Bionic nerve graft used for peripheral nervous recovery and preparation method thereof

A technology for peripheral nerve and nerve transplantation, applied in the field of bionic nerve grafts and its preparation, can solve problems such as poor repair of nerve conduits, and achieve good cell affinity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

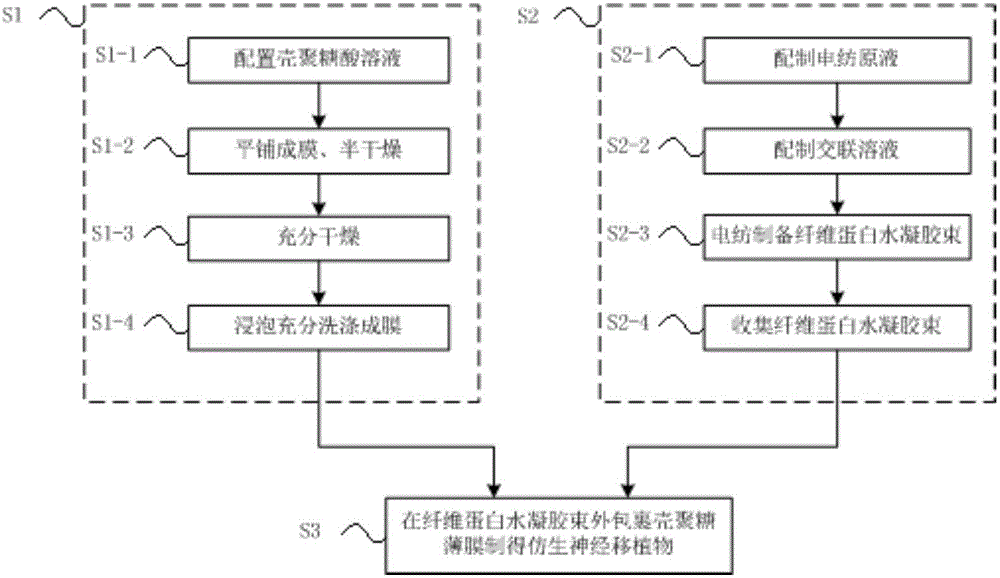

[0052] see figure 1 , is a flowchart of a method for preparing a bionic nerve graft for peripheral nerve repair according to a preferred embodiment of the present invention. Such as figure 1 As shown, this embodiment provides the above-mentioned preparation method of the bionic nerve graft for peripheral nerve repair, comprising the following steps:

[0053] Step S1, preparation of chitosan film catheter. Preferably, the chitosan film conduit is prepared by solvent evaporation, specifically comprising:

[0054] Step S1-1, dissolving chitosan in any one of dilute glacial acetic acid and hydrochloric acid to prepare an acid solution of chitosan, wherein the concentration of chitosan is 0.01-0.02g / ml (such as 0.01, 0.012, 0.015 , 0.018 or 0.02g / ml). Preferably, the concentration of glacial acetic acid used in this step is 0.015g / ml, and the concentration of hydrochloric acid is 0.01g / ml. The chitosan is preferably carboxymethyl chitosan.

[0055] Step S1-2, taking the chito...

Embodiment 1

[0078] 1. Chitosan is dissolved in 2% glacial acetic acid aqueous solution to prepare an acid solution of chitosan, wherein the concentration of chitosan is 0.015g / ml.

[0079] 2. Take the chitosan acid solution in a glass petri dish with a flat surface, ventilate and dry at normal temperature and pressure, and wait for the solvent to volatilize to obtain a semi-dry chitosan solution.

[0080] 3. Dry the semi-dry chitosan solution in an oven at 60°C for 48 hours.

[0081] 4. Soak the obtained chitosan film in pure water and fully wash it for use. The thickness of the chitosan film is 0.4 mm.

[0082] 5. Dissolve the fibrinogen in pure water, and mix it evenly with the PEO aqueous solution to obtain the electrospinning stock solution. The mass fraction of fibrinogen in the electrospinning stock solution is 4%, and the mass fraction of PEO is 1.2%. The electrospinning stock solution was then injected into a syringe for use.

[0083] 6. Add CaCl 2 The aqueous solution was mi...

Embodiment 2 to 23

[0088] Examples 2 to 23 were carried out in substantially the same manner as Example 1 except for the contents of Table 1 below.

[0089]

[0090]

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com