Patents

Literature

490 results about "Pozzolan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pozzolans are a broad class of siliceous or siliceous and aluminous materials which, in themselves, possess little or no cementitious value but which will, in finely divided form and in the presence of water, react chemically with calcium hydroxide at ordinary temperature to form compounds possessing cementitious properties. The quantification of the capacity of a pozzolan to react with calcium hydroxide and water is given by measuring its pozzolanic activity. Pozzolana are naturally occurring pozzolans of volcanic origin.

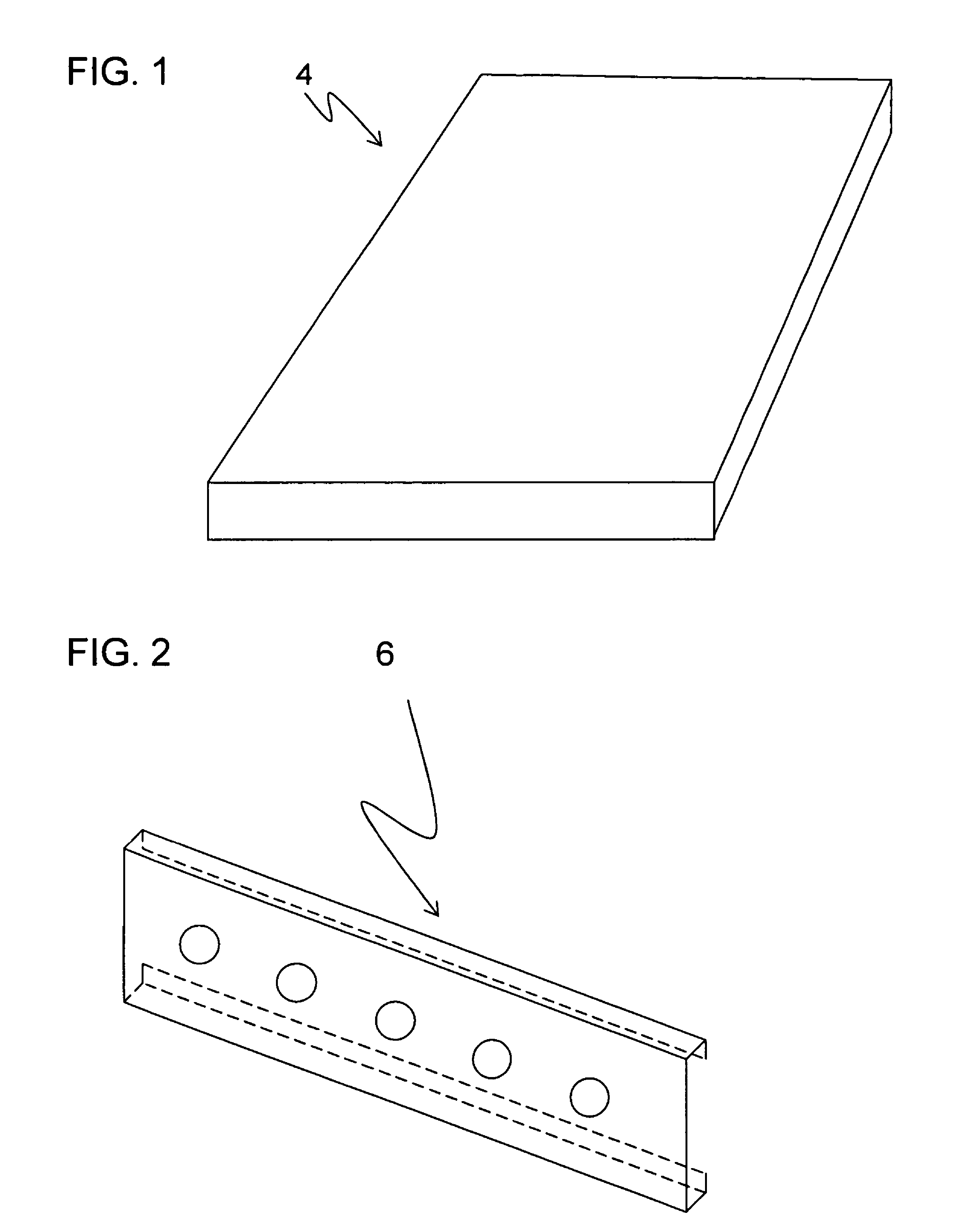

High performance non-combustible gypsum-cement compositions with enhanced water durability and thermal stability for reinforced cementitious lightweight structural cement panels

ActiveUS8038790B1Reduce weightPerformance requirementConstruction materialSolid waste managementOperating energyAir entrainment

