Patents

Literature

40 results about "Carbon plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bipolar plate for liquid flow energy storage battery and preparation method

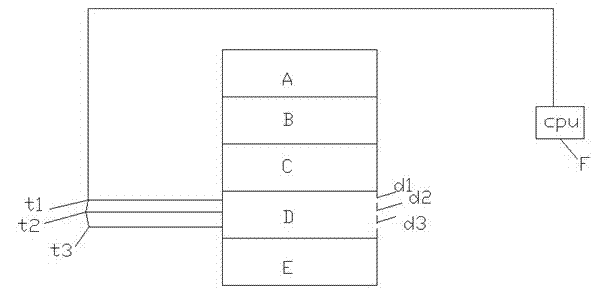

ActiveCN103633336AEasy to buildReduce contact resistanceCell electrodesElectrical batteryInternal resistance

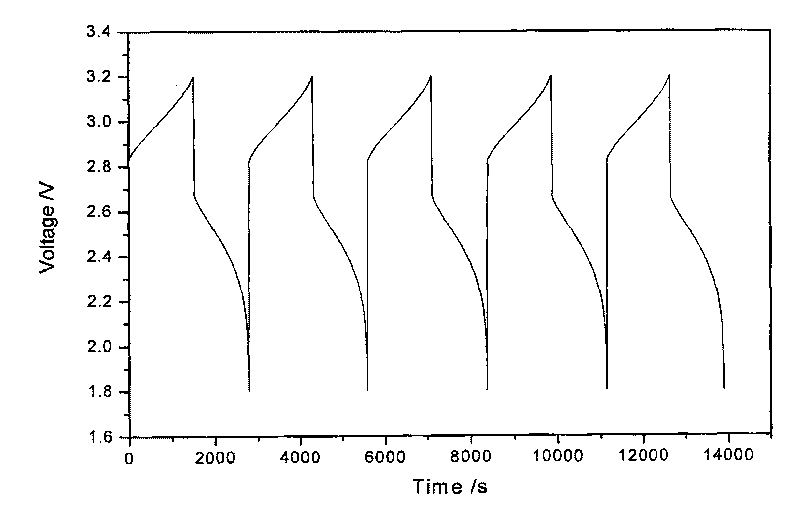

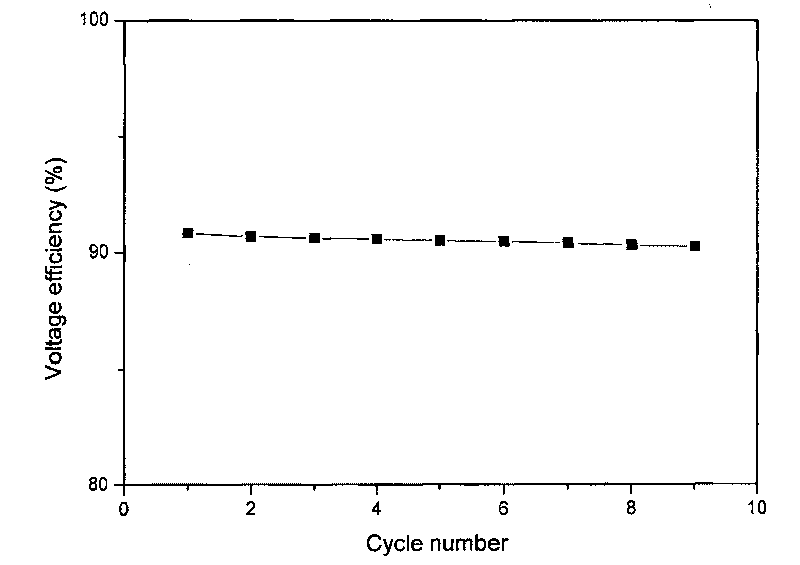

The invention relates to a bipolar plate for a liquid flow energy storage battery and a preparation method. The bipolar plate employs a carbon plastic composite plate with a thickness of 0.5-5mm as a matrix material. Conducting layers with a thickness of 1-1000 microns are coated on the surface of one side or surfaces of two sides of the matrix. The bipolar plate combines advantages of the carbon plastic composite plate and a graphite plate, decreases the contact resistance between an electrode and the bipolar plate, and finally decreases the Ohm internal resistance of the liquid flow energy storage battery. The bipolar plate raises the energy efficiency and the voltage efficiency of the liquid flow energy storage battery, and therefore the working current density is increased, thus weight, volume and cost of a battery with the same output power are all decreased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

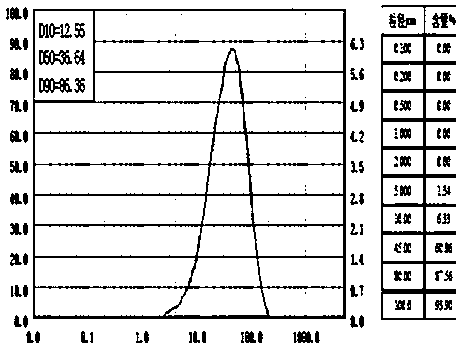

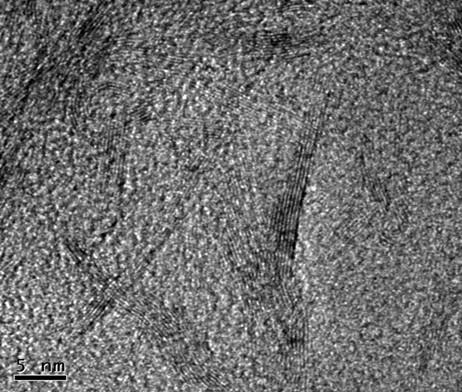

Controllable preparation method based on high-stacking-degree graphene modified high-thermal-conductivity carbon-plastic alloy

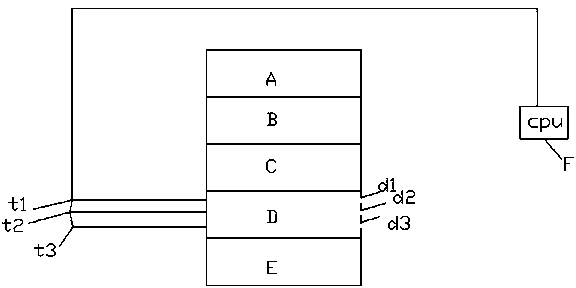

ActiveCN108976700AAchieving controllable equipmentAdd lessHeat-exchange elementsCompression moldingResin matrix

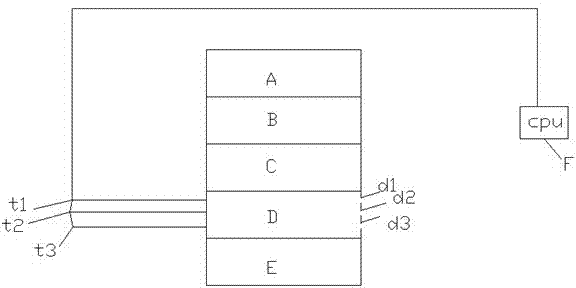

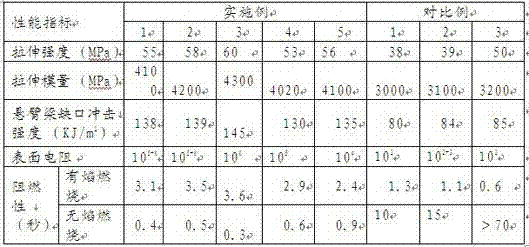

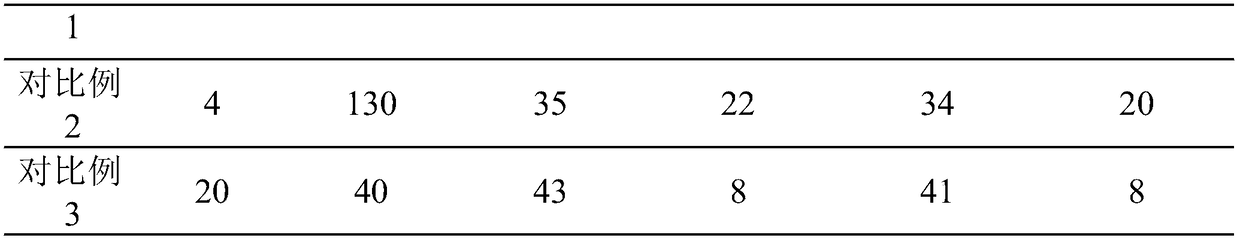

The invention discloses a controllable preparation method based on high-stacking-degree graphene modified high-thermal-conductivity carbon-plastic alloy. The carbon-plastic alloy is prepared from thefollowing components in percentage by weight: high-stacking-degree graphene filler: 5 to 50%, thermosetting resin: 30 to 55%, a coupling agent: 0.2 to 2%, a resin diluent: 1 to 5%, a curing agent: 7 to 15%, reinforcing filler: 5 to 20%, and an auxiliary agent: 2 to 5%. The high-stacking-degree graphene filler is composed of carbon materials of four different specifications, wherein graphene A accounts for 5 to 15%, graphene B accounts for 2 to 5%, nanographite microchip C accounts for 15 to 45%, and nanographite microchip D accounts for 35 to 78%. The high-stacking-degree graphene filler is added to a thermosetting resin matrix to form a perfect heat transfer passage, and the high-thermal-conductivity carbon-plastic alloy material having a thermal-conductivity coefficient of 10-25 W / m.K can be controllably prepared. The high-thermal-conductivity carbon-plastic alloy prepared by the invention can be processed into various heat dissipation components by compression molding or injection molding, and is suitable for industrial heat dissipation, illumination heat dissipation, heat dissipation of electronic devices, etc.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

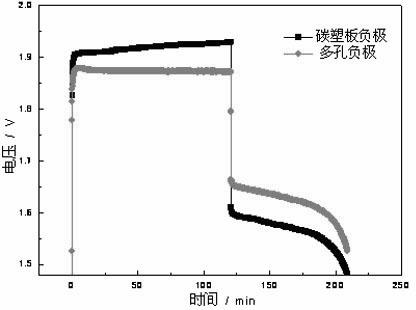

Positive electrode of zinc bromine redox flow battery and preparation thereof

The invention relates to a positive electrode of a zinc bromine redox flow battery and a preparation method thereof. The positive electrode comprises a carbon-plastic composite panel, and a catalyst layer which has high specific surface area, is adhered to one side surface of the carbon-plastic composite panel, and consists of a binder, namely chlorinated polypropylene or chlorinated polyethylene, a catalyst, namely activated carbon or carbon-supported metal, and a conductive agent, namely conductive graphite or carbon black. The catalyst layer with the high specific surface area is coated or bonded on a thermoplastic conductive plate made of polypropylene, polyethylene and the like, and high specific surface area and high conductivity are achieved simultaneously, so that the redox activity of positive bromine and the conductivity of the integral positive electrode are improved. Problems of overlarge electrode thickness, battery performance difference caused by carbon felt difference, and the like when the conventional carbon felt electrode is used are solved, and the novel positive electrode of the zinc bromine flow battery can replace the conventional carbon felt electrode.

