Patents

Literature

627 results about "Efflorescence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, efflorescence (which means "to flower out" in French) is the migration of a salt to the surface of a porous material, where it forms a coating. The essential process involves the dissolving of an internally held salt in water, or occasionally in another solvent. The water, with the salt now held in solution, migrates to the surface, then evaporates, leaving a coating of the salt.

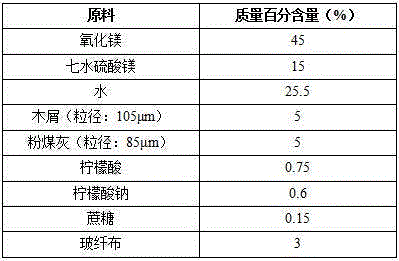

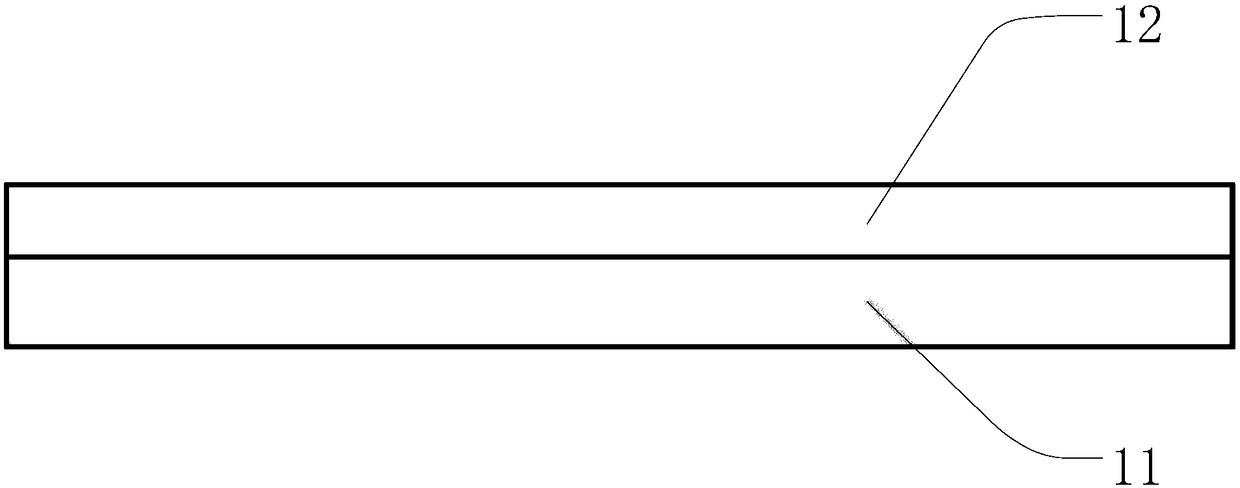

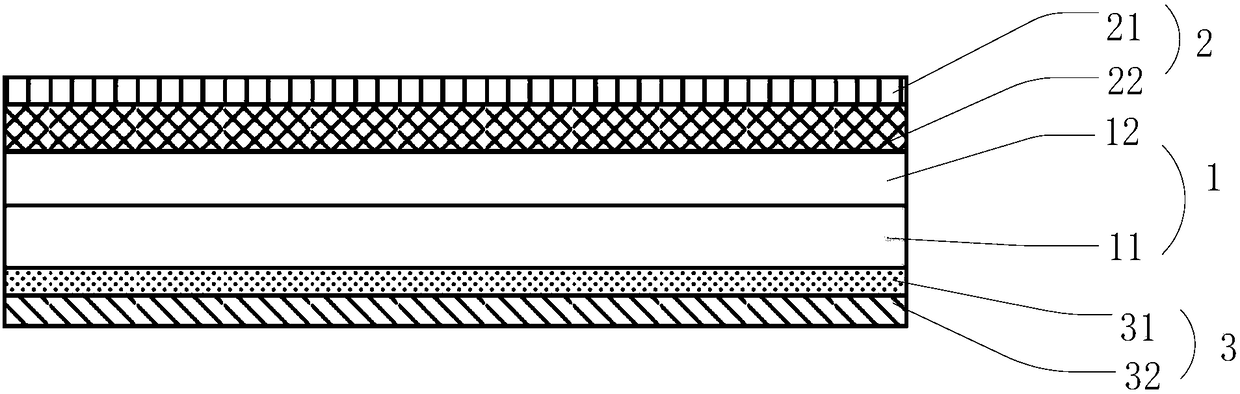

Novel inorganic decoration base material plate and preparation method thereof

InactiveCN105130350AImprove water and moisture resistanceAdjust clotting timeSucroseMoisture absorption

The present invention discloses a novel inorganic decoration base material plate and a preparation method thereof. The novel inorganic decoration base material plate is prepared from the following raw materials by weight: 45-50% of magnesium oxide, 15-20% of magnesium sulfate, 1-1.5% of a modifier, 5-10% of a filler, 1-5% of a reinforcing material, and the balance of water. According to the present invention, the magnesium sulfate is used to replace the magnesium chloride as the gelling material, such that the prepared base material plate almost does not contain chlorine ions; the mixture of citric acid, sodium citrate and sucrose is adopted as the modifier so as to adjust the condensation time and significantly increase the water resistance and the dampness resistance of the base material plate; and the prepared base material plate has characteristics of good waterproof performance, no moisture absorption efflorescence, high strength, cracking deformation resistance, good flexibility, good durability, significantly improved fireproof performance, no formaldehyde release during production and use processes, safety and environmental protection, and can be widely used as the base plates of fireproof plates, suspended ceiling plates, decorative plates, partition boards and other plates.

Owner:惠州美森板业有限公司

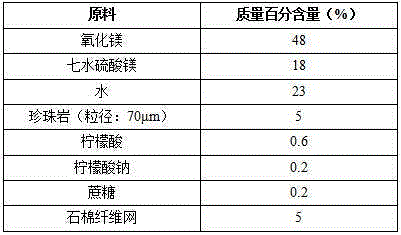

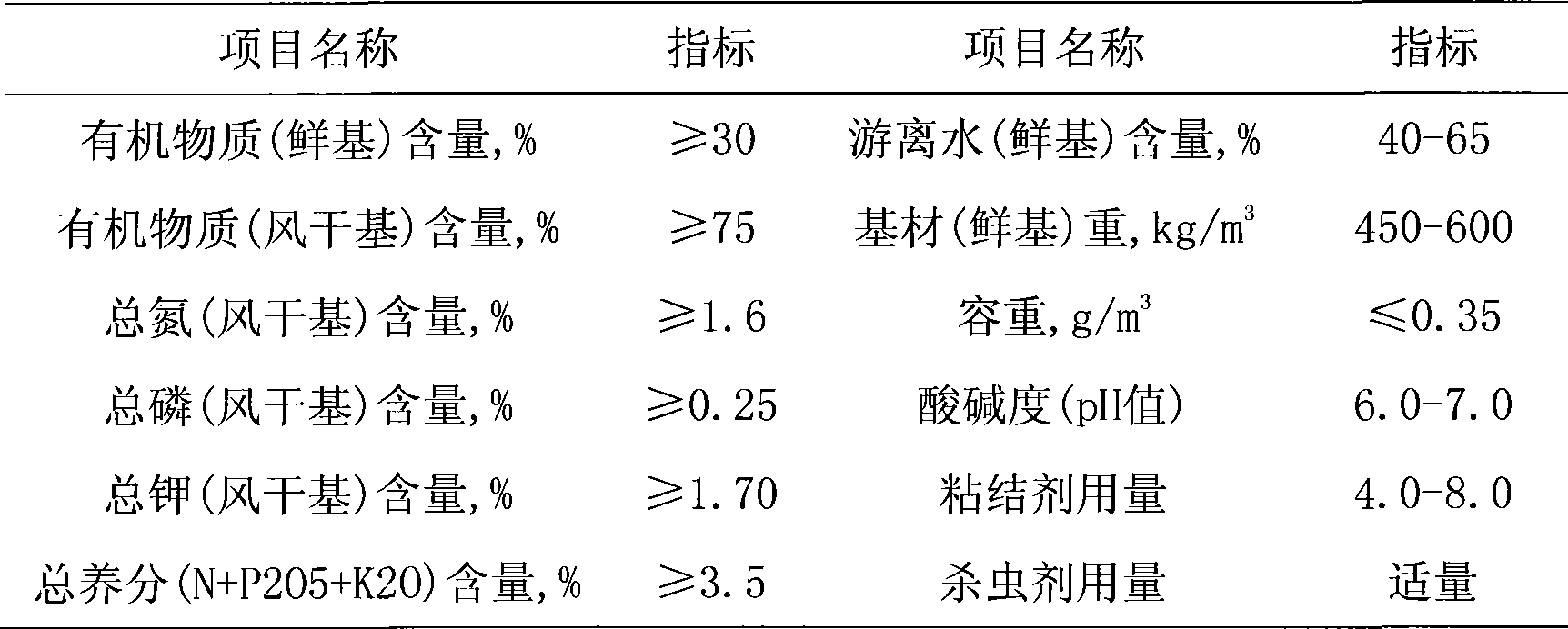

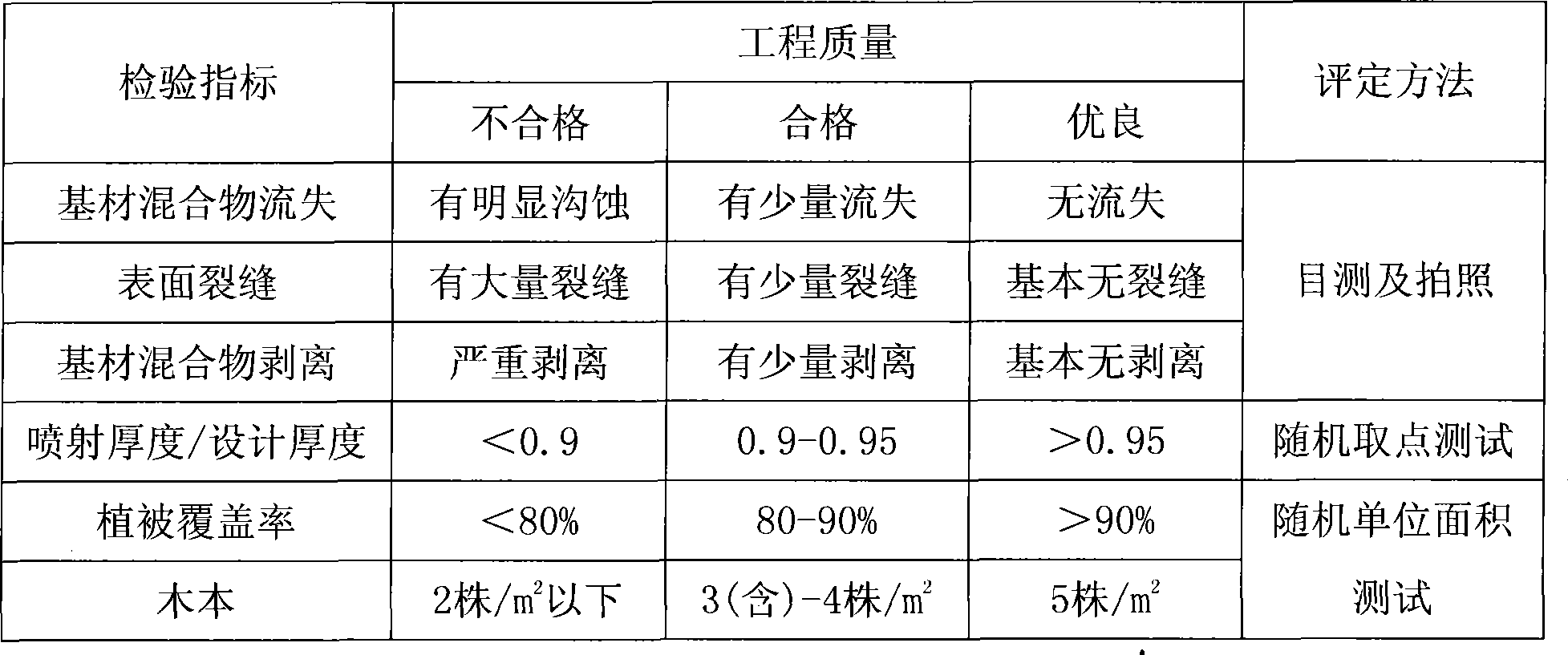

Ecological protection greening substrate for rock slope

InactiveCN101485282AQuick closurePrevent weathering and peelingCultivating equipmentsSoilless cultivationFiberSludge

The invention discloses a rock slope ecological protection afforestation substrate. The substrate is prepared by evenly mixing a mixture of mixed and fermented straw, cattle manure, edible fungus refuse (the waste after the edible fungus production), sludge and organic matter fibers, compound fertilizer, a soil moisture holding agent, a binding agent, attapulgite powder and a pH regulator. The rock slope ecological protection afforestation substrate is used to carry out the spray seeding and greening on the exposed rock slope, the discarded mine and the mountain gap, and can maximally restore the vegetation ecology in a shorter period, thereby reaching the aims of afforestation and slope protection. The substrate can supply a reasonable physical structure and nutrient contents needed by the growth of the vegetation, and ensure the sufficient cohesion force between the substrate mixture on the slope surface and the rock slope so as to ensure that the vegetation on the slope surface can take root and grow well on the rock slope. The substrate can ensure the stability of the substrate mixture on the slope surface so as to resist the rain erosion. The substrate can rapidly seal the slope surface and prevent the slope surface from flaking off due to efflorescence together with the vegetation.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Ultraviolet light cured printing ink

The invention discloses the ultra-violet light solidified printing ink. The ultra-violet light solidified printing ink hasn't volatile organic solvent, avoiding the pollution and improving the durability and flexible. The invention uses the national standard GB / T 1731-93 to test, and the baseboard uses soft PVC film. The invention uses national standard GB / T 1766-95 to test durability, and uses GB / T 1865-97 to test printing ink. The flexible is 1mm, the discoloration is 2 grade, the efflorescence is 0 grade, and the cracking is 0 grade.

