Patents

Literature

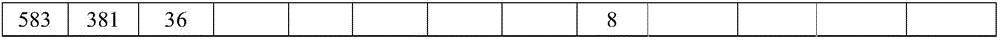

436results about How to "Reduced compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

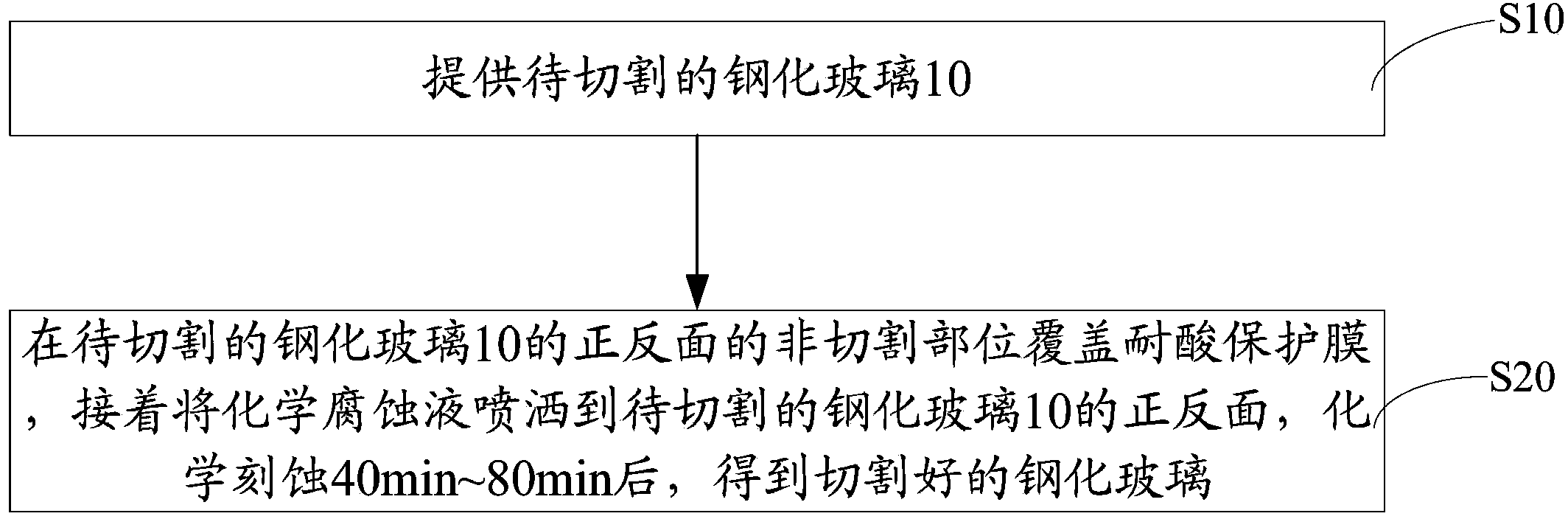

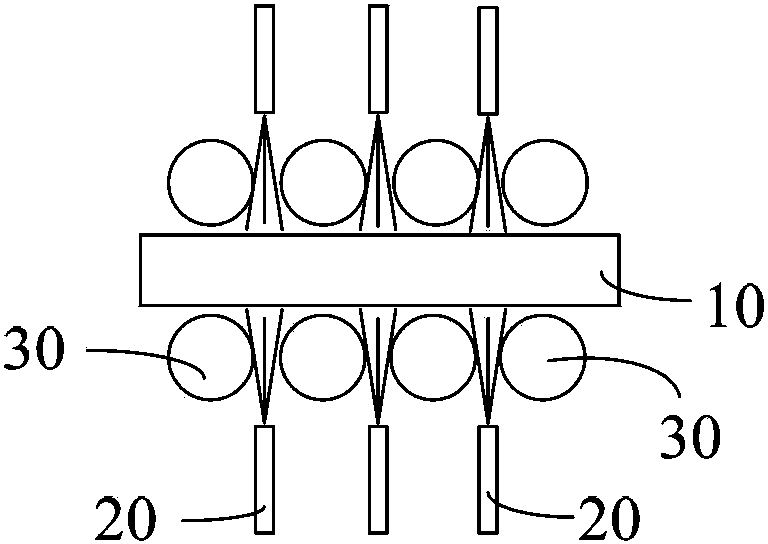

Method for cutting tempered glass

The invention discloses a method for cutting tempered glass. The method comprises the following steps of: providing a piece of tempered glass to be cut, covering acid-resisting protecting films on non-cut parts at the positive side and the back side of the tempered glass to be cut, subsequently spraying a chemical corrosive liquid to the positive side of the tempered glass to be cut, and carrying out chemical etching for 40-80 minutes so as to obtain cut tempered glass. According to the method for cutting the tempered glass, the tempered glass to be cut is cut by spraying the chemical corrosive liquid on the positive side and the back side of the tempered glass to be cut. Compared with the conventional method that the tempered glass is cut in a mechanical or laser mode, the method for cutting the tempered glass prevents the edge of the tempered glass from micro-crack, crack points and crack sides, so that the compressive strength of the edge of the tempered glass is not reduced.

Owner:深圳市伟光导电膜有限公司

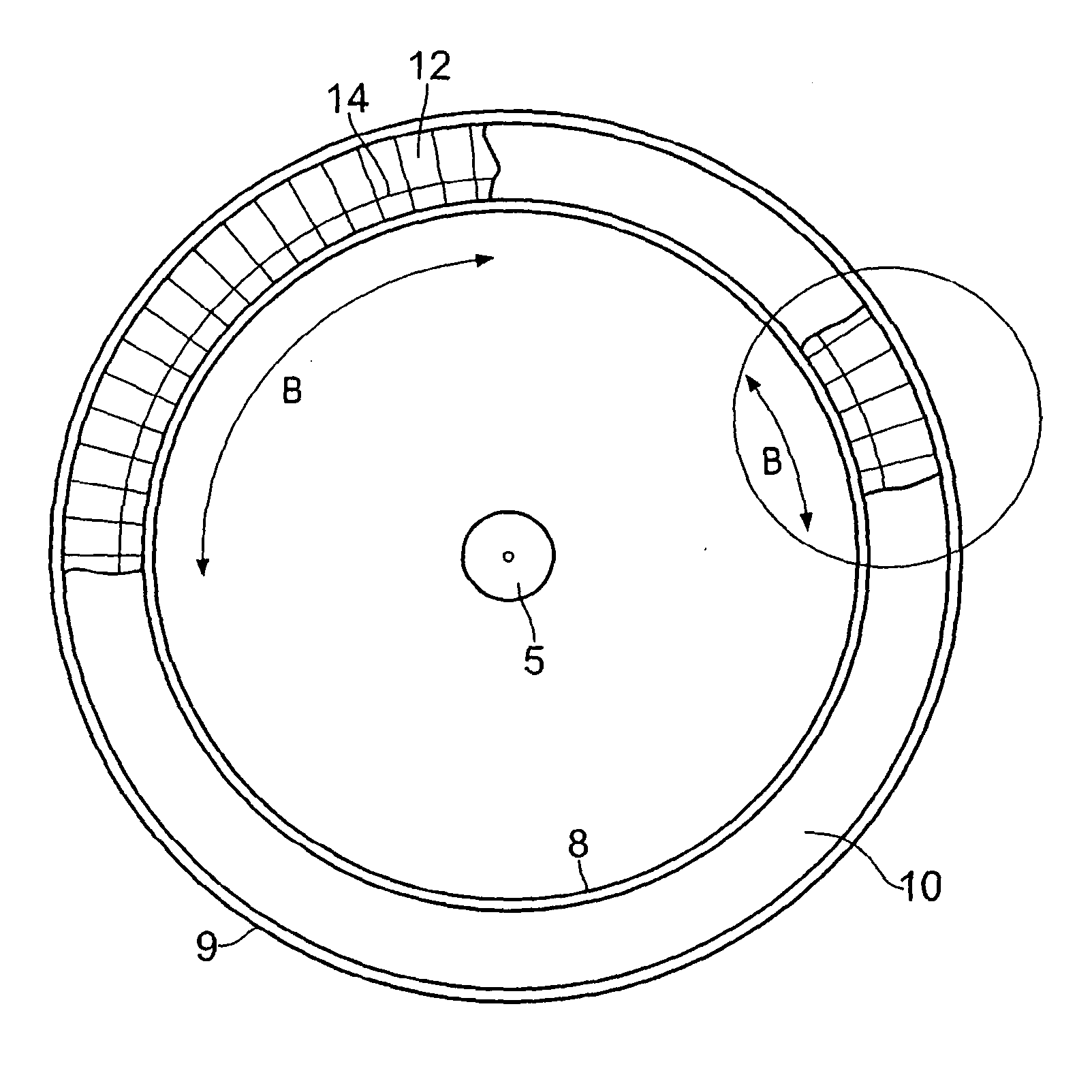

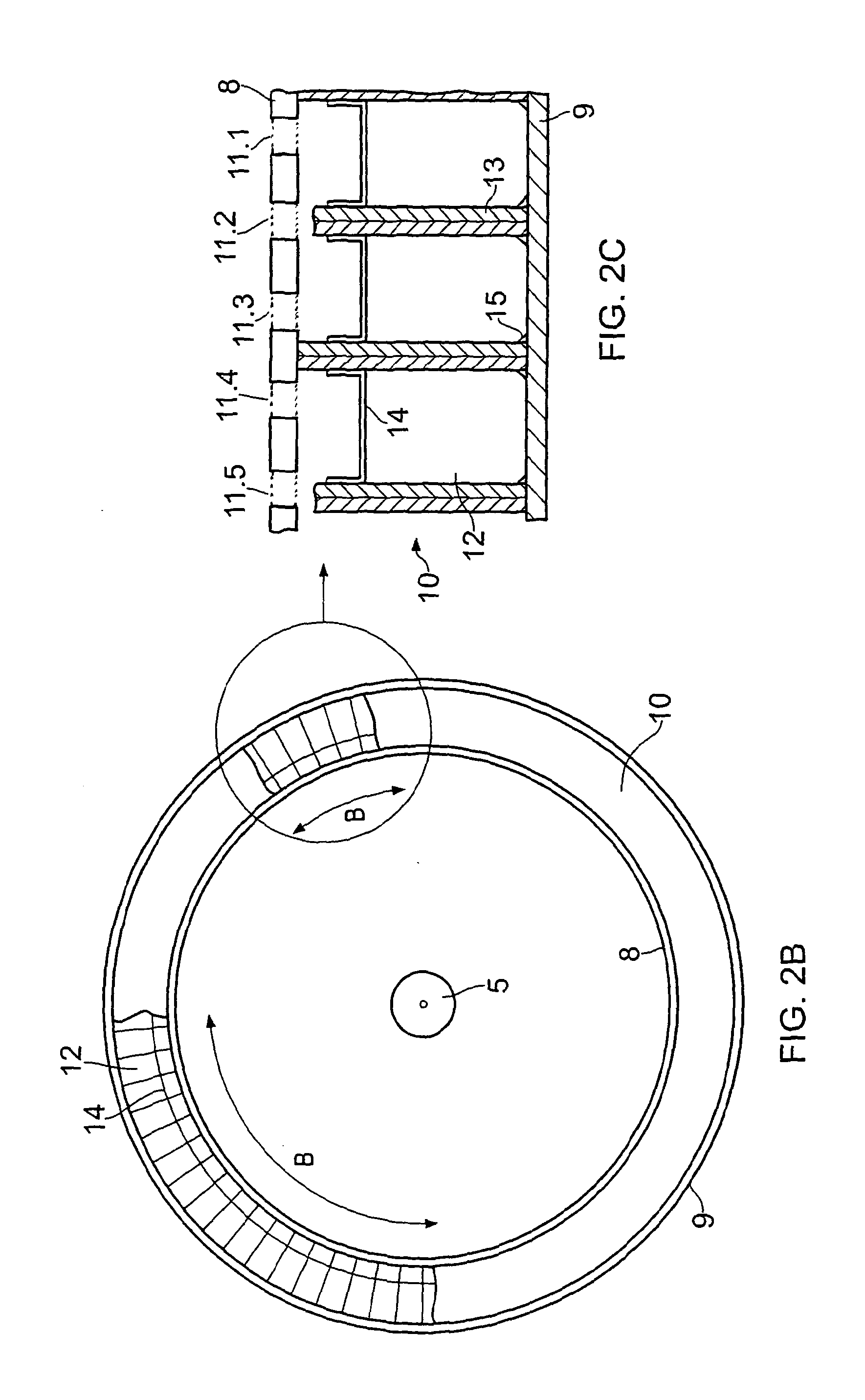

Seamless acoustic liner

ActiveUS20130075193A1Add partsAvoid introducingCeilingsTurning machine accessoriesEngineeringTurbine

The invention relates to a method of manufacturing a composite acoustic panel employed in an inlet passage of a gas turbine engine (1). The acoustic panel comprises a permeable face-layer (8), an impermeable backing sheet (9) and a sound absorbing layer (10) disposed therebetween. The method comprises a double polymerisation process for the face-layer and the remainder of the acoustic panel and finally a perforation step to perforate the face-layer according to a pre-determined perforation distribution (11.1, 11.2, 11.3, 11.4, 11.5).

Owner:GKN AEROSPACE SERVICES LTD

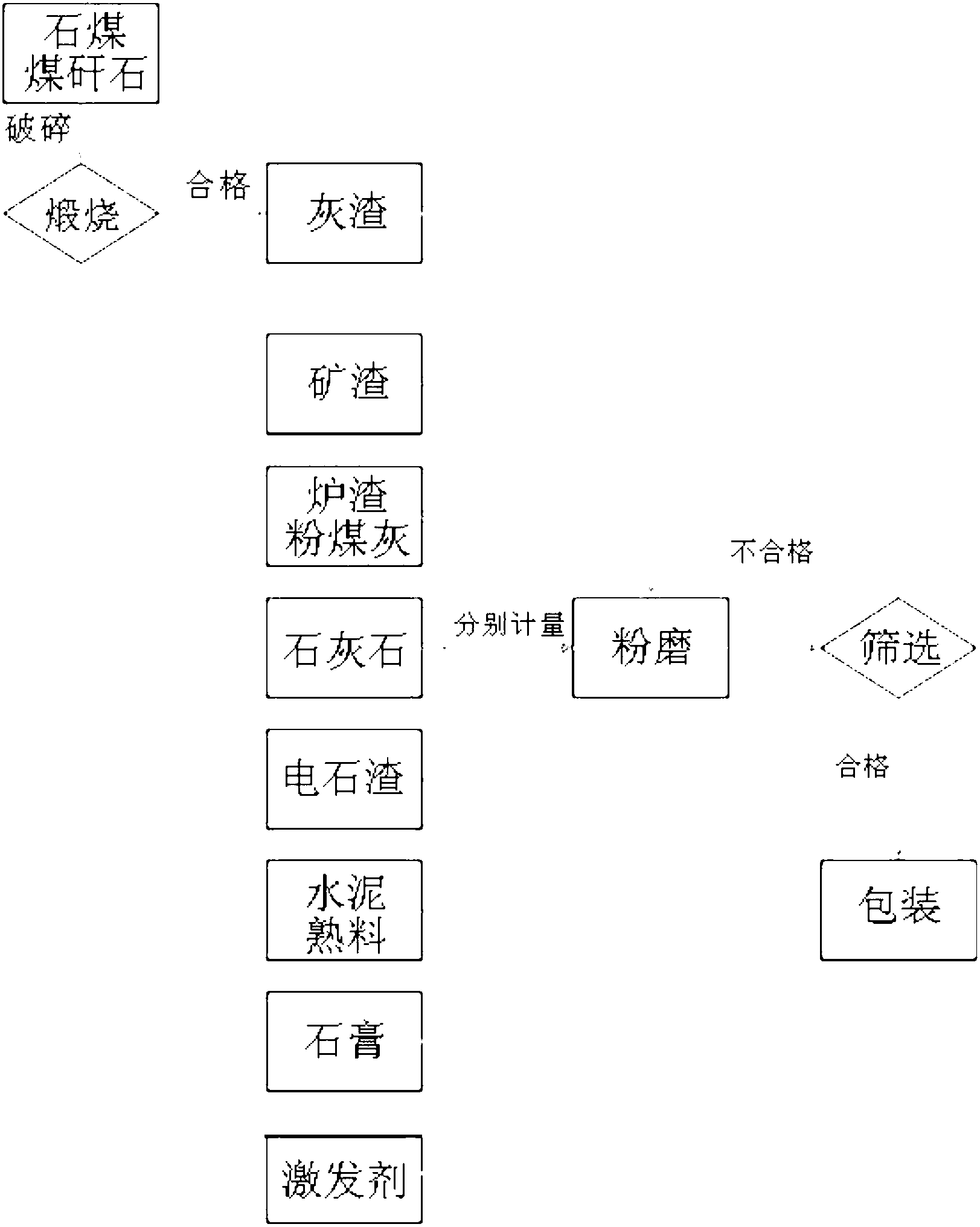

Coal gangue-fly ash foam concrete

InactiveCN101182175AEfficient use ofLow costSolid waste managementCeramicwareFoam concreteInsulation layer

A coal gangue-fly ash foam concrete relates to lightweight foam concrete. The invention is composed of coal gangue, fly ash, cement, lime, gypsum, filler and foaming agent. The invention utilizes coal gangue and fly ash industrial waste, which not only reduces product cost but also saves natural resources, and its product also has low cost, high strength, low thermal conductivity, good heat insulation performance, and can be directly plastered after masonry, etc. features. Therefore, the product of the present invention can be widely used in the single thermal insulation wall body (body of wall self-insulation and heat insulation) of outer wall, the internal and external partition wall of frame structure, the rear board wall of large closet; Inner wall of cold storage; thermal insulation layer of floor and roof; thermal insulation board.

