Patents

Literature

302results about How to "Easy to aggregate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of forming a conductive wiring pattern by laser irradiation and a conductive wiring pattern

InactiveUS20060057502A1Poor adhesionEasily eliminateMaterial nanotechnologyPhotomechanical apparatusResistCompound (substance)

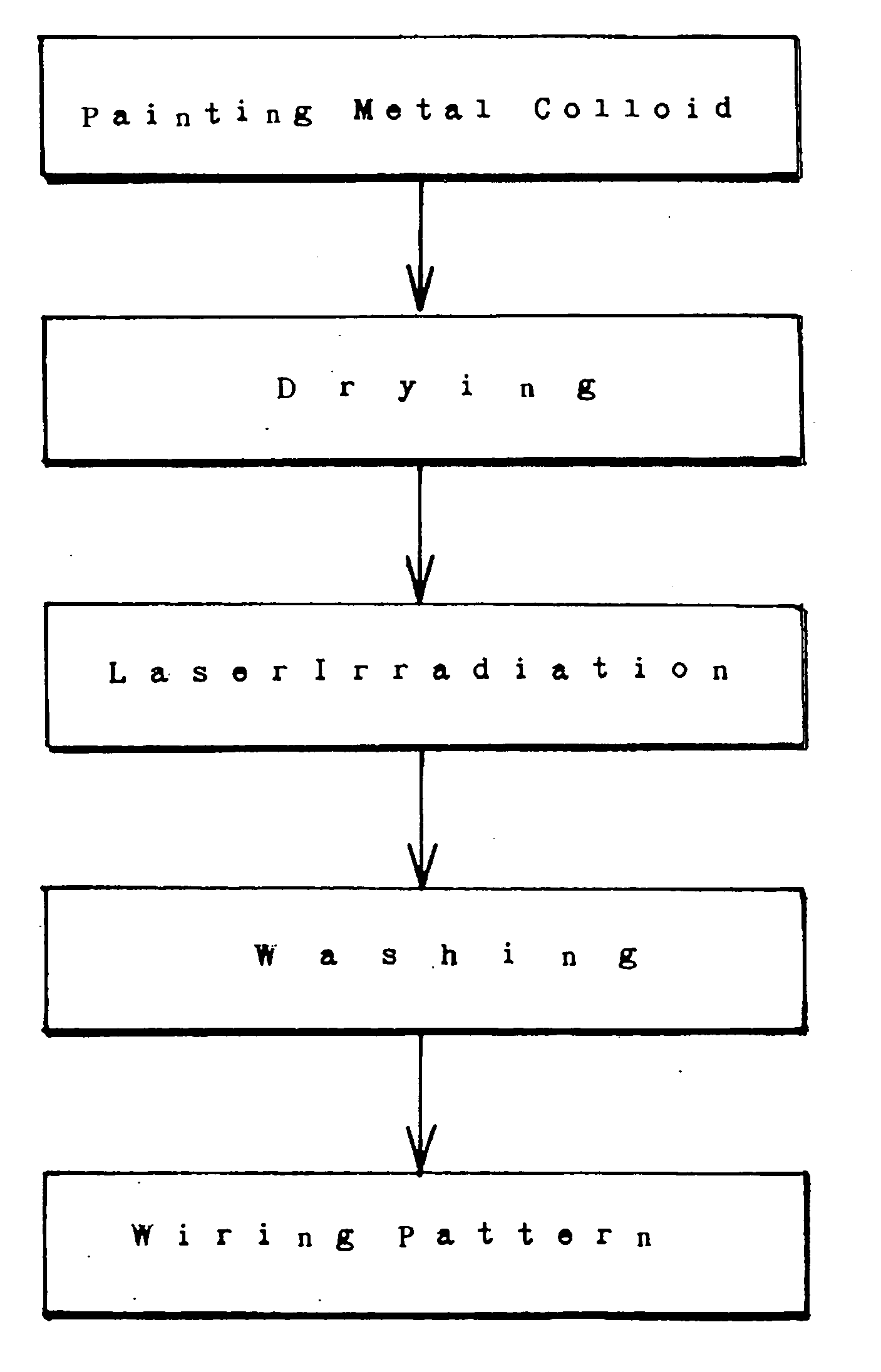

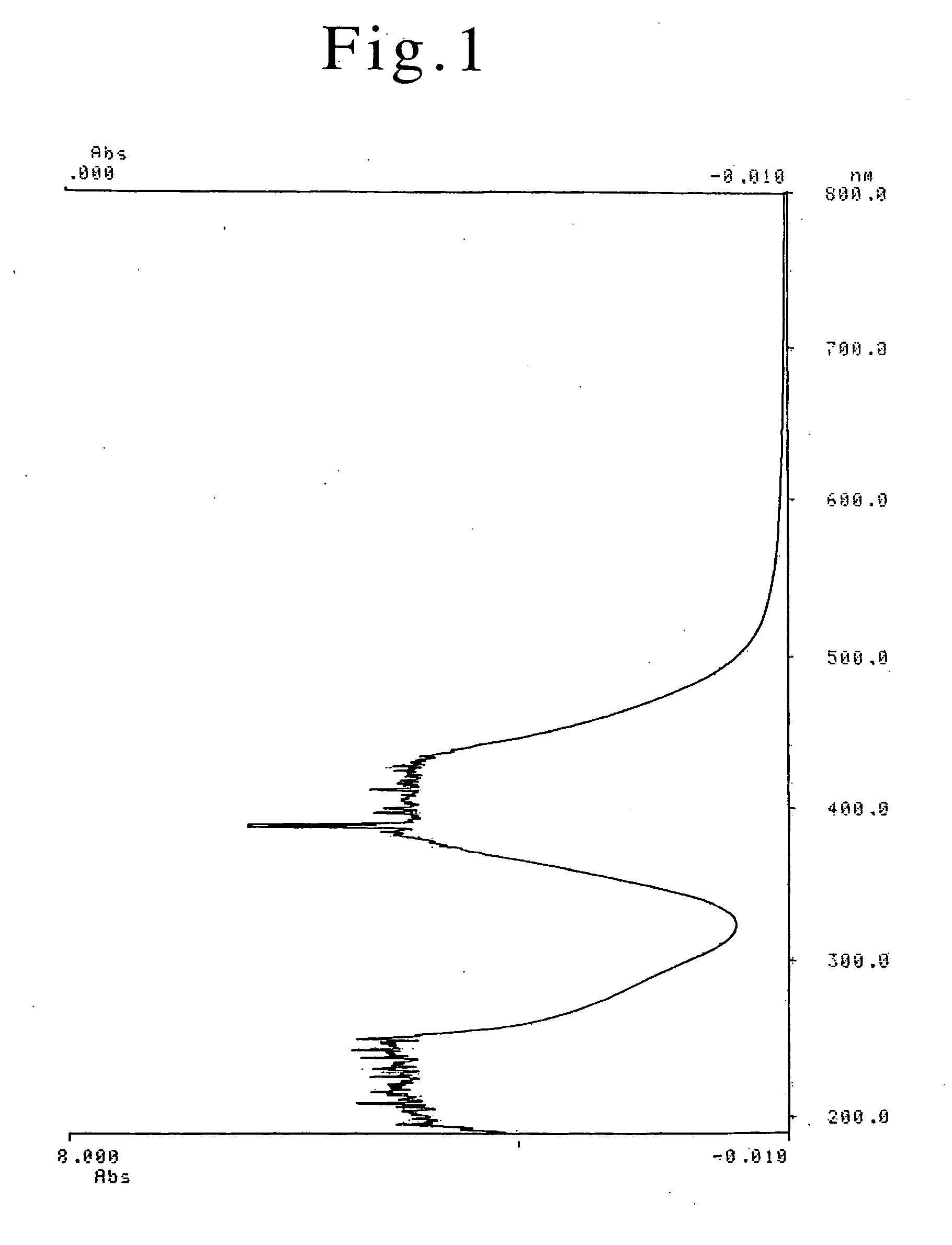

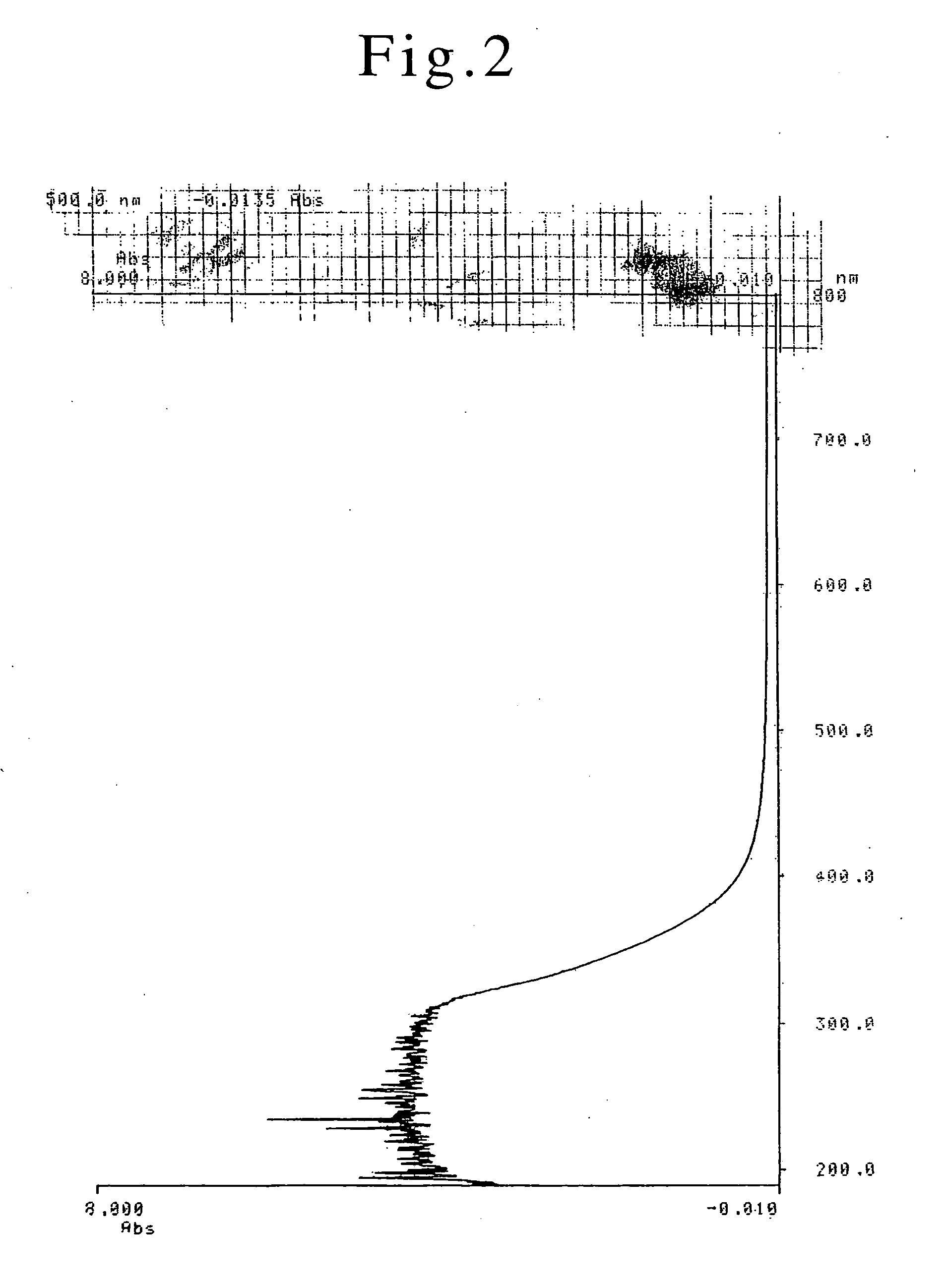

Fine wirings are made by a method having the steps of painting a board with metal dispersion colloid including metal nanoparticles of 0.5 nm-200 nm diameters, drying the metal dispersion colloid into a metal-suspension film, irradiating the metal-suspension film with a laser beam of 300 nm-550 nm wavelengths, depicting arbitrary patterns on the film with the laser beam, aggregating metal nanoparticles into larger conductive grains, washing the laser-irradiated film, eliminating unirradiated metal nanoparticles, and forming metallic wiring patterns built by the conductive grains on the board. The present invention enables an inexpensive apparatus to form fine arbitrary wiring patterns on boards without expensive photomasks, resists, exposure apparatus and etching apparatus. The method can make wirings also on plastic boards or low-melting-point glass boards which have poor resistance against heat and chemicals.

Owner:SUMITOMO ELECTRIC IND LTD

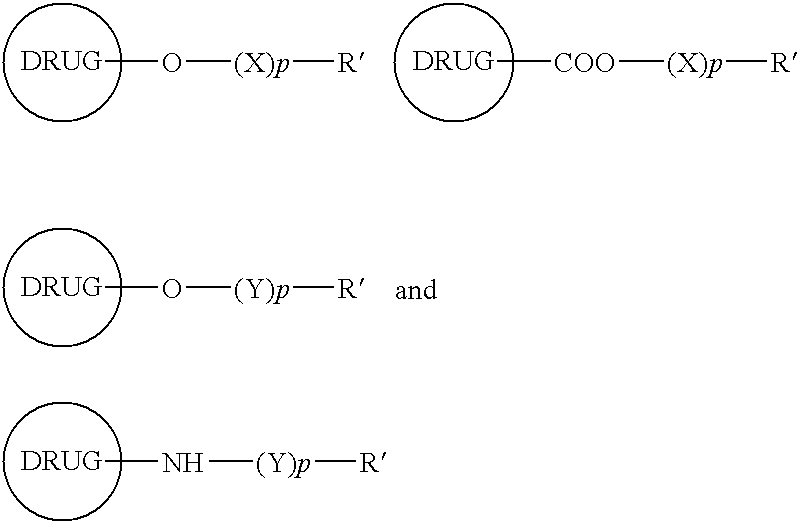

Functionalized drugs and polymers derived therefrom

ActiveUS20060172983A1Enhances native valueImprove usefulnessBiocideOrganic chemistryChemistryOligomer

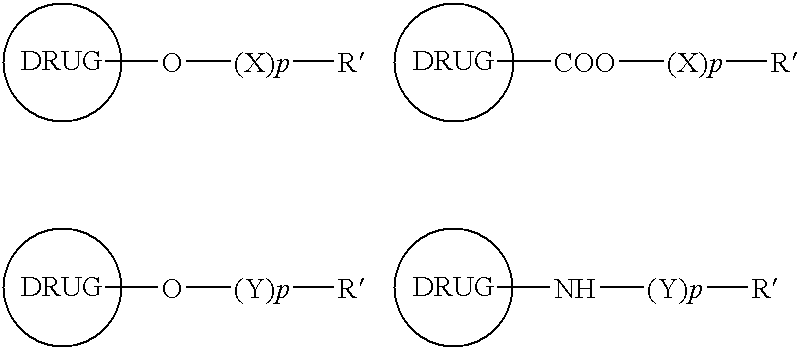

Compounds selected from: where DRUG-OH, DRUG-COOH and DRUG-NH2 are biologically active compounds; each X is independently selected from —CH2COO— (glycolic acid moiety), —CH(CH3)COO— (lactic acid moiety), —CH2CH2OCH2COO— (dioxanone moiety), —CH2CH2CH2CH2CH2COO— (caprolactone moiety), —(CH2)yCOO—, where y is 2-4 or 6-24 and —(CH2CH2O)zCH2COO—, where z is 2-24; each Y is independently selected from —COCH2O— (glycolic ester moiety), —COCH(CH3)O— (lactic ester moiety), —COCH2OCH2CH2O— (dioxanone ester moiety), —COCH2CH2CH2CH2CH2O— (caprolactone ester moiety), —CO(CH2)mO—, where m is 2-4 or 6-24 and —COCH2O(CH2CH2O)n— where n is between 2-24; R′ is hydrogen, benzyl or an alkyl group, the alkyl group being either straight-chained or branched; and p is 1-6. Multi-functional compounds and drug dimers, oligomers and polymers are also disclosed.

Owner:BEZWADA BIOMEDICAL LLC

Method for improving fermentability and nutritional property of gluten protein-free dough

ActiveCN104146020AImprove fermentation effectImproved ability to hold gasDough treatmentPre-baking dough treatmentNutritive valuesFermentation

The invention provides a method for improving fermentability and nutritional property of gluten protein-free dough. The method includes the steps of 1) activating glutamic acid transaminase, protease A and yeast; 2) peptizing food in water with temperature 50-100 degrees to be evenly mixed with whole flour free of gluten protein, proteins, starches, sugars and salts; 3) adding the activated glutamic acid transaminase and protease A to the mixture for evenly mixing; 4) adding and stirring the activated yeast in the mixture to form the dough; 5) fermenting the mixture within 40-90mins at the temperature of 36-40 degrees and at the humidity of 70-85%. The method is simple and greatly improves the nutritional property and the fermentability of the gluten protein-free dough at the same time. Thus fermentation size of the dough is increased by 1-3 times, contents of vitamin, protein, dietary fiber, mineral elements and the like are remarkably increased, structures and sizes of fermented products such as breads, steamed breads and steamed sponge cakes are improved, and nutritional value of the fermented products is increased.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

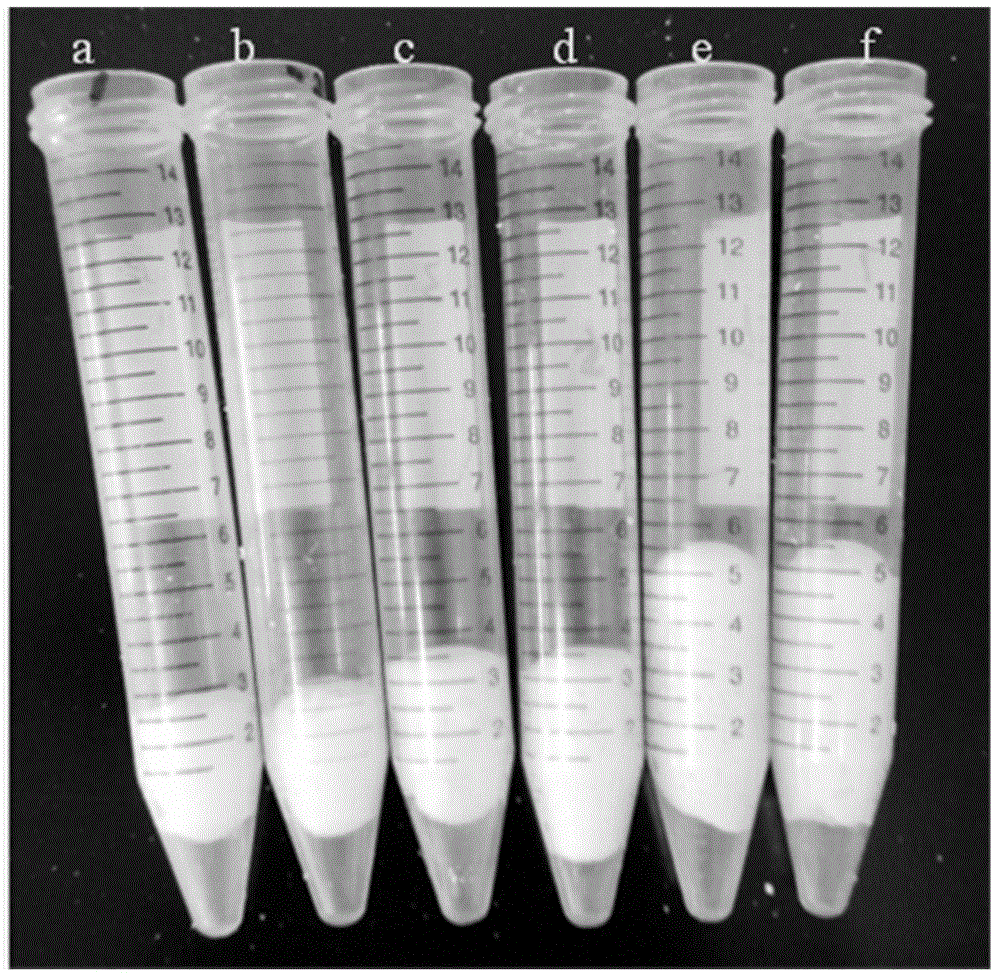

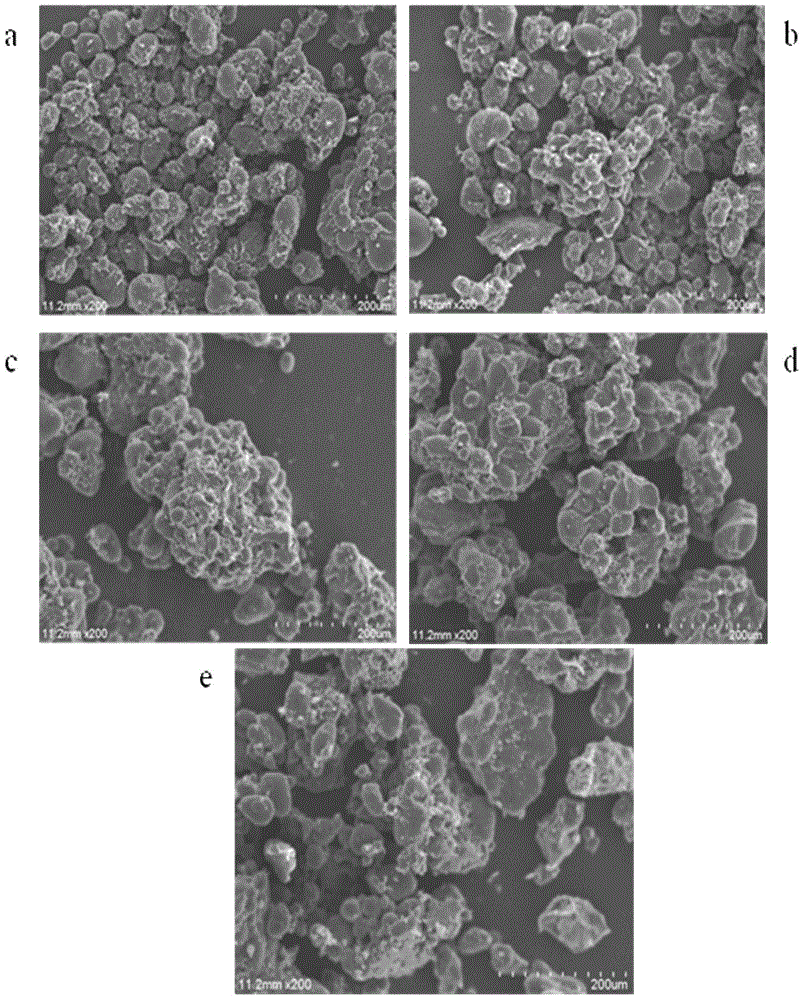

Method for preparing graphene oxide modified composite phase-change microcapsule

ActiveCN107417867AImprove thermal effectGood compatibilityHeat-exchange elementsMicroballoon preparationWater bathsCross-link

The invention discloses a method for preparing graphene oxide modified composite phase-change microcapsules. The method specifically comprises the following steps: preparing a graphene oxide solid from graphite powder, concentrated sulfuric acid, sodium nitrate, potassium permanganate and deionized water; mixing the obtained graphene oxide solid with absolute ethyl alcohol and a silane coupling agent, and performing a reaction so as to obtain a double-bond modified functional graphene oxide solid; uniformly mixing the obtained functional graphene oxide solid with a phase-change material, a reaction monomer, a cross-linking agent, a reactive emulsifier and deionized water, and performing ultrasonic dispersion so as to form an oil-in-water type pre-emulsion; and putting the obtained oil-in-water type pre-emulsion into a hot water bath, continuously stirring, further adding an initiator solution, and performing a heat-preservation reaction, thereby obtaining the graphene oxide modified composite phase-change microcapsules. By adopting the method disclosed by the invention, composite phase-change microcapsules which are high in encapsulation efficiency, stable in property, good in heat conductivity, appropriate in phase-change temperature and relatively high in phase-change latent heat enthalpy can be prepared.

