Patents

Literature

2153results about How to "Biodegradable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polylactic acid foam material

The invention relates to a preparation method for an expanded material of polylactic acid; the polylactic acid, a tackifying modifier, a chemical inhibitor, a vesicant, a foaming accessory ingredient, a abscess stabilizer and a parting agent are mixed under high temperature according to a certain proportion to obtain a basic mixture; then the basic mixture is arranged in a die to carry out moulding foaming on a vulcanizing machine with a certain temperature and a certain pressure to manufacture the foaming material of polylactic acid. The foaming material of polylactic acid manufactured by the method of the invention has excellent performances of being biodegradable, controllable density, easy processing as well as good barrier property, has similar foaming shaping performance and shock-absorbing capacity with polystyrene, can replace the foaming material of polystyrene, can be used as the materials for heat isolating, sound isolating and shock absorption and has broad application in the fields of cushion packaging, transportation, electric apparatus, refrigeration, agriculture and forestry and gardening.

Owner:SHANGHAI JIAO TONG UNIV

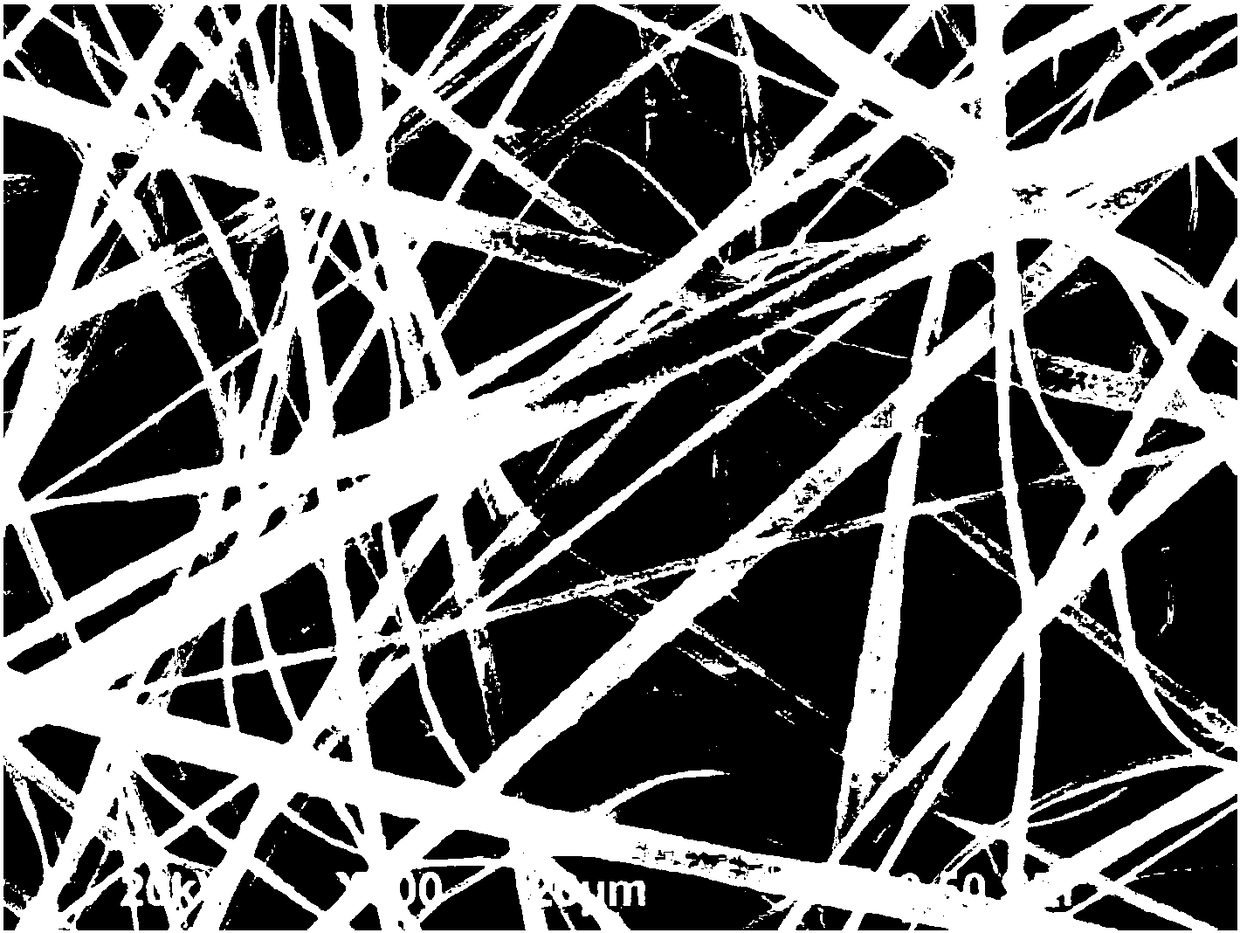

Preparation method and application of electrospinning nanofiber

PendingCN108866820AWith slow release functionPromote growthCosmetic preparationsCigar manufactureFiberFluorescence

The invention relates to a preparation method and application of electrospinning nanofiber. The preparation method is as follows: synthetic and / or natural polymer materials are dissolved in a volatilesolvent under normal temperature and normal pressure, functional substances are added, and nanofibers are obtained by electrospinning; the functional substances comprise, but are not limited to an odor substance, an organic fluorescent compound, a pigment, a temperature sensitive luminescent and color changing material, a cell growth factor, a hemostatic substance, one or a plurality of nutrientsincluding hyaluronic acid, collagen, and the like which promote skin growth. The nanofiber made by electrospinning has the special effects of sterilization, aromatic odor, fluorescent luminescence, multiple colors, temperature sensitive luminescence and color-changing, promoting wound healing, promoting inhibition and interfering with body function, maintaining skin cell vitality and the like. The method can be used in air purification, automotive air purification, fresh air systems, medical, beauty care, and other nanofiber products.

Owner:SHENZHEN RUXIANGJU TECHCAL DEV LTD

Polylactic acid foaming material and preparation method thereof

The invention provides a polylactic acid foaming material and a preparation method thereof. The polylactic acid foaming material is prepared from the following ingredients according to parts by weight: 45-93 parts of polylactic acid, 5-28 parts of toughener, 1-5 parts of nucleating agent and 1-10 parts of foaming agent. The polylactic acid is one of poly-L-lactic acid, poly-D-lactic acid and poly-DL-lactic acid or a mixture or a polymer thereof, and has the weight average molar mass of 0.8-3.5 million, molecular weight distribution of 1.2-2.5, and degree of crystallinity of 15-60 percent. The toughener is one of poly succinic acid butyl ester and poly adipate / butylene terephthalate or a mixture of two with random ratio. Other accessory ingredients can also be added. The preparation method comprises the following steps: evenly mixing the polylactic acid, the toughener, the nucleating agent, the foaming agent, the accessory ingredients and the like in a high mixing machine according to a certain proportion, then milling for 5-25 minutes at the temperature of 100-170 DEG C, and carrying out die pressing foaming on obtained materials at the temperature of 120-210 DEG C on a vulcanizing machine for 2-10 minutes to prepare the polylactic acid foaming material. The polylactic acid foaming material prepared by using the preparation method has the advantages of high resistance to shock, high elongation at break, high tensile strength and complete biodegradation after used.

Owner:南京冠创生物科技有限公司

Sewage purifier and sewage purification method

ActiveCN101928069AIncrease reproductive rateImprove purification effectSustainable biological treatmentBiological water/sewage treatmentPurification methodsMetal salts

The invention discloses a sewage purifier, which comprises polyhydroxyalkanoate, diatomite, humic acid, a bioactivator, inorganic metal salt and other substances. The invention also discloses a sewage purification method by utilizing the sewage purifier. A completely biodegradable material polyhydroxyalkanoate is used as a sustained material of the bioactivator, and the completely biodegradable material is slowly degraded and releases the bioactivator so as to realize the long-term high-efficiency purification function of the bioactivator; and by combining the effects of aquatic plants, phosphorus, nitrogen, polycyclic aromatic hydrocarbon and heavy metals in the sewage are purified and treated, so the sewage purifier has better sewage treatment effect.

Owner:SHENZHEN ECOMANN BIOTECH

Method for regulating dissolving speed of water-soluble film

A process for preparing the water-soluble film with regulatable soluble speed includes proportionally mixing partly alcoholzed polyvinyl alcohol, fully alcoholyzed polyvinyl alcohol, starch, plasticizer, surfactant, and drying agent at 85-95 deg.C and doctor blading. Its soluble speed can be regulated by controlling the ratio of partly alcoholyzed polyvinyl alcohol, fully alcoholyzed polyvinyl alcohol, and starch. Said film has good water soluability and bio-degradation.

Owner:郝喜海

Coating agent for slow release fertilizer

InactiveCN1528717ASimplify the production processEasy to operateFertilizer mixturesFertilizerChemistry

The invention relates to an enveloping agent applied to sustained release fertilizer, using chitosan 1-10wt%, amylum 30-40wt%, vinol 45-55wt%, cross-linking agent 2-10wt%, glycerol 6-8wt%, tween 1-3wt% and NH4Cl 0.5-1.5wt% as main raw materials, reacting for 1-2 hours at pH value of 2-5 and at 85-95 deg.C to make it. Its preparation is simple and its raw material source is wide and it has no environmental pollutions.

Owner:EAST CHINA UNIV OF SCI & TECH

Production of lignin modified water polyurethane

InactiveCN1939950AIncrease application value while its production costInexpensive application valueLignin derivativesPolyesterAlcohol

Production of lignin modified water polyurethane is carried out by adding into lignin while synthesizing water polyurethane emulsifier and obtaining the final product. The lignin consists of polyisocyanate, polyether polyhydric alcohol or polyester polyhydric alcohol and multifunctional-based small-molecular chain extender containing carboxy and hydrophilic group. It's simple, cheap, and degradable and has better extension rate at break and stretch strength and no environmental pollution. It can be used for coating and adhesion agent.

Owner:WUHAN UNIV OF TECH

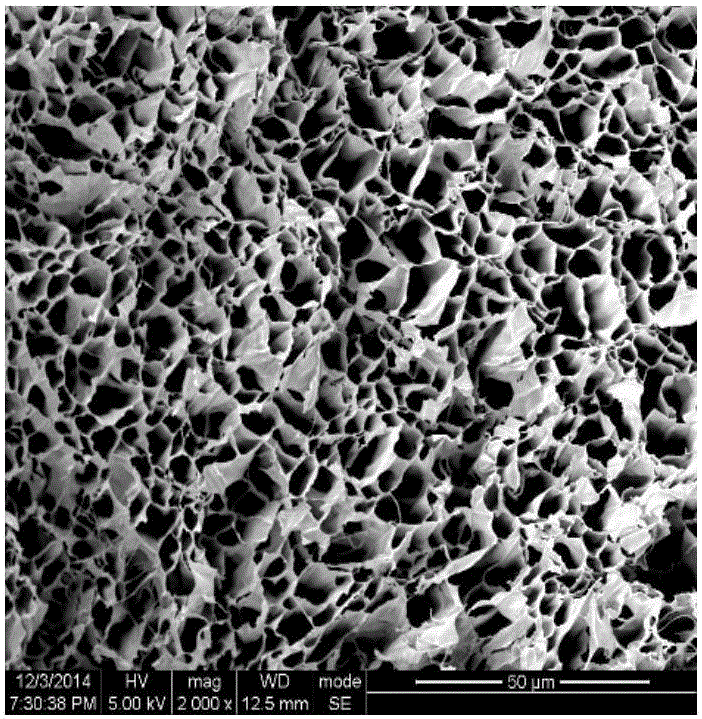

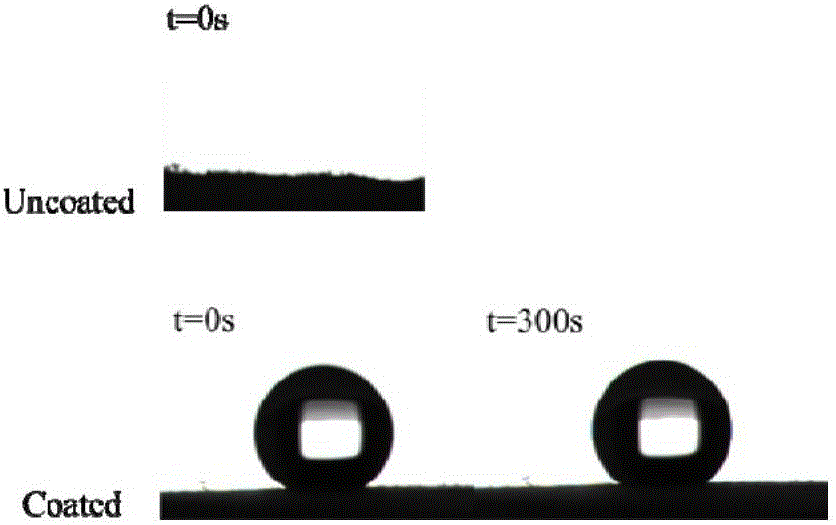

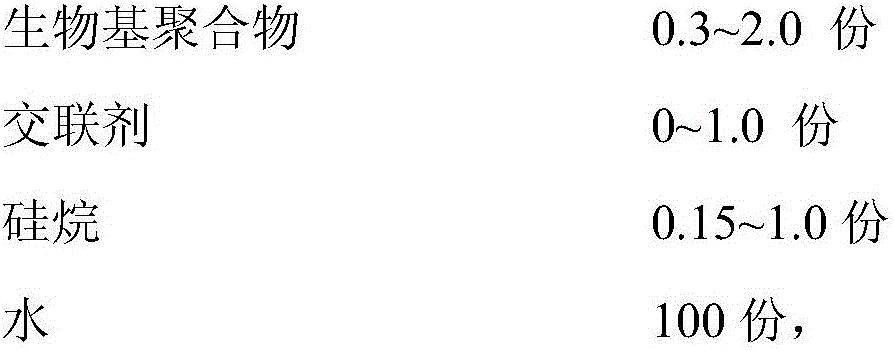

Biology base polymer aerogel oil absorption material and preparation method thereof

The invention discloses a biology base polymer aerogel oil absorption material. The oil absorption material is prepared by the following steps: at first, crosslinking biology base polymers by a crosslinking agent, to obtain a precursor liquid, then freeze-drying the precursor liquid to obtain aerogel, and finally grafting silane onto the aerogel surface to obtain the hydrophobic biology base polymer aerogel oil absorption material. The density of the oil absorption material is 3.8 to 23.1 kg / m3. The water contact angle is at least 117.8 degrees. The adsorption capacities on gasoline, paraffin oil, chloroform, and crude oil are 30.5-109.0 g / g, 33.2-131.2 g / g, 58.2-163.0 g / g, and 24.7-95.8 g / g. After 50 times of gasoline adsorption-extrusion circulation, the retention rate of adsorption capacity is 43 to 99%. The disclosed aerogel oil absorption material has the advantages of large oil absorption capacity and high oil absorption efficiency. Moreover, the oil absorption material can be repeatedly used by simply extruding the oil absorption material, while a high retention rate of adsorption capacity can be maintained. At the same time, the raw material sources are wide, the raw materials are cheap and easily available, the preparation is simple, the technology is matured, the method is environment-friendly, and the requirements of sustainable development can be met.

Owner:SICHUAN UNIV

Biodegradable sorbents

InactiveUS20030020043A1Disposal costs are highLower the volumeBiocideBiofuelsSorbentAmount of substance

Disclosed is a sorbent that includes spent grain germ, seed meal, or a mixture thereof. The sorbent may be used to introduce a material into an environment. For instance, the sorbent may be used to introduce a control agent, such as an insecticide or larvicide, into an environment. The sorbent also may be used to remove an unwanted material from an environment. For instance, the sorbent may be used to sorb oil or a hazardous chemical that has been spilled. The disclosed sorbents are biodegradable over a wide range of environmental conditions.

