Patents

Literature

1395results about "Mould handling equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

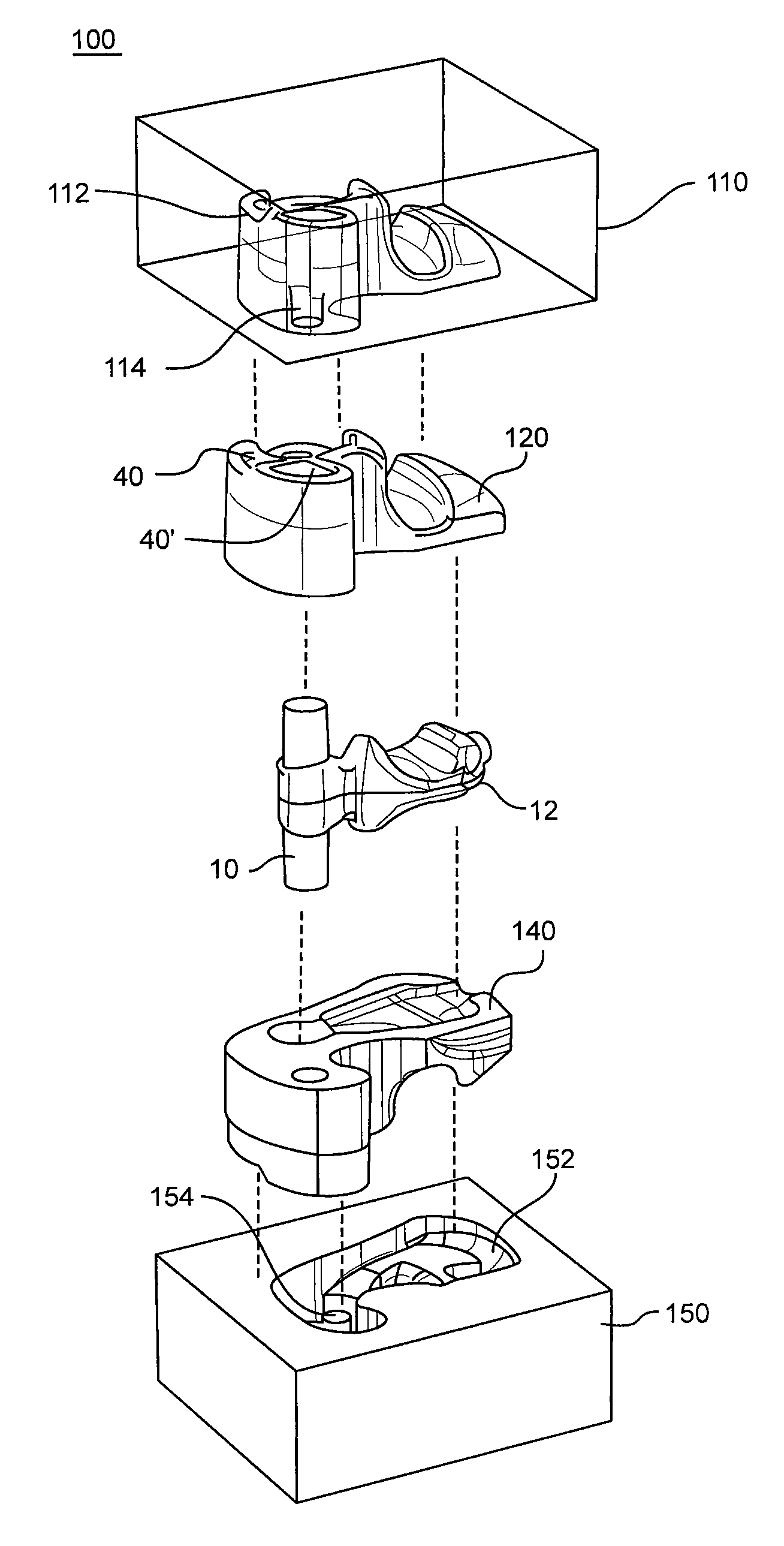

Method and system for manufacturing a coupler knuckle

ActiveUS20070125510A1Eliminates and reduces of disadvantageEliminates and reduces of and problemFoundry mouldsRailway couplingsEngineeringCope and drag