Owner:SHAANXI UNIV OF SCI & TECH

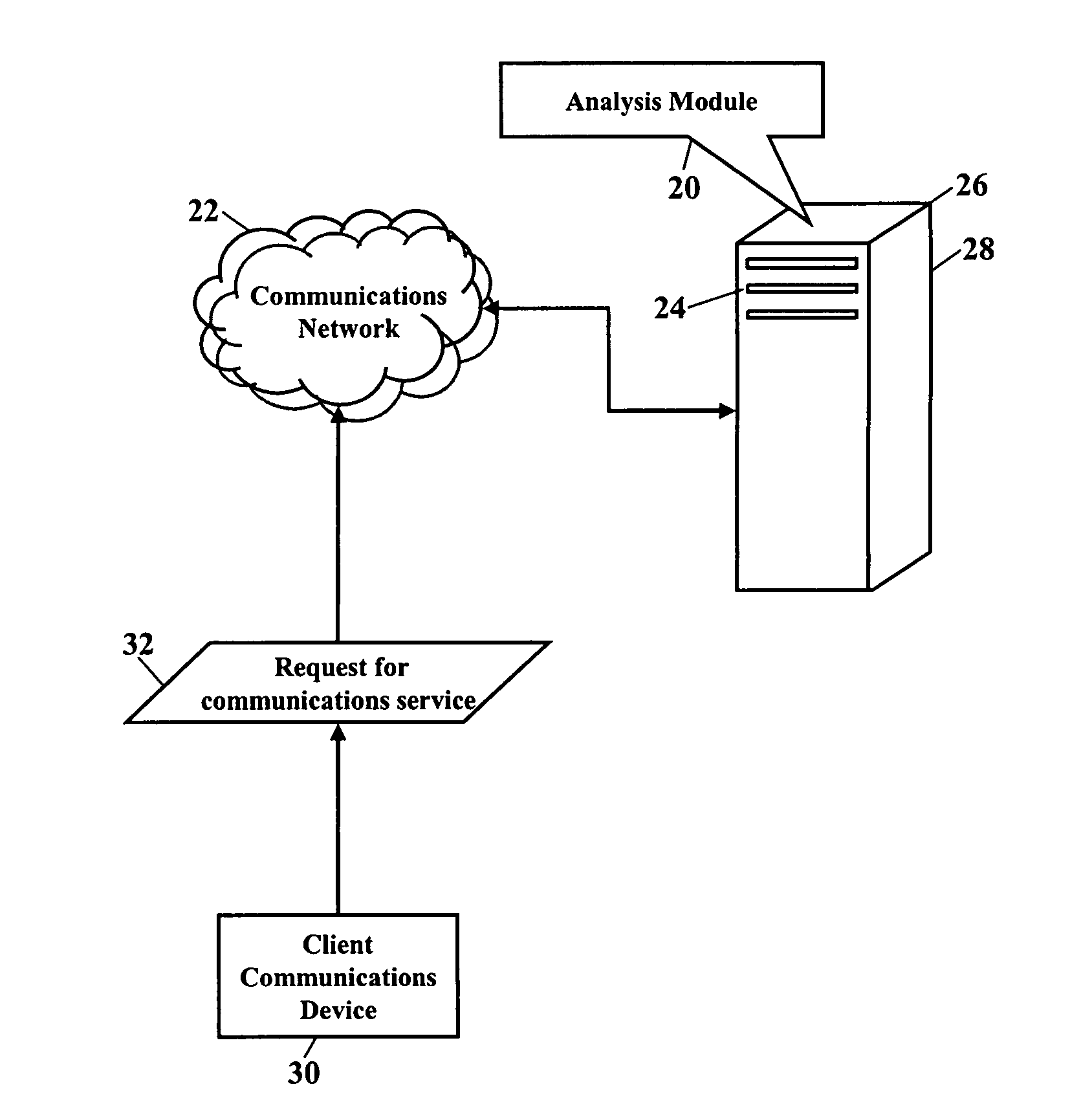

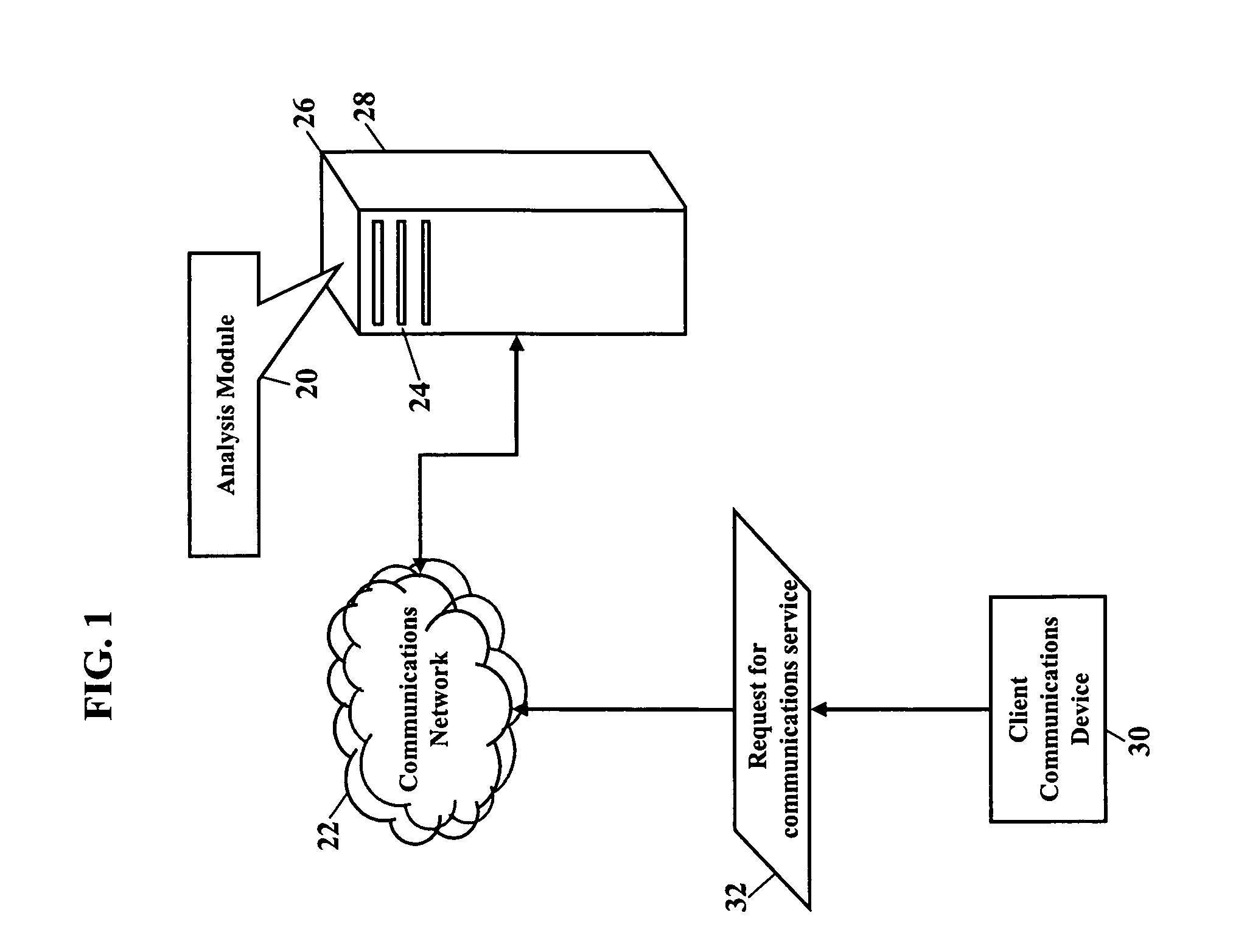

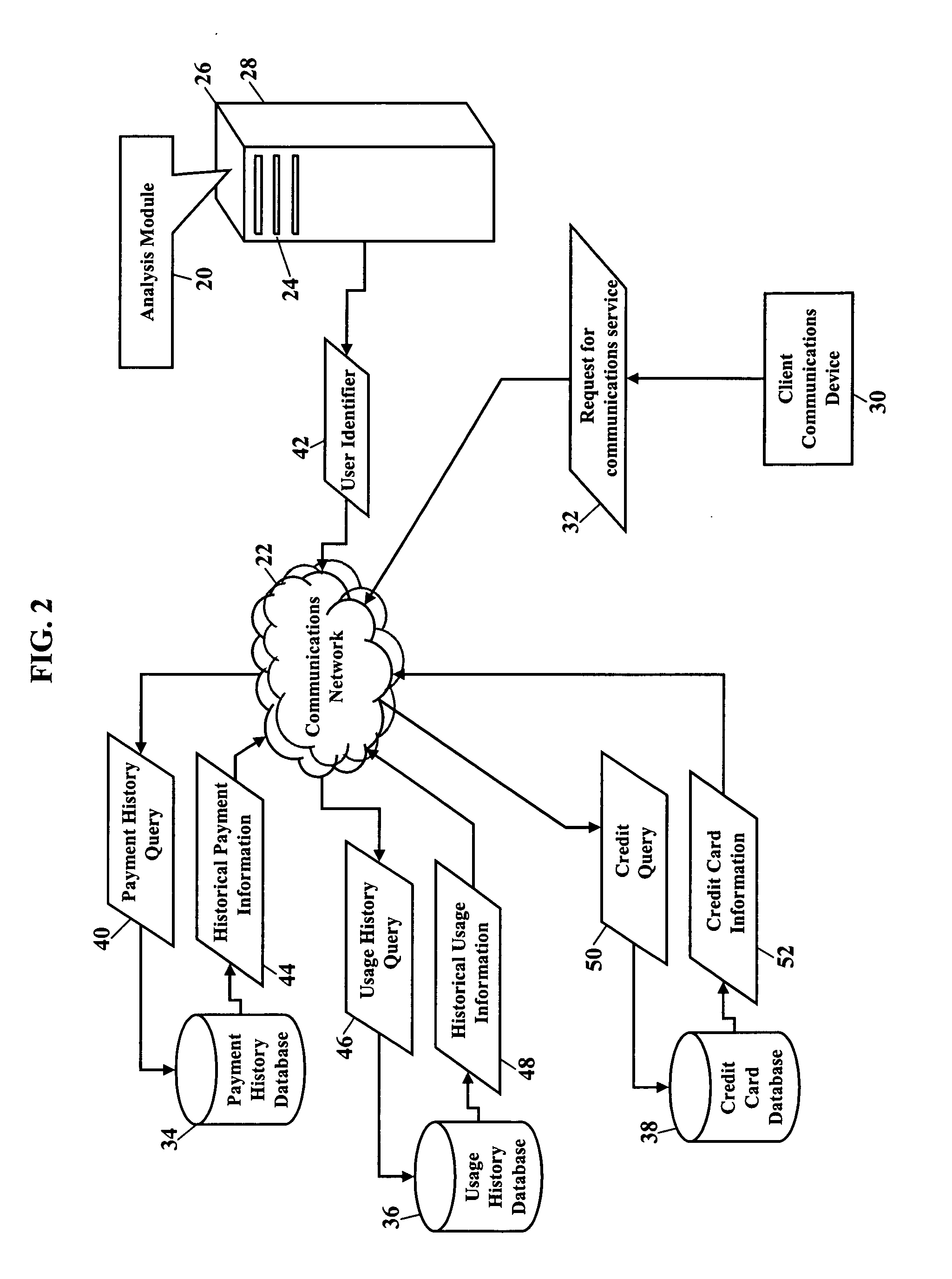

Methods for providing communications services

InactiveUS20050114155A1Easy to aggregateConvenient segmentationMetering/charging/biilling arrangementsFinanceCommunication deviceClient

Methods, systems, and products are disclosed for providing communications services. One method receives a request for communications service. The request for communications service originates from a client communications device associated with a user, and the request for communications service communicates via a communications network to a service provider of that communications network. The service provider then permits the user to negotiate with other service providers of other communications networks to fulfill the request for communications service.

Owner:BELLSOUTH INTPROP COR

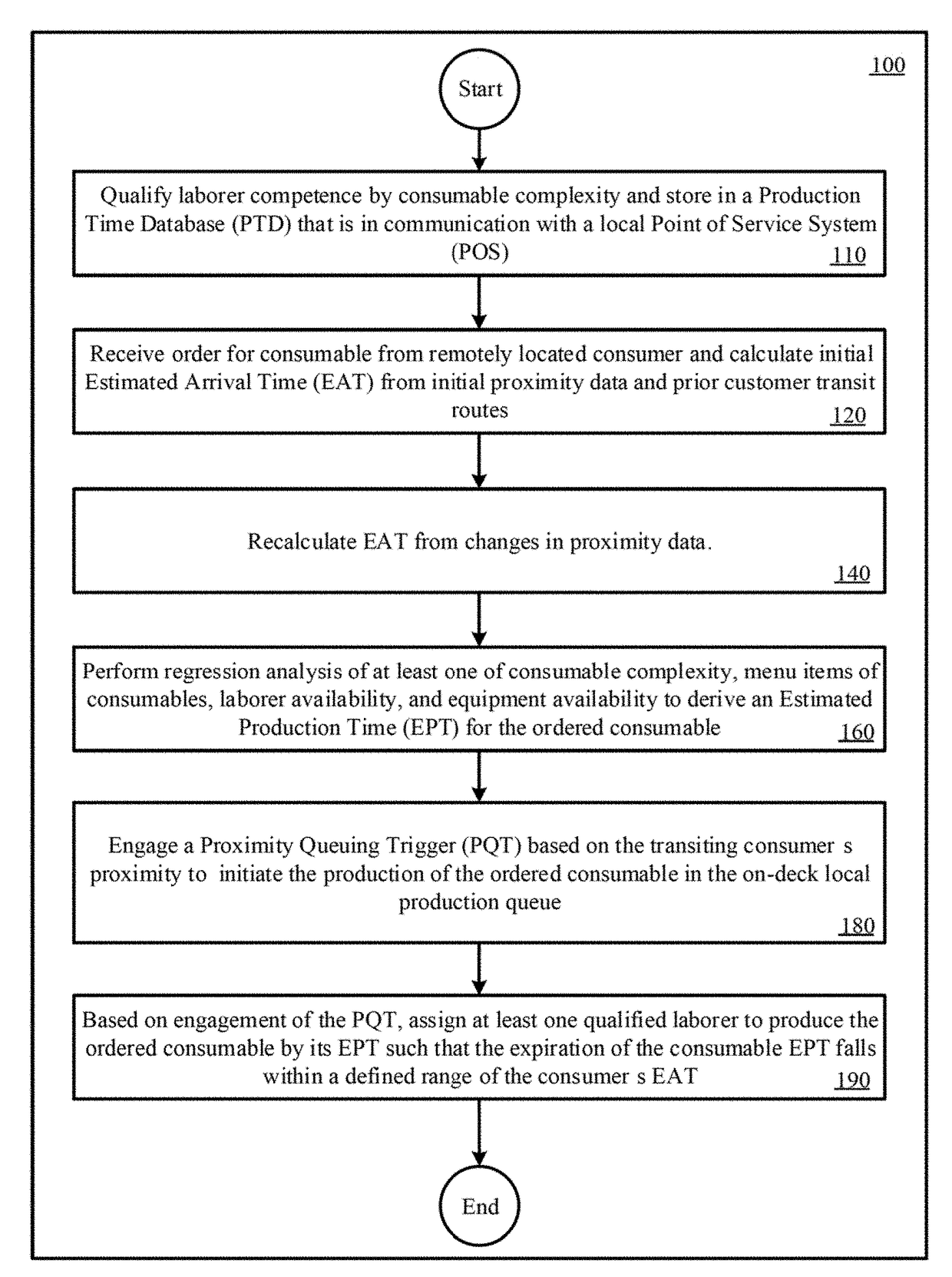

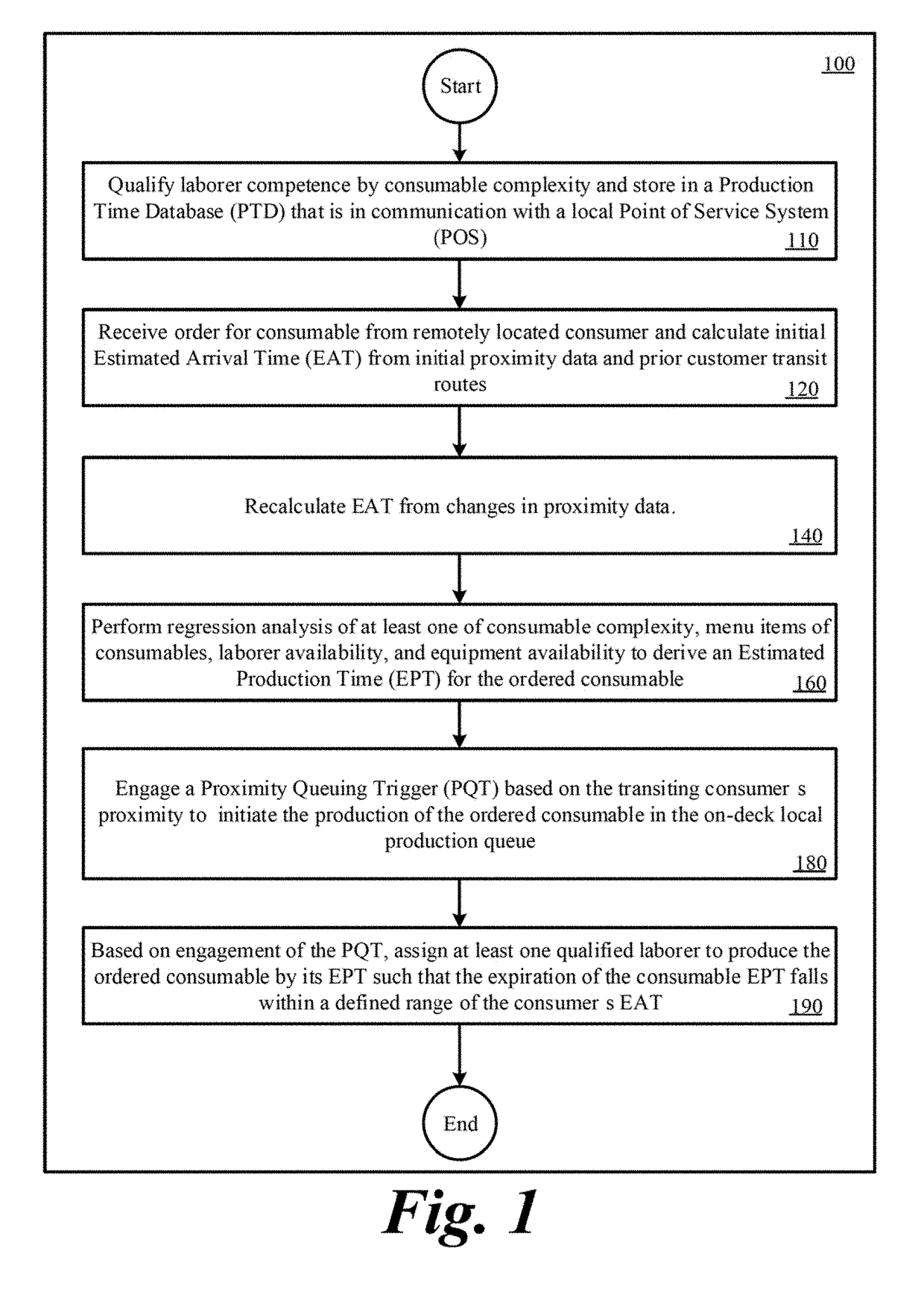

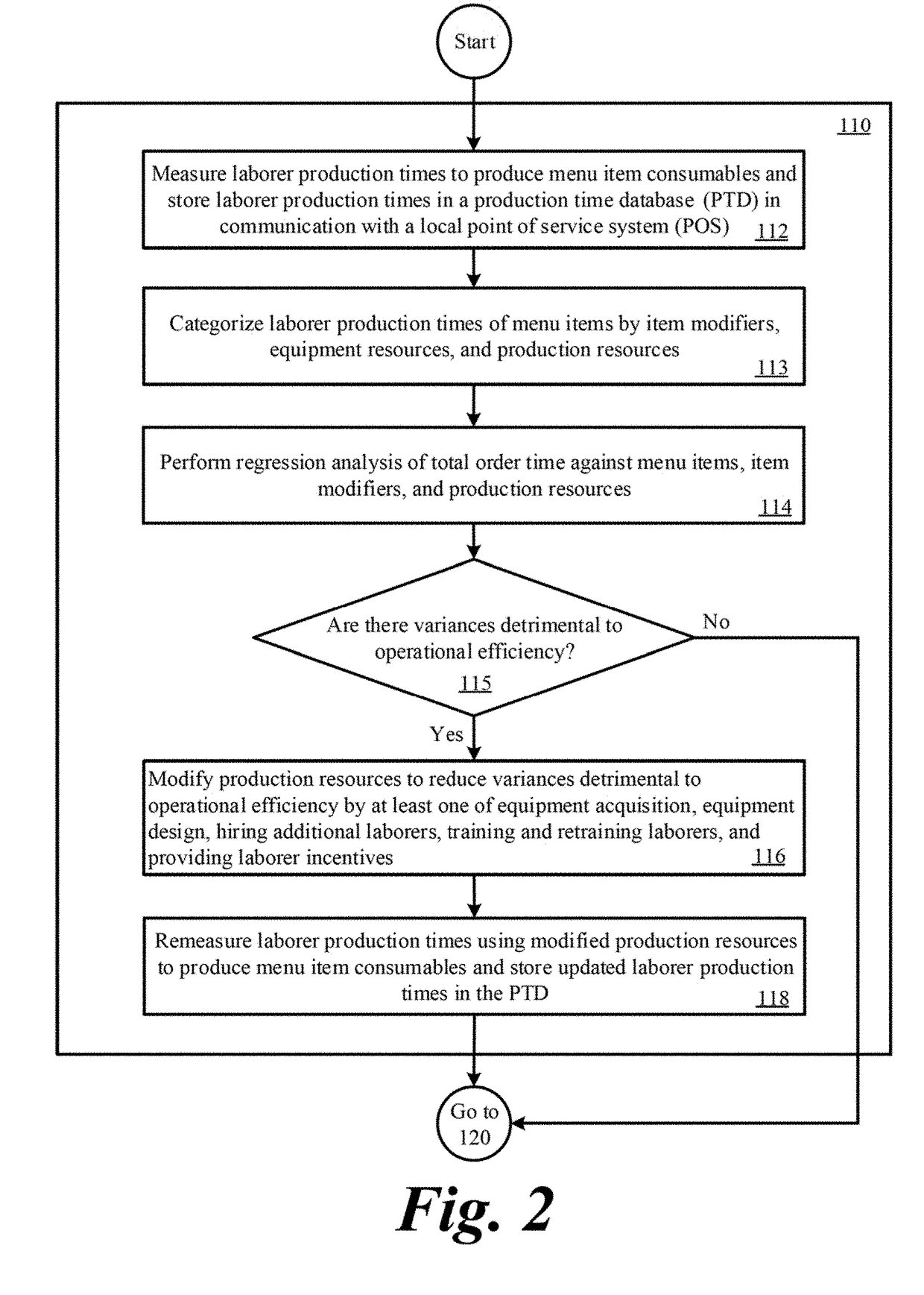

Methods and systems to optimize timing of customer arrival and order production completion for remote customer orders

InactiveUS20180075404A1Convenient timeEasy to aggregateBuying/selling/leasing transactionsResourcesCustomer orderArrival time

A method and system to timely execute the production or procurement of remotely ordered products while a consumer is in transit to the production and / or pickup site within a defined range of the consumer's estimated arrival time.

