Patents

Literature

373results about How to "Achieve transshipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro LED transfer apparatus and transfer method and manufacturing method of transfer apparatus

ActiveCN107863316AReduce manufacturing costReduce complexitySemiconductor/solid-state device manufacturingElectricityThermal energy

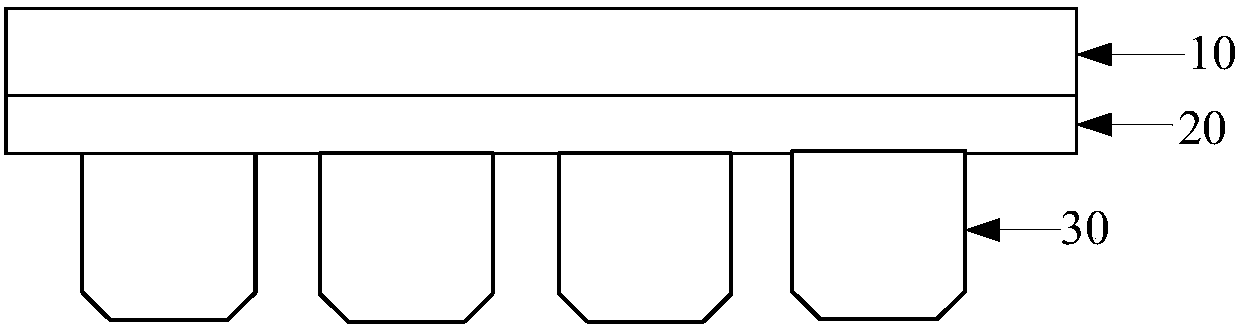

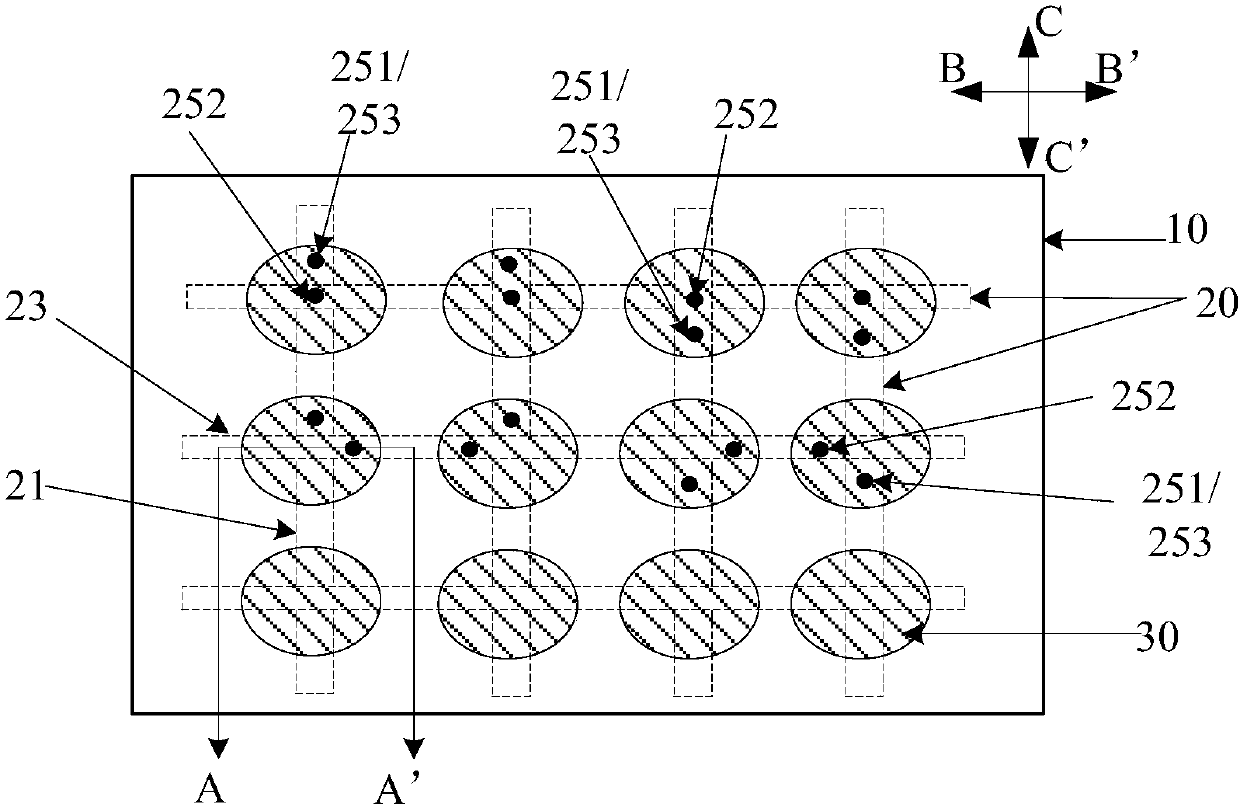

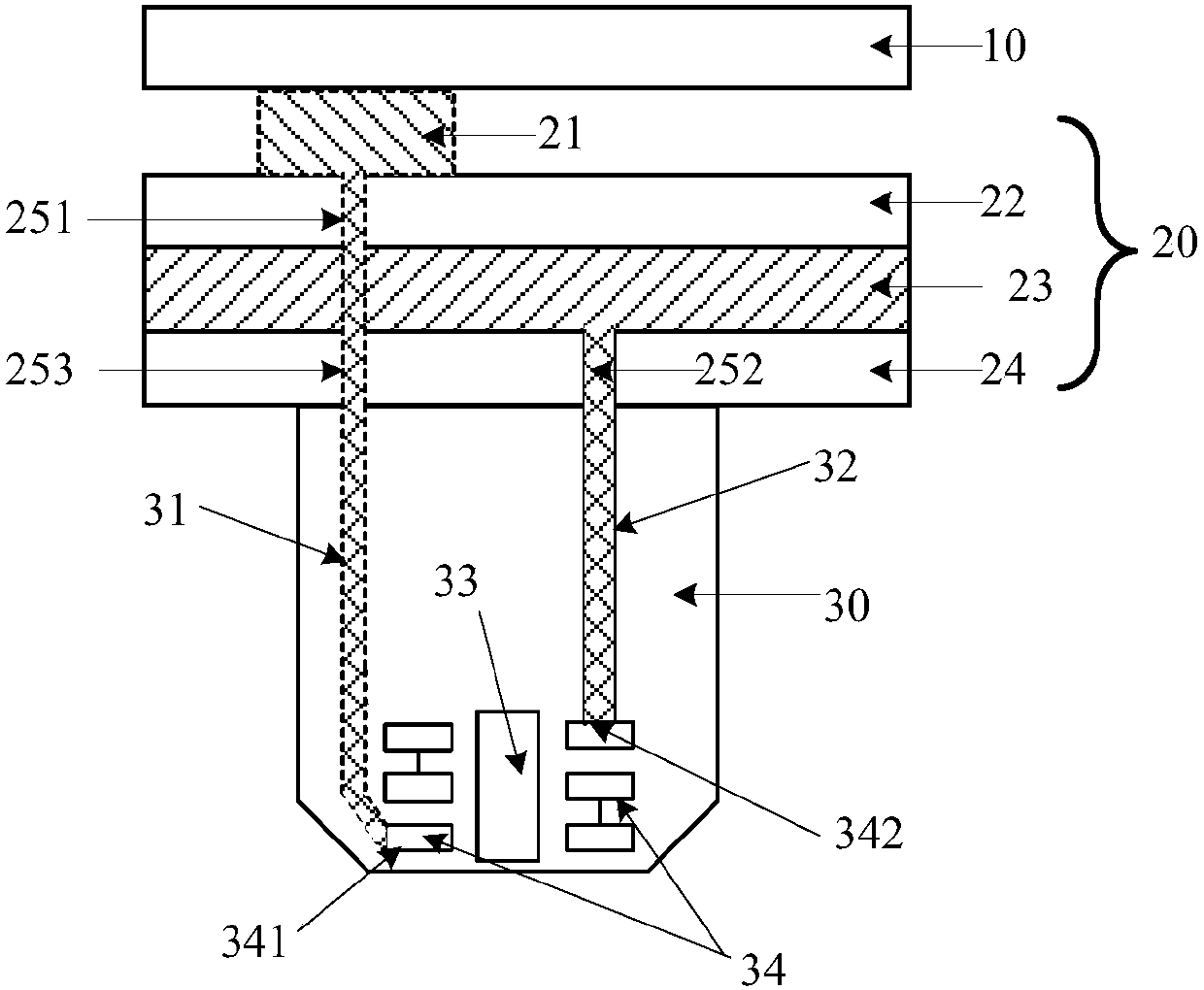

The invention provides a Micro LED transfer apparatus. The Micro LED transfer apparatus comprises a transfer substrate, a driving electrode and a transfer unit array; the transfer unit array comprisesa plurality of transfer units; the driving electrode is a conductive transmission line; one end of the driving electrode is directly connected with a driving chip while the other end is electricallyconnected with the transfer units; and a driving voltage output by the driving chip is transmitted by the driving electrode to be directly applied to the transfer units so as to enable the transfer units to generate electromagnetic force, or thermal energy or electrostatic in order to adsorb the Micro LED. The manufacturing cost of the Micro LED transfer apparatus is lowered on the basis of not influencing the Micro LED transfer effect.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

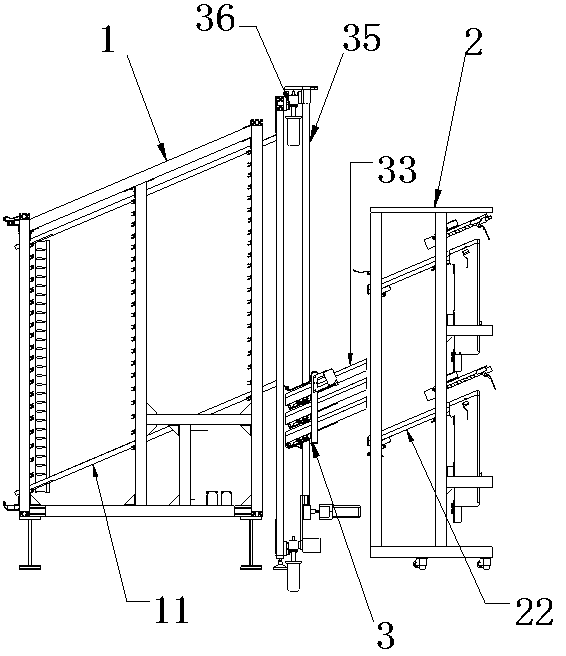

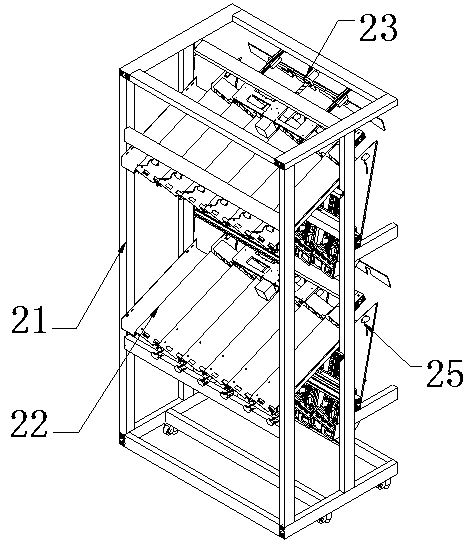

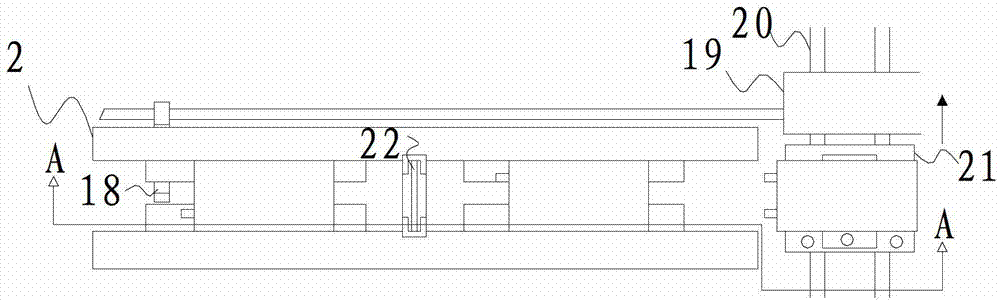

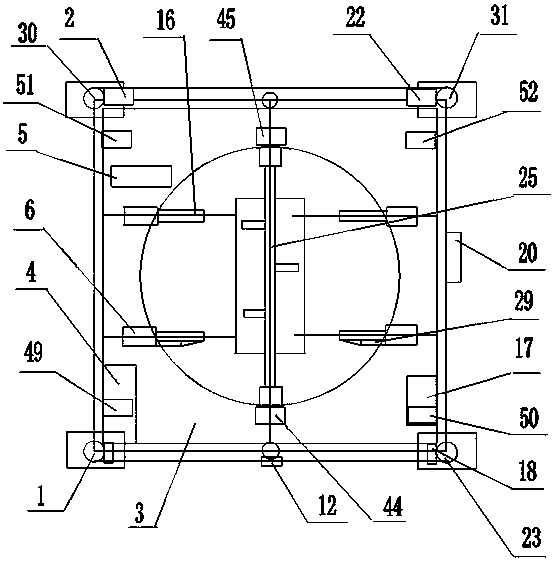

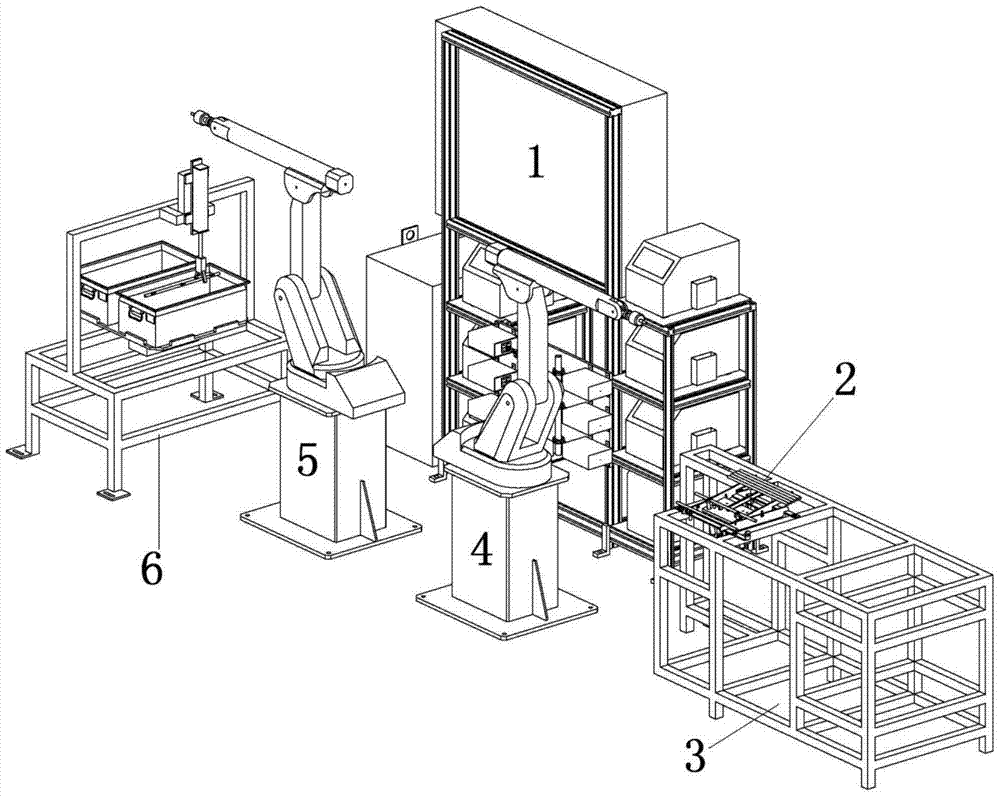

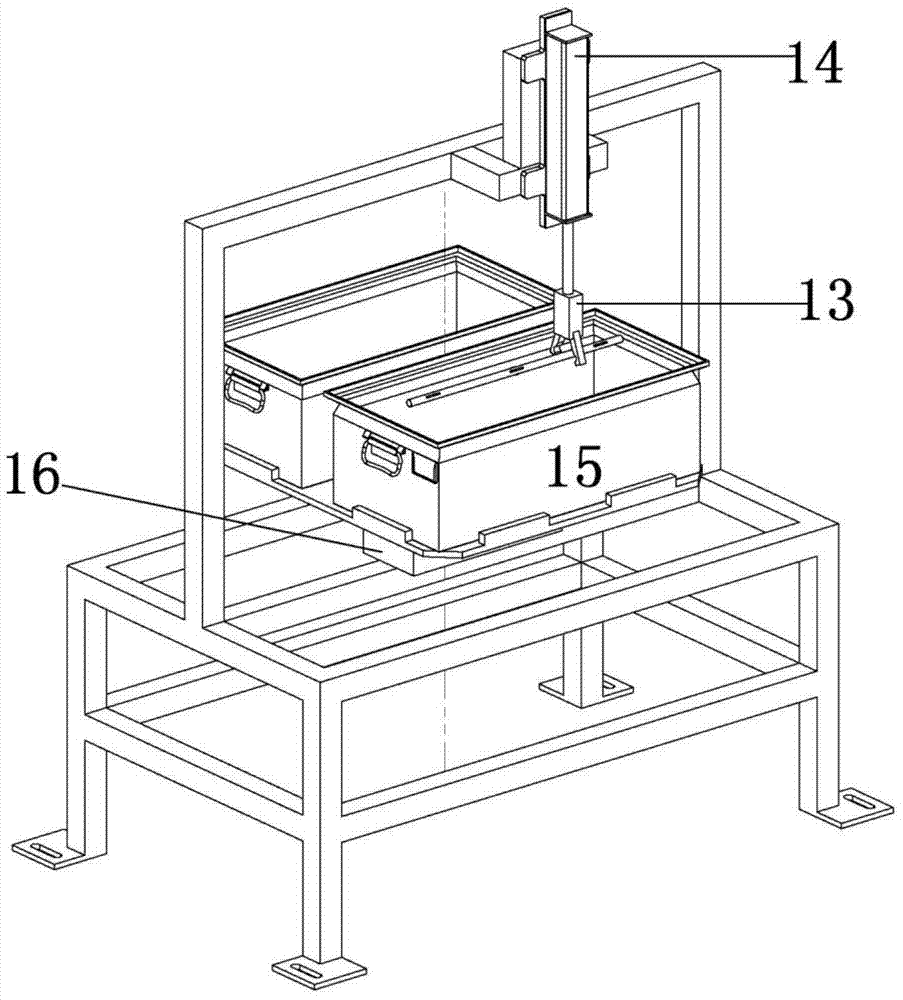

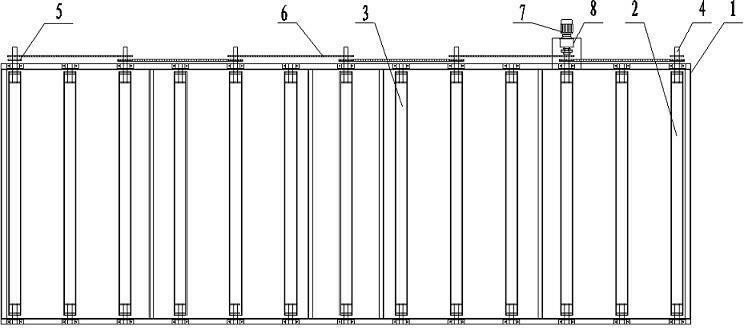

Intelligent pharmacy system capable of supplementing medicines automatically

The invention discloses an intelligent pharmacy system capable of supplementing medicines automatically. The intelligent pharmacy system capable of supplementing medicines automatically comprises a medicine cabinet framework, an intelligent pharmacy, a medicine charging mechanical arm, a secondary cache medicine charging mechanism and a central processing unit. The intelligent pharmacy is mounted at a front cavity of the medicine cabinet framework and is used for storing different kinds of medicines and dispensing medicines; the medicine charging mechanical arm is used for transporting the medicines and comprises a medicine delivery groove bracket and a medicine delivery groove; the secondary cache medicine charging mechanism is used for putting the medicines to the medicine delivery groove and temporarily storing the medicines; the central processing unit is in communication connection with the intelligent pharmacy, the medicine charging mechanical arm and the secondary cache medicine charging mechanism and is used for automatically dispensing medicines according to the prescriptions and automatically charging medicines and complementing medicines when the intelligent pharmacy is lack of medicines. The intelligent pharmacy system capable of supplementing medicines automatically is capable of automatically dispensing medicines according to the prescriptions and automatically supplementing medicines to the deficient medicines in the intelligent pharmacy, is capable of lowering the working strength of the pharmacist, and has high automatic degree.