Owner:华秦储能技术有限公司

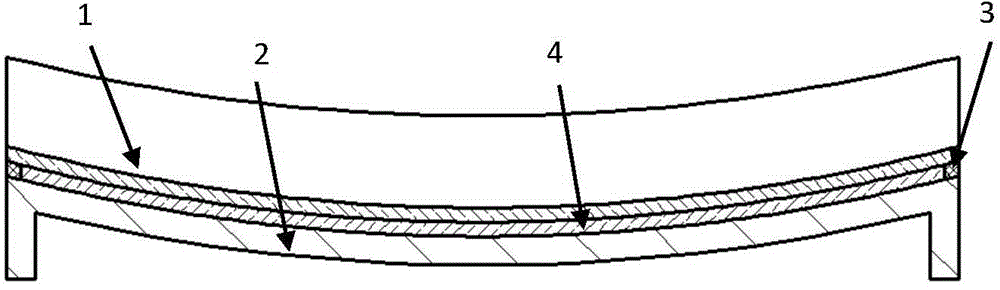

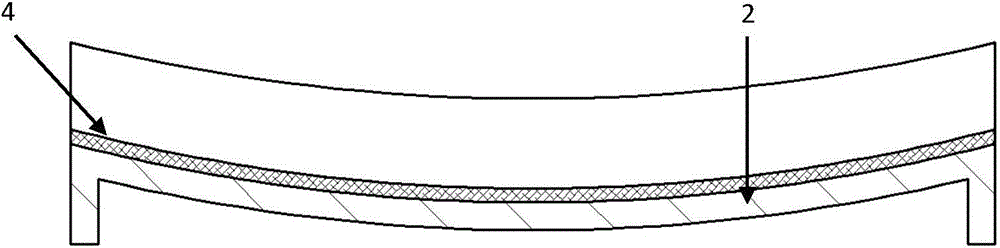

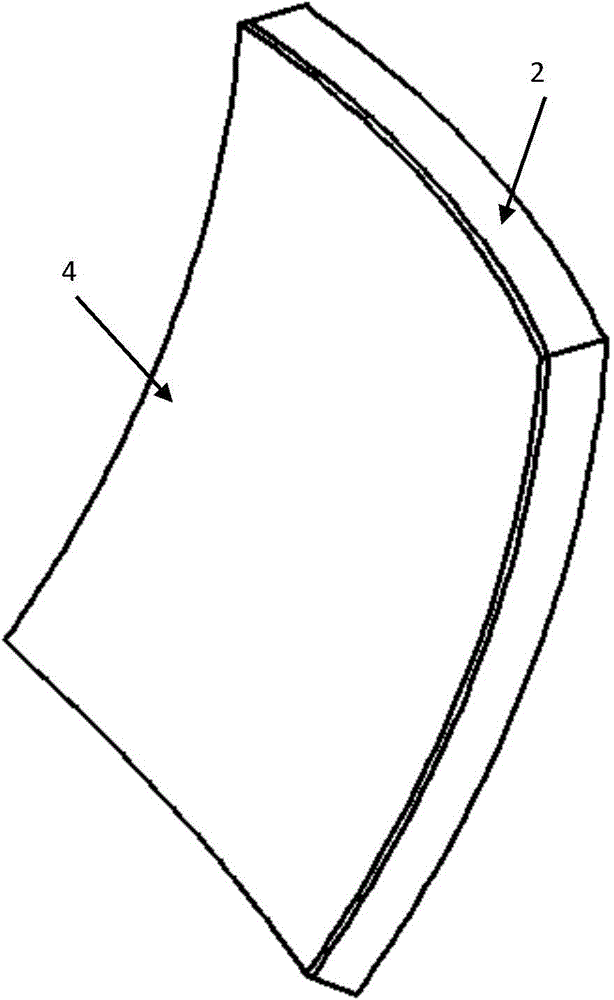

Pouring carbon plastic large spherical reflection lens and production method

ActiveCN105242337ALight in massShort preparation cycleMirrorsMountingsMaintainabilityOptoelectronics

The present invention relates to a pouring carbon plastic large spherical reflection lens and a production method, belonging to the technical field of optical display. The pouring carbon plastic large spherical reflection lens comprises a lens seat, a reflection lens substrate and a reflection film layer. The reflection lens substrate and the lens seat are bonded adsehively, and the reflection film layer is plated to the reflection lens substrate through a plating machine. The lens is made of glass, metal or composite materials. The reflection lens substrate is made of organic glass or other suitable optical plastic, and the convex surface fits the concave surface of the lens seat and is bonded and cured on the lens seat concave surface. Compared with a glass spherical reflection lens, the carbon plastic large spherical reflection lens has the advantages of light weight, short manufacturing cycle, low cost and good rigidity, compared with a film negative pressure formation large spherical reflection lens, the carbon plastic large spherical reflection lens has the advantages of high strength, a long life, good optical performance and maintainability. The simulation training requirements of a general aircraft, a large aircraft and other large equipment can be satisfied by a 1600-4000 mm large curvature radius. The pouring carbon plastic large spherical reflection lens is suitable for large-scale promotion.

Owner:BEIJING ROCKY AEROSPACE TECH DEV CO LTD

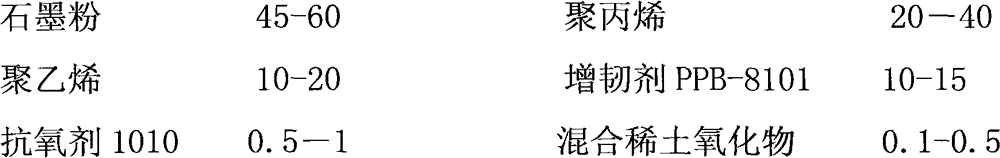

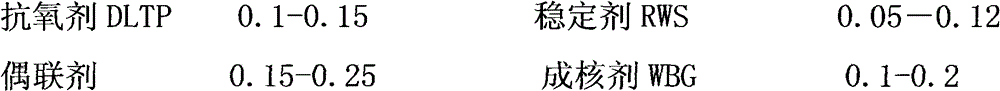

Production method of vegetable carbon plastics

InactiveCN102888044AImprove conductivityFunction increaseBiofuelsSpecial form destructive distillationAntioxidantPolypropylene

The invention relates to the field of polymers, and in particular relates to a production method of vegetable carbon plastics. The method comprises the following steps in sequence: feeding the raw vegetables into a microwave vacuum tank to undergo microwave treatment; drying, pre-carbonizing, carbonizing, calcining and cooling the pretreated raw vegetables in sequence; controlling combustion to raise the temperature to 700-750 DEG C or 900-1000 DEG C at a rate of 5-15 DEG C / min and maintaining the temperature for 40-80 minutes; then raising the temperature to 1000-1500 DEG C or 1600-1800 DEG C at a rate of 5-15 DEG C / min and maintaining the temperature for 2-8 hours to obtain vegetable carbon; and blending and modifying the base materials such as ultra-high molecular weight polyethylene with molecular weight of 4-7 million and high-density polypropylene with molecular weight of 1-1.4 million and adding a flame retardant, a toughening agent, a coupling agent, an antioxidant and the obtained vegetable carbon in the processing course. The prepared vegetable carbon plastics have the advantages of excellent toughness, higher rigidity and hardness and good antistatic property and flame retardance.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

Carbon plastic synthetic heat exchange material

InactiveCN102634112AImprove corrosion resistanceLow costHeat-exchange elementsPolymer scienceOxidation resistant

The invention provides a carbon plastic synthetic heat exchange material which is corrosion-resistant, light in specific gravity, antioxidant and low temperature resistant, and has a heat conduction effect being superior to that of similar products on the market at present; furthermore, the fluidity is improved technically; and carbon plastic synthetic heat exchange material overcomes the defects of easy oxidization and degradation.

Owner:律通控股集团有限公司

Carbon-plastic compound material prepared by virtue of charcoal and production method of carbon-plastic compound material

