Patents

Literature

73results about How to "Structural continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly halogen-free flame-proof copolymerized methanal complex and method for producing the same

InactiveCN101508820AImprove flame retardant performanceReduce the degree of toughness lossAntioxidantHeat rejection

The invention relates to an environment-friendly halogen-free flame-retardant copolyoxymethylene compound and a preparation method thereof, belonging to the field of the preparation of flame-retardant polymer material. The compound comprises the components with the mass percentage as follows: 56.0-69.0 percent of copolyoxymethylene resin, 15.0-22.0 percent of flame retardant, 5.0-7.0 percent of flame retardant synergist, 3.0-7.0 percent of char-forming agent, 3.0-5.0 percent of toughener, 0.1-0.5 percent of formaldehyde absorbent, 0.1-1.0 percent of antioxidant and 0.5-3.0 percent of heat rejection and dripping-resistant agent. In the invention, the flame retardant, the flame retardant synergist and the heat rejection and dripping-resistant agent are coated by the toughener to manufacture compound flame retardant; then the compound flame retardant is mixed with the copolyoxymethylene, the formaldehyde absorbent, the char-forming agent and the antioxidant uniformly and the mixture is extruded from a double-screw extruder and granulated; and the copolyoxymethylene compound is obtained. The compound has good flame-retardant performance, the flame-retardant grade reaches UL94V-0 grade, and the compound is friendly to the environment.

Owner:BEIJING UNIV OF CHEM TECH

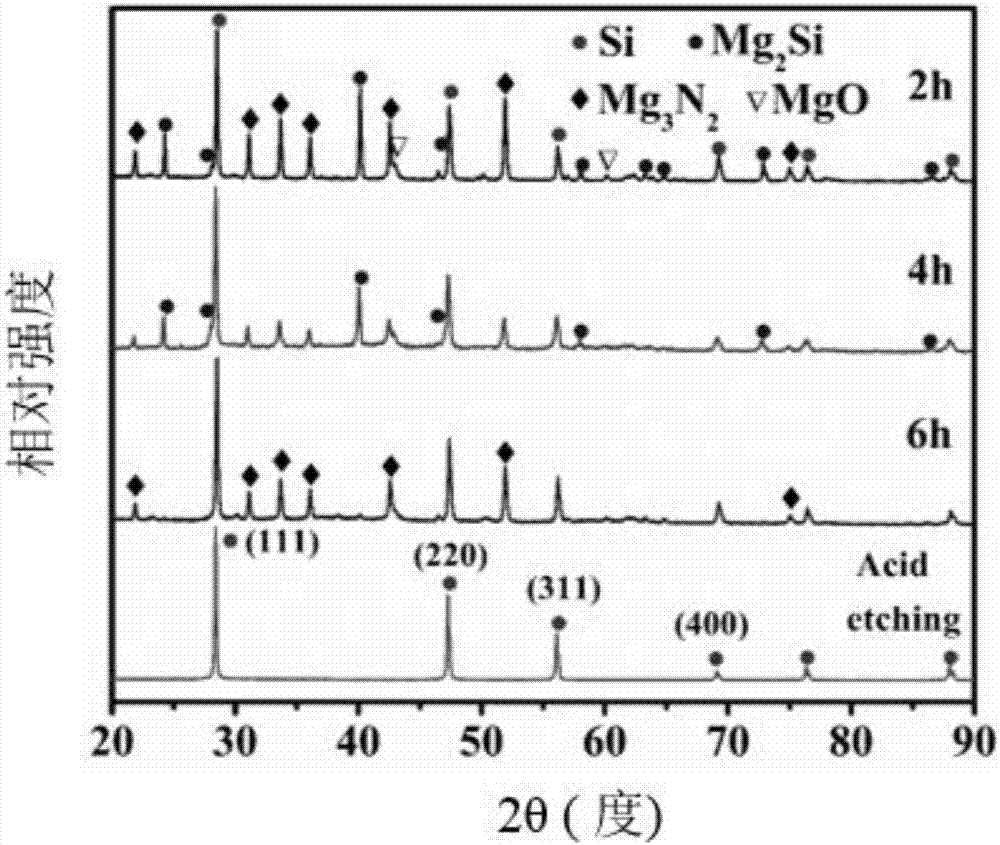

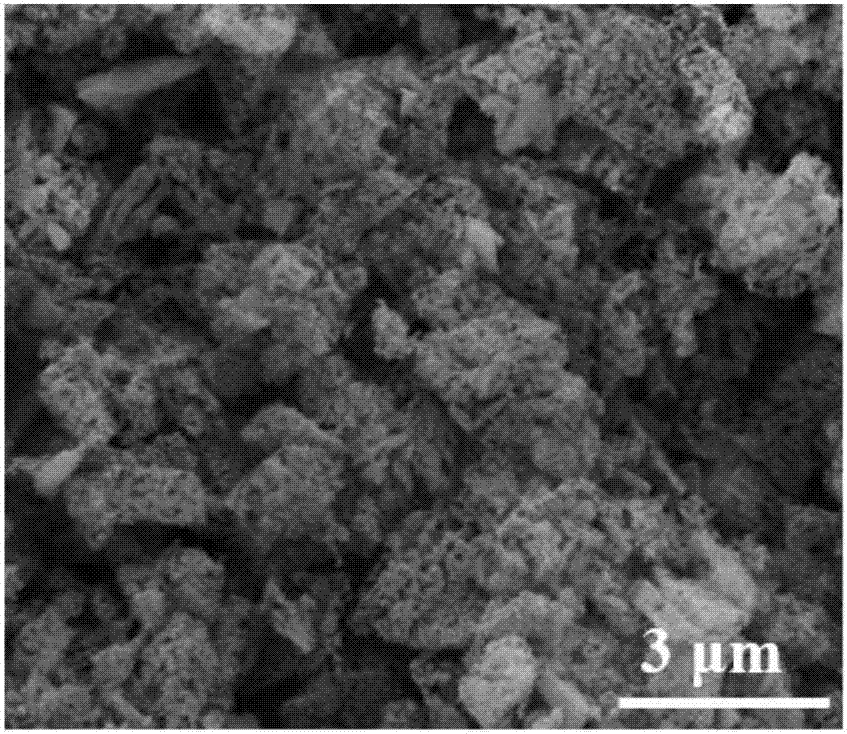

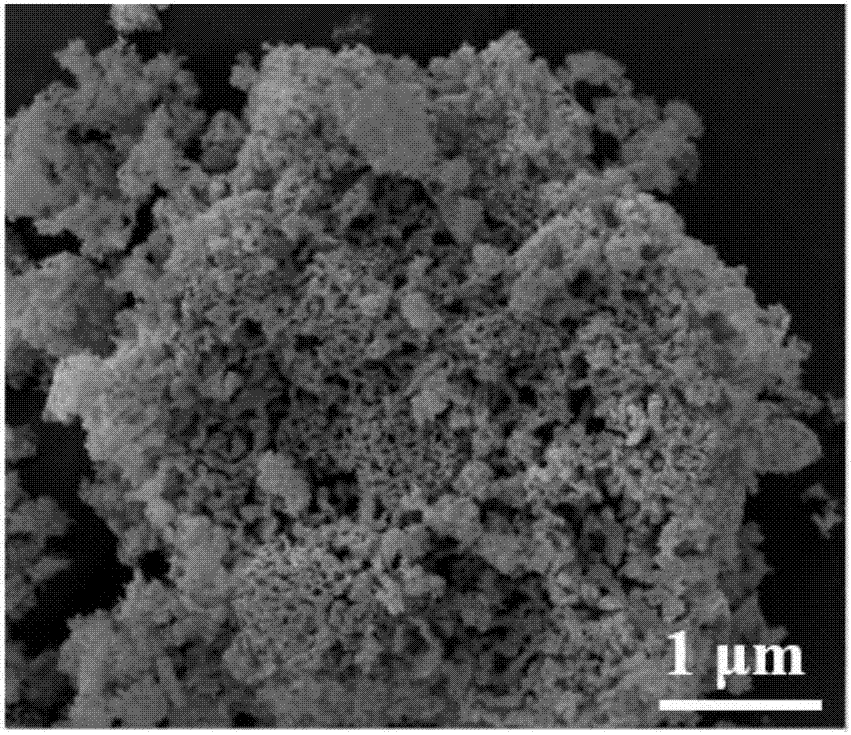

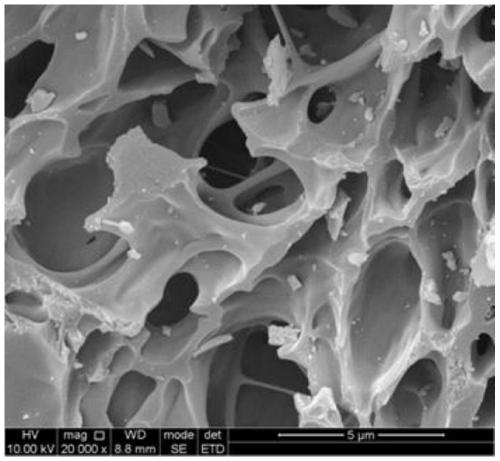

Preparation method of formicary-shaped porous silicon for lithium ion battery

ActiveCN107215874ASave raw materialsThe synthesis method is simpleCell electrodesSecondary cellsLithium-ion batteryReaction step

The invention discloses a preparation method of formicary-shaped porous silicon for a lithium ion battery. The preparation method comprises the following steps: (1) enabling a magnesium silicide raw material to react for 2 to 24h in an ammonia gas atmosphere at a temperature of 600 to 900 DEG C, and obtaining a crude product containing porous silicon (3Mg2Si+4NH3 to 3Si+2Mg3N2+6H2), wherein a particle size of the magnesium silicide raw material is 0.2 to 10 micrometers; and (2) acid pickling the crude product containing the porous silicon to obtain the formicary-shaped porous silicon for the lithium ion battery. By improving an overall process flow of the porous silicon key preparation method and parameters and conditions of various reaction steps, compared with the prior art, the preparation method has the advantage of simplicity and easiness, a great number of porous micrometer silicon can be obtained by directly heating the obtained magnesium silicide in ammonia gas (or mixed gas of the ammonia gas and inert gas), and the yield is high.

Owner:WUHAN UNIV OF SCI & TECH

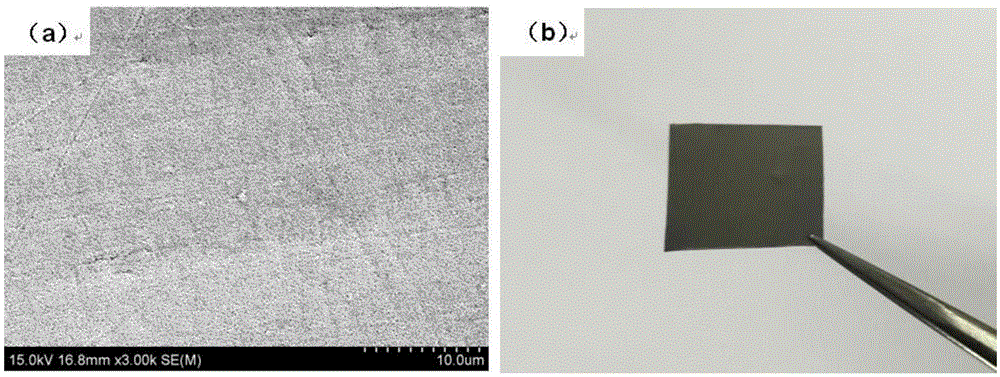

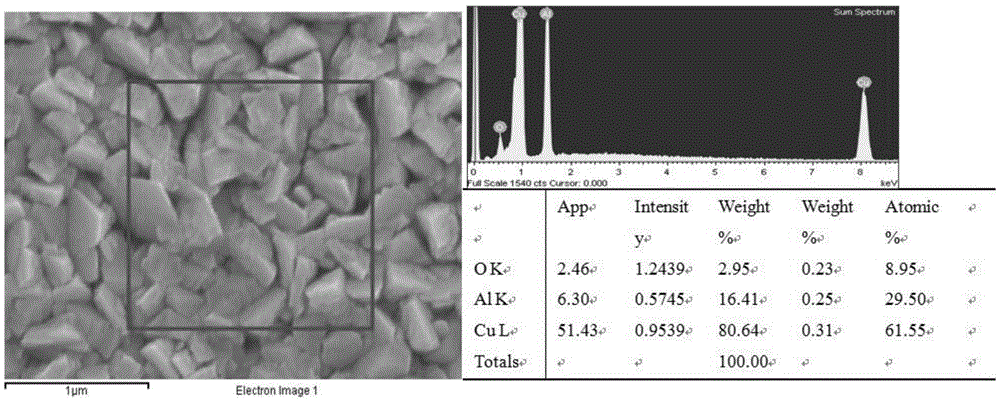

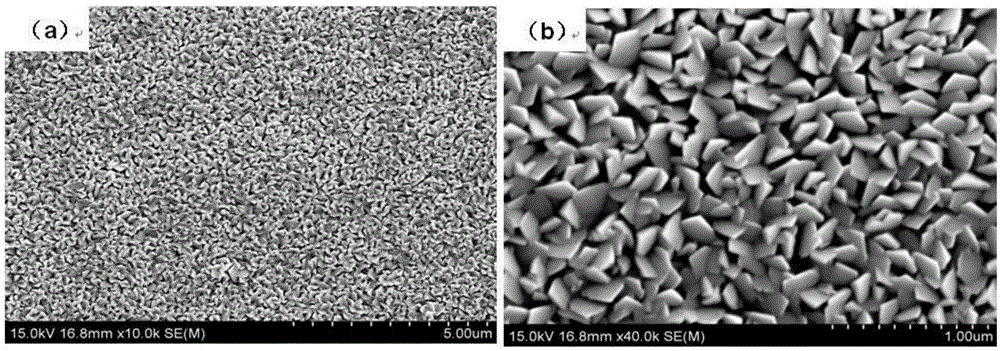

Method for preparing nano porous copper thin film material by magnetron sputtering

ActiveCN105543796AStructural continuityMeet the areaVacuum evaporation coatingSputtering coatingAlloyCopper foil

The invention relates to a method for preparing a nano porous copper thin film material by magnetron sputtering. The method takes a commercial copper foil as a base body material and takes high-purity copper target and aluminum target as sputtering materials; magnetron sputtering equipment is a preparation tool; a nano porous copper thin film is obtained by sputtering a copper-aluminum thin film through a glow discharge principle, and dealloying and corroding to remove an active component aluminum after annealing and alloying. The method provided by the invention is a two-step reaction method, the problems in the prior art that steps for carrying out smelting, ball milling and melt spinning on alloy auxiliary materials are complicated and consumed time is long are solved, and steps of a preparation process are simplified; a nano porous structure of nano porous copper is obtained and the size of the thin film is controllable; the obtained structure is better than a nano porous copper powder sample obtained by a traditional method; furthermore, an application range of the nano porous copper is enlarged and the nano porous copper has a commercial prospect.

Owner:SHANDONG UNIV

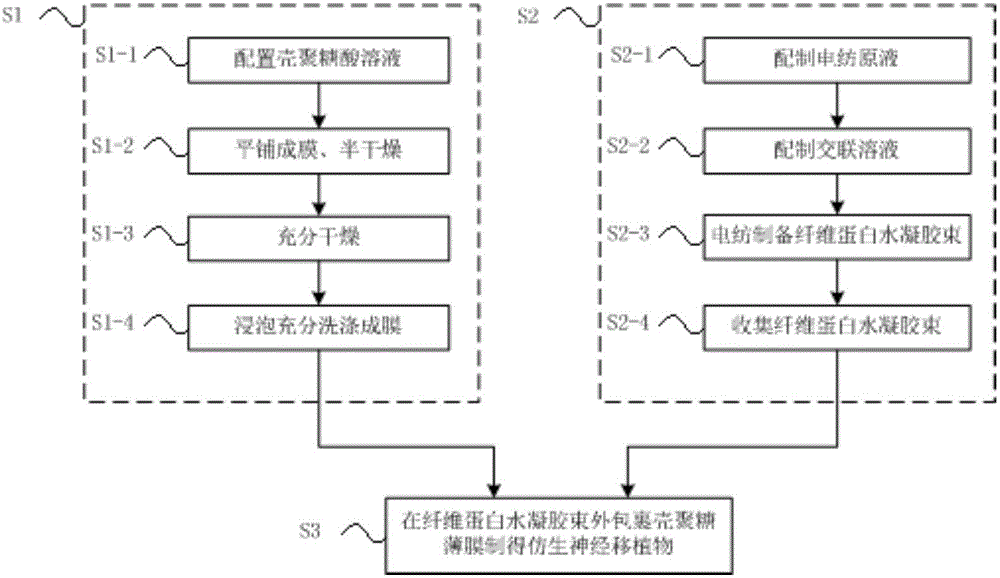

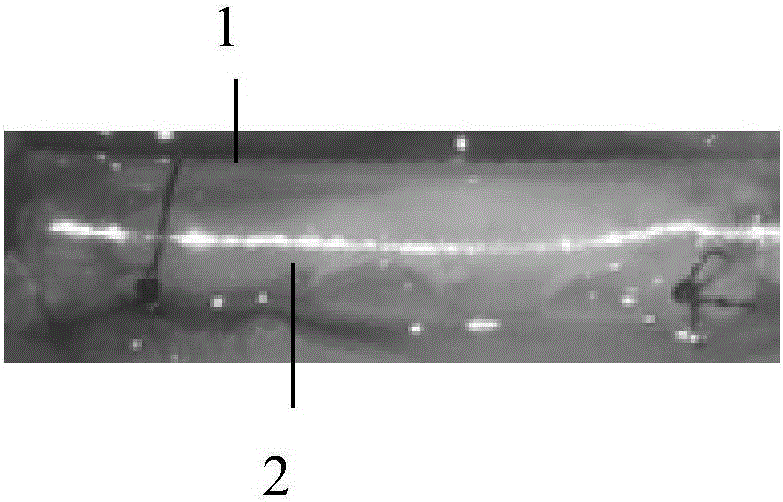

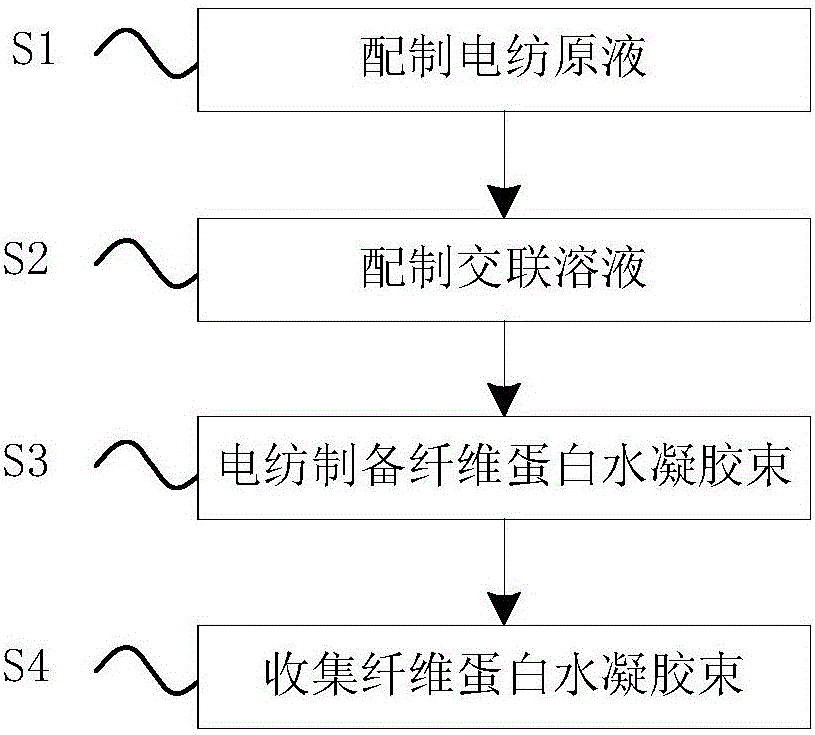

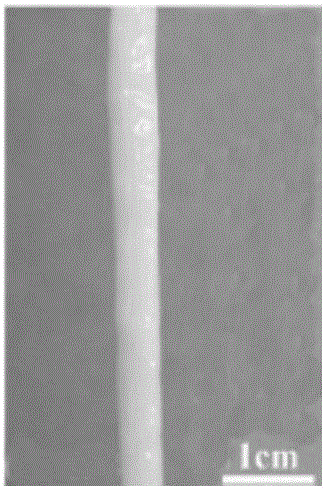

Bionic nerve graft used for peripheral nervous recovery and preparation method thereof

ActiveCN106729980ACell affinityImprove mechanical propertiesElectro-spinningTissue regenerationMedicineElectrospinning

The invention relates to a bionic nerve graft used for peripheral nervous recovery and a preparation method and application thereof. The bionic nerve graft comprises a chitosan film conduit and a fibrous protein hydrogel beam positioned in the chitosan film conduit, wherein the fibrous protein hydrogel beam is prepared from fibrous protein through an electrospinning technique. The bionic nerve graft prepared by the preparation method is formed by the filling of the chitosan film conduit and the fibrous protein hydrogel beam of a multi-stage orientation structure, wherein a nerve regrowth space is effectively supported by a chitosan film, the orientational regeneration of a nerve axon is effectively guided by the fibrous protein hydrogel beam of multi-stage orientation, the cell affinity and the mechanical property of whole materials are good, and in addition, degrading speed and the repairing speed of peripheral nervous tissues are matched.