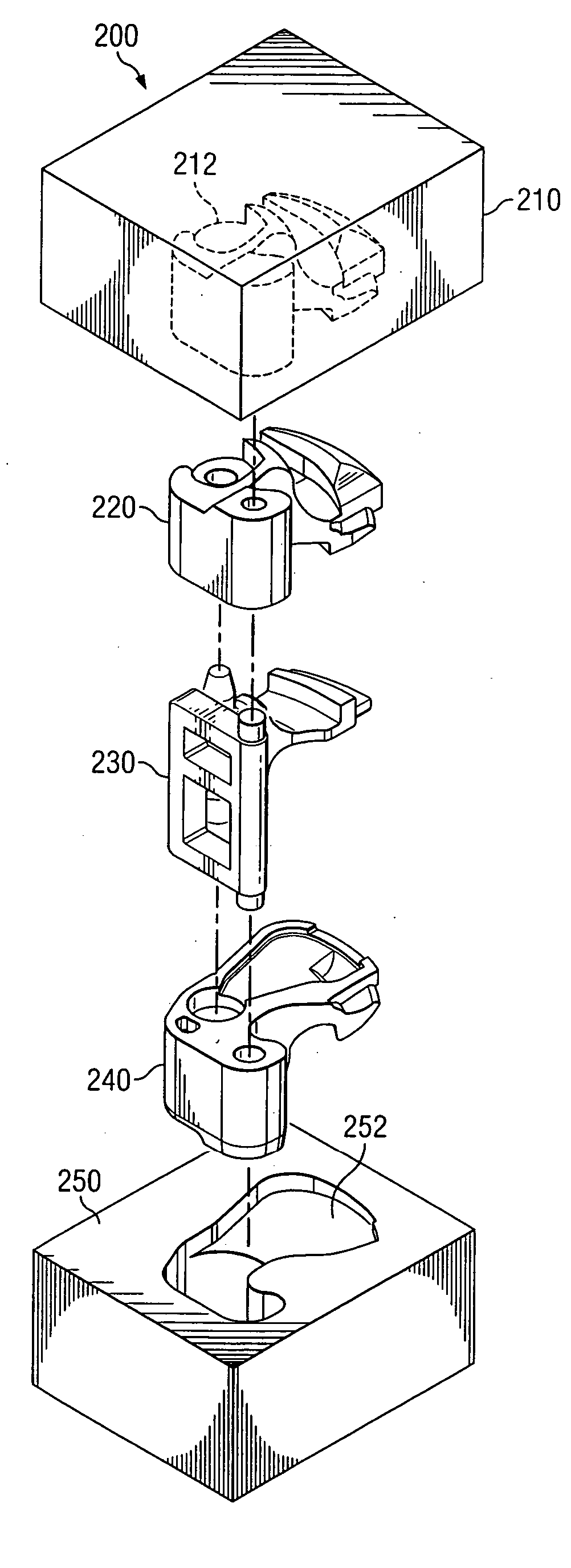

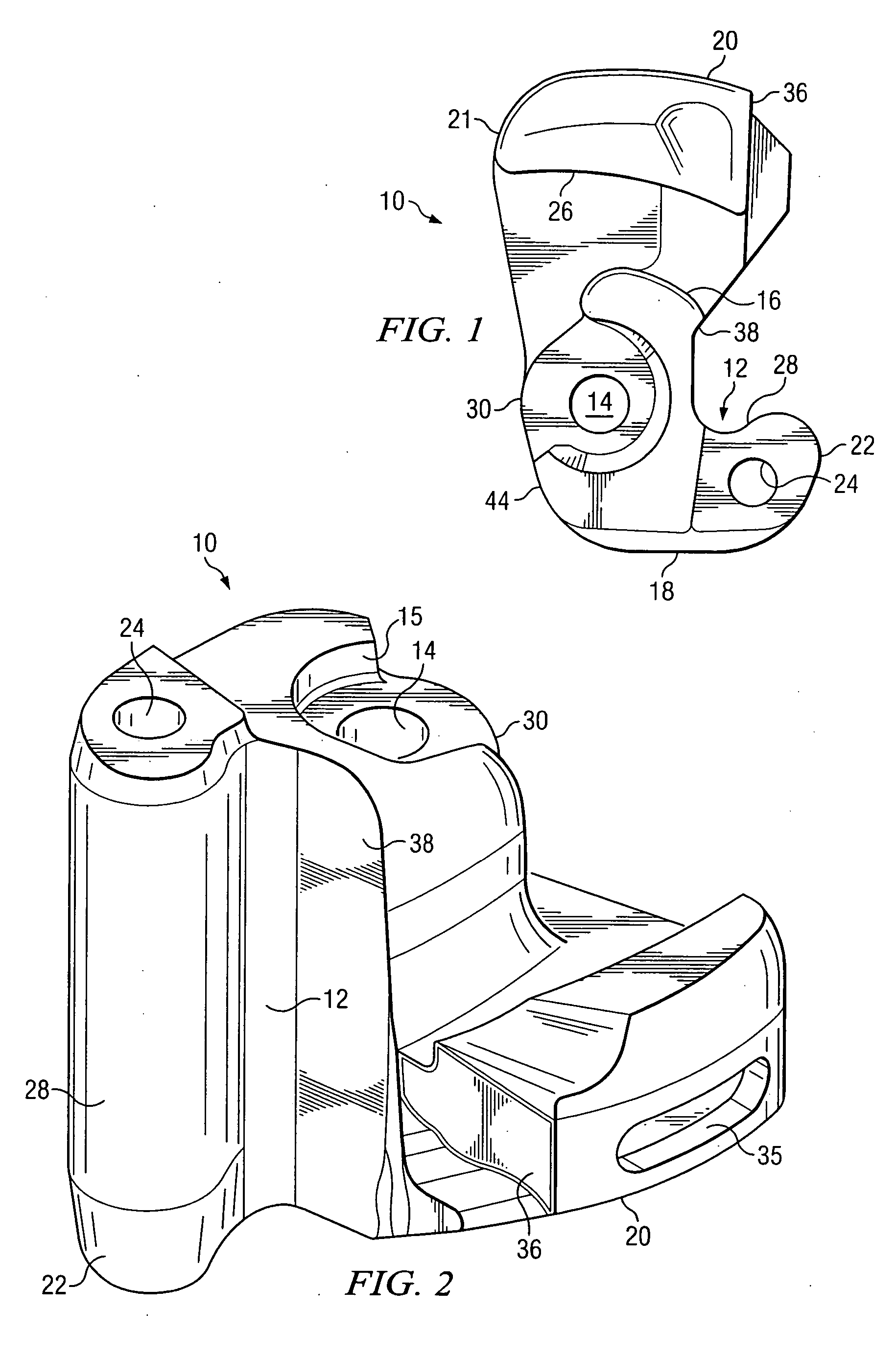

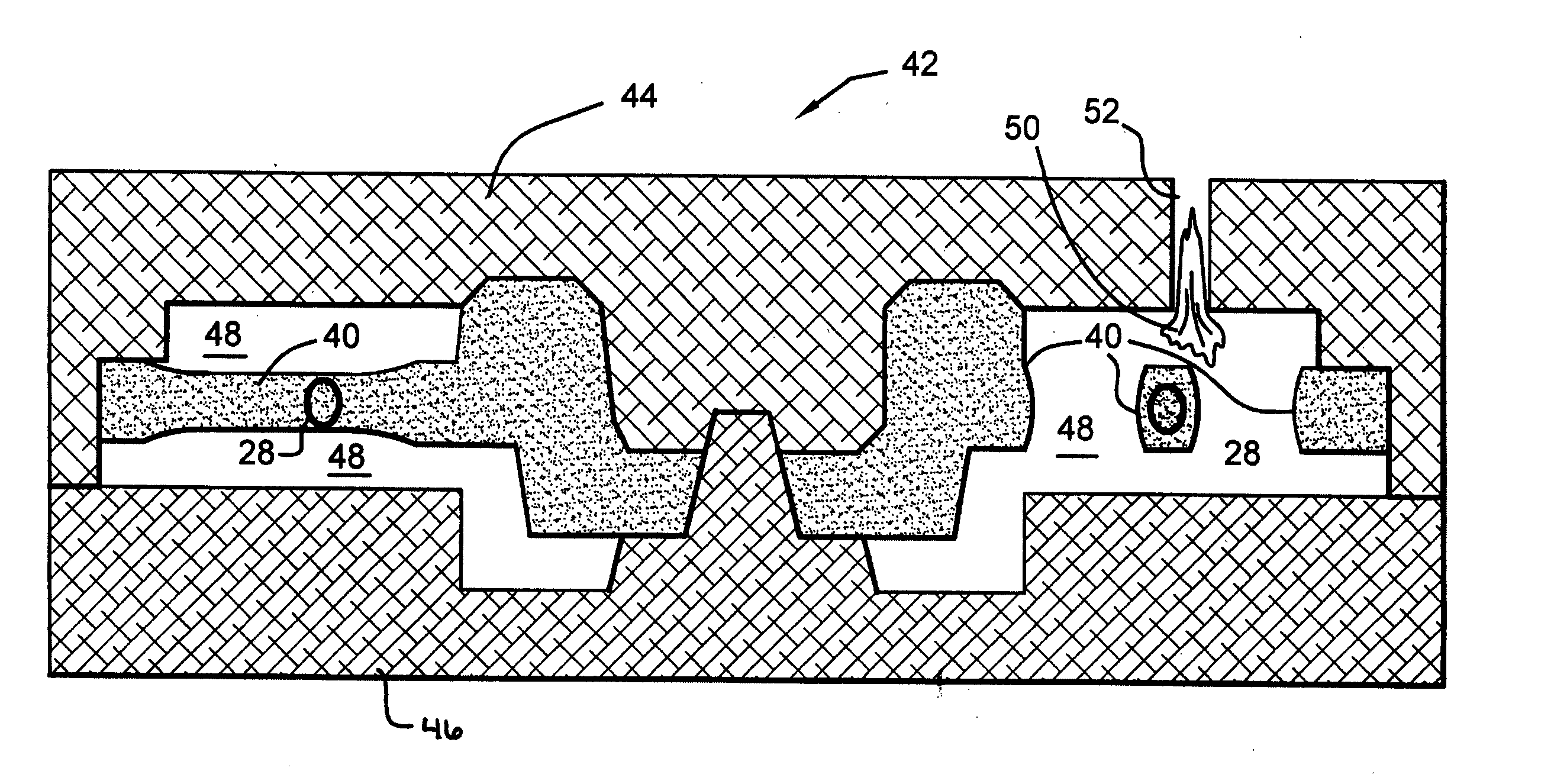

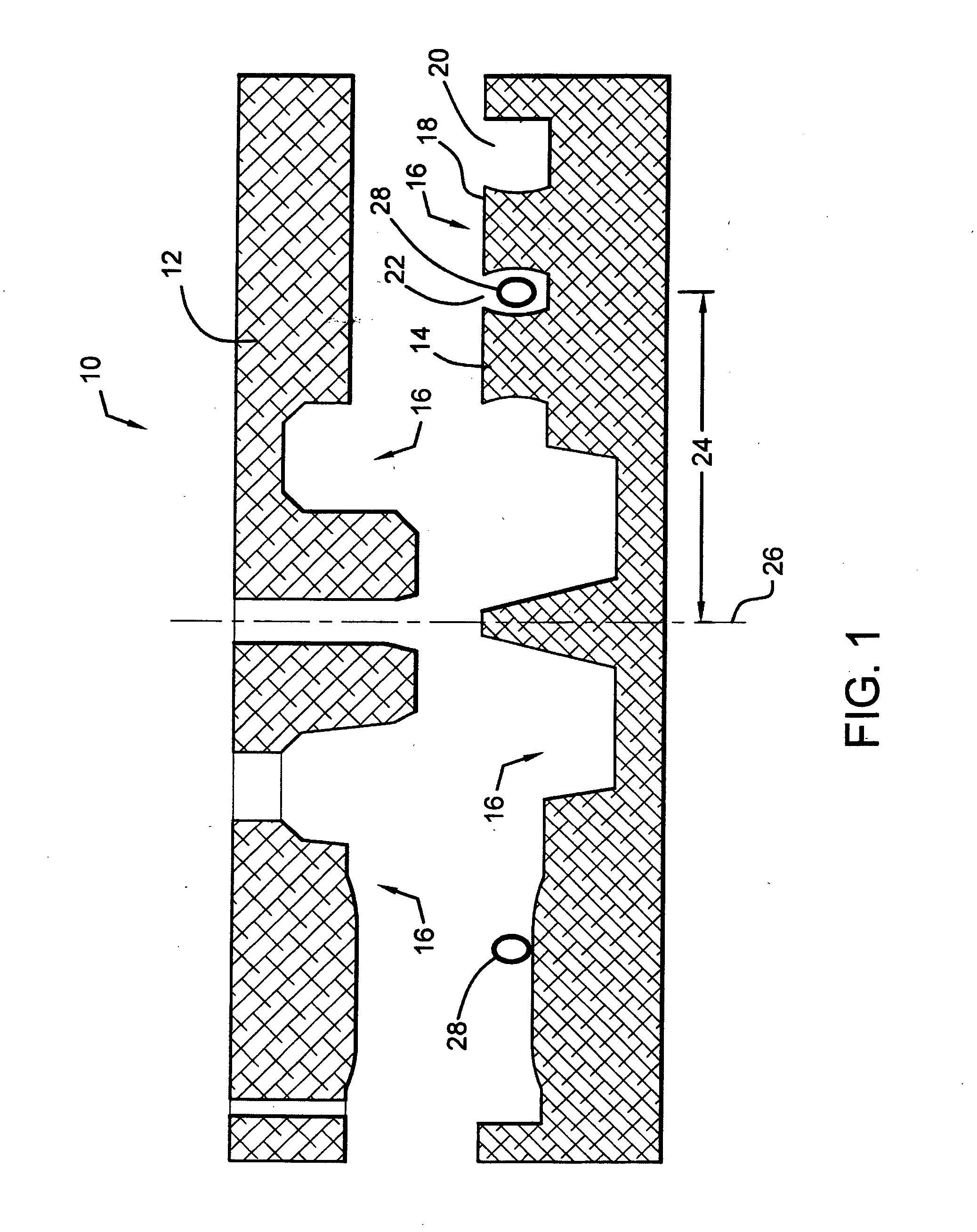

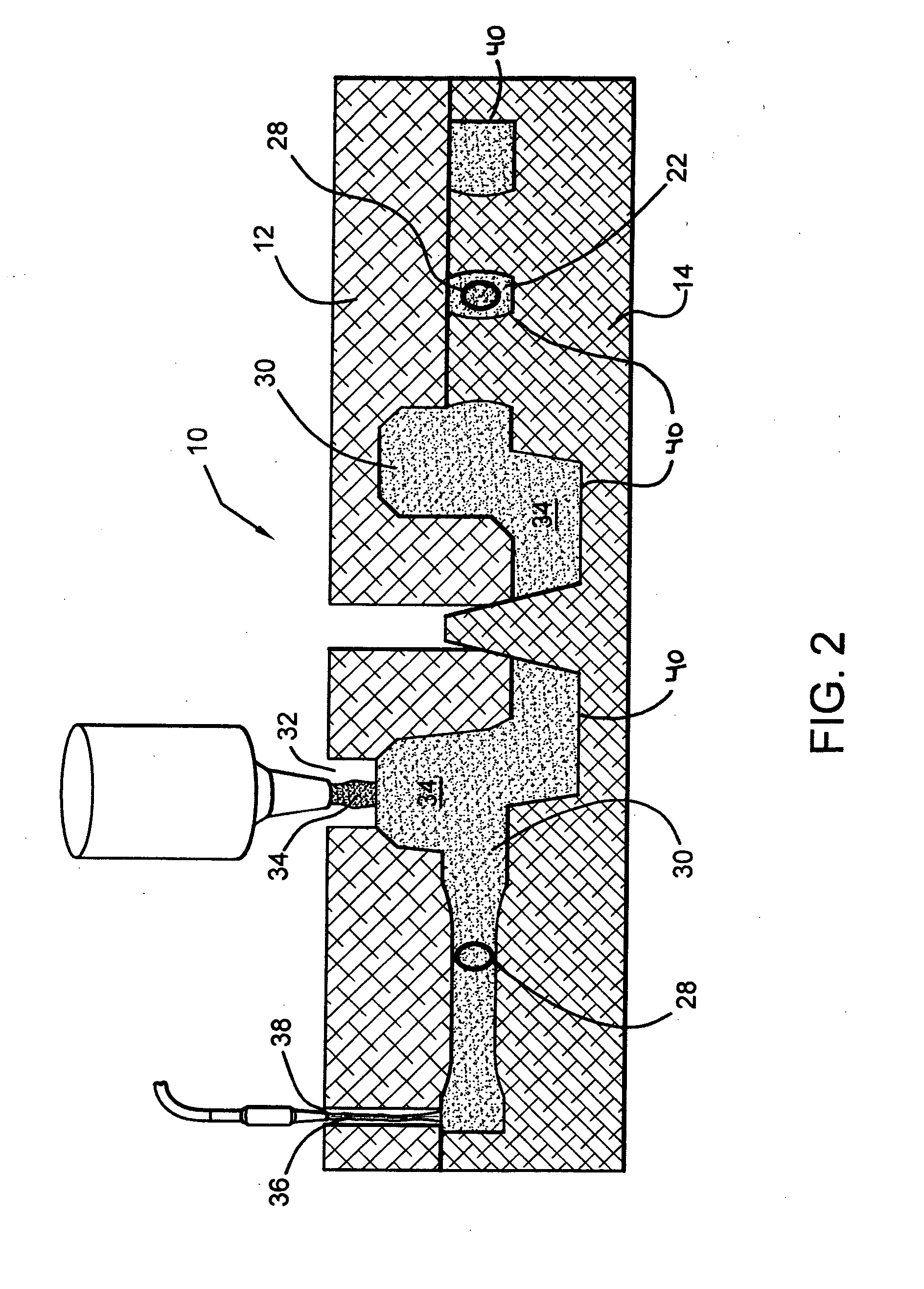

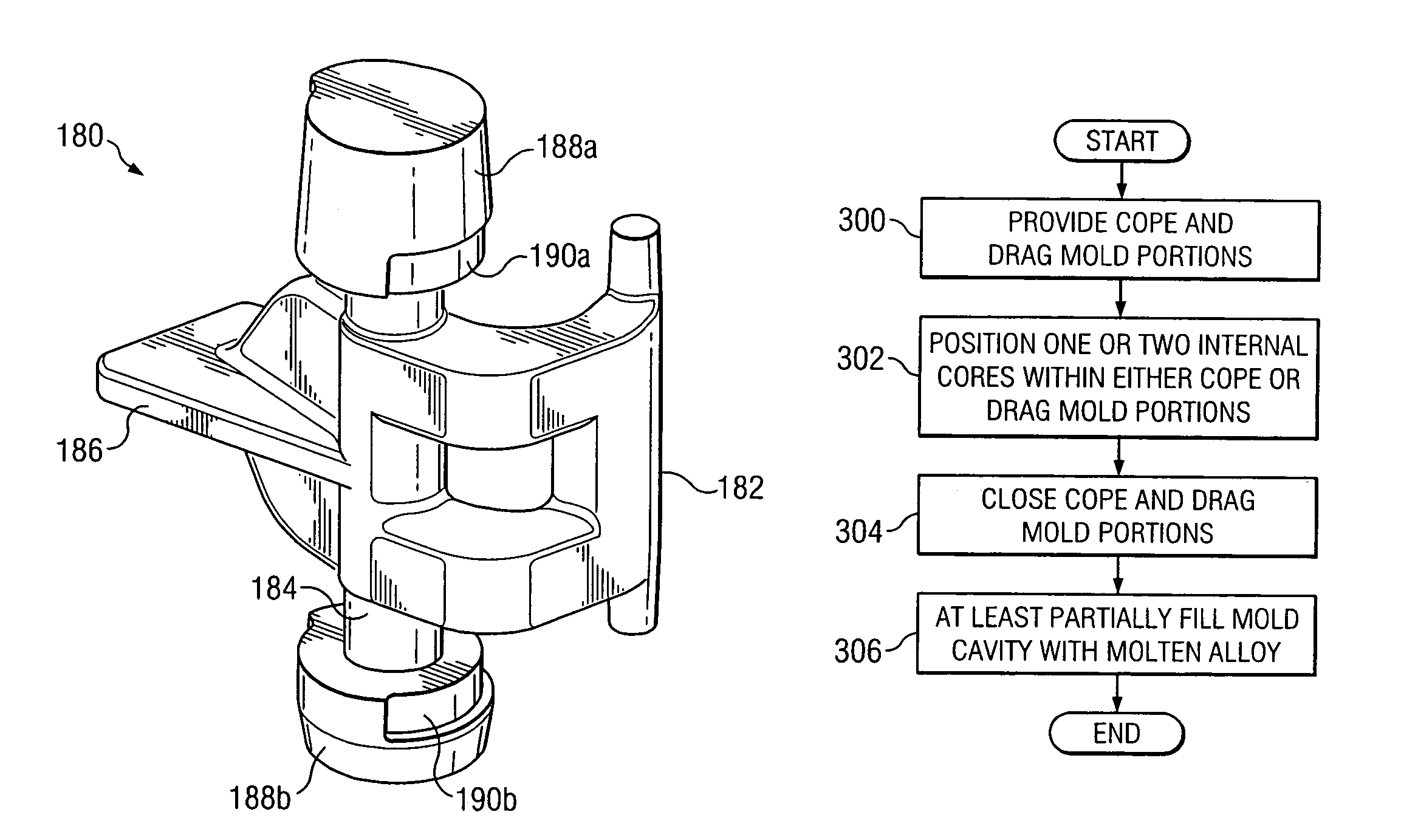

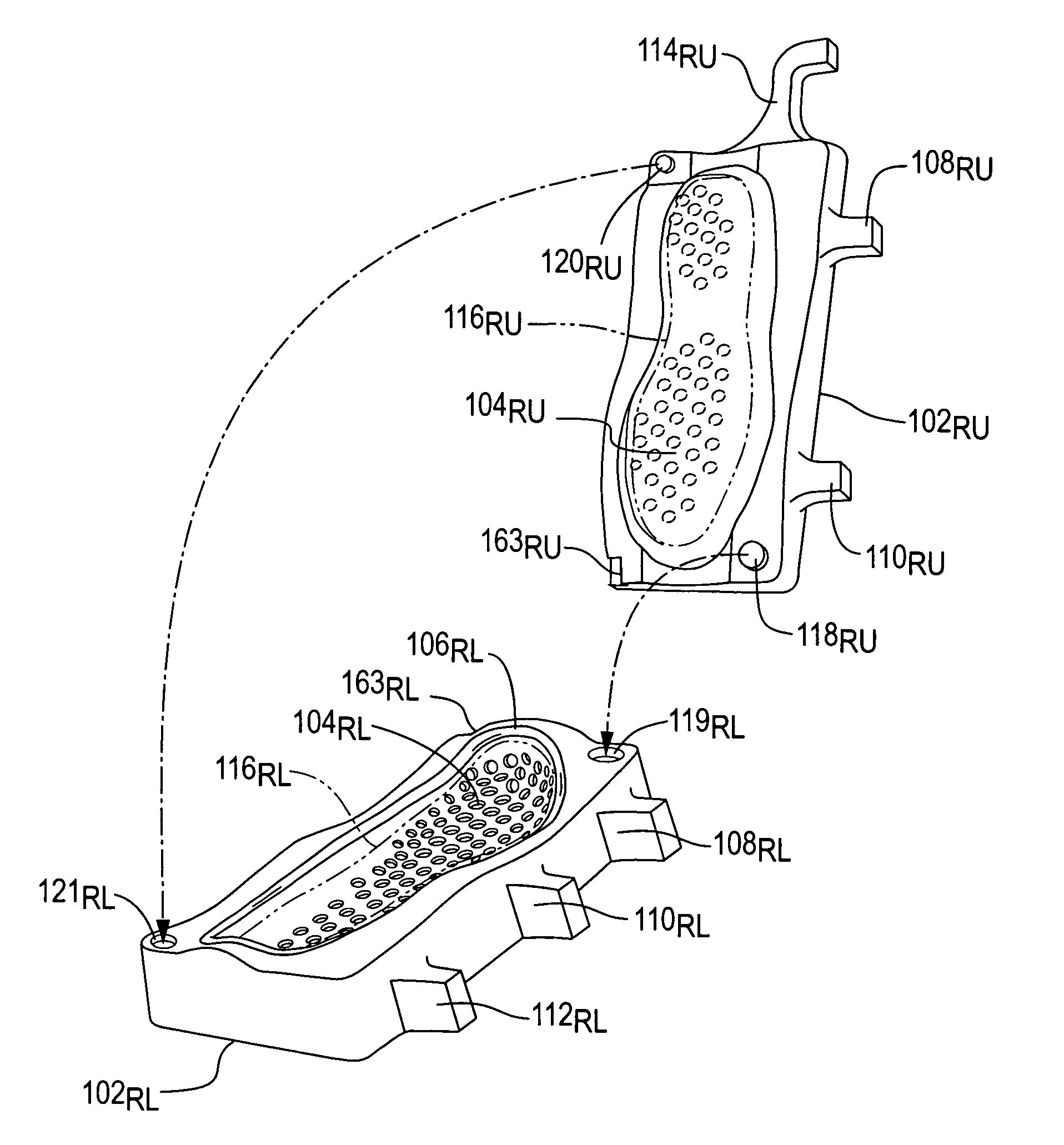

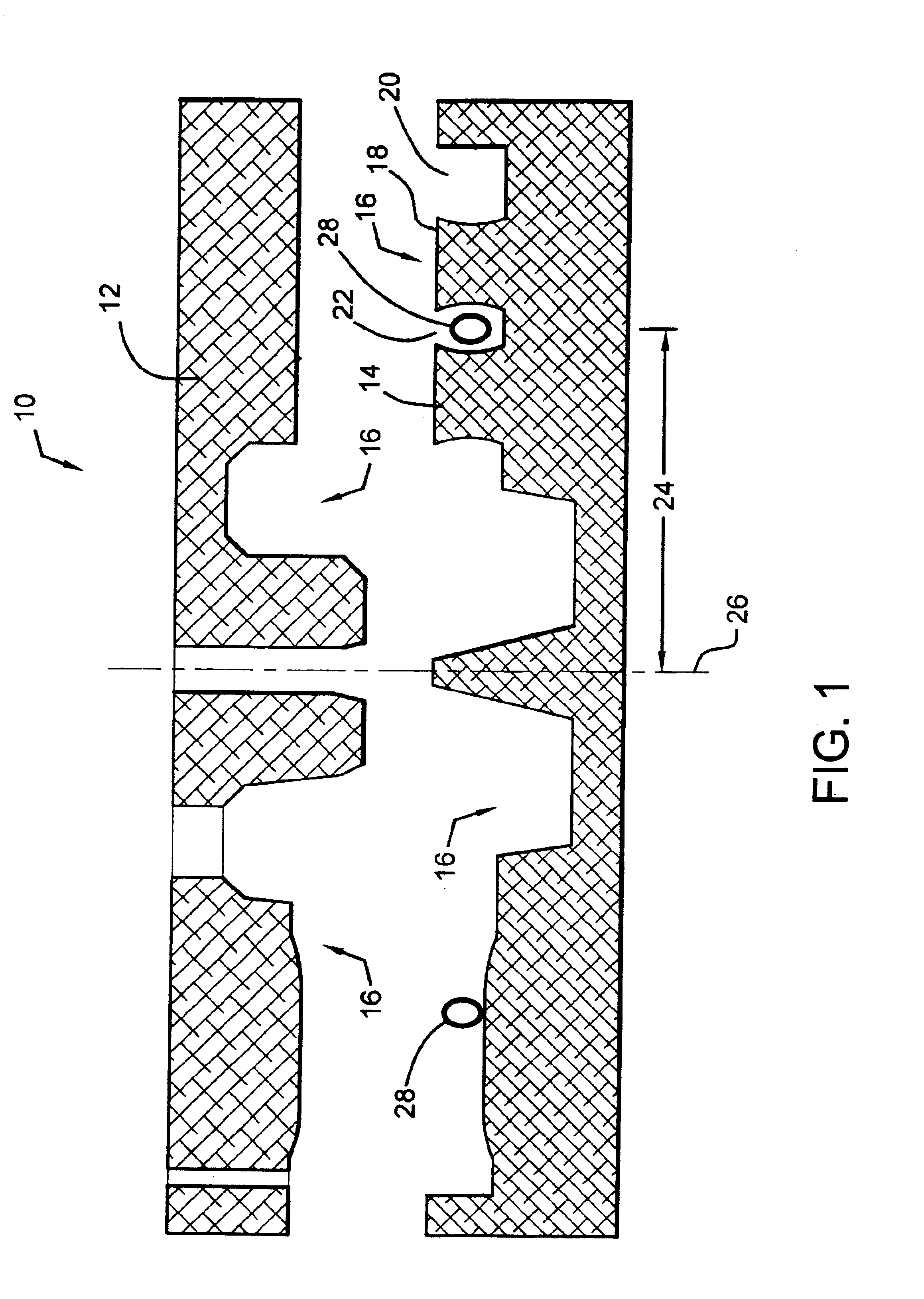

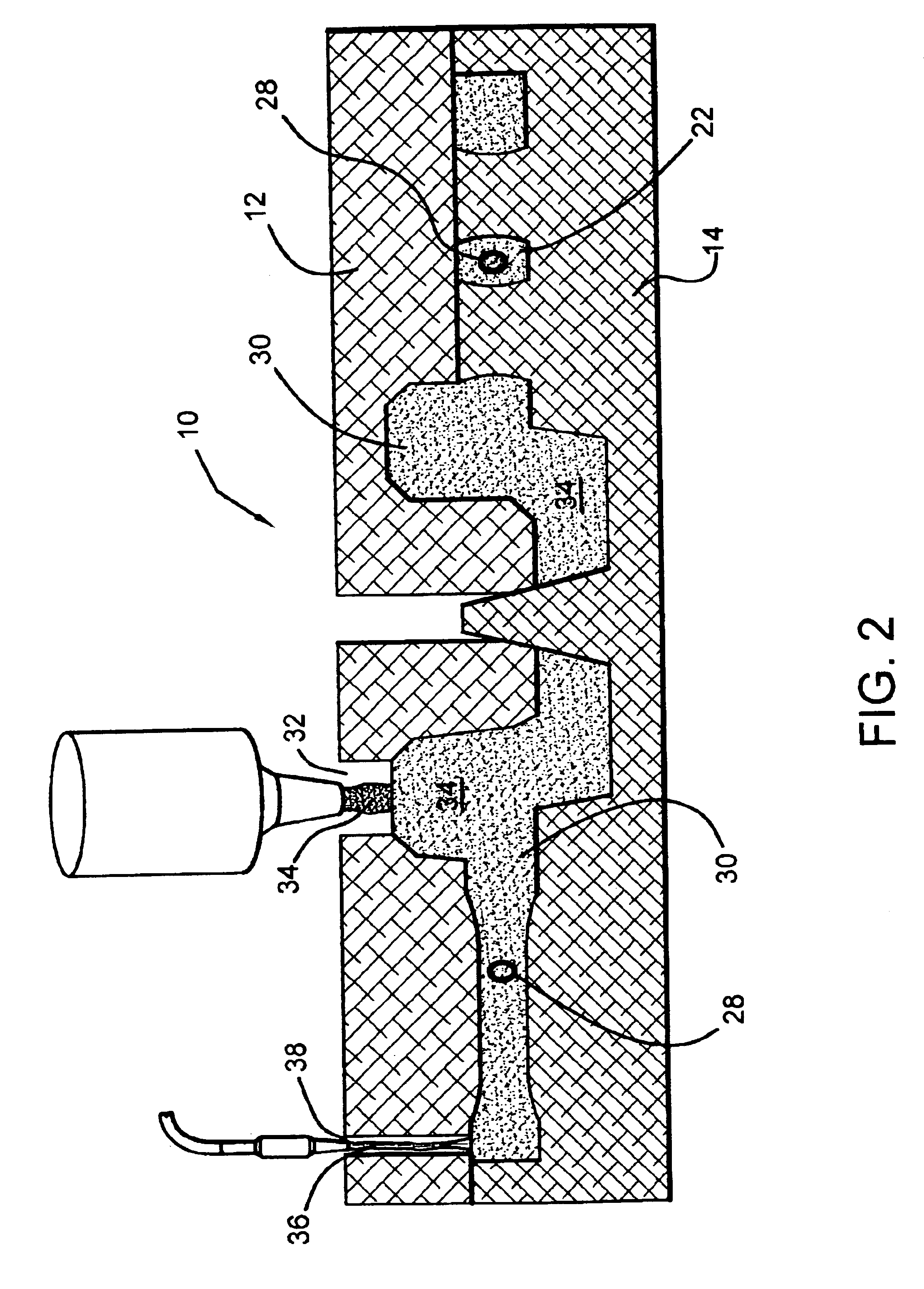

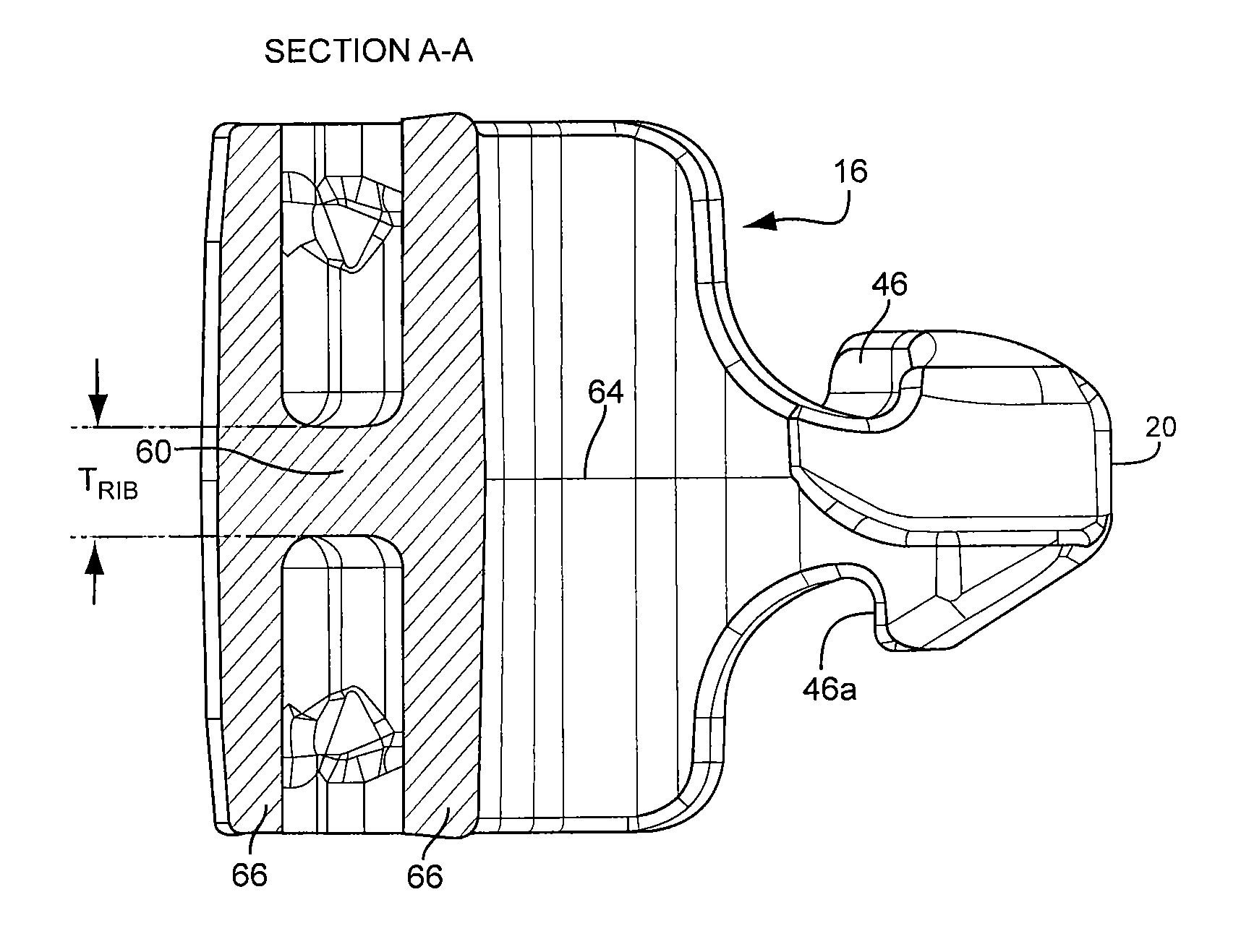

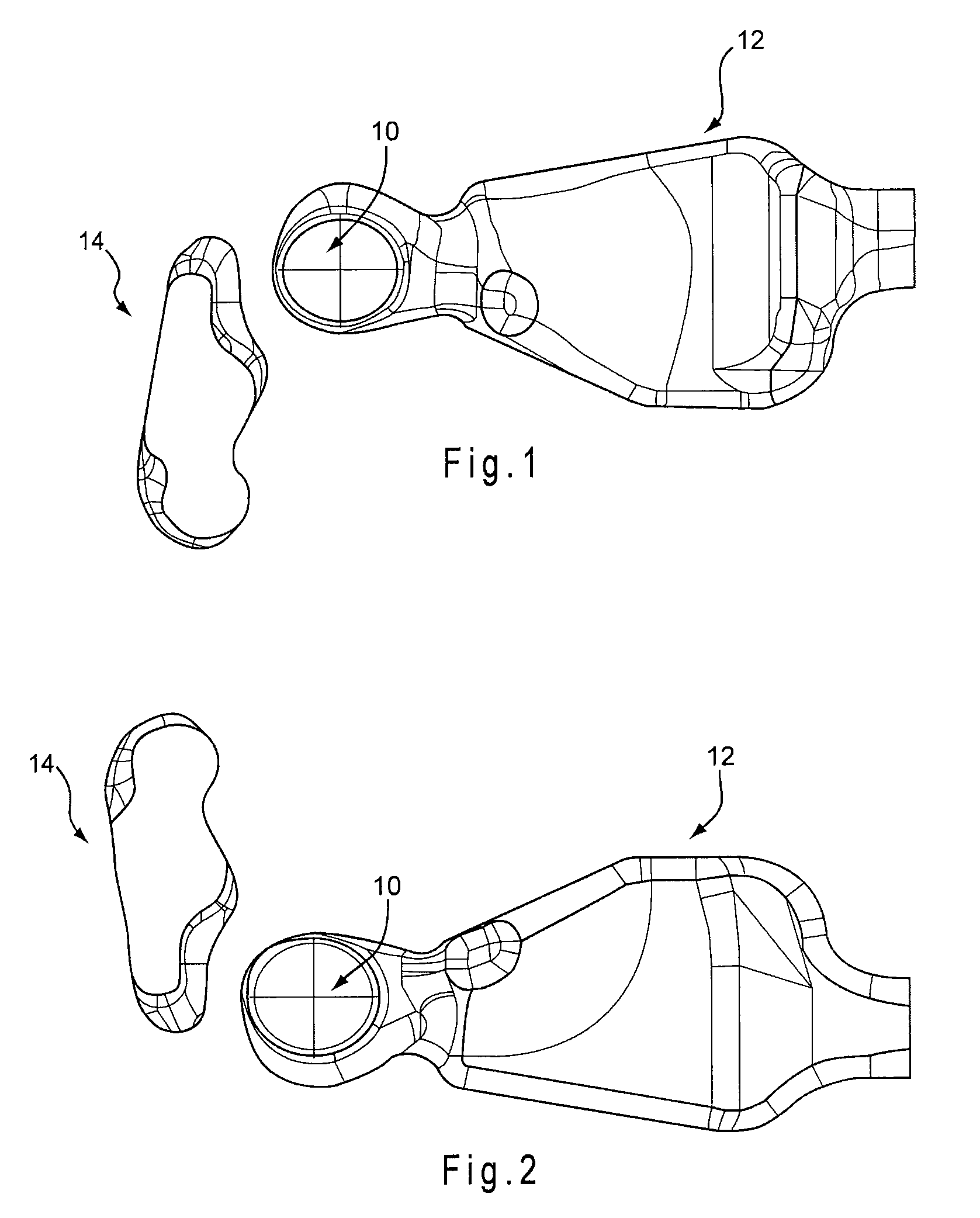

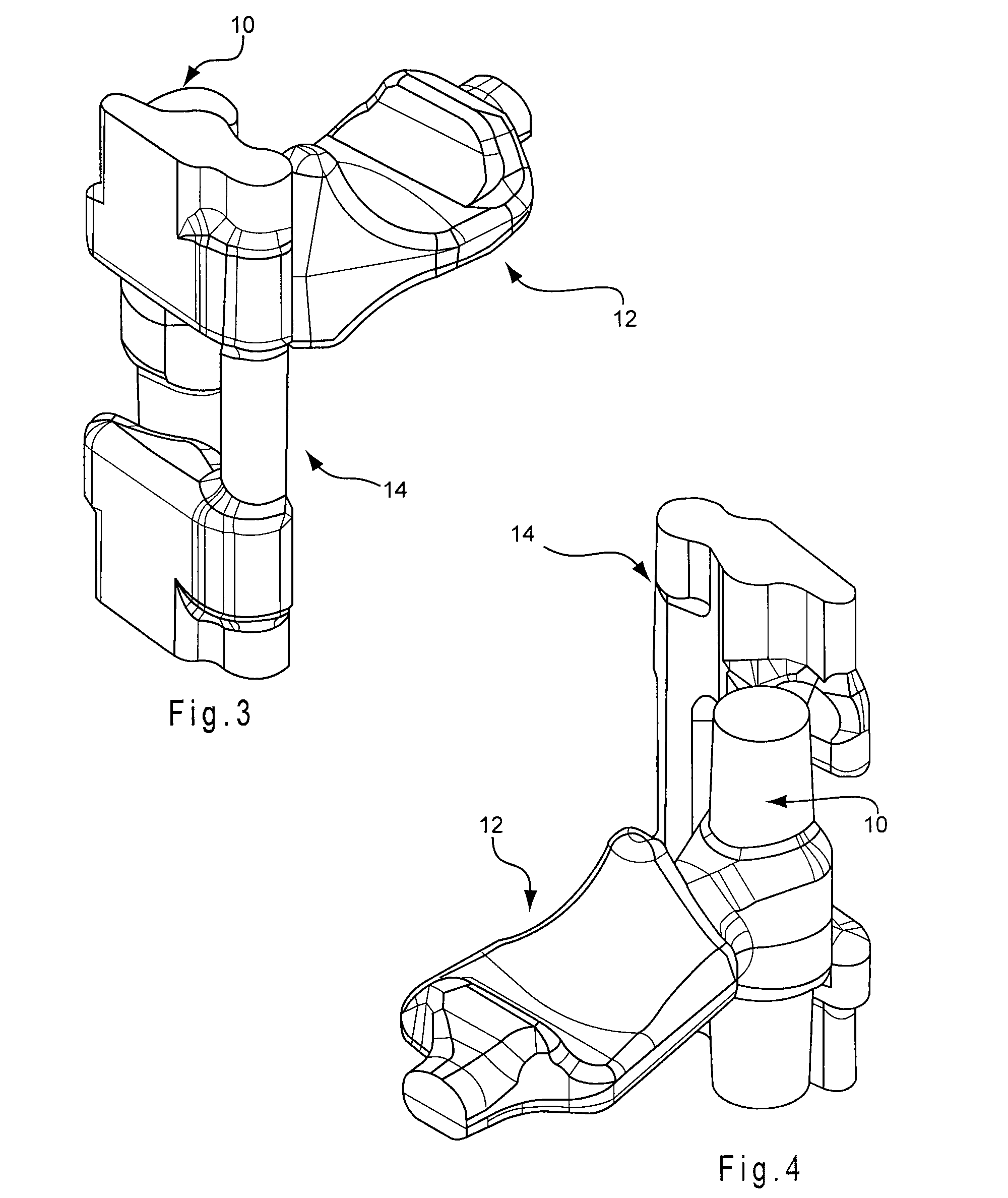

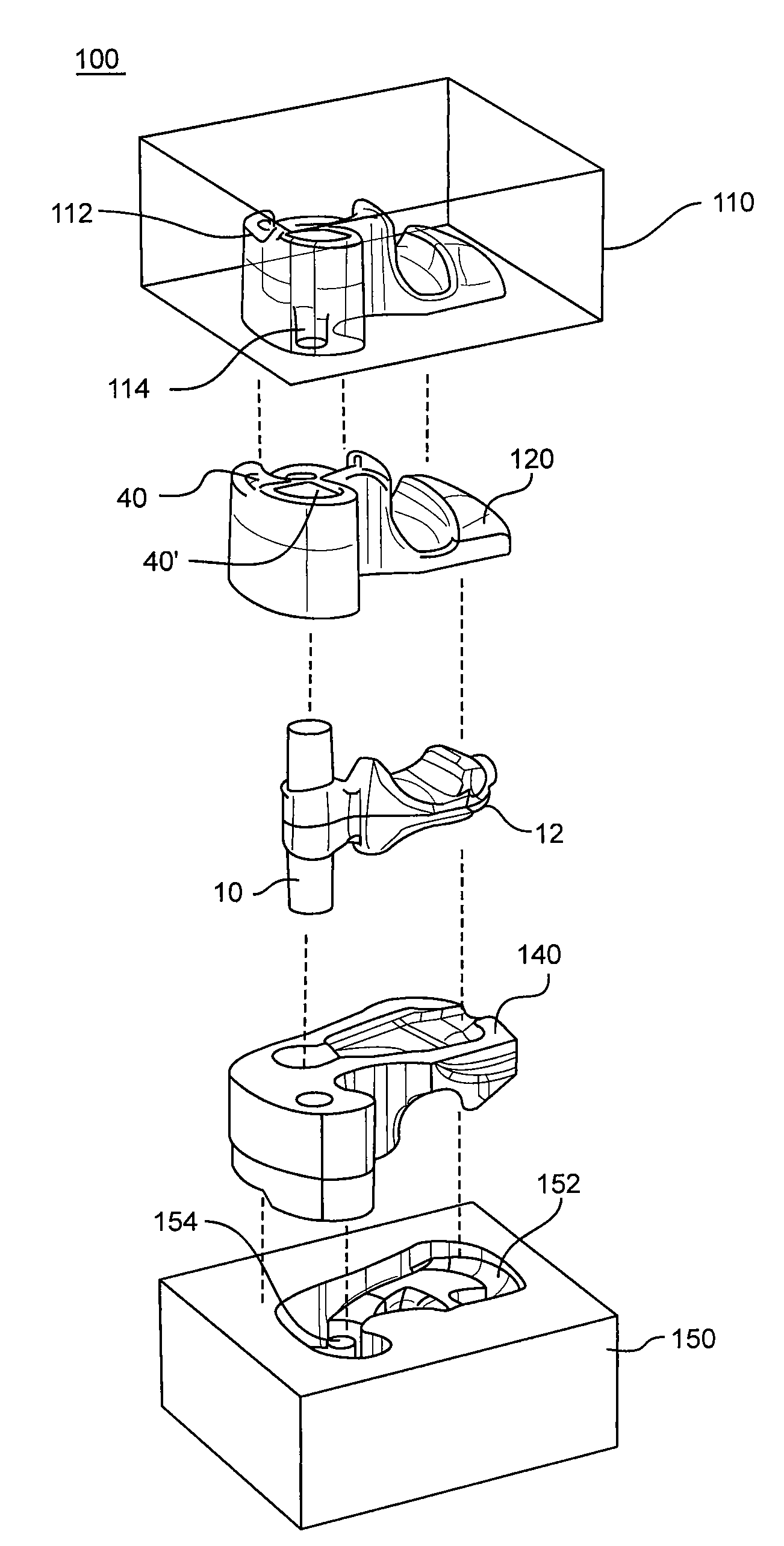

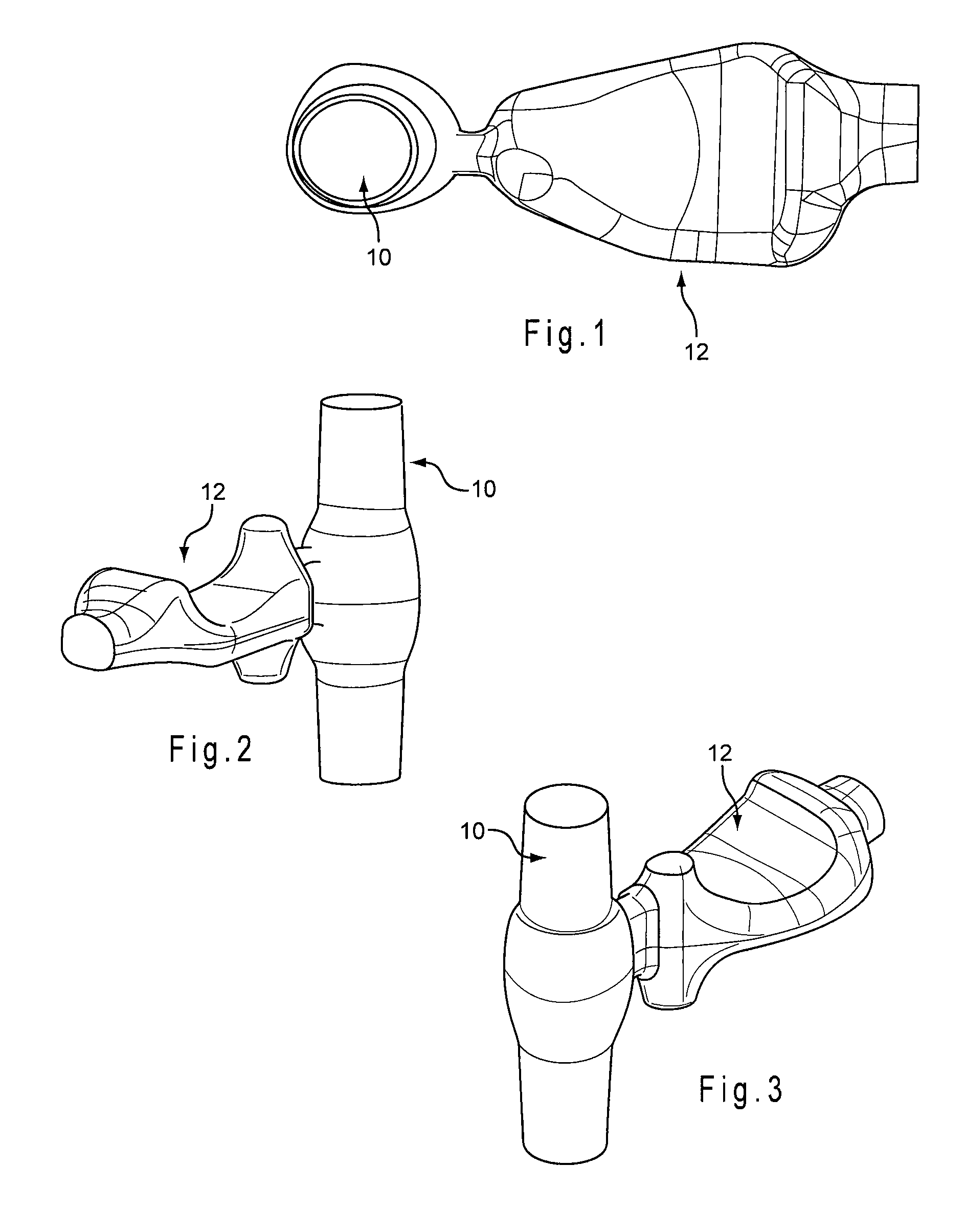

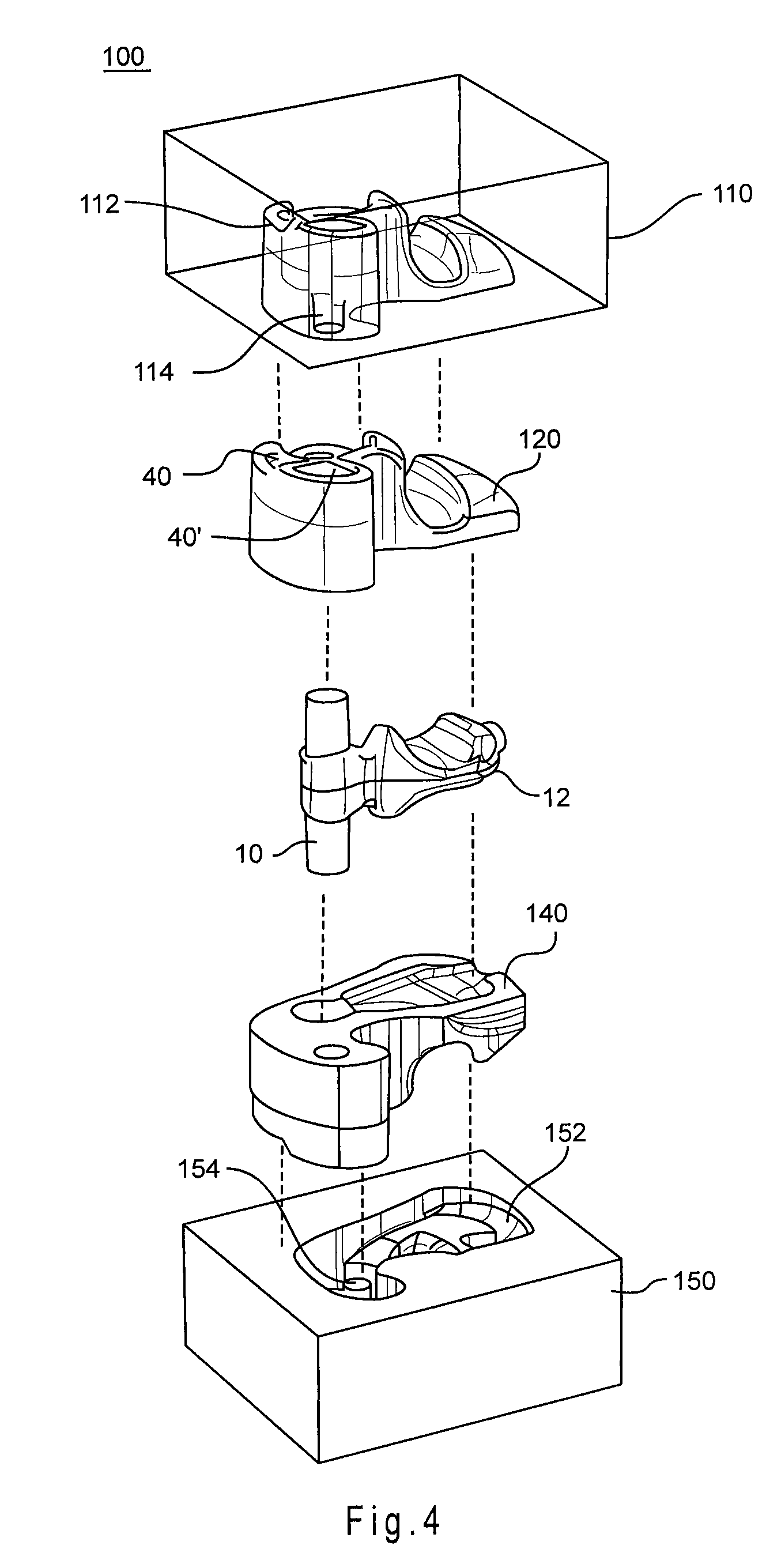

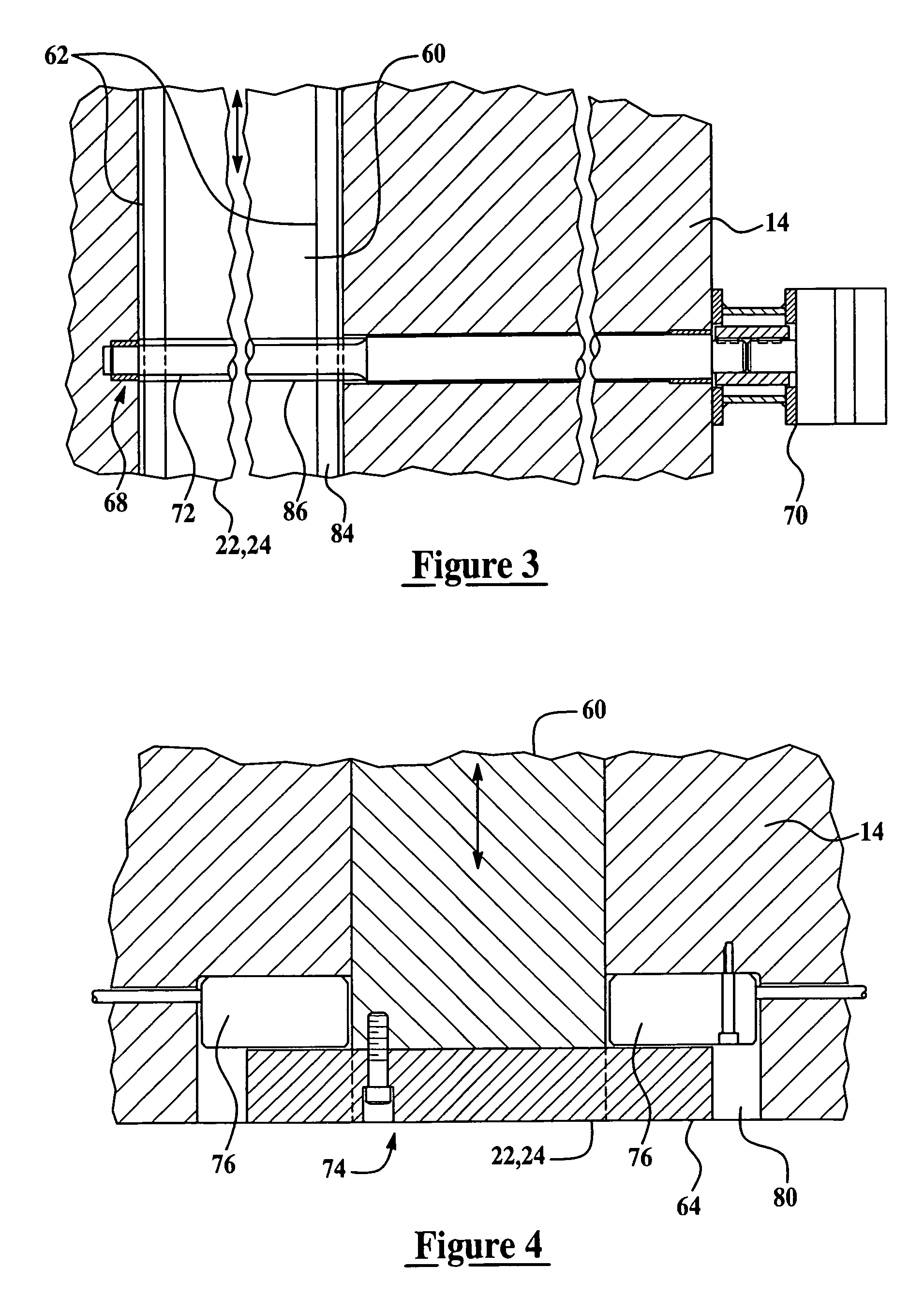

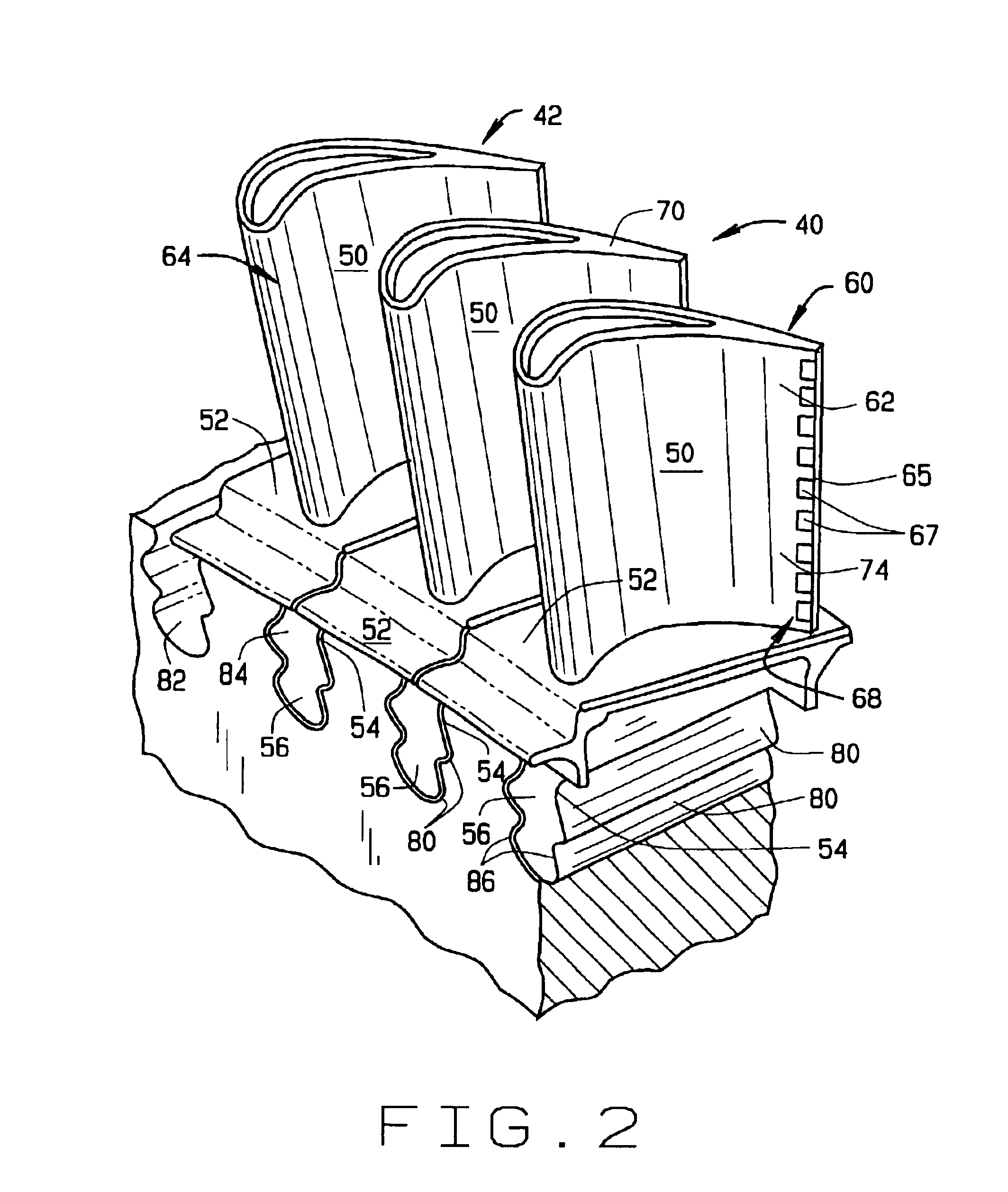

A method for manufacturing a railcar coupler knuckle includes providing a cope mold portion and a drag mold portion. The cope and drag mold portions have internal walls defining at least in part perimeter boundaries of a coupler knuckle mold cavity. The method includes positioning one or two internal cores within either the cope mold portion or the drag mold portion. The one or two internal cores are configured to define a kidney cavity, a finger cavity and a pivot pin cavity of a coupler knuckle. The method includes closing the cope and drag mold portions with the one or two internal cores therebetween and at least partially filling the mold cavity with a molten alloy, the molten alloy solidifying after filling to form the coupler knuckle.

Owner:MCCONWAY & TORLEY LLC

Method and apparatus for forming a part with dampener

InactiveUS20050011628A1Effectively and efficiently constructedDampening structureNoise/vibration controlFoundry mouldsMaterials scienceShock absorber

Owner:FRENI BREMBO SPA

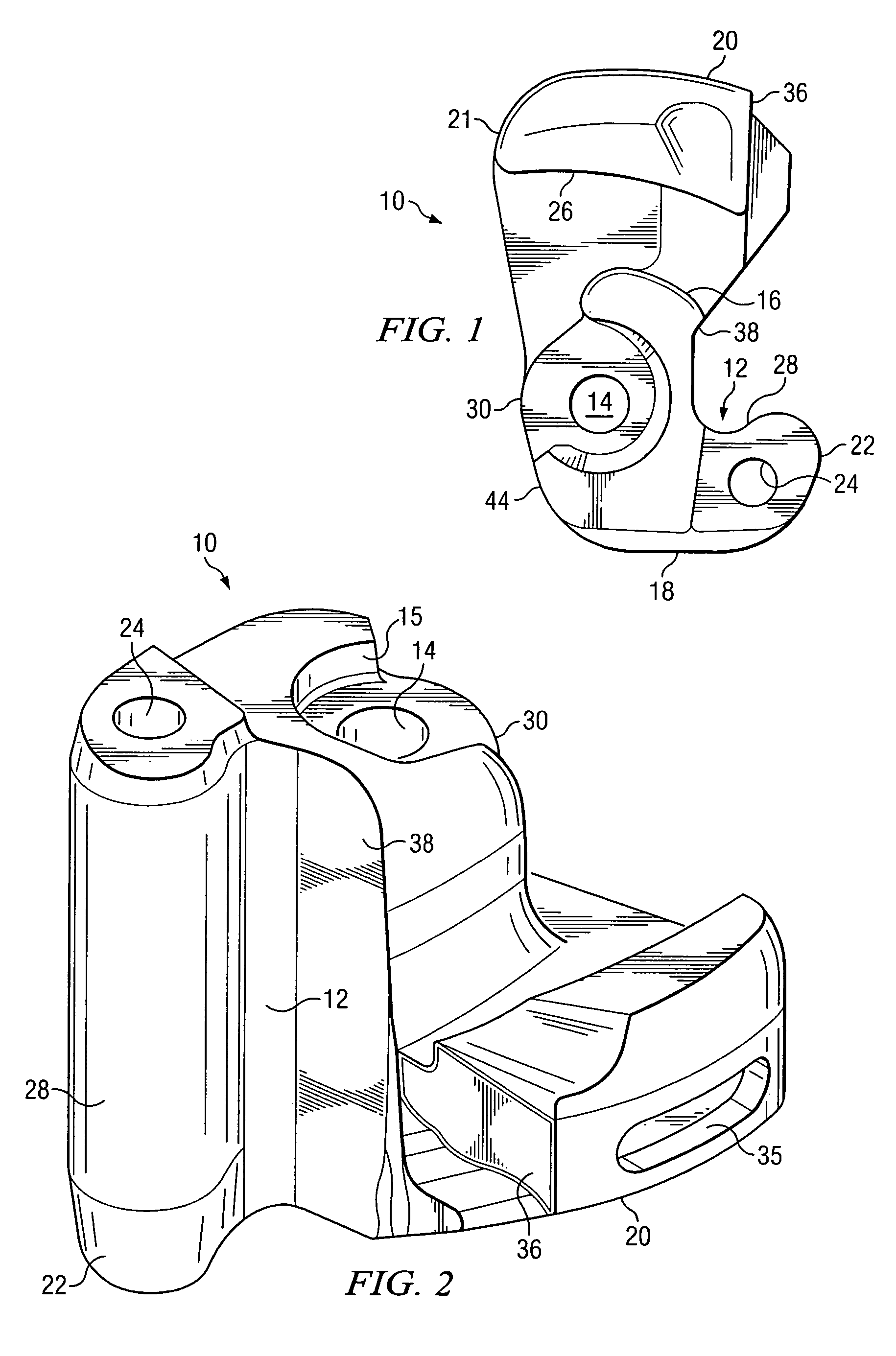

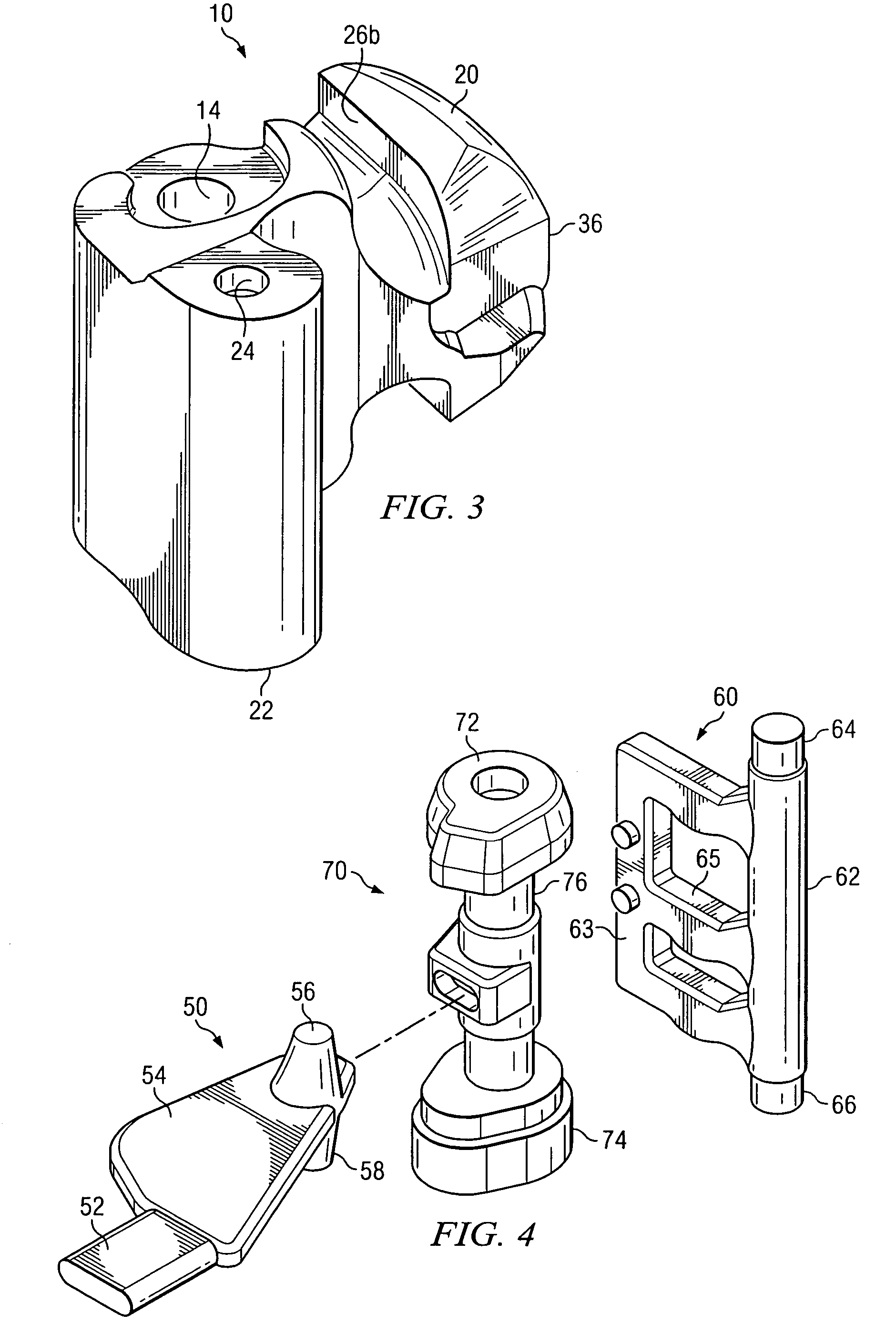

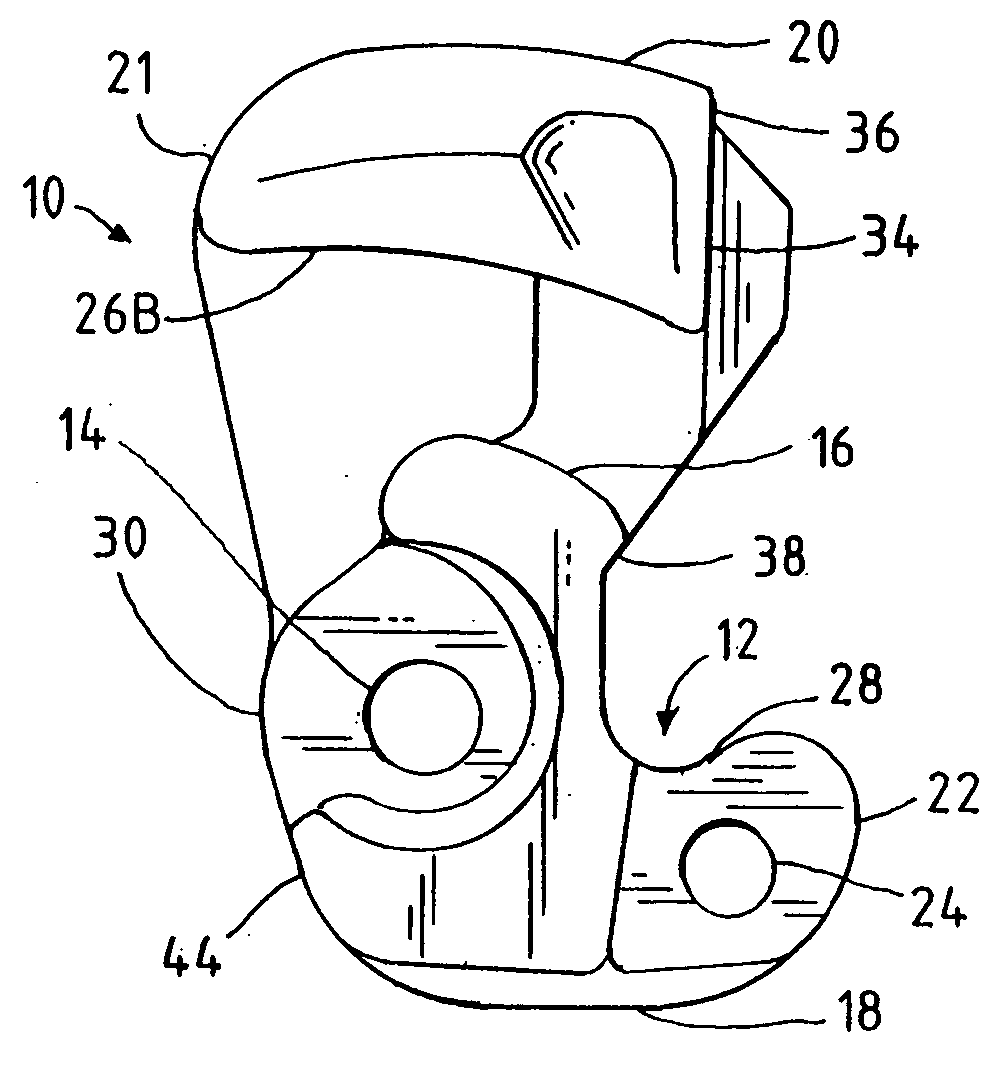

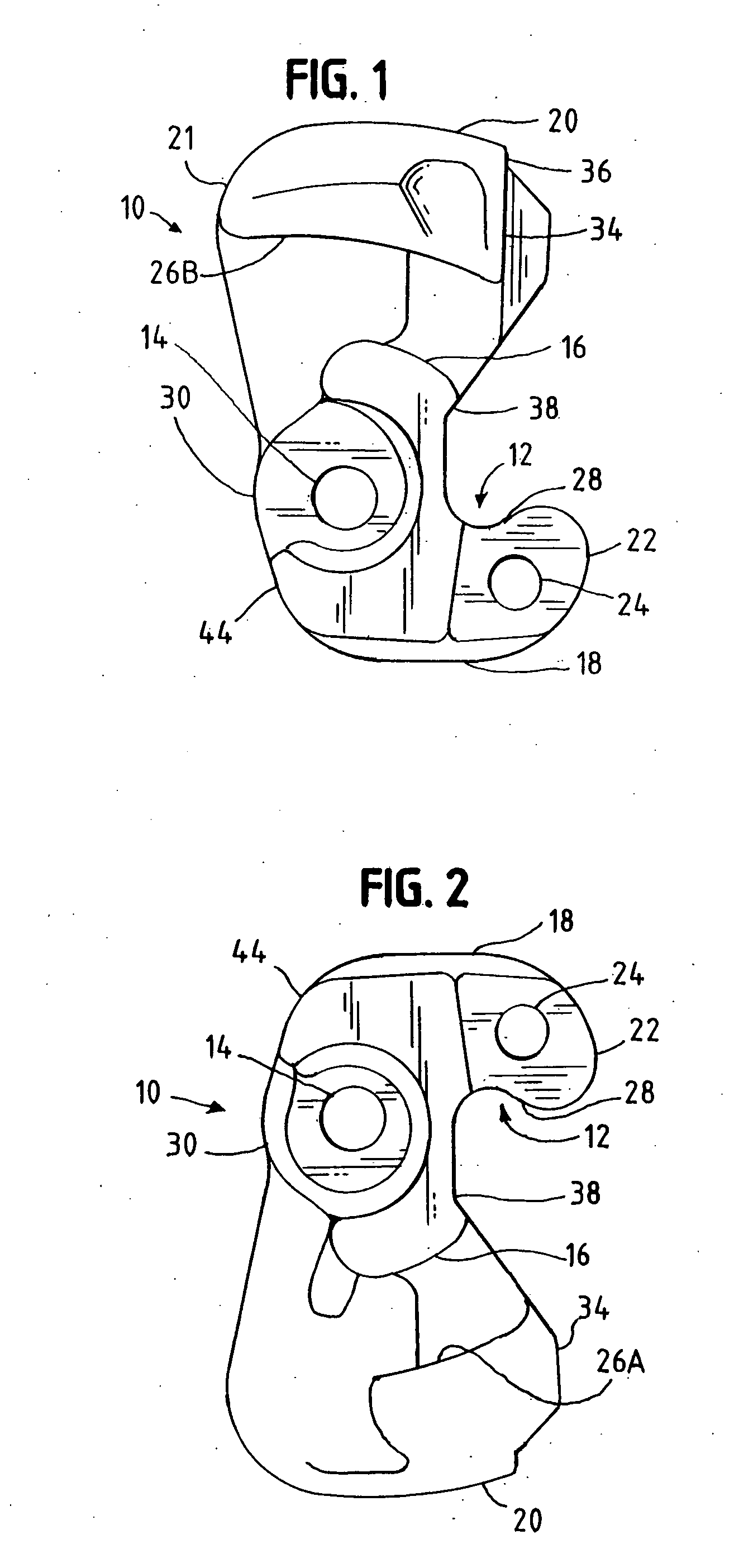

Railway car coupler knuckle having improved bearing surface

InactiveUS7337826B2Enhanced bearing surface areaIncrease surface areaFoundry mouldsFoundry coresEngineeringBearing surface

Owner:MCCONWAY & TORLEY LLC

Method and system for manufacturing a coupler knuckle

A method for manufacturing a railcar coupler knuckle includes providing a cope mold portion and a drag mold portion. The cope and drag mold portions have internal walls defining at least in part perimeter boundaries of a coupler knuckle mold cavity. The method includes positioning one or two internal cores within either the cope mold portion or the drag mold portion. The one or two internal cores are configured to define a kidney cavity, a finger cavity and a pivot pin cavity of a coupler knuckle. The method includes closing the cope and drag mold portions with the one or two internal cores therebetween and at least partially filling the mold cavity with a molten alloy, the molten alloy solidifying after filling to form the coupler knuckle.

