Patents

Literature

586 results about "Allyl glycidyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Allyl glycidyl ether is an organic compound used in adhesives and sealants and as a monomer for polymerization reactions. It is formally the condensation product of allyl alcohol and glycidol via an ether linkage. Because it contains both an alkene and an epoxide group, either group can be reacted selectively to yield a product where the other functional group remains intact for future reactions.

Polyamide and amine hybridized nanosilicon dioxide hyperbranched polymer and preparation method thereof

ActiveCN103865008AImprove temperature resistanceStrong salt resistanceDrilling compositionEthylenediaminePolymer science

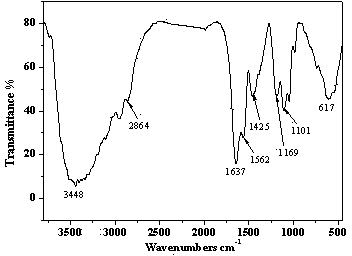

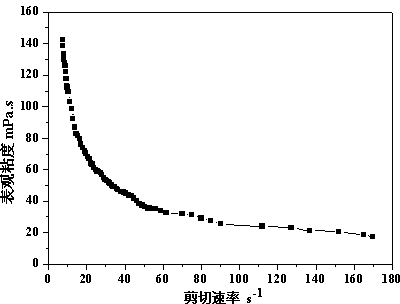

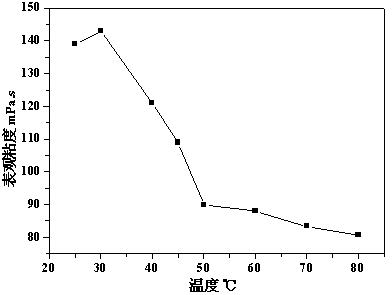

The invention discloses a polyamide and amine hybridized nanosilicon dioxide hyperbranched polymer and a preparation method thereof. The preparation method of the polymer comprises the following steps of firstly, modifying the surface of nanosilicon dioxide by using a coupling agent; then, carrying out Michael addition reaction and amidation reaction on the modified nanosilicon dioxide by using ethylenediamine and methyl acrylate; finally, carrying out functional modification by using allyl glycidyl ether to obtain a functional polyamide and amine hybridized nanosilicon dioxide monomer, and initiating polymerization reaction on the functional polyamide and amine hybridized nanosilicon dioxide monomer, acrylamide, acrylic acid and a heat-resistant and salt-tolerant monomer by using a redox initiator or azobis(isobutylamidine) initiator. The hyperbranched polymer has a network structure with a polyamide and amine hybridized nanosilicon dioxide unit as a center, has excellent shear resistance, strong thickening property, heat resistance and salt tolerance, and is wide in adaptability and capable of being used as an oil displacement agent for increasing the recovery rate of raw oil in an oil field environment with a high mineralization degree and a wide temperature range; the preparation method of the polyamide and amine hybridized nanosilicon dioxide hyperbranched polymer is reliable in principle, simple and convenient to operate and wide in application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Method for producing conductive thermoplastic elastomer composition and conductive roller composed of same

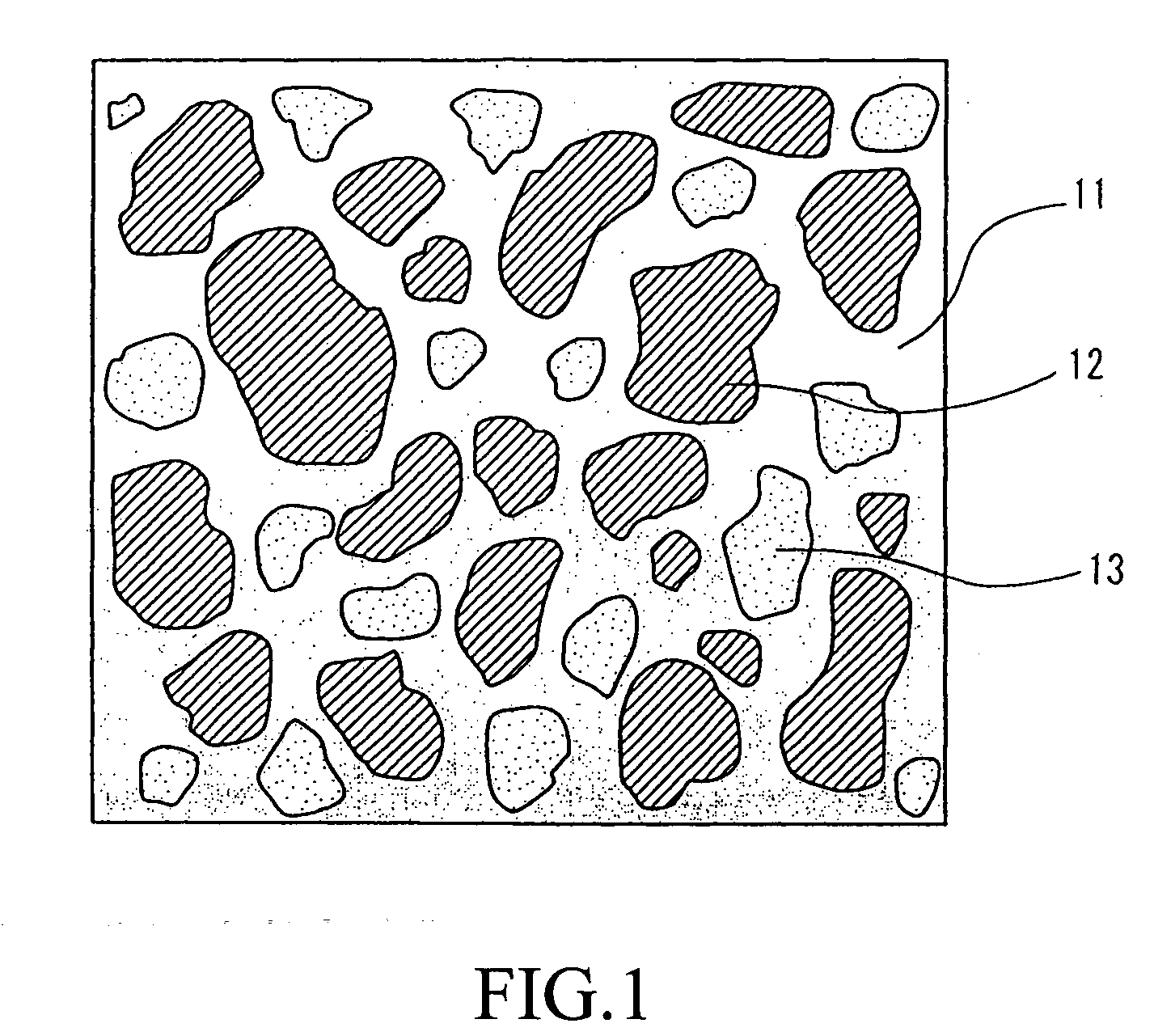

InactiveUS20080315159A1Low compression setDecreasing variation of electric resistanceShaft and bearingsConductive materialElastomerPolymer science