Owner:GRAIN PROCESSING CORP

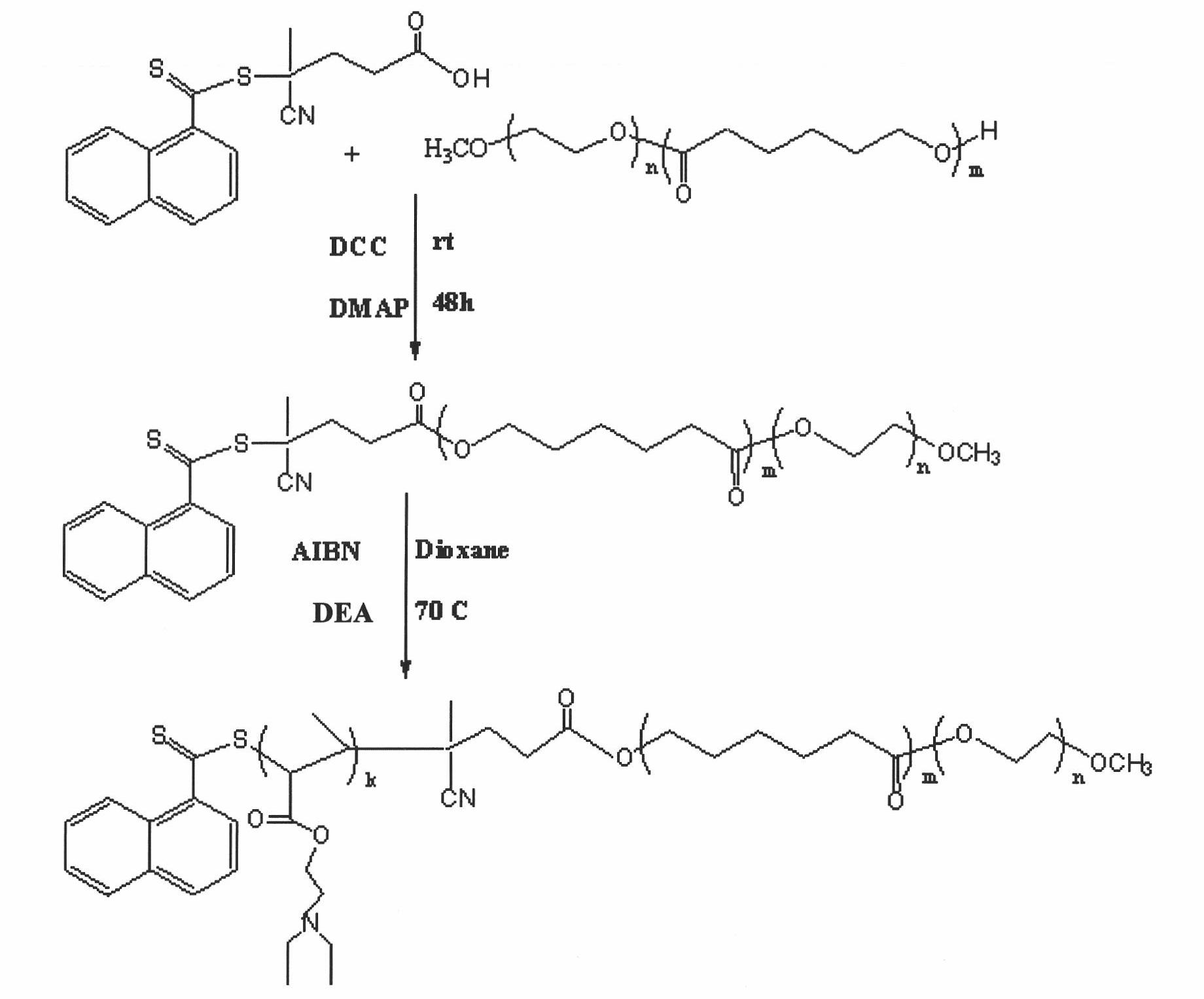

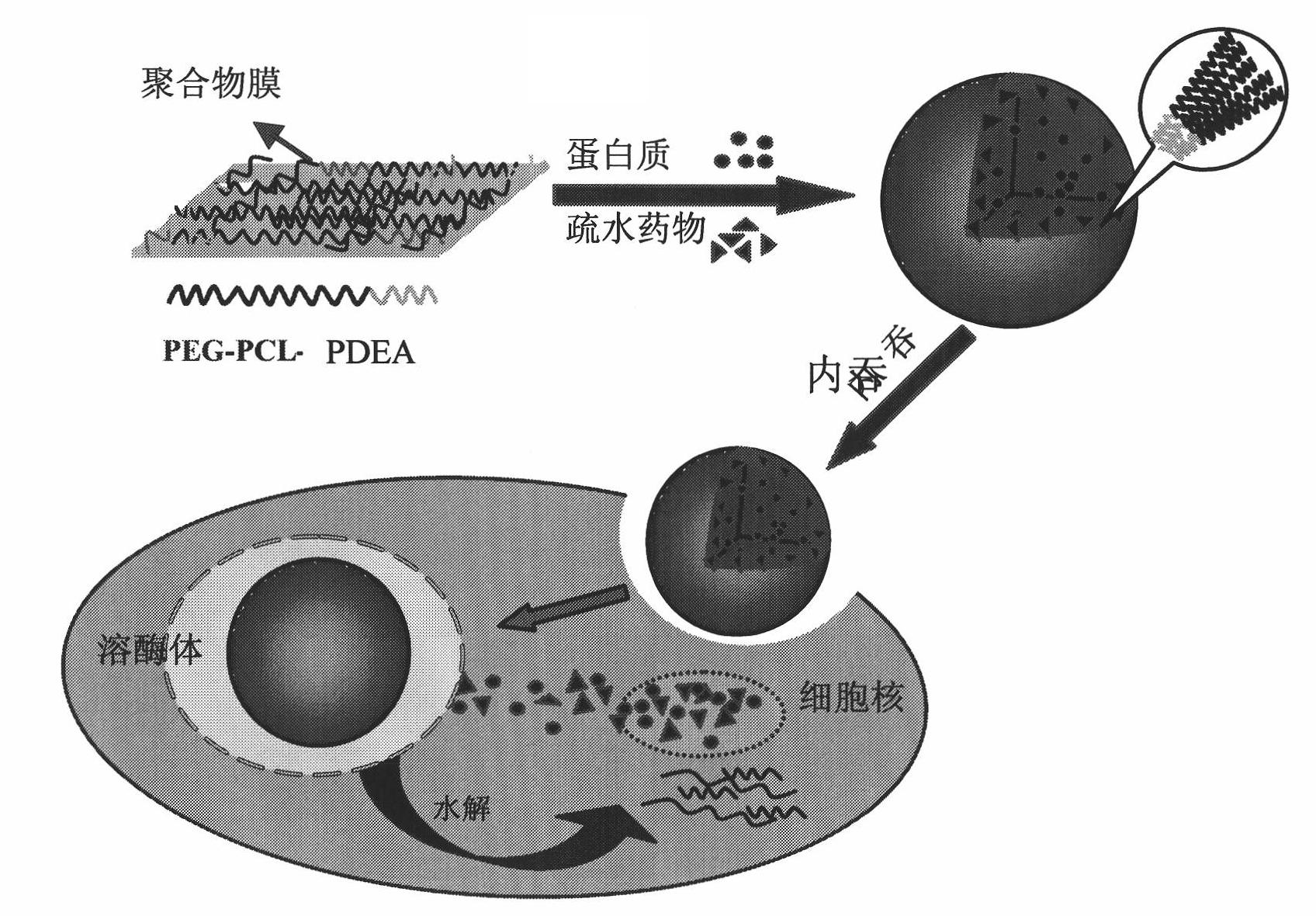

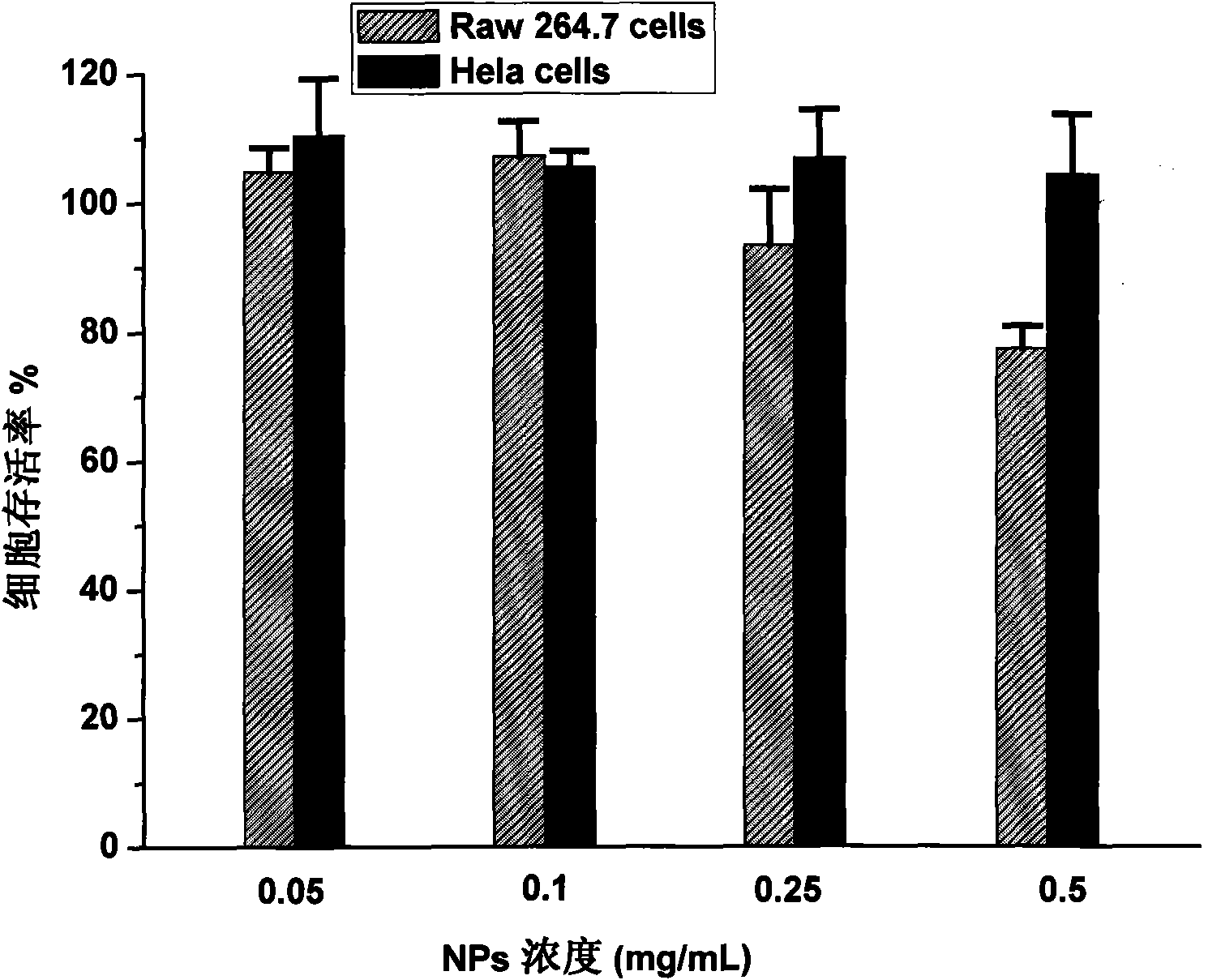

Biodegradable polymer vesicles and preparation and application thereof

InactiveCN101792516AEfficient packagingEliminate drug resistancePharmaceutical non-active ingredientsPolymer sciencePolyethylene glycol

The invention relates to a medicament carrier and a preparation method thereof, in particular to a medicament delivery system comprising biodegradable polymer vesicles with asymmetric membranes. The invention discloses the biodegradable polymer vesicles and preparation and application thereof. The biodegradable polymer vesicles are prepared from A-B-C type block polymer, wherein a block A is polyethylene glycol (PEG) distributed on outer surfaces of the vesicles; a block B is hydrophobic biodegradable polymer to form the nucleuses of the vesicles; and a block C is polyelectrolyte distributed on inner walls of the vesicular membranes and used for efficiently loading medicaments with opposite electric charge. The biodegradable polymer vesicles are formed in aqueous solution directly, can efficiently load protein and polypeptide medicaments, nucleic acid medicaments and micro-molecular medicaments, and are expected to be applied to the protein therapy and the combination therapy of cancers.

Owner:SUZHOU UNIV

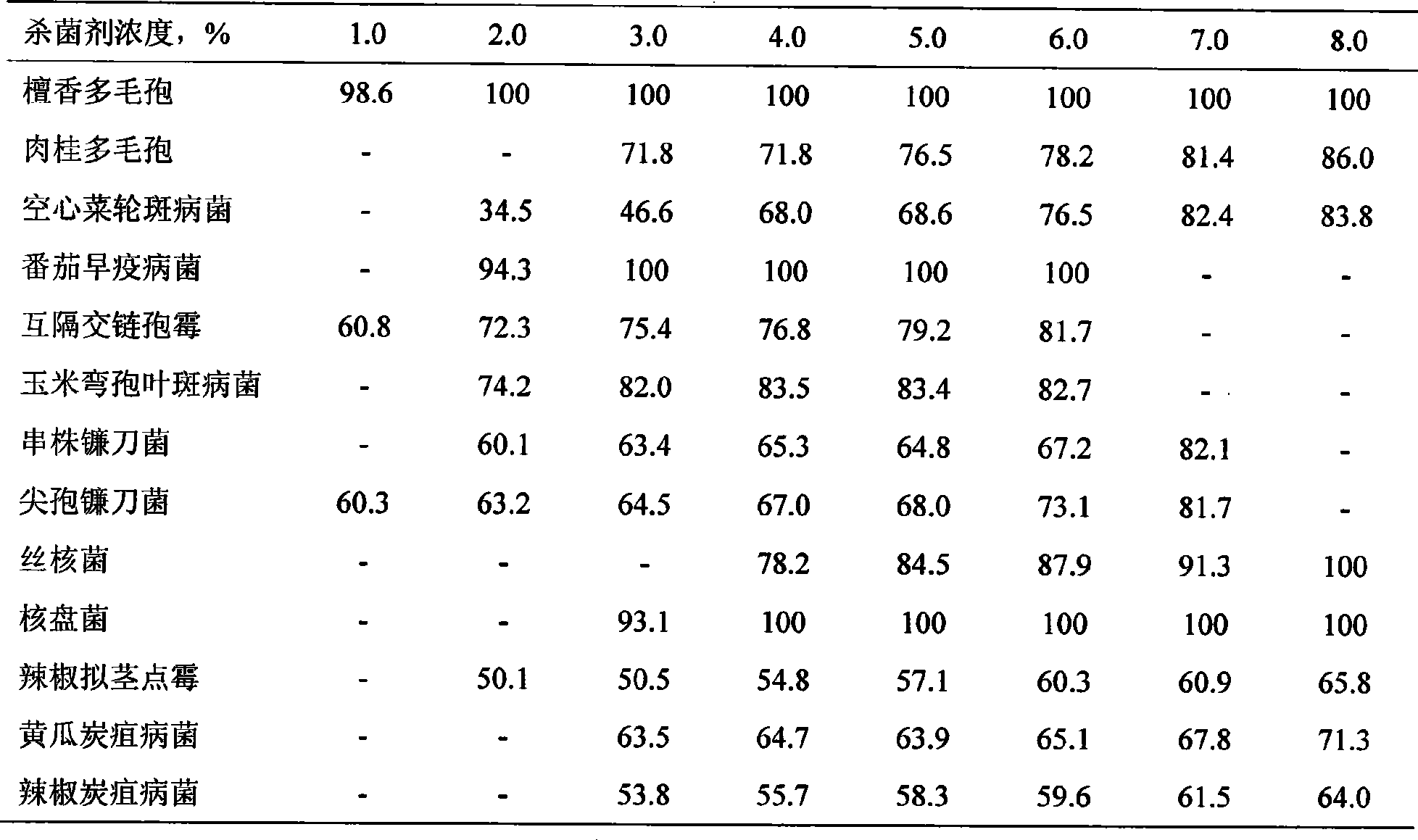

Plant source natural bactericidal agent

The invention relates to a botanical natural disinfectant, which is characterized in that the disinfectant is prepared by mixing active components including patchouli essential oil and composite of various plant essential oils and solvent; wherein, the active components are prepared by mixing 0.5 to 30.0 percent of patchouli essential oil, cinnamon essential oil, perilla essential oil, eucalyptus essential oil, litsea cubeba essential oil and citronella essential oil and are used for preventing the crop disease caused by plant pathogenic bacteria. Compared with the original disinfectant, the botanical natural disinfectant has the advantages of good broad spectrum sterilization, safety to non-target organism and environment-friendly biodegradation.

