Patents

Literature

110results about How to "Environmentally friendly and non-toxic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recipe and production process of artificial leather of thermoplastic polyurethane

InactiveCN101021046AEnvironmentally friendly and non-toxicBiodegradableTextiles and paperProduction linePolyol

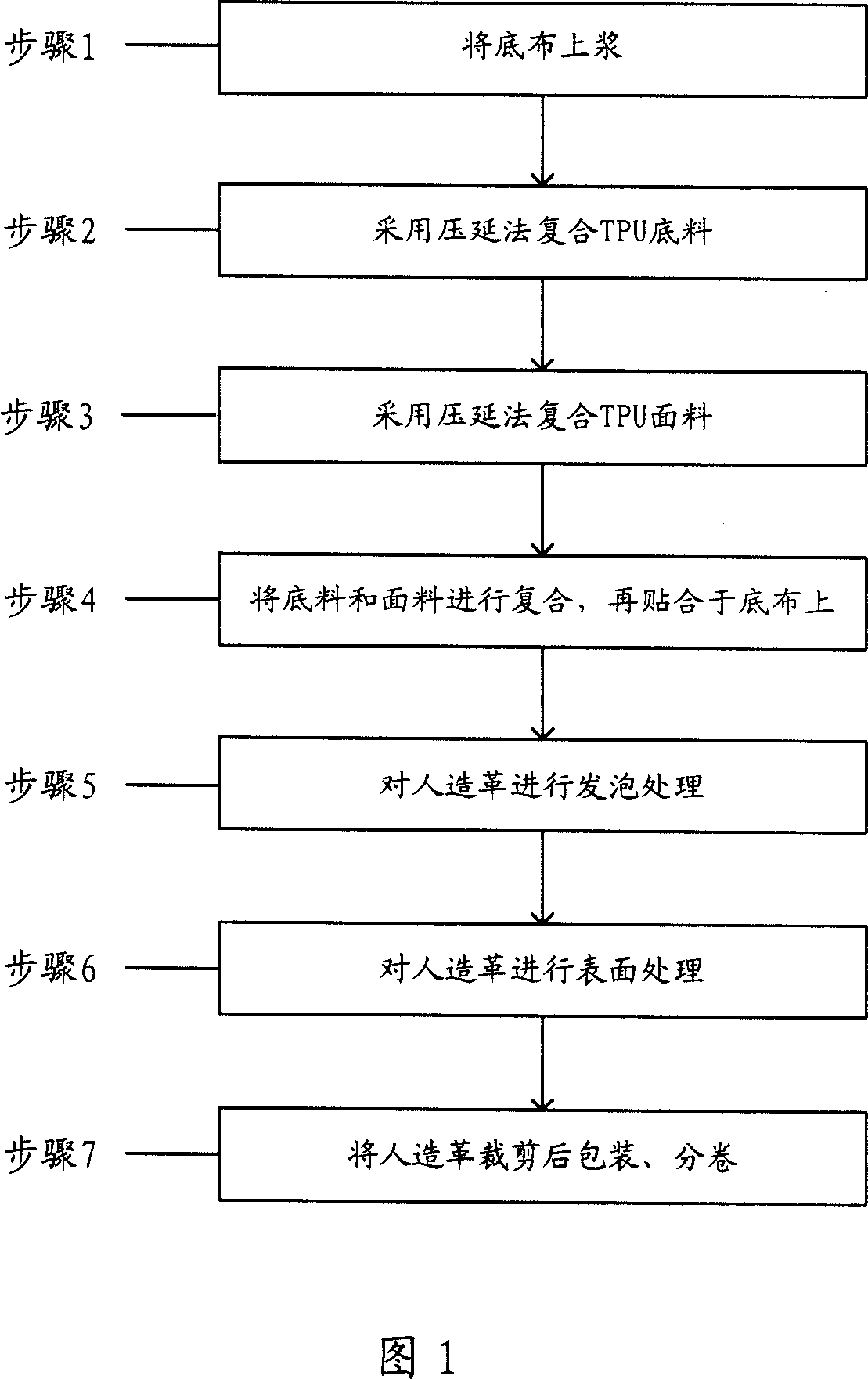

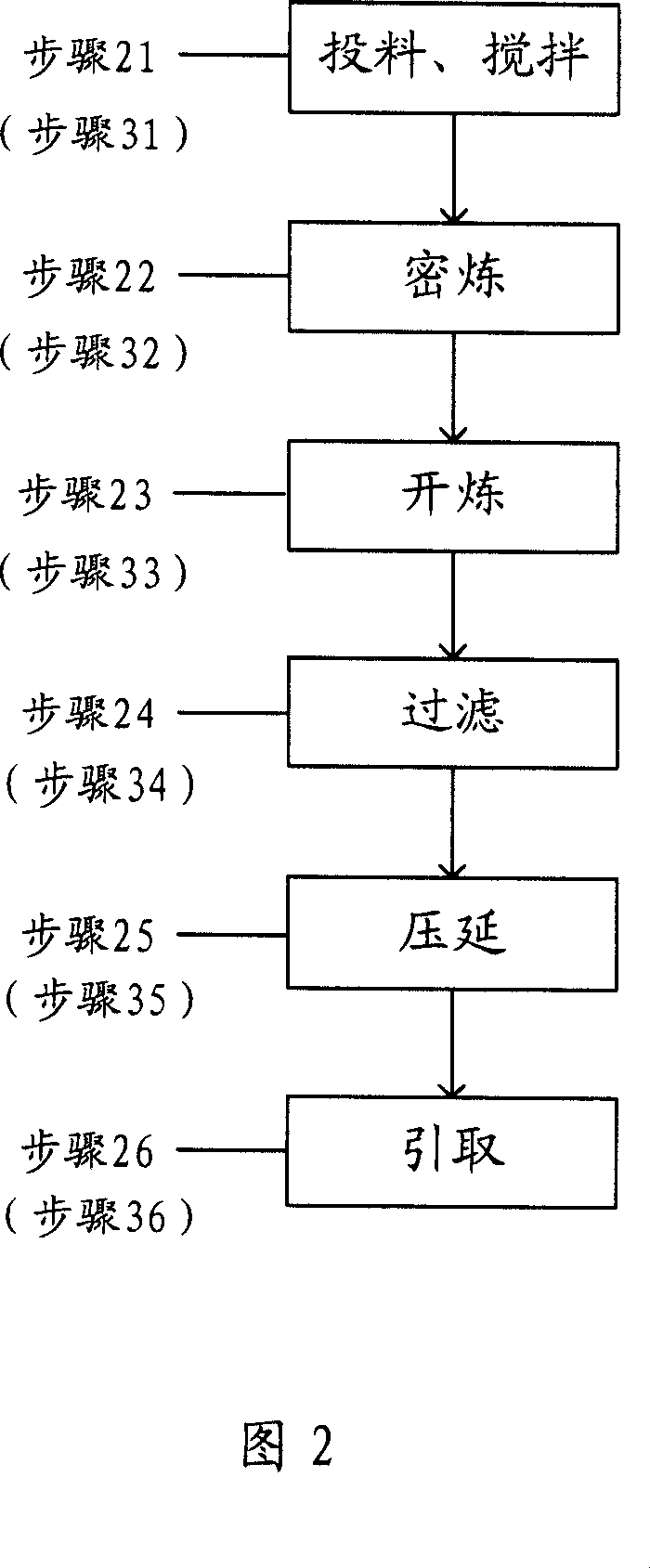

The present invention is the recipe and production process of artificial leather of thermoplastic polyurethane. The artificial leather has thermoplastic polyurethane elastomer resin as the main material, acrylic resin, plasticizer of non-toxic polyol derivative, dispersant, stuffing, etc. The rolling process of producing thermoplastic polyurethane artificial leather includes the following steps: 1. sizing the base fabric; 2. rolling to compound TPU base material and top material; 3. adhering the compounded TPU base material and top material onto the base fabric; and 4. post-treatment of the artificial leather to obtain the thermoplastic polyurethane artificial leather product. The production process may be completed in a conventional rolling production line.

Owner:叶志成

High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

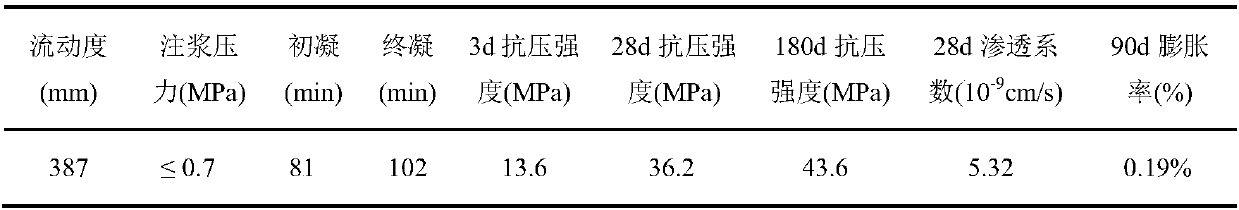

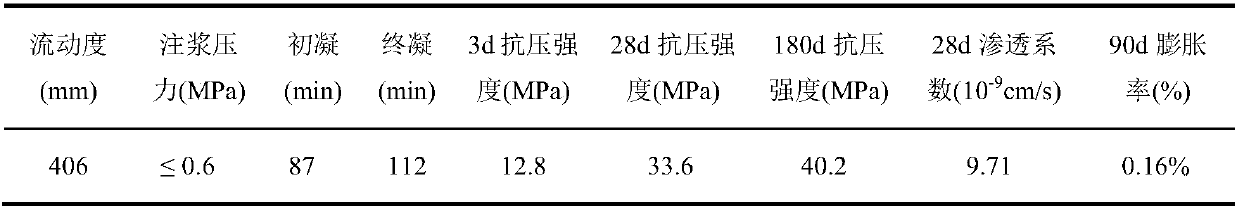

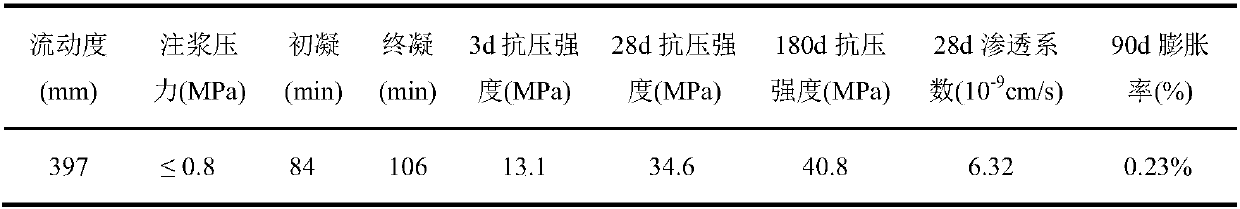

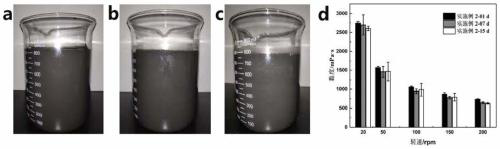

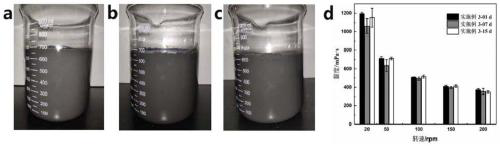

The invention discloses a high-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment, and application of the grouting material. The grouting material comprises the following ingredients in parts by weight: 50-79 parts of Portland cement clinker, 19-48 parts of an auxiliary cementing material and 2-7 parts of desulfurized gypsum, whereinthe auxiliary cementing material comprises the following ingredients in parts by weight: 25-57 parts of mineral slag, 8-21 parts of steel slag, 18-36 parts of pulverized fuel ash, 6-12 parts of limestone flour, 1-8 parts of silica fume and 2.5-12.8 parts of a high-performance composite regulator; the high-performance composite regulator comprises the following ingredients in parts by weight: 5-16parts of sodium hydroxide, 4-12 parts of sodium silicate, 4-14 parts of potassium metaaluminate, 12-21 parts of calcium chloride, 11-18 parts of lithium chloride, 4-12 parts of triethanolamine, 21-27parts of alum, 18-29 parts of aluminum sulfate, 0.2-1.5 parts of hydroxypropyl methyl cellulose, 0.1-3.0 parts of viscous polymer, 0-0.8 parts of polypropylene fiber and 0.5-3.0 parts of a superplasticizer; and the viscous polymer is an acrylic ester polymer or an ethylene-vinyl acetate copolymer.