Owner:CHONGQING UNIV

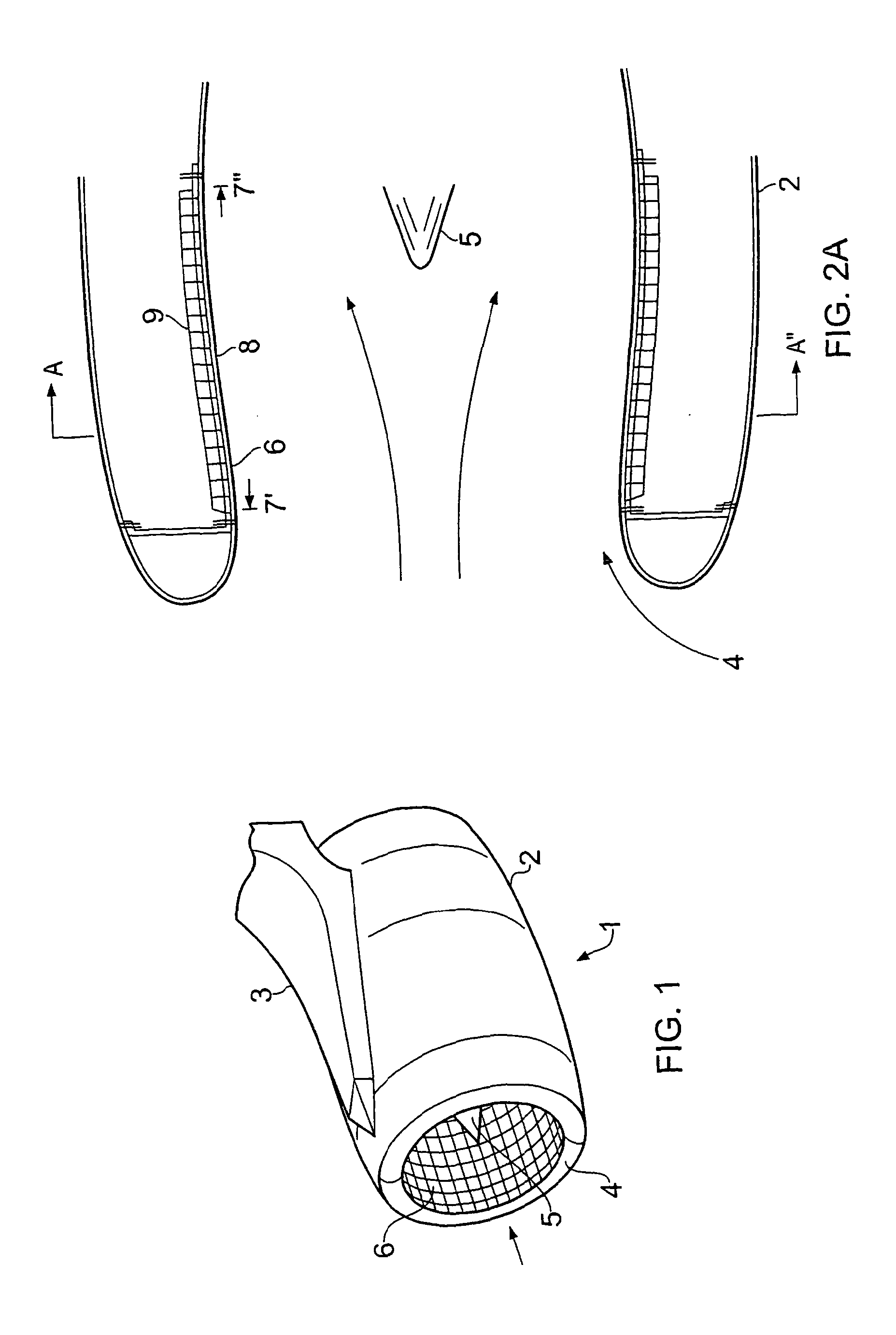

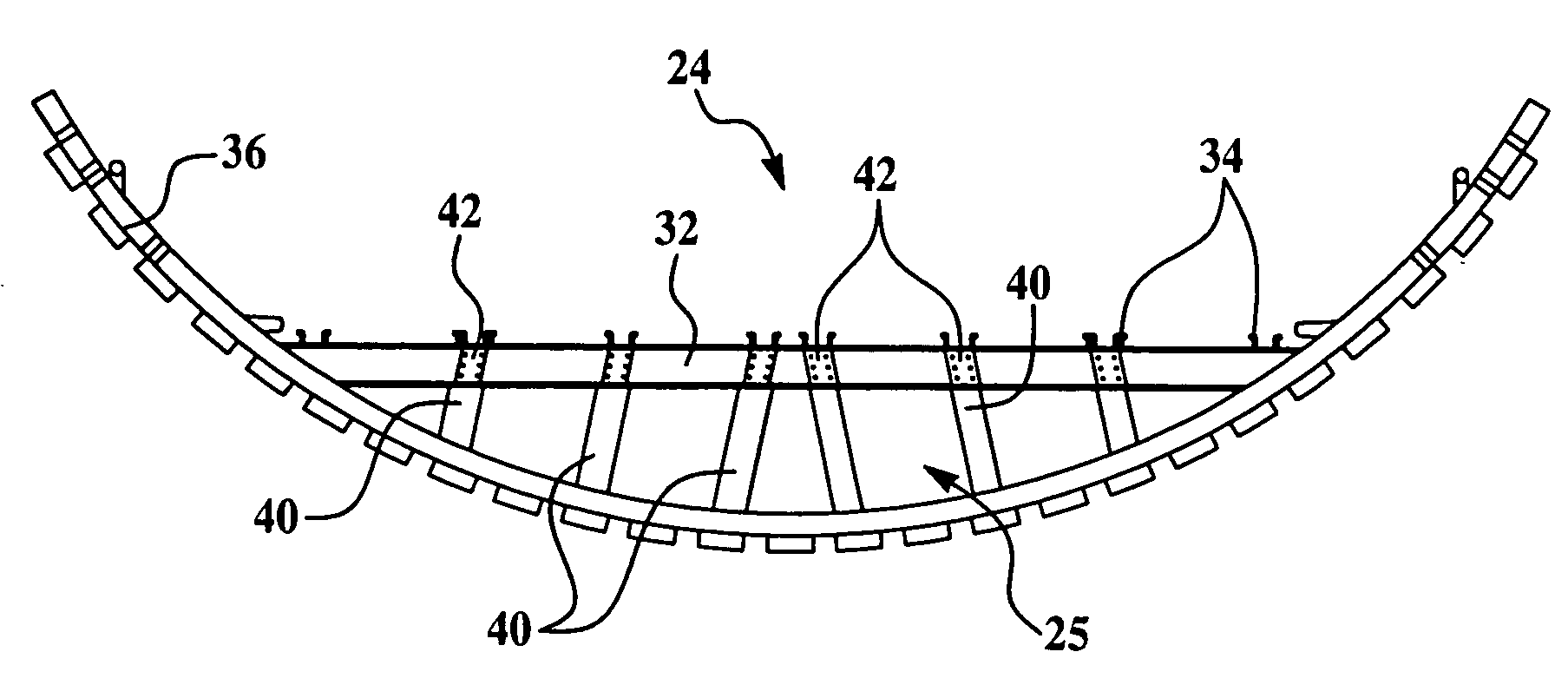

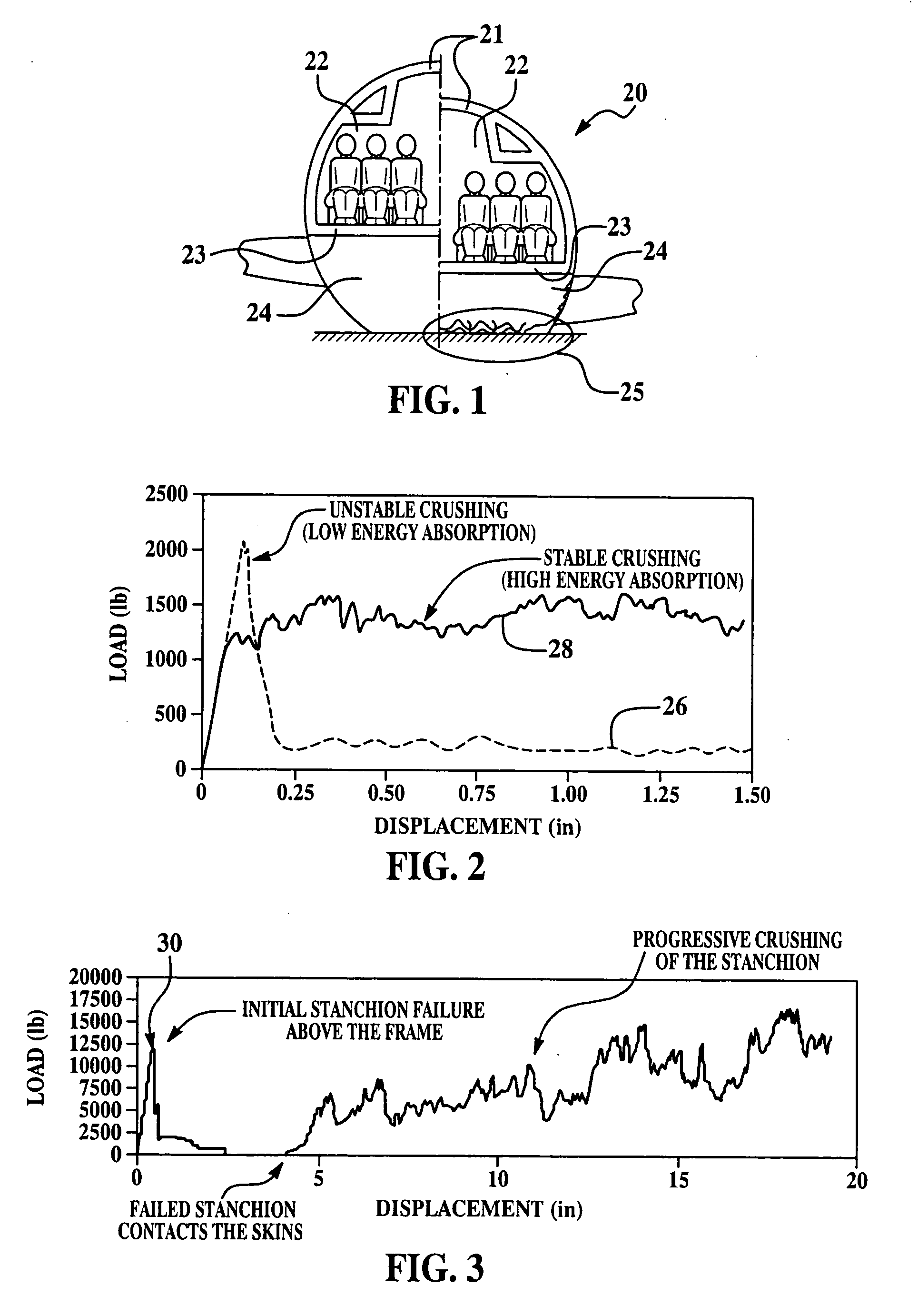

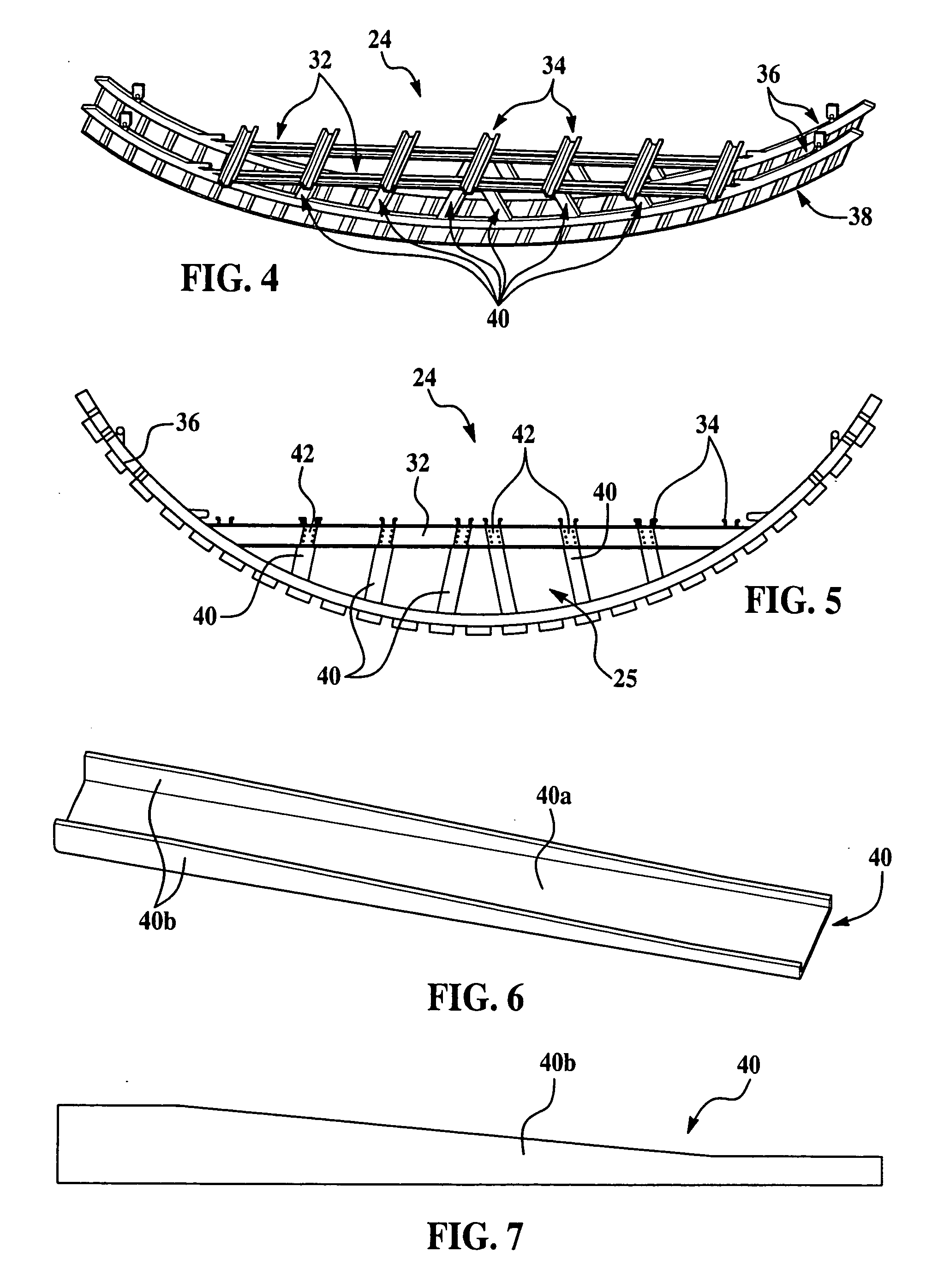

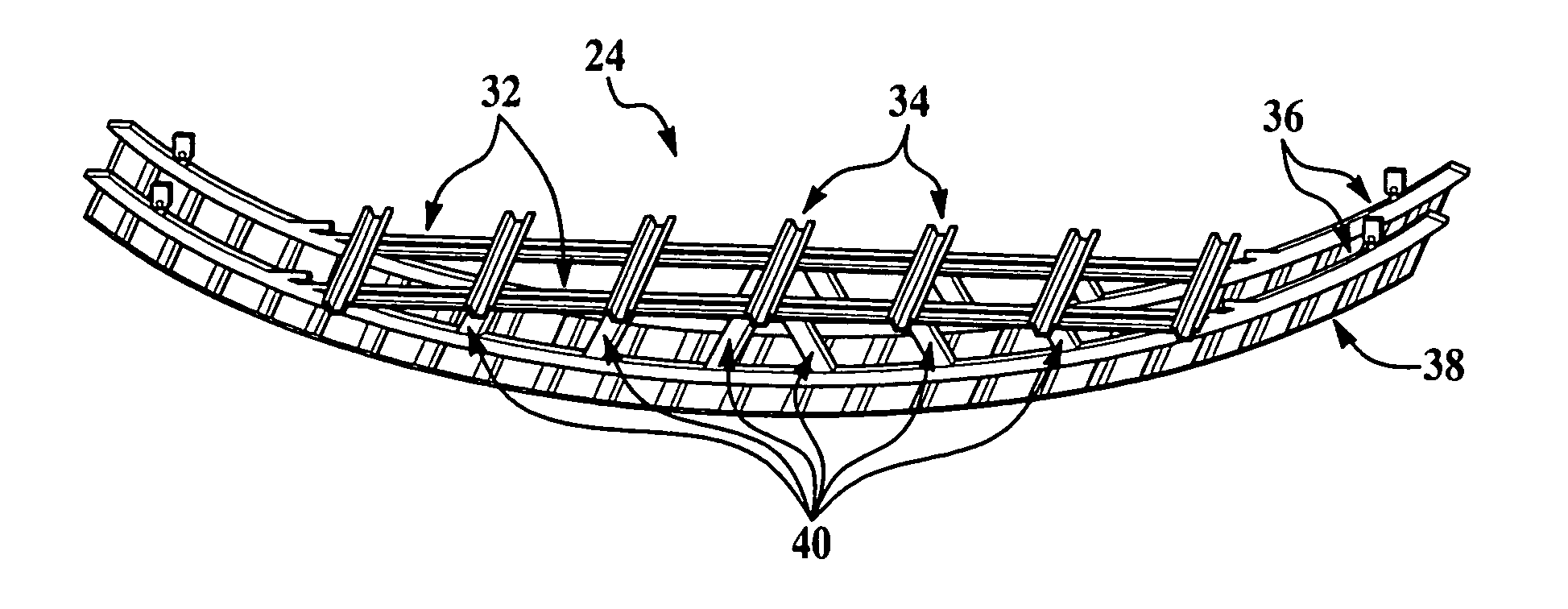

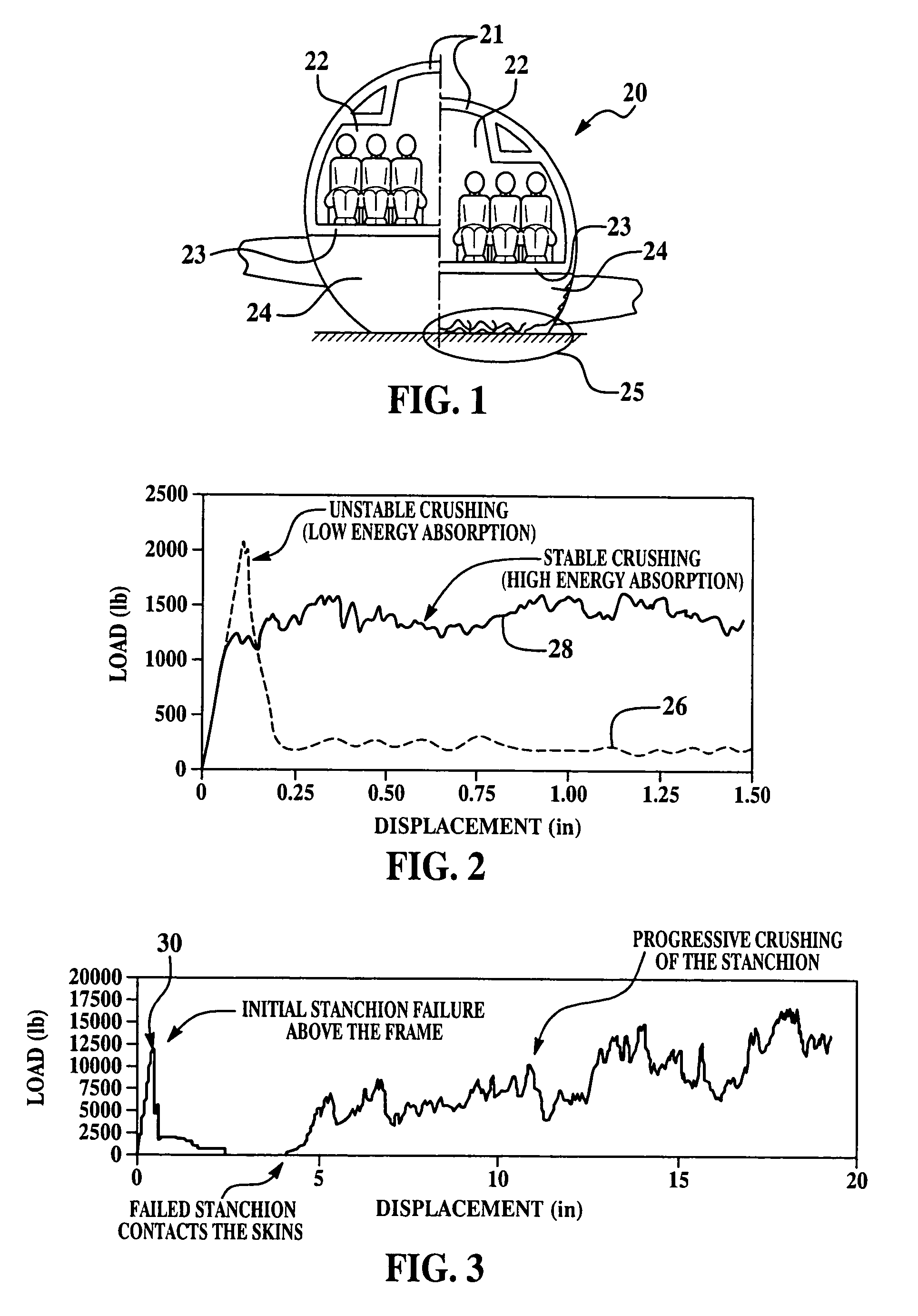

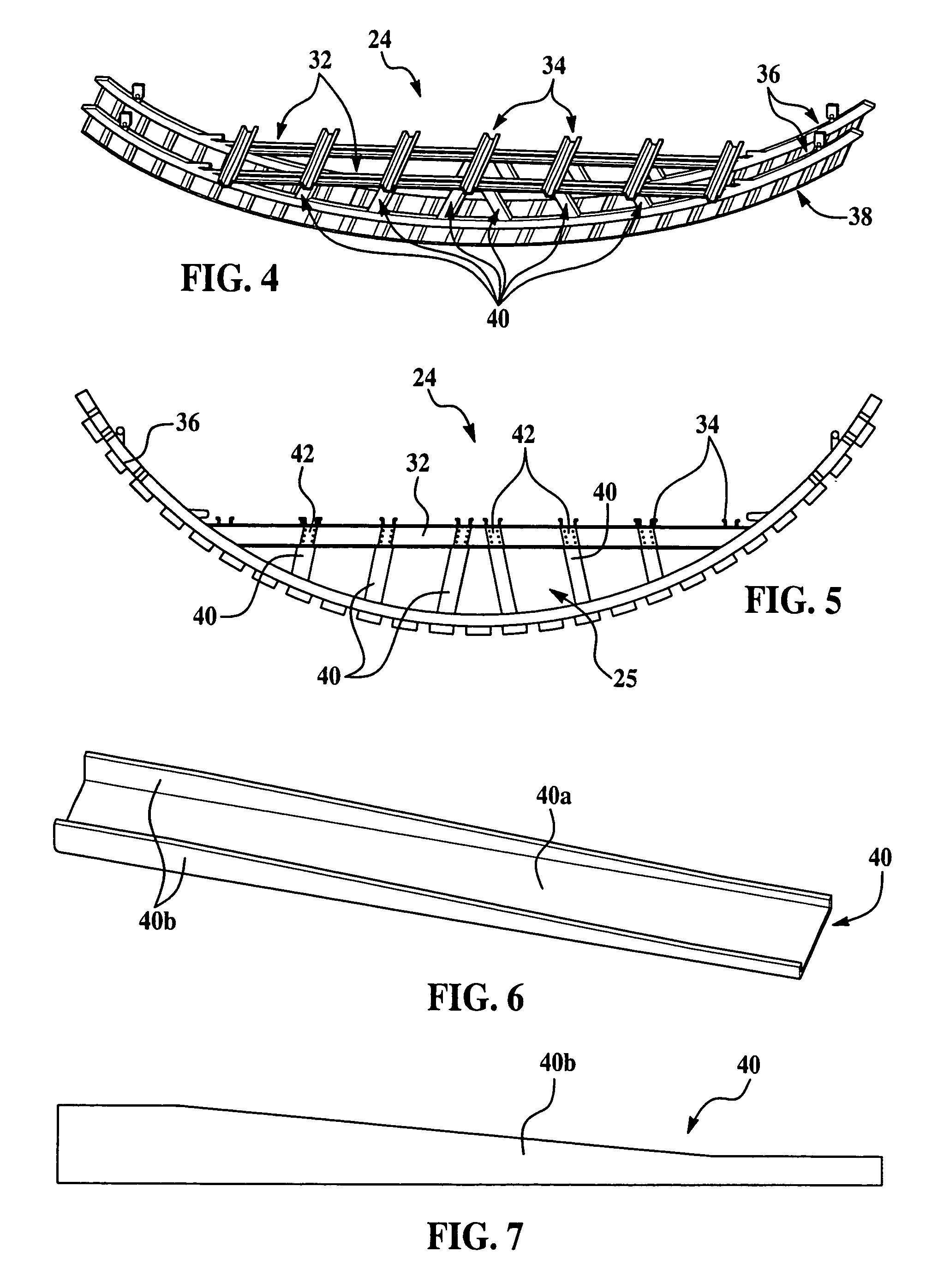

Energy absorbing structure for aircraft

ActiveUS20090206202A1Compression strength is lessSimple structureFuselage framesMilitary adjustmentFiberEpoxy

Energy absorbing structure disposed beneath the cargo area of an aircraft provides maximum energy absorption and structural strength using carbon fiber reinforced epoxy composites. The energy absorbing structure uses laminated stanchions having ply drop-offs to produce stable, progressive crushing of the stanchions during a wheels-up crash landing. Integrally formed flanges on the stanchions allow direct mounting of the stanchions on the structural members of the aircraft, without the need for specialized fittings.

Owner:THE BOEING CO +1

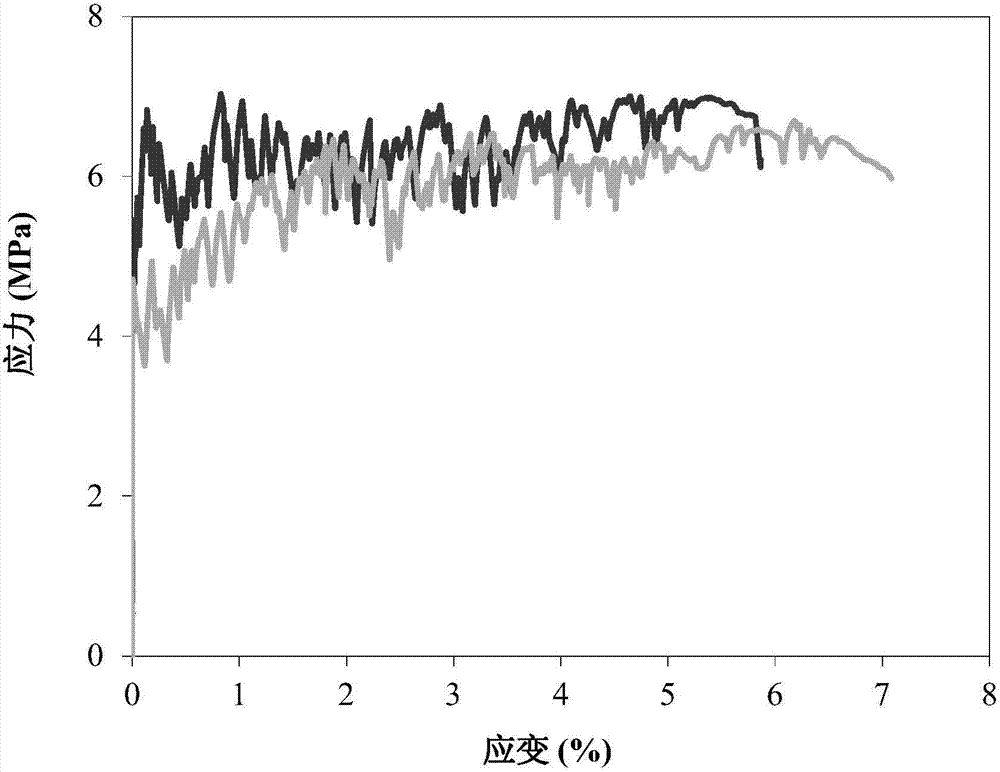

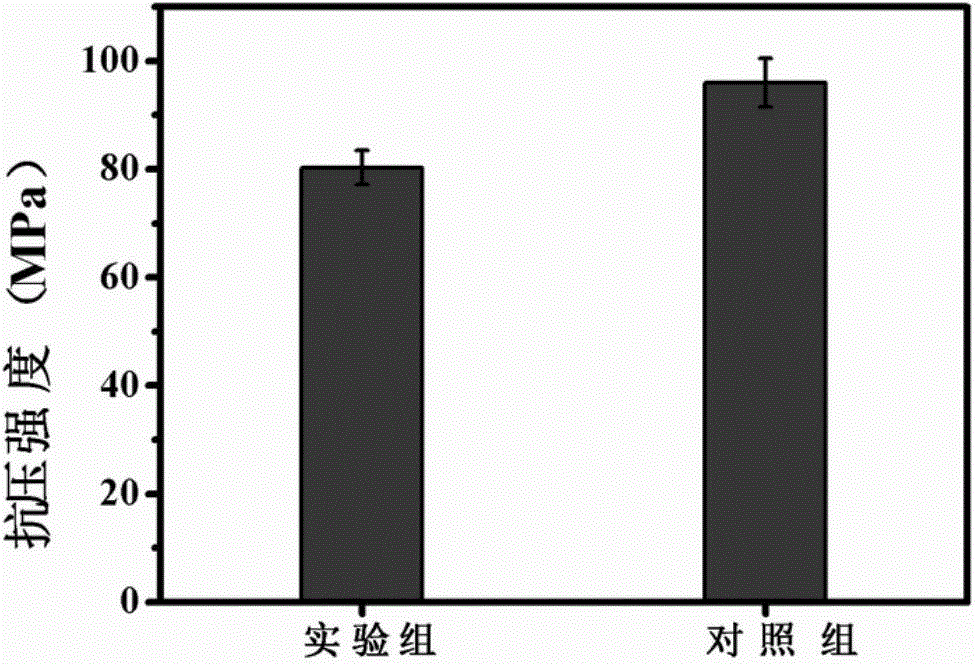

Fiber-hybrid high-ductility cement-based composite material and preparation method thereof

ActiveCN103664090AReduced compressive strengthLow costClimate change adaptationGlass fiberPolymer science

The invention provides a high-ductility cement-based composite material. The high-ductility cement-based composite material is prepared with the following raw materials by weight: 71.8-85 parts of base material, 12.9-25.2 parts of water, 0.89-2.67 parts of fiber and 0.11-1.23 parts of admixture, wherein the fiber is composed of two or more of polypropylene fiber, polyvinyl alcohol fiber, polyethylene fiber, aromatic polyamide fiber and glass fiber; the weight ratio between the polypropylene fiber, the polyvinyl alcohol fiber, the polyethylene fiber, the aromatic polyamide fiber and the glass fiber, and the total fiber is 15-89.5%, 0-68.4%, 0-75.6%, 0-73.5%, and 0-56.4% respectively. The high-ductility cement based composite material is high in compressive strength and low in preparation cost; the compressive strength can be up to higher than 50.5 MPa; the preparation cost is reduced to 15-50% of that of the prior art. The invention further provides a preparation method of the high-ductility cement based composite material.