Owner:HENDRICKSON KYLE JOHAN

Mesophase pitch and preparation method thereof

ActiveCN104004536AHigh carbon contentModerate carbon-hydrogen ratioWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionOrganic solventSolvent

The invention provides a method for preparing mesophase pitch from direct coal liquefaction residues. The method mainly comprises the following steps: 1, extracting the direct coal liquefaction residues by using an organic solvent I to obtain extracted pitch; 2, dissolving the extracted pitch by using a polar organic solvent II, and carrying out solvent recovery on the soluble part to obtain refined pitch; 3, carrying out thermal polycondensation on the obtained refined pitch at a high temperature to obtain a thermal polycondensation product; and 4, carrying out reduced pressure flash evaporation on the thermal polycondensation product to obtain the mesophase pitch. The invention also provides the mesophase pitch. The spinnable indexes of the mesophase pitch are characterized in that the softening point, the aromatic carbon rate and the quinoline insoluble substance content of the mesophase pitch are 250-280DEG C, not lower than 0.9 and 35-45% respectively.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

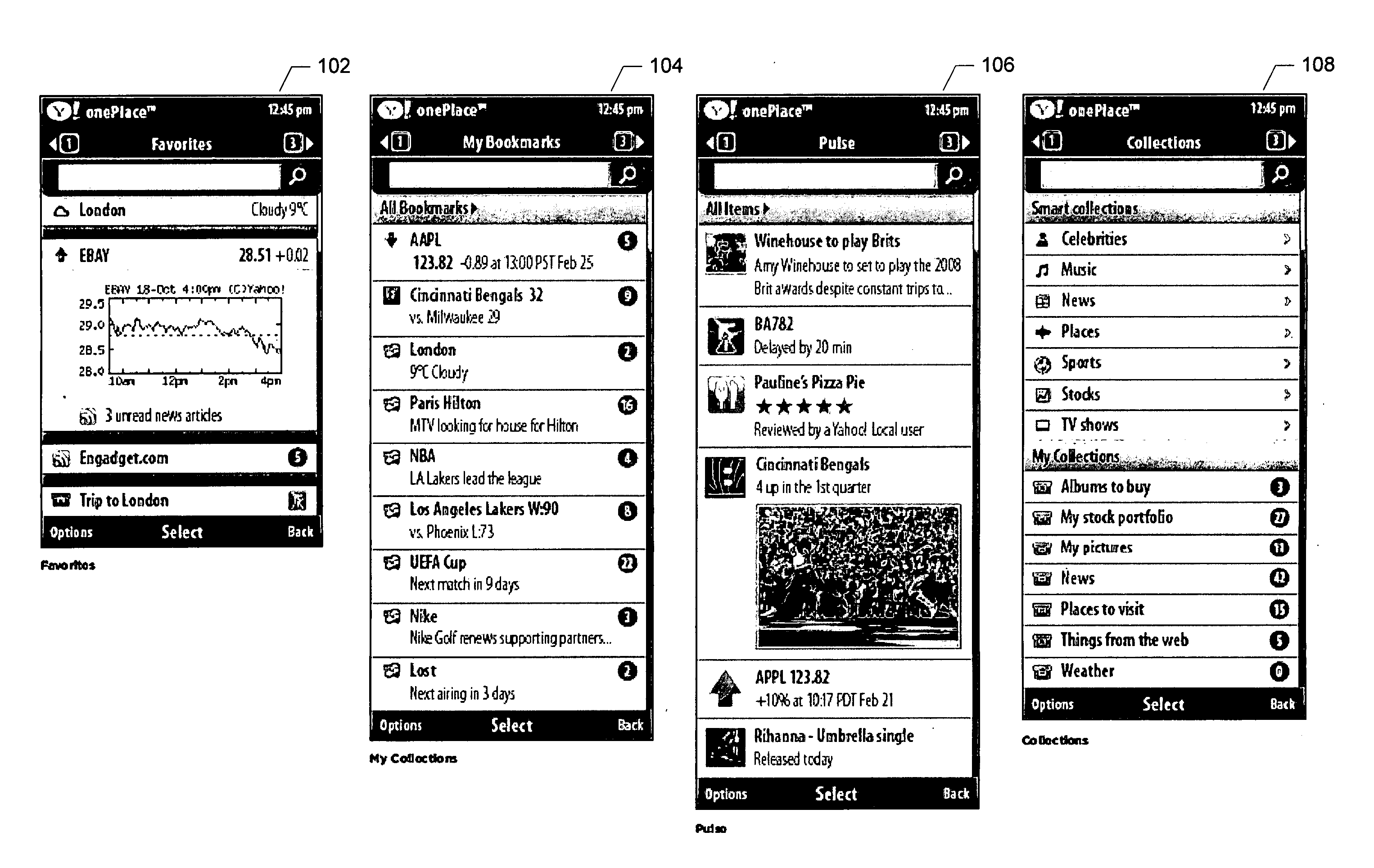

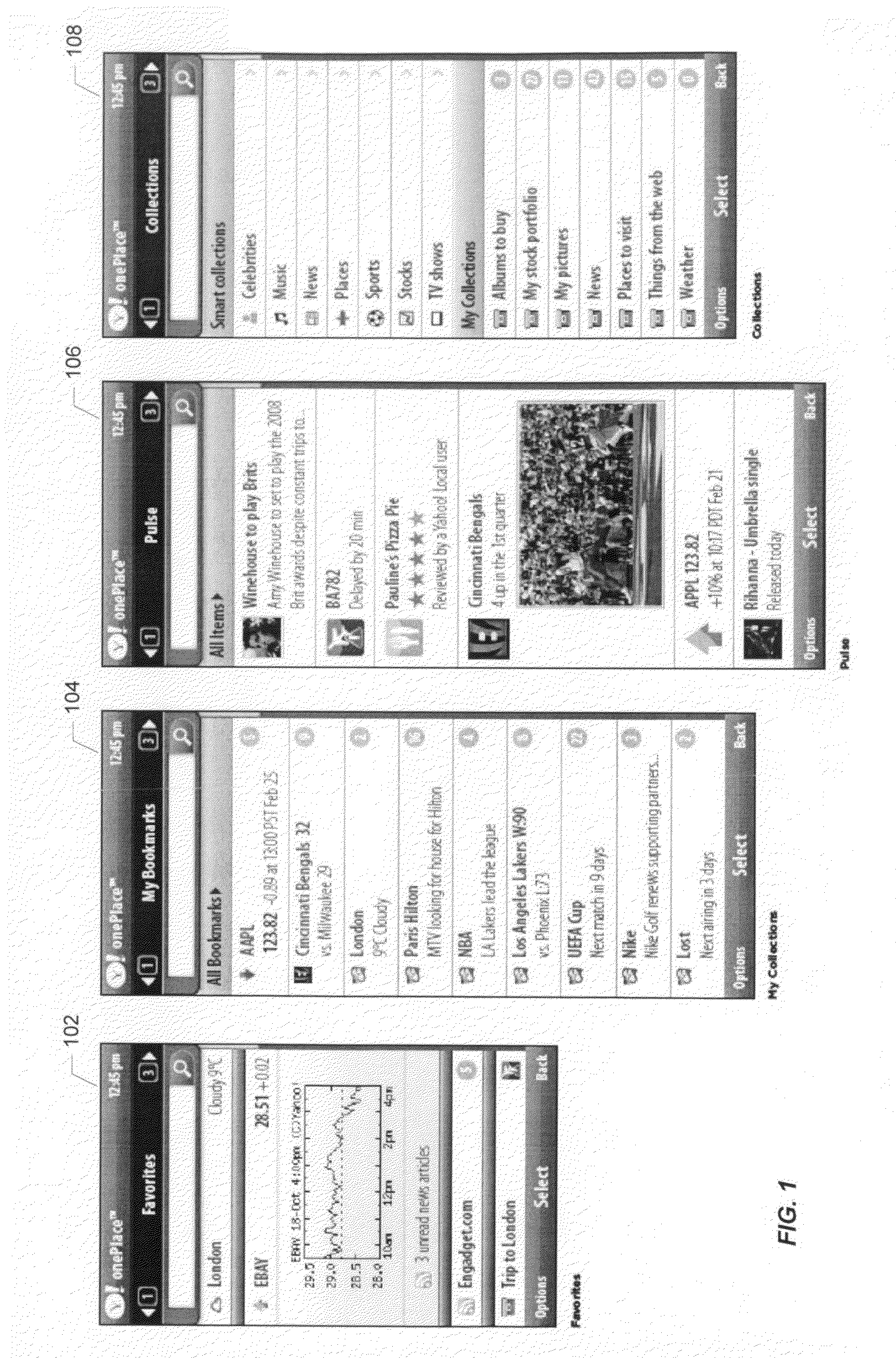

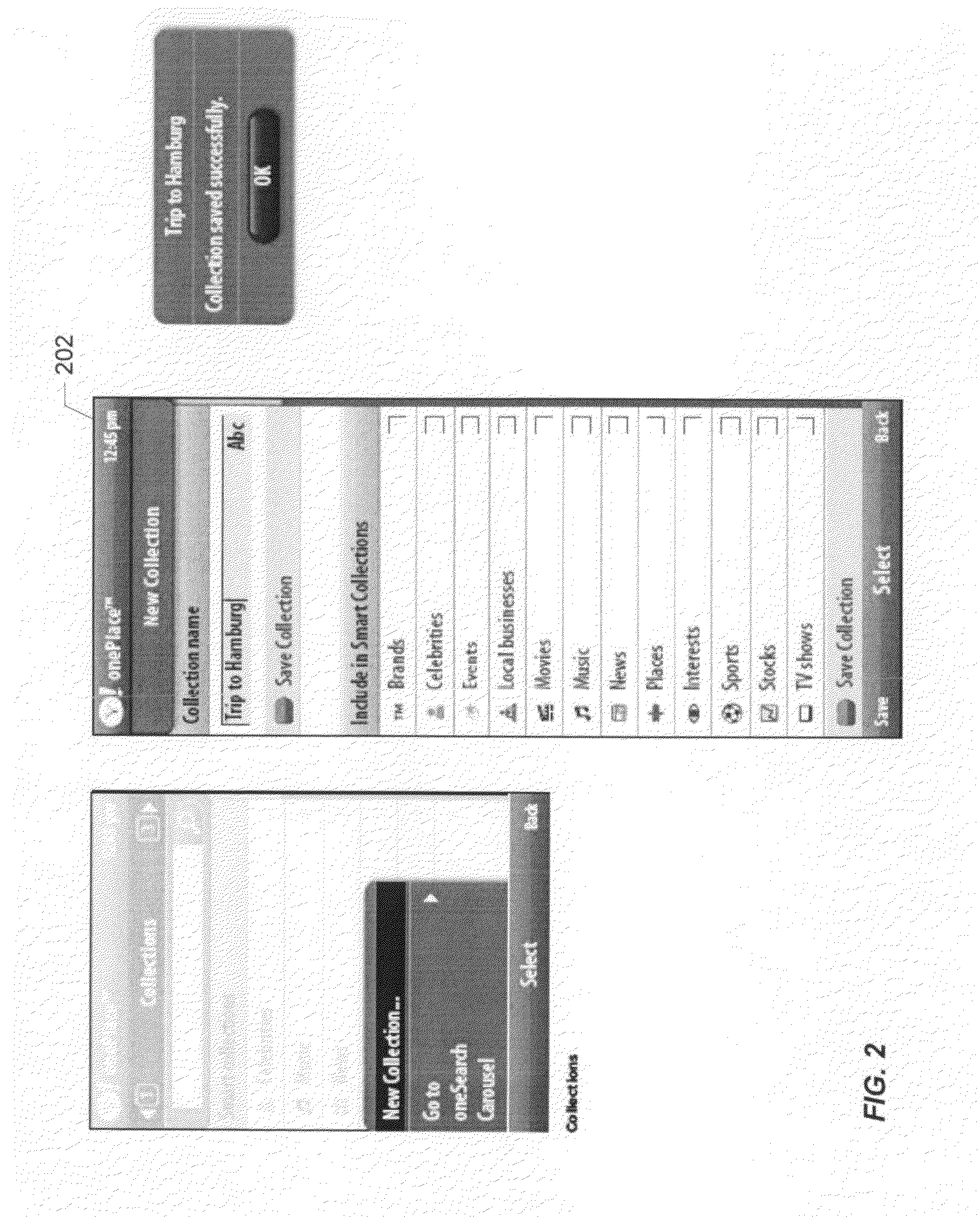

Mechanisms for content aggregation, syndication, sharing, and updating

ActiveUS20090222716A1Easy to aggregateEasy to shareDigital data information retrievalMultiple digital computer combinationsInformation retrieval

Owner:YAHOO ASSETS LLC

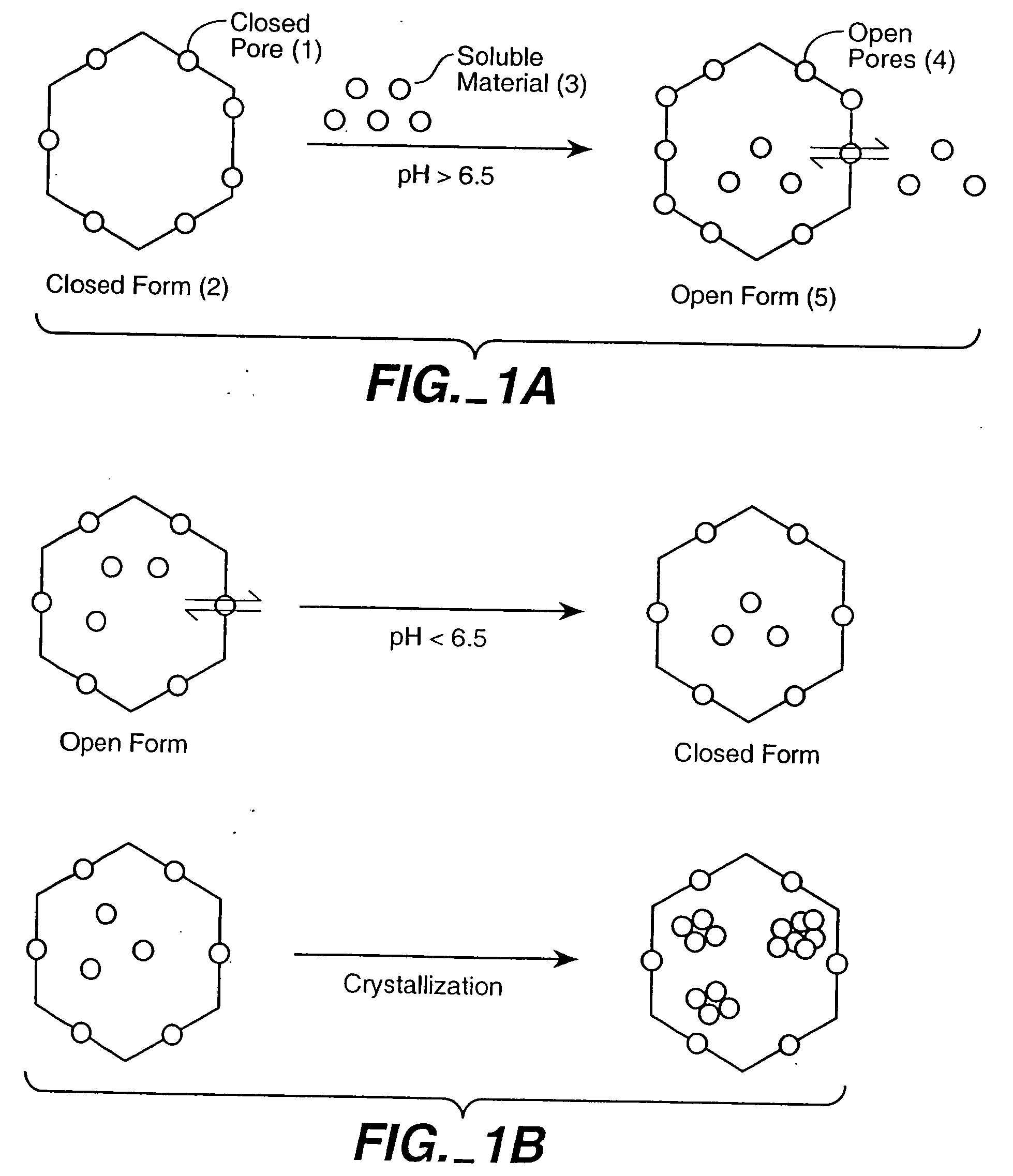

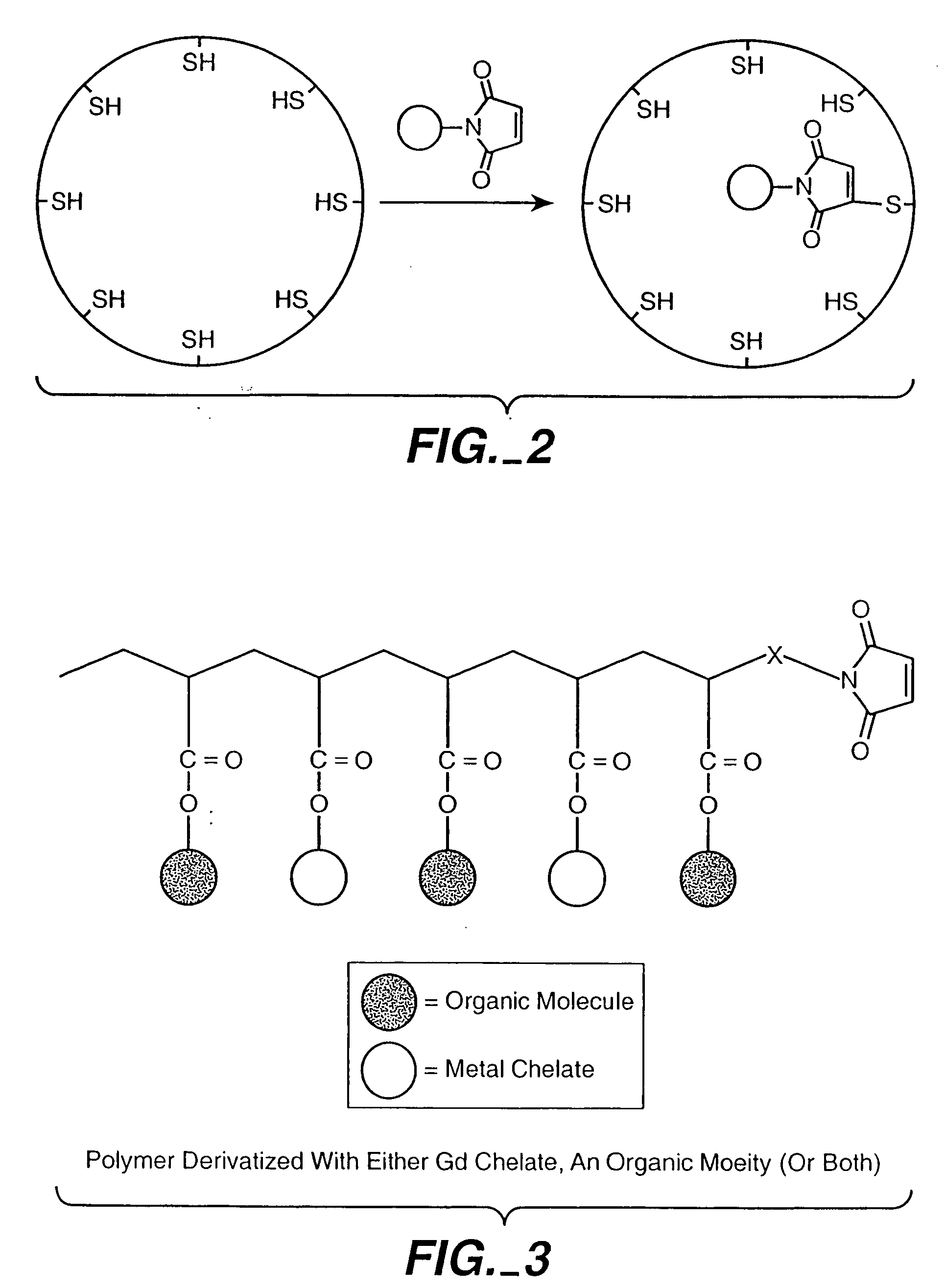

Protein cages for the delivery of medical imaging and therapeutic agents

InactiveUS20060204444A1Increase the number ofEasy to aggregateGeneral/multifunctional contrast agentsNanomedicineMedicineTherapeutic effect

The present invention is directed to novel compositions and methods utilizing delivery agents comprising protein cages, medical imaging agents and therapeutic agents.

Owner:MONTANA STATE UNIVERSITY

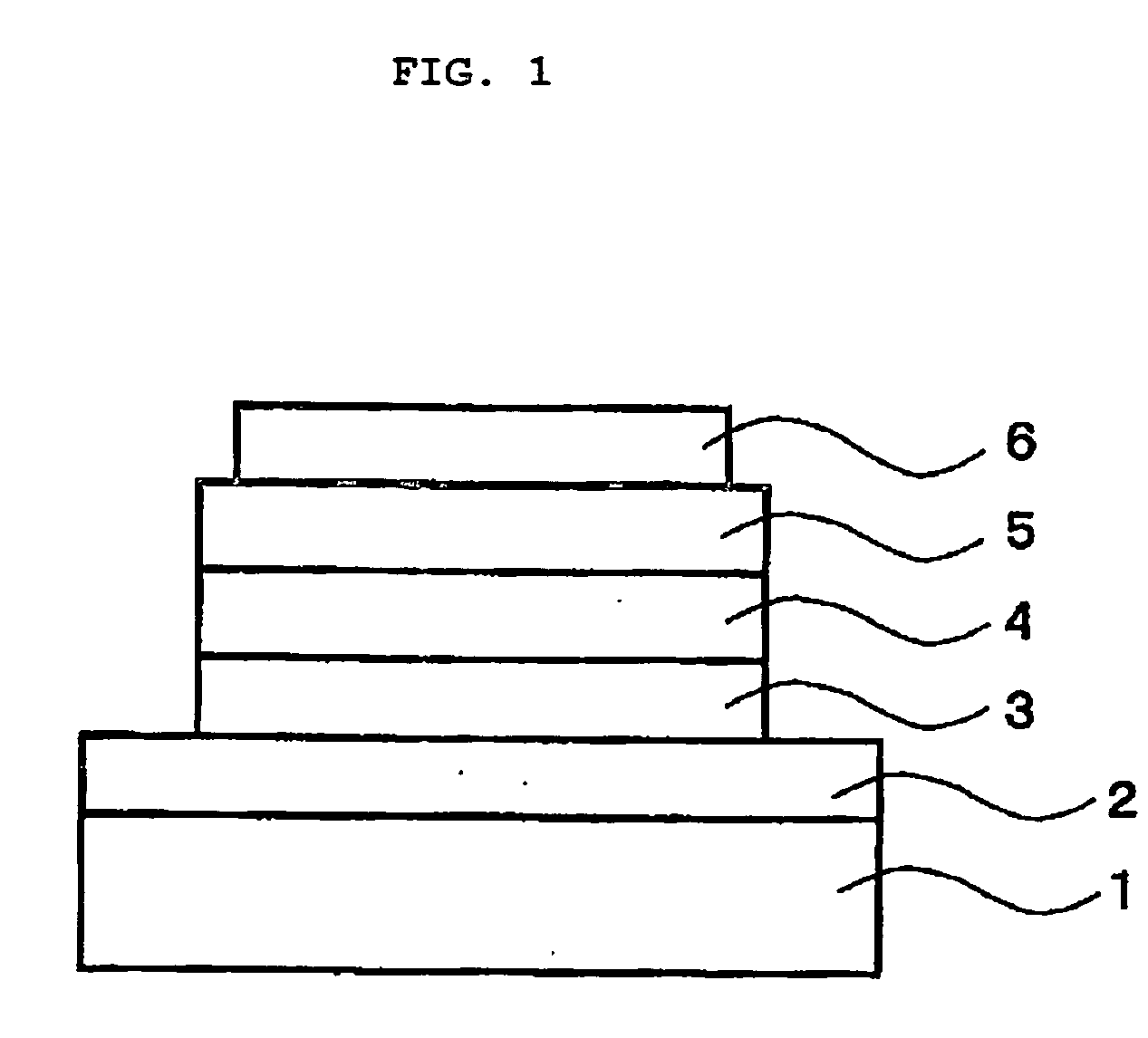

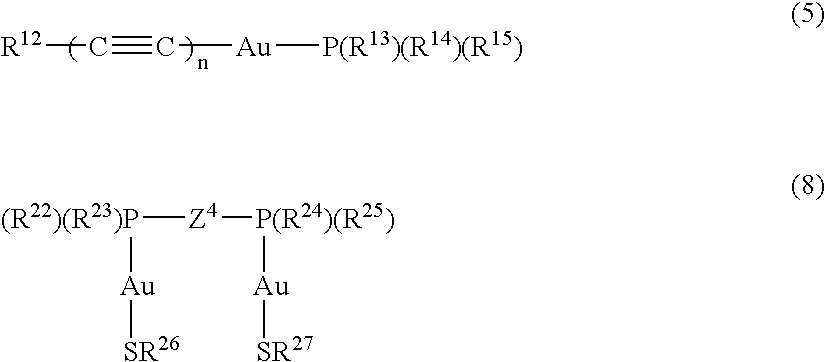

Organic polymer light-emitting element material having gold complex structure and organic polymer light-emitting element

ActiveUS20060269779A1Solve low luminous efficiencyHigh luminous efficiencyGroup 5/15 element organic compoundsElectroluminescent light sourcesSide chainOragene

The present invention provides an organic polymer light-emitting element material having a gold complex structure as a part of the side chain or crosslinking group as represented by formulae (5) and (8) and an organic polymer light-emitting element comprising layer(s) comprising the organic polymer light-emitting element material. The present invention provides a polymer-based phosphorescent material useful for a multicolor or white light-emitting organic EL device having high luminous efficiency and capable of large-area formation and mass production.