Owner:SHANDONG UNIV

Anti-ageing matt polyurethane composition and preparation method thereof

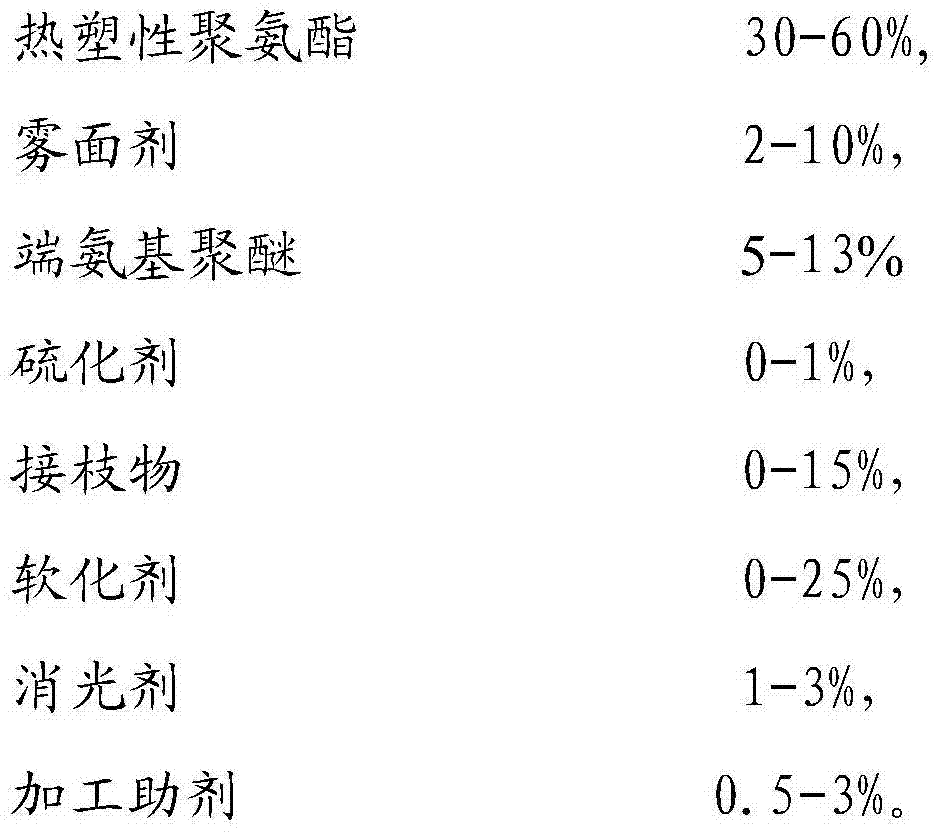

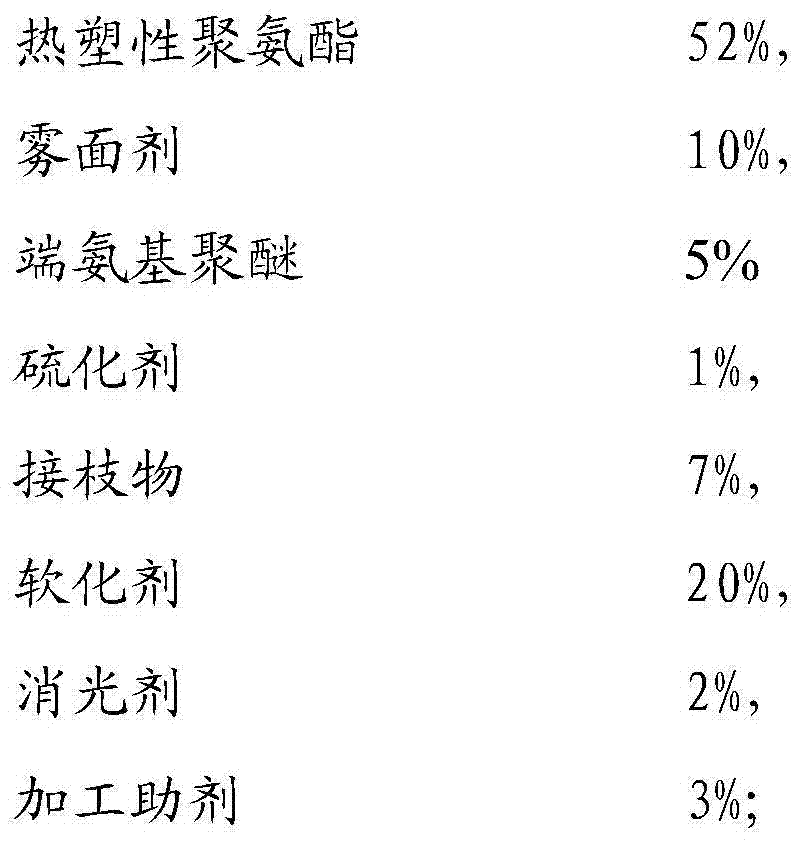

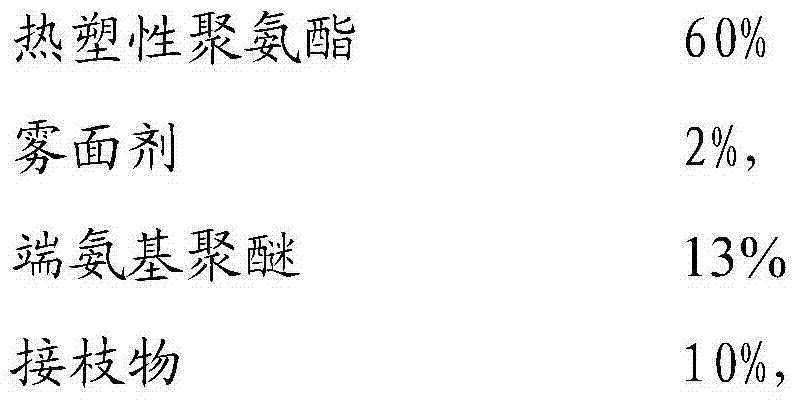

The invention provides an anti-ageing matt polyurethane composition, comprising the following components in percentage by weight: 30%-60% of thermoplastic polyurethane, 2%-10% of a matt agent, 5%-13% of amine-terminated polyether, 0-1% of a vulcanizing agent, 0-15% of graft, 0-25% of a softener, 1%-3% of a delustering agent and 0.5%-3% of a processing agent. According to the composition, rubber substances are replaced with high molecular weight amine-terminated polyether free of double bonds, thus the content of unsaturated double bonds in the composition is lowered; the composition has the advantages of excellent long-term ageing resistance, mechanical property and tensile break strength; and the matt degree of the surface of a cable or a wire prepared from the composition is kept.

Owner:马艳荣

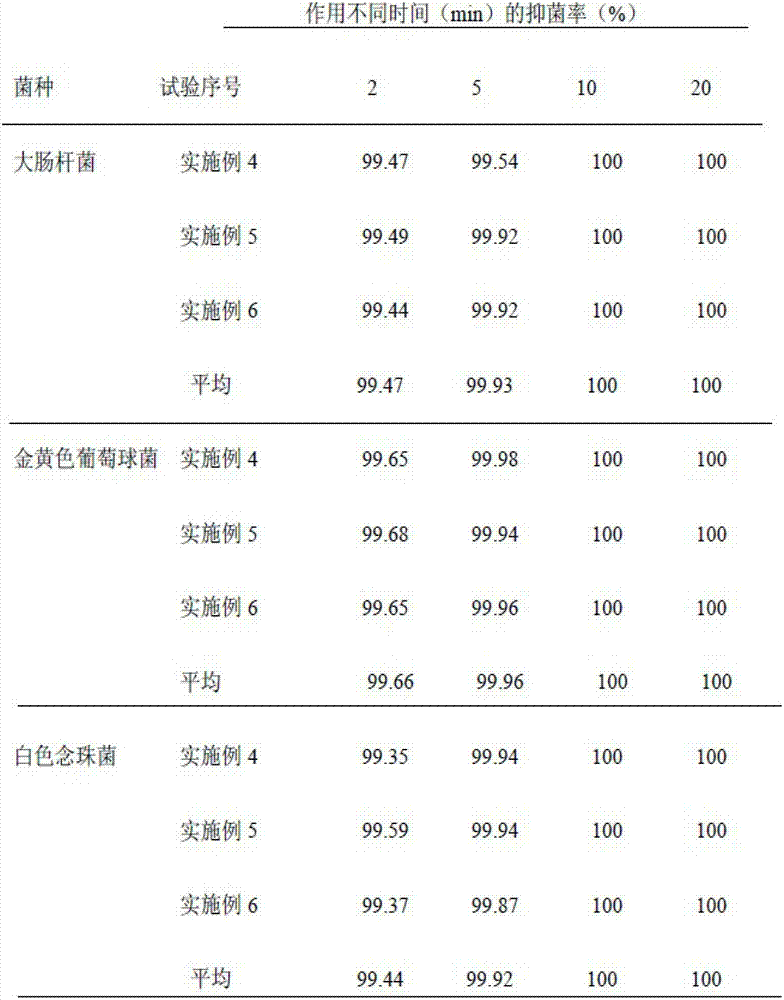

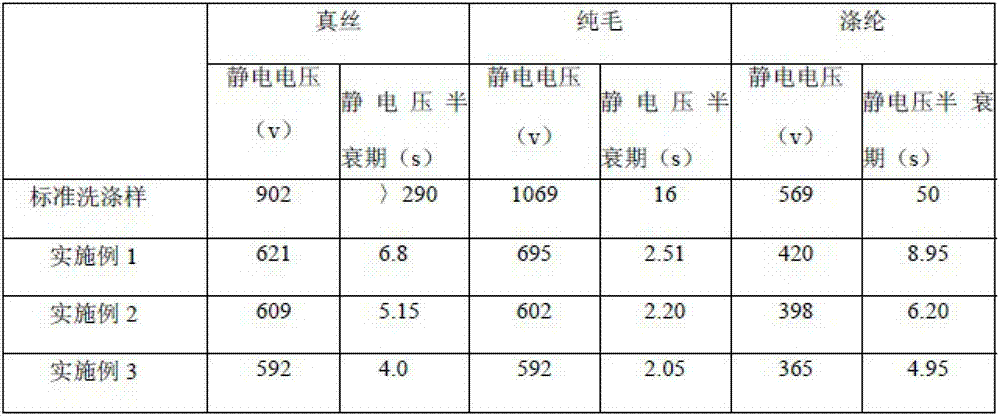

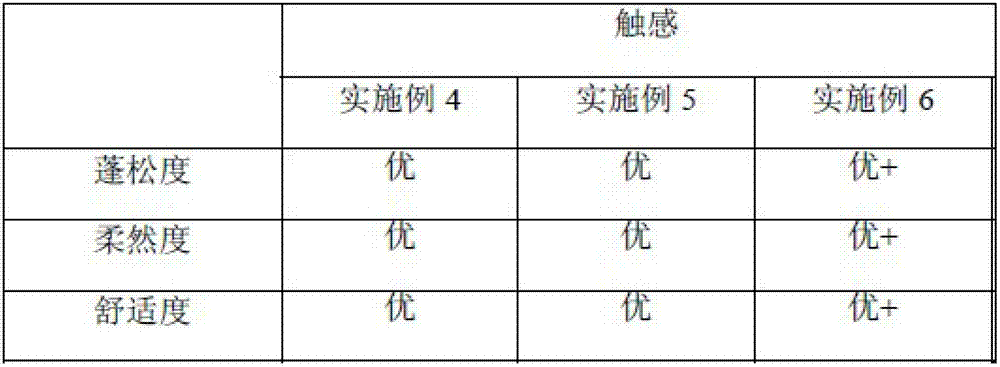

Marine biological antibacterial fabric softener and preparation method thereof

ActiveCN103046335AEfficient sterilizationEnvironmentally friendly and non-toxicBiochemical fibre treatmentFabric softenerCitric acid

The invention discloses a marine biological antibacterial fabric softener and a preparation method thereof. The marine biological antibacterial fabric softener comprises the following components by weight percent: 2.0-4.0% of marine biological bactericide, 2.0-4.0% of esterquat, 6.0-8.0% of citric acid, 2.0-3.5% of essence, and the balance of water. According to the invention, the marine biological antibacterial fabric softener can be effectively antibacterial and antistatic; with adoption of a small amount of the fabric softener, the fabrics can become clean and sterile, soft and smooth, and flat; and in addition, the fabric softener is further environment-friendly and nontoxic.

Owner:QINGDAO HIFUN MARINE BIOLOGICAL TECH

Low-smoke halogen-free flame-retarding ceramizable thermoplastic polyurethane elastomer composite material, preparation method and application thereof

The invention relates to the technical field of polyurethane elastomers and particularly relates to a low-smoke halogen-free flame-retarding ceramizable thermoplastic polyurethane elastomer composite material, a preparation method and an application thereof. The composite material comprises, by weight, 25-85 parts of thermoplastic polyurethane, 10-70 parts of a halogen-free flame retardant, 1-10 parts of a smoke inhibitor, 20-80 parts of a ceramization powder, 0.5-5 parts of a compatilizer, 0.02-0.1 parts of an antioxidant, and 0.02-0.1 parts of a hydrolysis inhibitor. The thermoplastic polyurethane elastomer composite material has excellent flame-retarding effect, low smoke density, high strength, good flexibility and high break elongation, can form a compact ceramized product at the temperature range of 600-1000 DEG C, is low in ceramization temperature and can form compact ceramic. The formed ceramized product has high high-temperature strength and anti-heat-flow-impact capability.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Halogen-free flame retardant PC/PBT alloy material and preparation method thereof

The invention discloses a halogen-free flame retardant PC / PBT alloy material and a preparation method thereof. The alloy material has a blending system consisting of plastic alloy formed by blending PC resin and PBT resin and additives blended into the plastic alloy; the additives comprise flame retardants, compatible toughening agent, lubricating dispersant and antioxidant; the number of the flame retardants is three, wherein the first flame retardant is phosphate, the second flame retardant is sulfonate and the third flame retardant is polysiloxane; and the alloy material comprises the following components in part by weight: 50 to 80 parts of PC resin, 20 to 50 parts of PBT resin, 5 to 25 of three flame retardants, 5 to 20 parts of compatible toughening agent, 1.0 to 3.0 parts of lubricating dispersant and 0.1 to 0.6 parts of antioxidant. The halogen-free flame retardant PC / PBT alloy material has the advantages of high comprehensive mechanical strength, good flame retardant property, good forming workability, environmental protection and non-toxicity.

