Capsule identification control method for beverage machine

A control method and beverage machine technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of high probability of printing quality problems of two-dimensional barcodes, unsatisfactory capsule recognition effect, and small number of two-dimensional barcodes, etc., to achieve recognition Continuous with brewing operation, saving preparation time and improving recognition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

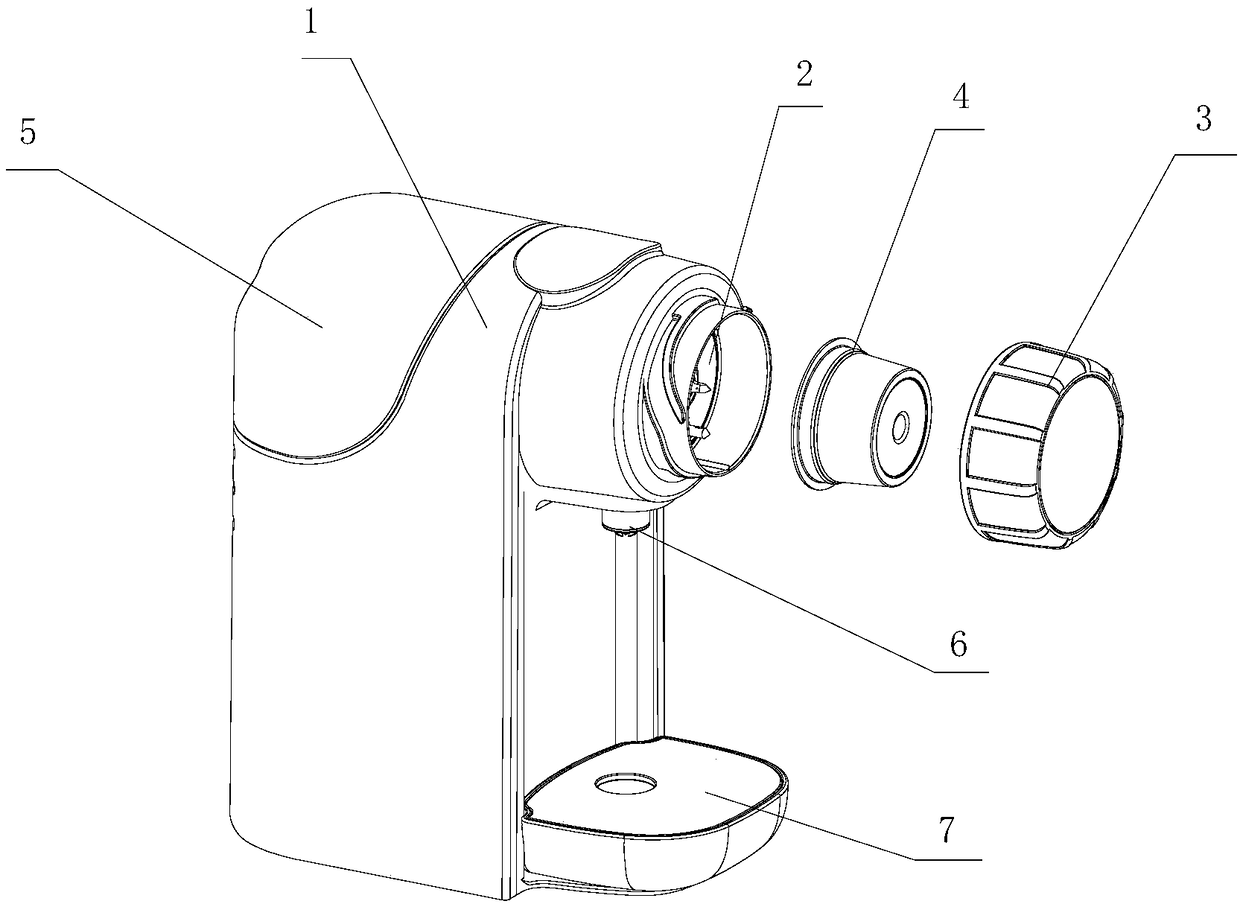

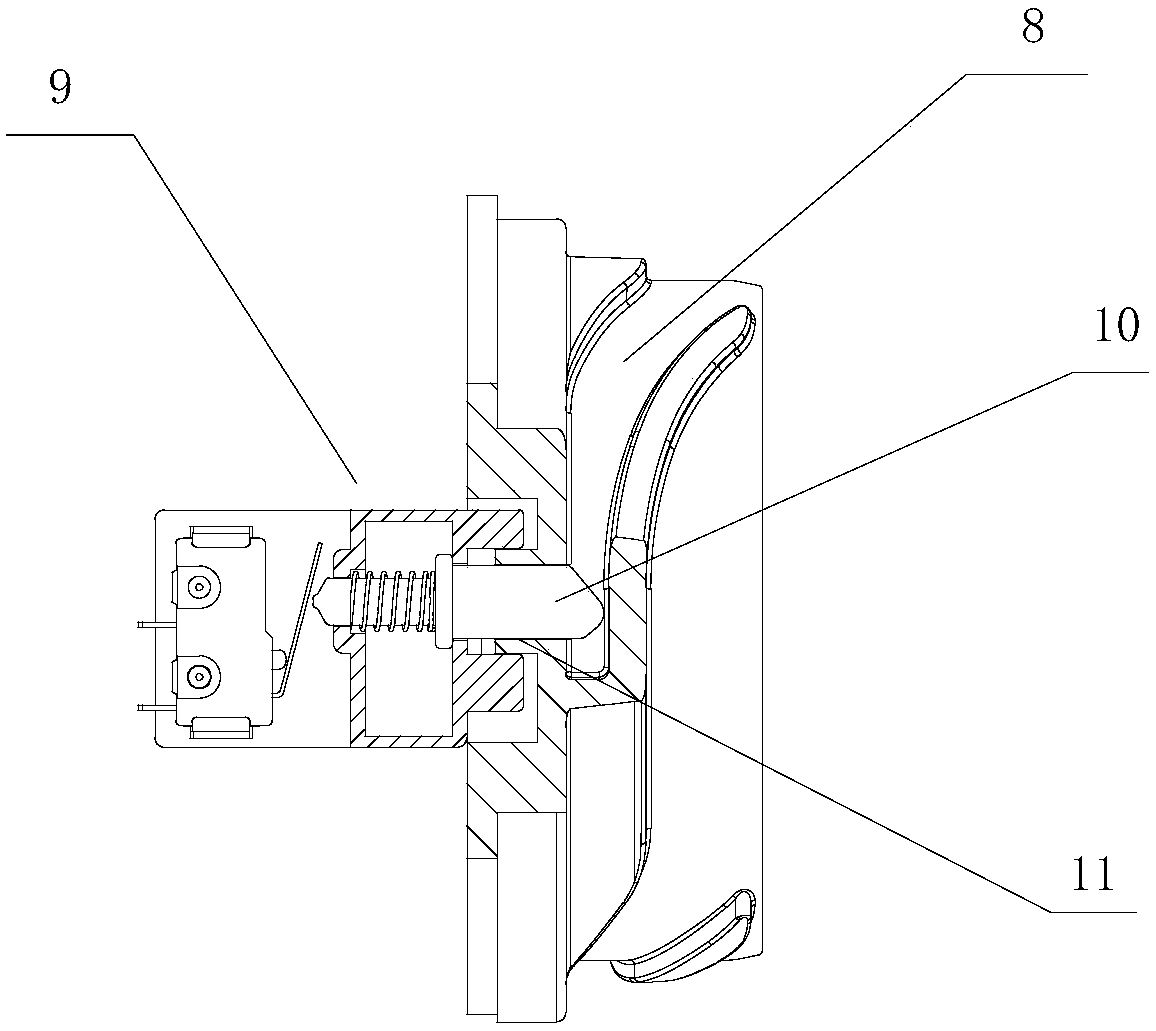

[0038] Such as Figure 1-2As shown, the present invention provides a capsule beverage machine, which is a horizontal beverage machine, including a machine base 1, a brewing head 2, a water supply assembly and a control unit, and the brewing head 2, the water supply assembly and the control unit The units are all arranged on the base 1, the water supply assembly provides water to the brewing head 2, the water supply assembly is electrically connected to the control unit, the brewing head 2 is provided with a water inlet needle and an outlet needle, and the inlet The water puncture needle and the extraction needle are both arranged laterally on the same side of the brewing head 2, and the extraction needle is located below the water inlet