Owner:SINOMA INT ENG

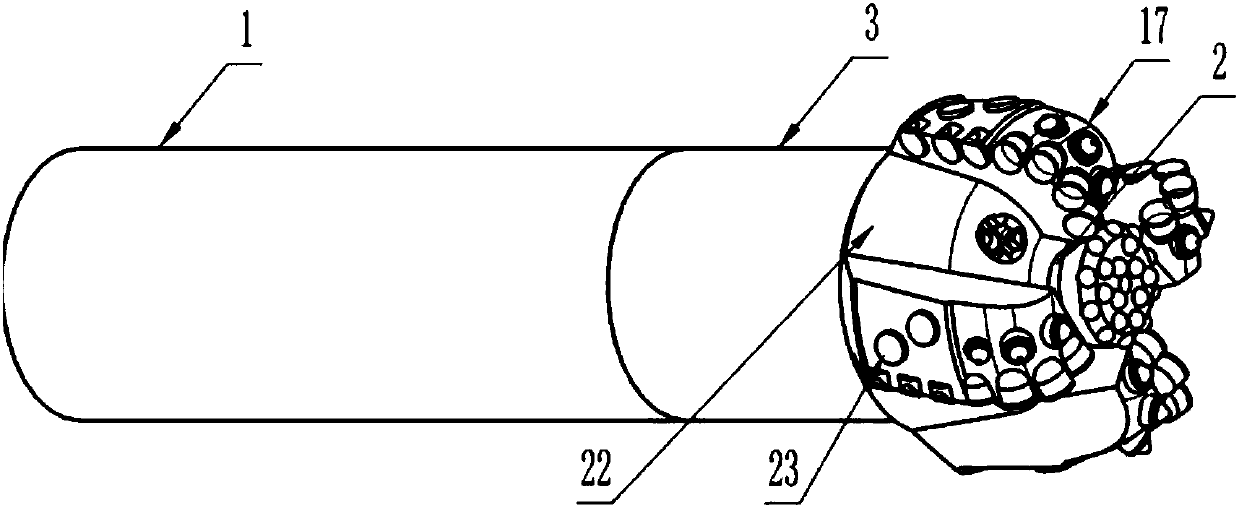

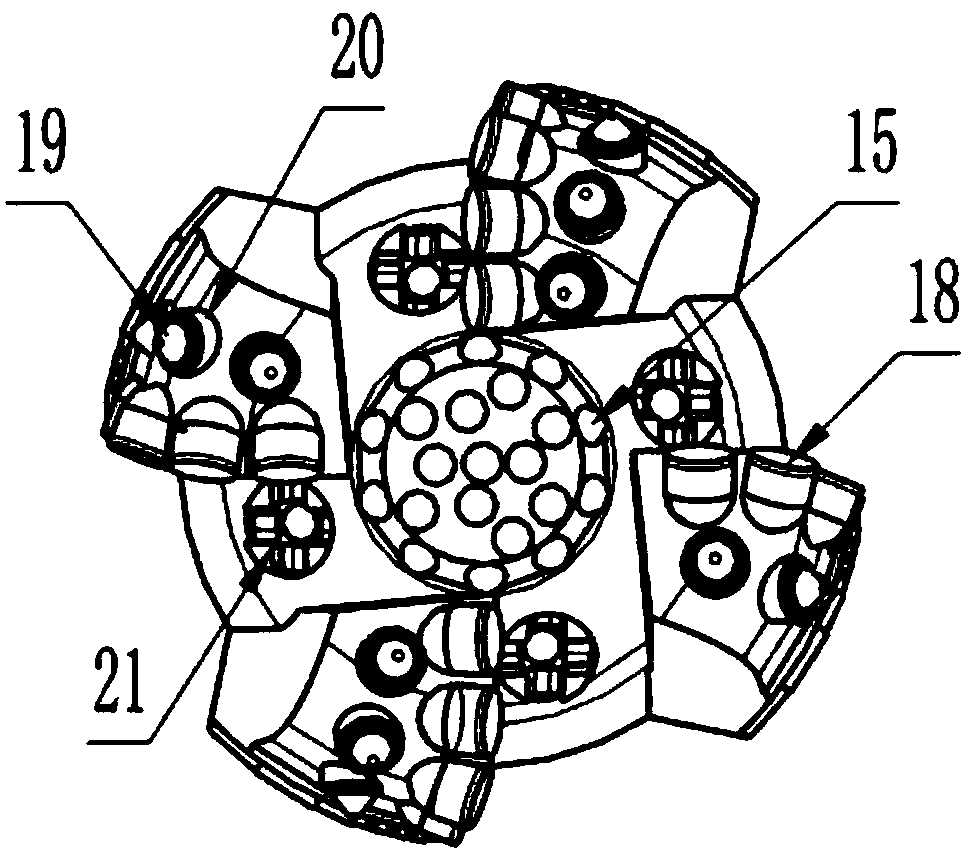

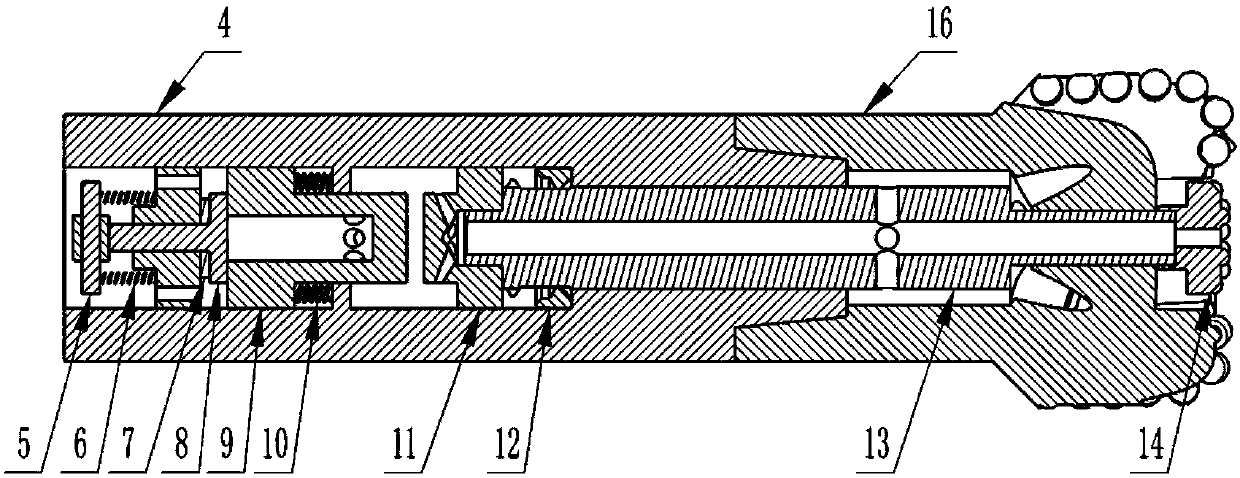

Punching-shear composite drill bit for hard rock drilling

ActiveCN107842317AReduced compressive strengthLow shear strengthDrill bitsTectonic stressPre cracking

The invention discloses a punching-shear composite drill bit for hard rock drilling. The punching-shear composite drill bit comprises three parts of an impactor, an internal punching bore bit and an external cutting drill bit, a lower joint of the impactor can be in threaded connection with the external cutting drill bit, and the upper part of the internal punching bore bit is connected with the impactor in a spline mode; and the lower end face of the internal punching bore bit extends out of the surface of the external cutting drill bit, the central axis of the internal punching bore bit is parallel to or coincident with the central axis of the external cutting drill bit, distributed teeth on the internal punching bore bit and distributed teeth on the external cutting drill bit are combined and can completely cover a downhole, and distributed teeth on the internal punching bore bit and the distributed teeth on the external cutting drill bit are independent of each other. In this way,rock crushing through shearing and rock crushing through impact are creatively combined together, a rock stratum at the hole bottom is pre-cracked first through the internal punching bore bit, the whole tectonic stress of the rock stratum is destroyed, the strength of compression resistance and shearing resistance of rock is reduced so that PDC column teeth and PDC cone teeth can more easily cut / plough-cut the rock, and the rock-breaking efficiency of the super hard rock stratum is greatly improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Sugar-Based Polyurethanes, Methods for Their Preparation, and Methods of Use Thereof

Polyurethane foams which are highly flame resistant are described, as well as the production of such polyurethane foams by the reaction between a natural polyol, such as sucrose or a blend of mono- or disaccharides in place of the standard hydrocarbon-based polyol component, a polyisocyanate and water in the presence of a suitable polyurethane forming catalyst and a flame retardant, and optionally one or more components such as surfactants and / or emulsifiers. The resultant polyurethane foam has a bio-based solid content ranging from about 17% to 30%, may be formulated in a variety of foam densities for a variety of applications, and exhibits a high degree of fire and burn resistance, as exhibited by the flame spread index and the smoke spread values.

Owner:INNOVATIVE URETHANE LLC

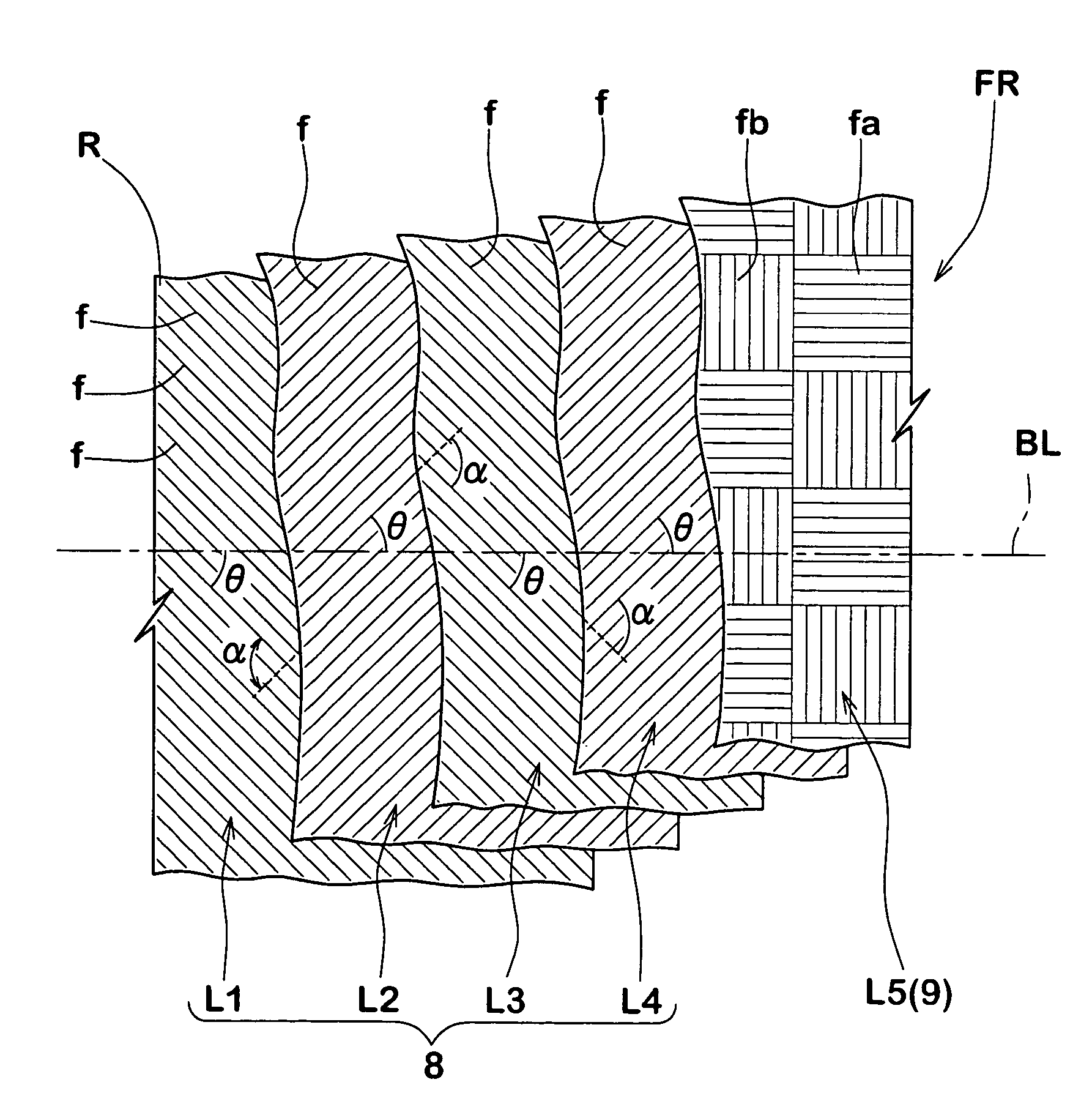

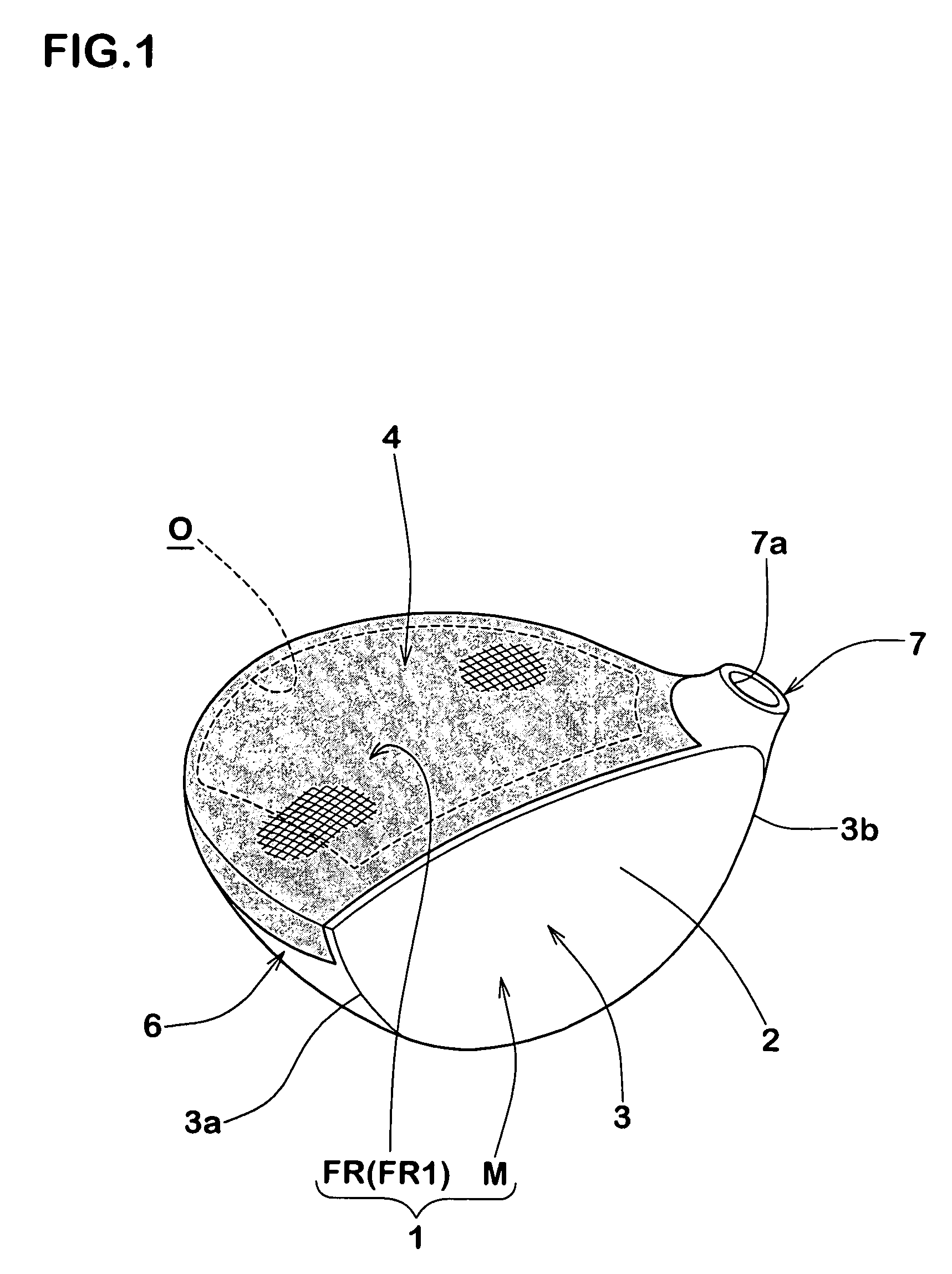

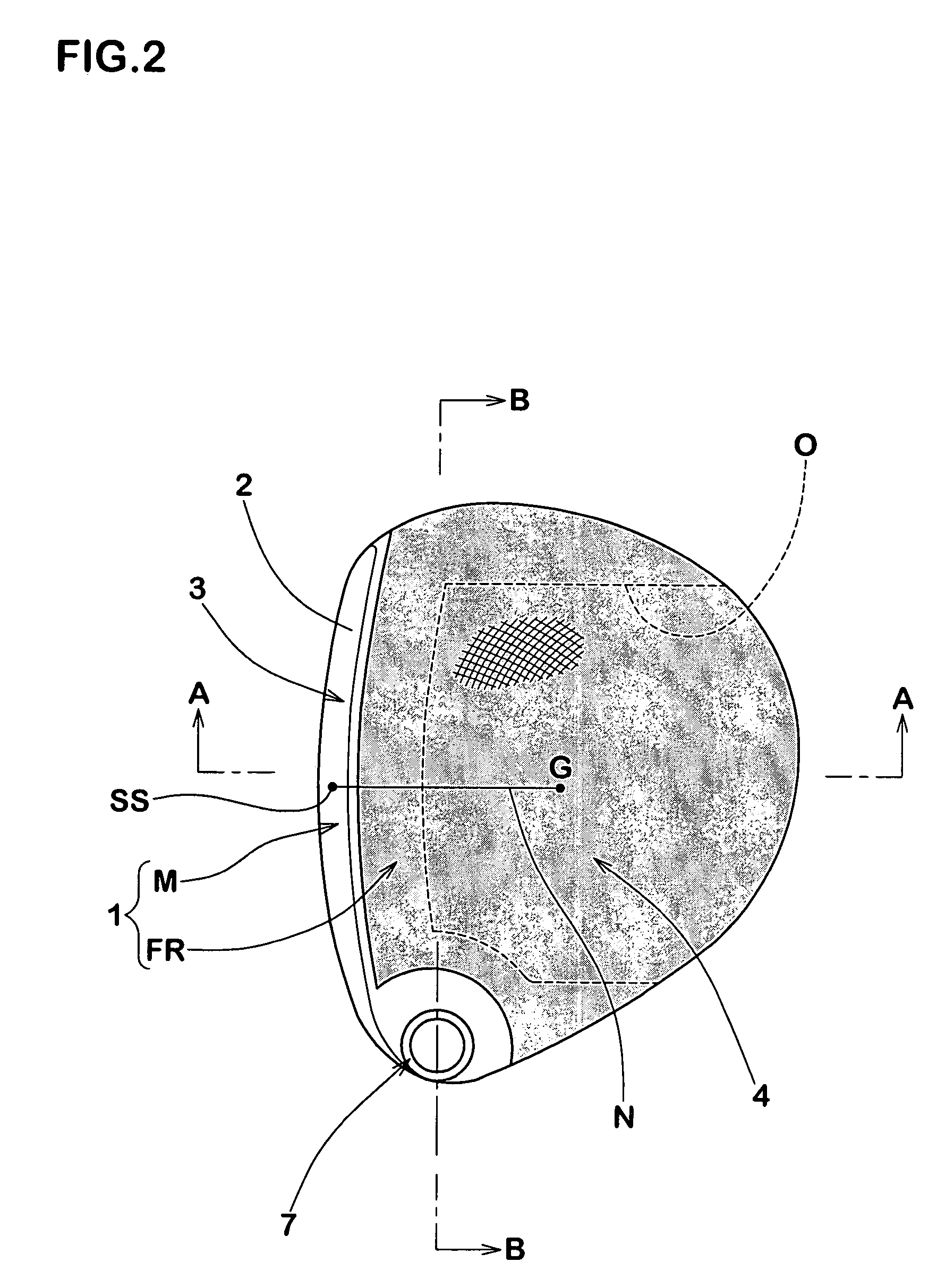

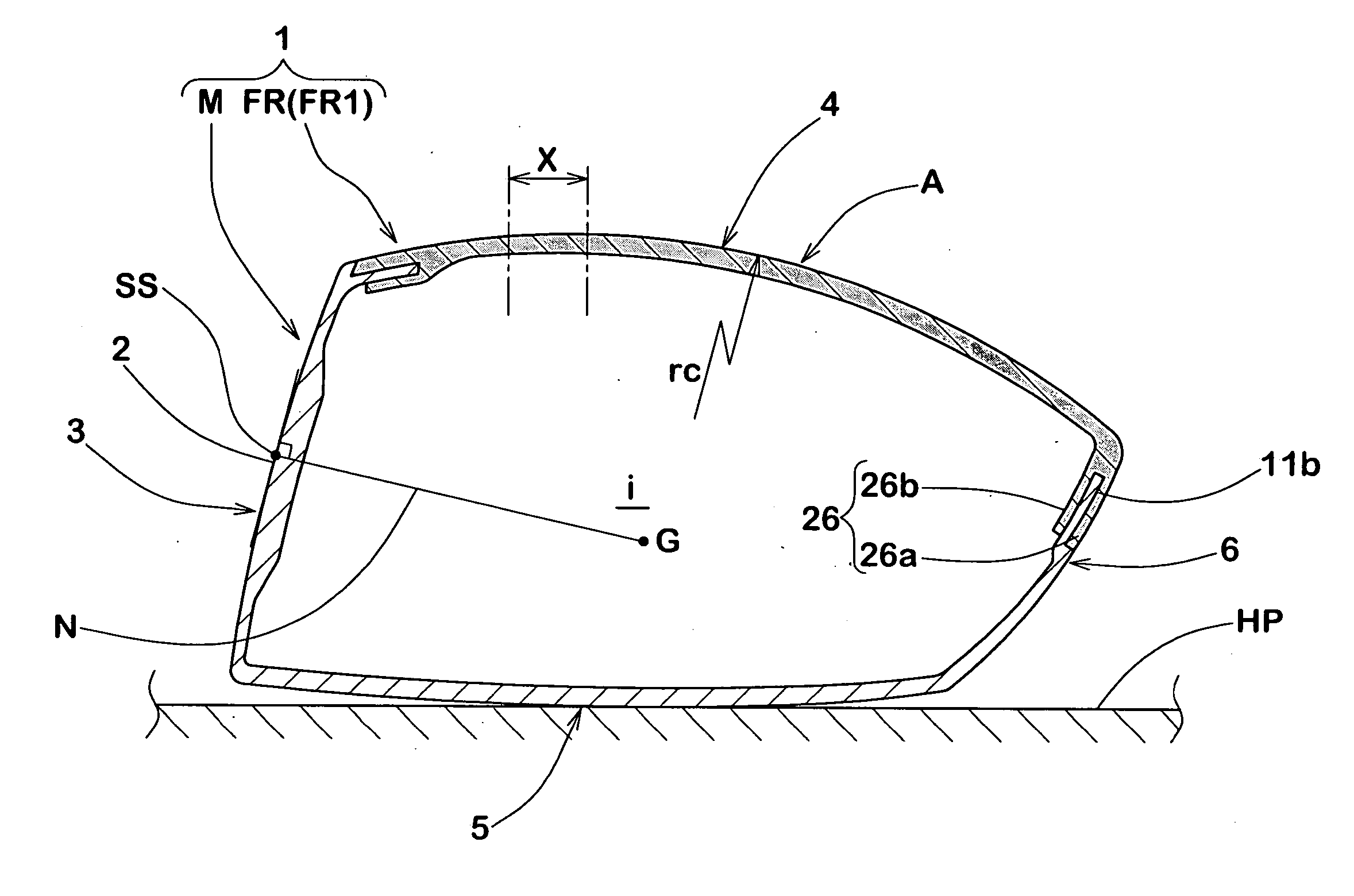

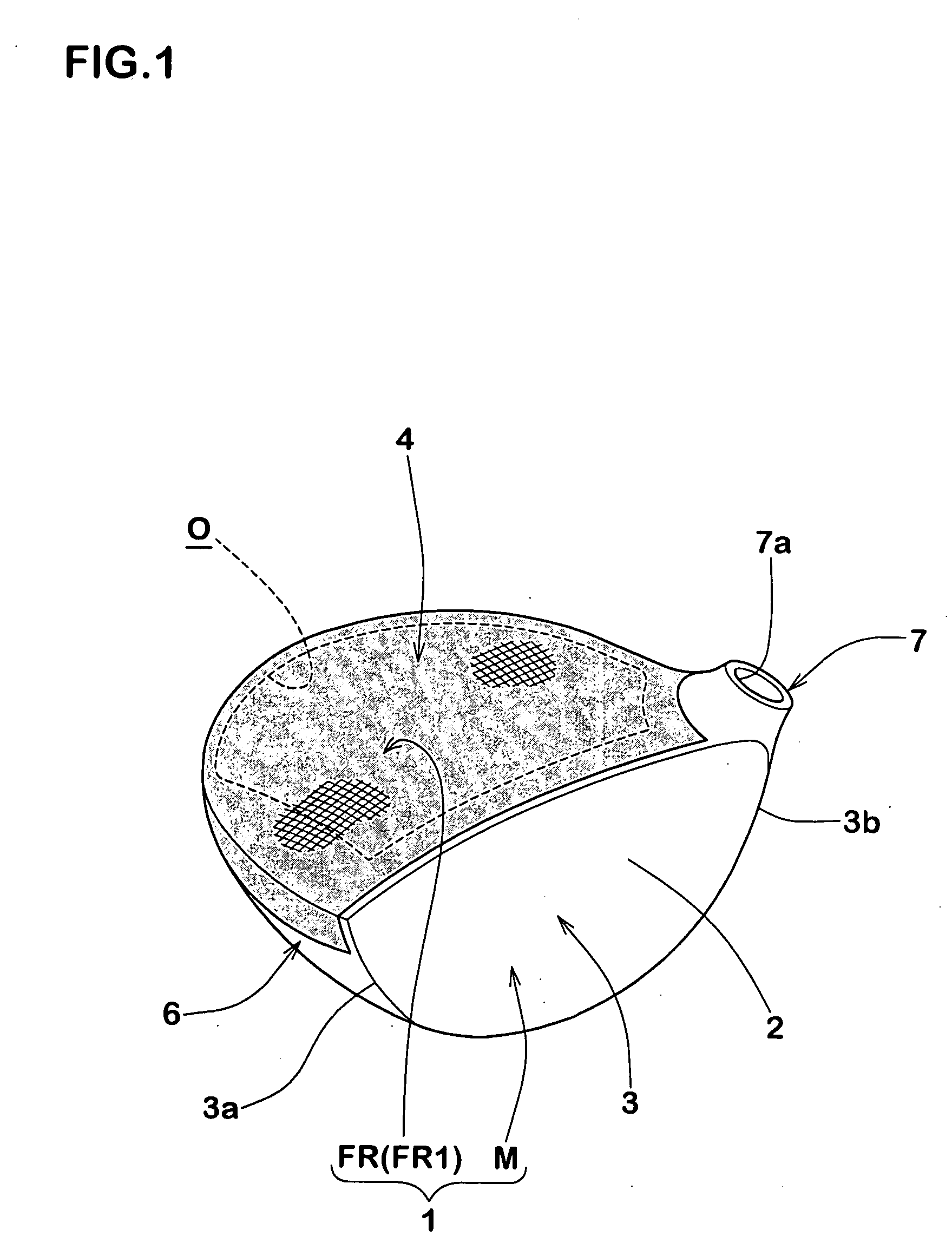

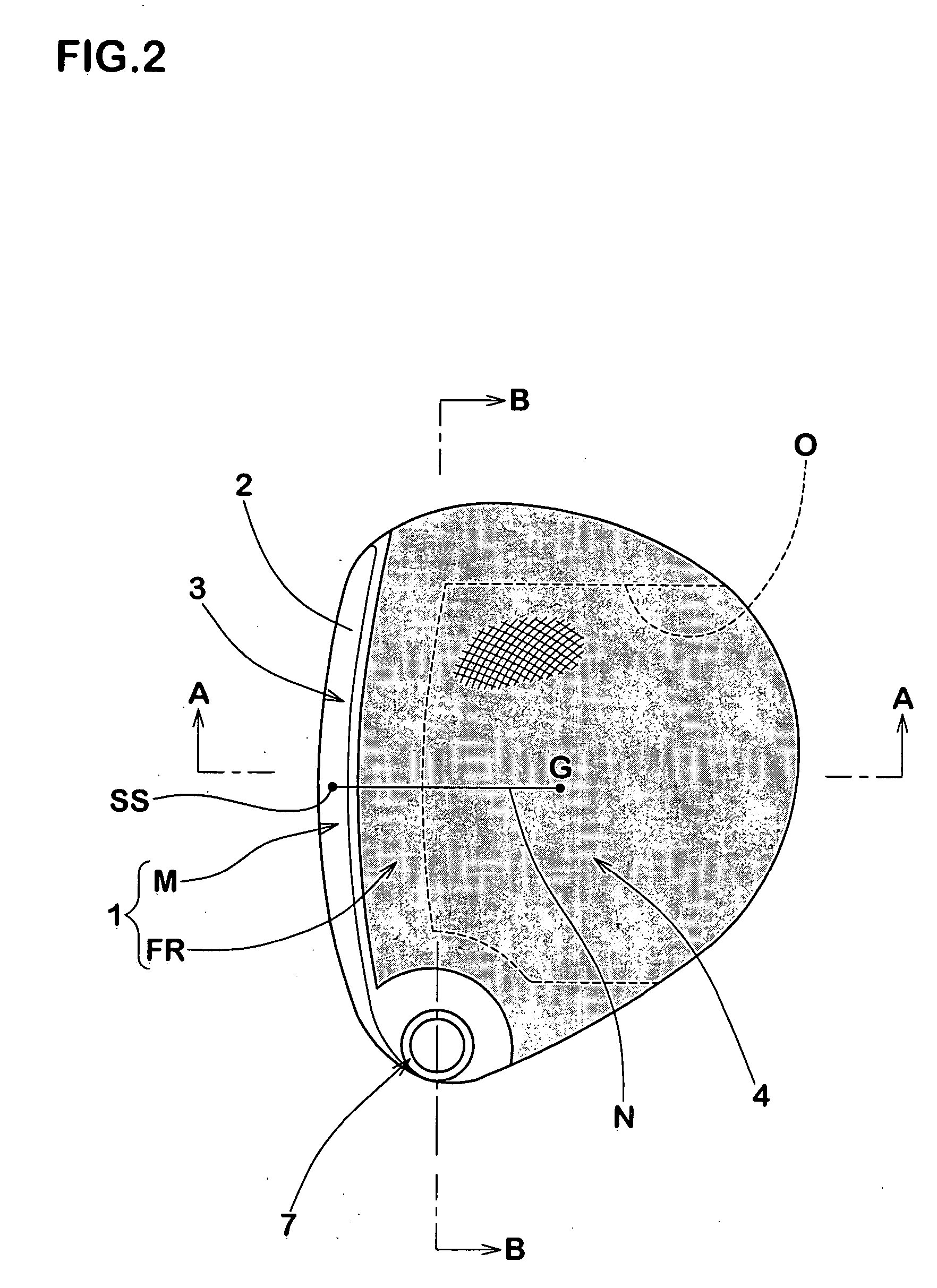

Golf club head

ActiveUS7468005B2Increased durabilityAvoid breakingGolf clubsRacket sportsEngineeringCompressive strength