Owner:JIANGSU XINGHUA RUBBER BELT +1

Floor protective paint

InactiveCN102477240AEnvironmentally friendly and non-toxicAlkali resistantCoatingsCrack resistanceDisinfectant

The invention relates to a material for construction and decoration and in particular relates to a floor protective paint. The formula of the floor protective paint is as follows: 10 to 20 parts of water, 20 to 40 parts of latex emulsion, 5 to 20 parts of titanium dioxide, 3 to 5 parts of barite powders, 10 to 15 parts of calcium carbonate, 3 to 5 parts of kaolin, 3 to 5 parts of mica powders, 0.5 to 1 part of wetting and dispersing agents, 0.2 to 0.4 parts of a defoaming agent, 0.4 to 0.6 parts of a leveling agent, 2.5 to 3.8 parts of a thickener, 0.2 parts of a multifunctional auxiliary agent, 0.8 to 1.6 parts of a film-forming agent, and 1 to 4 parts of a disinfectant and anti-mildew agent. The floor protective paint is made from high-quality natural mineral powders and multiple auxiliary agents and refined by the advanced production process. The floor protective paint has the characteristics of environmental friendliness, no toxicity, alkali resistance, mildew protection, primer-coat property, crack resistance, energy saving, flame retardancy, sound insulation, moisture protection, leakage resistance, strong adhesion, high hardness and dry friction resistance, and can provide different colors by being added with color pastes.

Owner:SHENZHEN MINGDIAO DECORATION CO LTD

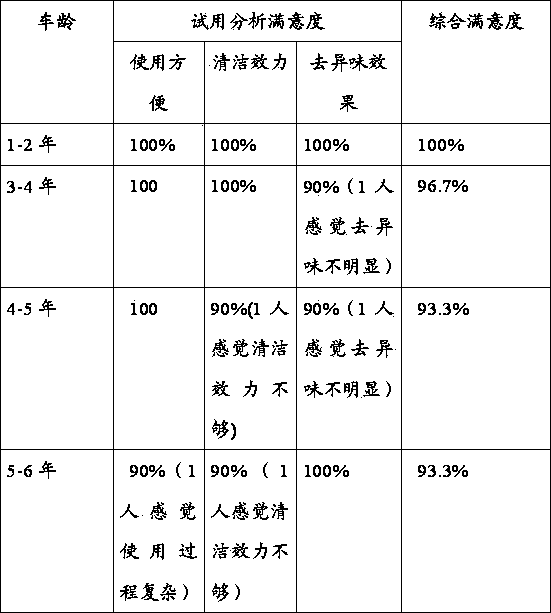

Vehicle air-conditioning antibacterial cleaning agent, and preparation method thereof

InactiveCN103897865AEfficient removalNo smellOrganic detergent compounding agentsSurface-active detergent compositionsCleansing AgentsAir conditioning

The invention relates to a cleaning agent, and especially relates to a vehicle air-conditioning antibacterial cleaning agent, and a preparation method thereof. The vehicle air-conditioning antibacterial cleaning agent comprises, by weight, 3.0 to 5.0% of a marine organism degerming agent, 1.5 to 3.0% of alkyl glycoside, 2.0 to 4.0% of coconut diethanol amide, 1.5 to 3.0% of sodium carbonate, 15 to 20% of ethanol, 1% of ethylene diamine tetraacetic acid, and the balance purified water. The vehicle air-conditioning antibacterial cleaning agent is capable of removing dust and stains in vehicle air-conditioning filter screens and evaporators effectively, and possesses high efficient antibacterial functions; the internals of the cleaned air-conditionings are clean and aseptic, and no peculiar smell is observed at air outlets. In addition, the vehicle air-conditioning antibacterial cleaning agent is friendly to the environment, and possesses no toxicity.

Owner:QINGDAO HIFUN MARINE BIOLOGICAL TECH

Water-based varnish

The invention relates to a material for construction and decoration and in particular relates to water-based varnish. The formula of the water-based varnish is as follows: 15 to 30 parts of water, 10 to 20 parts of acrylic polymers, 12 to 20 parts of titanium dioxide, 3 to 5 parts of barite powders, 5 to 15 parts of ground calcium carbonate, 3 to 5 parts of kaolin, 3 to 5 parts of mica powders, 0.4 to 0.8 parts of wetting and dispersing agents, 0.3 to 0.4 parts of a defoaming agent, 0.3 to 0.6 parts of a leveling agent, 0.5 to 2 parts of a thickener, 0.2 parts of a multifunctional auxiliary agent, 0.8 to 1 part of a film-forming agent, and 0.8 to 2 parts of a disinfectant and anti-mildew agent. The water-based varnish is made from high-quality acrylic polymers, natural mineral powders and multiple auxiliary agents and refined by the advanced production process. The water-based varnish has the characteristics of environmental friendliness, no toxicity, alkali resistance, mildew resistance, primer-coat property, crack resistance, energy saving, flame retardancy, sound insulation, moisture protection, leakage resistance, strong adhesion, high hardness and dry friction resistance.

Owner:深圳市名雕丹迪设计有限公司

Biaxially-oriented polypropylene (BOPP) pearlised film environment-friendly ink and preparation method thereof

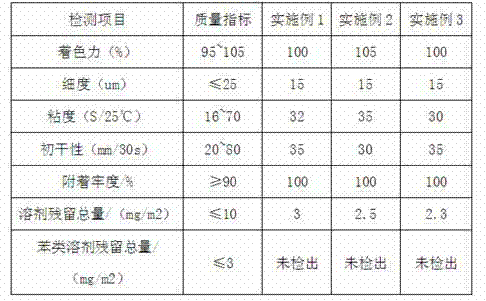

The invention discloses biaxially-oriented polypropylene (BOPP) pearlised film environment-friendly ink, and relates to ink. The BOPP pearlised film environment-friendly ink is prepared by the following raw materials by weight percent: 15-35% of combined resin, 8-11% of organic color pigment, 2-5% of auxiliary agent and 55-65% of combined solvent, wherein the combined resin comprises alcohol soluble polyamide resin liquid, alcohol soluble aldehyde ketone resin liquid, alcohol ester soluble nitrocellulose resin liquid and maleic acid resin liquid; the auxiliary agent comprises polyethylene wax, an anti-settling agent, Texanol ester alcohol and acrylate; the combined solvent comprises absolute ethyl alcohol, isopropanol, n-propyl acetate and acetic ether. Compared with the prior art, the BOPP pearlised film environment-friendly ink has the advantages of being environment-friendly, non-toxic, bright in color, high in color saturation, good in shallow network transfer performance and good in level reproducibility.

Owner:CHENGDU PRESSTER NEW MATERIALS

Preparation method for lignin drug sustained release microspheres

InactiveCN106562933AEnvironmentally friendly and non-toxicUniform particle sizeOrganic active ingredientsPharmaceutical non-active ingredientsControlled releaseMicrosphere

The invention discloses a preparation method for lignin drug sustained release microspheres. The preparation method comprises the steps of (1) preparation of an internal phase solution; (2) preparation of a middle phase solution; (3) preparation of an external phase solution; (4) preparation of an oil-water-oil (o / w / o) dual emulsion; and (5) synthesis of mono-dispersed lignin drug sustained release microspheres. By adoption of the preparation method for the lignin drug sustained release microspheres disclosed by the invention, the obtained microspheres are uniform in particle size and controllable in appearance, and have the characteristics of environment protection, non-toxic property and the like; in addition, the preparation method is simple and effective, low in cost, and capable of effectively controlling release of a target drug, so that an efficient, simple and convenient method is provided for drug release; and therefore, the preparation method has high industrial application prospect.

Owner:GUANGXI UNIV

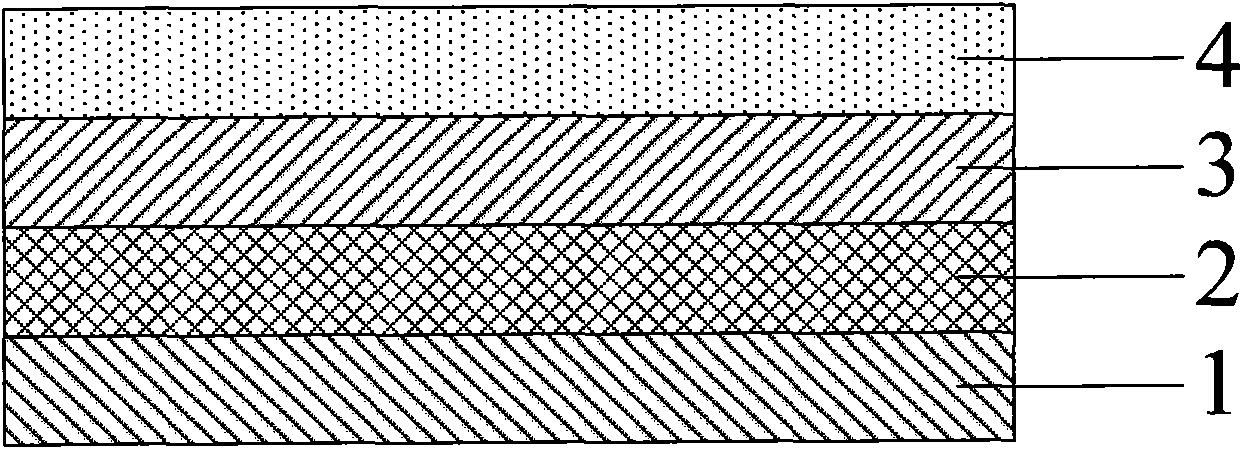

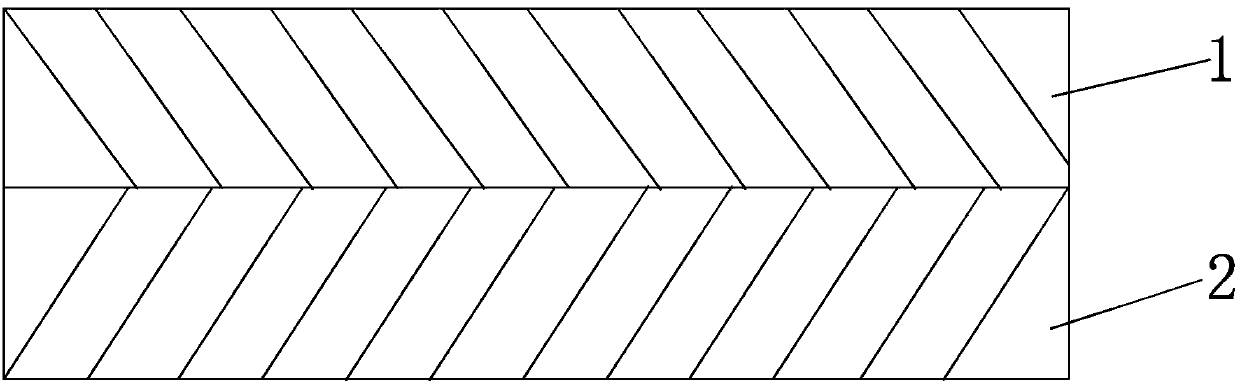

Colored crystal composite plate

InactiveCN102152548AColorful appearanceSimple preparation processSynthetic resin layered productsSpecial ornamental structuresPolyethylene terephthalateComposite film

The invention provides a colored crystal composite plate. The base material is toughened grass felted with a temperature-resistant double faced adhesive tape; and the double faced adhesive tape is covered by a composite film consisting of polyethylene terephthalate (PET), colored crystal printing layer and polrvinyl chloride (PVC). The surface of the toughened glass is compounded with the PET / colored crystal printing layer / PVC composite film. The colored crystal composite plate has decorative, protective and good-looking effects and the manufacturing process is simple.