Owner:SAMSUNG ELECTRONICS CO LTD

Hydrogel antifouling fiber, preparation method thereof and preparation method of implanted type high-strength hydrogel antiflouling coating layer

InactiveCN103757744AHigh strengthHas superhydrophilic propertiesLiquid surface applicatorsWet spinning methodsFiberPolymer science

The invention discloses a hydrogel antifouling fiber, a preparation method of hydrogel antifouling fiber and a preparation method of an implanted type high-strength hydrogel antiflouling coating layer, and relates to antiflouling materials, preparation methods of the antiflouling materials, and preparation methods of vessel antifouling coating layers, for mainly solving the technical problems that the conventional PVA (Polyvinyl Acetate) fiber implanted type vessel antiflouling coating layer is poor in antifouling effect and short in service life. The hydrogel antifouling fiber disclosed by the invention is a fiber with a core-shell structure, the shell layer of the fiber is made of polyacrylamide, and the core layer is made of carbon nano tube modified polyacrylamide. The preparation method comprises the following steps: 1, preparing polyacrylamide hydrogel, 2, preparing a core layer spinning dope, 3, preparing a shell layer spinning dope, 4, spinning by using a wet method to obtain the hydrogel antifouling fiber. The preparation of the antifouling coating layer comprises the following steps: spraying implantation gel onto a substrate, further implanting the hydrogel antifouling fiber into the substrate through a high-pressure static implantation technique, and drying to obtain the implanted type high-strength hydrogel antifouling coating layer. The coating layer is not changed when being soaked in seawater or industrial water for 6 months, so that the coating layer can be applied to vessel antifouling.

Owner:HARBIN ENG UNIV

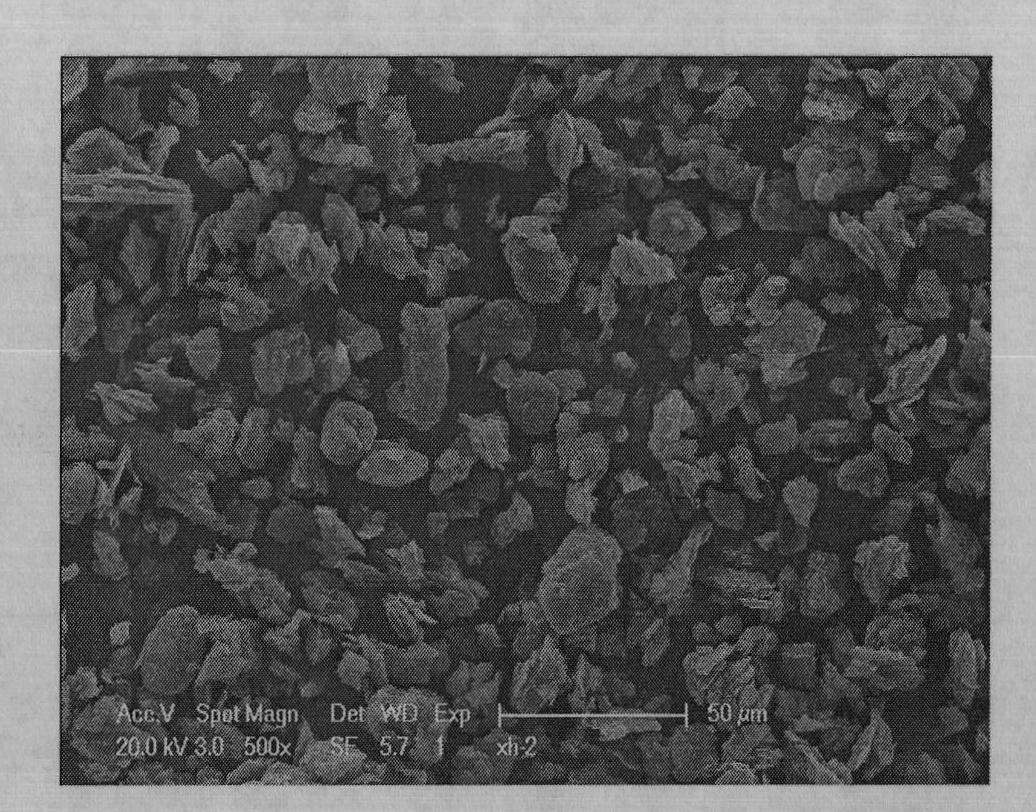

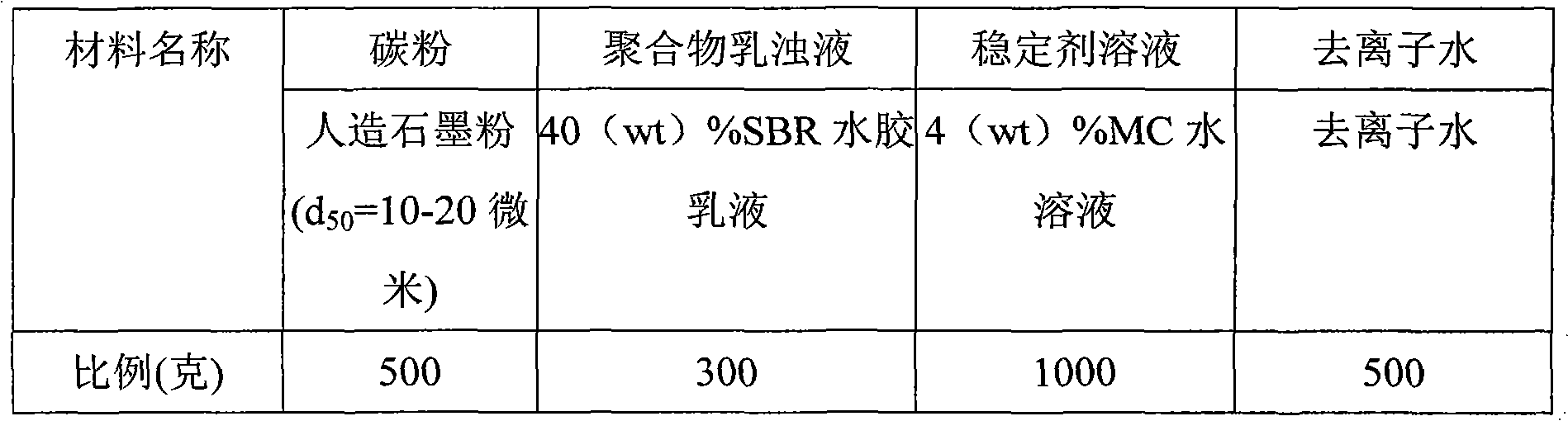

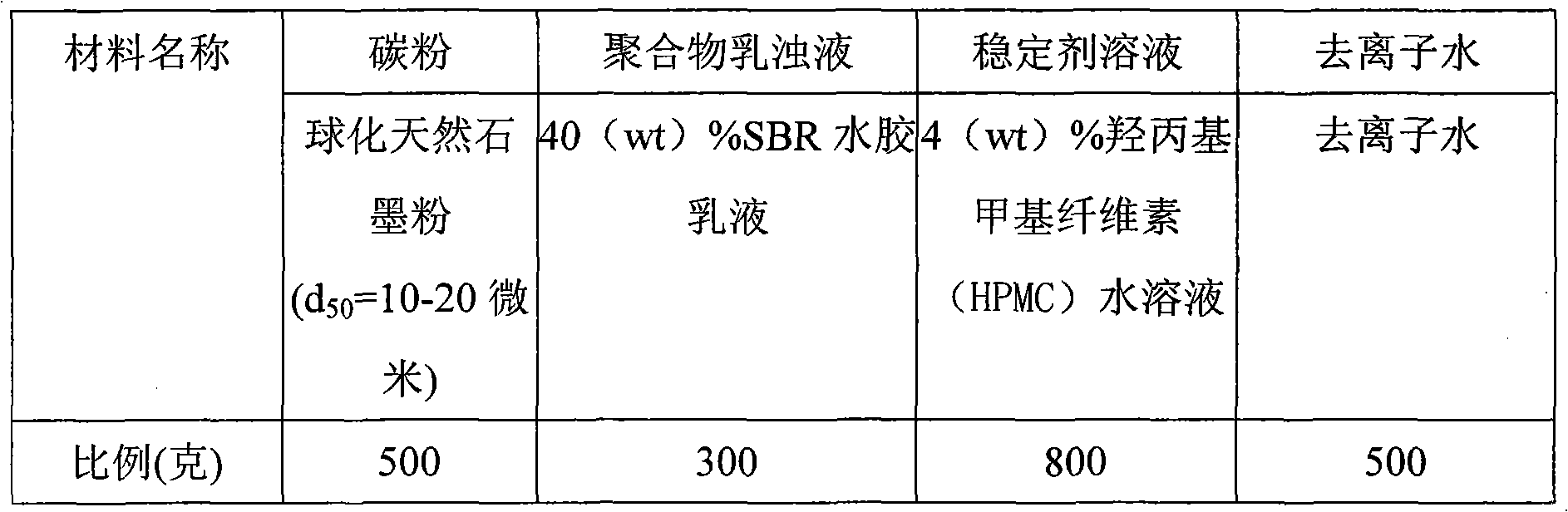

Preparation method of lithium ion battery carbon cathode material coating layer

The invention relates to a preparation method of a lithium ion battery carbon cathode material coating layer. The method is characterized by adopting a liquid-phase spray granulation method and comprising the following steps of: mixing carbon powder, polymer emulsion, stabilizer and water according to certain proportions to prepare slurry; feeding the slurry into a spray drying granulator for granulation coating; dispersing the slurry emulsion into droplets by an atomizer, wherein the droplets are in contact with the hot dry air to remove water and change into powdery particles so as to coat the surface of the carbon powder with polymer; and finally, placing the carbon powder coated with polymer in carbonization equipment, and performing carbonization treatment under the protection of nitrogen to obtain the required lithium ion battery carbon cathode material coating layer, wherein the carbonization temperature is 600-2,500 DEG C. The preparation method provided by the invention has the advantages of simple technology, easy polymerization and good safety, and can remarkably improve the production efficiency; and moreover, the preparation method has low cost and is suitable for batch production.

Owner:NINGBO HONGYUAN CARBON IND

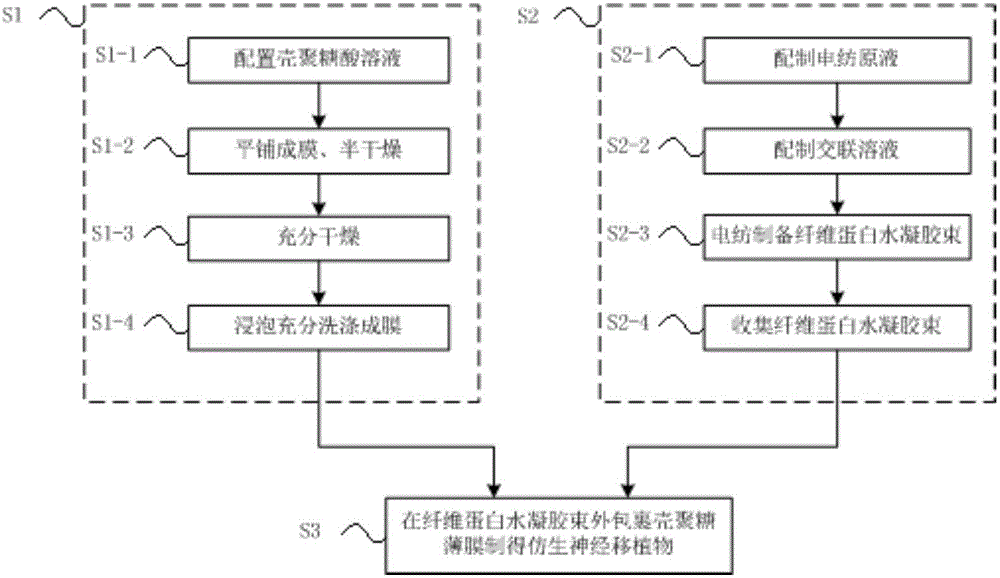

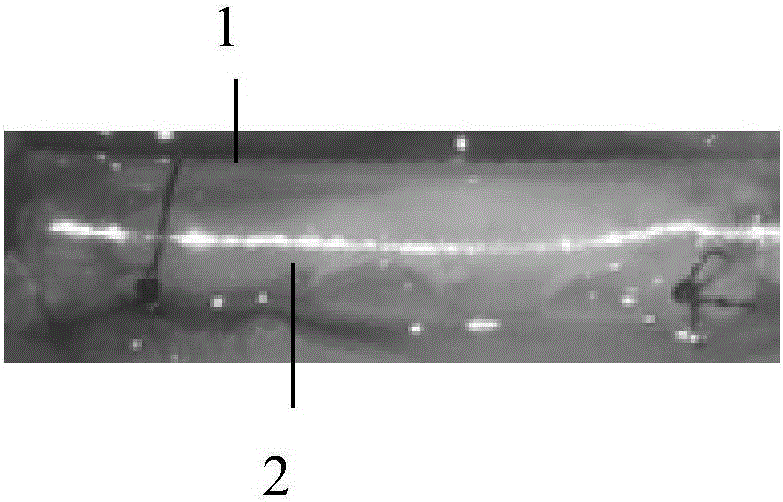

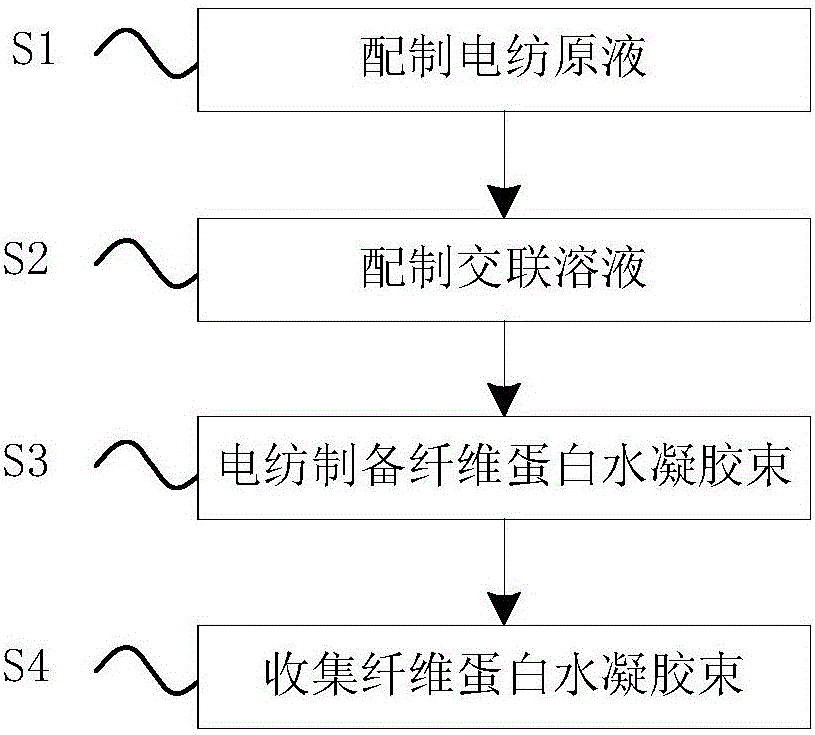

Bionic nerve graft used for peripheral nervous recovery and preparation method thereof

ActiveCN106729980ACell affinityImprove mechanical propertiesElectro-spinningTissue regenerationMedicineElectrospinning

The invention relates to a bionic nerve graft used for peripheral nervous recovery and a preparation method and application thereof. The bionic nerve graft comprises a chitosan film conduit and a fibrous protein hydrogel beam positioned in the chitosan film conduit, wherein the fibrous protein hydrogel beam is prepared from fibrous protein through an electrospinning technique. The bionic nerve graft prepared by the preparation method is formed by the filling of the chitosan film conduit and the fibrous protein hydrogel beam of a multi-stage orientation structure, wherein a nerve regrowth space is effectively supported by a chitosan film, the orientational regeneration of a nerve axon is effectively guided by the fibrous protein hydrogel beam of multi-stage orientation, the cell affinity and the mechanical property of whole materials are good, and in addition, degrading speed and the repairing speed of peripheral nervous tissues are matched.

Owner:TSINGHUA UNIV

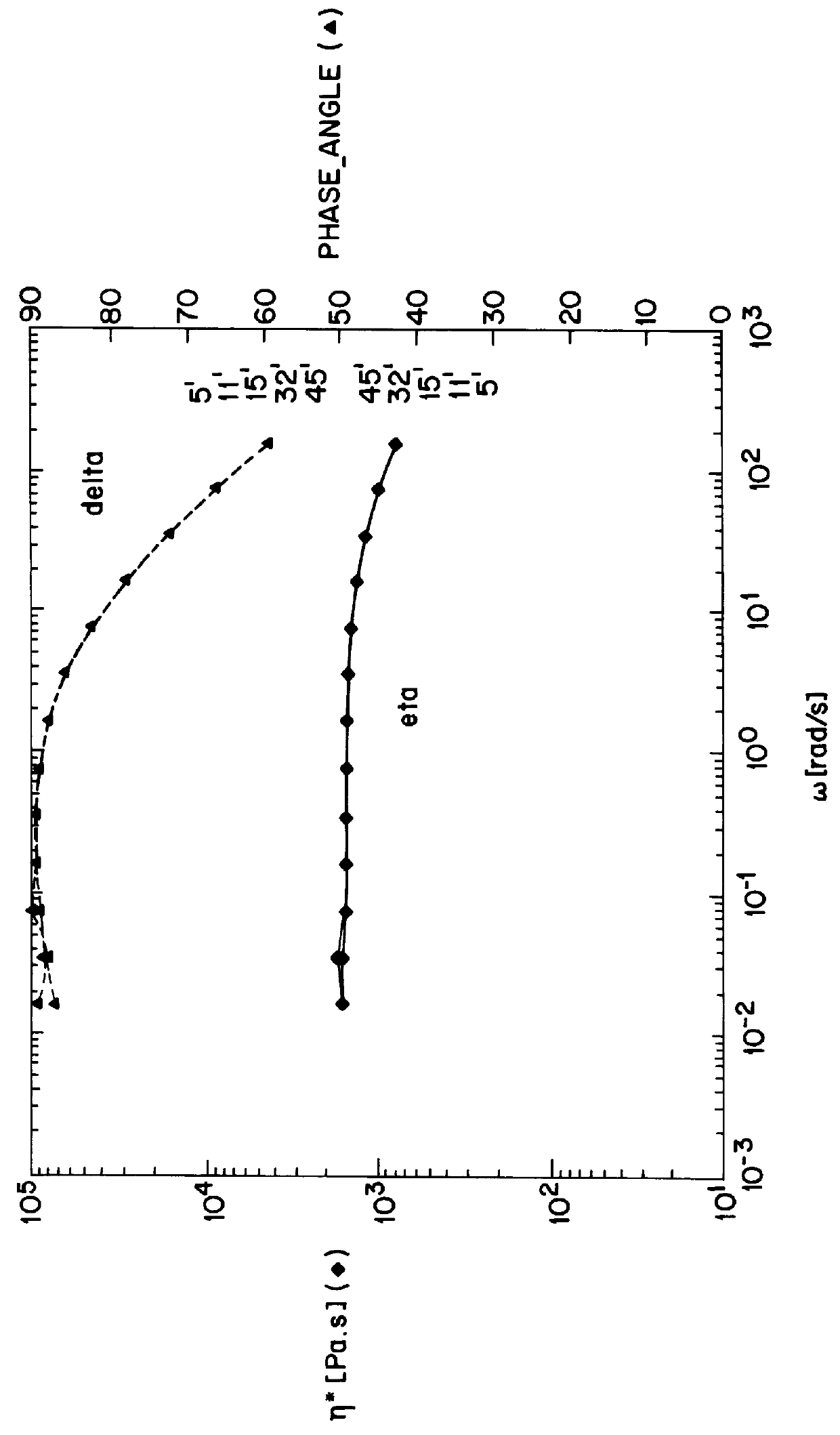

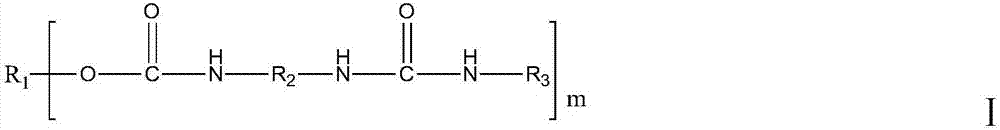

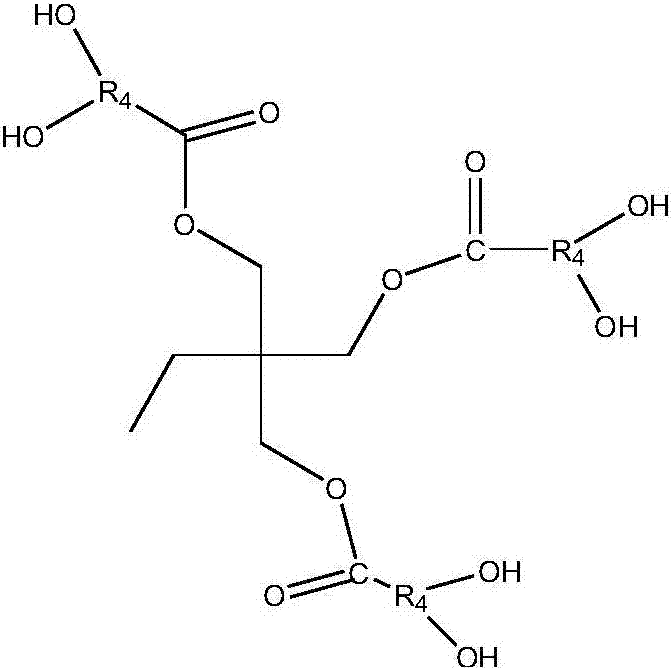

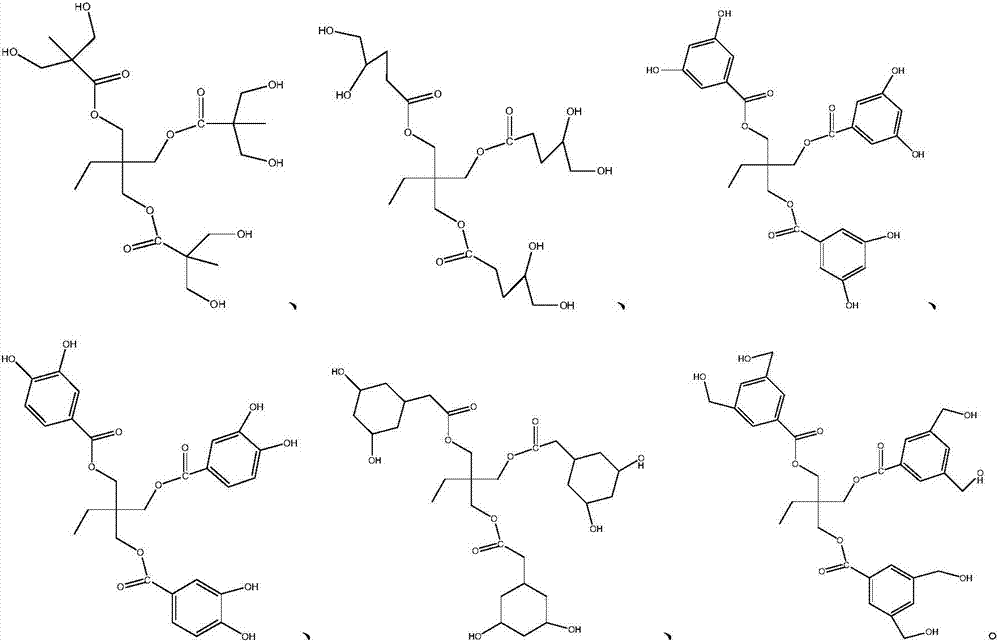

Star-shaped branched polyamide

InactiveUS6060580AReduce melt viscositySimple methodDrug compositionsDevelopers1,3,5-TriazinePolyamide

The invention relates to a star-shaped branched polyamide that has a high thermal stability and can be produced in existing production facilities for the corresponding linear polyamide. This is achieved by allowing the polyamide branches, at least three, to be formed from a multifunctional core having functional groups chosen from the group comprising amine and carboxyl groups, the amine or carboxyl groups being bound to an acyclic compound in which branching occures, if it is branched, at a carbon atom, or via an acyclic chain to a heterocyclic compound showing point symmetry. The process for the preparation is carried out under the conditions of the preparation of the corresponding linear polyamide. It proves to be possible to obtain, after shorter polymerization times, a product with mechanical properties that are comparable with those of the linear polyamide after significantly longer polymerization times. Examples of suitable multifunctional nuclei are 2,4,6-trisaminocaproic acid-1,3,5-triazine and 4-aminomethyl-1,1-octanediamine.