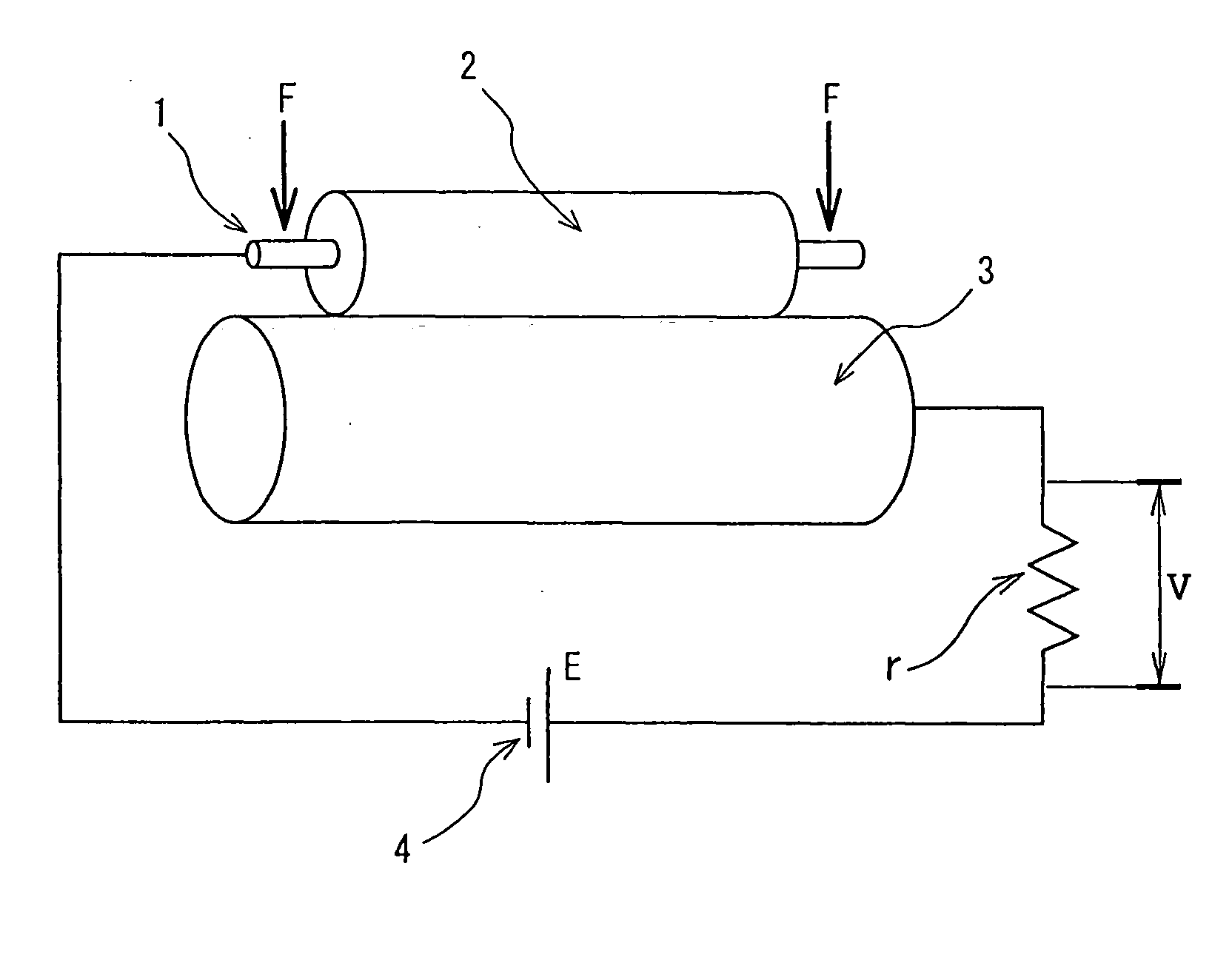

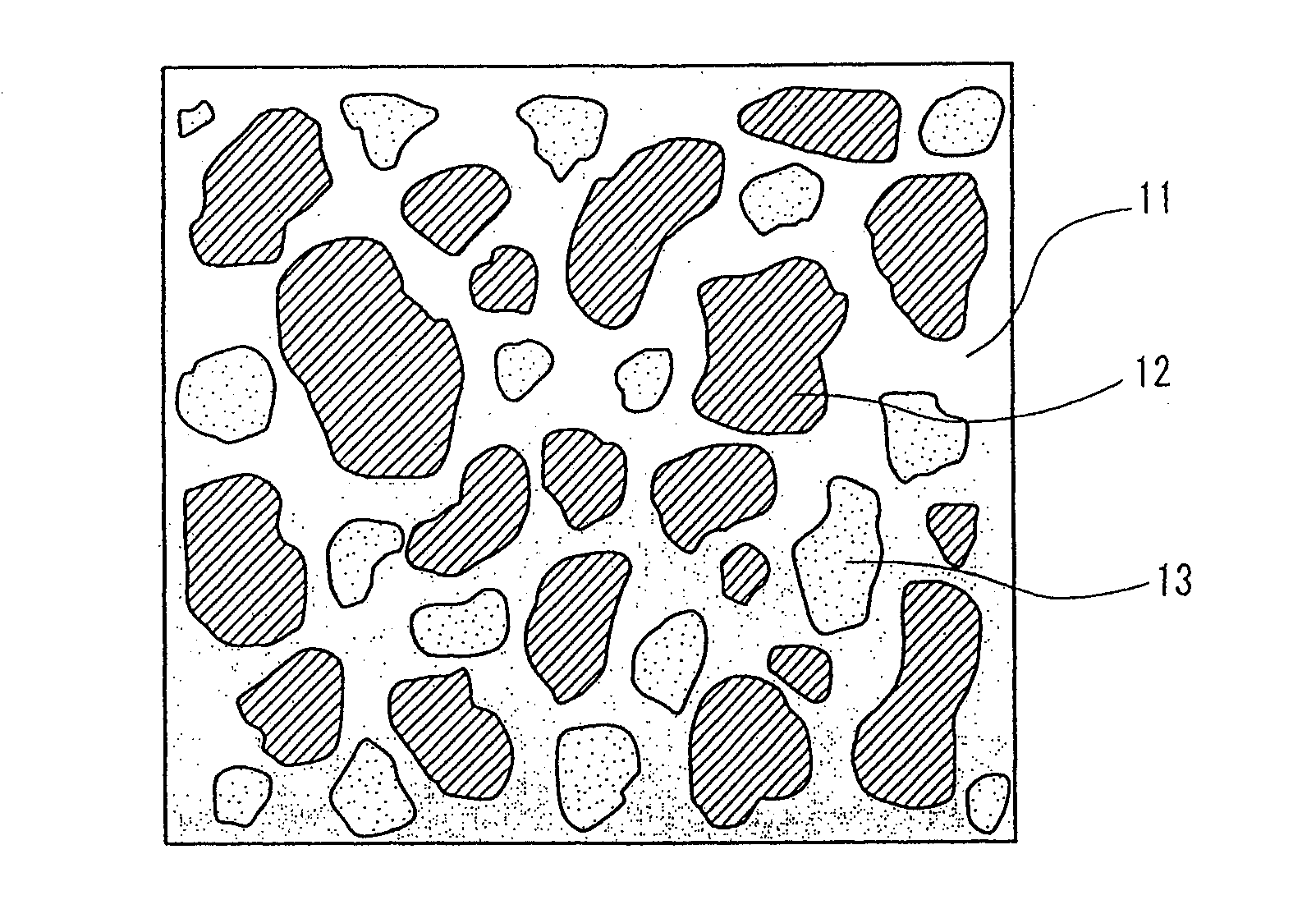

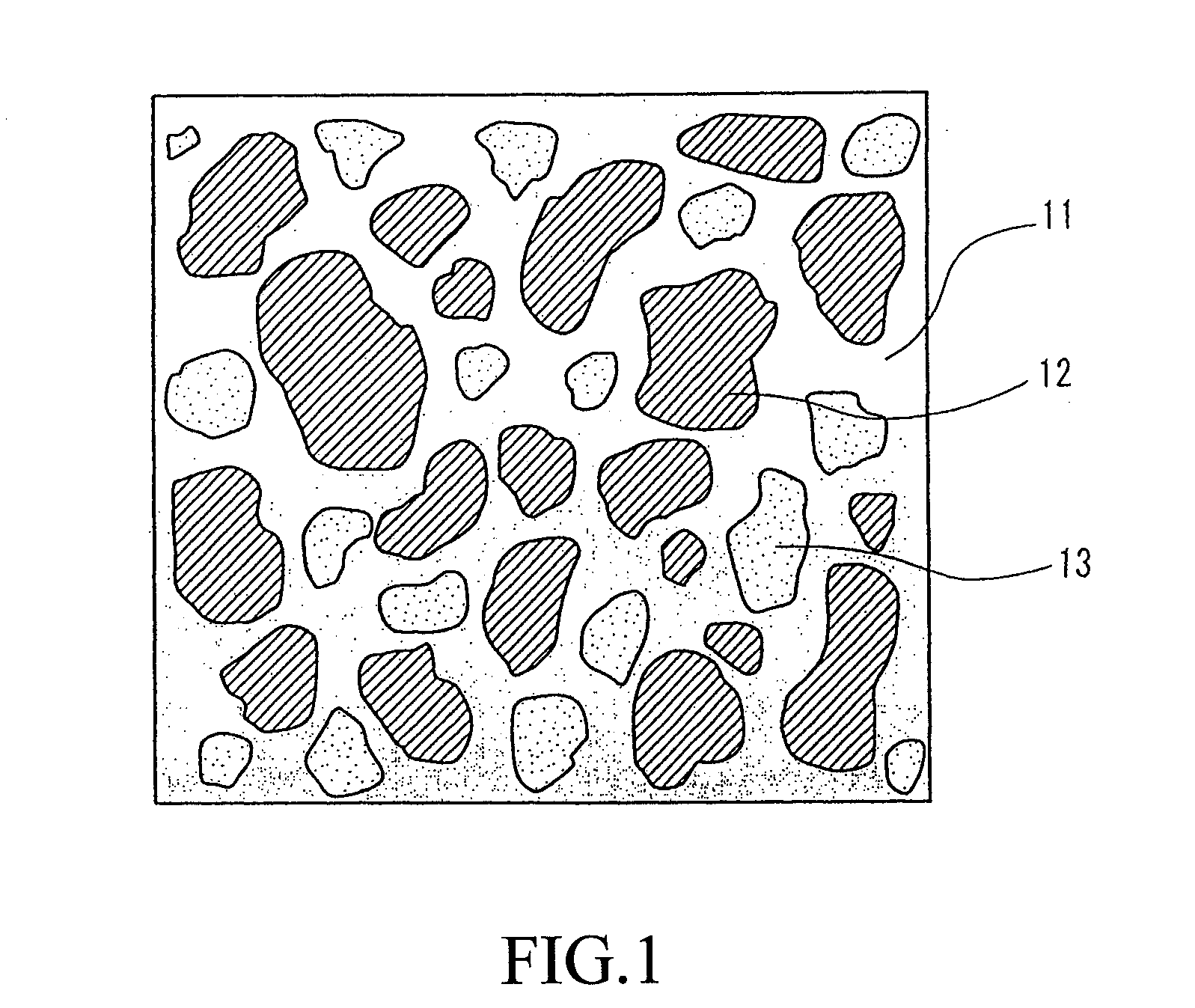

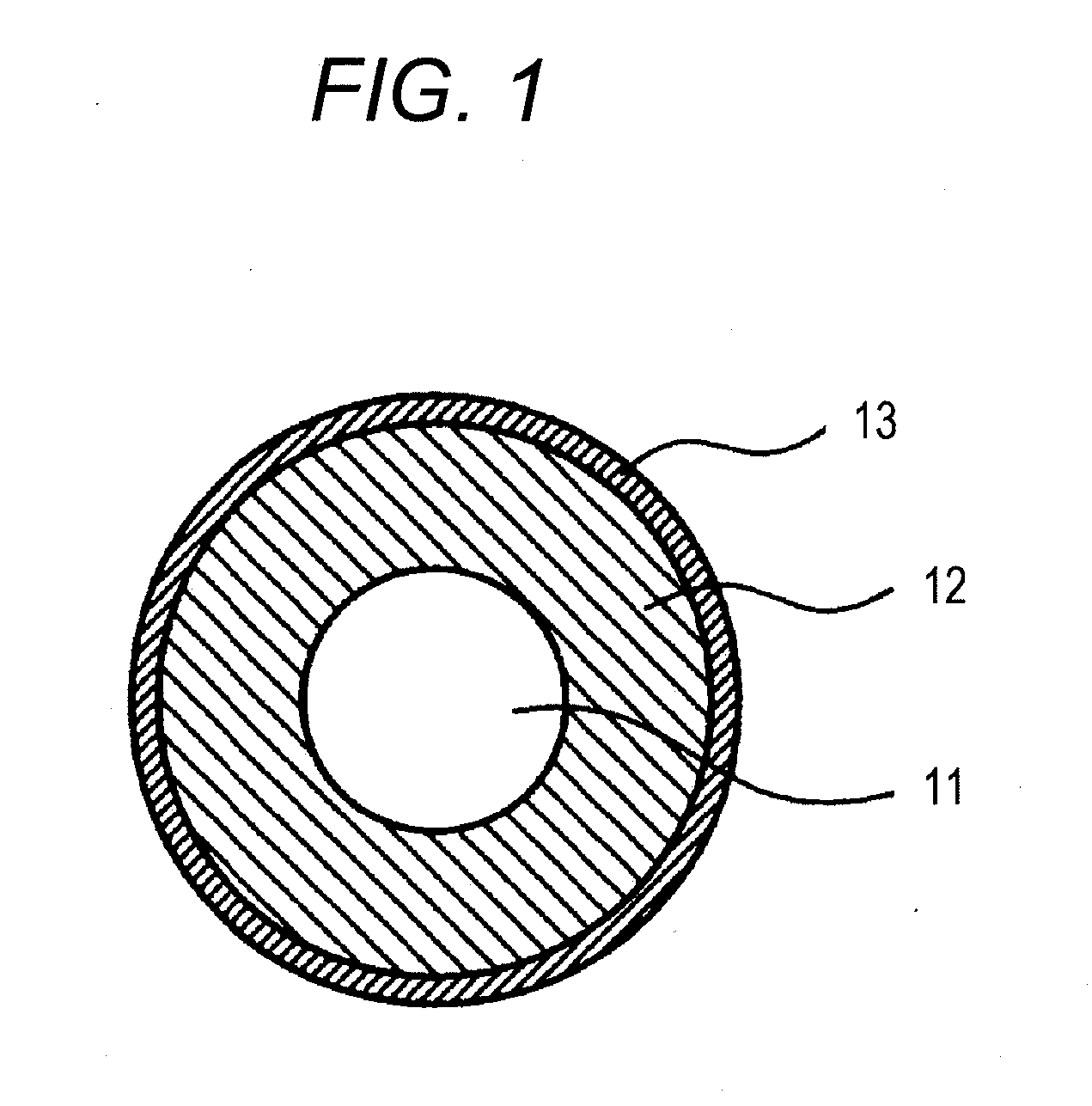

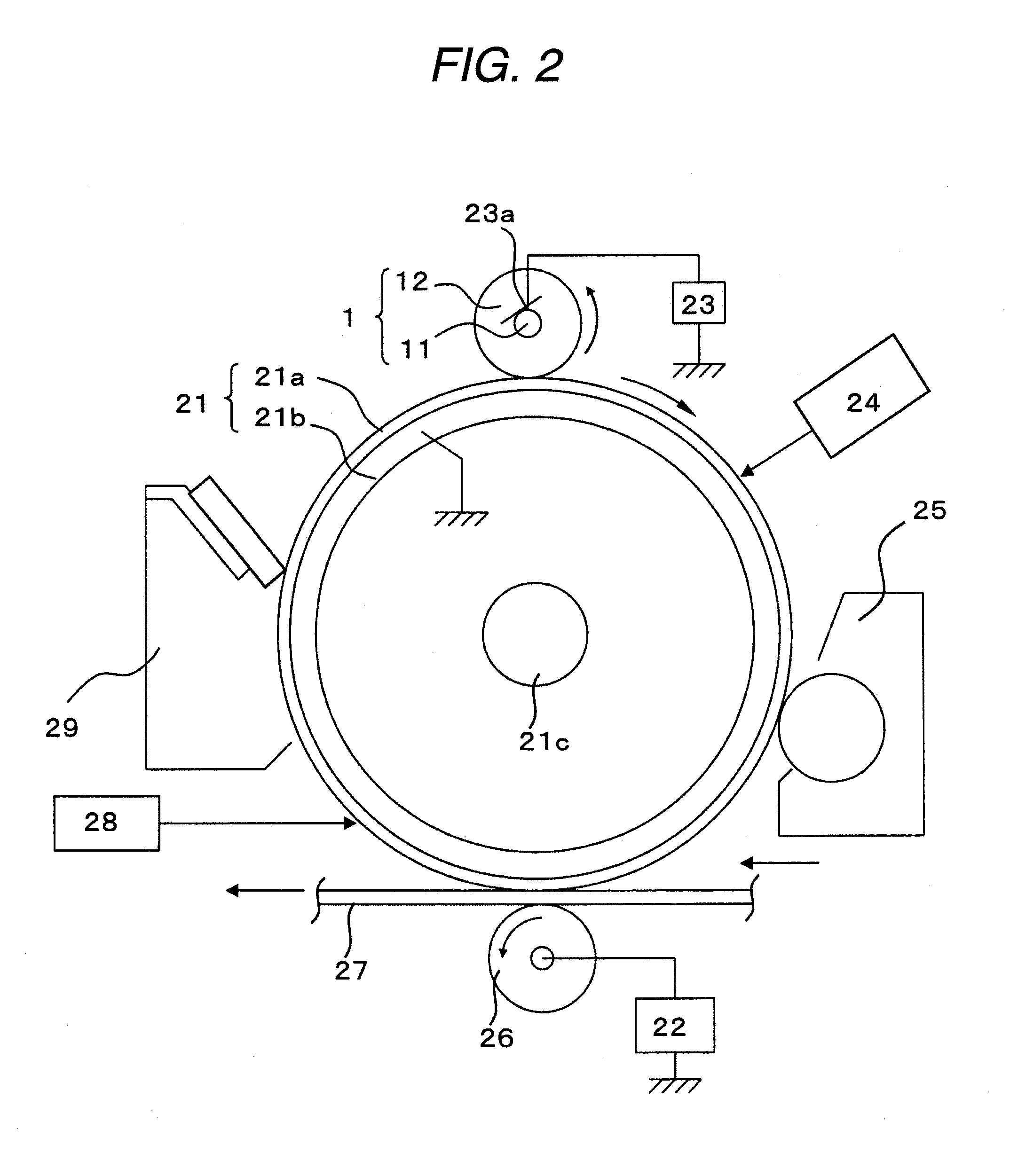

A conductive thermoplastic elastomer composition including a continuous phase and first and second uncontinuous phases. The continuous phase and the first and second uncontinuous phases form a sea-island structure; and the first and second uncontinuous phases independently forming island structures. In this structure, the continuous phase contains a composition (A) which is a mixture of a thermoplastic elastomer and a thermoplastic resin; the first continuous phase contains a rubber component (B) containing at least one of diene rubber and ethylene-propylene-diene rubber; and the second continuous phase contains an ethylene oxide-propylene oxide-allyl glycidyl ether copolymer containing an anion-containing salt having a fluoro group and a sulfonyl group (component (C)).

Owner:SUMITOMO RUBBER IND LTD

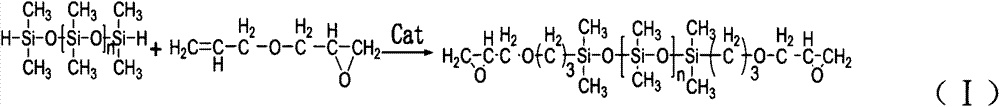

Organic silicon fibre retardant containing phosphorus and epoxy radical and its preparation method

The invention relates to organic silicon fire retardant containing phosphor and epoxy radical. It is made up of 100 portions methyl containing hydrogen silicone oil, 1-150 portions allylglycidyl ether, 0-50 portions end reaction contained double organic silane coupler and 1-200 portions active material containing phosphor after compounding. The invention also relates to the manufacturing method of taking polyaddition reaction of methyl containing hydrogen silicone oil, allylglycidyl ether, and end reaction contained double organic silane coupler, and compounding with phosphor contained active material. The condensate compounded by the invention and common epoxy resin the limiting oxygen index would reach 23-29, and vitrifying transforming temperature would reach 168-185degree centigrade.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

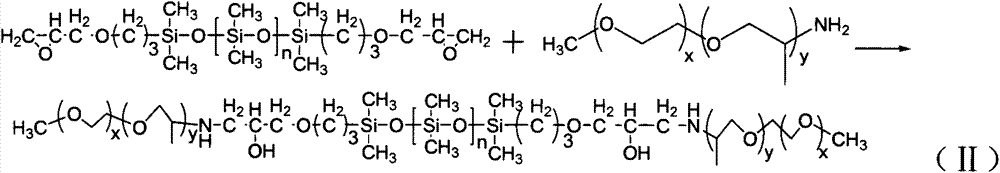

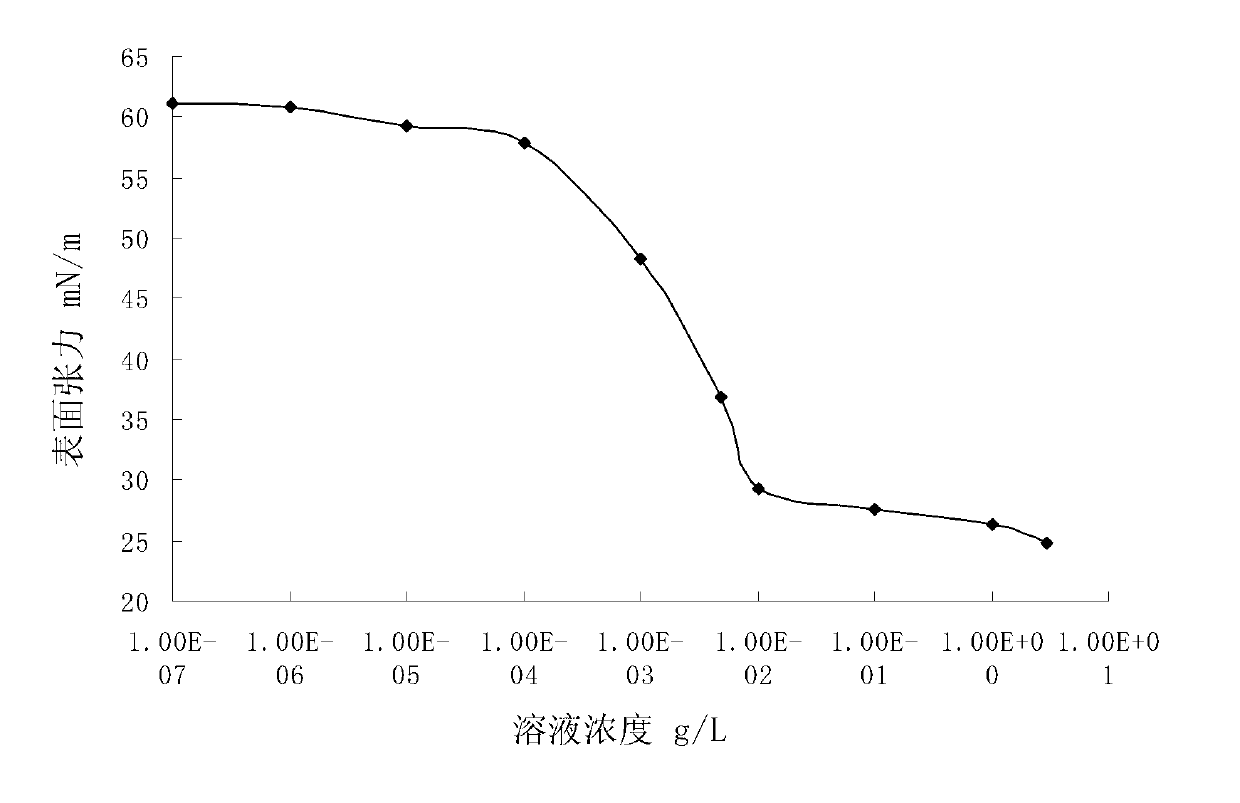

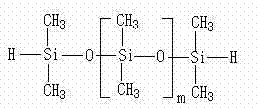

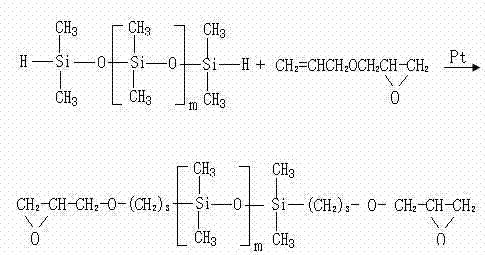

Preparation method of amino polyether organic silicon compounded antifoaming agent

The invention relates to a preparation method of an amino polyether organic silicon compounded antifoaming agent. The method comprises the following technological steps: (1) adding allyl glycidyl ether and a platinum catalyst into a container, heating under stirring and reflux condensing conditions in the protection of N2, adding a toluene solution of hydrogen-containing silicone oil when the temperature rises to a certain level, after the reactions, removing the solvent and substances with low boiling points in a rotary evaporator, and drying so as to obtain epoxy modified silicone oil; (2) adding the epoxy modified silicon oil obtained in the step (1) and an ethanol solution of polyether amine into a container, heating under stirring, carrying out reactions under the reflux condensing conditions in the protection of N2, after the reactions, removing ethanol in a rotary evaporator, and drying so as to obtain amino polyether organic silicon; (3) compounding the amino polyether organic silicon obtained in the step (2) with a certain amount of silicone cream, a mixed emulsifier, and a thickening agent to prepare the amino polyether organic silicon compounded antifoaming agent. In the provided method, amino polyether organic silicon is prepared through a silicon-hydrogen addition / amination reaction and then is compounded with an emulsifier, a thickening agent, and silicon cream so as to prepare the amino polyether organic silicon compounded antifoaming agent, which can be dissolved in water quickly, has the advantages of excellent heat resistance, acid resistance, alkali resistance, and antifoaming property, and has the same performance as that of antifoaming agents in the market.