Owner:广东省中药研究所

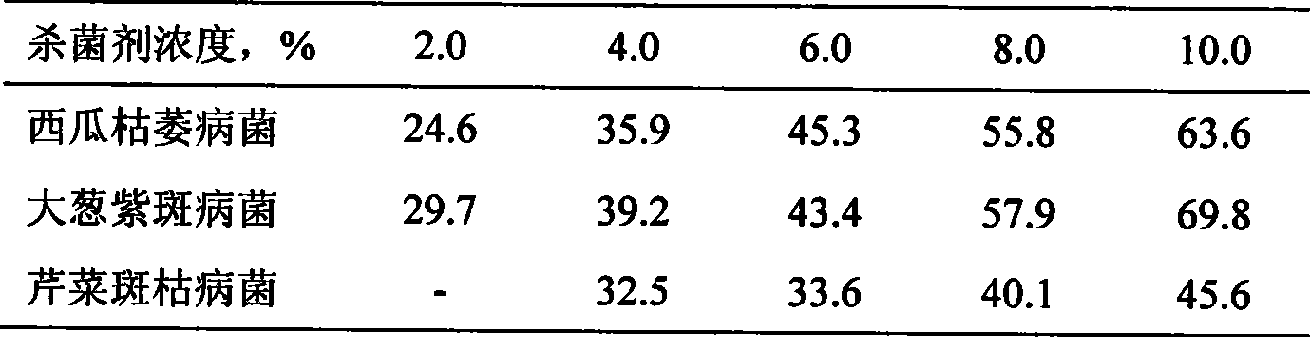

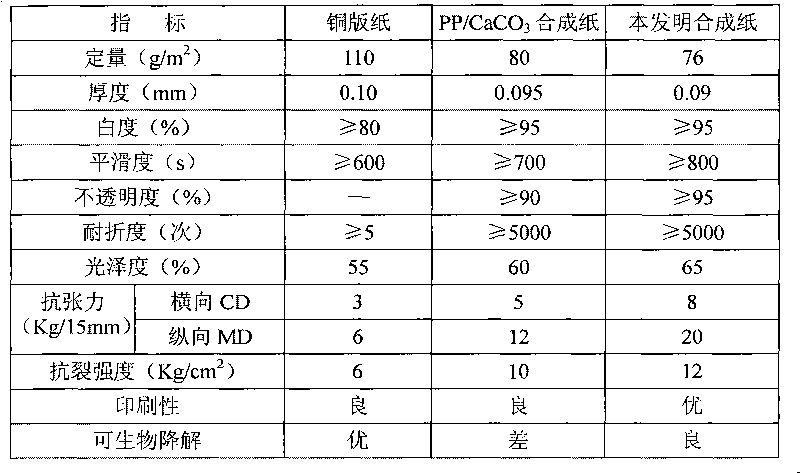

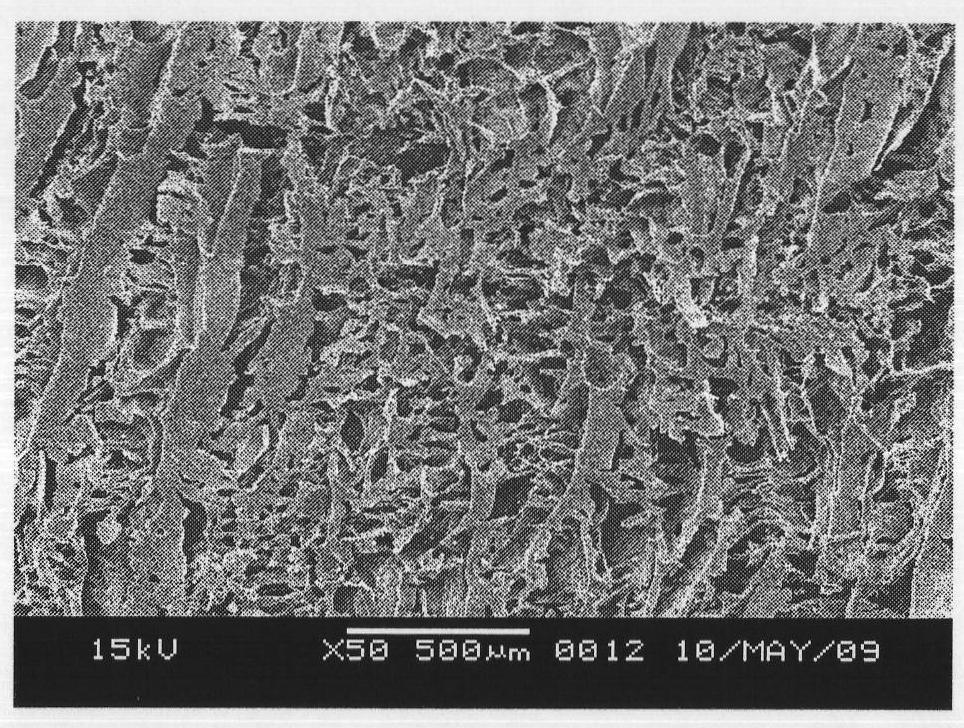

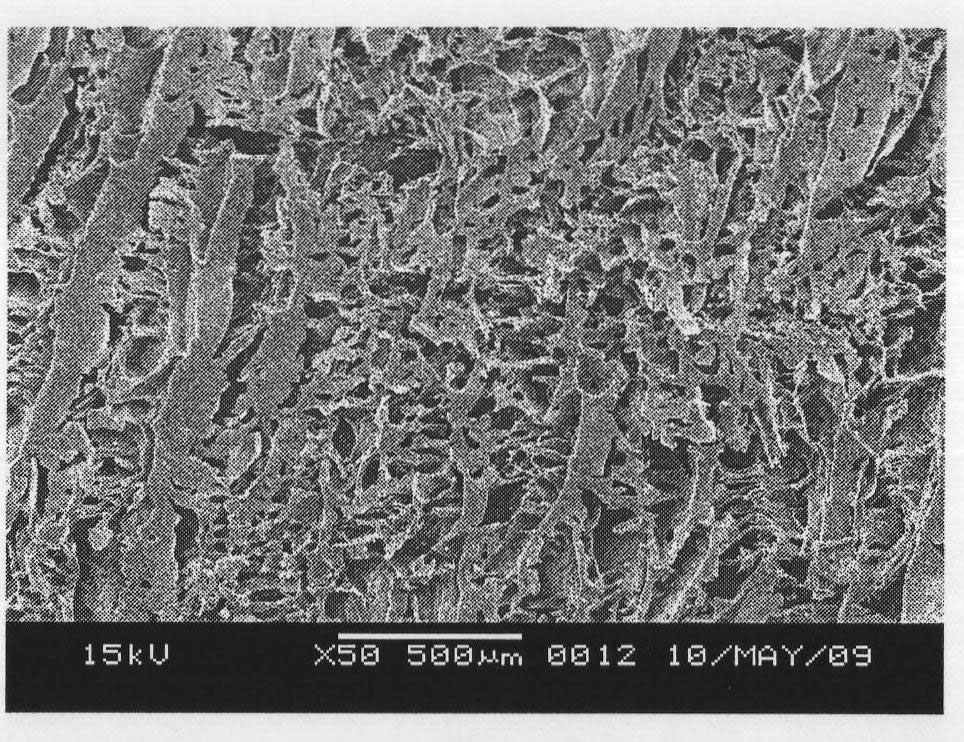

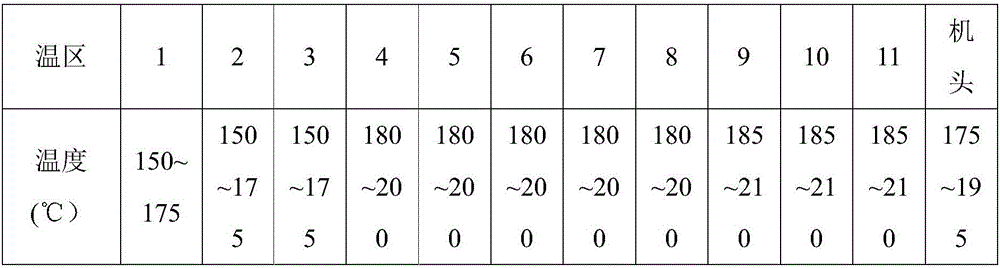

Paper making material, preparation method and paper making method of environment-friendly synthetic paper

ActiveCN101760990AImprove stabilityImprove heat resistanceNon-fibrous pulp additionSpecial paperFiberBlow molding

The invention relates to a paper making material, a preparation method and a paper making method of environment-friendly synthetic paper. The material comprises modified mineral fiber, thermoplastic starch, cellulose derivative, compatilizer, auxiliary components and the like, wherein the average particle diameter of the modified mineral fiber is 5-10 micrometers, the ratio of the length of the modified mineral fiber to the diameter of the modified mineral fiber is 8-15:1, and the modified mineral fiber is treated by fibrosis ultrafine grinding and surface recombination modification; the thermoplastic starch is formed by performing micronization and plasticization modification on norm starch; and the auxiliary components comprise lubricant and colorant. The paper making material is prepared by sequentially mixing the raw material components fully and then extruding and granulating the mixture by a screw extruder at 60-180 DEG C. According to the plastic process mode, the material can be treated by blow molding through a calender or a paper film machine for carrying out two-way stretch to prepare corresponding paper products. The paper making material can overcome the defects of the current synthetic paper and can be widely applied to the fields of commercial printing, publications, office paper, packing and the like, and the processing procedure of making paper by using plastic processing equipment has environmental protection and low cost.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Preparation method of chitosan/polyvinyl alcohol/polylactic acid blended porous membrane

The invention relates to a preparation method of a chitosan / polyvinyl alcohol / polylactic acid blended porous membrane, which comprises the following steps of: (1) using an acetic acid solution as the solvent to dissolve chitosan at 30-40 DEG C to obtain a chitosan solution of which the weight percentage is 3%; (2) using a dimethyl sulfoxide solution as the solvent to dissolve polyvinyl alcohol at room temperature to obtain a polyvinyl alcohol solution of which the weight percentage is 5%; (3) using deionized water as the solvent to dissolve polyvinyl alcohol at 80-120 DEG C, and stirring until the polyvinyl alcohol is completely dissolved to obtain a polyvinyl alcohol solution of which the weight percentage is 7%; (4) mixing the three solutions based on a certain ratio, stirring for 15-30 minutes at the constant temperature of 20-30 DEG C, standing, and defoaming; and (5) using a freeze drying method to prepare the blended porous membrane. The invention has the advantages of no toxic material in the membrane preparation process, simple membrane preparation device and process, biodegradability and convenient clinical use, and can be used for artificial skins, dressing and the like in the biomedical field.

Owner:DONGHUA UNIV

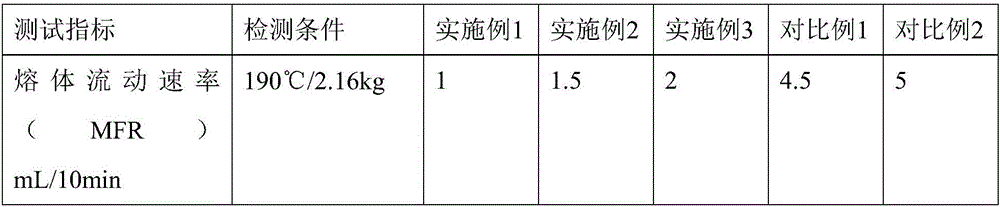

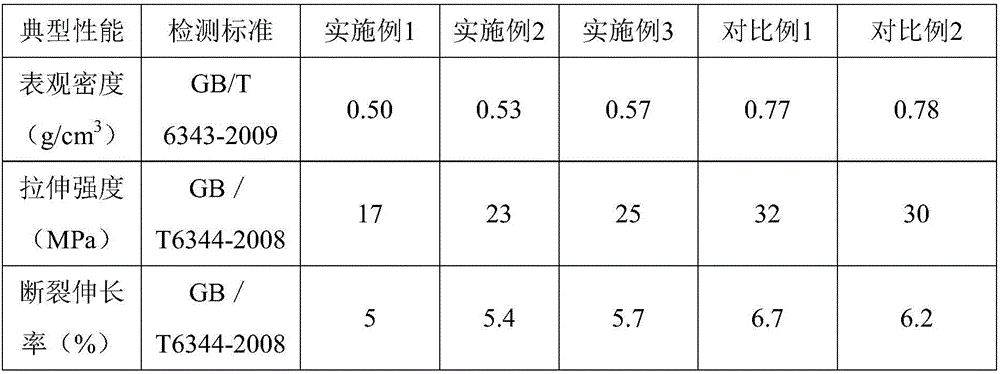

Special resin with high melt strength for foaming of polylactic acid and preparation method thereof

The invention relates to special resin with high melt strength for foaming of polylactic acid and a preparation method thereof, and belongs to the technical field of macromolecules. The special resin is prepared from the following raw materials in parts by weight: 60 to 95 parts of polylactic acid, 1 to 20 parts of biodegradable copolymer, 0.1 to 1 part of chain expander, 1 to 5 parts of melt enhancer, 0.1 to 5 parts of nucleating agent, and 0.5 to 2 parts of lubricant. The special resin has the advantages and beneficial effects that by improving the melt strength of the polylactic acid and enhancing the adsorbing ability of polylactic acid on CO2 (carbon dioxide), the foaming property of the polylactic acid is enhanced. The used devices are universal devices in the technical field of macromolecules, such as a double-screw extruder, a crystallizing drier and a plastic extrusion foaming machine. The special resin has the advantages that the operation is simple and convenient, the control is easy, the industrialized implementing is easy, and the economic benefit is high.

