Harmless treatment method for electroplating sludge

A technology of harmless treatment and electroplating sludge, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high curing cost, poor corrosion resistance of solidified body, complicated operation, etc., and achieve solidification The effect of large quantity, strong corrosion resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

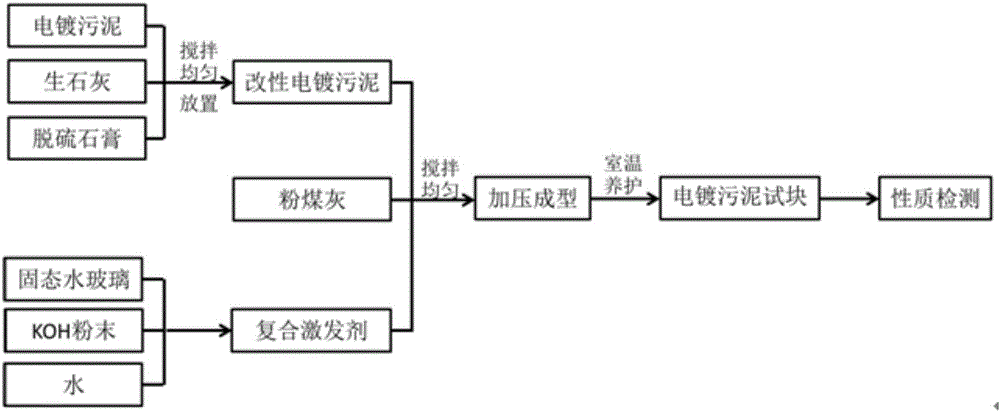

[0033] A method for harmless treatment of electroplating sludge, comprising the steps of:

[0034] (1) electroplating sludge pretreatment: get electroplating sludge, add quick lime and 5% desulfurization gypsum of electroplating sludge mass, fully crush and stir, leave standstill for 24 hours, obtain modified electroplating sludge, described The moisture content of the modified sludge is 55%;

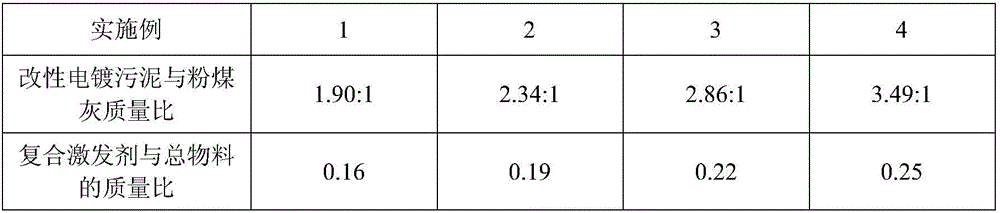

[0035] (2) Take the modified electroplating sludge and fly ash (particle size 74 μm), the mass ratio of the two is 1.54~3.49:1, stir evenly, and then add a certain amount of composite activator, the composite activator and the total material ( The mass ratio of modified electroplating sludge and fly ash) is 0.15~0.25:1, and Na in the composite activator 2 SiO 3 The concentration of KOH is 5mol / L, the concentration of KOH is 2.5mol / L, fully stir again, obtain the mixture;

[0036] (3) Take the mixture obtained in step (2) and pressurize and form it to obtain a test block of electropla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com