Patents

Literature

399results about How to "Speed up the reaction process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating farmland soil polluted by cadmium

ActiveCN103817145ASpeed up the reaction processImprove the effect of chemical stabilizationContaminated soil reclamationAshingSoil science

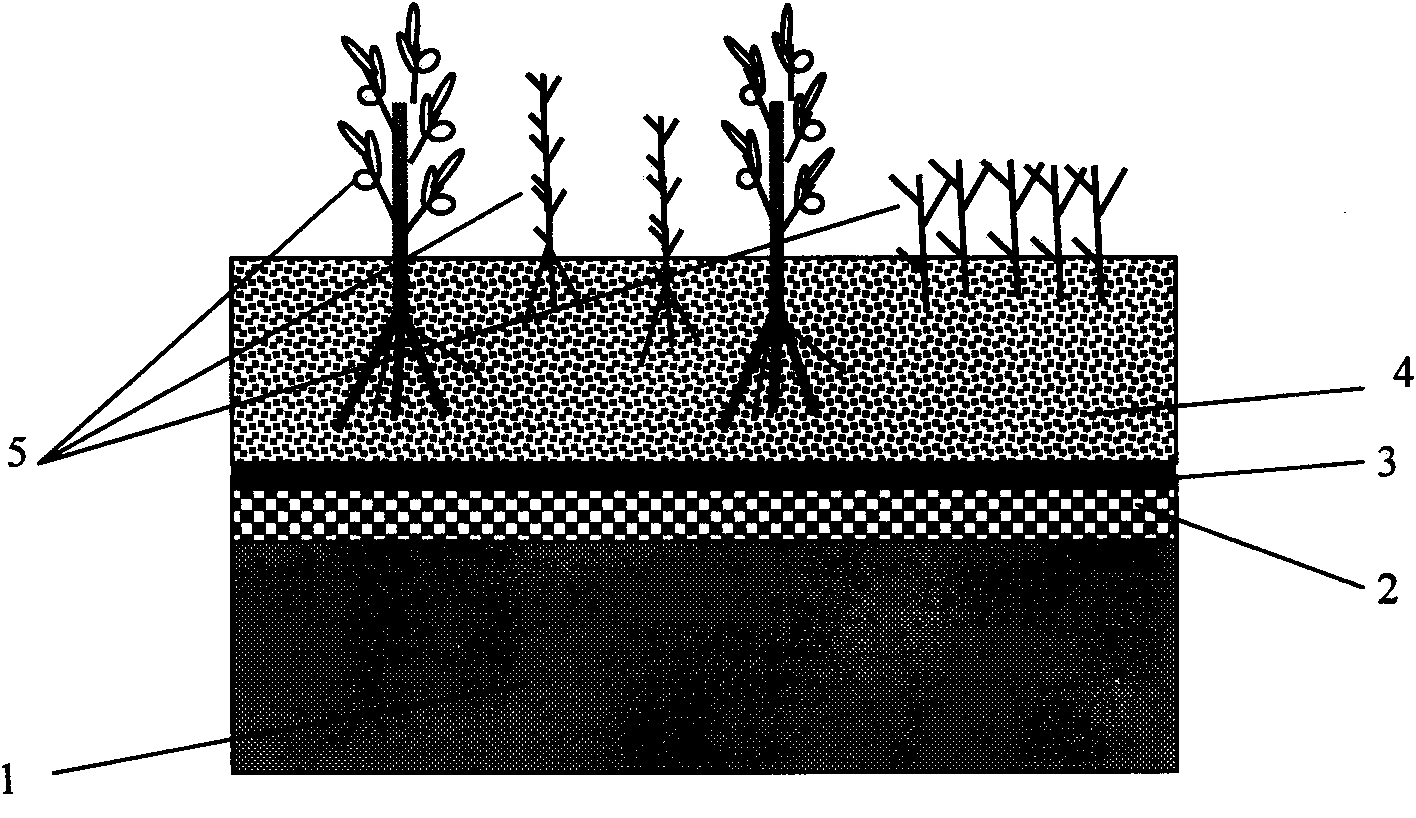

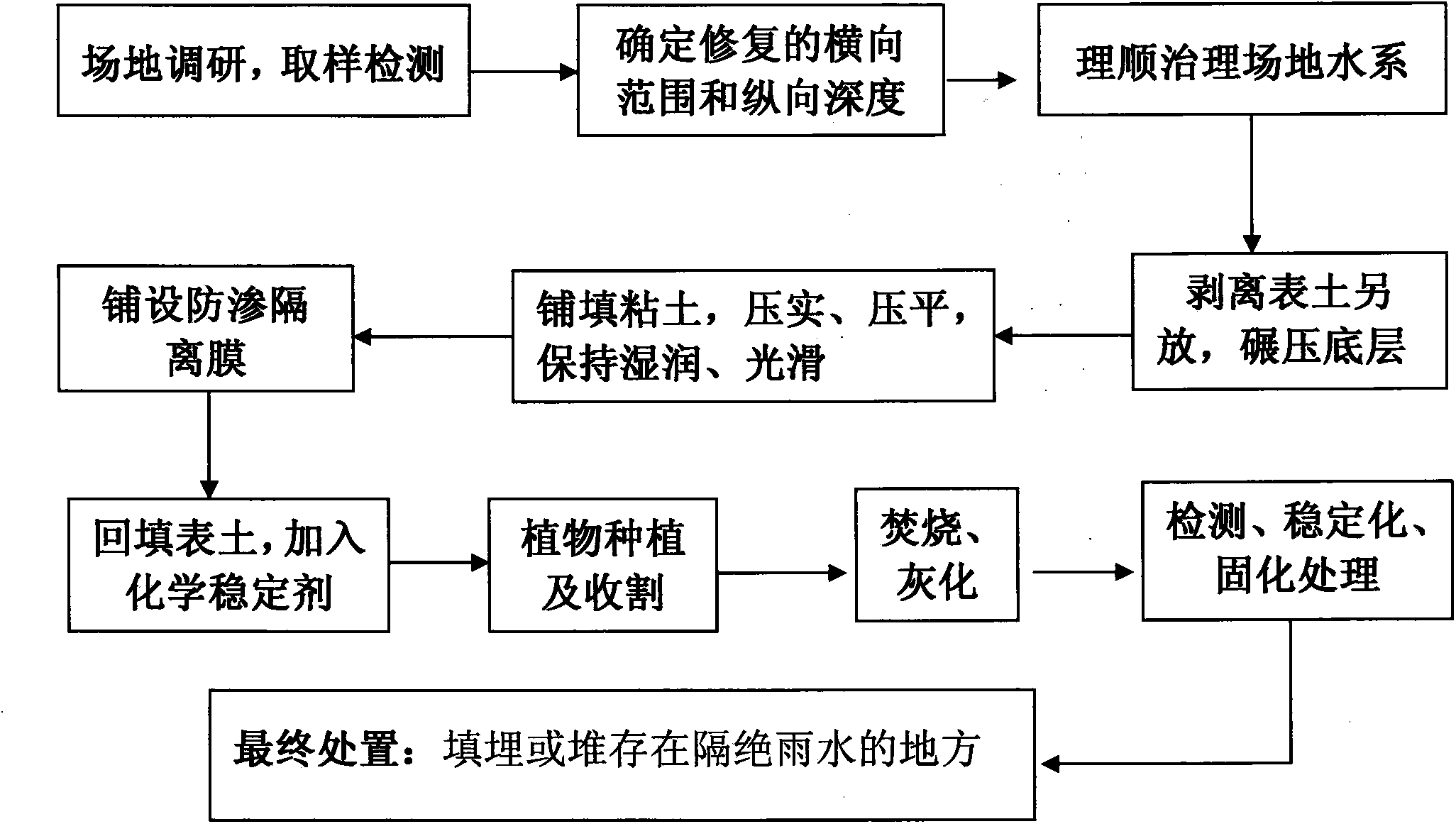

The invention provides a method for treating farmland soil polluted by cadmium. The method integrates technical measurements such as seepage-proofing isolation, chemical stabilizing treatment, phytoremediation and the like, and comprises technical steps as follows: sampling detection, repairing range determination, dredging of river systems, surface soil stripping, bottom layer grinding, clay pavement, laying of a seepage-proofing isolating membrane, surface soil backfilling, addition of a chemical stabilizing agent, plant planting and harvesting, incineration and ashing, ash content stabilizing and curing treatment, terminal treatment and the like. The method for treating the farmland soil polluted by cadmium has the advantages of on-site treatment, simple process, convenience in construction, instant effect, high efficiency, low cost and the like, and is wide in popularization and application prospect.

Owner:SHENZHEN WANXINDA ECOLOGICAL ENVIRONMENT CO LTD

Composite curing agent for dredged silt in watercourse

InactiveCN102060480AHigh strengthSpeed up the reaction processSludge treatmentSolid waste managementPolyvinyl alcoholCompressive strength

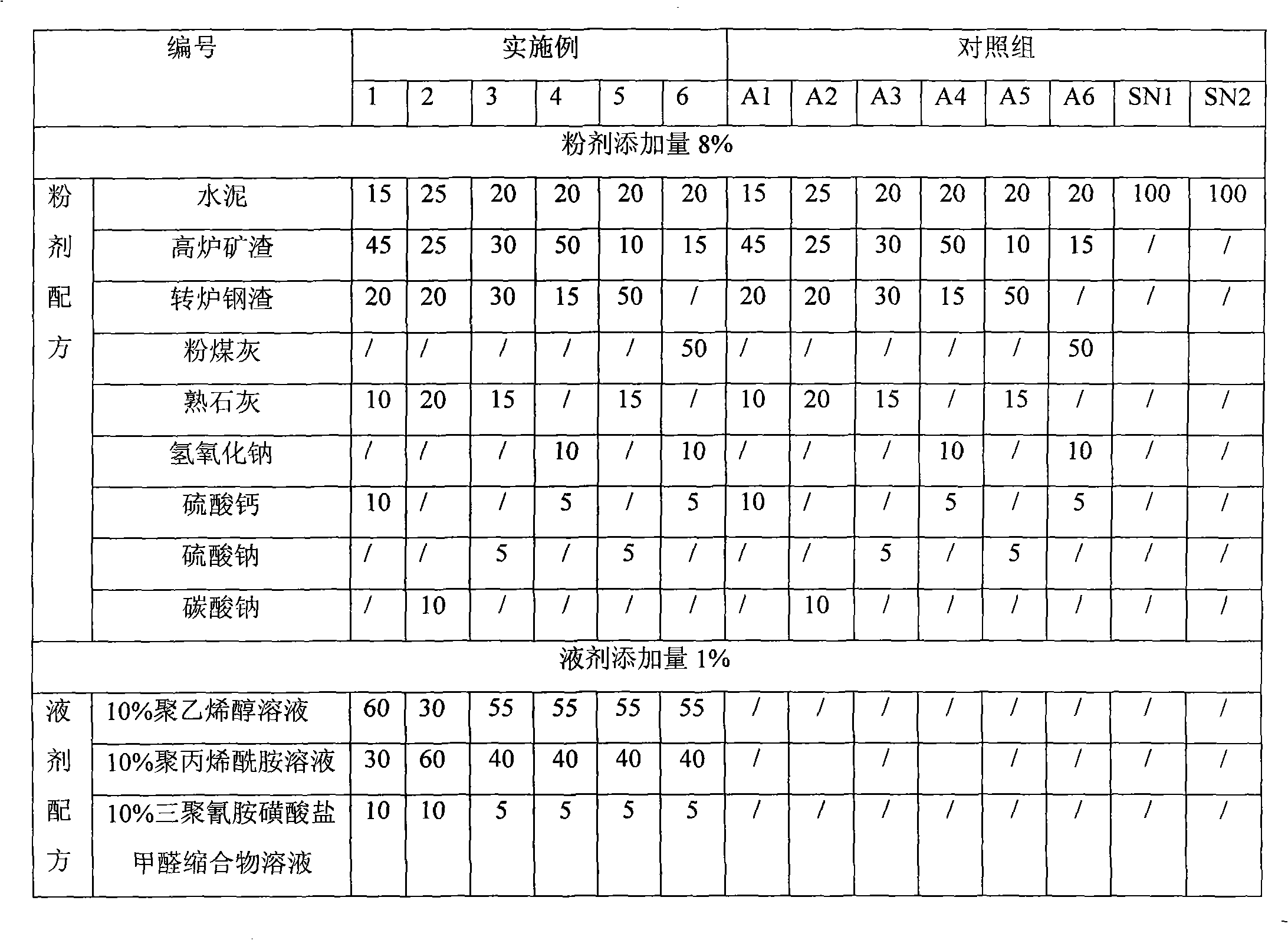

The invention discloses a composite curing agent for dredged silt in a watercourse, comprising a powdered agent and a liquid agent, wherein the powdered agent consists of the following components on the basis of 100 percent of the total mass fraction: 15-25 percent of cement, 45-65 percent of pozzolanic material, 10-20 percent of alkali activator and 5-10 percent of salt activator; and the liquid agent consists of the following components on the basis of 100 percent of the total mass fraction: 2-7 percent of polyvinyl alcohol, 2-7 percent of polyacrylamide, 0.5-1 percent of melamine sulfonate formaldehyde condensate and the balance of water. The dredged silt has high compressive strength after being solidified by the composite curing agent for the watercourse silt, and can meet the requirements of road construction.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI +1

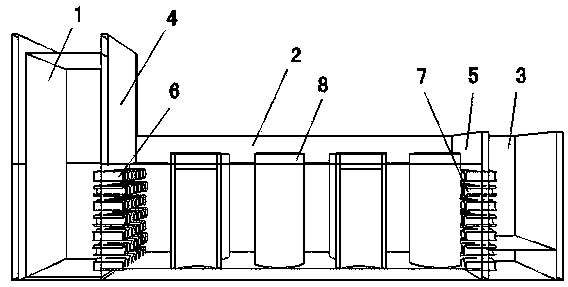

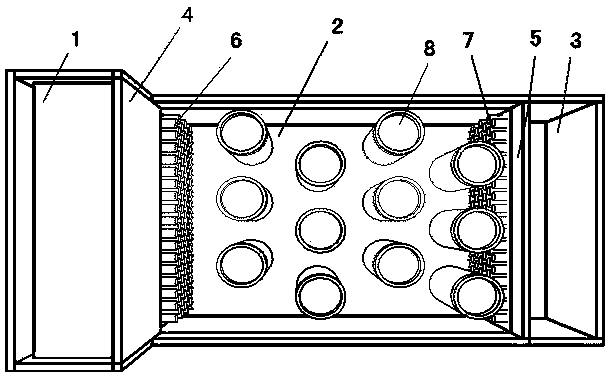

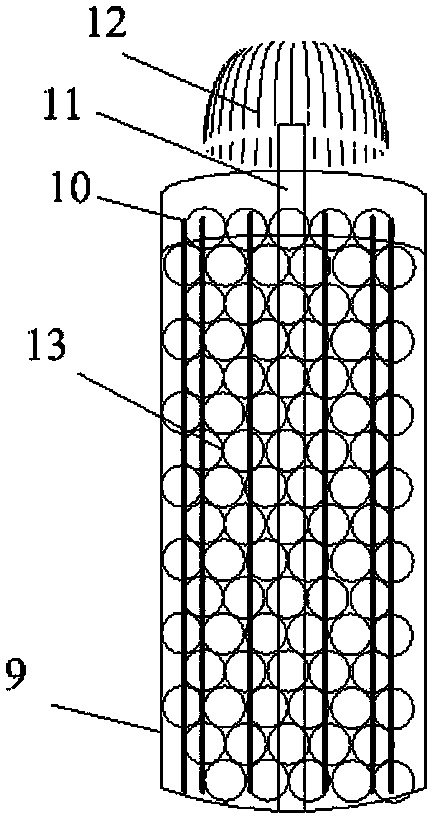

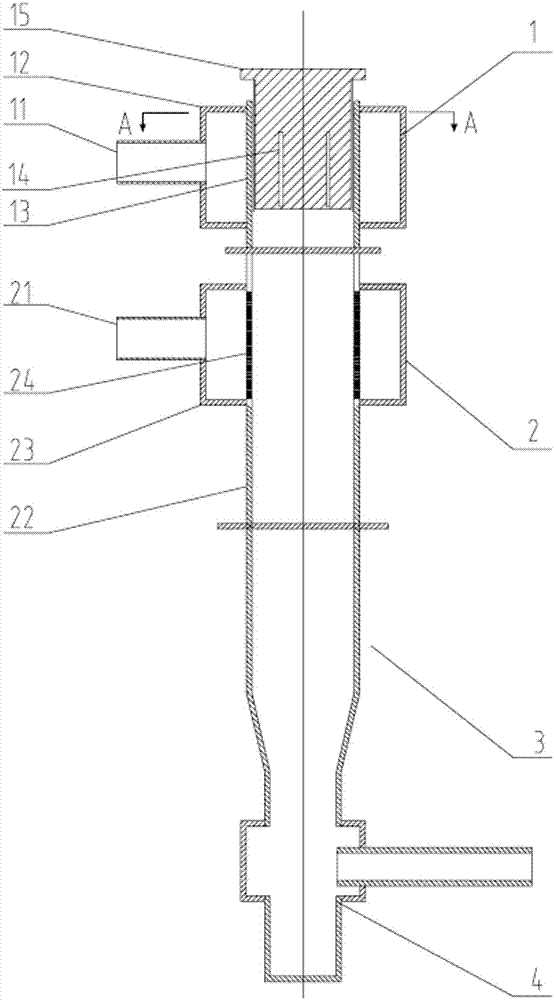

Magnetorheological fluid multi-stage treatment device and control method and component manufacturing method thereof

ActiveCN105457392AWell mixedSpeed up the reaction processMagnetic liquidsMembrane filtersMagnetorheological fluidEngineering