Owner:MCCONWAY & TORLEY LLC

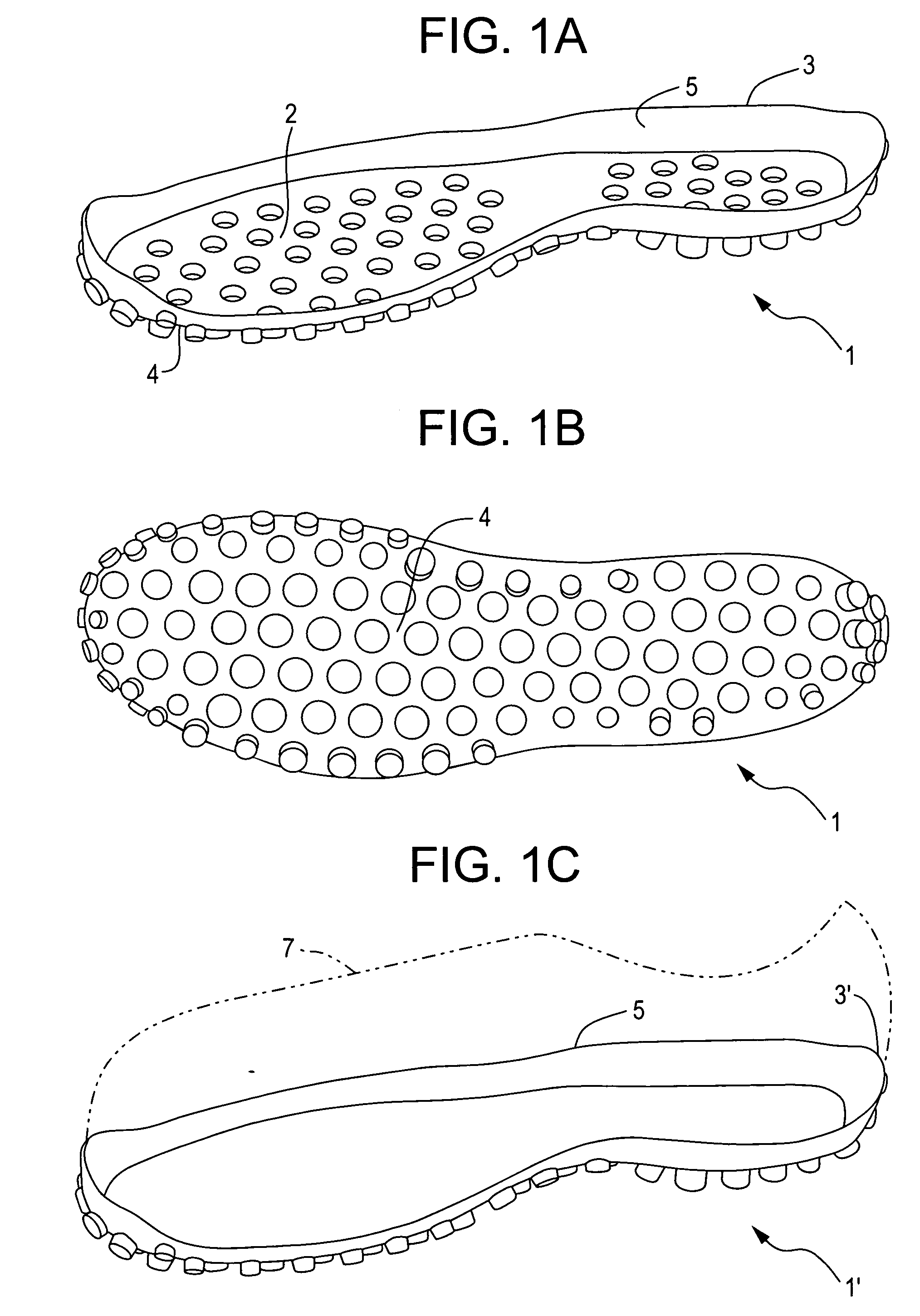

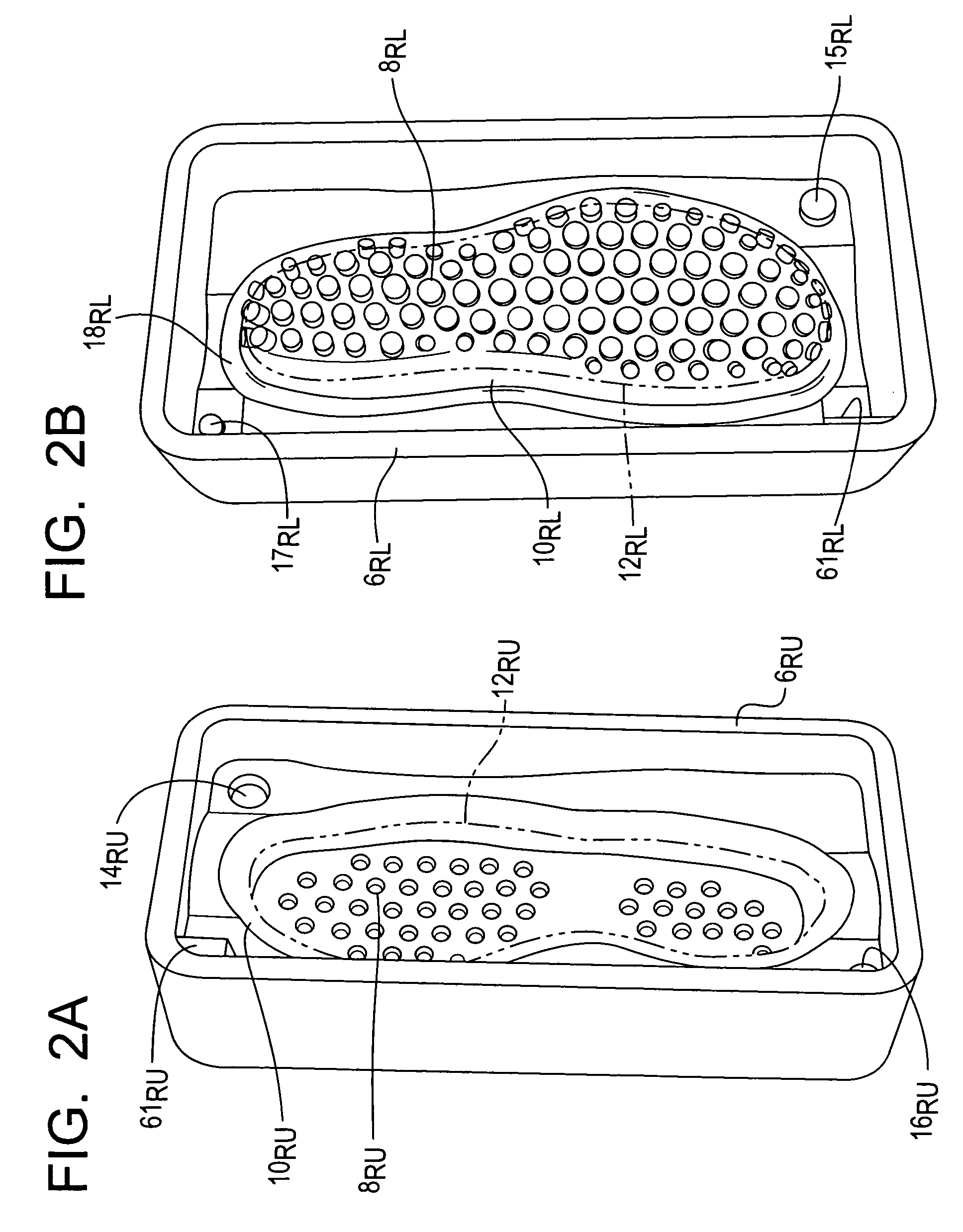

Method of making a multi-element mold assembly for, e.g., footwear components

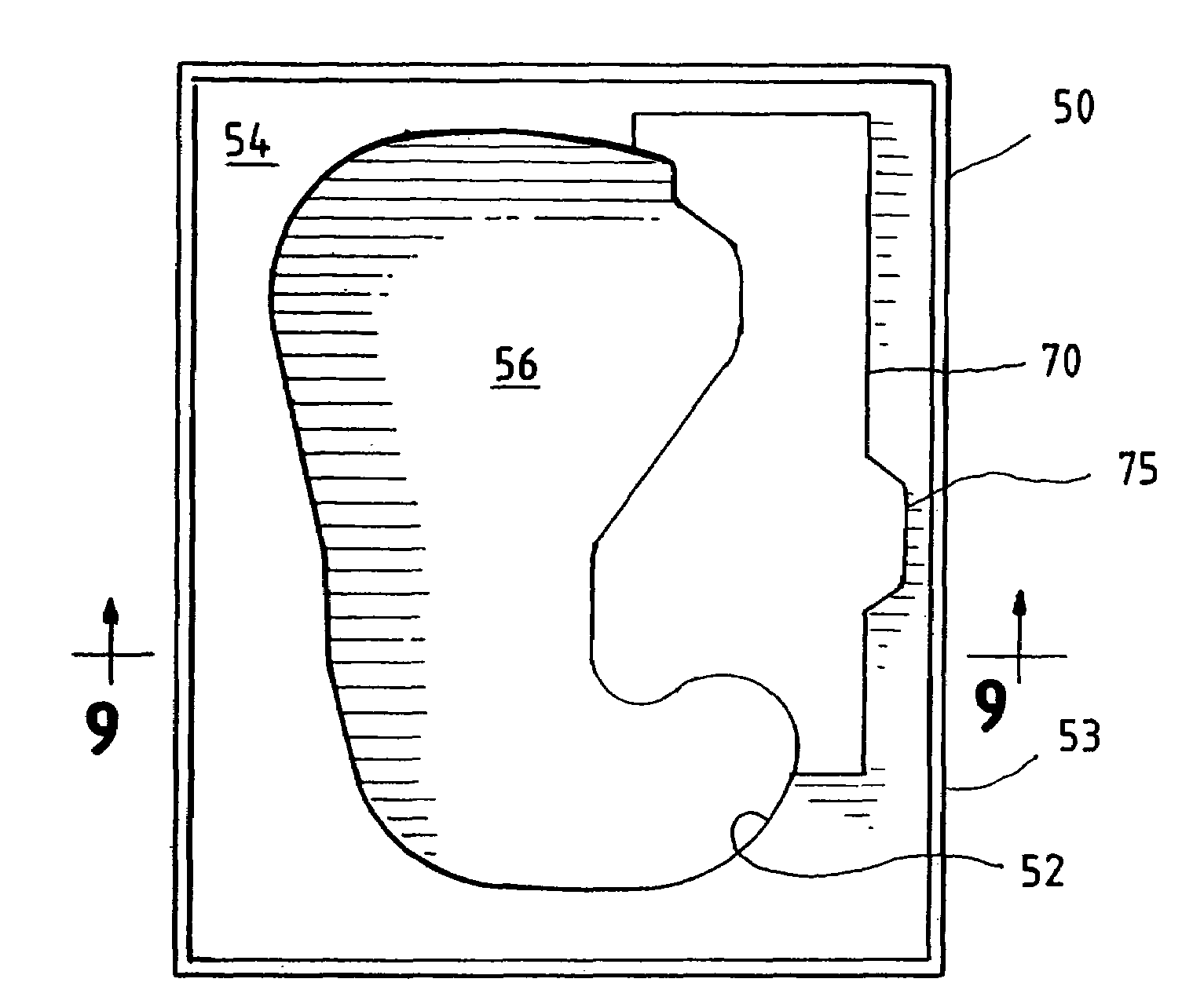

A mold assembly for footwear components is cast as a collection of mold elements having integral attachment members. Attachment members of separate mold elements may then be joined by, e.g., welding. Handles may also be formed into one or more mold elements as part of the casting process. Outsole negatives are juxtaposed with templates for attachment tabs and / or handles and used to form ceramic casting molds. The ceramic casting molds can then be used to cast individual mold elements.

Owner:NIKE INC

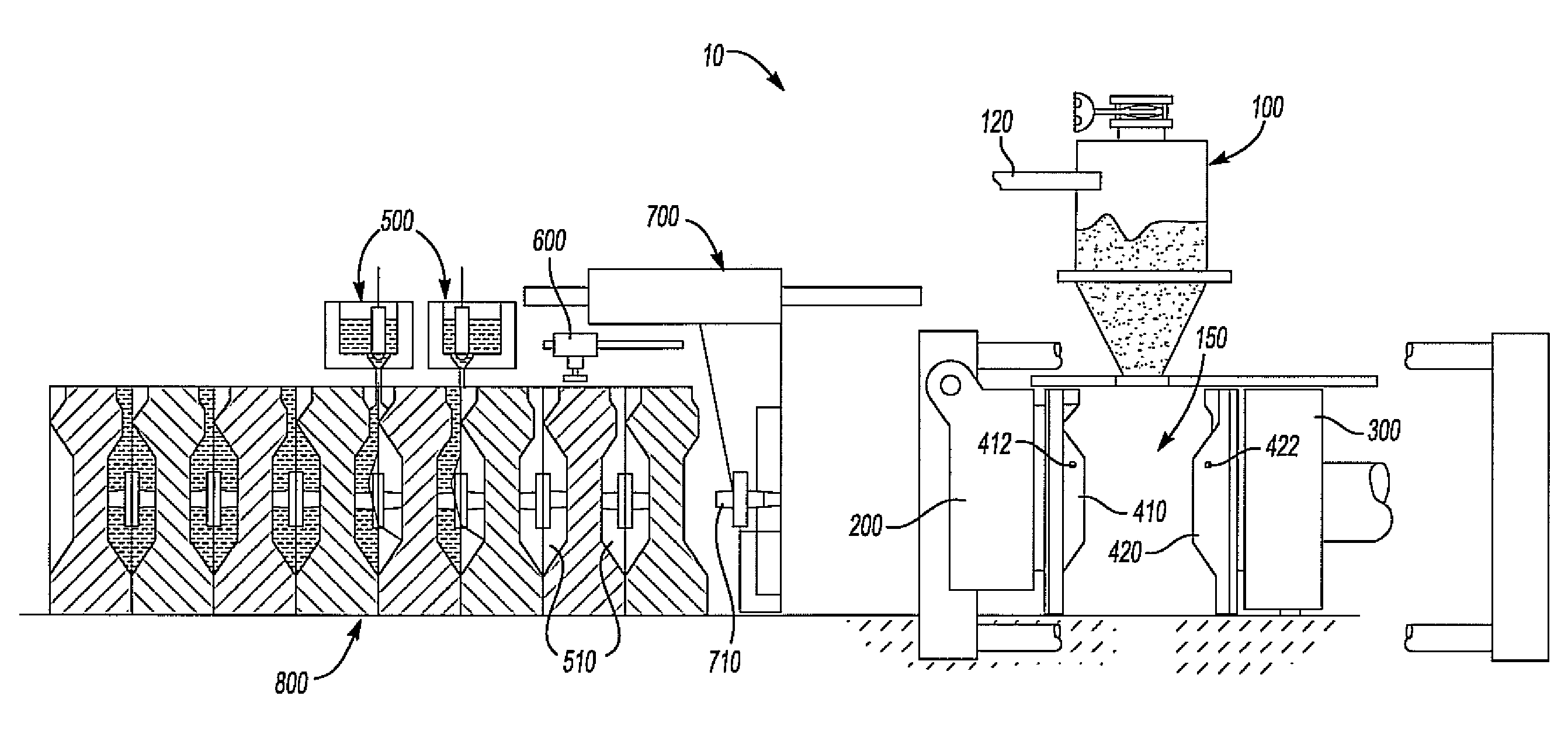

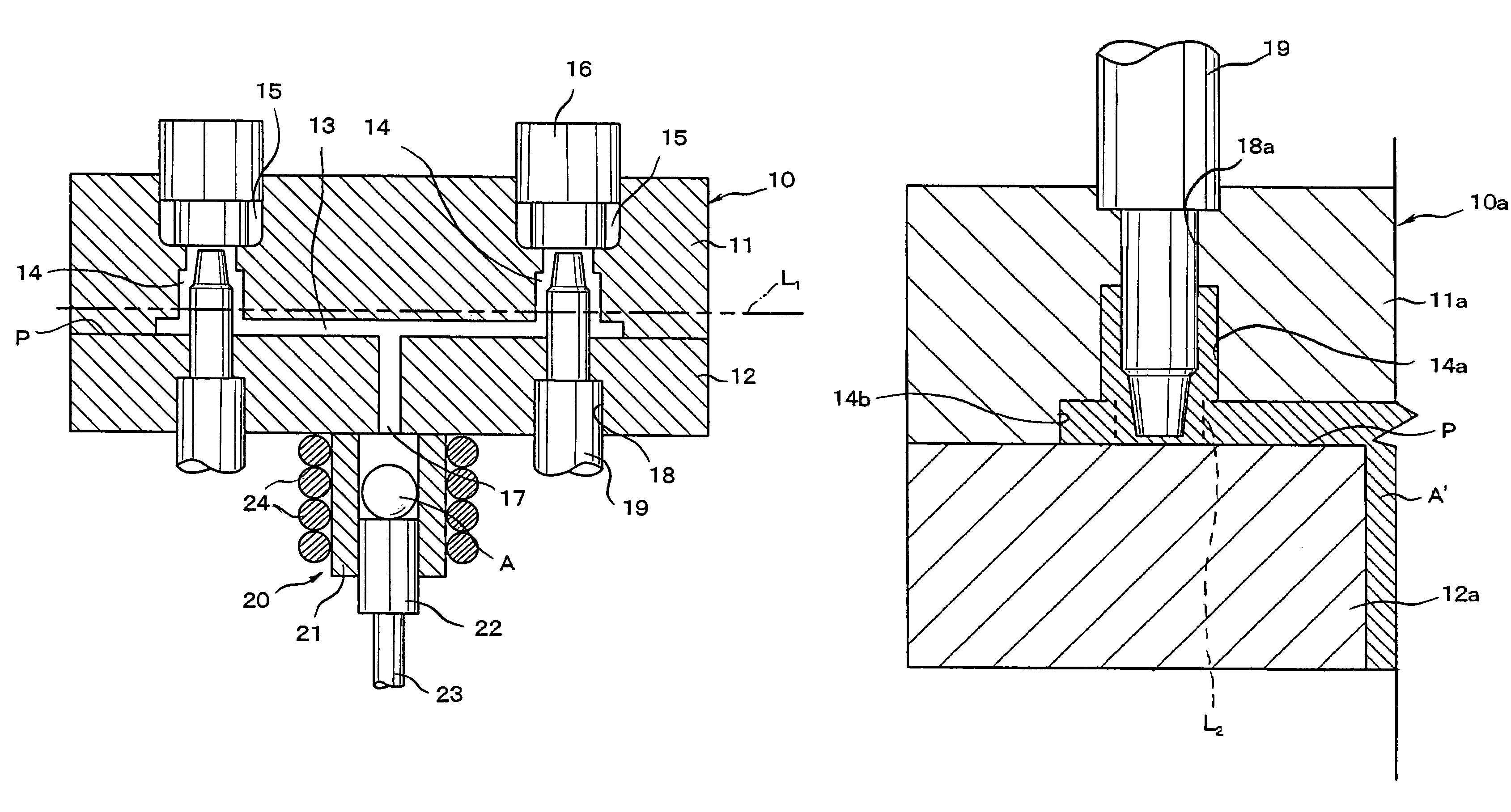

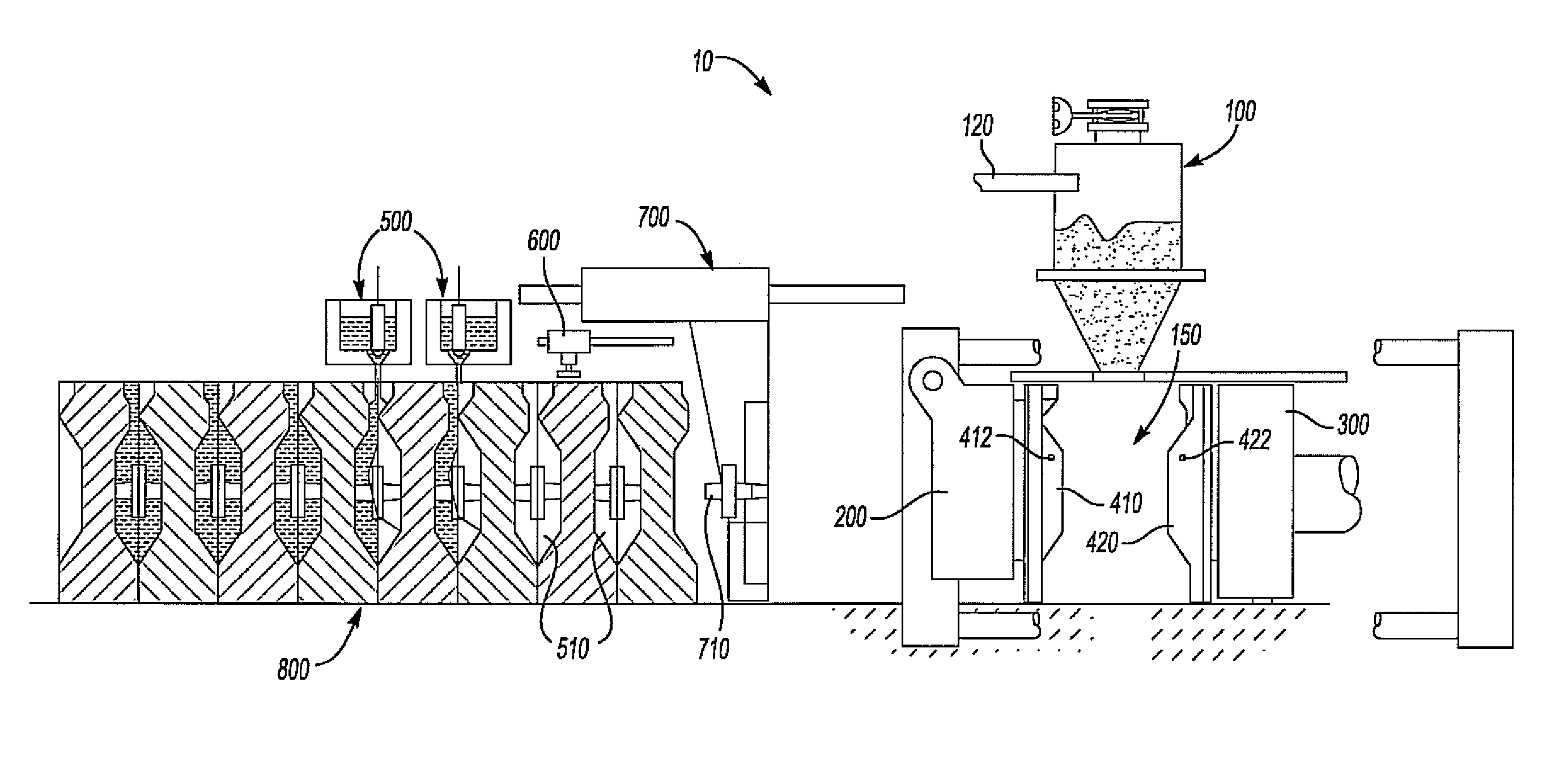

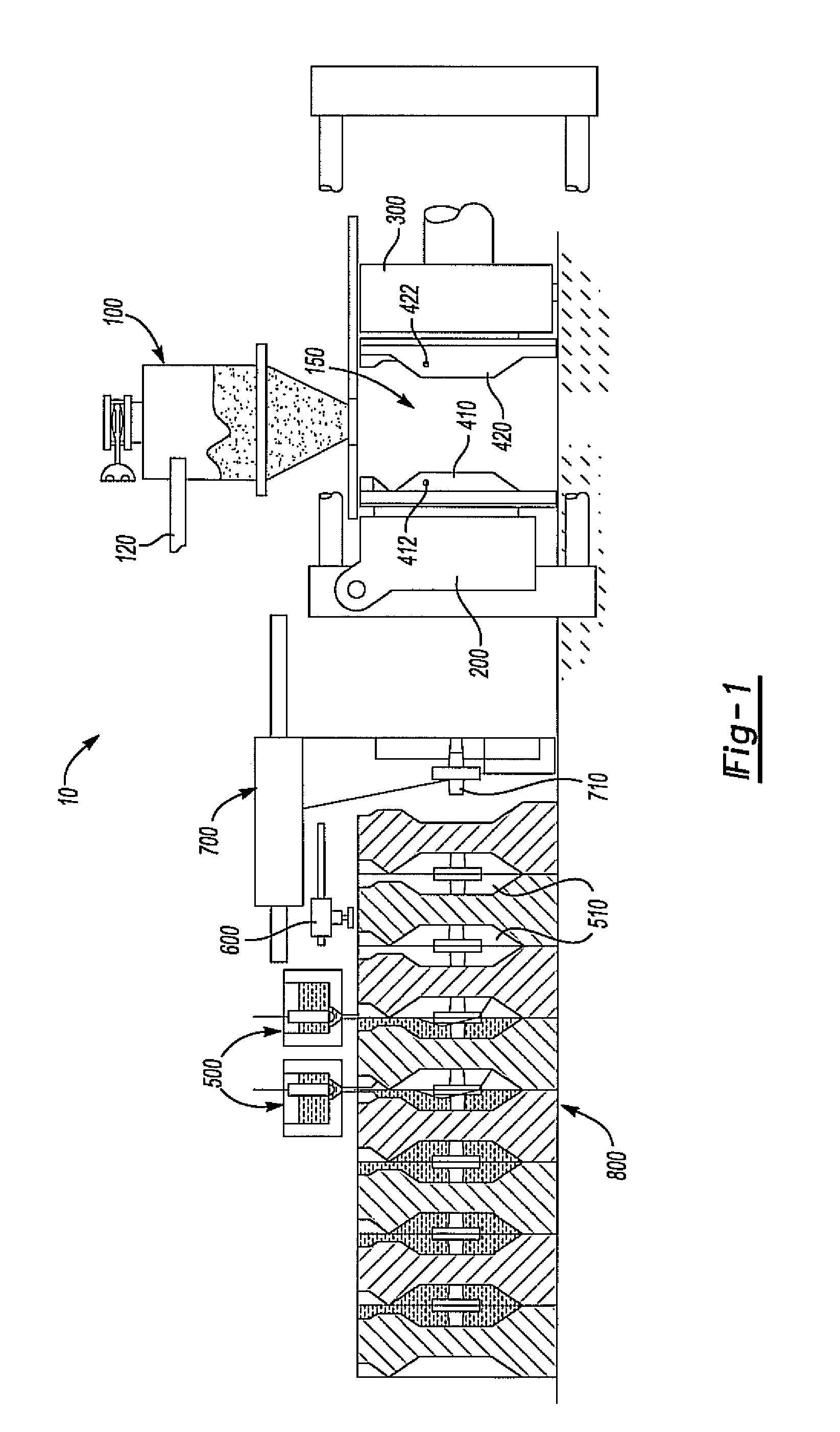

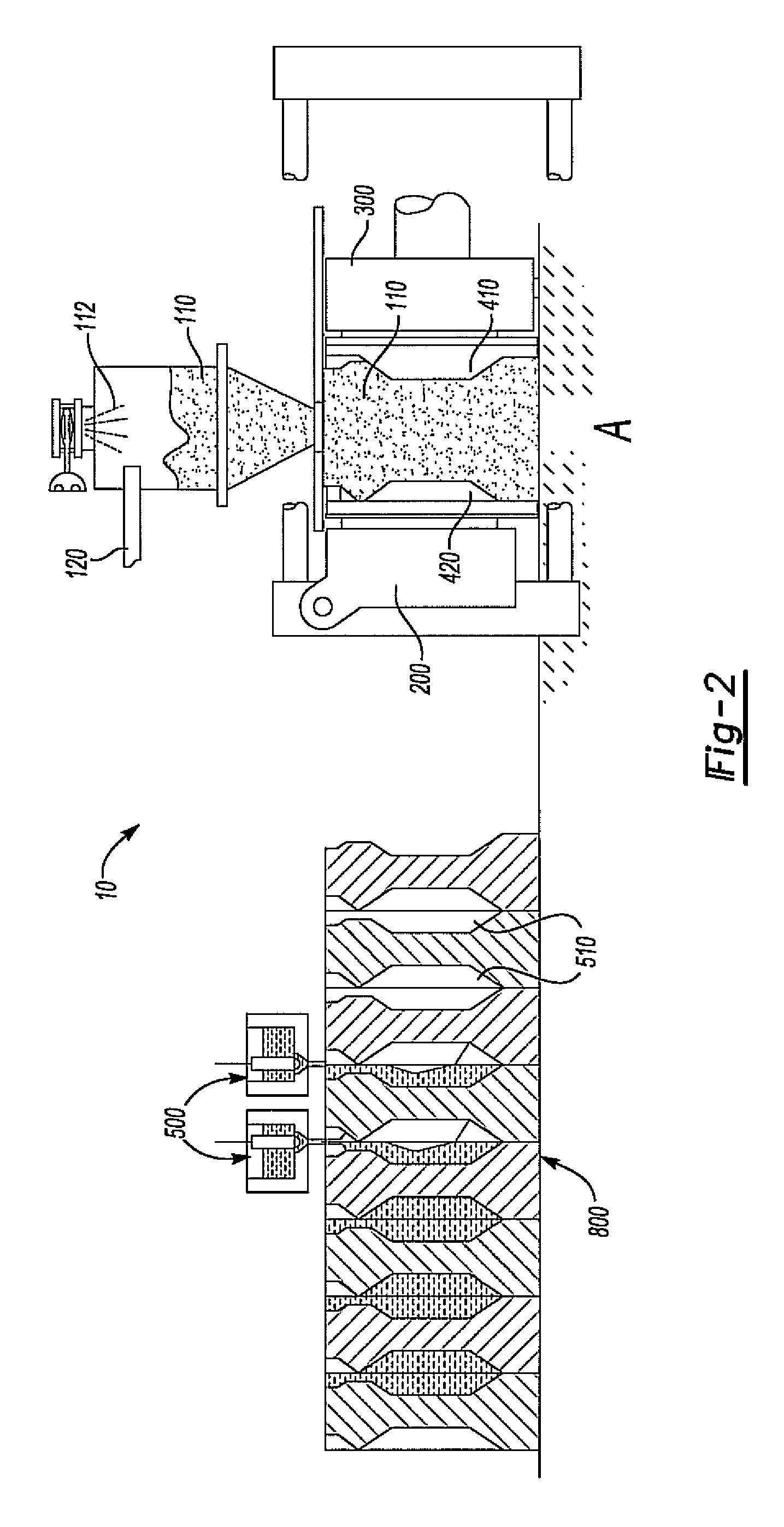

Molding and casting machine

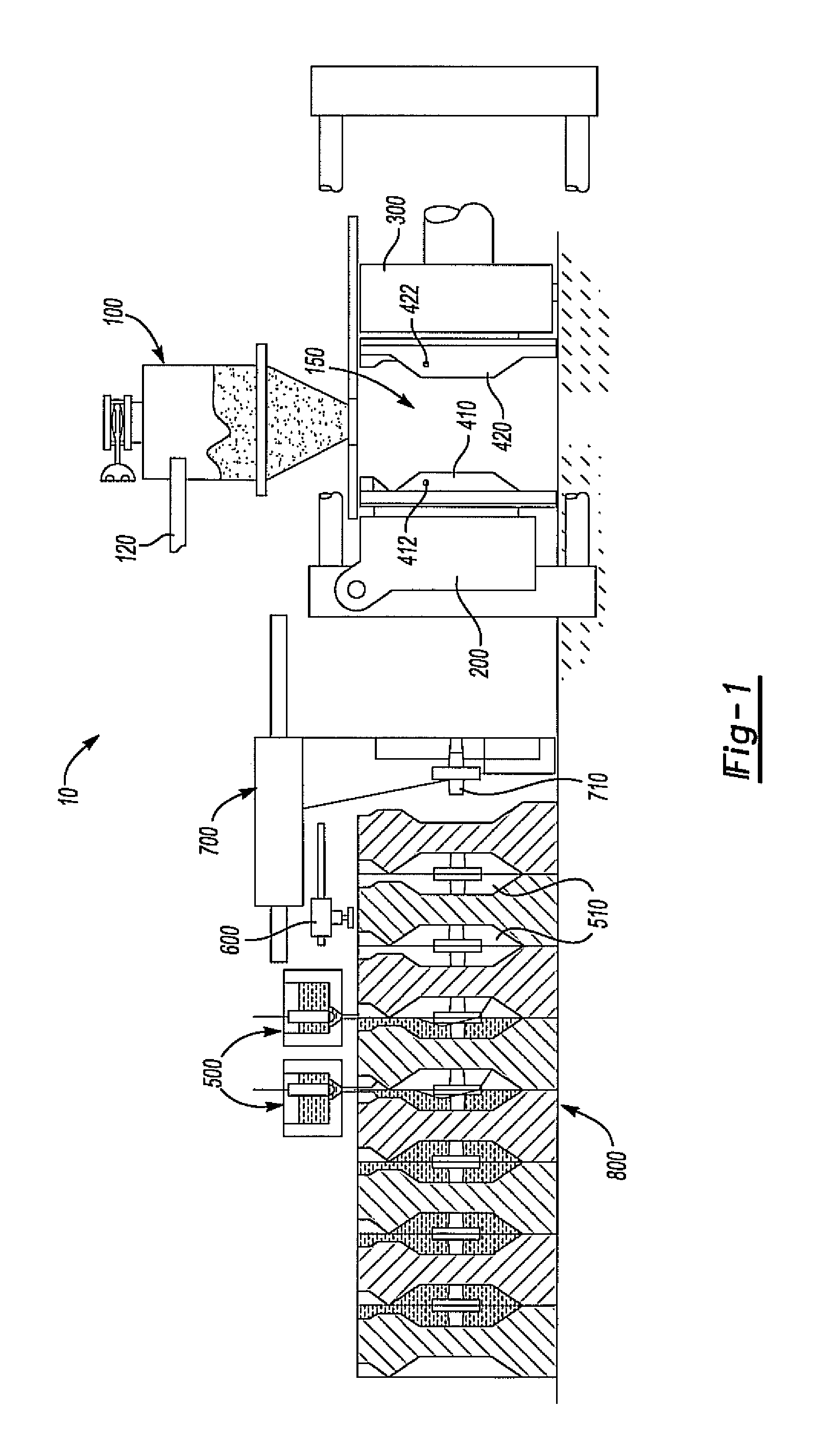

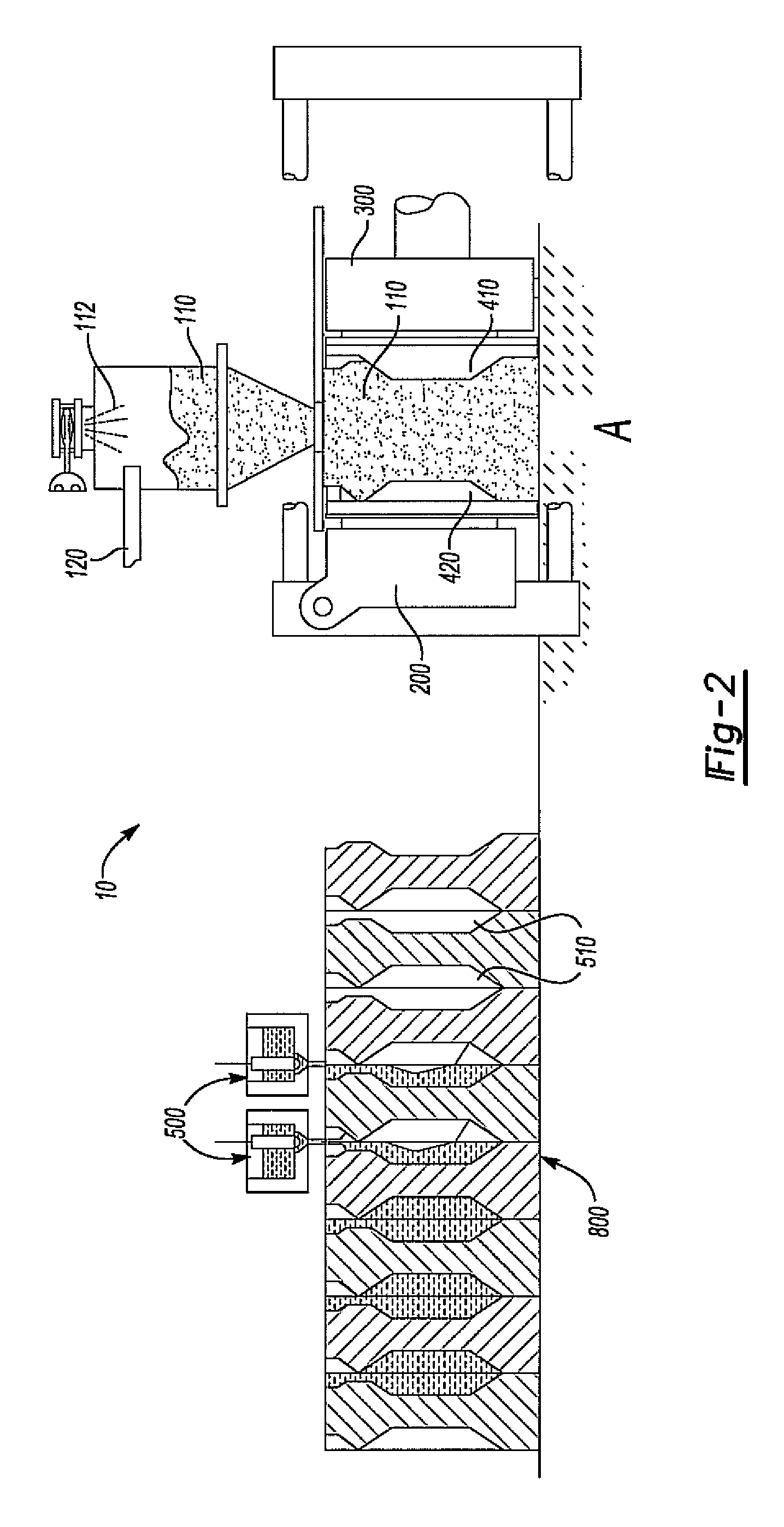

ActiveUS20080135205A1Improved swing movementEasy to adjustPig casting plantsCasting safety devicesMolding machineSand casting

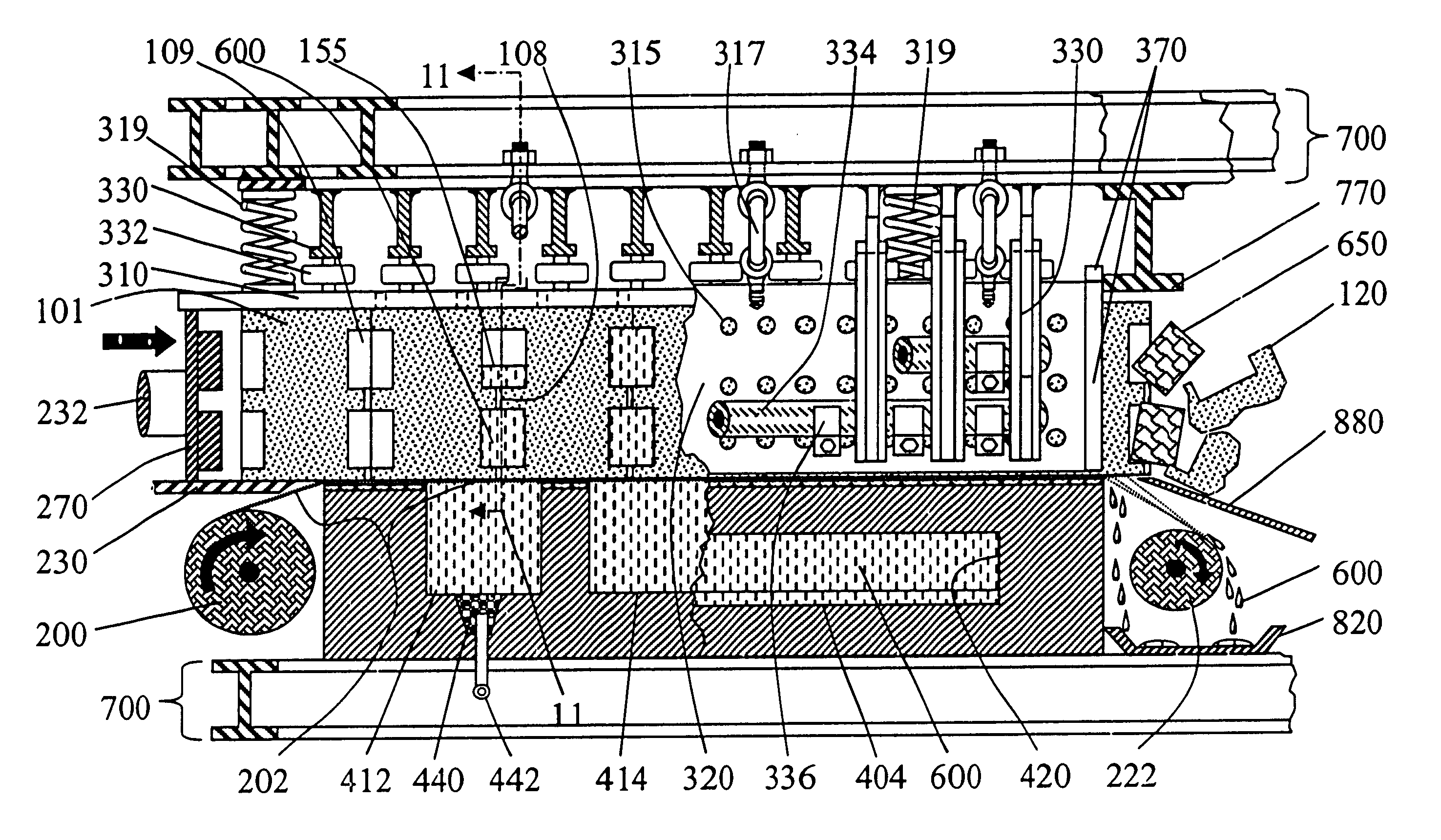

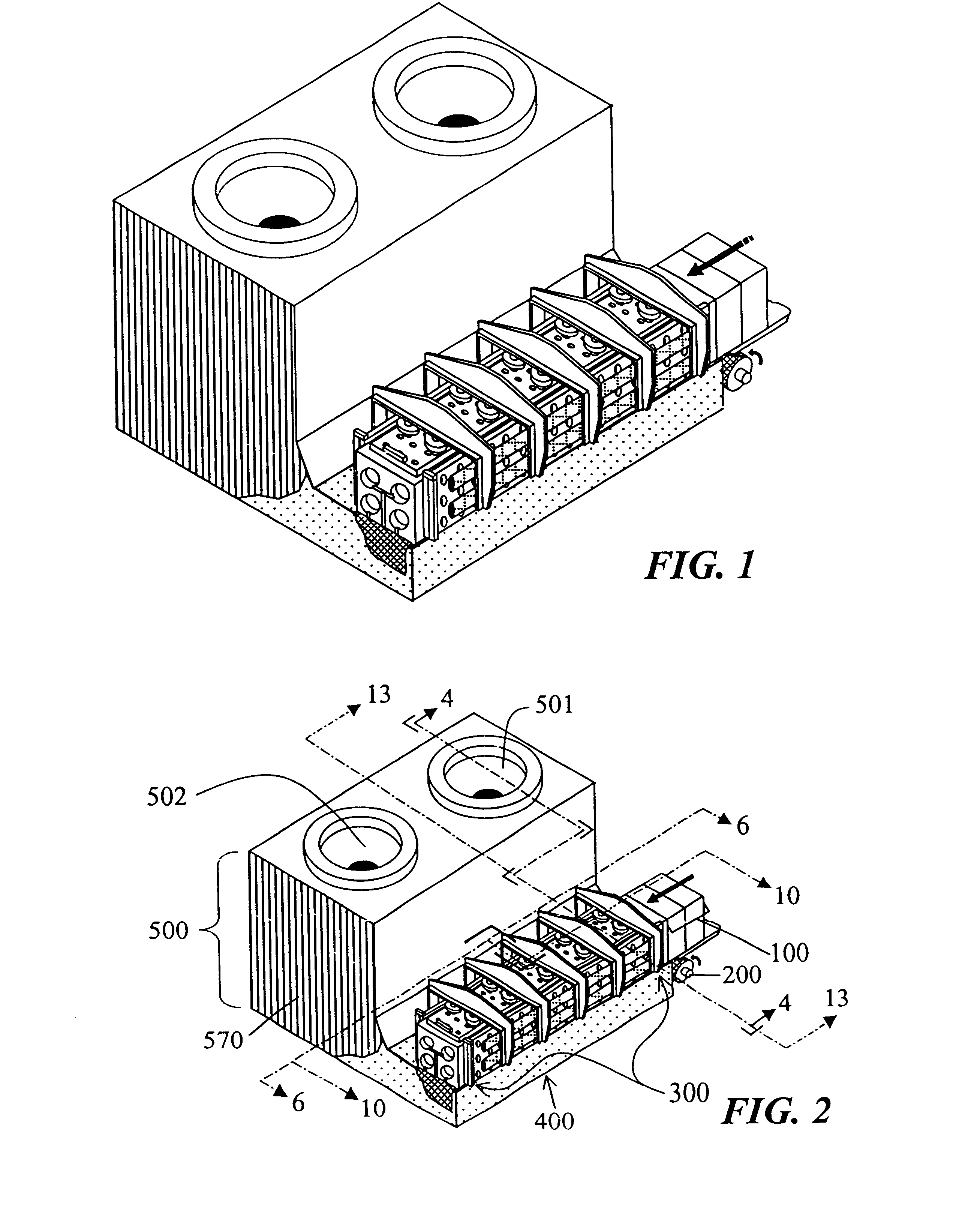

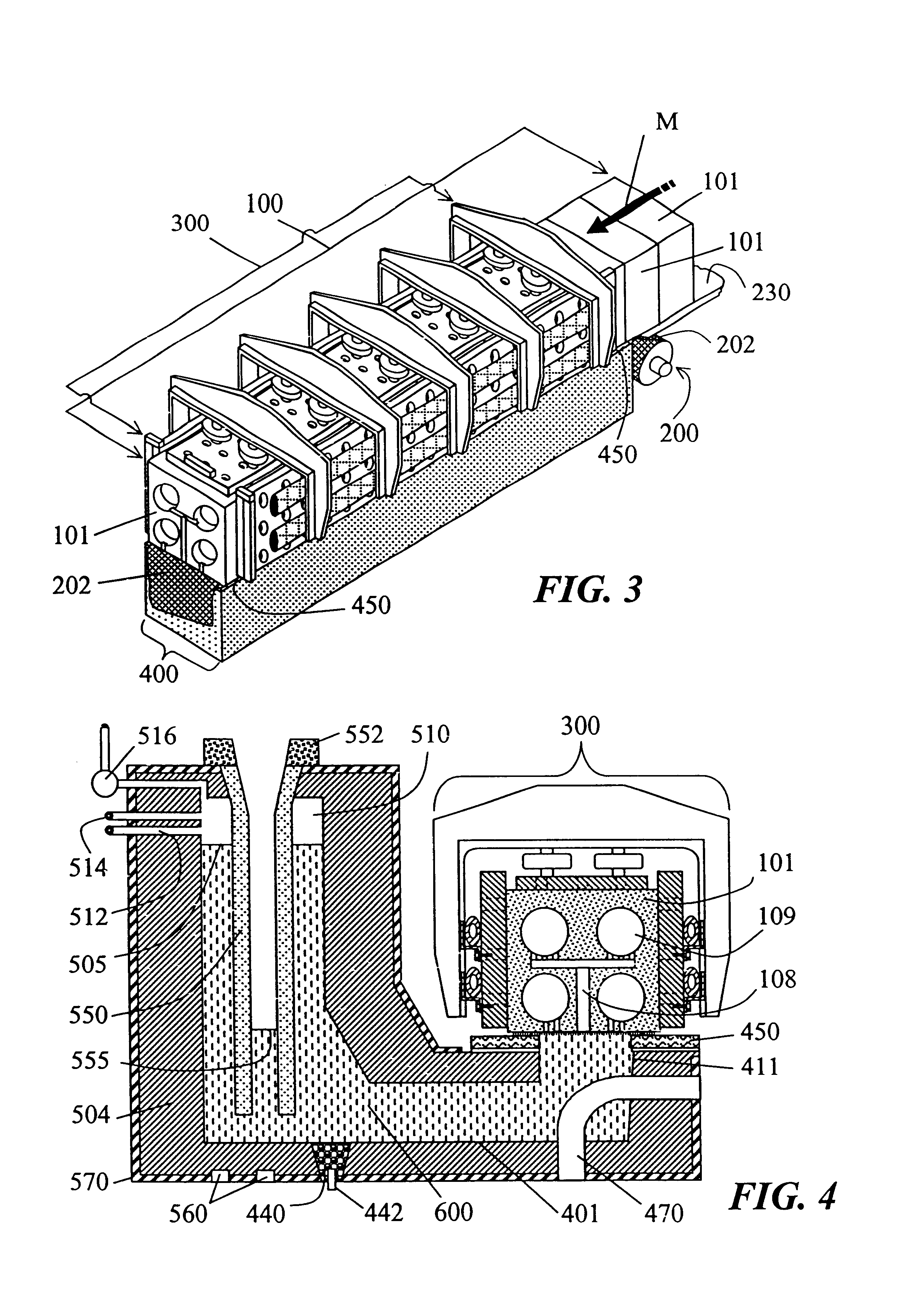

Disclosed is a sand casting molding machine for double indexing molds in a mold string. The machine can include a shot chamber having sand, a swingable squeeze head, a lateral squeeze head, a core setter, a mold hold down, a mold retention device and a mold string conveyor.

