Patents

Literature

476results about How to "Achieving controllable equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

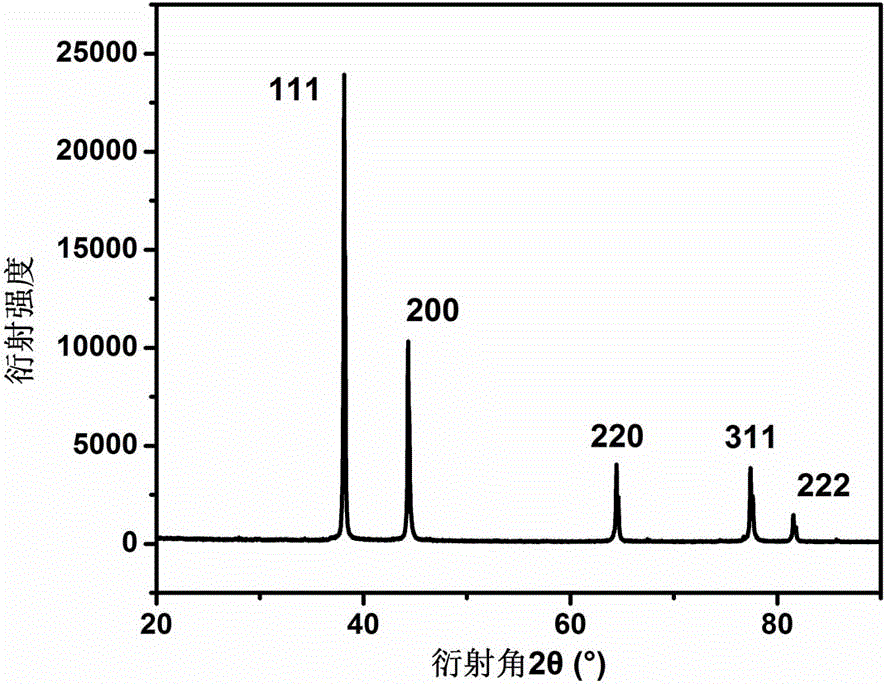

Preparation method of high-dispersity supported nano metal catalyst

ActiveCN102553579AGood dispersionReduce loadMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetallurgy

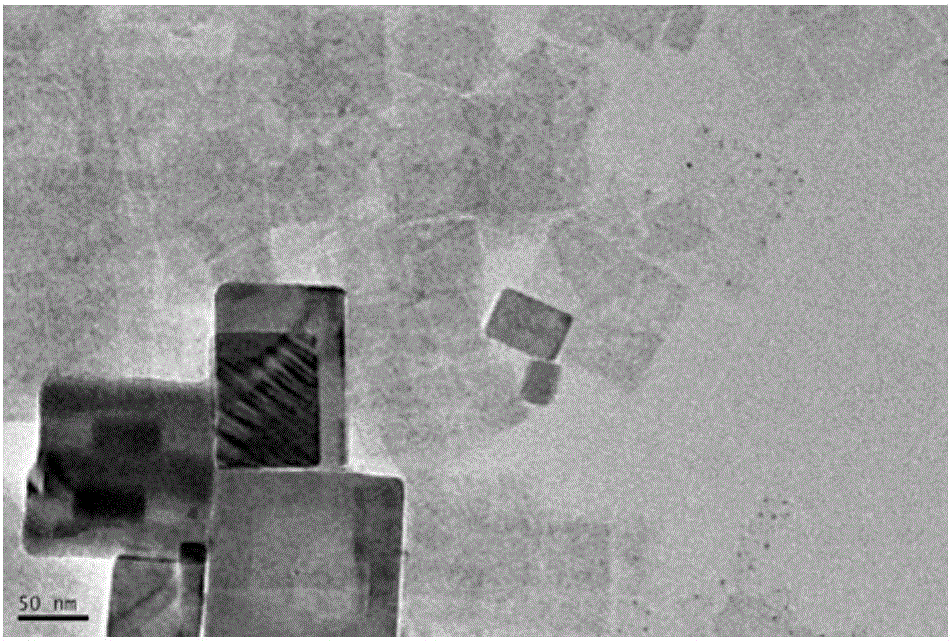

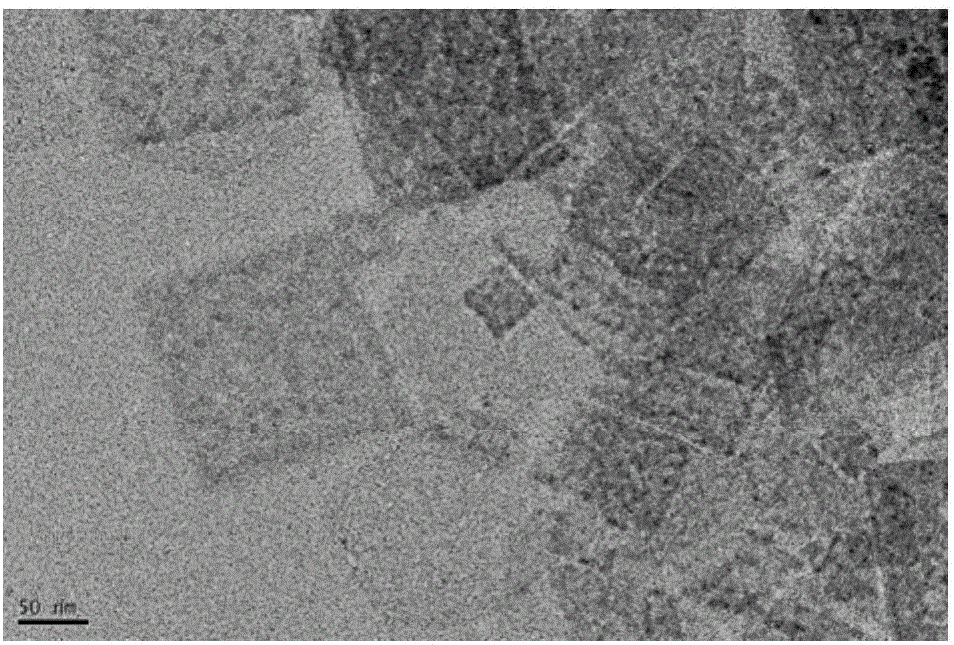

The invention discloses a preparation method of a high-dispersity supported nano metal catalyst, particularly a preparation method of a supported nano noble metal catalyst, belonging to the technical field of catalyst preparation. The preparation method comprises the following steps: 1) impregnating a support into a metal precursor solution, and uniformly stirring; 2) carrying out ultrasonic dispersion under heating conditions; 3) drying, and roasting; 4) carrying out alkali-free liquid-phase controllable reduction; and 5) carrying out vacuum drying. By utilizing the actions of stirring and ultrasonic dispersion, the metal precursor is evenly adsorbed to the surface of the support, thereby implementing high dispersity of the active component; the roasting is utilized to enhance the interactions between the metal and the support; and the alkali-free liquid-phase controllable reduction is utilized to synthesize the nano metal catalyst of which the dimension is 2-10nm, the shape is spherical, cubic or polyhedral and the bare crystal face is (111), (100) or (110), thereby implementing the controllable preparation of the high-dispersity supported nano metal catalyst.

Owner:贵州鑫醇科技发展有限公司

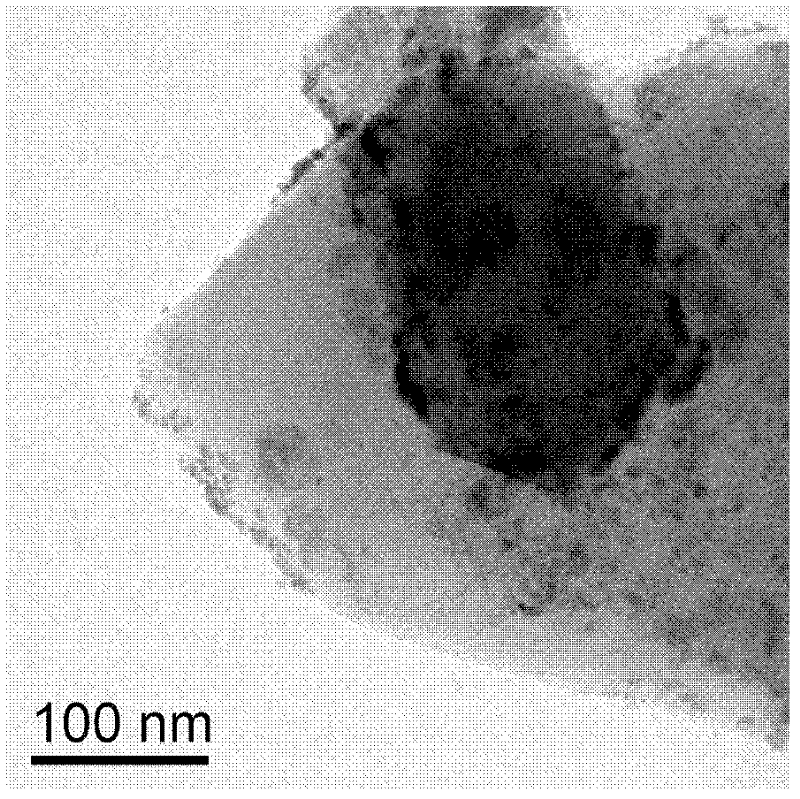

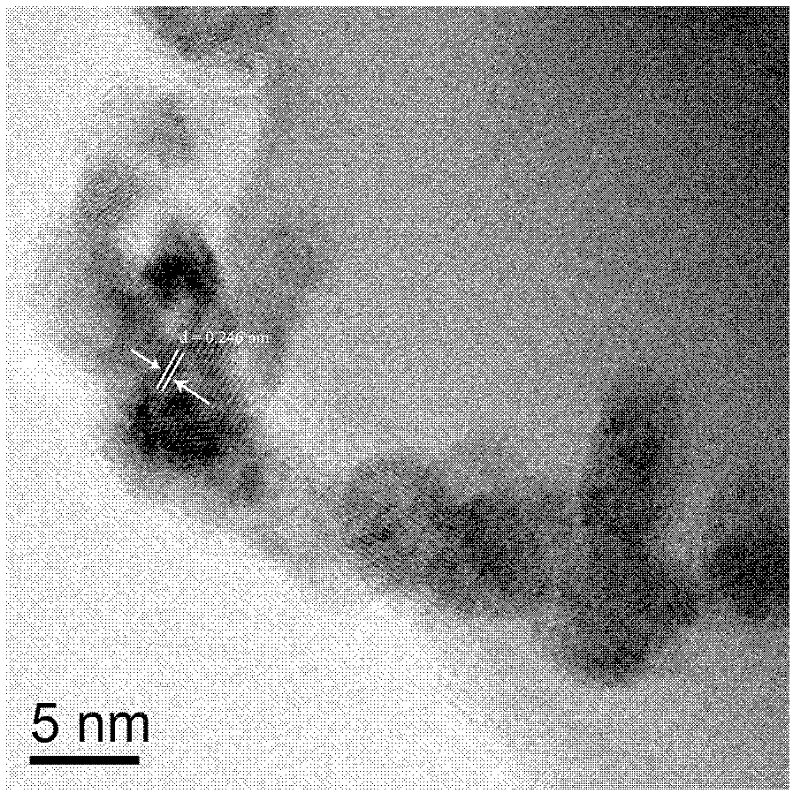

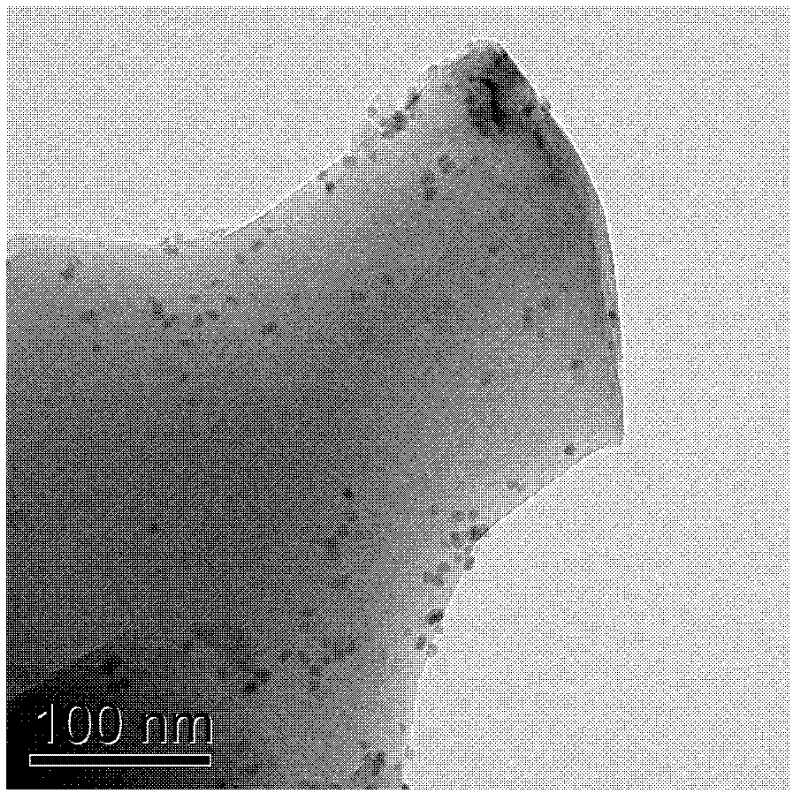

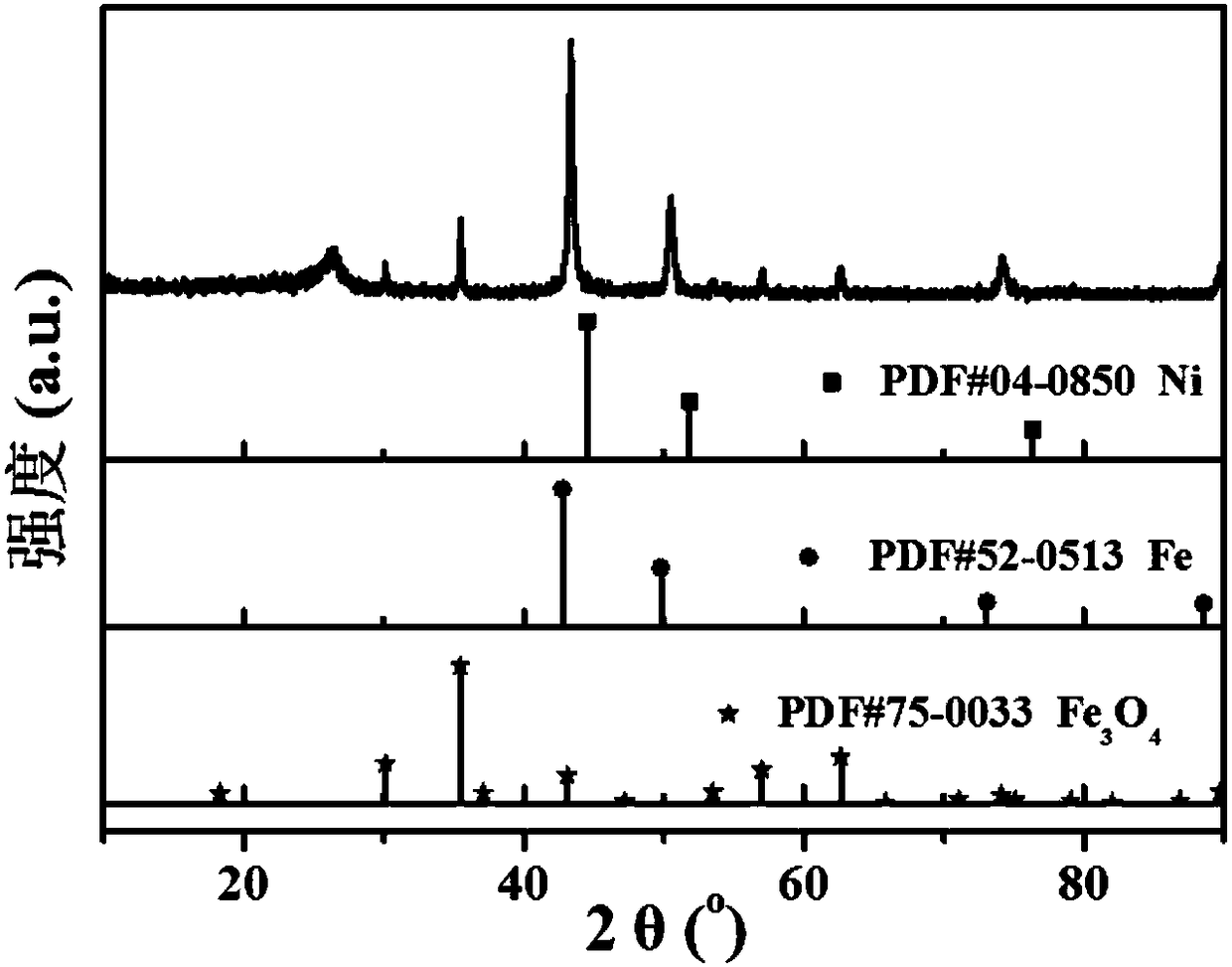

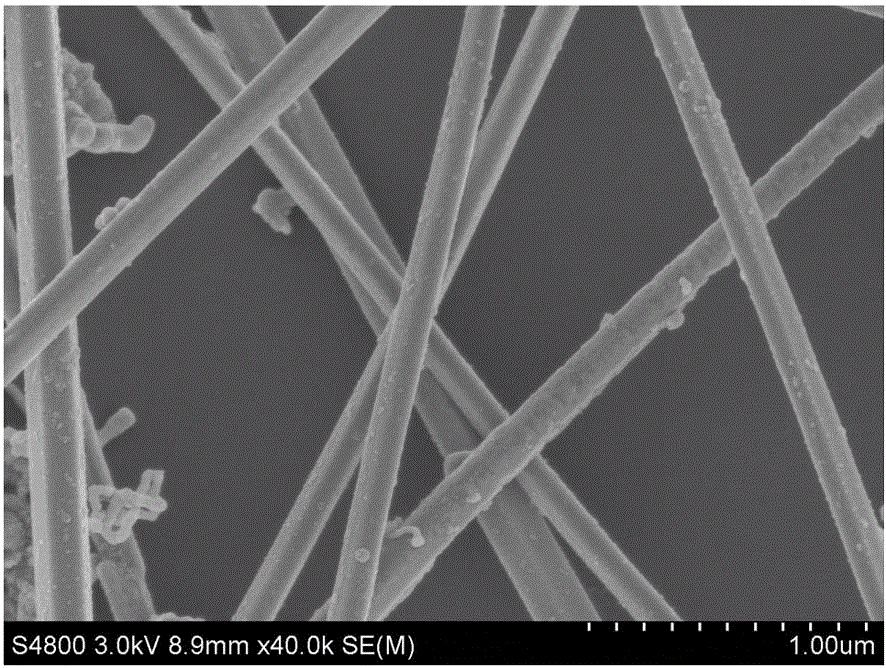

Fe, Ni and N three-doped carbon nanotube coated type FeNi@NCNT catalyst as well as preparation method and application thereof

InactiveCN108543545AIncrease the areaImprove conductivityPhysical/chemical process catalystsCell electrodesMetal particleOxygen

The invention discloses a Fe, Ni and N three-doped carbon nanotube coated type FeNi@NCNT catalyst as well as a preparation method and application thereof, and belongs to the fields of energy materialsand electrochemistry. The catalyst is prepared by using dicyandiamide as a C source and N source and ammonium ferric citrate and NiCl2.6H2O as metal sources, adopting one pot method and performing pyrolysis in two steps; and a plurality of Fe and Ni metal particles in the catalyst are uniformly wrapped in walls of ''bamboo-like'' N-doped carbon nanotubes, and a small number of the particles are distributed at the tip ends of the carbon nanotubes. Compared with a common metal alloy oxygen reduction reaction and oxygen evolution reaction bifunctional catalyst, the catalyst disclosed by the invention exhibits good oxygen evolution reaction activity and stability under alkaline conditions; the preparation method is simple, and raw materials used in the method have low costs and wide sources;and the catalyst can be widely used in the fields of proton exchange membrane fuel cells, electrolyzed water, metal-air batteries and the like, and has higher practical value.

Owner:DALIAN UNIV OF TECH

Ultrathin nanosheet array electro-catalytic material with nano-porous structure and oxygen vacancies

The invention relates to an ultrathin nanosheet array electro-catalytic material with a nano-porous structure and oxygen vacancies. The material is a cobaltosic oxide primary nanosheet array which grows vertically on a conductive substrate and is doped with a metal; an ultrathin nanosheet with oxygen vacancies and nanopores is obtained on each primary nanosheet; the conductive substrate is a titanium sheet or a foamed nickel sheet, and the doped metal is zinc, nickel or manganese; and the thickness of each cobaltosic oxide ultrathin nanosheet doped with the metal is 1.22 nm, nanosheets are in a three-dimensional porous structure, and the nano-pore diameter is 3-6 nm. The ultrathin nanosheet array electro-catalytic material with the nano-porous structure and oxygen vacancies has the following advantages: the material can effectively reduce the overpotential and the spike potential of an oxygen evolution reaction, increase the conversion rate of a single cobalt atom and work continuously and stably in an alkali environment; the steps of a preparation method of the material are simple, the operation is convenient, the cost is low, and the material is environmental-friendly; and new ideas and strategies are provided for the function-oriented design and the performance optimization of an oxygen evolution catalyst of a water electrolysis system.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