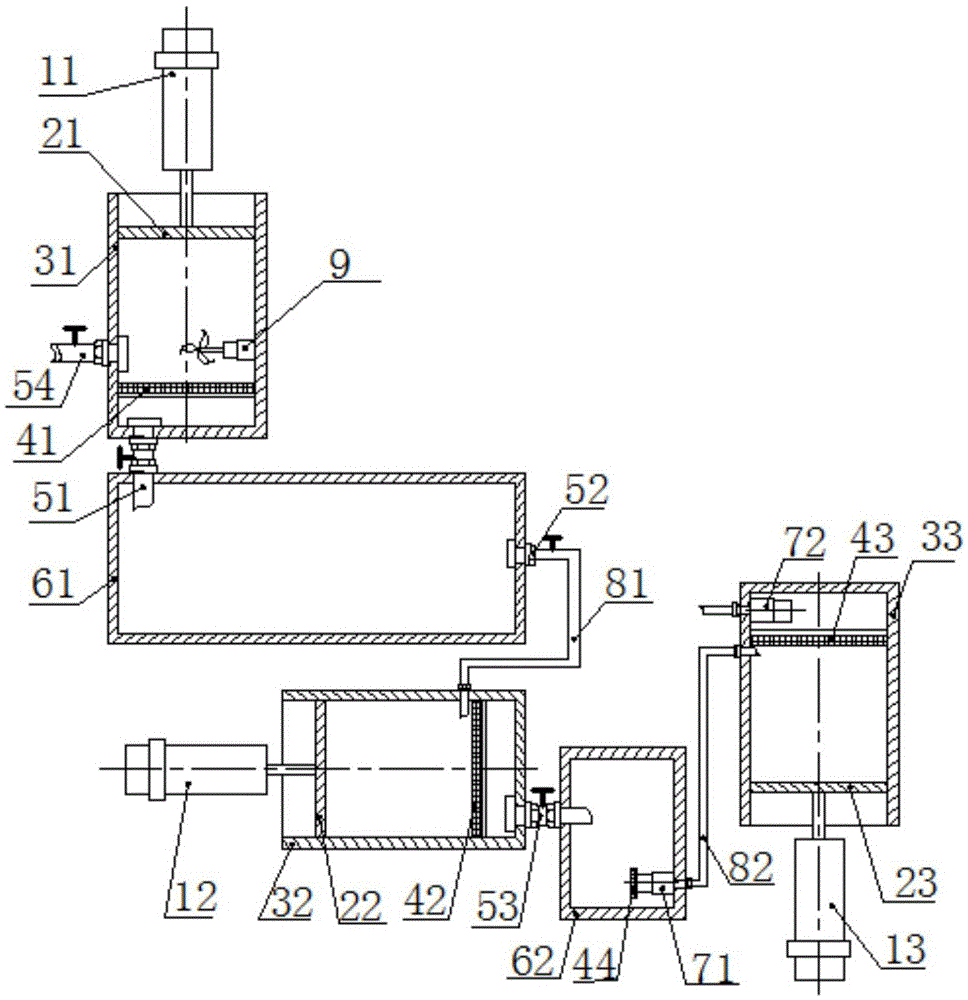

The invention discloses a magnetorheological fluid multi-stage treatment device and a control method and component manufacturing method thereof and belongs to the technical field of machine manufacturing. The magnetorheological fluid multi-stage treatment device comprises a preposition piston cylinder, a middle piston cylinder, a postposition piston cylinder, a preposition piston, a middle piston, a postposition piston, a preposition filtering box, a middle filtering box, a postposition filtering box, a preposition filtering mesh, a middle filtering mesh and a postposition filtering mesh. The preposition piston cylinder is connected with the preposition piston through a bolt, the preposition bolt is matched with an inner cavity of the preposition filtering box, the preposition filtering box is vertically arranged, and the axis is in the vertical direction; meanwhile, the invention further provides corresponding control method and a key component manufacturing method of the device. According to the magnetorheological fluid multi-stage treatment device and the control method and component manufacturing method thereof, a two-standing three-filtering mode is adopted to filter mixed liquid, the characteristic of the mixed liquid at each stage is fully utilized, and the purpose of fast and thoroughly separating magnetic substances and solvent is finally achieved.

Owner:浙江永金生物科技有限公司

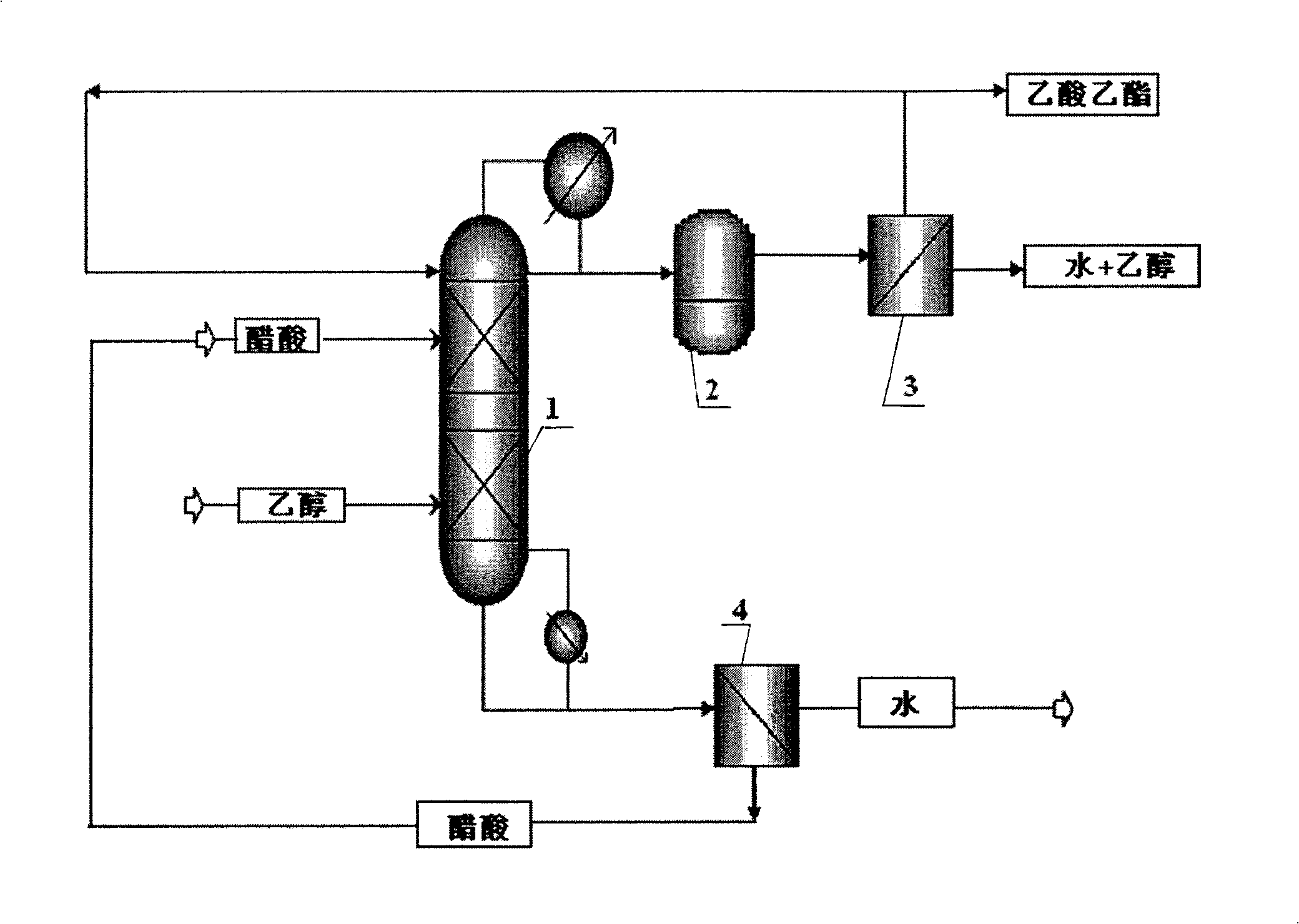

Method for producing ethyl acetate with coupled reaction distillation and permeation steam generation

ActiveCN101402568ALarge amount of processingMature technologyOrganic compound preparationChemical industryPervaporationMoisture

The invention relates to a method for producing ethyl acetate by reaction rectification and pervaporation coupling. The method is as follows: raw materials, namely acetic acid and ethanol are catalyzed in a reaction rectification tower and rectified, an organic phase is separated out from the distillate at the top of the tower and passes through a pervaporation permeable film component, wherein the contained water and ethanol selectively permeate the film and then enrich on the permeable side of the film to be removed; the ethyl acetate is obtained from the non-permeable side of the film; and part of the ethyl acetate as dehydrating agent is returned to the reaction rectification tower while the rest as a product is extracted; at the same time, part of liquor extracted from the tower bottom of the reaction rectification tower is introduced into another pervaporation permeable film component, the contained moisture is enriched on the permeable side of the film to be separated and removed, the ethyl acetate is obtained from the non-permeable side of the film, and the ethyl acetate is circularly returned to an acetic acid feeding hole of the reaction rectification tower. Compared with the prior art, the method can reduce reflux ratio greatly, has the advantages of simple technical route, energy saving, environmental protection and compact device, and reduces equipment investment and production cost for the ethyl acetate remarkably.

Owner:NANJING UNIV OF TECH

Preparation method of hollow fiber nanofiltration membrane

ActiveCN103041713AAvoid the problem that it is difficult to distribute fully and evenly on the surface of the membrane filamentHigh affinitySemi-permeable membranesDouble diffusionSolvent

The invention discloses a preparation method of a hollow fiber nanofiltration membrane, and provides the preparation method of the hollow fiber nanofiltration membrane continuous in technical process, uniform in nanofiltration functional layer and few in deficiencies. The method comprises the following steps of: using polyelectrolyte aqueous alkali as an outer coagulating bath and a mixed liquor of water and a solvent for the coagulating bath as an inner coagulating bath, spinning and forming a hollow fiber nanofiltration membrane spinning and membrane forming system through a hollow spinning nozzle and a double diffusion process, and initially curing and forming a hollow fiber membrane; and adding the initially cured hollow fiber nanofiltration membrane into an aqueous liquor of polyamine, erasing the suspended liquid on the surface, adding the membrane into an organic liquor of polyacyl chloride, and drying and curing the membrane to obtain the hollow fiber nanofiltration membrane. The method provided by the invention is continuous in technical process, uniform and controllable in nanofiltration functional layer and few in defects, and has a wide prospect in the fields of seawater and brackish water desalination, treatment and recovery of sewage and wastewater, preparation of ultrapure water and the like.

Owner:ZHEJIANG JINMO ENVIRONMENT TECH CO LTD

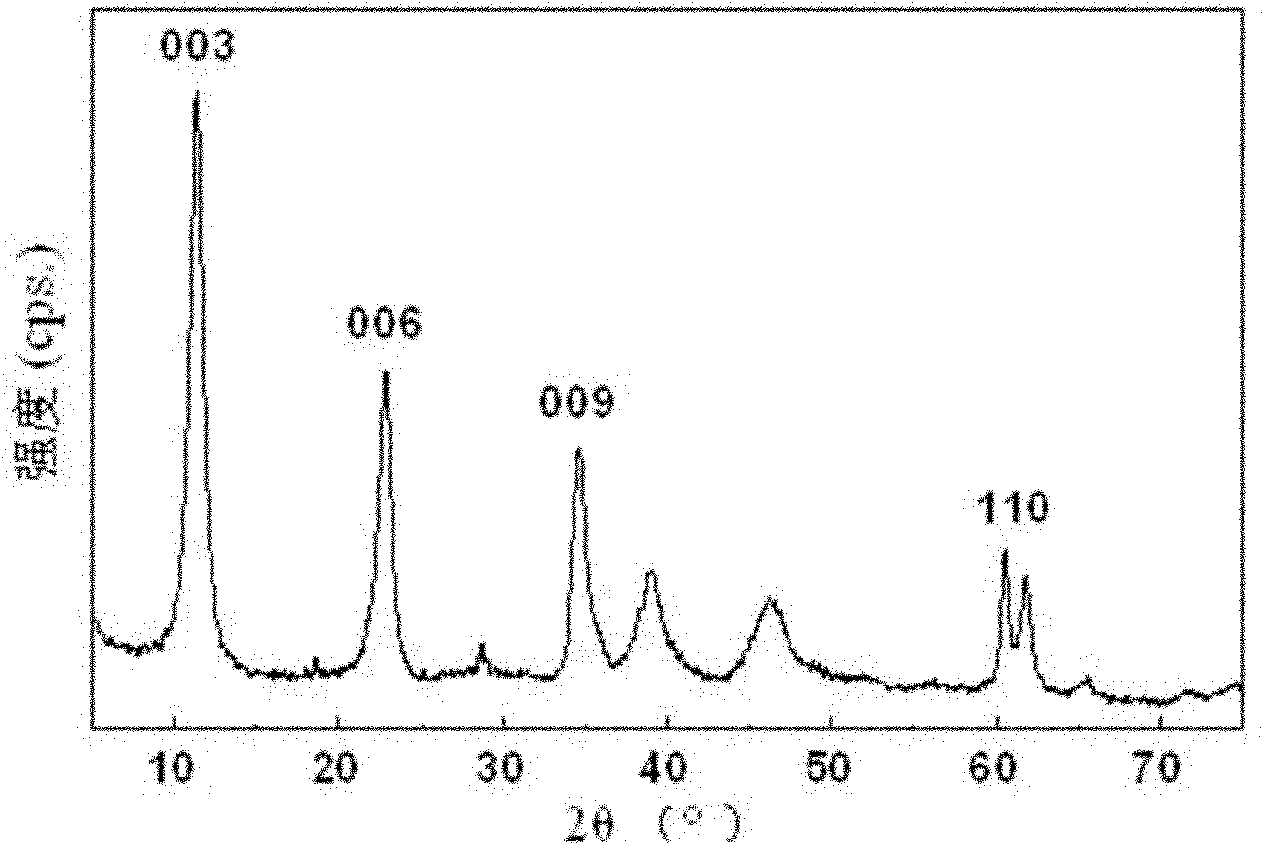

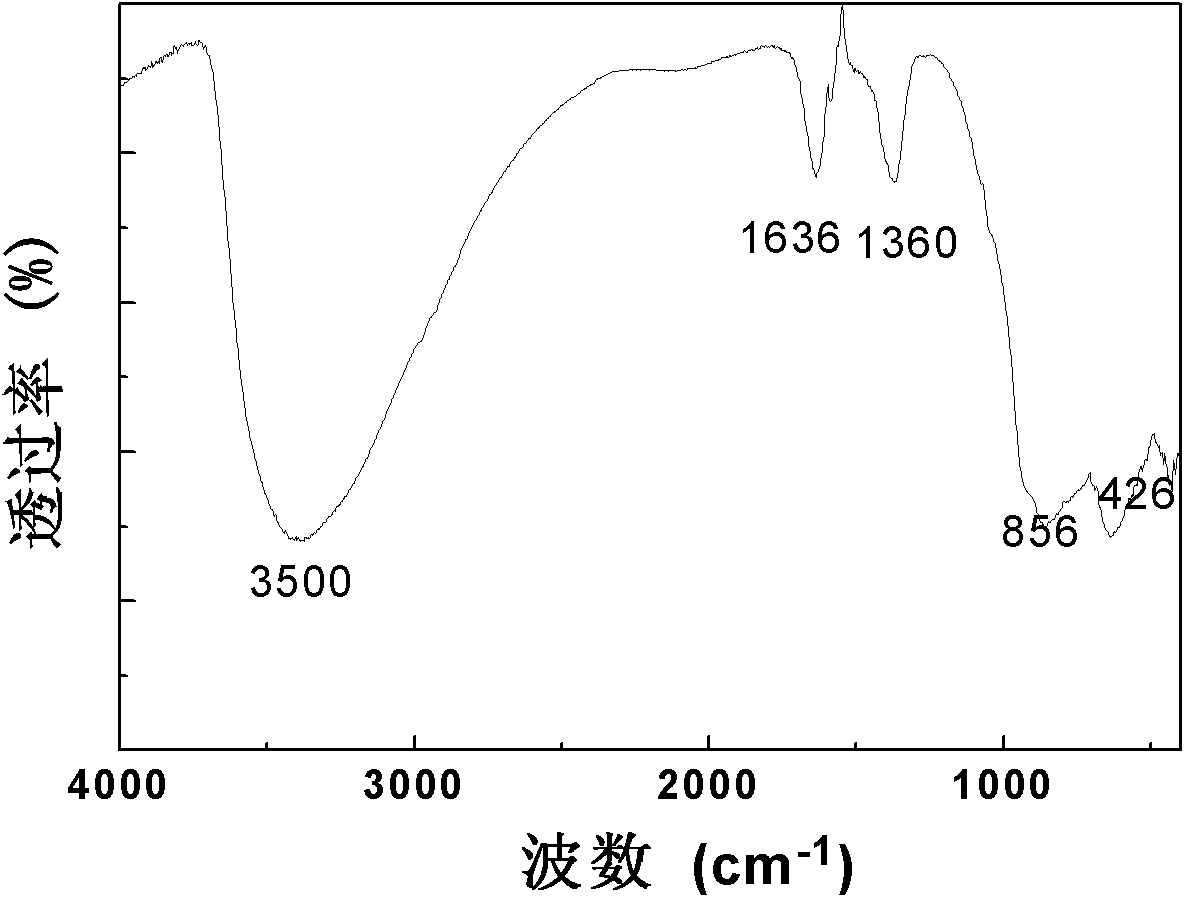

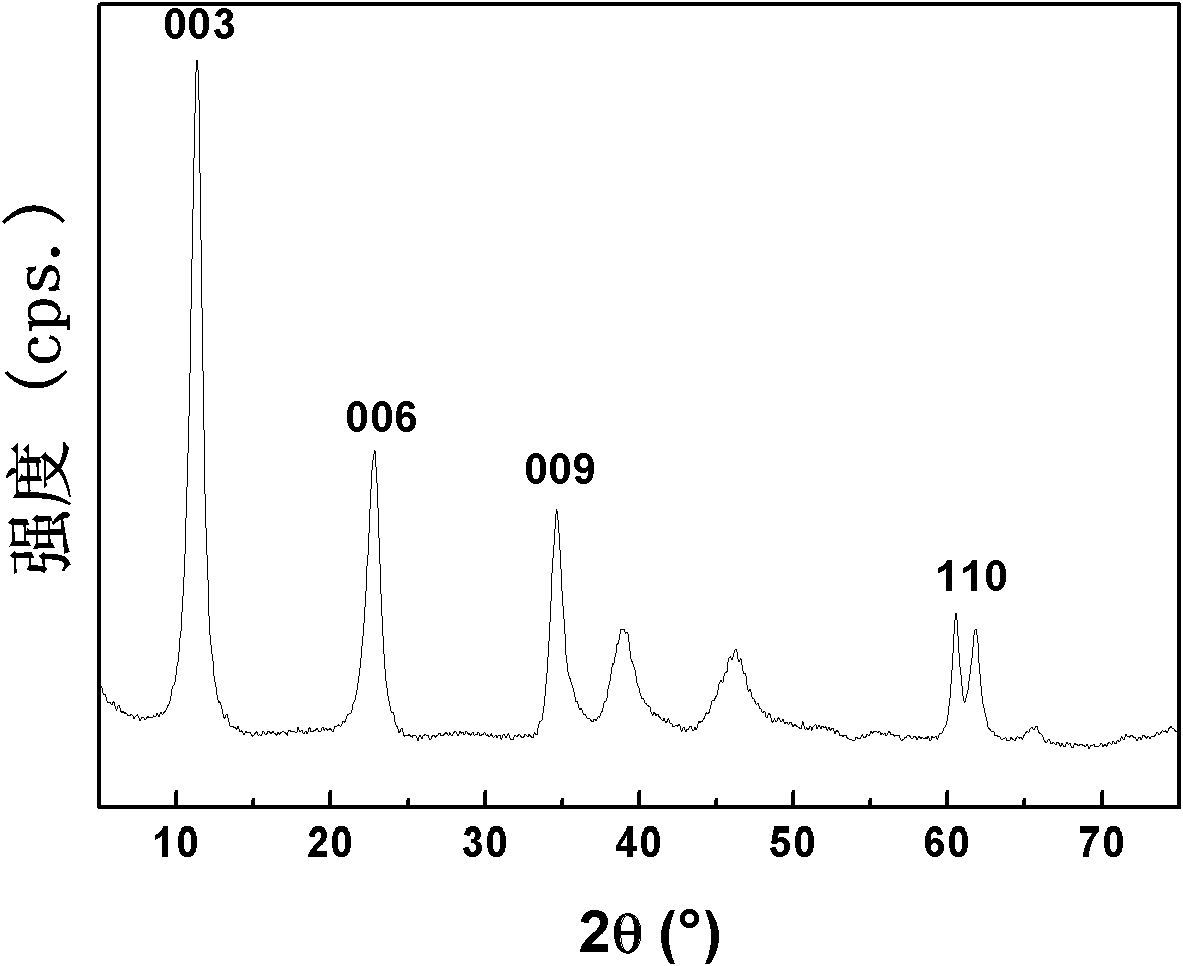

Pillared hydrotalcite and preparation method thereof

InactiveCN101913570AIncrease profitHigh crystallinityOxide/hydroxide preparationTungsten compoundsIon exchangeStructural formula