Owner:JIANGNAN UNIV

Method for preparing nanometer silicon dioxide grafted carbon fiber reinforcements by aid of mercapto-alkene click reaction

The invention relates to a method for preparing nanometer silicon dioxide grafted carbon fiber reinforcements by the aid of mercapto-alkene click reaction. The method includes particular steps of 1), carrying out sulfhydrylation treatment on nanometer silicon dioxide; 2), carrying out acidification treatment on carbon fibers; 3), carrying out amination treatment on the surfaces of the carbon fibers; 4), preparing allyl glycidyl ether grafted carbon fibers; 5), preparing the nanometer silicon dioxide grafted carbon fiber reinforcements by the aid of the mercapto-alkene click reaction. The method has the advantages that the surface roughness can be improved after the nanometer silicon dioxide is grafted on the surfaces of the carbon fibers, the carbon fiber and resin wettability can be obviously improved, the method is favorable for increasing interface binding force between the carbon fibers and resin matrixes, and mechanical properties of carbon fiber reinforcement composite materials can be improved; the heat stability of the carbon fibers can be obviously improved after the nanometer silicon dioxide is grafted on the surfaces of the carbon fibers; the method is short in reaction period, high in yield and favorable for large-scale production, and byproducts are harmless.

Owner:NANCHANG HANGKONG UNIVERSITY

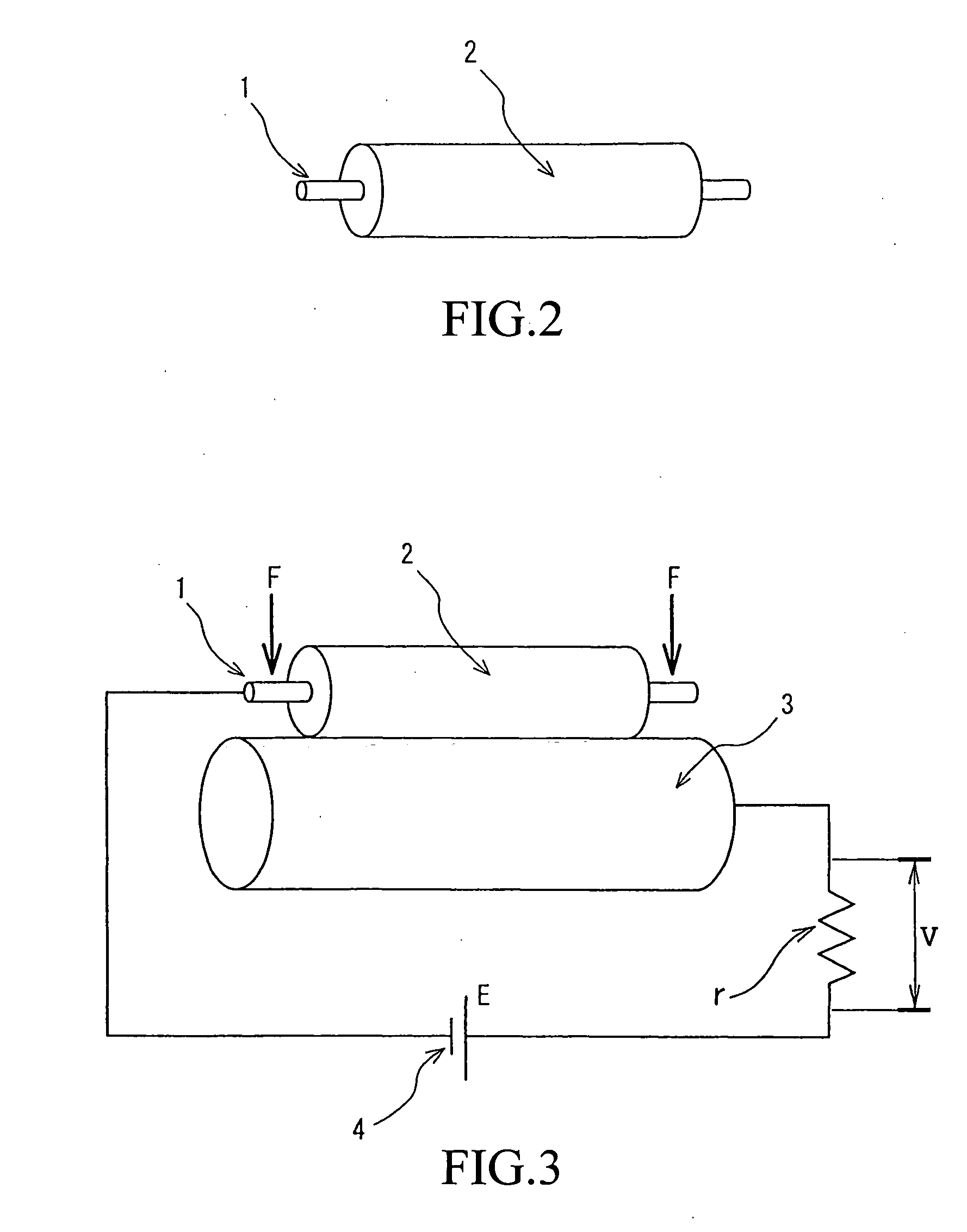

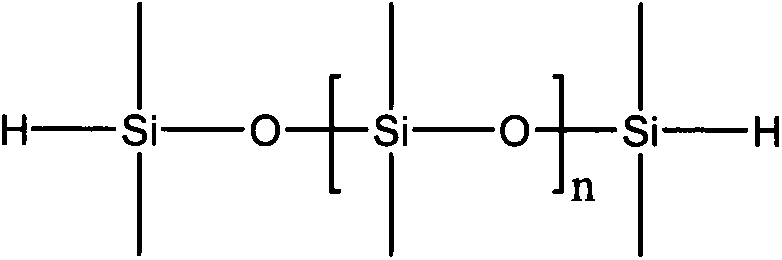

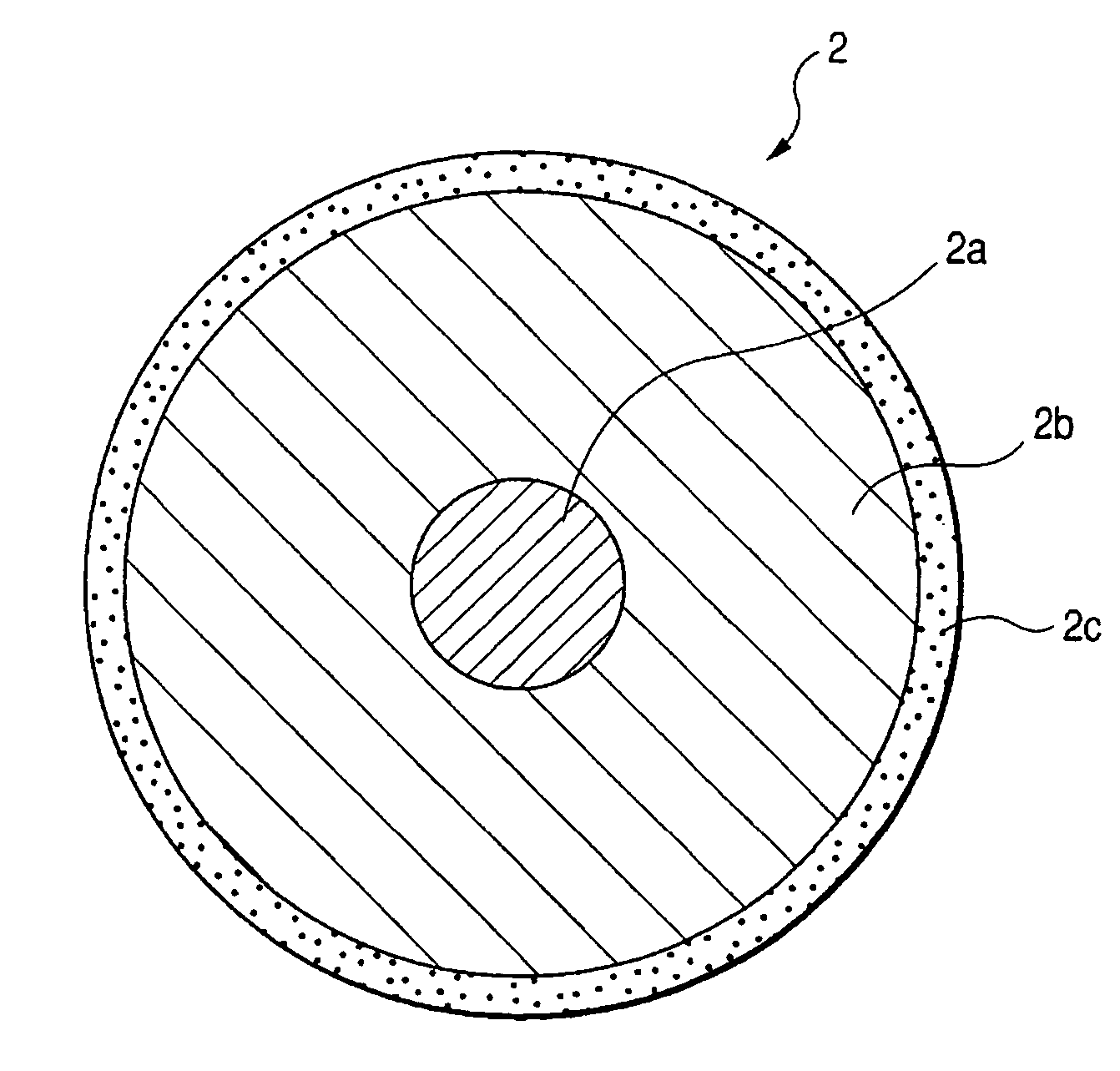