needle. The beverage machine also includes a brewing cup. The brewing head has an opening exposed to the outside of the machine base. The brewing cup There is a turnbuckle structure between the brewing head and the detachable connection between...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that: the capsule identification control method further includes a function executing step.

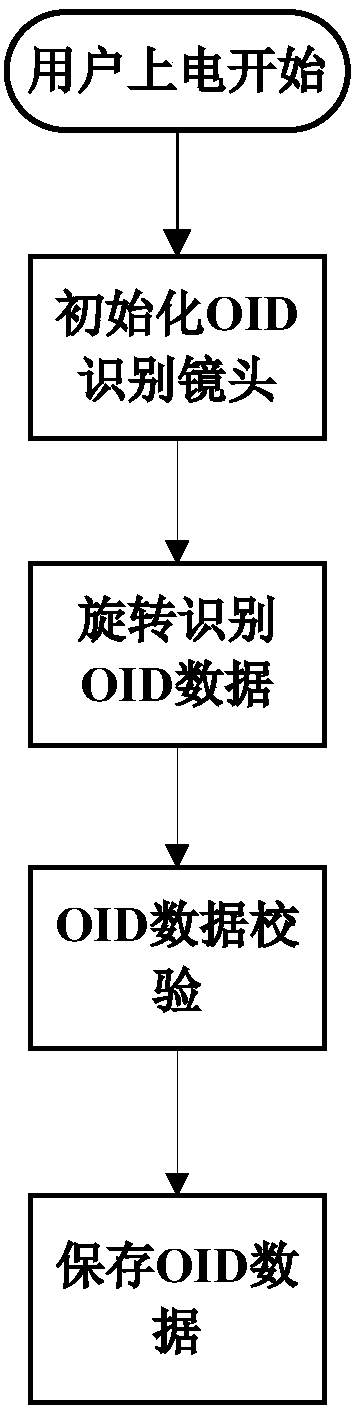

[0061] Such as Figure 7 As shown, the capsule identification control method further includes a function execution step, and the beverage machine is provided with a function selection button for the user to choose to execute a brewing program and a cleaning program. When the user selects the brewing program, the control unit detects the OID identification data within the fourth set period, and when the identification data is detected, the brewing program corresponding to the OID data is executed; when the identification data is not detected, the default brewing is executed program. By detecting the identification data in the fourth setting period of the process of executing the brewing program, the identification device has a secondary identification process before performing a specific brewing operation, providing mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com