Owner:THYSSENKRUPP WAUPACA

Method and apparatus for forming a part with dampener

InactiveUS6945309B2Dampening structureEffectively and efficiently constructedNoise/vibration controlBraking discsMaterials scienceShock absorber

Owner:FRENI BREMBO SPA

Method for manufacture of a physical quantity detector

InactiveUS7708051B2High dimensional accuracyImprove surface smoothnessFluid pressure measurement by electric/magnetic elementsMetallic material coating processesMetal moldPressure sensor

Owner:NAGANO KEIKI

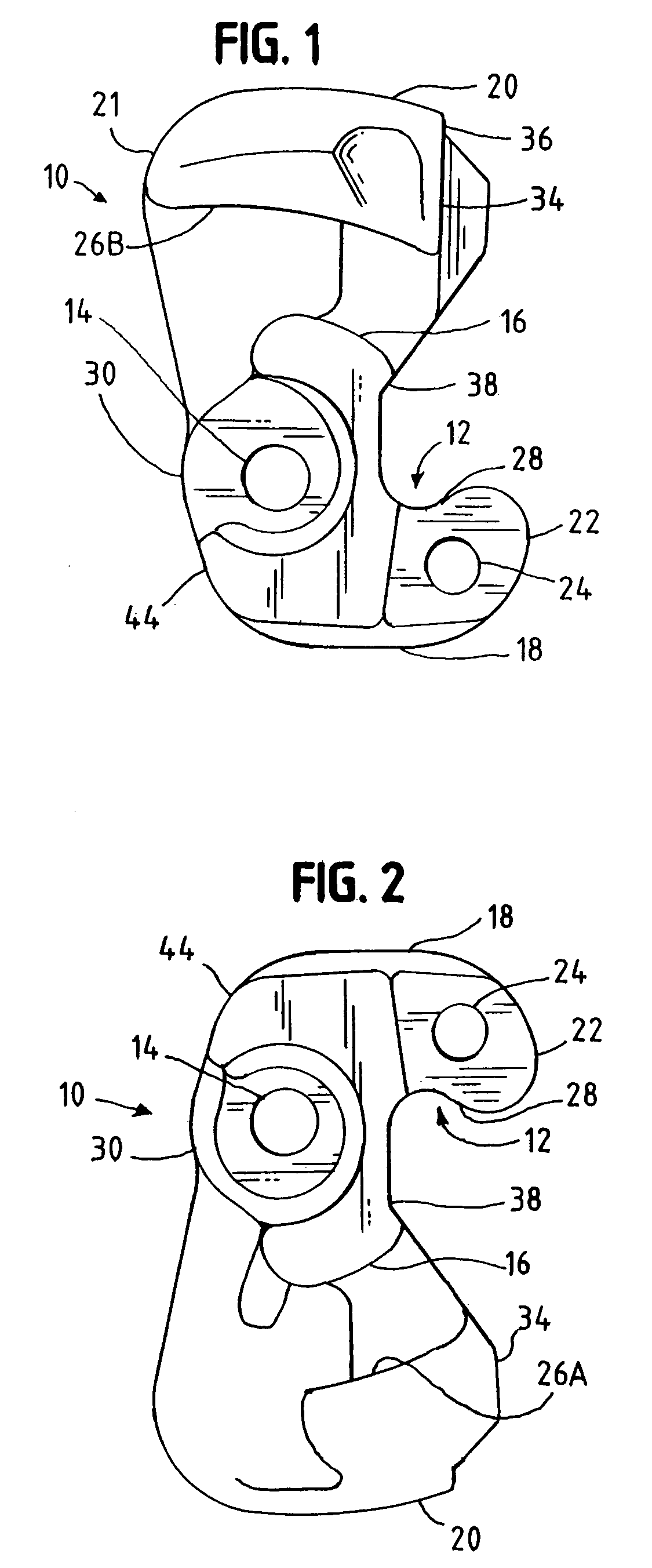

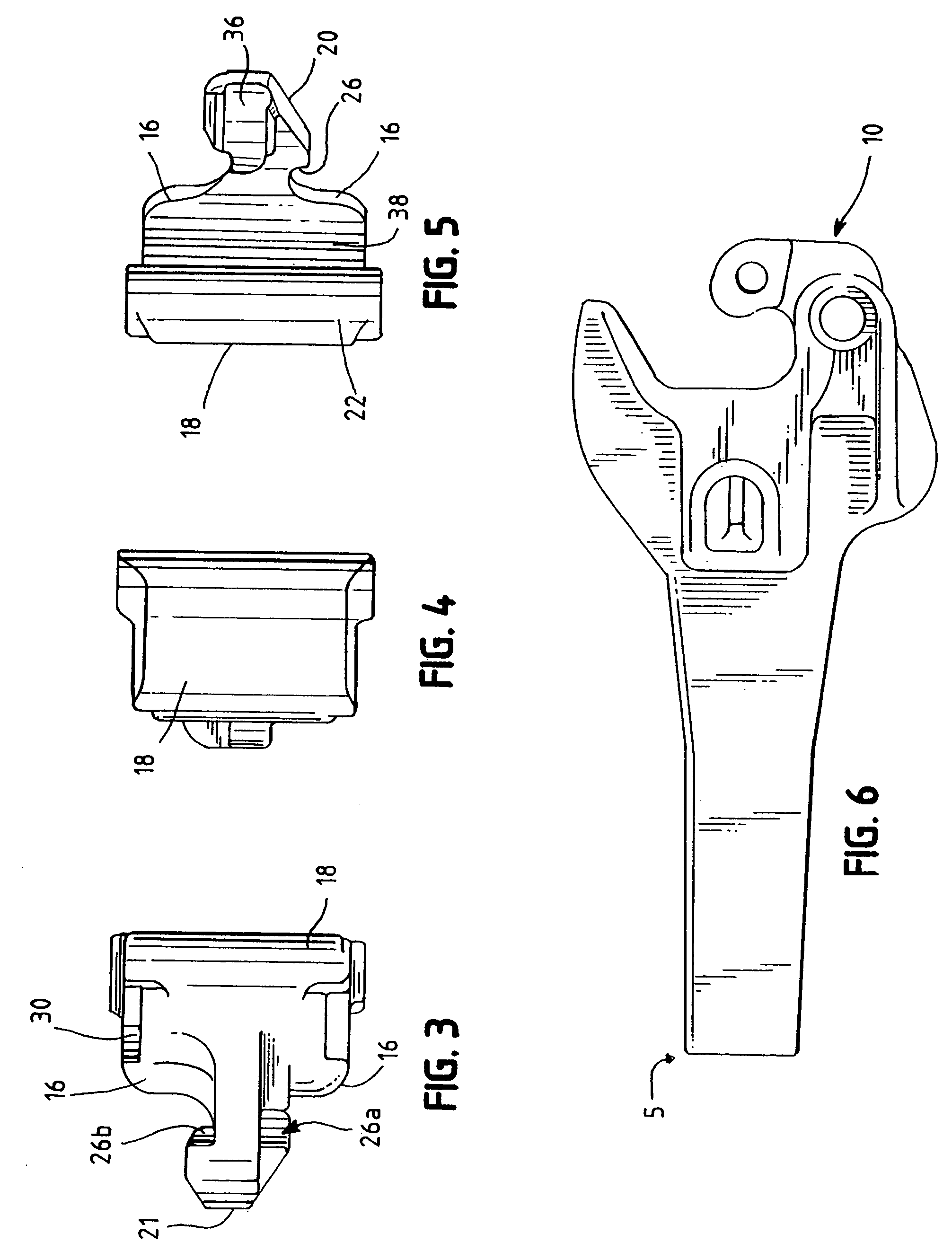

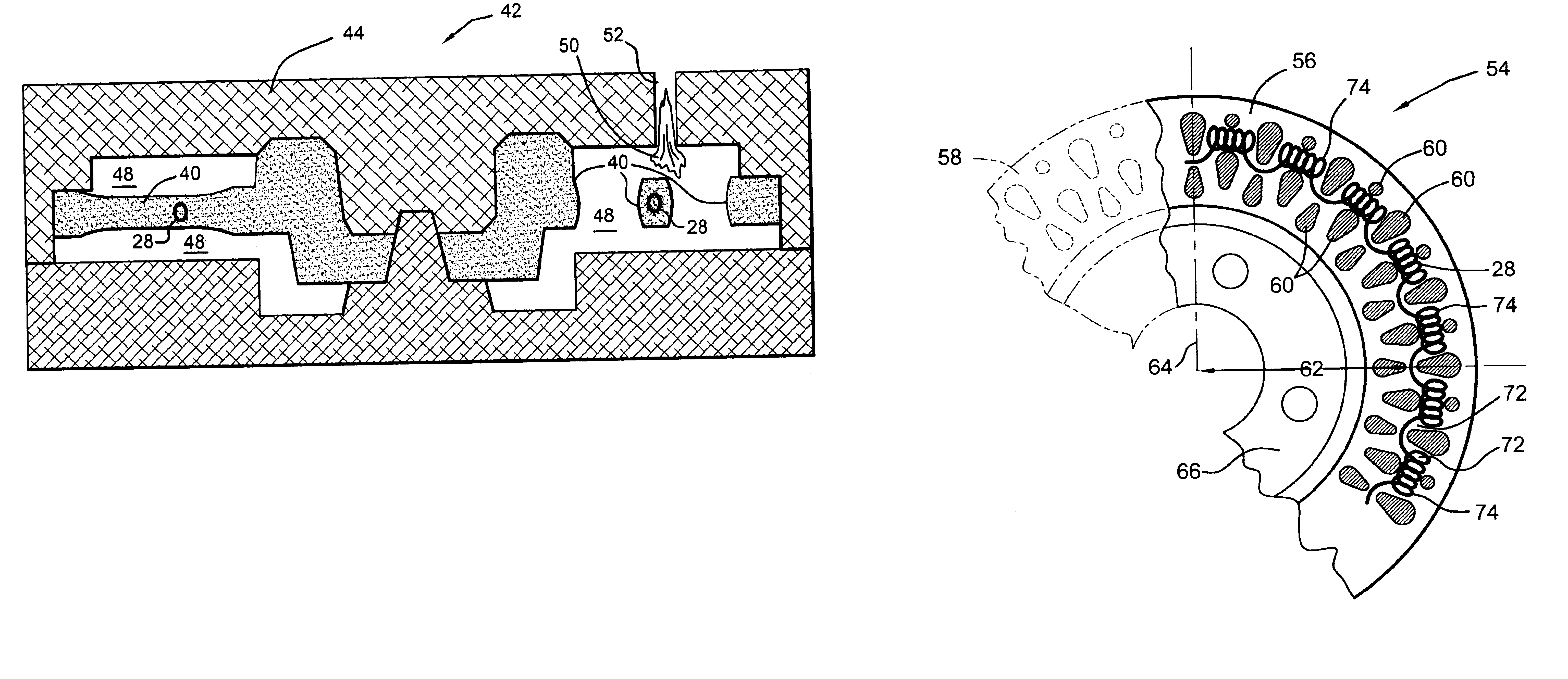

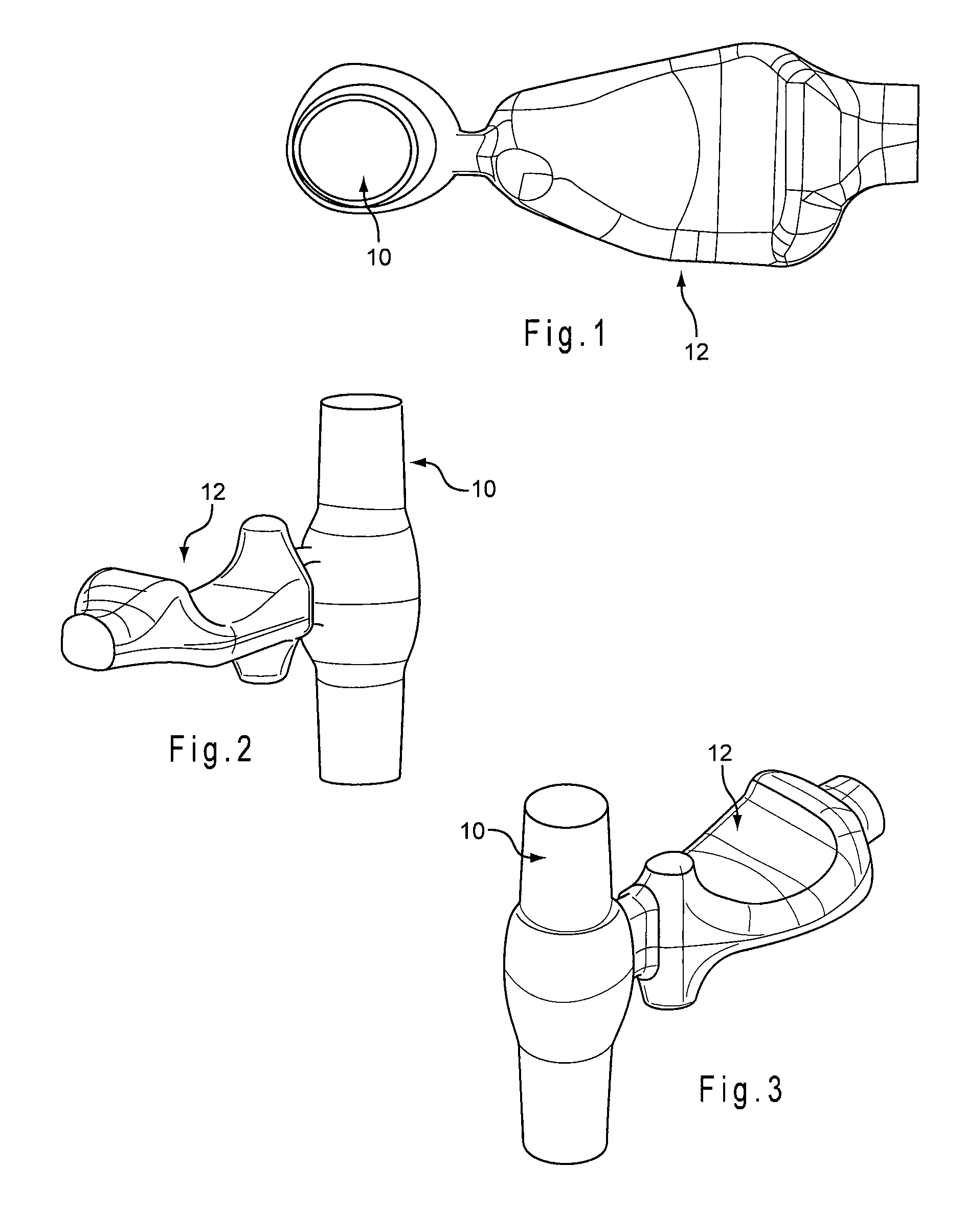

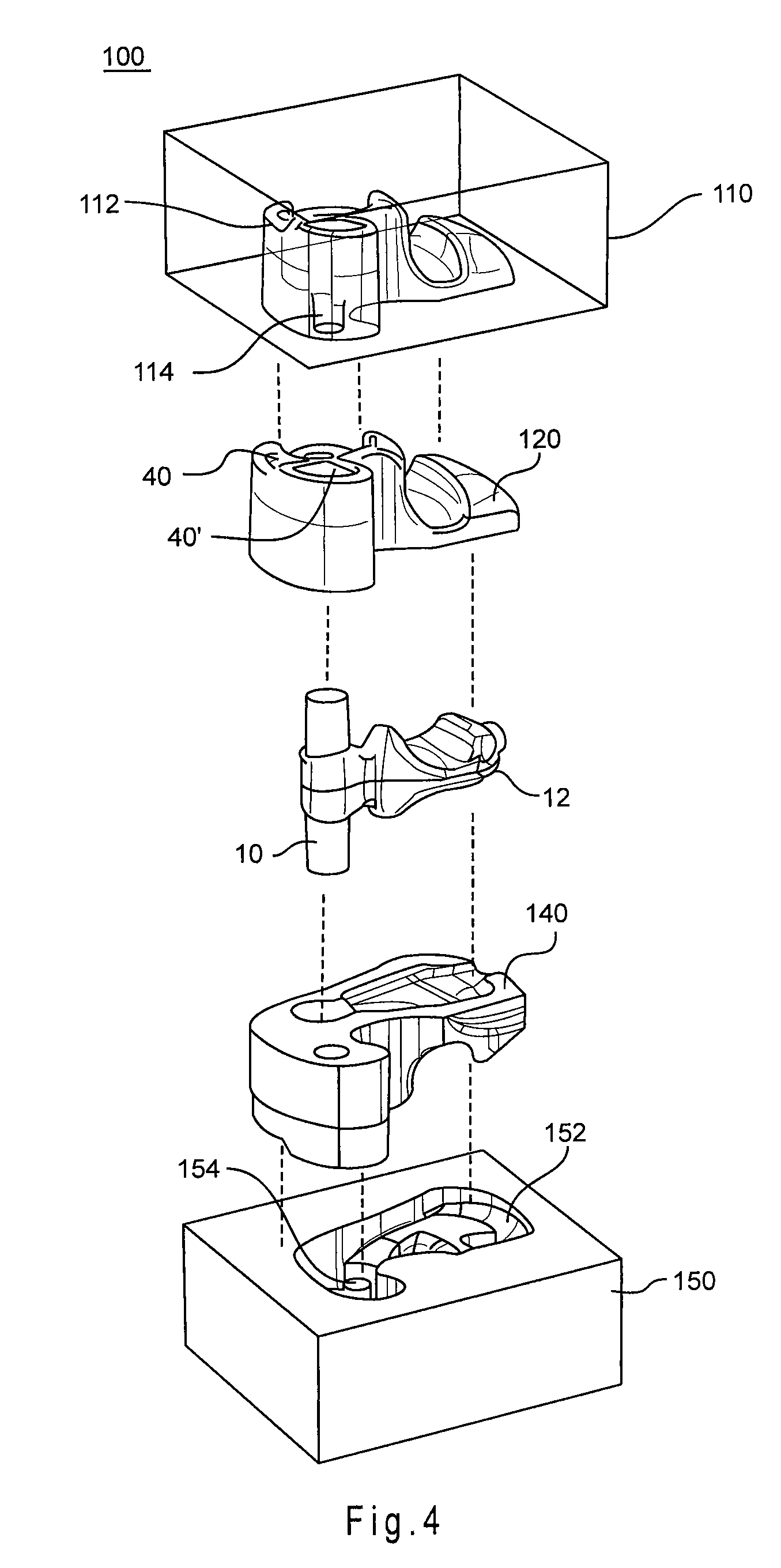

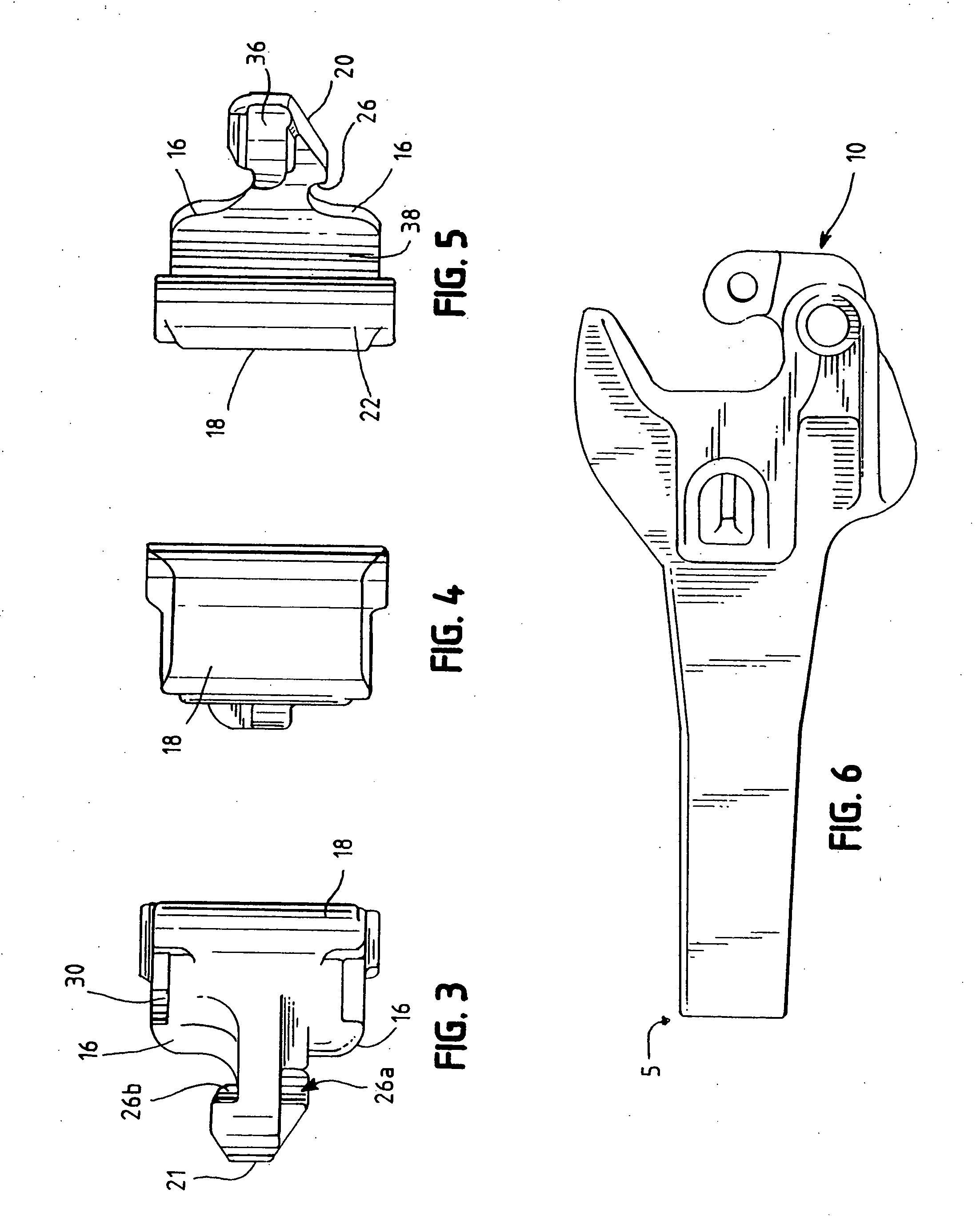

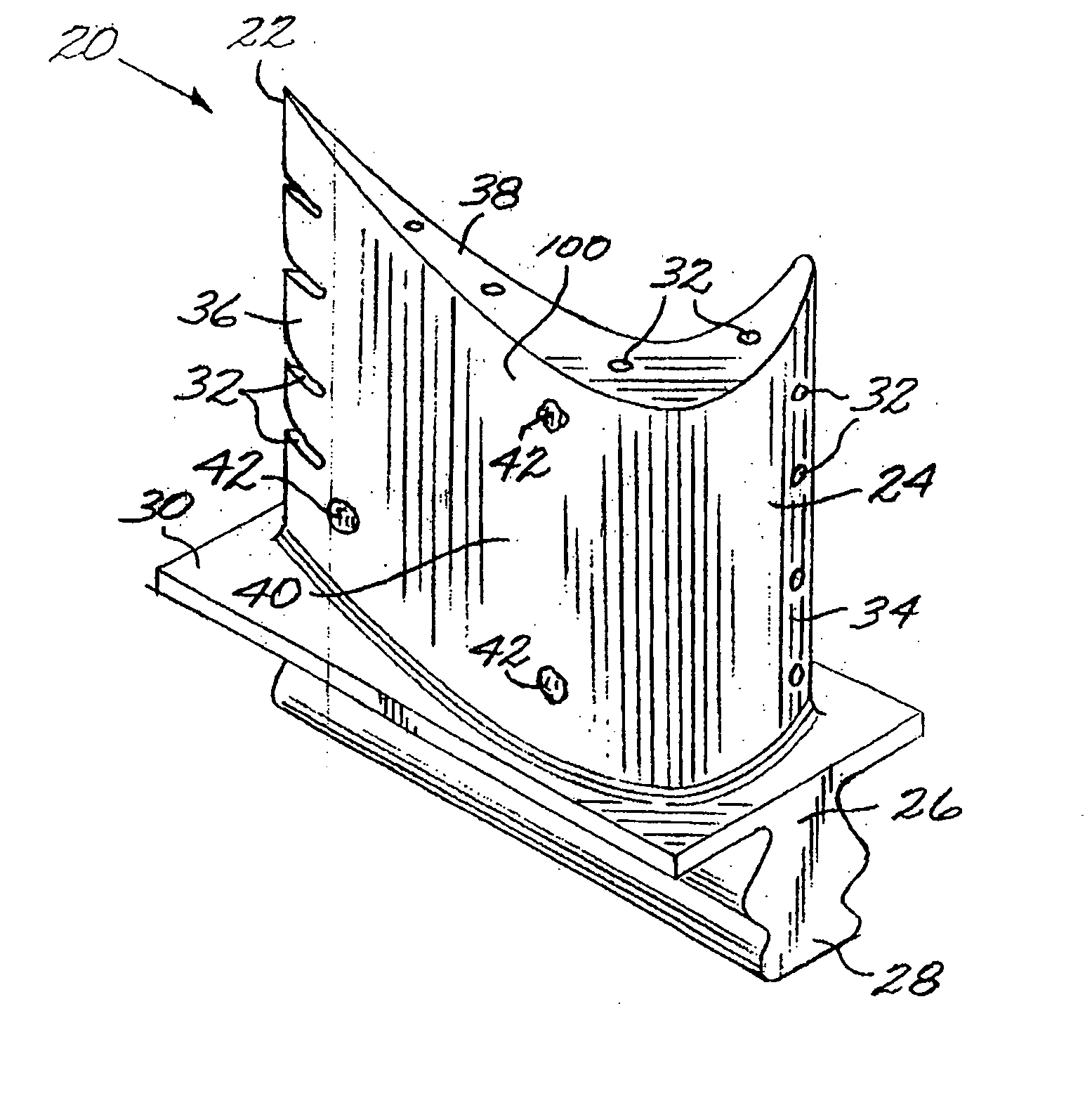

Knuckle formed from pivot pin and kidney core and isolated finger core

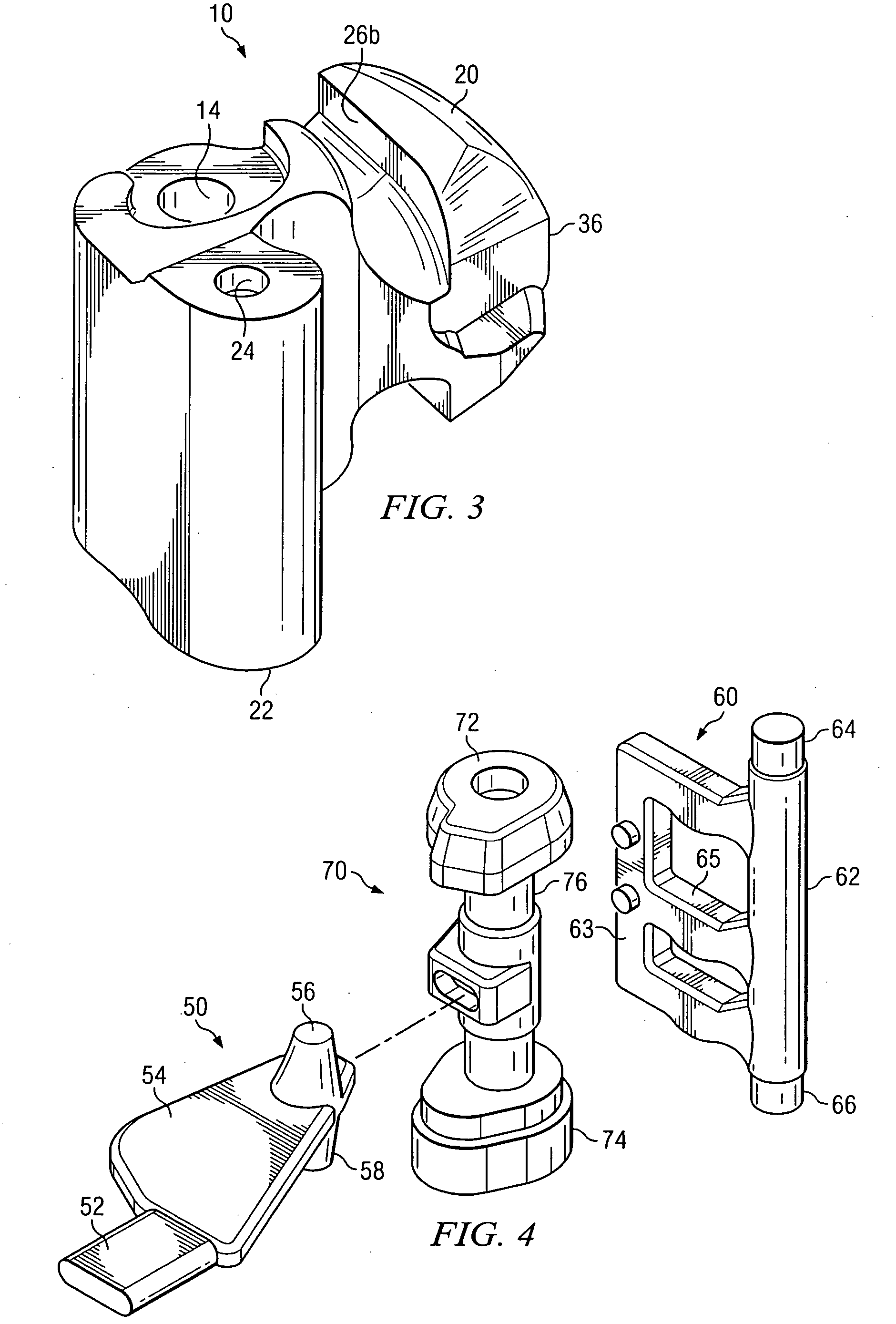

A method for manufacturing a railcar coupler knuckle includes providing cope and drag mold portions having internal walls defining at least in part perimeter boundaries of a knuckle mold cavity; positioning a first internal core within either the cope mold or the drag mold portions, the first internal core configured to define a kidney cavity and a pivot pin hub as a single void within the knuckle; positioning a second internal core within either the cope mold portion and the drag mold portion, the second internal core configured to define a finger cavity; closing the cope and drag mold portions with the two internal cores therebetween; and at least partially filling the mold cavity with a molten alloy, the molten alloy solidifying after filling to form the knuckle, wherein the first internal core defines the kidney cavity and the pivot pin hub of the coupler knuckle, and wherein the second internal core defines the finger cavity of the knuckle.

Owner:BEDLOE IND LLC

Knuckle formed without a finger core

A method for manufacturing a railcar coupler knuckle includes providing a cope mold portion and a drag mold portion, the cope and drag mold portions having internal walls defining at least in part perimeter boundaries of a coupler knuckle mold cavity, wherein the mold cavity includes a finger section; positioning at least one internal core within either the cope mold portion or the drag mold portion, the at least one internal core configured to define a kidney cavity and a pivot pin cavity within a coupler knuckle; closing the cope and drag mold portions with the single core therebetween; and at least partially filling the mold cavity with a molten alloy, the molten alloy solidifying after filling to form the coupler knuckle, wherein the at least one core defines the kidney and pivot pin cavities, and the finger section of the mold cavity defines at least one finger cavity of the coupler knuckle.

