Patents

Literature

77results about How to "Small physical and mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial lignin reinforcing rubber and preparation method of industrial lignin reinforcing rubber

The invention relates to industrial lignin reinforcing rubber and a preparation method of the industrial lignin reinforcing rubber. The industrial lignin reinforcing rubber is characterized in that 1, the industrial lignin reinforcing rubber comprises lignin dispersoid, rubber latex, a small number of plasticizers and operation oil or comprises multi-component lignin dispersoid, rubber latex, a small number of plasticizers and operation oil; 2, the lignin dispersoid is suspension of lignin in water, the weight part of the lignin is 5 to 30 percent, the multi-component lignin dispersoid is suspension of the lignin and inorganic fillers in water, and the weight proportion of the lignin to the water is (5-30):(95-70); and 3, in the lignin dispersoid and the multi-component lignin dispersoid, the lignin is hydroxymethylation modified dispersoid. The preparation method comprises the steps of 1. lignin preparation, 2, lignin dispersoid preparation, 3, rubber latex preparation, 4, cosedimentation and solidification and 5, industrial lignin reinforcing rubber obtaining. The industrial lignin reinforcing rubber and the preparation method have the advantages that the physical and mechanical properties of the rubber are not reduced, meanwhile, the drying processes in the lignin and rubber production process are combined, and the motive power consumption of rubber mixing is reduced.

Owner:广西合山林格高分子材料科技有限公司

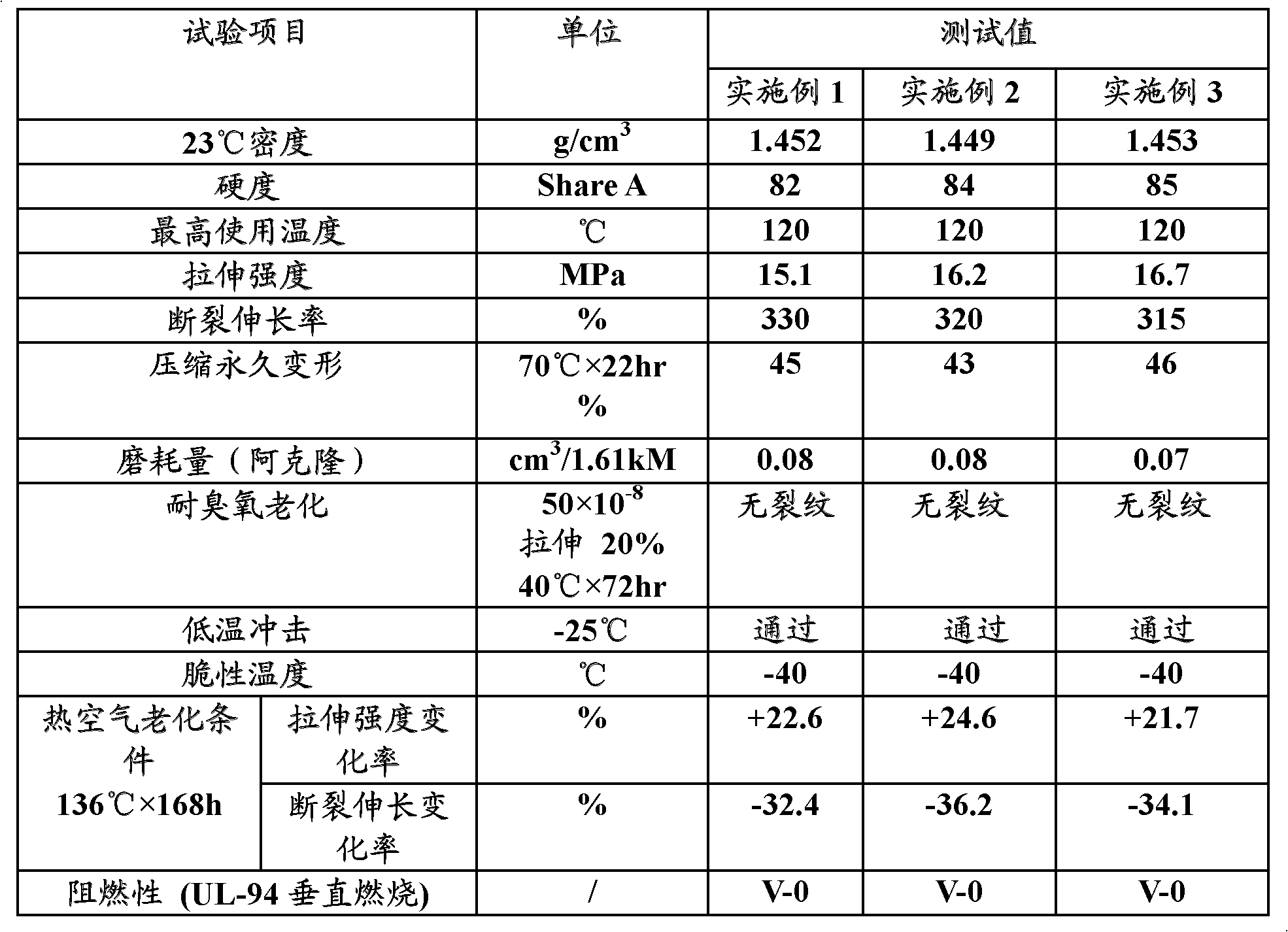

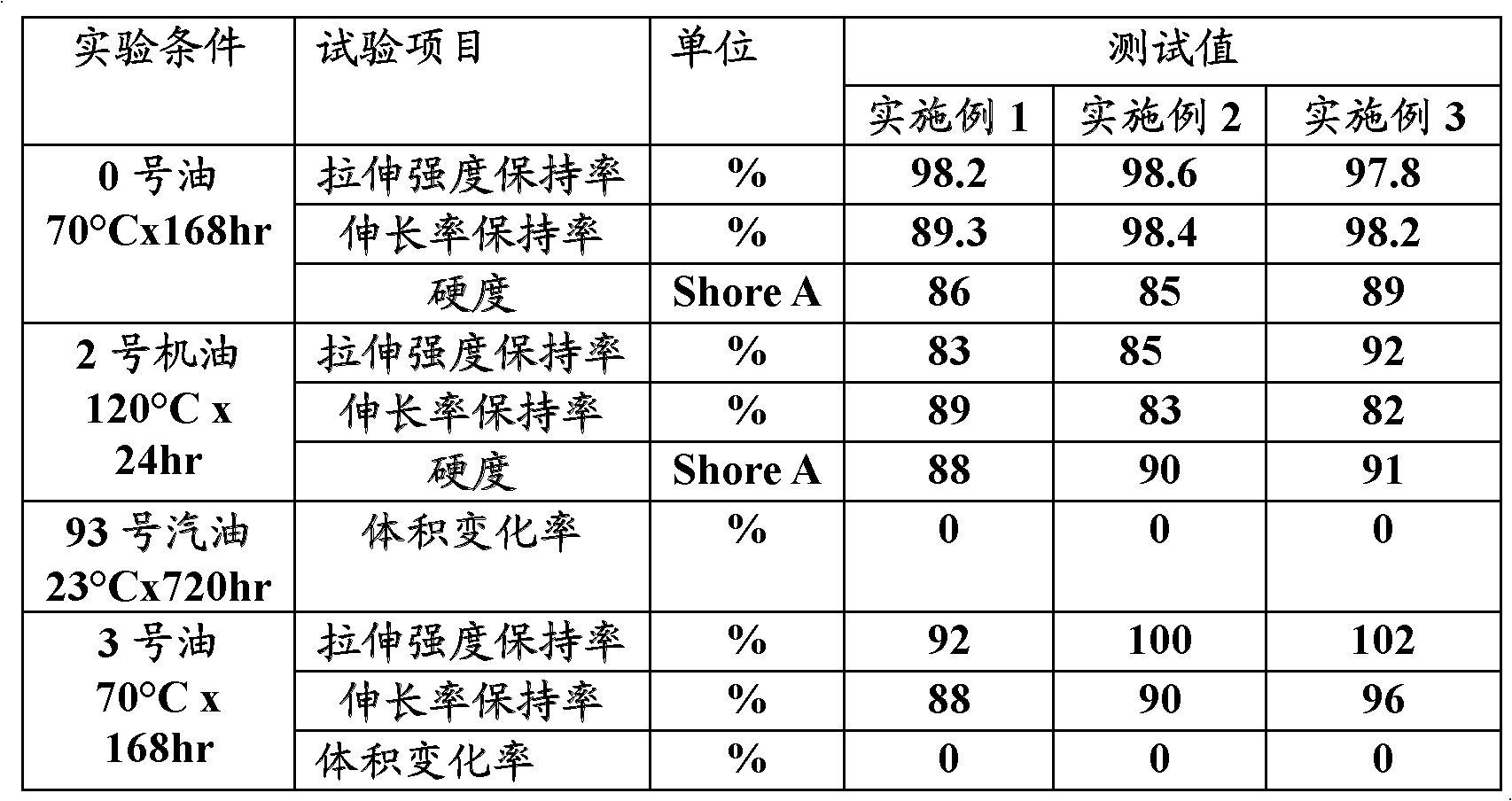

Environmentally friendly, high and low temperature resistant, oil resistant, wear resistant and fire retardant rubber plastic composition

The invention relates to a rubber plastic composition, which is made from the following components of: by weight, 40-50 parts of an acrylonitrile butadiene rubber powder, 30-40 parts of a preplastic polrvinyl chloride powder, 5-15 parts of ternary copolymerized polyamide, 5-15 parts of magnesium hydroxide, 5-15 parts of antimonous oxide and 0.5-1.5 parts of a processing aid. The acrylonitrile butadiene rubber powder is made from components of: by weight, 90-98% of nitrile rubber, 0.15-1% of a vulcanizator, 0.5-3% of an anti-aging agent, 0.5-3% of an activating agent, 0.3-3% of a vulcanizationaccelerator and 0.5-1.2% of an isolating agent. The preplastic polrvinyl chloride powder is made from components of: by weight, 75-90% of a PVC resin, 0.2-1% of an antioxidant, 1-8% of a calcium zincstabilizer and 8-18% of a plasticizer DITDP diisotridecyl phthalate. The composition provided by the invention has excellent high and low temperature resistance, oil resistance, wear resistant and fire retardant performance. In addition, raw materials which are not environmentally friendly are not used. Therefore, the invention is especially applicable to be used as a sheathing compound for wire and cable.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