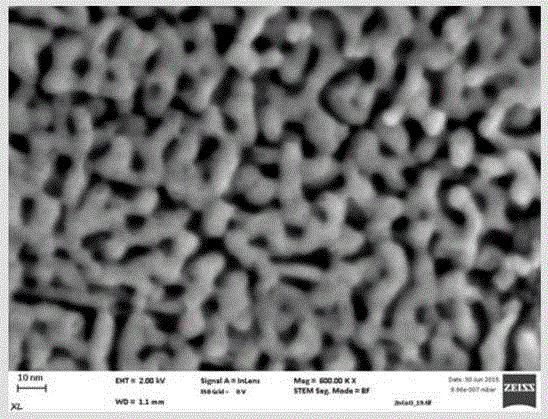

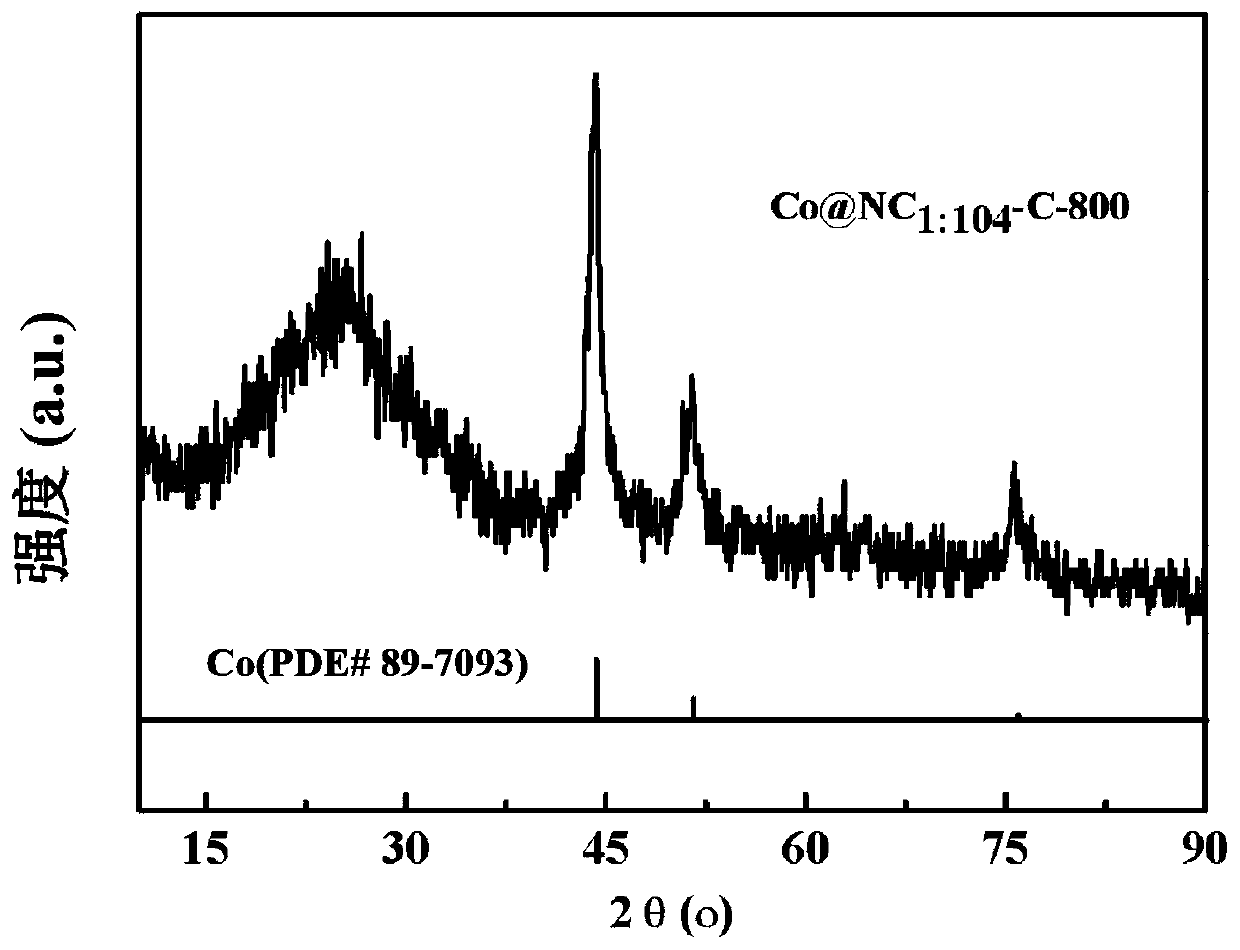

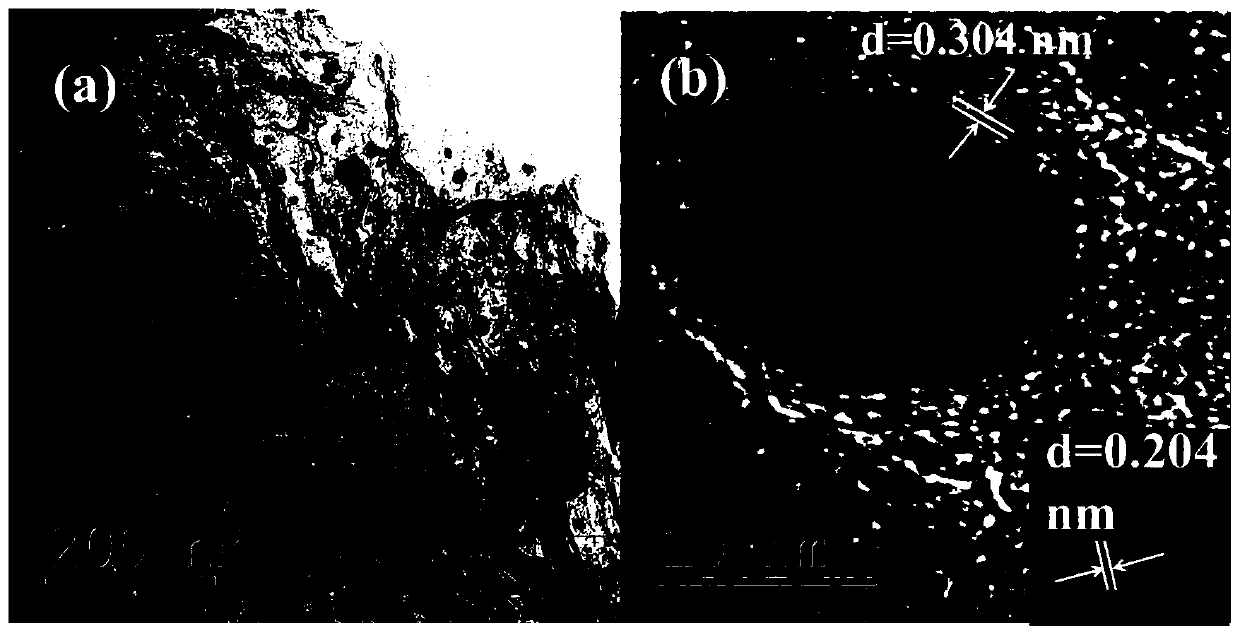

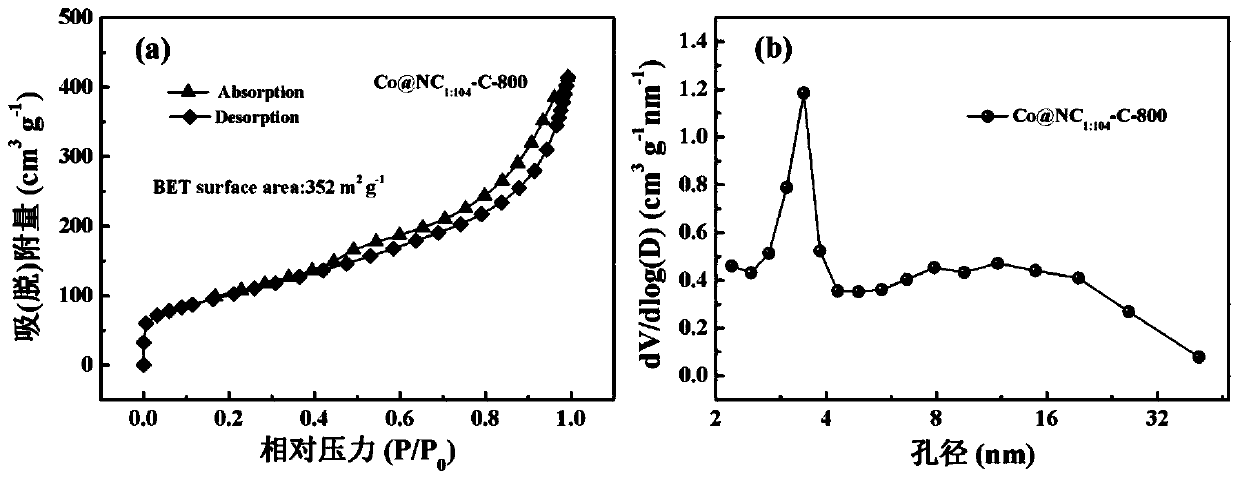

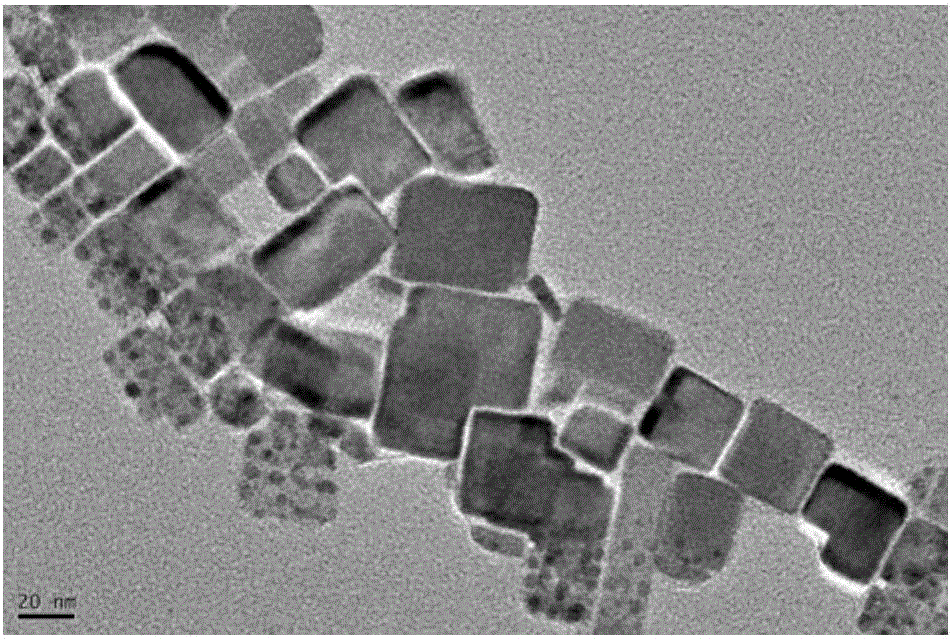

Co@NC high-dispersion core-shell structure catalyst, and preparation method and application of catalyst

InactiveCN110176606AImprove stabilityHigh resistance to methanolMaterial nanotechnologyPhysical/chemical process catalystsCvd grapheneDecomposition

The invention discloses a Co@NC high-dispersion core-shell structure catalyst, and a preparation method and an application of the catalyst, and belongs to the technical field of energy source materials and electrochemistry. The preparation method of the catalyst comprises the steps of taking glucose as a C source, taking cyanoguanidine as a C-N source, taking Co(No3).6H2O as a Co source, and performing high temperature calcination. The cyanoguanidine performs high temperature decomposition to generate two-dimensional flaky g-C3N4; the glucose performs high temperature decomposition to generatea carbon intermediate and a metal species which are inserted into flakes of g-C3N4; and Co nanoparticles coated by an N-C layer in the catalyst are uniformly dispersed on a graphene carbon layer. Thecatalyst can serve as a cathode oxygen reduction electrocatalyst of a metal-air battery and a fuel battery. The catalyst is cheap and easy obtaining in raw material, and simple in preparation technology; amplification production is facilitated; in-situ decomposition of the cyanoguanidine provides rich N doped active sites for the catalyst; rich mesoporous structures are formed; the activity of the catalyst is improved; a channel is provided for transfer and transport of reaction participation substances in an ORR process; a mass transfer demand of a reaction process is met; and the catalyst is good in stability and high in methanol resistance.

Owner:DALIAN UNIV OF TECH

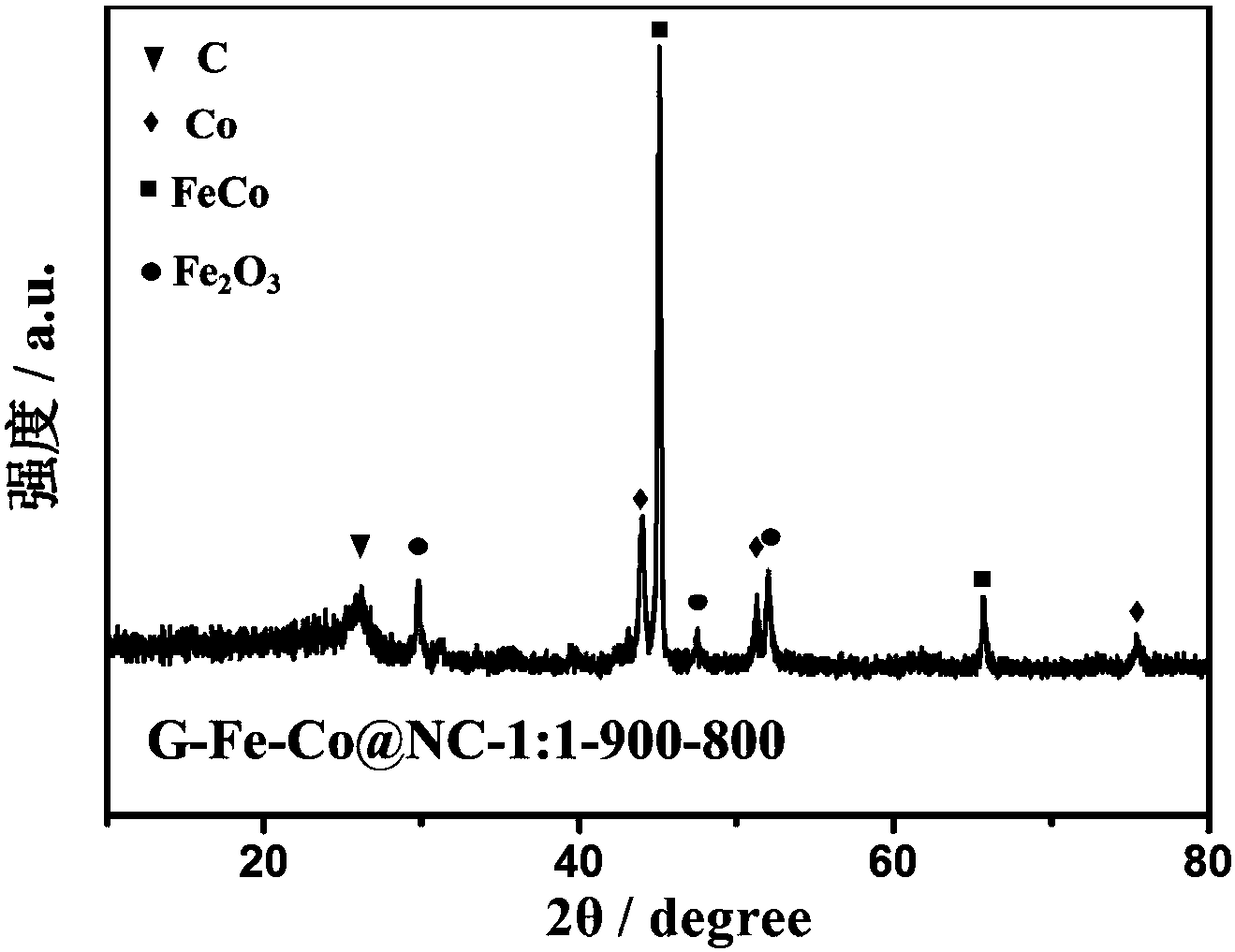

N-doped porous carbon coated Fe and Co bi-metal nanoparticle catalyst and preparation method thereof

InactiveCN108493461AIncrease varietyInhibit aggregationMaterial nanotechnologyFinal product manufacturePorous carbonMetal alloy

The invention discloses a N-doped porous carbon coated Fe and Co bi-metal nanoparticle catalyst and a preparation method of the N-doped porous carbon coated Fe an Co bi-metal nanoparticle catalyst, and belongs to the field of energy materials and electrochemistry. The catalyst takes glucose as the C source, g-C3N4 as the N source, the C source and the template, F3Cl3.6H2O and Co(NO3)2.6H2O are metal sources, a high-temperature stepwise calcining method is used to prepare the N-doped porous carbon coated Fe and Co Fe-Co@NC catalyst, and the catalyst is in a three-dimensional porous unordered stacking structure. Fe and Co exists in the forms of Fe0.3Co0.7, Fe2O3, and Co, and is evenly coated in the N-doped porous carbon. Compared with the commonly used Pt-based catalyst, the ORR (Overall Response Rate) performance in an alkaline medium is not much different from that of the commercial Pt / C catalysis, the OER (Oxygen Enhancement Ratio) performance is far better than that of the Pt / C catalyst, and the stability and the methanol tolerant property are better. Compared with the commonly seen bi-metal alloy catalyst, the catalyst has more active species, and the specific surface area is larger. In addition, the cost of the raw materials of the catalyst is low, the source of the raw materials is wide, the preparation process is simple and is favorable for large-scale production, and thecatalyst has a higher practical value.

Owner:DALIAN UNIV OF TECH

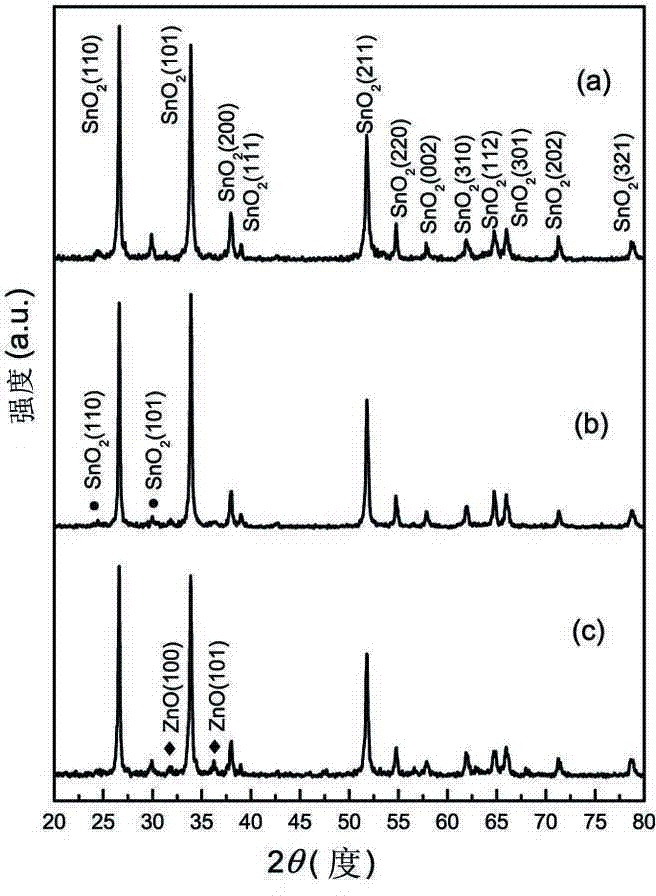

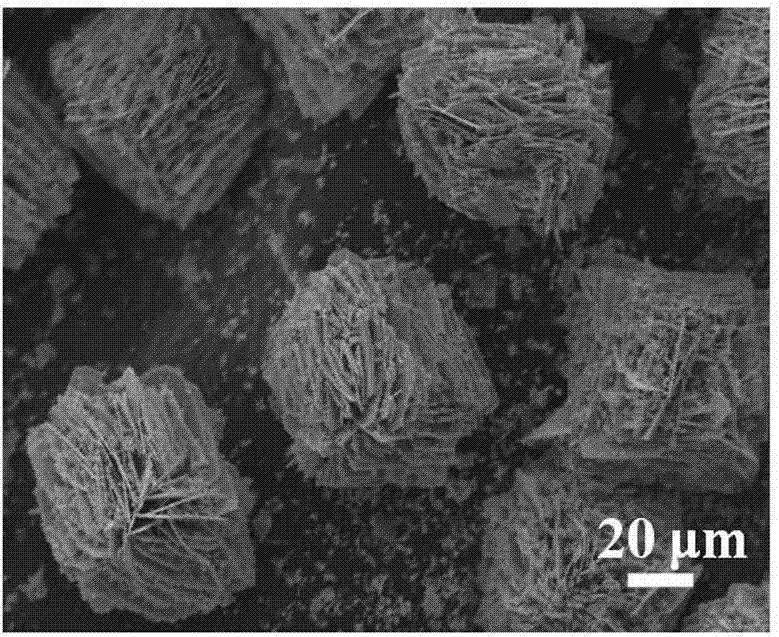

ZnO/SnO2 nano composite gas-sensitive material with flower-shaped grading structure and preparation method of material

InactiveCN103776870AReduced ethanol gas sensitivity performanceGood dispersionMaterial nanotechnologyMaterial analysis by electric/magnetic meansAir atmosphereSTANNOUS OXIDE

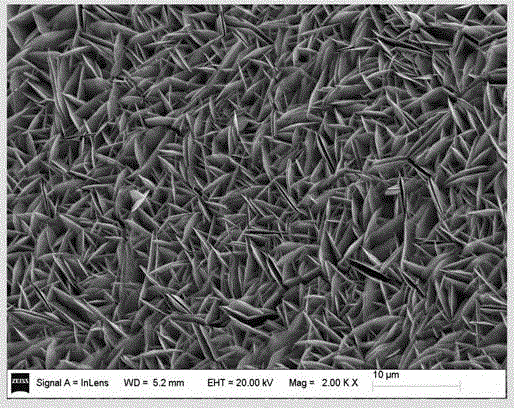

The invention provides a ZnO / SnO2 nano composite gas-sensitive material with a flower-shaped grading structure. The ZnO / SnO2 nano composite gas-sensitive material is prepared by the following steps: dripping a sodium hydroxide water solution into an ethanol solution of cetyl trimethyl ammonium bromide and stannous chloride dihydrate under electromagnetic stirring; after dripping, preparing a precursor solution by the continuous electromagnetic stirring; adding the precursor solution into a reaction kettle, reacting at 130 DEG C; carrying out centrifuging on a reactant, washing and drying to obtain a flower-shaped stannous oxide sacrifice template; adding the flower-shaped stannous oxide sacrifice template into a zinc acetate solution; agitating and carrying out ultrasonic treatment; removing a solvent to obtain a ZnO / SnO2 precursor; and carrying out heat preservation on the ZnO / SnO2 precursor for 2-4 hours in an air atmosphere of 700 DEG to obtain the composite gas-sensitive material. According to the ZnO / SnO2 nano composite gas-sensitive material with the flower-shaped grading structure, the controllable preparation of the composite gas-sensitive material on the appearance and components can be realized; the mass percent content of zinc oxide in the composite gas-sensitive material is 5%-15%; a flower shape is assembled by sheet-shaped tin dioxide and zinc oxide nano particles; the ZnO / SnO2 nano composite gas-sensitive material has a good gas sensitive performance and has a wide application prospect in the aspect of manufacturing a novel high-efficient gas sensor.

Owner:HENAN POLYTECHNIC UNIV

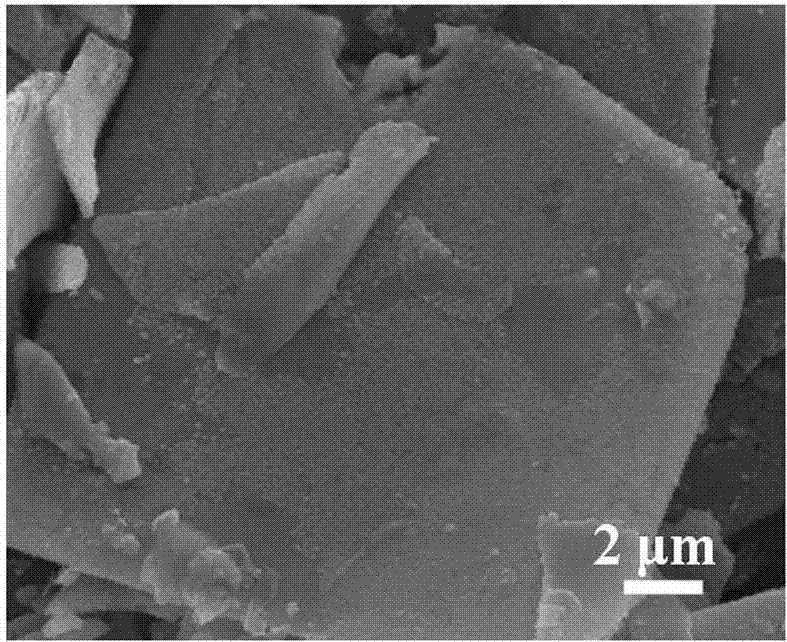

Preparation method of lithium ferric phosphate / grapheme composite positive electrode material

ActiveCN102169986AAchieving controllable equipmentUniform growthCell electrodesPhosphateNitrogen gas

The invention discloses a preparation method of a lithium ferric phosphate / grapheme composite positive electrode material. The method comprises the following steps of: (1) preparing a lithium ferric phosphate precursor, namely weighing raw materials such as a catalyst, lithium salt, ferric salt and phosphate, adding the raw materials into a dispersing agent, and ball-milling to obtain the lithium ferric phosphate precursor; and (2) growing grapheme on the lithium ferric phosphate precursor first, then closing carbon source gas and ammonia gas, introducing hydrogen into a reactor, adjusting the temperature of the interior of the reactor to be 600 to 800 DEG C at a speed of 10 to 20 DEG C per minute in the process of hydrogen introduction, keeping the temperature of the interior of the reactor constant for 24 to 48 hours, and then cooling a product which is obtained in the reactor in the nitrogen atmosphere to room temperature so as to prepare the lithium ferric phosphate / grapheme composite positive electrode material. The lithium ferric phosphate / grapheme composite positive electrode material which is prepared by the method is high in conducting performance and high in power multiplying performance.