Owner:BEDLOE IND LLC

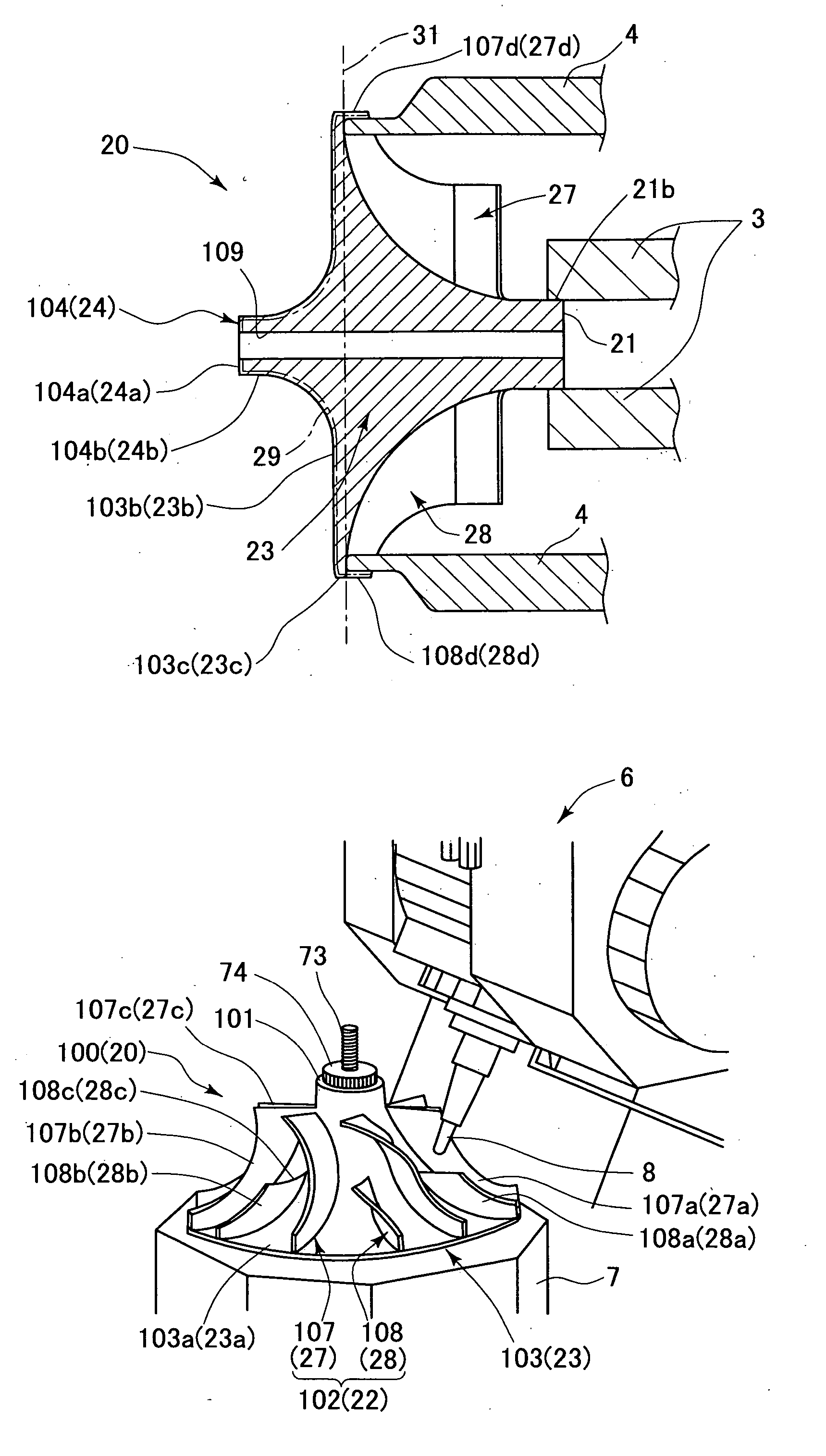

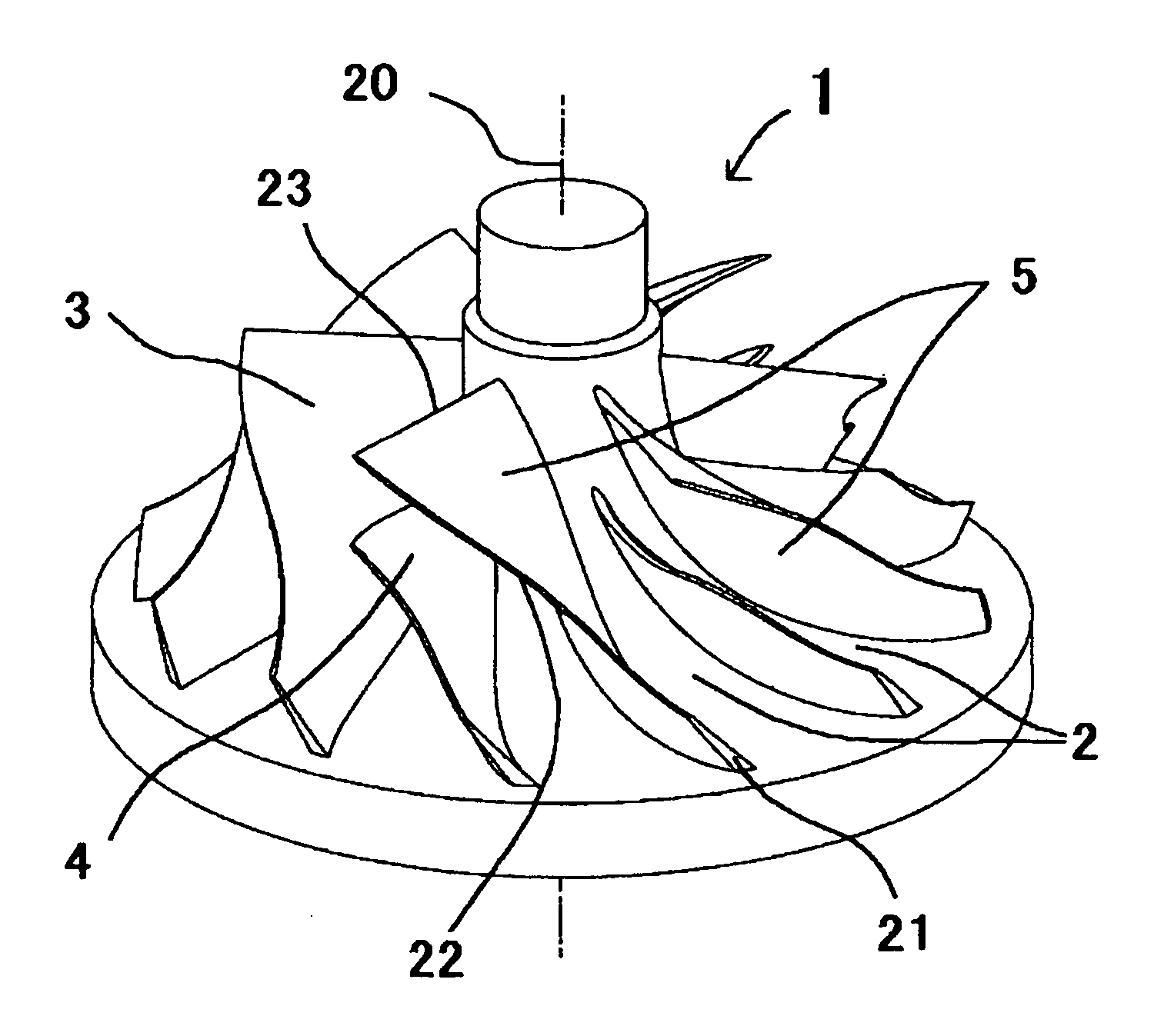

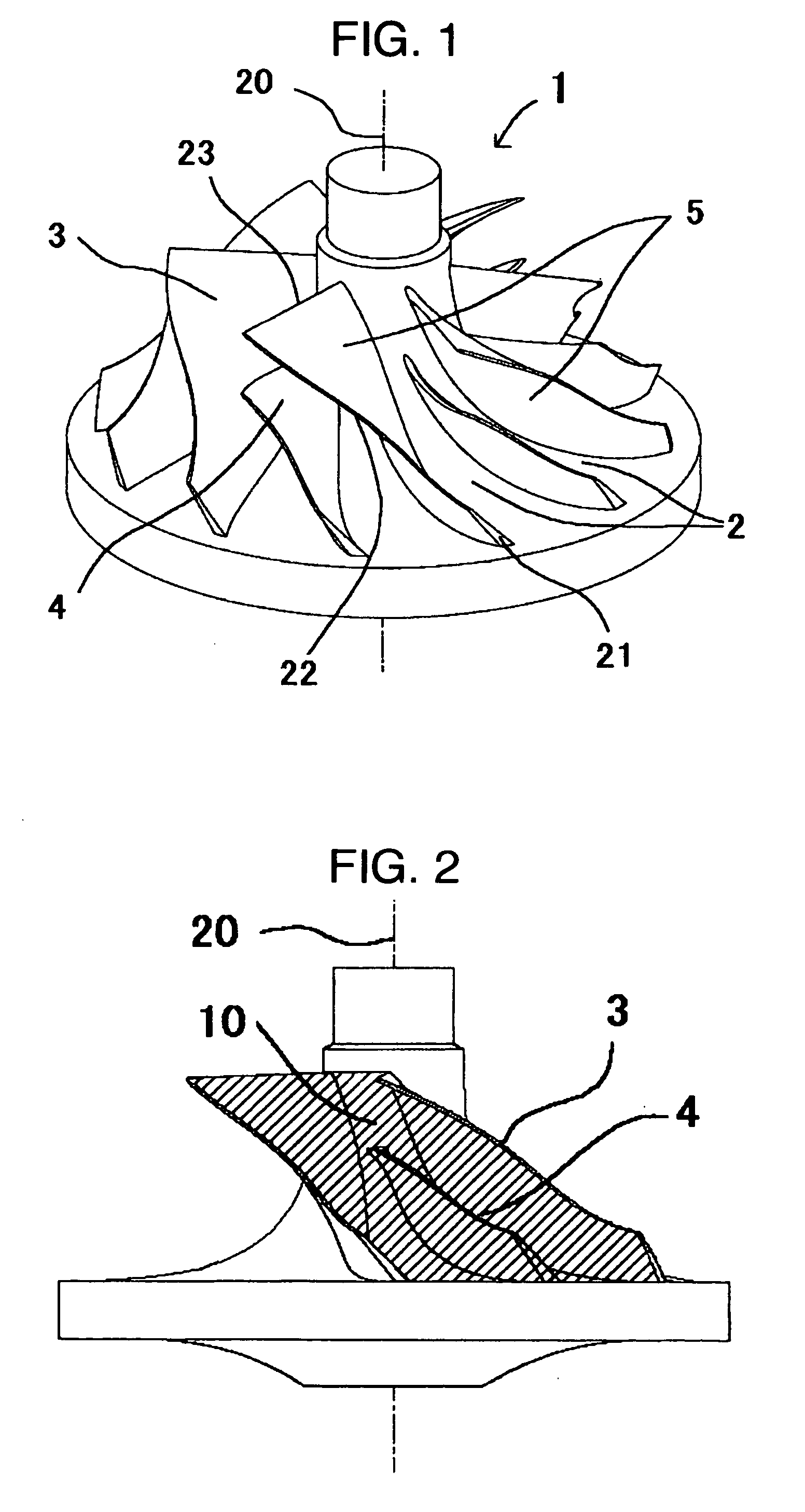

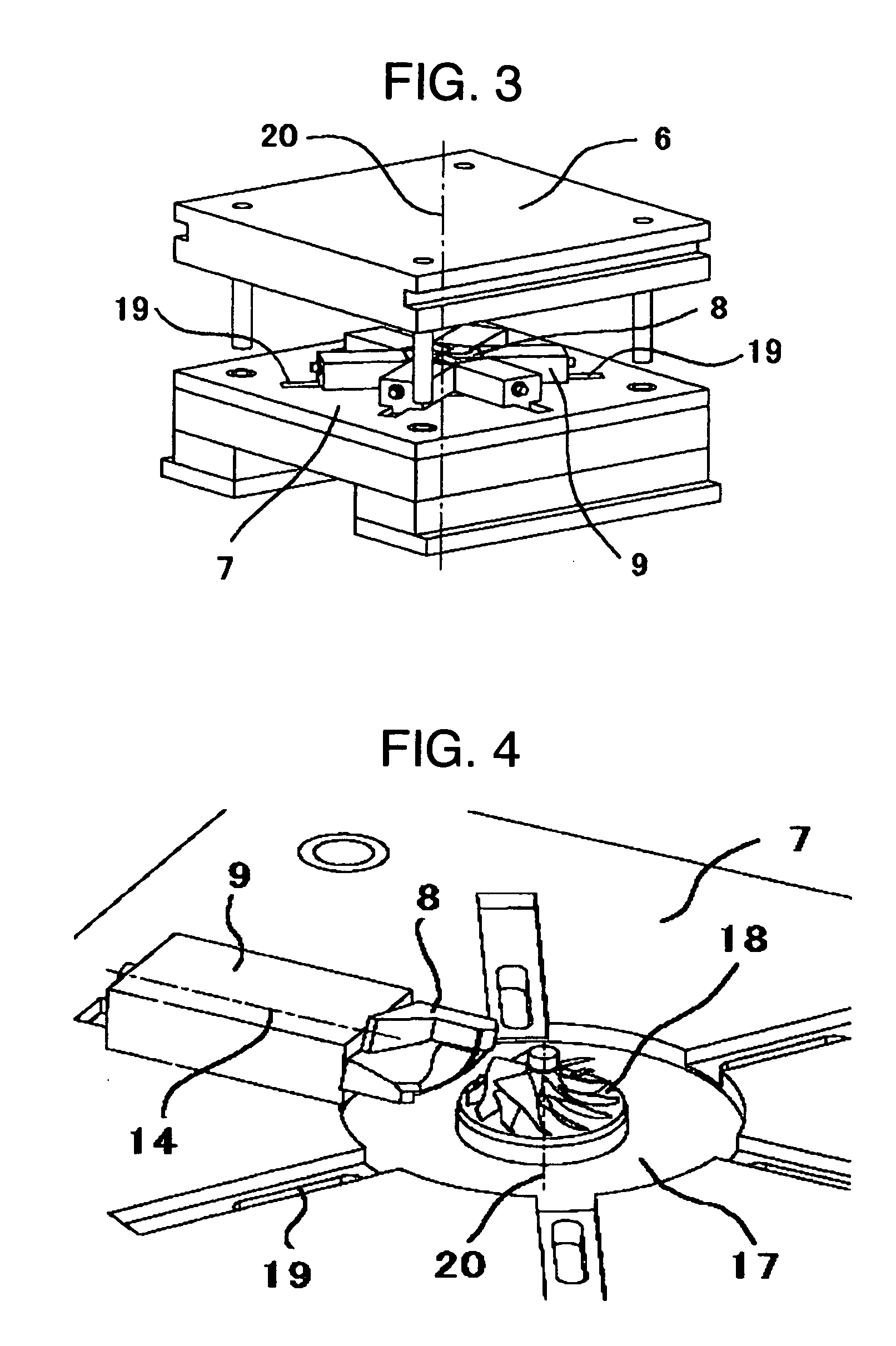

Manufacturing method of titanium compressor wheel

InactiveUS20070039709A1Increase productionImprove accuracyCasting plantsFoundry mouldsImpellerDynamic balance

Owner:AIKOKU ALPHA

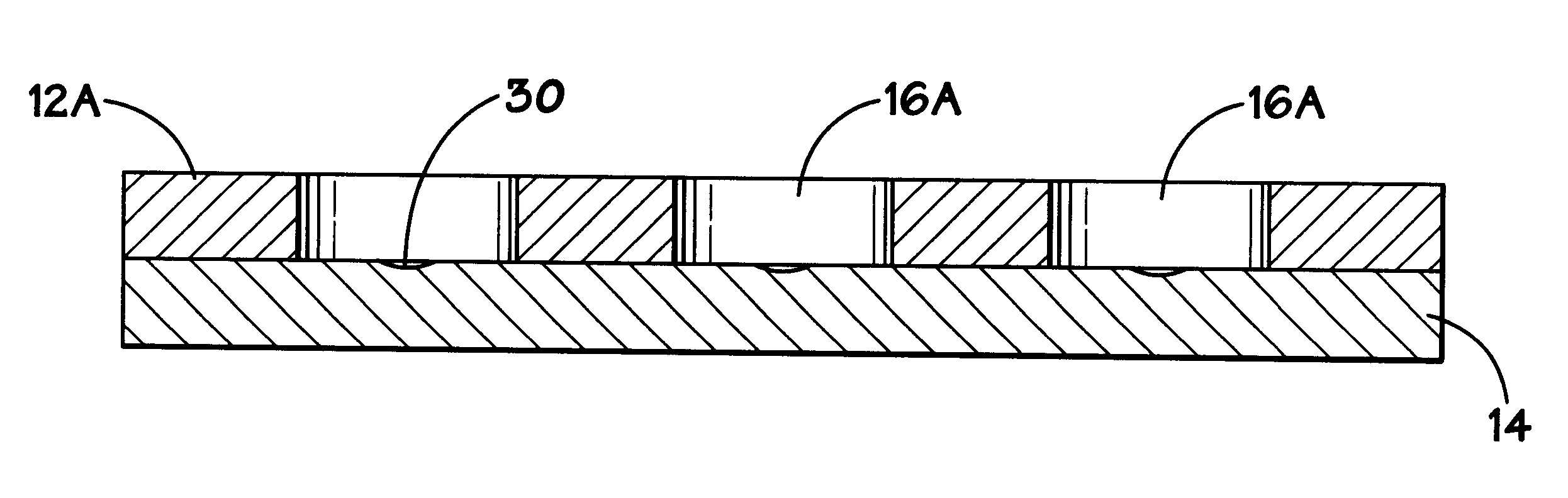

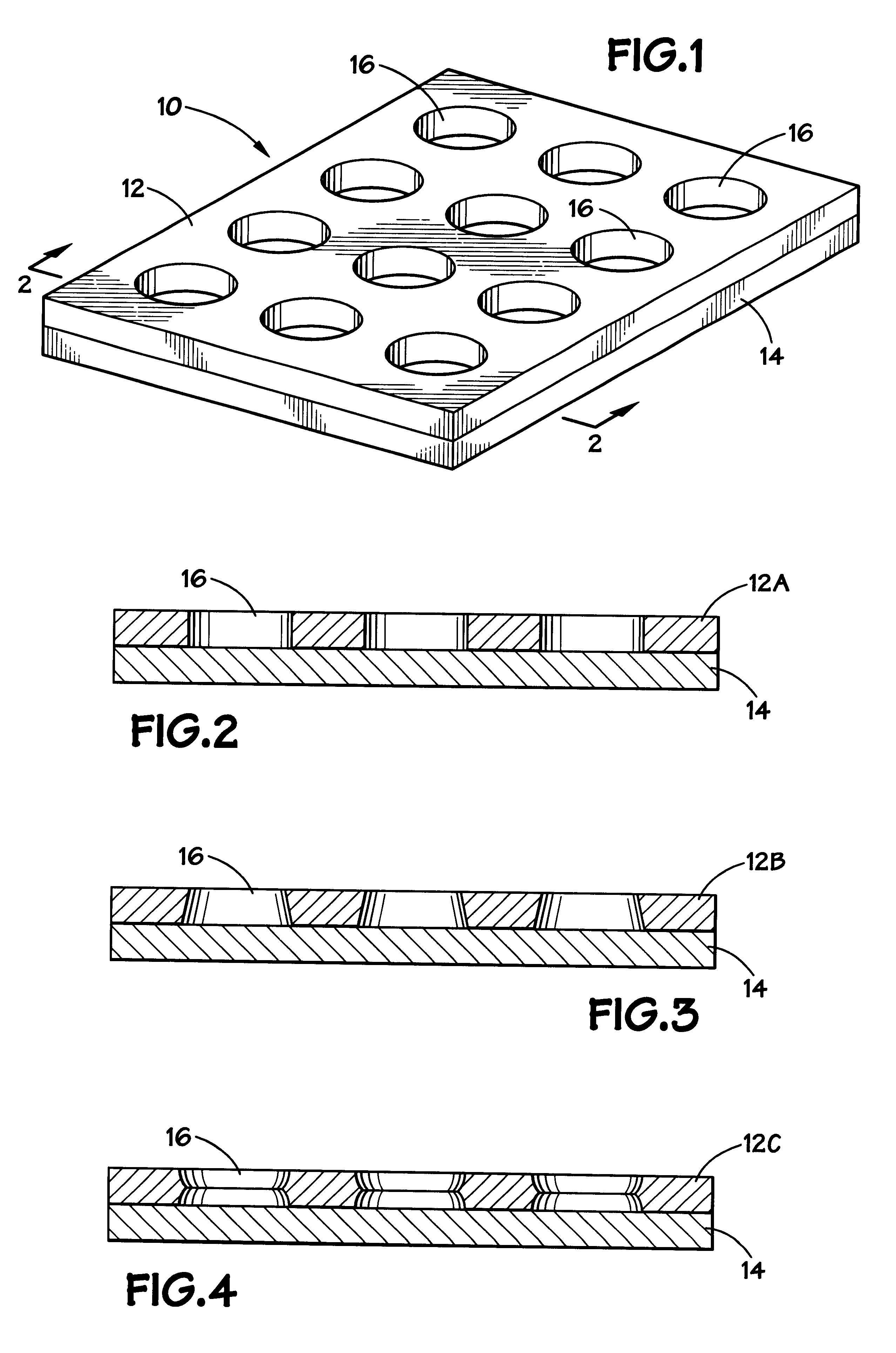

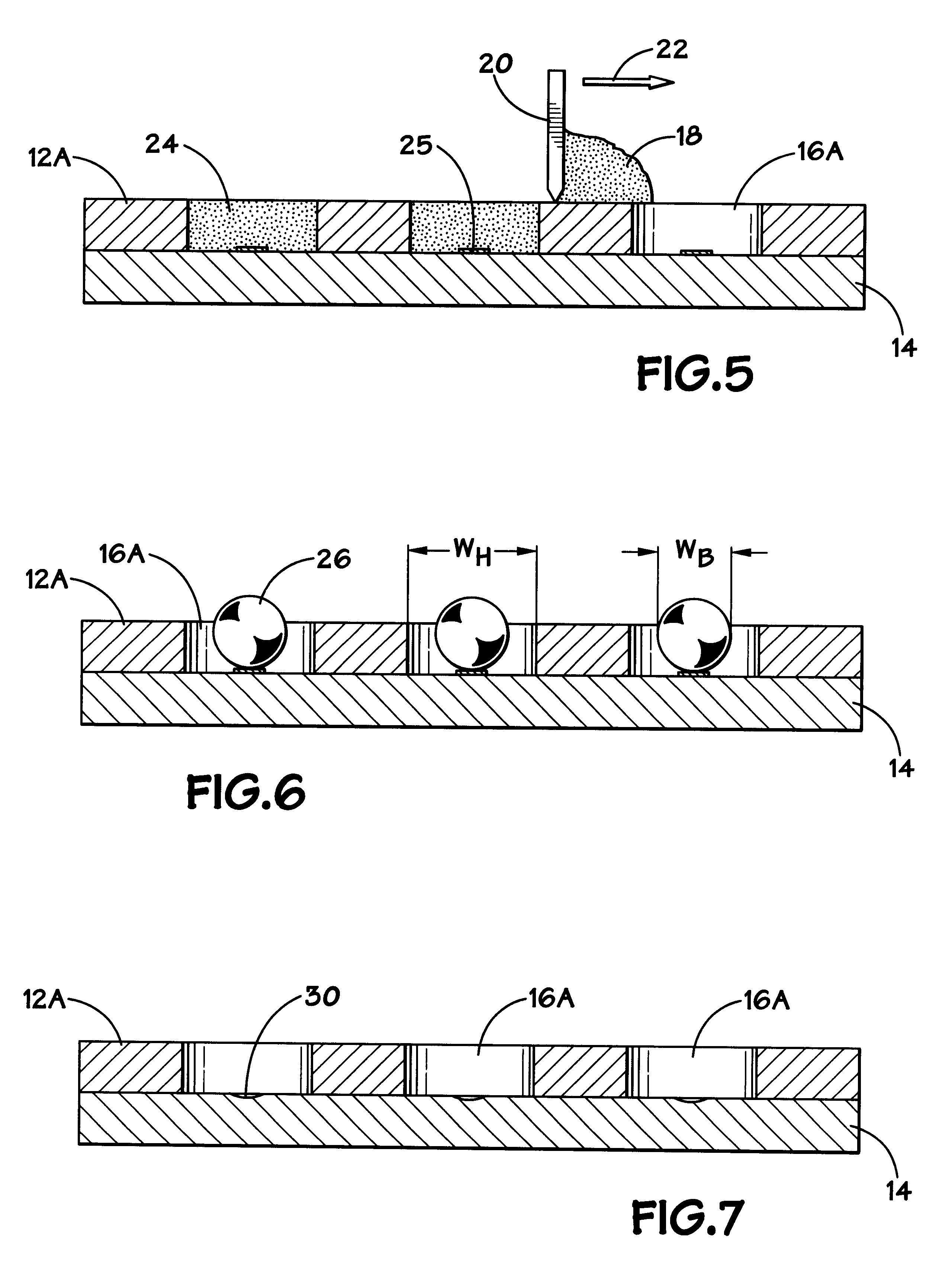

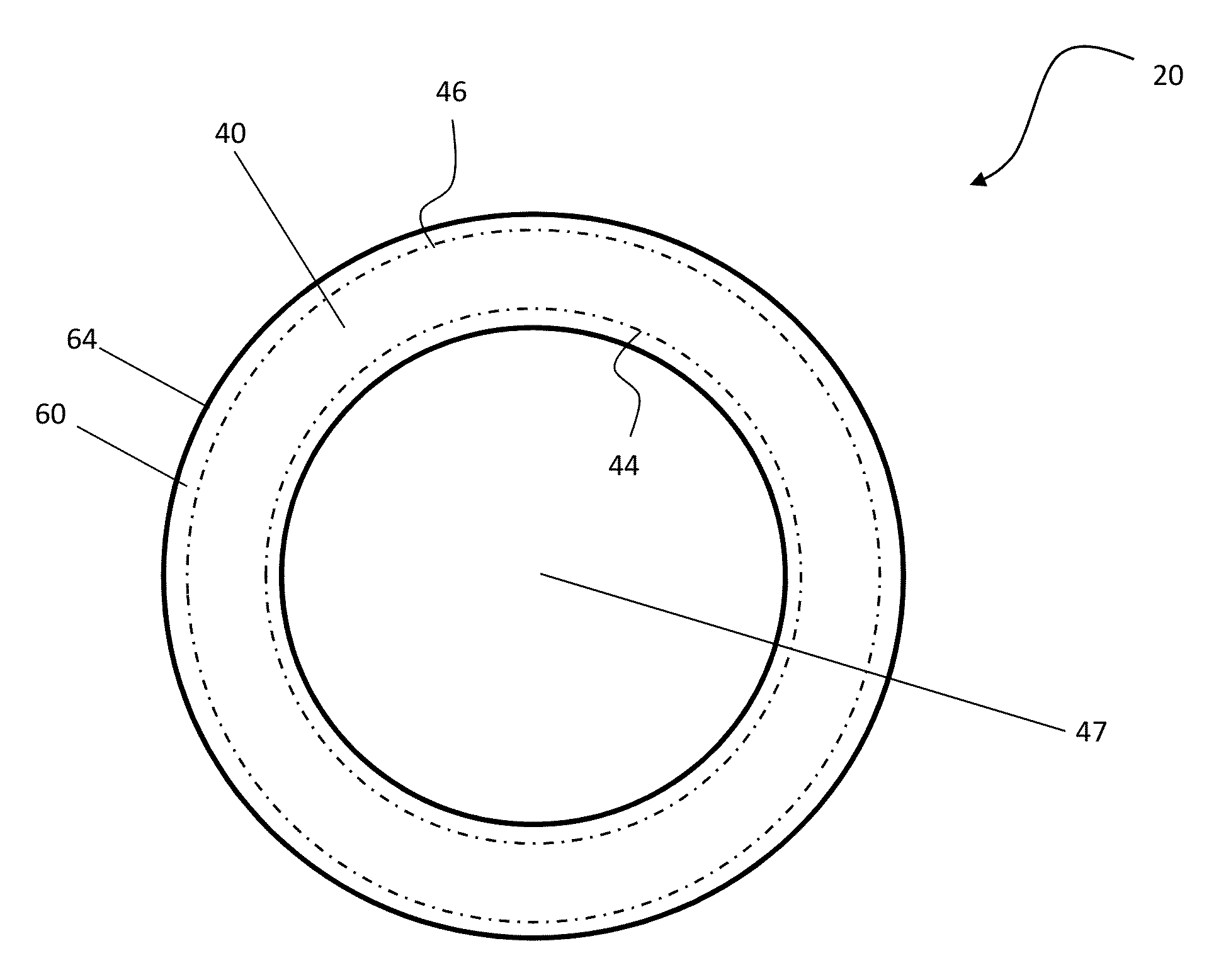

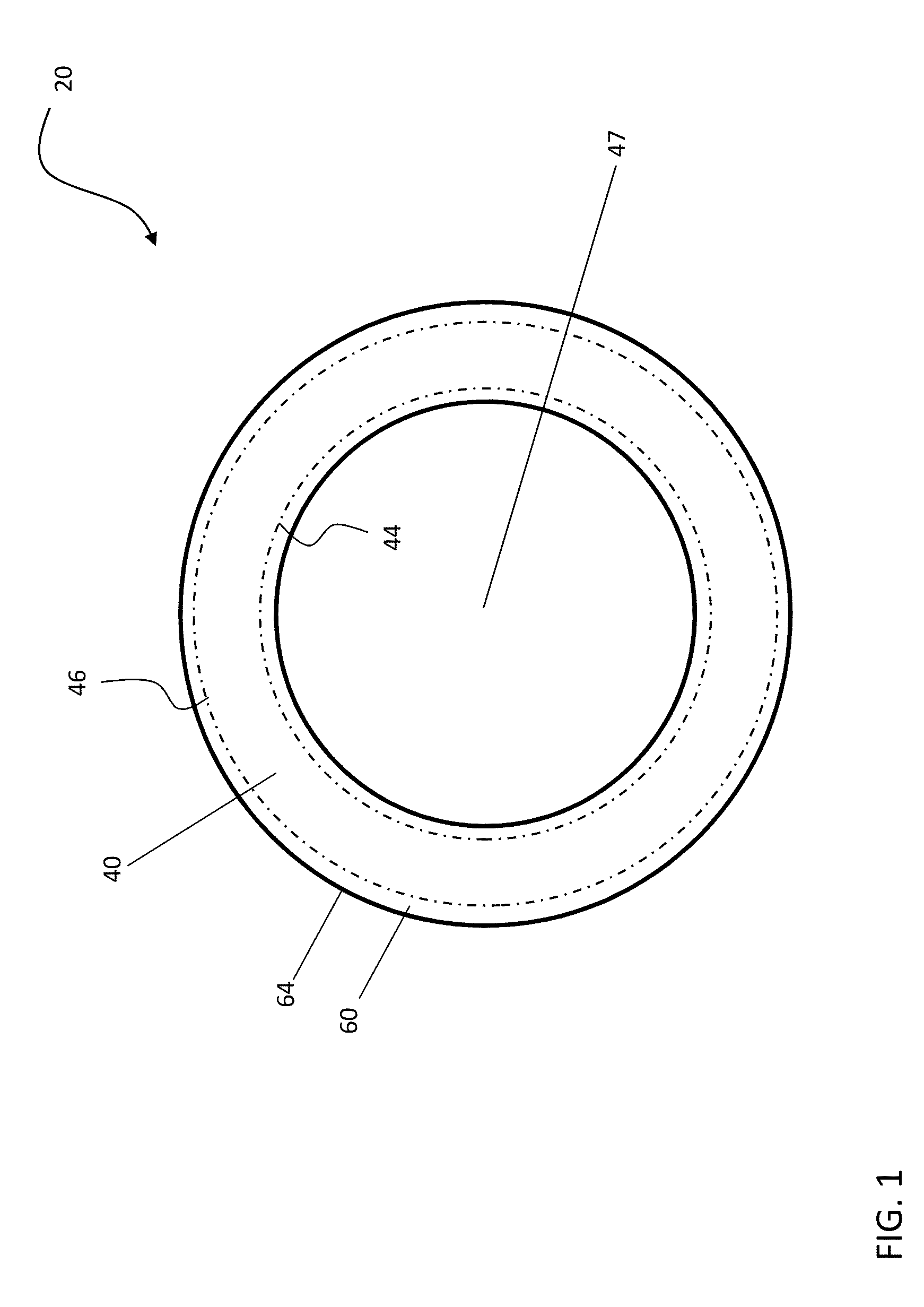

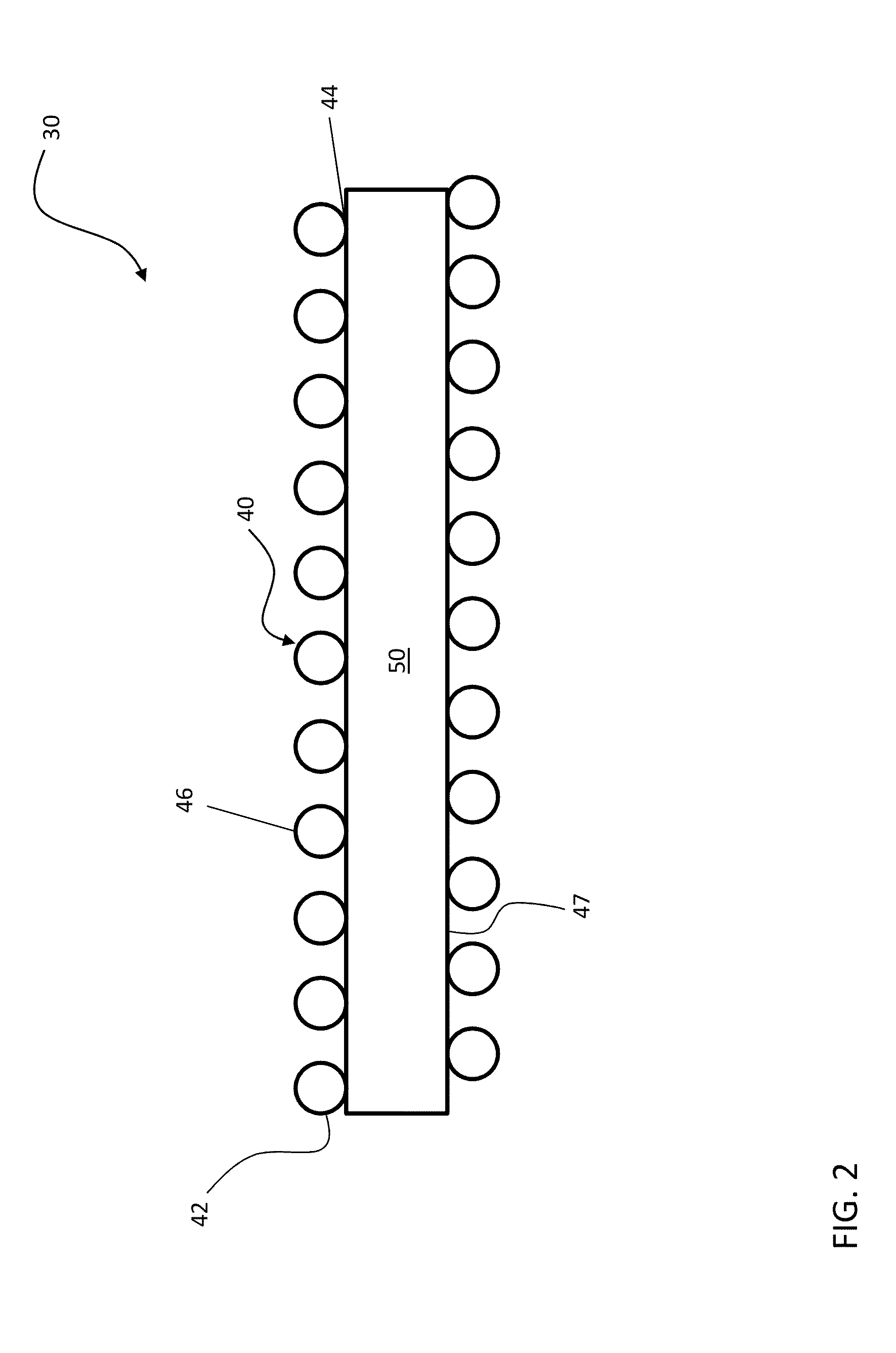

Methods and apparatus for forming solder balls

Methods and apparatus for forming a plurality of uniformly sized solder balls utilize a stencil having a plurality of holes of uniform volume disposed on a substrate. Solder is disposed in the holes of the stencil on the substrate. Typically, the solder is in the form of solder paste which is distributed into the holes using a squeegee. While within the holes of the stencil on the substrate, the solder is melted to form solder balls. The stencil may then be removed to leave the solder balls on the substrate, or the solder balls may be removed while the stencil remains on the substrate.

Owner:MICRON TECH INC

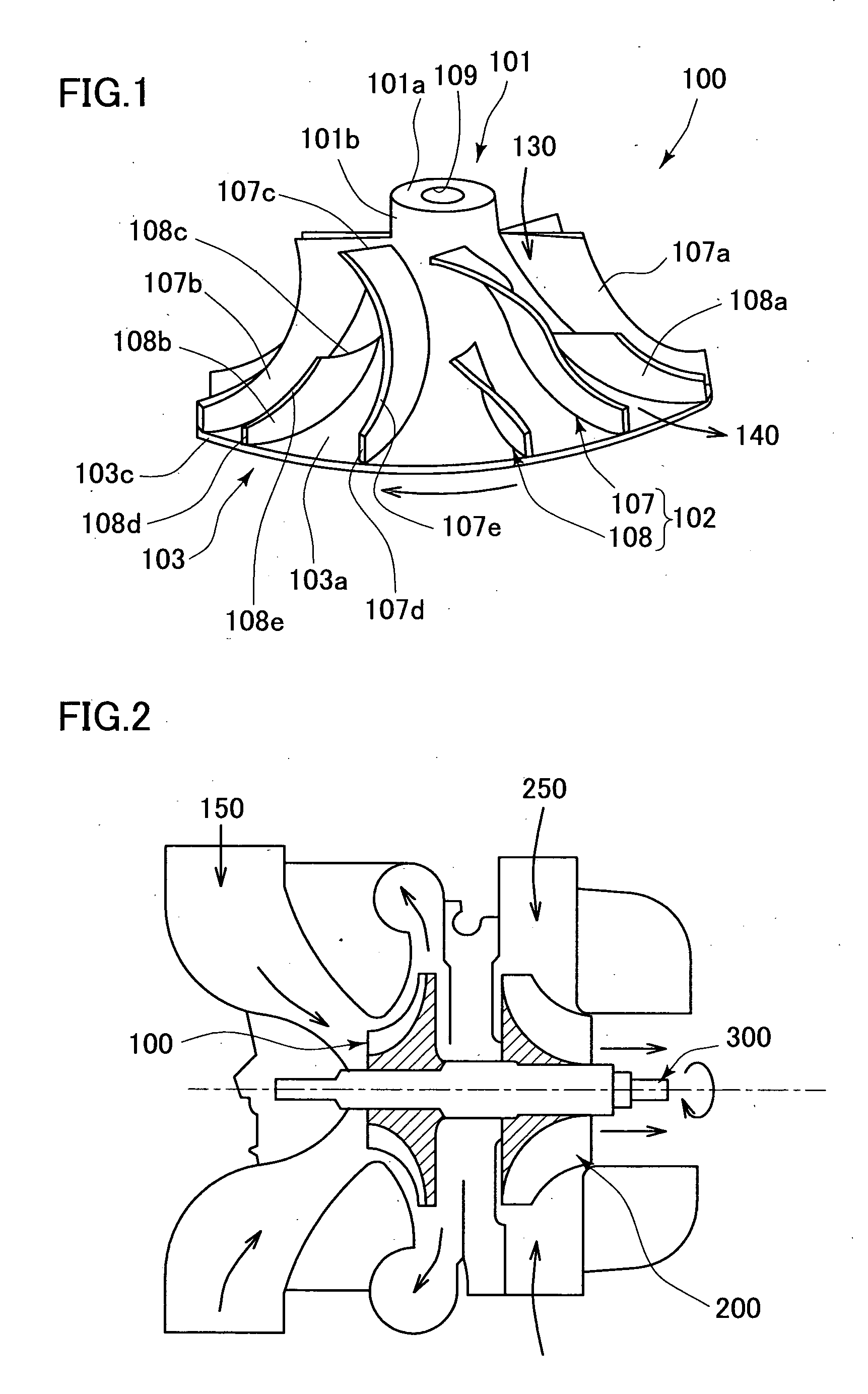

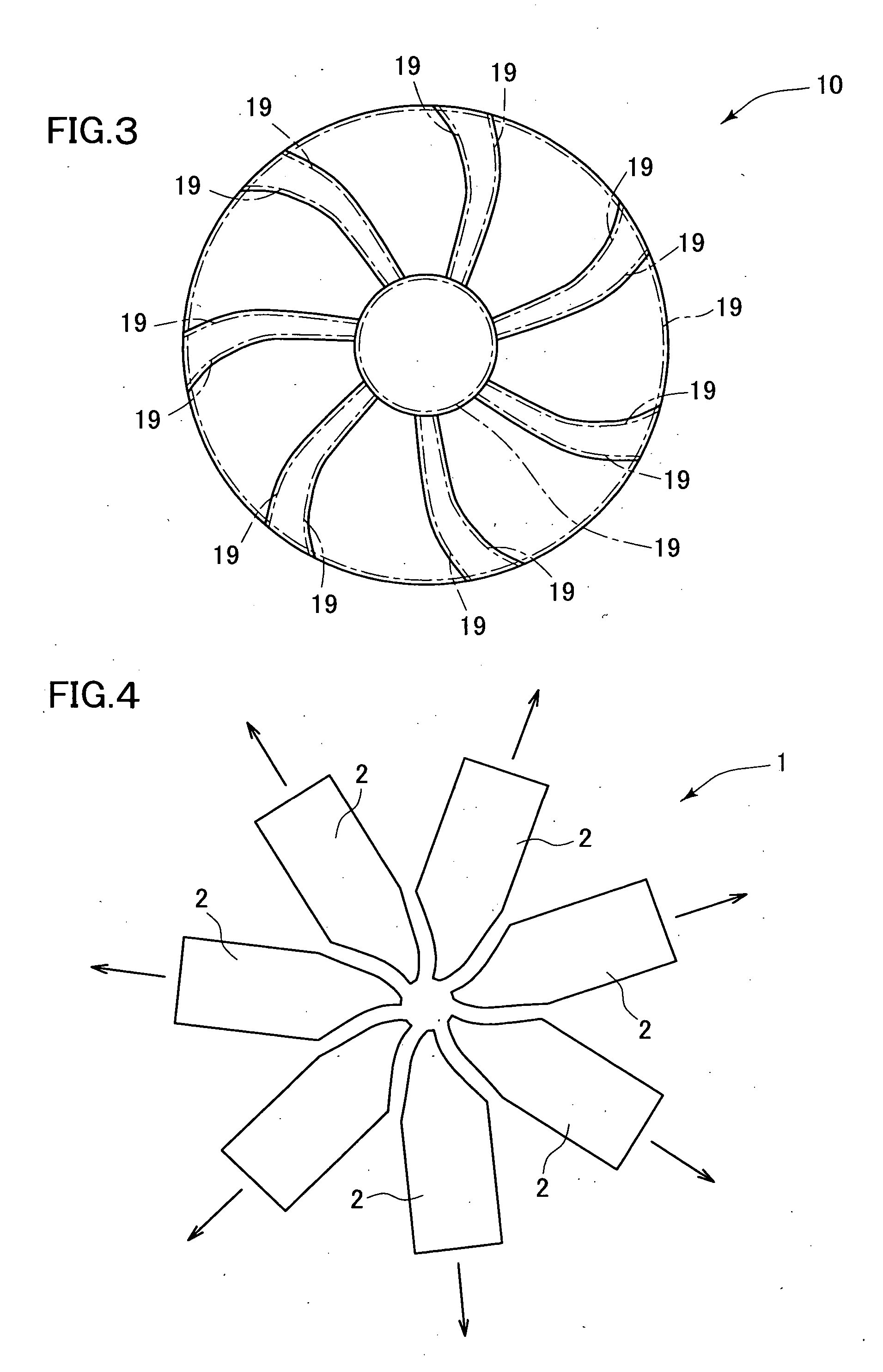

Impeller for supercharger and method of manufacturing the same

InactiveUS20060291996A1Improve aerodynamic performanceDifficult to obtainPump componentsBlade accessoriesImpellerRefractory

[Problems]To provide a lost-wax cast impeller for a supercharger having no parting line corresponding part on a hub surface and a blade surface in each space demarcated by pairs of long blades adjacent to each other and having excellent aerodynamic performance. [Means for Solving Problems]This method of manufacturing the impeller comprises a step for forming a lost form pattern formed in the substantially same shape as the impeller for the supercharger, a step for forming a mold by eliminating and removing the lost form pattern after the lost form pattern is coated with a refractory, and a step for pouring a molten metal in the mold for casting. In the step for molding the lost form pattern, a lost material is injection-molded in a space demarcated by radially arranging, toward a center shaft, a plurality of slide molds having short blade-shaped bottomed groove parts and space shapes between the pairs of long blades adjacent to each other, and the slide molds are released by moving in the radial direction of the center shaft while rotating. Thus, the parting line corresponding part is not present on any of the hub surface and the blade surface in the spaces demarcated by the pairs of long blades adjacent to each other.

Owner:HITACHI METALS PRECISION LTD +1

Knuckle formed without a finger core

A method for manufacturing a railcar coupler knuckle includes providing a cope mold portion and a drag mold portion, the cope and drag mold portions having internal walls defining at least in part perimeter boundaries of a coupler knuckle mold cavity, wherein the mold cavity includes a finger section; positioning at least one internal core within either the cope mold portion or the drag mold portion, the at least one internal core configured to define a kidney cavity and a pivot pin cavity within a coupler knuckle; closing the cope and drag mold portions with the single core therebetween; and at least partially filling the mold cavity with a molten alloy, the molten alloy solidifying after filling to form the coupler knuckle, wherein the at least one core defines the kidney and pivot pin cavities, and the finger section of the mold cavity defines at least one finger cavity of the coupler knuckle.

Owner:BEDLOE IND LLC

Railway car coupler knuckle having improved bearing surface

InactiveUS20060113267A1Extend the life cycleMinimize setFoundry mouldsFoundry coresEngineeringBearing surface

Owner:MCCONWAY & TORLEY LLC

Molding and casting machine

ActiveUS7806161B2Easy to moveEasy to adjustPig casting plantsCasting safety devicesMolding machineSand casting

Disclosed is a sand casting molding machine for double indexing molds in a mold string. The machine can include a shot chamber having sand, a swingable squeeze head, a lateral squeeze head, a core setter, a mold hold down, a mold retention device and a mold string conveyor.

