Composite curing agent for dredged silt in watercourse

A composite curing agent and river dredging technology, which is applied in the direction of sludge treatment, solid waste management, chemical instruments and methods, etc., can solve the problems of unsatisfactory treatment effect, large amount of curing agent added and uneconomical, etc., and achieve strength improvement and improvement Strength, effect of increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

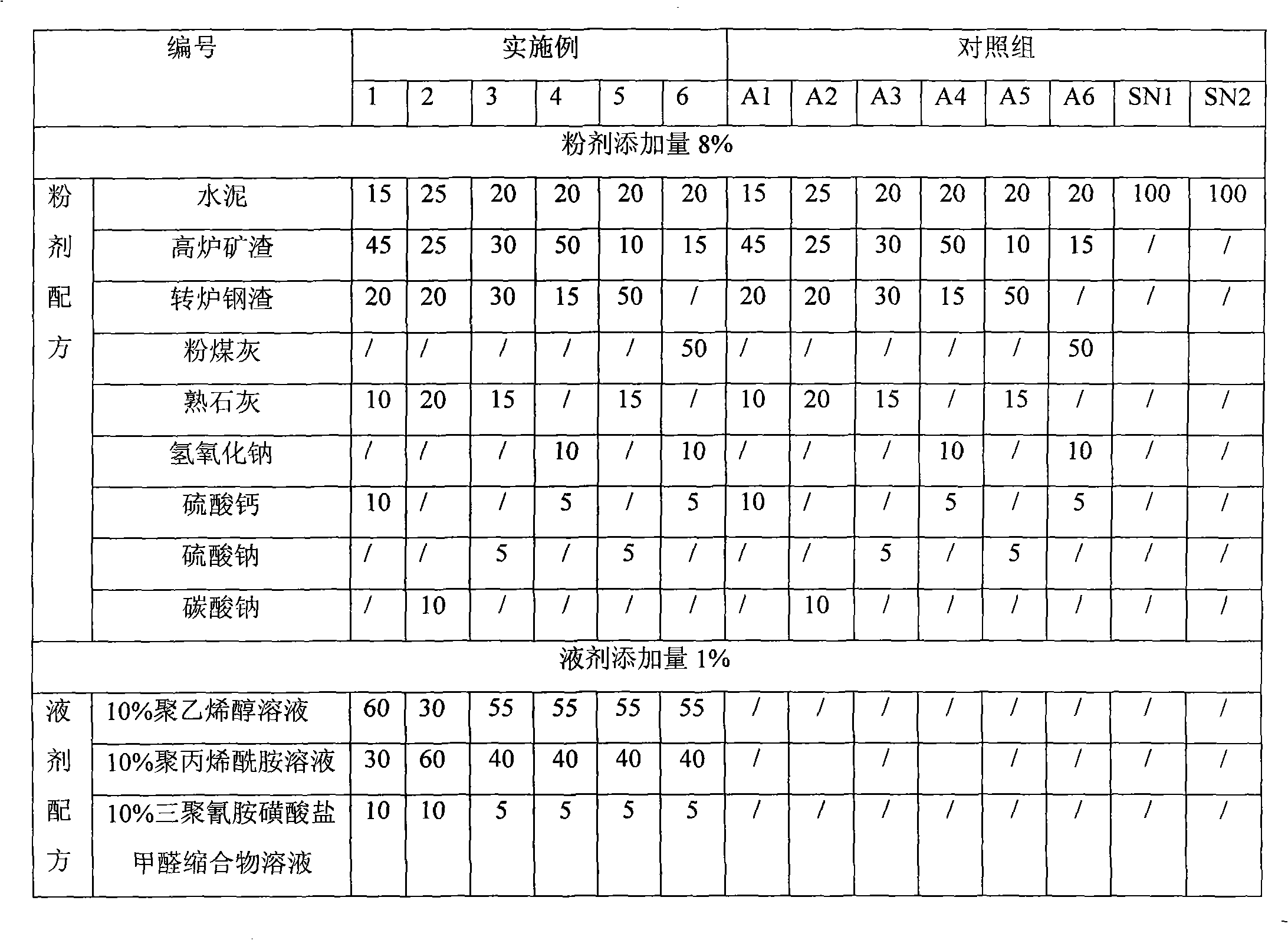

Embodiment 1

[0025] Grind No. 425 ordinary silicon cement, blast furnace slag, converter steel slag, slaked lime and calcium sulfate until the Blaine specific surface area is 400-600m 2 / kg, the ratio by weight is: 15 parts by weight of No. 425 ordinary silicon cement, 45 parts by weight of blast furnace slag, 20 parts by weight of converter steel slag, 10 parts by weight of slaked lime and 10 parts by weight of calcium sulfate. Mix the above materials evenly to obtain the powder of the river dredging silt composite solidifying agent in this embodiment.

[0026] Dissolve polyvinyl alcohol, polyacrylamide and melamine sulfonate formaldehyde condensate in water respectively to form a solution with a solid content of 10%, and then proportion by weight: 30 parts by weight of polyacrylamide solution, 60 parts by weight of polyvinyl alcohol solution part, 10 parts by weight of melamine sulfonate formaldehyde condensate solution. Mix the above-mentioned substances evenly to obtain the liquid age...

Embodiment 2

[0028] Grind No. 425 ordinary silicon cement, blast furnace slag, converter steel slag, slaked lime and sodium carbonate until the Blaine specific surface area is 400-600m 2 / kg, the ratio by weight is: 25 parts by weight of No. 425 ordinary silicon cement, 25 parts by weight of blast furnace slag, 20 parts by weight of converter steel slag, 20 parts by weight of slaked lime and 10 parts by weight of sodium carbonate. Mix the above materials evenly to obtain the powder of the river dredging silt composite solidifying agent in this embodiment.

[0029] Dissolve polyvinyl alcohol, polyacrylamide and melamine sulfonate formaldehyde condensate in water respectively to form a solution with a solid content of 10%, and then proportion by weight: 60 parts by weight of polyacrylamide solution, 30 parts by weight of polyvinyl alcohol solution part, 10 parts by weight of melamine sulfonate formaldehyde condensate solution. Mix the above-mentioned substances evenly to obtain the liquid a...

Embodiment 3

[0031] Grind No. 425 ordinary silicon cement, blast furnace slag, converter steel slag, hydrated lime and sodium sulfate until the Blaine specific surface area is 400-600m 2 / kg, the ratio by weight is: 20 parts by weight of No. 425 ordinary silicon cement, 30 parts by weight of blast furnace slag, 30 parts by weight of converter steel slag, 15 parts by weight of slaked lime and 5 parts by weight of sodium sulfate. Mix the above materials evenly to obtain the powder of the river dredging silt composite solidifying agent in this embodiment.

[0032]Dissolve polyvinyl alcohol, polyacrylamide and melamine sulfonate formaldehyde condensate in water respectively to form a solution with a solid content of 10%, and then the ratio by weight is: 40 parts by weight of polyacrylamide solution, 55 parts by weight of polyvinyl alcohol solution parts, 5 parts by weight of melamine sulfonate formaldehyde condensate solution. Mix the above-mentioned substances evenly to obtain the liquid age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com