The invention discloses pillared hydrotalcite and a preparation method thereof, relates to hydrotalcite and a preparation method thereof, and solves the problems of easy agglomeration and long preparation time of the conventional pillared hydrotalcite. The structural formula of the pillared hydrotalcite is [M2+1-xM3+x(OH)2]x+[An-]x / n.zH2O, wherein M2+ and M3+ are laminar main body ions, An- is an interlayer ion, x is more than or equal to 0.20 and less than or equal to 0.34, and z is the number of crystal water. The method comprises the following steps of: dripping aqueous solution of mixed salt containing M2+ and M3+ and aqueous solution of alkali sodium carbonate into the stirring water, and obtaining a bimetallic composite oxide by microwave crystallization and sintering; and preparing reduction solution from the bimetallic composite oxide, sodium hydroxide and soluble salt of the interlayer ion An-, and performing microwave crystallization and sintering on the reduction solution to obtain the pillared hydrotalcite. The pillared hydrotalcite of the invention is difficult to agglomerate, the exchange time of the interlayer negative ions is only 10 to 20 minutes, and the pillared hydrotalcite can be used in the macromolecular flame-retardant field.

Owner:NORTHEAST FORESTRY UNIVERSITY

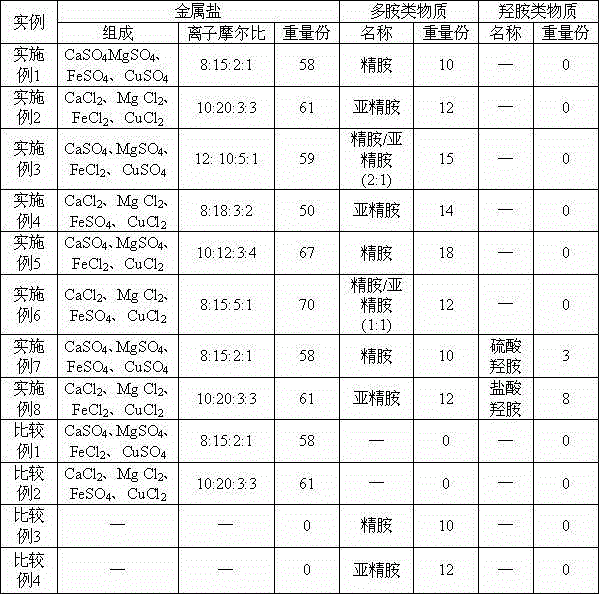

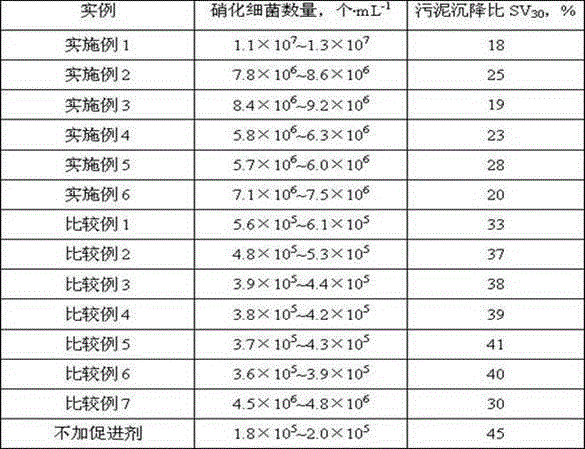

Nitrifying bacterial growth promoting agent, preparation method and applications thereof

ActiveCN105543158AImprove settlement performanceImprove stabilityBacteriaTreatment with aerobic and anaerobic processesMagnesium saltFerrous salts