Owner:SUZHOU HESHENG NEW MATERIALS

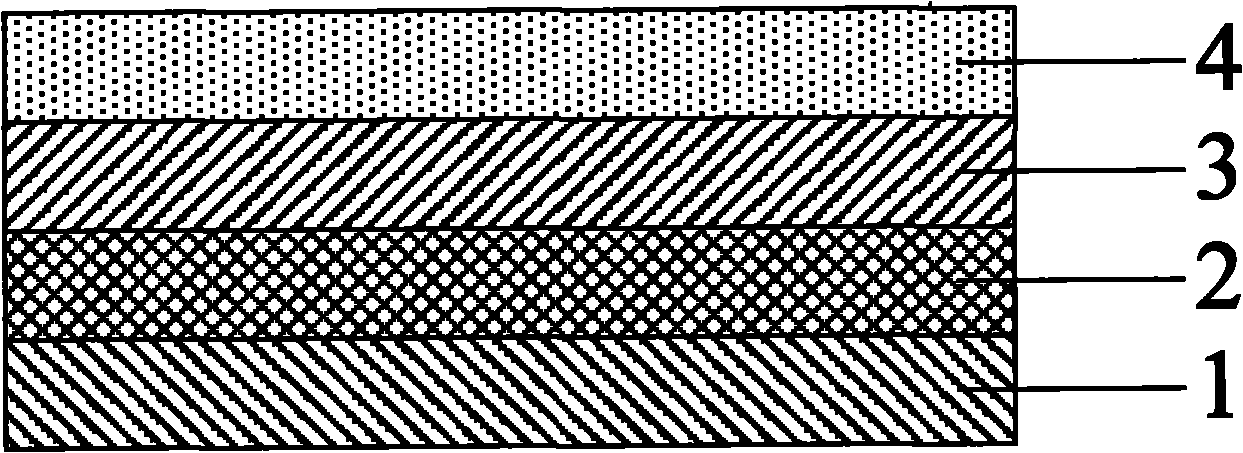

Lace printing sheet and double-fitting process thereof

The invention relates to the technical field of sheets, in particular to a lace printing sheet and a double-fitting process thereof. The lace printing sheet is prepared from, by weight, 45-55 parts of PVC resin, 55-65 parts of filler, 23-35 parts of plasticizer, 2-4 parts of heat stabilizer, 1-3 parts of foaming agent, 0.4-1.0 part of lubricant, 0.01-0.15 part of titanium dioxide, 0.01-0.16 part of pigment powder and 0.15-0.70 part of other additives. The lace printing sheet is good in abrasion resistance, good in anti-slipping effect, delicate in texture, exquisite in pattern, gorgeous in color, smooth in surface and comfortable in hand feeling, also has the advantages of being environmentally friendly, non-toxic, waterproof, oilproof, high in cold resistance, antistatic, flame-retardant, easy to clean and the like and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Environment-friendly aging-resistant nitrile rubber and preparation method thereof

InactiveCN108084518AAccelerated vulcanizationImprove thermal stabilityEnvironmental resistancePolymer science

The invention belongs to the technical field of nitrile rubber materials and relates to environment-friendly aging-resistant nitrile rubber and a preparation method thereof. The environment-friendly aging-resistant nitrile rubber is made from the following raw materials in parts by weight: 100 to 155 parts of nitrile rubber, 70 to 95 parts of white carbon black, 3 to 11 parts of zinc oxide, 5 to 15 parts of stearic acid, 20 to 45 parts of a plasticizer, 2 to 6 parts of white factice, 1 to 5 parts of an accelerant and 1 to 5 parts of an anti-aging agent. The environment-friendly aging-resistantnitrile rubber has the advantages of good thermal stability, environmental friendliness and no toxicity, and the like. The preparation method is simple in operation.

Owner:SHENYANG SAIYA RUBBER PRODS

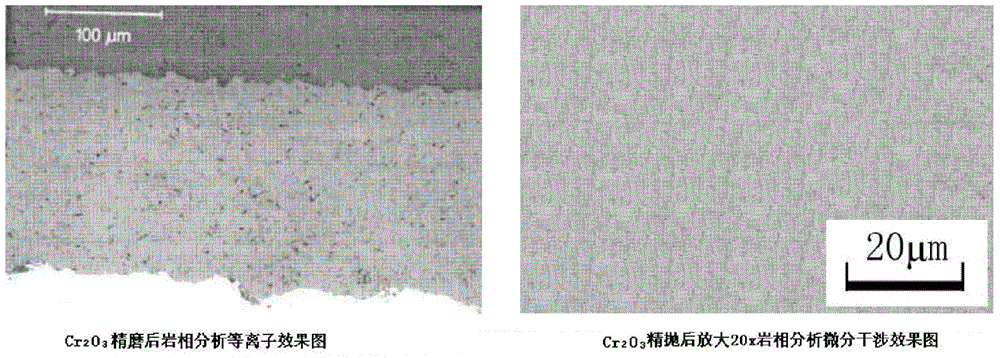

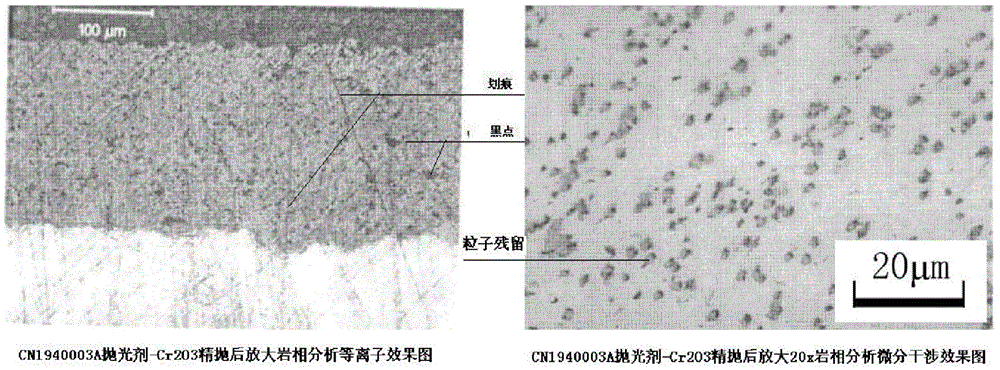

High-efficiency diamond polishing agent and preparation method thereof

ActiveCN104059539APlay a buffer roleImprove polishing effectPolishing compositions with abrasivesOctahedronHigh carbon

The invention discloses a high-efficiency diamond polishing agent which is prepared from the following raw materials in percentage by weight: 5-20 percent of ultra-precision diamond micro powder, 10-20 percent of ethyl orthosilicate, 20-30 percent of solvent, 0.2-0.8 percent of strong acid, 10-30 percent of surface active agent, 10-25 percent of wetting agent, 5-15 percent of dispersing agent and 0.1-5 percent of PH conditioning agent. According to the high-efficiency diamond polishing agent, the diamond micro powder is subjected to surface modification by using ethyl orthosilicate, so that a silicon dioxide coating layer is formed on the surface of the diamond micro powder, and during polishing, the coating layer plays a role in buffering the diamond micro powder on the inner layer; through performing multiple times of crushing and shaping on the diamond micro powder and improving surface modification process, the morphology of the diamond micro powder is closer to an octahedron; the prepared polishing agent has a better polishing effect to high-hardness metal materials such as high-carbon steel, also has a better polishing effect to crisp and hard materials such as Cr2O3, ceramics, jade and quartz, and is capable of completely preventing the damage on the surface of a material to be polished, and free from generating scratches, black points, and particle surface residues during polishing.