Owner:JIANGSU LENENG BATTERY INC

Preparation method of graphene composite anticorrosive coating

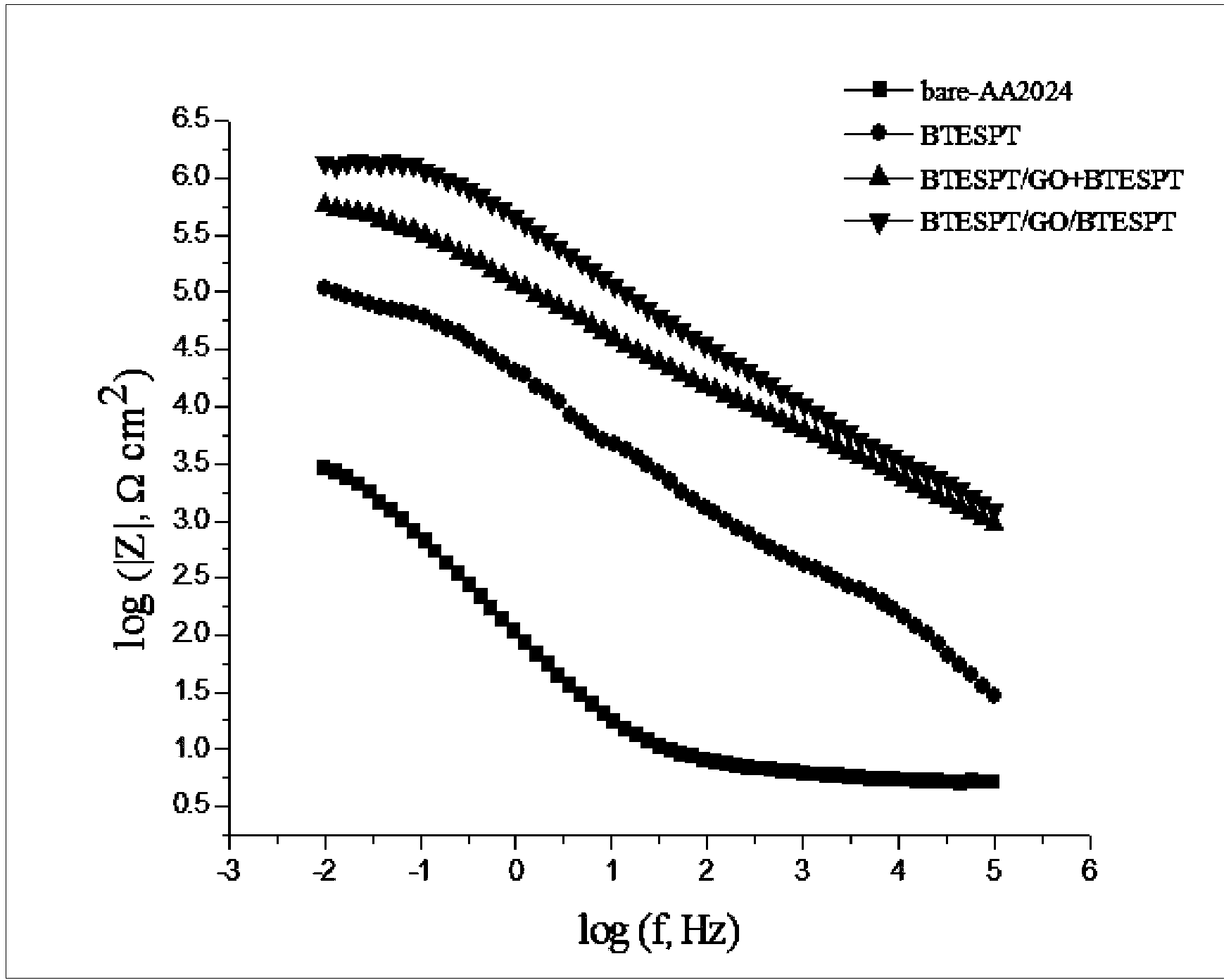

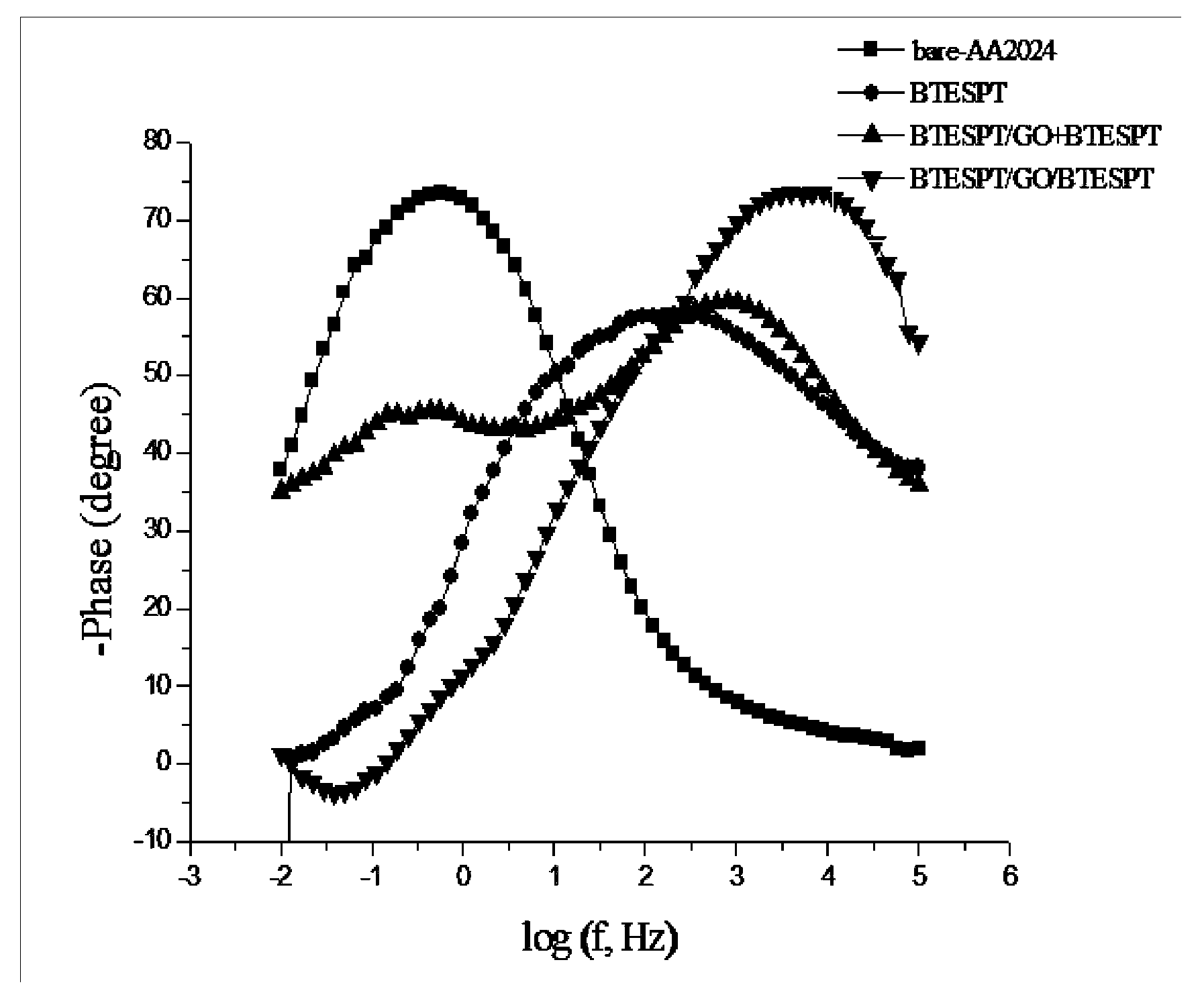

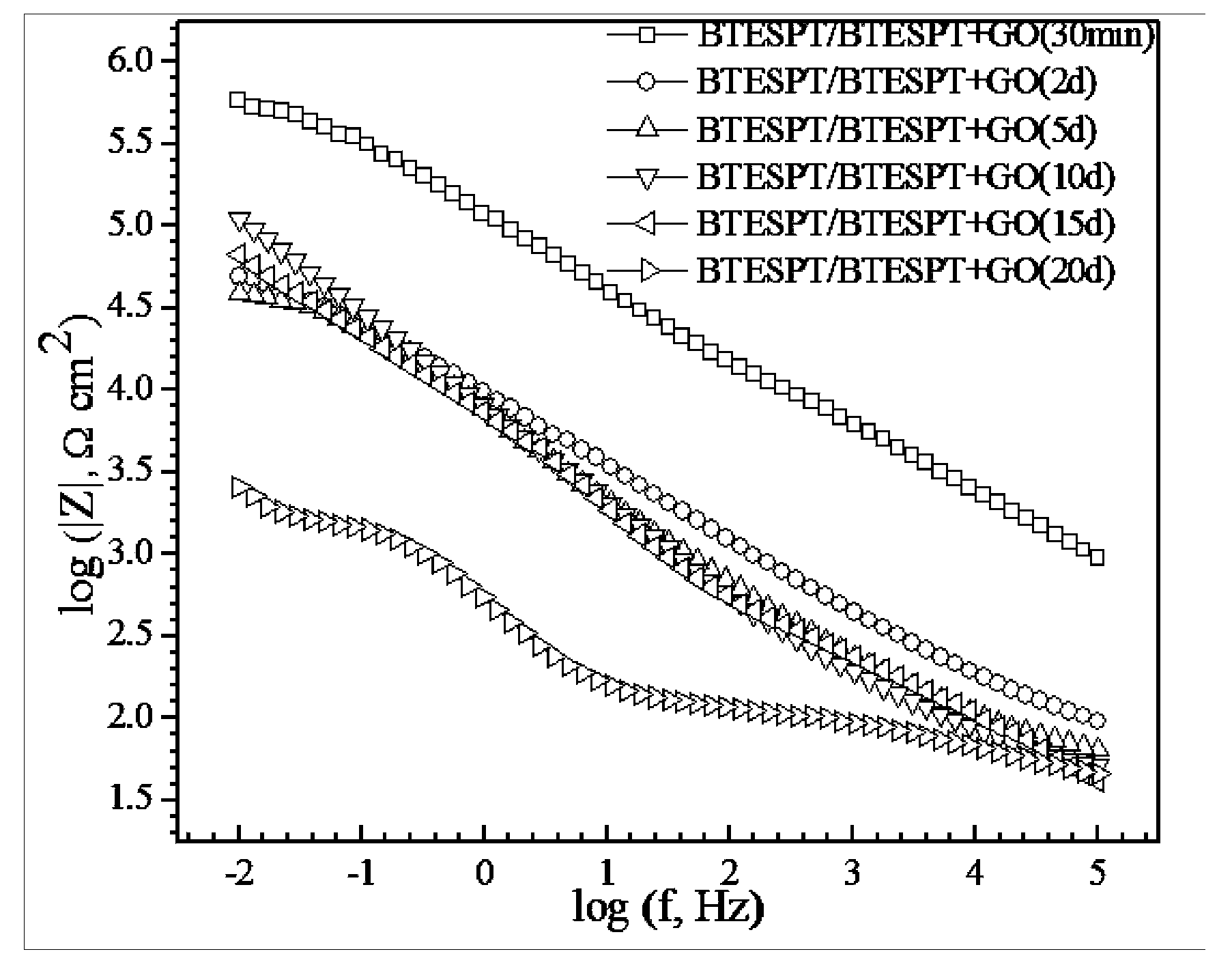

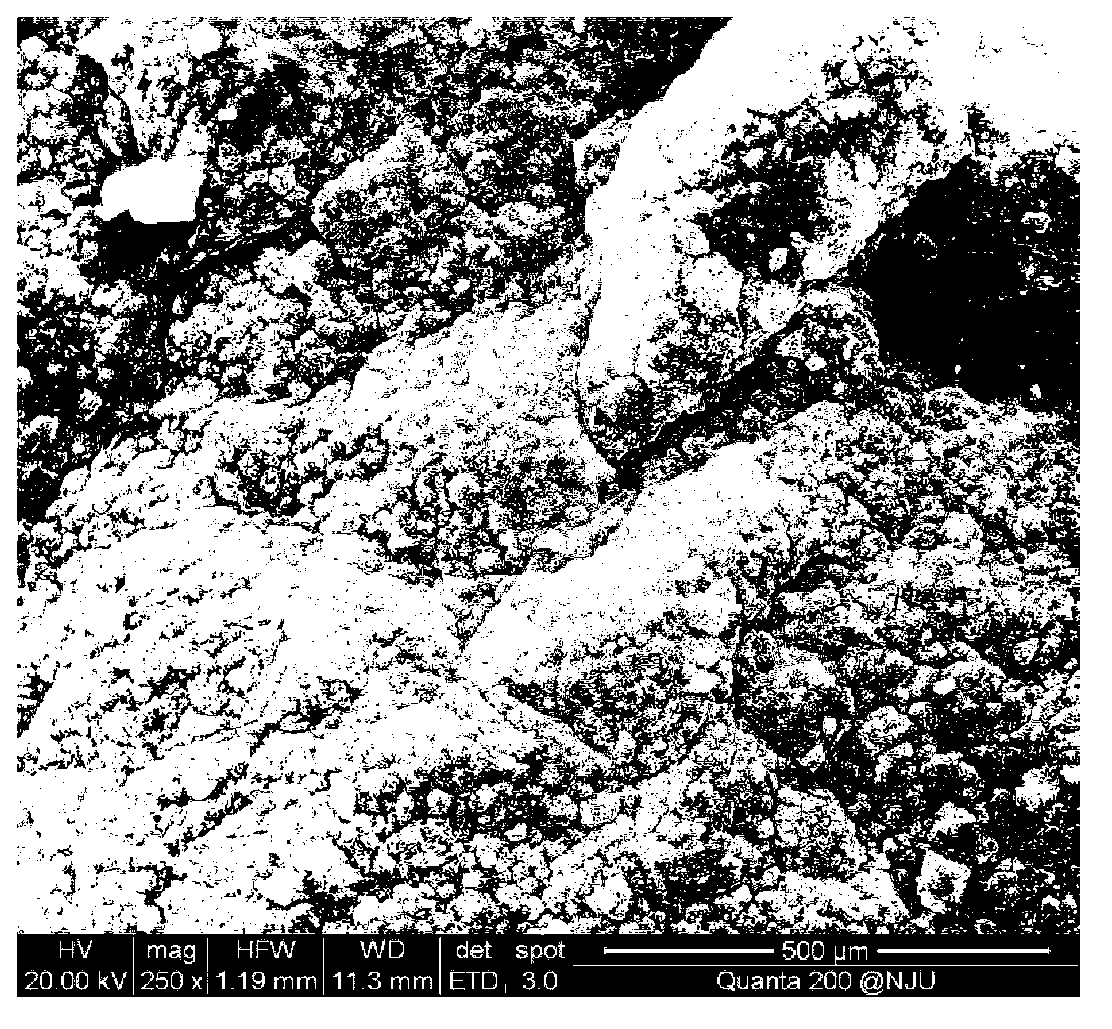

ActiveCN104231703ASimple manufacturing processFast film formationAnti-corrosive paintsElectrolytic organic material coatingPower flowDip-coating

The invention discloses a preparation method of a graphene composite anticorrosive coating. The preparation method comprises the following steps: (1) preparing an organic coating solution with a plurality of hydroxyls or amino groups; (2) preparing an oxidized graphene or modified graphene solution; (3) performing metal surface pretreatment; (4) performing electrodeposition to form an organic coating film; and (5) preparing the graphene composite anticorrosive coating. The method is simple and feasible in technology, the film forming speed is obviously improved, and the prepared coating is more compact and uniform; compared with a plain sample, the low-frequency impedance modulus value of the prepared composite coating is improved to 10<6.2> from 10<3.5> by performing electrochemical testing in 3.5wt% NaCl neutral electrolyte solution, the self-corrosion current is also remarkably reduced, and longer effective prevention effect on a matrix can be achieved. Compared with the conventional dip-coating method, the preparation method has lower requirement on the flatness of a metal surface, and controllable preparation can be effectively realized; the prepared coating is non-toxic and environment-friendly, controllable in thickness, and more compact and uniform, and more durable and stable protection effect on the metal matrix can be achieved.

Owner:OCEAN UNIV OF CHINA

Method for preparing graphene film

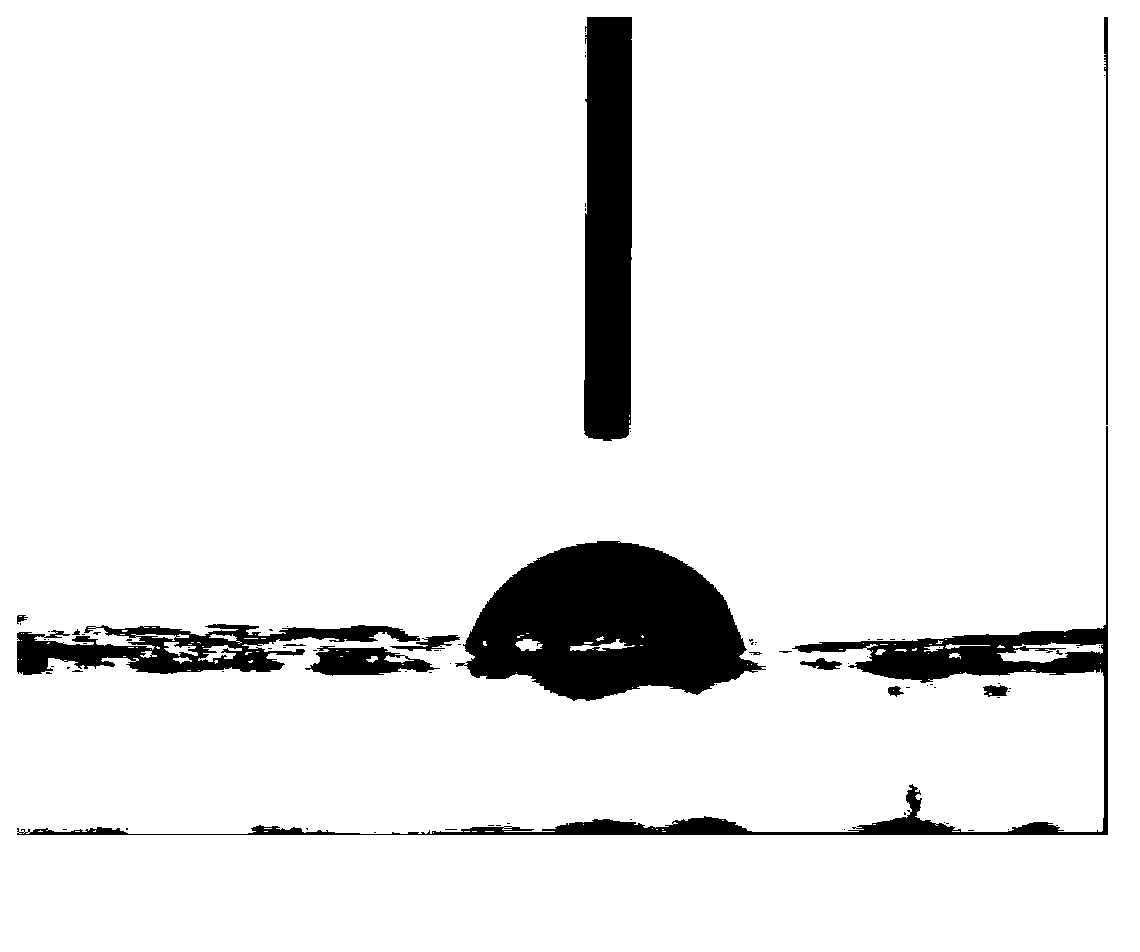

ActiveCN103101908AImprove wear resistanceWith controllableCarbon compoundsCvd grapheneSurface structure

The invention discloses a method for regulating the wetting property of a graphene film. The regulating method comprises the following specific steps of spraying oxidized graphene dispersion liquid on a heated substrate with a spray gun, then carrying out hydrazine steam reduction on an obtained sample. In the process, the surface structure of the graphene film is changed by the change of the substrate temperature, and in order to achieve the super-hydrophobic characteristic, carbon granule modification needs to be conducted on the sample. In short, conversion of hydrophilicity-hydrophobicity-strong hydrophobicity-super-hydrophobicity is realized by changing the surface structure.