Owner:CHINA PETROLEUM & CHEM CORP +1

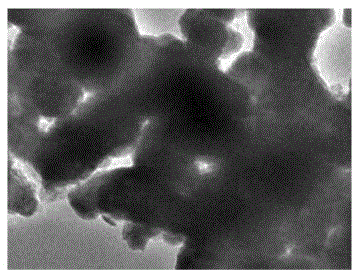

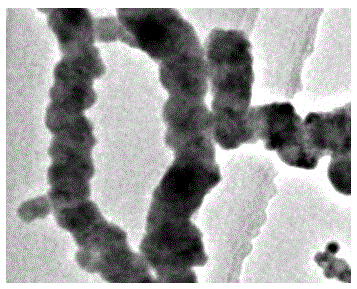

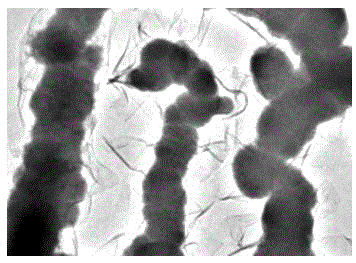

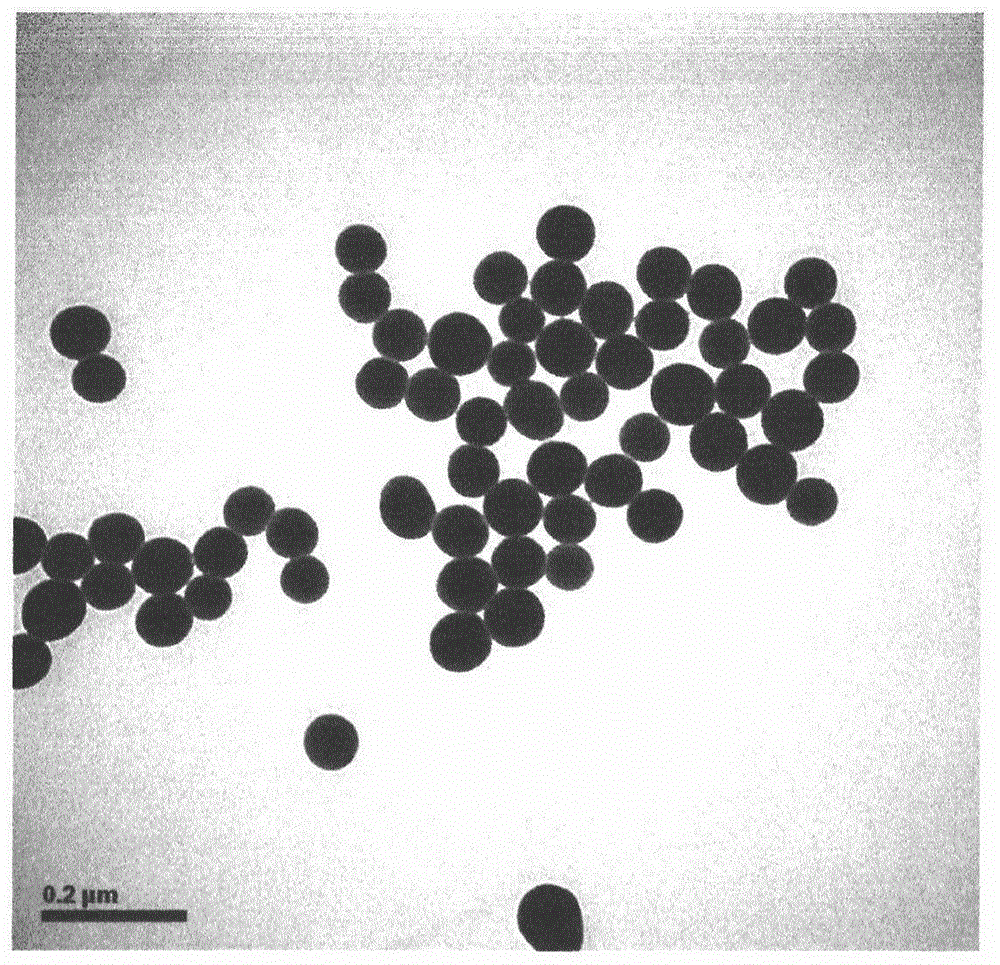

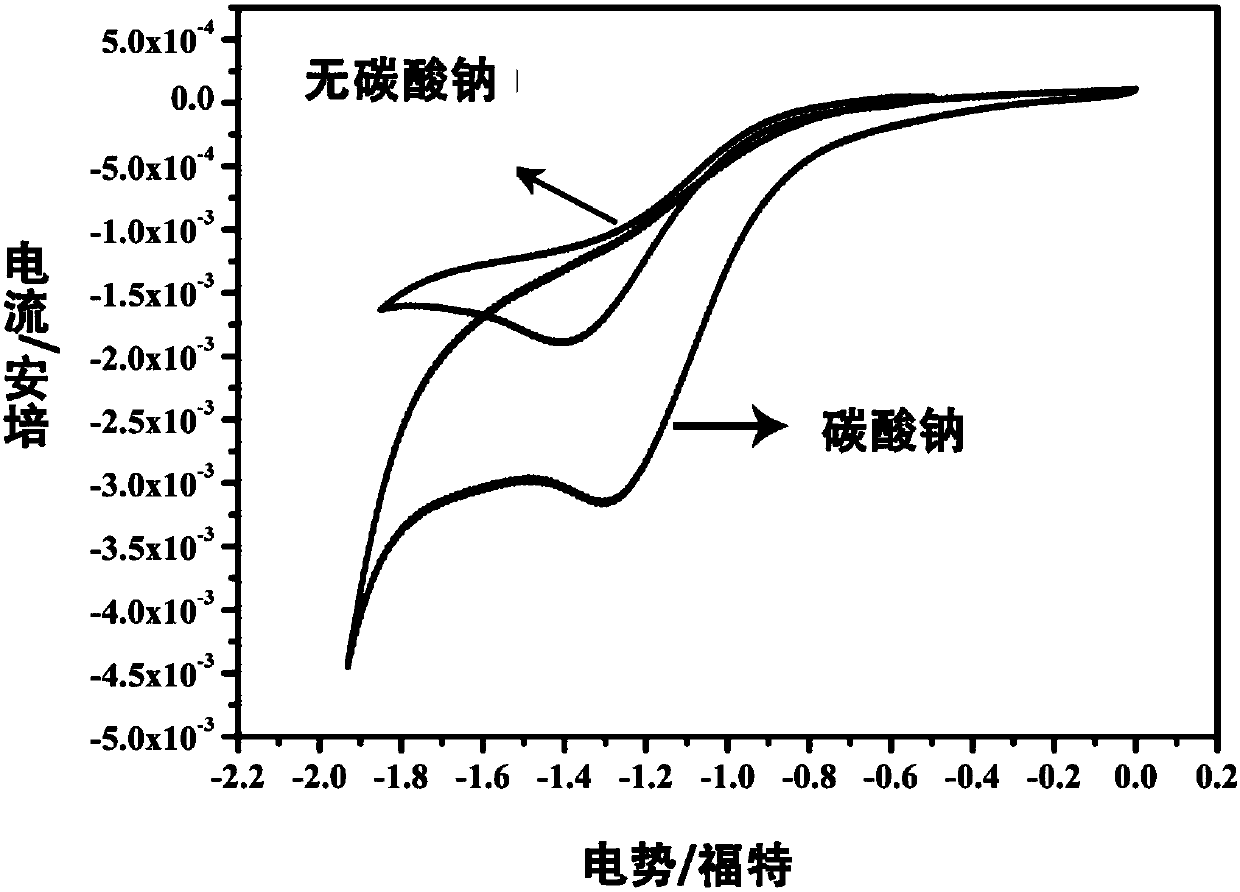

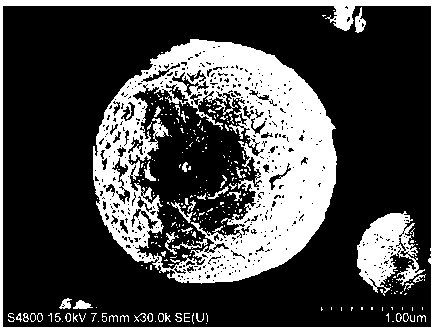

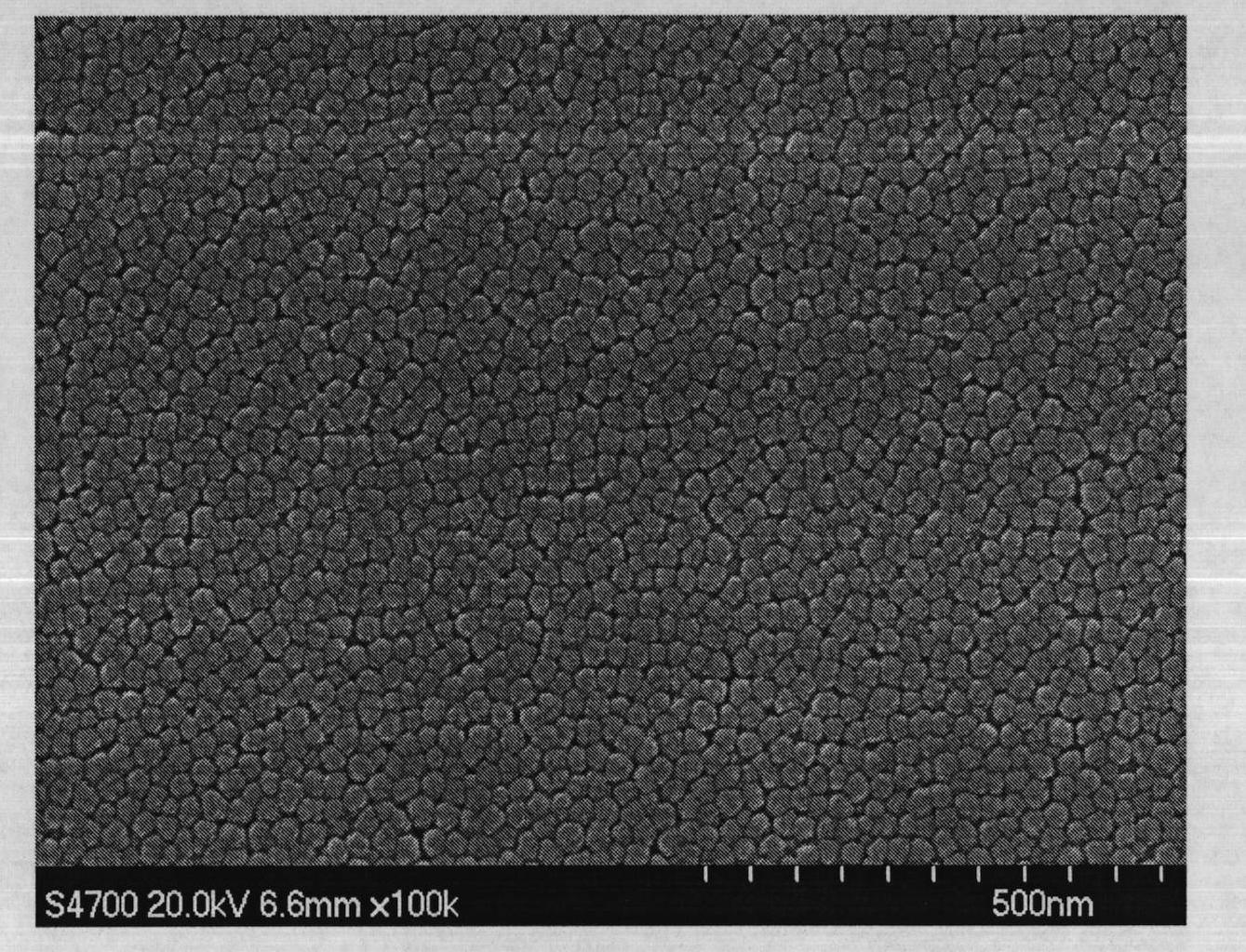

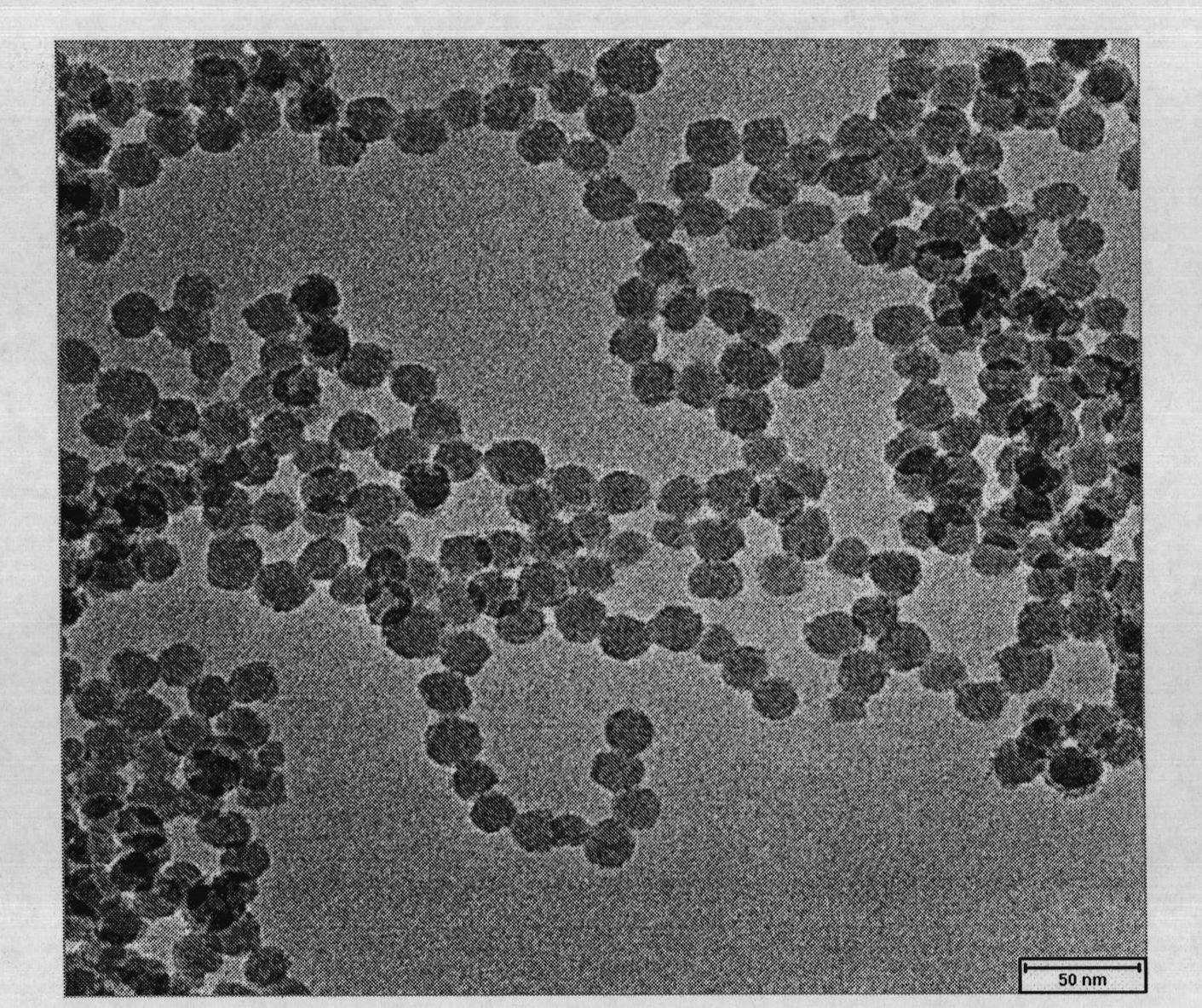

Dispersant modified nano zero-valent iron and preparing method and application thereof

The invention discloses a preparing method for dispersant modified nano zero-valent iron. Through a polymerization inhibitor, MEHQ or PEI serves as a dispersant to modify nano zero-valent iron; through the space steric hindrance effect and the electrostatic steric hindrance effect, the agglomeration phenomenon of the nano zero-valent iron is reduced; in the preparing process of the nano zero-valent iron, the surface of the nano zero-valent iron is modified, agglomeration of the nano zero-valent iron is reduced, dispersibility of the nano zero-valent iron is improved, and the nano zero-valent iron with the higher dispersibility is prepared; nano zero-valent iron particles prepared through the method have the good dispersion stability, inoxidizability and higher reducibility; in the synthetic process of the nano zero-valent iron particles, protection by nitrogen or other inert gases is not needed; and the method is low in cost, easy to operate and environment-friendly. Chlorinated organic compounds, heavy metal, antibiotics, coloring matter and the like in water can be effectively degraded, and the method has a wide application prospect.

Owner:KUNMING UNIV OF SCI & TECH

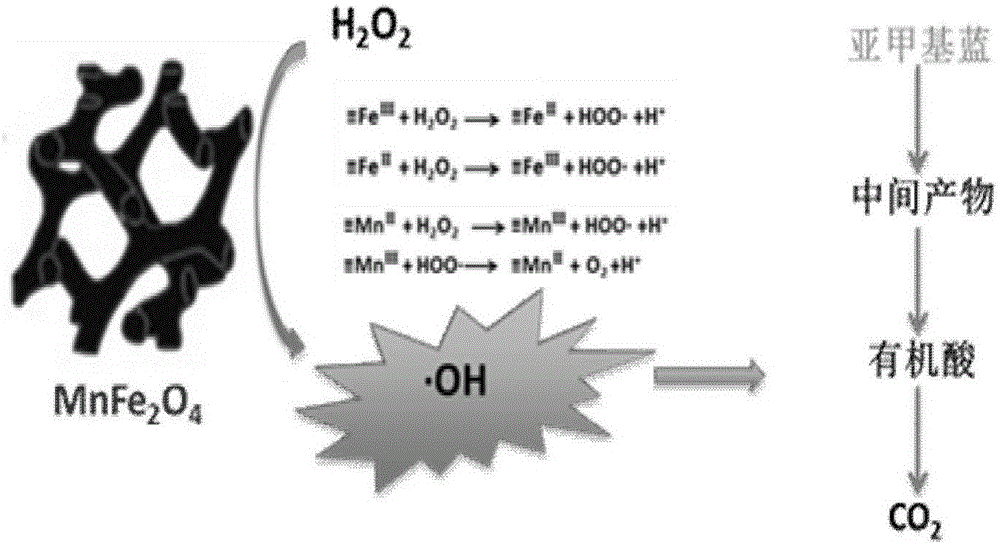

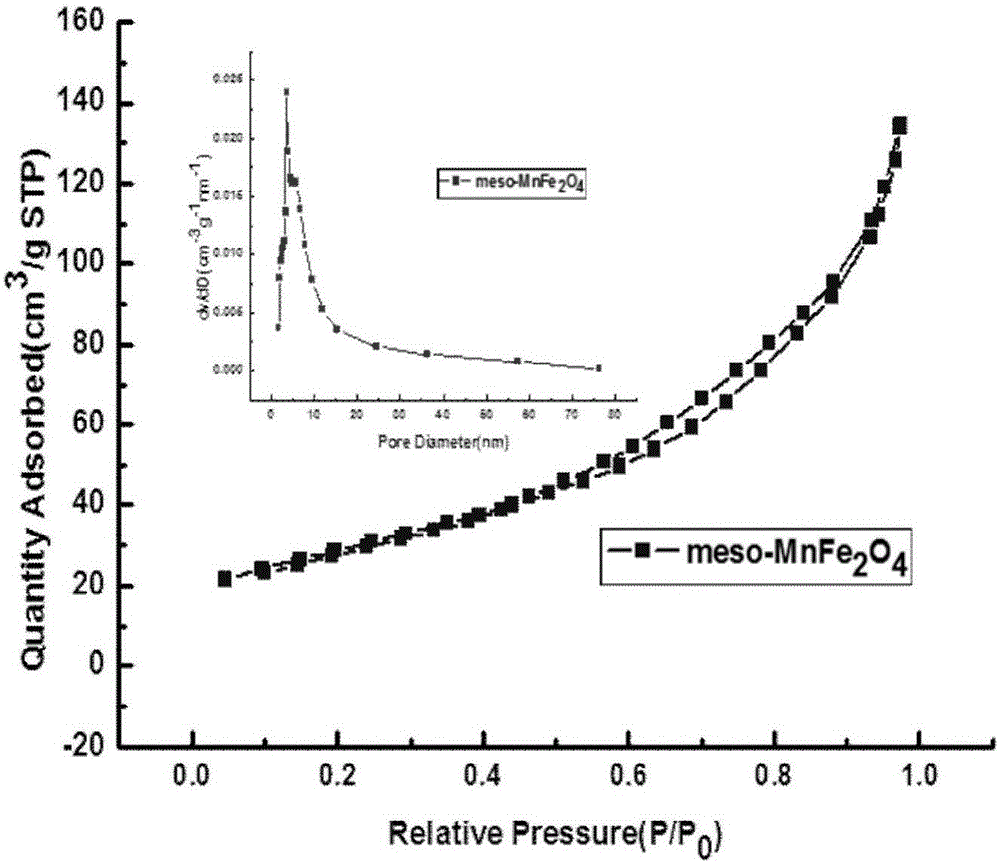

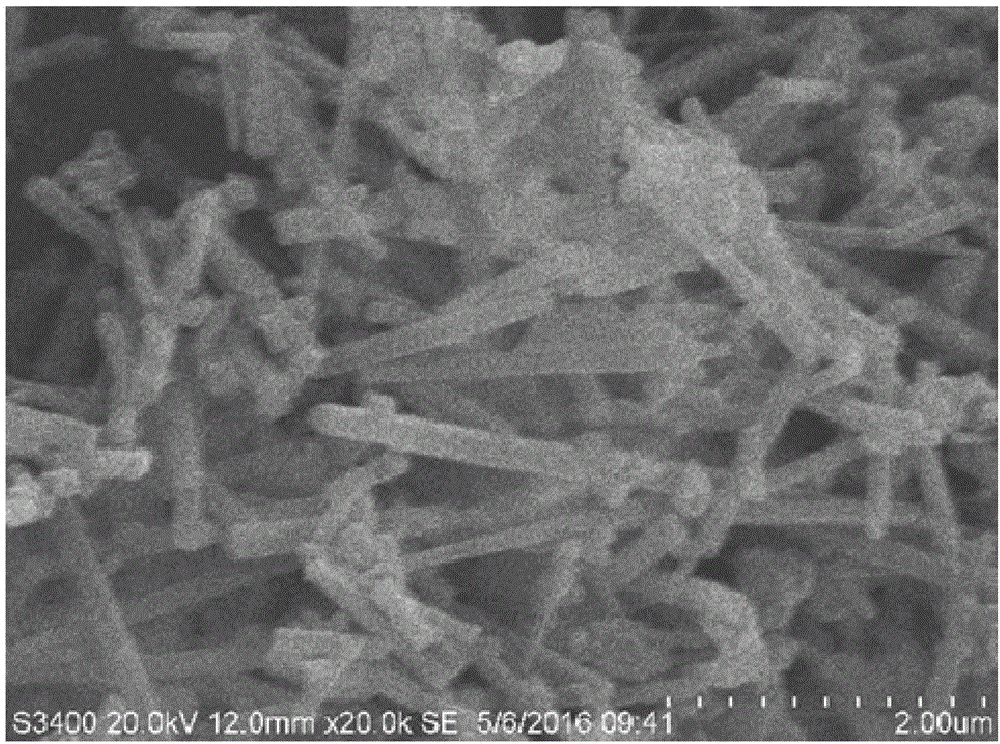

Mesoporous manganese ferrite Fenton-like catalyst and preparation method and application thereof

InactiveCN106391042ALarge specific surface areaGood mesoporous structureWater treatment compoundsWater contaminantsFenton reactionWastewater

Owner:NANJING UNIV

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

Composition for rapidly culturing nitrifying bacteria and applications of composition

ActiveCN105624091AImprove settlement performanceImprove stabilityTreatment with aerobic and anaerobic processesChemical cell growth stimulationOrganic acidHydroxylamine

The invention discloses a composition for rapidly culturing nitrifying bacteria. The composition comprises the following components in parts by weight: 40-100 parts of metal salts, preferably 50-80 parts of metal salts, 5-30 parts of polyamine substance, preferably 10-20 parts of polyamine substance, and 0.5-15 parts of hydroxylamine organic acid, preferably 2-10 part of hydroxylamine organic acid, wherein the metal salts comprise calcium salt, magnesium salt and copper salt, and the molar ratio of Ca<2+> to Mg<2+> to Cu<2+> is (5-15) to (5-25) to (0.5-5), preferably (8-12) to (10-20) to (1-4). The composition is simple in formula and easy to prepare, can be used in a culture process of nitrifying bacteria, and also can be directly fed into a sewage treatment system, so that the nitrifying bacteria can rapidly grow and breed within a short time, and the cultured nitrifying bacteria have high activity and strong impact tolerance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hemicellulose-based heavy metal ion adsorbent

InactiveCN102407097AActivated surface hydroxylHigh degree of substitutionOther chemical processesWater/sewage treatment by sorptionAbsorption capacitySorbent

The invention discloses a preparation method of hemicellulose-based heavy metal ion adsorbent mainly comprising conducting graft copolymerization triggered by free radial under the intensifying effect of ultrasonic. The adsorbent prepared by the invention not only retains excellent properties of hemicellulose, but also has heavy metal ion absorption capacity. The adsorbent is an important adsorbing material with sustainable development.