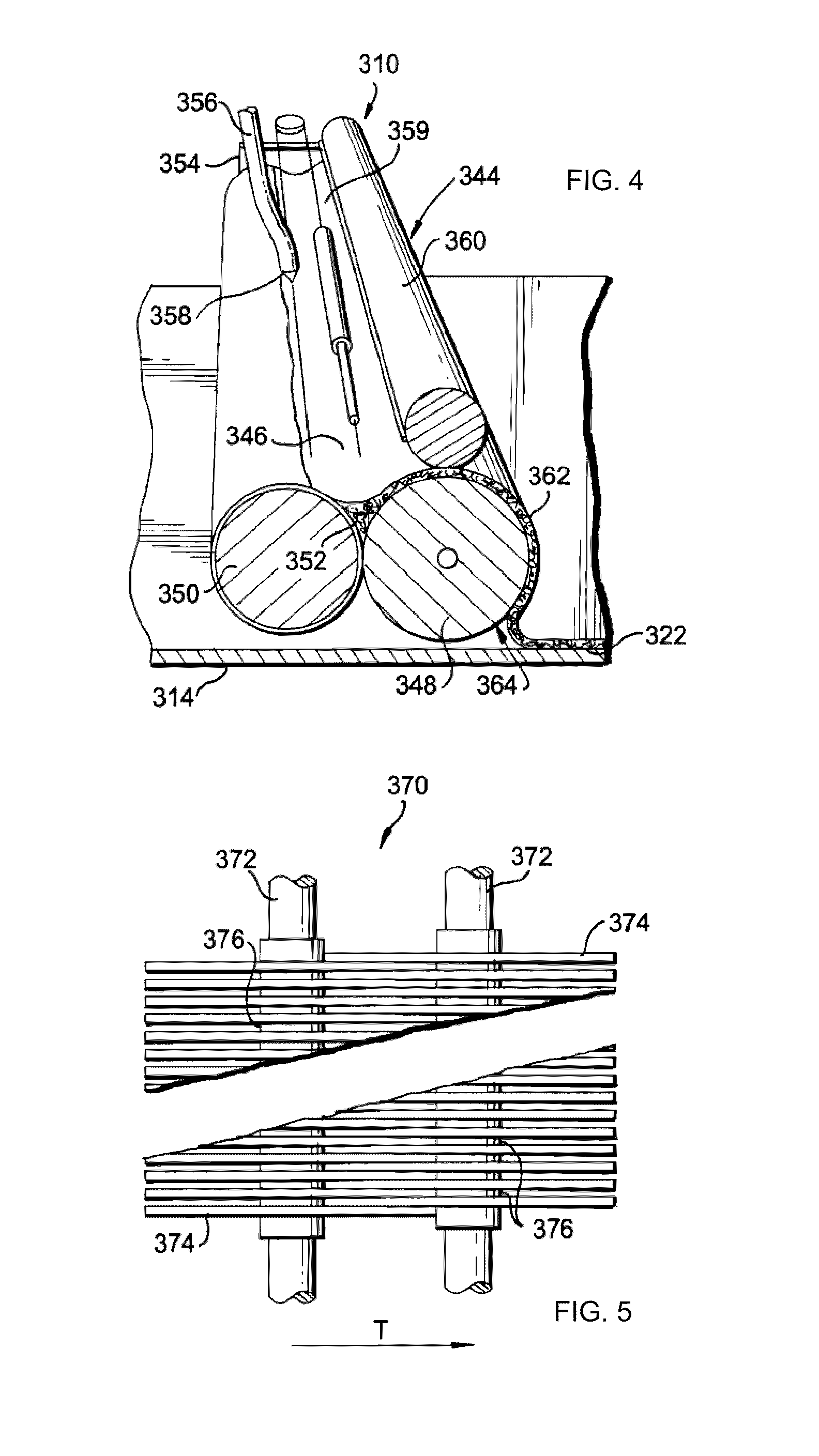

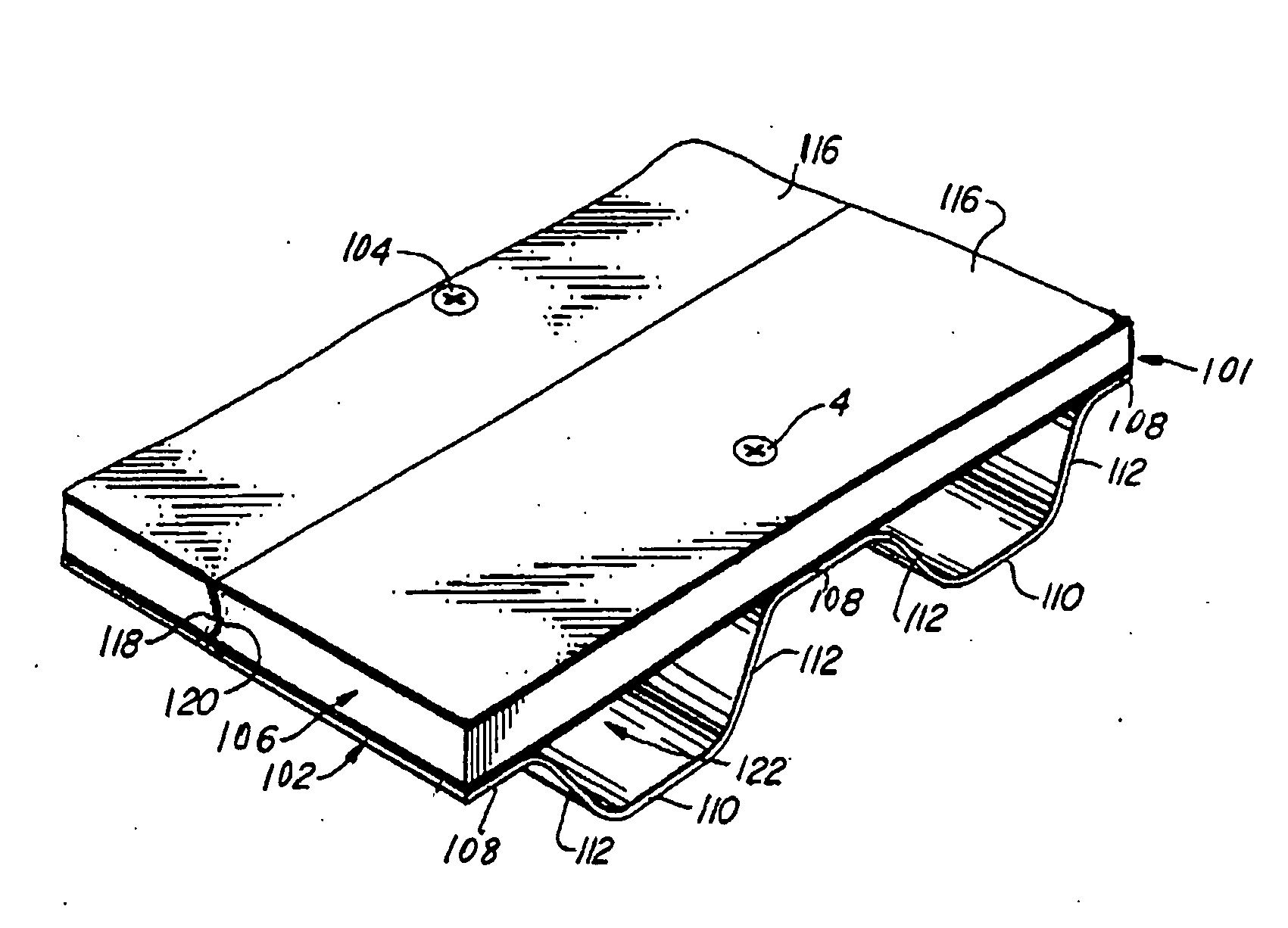

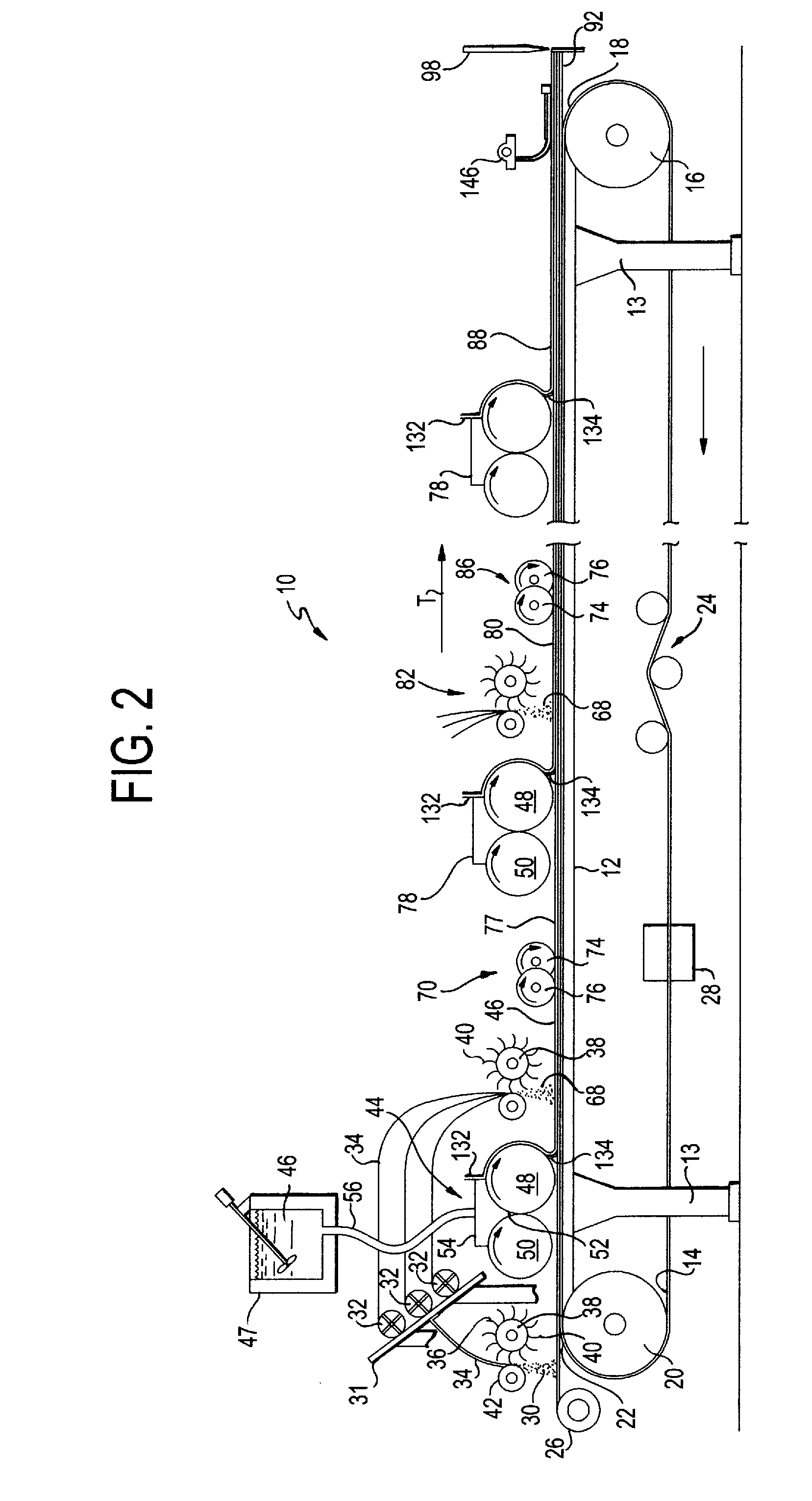

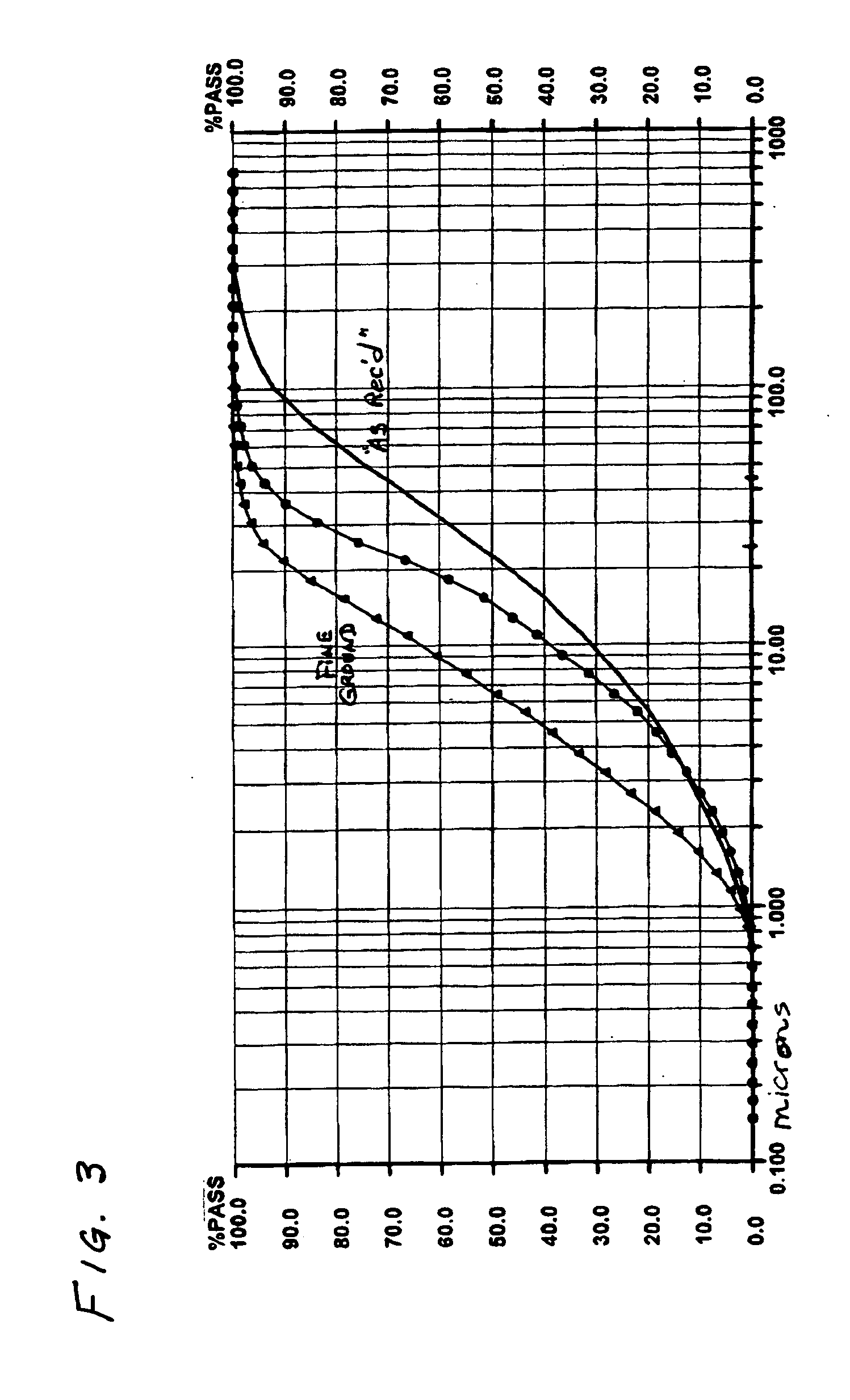

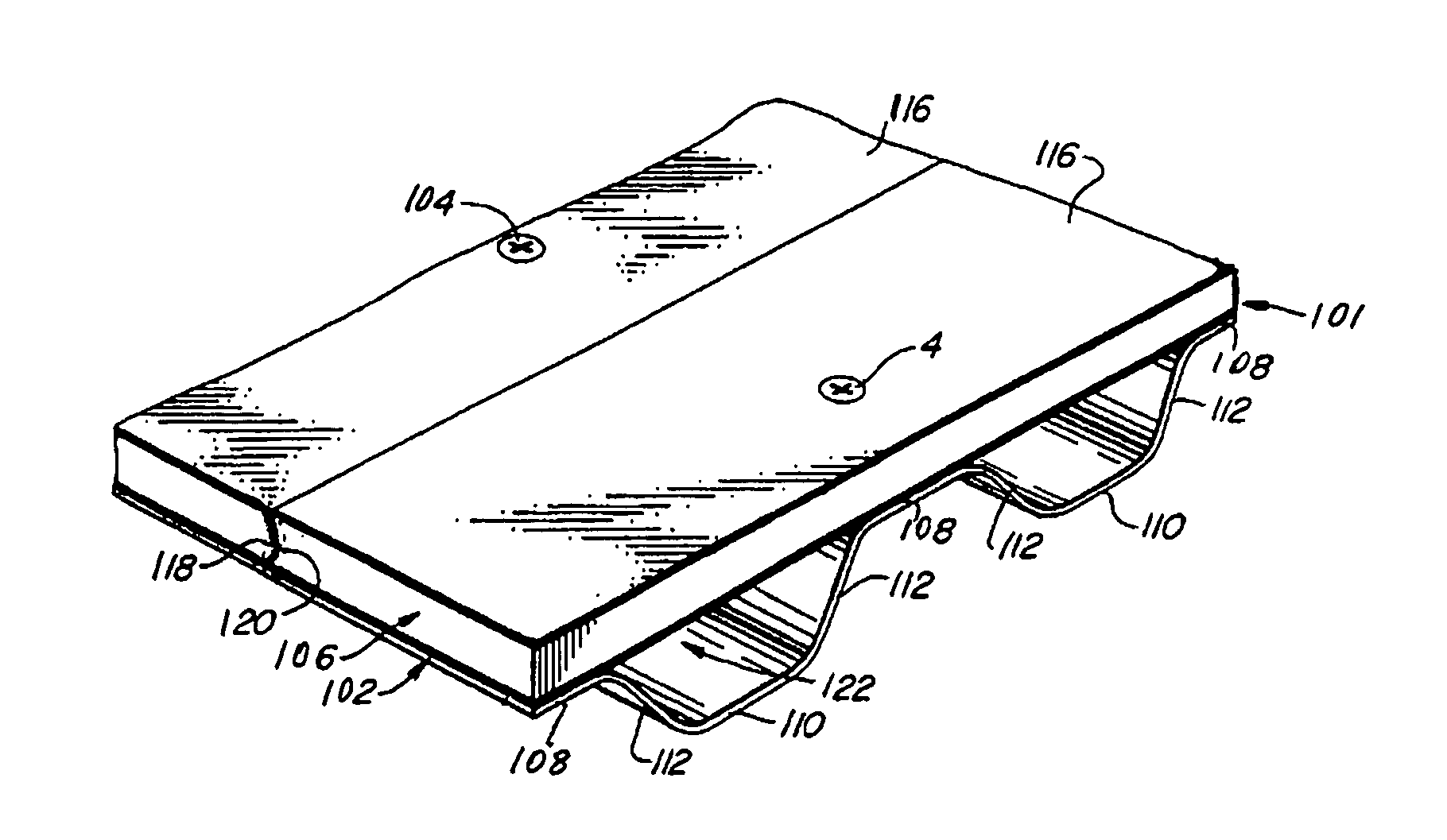

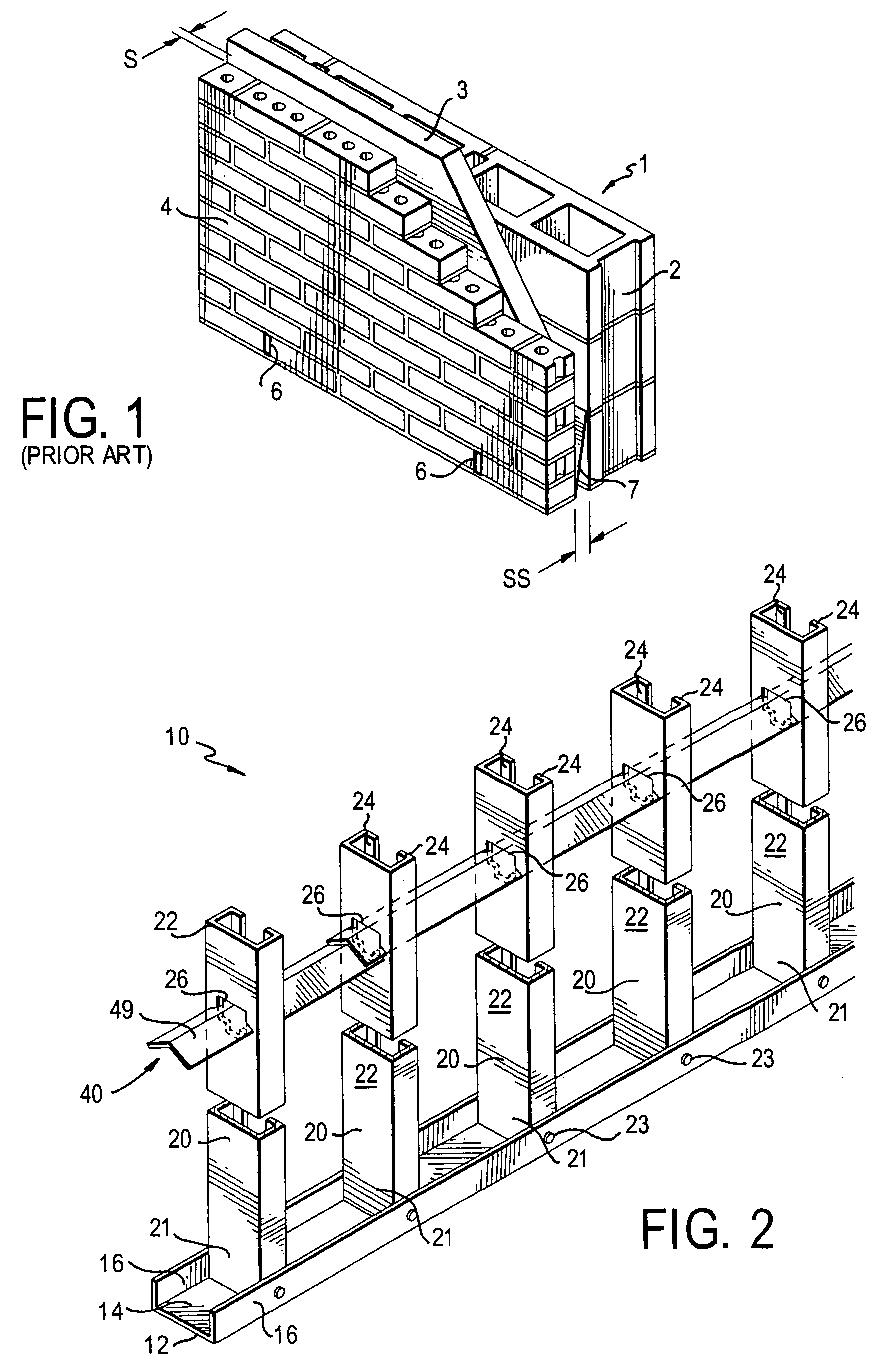

Structural cement panel for resisting transverse and shear loads equal to transverse and shear loads provided by plywood and oriented strain board, when fastened to framing for use in shear walls, flooring and roofing systems. The panels provide reduced thermal transmission compared to other structural cement panels. The panels employ one or more layers of a continuous phase resulting from curing an aqueous mixture of calcium sulfate alpha hemihydrate, hydraulic cement, coated expanded perlite particles filler, optional additional fillers, active pozzolan and lime. The coated perlite has a particle size of 1-500 microns, a median diameter of 20-150 microns, and an effective particle density (specific gravity) of less than 0.50 g / cc. The panels are reinforced with fibers, for example alkali-resistant glass fibers. The preferred panel contains no intentionally added entrained air. A method of improving fire resistance in a building is also disclosed.

Owner:UNITED STATES GYPSUM CO

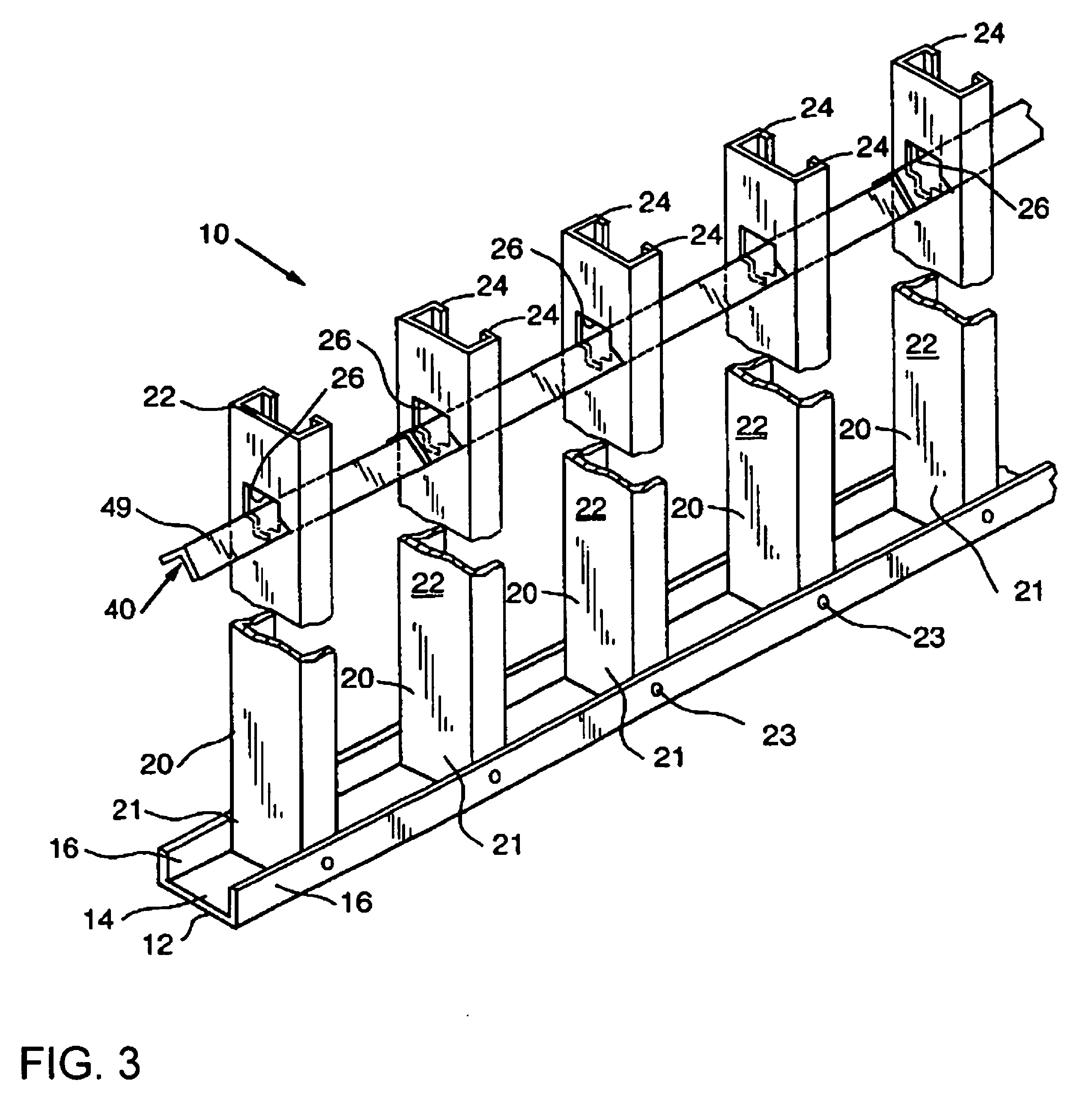

Non-combustible reinforced cementitious lighweight panels and metal frame system for a fire wall and other fire resistive assemblies

ActiveUS20060168906A1Reduce buildReduce capacityBuilding roofsSolid waste managementMicrosphereMetal framework

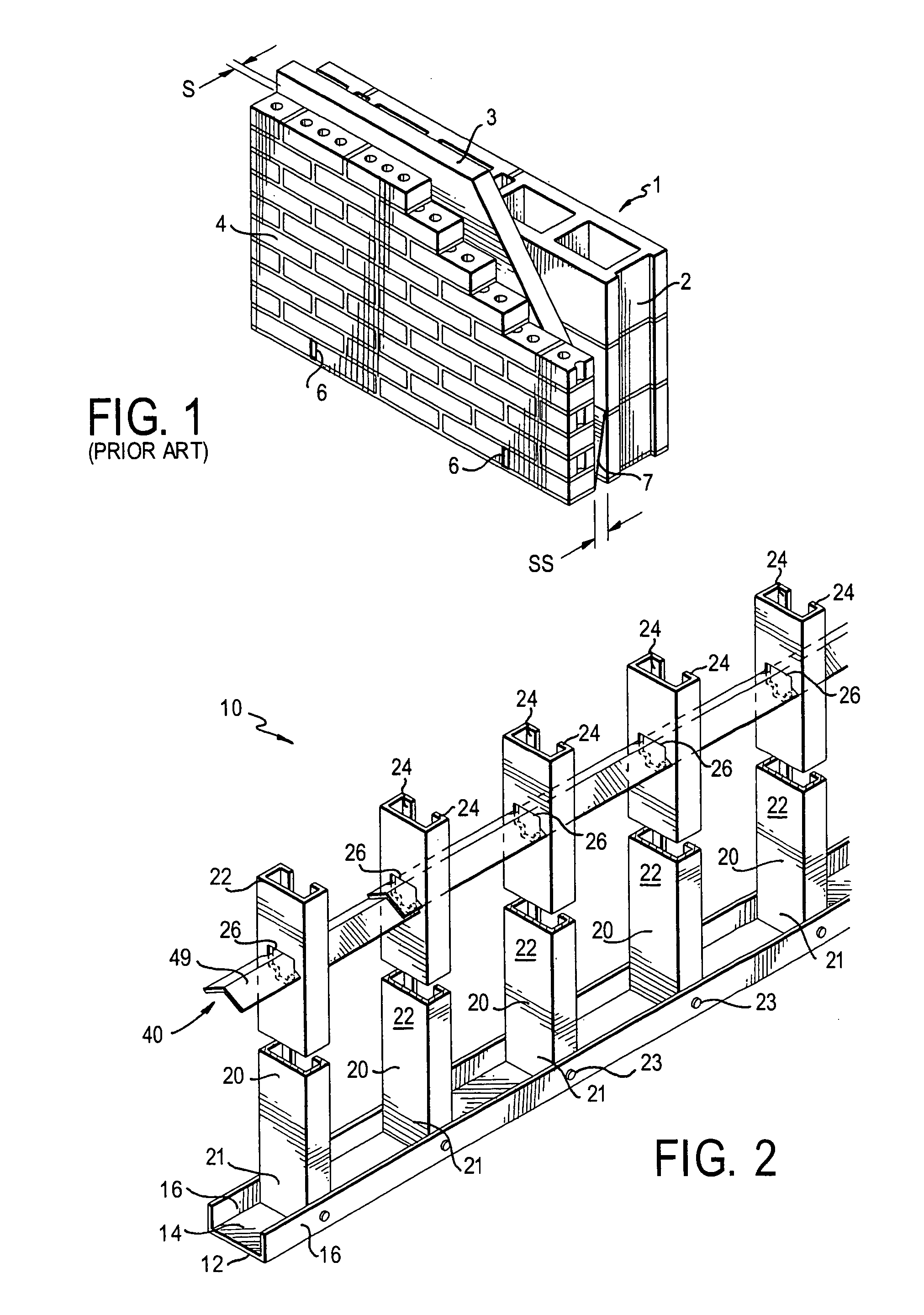

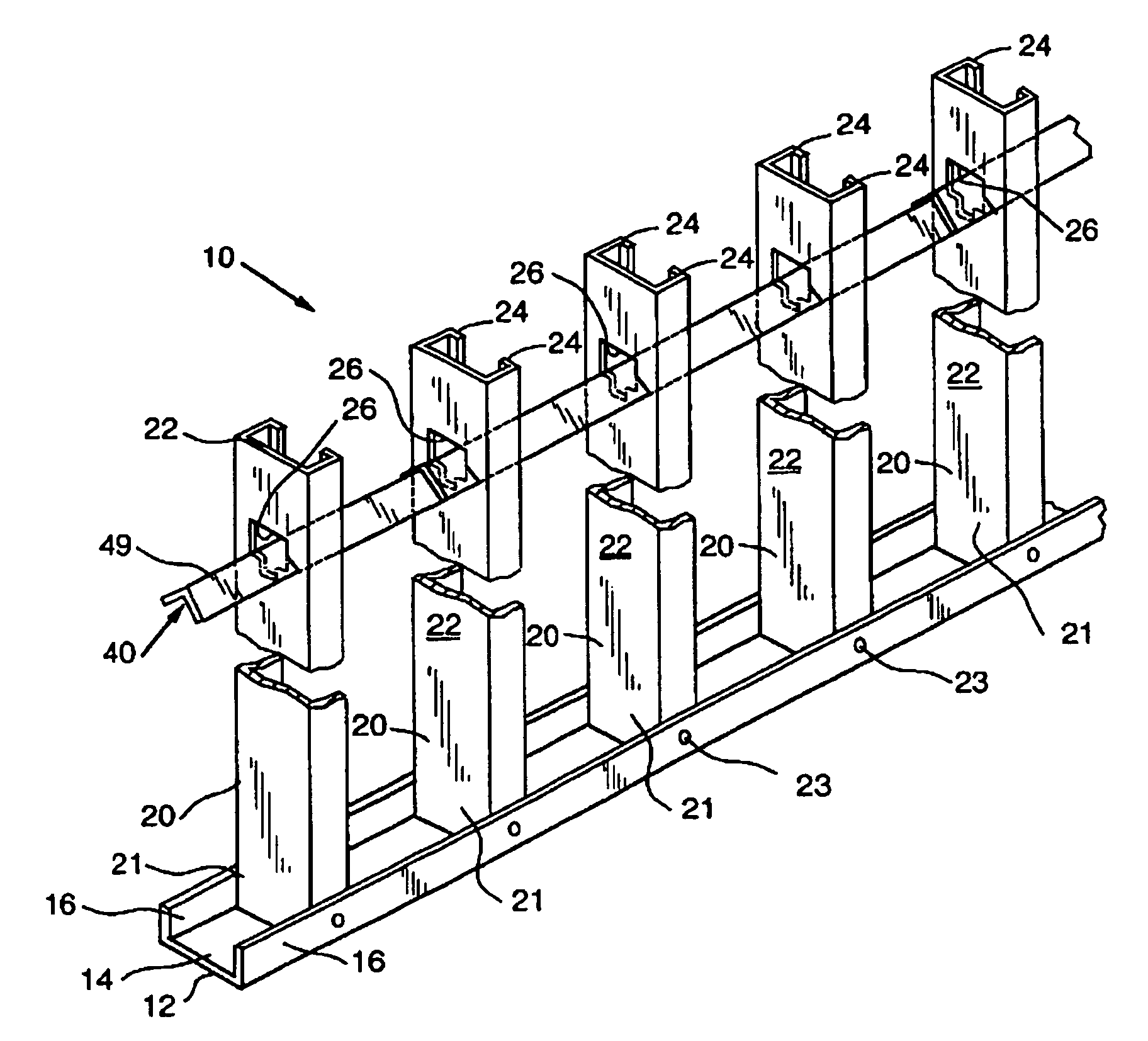

A fire resistive assembly including metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The assembly is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

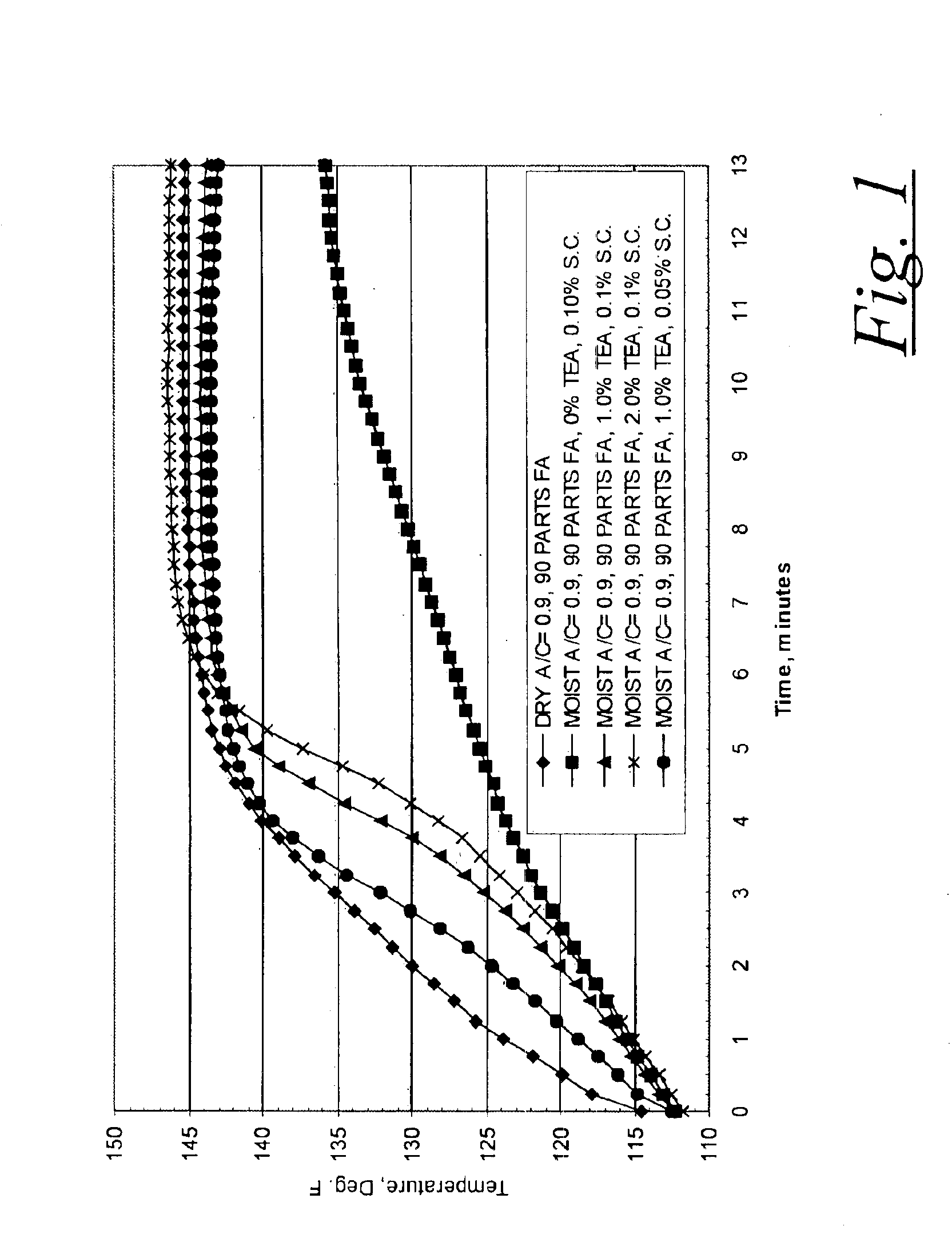

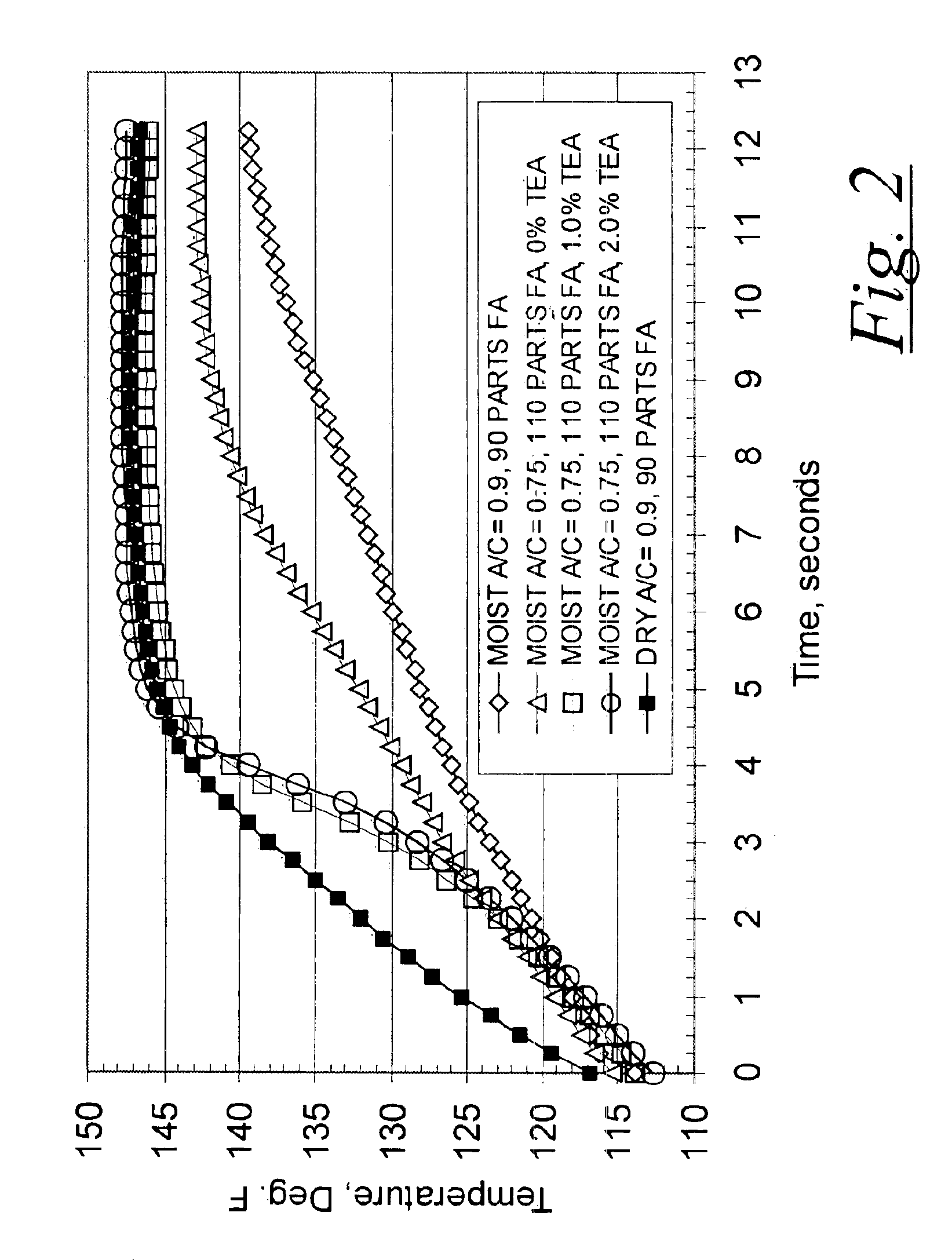

Very fast setting cementitious composition

Extremely fast setting of cementitious compositions for producing cement-based products such as cement boards is made possible by adding an alkanolamine to a hydraulic cement such as portland cement, and forming a slurry with water under conditions that provide an initial slurry temperature of at least 90° F. Use of alkanolamine under conditions disclosed herein allows an extremely rapid setting of the cementitious composition. Additional reactive materials may be included such as high alumina cement, calcium sulfate and a pozzolanic material such as fly ash. The extremely fast rapid set permits rapid production of cementitious products.