Owner:THYSSENKRUPP WAUPACA

Automotive and aerospace materials in a continuous, pressurized mold filling and casting machine

Owner:HERRON DAVID J

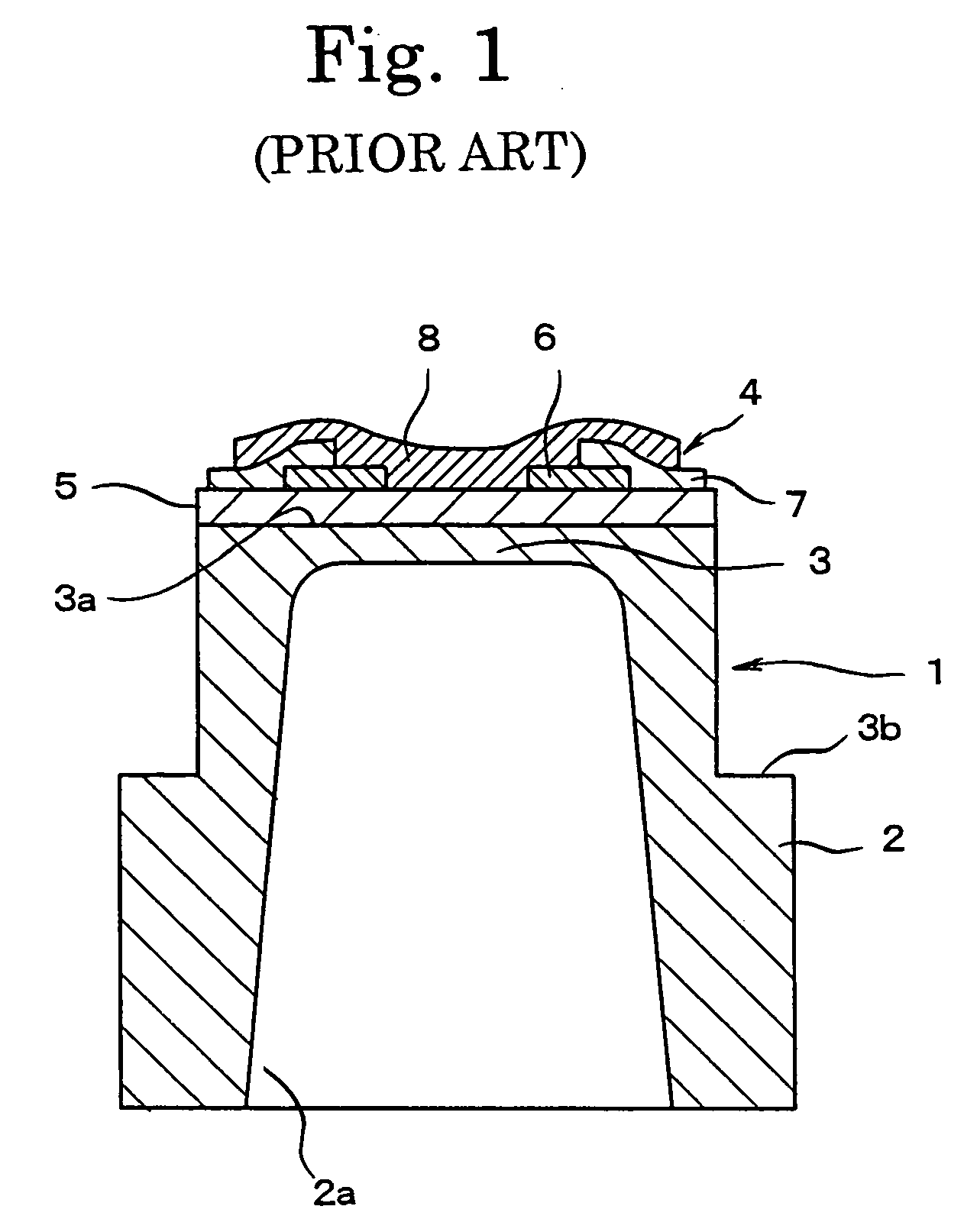

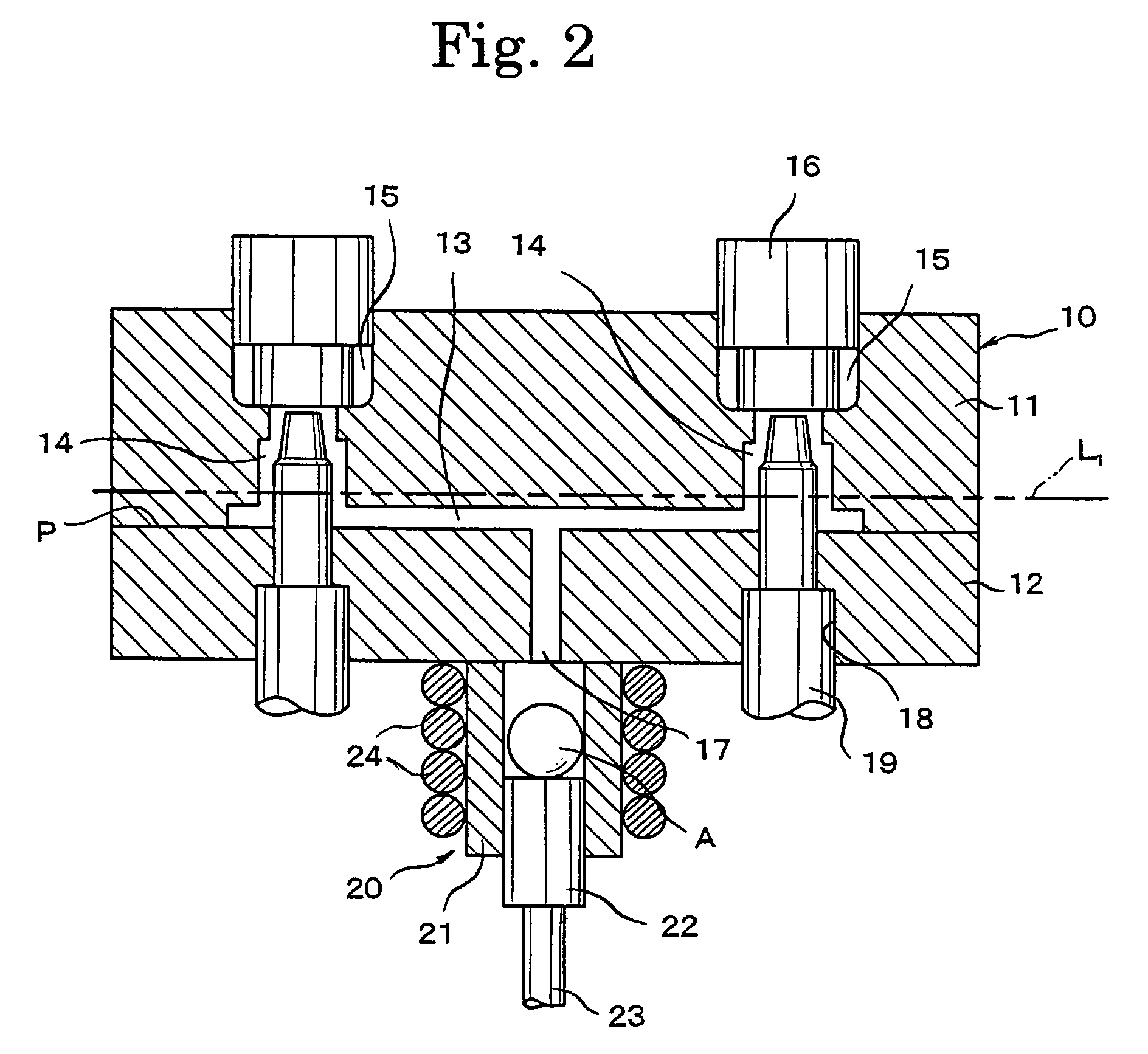

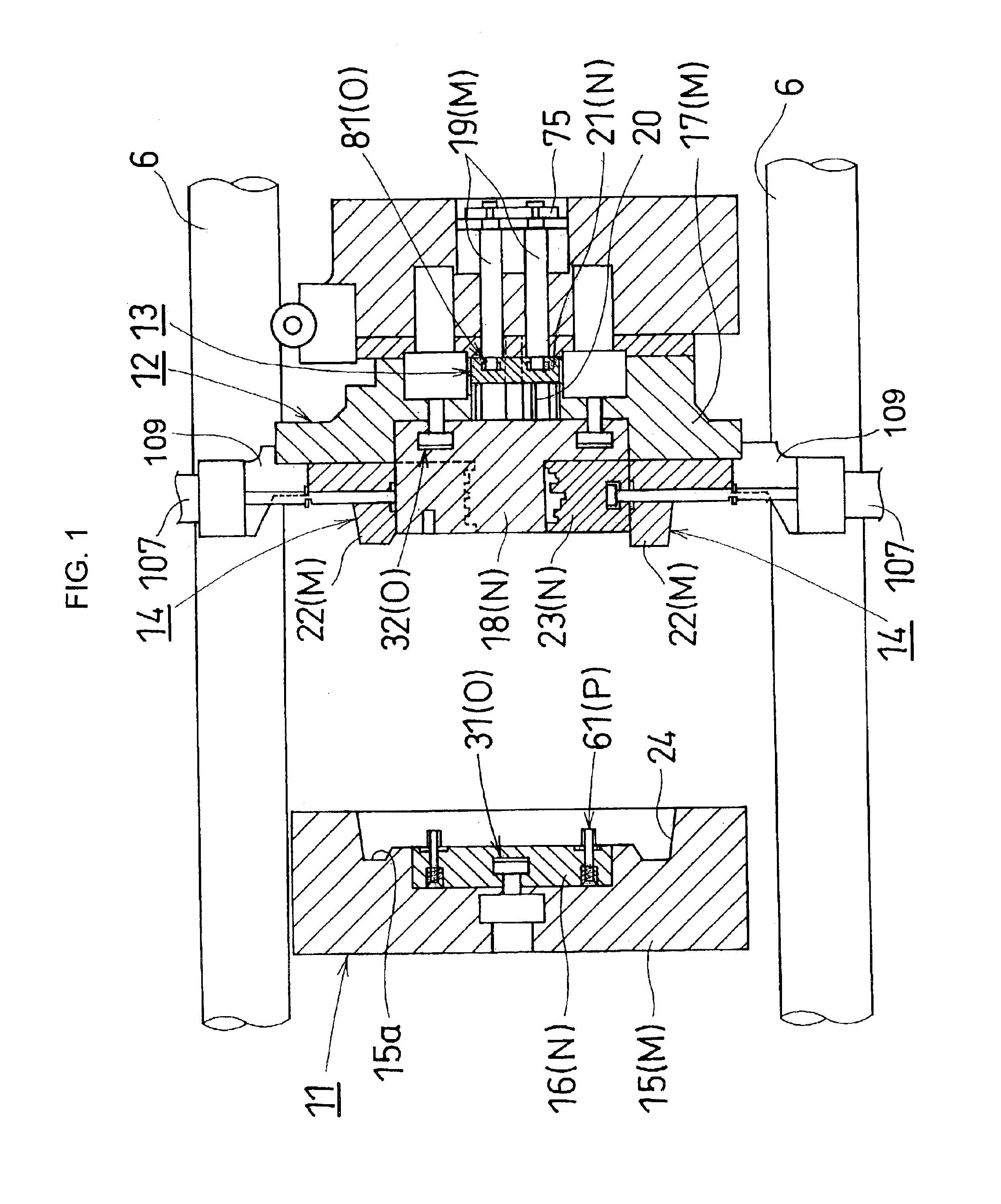

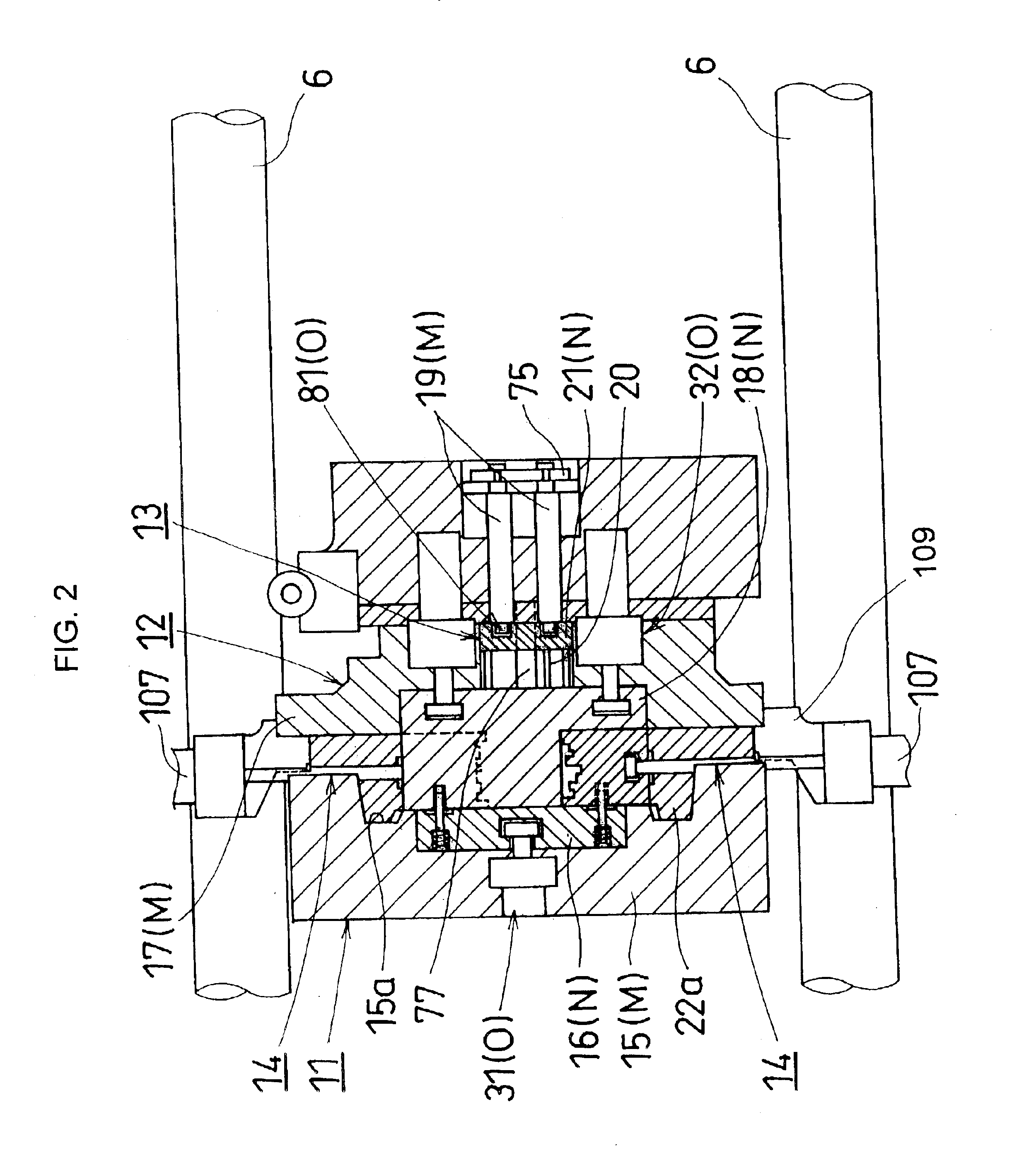

Molding die and die changing method of the same

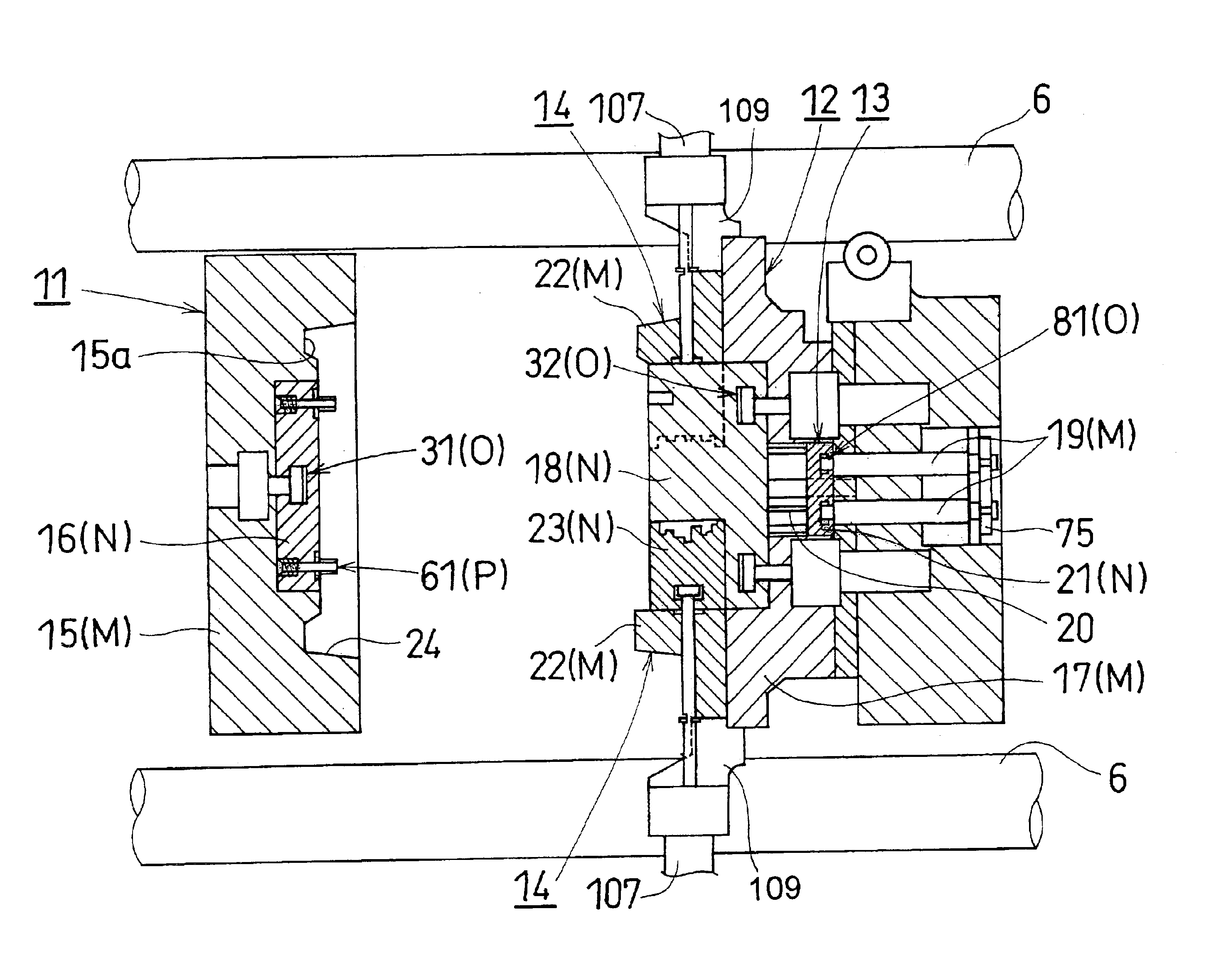

InactiveUS6955210B2Efficient executionSwiftly dealMould handling equipmentsMolding machineEngineering

The invention provides a molding die in which a whole or a part of an exclusive portion forming a cavity can be swiftly changed while leaving a general portion in a molding machine. A fixed insert, a movable insert, a pressing plate and a slide core which correspond to an exclusive portion can be automatically attached to and detached from a fixed main die, a movable main die, a pressing rod and a slide holder which correspond to a general portion by an attaching and detaching mechanism. Further, the fixed insert, the movable insert, the pressing plate and the slide core can be integrated in a die close state by a connection mechanism. By utilizing cross-feed means of a die changing apparatus and a die opening and closing motion on a molding machine side, the exclusive portion is automatically removed from the general portion in a form of an assembly, and the exclusive portion assembly which is transferred into the molding machine from outside the molding machine is automatically mounted to the general portion.

Owner:TOYOTA JIDOSHA KK

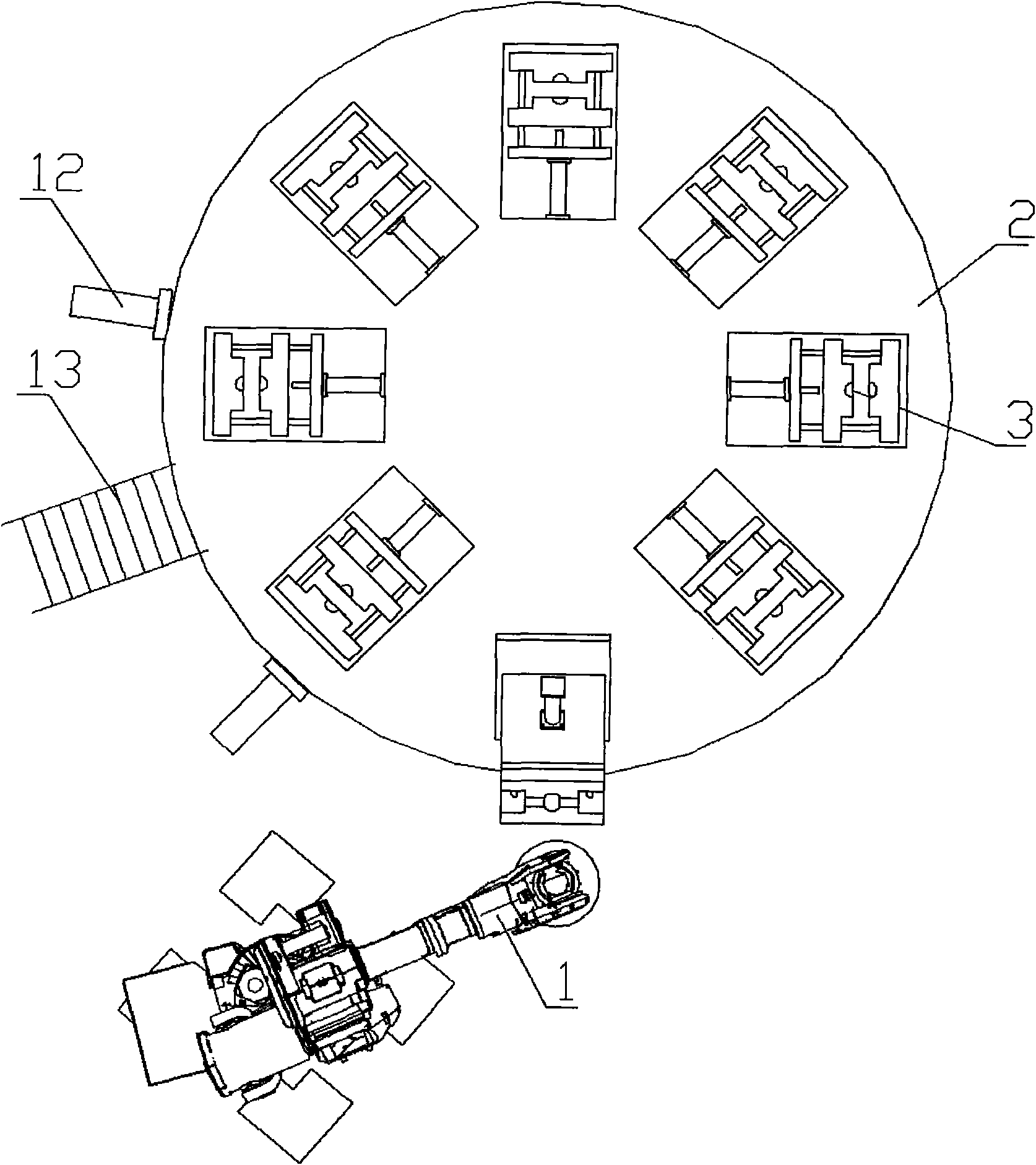

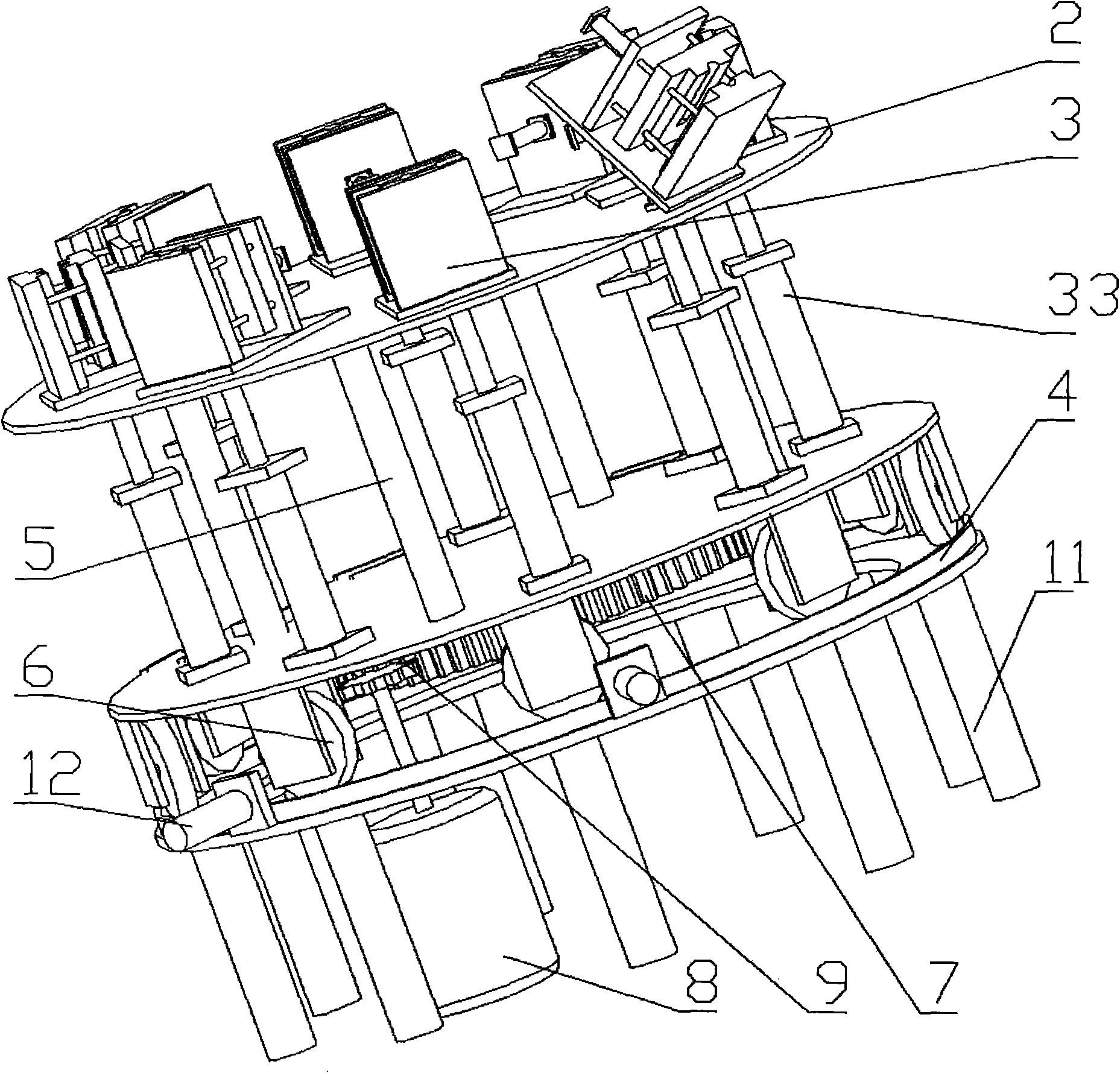

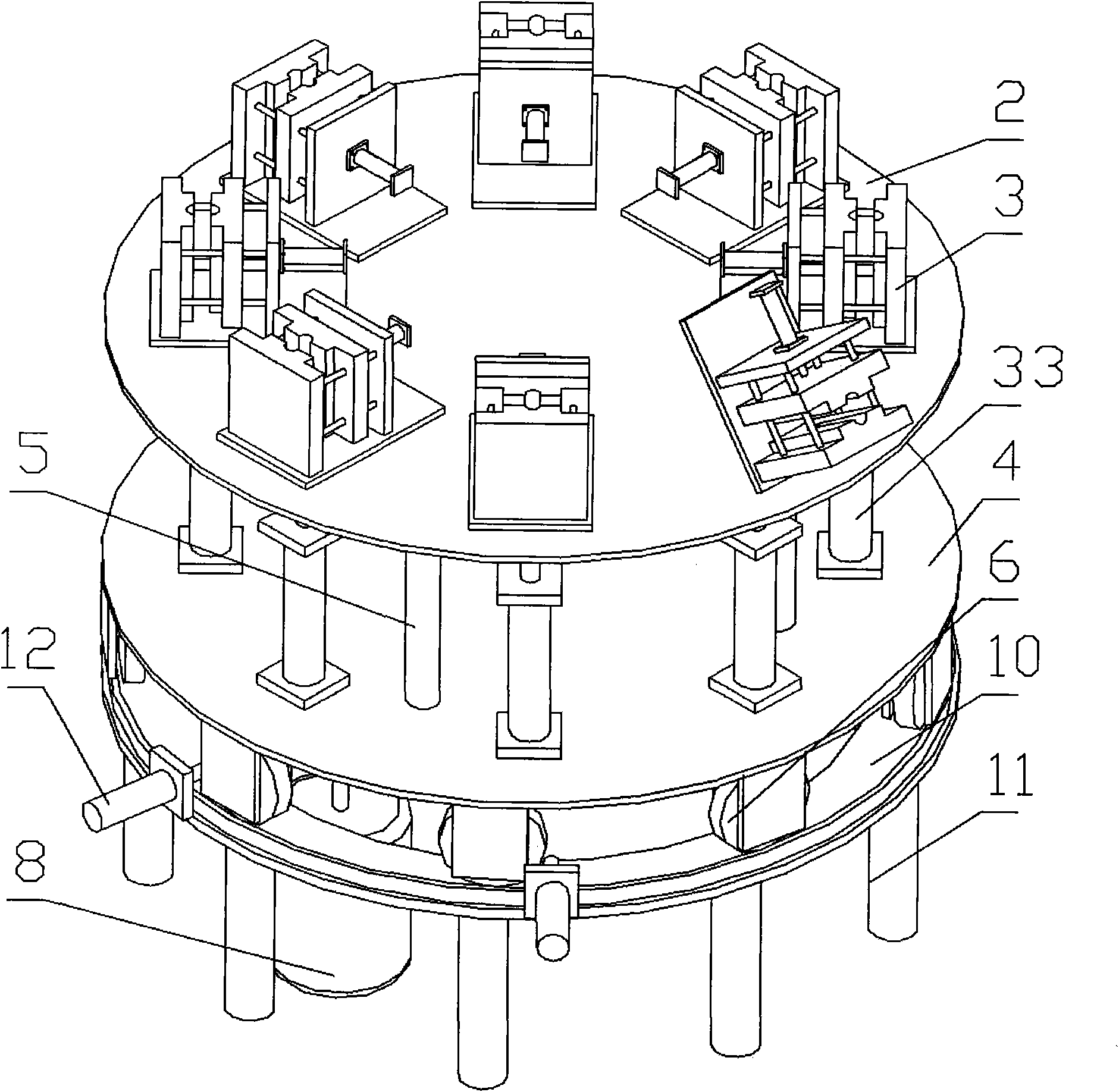

Multi-station casting machine

ActiveCN102009168ARealize automatic controlImprove work efficiencyMould handling equipmentsMotor driveAutomatic control

The invention relates to a multi-station casting machine, comprising a pouring robot, wherein the pouring robot is fixed at one side of an operating platform, the operating platform is distributed with at least three casting units in an annular array mode; a motor drives the operating platform to rotate, pouring is carried out by the pouring robot when the operating platform rotates to each casting unit and stops, a cylinder is rotated to cause a mould to slowly rotate while pouring is carried out, and meanwhile one part in the mould is subject to water cooling by virtue of a water-cooling channel, and one part in the mould is heated by virtue of an electrical heating pipe. One worker can pour moulds on multiple stations, the production efficiency is improved, and the manpower cost of a factory is saved; and meanwhile the lifting and falling of a mould and the temperature at everywhere of the mould are automatically controlled, thus the product crystallization is better and the product quality is improved.