Owner:JILIN COFCO BIOCHEM

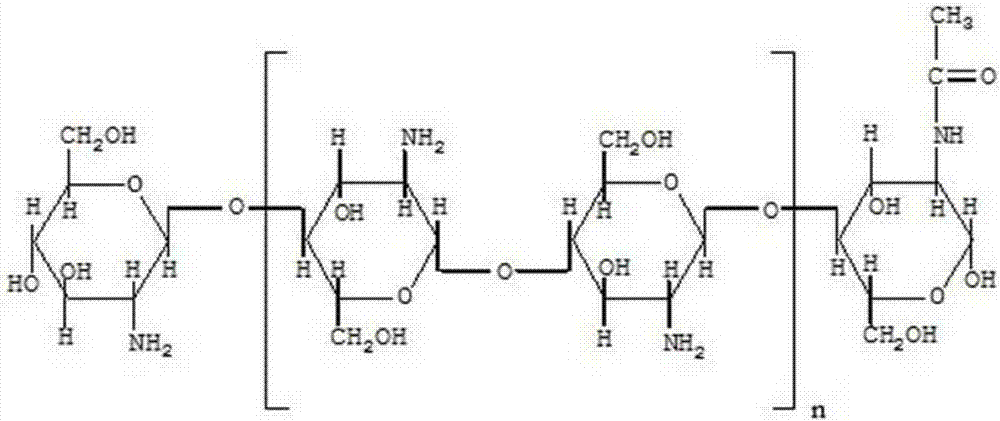

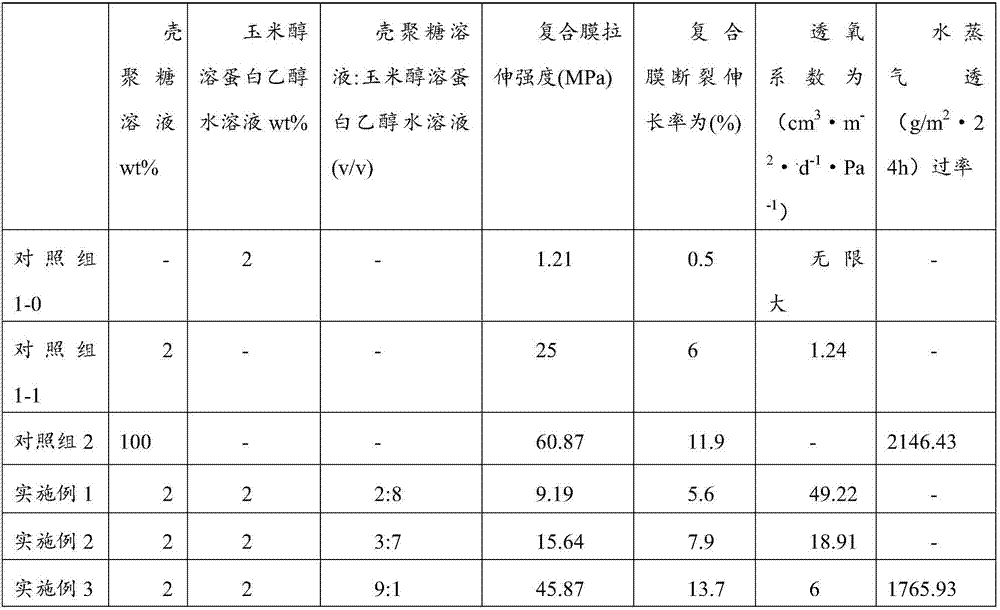

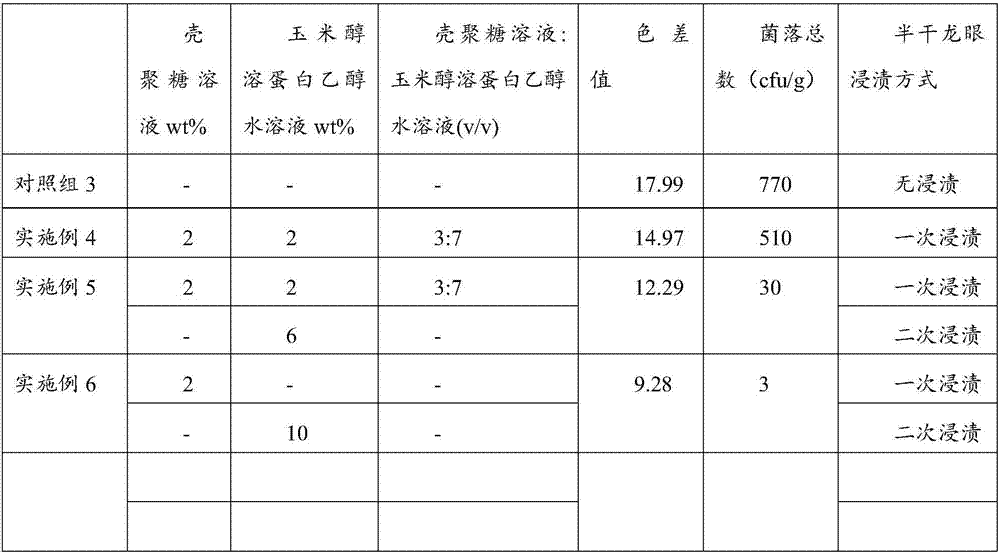

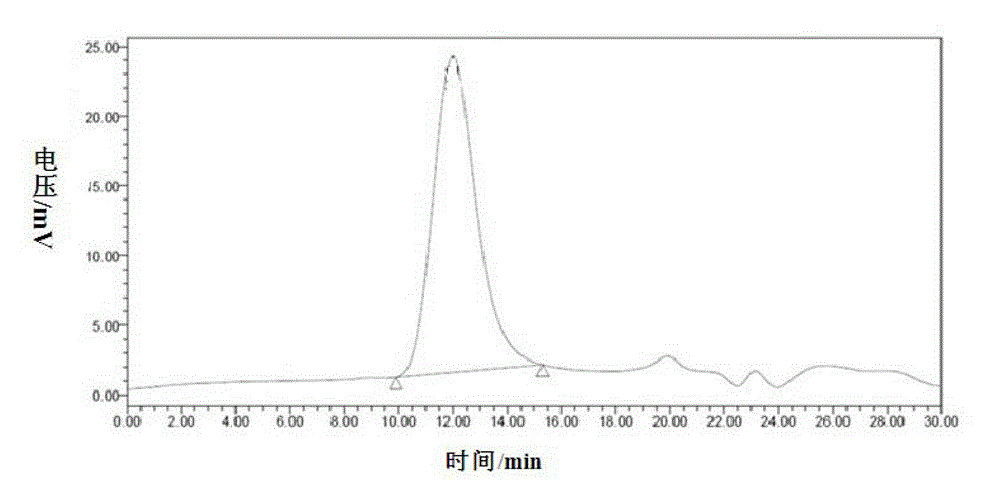

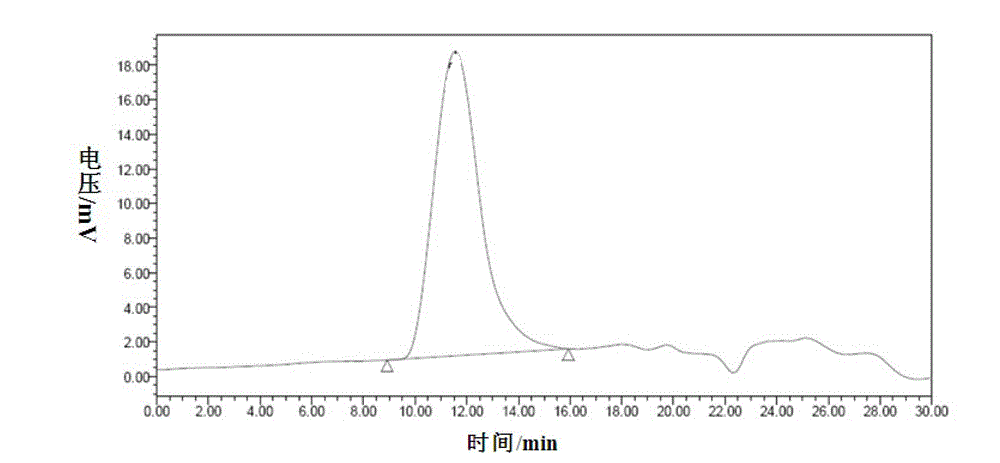

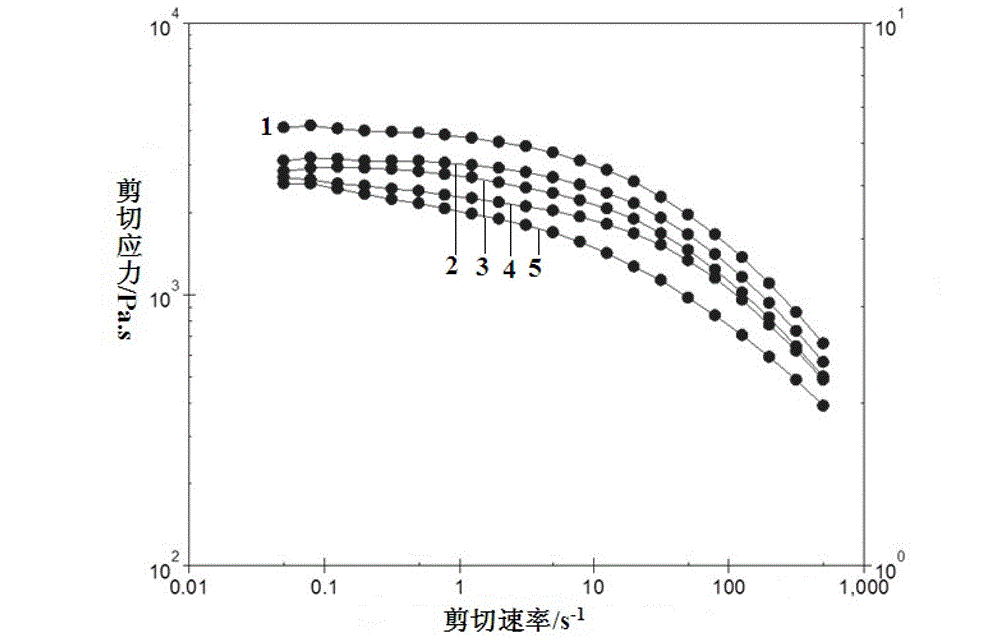

Method of preparing composite preservative film or coating from chitosan and alcohol soluble corn protein

InactiveCN106957458AStrong machineryLow costCoatingsFruits/vegetable preservation by coatingChemistryAqueous solution

The invention relates to a method of preparing a composite preservative film or coating from chitosan and alcohol soluble corn protein. The method mainly comprises the following steps: (1) preparing 2wt% chitosan solution; (2) preparing 1-10wt% ethanol aqueous solution of alcohol soluble corn protein; (3) mixing the solutions prepared in the steps (1) and (2) in a volume ratio of 1:9 to 9:1 (v / v) to obtain a composite film solution; (4) flow casting the composite film solution obtained in step (3) and drying to obtain a film; or sequentially overlaying the solutions prepared in the steps (1) and (2) to obtain a double-layer preservative film. The chitosan-alcohol soluble corn protein composite preservative film or coating prepared in the invention is not only improved in the moisture resistance and ultraviolet resistance of a chitosan film, but also improved in the barrier property, mechanical properties and antibacterial activity of a alcohol soluble corn protein film, and is degradable, edible, etc. When the chitosan-alcohol soluble corn protein composite preservative film or coating prepared in the invention is used to package or wrap foods such as meat, oils and fats, fruits and vegetables, the quality guarantee period thereof can be effectively prolonged. Thus, the method has an extensive application prospect.

Owner:GUANGXI UNIV

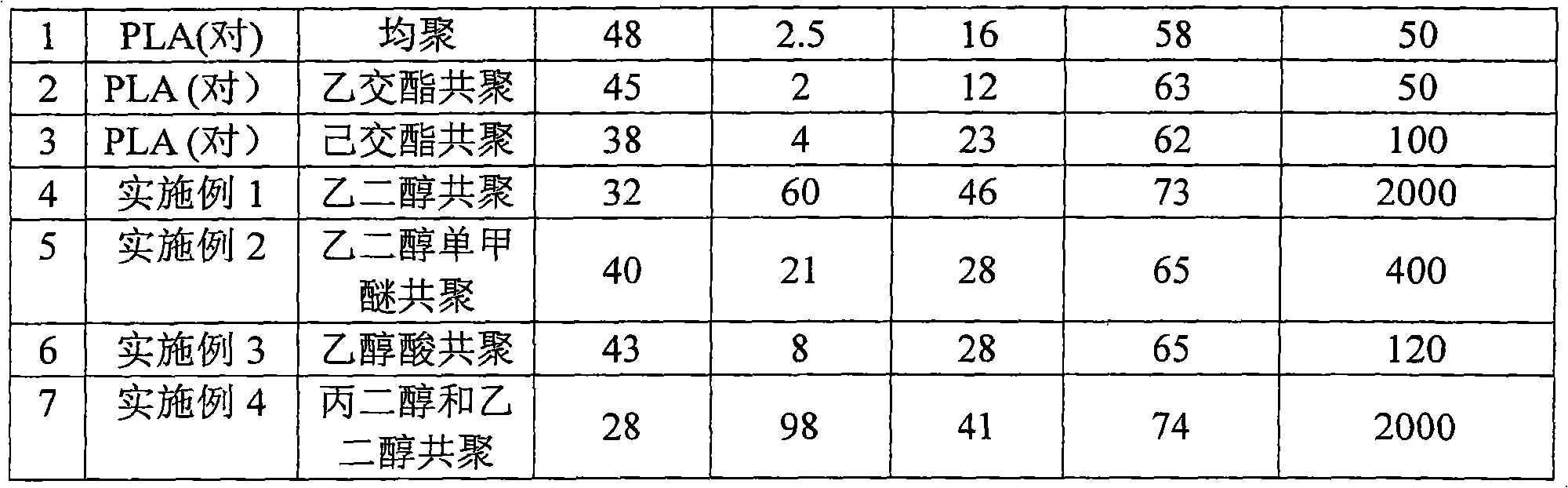

Degradable polylactic acid diblock copolymer, preparation method and application to modified polylactic acid

The invention discloses a degradable polylactic acid diblock copolymer, a preparation method and application to modified polylactic acid, solving the problems of instable performance, high preparation cost and unsuitability for industrialized continuous production of modified polylactic resin in the prior art. The preparation method of the degradable polylactic acid diblock copolymer comprises the following steps of: adding dried and dewatered polylactic acid A with an end group being hydroxy into a reaction device under the protection of an inert atmosphere, adding diisocyanate B, heating to 185-190 DEG C, reacting with stirring for 5-8h, adding degradable high polymer C containing hydroxy, reacting with stirring for 1-2h at the temperature of 185-190 DEG C, adding the diisocyanate B, and reacting at the temperature of 185-190 DEG C until the stirring is difficult to obtain the degradable polylactic acid diblock copolymer. The degradable polylactic acid diblock copolymer disclosed by the invention is good in compatibility with the polylactic resin, is used for modifying the polylactic resin, is capable of remarkably improving processing property and mechanical property of the polylactic resin, and has the elongation at break reaching 60 percent.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

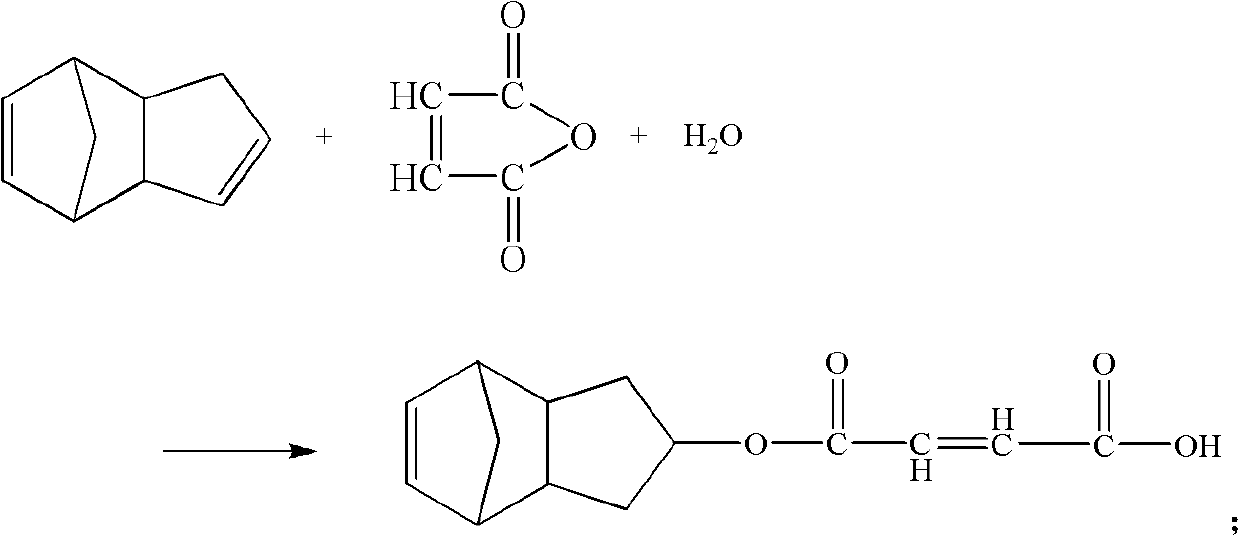

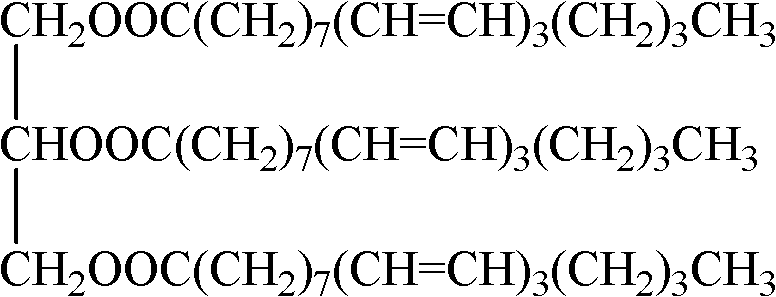

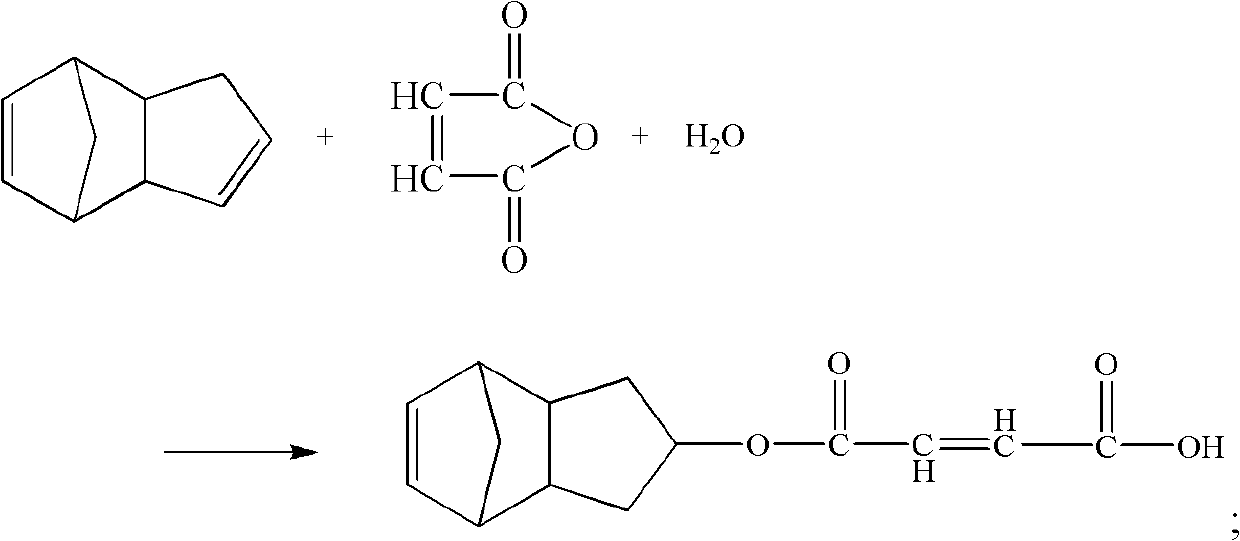

Dicyclopentadiene type unsaturated polyester modified by tung oil, and preparation method and application thereof

InactiveCN102115534AEasy to operateImprove product qualityPlastic/resin/waxes insulatorsOther chemical processesAlcoholAcid value

The invention discloses a dicyclopentadiene type unsaturated polyester modified by tung oil, and a preparation method and application thereof. The method comprises the following steps: reacting raw materials maleic anhydride and dicyclopentadiene under the action of a catalyst to obtain dicyclopentadiene semi-maleate; adding dihydric alcohol, dibasic acid and polymerization inhibitor, and heatingto 190-210 DEG C for dehydration and esterification; when the acid value reaches 50-120 mg KOH / g, cooling to 120-180 DEG C, adding a certain amount of tung oil, and heating to 200-210 DEG C to continue the reaction; and after the acid value reaches 20-35 mg KOH / g under the action of esterification, cooling to 100-120 DEG C, diluting with styrene dissolved with a small amount of polymerization inhibitor, and uniformly dispersing to obtain the product. The dicyclopentadiene type unsaturated polyester modified by tung oil according to the method has the advantages of favorable air-drying property, aging resistance, biodegradability and the like. The product is suitable to be used as an unsaturated polyester paint for corrosion protection, insulation and binding.

