Textile fabric washing device and washing method thereof

A technology for textile fabrics and washing devices, which is applied in the direction of cleaning devices for processing textile materials, equipment configuration for processing textile materials, and processing textile material carriers, etc. It can solve problems such as residual cleaning liquid, difficulty in discharging the box, and affecting drying operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

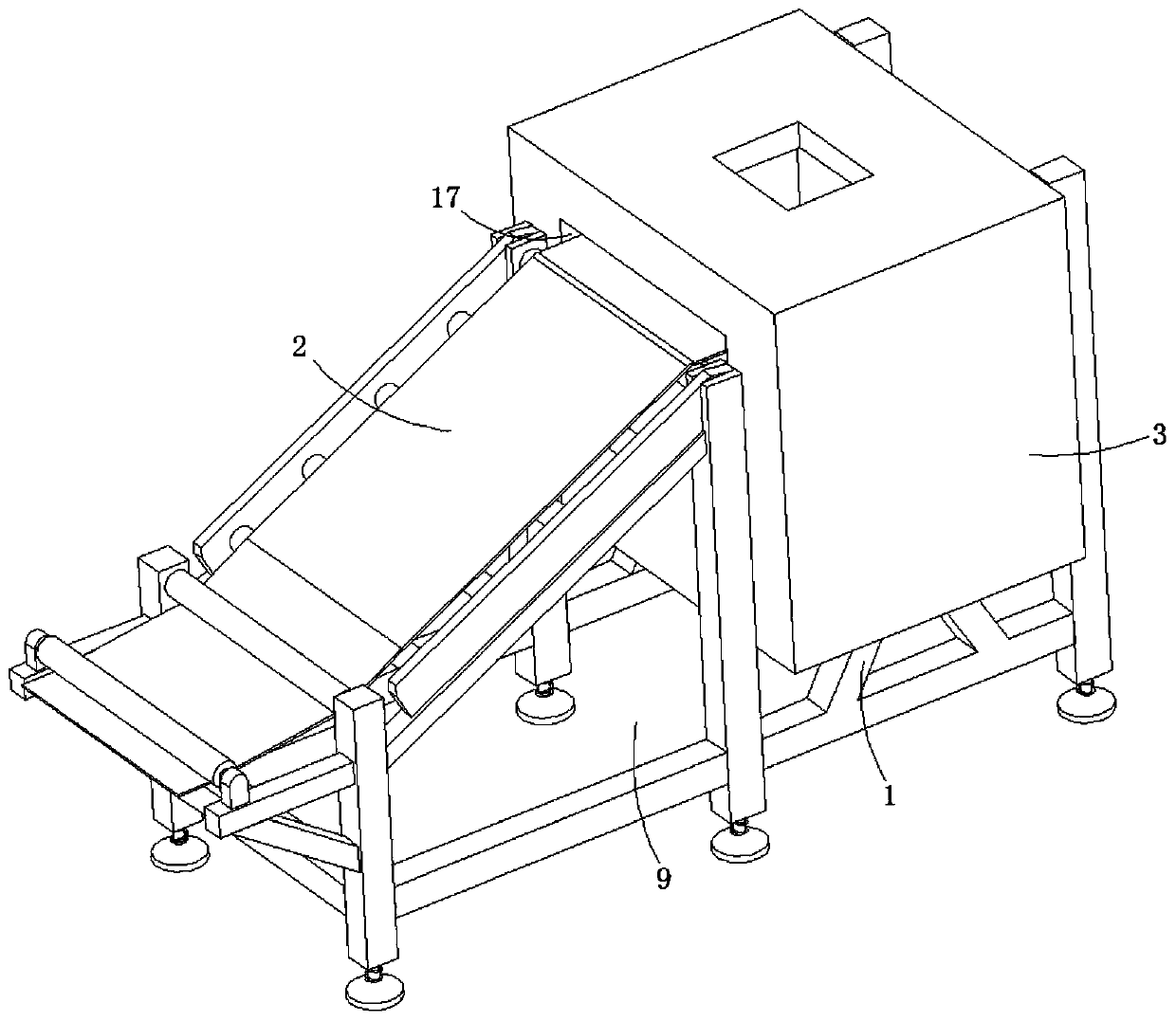

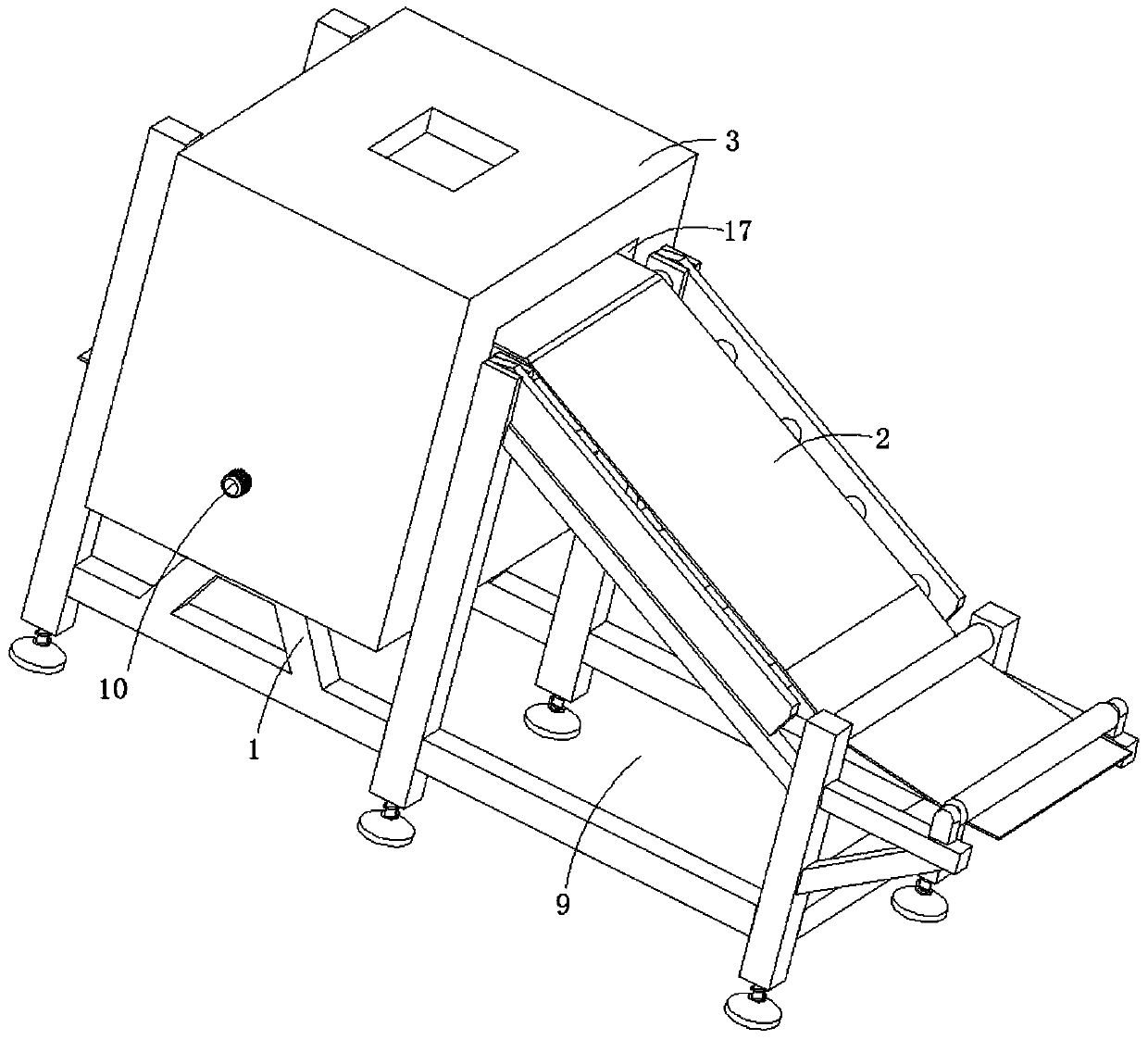

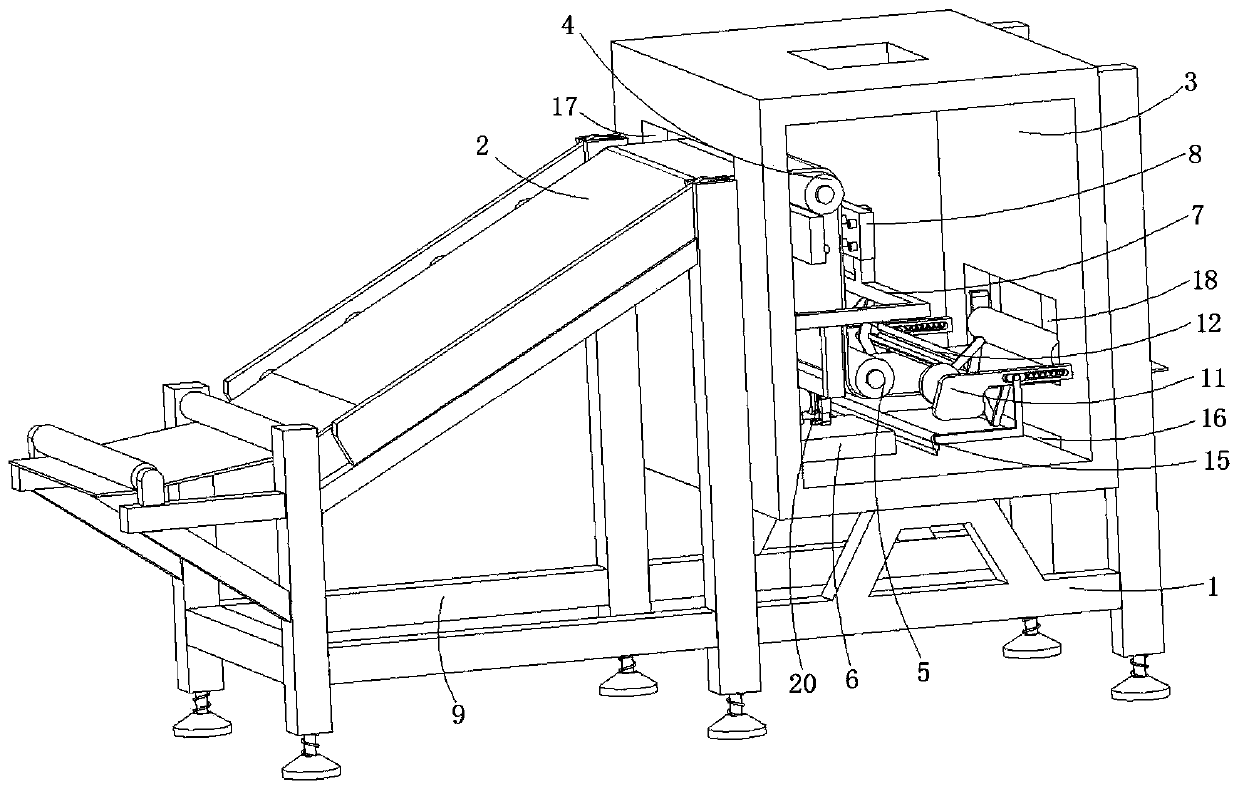

[0041] refer to Figure 1-9 , a textile cloth washing device, comprising a washing frame 1, a textile cloth 2, a box body 3 is fixed on the washing frame 1, and a first roller 4 for transporting the textile cloth 2 is arranged on the inner wall of the box body 3 for rotation. The