Owner:SOUTHEAST UNIV

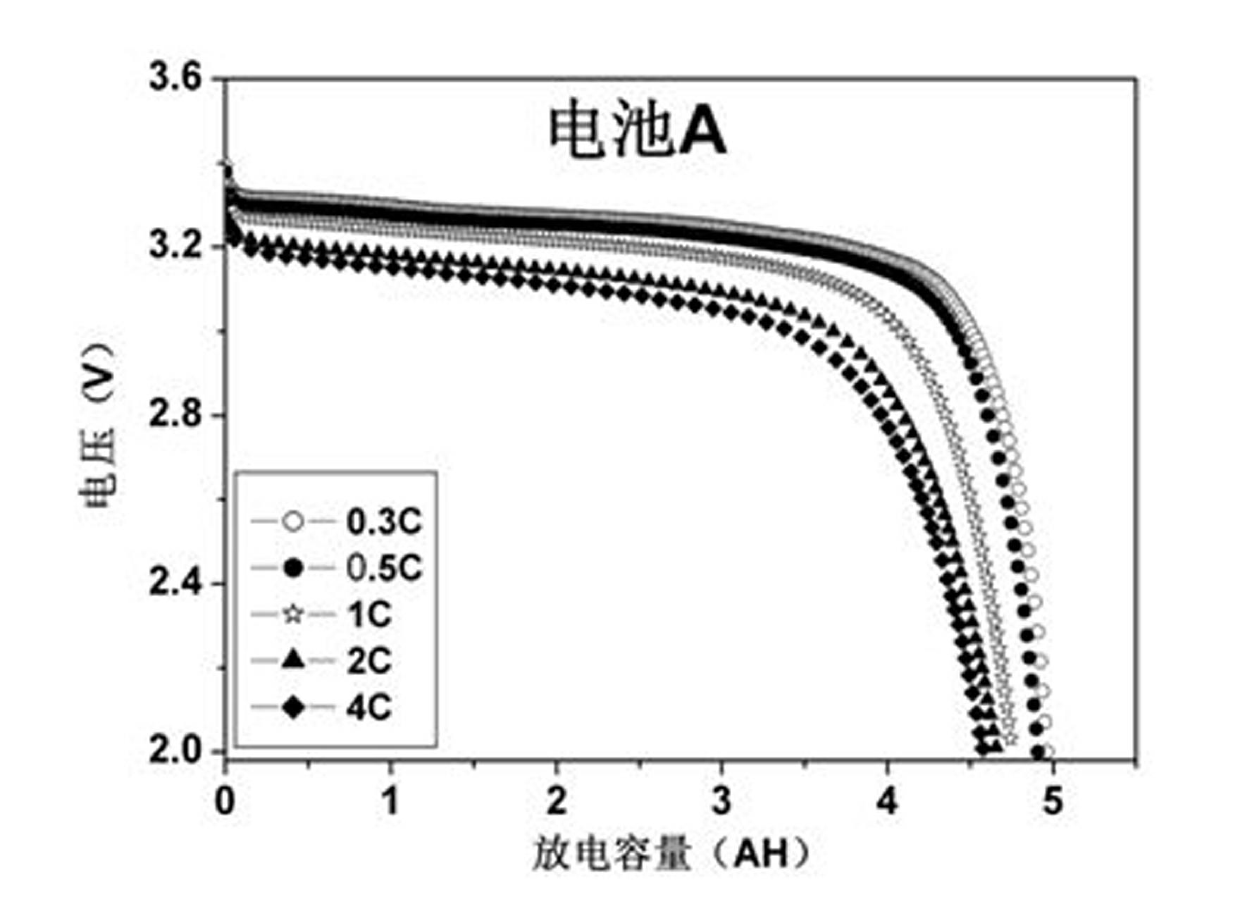

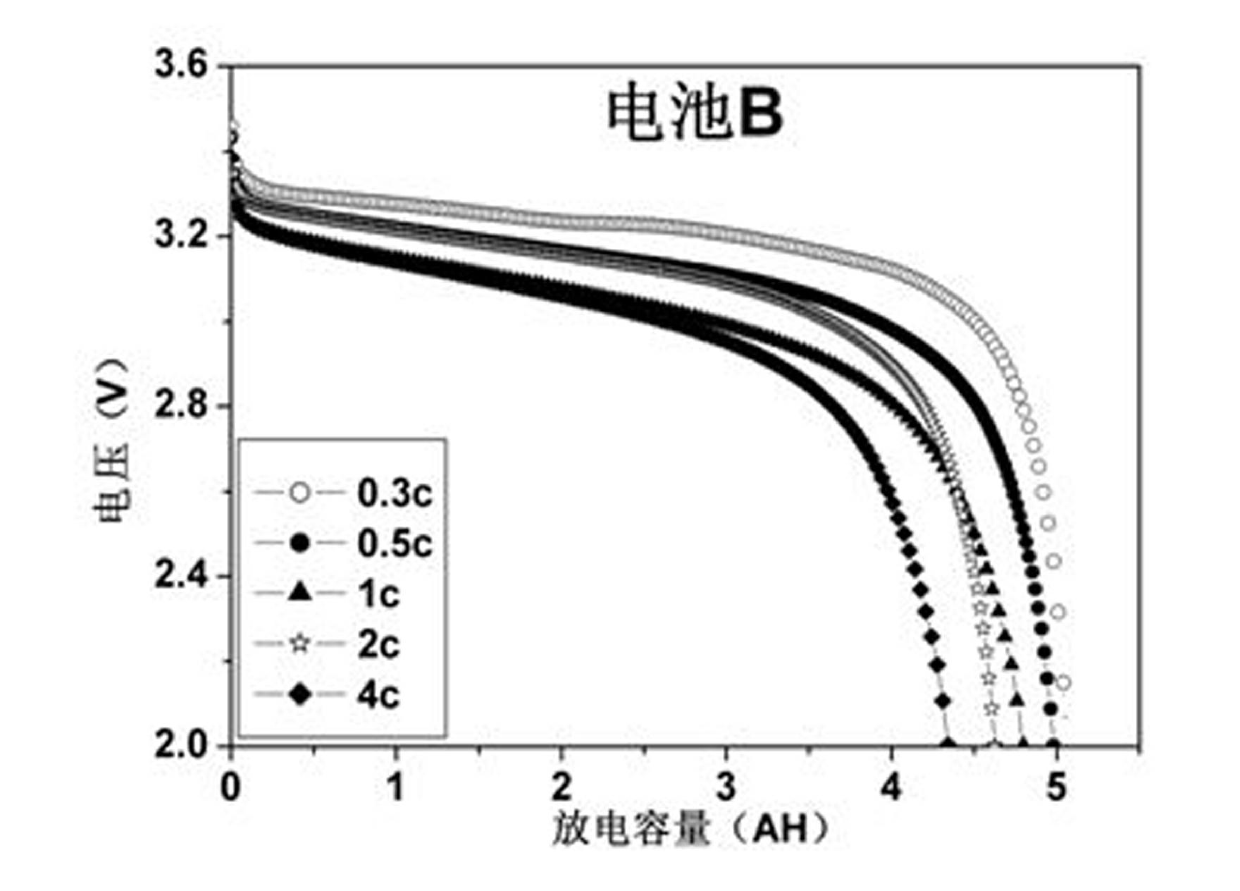

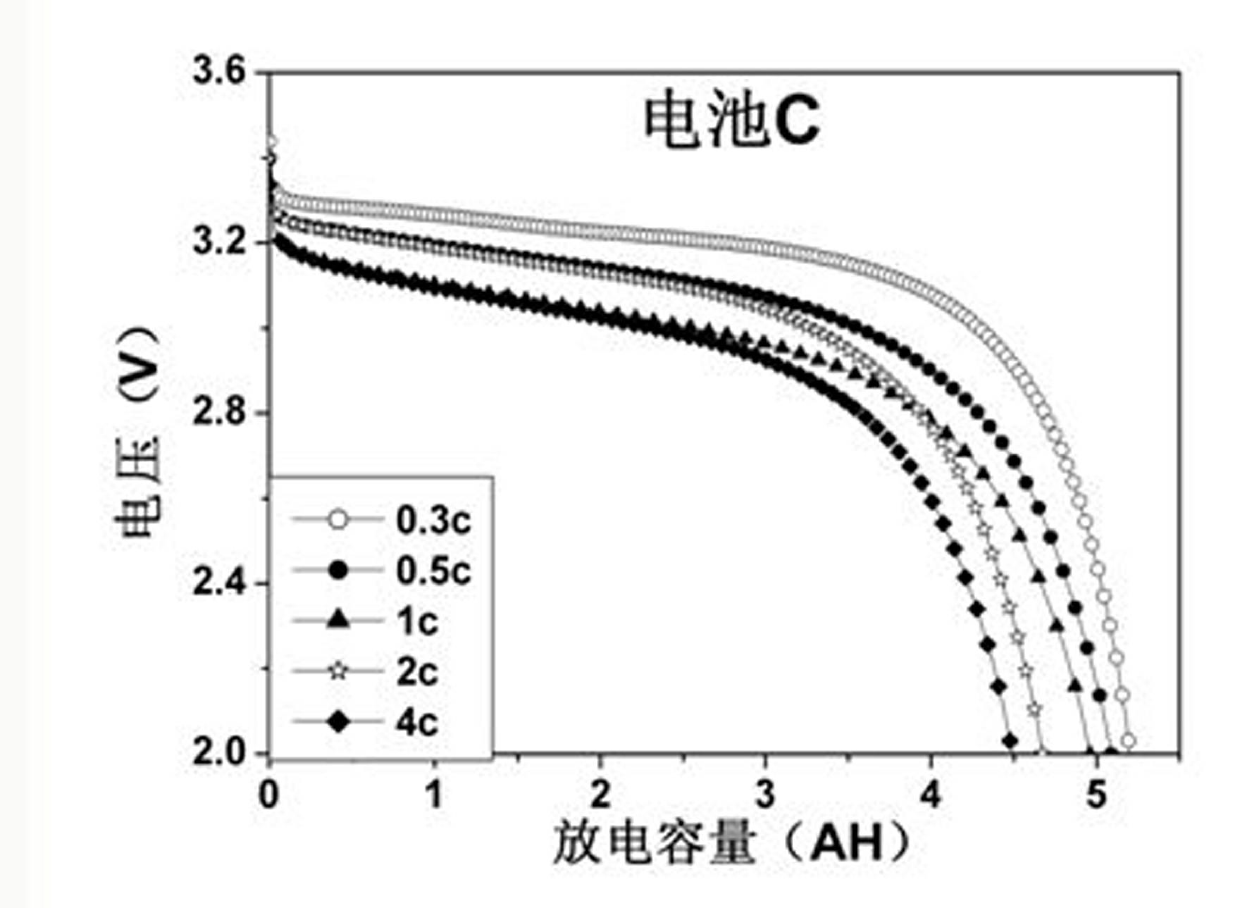

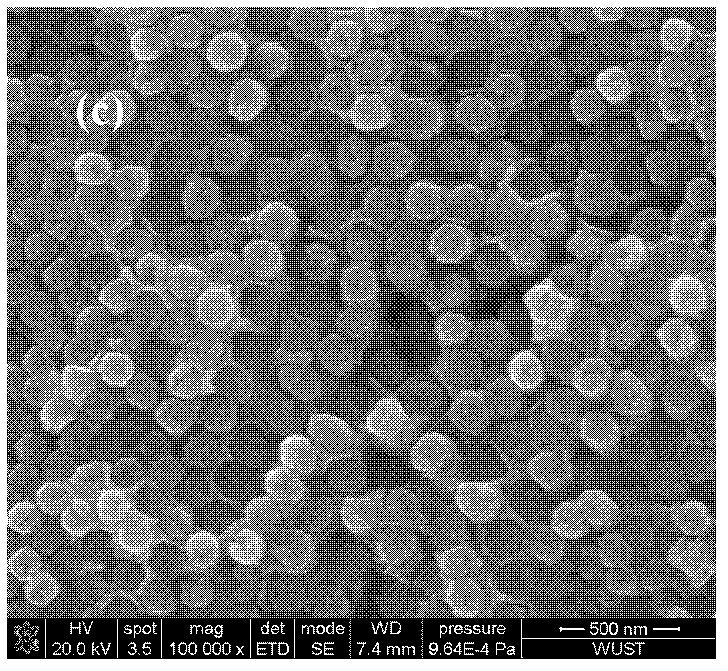

Ternary positive-electrode material prepared by solvothermal method and preparation method thereof

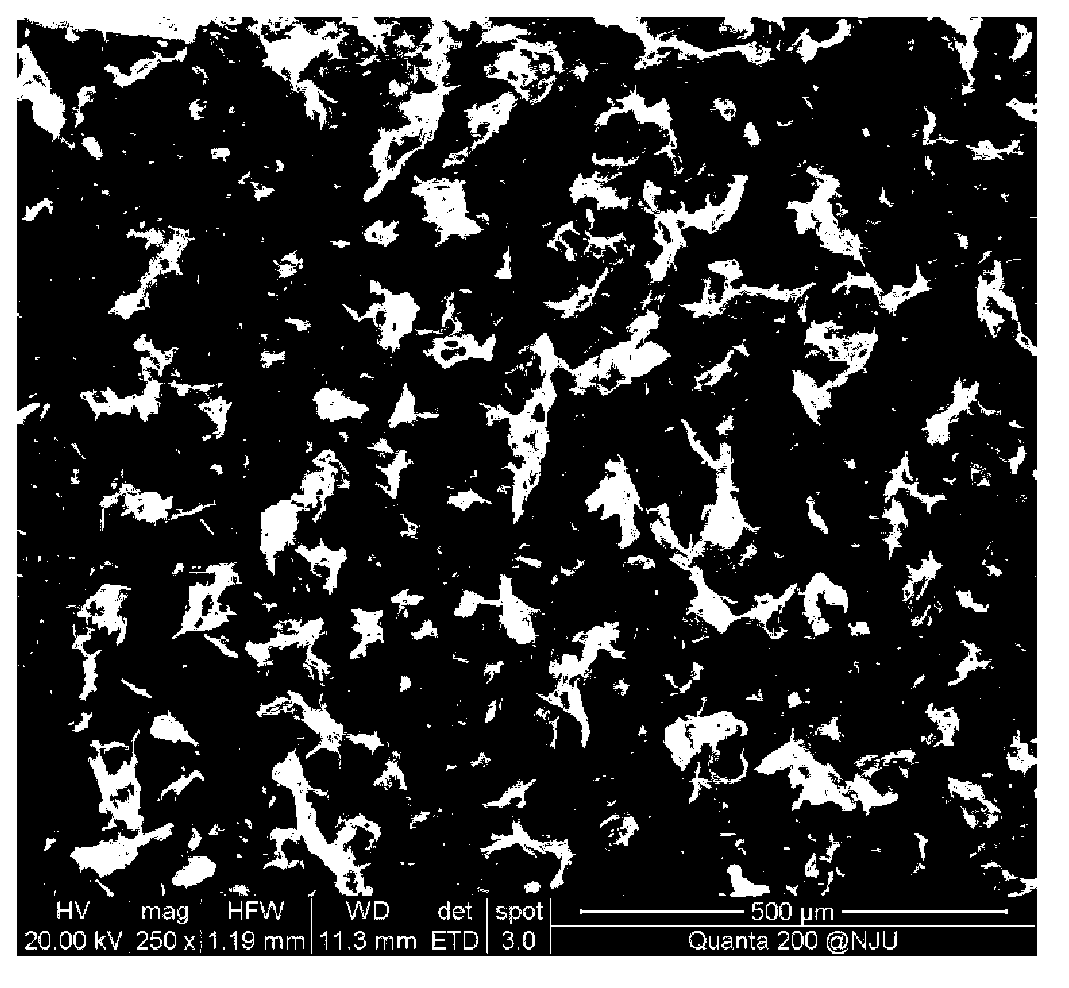

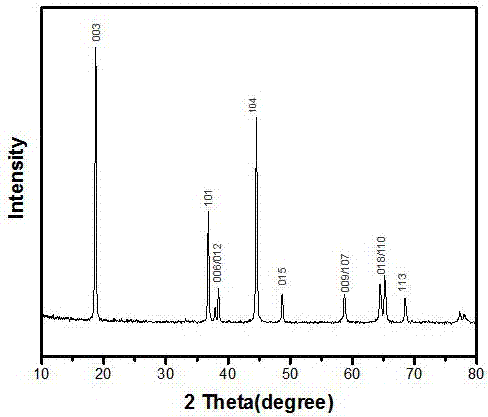

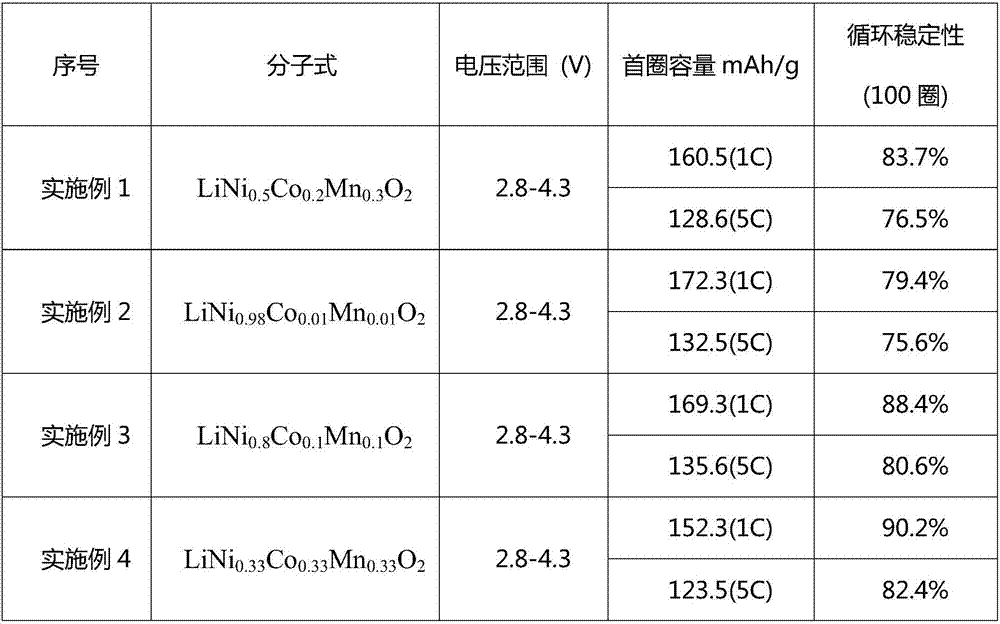

InactiveCN107959022ARegulatory TopographySmall sizeCell electrodesSecondary cellsFiltrationManganese

The invention discloses a ternary positive-electrode material prepared by a solvothermal method and a preparation method thereof. The preparation method includes: dissolving nickel cobalt manganese salt in a solvent, adding a surfactant and hydrolysis auxiliaries, sufficiently stirring, transferring into a reaction kettle, performing solvothermal reaction under certain temperature for 2-24 hours,cooling to room temperature, using a suction filtration method to separate out a nickel cobalt manganese ternary product, washing, drying, and pre-calcining in air to obtain a precursor; grinding andmixing the precursor and a lithium compound, and calcining to obtain the ternary positive-electrode material. The ternary positive-electrode material and the preparation method thereof have the advantages that the ternary oxide precursor prepared by the solvothermal method is small in particle size, uniform in particle distribution and controllable in morphology as compared with a ternary precursor prepared by a conventional precipitation method, so that the finally prepared ternary material is small in granularity, uniform in particle size distribution and controllable in morphology and has excellent electrochemical performance, and the capacity and stability of the prepared ternary material are better than those of a ternary positive-electrode material prepared by the precipitation method.

Owner:SOUTH CHINA UNIV OF TECH

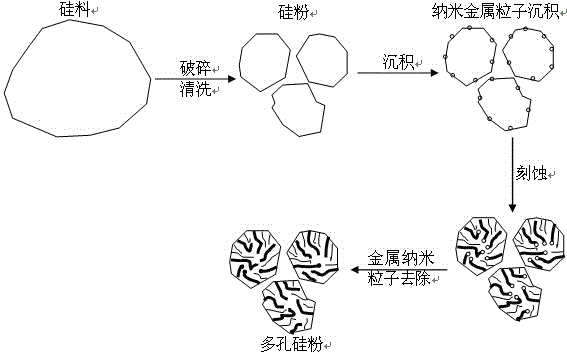

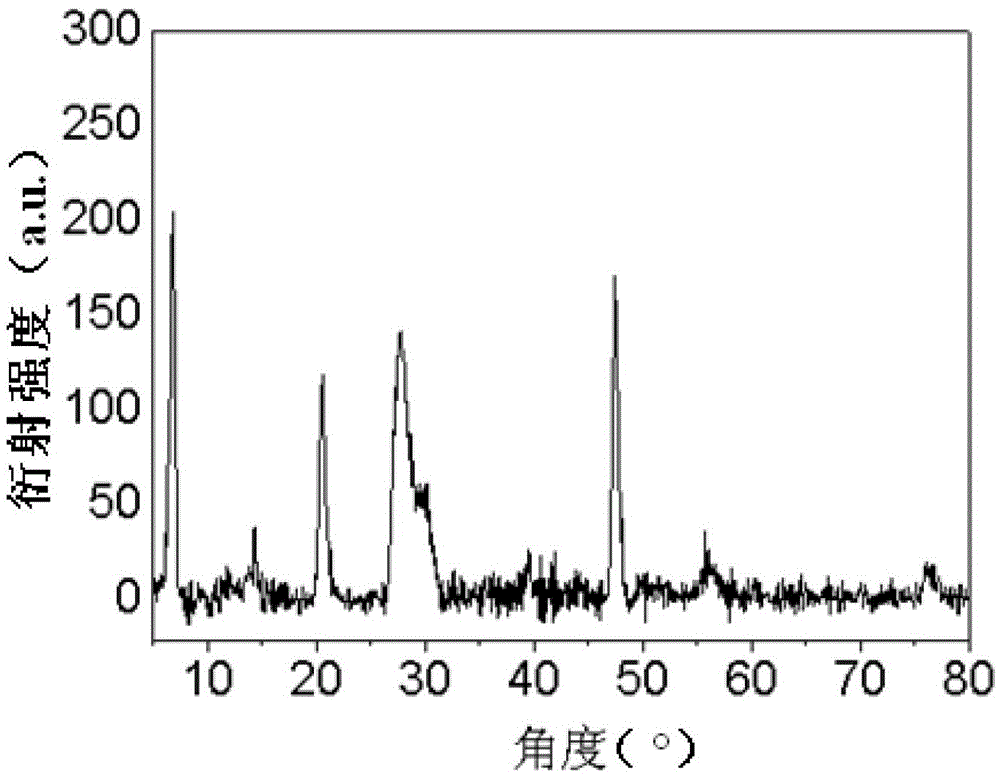

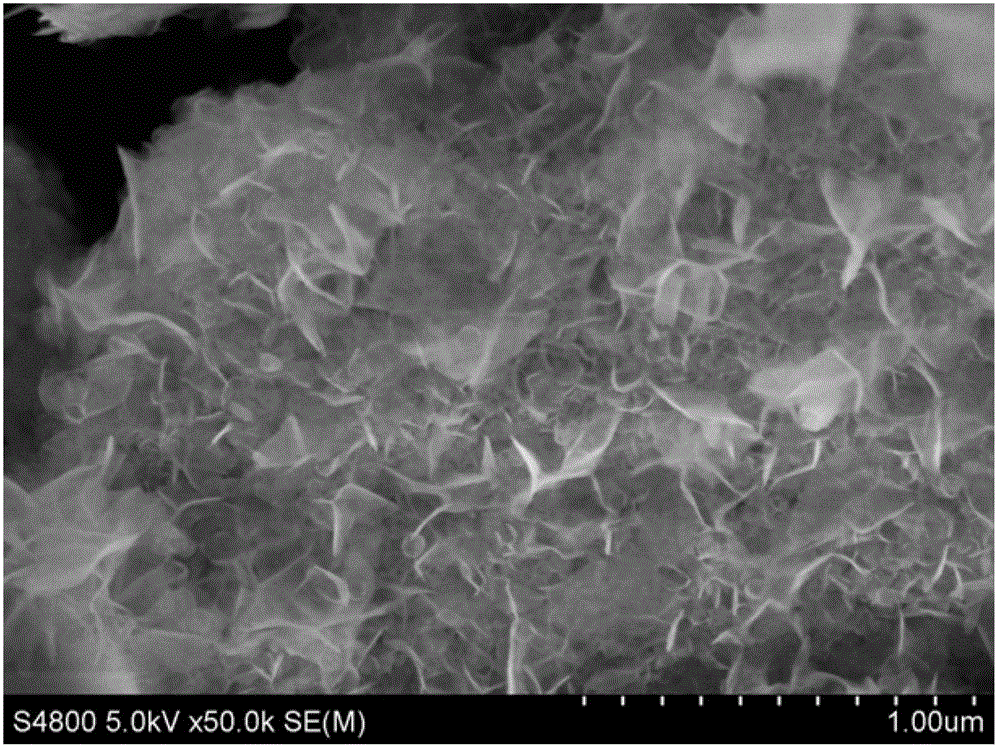

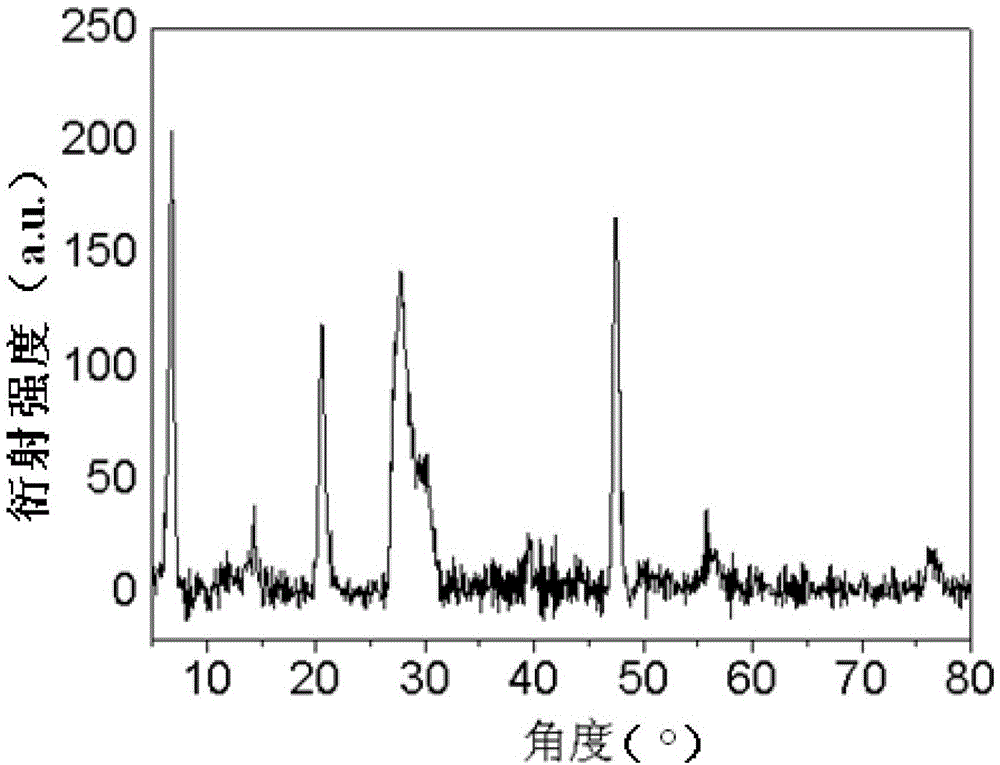

Preparation method of three-dimensional porous silica powder

The invention discloses a preparation method of three-dimensional porous silica powder, relates to a porous nanometer function material and belongs to the field of preparation of porous nanometer function materials. Silica powder with different purities fume is taken as a raw material, and metal nanoparticles (Ag, Au, Pd, Pt, Cu and the like) taken as catalysts are introduced on the surface of the silica Powder; in a reaction system with HF acid and an oxidizing agent, an MACE (metal-assisted chemical etching) method is adopted, and the porous silica powder with different pore structures and porosities is prepared under the room temperature condition. Compared with a traditional electrochemistry anode etching method, a magnesiothermic reduction method and the like, the method provided by the invention has the advantages of avoiding expensive single crystal silicon raw materials, harsh high-temperature reaction equipment and operation, being simple in equipment, easy in operation, low in cost, controllable in material structure and suitable for large-scale industrial production, and the like. The preparation method of the three-dimensional porous silica powder has wide application prospect in the fields of lithium ion batteries, photoelectric materials, biomedicine, sensors and the like.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of MoS2/ZnIn2S4 nanosheet composite material

InactiveCN103331175AAchieving controllable equipmentImprove stabilityPhysical/chemical process catalystsHydrogen productionIndiumSulfur

The invention relates to a preparation method of a composite material, and concretely relates to a preparation method of an MoS2 / ZnIn2S4 nanosheet composite material by using sheet MoS2. The low photocatalytic activity of a single ZnIn2S4 photocatalyst at present is a problem that remains to be solved in the invention. The method comprises the following steps: 1, mixing sheet MoS2 with anhydrous ethanol; 2, adding to a mixed solution comprising an indium salt, a sulfur source, a zinc salt, a polyol and anhydrous ethanol; and 3, reacting, washing, and drying. The method realizes the controllable preparation of the MoS2 / ZnIn2S4 nanosheet composite material; and the prepared MoS2 / ZnIn2S4 nanosheet composite material has a very good stability. The method is used for preparing the MoS2 / ZnIn2S4 nanosheet composite material.