Owner:SHANGHAI HUAMING HI TECH GRP

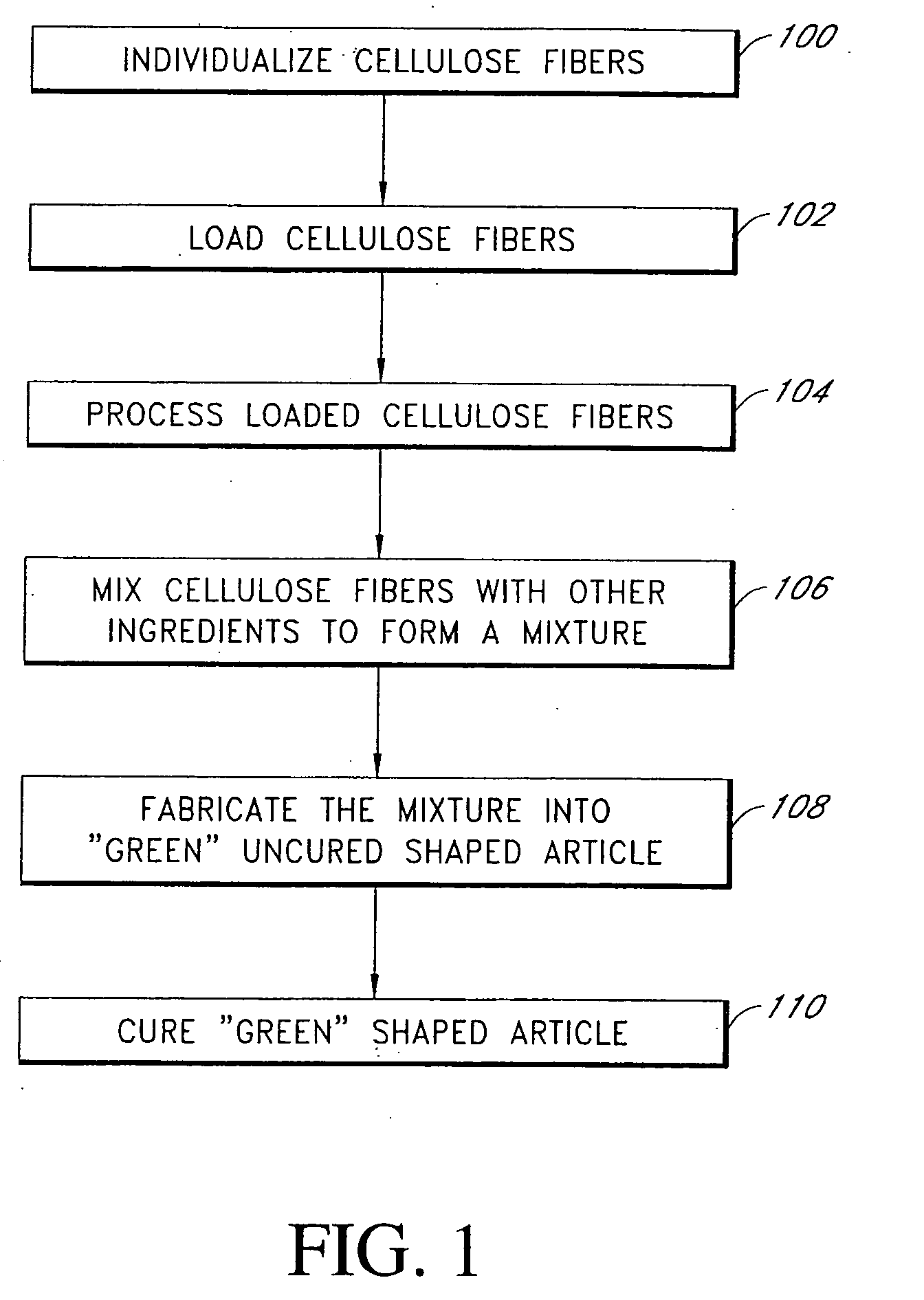

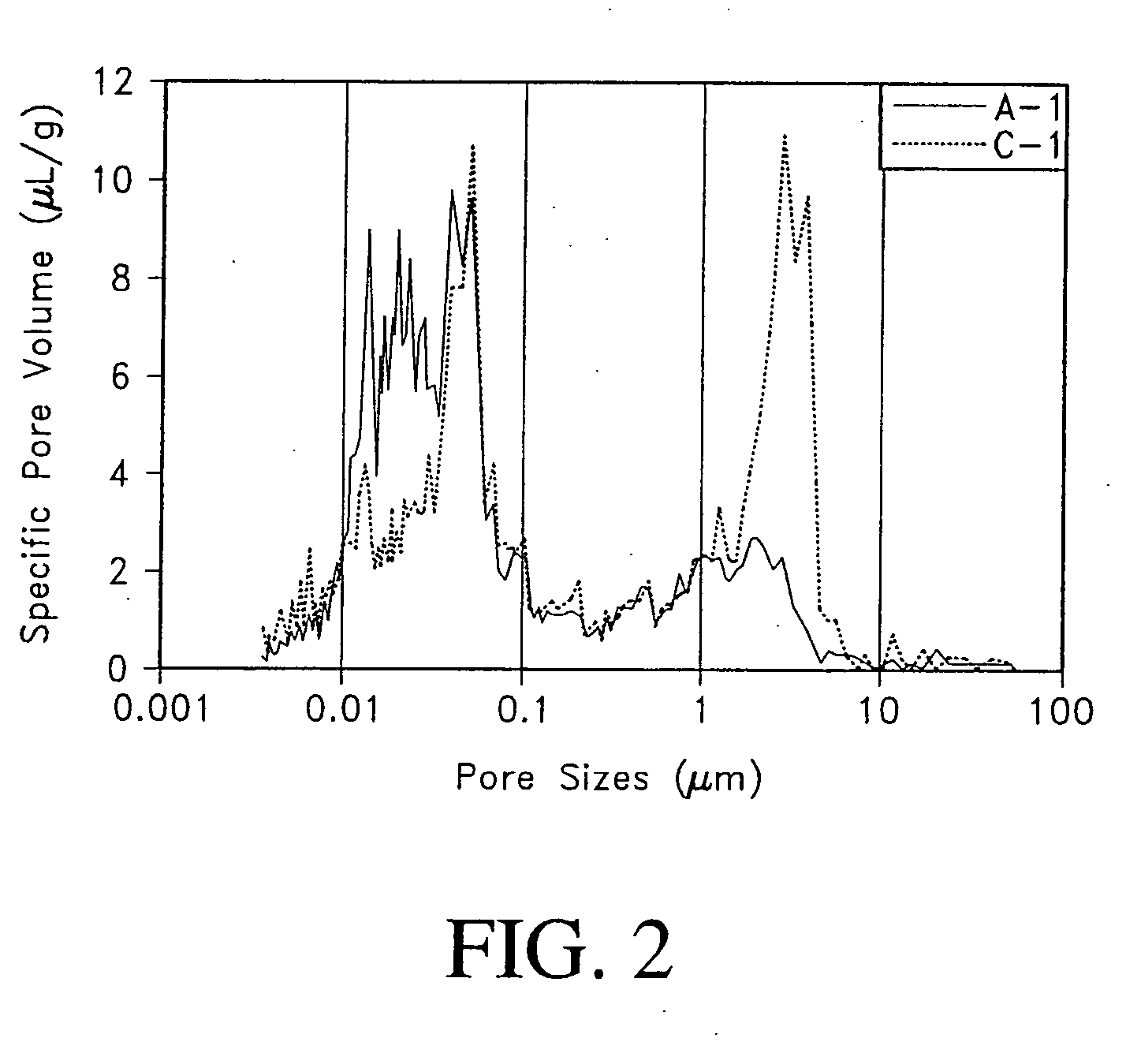

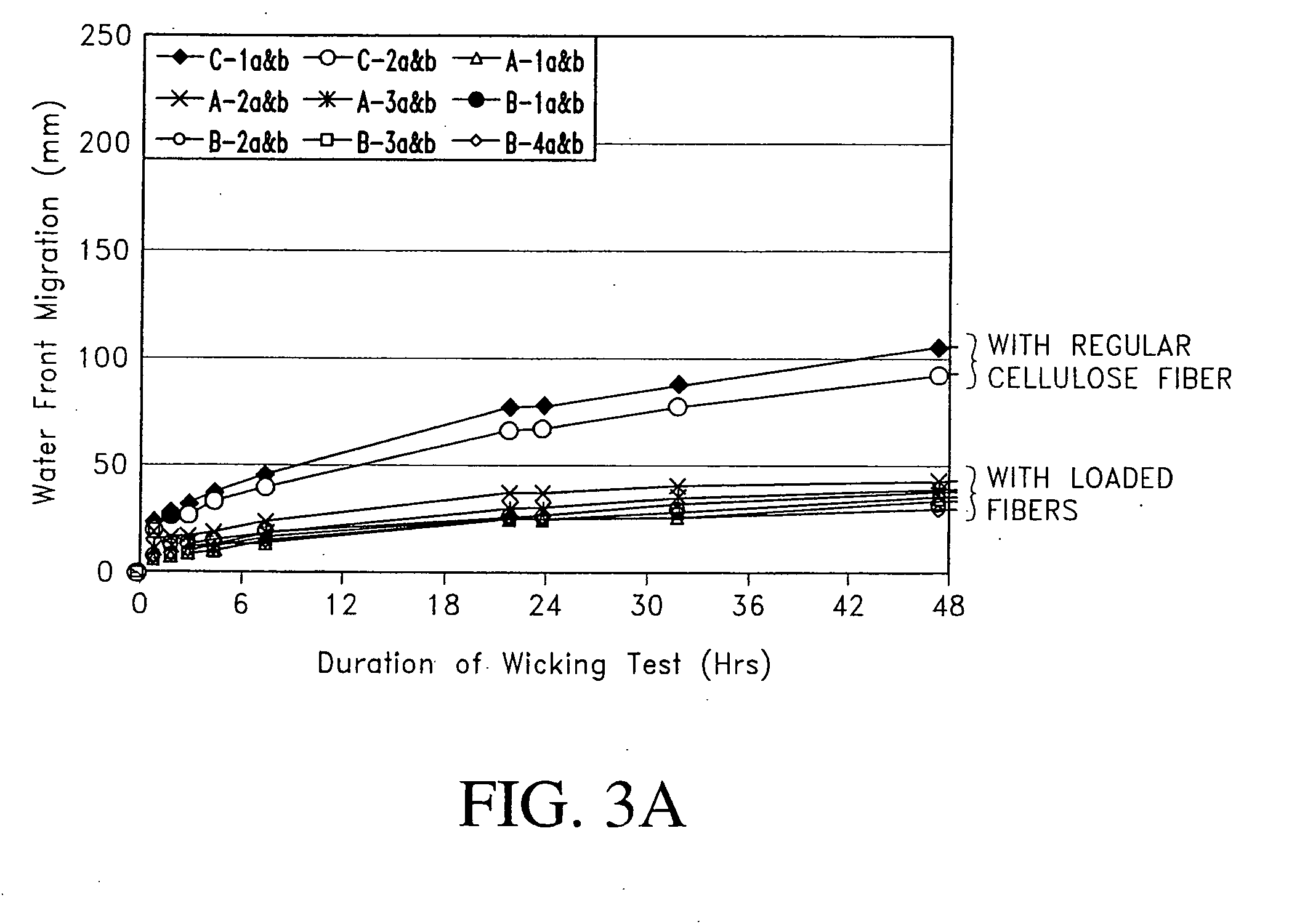

Fiber cement composite materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveUS20050235883A1Low water absorptionLow water migrationConstruction materialWater-repelling agents additionCement compositesCellulose fiber

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using the loaded cellulose fibers. This invention discloses four aspects of the technology: fiber treatment, formulation, method and final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, reduced chemical dissolution and re-deposition, and improved rot and fire resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness.