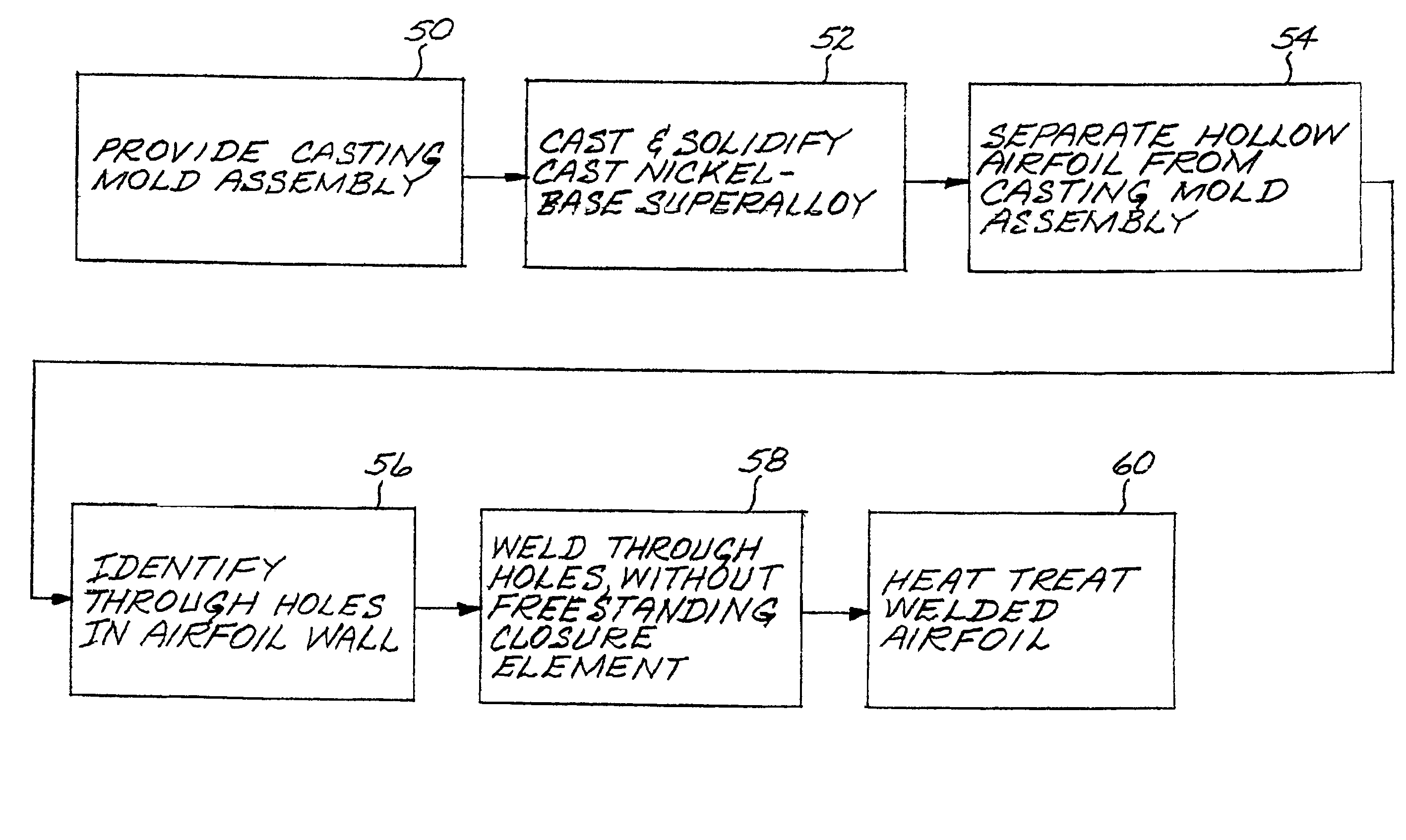

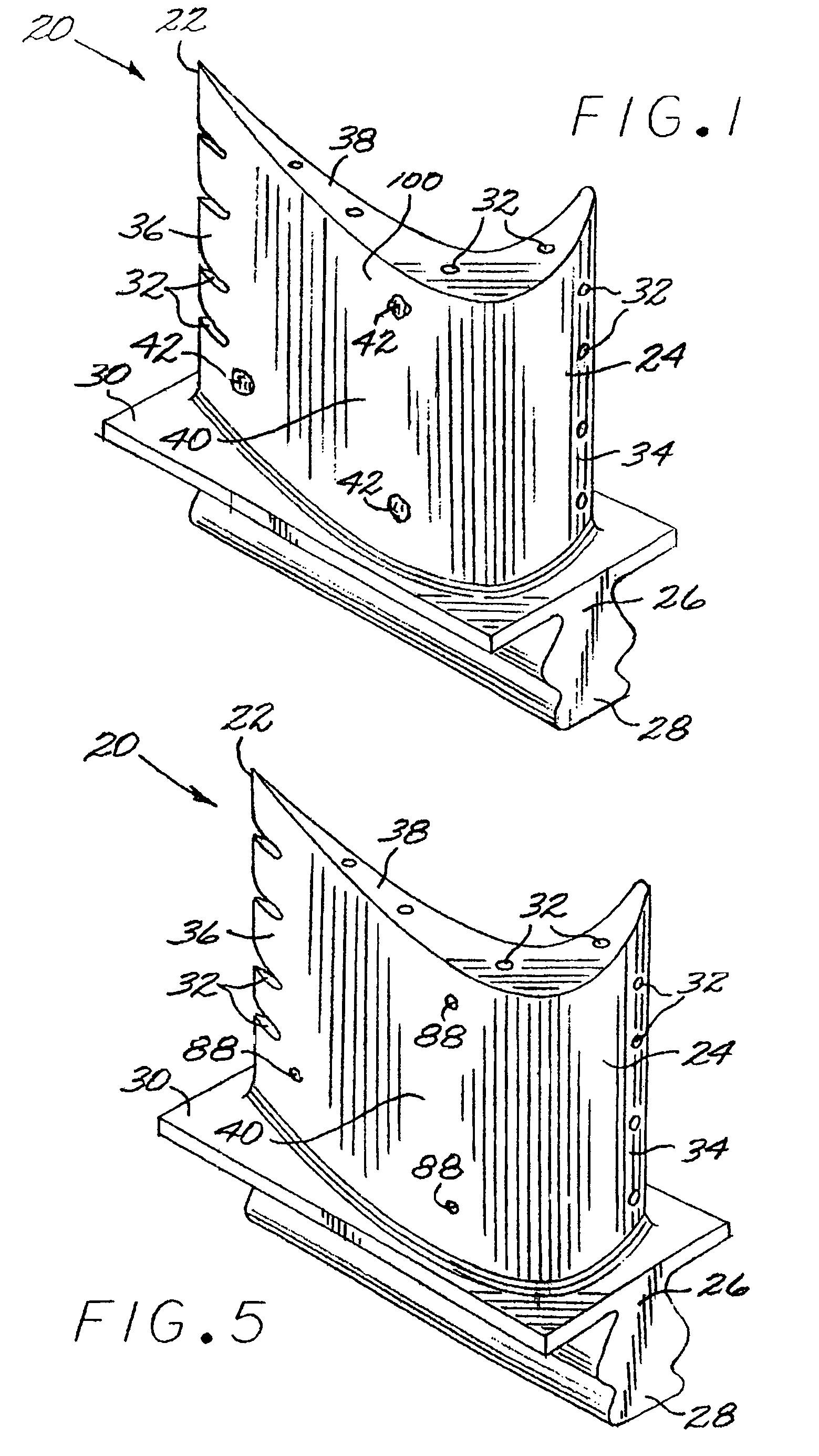

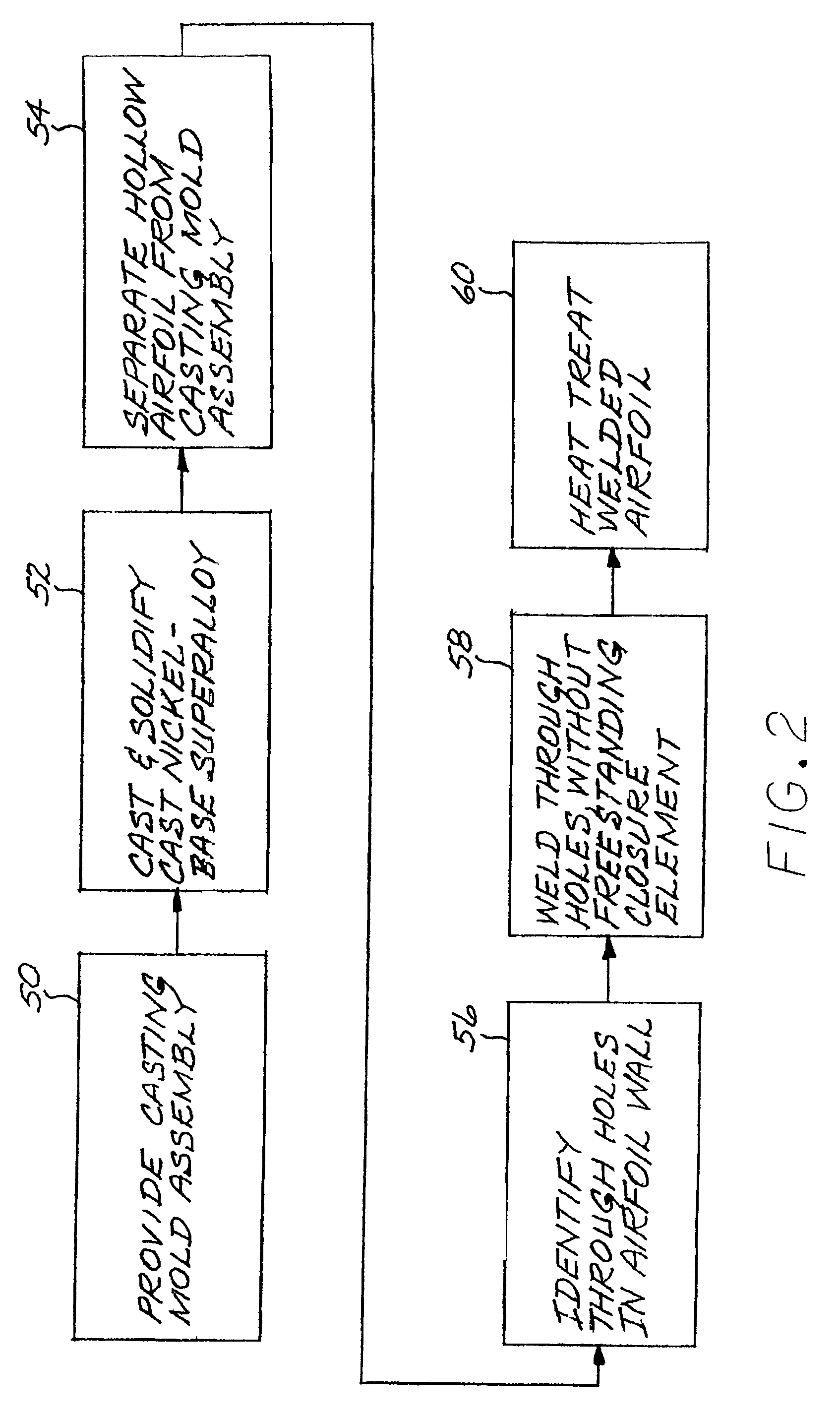

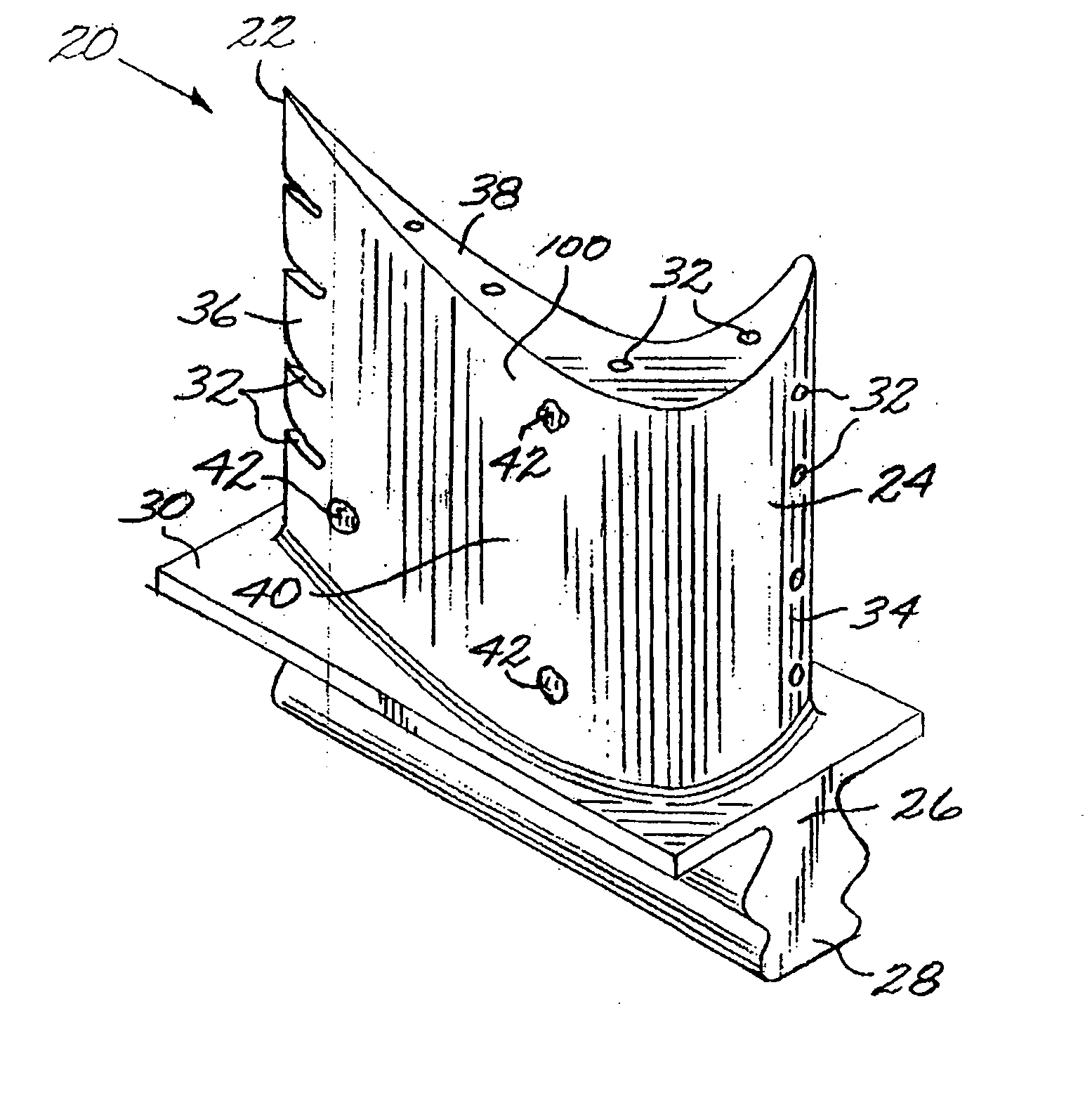

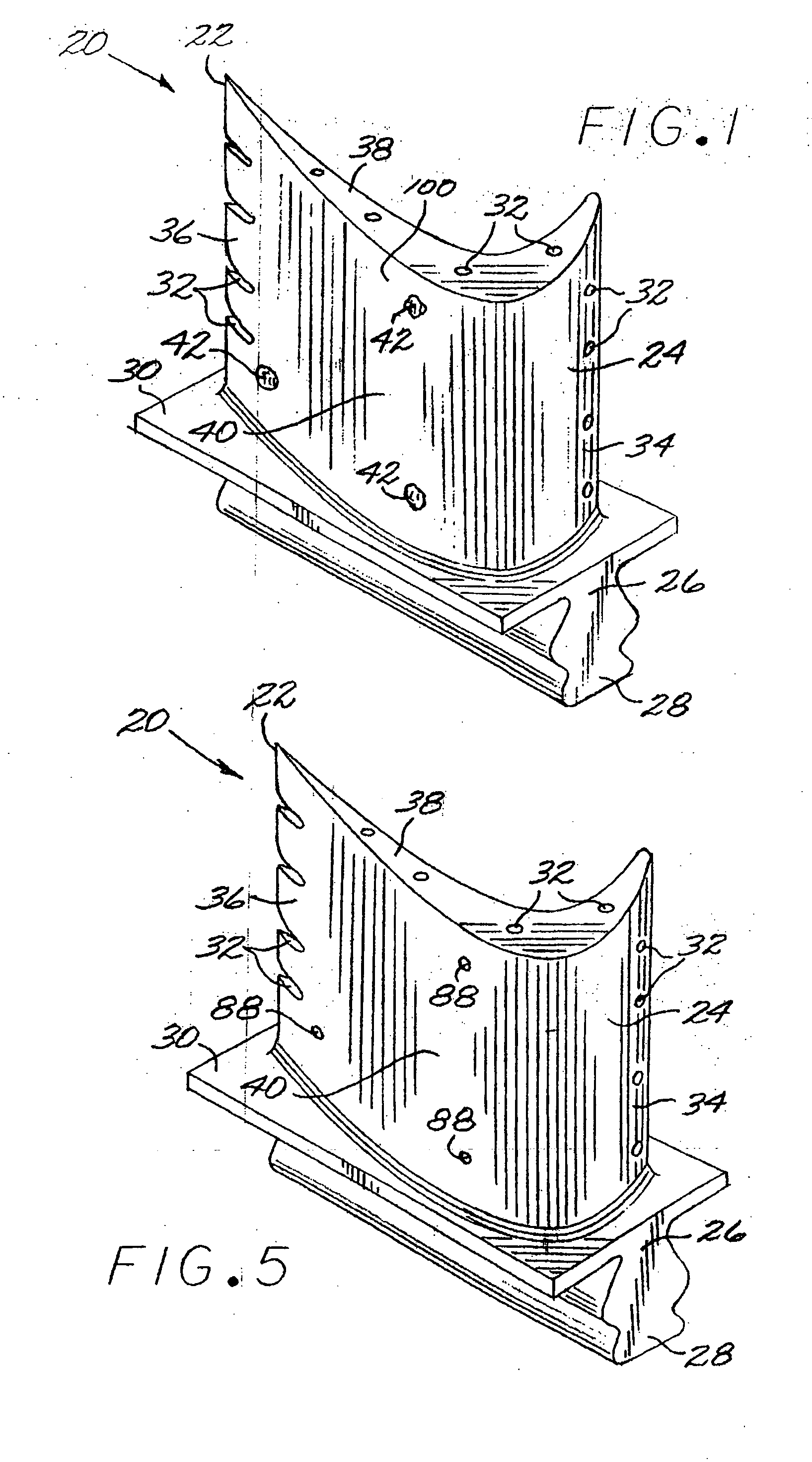

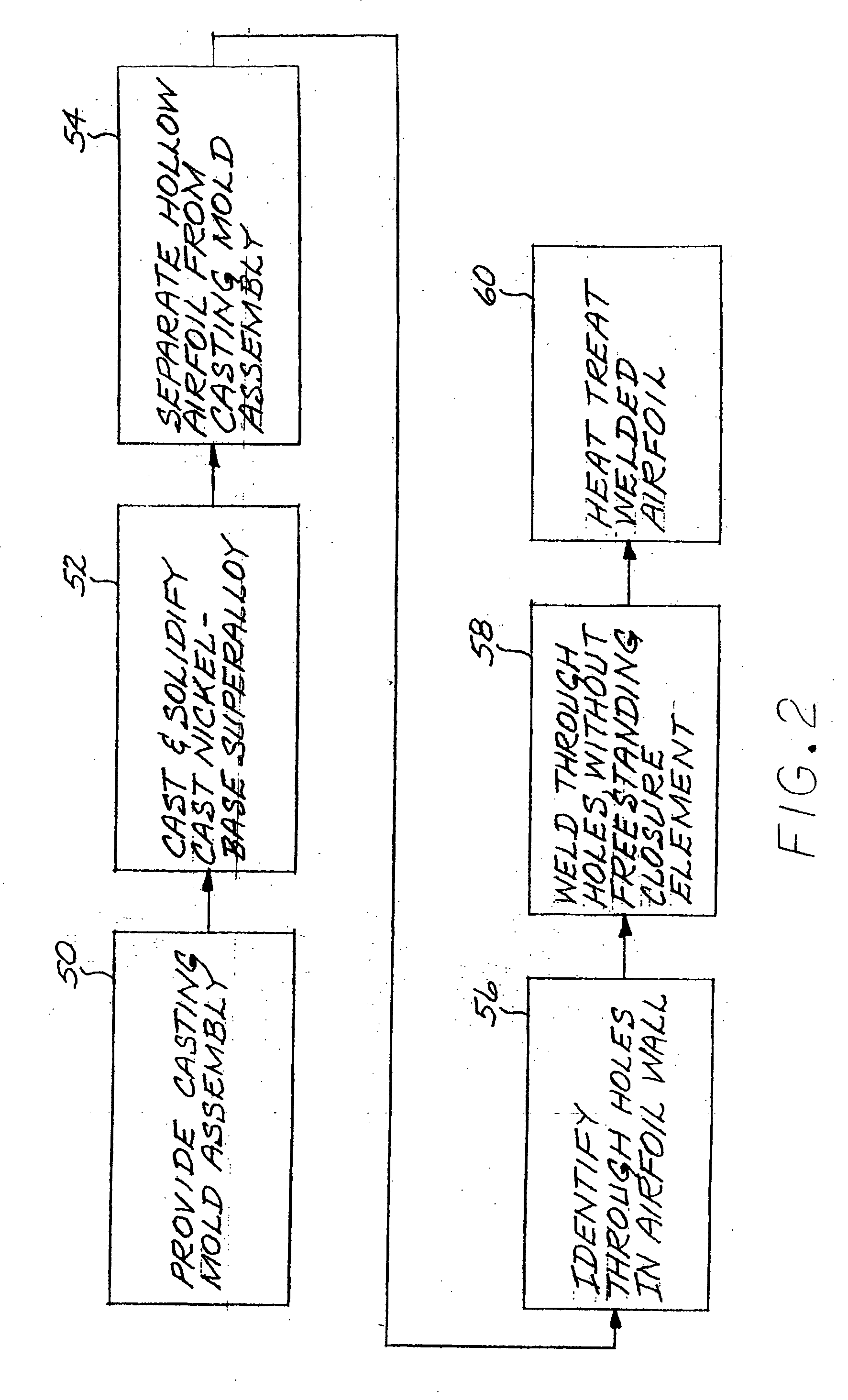

Weld closure of through-holes in a nickel-base superalloy hollow airfoil

InactiveUS7322396B2Small physical and mechanical propertiesImprove adhesionTurbinesBlade accessoriesCasting moldNickel based

A hollow airfoil is fabricated by providing a casting mold assembly including a casting mold, a casting core, and a standoff spacer that prevents the casting core from contacting the casting mold to define a casting space. A first nickel-base superalloy is cast into the casting space and solidified to form the hollow airfoil. The presence of a through-hole extending through a wall of the hollow airfoil is identified, and the through-hole is closed by welding using a second nickel-base superalloy, without using any freestanding closure element.

Owner:GENERAL ELECTRIC CO

Sizing formula of flame-retarding elastic support rubber product

The invention discloses a sizing formula of a flame-retarding elastic support rubber product. The sizing formula is characterized in that components of the rubber product are as follows (parts by mass of each component are shown in brackets): 21-type-322 neoprene (25-35), standard 1# natural rubber (65-75), zinc oxide (7-9), light magnesium oxide (4-6), sulfur (0.1-1.0), an accelerant CZ (1.3-1.7), an accelerant Na-22 (0.4-0.6), an ageing inhibitor 4,010 (0.8-1.2), 2,500-mesh diantimony trioxide (15-25), 2,500-mesh aluminium hydroxide (50-60) and semi-reinforcing carbon black (10-20). In the invention, unvulcanized rubber is a combination of the neoprene and the natural rubber, a vulcanizing system is a combination of metal oxide and the sulfur, a flame retardant is a combination of the diantimony trioxide and aluminium hydroxide, and the semi-reinforcing carbon black is used for reinforcing; therefore, the prepared rubber product has good physicochemical properties, especially has high oxygen index and low smoke index. The invention is applicable to preparing the elastic support rubber product used between a floor board and a floor board framework when floor boards are laid in a public place and on a passenger train, a subway as well as a bus.