Owner:UNITED STATES GYPSUM CO

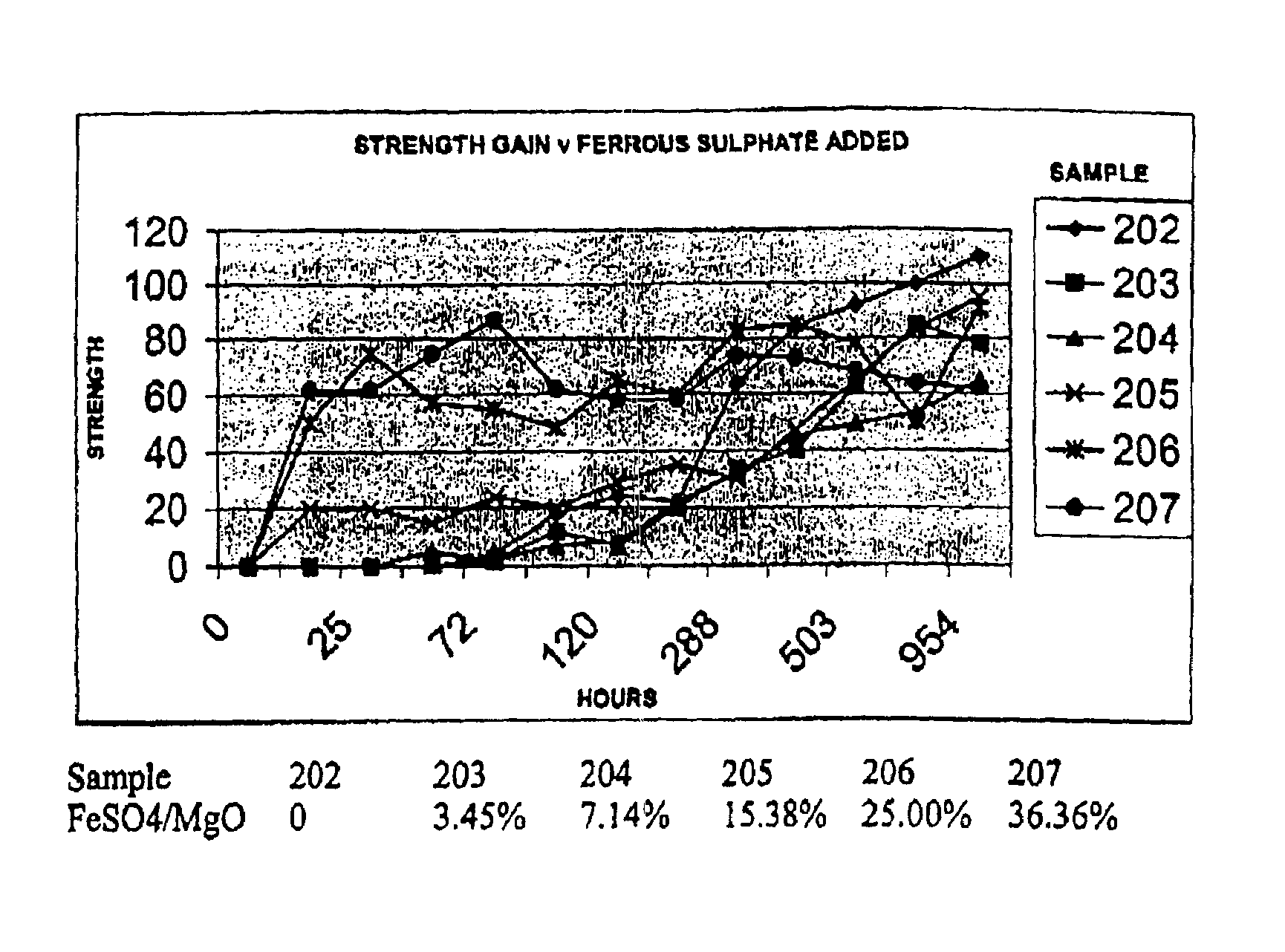

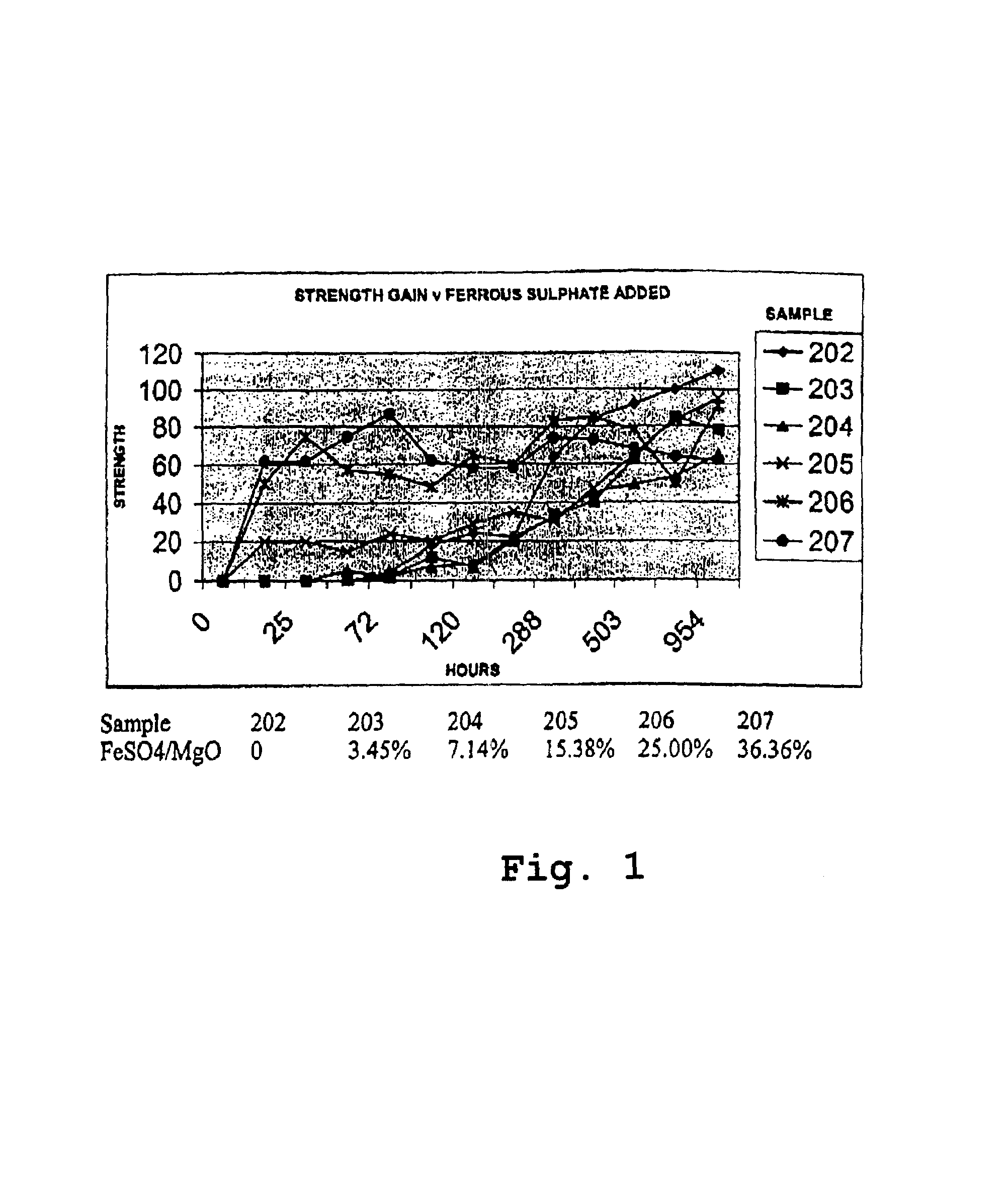

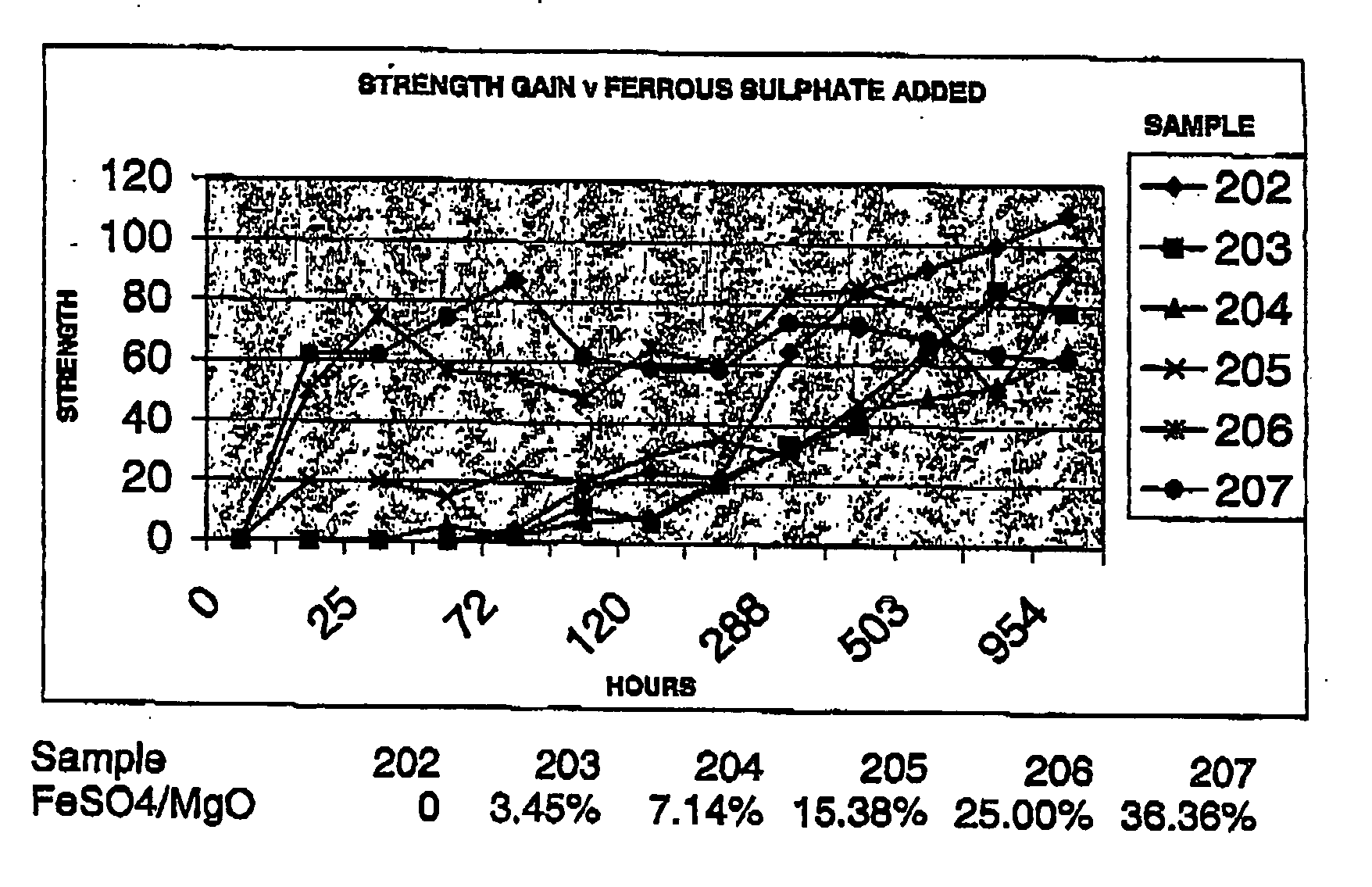

Reactive magnesium oxide cements

Novel hydraulic cements are disclosed that include reactive magnesium oxide prepared by low temperature calcination. The cements can be formulated to suit a large number of applications with various setting times, strength and levels of sustainability either by adding iron salts such as ferrous sulfate or blending with other compatible faster setting hydraulic cements such as Portland cement or by using both methods.The compositions are able to incorporate relatively large amounts of low cost pozzolans such as fly ash to advantage as well as wastes. Many excellent properties are exhibited and in particular good comprehensive strength and resistance to sulfates is able to be achieved.

Owner:TECECO

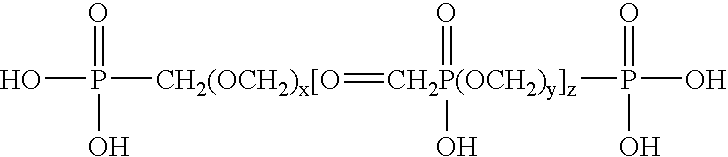

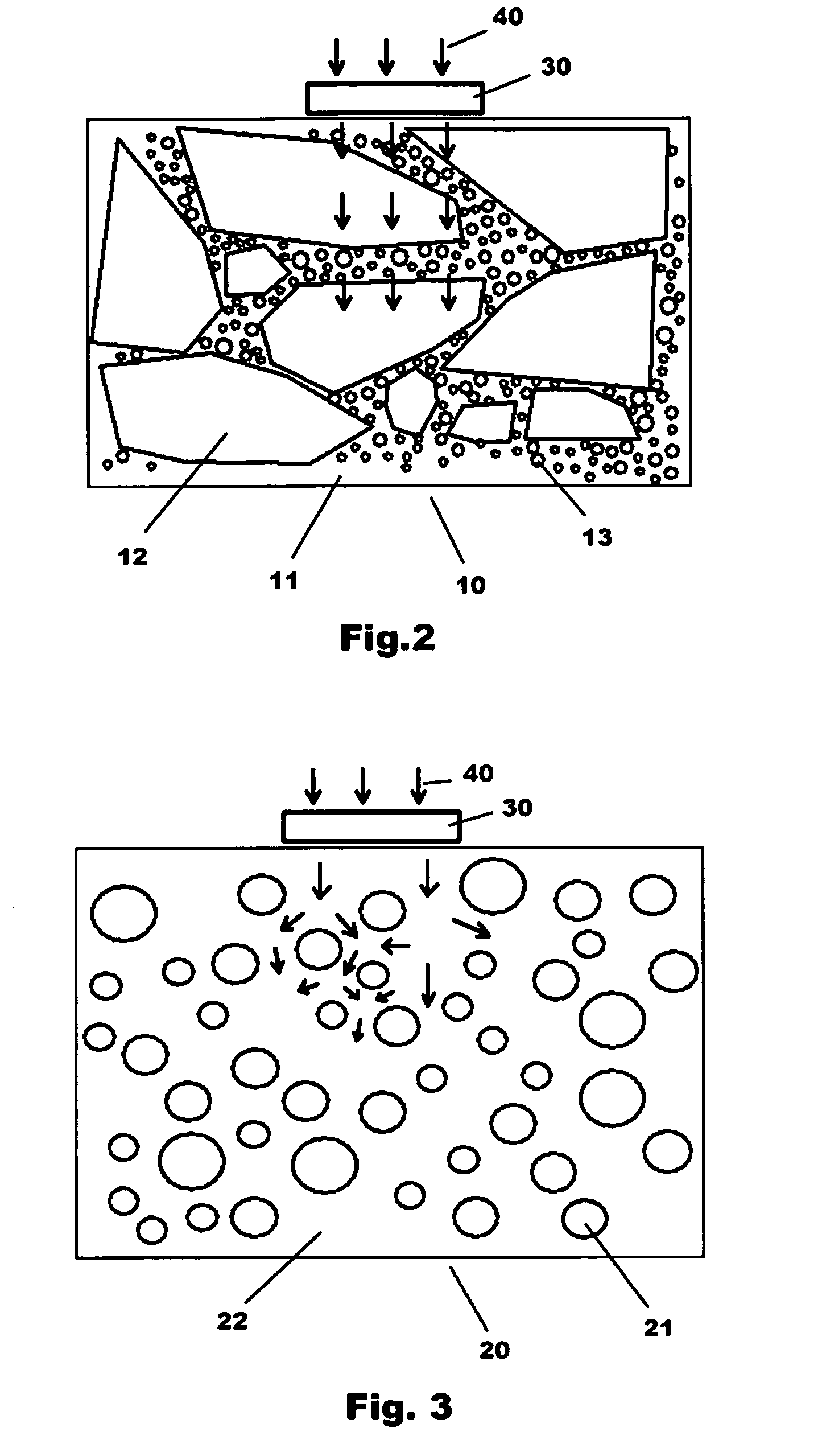

Concrete mixtures incorporating high carbon pozzolans and foam admixtures

InactiveUS20070056479A1High strengthReduce the amount requiredSolid waste managementPolymer scienceOligomer

Concrete mixtures are manufactured to include high carbon pozzolans and a foam admixture (for air entrainment). The foam bubbles in the foam admixture are stabilized in the presence of the high carbon fly ash by a fluorochemical surfactant. The fluorochemical surfactant preferably comprises an oligomer comprising hydrophilic nonionic monomers and hydrophilic anionic monomers. The high carbon pozzolans can preferably have an LOI greater than between about 1.5% and about 6.0%, without substantially affecting the durability of the foam bubbles in the concrete mixture.