Owner:SUZHOU IRON TECH

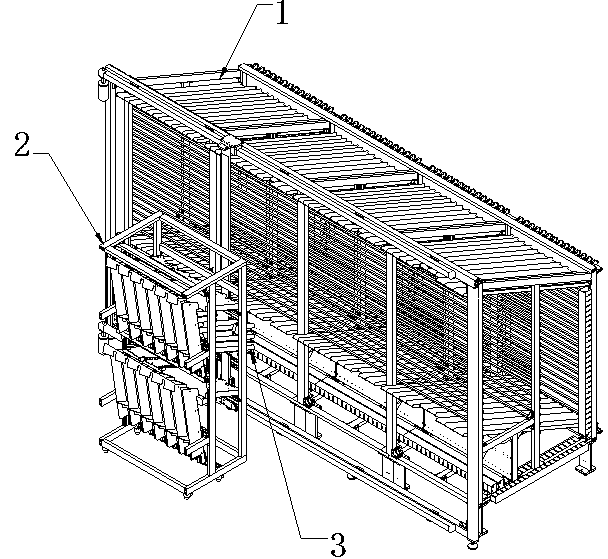

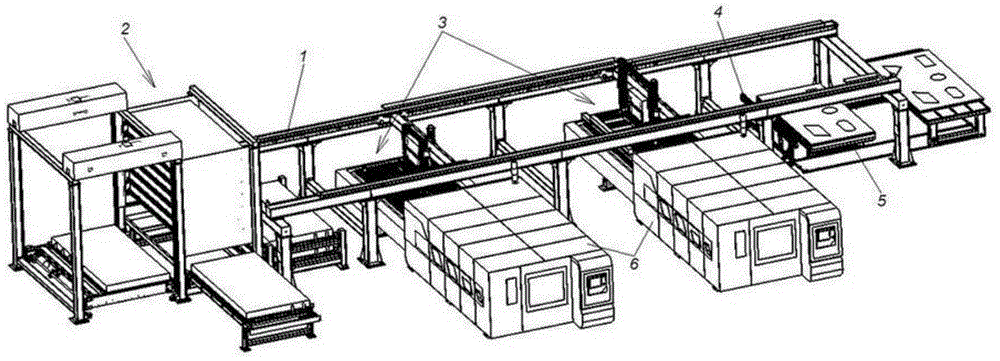

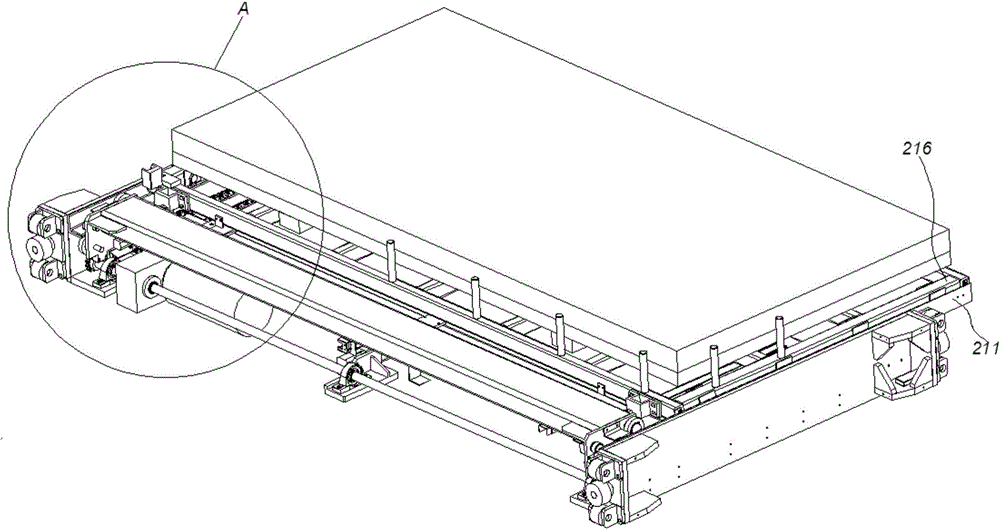

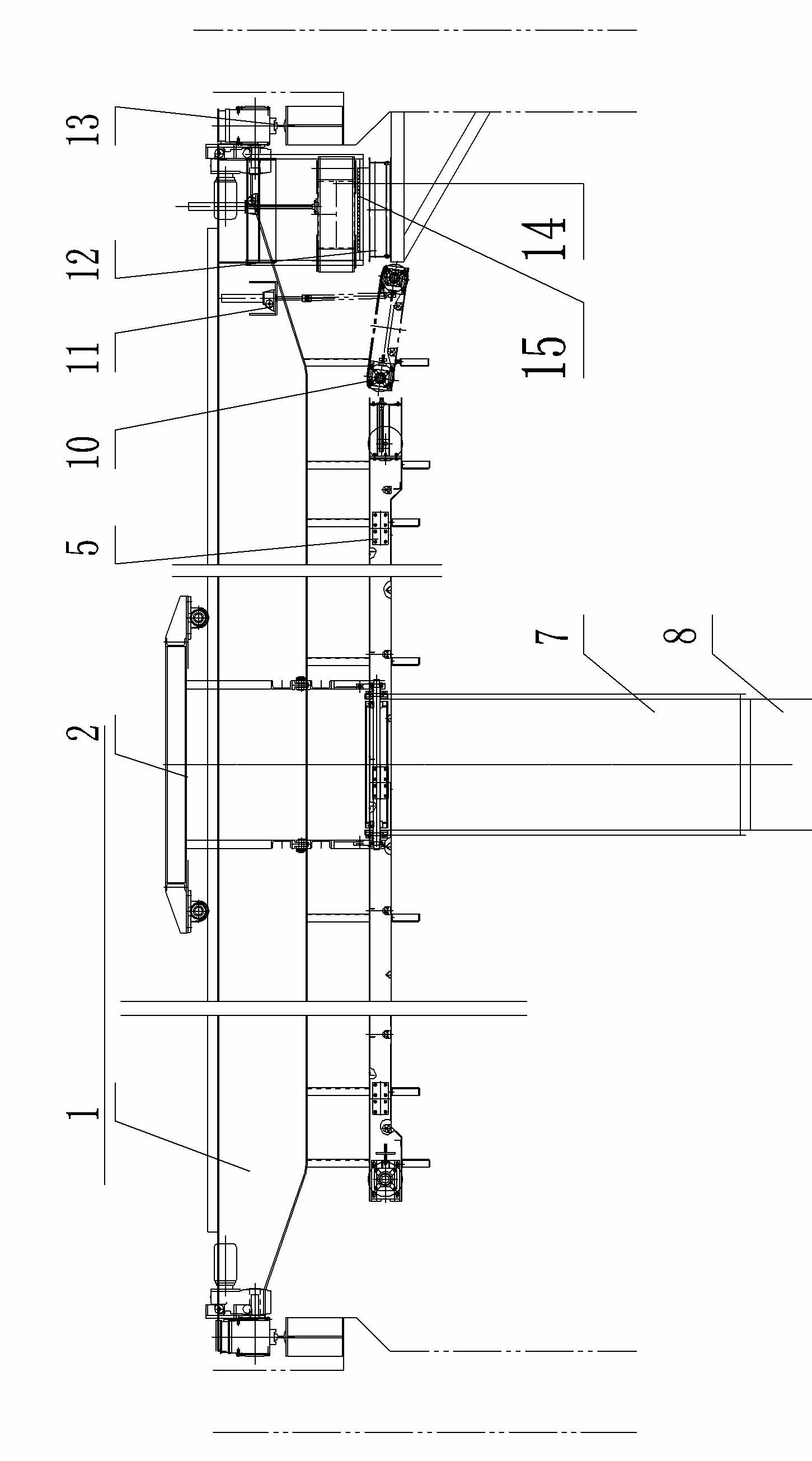

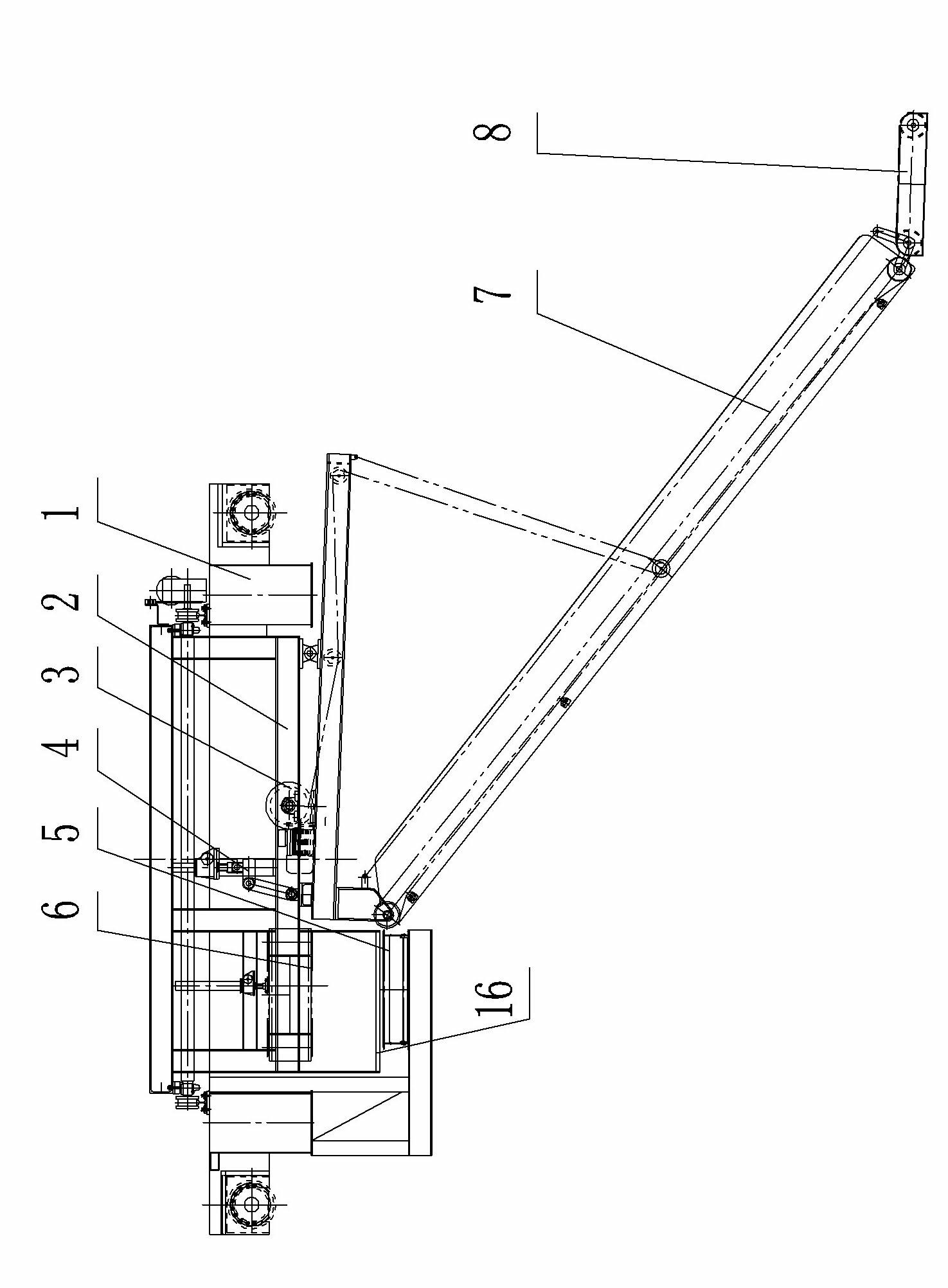

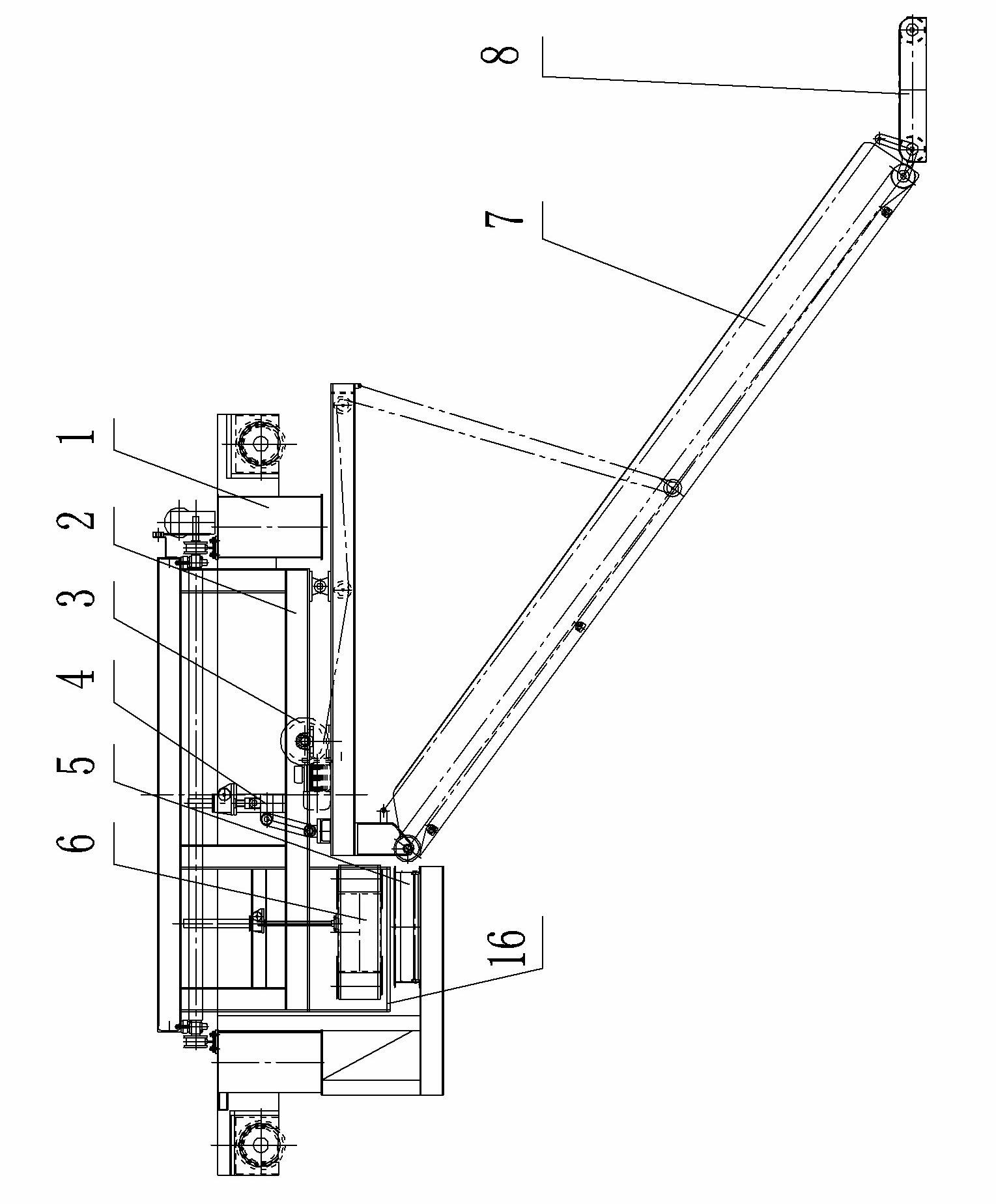

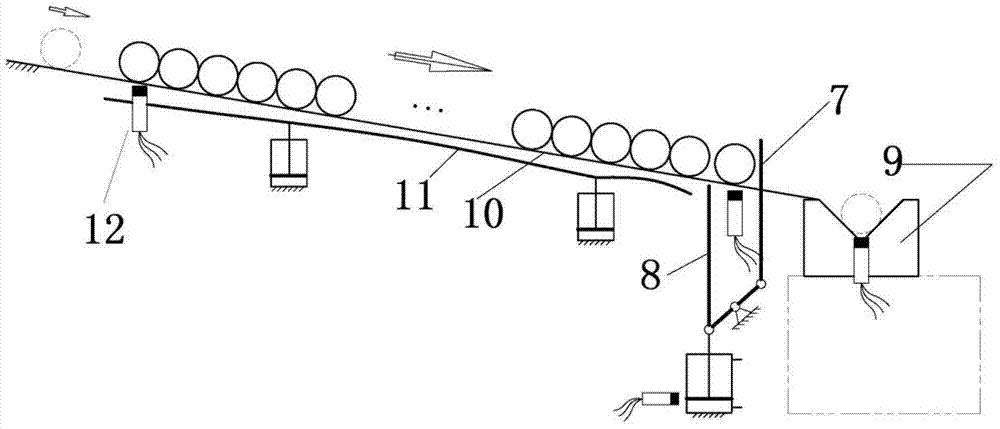

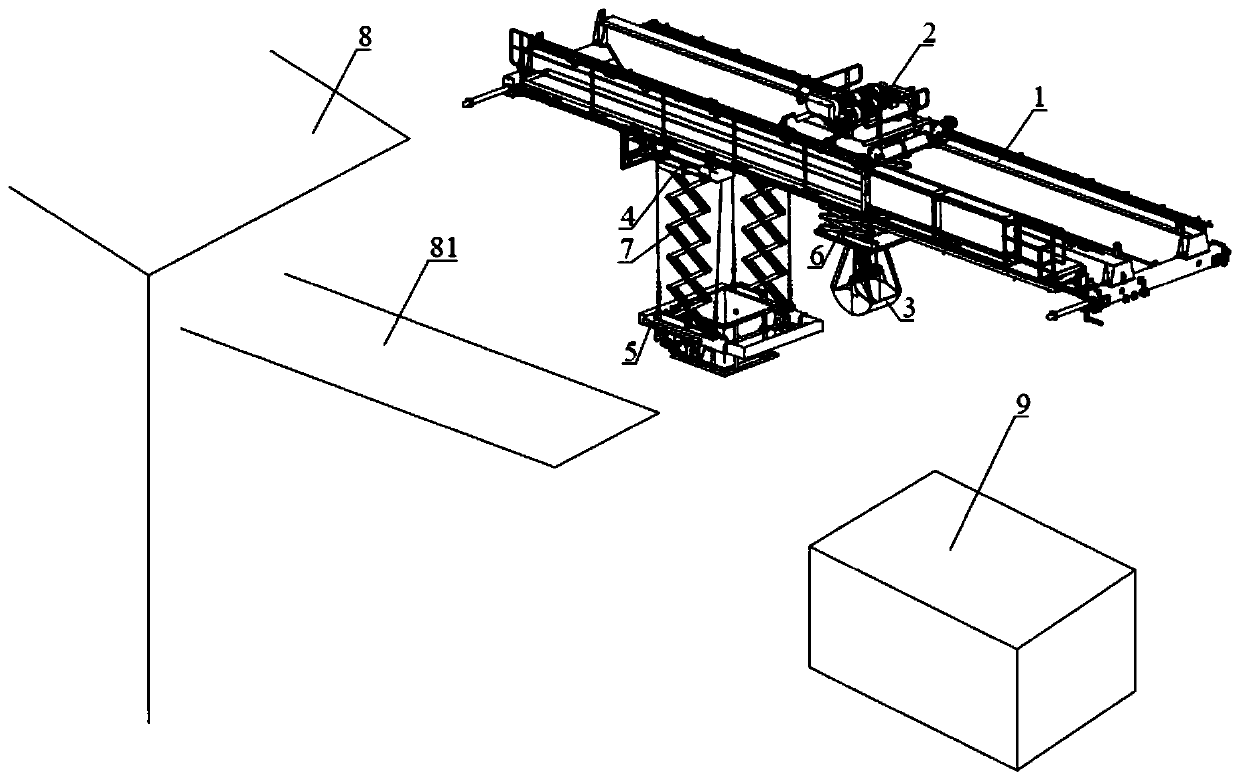

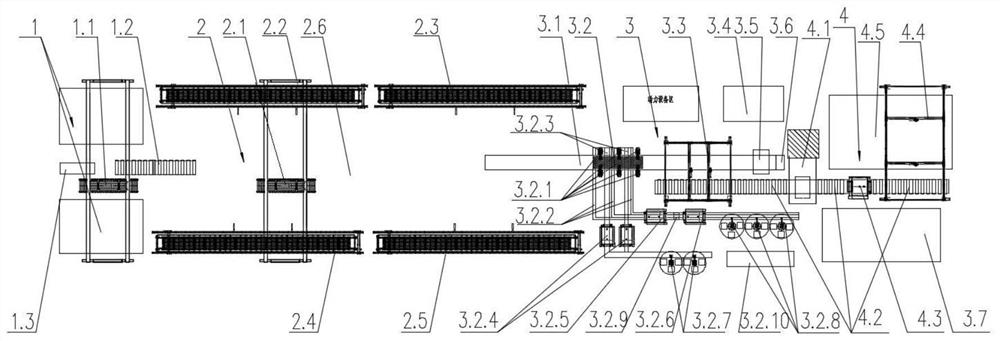

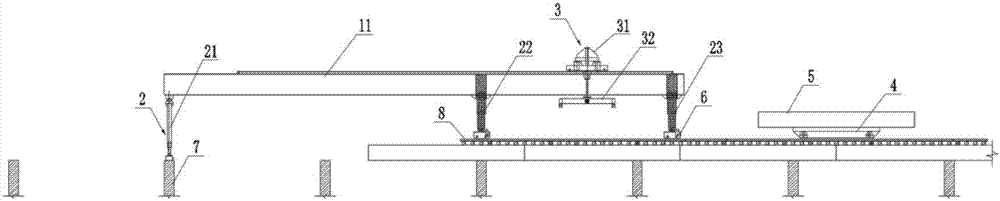

Fully-automatic laser cutting production line

ActiveCN104648931AHigh degree of automationImprove work efficiencyLaser beam welding apparatusMechanical conveyorsProduction lineEngineering

The invention discloses a fully-automatic laser cutting production line. The fully-automatic laser cutting production line comprises a line body, a material warehouse, a truss mechanical arm, a finished product trolley and a laser cutting machine; the material warehouse, the truss mechanical arm and the finished product trolley are arranged sequentially along the line body; the laser cutting machine is arranged between the material warehouse and the finished product trolley; the truss mechanical arm is used for capturing materials from the material warehouse and transferring to the laser cutting machine, then capturing finished products from the laser cutting machine and then transferring to the finished product trolley; the finished product trolley is used for transferring the finished products. The automation degree of the processing and transporting processes of the production line disclosed by the invention is high, and the working efficiency is improved.