Owner:TSINGHUA UNIV

Medical polyvinyl alcohol sponge and preparation method

ActiveCN106916333AEasy to clean and removeGood biocompatibilityAbsorbent padsBandagesPolyvinyl alcohol spongeCross-link

The invention provides a medical polyvinyl alcohol sponge and a preparation method. The preparation method comprises the following steps: adding polyvinyl alcohol and starch into distilled water carrying out dissolving at 50 to 95 DEG C under stirring so as to obtain a mixed solution; adding a cross-linking agent, an emulsifier and a foam stabilizer into the mixed solution and carrying out stirring at 20 to 60 DEG C for 2 to 8 h so as to obtain a second mixed solution; adding an acidic catalyst into the second mixed solution and carrying out an acetalation cross-linking reaction at a constant temperature of 20 to 90 DEG C for 30 to 180 min so as to obtain emulsion-like liquid; and completion of the reaction, pouring the emulsion-like liquid into a mold, carrying out heating at 50 to 95 DEG C for curing, carrying out demoulding and washing after cooling, and then carrying out cutting and sterilization so as to obtain the medical polyvinyl alcohol sponge. The medical polyvinyl alcohol sponge prepared in the invention has a through hole structure, uniform pore diameter, good biocompatibility, excellent affinity, high porosity and fast liquid absorption rate, and is applicable to the field of surgical sciences, especially as a sponge consumable for vacuum sealing drainage.

Owner:WUHAN DRAGONBIO ORTHOPEDIC PROD

Optical cable splice box

ActiveCN103995327AStructural continuityImprove stress resistanceFibre mechanical structuresEngineeringUltimate tensile strength

The invention discloses an optical cable splice box, and aims at providing a splice box which is good in matching and low in accuracy requirement and can ensure a sealing effect during bearing and heating. The optical cable splice box comprises an upper half box and a lower half box, wherein the upper half box and the lower half box are connected to forma box body; at least two optical fiber hole frames are arranged at the two ends of the box body respectively; each optical fiber hole frame comprises an outer section and an inner section; optical fiber inlet sleeves are arranged in the outer sections; the inner sections consist of half slots in the lower half box and half slots in the upper half box; corresponding elastic clamp sleeves are arranged in the half slots; sealing grooves are formed in the upper half box and the lower half box; sealing strips are arranged in the sealing grooves; the sealing strips and the elastic clamp sleeves are connected to form sealing rings; each sealing strip is 0.5-1mm higher than an opening of each sealing groove; and cross sections of the sealing strips are trapezoids with outward large bottom edges. The optical cable splice box has the benefits that an assembling accuracy requirement is low; the cost is saved; displacement is not easy to generateat butting parts of the sealing rings; the sealability is good; and a reinforcing structure is arranged in the box body, so that the compressive capacity and the overall strength are high.

Owner:杭州华宏通信设备有限公司

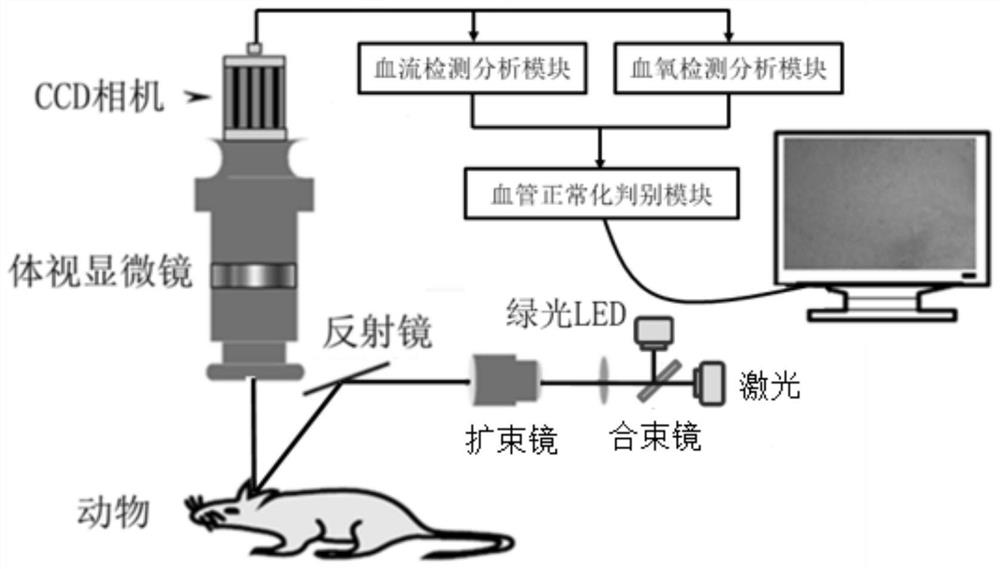

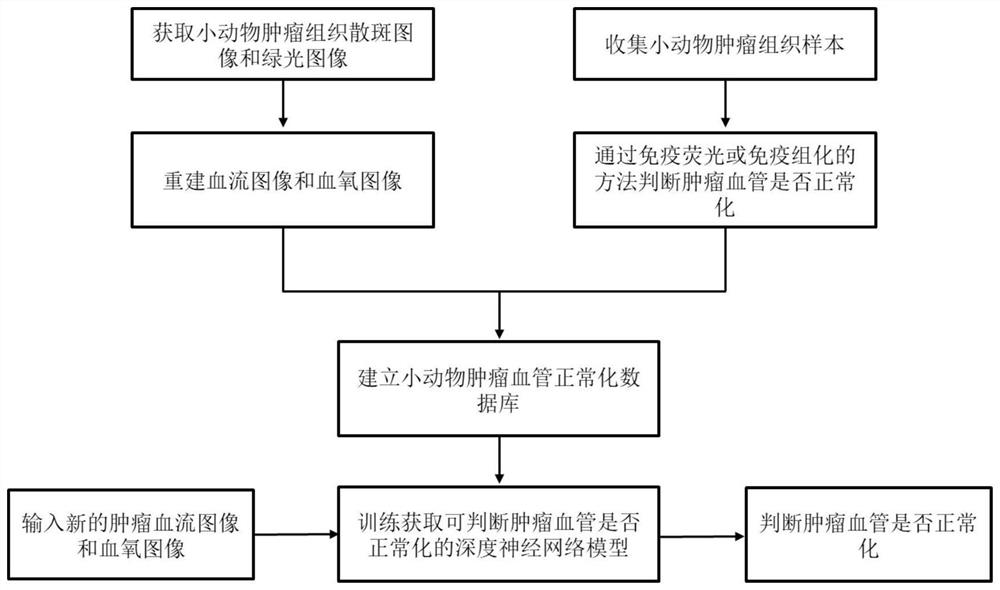

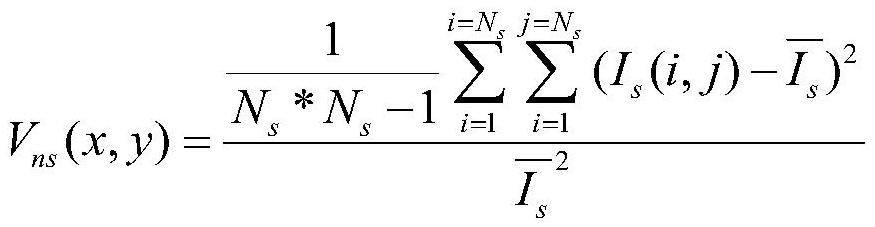

Multi-parameter tumor blood vessel normalization detection system and detection method

InactiveCN111870230AStructural continuityContinuous functionImage enhancementImage analysisNerve networkBlood flow

The invention discloses a multi-parameter tumor blood vessel normalization detection system and detection method. The system comprises a light source module, an imaging module, a blood flow detectionand analysis module, a blood oxygen detection and analysis module, a blood vessel normalization judgment module and a display module. According to the method, a two-dimensional blood flow image is reconstructed through an algorithm, blood vessel morphology characteristics are extracted through an image processing method, a two-dimensional tumor blood oxygen image is calculated through a laser image and a narrow-band green light image, tumor tissue hypoxia degree information is provided, and through a deep neural network discrimination method and combination with blood flow image characteristics and blood oxygen image characteristics whether tumor vessels are normalized or not can be judged. The method has the advantages of being multi-parameter, non-invasive, non-radiative, intelligent indiagnosis and the like, whether tumor blood vessels are in a normal window period or not is intelligently judged by monitoring tumor blood supply, oxygen supply and blood vessel forms, and a basis isprovided for making a more reasonable anti-tumor combined treatment scheme.

Owner:WUHAN UNIV

Bionic fibrous protein hydrogel micelle for spinal cord injury repair and preparation method of bionic fibrous protein hydrogel micelle

InactiveCN106730031AEffective guidance for directed regenerationPromote regeneration and repairMonocomponent protein artificial filamentConjugated cellulose/protein artificial filamentsFiberCell-Extracellular Matrix

The invention relates to a bionic fibrous protein hydrogel micelle for spinal cord injury repair as well as a preparation method and application of the bionic fibrous protein hydrogel micelle. The bionic fibrous protein hydrogel micelle is prepared from fibrous proteins by an electrostatic spinning technology. The bionic fibrous protein hydrogel micelle prepared by the single-channel electrostatic spinning technology is a hydrogel material with high water content and is formed by multi-stage oriented nano-fibers highly simulating spinal cord tissues; and the multi-stage oriented fibrous protein hydrogel micelle expresses compositions and extracellular matrix environment similar to natural spinal cord tissues, has the mechanical properties similar to natural nerves, can effectively promotes orientated growth of nerve fibers and has the degradation velocity matched with the repair velocity of the spinal cord injured tissues.

Owner:TSINGHUA UNIV

Core three-dimension image repairing method

The invention discloses a core three-dimension mage repairing method including the steps of (1), extracting initial boundary of a to-be-repaired area of an original three-dimension image, namely a core three-dimension image with information loss, and setting the template size; (2), dividing the known area of the original three-dimension image; (3), calculating priority values of boundary templates of all voxels at the boundary of the original three-dimension image; (4), searching the boundary template of the maximum priority value and reserving coordinates of corresponding boundary voxels; (5), judging the area type of the boundary voxels and setting the global search area of a matching block of the boundary template; (6), searching the optimal matching block within a corresponding range and performing gray filling to corresponding voxels; (7), updating or setting different parameter information; (8), repeating the step (4) to the step (7) until filling the to-be-repaired area completely. The restoring degree of the core three-dimension image repaired by the method is high, and structure and details of the real three-dimension image can be remained.

Owner:SICHUAN UNIV

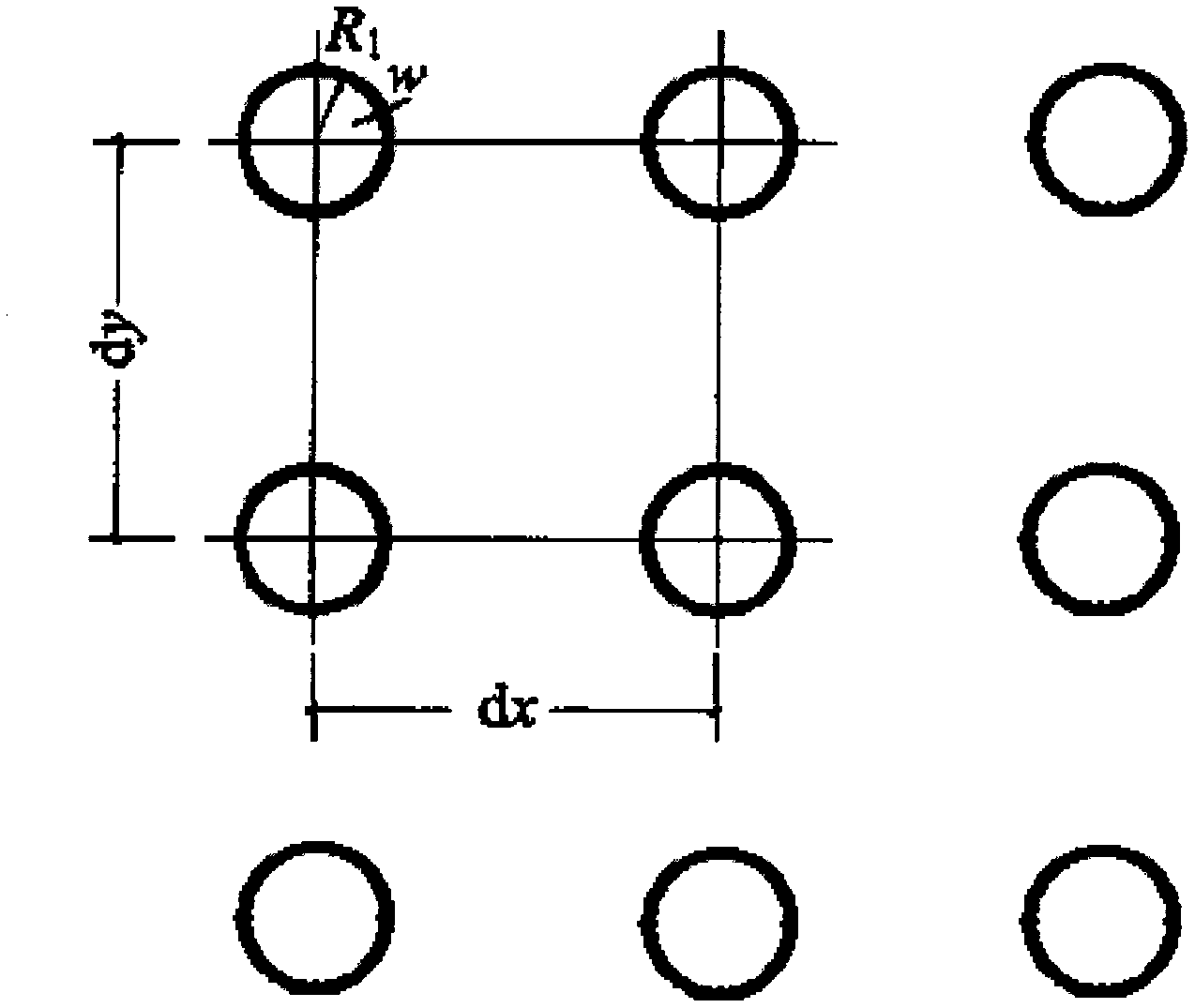

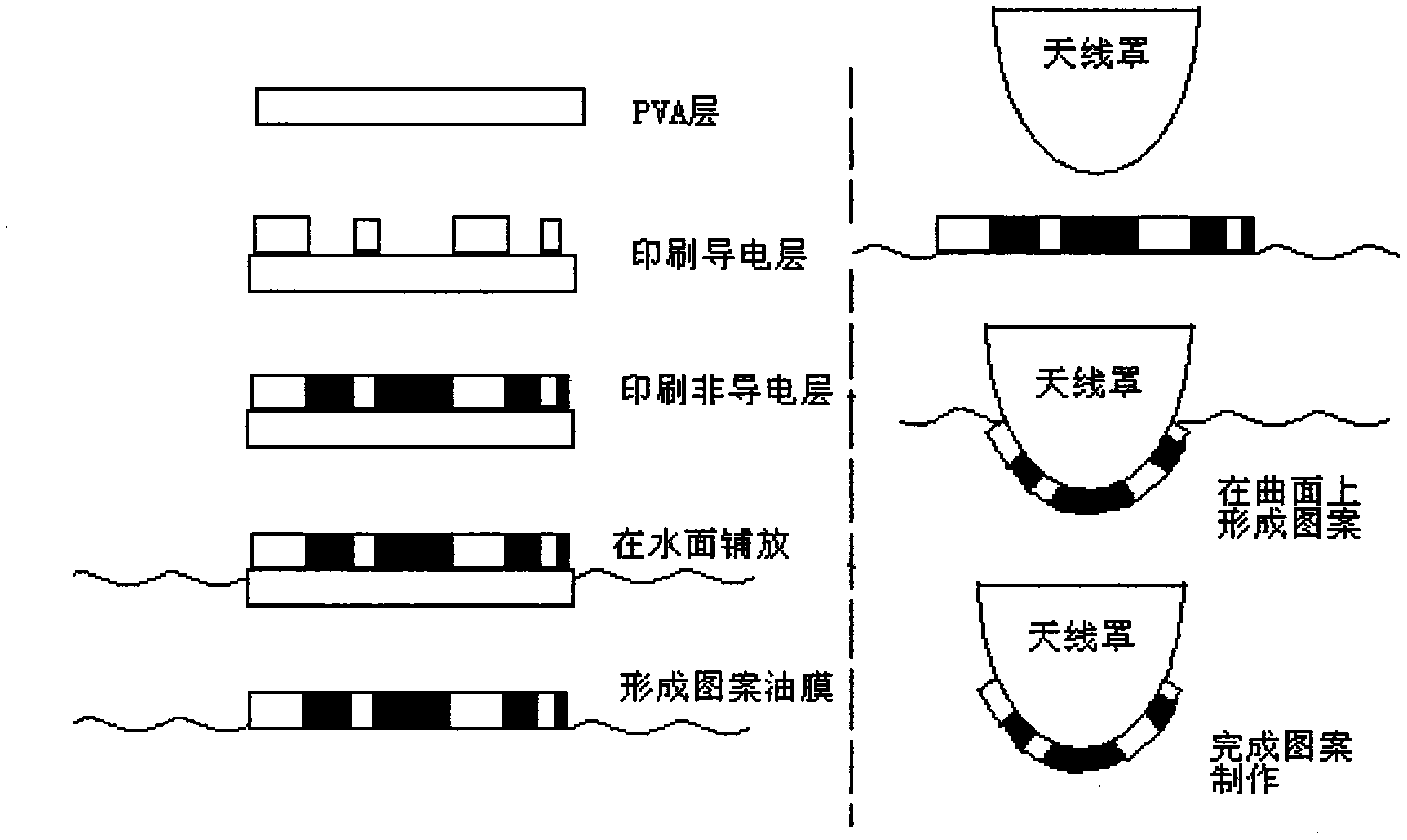

Method for forming frequency selective surface structure on folding-unavailable curved surface