Owner:铁岭华晨橡塑制品有限公司

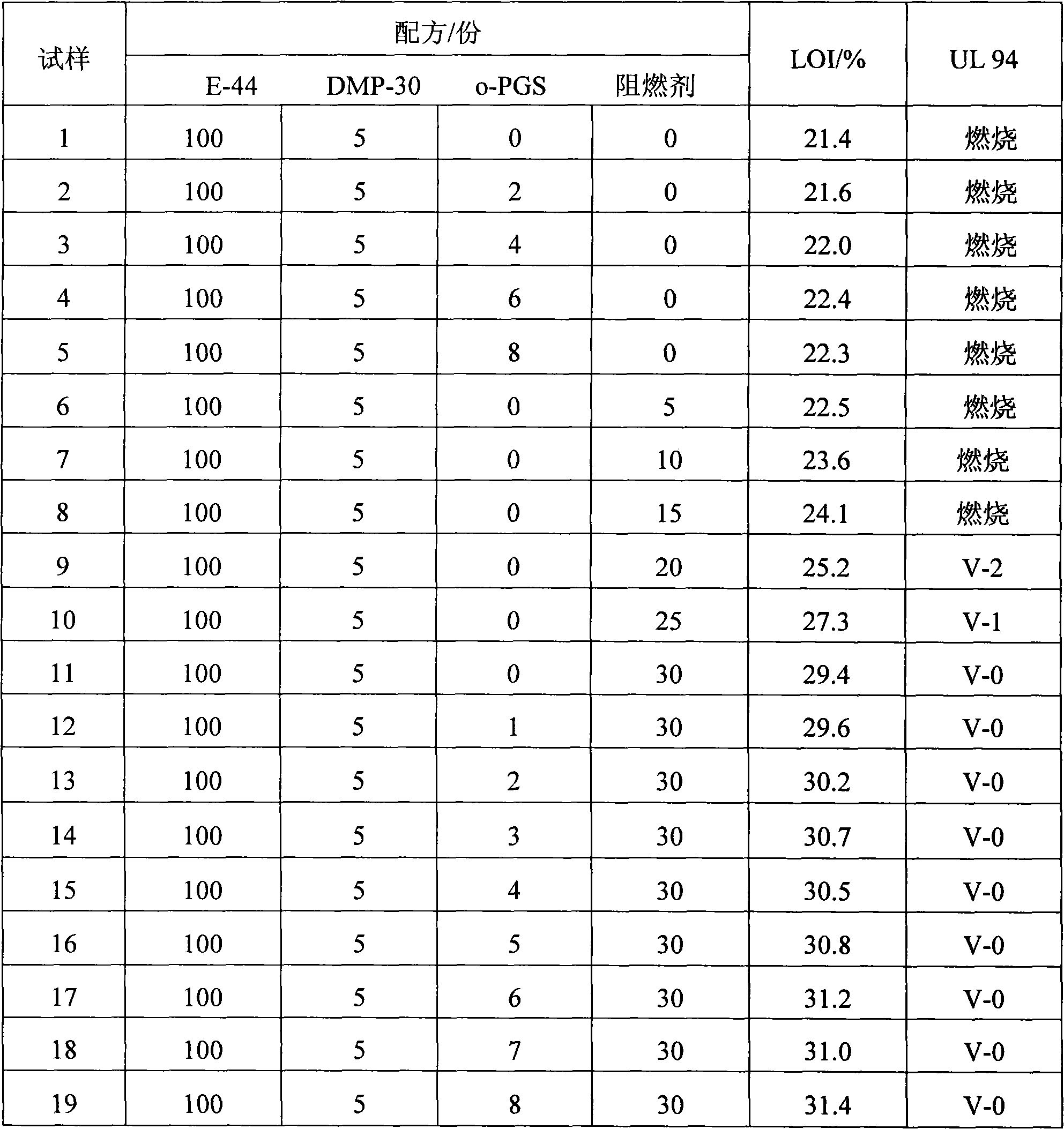

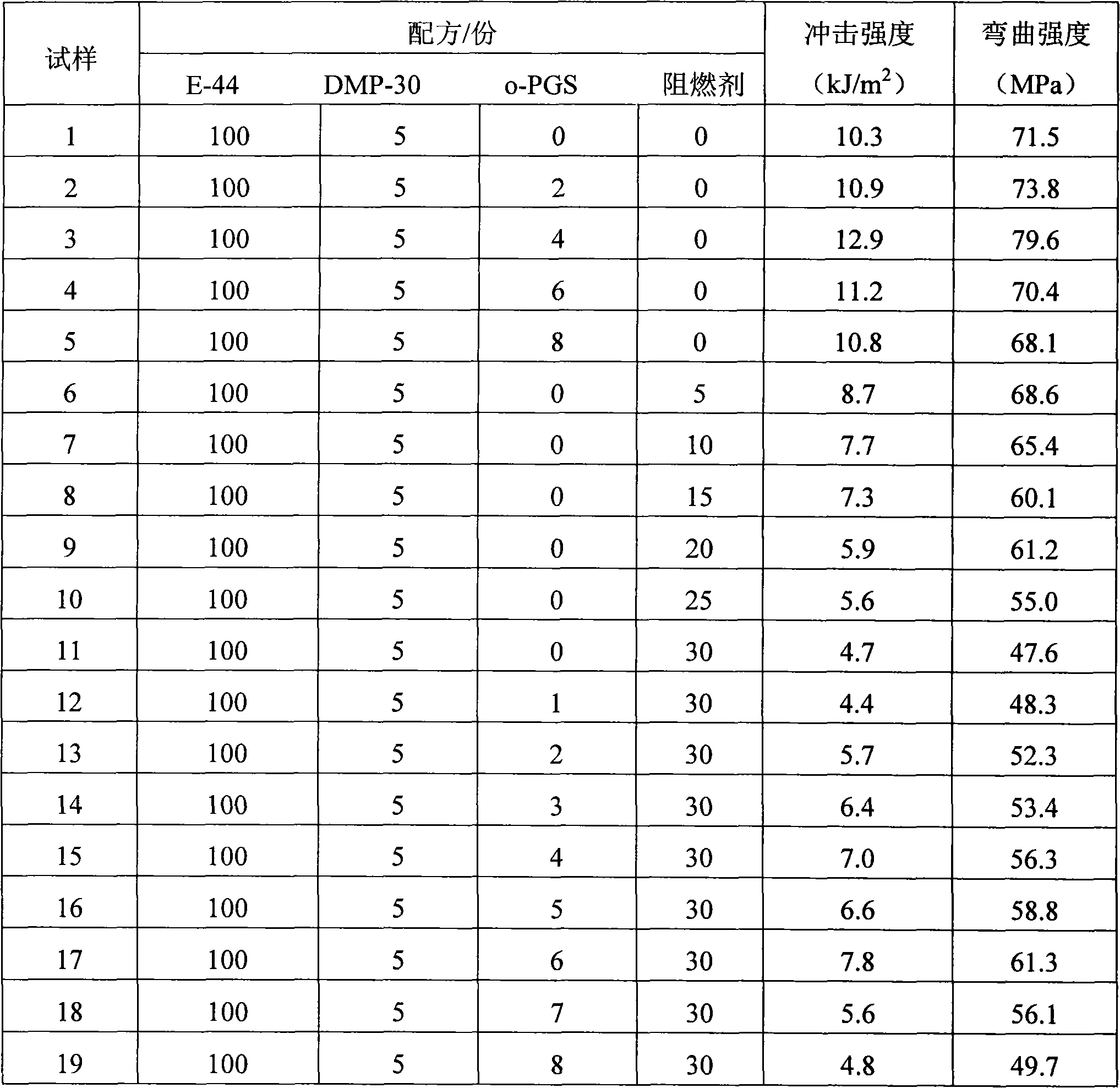

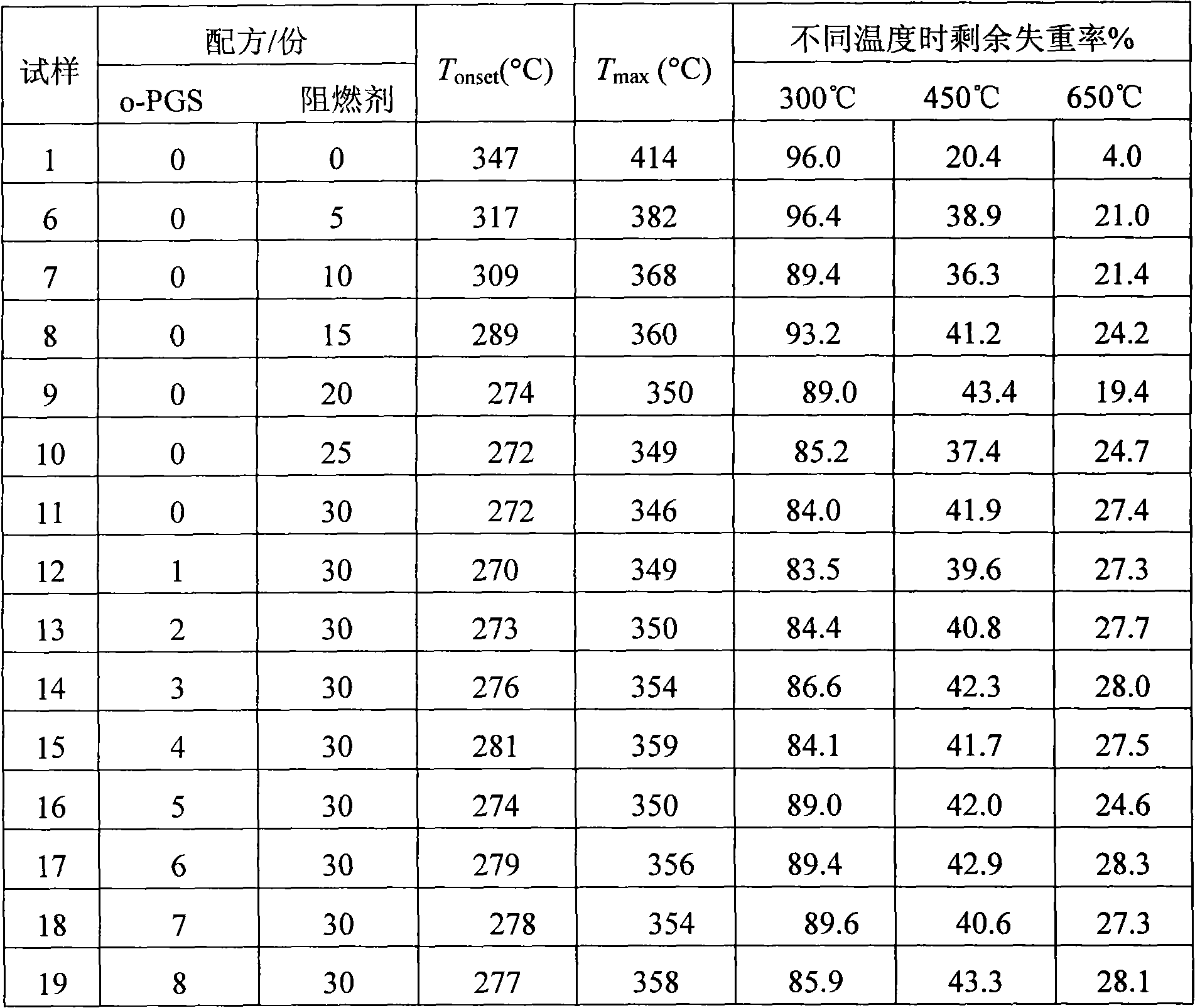

Nanometer grade paligorskite-flame retardant epoxide resin composite material

The invention provides a nano-palygorskite reinforced flame retarding epoxy resin composite material which disperses the nano-palygorskite into epoxy resin matrix by means of ultrasonic dispersion by mass ratio between 1:100 and 8:100 after surface treatment is carried out to the nano-palygorskite, then mix the obtained palygorskite epoxy resin mixture with a reactive-type flame retardant by the mass ratio between 100:5 and 100:30, and casting and curing are carried out. A plurality of P-N bond intermediates formed in the reactive-type flame retardant of the invention are phosphorylating agents better than routine phosphorus compounds, and water vapor generated from nano-palygorskite acting as a synergistic flame retardant during burning is in great favor for a phosphorous flame retardant, and the reinforcement of appropriate amount of nano-palygorskite compensates for the reduction of the mechanical property of the epoxy resin caused by adding the flame retardant to some extent, serving double effect of flame retardation and reinforcement, thus, the flame retarding epoxy resin composite material of the invention has the advantages of high oxygen index, good smoke suppression effect and excellent physical and mechanical properties.

Owner:NORTHWEST NORMAL UNIVERSITY

Weld closure of through-holes in a nickel-base superalloy hollow airfoil

InactiveUS20070084582A1Small mechanical propertiesSmall physical propertiesTurbinesBlade accessoriesCasting moldMaterials science

A hollow airfoil is fabricated by providing a casting mold assembly including a casting mold, a casting core, and a standoff spacer that prevents the casting core from contacting the casting mold to define a casting space. A first nickel-base superalloy is cast into the casting space and solidified to form the hollow airfoil. The presence of a through-hole extending through a wall of the hollow airfoil is identified, and the through-hole is closed by welding using a second nickel-base superalloy, without using any freestanding closure element.

Owner:GENERAL ELECTRIC CO

Irradiation type ceramic fire-resistant silicone rubber, preparation method of rubber and application to wires and cables

ActiveCN103013129AImprove insulation performanceImprove compactnessInsulated cablesInsulated conductorsPolymer scienceVulcanization

The invention discloses irradiation type ceramic fire-resistant silicone rubber, a preparation method of the rubber and application to wires and cables. The rubber comprises the following components in parts: 100 parts of methyl vinyl silicone rubber, 60-100 parts of white carbon black, 20-50 parts of alumina, 3-10 parts of structure control agent, 3-5 parts of sintering additive, 0.25-1.5 parts of surface treating agent and 1-1.5 parts of sensitizing agent. The preparation method of the silicone rubber comprises the steps that raw methyl vinyl silicone rubber is subjected to roller coating and mixing; white carbon black and alumina that are treated by the surface treating agent, the structure control agent, the treated sintering additive, and the sensitizing agent are added in sequence, and subjected to mixing uniformly; a sizing material after placing is subjected to remixing and plasticity recovery; and the balance of white carbon black is added. The fire-resistant silicone rubber material is subjected to extrusion processing and electron irradiation vulcanization, and has the advantages that the fire-resistant silicone rubber material is compact in ceramic body, stable in structure, stable in fire resistance, good in insulating property, less in environmental pollution, good in crosslinking uniformity and convenient in control measure, and the control measure can be conducted at a room temperature.

Owner:WUXI JIANGNAN CABLE

Moisture-absorbing antistatic dyeable polypropylene fibre and preparation method thereof

InactiveCN101748514AImprove spinnabilityGood moisture absorptionFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate glycol

The invention discloses a moisture-absorbing antistatic dyeable composite type polypropylene fibre and a preparation method thereof. The fibre is a skin core--blending composite type polypropylene fibre manufactured in composite spinning technology by taking copolyether ester with the moisture-absorbing, dyeable and antistatic characteristics as a core layer and taking the mixture of polypropylene and the copolyether ester as a skin layer. The copolyether ester one of the copolymers formed from polyethylene terephthalate and poly alkylene ether glycol, the mass ratio of the skin layer to the core layer is 88:12 to 60:40, and the blending mass ratio of the polypropylene to the copolyether ester in the skin layer is 95:5 to 75:25. The fibre has good spinnability and white color in the machining process; and the fibres can be used for spinning long and short fibres and used as woven fabrics, knitted fabrics or nonwovens and endow the fabrics with good moisture absorption, antistatic behaviour, dryness and high color fastness.