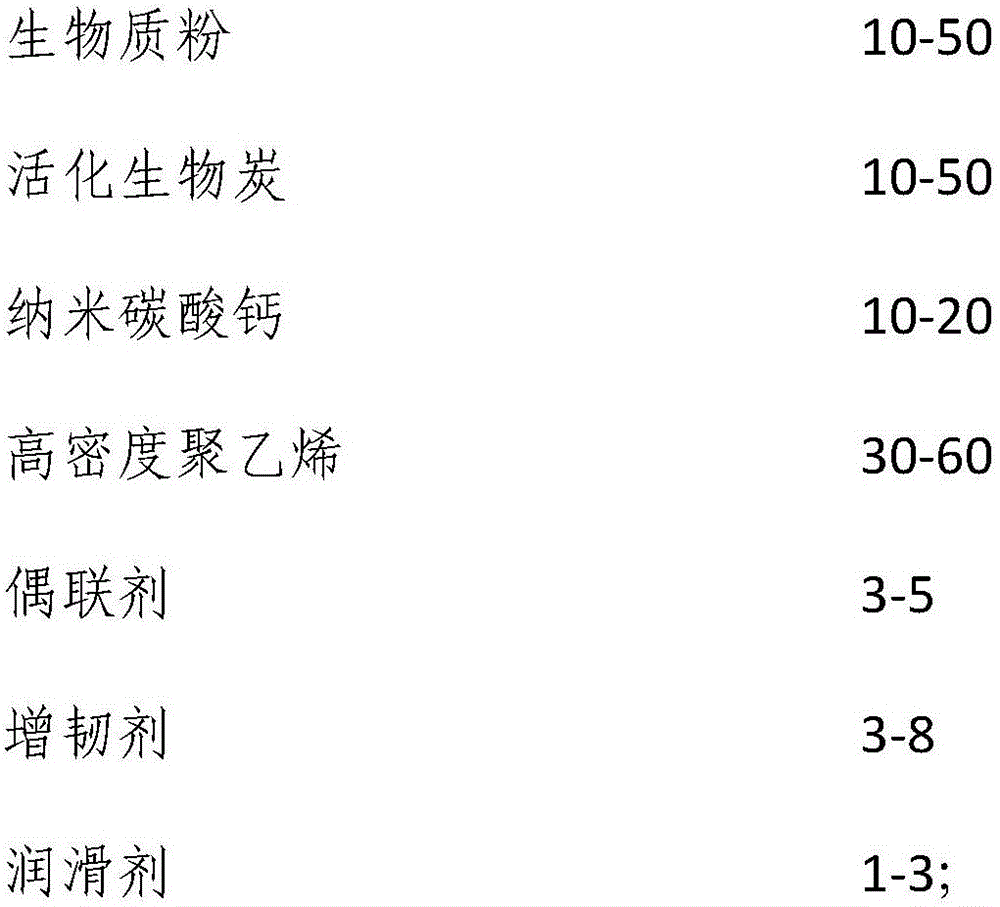

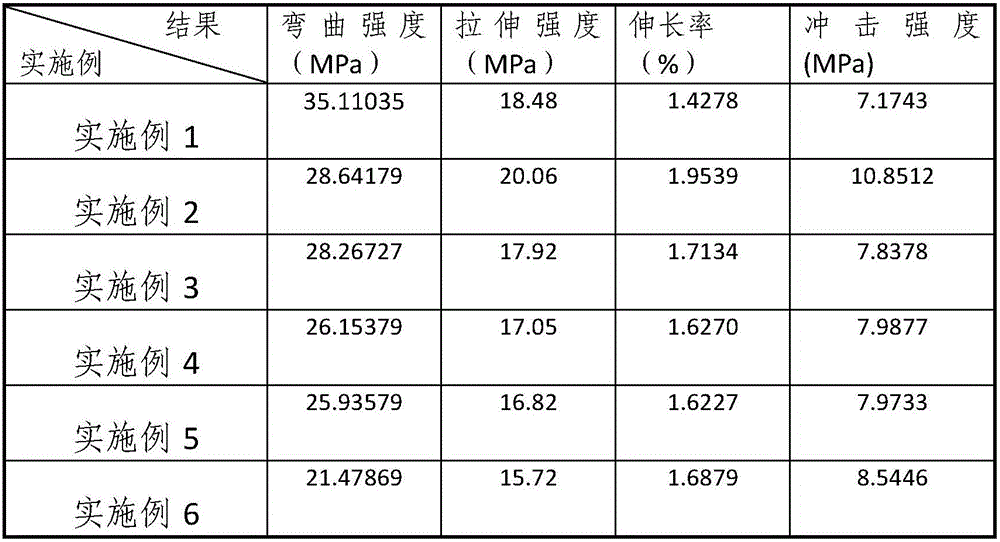

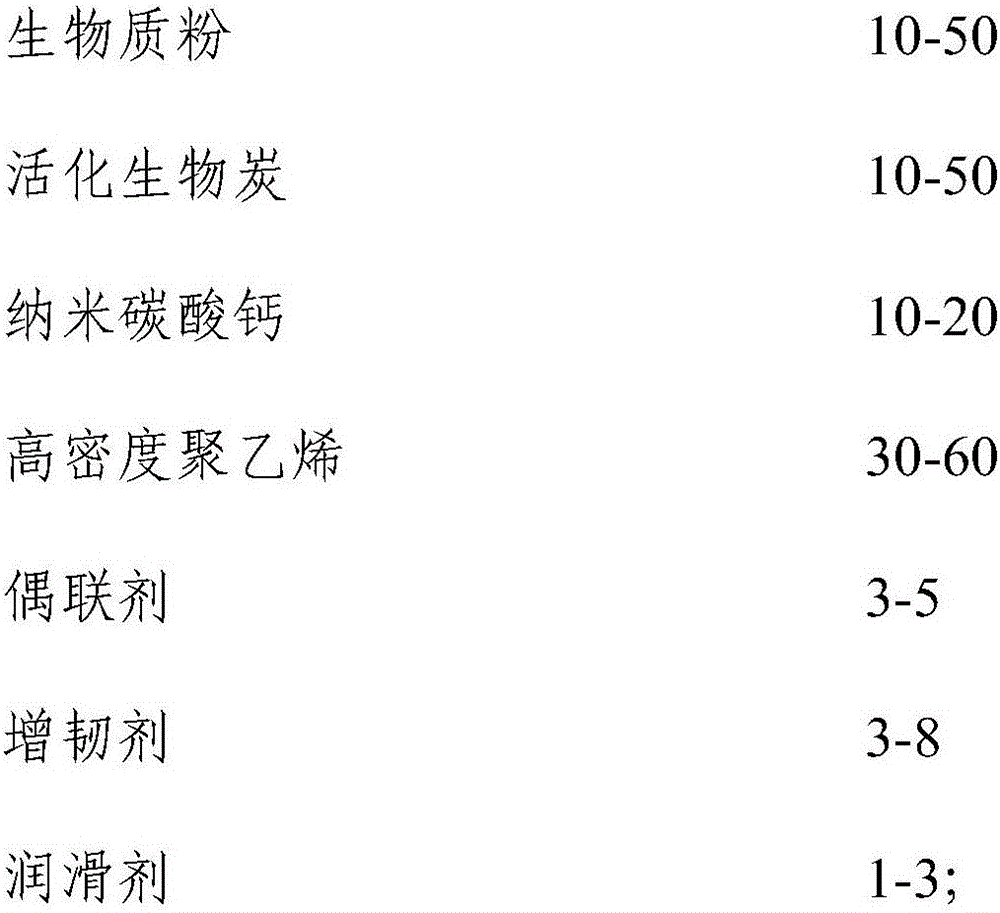

The invention discloses a carbon-plastic compound material prepared by virtue of charcoal, and belongs to the technical field of compound materials. The compound material is characterized in that the compound material is prepared from the following raw materials in parts by weight: 10 to 50 parts of pulverized biomass, 10 to 50 parts of activated biological carbon, 10 to 20 parts of nanometer calcium carbonate, 30 to 60 parts of high density polyethylene, 3 to 5 parts of a coupling agent, 3 to 8 parts of a toughening agent and 1 to 3 parts of a lubricant, wherein the ratio of the total addition of the pulverized biomass, the activated biological carbon and the nanometer calcium carbonate to the total weight of the raw materials is more than 50 percent; the activated biological carbon is a mixture of biological carbon and 2 to 3 percent of maleic anhydride grafted polypropylene, the specific surface area of the activated biological carbon is 1.5 to 2.5m<2> / g, and the aperture of the activated biological carbon is 20 to 30nm. According to the carbon-plastic compound material, a novel compound material is obtained by regulating ingredient formulae and processing aids of proper components and effectively utilizing the biological carbon, so that the biological carbon is recycled more widely.

Owner:SHANDONG UNIV OF TECH

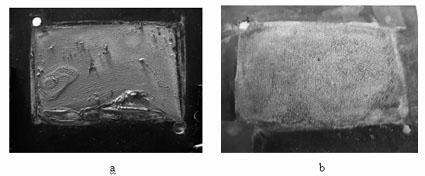

Negative electrode of zinc-bromine flow battery for energy storage and manufacture method thereof

InactiveCN102569832AIncrease contact areaReduces electrochemical polarizationCell electrodesElectrolytic agentElectrical battery

The invention relates to a negative electrode of a zinc-bromine flow battery for energy storage and a manufacture method of the negative electrode. The electrode comprises a carbon plastic composite material plate, and a porous layer having high specific surface area and adhered onto one side surface of the carbon plastic composite material plate. The porous layer is composed of a binding agent and a porous material, wherein the binding agent is selected from chlorinated polypropylene or chlorinated polyethylene; the porous material includes active carbon, carbon-supported metal, graphite or carbon black, with a weight ratio of (1 to 5): (1 to 15); the loading amount of the porous material on the carbon plastic composite material plate is 0.5mg / cm<2> to 10mg / cm<2>. The negative electrode adopting the porous carbon plastic composite material with high specific surface area can increase the contact area between electrolyte and the electrode and suppress electrochemical polarization of zinc deposition and dissolving of the negative electrode, and has higher conductivity, thereby greatly improving battery performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Preparation method of vegetable carbon plastic composites

The invention relates to the field of polymers, and in particular relates to a preparation method of vegetable carbon plastic composites. The method comprises the following steps in sequence: feeding the raw vegetables into a microwave vacuum tank to undergo microwave treatment; drying, pre-carbonizing, carbonizing, calcining and cooling the pretreated raw vegetables in sequence; controlling combustion to raise the temperature to 700-750 DEG C or 900-1000 DEG C at a rate of 5-15 DEG C / min and maintaining the temperature for 40-80 minutes; then raising the temperature to 1000-1500 DEG C or 1600-1800 DEG C at a rate of 5-15 DEG C / min and maintaining the temperature for 2-8 hours to obtain vegetable carbon; and blending and modifying the base materials such as high impact polystyrene, polyvinyl chloride and ultra-low-density polyethylene with molecular weights of 3-5 million and adding a flame retardant, a toughening agent, a coupling agent, an antioxidant and the obtained vegetable carbon in the processing course. The prepared vegetable carbon plastics have the advantages of excellent toughness, higher rigidity and hardness and good antistatic property and flame retardance.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

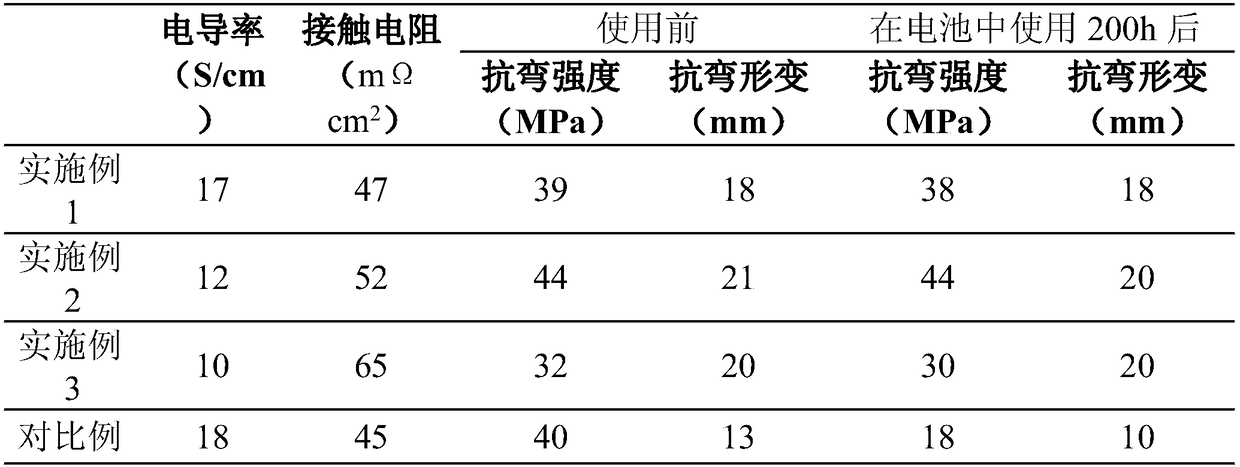

Composite bipolar board for fuel cell and preparation method and application of composite bipolar board

ActiveCN109546160AHigh mechanical strengthImprove mechanical propertiesCell electrodesFiberFuel cells

The invention belongs to the field of fuel cells, and discloses a preparation method of a composite bipolar board. The bipolar board is a carbon-plastic composite board which is composed of polymethylmethacrylate resin, polystyrene resin, a hydrogenated ethylene- butylene-styrene triblock copolymer, a conductive filler and a fiber reinforced material. The composite bipolar board has the advantages of good machining performances, excellent conductivity and excellent durability. The body resistance and the contact resistance of the bipolar board can be reduced on the premise of ensuring the assembly of an electric pile, and the performance of the whole battery is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for producing crystallitic carbon plastic plate from waste plastics and fly ash

The invention discloses a method for producing a crystallitic carbon plastic plate from waste plastics and fly ash. According to the method, waste polymer products are fully utilized and taken as main gel materials, and fly ash is taken as filler for further performing modification treatment to obtain the crystallitic carbon plastic plate; and simultaneously, nano-silicon dioxide-modified unsaturated polyester resin is used for performing surface treatment on the plate, so that the surface wear resistance, hardness, heat resistance and other performances of the crystallitic carbon plastic plate are improved, and the quality of the crystallitic carbon plastic plate is ensured. According to the method for producing the crystallitic carbon plastic plate from the waste plastics and the fly ash, disclosed by the invention, the waste polymer products can be fully utilized, and the crystallitic carbon plastic plate with excellent quality can be produced.

Owner:HENGYANG JIANXIANG DECORATION MATERIALS

High-adsorption carbon-plastic composite material manufacturing technology

InactiveCN109135306AObvious porous structureImprove adsorption capacityManufacturing technologyCatalytic decomposition

The invention discloses a high-adsorption carbon-plastic composite material manufacturing technology. The technology comprises the steps that bamboo charcoal particles and nanometer titania are addedin a single-layer graphene oxide aqueous phase dispersing agent, soaking, stirring, drying and calcining are conducted, and modified bamboo charcoal particles are obtained; resin powder, nanocelluloseand a foaming agent, a reaction is conducted at 115-135 DEG C for 20-26 h in a heating kettle, and a mixed base material B is obtained; the modified bamboo charcoal particles and the mixed base material B are mixed and stirred for compounding, hot-pressing extrusion molding is conducted, cooling is conducted to reach the room temperature, and a product is obtained; by means of bamboo charcoal particle loaded carbon dioxide and graphene modification treatment, a finished carbon-plastic composite material product is synthesized, the bamboo charcoal particles subjected to modification treatmentcan adsorb harmful gas such as formaldehyde, catalytic decomposition can be conducted, the adsorption rate is greatly increased, and the adsorption duration is greatly prolonged.

