Preparation method of novel polyurethane-modified organic silica gel

A polyurethane modification, polyurethane prepolymer technology, applied in the field of silicone, can solve the problems of poor resin hardness stability and mechanical properties, difficult durability, poor adhesion, etc., to achieve excellent weather resistance, fast mechanical strength, phase Good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

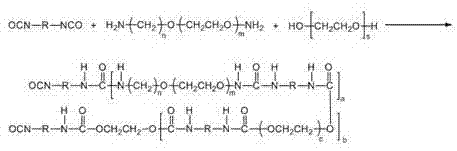

Method used

Image

Examples

Embodiment 1

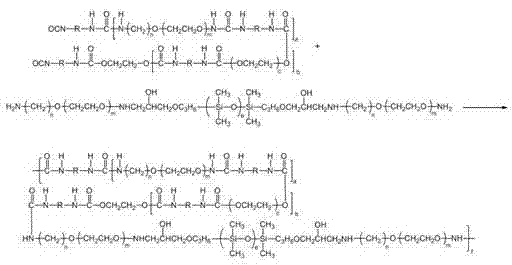

[0031] The steps of preparing polyurethane modified silica gel are as follows:

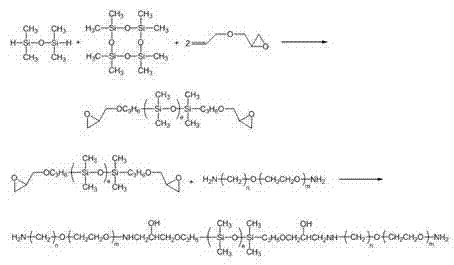

[0032] (1) Preparation of amino-terminated silicone:

[0033] Put octamethylcyclotetrasiloxane and tetramethyldisiloxane into the reaction kettle at a mass ratio of 4:1, stir and react at 65°C for 0.5h, and then add 0.0005% of the total mass of the reactants Concentrated sulfuric acid with a mass fraction of 98%, at a temperature of 70°C, carried out an equilibrium reaction for 3 hours, then neutralized with anhydrous sodium carbonate, filtered and vacuumized to obtain a methyl hydrogen-containing siloxane intermediate; The prepared methyl hydrogen-containing siloxane intermediate and allyl glycidyl ether were put into the reaction kettle at a mass ratio of 1:1.5, stirred and reacted at 70°C for 3 hours, and then added dropwise to account for 0.00005% of the total mass of the reactants The platinum catalyst was reacted for 3 hours to obtain a diepoxy-terminated silicone oil; the diepoxy-terminate...

Embodiment 2

[0040] The steps of preparing polyurethane modified silica gel are as follows:

[0041] (1) Preparation of amino-terminated silicone:

[0042] Put octamethylcyclotetrasiloxane and tetramethyldisiloxane into the reactor at a mass ratio of 9:1, stir and react at 70°C for 1 hour, and then add 0.25% mass fraction of the total mass of the reactants It is 98% concentrated sulfuric acid, and at a temperature of 70°C, carry out an equilibrium reaction for 5 hours, and then neutralize it with anhydrous sodium carbonate, filter and vacuumize to obtain a methyl hydrogen-containing siloxane intermediate; The methyl hydrogen-containing siloxane intermediate and allyl glycidyl ether are put into the reactor at a mass ratio of 1:3, stirred and reacted at 60°C for 3 hours, and then 0.0005% of the total mass of the reactant is added dropwise. The catalyst was reacted for 3 hours to obtain diepoxy-terminated silicone oil; the diepoxy-terminated silicone oil and difunctional amino-terminated p...

Embodiment 3

[0049] The steps of preparing polyurethane modified silica gel are as follows:

[0050] (1) Preparation of amino-terminated silicone:

[0051] Put octamethylcyclotetrasiloxane and tetramethyldisiloxane into the reactor at a mass ratio of 19:1, stir and react at 60°C for 0.75h, and then add 0.0005% of the total mass of the reactants Concentrated sulfuric acid with a fraction of 98%, at a temperature of 60°C, conduct an equilibrium reaction for 7 hours, then neutralize with anhydrous sodium carbonate, filter and vacuumize to obtain a methyl hydrogen-containing siloxane intermediate; The obtained methyl hydrogen-containing siloxane intermediate and allyl glycidyl ether were put into the reactor at a mass ratio of 1:3, stirred and reacted at 75°C for 3 hours, and then added dropwise 0.0003% of the total mass of the reactants The platinum catalyst was stirred and reacted for 2 hours to obtain diepoxy-terminated silicone oil; the diepoxy-terminated silicone oil and the difunctiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com