Owner:CTA HIGH TECH FIBER +1

Single-component room temperature vulcanization type ceramic fireproof silicon rubber coating material as well as preparation method and application thereof

The invention discloses a single-component room temperature vulcanization type ceramic fireproof silicon rubber coating material as well as a preparation method and an application thereof. The coating material comprises the following components in parts by weight: 100 parts of alpha, omega-dihydroxy polydimethylsiloxane, 10-20 parts of fumed silica, 5-10 parts of aluminum oxide, 0.5-2 parts of a sintering additive, 5-15 parts of a cross-linking agent, 0.1-0.5 part of a catalyst, 20-60 parts of a plasticizer, 0.5-1.5 parts of a tackifier and 0.1-0.5 part of a surface treating agent. The coating material does not need to be extruded at high temperature, can be vulcanized at room temperature after being applied, has the characteristics of a dense ceramic body, a stable structure, stable fireproof performance, good insulation performance and the like, and is applied to electric wires and cables; the thickness of a conventional silicon rubber fireproof layer is greatly reduced.

Owner:WUXI JIANGNAN CABLE

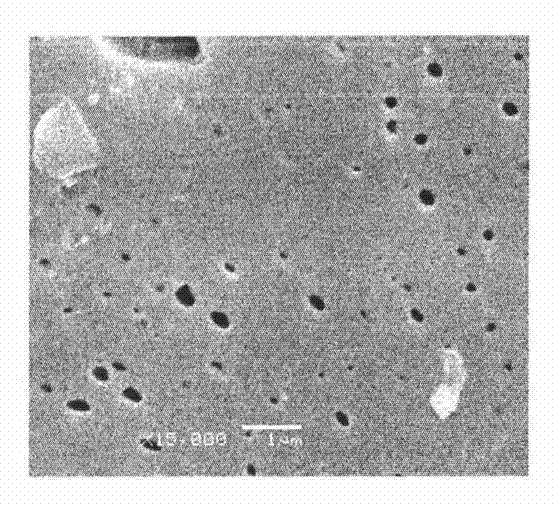

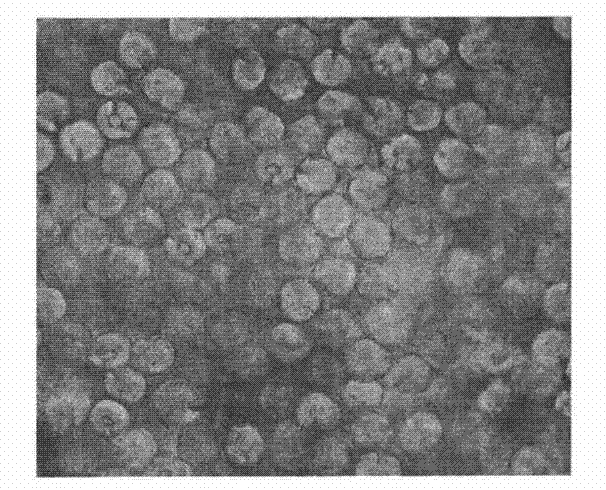

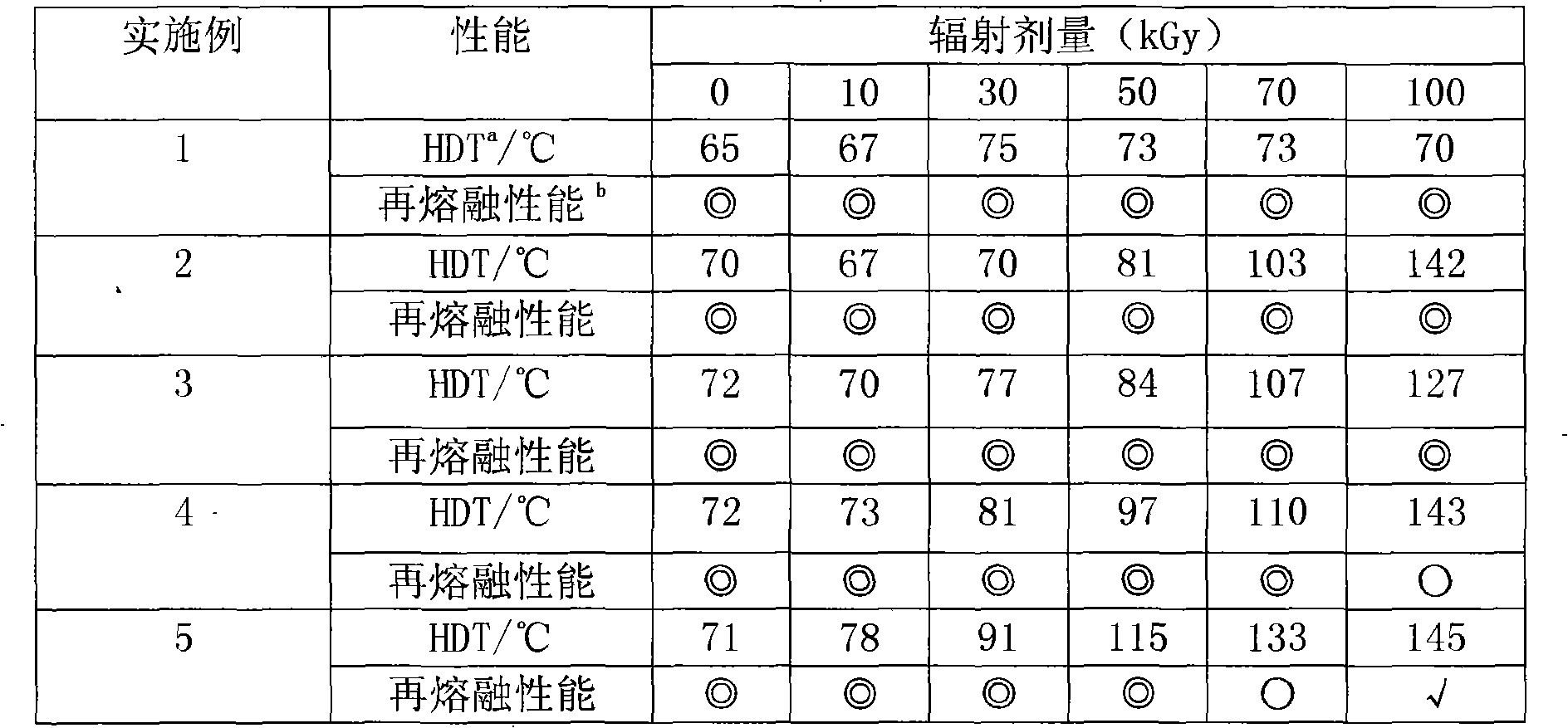

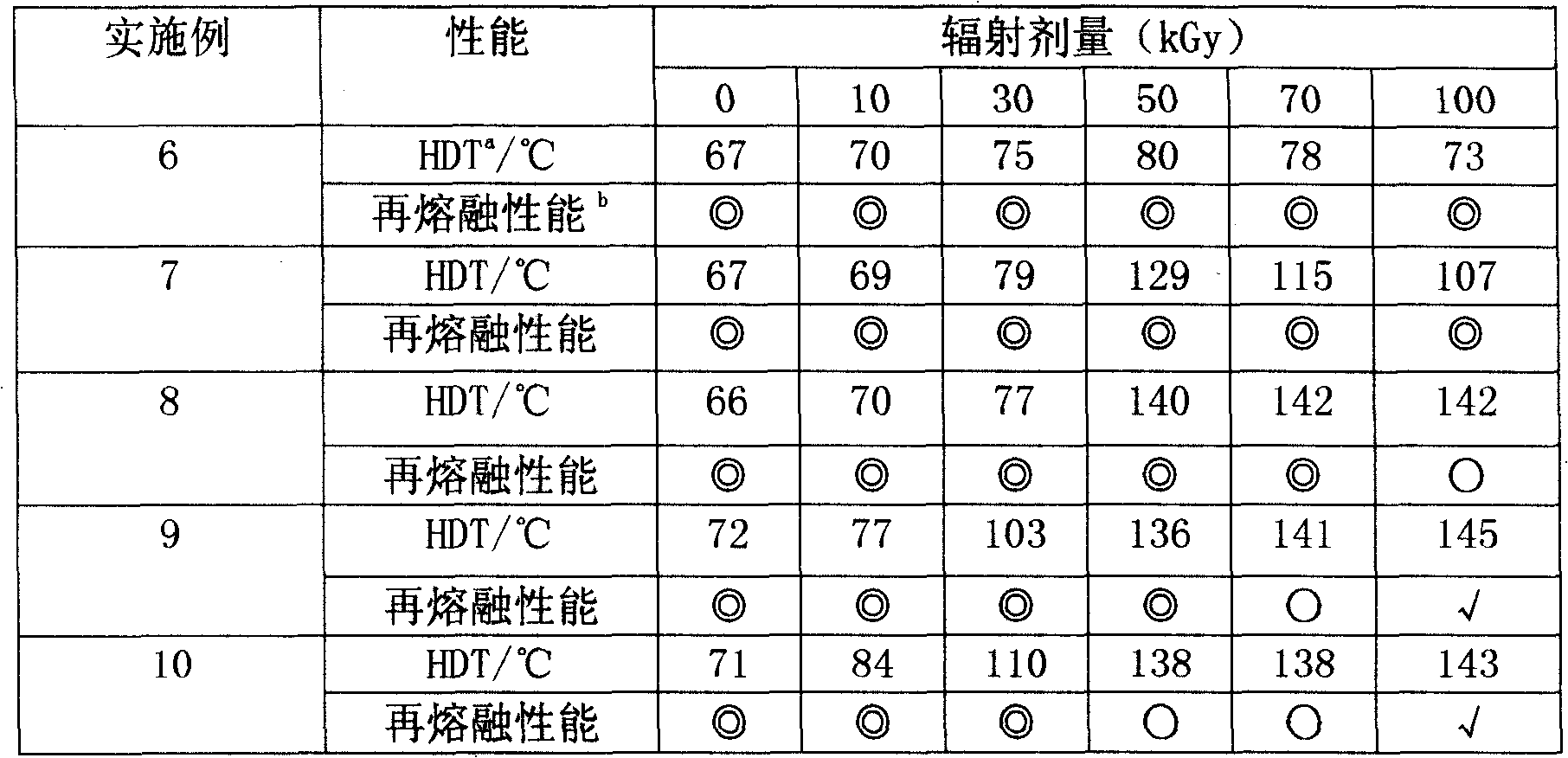

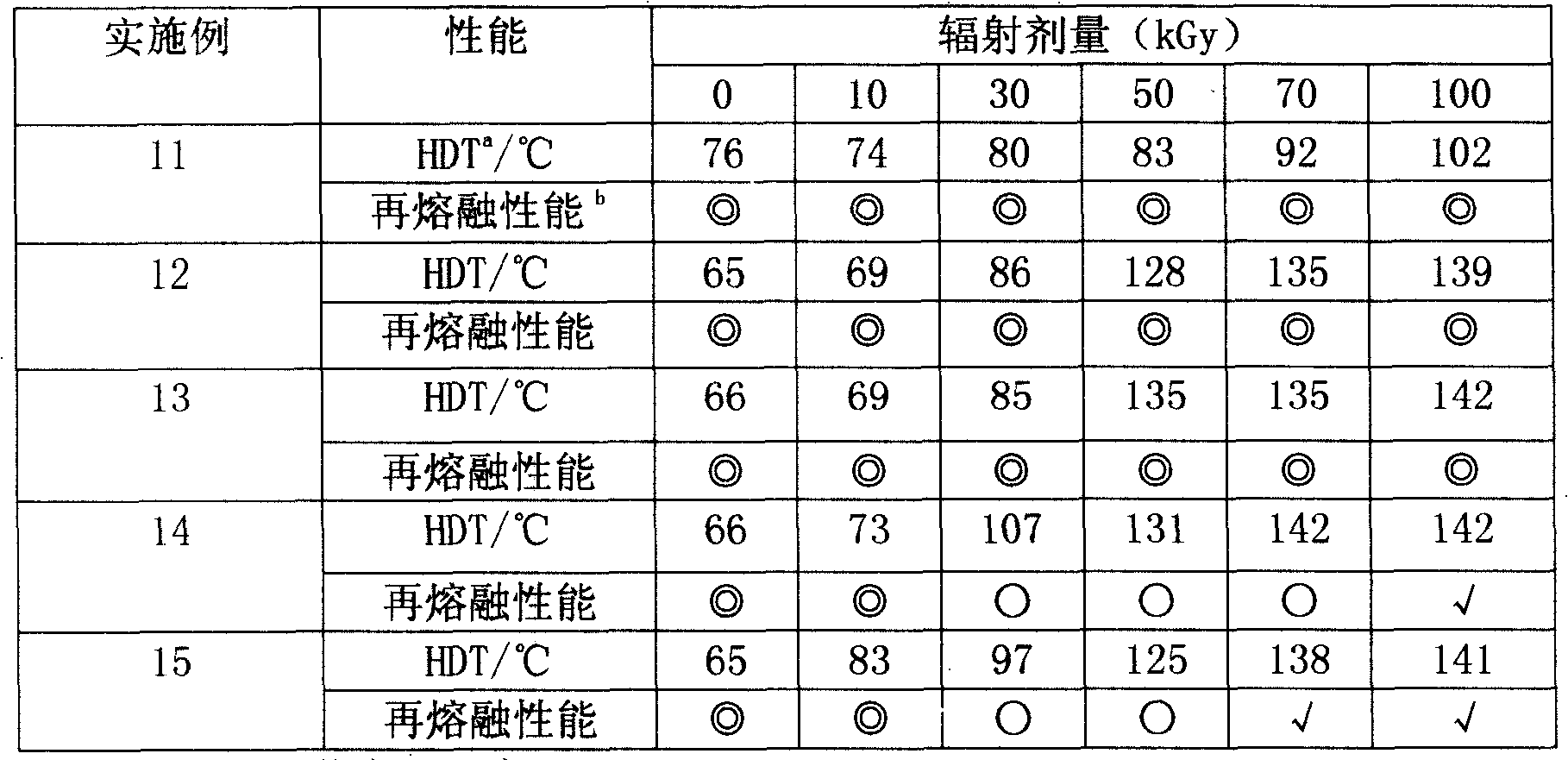

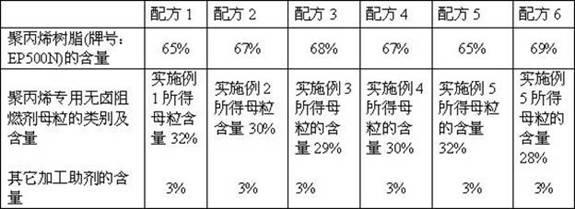

Preparation method of heat resisting polylactic acid based resin

InactiveCN101284934AImprove featuresImprove mechanical propertiesHeat deflection temperaturePolymer science

The invention relates to heat resistant polylactic resin and a method for preparing the same. The compositions of the raw materials in percentage by weight are: 50 to 80 percent of polylactic acids, 20 to 50 percent of ethylene-ethanol copolymer, 3 to 10 percent of ethylene polyfunctional group monomer and 1 to 3 percent of combined addition agent. The method comprises the following steps that: the raw materials which are uniformly mixed according to the mixture ratio are prepared into non-crosslinked resin master batches through the melting and processing means and then the master batches are radiated to determined dosage by utilization of cobalt source so as to prepare the radiant micro-crosslinking polylactic matrix resin with low gel content. The thermal distortion temperature of the resin is greatly raised from 70 DEG C or so under the non-crosslinked condition to over 100 DEG C. Moreover, the resin has the capacity of secondary melting and processing, thereby the resin can be used as matrix resin and can be mixed with other materials to prepare high-performance polylactic products, thereby the resin has wide application prospect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Antimony trioxide master batch and preparation method thereof

The invention discloses antimony trioxide master batch and a preparation method thereof. The antimony trioxide master batch comprises the following components by mass percent: 85 to 95 percent of nano antimony trioxide, 3 to 14 percent of carrier, and 0.1 to 5 percent of modified ethylene bis-fatty-acid amide. The high-efficiency antimony trioxide master batch prepared by the invention has the characteristics of easiness in dispersion, high flame-retardant efficiency and low production cost, and has smaller influence on the physical and mechanical properties, the heat resistance, the processability and the surface color of a composite material than the traditional antimony trioxide master batch.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Regenerative latex and preparation thereof

InactiveCN101280078AReduce energy consumptionNo pollution in the processPlastic recyclingChemical recyclingPolymer sciencePlasticizer

The invention discloses a method for preparing renewable latex; waste latexes are sorted, cleaned and classified, then cut and crushed by an open-type rubber mixing or open-type fluted roll rubber breaking machine; the particle size of the crushed rubber compounds are 4-20-mesh granules or small strip blocks; the crushed rubber compounds are put into a self-heating mixer and are stirred, then desulfurizers are added, followed cocatalysts, promoters and softeners; the mixture is stirred constantly, then after solid tackifiers, plasticizers, active modifiers are added into the mixture, the reaction is terminated and the materials are discharged and cooled; then, the rubber compounds terminated by reactive plasticization are discharged into the cylinder of a cooling machine for cooling; after being discharged from the cylinder, the materials are continuously cooled and stacked to avoid natural burning; the plasticized rubber compounds are mixed with rubber compounds of masterbatches and added into an open-type rubber refiner for production; then finished products are obtained through kneading, refining, mixing, plasticating, defilming and packaging. The method of the invention has the advantages of low energy consumption, energy saving effect, no pollution, good physical properties, as well as simple and safe process, which enables production in normal temperature and pressure and uses waste to treat waste to achieve comprehensive utilization.

