Controllable preparation method based on high-stacking-degree graphene modified high-thermal-conductivity carbon-plastic alloy

A graphene modification, graphene technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low thermal conductivity of composite materials, large contact thermal resistance of graphene, high filler addition, etc., to achieve The best cost performance, to achieve the effect of cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

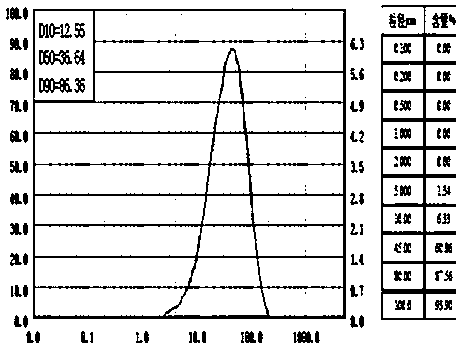

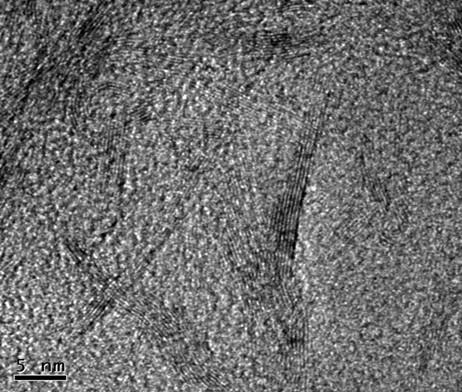

[0039] Weigh 0.1 g of anionic surfactant sodium dodecylbenzene sulfonate and dissolve it in 1984.9 g of medium to obtain a surfactant solution. Get 10g graphene A (particle size D 50 7-20μm, the number of layers is 3-10 layers, the bulk density is 0.01-0.03g / ml) and 5g graphene B (particle size D 503-7 μm, the number of layers is 1-3, and the bulk density is 0.01-0.02g / ml) respectively added to the above surfactant solution, fully stirred, moistened, and mixed uniformly in a homogenizer to obtain a graphene solution.

[0040] Weigh 0.5 g of anionic surfactant sodium dodecylbenzene sulfonate and dissolve it in 1874.5 g of medium to obtain a surfactant solution. Get 40g nano-graphite microchip C (particle size D 50 40-200μm, the number of layers is 100-300 layers, the bulk density is 0.4-1.0g / ml) and 85g nano-graphite microflake D (particle size D 50 5-40μm, the number of layers is 10-100 layers, and the bulk density is 0.1-0.4g / ml) respectively added to the above-mentioned s...

Embodiment 2

[0044] Weigh 0.8 g of anionic surfactant sodium lauryl sulfate and dissolve it in 1960.2 g of medium to obtain a surfactant solution. Get 30g graphene A (particle size D 50 7-20μm, the number of layers is 3-10 layers, the bulk density is 0.01-0.03g / ml) and 9g graphene B (particle size D 50 3-7 μm, the number of layers is 1-3, and the bulk density is 0.01-0.02g / ml) respectively added to the above surfactant solution, fully stirred, moistened, and mixed uniformly in a sand mill to obtain a graphene solution.

[0045] Weigh 1.5 g of anionic surfactant sodium lauryl sulfate and dissolve it in 1821.5 g of medium to obtain a surfactant solution. Get 62g nano-graphite microchip C (particle size D 50 40-200μm, the number of layers is 100-300 layers, the bulk density is 0.4-1.0g / ml) and 115g nanographite microflake D (particle size D 50 5-40 μm, the number of layers is 10-100 layers, and the bulk density is 0.1-0.4g / ml) respectively added to the above-mentioned surfactant solution, ...

Embodiment 3

[0049] Weigh 2g of hydroxymethylpropylcellulose and dissolve it in 1974g of medium to obtain a surfactant solution. Get 18g graphene A (particle size D 50 7-20μm, the number of layers is 3-10 layers, the bulk density is 0.01-0.03g / ml) and 6g graphene B (particle size D 50 3-7 μm, the number of layers is 1-3 layers, and the bulk density is 0.01-0.02g / ml) respectively added to the above surfactant solution, fully stirred, moistened, and mixed uniformly in a ball mill to obtain a graphene solution.

[0050] Weigh 2.15g of hydroxymethylpropylcellulose and dissolve it in 1814.85g of medium to obtain a surfactant solution. Get 35g nano-graphite microchip C (particle size D 50 40-200μm, the number of layers is 100-300 layers, the bulk density is 0.4-1.0g / ml) and 148g nanographite microflake D (particle size D 50 5-40 μm, the number of layers is 10-100 layers, and the bulk density is 0.1-0.4g / ml) respectively added to the above-mentioned surfactant solution, fully stirred, moistene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com