The invention prevents a resin member from being broken so as to improve durability. The invention provides a golf club head (1) in which at least apart of a crown portion (4) forming an upper surface of the head is formed by a resin member (FR) made of a fiber reinforced resin in which a fiber is oriented in a matrix resin. The resin member (FR) includes a one-way fiber reinforced resin layer in which the fiber is oriented in one direction, and a fiber intersection lamination portion which is laminated so as to differentiate a direction of the fiber. At least two one-way fiber reinforced resin layers which are adjacent in a thickness direction are intersected at an angle of 30 to 130 degrees of the fiber. Further, a compressive strength of the fiber of the one-way fiber reinforced resin layer which is arranged in an innermost side in the fiber intersection lamination portion is set to be equal to or more than 1.3 GPa.

Owner:SUMITOMO RUBBER IND LTD

Aluminium-magnesia carbon brick and preparation method thereof

The invention provides an aluminium-magnesia carbon brick and a preparation method thereof, belonging to the field of refractory materials. The raw materials of the aluminium-magnesia carbon brick include 30-80 parts of waste aluminium-magnesia carbon brick grains, 3-40 parts of special grade bauxite chamotte, 3-10 parts of magnesia, 3-10 parts of magnesia-alumina spinel, 5-8 parts of graphite, 3-15 parts of micro powder additives and 2.2-3.5 parts of organic bonds by weight. The preparation method is characterized by sorting, hydrating, drying and grinding the waste aluminium-magnesia carbonbricks from the steel mills and then mulling the waste aluminium-magnesia carbon brick grains with other raw materials, forming and carrying out heat treatment to prepare the aluminium-magnesia carbon brick. The energy-saving and environment-friendly aluminium-magnesia carbon brick prepared by the invention has high compression strength, low porosity, good resistance to molten steel corrosion andservice life reaching or exceeding the service lives of the traditional aluminium-magnesia carbon bricks. In the invention, the waste aluminium-magnesia carbon bricks are rationally utilized and consumption of the mineral resources is reduced.

Owner:ZHENGZHOU DONGFANG SANLI REFRACTORY MATERIALS

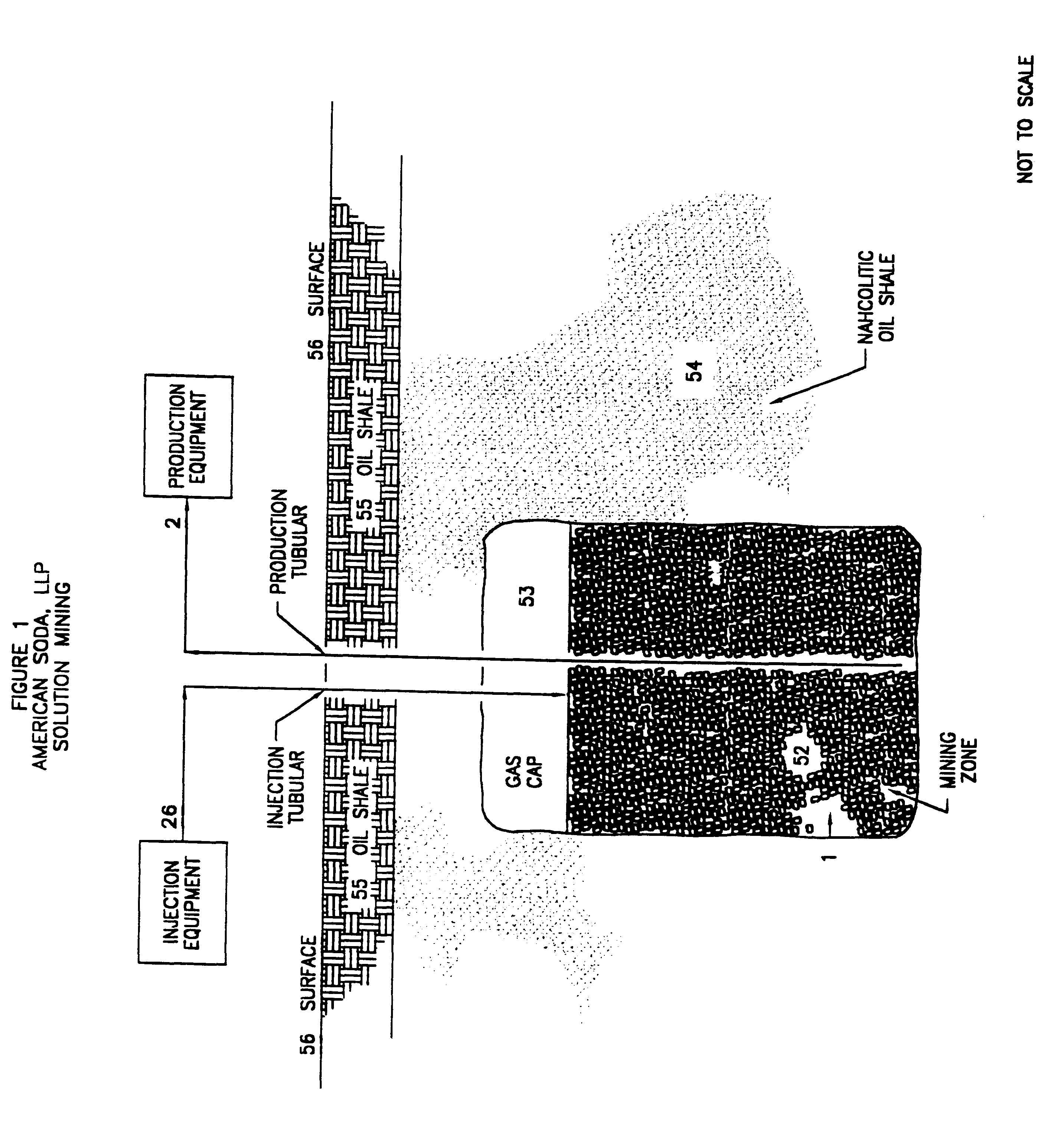

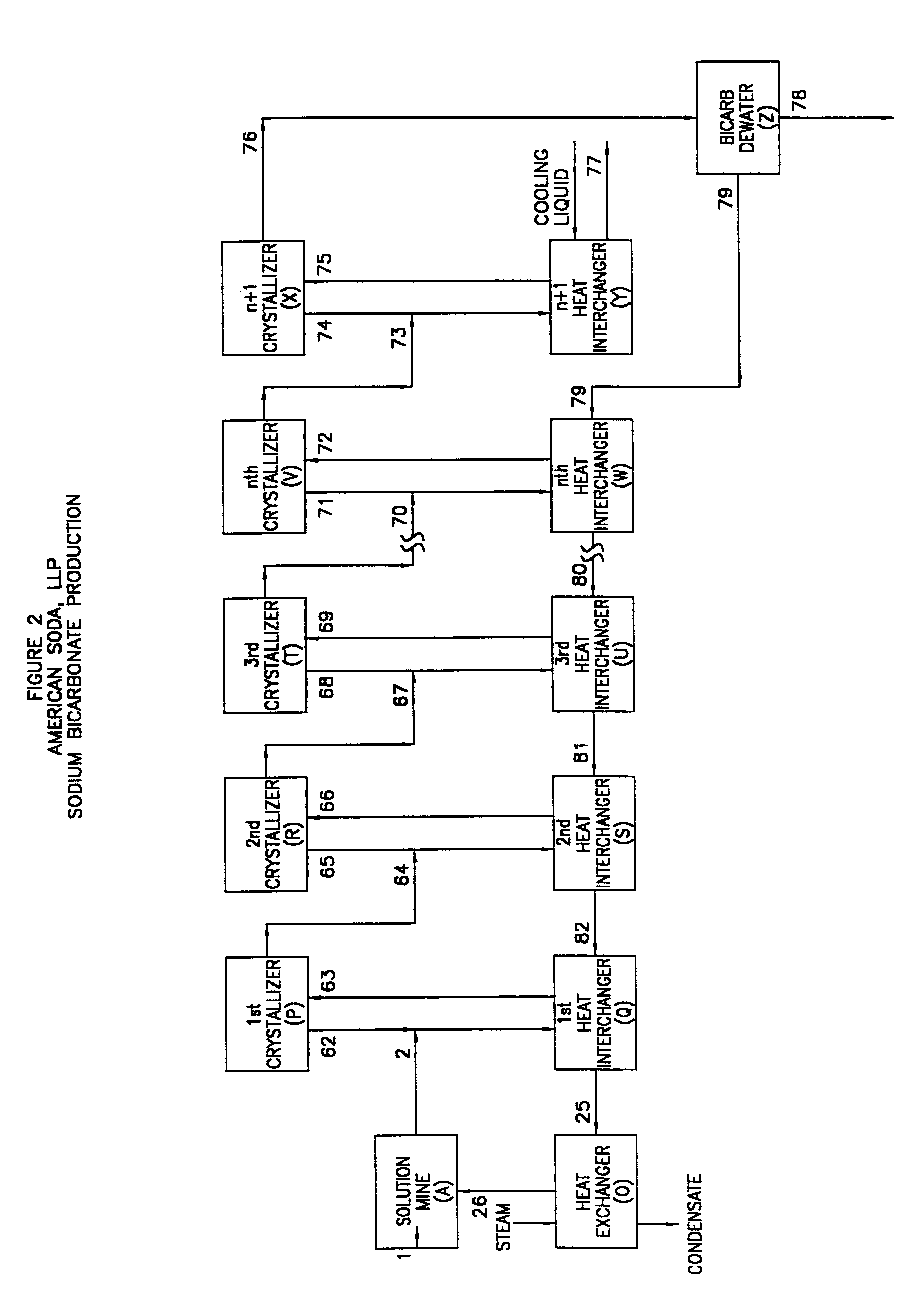

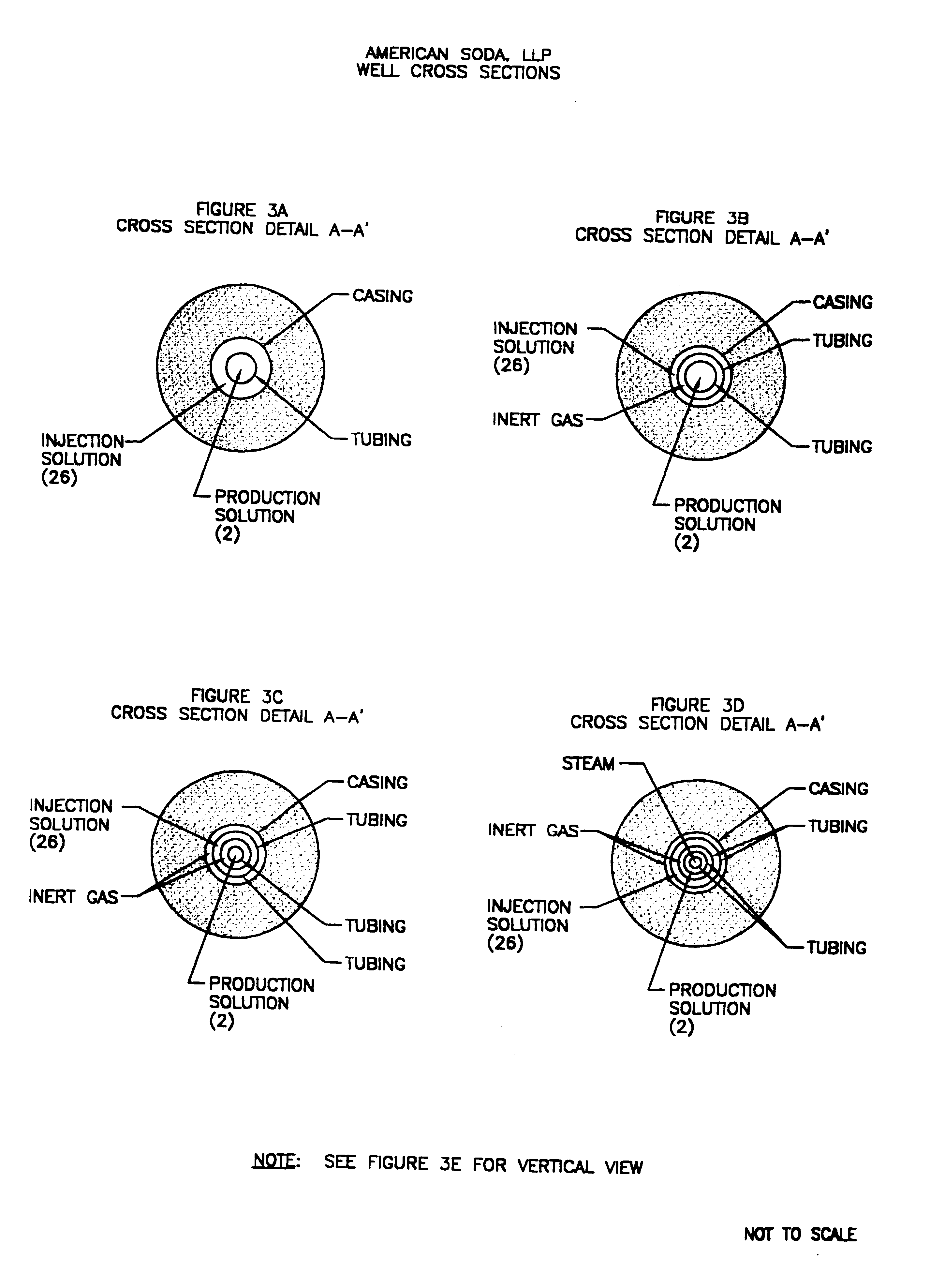

Sodium bicarbonate production from nahcolite

InactiveUS6699447B1Decrease it compression strengthIncrease stressVarying alkali metal carbonate water contentRubidium/caesium/francium compoundsChemistrySodium bicarbonate

A method for producing sodium bicarbonate from a nahcolite deposit comprising injecting water or other aqueous solution at a temperature of at least 250° F. into the deposit, dissolving sodium bicarbonate in the hot water to form a production solution and subjecting the production solution to multiple stages of crystallization. The sodium bicarbonate crystals may be dewatered and dried to form a commercial sodium bicarbonate product.

Owner:AMERICAN SODA

Method for preparing porose glass composite material using iron ore tailings

The invention is a method for preparing multiporous glass composite with ironstone gangue, adopting two steps: 1. adopting iron gangue, bauxite, calcium carbonate and waste glass as raw materials to prepare basic glass powder, crushing and finely grinding the iron gangue, and batching the iron gangue 48-65wt%, bauxite 5-9wt%, calcium carbonate 10-20wt%, and waste glass 15-30wt%; mixing them uniformly, melting and baking, water- quenching and grinding and finally obtaining the glass powder; 2. preparing multiporous glass ceramic materials, and adding in calcium carbonate in 1-5wt% of the basic glass, sodium phosphate in 6-10wt% of the basic glass, anhydrous sodium carbonate in 1-3wt% of the basic glass and borax in 1-6wt% of the basic glass, grinding and mixing them, and moulding and obtaining raw blanks, sintering the raw blanks at high temperature and cooling to normal temperature and finally obtaining the products. And the products have bulk densities of 1.5-2.8 g / cm3, normal- temperature tensile strength of 32-60 MPa and are good heat- insulating materials.

Owner:NORTHEASTERN UNIV

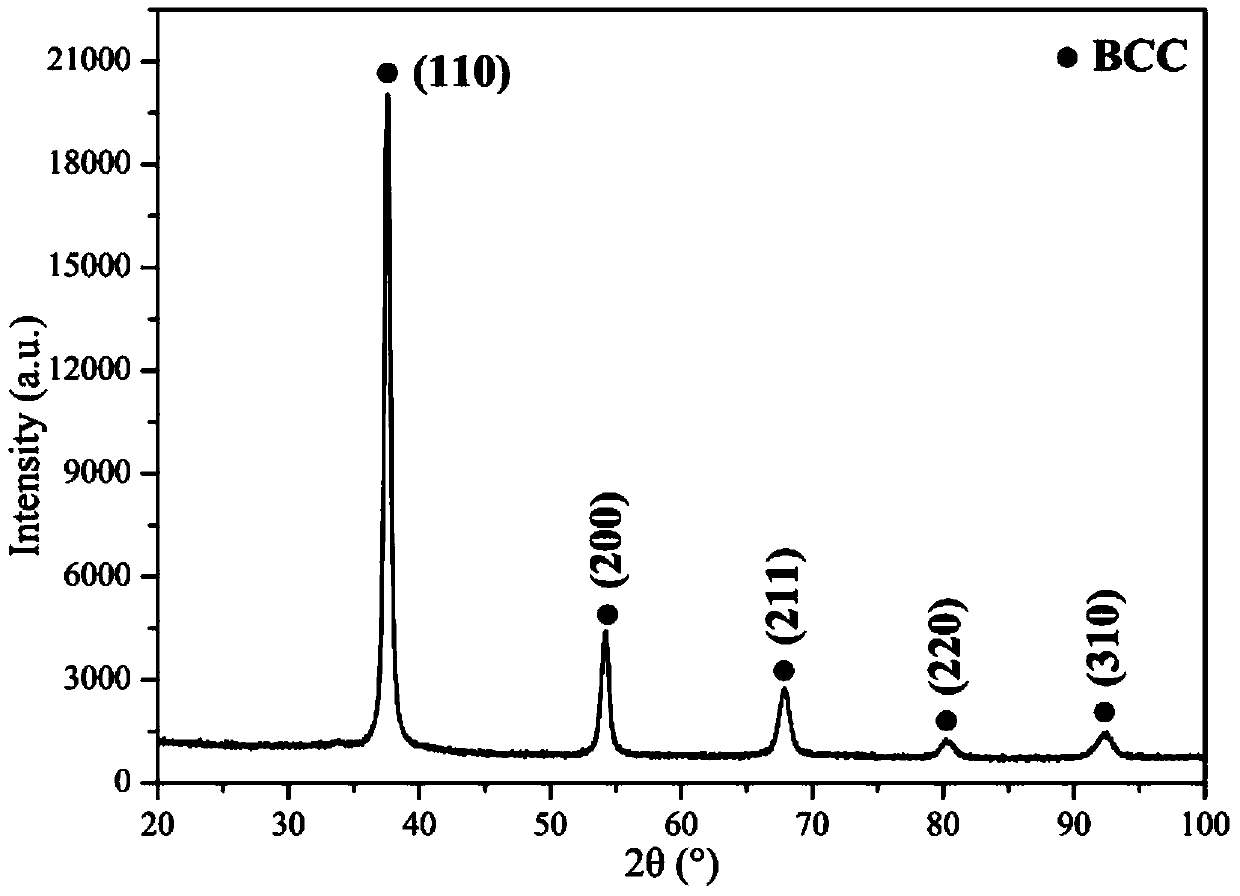

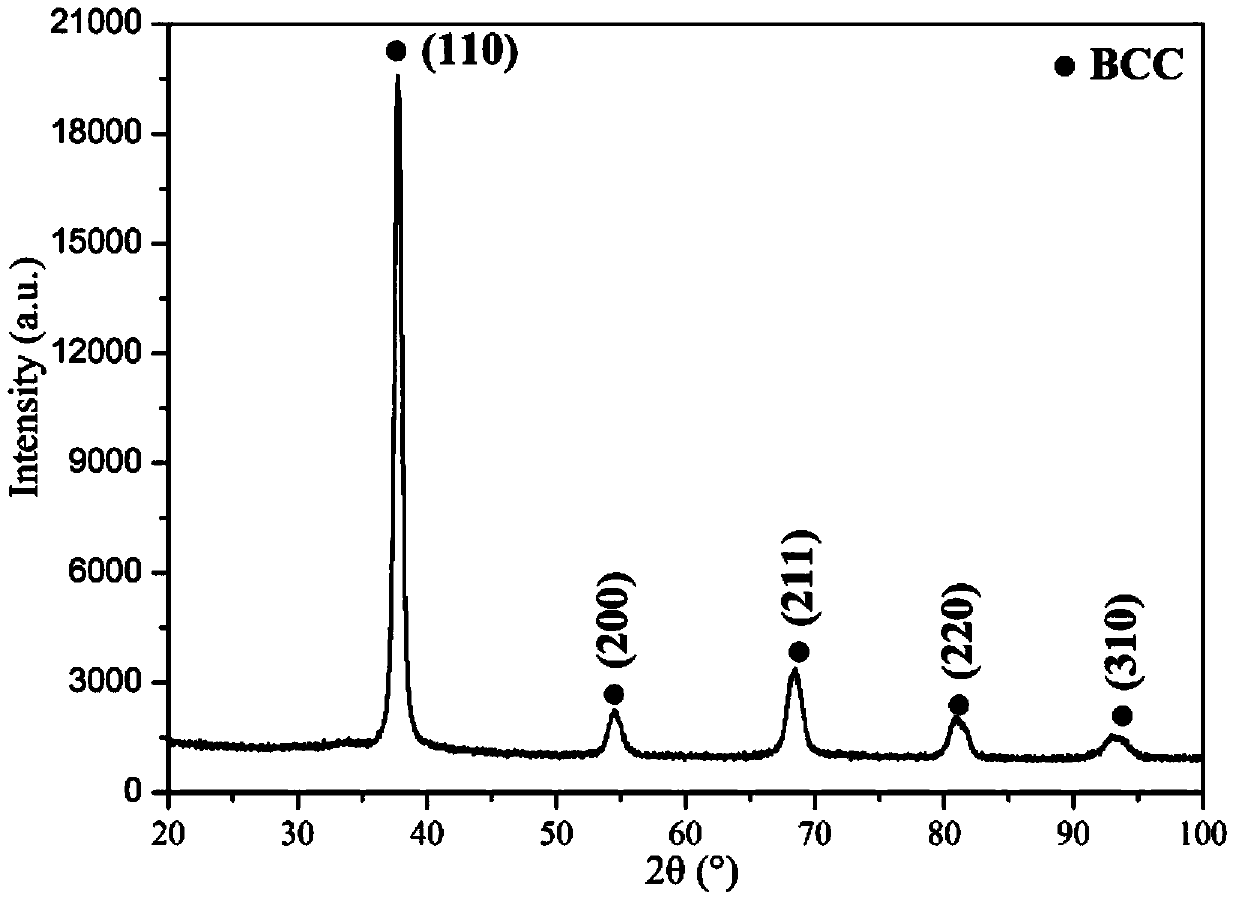

Multi-main-phase Nd-Fe-B type permanent magnet with high crack resistance and high coercive force and preparation method thereof

ActiveCN105244131AAvoid wastingReduce defectsInductances/transformers/magnets manufactureMagnetic materialsHigh resistanceCrack resistance

The invention pertains to the technical field of rare earth magnetically hard material, in particular to a multi-main-phase Nd-Fe-B type permanent magnet with high crack resistance and high coercive force and a preparation method thereof.A final magnet contains multiple differently-sized hard-magnetic main-phase particles having different anisotropic fields HA. Different main-phase particles account for different volume fractions and are differently distributed, wherein Nd denotes a red earth element having the most content based on the mass percent. According to mass percent, the chemical formula of the permanent magnet is expressed as (Dd, Re) aFe100-a-b-cBbTmc. By respective selection, different types of main-phase materials such as (Nd, Pr)-Fe-B, (PR, La, Ce)-Fe-B, (Dy, Tb, Ho, Gd, Er)-Fe-B in the ratio of 2:14:1 in order to prepare corresponding coarse magnetic powder, thin magnetic powder and magnetic nanocrystalline powder. Power is utilized for absorbing hydrogen and controlling oxygen. Liquid-phase sintering technology on the pressurized condition at low temperature is adopted for preparation. The multi-main-phase Nd-Fe-B type permanent magnet with high crack resistance and high coercive force and the preparation method thereof have following beneficial effects: a large piece of magnet does not easily have crack; crack resistance of the magnet is improved; high coercive force and high magnetic energy product are obtained; and the preparation technology is suitable for scale production in engineering.