Owner:武汉三灵新材料有限责任公司

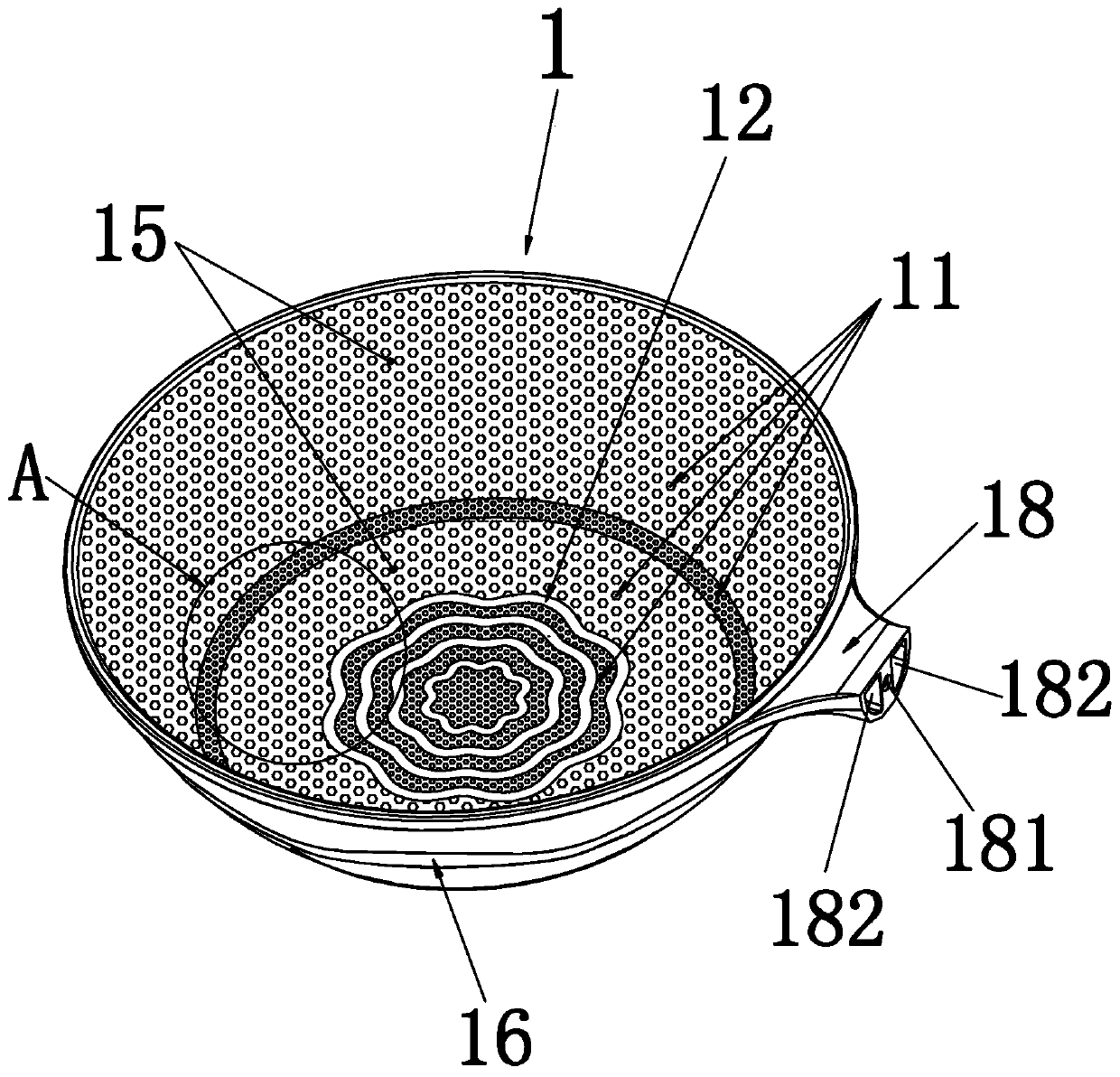

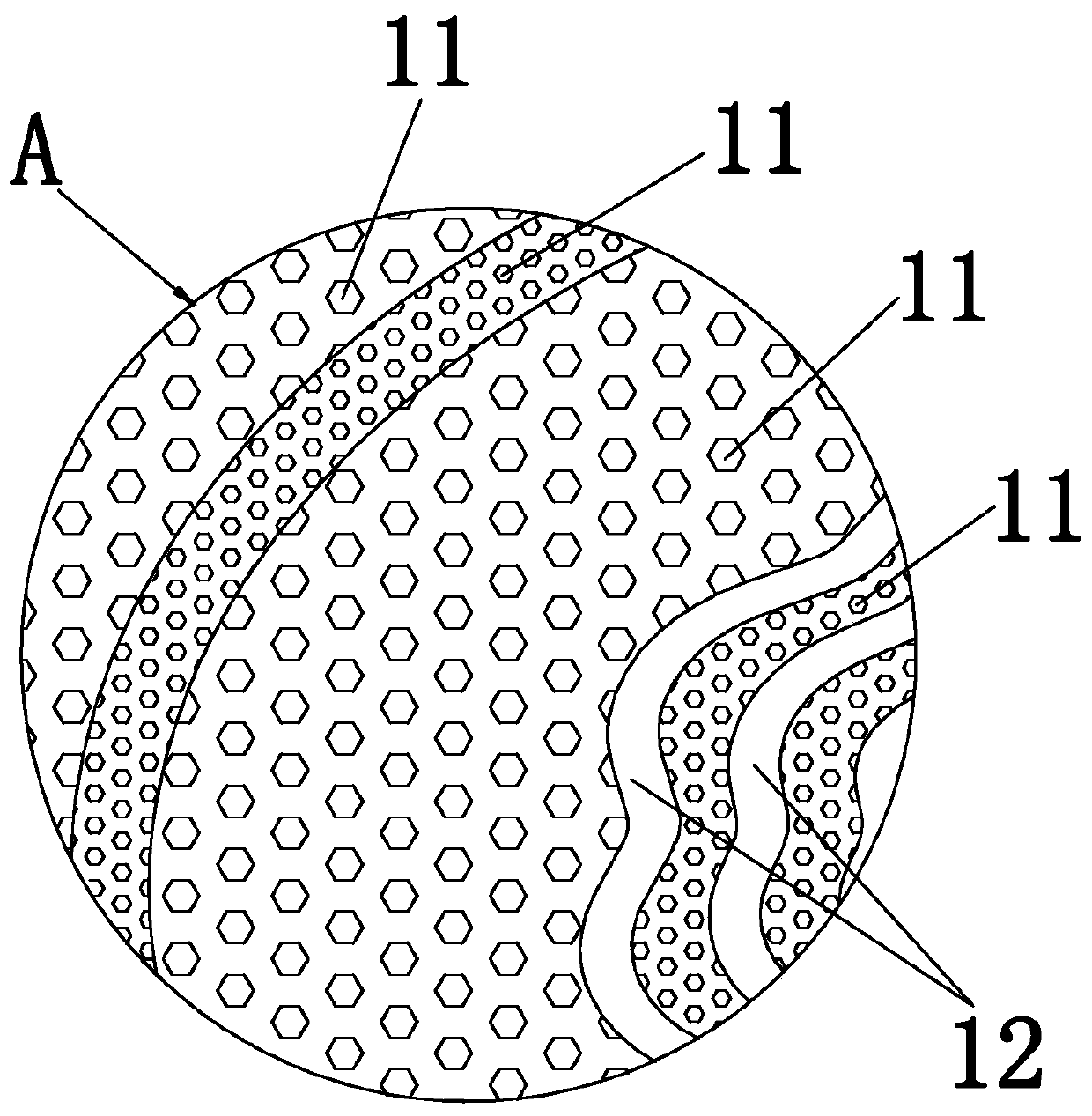

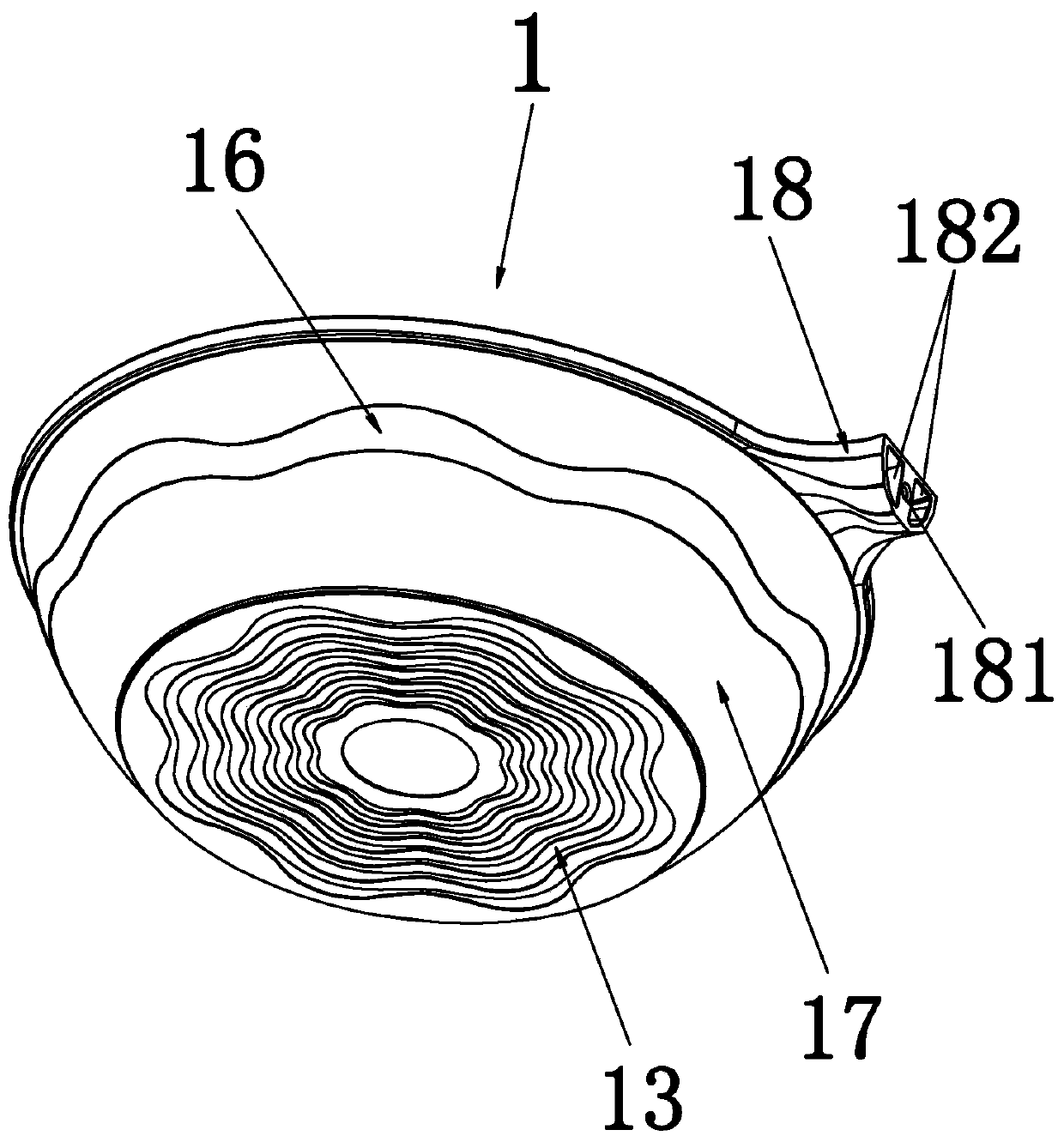

Non-stick pot body and preparation process thereof

PendingCN110403478ALong-term non-stickLong-term durabilityCooking-vessel materialsCeramic coatingPolytetrafluoroethylene

The invention provides a non-stick pot body; the non-stick pot body comprises a pot body, wherein the pot body is integrally formed in a die-cast mode; a plurality of small salient points which are densely distributed are arranged on the inner surface of the pot body; a plurality of circles of annular oil storage grooves distributed at intervals are formed in the upper surface of the pot bottom ofthe pot body, and a plurality of circles of annular grooves distributed at intervals are formed in the lower surface of the pot bottom of the pot body; the inner surface of the pot body is providedwith a ceramic coating layer and a polytetrafluoroethylene coating layer in a sprayed manner, and the polytetrafluoroethylene coating layer is attached above the ceramic coating layer; the outer surfaceof the side wall of the pot body is provided with a circle of wave-shaped convex lines surrounding the side wall of the pot body, the outer surface of the side wall of the pot body is coated with a high-temperature-resistant paint layer, and the top of the side wall of the pot body is provided with an installing part used for installing a pot handle. The invention further provides a preparation process of the non-stick pot body. The non-stick pot body can keep long non-adherence and durability, and has a better cooking effect; andthe small salient points and the annular oil storage grooves ofthe pot bottom can generate steam for local accumulation and supporting the cooking food, so that the pot body has the physical non-stick effect.

Owner:WUYI HUAKANG ELECTRICAL APPLIANCE CO LTD

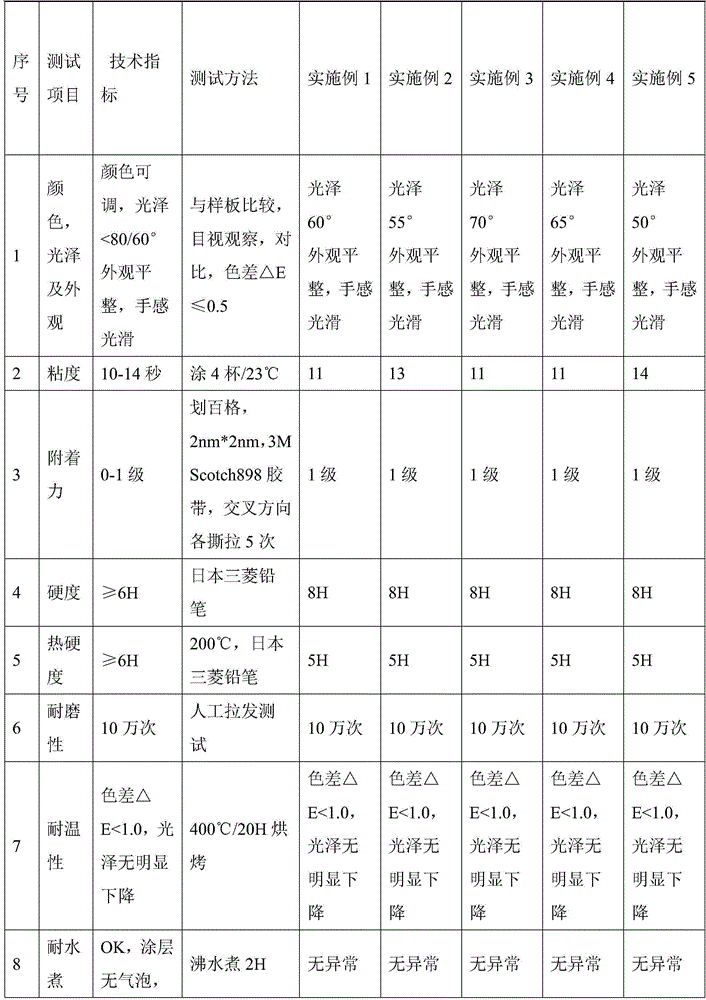

High-abrasion-resistance, high-temperature-resistant and water-cooking-resistant aqueous ceramic paint

The invention discloses high-abrasion-resistance, high-temperature-resistant and water-cooking-resistant aqueous ceramic paint, which is prepared by mixing a component A, a component B and a component C according to a mass ratio of 666: 333: 1, wherein the component A is prepared from the following components in percentages by mass: 26 percent to 30 percent of silica sol, 13 percent to 15 percent of antimony solution, 5 percent to 13 percent of inorganic high-temperature-resistant pigment and 8 percent to 12 percent of silicon dioxide; the component B is prepared from the following components in percentages by mass: 30 percent to 34 percent of silicane, 0.4 percent to 0.6 percent of wetting agent and 0.4 percent to 0.6 percent of flatting agent; the component C is 0.1 percent of catalyst. The paint prepared by the invention not only has the attractive luster and appearance and the nice hand feeling of conventional aqueous ceramic paint, but also has ultrahigh hardness and hot hardness and excellent abrasion resistance, can be up to over 100,000 times in manual hair pulling test, and further has excellent water cooking resistance, temperature resistance and corrosion resistance. The ceramic paint which is provided by the invention and is prepared by adopting a silane coupling agent has many advantages of high temperature resistance, high hardness, noninflammability, no smoke, super weatherability, environment friendliness, nontoxicity, colorfulness and the like.

Owner:DONGGUAN RUNTIAN CHEM CO LTD

High conductivity carbon fiber board and preparation method thereof

InactiveCN108340639AHigh strengthEnhanced electrical conductivity and flame retardant propertiesNon-macromolecular adhesive additivesLaminationCarbon nanotubeFire retardant

The invention relates to the technical field of new energy automobile materials, and in particular relates to a high conductivity carbon fiber board and a preparation method thereof. The high conductivity carbon fiber board comprises multi layers of carbon fiber cloth and a conductive flame-retardant deposit attached to the carbon fiber cloth. The conductive flame-retardant deposit comprises 0.3-5parts by weight of a conductive filler which is carbon nanotubes, 2-5 parts by weight of a flame retardant, 10-40 parts by weight of a curing agent and 40-60 parts by weight of binder resin. The object of the present invention is to provide the high conductivity carbon fiber board with good flame retardancy and good electrical conductivity and the preparation method thereof.

Owner:ANHUI XUSHENG NEW CONCEPT MATERIAL CO LTD

Water-based varnish

The invention relates to a material for construction and decoration and in particular relates to water-based varnish. The formula of the water-based varnish is as follows: 15 to 30 parts of water, 10 to 20 parts of acrylic polymers, 12 to 20 parts of titanium dioxide, 3 to 5 parts of barite powders, 5 to 15 parts of ground calcium carbonate, 3 to 5 parts of kaolin, 3 to 5 parts of mica powders, 0.4 to 0.8 parts of wetting and dispersing agents, 0.3 to 0.4 parts of a defoaming agent, 0.3 to 0.6 parts of a leveling agent, 0.5 to 2 parts of a thickener, 0.2 parts of a multifunctional auxiliary agent, 0.8 to 1 part of a film-forming agent, and 0.8 to 2 parts of a disinfectant and anti-mildew agent. The water-based varnish is made from high-quality acrylic polymers, natural mineral powders and multiple auxiliary agents and refined by the advanced production process. The water-based varnish has the characteristics of environmental friendliness, no toxicity, alkali resistance, mildew resistance, primer-coat property, crack resistance, energy saving, flame retardancy, sound insulation, moisture protection, leakage resistance, strong adhesion, high hardness and dry friction resistance.