Owner:维特罗伯特机械(苏州)有限公司

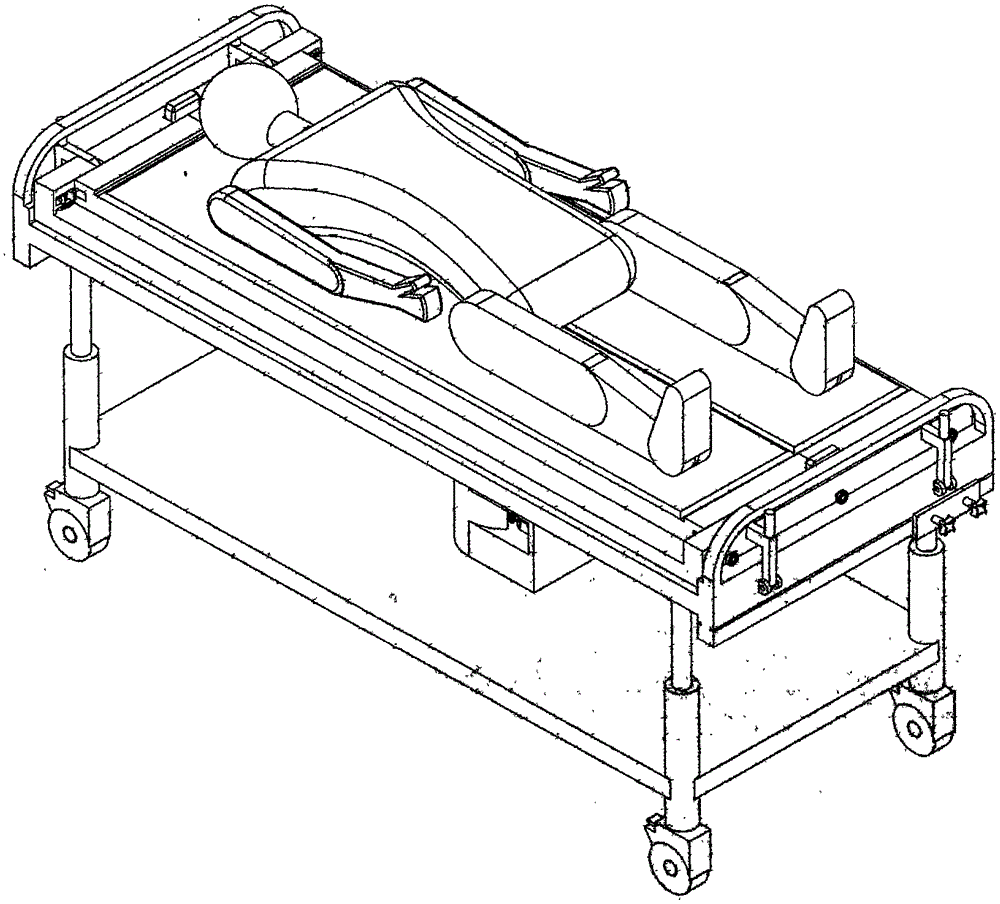

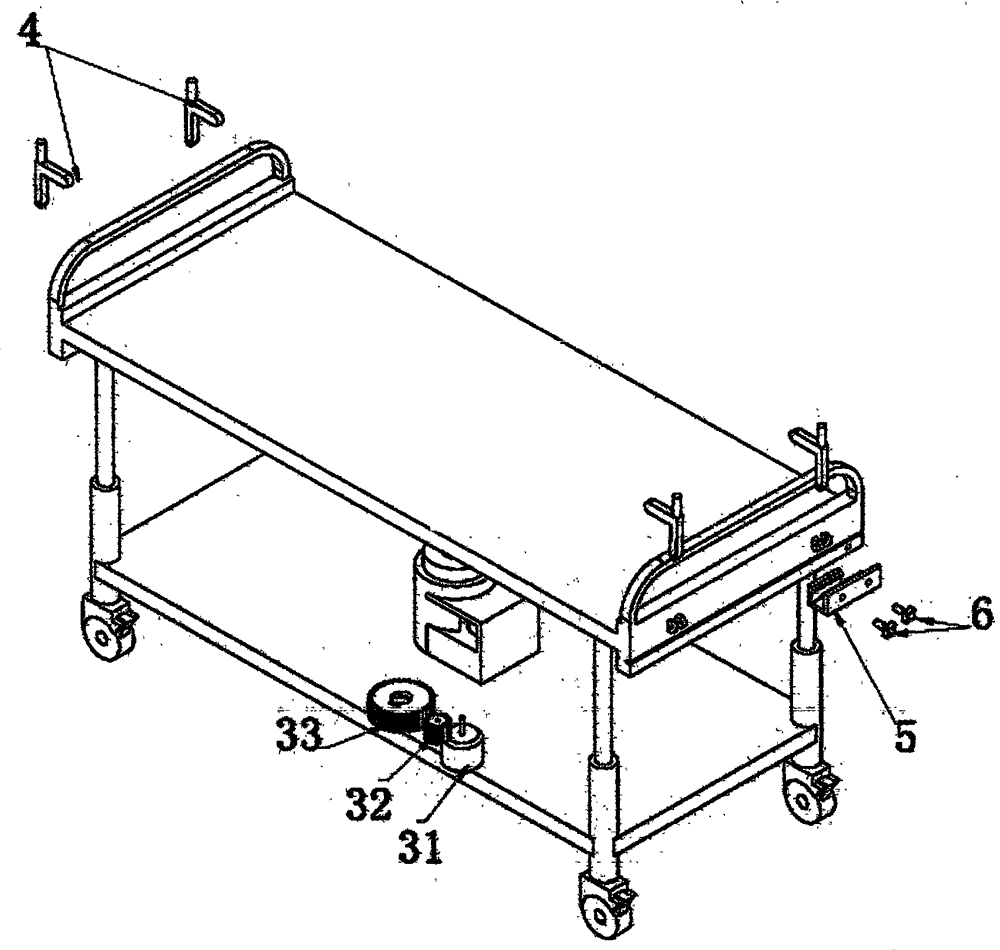

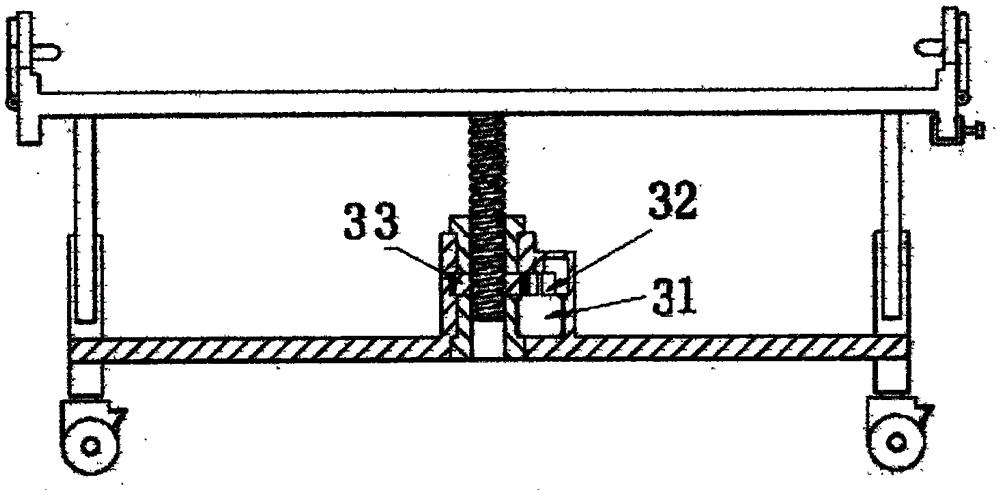

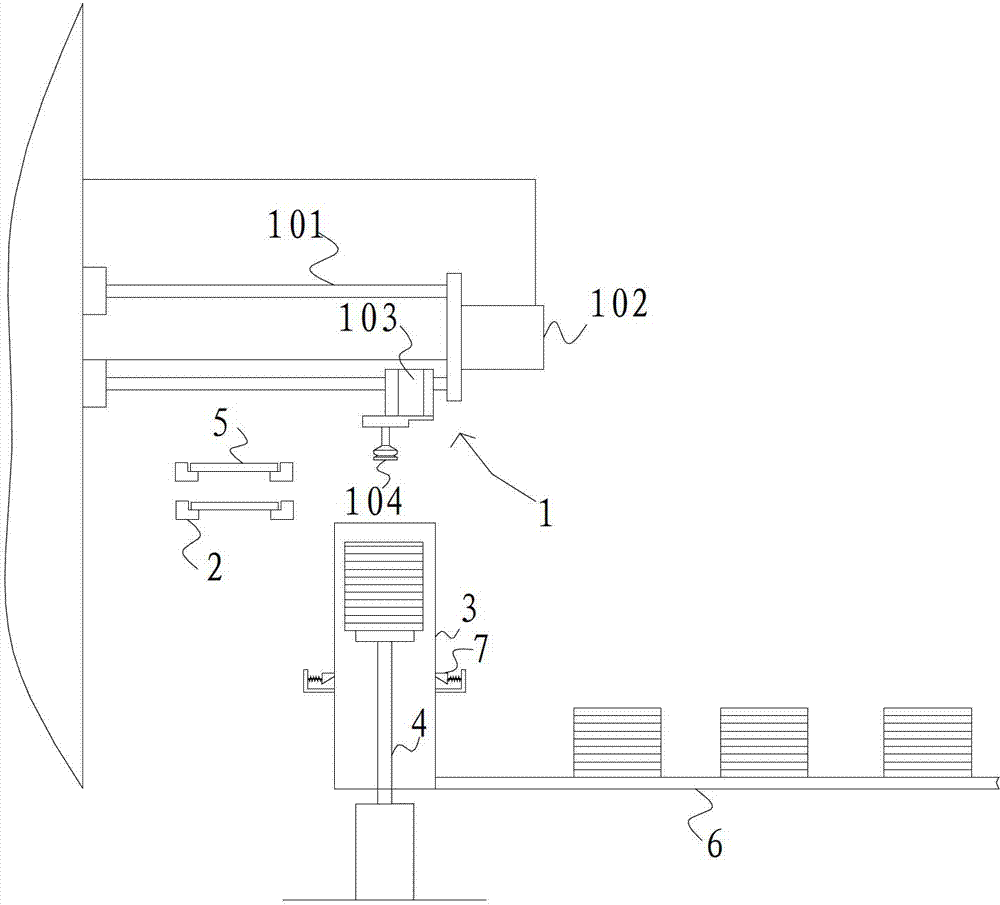

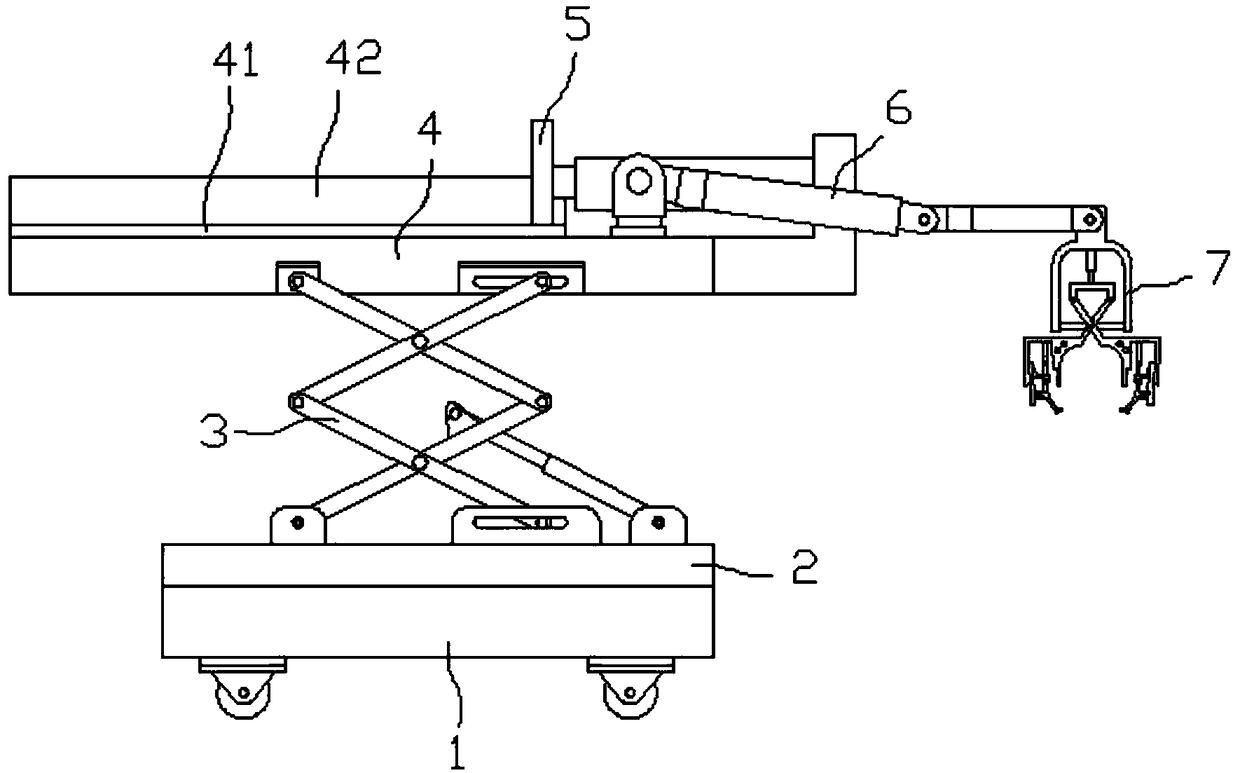

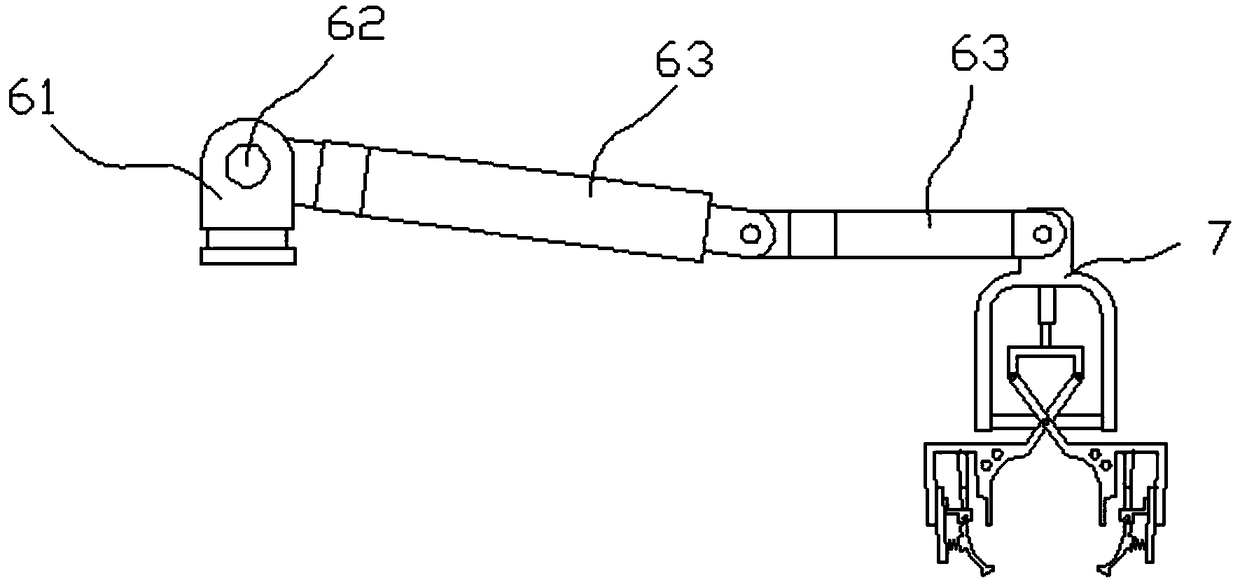

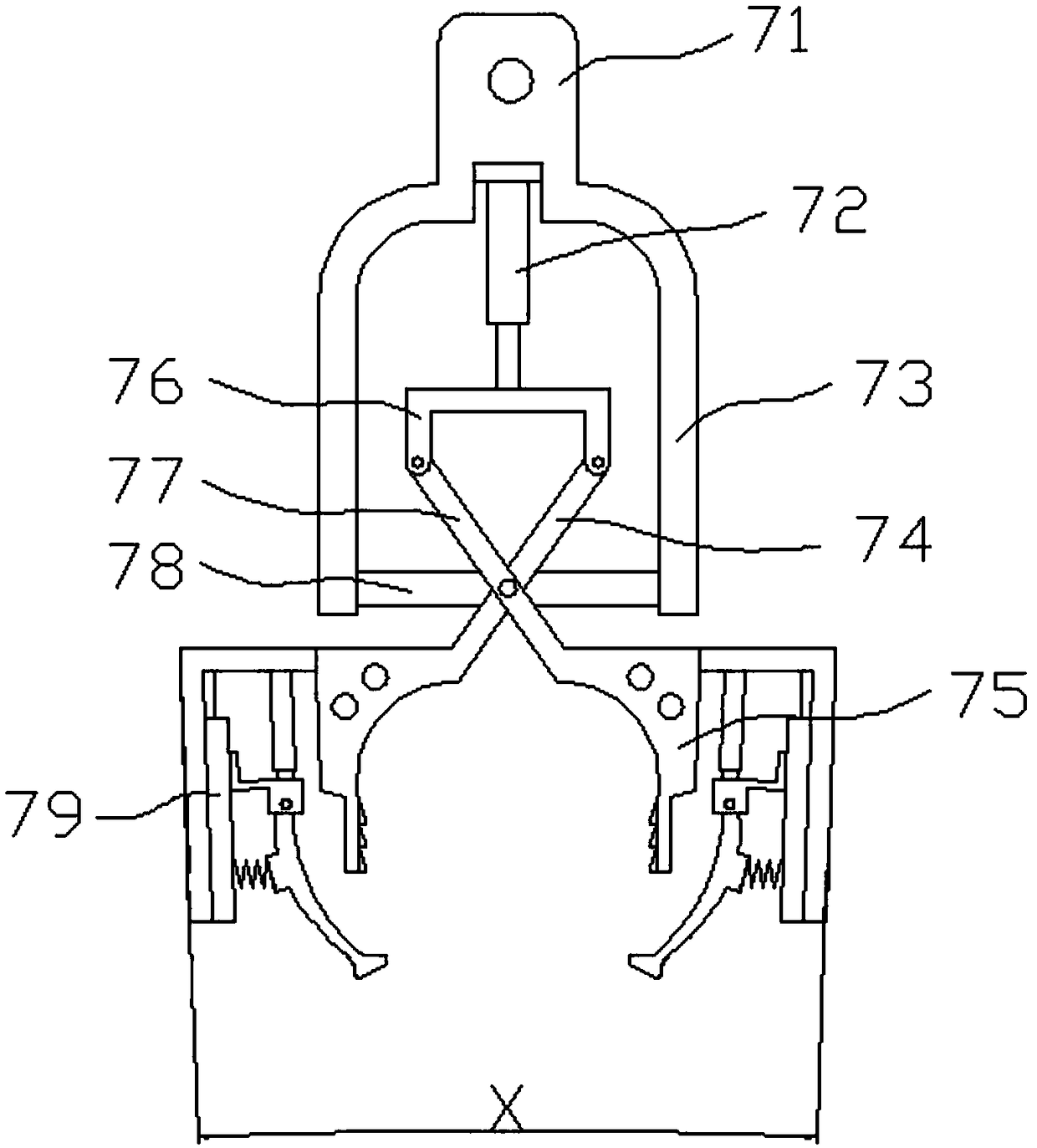

Intelligent mechanical transfer device for operation patients

InactiveCN105559982AAchieve transshipmentRelieve painStretcherNursing bedsEngineeringPhysical Exertions

The invention discloses an intelligent mechanical transfer device for operation patients. The transfer device comprises a cart and a movable stand, wherein the cart is composed of a cart main body, a screw rod lifting mechanism, a fixing device and a connecting device; the cart main body is composed of a lifting bed surface bracket and sliding wheels; the sliding wheels are arranged at the bottom of the lifting bed surface bracket; the lifting bed surface bracket is formed by fixedly connecting four telescopic vertical pillars, a bed board and a bed panel; and the screw rod lifting mechanism is arranged between the bed board and the bed panel. The mechanical transfer device disclosed by the invention is reasonable in structure; the device is capable of effectively transferring the patients, and the process is convenient and rapid, intelligent to operate and low in pain in patients, therefore the circumstance that the patients get hurt is avoided and the process is quite safe; and through the intelligent operation, the purpose of operating by a single person is achieved, and the physical exertion of medical personnel is reduced.

Owner:杨博文

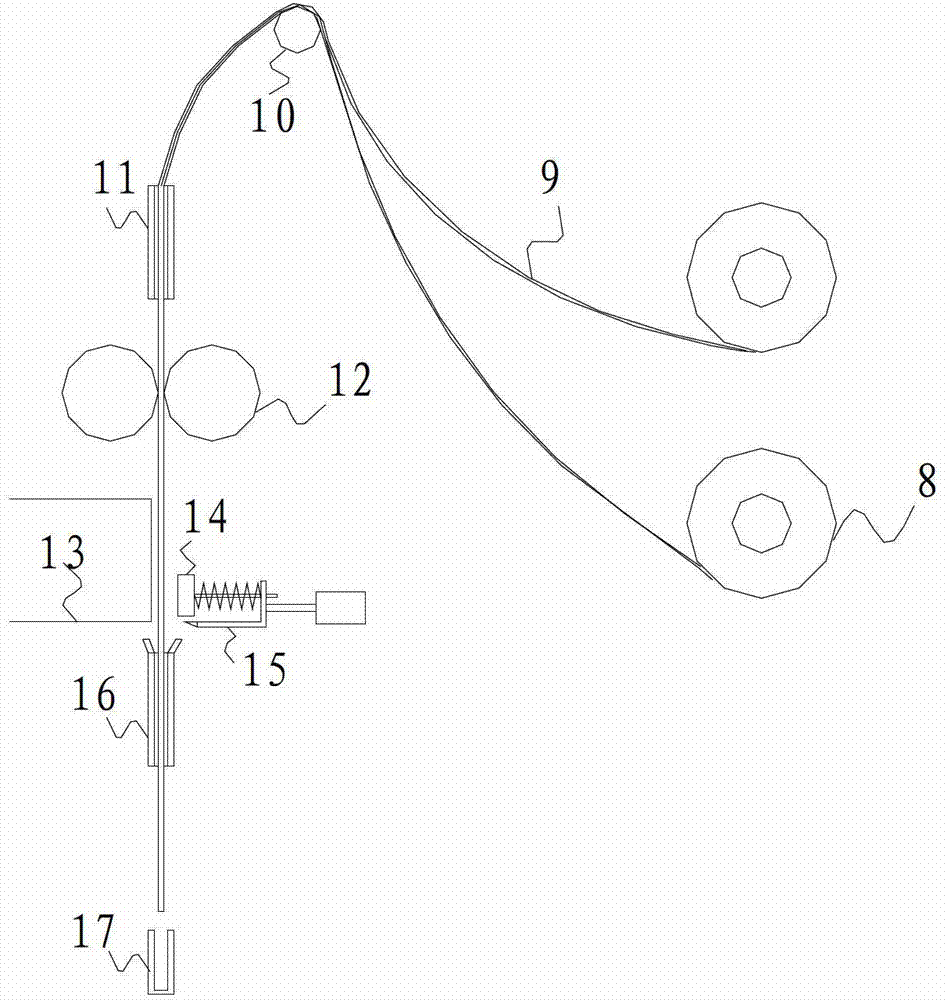

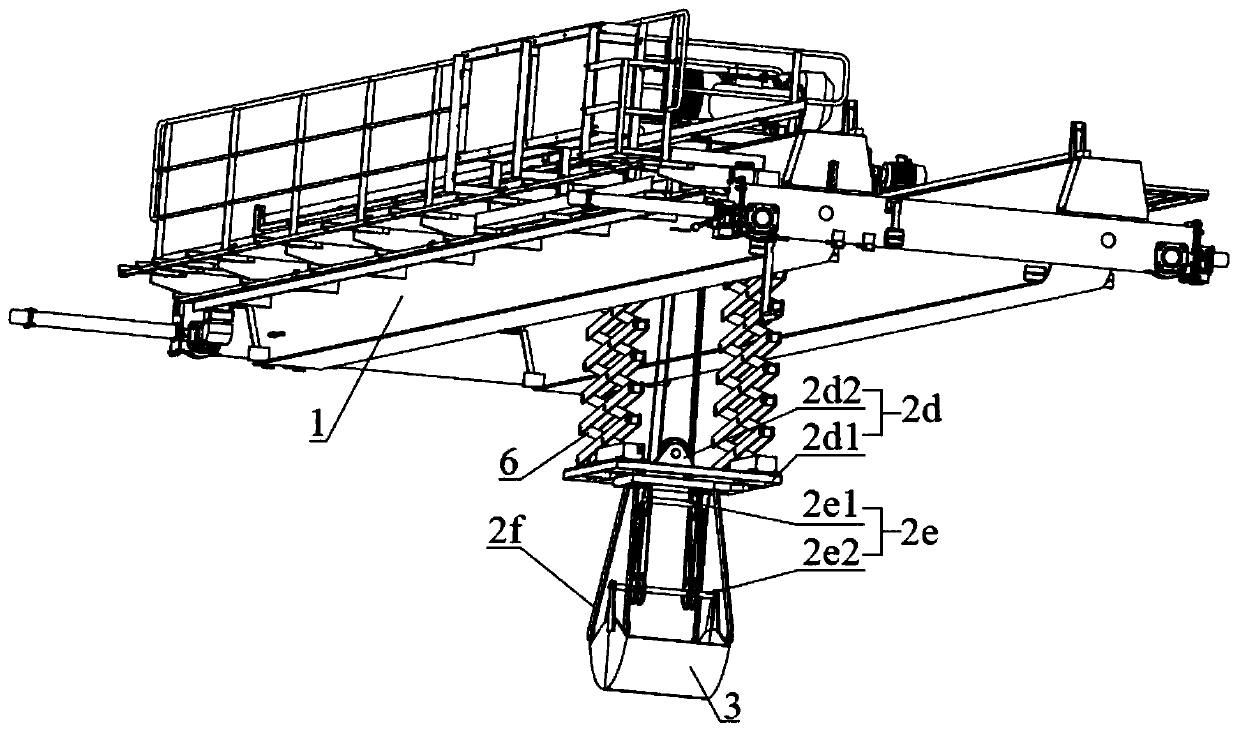

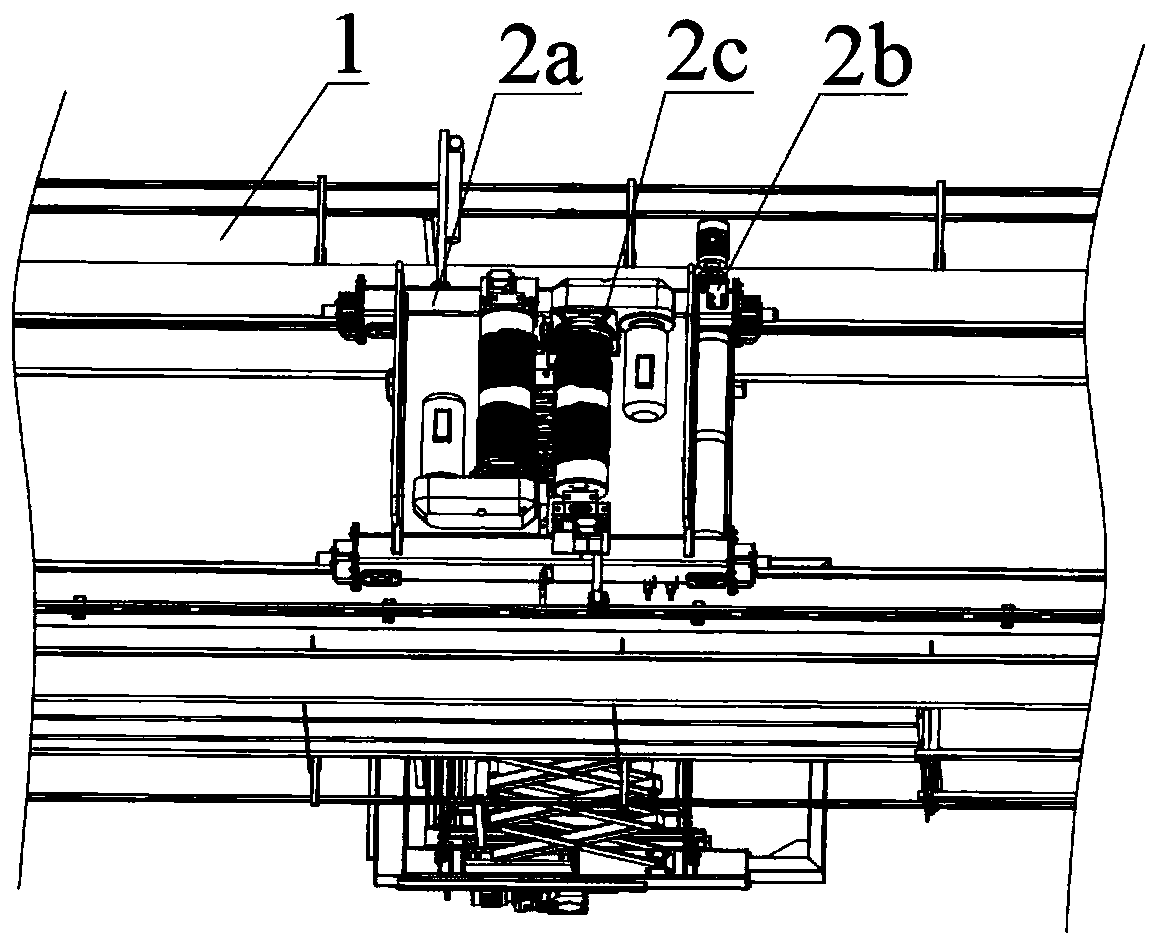

Automatic stacking machine for pole plates

ActiveCN103401027ARealize automatic assemblyAchieve transshipmentFinal product manufactureSecondary cells manufactureStack machineEngineering

The invention discloses an automatic stacking machine for pole plates. The automatic stacking machine comprises a pole plate supplying mechanism, a division plate supplying mechanism and a pole plate stacking mechanism, wherein the pole plate supplying mechanism comprises two pole plate conveying belts, two pole plate storage frames and pole plate top rods arranged under the corresponding pole plate storage frames; the division plate supplying mechanism comprises two raw material rolls, a first guide cylinder used for bearing division plates, a pair of division plate pull rolls, a division plate cutting-off mechanism, a second guide cylinder used for bearing the division plates and a division plate bracket, and a gap through which the pole plates can pass is formed between the division plate bracket and an outlet of the second guide cylinder; the pole plate stacking mechanism comprises two guide rails, two transferring arms, a conveying chain, a plurality of pole plate transferring boxes and a pole plate push hook; a channel through which the division plate can pass is formed in the guide rail positioned at the lower part; the pole plate transferring boxes are fixedly arranged on the conveying chain; the pole plate push hook is used for transferring the pole plates from the two guide rails onto the pole plate transferring boxes. The automatic stacking machine for the pole plates realizes the automatic supply of the positive and negative pole plates and the division plates, the automatic stacking of the positive and negative pole plates and the automatic assembly and transfer of pole groups.

Owner:ZHEJIANG TIANNENG POWER ENERGY

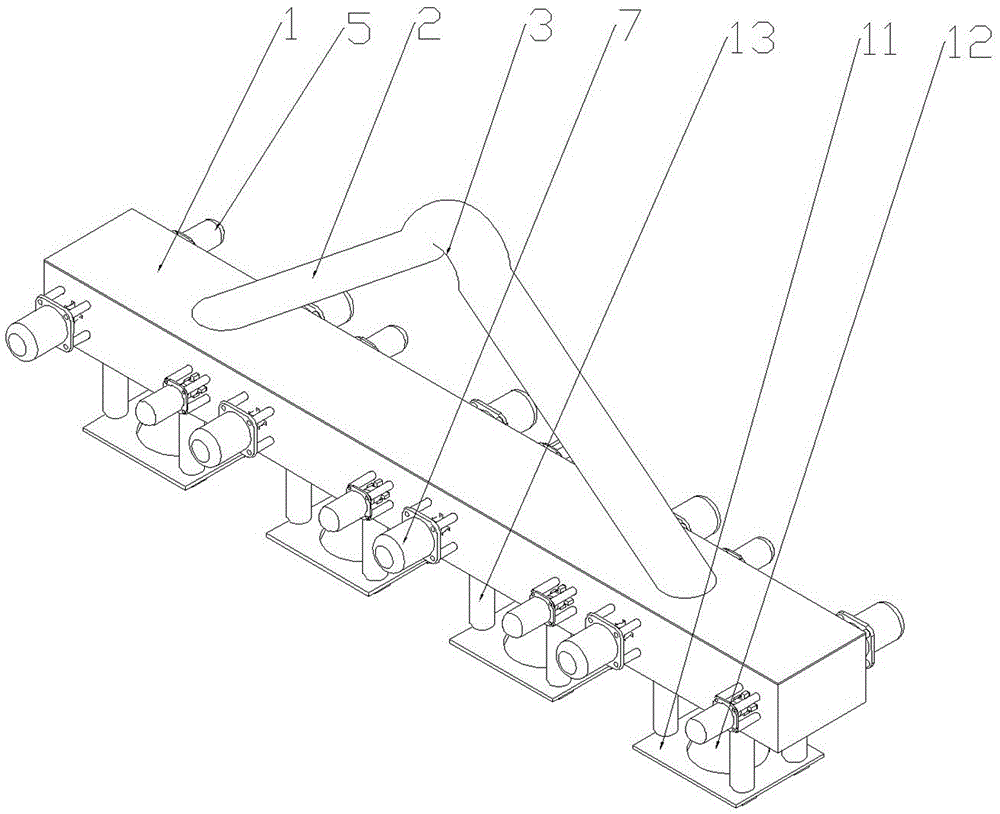

Bulk material discharging, storage and transportation equipment and transportation method

PendingCN108328360ARealize human-computer interactionReduce misuseConveyorsLarge containersControl systemHouse building

The invention discloses bulk material discharging, storage and transportation equipment which comprises a transportation hopper installed on the upper portion of a frame. The lower end of the transportation hopper is provided with a discharge outlet, and the discharge outlet is provided with a bin door capable of being opened and closed. The equipment further comprises a bin door opening-closing and detection system, a vehicle positioning indication human-machine interaction system, a transportation hopper material level detection and indication system, an upper spraying device and a lower spraying device which are connected with a control system, wherein the upper spraying device is installed on the upper portion of the transportation hopper, and the lower spraying device is installed onthe lower portion of the transportation hopper. Transportation vehicle automatic monitoring and reminding are achieved, a boat discharging door machine can work without interruption, the storage capacity of the transportation hopper can be displayed in real time, the bin door is automatically opened and closed for discharging, the lower portion of the transportation hopper is provided with a material weighing system, an empty vehicle weight house, a heavy vehicle weight house and a discharging, storage and transportation device are integrated into a whole, loading and weighing are completed ina one-stop mode, the automobile weight house building cost is reduced, processes are reduced, and production efficiency is improved. The invention further provides a transportation method for transporting bulk materials through the bulk material discharging, storage and transportation equipment.

Owner:RIZHAO PORT +1

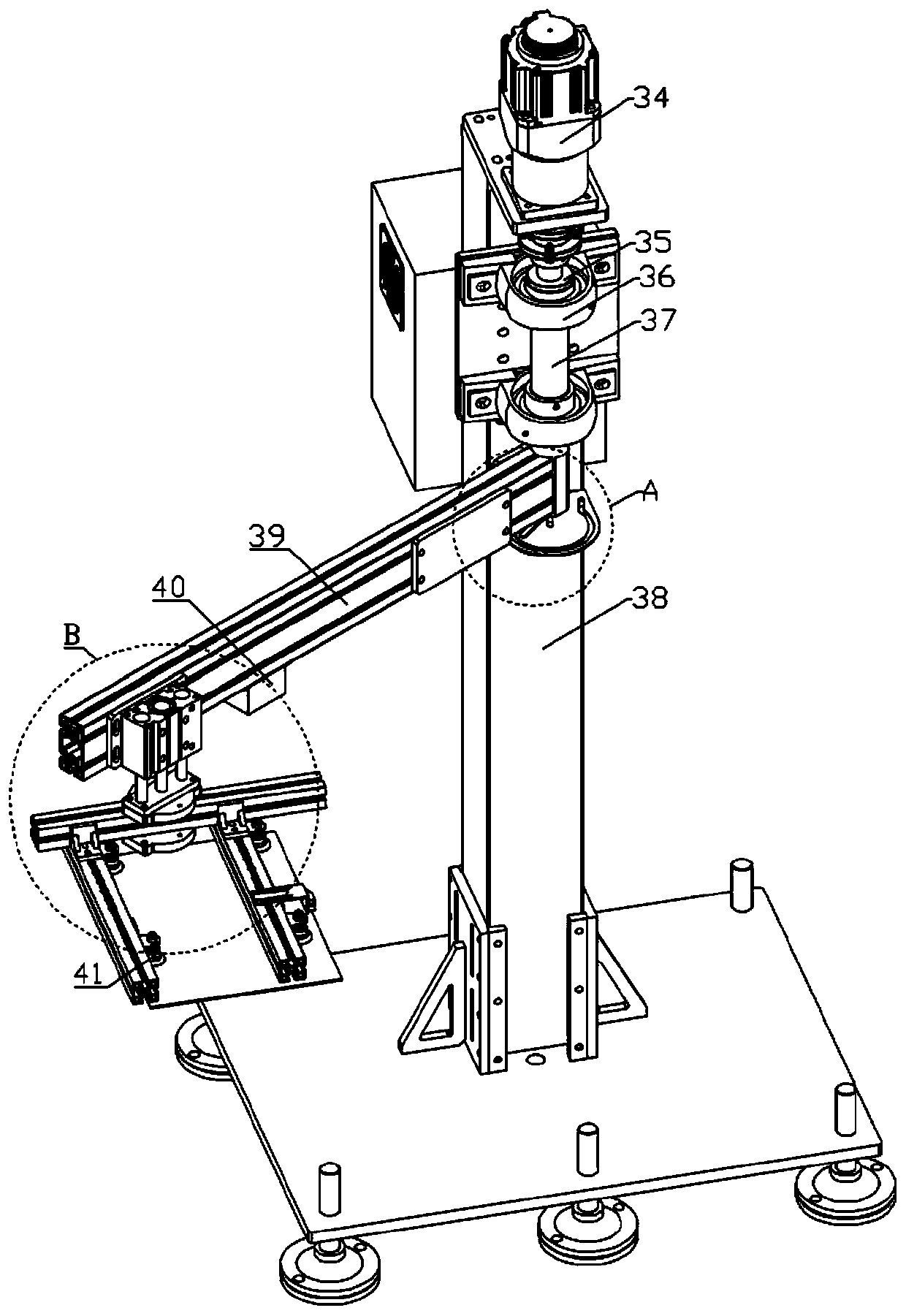

Clamping type manipulator

ActiveCN105459150AGuarantee product qualityAvoid pollutionArmsConveyor partsManipulatorDust particles

The invention discloses a clamping type manipulator. The clamping type manipulator comprises a manipulator base, a lifting driving mechanism arranged on the manipulator base, and a clamping mechanism arranged at the top end of the lifting driving mechanism, wherein the a manipulator base lateral movement driving mechanism is arranged on one side of the manipulator base; the clamping mechanism comprises a pair of rotary driving assemblies which are arranged at the top end of the lifting driving mechanism in a spaced mode; the rotary output end of each rotary driving assembly is connected with a revolving arm; the pair of revolving arms is arranged in parallel and the rotation directions of the revolving arms are opposite; clamping jaw fixing blocks are arranged on the revolving arms; clamping jaws used for clamping the edges of chip containing boxes are arranged on the clamping jaw fixing blocks; position sensors are arranged on the clamping jaw fixing blocks. The clamping type manipulator has the beneficial effects that 1, according to the clamping type manipulator, the chip containing boxes are directly clamped through the clamping jaws, and dust particle pollution and metal pollution are prevented, and thus the production quality of chips is ensured; and 2, clamping and transferring of the chip containing boxes can be achieved conveniently; the transferring speed is greatly increased; the transferring time is shortened; the work efficiency is improved.

