Patents

Literature

503results about "Textile treatment cleaning apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

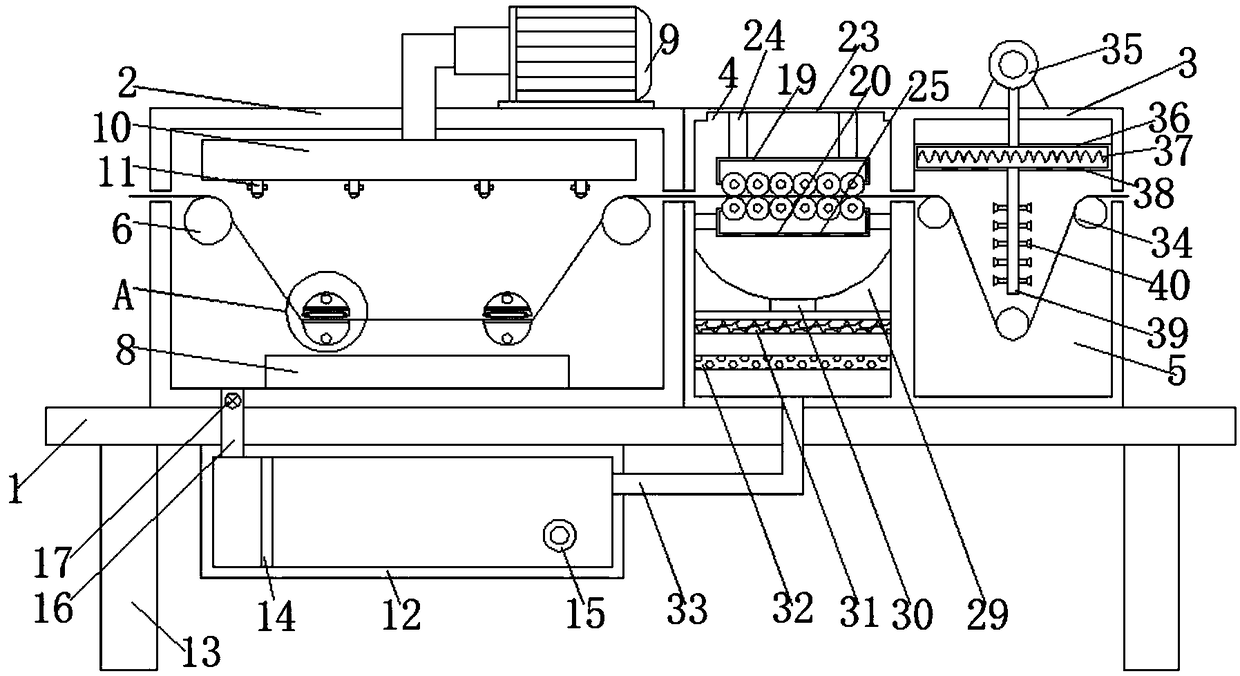

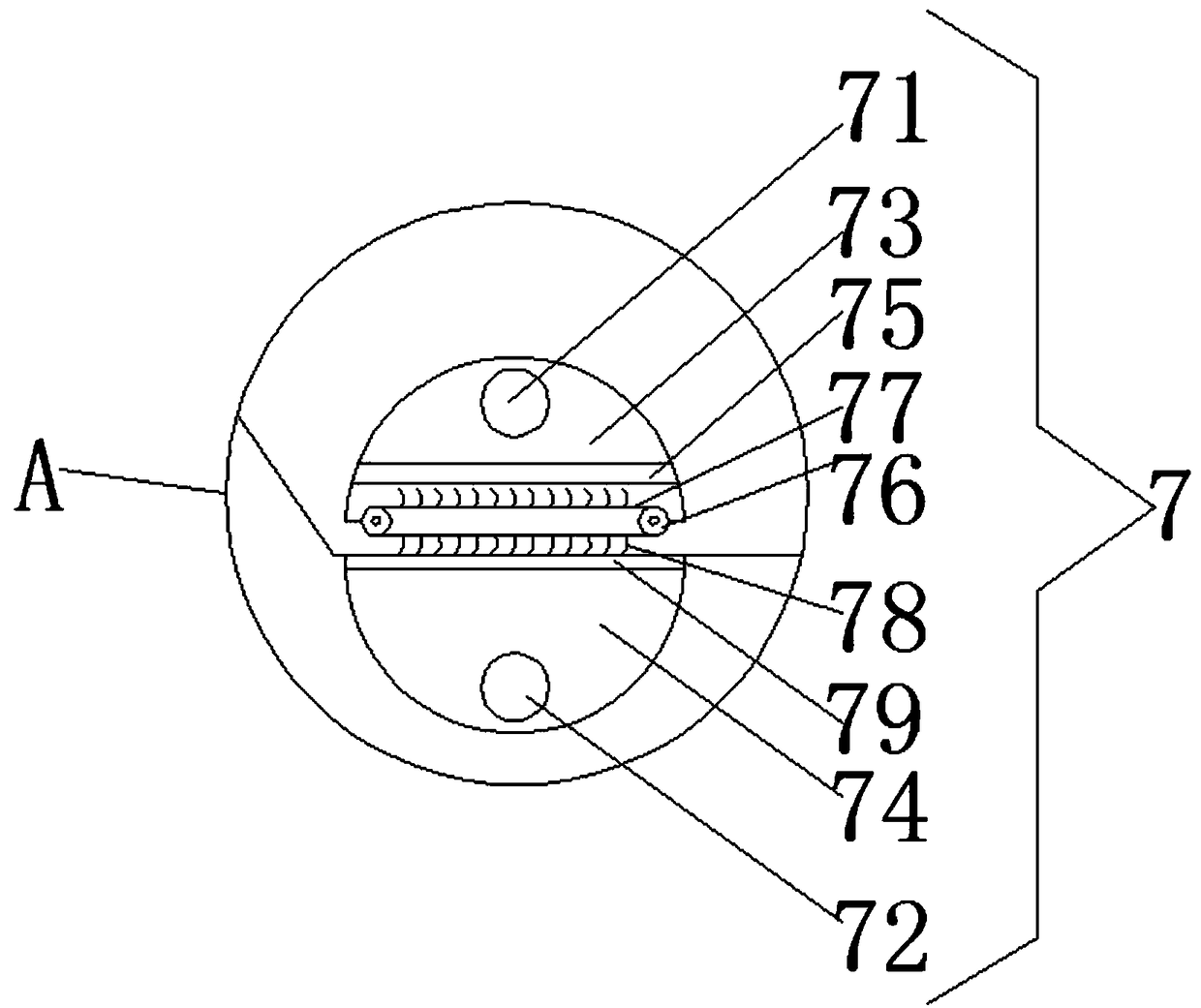

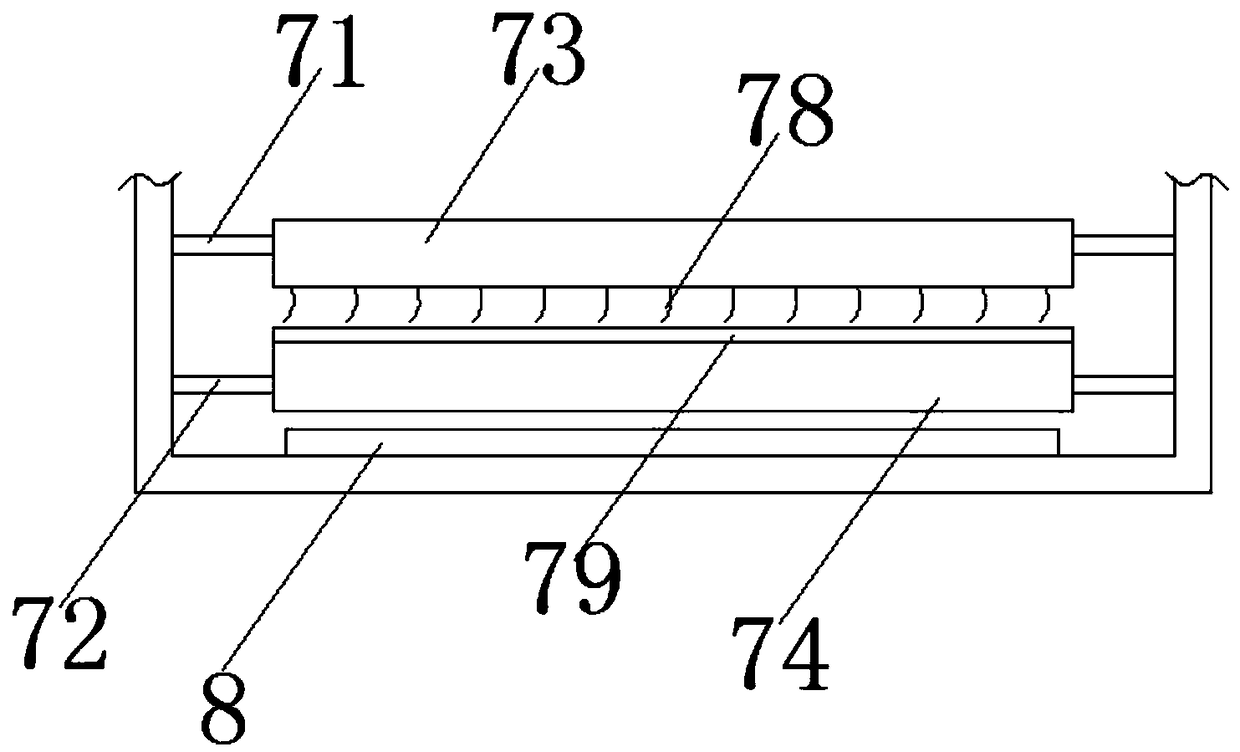

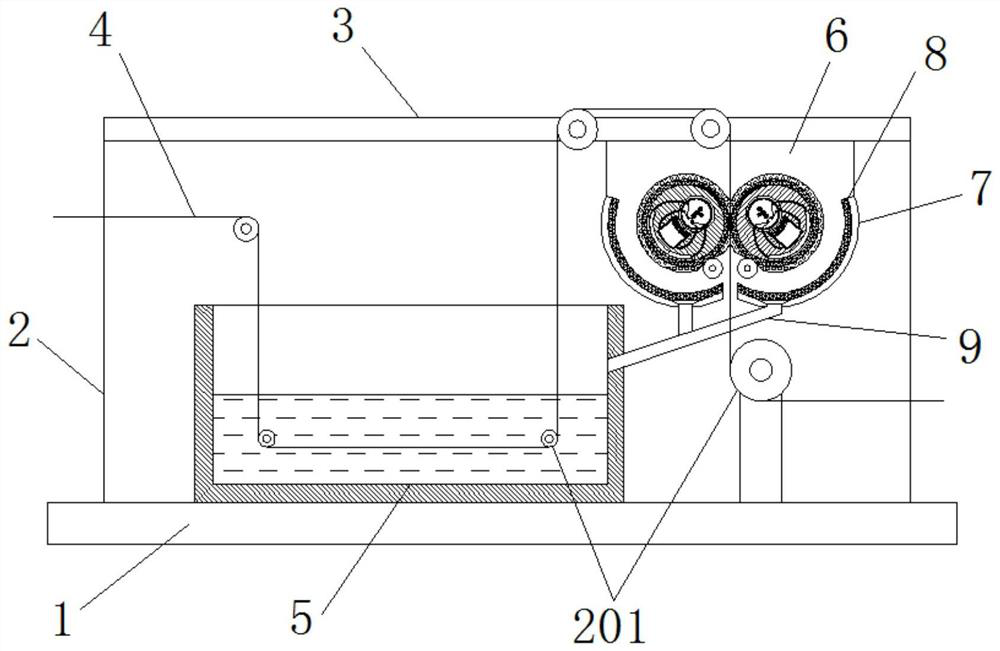

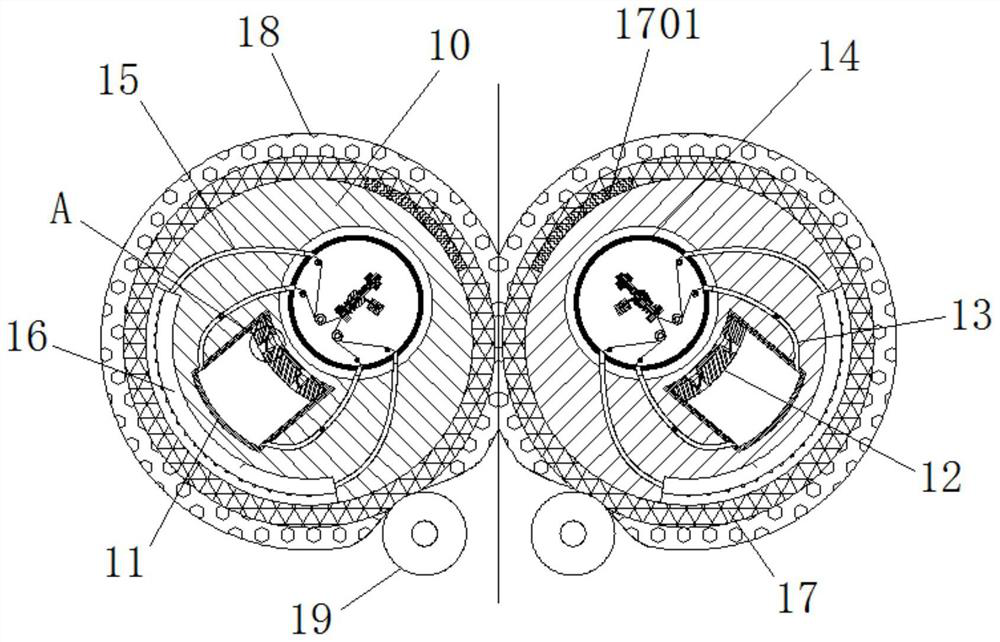

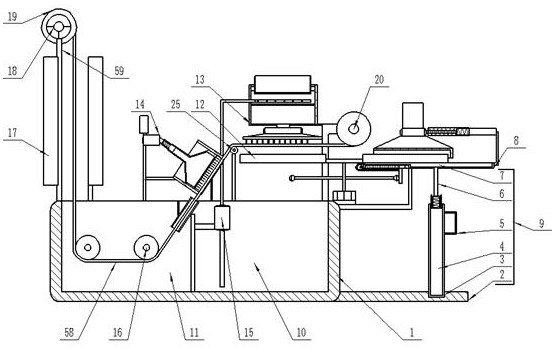

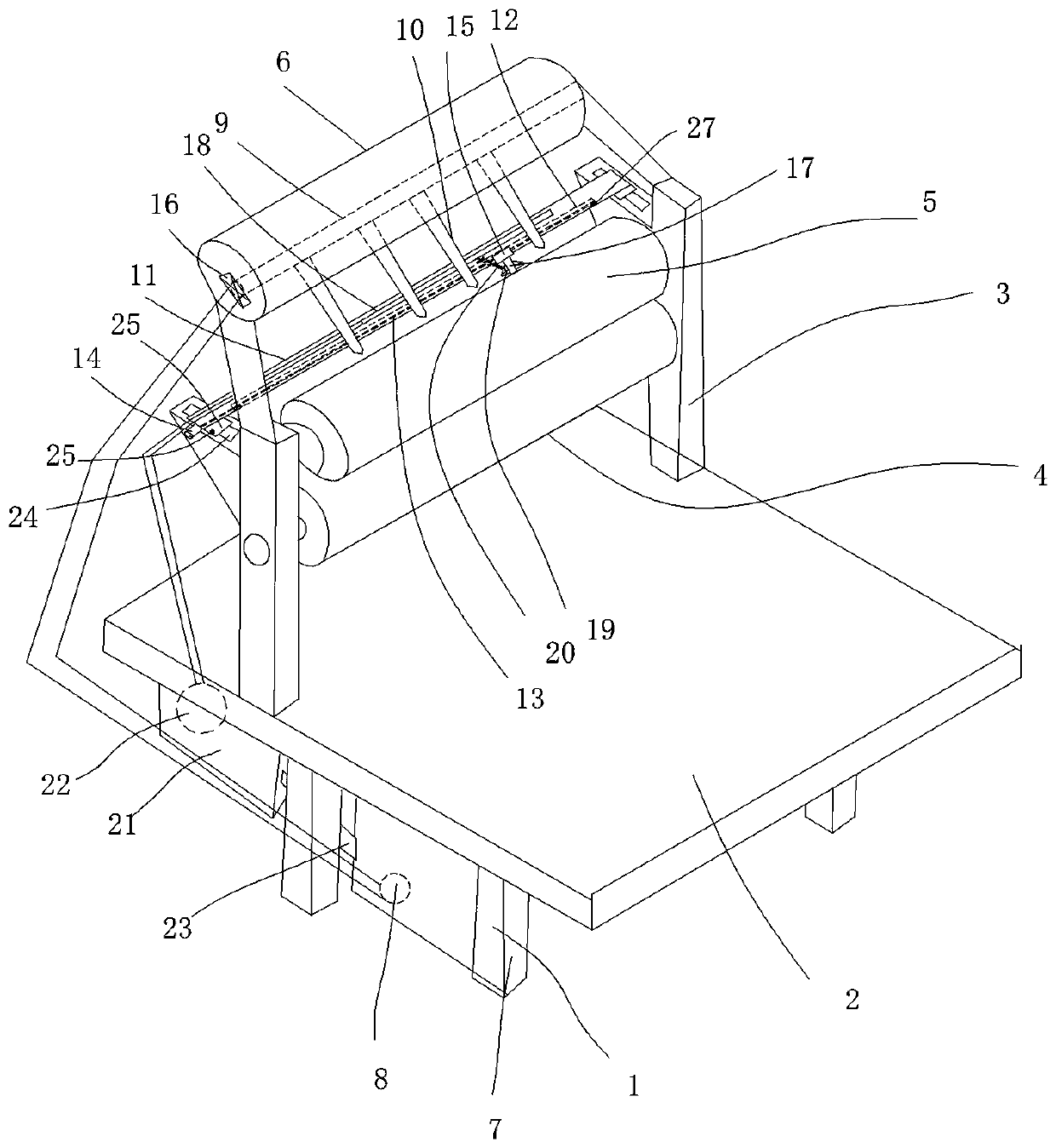

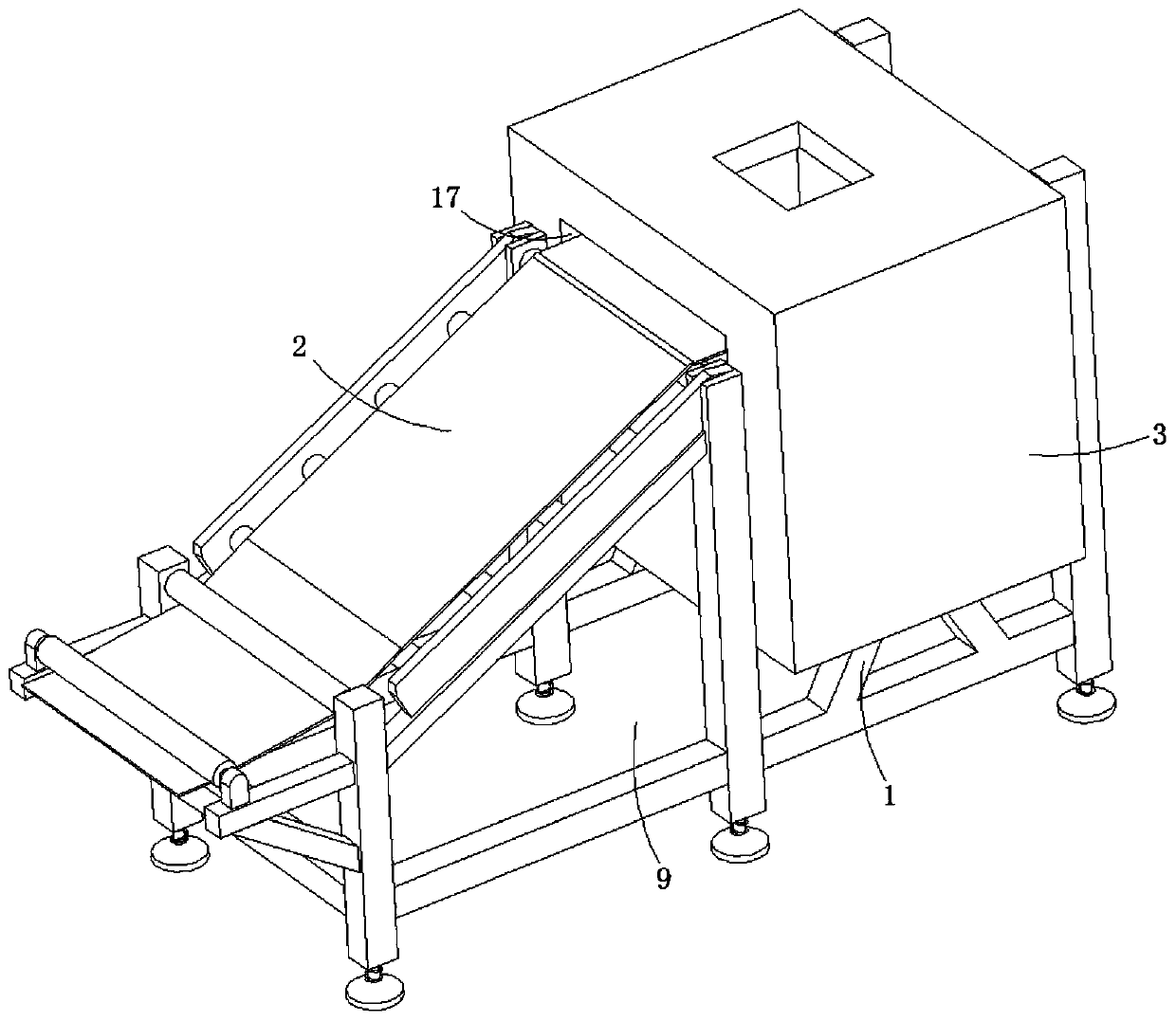

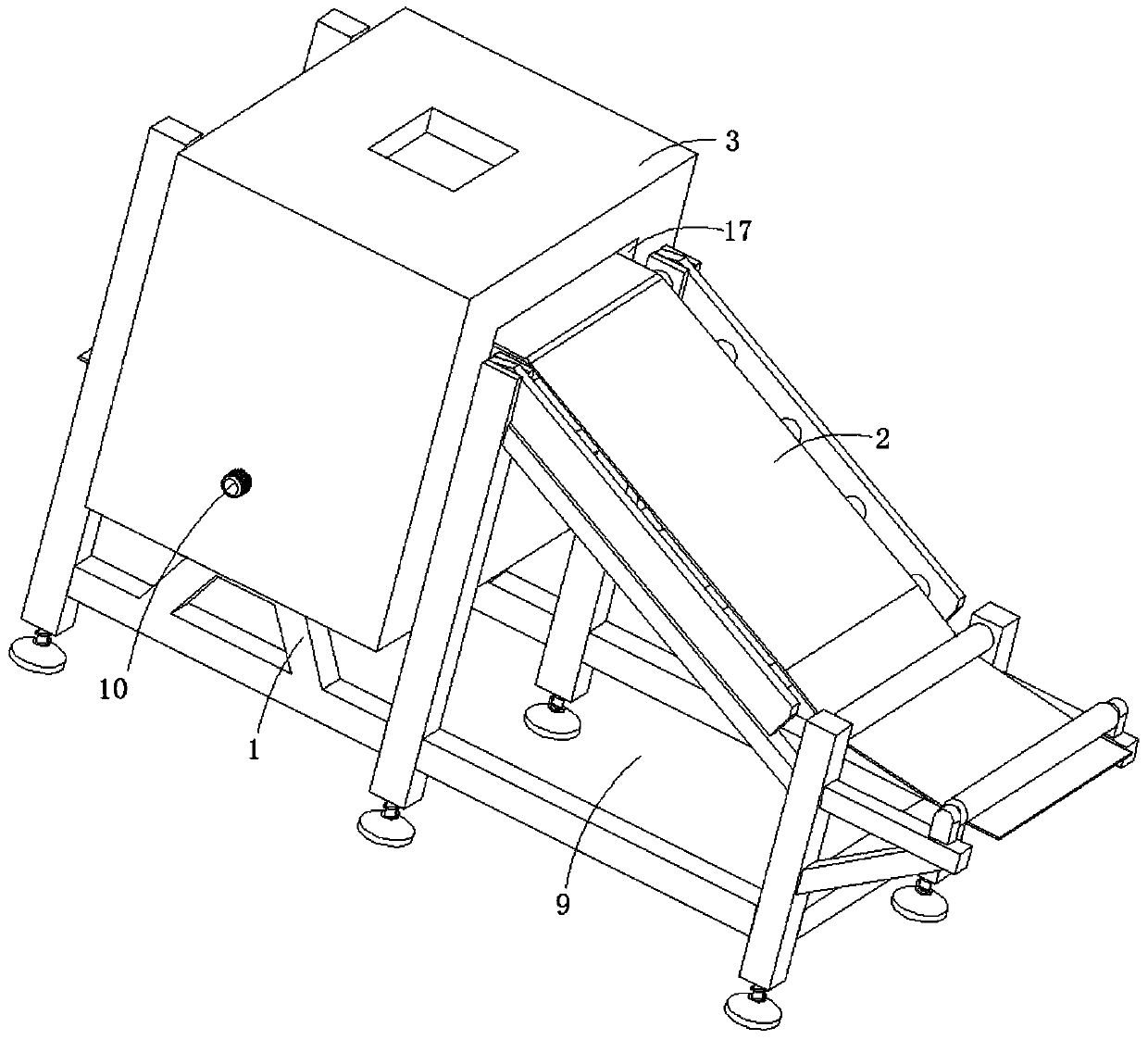

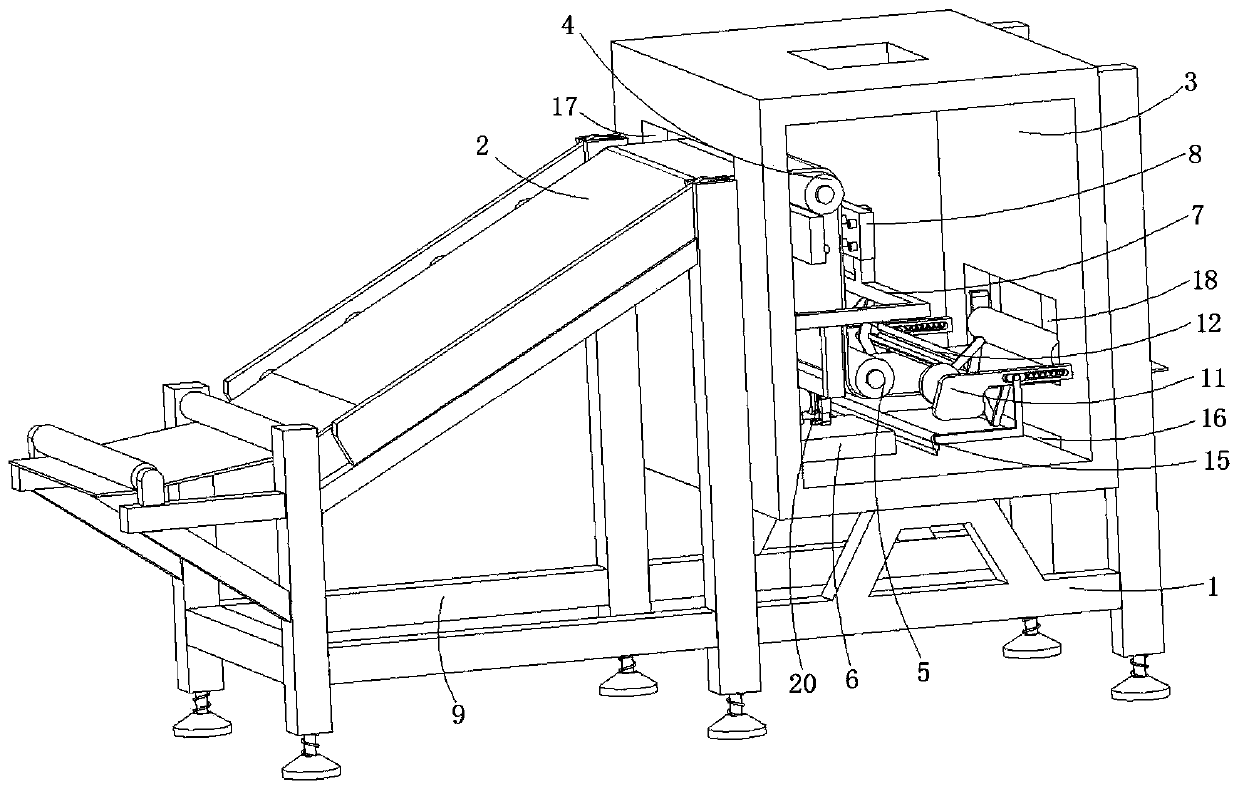

Cleaning drying device used for gauze production

ActiveCN108930110AImprove product qualityAvoid secondary adsorptionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsPulp and paper industryImpurity