Owner:ZHEJIANG FORESTRY UNIVERSITY

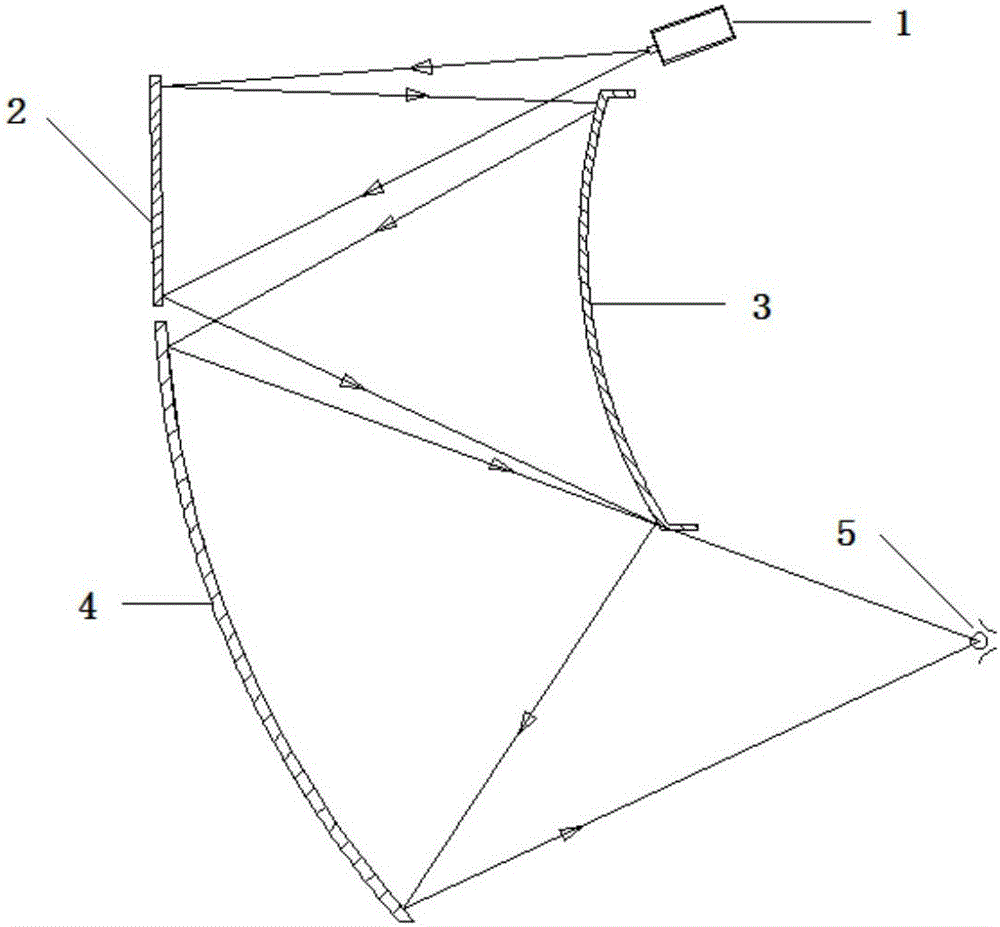

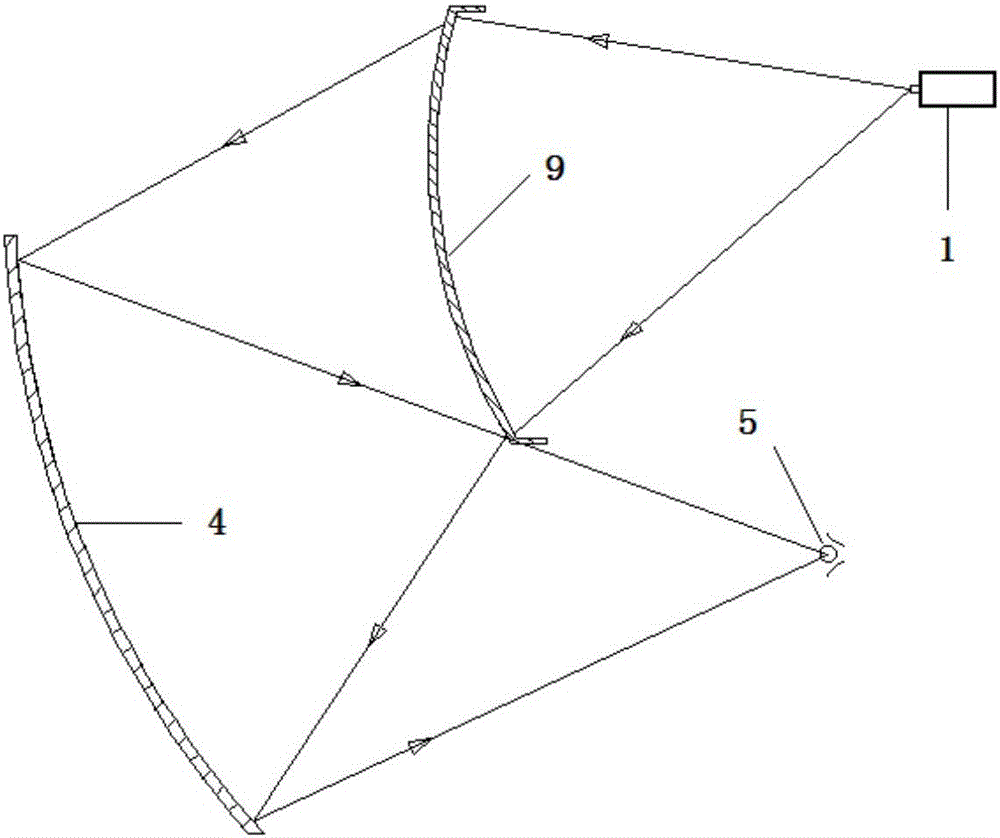

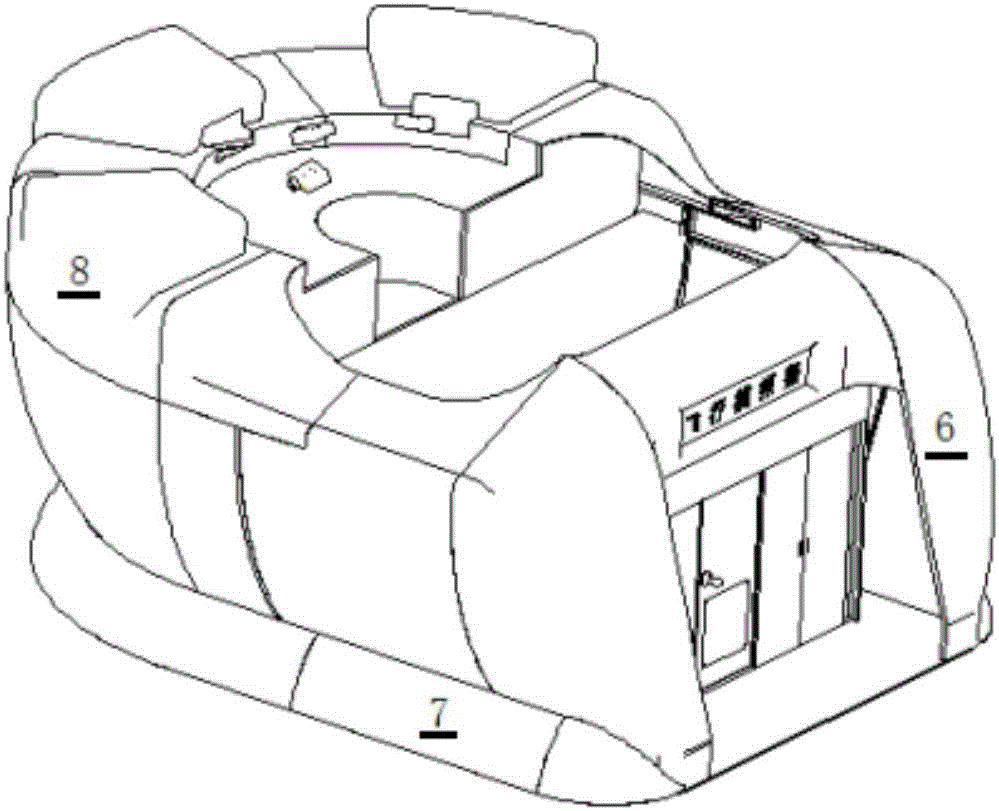

Off-axis virtual image plus stereoscopic display system and method

InactiveCN106526880AReduce image distortionIncrease close-up depth of fieldProjectorsOptical elementsProjection screenDepth of field

The invention discloses an off-axis virtual image plus stereoscopic display system, which mainly comprises a projector, an optical front reflector, a front projection screen and a carbon plastic spherical reflector, wherein the optical front reflector, the projector and the front projection screen are arranged on a centripetal concave surface side of the carbon plastic spherical reflector from top to bottom; an eyespot is arranged below the front projection screen, and is outside one time of focal length of the carbon plastic spherical reflector; and the projector projects stereoscopic images in a close shot display stage. Accordingly, the invention further discloses an off-axis virtual image plus stereoscopic display method. The off-axis virtual image plus stereoscopic display system adopts the hard carbon plastic spherical reflector, reduces the manufacturing cost, improves the space utilization rate, is small in image distortion, and further has the advantage of being cleanable. The off-axis virtual image display system plus stereoscopic display increases the close-shot depth of field in a mirror surface of a simulator visual display system, and makes the sense of depth of field of the simulator visual display system stronger.