ActiveCN104078762AStructural continuitySimple structureRadiating element housingsWaveguide type devicesGraphicsOrganic solvent

The invention provides a method for forming a frequency selective surface structure on an folding-unavailable curved surface. The method includes the steps that printing ink is used for overprinting an FSS cycle array graph on a water-soluble PVA thin film, a water-soluble PVA thin film graph with the FSS cycle array graph overprinted is upward laid on a peaceful water surface, atomized organic solvents are sprayed on the FSS cycle array graph, an oil film graph is stuck to the surface of a product with the folding-unavailable curved surface, and the FSS cycle array graph is obtained on the surface of the product with the folding-unavailable curved surface. According to the method for forming the frequency selective surface structure on the folding-unavailable curved surface, an original technology and materials of the product do not need to be changed, the FSS graph can be produced on any curved surface shape (especially the folding-unavailable curved surface), the produced FSS array structure is continuous and fine, and the graphics solution line width reaches 0.1 mm.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

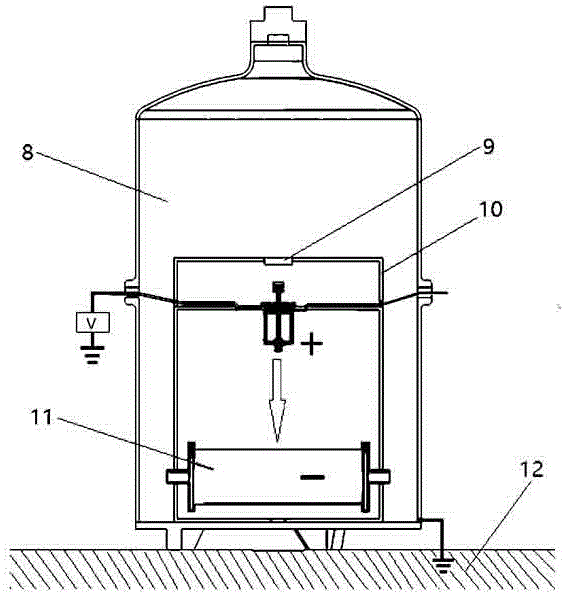

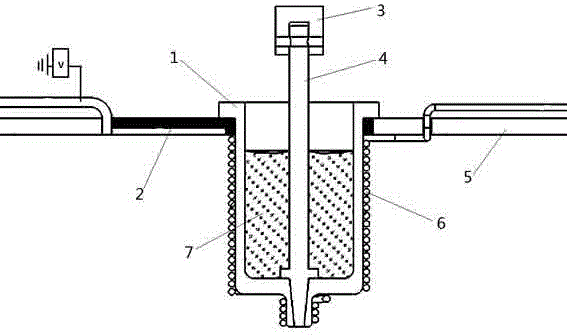

Melt electrostatic spinning preparation method of nano inorganic salt fibers

ActiveCN105734695ASimple production processExtend your lifeGlass making apparatusFilament/thread formingElectrospinningSolvent

The invention discloses a melt electrostatic spinning preparation method of nano inorganic salt fibers. The melt electrostatic spinning preparation method comprises the following steps: building a temperature field, a pressure field and an electrostatic field with graphite pipes, then preparing inorganic salt melt liquid via the temperature field, spraying the inorganic salt melt liquid from a spraying head via the pressure field, enabling a sprayed inorganic salt material to enter the electrostatic field and be provided with static electricity, and blowing cold inert gas in the spinning direction, wherein the inorganic salt material is quickly stretched in the electrostatic field to form nano fibers; receiving the fibers with a roller serving as a fiber receiver. The melt electrostatic spinning preparation method has the benefits: due to the melt electrostatic spinning method, inorganic non-metal salt with high melting point or high surface tension is pushed to be developed towards the nano-level direction; no solvent is used, so that the method is a green manufacturing method capable of preparing continuous nano fibers with smooth surfaces; no other substance molecules can be doped into the nano fibers, so that the purity is high; due to no solvent and high temperature, the production procedure for preparing glass nano fibers of the melt electrostatic spinning method is simple and extremely high in industrialization potential.

Owner:QINGDAO UNIV OF SCI & TECH

Rapid repairing construction method for old road through polyurethane-modified early-strength cement concrete

InactiveCN109930462AStructural continuityImprove physical and mechanical propertiesRoads maintainenceSurface layerMaterials science

The invention discloses a rapid repairing construction method for an old road through polyurethane-modified early-strength cement concrete. The method comprises the following steps of 1, designing a polyurethane-modified early-strength cement concrete matching ratio, wherein step 1 comprises the following procedures that 2.1) raw materials are selected, and 2.2) an orthogonal experiment is designed for determining the optimal matching ratio; 2, implementing the rapid repairing construction method for an old cement pavement through the polyurethane-modified early-strength cement concrete, wherein step 2 comprises the following procedures that 2.1) the materials are mixed, 2.2) the materials are conveyed, 2.3) an interface agent is sprayed, 2.4) the polyurethane-modified early-strength cement concrete is laid, 2.5) overlay face grooving and maintenance are conducted, and 2.6) a color surface layer is sprayed. Compared with a traditional asphalt concrete overlay face method, the polyurethane-modified early-strength cement concrete ultra-thin overlay face technology is advanced, the old cement pavement can be quickly repaired, and the method has obvious economic and technical advantages.

Owner:ZHEJIANG UNIV OF TECH

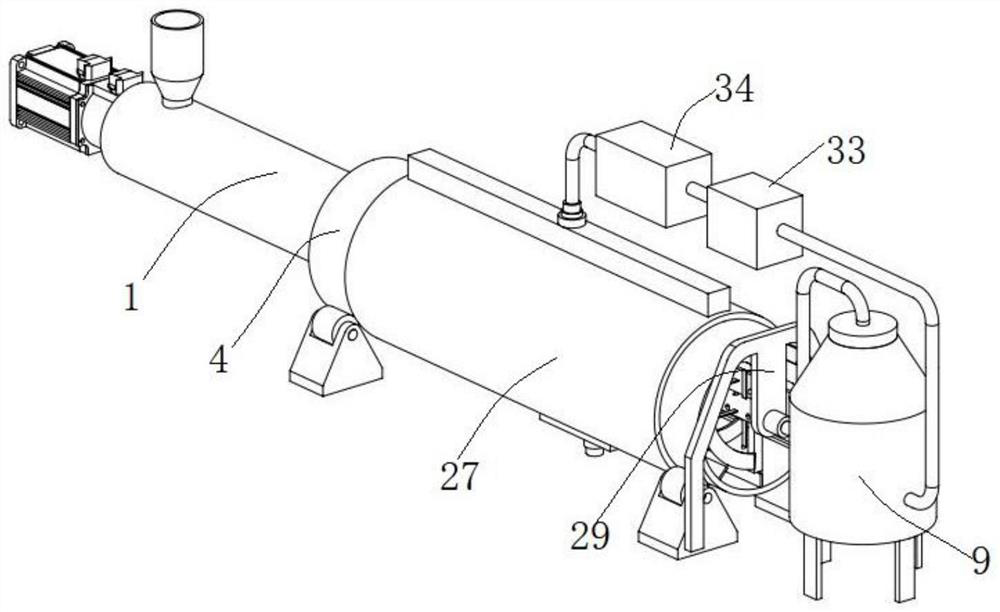

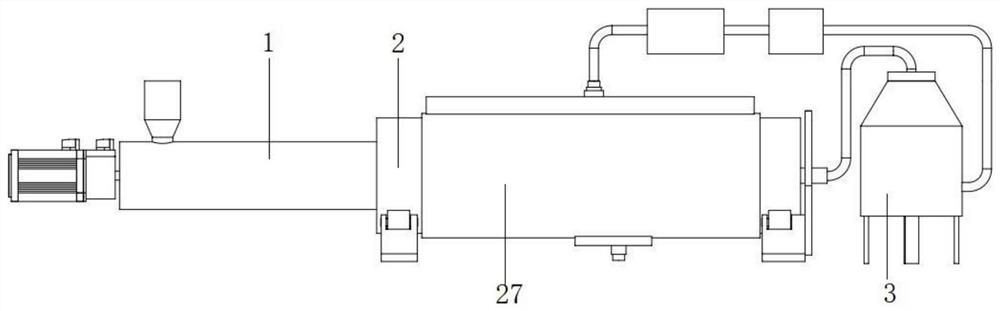

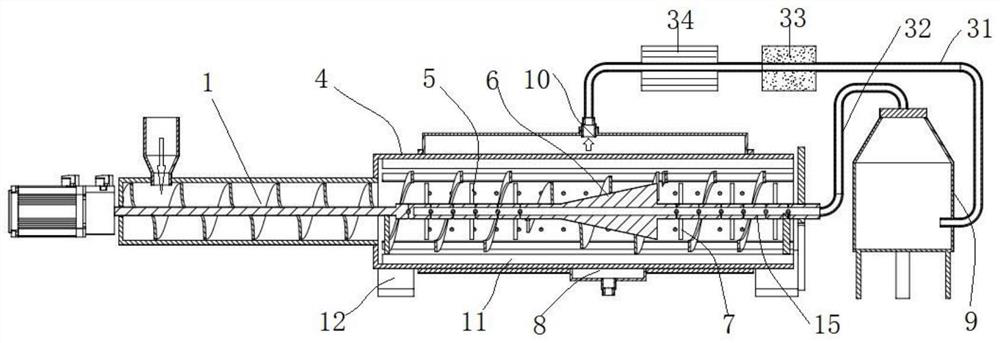

Ultralow-water-content sludge dewatering and drying system and drying treatment method thereof

InactiveCN111908758AReduce moisture contentIncrease solid contentSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludge cakeIncineration

The invention discloses an ultralow-water-content sludge dewatering and drying system and a drying treatment method thereof. The ultralow-water-content sludge dewatering and drying system comprises adewatering device, a drying device and a waste gas treatment device. The drying device comprises a drying container, and a primary crushing mechanism, a mud cake forming mechanism and a secondary crushing mechanism that are sequentially arranged in the length direction of the drying container at intervals; wherein the primary crushing mechanism is arranged corresponding to a discharge port of thedehydration device, the sludge cake forming mechanism is used for filter-pressing sludge passing through the primary crushing mechanism into a sludge cake, the secondary crushing mechanism is used forcrushing the sludge cake passing through the sludge cake forming mechanism into sludge particles, and high-temperature gas in the incineration tower is introduced into an inner cavity of the drying container. A waste gas recovery opening is formed in the wall body of the drying container, one end of the waste gas recovery assembly is arranged corresponding to the waste gas recovery opening and the other end of the waste gas recovery assembly is introduced into the incineration tower, and therefore, sludge can be dewatered and dried quickly and sufficiently.

Owner:唐汉平

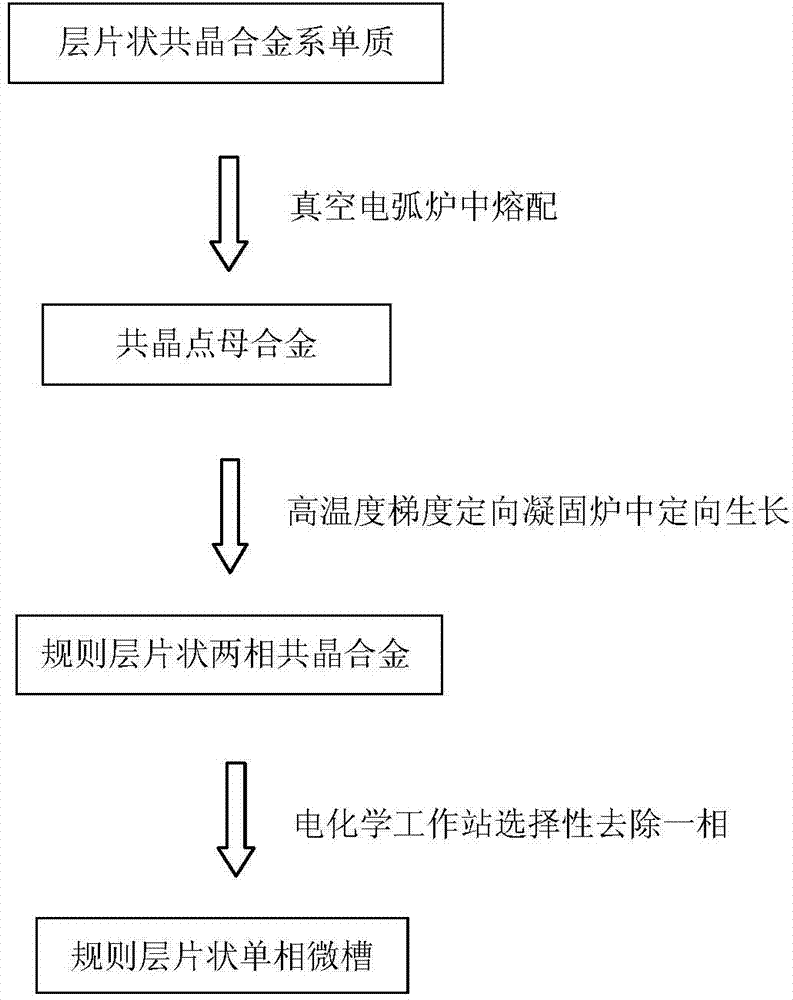

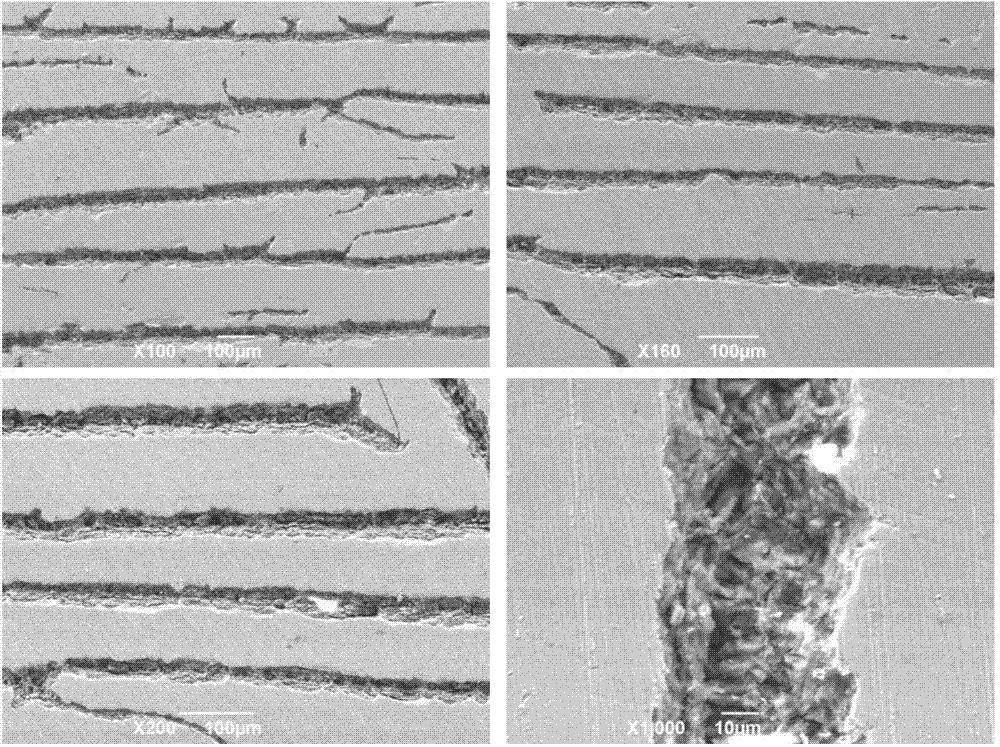

Method for preparing continuous regular lamellar microgroove based on lamellar eutectic alloy system

ActiveCN104846430AHigh dimensional control accuracyEasy to makePolycrystalline material growthFrom frozen solutionsElectrode potentialSelective leaching