Owner:GUANGXI UNIV

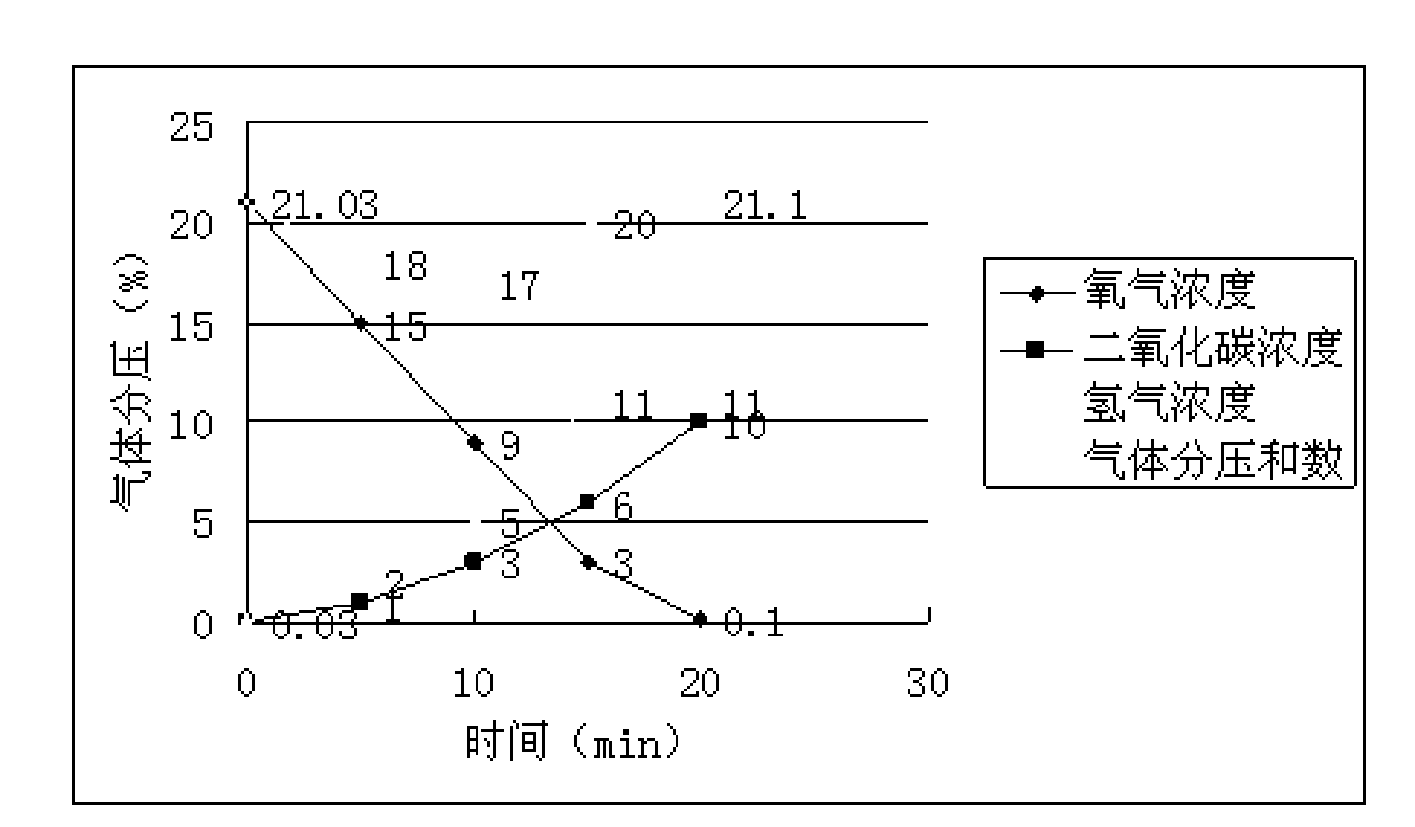

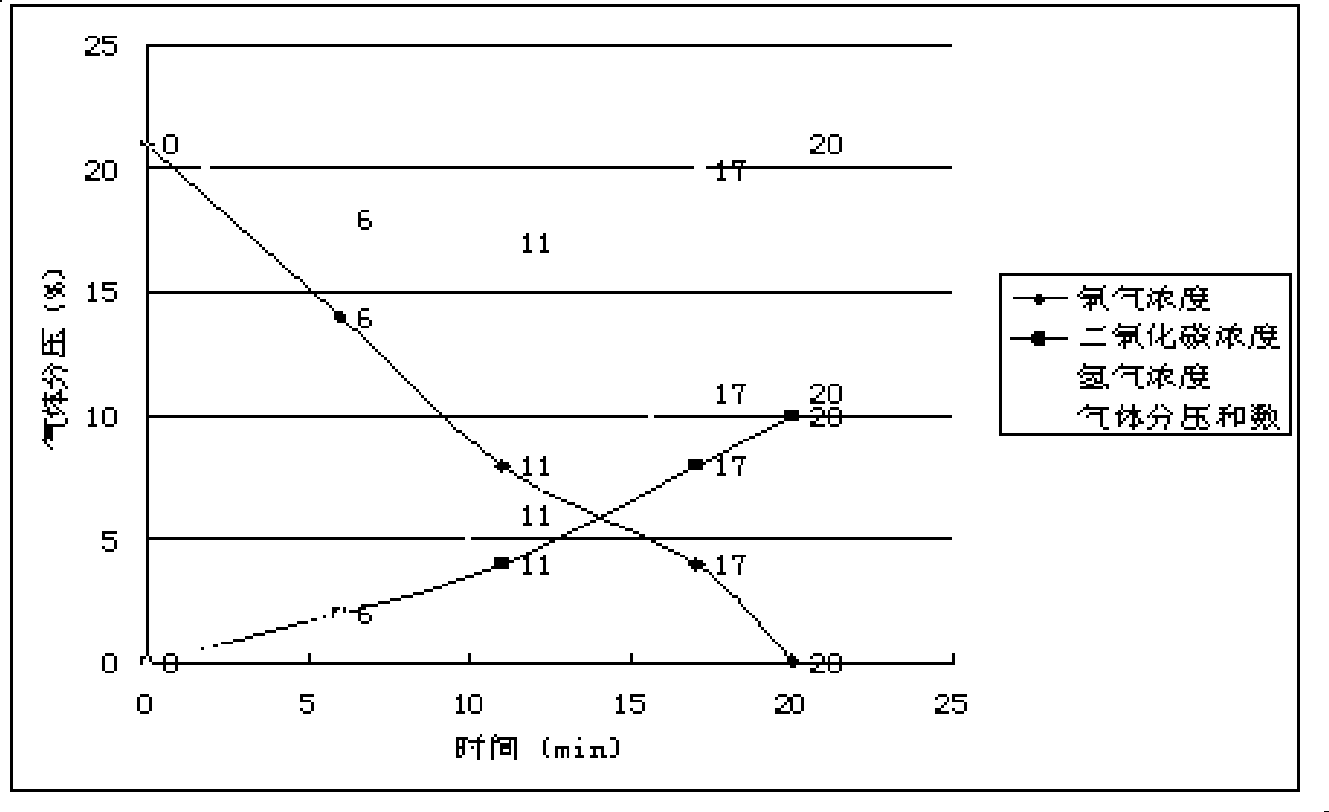

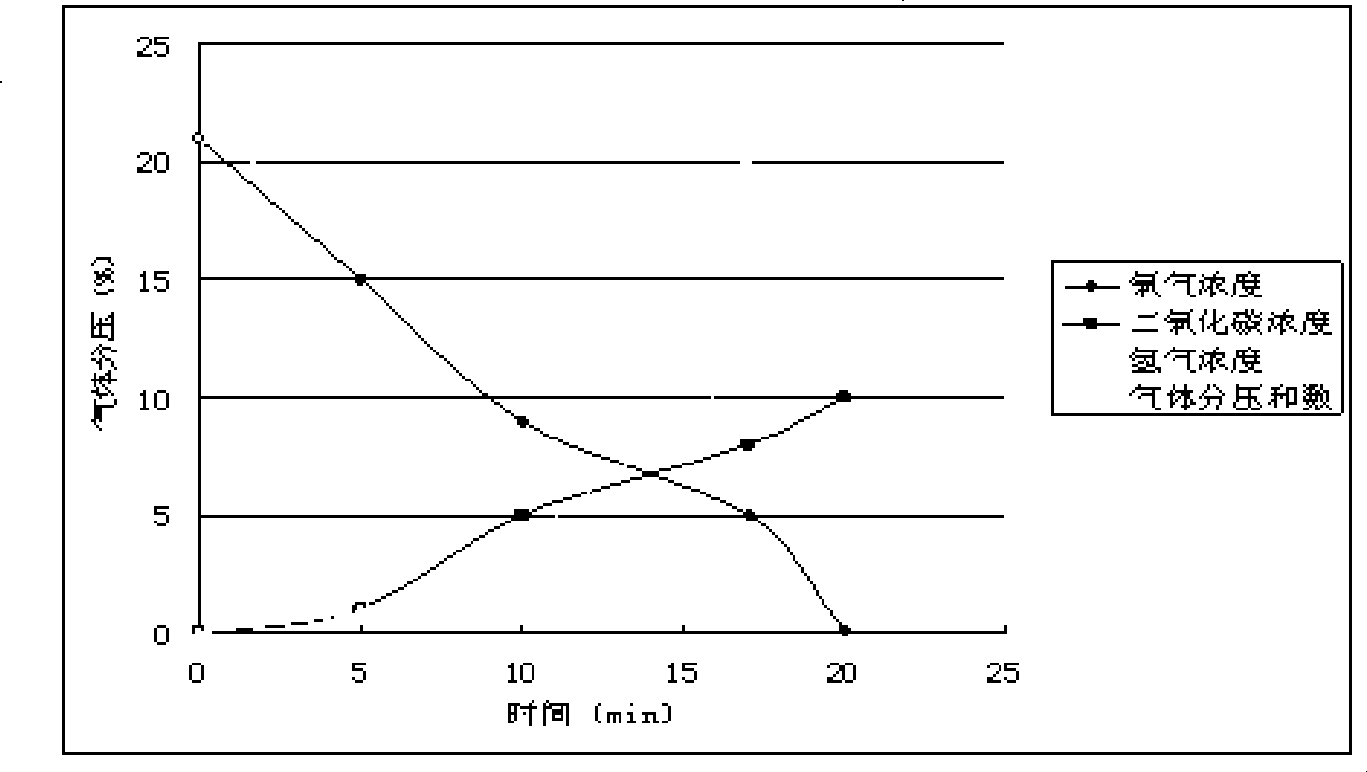

Quick-speed generation method of anaerobic microorganism culture environment

InactiveCN101397546ALower energy barrierQuick responseBacteriaMicroorganism based processesHydrogenCooperative interaction

The invention provides a fast generation method of anaerobe culture environment with convenience, fastness, high efficiency and low cost, which adds a deoxidant, a carbon dioxide propellant and a hydrogen propellant in a sealed case so as to remove the oxygen in the case, generate carbon dioxide and hydrogen with a proper proportion, and achieve the purpose of maintaining the pressure balance in the case through the cooperative interaction of the deoxidant, the carbon dioxide propellant and the hydrogen propellant; the whole phenomenon is observed through the color change of an indicator. Theinvention also provides a combined reagent for realizing the fast generation method of anaerobe culture environment, which consists of the deoxidant, the carbon dioxide propellant and the hydrogen propellant.

Owner:HANGZHOU BASEBIO BIO TECH

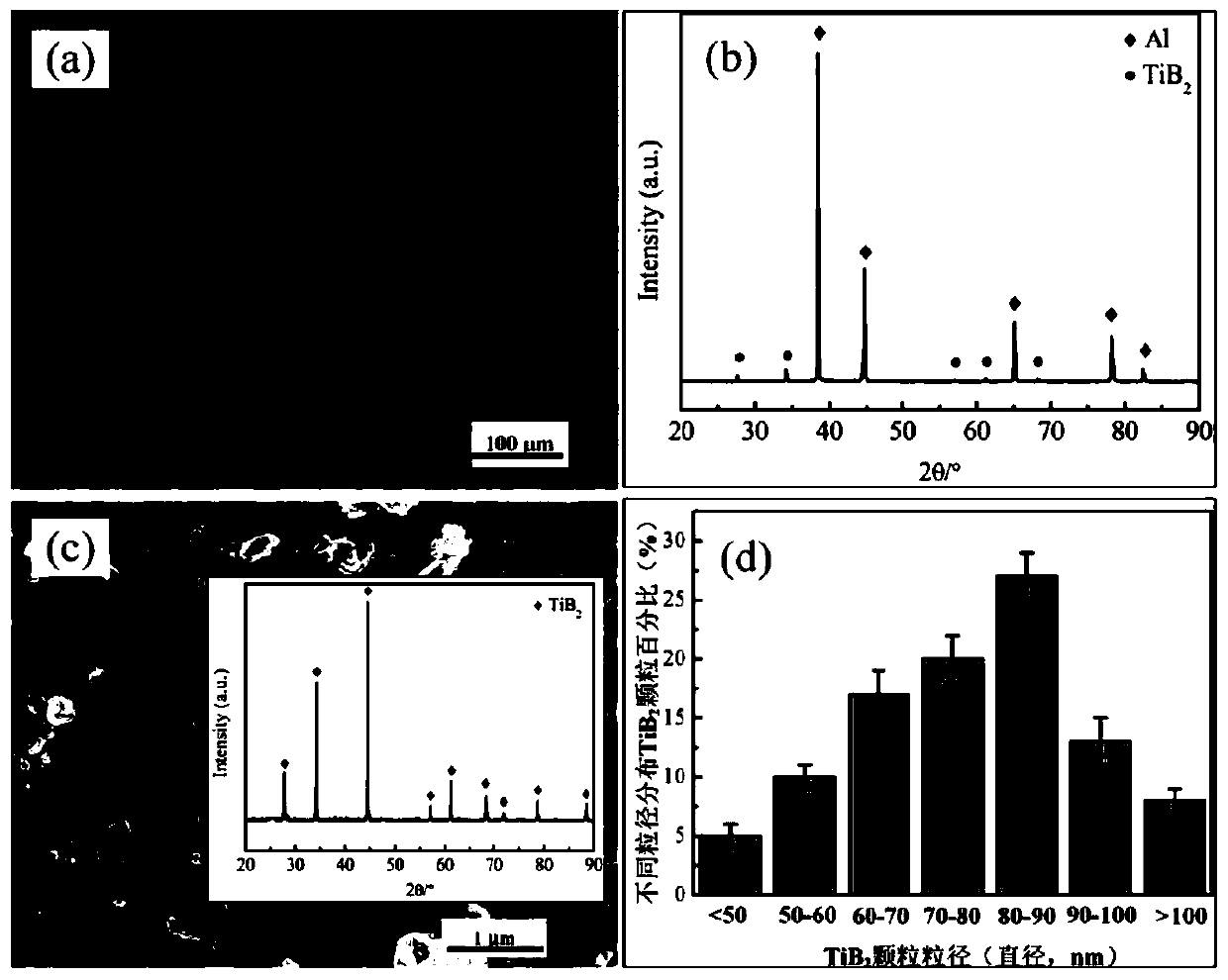

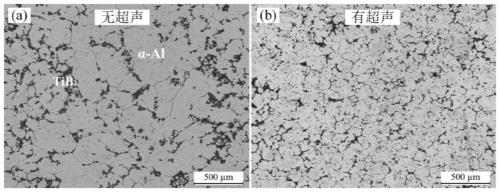

High-dispersive-distribution nano-titanium diboride particle reinforced aluminum matrix composite material and preparation method thereof

The invention discloses a high-dispersive-distribution nano-TiB2 particle reinforced aluminum matrix composite material and a preparation method thereof. Firstly, a uniform-structure Al-TiB2 intermediate alloy is prepared through an ultrasound assisted mixed salt reaction (K2TiF6 / KBF4-Al), wherein the average particle diameter of in-situ endogenous TiB2 particles is smaller than 100nm; the Al-TiB2 intermediate alloy and Al are used as raw materials, or Al-TiB2 intermediate alloy, Al and alloy elements are used as raw materials, the nano-TiB2 particles are introduced into an aluminum (alloy) matrix through an intermediate alloy dilution method, ultrasound agitation treatment is used as assistance, then pouring into a mold is performed, and ultrasound is applied during solidification (introduction through a bottom introduction method); and thus the high-dispersive-distribution nano-TiB2 particle reinforced aluminum matrix composite material is obtained.

Owner:咸阳瞪羚谷新材料科技有限公司

Method for preparing modified nanosilicon dioxide

The invention provides a method for preparing modified nanosilicon dioxide. Firstly, nanosilicon dioxide is reunited as little as possible by adding chitosan during the nucleation process, thereby obtaining modified nanosilicon dioxide which is uniform, steady and excellent in dispersivity. Secondly, ethylene diamine tetraacetic acid and the nanosilicon dioxide react to enable the surface of the ethylene diamine tetraacetic acid to modify a certain amount of amino. Thirdly, silanol and aminosilylation are arranged on the outer layer of the nanosilicon dioxide, added stannous chloride enables the silanol and the aminosilylation to have excellent activities to epoxy groups, speeds up reaction progress, and greatly improves modified grafting ratio of surface of the nanosilicon dioxide.

Owner:杭州爱净科技有限公司

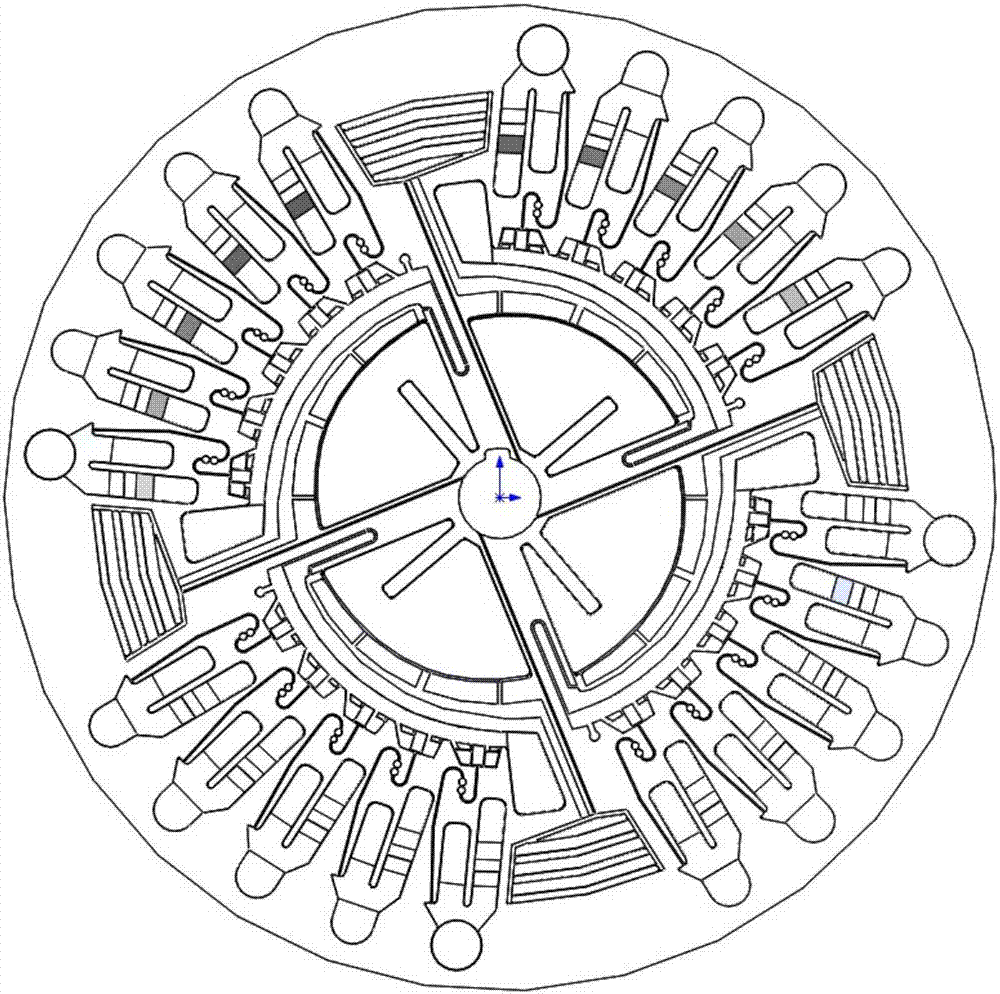

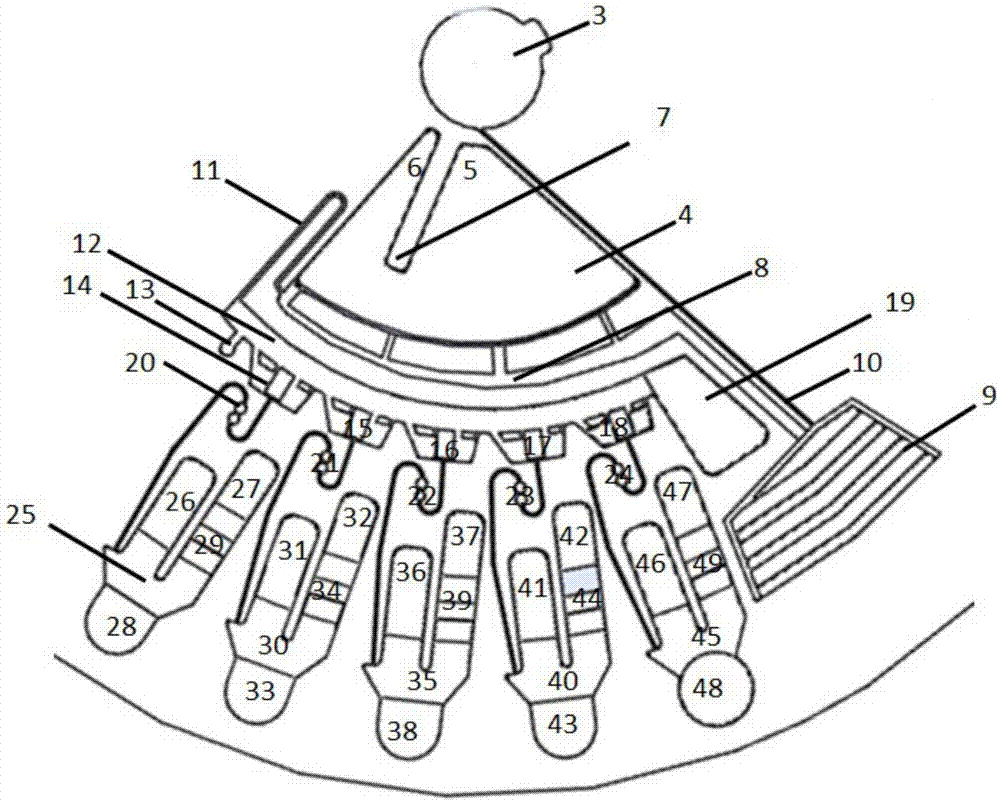

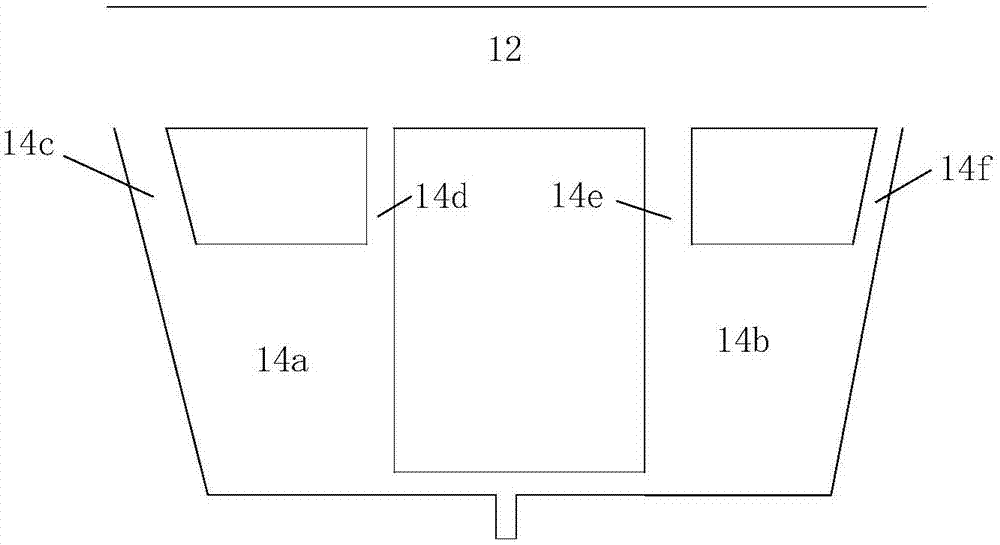

Microfluidic blood coagulation detection device and method

ActiveCN107051305AEfficient processProcess stabilityShaking/oscillating/vibrating mixersTransportation and packagingCentre of rotationBlood coagulations

The invention provides a microfluidic blood coagulation detection device and method. The microfluidic blood coagulation detection device includes a disc, the disc comprises micro-channel units, each micro-channel unit comprises: an injection groove, which is equipped with a sample adding hole, a vent hole and a partition plate, wherein the sample adding hole and the vent hole are separated by the partition plate; a first channel, which is distributed along the circumferential direction of the disc, has a gradually increasing width in the radial direction of the disc, and is located at the periphery of the injection groove that is communicated with a storage groove through the first channel; communication channels, which are used for communicating with the injection groove and the first channel and are disposed in the radial direction of the disc; the storage groove, which is further away from a rotation center of the disc compared with the first channel and is communicated with a widest part of the first channel. The device and the method provided by the invention have the advantages of high efficiency, stability and simplicity, etc., and can achieve direct injection of a whole blood sample.