Owner:SHANGHAI TUNA ELECTRIC MECHANIC EQUIP CO LTD

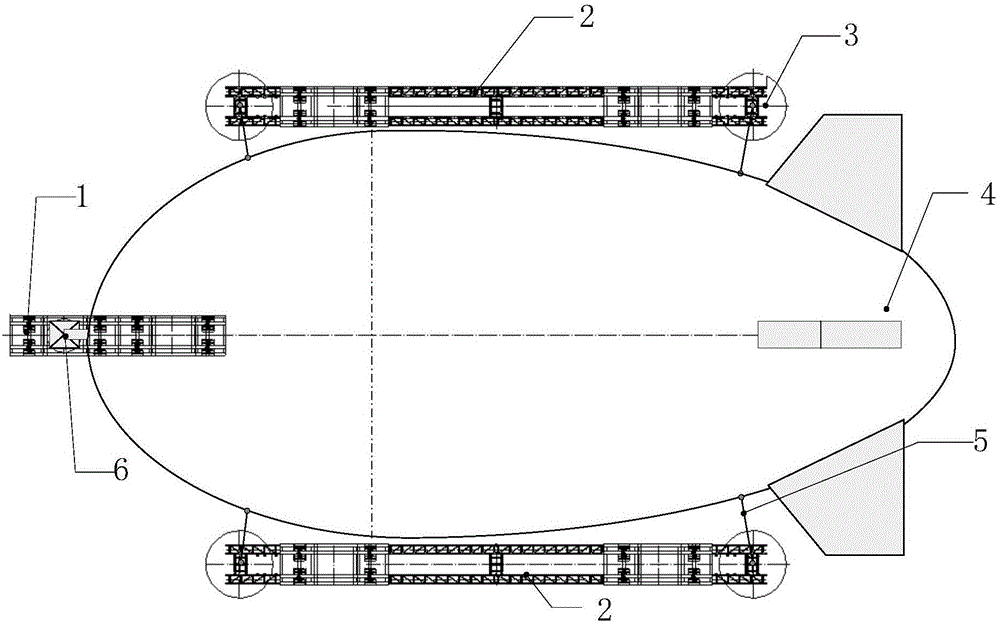

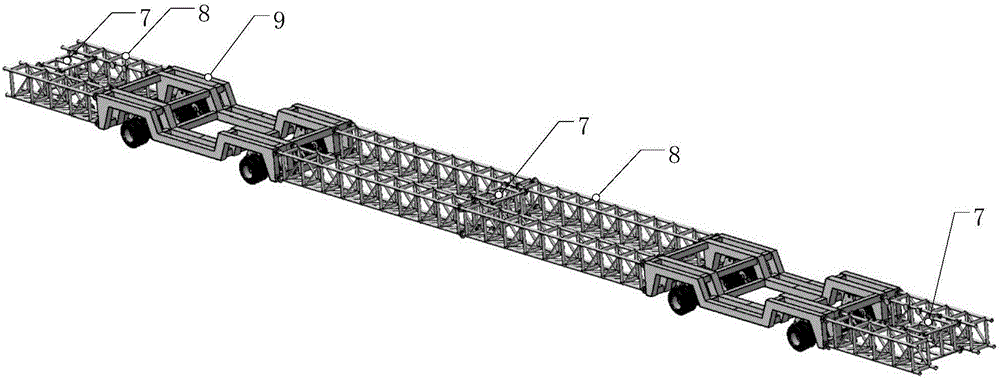

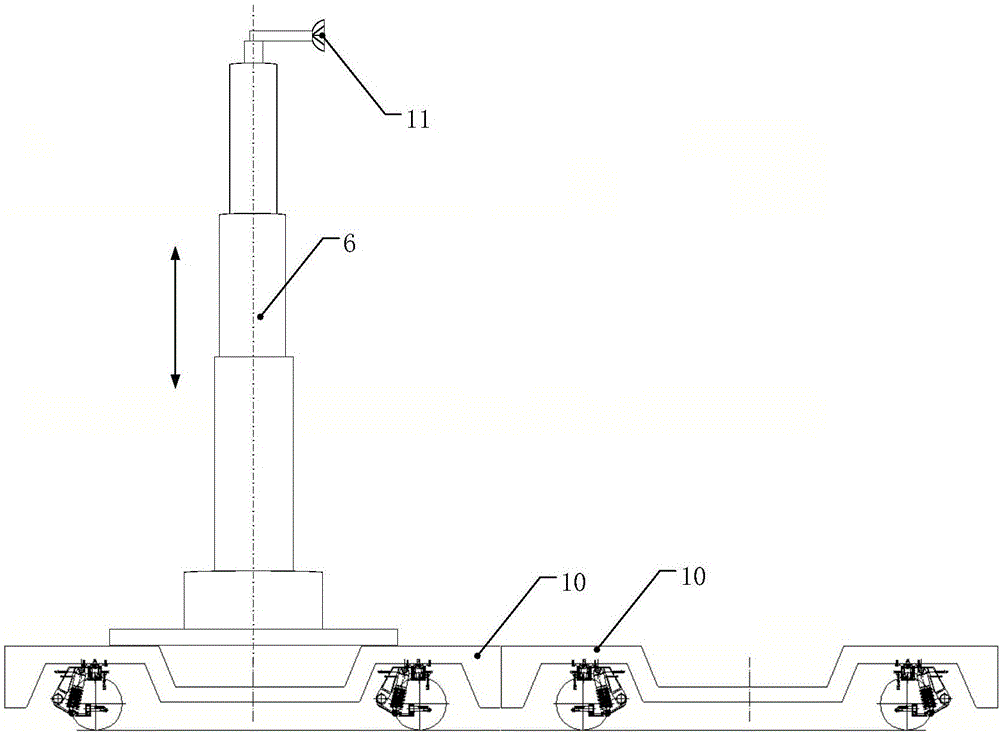

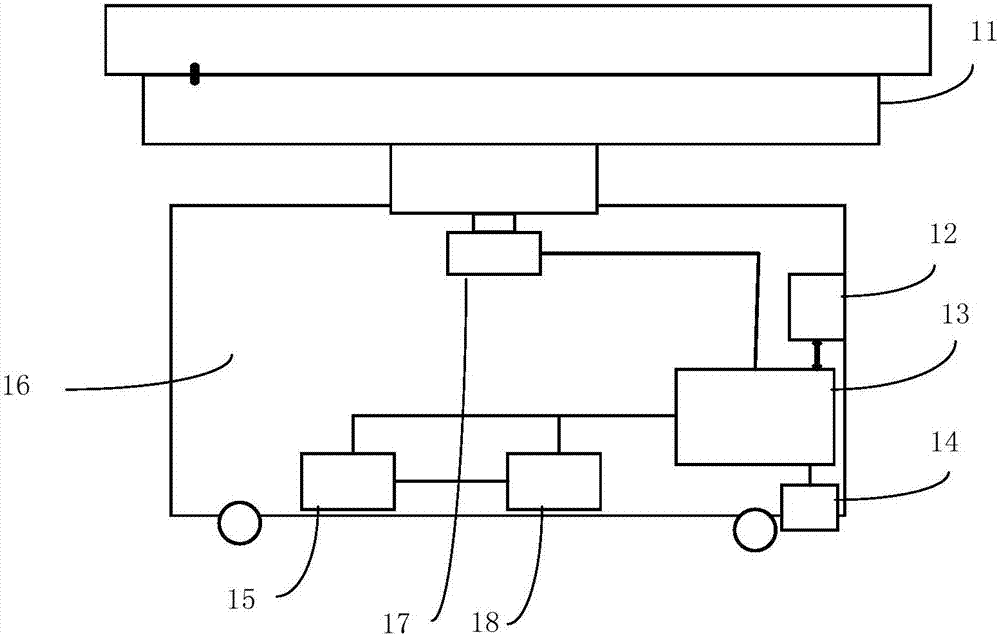

Discrete modular large airship transshipment and flying system and method

ActiveCN106275485AStrong scalabilityEasy to transportAnchoring installationsSynchronous controlWind field

The invention discloses a discrete modular large airship transshipment and flying system and method. The discrete modular large airship transshipment and flying system comprises a transshipment and flying platform and a synchronous control system. The transshipment and flying platform comprises a pulling vehicle set and two transshipment vehicle sets, and the pulling vehicle set and the two transshipment vehicle sets are independent of one another. The pulling vehicle set ties the head of an airship through pulling of a pulling tower. The two transshipment vehicle sets are arranged on the two sides of the airship correspondingly, and the two sides of the airship are fixed through mooring ropes. The pulling vehicle set and the transshipment vehicle sets are all of modular structures, and all modules can be modularly combined as needed through installation connectors. The synchronous control system controls the transshipment and flying platform to pull the airship to move and adjusts the movement direction of the transshipment and flying platform according to the change of a wind field. The discrete modular large airship transshipment and flying system and method are suitable for transshipment, mooring and flying tasks of large near space airships. The discrete modular large airship transshipment and flying system is convenient to operate, high in environment adaptability and especially suitable for transshipment and flying occasions of large airships.

Owner:NO 63655 TROOPS OF THE CHINESE PEOPLES LIBERATION ARMY

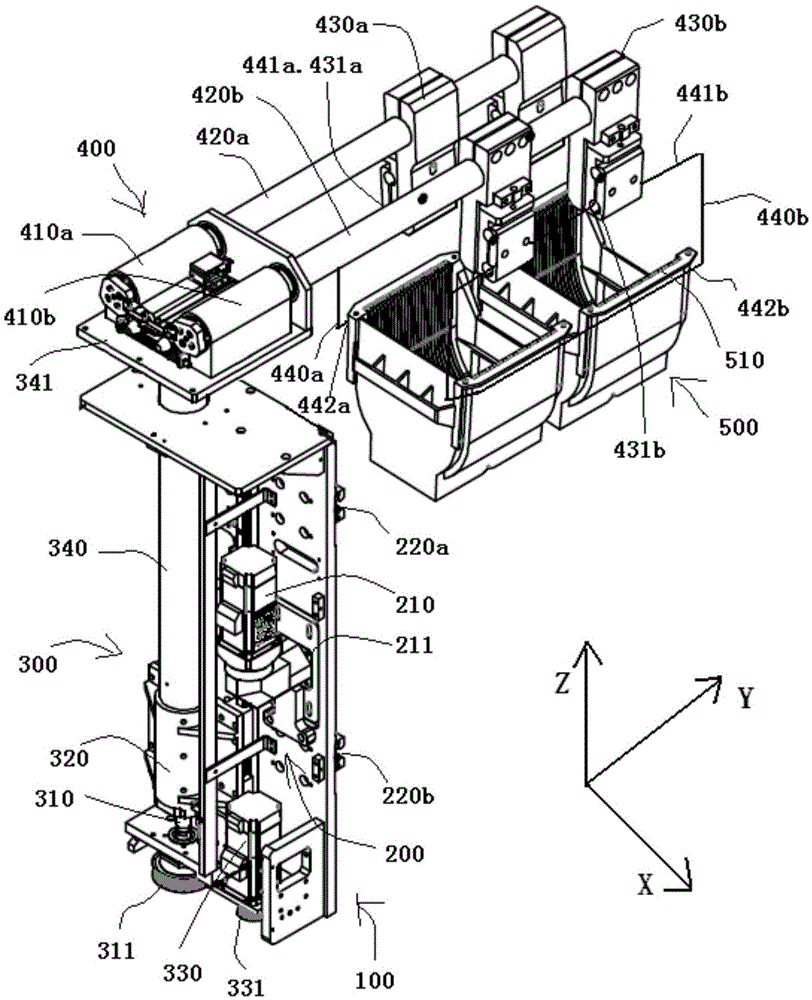

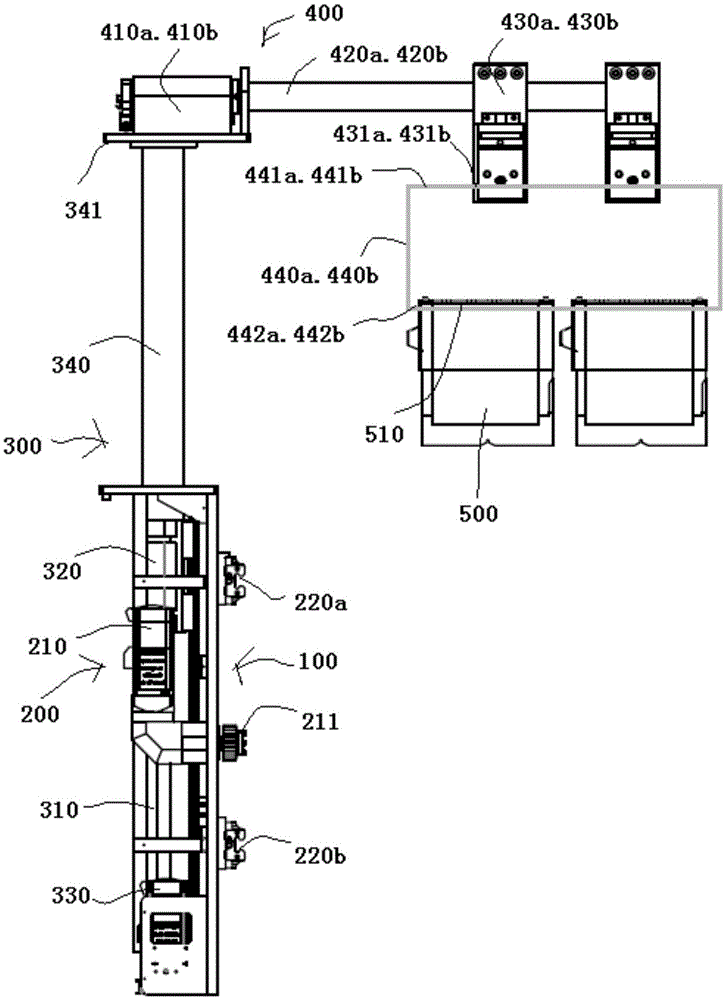

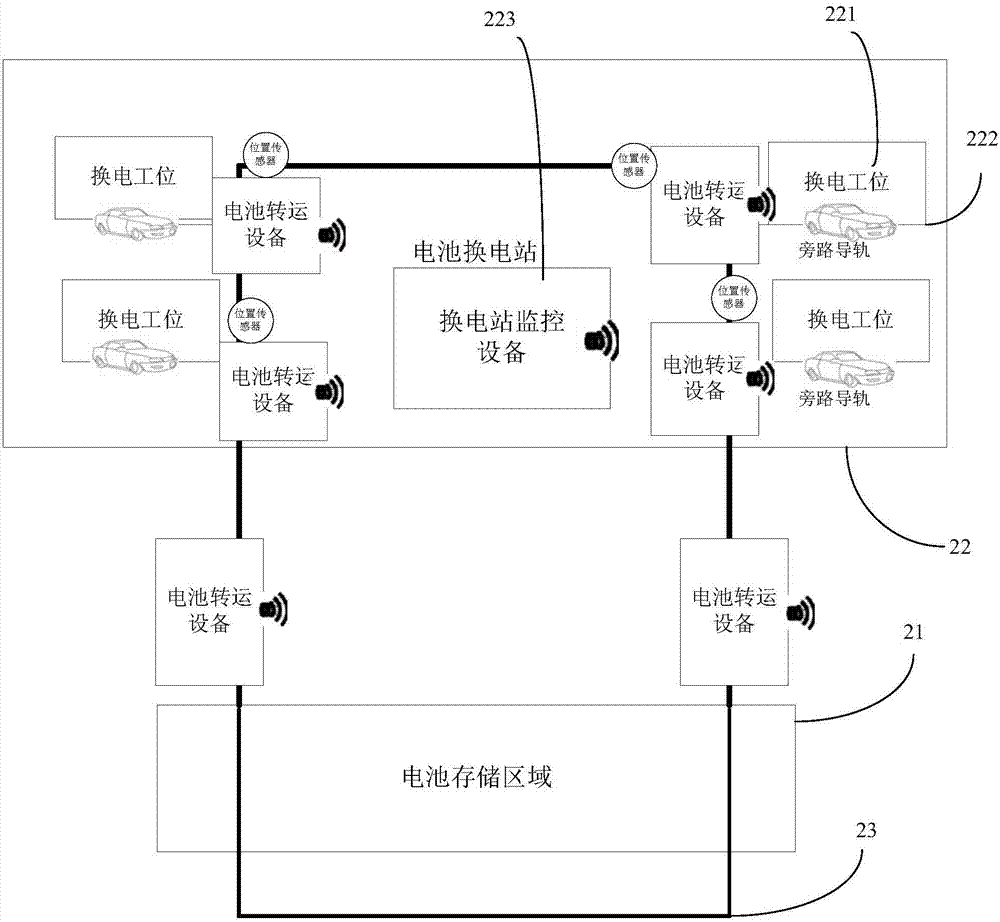

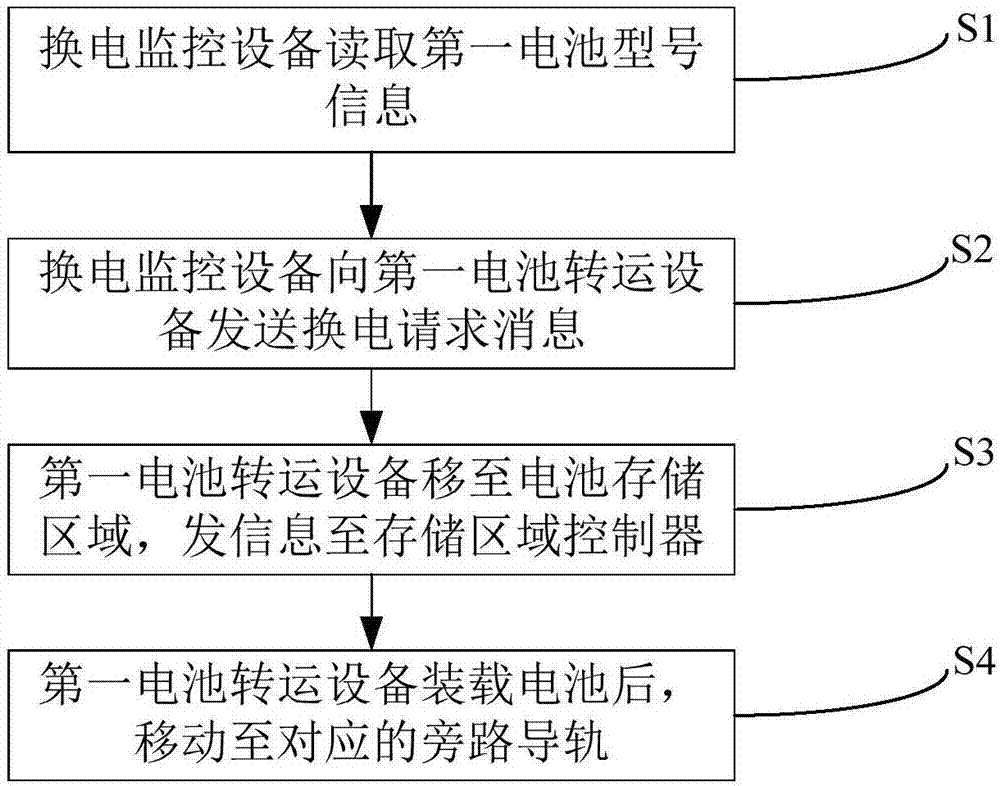

Battery transferring equipment, battery transferring system and battery transferring method

ActiveCN107499319ASolve the problem of long-distance transshipmentImprove transport efficiencyTransmission systemsElectric propulsion mountingElectricityElectrical battery

The invention provides battery transferring equipment, a battery transferring system and a battery transferring method, and relates to the field of electromobile battery replacement. The battery transferring equipment comprises a transferring bodywork, a first drive motor, a second drive motor, a bodywork control module, a first wireless communication module and a position sensor, wherein the a rotary table arranged at the top of the transferring bodywork, and a battery tray is arranged on the rotary table; the first drive motor is used for driving the rotary table to rotate; the second drive motor is used for driving the transferring bodywork to move; the bodywork control module is used for controlling the first drive motor and the second drive motor to work; the first wireless communication module is used for receiving a control instruction and sending the control instruction to the bodywork control module; the position sensor is used for collecting the geographical position information of the transferring bodywork and sending the information to the bodywork control module. The battery transferring problem of multiple battery replacement parking places of a battery replacement station can be solved, the operation efficiency of the battery replacement station can be promoted, the potential safety hazards of consolidated battery storage are reduced, and long-distance battery transferring between a battery replacement region and a storage region is achieved.

Owner:BEIJING ELECTRIC VEHICLE

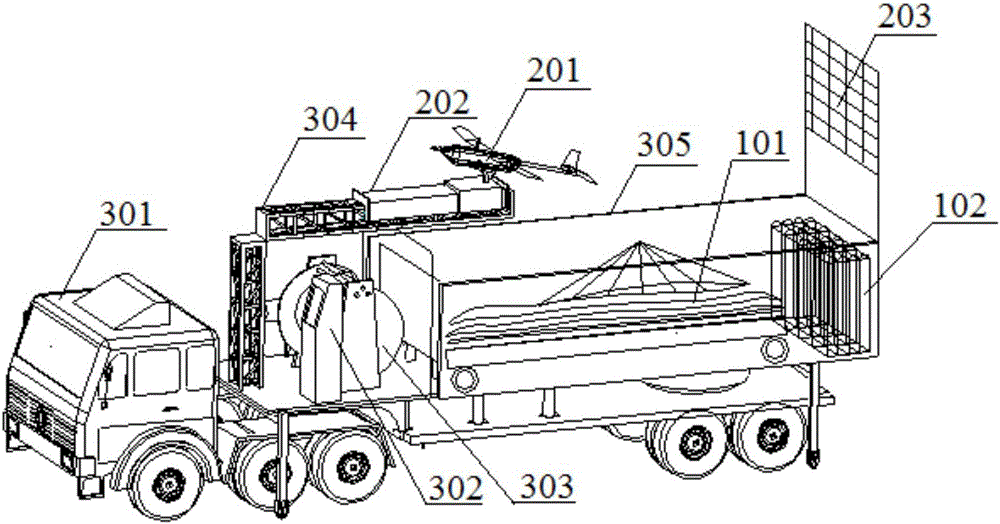

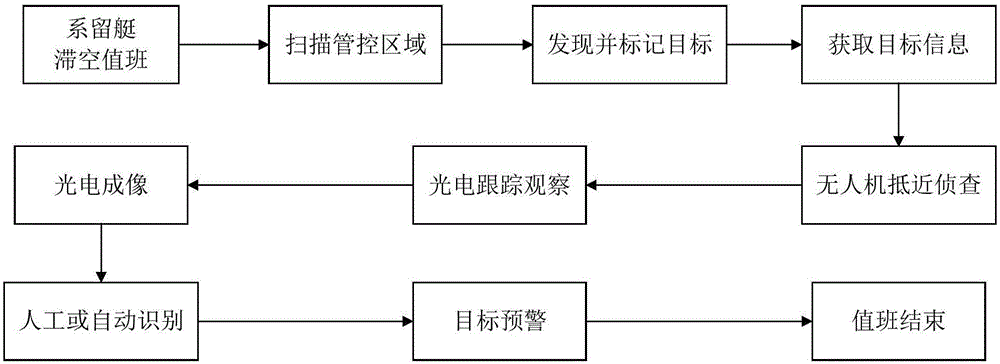

Boat, ground and vehicle combined monitoring method and monitoring system

ActiveCN106274617ALow costEasy to use and maintainLaunching/towing gearItem transportation vehiclesMonitoring systemEngineering

The invention discloses a boat, ground and vehicle combined monitoring method. Searching load equipment on a bag body of a moored boat is used for conducting region searching, tracking and recognizing load equipment on an unmanned aerial vehicle is used for conducting close tracking and recognizing on a target searched by the load searching equipment, and recognition results are sent back to a ground monitoring station. The invention further discloses a boat, ground and vehicle combined monitoring system which comprises the moored boat, the unmanned aerial vehicle, ground equipment and the load equipment. The ground equipment comprises a multifunctional truck and the ground monitoring station. The load equipment comprises the searching load equipment and the tracking and recognizing load equipment. The moored boat carries the searching load equipment for achieving long-term hover and region searching; the unmanned aerial vehicle carries the tracking and recognizing load equipment for achieving rapid departure and close investigation; and the multifunctional truck enables the moored boat, the unmanned aerial vehicle and the load equipment to be integrated, rapid and mobile deployment is achieved, and the ground monitoring station is used for achieving information fusion and commanding and coordinating work, so that a combined monitoring function of the boat, ground and vehicle combined monitoring system is achieved.

Owner:湖南航天远望科技有限公司 +1

Un-stacking and stacking machine

InactiveCN102658944ATake advantage ofReduce in quantityStacking articlesDe-stacking articlesEngineeringMechanical engineering

The invention provides an un-stacking and stacking machine, comprising a large travelling crane mounted in a storeroom, and an in-storeroom conveyer which is located at the lower part of a rail of the large travelling crane and is parallel to the rail. The rail is arranged on the large travelling crane; a small travelling crane is arranged on the rail; a transverse conveyor is arranged at the lower part of the large travelling crane; the upper part of the small travelling crane is provided with a small travelling crane frame body, and the lower part of the small travelling crane is provided with a slope conveyor mounting frame; the slope conveyor is mounted below the slope conveyor mounting frame; a bag stopping and direction changing device A and a transition overturn conveyor A are arranged at a crossed adjacent position of the transverse conveyor and the in-storeroom conveyer; a bag stopping and direction changing device B is arranged at a crossed adjacent position of the transverse conveyor and the slope conveyor; a bag collecting conveyor is arranged at the lower end of the slope conveyor; and the in-storeroom conveyer, the transverse conveyor, the bag stopping and direction changing device A, the transition overturn conveyor A, the bag stopping and direction changing device B, the slope conveyor and the bag collecting conveyor can operate in two directions. The un-stacking and stacking machine provided by the invention not only can un-stuck but also can stack. The work which can be completed by multiple former machines can be completed by one un-stacking and stacking machine.

