Non-stick pot body and preparation process thereof

A non-stick pan and pan body technology, applied in the field of kitchen utensils, can solve the problems that the coating cannot maintain non-stick property and durability, uneven distribution of edible oil, unfavorable cooking effect, etc., to improve the effect of non-stick pan, adsorption Strong and reliable, the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

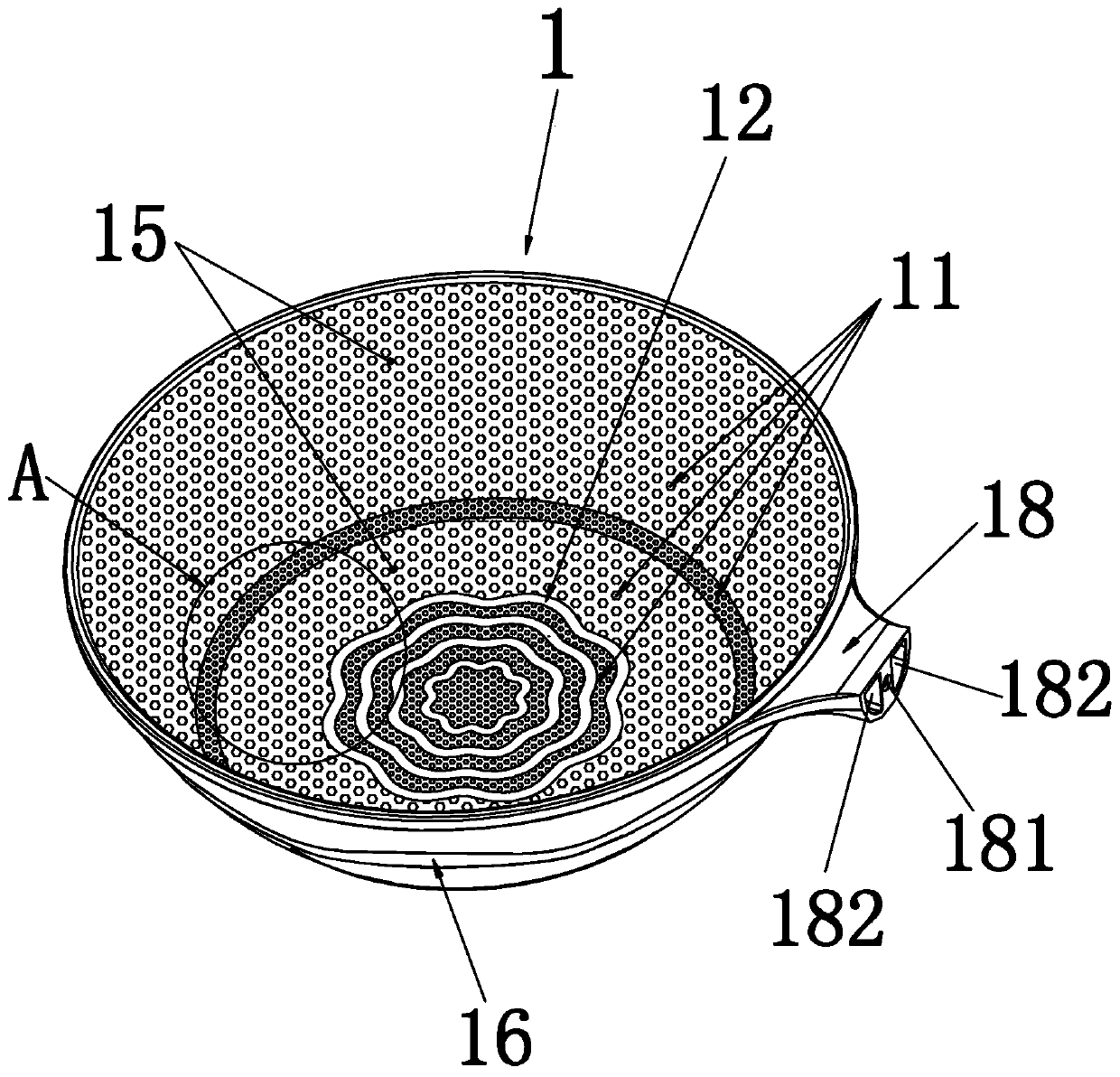