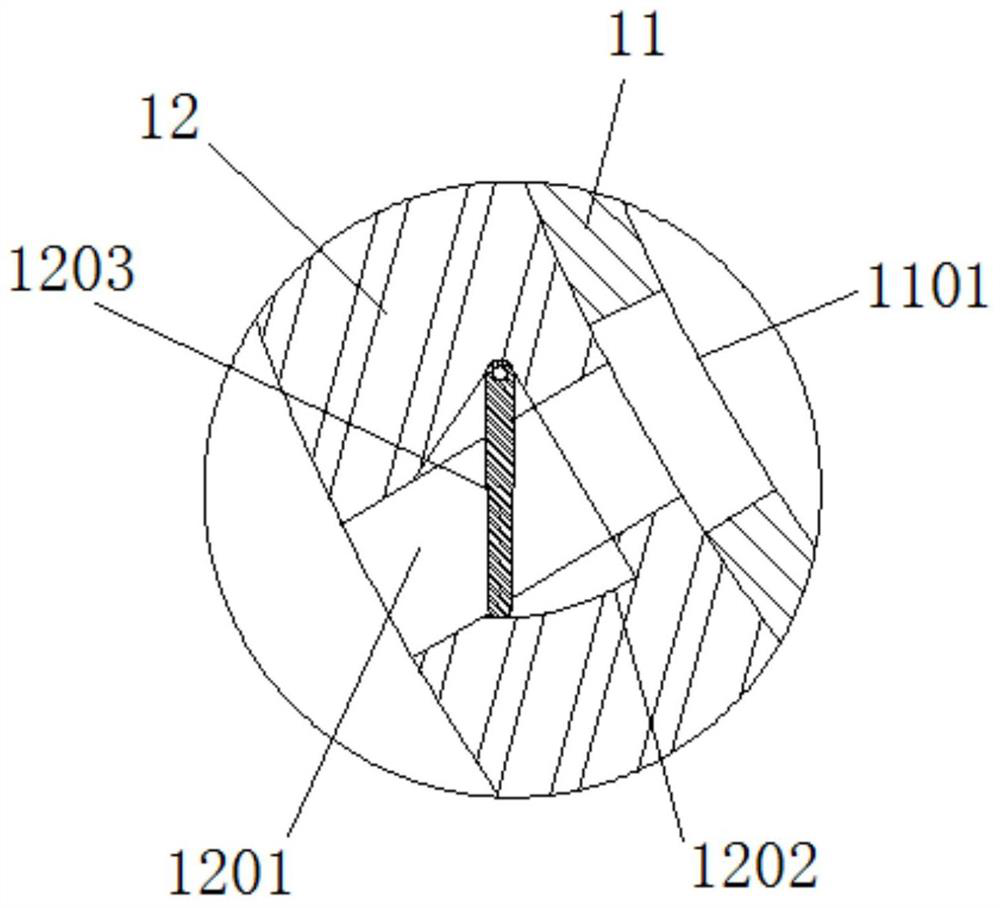

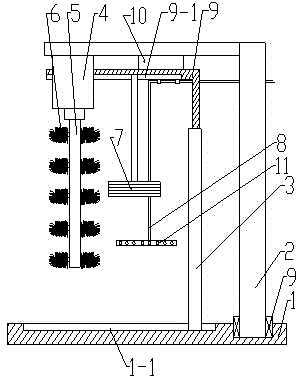

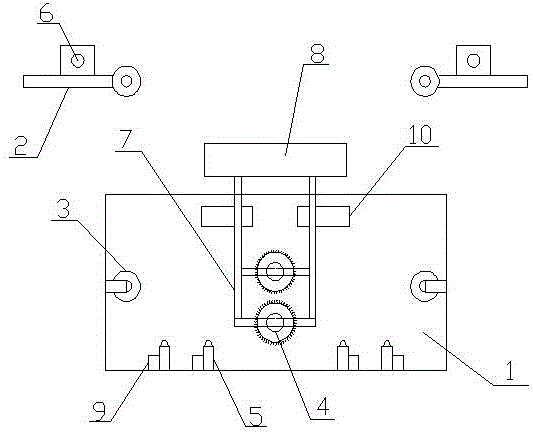

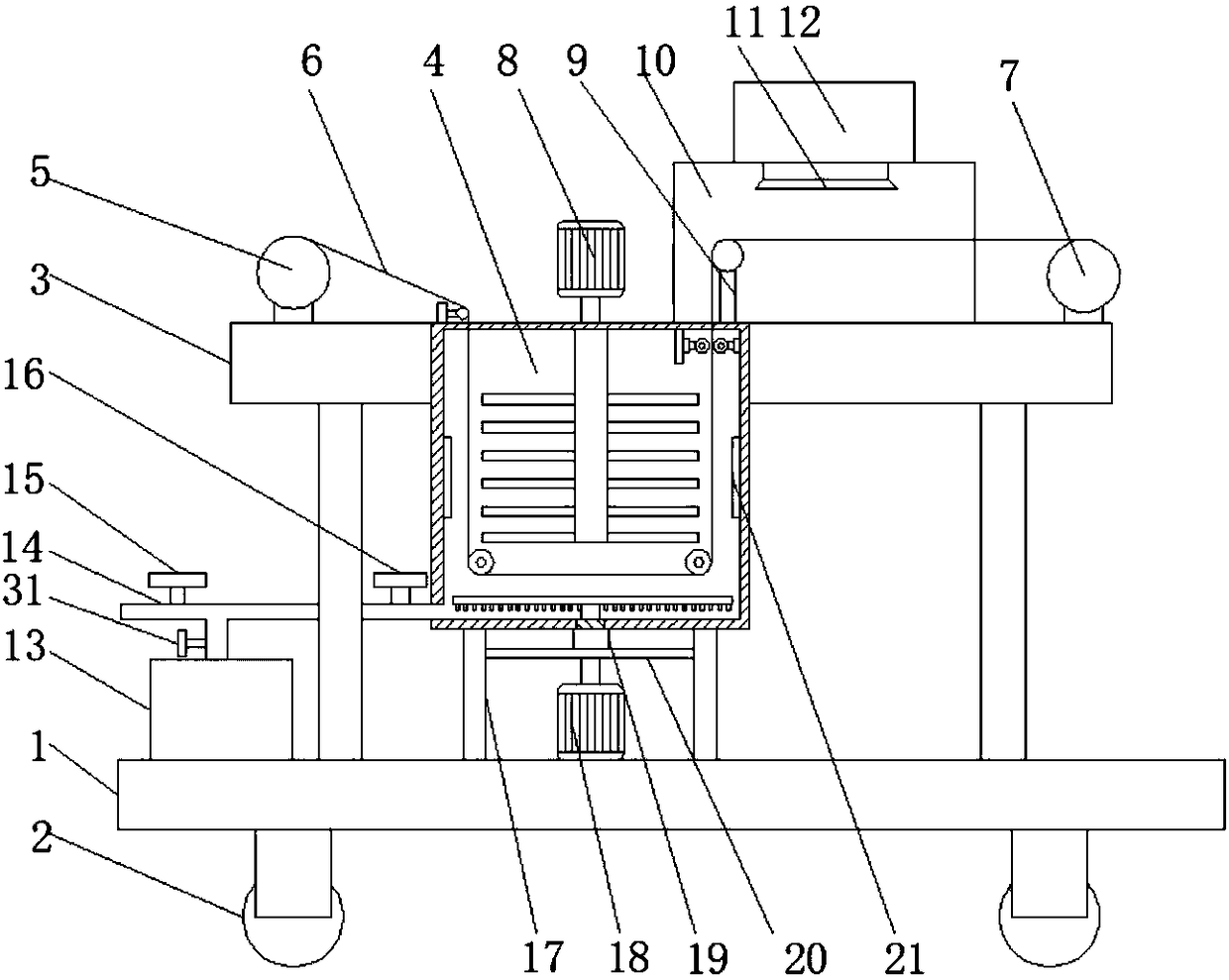

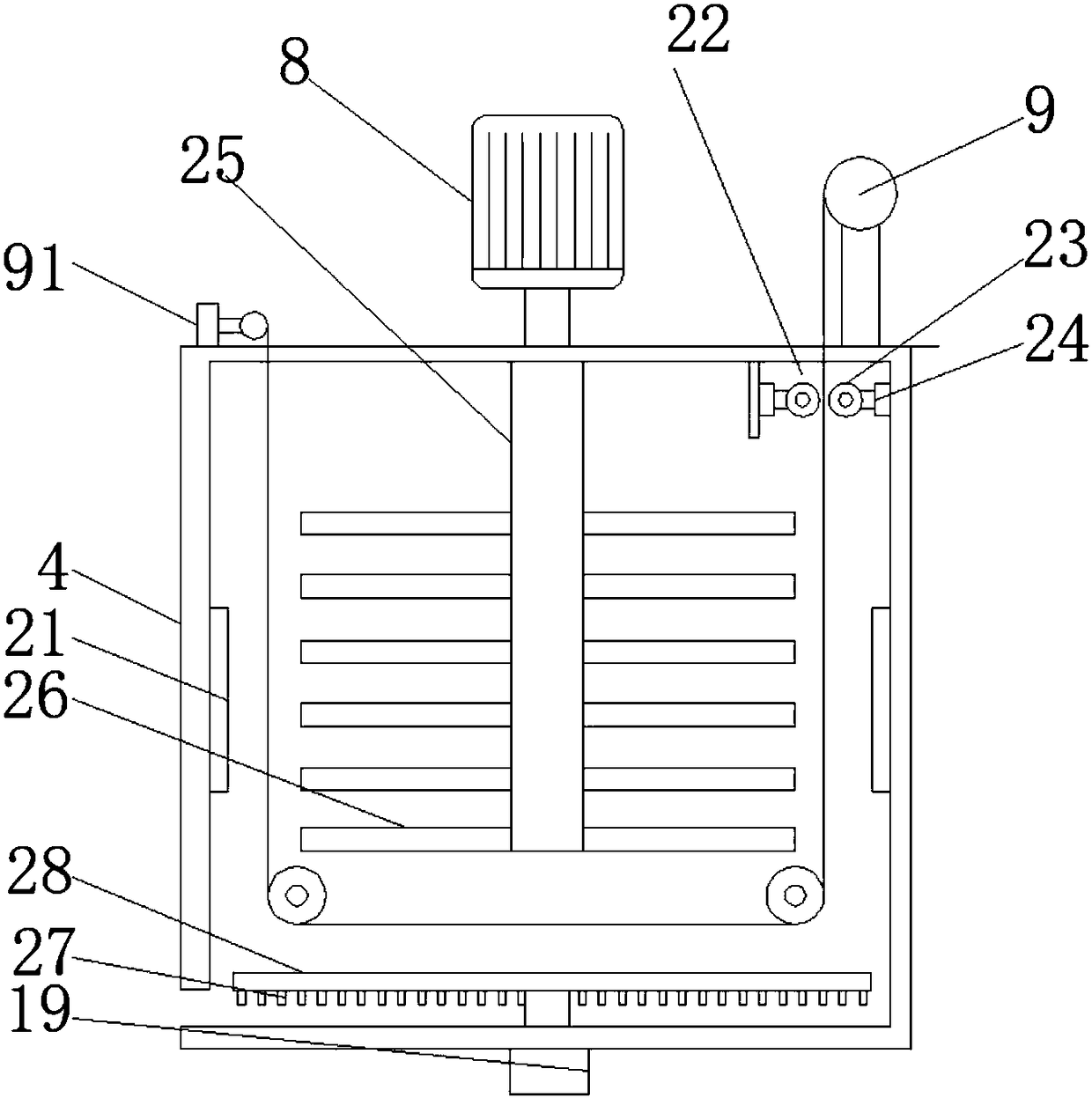

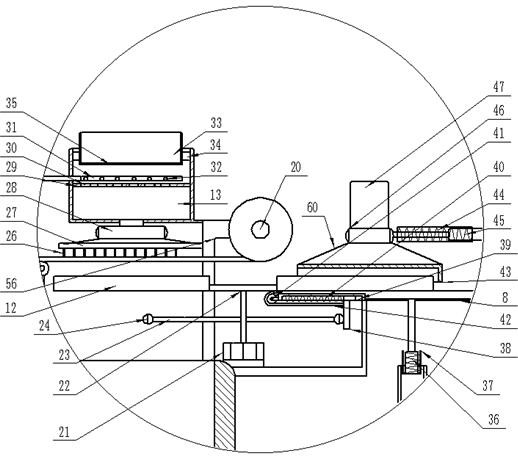

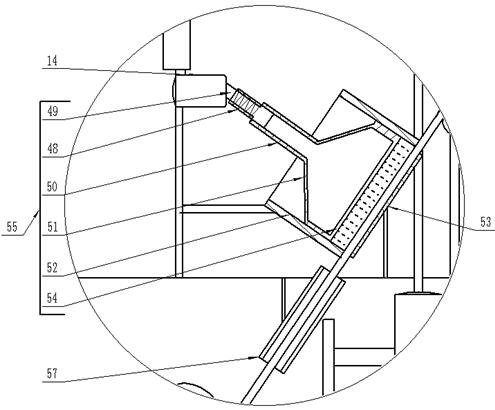

The invention provides a cleaning drying device used for gauze production, and relates to the technical field of gauze production and manufacturing equipment. The cleaning drying device used for gauzeproduction comprises a base. The top of the base is fixedly provided with a cleaning box and a drying box. The drying box is divided into a dehydration chamber and a drying chamber. The cleaning boxis internally provided with a first cloth guide roller and a cleaning device. The cleaning device comprises an upper supporting rod and a lower supporting rod. Using the leaning drying device used forgauze production, through cooperation of an upper supporting rod, a lower supporting rod, an upper cleaning roll, a lower cleaning roll, a scraper blade, a rotating disk, and a banister brush, gauzedrives a driving belt to drive on the rotating disk, and the banister brush on the driving belt cleans the surface of the gauze. Under operation of the driving belt, the banister brush drives impurities into the upper cleaning roll, and the impurities on the banister brush are removed through the scraper blade. Impurities pass through the scraper blade and enter into the upper cleaning roll, and the impurities on the surface of the gauze are removed in cleaning, so that product quality of the gauze is improved.