Owner:BEIJING ROCKY AEROSPACE TECH DEV CO LTD

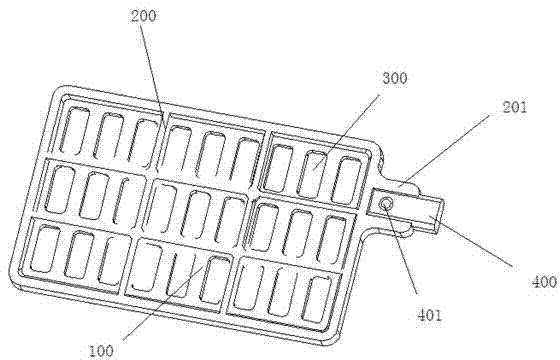

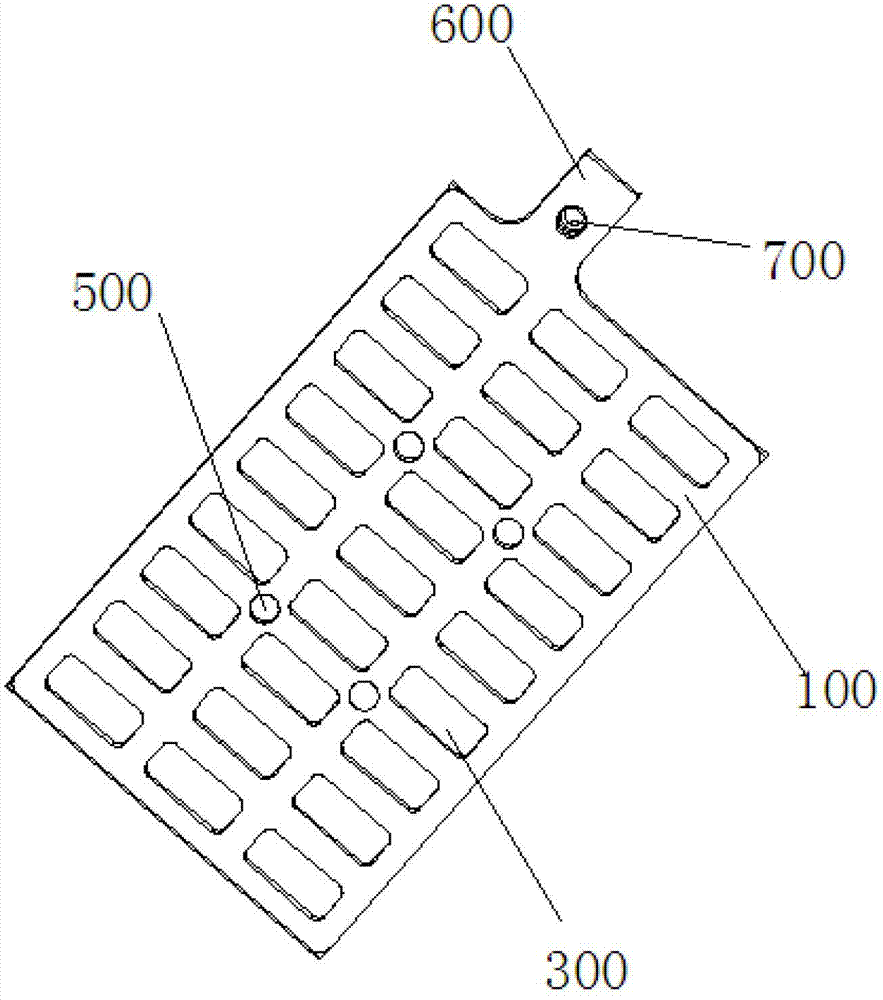

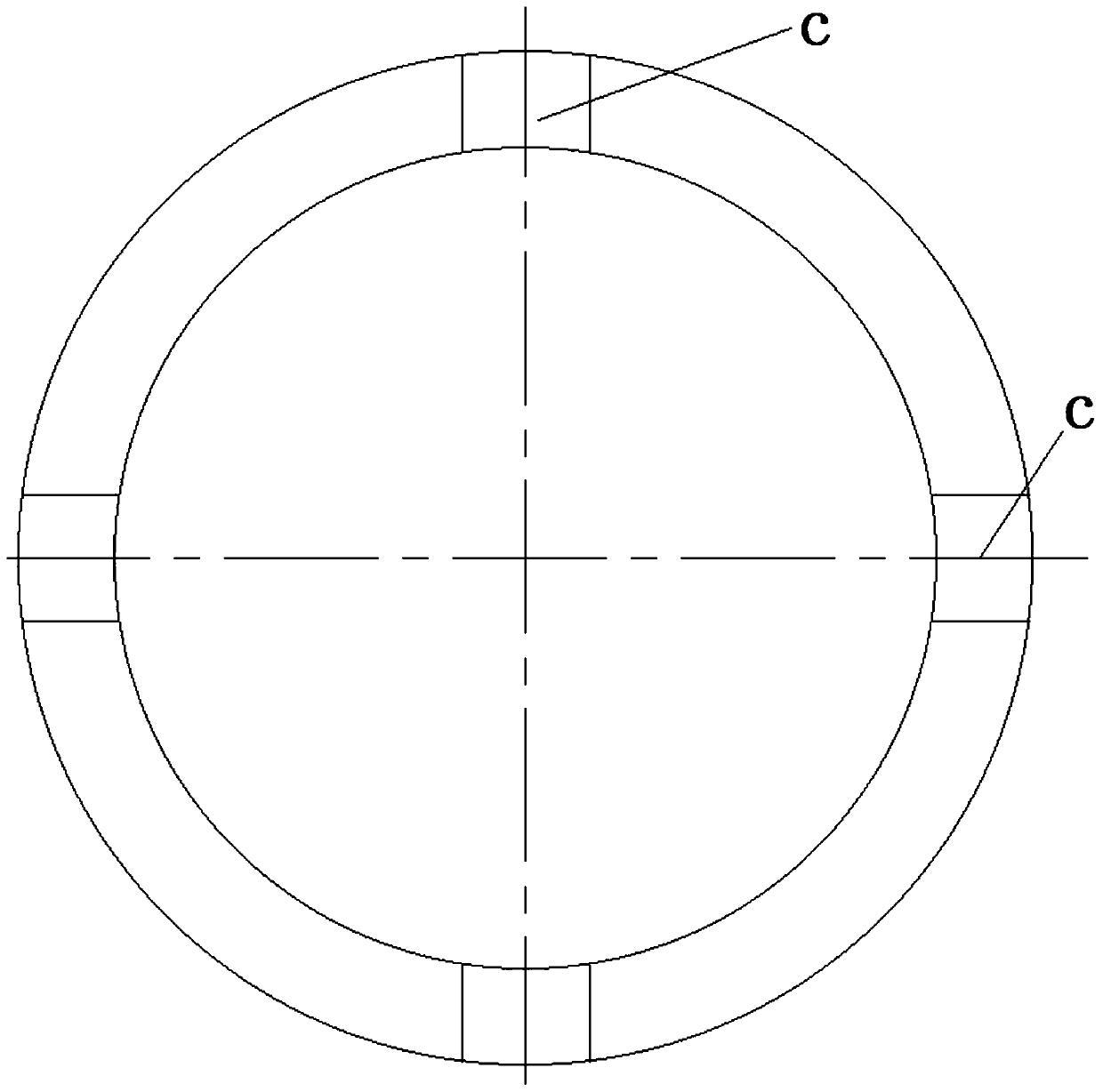

Carbon plastic composite polar plate grid and preparation method thereof

ActiveCN102903933AReduce pollutionReduce weightElectrode carriers/collectorsAcrylonitrileEngineering plastic

The invention relates to a carbon plastic composite polar plate grid, and belongs to the storage battery technology. The carbon plastic composite polar plate grid comprises an electric-conducting base plate, a support and a tab, wherein the electric-conducting base plate is provided with a plurality of reaction through holes; the outer frame of the electric conducting base plate is provided with a support; the reaction through hoes are provided with lead plaster; the tab is made of lead alloy; the electric-conducting base plate is formed by rolling graphite; and the support is directly subjected to injection molding on the electric-conducting base plate through a mold by ABS (Acrylonitrile Butadiene StyreneAcrylonitrile Butadiene Styrene) engineering plastics. According to the invention, the previous lead alloy material is replaced by graphite, so that the pollution to the environment is reduced; the quality of the battery is improved greatly because of super high conductivity of graphite; because graphite and sulfuric acid can not react, the service life of the battery is prolonged; the preparation process is simple; materials are cheap; resources are rich; cost is saved; the weight of the storage battery is reduced greatly; and thin steel plates added into the electric-conducting base plate which is made of graphite, and the supports in injection molding are used for improving the stability of the electric conducting base plate, and the loss caused by graphite cracking is reduced.

Owner:台州仁信模具有限公司

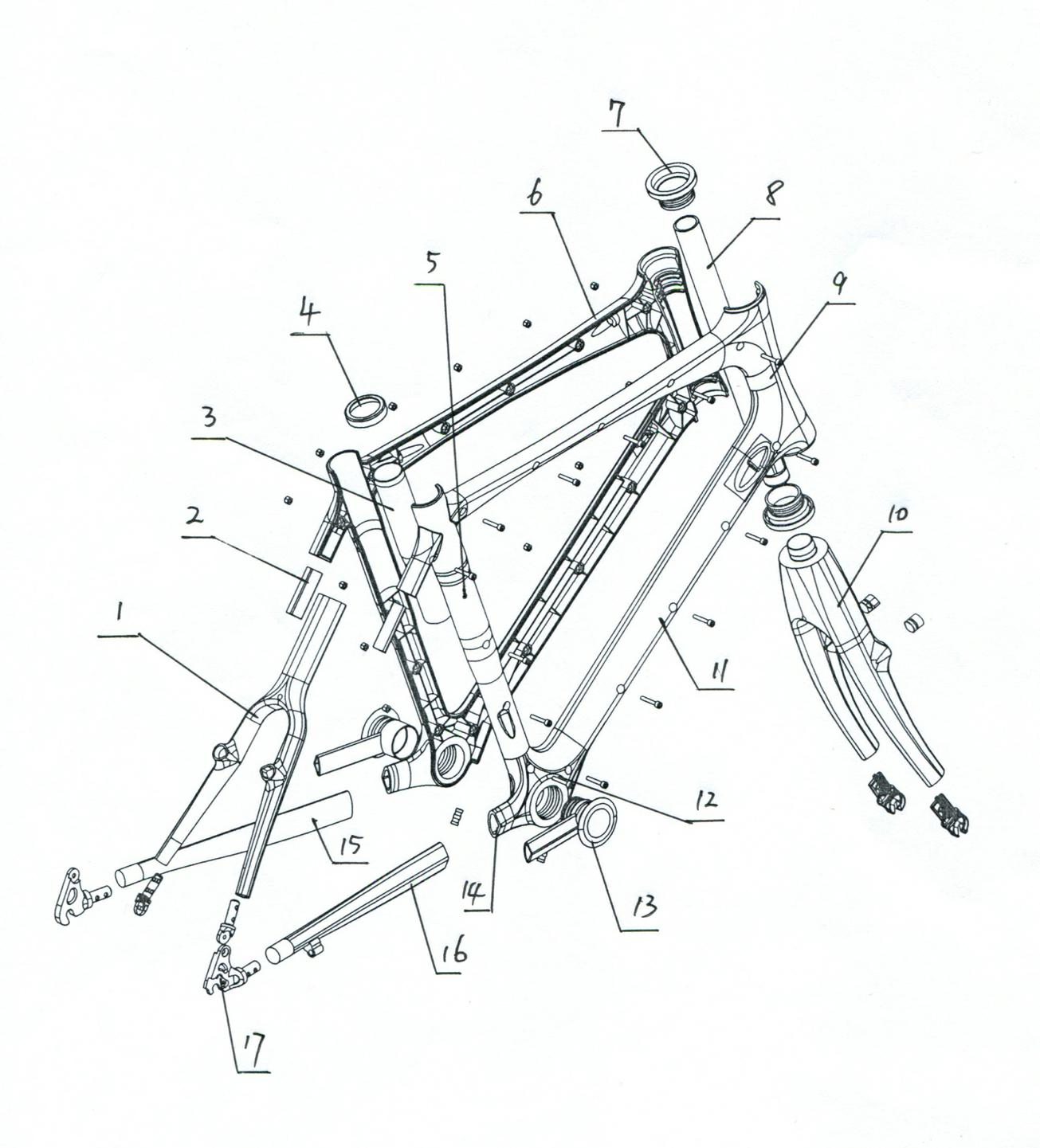

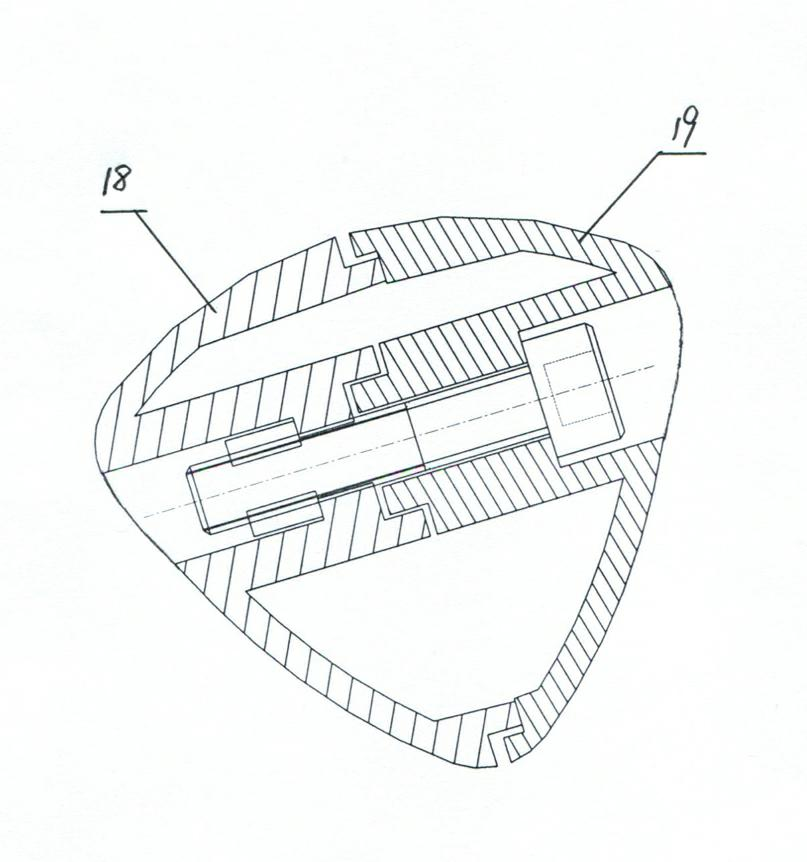

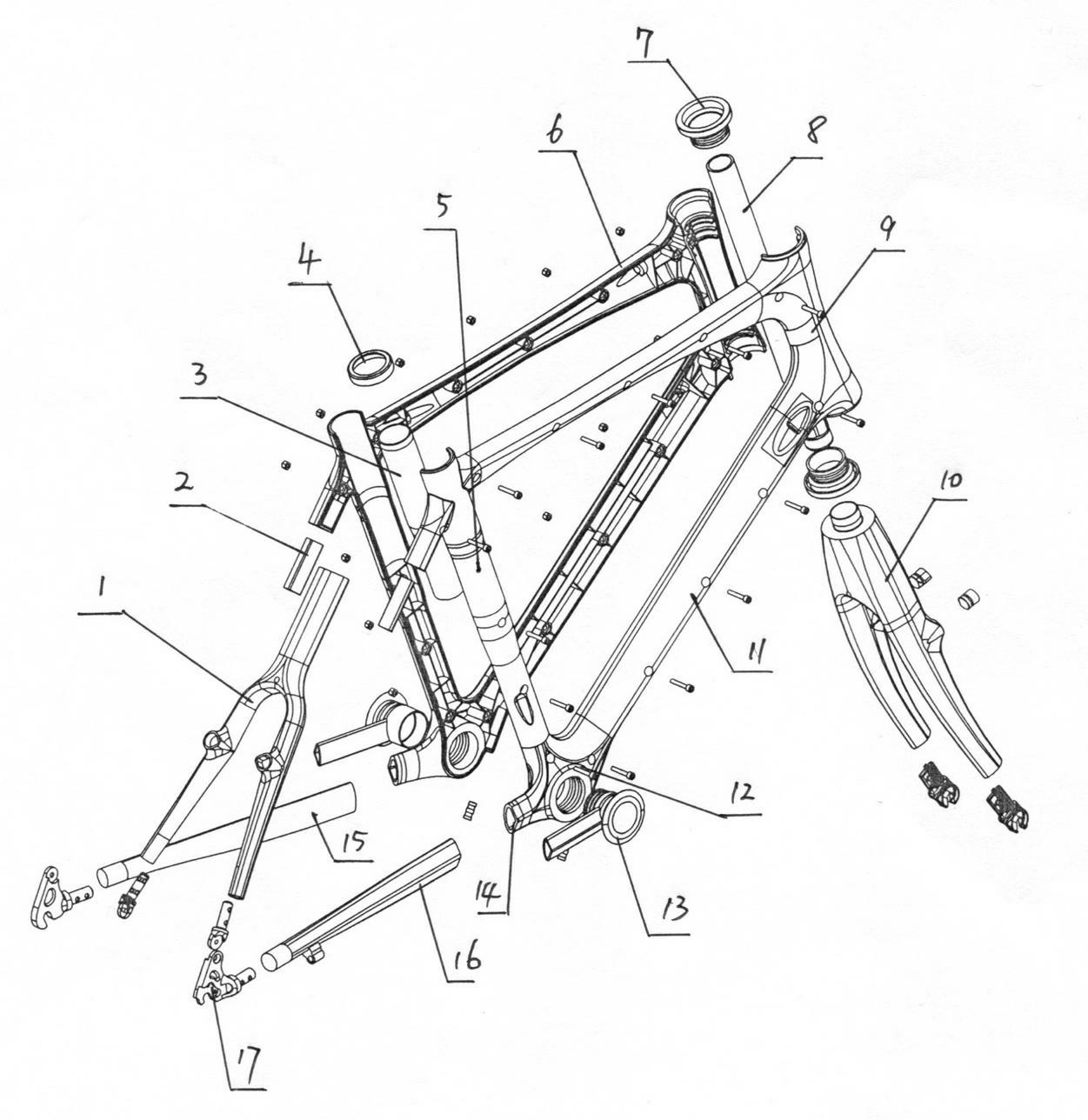

Injection-molded bicycle frame by using carbon-plastic material

The invention provides an injection-molded bicycle frame by using a carbon-plastic material. The bicycle frame comprises a frame main body as well as a front fork, a seat stay, a left chain stay and a right chain stay which are integrally injected and molded by using the carbon-plastic material, wherein, the frame main body is composed of a left half frame and a right half frame which are respectively and integrally prepared from the carbon-plastic material in the injection molding mode. In the invention, the bicycle frame is produced by a new carbon-fiber injection molding process, wherein, the frame body is divided into the left and right parts which are respectively prepared in the injection molding mode, which belongs to original innovation of the manufacturing technology in the carbon-fiber bicycle industry, provides an effective and feasible process for large-scale and efficient production of carbon-fiber bicycles and realizes successful application of cladding and granulating and injection molding processes to production of the bicycle frame. The process has the advantages of accelerating popularization of the carbon-fiber bicycles in China with low fabrication cost so that the bicycles become popular commodities, promoting development of the carbon-fiber bicycle industry in China and providing rich experience for development of subsequent carbon-fiber products.