Owner:浙江恒吉智能科技有限公司

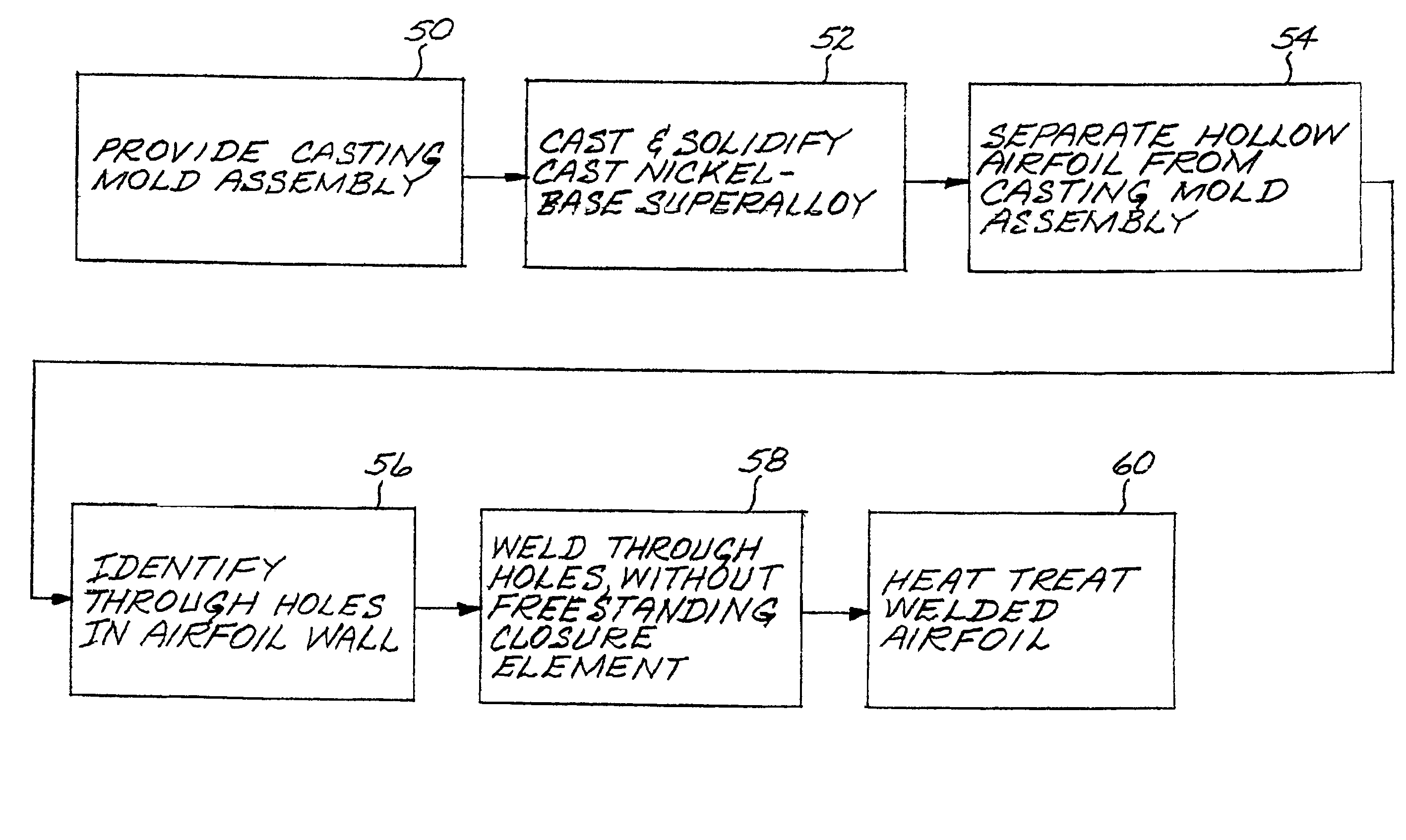

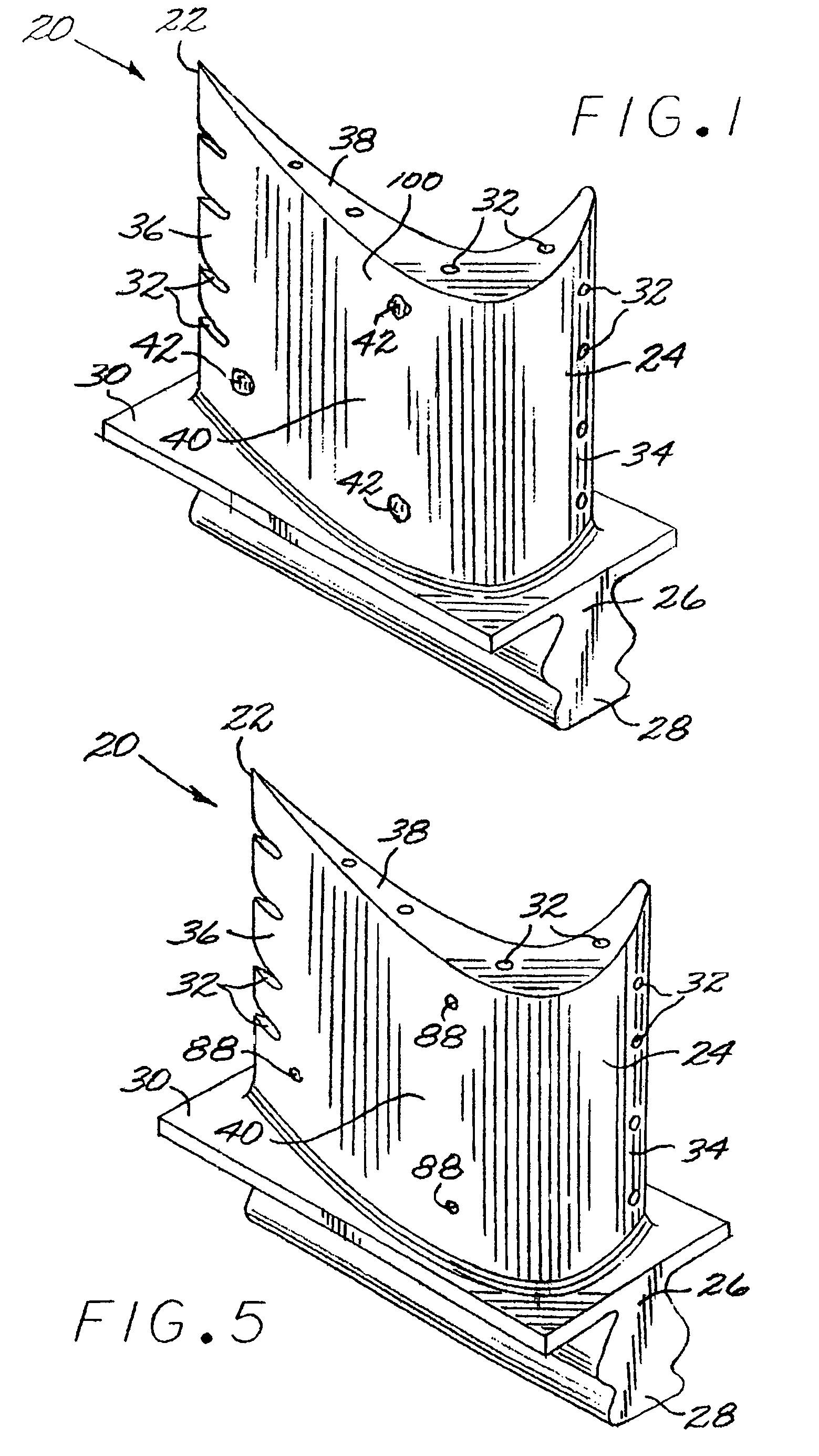

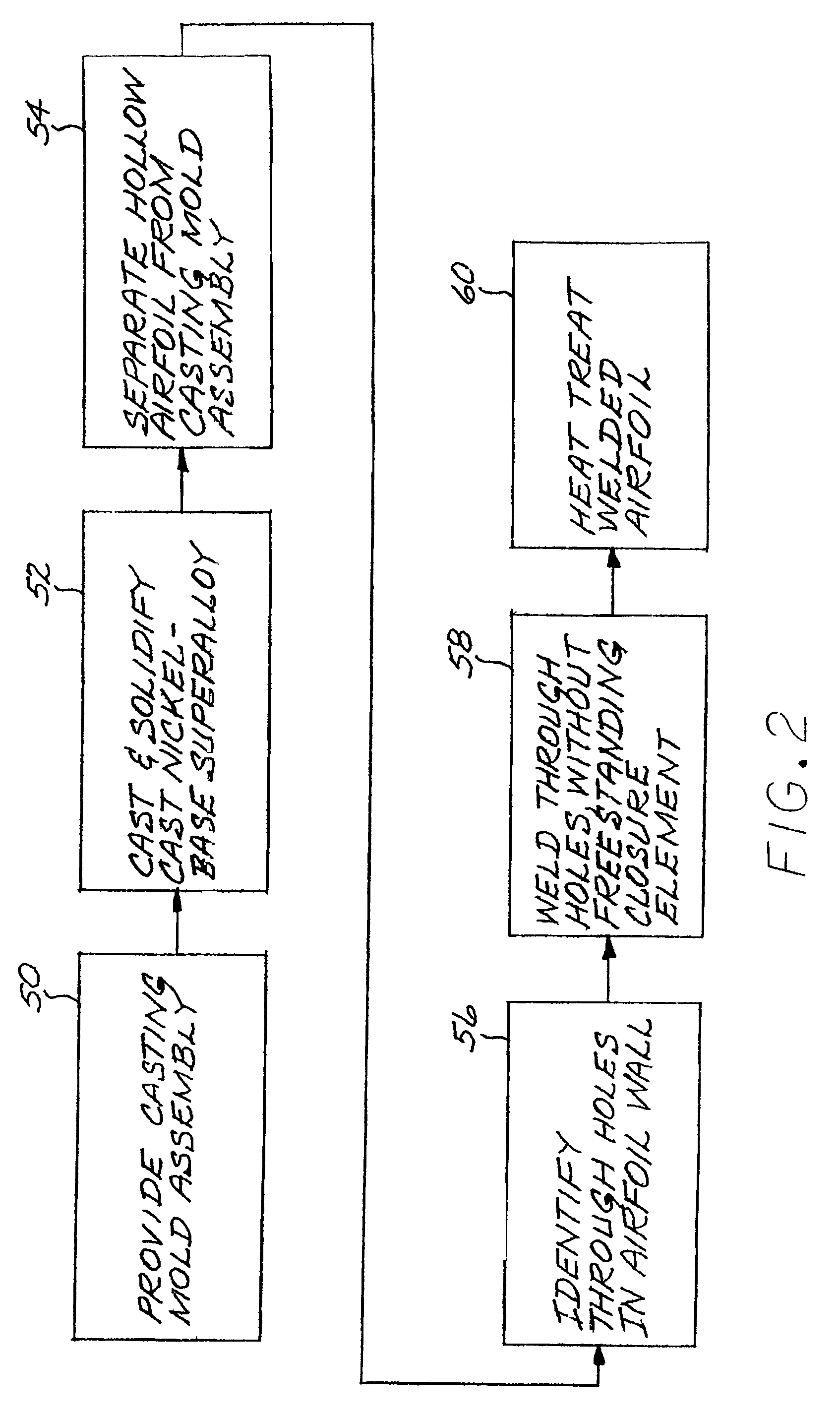

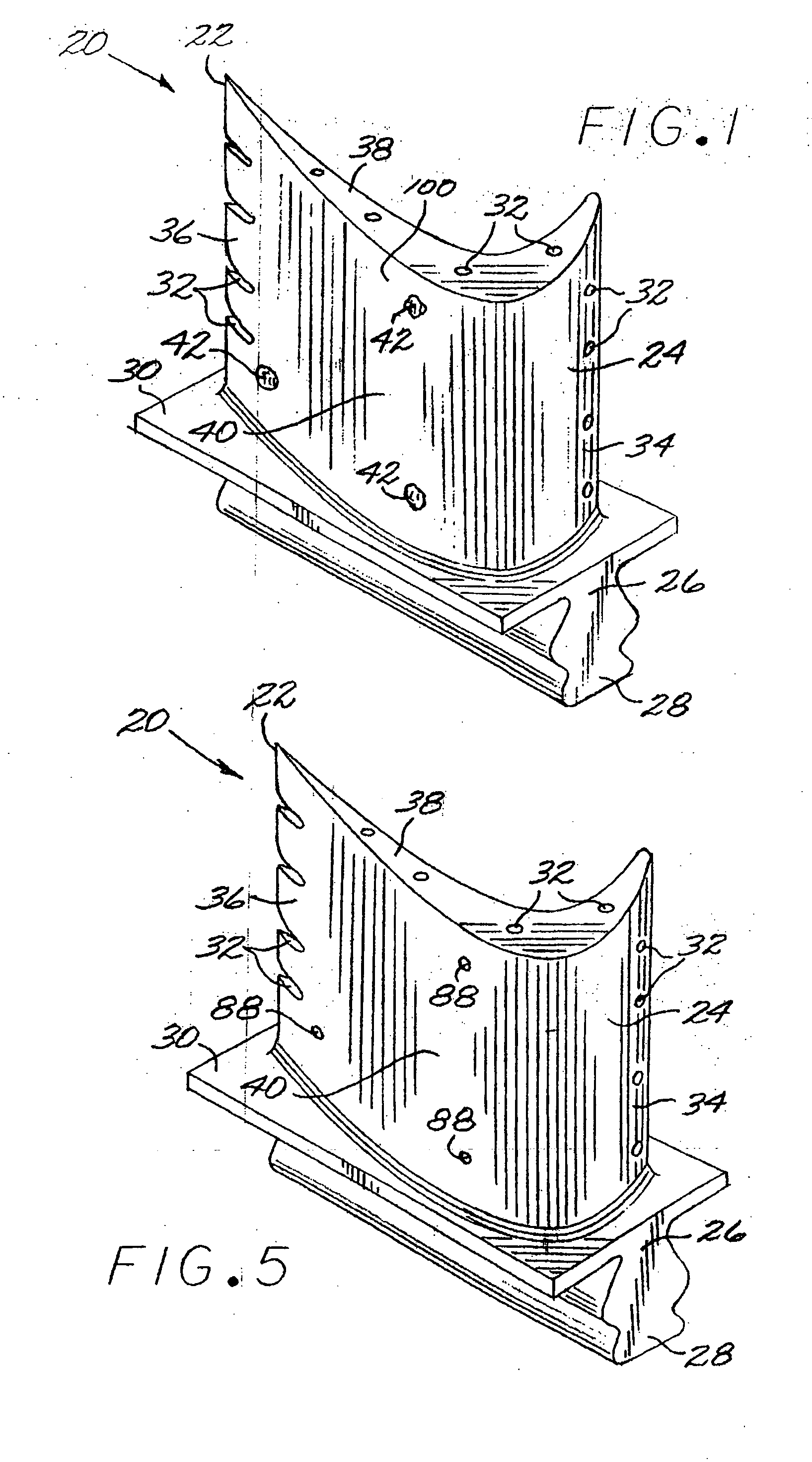

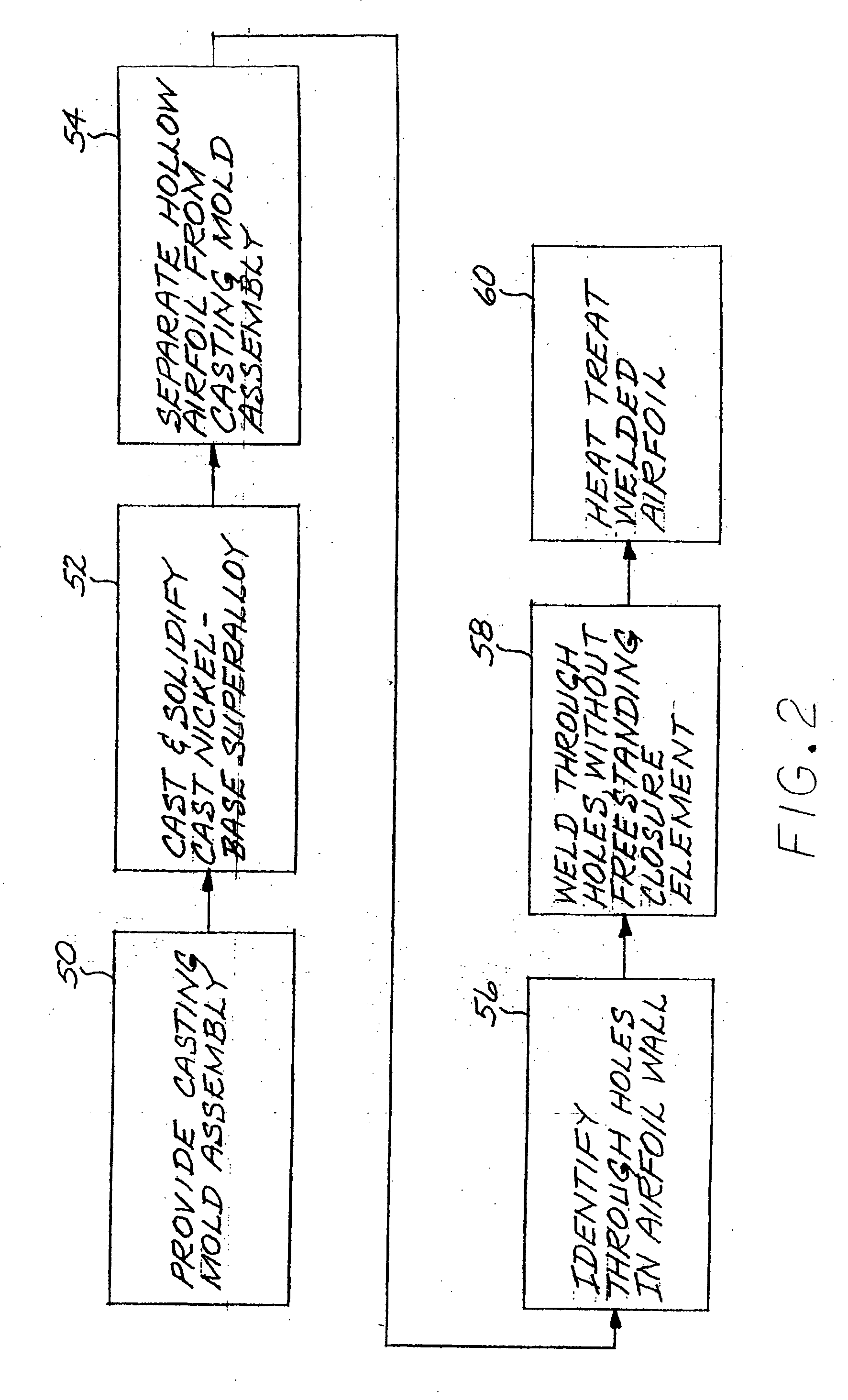

Weld closure of through-holes in a nickel-base superalloy hollow airfoil

InactiveUS7322396B2Small physical and mechanical propertiesImprove adhesionTurbinesBlade accessoriesCasting moldNickel based

A hollow airfoil is fabricated by providing a casting mold assembly including a casting mold, a casting core, and a standoff spacer that prevents the casting core from contacting the casting mold to define a casting space. A first nickel-base superalloy is cast into the casting space and solidified to form the hollow airfoil. The presence of a through-hole extending through a wall of the hollow airfoil is identified, and the through-hole is closed by welding using a second nickel-base superalloy, without using any freestanding closure element.

Owner:GENERAL ELECTRIC CO

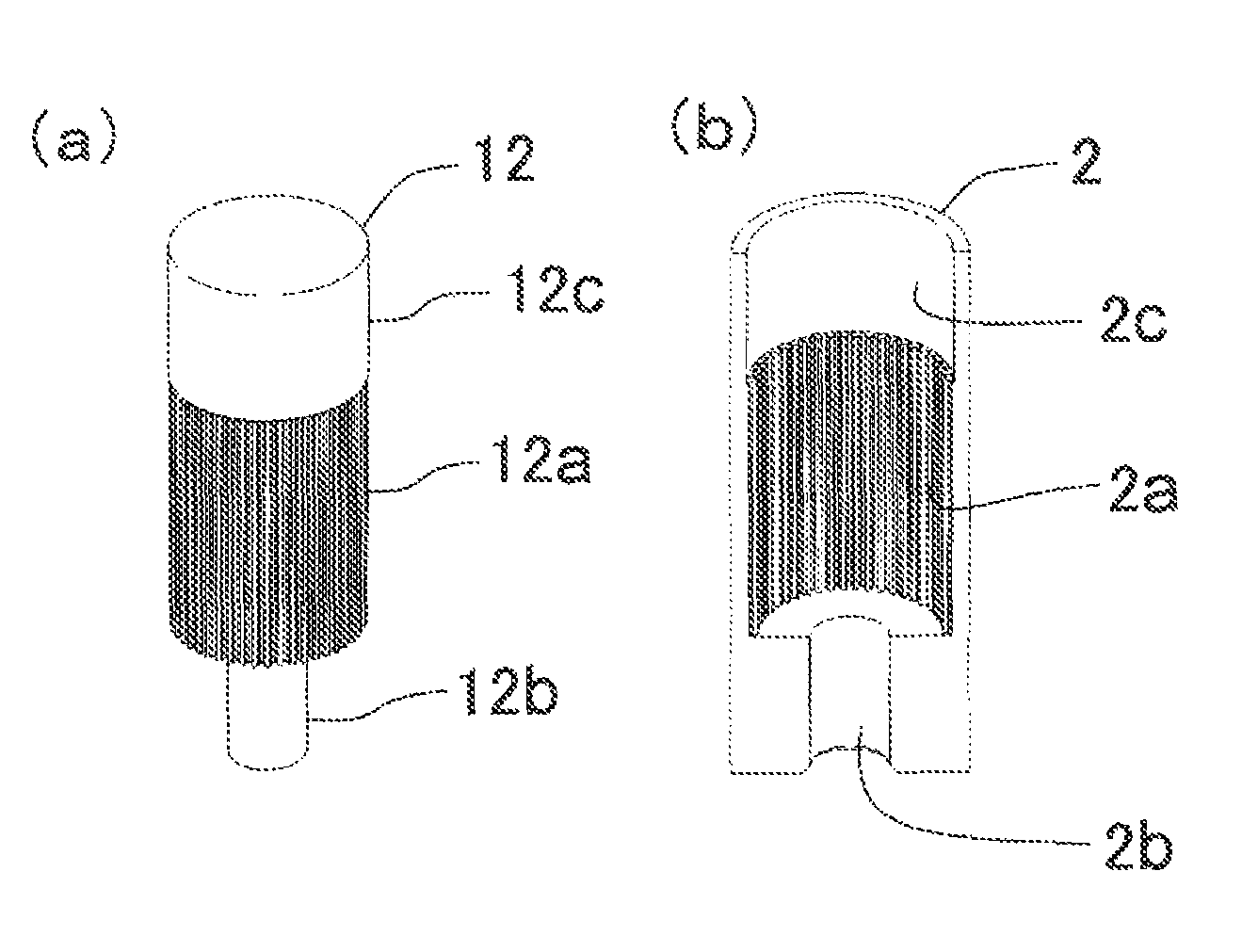

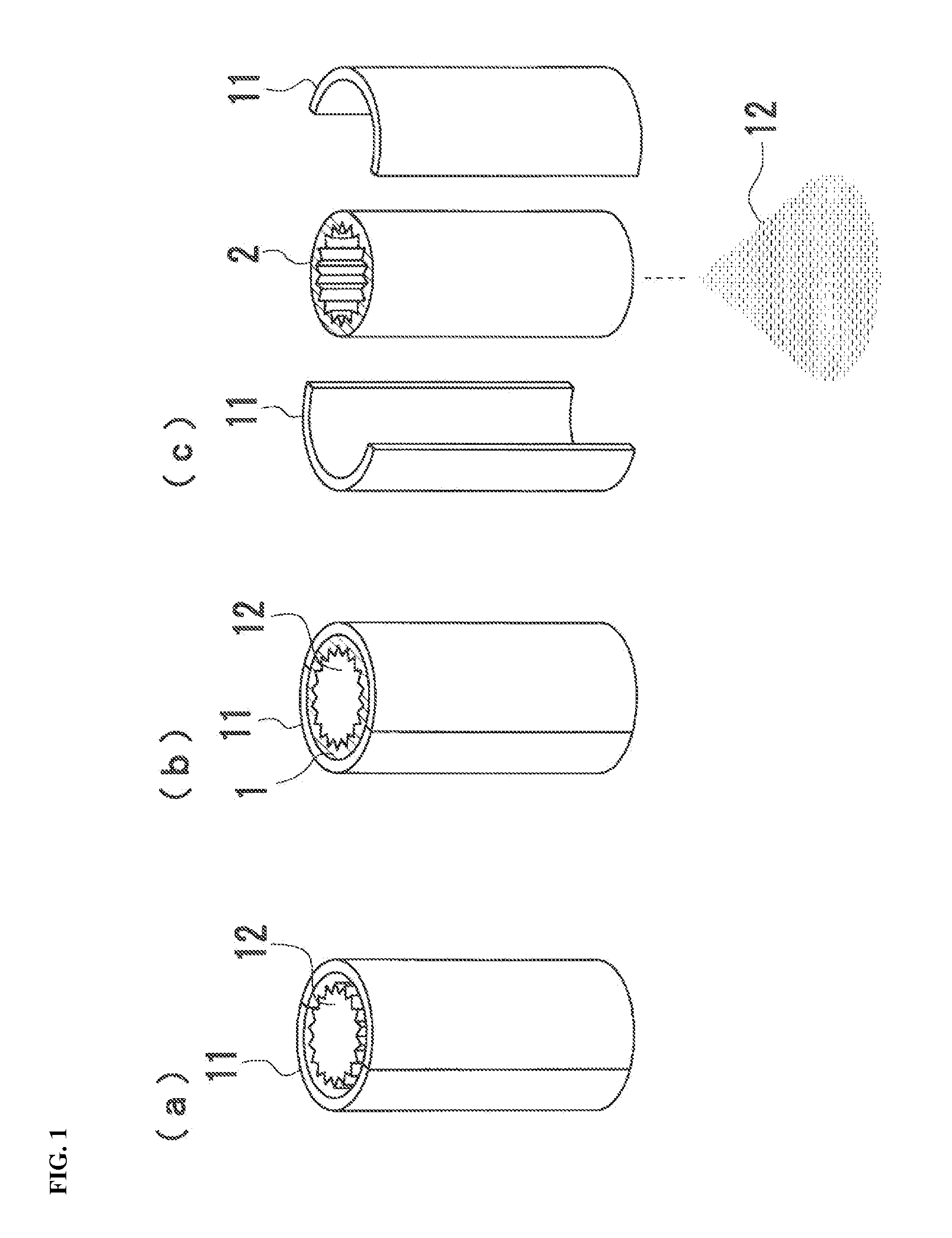

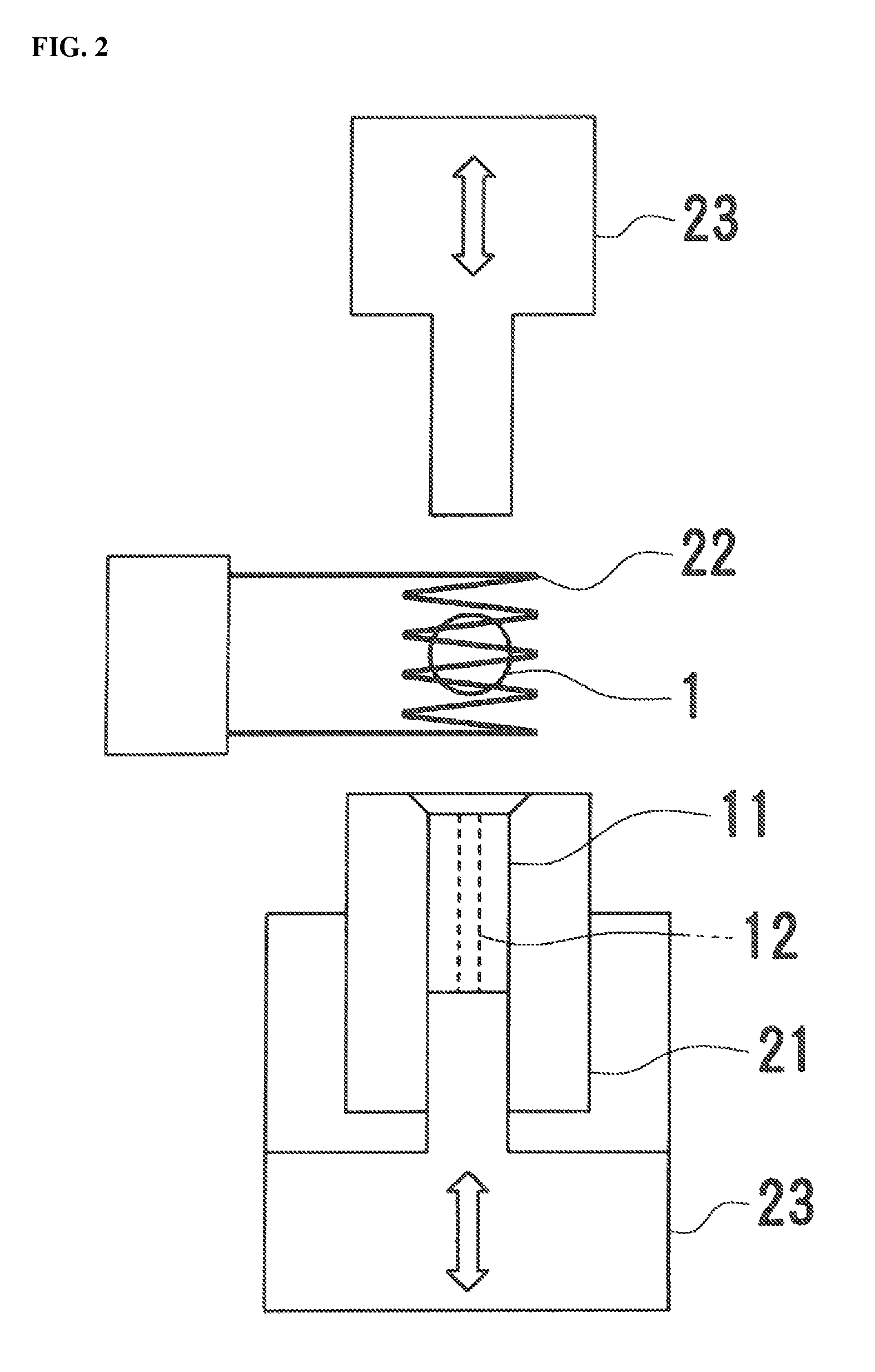

Internal gear manufacturing method and metallic glass internal gear manufactured thereby

InactiveUS8418366B2Shorten production timeImprove productivityMetal rolling stand detailsGearingMetallic materialsDissolution

Owner:NAMIKI PRECISION JEWEL CO LTD +1

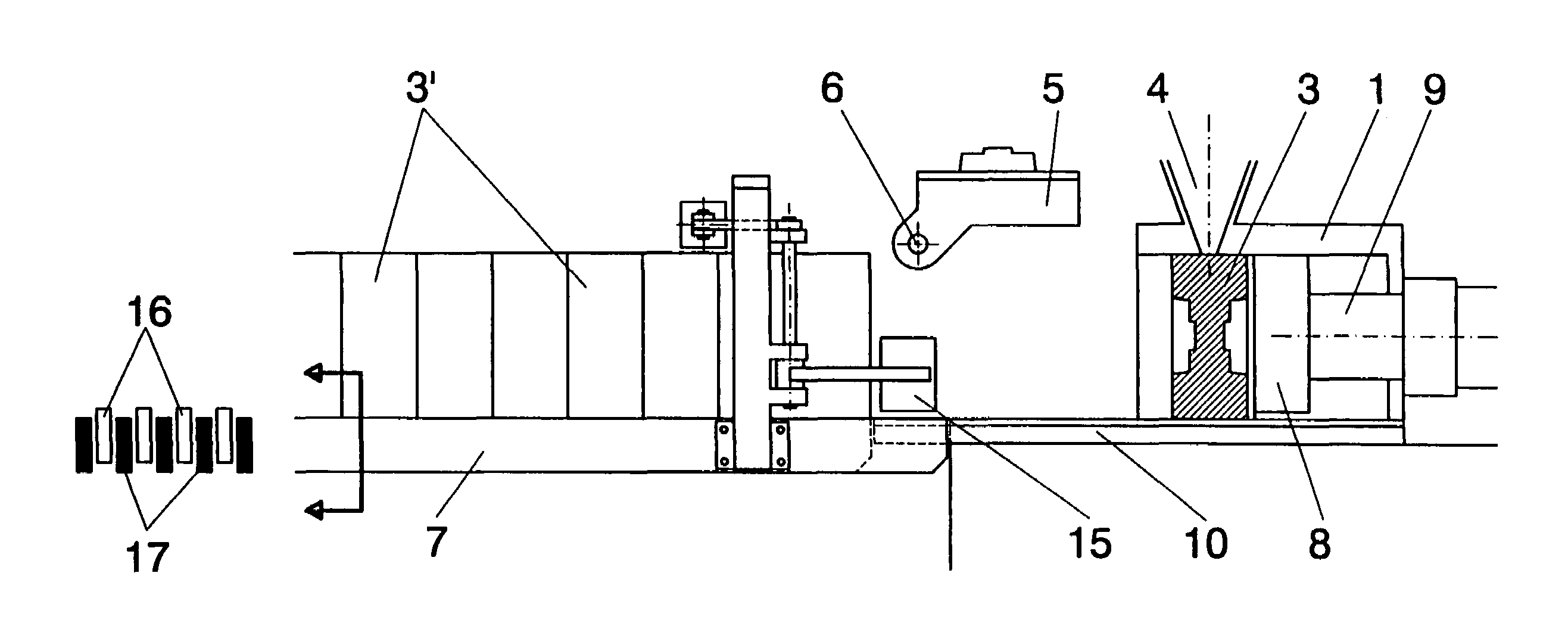

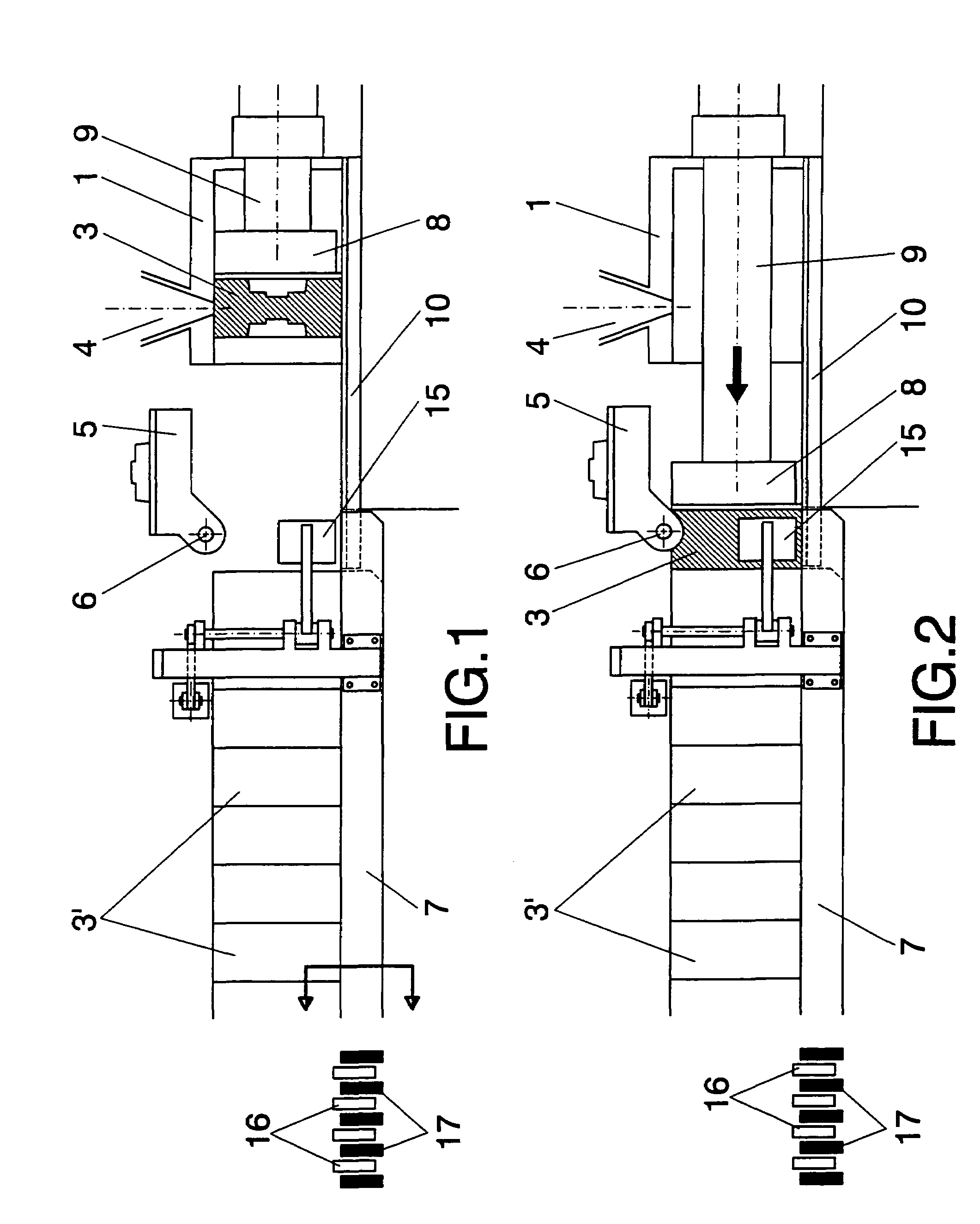

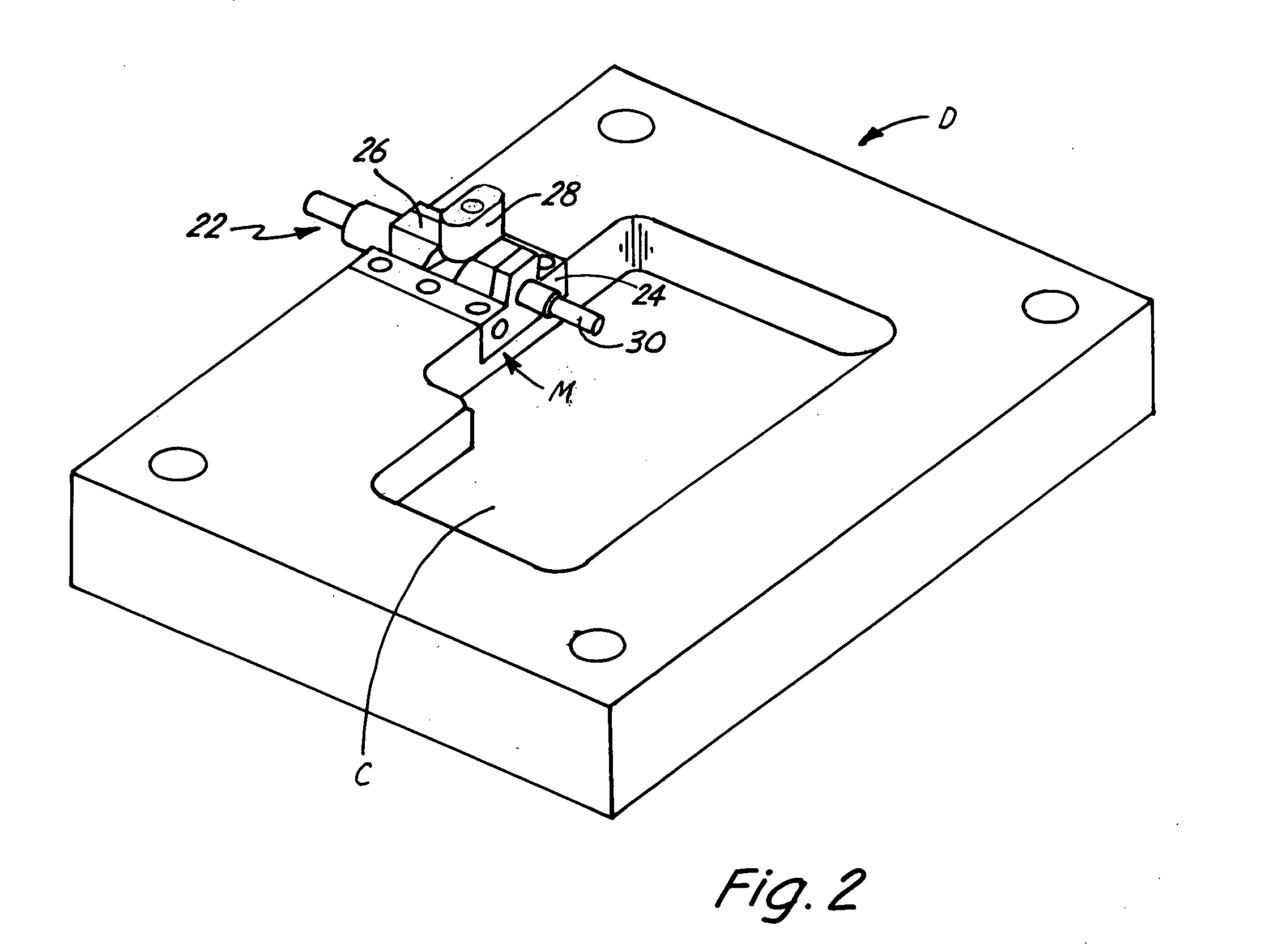

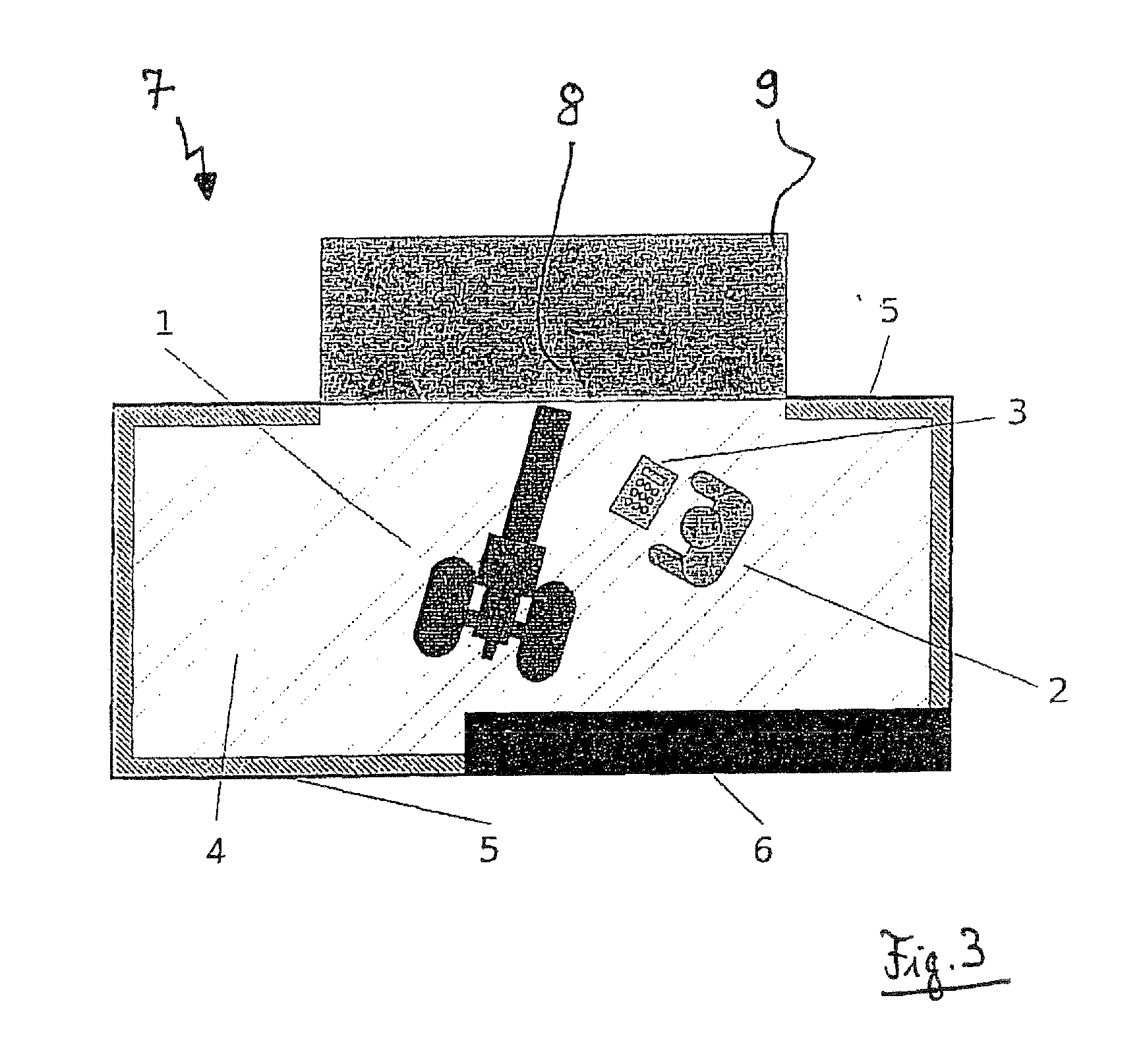

Vertical boxless mould casting machine

InactiveUS7007738B2Avoid waiting timeSynchronization is simplePig casting plantsFoundry mouldsMolding machineWork cycle

The molding machine comprises a station (1) with a chamber (2) that is closed between a front plate (5) that can move and swivel and a rear plate (8) associated to an extraction piston (9), forming a shell (3) in said chamber (2) by blowing sand through an upper hopper (4). The shell (3) obtained is pushed by the piston (9) until the rear of a row of shells (3′) placed on a conveyor (7) that places them opposite a casting station. The motion of the shell (3) pushed by the extraction piston (9) is independent of the motion of said piston after being incorporated in the row of shells, and is provided exclusively by the conveyor system (7), thereby providing a shorter working cycle while preventing deterioration of the shells as they are not compressed by the piston (9) when it pushes against the rear of the row of shells (3′).