Owner:山东中洋新创复合材料有限公司

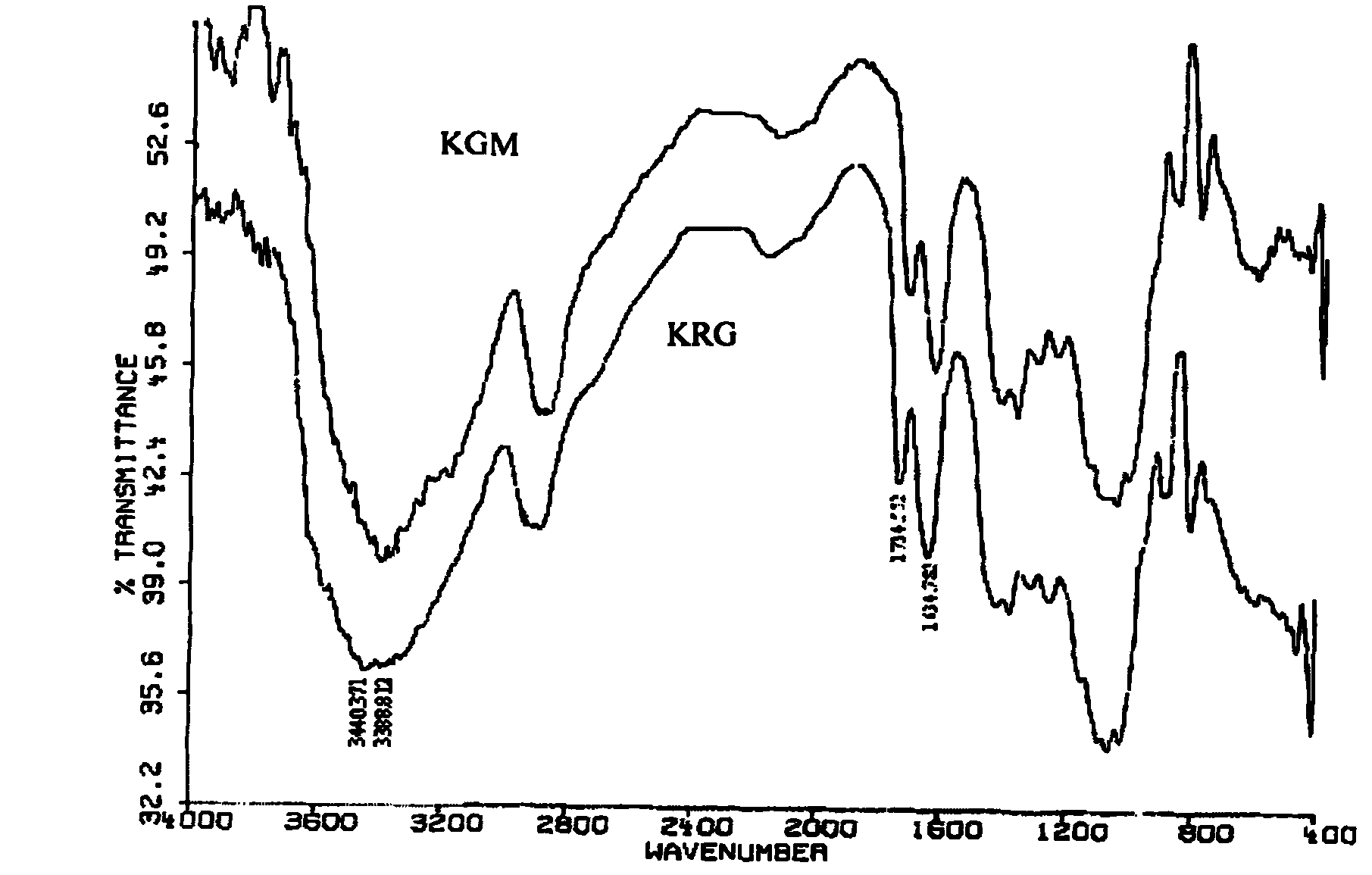

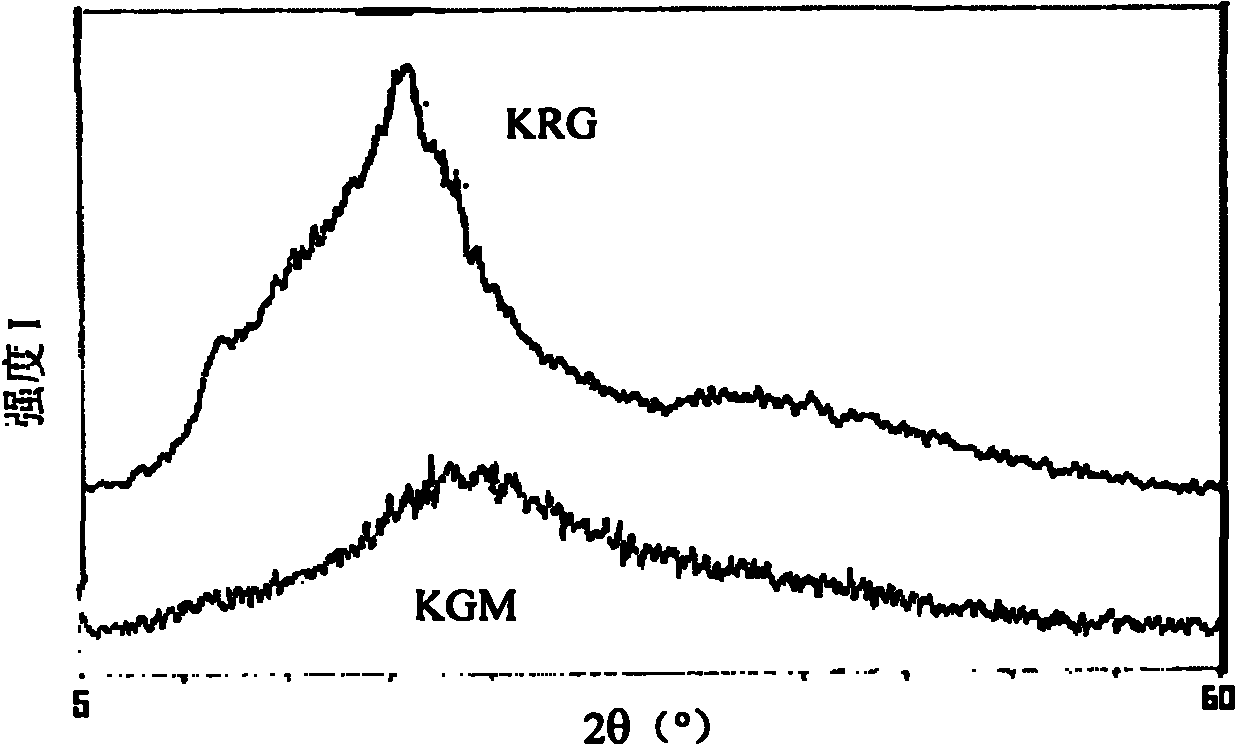

Method for preparing konjac glucomannan adsorbing material

InactiveCN101884909ABiodegradableSimple methodOther chemical processesWater/sewage treatment by sorptionWater bathsHigh concentration

The invention discloses a method for preparing a konjac glucomannan adsorbing material. Water-resistant konjac glucomannan which keeps acetyl functional groups is prepared by a high concentration swelling method. The method comprises the following steps of: purifying refined konjac powder to obtain high-purity konjac glucomannan; swelling the high-purity konjac glucomannan in water for 10 minutes, adding a small amount of dimethyl sulfoxide and fully swelling at the temperature of between 40 and 70 DEG C; extruding the fully swelled konjac glucomannan after taking out to form filaments with the diameter of 0.5 to 1.0mm; adding the filaments into 70 to 95 volume percent solution of dimethyl sulfoxide, and putting the solution into a boiling water bath for 30 minutes; and shearing the product after taking out to form particles with the diameter of 0.5 to 1.0mm and the height of 0.5 to 1.0mm, and drying the particles to constant weight. Compared with the chemical modification method, the method has the advantages of simple preparation process and low energy consumption; and the obtained product has high water resistance, can be used as an adsorbing material and has good application prospect in the aspect of dyeing and finishing wastewater.

Owner:湖北李泽园食品有限公司

Straw powder-based anti-blocking agent of compound fertilizer

InactiveCN102050679APromote decompositionEasy to decompose naturallyFertilizer mixturesOil and greaseParaffin wax

The invention provides a straw powder-based anti-blocking agent of a compound fertilizer, which is prepared by mixing the following raw materials in parts by weight: 7.5-9 parts of straw powder, 0.5-5 parts of stearic acid, 0.1-1 part of stearin, 0.1-0.5 part of hydramine, 0.5-5 parts of white oil or paraffin wax and 2-15 parts of natural oil, the six components are uniformly stirred at 60-120 DEG C and then cooled to the room temperature after reaction for 5-60 minutes so that the finished-product anti-blocking agent is obtained. The main component of the straw powder-based anti-blocking agent is straw which belongs to natural biological raw material so that the straw powder-based anti-blocking agent has biodegradability and favorable environment friendliness and can be repeatedly used for a long term without resulting in adverse influences on soil, crops and farm environments. The straw powder-based anti-blocking agent has the advantages of high-efficiency and full utilization of straw resources, environmental protection, convenience for processing and high cost performance without using engine oil.

Owner:FUJIAN UNIV OF TECH

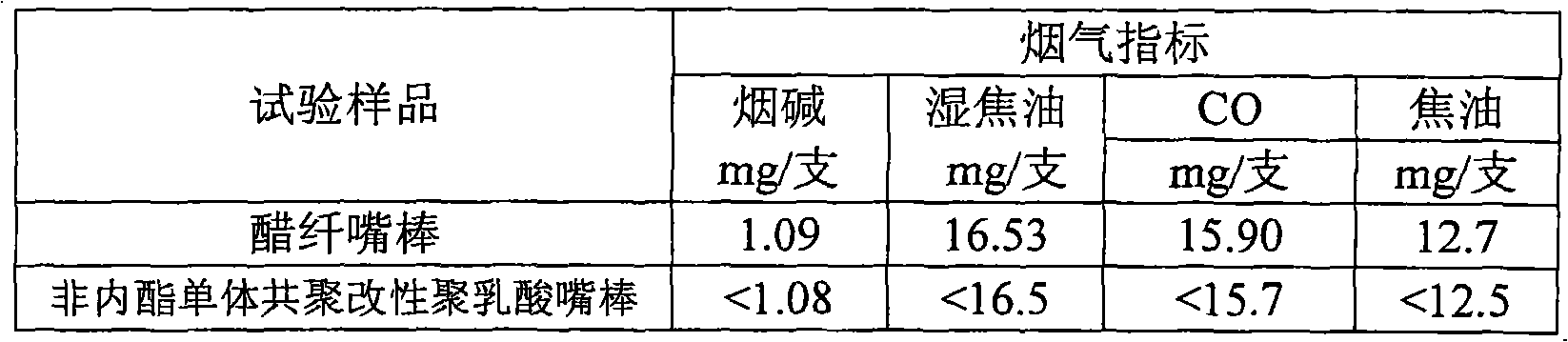

Biodegradable cigarette fiber material and cigarette filter

ActiveCN102080275APromote degradationDegradation meetsTobacco smoke filtersFilament/thread formingFiberPolymer science

The invention provides a biodegradable cigarette fiber material and a cigarette filter. The biodegradable cigarette fiber material comprises the following raw materials of 90-100 percent of polylactic acid modified by a non-lactone monomer through copolymerization and 0-10 percent of stabilizing agent as well as the balance of high polymer of the polylactic acid chain segments, wherein the polylactic acid modified by the non-lactone monomer through copolymerization is a non-lactone monomer chain segment in a molecular chain containing 1-30 percent of the total quantity of the chain segments, the weight-average molecular weight of the high polymer is 0.5-3.5 millions and the dispersion index of the high polymer is 1.2-3.0. The biodegradable cigarette fiber material is prepared from the raw materials through using a melting spinning process. The invention also provides a biodegradable cigarette filter rod prepared from the cigarette fibre material through sizing processing, and a cigarette product. The processing and using properties of the raw materials are remarkably improved. The provided cigarette filter has a property equivalent to the property of the traditional general cigarette filter, a cigarette end discarded by a smoker can be decomposed within shorter time in the natural environment, and the pollution of the cigarette waste to the environment is avoided at present while the requirement of cigarette production is met.

Owner:海南海福新材料有限公司

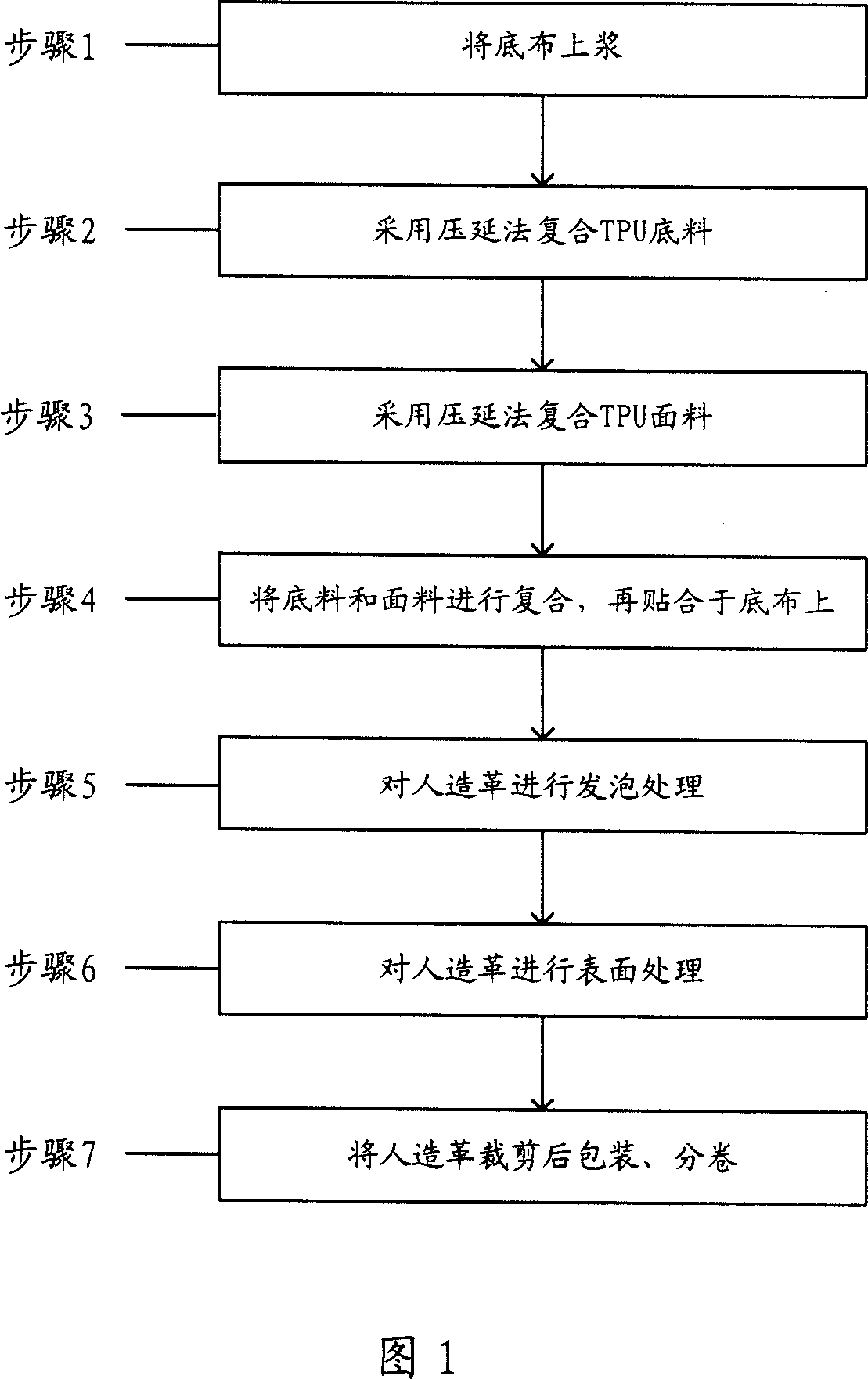

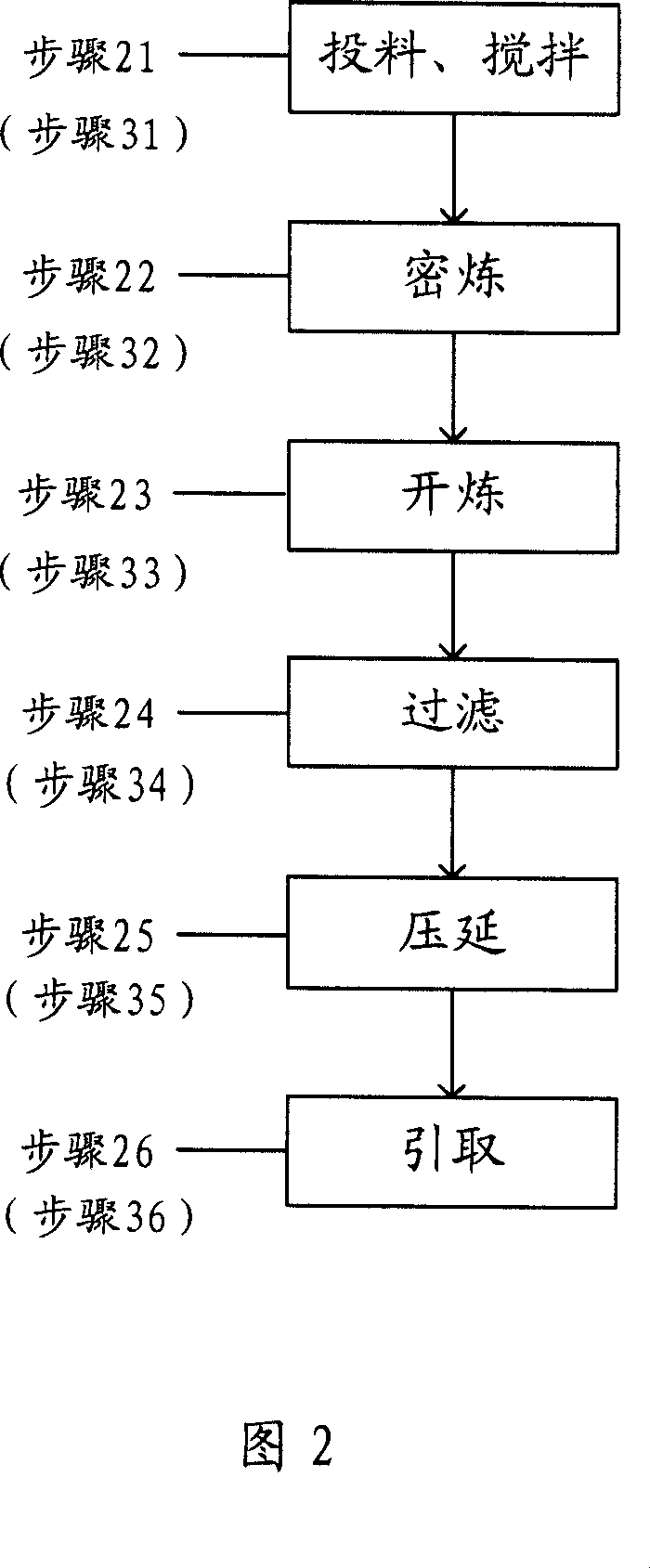

Recipe and production process of artificial leather of thermoplastic polyurethane

InactiveCN101021046AEnvironmentally friendly and non-toxicBiodegradableTextiles and paperProduction linePolyol

The present invention is the recipe and production process of artificial leather of thermoplastic polyurethane. The artificial leather has thermoplastic polyurethane elastomer resin as the main material, acrylic resin, plasticizer of non-toxic polyol derivative, dispersant, stuffing, etc. The rolling process of producing thermoplastic polyurethane artificial leather includes the following steps: 1. sizing the base fabric; 2. rolling to compound TPU base material and top material; 3. adhering the compounded TPU base material and top material onto the base fabric; and 4. post-treatment of the artificial leather to obtain the thermoplastic polyurethane artificial leather product. The production process may be completed in a conventional rolling production line.