Owner:陈剑璋

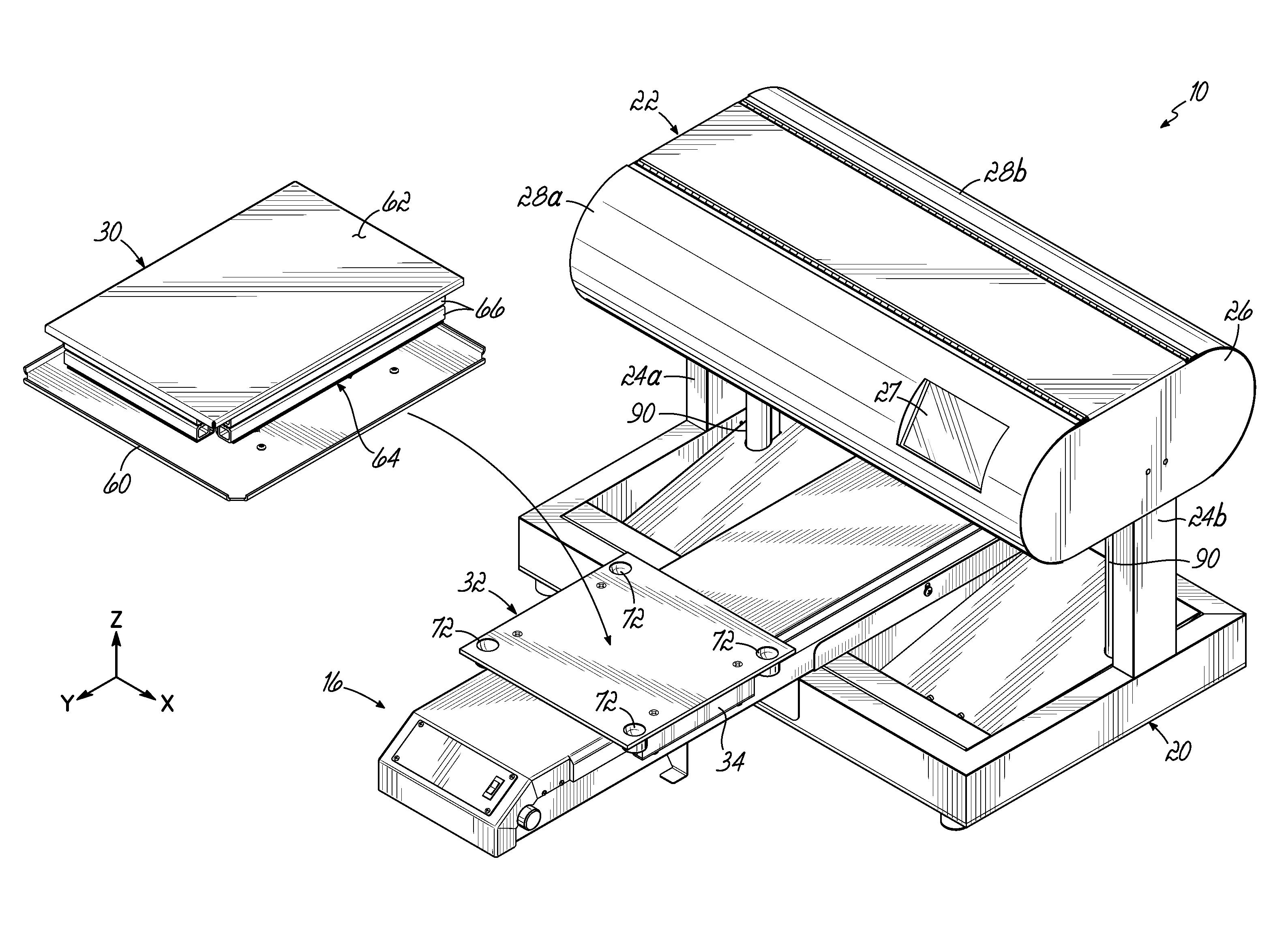

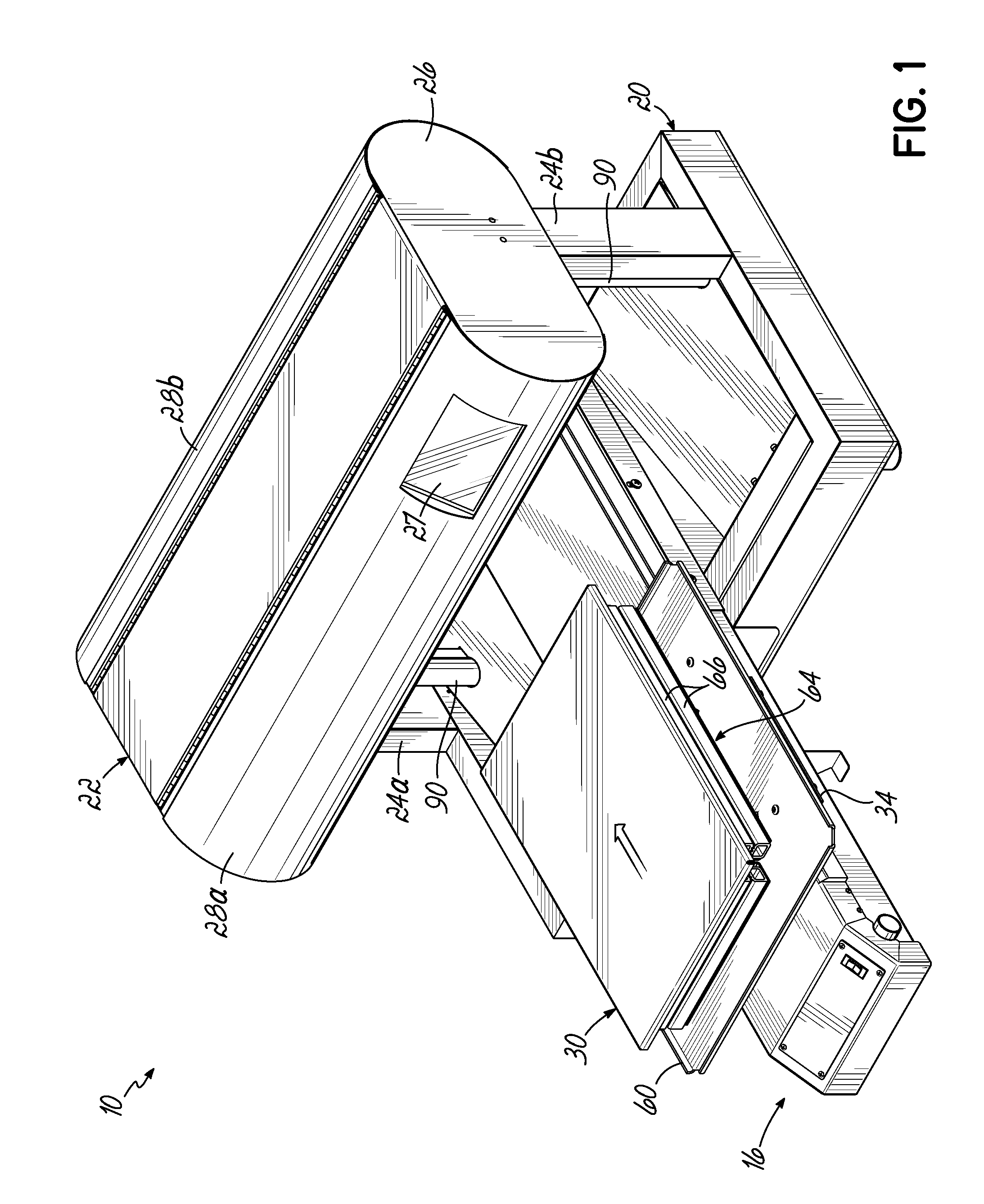

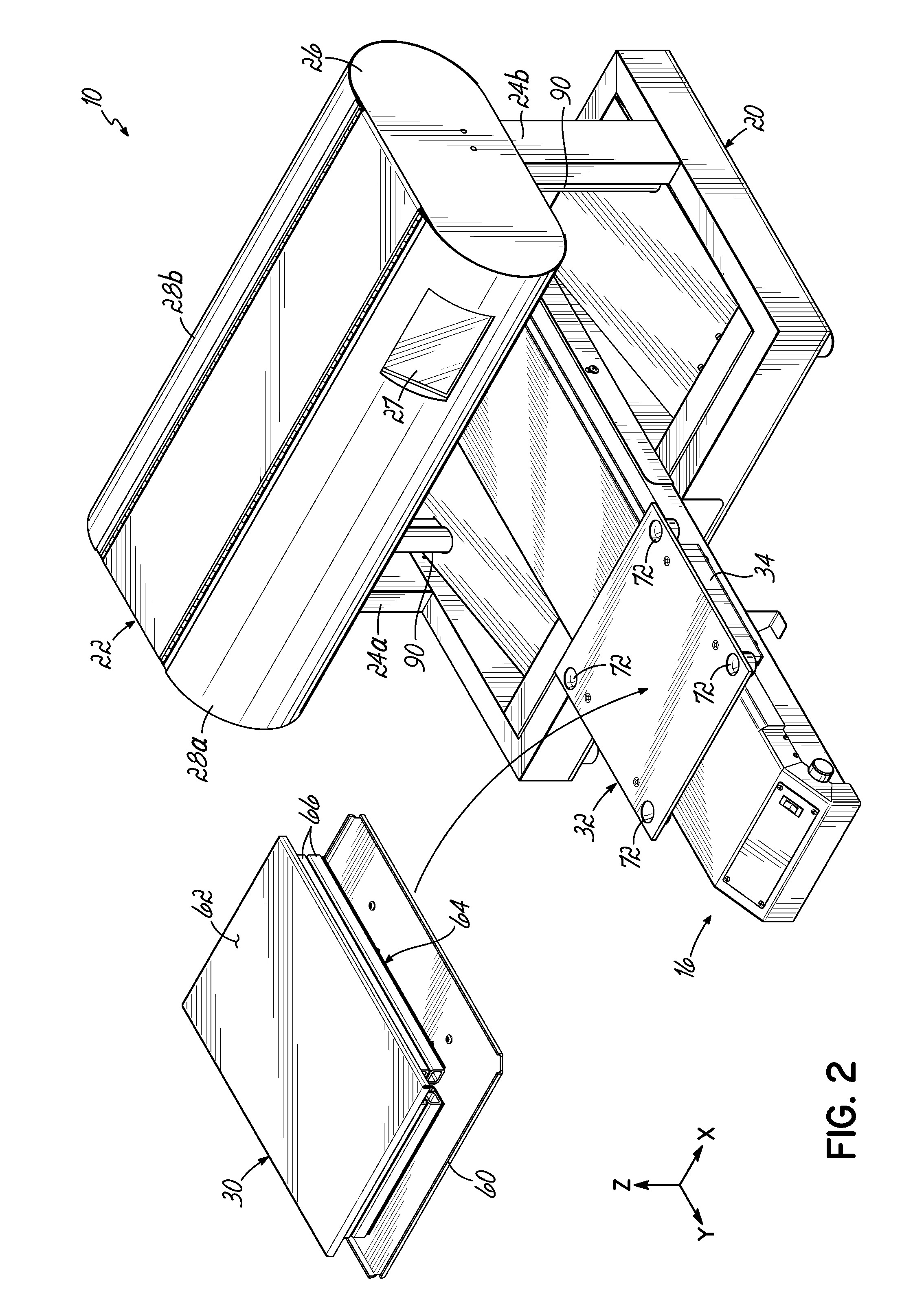

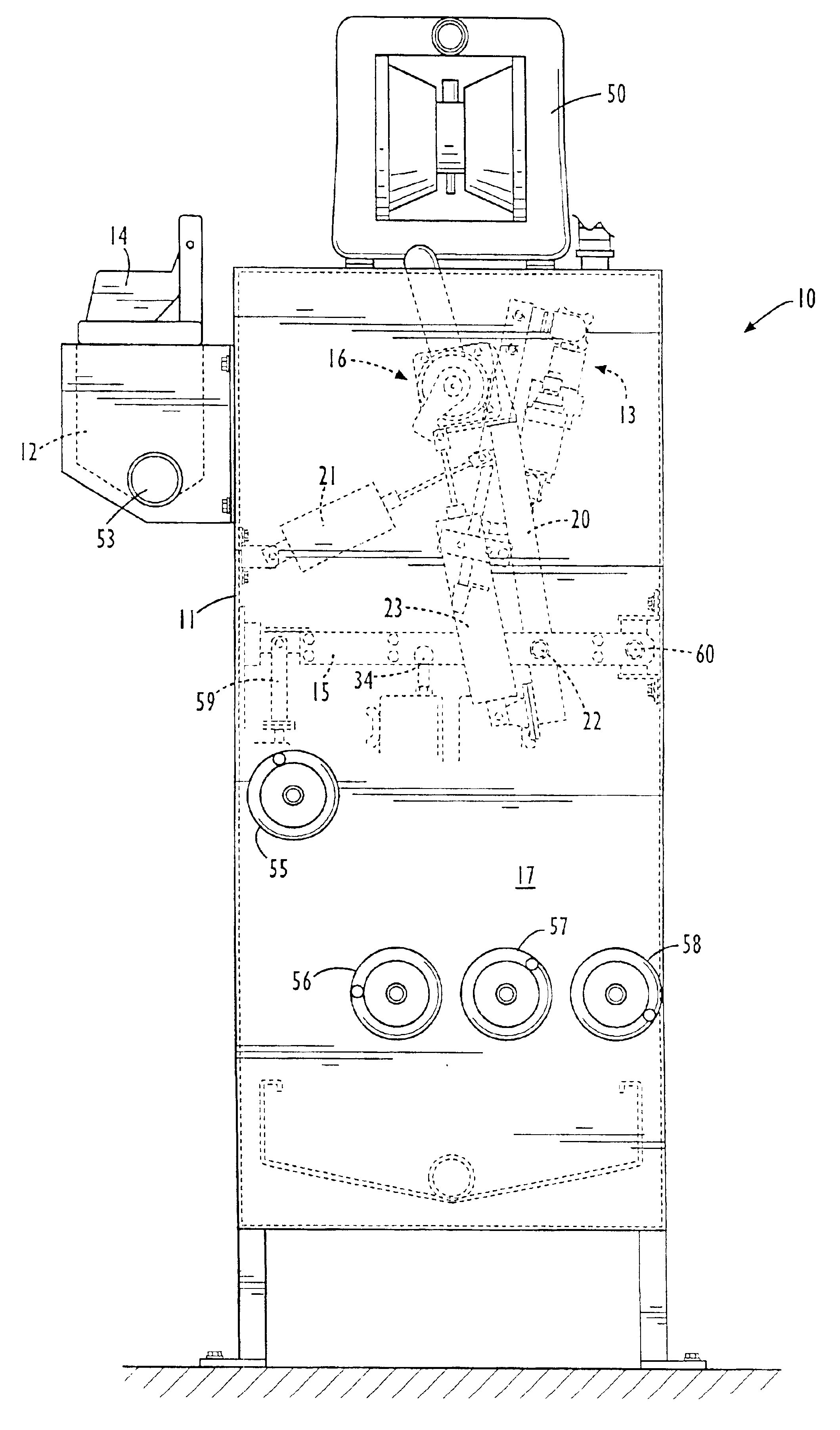

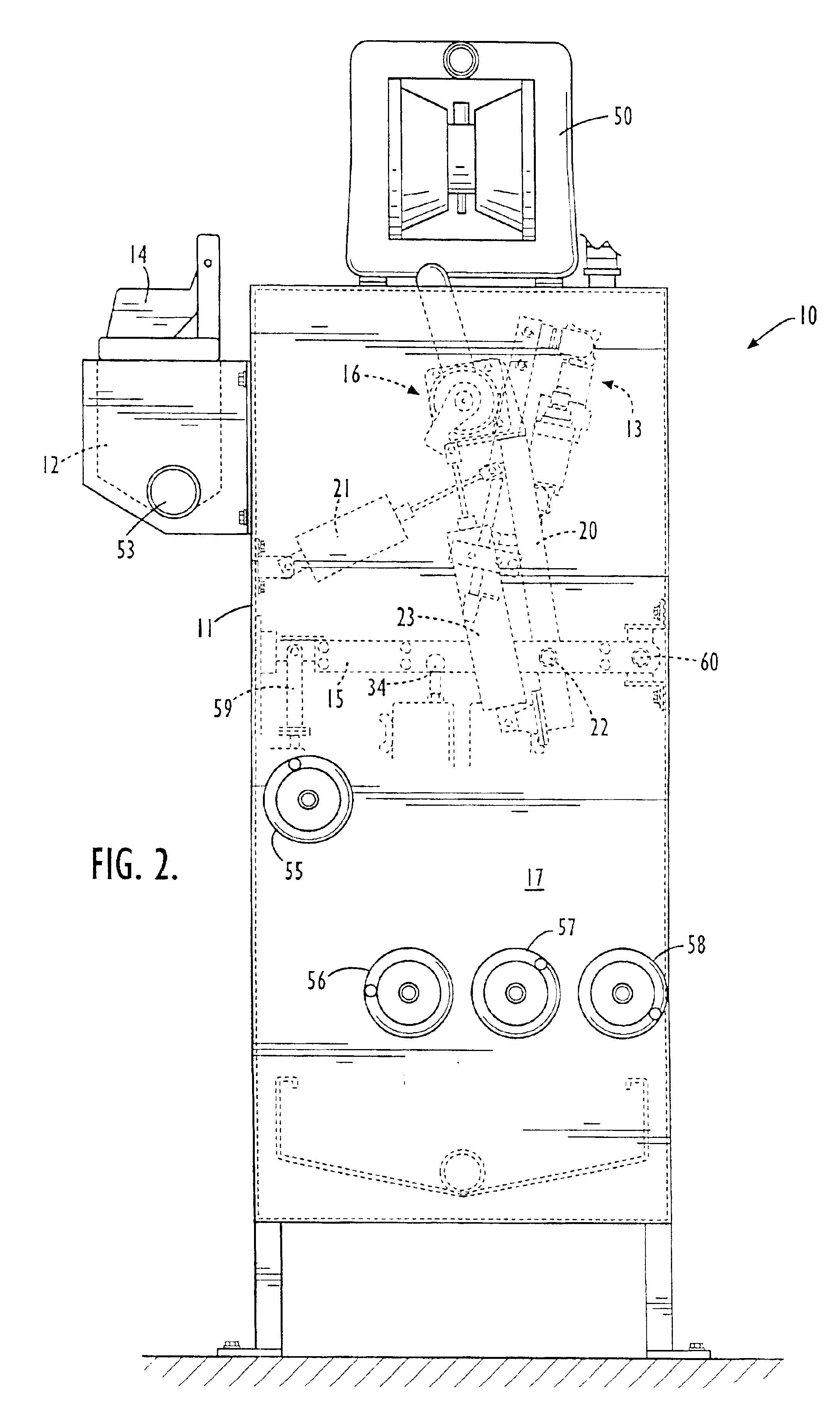

Systems For Treating A Garment With Pre-Treatment Solution, And Related Methods

InactiveUS20140020189A1Hollow article cleaningOther washing machinesPre treatmentBiomedical engineering

A system for treating a garment with a pre-treatment solution includes a fluid application assembly configured to dispense pre-treatment solution onto pre-determined target areas of the garment. A fluid supply and delivery assembly is coupled with the fluid application assembly and configured to provide a supply of pre-treatment solution to the fluid application assembly for dispensing onto the garment at fluid pressures of between about 5 and about 30 psig. A garment movement assembly is configured to move the garment with respect to the fluid application assembly so that the target areas of the garment can receive the pre-treatment solution.

Owner:BELQUETTE

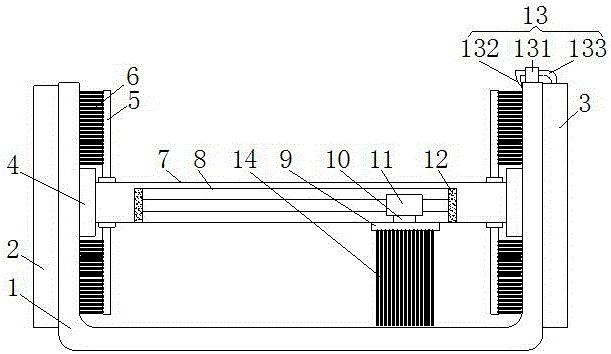

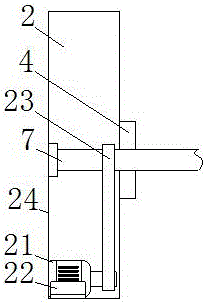

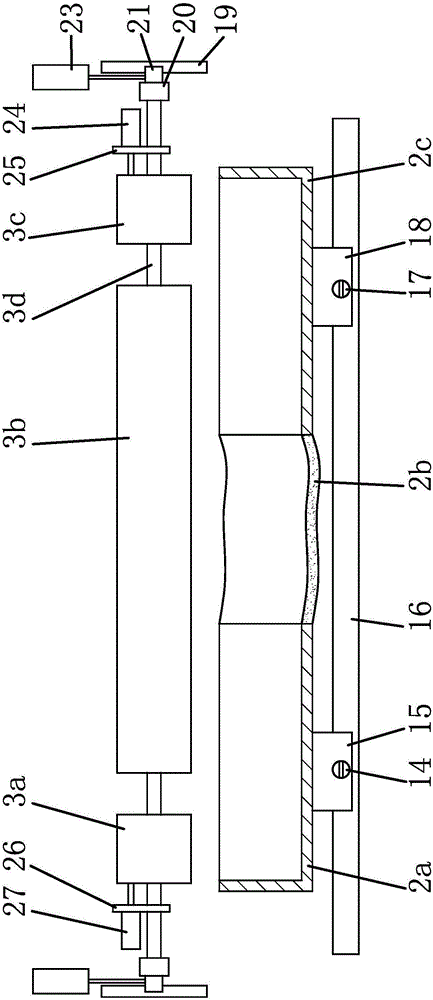

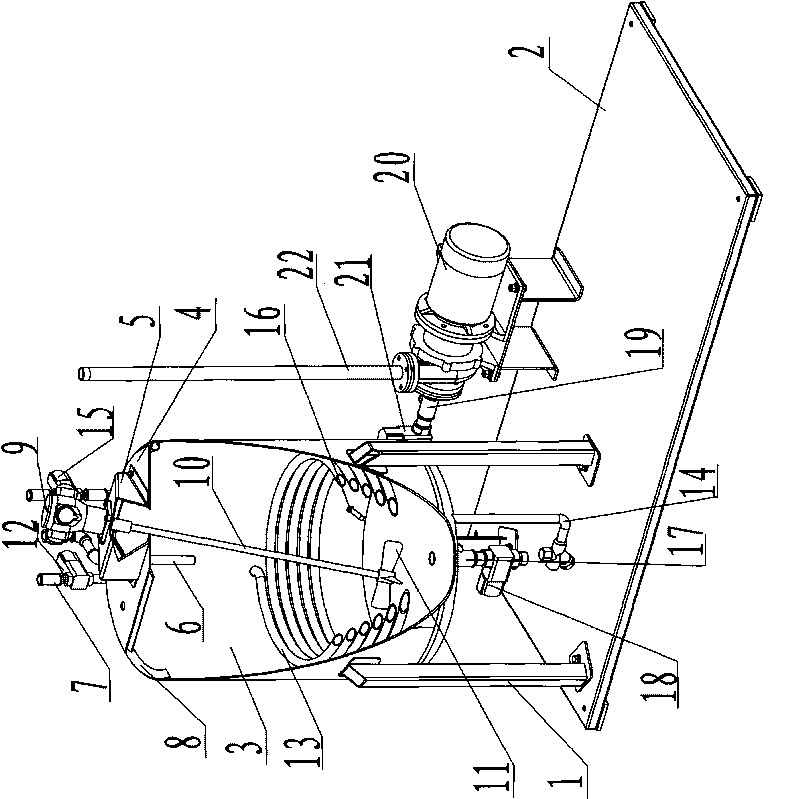

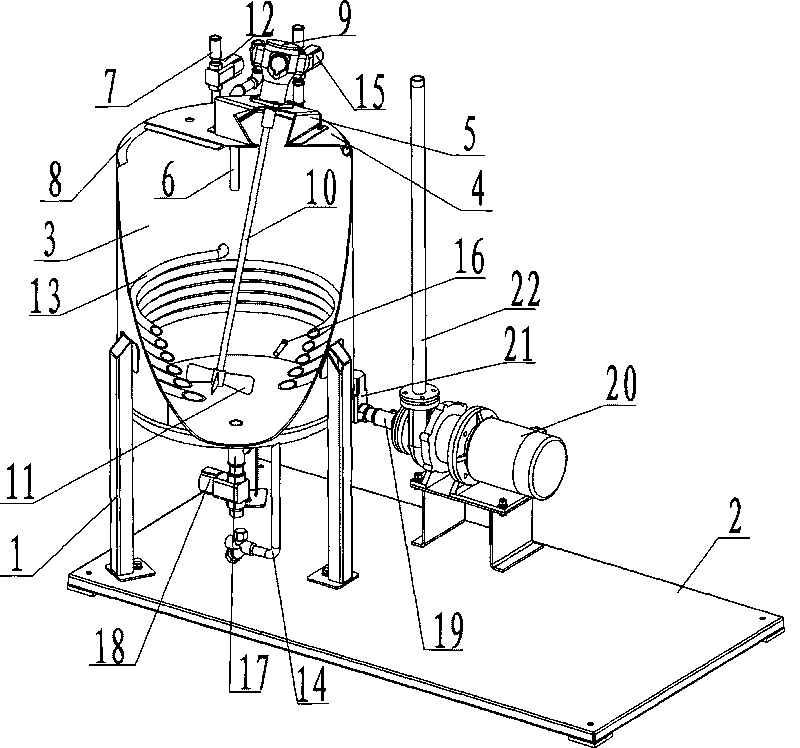

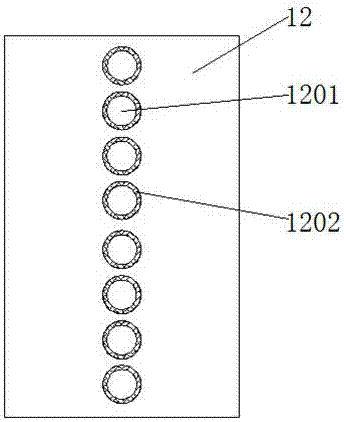

Non-woven fabric rapid cleaning, dewatering and clearing device for textile production

InactiveCN111748941ASolve efficiency problemsResolution timeLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionStructural engineeringNonwoven fabric

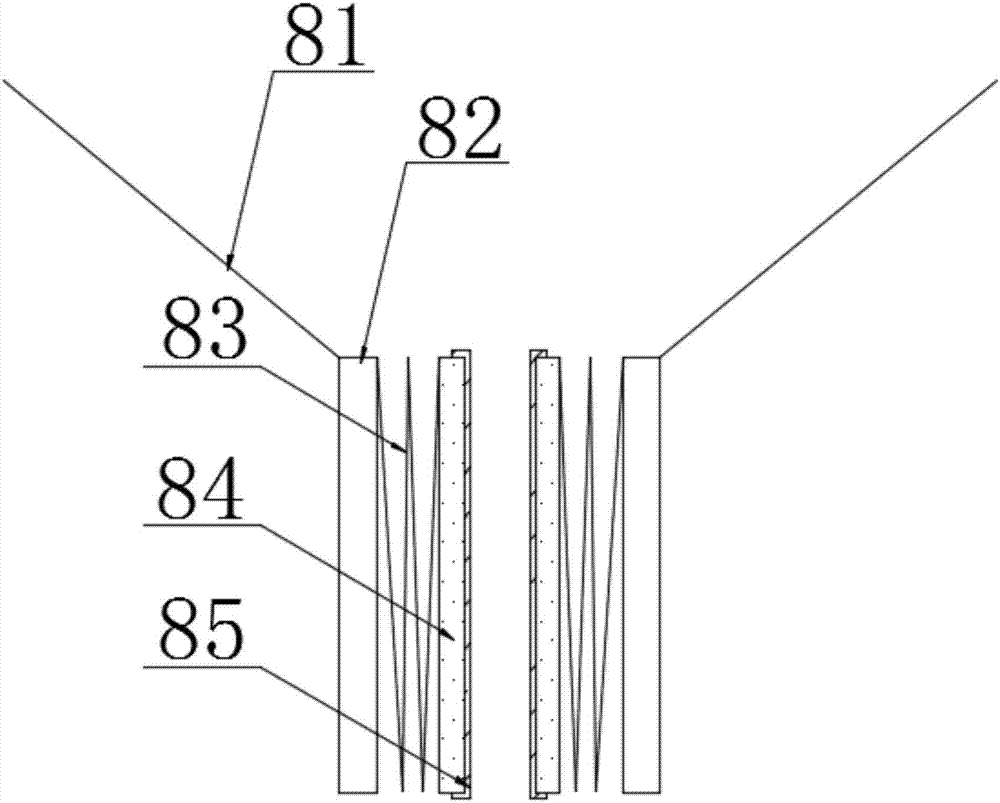

The invention relates to the technical field of non-woven fabric processing equipment, and discloses a non-woven fabric rapid cleaning, dewatering and clearing device for textile production. The non-woven fabric rapid cleaning, dewatering and clearing device comprises a fixing plate, wherein the fixing plate comprises a guide block, a fixing block, a sliding rod, a third spring and a second guideroller; a magnet piston comprises a vent groove, an arc-shaped groove and a swing plate; an arc-shaped magnetic block is arranged on the inner wall of a driving roller; a T-shaped magnetic block is connected to the interior of the guide block in a sliding mode; and a rubber ball is connected to the outer side end of a rope. The arc-shaped magnetic block moves upwards, the arc-shaped magnetic blockadsorbs the magnet piston to move downwards, and gas in the magnet piston enters an air bag through an air inlet pipe; and when the arc-shaped magnetic block moves to the upper side, the arc-shaped magnetic block adsorbs the magnet piston to move upwards, the lower part of the T-shaped magnetic block drives the rope to pull the rubber ball through the second guide roller, and the gas in the air bag clears fluff on sponge, so that the fluff on the sponge is prevented from being adhered to the non-woven fabric again or accumulated on the sponge again.

Owner:池志琴

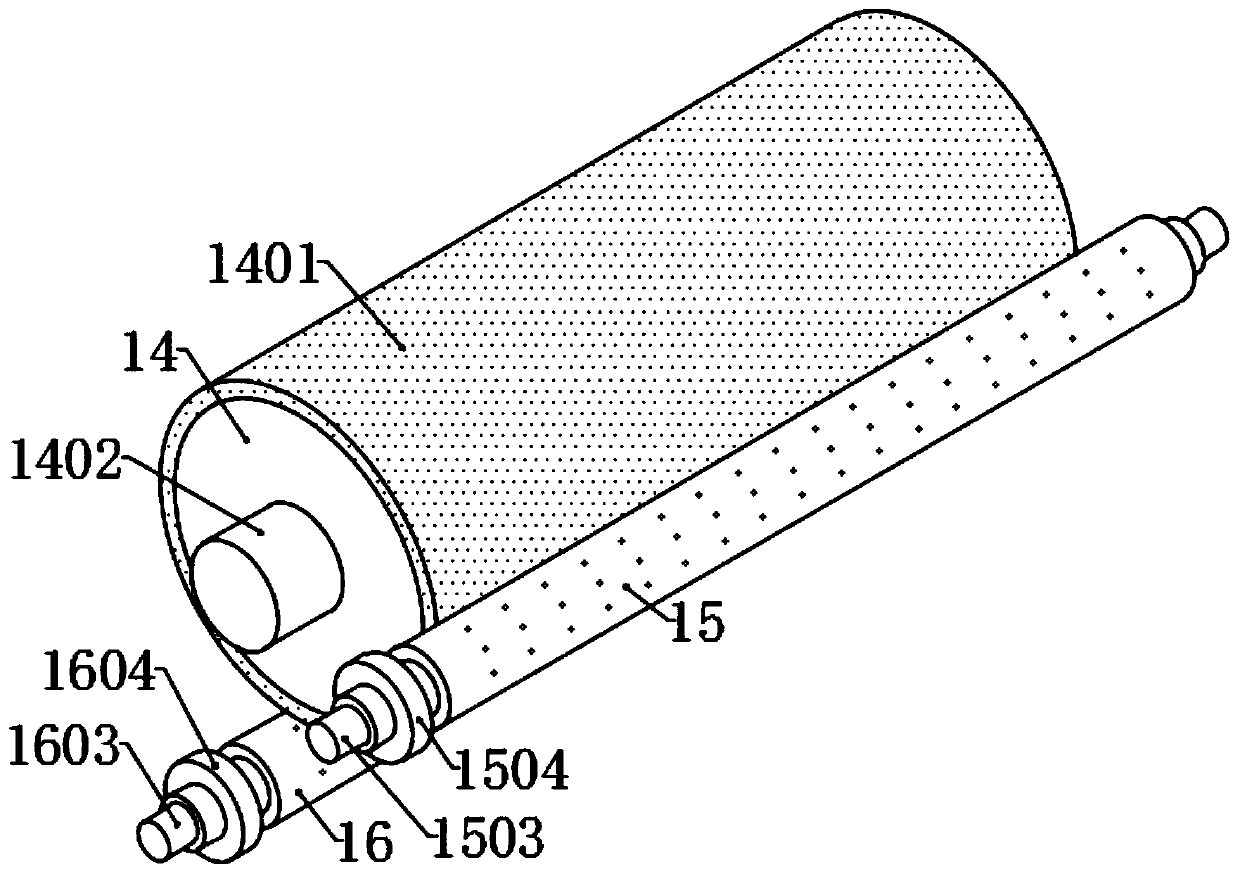

Dyeing roller cleaning device

ActiveCN104790157AEasy to cleanTextile treatment cleaning apparatusAgricultural engineeringWater spray

The invention discloses a dyeing roller cleaning device. The dyeing roller cleaning device comprises a fixed base, a rotary shaft, a supporting shaft, a rotary cleaning unit, a heating pipe and a water spray pipe, the rotary shaft and the supporting shaft are arranged on the fixed base in parallel, a swivel bearing is arranged at the bottom of the rotary shaft, the rotary cleaning unit comprises a rotary motor, a connecting shaft and brush heads, the rotary motor is fixed to the upper portion of the rotary shaft, the connecting shaft is connected with the rotary motor, the brush heads are arranged on the circumferential surface of the connecting shaft, and the heating pipe and the water spray pipe are fixed to the supporting shaft. In this way, the dyeing roller cleaning device can be used for cleaning up various coloring materials on a dyeing roller, has the advantages of being efficient, rapid and simple and facilitating cleaning, and is especially suitable for cleaning roller type parts.