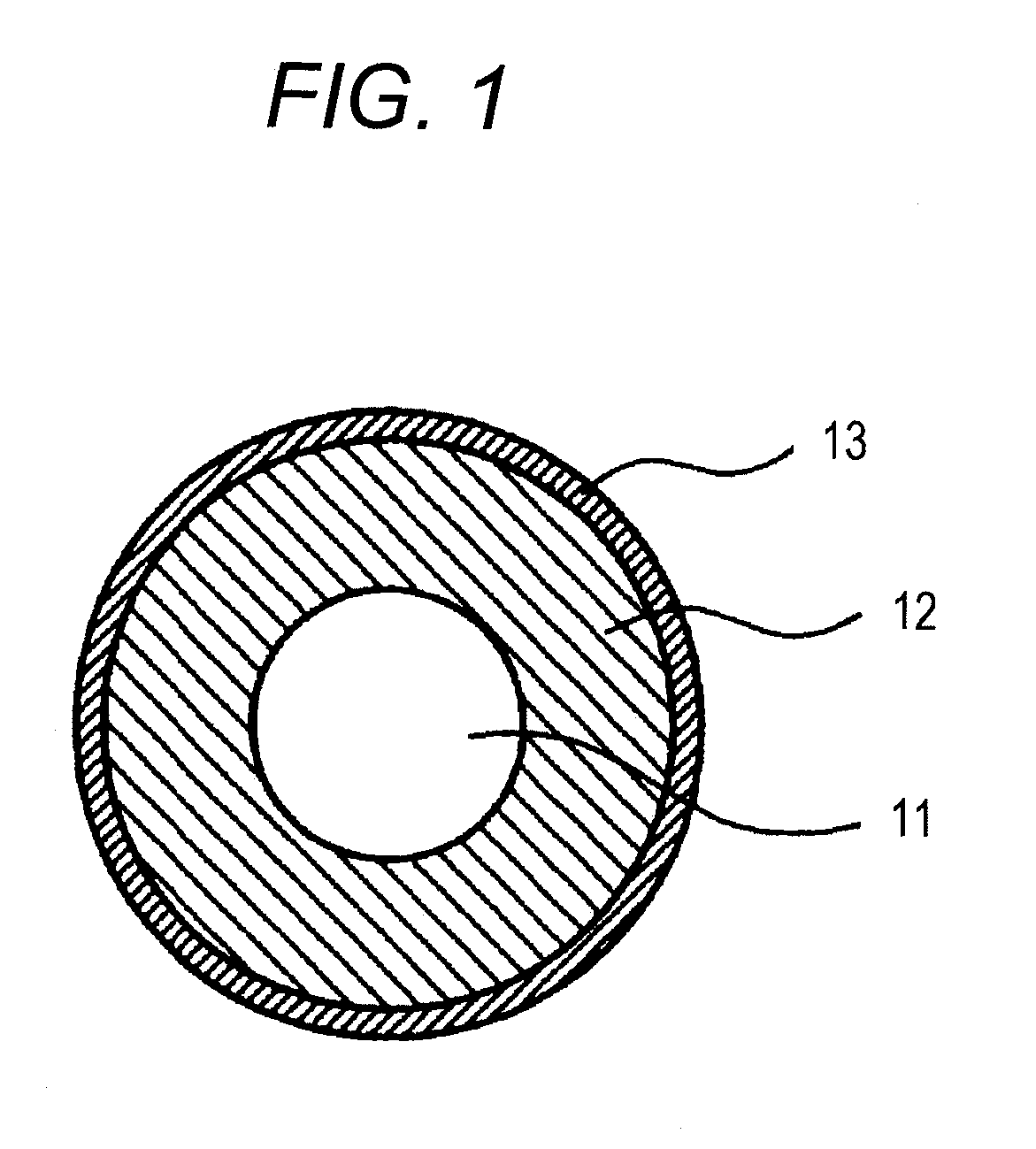

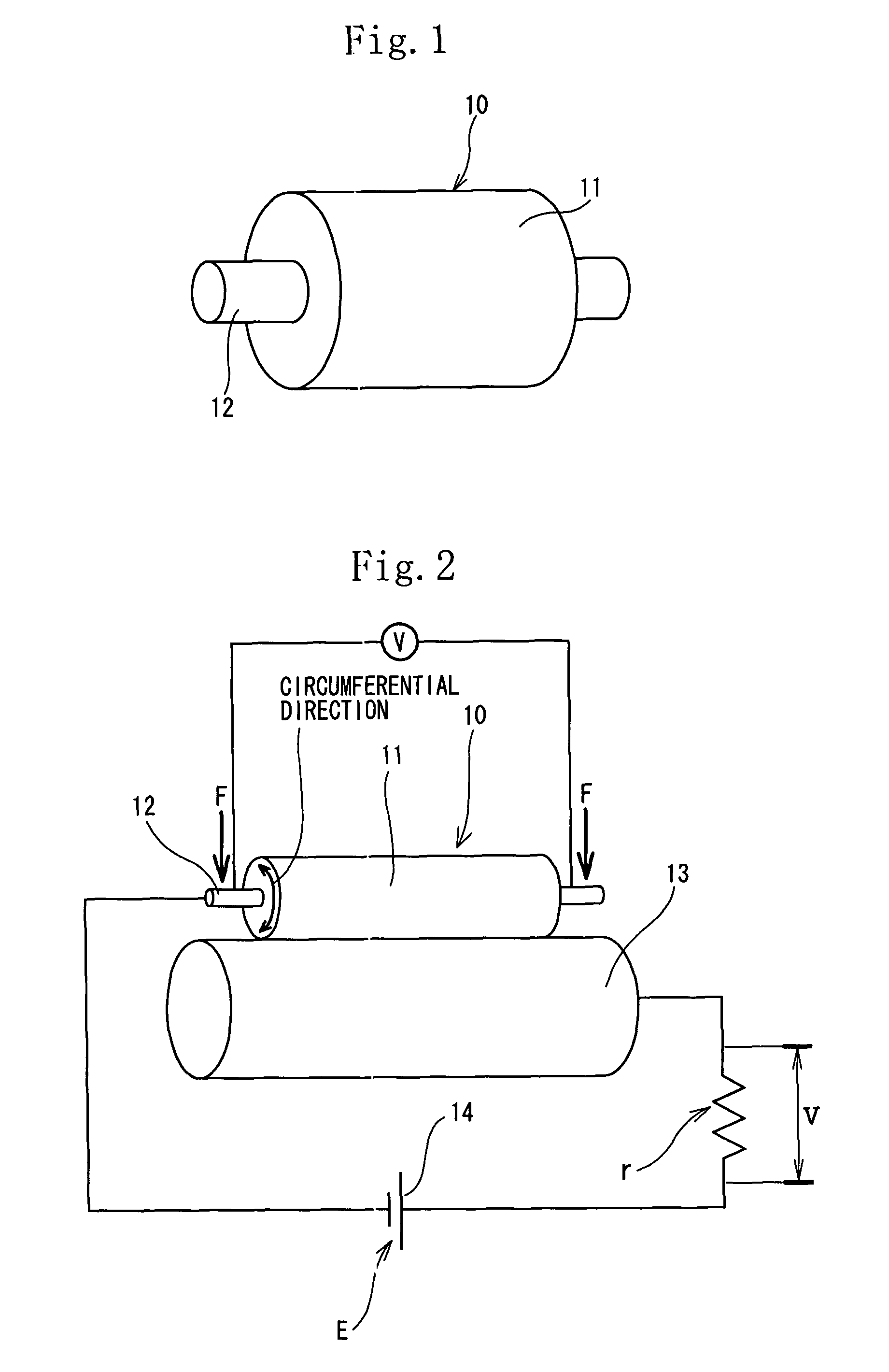

Electroconductive rubber roller

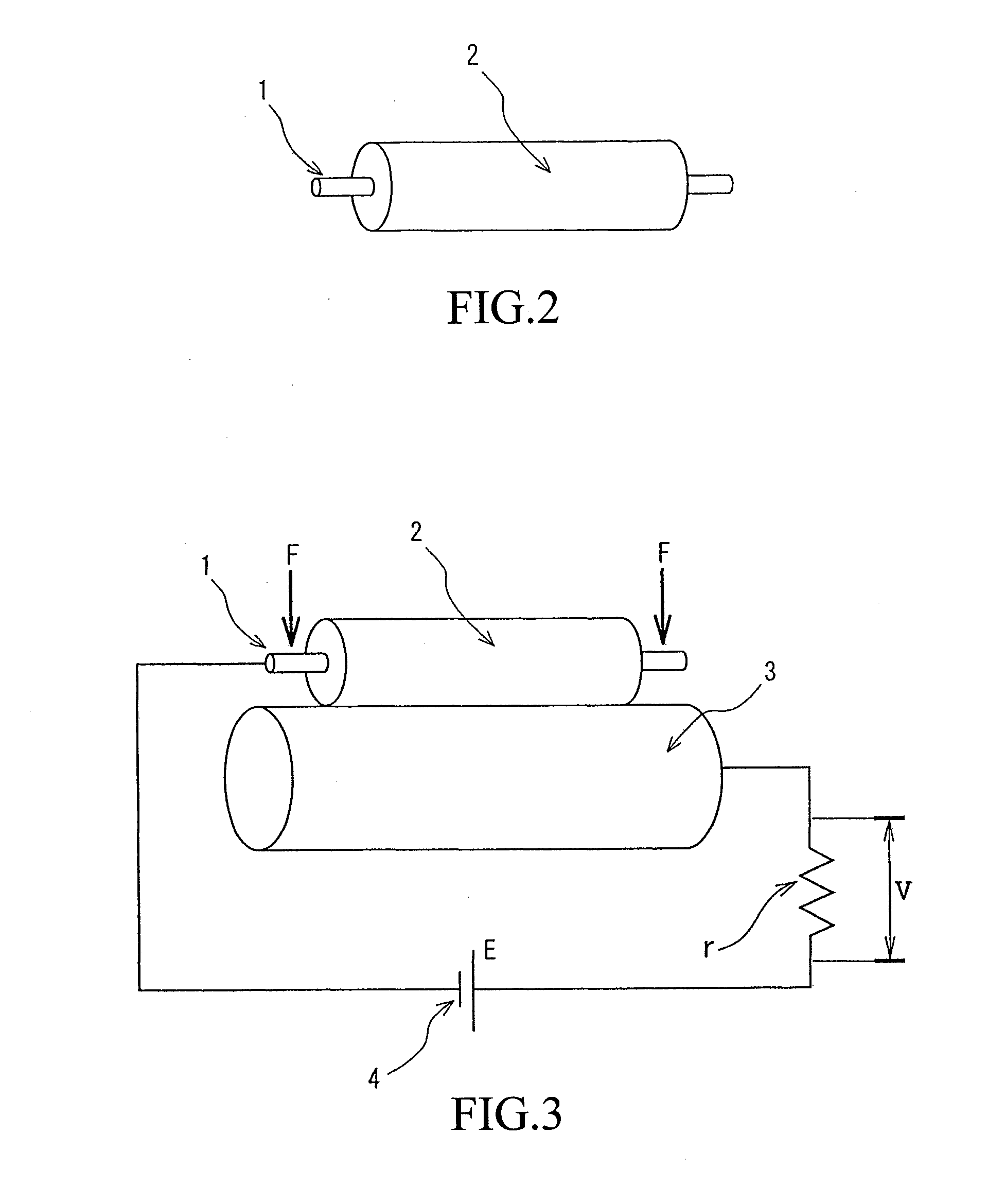

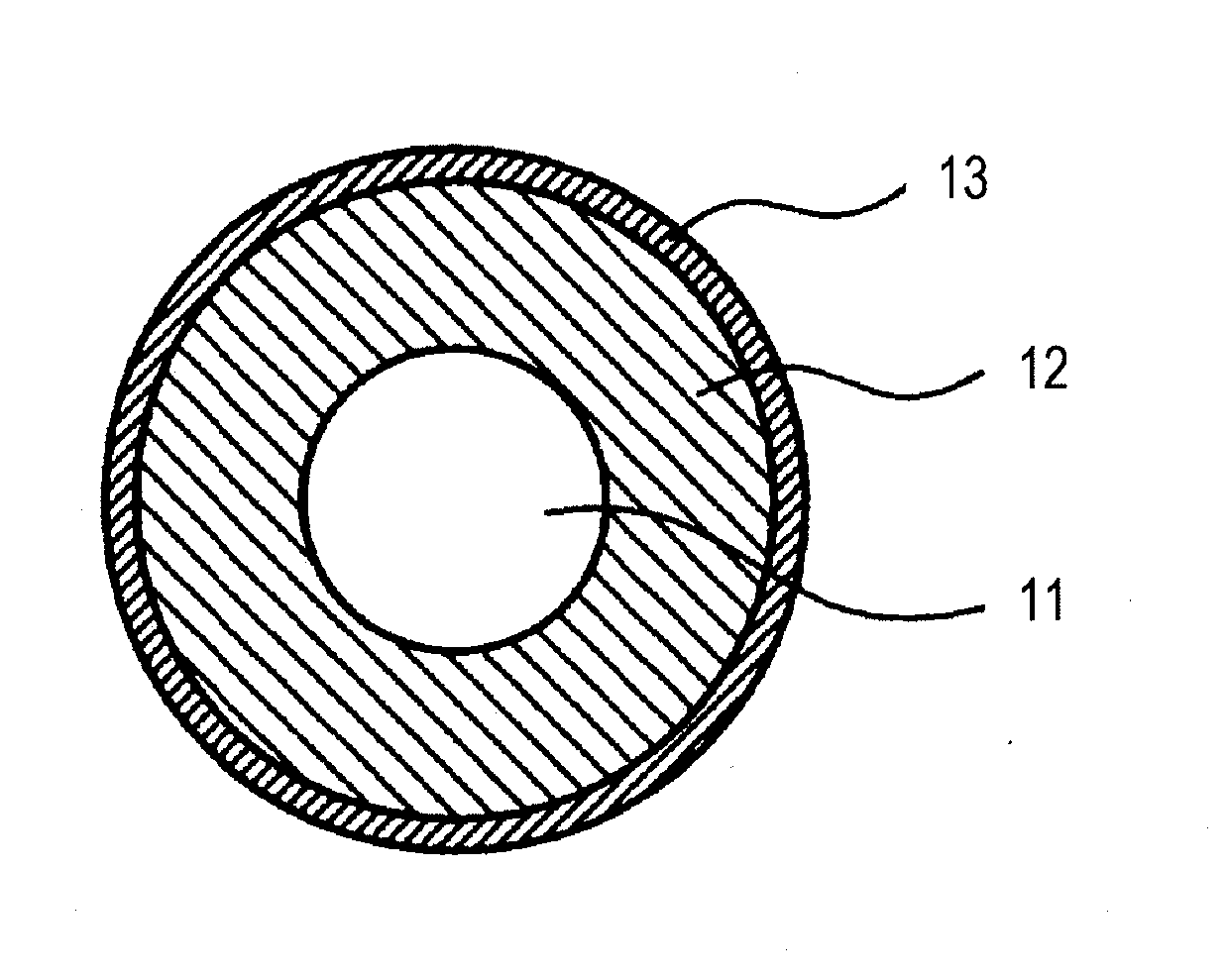

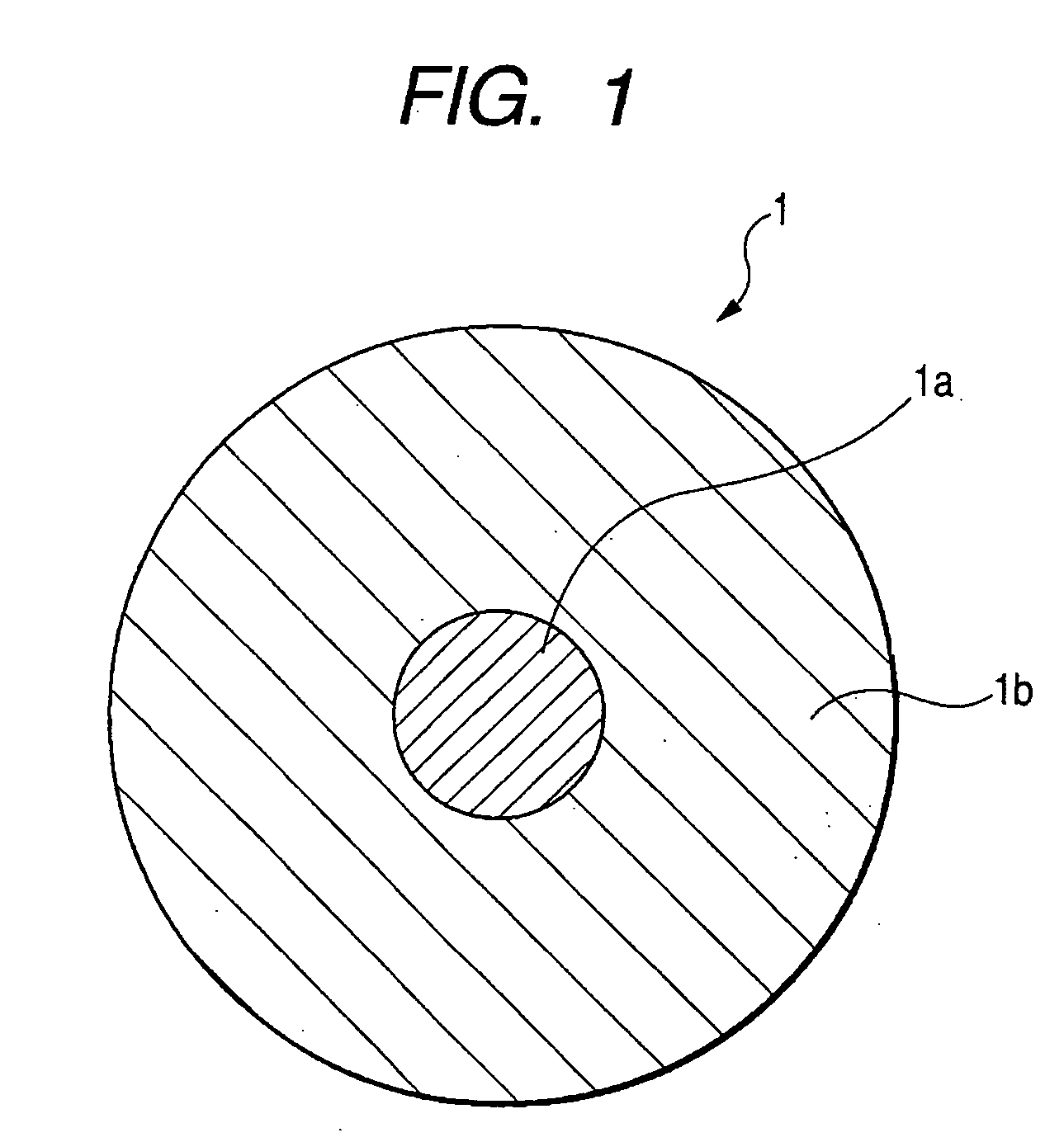

ActiveUS7544158B2Desirable electrical characteristicExcellent permanent compression strain resistanceShaft and bearingsPortable power-driven toolsPolymer scienceEthylene oxide

An electroconductive rubber roller constituted of an electroconductive metal core and an electroconductive crosslinked rubber layer including an epichlorohydrin-based rubber, wherein the epichlorohydrin-based rubber is at least one copolymer selected from the group consisting of an epichlorohydrin-ethylene oxide copolymer and an epichlorohydrin-ethylene oxide-allyl glycidyl ether ternary copolymer. The ethylene oxide unit in the epichlorohydrin-based rubber is in a content of 40 to 90 mol %, and, the electroconductive crosslinked rubber layer has a heat quantity (enthalpy: ΔH) 5 mJ / mg or less as measured by a differential scanning calorimetry (DSC) and indicated by a peak appearing within a range of −20 to 150° C.

Owner:CANON KK

Method for producing conductive thermoplastic elastomer composition and conductive roller composed of same

InactiveUS20110042624A1Good molding effectEasy to recycleConductive materialNon-conductive material with dispersed conductive materialElastomerPolymer science

Owner:MINAGOSHI AKIRA

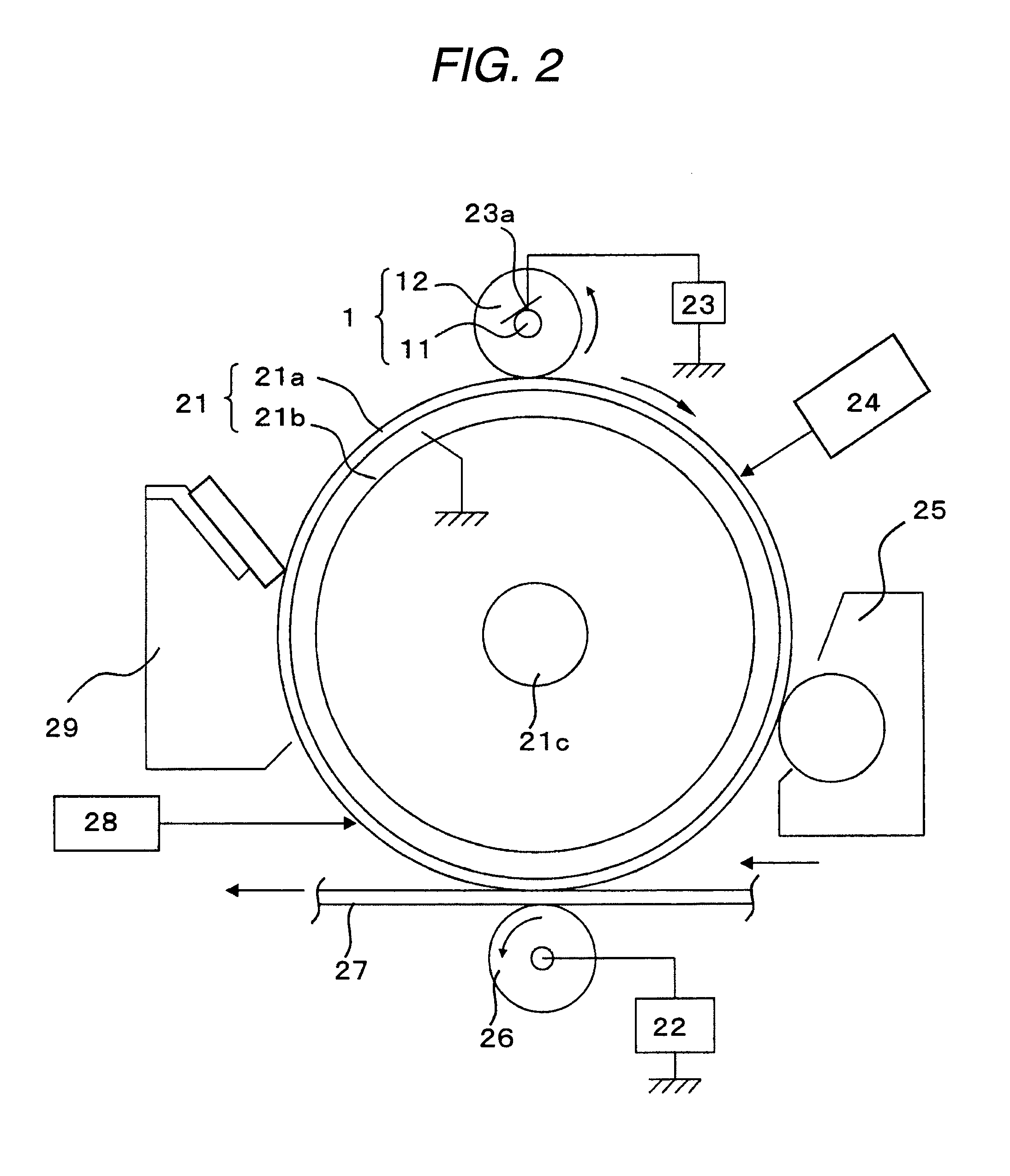

Conductive rubber elastic material, charging member and electrophotographic apparatus