Owner:JACK B PARSON

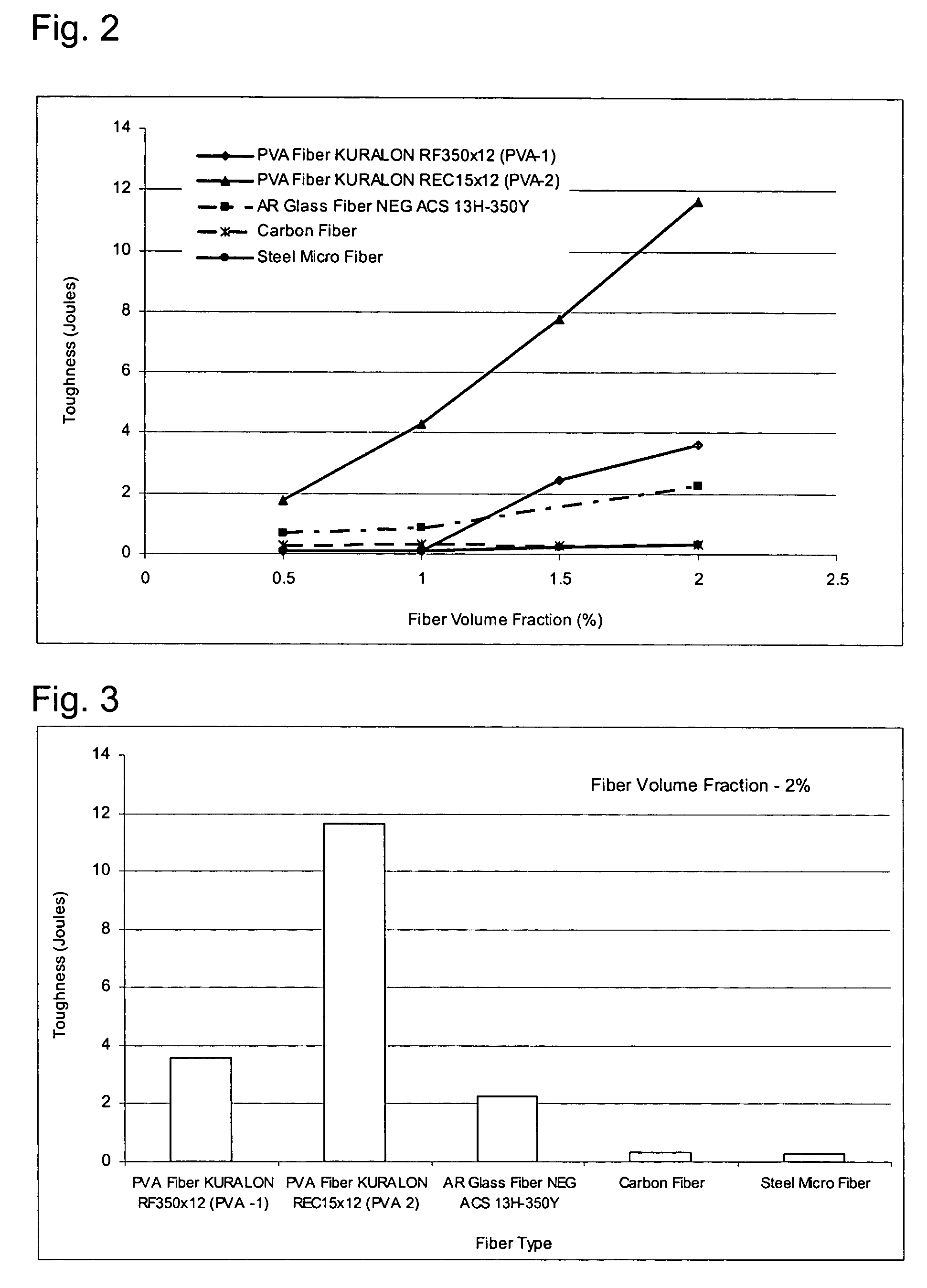

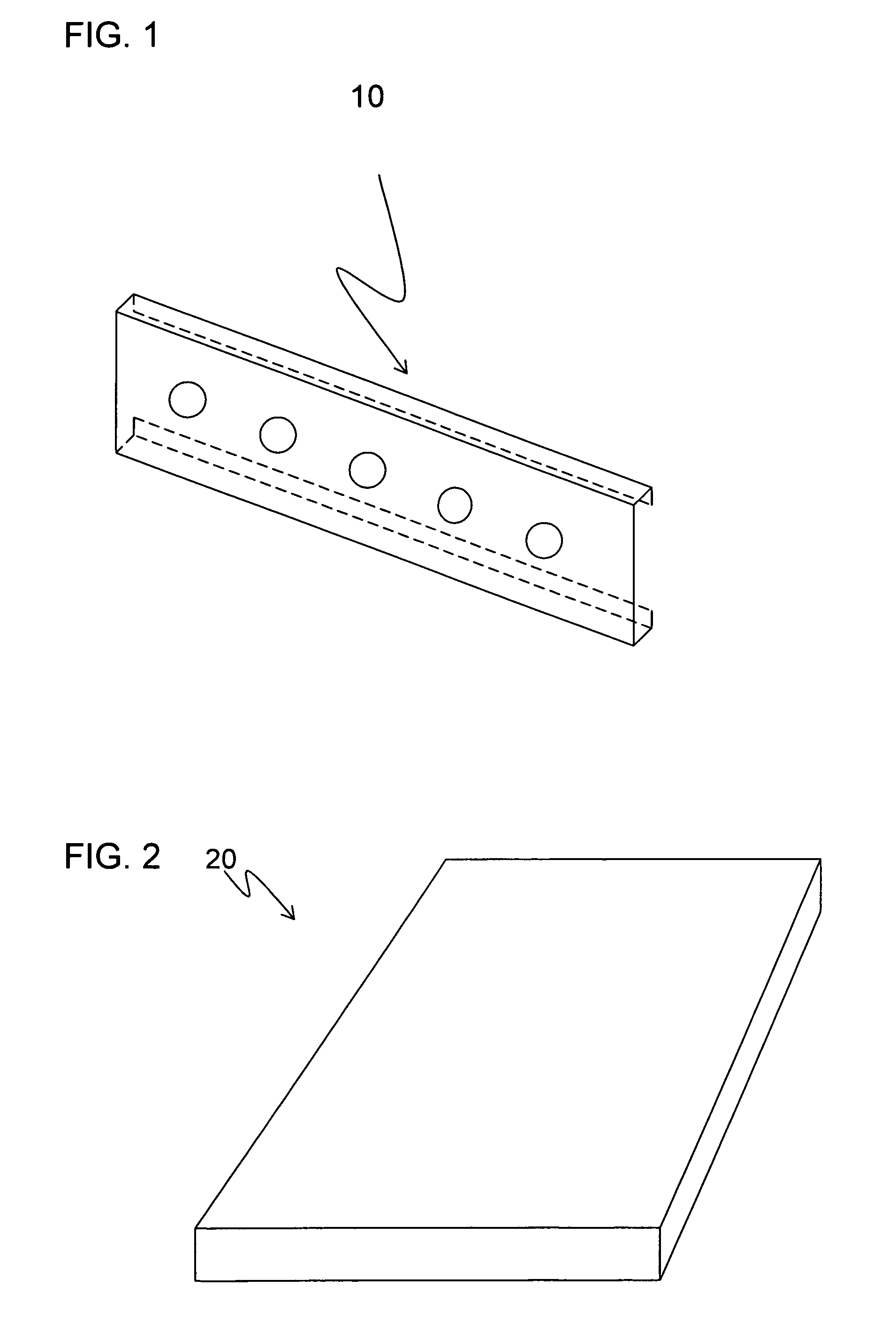

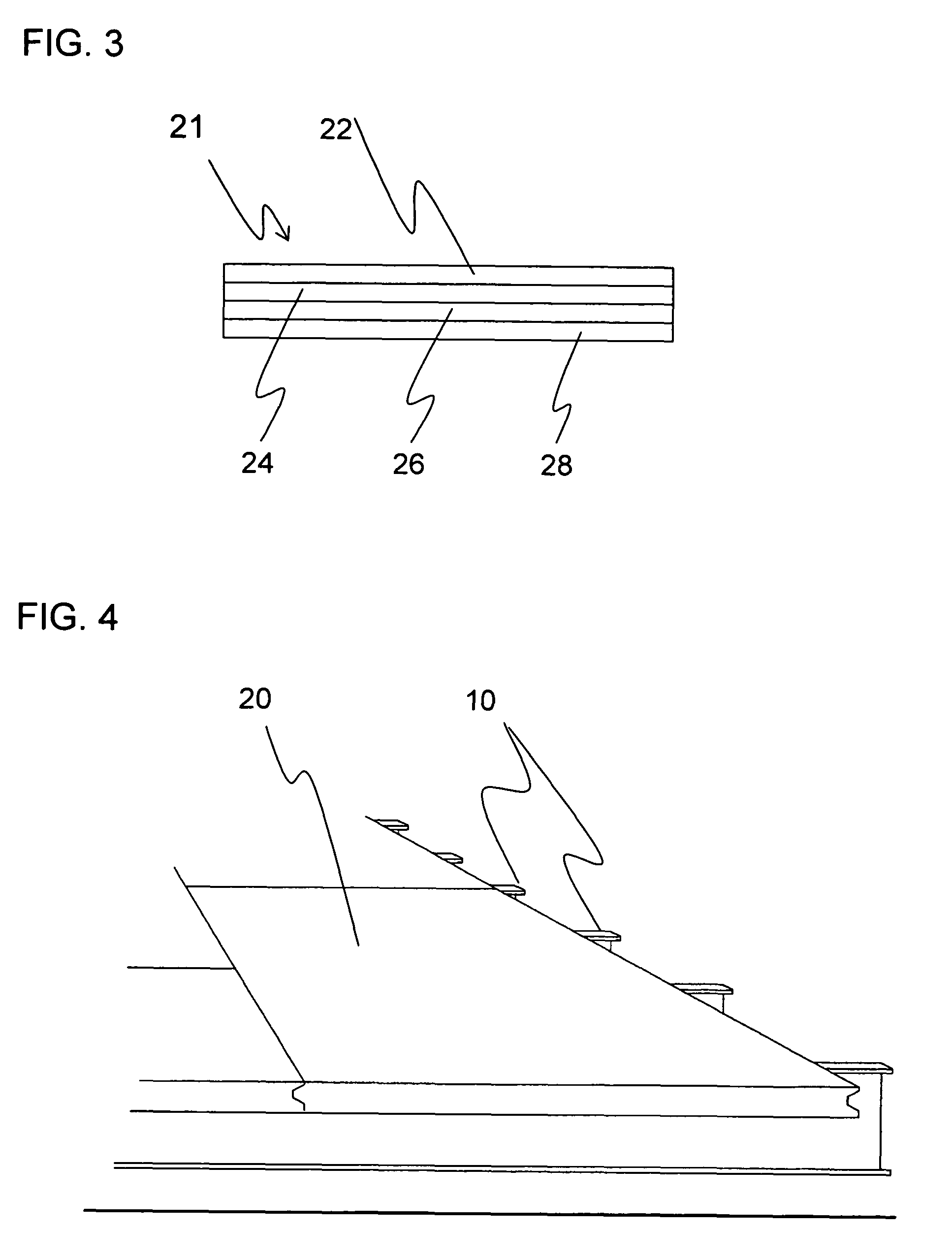

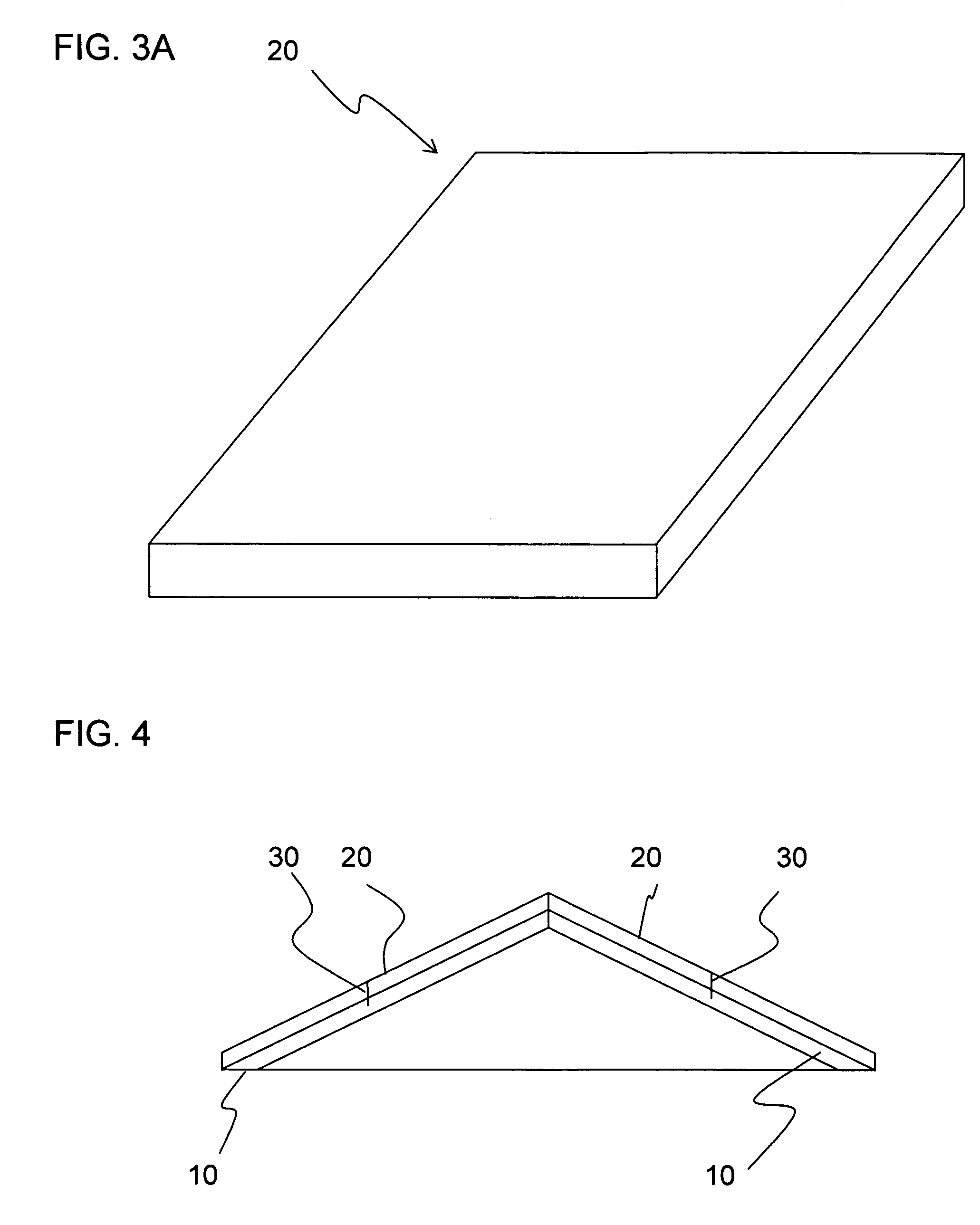

Lightweight, fiber-reinforced cementitious panels

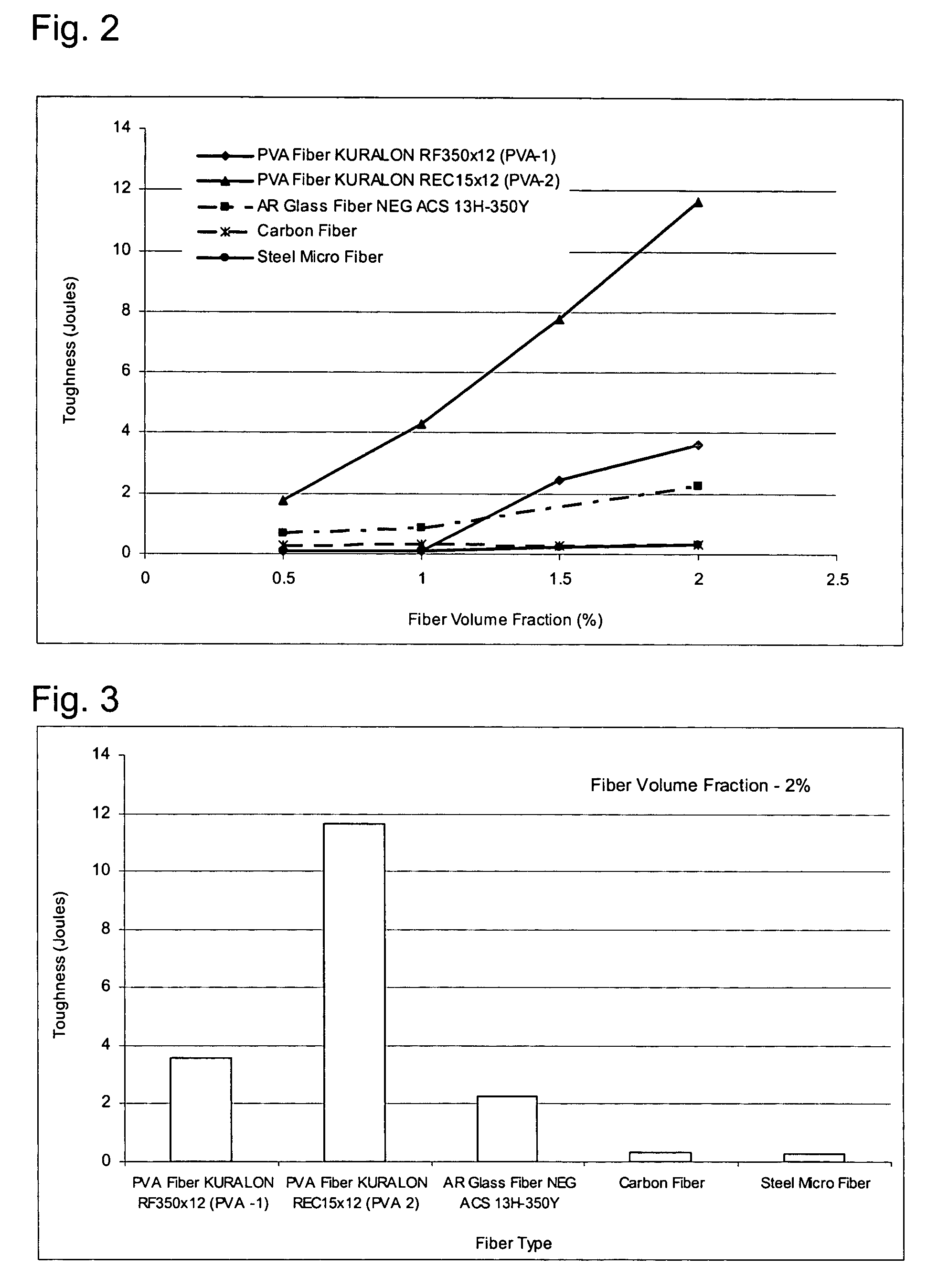

ActiveUS20060147681A1Significant toughnessComposite goodConstruction materialCovering/liningsCement boardToughness

Lightweight, fiber reinforced, cementitious panels possessing exceptional toughness for use as building components in applications such as roofing elements, siding elements, framing and sheathing elements, and substrate elements for installation of floor finishes in residential and other building construction types. The panels employ a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, PVA fibers and lightweight filler. The inorganic binder may be, for example, hydraulic cement alone, or a combination of hydraulic cement and pozzolan / s, or a combination of hydraulic cement, alpha hemihydrate, active pozzolan and optionally lime. The PVA fibers reinforce the continuous phase and are randomly distributed throughout the composite. Typical panels of the invention have a density of 60-85 pcf.