Owner:MERKLEY DONALD J +1

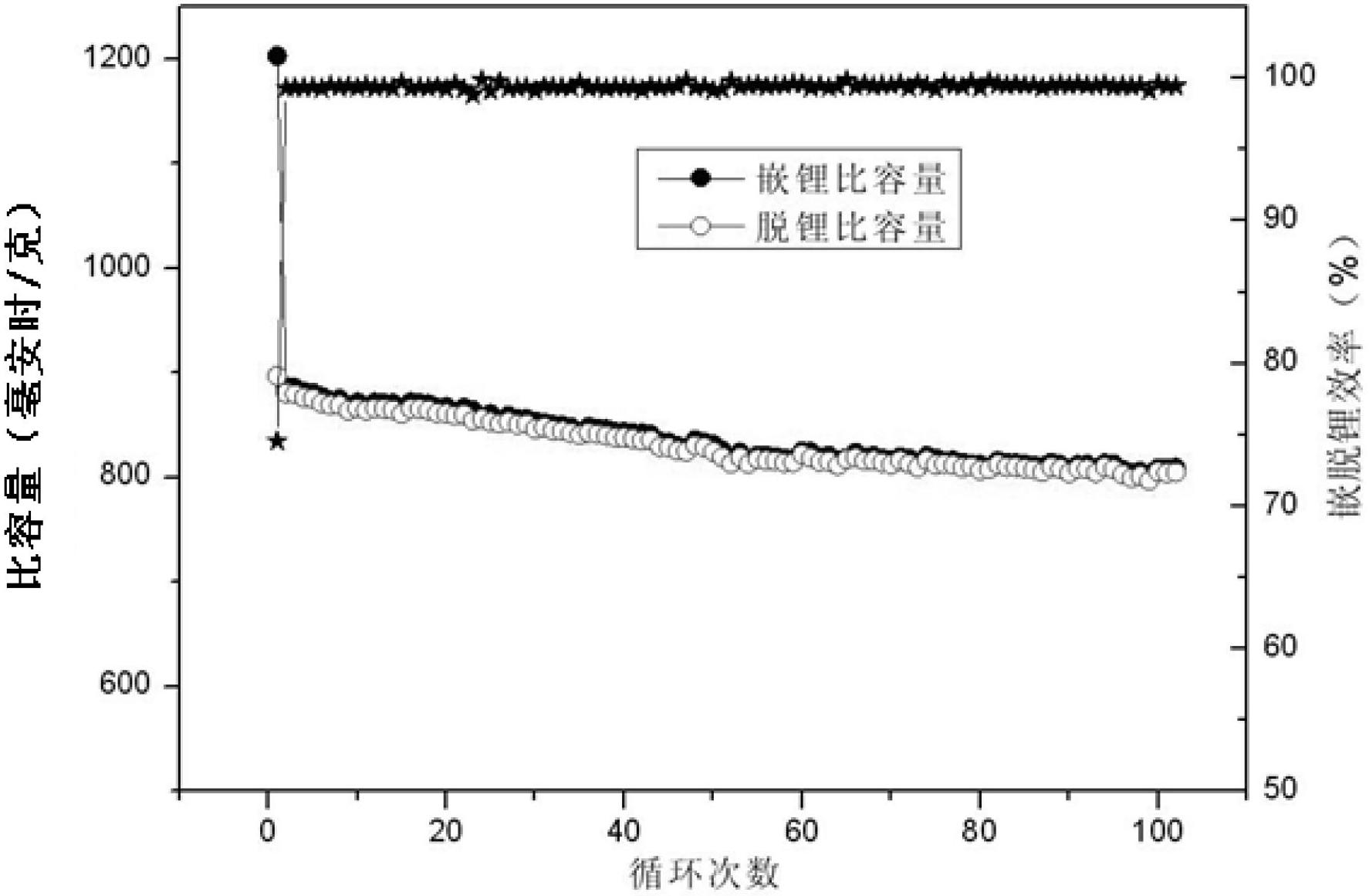

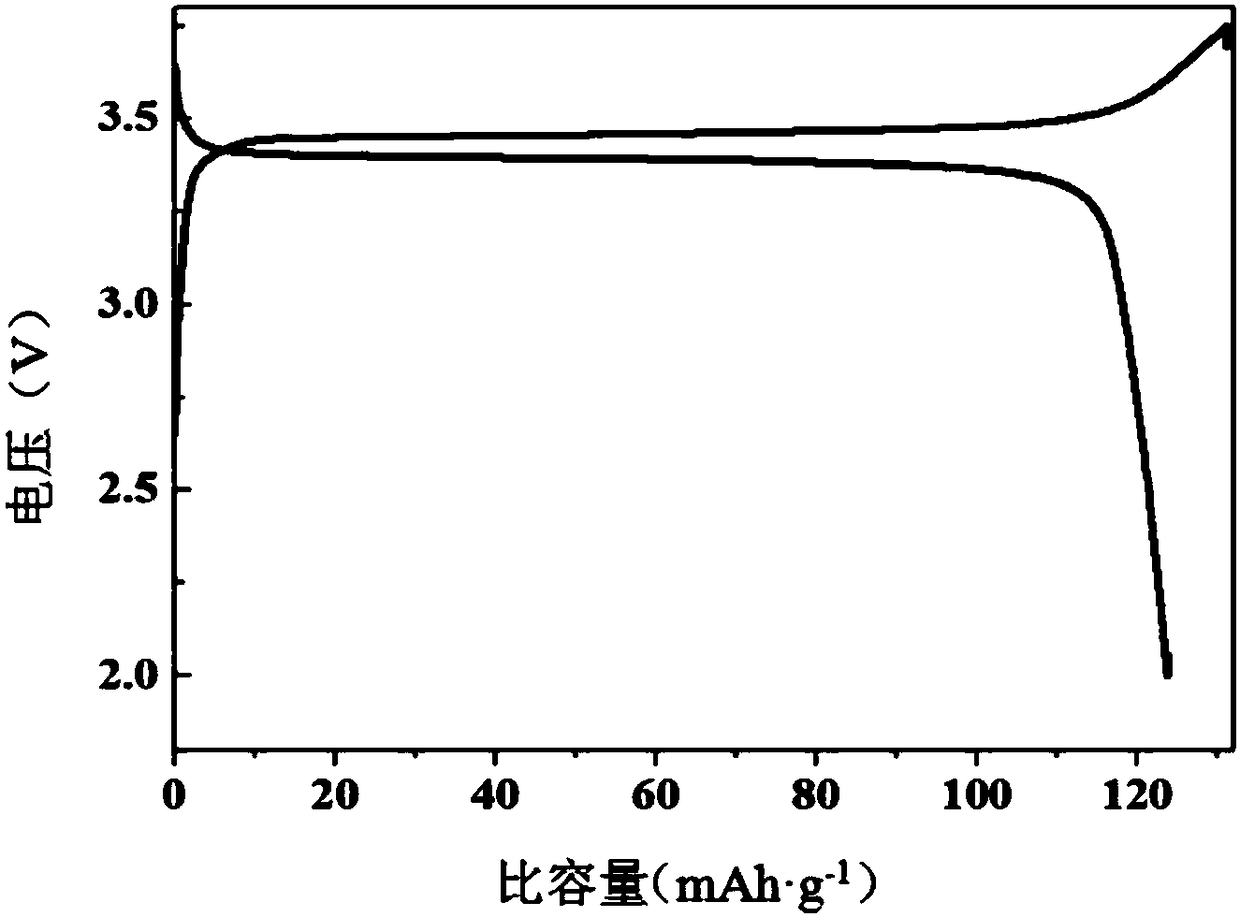

Silicon-carbon composite material, preparation method thereof and lithium ion battery employing same

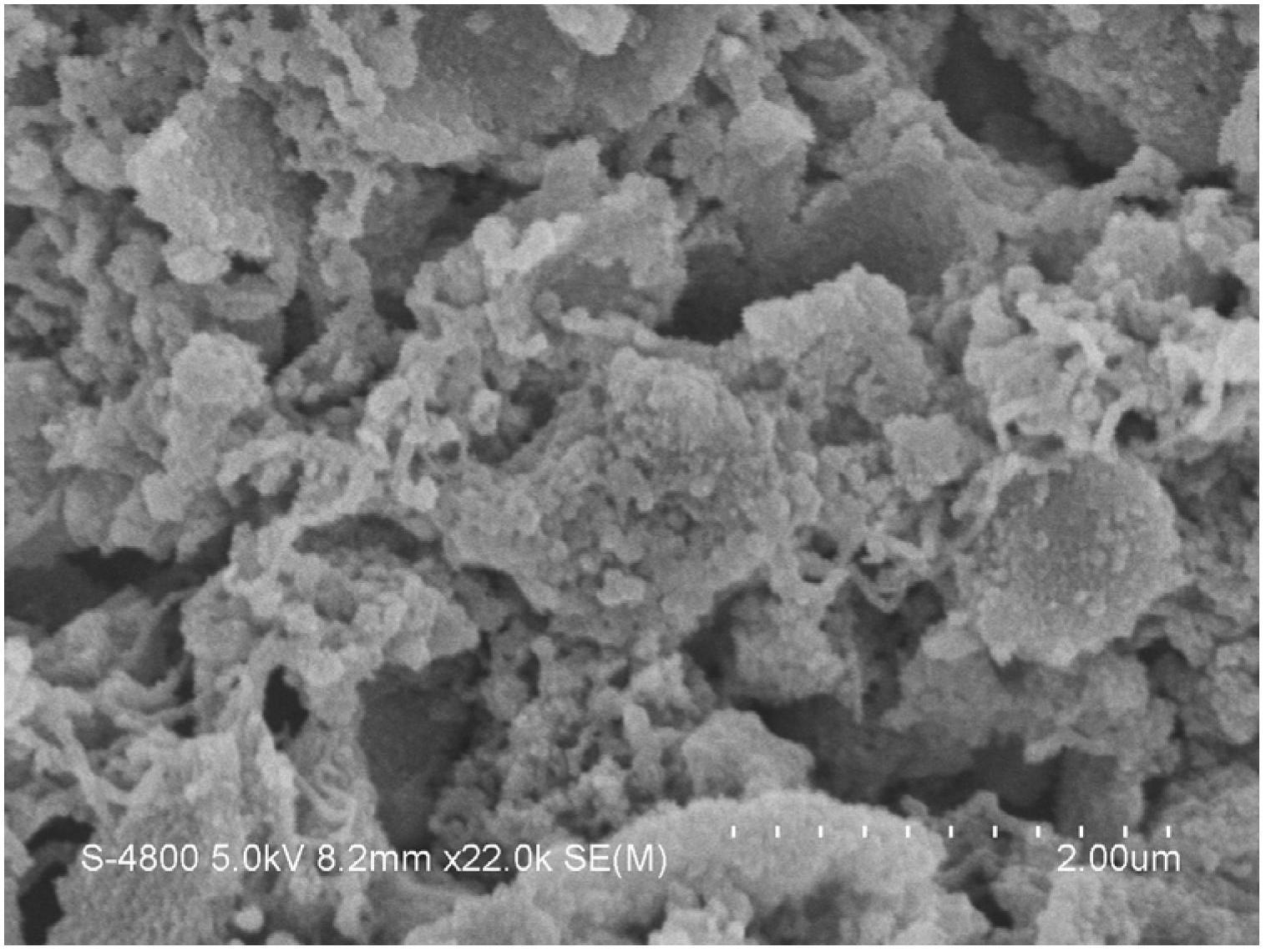

ActiveCN102694155APossesses electrochemical reversible intercalation and delithiation performanceAlleviate chalking and sheddingMaterial nanotechnologyCell electrodesCarbon compositesSilicon monoxide

The invention discloses a silicon-carbon composite material, a preparation method thereof and a lithium ion battery prepared by adopting the material. The preparation method of the silicon-carbon composite material comprises the following steps: (1) mixing a composite material (silica-coated nano-silicon) manufactured by silicon monoxide, a porous carbon-based material and excessive hydrofluoric acid solution to obtain another composite material in which nano-silicon particles are compounded in pores of the porous carbon-based material; and (2) heating a composite material in which nano-silicon particles are compounded in pores of a high polymer-coated porous carbon-based material under an inert atmosphere to obtain the silicon-carbon composite material coated by porous carbon spheres. The process raw materials are accessible and simple to prepare. The silicon-carbon composite material has electrochemical reversible embedded lithium removal performance, greatly relieves efflorescence and falling-off phenomena of active particles in the charge-discharge process and has the high lithium storage capacity characteristic of silicon materials and the high cycling stability of carbon materials, and a battery prepared by the silicon-carbon composite material has better cyclicity.

Owner:CHERY AUTOMOBILE CO LTD

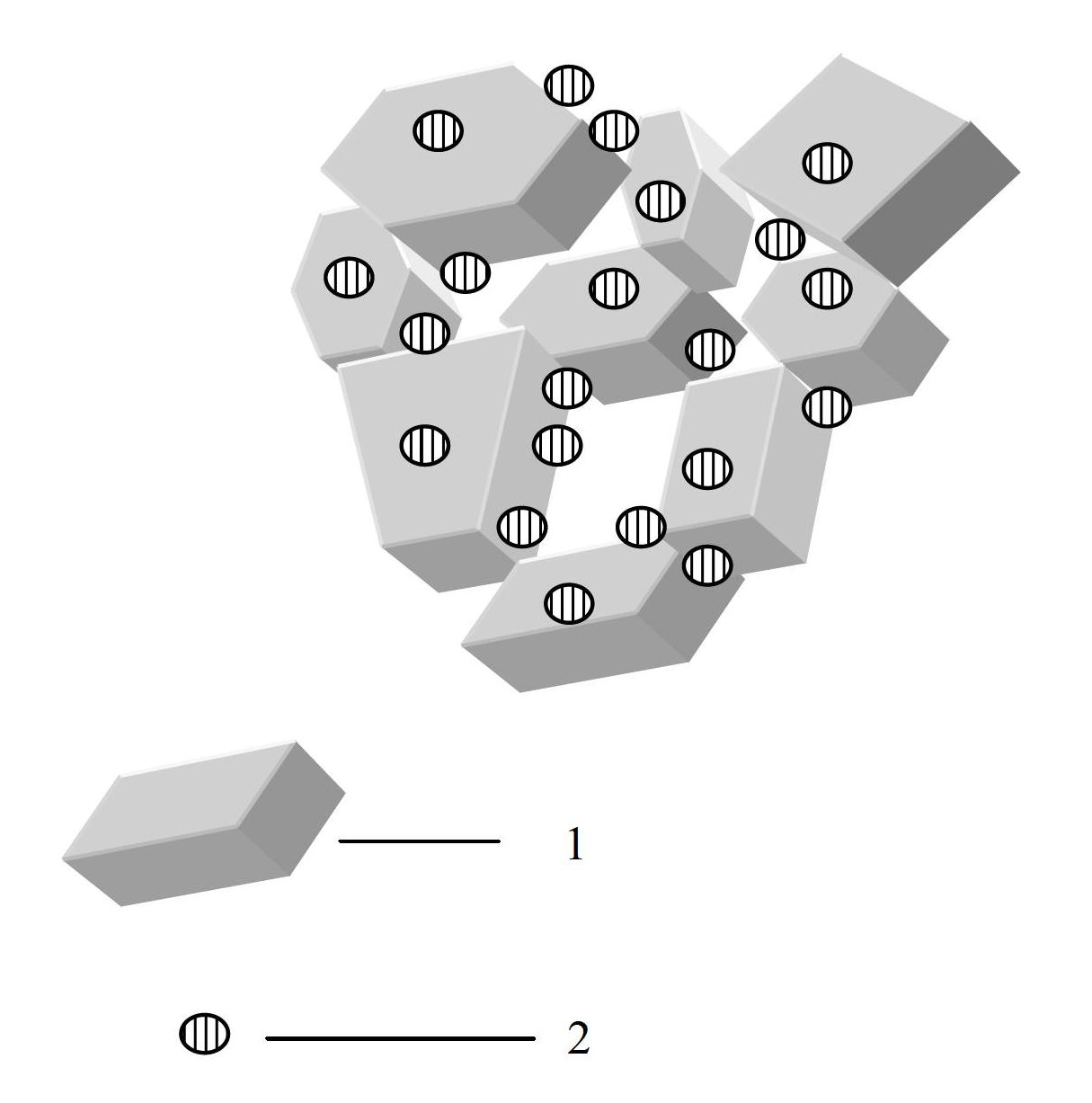

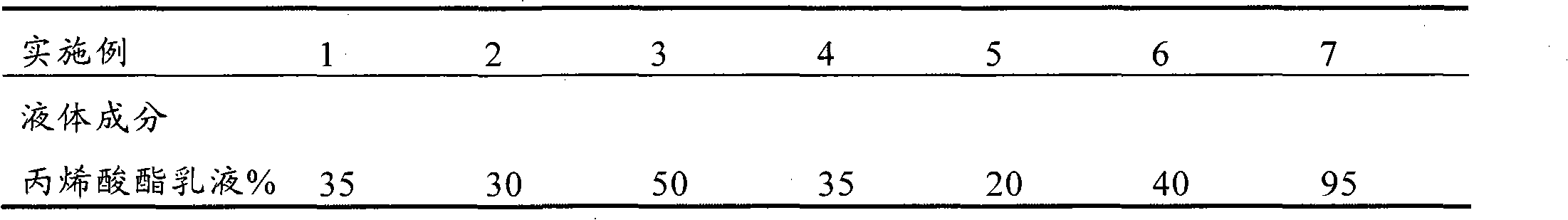

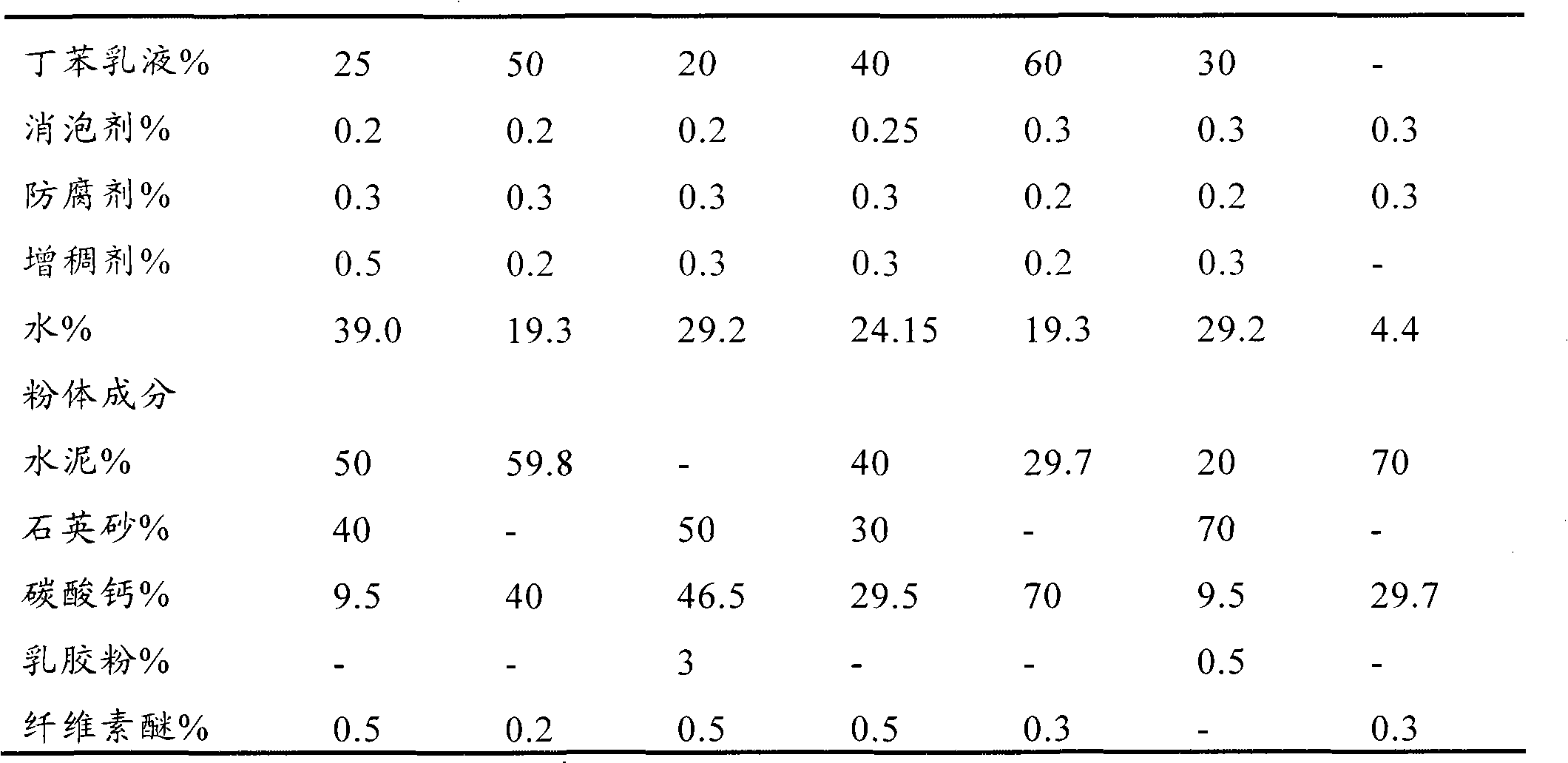

Water-proof back adhesive for stone

InactiveCN101935507AImprove adhesionDoes not affect the decorative effectNon-macromolecular adhesive additivesEster polymer adhesivesEmulsionAdhesive