Owner:浙江丰林染整有限公司

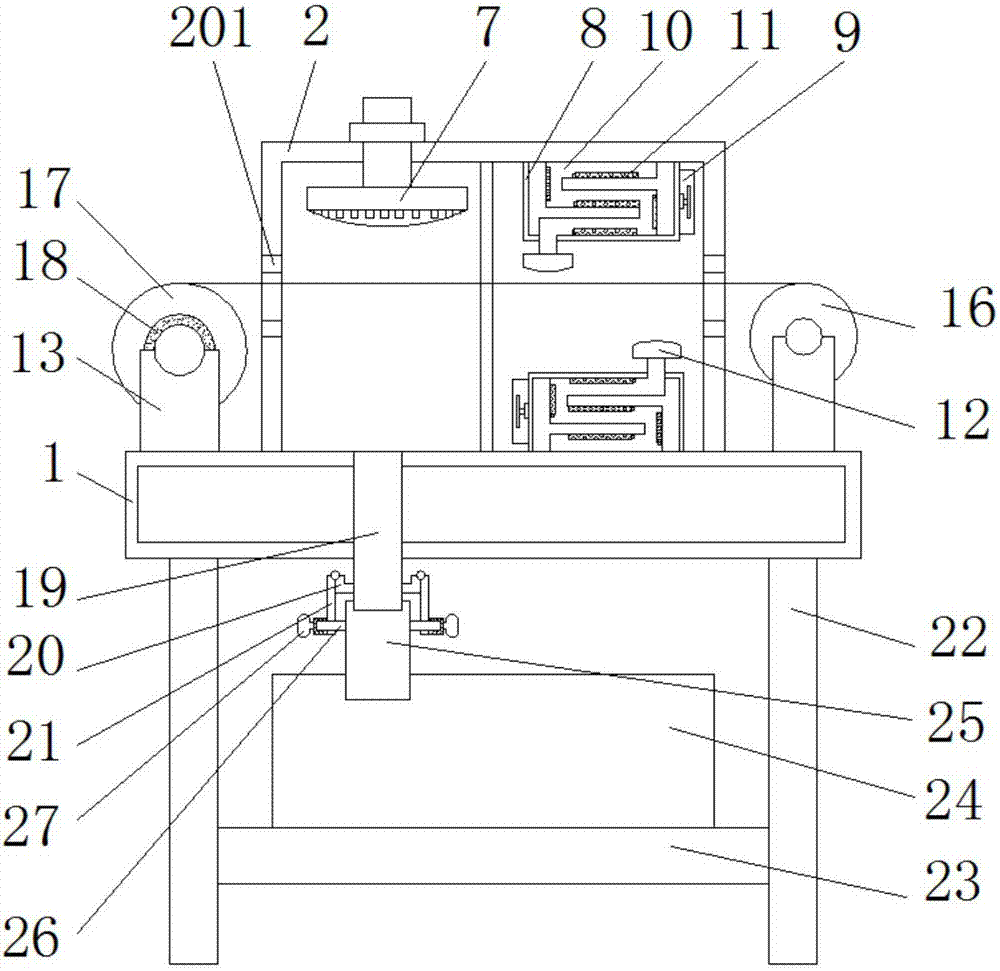

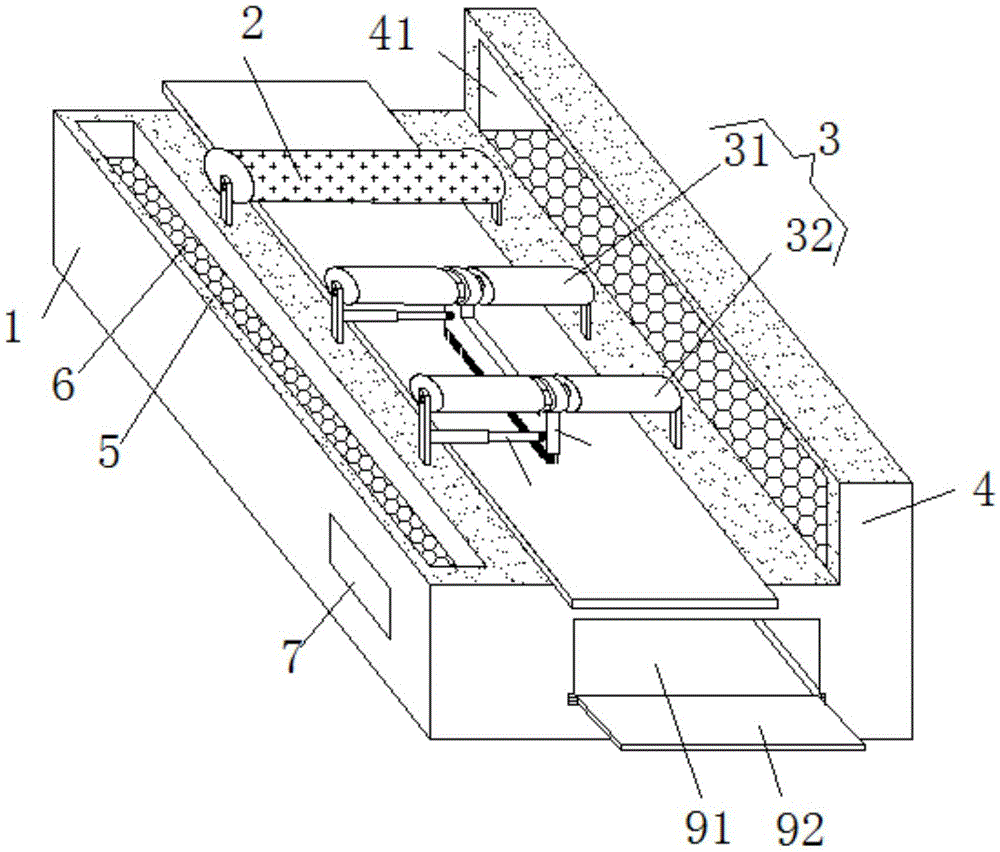

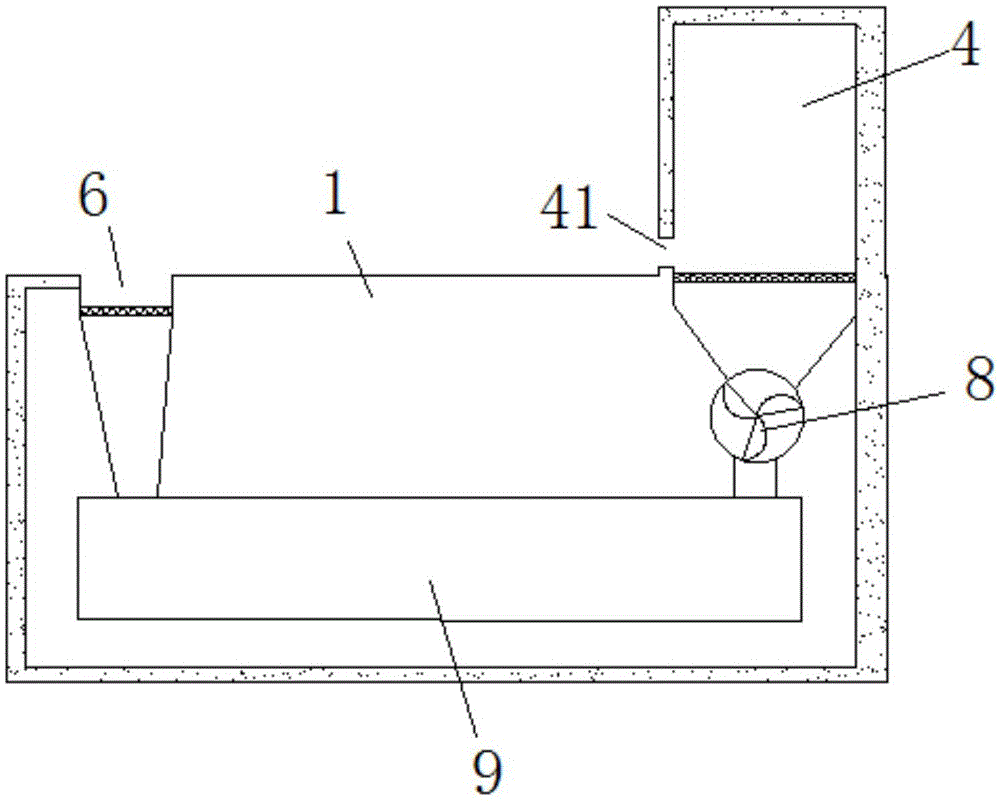

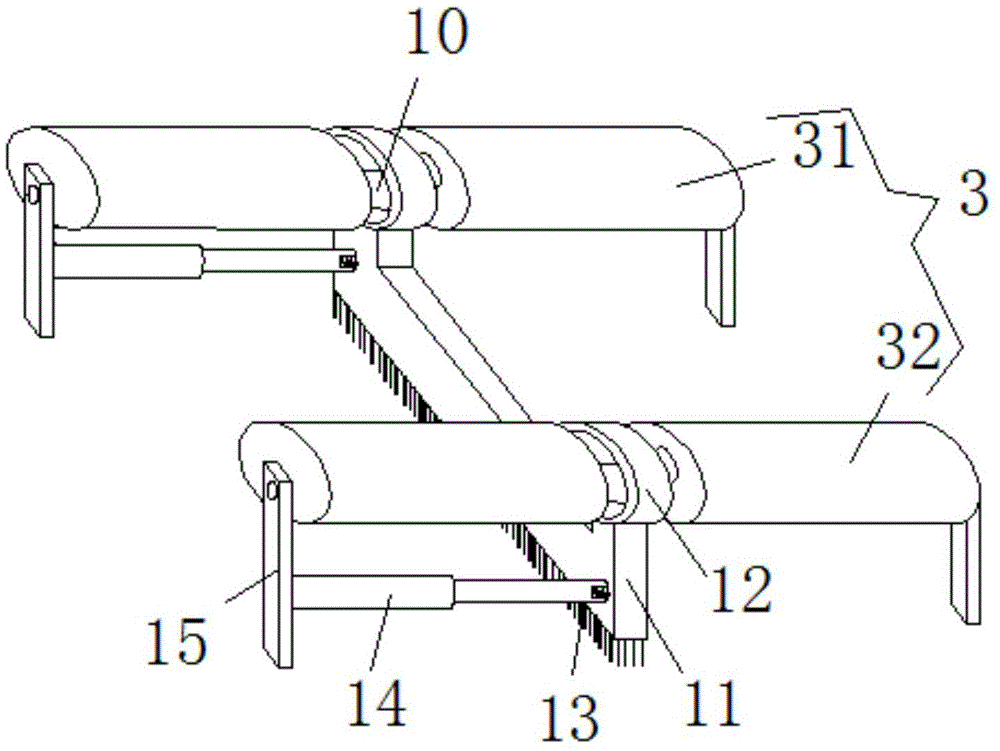

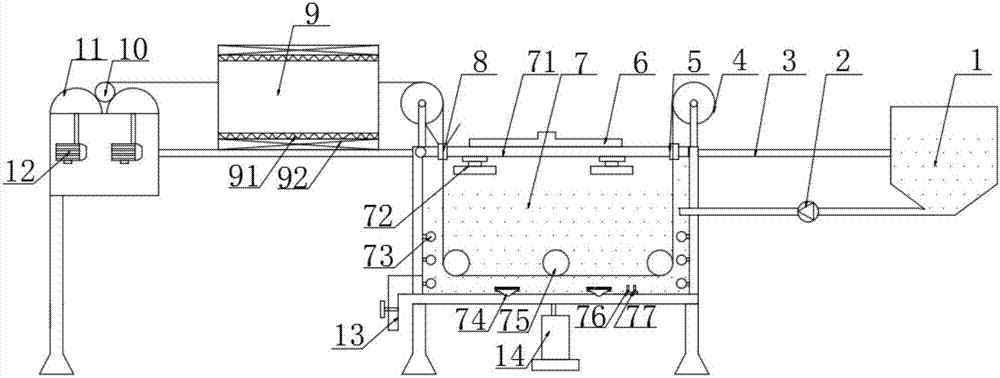

Rapid cloth cleaning equipment for textile processing

InactiveCN110924001AEasy to cleanEasy to dryLiquid/gas/vapor removal by suctionTextile treatment cleaning apparatusProcess engineeringMechanical engineering

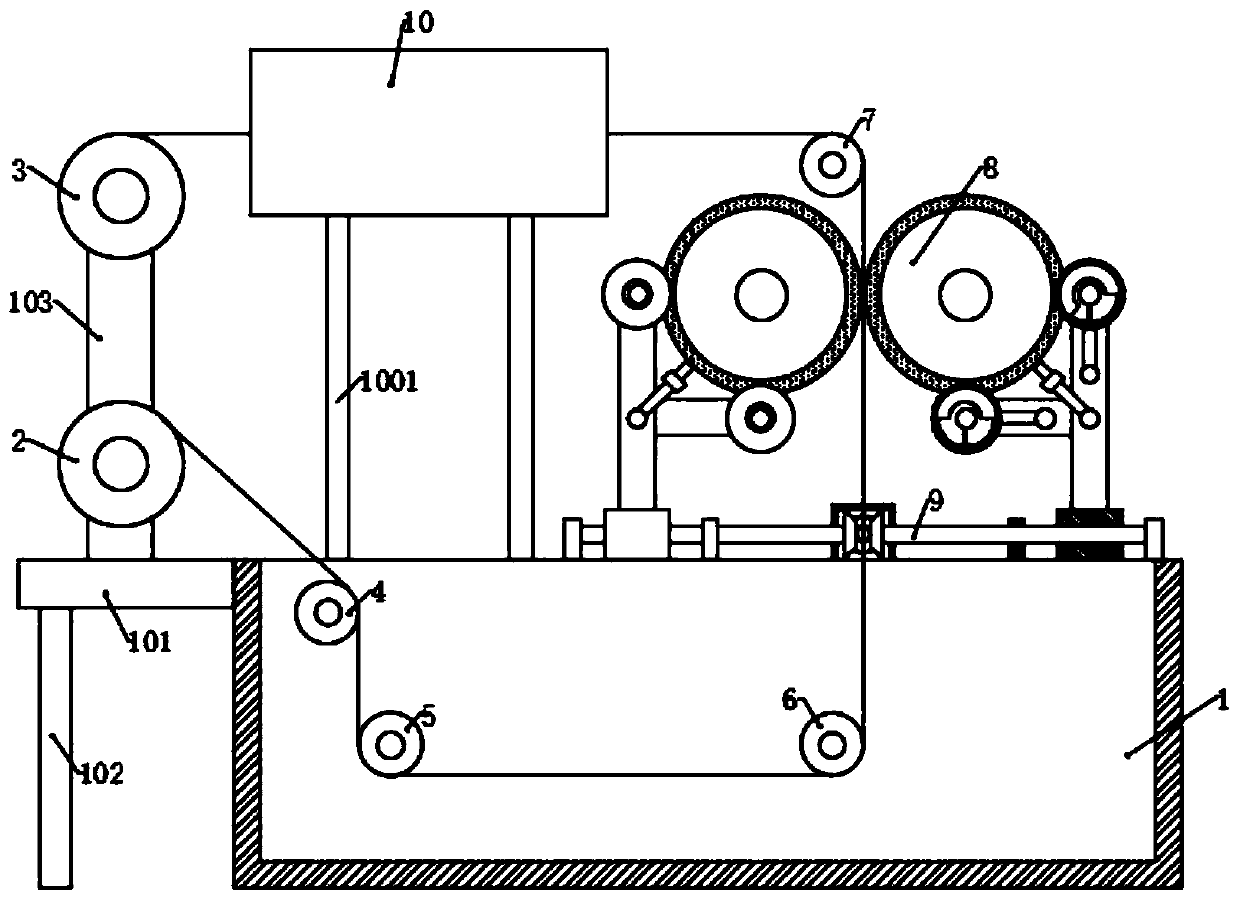

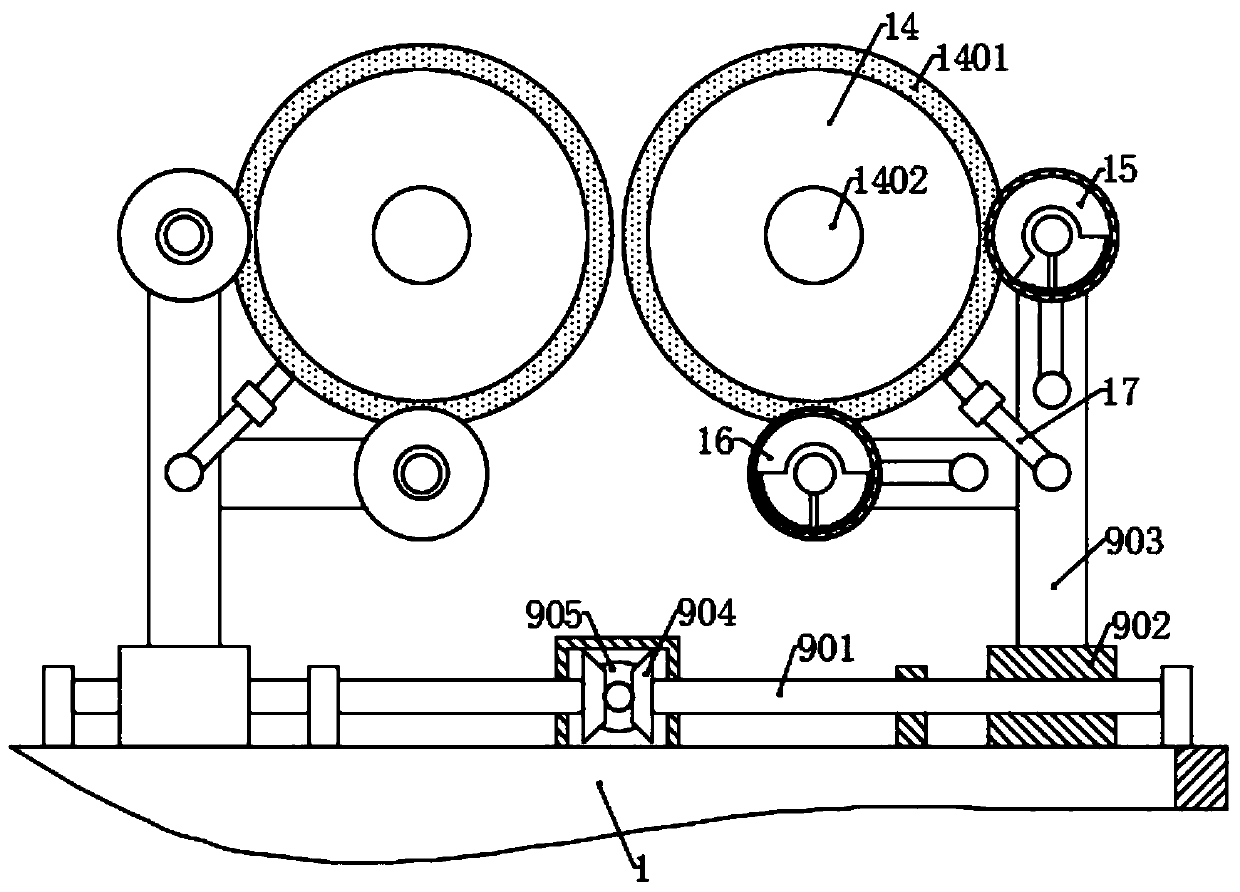

The invention discloses rapid cloth cleaning equipment for textile processing, and belongs to the technical field of textile processing. The rapid cloth cleaning equipment comprises a cleaning tank, adischarging cylinder, a material collecting cylinder, a drying mechanism, a hot air drying mechanism and adjusting mechanisms. According to the rapid cloth cleaning equipment for textile processing,the cloth is discharged through the discharging cylinder, and then the cloth is movably cleaned in water through the effects of a first guide wheel, a second guide wheel and a third guide wheel; thenwater absorption is carried out through sponge layers on two oppositely rotating drying cylinders after cleaning is performed, and hot air drying is conducted through the hot air drying mechanism after water absorption is performed; when the sponge layer after water absorption is subjected to the extrusion of a first water squeezing cylinder, the sponge layer is kept at relative humidity so as tocontinuously absorb water and dry the subsequent cloth; a second water squeezing cylinder further squeezes the sponge layer, and after the sponge layer works for a period of time, the sponge layer issprayed with clean water through a water outlet pipe; and then a second water collecting pipe is adopted for squeezing and de-watering, and the sponge layer is cleaned, so that the sponge layer is kept relatively clean.

Owner:安徽云至信电子商务有限公司

Cloth dyeing machine convenient to detach

InactiveCN107326577AEasy to disassembleStir wellTextile treatment machine arrangementsTextile treatment cleaning apparatusCouplingEngineering

The invention discloses a cloth dyeing machine which is easy to disassemble, comprising a support platform, a cloth dyeing box is welded in the middle of the outer surface of the support platform, a stirring box is arranged on the rear side of the cloth dyeing box, and a first motor box is welded on the top of the stirring box A stirring motor is fixedly installed inside the first motor box. The rotating shaft of the stirring motor runs through the first motor box and the stirring box in turn and is connected to the stirring rod through a coupling transmission. The water outlet on one side of the stirring box is fixedly connected to the first As for the water outlet pipe, one end of the first water outlet pipe is fixedly connected with a water pump, one side of the water pump is fixedly connected with a second water outlet pipe, and one end of the second water outlet pipe is fixedly connected with a nozzle through a flange bearing. This easy-to-disassemble cloth dyeing machine can stir the dye evenly by setting the stirring motor and the stirring box, and then make the dyeing of the cloth more uniform when the dye is dyed, and avoid the situation that the dyed cloth has different shades of color. Thereby improving the quality of the dyed cloth.

Owner:范威

Printing and dyeing vat cleaning device

ActiveCN105970532AEfficiencyEffect achievedTextile treatment containersTextile treatment cleaning apparatusWater storage tankEngineering

The invention discloses a printing and dyeing vat cleaning device comprising a vat body; two sides of the vat body are respectively provided with a drive unit and a water storage tank; two sides of the inner wall of the vat body are respectively provided with a connecting plate; one side, far away from the vat inner wall, of the connecting plate is connected with a cleaning shaft; one end, far away from the water storage tank, of the cleaning shaft penetrates the vat body inner wall and extends into the drive unit; the cleaning shaft is vertically provided with a cleaning rod penetrating the top and bottom of the cleaning shaft; the side face of the cleaning rod is provided with first cleaning brush; a drive slot is arranged in the cavity of the cleaning shaft, two sides of the drive slot are respectively provided with an unloading pad, and the bottom of the drive slot is provided with a mobile block. The drive units allow the cleaning shaft to drive the cleaning rod to rotate, so the first cleaning brush on the cleaning rod can clean the inner wall, thus cleaning two sides of the inner wall of the vat body, and improving work efficiency.

Owner:浙江金兆纺织有限公司

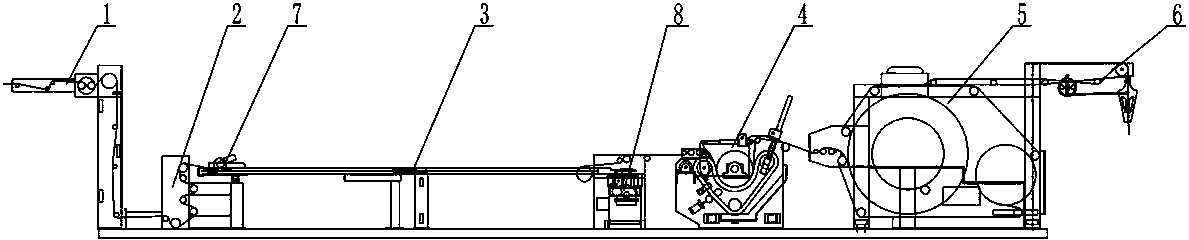

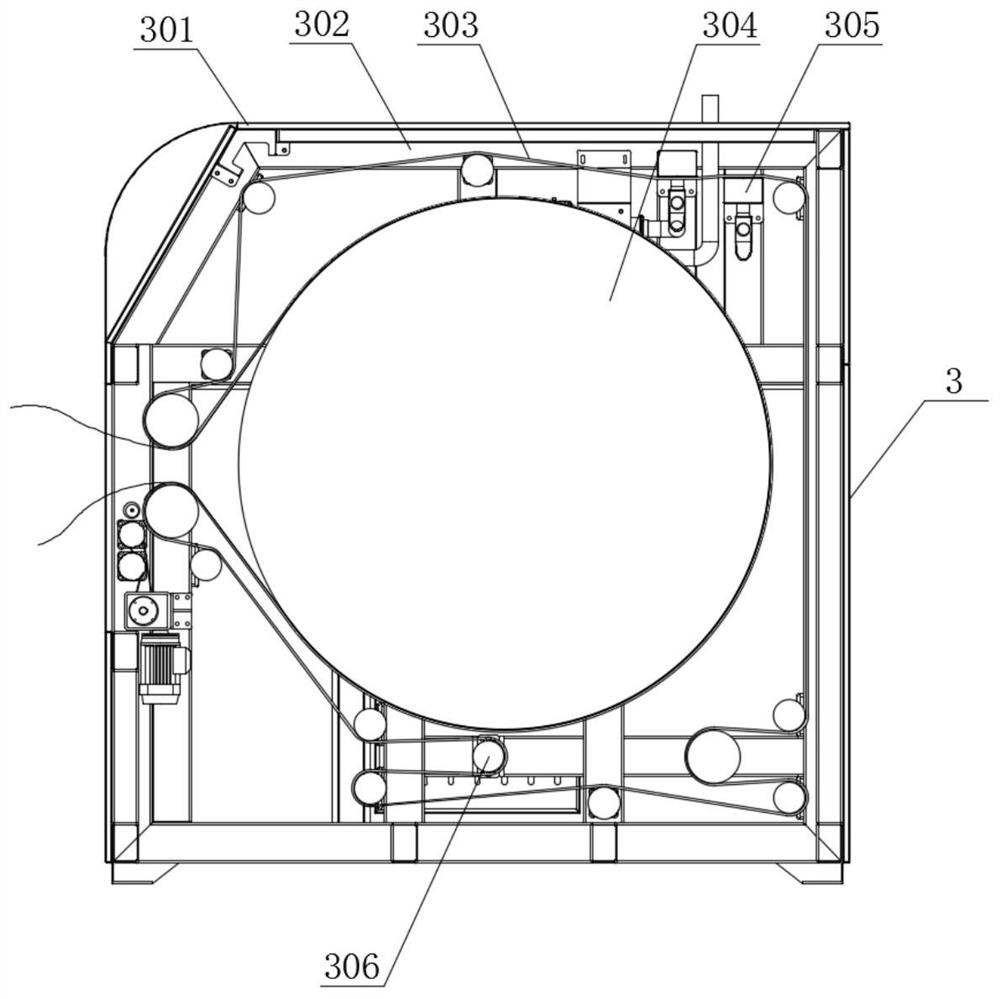

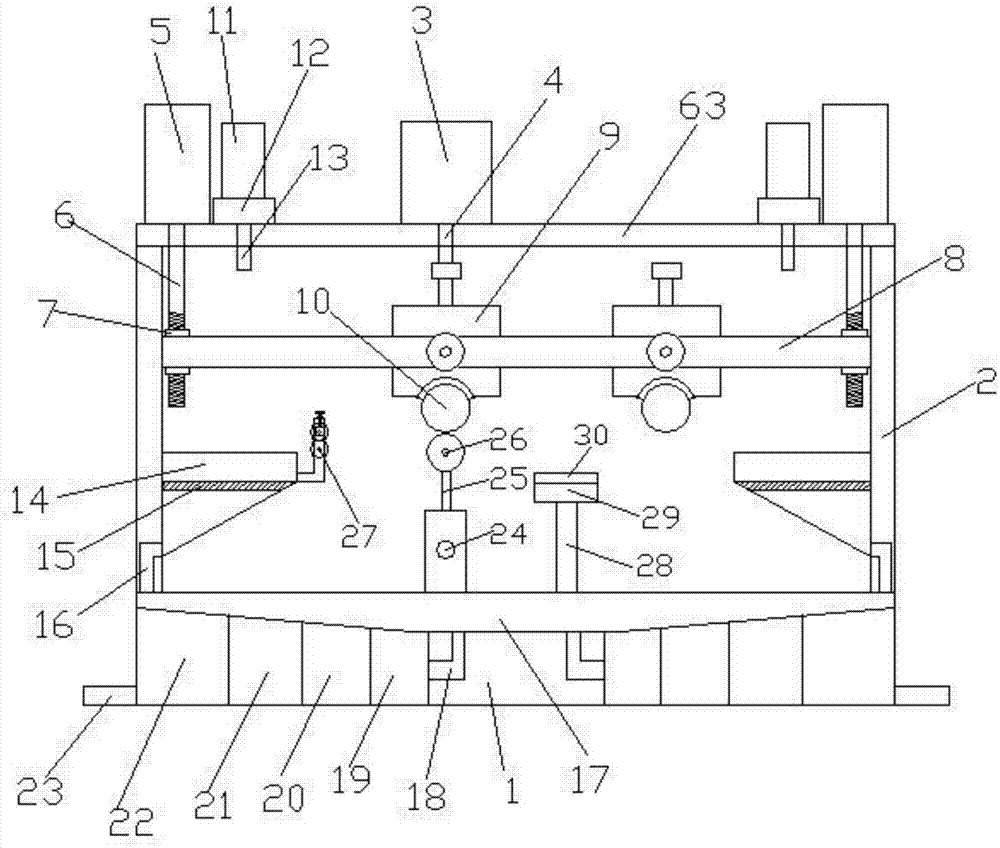

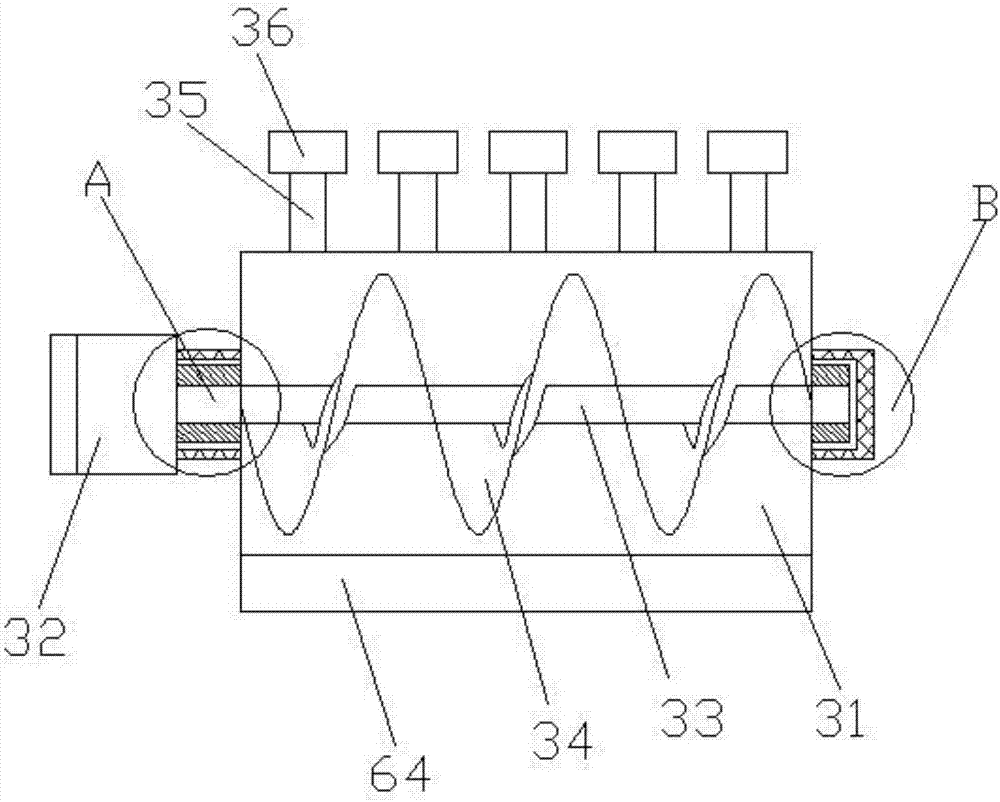

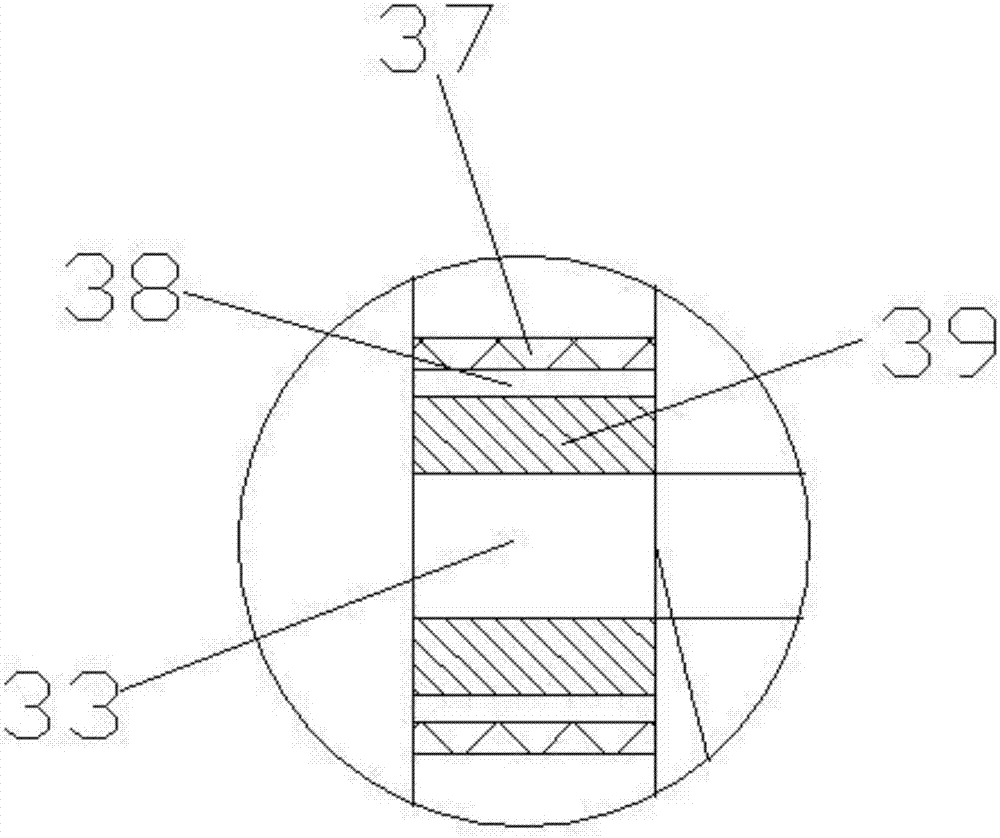

Open-width knitted fabric pre-shrinking machine and pre-shrinking process thereof

ActiveCN104018311AGuaranteed dryingMake sure to ironShrinkingTextile treatment cleaning apparatusShrinkage rateAgricultural engineering

The invention discloses an open-width knitted fabric pre-shrinking machine, comprising an open-width cloth-feeding device, a mechanical weft-straightening device, a steam conditioning and stentering device, a rubber blanket pre-shrinking device and an open-width plaiting device, wherein the front end of the steam conditioning and stentering device is provided with an overfeed pinning device; and a felt finishing device is arranged between the rubber blanket pre-shrinking device. The open-width knitted fabric pre-shrinking machine comprises the felt finishing device; and the fabric is finished by the felt finishing device after passing through the rubber blanket pre-shrinking device, thereby guaranteeing the fabric to be dried and flatten, further improving handfeel of the fabric and increasing glossiness of the fabric surface. Meanwhile, shrinkage rate of the fabric can be more stable, so that the open-width knitted fabric with flat cloth surface, good surface glossiness, good handfeel and stable shrinkage rate can be processed.