Owner:UNITED STATES GYPSUM CO

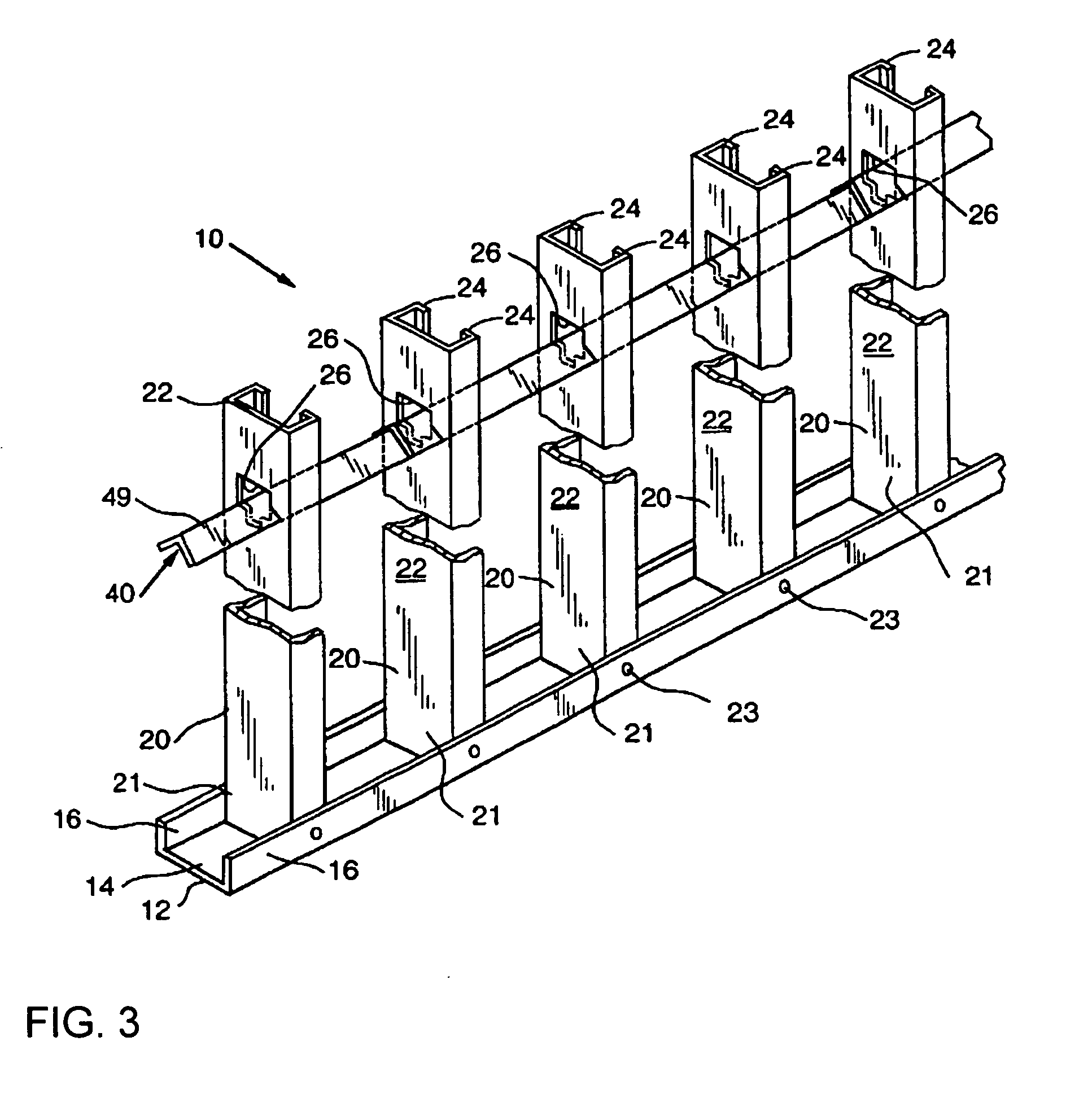

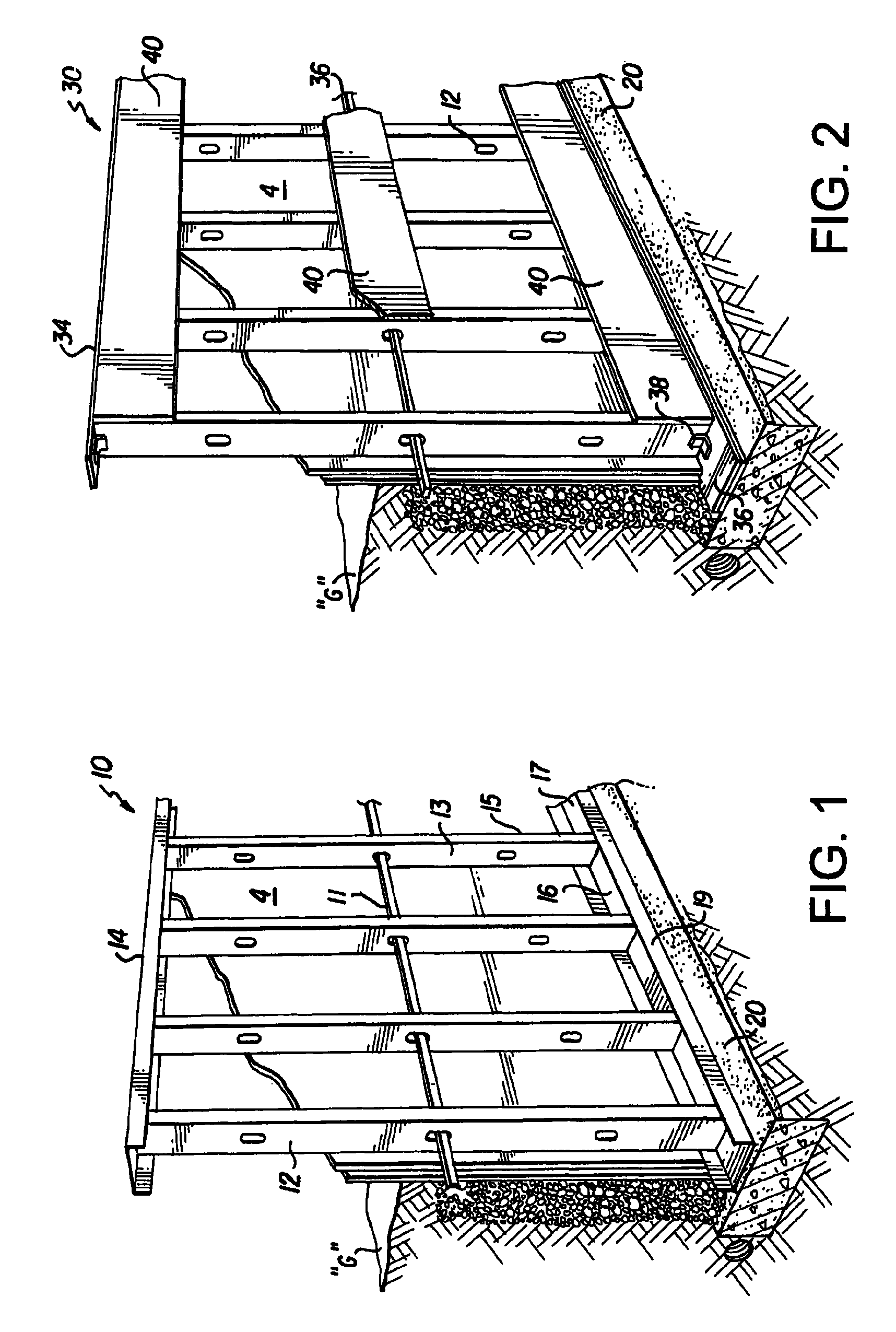

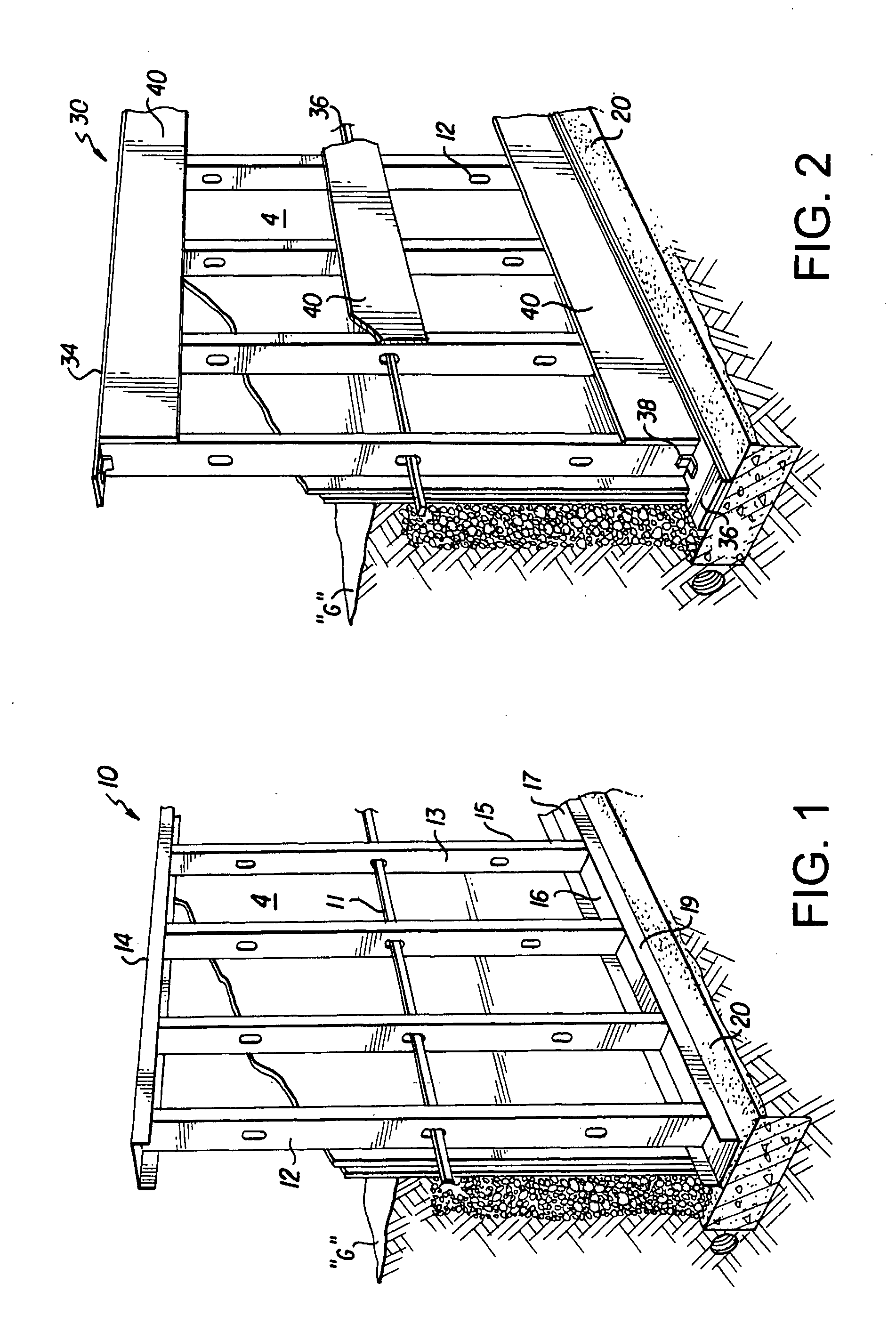

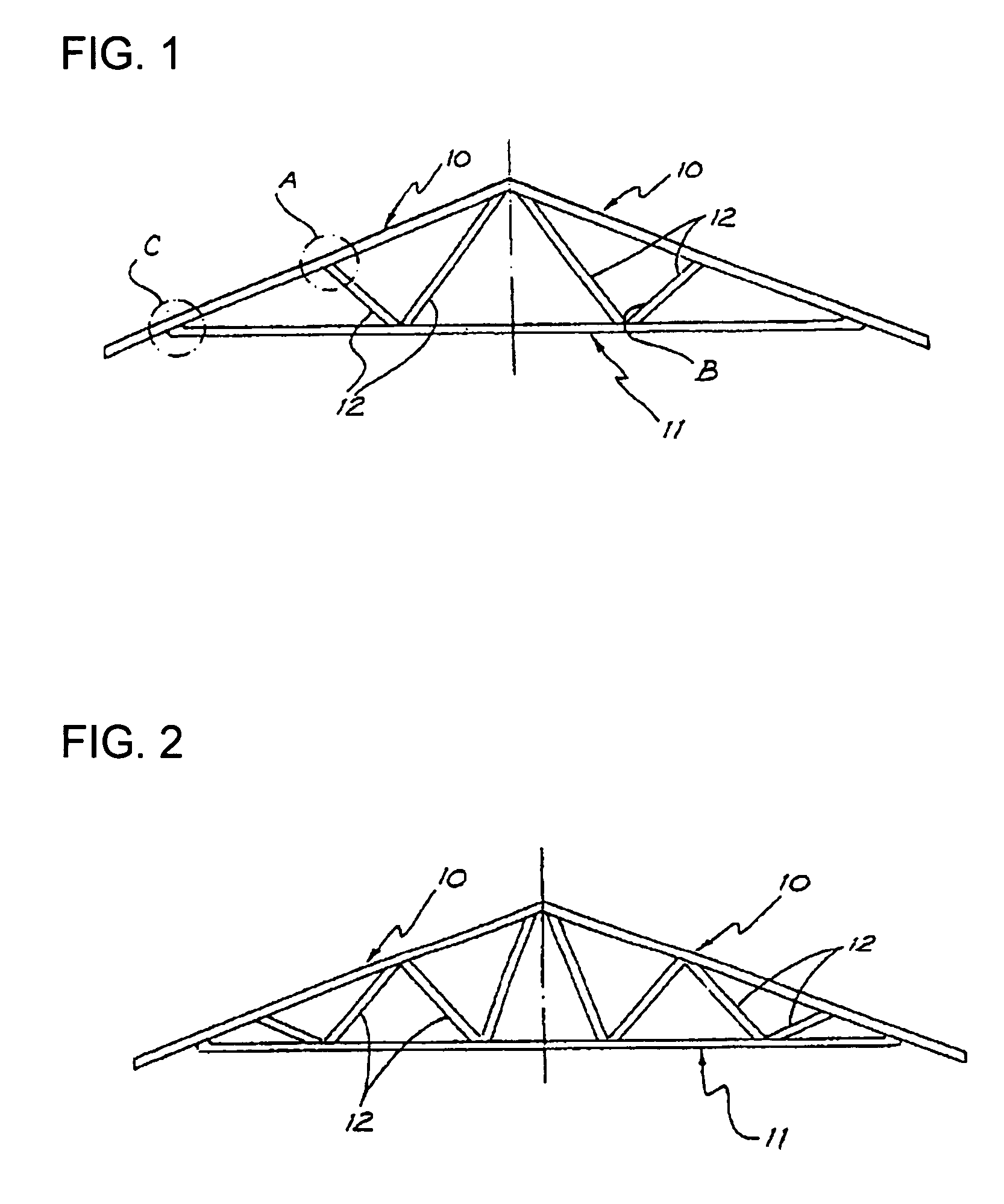

Non-combustible reinforced cementitious lightweight panels and metal frame system for flooring

ActiveUS20060144005A1Easy constructionIncreasing builder productivitySolid waste managementFloorsMicrosphereEngineering

A flooring system including horizontal metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The flooring system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