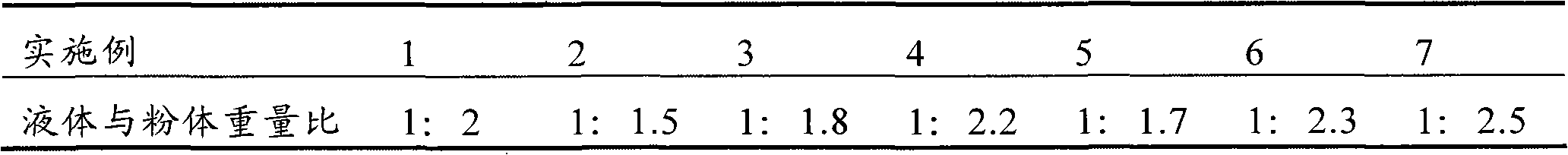

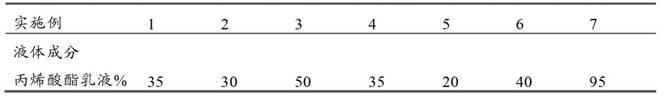

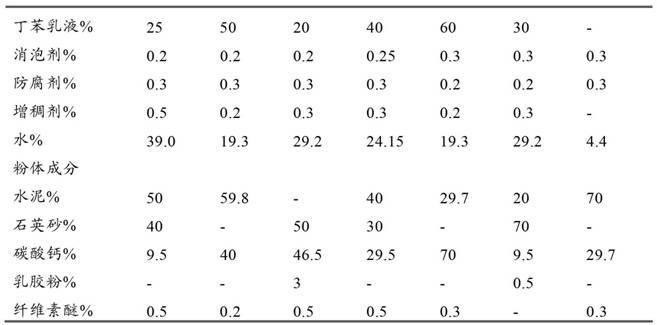

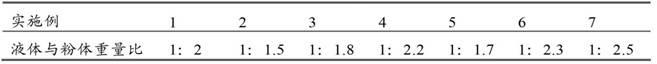

The invention discloses a water-proof back adhesive for stone. The adhesive consists of a liquid component and a powder component in a weight ratio of 1:1-3, wherein the liquid component comprises 20 to 95 percent of acrylic ester emulsion, no more than 5 percent of antifoaming agent, no more than 4 percent of preservative and 4 to 75 percent of water; and the powder component comprises at least two of 0 to 70 percent of cement, 0 to 70 percent of quartz sand and 0 to 70 percent of calcium carbonate. The water-proof back adhesive for the stone slows down stone weathering by reducing the immersion of water and other harmful substances into the stone and has high bonding performance with a substrate during wet combining construction, so that the stone is free from phenomena such as efflorescence, water stain, flaking, hollowing, falling, cracking and the like.

Owner:余春冠

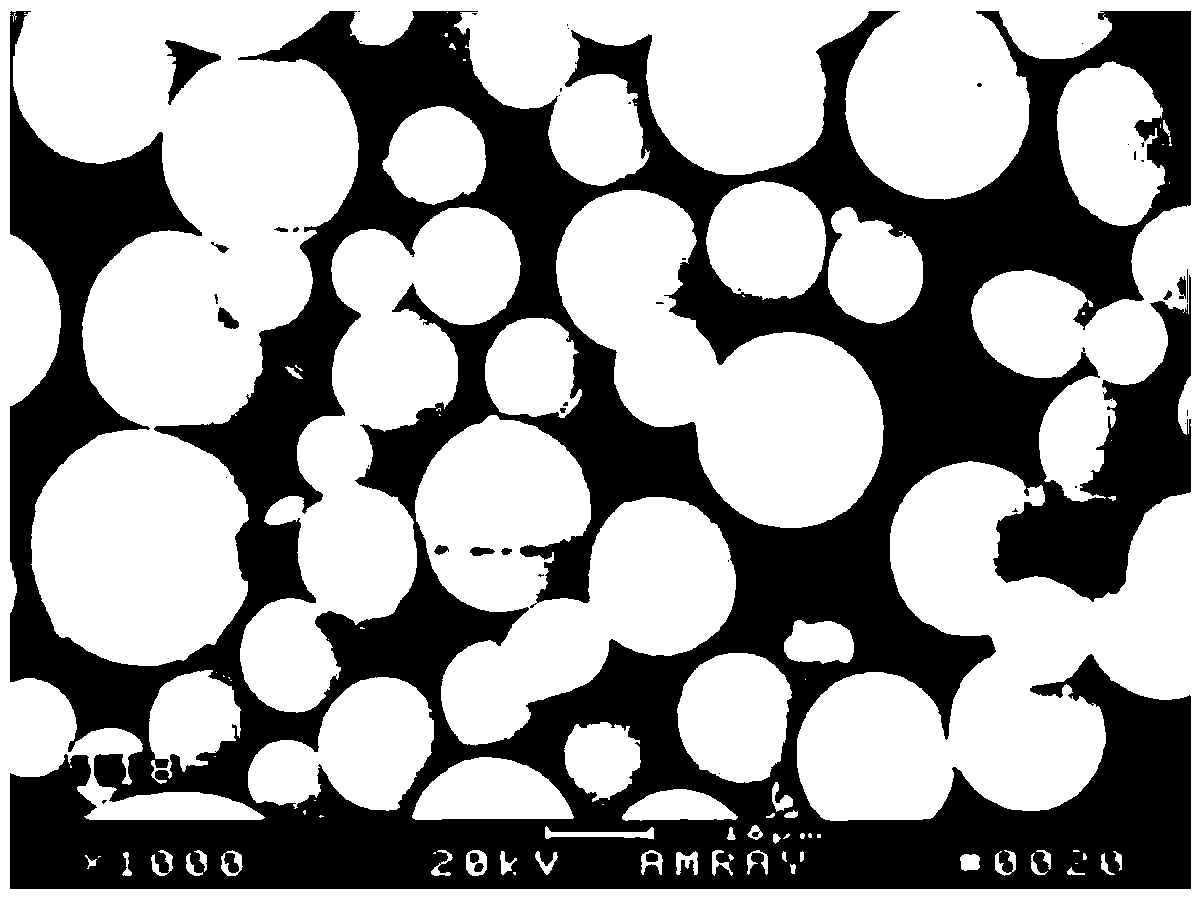

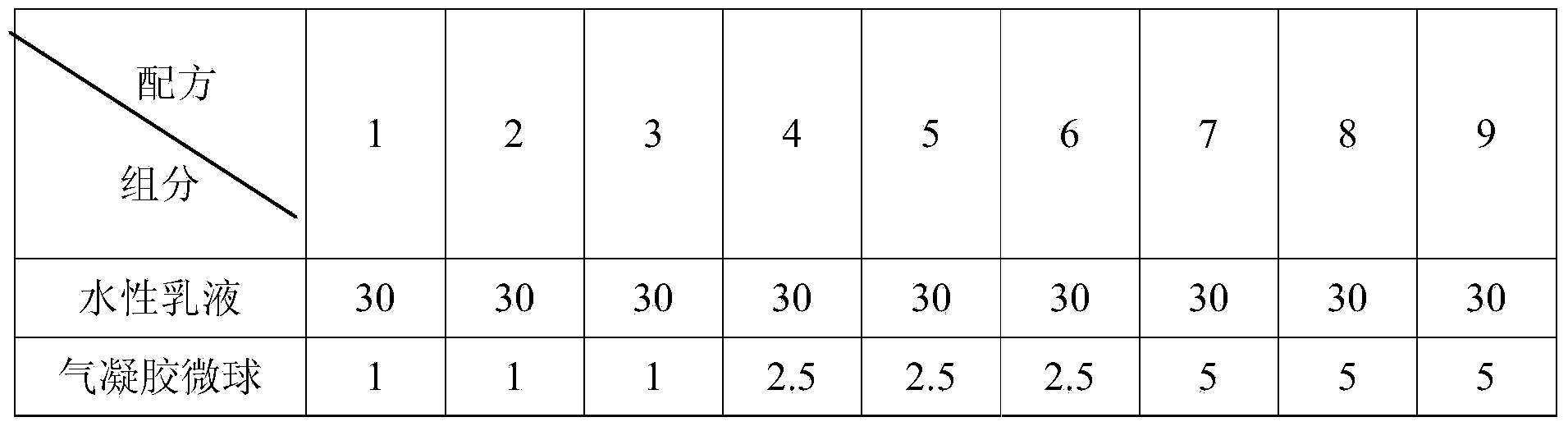

Microspherical SiO2 aerogel compound heat-insulating/warm-keeping external wall paint and preparation method thereof

InactiveCN103709868ALow thermal conductivityImprove insulation effectSilicaPolyurea/polyurethane coatingsWater basedEmulsion

The invention discloses microspherical SiO2 aerogel compound heat-insulating / warm-keeping external wall paint and a preparation method thereof. The paint comprises the following components: 1-20 parts by weight of microspherical SiO2 aerogel powder, 10-20 parts by weight of titanium white, 10-20 parts by weight of water-based emulsion, 20-35 parts by weight of filler and 20-30 parts by weight of other paint assistant. According to the invention, the microspherical SiO2 aerogel and the titanium white are compounded, so that the paint has low heat transfer coefficient and high sunlight reflectivity, thus ensuring that the paint has excellent heat-insulating / warm-keeping property; meanwhile, the directly prepared hydrophobic SiO2 aerogel is micron-level microspheres of 1-50 mu m, thus avoiding causing the problems on defoaming and flowability to paint production in the efflorescence process of large aerogel; and the addition of the hydrophobic microspherical SiO2 greatly enhances the brushability of the paint.

Owner:GUANGZHOU TAIXIANG IND NEW MATERIAL TECH XINFENG CO LTD

Process for producing manufactured concrete products with reduced efflorescence

InactiveUS20060054056A1Reduce weatheringPromoting the dispersal of the pigment in the concreteOther chemical processesCompound (substance)Super absorbent

A process to manufacture concrete products with reduced or no efflorescence by using one or more chemicals that can act as water absorbents, which can be absorbents, super absorbents, or thickeners, either alone or in combination with other common concrete additives. A liquid color preparation and a granular color preparation with integrated water absorbents are also disclosed.

Owner:ROCKWOOD PIGMENTS NA INC

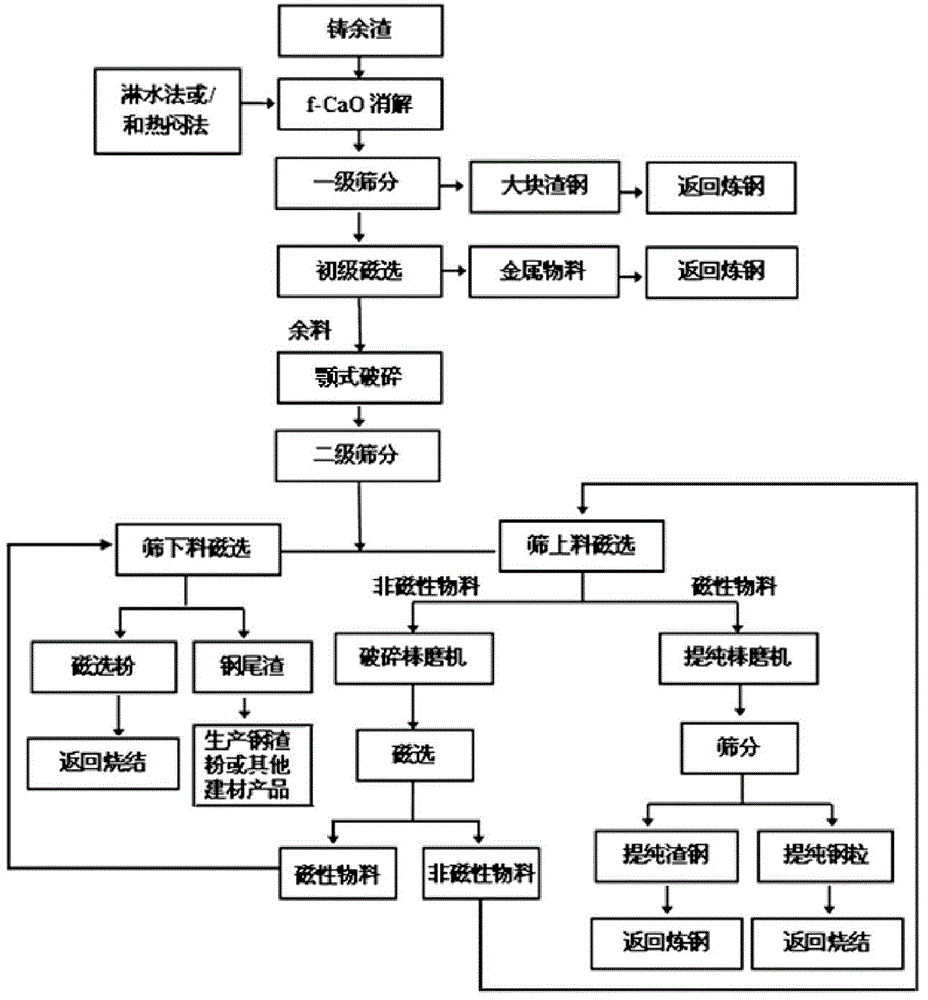

Molten steel casting residue treatment and recycling method

ActiveCN102978305APromote expansion and pulverizationSolve the separation problemSievingScreeningSlagMolten steel

The invention discloses a molten steel casting residue treatment and recycling method which comprises the circular treatment steps of slaking, screening, magnetic separation and the like. The f-CaO in casting residue is slaked by vapor to accelerate the expansion and efflorescence of the casting residue, thereby solving the problem on the separation of the casting residue from a tank body and reducing dust nuisance. According to the method, a mixture of water spray casting residue and pyrolytic steel slag is used as the raw material, and the pyrolytic steel slag has the advantage of low f-CaO content, thereby ensuring that the f-CaO content of the final product can meet the requirements of cement and construction material industries; and a rod grinder treatment process is used, thereby achieving favorable grinding effect and ensuring that the product is uniform and stable in particle size. For the product disclosed by the invention, slag steel of which the grade is greater than 80% can be returned for steel making; purified steel shots and magnetic separation powder of which the grade is greater than 42% can be used for a sintering procedure; and steel tailings of which the iron content is smaller than 2% and the f-CaO content is smaller than 3% can be used for producing steel slag powder, steel slag cement, construction material products and road materials. The invention maximally recycles the metal material in the casting residue, realizes the zero discharge of industrial solid waste and ensures that the casting residue can be recycled 100% at a high added value.