Owner:DSM NV

Preparation method of isocyanates

ActiveCN107337615AAvoid yellowingAvoid reactionIsocyanic acid derivatives preparationOrganic compound preparationHigh concentrationPolyester

The invention discloses a preparation method of isocyanates. A high-concentration isocyanate actinic solution is prepared based on a salification phosgenation reaction, and a polyester hyperdispersant is added in a diamine salification procedure; and anchoring groups of the hyperdispersant are converted into tertiary amine salts which are adsorbed to the surface of diamine hydrochloride particles in the salification procedure, and steric hindrance is formed through the solvation chain, so that hydrochloride particles are separated, thereby avoiding the phenomena of aggregation, agglomeration and the like, obviously enhancing the salification concentration and effects, and further greatly enhancing the yield of the isocyanate product.

Owner:WANHUA CHEM GRP CO LTD

Method for preparing n-phenylglycinonitrile

ActiveCN101514170ARapid responseModerate responseCarboxylic acid nitrile preparationOrganic compound preparationAutomatic controlAcetonitrile

The present invention provides a method for preparing n-phenylglycinonitrile, wherein the method comprises a step of executing condensation reaction for generating n-phenylglycinonitrile when the phenylamine and glycolonitrile are used as raw materials. The invention is characterized in that according to the continuous production method, the raw materials continuously pass through a pipe type preheater, a pipe type mixer, a pipe type reactor and a reaction still for executing condensation reaction for generating the n-phenylglycinonitrile. The method of the invention has the advantages of fewer devices, simple and brief technical route, saved costs of man power, device, raw materials, energy, etc., improved operating environment, extraordinary automatic control realization, excellent guaranteed safety production operability and continuity, equitability and stability of production thereby guaranteeing the stability of product quality, increasing the product purity and yield. The product purity in the invention is above 95.5%, and the product yield is above 99.8%.

Owner:重庆渝化新材料有限责任公司

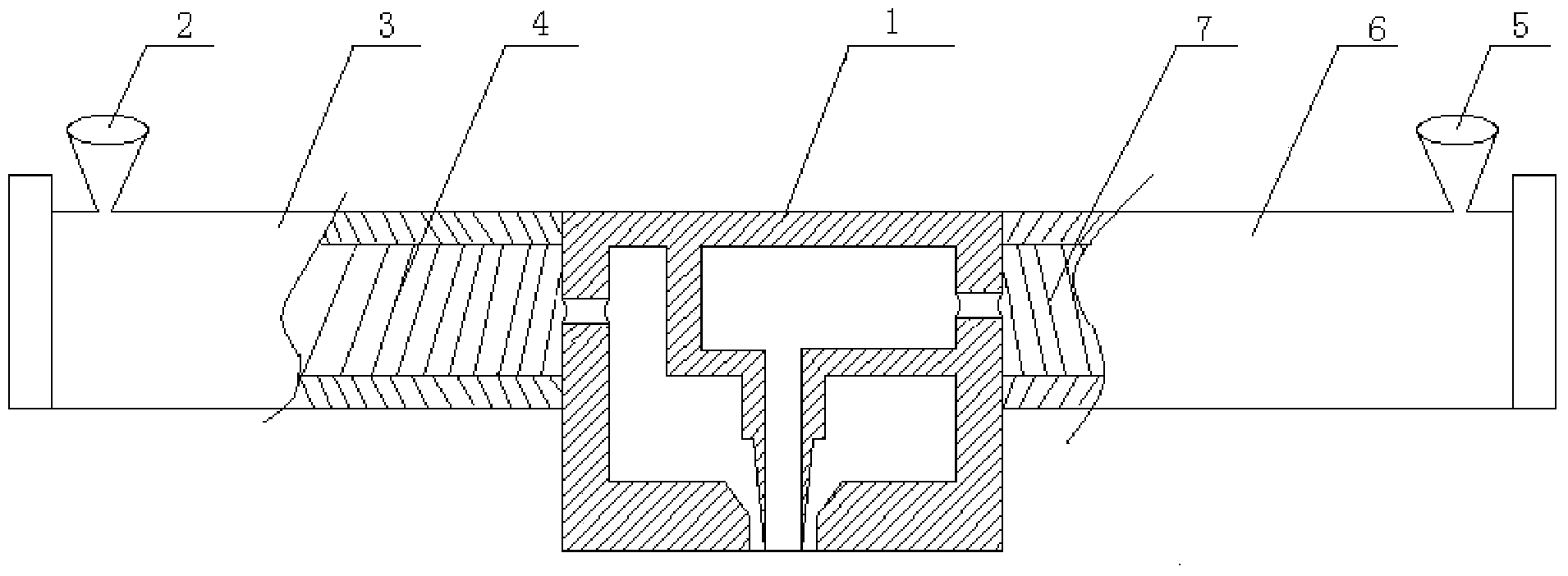

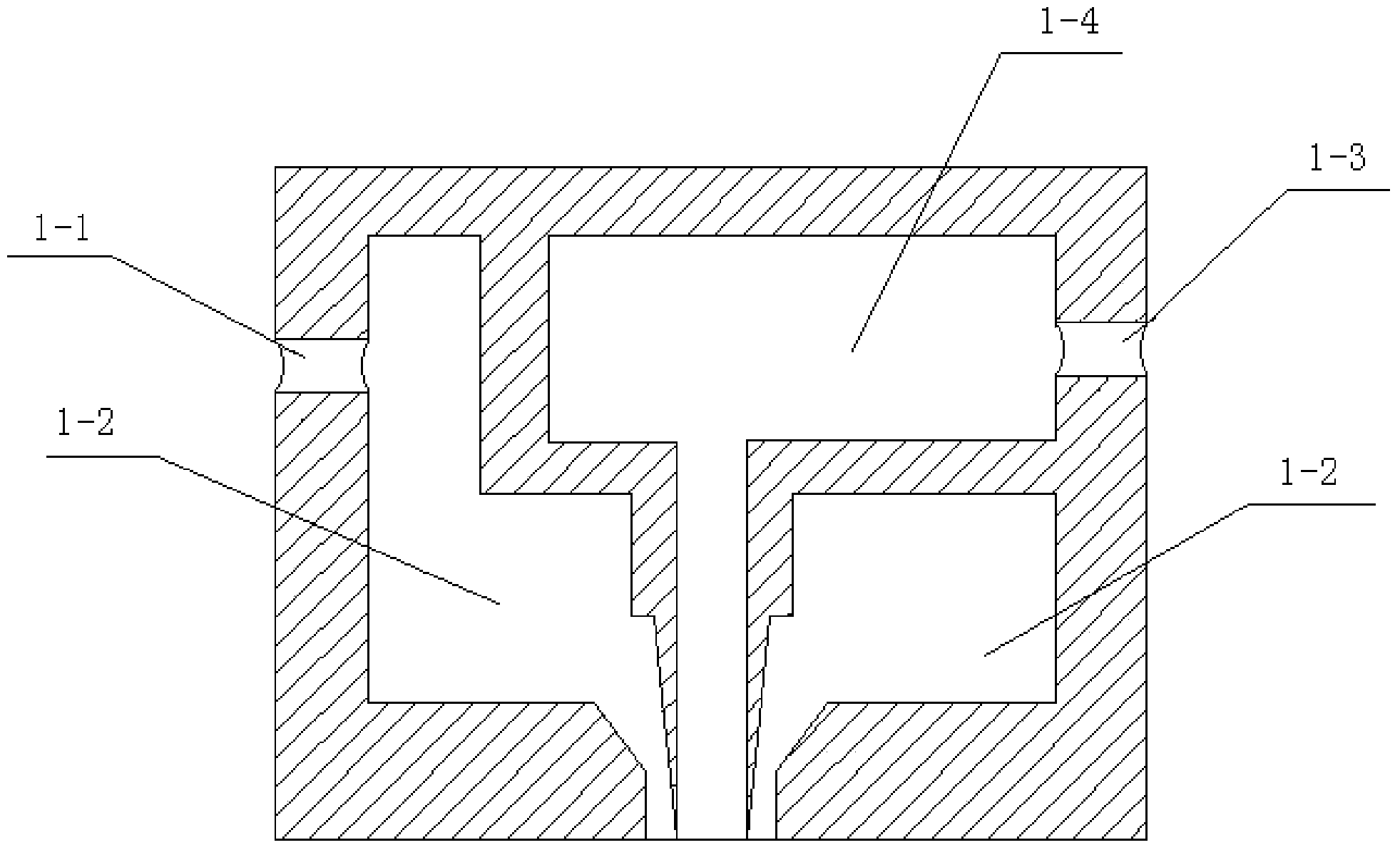

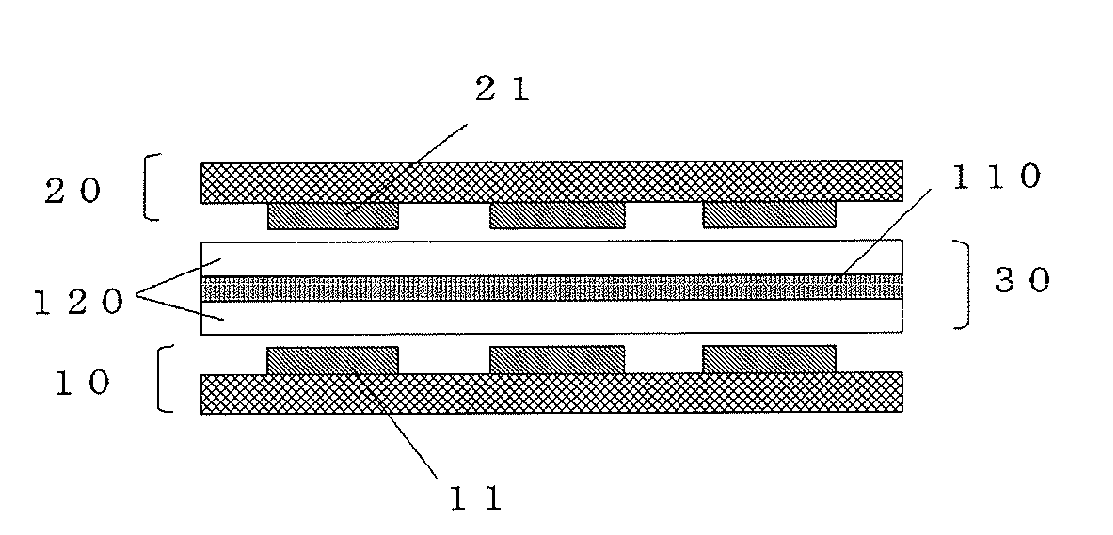

Conductive connecting material, method for producing electronic component, electronic member with conductive connecting material and electronic component

InactiveUS20120261174A1Improve insulation reliabilityReliable electrical connectionSingle bars/rods/wires/strips conductorsSolid-state devicesEngineeringElectronic component

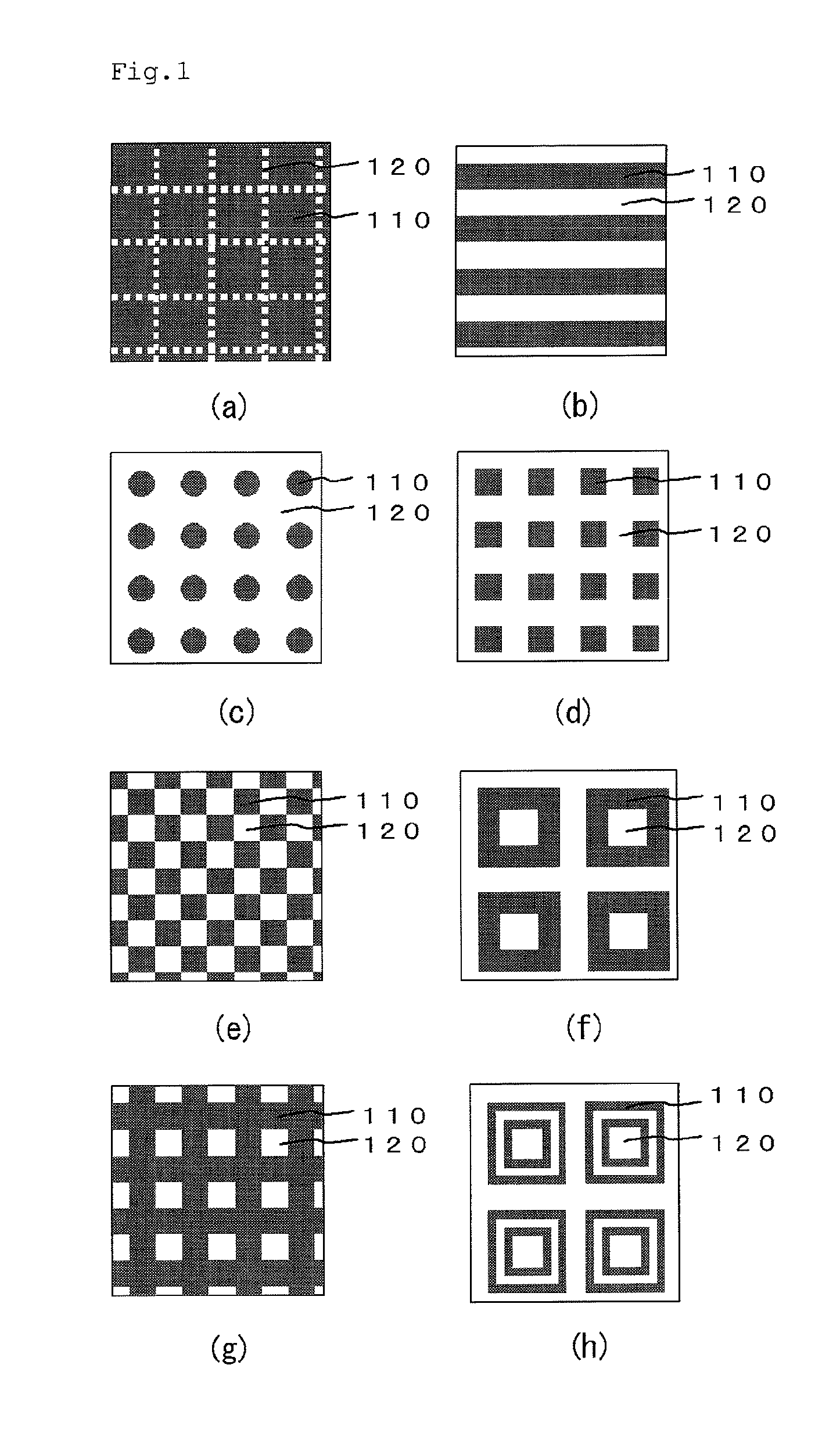

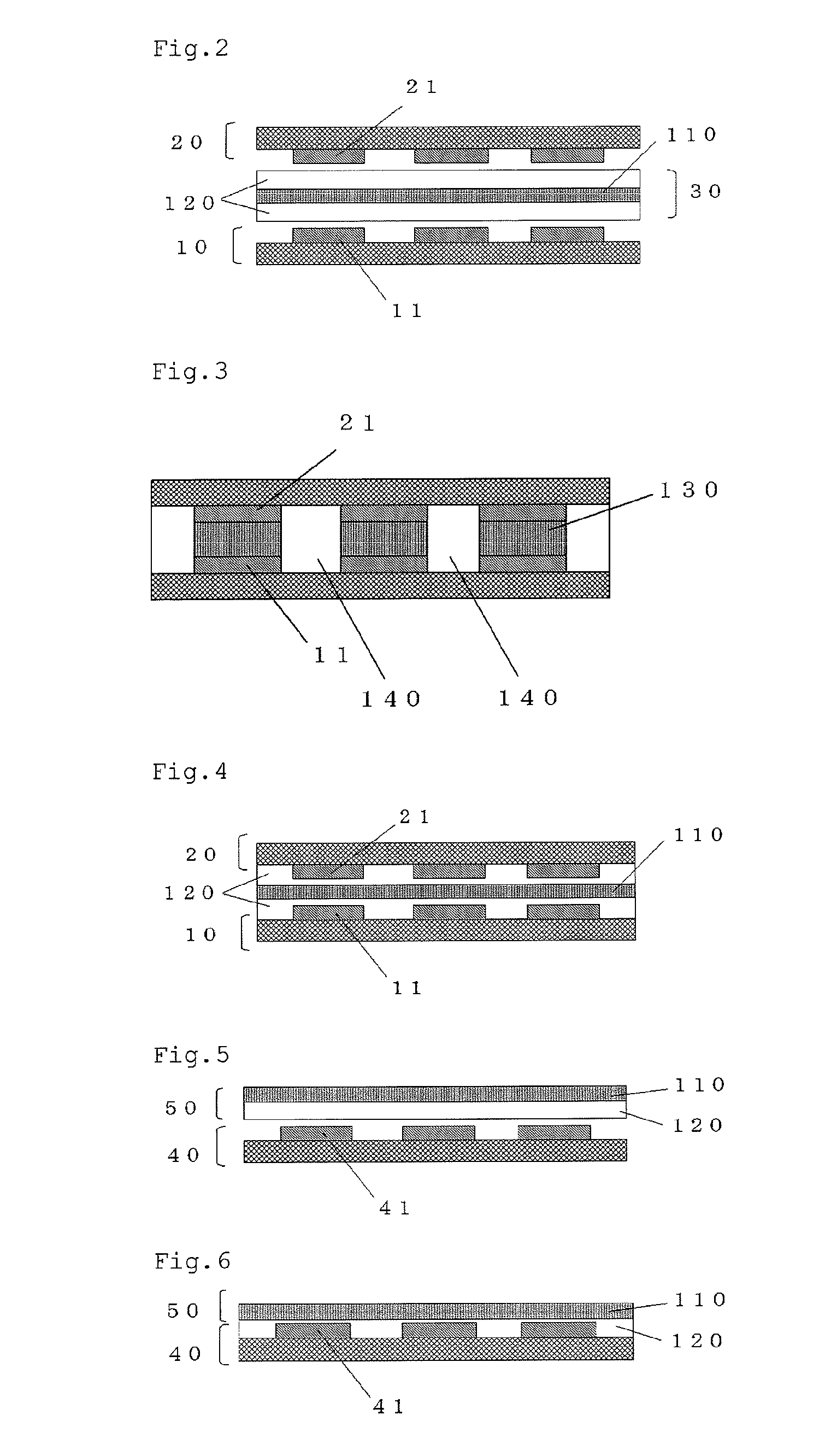

Disclosed is a conductive connecting material 30 used to form conductive portions on a plurality of terminals 11 of an electronic member having a substrate 10 and the plurality of terminals 11 provided on the substrate 10, comprising a metal layer 110 and a resin layer 120 having a resin component and a filler, in which the metal layer is aggregated on each of terminals to form the conductive portions on the plurality of terminals by bringing the conductive connecting material into contact with the plurality of terminals and heating the conductive connecting material.

Owner:SUMITOMO BAKELITE CO LTD

Compositions and methods for treating materials with insecticides and potentiating agents

InactiveUS20120301532A1Reduce and eliminate populationEasy to moveBiocideOrganic chemistryAnimal usePreviously treated

In accordance with the present disclosure, compositions and methods are described for potentiating the effectiveness of insecticides with which materials or objects are treated or impregnated to reduce or eliminate insect populations that infest or inhabit materials, articles and furnishings associated with human or animal use. Materials or articles may be treated or impregnated with compositions comprising one or more insecticides in combination with one or more potentiating agents that effectively promote the movement or aggregation of insects to a designated area that has been treated or impregnated with insecticide, and delivery devices containing a potentiating agent or agents may be associated with a material or article that has been previously treated or impregnated with insecticide.