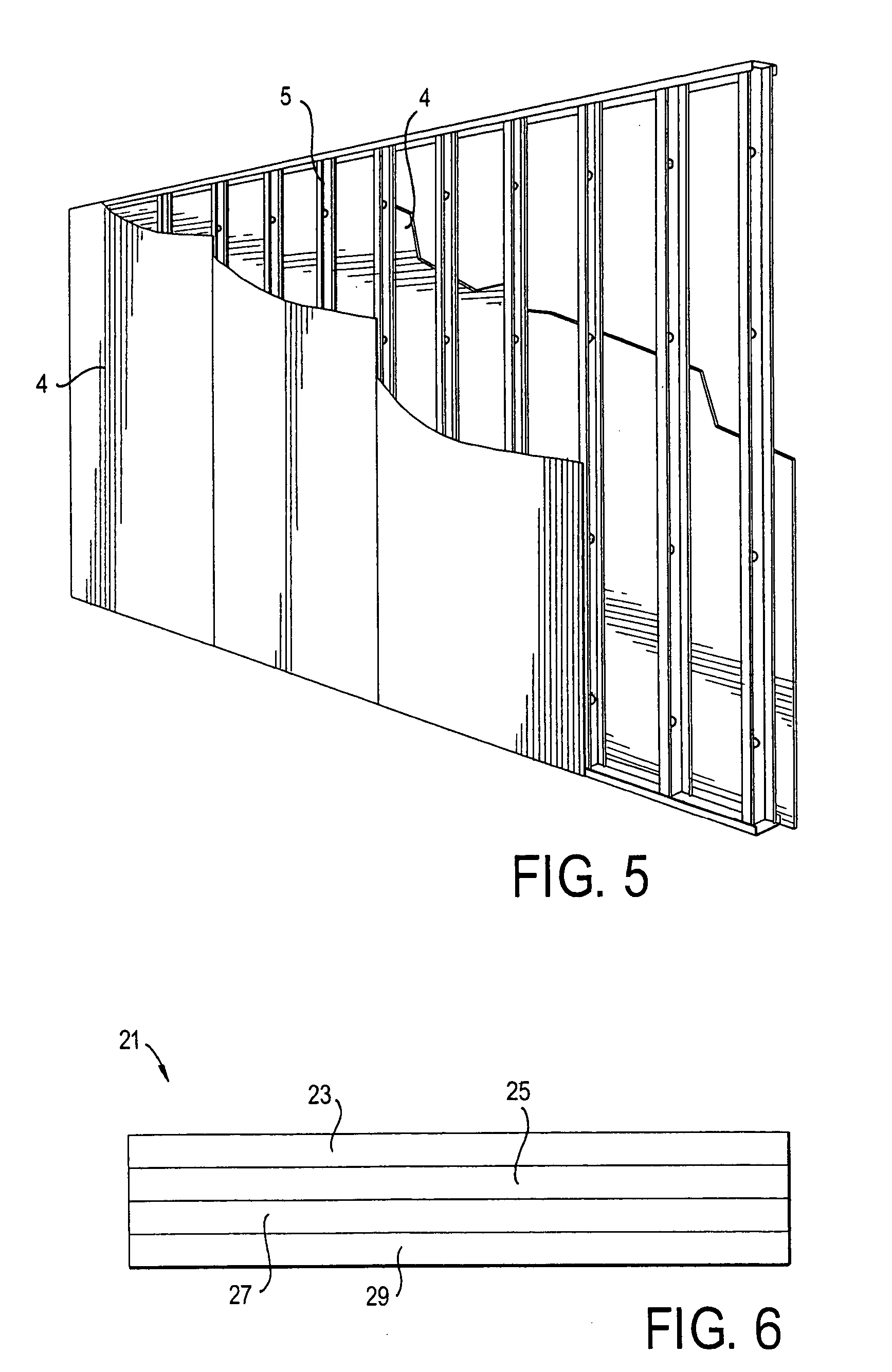

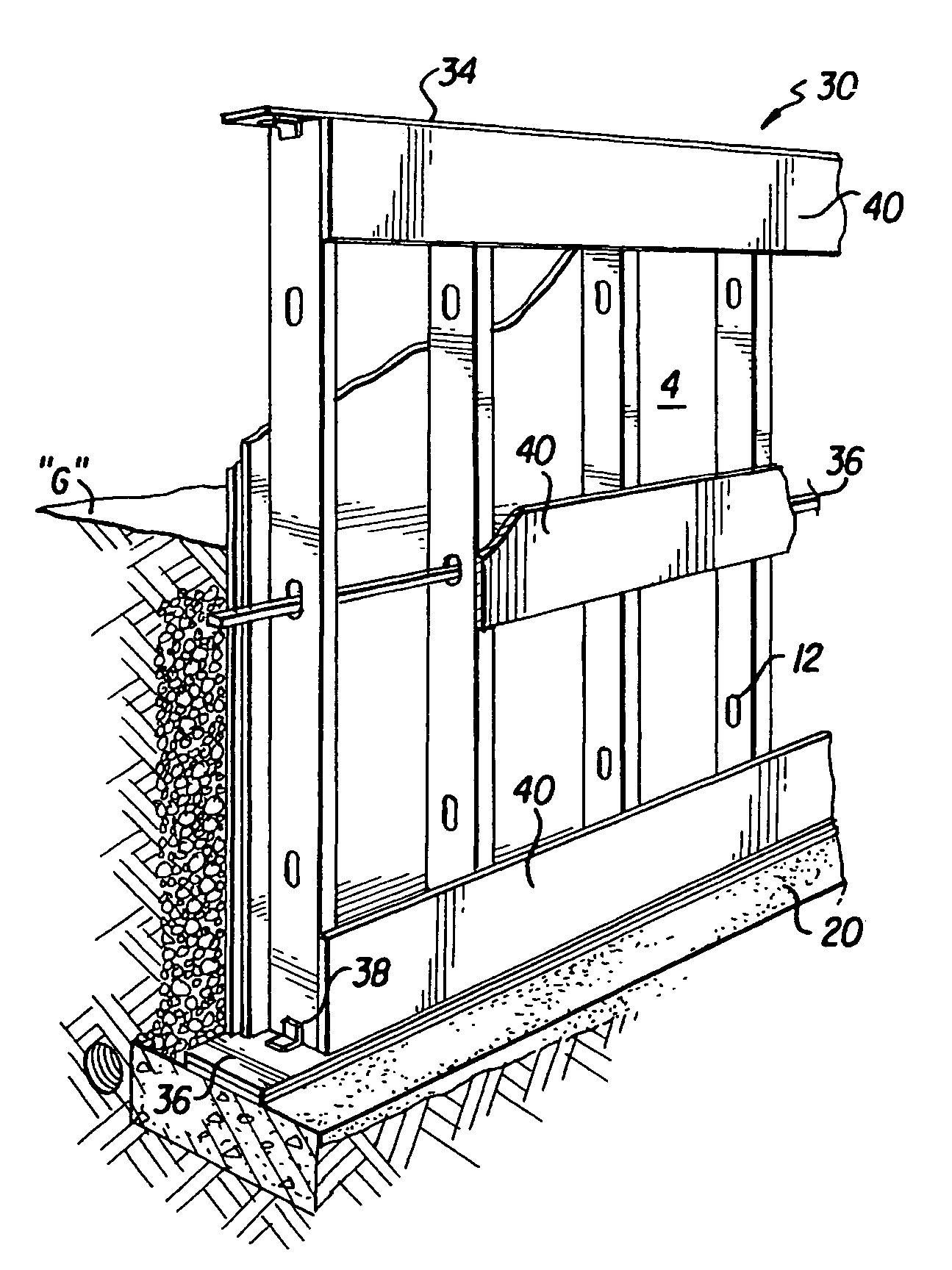

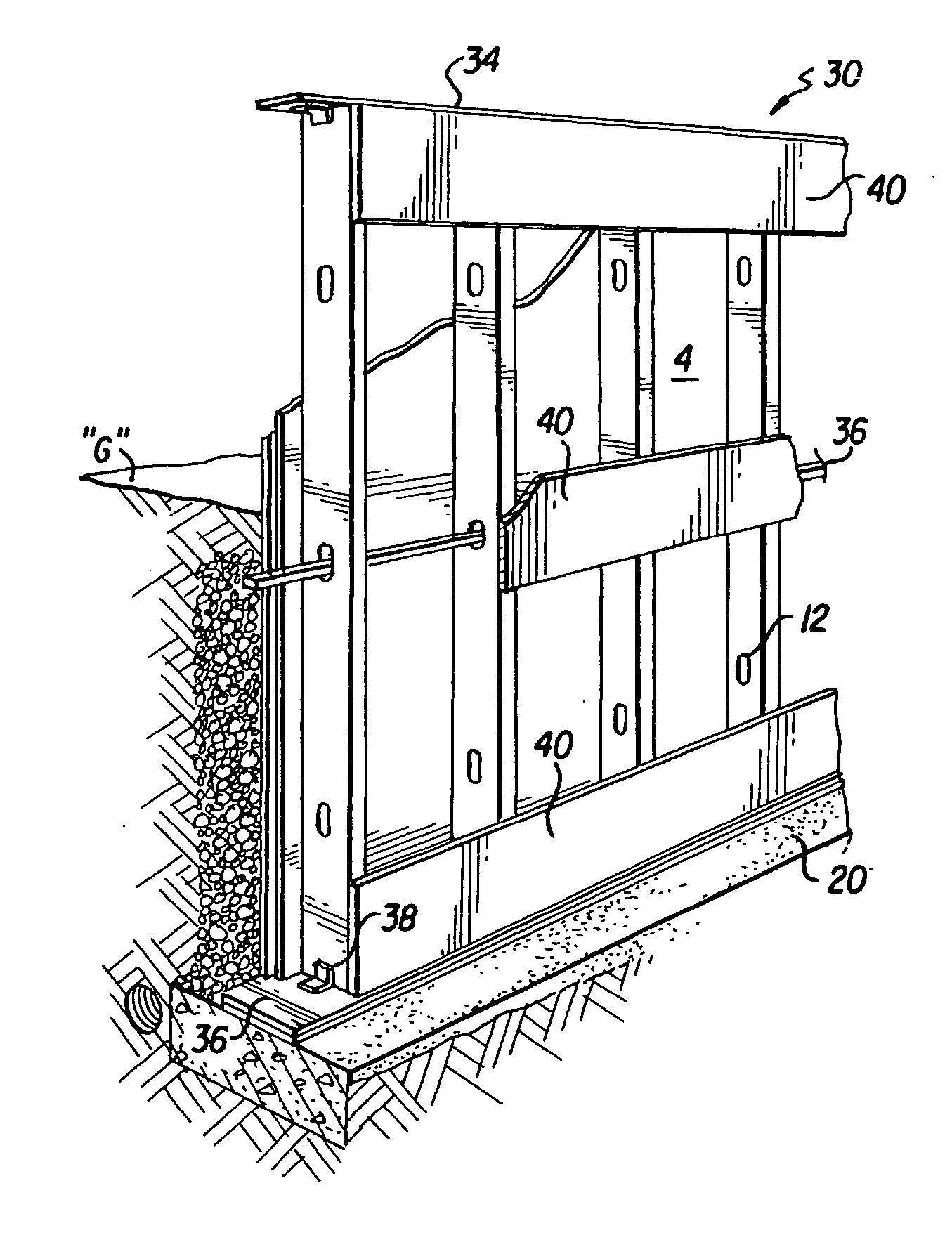

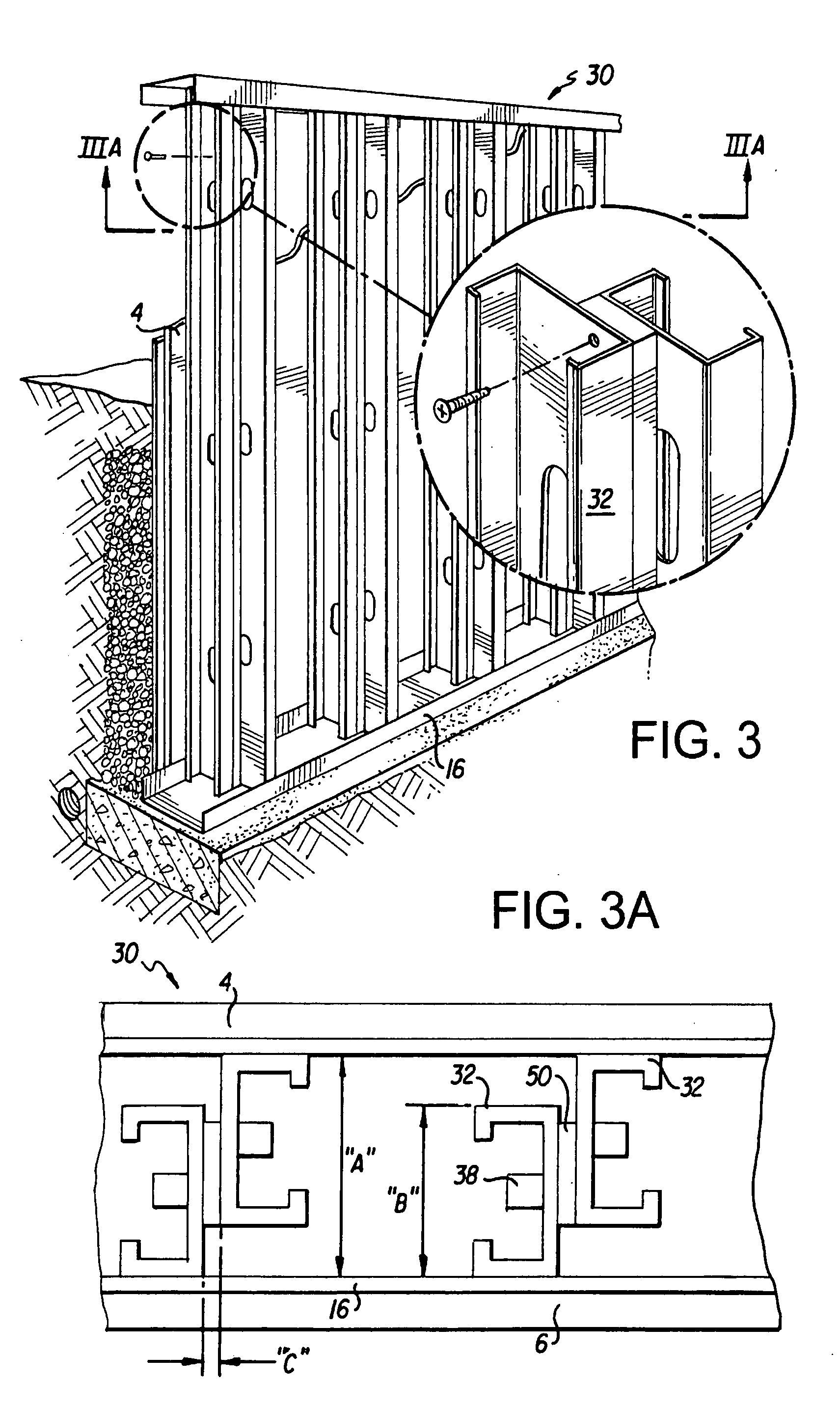

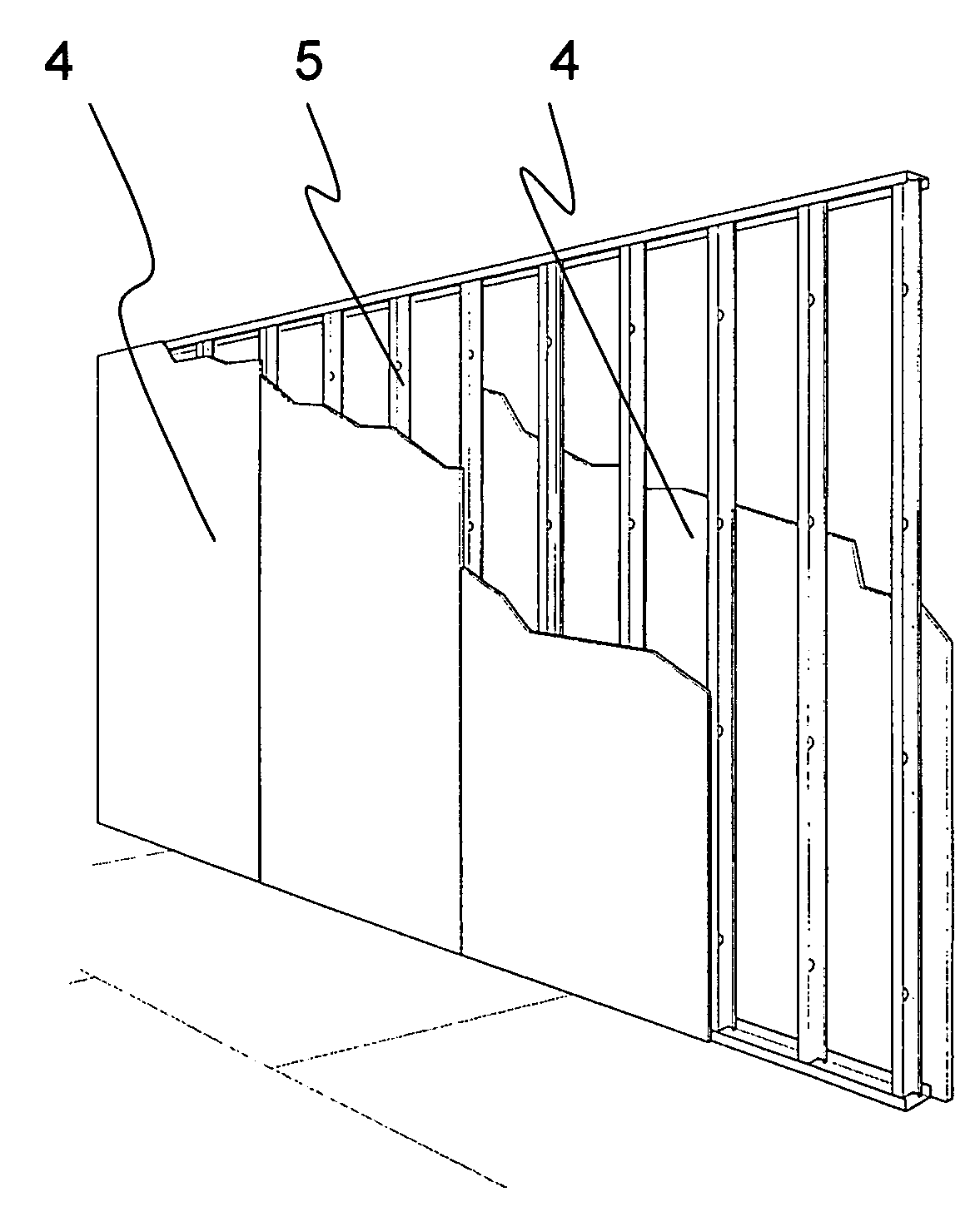

Non-combustible reinforced cementitious lightweight panels and metal frame system for shear walls

ActiveUS20060174572A1Heavy loadMaximization of building volumeSolid waste managementWallsMicrosphereVertical shear

A vertical shear wall system including vertical metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The shear wall system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Low density cements for use in cementing operations

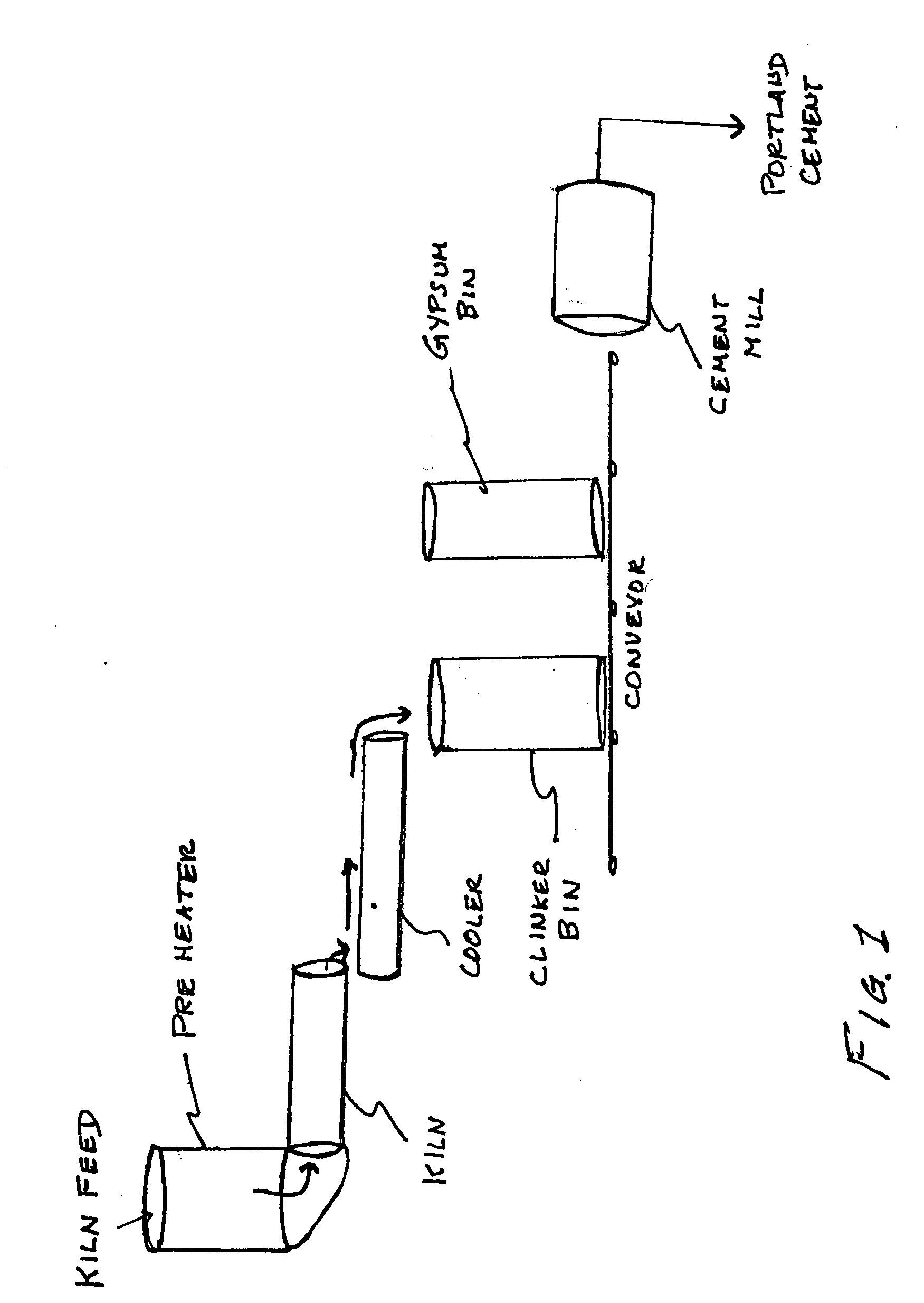

A cement mix suitable for blocking or plugging an abandoned pipeline or back filling a mine shaft, tunnel or excavations contains Portland cement or a cement blend of two components selected from Portland cement, fly ash, pozzolan, slag, silica fume and gypsum; diatomaceous earth; zeolite and an inorganic salt accelerator. The cement mix may further contain an alkali metasilicate and / or alkali silicate. A cementitious slurry, formulated from the cement mix, may have a density less than or equal to 1500 kg / m3, and exhibits good compressive strength.

Owner:BAKER HUGHES INC

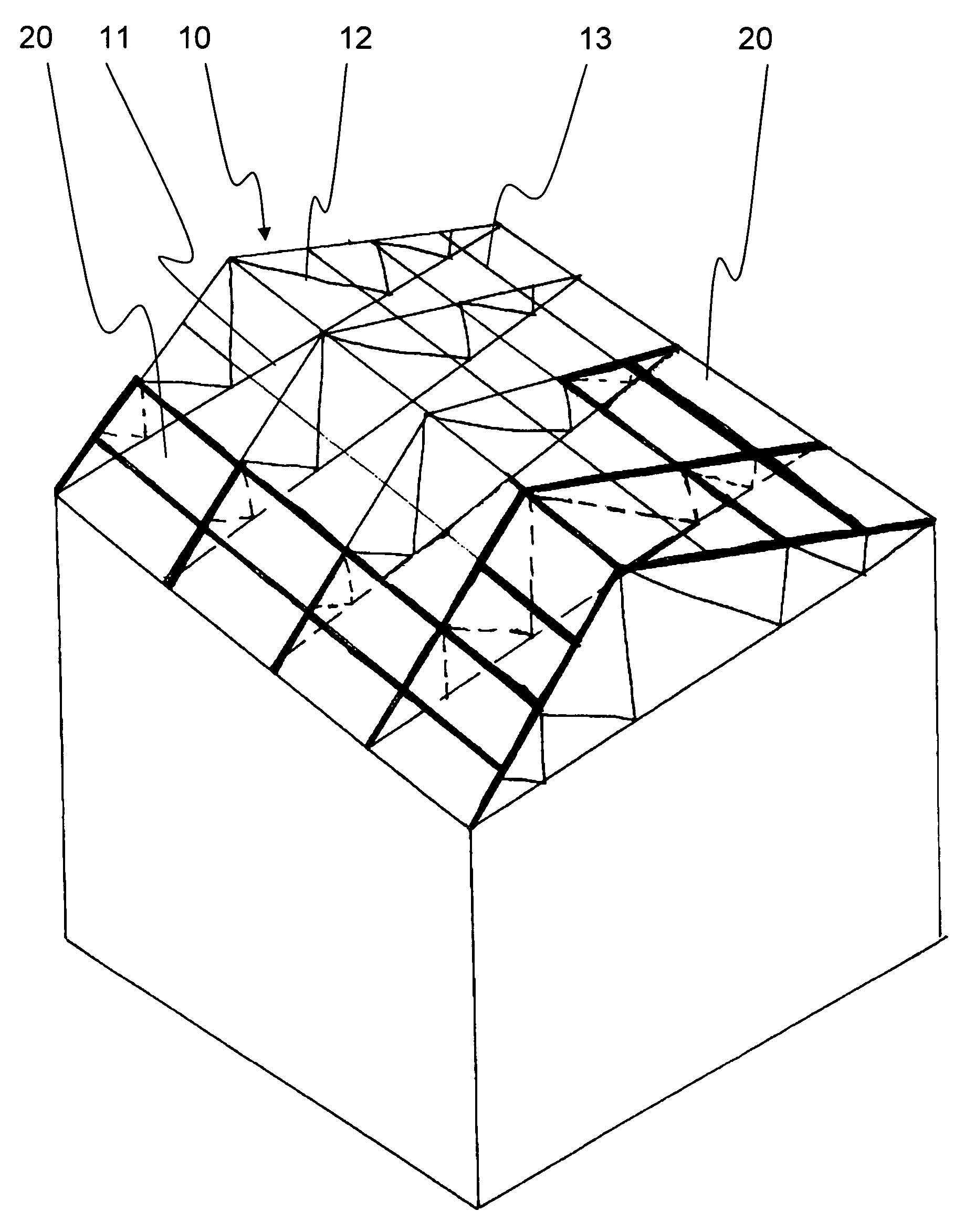

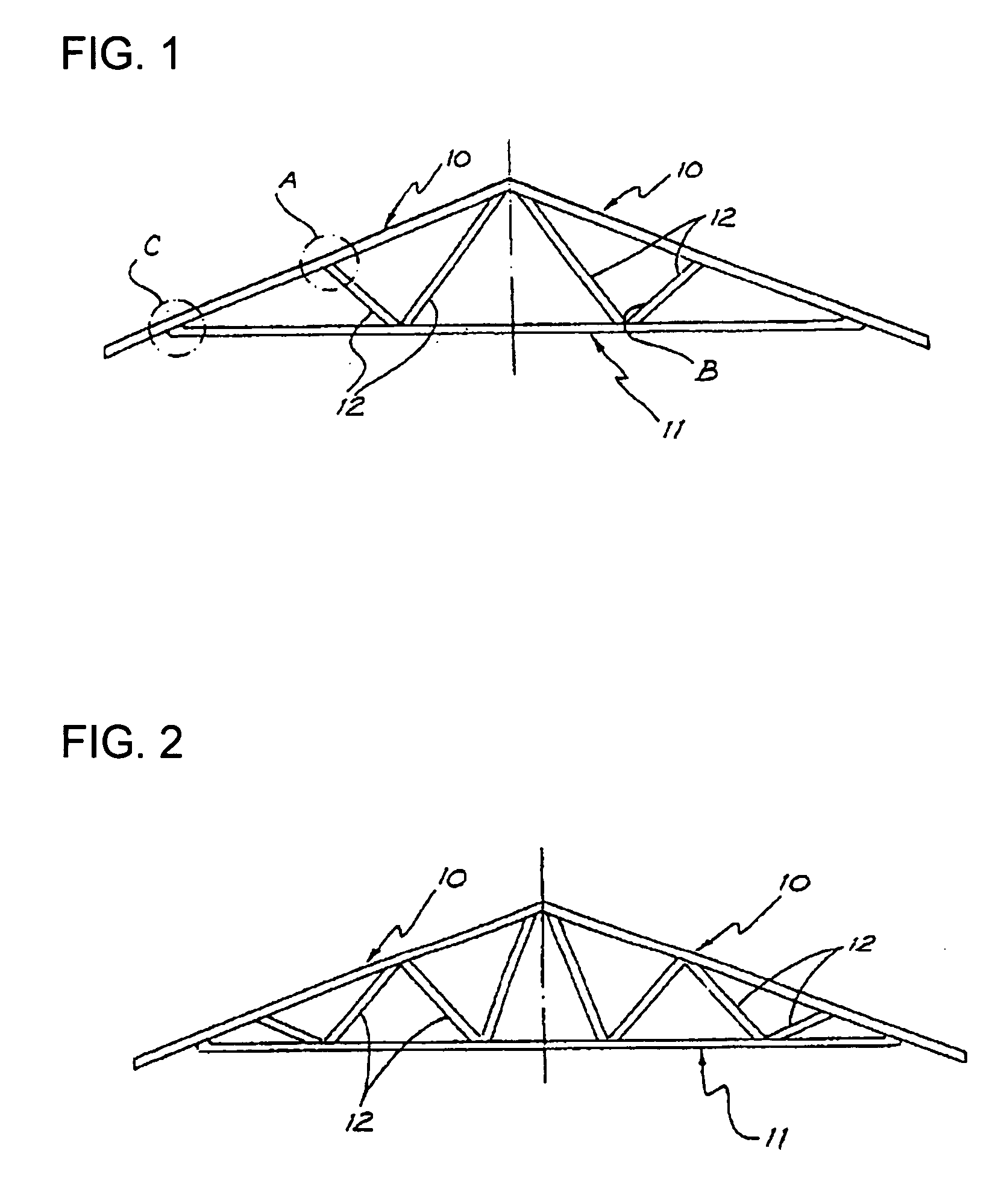

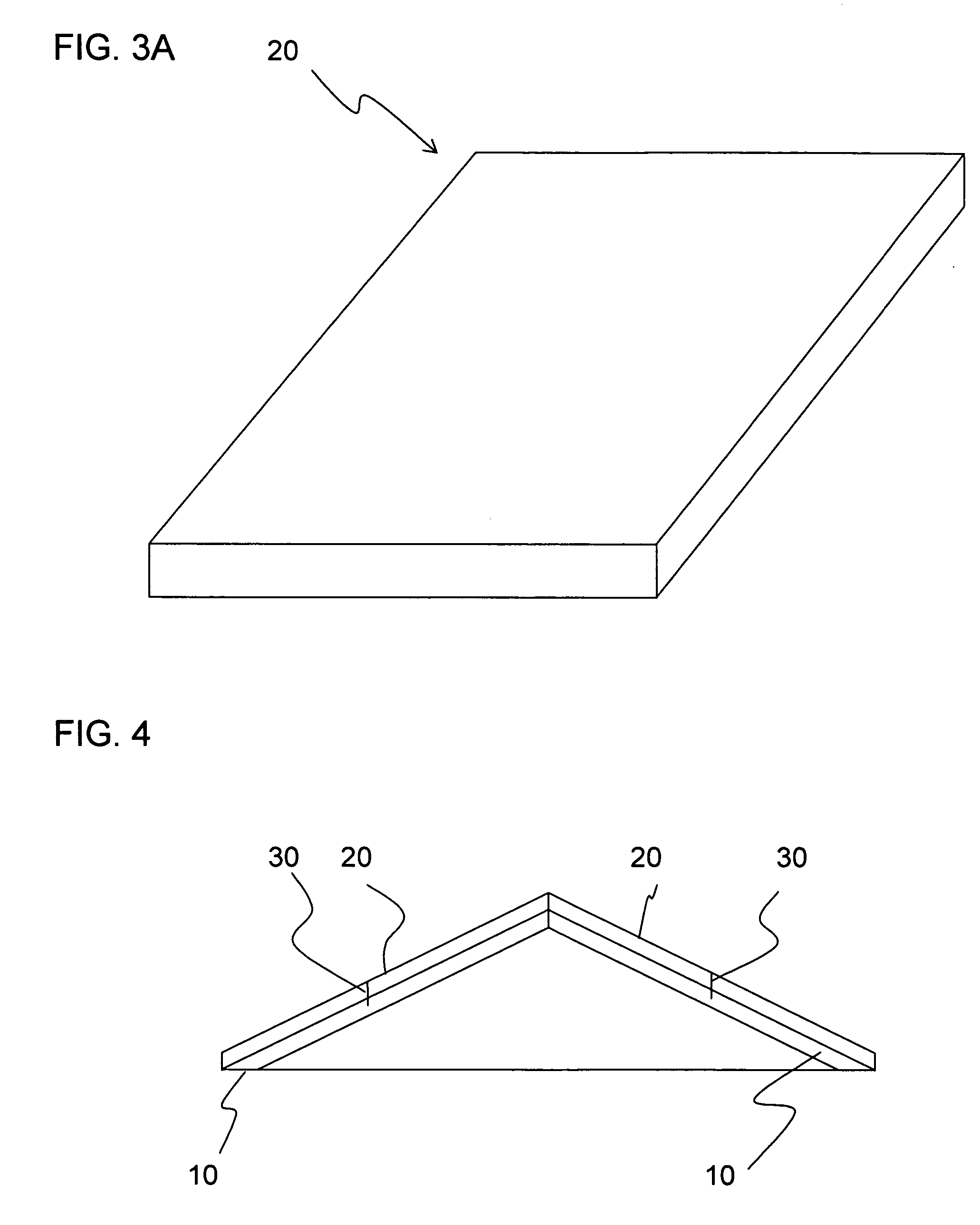

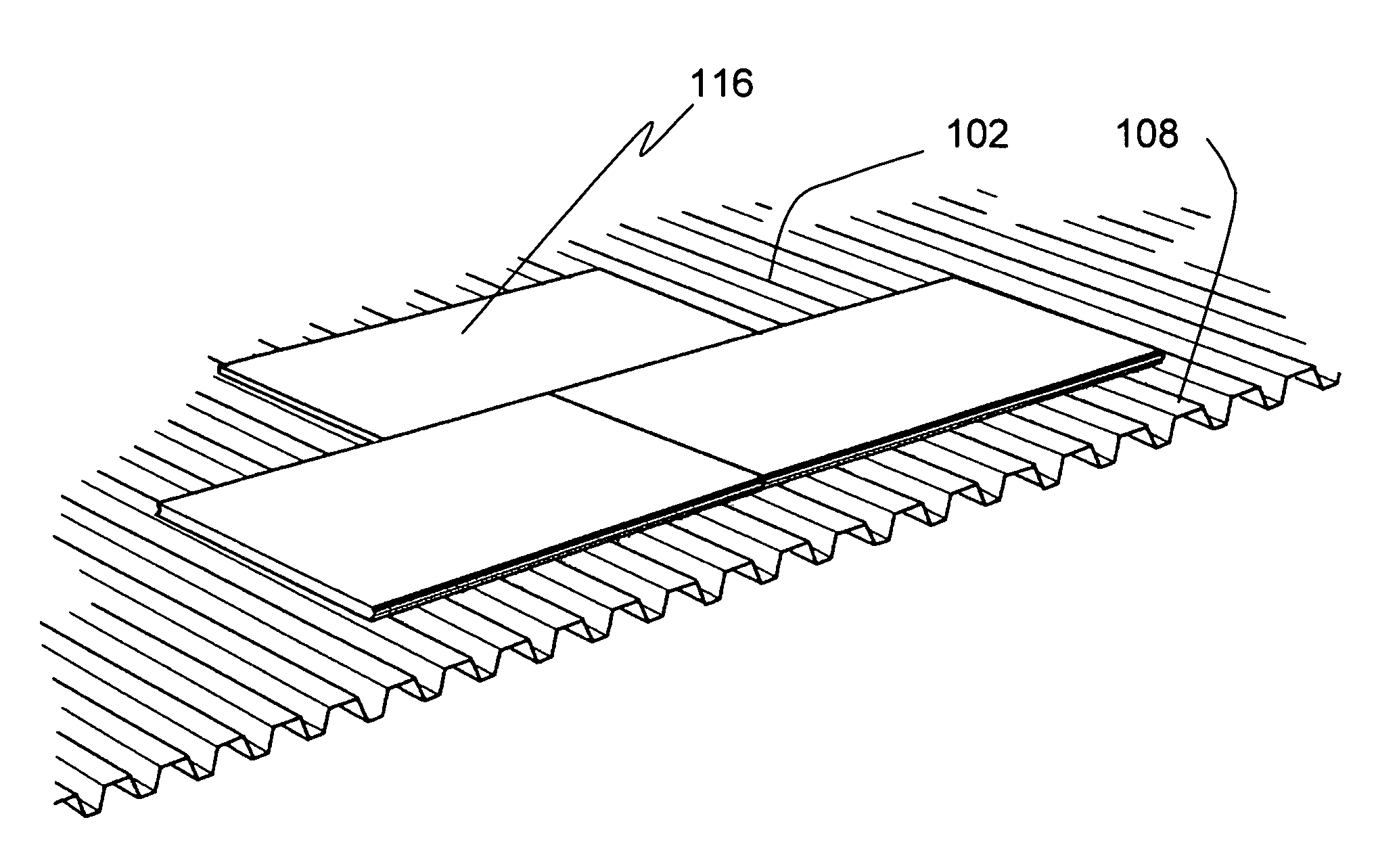

Non-combustible reinforced cementitious lightweight panels and metal frame system for roofing