Owner:常州神鹰碳塑复合材料有限公司

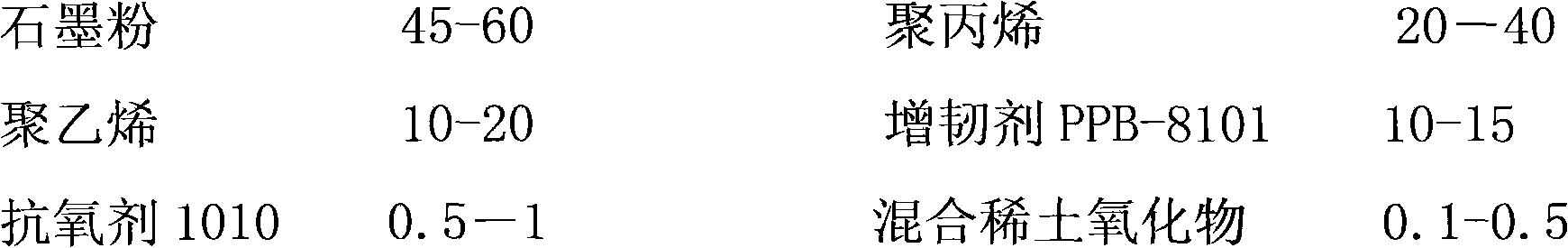

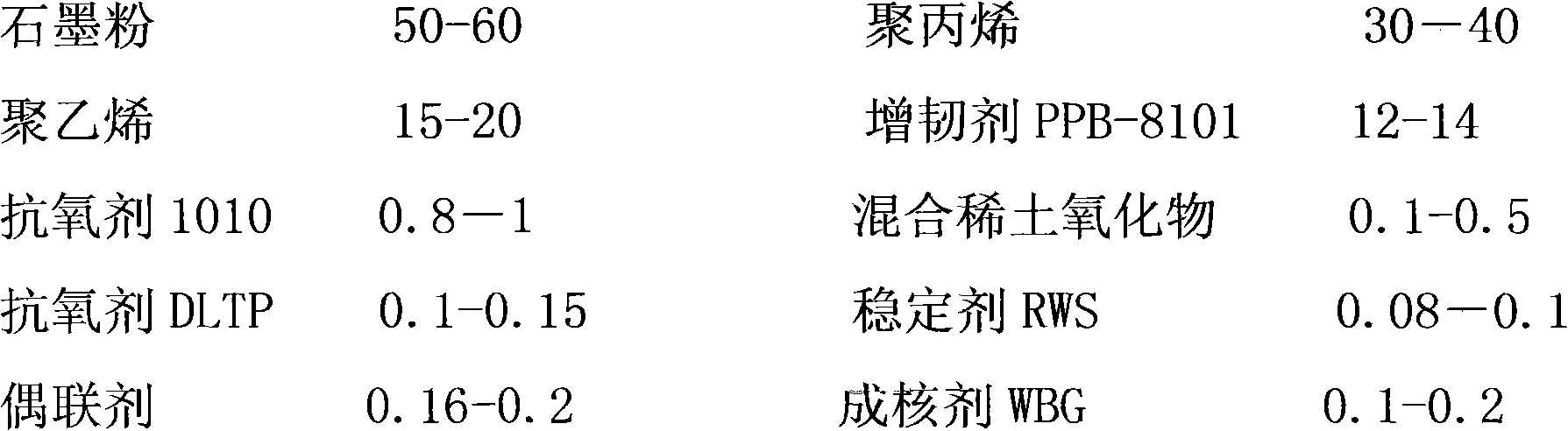

Carbon plastic modified polypropylene plastic

The invention relates to a plastic technology, in particular to a plastic used as an inner chamber of a water tank of a solar water heater. A carbon plastic modified polypropylene plastic comprises 1-10wt% of carbon plastic fiber, 30-50wt% of mixed polypropylene, 30-60wt% of maleic anhydride grafted polypropylene, 3-10wt% of metallocene polyethylene, 0.1-0.3wt% of composite antioxidant, 0.1-0.3wt% of light stabilizer and 10-20wt% of calcium carbonate. The invention solves the problem that the current inner chambers made of stainless steel and enamel can be corroded easily and leak water.

Owner:张国良 +2

Spiral nut made of carbon-plastic alloy and used for percussion borer

The invention relates to a spiral nut manufactured from a carbon alloy for a rock drill. A material formula for manufacturing consists of the following raw materials by weight portion: 40 to 65 portions of polyether sulphone, 15 to 30 portions of carbon fiber and 2 to 10 portions of teflon. In specific implementation, the raw materials can be also added with 20 to 30 portions of polyimide, 1 to 5 portions of graphite and 2 to 10 portions of bronze powder respectively. Compared with the prior art, the spiral nut manufactured from the novel material has the advantages of low manufacturing cost, long service life and high working efficiency and can also prolong the service life of a spiral rod in a high-speed motion state.

Owner:吴立坤

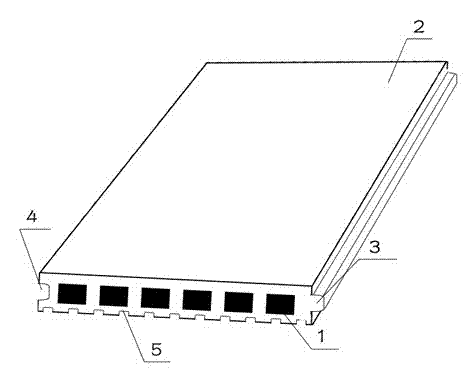

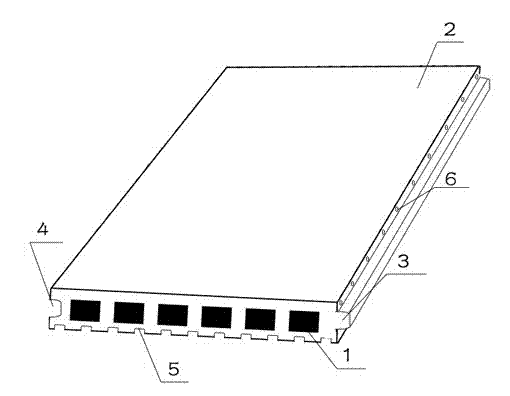

Carbon-plastic composite floor and manufacturing method thereof

The invention discloses a carbon-plastic composite floor and a manufacturing method thereof. The manufacturing method includes filling formable activated carbon materials in holes of various plastic hollow floors which are commercially available, and drilling a plurality of small holes on seams or backs of the floors to improve breathability of the composite floor. Performances of original hollow floors are retained while functions of activated carbon such as adsorption, deodorization and moisture proofing are added, so that the carbon-plastic composite floor has effects such as air purification and pollution elimination. The manufacturing method is simple, easy to implement and low in cost, and has important environmental benefits and excellent market prospects.

Owner:FUZHOU UNIV +1

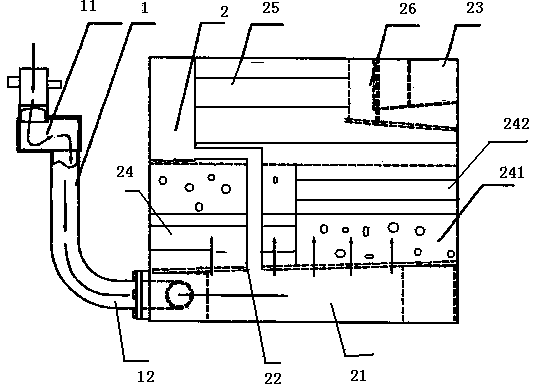

Environment-friendly automobile tail gas absorption device

InactiveCN103736362ACombination absorbs wellPromote absorptionDispersed particle separationProcess engineeringCarbon plastic

The invention relates to a tail gas absorption device, and in particular relates to an environment-friendly automobile tail gas absorption device. The environment-friendly automobile tail gas absorption device comprises a tail gas pipe, wherein a gas inlet and a gas outlet are formed in two ends of the tail gas pipe, respectively; the gas outlet is connected with a tail gas absorption box; an absorption liquid groove is formed in the bottom of the tail gas absorption box and is communicated with a liquid inlet which is formed inside the top of the tail gas absorption box; a purified gas outlet is formed in one side of the top of the tail gas absorption box; a first environment-friendly filter layer is arranged above the absorption liquid groove and comprises plant carbon plastic layers and sponge layers, which are arranged in a staggered manner; according to a specific arrangement mode, the plant carbon plastic layers are arranged on one side of the upper part of the first environment-friendly filter layer, the sponge layers are arranged on the other side of the upper part of the first environment-friendly filter layer, each sponge layer is arranged at the lower end of the corresponding plant carbon plastic layer, and another plant carbon plastic layer is arranged at the lower end of the corresponding sponge layer. The environment-friendly automobile tail gas absorption device has a flame-retardant effect, and can thoroughly absorb tail gas pollutants.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

Manufacturing process of carbon plastic plate with high flame resistance

The invention discloses a manufacturing process of a carbon plastic plate with high flame resistance. The manufacturing process comprises the following steps: adding bamboo charcoal particles, carbonized coconut shell powder and shell powder into NaOH, soaking for 12 to 24 hours, filtering to remove solution, and mixing, stirring and dissolving by using deionized water to obtain a mixed base material A; mixing and stirring resin and graphene loaded with a flame retardant at 60 DEG C, adding a composite stabilizer, and performing heating reaction for 20 to 26 hours to obtain a mixed base material B; and mixing and stirring the mixed base material A and the mixed base material B, performing pelleting, extrusion molding and molding, cooling to room temperature to obtain a product and adding the graphene loaded with the flame retardant into the resin, so the use amount of the flame retardant is greatly reduced, the carbon plastic plate has good flame-resistant effect, and the flame retardant can be distributed in the carbon plastic plate uniformly.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Bipolar plate for flow batteries as well as preparation and application of bipolar plate

ActiveCN108134095AImprove corrosion resistanceLong-term useCell electrodesPolymer scienceComposite plate

The invention discloses a bipolar plate for flow batteries as well as preparation and an application of the bipolar plate. The bipolar plate is a carbon-plastic composite plate prepared from, in percentage by mass, 25%-35% of high-density polyethylene with the melt index being 2-10, 65%-75% of conducive filler and 0-2% of a lubricant or prepared from 25%-35% of high-density polyethylene with the melt index being 2-10 and 65%-75% of conductive filler. The bipolar plate solves the problems of poor halogen corrosion resistance and poor toughness of carbon-plastic composite bipolar plates taking polypropylene as a matrix as well as low conductivity of carbon-plastic composite bipolar plates, thus, the bipolar plate has high conductivity and good corrosion resistance and can reduce ohm internalresistance of flow energy storage batteries and prolong the service life of piles.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Antiflaming tail gas absorption device