ActiveUS20120224887A1Improve charging effectEasy to changeNon-metal conductorsConductive materialRubber materialPolymer science

A conductive rubber elastic material is stably provided which can produce a charging member that may less vary in electrical resistance even with changes in applied voltage, promises uniform electrical properties, has charge characteristics not affected by changes in environments such as temperature and humidity, and enables a charging object member such as a photosensitive member to be kept from being contaminated. It is a conductive rubber elastic material which contains a matrix containing at least one ionically conductive rubber selected from the group consisting of epichlorohydrin rubber, epichlorohydrin-ethylene oxide rubber, epichlorohydrin-ethylene oxide-allyl glycidyl ether rubber, acrylonitrile-butadiene rubber and a hydrogenated product of acrylonitrile-butadiene rubber and domains composed of an electronically conductive rubber material containing i) a rubber having a butadiene skeleton and ii) carbon black, and the rubber having a butadiene skeleton is modified at a molecular terminal thereof with a specific atomic group.

Owner:CANON KK

Electroconductive rubber roller

ActiveUS20060252619A1Excellent permanent compression strain resistanceLower resistanceShaft and bearingsPortable power-driven toolsPolymer scienceEthylene oxide

An electroconductive rubber roller constituted of an electroconductive metal core and an electroconductive crosslinked rubber layer including an epichlorohydrin-based rubber, wherein the epichlorohydrin-based rubber is at least one copolymer selected from the group consisting of an epichlorohydrin-ethylene oxide copolymer and an epichlorohydrin-ethylene oxide-allyl glycidyl ether ternary copolymer. The ethylene oxide unit in the epichlorohydrin-based rubber is in a content of 40 to 90 mol %, and, the electroconductive crosslinked rubber layer has a heat quantity (enthalpy: ΔH) 5 mJ / mg or less as measured by a differential scanning calorimetry (DSC) and indicated by a peak appearing within a range of −20 to 150° C.

Owner:CANON KK

Hybridization structured polysiloxane flame retardant and preparation method thereof

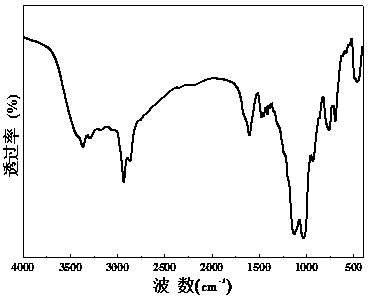

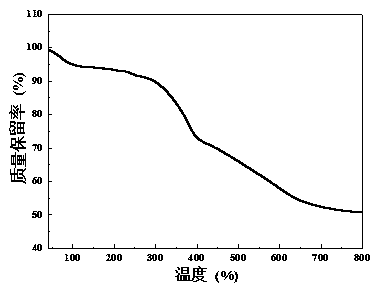

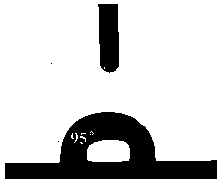

The invention discloses a hybridization structured polysiloxane flame retardant and a preparation method thereof. The hybridization structured polysiloxane flame retardant is prepared by enabling hydrogen-containing silicone oil, allyl glycidyl ether, vinyl silane substances, phosphorus-containing active substances and a silane coupling agent to react with one another under the action of a catalyst. The flame retardant comprises a great amount of organic groups such as benzene rings, a relatively long -Si-O-Si-main chain and a hybridization structure, has hydrophobicity, is relatively high in thermal stability, comprises a great number of elements such as carbon, nitrogen, phosphorus and silicon, can be used as a carbon source and a gas source in an intumescent system, meanwhile has a synergistic flame retardant effect of multiple flame-retardant elements, is good in carbonization property and high in flame-retardant efficiency, the contact angle of the composition is up to 95 DEG C, the compatibility of the composition and a high polymer can be improved, and processing requirements of the high polymer can be met.

Owner:TAIYUAN UNIV OF TECH

Preparation method of aminopolyether modified polysiloxane deforming agent

InactiveCN103214679AImprove stabilityImprove conversion rateFoam dispersion/preventionSolubilityEpoxy

The invention relates to a preparation method of an aminopolyether modified polysiloxane deforming agent. The preparation method comprises the following steps of: (1) adding allyl glycidyl ether and a platinum catalyst to a container, stirring and heating under the conditions of nitrogen protection and reflux condensing; after heating to a certain temperature, dropwise adding a toluene solution containing hydrogen silicon oil; at the end of reaction, removing a solvent and low-boiling-point substances on a rotary evaporator and drying to obtain epoxy modified silicon oil; and (2) adding the epoxy modified silicon oil obtained in the step (1) and an ethanol solution of polyether amine to the container, heating and stirring, reacting under the conditions of nitrogen protection and reflux condensing; at the end of the reaction, removing ethanol on the rotary evaporator and drying to obtain the aminopolyether modified polysiloxane product. According to the preparation method, hydrosilylation / ring opening amination is used, simultaneously amino groups and polyether chain segments are introduced to a polysiloxane skeleton, the obtained deforming agent has good water solubility and stability, no additives and compounding are not added, and the aminopolyether modified polysiloxane deforming agent has good defoaming and foam inhibition performances at normal temperature.

Owner:JIANGNAN UNIV +1

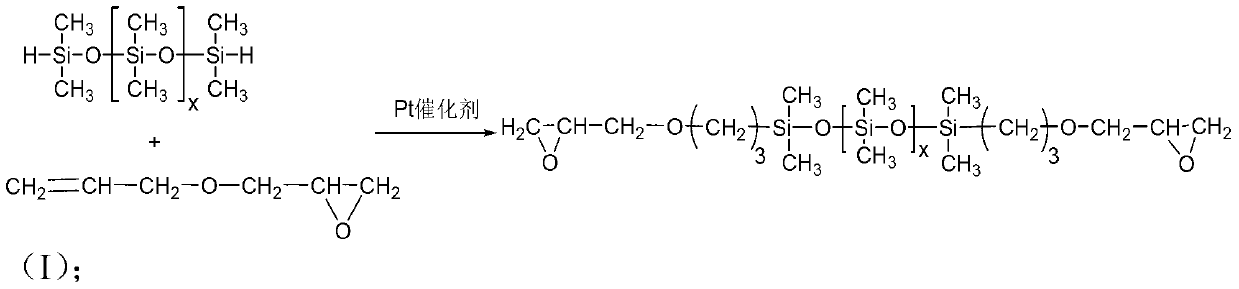

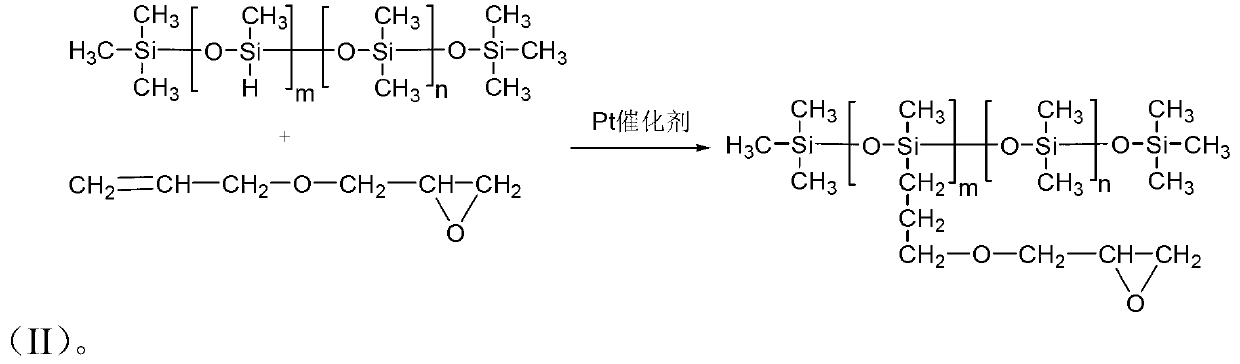

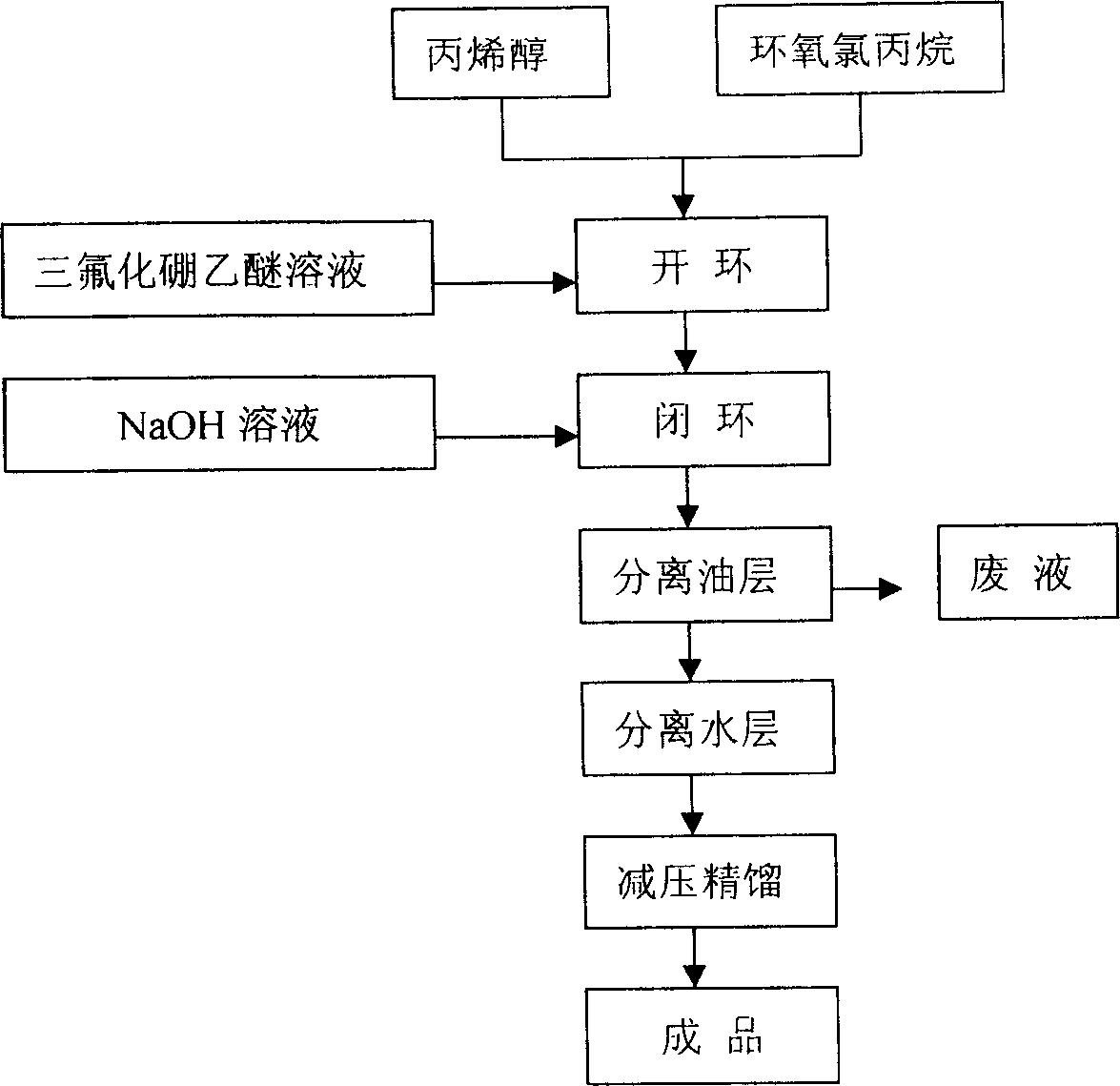

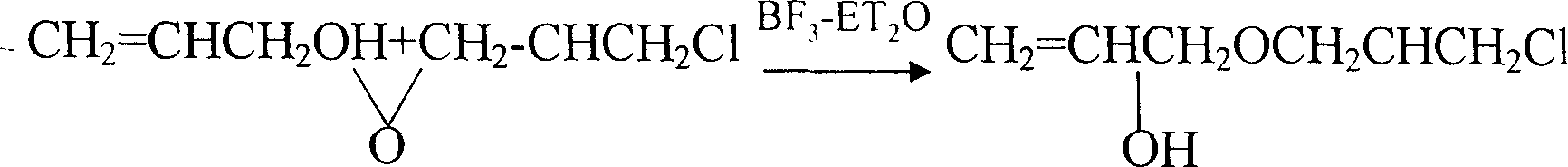

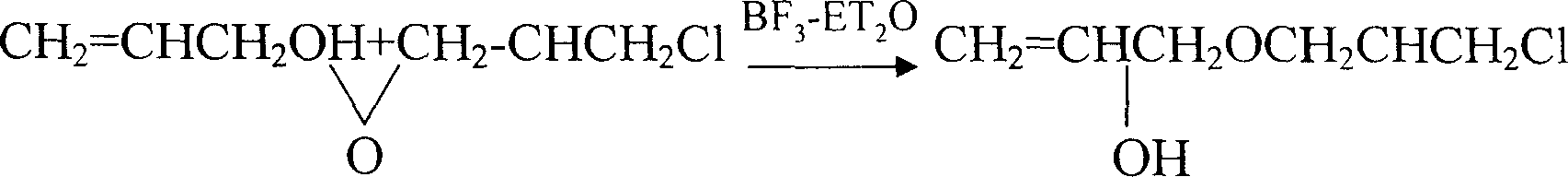

Process of industrialized preparing allyl glycidol ether

This invention provides an allyl glycidyl ether industrialized preparation method. It uses Boron trifluoride diethyl ether comoles compound as catalyst, propylene alcohol and epichlorohydrin as raw material, pass through the condensation ring-opening reactions generate 1-chloro-2-hydroxy-3- allyloxy propane, then under alkaline conditions through close-loop to obtain allyl glycidyl ether; the product yield rate is 78%, the content of 98%.

Owner:樊福定

Conductive rubber elastic material, charging member and electrophotographic apparatus

ActiveUS8491994B2Improve charging effectEasy to changeNon-metal conductorsConductive materialElectrical resistance and conductanceEthylene oxide

A conductive rubber elastic material is stably provided which can produce a charging member that may less vary in electrical resistance even with changes in applied voltage, promises uniform electrical properties, has charge characteristics not affected by changes in environments such as temperature and humidity, and enables a charging object member such as a photosensitive member to be kept from being contaminated. It is a conductive rubber elastic material which contains a matrix containing at least one ionically conductive rubber selected from the group consisting of epichlorohydrin rubber, epichlorohydrin-ethylene oxide rubber, epichlorohydrin-ethylene oxide-allyl glycidyl ether rubber, acrylonitrile-butadiene rubber and a hydrogenated product of acrylonitrile-butadiene rubber and domains composed of an electronically conductive rubber material containing i) a rubber having a butadiene skeleton and ii) carbon black, and the rubber having a butadiene skeleton is modified at a molecular terminal thereof with a specific atomic group.