Owner:HEILONGJIANG UNIV

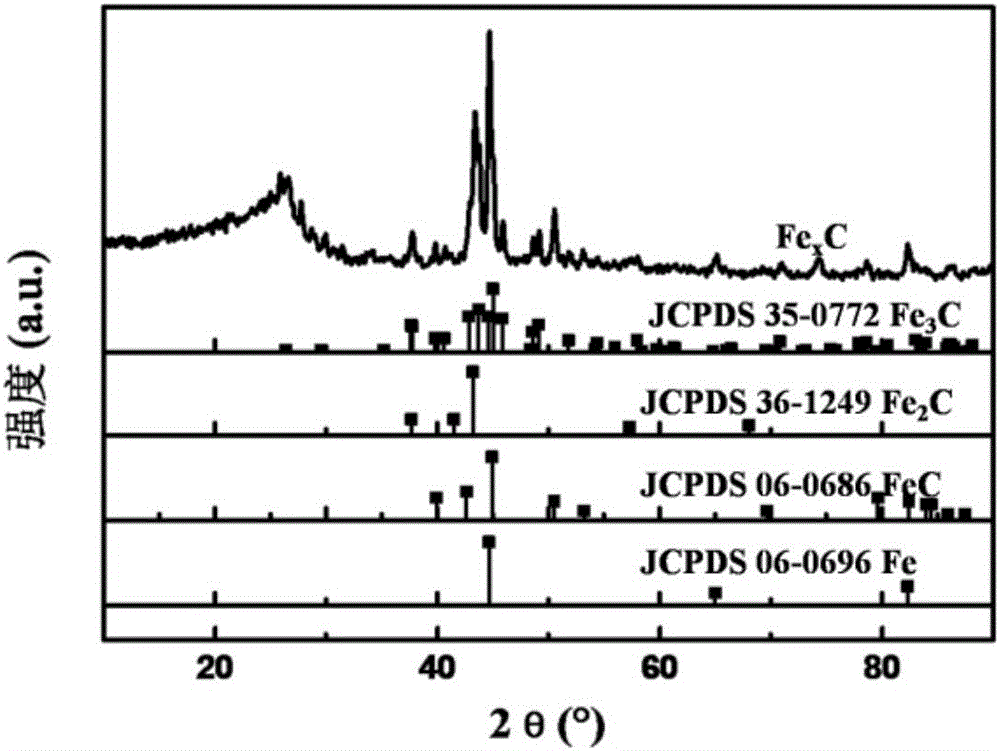

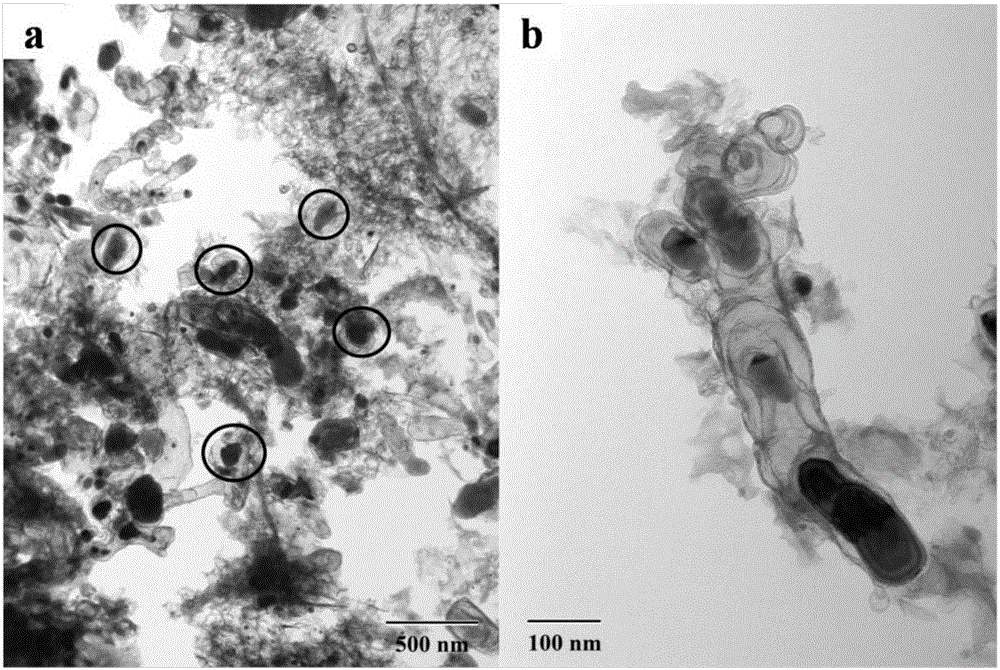

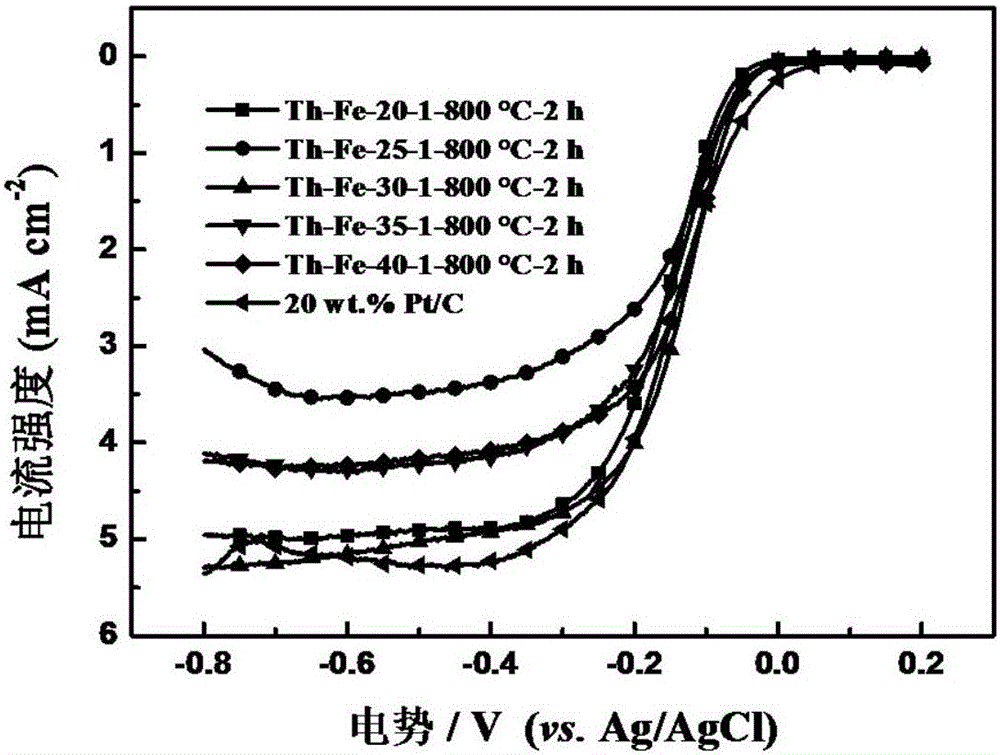

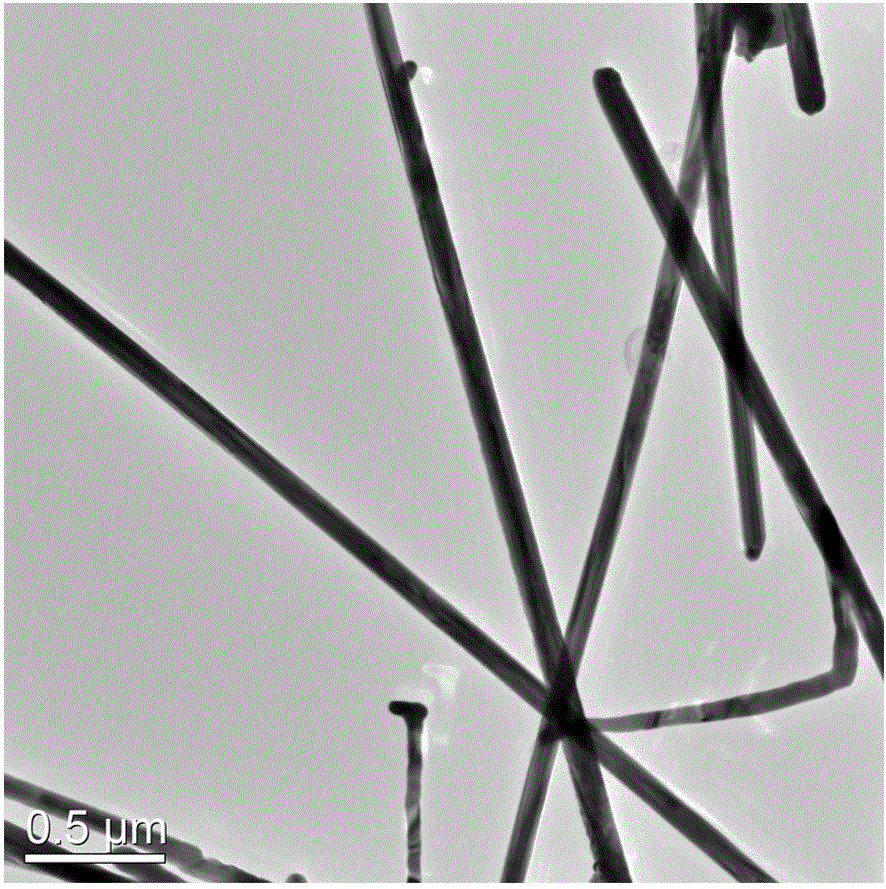

N and S dual-doped carbon nanotube-coated FexC catalyst and preparation method and application thereof

The invention provides a N and S dual-doped carbon nanotube-coated FexC catalyst and a preparation method, and belongs to the field of energy materials and electrochemistry. The N and S dual-doped carbon nanotube-coated FexC catalyst is prepared through pyrolysis in an inert atmosphere by taking thiourea as a C source, a N source and a S source, taking FeCl3.6H2O as a metal source and adopting a one-step method. According to the catalyst, metal particles are coated with N and S dual-doped carbon nanotubes, therefore, direction contact of the metal particles and an electrolyte solution in the reaction process can be effectively avoided, and the catalyst is beneficial for improving the material stability; the catalyst not only shows the oxygen reduction catalyzing performance equivalent to a Pt-C catalyst and the better stability and methanol tolerance under the alkaline condition, but also has the oxygen reduction catalyzing performance under the acidic condition; compared with a common coated-type FexC catalyst, the catalyst has the advantages that the preparation method is simple, the raw materials are easy to obtain, scale production is convenient to achieve, and the high practical value is achieved.

Owner:DALIAN UNIV OF TECH

Method for preparing CsPbBr3 nanosheets with quantum size effects

InactiveCN106809872APreserve quantum size effectsAchieving controllable equipmentMaterial nanotechnologyLead compoundsOleic Acid TriglycerideQuantum size

The invention discloses a method for preparing CsPbBr3 nanosheets with quantum size effects. The method includes dissolving cesium carbonate in oleic acid under argon filling conditions, and stirring the cesium carbonate and the oleic acid under heating conditions until the cesium carbonate is dissolved to obtain cesium oleate precursors; adding lead bromide, long-chain ligands and short-chain ligands into octadecene under argon filling conditions, carrying out reaction at the temperature of 100-150 DEG C until the lead bromide is dissolved, heating first reaction products until the temperature of the first reaction products reaches 120-150 DEG C, then injecting the cesium oleate precursors into the first reaction products, carrying out reaction for 5-15 s, then continuing to carry out reaction at the temperature of 100-130 DEG C for 1-5 min to obtain second reaction products and centrifuging the second reaction products. The method has the advantages that the transverse sizes of the CsPbBr3 nanosheets can be assuredly regulated and controlled in the range from 100 nm to 1 micrometer while the thicknesses which are equal to the thicknesses of a few atomic layers can be guaranteed; the thicknesses which are lower than the diameters of Bohr excitons can be kept, and accordingly the quantum size effects of the CsPbBr3 nanosheets can be reserved.

Owner:XI AN JIAOTONG UNIV

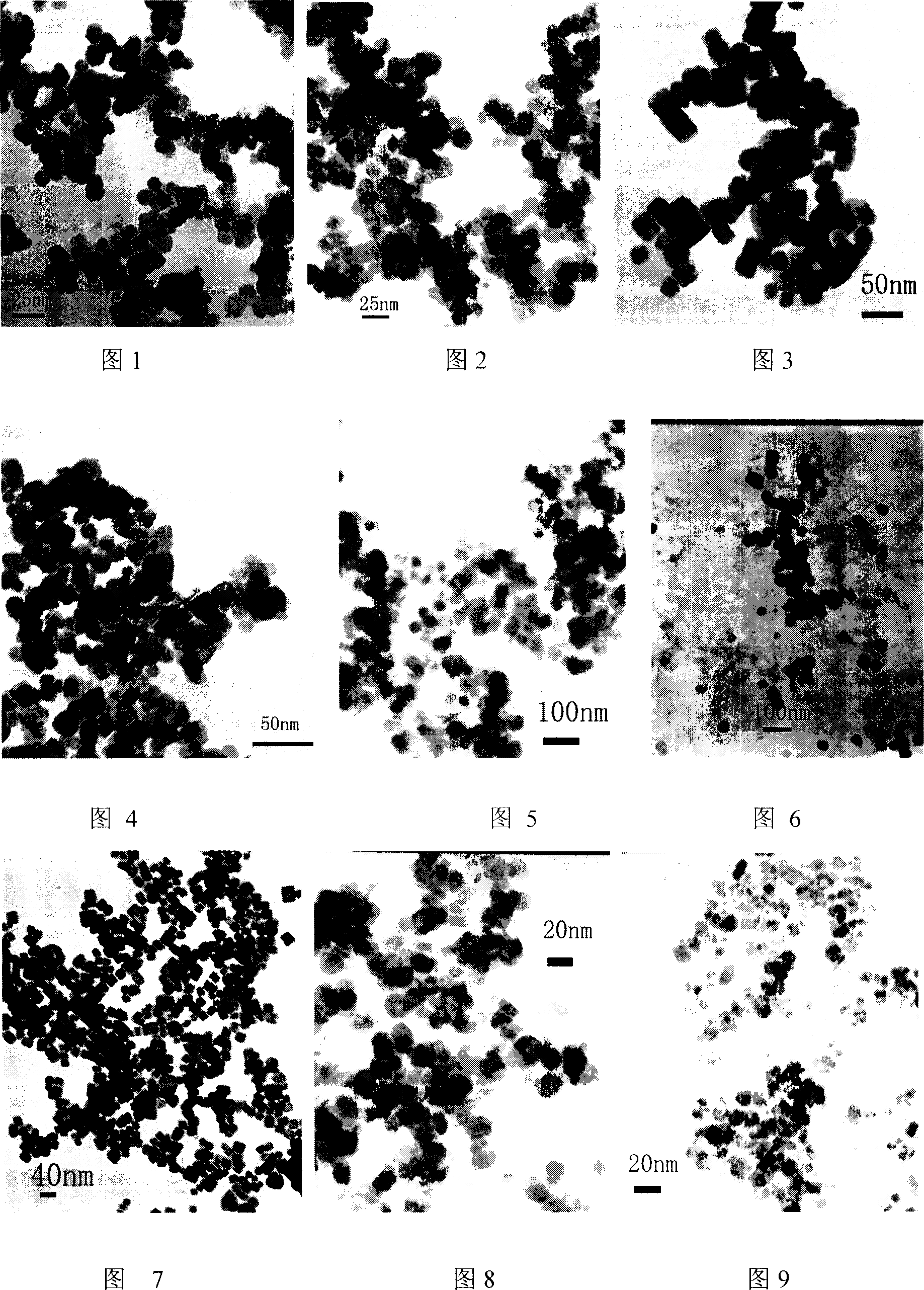

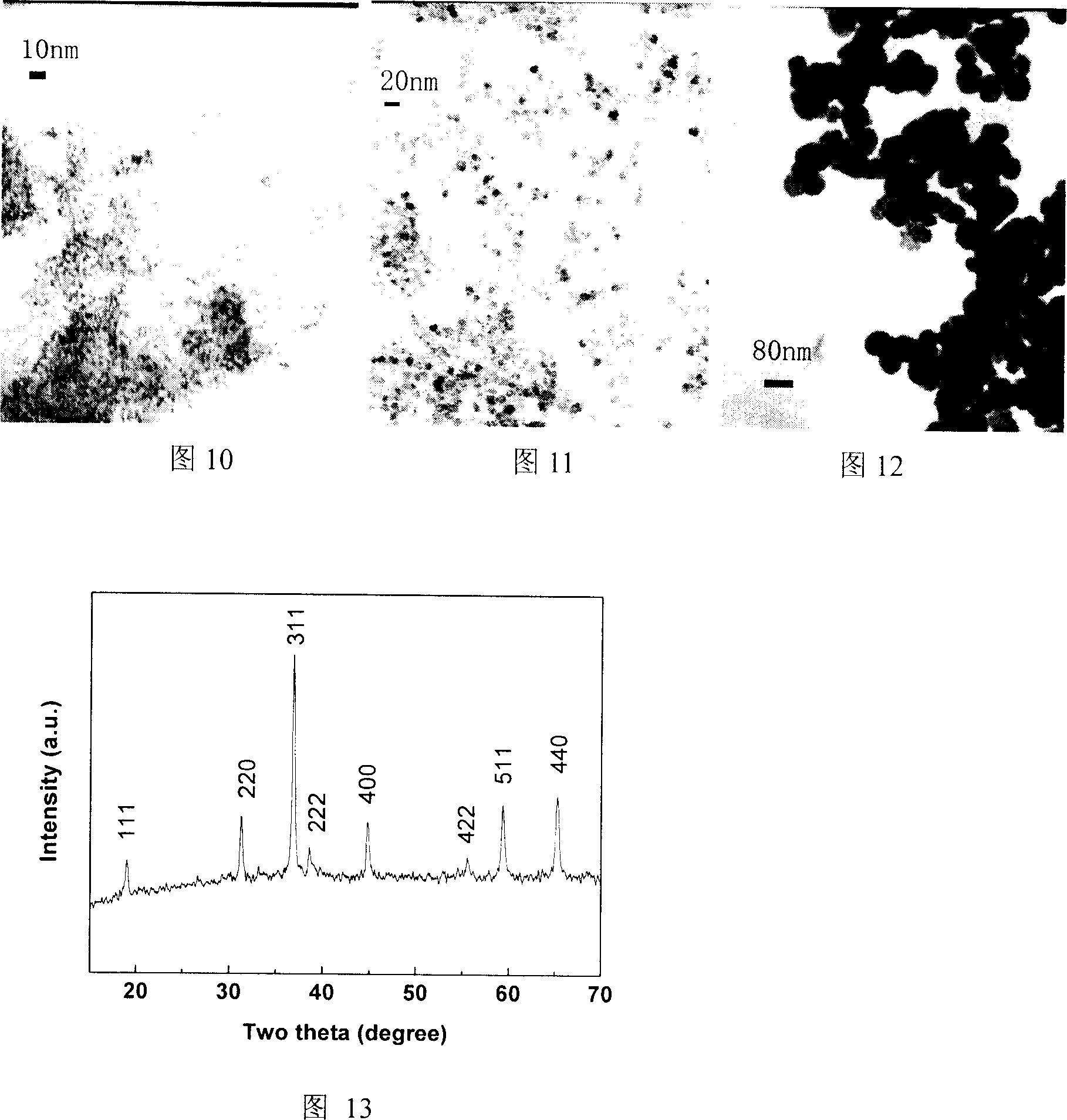

Process for preparing nanometer cobalt oxide

InactiveCN1962462AEasy to operateUniform scaleNanostructure manufactureCobalt oxides/hydroxidesAlcoholSolvent

The invention discloses a preparing method of nanometer cobalt oxide, which comprises the following steps: (1) dissolving bivalent soluble salt in the water or alcohol or composite solvent of water and alcohol; obtaining the solution with bivalent cobalt ion; (2) adding certain quantity of ammonia in the bivalent cobalt ion solution; blending evenly; refluxing and heating in the reactor; or transmitting into autoclave to do close heat; (3) separating sediment; washing; drying; obtaining nanometer material of black cobalt oxide with different size or shape; realizing controllable equipment of nanometer cobalt oxide within certain scale.

Owner:NANJING UNIV

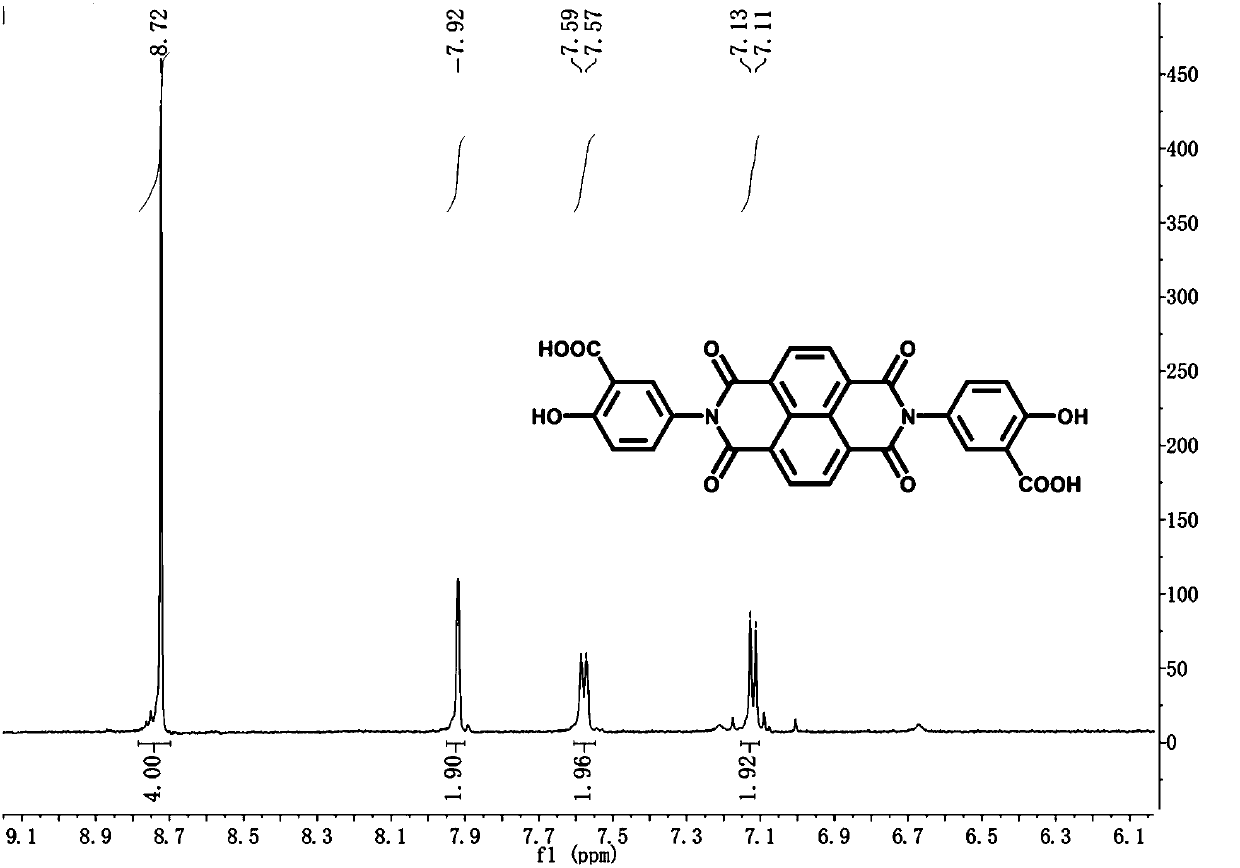

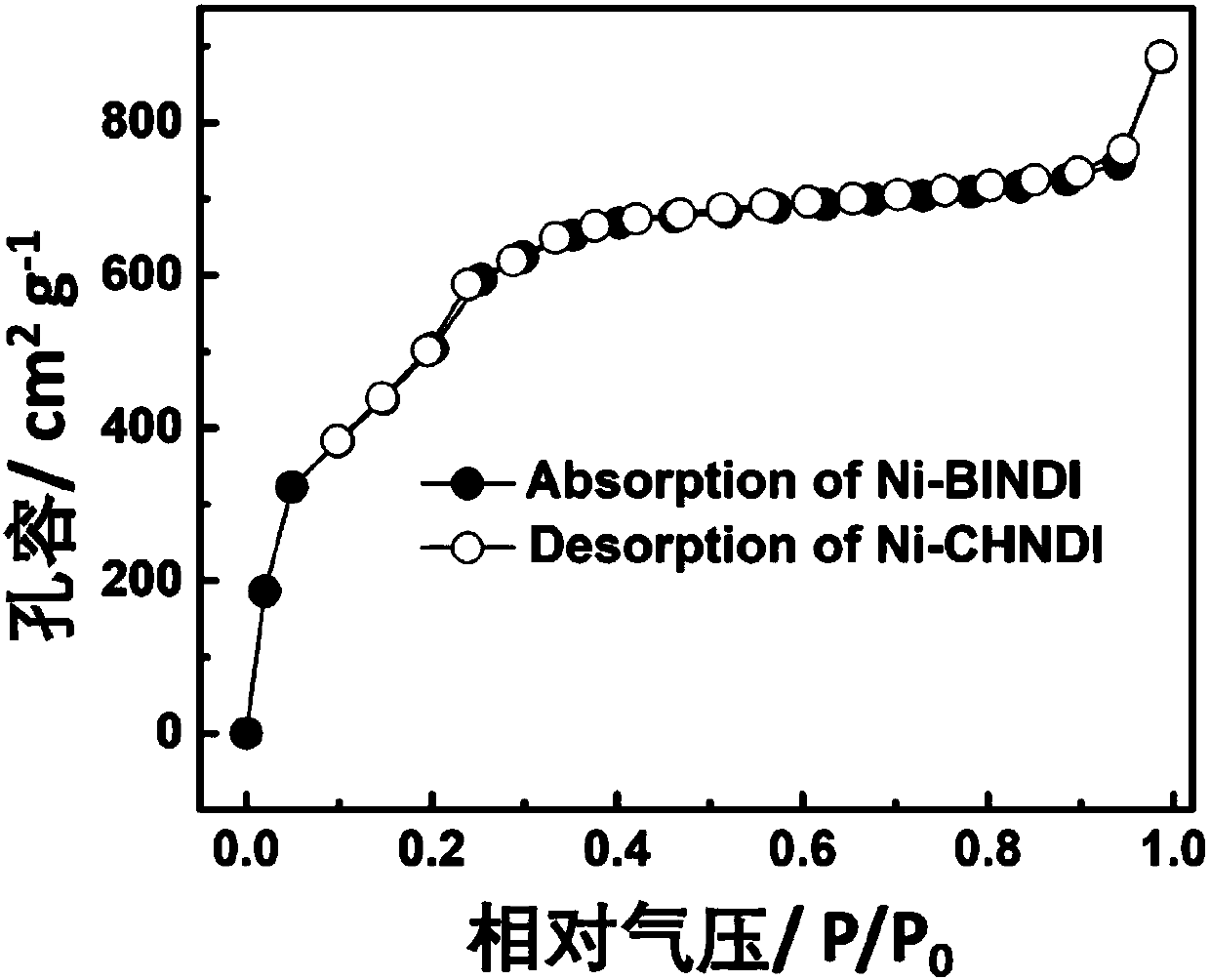

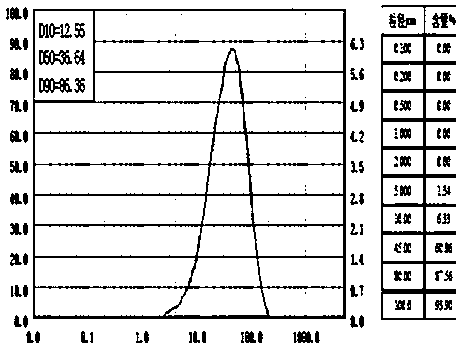

Preparation method of self-assembly Ni-MOFs electrochromic QR code device

ActiveCN108017789AImprove mechanical propertiesReduce the driving voltageTenebresent compositionsNaphthalenetetracarboxylic dianhydrideNickel salt

The invention relates to a preparation method of a self-assembly Ni-MOFs electrochromic QR code device. The method comprises the steps as follows: 1,4,5,8-naphthalenetetracarboxylic dianhydride and 5-amino-2-hydroxybenzoic acid are put in toluene, and an anhydride ligand is obtained; the ligand is dissolved in DMF and a solution A is obtained; nickel salt is dissolved in ethanol and a solution B is obtained; pretreated FTO glass is irradiated by ultraviolet ozone, the obtained FTO glass is sequentially placed in the solution A, ethanol, the solution B and ethanol for self-assembly, circulatingoperation is performed, and an FTO electrode with a Ni-MOFs film attached on the surface is obtained; a working electrode displaying QR code patterns is formed through laser etching, another FTO glass is used as a counter electrode, gel electrolyte is injected, and the device is obtained after packaging. Controllable preparation of the Ni-MOFs film is realized, the prepared QR code device can beswitched between display and hiding when positive and negative voltage is applied, and meanwhile, the device has good electrochromic performance and has wide application prospects in the fields of Internet of Things, intelligent wearable devices and the like.