A roofing system including horizontal or sloped metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The roofing system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

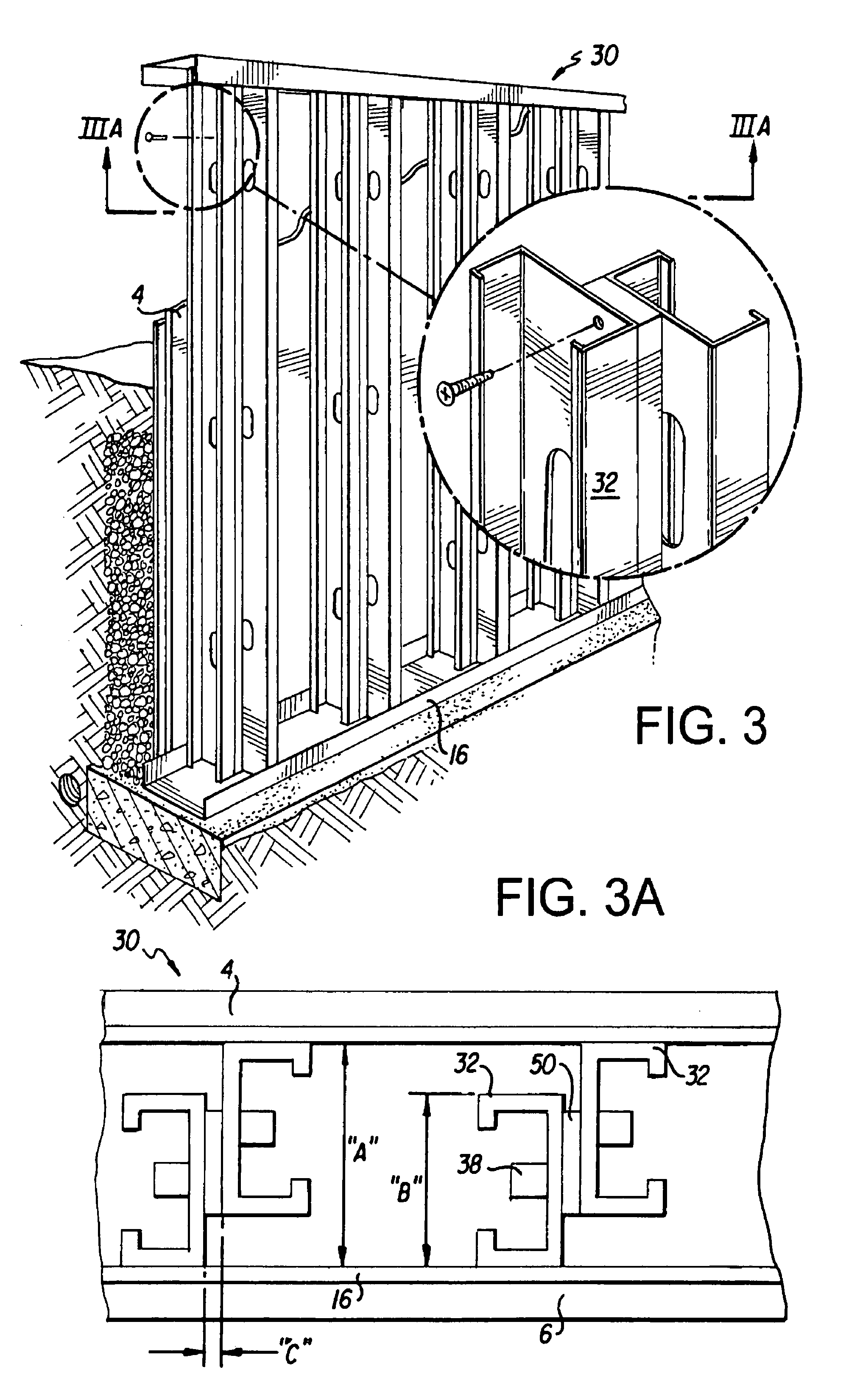

Non-combustible reinforced cementitious lightweight panels and metal frame system for building foundations

ActiveUS7870698B2Stiffen and strengthen and toughen panelSolid waste managementWallsGlass fiberMicrosphere

A foundation system includes metal framing members that support a reinforced, lightweight, dimensionally stable cementitious panel. The foundation system is non-combustible, water durable, mold and rot resistant, and termite resistant. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Self-leveling cementitious composition with controlled rate of strength development and ultra-high compressive strength upon hardening and articles made from same

ActiveUS20090239977A1High strengthImprove the immunitySolid waste managementTriethanolamineFiber reinforcement

A self-leveling cementitious mixture with excellent flow properties and which hardens with a controlled rate of strength development to an ultra-high compressive strength composite composition for use in making articles such as cementitious armor panel with ballistic and blast resistant properties including: a continuous phase resulting from the curing of an aqueous mixture, in the absence of silica flour, of inorganic cement binder, inorganic mineral filler having a particle size of about 150-450 microns, pozzolanic mineral filler, polycarboxylate based self-leveling agent and water. The cementitious mixture may include alkanolamine, such as triethanolamine, and acid or acid salt, such as tartaric acid. The cementitious composition may be reinforced with reinforcing fibers, e.g. glass fibers, in an amount of about 0.5-6.0% by volume of the overall cementitious composition. The fibers are uniformly dispersed in the cementitious composition before it is cured to form a final cementitious armor panel.

Owner:UNITED STATES GYPSUM CO +1

Compositions and methods for producing high strength composites

ActiveUS20100016459A1Improve mechanical propertiesGood physical propertiesOther chemical processesCeramic shaping apparatusHigh intensityPolymer chemistry

The present invention relates to compositions and methods for producing high strength composites. In one embodiment, a polymer matrix and a naturally-occurring inorganic material are melt processed to produce a high strength composite. In a preferred embodiment, the naturally-occurring inorganic material is volcanic ash. High strength composites of this invention have particular utility as building materials and automotive components.

Owner:INTERFACIAL CONSULTANTS LLC

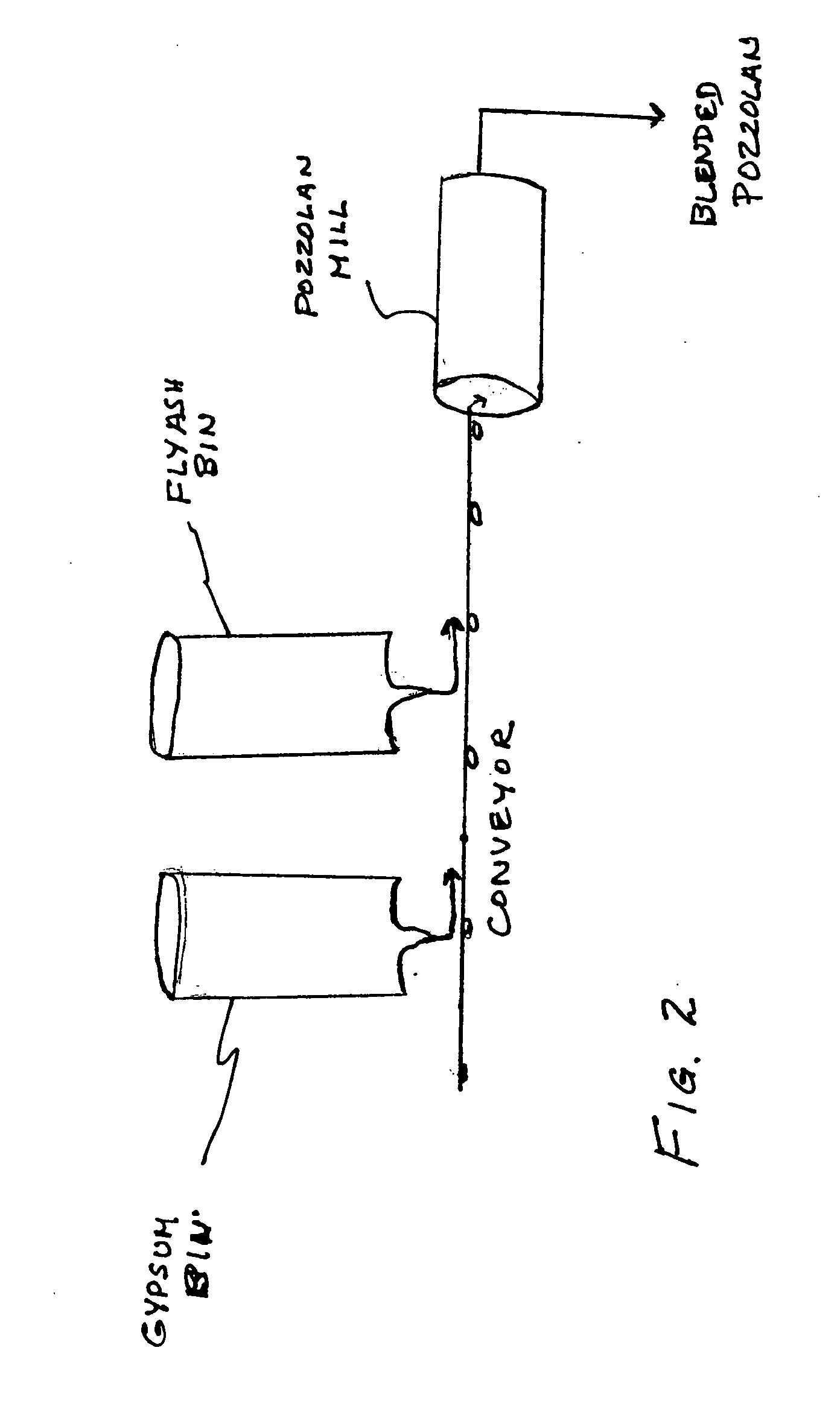

Blended fly ash pozzolans

InactiveUS20060201395A1Improved sulfate resistanceReduce penetrationSolid waste managementVolcanoCoal

Novel premium blended pozzolans for use with hydraulic cement are created by intergrinding an ASTM Class F or Class C coal fly ash and a source of calcium sulfate, such as gypsum, so that the resultant mixture has a fineness of at least 90% passing through a 45 micron sieve. The novel mixture meets the requirements of ASTM C 618. Alternately, a novel concrete composition can be formed using the blended pozzolan with a hydraulic cement, aggregate and water so as to produce a concrete having improved strength, ASR mitigation, improved sulfate resistance and lowered permeability. The novel pozzolans not only reduce production costs by decreasing fuel and raw material consumption per ton of cement, but they also use by-product waste materials from another industry to create a premium product for the construction industry.

Owner:ASH GROVE CEMENT

Reactive magnesium oxide cements

Novel hydraulic cements are disclosed that include reactive magnesium oxide prepared by low temperature calcination. The cements can be formulated to suit a large number of applications with various setting times, strength and levels of sustainability either by adding iron salts such as ferrous sulfate or blending with other compatible faster setting hydraulic cements such as Portland cement or by using both methods. The compositions are able to incorporate relatively large amounts of low cost pozzolans such as fly ash to advantage as well as wastes. Many excellent properties are exhibited and in particular good comprehensive strength and resistance to sulfates is able to be achieved.

Owner:TECECO

Non-combustible reinforced cementitious lightweight panels and metal frame system for building foundations

ActiveUS20070294974A1Alleviate bearing capacityStiffen and strengthen and toughen panelSolid waste managementWallsMicrosphereCement board

A foundation system includes metal framing members that support a reinforced, lightweight, dimensionally stable cementitious panel. The foundation system is non-combustible, water durable, mold and rot resistant, and termite resistant. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Non-combustible reinforced cementitious lightweight panels and metal frame system for flooring

A flooring system including horizontal metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The flooring system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Non-combustible reinforced cementitious lightweight panels and metal frame system for roofing

Owner:UNITED STATES GYPSUM CO

Composite gelate material and method of producing the same

InactiveCN101549977AImprove early strengthImprove internal crystal structureSolid waste managementCement productionSlagPortland cement

The present invention disclose a composite gelate material and method of producing the same, including portland cement, fly ash, steel scoria powder, granulated blast furnace slag, admixture of pozzuolana, silicon gray, sulphates excitant, alkaline excitant, additive etc, through technics of mix grinding, agitating to get the needed powder; possessing advantages of high high-early strength, perfect workability, perfect antifreezing and impervious ability, high dose of waste, no environment polluting etc, simultaneity being able to improve concrete stability with a low cost and simple technics, which can be used as cementing materials of high-performance concrete.

Owner:CHANGSHA YUANPENG CHEM TECH

Method of Producing Recycled Hardened Materials Using Waste Gypsum

InactiveUS20080066651A1High strengthImprove the immunitySolid waste managementCeramicwareSludgeMaterials science

Disclosed herein is a method for producing a recycled hardened material using waste gypsum. The method comprises treating acidic wastewater generated in the production of copper, zinc or titanium or the production of sodium hydroxide (caustic soda) and chlorine using saline water, with calcium hydroxide (slaked lime), so as to precipitate sludge, and mixing the precipitated sludge with pulp sludge ashes having pozzolanic properties.

Owner:PARK JONG WON

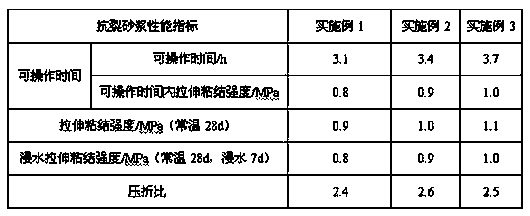

Phosphorus slag powder doped dry powdered anti-crack mortar

Owner:TONGJI UNIV

Lightweight, fiber-reinforced cementitious panels

ActiveUS7732032B2Significant toughnessComposite goodConstruction materialCovering/liningsCement boardToughness

Lightweight, fiber reinforced, cementitious panels possessing exceptional toughness for use as building components in applications such as roofing elements, siding elements, framing and sheathing elements, and substrate elements for installation of floor finishes in residential and other building construction types. The panels employ a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, PVA fibers and lightweight filler. The inorganic binder may be, for example, hydraulic cement alone, or a combination of hydraulic cement and pozzolan / s, or a combination of hydraulic cement, alpha hemihydrate, active pozzolan and optionally lime. The PVA fibers reinforce the continuous phase and are randomly distributed throughout the composite. Typical panels of the invention have a density of 60-85 pcf.

Owner:UNITED STATES GYPSUM CO

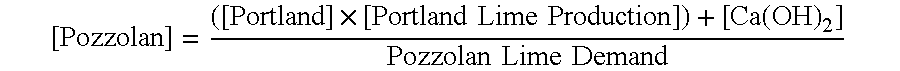

Cementitious composition incorporating high levels of glass aggregate for producing solid surfaces

ActiveUS7771529B1Moderate pHControllable brightness coefficientSolid waste managementPorosityHigh density

A cementitious composition for high density, low porosity sheet-form building materials having solid surfaces is comprised of cement, pozzolans, and a high percentage of fine and / or coarse glass aggregate, preferably present in an amount which by weight is at least 60% of the composition. The cement content is relatively low, preferably in the range of about 3% to 20% by weight, and the pozzolan to cement ratio is relatively high, preferably equal to or greater than unity, but which can suitably be in the range from 0.25 to 4. The composition preferably uses recycled glass and preferably has a high recycle content. The sheet-form material made in accordance with the invention can be used to provide exposed solid surfaces, for example, surfaces for shower walls and floors, counter-tops, table-tops, and the like, where low hydraulic permeability and high compressive and tensile strength are desired.

Owner:POLYCOR STONE CORP +5

Non-combustible reinforced cementitious lightweight panels and metal frame system for a fire wall and other fire resistive assemblies

A fire resistive assembly including metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The assembly is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

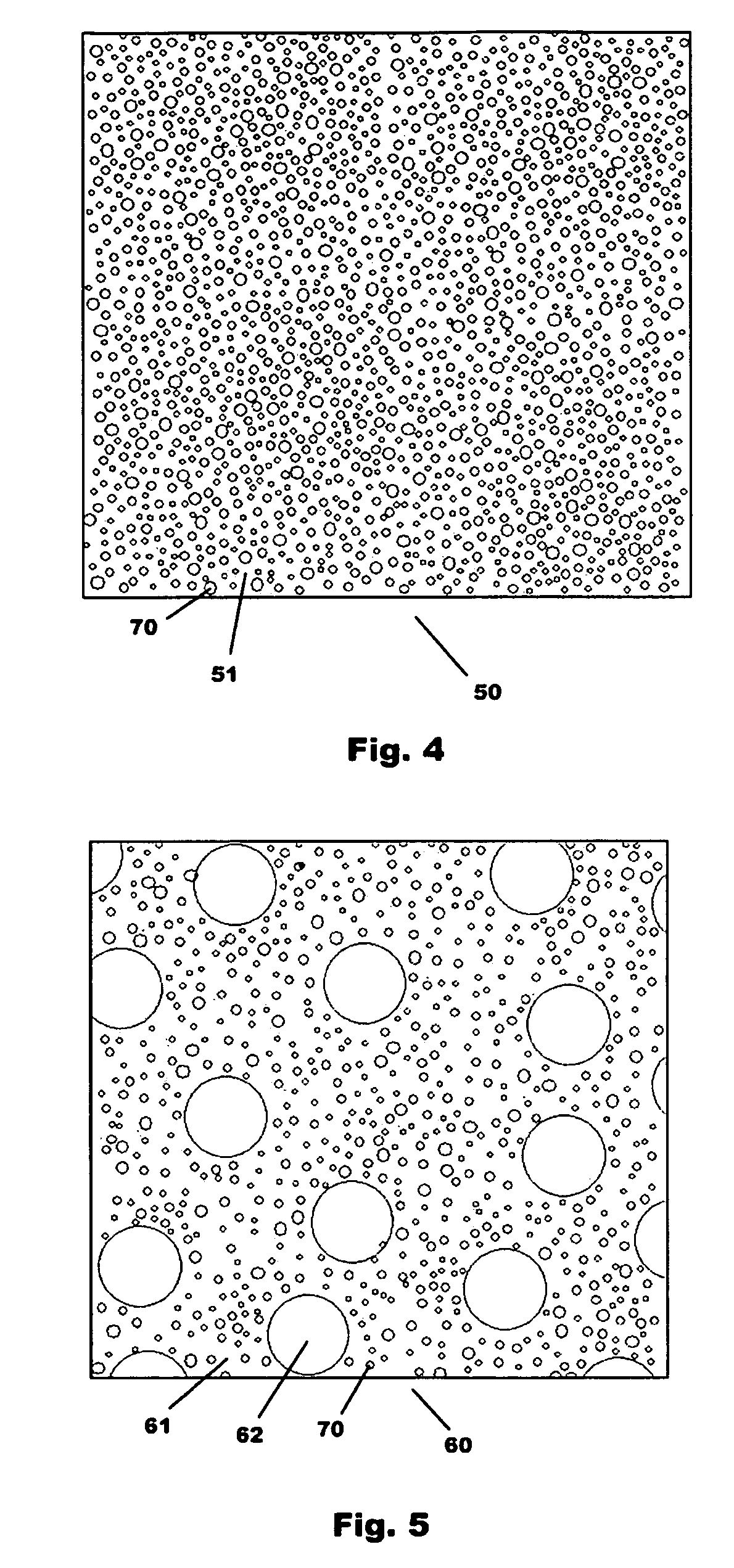

Lightweight structural concrete provided with various wood properties

InactiveUS20070125275A1Prevent crack propagationProvide structureSolid waste managementCoatingsFiberAir cell

A lightweight structural concrete with screw-ability and nail-ability similar to wood is composed of non-structural and ultra lightweight aggregate such as expanded perlite of a particular size distribution and amount, entrained air cells of another specific size distribution and amount, and dense cementitious composition of a cement binder, a fine grade structural filler no larger than masonry sand grade, a pozzolan, and optional micro-fibers for reinforcement. This structural concrete matrix is optimized to hold 13 gauge T-nails and bugle head wood screws with thread ranging from 8 to 11 threads per inch and diameter of 0.10″ to 0.137″. The resulting concrete will have consistent screw-ability and nail-ability similar that of wood.