Owner:浙江瑞格机械科技有限公司

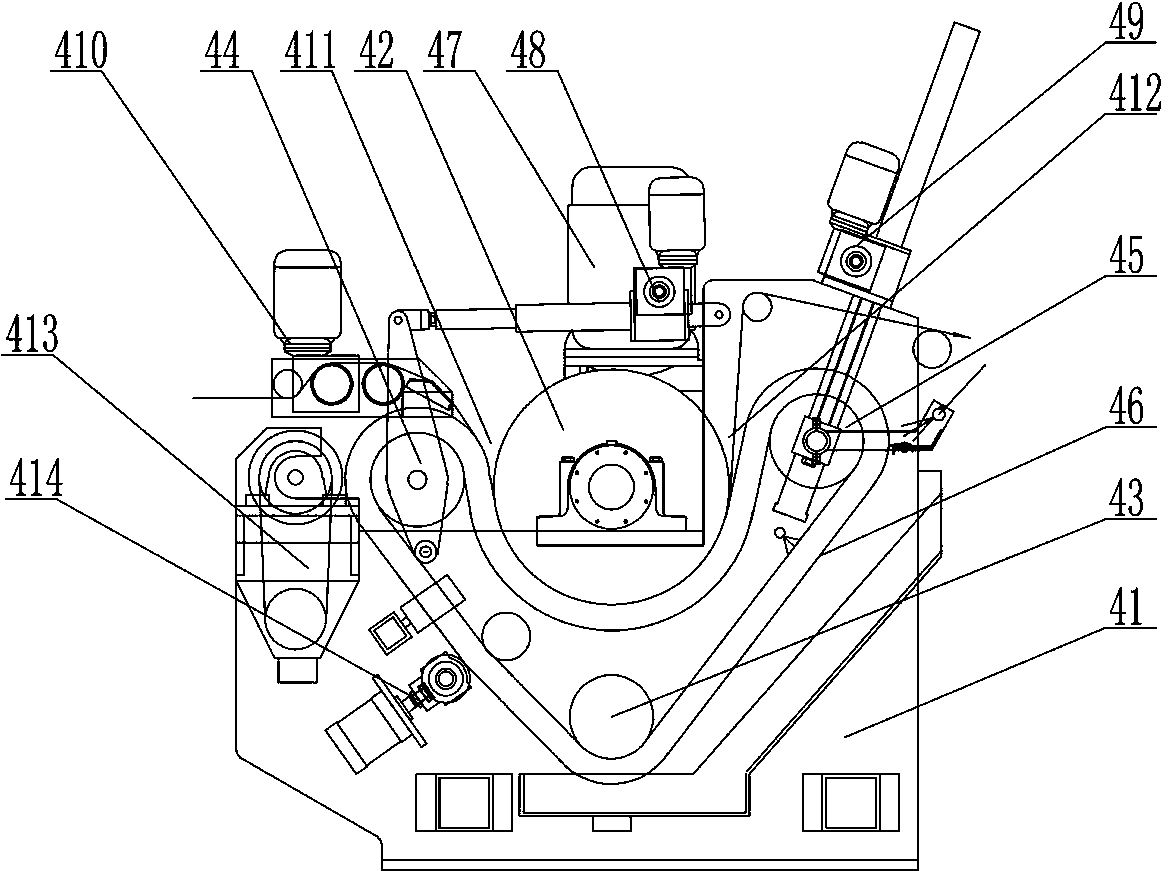

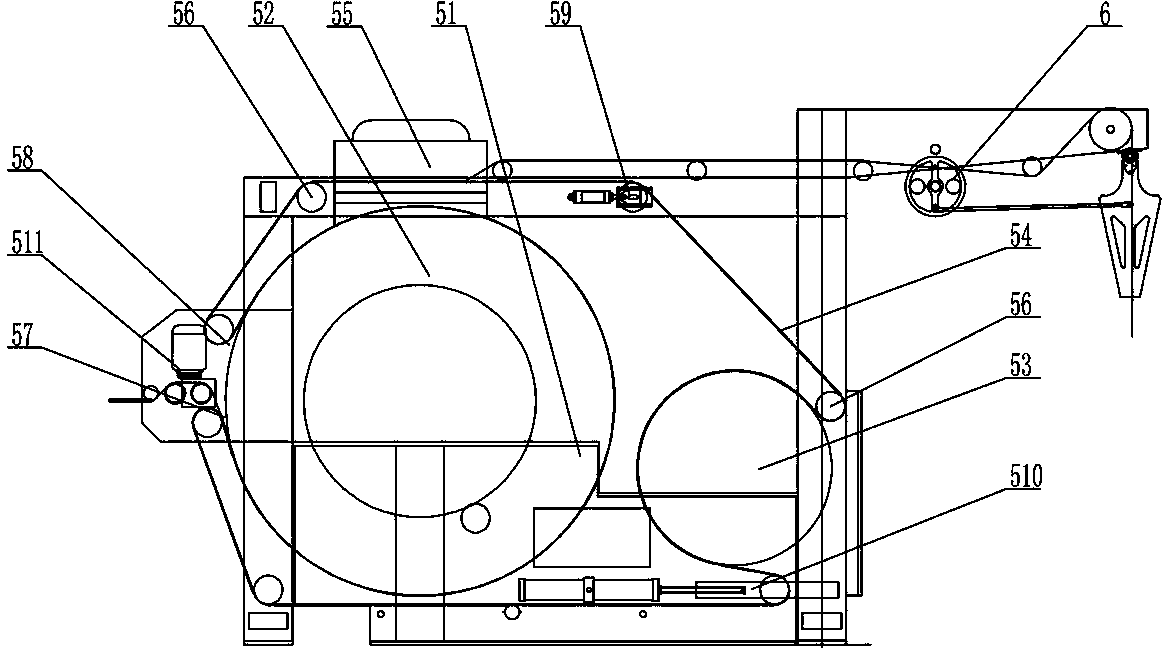

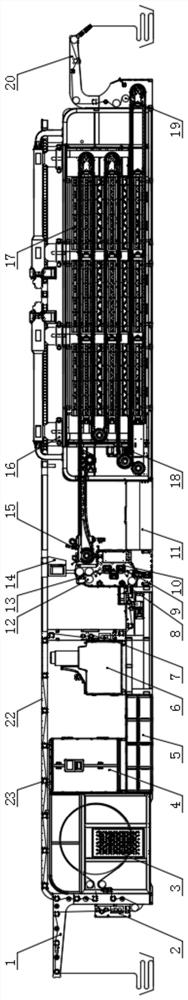

Integrated intelligent equipment of waterless dyeing and finishing process for textile fabric

PendingCN111945333AUniform dyeingReduce creasesSucessive textile treatmentsLiquid/gas/vapor removalProcess engineeringSewage

The invention discloses an integrated intelligent equipment of waterless dyeing and finishing process for textile fabric. The equipment comprises an ironing and pre-shrinking integrated system, a fixing frame, a main control operation platform and a drying room, wherein a plurality of cloth guide rollers are evenly arranged on the fixing frame, and the ironing and pre-shrinking integrated system,the main control operation platform and the drying room are all located in the fixing frame. The integrated intelligent equipment of waterless dyeing and finishing process also comprises a cloth feeding frame, arranged on the side wall of the ironing and pre-shrinking integrated system; a cloth feeding centering device, arranged on the side wall of the cloth feeding frame, for solving the problemthat cloth deviates due to various reasons; and a sewage concentration treatment device, arranged on the side, far away from the cloth feeding frame, of the ironing and pre-shrinking integrated system. The equipment has the advantages that waterless dyeing and cloth ironing are integrated, meanwhile, all steps are intelligently detected and controlled in cloth processing, and the conditions of thecloth in all the steps and the operation condition of the equipment can be known in time.

Owner:广东亚生新能源科技有限公司

Textile printing and dyeing device

ActiveCN107974782AReduce pollutionQuick switchLiquid/gas/vapor removalTextile treatment machine arrangementsTextile printerEngineering

The invention discloses a textile printing and dyeing device belonging to the technical field of textile equipment. The textile printing and dyeing device comprises a base, and is characterized in that supporting columns are fixedly connected to the left and right sides of the upper part of the base; the upper ends of the supporting columns are fixedly connected with a top plate; a plurality of dye tanks are arranged at middle positions on the upper part of the top plate; the lower parts of the dye tanks are connected with a liquid supply pipe; four drive parts are arranged on the upper part of the top plate and respectively distributed at four corners of the top plate; the lower parts of the drive parts are connected with drive rods; a support frame is arranged below the top plate; and the drive rods penetrate through the support frame. The textile printing and dyeing device provided by the invention comprises two printing and dyeing boxes which are respectively located in an operating state and a ready state, the two states can be rapidly switched according to printing and dyeing needs, and the printing and dyeing effects are ensured.

Owner:SHAOXING JINCHEN BIOLOGICAL TECH CO LTD

Cotton yarn dyeing process

ActiveCN106283448AStir wellWell mixedTextile treatment machine arrangementsTextile treatment cleaning apparatusYarnPulp and paper industry

The invention provides a cotton yarn dyeing process, and belongs to the technical field of dyeing treatment. A method for dyeing cotton yarns used for weaving a jean fabric comprises the following steps: a, preparing the cotton yarns; b, performing surface treatment on the cotton yarns; c, rinsing the cotton yarns for the first time; d, rinsing the cotton yarns for the second time; e, dyeing the cotton yarns; f, drying the cotton yarns; and g, rolling up the cotton yarns. The cotton yarn dyeing process disclosed by the invention has the advantage of capability of dyeing the cotton yarns used for weaving the jean fabric more effectively.

Owner:HAINING DENIM WEAVING CO LTD

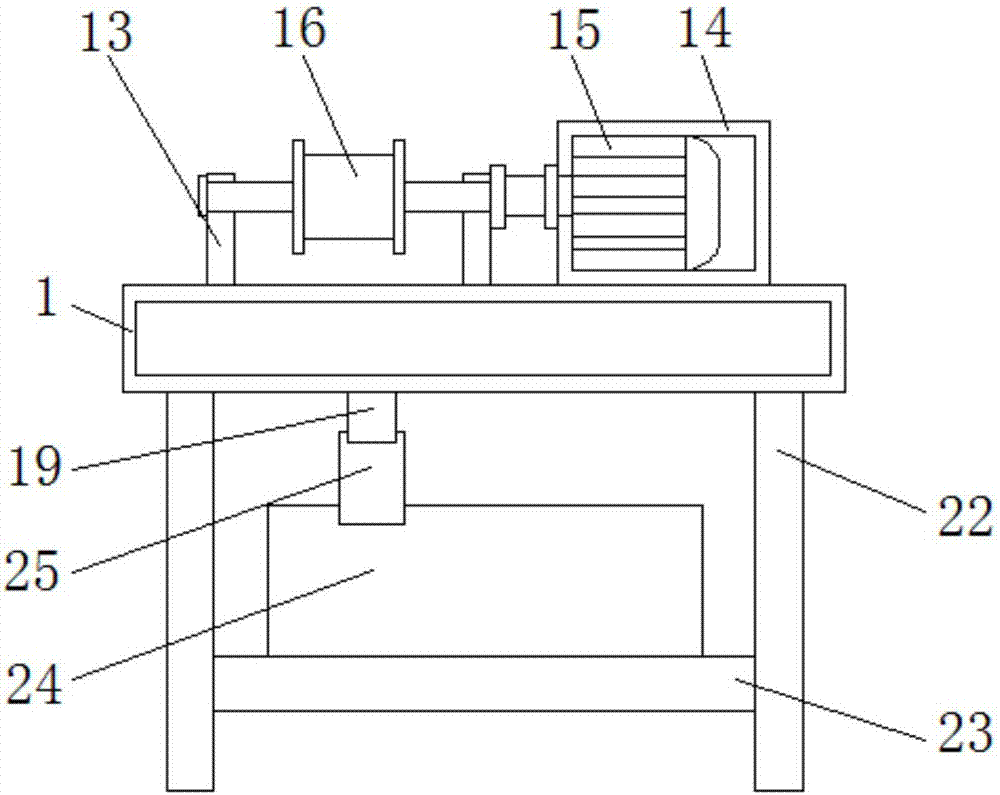

Cheese dyeing and dewatering device and equipment using same and using method of device

InactiveCN106012386AHigh emission concentrationReduce processing energy consumptionSucessive textile treatmentsTextile treatment containersPulp and paper industryEquipment use

Owner:王博敏

Cleaning device for spinning machine

ActiveCN105603592AAffect qualityAffect normal workFibre cleaning/openingTextile treatment cleaning apparatusEngineering

The invention discloses a cleaning device for a spinning machine. The cleaning device comprises a workbench, a sweeping device, an ash intake cavity, a colleting cavity and a fixing part. The collecting cavity is arranged in the inner cavity of the workbench. A groove is formed in the left end of the upper portion of the workbench. The sweeping device and a cleaning roller are arranged in the middle of the upper portion of the workbench. The sweeping device comprises a first fixing shaft and a second fixing shaft. A fixing rod is arranged in the middle of each of the first fixing shaft and the second fixing shaft. A sweeping plate is arranged at the lower ends of the first fixing shaft and the second fixing shaft. Two ends of the upper portion of the sweeping plate are respectively provided with clamp rings corresponding to the fixing rods. A brush is arranged at the lower end of the sweeping plate. The left side of the sweeping plate is connected with the fixing part through a telescopic rod. The ash intake cavity is arranged in the right end of the upper portion of the workbench. The lower end of the inner cavity of the ash intake cavity is connected with one end of an exhaust fan through a pipeline. The cleaning device is novel in structure, high in practicality, convenient to use and evident in cleaning effect.

Owner:南通景群纺织品有限公司

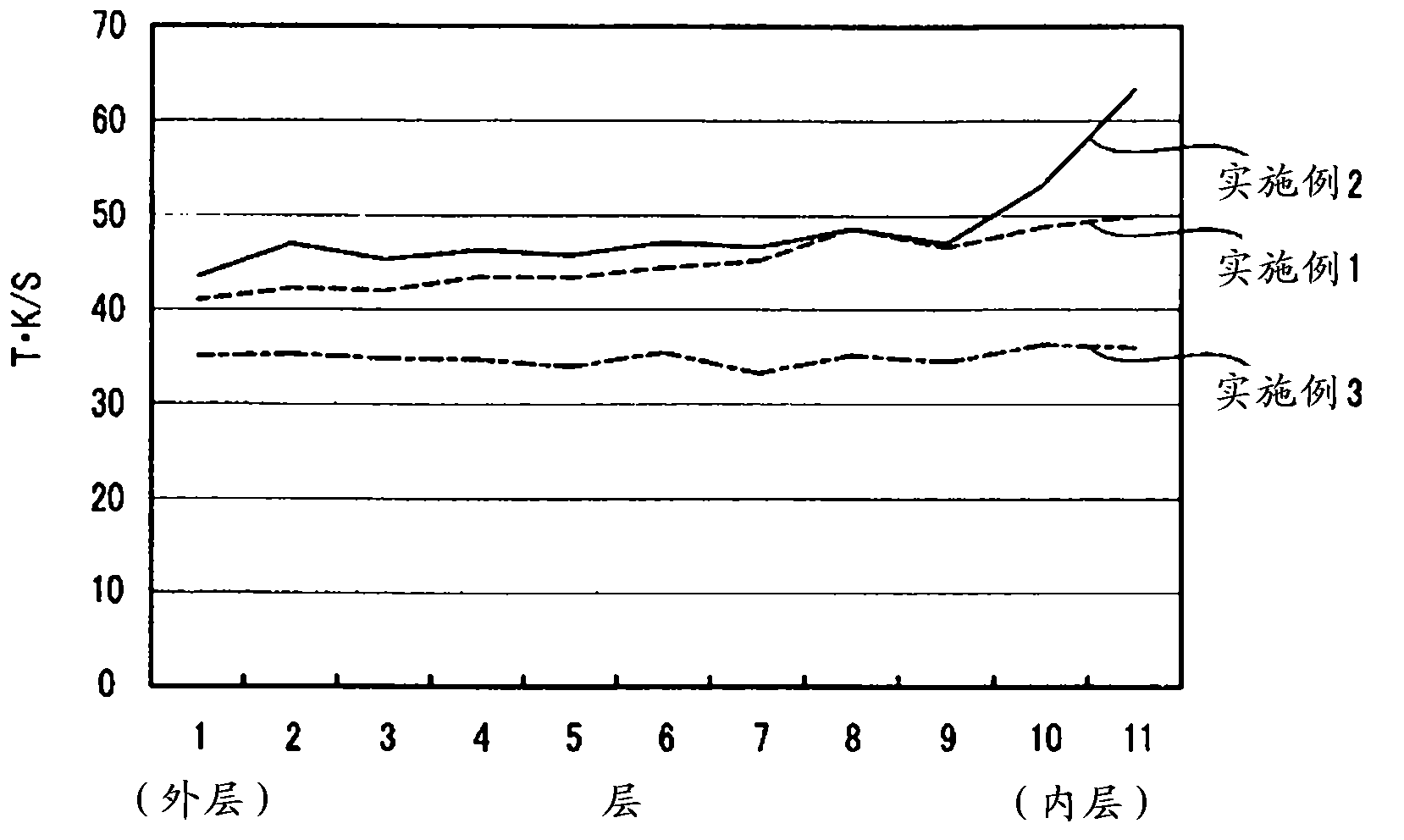

Building tent membrane and processing technology thereof

ActiveCN106192446AExtended service lifeExtended use timeFireproof paintsLiquid surface applicatorsAdhesivePlasticizer

The invention provides a building tent membrane and a processing technology thereof. The technical problems of great shortening of the service life and short use time of present tent clothes with no flame retardation or mildew resisting characteristics are solved in the invention. The building tent membrane comprises a base cloth layer, the upper side of the base cloth layer is provided with a PVC coating layer, and the PVC coating layer comprises, by weight, 90-110 parts of PVC paste resin, 2-4 parts of a stabilizer, 6-8 parts of an adhesive, 60-70 parts of a plasticizer, 3-5 parts of a flame retardant and 0.5-2 parts of a mildew inhibitor. The invention also provides the processing technology of the building tent membrane. The building tent membrane has long use time.

Owner:ZHEJIANG HUIFENG NEW MATERIALS

Novel fabric dyeing machine used in textile field

InactiveCN106868751ARoll up and store quicklyQuick clean upTextile treatment machine arrangementsTextile treatment cleaning apparatusMagnetDyeing

The invention discloses a new cloth dyeing machine used in the textile field, which comprises a batching box, a pump, a support plate, a guide wheel, a cloth inlet, a tap water inlet, a cloth dyeing box, a top cover, a nozzle, a heating pipe, and an aeration pan , aeration hole, guide wheel, temperature sensor, liquid level sensor, cloth outlet, inclined plate, fixed plate, spring, magnet, scraper, drying box, heating wire, fan, cloth roll, take-up roll, adjusting speed motor, outlet and aeration motor. In the present invention, fast dyeing can be achieved by adding a heating device inside the dyeing box, and the aeration plate at the bottom speeds up the flow of the internal dyeing liquid, preventing the precipitation of the dyeing agent inside, causing uneven dyeing of the cloth and affecting the quality of the cloth; and the cloth is discharged The design of the mouth can carry out the clamping and drying treatment of the cloth to prevent the dyeing solution from dripping into the outside and cause waste. At the same time, the drying box shell realizes the drying treatment on both sides of the cloth, which is convenient for the cloth to be quickly rolled up and stored.

Owner:扬州市嘉鑫织造实业有限公司

Color yarn cleaning device

InactiveCN105734865AAvoid wastingImprove work efficiencyMechanical cleaningPressure cleaningYarnBristle

The invention provides a dyed yarn cleaning device, which includes a cleaning bucket, a wire rack is arranged above the cleaning bucket, a wire roller is arranged inside the cleaning bucket, and the wire rollers are arranged on both sides of the inside of the cleaning bucket. A cleaning roller is arranged between the rollers, the number of the cleaning rollers is two, and they are arranged oppositely. The cleaning rollers are provided with bristles, and the lower end of the cleaning bucket is provided with a spray head. For flushing, a rotating motor is arranged on the wire rack. The colored yarn is guided by the wire rack and the wire roller, and the colored yarn is cleaned by the cleaning roller in the cleaning bucket, and the colored yarn is washed by the nozzle, and the colored yarn is automatically cleaned to improve the work efficiency. Set up a detection device The position of the colored yarn is detected to avoid the waste of resources caused by the idling of the equipment.

Owner:WUHU FUCHUN DYEING & WEAVING

Garment processing cloth dyeing machine convenient to clean

InactiveCN108532166ASolve the problem of residual material residueEasy to replaceLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDrive shaftPulp and paper industry

The invention discloses a garment processing cloth dyeing machine convenient to clean. The garment processing cloth dyeing machine comprises a bottom plate, a worktable, a dye chamber and a drying chamber. Universal wheels are mounted at four corners of the bottom of the bottom plate via vertical legs, the worktable is arranged above the bottom plate and is fixedly connected with the bottom plateby support columns, the dye chamber is arranged at the lower end of the worktable, the bottom of the dye chamber is fixed to the bottom plate by the aid of support rods, a stirring motor is mounted atthe upper end of the dye chamber, a cleaning motor is mounted on the bottom plate and is positioned at the lower end of the dye chamber, and a stirring rod is fixedly connected with a transmission shaft of the stirring motor and is arranged in the dye chamber. The garment processing cloth dyeing machine convenient to clean has the advantages that telescoping of a second electric telescopic rod can be adjusted, and accordingly cloth with diversified thicknesses can be squeezed and stripped and can be completely stripped; the dye chamber can be cleaned when dye is replaced, the cleaning speedscan be increased, the cleaning quality can be improved, and accordingly the garment processing cloth dyeing machine is convenient to use in next procedures.