Owner:DONGHUA UNIV

Controllable preparation method based on high-stacking-degree graphene modified high-thermal-conductivity carbon-plastic alloy

ActiveCN108976700AAchieving controllable equipmentAdd lessHeat-exchange elementsCompression moldingResin matrix

The invention discloses a controllable preparation method based on high-stacking-degree graphene modified high-thermal-conductivity carbon-plastic alloy. The carbon-plastic alloy is prepared from thefollowing components in percentage by weight: high-stacking-degree graphene filler: 5 to 50%, thermosetting resin: 30 to 55%, a coupling agent: 0.2 to 2%, a resin diluent: 1 to 5%, a curing agent: 7 to 15%, reinforcing filler: 5 to 20%, and an auxiliary agent: 2 to 5%. The high-stacking-degree graphene filler is composed of carbon materials of four different specifications, wherein graphene A accounts for 5 to 15%, graphene B accounts for 2 to 5%, nanographite microchip C accounts for 15 to 45%, and nanographite microchip D accounts for 35 to 78%. The high-stacking-degree graphene filler is added to a thermosetting resin matrix to form a perfect heat transfer passage, and the high-thermal-conductivity carbon-plastic alloy material having a thermal-conductivity coefficient of 10-25 W / m.K can be controllably prepared. The high-thermal-conductivity carbon-plastic alloy prepared by the invention can be processed into various heat dissipation components by compression molding or injection molding, and is suitable for industrial heat dissipation, illumination heat dissipation, heat dissipation of electronic devices, etc.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

Method for preparing silver nanowires

ActiveCN104439281AUniform size and shapeStrong controllabilityNanotechnologySolventPolymer dissolution

The invention discloses a method for preparing silver nanowires. The silver nanowires are prepared controllably by the self-assembly characteristic of micelle of amphiphilic hyperbranched polymer. The method comprises the following specific steps of dissolving or dispersing the amphiphilic hyperbranched polymer in polyhydric alcohol; adding halogenous inorganic salt or sulfurated inorganic salt in the mixture; adding silver salt in the mixture after the halogenous inorganic salt or sulfurated inorganic salt is dissolved in the mixture completely; placing obtained mixed solution in a sealed reaction kettle; performing constant-temperature reaction at a certain temperature in a range of 120-240 DEG C; naturally cooling down a reaction product to obtain raw products of silver nanowires; and washing the raw products by using organic solvent and centrifugally separating the raw products to obtain the silver nanowires. A one-kettle solvothermal method is used, the amphiphilic hyperbranched polymer is used for preparation of the silver nanowires, and the silver nanowires with uniform sizes and morphologies can be obtained. The steps of the method are simple and are easy to operate; the controllability and the reproducibility are high; and the silver nanowires are easily produced in batches.

Owner:苏州恒拓服饰有限公司

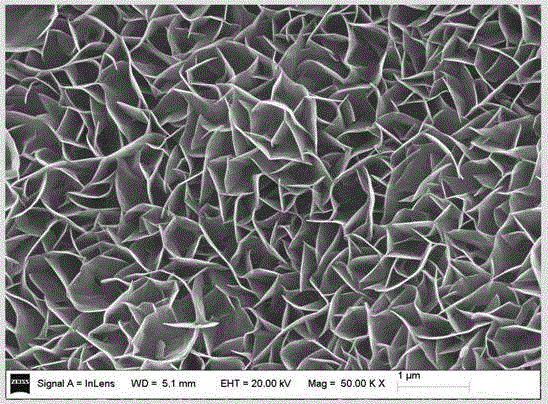

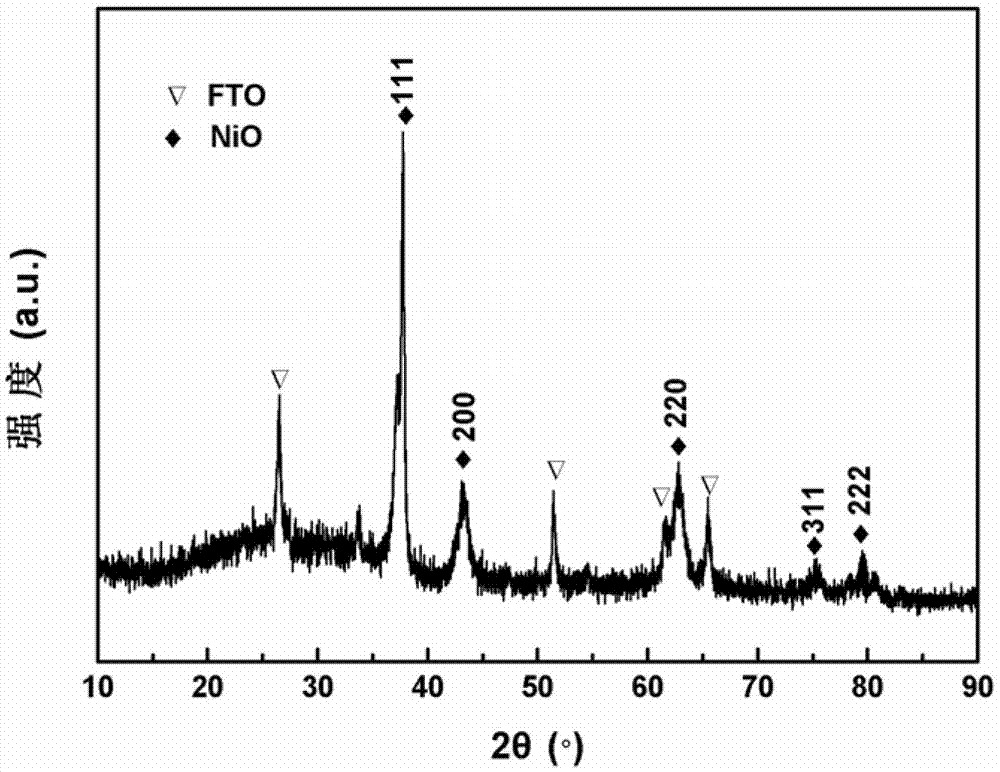

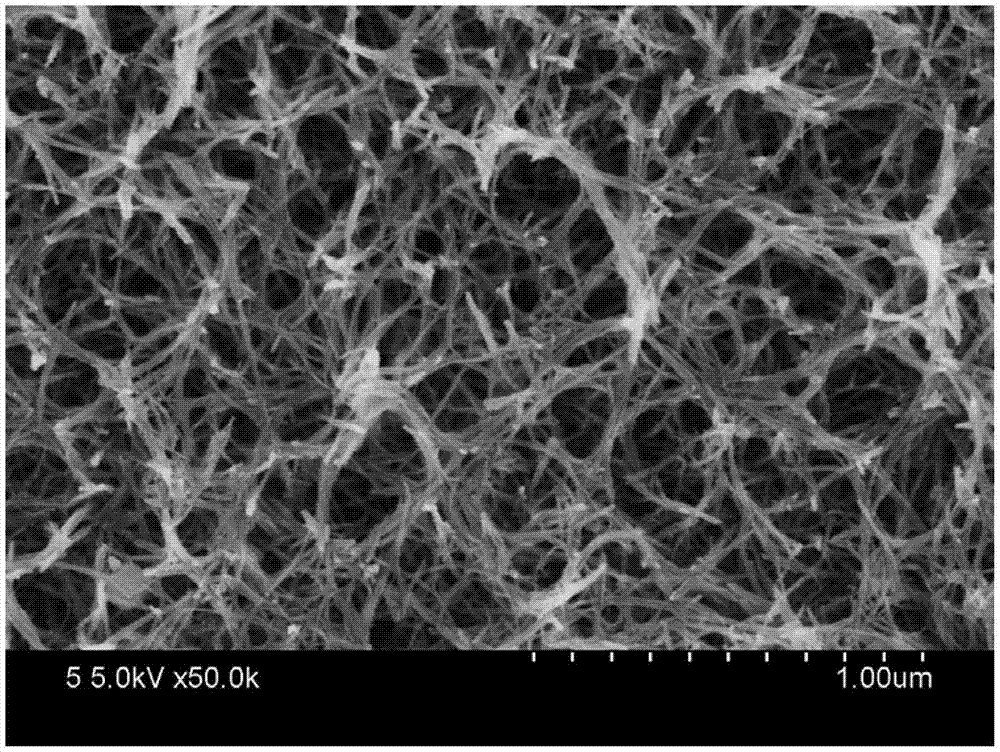

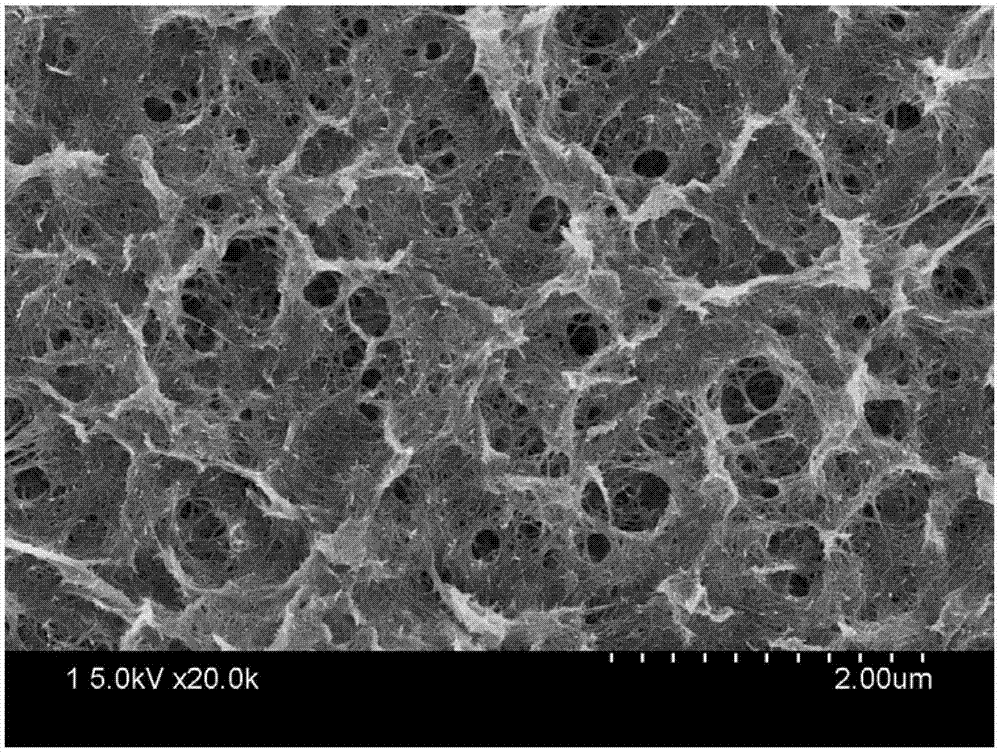

Method for preparing nickel oxide electrochromic film by hydrothermal method

ActiveCN103172273ALarge specific surface areaReduce path lengthNickel oxides/hydroxidesNickel acetate tetrahydrateSolvent

The invention relates to a method for preparing a nickel oxide electrochromic film by a hydrothermal method. The method comprises the following steps of: dissolving nickel acetate tetrahydrate in a mixed solution of alcohol and n-butyl alcohol, dropwise adding ammonia water to the mixed solution after the nickel acetate tetrahydrate is dissolved to obtain sol; coating the sol to the surface of FTO (Fluorine-doped Tin Oxide) conductive glass in a rotary manner, drying the sol to obtain the FTO conductive glass with a crystal seed layer; mixing the nickel acetate tetrahydrate, urea and a solvent to obtain a reaction solution; immersing the FTO conductive glass with the crystal seed layer to the reaction solution for carrying out hydrothermal reaction; keeping the reaction solution for 6 hours to 12 hours under the condition of 160 DEG C to 180 DEG C, cooling the reaction solution to the room temperature, cleaning, drying and roasting to obtain the nickel oxide electrochromic film. The preparation method disclosed by the invention is simple, low in cost and likely applied to the glass surface film-making industry. The nanometer structure nickel oxide film directly grows on the surface of the FTO conductive glass by a hydrothermal method, so that the nickel oxide and the substrate have better binding force for being beneficial to electron conduction. Meanwhile, the electrochemical stability of the film is also improved.

Owner:DONGHUA UNIV

Multi-component Janus composite nanometer material and preparation method thereof

InactiveCN108530582AAchieving controllable equipmentPrecise regulation and controllable equipmentControlled releaseNanoparticle

The invention relates to a multi-component Janus composite nanometer material and a preparation method thereof. Based on Janus nanoparticle consisting of a polymer single chain and nanoparticles, themulti-component Janus composite nanometer material is prepared by growing part of composite functional materials on the nanoparticles or grafting a polymer molecular brush on the polymer single chainpart. The Janus composite nanometer particles consisting of the polymer single chain and the nanoparticles are prepared through ionic polymerization; and the structural model can be selected from anyone of polymer single chain and spherical nanoparticle connecting sequence any combination arrangement models. The functional materials are selected from metal, metal compounds and non-metallic compounds. Controllable preparation of the Janus composite nanometer material capable of accurately regulating and controlling composition and structure is realized, the excellent properties of the composite material and the nanometer material are combined, and important significance in the fields of catalysis, medicine controlled release, enzyme fixation, pollutant treatment and the like is achieved.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

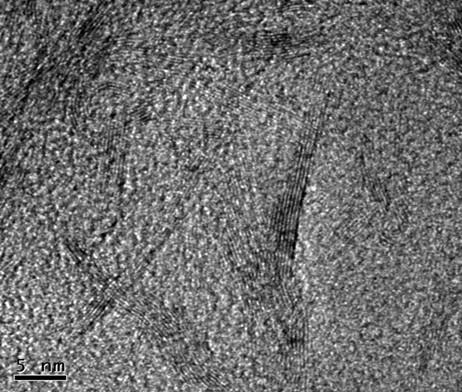

Preparation method for carbon nanotube or graphene nano-carbon material

InactiveCN102190294AAchieving controllable equipmentGood repeatabilityGraphene nanoribbonsThermal decomposition method

The invention discloses a novel preparation method for nano-carbon material without metal catalyst. The method is a silicon carbide high temperature thermal decomposition method, wherein the high-efficiency and controllable preparation of carbon nanotube and graphene nano-carbon material is realized through modulating the atmosphere in the preparation process. According to the method, high purity nano-carbon material without metal catalyst is produced, thus the influence of metal on the physicochemical property of nano-carbon material is overcome fundamentally. The method is a simple high-efficiency novel method with good repeatability for producing nano-carbon material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