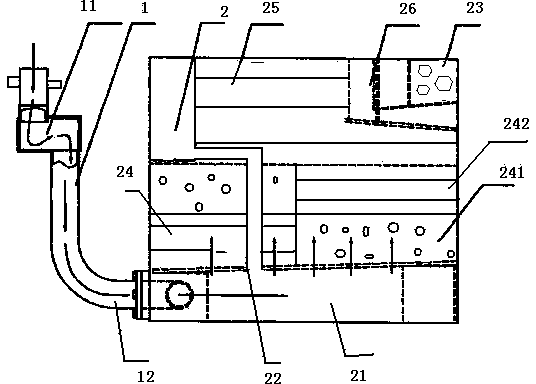

InactiveCN103758615ACombination absorbs wellPromote absorptionCombination devicesExhaust apparatusEnvironmental resistanceEngineering

The invention relates to a tail gas absorption device, in particular to an antiflaming tail gas absorption device comprising a tail gas pipe. Two ends of the tail gas pipe are respectively provided with a gas inlet and a gas outlet, a tail gas absorption case is connected with the gas outlet, an absorption liquid groove is arranged on the bottom of the tail gas absorption case, the absorption liquid groove is communicated with a liquid inlet arranged in the top portion of the tail gas absorption case, one side of the top portion of the tail gas absorption case is provided with a purified gas outlet with hexagonal cross section, a first environmental protection filtering layer is arranged above the absorption liquid groove, one side of the purified gas outlet is provided with a second environmental protection filtering layer and a guide plate which are arranged at the upper end of the first environmental protection filtering layer, the first environmental protection filtering layer comprises plant carbon plastic and sponge arranged in intersection, one side of the upper portion of the first environmental protection filtering layer is a plant carbon plastic layer, the other side of the first environmental protection filtering layer is a sponge layer, and the lower end corresponding to the sponge layer is the plant carbon plastic layer. The tail gas absorption device has antiflaming property and can absorb tail gas pollutant completely.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

Method for preparing polyvinyl chloride carbon plastic product from coal gangue

The invention relates to a method for preparing a polyvinyl chloride carbon plastic product from coal gangue, belongs to the technical field of polyvinyl chloride carbon plastic product preparation processes, and mainly solves the technical problems of high price, high processing cost and limited resources in the prior art. According to the technical scheme, the method for preparing the polyvinyl chloride carbon plastic product from the coal gangue comprises the following steps: 1) pretreating the coal gangue; 2) coupling and wrapping the coal gangue powder ash; 3) performing coal gangue fiber reinforced modification treatment; 4) preparing a primary material of the polyvinyl chloride carbon plastic product; and 5) performing extrusion forming. The method has the advantages of green environmental protection, good water resistance, high plasticity, no harmful gas release and the like.

Owner:长治市宏瑞祥环保科技有限公司

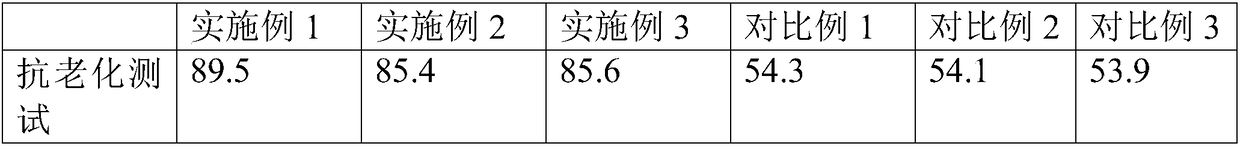

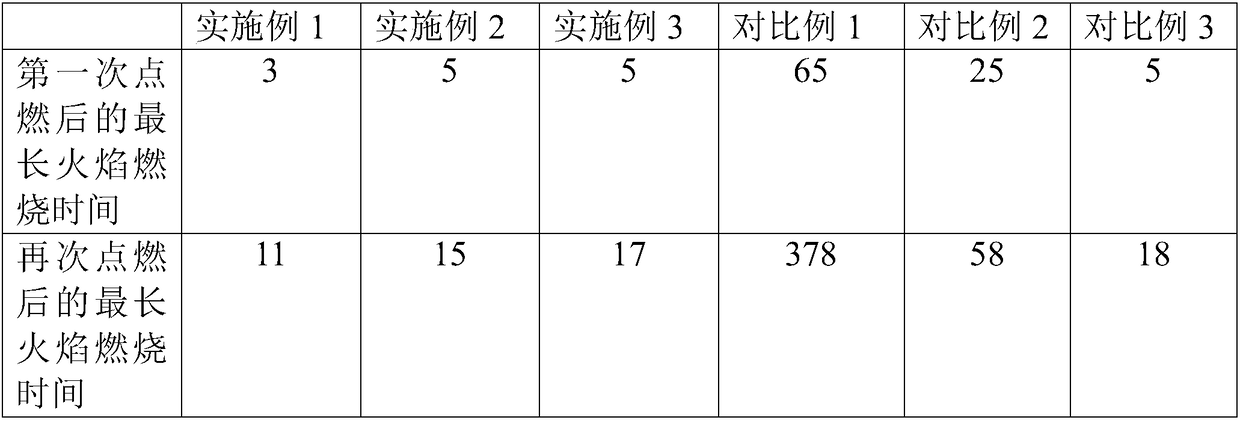

Good-appearance low-carbon environment-friendly fiber-reinforced PC/PLA composite material and preparation method thereof

The invention discloses a good-appearance low-carbon environment-friendly glass fiber reinforced PC / PLA composite material and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 15 to 30 parts of polycarbonate, 20 to 30 parts of polylactic acid, 5 to 10 parts of a flexibilizer, 15 to 18 parts of a compatilizer, 10 to 15 parts of chopped glass fibers, 10 to 20 parts of a polycarbonate reclaimed material, 1 to 2 parts of an anti-hydrolysis agent, 0.1 to 0.3 part of an antioxidant, 0.5 to 1 part of a lubricant, 0.3 to 0.5 part of a chain extender, 0.2 to 0.5 part of an ester exchange inhibitor and 3 to 5 parts of a plasticizer. The composite material prepared by the invention has excellent processing stability, good appearance and strength, and has no defects such as material patterns, white lines, flash, carbonization and the like, and surface floating fibers and luster are obviously improved; the carbon emission of traditional plastics can be reduced, meanwhile, the low-carbon plastic has good strength, appearance and molding processing performance, and development and application of low-carbon materials are promoted.

Owner:合肥市皖能塑业有限公司

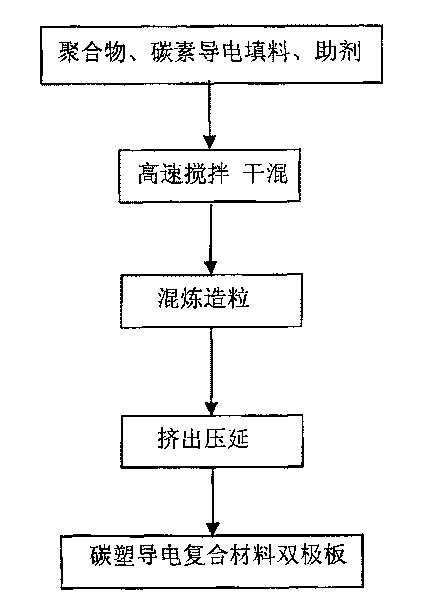

Carbon-plastic electricity-conductive bipolar board for liquid energy-storing battery and manufacture thereof

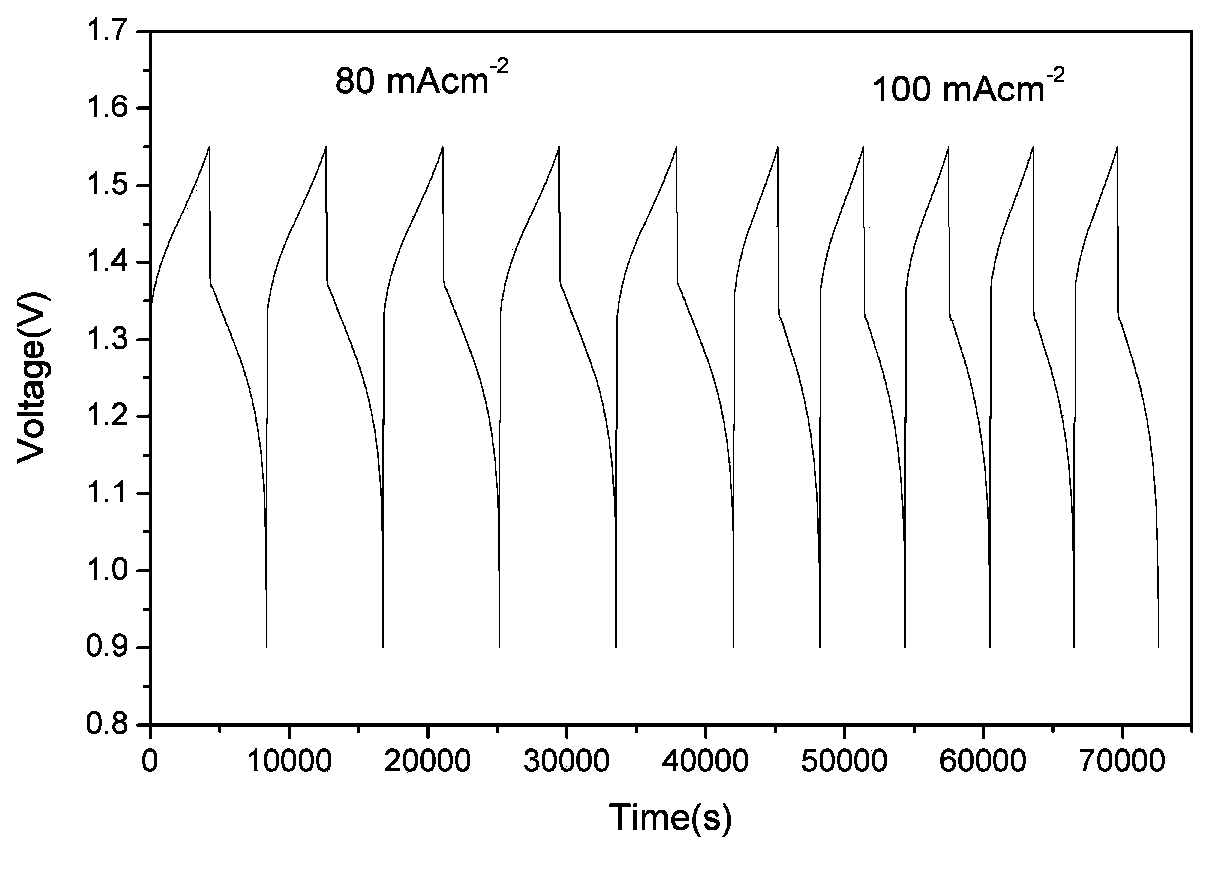

ActiveCN101308923BImprove energy efficiencyImprove power densityElectrode manufacturing processesActive material electrodesElectricityPolymer science

The invention relates to a redox flow storage battery, in particular to a redox flow storage battery which adopts carbon conductive composite bipolar plates. The redox flow storage battery is characterized in that the redox flow storage battery contains polymer resin, carbon conductive filling and accessory ingredient; the quality ratio of polymer resin to carbon conductive filling is 1-7:9-3, andthe quality ratio of accessory ingredient to polymer resin is 0.05-0.7:10; the sap flow storage battery is made through mixing and granulation, extrusion and calendaring. The material is of high conductivity and good liquidity resistance and mechanical property. Bipolar plates with small thickness and large area can be made through extrusion and calendaring technique. The extrusion and calendaring technique is high in production efficiency and can effectively reduce the cost of the battery, which is good for the commercialization of the battery.