Owner:CANON KK

Vulcanized rubber laminate

The invention provides a vulcanized rubber laminate obtained by firmly bonding an unvulcanized epichlorohydrin rubber layer and an organic peroxide-containing fluororubber layer. The laminate is obtained by thermal adhesion a layer of an unvulcanized epichlorohydrin rubber composition to a layer of an unvulcanized fluororubber composition. The epichlorohydrin rubber composition comprises 1) an unvulcanized epichlorohydrin rubber containing 3 to 15 mol % of allyl glycidyl ether unit, 2) quinoxaline-based vulcanizing agents, mercaptotriazine-based vulcanizing agents or bisphenol-based vulcanizing agents, and 3) 1,8-diazabicyclo(5,4,0)undecene-7 salts, 1,5-diazabicyclo(4,3,0)nonene-5 salts, quaternary ammonium salts, quaternary phosphonium salts, basic white carbons or an alkaline metal salt of higher fatty acid the fluororubber composition comprises an fluororubber and an organic peroxide-based vulcanizing agent.

Owner:OSAKA SODA CO LTD

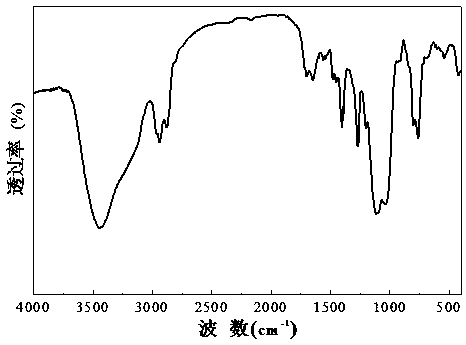

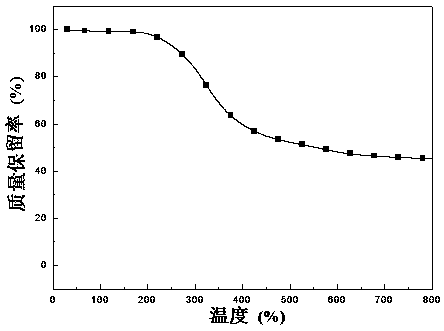

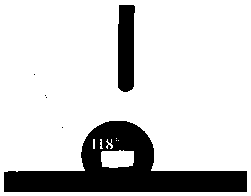

Polysiloxane fire retardant containing nitrogen, phosphorus and silicon, and preparation method thereof

The invention discloses a polysiloxane fire retardant containing nitrogen, phosphorus and silicon, and a preparation method thereof. The polysiloxane fire retardant is prepared through utilizing mutual reaction of hydrogen-containing silicone oil, allyl glycidyl ether, isocyanate silane and a phosphorus-containing active matter in a solvent. The fire retardant has a certain degree of polymerization, organic groups such as a benzene ring and longer -Si-O-Si- main chain are contained in a molecule, the fire retardant has favorable hydrophobicity, a contact angle reaches 118 degrees, and the compatibility of the fire retardant and a high polymer can be remarkably improved; the fire retardant is rich in carbon, nitrogen, phosphorus and silicon elements so as to have a synergistic flame retardant effect of various flame retardant elements, a high carbonization ability, and high flame retardant efficiency; the fire retardant has higher heat stability, and can meet the processing requirement of the high polymer; the polysiloxane fire retardant is rich in -Si-O-CH2CH3 group, and can be used as a modifying agent to modify other substances so as to obtain a functional fire retardant.

Owner:TAIYUAN UNIV OF TECH

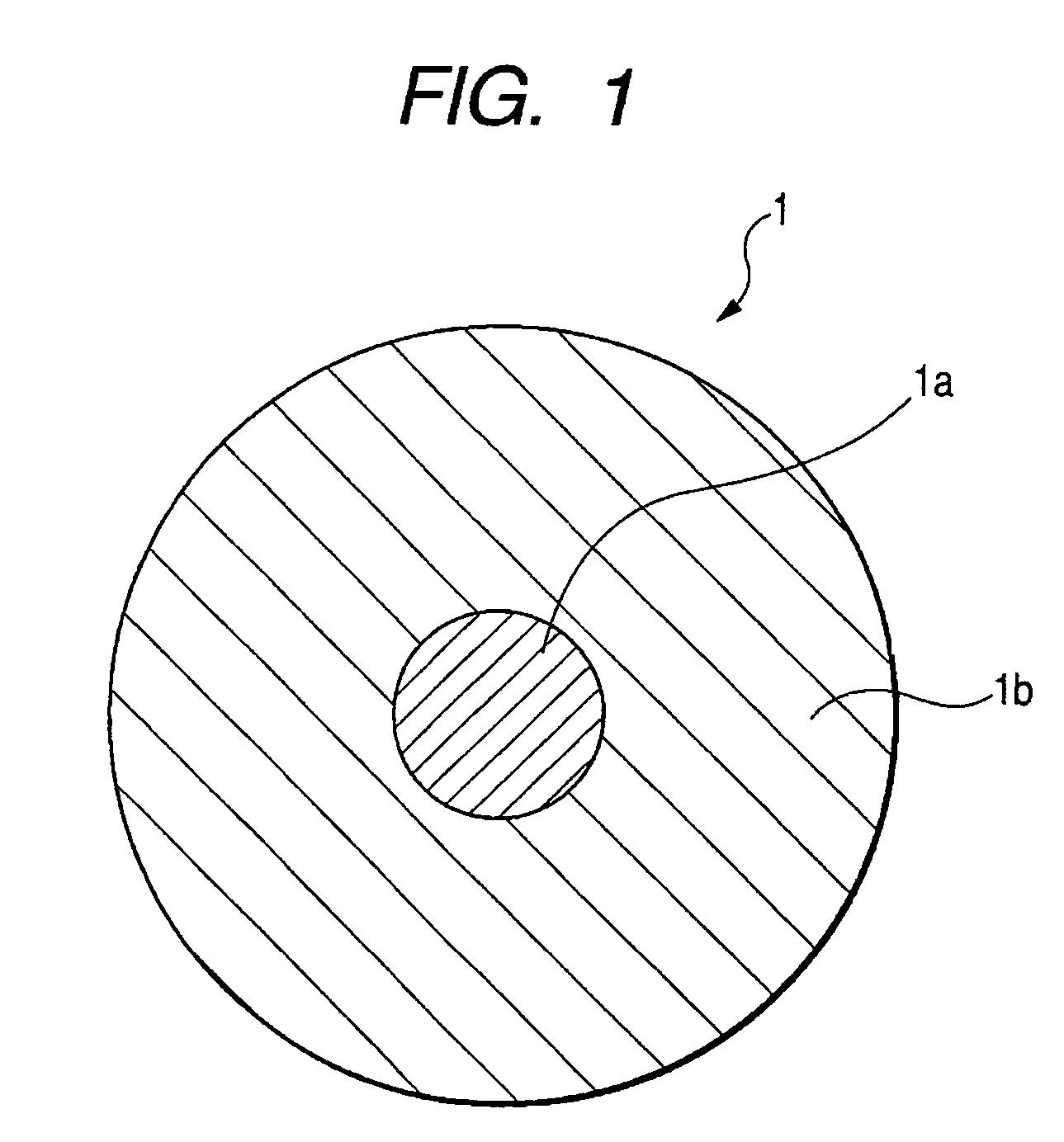

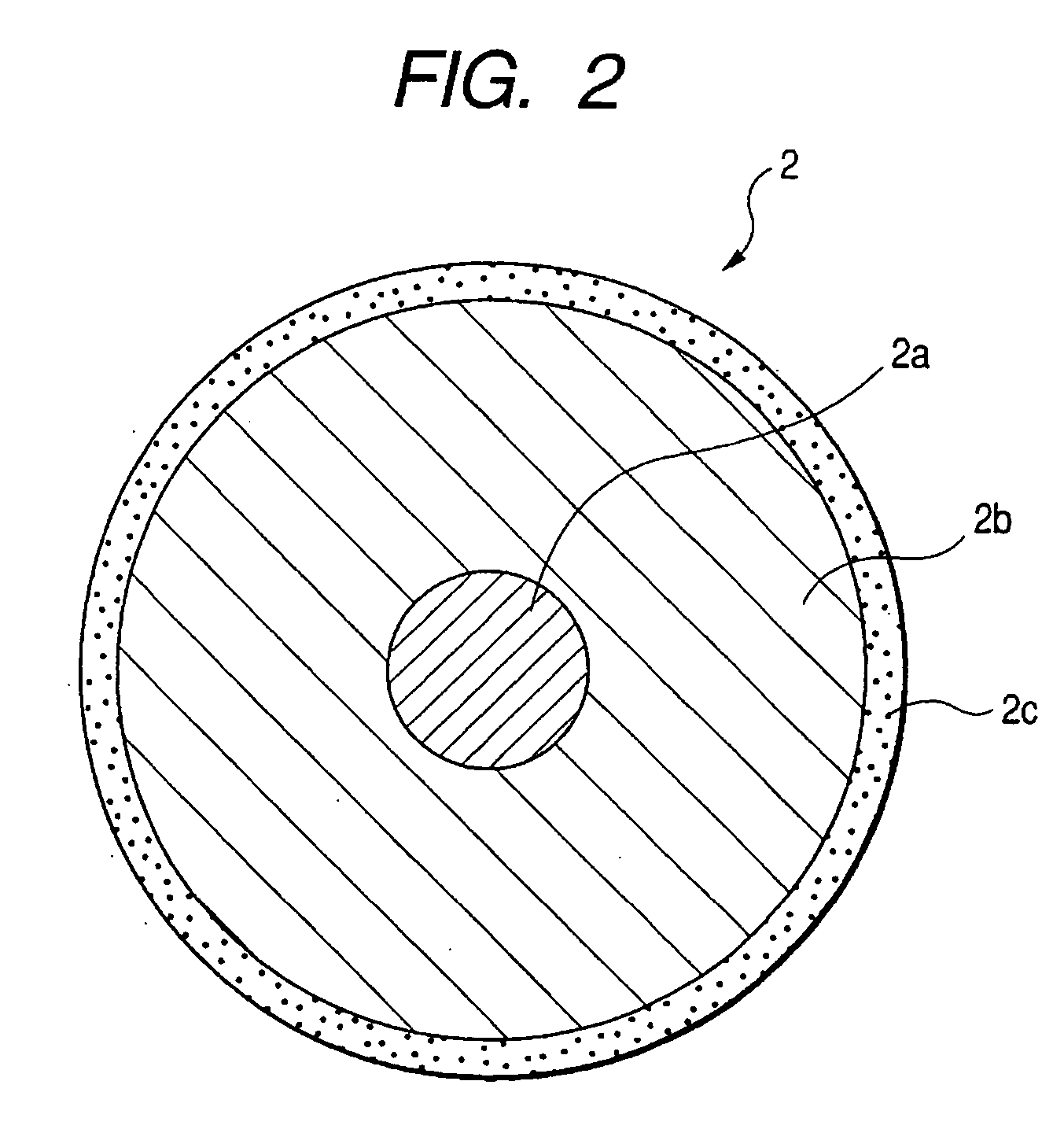

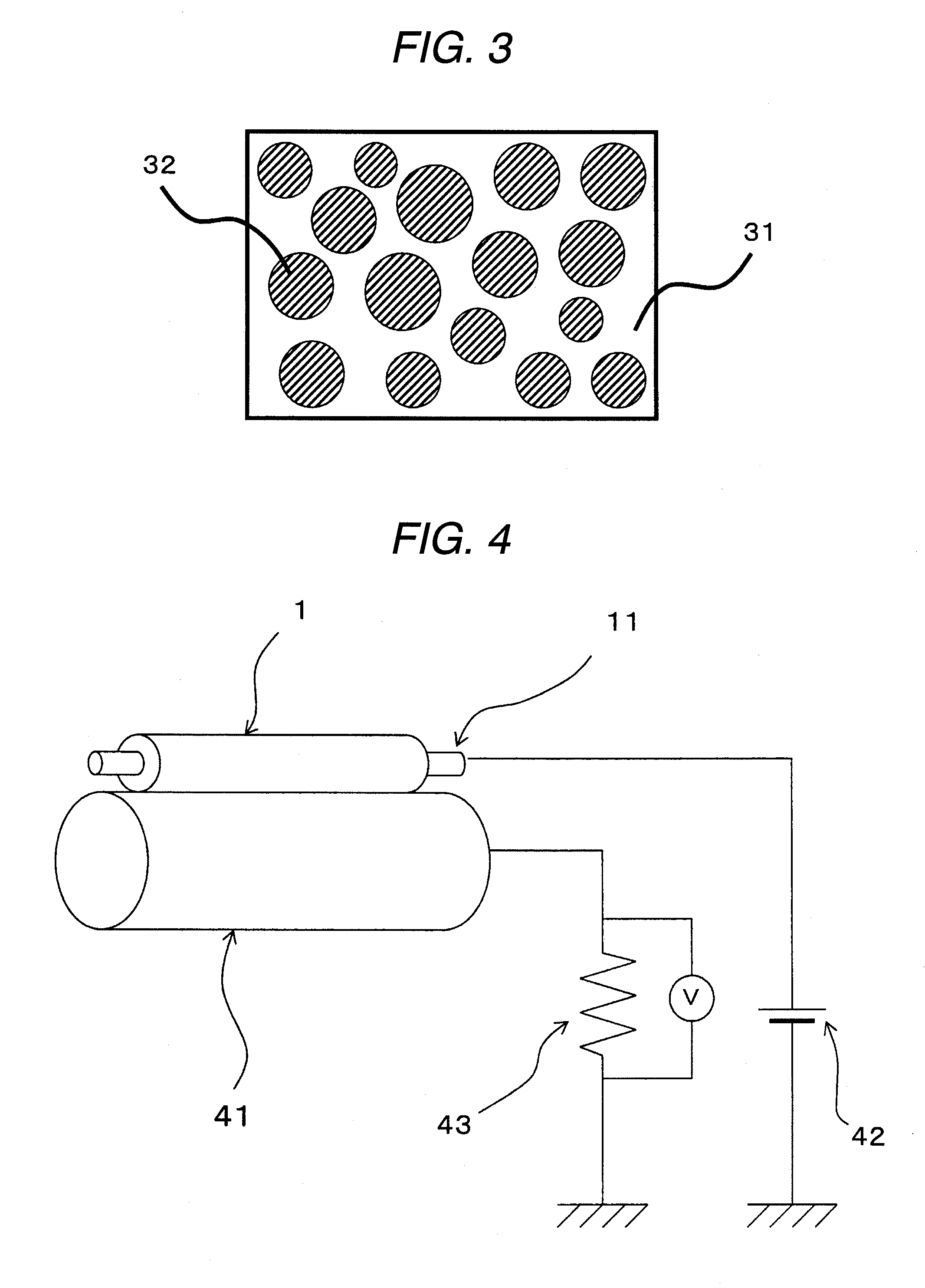

Conductive rubber roller

InactiveUS20060252620A1Low resistivityIncreased durabilityLiquid surface applicatorsLayered productsPolymer scienceAllyl glycidyl ether

A conductive rubber roller comprising a conductive core material and provided thereon a rubber layer; the rubber layer being formed by using a rubber composition containing as rubber components at least a polar rubber and an ethylene oxide-propylene oxide-allyl glycidyl ether terpolymer; the ethylene oxide-propylene oxide-allyl glycidyl ether terpolymer having a melt peak temperature of from 20 to 30° C. and a melt enthalpy change ΔH of from 40 to 70 mJ / mg as measured with a differential scanning calorimeter; and the allyl glycidyl ether in the ethylene oxide-propylene oxide-allyl glycidyl ether terpolymer being in a copolymerization ratio of from more than 10 mol % to 20 mol % or less.