Owner:ALLERGY TECH

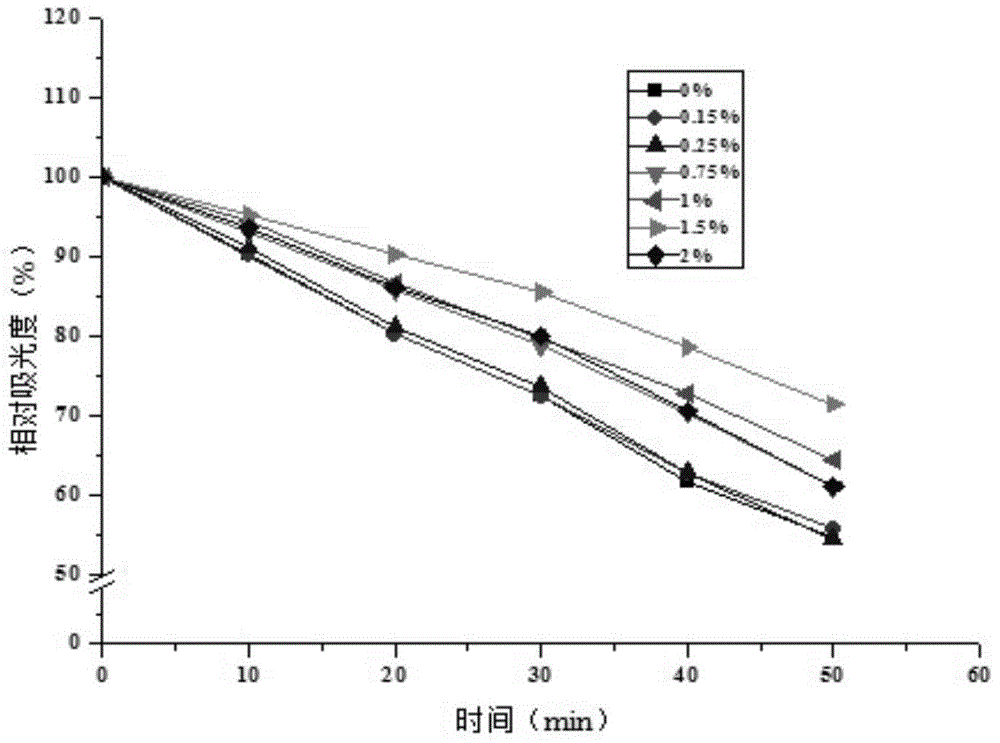

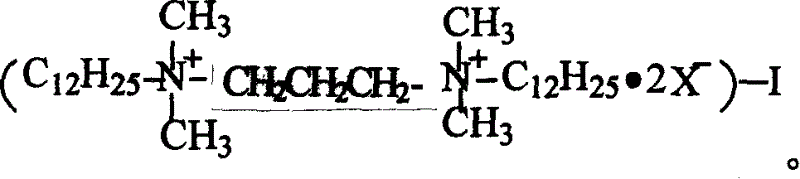

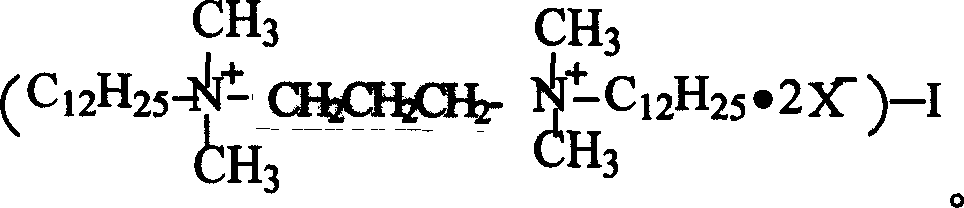

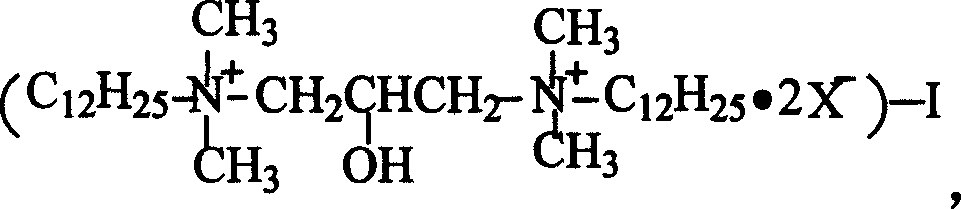

Bi-dodecyl double quaternary ammonium salt iodine attached bactericide

The invention relates to a disinfecting agent, more specifically, to a Gemini-tamed iodine composite bactericide, wherein the agent is recombined from Gemini and I2, the effective iodine content is 6-10 wt%, the constitutional formula is disclosed in the specification. The Gemini-tamed iodine bactericidal agent is an organic-inorganic compound system with greatly improved stability and lowered excitation.

Owner:HARBIN INST OF TECH

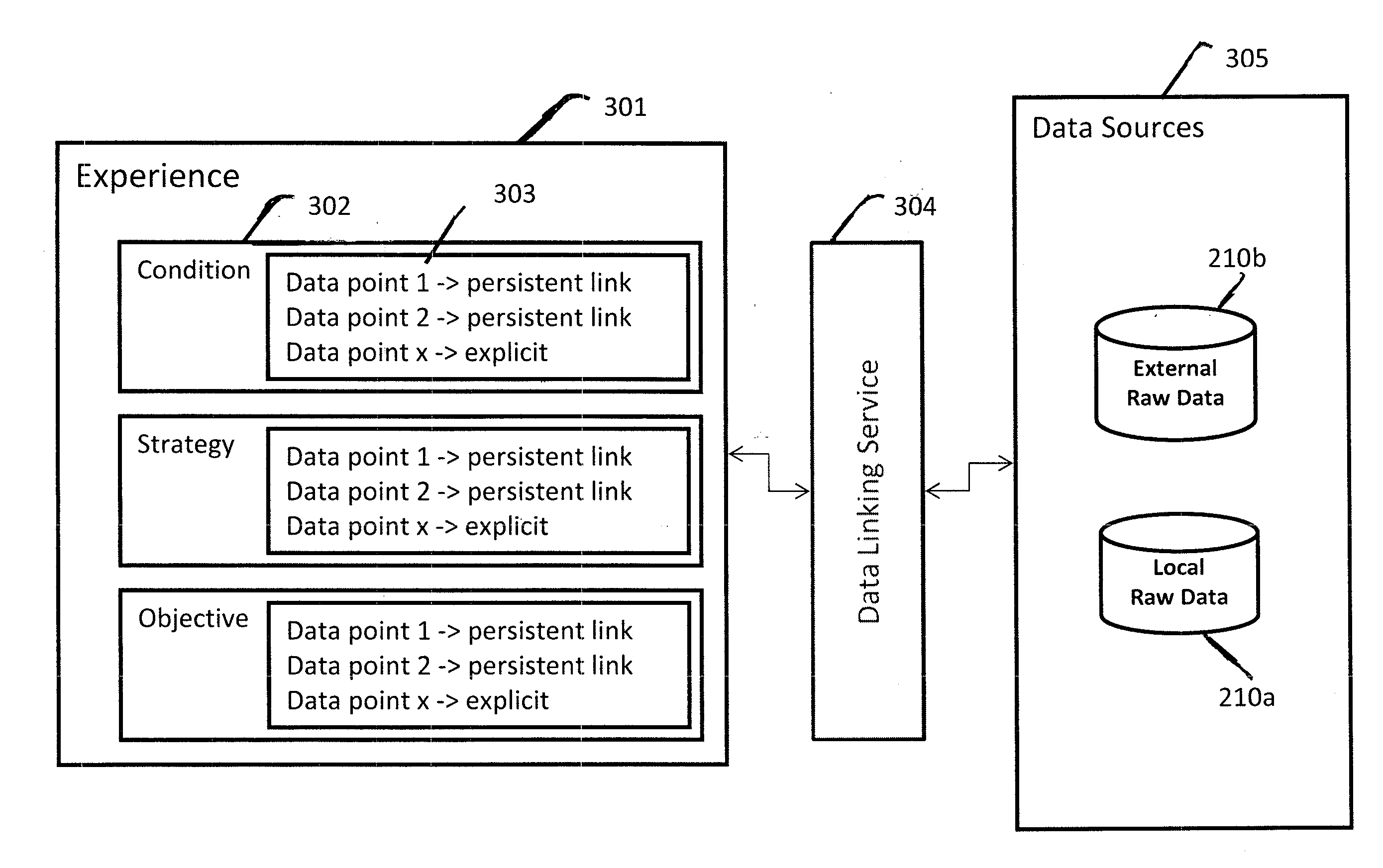

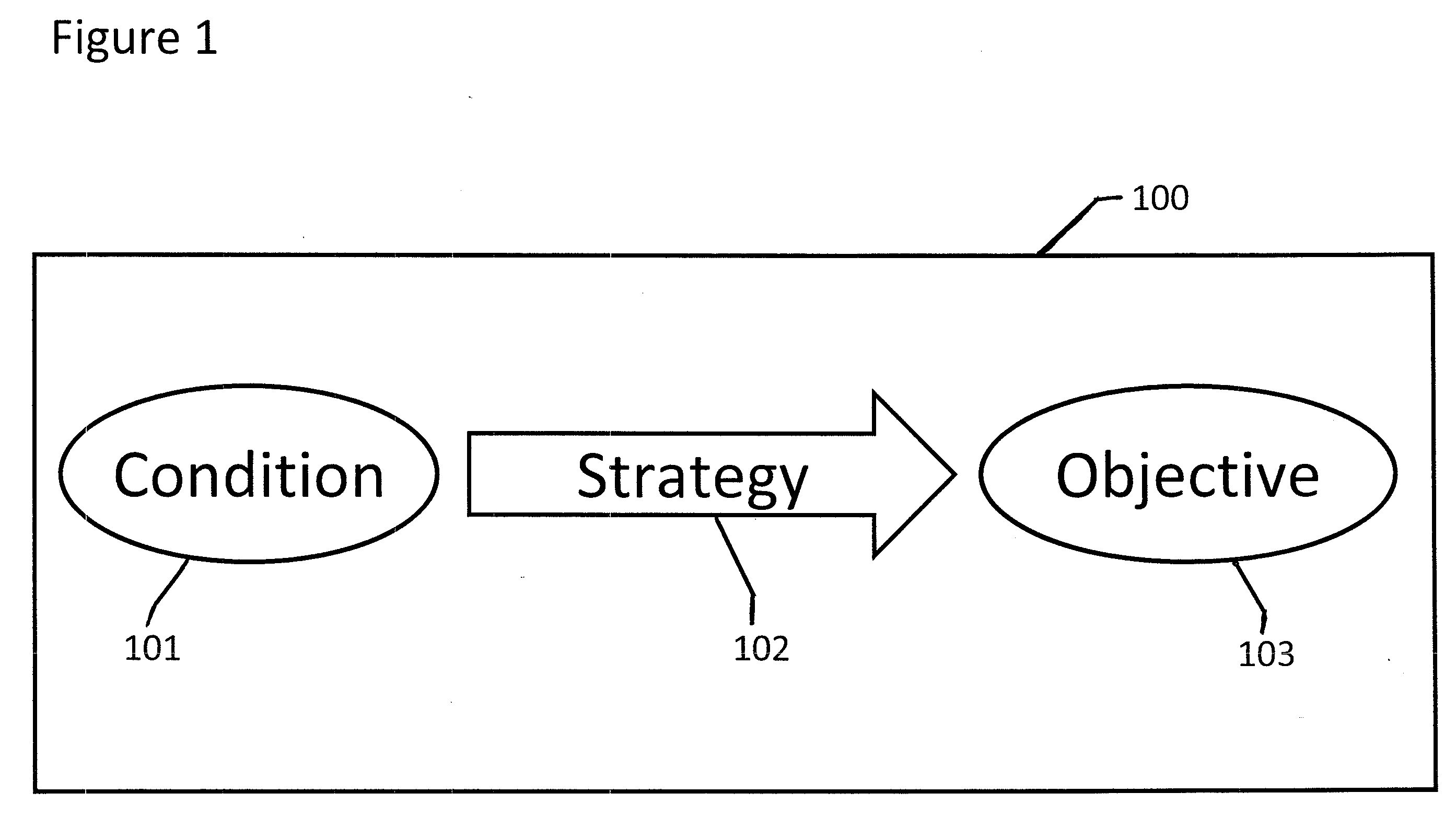

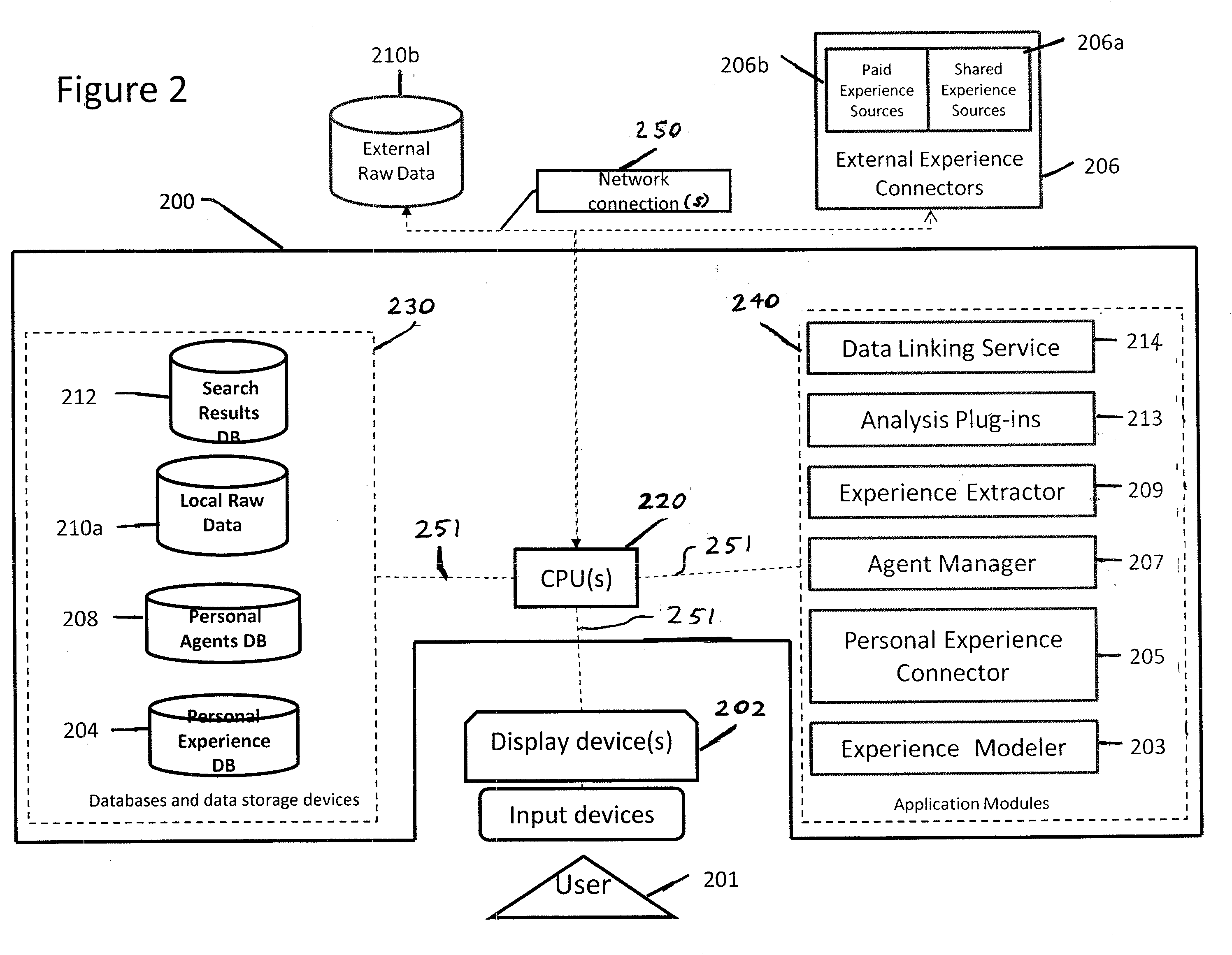

System and Method for Modeling Human Experiences, and Structuring and Associating Experience Information so as to Automate the Production of Knowledge

InactiveUS20120109953A1Easy accessAvoid Modeling DifficultiesDigital data processing detailsResourcesRelevant informationLabeled data

The present invention creates a system for describing human experience, and creating, accessing and analyzing information that allows human experiences to be shared, compared, and analyzed. An Experience is described using Condition (C), Objective (O), and Strategy (S) attributes. Data is identified or tagged using C, O and S attributes, allowing the data to be combined to describe an experience, then making it searchable in such as way so that highly relevant information is selected, organized, and presented to the user. The system allows multiple individuals to share their experience data so that individuals can compare experiences, and make more informed choices. A system composed of experience databases, an individual's current needs, and automated computer agents, is presented to search for, select, display and update highly relevant information to the user as the user's situation changes, making information self-organizing, and automating the production of knowledge and taking actions based thereon.

Owner:BROWN STEPHEN P

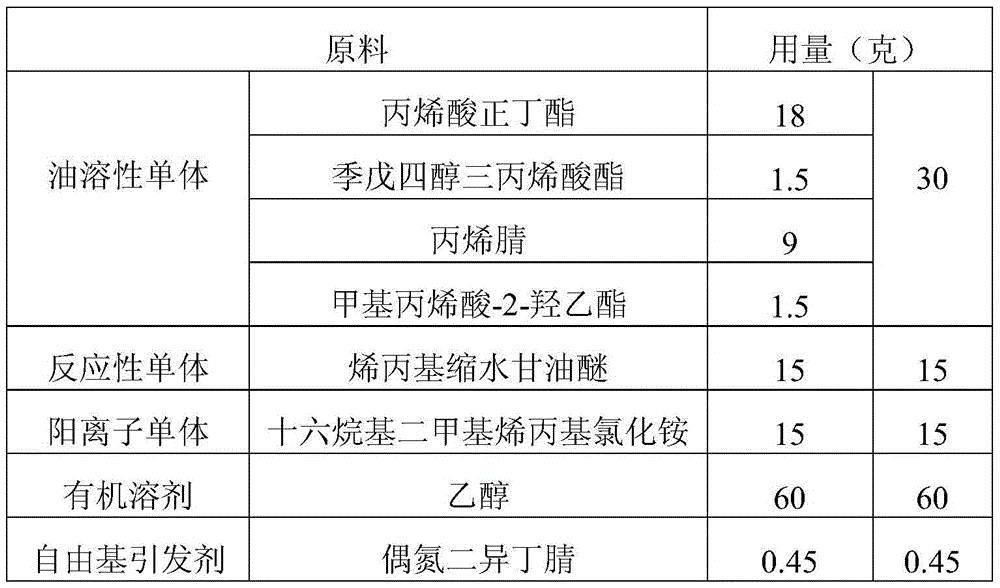

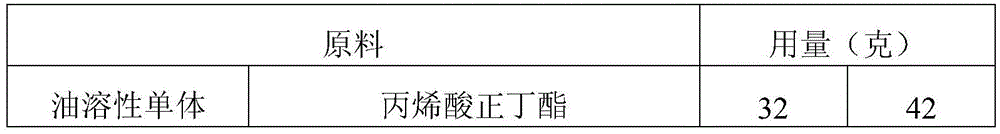

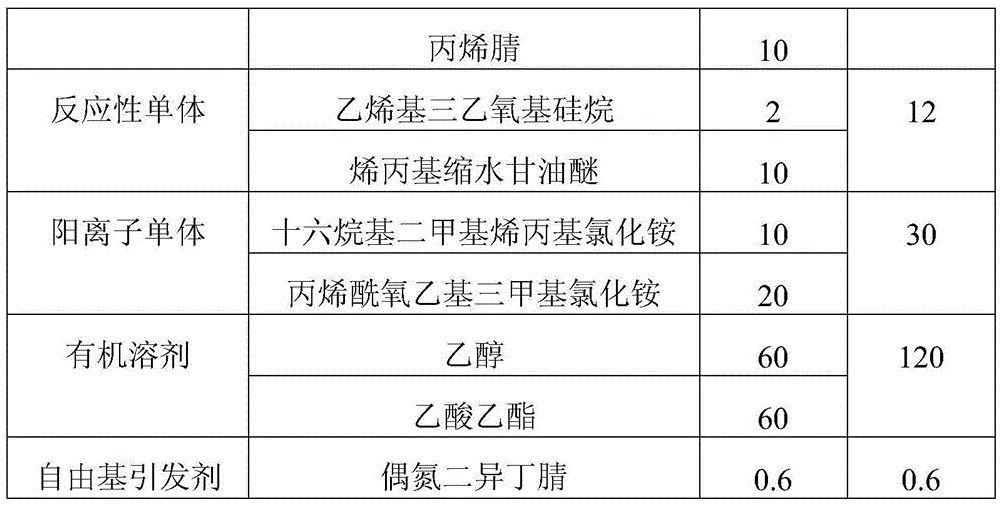

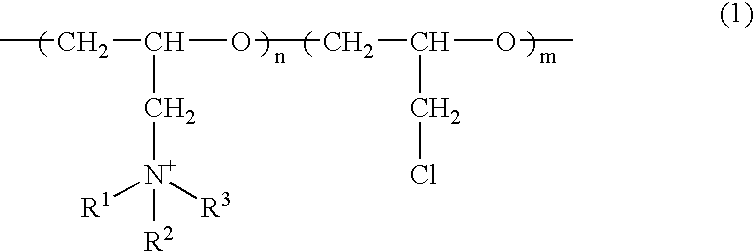

Cationic color fixing agent and preparation method and application thereof

The invention provides a cationic color fixing agent and a preparation method and application thereof. The cationic color fixing agent is obtained by polymerization reaction of an oil-soluble monomer, a cationic monomer and a reactive monomer in a solvent under the action of a radical initiator, wherein the oil-soluble monomer is one or the combination of several of styrene, acrylonitrile and acrylate; the cationic monomer is one or the combination of acryloxyethyl alkyl quaternary ammonium salt and / or allyl alkyl quaternary ammonium salt; the reactive monomer is one or the combination of several of allyl glycidyl ether, hydroxyl-containing acrylics, vinyl trimethoxy silane, vinyl triethoxy silane, acrylamide, crylic acid and methacrylic acid. The cationic color fixing agent is insoluble in water and can be dissolved in a weak polar solvent and / or non-polar solvent; besides, after non-aqueous solvent dyeing of reactive dyes, the cationic color fixing agent can be directly used in the on-going fixing process without washing.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