Owner:WUKUN STEEL

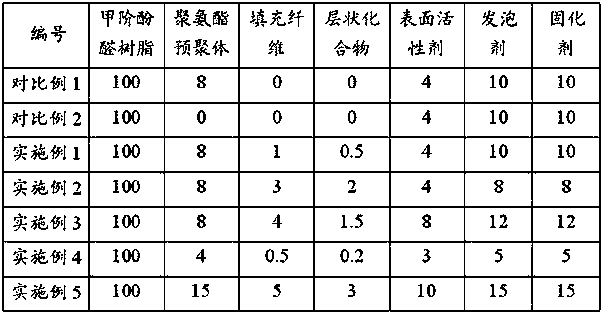

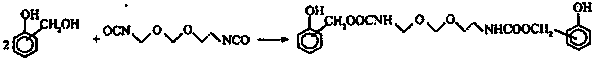

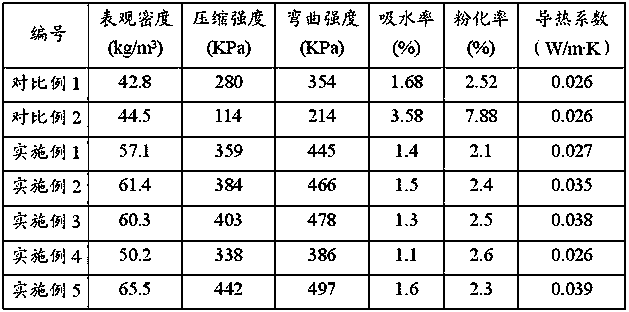

Modified phenolic foam and preparation method thereof

The invention discloses a modified phenolic foam and a preparation method thereof. The modified phenolic foam is prepared from the following components by weight: 100 parts of a resol resin, 3 to 15 parts of a toughening modifier, 5 to 15 parts of a foaming agent, 3 to 10 parts of a surfactant, 5 to 15 parts of a curing agent, 0.5 to 5 parts of a glass fiber and 0.2 to 3 parts of a lamellar compound which is preferably organically modified montmorillonite. According to the invention, a polyurethane performed polymer is used as the toughening modifier, the glass fiber and the lamellar compound are introduced for modification of phenolic foam, so toughness of the phenolic foam is improved, and the disadvantages of easy efflorescence and scaling-off, fragility, small strength, no ductility and high water absorption of the phenolic foam are overcome; thermal stability and flame retardation of the phenolic foam are improved; and thus, the modified phenolic foam is an upgrading product for external wall insulation materials. Moreover, toughening of the polyurethane performed polymer and phenolic foaming and curing are carried out at the same time, operation is simple and easily practicable, so the method is suitable for large-scale production.

Owner:HEFEI GENIUS NEW MATERIALS

Filling-reclaiming method for building land in coal mining subsidence areas

InactiveCN101713291AEase the growing tensionSave the occupied landUnderground miningSurface miningSpontaneous combustionPorosity

The invention provides a filling-reclaiming method for building land in coal mining subsidence areas, which belongs to the technical field of mining and is used to solve the problem of developing and utilizing coal gangue. The invention adopts a technical scheme that the method is implemented according to the following steps: a, draining accumulated water in reclamation areas and clearing silt; b, striping and stockpiling surface soil; c, determining the thickness and density of coal gangue for hierarchical backfilling through a vibration pressure test; and d, performing hierarchical backfilling compaction on the coal gangue and soil. The method has the following main advantages that: 1, the ways of utilizing the coal gangue are expanded, and environmental pollution caused by stockpiling the coal gangue on ground is reduced; 2, the situation that building land is increasingly short is alleviated by reclaiming subsidence land to be the building land; and 3, the treatment for coal gangue for large-area hierarchical backfilling by a hierarchical vibration-compaction method is economical, reasonable and ideal in compaction effect, can improve the compactness and bearing capacity of coal gangue layers, and can prevent the spontaneous combustion or efflorescence of coal gangue foundations and the separation of harmful substances from polluting local environment because hierarchical compaction greatly reduces porosity and isolates air.

Owner:煤炭科学研究总院唐山研究院

Self-leveling terrace powder mortar composite

The invention provides a self-leveling terrace powder mortar composite and the composite comprises the following components in parts by weight: 250-350 parts of ordinary silicate cement, 50-100 parts of aluminate cement, 250-550 parts of quartz sand, 50-250 parts of heavy calcium carbonate, 10-30 parts of anhydrite and 40-80 parts of zeolite graft re-dispersible emulsion powder. The invention adopts zeolitic inner hole adsorption principle to disperse zeolite evenly in mortar; solid zeolite is crosslinked with graft zeolite inside and outside; in the hydration process of silicate cement, the dense doping among anhydrite, heavy calcium carbonate and crosslinked zeolite changes the lattice of cement so as to ensure the stable long-term strength of mortar and eliminate the phenomenons such as the efflorescence of the self-leveling terrace mortar in later period, sand-stripping and cracking and the like; in addition, aluminum powder is added to increase the wearability and antishrinking property of the terrace mortar and the flexibility of the polymer is increased to improve the breaking strength of the mortar.

Owner:常熟市金龙装饰有限责任公司

Waterproof gum for stone

InactiveCN102674769AImprove adhesionDoes not affect the decorative effectCoatingsMaterials scienceLiquid composition

The invention discloses a waterproof gum for stone. The waterproof gum is composed of liquid components and powdery components in a weight ratio of 1:(1-3), wherein the liquid components comprise 20-95% of acrylate emulsion, not more than 5% of antifoaming agent, not more than 4% of preservative and 4-75% of water; the powdery components comprise 0-70% of cement, 0-70% of quartz sand and 0-70% of calcium carbonate; and the powdery components comprise at least two of cement, quartz sand and calcium carbonate. By the adoption of the waterproof gum for the stone, disclosed by the invention, immersion of water and other harmful substances on the stone is reduced, so that the weathering of the stone is slowed down; and meanwhile, a good bonding performance is existent between the waterproof gum and base courses in the wet-sticking construction process, so that the phenomena, such as efflorescence, waterlogging, peeling, hollowing, dropping and cracking, on the stone are prevented.

Owner:余春冠

Elastomeric Emulsion Polymers For Masonry Coatings

ActiveUS20070248837A1Sufficient long-term elasticityLimited amountLiquid surface applicatorsSynthetic resin layered productsVitrificationAlcohol

Acrylate latexes are described which provide properties of good balance of moderate elongation, low dirt pick up, alkaline resistance, UV light resistance, and efflorescence resistance for masonry coatings. These latexes have a large portion of repeating units from C8-C12 alcohol esters of acrylic acid and / or vinyl versatates along with 5-15 weight percent of repeating units from acrylonitrile. They have a glass transition temperature of −50 to +10° C.

Owner:LUBRIZOL ADVANCED MATERIALS INC

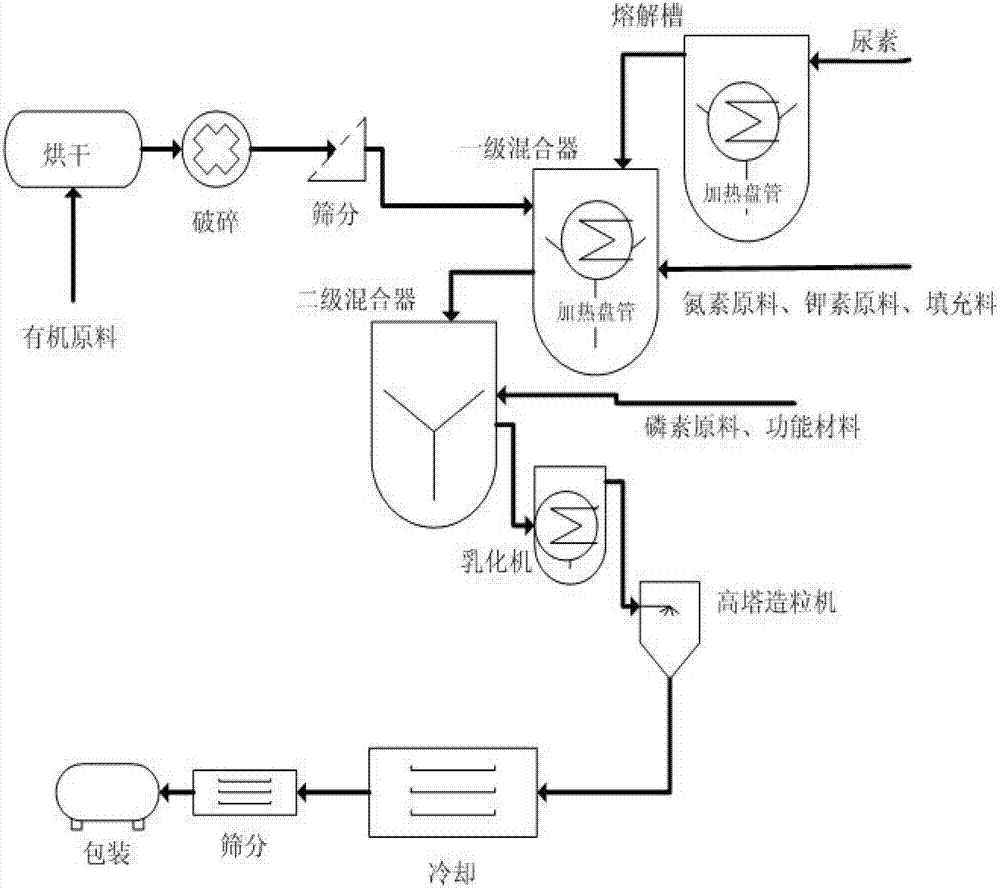

Method for producing organic-inorganic compound fertilizer by using high tower melting granulation process

InactiveCN102731198AAdd emulsification stepMelt and mix uniformlyFertilizer mixturesCross-linkEnvironmental resistance

The invention provides a method for producing an organic-inorganic compound fertilizer by using a high tower melting granulation process. The method comprises the following steps that a pretreated organic raw material enters into a mixer of a high tower and is mixed and cross-linked with molten urine slurry, a nitrogen raw material, a potassium raw material, a filling material, a phosphorus raw material and a functional material, a resultant is activated and is then emulsified in a slurry emulsifying machine, slurry obtained after emulsification directly enters into a high tower granulator for spray granulation and obtained particles undergo the procedures of cooling, screening and surface treatment so as to obtain the high tower organic-inorganic compound fertilizer. The fertilizer contains, by mass, 20 to 30% of organic matters, 30 to 35% of inorganic nutrients and 0.5 to 5.0% of water. The fertilizer prepared by using the method provided in the invention has the following advantages: the particles of the fertilizer are smooth, round and transparent, have high strength and hardly suffer from efflorescence; production process for the fertilizer enables low energy consumption to be realized and is clean and environment friendly, so the fertilizer belongs to the domain of national low carbon agricultural development strategies.

Owner:徐州市芭田生态有限公司

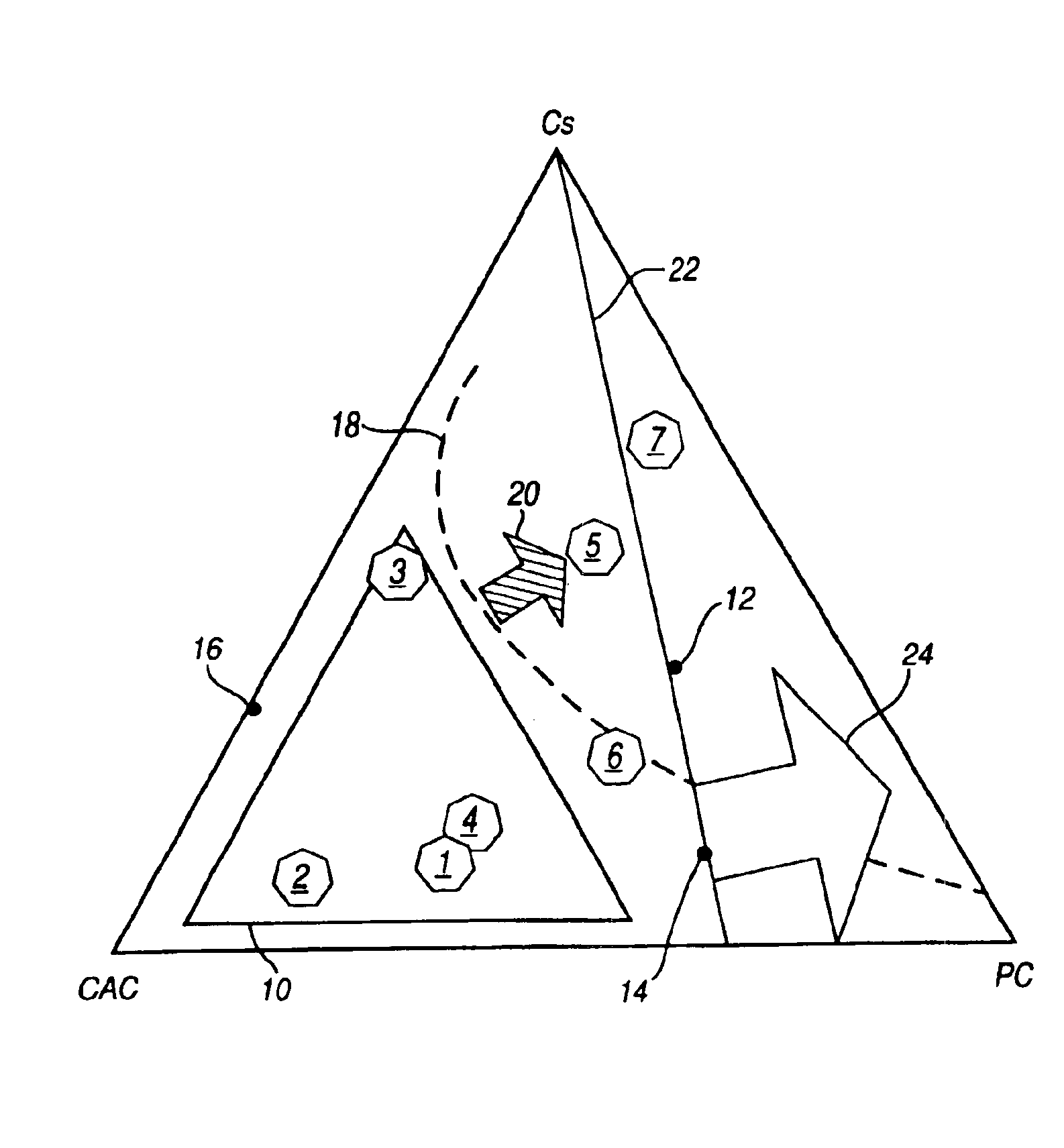

Non-efflorescing cementitious bodies

InactiveUS6923857B2Satisfactory physical propertyReduce weatheringSolid waste managementPretreated surfacesCalcium silicateHydrated alumina

A non-efflorescing cementitious body is formed from sources of calcium aluminate, calcium silicate, calcium sulphate and reactive silica, these ingredients being present in such relative proportions that, upon hydration, both monosulphate (C3A.CŜ.12H) and hydrated alumina (AH3) are formed. Also disclosed is a hydraulic binder and a paste from which such bodies can be formed and a method for forming such bodies. In addition to exhibiting low efflorescence, these bodies retain satisfactory physical properties, especially good durability to natural weathering conditions.