Owner:CANON KK

Preparation method of quaternary copolymer block organic silicon oil

The invention relates to a preparation method of quaternary copolymer block organic silicon oil. The preparation method is characterized by comprising the following steps of: A, preparation of a hydrogen-containing silicon oil intermediate I: blocking with a hydrogen-containing sealing agent by taking the polysiloxane as a main raw material to obtain the hydrogen-containing silicon oil intermediate I; B, preparation of an epoxy-terminated block organic silicon oil intermediate II: adding the intermediate I and allyl glycidyl ether to obtain the epoxy-terminated block organic silicon oil intermediate II; and C, preparation of a finished product: grafting anhydrous piperazine and amino-terminated polyether to the main chain of the intermediate II, and finally obtaining the quaternary copolymer block organic silicon oil. Through the invention, the prepared quaternary copolymer block organic silicon oil does not cause the yellowing phenomenon, and has good hydrophily and strong emulsion stability; and good comprehensive handfeel can be obtained by applying a small amount of the quaternary copolymer block organic silicon oil to the textile.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

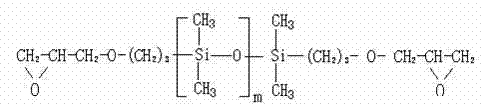

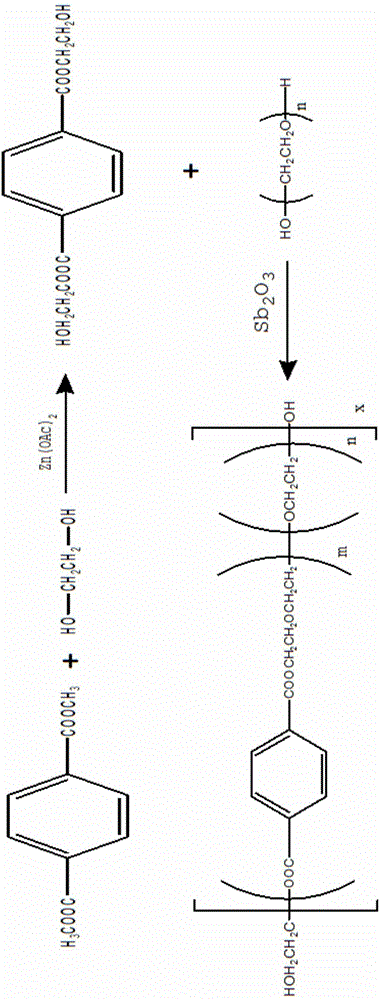

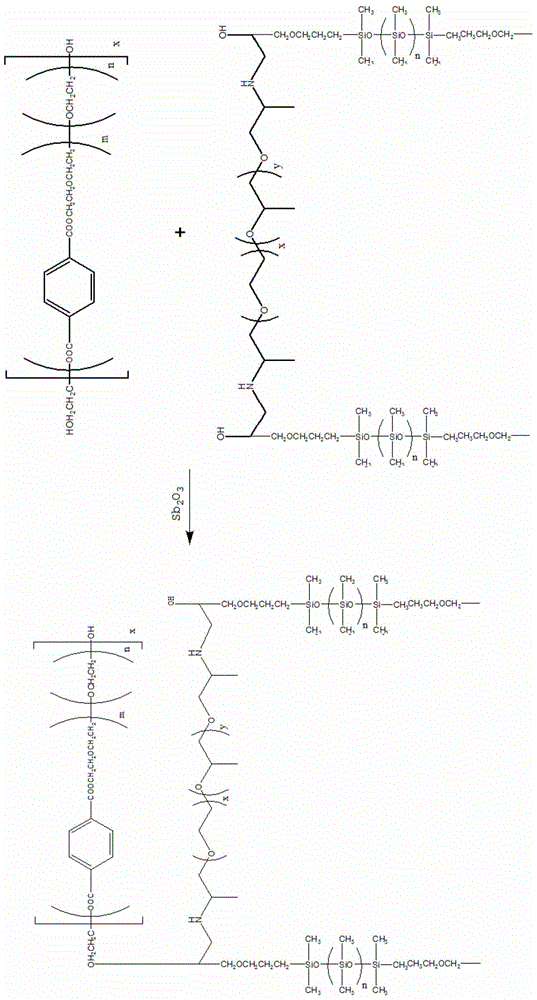

Preparation method of polyether polyester modified silicone oil

Belonging to the technical field of organic silicon products, the invention relates to a preparation method of polyether polyester modified silicone oil. Involving ester exchange reaction and condensation polymerization techniques, the method consists of: firstly adding dimethyl terephthalate, ethylene glycol and zinc acetate into a reaction container to undergo ester exchange reaction, adding ethylene terephthalate, antimony oxide and polyethylene oxide into a reaction container to undergo condensation polymerization so as to obtain a polyether polyester segmented copolymer; then terminal hydrogen-containing silicone oil, allyl glycidyl ether and a Pt catalyst are added into a reaction container to undergo heat preservation reaction, performing vacuum pumping to remove low-boiling-point substances; adding polyether amine and a solvent into terminal epoxy modified silicone oil to undergo reflux reaction, conducting pressure reduction to remove the solvent so as to obtain polyether amino modified silicone oil; and mixing the polyether polyester segmented copolymer and the polyether amino modified silicone oil evenly, and carrying out heat preservation reaction to obtain the polyether polyester modified silicone oil. The emulsion has good stability, is difficult to yellow and stick rolls. Also the use effect is better than that of compounding, and the tedious compounding procedure in the application process is omitted.

Owner:安徽科光新材料有限公司

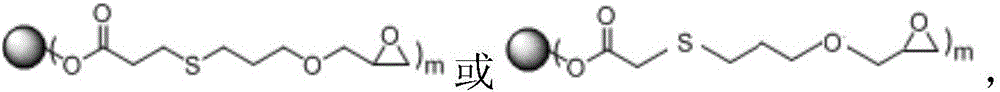

Phosphorus-nitrogen containing halogen-free flame-retardant hyperbranched epoxy resin and preparation method thereof

The invention discloses a phosphorus-nitrogen containing halogen-free flame-retardant hyperbranched epoxy resin and a preparation method thereof. The preparation method for the phosphorus-nitrogen containing halogen-free flame-retardant hyperbranched epoxy resin comprises the steps: firstly, enabling 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, itaconic anhydride, polyol amine and trimethylolpropane to react with one another under an effect of an acidic ionic liquid catalyst to obtain hydroxyl-terminated hyperbranched polyester-amide; and enabling hydroxyl-terminated hyperbranched polyester-amide to react with mercaptoacetic acid or mercaptopropionic acid and allyl glycidyl ether in sequence to obtain the phosphorus-nitrogen containing halogen-free flame-retardant hyperbranched epoxy resin. The phosphorus-nitrogen containing halogen-free flame-retardant hyperbranched epoxy resin and the preparation method thereof, disclosed by the invention, have the advantages of simple process, narrow intermediate product molecular weight distribution, higher purity, good enhancing, toughening and flame retardant functions of the final product and wide application prospect.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

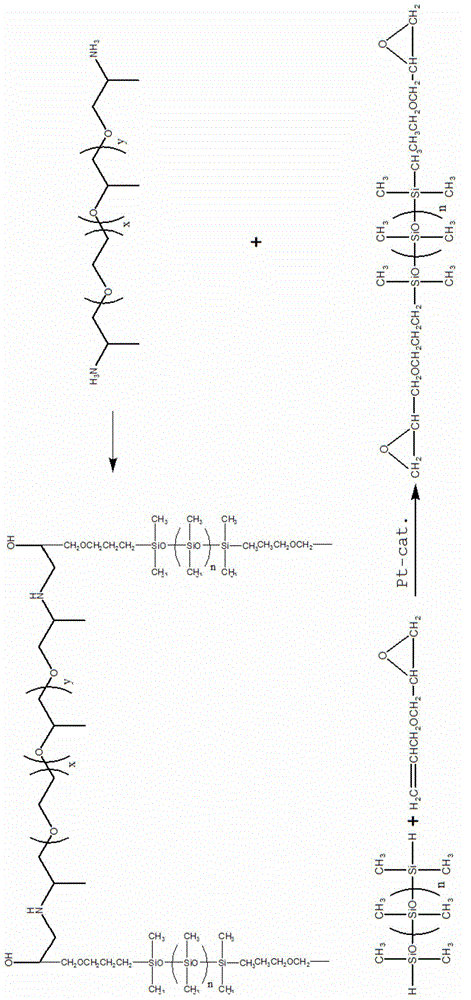

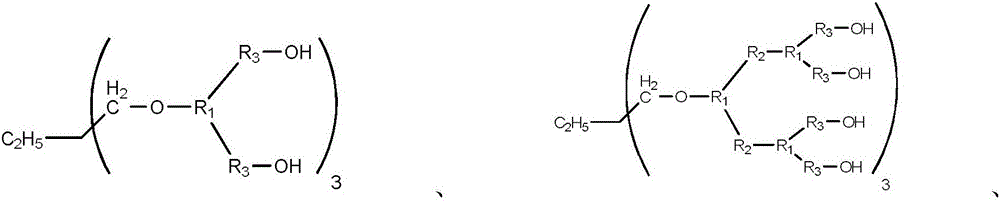

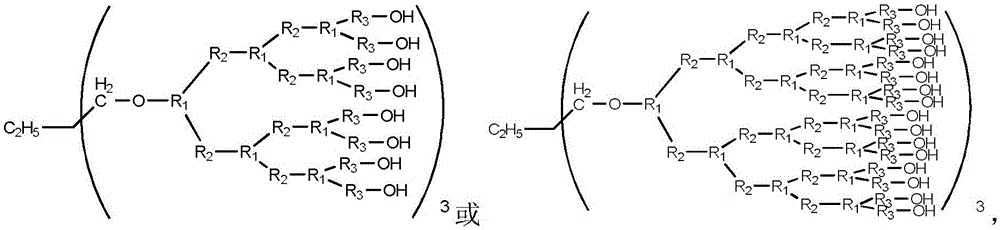

Hyperbranched polymer and its modification and application

The invention relates to a hyperbranched polymer, hyperbranched polymer modified organic silicone oil and application of the organic silicone oil. According to the invention, the hyperbranched polymer is mainly obtained through the reaction of polyol, acrylate and amine compounds; and hydrogen-containing silicone oil is modified with the hyperbranched polymer, allyl polyether and allyl glycidyl ether which are used as modifying agents, and the obtained modified silicone oil can well disperse an organic pigment with a low-polar surface or polar-free surface.

Owner:SHANGHAI GANTIAN OPTICAL MATERIALS

Immobilized catalytic synthesis method of allyl glycidyl ether molecular sieve

ActiveCN104592166AHigh selectivity of the main reactionLess side effectsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxySynthesis methods

The invention relates to an immobilized catalytic synthesis method of an allyl glycidyl ether molecular sieve. According to the method, allyl alcohol and epoxy chloropropane at a feed weight ratio of (1.2-2): 1 are adopted as raw materials and are subjected to ring-opening reaction in the presence of a mixed catalyst of concentrated sulfuric acid and trifluoromethanesulfonic acid which are immobilized on the molecular sieve at an ring-opening reaction temperature of 50-70 DEG C, wherein the addition of concentrated sulfuric acid is 10%-30% of mass of the molecular sieve, the addition of trifluoromethanesulfonic acid is 10%-30% of mass of the molecular sieve, and the usage amount of the catalyst is 1-5% of the total mass of the reactants. The novel immobilized catalyst is high in main ring-opening reaction selectivity, small in secondary reactions and low in device corrosion; after the ring-opening reaction is completed, the catalyst easily separates from reaction products and can be recycled for at least 10 times after being separated, the environmental pollution is avoided, the production cost is decreased and meanwhile, the problem that excessive allyl alcohol is smoothly recovered and recycled is solved.

Owner:HUBEI GREENHOME MATERIALS TECH INC

Click chemistry based preparation method of carbon nanotube grafted carbon fiber reinforcement

The invention discloses a click chemistry based preparation method of carbon nanotube grafted carbon fiber reinforcement. The preparation method specifically comprises the following steps: carrying out surface treatment on carbon fibers by utilizing a mixed acid to obtain acid treated carbon fibers; obtaining thiol-containing silane coupling agent grafted carbon fibers through reaction between the acid treated carbon fibers and a thiol-containing silane coupling agent; successively treating a carbon nanotube by utilizing nitric acid and hydrogen peroxide to obtain an oxidized carbon nanotube; obtaining an amino-containing silane coupling agent grafted carbon nanotube through reaction between the oxidized carbon nanotube and an amino-containing silane coupling agent; obtaining an allyl glycidyl ether grafted carbon nanotube through reaction between allyl glycidyl ether and the amino-containing silane coupling agent grafted carbon nanotube; finally obtaining the carbon nanotube grafted carbon fiber reinforcement by utilizing ultraviolet light to trigger thiol-ene click reaction. The preparation method has the advantages that the obtained carbon nanotube grafted carbon fiber reinforcement has the advantages of high surface roughness, high carbon nanotube grafting ratio, good adhesion to matrices, and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

Conductive thermoplastic elastomer composition, method of producing same, and molding

InactiveUS7744781B2Good dispersionEasy to processConductive materialOrganic conductorsThermoplastic elastomerEthylene oxide-propylene oxide copolymer

A conductive thermoplastic elastomer composition comprising a component (A) containing a thermoplastic resin or / and a thermoplastic elastomer; a component (B) comprising an ionic-conductive agent containing an ethylene oxide-propylene oxide copolymer or / and an ethylene oxide-propylene oxide-allyl glycidyl ether copolymer and a metal salt contained in the ethylene oxide-propylene oxide copolymer or / and the ethylene oxide-propylene oxide-allyl glycidyl ether copolymer; and a component (C) comprising an ethylene-acrylic ester-maleic anhydride copolymer.