Owner:吴丽玲

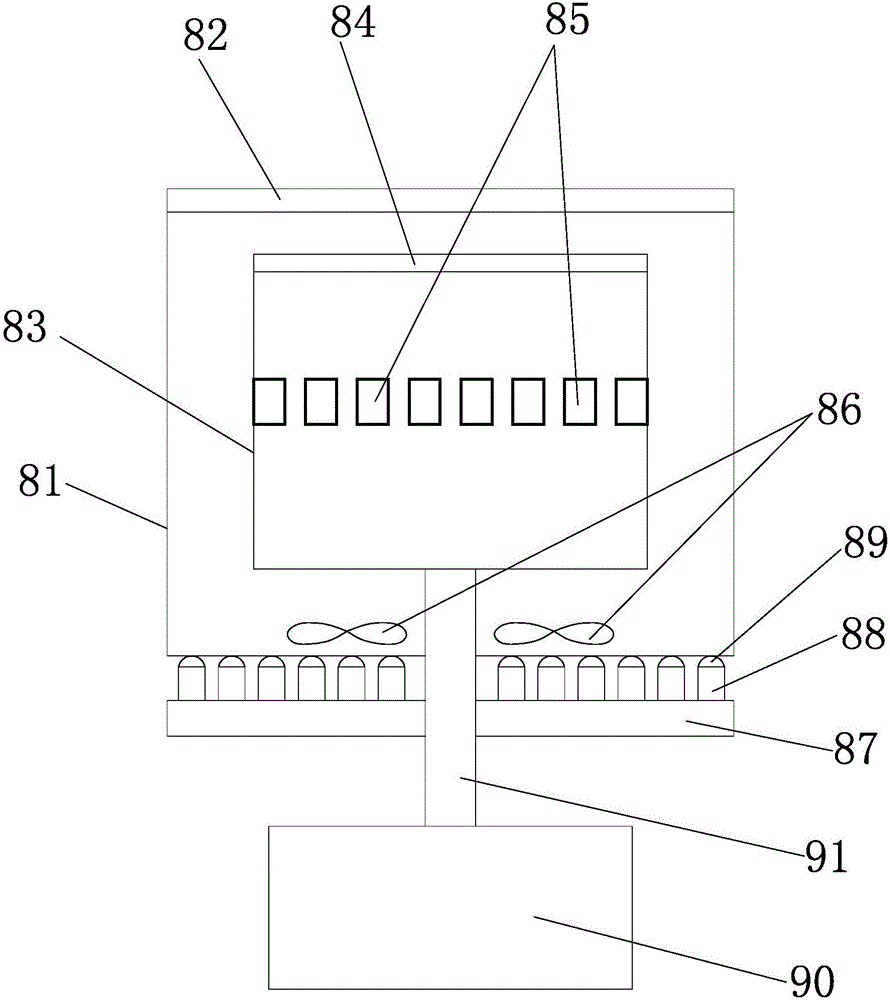

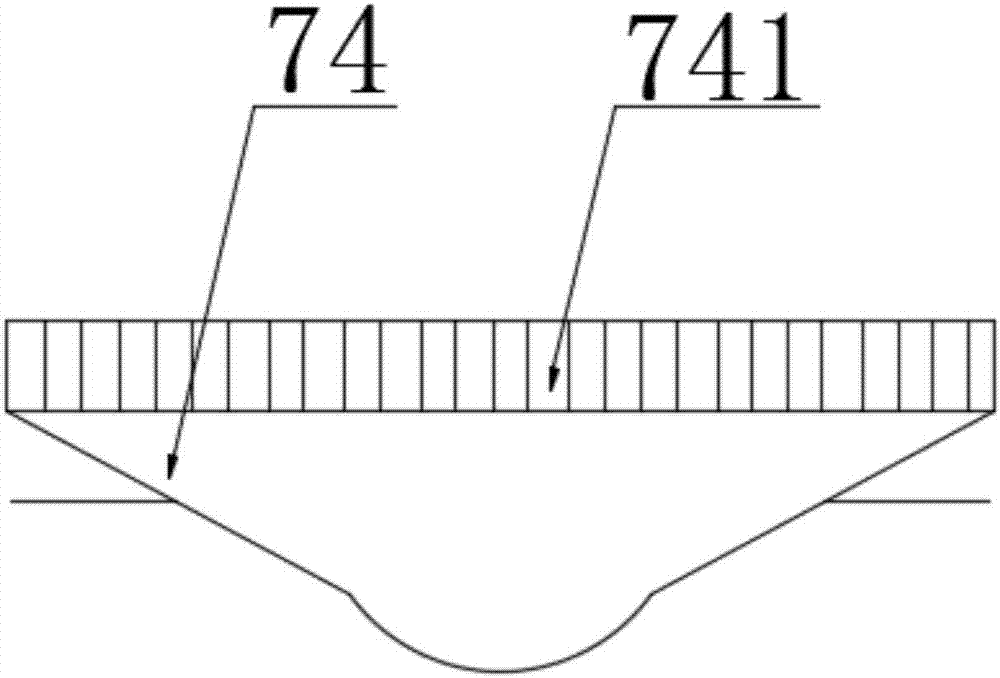

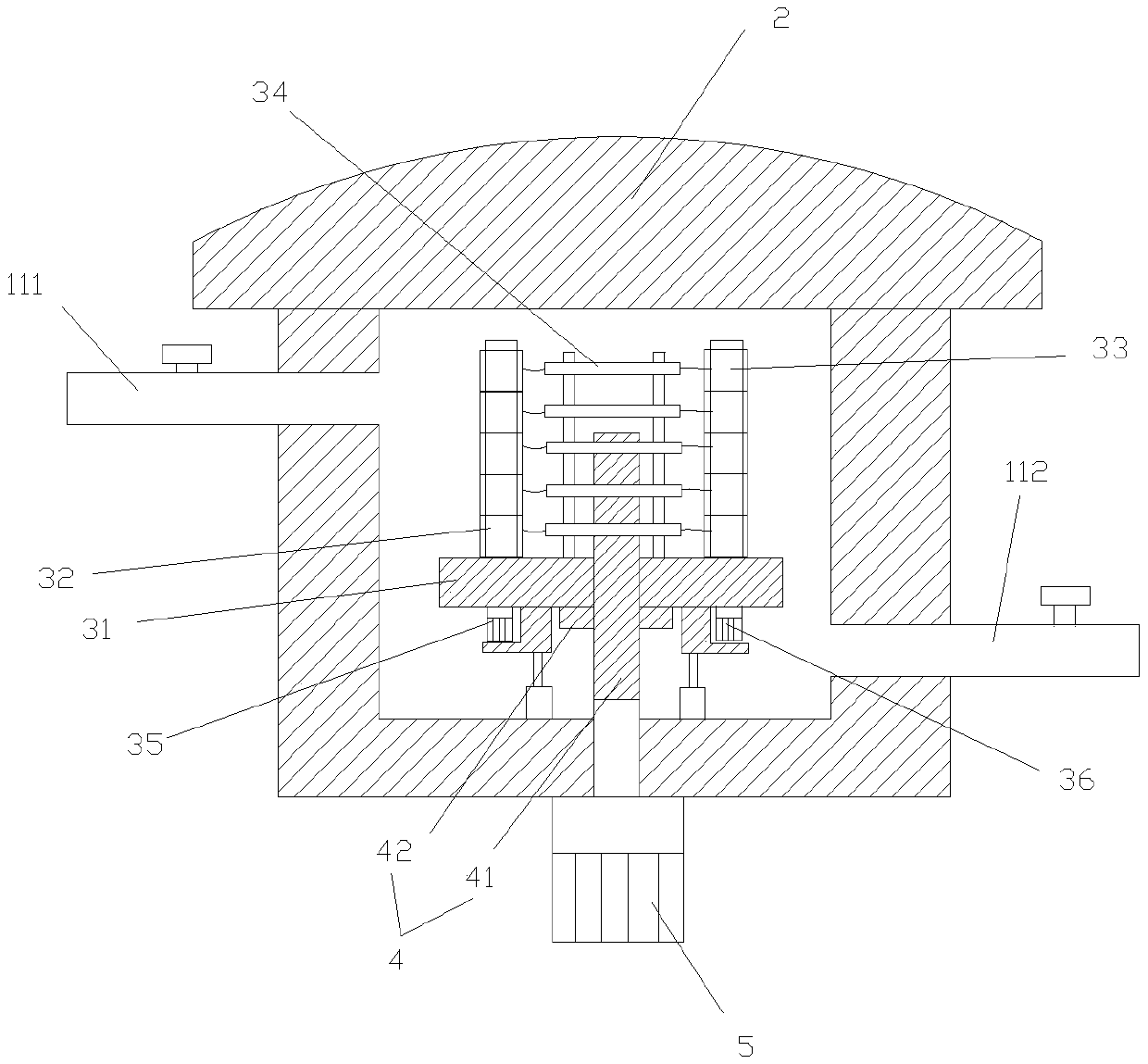

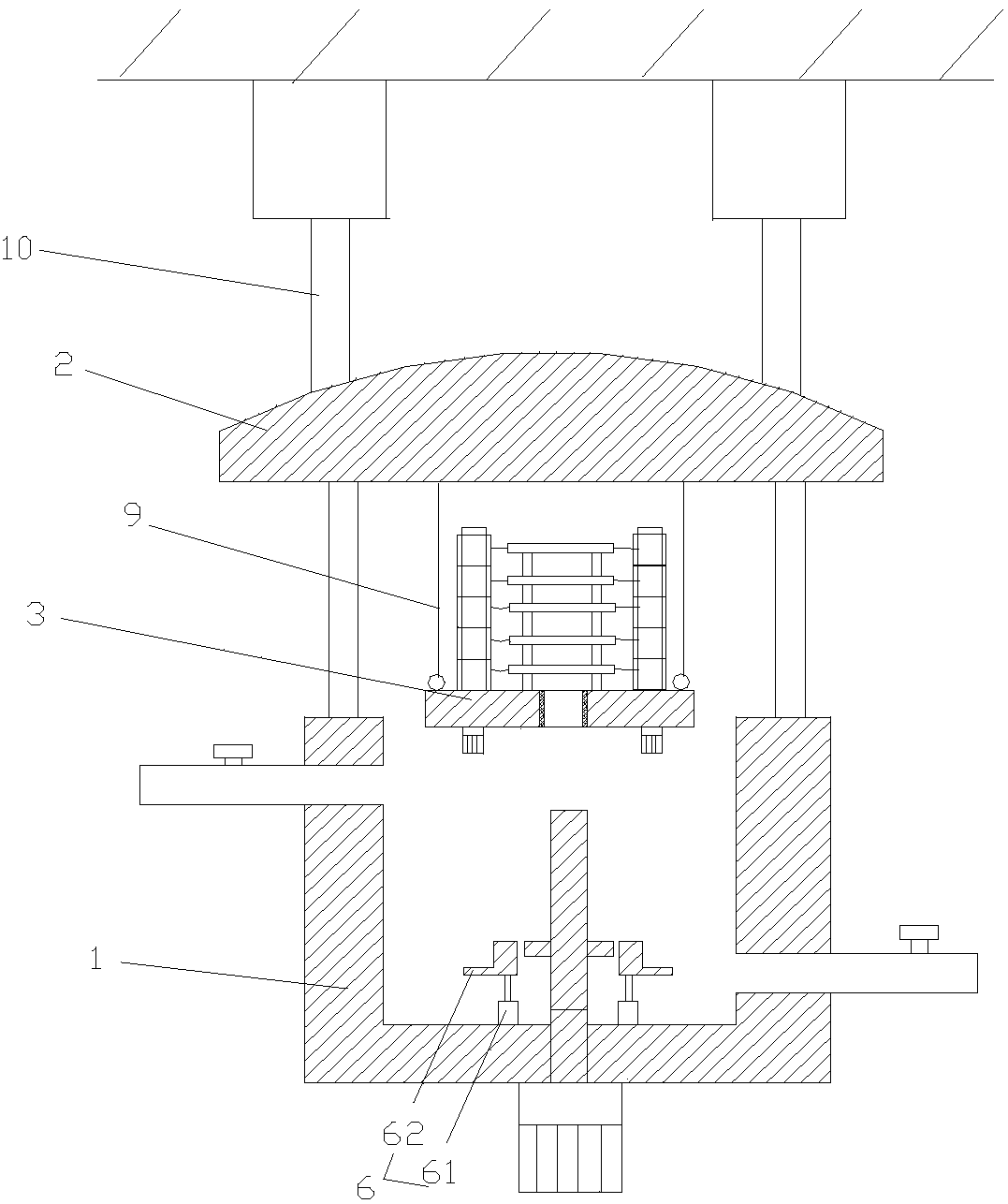

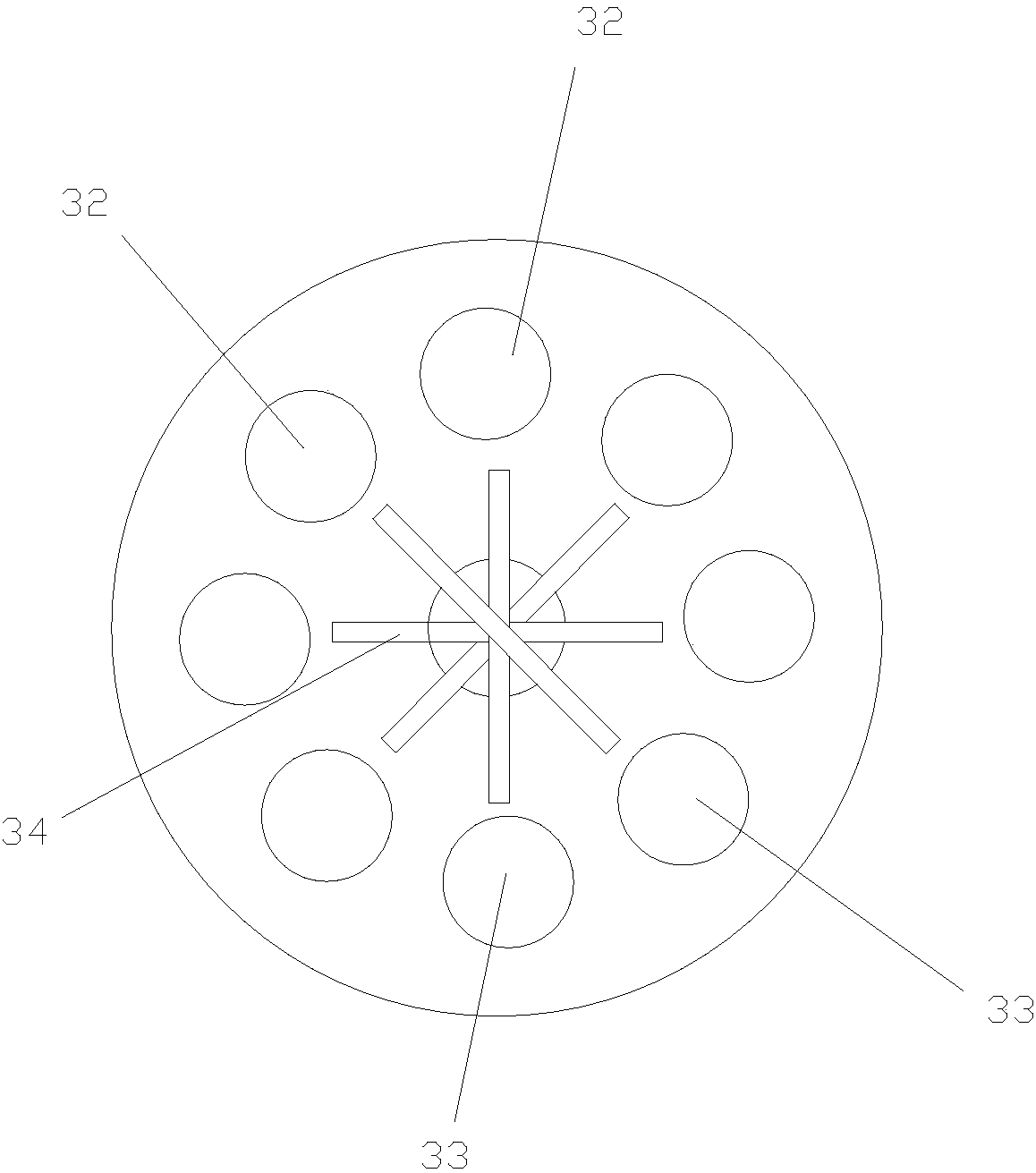

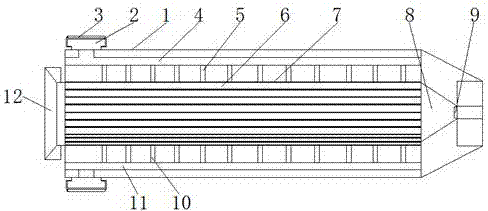

Apparatus and process for producing absorbent

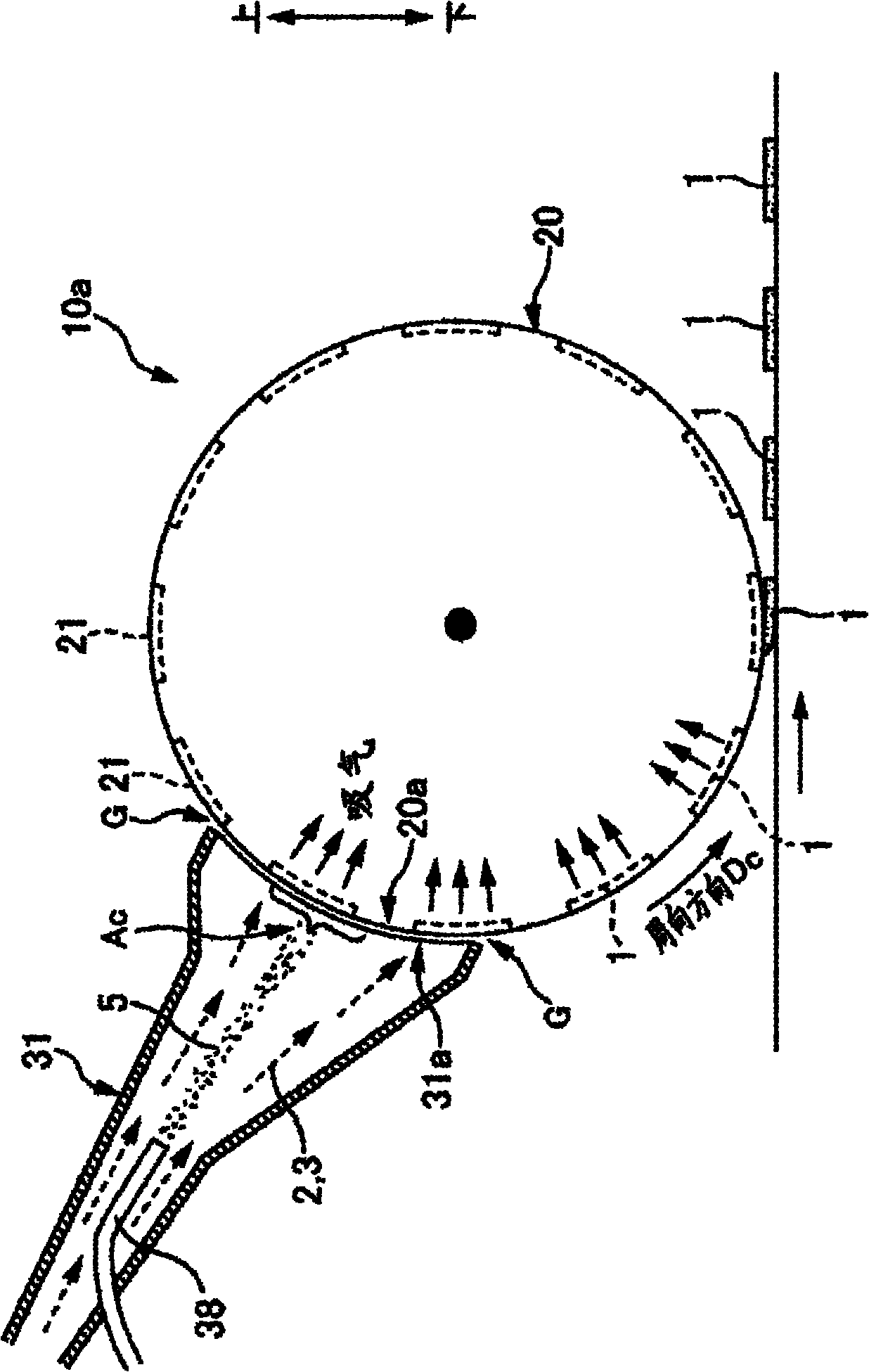

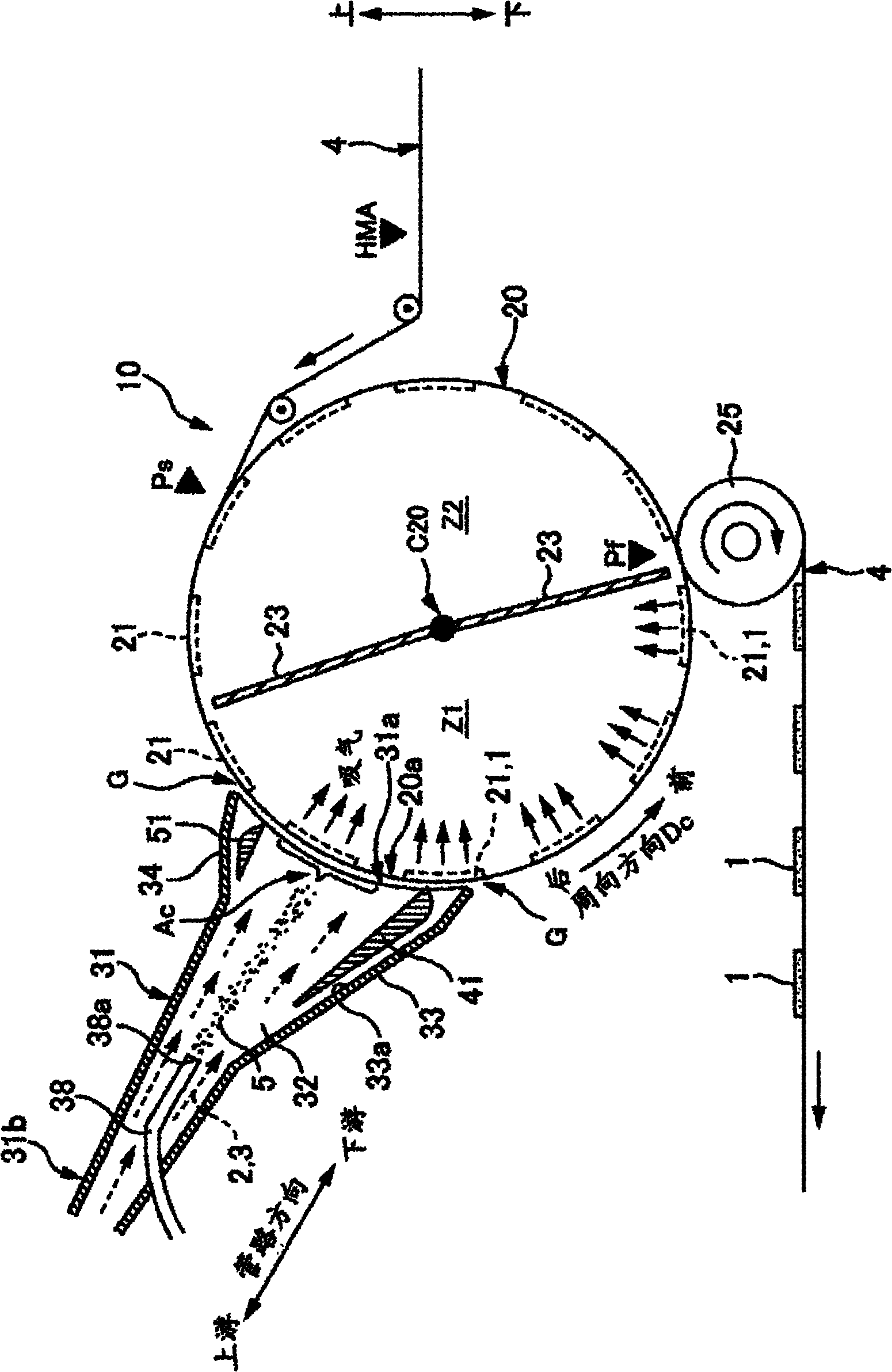

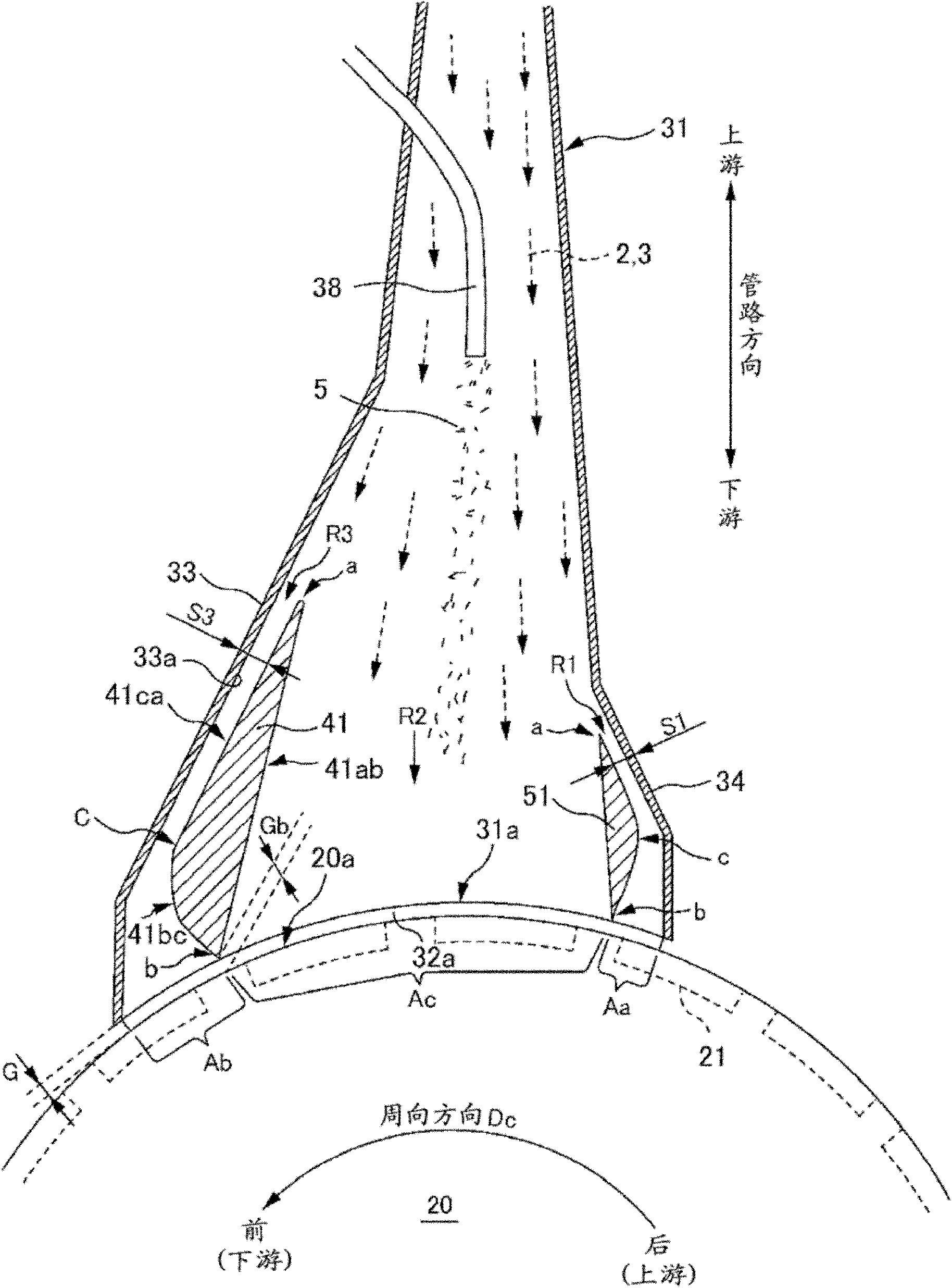

The present invention relates to a production apparatus which includes a rotating drum (20) having a die (21) formed therein and in which, when the die (21) passes through the position of a duct (31), the drum (20) draws a gas (3) through suction holes formed in the bottom of the die (21), whereby liquid-absorbing fibers (2) and a highly absorbing polymer (5) which are contained in the gas (3) are stacked in the die (21) to mold an absorbent (1). The duct (31) includes a duct inner-wall part (41) disposed therein so as to face the inner surface (33a) of a wall part (33) of the duct (31) and to leave a space (S3) therebetween. Outside air which has come into the duct (31) through the gap (G) between the peripheral surface (20a) of the rotating drum (20) and the opening (31a) of the duct (31) is controlled by the duct inner-wall part (41) so as not to flow into a central area (Ac) of the duct (31).

Owner:UNI CHARM CORP

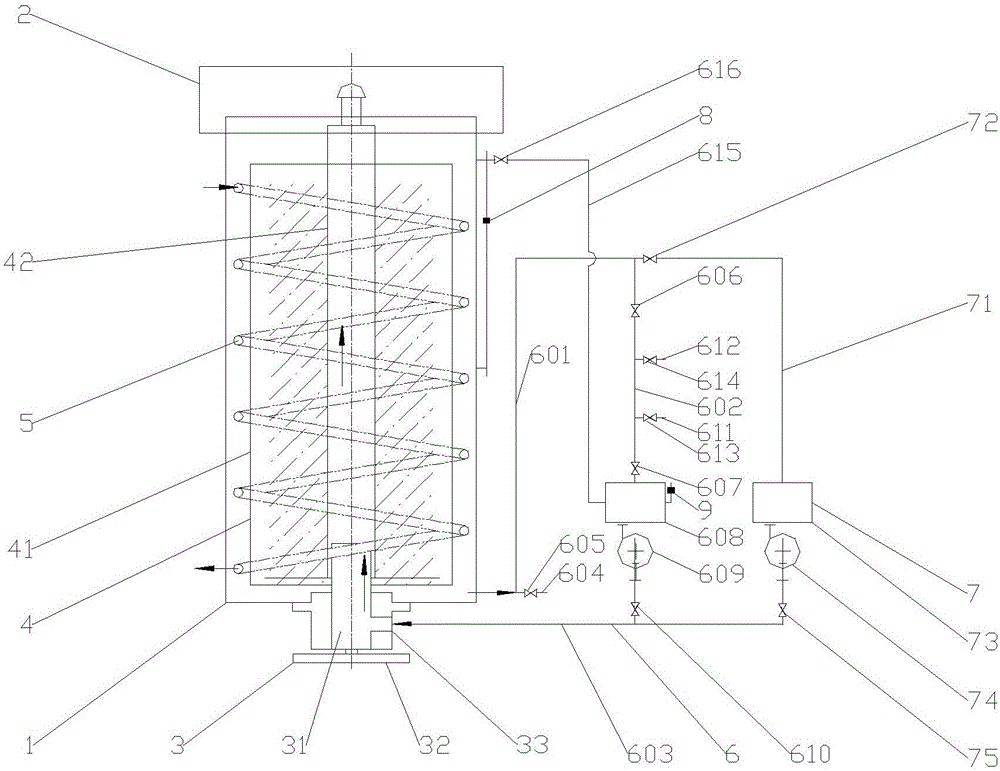

Chemical fiber yarn tube dyeing device and method for using device to achieve bobbing dyeing of aramid yarn

InactiveCN107893294AReduce uneven dye uptakePath maximizationFibre typesTextile treatment machine arrangementsYarnBobbin

The invention discloses a chemical fiber yarn tube dyeing device. The device comprises a dyeing cylinder, a cylinder cover, a bobbin frame and a heating device; the bobbin frame can be placed into thedyeing cylinder, the cylinder cover covers the dyeing cylinder, and the heating device is used for heating the dyeing cylinder; the bobbin frame comprises a chassis, a first supporting circular rod,a second supporting circular rod, a yarn channel pipe, a first motor and a second motor; the bottom of the first supporting circular rod and the bottom of the second supporting circular rod are both rotatably connected with the chassis, the top of the first supporting circular rod and the top of the second supporting circular rod both extend upwards vertically, and a yarn pipe is sleeved with a second supporting pipe; the yarn channel pipe is arranged between the first supporting circular rod and the second supporting circular rod; the first motor is connected with the first supporting circular rod, and the second motor is connected with the second supporting circular rod. The invention further discloses a method for using the chemical fiber yarn tube dyeing device to achieve bobbing dyeing of aramid yarn. The chemical fiber yarn tube dyeing device and the method for using the chemical fiber yarn tube dyeing device to achieve bobbing dyeing of the aramid yarn have the advantages that the mobility of the yarn in the dyeing cylinder is improved, and the contact degree between the yarn and dye is increased.