Owner:韩建渠

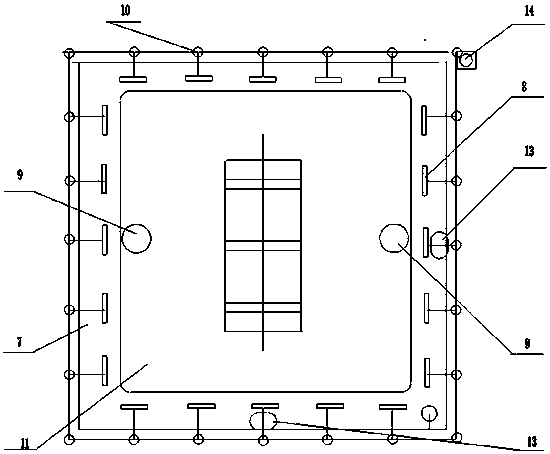

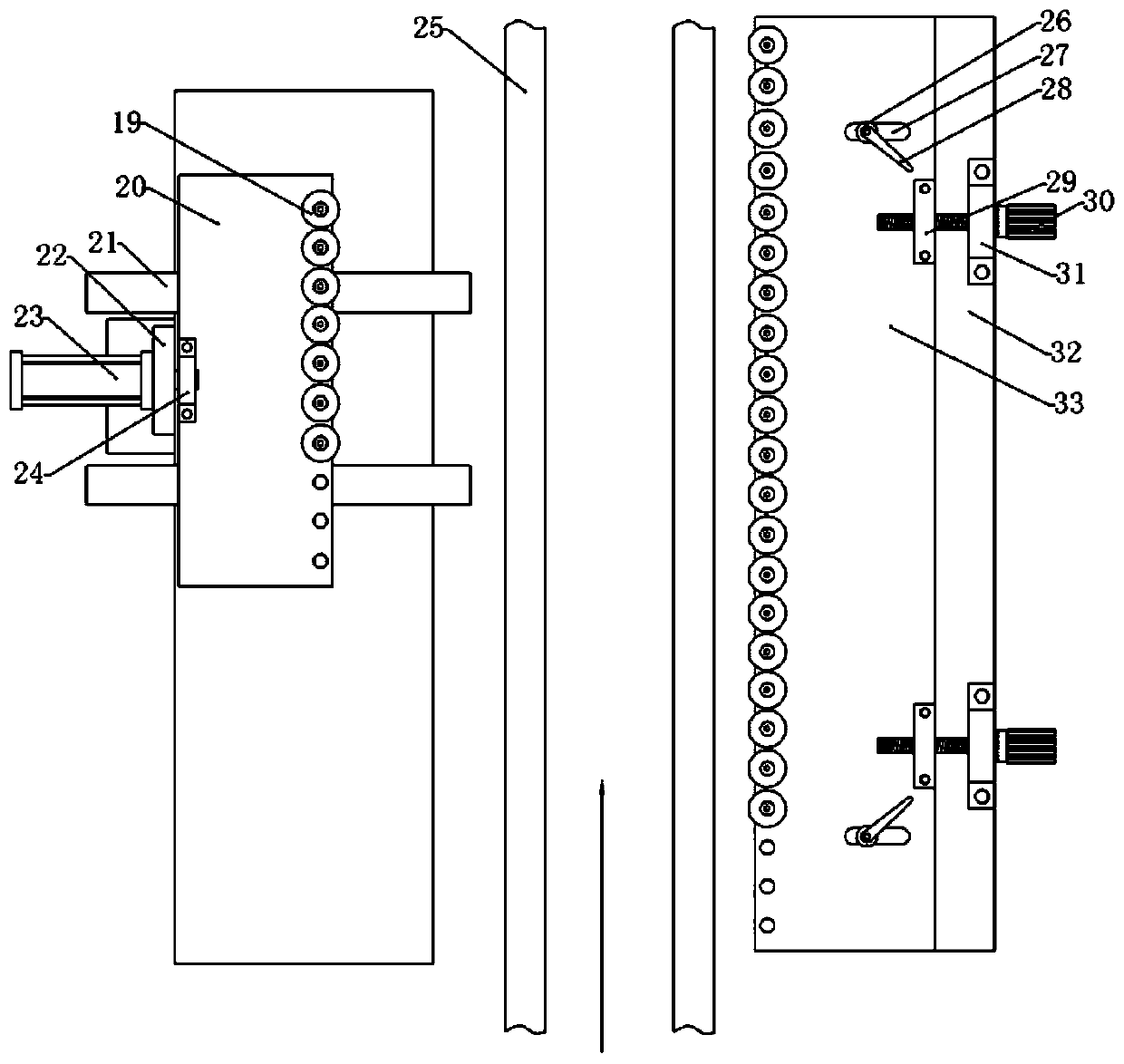

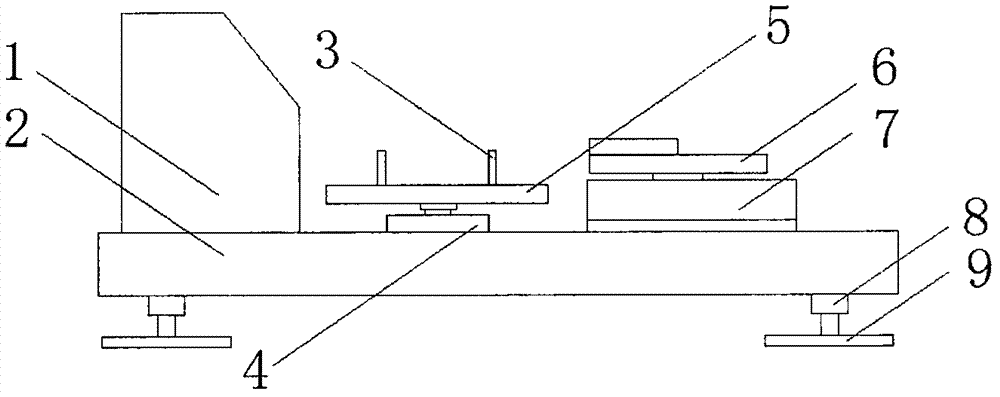

Glass piece four-side polishing production line

ActiveCN111571362AAchieve regulationSimple structureEdge grinding machinesGrinding feedersPolishingEngineering

The invention relates to the technical field of electronic product machining, in particular to a glass piece four-side polishing production line. The glass piece four-side polishing production line comprises a first polishing mechanism and a second polishing mechanism, the first polishing mechanism and the second polishing mechanism each comprise a lower conveying belt, the glass piece four-side polishing production line further comprises a positioning assembly, the positioning assembly comprises a positioning plate used for clamping a glass piece and a movable plate, the positioning plate andthe movable plate are relatively arranged, the sides, close to the lower conveying belt, of the positioning plate and the movable plate are parallel to the lower conveying belt, a plurality of guiderollers are rotationally arranged on the sides, close to the lower conveying belt, of the positioning plate and the movable plate, and the roller faces of the guide rollers protrude out of the side face of the positioning plate or the movable plate, the guide rollers on the positioning plate is aligned with a polishing piece on the same side of the positioning plate in the conveying direction of the conveying belt; ad the movable plate is slidably arranged and connected with an air cylinder used for driving the movable plate to move towards the conveying belt. According to the glass piece four-side polishing production line, the problems that in the prior art, a feeding mechanism cannot be suitable for conveying of glass of different sizes, and the glass is prone to being damaged in the positioning process can be solved.

Owner:重庆嘉涌电子有限公司

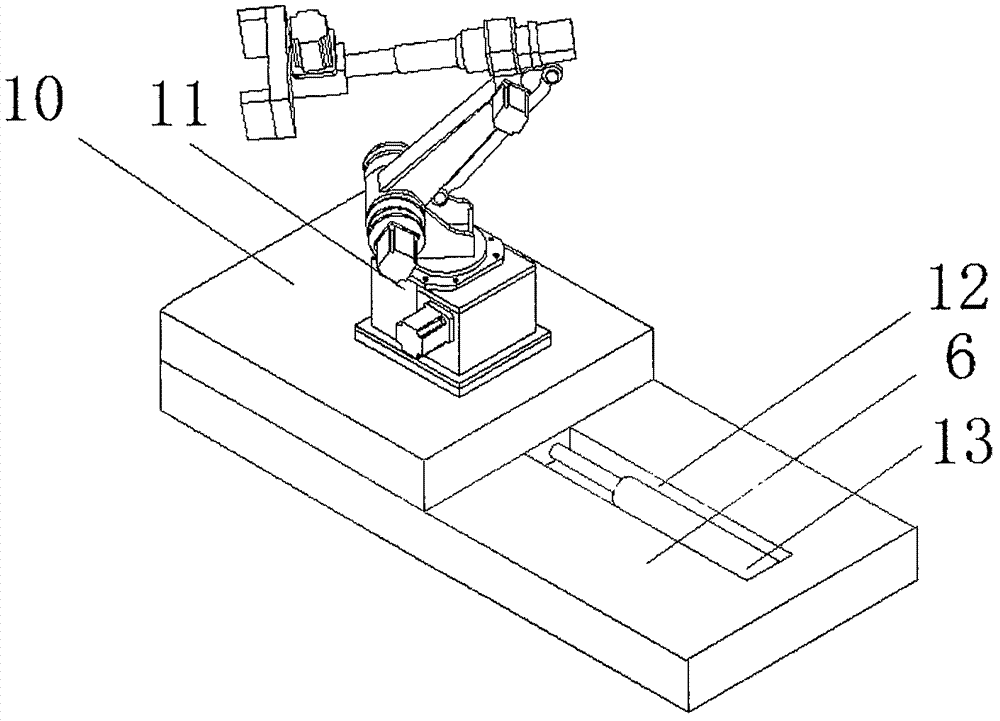

Spot welding and brazing integrated device of nuclear fuel element cladding pipe

ActiveCN104511673ARealize automatic sequenceRealize automatic unloadingWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingIntegrated devices

The invention belongs to the technical field of nuclear fuel element machining electromechanical integration, in particular relates to a spot welding and brazing integrated device of a nuclear fuel element cladding pipe. The device comprises a brazing system, a spot welding system, a feed mechanism, a discharge mechanism, a loading robot and an unloading robot, wherein the spot welding system performs the spot welding of a support pad and an isolation block on the cladding pipe; two robots are symmetrically mounted on the central surface of the brazing system; the feed mechanism and the loading robot are arranged at the feed side of the brazing system; the discharge mechanism and the unloading robot are arranged at the discharge side of the brazing system; and in working, the spot welding system works firstly to prepare materials for the brazing system. Two ABB robots are used as intermediate links, and the spot welding and the brazing are integrated as a whole, so that the automatic sequence transfer after the spot welding and the automatic discharge after the brazing of the cladding pipe are realized, the research on the nuclear fuel element manufacturing aspect is enriched, and the foundation of developing the fuel element manufacturing develops to the direction of integration and full automatization and reducing the inference of manmade middle link factors as far as possible is laid.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

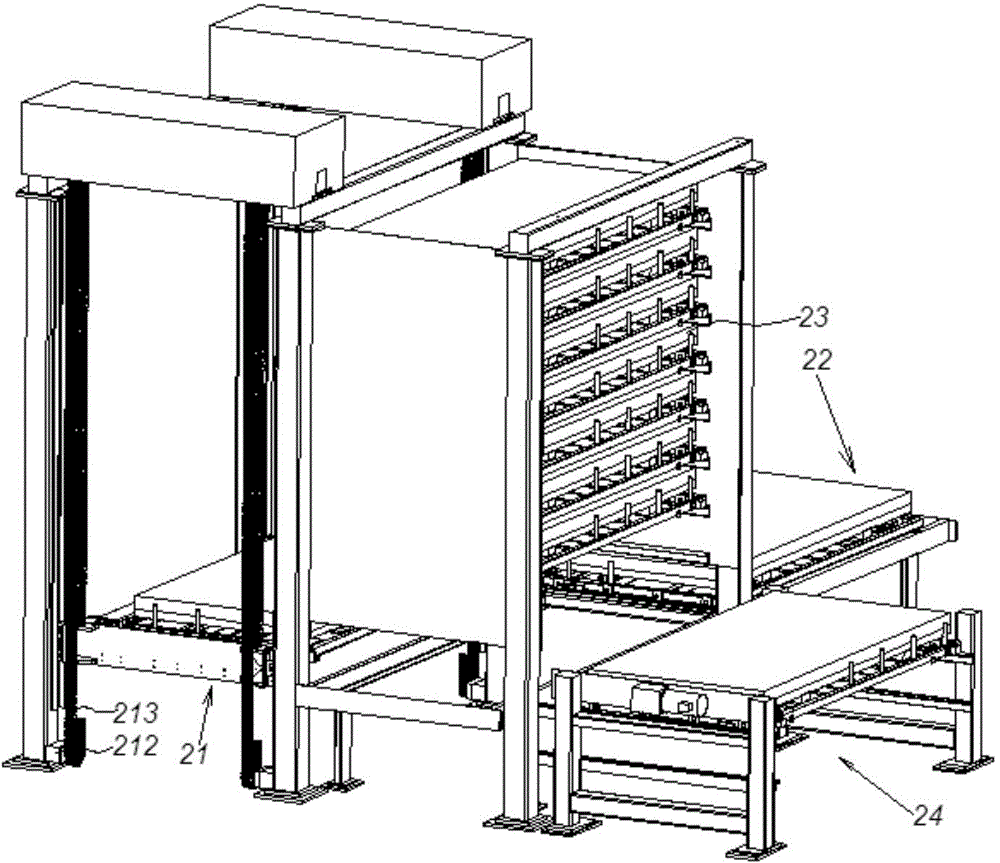

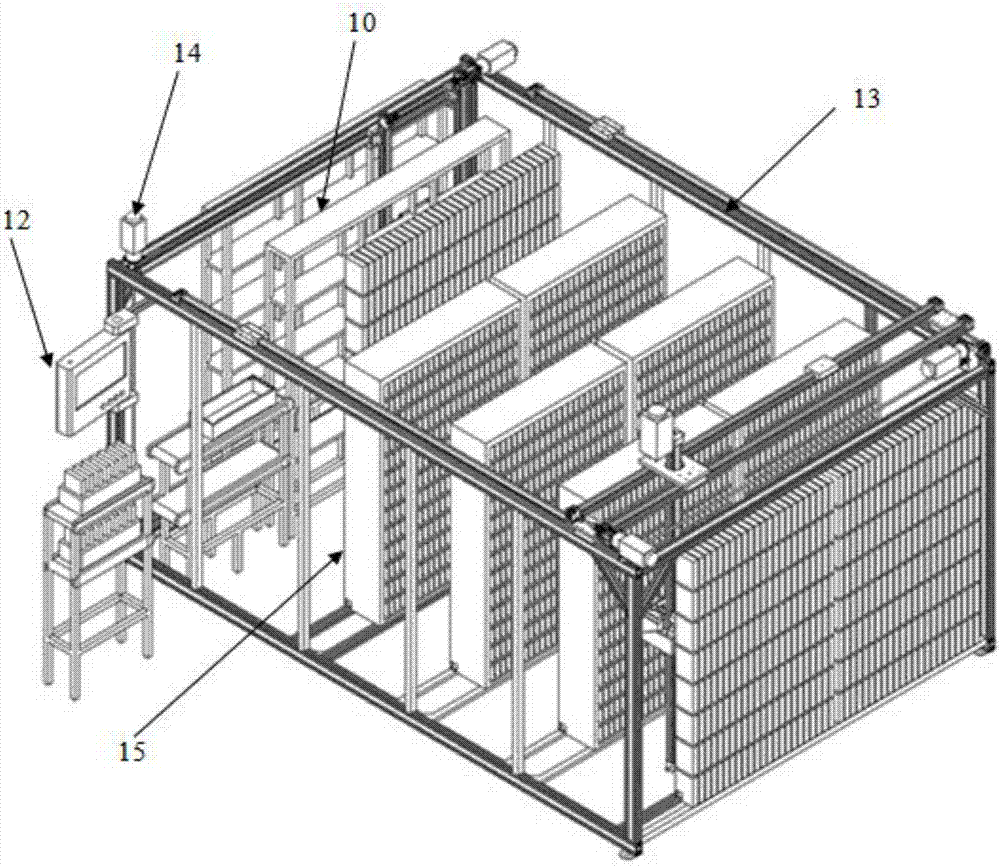

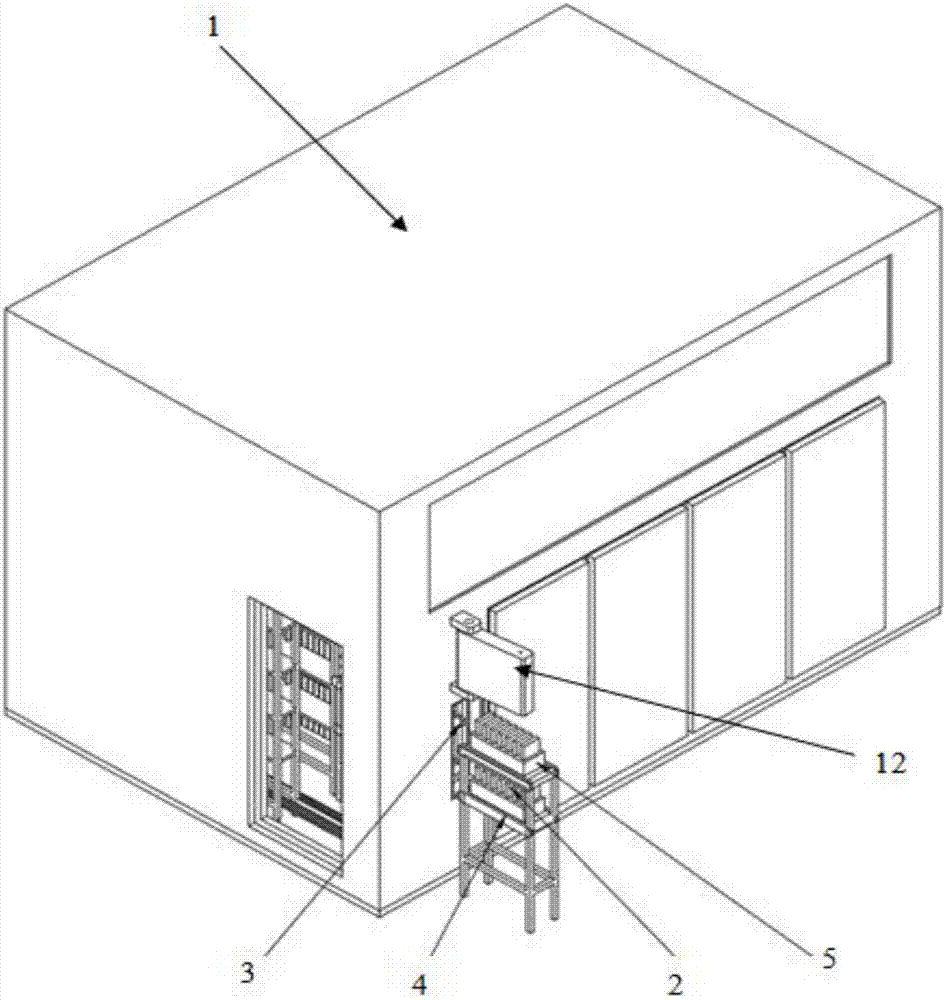

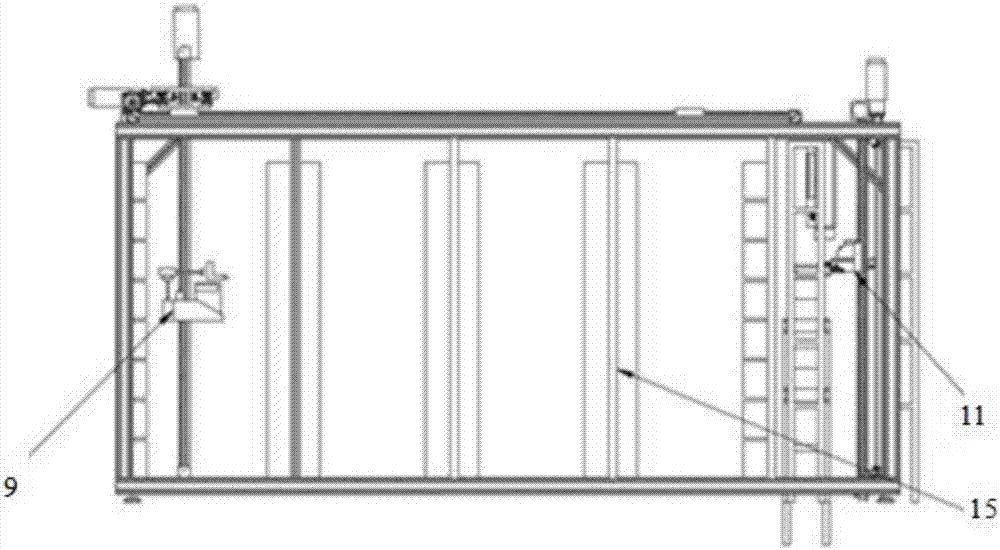

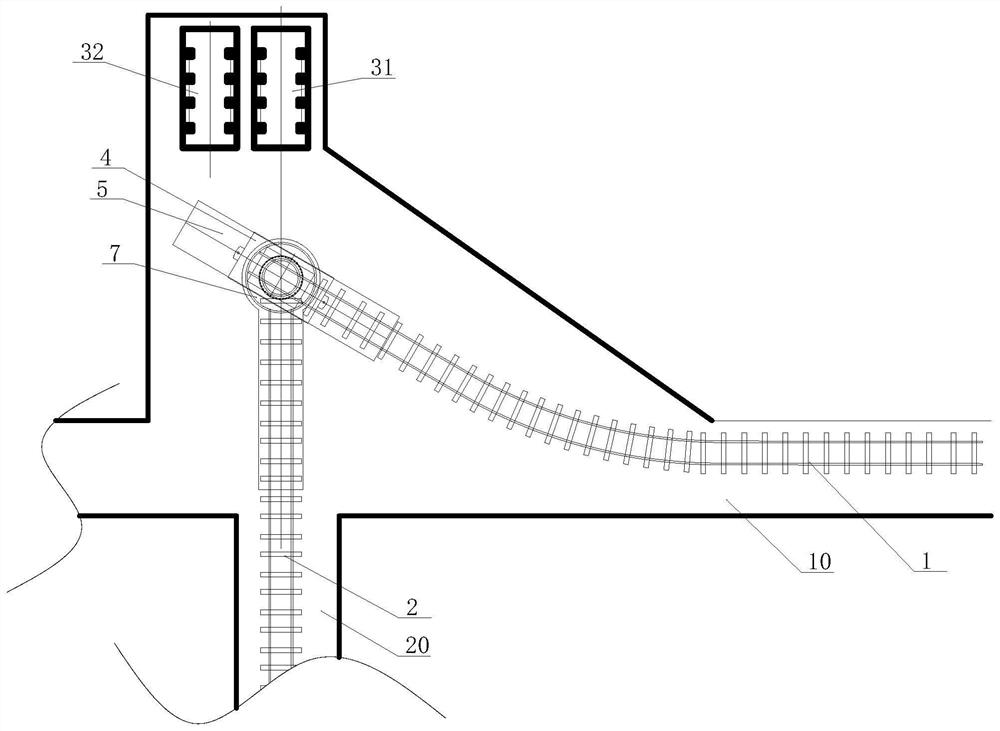

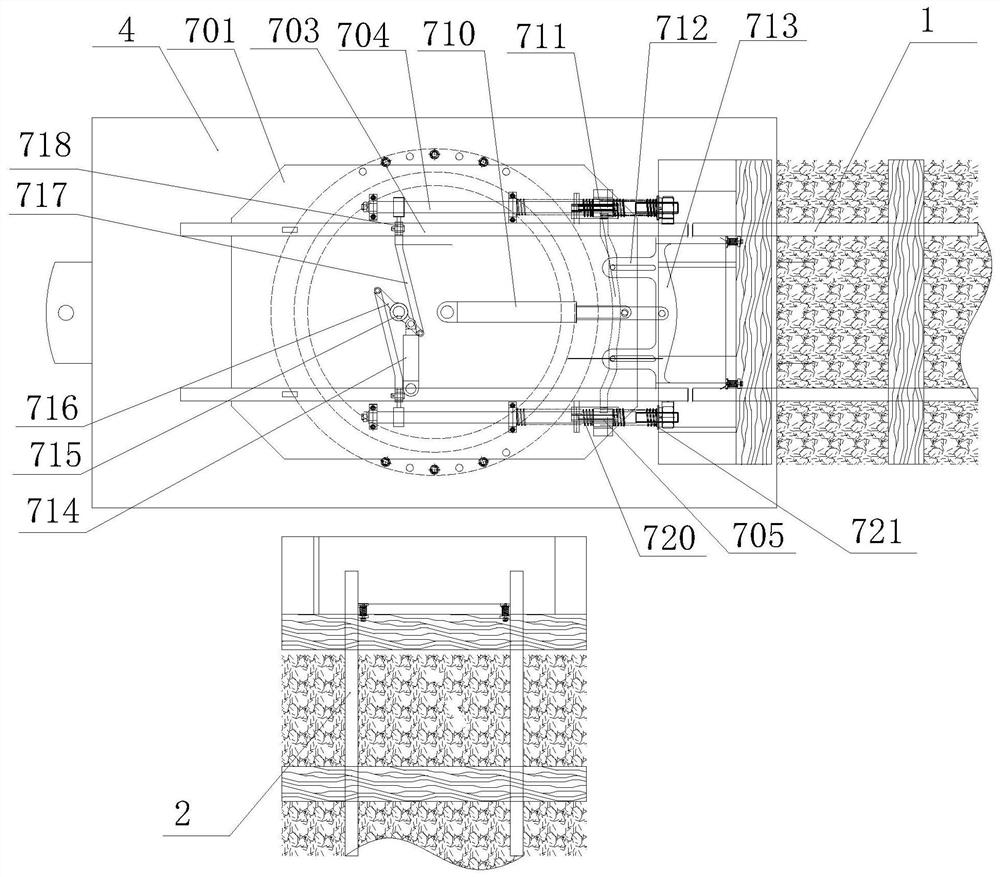

Full-automatic refrigerating storeroom based on erythrocyte refrigerating

PendingCN108007046AReduce waiting timeAchieve transshipmentLighting and heating apparatusStationary refrigeration devicesButt jointEngineering

The invention discloses a full-automatic refrigerating storeroom based on erythrocyte refrigerating. The full-automatic refrigerating storeroom based on erythrocyte refrigerating comprises a storeroombody. A transportation mechanism is arranged at the position of a storeroom door outside the storeroom body. The transportation mechanism comprises two double-layer step type movable belt lines whichare arranged in a movable butt joint manner and two inner double-layer belt lines. The double-layer step type movable belt lines are provided with recycle cases. The recycle cases are internally provided with a plurality of sets of sample boxes. The storeroom body is internally provided with a temporary storage area, a clamping area and a storage area. The clamping area is provided with a stacking mechanical arm. The temporary storage area is provided with a temporary storage frame and a three-coordinate mechanical arm. The storage area comprises a plurality of sets of intensive storage cabinets. Single blood boxes are densely stored, and any blood bag can be taken at will. The temporary storage area is arranged, a temporary storage goods shelf is arranged, and the waiting time within a batch is shortened through transferring of the recycle cases. The stacking mechanical arm is adopted, and stacking of the recycle cases in the temporary storage area is achieved. The three-coordinate mechanical arm is adopted, and precise transferring from the temporary storage area to the storage area is achieved.