Owner:LAFARGE ALUMINATES

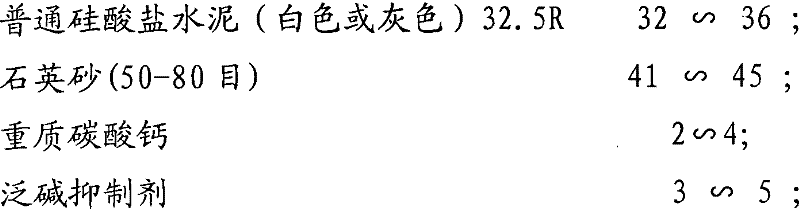

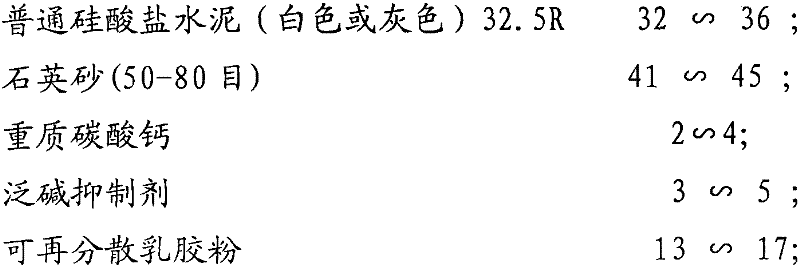

Tile glue

ActiveCN102206066ANo yellowingThere will be no pan-alkaline vomiting phenomenonEmulsionPortland cement

The invention discloses a tile glue, comprising ordinary portland cement, quartz sand, re-dispersible emulsion powder, heavy calcium carbonate, water reducer, cellulose ether and efflorescence inhibitor. By utilizing the technical scheme, since the efflorescence inhibitor is added, there is no yellowing and efforescence phenomenon after construction; and the portion of the re-dispersible emulsionpowder is increased, so that the technical effect of pasting glass onto glass directly can be achieved.

Owner:XIAMEN LIKASAM WATERPROOF ENG

Composite solid electrolyte, and preparation method and applications thereof

ActiveCN108598560AGrowth inhibitionAvoid chalkingFinal product manufactureSecondary cellsElectrochemical windowElectrical resistivity and conductivity

Owner:蓝谷智慧(北京)能源科技有限公司

Baking-free brick prepared from red mud

ActiveCN103641402ATo overcome the shortage of low dosageImprove performanceSolid waste managementCement productionBrickRed mud

The invention discloses a baking-free brick prepared from red mud. Bayer process red mud is high in alkali content, and the problem of efflorescence can be easily caused during the production of a building material. A geopolymer synthesis technology is used for converting alkali in the red mud into an activator in an activation way, so that problems caused by the alkali during the utilization of the red mud are solved. The baking-free brick is mainly prepared from the following raw materials in parts by weight: 3 to 8 parts of water glass, 15 to 20 parts of active initiator, 70 to 80 parts of red mud and 0.5 to 1 part of micro silicon powder. The baking-free brick is prepared by the following steps of sequentially adding the red mud, the active initiator, the water glass and the micro silicon powder into a forced mixer, performing extrusion forming by using a brick making machine after uniform mixing, standing a brick blank for 1 to 2 hours under natural conditions to endow certain hardness to the brick blank, feeding the brick blank to an autoclave, and performing autoclaved curing for 2 to 4 hours under pressure of 0.8 to 1.2MPa to obtain a finished product. The baking-free brick prepared from red mud is low in cost, stable in product performance, strong in compressive strength and high in freezing and thawing cycle resistance, a production process is simple, the production site is small, and efflorescence after building is avoided.

Owner:广东新立晟环保科技股份有限公司

Autoclaved red mud brick and preparation method thereof

The invention discloses an autoclaved red mud brick and a preparation method thereof, belonging to the field of building materials and solving the problem that alkali can be precipitated in a form of compound to cause efflorescence phenomenon resulting from high alkaline content in the Bayer process red mud brick in the prior art. The autoclaved red mud brick comprises the following raw materials in percentage by dry weight: 35 to 43 percent of Bayer process red mud, 12 to 20 percent of cementing material, 2 to 10 percent of blast furnace slag and 27 to 35 percent of active material. The cementing material is at least one of calcined lime, cement, gypsum or carbide slurry; the active material is at least one of silica sand, pulverized fuel ash, slag, granulated blast furnace slag, phosphorous slag or artificial sand; and SiO2 in the active material is more than 45%. The autoclaved red mud brick is mainly used for making bricks from Bayer process red mud in an autoclaved way.

Owner:四川方大新型建材科技开发有限责任公司

Chemical additive for sintering iron ore fine

The invention relates the chemical addition agent used for iron ore powder caking. The grain size is above 50mesh, oxygenation agent is 20-45wt%, free radical initiation agent is 5-15%, fluxing agent is 5-15%, hardening agent is 2-15%, accelerating agent is 2-15%, and crystal nucleus agent is 5-20%. The invention doesní»t contain the unwanted K and Na, and the characters are following: using free radical initiation to improve sintered layer air permeability; using rare-earth element to accelerate the association and crystallization of caking solid-liquid; using crystal nucleus agent to reject the sintered ore spontaneous efflorescence and low-temperature deacidizing efflorescence. The addition agent is 0.1-0.3íÙ, improving the output by 5%, rotary drum intensity by 3.4%, SFCA content by 15%, RI by 7.83%, low-temperature deacidizing efflorescence index by 8.2%, and reducing caking solid burn-up by 8%.

Owner:刘虎生

Anti-efflorescence joint sealing mortar

The invention relates to an anti-efflorescence joint sealing mortar. The motor comprises, by weight, 210-250 parts of ordinary Portland cement, 25-35 parts of high alumina cement, 440-540 parts of sand, 40-60 parts of silica fume, 180-220 parts of coal ash, 3-8 parts of bentonite, 2-4 parts of redispersable latex powder, 1-1.5 parts of cellulose ether, 2-3 parts of a wood fiber, 0.2-0.6 parts of citric acid, and 3-5 parts of a stearate. The anti-efflorescence joint sealing mortar provided in the invention allows the ordinary Portland cement and the high alumina cement to be mixed according to a ratio of 6:1-10:1 through a compound technology, so factors causing the mortar efflorescence are fundamentally eliminated, the compactness of the mortar is improved, the mortar aperture number is reduced, and no efflorescence phenomenon appearance in the use process of the mortar is guaranteed.

Owner:奥捷科技股份有限公司

Concrete hardener with silicon crystals

InactiveCN107954624AAchieving wear resistanceImprove chemical resistanceOrganic solventChemical reaction

The invention relates to a concrete hardener with silicon crystals. The concrete hardener comprises silicate mixtures, nanometer silica sol and organic solvents. According to the scheme, the concretehardener with the silicon crystals has the advantages that the concrete hardener can be permeated into concrete, continuous chemical reaction can be carried out on the concrete hardener and the concrete, non-expansion, non-contraction and high-strength vitreous compounds with stable properties can be generated, concrete matrixes can be reinforced, sealed and hardened to form compact integral structures, the strength of the compact integral structures can be continuously reinforced along with the passage of time, and accordingly effects of sealing the hardened, strong, impervious, weather-resistant, abrasion-resistant, dust-free, efflorescence-free and gorgeous concrete which has enhanced chemical resistance and is firm just like steel can be realized; the concrete hardener is waterborne liquid and is safe and environmentally friendly; the concrete hardener is applicable to diversified new and old concrete floors including raw stock floors, terrazzo floors, carborundum abrasion-resistant floors and the like, and excellent effects of hardening and reinforcing loose floors with severe dusting can be realized by the concrete hardener.