Owner:广州市再生资源利用研究所

Special halogen-free flame-retardant master batch for polypropylene and preparation method for halogen-free flame retardant master batch

The invention discloses a special halogen-free flame-retardant master batch for polypropylene and a preparation method for the halogen-free flame retardant master batch. Components of the master batch comprise, in mass percent, 75-90% of phosphorus-nitrogen halogen-free flame retardant, 8-22% of carrier and 0.1-5% of modified ethylene bis-fatty acid amide. By the aid of the master batch, quality instability of materials due to non-uniform mixing of powder and granules is effectively avoided, easiness in generation of chippings or powder during granule cutting is avoided, production efficiency is improved, and production cost is lowered. Adopting a continuous banburying-extrusion production process leads production efficiency to be high. The master batch effectively solves the problems of easiness in moisture absorption, degradation and foaming of halogen-free flame retardant, so that storage time of the phosphorus-nitrogen halogen-free flame retardant is prolonged, and processability of the phosphorus-nitrogen halogen-free flame retardant is improved. Besides, the special halogen-free flame-retardant master batch for the polypropylene has the advantages of easiness in dispersion, high flame-retardant efficiency and low production cost, and has less influence on physical and mechanical properties, heat resistance, processability and surface color of composite materials than a special traditional halogen-free flame-retardant master batch for polypropylene.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

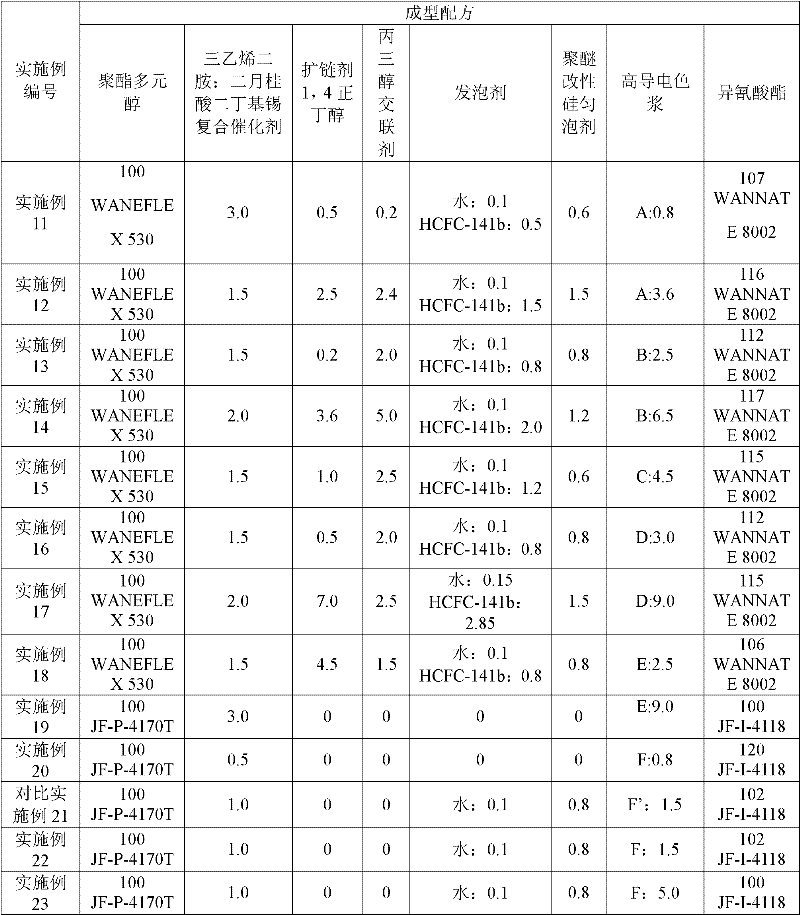

Electroconductive color slurry and low-resistance polyurethane material thereof

The invention discloses electroconductive color slurry and a low-resistance polyurethane material thereof. The electroconductive color slurry is prepared from the following raw materials in parts by weight: 35-55 parts of carbon powder, 30-60 parts of ionic liquid and 0.2-1 part of dispersant. The low-resistance polyurethane material is prepared from the following raw materials in parts by weight: 100 parts of polyester polyol, 0.8-9 parts of electroconductive color slurry, 100-120 parts of isocyanate and 0.5-3 parts of catalyst. The electroconductive color slurry provided by the invention has low addition amount and good electrical conductivity; and the low-resistance polyurethane material provided by the invention is applicable to dust-free room and other clean places, and has good antistatic property, low humidity dependence and good physical and mechanical properties.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Gutta-percha/natural latex sponge product and preparation method thereof

ActiveCN110437510ASignificant technological progressHigh total solid contentFoaming agentGutta-percha

The invention provides a gutta-percha / natural latex sponge product. The gutta-percha / natural latex sponge product is prepared from the following components: gutta-percha emulsion, natural latex, a vulcanizing agent, an active agent, an accelerant, an antiager, a filler, a stabilizer, a PH value adjust, a gelatinizer, a foaming agent, a foam stabilizer, and a blowing agent in proportion, and the gutta-percha emulsion and the natural latex are correspondingly concentration emulsion. A preparation method of the gutta-percha / natural latex sponge product comprises the steps that first, the gutta-percha emulsion and the natural latex are mixed in proportion, deammoniation is conducted through a simultaneous ongoing method of mechanical stirring and air drafting, thenvarious kinds of powder typeauxiliaries and emulsifying oil auxiliaries which are grinded into dispersoid are added into a mixture latex material, after ripening, air is inflated under the mechanical stirring, foam is generatedto expand foam, after foaming, the foam is solidified with the gelatinizer, after vulcanization, washing and dewatering and drying of the solidified foam, the gutta-percha / natural latex sponge is obtained. According to the gutta-percha / natural latex sponge product and the preparation method thereof, successfully development of the gutta-percha / natural latex sponge product expands application prospects of gutta-percha, and promotes the technical progress of the gutta-percha.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

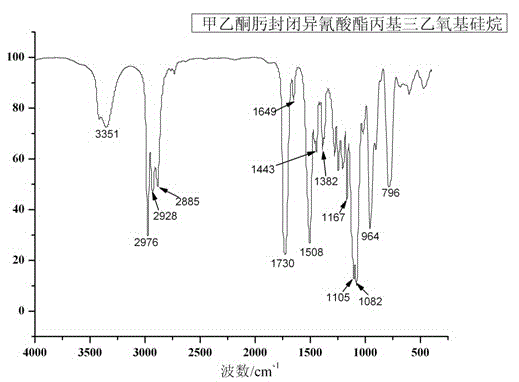

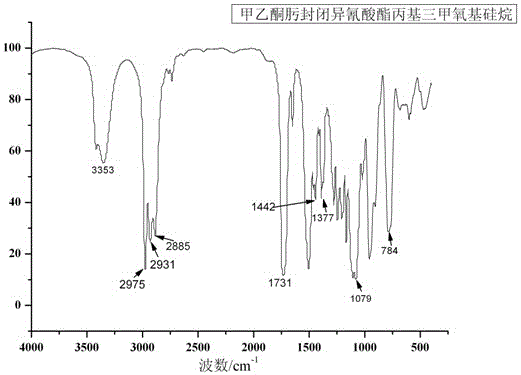

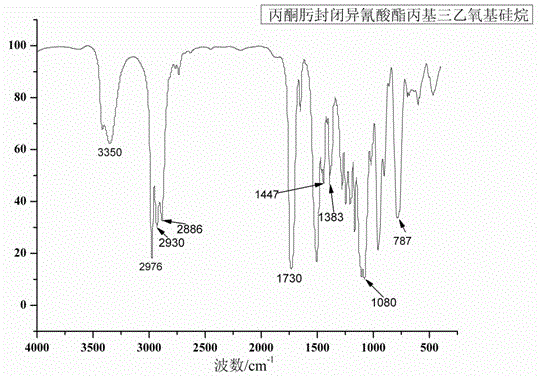

Closed isocyanate coupling agent and application thereof

ActiveCN103819498AIncrease the amount addedPlay a role in chain extensionGroup 4/14 element organic compoundsPigment treatment with organosilicon compoundsPolymer sciencePhysisorption