second cylinder 5, the bottom wall of the casing 3 is also connected with the upper water pipe 7 through the liquid tank 6, and the top of the upper water pipe 7 is provided with a nozzle 8, and also includes a delivery frame 9, which is fixed on the bottom of the flushing frame 1. On the side wall, the textile fabric 2 is transported to the flushing frame 1 through the conveying frame 9; the outer wall of the box body 3 is provided with a driving motor 10, and the rotating shaft at the output end of the driving motor 10 extends to the inside of the box body 3 and is connected with a swing mechanism 11, swinging The mechanism 11 is symmetrically distributed along the textile cloth 2, the swing mechani...

Embodiment 2

[0054] refer to Figure 9 , is basically the same as Embodiment 1, the difference is that the transport frame 9 includes a front bracket 9-1 and a delivery bracket 9-2, and the front bracket 9-1 is fixed on the front side of the delivery bracket 9-2, and the delivery The bracket 9-2 is fixed on the side wall of the flushing frame 1;

[0055] The top of the front bracket 9-1 is rotatably connected with a front roller shaft 9-11, the front side wall of the delivery bracket 9-2 is rotated to be provided with a limiting roller shaft 9-21, and the inner rotation of the delivery bracket 9-2 is provided with multiple The conveying roller shaft 9-22 extending obliquely upward, and a plurality of conveying roller shafts 9-22 are distributed on the side wall of the conveying support 9-2 at intervals, and the textile cloth 2 is conveyed into the box body 3 through the conveying frame 9 for washing treatment Specifically, it is delivered to the box body 3 across the front roller shaft 9-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com