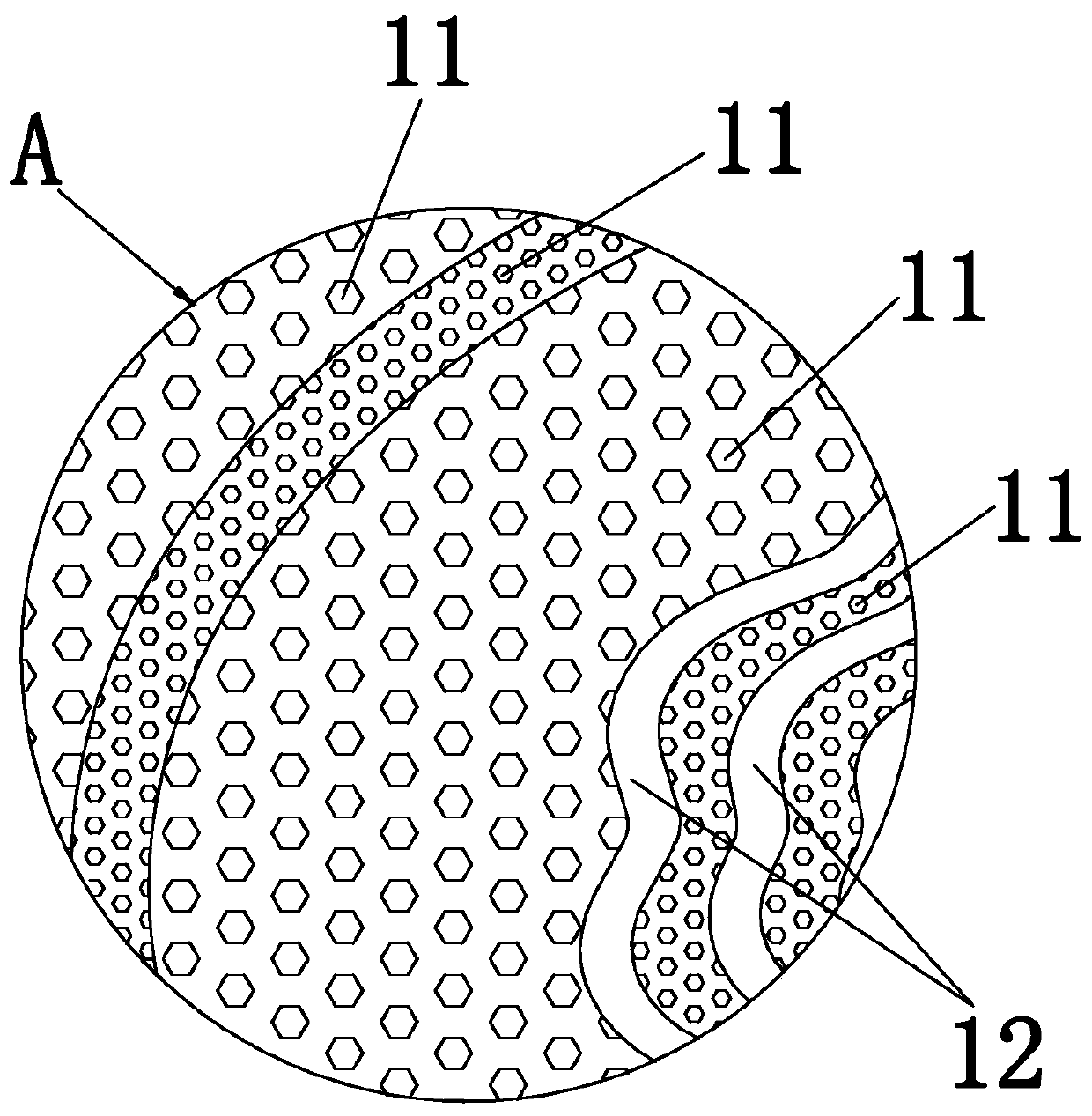

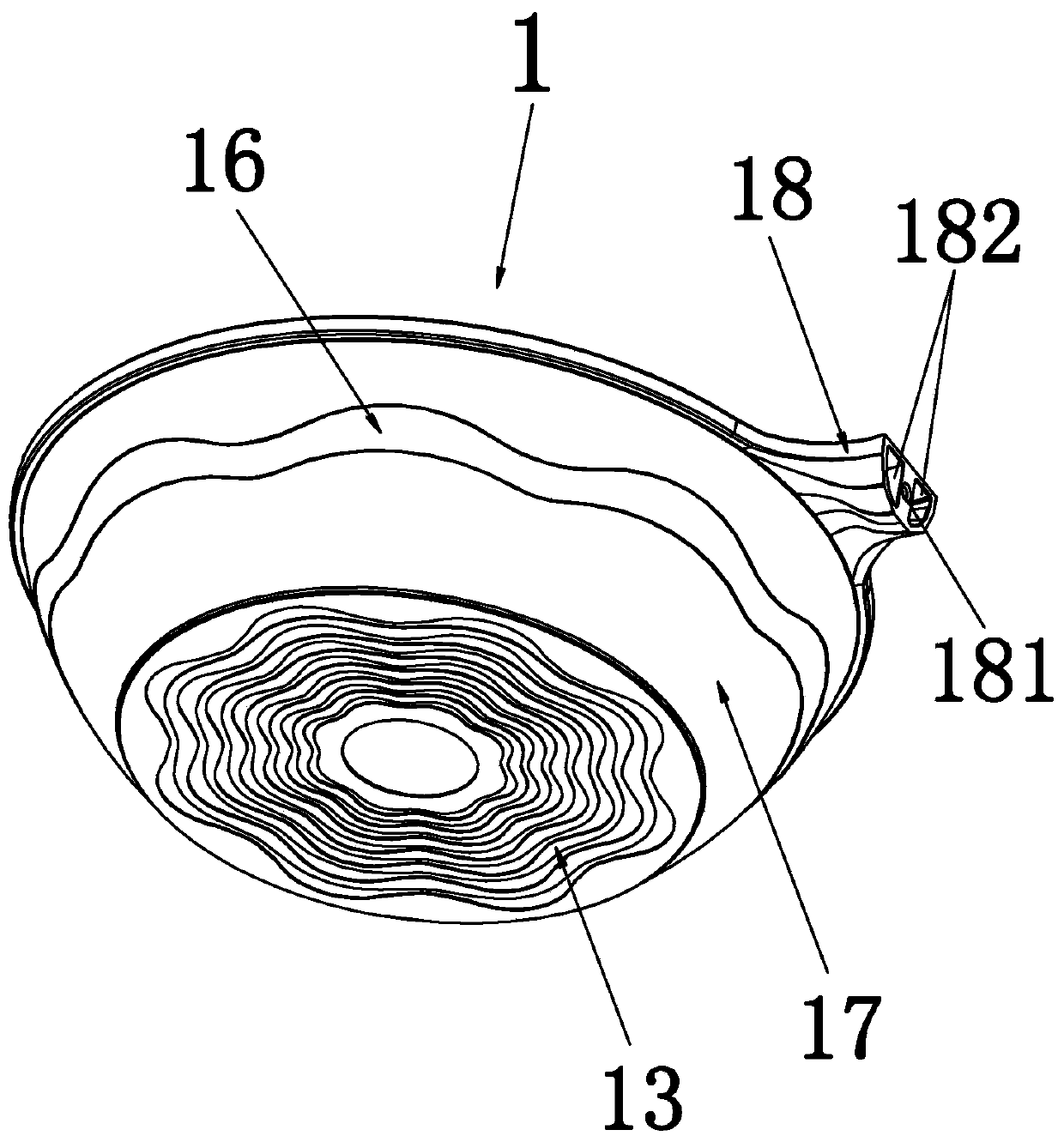

[0030] Such as Figure 1 to Figure 6 As shown, a non-stick pan body includes a pan body 1, the pan body 1 is integrally formed by die-casting, and the inner surface of the pan body 1 is integrally formed with a number of finely distributed small bumps 11, and the small bumps 11 are arranged The inner surface of the entire pot body 1 is covered, and the small bumps 11 are distributed irregularly and densely. The raised height of the small bumps 11 is 0.3-0.5 mm, and the raised surface area of each small bump 11 is 0.3-1 mm. 2 , the distance between adjacent small bumps 11 is 0.3-0.6mm; when spraying, the small bumps 11 provided on the inner surface of the pot body 1 can absorb more spraying materials, and at the same time, can increase the amount of spraying Adhesion between the coating and the inner surface of the pot body 1. The center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com