The invention discloses a closed isocyanate coupling agent used for surface treatment for thermal conductive fillers and a thermal conductive insulating nylon composite material. When the coupling agent treats the thermal conductive fillers, a closed isocyanate group is not unblocked and generates a chemical bonding or physical adsorption action with the surfaces of the thermal conductive fillers. In the melting process, the isocyanate group can be unblocked and chemically reacts with amidogen or carboxyl on a nylon molecular chain end. The thermal conductive insulating nylon composite material comprises 100 parts of nylon, 25-40 parts of modified thermal conductive insulating filler, 5-25 parts of a flexibilizer and 1-10 parts of an addition agent. The materials are added into a high-speed mixing machine for mixing and then are extruded to obtain the thermal conductive insulating nylon composite material. The closed isocyanate coupling agent is used for a nylon substrate and can obviously improve the dispersity of the fillers in nylon. Meanwhile, the closed isocyanate coupling agent plays a role of chain extension, the thermal conductivity of the composite material achieves the operating requirement, the physical and mechanical properties cannot greatly decline, and actual use requirements are met.

Owner:HEFEI UNIV OF TECH

Process for producing antistatic polyamide 6 (PA6) bulk yarns through one-step process

ActiveCN104278385ASoftness is consistent withAvoid separation or protruding of conductive fibersMelt spinning methodsYarnElectrically conductiveChemistry

The invention discloses a process for producing antistatic polyamide 6 (PA6) bulk yarns through a one-step process. According to the technology, the polyamide 6 (PA6) bulk yarn fibers produced by the one-step production process have excellent electrical conductivity, and the manufactured carpet is rubbed to generate static electricity so as to be timely conducted out under severe pedaling, so the carpet has excellent antistatic properties. According to the technology, the polyamide 6 conductive fibers refer to 10-20-denier polyamide 6 carbon black composite fibers, and the composite fiber refers to a core-sheath composite fiber which takes the polyethylene dispersed with carbon black as the core and takes polyamide 6 as the core, is a conductive fiber with physical and chemical performances of polyamide 6 fibers, and can finish the drafting and bulking deformation process with polyamide 6 (PA6) fibers in high-speed production process.

Owner:TAICANG UNIVERSAL FIBERS COMPANY

Regenerative vulcanized butadiene nitrile rubber and preparation thereof

InactiveCN101280077AReduce energy consumptionNo pollution in the processPlastic recyclingChemical recyclingPolymer scienceNitrile rubber

The invention discloses a method for preparing renewable vulcanized nitrile rubber; waste vulcanized nitrile rubbers are sorted, cleaned and classified, then cut and crushed by an open-type rubber mixing or open-type fluted roll rubber breaking machine; the particle size of the crushed rubber compounds are 4-20-mesh granules or small strip blocks; the crushed rubber compounds are put into a self-heating mixer and stirred, then desulfurizers are added, followed cocatalysts, promoters and softeners; the mixture is stirred constantly, then after solid tackifiers, plasticizers, active modifiers are added into the mixture, the reaction is terminated and the materials are discharged and cooled; then, the rubber compounds terminated by reactive plasticization are discharged into the cylinder of a cooling machine for cooling; after being discharged from the cylinder, the materials are continuously cooled and stacked to avoid natural burning; the plasticized rubber compounds are mixed with rubber compounds of masterbatches and added into an open-type rubber refiner for production; then finished products are obtained through kneading, refining, mixing, plasticating, defilming and packaging. The method of the invention has the advantages of low energy consumption, energy saving effect, no pollution, good physical properties, as well as simple and safe process, which enables production in normal temperature and pressure and uses waste to treat waste to achieve comprehensive utilization.

Owner:广州市再生资源利用研究所

Preparation method of magnetic cotton fabric

The invention provides a preparation method of magnetic cotton fabric. The method comprises the following steps: (1) preparation of a magnetic dissolving solution: cooling an aqueous solution containing sodium hydroxide and urea to minus 10 DEG C, adding magnetic particles, violently stirring at low temperature to prepare a magnetic dissolving solution; (2) carrying out dip padding on cotton fabric in the magnetic dissolving solution obtained in the Step (1) for many times; and (3) impregnating the cotton fabric which has undergone dip padding into an aqueous solution containing sulfuric acid and sodium sulfate to be solidified for 10 min, washing and drying. The preparation technology is simple and practicable, and preparation cost is low. The prepared cotton fabric has lasting magnetism, and surface properties of cotton fiber will not be changed. During the preparation process, no adhesive is used. The product is nontoxic and harmless.

Owner:SOUTHWEST UNIV

A defatting method of neutral pine

InactiveCN101157230AIncrease added valueFulfil requirementsPressure impregnationWastewaterEngineering

The invention discloses a neutral pine degreasing method. The invention comprises the following steps that: (1) degreasing fluid is dispensed; (2) the degreasing fluid is canned; (3) the degreasing processing is performed. The invention enables the pine degreasing depth to reach 5 to 6 cm, the fresh wood color of the pine is kept, the decline of the physical mechanical properties is smaller, and the requirements of the furniture can be completely satisfied. The invention is easy to realize, the operation is convenient, the production cost is low, thereby being more important, the utilization of the technology does not produce waste water, the added value of the pipe is enhanced, and more employment posts are created, and the invention is advantageous in the promotion of the harmonious development of artificial forest resources and the ecology and the society.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Degreasing method for wood

InactiveCN102837342AIncrease added valueFulfil requirementsWood treatment detailsMass ratioSodium sulfite

The invention discloses a degreasing method for wood, which comprises the following steps: (1) preparing a color maintaining solution, to be specific, uniformly mixing sodium hydrosulfite with sodium chloride according to a mass ratio of m sodium hydrosulfite to m sodium chloride being equal to (10:0.1)-(10:2), and then preparing an aqueous solution with a mass percent concentration being 0.5%-3.5%, thereby obtaining the color maintaining solution; (2) canning: placing the color maintaining solution and wood into a high-pressure degreasing can according to a volume ratio of V wood to V color maintaining solution being equal to (1:0.5)-(1:1.5); (3) performing color maintaining treatment: keeping the temperature for 5-7h under the conditions of the temperature at 20-40 DEG C and the pressure at 0.4-0.9MPa, and then discharging the liquid, after completely discharging the liquid, opening the degreasing can and discharging the color maintained wood; and (4) drying the color maintained wood for 2-3 days in the smoke at 50-60 DEG C, drying for 2-3 days in the smoke at 80-90 DEG C, and then drying for 0.5-1 day in the smoke at 95-105 DEG C, thereby obtaining the degreased wood. The degreasing method for wood provided by the invention is easy to realize, convenient to operate, low in production cost and environment-friendly.

Owner:湖南湘益竹木新材科技有限公司

PVC and PET anti-scratch printing sheet material

InactiveCN110240725AImprove stabilityAvoid degradation of physical and mechanical propertiesPolyester coatingsDecompositionChemistry

The invention discloses a PVC and PET anti-scratch printing sheet material. Chloroethylene resin and polyethylene glycol terephthalate are used as raw materials; through a series of processing, the printing sheet material is prepared; organic tin stabilizing agents are used; high temperature decomposition of chloroethylene resin is avoided; the stability is improved; the physical and mechanical performance reduction is avoided; bis(2-ethylhexyl) phthalate is used; the plasticity and the softness of vinyl chloride resin are improved; the fragility is reduced; the processing formation is easy; photocuring paint is used, so that the wear-resisting performance of the printing sheet material is improved; the anti-scratch function is realized; the adhesive force is improved; during the printing, falling cannot occur; nanometer silicon dioxide and nanometer negative ions are used for improving the corona resistance of the photocuring paint; through corona treatment, the adhesive force of the sheet material is improved. The manufactured sheet material cannot be easily scratched; during the printing, the falling cannot easily occur; the wear-resisting performance of the sheet material body is greatly improved; the service life is prolonged.

Owner:ZHEJIANG ZHONGBANG PLASTIC CO LTD

Butadiene acrylonitrile rubber sheath formula

InactiveCN104327329AImprove working conditionLow costInsulated cablesInsulated conductorsPolymer sciencePolystyrene

The invention relates to a butadiene acrylonitrile rubber sheath formula. The formula comprises the following components: 100 parts of butadiene acrylonitrile rubber, 3 parts of polystyrene, 5 parts of ultralow density polyethylene, 6 parts of chlorinated paraffin, 6 parts of polyurethane, 2 parts of butyl acetate, 6 parts of calcined clay, 3 parts of talcum powder, 4 parts of ethylene glycol, 7 parts of phthalo blue, 3 parts of ethylene-vinyl acetate and 10 parts of dicyclopentadiene. The rubber sheath formula has the advantages of low cost, reasonable proportion, excellent performance, use stability and the like, improves the production benefits of factories and reduces the consumption of rubber, and the physical and mechanical properties of rubber sheaths are not reduced.

Owner:QINGDAO DTCN NEW MATERIAL TECH DEV

Brominated polystyrene masterbatch and preparation method thereof

ActiveCN102627812AImprove flame retardant performanceSmall mechanical propertiesMasterbatchPolymer science

The invention discloses a brominated polystyrene masterbatch and a preparation method thereof. The brominated polystyrene masterbatch is prepared from the following components, by mass, 85-95% of brominated polystyrene, 3-14% of a carrier and 0.1-5% of modified ethylene bisfatty acid amide. The brominated polystyrene masterbatch prepared in the invention can effectively avoid unstable material quality caused by nonuniform mixing of powder and pellets; the preparation method which adopts a mixing-extruding continuous production technology has the advantages of high production efficiency, low production cost, clean production, good dispersion effect, substantial improvement of the loading amount of the brominated polystyrene masterbatch, and good mixing effect; and the brominated polystyrene masterbatch prepared in the invention has the characteristics of easy dispersion, high flame resisting efficiency, and low production cost, and has influences on physical and mechanical properties, the heat resistance, the processing performance and the surface color of a composite material smaller than influences of brominated polystyrene powder.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Industrial lignin reinforcing rubber and preparation method thereof

Owner:广西合山林格高分子材料科技有限公司

Polyvinyl chloride-polyethylene composite plastic

InactiveCN104072906AGood weather resistanceImprove thermal stabilityPolyvinyl chlorideHeat stability

The invention relates to a polyvinyl chloride-polyethylene composite plastic. The polyvinyl chloride-polyethylene composite plastic comprises the following components in parts by weight: 70-90 parts of polyvinyl chloride, 15-25 parts of polyethylene, 20-35 parts of plastic additives, 5-10 parts of m-phenylene dibenzoate, 6-18 parts of auxiliaries and 3-8 parts of dibasic lead phthalate. The polyvinyl chloride-polyethylene composite plastic disclosed by the invention has good weather fastness, excellent flowability, good heat stability, low shrinking percentage and high mechanical strength.