Owner:CHANGSHA IMADEK INTELLIGENT TECH CO LTD

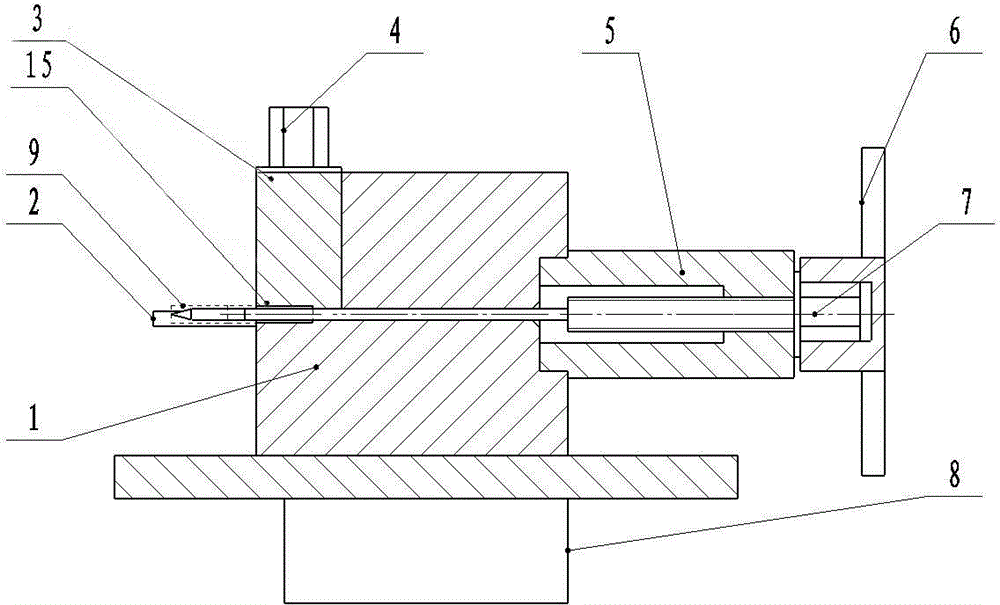

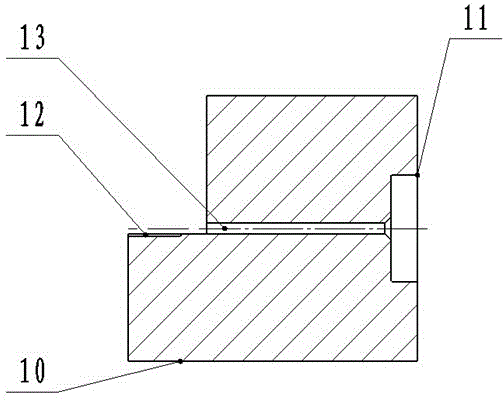

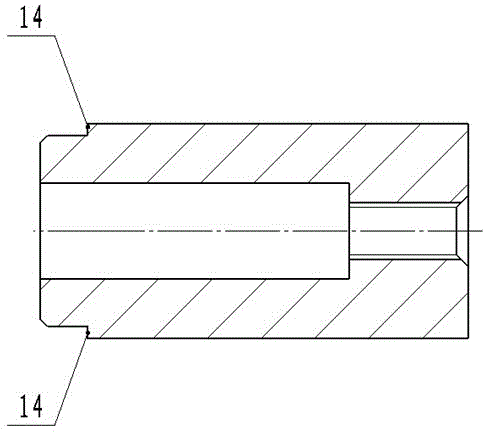

Nuclear fuel element core body removing device

ActiveCN103606387AAvoid secondary damageCollinear Accurate RealizationNuclear energy generationReactor fuel elementsEngineeringTwo step

The invention discloses a nuclear fuel element core body removing device including a fixed clamping block, a movable clamping block, an eject pin and a guide sleeve. The upper end face of the fixed clamping block is formed in a two-step stepped shape; the movable clamping block is arranged on a region at a lower horizontal position of the upper end face of the fixed clamping block and is connected with the fixed clamping block; the end part of one end of the guide sleeve is connected with the side wall of one side at a higher horizontal position of the upper end face of the fixed clamping block. The lower end face of the movable clamping block is provided with an upper semicircular groove, the upper end face of the fixed clamping block is provided with a lower semicircular groove corresponding to the upper semicircular groove position, the fixed clamp block is provided with a circular pore channel for communicating the lower semicircular groove with a guide sleeve internal channel, the center lines of the upper semicircular groove, the lower semicircular groove, the circular pore channel and the guide sleeve internal channel are justified, and one end of the eject pin successively passes through the guide sleeve internal channel and the circular pore channel. By adopting the above structure, the nuclear fuel element core body removing device has compact structure, is easy to transport, can improve the removal efficiency of a core body while being used for removing a core body in a cladded shell, and can avoid the cladded shell from being suffered from secondary damage.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

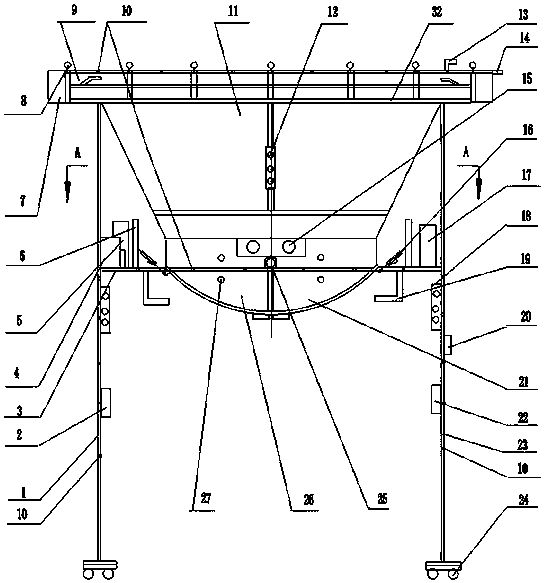

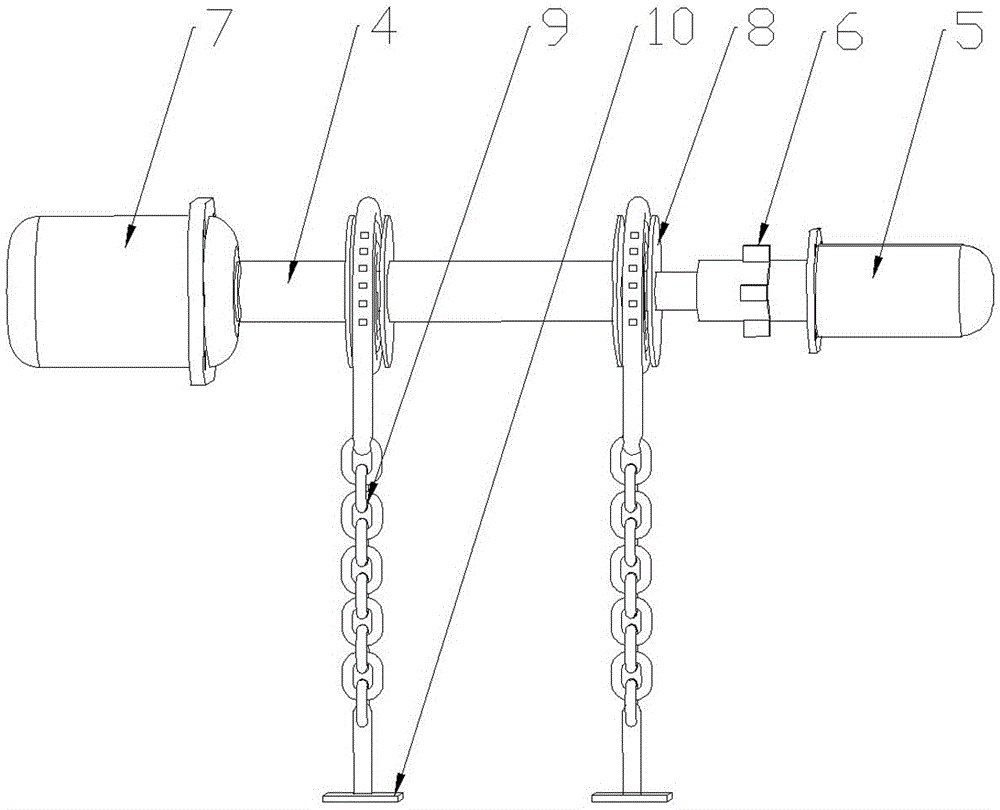

Double-beam crane and vinasse conveying system adopting double-beam crane

PendingCN110963419AReduce manual labor intensityLower winemaking costsAlcoholic beverage preparationLifting devicesControl engineeringVinasse

The invention relates to the technical field of hoisting devices, in particular to a double-beam crane and a vinasse conveying system adopting the double-beam crane. The vinasse conveying system comprises a distillation production line and a fermentation tank, wherein a conveying device is arranged in the distillation production line, and the double-beam crane is arranged at the upper ends of theconveying device and the fermentation tank. The double-beam crane comprises a main beam, wherein a hoisting device is installed at the upper end of the main beam; a grab bucket mechanism is arranged at the lower end of the hoisting device; the hoisting device is used for moving along the inner side of the main beam and lifting the grab bucket mechanism; the grab bucket mechanism is used for takingand placing materials; a lifting device is mounted at the lower end of the main beam; a turnover device is arranged at the lower end of the lifting device; the lifting device is used for moving alongthe lower end of the main beam and lifting the turnover device; and the turnover device is used for dumping materials. In the whole system, the double-beam crane replaces a large number of workers who are cooperated with each other to transfer distillers' grains, hoist a hopper and turn over the hopper to dump the distillers' grains, so the labor intensity of the workers is reduced, working timeis shortened, and working efficiency is improved; and therefore, wine brewing cost is reduced.

Owner:CHENGDU WEST TAILI INTELLIGENT EQUIP CO LTD +1

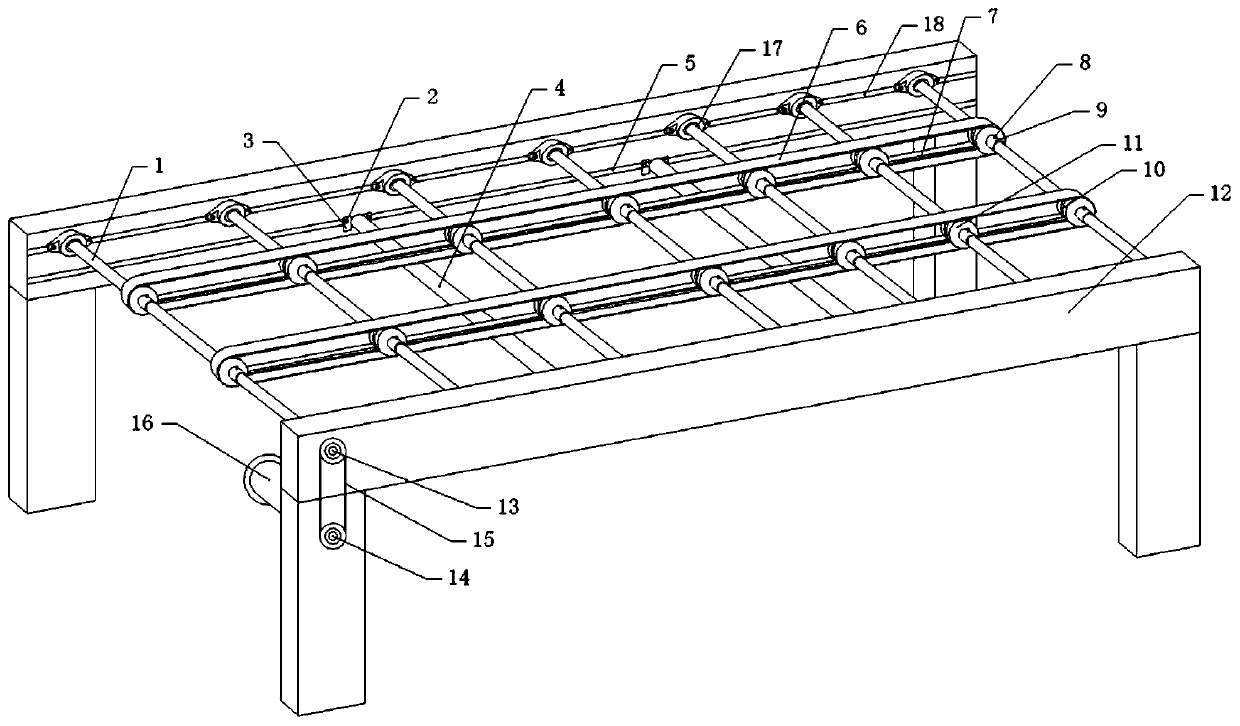

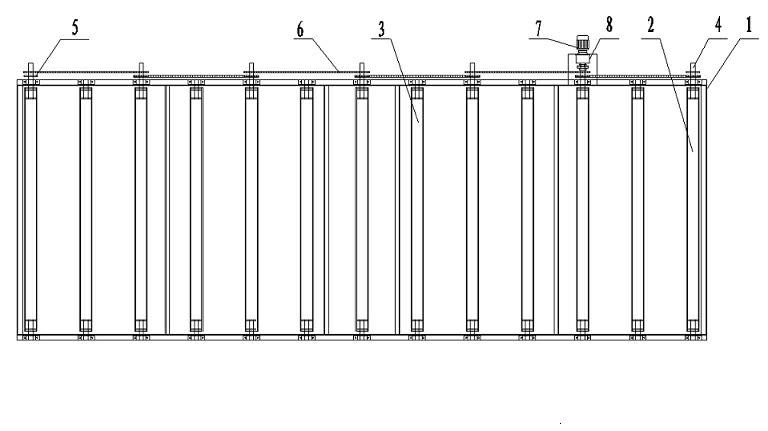

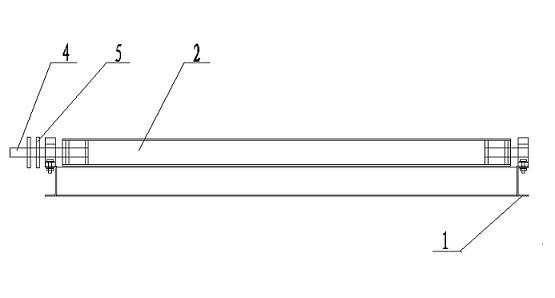

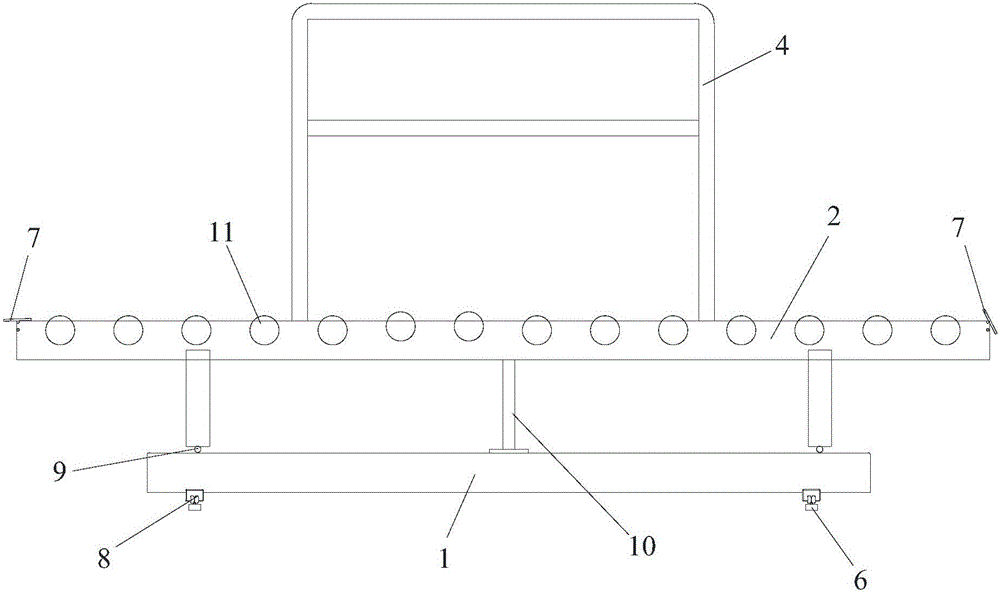

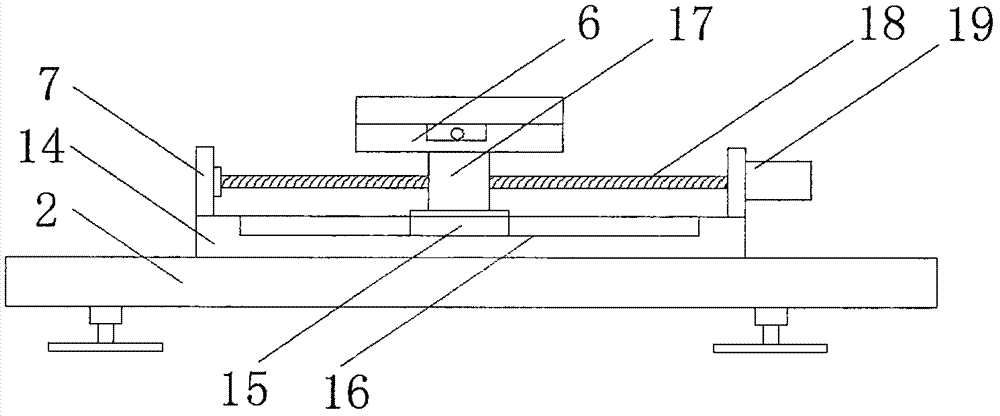

Plate conveyer table

The invention discloses a plate conveyer table. The plate conveyer table comprises a rack, a plurality of rollers and a power device; the rollers comprise power rollers and unpowered rollers; the power rollers and the unpowered rollers are arranged at intervals; the two ends of the rollers are fixed on the rack by supporting shafts and bearings; the supporting shaft at one end of the power roller protrudes out of the outer side of the rack and the supporting shaft is provided with chain wheels; the adjacent two power rollers are driven by chains and chain wheels; the power device comprises a motor and a speed reducer; the motor is connected with the speed reducer; and then the motor and the supporting shaft of one of the power rollers are driven by the chains and the chain wheels. According to the plate conveyer table, the rotary circular motion of the rollers drives the plates on the rollers to carry out linear motion; and the conveying of the plates is realized on the condition that the starting zone and the target zone are not on the same horizon line in the conveying process.

Owner:新疆新能钢结构有限责任公司

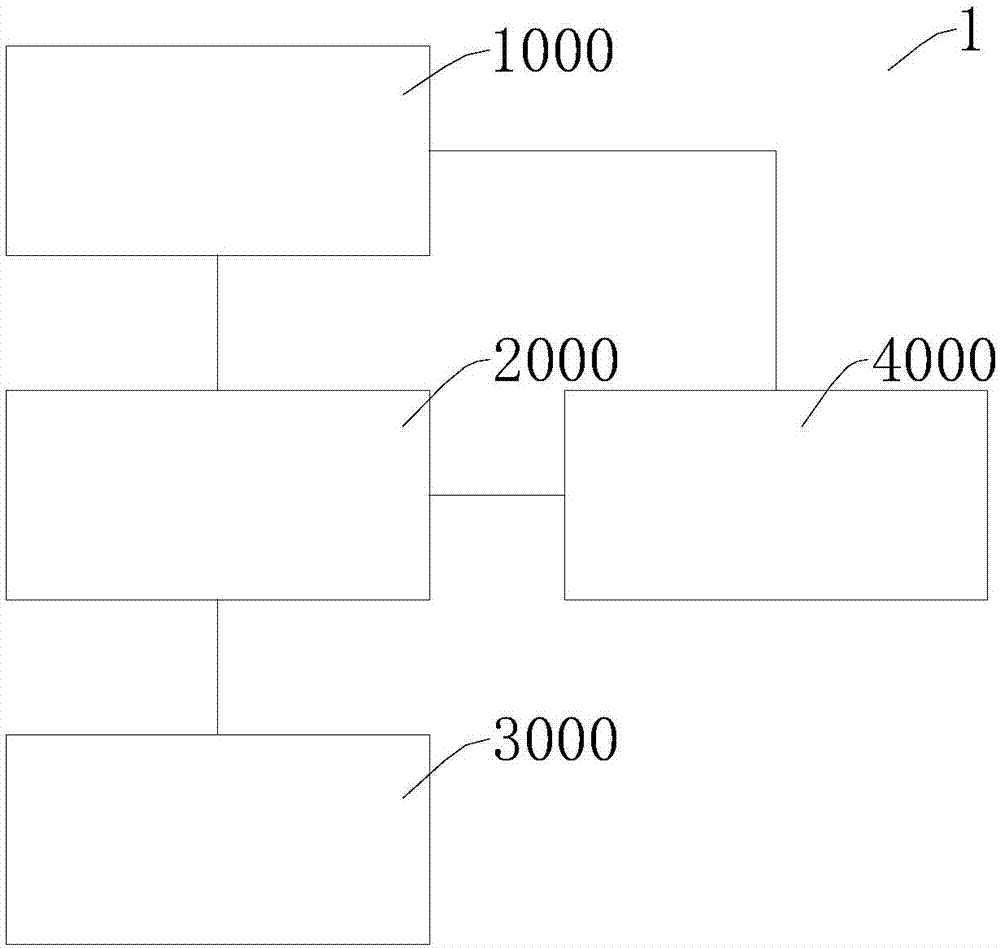

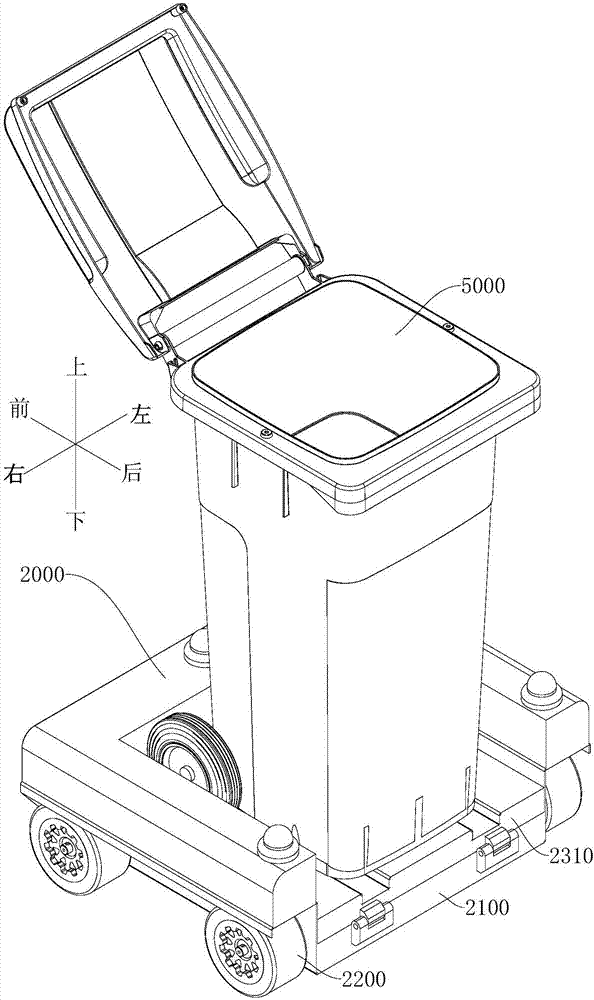

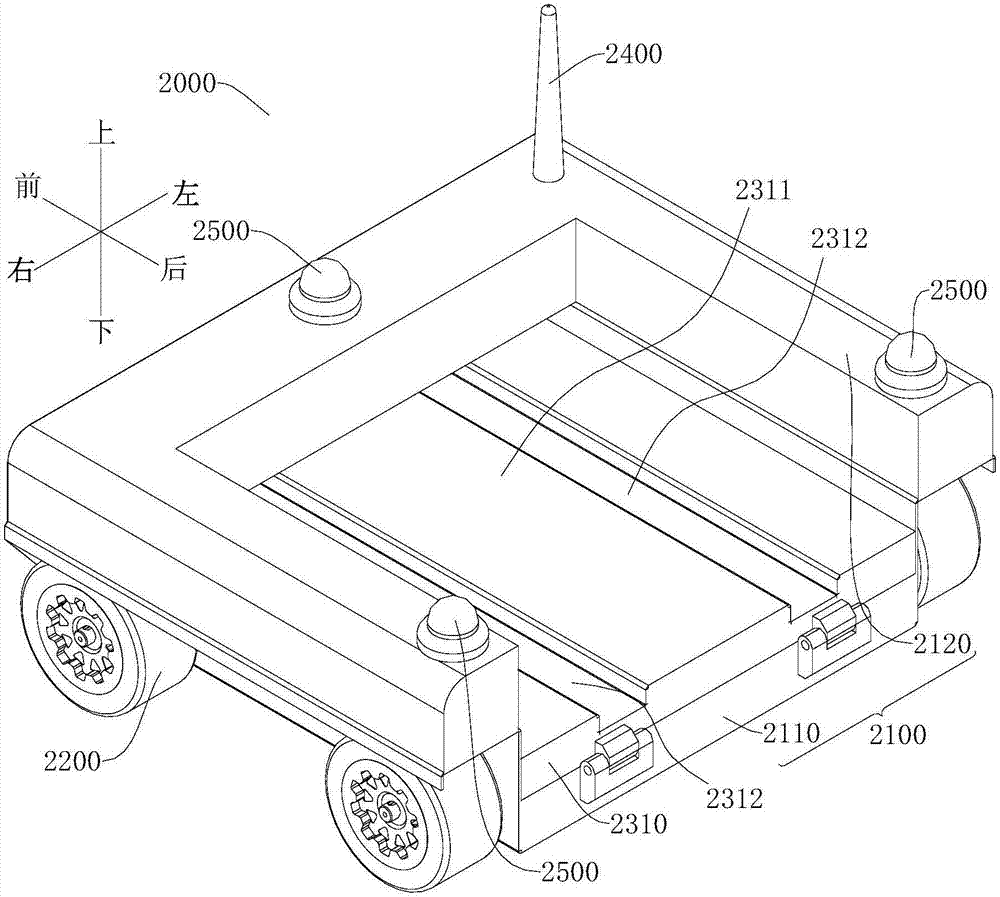

Waste transfer system

InactiveCN107878980ATimely processingImprove transport efficiencyRefuse transferringStorage devicesTelecommunicationsTransfer system

The invention discloses a garbage transfer system, which includes a garbage can placement platform for placing garbage cans and detecting whether the placed garbage cans are full, a garbage processing station for processing garbage, and a garbage can transfer robot for transporting garbage cans And the central control station, the central control station communicates with the garbage can placement platform and the garbage can transfer robot respectively, when the garbage can placement platform detects that the placed garbage can is full, the central control station controls The garbage can transfer robot transports the garbage cans filled on the garbage can placement platform to the garbage processing station. The garbage transfer system according to the invention has the advantages of sanitation, environmental protection, manpower saving and high efficiency.

Owner:北京新知通宇科技有限公司

Intelligent steel plate cutting and blanking production line and production method thereof

ActiveCN111958326AImplement production modeSmall footprintMetal working apparatusProcess engineeringWaste treatment

The invention discloses an intelligent steel plate cutting and blanking production line and a production method thereof. The intelligent steel plate cutting and blanking production line comprises a steel plate incoming material buffer area, a steel plate cutting area, a part sorting and waste treatment area, a large piece leveling sanding area, and an automatic transfer device running through thesteel plate incoming material buffer area, the steel plate cutting area, the part sorting and waste treatment area and the large piece leveling sanding area. The intelligent steel plate cutting and blanking production line and the production method thereof greatly improve the production efficiency, reduce the labor cost and simultaneously improve the intelligent level of a blanking workshop.

