Ceramic tile ready-mixed mortar and production method thereof

A technology for ready-mixed mortar and ceramic tiles, which is applied in the field of ready-mixed mortar, which can solve problems such as easy warping of tiles, poor viscosity, and safety accidents, and achieve the effects of saving manpower, improving impermeability, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

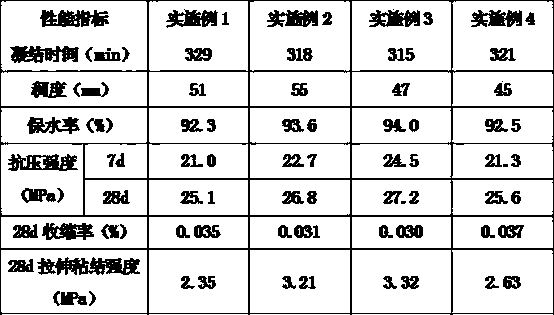

Examples

Embodiment 1

[0026] (1) Raw material and weight:

[0027] 50 parts of artificial sand, 30 parts of cement, 10 parts of class II fly ash, 2 parts of redispersible latex powder, 2 parts of cold-melt polyvinyl alcohol powder, 1 part of hydroxypropyl methylcellulose ether, 0.1 part of additives;

[0028] The additive includes raw materials in the following weight ratio: high-performance polycarboxylate water reducer: ferric chloride: sodium gluconate: defoamer: air-entraining agent in a weight ratio of 50:15:5:2:0.5, so The above-mentioned high-performance polycarboxylate water reducer has a polyester structure; or a polyether structure.

[0029] (2) Production

[0030] After weighing the artificial sand, cement, class II fly ash, functional additives and additives by weight, first put the class II fly ash, functional additives and additives into the mixer for stirring and mixing, and then put Cement is added to the mixer and mixed, and finally the artificial sand is added to the mixer and m...

Embodiment 2

[0032] (1) Raw material and weight:

[0033] 55 parts of artificial sand, 32 parts of cement, 11 parts of class II fly ash, 2 parts of redispersible latex powder, 3 parts of cold-melt polyvinyl alcohol powder, 1 part of hydroxypropyl methylcellulose ether, 0.2 parts of additives;

[0034] The additive includes raw materials in the following weight ratio: high-performance polycarboxylate water reducer: ferric chloride: sodium gluconate: defoamer: air-entraining agent in a weight ratio of 52:16:6:2:0.5, so The above-mentioned high-performance polycarboxylate water reducer has a polyester structure; or a polyether structure.

[0035] (2) Production

[0036] After weighing the artificial sand, cement, class II fly ash, functional additives and additives by weight, first put the class II fly ash, functional additives and additives into the mixer for stirring and mixing, and then put Cement is added to the mixer and mixed, and finally the artificial sand is added to the mixer and ...

Embodiment 3

[0038] (1) Raw material and weight:

[0039] 58 parts of artificial sand, 34 parts of cement, 11 parts of Class II fly ash, 3 parts of redispersible latex powder, 2 parts of cold-melt polyvinyl alcohol powder, 1 part of hydroxypropyl methylcellulose ether, and 0.4 parts of additives;

[0040]The additive includes raw materials in the following weight ratio: high-performance polycarboxylate water reducer: ferric chloride: sodium gluconate: defoamer: air-entraining agent in a weight ratio of 54:18:8:2:0.5, so The above-mentioned high-performance polycarboxylate water reducer has a polyester structure; or a polyether structure.

[0041] (2) Production

[0042] After weighing the artificial sand, cement, class II fly ash, functional additives and additives by weight, first put the class II fly ash, functional additives and additives into the mixer for stirring and mixing, and then put Cement is added to the mixer and mixed, and finally the artificial sand is added to the mixer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com