Owner:李雪红

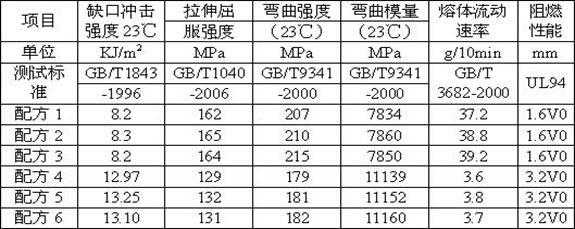

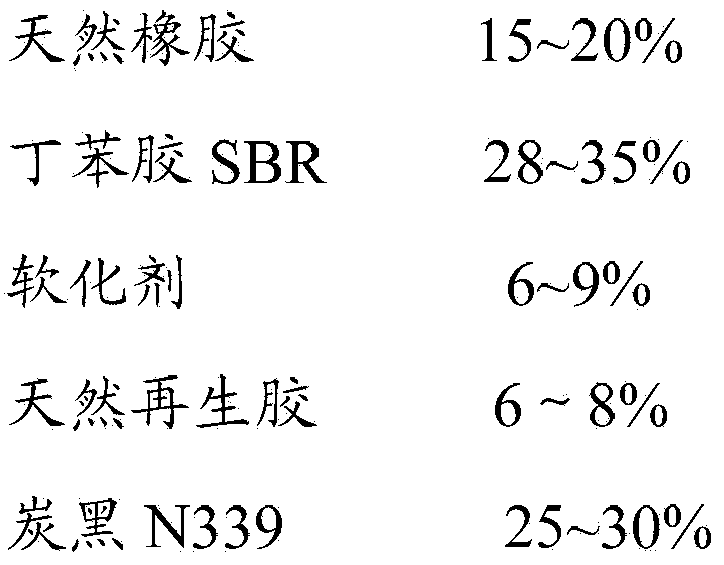

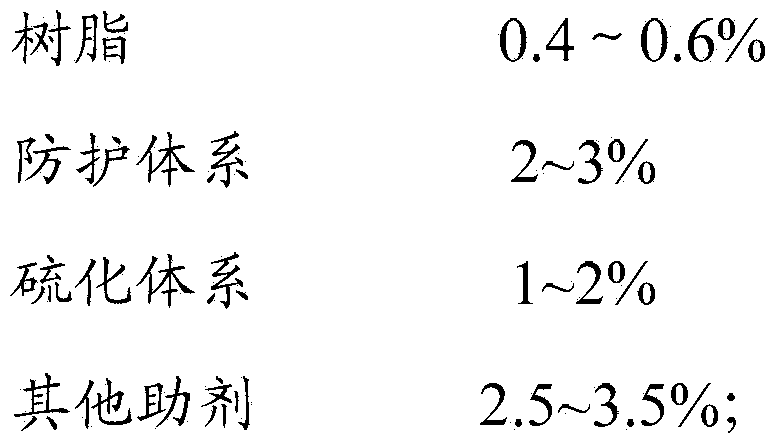

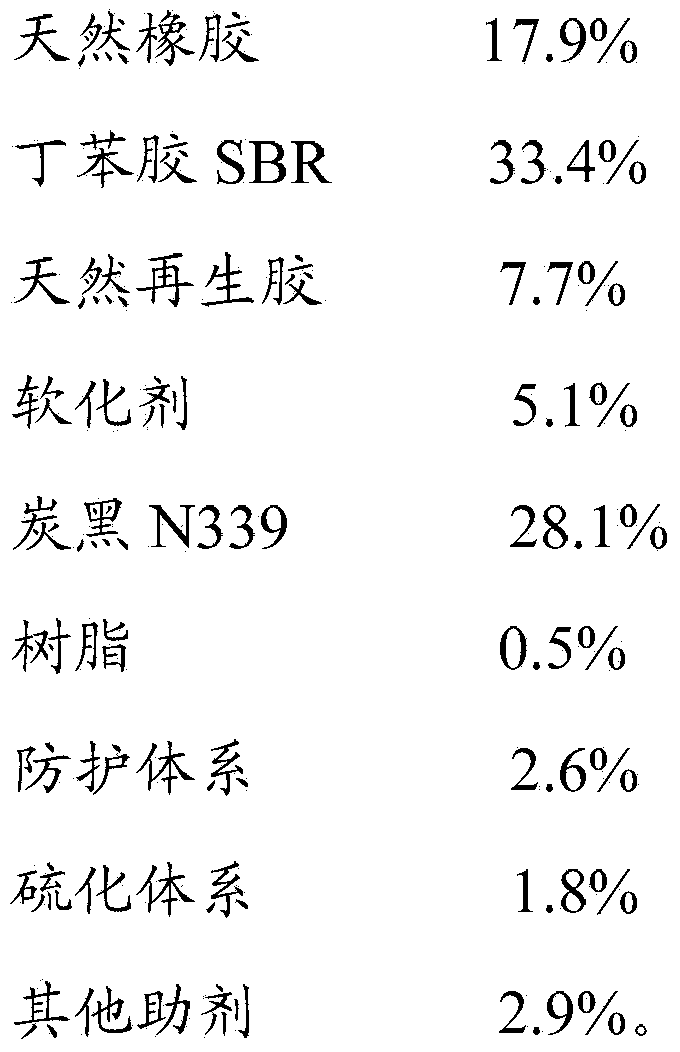

Tyre sizing material of agricultural vehicle and preparation method of tyre sizing material

ActiveCN103881171ASmall physical and mechanical propertiesGood physical propertiesSpecial tyresVulcanizationHeat resistance

The invention discloses a tyre sizing material of an agricultural vehicle. The tyre sizing material is prepared from the following components in percentage by weight: 15-20% of natural rubber, 28-35% of butadiene-styrene rubber (SBR), 6-9% of a softener, 6-8% of natural reclaimed rubber, 25-30% of carbon black N339, 0.4-0.6% of resin, 2-3% of a protective system, 1-2% of a vulcanization system and 2.5-3.5% of other assistants. The tyre sizing material disclosed by the invention is low in cost and excellent in physical property, the excellent physical and mechanical property is maintained under the condition of greatly lowering the cost, and the abrasion performance is far beyond the benchmark. The tyre sizing material has good heat resistance and resistance to ozone aging, and the aging characteristic change rate is lower than that of similar products under same aging conditions.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

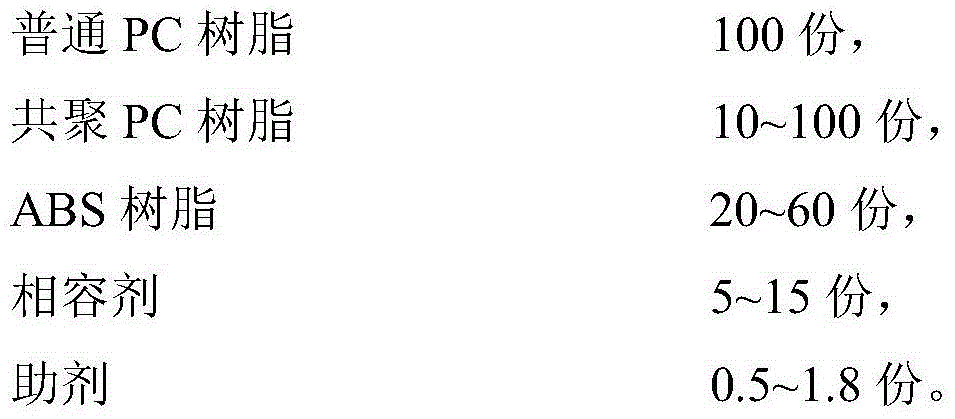

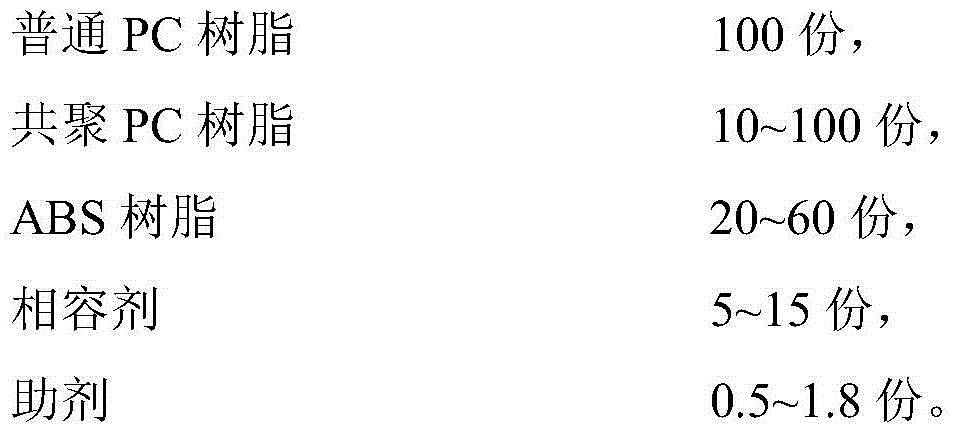

Heat-resistant PC/ABS alloy material and preparation method thereof

The invention discloses a heat-resistant PC / ABS alloy material which is prepared from the following components in parts by weight: 100 parts of a common PC resin, 10-100 parts of a copolymerized PC resin, 20-60 parts of an ABS resin, 5-15 parts of a compatilizer and 0.5-1.8 parts of aids. The preparation method comprises the following steps: uniformly mixing 100 parts of the common PC resin, 10-100 parts of the copolymerized PC resin, 20-60 parts of the ABS resin, 5-15 parts of the compatilizer and 0.5-1.8 parts of the aids, and bracing and granulating by virtue of a screw extruder, thereby obtaining the heat-resistant PC / ABS alloy material. The material provided by the invention has the characteristics that the heat resistance is excellent, the vicat softening point temperature is greatly improved, and the mechanical property is excellent.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

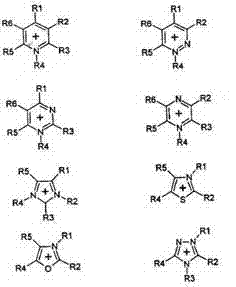

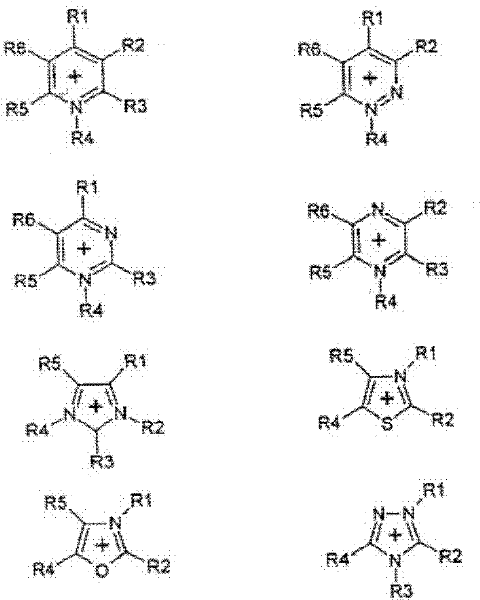

Prickle and itch feeling-resisting finishing method for ramie fabric by imidazole ionic liquid

InactiveCN105484025ADoes not change surface propertiesWon't hurtVegetal fibresAqueous sodium hydroxideChloride

The invention provides a prickle and itch feeling-resisting finishing method for a ramie fabric by imidazole ionic liquid. The method comprises the following steps: (1) heating 1-butyl-3-methylimidazole chloride to 90 DEG C; (2) putting the ramie fabric into a 26 percent (w / w) sodium hydroxide aqueous solution, soaking for 1min, washing, and drying; (3) padding the pretreated ramie fabric into a 1-butyl-3-methylimidazole solution for multiple times, wherein pick-up is 100 percent-120 percent; (4) heating the padded ramie fabric to 100 DEG C-120 DEG C, and keeping warm for 3h; (5) taking out the ramie fabric, putting into an ethanol / water solution, solidifying for 20min, then washing, and drying. The finishing method is simple and easy, and the finished ramie fabric has good prickle and itch feeling-resistance, and also remains the good characteristic of the original ramie fabric.

Owner:SOUTHWEST UNIVERSITY

Anti-mite health care quilt cover

InactiveCN104273994AAnti-mite and anti-wrinkle function hasSmall physical and mechanical propertiesFibre treatmentBed-coversEngineeringTraditional medicine

The invention discloses an anti-mite health care quilt cover. The quilt cover has anti-wrinkle and anti-mite functions after being processed with special technologies and has a good health care function due to the adoption of a plurality of Chinese herbal medicine ingredients. The anti-mite health care quilt cover has the advantages that the anti-mite function and the anti-wrinkle function are combined, non-ironing anti-wrinkle processing is conducted firstly, and then anti-mite antibiotic finishing is conducted. According to the quilt cover made in this way, the non-ironing and anti-mite functions are realized, reduction of physical and mechanical properties such as strength is slight, and color fading is avoided; due to the fact that the quilt cover is provided with the plurality of Chinese herbal medicine ingredients, medicine seeps out continuously from the quilt cover after the human body makes contact with the quilt cover for a long time, and in this way, health care medicine can effectively permeate into the human body, the purpose of treating an internal illness by external treatment is realized, the burden on the liver is relieved, and then medication safety and effectiveness are improved; water serves the solvent of the finishing agent adopted, the machining process is free of pollution, the finishing agent can be repeatedly used, and clean production and environment protection are facilitated.

Owner:陈晴川

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com