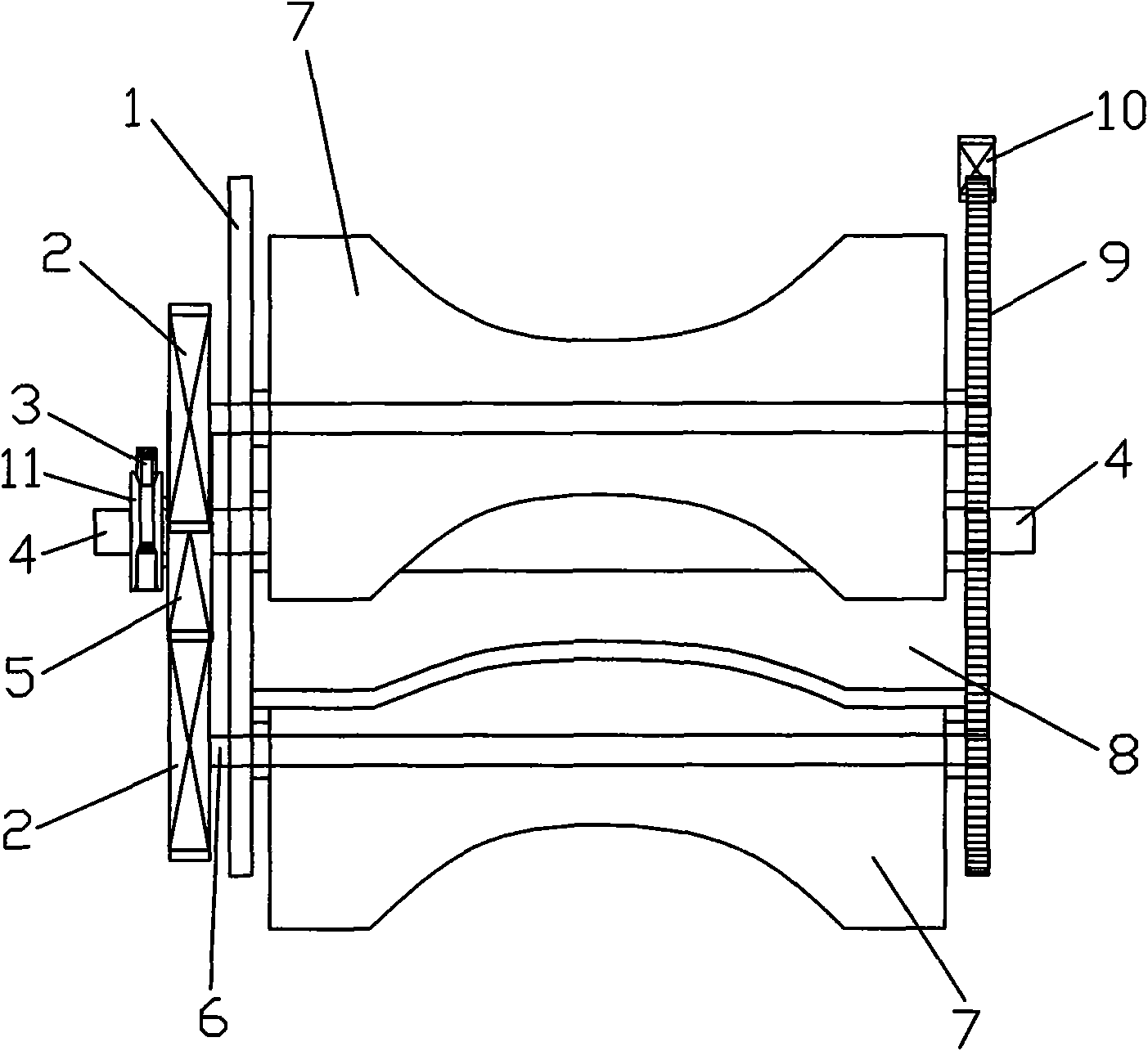

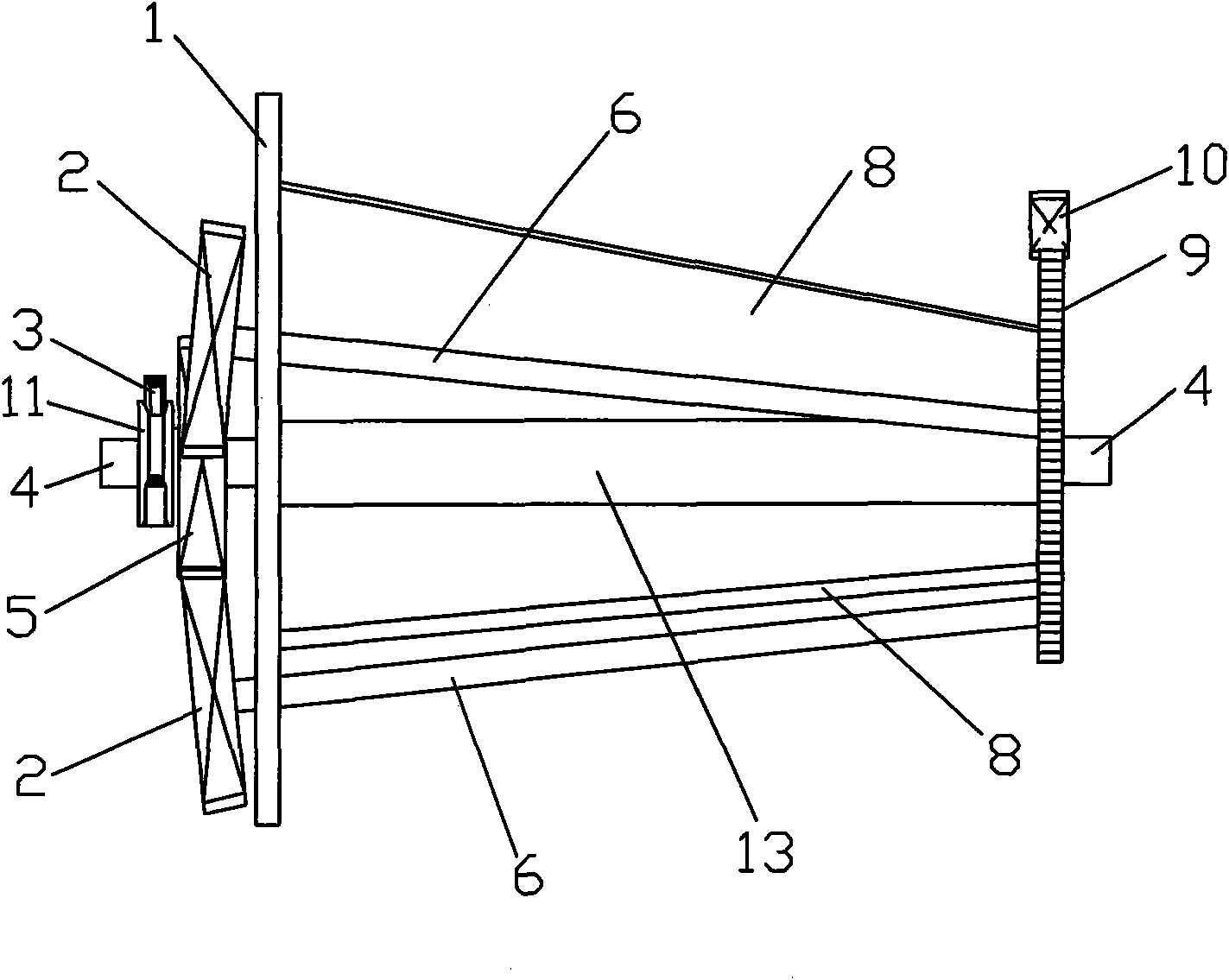

[0015] like figure 1 , figure 2 As shown, a preferred embodiment 1 of a U-shaped roller device for an automatic shoe polisher three-color shoe polish brush includes a roller, which is composed of a circular left side plate 1 and a right side plate 9 arranged in parallel, and a main shaft 4 simultaneously Penetrate the center of circle of left side plate 1 and right side plate 9. Between the left side board 1 and the right side board 9, there are three partition boards 9 used to isolate the color of the brush from mixing at an interval of 120 degrees. The partition board 9 divides the roller into three equal cavities. A hairbrush 7 is arranged in each cavity; the middle part of the hairbrush 7 is fixedly connected with a connecting shaft 6, and the left and right ends of the connecting shaft 6 are respectively matched with the left side plate 1 and the right side plate 9, and can be mounted on the mating surface. Internal rotation. There is also a U-shaped notch on the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com