Owner:深圳市脑潜能实业发展有限公司

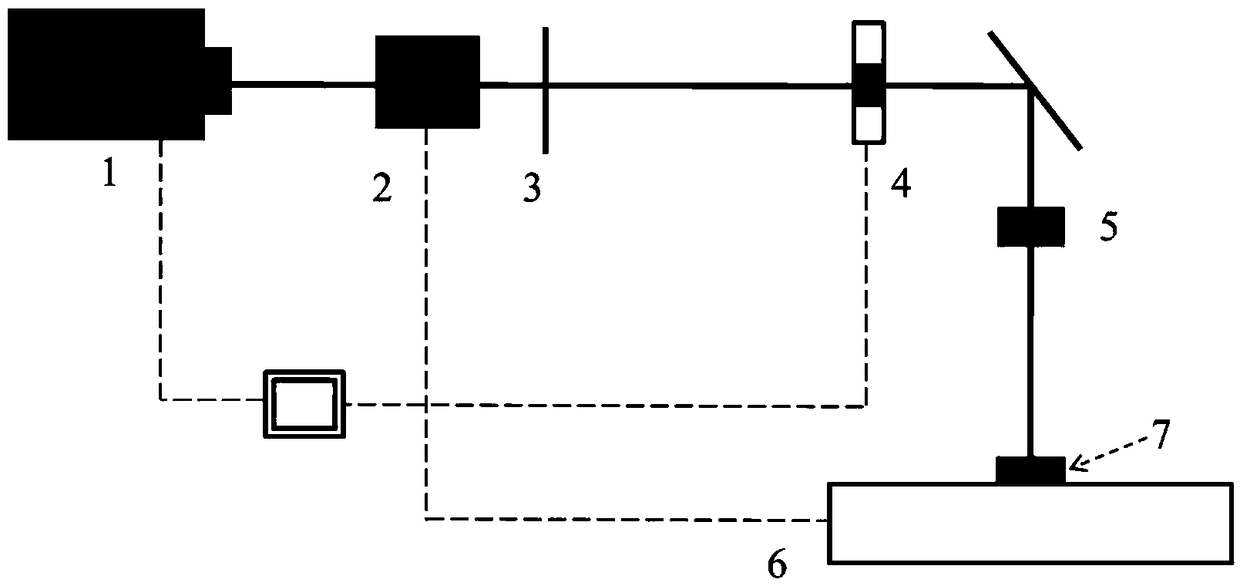

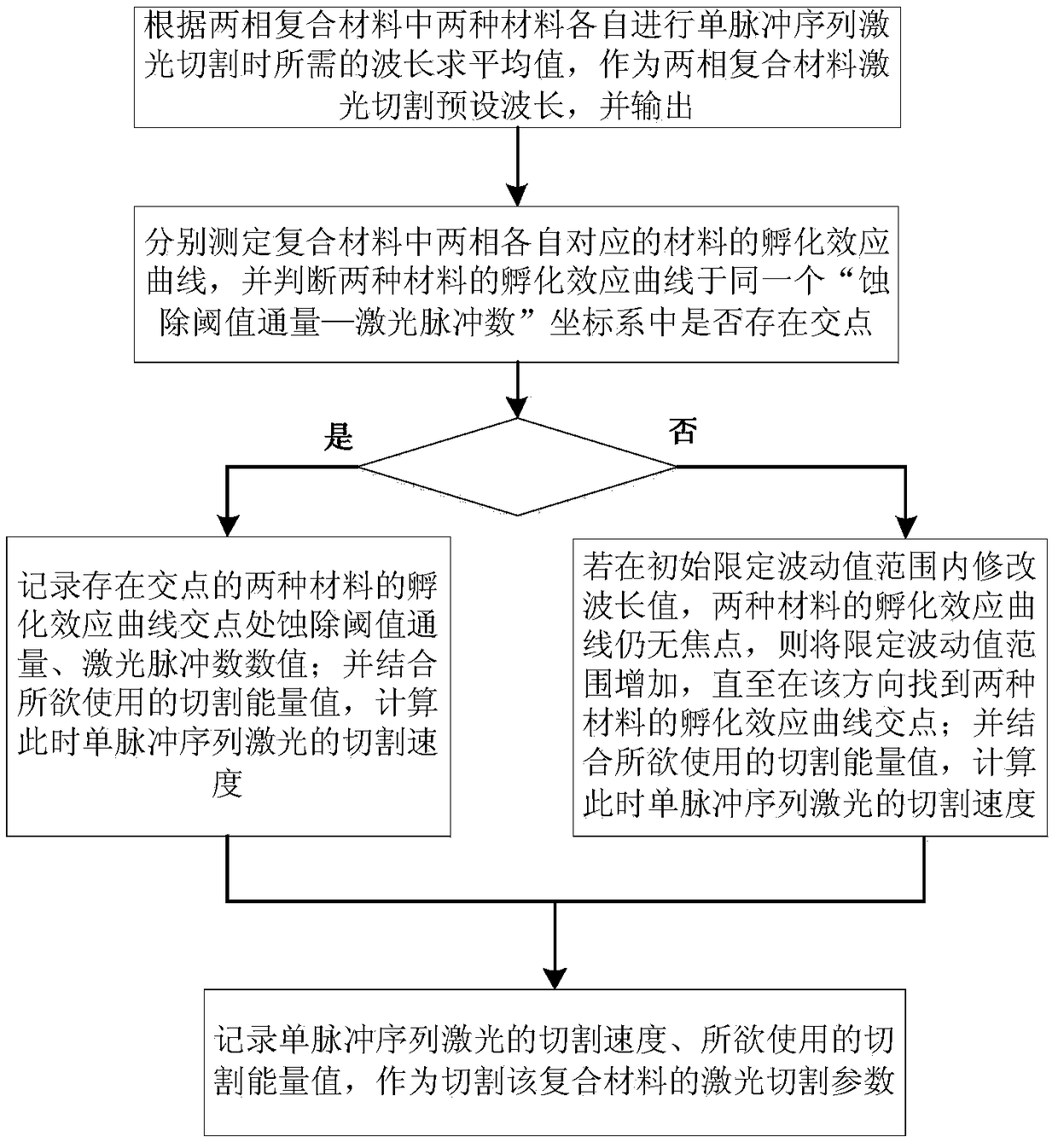

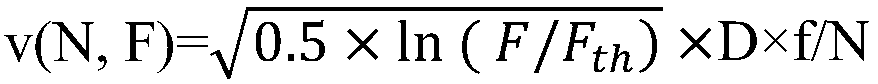

Method for cutting two-phase composite through ultrafast laser

ActiveCN108817699ASmall heat affected zoneStructural continuityWelding/soldering/cutting articlesLaser beam welding apparatusFine structureTwo phase composite

The invention provides a method for cutting a two-phase composite through an ultrafast laser. According to the method for cutting the two-phase composite through the ultrafast laser, through finding of the intersection point of incubation effect curves of two different materials in the composite, the cutting speed, wavelength and cutting energy needed by the laser at the intersection point are obtained; the problem that in the prior art, the two-phase common threshold value, capable of meeting two materials, of the composite cutting single-pulse laser in the two-phase component is difficult tofind is solved, and the problem that in the two-phase component, a reinforcement phase or a matrix phase locally falls off, and a fine structure is discontinuous are solved; and the method is simplein process, clear in step and good in reliability.

Owner:BEIJING SATELLITE MFG FACTORY

Method for preparing carbon aerogel by utilizing normal-pressure drying

InactiveCN111498828AAvoid complex processesLow shrinkageCarbon preparation/purificationAerogel preparationSupercritical dryingPtru catalyst

The invention belongs to the technical field of preparation of carbon aerogel, and specifically relates to a method for preparing carbon aerogel by using normal-pressure drying. The preparation methodcomprises the following steps: introducing a reinforcing agent into a reaction monomer and catalyst system, preparing wet gel by using a sol-gel method, carrying out aging treatment on the wet gel, replacing moisture in the wet gel by using a low-surface-tension solvent, putting the wet gel into air, carrying out normal-pressure drying to obtain organic aerogel, and carbonizing the organic aerogel to obtain carbon aerogel, wherein the reaction monomers are resorcinol and formaldehyde, and the reinforcing agent is high-molecular polymer F127; according to the method disclosed by the invention,complex processes of a conventional supercritical drying method and a freeze drying method are avoided, meanwhile, the shrinkage rate of the carbon aerogel material in a normal-pressure drying process is greatly reduced, and the supercapacitor electrode material with excellent performance can be obtained at a low price.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

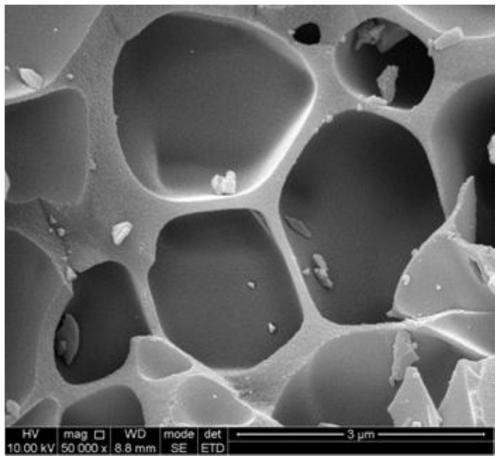

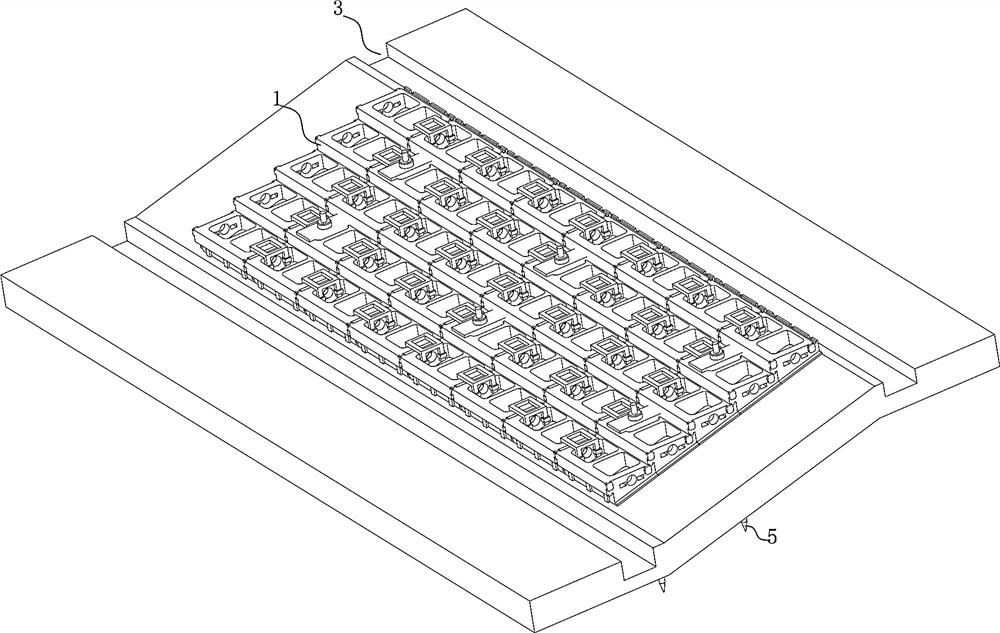

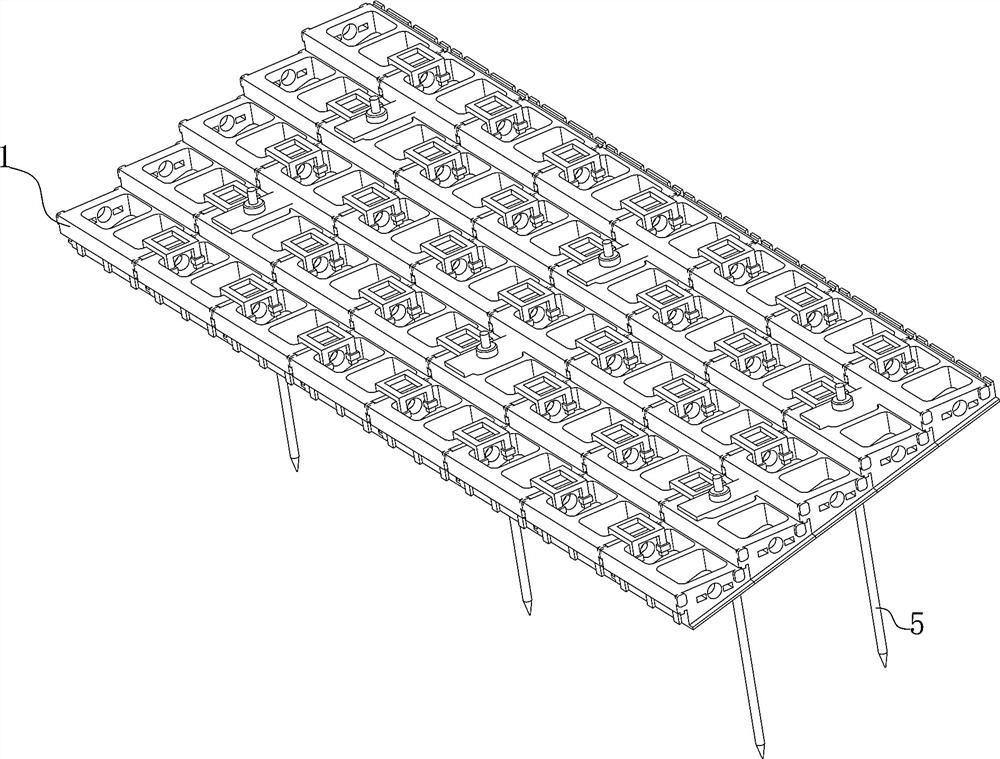

Fabricated prefabricated slope protection device and construction method thereof

InactiveCN112482405AImprove greening effectStructural continuityExcavationsArchitectural engineeringStructural engineering

The invention discloses a fabricated prefabricated slope protection device and a construction method thereof. Slope protection blocks are formed through one-time pouring; at least one planting hole isformed in each slope protection block; clamping devices are arranged at the two sides of each slope protection block; the multiple slope protection blocks are connected through the clamping devices on the side faces; the ends of the multiple slope protection blocks are connected through transverse fixing frames; lug plates are arranged at the two ends of each slope protection block; the lug plates at the ends of every two adjacent slope protection blocks are connected with form a drainage groove; and single slope protection elements are connected through the clamping devices at the two sidesin a spliced mode. According to the fabricated prefabricated slope protection device and the construction method thereof, after assembly is completed, a continuous and complete three-dimensional structure is rapidly formed, a slope protection structure has excellent water permeability, ultrahigh strength, excellent durability, and the fabricated prefabricated slope protection device has a good greening effect and has good popularization value.

Owner:HUBEI PEI HAN CONSTR CO LTD

Rigid polyurethane foam culture stone and production method thereof

InactiveCN101649674ASmall adjustment rangeHigh closed cell rateCovering/liningsThermal insulationEngineering

The invention aims at the shortcomings that the current culture stones are heavy in weight, high in cost or poor in thermal insulation properties and have poor bondability with the building blocks, masonries and the like, are easily spalled, have short service lives and the like, and provides a rigid polyurethane foam (RPUF) culture stone and a production method thereof. The RPUF product with goodbondability, good thermal insulation property, light materials and long service life is obtained by improving the culture stone raw materials, production steps and technological conditions, which issuitable for the indoor and outdoor decoration in various environments.