Owner:DALIAN RONGKE POWER

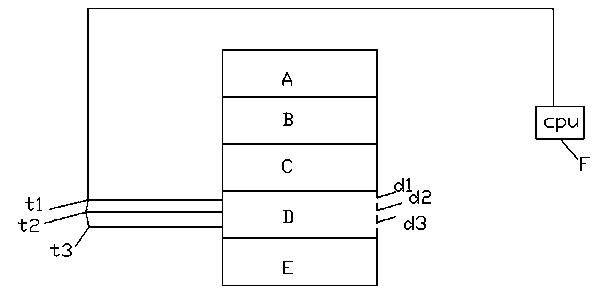

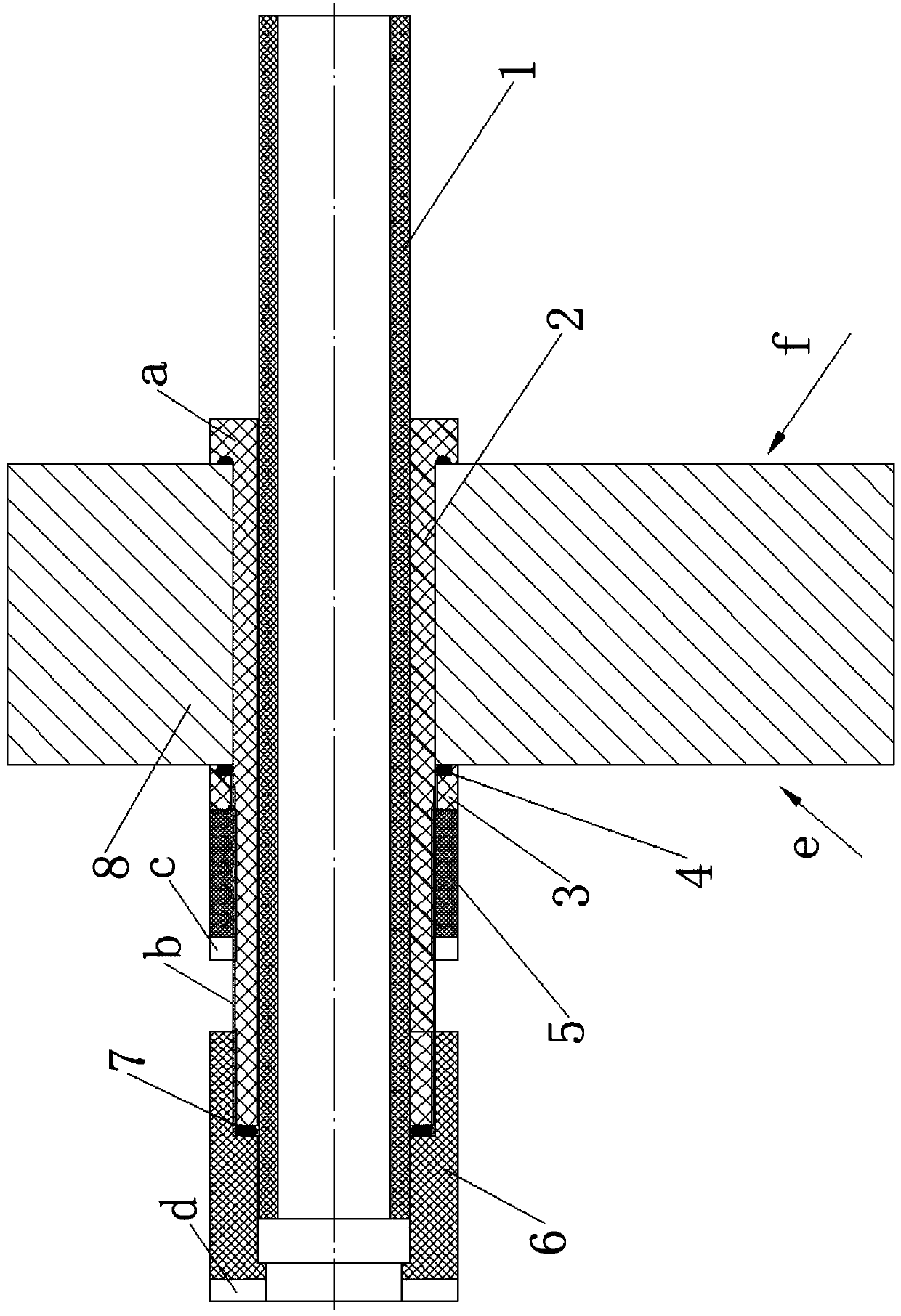

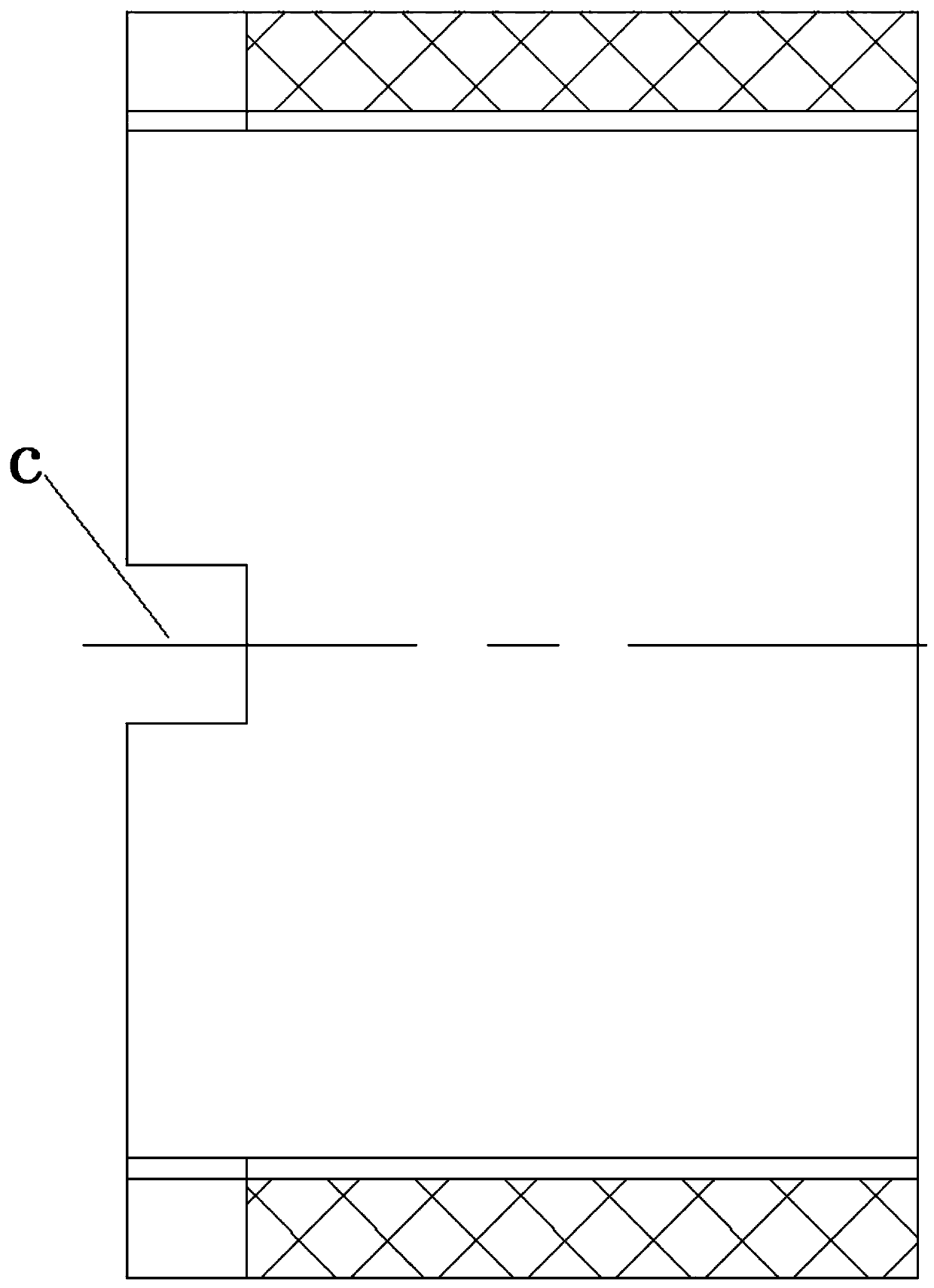

Flue gas treatment heat exchange tube and tube plate connection system

PendingCN109945733AHeat resistantHas excellent heat resistanceCorrosion preventionHeat exchanger casingsFlue gasWastewater

A flue gas treatment heat exchange tube and tube plate connection system is characterized by comprising a carbon plastic heat exchange tube, a connection sleeve type tube connector with one end with atube plate stop table and the other end with an outer thread and arranged between the carbon plastic heat exchange tube and a tube plate, an isolation sleeve abutting against the end face of the tubeplate and installed on the connection sleeve type tube connector, an isolation sleeve sealing ring installed between the isolation sleeve and the connection sleeve type tube connector, a fastening nut with the tail end with a mounting tool embedding inlet, abutting against the end face of the isolation sleeve and installed on the connection sleeve type connector, a nut type tube hoop, and a tubehoop sealing ring installed among the nut type tube hoop, the connection sleeve type tube connector and the carbon plastic heat exchange tube, wherein the tail end of the nut type tube hoop is provided with a mounting tool embedding inlet, an inner hole of the nut type tube hoop is in a step type, a large hole of the nut type tube hoop is provided with an inner thread, and the nut type tube hoop is installed at the tail end of the connection sleeve type tube connector. The system has the good mechanical performance and heat performance, and is convenient to mount and dismount. The flue gas treatment heat exchange tube and tube plate connection system can be widely applied to flue gas treatment systems, especially wet desulphurization white plume and wastewater reduction cooperative treatment systems.

Owner:QINGDAO DANENG ENVIRONMENTAL PROTECTION INC

Carbon plastic synthetic heat exchange material

InactiveCN102634112BImprove corrosion resistanceLow costHeat-exchange elementsPhysical chemistryCarbon plastic

Owner:律通控股集团有限公司

Preparation method of vegetable carbon plastic composites

The invention relates to the field of polymers, and in particular relates to a preparation method of vegetable carbon plastic composites. The method comprises the following steps in sequence: feeding the raw vegetables into a microwave vacuum tank to undergo microwave treatment; drying, pre-carbonizing, carbonizing, calcining and cooling the pretreated raw vegetables in sequence; controlling combustion to raise the temperature to 700-750 DEG C or 900-1000 DEG C at a rate of 5-15 DEG C / min and maintaining the temperature for 40-80 minutes; then raising the temperature to 1000-1500 DEG C or 1600-1800 DEG C at a rate of 5-15 DEG C / min and maintaining the temperature for 2-8 hours to obtain vegetable carbon; and blending and modifying the base materials such as high impact polystyrene, polyvinyl chloride and ultra-low-density polyethylene with molecular weights of 3-5 million and adding a flame retardant, a toughening agent, a coupling agent, an antioxidant and the obtained vegetable carbon in the processing course. The prepared vegetable carbon plastics have the advantages of excellent toughness, higher rigidity and hardness and good antistatic property and flame retardance.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

Production method of vegetable carbon plastics

InactiveCN102888044BImprove toughnessImprove rigidityBiofuelsSpecial form destructive distillationAntioxidantPolypropylene

The invention relates to the field of polymers, and in particular relates to a production method of vegetable carbon plastics. The method comprises the following steps in sequence: feeding the raw vegetables into a microwave vacuum tank to undergo microwave treatment; drying, pre-carbonizing, carbonizing, calcining and cooling the pretreated raw vegetables in sequence; controlling combustion to raise the temperature to 700-750 DEG C or 900-1000 DEG C at a rate of 5-15 DEG C / min and maintaining the temperature for 40-80 minutes; then raising the temperature to 1000-1500 DEG C or 1600-1800 DEG C at a rate of 5-15 DEG C / min and maintaining the temperature for 2-8 hours to obtain vegetable carbon; and blending and modifying the base materials such as ultra-high molecular weight polyethylene with molecular weight of 4-7 million and high-density polypropylene with molecular weight of 1-1.4 million and adding a flame retardant, a toughening agent, a coupling agent, an antioxidant and the obtained vegetable carbon in the processing course. The prepared vegetable carbon plastics have the advantages of excellent toughness, higher rigidity and hardness and good antistatic property and flame retardance.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

Positive electrode of zinc bromine redox flow battery and preparation thereof

The invention relates to a positive electrode of a zinc bromine redox flow battery and a preparation method thereof. The positive electrode comprises a carbon-plastic composite panel, and a catalyst layer which has high specific surface area, is adhered to one side surface of the carbon-plastic composite panel, and consists of a binder, namely chlorinated polypropylene or chlorinated polyethylene, a catalyst, namely activated carbon or carbon-supported metal, and a conductive agent, namely conductive graphite or carbon black. The catalyst layer with the high specific surface area is coated or bonded on a thermoplastic conductive plate made of polypropylene, polyethylene and the like, and high specific surface area and high conductivity are achieved simultaneously, so that the redox activity of positive bromine and the conductivity of the integral positive electrode are improved. Problems of overlarge electrode thickness, battery performance difference caused by carbon felt difference, and the like when the conventional carbon felt electrode is used are solved, and the novel positive electrode of the zinc bromine flow battery can replace the conventional carbon felt electrode.

Owner:华秦储能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com