Owner:CENT IRON & STEEL RES INST

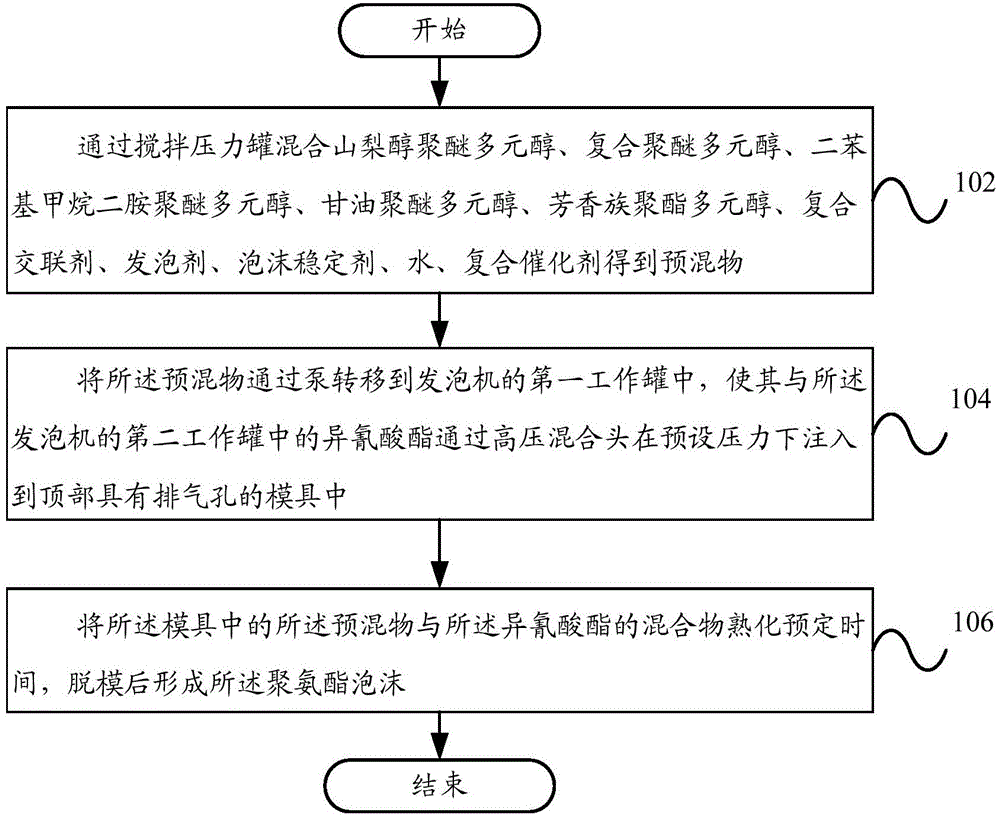

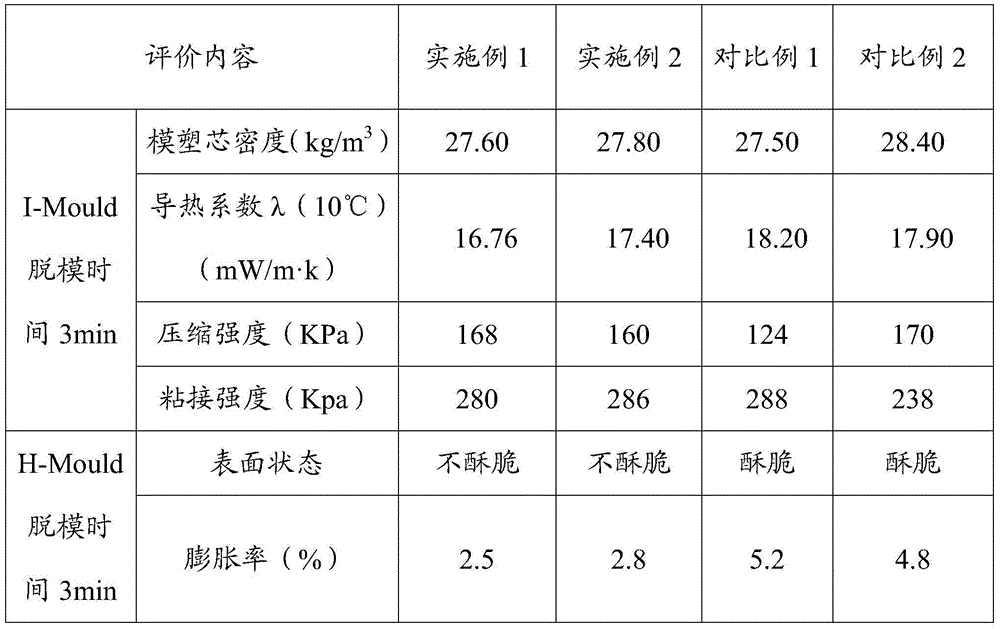

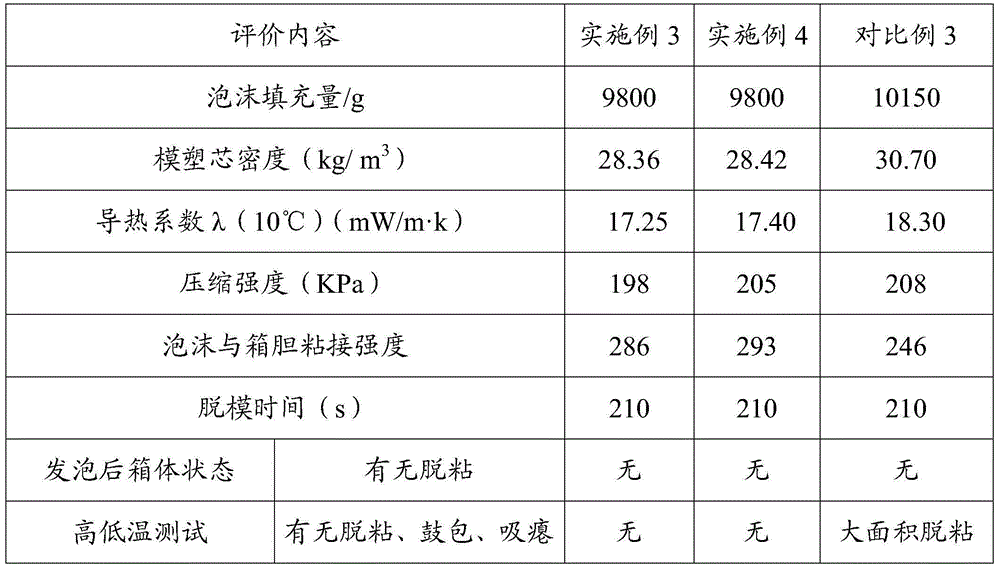

Polyurethane composition, polyurethane foam as well as manufacture method thereof and fridge

The invention discloses a polyurethane composition, polyurethane foam as well as a manufacture method thereof and a fridge. The polyurethane composition comprises the following raw materials in parts by weight: 25-60 parts of sorbitol polyether polyol, 15-40 parts of composite polyether polyol, 3-30 parts of diphenylmethane diamine polyether polyol, 3-15 parts of glycerin polyether polyol, 3-20 parts of aromatic polyether polyol, 0-5 parts of composite crosslinking agent, 1-55 parts of foaming agent, 1.0-5.0 parts of foam stabilizer, 0.5-2.0 parts of water, 1.0-3.5 parts of composite catalyst and 120-160 parts of isocyanate, wherein the index of the isocyanate is 0.95-1.10. The polyurethane composition provided by the technical solution is low in density and heat conductivity coefficient and strong in adhesive property. The fridge containing the polyurethane composition is good in insulation effect and low in energy consumption.

Owner:HEFEI HUALING CO LTD +1

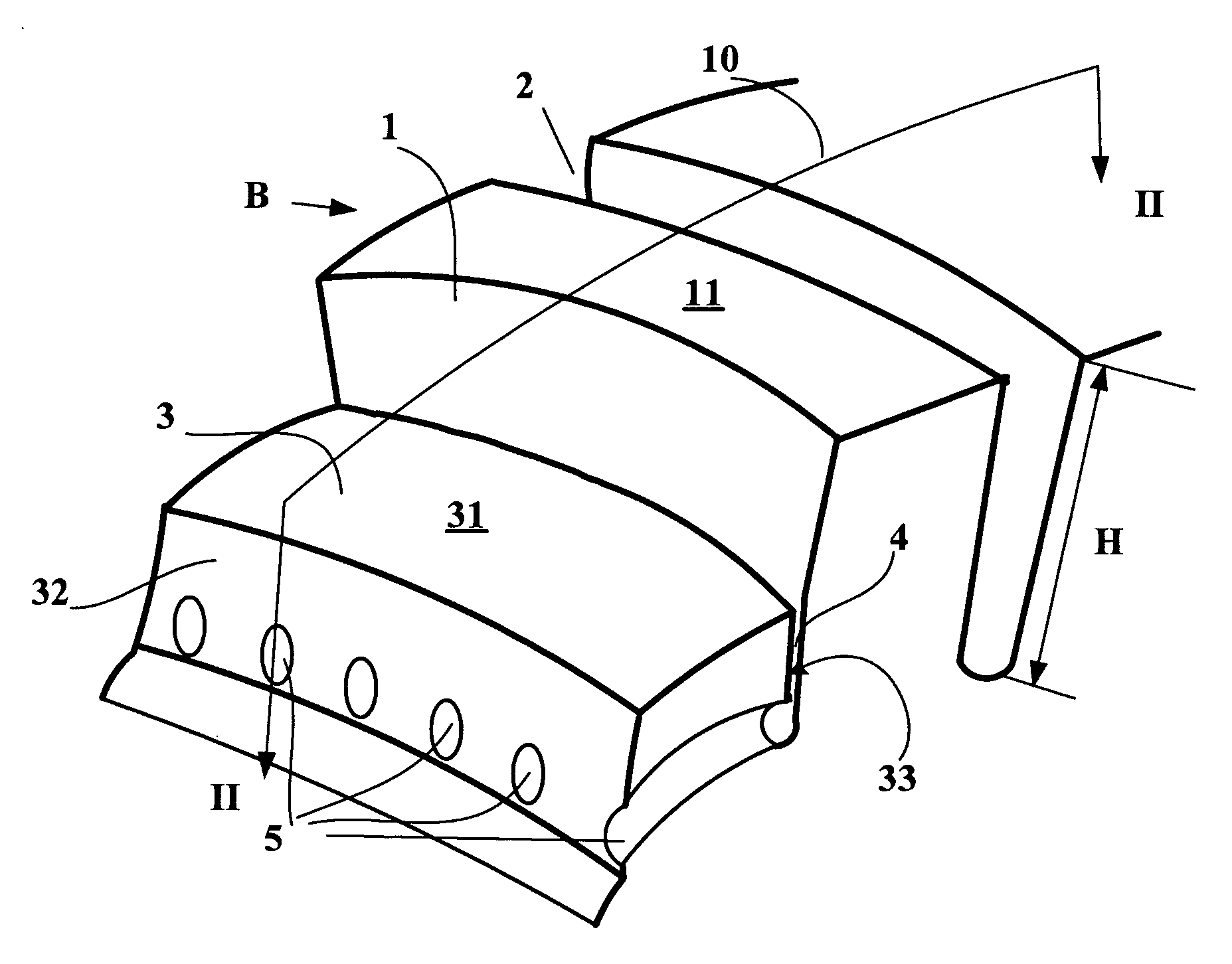

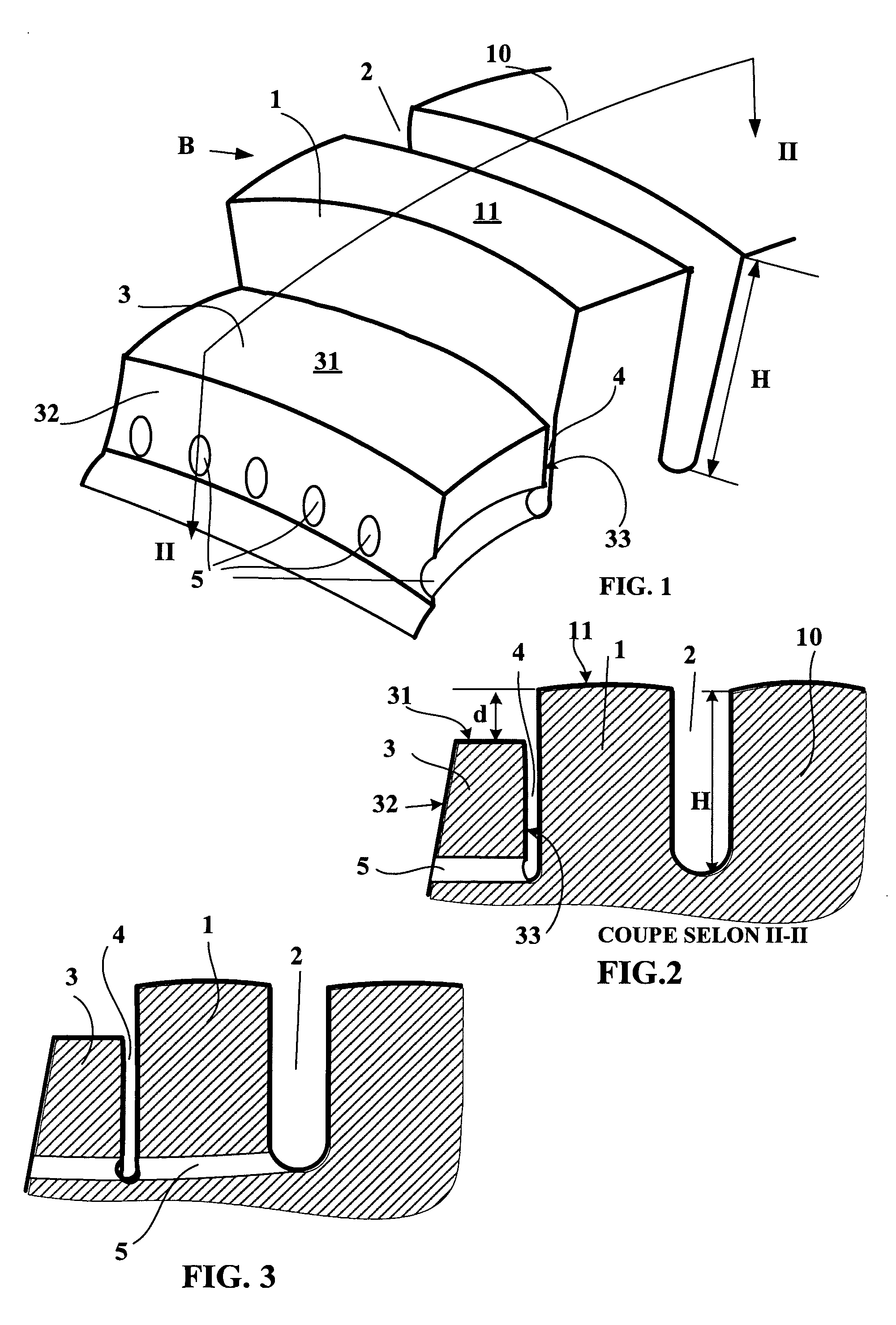

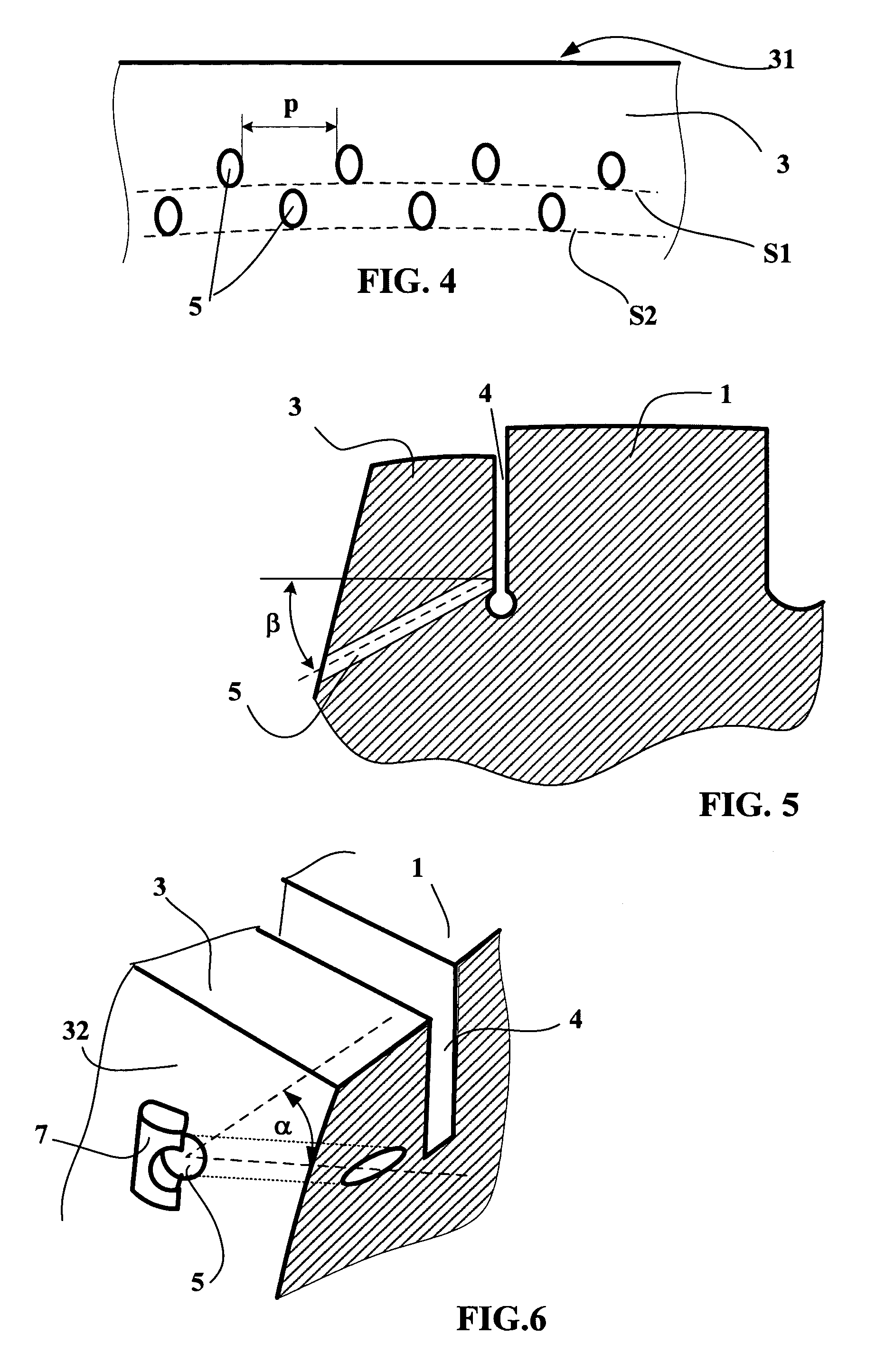

Tread comprising a ventilated device for countering irregular wear

InactiveUS20060090827A1Lower Level RequirementsWithstanding impactTyre tread bands/patternsNon-skid devicesEngineeringTread

A tread (B) provided with a tread pattern formed of a plurality of elements in relief (1, 10) which are defined by grooves and / or incisions (2), this tread pattern comprising on each of its edges, that is to say axially furthest to the outside of the tread, an edge rib (1) of circumferential orientation defined axially to the inside by a groove (2) of the same general orientation and of depth H, this tread furthermore comprising, axially to the outside of each edge rib (1), a rib (3) offset relative to the outer contact surface (11) of the neighboring edge rib (1) by a distance d other than zero, this offset rib (3) being separated from the edge rib (1) by a groove (4) of a depth identical or close to the depth H of the groove (2) defining the edge rib (1), wherein the tread comprises, on either side where a sacrificed rib (3) is formed, a plurality of channels (5) opening on to the lateral faces of the tread, these channels (5) being extended in the tread until they open into the groove (4) between the offset rib (3) and the neighboring edge rib (1).

Owner:MICHELIN RECH & TECH SA

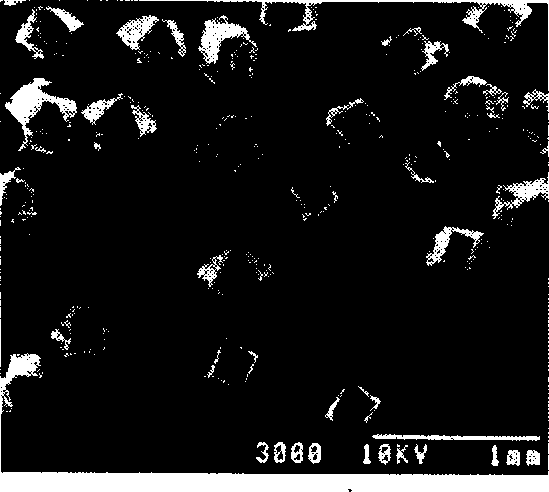

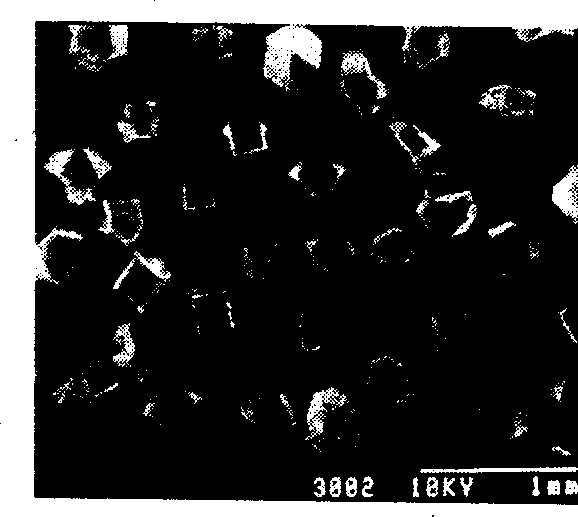

Pollution-free gas-phase oxidation separation purification method for artificial diamond

InactiveCN1404913AAvoid harsh working conditions and severe environmental pollutionSimple post-processingUltra-high pressure processesGrain treatmentsChemistryMagnetic separation

The artificial diamond pollutionless separation purification gas phase oxidation separation method includes the following steps: 1. primary breaking, adopting mechanical breaking mode, breaking synthetic rod into fine granules, grain diameter is less than 5 mm; 2. pyrolytic process, its temperature is controlled at below 650 deg.C, using aqueous vapor and inert gas to make protection; 3. crushing dissociation process; 4. separation purification process, adopting screening, magnetic separation, heavy liquid separation and chemical oxidation combined mode to separate diamond granules from mixture and making purification; 5. granules grading process, according to the grain size dividing the diamond granules into different grades.