Owner:宿迁特力新材料有限公司

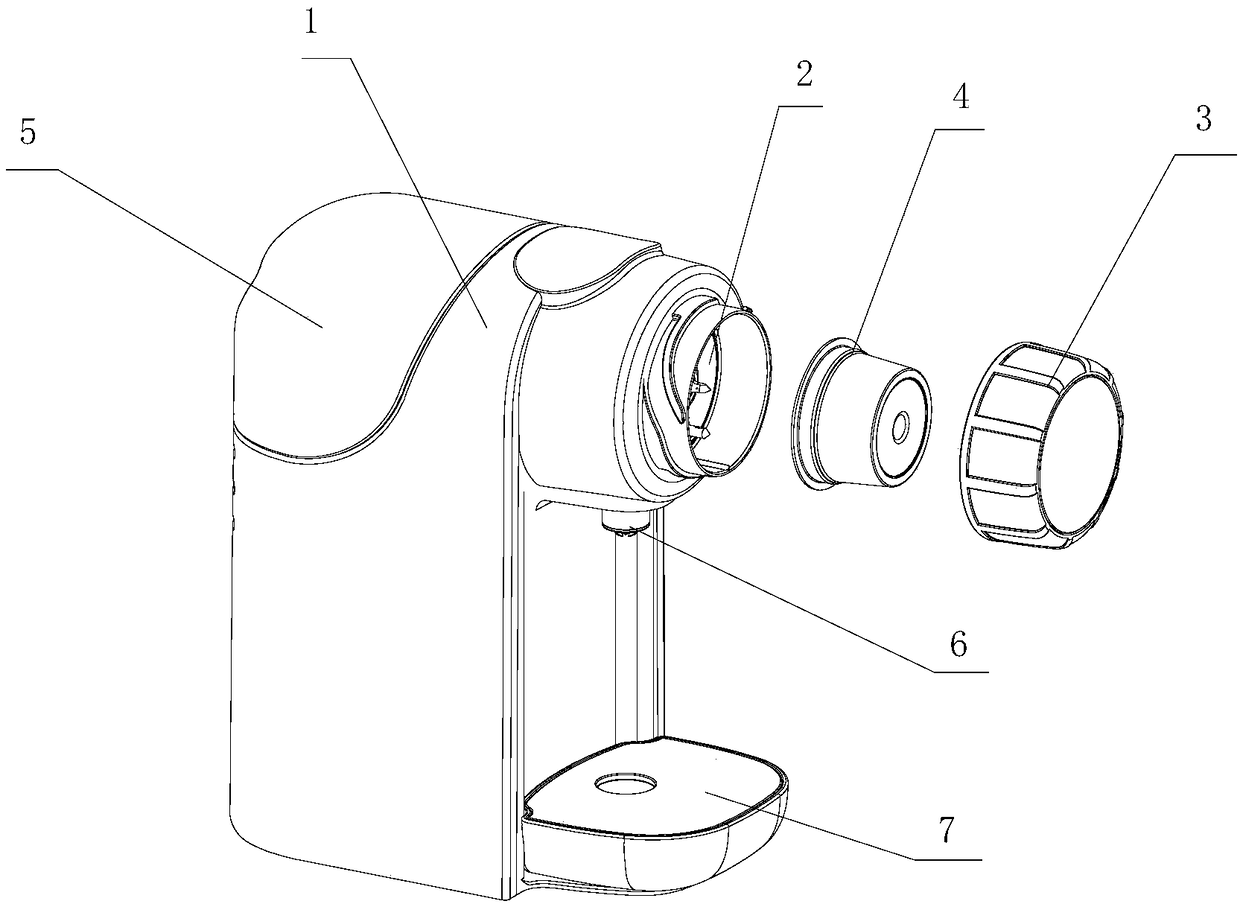

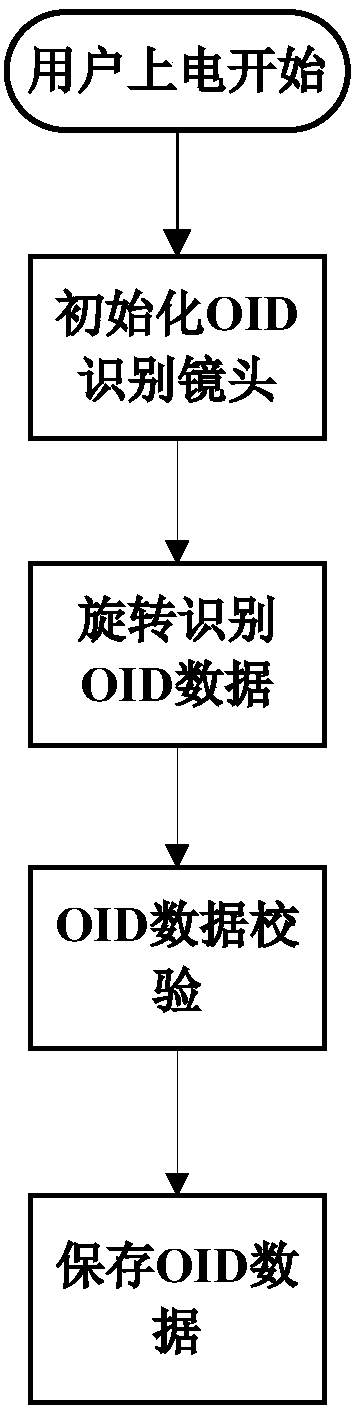

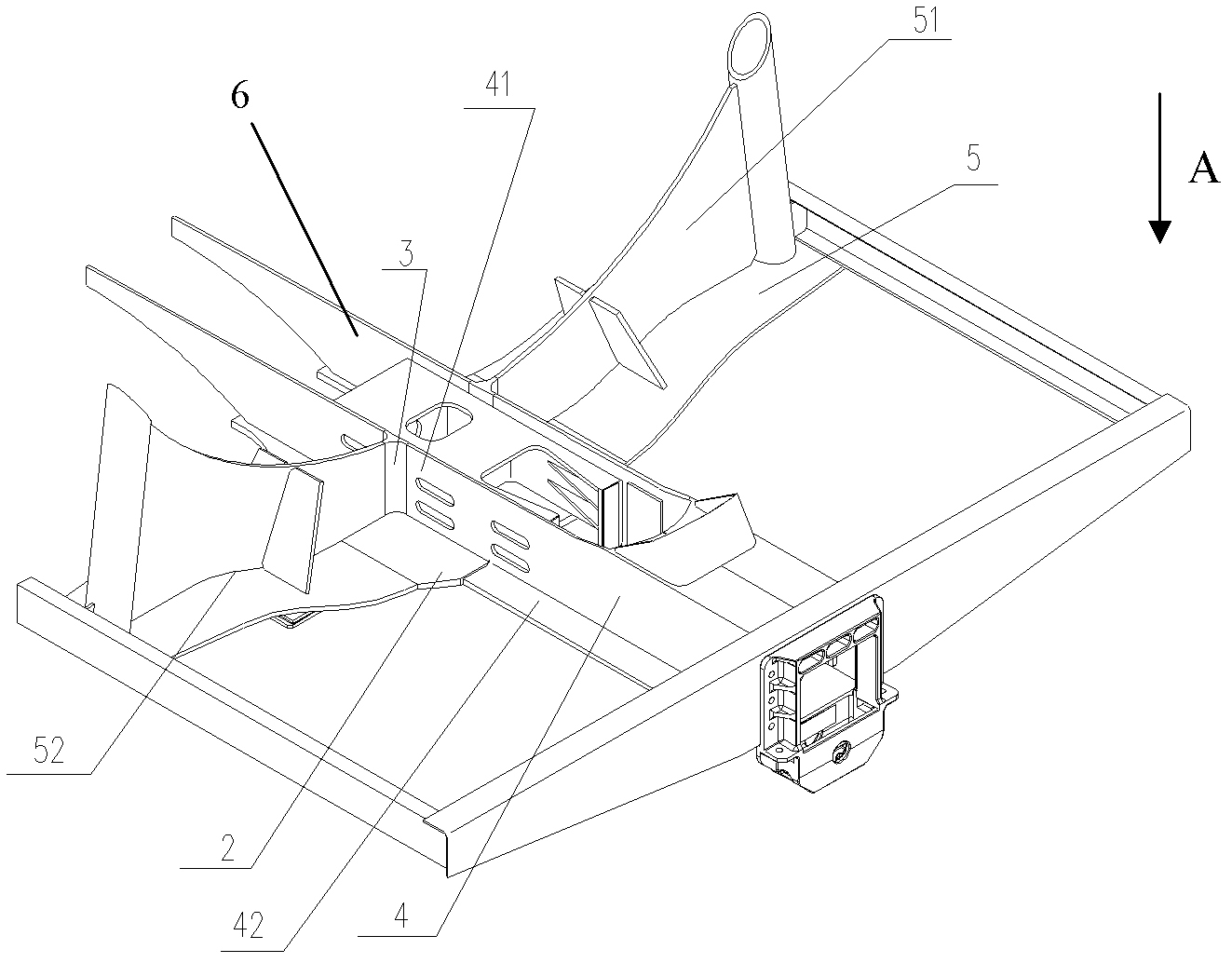

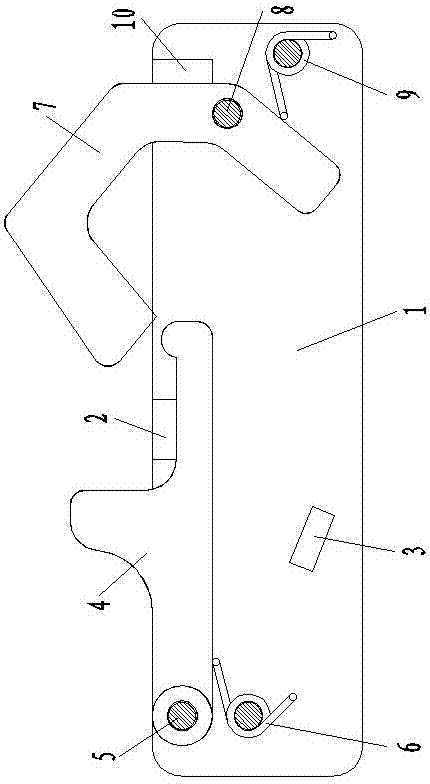

Capsule identification control method for beverage machine

ActiveCN108125563AShort manufacturing timeEasy to useBeverage vesselsIdentification deviceMechanical engineering

The invention provides a capsule identification control method for a beverage machine. The beverage machine comprises a base, a brewing cup, a brewing head and an identification device, the brewing head and the identification device are both arranged on the base, a capsule is contained in the brewing cup, the brewing cup is rotatably matched with the brewing head, and the capsule comprises a diaphragm having an identification code. The capsule identification control method comprises a rotation identification step, wherein the brewing cup drives a capsule relative identification device to rotate, and the identification device detects the identification code on the diaphragm in real time and obtains identification data. According to the control method, in the rotation identification step, inthe process when the brewing cup is rotatably matched with the brewing head and the diaphragm is in a rotating state, the identification device detects the identification code and obtains the identification data. In the process of installing the brewing cup, the capsule identification process is completed, the identification efficiency is high, and the time for preparing a beverage is saved. In addition, the identification device and a brewing device are integrated, the structure is simple, the identification and brewing operation is continuous, and more convenience is provided for a user during use.

Owner:杭州九创家电有限公司

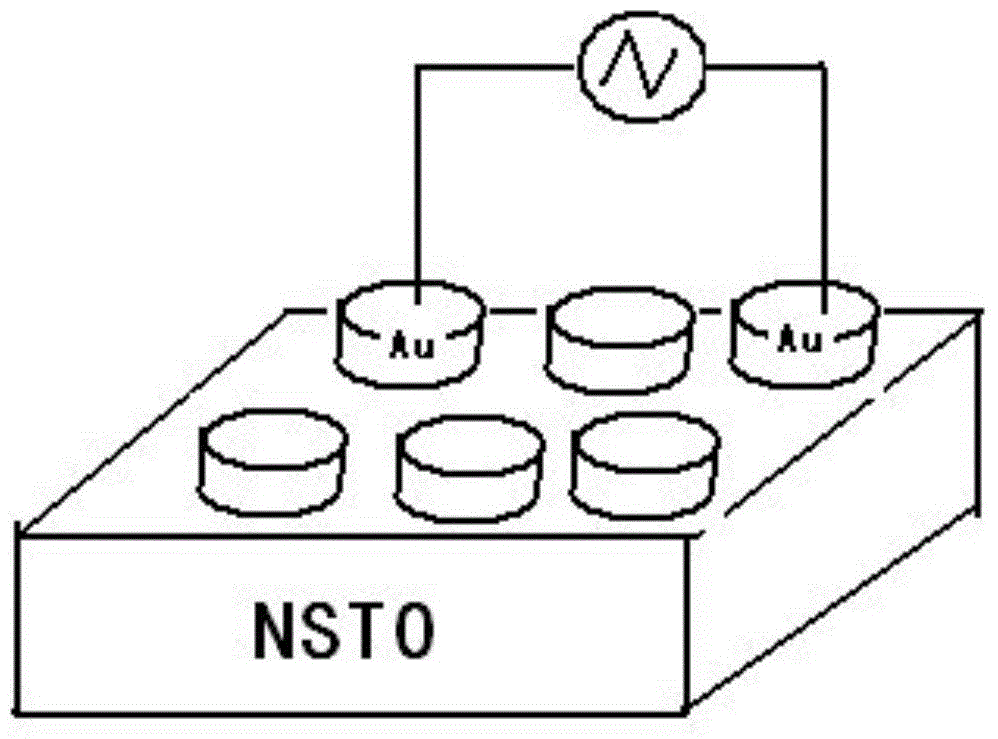

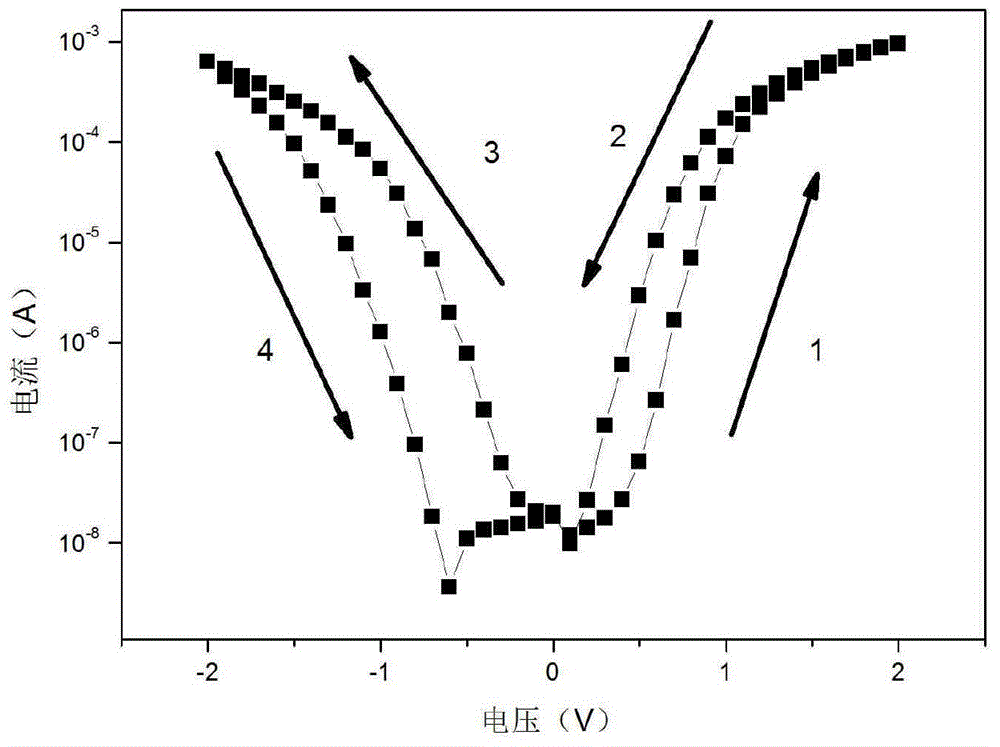

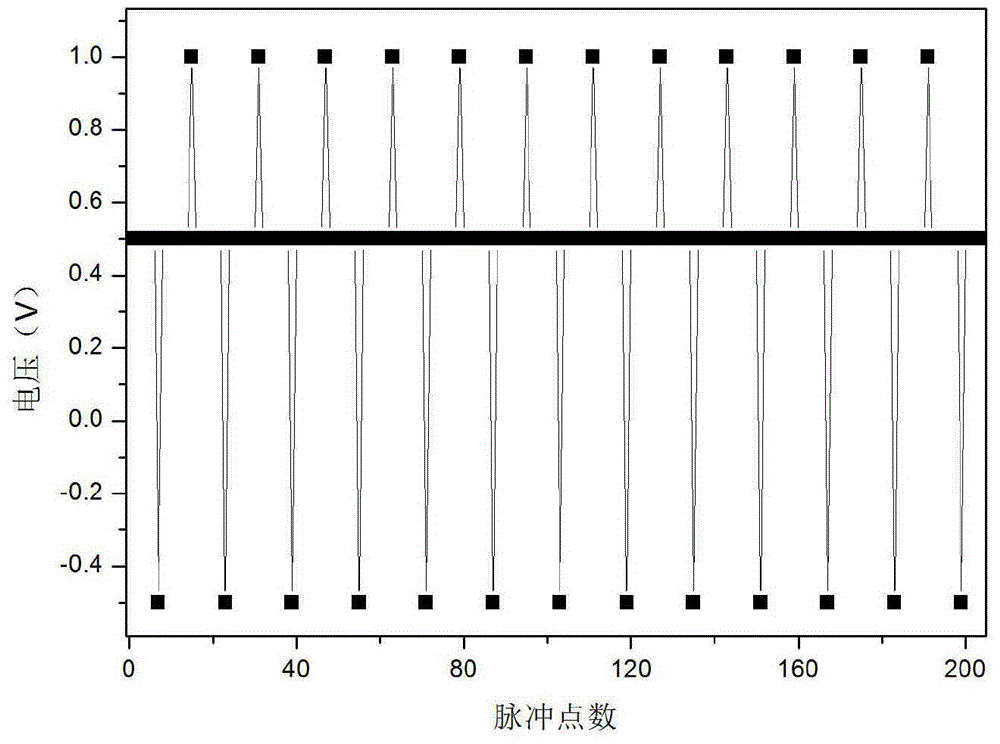

Interface oxygen vacancy based stable-storage resistive random access memory achieving method

InactiveCN104393172AStructural continuitySimple structureElectrical apparatusSputteringStatic random-access memory

The invention discloses an interface oxygen vacancy based stable-storage resistive random access memory achieving method and relates to a Schottky contact based method for achieving resistive random access memories which is optimal in storage performance and simple in structure. According to the method, a magnetron sputtering method is used for sputtering metal Au film on an Nb: SrTiO3 mono-crystal substrate to obtain memories in an Au / Nb: Sr TiO3 / Au plane structure, and accordingly, the stable-maintaining resistive random access memory performance is obtained. The method has the advantages that resistive random access memories are produced by plating Au on a mono-crystal Nb: SrTiO3 substrate through magnetron sputtering, the production process is achieved through one step, the memory production process is simple, other complex steps are not needed, and resistive random access memories are simple in structure and applicable to industrial production. The performance test result shows that compared with prior inventions, a good maintaining performance is provided, which is one of key factors determining the memory performance.

Owner:ZHEJIANG SCI-TECH UNIV

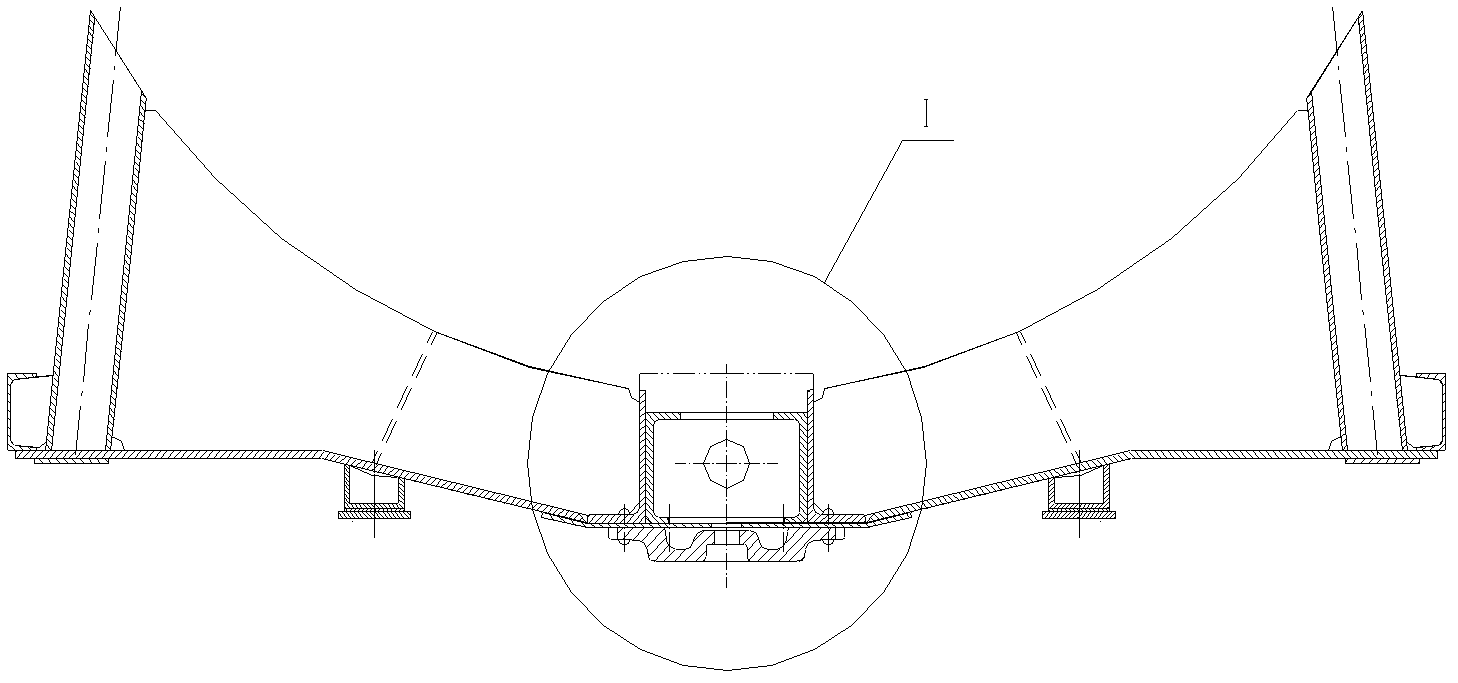

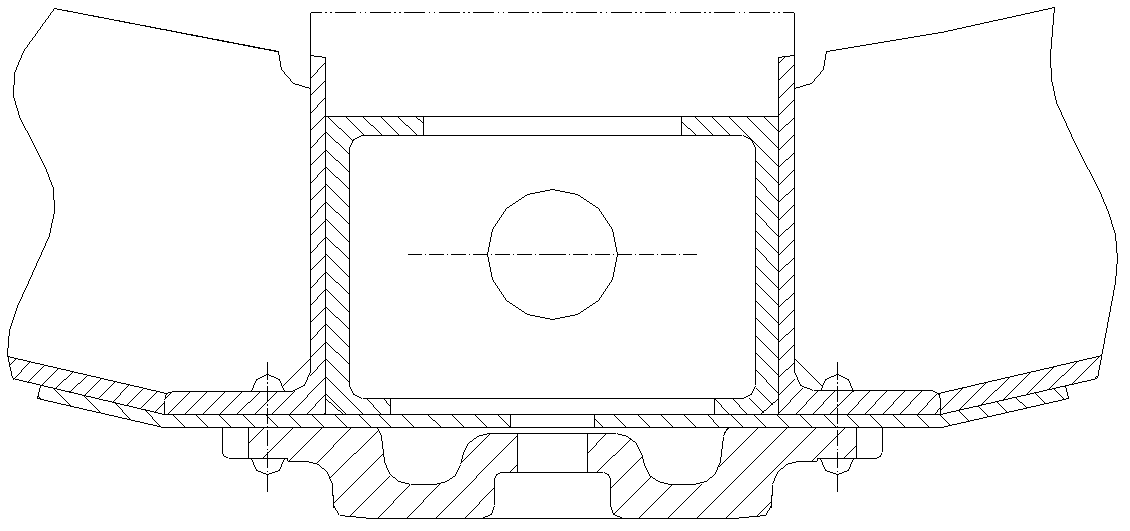

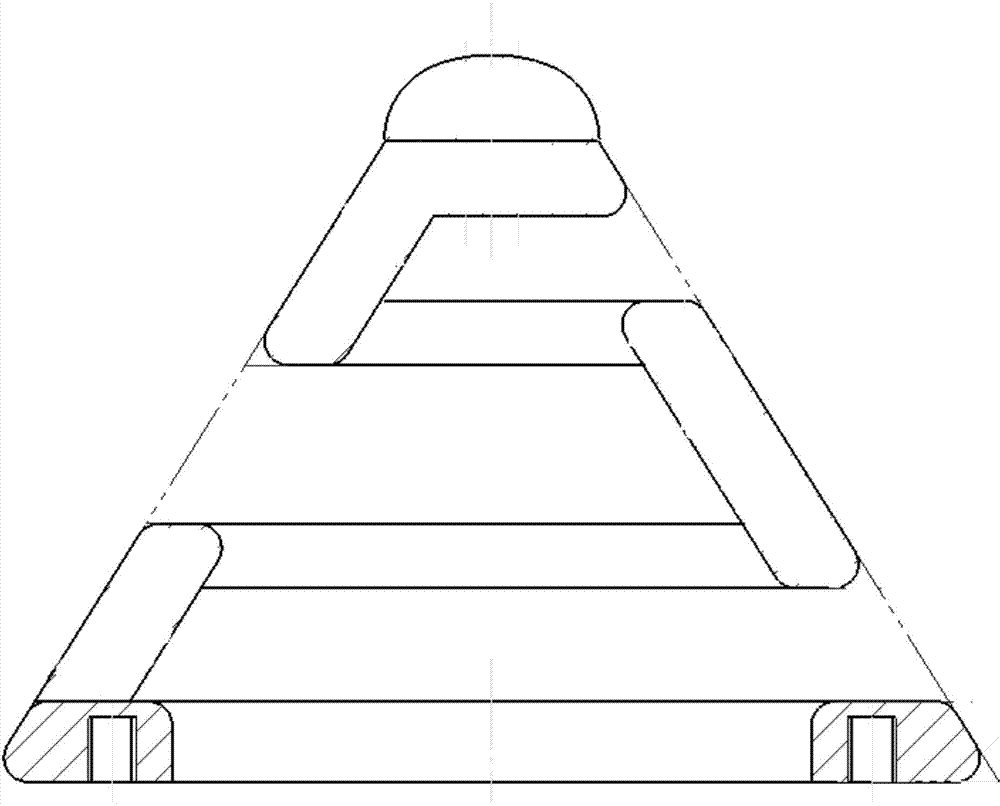

Traction and bolster center plate structure of railway tank car

ActiveCN102963370AAvoid the problem of bad stress or even crackingImprove reliabilityTank wagonsStress conditionsClose contact