Owner:ZHEJIANG PUSHKANG BIOTECHNOLOGY CO LTD

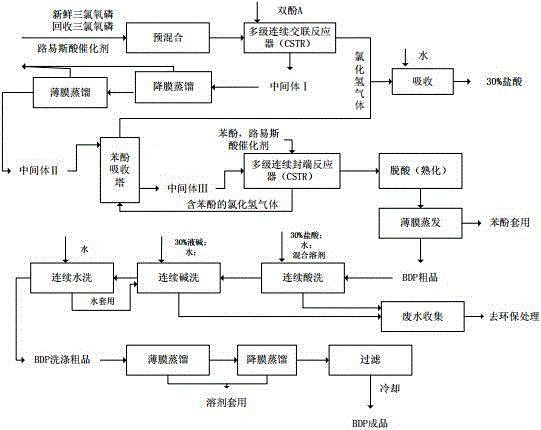

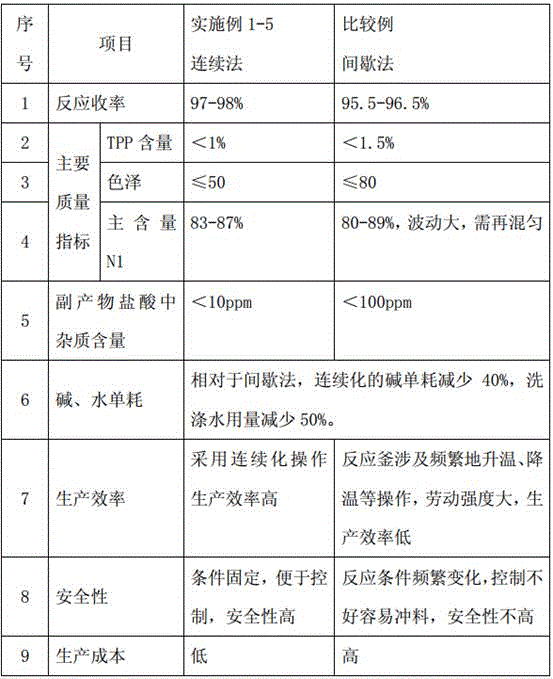

Continuous preparation method for bisphenol A-di(diphenyl phosphate)

ActiveCN106496264AReduce labor intensityMeets requirementsGroup 5/15 element organic compoundsCustomer requirementsDiphenyl phosphate

The invention discloses a continuous preparation method for bisphenol A-di(diphenyl phosphate). The continuous preparation method for the bisphenol A-di(diphenyl phosphate) comprises a multistage crosslinking reaction process, a continuous phosphorus oxychloride recycling process, a continuous multistage end capping reaction and phenol recycling process, a continuous crude product refining process, and a continuous solvent recycling and filtering process. The BDP is prepared by the continuous processes, the production cost is reduced, the labor intensity of operators is greatly reduced, the labor efficiency is improved, and the product yield is greatly improved, so the lot production quality is stable, and the production is safe and environment-friendly. The yield is improved by 1-1.5%, the color number is improved below 50, and the TPP is controlled to be 1%, and is reduced by 50% compared by an original intermittence device. The high-end customer requirement is satisfied, and the quality index fluctuation of each product is small.

Owner:ZHEJIANG WANSHENG

Carbon tetrachloride polluted water source treatment device and application thereof

InactiveCN104163483AFlexible replacementEasy constructionWater/sewage treatment by sorptionWater/sewage treatment by reductionPollutantPollution

The invention provides a carbon tetrachloride polluted water source treatment device and application thereof. The device comprises a water inlet tank, a simulated soil layer tank and a water outlet tank, wherein the water inlet tank is connected with the simulated soil layer tank through a left partition; the simulated soil layer tank is connected with the water outlet tank through a right partition; the lower part of the left partition is provided with an influent water guide tube set; the influent water guide tube set is communicated between the simulated soil layer tank and the water outlet tank; and the inner side of the bottom of the simulated soil layer tank is vertically provided with a reaction well casing set. The treatment device provided by the invention can effectively remove the carbon tetrachloride pollutant in the water body, and can not generate secondary pollution.

Owner:XUZHOU UNIV OF TECH

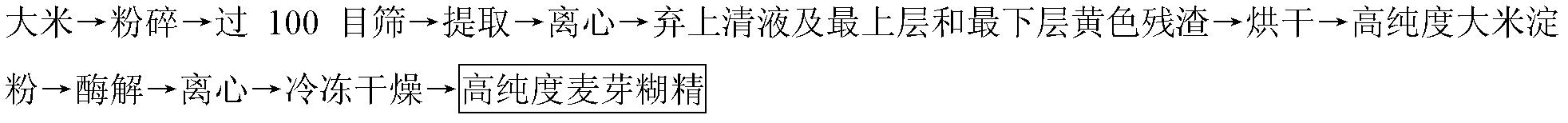

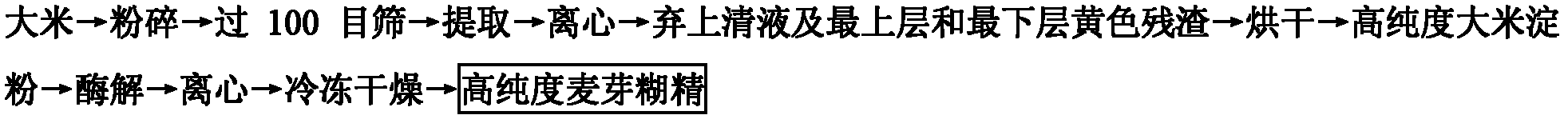

A kind of preparation method of rice starch-based fat substitute

The invention relates to preparation of a rice starch-based fat replacer, in particular to a method for preparing high-purity low-DE (dextrose equivalent) value malto dextrin by utilizing rice. The method comprises the following concrete steps of: smashing and sieving rice, soaking and extracting with alkali liquor; then centrifuging to remove supernate and surface layer and lowermost yellow residue, and drying for 40-50 hours to obtain rice starch; mixing rice starch feed liquor with water at the mass percent ratio of 1:(4-6); then adding alpha amylase to ensure the alpha amylase to account for 0.5-1.5% of size in mass fraction, carrying out enzymolysis for 10-15 minutes at the temperature of 85-95 DEG C, centrifuging for 8-12 minutes, freezing the supernate, and carrying out freeze drying treatment after the supernate is completely frozen, thus malto dextin is obtained. By adopting the method in the invention, the high-purity low-DE value malto dextin fat replacer is prepared, and preparation process of the malto dextin is changed while basic physicochemical properties of the malto dextin are not changed, thus the aims of energy conservation and consumption reduction are achieved during preparation of the malto dextin.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

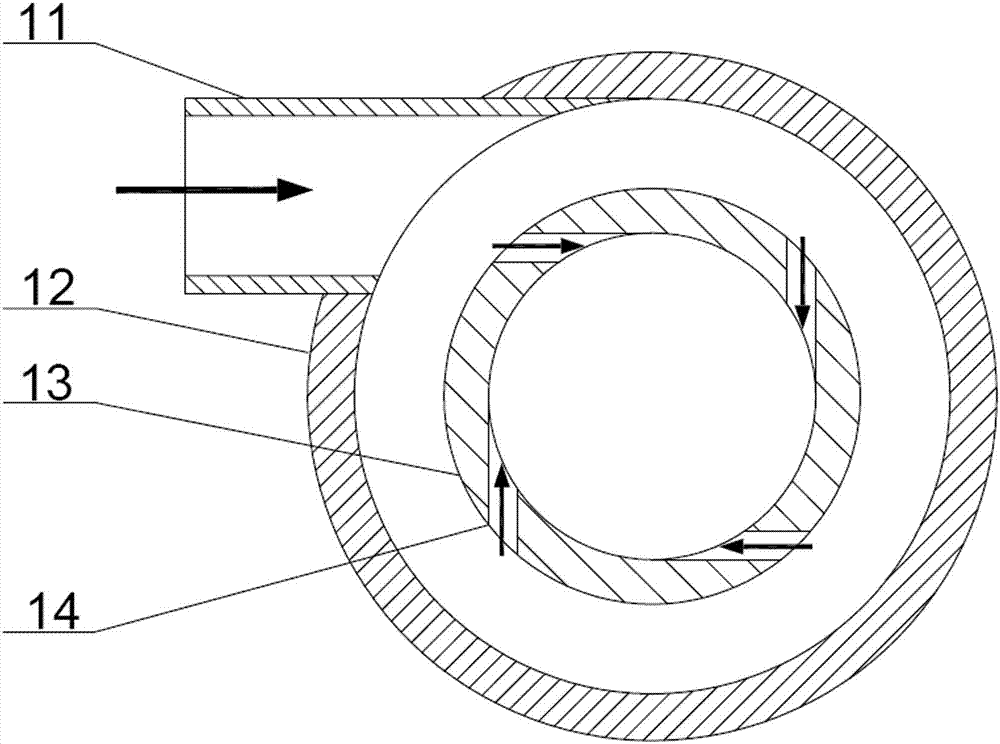

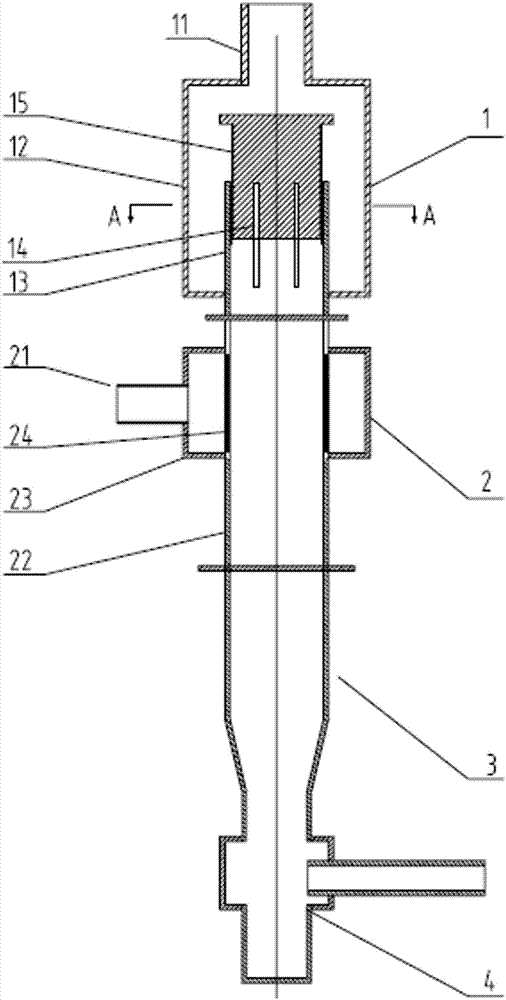

Multi-phase pipe type cyclone reactor capable of accurately regulating and controlling cyclone flow speed of liquid phase

InactiveCN107213855AAdapt to mix strengthRealize the mixing effectChemical/physical processesCycloneChemical industry

The invention discloses a multi-phase pipe type cyclone reactor. The multi-phase pipe type cyclone reactor comprises a flow speed regulation cyclone device, a gas-phase injector, a reaction pipe and a discharging control valve, wherein the flow speed regulation cyclone device is composed of a feeding pipe, a cyclone pipe, a cyclone tangential slit, a flow speed regulation valve and an outer jacket. A liquid phase enters the flow speed regulation cyclone device from the feeding pipe; axial flowing is changed into cyclone flowing and rotary and axial common flowing is formed in the cyclone reaction pipe; a cyclone flow speed of the liquid phase is regulated by conveniently and accurately regulating the size of an inlet of the cyclone tangential slit through the flow speed regulation valve, and the mixing strength of different reaction systems and the retention time in reaction pipe systems are realized; the multi-phase pipe type cyclone reactor disclosed by the invention is simple in structure, less in investment, convenient to operate and strong in adaptive capacity and is suitable for industries including metallurgy, chemical industry, materials, sewage treatment, medicines and the like.

Owner:李尽善

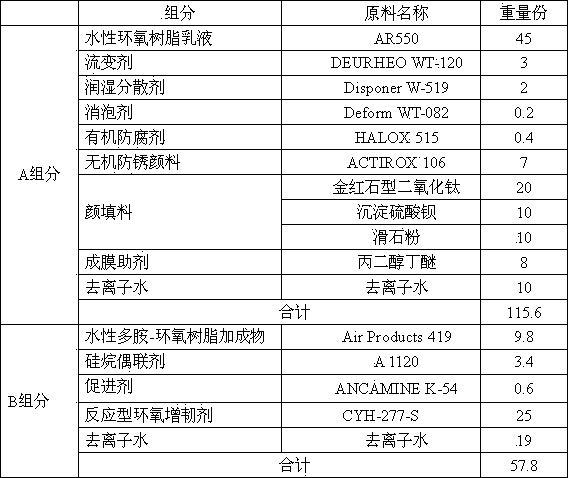

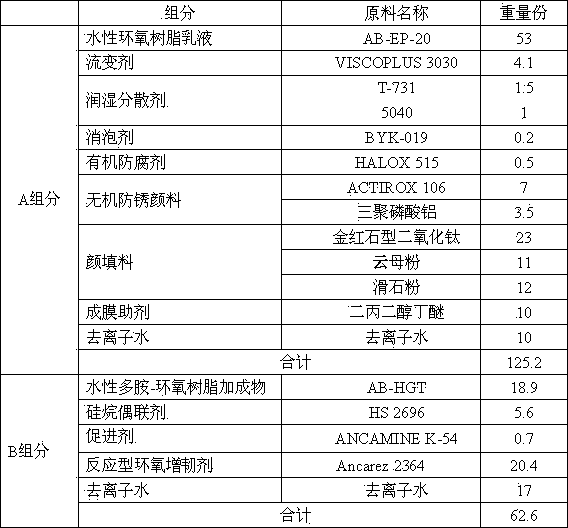

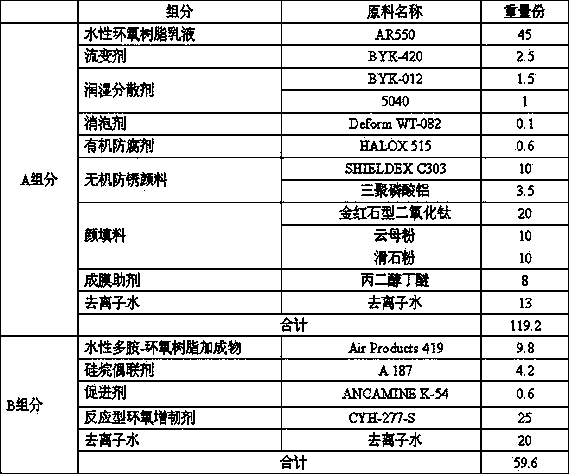

Aqueous epoxy corrosion-resistant coating for mechanical equipment and preparation method of aqueous epoxy corrosion-resistant coating

InactiveCN104277660ASpeed up the reaction processAvoid coating film brittle defectsAnti-corrosive paintsEpoxy resin coatingsIonEmulsion

The invention relates to an aqueous epoxy corrosion-resistant coating for mechanical equipment. According to the aqueous epoxy corrosion-resistant coating, a component A comprises an aqueous epoxy resin emulsion, a rheological agent, a wetting and dispersing agent, a defoaming agent, an organic preservative, an inorganic anti-rust pigment, a pigment filler, deionized water and a film-forming aid, a component B comprises an aqueous polyamine-epoxy resin adduct, deionized water, a silane coupling agent, a promoter and a reactive epoxy toughening agent, and the aqueous epoxy corrosion-resistant coating is prepared by preparing the component A, preparing the component B and mixing the component A and the component B. Test results show that under the situation of coating a 150mu m wet film, the surface drying time is less than 40min, the solid drying time is less than 12h, the thickness of a dry film is 80mu m, a coating has no cracks under the impact condition of 120kg.cm, an anti-flash rust agent which produces harm to a human body or an environment is eliminated, and the aqueous epoxy corrosion-resistant coating is environment-friendly and high in safety.