Owner:叶志成

Novel use of ploy-L-lactic acid as medical shape memory material

InactiveCN1569261AShape memory properties haveBiodegradableSurgeryPharmaceutical containersInsertion stentMinor trauma

A novel usage of poly-L-lactic acid as medical shape memory material is provided. Forming the poly-L-lactic acid to initial shape under the temperature of 190í½210íµ and pressure of 2í½10Mpa to obtain the poly-L-lactic acid with shape memory property. The present invention uses poly-L-lactic acid as medical degradable shape memory material for the first time. It can be widely applied in minor trauma invasive stent, vessel jointing, operation suture line, bone fracture fixation and other medical field.

Owner:HARBIN INST OF TECH

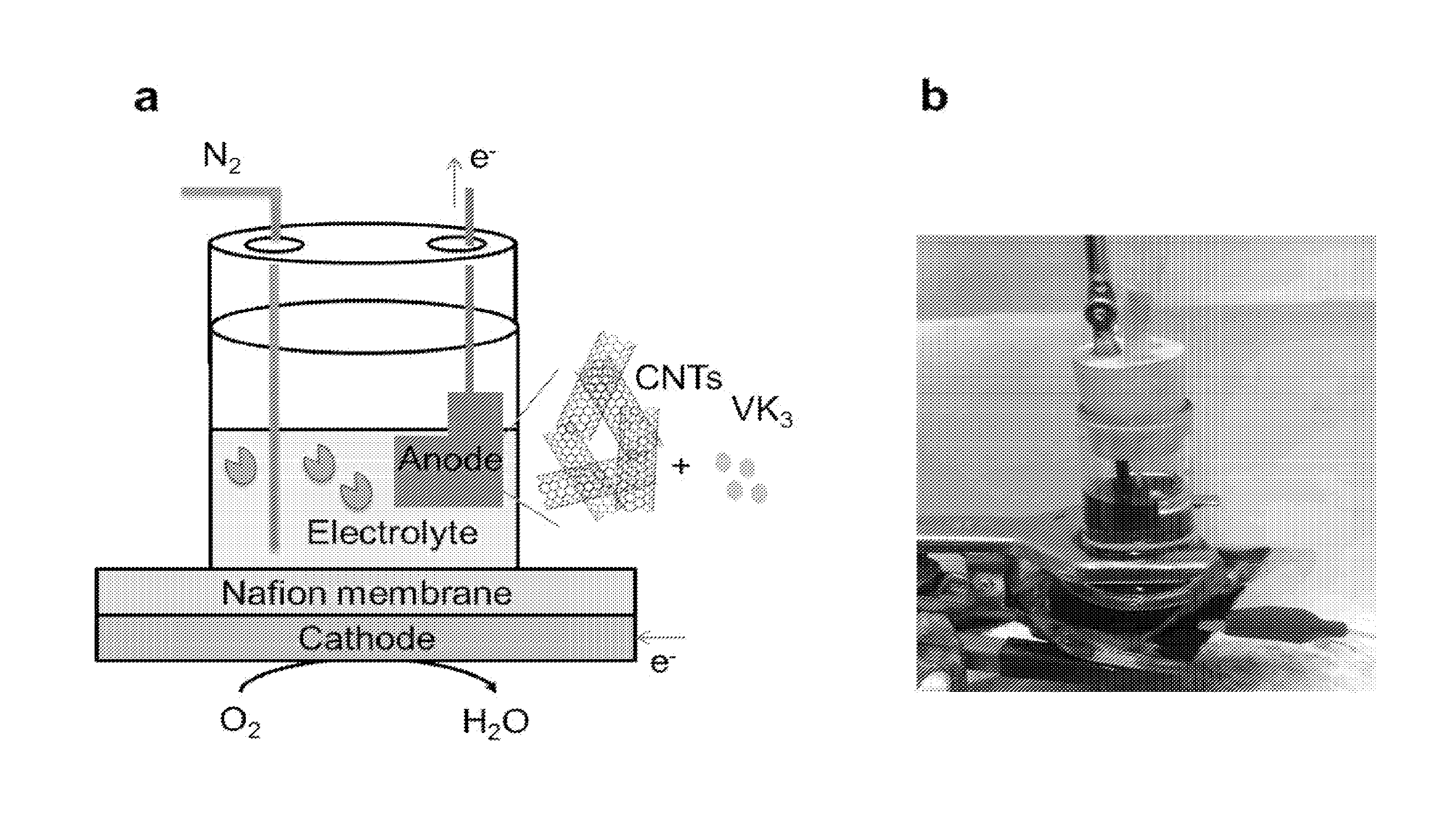

Complete Oxidation of Sugars to Electricity by Using Cell-Free Synthetic Enzymatic Pathways

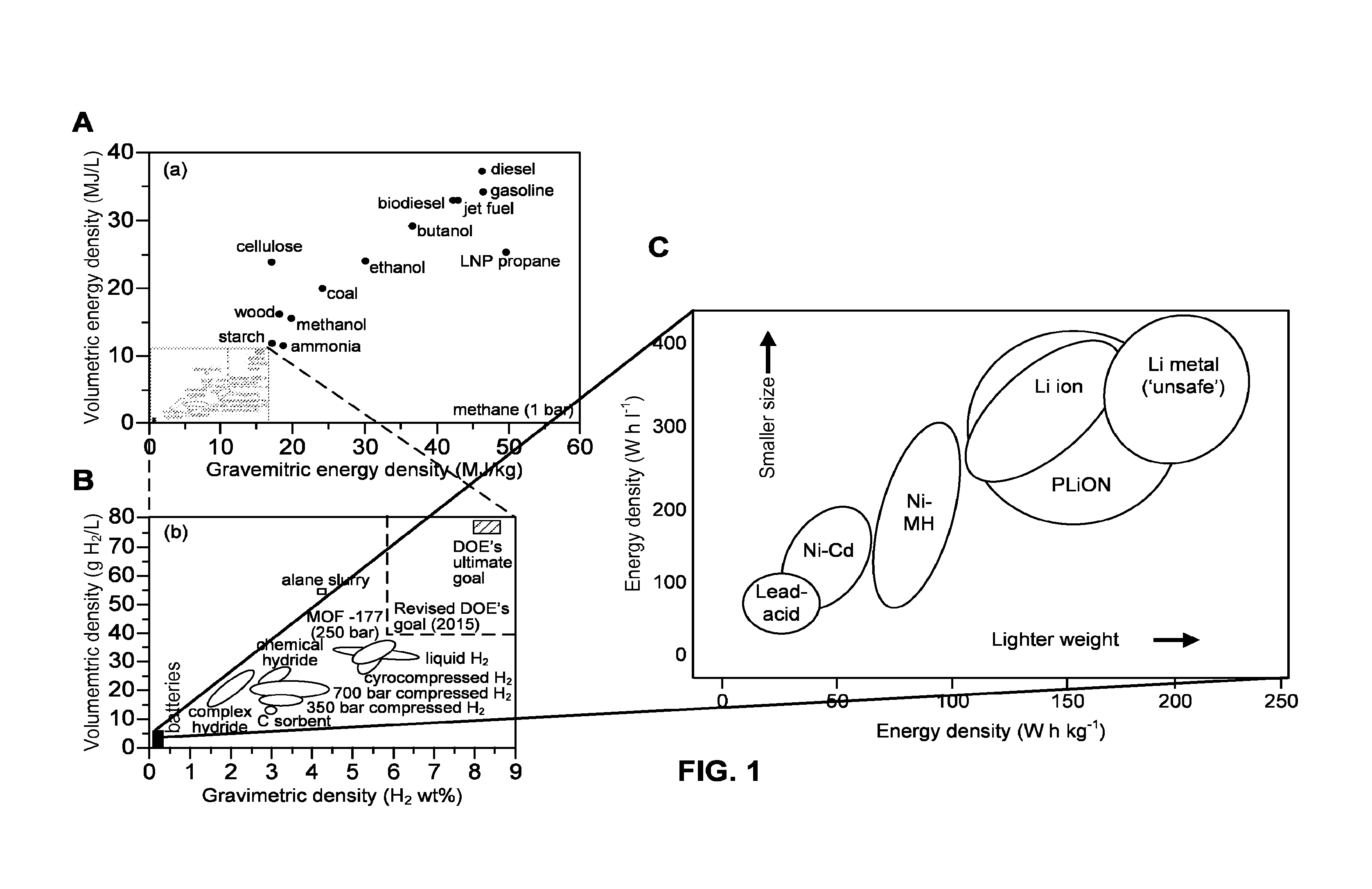

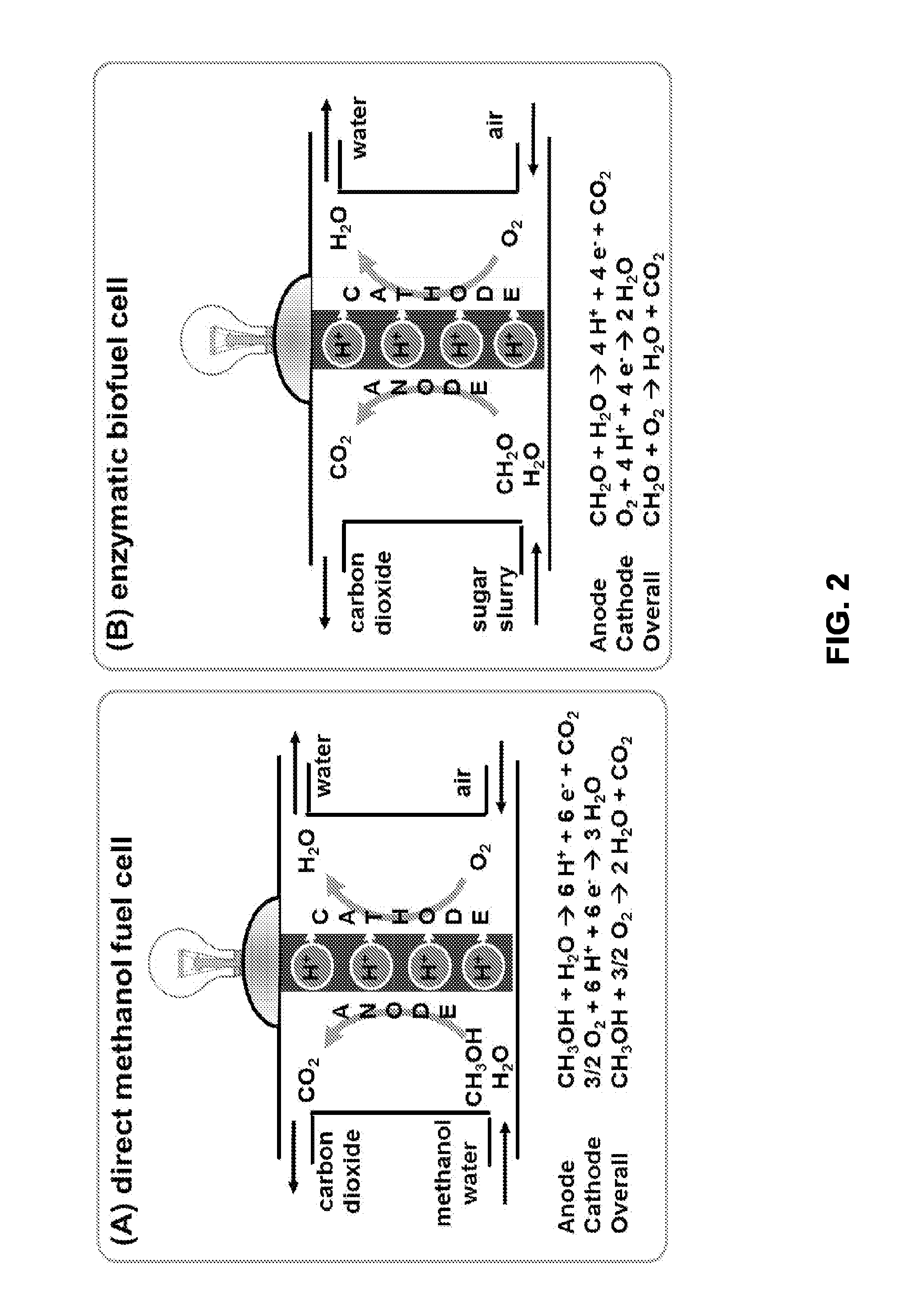

ActiveUS20160028101A1High densityHigh energy storage densityBiochemical fuel cellsElectricityCell free

The present invention is in the field of bioelectricity. The present invention provides energy generating systems, methods, and devices that are capable of converting chemical energy stored in sugars into useful electricity.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