Owner:ZHONGBEI UNIV

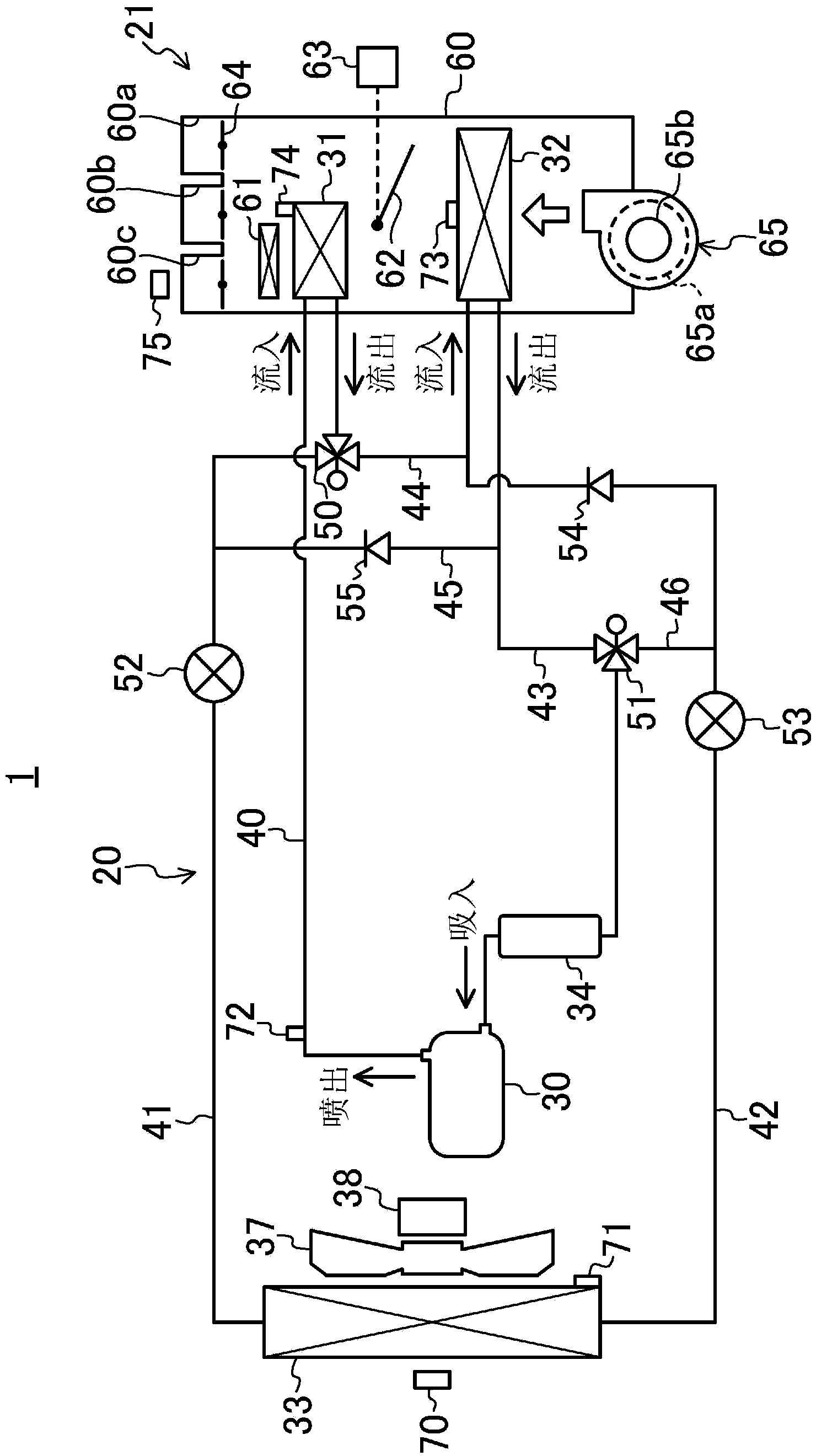

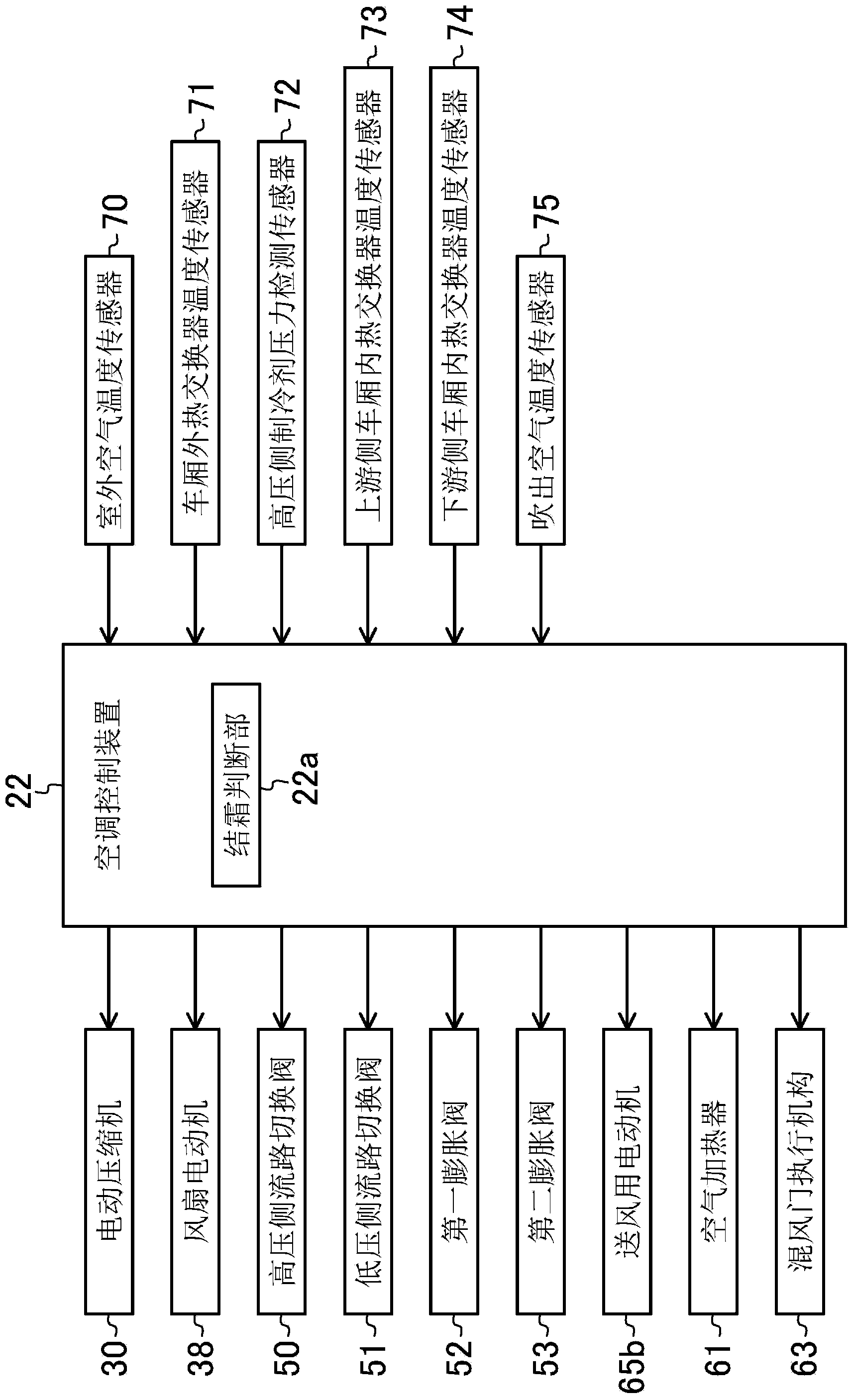

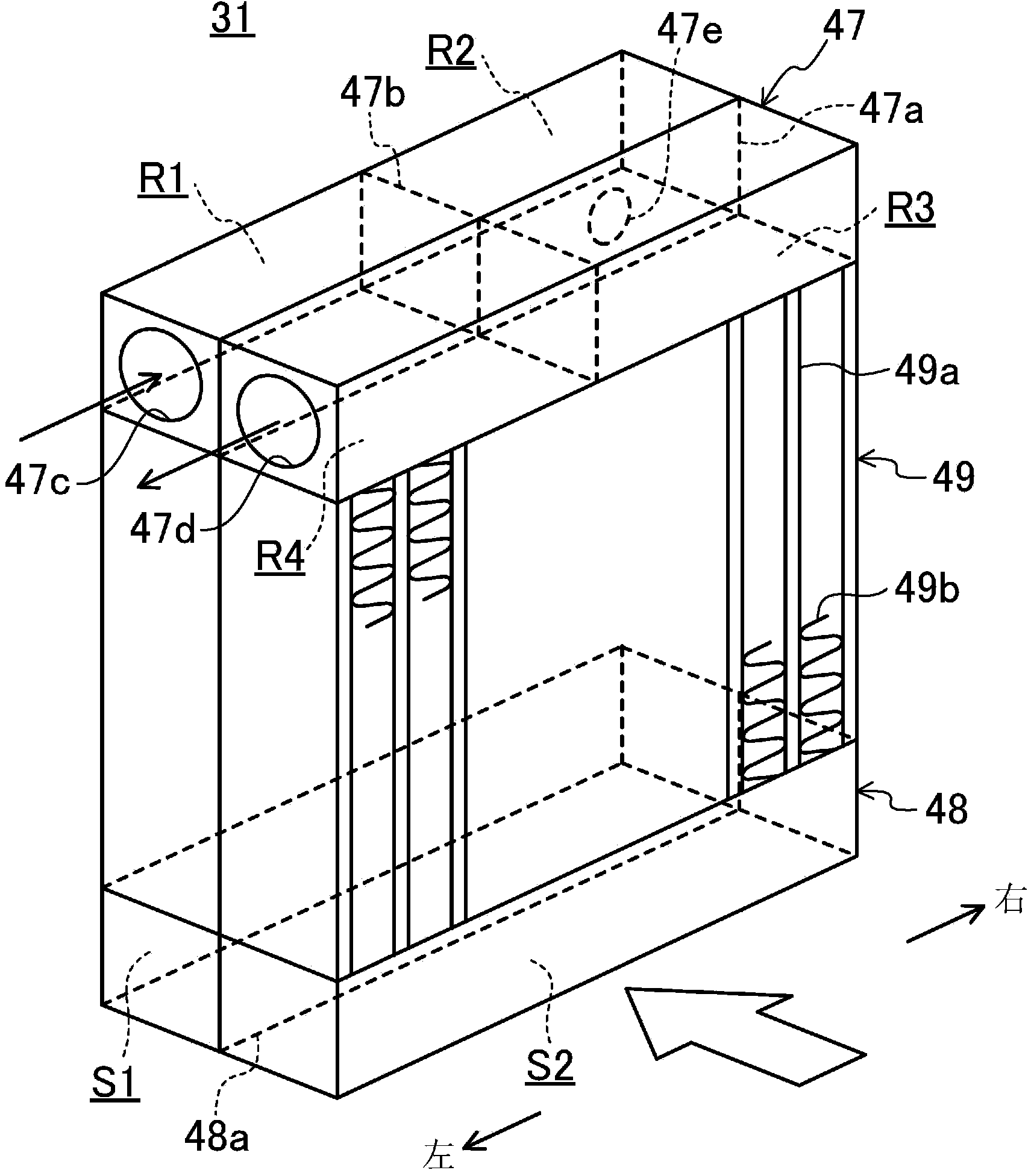

Air conditioning device for vehicle

InactiveCN104271373AGood refrigerant flowImprove heat exchange capacityAir-treating devicesMechanical apparatusRefrigerant distributionOperation mode

A heat pump device 20 includes an air conditioning control device 22 configured to switch the heat pump device 20 among a plurality of operation modes including an air-heating operation mode in which an indoor heat exchanger 32 serves as a radiator and an outdoor heat exchanger 33 serves as a heat absorber, and an air-cooling operation mode in which the indoor heat exchanger 32 serves as a heat absorber and the outdoor heat exchanger 33 serves as a radiator. The air conditioning control device 22 switch a refrigerant pipe such that refrigerant is, in the air-cooling operation mode, supplied to part of the outdoor heat exchanger 33 serving as a refrigerant inlet in the air-heating operation mode.

Owner:JAPAN CLIMATE SYSTEMS CORP +1

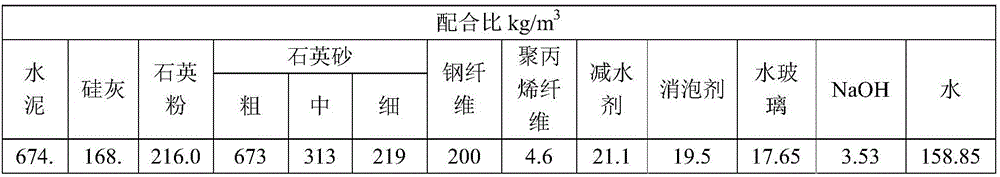

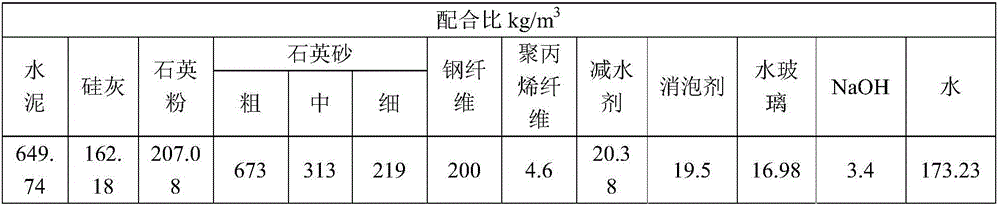

Alkali-activating-agent-doped early strength super-high performance concrete and preparation method thereof

ActiveCN106517934AShort initial setting timeImprove early strengthHigh performance concreteSetting time

The invention discloses alkali-activating-agent-doped early strength super-high performance concrete and a preparation method thereof. The concrete comprises, by mass, 1019-1059 parts of a cementing material, 1120-1271 parts of quartz sand, 165-205 parts of fibers, 20.38-21.18 parts of a water reducing agent, 12.2-25.6 parts of a de-foaming agent, 20.38-21.18 parts of an alkali activating agent and 152.85-180.03 parts of water. Under the effect of the alkali activating agent, the cementing material contains lots of Si-O and Al-O bond rupture, SiO4 and AlO4 tetrahedrons are made to be fast dissolved out, lots of inorganic high-molecular polymers are fast formed through a polycondensation reaction, the early strength of the concrete is improved fast, and the super early strength effect is achieved. The alkali activating agent is doped in, the initial setting time of the super-high performance concrete is greatly shortened, the super-high performance concrete is made to have very high early strength, the stripping time is shortened, and the circulation efficiency of preparation of the concrete is accelerated.