Owner:ANHUI HANLIAN TEXTILE CO LTD

Dye cylinder device for garment dyeing machine

ActiveCN101760924AConsistent temperatureImprove dyeing effectTextile treatment containersLiquid/gas/vapor article treatmentEngineeringWater temperature

The invention discloses a dye cylinder device for a garment dyeing machine, which comprises a cylinder. The upper end of the cylinder is provided with a cover plate of the cylinder. A stirrer fixing plate, a water inlet pipe, a steam inlet pipe and a sprinkling pipe are fixed on the cover plate of the cylinder. The invention has the advantages that the dye cylinder device can realize automatic dye adding, water adding, heating, stirring and cleaning; the dye temperature in the dyeing cylinder is consistent with the water temperature in the dyeing cylinder; and the dye cylinder device has gooddyeing effect, high automation degree, simple operation, and convenient use.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

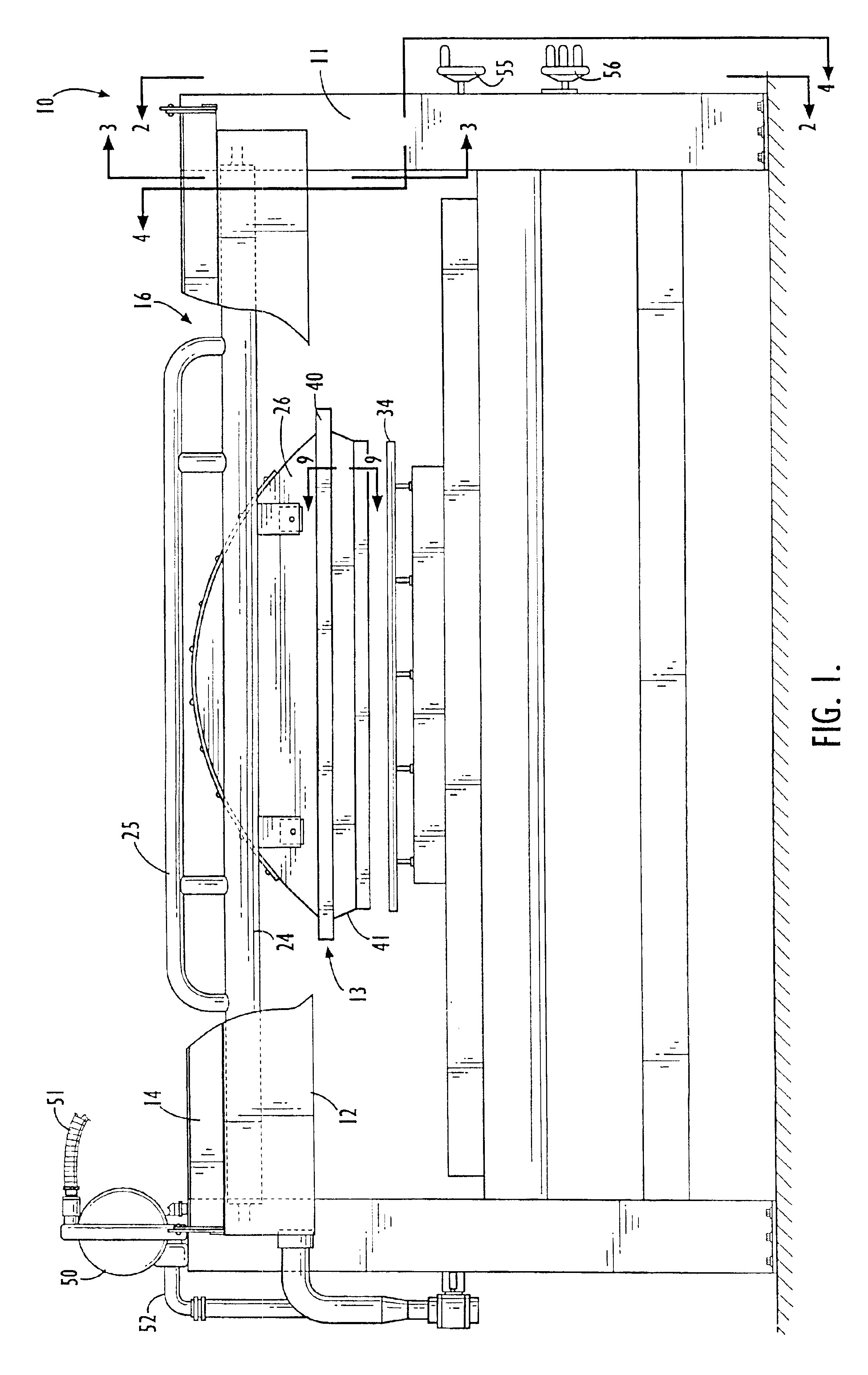

Apparatus for applying foamed coating material to a traveling textile substrate

InactiveUS6858256B2Facilitate conductionProcess cleaningPretreated surfacesTextile treatment using short bath ratio liquorStop flowViscosity

A coater for applying foamed coating material to a traveling textile substrate including a frame, a flush pan, an applicator having an open slot, a pivot shaft journaled in a pair of support arms that are pivotally mounted to the frame and piston-cylinder mechanisms to move the applicator between an operating position wherein the open slot is adjacent the traveling substrate and a flush position wherein the open slot is adjacent the flush pan by pivoting the support arms and rotating the pivot shaft. Foamed coating material is applied by supporting the traveling substrate between two spaced support elements, contacting the traveling substrate with a foam applicator, and forcing a metered amount of foamed material at least partially into the interstices of the textile substrate before the foamed coating material collapses. A metered amount of foamed coating material is applied onto or into a textile substrate regardless of textile substrate structure and regardless of the viscosity of the coating material. The foamed coating material may be flushed from the coater by stopping flow of foamed material through the applicator, moving the applicator to the flush position, and commencing flow of a flushing fluid through the applicator and into the flush pan. Foamed coating material may also be flushed from the applicator by stopping flow of foamed material through the applicator, commencing flow of a flushing foam through the applicator, stopping flow of flushing foam through the applicator, and commencing flow of a flushing fluid through the applicator.

Owner:GASTON SYST INC

Cleaning method and cleaning device

ActiveCN103339316APrevent precipitationReduce the amount of adhesionDetergent mixture composition preparationSolvent treatment with solvent recoveryCleaning methodsPrecipitation

Provided is a cleaning method for cleaning a product which is contained in an autoclave (11) and is dyed by circulating a fluid in a supercritical state in which dye is dissolved and the autoclave (11) after the dyeing is terminated, the cleaning method being characterized in that after the dyeing is terminated, a pure fluid in the supercritical state which does not contain the dye is continuously introduced into the autoclave (11), thereby gradually reducing the concentration of the dye in the fluid in the supercritical state which exists in the autoclave (11) to perform the cleaning continuously. As a result, it is possible to effectively clean the product and the autoclave (11) with the supercritical fluid while suppressing precipitation of the dye dissolved in the supercritical fluid, and significantly improve the cleaning efficiency because the cleaning process is performed continuously from the dyeing process.

Owner:YKK CORP +1

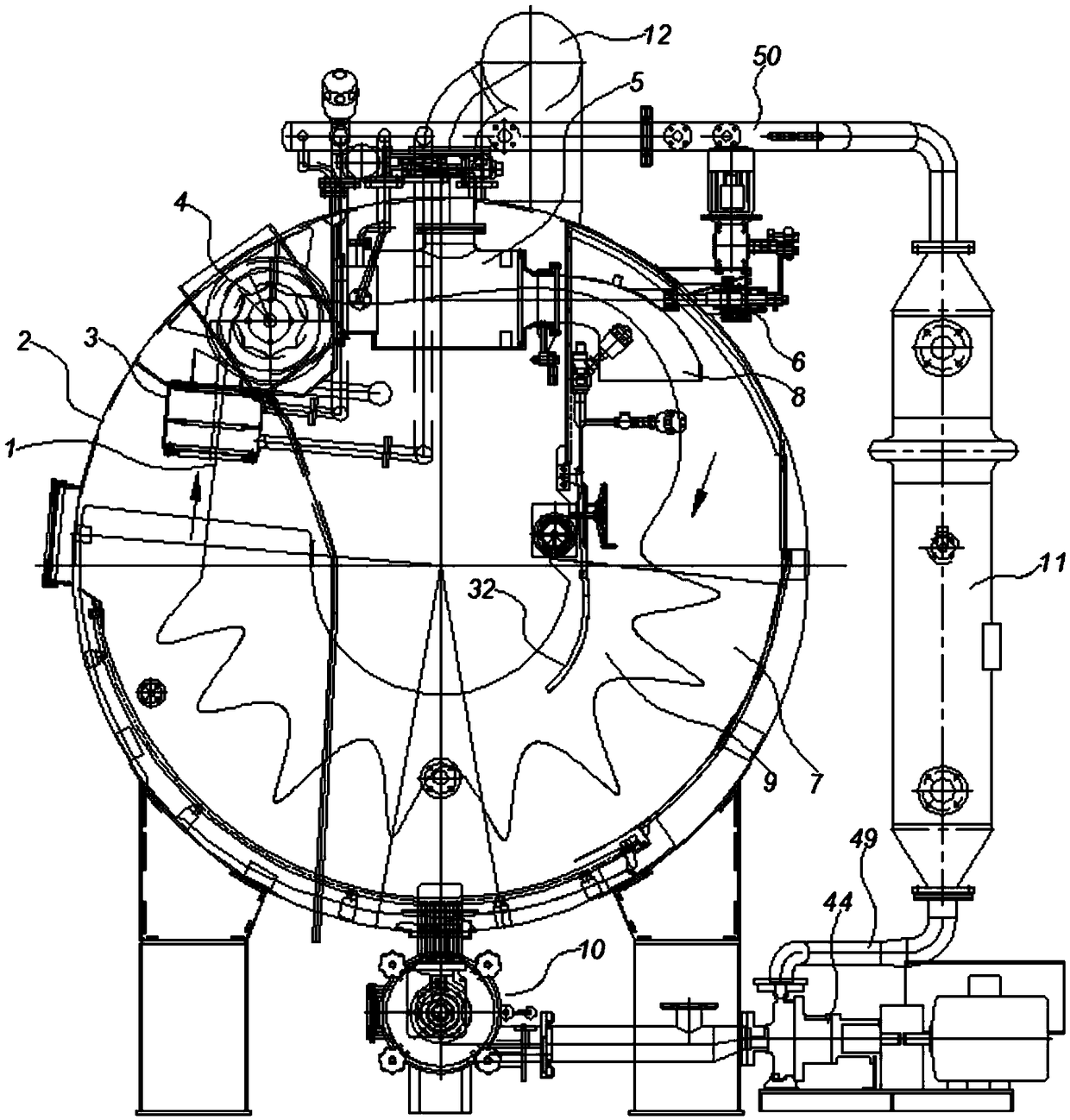

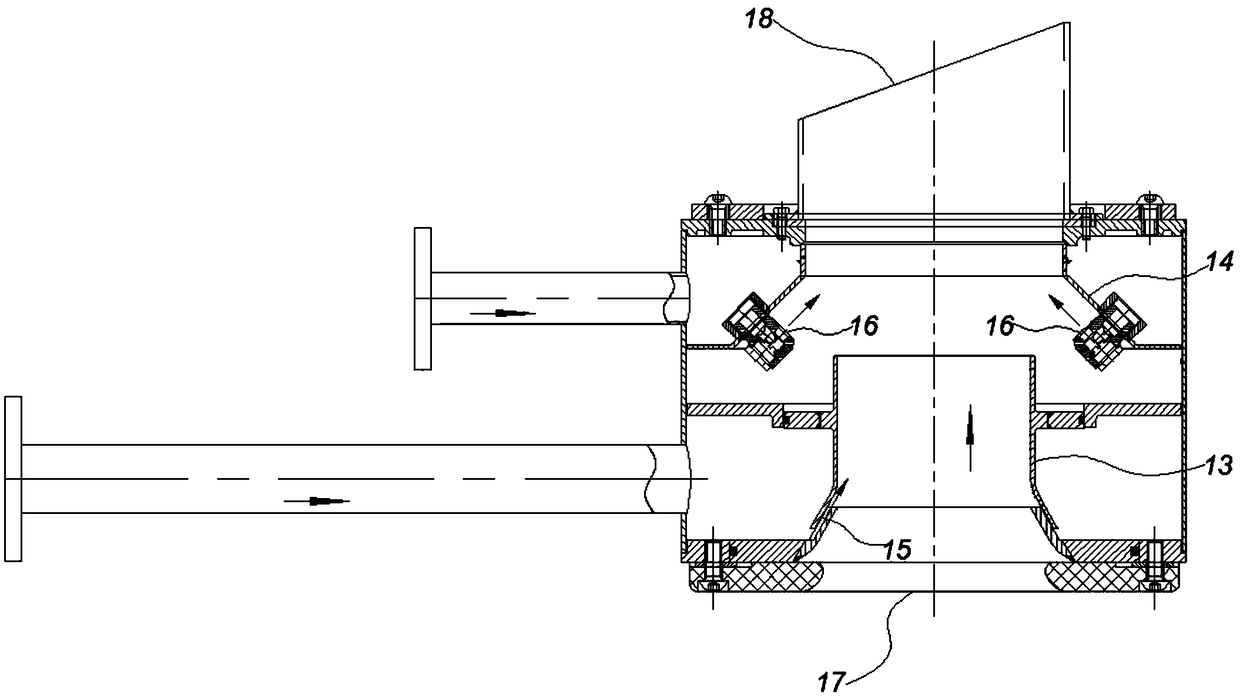

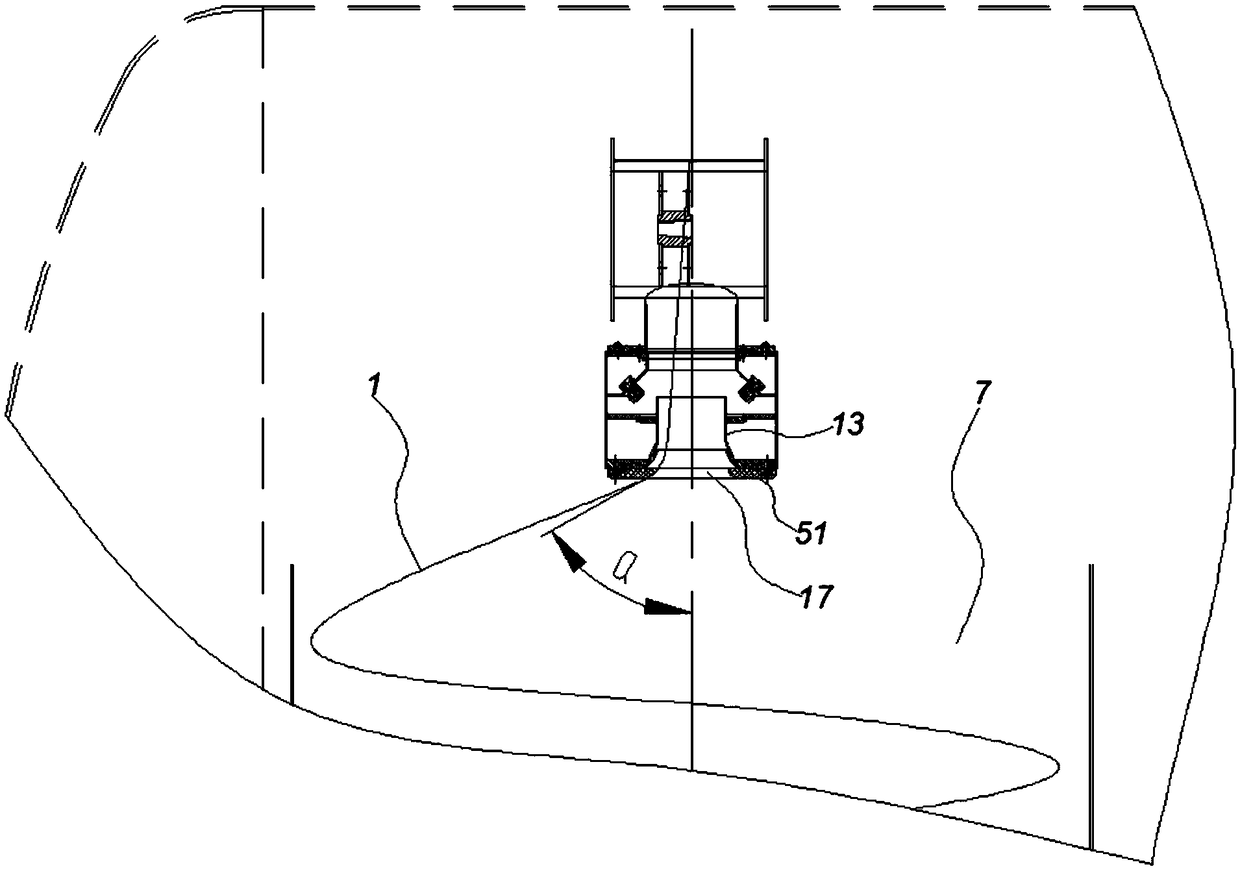

High-temperature gas-liquid dyeing machine

PendingCN109440331AReduce creasesImprove Cloth EffectsLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine arrangementsElectricityEngineering

Owner:FOSHAN SON TECH PRECISION MACHINERY

Permeation type textile cloth dyeing machine and dyeing method thereof

InactiveCN112195593AEasy to sprayImprove permeabilityLiquid/gas/vapor removalTextile treatment machine arrangementsAir compressionPolymer science

The invention discloses a permeation type textile cloth dyeing machine and a dyeing method thereof. The permeation type textile cloth dyeing machine comprises a dye box; a raw material winding drum isarranged on the upper right side of the dye box; a dye winding drum is arranged on the upper left side of the dye box; needle head spray pipes and a magnet plate are arranged on the upper right sideof the dyeing box; and an an air compression mechanism is arranged on the left side of the magnet plate. When the cloth body moves to the lower sides of the needle head spray pipes, a second dye conveying pump is started, so that when dye mixed with iron powder in a material guide box is guided to the position of a fan-shaped spray head, the dye mixed with the iron powder is sprayed out from the needle head spray pipes at all the positions, and due to limitation of the needle head spray pipes, the sprayed dye is a fine line body, and the dye can spray into cloth holes of the cloth body conveniently; meanwhile, due to the fact that iron powder is mixed in the dye, magnetism generated by the magnet plate on the lower portion attracts the dye sprayed to the cloth body, and the dye can conveniently permeate into the cloth body to be dyed; and strong-pressure airflow is impacted to the cloth through the air compression mechanism, so that the dye permeation effect is improved.