Owner:苏州金润新材料科技有限公司

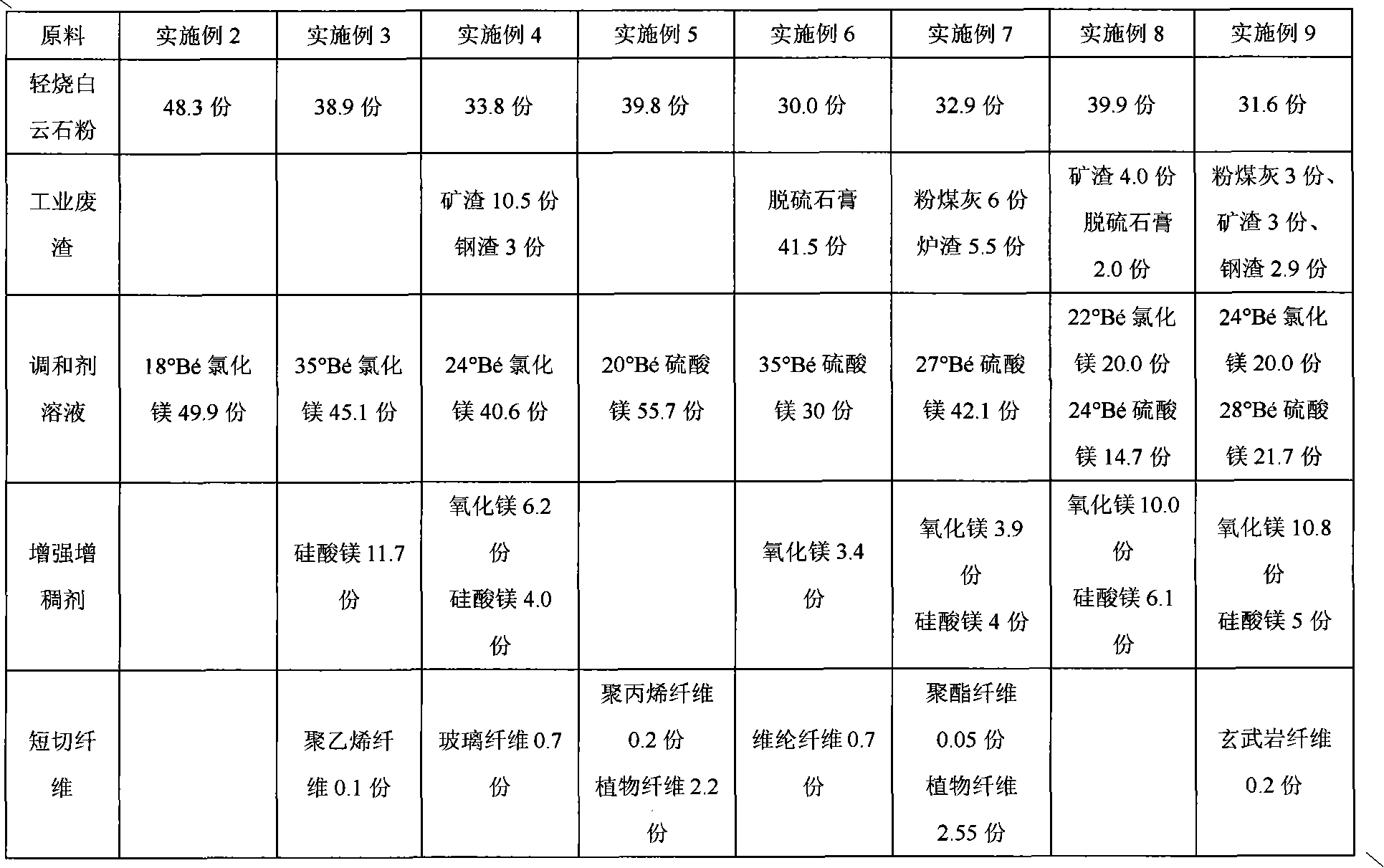

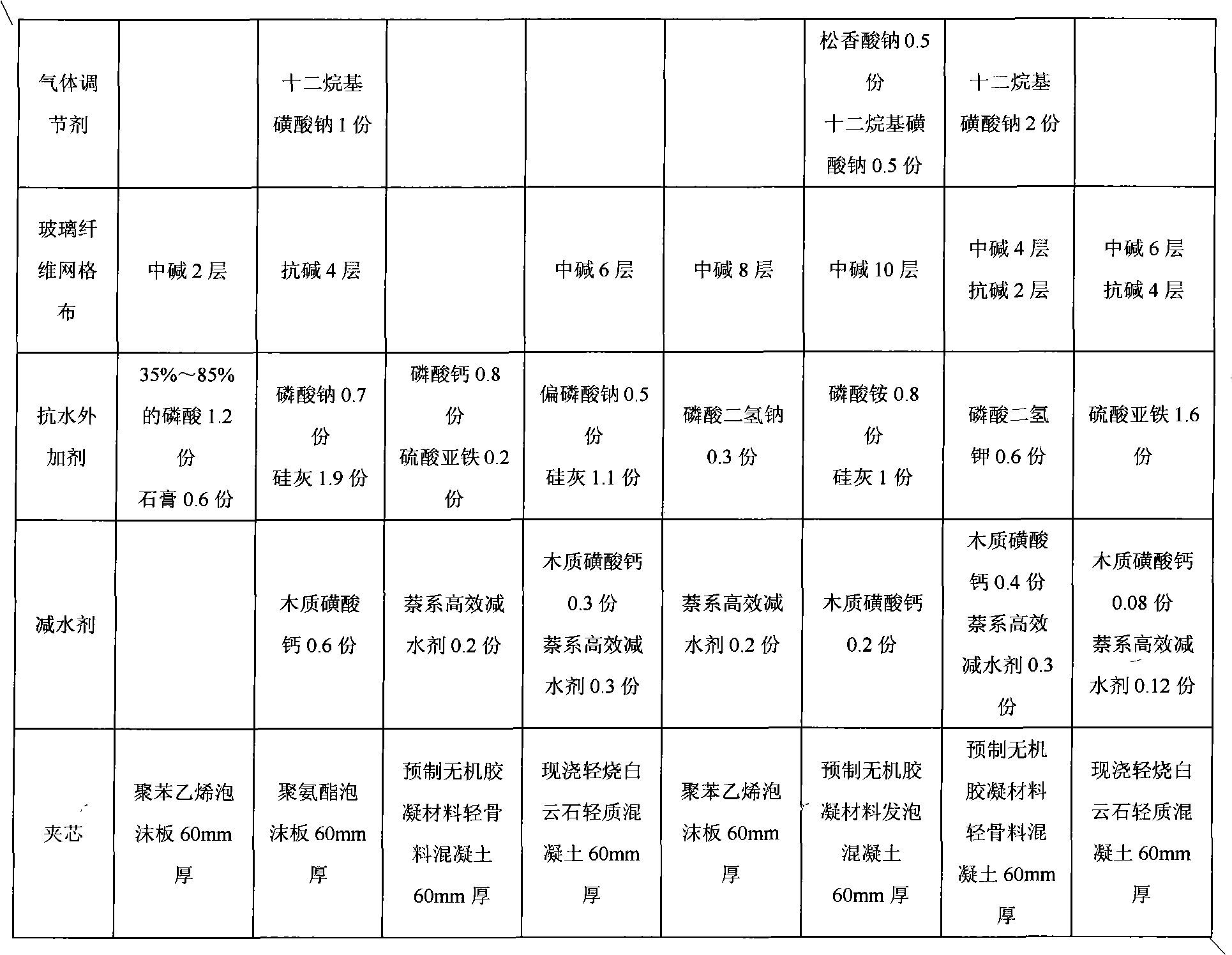

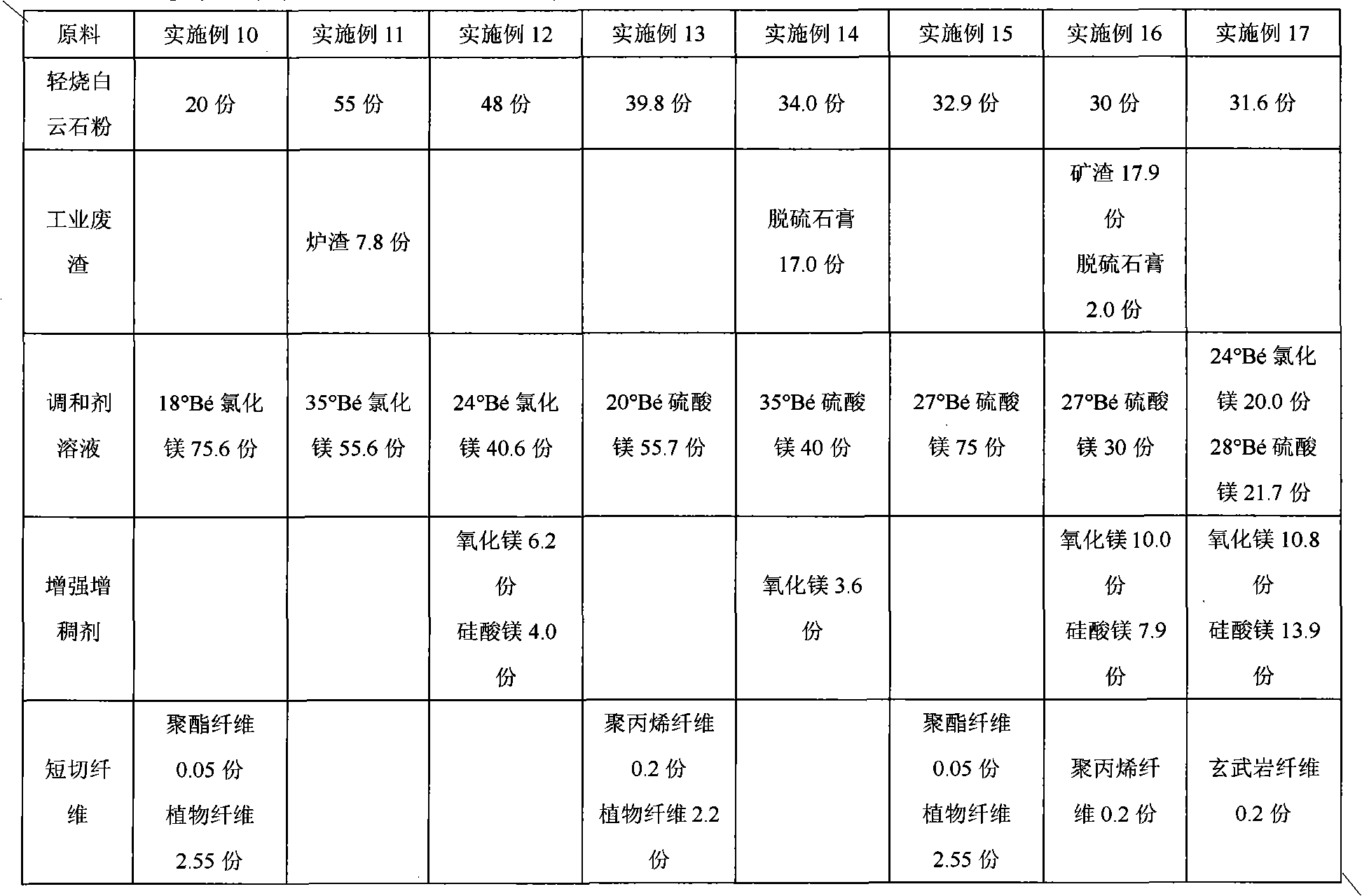

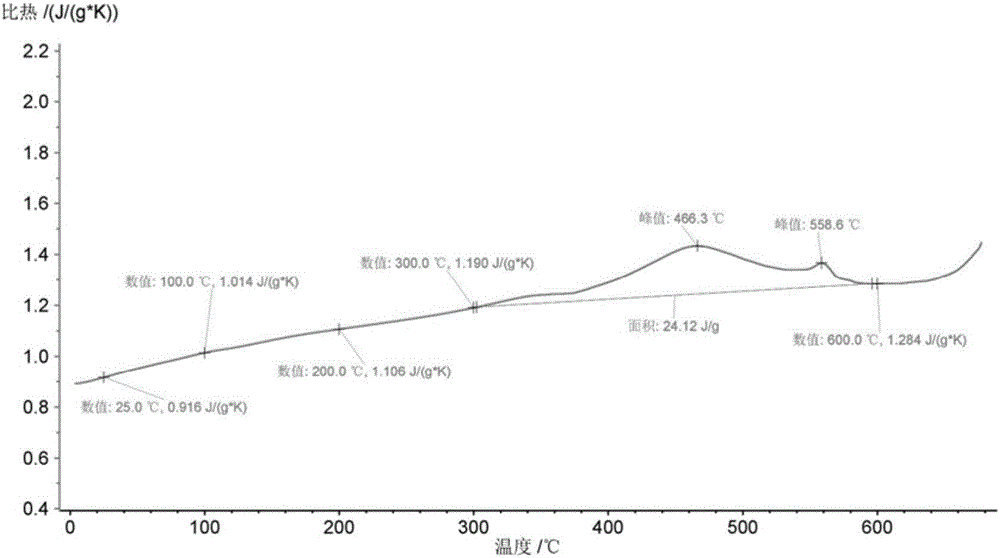

Lightly-calcined-dolomite sandwich composite partition wall plate and manufacturing method thereof

InactiveCN102041871ACuring reaction at room temperatureHarden fastClimate change adaptationBuilding componentsGlass fiberFiberglass mesh

The invention relates to a lightly-calcined-dolomite sandwich composite partition wall plate and a manufacturing method thereof. The lightly-calcined-dolomite sandwich composite partition wall plate is of a composite structure comprising a shell and a core, wherein the core is a heat-insulating layer, and the shell is made of a fiberglass mesh enhanced lightly-calcined dolomite mixture. The manufacturing method comprises the following steps of: (1) preparing a lightly-calcined dolomite mixture; (2) pouring the lightly-calcined dolomite mixture 2-5 mm in thickness on the bottom surface of a mold; (3) spreading a fiberglass mesh; (4) pouring lightly-calcined dolomite mixture 2-5 mm in thickness; and (5) placing or pouring the heat-insulating core layer. The lightly-calcined-dolomite sandwich composite partition wall plate provided by the invention has the advantages of steam-free or autoclaving maintenance, quick normal-temperature reaction curing, high strength, good water resistance, no moisture absorption or helogenation, no efflorescence, frost resistance, sound insulation, heat insulation, flame retarding, utilization of a great amount of industrial solid wastes and agricultural wastes, resource and energy saving, no emission of three wastes and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

Solid composite phase-change thermal storage material and preparation method thereof

InactiveCN106701034ANo pollution in the processHigh heat storage densityHeat-exchange elementsVolumetric Mass DensityHydroforming

The invention discloses a solid composite phase-change thermal storage material, belonging to the technical field of energy storage materials. The solid composite phase-change thermal storage material comprises water, sodium carbonate, potassium carbonate, magnesium oxide, kieselguhr, quartz sand and kaolin. The thermal storage material is non-toxic, harmless and free of pollution. The invention further discloses a preparation method of the solid composite phase-change thermal storage material. The preparation method comprises the following steps: stirring, rubbing sand, filtering, performing hydraulic molding, and performing sintering molding. By adopting the preparation method, the thermal storage density is improved, the thermal storage density of the material is 2 times better than that of a common material, the thermal storage material can endure high temperature, can be heated to be greater than 650 DEG C, and is not liable to efflorescence when being used for a long time.

Owner:BEIJING SONDEX ENERGY TECH

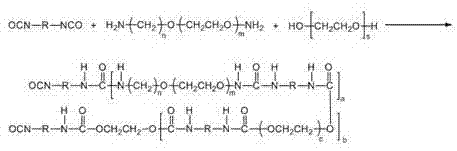

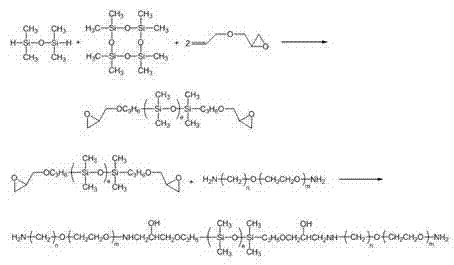

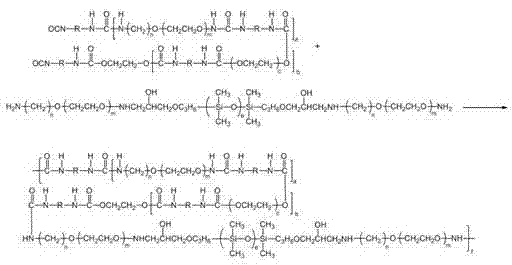

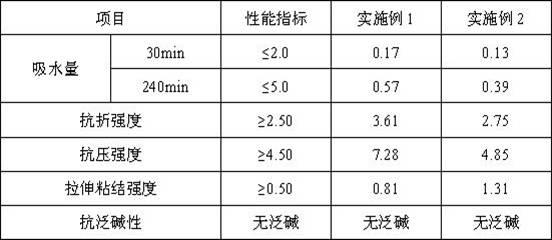

Preparation method of novel polyurethane-modified organic silica gel

The invention provides a preparation method of novel polyurethane-modified organic silica gel. The novel polyurethane-modified organic silica gel is a segmented copolymer comprising polyurethane chain segments, polyether chain segments and organic silicon chain segments. Through introduction of the polyurethane chain segments, the novel polyurethane-modified organic silica gel retains excellent weatherability, electric insulativity, hear resistance, stain resistance, gloss and color retention, vibratrion impact resistance, adhesiveness, solvent resistance, flexibility, chemical corrosion resistance and water resistance, and short curing time, and the adhesion between the novel polyurethane-modified organic silica gel and terylene or polyester / cotton fabric is effectively improved. Throughintroduction of an amino active group-containing cross-linking agent, the novel polyurethane-modified organic silica gel has the advantages of excellent gloss retention, cohesiveness, electric insulativity and hear resistance, high surface hardness, good bending resistance, fast curing speed, good tearing resistance and no efflorescence. The novel polyurethane-modified organic silica gel as a segmented copolymer has a controllable structure, greatly develops polyurethane-modified silica gel performances and widens a polyurethane-modified silica gel application scope.

Owner:ZHEJIANG JINGYE BIOCHEM

Composite deoxidizing agent aluminum-calcium-iron alloy for smelting steel

The invention provides steel-smelting complex deoxidizing agent- calcium-aluminium- ferrum alloy. It is to solve problems of great loss of aluminium during deoxidation process, low effective component content, bad utilization rate and large consumption, easy secondary oxidation and Al2O3 generation. The alloy comprises aluminium 20- 70%, calcium 1- 10% and left is ferrum and inevitable foreign substance. The manganese 1- 20%, silicon 1- 20% and titanium 1- 5% can be added into said alloy to prevent alloy efflorescence and increase steel alloy element. The invention is characterized by high deoxidation efficiency, lowered foreign substance content in steel, smooth steel smelting process, improved steel quality and reduced cost.

Owner:谢应凯

Colored decorative mortar with excellent performance

The invention relates to colored decorative mortar with excellent performance. The raw materials of the decorative mortar includes double components, i.e., a dry component and a wet component, wherein the dry component consists of cement, emulsion powder, calcium carbonate, quartz sand, pigment and additives such as thickening agent, water repellent, defoamer and the like, and the wet component consists of polymer microemulsion and water. The decorative mortar provided by the invention has the advantages that the using amount of the cement is reduced, and meanwhile, nano-grade polymer microemulsion is creatively added so as to have excellent stain resistance due to extremely low surface energy on the surface of the mortar. All the performances of the decorative mortar obtained in the invention accord with the standard of JC / T1024-2007 wall decorative mortar; the decorative mortar has good coating compactness and no efflorescence or chromatic aberration phenomena after being exposed tothe sun and rain outdoors for a long time, various kinds of plump mortar with bright colors can be obtained if different pigments are added; and the decorative mortar is very rich in model and remarkable in stain resistance so as to be particularly suitable for decorating outer walls of high-quality residences or vills.

Owner:TONGJI UNIV

Graphite powder for negative electrode of lithium ion secondary cell and manufacturing method thereof

The invention discloses graphite powder for negative electrodes of lithium ion secondary cells and method for its preparation, wherein the graphite powder is in spherical shape and has an end portion construction with closed surfaces, wherein the method comprises the steps of, (1) charging natural crystaline flake graphite into high speed disintegrator, performing efflorescence 10 to 80 minutes under the condition of 3000 to 6000 rotations per minute, (2) charging into slow run impulse type globurizing crushing machine, performing globurizing and dressing treatment for 40 to 180 minutes under the condition of 600-3000 rotations per minute.