Owner:西安华清科教产业(集团)有限公司

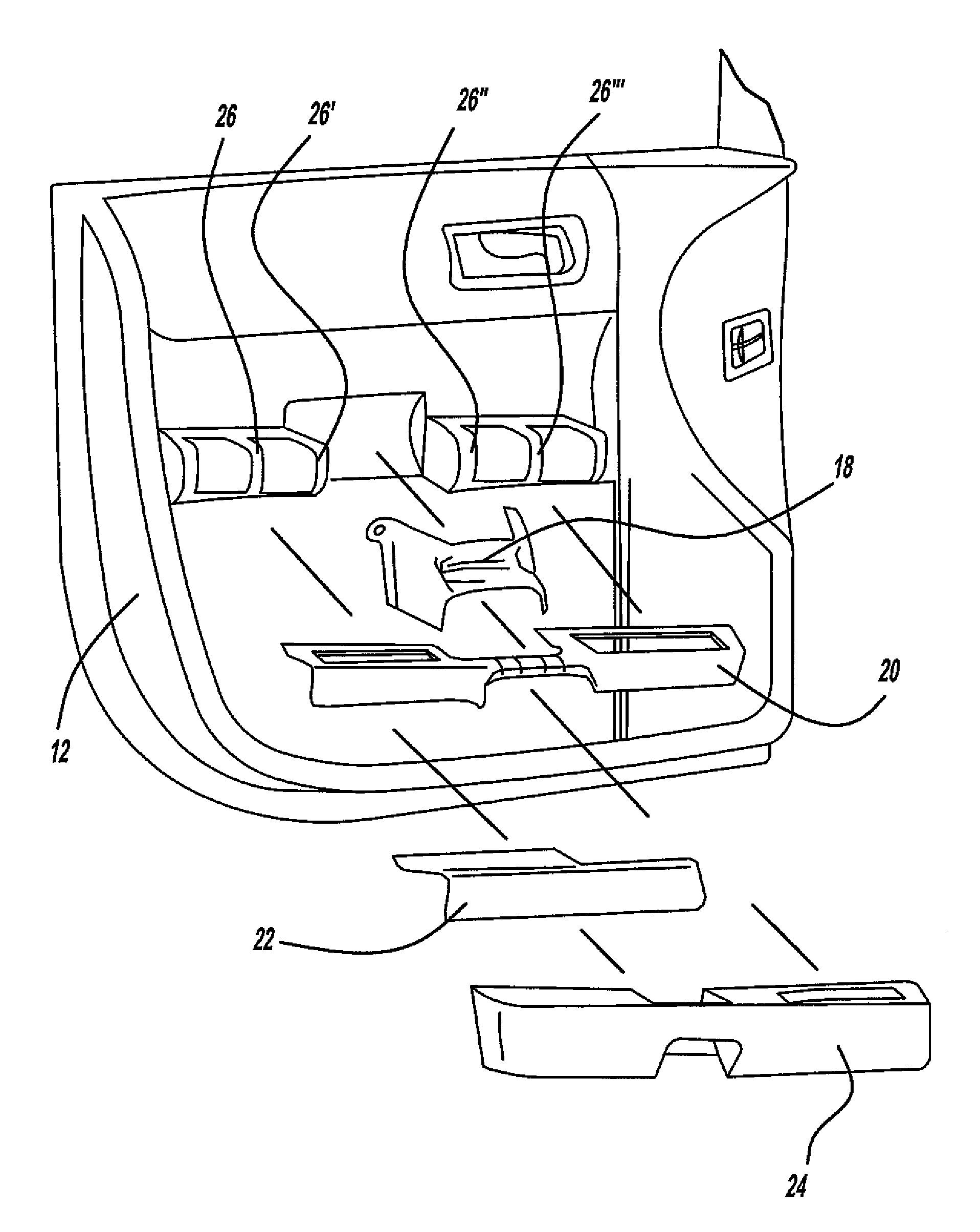

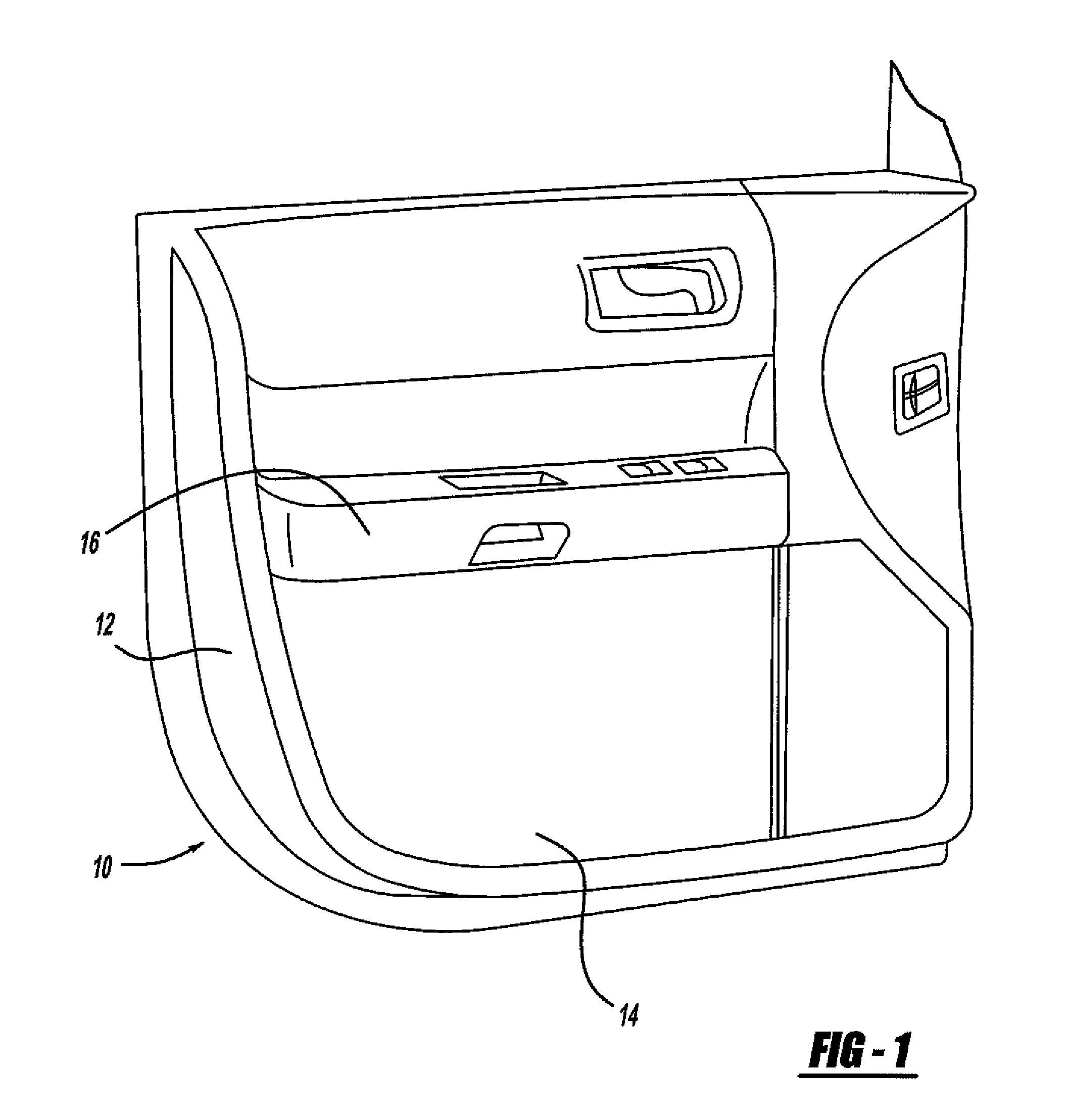

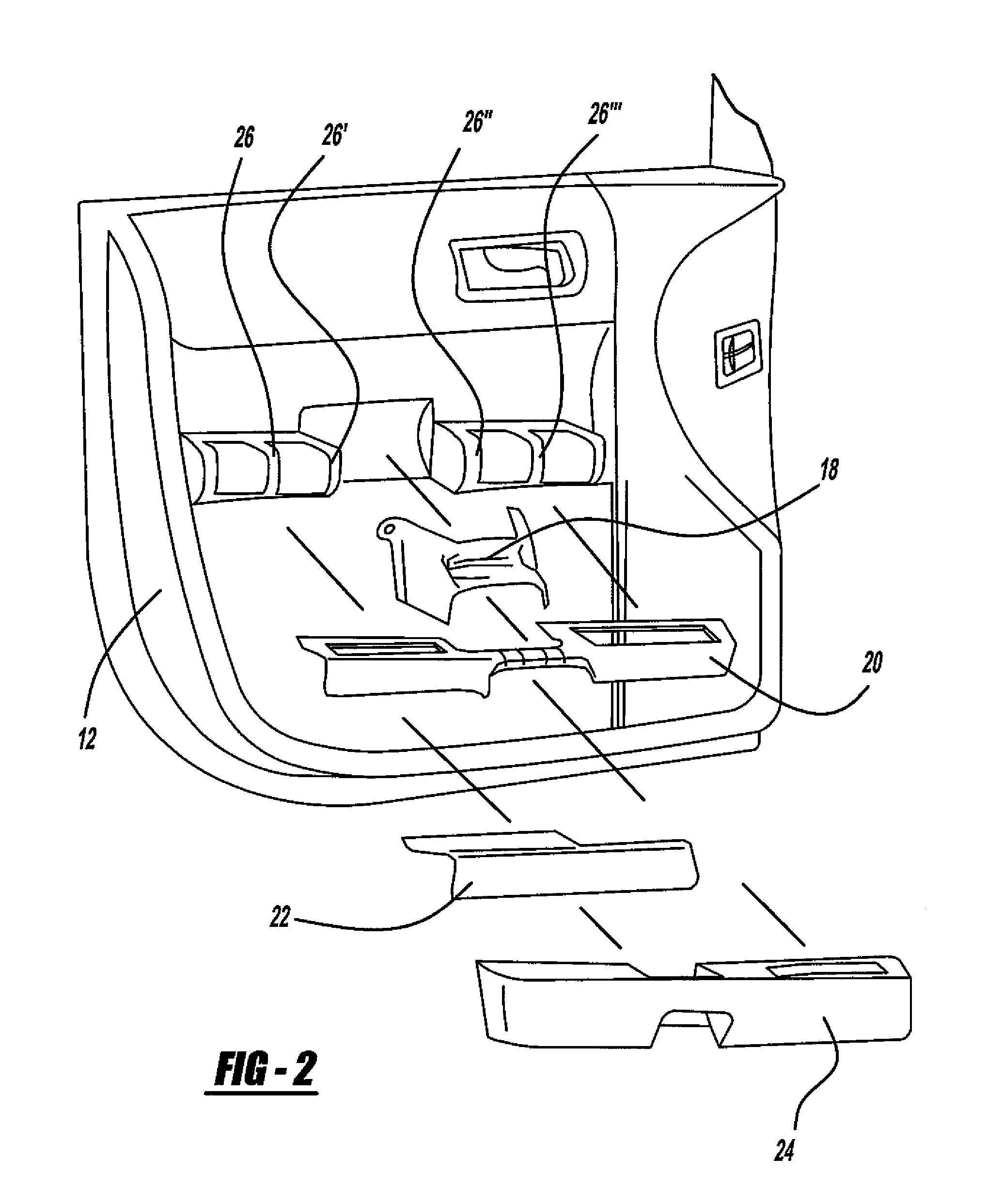

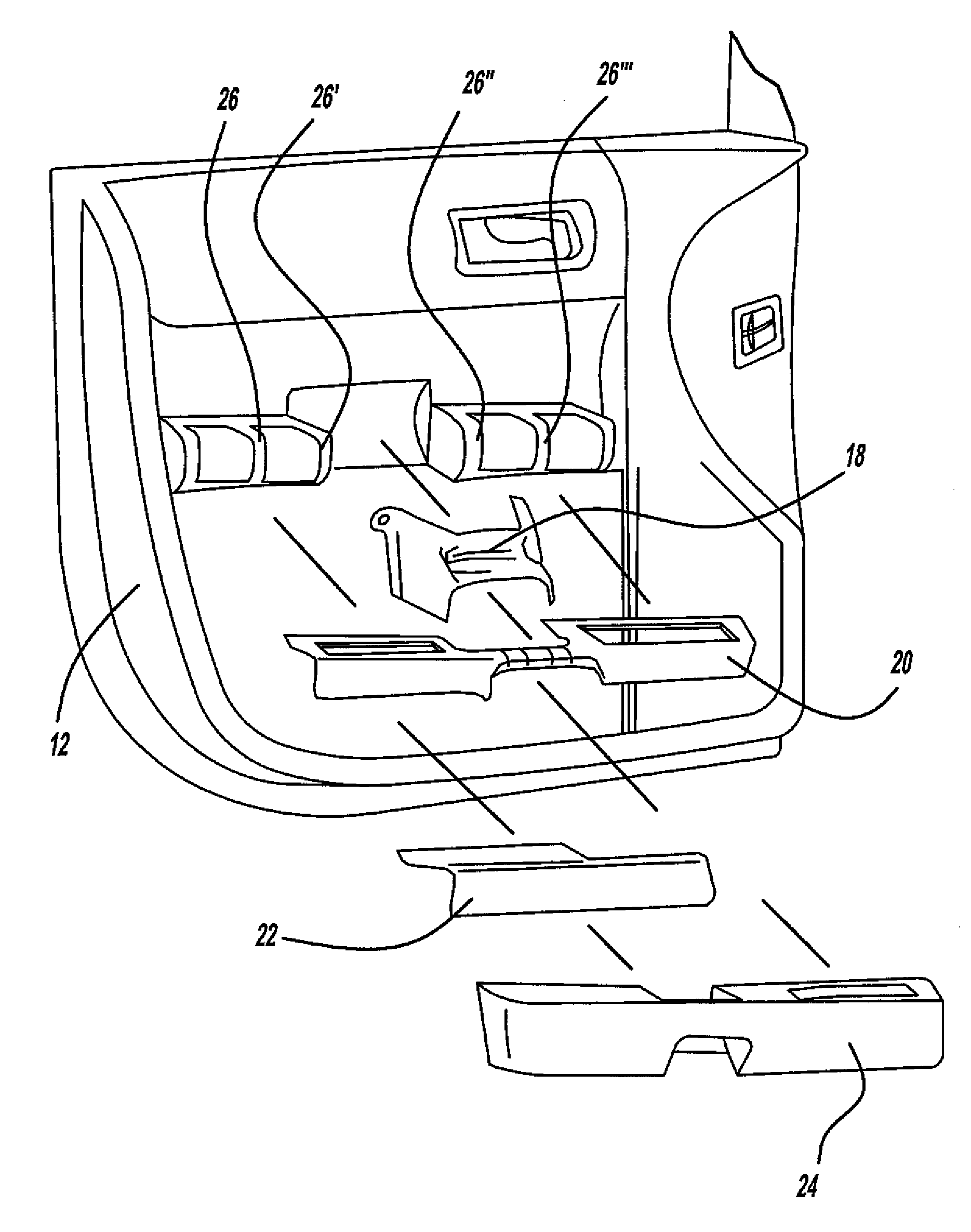

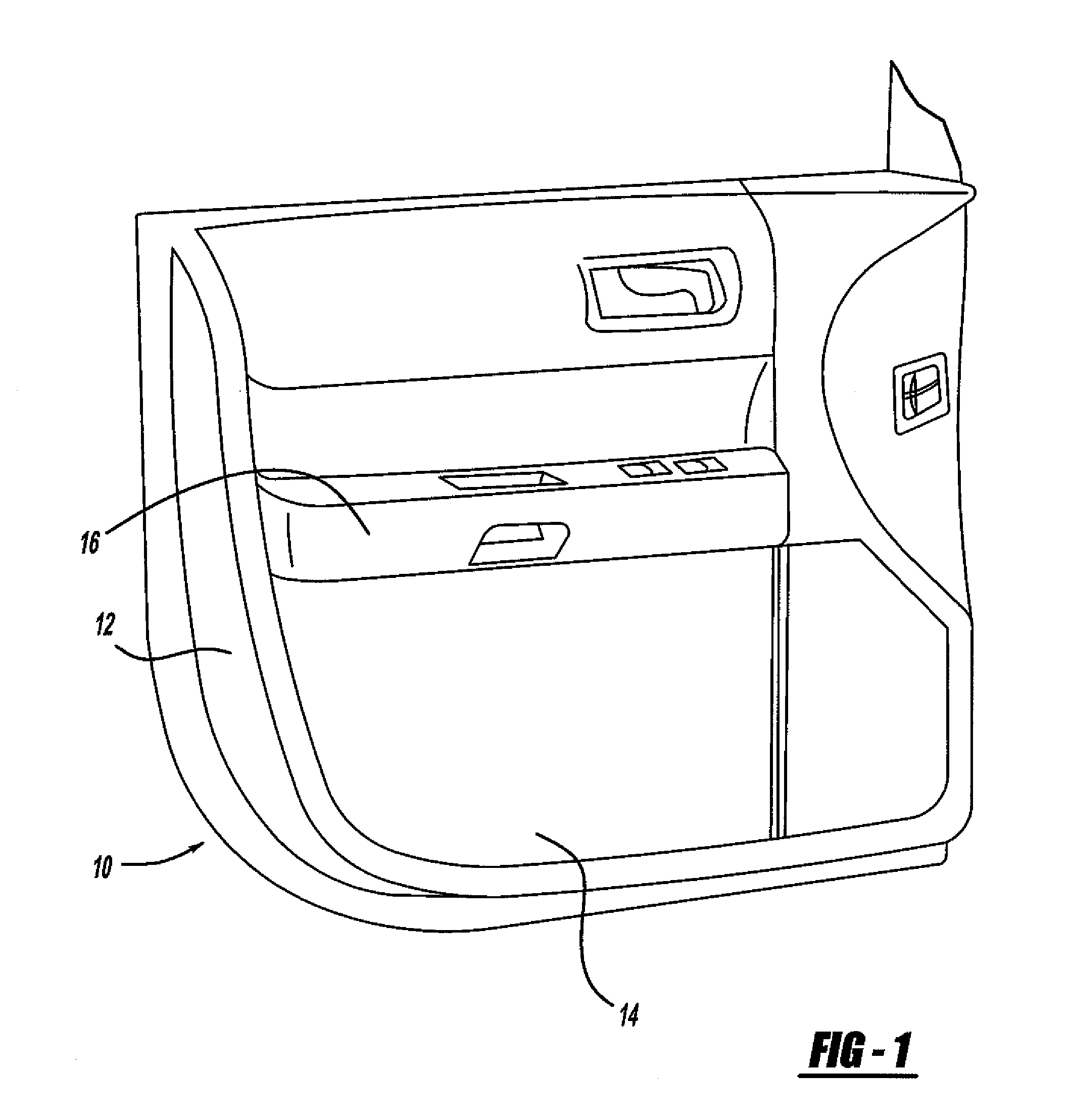

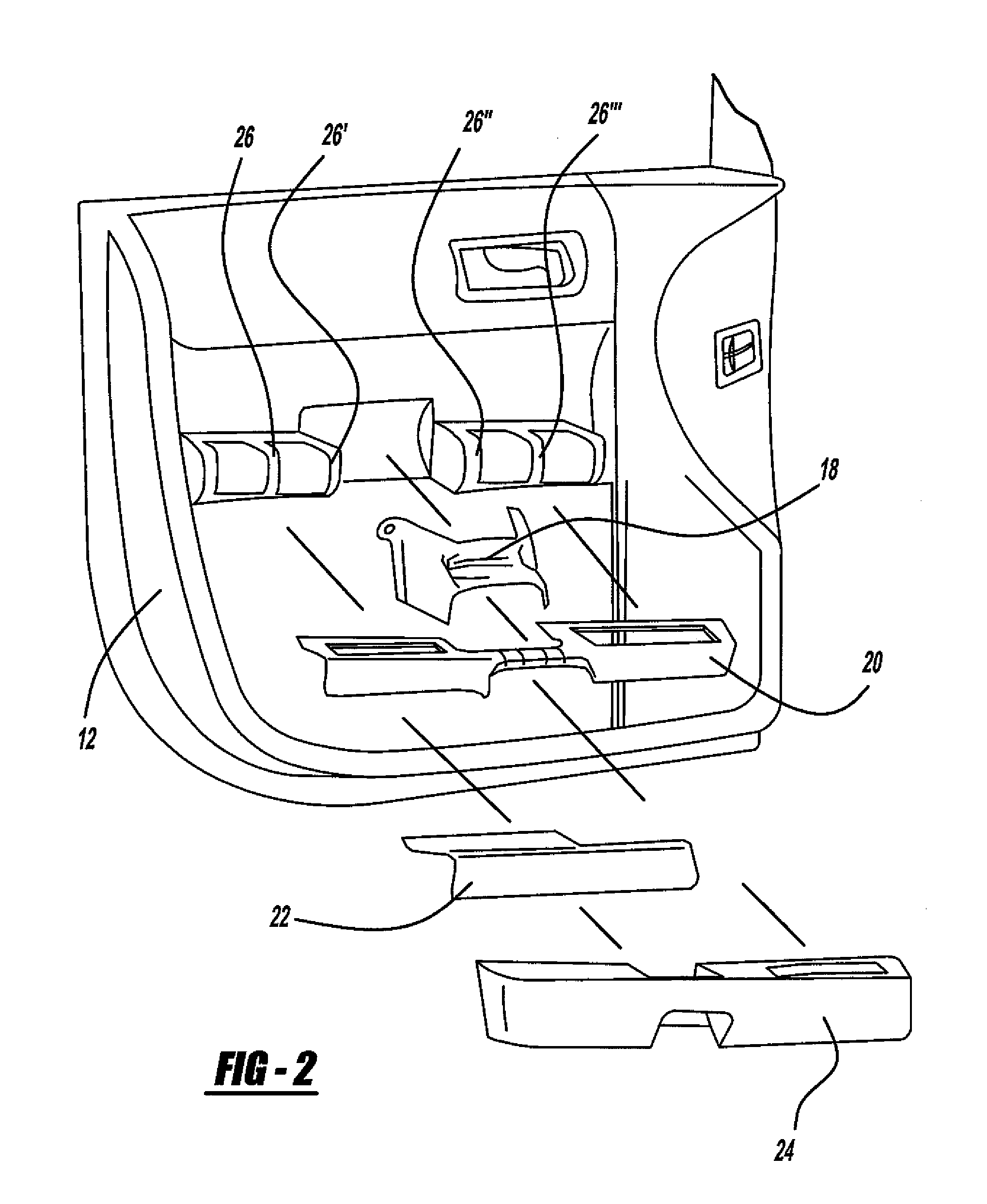

Side impact door trim buckle initiatory design in armrest and grab handle region

InactiveUS7794009B2Acceptable durabilityAcceptable strengthArm restsMonocoque constructionsTrim tabEngineering

A side impact door trim buckle initiator design is provided in a vehicle armrest and grab handle region. The disclosed support structure design induces buckling in the door handle supports while continuing to provide acceptable durability and strength. Two modifications to the door armrest and grab handle structures are made. First, an angled section is added to the material flow strap of the armrest supporting structure to promote buckling. This approach overcomes the difficulty of known material flow straps which tend to be horizontal, thus introducing a strong compressive load path. By adding an angle to the flow straps the vertical motion is forced upon a lateral impact. Second, vertical components of the door handle support structure are removed while a buckle initiator in the door handle support is added.

Owner:FORD GLOBAL TECH LLC

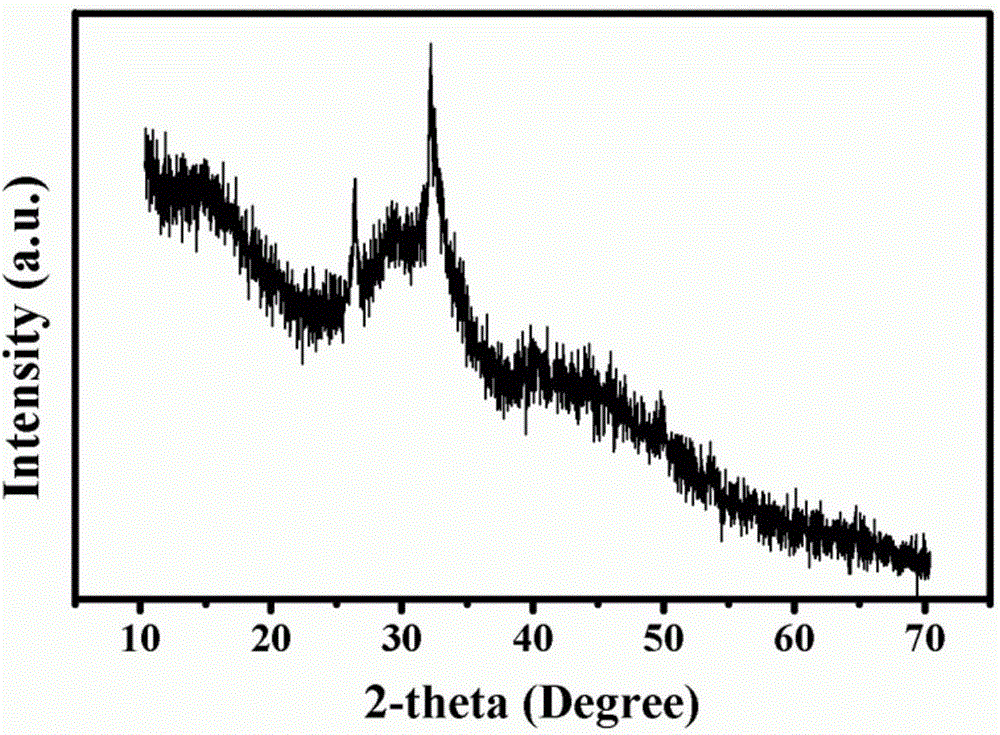

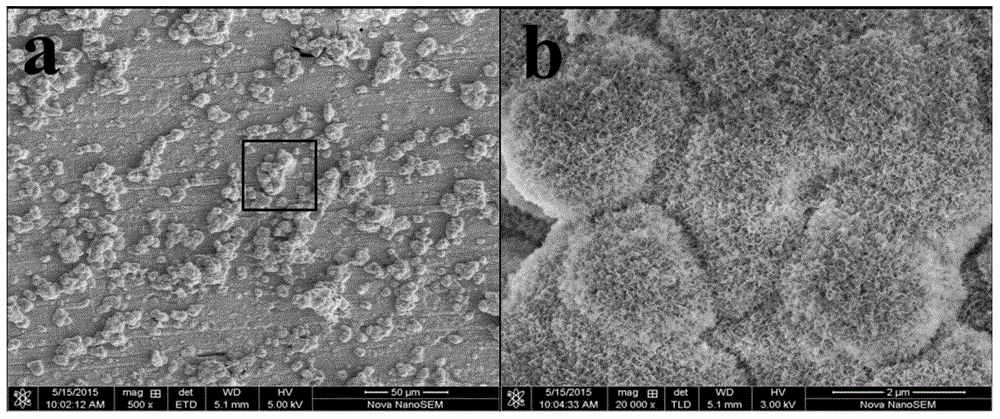

Compound bone cement precursor as well as preparation method and application of strontium borate bioglass/polymethyl methacrylate compound bone cement

ActiveCN104922731AGood injectabilityImprove biological activityProsthesisSolid phasesStrontium borate

The invention discloses a polymethyl methacrylate (PMMA) compound bone cement precursor which comprises solid phase powder and solidification liquid, wherein the solid phase powder comprises strontium borate bioglass, polymethyl methacrylate powder and a polymerization initiator, the solidification liquid comprises methyl methacrylate and a polymerization activator, and the mass of the solid phase powder is 50 to 80 percent of the mass sum of the solid phase powder and the solidification liquid. The invention also provides a preparation method of polymethyl methacrylate compound bone cement, the compound bone cement combines the performance of the strontium borate bioglass and pure PMMA bone cement, has excellent biological activity, biological degradability, biological compatibility as well as mechanical strength matched with bones, so as to achieve a good effect on prompting bone reconstruction; the invention also provides an application of the strontium borate bioglass / polymethyl methacrylate compound bone cement.

Owner:深圳市中科海世御生物科技有限公司

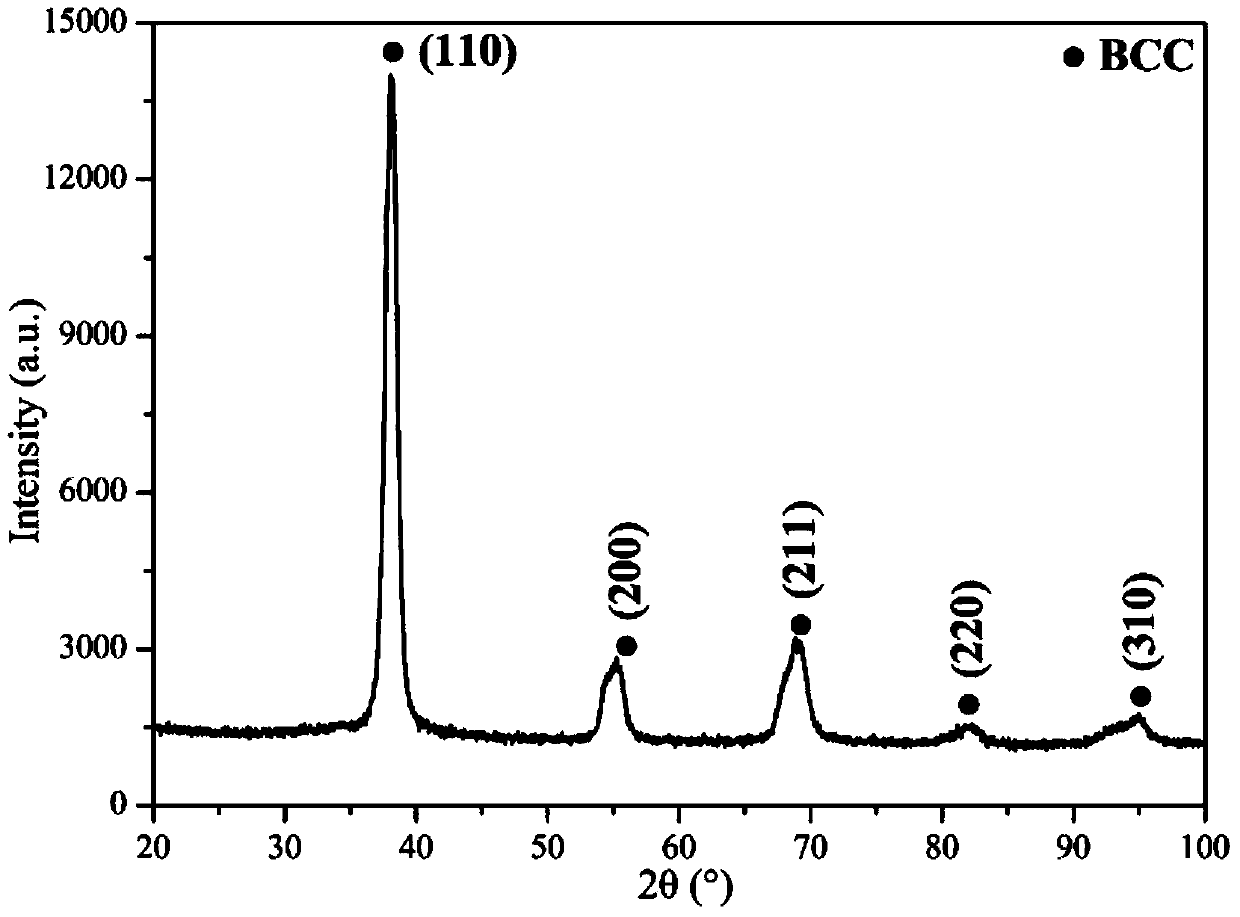

TiZrNbMoxHfy multi-principal component high temperature alloy and preparation method thereof

Owner:HARBIN INST OF TECH

Energy absorbing structure for aircraft

ActiveUS8376275B2Prevent excessive compressionSimple structureMilitary adjustmentFuselage bulkheadsEpoxyFiber

Owner:THE BOEING CO +1

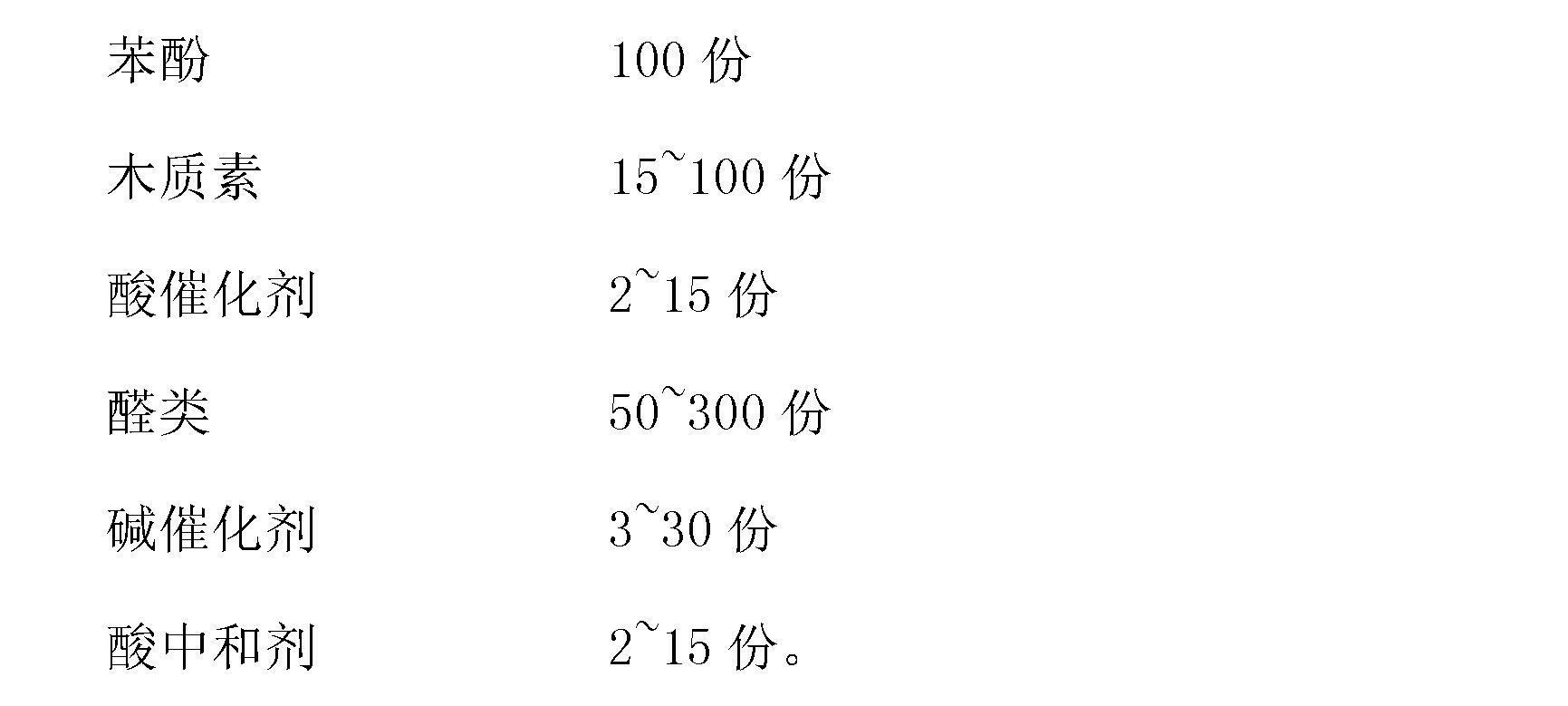

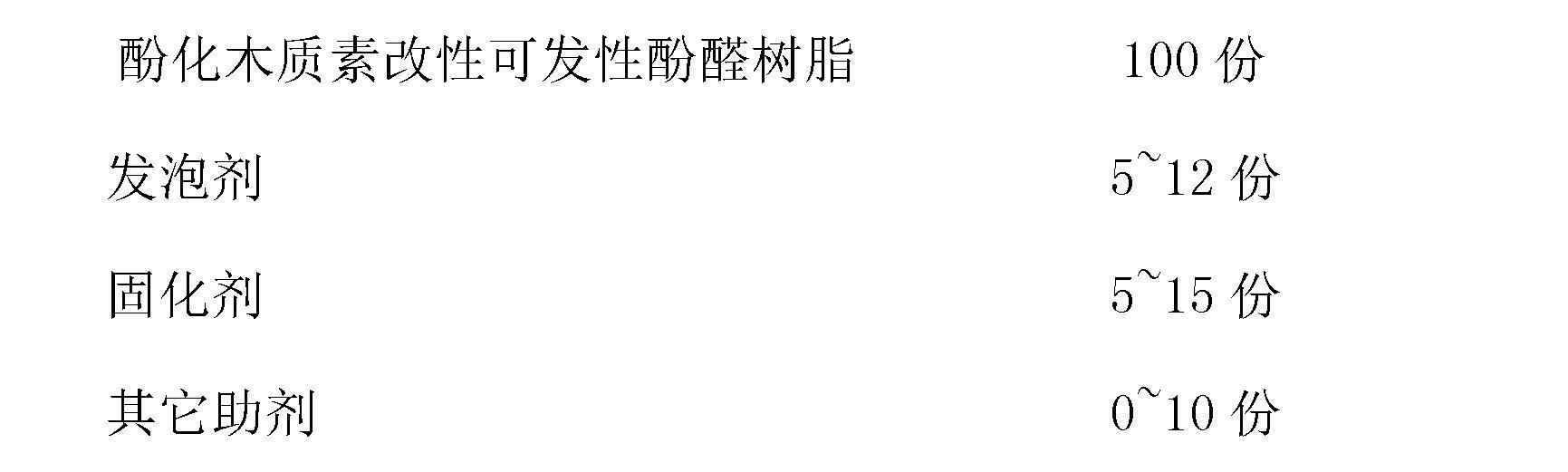

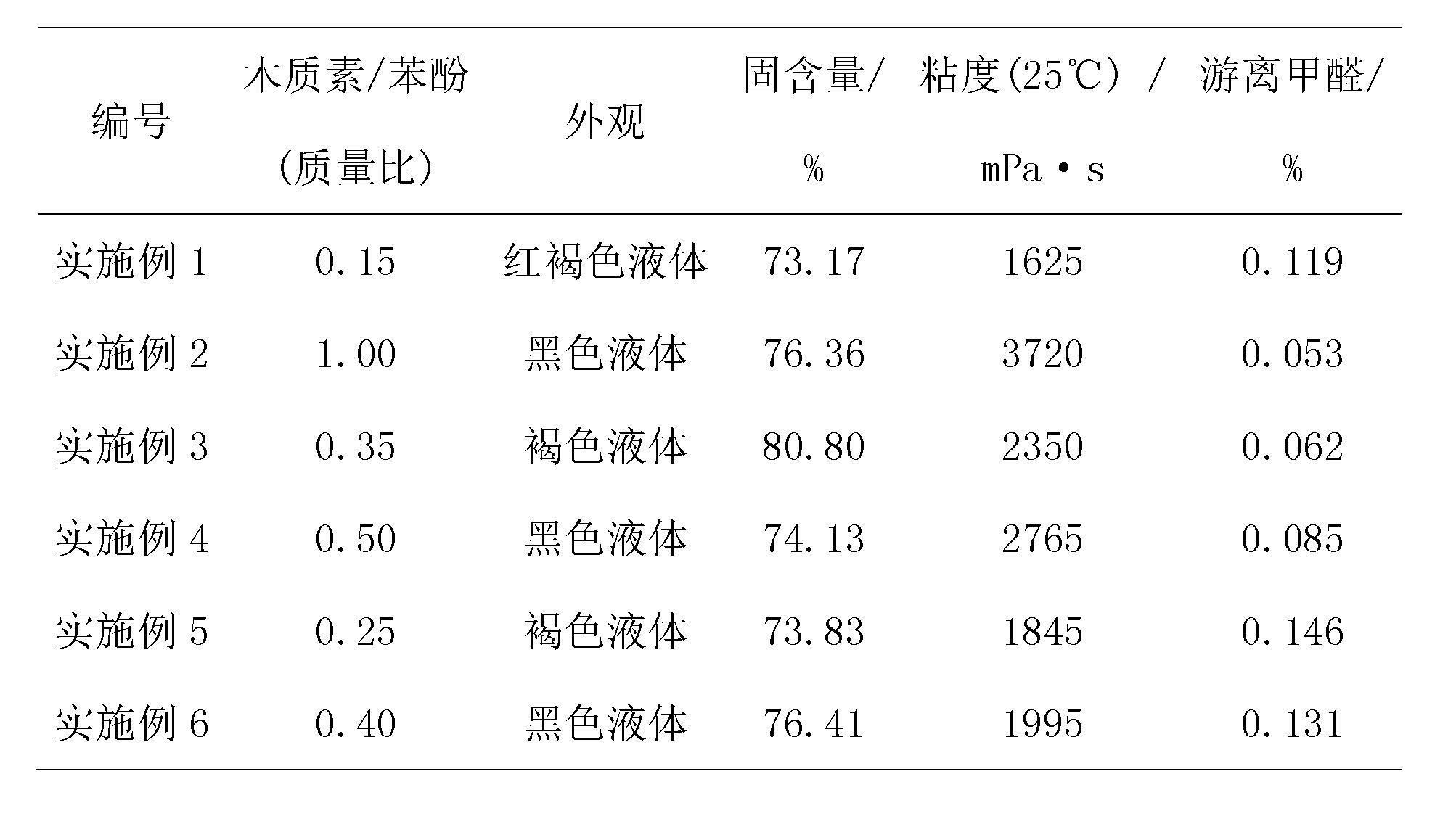

Phenolic lignin-based modified foaming phenolic resin, foamed plastic and preparation method of phenolic lignin-based modified foaming phenolic resin

The invention discloses a phenolic lignin-based modified foaming phenolic resin, foamed plastic and a preparation method of the phenolic lignin-based modified foaming phenolic resin. The foaming phenolic resin comprises phenol, lignin, an acid catalyst, aldehydes, a base catalyst and an acid neutralizer. Compared with the existing lignin-based phenolic resin and the foamed plastic of the lignin-based phenolic resin, the phenolic lignin-based modified foaming phenolic resin has the beneficial effects that a high-activity lignin phenolized liquid is directly adopted to replace phenol for preparing the foaming phenolic resin, so that the foaming phenolic resin has less free formaldehyde (with the content of less than or equal to 0.15%), and has the advantages of being lower in production cost, rapider in curing speed and the like; and compared with the traditional phenolic resin foamed plastic, the foamed plastic prepared by the phenolic lignin-based modified foaming phenolic resin has the advantages of lower coefficient of heat conductivity and higher compression strength.