Owner:BUI THUAN H

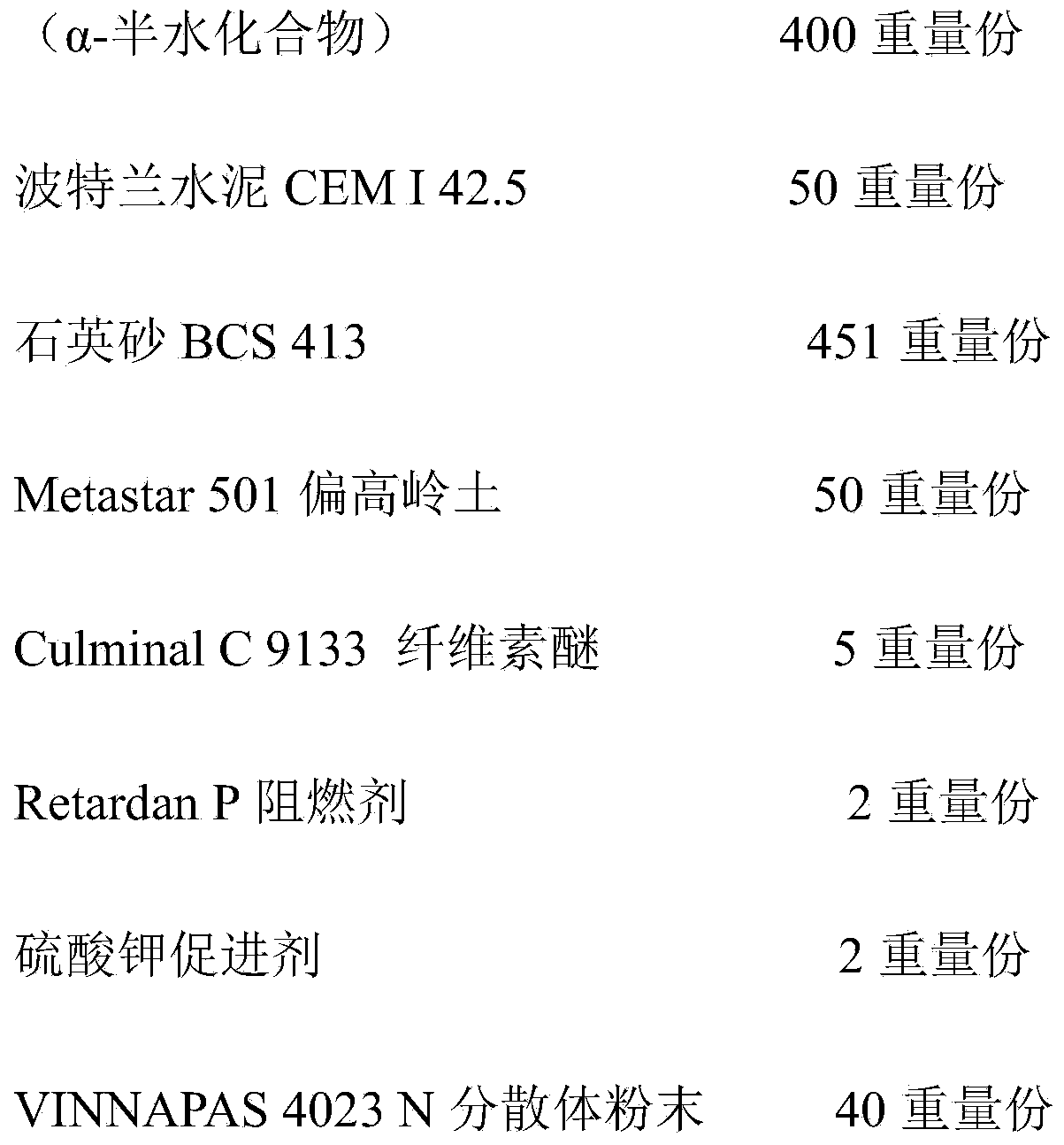

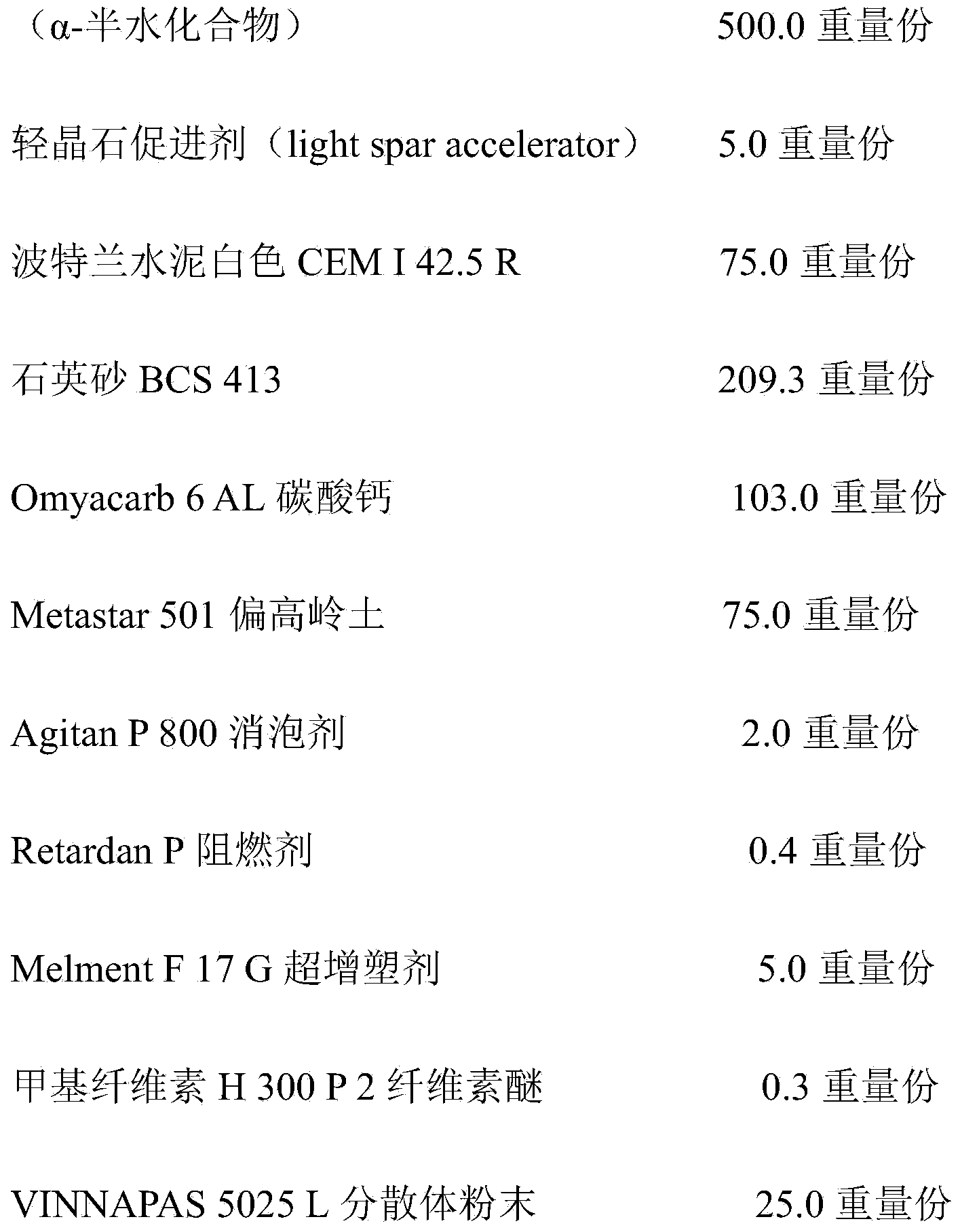

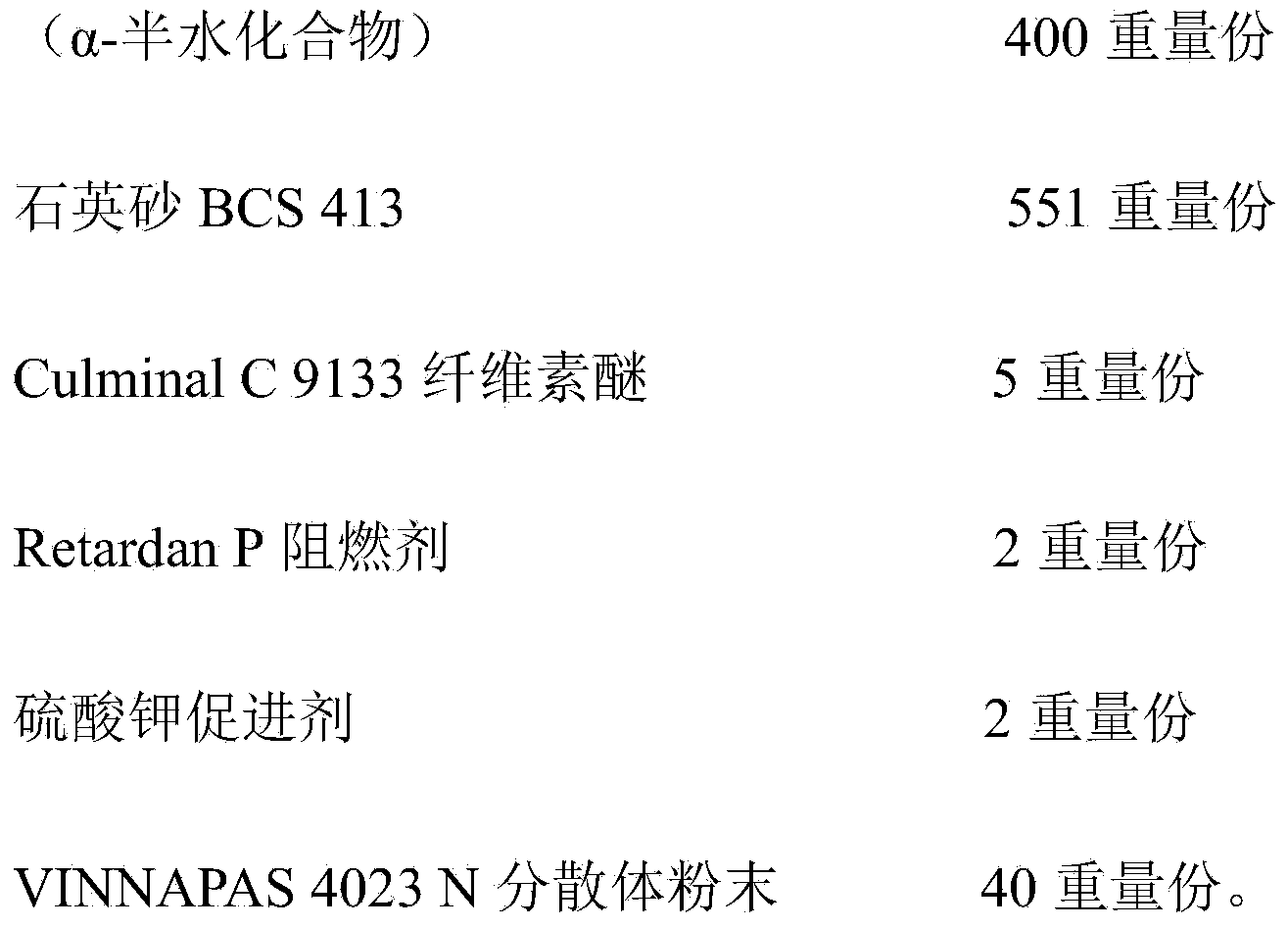

Gypsum-containing construction material compounds

ActiveCN103649006AImproved tensile bond strengthImproved tensile flexural strengthSolid waste managementPolymer scienceGypsum

The invention relates to gypsum-containing construction material compounds, containing gypsum, if necessary one or more polymers, if necessary one or more aggregates, and if necessary one or more additives, characterized in that the gypsum-containing construction material compounds contain one or more types of cement and one or more types of pozzolana.

Owner:WACKER CHEM GMBH

Masonry, mortar, and stucco cement compositions

This invention pertains to a process of making ASTM quality masonry cement, mortar cement, and stucco cement (also called plastic cement) and to the products themselves which are useful in making ASTM quality mortar for masonry construction or ASTM quality stucco for plastering construction. These cements are classified as hydraulic cements and are made using selected pozzolan(s), such as natural pozzolan and fly ashes, Portland Cement, hydrated lime, and an air-entraining agent. Other additives, such as fibers, may be added to further modify its properties. The pozzolans act as functional ingredients in the mix rather than as a filler. As a result, concentrations of greater than 25 wt. % and more pozzolan can be produced.

Owner:OLDCASTLE ARCHITECTURAL

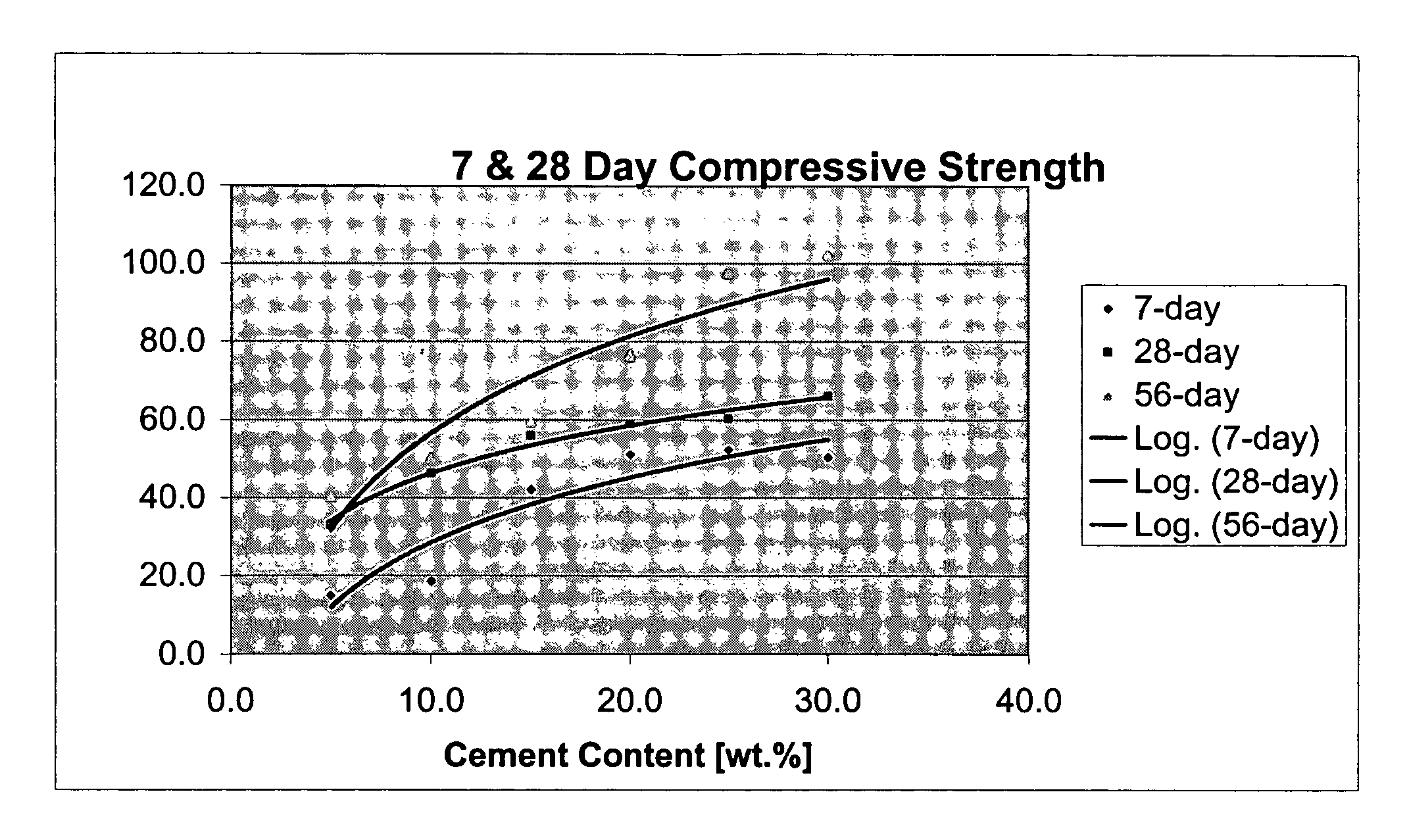

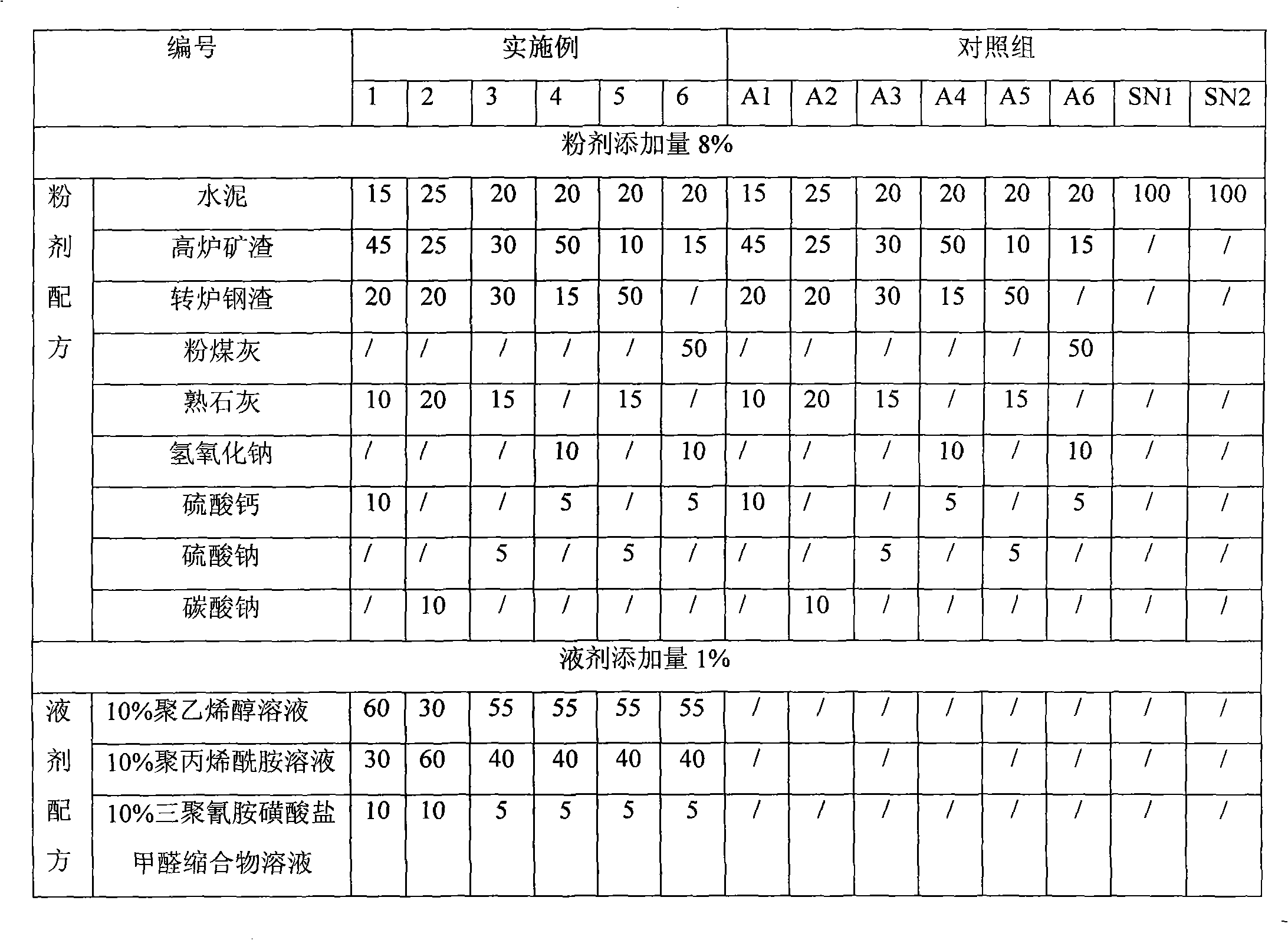

Composite curing agent for dredged silt in watercourse

InactiveCN102060480AHigh strengthSpeed up the reaction processSludge treatmentSolid waste managementPolyvinyl alcoholCompressive strength

The invention discloses a composite curing agent for dredged silt in a watercourse, comprising a powdered agent and a liquid agent, wherein the powdered agent consists of the following components on the basis of 100 percent of the total mass fraction: 15-25 percent of cement, 45-65 percent of pozzolanic material, 10-20 percent of alkali activator and 5-10 percent of salt activator; and the liquid agent consists of the following components on the basis of 100 percent of the total mass fraction: 2-7 percent of polyvinyl alcohol, 2-7 percent of polyacrylamide, 0.5-1 percent of melamine sulfonate formaldehyde condensate and the balance of water. The dredged silt has high compressive strength after being solidified by the composite curing agent for the watercourse silt, and can meet the requirements of road construction.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI +1

Non-combustible reinforced cementitious lightweight panels and metal frame system for shear walls

ActiveUS7849649B2Maximization of building volumeEffective volumeSolid waste managementWallsMicrosphereVertical shear

A vertical shear wall system including vertical metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The shear wall system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Compositions and methods for producing high strength composites

ActiveUS8106105B2Inferior mechanical propertyIncrease resistanceOther chemical processesCeramic shaping apparatusHigh intensityInorganic materials

The present invention relates to compositions and methods for producing high strength composites. In one embodiment, a polymer matrix and a naturally-occurring inorganic material are melt processed to produce a high strength composite. In a preferred embodiment, the naturally-occurring inorganic material is volcanic ash. High strength composites of this invention have particular utility as building materials and automotive components.

Owner:INTERFACIAL CONSULTANTS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com