The invention provides a traction and bolster center plate structure of a railway tank car. The center plate structure is arranged between two traction beams of the tank car. Each traction beam comprises an upright traction beam web and a horizontal traction beam lower wing surface. The center plate structure comprises a center plate seat which is connected with the traction beam lower wing surface. The center plate seat comprises a center plate seat bottom plate. One end of a bolster beam web, which is connected with the traction beam web, is arranged on the center plate seat bottom plate. The center plate seat bottom plate, the traction beam lower wing surface and a bolster beam are arranged in the same plane, and the center plate seat bottom plate and the traction beam lower wing surface are an integral whole. Since an upper center plate is installed an integral single-layer steel plate, i.e. the center plate seat bottom plate, and the center plate seat bottom plate and the traction beam lower wing surface are integrated, the center plate seat bottom plate and the traction beam lower wing surface are of an integral body, the traction and bolster center plate structure of the railway tank car solves the problems that a middle cover plate under a bolster cannot be in fully close contact with an installation surface, a gap exists and the middle cover plate under the bolster and the upper center plate are in a bad stressed condition and are even cracked in the existing multilayer structure.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

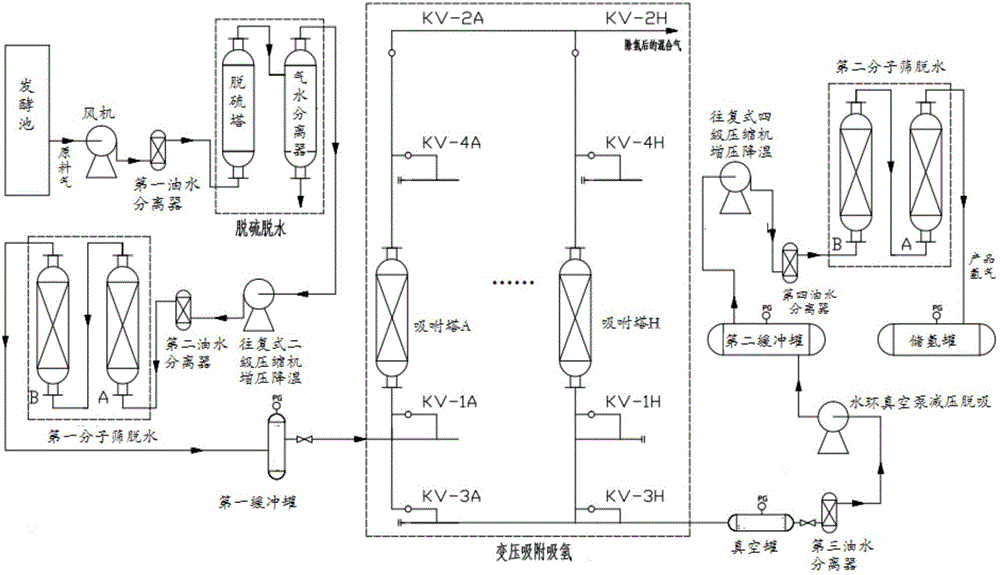

Method using pressure swing adsorption to purify hydrogen produced from anaerobic fermentation of kitchen garbage

ActiveCN106390679AStructural continuitySimple structureGas treatmentMethane captureSorbentDesorption

The invention discloses a method using pressure swing adsorption to purify hydrogen produced from anaerobic fermentation of kitchen garbage. The method includes: using a reciprocating type two-stage compressor to increase the pressure of dewatered and desulfurized raw material gas to 3.8-4.0MPa and lower the temperature of the dewatered and desulfurized raw material gas to 5-15 DEG C; using the bottom of an absorption tower to absorb hydrogen in the high-pressure and low-temperature mixed raw material gas, and discharging methane and carbon dioxide; desorbing the hydrogen absorbed in absorbent; subjecting an absorption bed to vacuumizing regeneration, and allowing the absorption bed to enter the next absorption cycle; allowing the hydrogen obtained by the desorption to sequentially pass a vacuum tank and an oil-water separator, and using a water ring vacuum pump to pump the hydrogen into a second buffer tank; using a reciprocating type four-stage compressor to increase the pressure and lower the temperature, and performing molecular sieve deep dewatering to obtain the product hydrogen. The method has the advantages that gases such as methane and carbon dioxide can be recycled, and the purification and enrichment degree of the hydrogen reaches more than 99%; the method is suitable for large-scale continuous production, simple and continuous in equipment structure, convenient to operate and capable of reducing energy consumption.

Owner:GUANGXI UNIV

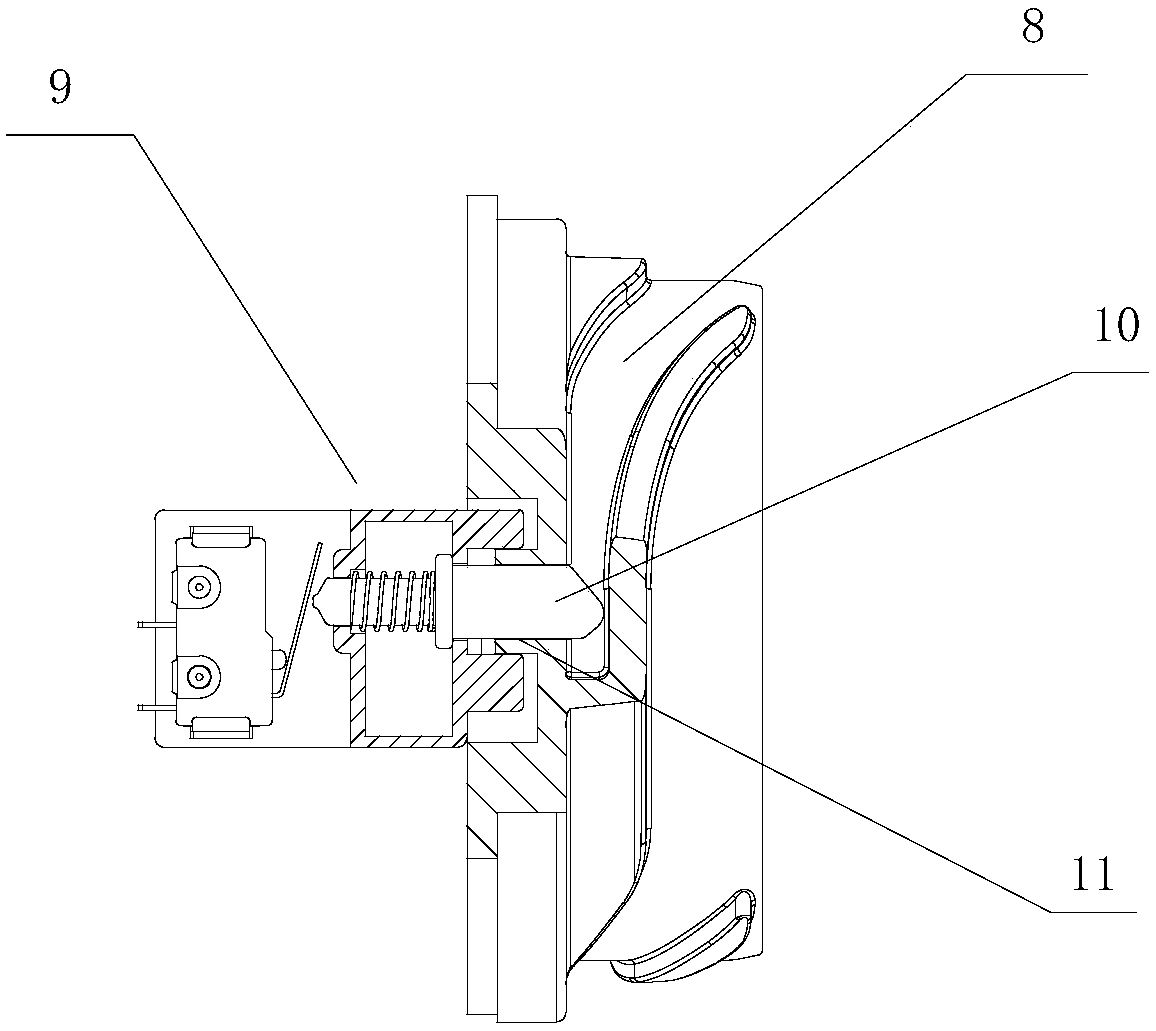

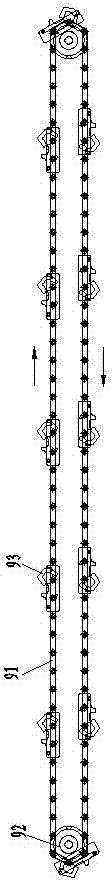

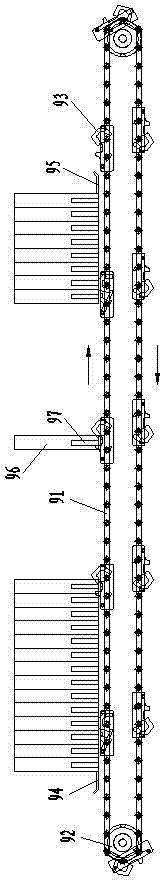

Press-filter unidirectional continuous plate pulling device

The invention relates to a press-filter unidirectional continuous plate pulling device, and aims to provide a press-filter unidirectional continuous plate pulling device with a reliable performance and high work efficiency to fill the technical blank. The device comprises a chain, two chain wheels and a plurality of mechanical arms; and is characterized in that: each mechanical arm comprises a frame, an upper limiting block, a lower limiting block, an executing member, an executing pin shaft, an executing torsion spring, a control member, a control pin shaft, and a control torsion spring; the executing member comprises an executing rod, a hooked hand, and an top pressing head; the upper limiting block, the lower limiting block, the executing pin shaft and the executing torsion spring are all fixed on the frame; the control member comprises a top torsion spring section, a position limiting section, a filter plate top pressing section, and a control section; a rotation hole is arranged on the joint part between the top torsion spring section and the position limiting section; the control pin shaft and the control torsion spring are both arrange on the frame; and the control member is movably connected to the control pin shaft through the rotation hole. The press-filter unidirectional continuous plate pulling device can unidirectionally, continuously and rapidly pull the filter plates in a press-filter and finishes the cake-unloading operation of the press-filter.

Owner:ZHEJIANG HUAZHANG TECH

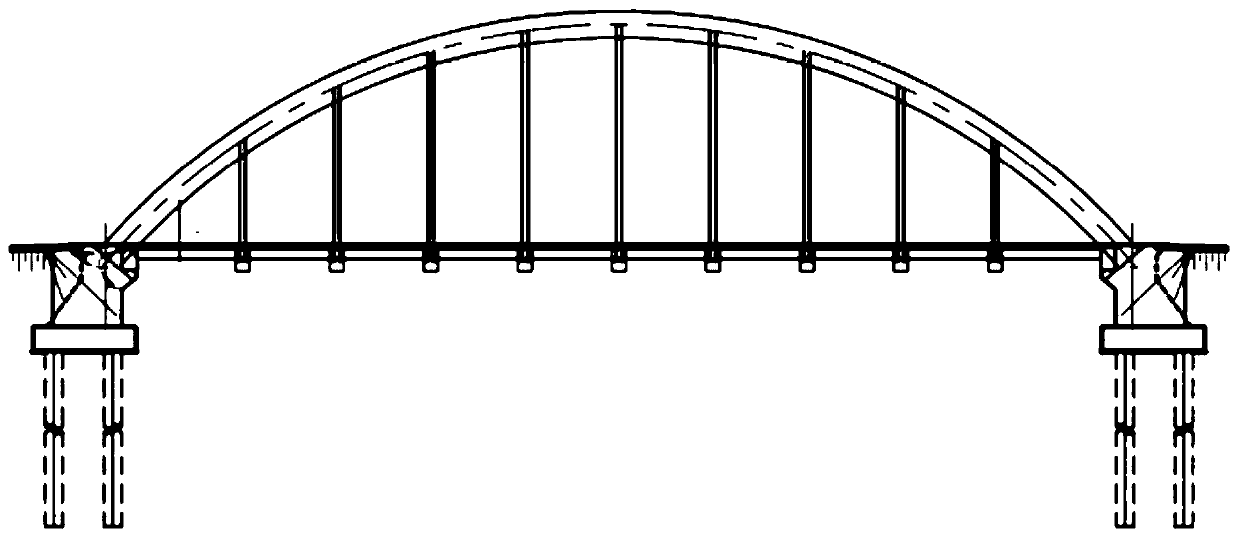

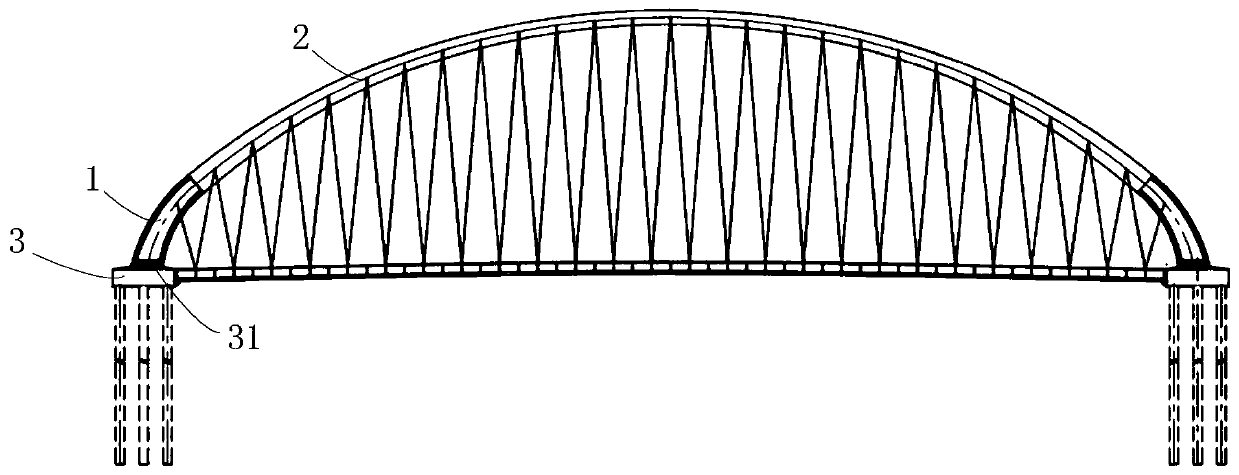

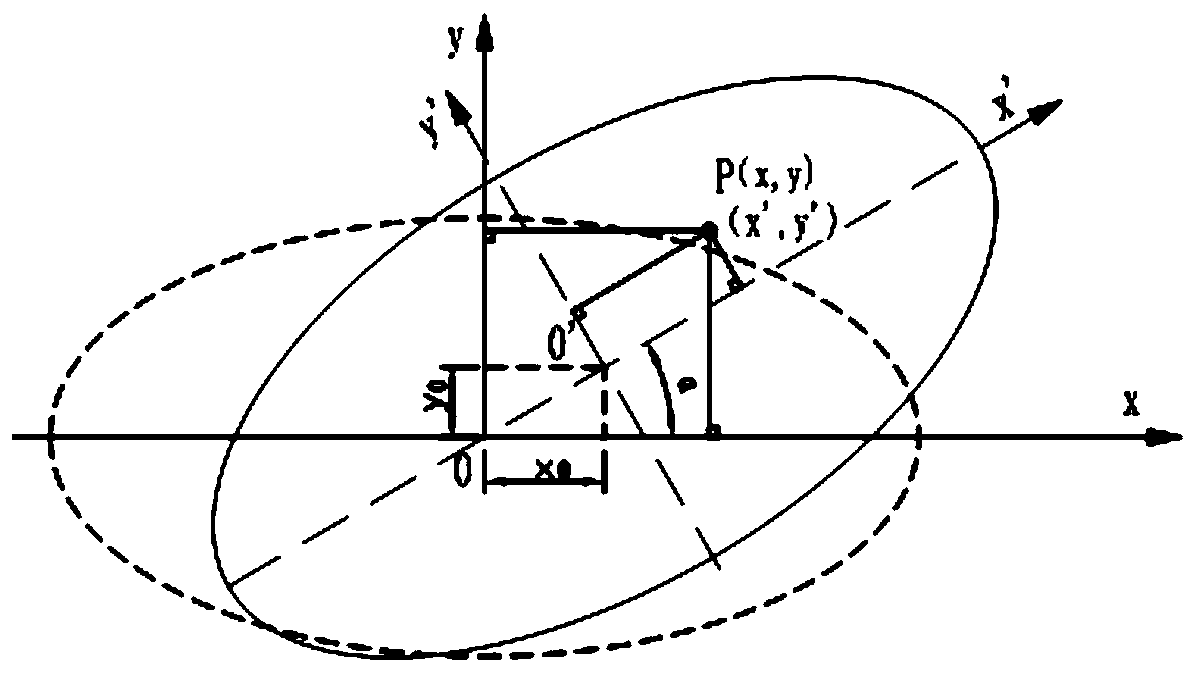

Large-span combined arch bridge based on bending pressure design theory and design and construction method thereof

ActiveCN111041969AAvoid attenuationAvoid the problem of arch rib crackingArch-type bridgeBridge materialsWeb structureArchitectural engineering

The invention discloses a large-span combined arch bridge based on a bending pressure design theory and a design and construction method thereof. The arch bridge comprises an arch springing section capable of bearing the action of tension or pressure and an arch web-arch crown section of an open web structure. The arch axis part of the arch foot section is a convergent composite curve; the curvature is changed, the arch foot section is rigidly connected with the arch web-arch crown section; the structure is continued, the tangent slopes of connecting points between the two are consistent, thecurvature of the arch foot section is gradually increased to be close to 90 degrees, only vertical component force exists, the horizontal component force is close to 0, the horizontal thrust of the main arch is reduced by 30%-64%, and the transverse stability is improved by 35%-55%; and horizontal tie bars required for overcoming horizontal thrust are reduced or canceled, so that the manufacturingcost is saved, the mechanical advantage that the composite structure material can be pressed and can be tensile and the economic spanning capacity of the large-span arch bridge can be fully exerted,and the section efficiency is improved.