Owner:SUMITOMO RUBBER IND LTD

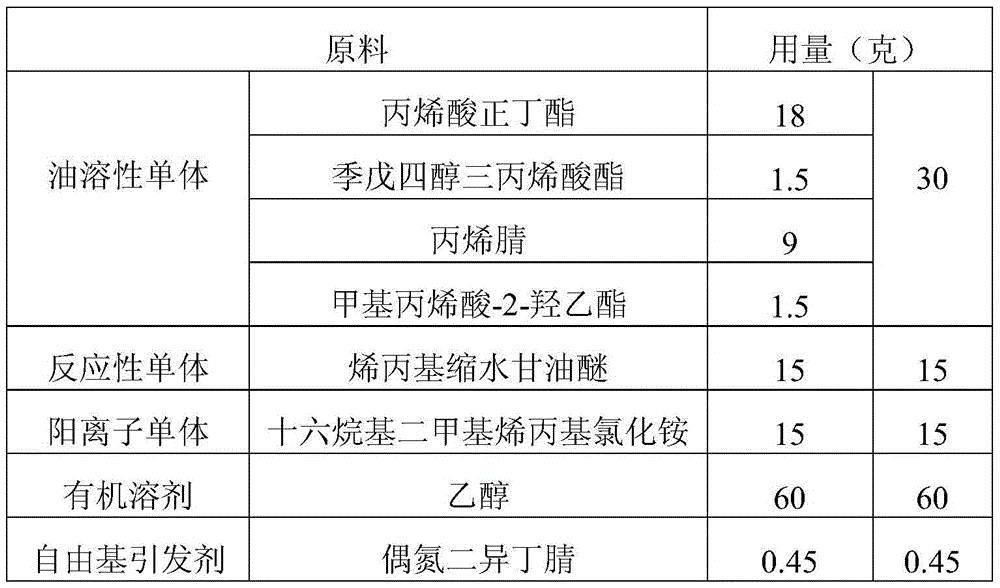

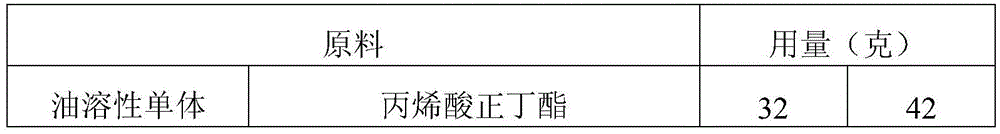

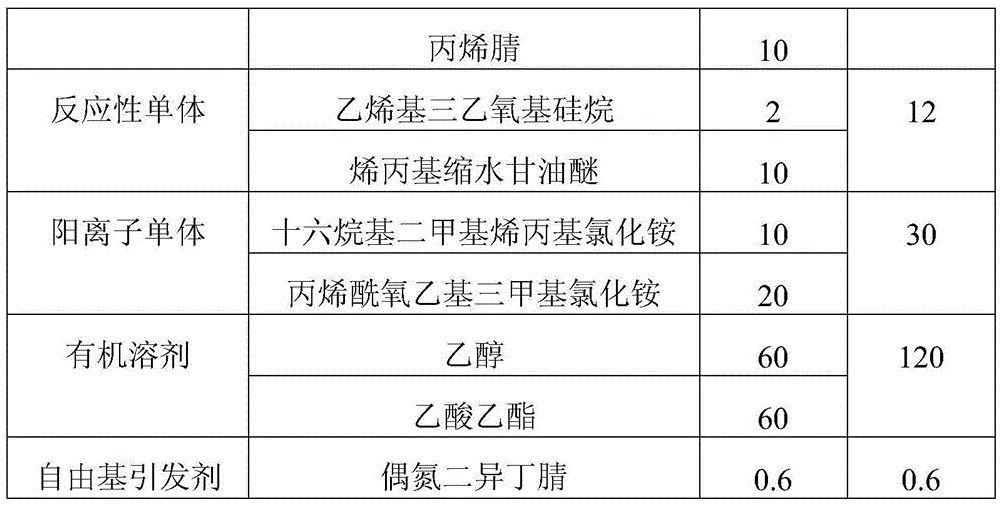

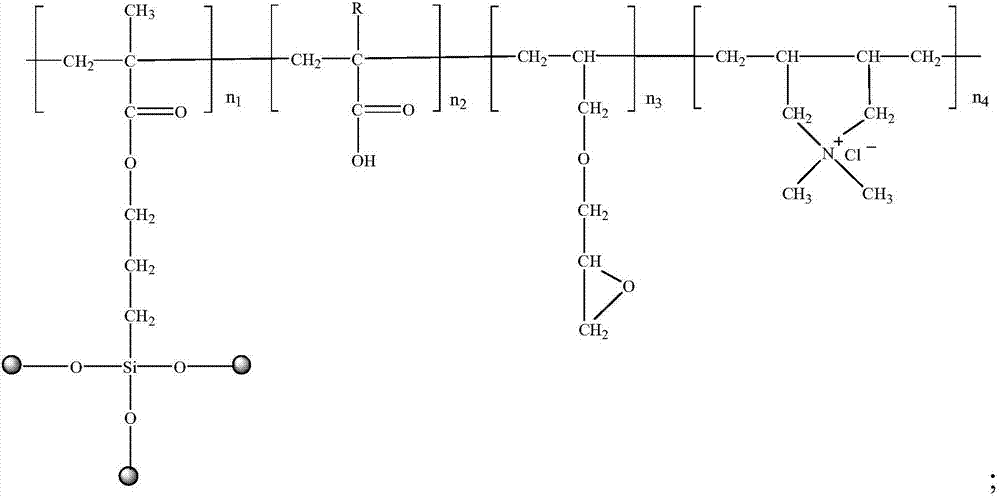

Cationic color fixing agent and preparation method and application thereof

The invention provides a cationic color fixing agent and a preparation method and application thereof. The cationic color fixing agent is obtained by polymerization reaction of an oil-soluble monomer, a cationic monomer and a reactive monomer in a solvent under the action of a radical initiator, wherein the oil-soluble monomer is one or the combination of several of styrene, acrylonitrile and acrylate; the cationic monomer is one or the combination of acryloxyethyl alkyl quaternary ammonium salt and / or allyl alkyl quaternary ammonium salt; the reactive monomer is one or the combination of several of allyl glycidyl ether, hydroxyl-containing acrylics, vinyl trimethoxy silane, vinyl triethoxy silane, acrylamide, crylic acid and methacrylic acid. The cationic color fixing agent is insoluble in water and can be dissolved in a weak polar solvent and / or non-polar solvent; besides, after non-aqueous solvent dyeing of reactive dyes, the cationic color fixing agent can be directly used in the on-going fixing process without washing.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

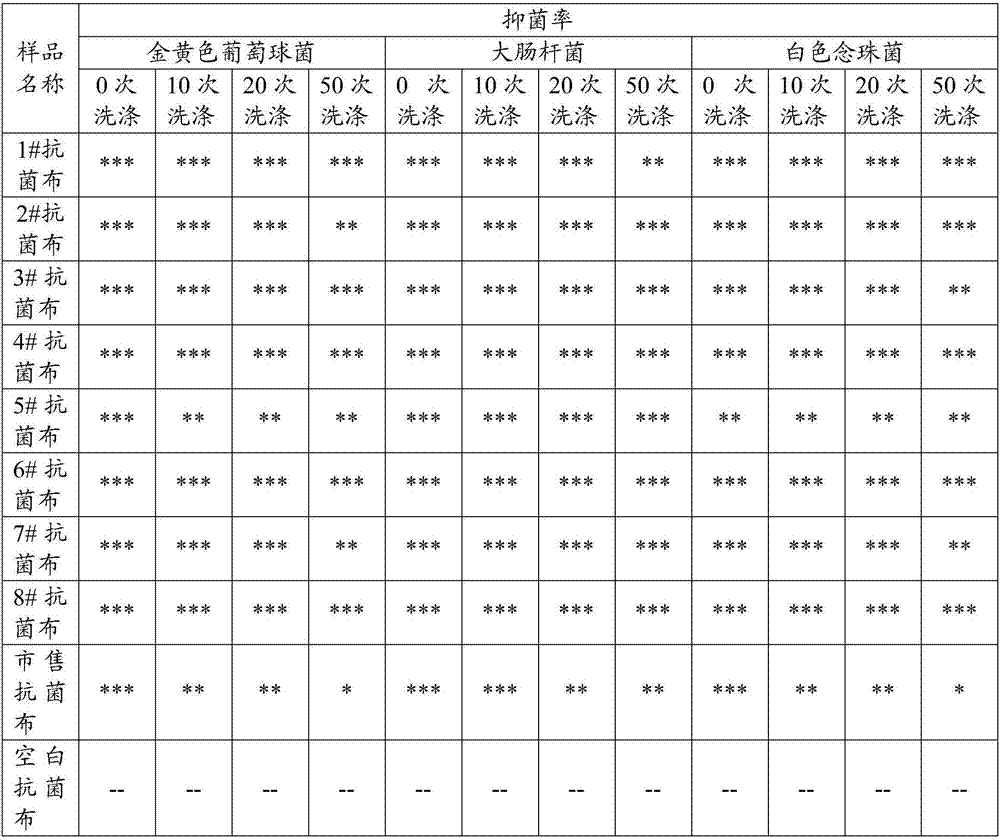

Polymer/Ag doped nanometer ZnO long-acting antibacterial and mildew-proof finishing agent for cotton fabric and preparation method of finishing agent

InactiveCN106283617AGood antibacterial and antifungal effectSimple manufacturing methodBiochemical fibre treatmentVegetal fibresIn situ polymerizationDissolution

The invention relates to a polymer / Ag doped nanometer ZnO long-acting antibacterial and mildew-proof finishing agent for a cotton fabric and a preparation method of the finishing agent. The existing antibacterial material for the cotton fabric is low in antibacterial performance, great in one-time dissolution, and not lasting in the antibacterial and mildew-proof performance. Ag doped nanometer ZnO is prepared by using zinc acetate and silver nitrate as precursors by a coprecipitation method; the polymer / Ag doped nanometer ZnO long-acting antibacterial and mildew-proof finishing agent is prepared by using Ag doped ZnO, allyl glycidyl ether and dimethyl diallyl ammonium chloride as raw materials via an in-situ polymerization method. The antibacterial and mildew-proof finishing agent is applied to the afterfinish of the cotton fabric; the Ag doped ZnO in the composite material and N+ in the dimethyl diallyl ammonium chloride can jointly resist bacteria to achieve the efficient antibacterial and mildew-proof performance; the hydroxyl of the cotton fabric surface can be crosslinked with the epoxy group in the polymer; the long-acting antibacterial and mildew-proof performance of the cotton fabric is improved; meanwhile, the injury to the human body caused by one-time dissolution of the nanometer antibacterial material used by the fabric is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Organic silicon hydrogen-containing tackifying crosslinking agent for addition type silicon rubber and preparation method thereof

InactiveCN108384014ASimple preparation processMild reaction conditionsCyclohexene oxideRefractive index

The invention belongs to the technical field of a tackifying crosslinking agent, and particularly relates to an organic silicon hydrogen-containing tackifying crosslinking agent for addition type silicon rubber and a preparation method thereof. The tackifying crosslinking agent is prepared by performing addition reaction on high-hydrogen-content silicon oil or D4H and vinyl cyclohexene oxide or allyl glycidyl ether and then adding inhibitors. The process is simple; the reaction conditions are mild; the therepeatability and the controllability are good; the impurities in the reaction process are few; organic solvents are not used; the environment is protected; no pollution is caused. The obtained tackifying crosslinking agent has the stable performance; the tackifying and crosslinking effects can be achieved at the same time. The compatibility with silicon rubber is good; no catalyst poisoning phenomenon exists; the bonding performance of the addition type silicon rubber with metal suchas copper foil can be obviously improved; in addition, the refractive index of the organic silicon hydrogen-containing tackifying crosslinking agent is adjustable and controllable in a range of 1.40to 1.55, so that the tackifying crosslinking agent is applicable to the silicon rubber with (high and low) different refractive indexes.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of cellulose ion conductive hydrogel and prepared hydrogel prepared

ActiveCN109503765AFrost resistantImprove ionic conductivityMeasurement devicesConductive materialCelluloseEvaporation

The invention discloses a preparation method of a cellulose ion conductive hydrogel and the prepared hydrogel. The preparation method comprises the following steps: S1, adding cellulose in a water solution of sodium hydroxide and urea, dissolving at the temperature of -5 DEG C to -20 DEG C, and stirring to obtain a transparent cellulose solution; S2, dropwise adding allyl glycidyl ether in the cellulose solution, reacting for 20-30 hours at the temperature of 25-35 DEG C and under the protection of an inert gas; S3, cleaning a product obtained in the step S2 with diethyl ether, performing rotary evaporation so as to remove the residual diethyl ether to obtain an allyl cellulose solution; and S4, adding ammonium persulfate in the allyl cellulose solution, stirring for 3-10 minutes, then centrifuging for defoaming, and reacting for 20-30 hours at the temperature of 25-35 hours so as to obtain the hydrogel. The cellulose ion conductive hydrogel provided by the invention has high stretchability, high compressibility, high freezing resistance and excellent ionic conductivity.

Owner:SOUTH CHINA UNIV OF TECH

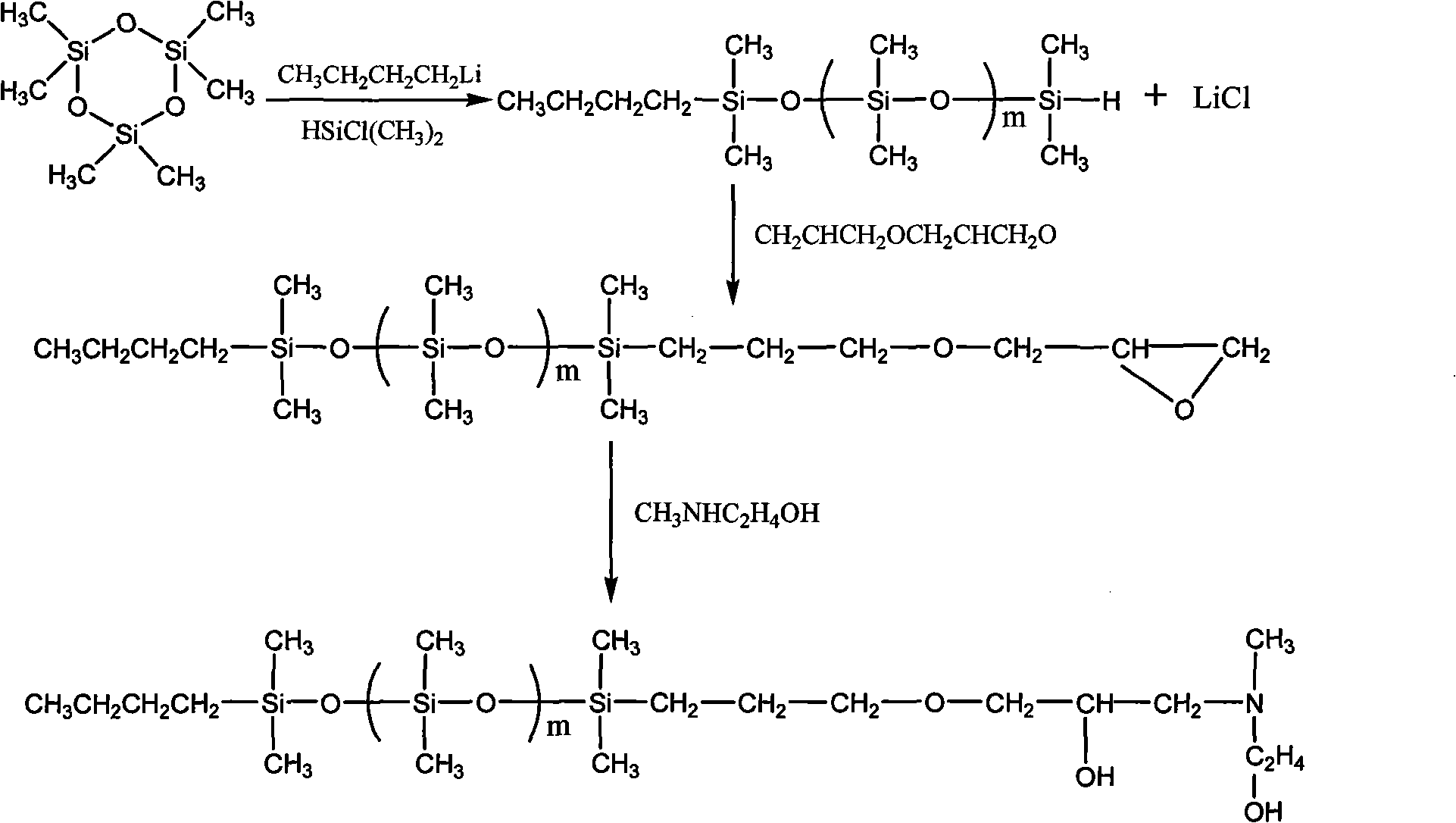

Dihydroxyl-terminated polydimethylsiloxane and preparation thereof

The invention provides a new method for preparing single-ended double-hydroxyl alkyl polydimethylsiloxane and the preparation method of the invention is different from prior synthetic methods. The preparation method takes D3 (Hexamethylcyclotrisiloxane), allyl glycidyl ether and methylaminoethanol as starting raw materials which go through three-step reactions of anion ring-opening polymerization, hydrosilylation and epoxy ring-opening to synthesize the target product of the single-ended double-hydroxyl alkyl polydimethylsiloxane of which the product purity is over 98 percent. The invention has the advantages of simple and convenient reaction steps, easily accessible raw materials, low production cost, high product yield, high purity, etc.

Owner:QILU UNIV OF TECH

Preparation method of composite antibacterial finishing agent

The invention relates to a preparation method of a composite antibacterial finishing agent. The preparation method comprises the following steps: modifying nano zinc oxide by a silane coupling agent containing double bonds to obtain modified active nano zinc oxide; providing reaction raw materials; taking water as the solvent, and carrying out polymerization reactions among active nano zinc oxide, dimethyl diallyl ammonium chloride, carboxyl acrylic acid monomers, and allyl glycidyl ether in the presence of an initiator to obtain the composite antibacterial finishing agent. The composite antibacterial finishing agent prepared by the provided preparation method is a complex of quaternary ammonium salt copolymer and nano zinc oxide. Through the synergistic effect between quaternary ammonium cations and nano zinc oxide, the antibacterial properties of inorganic materials and organic materials can be fully exerted, the finishing agent can enable textiles to have a very good antibacterial performance, at the same time, the antibacterial finishing agent contains active groups that can interact with cotton fibers, and the antibacterial effect can last for a long term.

Owner:科凯精细化工(上海)有限公司

Wear resistant paint

Belonging to the technical field of paint, the invention relates to a wear resistant paint. According to a technical scheme adopted by the invention, the wear resistant paint comprises the following components: epoxy resin, FEVE fluorocarbon resin, ceramic micro-powder, titanium dioxide, graphite fluoride, silicon carbide micro-powder, an epoxy resin curing agent, allyl glycidyl ether of monoepoxy, 10% silicone oil, a leveling agent, and a curing agent. The paint produced according to the technical scheme has the advantages of high mechanical strength, good impact resistance, good adhesion, good scratch and wear resistance, and low cost.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com