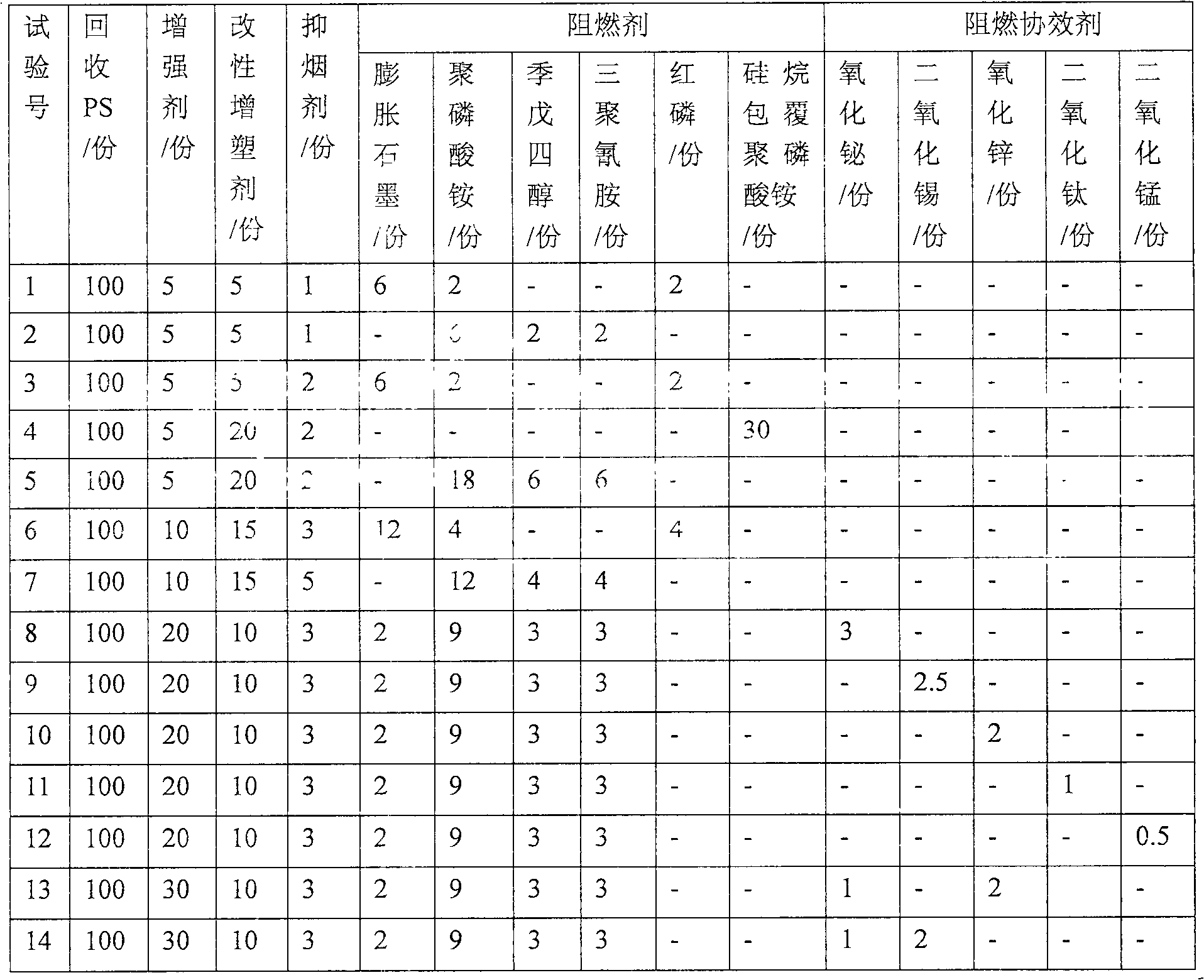

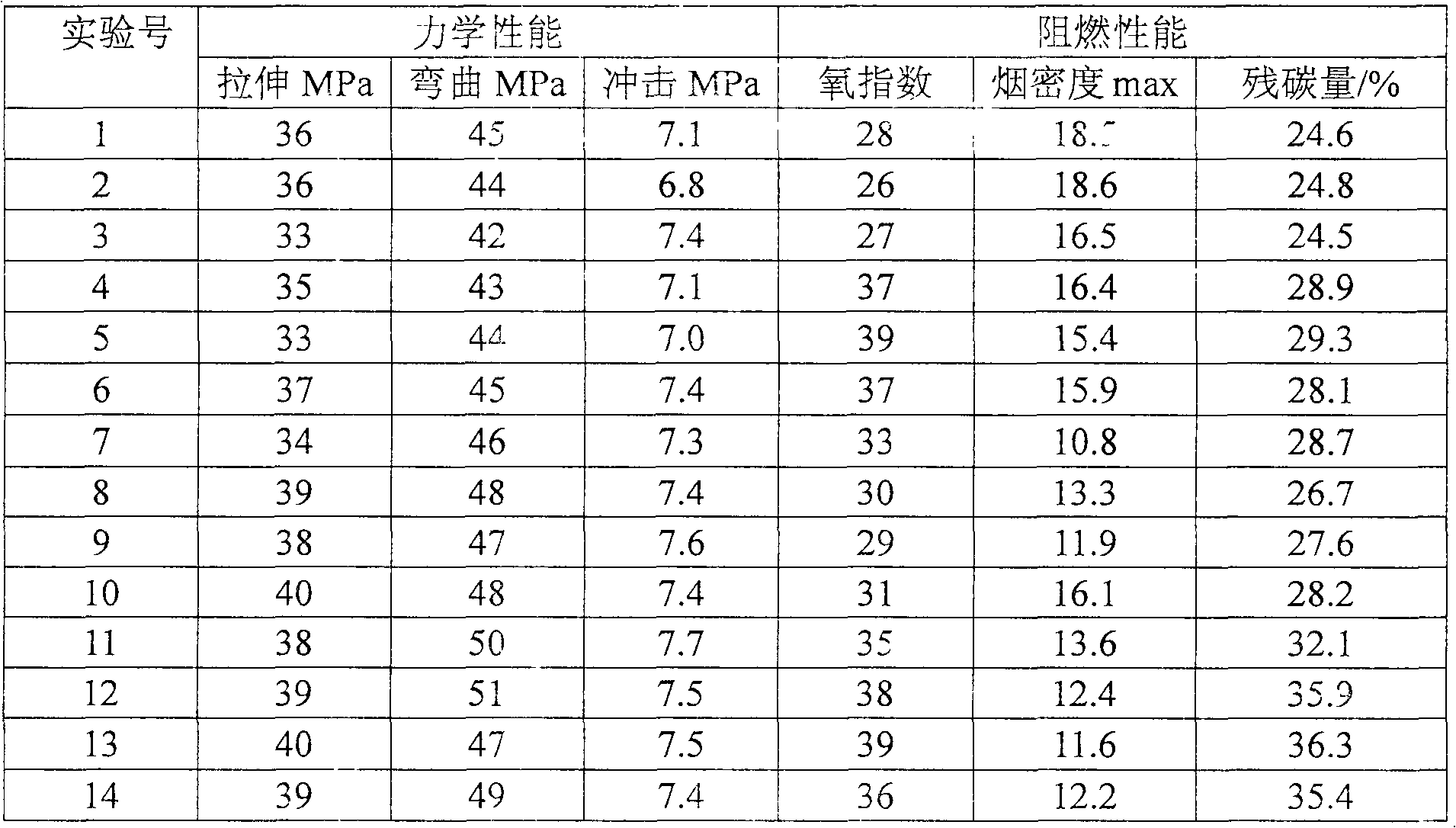

Preparation method of flame retarding styrene polymer composite material

The invention discloses a preparation method of a flame retarding styrene polymer composite material. The raw materials of the composite material (weight) includes 100 parts of recovered styrene polymer, 10-30 parts of flame retardant, 1-5 parts of smoke inhibitor and 5-30 parts of intensifier. The preparation method includes the following steps: 1. stirring the intensifier in a high speed mixingmachine to have the water content of 1-2% at the temperature of 105-150 DEG C and at the revolving speed of 600-1000r / min; 2. crushing the recovered styrene polymer product in a high speed crushing machine and then adding the crushed product in a double-screw machine to be extruded and pelletized; 3. sequentially adding the pellet, dry wood powder, flame retardant and smoke inhibitor in the high speed mixing machine for 5-10 min of premixing, and then discharging the mixture to a low speed cold mixing machine for 5-10 min of mixing to obtain premix; and 4. melting down the premix through the double-screw machine until or single-screw machine for pelleting to obtain the flame retarding styrene polymer composite material.