Owner:SHENZHEN UNIV +1

Glass clinker added into peritectic steel casting powder and preparation and application method thereof

The invention relates to glass clinker added into peritectic steel casting powder. The glass clinker comprises, by weight, 78.00-86.00 Wt% of gold and copper tailings, 5.00-10.00 Wt% of SiO2, 5.00-9.00 Wt% of CaF2, 1.00-2.00 Wt% of BaO, 0.50-1.50 Wt% of CO2O3, 0-0.2 Wt% of MnO2 and 0-0.1 Wt% of Ni2O3. In the using process, the weight percentage meets the requirement of 100 Wt%. The composite peritectic steel casting powder with excellent performance can be obtained by ball milling and even mixing of 40.00-60.00 Wt% of the peritectic steel casting powder, 30.00-50.00 Wt% of the prepared glass clinker and 3.00-12.00 Wt% of carbon dust. The composite peritectic steel casting powder has the advantages of being high in glass forming speed, high in crystallization rate, dark black in color, low in density of heat flow, small in release gas amount in the using process, even in slag film, capable of obviously reducing longitudinal cracking of peritectic steel casting blank and the like.

Owner:WUHAN UNIV OF TECH

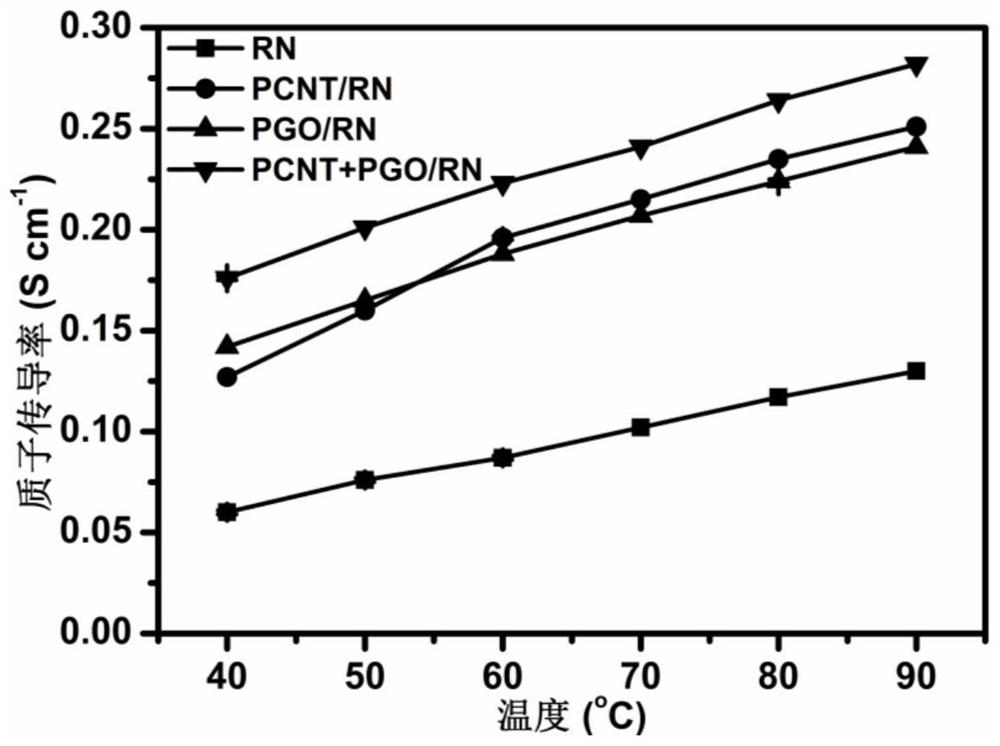

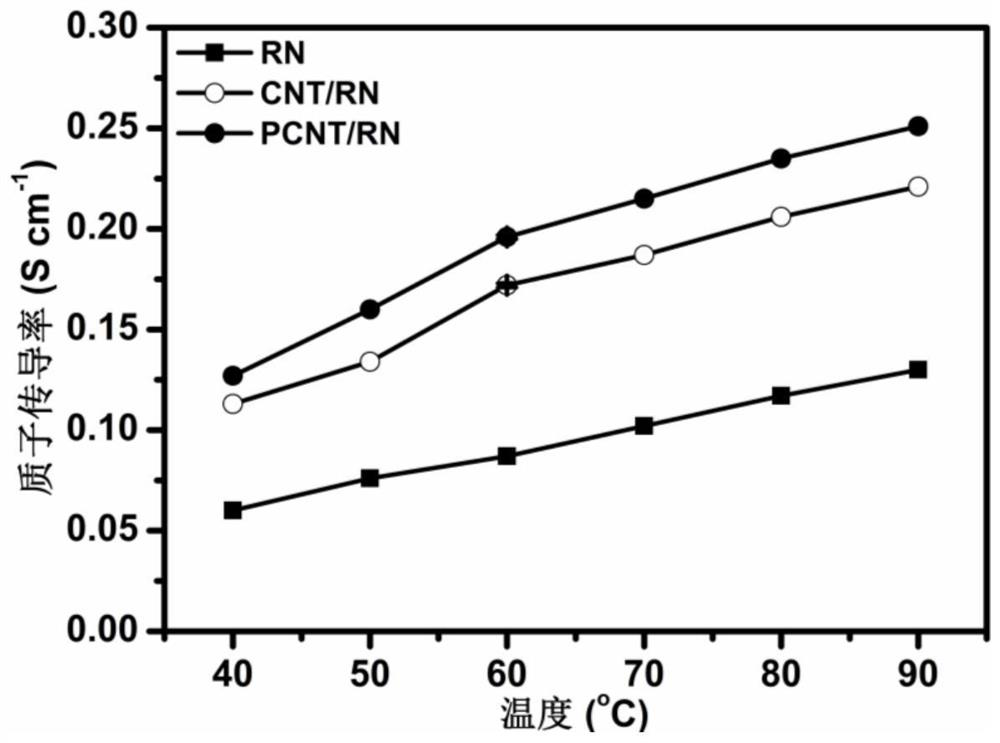

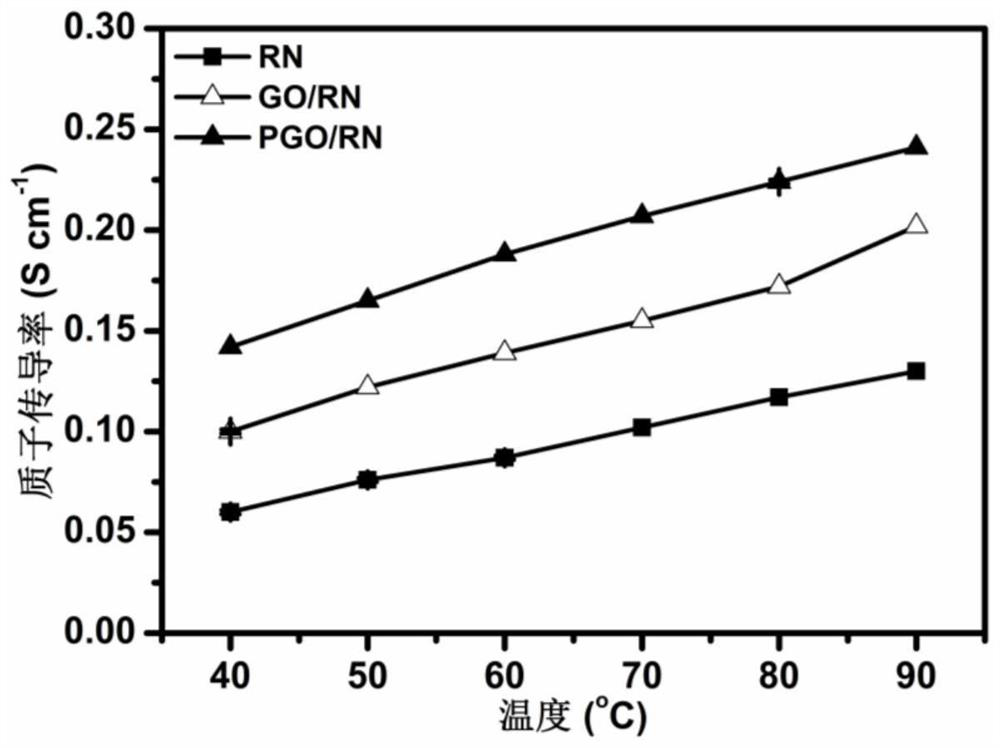

Polymeric hybrid proton exchange membrane synergistically modified by PCNT and PGO and preparation method thereof

ActiveCN114634642AEasy to operateReduce manufacturing costMaterial nanotechnologyFuel cellsModified carbonAcide Alendronique

The invention belongs to the technical field of membranes, and discloses a PCNT and PGO synergistically modified polymer hybrid proton exchange membrane and a preparation method thereof, and the preparation method comprises the following steps: (1) preparing a polydopamine modified carbon nanotube DCNT; (2) preparing graphene oxide DGO modified by polydopamine; (3) carrying out a reaction on alendronate and DCNT to obtain a phosphorylated carbon nanotube PCNT; (4) carrying out reaction on alendronate and DGO to obtain phosphorylated graphene oxide PGO; and (5) obtaining a membrane casting solution based on the sulfonated polymer solution, PCNT and PGO to form a membrane material, and further treating to obtain the PCNT and PGO synergistically modified polymer hybrid proton exchange membrane. The structure and composition of key functional components in the proton exchange membrane are improved, and the proton conductivity of the prepared proton exchange membrane is greatly improved based on the synergistic effect of the functional components PCNT and PGO.

Owner:HUAZHONG UNIV OF SCI & TECH

Environment-friendly halogen-free flame-proof copolymerized methanal complex and method for producing the same

The invention relates to an environment-friendly halogen-free flame-retardant copolyoxymethylene compound and a preparation method thereof, belonging to the field of the preparation of flame-retardant polymer material. The compound comprises the components with the mass percentage as follows: 56.0-69.0 percent of copolyoxymethylene resin, 15.0-22.0 percent of flame retardant, 5.0-7.0 percent of flame retardant synergist, 3.0-7.0 percent of char-forming agent, 3.0-5.0 percent of toughener, 0.1-0.5 percent of formaldehyde absorbent, 0.1-1.0 percent of antioxidant and 0.5-3.0 percent of heat rejection and dripping-resistant agent. In the invention, the flame retardant, the flame retardant synergist and the heat rejection and dripping-resistant agent are coated by the toughener to manufacturecompound flame retardant; then the compound flame retardant is mixed with the copolyoxymethylene, the formaldehyde absorbent, the char-forming agent and the antioxidant uniformly and the mixture is extruded from a double-screw extruder and granulated; and the copolyoxymethylene compound is obtained. The compound has good flame-retardant performance, the flame-retardant grade reaches UL94V-0 grade, and the compound is friendly to the environment.

Owner:BEIJING UNIV OF CHEM TECH

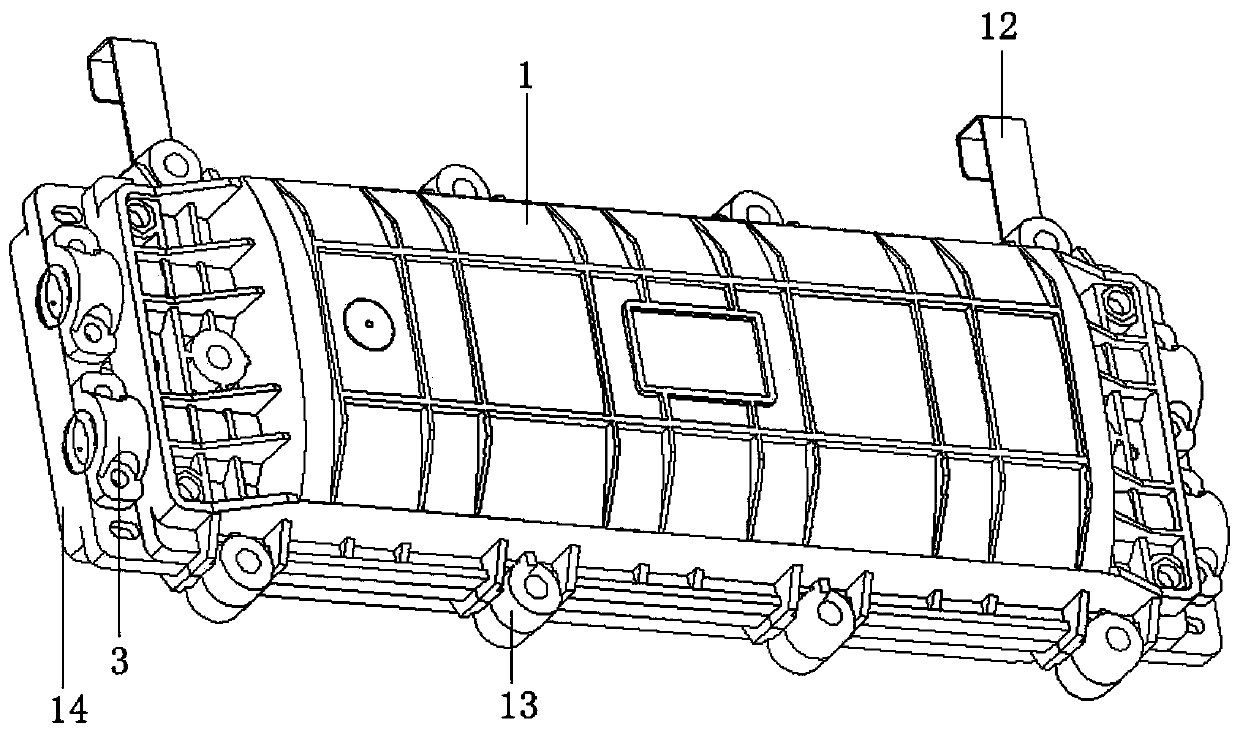

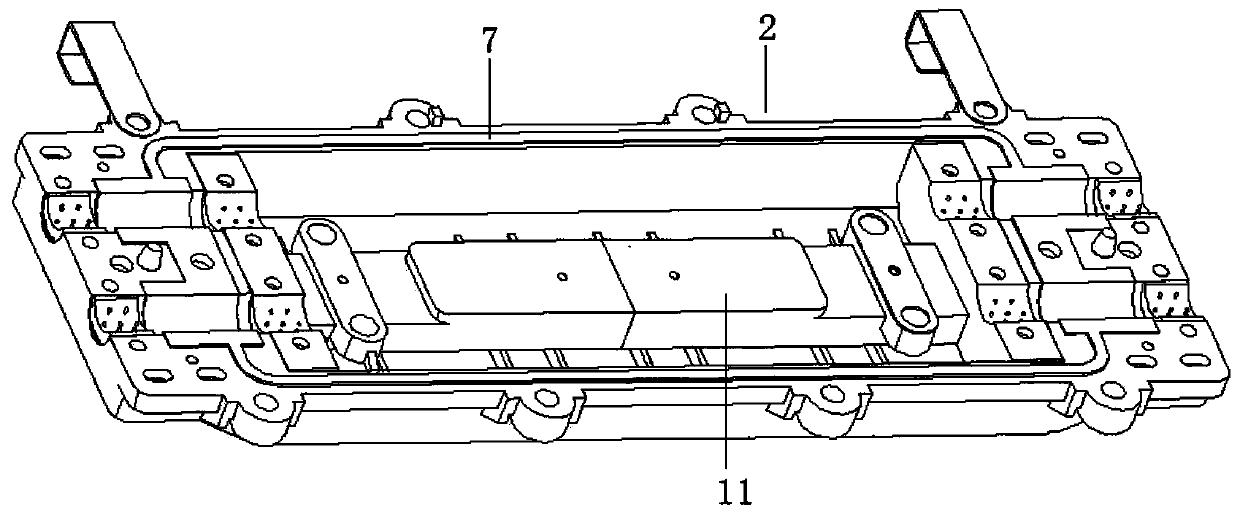

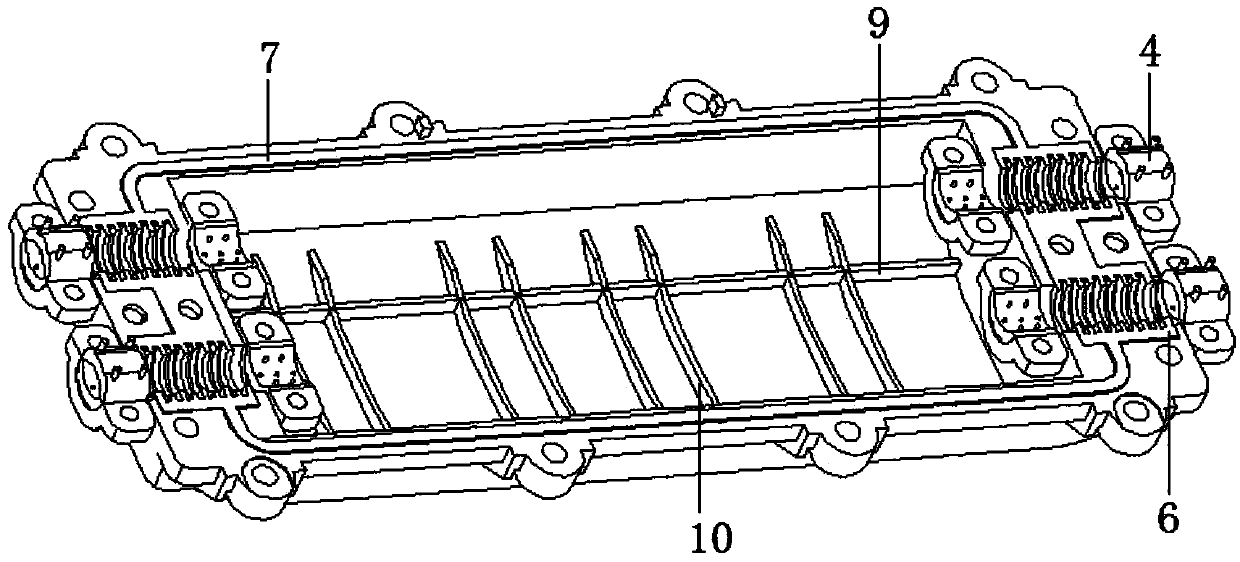

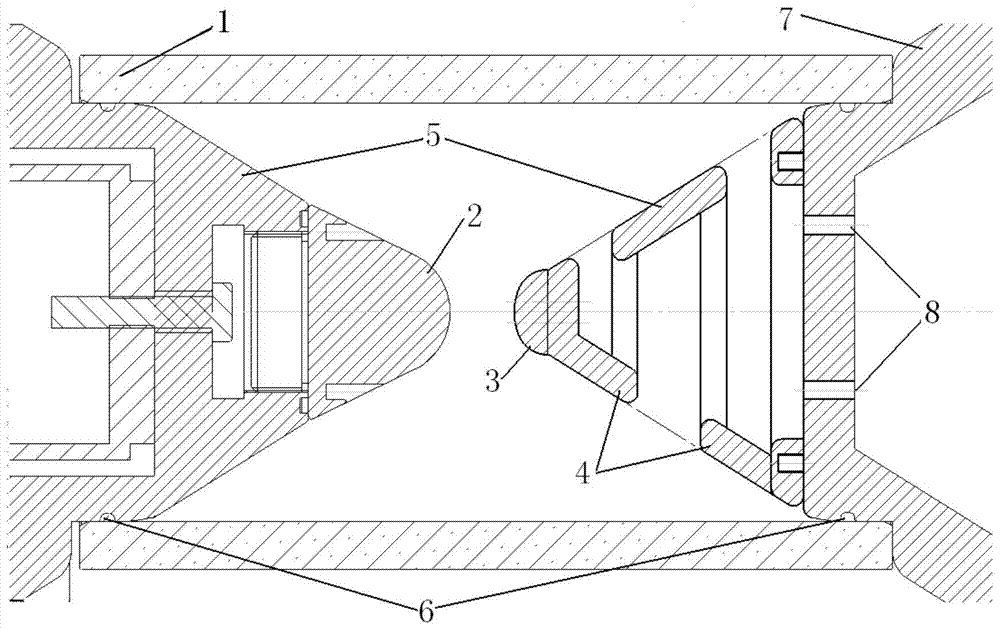

Compact inductor and load integrated gas switch

ActiveCN103944072AOptimal Control StructureMeet Frontier RegulationCorona dischargeEngineeringInductor

The invention provides a compact inductor and load integrated gas switch. The compact inductor and load integrated gas switch comprises an outer insulating cylinder, a conical cathode electrode tip and a conical anode electrode tip; the two ends of the outer insulating cylinder are sealed by the conical cathode electrode tip and the conical anode electrode tip respectively, the outer insulating cylinder is filled with high-pressure insulation gas, and at least one of the cathode electrode tip and the anode electrode tip is a hollow conical surface electrode structure. The hollow conical surface electrode structure comprises an electrode tip, an electrode base plate and an inductance unit arranged between the electrode tip and the electrode base plate, the electrode base plate is of a circular ring structure, the electrode tip, semi-circular-ring-shaped inductors and an inductor supporting section form a hollow conical surface layout. The inductors, load and switch integrated structure is obtained under the high-voltage and high-field conditions, so that a switch circuit structure is more compact, and self inductance is controllable.