Owner:深圳市名雕丹迪设计有限公司

Crown-printing process for yarn tablecloth

ActiveCN109517303AEnvironmentally friendly and non-toxicHas high cold resistanceLamination ancillary operationsLaminationYarnEngineering

The invention discloses a crown-printing process for yarn tablecloth. The crown-printing process comprises the step of preparing a PVC (Polyvinyl Chloride) film layer and a yarn layer. The yarn tablecloth is prepared by embossing and fitting, printing and winding two sides of the PVC film layer and the yarn layer. The tablecloth product prepared by the invention has elegant appearance, strong three-dimensional effect, thick texture, softness and high breathability and good water absorption, and the all-PVC material is replaced with cotton.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

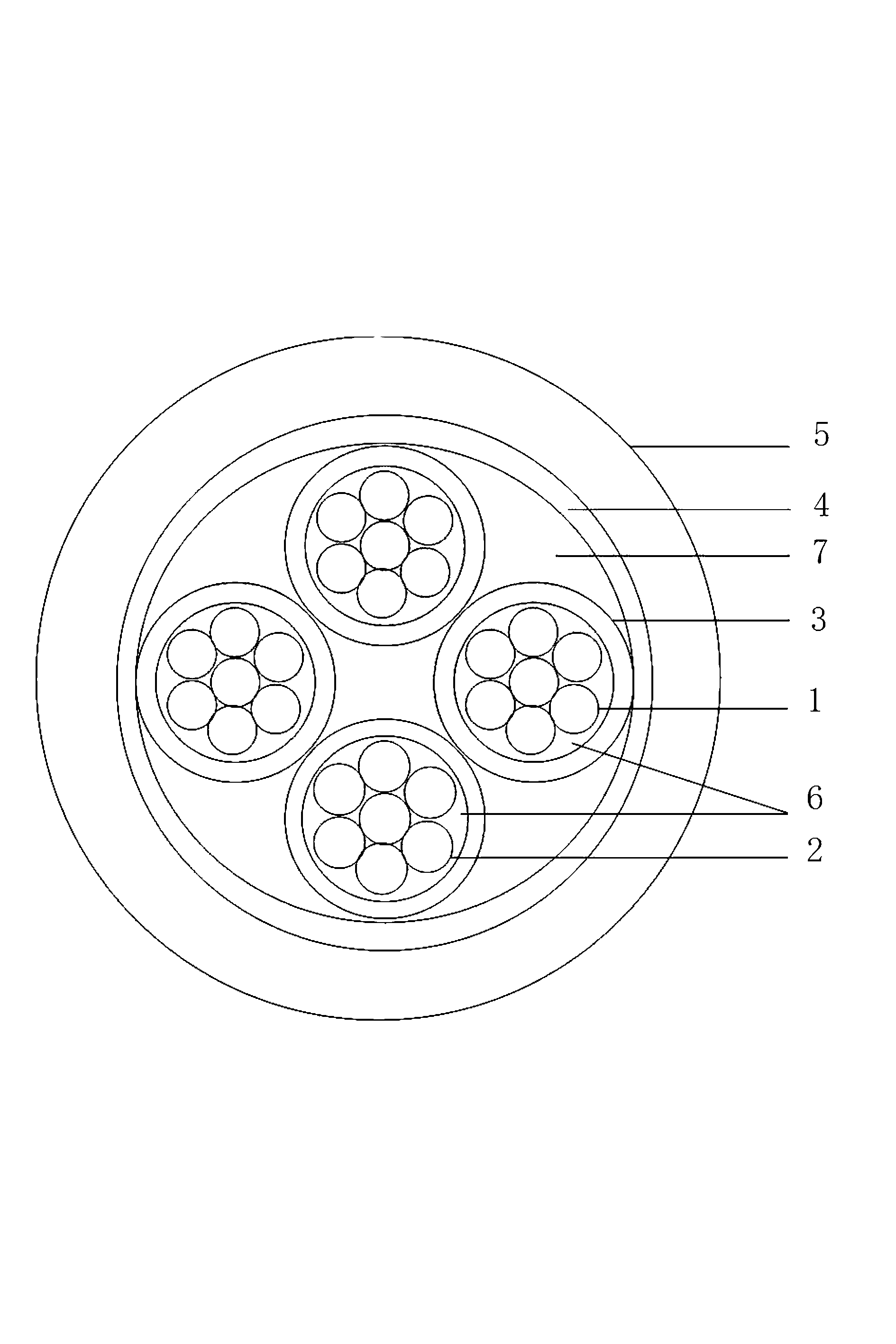

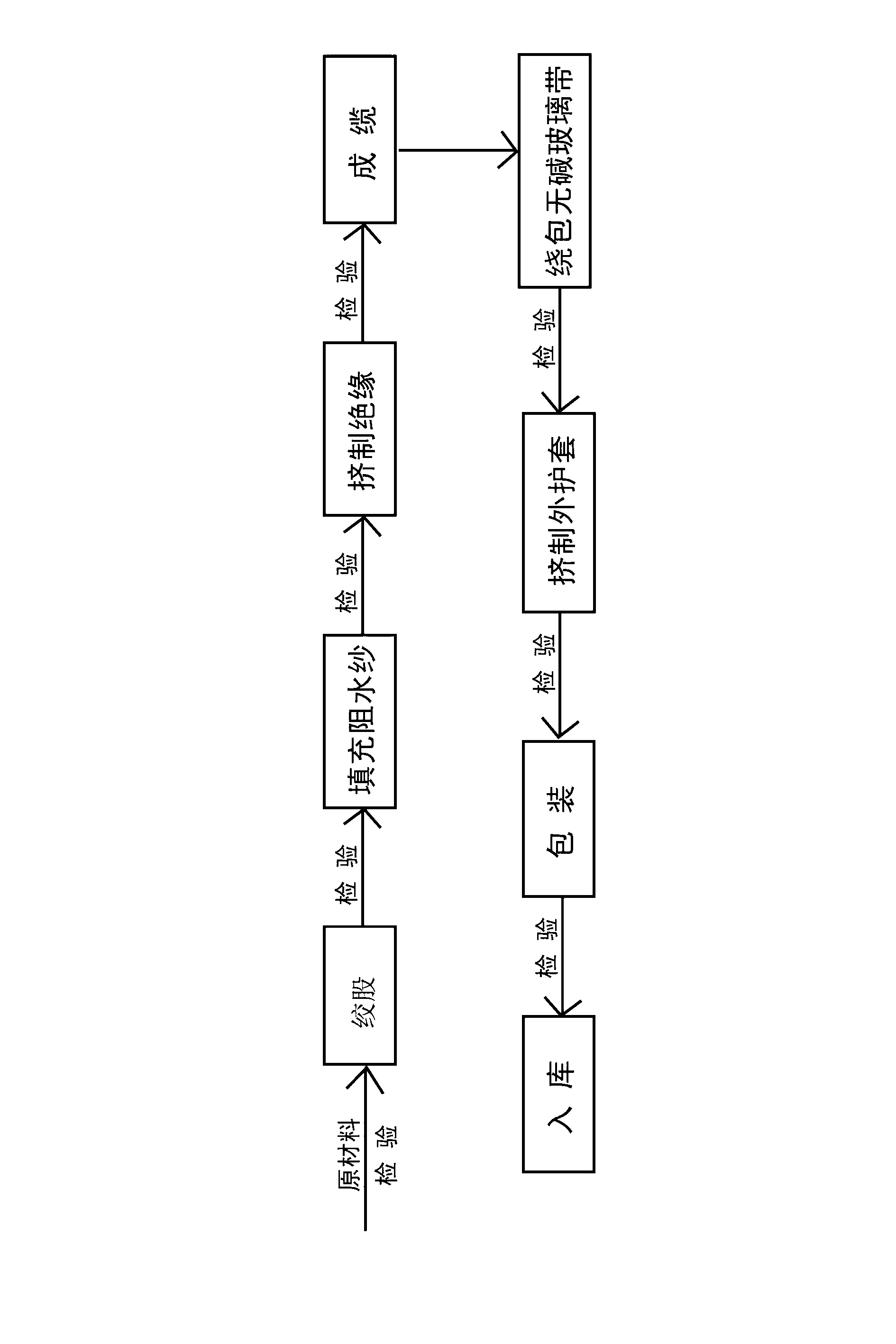

Environment-friendly copper-aluminum composite cable and production method thereof

ActiveCN102881362AReduce weightEffective installationPlastic/resin/waxes insulatorsInsulated cablesLow smoke zero halogenEnvironmental resistance

The invention relates to an environment-friendly copper-aluminum composite cable. The environment-friendly copper-aluminum composite cable is characterized in that a conductor consists of a copper conductor and an aluminum conductor, a wrapping tape is arranged outside an insulating layer, a main line of the conductor is made of a copper neutral line, an earthing line of the conductor is made of the aluminum conductor, and a waterproof layer is arranged between the conductor and the insulating layer. When the cable is used, the conductor consists of the copper conductor and the aluminum conductor, a sheath layer is made of low-smoke zero-halogen polyolefin materials, and in the use process, not only can the requirement of electric power operation be met, but also the material cost can be lowered, copper materials are saved, the recycling of waste cables are facilitated, the transportation cost is lowered at the same time, and the construction is also more convenient.

Owner:上海朗达电缆(集团)有限公司

Environmental-friendly human pipeline casting filler and preparation method thereof

InactiveCN102010575AImprove adhesionGood flexibilityDead animal preservationEducational modelsEpoxyEnvironmental resistance

The invention relates to an environmental-friendly human pipeline casting filler and a preparation method thereof. The filler is prepared from the following compositions in parts by weight: 100 parts of CYD-128(E-51) epoxy, 15ml of epoxy high performance toughening modifier RF-400, 5 parts of 2, 4, 6 tri(dimethylamino methyl) phenol (DMP-30), 0.3-0.5 part of epoxy defoamer and 45-50 parts of modified alicyclic amine epoxy curing agent ZY-1618. The invention has the advantages of easy preparation, convenient operation, finishing by once perfusion, good filler fluidity, little perfusion resistance, vigorous and plump forming, fineness, beauty, small shrinkage factor, environmental protection, no toxicity, very strong support force of a casting trunk and good flexibility of a branch.

Owner:黄海龙

Glass and pumice water-permeable bricks and preparation method of glass and pumice water-permeable bricks

ActiveCN106746683AReduce weightUnique thermal insulationSingle unit pavingsPaving gutters/kerbsPumice dustBrick

The invention discloses glass and pumice water-permeable bricks and a production process of the glass and pumice water-permeable bricks. The glass and pumice water-permeable bricks are prepared from the following formula components in percentage by weight: 28 to 36 parts of high-strength cement, 6 to 10 parts of a water permeation agent and 54 to 66 parts of honeycomb glass and pumice particle. The glass and pumice water-permeable bricks have the advantages of light weight, good water permeation property and water retention property, and especially accords with a design concept of current sponge cities; the glass and pumice water-permeable bricks are of an effective product of sponge measures including permeation, retention, accumulation, purification, utilization and exhausting. The glass and pumice water-permeable bricks have the advantages that pollution to the environment is not caused in production and utilization processes and solid wastes of renewable resources are utilized.