Owner:LUOYANG GUANQI INDAL & TRADE

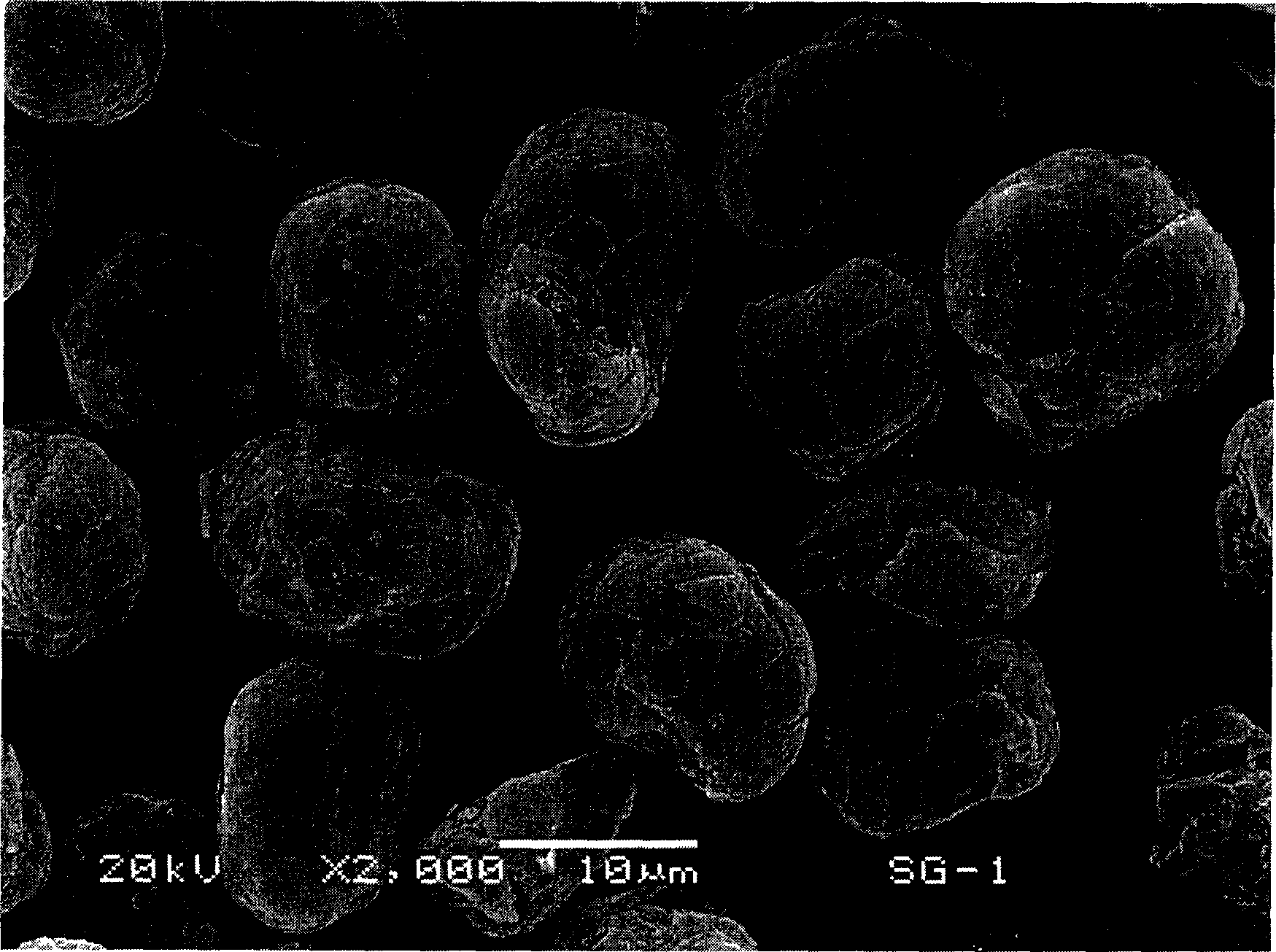

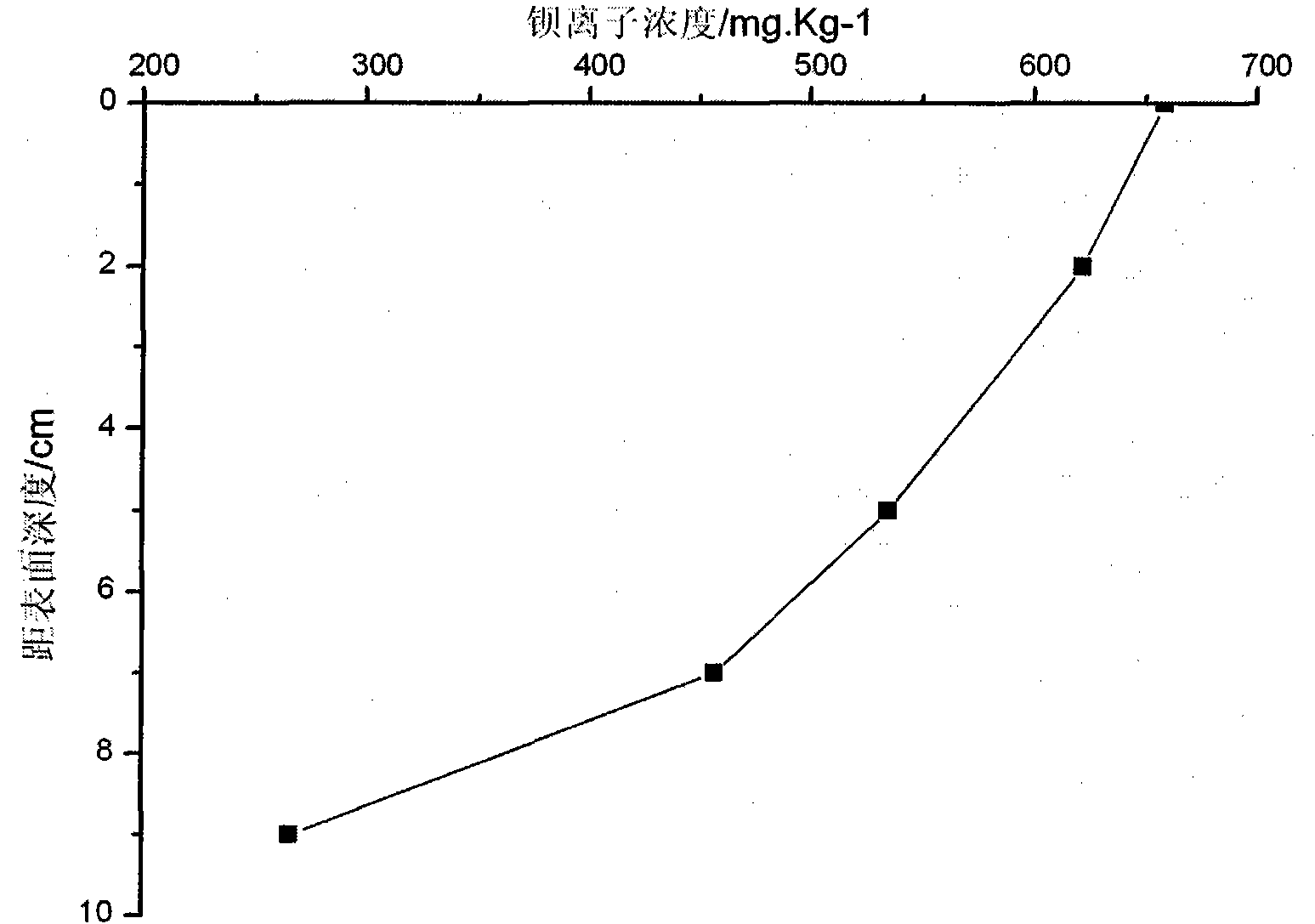

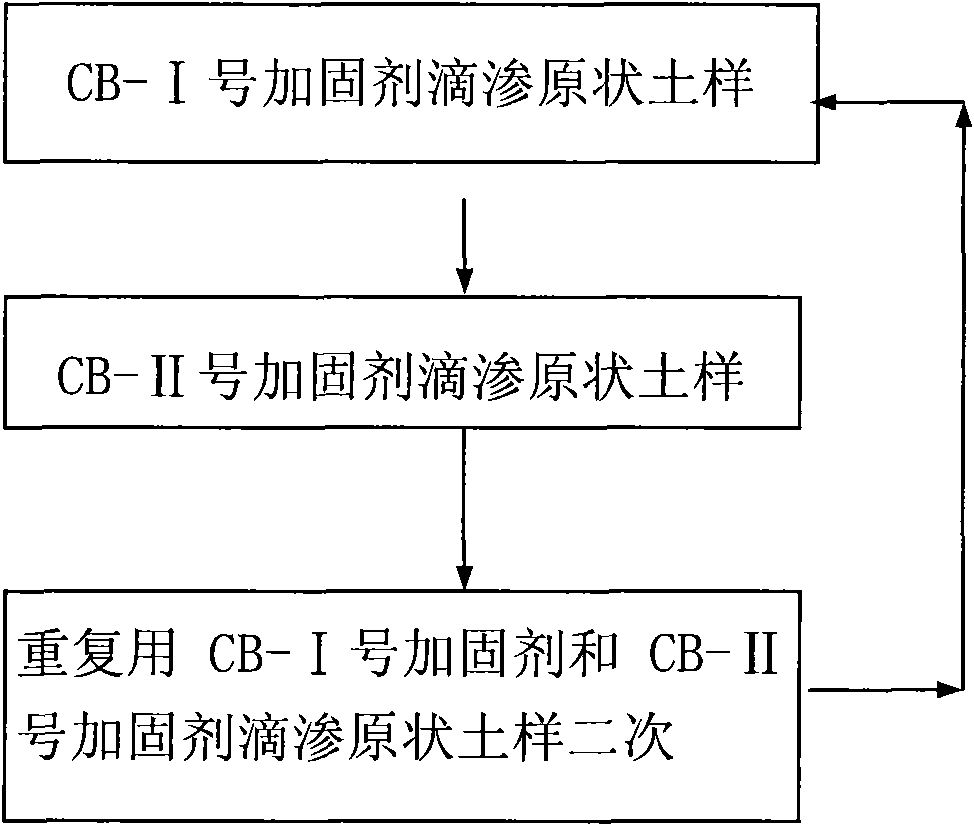

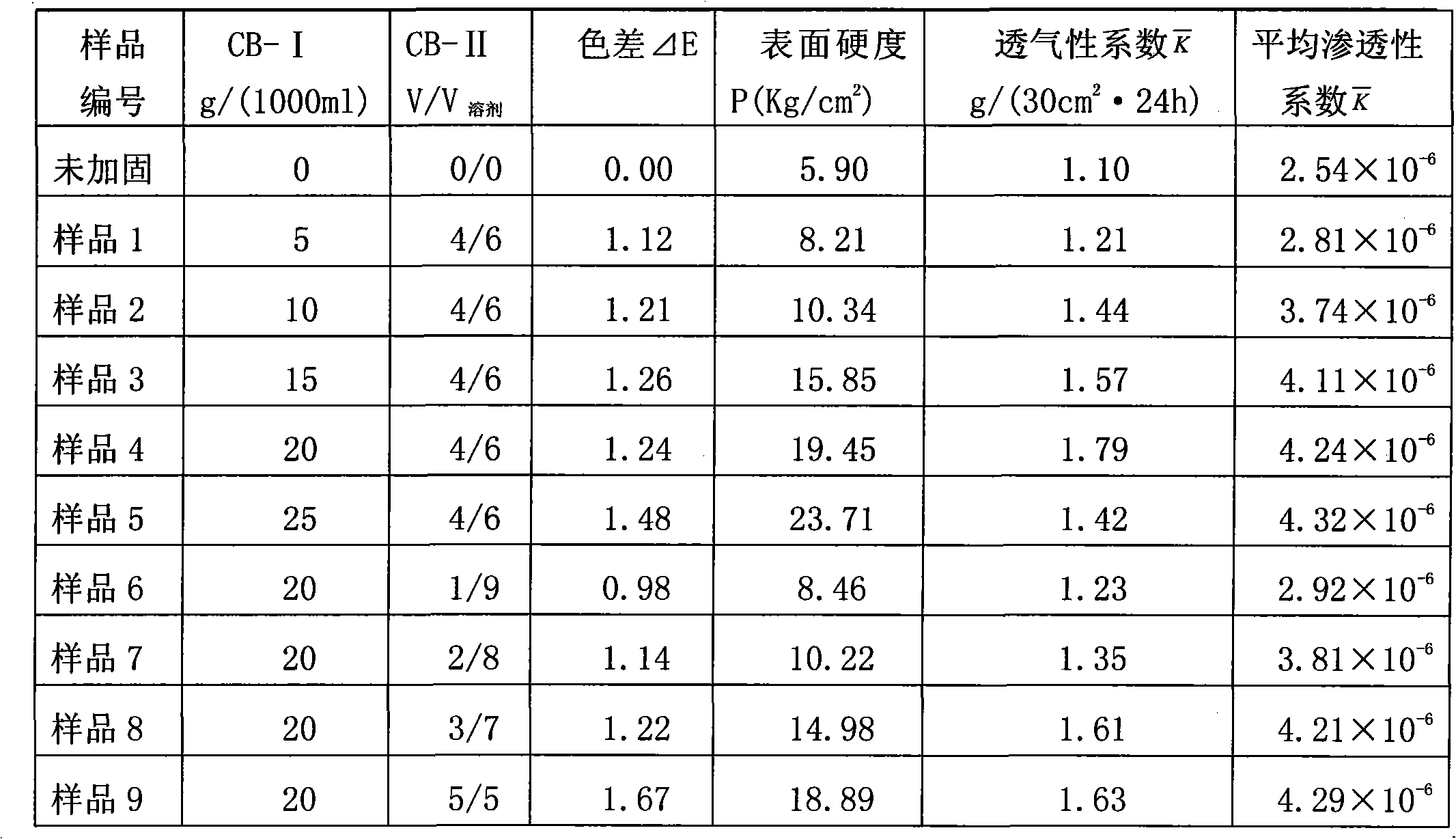

Loess relic efflorescence-proof reinforcing agent and preparation and reinforcing method thereof

ActiveCN101935531AImprove reinforcementLow costOther chemical processesOrganic fertilisersOxalatePolymer science

The invention relates to a loess relic efflorescence-proof reinforcing agent and a preparation and reinforcing method thereof. The method comprises the following steps: dissolving 5-25g of oxalate and 1-15ml of CB-I reinforcing agent prepared from phosphoric acid in every 1000ml of ethanol, and dissolving 15-150g of CB-II reingorcing agent prepared from barium hydroxide in every 2500ml of carbinol; and utilizing a dual reinforcing method of carrying out microprecipitation and adsorption on the losess relic by the CB-I reingorcing agent and the CB-II reingorcing agent, and utilizing a three-step dripping mode to achieve the reinforcing effect. By adopting the technical scheme of the invention, a loess relic efflorescence-proof reinforcing material and the reinforcing method which are suitable for dry, semi-dry and humid environment conditions of a semihumid area are obtained. The chemical raw materials of the invention are technical pure, and has the advantages of low cost, simple manufacturing process and reinforcing method, and easy operation, thereby having good market development prospect. After being processed by the loess relic efflorescence-proof reinforcing material of the invention according to the reinforcing method, the loess relic shows excellent reinforced effect.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com