Owner:TIANJIN POLYTECHNIC UNIV

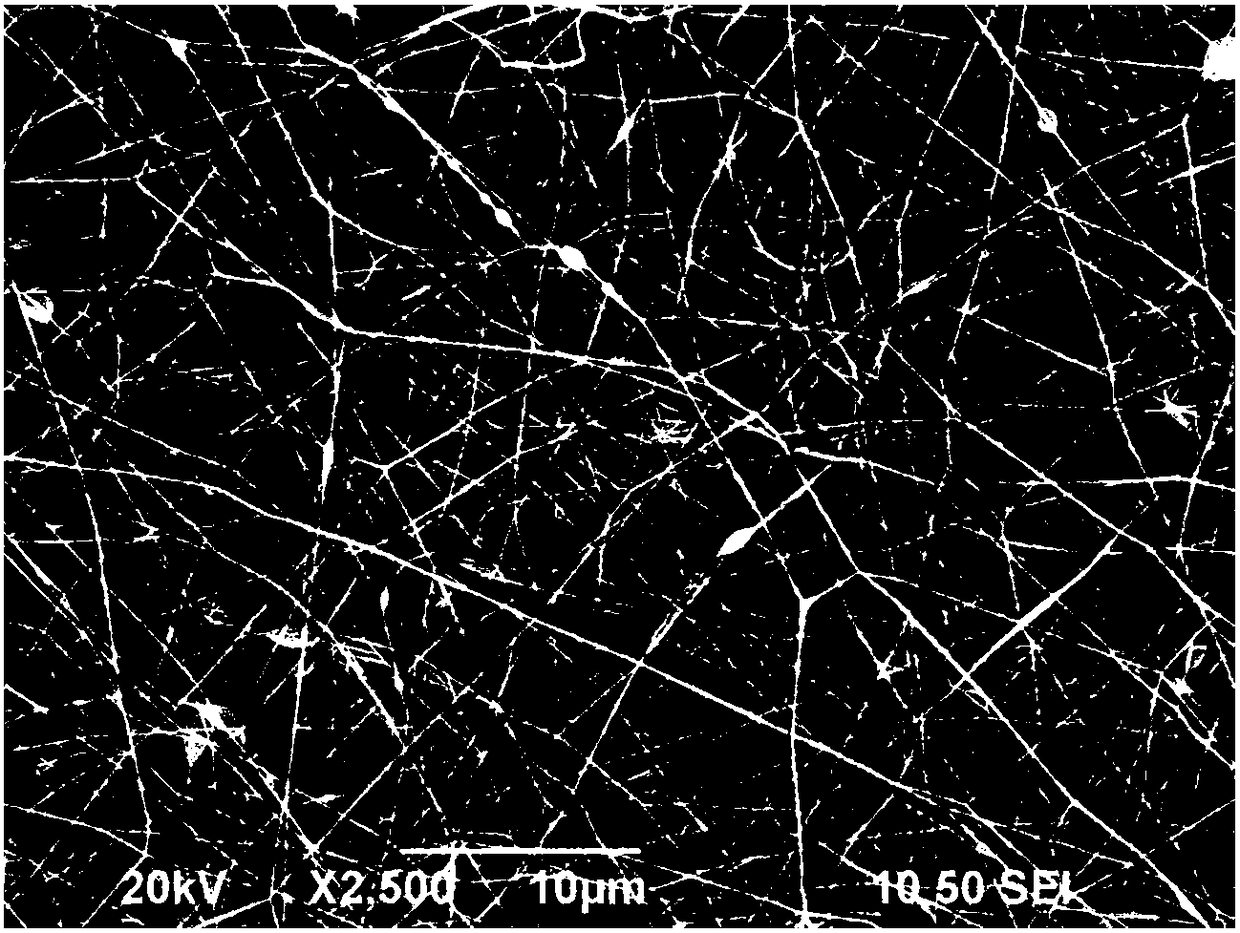

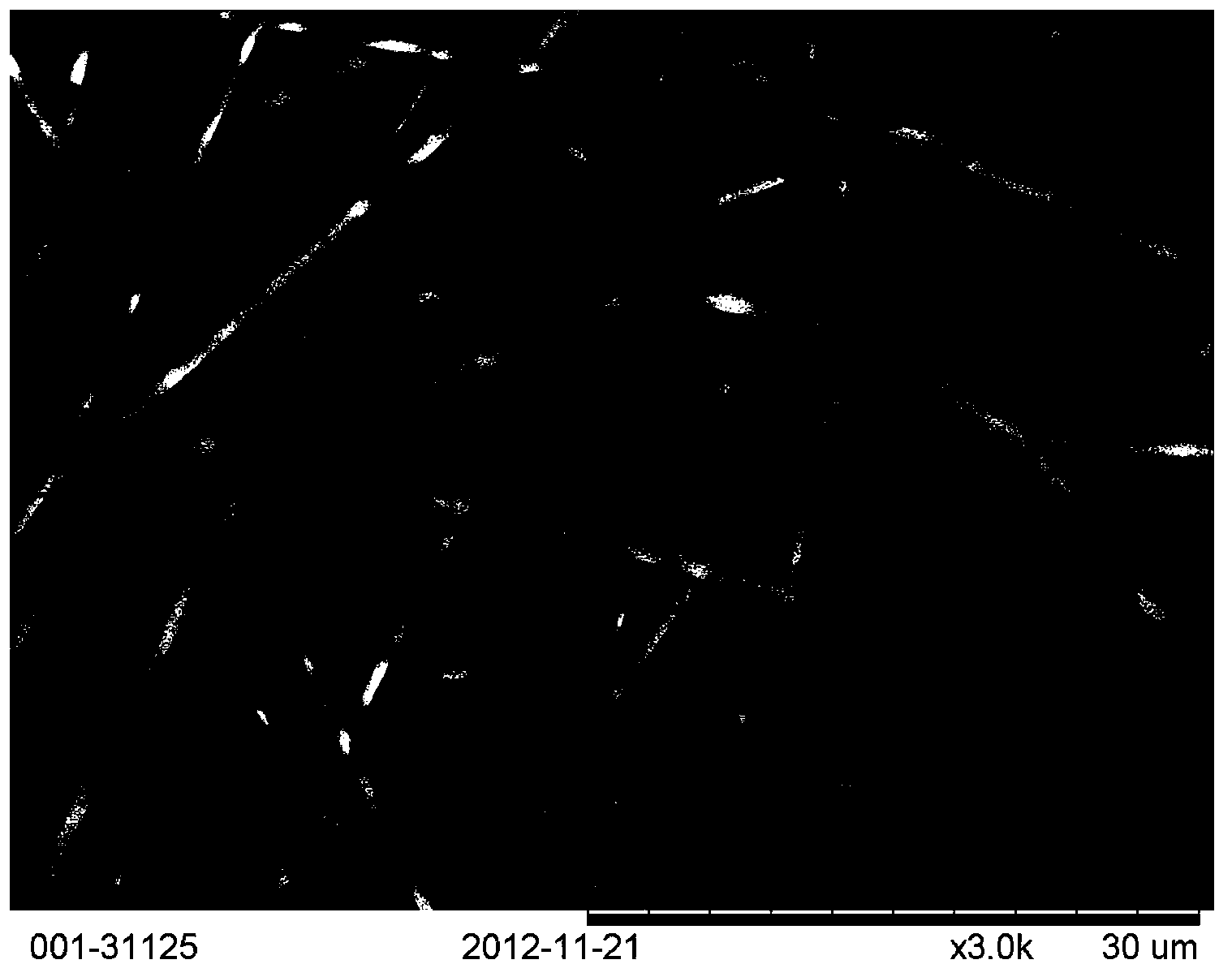

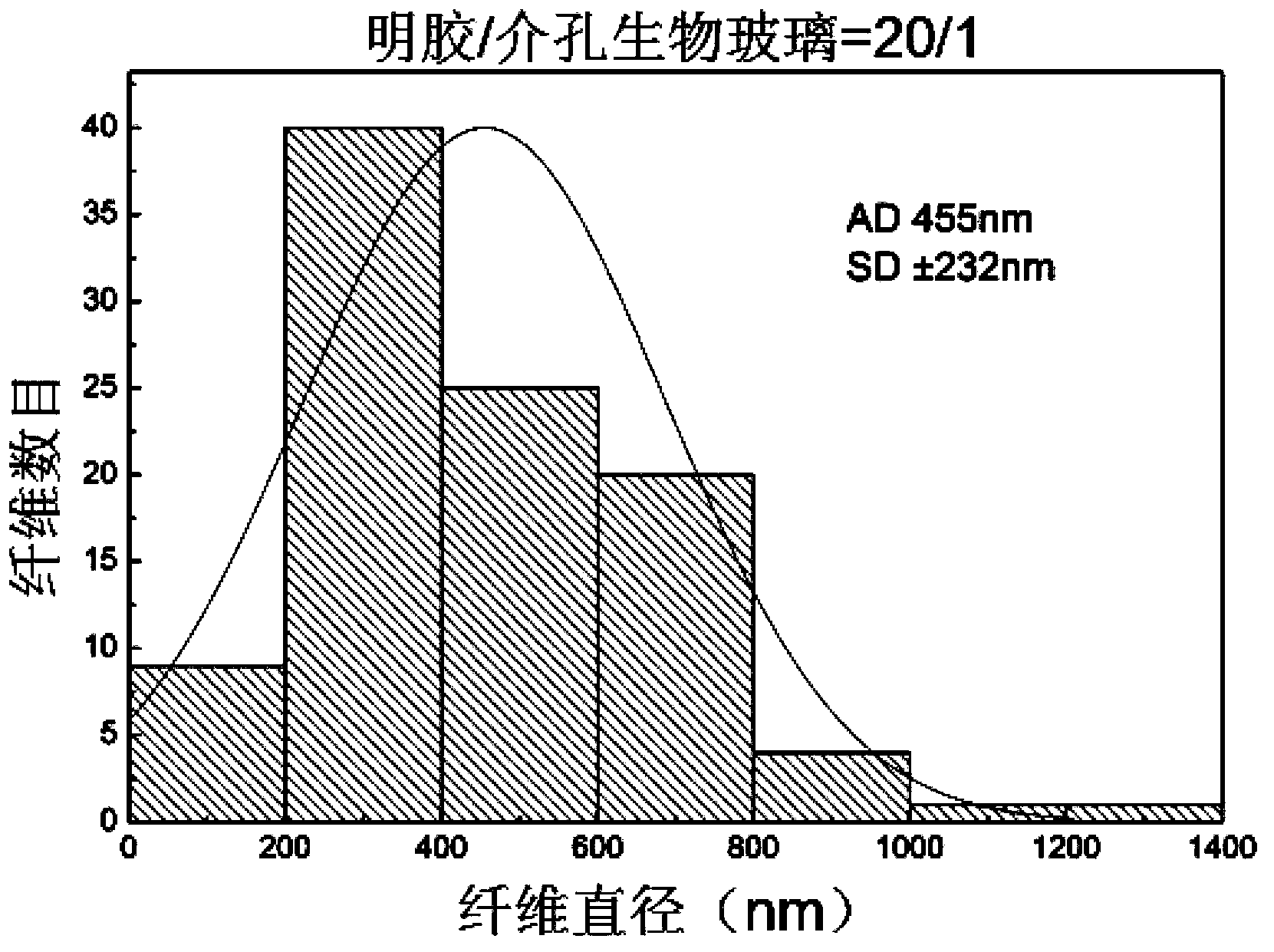

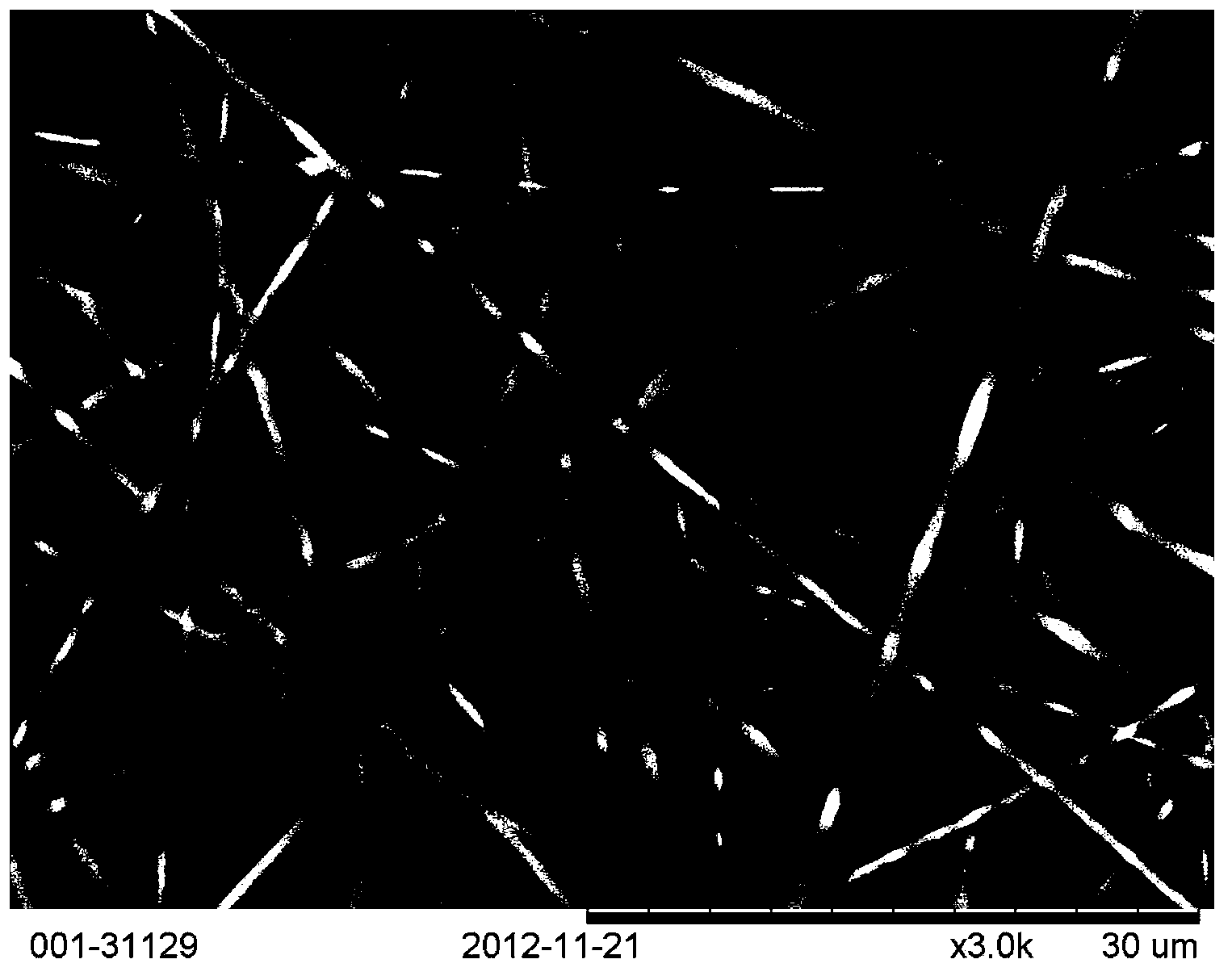

Gelatin / mesoporous bioactive glass composite nanofiber membrane material and preparation method thereof

The present invention provides a gelatin / mesoporous bioactive glass composite nanofiber membrane material and a preparation method thereof, and gelatin solution and mesoporous bioactive glass gel are mixed for preparation of a gelatin / mesoporous bioactive glass composite nanofiber membrane by an electrostatic spinning method. The gelatin / mesoporous bioactive glass composite nanofiber membrane is high in porosity and specific surface area and good in mechanical properties, and can be used for the technical field of tissue repair.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +1

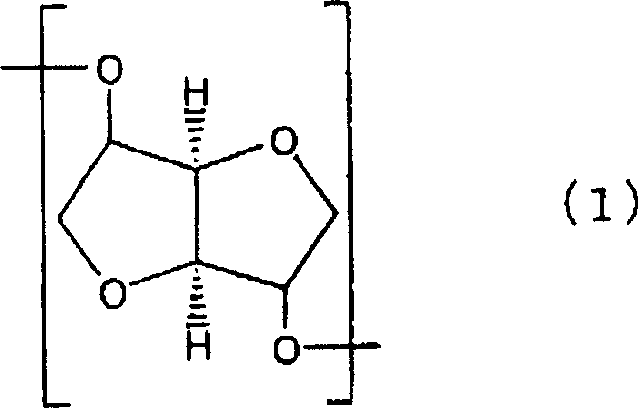

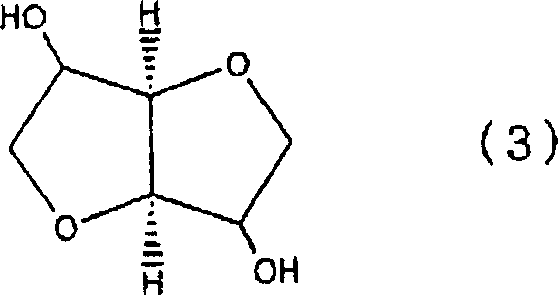

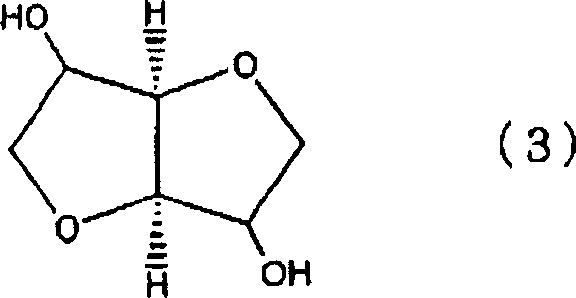

Polycarbonate and process for producing the same

A polycarbonate comprising ether diol residues which can be produced from a carbohydrate of the formula: (1) and comprising diol residues of the formula: -O-(CmH2m)-O- (2) (wherein m is an integer of 2 to 12), wherein the ratio of ether diol residues to all the diol residues is in the range of 65 to 98 wt.%, the polycarbonate having a glass transition temperature of 90 DEG C or higher.

Owner:TEIJIN LTD

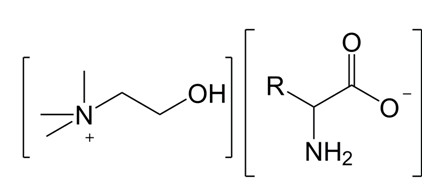

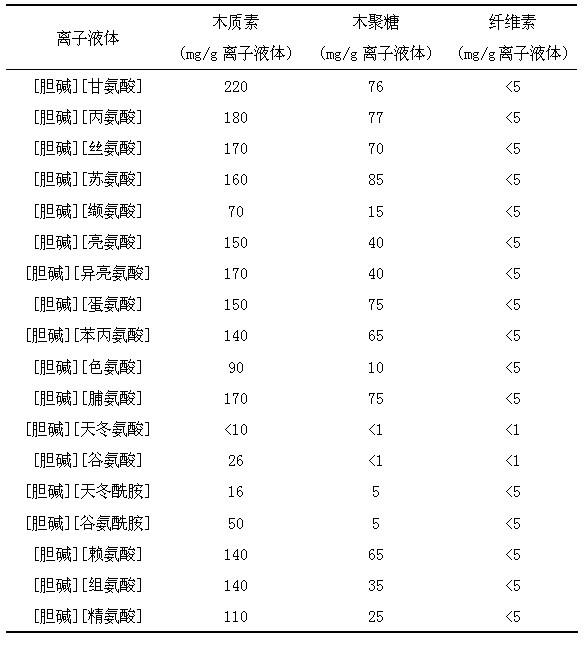

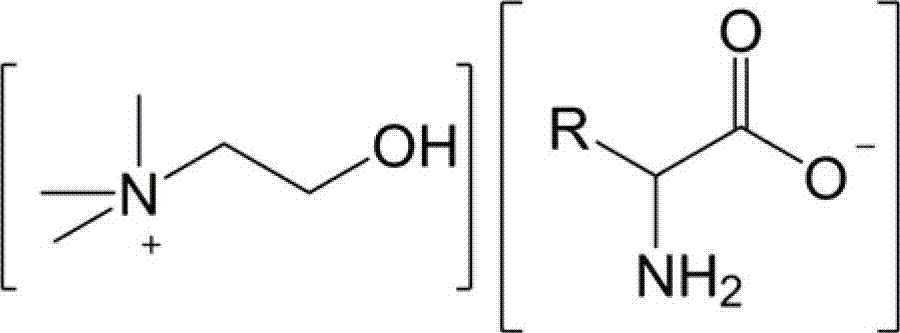

Method for increasing enzymolysis efficiency of rice straws through choline and amino acid ionic liquid pretreatment

InactiveCN102533907ARealize comprehensive utilizationOvercome the disadvantage of waste of resources (waste of hemicellulose components)FermentationBulk chemical productionCellulaseXylanase

The invention discloses a method for increasing enzymolysis efficiency of rice straws through choline and amino acid ionic liquid pretreatment, which comprises the following steps: firstly, performing pretreatment on the rice straws at certain temperature for a certain period of time by taking choline and amino acid ionic liquid as a solvent; then filtering and separating to obtain residues; drying the residues to obtain the pretreated rice straws. The residues of the rice straws are used as substrates, and enzymolysis is performed on the substrates by utilizing cellulase and xylanase to finally obtain sugar liquor taking glucose and xylose as main components. The method for increasing the enzymolysis efficiency of the rice straws through the choline and amino acid ionic liquid pretreatment not only is capable of effectively increasing the enzymolysis efficiency of the rice straws and increasing the yield of reducing sugar (the glucose and the xylose) which can be fermented, but also is capable of overcoming the defects that a traditional ionic liquid pretreatment process environment is not friendly and the like.

Owner:SOUTH CHINA UNIV OF TECH

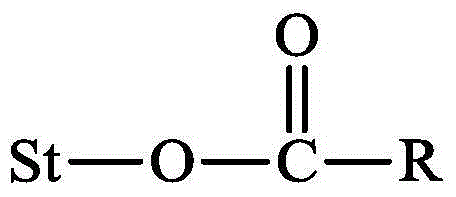

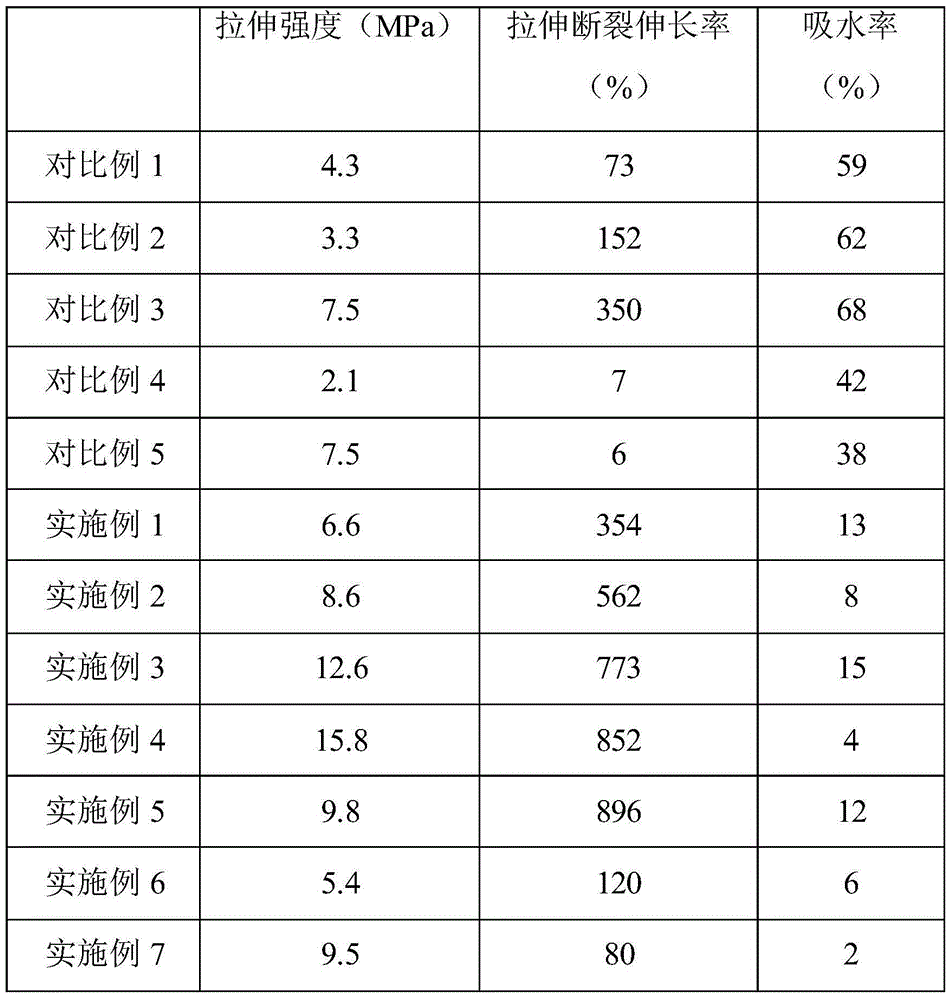

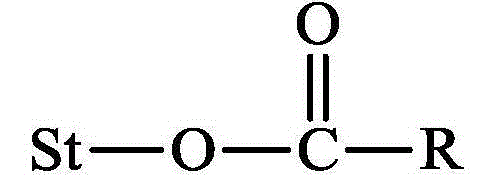

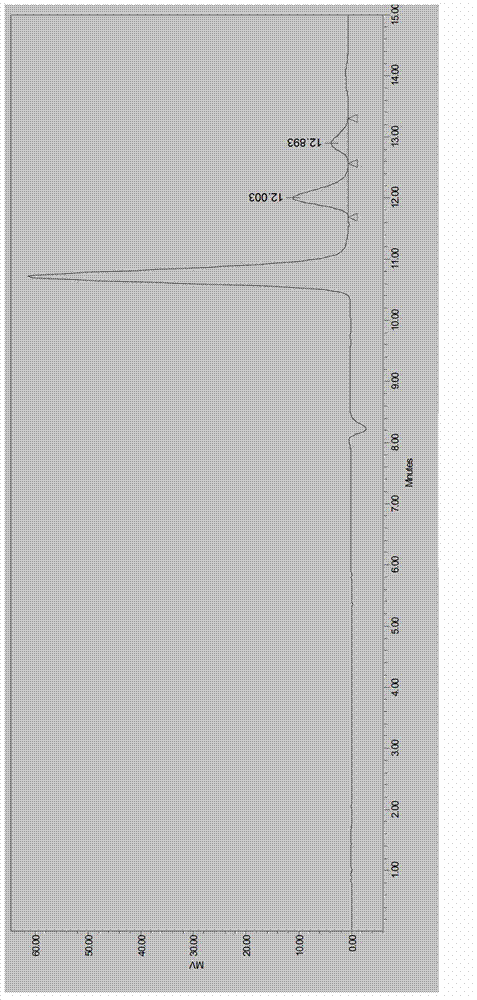

Starch-based composite and preparation method thereof

The invention discloses starch-based composite and a preparation method thereof. The composite is formed by, by weight, 100 parts of modified starch and 10-100 parts of polyester through melt blending. The structural formula of the modified starch is showed in the description and claims, wherein St refers to starch molecules and R group is alkyl group (CnH2n+1). Esterified starch comprises, by weight, 100 parts of natural starch, 0-200 parts of solvent, 10-50 parts of catalyst and 1-50 parts of modifier. The preparation method includes melt blending the components according to the weight to obtain the starch-based composite. The preparation method is high in efficiency, low in cost, simple in process, controllable in performance, and suitable for preparing thermoplastic materials with various performance requirements.

Owner:JIANGNAN UNIV

Method for pretreating lignocellulose by using renewable ionic liquid aqueous solution

The invention discloses a method for pretreating lignocellulose by using a renewable ionic liquid aqueous solution, including the steps of: (1) taking a choline and amino acid ionic liquid aqueous solution as a pretreatment solvent, mixing lignocellulose and the pretreatment solvent under the protection of nitrogen, stirring at 50-120 DEG C, cooling to room temperature, filtering, washing residue, and drying to obtain the pretreated lignocellulose; and (2) weighing the pretreated lignocelluloses, adding a citrate buffer, adding cellulase, reacting for 3-12 h with 150-250 r / min at 40-60 DEG C to obtain sugar liquid mainly including glucose and xylose. The pretreatment process not only can effectively enhance the efficiency of enzymatic hydrolysis of lignocelluloses, and improve the yield of fermentable reducing sugar, but also has the advantages of environmental protection, renewability, low viscosity, easy operation, low cost, and low power consumption.

Owner:SOUTH CHINA UNIV OF TECH

3D printed digital artificial bone and preparation method thereof

ActiveCN105031737AFast preparationStable uniform sizeAdditive manufacturing apparatusProsthesisPorosityPolyester

The invention discloses a 3D printed digital artificial bone. The artificial bone consists of a cortical bone, a cancellous bone and a marrow cavity, wherein the cortical bone is composed of poly-L-lactic acid or polyester-ester-ketone; the cancellous bone is formed by mixing poly-L-lactic acid and hydroxyapatite; the molecular weight of the poly-L-lactic acid of which the cortical bone is composed higher than that of which the cancellous bone composed; the cortical bone and the cancellous bone are simultaneously prepared by a 3D printing technology. The invention also discloses a 3D printing method for the digital artificial bone. According to the artificial bone disclosed by the invention, in micrometer and millimeter scales, the porosity of the cortical bone is 10 percent; the porosity of the cancellous bone is 60-80 percent, and the pore size of the cancellous bone is 120-220 micrometers. The 3D printed digital artificial bone has the porosity, the pore size and the mechanical property as those of a bone structure of human beings.

Owner:上海浦卫生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com