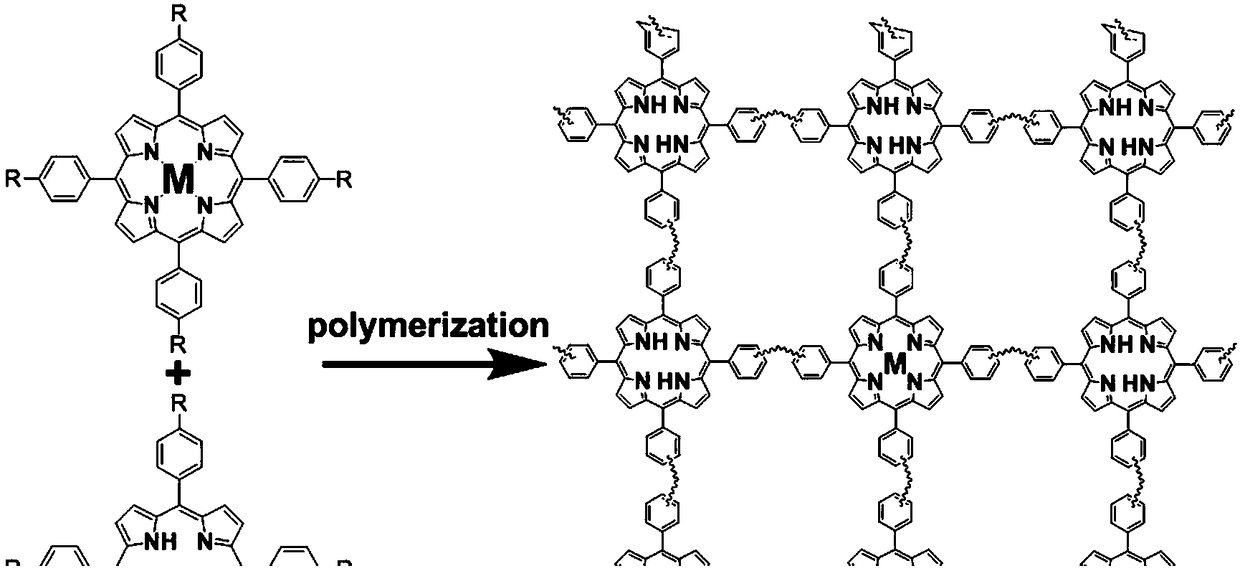

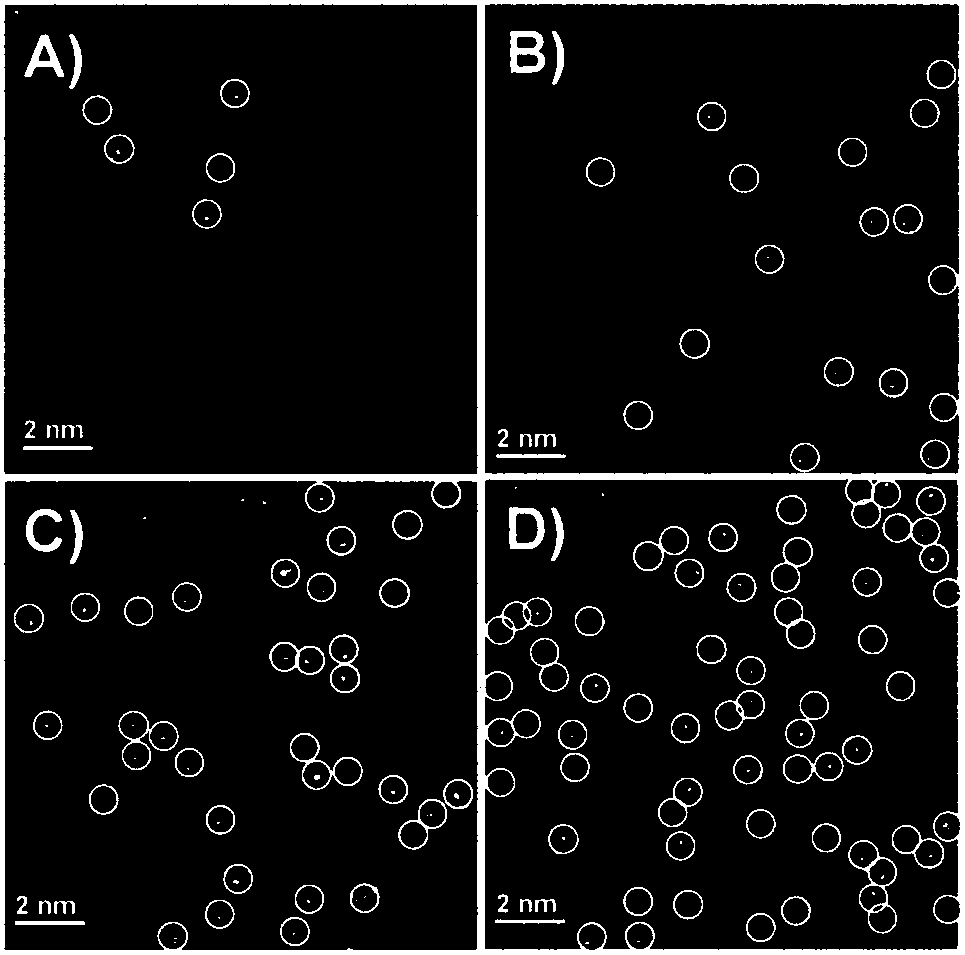

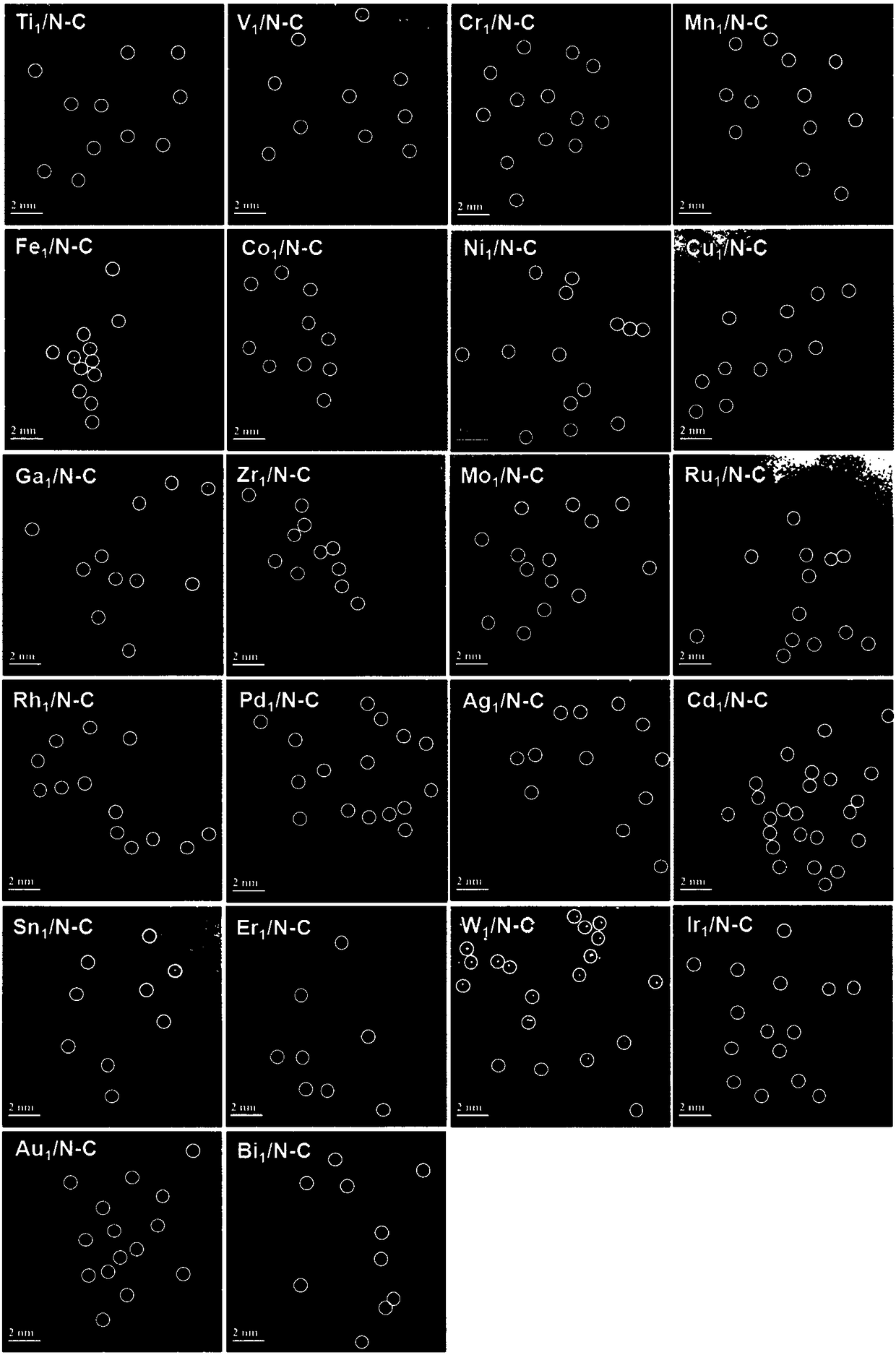

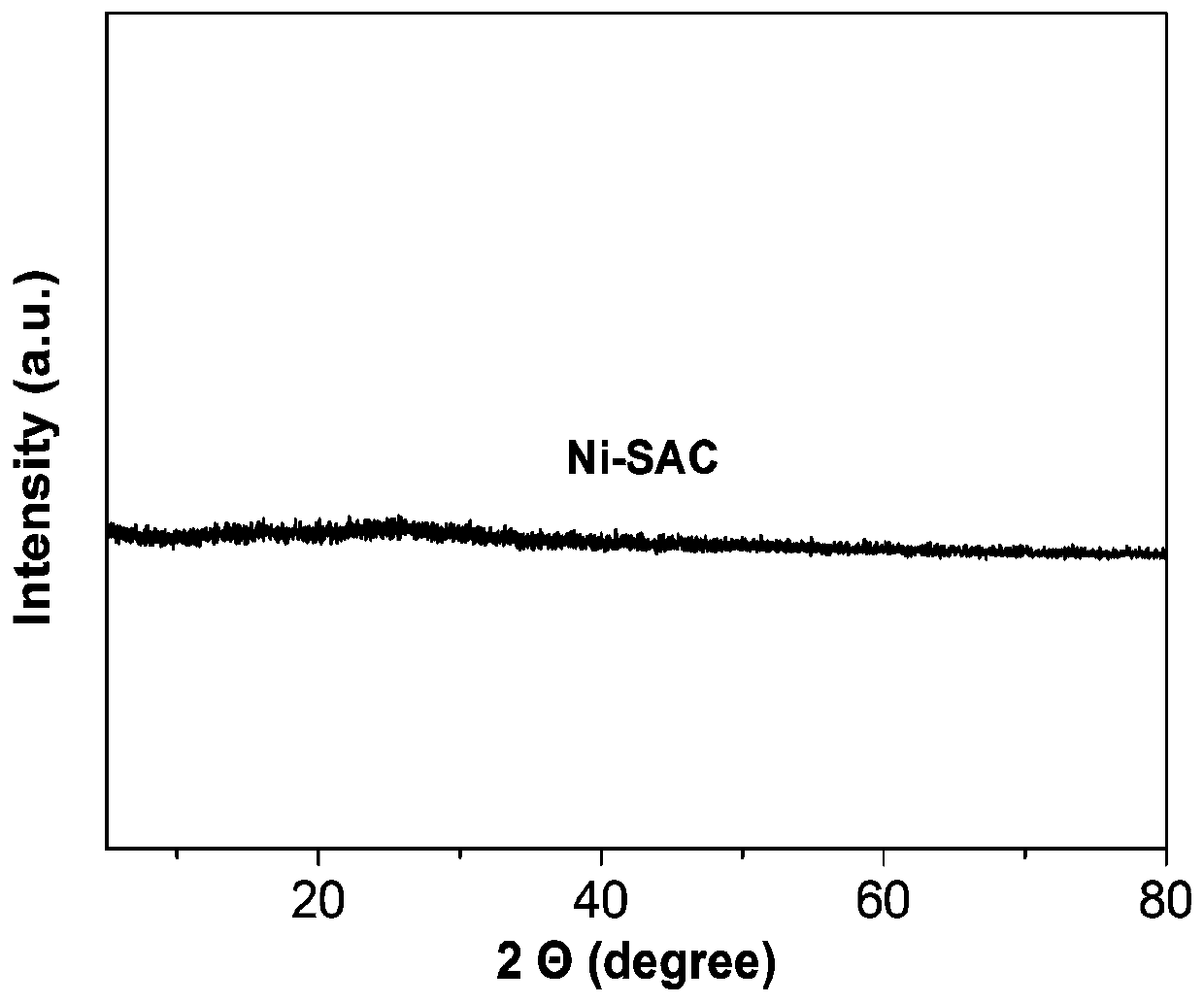

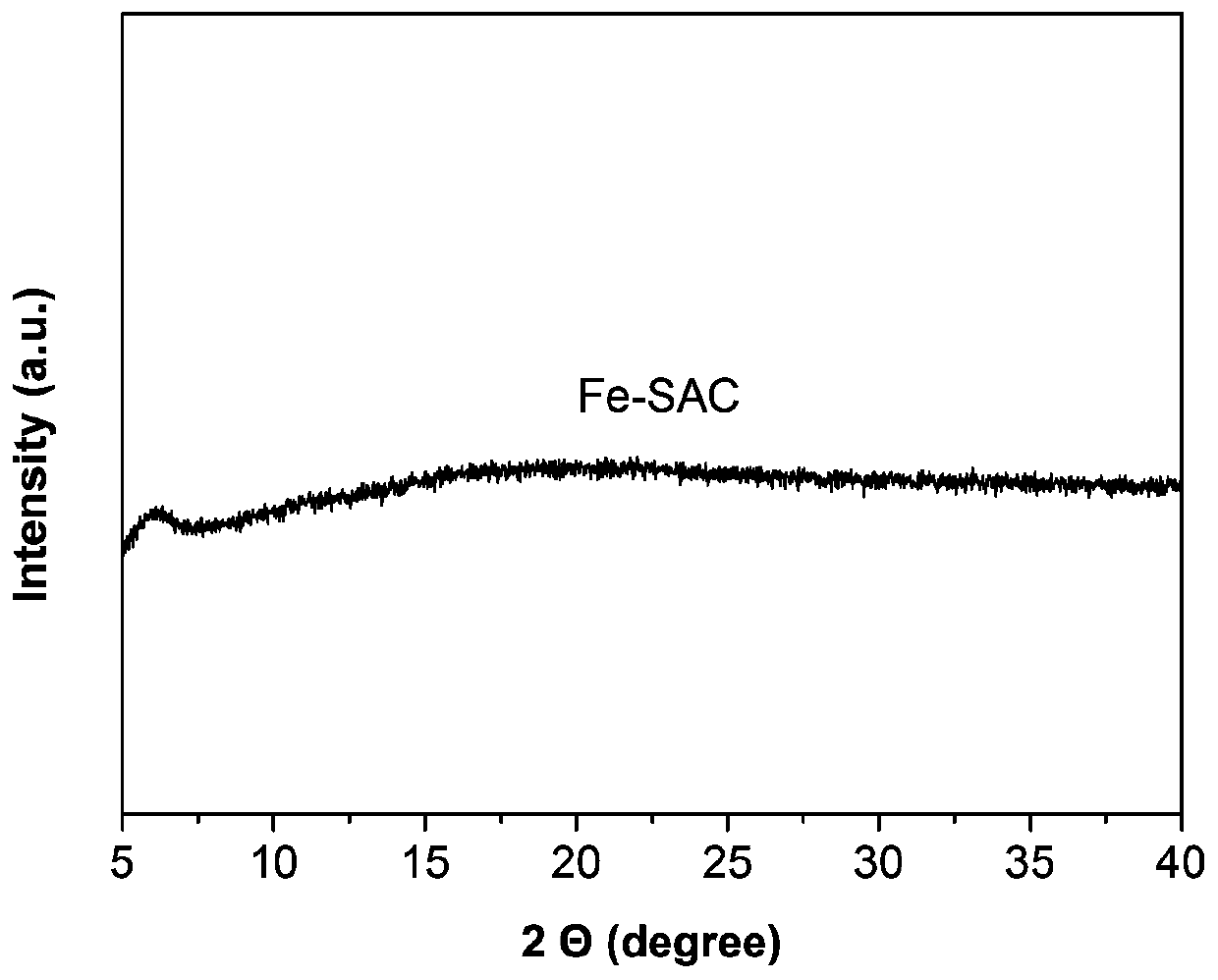

Preparation method of nitrogen-doped porous carbon-supported metal monoatomic material

ActiveCN108579783AGood dispersionImprove stabilityCatalyst activation/preparationPorous carbonPorphyrin

The present invention relates to a controllable preparation method of a nitrogen-doped porous carbon-supported metal monoatomic material, and belongs to the technical field of material science and engineering. According to the present invention, porphyrin and a metalloporphyrin are polymerized through a polymerization reaction. The proportions of the porphyrin and the metalloporphyrin are regulated to regulate a metal content (0.06-4.00wt%), and monoatomic metal types (A type, AB type, ABC type) are regulated by regulating different types of metalloporphyrins. According to the present invention, controllable preparation of a metal monoatomic material is realized with good expansibility and reproducibility; meanwhile, the problems of low metal content, few types and the like in the prior art are solved, and researches in the related fields such as the synthetic methodology of metal monoatomic materials and the like.

Owner:SUN YAT SEN UNIV

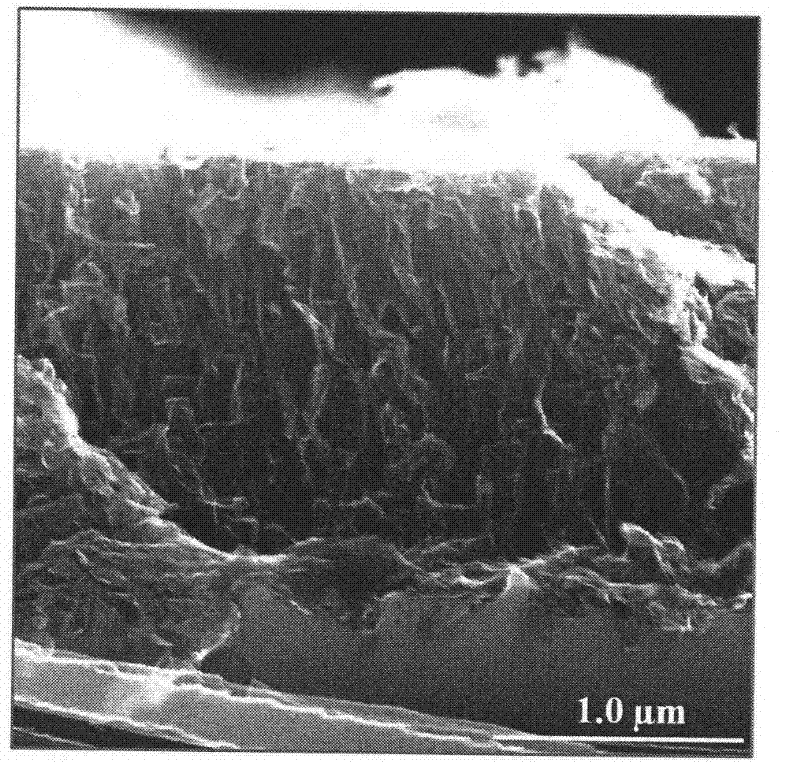

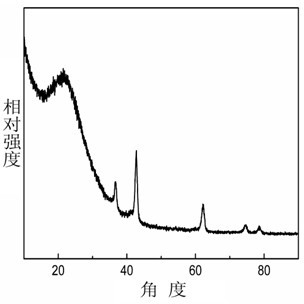

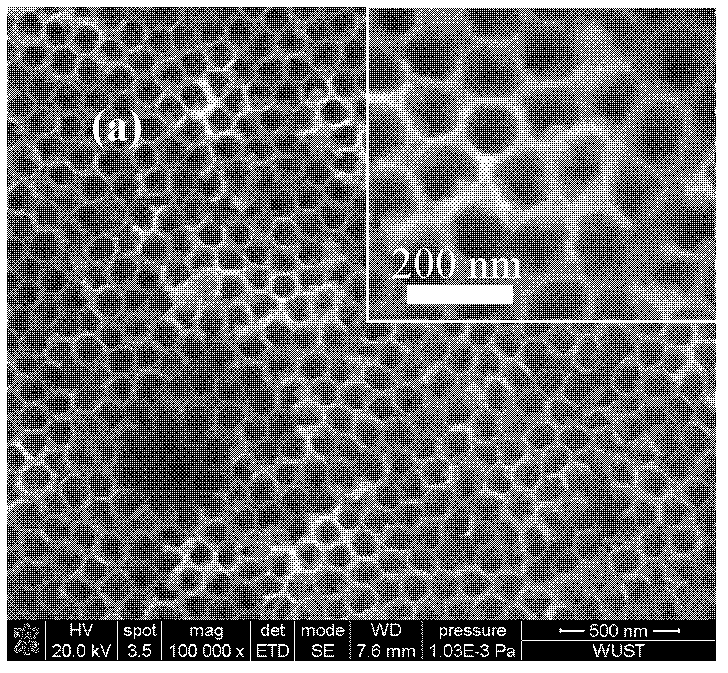

Porous titanium nitride nanotube array film and preparation method thereof

InactiveCN102534630AImprove conductivityLarge specific surface areaSurface reaction electrolytic coatingElectrolytic agentTitanium metal

The invention particularly relates to a porous titanium nitride nanotube array film and a preparation method thereof. The technical scheme of the method is that: first, a polished and buffed titaniferous metal sheet is used as an anode to be put into electrolyte for carrying out anodic oxidation, the voltage of anodic oxidation is 10-60 V, and the time of anodic oxidation is 0.5-5 hours; then the titaniferous metal sheet after anodic oxidation is washed and dried, and the dried titaniferous metal sheet is subjected to annealing treatment at the temperature of 300 to 600 DEG C in the air; finally the titaniferous metal sheet after the annealing treatment is subjected to annealing at the temperature of 300 to 600 DEG C in the atmosphere that the volume of a nitrogenous precursor is 10-100 percent at a speed of 1-20 DEG C / min, and is cooled along a furnace; and the titanium nitride nanotube array film is obtained on the surface of the titaniferous metal sheet. The preparation method disclosed by the invention is simple, and the process is reliable. The prepared porous titanium nitride nanotube array film is uniformly distributed with nanometer-size holes from a tube mouth to a tube bottom, and the size of the holes can be adjusted. The porous titanium nitride nanotube array film is suitable for the field of electrochemistry.

Owner:WUHAN UNIV OF SCI & TECH

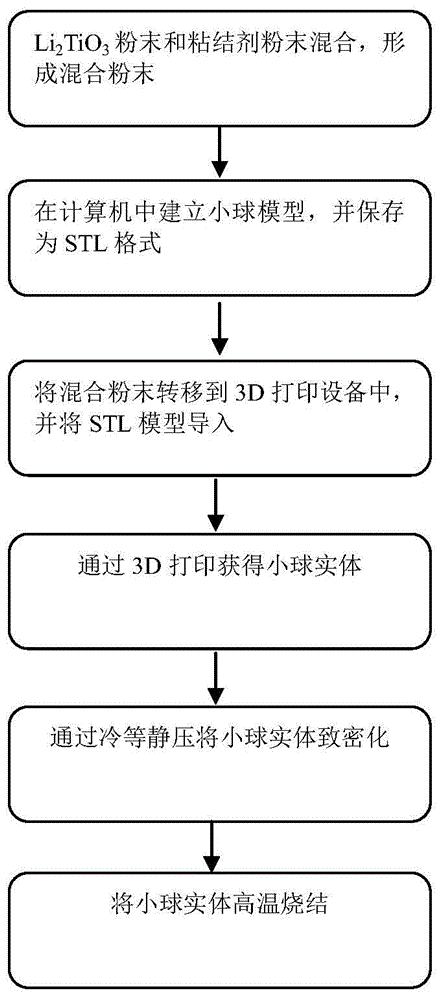

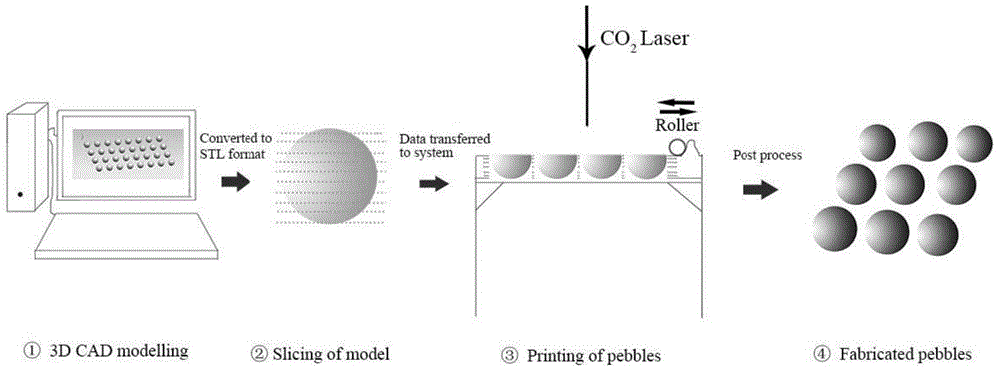

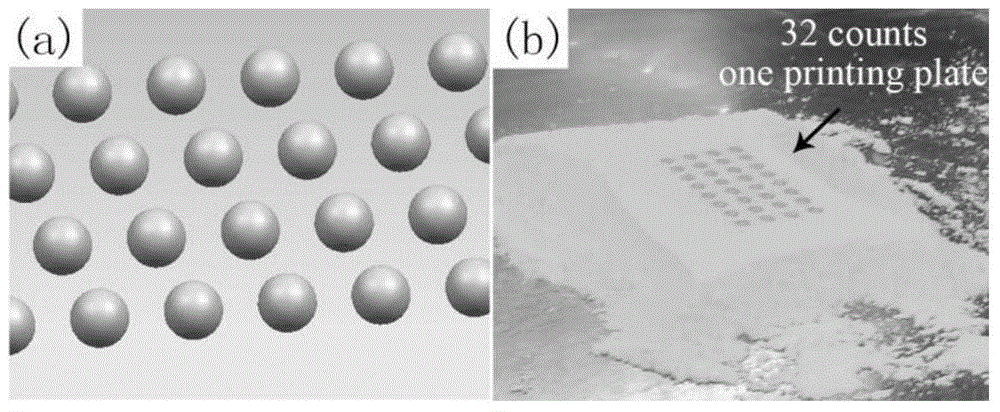

Method for quickly manufacturing Li2TiO3 tritium breeding small balls

ActiveCN104140259AAchieving controllable equipmentHigh densityCeramic shaping apparatusIn degreeSphericity

The invention provides a method for quickly manufacturing Li2TiO3 tritium breeding small balls. The method comprises the following steps that (1) Li2TiO3 powder and binder powder are mixed to form mixed powder; (2) a small ball three-dimensional model is established in a computer and is stored in the format of STL; (3) the mixed powder obtained in the step (1) is transferred into 3D printing equipment, the small ball three-dimensional model in the format of STL is introduced into a system of the 3D printing equipment; (4) technological parameters are set and the 3D printing equipment is started to obtain small ball entities; (5) the small ball entities are placed into a cold isostatic press to be compacted; (6) binder removal processing is conducted on the small ball entities; (7) the small ball entities are sintered in a sintering furnace. The Li2TiO3 small balls manufactured through the method are high in degree of sphericity, compactness and crushing strength, and large-scale and mechanical production of the Li2TiO3 tritium breeding small balls can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Monatomic catalyst prepared based on surface immobilizing method

ActiveCN111013576AImprove catalytic performanceAchieving controllable equipmentCatalyst activation/preparationHydrocarbonsPtru catalystOrganic chemistry

The invention belongs to the field of material preparation and application thereof, and discloses a method for preparing a high-performance monatomic catalyst by immobilizing catalytic active sites onthe surface of an organic material. Compared with a traditional noble metal catalyst and reported unit point and monatomic catalysts, the monatomic catalyst prepared by the invention has the characteristics of excellent performance, controllable structure and concentration of active sites, mild preparation conditions, low cost, simple process, high yield and the like. The catalyst shows excellentperformance in electrocatalysis and thermocatalysis, and has a wide and excellent industrial application prospect.