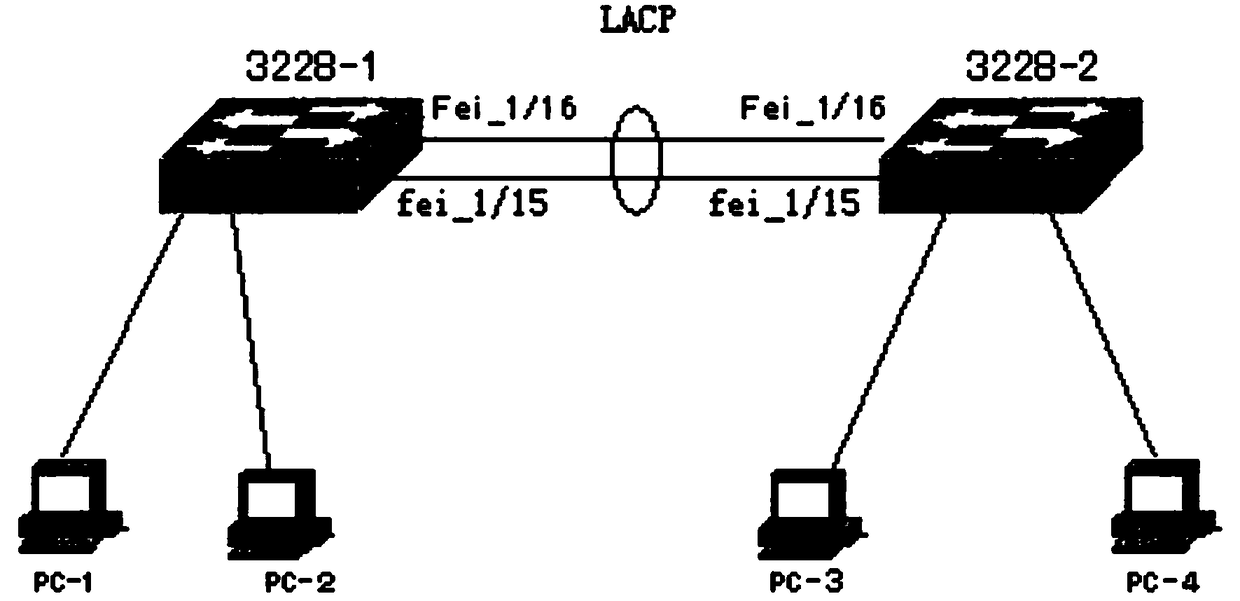

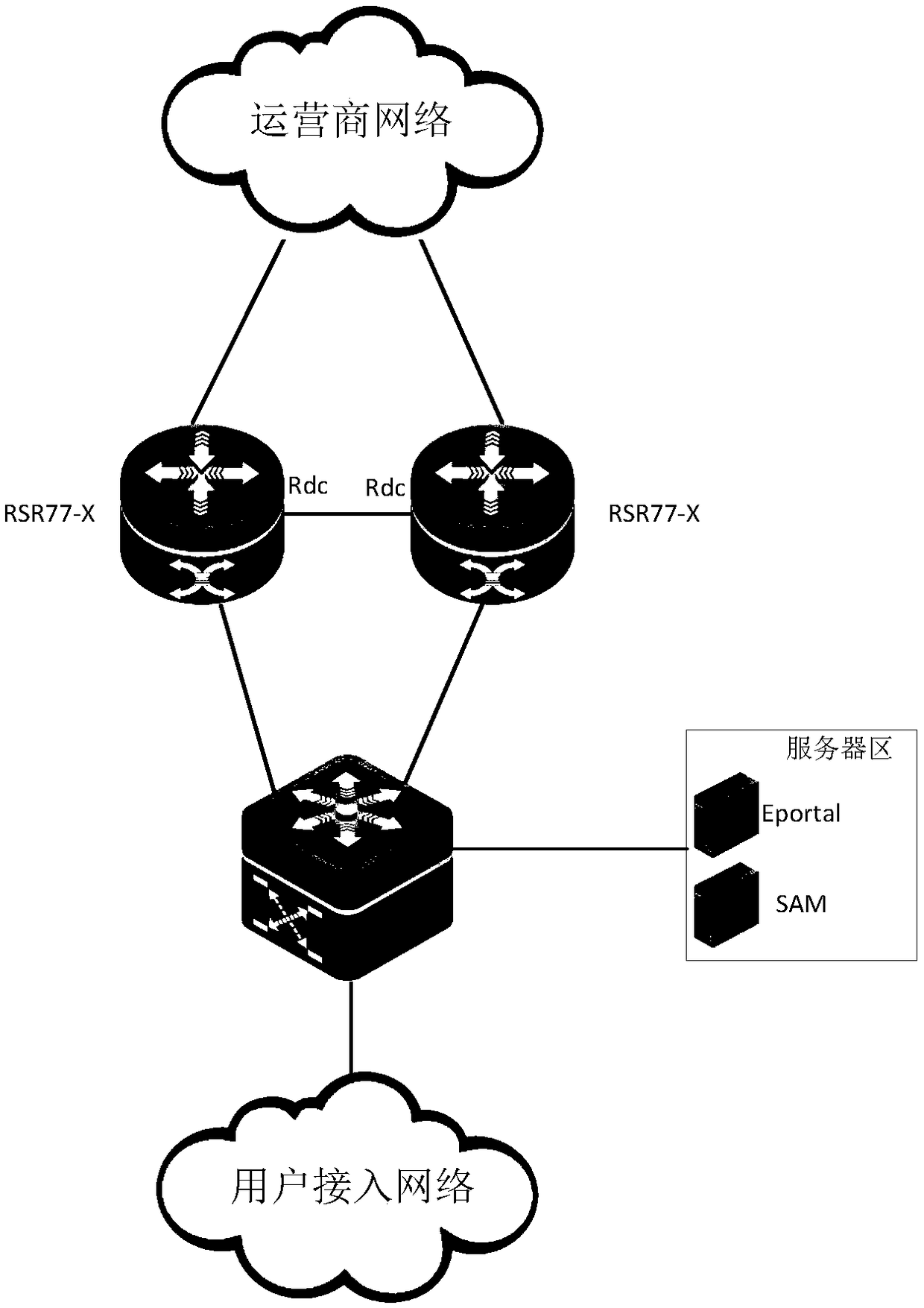

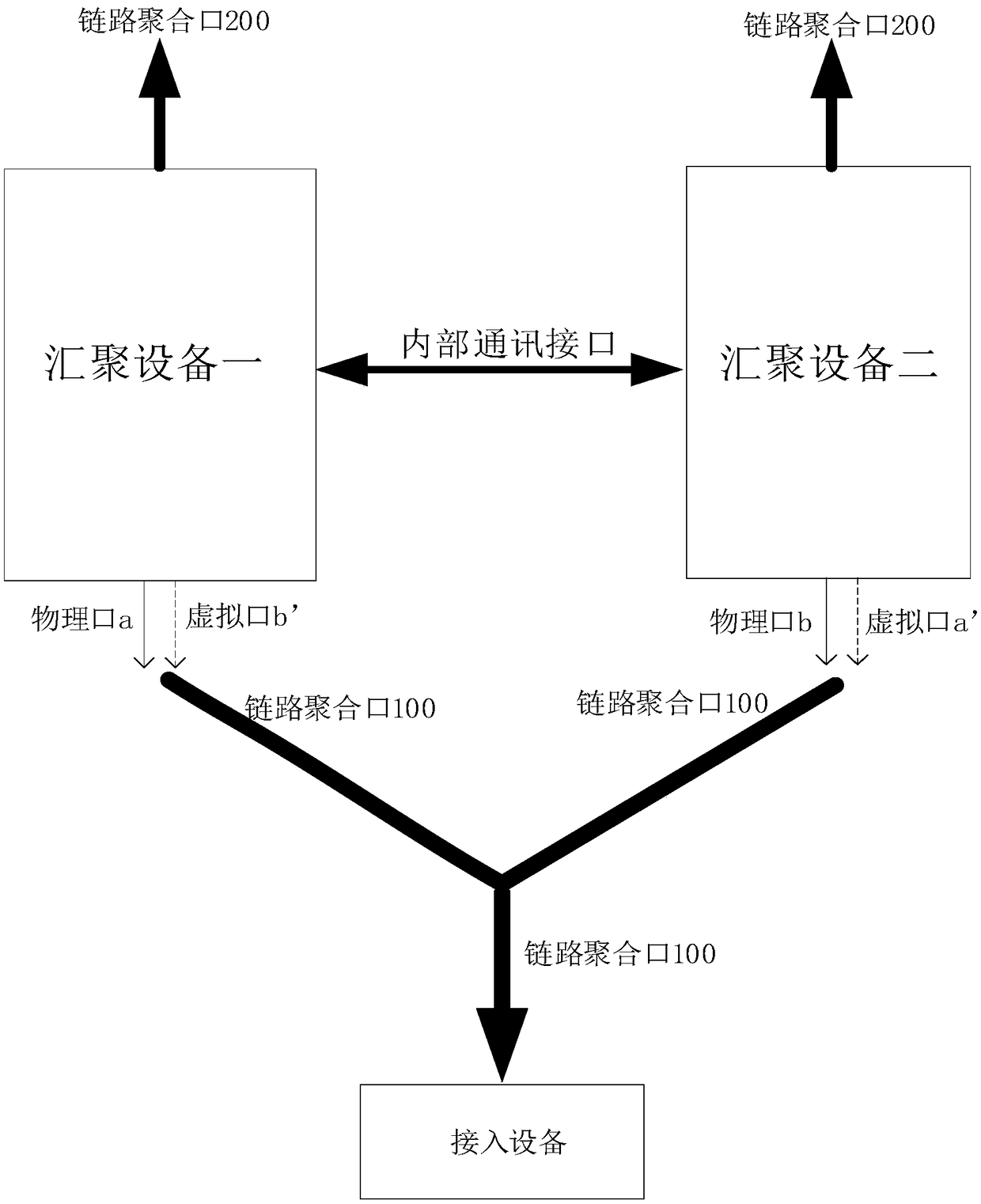

Cross-device link aggregation method, apparatus, computing device and storage medium

ActiveCN109088820AEasy to implementReduce couplingData switching networksCommunication interfacePhysical interface

A method, apparatus, computing device and storage medium for cross-device link aggregation relate to the field of data communication and is used to solve the problem of cross-device link aggregation.In the method, the aggregation device is connected through an internal communication interface, and the cross-device link aggregation is realized according to the corresponding relationship between the interface identifier of the physical interface and the interface identifier of the virtual interface, so that the realization is simpler. At the same time, because the convergence equipment is independent of each other software system, coupling is less.

Owner:RUIJIE NETWORKS CO LTD

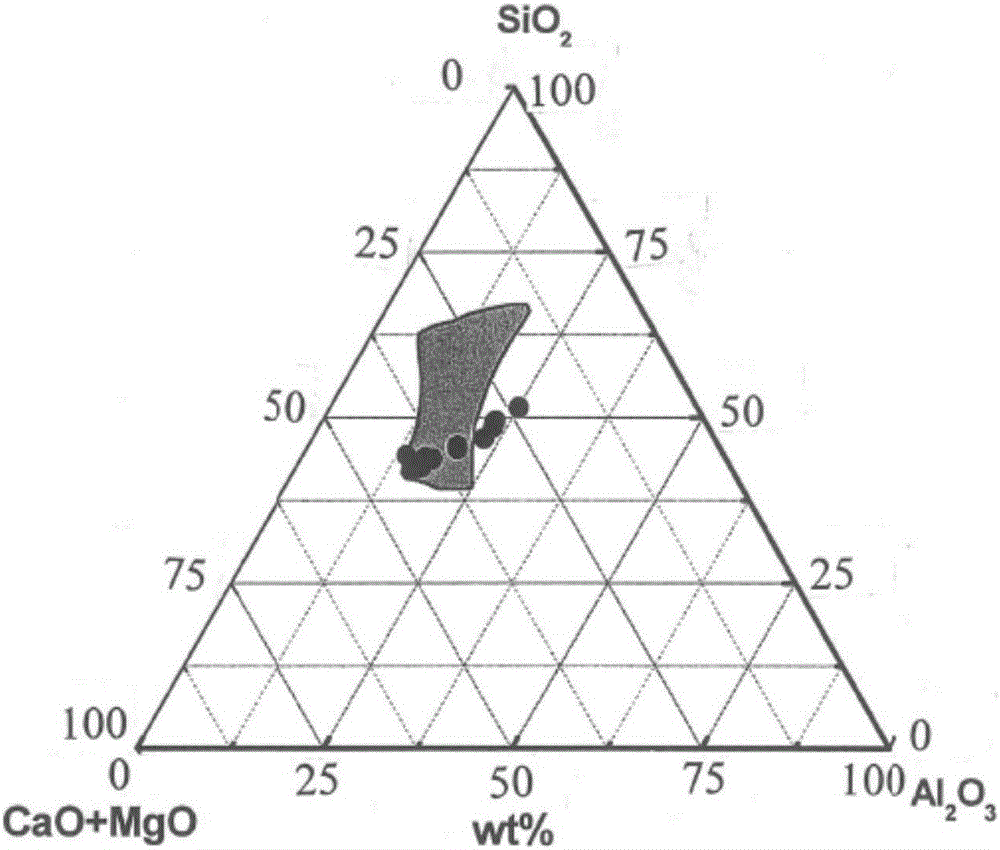

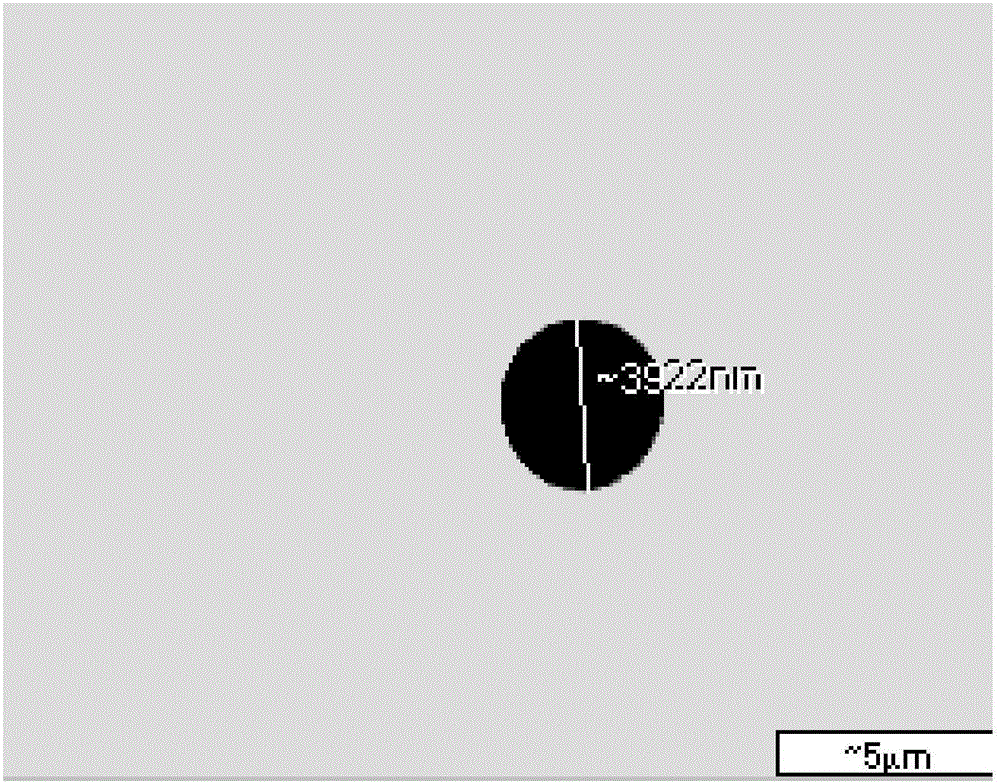

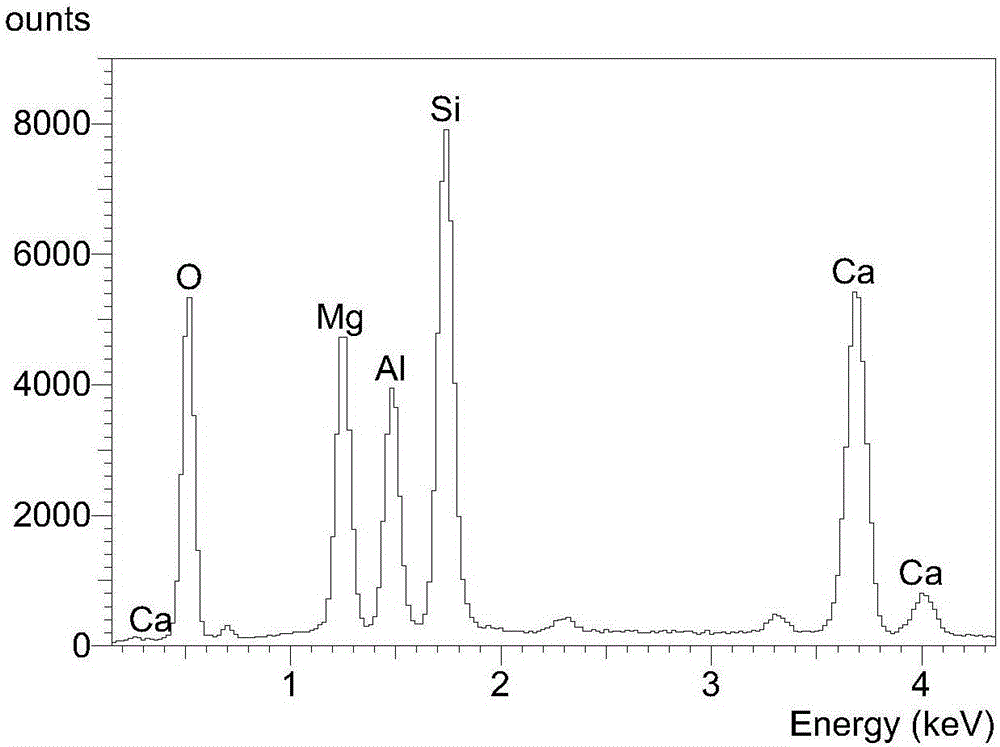

Smelting method capable of reducing inclusions of spring steel

The invention discloses a smelting method capable of reducing inclusions of spring steel. The smelting method includes the following steps of (1) smelting through a high carbon withdrawing process; (2) argon blowing; (3) refining in an LF furnace; (4) vacuum treatment; (5) LF soft blowing; and (6) spring steel rolling. Especially, aluminum-free deoxidation is adopted during smelting through the high carbon withdrawing process, and a low-alkalinity slag process is adopted during refining in the LF furnace. According to the smelting method capable of reducing inclusions of spring steel, on the basis of researching thermodynamics and kinetics for separation out of inclusions, the content of oxides is lowered by controlling the deoxidation depth during smelting, the low-alkalinity slag process facilitates plasticization of inclusions, the plasticized inclusions can easily aggregate and grow up, flotation removal is facilitated during soft blowing in secondary refining, and therefore the purpose of controlling the level of nonmetal inclusions of spring steel is achieved; and the problem of judgment amending caused by exceeding of inclusions is completely solved, and the production cost is greatly lowered.

Owner:武汉钢铁有限公司

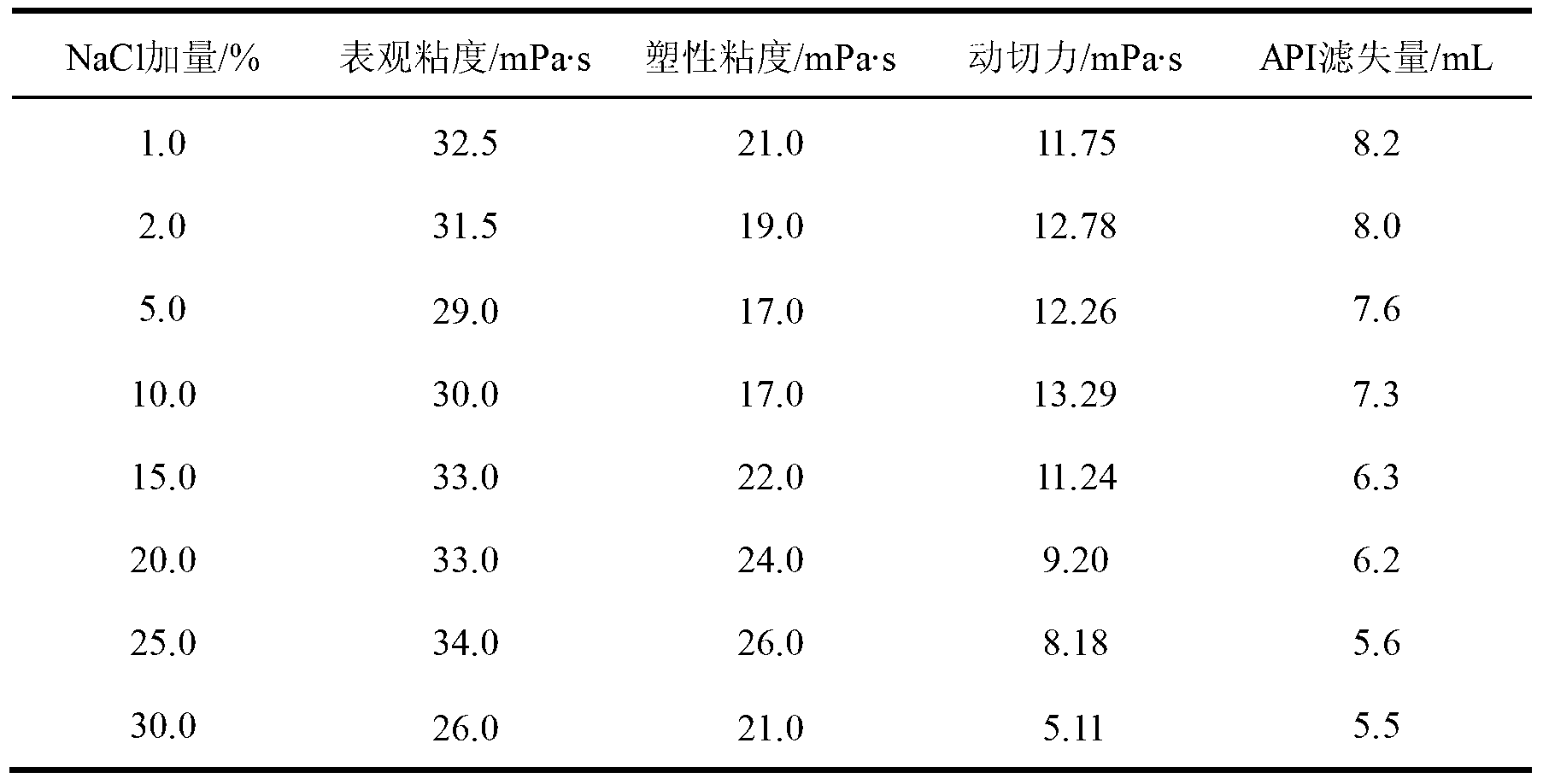

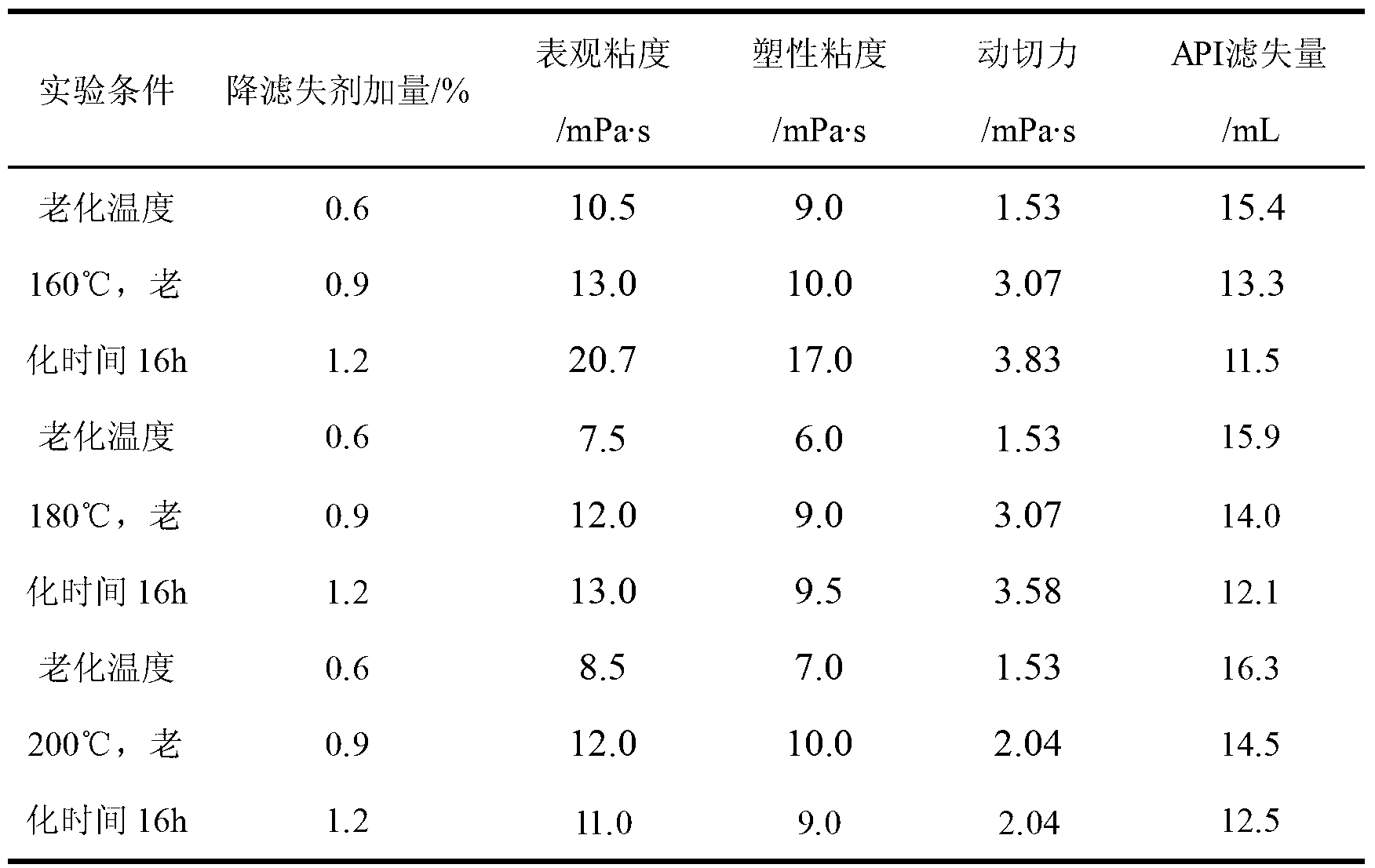

Preparation method and application of polyoxyethylene-based polymer filtrate reducer

ActiveCN103254366AWide variety of sourcesEasy to dehydrateDrilling compositionSalt resistancePolymer science

The invention relates to a preparation method and application of a polyoxyethylene-based polymer filtrate reducer for oil and gas field drilling fluid, aiming at solving the problems that an existing filtrate reducer for the drilling fluid has poor high temperature resistance and hypersalinity resistance and poor rheological property at high temperature. According to the technical scheme, the preparation method comprises the following steps of adding allyl polyoxyethylene ether into water and heating for dissolving; then adding 2-acrylamide-2-methyl propanesulfonic acid and acrylamide, adding an initiator and stirring uniformly, and regulating the pH of a system to be 8-10 by using an NaOH solution; and finally reacting for 2-5 hours at 50-80 DEG C to obtain a gel product through a copolymerization reaction, purifying and extracting by using absolute ethyl alcohol, cutting and pelleting, drying in vacuum, and smashing so as to prepare the polymer filtrate reducer. According to the evaluation of the temperature resistance, the salt resistance and rheological property of the polymer basic mud by adding the filtrate reducer into fresh water basic mud and salt water base, the filtrate reducer has strong salt resistance, good high temperature resistance and stable rheological property. The preparation method is simple and mild in synthesis conditions.