Owner:武汉东研智慧设计研究院有限公司

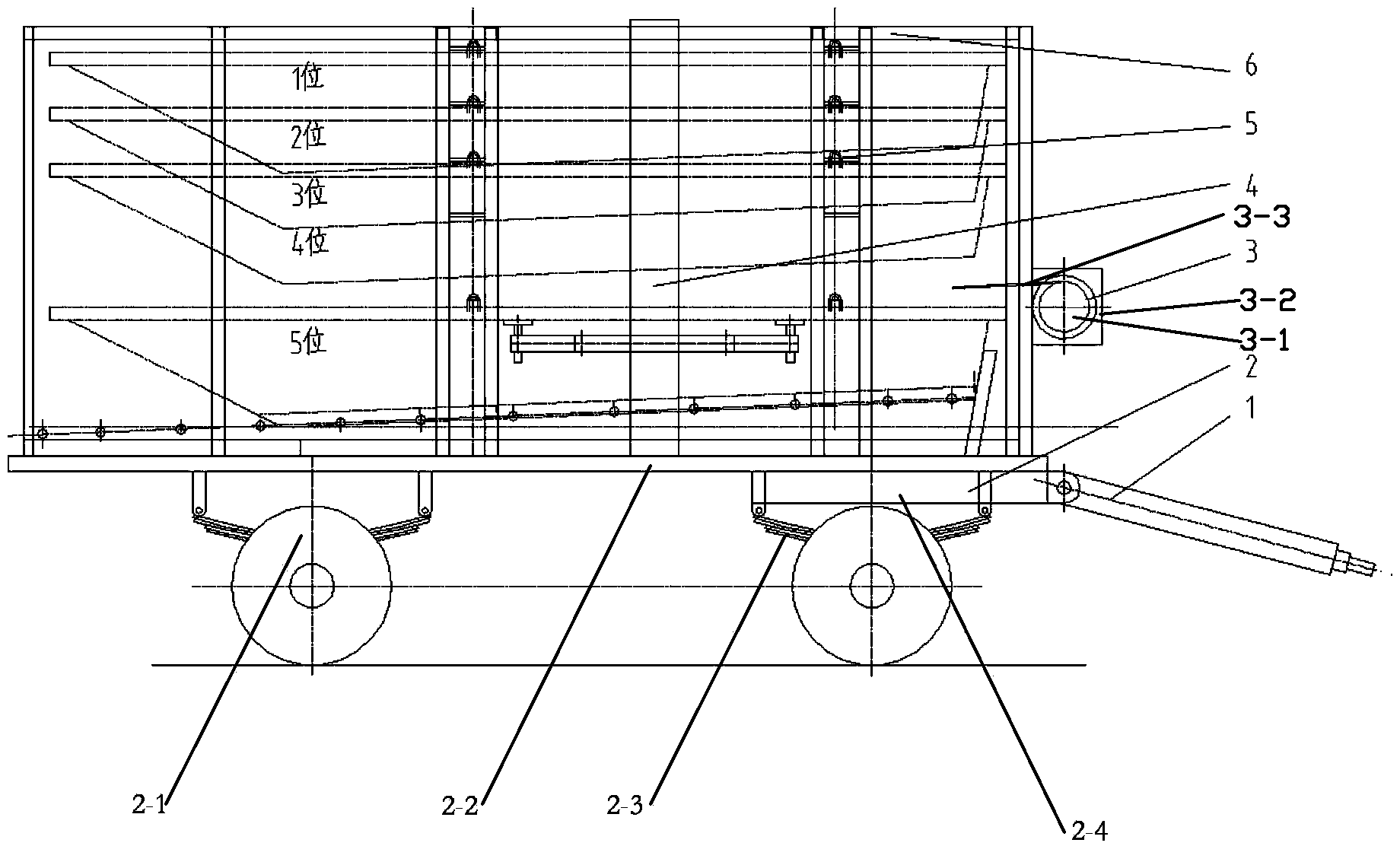

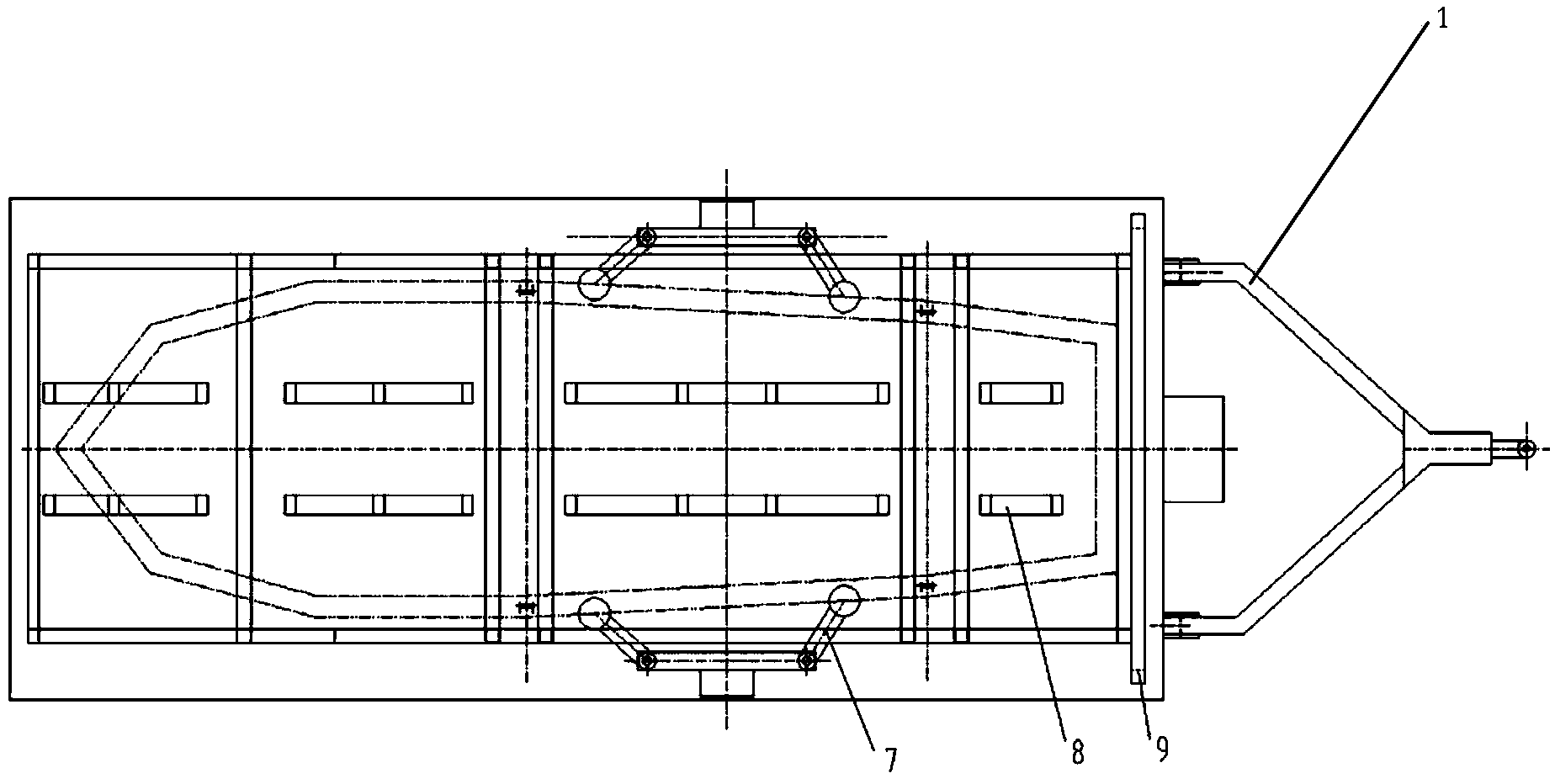

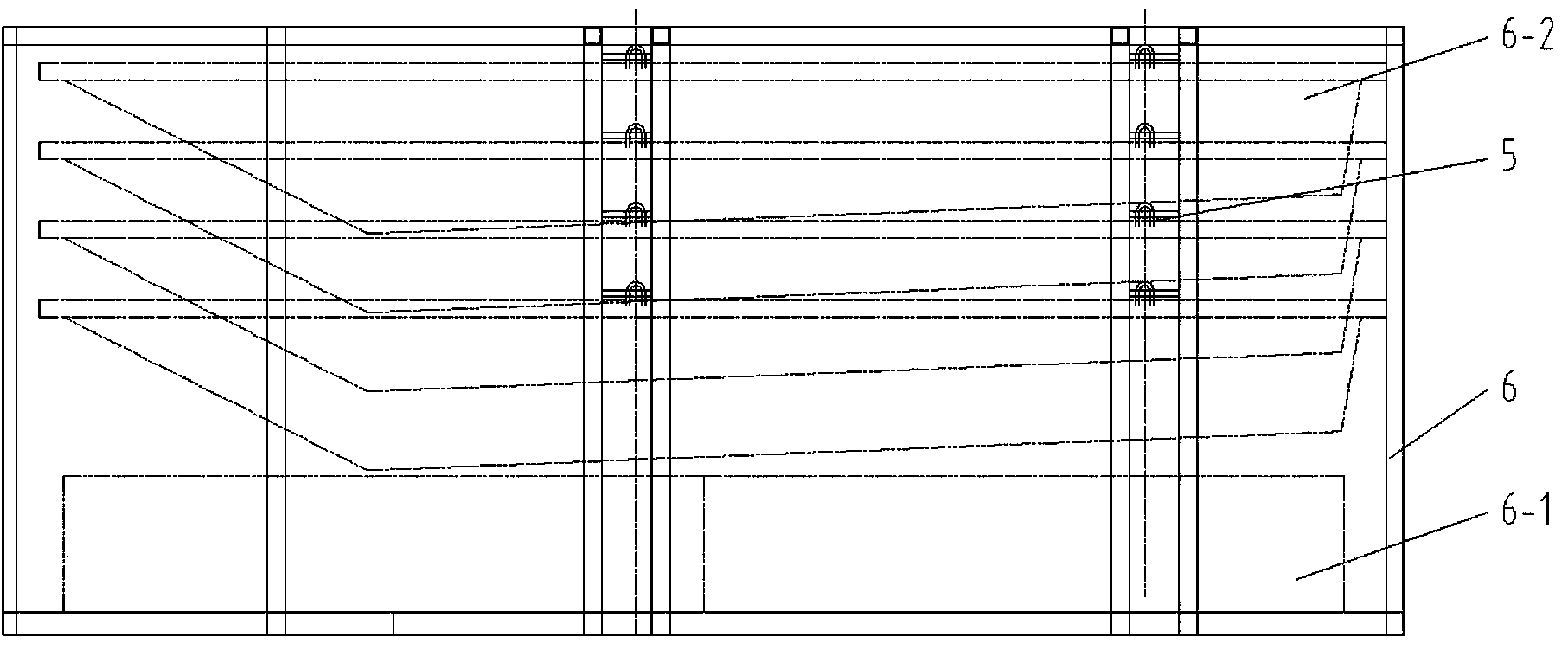

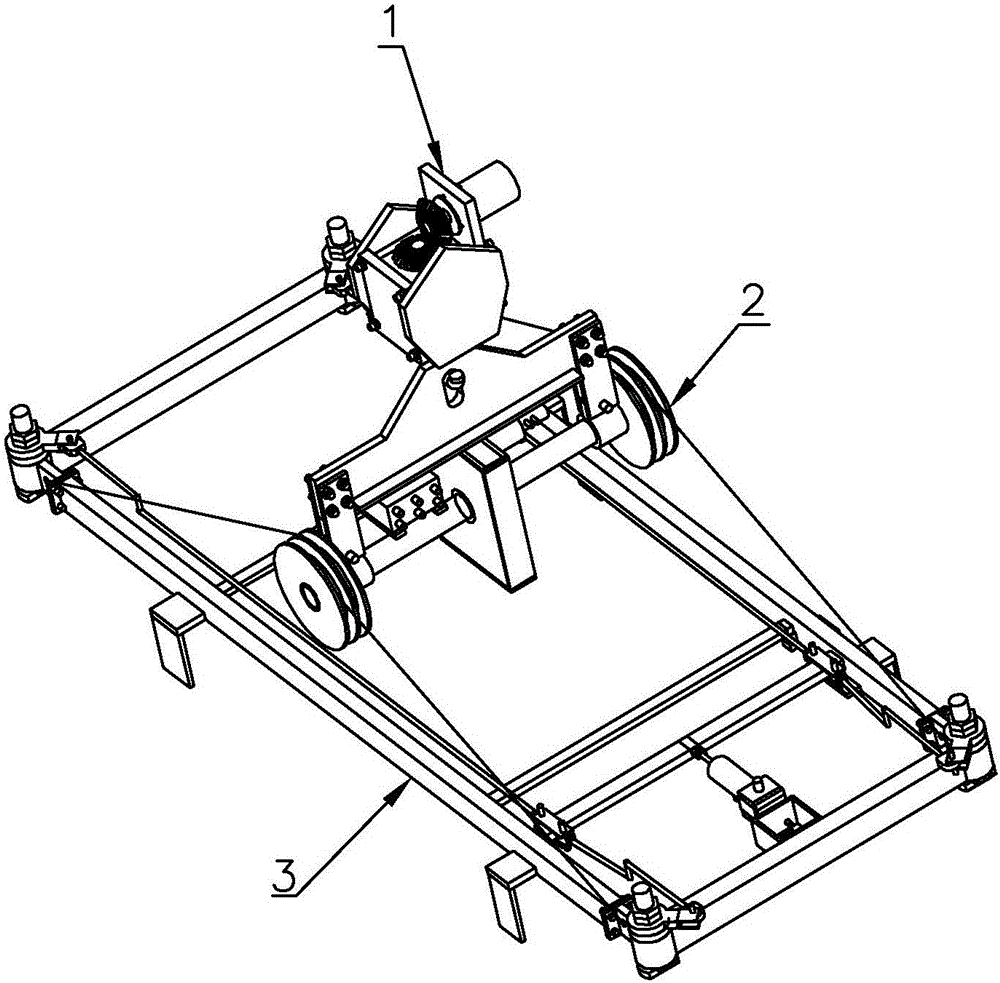

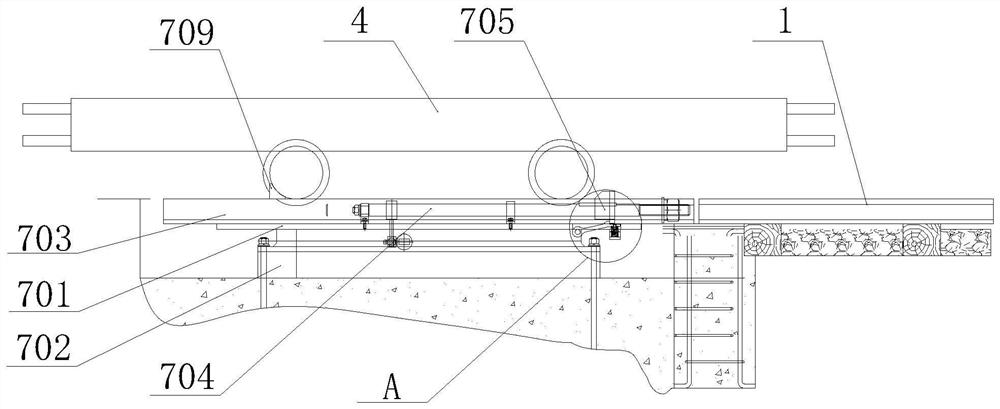

Container type storage vehicle for storing multiple inflatable boats

InactiveCN103522933AReduce storage areaAchieve transshipmentLoading/unloading vehicle arrangmentLoad securingInflatable boatTraction frame

The invention relates to a container type storage vehicle for storing multiple inflatable boats and aims to solve the problem that a trailer is used to transport one or more inflatable boats, related works of a hanging manner, lifting manner and a manual loading and unloading manner are completed by the assistance of a large amount manpower and material resources, and loading and unloading efficiency is low in the prior art. A traction frame (1) is hinged to the front end of a trailer (2). A limit plate (9) is vertically disposed in the front of the trailer (2). A traction winch (3) is disposed on the front end face of the limit plate (9). A lifting mechanism (4) is disposed on the trailer (2). A slideway system (8) is disposed on the trailer (2) from left to right. The included angle between the slideway system (8) and the horizontal plane ranges from 10 degrees to 30 degrees. A container frame (6) is disposed on the trailer (2). A inflatable boat fixing mechanism (5) is disposed on the container frame (6). The container type storage vehicle is applicable to storage and transportation of inflatable boats.

Owner:李伟明

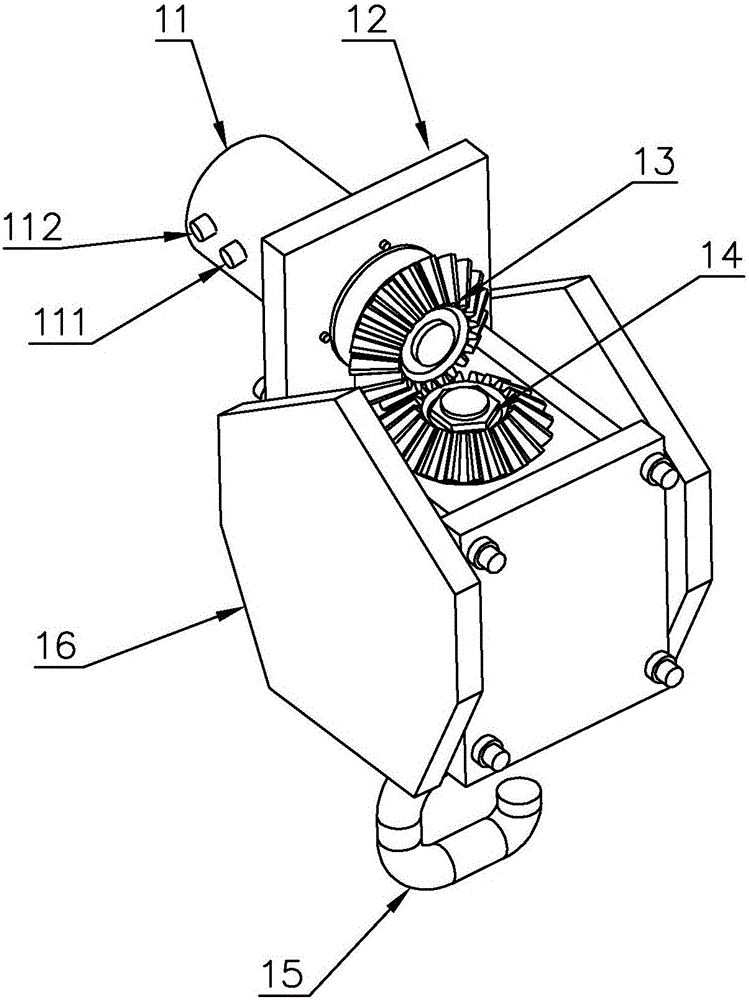

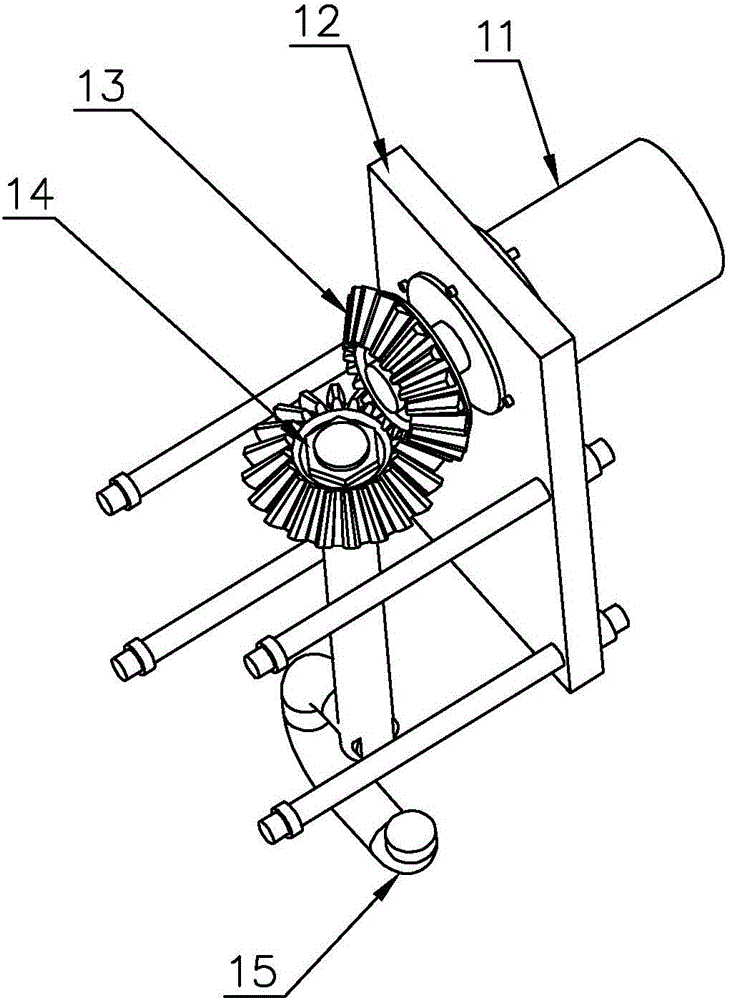

Container truck-mounted crane type angle adjusting device

ActiveCN105692424AAchieve transshipmentAchieve translationLoad-engaging elementsHydraulic motorSelf locking

The invention discloses a container truck-mounted crane type angle adjusting device. The container truck-mounted crane type angle adjusting device comprises a self-locking control rack, a hoisting adjusting mechanism and a lifting hook mechanism. The lifting hook mechanism comprises a hook, a hook support, a hydraulic motor II, a fixing plate and a bevel gear. The hook is located in a hanging hole of the hoisting adjusting mechanism. The hoisting adjusting mechanism comprises a lifting rack, a rotary shaft and rope winders. A steel wire rope is arranged on the rope winders, one end of the steel wire rope is fixed to the rope winders, and the other end of the steel wire rope is fixed to a connecting hole in the self-locking control rack. The self-locking control rack comprises connecting rods II, lock hooks, connecting rods I, a movable rod and pull rods. Transfer and horizontal movement of a container can be achieved, the container can incline relative to the ground at a large angle, bulk or barreled goods in the container can be rapidly dumped, time and labor are saved, manual loading and unloading are avoided, the labor intensity of workers is relieved, and working efficiency is improved.

Owner:张丙梓

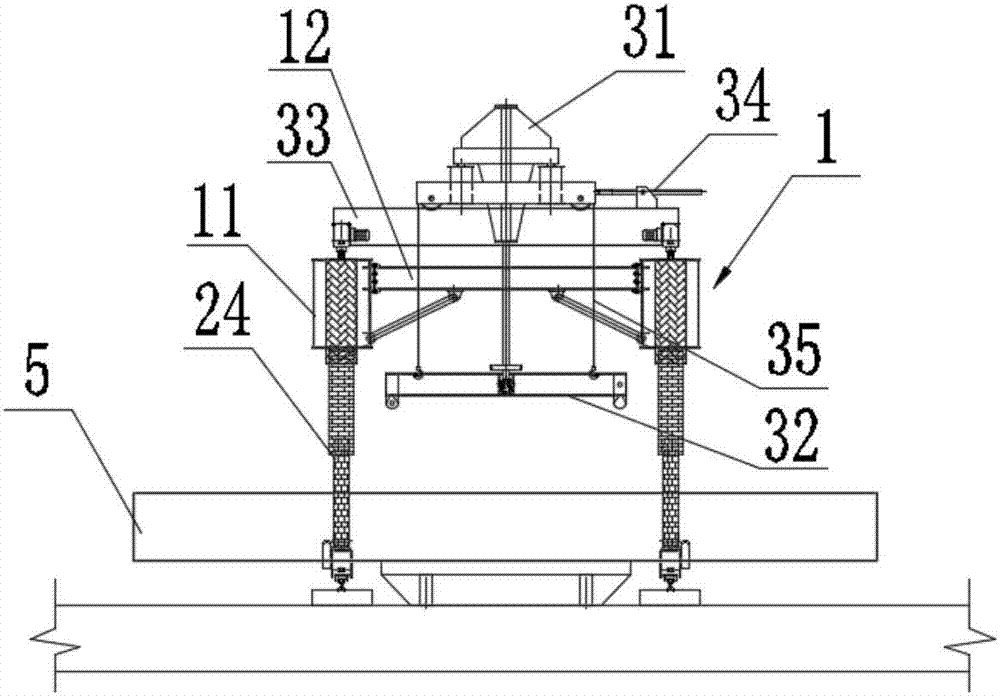

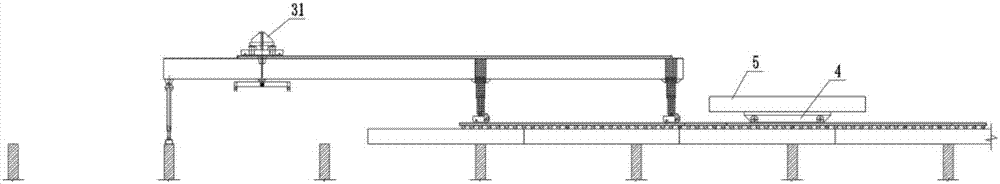

Wide-body steel main girder erecting machine and erecting method thereof

InactiveCN106939554AAchieve transshipmentQuick placementBridge erection/assemblyEngineeringLeg extension

The invention discloses a wide-body steel girder erecting machine and a girder erecting method thereof, and relates to the technical field of bridge engineering construction, comprising: a main structure, which includes two oppositely arranged main girders, and the two ends of the two main girders are fixed There is a main beam connecting two main beams; a supporting mechanism, which includes front outriggers, middle outriggers and rear outriggers fixed on the two main beams, and the front outriggers, middle outriggers and rear outriggers are all set There are telescopic devices, which can extend and contract the front outriggers, middle outriggers and rear outriggers; and hoisting devices, which include a crane and a spreader. The spreader is set under the crane, and the crane can be retracted and retracted. The spreader is lowered, and the crane can also move longitudinally and laterally along the bridge. The present invention can realize the efficient, stable and safe erection of wide-body steel girders under the working conditions of existing bridge support space, limited foundation bearing capacity and inability to use large-scale equipment.