Owner:大连长兴恒泰新材料科技有限公司

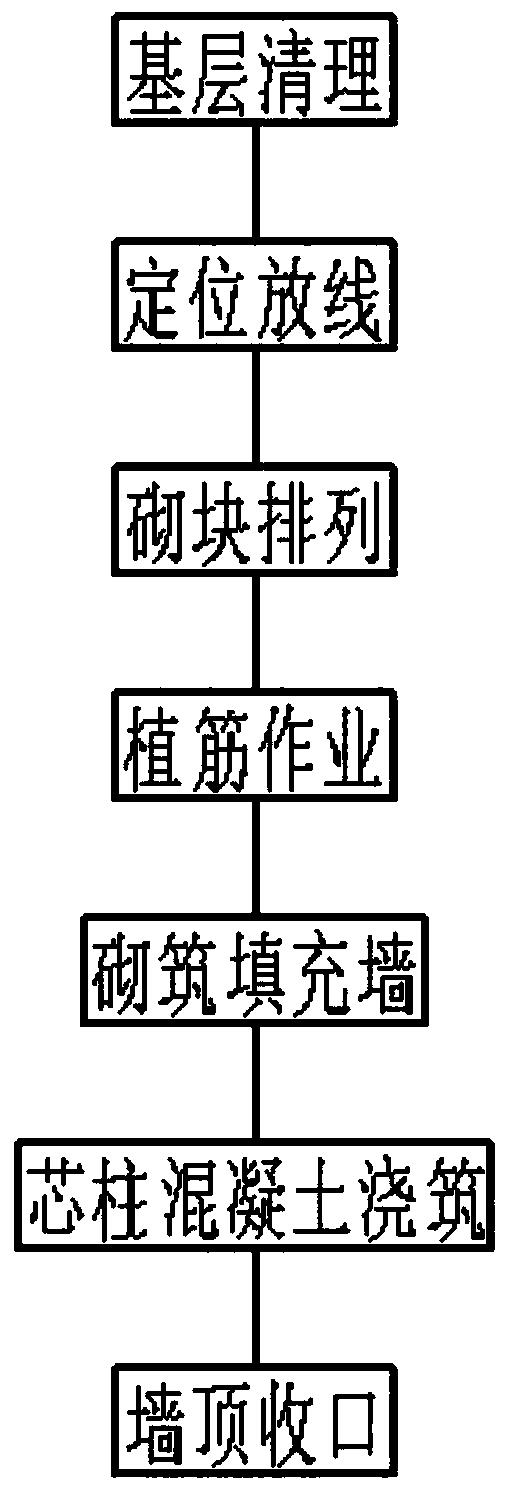

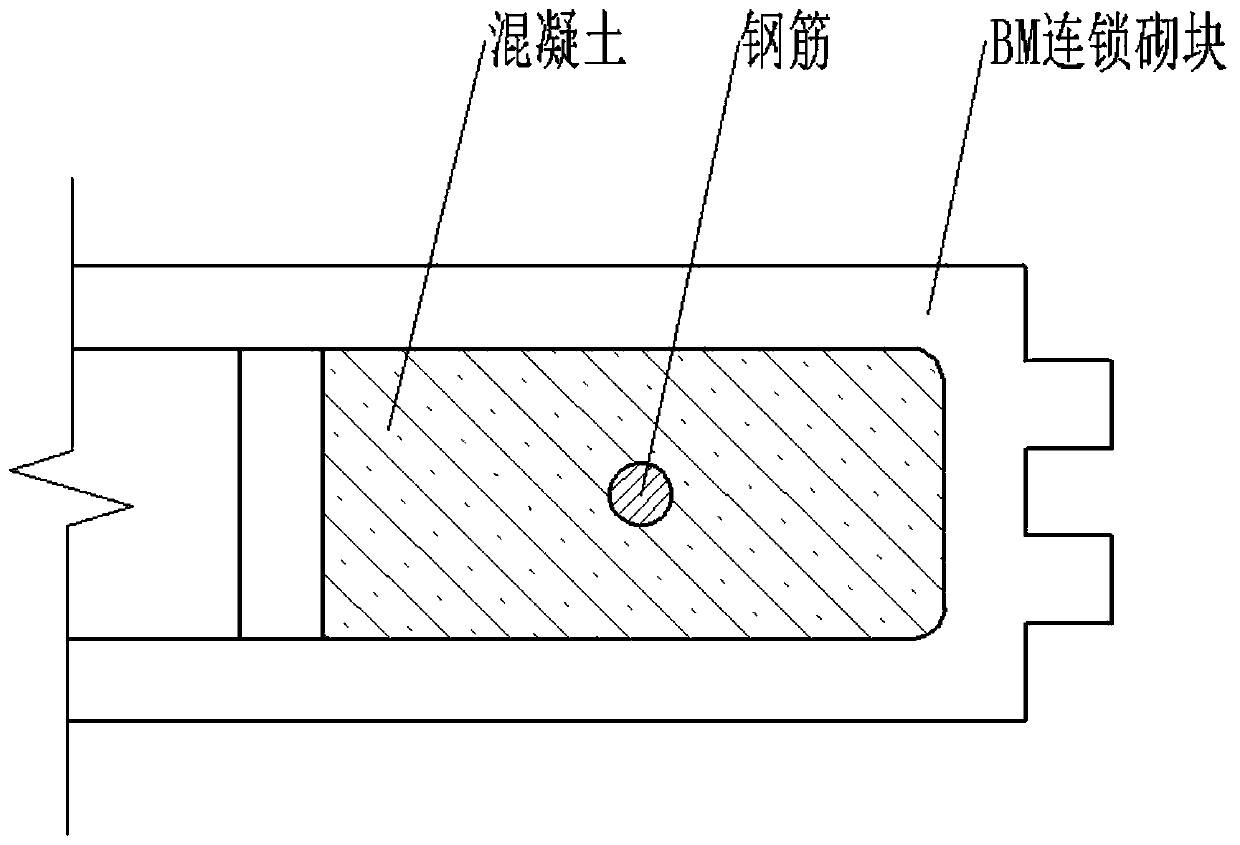

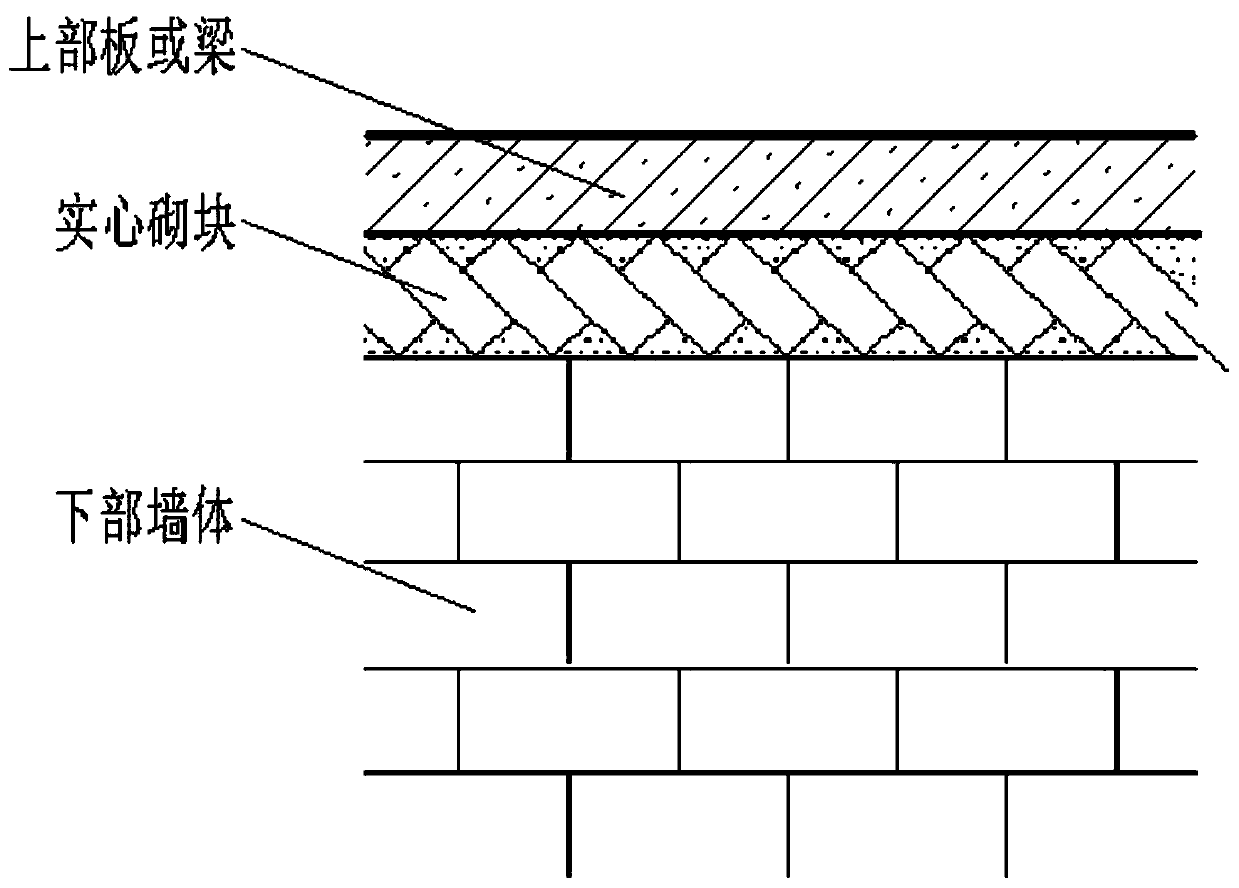

Secondary structure masonry construction method

The invention discloses a secondary structure masonry construction method. The secondary structure masonry construction method specifically comprises the following steps that S1, a base layer is cleaned; S2, positioning and paying off are conducted, specifically, a foundation surface or a floor structural surface is leveled according to the elevation, wall side lines, door and window openings andcore column position lines are paid off on a floor slab, a building + 0.5m line is paid off on each layer of wall and column, and door and window opening elevation control points are marked; S3, building blocks are arranged; S4, steel bar planting operation is conducted, specifically, drilling, glue injection and steel bar planting are conducted on the core column and lintel according to the design requirements, and the planted steel bars are anchored and tied with an original structural wall and plate; S5, a filler wall is built, specifically, the filler wall is built according to an engineering design construction drawing; S6, core column concrete is poured, specifically, after the strength grade of wall masonry mortar reaches 1MPa, concrete is poured into an inner cavity of the BM interlocking building blocks to form a core column structure; and S7, a wall top is closed. According to the secondary structure masonry construction method, in the secondary structure construction process, a formwork supporting procedure in the traditional sense is omitted, surface layer construction can be conducted without plastering after masonry is completed, and the advantages of energy saving, material saving and environmental protection are achieved.