Owner:HUANGSHAN UNIV

Side impact door trim buckle initiator design in armrest and grab handle region

InactiveUS20090134660A1Acceptable durabilityAcceptable strengthArm restsMonocoque constructionsEngineeringSide impact

A side impact door trim buckle initiator design is provided in a vehicle armrest and grab handle region. The disclosed support structure design induces buckling in the door handle supports while continuing to provide acceptable durability and strength. Two modifications to the door armrest and grab handle structures are made. First, an angled section is added to the material flow strap of the armrest supporting structure to promote buckling. This approach overcomes the difficulty of known material flow straps which tend to be horizontal, thus introducing a strong compressive load path. By adding an angle to the flow straps the vertical motion is forced upon a lateral impact. Second, vertical components of the door handle support structure are removed while a buckle initiator in the door handle support is added.

Owner:FORD GLOBAL TECH LLC

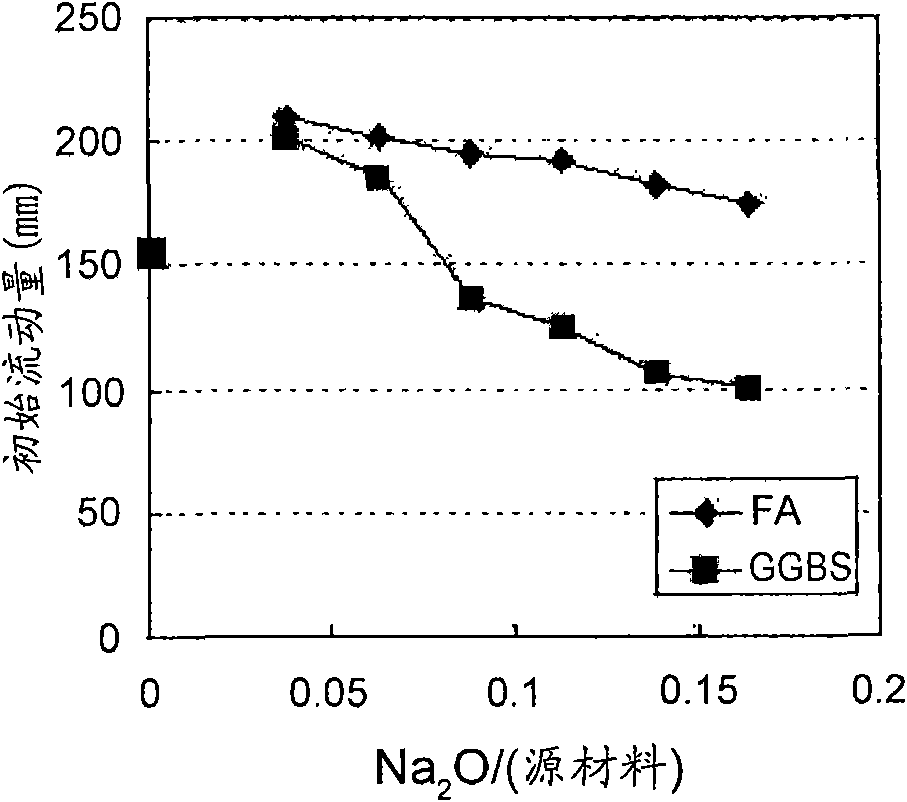

Alkali-activated binder with no cement, method for fabricating mortar using it, and method for fabricating alkali-activated reinforcement mortar with no cement

InactiveCN101687704AImprove initial strengthLow heat of hydrationSolid waste managementCement productionPortland cementKaolin clay

The present invention relates to a cement-free alkali activated binder in which alkaline inorganic materials are appropriately added to an industrial waste such as blast furnace slag, fly ash, meta kaolin and the like, a method for producing mortar using the same and a method for producing cement-free alkali activated reinforcement mortar. Specifically, the present invention relates to a cement-free alkali activated binder that is not only environmentally friendly as being capable of dramatically reducing the carbon dioxide emission, which has been remained as a problem for producing Portlandcement, but also has an excellent property, a method for producing mortar using the same and a method for producing cement-free alkali activated reinforcement mortar.

Owner:IND FOUND OF CHONNAM NAT UNIV

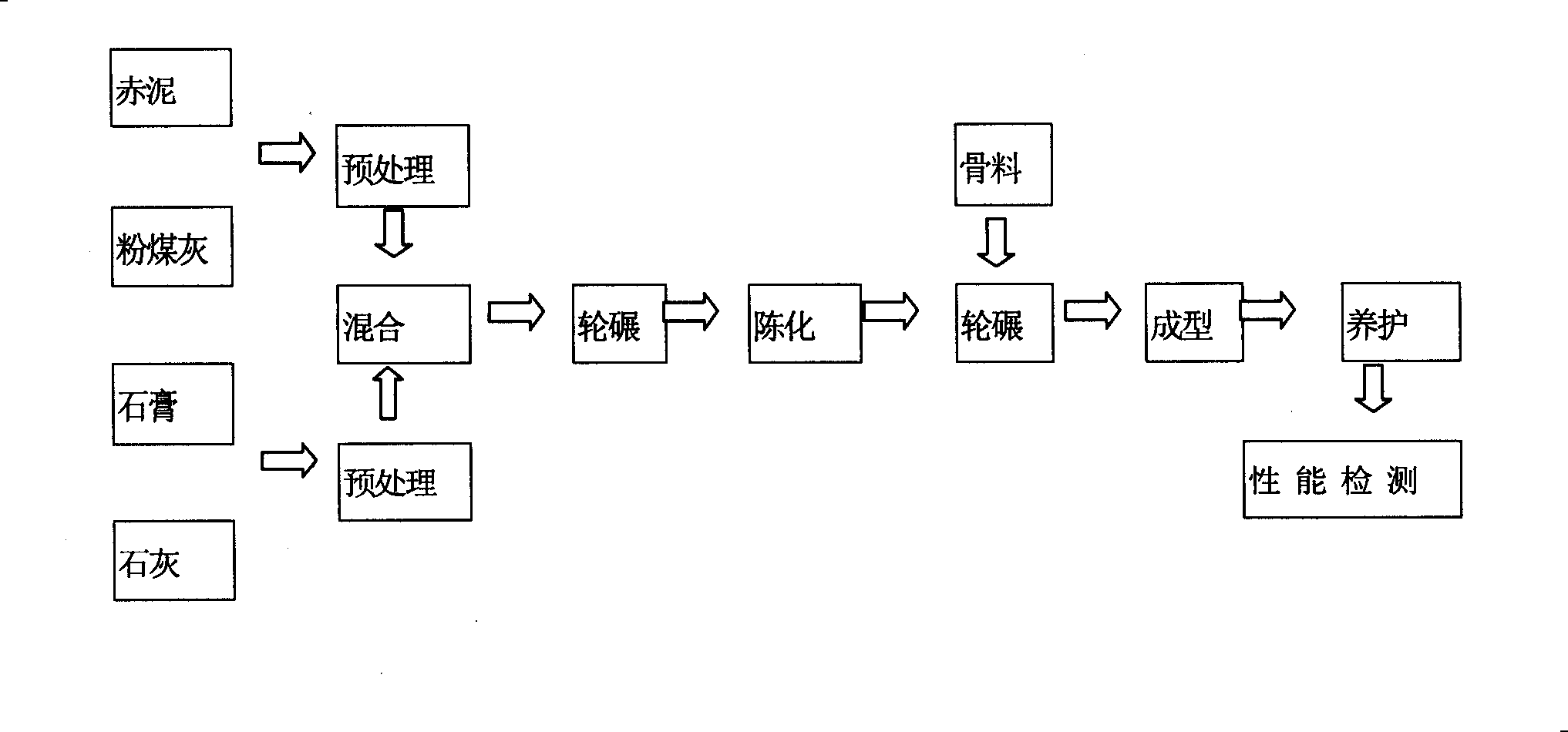

Red-mud coal ash baking-free brick

The invention belongs to construction material,Which provides material components and weight percentage rate of a baking-free brick with red mud and flyash are: 22-40 of the red mud, 20-35 of the flyash, 20-40 of aggregate, 8-12 of lime and 1-3 of plaster.With the aim of realizing the largest utilization quantity of the red mud and economizing the cost, through the researches and experiments, the invention uses the red mud and the flyash as main material and uses grit and friable rubbles as the aggregate so as to facilitate compressive strength of the products; the lime and the plaster is added to improve plasticity of the blank material, strength of a semi-finished blank brick and the compressive strength of the products. The invention can satisfy the utilization performance of the products and at the same time completely can meet the national standard requirement, thus solving the problem of the environmental pollution caused by the discharge of the red mud in larger sense.

Owner:LUOYANG ZHONGCHAO NEW MATERIAL SHARES CO LTD

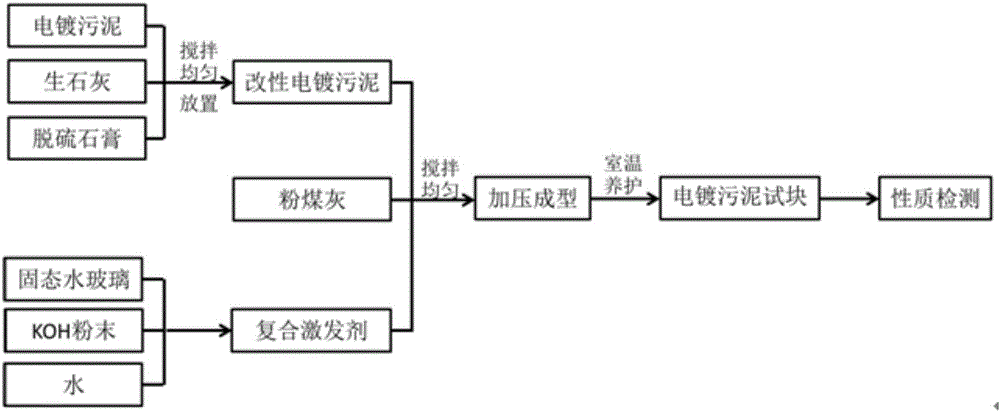

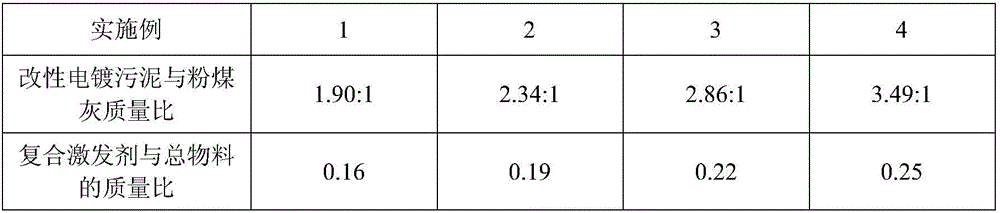

Harmless treatment method for electroplating sludge

ActiveCN105948589AImprove developmentSimple processSolid waste managementCorrosion resistantHeavy metals

The invention belongs to the technical filed of environmental protection engineering and particularly relates to a harmless treatment method for electroplating sludge. The harmless treatment method comprises the following steps: the electroplating sludge is taken, certain amount of quicklime and flue gas desulfurization gypsum is added, crushed sufficiently and stirred uniformly, the mixture is left to stand for a period of time, and modified electroplating sludge is obtained; the modified electroplating sludge and fly ash are taken and stirred uniformly, a certain amount of a composite activator is added and stirred sufficiently again, and a mixture is obtained; an electroplating sludge test block is obtained in a pressure forming manner and cured in a room-temperature environment for 7-28 days, and a solidified electroplating sludge body is obtained. The harmless treatment method adopted for treating the electroplating sludge has the advantages of simple process, low cost, large electroplating sludge curing amount, small capacity increase and the like, meanwhile, the solidified electroplating sludge body obtained after treatment is highly corrosion-resistant, stable for a long time and low in heavy metal leaching toxicity, has certain compressive strength and can be taken as general solid waste to be subjected to landfill treatment.

Owner:SAFECLEEN TECH

Polyurethane semi-rigid foam composition and preparation method thereof

The invention provides a polyurethane semi-rigid foam composition which is formed by the following components in parts by weight: 100 parts of premixed polyether A and 120-170 parts of isocyanate B. The invention also provides a preparation method of the polyurethane semi-rigid foam composition. The polyurethane semi-rigid foam composition provided by the invention has excellent sound absorption effect and low VOC (Volatile Organic Compounds) content and is especially suitable for automobile roofs.

Owner:上海井上高分子制品有限公司

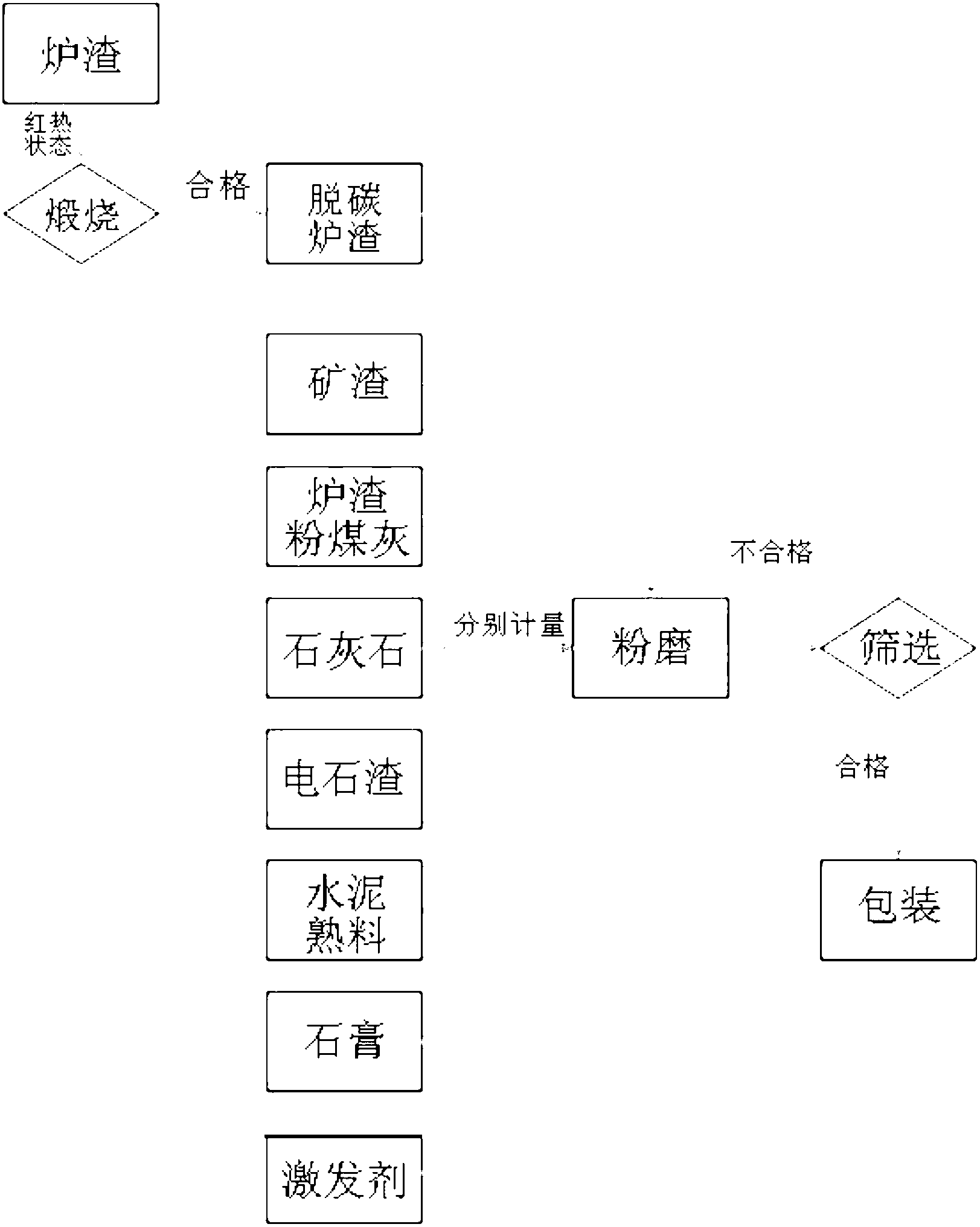

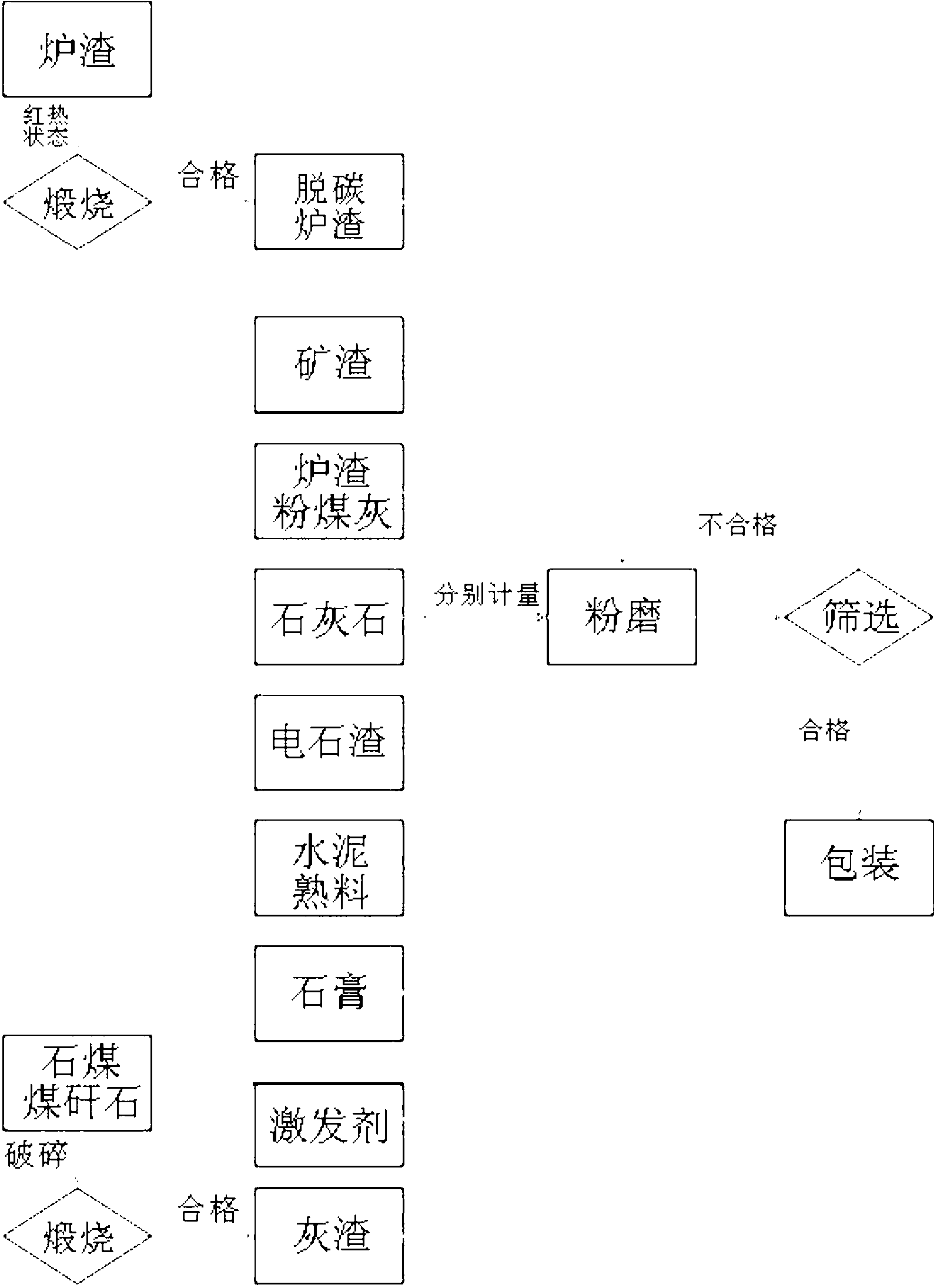

Inorganic waterproof cementitious material and preparation method thereof

The invention discloses an inorganic waterproof cementitious material. The inorganic waterproof cementitious material is characterized by comprising the materials in parts by weight: 35-55 parts of ash and / or decarburized slag, 10-30 parts of blast furnace slag / mineral powder, 8-16 parts of slag and / or coal ash, 4-8 parts of carbide slag, 0-10 parts of cement clinker, 4-8 parts of gypsum, 0-5 parts of lime stone and 0.5-5 parts of booster. All materials adopted by the inorganic waterproof cementitious material are inorganic materials, and aim at overcoming the defects generated by organic matters contained in polymer waterproof mortar. Thus, the inorganic waterproof cementitious material is good in weather fastness, not easy to age, good in affinity with a base layer, convenient to construct, and long in service life; and no harmful gas is released in the constructing and using processes.

Owner:溆浦大盛建材有限责任公司

Method of making cement from tailings or rock fines containing silicate or siliceous compounds

InactiveUS20020033120A1Eliminate riskSolve the real problemSolid waste managementCompound aCrushed stone

A method of making cement from tailings or rock fines containing silicate or siliceous compounds includes grinding the tailings or rock fines to a size in the range of from about -250 to about 425 mesh to produce ground pozzolan. The ground pozzolan is mixed with Type 1 normal Portland cement or Type 3 high early strength Portland cement in a ratio of at least about 0.1:1 by weight to produce a blended cement.

Owner:FENICEM MINERALS

Golf club head

ActiveUS20050245328A1Increased durabilityAvoid breakingGolf clubsRacket sportsEngineeringCompressive strength

The invention prevents a resin member from being broken so as to improve durability. The invention provides a golf club head (1) in which at least apart of a crown portion (4) forming an upper surface of the head is formed by a resin member (FR) made of a fiber reinforced resin in which a fiber is oriented in a matrix resin. The resin member (FR) includes a one-way fiber reinforced resin layer in which the fiber is oriented in one direction, and a fiber intersection lamination portion which is laminated so as to differentiate a direction of the fiber. At least two one-way fiber reinforced resin layers which are adjacent in a thickness direction are intersected at an angle of 30 to 130 degrees of the fiber. Further, a compressive strength of the fiber of the one-way fiber reinforced resin layer which is arranged in an innermost side in the fiber intersection lamination portion is set to be equal to or more than 1.3 GPa.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com