Aqueous epoxy corrosion-resistant coating for mechanical equipment and preparation method of aqueous epoxy corrosion-resistant coating

An epoxy anti-corrosion coating, water-based epoxy technology, applied in the field of coatings, can solve the problems that cannot meet the coating requirements of mechanical equipment products, cannot meet the coating requirements of mechanical equipment, and the adhesion and anti-corrosion performance indicators are not high, so as to avoid coating Film brittle defects, enhanced wetting and adhesion capabilities, and the effect of improving wet adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

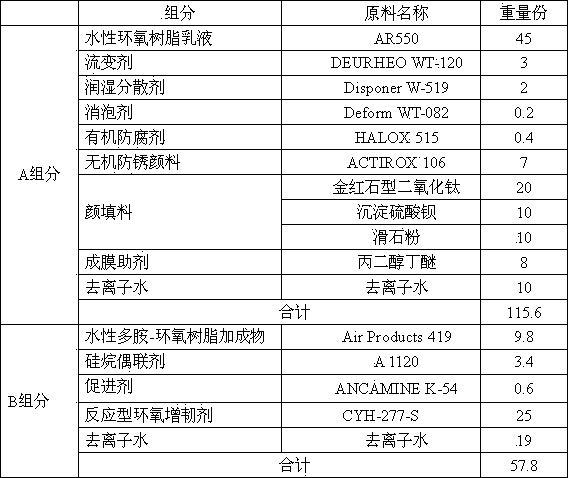

[0038] The formula of embodiment 1 sees the following table:

[0039]

Embodiment 2

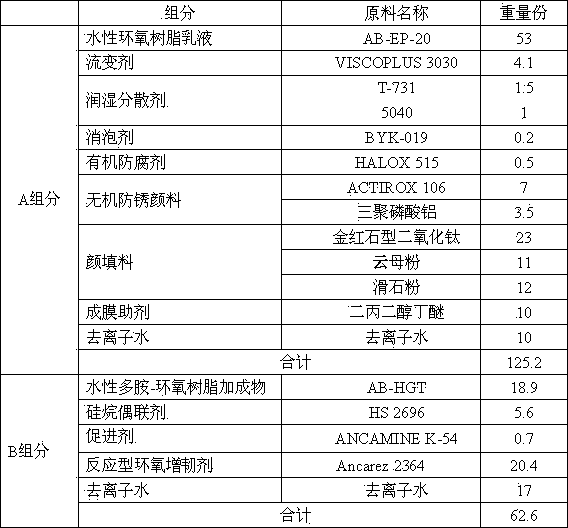

[0040] The formula of embodiment 2 sees the following table:

[0041]

Embodiment 3

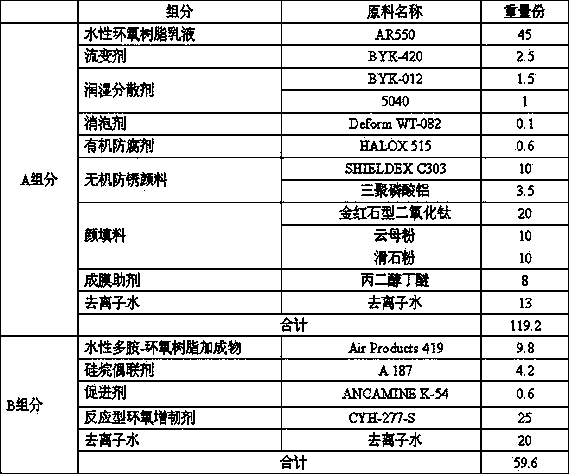

[0042] The formula of embodiment 3 sees the following table:

[0043]

[0044] The preparation method of coating of the present invention is as follows:

[0045] 1. Preparation of Component A

[0046] According to the formula amount of the above-mentioned examples 1-3, first add deionized water, slowly add rheological agent under stirring, disperse at high speed for about 10 minutes until it becomes a uniform viscous slurry liquid, then add water-based epoxy resin emulsion, wetting and dispersing agent Stir with defoamer for 25-30 minutes, then add inorganic anti-rust pigments and pigments and fillers, disperse evenly, and use sand milling until the fineness is less than 40 μm, add organic preservatives and film-forming aids, and prepare component A after filtration .

[0047] 2. Preparation of Component B

[0048] Mix and disperse the water-based polyamine-epoxy resin adduct, deionized water, silane coupling agent, accelerator and reactive epoxy toughener according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com