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU +1

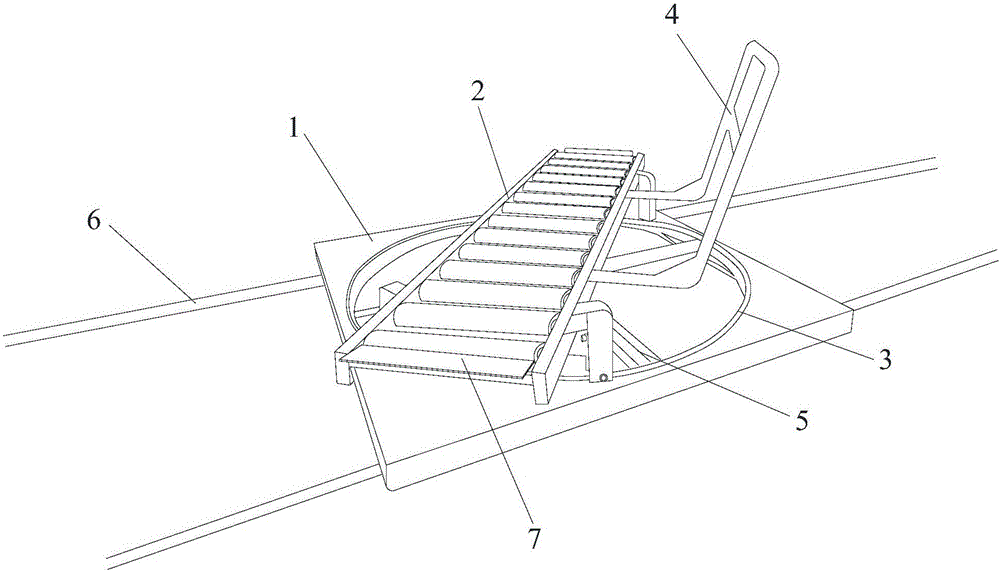

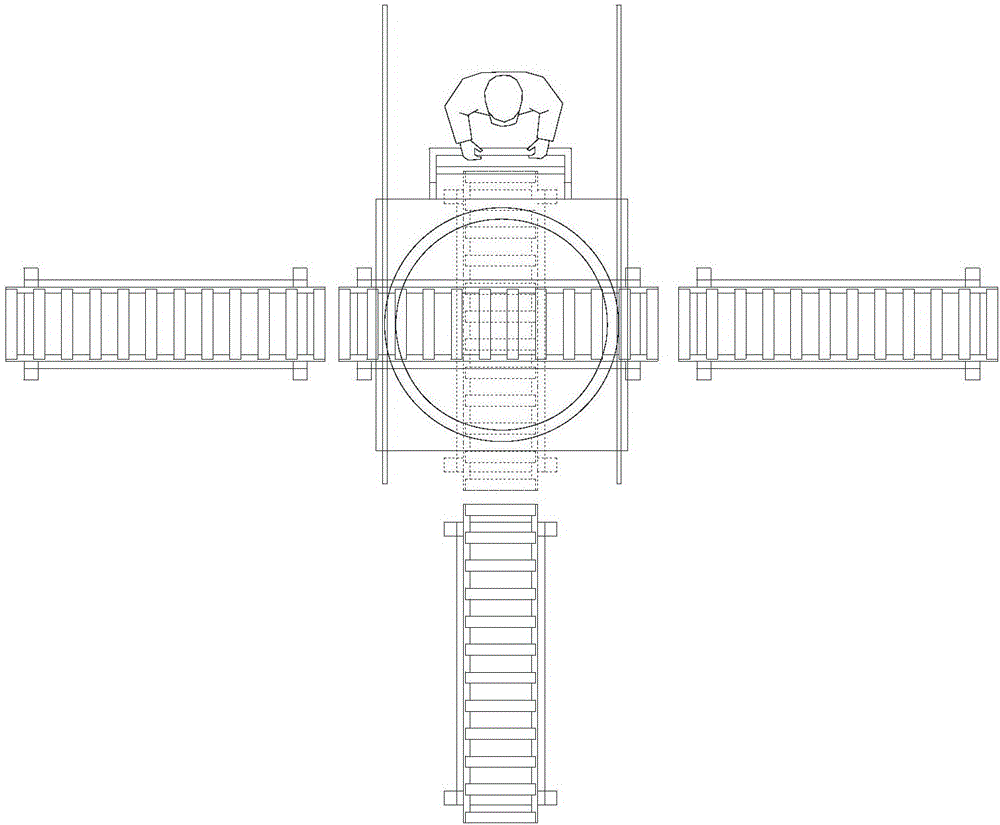

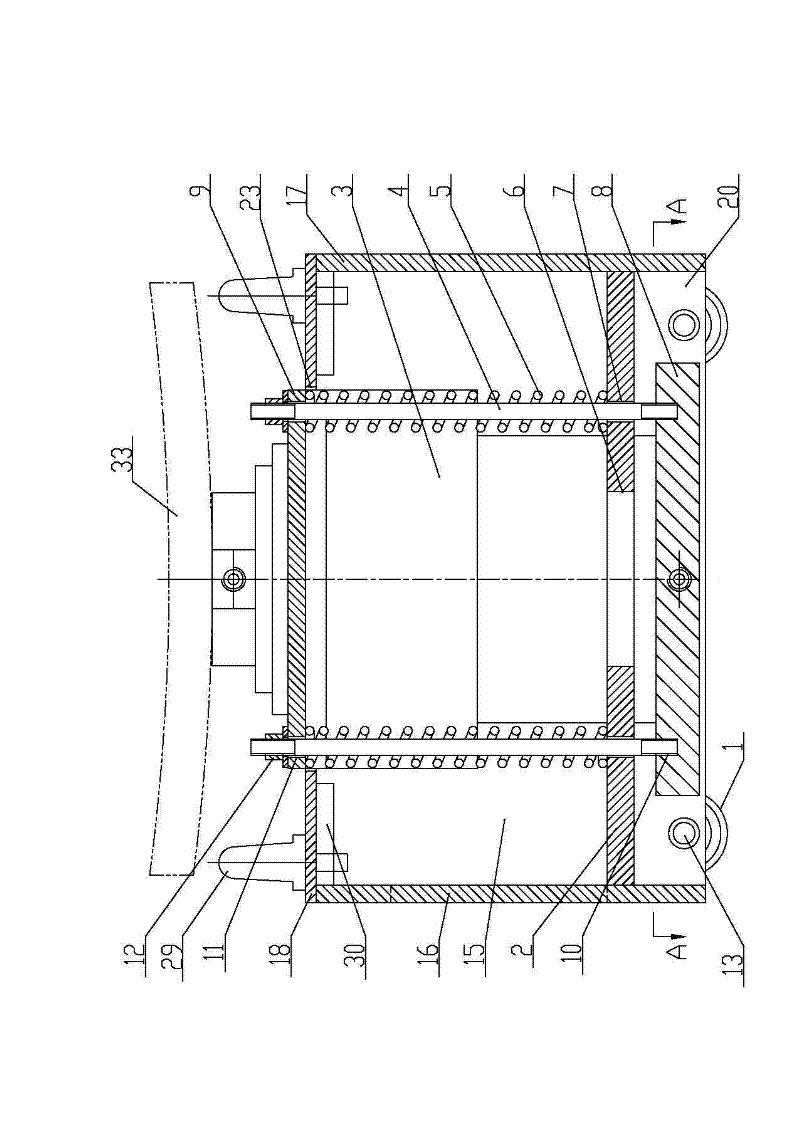

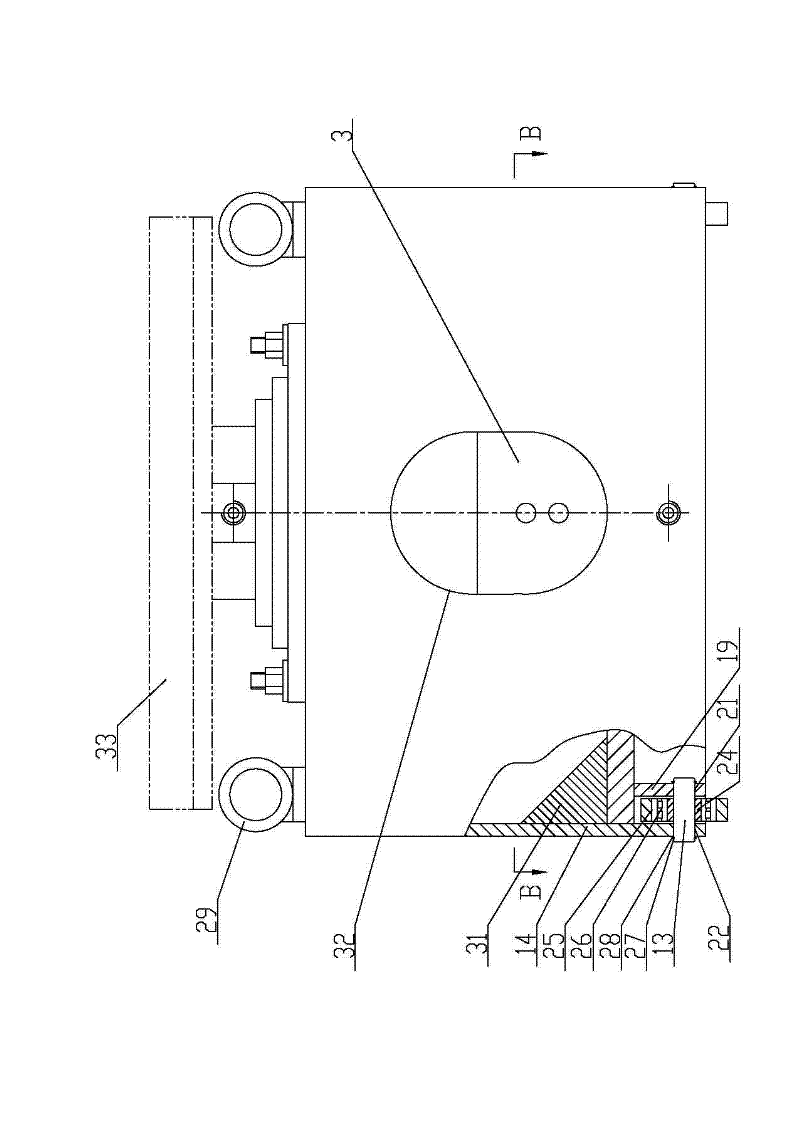

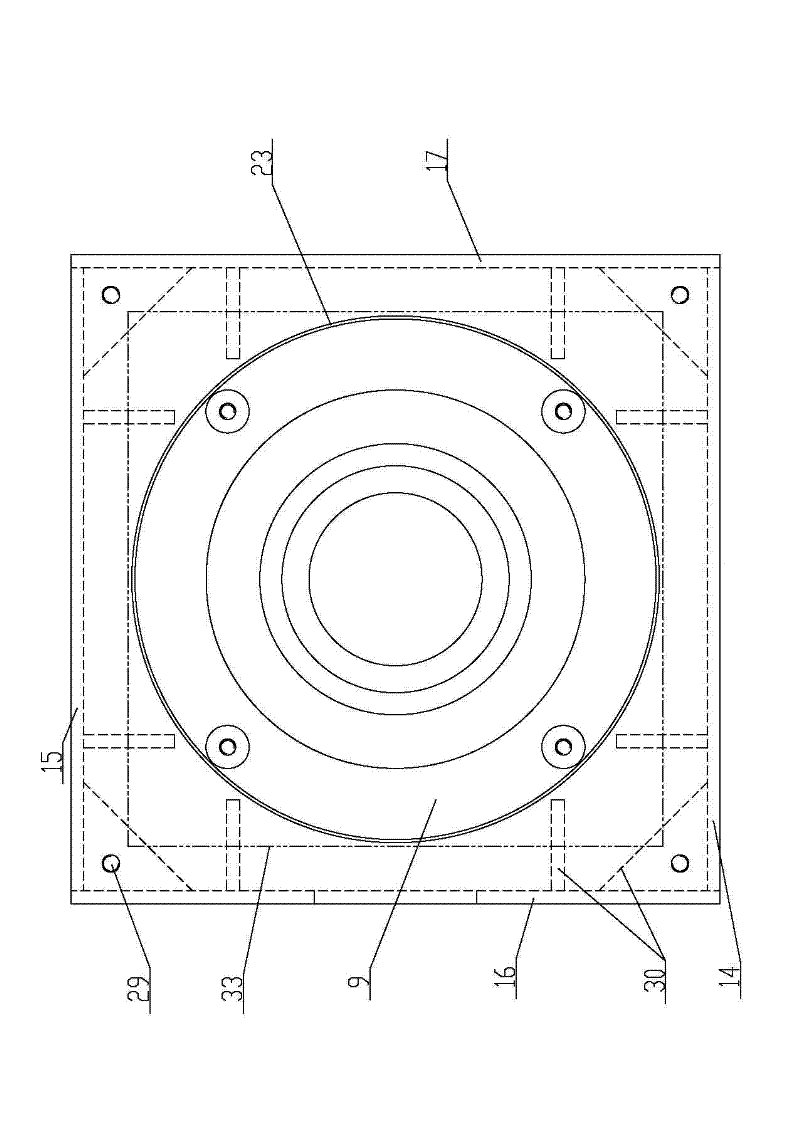

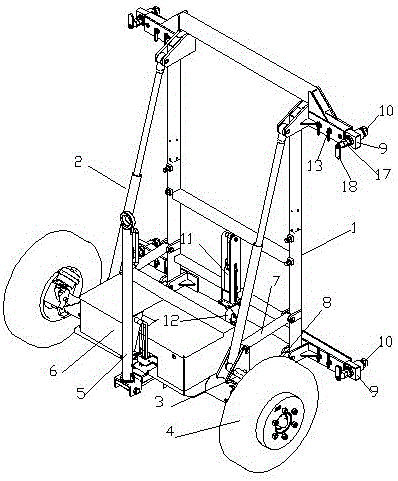

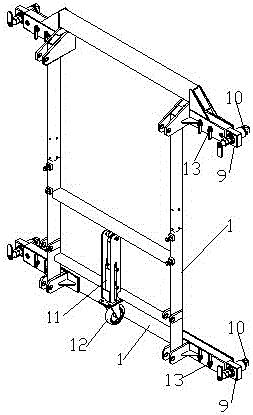

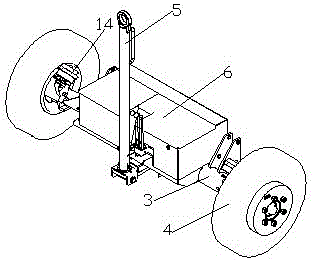

360-degree transfer trolley

InactiveCN106494868AAchieve transshipmentStable structureConveyor partsOperating pointTransfer mechanism

The invention discloses a 360-degree transfer trolley. The 360-degree transfer trolley comprises a carrying mechanism and a transferring mechanism, wherein the carrying mechanism comprises a carrying platform and a circular track which is arranged on the carrying platform; moving parts are arranged at the bottom part of the carrying platform; the transferring mechanism comprises a transferring line and moving wheels; the transferring line is connected with the carrying platform through a rotating shaft which is arranged on a center position of the circular track; the moving wheels are arranged on the transferring line which can be rotated around the rotating shaft through the moving wheels on the circular track. Compared with the prior art, the 360-degree transfer trolley has the advantages that the 360-degree transfer trolley can automatically move, and the transferring line can be rotated by 360 degrees around the rotating shaft through the moving wheels on the circular track, and thus the transferring line can be abutted with operating lines in different directions; the 360-degree transfer trolley is simple and firm in structure, and can transfer cargo in a plurality of directions within a small space, so that the production demand can be met.

Owner:广州市亚丹柜业有限公司

Hydraulic jacking device and method of using the same

The invention relates to the technical field of hoisting equipment, in particular to a hydraulic hoisting device and a using method thereof. The hydraulic hoisting device comprises a case body, a roller, a support plate, a hydraulic cylinder, a support rod and a compression spring, wherein the lower part of the case body is provided with the roller; the support plate is fixed in the inner cavity of the case body; a support plate cylinder hole is formed in the middle of the support plate; a connecting rod through hole is formed in the support plate around the support plate cylinder hole; the upper part of the hydraulic cylinder is provided with a piston rod which can be extended upwards to the upper side of the case body and support heavy objects; the upper part of the cylinder body of thehydraulic cylinder is provided with a hydraulic cylinder flange; and the lower end of the cylinder body of the hydraulic cylinder is fixedly provided with a hydraulic cylinder base plate. The hydraulic hoisting device is convenient to use; by the using method, heavy-tonnage tower barrel workpieces can be effectively transferred; when supported by the compression spring, the hydraulic cylinder canbe away from the ground and freely moved along with the case body; when loaded, the hydraulic cylinder falls down and compresses the compression spring; and the hydraulic cylinder base plate is supported on the ground to make the roller and the case body not stressed. The hydraulic hoisting device has the characteristics of saving labor, along with high efficiency, is safe, simple and convenient and greatly lowers manufacturing cost and transportation cost.

Owner:王勇

Die transfer robot used in casting process

InactiveCN108907161AImprove securityAchieve crawlingMould handling equipmentsHydraulic cylinderRotary stage

The invention relates to a die transfer robot used in the casting process. The die transfer robot comprises a transfer vehicle body, a rotary table, a lifting mechanism and a loading platform. The upper end of the loading platform is provided with a material pushing mechanism and a mechanical arm, and an anti-dropping mechanical claw is mounted at the tail end of the mechanical arm. The anti-dropping mechanical claw includes a first clamping connecting arm, a second clamping connecting arm and a seat body. The lower end of the seat body is provided with a first U-shaped bracket, and a horizontal plate is disposed in the first U-shaped bracket. The first clamping connecting arm and the second clamping connecting arm are cross and hinged to the middle portion of the horizontal plate. The first clamping connecting arm and the second clamping connecting arm are hinged to a second U-shaped bracket, and the middle portion of the second U-shaped bracket is connected with the extending-out endof a first hydraulic cylinder located at the middle lower end of the seat body. The lower ends of both the first clamping connecting arm and the second clamping connecting arm are provided with clamping blocks, and the outer sides of the clamping blocks are provided with supporting arm mechanisms. The die transfer robot is high in safety performance, the capture, transfer and push and placement of a die can be achieved, and the technical problem of inconvenience in lifting and transfer of an existing casting die is solved.

Owner:湖南紫荆新材料科技有限公司 +4

Aluminum bar transferring device

ActiveCN105584929AAchieve transshipmentReduce stepsLoad-engaging elementsEngineeringMechanical engineering

Owner:佛山金兰铝厂有限公司

Automatic ring bobbin inserting device of robot

The invention discloses an automatic ring bobbin inserting device of a robot. The automatic ring bobbin inserting device is used for automatically inserting a ring bobbin of a winding machine in a spinning mill. The device comprises a base, an operation platform is arranged on one side of the upper end of the base, a transfer device is arranged on one side of the operation platform, an installation plate is arranged on one side of the transfer device, the installation plate is provided with a conveying device, the conveying device is provided with a clamping mechanical hand, and the lower end of the base is provided with a damping device. By combining the transfer device and the conveying device, automatic clamping and transfer for the ring bobbin are achieved, the labor cost is reduced, the transfer efficiency is improved, and the automatic ring bobbin inserting device of the robot is suitable of being popularized.

Owner:广州赫伽力智能科技有限公司

Shelter transferring device

PendingCN105731305AAchieve transshipmentReduce the difficulty of transshipmentLifting devicesHydraulic cylinderArchitectural engineering

The invention discloses a shelter transferring device. The shelter transferring device comprises two transferring mechanisms; each transferring mechanism comprises a travelling mechanism which enables a shelter to move horizontally, and a lifting mechanism which is rotatably connected with the travelling mechanism and lifts the shelter; the lifting mechanism comprises a lifting frame provided with a locking mechanism which is matched with the shelter, and a lifting hydraulic cylinder which enables the lifting frame to ascend or descend. When the shelter transferring device is used, the lifting mechanism is matched with the fixing hole positions at the four corners of the shelter for fixing first, and then the lifting frame is raised by the lifting hydraulic cylinder; the travelling mechanism is movably connected with the lifting mechanism, so that when the lifting hydraulic cylinder works, the lifting frame can rise to enable one end of the shelter to leave the ground. The other end of the shelter is enabled to leave the ground by adopting the same method; the overall shelter is fixed to the shelter transferring device and leaves the ground. When the shelter is moved, the shelter is transferred through a drawing and travelling mechanism; a variety of large equipment are not required to be used; the shelter transferring device is operated by only one person; the transferring difficulty is reduced; the transferring cost is reduced; the operation is simple and convenient.

Owner:深圳瑞朗特防爆车辆有限公司

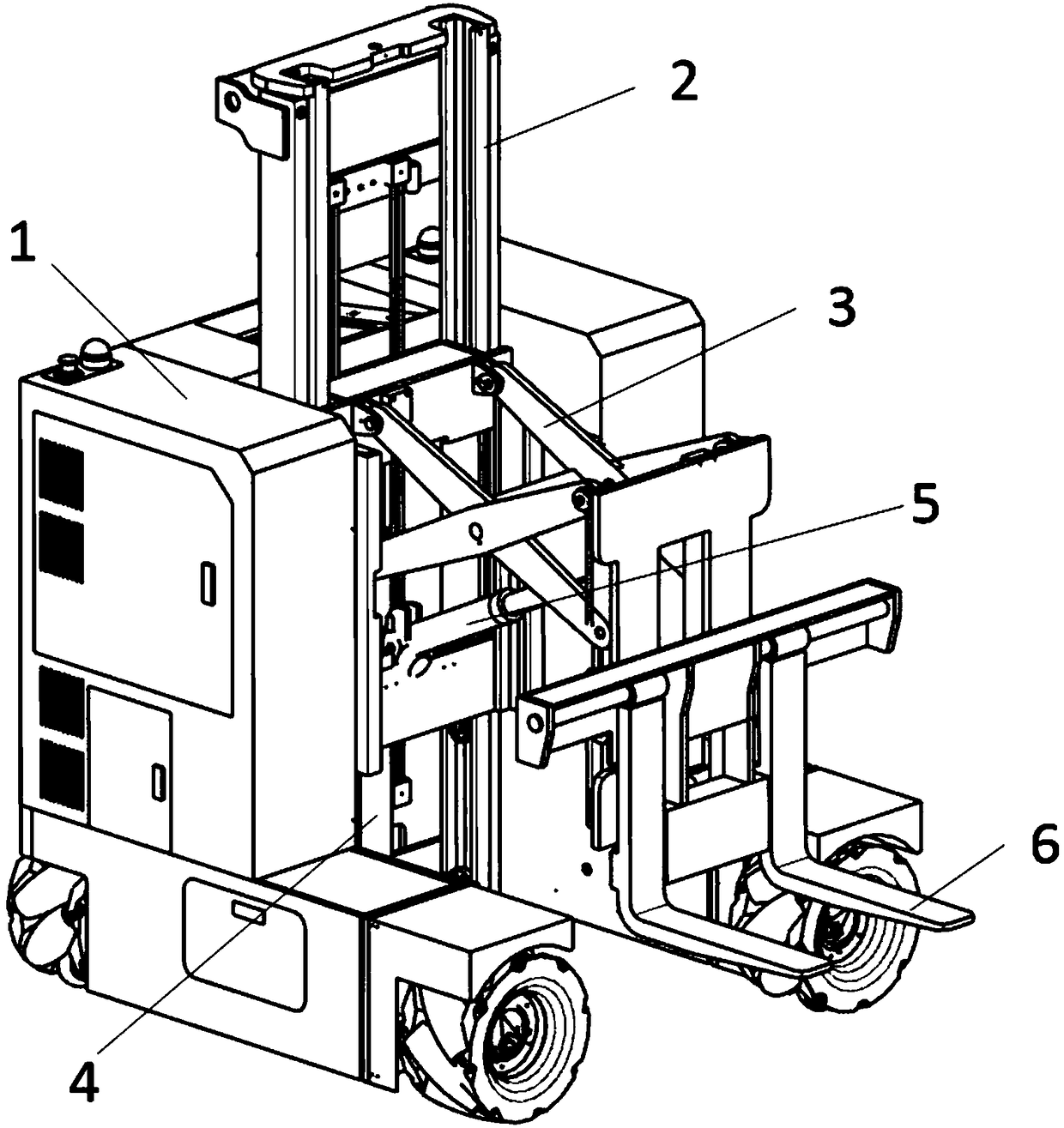

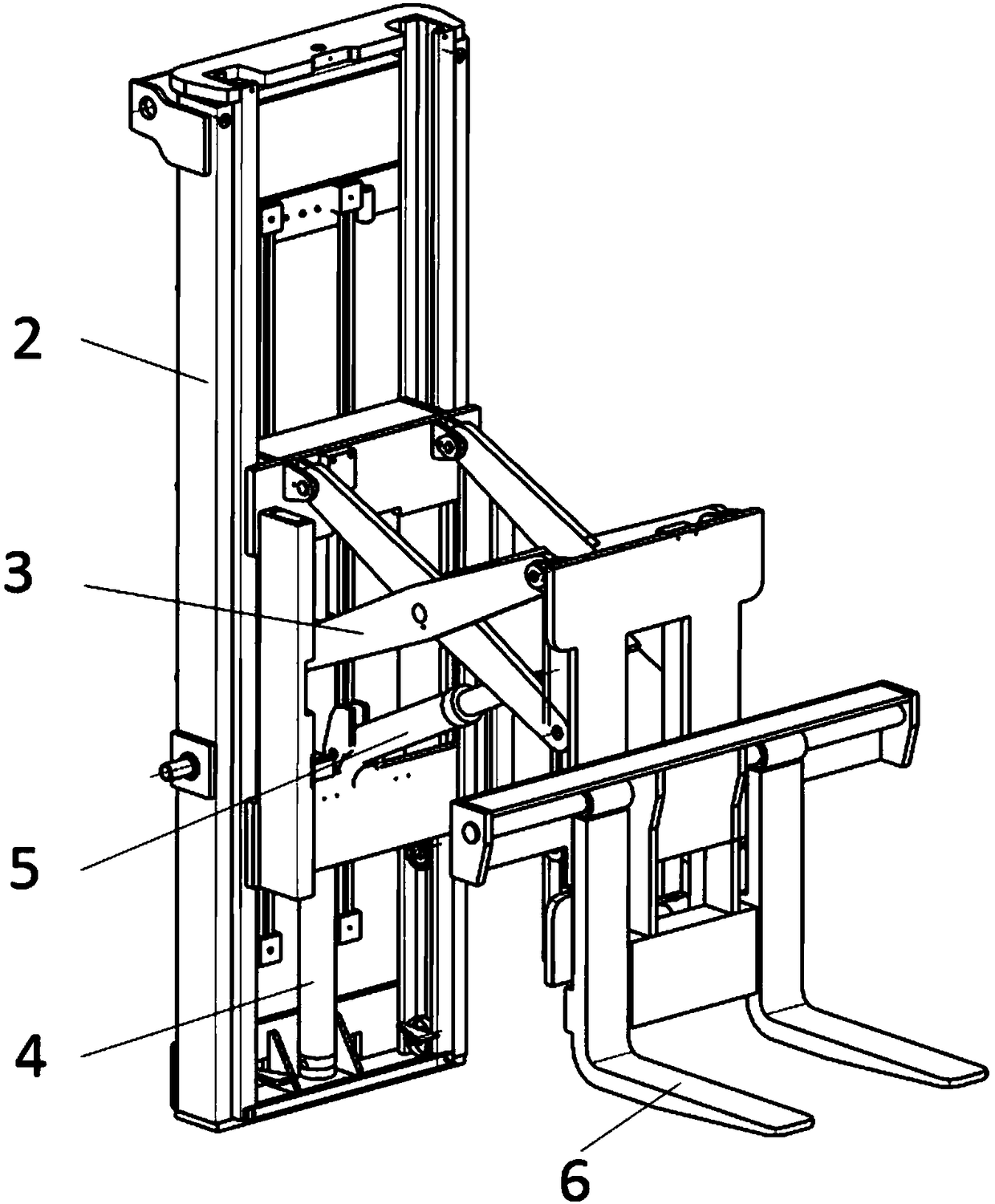

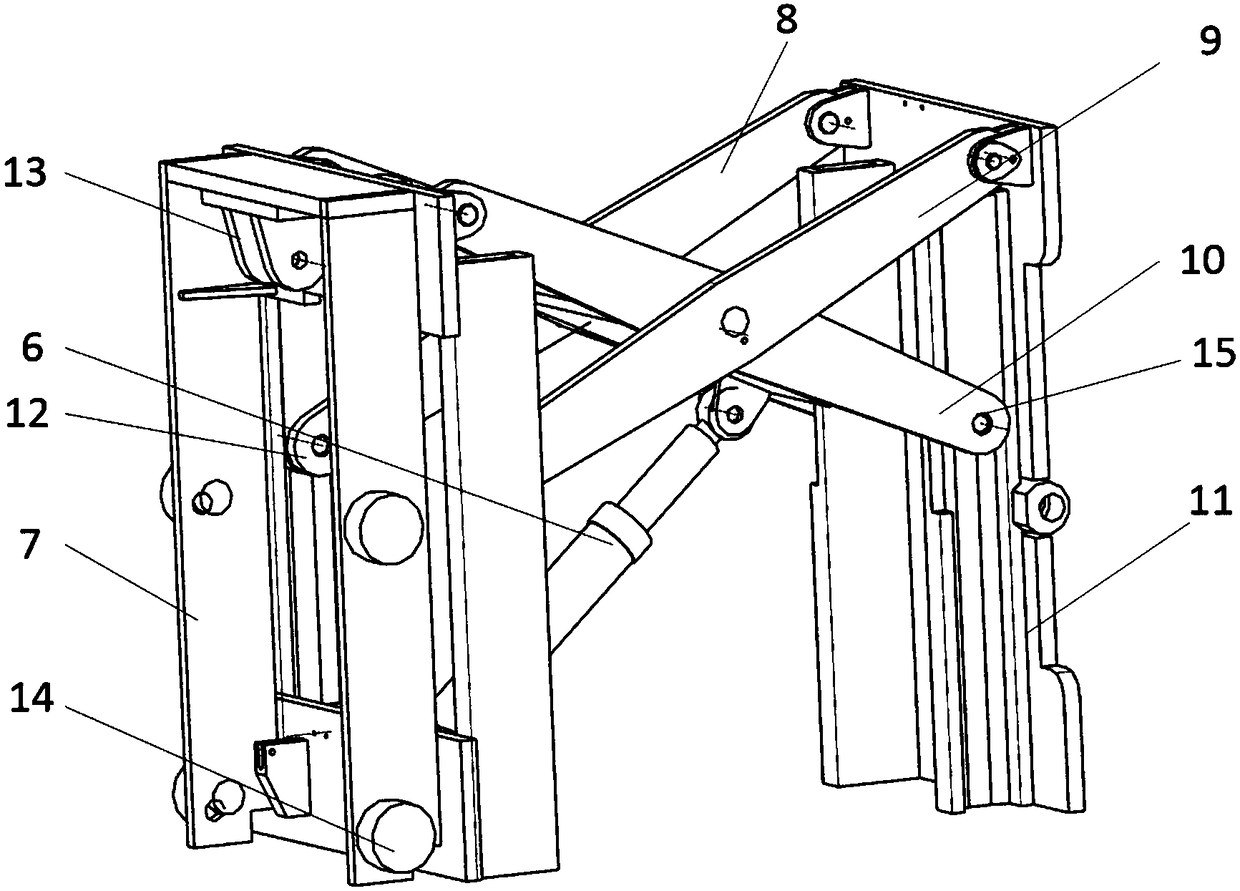

Stacking and transferring device based on omni-directional mobile platform

The invention relates to a stacking and transferring device based on an omni-directional mobile platform, and relates to the technical field of storage operation. The stacking and transferring devicebased on the omni-directional mobile platform can freely move in a warehouse in all directions, flexible transferring in the warehouse is achieved, and the operation efficiency is improved; the functions of obtaining, placing, stacking and transferring cargos in the warehouse can be achieved; the storage density can be increased, and the utilization rate of the warehouse can be effectively increased.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

Rotating platform for support installation

ActiveCN111852523AAchieve transshipmentEasy to recycleMine roof supportsProps/chocksClassical mechanicsAccident risk

The invention relates to the technical field of coal mining and discloses a rotating platform for support installation. The rotating platform comprises a base and a rotating seat, the rotating seat isconnected to the base through rotation, linking guide rails are arranged on the rotating seat, front pushing mechanisms are connected to the linking guide rails, rotating shafts are arranged beside the linking guide rails, movable car stoppers are arranged on the rotating shafts, the movable car stoppers and the rotating shafts are fixed in the circumferential direction and are in sliding fit inthe axial direction, fixed car stoppers are arranged at the other ends, opposite to the movable car stoppers, of the linking guide rails, the front pushing mechanisms are connected with the movable car stoppers, rotation driving mechanisms are connected to the rotating shafts, and the movable car stoppers are located beside the linking guide rails in an opening state and located on the rail surfaces of the linking guide rails to be transformed into a car stopping state when the movable car stoppers are driven to rotate by the rotating shafts. The rotating platform is used for supporting installation of a comprehensive mechanized coal mining face and can effectively improve the installation efficiency of movable pulleys, improve construction safety and reduce accident risks.

Owner:SICHUAN CHUANMEI HUARONG ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com