Rotating platform for support installation

A technology of rotating platform and rotating seat, which is applied in the direction of mine roof support, pillar/support, transportation and packaging, etc., to reduce the risk of accidents, improve efficiency and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below.

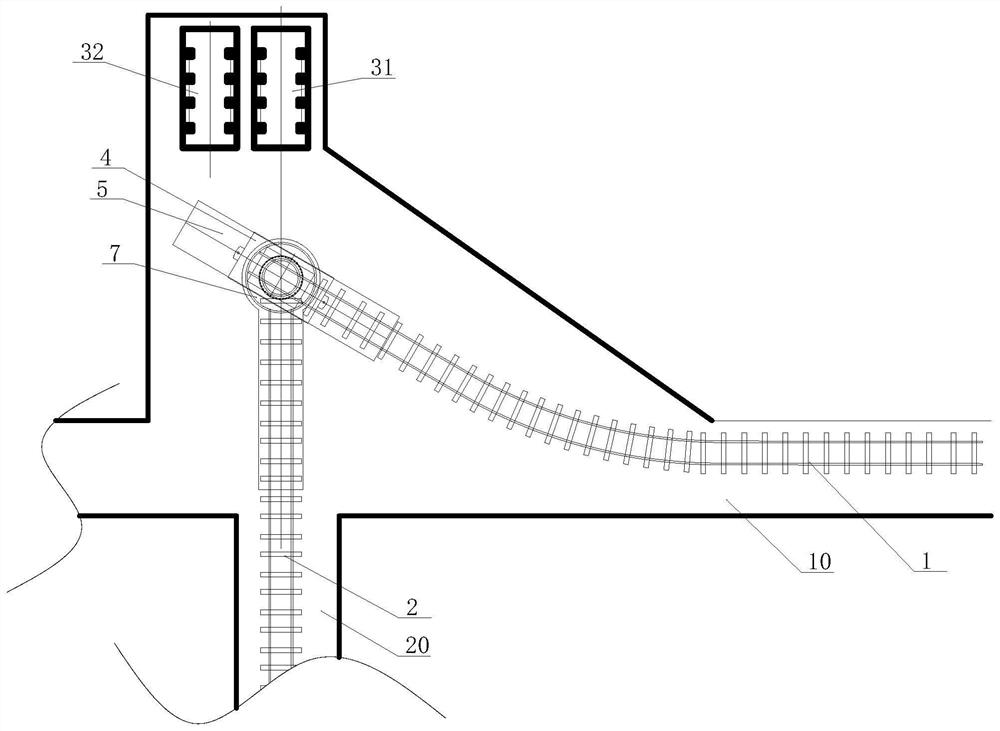

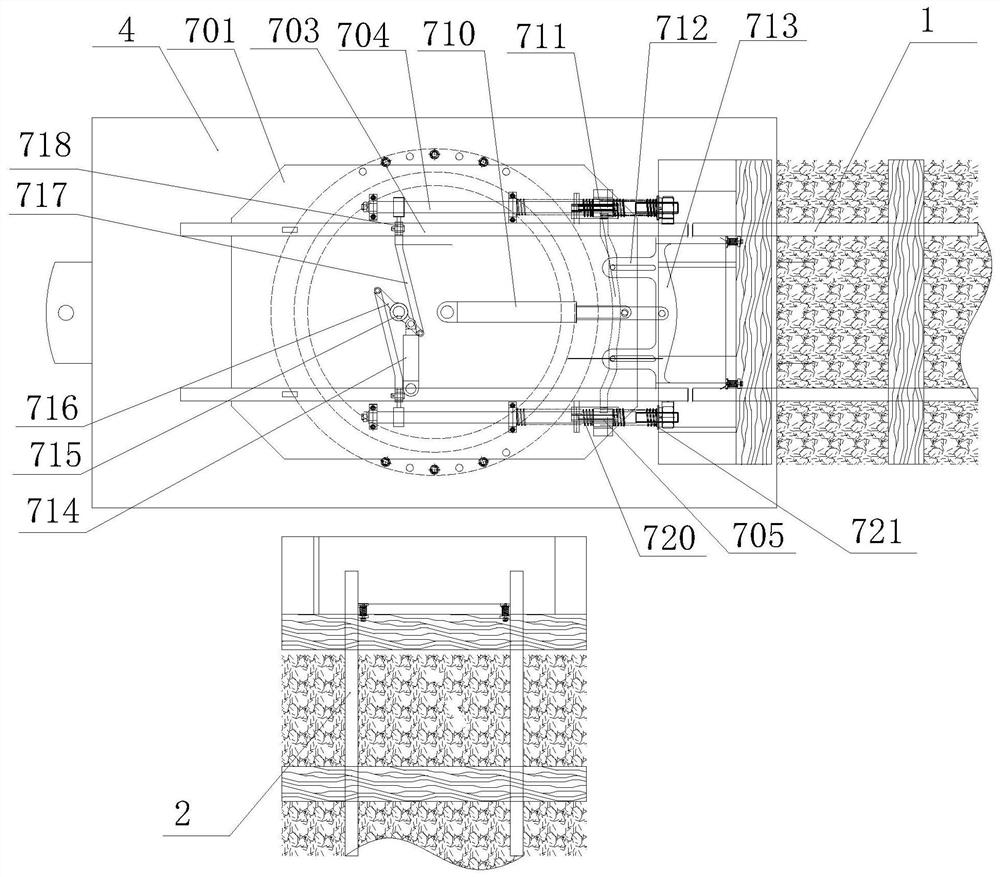

[0030] The method for installing the support of the fully mechanized mining face invented by the applicant, such as figure 1 shown, including the following steps:

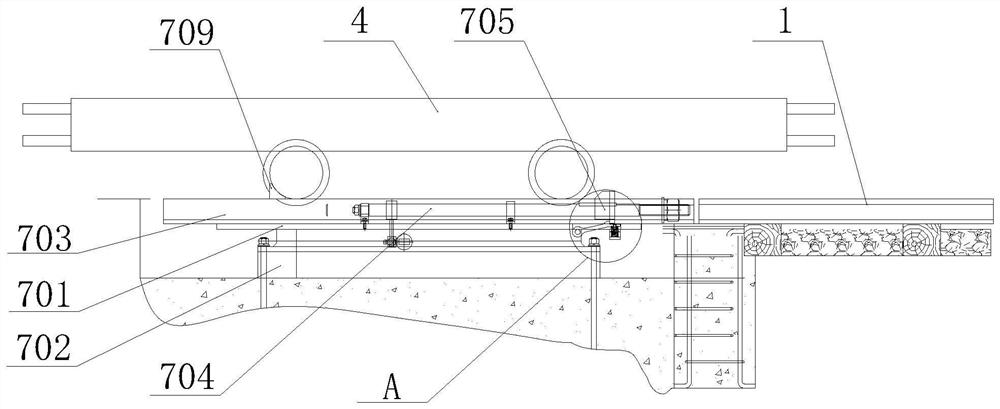

[0031] Tracks are respectively laid in the entryway 10 and the incision guideway 20, and a rotating platform is set between the entryway track 1 and the incision guideway track 2; It can be further divided into transport lane and return air lane, etc. The installation of support 5 needs to be transported from the level lane 10 through the cut-out guide tunnel 20 to reach the installation position of support 5 for installation.

[0032] When the support 5 is installed, the support 5 is longitudinally fixed on the mobile block 4, and is moved along the track 1 of the level road. The longitudinal fixation of the support 5 means that the length direction of the support 5 is consistent with the moving direction of the mobile block 4, so that the support 5 can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com