Owner:广东蕉岭建筑工程集团有限公司

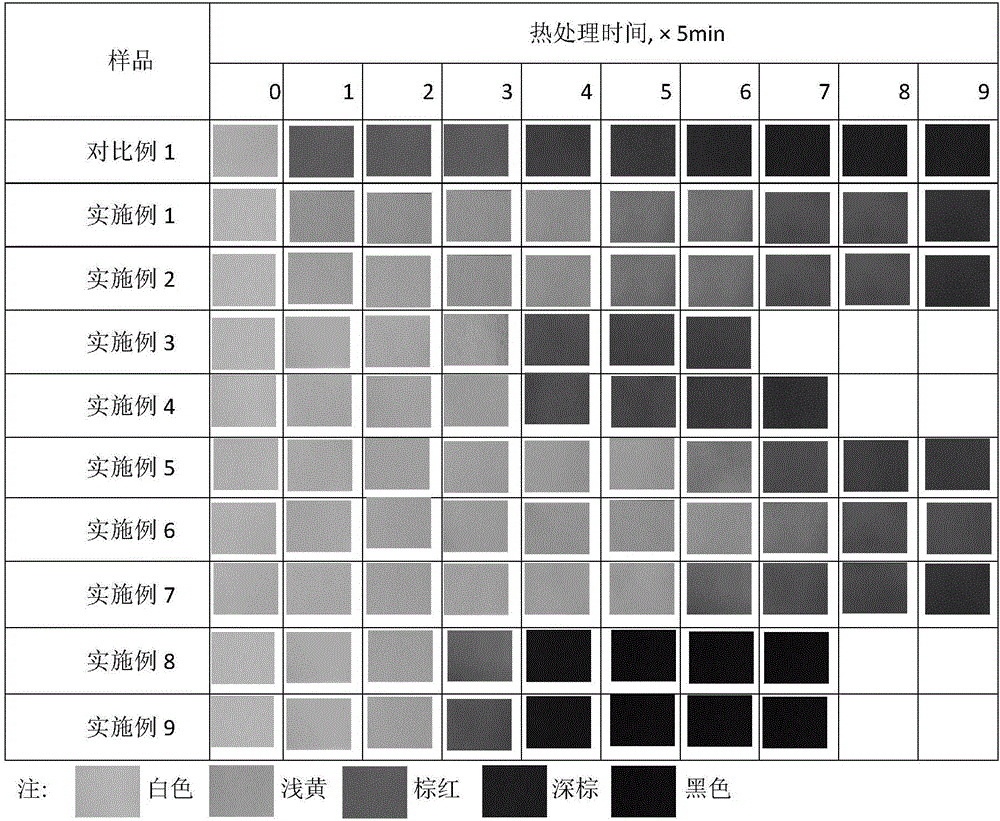

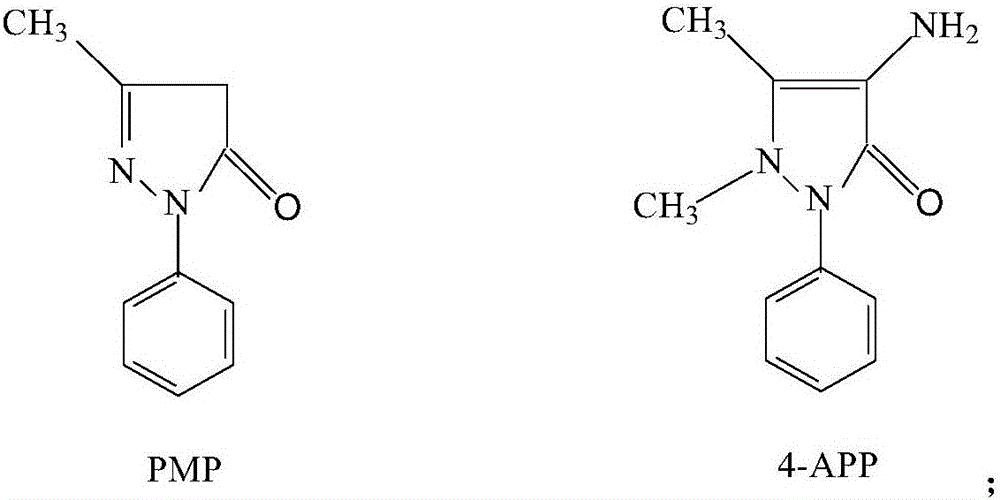

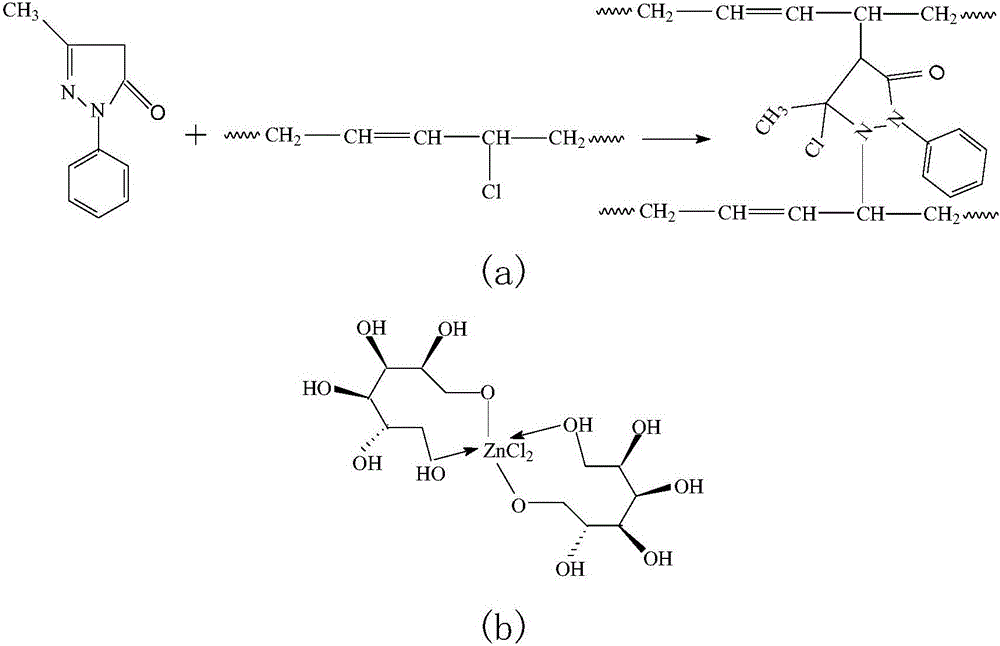

Heterocyclic organic matter and polyhydric alcohol composite PVC (polyvinyl chloride) heat stabilizing agent and preparation method thereof

InactiveCN106751229AEnvironmentally friendly and non-toxic"delayed burning" phenomenonAge methodCongo red

The invention relates to a heterocyclic organic matter and polyhydric alcohol composite PVC (polyvinyl chloride) heat stabilizing agent and a preparation method thereof. A composite thermal stabilizing agent is prepared from the following ingredients in parts by mass through being metered by 100 mass parts of PVC: 15 parts of calcium carbonate, 0.5 to 0.9 part of zinc stearate, 0.1 to 0.5 part of pyrazolone type heat stabilizers, 0.1 to 0.5 part of polyols and 1.6 parts of lubricating agents. According to the preparation method, the PVC, the composite heat stabilizers, the composite heat stabilizers, the calcium carbonate and the lubricating agents are put into a high-speed mixing machine to be uniformly mixed; blending is performed on a 170 DEG C double-roller mill mixer; after the sufficient mixing and plasticization for 5 min, sheet cutting is performed, and the sheet thickness is 1mm; then, a static state heat aging method and a Congo red color change method are used for performing performance test. The pyrazolone type thermal stabilizing agents are used for replacing active chlorine atoms; the generation capability of the conjugated polyene sequence is blocked; the zinc burning phenomenon can be delayed by using polylol; the stability is high. The preparation method has the advantages that the preparation process is simple; the environment is protected; no toxicity exists; the efficiency is high, and the like.

Owner:HUBEI UNIV OF TECH

Low-resilience high-strength shotcrete enhancer

The invention discloses a high-strength shotcrete enhancer with low resilience and high stability. The high-strength shotcrete enhancer is prepared from rice hull ash, cellulose nanofibers, a six-carbon water reducing agent, plant polysaccharide and water. The plant polysaccharide powder is fully swollen, a water reducing agent is added and fully stirred, then rice hull ash and cellulose nanofibers are added and rapidly stirred, and the high-strength sprayed concrete enhancer with low resilience rate and high stability is obtained. According to the invention, the rebound rate of shotcrete andthe like can be reduced to below 2% while the dispersity and fluidity of the reinforcer are ensured, the stability is improved, the problems of layering and precipitation caused by long-time placementare solved, and the performance of the reinforcer is prevented from being damaged. Furthermore, in the actual application process, the enhancer can be used in real time after being conveyed to a construction site, has the advantages of accurate on-site addition and measurement, easiness in uniform mixing, environmental friendliness, no pollution and the like, can effectively reduce the rebound rate of sprayed concrete and improve the compression resistance, impermeability, wear resistance and other properties, provides convenience for actual construction, and has very good performance and very high operation practicability.

Owner:天津如米基业新材料有限公司

Environment-friendly stone prepared through waste stone and preparing method thereof

InactiveCN106830762ABeautiful appearanceWear-resistantSolid waste managementCeramic shaping apparatusAluminium hydroxideWaste rubber

The invention relates to an environment-friendly stone prepared through waste stone and a preparing method thereof, and belongs to the technical field of building materials. Firstly stone powder is obtained by smashing and sifting the waste stone, then unsaturated resin, an accelerator, a curing agent, a modifier, a pigment and aluminum hydroxide powder are added into the stone powder, and after work procedures of mixing stirring, pouring, vacuum defoaming, curing molding, demolding drying and surface treatment, the environment-friendly stone prepared through the waste stone is prepared, wherein the environment-friendly stone prepared through the waste stone is prepared from, by mass, 35-40 parts of the stone powder, 7-10 parts of the accelerator, 3-4 parts of the curing agent, 32-48 parts of the curing agent, 1-5 parts of the modifier, 0.1-0.5 part of the pigment and 0.5-1 part of the aluminum hydroxide powder; the modifier is modified waste rubber tire powder. The environment-friendly stone prepared through the waste stone has the advantages of being attractive in appearance, resistant to abrasion and corrosion, resistant to oil stain, environmentally friendly, poisonless and the like.

Owner:尤志钢

Novel environment-friendly fireproof sealing gypsum

The invention discloses an environment-friendly fireproof sealing gypsum, which comprises the following components in percentage by weight: 0.2 to 8 percent of non-metallic mineral fireproof material, 0.1 to 5 percent of modifier, 0.01 to 0.8 percent of water retention thickening agent, 0.01 to 0.2 percent of bonding agent, 0.01 to 0.5 percent of retarder, 0.1 to 2 percent of intensifier, and the balance of construction gypsum. Because the non-metallic mineral fireproof materials such as mica powder or vermiculite and the like are added, and the modifier, the intensifier and the like are also added, the environment-friendly fireproof sealing gypsum can ensure the basic performances of the sealing gypsum and simultaneously has the characteristics of fire resistance, crack resistance, environmental protection, no toxin, no irritation, and the like.

Owner:北新建材(苏州)有限公司

External thermoplastic elastomer material of halogen-free flame-retardant cable

InactiveCN105860499AHigh flame retardant efficiencyImprove rigidityPlastic/resin/waxes insulatorsInsulated cablesAntioxidantSolvent

The invention discloses an external thermoplastic elastomer material of a halogen-free flame-retardant cable. The material is prepared from, by weight, 105-115 parts of TPU, 30-40 parts of SEBS, 6-7 parts of organic rectorite, 1-3 parts of tetraisopropyl titanate, 15-25 parts of precipitated silica, 10-20 parts of plasticizer, 10-20 parts of mica, 4-6 parts of talcum powder, 4-6 parts of fire retardant, 3-5 parts of lubricant, 0.2-0.6 part of antioxidant, 3-5 parts of silane coupling agent with the fineness smaller than 300 and 4-6 parts of carbon black. The defects in the prior art are overcome, and the comprehensive performance of resisting oil, resisting heat, being soft, good in resilience force and low in smoke, resisting solvents and cold and the like is achieved.

Owner:ANHUI TIANYUAN CABLE

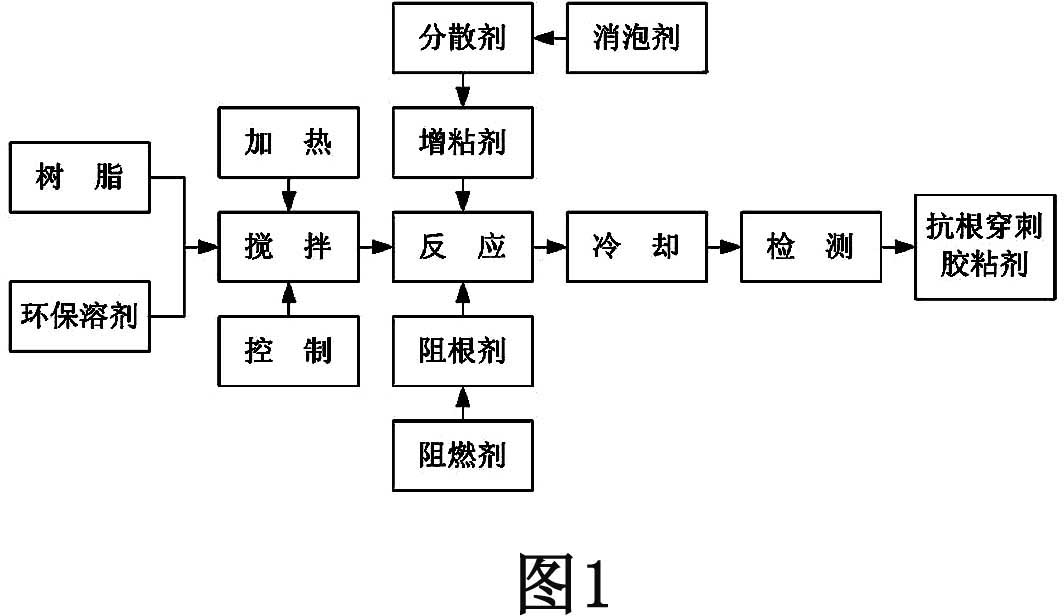

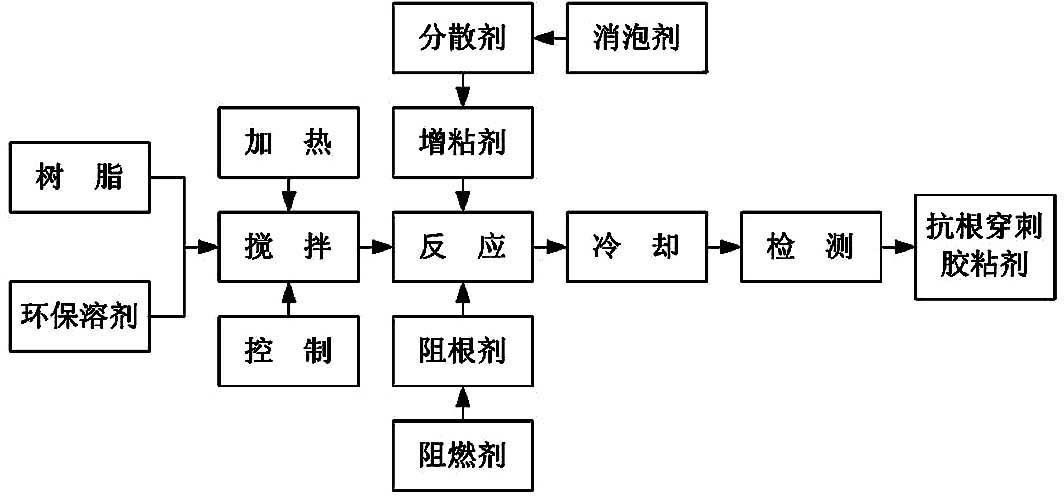

Plant root puncture-resistant adhesive and preparation method thereof

InactiveCN101935509ASolve the problem of seam jointSolving the problem of lap jointsMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesSolventPlant root

The invention relates to a plant root puncture-resistant adhesive and a preparation method thereof. The preparation method comprises the following steps of: adding an SBS resin, a petroleum resin and an environmentally-friendly solvent weighed according to a prescription into a container, starting to stir and raising temperature to 85-90 DEG C, dissolving all resins, then adding a tackifying resin, a root-resistant agent, a flame retardant, an anti-aging agent, a dispersing agent and an antifoaming agent, continuously heating to react for 1.5-2.0 h, reducing temperature to the room temperature, detecting to be qualified and then packaging into the container. The plant root puncture-resistant adhesive is environmentally-friendly and nontoxic and has the advantages of high cohesive strength, favorable weathering resistance, excellent plant root puncture-resistant effect and convenient construction application. The product can be optionally and firmly adhered to asphalt coiled material, high molecular sheet, concrete and metal substrates to form an integrated protective layer and does not puncture a plant root or leak due to lapped seams.

Owner:北京立高科技股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com