Preparation method of heat resisting polylactic acid based resin

A technology of matrix resin and polylactic acid is applied in the field of preparation of heat-resistant polylactic acid matrix resin, which can solve the problems of poor heat resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

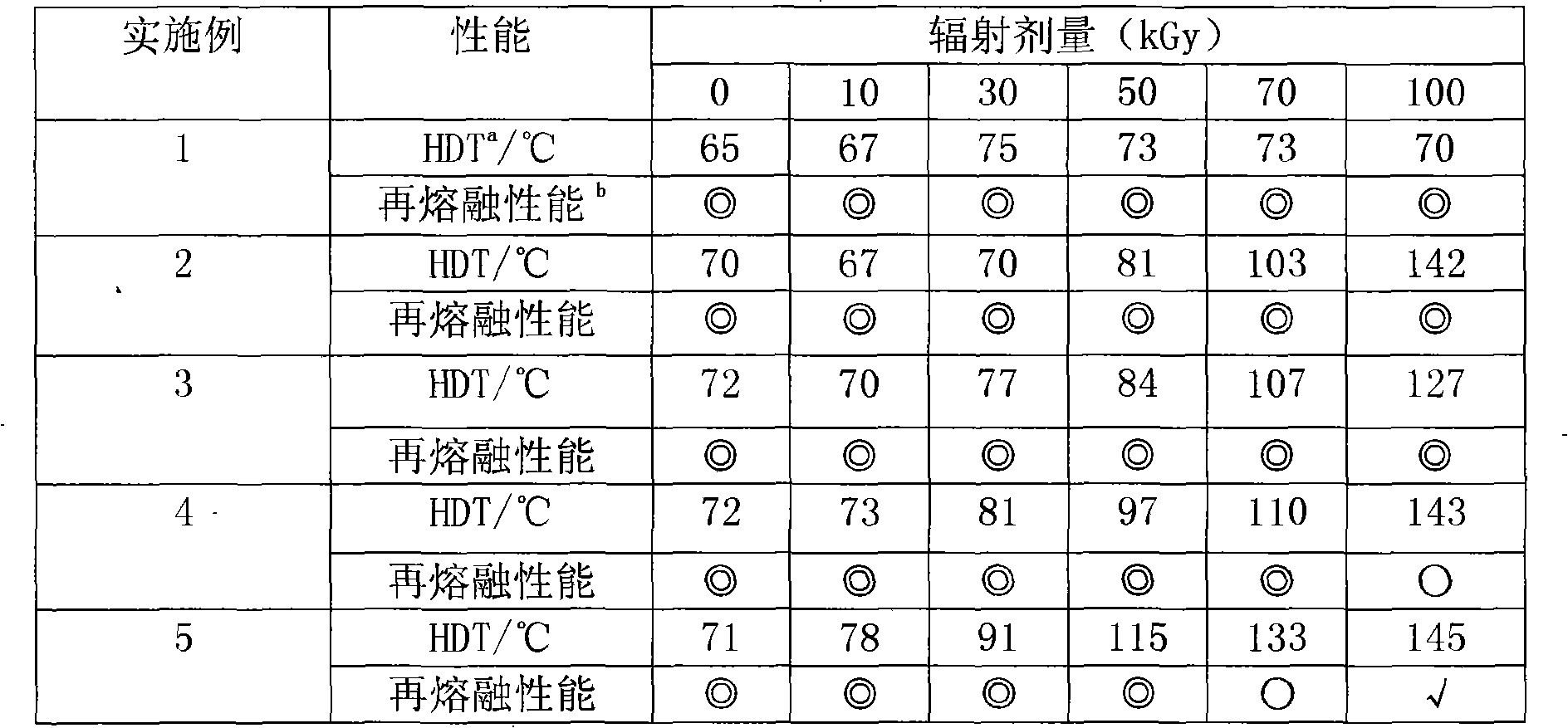

Embodiment 1-5

[0015] In Example 1-5, 8.0kg of dried polylactic acid resin was weighed, 2.0kg of ethylene vinyl alcohol resin (the molar percentage of vinyl alcohol was 56%), 150g of combined auxiliary agent, and 100g of vinyl multifunctional monomer TAIC , 300g, 500g, 700g and 1.0kg. The above materials are mixed evenly, and then put into a twin-screw extruder with 6 heating zones for melt blending. The temperature range of each zone is 135±5°C, 155±5°C, 175±5°C, 185±5°C. ℃, 195±5℃, 185±5℃, the die head temperature is 180±5℃, and the basic material is prepared into a masterbatch through cold granulation. After the masterbatch is dried at 100°C, it is vacuum-packed with a polyethylene plastic bag, and then put into a cobalt source to irradiate 10kGy, 30kGy, 50kGy, 70kGy and 100kGy respectively to obtain a heat-resistant polylactic acid matrix resin.