Owner:LORAMENDI

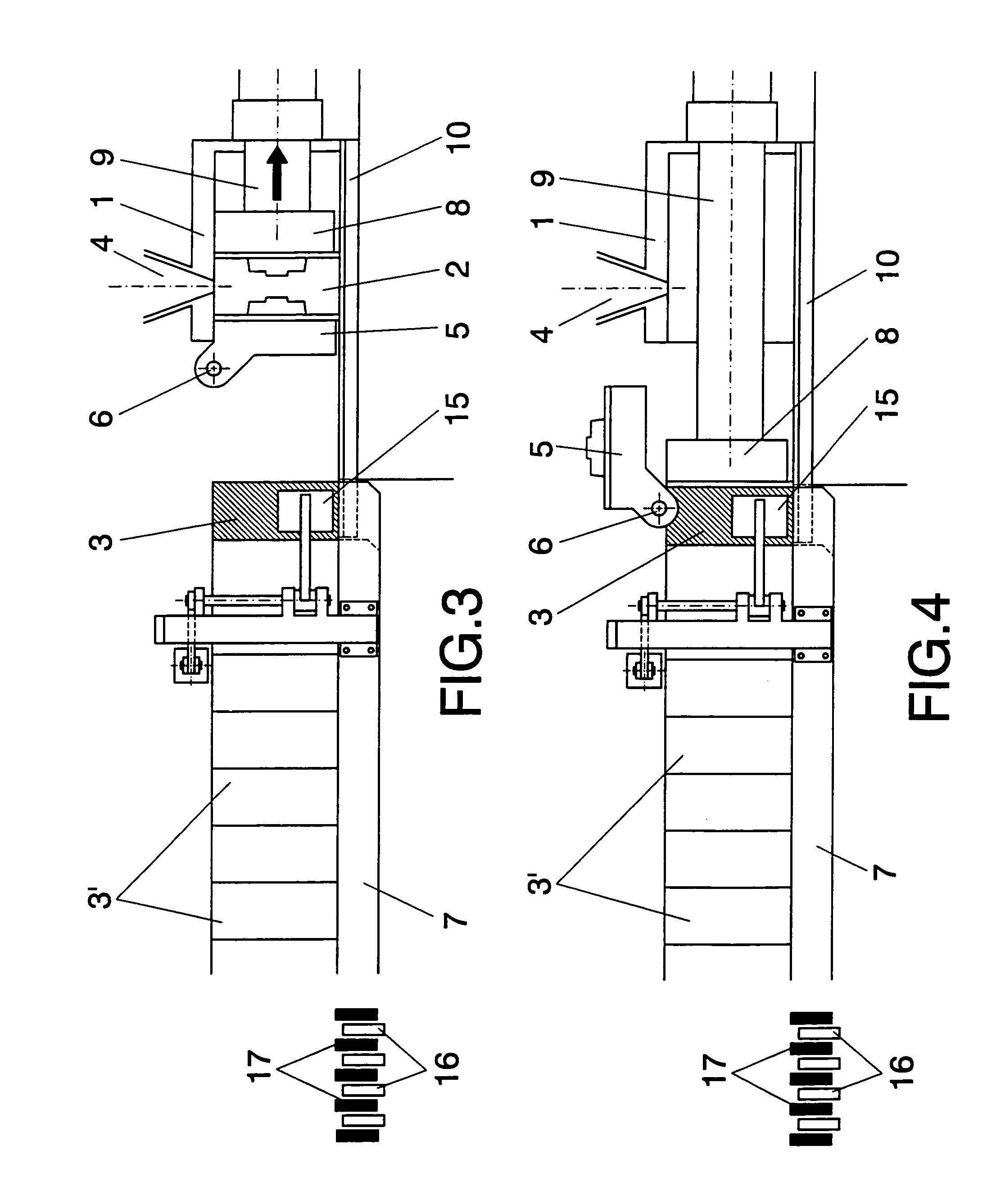

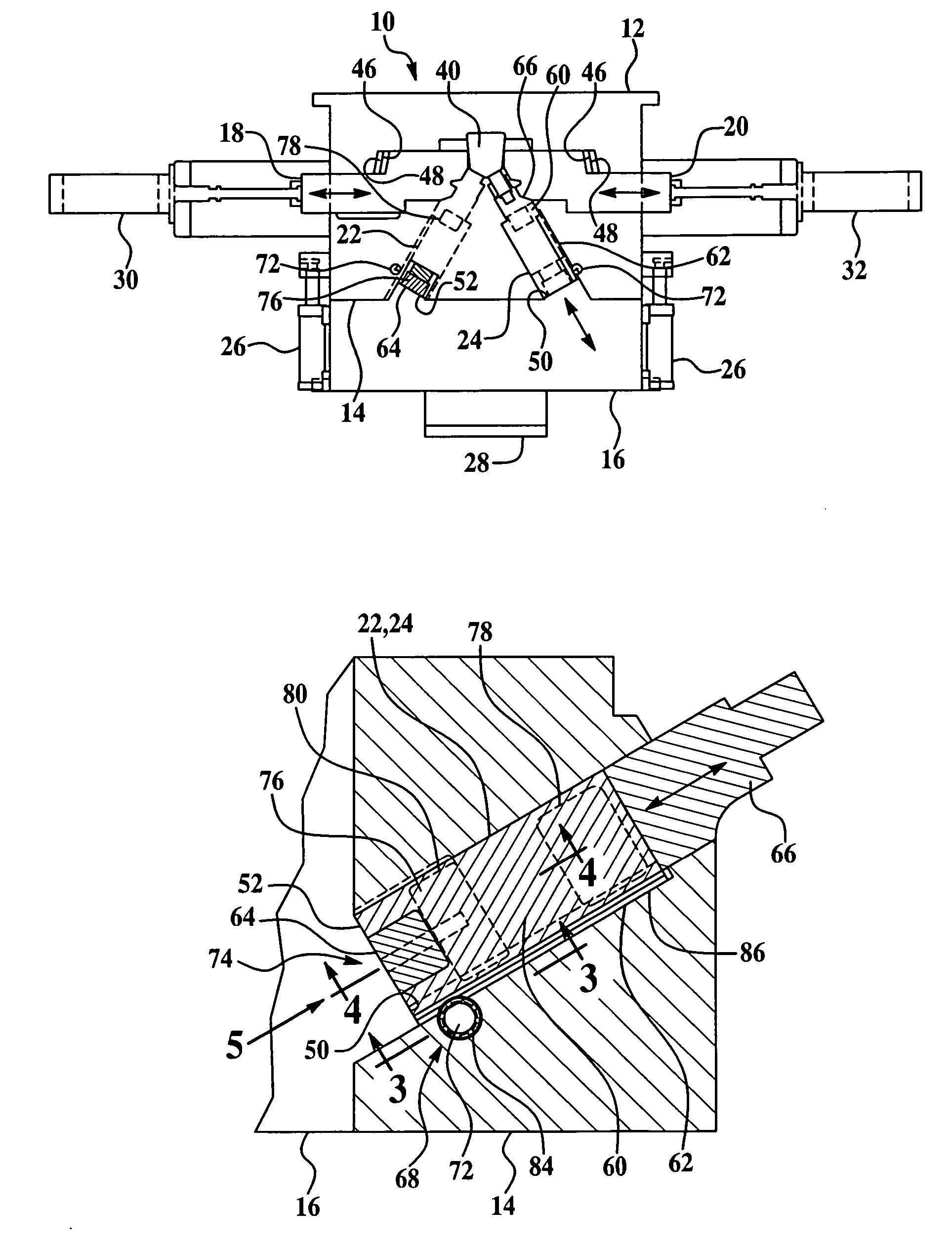

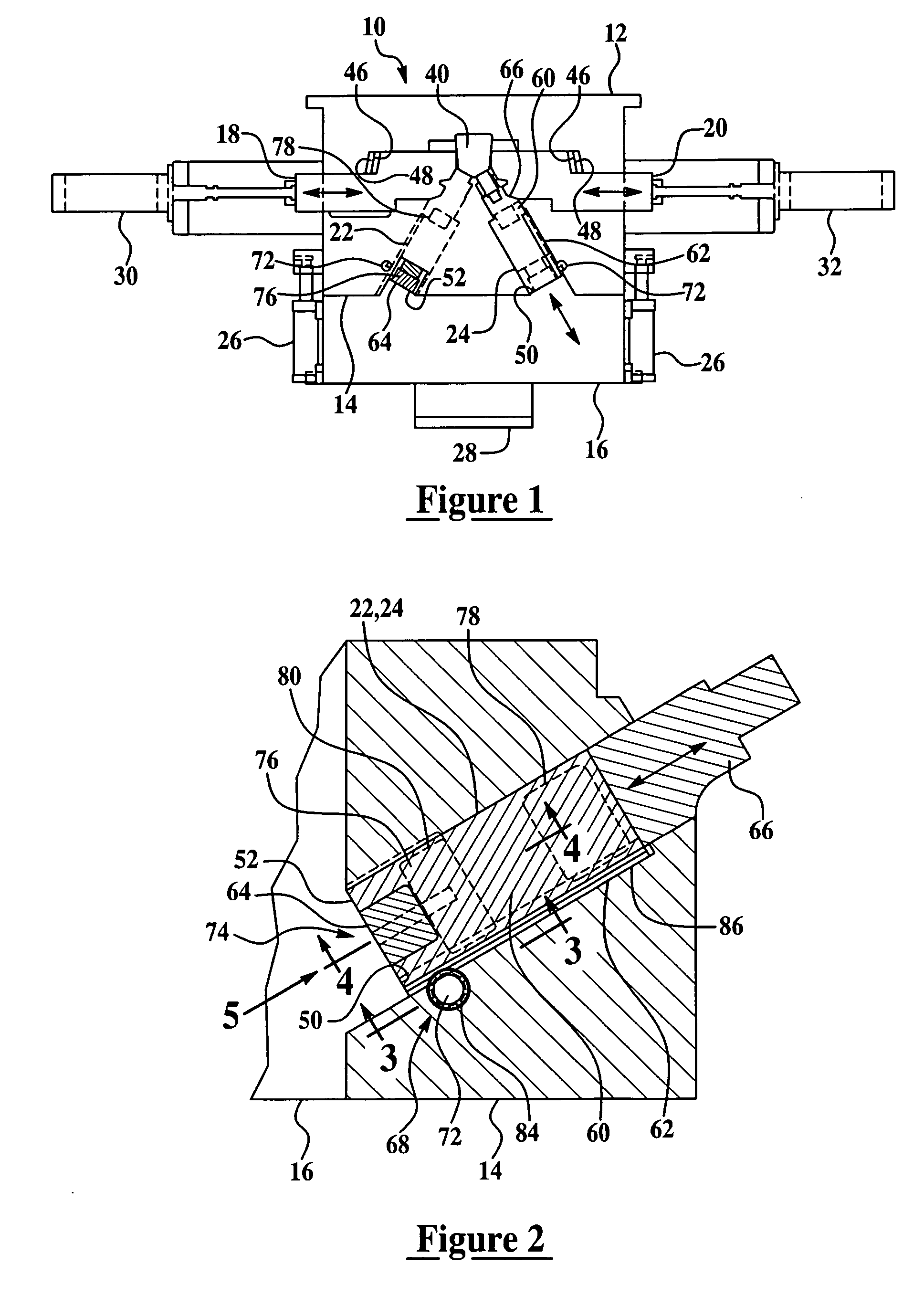

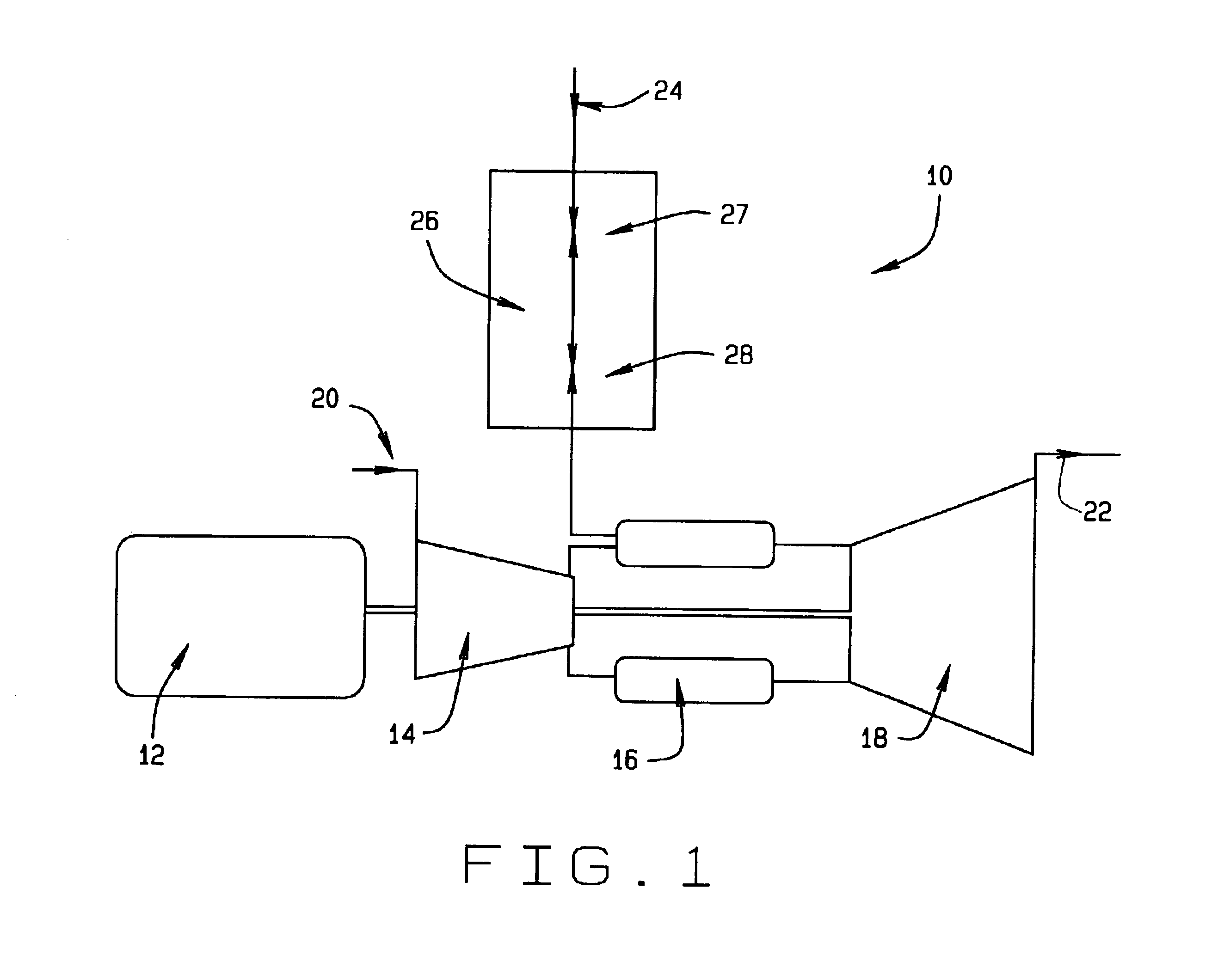

Engine block die-casting apparatus having mechanically actuated bank core slides

InactiveUS7278462B2Overcoming inefficienciesGood dimensional stabilityMould handling equipmentsDie castingEngineering

An engine block die-casting apparatus of the present invention includes a stationary element, an ejector holder block adapted to be operatively movable to and from the stationary element, and an ejector box. The apparatus also includes a pair of side slide cores and at least one bank core slide assembly that is slidably mounted and mechanically actuated within the ejector holder block. The stationary element, the ejector holder block, the pair of side slide cores, and the bank core slide assembly are adapted to be moved proximate each other so as to create a closed die-cast cavity and to be drawn apart from one another to allow extraction of the cast engine block.

Owner:AAR KEL ENTERPRISES

Methods and apparatus for fabricating turbine engine airfoils

A method for casting an airfoil for a turbine engine is provided. The method includes forming a casting core to define a hollow portion in the airfoil and forming a print out region at one end of the casting core. The method also includes coupling the casting core to the print out region with at least one frusto-conical member to facilitate structurally supporting the casting core.

Owner:GENERAL ELECTRIC CO

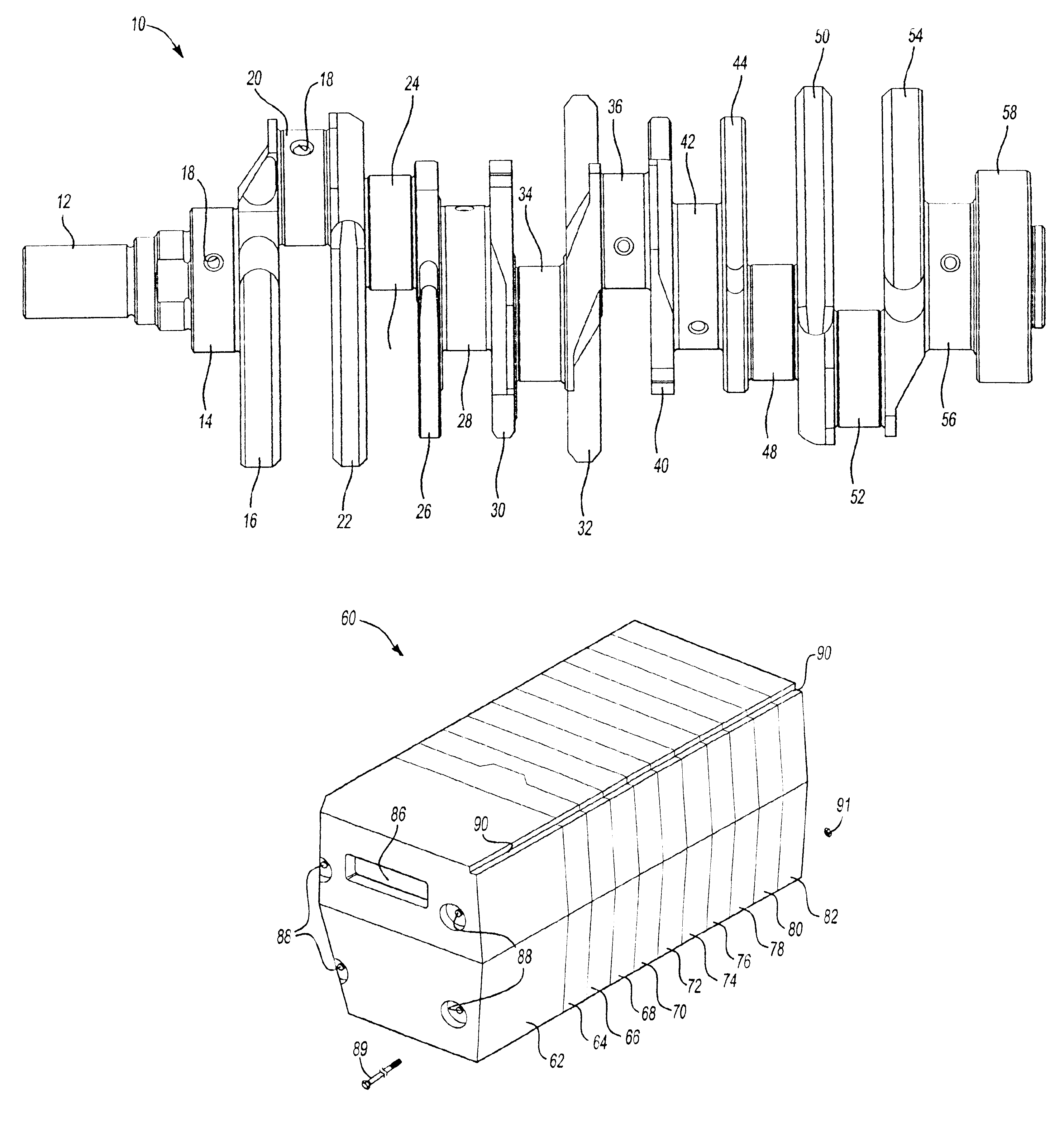

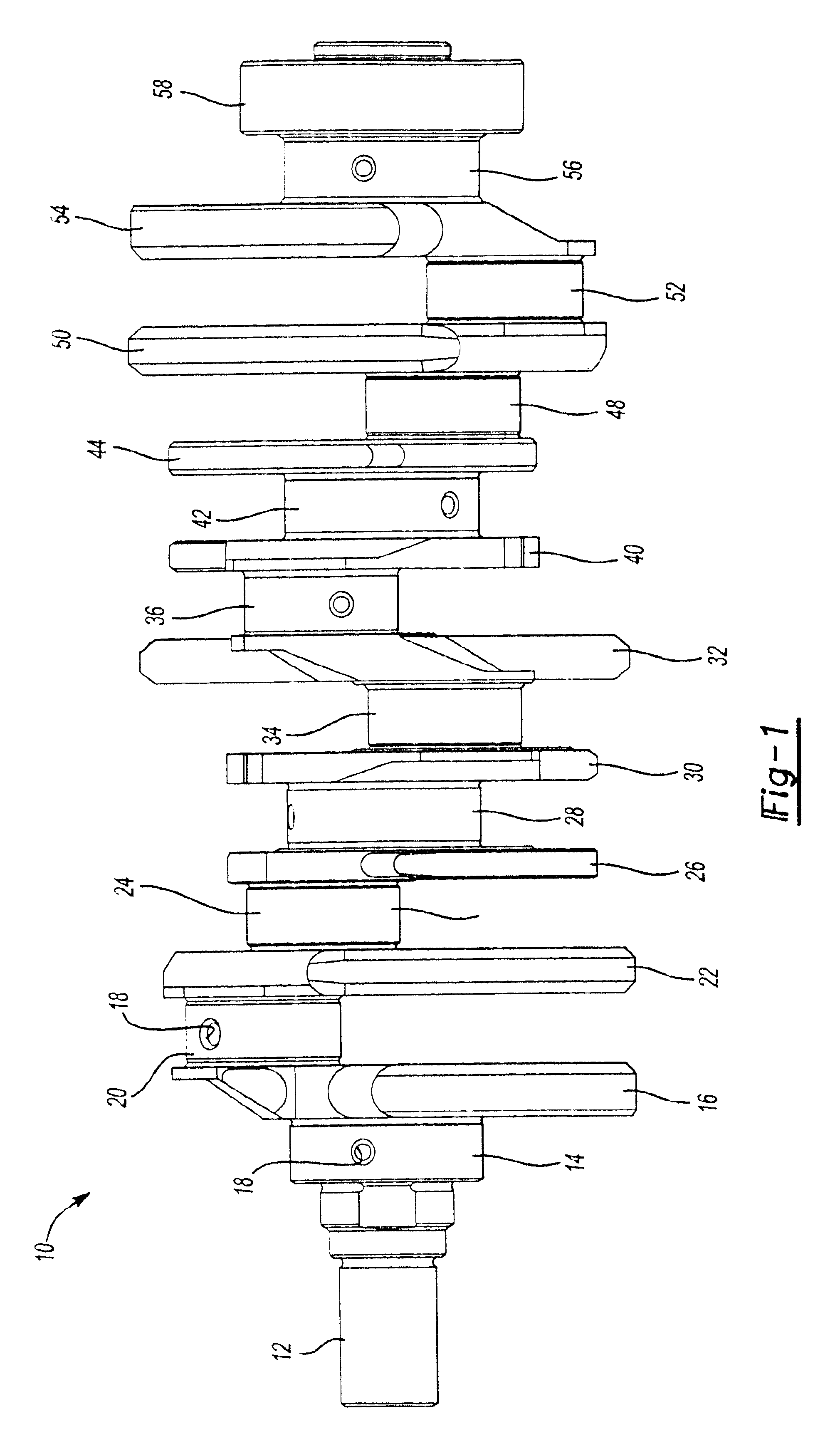

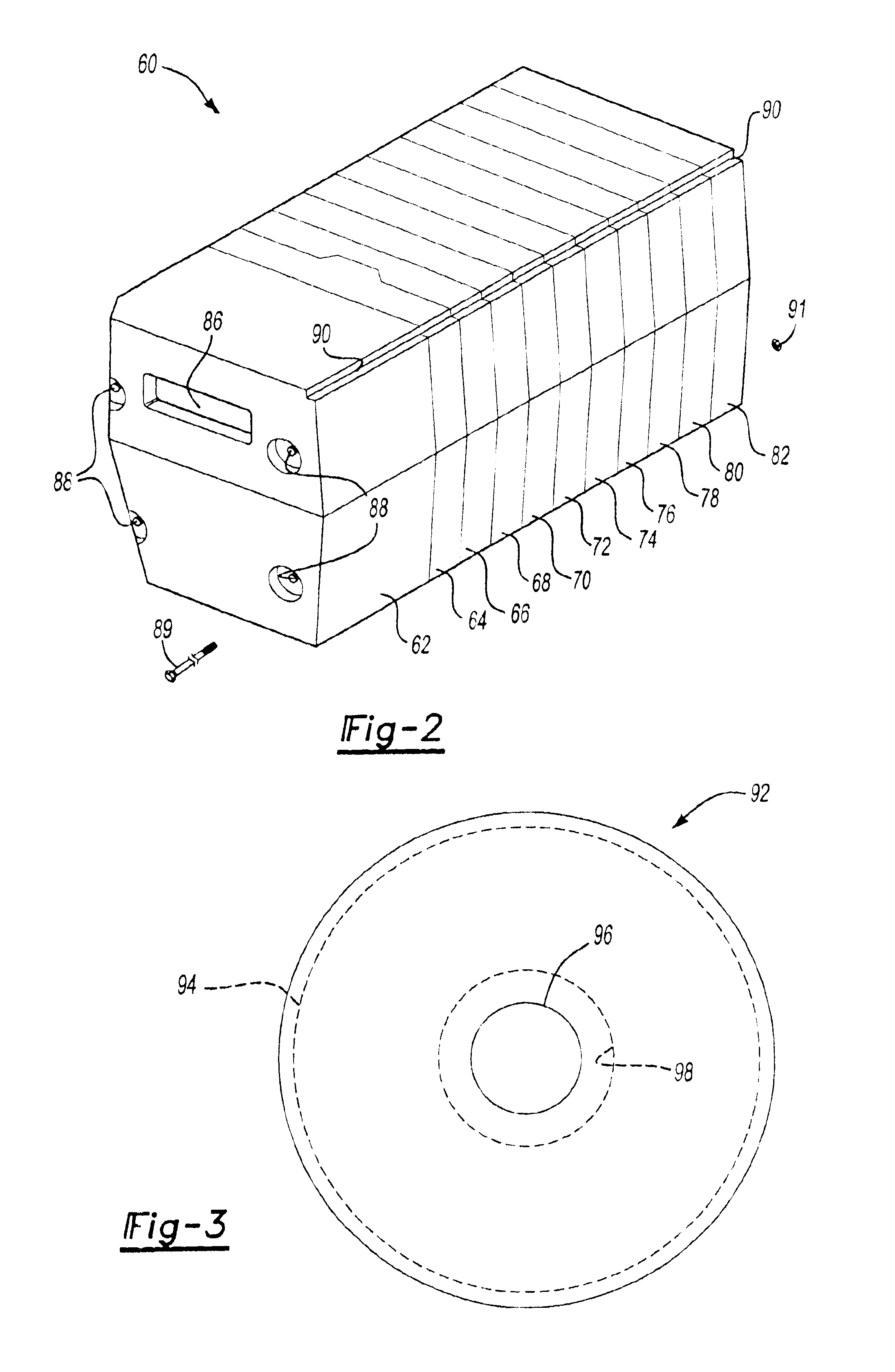

Metal casting core assembly for casting a crankshaft

A core box assembly for casting a crankshaft. The core box assembly comprises axially aligned cores that define different axial portions of a cavity that receives molten metal to cast the crankshaft. Oil gallery cores are placed in the core box assembly to form as-cast oil galleries in the crankshaft. Heavy metal inserts are held by sand cores disposed in the portions of the cavity that form the counterweights of the crankshaft.

Owner:FORD MOTOR CO

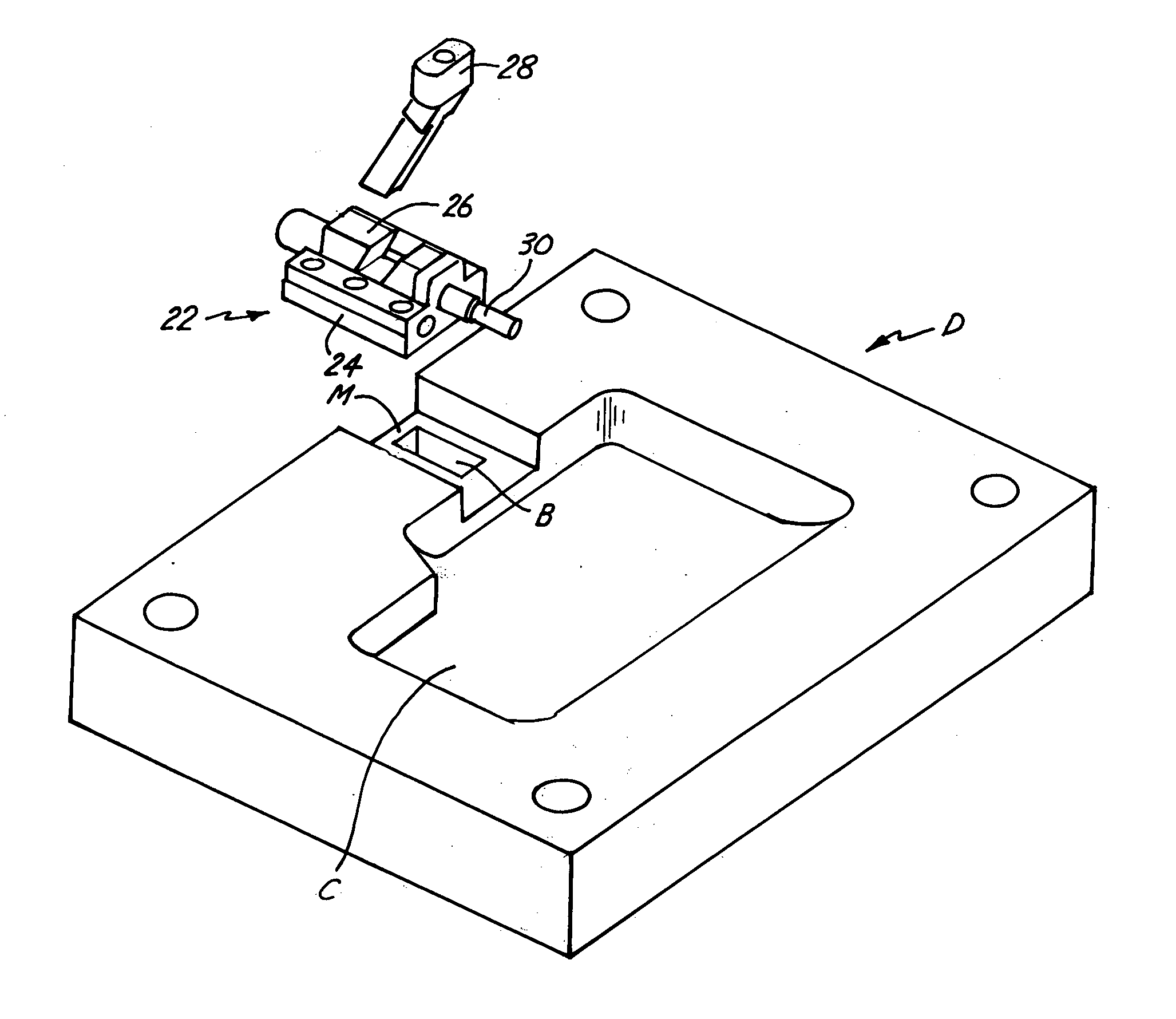

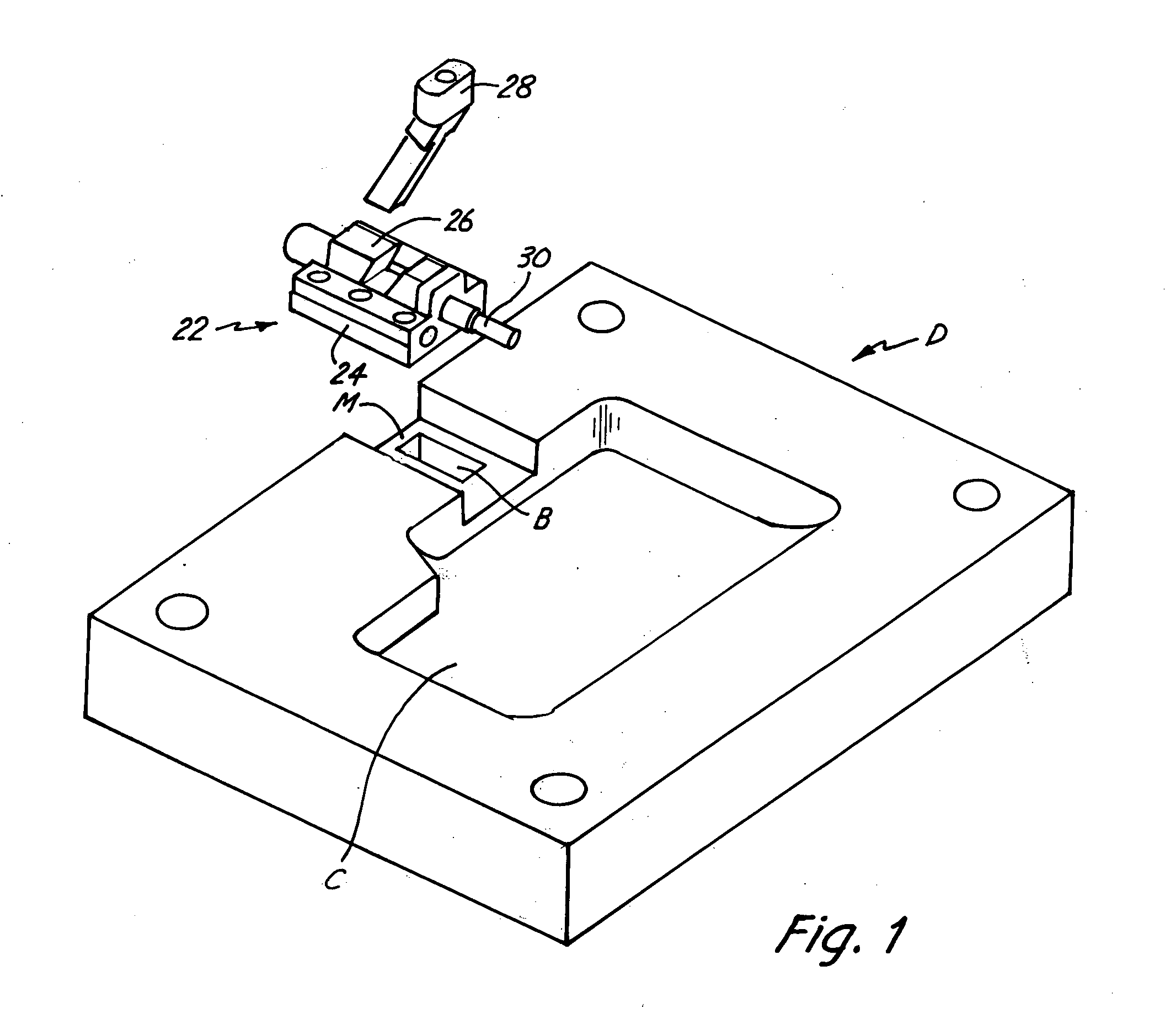

Universal slide assembly for molding and casting systems

InactiveUS20050098295A1Easy to installEasy to operateButtonsRecord carriersCost effectivenessEngineering

The present invention is a universal slide assembly for molding or casting systems used to introduce complex designs to moldings and castings, which is cost effective, easy to install, and easy to operate, and includes a base, a slide, and a cam lever. The base is directly insertable into a movable-die half for immediate use without requiring the slide to be individually designed or adapted to a particular movable-die half. The cam lever is capable of moving the slide towards and away from a core without the use of hydraulic power, through cam action.

Owner:DUBAY RICHARD L

Robot interaction system

InactiveUS8700197B2Performed quickly and efficientlyFlexibilityProgramme-controlled manipulatorMelt-holding vesselsInteraction systemsHuman–machine interface

In the case of a robot interaction system comprising a robot (1) having a robot controller with types of operation and operating modes which influence an associated man-robot interface, the aim is to provide a solution which allows flexible matching of a robot or robot system to different degrees of a man-robot interaction. This is achieved in that the robot controller is equipped with types of operation and operating modes which influence an associated man-robot interface and are designed to be matched and / or to be capable of being matched to different automation degrees of the robot (1) and / or to different time and / or physical positions of the man and robot as interaction partners in a working area.

Owner:SMS DEMAG AG

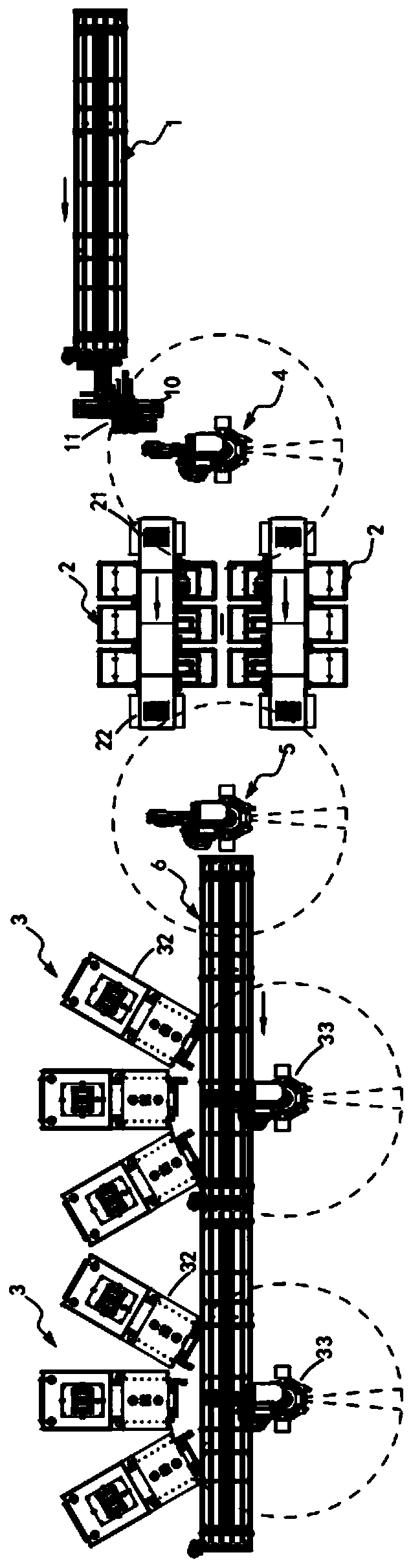

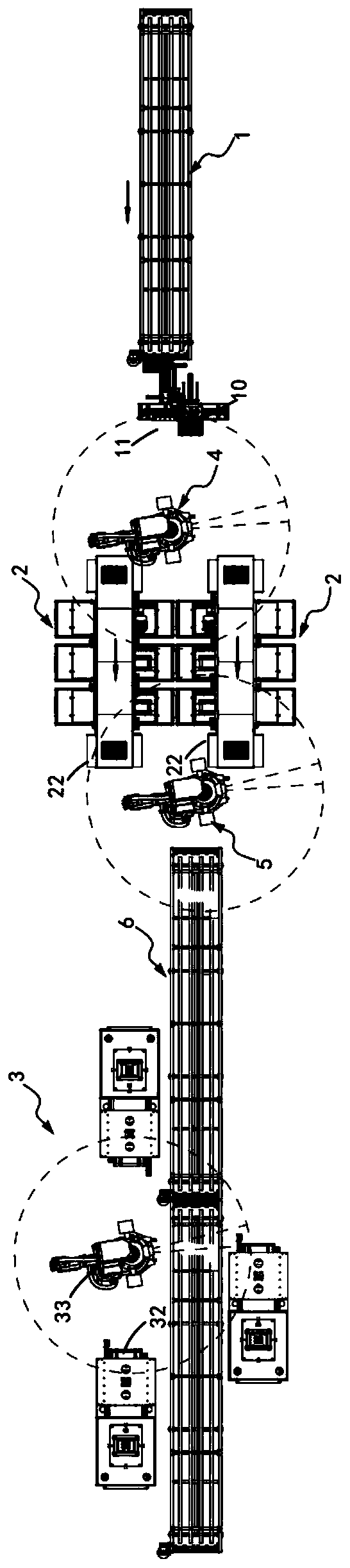

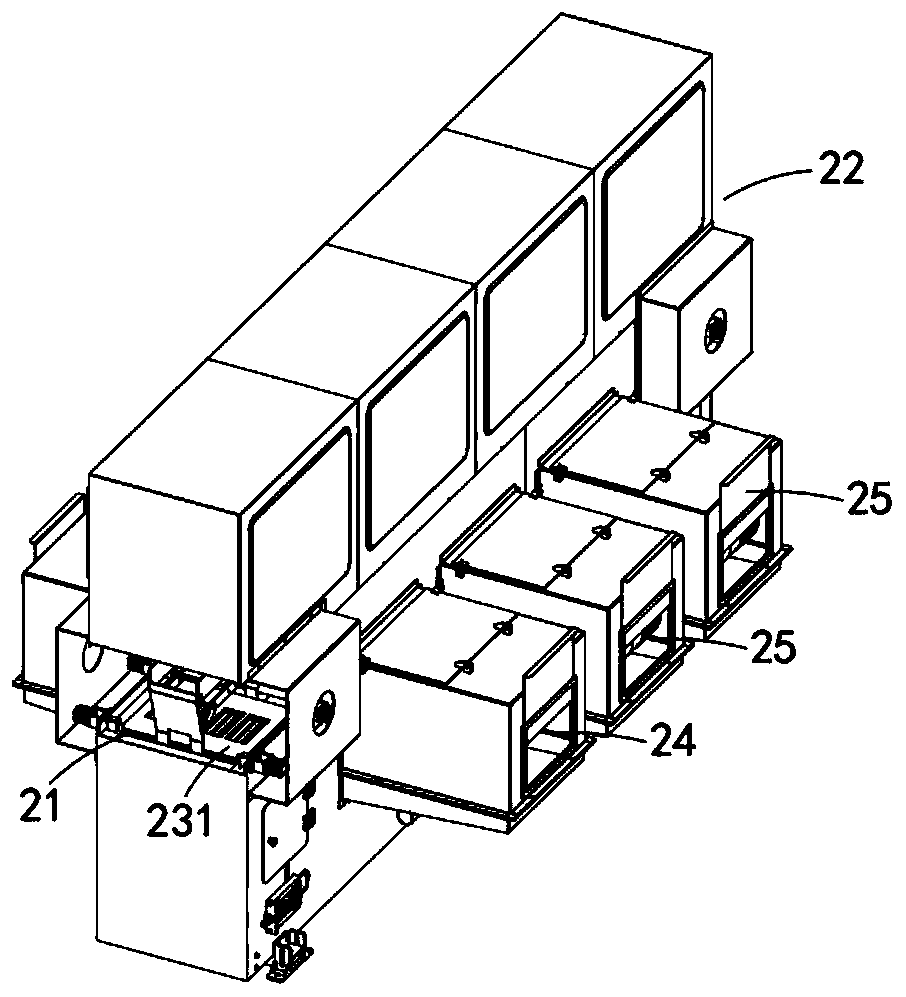

Lead-acid storage battery intelligent full-automatic cast-weld production line and process thereof

ActiveCN111299550AAvoid heavy useImprove processing efficiencyMould handling equipmentsConveyor partsProcess engineeringMachining process

The invention relates to the technical field of lead-acid battery production, and particularly discloses a lead-acid storage battery intelligent full-automatic cast-weld production line and a processthereof. In the production line, lead-acid batteries are transferred, conveyed, cut and machined through mutual cooperation of cutting equipment, a second grabbing manipulator, a conveying line and atransferring manipulator, and alternative automatic loading and unloading work of a plurality of groups of cast-weld machines is realized, so that the technical problem of low machining efficiency during the automatic processing of existing lead-acid batteries is solved. In the process, the transferring, conveying and cutting of the lead-acid batteries are realized through automatic tight joint ofa cutting step and a cast-weld step, and alternative automatic loading and unloading work of the plurality of groups of cast-weld machines is realized, so that the plurality of groups of cast-weld machines can perform cast-weld machining simultaneously; the machining efficiency is improved; and the technical problem of low machining efficiency in the automatic machining process of the existing lead-acid batteries is solved.

Owner:长兴玖佳机械股份有限公司

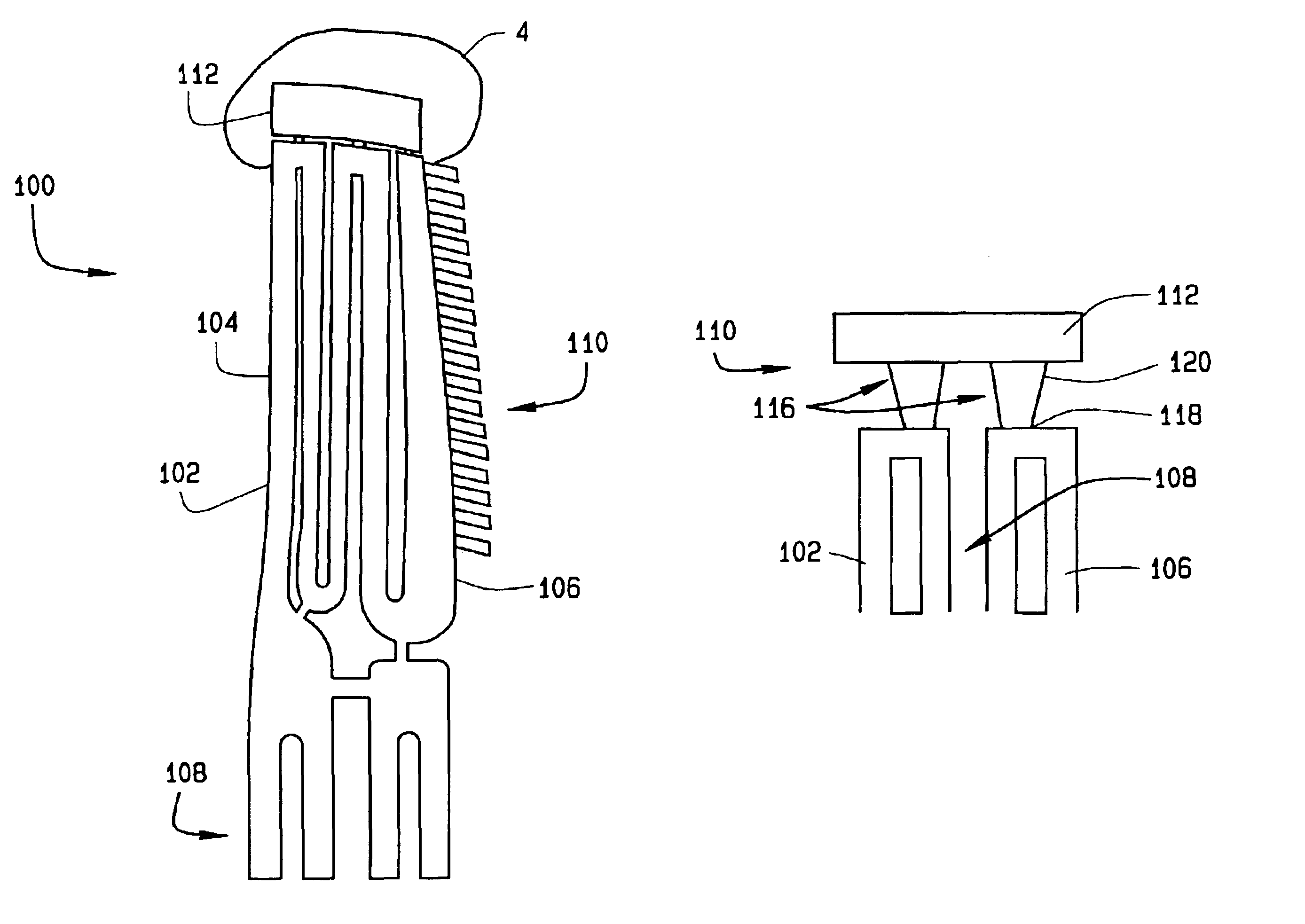

Quasi self-destructive core for investment casting

A composite core for forming a passage in an investment casting mold is provided including a generally hollow structural element. The structural element is configured to deform when a force is applied to an end thereof. A rigid shell element is formed about the structural element. The shell element extends beyond both an interior surface and an exterior surface of the structural element. The shell element is configured to shatter when the structural element deforms.

Owner:SIKORSKY AIRCRAFT CORP

Weld closure of through-holes in a nickel-base superalloy hollow airfoil

InactiveUS20070084582A1Small mechanical propertiesSmall physical propertiesTurbinesBlade accessoriesCasting moldMaterials science

A hollow airfoil is fabricated by providing a casting mold assembly including a casting mold, a casting core, and a standoff spacer that prevents the casting core from contacting the casting mold to define a casting space. A first nickel-base superalloy is cast into the casting space and solidified to form the hollow airfoil. The presence of a through-hole extending through a wall of the hollow airfoil is identified, and the through-hole is closed by welding using a second nickel-base superalloy, without using any freestanding closure element.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com