Owner:NORTHWEST INST OF NUCLEAR TECH

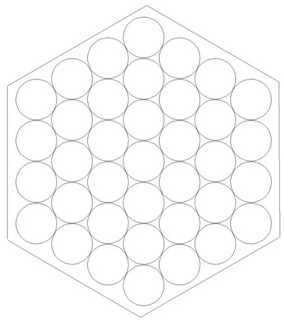

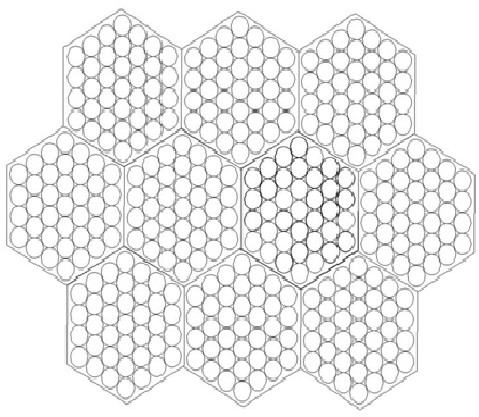

Polymer optical fiber panel, manufacturing method and large-area polymer optical fiber panel

The invention relates to a polymer optical fiber panel, a manufacturing method and a large-area polymer optical fiber panel, and belongs to an optical fiber panel used in an imaging technology. According to the technical scheme, the overall structure of the polymer optical fiber panel is a regular polygon, polymer optical fiber monofilaments arranged in an array mode are arranged in the polymer optical fiber panel, each polymer optical fiber monofilament comprises a polymer core material and a polymer skin material wrapping the polymer core material, the polymer core material is located in the center, and the polymer skin material wraps the polymer core material. Compared with the prior art, the polymer optical fiber prepared by adopting a composite spinning method is low in cost, high in manufacturing speed and capable of being continuously and efficiently manufactured. According to the polymer optical fiber panel, the polymer optical fibers are adopted to manufacture the polymer optical fiber panel through the fusion-wire drawing-fusion process, each unit of the manufactured polymer optical fiber panel can independently transmit images, the unit structure of the single polymer optical fiber panel is regular, the internal structure is stable, and the resolution ratio is high when the polymer optical fiber panel is used.

Owner:中建材光芯科技有限公司

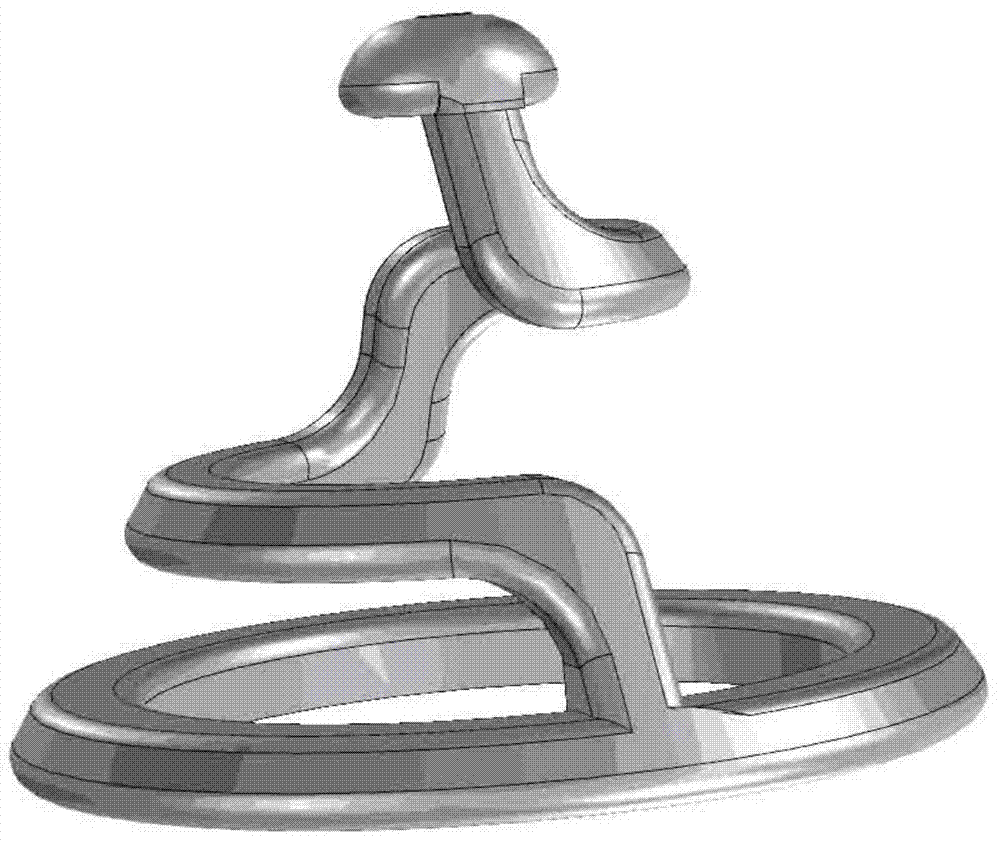

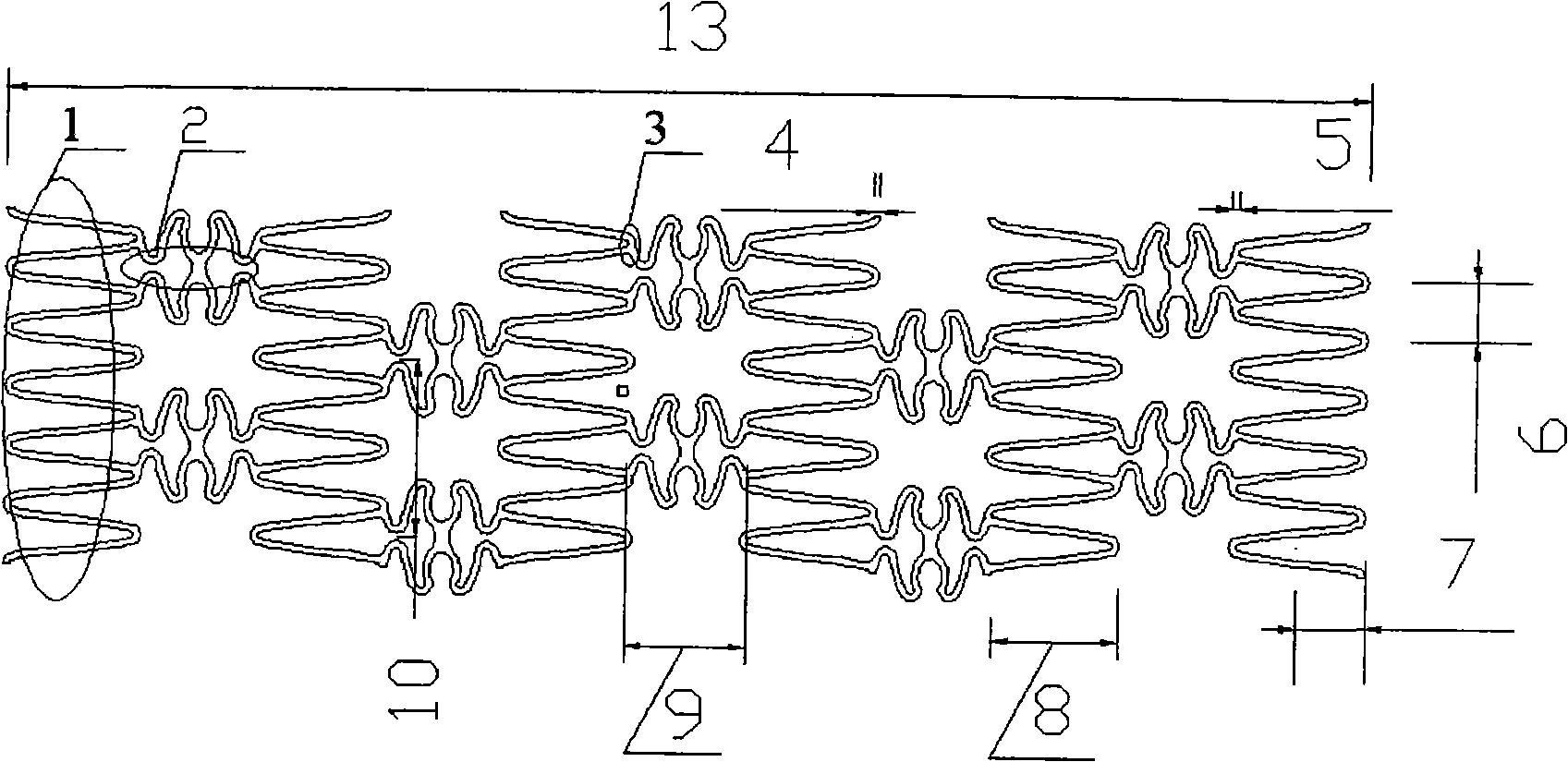

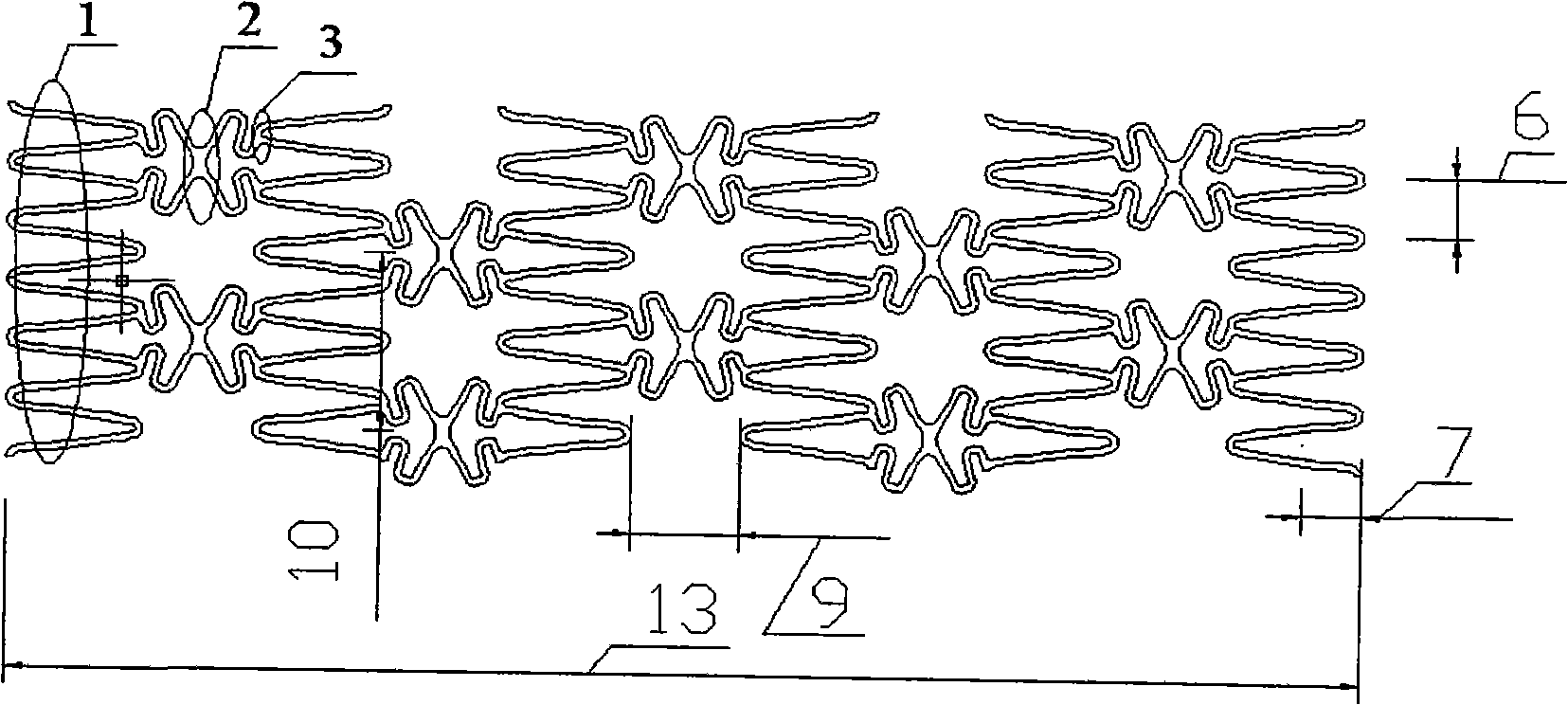

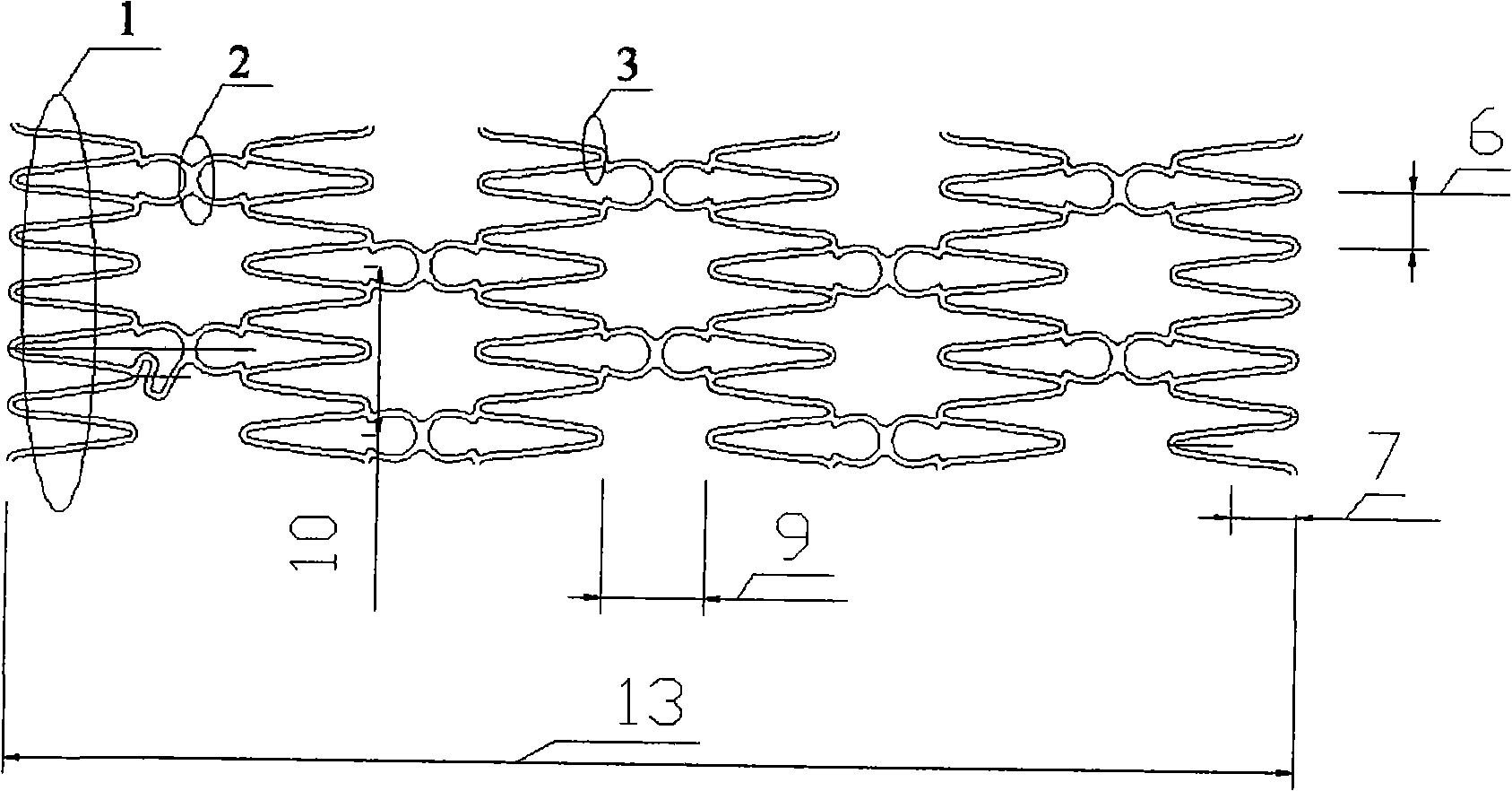

Human endoluminal stent with radial large deformation large holding power

InactiveCN101288610AStructural continuityImprove structural stabilityStentsSurgeryEndoluminal stentTitanium alloy

A human body lumen stent with radial large deformation and large support force is formed by etching a metal tube and is a tubular net-shaped structure, which is composed of a plurality of sine wave-shaped circular ring-shaped basic structures (1) which are distributed along the axial direction, the wave peaks of the sine waves between every adjacent two sine wave-shaped circular ring-shaped basic structures (1) are opposite and are connected by connecting parts (2) with Omega-shaped structures which are arranged at the both sides and combined back-to-back, and the connecting points (3) are selected at the vertex of the wave peaks of the sine wave-shaped circular ring-shaped basic structures (1). The rib width (5) of the connecting parts (2) is less than or equal to the rib width (4) of the sine wave-shaped circular ring-shaped basic structures (1). The end part of the lumen stent can be made into horn shape, and the internal surface and the external surface of the stent can be covered with a metal membrane, an oxide membrane, a polymer membrane or a sustained-release drug membrane. The material for etching the metal tube of the lumen stent can be nickel-titanium alloy, stainless steel, titanium alloy and pure metals, such as tantalum or gold etc. The structure of the invention has the radial large deformation and the large support force.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com