[0016] Then hot press it into a 4mm plate, and test the heat distortion temperature of the sample according to GB / T1633. The results are show...

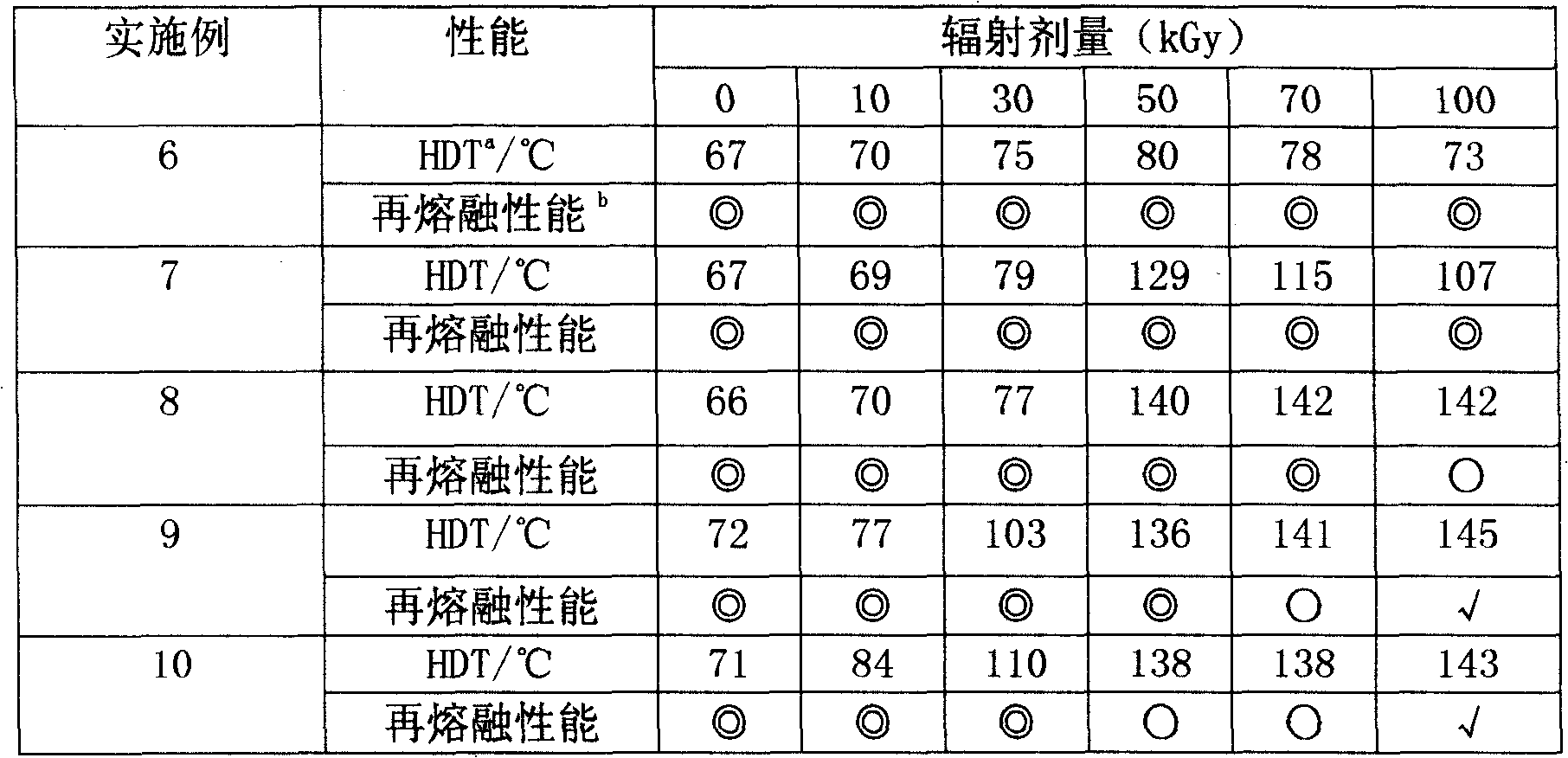

Embodiment 6-10

[0022] In Examples 6-10, 6.0kg of polylactic acid, 4.0kg of ethylene vinyl alcohol (the molar percentage of vinyl alcohol is 68%), 300g of combined auxiliary agent, and 100g, 300g, and 500g of vinyl polyfunctional monomer TAIC were weighed in sequence. , 700g and 1.0kg. Processing technology and test sample preparation and testing methods are the same as in Examples 1-5.