Owner:何国洋

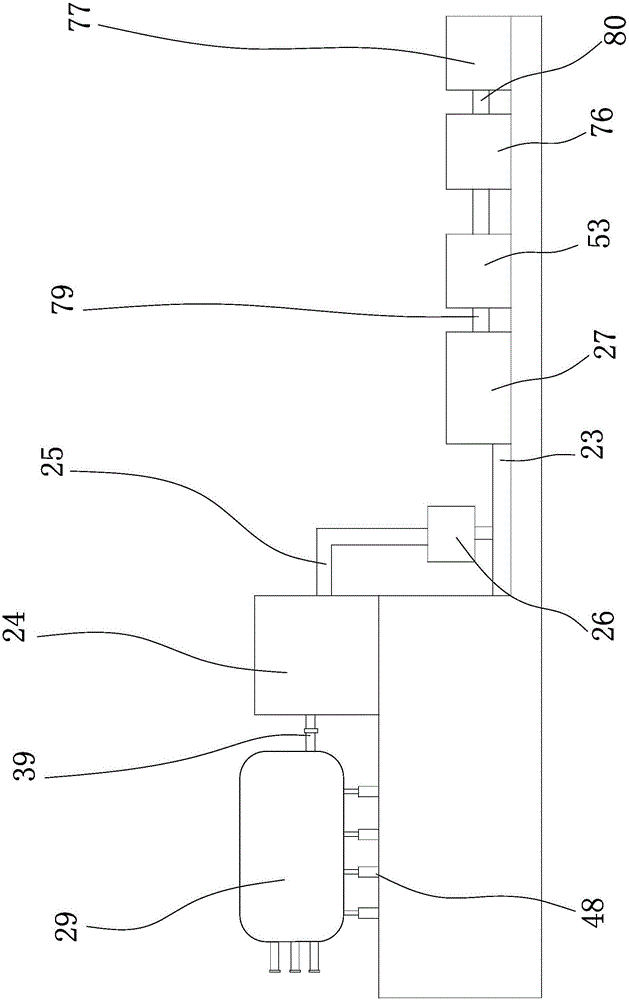

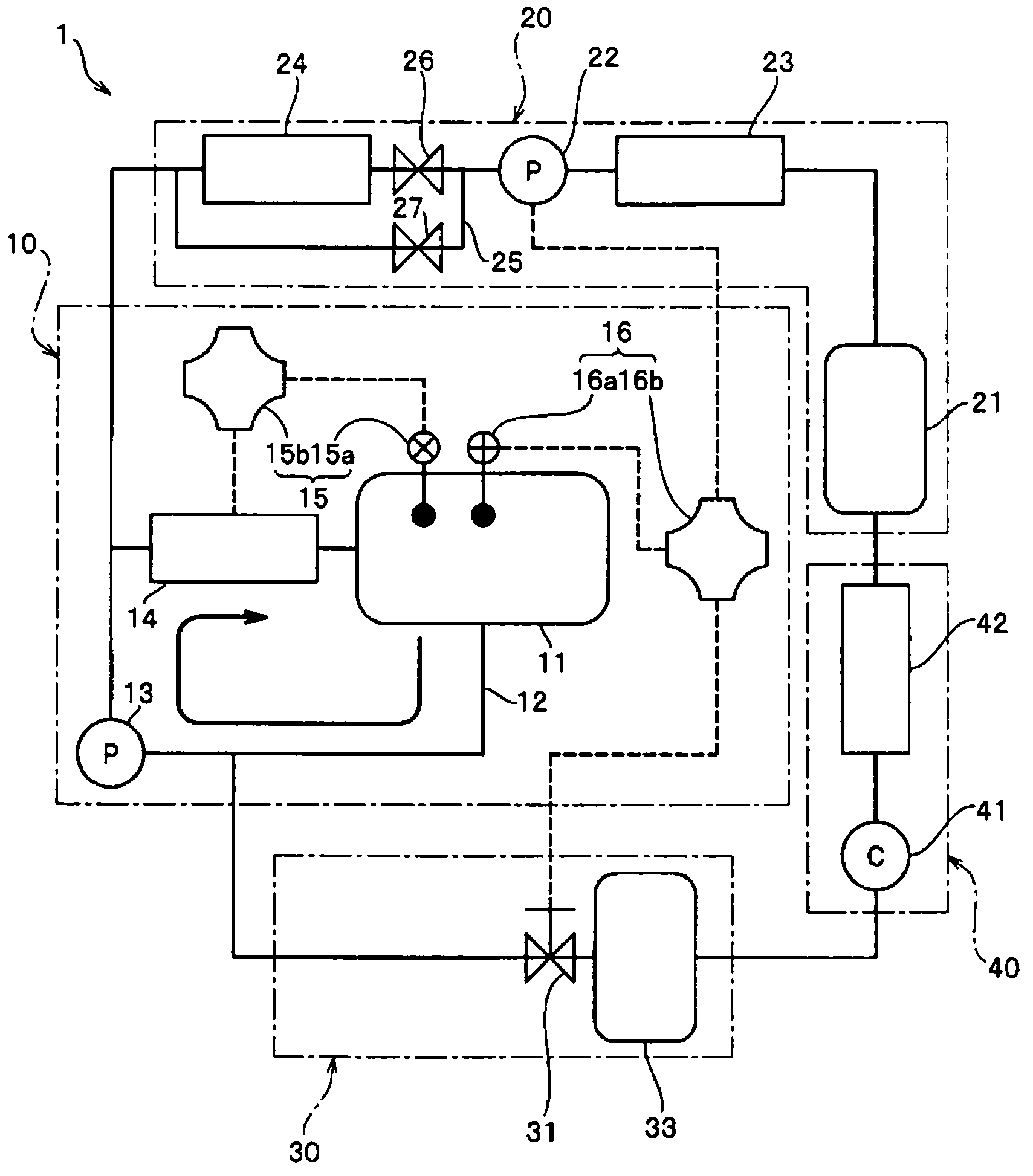

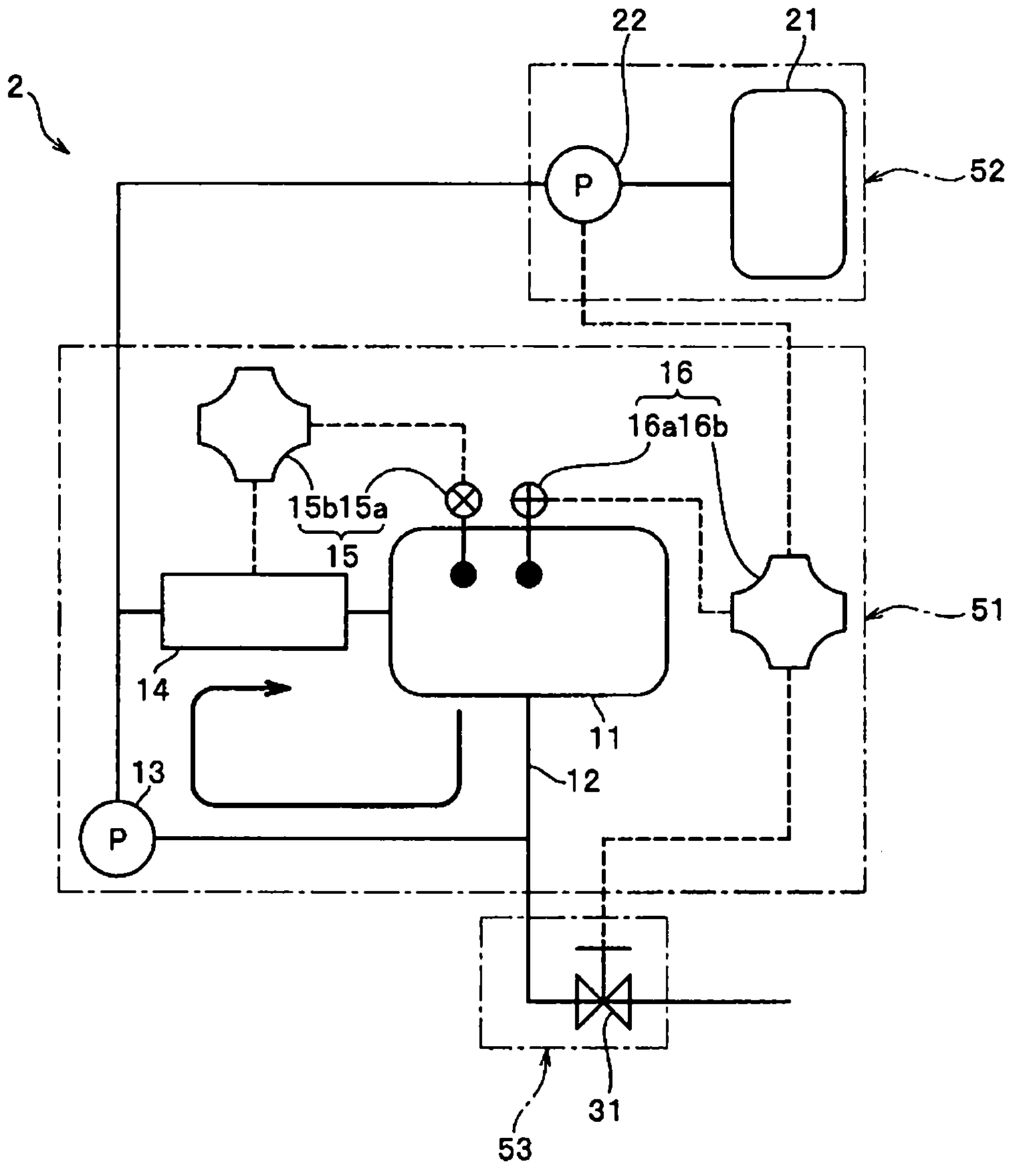

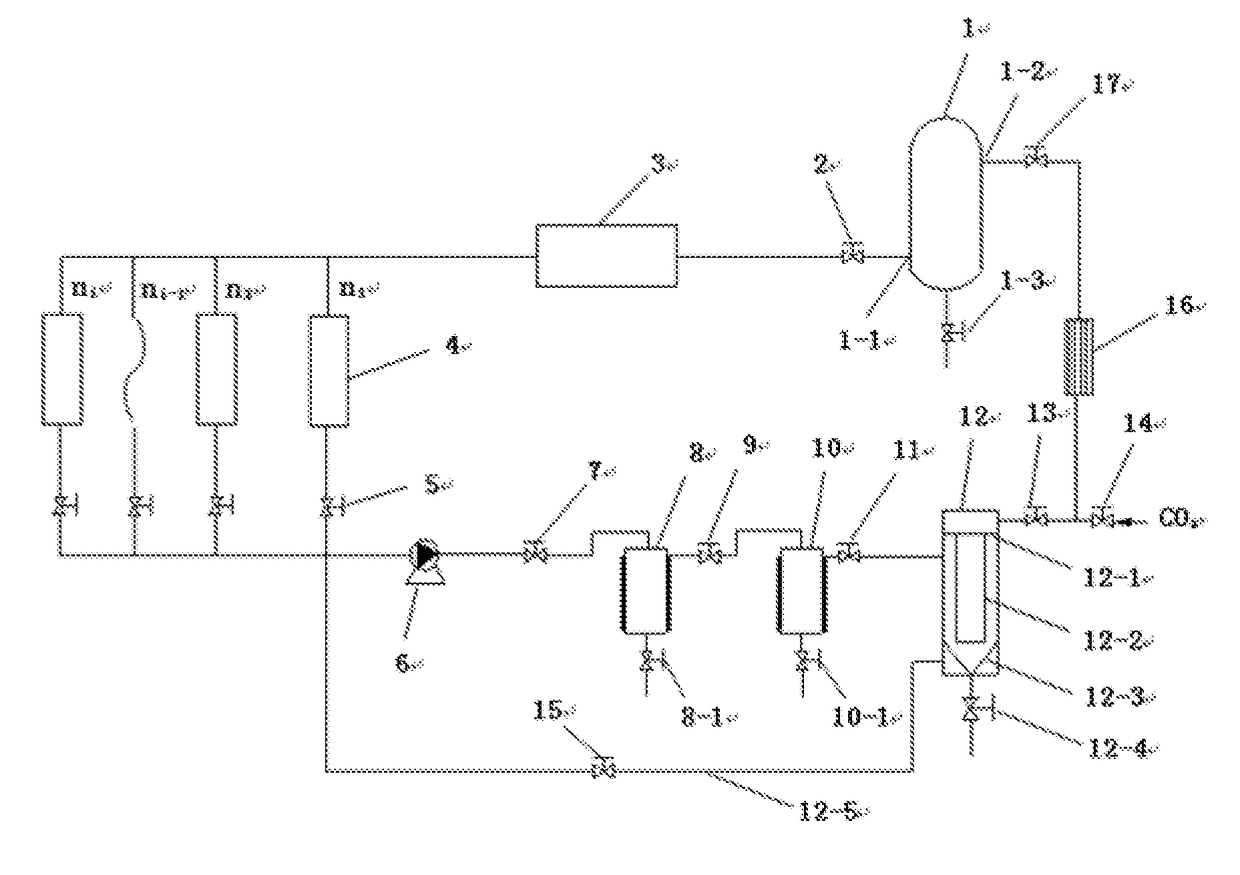

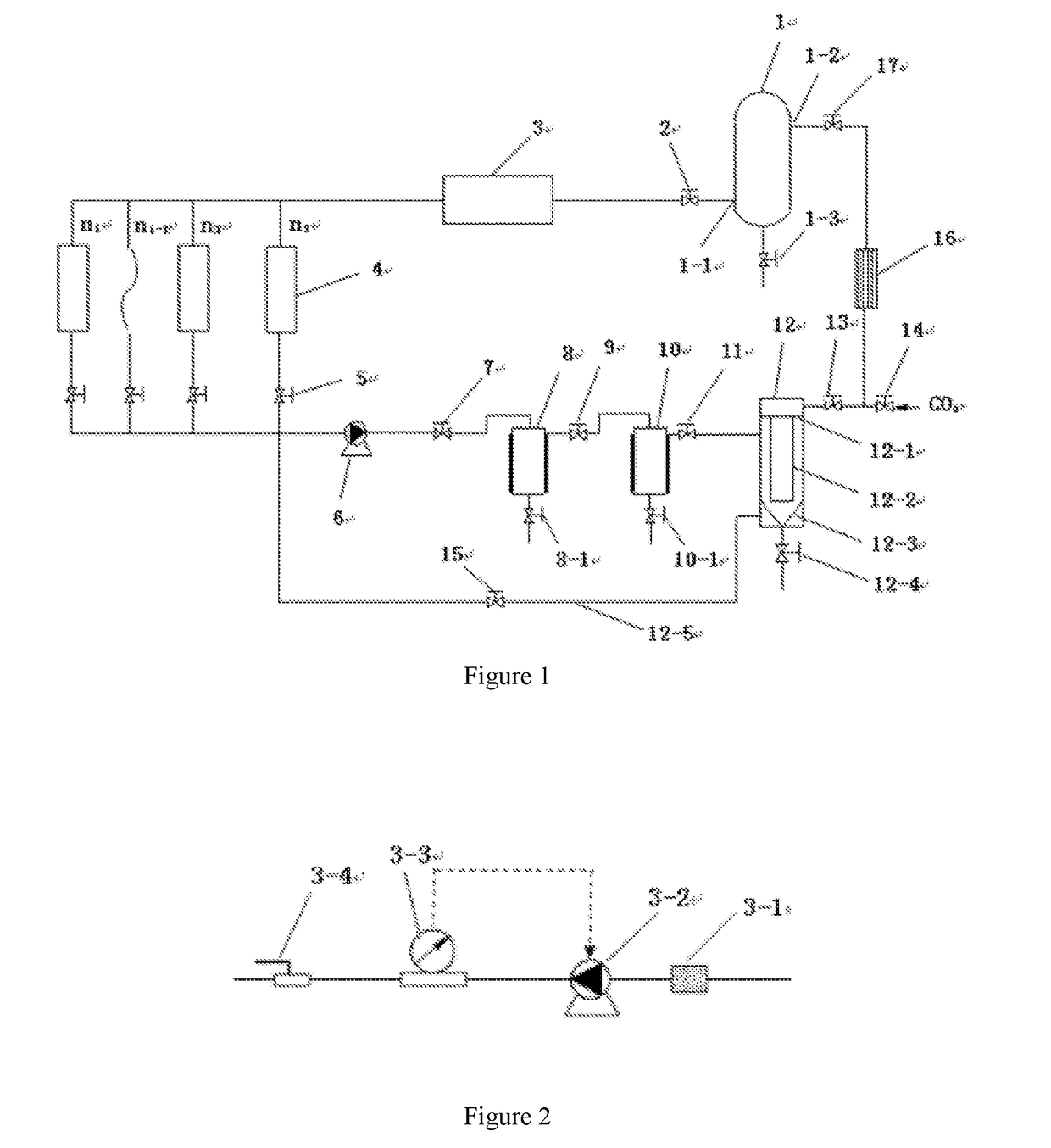

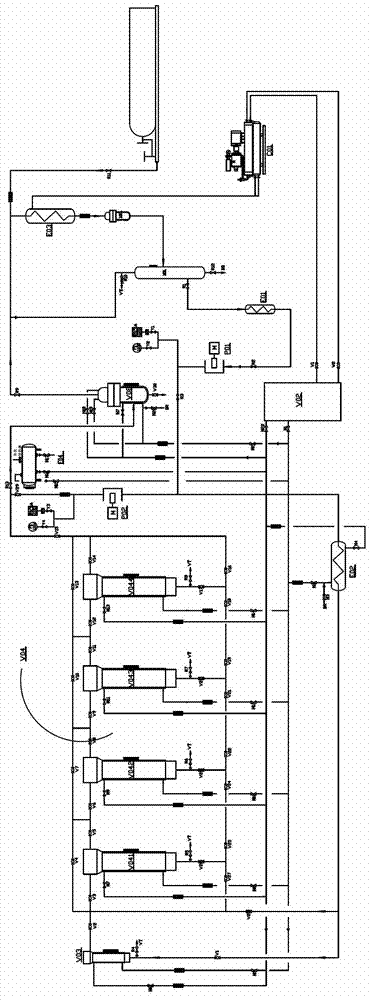

Separation, recycling and self-cleaning system of supercritical fluid dyeing machine

ActiveUS20180119324A1Easy to separateIncrease productionTextile treatment containersDispersed particle filtrationEngineeringHigh pressure

The invention relates to a separation, recycling and self-cleaning system of a supercritical fluid dyeing machine. The system includes a supercritical fluid medium reservoir, one or more parallel dyeing units, a high-pressure pump, a primary separator, a secondary separator and a membrane separator sequentially connected. A dyeing medium and residual dye in dyeing units can be efficiently separated and recycled simultaneously, and when the separation and recycling is finished, each dyeing unit can be directly opened so that the dyeing units and products can be cleaned after dyeing, thereby improving the production and processing efficiency of supercritical fluid waterless dyeing and achieving simple operations, complete separation, stability and reliability and a blowback self-cleaning. The invention has a broad application prospect and practical significance in fundamentally addressing generation and emission of pollutants in the textile printing and dyeing industry and realizing energy conservation, consumption reduction, emission reduction and clean production.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Sizing device for textile fabric

InactiveCN110144682AGuaranteed uniformityGuaranteed reliabilityTextile treatment cleaning apparatusLiquid/gas/vapor textile treatmentSpray nozzleDrive motor

The invention discloses a sizing device for textile fabric. The sizing device comprises a bracket and a sizing platform arranged on the bracket, wherein a sizing support is arranged on the bracket, aguide roller and a sizing roller which are parallel to each other are arranged on the sizing support, a size spray support rod parallel to the sizing roller is fixed on the sizing support, a size storage box is fixed on the bracket, a booster pump is arranged in the size storage box, a size guide channel is formed in the size spray support rod, spray nozzles communicated with the size guide channel are uniformly arranged on the size spray support rod, a scraping support rod is also arranged on the sizing support, a moving groove is formed in the scraping support rod, a movable screw rod is arranged in the moving groove, a drive motor connected with the movable screw rod is fixed at the end part of the scraping support rod, a moving block is arranged in the moving groove, and a rubber scraper is fixed on the moving block. The sizing device is reasonable in structure, good in use stability and high in practicability, guarantees uniform sizing of the sizing roller, enables sizing to be more uniform and improves quality of processed products.

Owner:黄杰

Cleaning method for supercritical carbon dioxide dyeing equipment

ActiveCN102787463ALow costRealize diverse productionLiquid/gas/vapor article treatmentTextile treatment cleaning apparatusAlcoholEconomic benefits

The invention relates to a cleaning method for supercritical carbon dioxide dyeing equipment, which takes a mixture of supercritical carbon dioxide, anhydrous alcohol and acetone as a detergent; the equipment is cleaned at least 2 times at 70-110 DEG C and 15-20 MPa for at least 10 minutes every time. The cleaning method realizes non-corrosive and nondestructive cleaning of the existing supercritical carbon dioxide equipment. The cleaned supercritical carbon dioxide equipment is free from dye residuals, thereby being beneficial for realizing the diversity production of products. The cleaning method has the characteristics of low comprehensive cost and significant economic benefits and environment benefits, and is wide in application prospect.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Colored-spun-yarn dyeing die convenient to clean

InactiveCN106988066ASimple structureEasy to useTextile treatment containersTextile treatment cleaning apparatusYarnColored

The invention discloses a yarn-splitting colored-spun-yarn dyeing die convenient to clean. The colored-spun-yarn dyeing die convenient to clean comprises a die body and material spraying pipes; pigment inlets are formed in the upper end of the die body, stopping plates are arranged on the pigment inlets, rotating shafts are fixed to the left ends of the stopping plates, a flowing channel is formed below the pigment inlets, a pigment flowing pipe is connected to the lower end of the flowing channel, a clamping plate is fixed to the bottom end of the pigment flowing pipe, a dye groove is formed in the inner side of the clamping plate, circular holes are formed in the clamping plate in an embedded mode, a yarn outlet is formed in the right end of the dye groove, a limiting hole is fixed to the right side of the yarn outlet, the clamping plate is installed above the material spraying pipes, a material spraying channel is formed in the bottom sides of the material spraying pipes, and a yarn inlet is formed in the left side of the die body. The yarn-splitting colored-spun-yarn dyeing die convenient to clean is simple in structure and convenient to use, the stopping plates can be buckled through rotating of the rotating shafts when the colored-spun-yarn dyeing die is not used, and it is avoided that impurities fall into the die body.

Owner:响水利滋纺织品有限公司

Textile fabric washing device and washing method thereof

ActiveCN111350036AScrape achievedTextile treatment machine arrangementsTextile treatment cleaning apparatusProcess engineeringLiquid tank

The invention discloses a textile fabric washing device and a washing method thereof, belonging to the technical field of textile fabric production. The textile fabric washing device includes a washing rack and a textile fabric; a box is fixed on the washing rack; a first roller and a second roller for conveying the textile fabric are rotatably arranged on the inner wall of the box; the bottom wall of the box is also connected with a water supply pipe through a liquid tank; and a spray head is arranged on the top end of the water supply pipe. The textile fabric washing device also includes a conveying rack; the conveying rack is fixed on the side wall of the washing rack, and the textile fabric is conveyed into the washing rack through the conveying rack; and a driving motor is arranged onthe outer wall of the box. According to the invention, an arranged swing mechanism drives a filtering mechanism to work, so that the cleaning liquid and impurities remaining on the textile fabric arefiltered out and fall to the bottom wall of the box; and the swing mechanism can simultaneously drive a scraping mechanism to move along the bottom wall of the box, so as to scrape the cleaning liquid and impurities to one side of the box and discharge the cleaning liquid and impurities out of the box through a liquid discharge outlet.

Owner:吴江市万利来丝绸整理有限公司

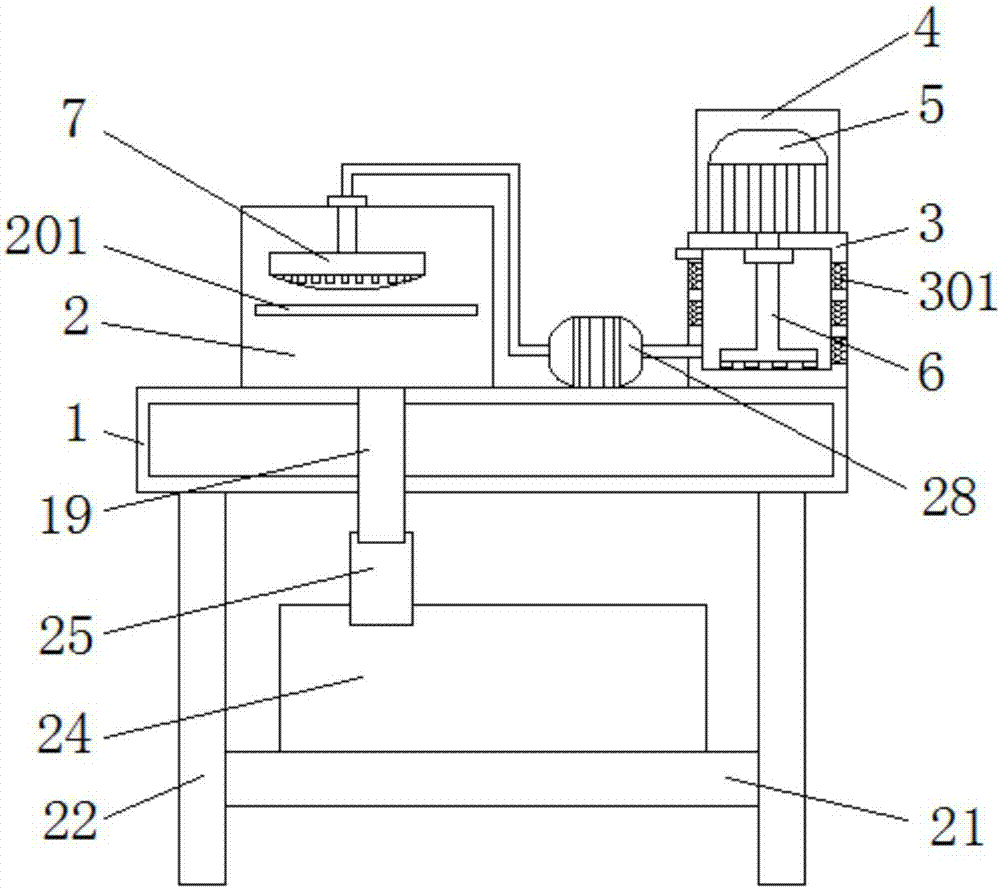

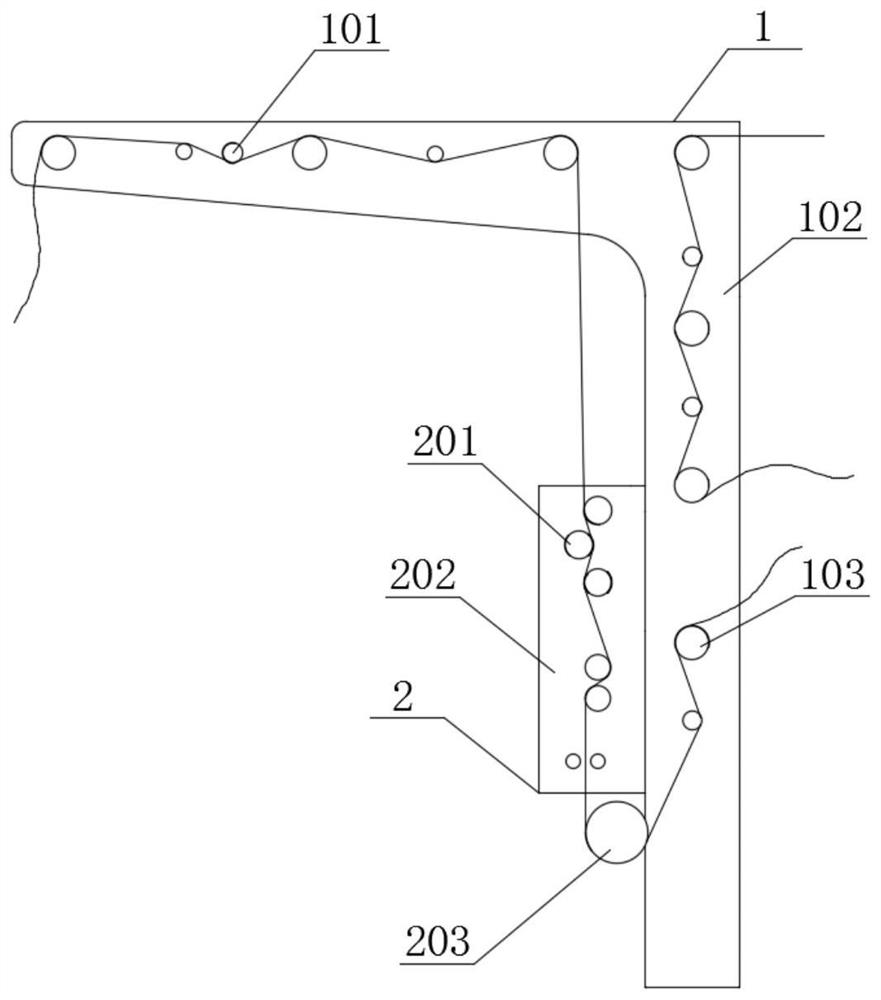

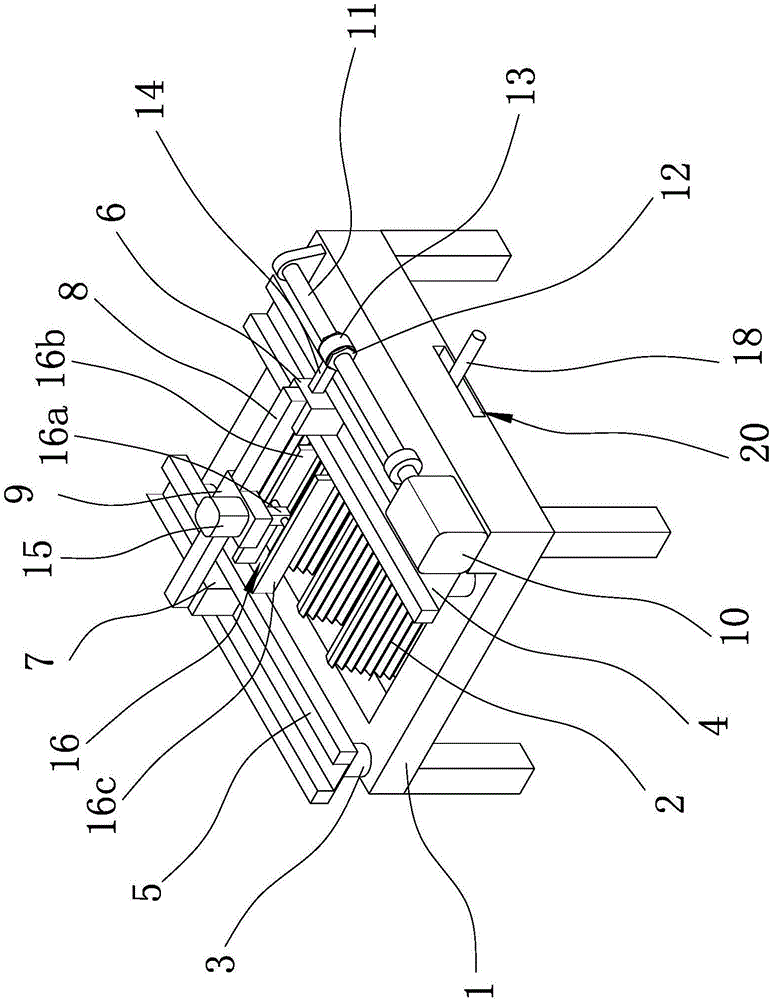

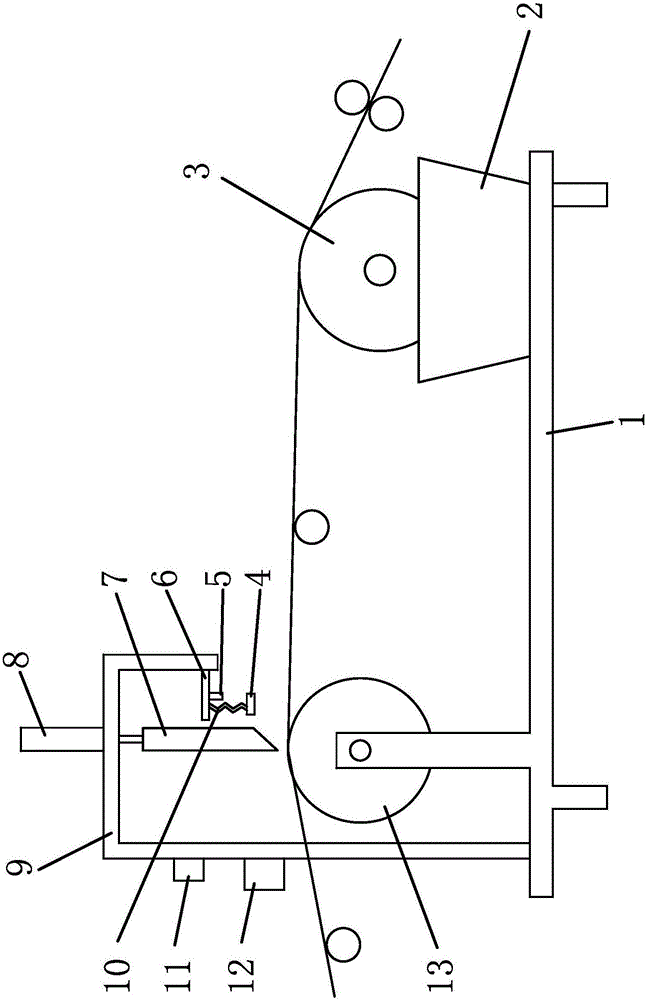

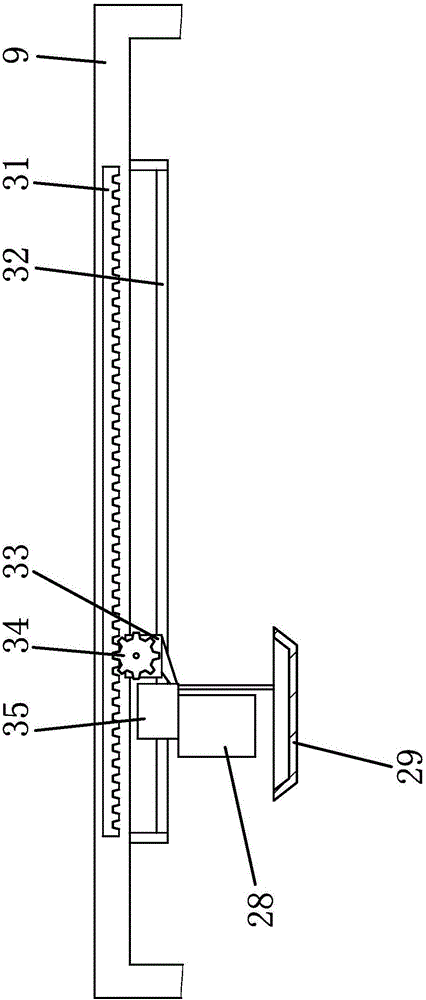

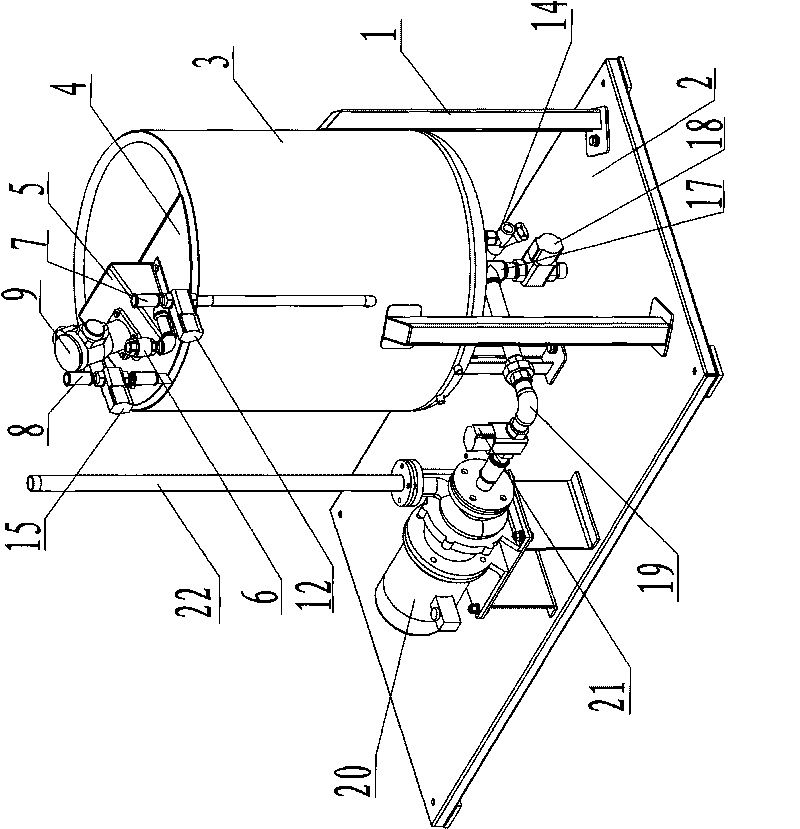

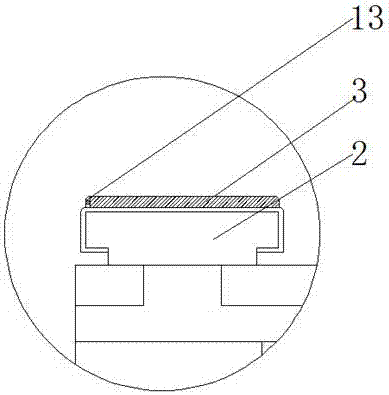

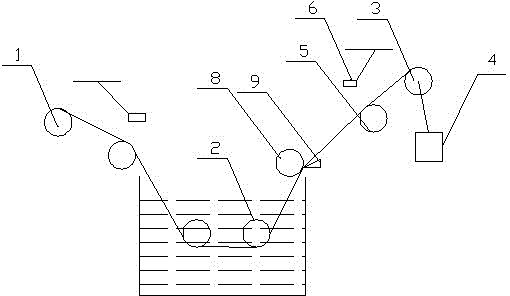

Gum dipping device for cord fabric

InactiveCN104372549AQuality improvementTextile treatment cleaning apparatusTextile treatment carriersEngineeringMechanical engineering

The invention relates to a gum dipping device for cord fabric. The gum dipping device comprises an unwinding roller (1), a gum dipping roller (2) and a winding roller (3), and the winding roller (3) is connected with a motor (4). The gum dipping device is characterized in that correction rollers (5) are arranged between the unwinding roller (1) and the gum dipping roller (2) as well as between the gum dipping roller (2) and the winding roller (3), each of two ends of each correction roller (5) is provided with a regulating motor (6), a photoelectric sensor (7) is installed above the correction rollers (5), and a gum scraping device is arranged nearby gum slots of the gum dipping roller (2) and the correction rollers (5) and comprises a gum scraping roller (8) and a scraper (9). Deviation is controlled by increasing the correction rollers during the gum dipping process, the gum liquid on the surface of the cord fabric is ensured to be even by increasing the gum scraping devices, and quality of gum dipping of the cord fabric is improved.

Owner:JIANGYIN QIANGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com