Owner:洛阳双瑞防腐工程技术有限公司

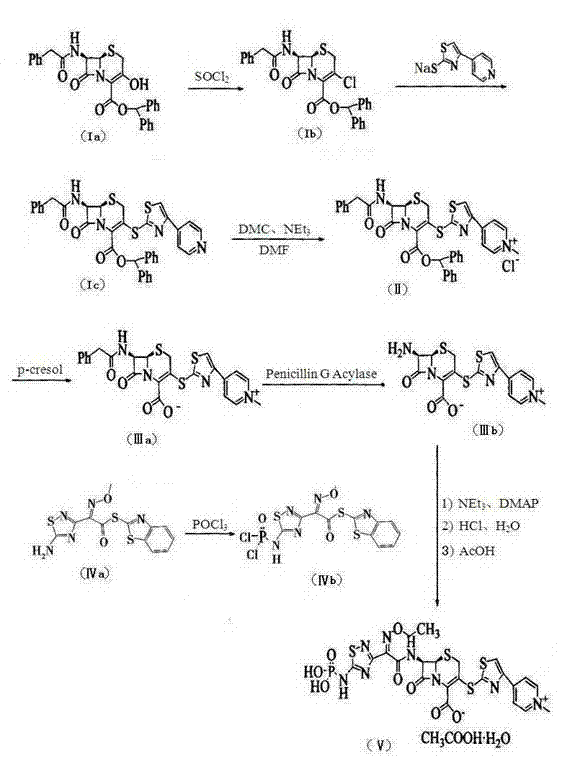

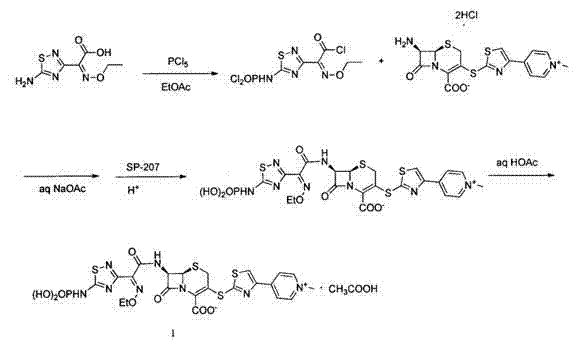

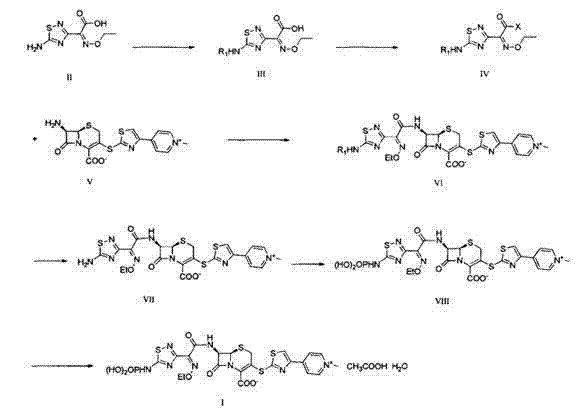

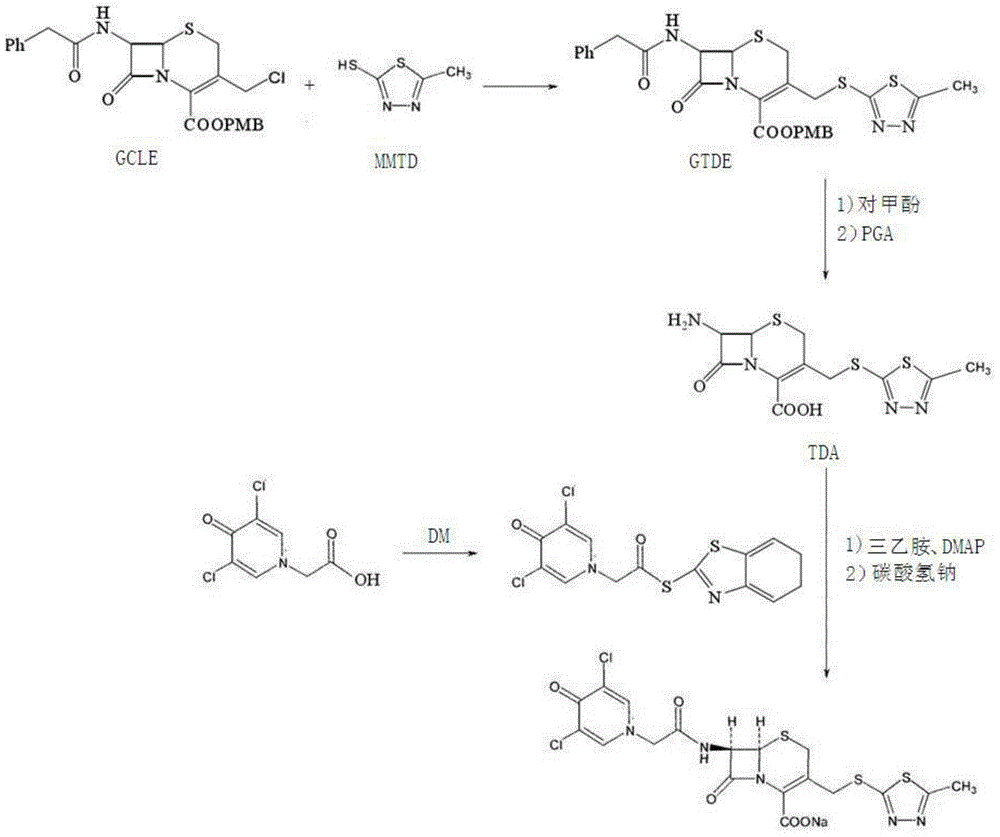

Preparation method for ceftaroline fosamil

ActiveCN104725425AMild reaction conditionsLess side effectsGroup 5/15 element organic compoundsBulk chemical productionCarboxylic groupG penicillin

The invention relates to a synthetic method for ceftaroline fosamil. According to the synthetic method, 7-phenylacetamide-3-hydroxy-3-cephalosporin-4-carboxylate-diphenylmethyl is selected as a raw material to be chloridized and reacts with 4-(4-pyridyl)-1,3-thiazole-2-thiol sodium salt at a C-3 site to obtain a thioether compound, p-cresol and immobilized penicillinase are adopted for removing carboxyl and amino protecting groups respectively, the thioether compound and the acylated AE-active ester are subjected to C-7 site condensation reaction, and crystallization in acetic acid is performed after hydrolyzation to prepare the ceftaroline fosamil successfully. The preparation method has the advantages that use of toxic and harmful substances such as trifluoroacetic acid and phosphorus pentachloride is avoided, reaction conditions are moderate, side reactions are few, technology is simple, yield and product purity are high, cost is low, raw materials are cheap and easy to obtain, and the preparation method is applicable to industrial production.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

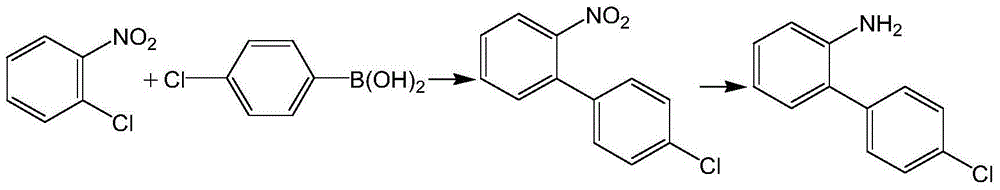

Method for preparing boscalid intermediate 2-(4-chlorophenyl) aniline

ActiveCN104529794AReduce dosageIncrease Cl activityOrganic compound preparationAmino compound preparationNitrobenzeneSolvent

The invention belongs to the field of pesticides, relates to a technology for preparing agricultural fungicide intermediates and particularly relates to a technology for preparing boscalid intermediate 2-(4-chlorophenyl) aniline. The technology comprises the following steps of by adopting alcohol or formamide solvent, in an alkaline reagent and a KI system, under the action of Pd catalyst, carrying out Suzuki coupling reaction on o-chloronitrobenzene and p-chlorophenylboronic acid as raw materials to generate 2-(4-chlorophenyl)nitrobenzene, simply filtering the reaction system and directly carrying out catalytic hydrogenation on the reaction system to obtain the product. By the technology, the problems of high price of the raw materials, low yield, complex after-treatment and harsh reaction conditions of the traditional synthesis process of the boscalid intermediate are solved, the simple reaction is achieved in a true sense, the manufacturing cost is decreased, the content and yield of the product are increased and the technology is more conducive to industrial production.

Owner:JINGBO AGROCHEM TECH CO LTD

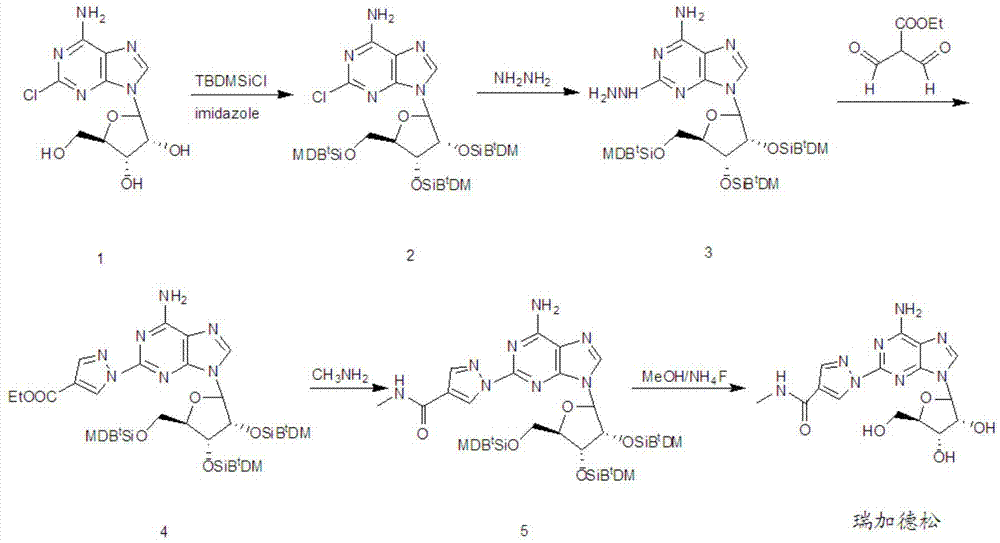

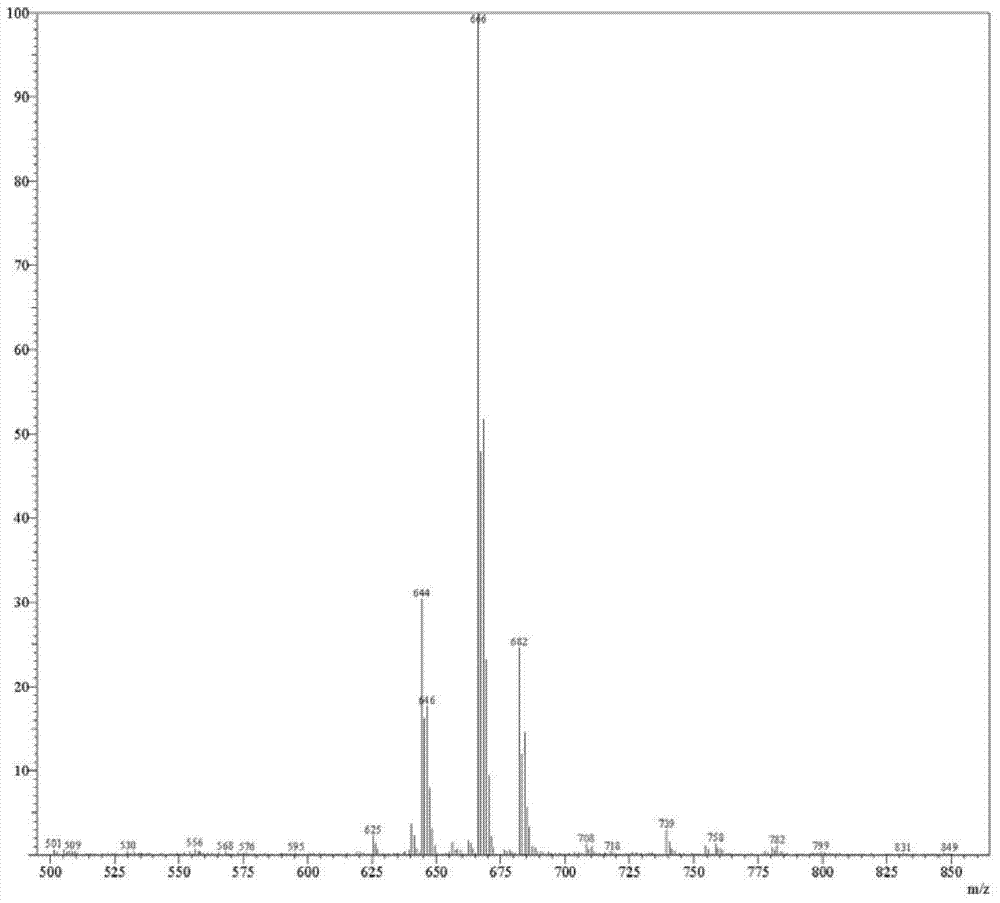

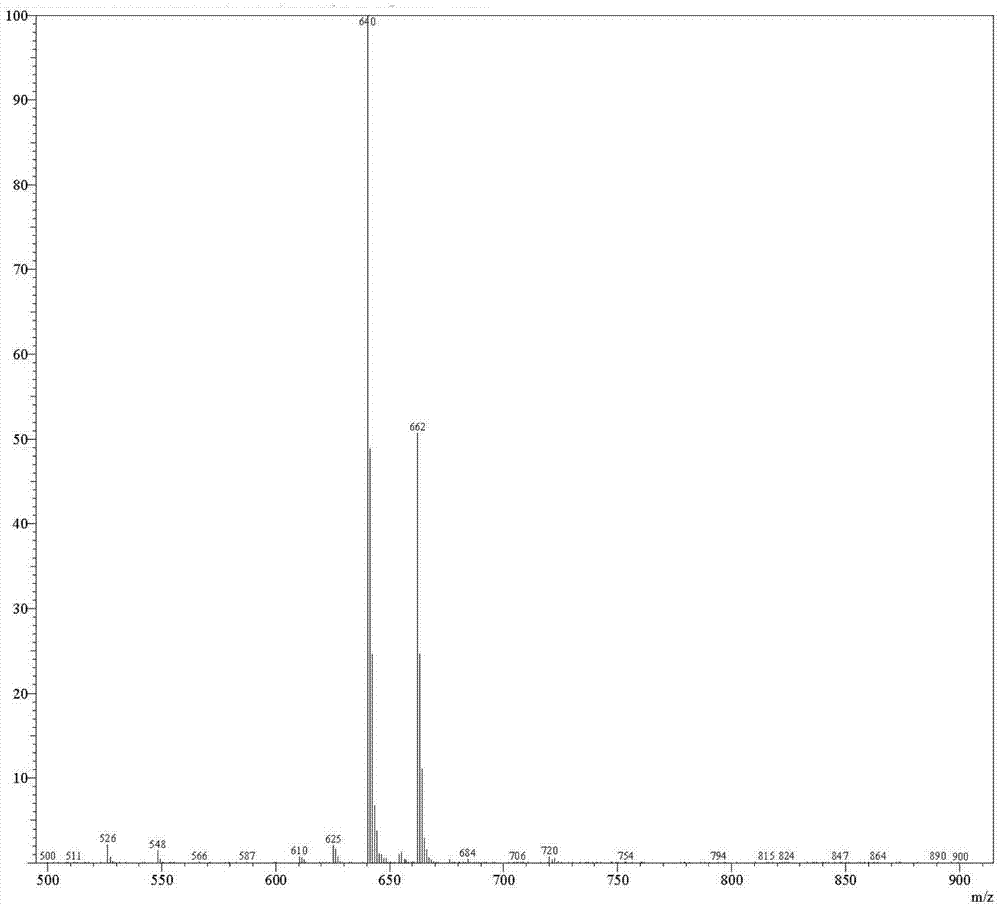

Preparation method for regadenoson

InactiveCN104744540AHigh purityFew reaction stepsSugar derivativesSugar derivatives preparationCarboxylic acidOxygen

The invention discloses a preparation method for regadenoson, belonging to the field of pharmaceutical chemistry. The preparation method for regadenoson comprises the following steps: with a compound as shown in a formula III as a reaction raw material, subjecting the compound and 2-formyl-3-oxoethyl propanoate to a cyclization reaction in isopropanol so as to produce a compound as shown in a formula IV; then with the compound as shown in the formula IV as a substrate, subjecting the substrate and a methanol solution of methylamine to an acylation reaction so as to produce a compound as shown in a formula V; and reacting the compound as shown in the formula V with tetrabutyl ammonium fluoride in a methanol solution to remove hydroxyl protection so as to prepare regadenoson. According to the preparation method in the invention, the methanol solution of methylamine is used as a reaction medium and reagent, a methanamide compound is produced through one-step reaction under normal pressure, and the acylation reaction is carried out without hydrolysis for formation of a carboxylic acid derivative; thus, reaction steps are reduced, high pressure reaction equipment is not used, cost for production input is lowered, the safety factor of production is increased, and the method is more applicable to large scale production.