[0023] Table 2: Changes in heat resistance and secondary melting properties of polylactic acid matrix resin after irradiation

[0024]

[0025] a: HDT is heat distortion temperature

[0026] b: ◎The reworkability is excellent, ○The reworkability is good, √The reworkability is fair

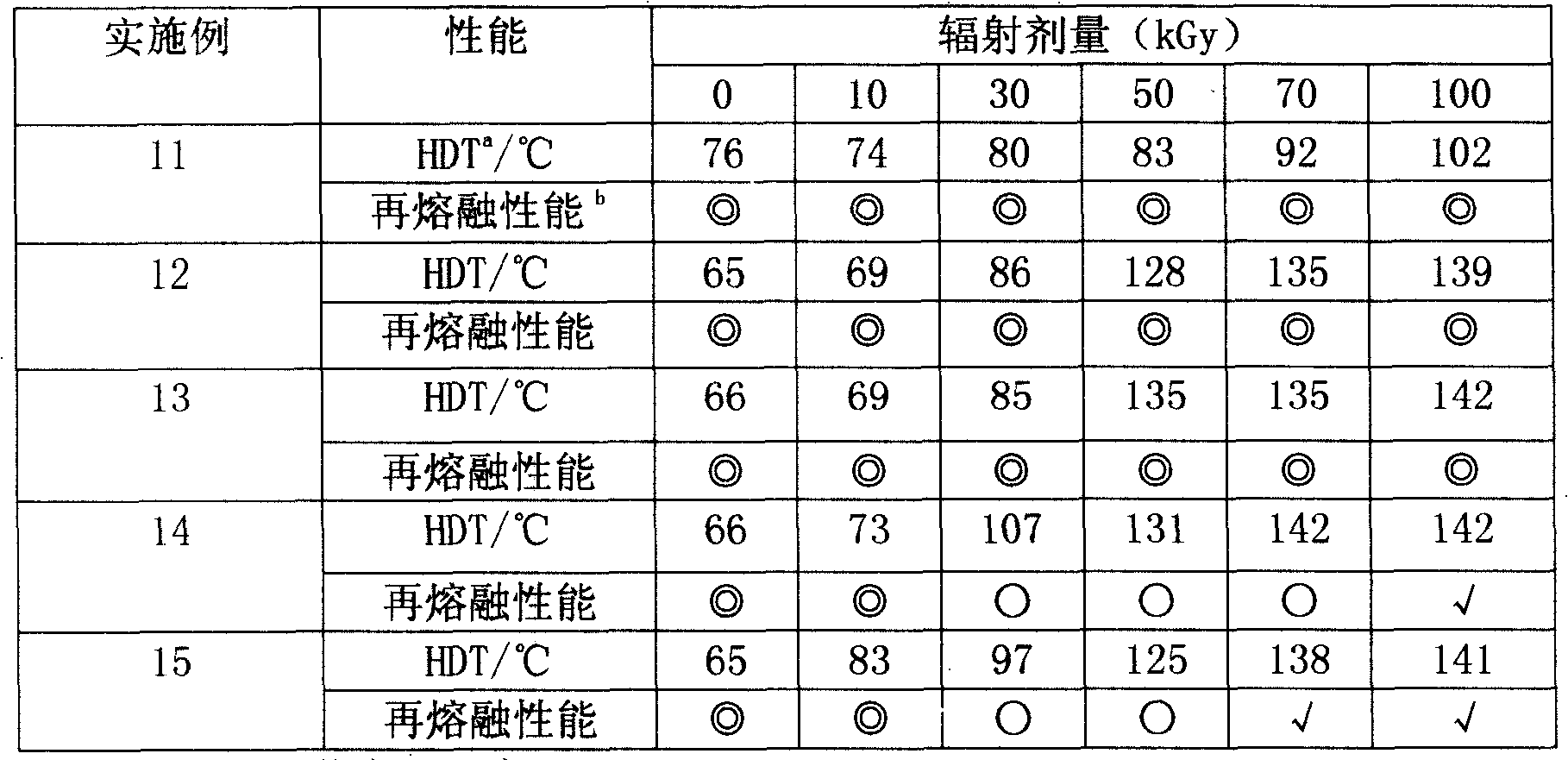

Embodiment 11-15

[0028] In Examples 11-15, 5.0 kg of polylactic acid, 5.0 kg of ethylene vinyl alcohol (the molar percentage of vinyl alcohol is 56%), 100 g of combined additives, and 100 g, 300 g, and 500 g of vinyl polyfunctional monomer TAIC were weighed in sequence. , 700g and 1.0kg. Processing technology and test sample preparation and testing methods are the same as in Examples 1-5.

[0029] Table 3: Changes in heat resistance and secondary melting properties of polylactic acid matrix resin after irradiation

[0030]

[0031] a: HDT is heat distortion temperature

[0032] b: Excellent in ◎ reworkability, good in ○ reworkability, and fair in √workability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com