Owner:SOUTHWEST PETROLEUM UNIV

Coating slurry for diaphragm, composite heat resisting diaphragm and preparation method of composite heat resisting diaphragm

ActiveCN106252570ALow closed cell temperatureEasy to aggregateCell seperators/membranes/diaphragms/spacersSecondary cellsMetallurgySlurry

The invention provides coating slurry for a diaphragm, a composite heat resisting diaphragm, and a preparation method of the composite heat resisting diaphragm, wherein the coating slurry for the diaphragm comprises and is prepared from the following materials: organic particles, ceramic particles, a binder and water; by solid content, the organic particles account for 24.5%-99.5% by weight, the ceramic particles account for 0-75% by weight, and the binder accounts for 0.5%-15%; the solid content is 20%-50% of the total weight of the coating slurry. Compared with a diaphragm in the prior art, the closed pore temperature in an electrolyte / battery is lower, and a current is cut off before the accelerated heat release of the battery.

Owner:TIANJIN ENERGIES

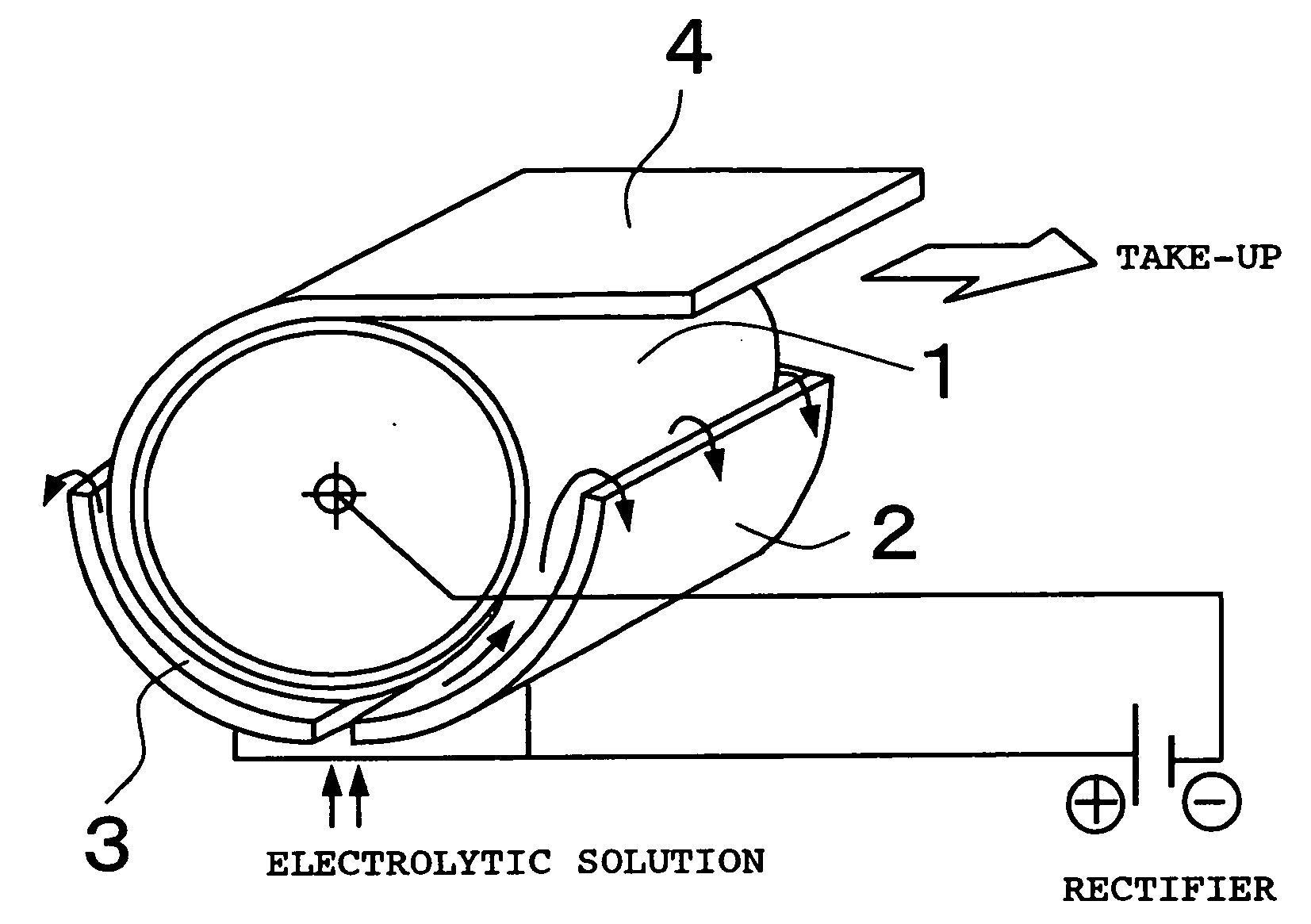

Copper electrolytic solution and electrolytic copper foil produced therewith

ActiveUS20060166032A1Improve smoothnessHigh elongationOrganic compound preparationLiquid/solution decomposition chemical coatingElectrolysisCopper foil

Owner:JX NIPPON MINING& METALS CORP

Bionic fibrous protein hydrogel micelle for spinal cord injury repair and preparation method of bionic fibrous protein hydrogel micelle

InactiveCN106730031AEffective guidance for directed regenerationPromote regeneration and repairMonocomponent protein artificial filamentConjugated cellulose/protein artificial filamentsFiberCell-Extracellular Matrix

The invention relates to a bionic fibrous protein hydrogel micelle for spinal cord injury repair as well as a preparation method and application of the bionic fibrous protein hydrogel micelle. The bionic fibrous protein hydrogel micelle is prepared from fibrous proteins by an electrostatic spinning technology. The bionic fibrous protein hydrogel micelle prepared by the single-channel electrostatic spinning technology is a hydrogel material with high water content and is formed by multi-stage oriented nano-fibers highly simulating spinal cord tissues; and the multi-stage oriented fibrous protein hydrogel micelle expresses compositions and extracellular matrix environment similar to natural spinal cord tissues, has the mechanical properties similar to natural nerves, can effectively promotes orientated growth of nerve fibers and has the degradation velocity matched with the repair velocity of the spinal cord injured tissues.

Owner:TSINGHUA UNIV

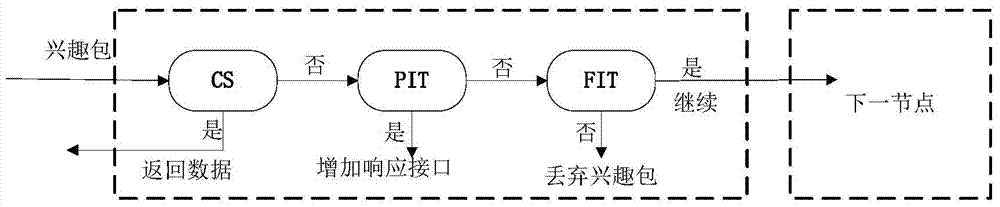

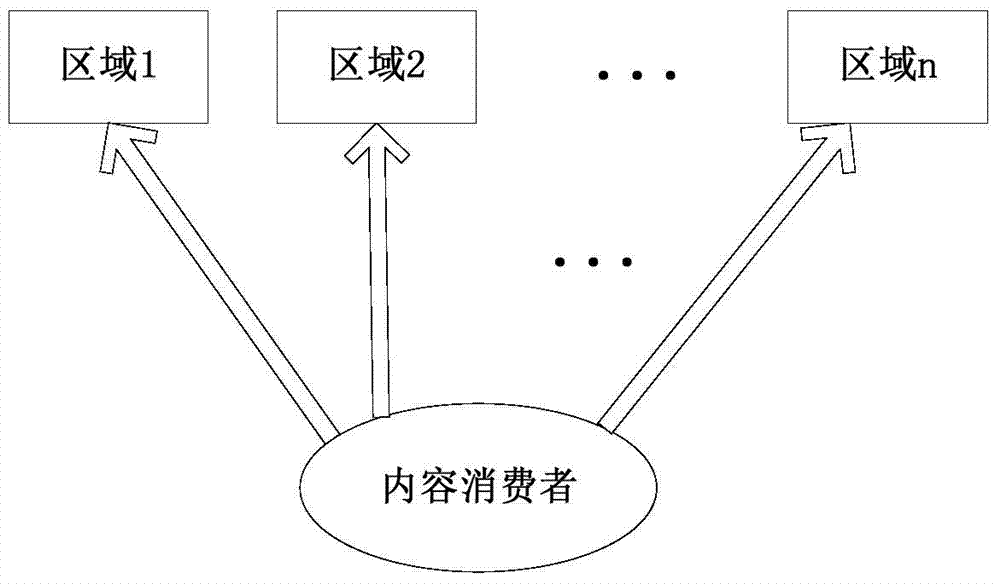

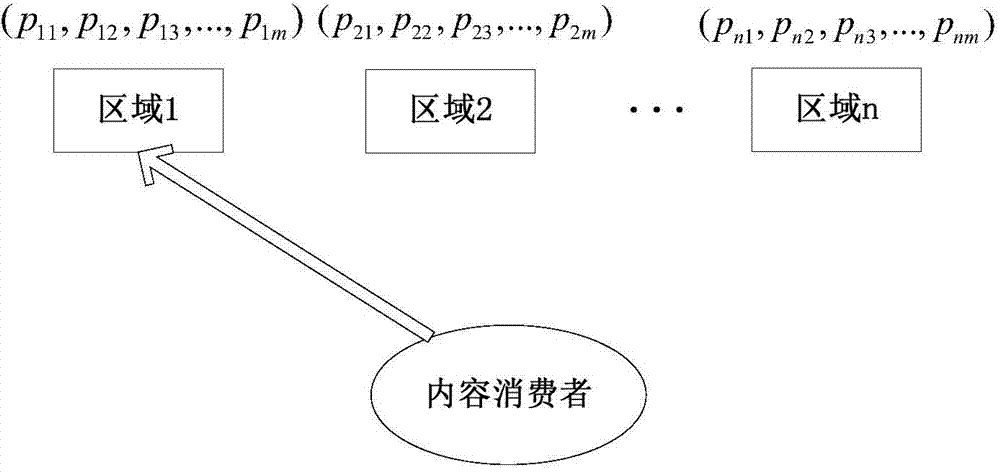

Routing method realized on basis of content attribute part of name in content-centric networking

InactiveCN104767678AHas layered propertiesAchieve uniquenessData switching networksContent distributionDistributed computing

The invention relates to a routing method realized on a basis of a content attribute part of a name in a content-centric networking. The method comprises the steps that a content consumer checks the name of a to-be-sent interest packet, and determines the content of the interest packet according to the information contained in the name of the interest packet; according to the attribute of the content and the distribution probabilities of the content in all areas, the content consumer sends the interest packet to an area with the highest content distribution probability; after receiving the interest packet, a node in the area checks the name of the received interest packet, and performs matching according to the name of the interest packet; and if getting no response, the content consumer sends the interest packet to another area with the second highest content distribution probability, and then the previous step is performed until the interest packet is sent successfully or an end condition is met.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

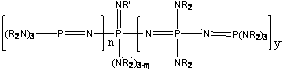

One-step synthetic method of degradable branched polyester

The invention discloses a one-step synthetic method of degradable branched polyester, and belongs to the technical field of polymer synthesis. According to the method, a reactive monomer comprises internal ester, anhydride, cyclic carbonate and the like; a self-initiated monomer comprises acrylic acid hydroxy ester and a methacrylic acid hydroxy ester compound, and a catalyst is a phosphine nitrile alkali compound structurally containing a double bond in which P is equal to N. The one-step synthetic method has the advantages that all raw materials for the polymerization reaction are commercialized and the conditions of the polymerization reaction are mild, is suitable for industrialized production, has an excellent application prospect, and is mainly used for the technical field of the polymer synthesis.

Owner:安徽壹敏新材料有限公司

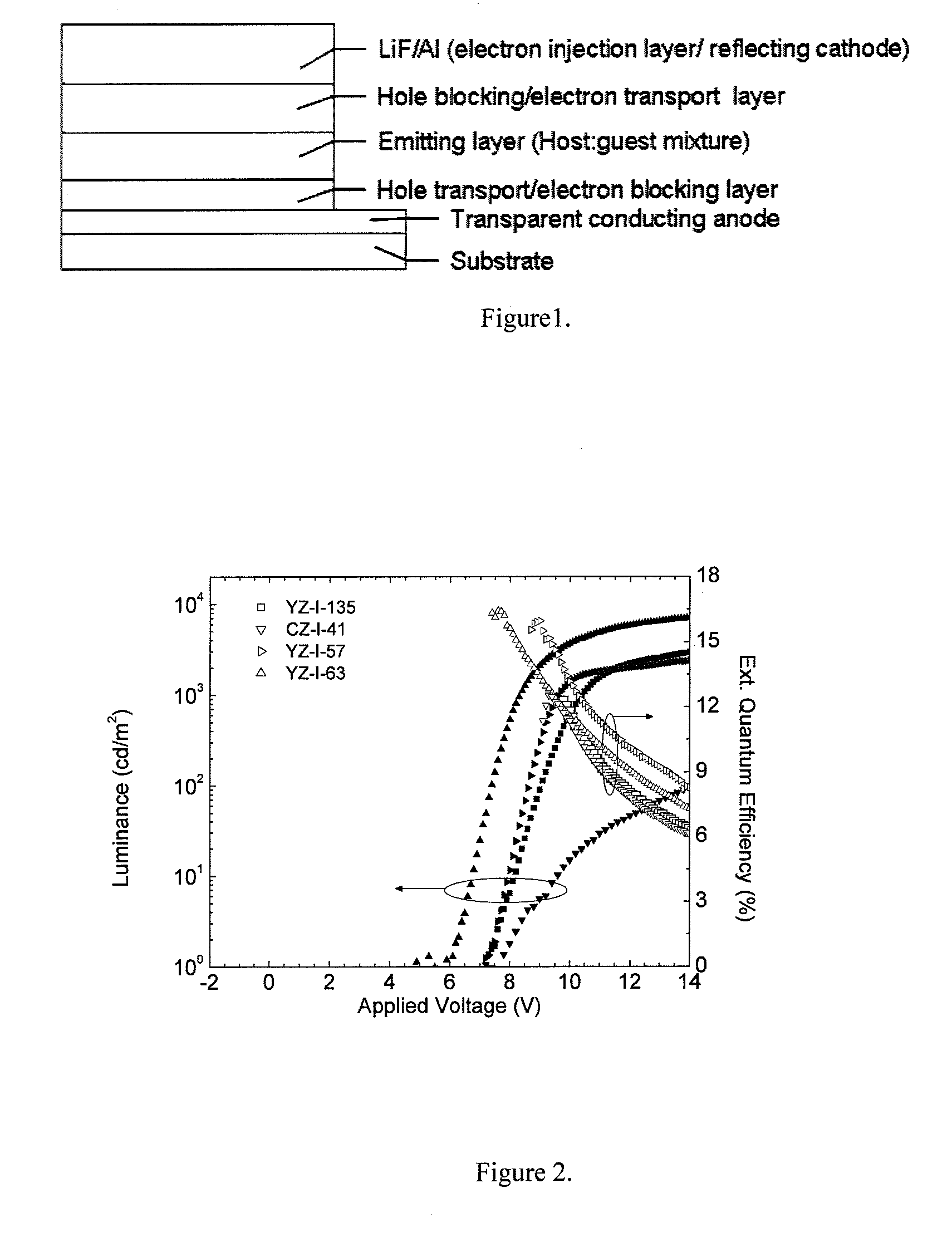

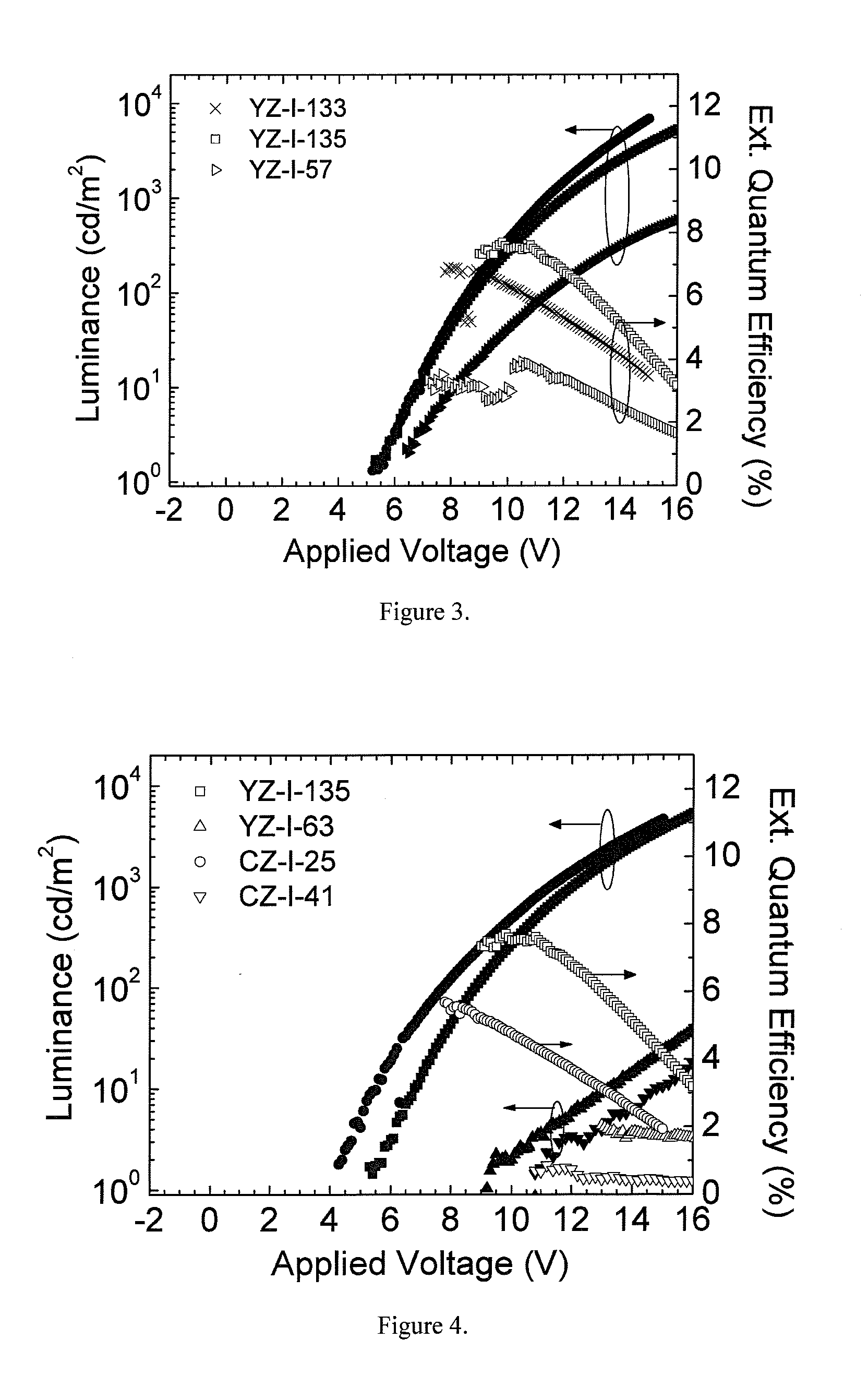

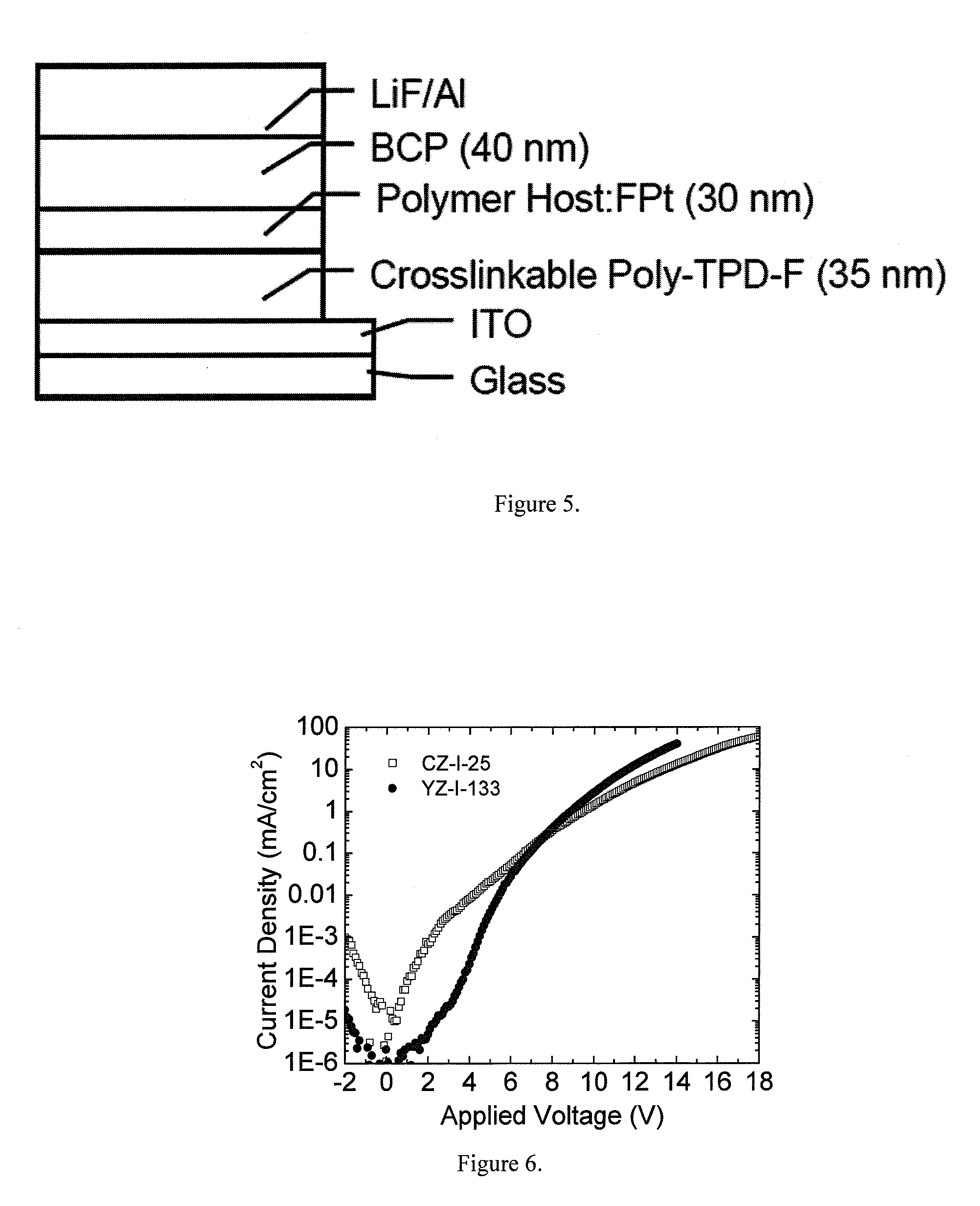

Carbazole-based hole transport and/or electron blocking materials and/or host polymer materials

InactiveUS20100331509A1Readily polymerizeEasy to aggregateOrganic chemistrySolid-state devicesNorborneneSide chain

This invention relates generally to norbornene-monomer, poly(norbornene)homopolymer, and poly(norbornene)copolymer compounds containing a functionalized carbazole side chain, having desirable solution processability and host characteristics. It also relates to hole transport and / or electron blocking materials, and to organic host materials for an organic luminescence layer, an OLED device, and compositions of matter which include these compounds.

Owner:GEORGIA TECH RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com