Owner:CENT SOUTH UNIV

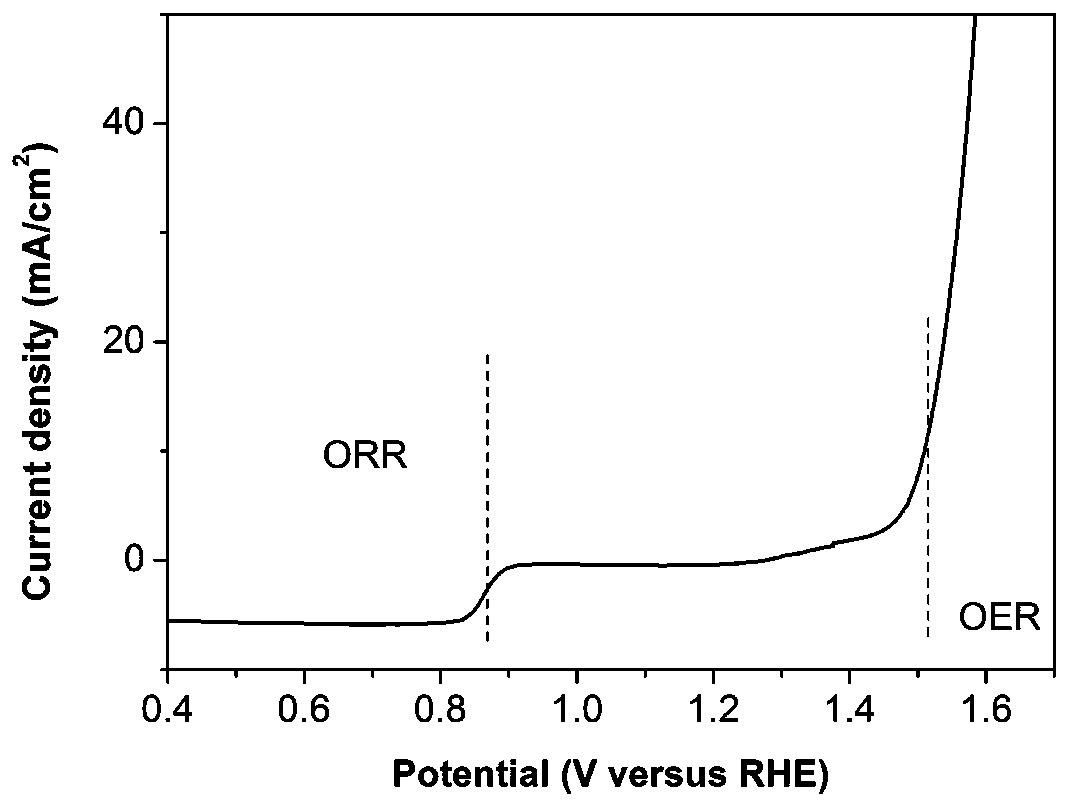

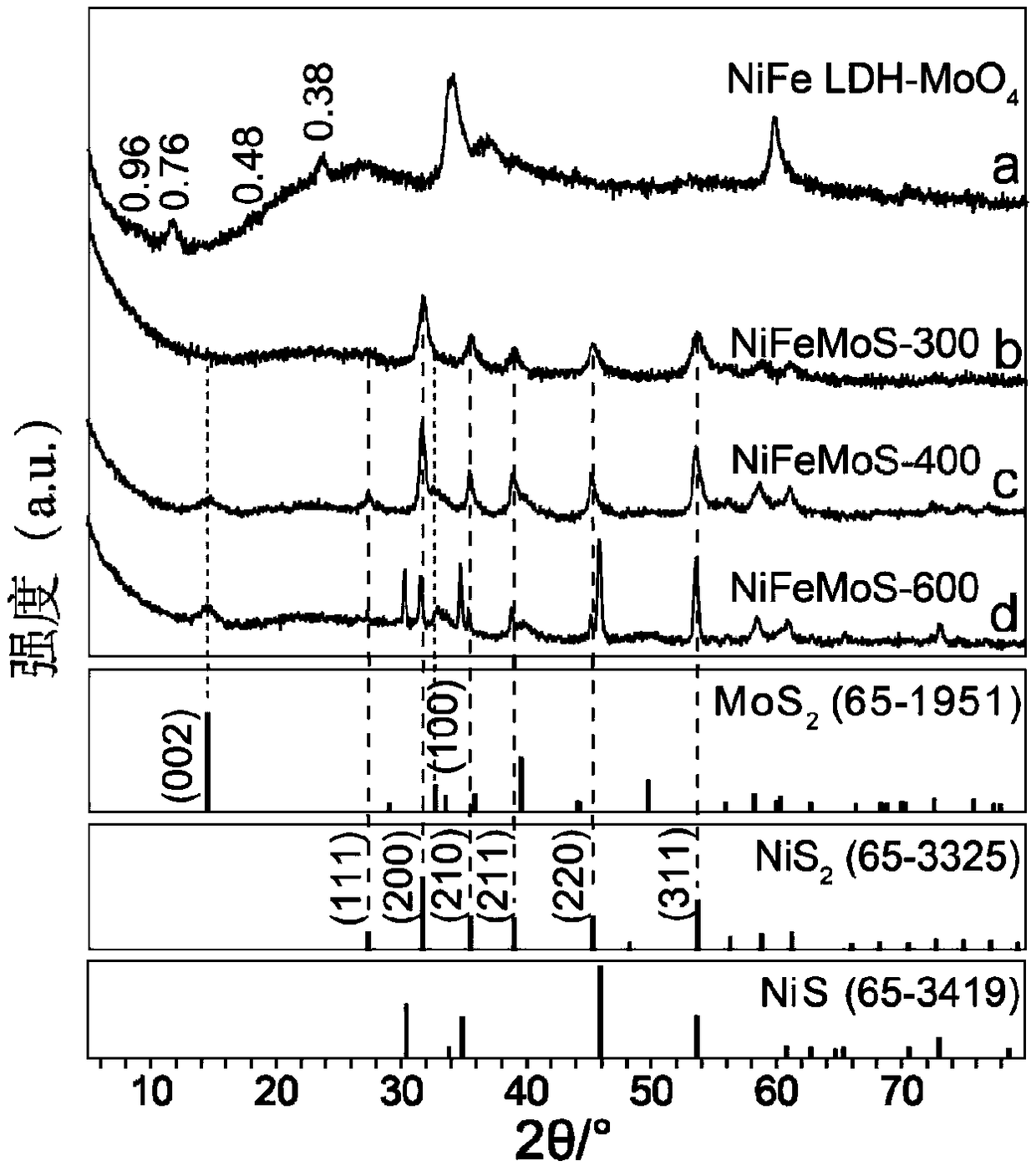

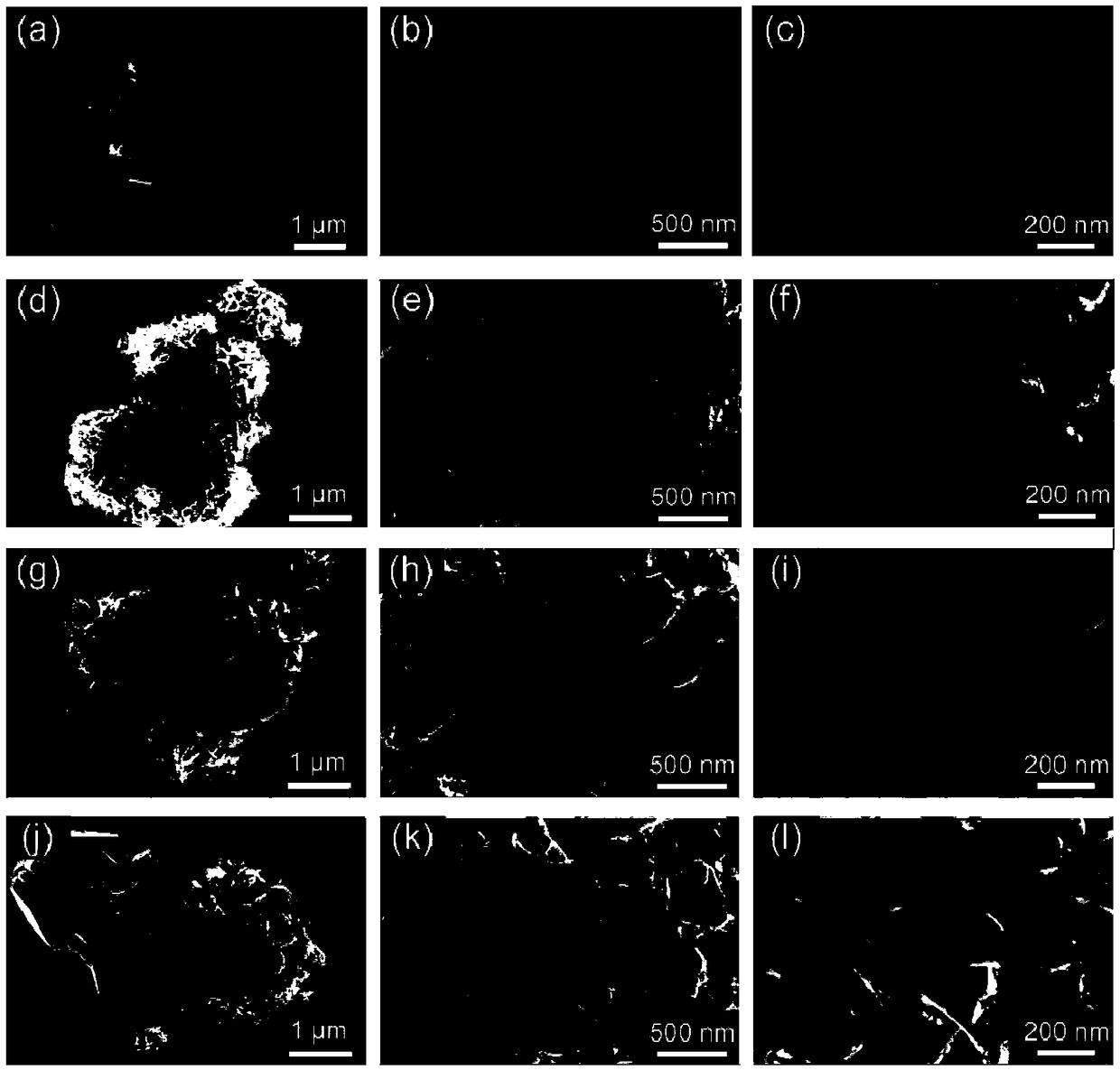

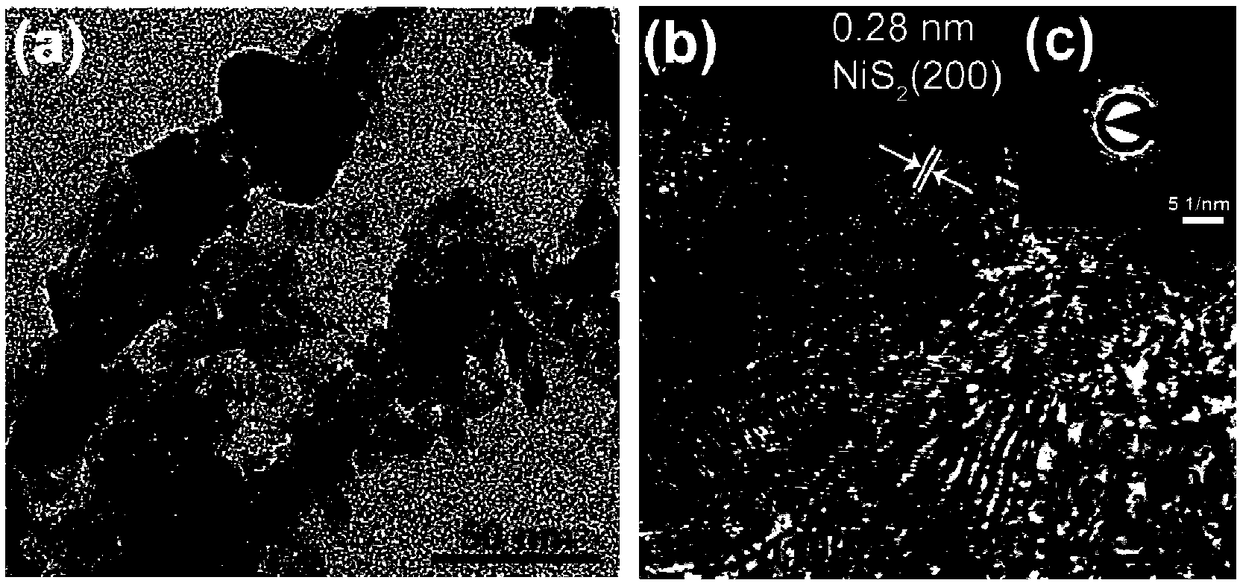

NiFeMoS complex and a preparation method thereof

ActiveCN108855146AGood catalytic performance for hydrogen evolution reactionAchieving controllable equipmentPhysical/chemical process catalystsElectrodesNickel saltHydrogen

The embodiment of the invention provides a NiFeMoS complex and a preparation method thereof. The preparation method of the NiFeMoS complex comprises the following steps: obtaining a reactant aqueous solution containing nickel salt, iron salt, molybdenum salt and urea; carrying out a hydrothermal reaction on the reactant aqueous solution at the temperature of 150 to 170 DEG C for 8 to 15 hours, andthen performing separation and washing to obtain a complex precursor; calcining and vulcanizing the complex precursor and sulfur powder in inert gas at the temperature of 300 to 600 DEG C for 0.5 to3 hours, wherein the heating rate is 3 to 8 DEG C / min. The NiFeMoS complex prepared by the preparation method provided by the embodiment of the invention has high catalytic performance for hydrogen evolution reactions.

Owner:BEIJING NORMAL UNIVERSITY +1

Preparation method for polyimide film with low water absorption

The invention discloses a preparation method for a polyimide film with low water absorption. The preparation method comprises the following steps: under the protection of N2, mixing a diamine monomer A and a dianhydride monomer A in a polar solvent to obtain a flexible polyamide acid resin solution A; under the protection of N2, mixing a diamine monomer B and a dianhydride monomer B in the polar solvent to obtain a rigid polyamide acid resin solution B; under the protection of N2, co-mixing the flexible polyamide acid resin solution A with the rigid polyamide acid resin solution B, stirring, stopping reaction when viscosity of a to-be-reacted matter reaches 2000-3500 poises; and finally, adding an accelerant and a dehydrator to uniformly mix, salivating to form a film, and performing imidization treatment to obtain the polyimide film with the low water absorption. The polyimide film obtained by the preparation method provided by the invention has a water absorption rate lower than 1.2% which is far lower than a water absorption rate (2.3%-2.4%) of conventional polyimide; and meanwhile, excellent comprehensive performance such as mechanical and electrical performance is kept.

Owner:株洲时代华鑫新材料技术有限公司

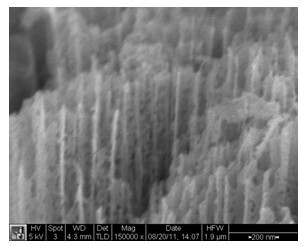

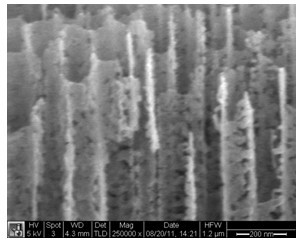

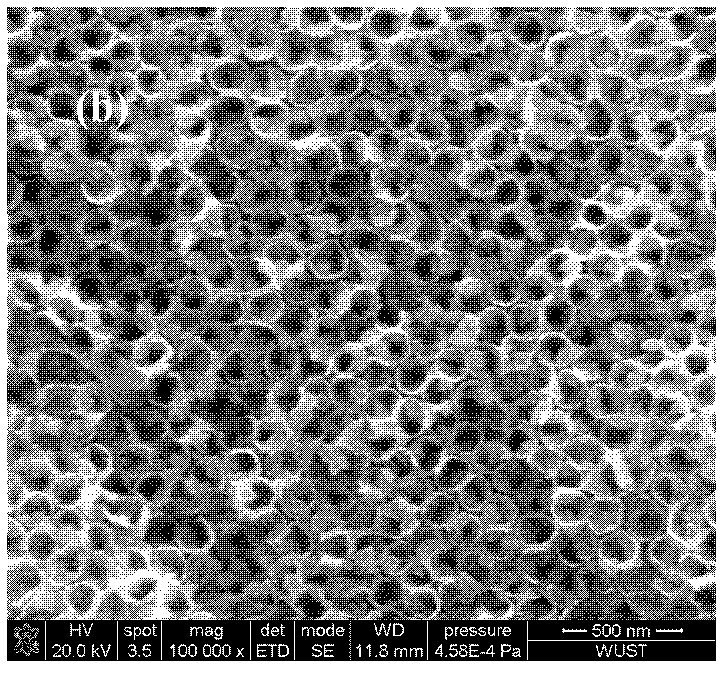

Titanium dioxide nanometer composite structure film and preparation method thereof

InactiveCN102251265AImprove adsorption capacityHigh reactivitySurface reaction electrolytic coatingNanotubeElectrolyte

The invention relates to a titanium dioxide nanometer composite structure film and a preparation method thereof. The technical scheme of the preparation method comprises the following steps: using a polished titanium-containing metal plate as an anode to be placed in an electrolyte and perform anodic oxidation, wherein the voltage of anodic oxidation is 10-60V and the time of anodic oxidation is 0.5-5 hours; then cleaning the obtained titanium-containing metal plate after anodic oxidation, drying, then placing the dried titanium-containing metal plate in H2O or the mixed solution containing 5-95wt% H2O and 5-95wt% alcohol organic matter, performing a hydrothermal reaction in a sealed container at 80-300 DEG C for 0.5-24 hours, and naturally cooling to obtain the titanium dioxide nanometercomposite structure film on the surface of the titanium-containing metal plate. The preparation method is simple and reliable without adding a foreign material as a Ti source; and the load of TiO2 nanoparticles in nanotubes is controllable. In the prepared composite structure of TiO2 nanoparticles and nanotubes, TiO2 nanoparticles are distributed in the nanotubes evenly.

Owner:WUHAN UNIV OF SCI & TECH

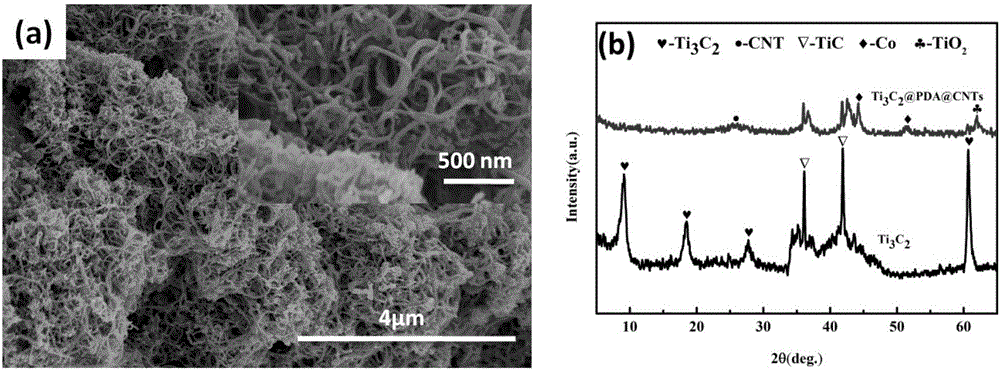

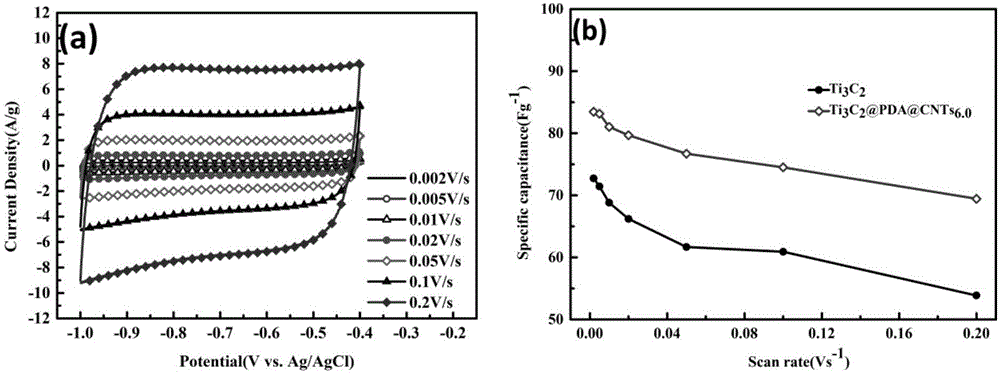

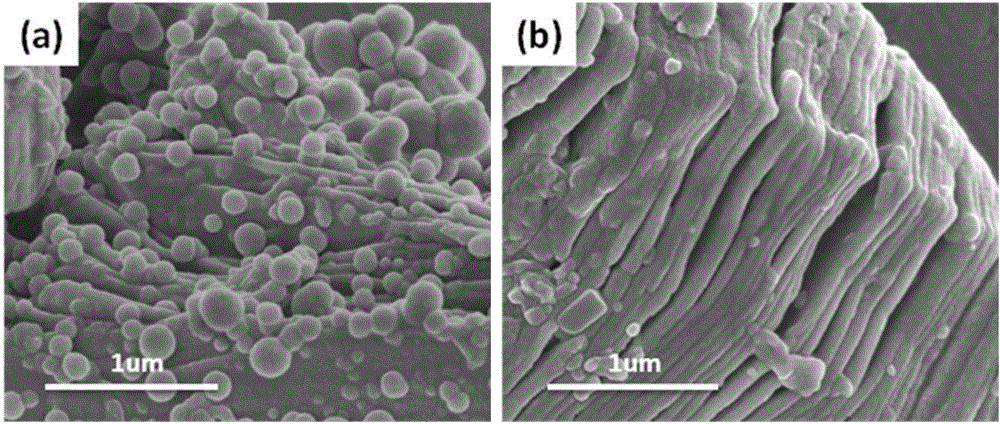

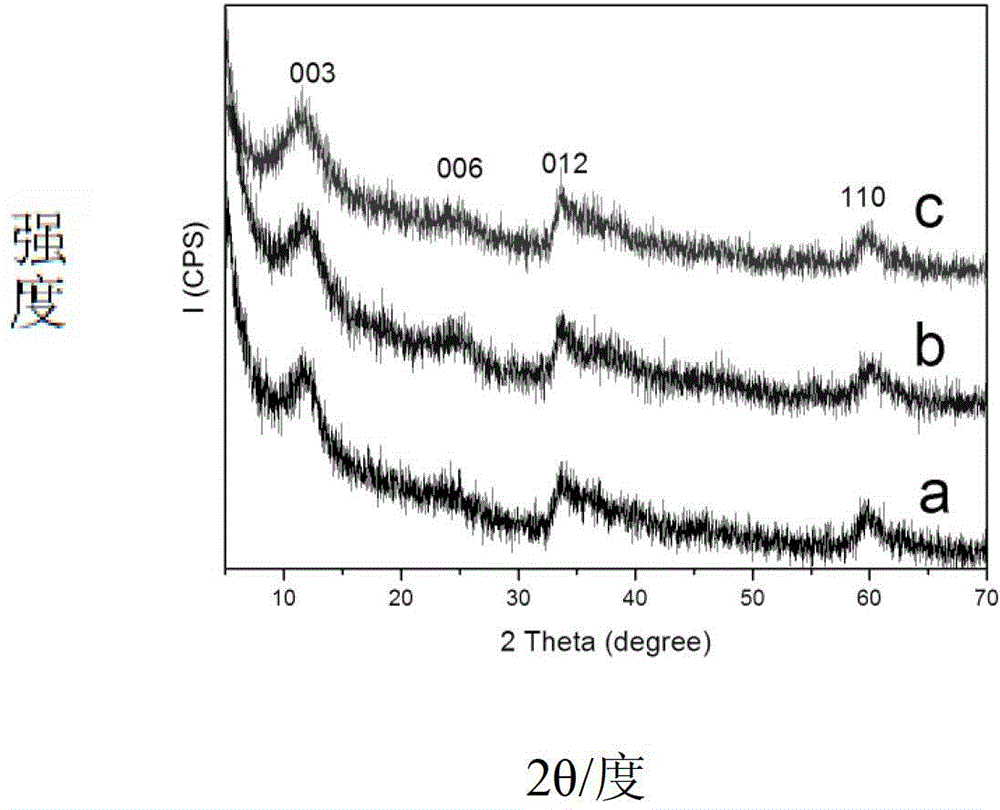

Titanium carbide in-situ growth CNTs three-dimensional composite with polydopamine serving as transition layer and preparation method thereof

ActiveCN106698430AContent regulationContent changeMaterial nanotechnologyHybrid capacitor electrodesTitanium carbideBuffer solution

The invention relates to a titanium carbide in-situ growth CNTs three-dimensional composite with polydopamine serving as a transition layer and a preparation method thereof. The method includes the steps that Ti3C2 nano-powder and dopamine hydrochloride are dispersed into ultrapure water respectively, even mixing is conducted, and stirring is conducted under the shading condition; a Tris- buffer solution is added, and stirring continues under the shading condition; the obtained mixed solution is subjected to separation, washing and drying, and Ti3C2@PDA nano-powder is obtained; the Ti3C2@PDA nano-powder is added into ultrapure water, Co(NO3)2.6H2O is added after uniform dispersion, and stirring is conducted for a reaction; urea is added after the reaction is finished, stirring is continuously conducted under a constant temperature to evaporate water, and precursor powder is obtained; the precursor powder is subjected to heat treatment, and the titanium carbide in-situ growth CNTs three-dimensional composite with polydopamine serving as the transition layer is obtained. The Ti3C2@PDA@CNTs three-dimensional composite is successfully prepared through a simple pyrolysis method.

Owner:SHAANXI UNIV OF SCI & TECH

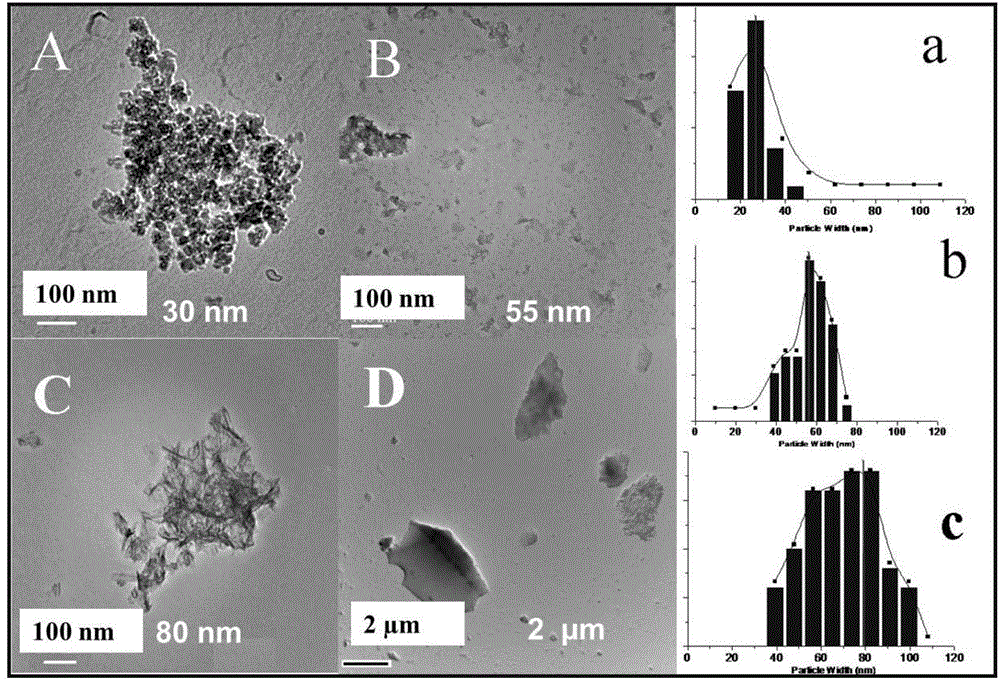

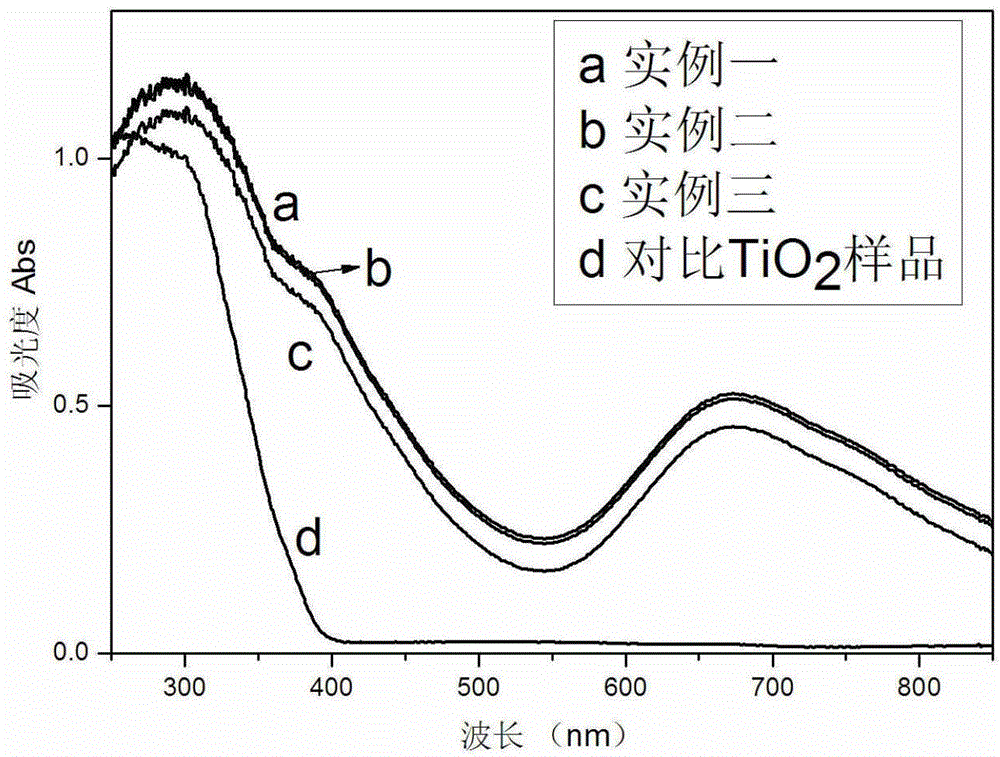

NiTi hydrotalcite nanosheet catalyst responding to visible light, and preparation method of catalyst

InactiveCN102872894AAchieving controllable equipmentLow costPhysical/chemical process catalystsOxygen preparationMaterials preparationDecomposition

The invention belongs to the technical field of novel catalytic material preparation and discloses a NiTi hydrotalcite nanosheet catalyst responding to visible light and a preparation method of the catalyst. According to the invention, NiTi hydrotalcite nanosheets are synthesized by an anti-phase microemulsion method and show excellent catalytic performance by visible light. The preparation method realizes controllability of a microemulsion environment by adjusting and controlling the proportions of a surface active agent and water; and hydrotalcite is crystallized and grows in the microemulsion and the particle size of the hydrotalcite ranges from 30 nm to 80 nm. A solvent used in the method is low in cost and simple to operate and can be recycled. The obtained hydrotalcite nanosheet catalyst has the advantages of simple synthesizing conditions, cheap raw materials and easiness in large-scale industrial production. The NiTi hydrotalcite nanosheet catalyst prepared in the invention has an excellent characteristic of responding to visible light, is five times quicker than micron-sized hydrotalcite synthetized with a traditional codeposition method in water decomposition performance by visible light, and is hopefully expected to be widely applied to the fields like solar thermal utilization, adsorption and additives.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com