Cationic color fixing agent and preparation method and application thereof

A cationic color-fixing agent and color-fixing agent technology, which can be used in dyeing, textiles and papermaking, and can solve problems such as inapplicability of weak polar or non-polar organic solvents, high operating requirements in the washing process, and easy occurrence of flocculation and precipitation. , to achieve the effect of easy control of the reaction process, excellent bactericidal and antibacterial performance, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

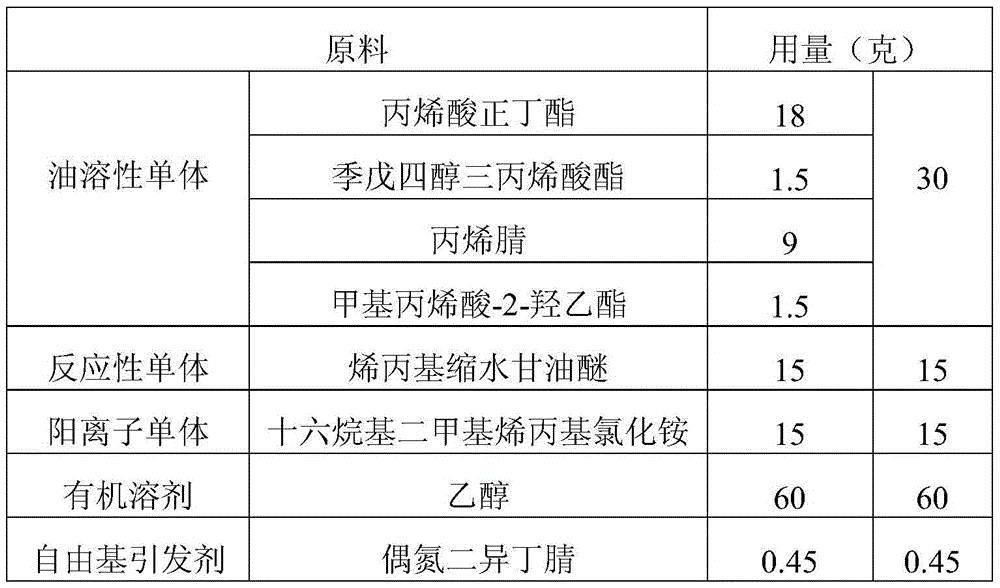

[0057] This embodiment provides a cationic color-fixing agent, and the raw material composition of the color-fixing agent is shown in Table 1.

[0058] The preparation method of this color fixing agent is as follows:

[0059] Add 60g of ethanol and all the monomers in the above table 1 (oil-soluble monomer, reactive monomer and cationic monomer) to the three-necked flask, stir and mix evenly, raise the temperature to 70°C, and add 0.3g of azobisisobutyl Nitrile, add 0.15 g of azobisisobutyronitrile after 2 hours of heat preservation, then raise the temperature to 80° C. to continue the reaction for 5 hours, terminate the polymerization reaction, and lower the temperature to obtain color fixing agent 1.

[0060] The raw material composition of table 1 color-fixing agent

[0061]

Embodiment 2

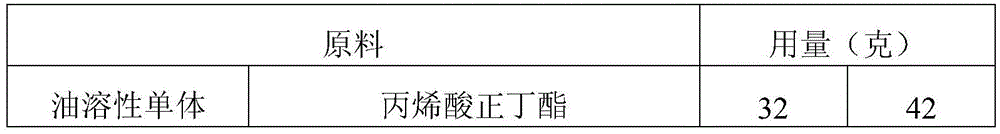

[0063] This embodiment provides a cationic color-fixing agent, and the raw material composition of the color-fixing agent is shown in Table 2.

[0064] The raw material composition of table 2 color-fixing agent

[0065]

[0066]

[0067] The preparation method of this color fixing agent is as follows:

[0068]Add 40g of ethanol, 40g of ethyl acetate, 16g of n-butyl acrylate, 5g of acrylonitrile, 1g of vinyltriethoxysilane, 4g of allyl glycidyl ether, 10g of hexadecyldimethylallyl into a three-necked flask ammonium chloride, 20g of acryloyloxyethyltrimethylammonium chloride, stir and mix evenly, raise the temperature to 70°C, and add 0.3g of azobisisobutyronitrile; Add the remaining monomer mixture (16g n-butyl acrylate, 5g acrylonitrile, 1g vinyltriethoxysilane, 6g allyl glycidyl ether, 20g ethanol and 20g ethyl acetate) dropwise to the drop funnel, within 2h After adding the monomer dropwise, add 0.3 g of azobisisobutyronitrile, then raise the temperature to 80° C. to...

Embodiment 3

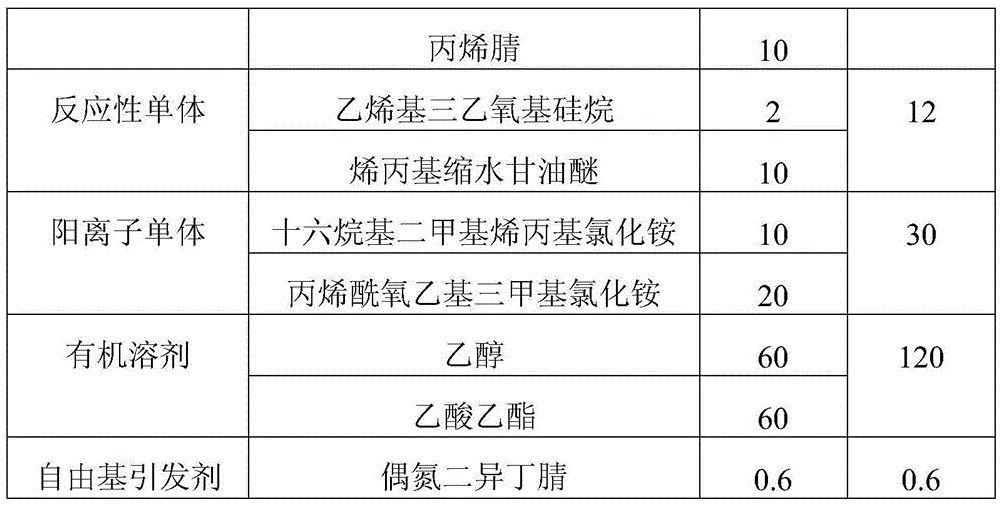

[0070] This embodiment provides a cationic color-fixing agent, and the raw material composition of the color-fixing agent is shown in Table 3.

[0071] The raw material composition of table 3 color-fixing agent

[0072]

[0073]

[0074] The preparation method of this color fixing agent is as follows:

[0075] Add 100g ethanol, 20g butyl acetate, 20g hexadecyldimethylallyl ammonium chloride, 20g acryloyloxyethyltrimethylammonium chloride, 20g dimethyldiallyl chloride to the three-necked flask Ammonium chloride, stir and mix evenly, heat up to 75°C, and add 0.5g of azobisisobutyronitrile; at 70-75°C, add the remaining monomer mixture (10g of acrylic acid n- Butyl ester, 2g pentaerythritol triacrylate, 8g methyl methacrylate, 8g isobutyl acrylate, 2g vinyltriethoxysilane, 15g allyl glycidyl ether, 20g glycidyl acrylate), dropwise within 2h After the monomer is finished, add 0.2 g of azobisisobutyronitrile, then raise the temperature to 80° C. to continue the reaction (re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com