Owner:SHANGHAI ZIYUAN PHARMA

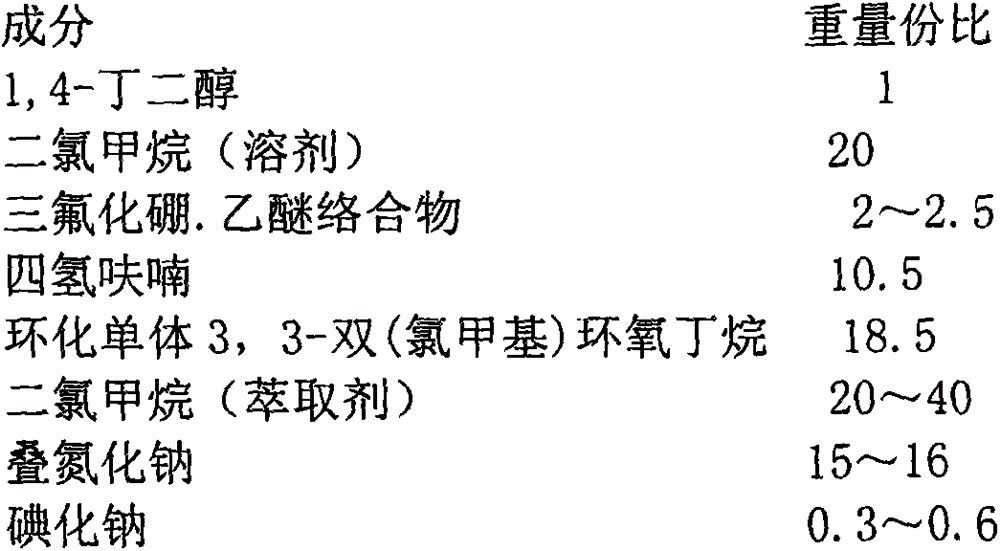

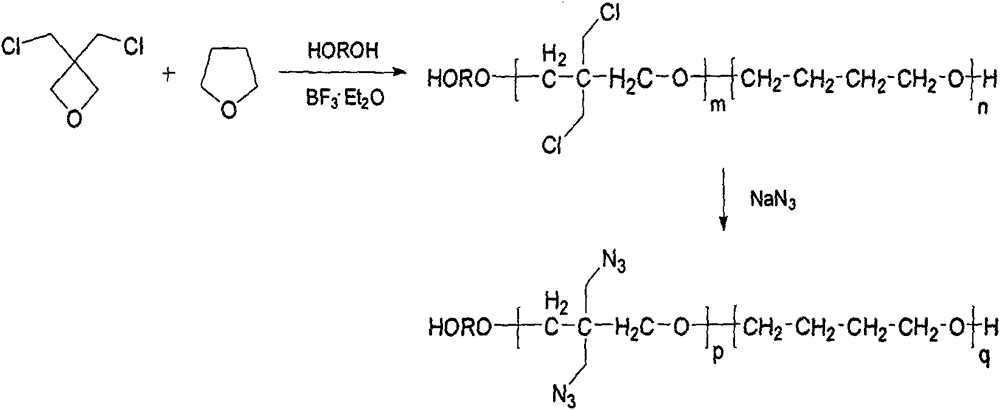

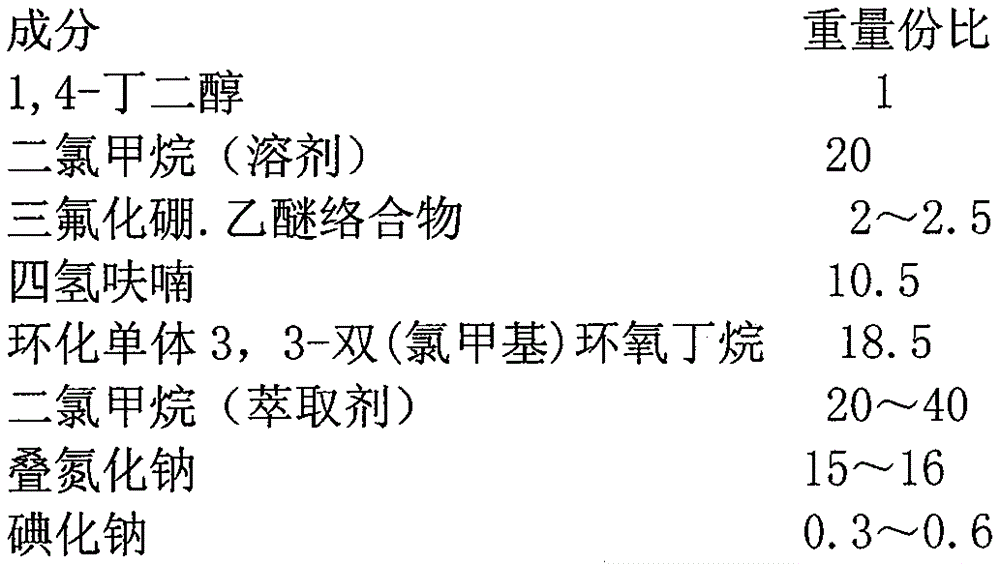

Preparation method of 3,3-bi(nitrine methyl) epoxybutane and tetrahydrofuran copolymer

The invention discloses a preparation method of a 3,3-bi(nitrine methyl) epoxybutane and tetrahydrofuran copolymer, relates to a preparation method of the 3,3-bi(nitrine methyl) epoxybutane and tetrahydrofuran copolymer, and in particular relates to a method for preparing the 3,3-bi(nitrine methyl) epoxybutane and tetrahydrofuran copolymer by performing ring opening copolymerization and catalytic nitrogenization on 3,3-bi(chloromethyl) epoxybutane. The method is simple and easy to carry out. Because a method for preparing bi(chloromethyl) polyether at first and nitriding at last to obtain a nitrine rubber product is adopted, a high-sensitivity nitrine monomer purification step is avoided, the safety hidden troubles of operation site are eliminated, and the problem of an existing production method is solved. In a process for preparing the nitrine rubber by nitrogenization of the bi(chloromethyl) polyether, a method of addition of sodium iodide is adopted, and double-decomposition exchange reaction on iodine atoms of halogen elements and chloride atoms in the bi(chloromethyl) polyether is utilized, so that a nitrogenization reaction process is accelerated, and the complete nitrogenization reaction is carried out; and therefore, the reaction effect is achieved and the product quality is greatly improved.

Owner:天元航材(营口)科技股份有限公司

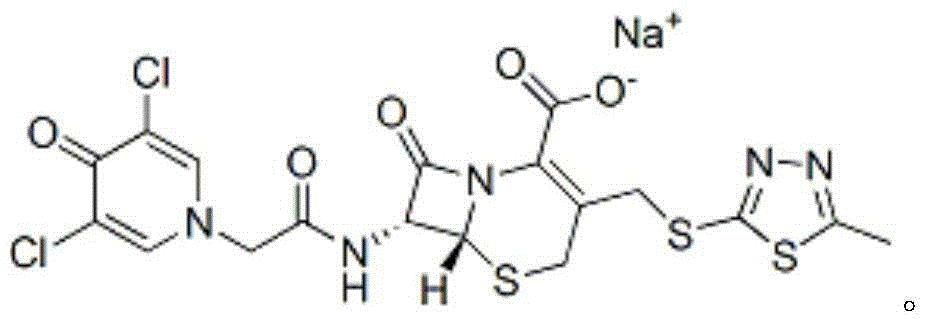

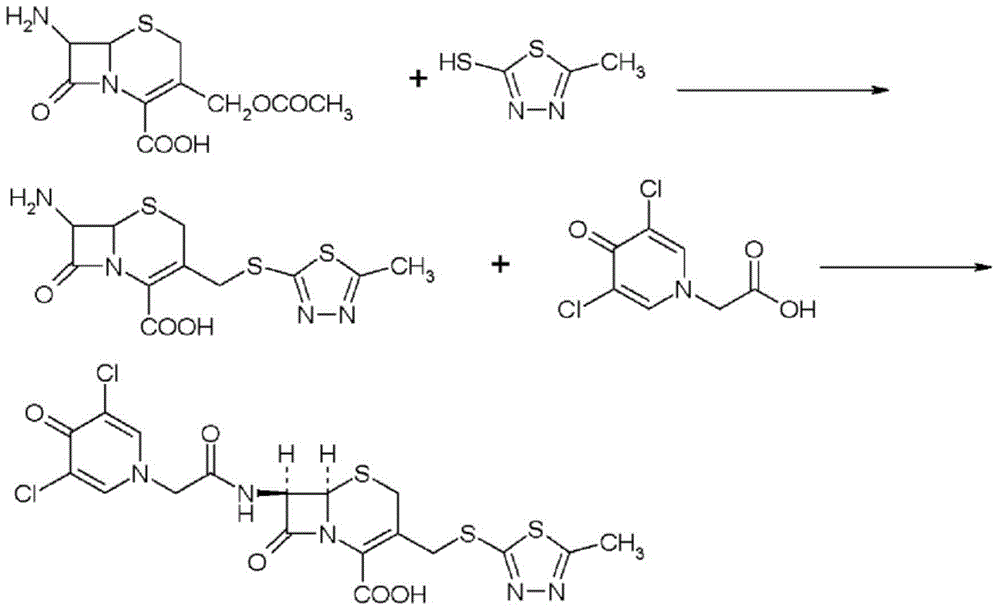

Preparation method for cephalosporin anti-infective drug

ActiveCN105017286ASimple preparation processReduce generationOrganic chemistry7-ACACefazedone sodium

The invention relates to a preparation method for a cephalosporin anti-infective drug-cefazedone sodium, belonging to the field of pharmaceutical synthesis. According to the invention, the method uses GCLE as a raw material to substitute 7-ACA and overcomes the defects of low yield, high pollution and the like in prior art; the preparation method with mild reaction conditions, little side reaction and simple process is provided; meanwhile, the method has the advantages of cheap and easily-available raw materials, low cost, high product yield, high product purity and applicability to industrial production.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

Geopolymer-based artificial flood control stone prepared from all wastes and preparation method thereof

The invention discloses a geopolymer-based artificial flood control stone prepared from all wastes and a preparation method of the geopolymer-based artificial flood control stone. The geopolymer-basedartificial flood control stone comprises the following raw materials in parts by weight: 288-412 parts of a waste silicon-aluminum material; 85-150 parts of alkali-containing waste; 29-75 parts of waste sulfate mineral; 1501-1860 parts of recycled aggregate; 216-241 parts of reclaimed water; 0-2 parts of waste fiber; and 0-5 parts of crop waste. The process is simple, the prepared artificial flood control stone has no appearance defect; the stone has the advantages of large volume density, high strength (more than 34 MPa), good weathering resistance, freezing resistance and abrasion resistance and the like, is convenient to throw, good in integrity, strong in stability, freeze-thaw resistance, weathering resistance and high-speed sand-containing water flow abrasion resistance in the usingprocess, is not easy to lose under high-speed water flow, and is an ideal substitute product for natural stone standby stone prevention.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

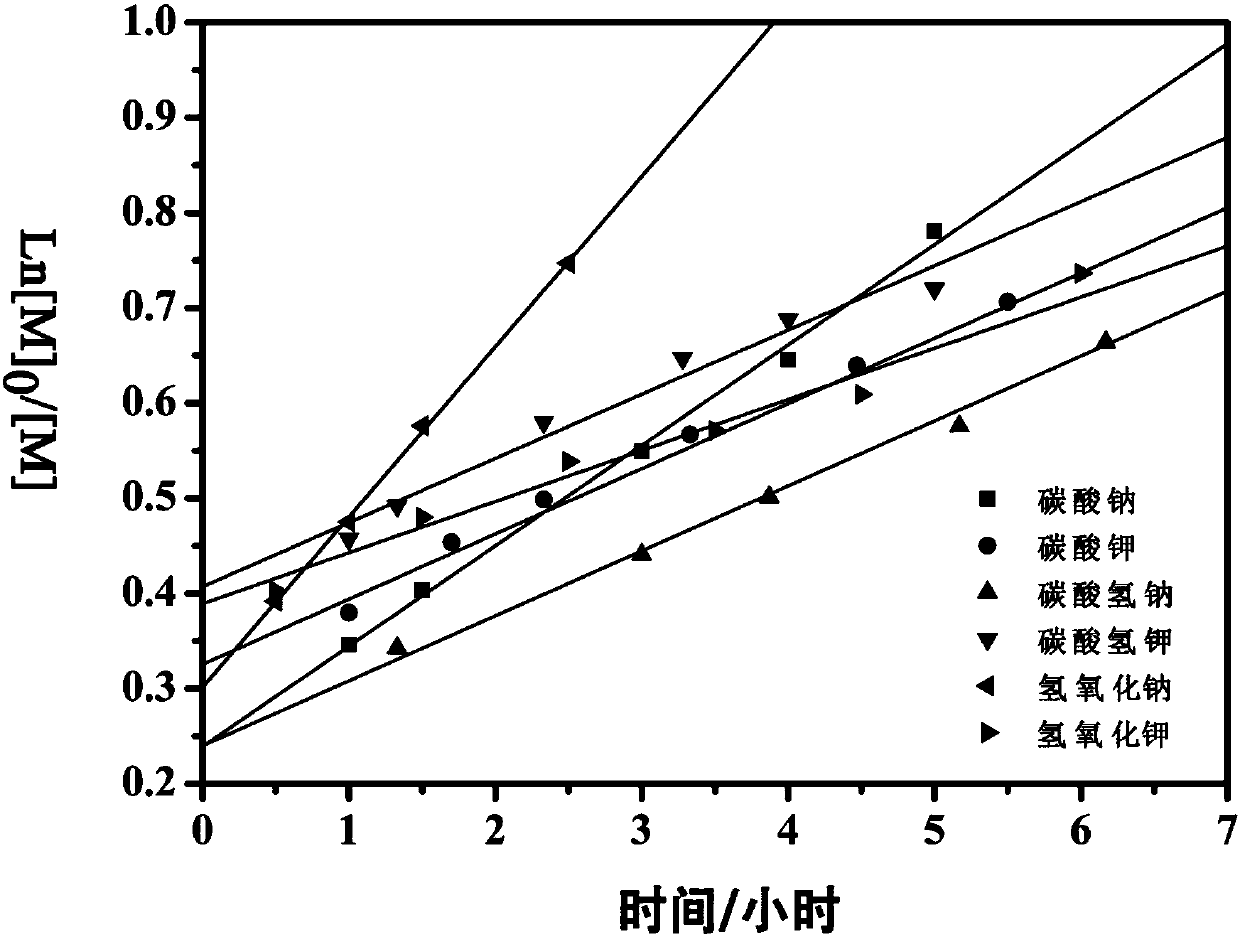

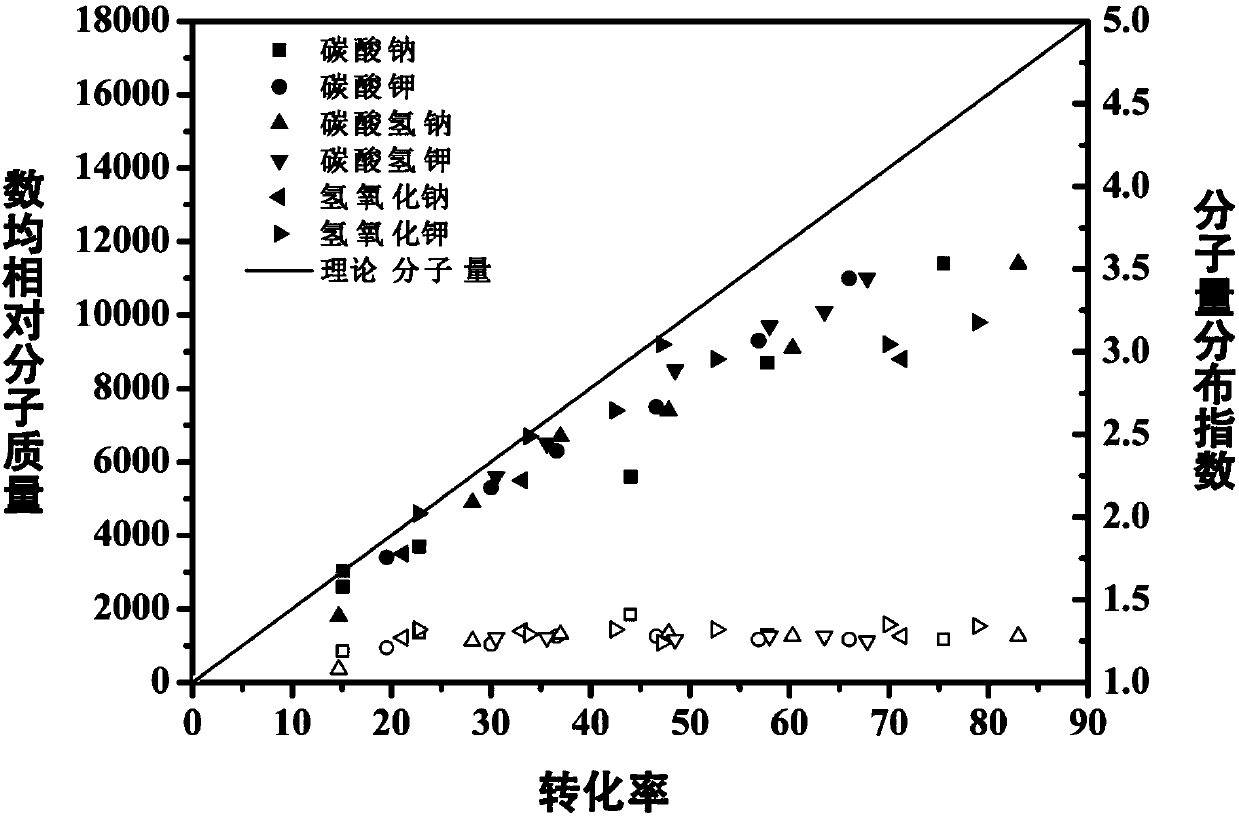

Ligand-free atom transfer radical polymerization method under action of alkali

The invention discloses a ligand-free atom transfer radical polymerization method under the action of alkali. The method is characterized by comprising the following step: mixing reaction raw materials comprising a monomer, an initiator and a catalyst without using a ligand under the action of alkali, so that the monomer is subjected to atom transfer radical polymerization reaction to generate a corresponding polymer. The ligand-free atom transfer radical polymerization method improves the reaction raw materials adopted in the key atom transfer radical polymerization reaction, uses alkali to participate in the reaction, can further optimize components of an atom transfer radical polymerization system, overcomes defects that toxic and volatile organic compounds or polar solvents used by the atom transfer radical polymerization system as the ligands are expensive, highly toxic and volatile in the prior art, and reduces the degree of damage to the environment and the reaction cost.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing doping porous silicon ball

InactiveCN103979487AAchieving controllable equipmentEasy to operateNanostructure manufactureReaction temperatureOperability

The invention discloses a method for preparing a doping porous silicon ball. The method includes the steps that a silicon ball with certain doping content is selected, after being washed by hydrofluoric acid, the silicon ball is immersed in solutions formed by nitrate and hydrofluoric acid, after ultrasonic processing is carried out, the silicon ball is immersed in solutions prepared by the hydrofluoric acid and oxidizing agents and reacts at a certain temperature for a certain time period, then the silicon ball is washed in a centrifugal mode, and ultimately the nano porous silicon ball is prepared after nitric acid washing and other post-processing procedures. The best variety and the best concentration of reaction solutions, the optimum proportion of components, the best reaction temperature, the best reaction time, best ultrasonic frequency and best ultrasonic processing time are screened out through a large quantity of experiments. According to the whole preparation method, process design is reasonable, operability is high, production cost is low, production efficiency is high, and large-scale industrial production can be achieved. According to the high-purity doping porous silicon ball prepared in the method, the shapes of holes are regular, the holes are uniformly distributed and honeycomb-shaped, the shape of the silicon ball is regular, and the method can be widely used in the field of lithium batteries, solar batteries, semi-conductors, sensors and the like.

Owner:YANCHENG INST OF TECH

Method for preparing high-purity mono-disperse silicon dioxide hydrosol

The invention discloses a method for preparing high-purity mono-disperse silicon dioxide hydrosol. The method comprises the following steps: a hydrolysis reaction is performed on monocrystal silicon powder serving as a silicon source by taking ammonia as a catalyst, the reaction is performed in a heating, stirring and ammonia (99.99 percent) atmosphere; the reactive liquid is filtered after the reaction is completed to obtain the high-purity mono-disperse silicon dioxide hydrosol product. In the silicon dioxide hydrosol prepared by adopting the method, the solid content is between 20 and 35 percent, and the sphere particle size distribution is between 25 and 35nm. In the preparation process, high-purity silicon powder is used as a silicon source instead of sodium silicate and other soluble silicate or orthosilicate, ammonia is used as the catalyst instead of alkaline metal, so metal impurities (such as sodium, iron, aluminum and the like) introduction or residual ester and alcohol is effectively avoided, and high purity of the product is ensured. The product has great potential application value in self assembly of photonic crystal, chromatography packing, size reference material, planar display and other fields.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com